Patents

Literature

30results about How to "Increase the degree of bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

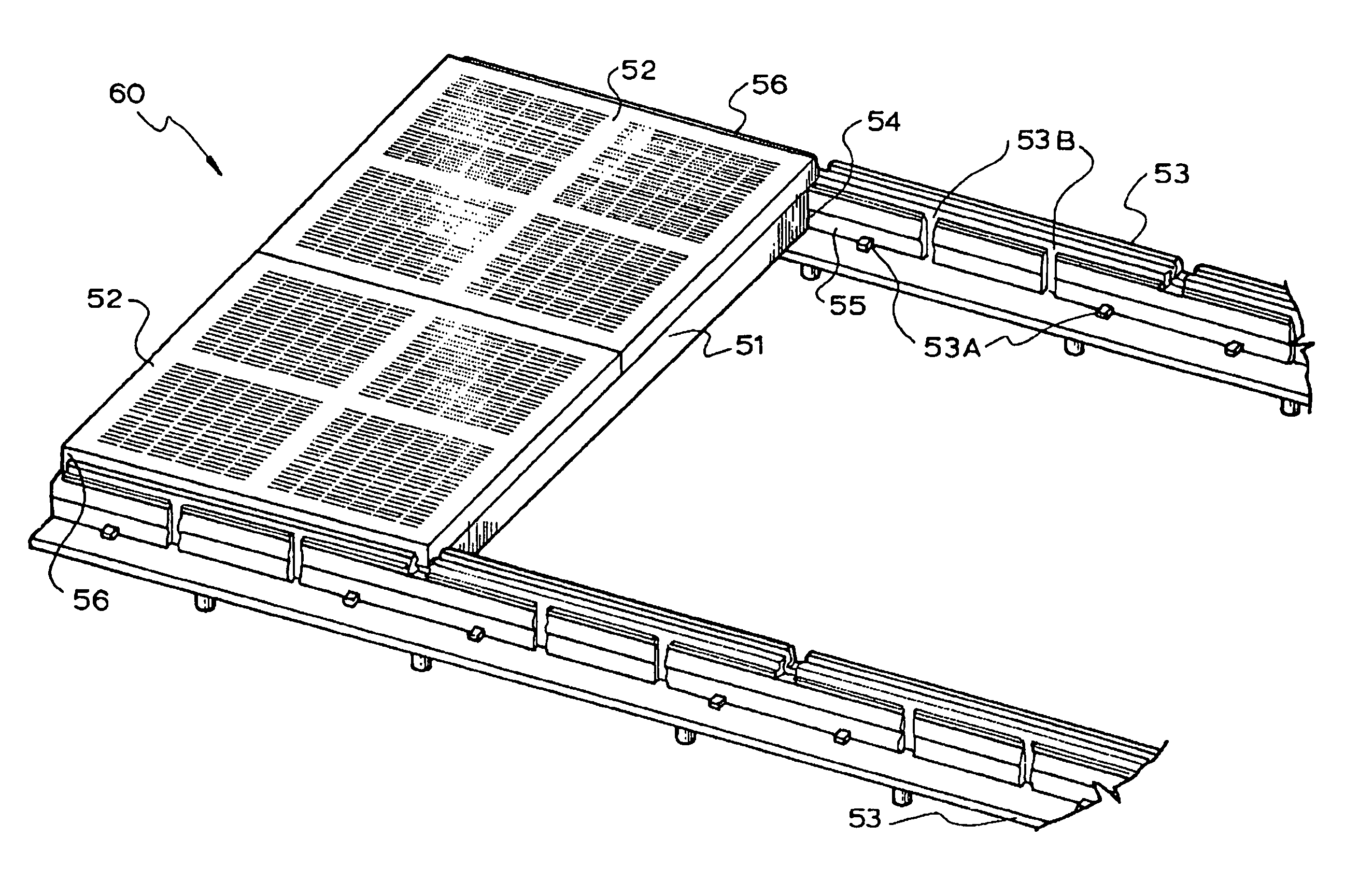

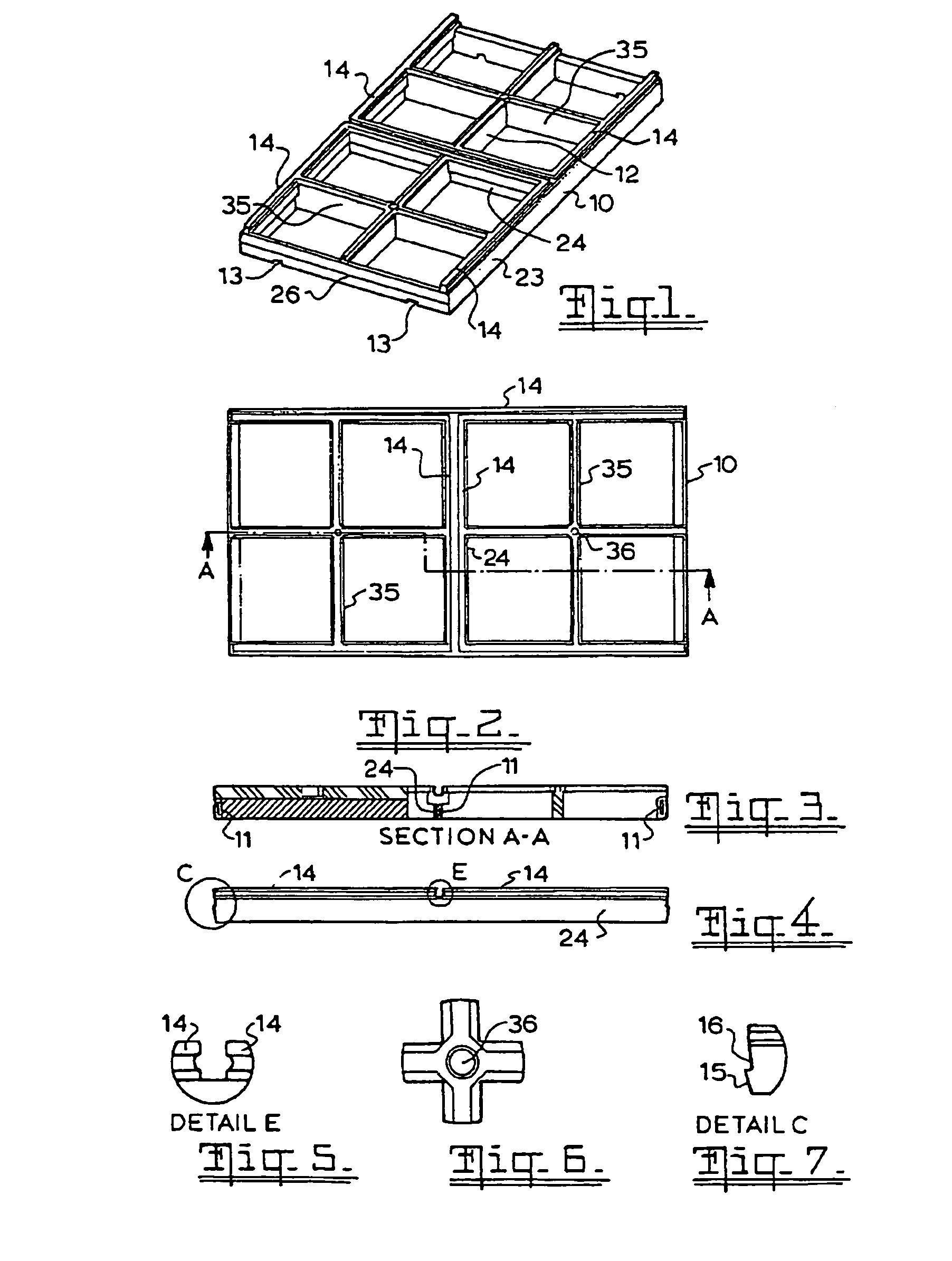

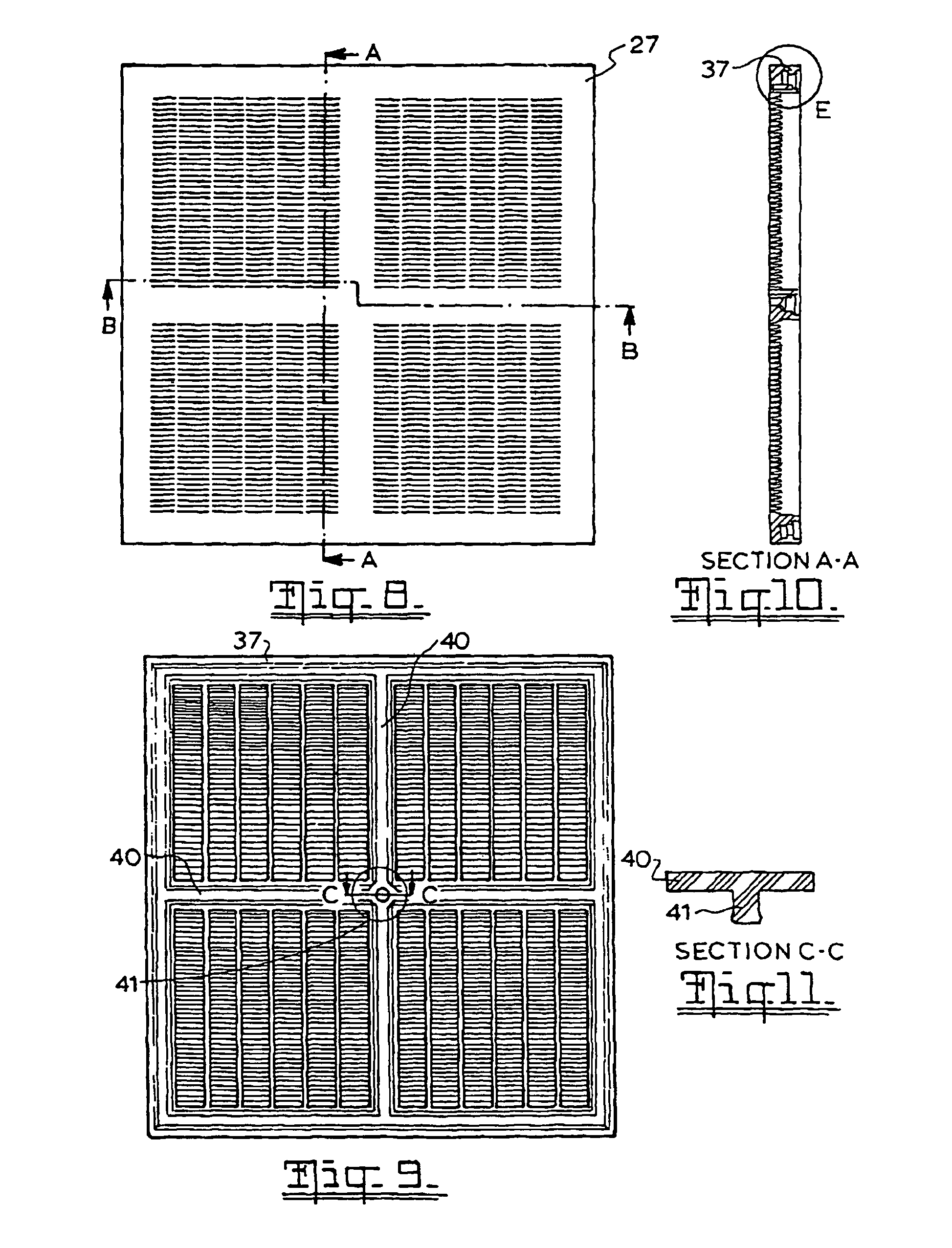

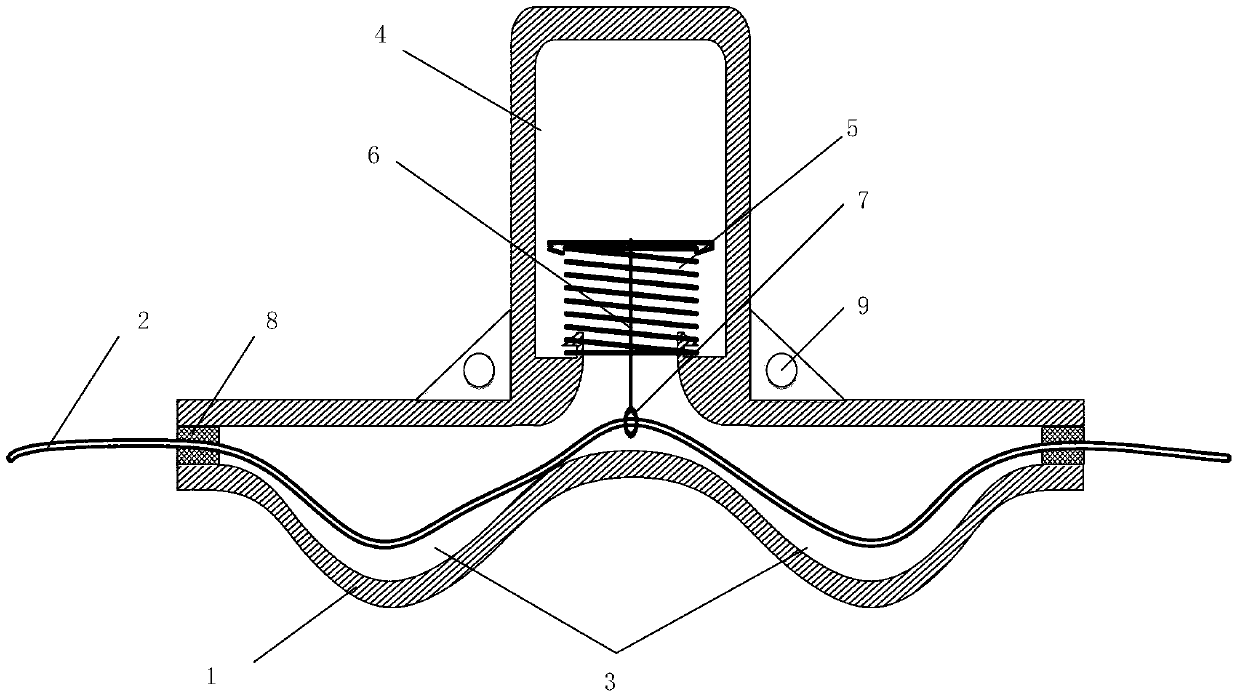

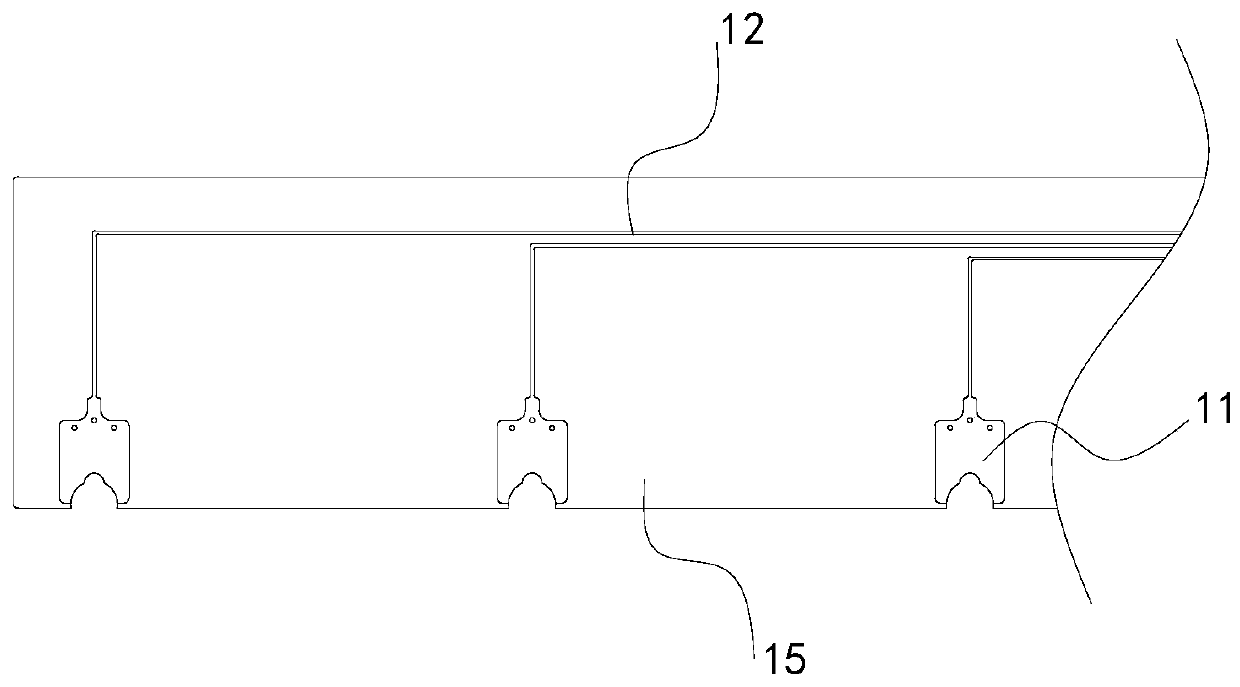

Screen module for vibratory screening apparatus

ActiveUS8127932B2Alleviates excessive flexFacilitates easy assembly of moduleSievingScreeningEngineeringFrame and panel

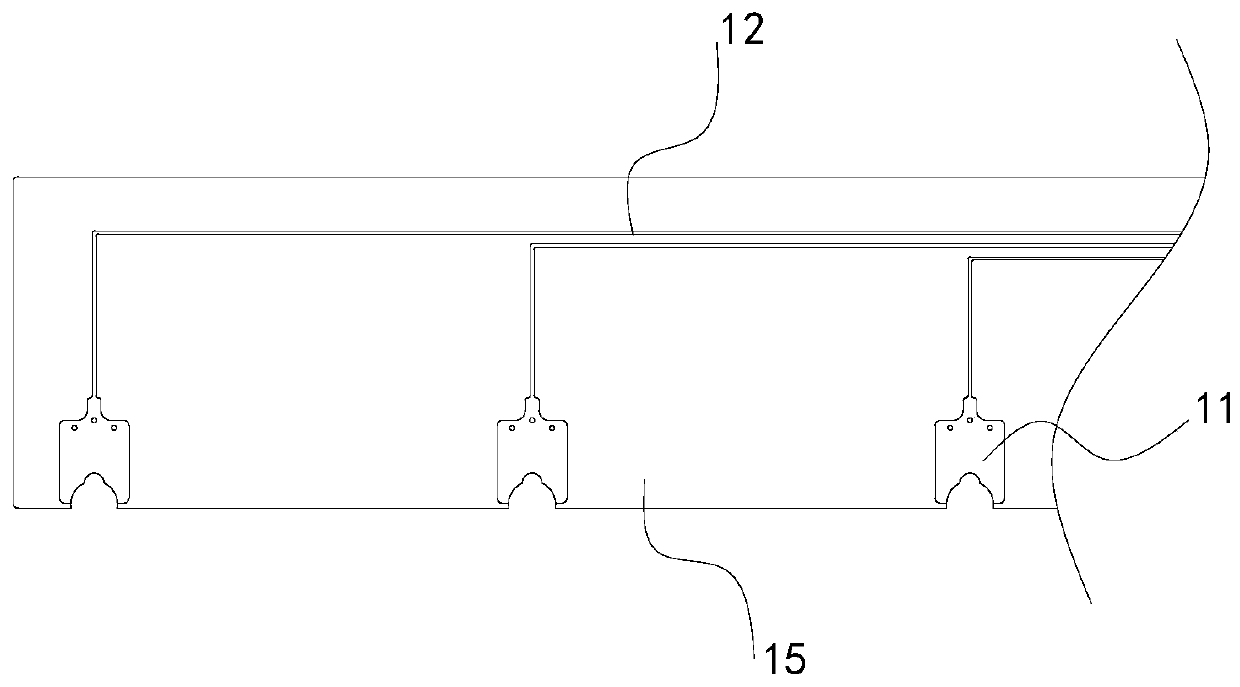

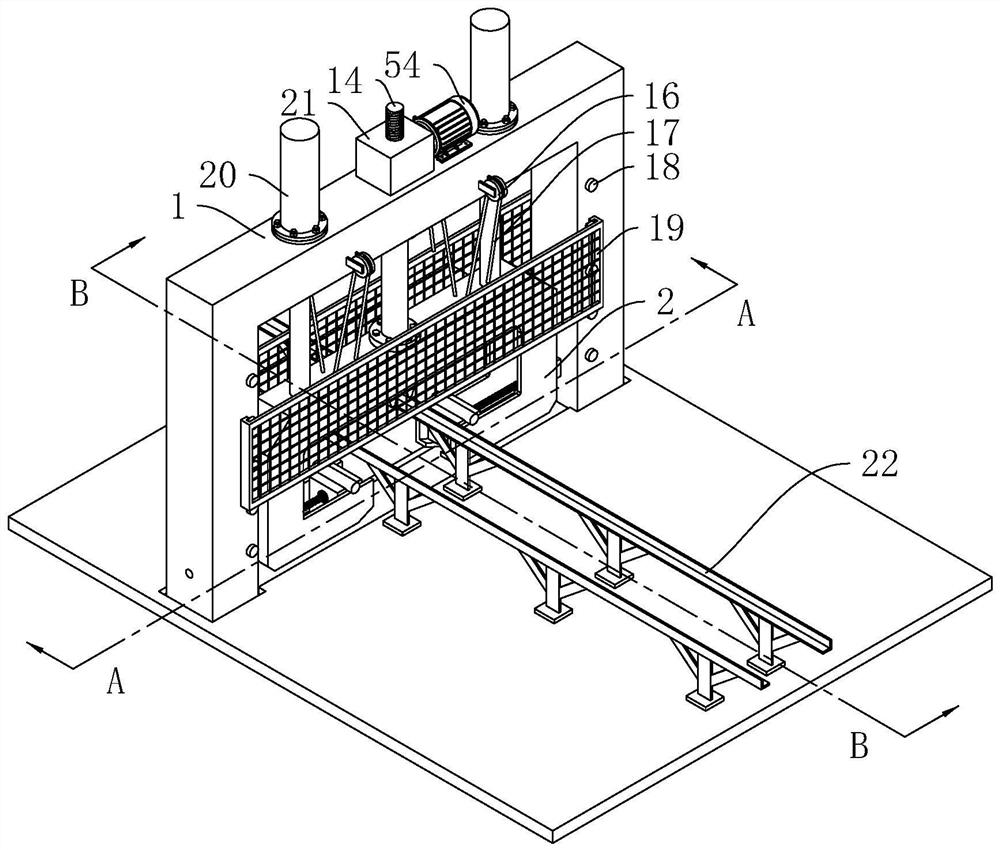

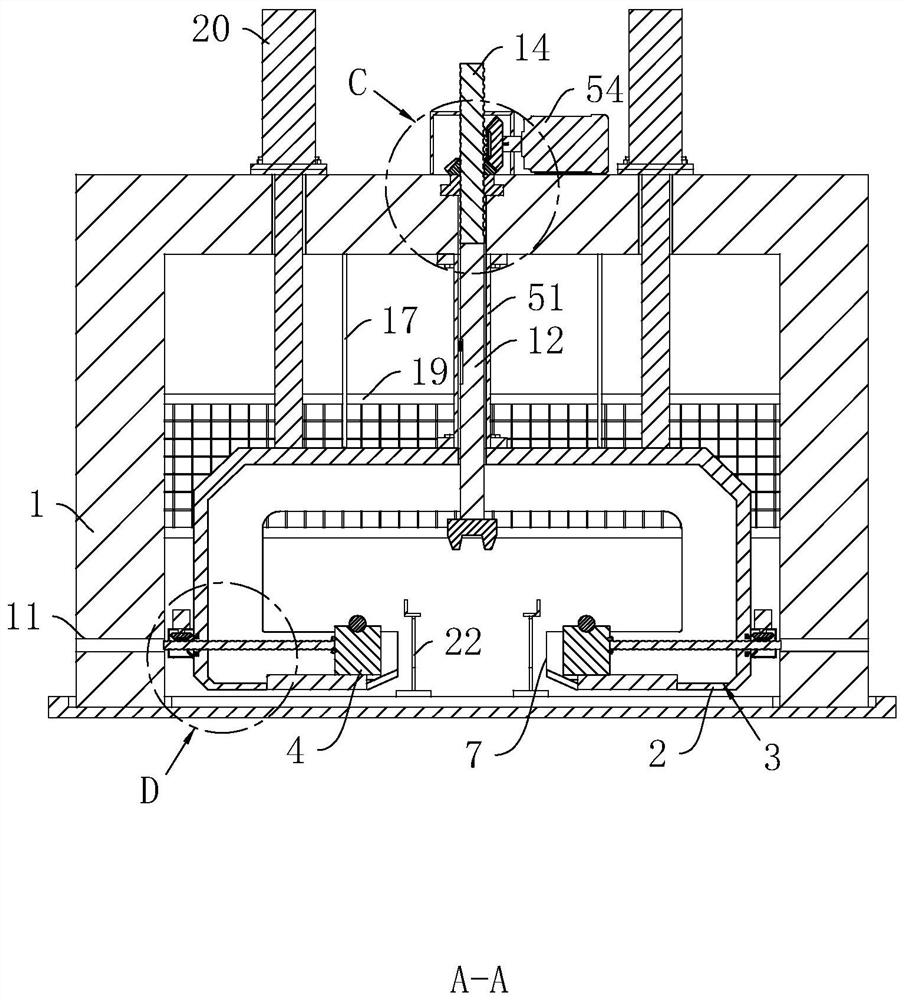

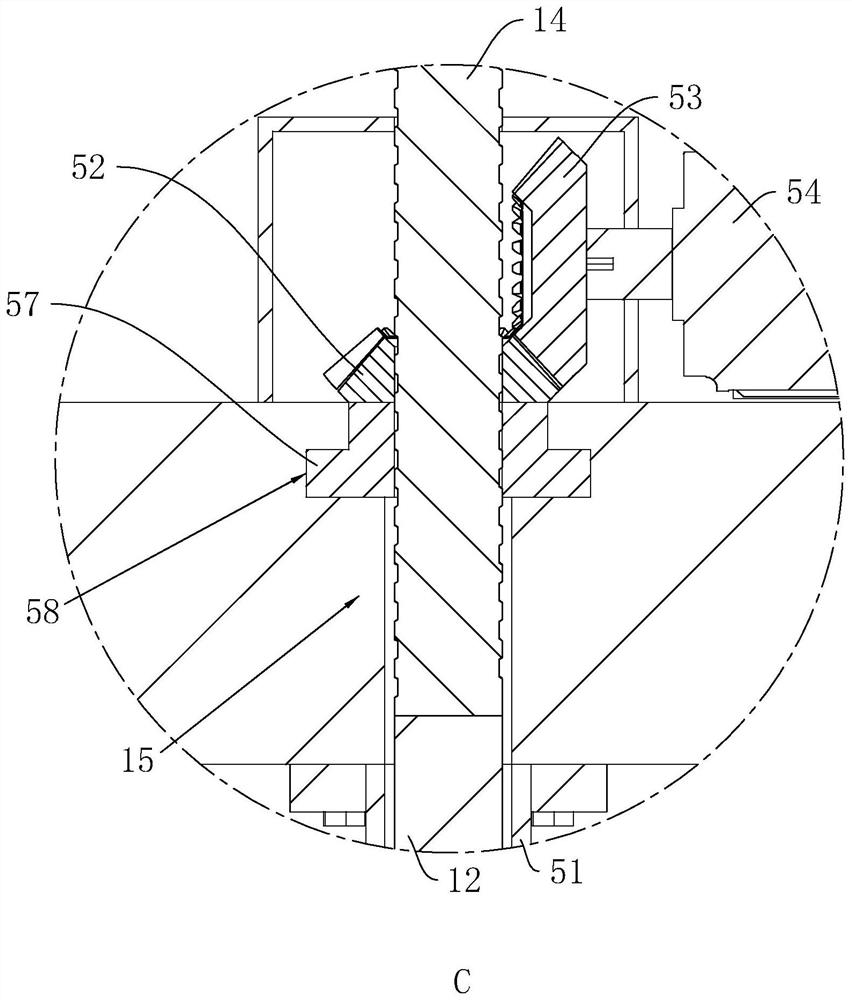

The invention provides a screen module for use on vibratory screening apparatus. The screen module includes: a panel frame having opposed side portions joined by opposed end portions, the end portions being configured for locating the panel frame between spaced panel support rails of the vibratory screening apparatus; at least one intermediate portion extending between the opposed side portions and / or opposed end portions and dividing the panel frame into panel portions; the side portions and said at least one intermediate portion having engagement formations provided on upper surfaces thereof that, together with engagement formations provided on each of the panel support rails of the vibratory screening apparatus, in use, form peripheral panel engagement formations about the panel portions; and at least one pair of screen panels, said screen panels overlying respective panel portions of the panel frame and including complementary engagement formations on an underside periphery thereof for engagement with the peripheral panel engagement formations, defined by the engagement formations of the panel frame and panel support rails.

Owner:F L SMIDTH & CO AS

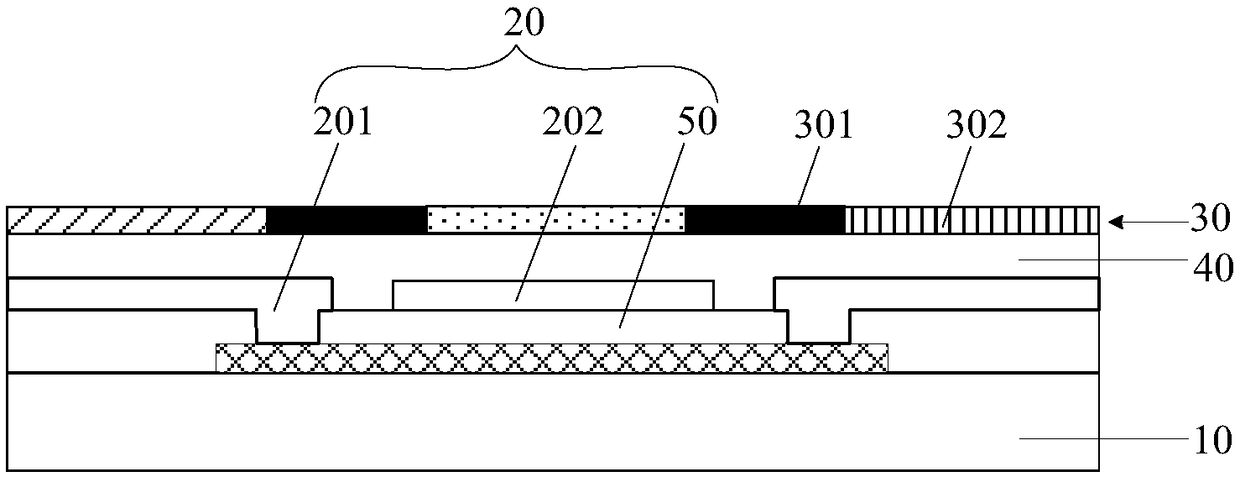

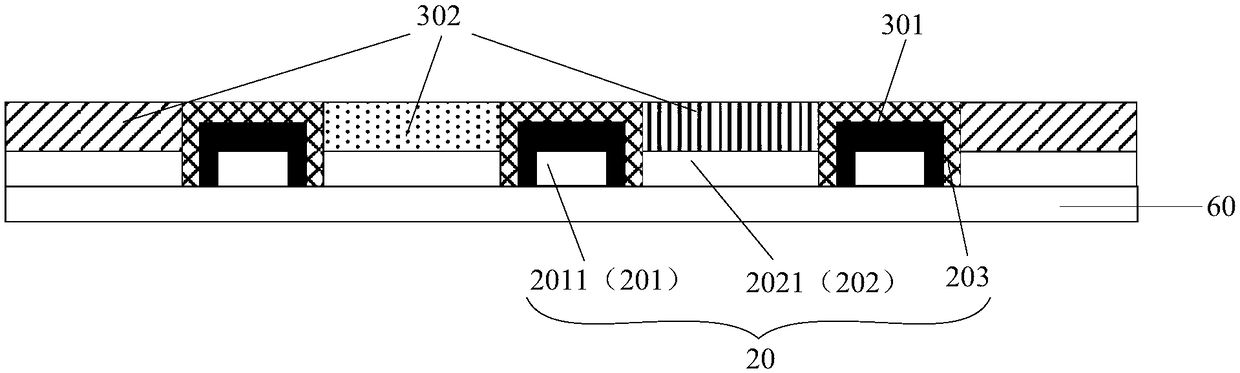

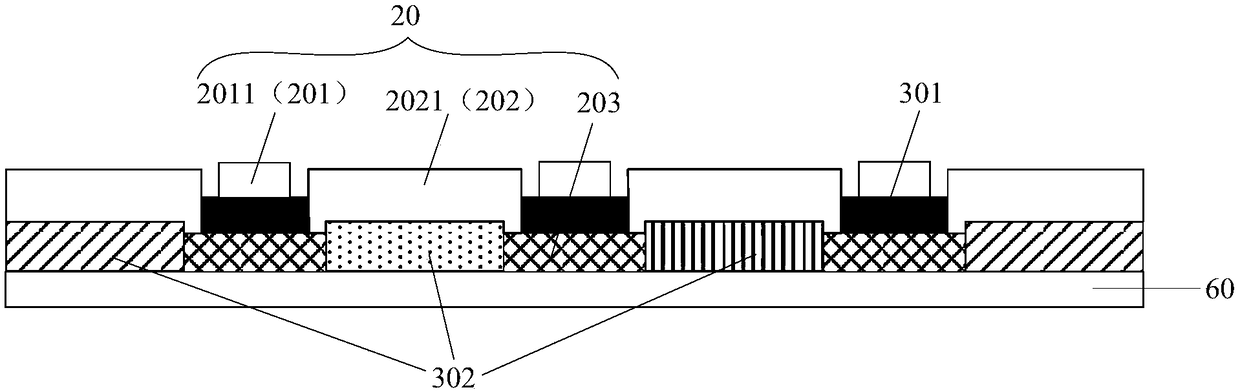

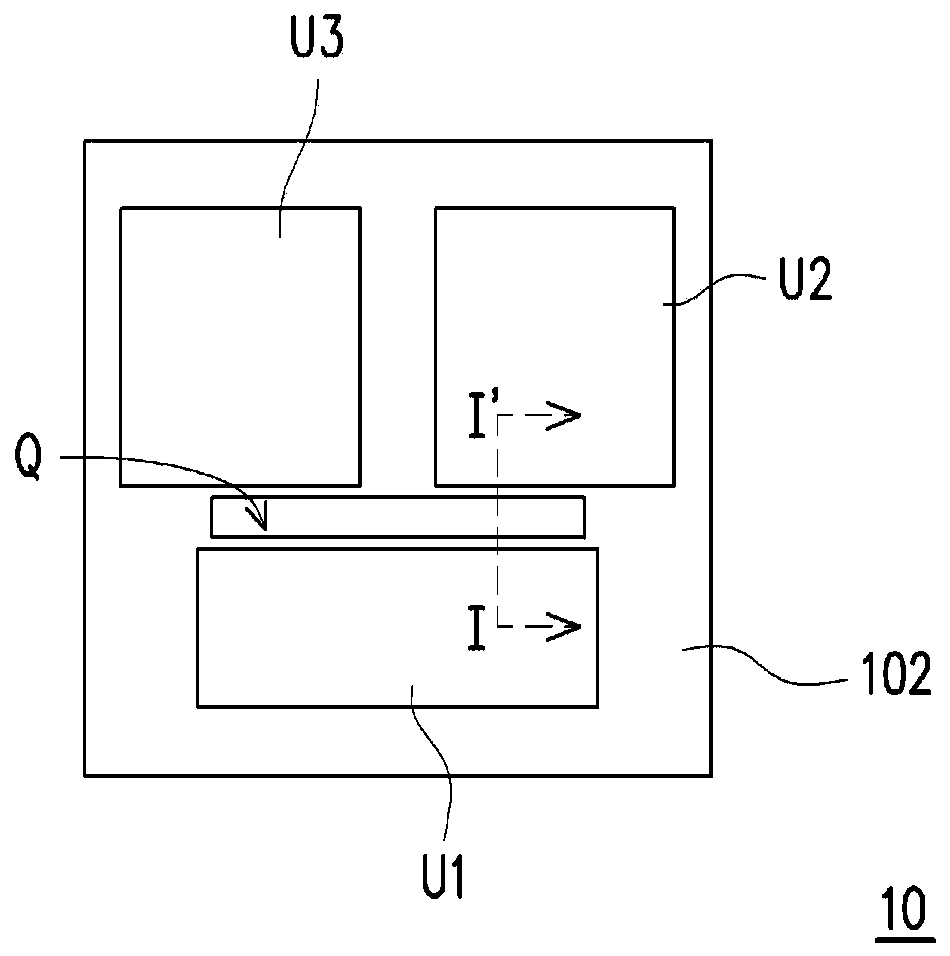

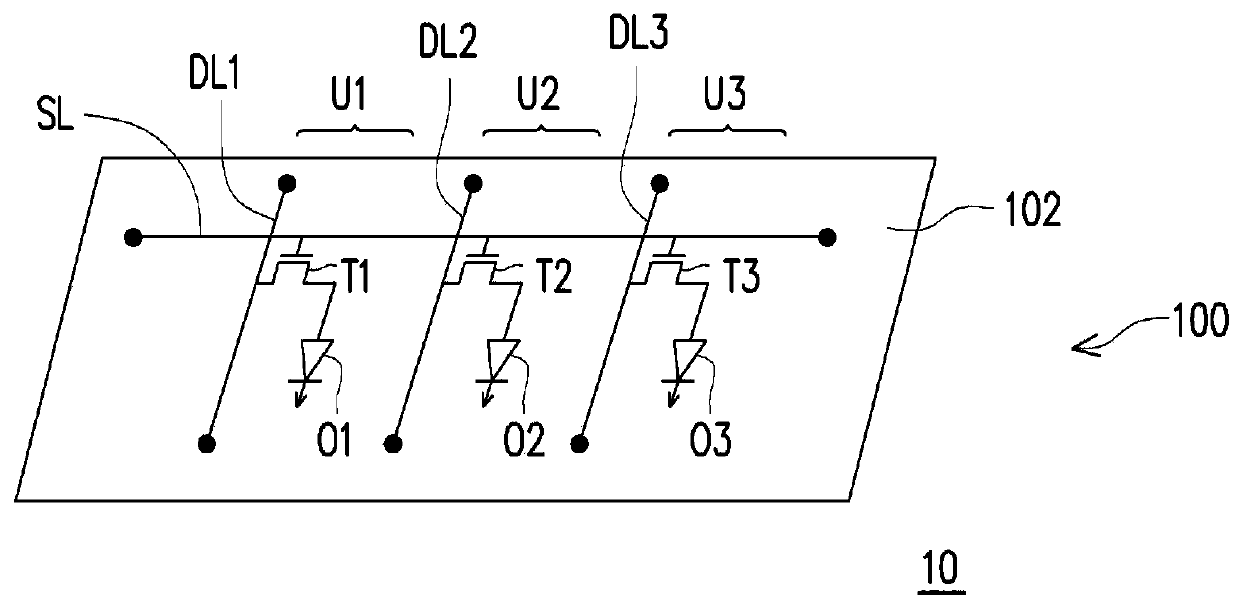

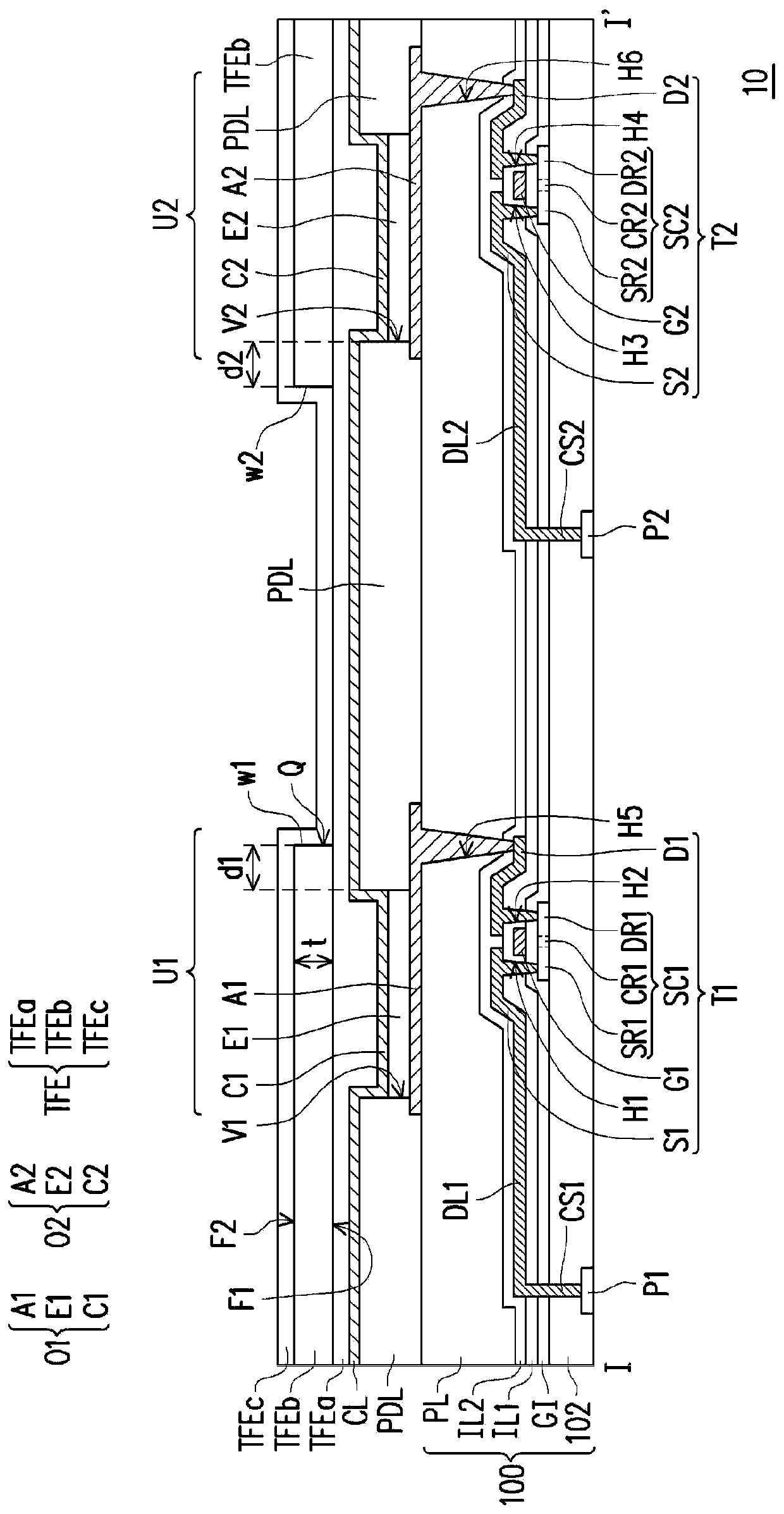

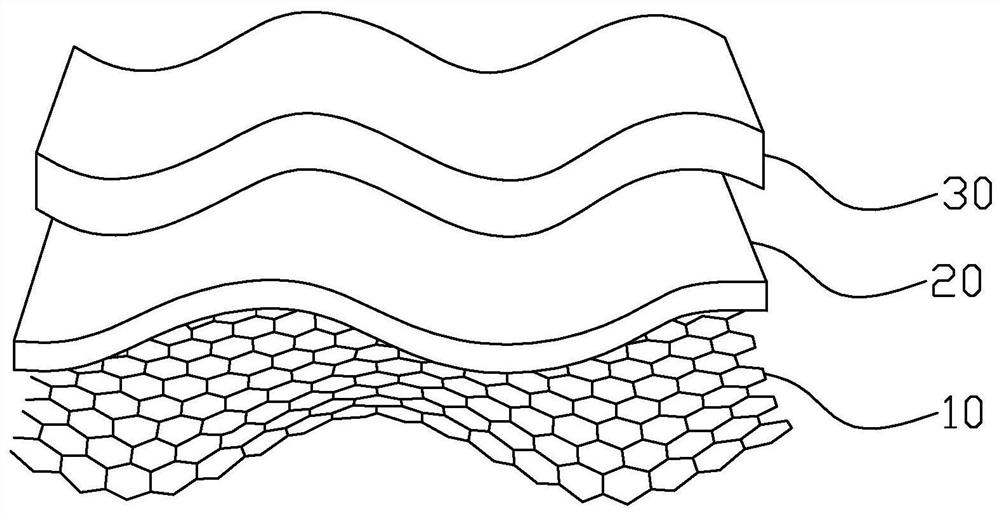

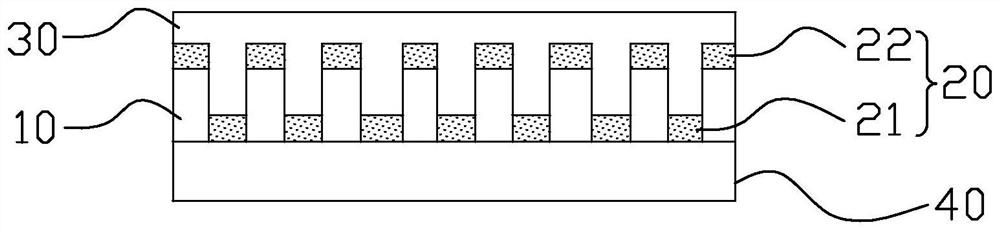

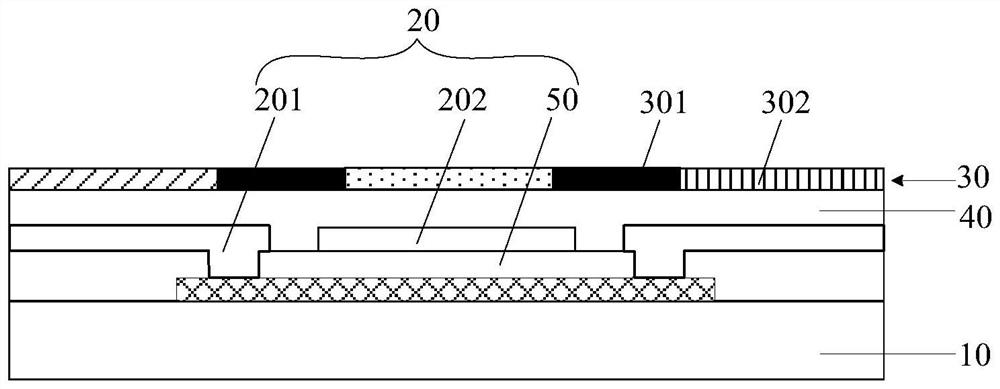

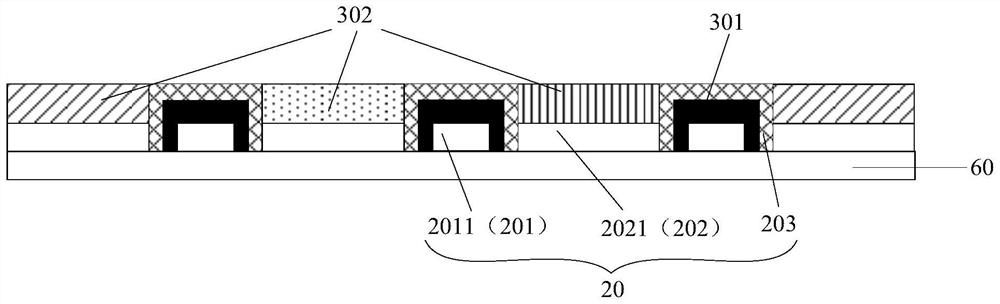

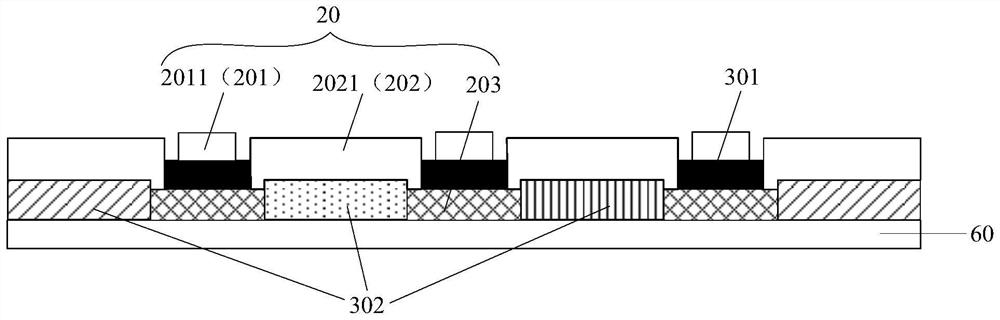

Touch display substrate and preparation method thereof, and touch display device

ActiveCN109343735AReduce thicknessImprove production efficiencyNon-linear opticsInput/output processes for data processingDisplay deviceHuman–computer interaction

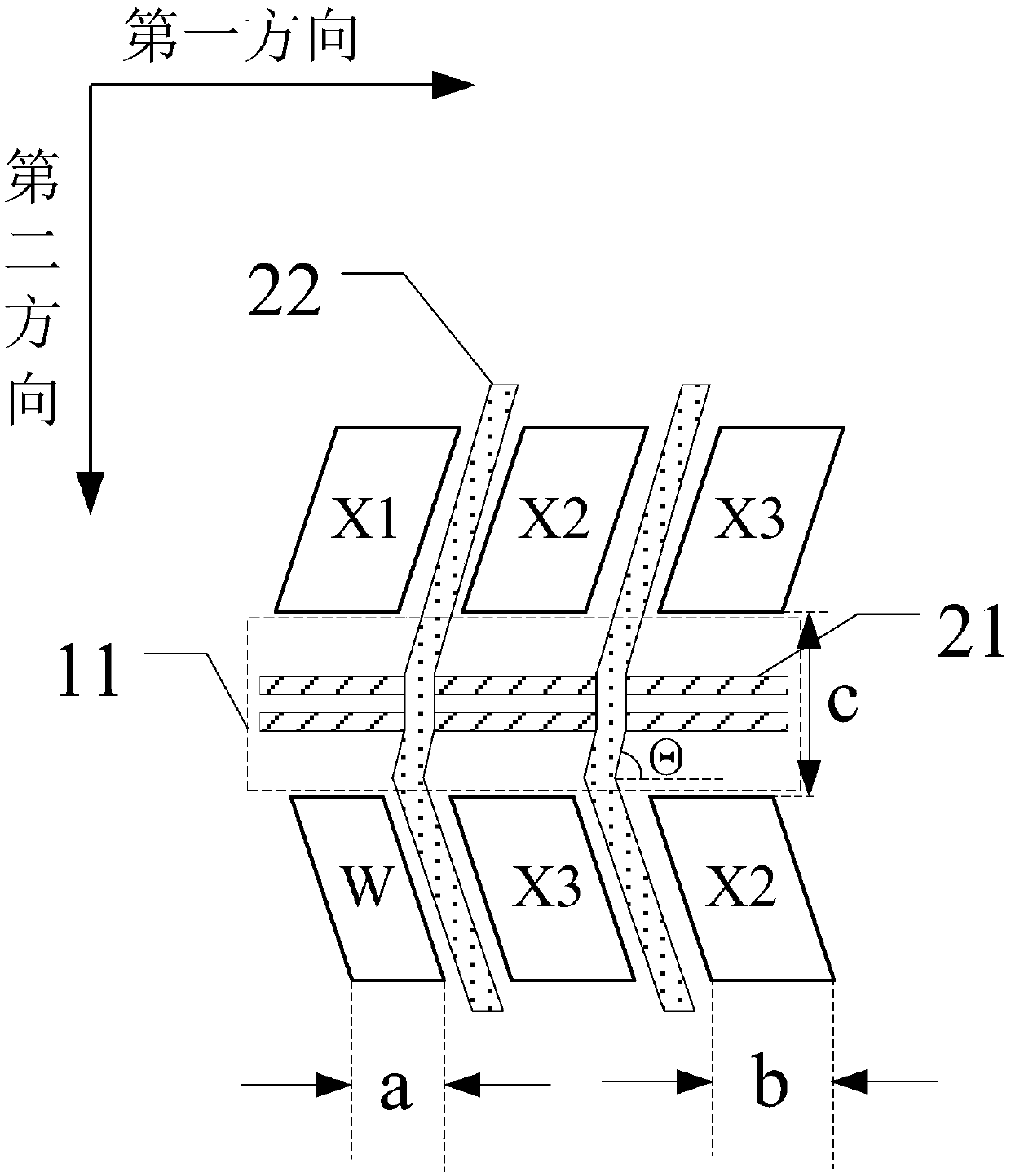

The embodiment of the invention provides a touch display substrate and a preparation method thereof. The touch display device relates to the technical field of touch display and can solve the problemthat the touch display device has a large thickness. A touch display substrate includes a substrate, a color photoresist pattern disposed on the substrate, and a black matrix pattern for spacing the color photoresist pattern. The touch layer includes a plurality of first touch electrodes arranged in order along a first direction and a plurality of second touch electrodes arranged in order along asecond direction. The touch layer includes a plurality of first touch electrodes arranged in order along a first direction and a plurality of second touch electrodes arranged in order along a second direction. Wherein the first touch electrode and the second touch electrode are arranged crosswise, and the crosswise positions are insulated from each other by the black matrix pattern. The inventionis used for reducing the thickness of the touch display device.

Owner:BOE TECH GRP CO LTD +1

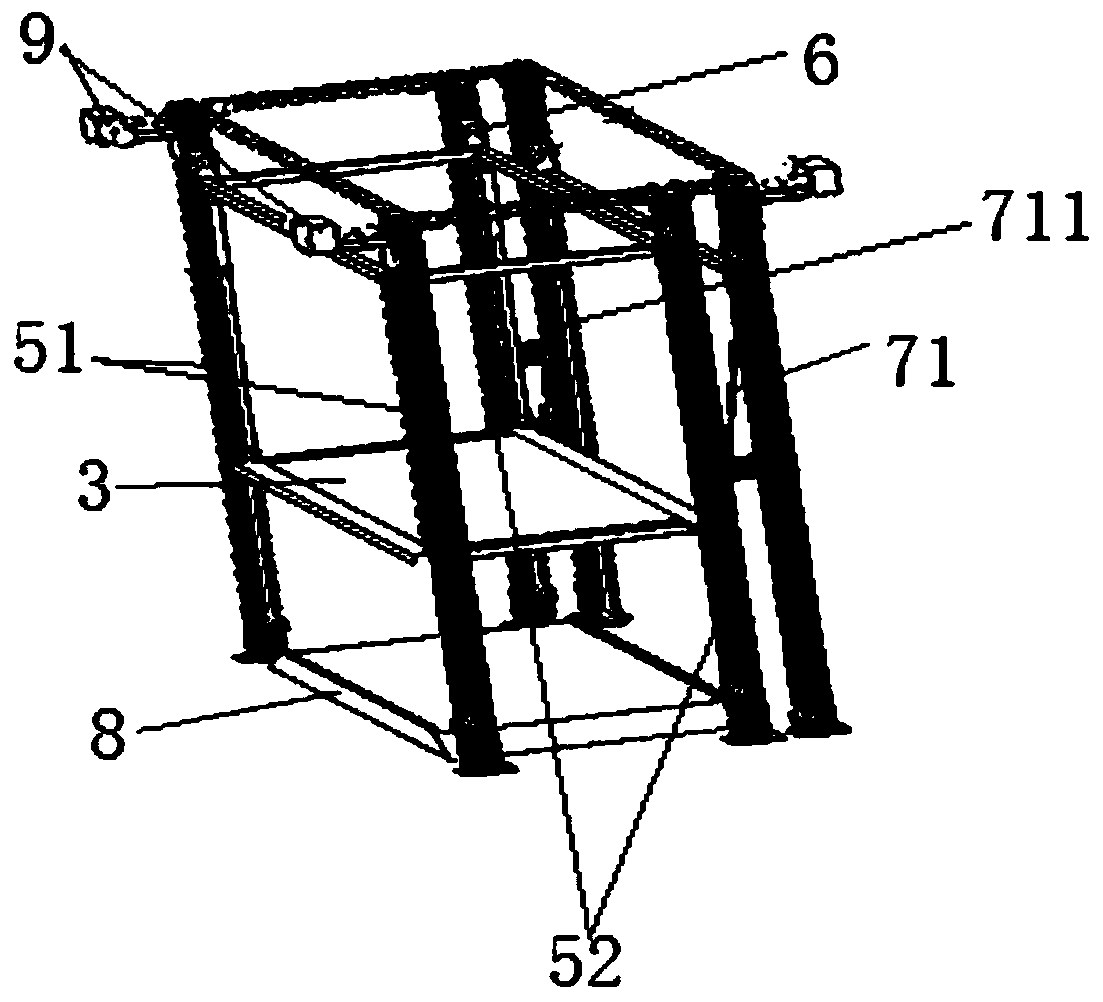

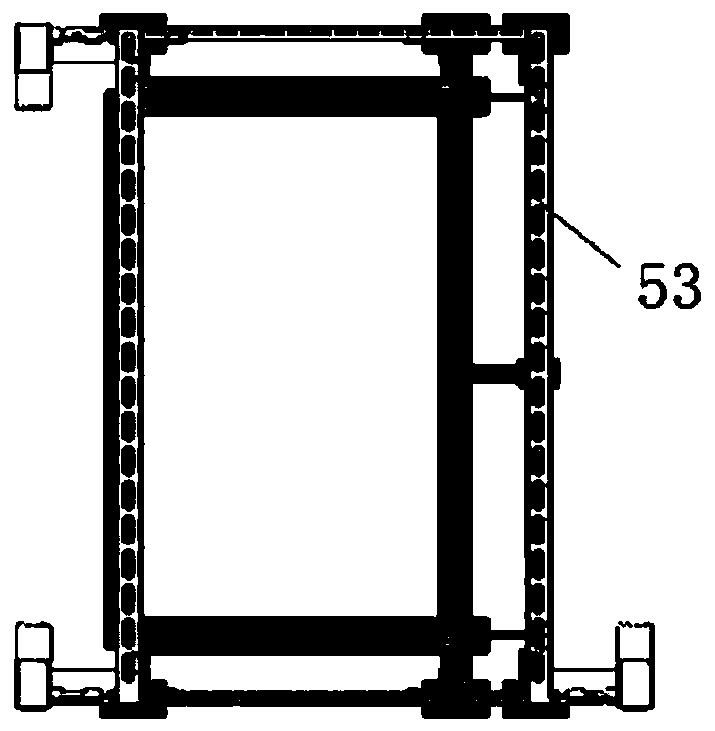

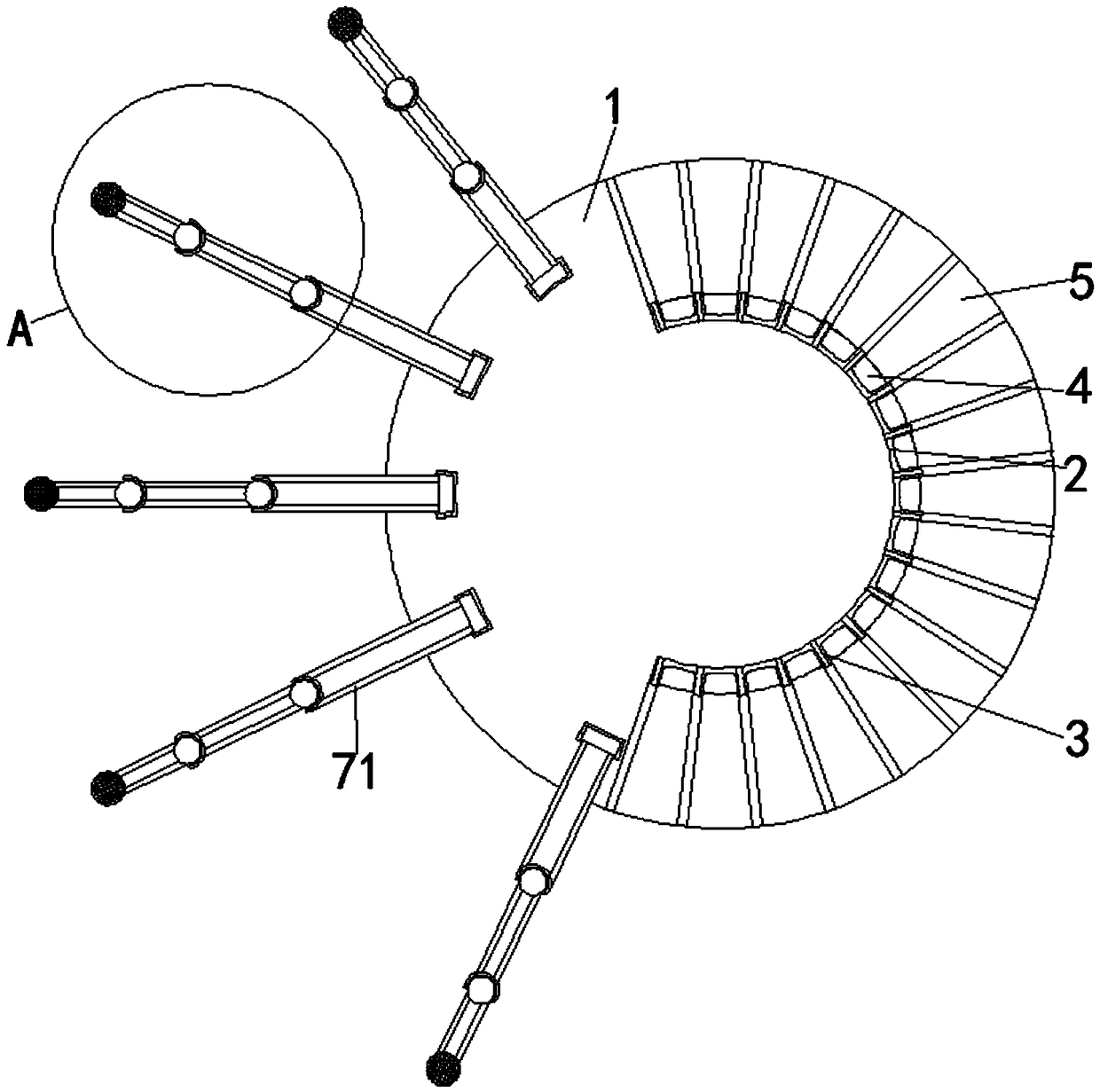

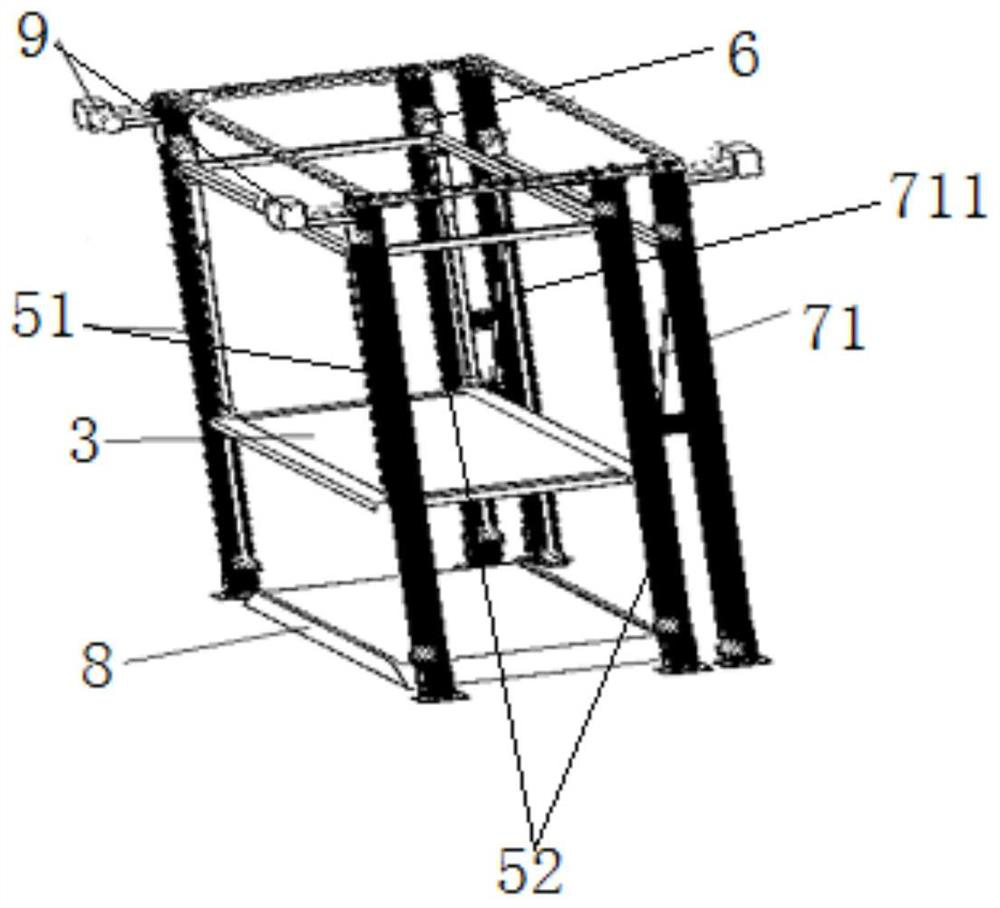

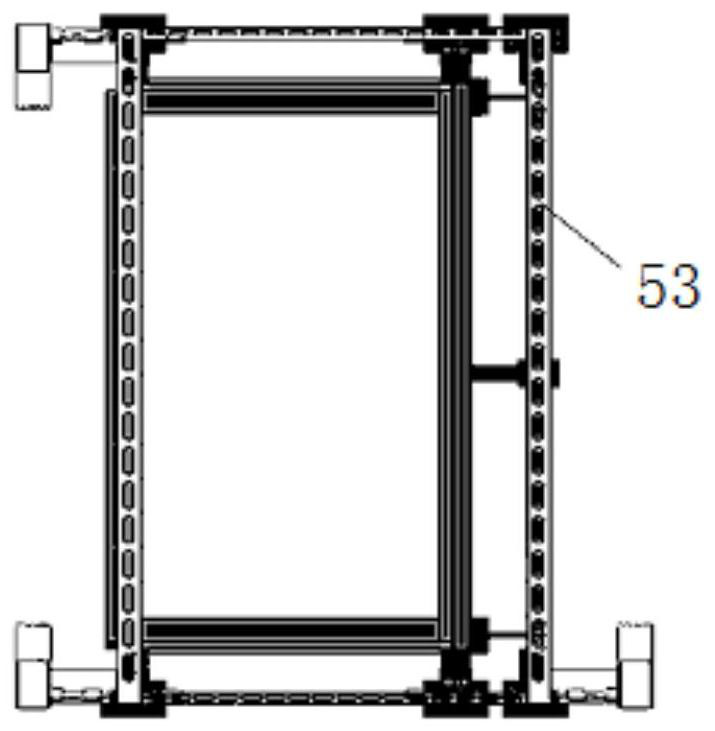

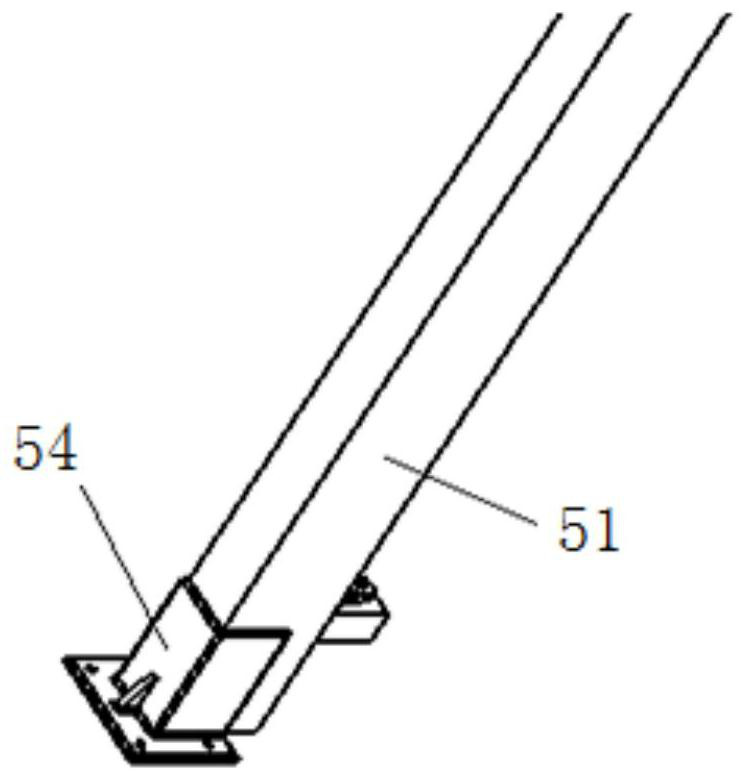

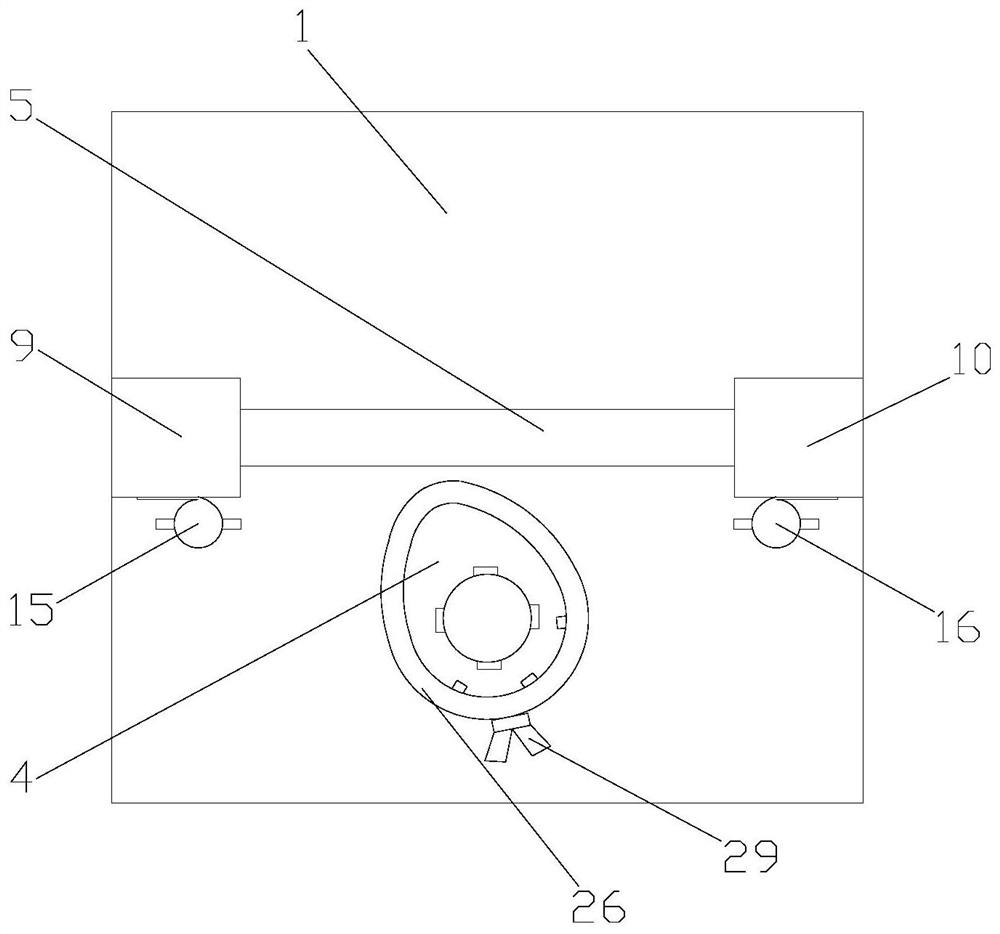

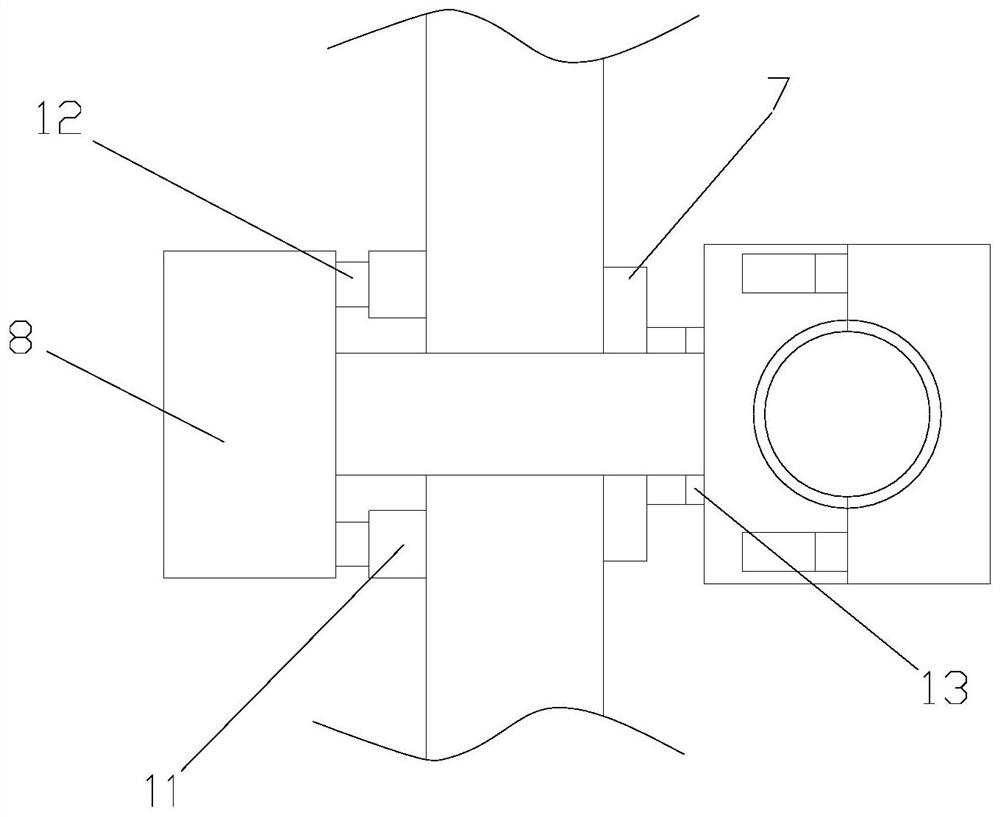

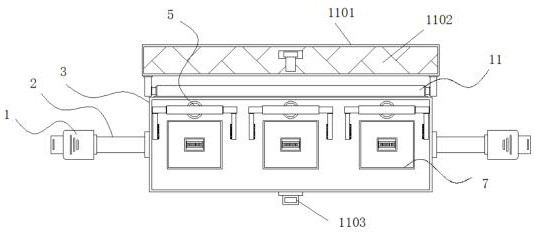

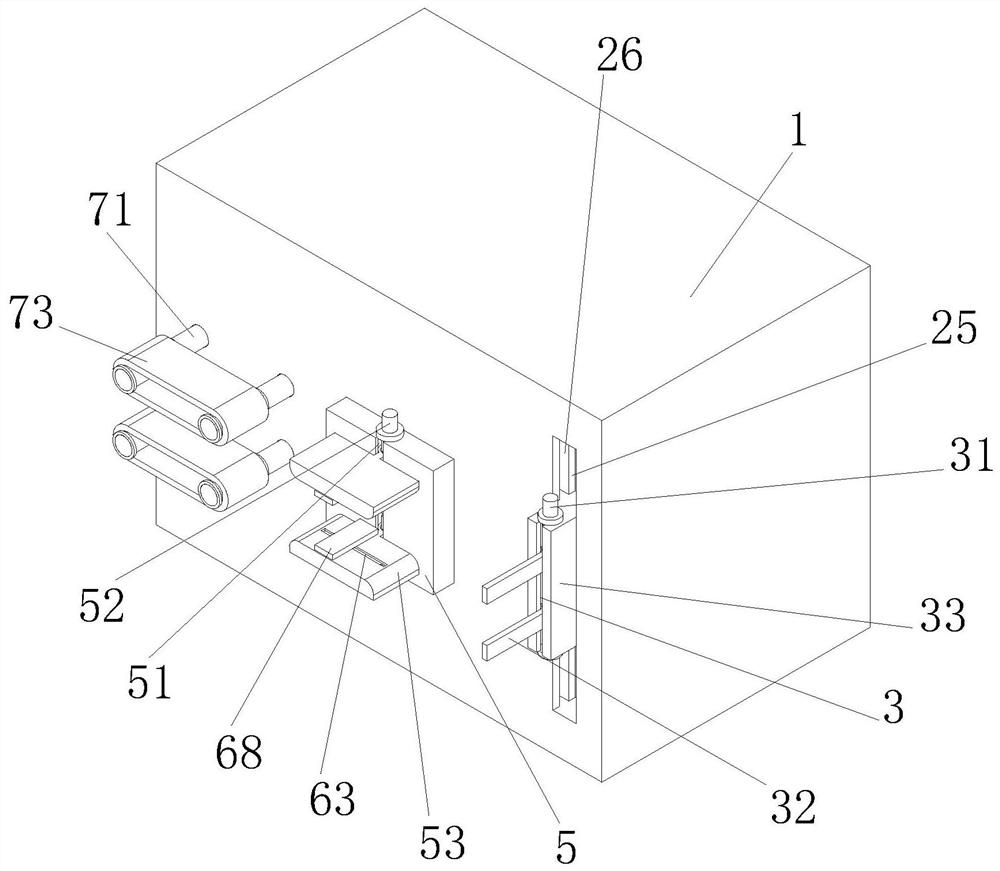

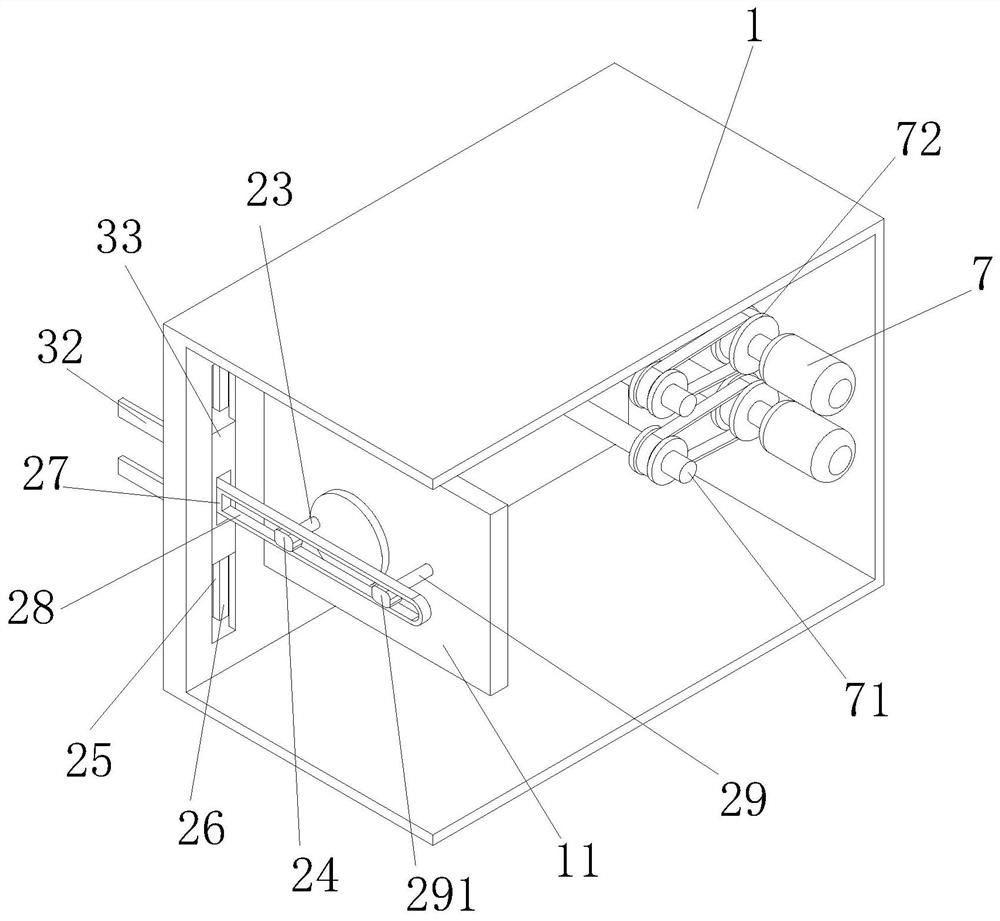

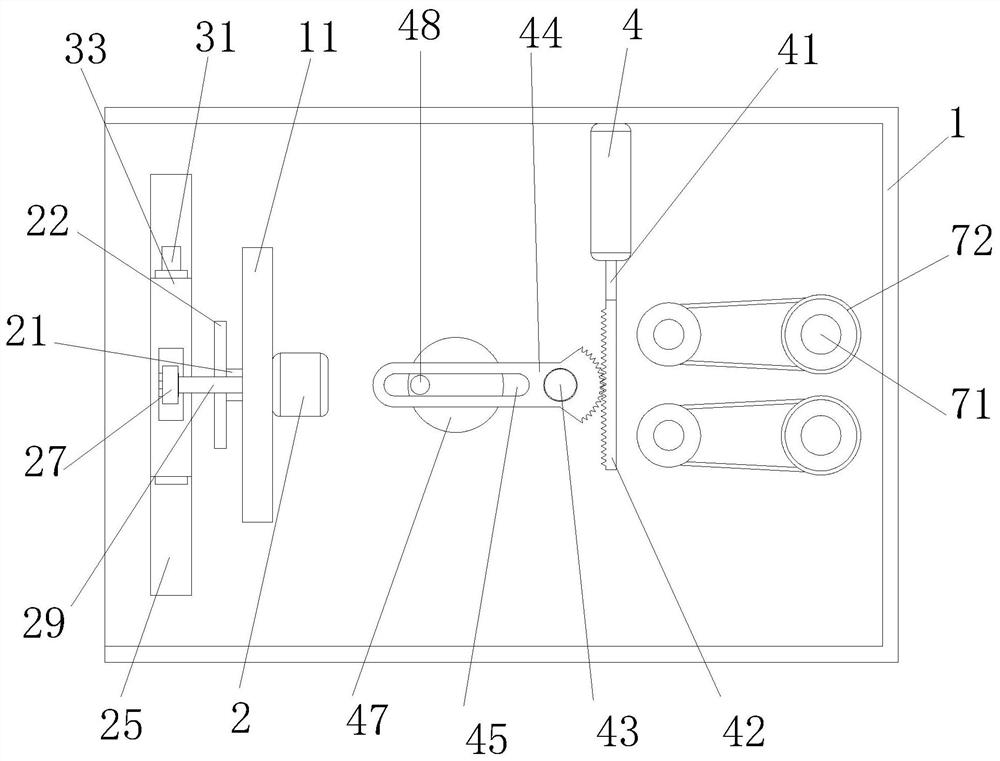

Small double-layer parking device with no avoidance at side position

The invention belongs to the technical field of stereo parking equipment, and particularly relates to a small double-layer parking device with no avoidance at a side position. The small double-layer parking device comprises an upper-layer parking device, a sliding block device, a stand column frame, a driving device, a push rod device and a lower-layer parking mechanism. The upper-layer parking device comprises bending rod mechanisms, a vehicle carrying frame and an upper-layer vehicle carrying plate. Four corner bottoms of the vehicle carrying frame are hinged to one ends of the four bendingrod mechanisms correspondingly. The other ends of the four bending rod mechanisms are hinged to the upper-layer vehicle carrying plate. The four corners of the vehicle carrying frame are connected with the stand column frame through the sliding block device. The driving device is connected with the sliding block device and is used for controlling the upper-layer parking device to ascend and descend as a whole. The push rod device is arranged on the ground on one side of the stand column frame, is connected with the upper-layer vehicle carrying plate, and is used for pushing the upper-layer vehicle carrying plate out of the stand column frame. The small double-layer parking device has the advantages of being simple and convenient to install, small in occupied space and stable in vehicle ascending and descending control and facilitating vehicle leaving and entering.

Owner:SICHUAN UNIV

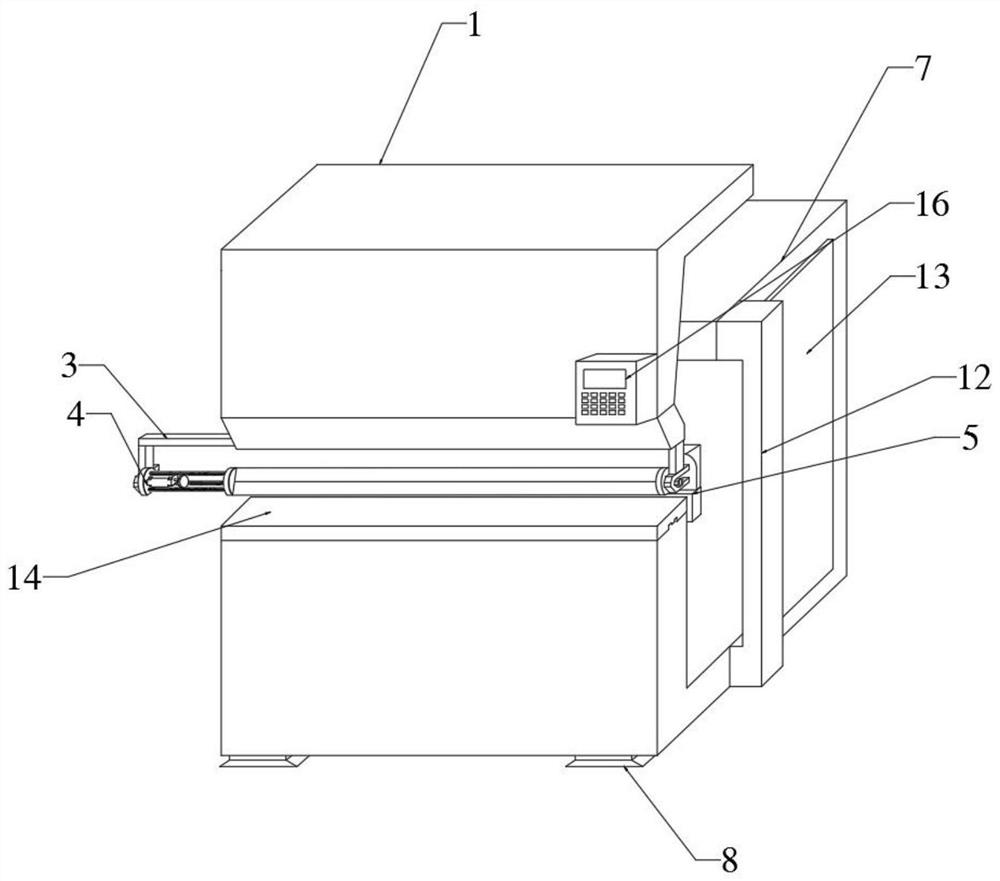

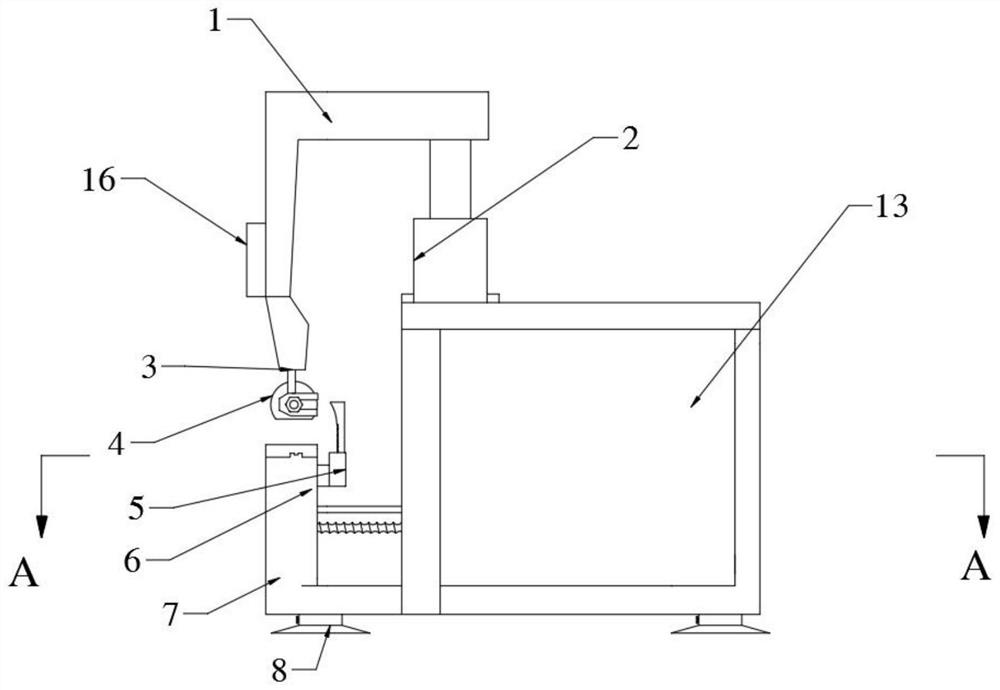

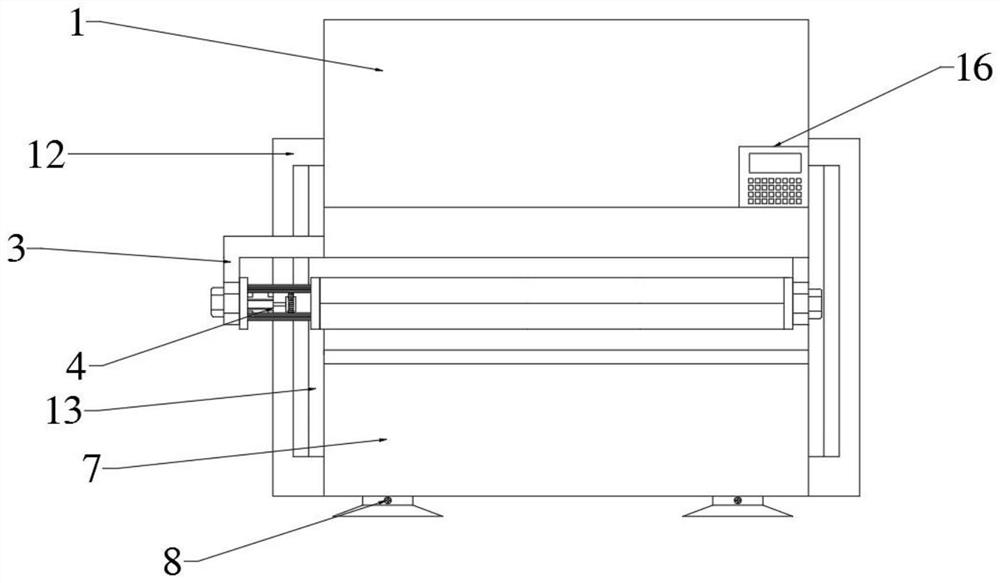

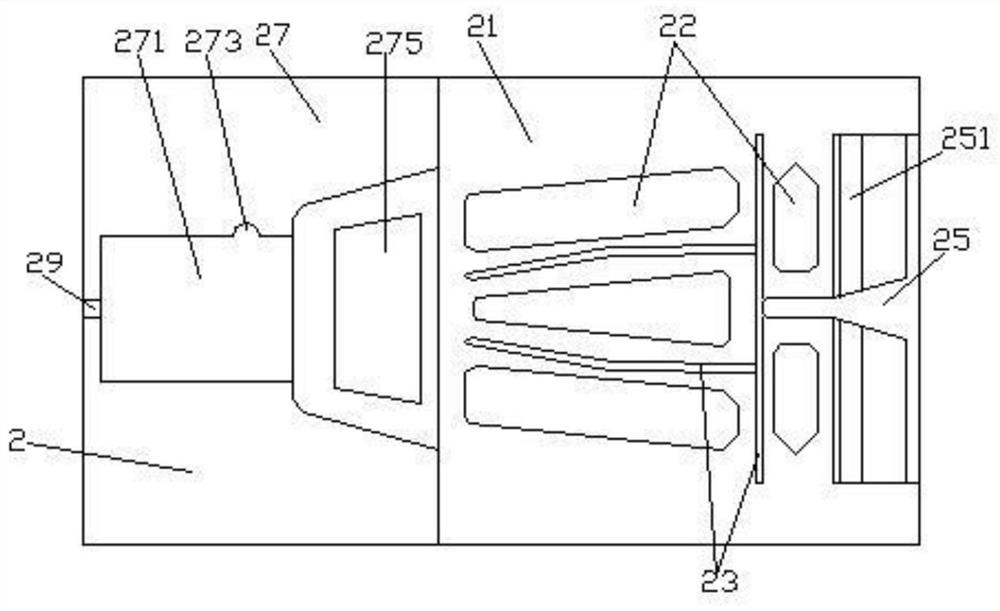

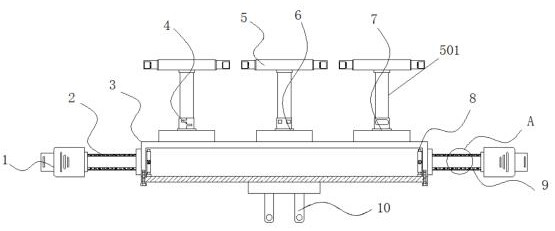

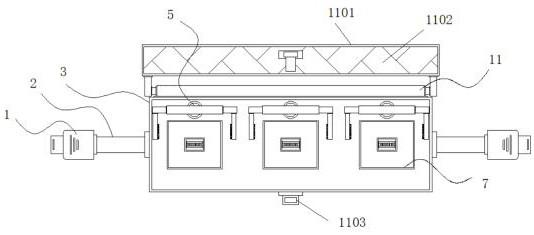

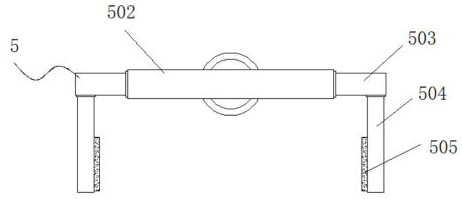

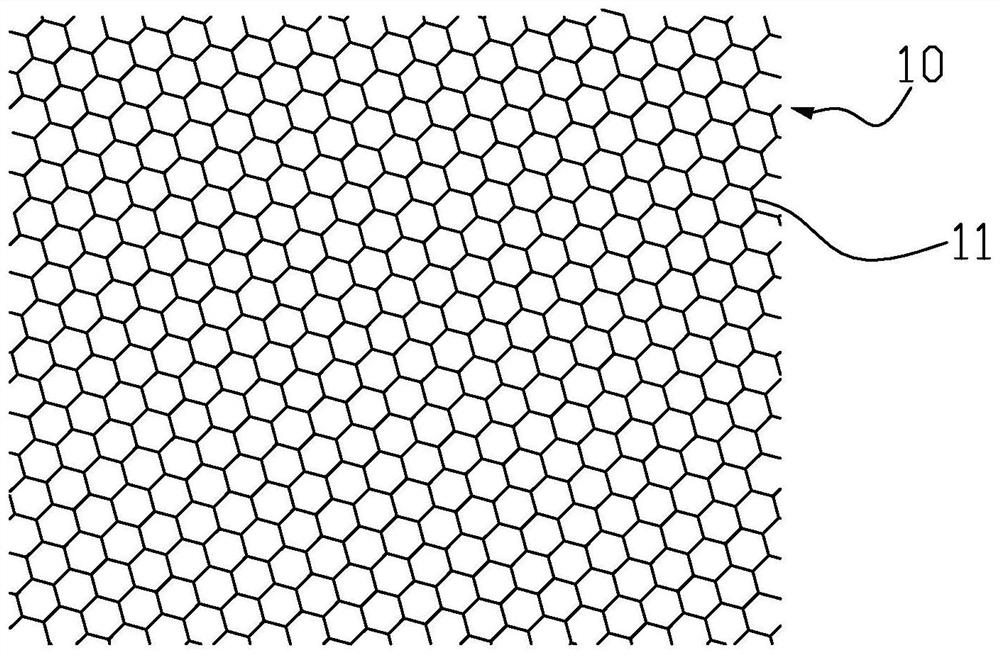

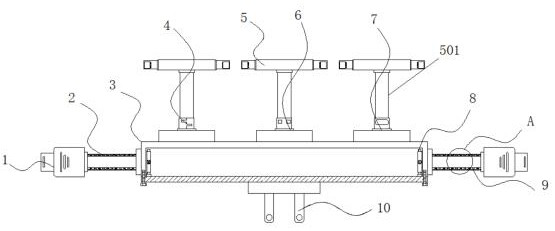

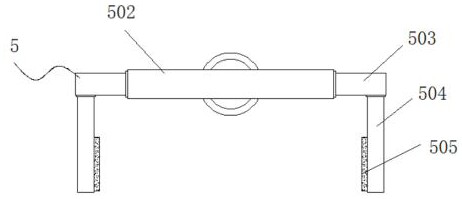

Flexible bending center

PendingCN113968016ASolve the deformationIncrease the degree of bendingGlass productionClassical mechanicsEngineering

The invention discloses a flexible bending center, and belongs to the technical field of bending machines. The flexible bending center comprises a bending assembly and a positioning assembly, the bending assembly comprises a downward pressing cross beam, downward pressing hydraulic rods, cutter frames, downward pressing cutters, an upward pressing assembly, a compensation hydraulic rod, an upward pressing base plate and supporting cross beams; the cutter frames are correspondingly arranged on the two sides of the bottom end of the downward pressing cross beam, the downward pressing cutters are arranged on the cutter frames, the downward pressing hydraulic rods are arranged at the ends, away from the cutter frames, of the downward pressing cross beam, cylinder parts of the downward pressing hydraulic rods are fixedly connected with the upward pressing base plate, the output ends of the downward pressing hydraulic rods are fixedly connected with the downward pressing cross beam, a plurality of compensation hydraulic rods are arranged on the upward pressing base plate, a downward pressing assembly is arranged at the output end of the compensation hydraulic rod, the upward pressing assembly is located below the downward pressing cutter, and the supporting cross beams are arranged on the two sides of the upward pressing base plate. The flexible bending center has the effect of accurately bending flexible materials.

Owner:QINGDAO SHENGTONG MECHANICAL TECH

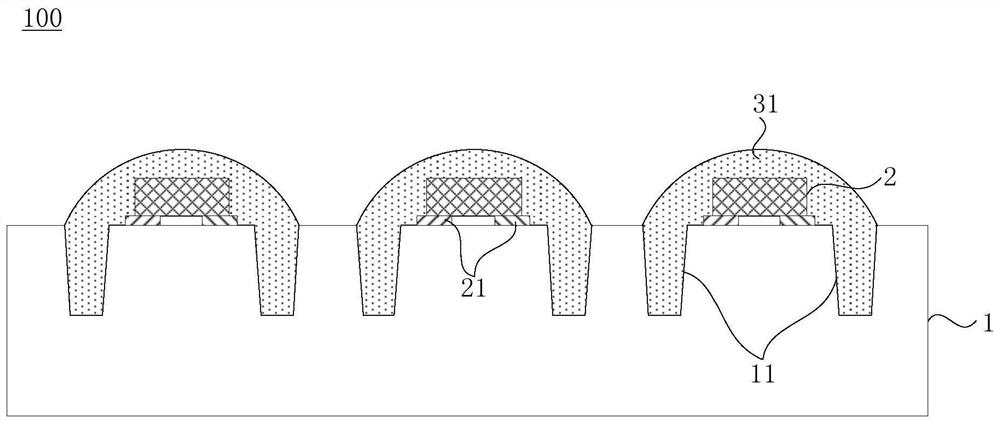

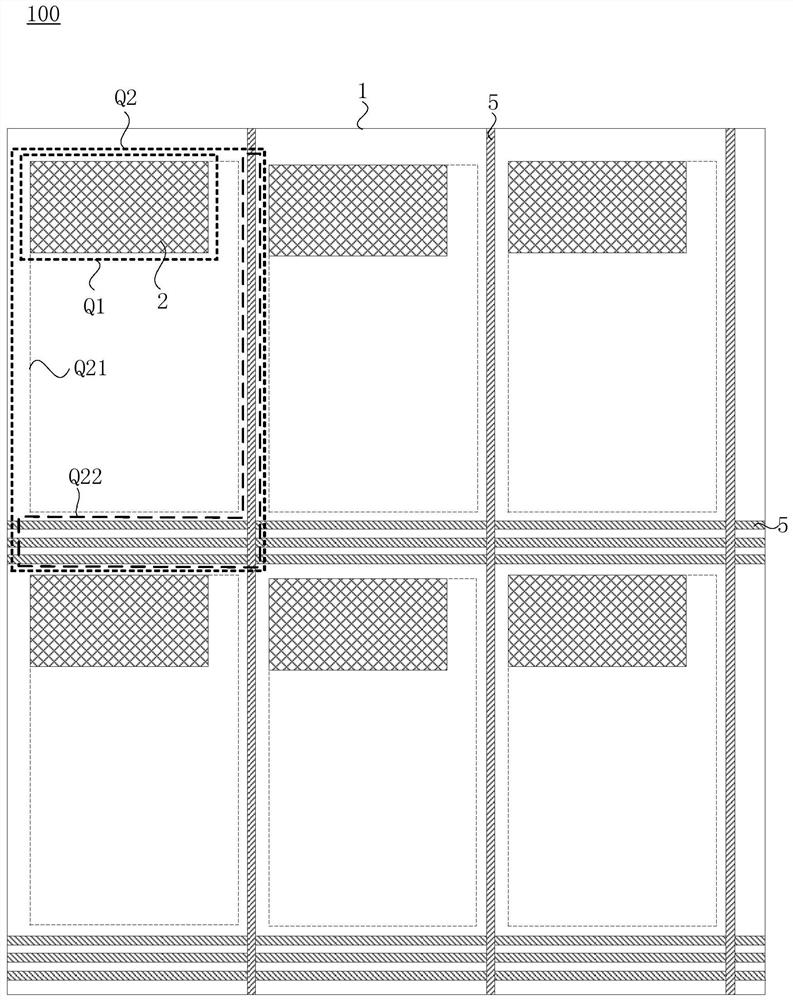

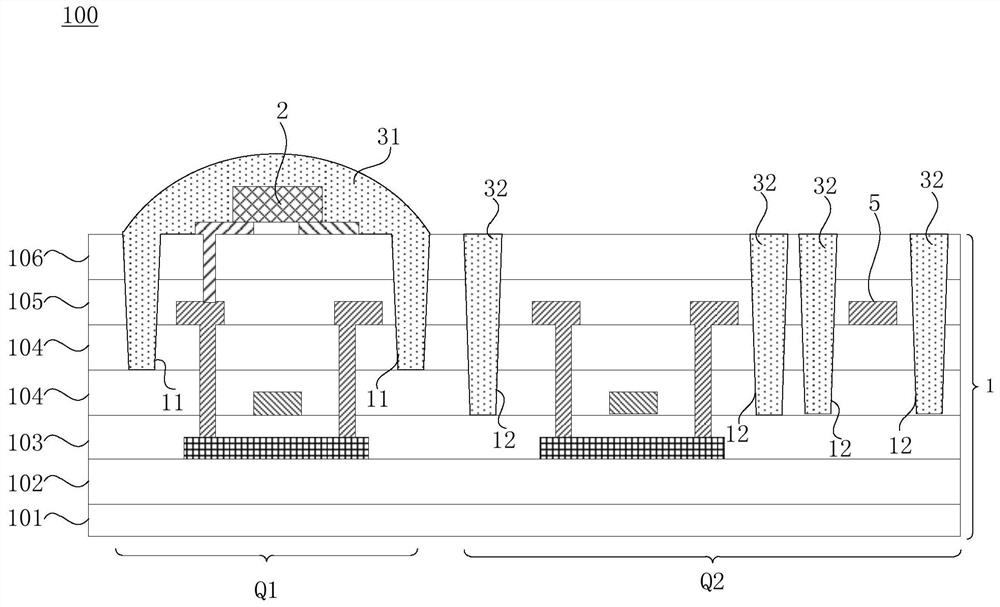

Pixel structure

ActiveCN109742127AImprove flexibilityIncrease the degree of bendingSolid-state devicesIdentification meansLight-emitting diode

A pixel structure includes a first element substrate, adjacent first and second light emitting elements, a first inorganic encapsulation layer, an organic encapsulation layer, and a second inorganic encapsulation layer. The first light emitting element and the second light emitting element are disposed on and electrically connected to the first element substrate, wherein the first light emitting element includes a first light emitting layer and the second light emitting element includes a second light emitting layer. The first inorganic encapsulation layer covers the first light emitting element and the second light emitting element. The organic encapsulation layer is disposed on the first inorganic encapsulation layer, and the organic encapsulation layer has a first opening positioned between the first light emitting layer of the first light emitting element and the second light emitting layer of the second light emitting element. The second inorganic encapsulation layer is disposed on the organic encapsulation layer.

Owner:AU OPTRONICS CORP

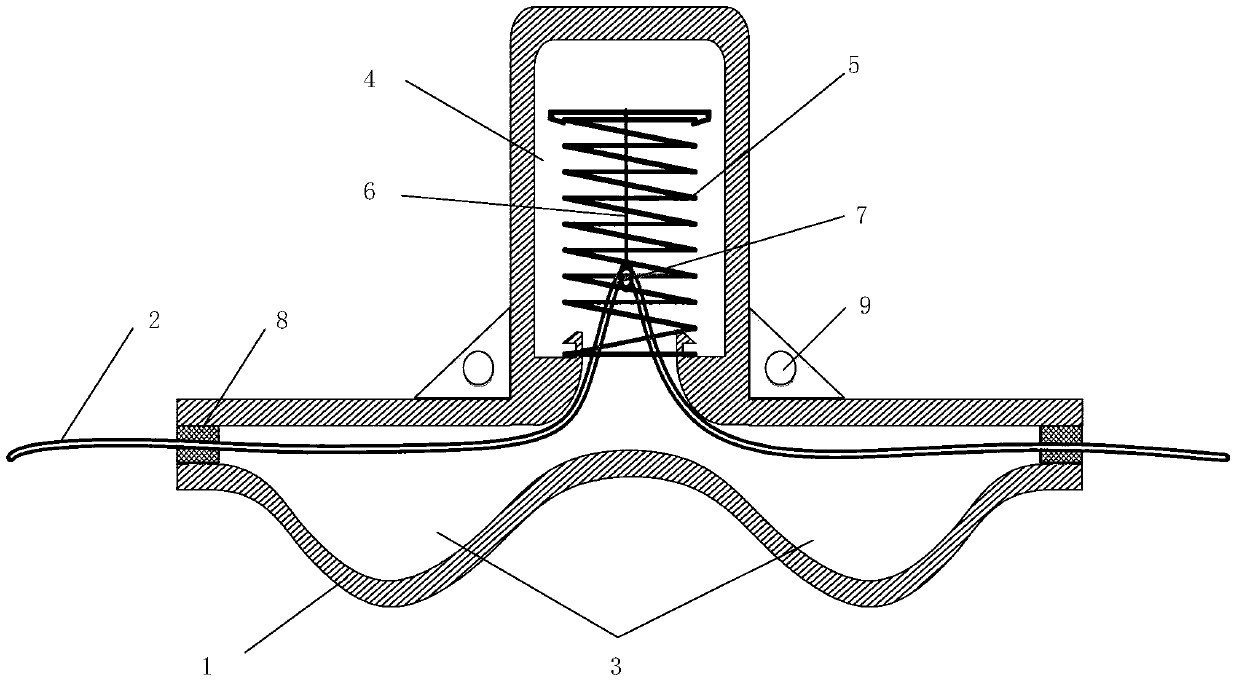

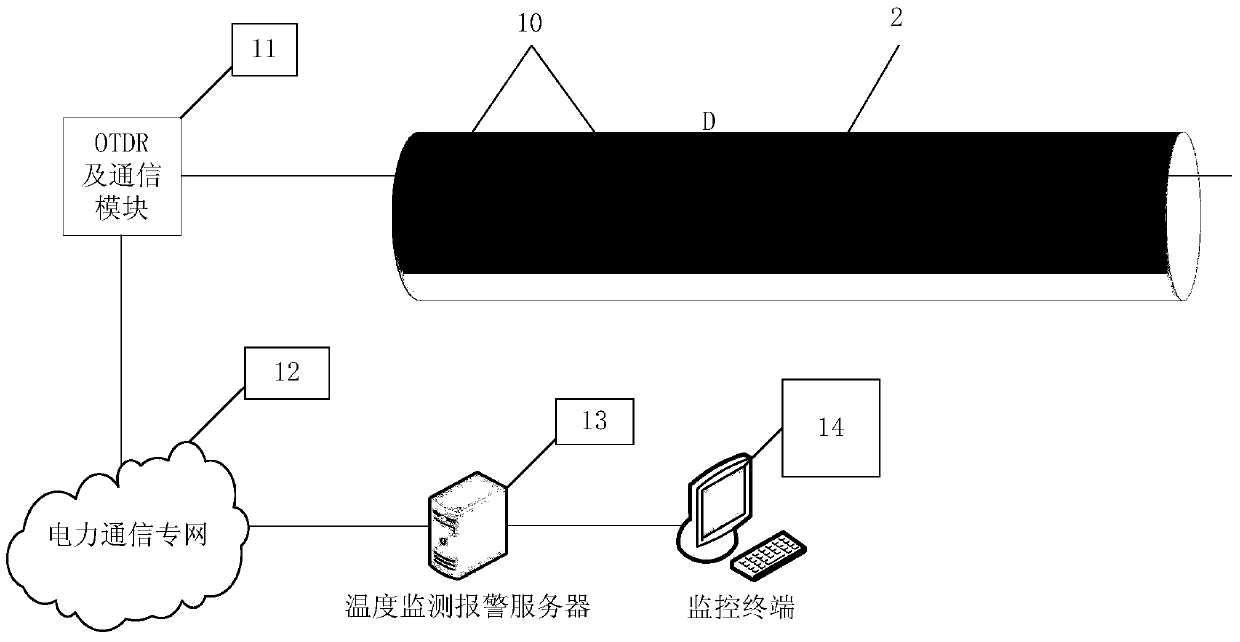

A temperature threshold actuator and temperature monitoring system

ActiveCN105588662BImprove reliabilityTimely perceptionThermometers using physical/chemical changesThermodynamicsShape-memory alloy

The temperature threshold actuator provided by the present invention includes a first chamber and a second chamber, the first chamber is used for the actuator to pass through, the second chamber is provided with a shape memory alloy spring, one end of the spring is fixed, and the spring is movable. The end and the executed part are linked and connected through a linkage rod. In this solution, when the temperature of the monitored environment rises, the temperature of the actuator will rise rapidly. Once the temperature of the shape memory alloy spring reaches the transition temperature, it will extend rapidly. At this time, the movable end of the spring drives the executed part to move through linkage. Extending into the second cavity causes the actuated part to have a larger bend, so that the loss caused by the bend exceeds a threshold value, and realizes the timely perception of the temperature change of the monitored environment. The device has a simple structure and high reliability, and can work stably in harsh environments such as humidity and dust.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

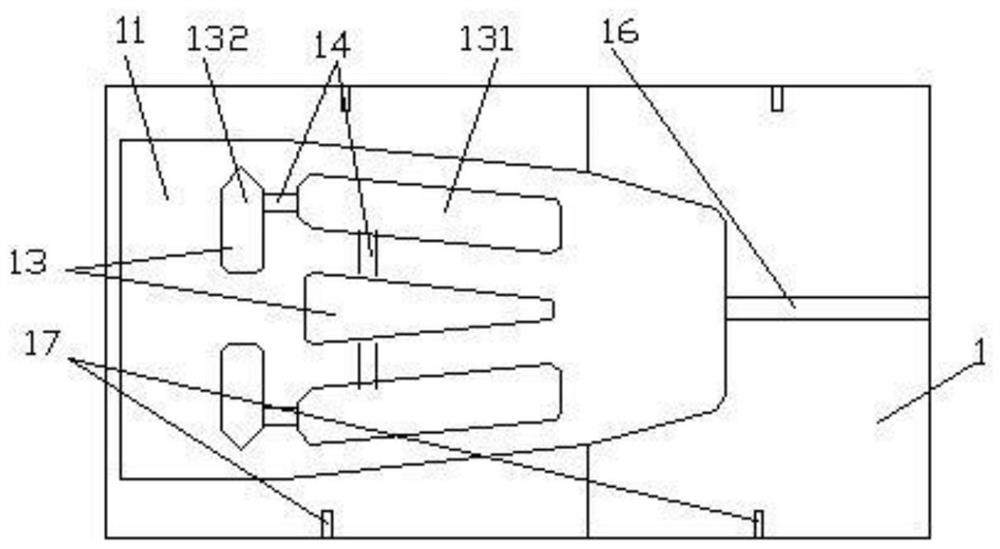

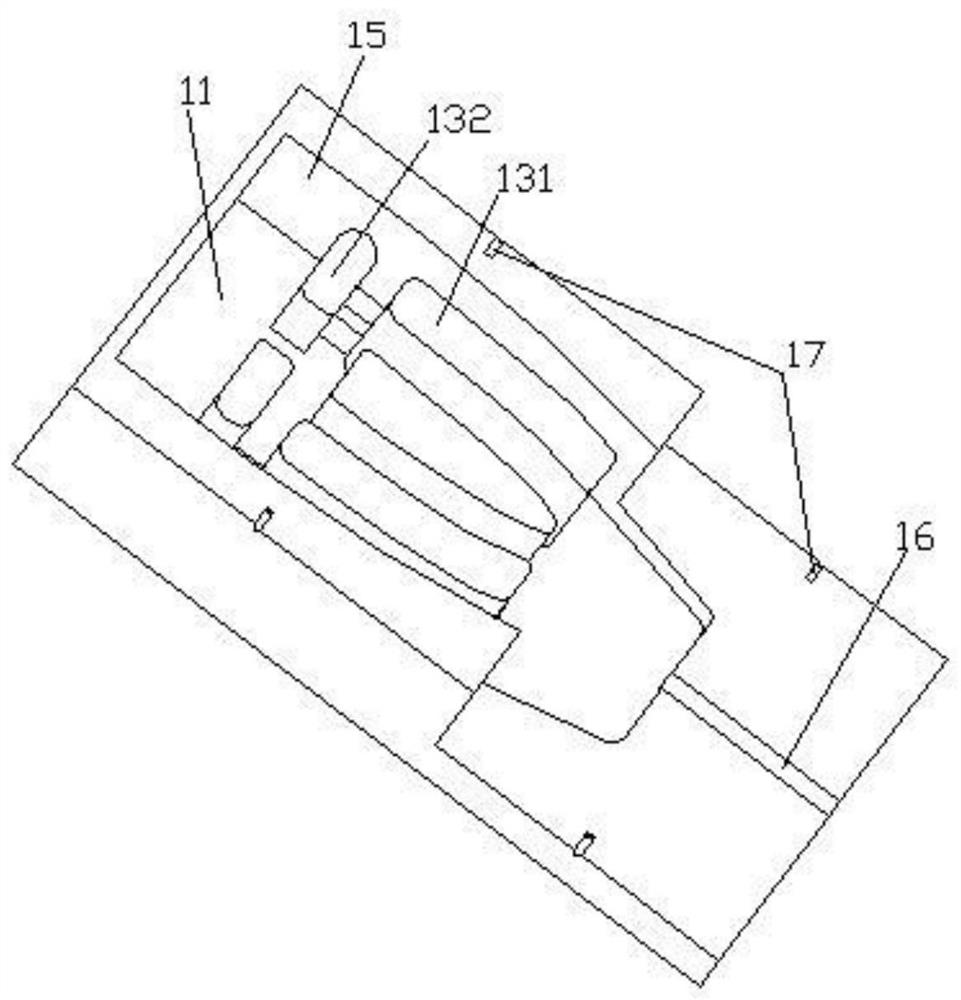

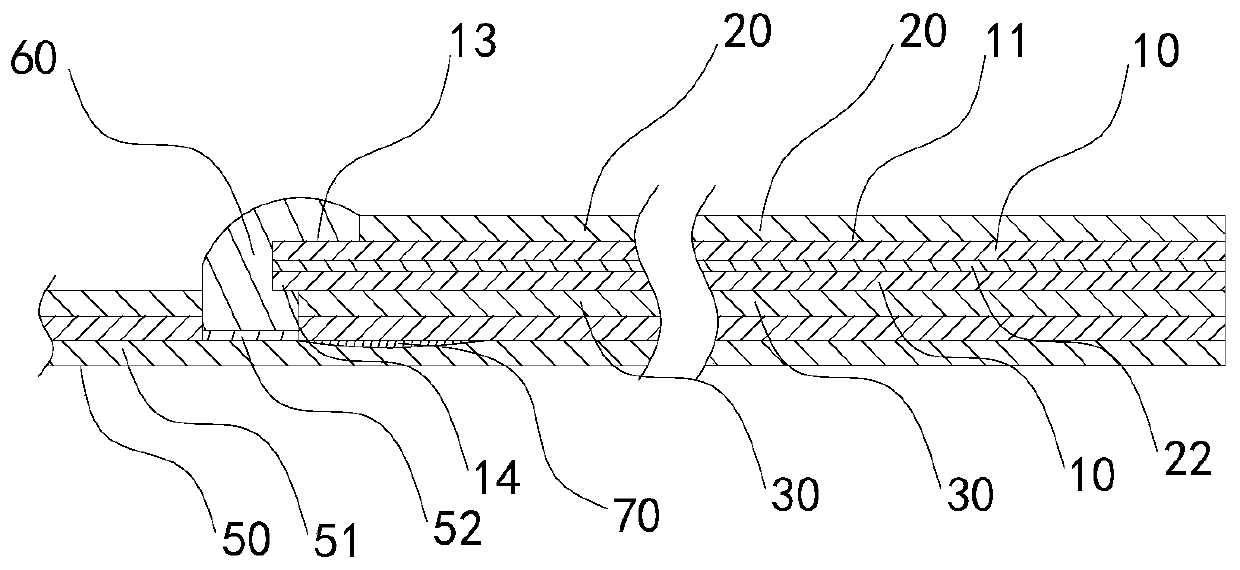

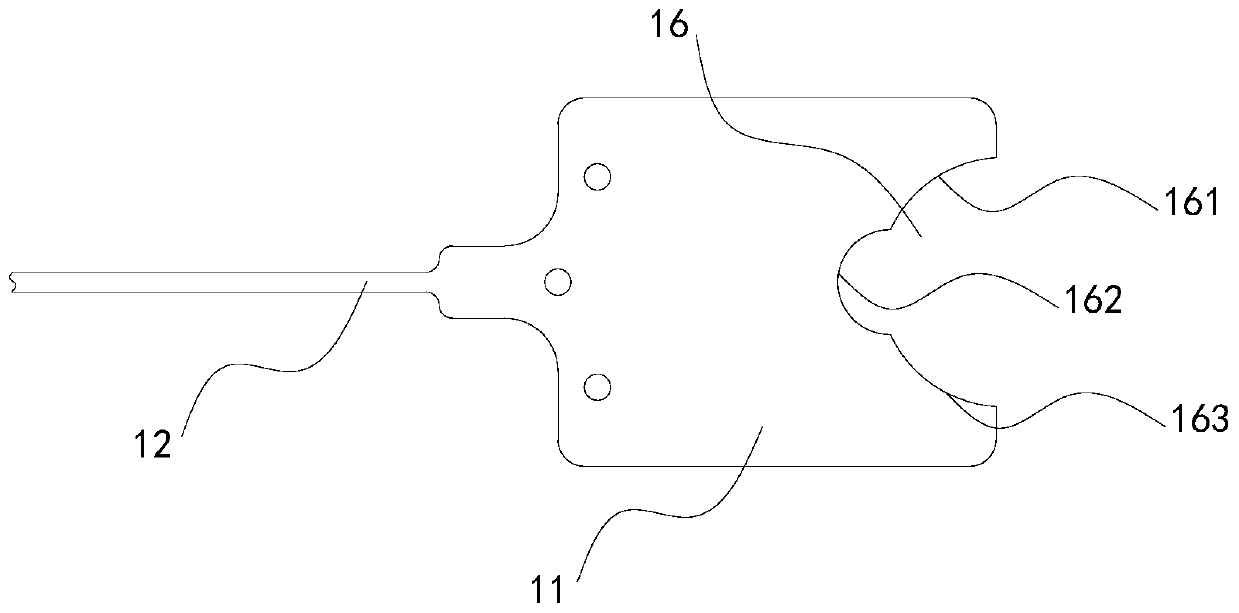

Flexible circuit board, capacitive screen and processing method of flexible circuit board

ActiveCN109757031AImprove conductivityIncrease contactElectrical connection printed elementsInput/output processes for data processingFlexible circuitsEngineering

The invention discloses a flexible circuit board, a capacitive screen and a processing method of the flexible circuit board. The flexible circuit board comprises a base layer and a conductive layer, wherein the conductive layer is attached to the base layer, the conductive layer is at least provided with a conductive sheet and a conductive wire, the conductive sheet and the conductive wire are electrically connected with each other, the conductive sheet is positioned on the conductive connection side, the conductive sheet is provided with a first abdication gap, and the opening width of the first abdication gap gradually decreases from the outside to the inside. According to the scheme of the invention, the conductive connection structure is stable, the problems of poor contact and bindingopen circuit of the flexible circuit board can be solved, the process flow time for processing the conductive sheet is short, the drilling operation is convenient, and the structure is more stable and reliable.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

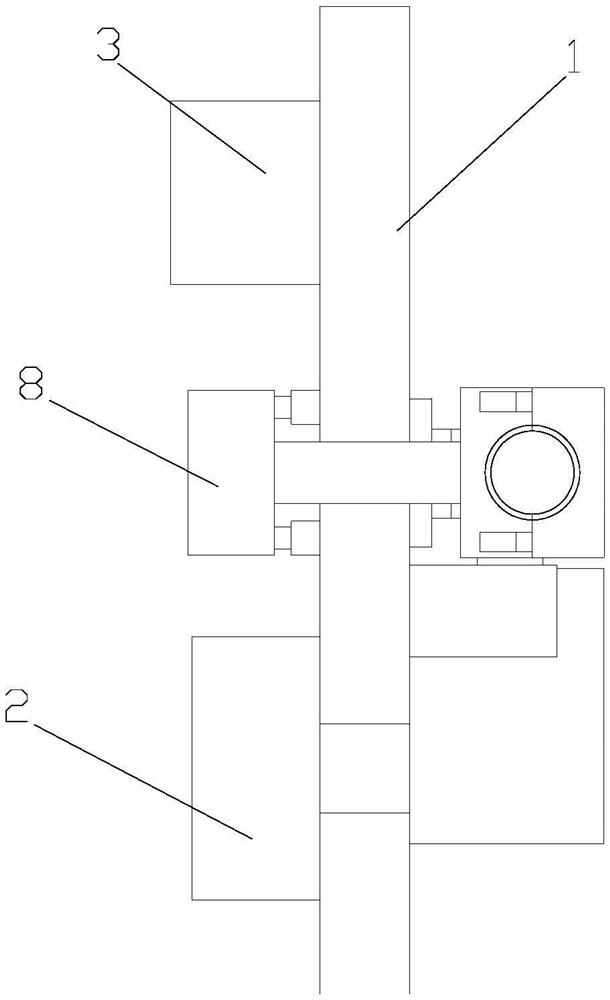

Mechanical pre-pressing machine adjustable in pre-pressing stroke for leaf spring

InactiveCN112264491AExpected bending effectIncrease lift strokeVehicle componentsClassical mechanicsEngineering

The invention relates to the field of leaf spring machining, in particular to a mechanical pre-pressing machine adjustable in pre-pressing stroke for a leaf spring. The mechanical pre-pressing machinecomprises a portal frame body erected on the ground, a frame body vertically ascends and descends in the portal frame body, the center of the bottom of the frame body is open, and a circle of embedding groove is vertically formed in the inner wall of the frame body in an inwards-concave mode; a pair of bearing blocks used for bearing the leaf spring to be machined are horizontally arranged in thepositions, located at openings in the two ends of the frame body, of the inner wall of the embedding groove in a sliding mode, first lead screws are detachably installed on the side walls of the twobearing blocks, and the peripheral sides of the first lead screws are horizontally arranged in the frame body in a threaded and penetrating mode; and driving pieces for driving the two bearing blocksto move in the same direction or opposite directions are arranged on the outer wall of the frame body. The mechanical pre-pressing machine has the effect that use universality of the pre-pressing machine is improved so that steel plate springs of various types can be machined.

Owner:湖北东风钢板弹簧有限公司

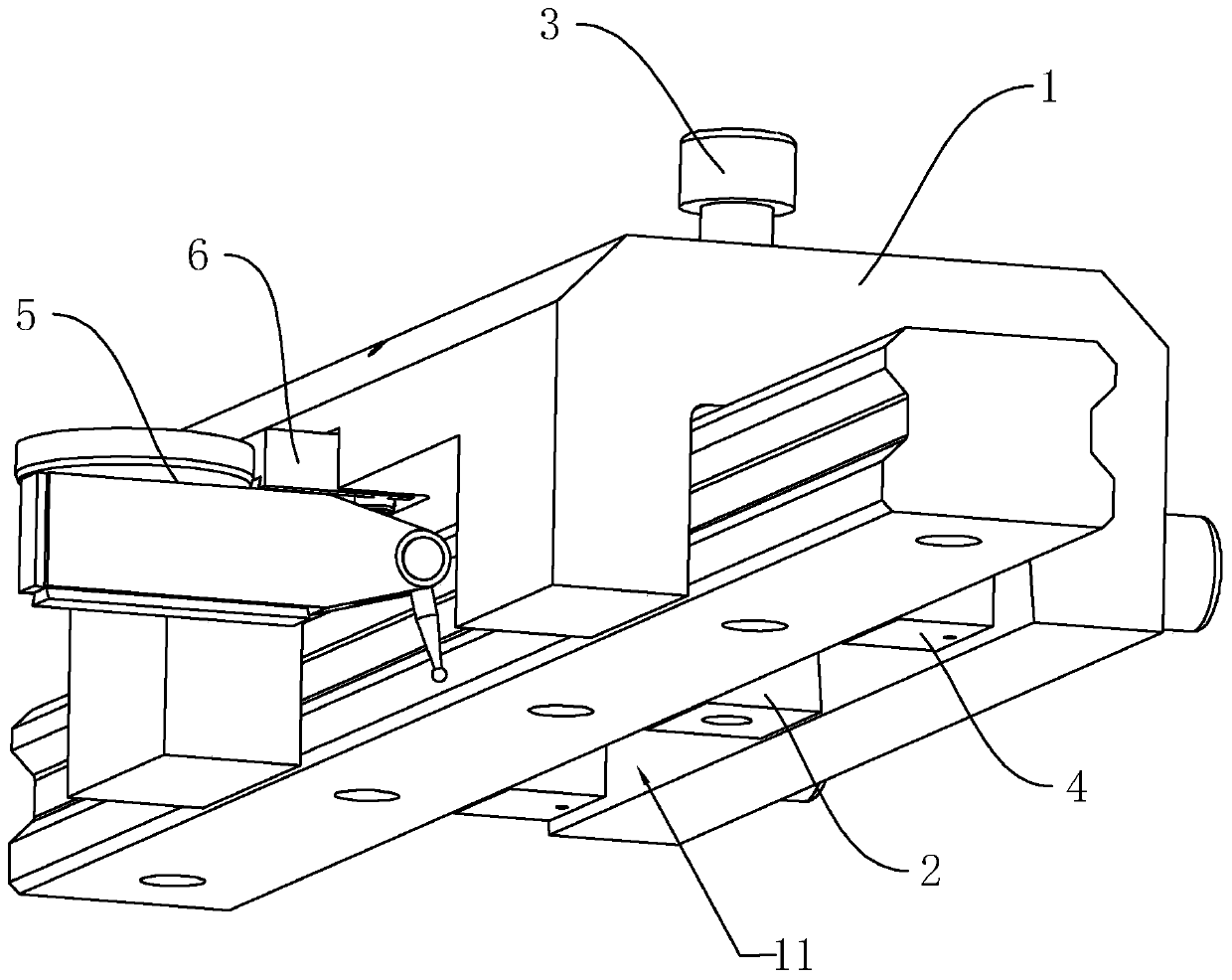

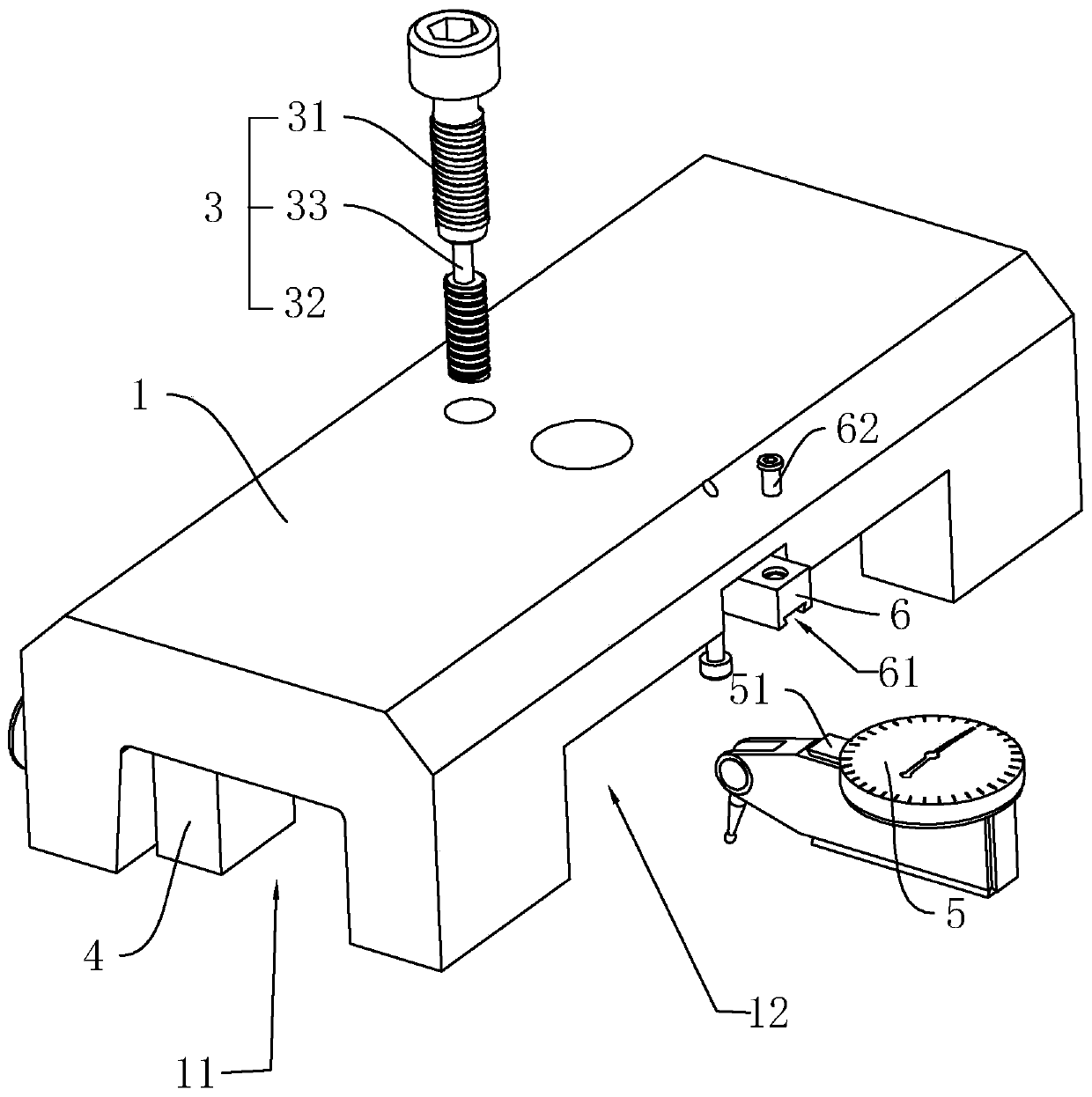

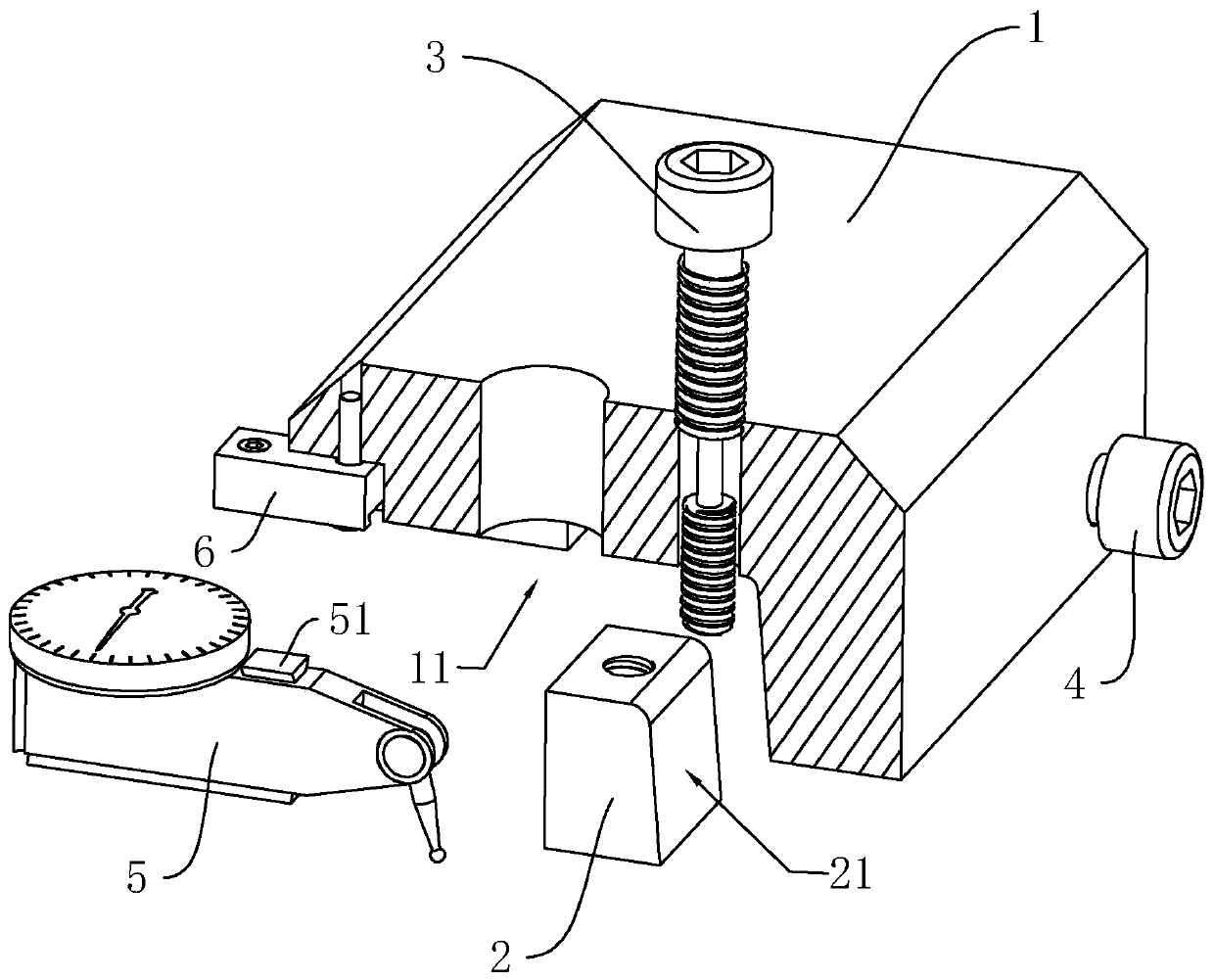

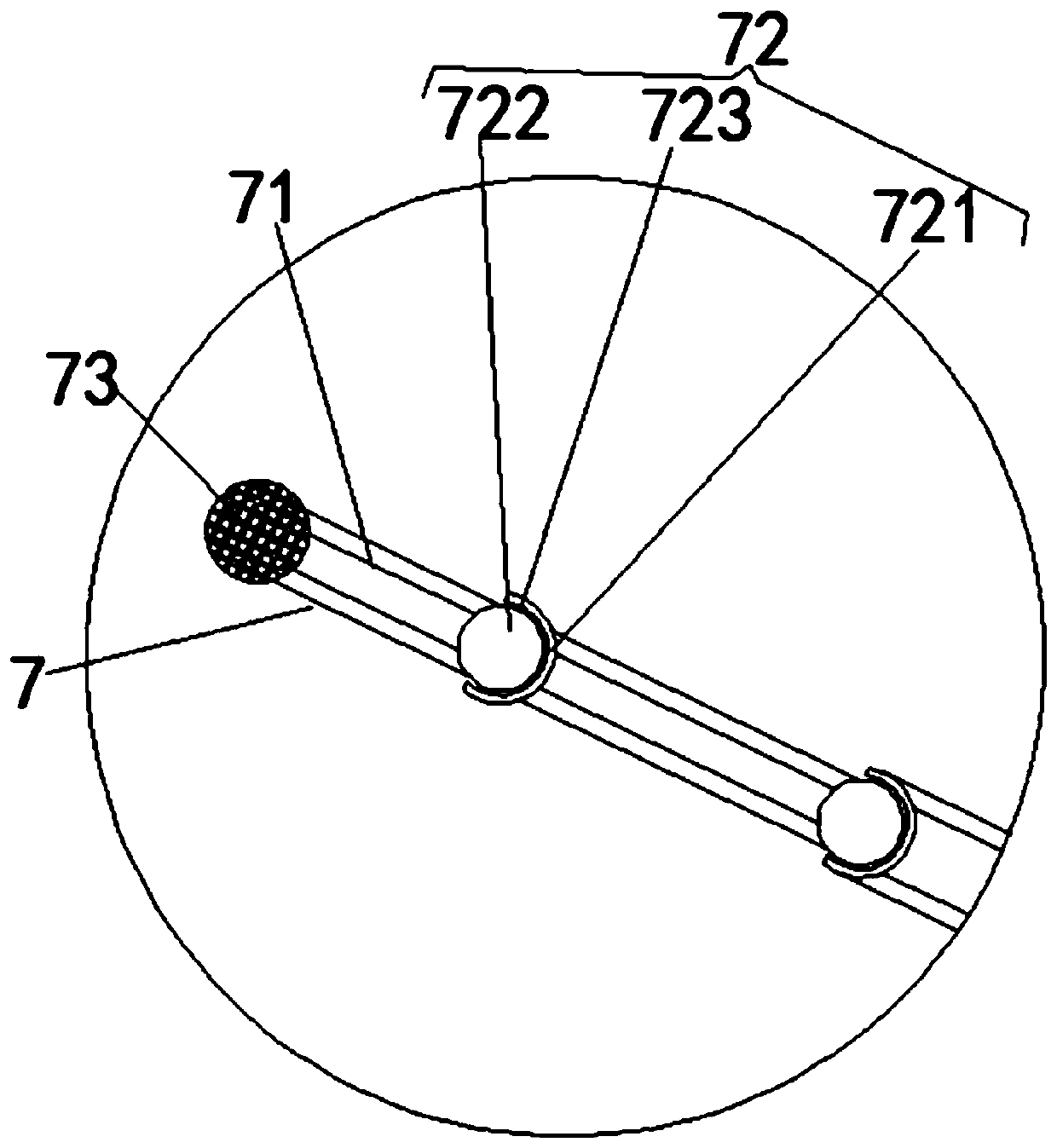

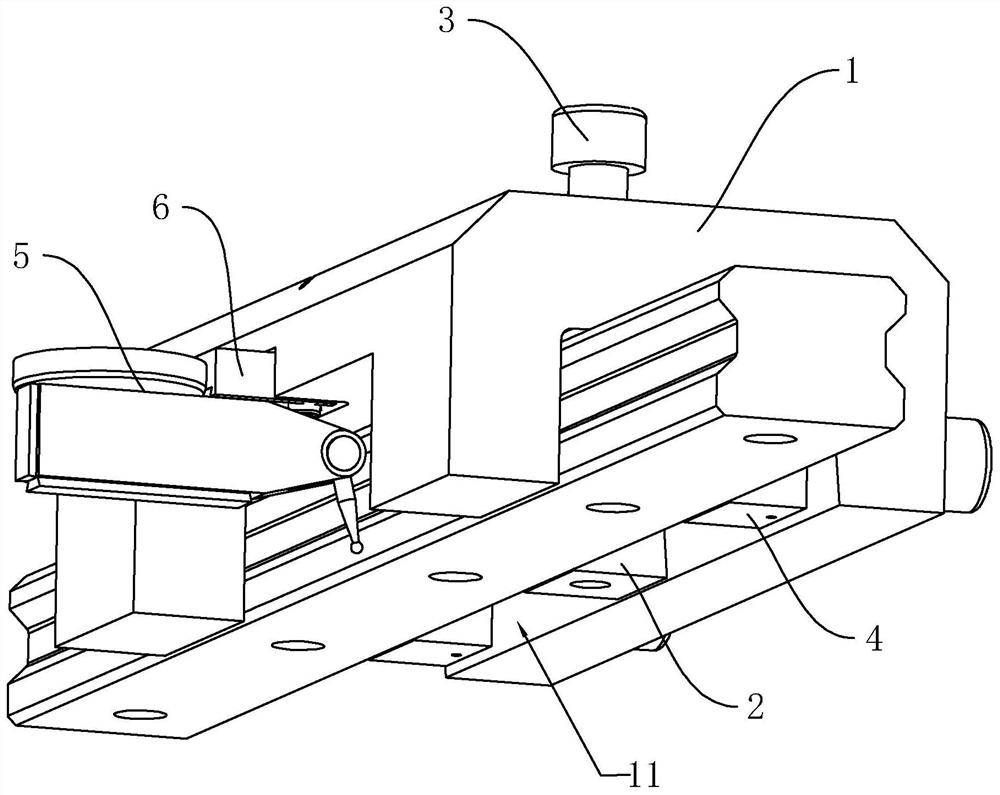

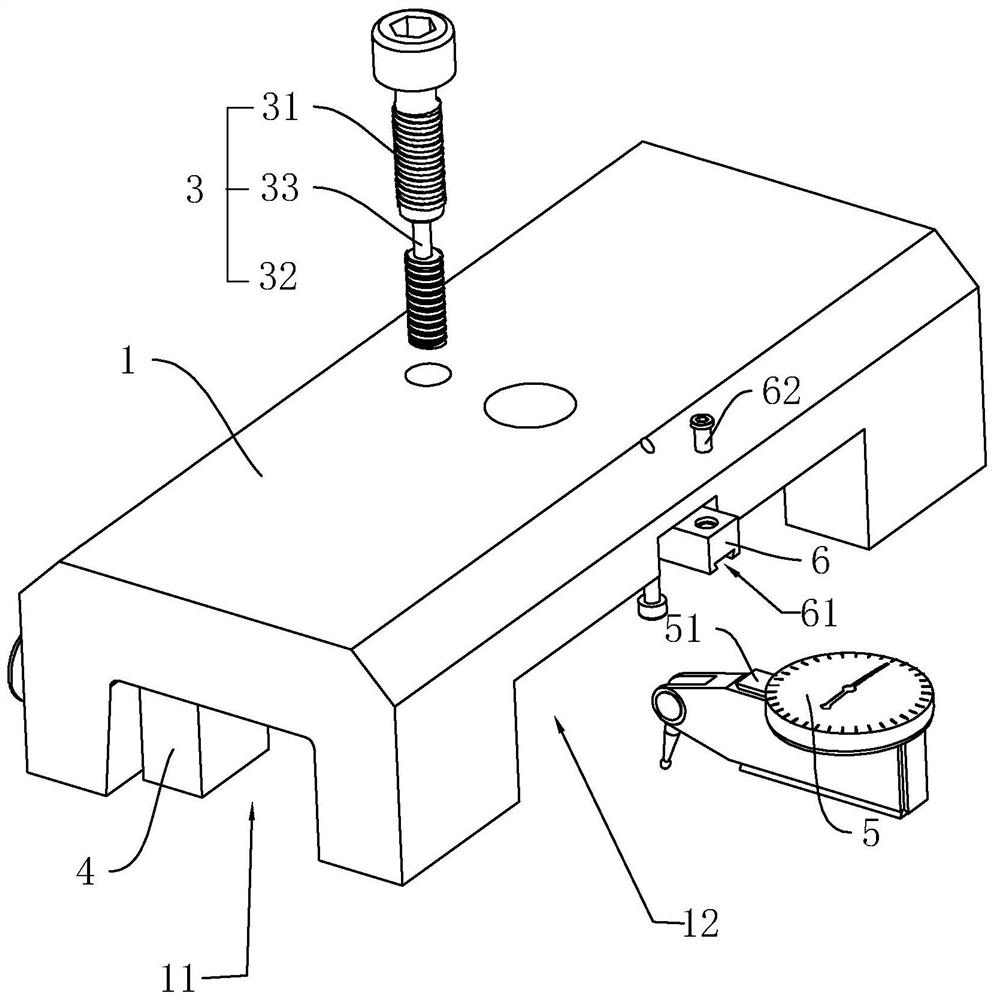

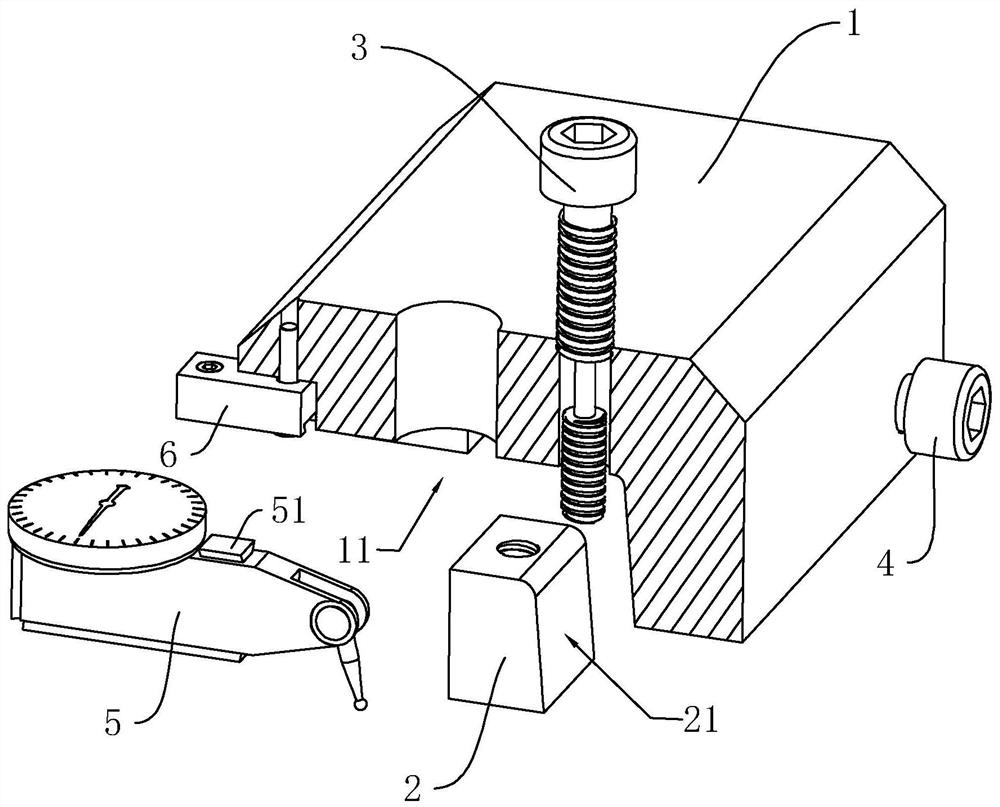

High-precision guide rail correction device

ActiveCN111251053AReduce processing costsReduce processing difficultyMaintainance and safety accessoriesStructural engineeringMechanical engineering

Owner:深圳市强华科技发展有限公司

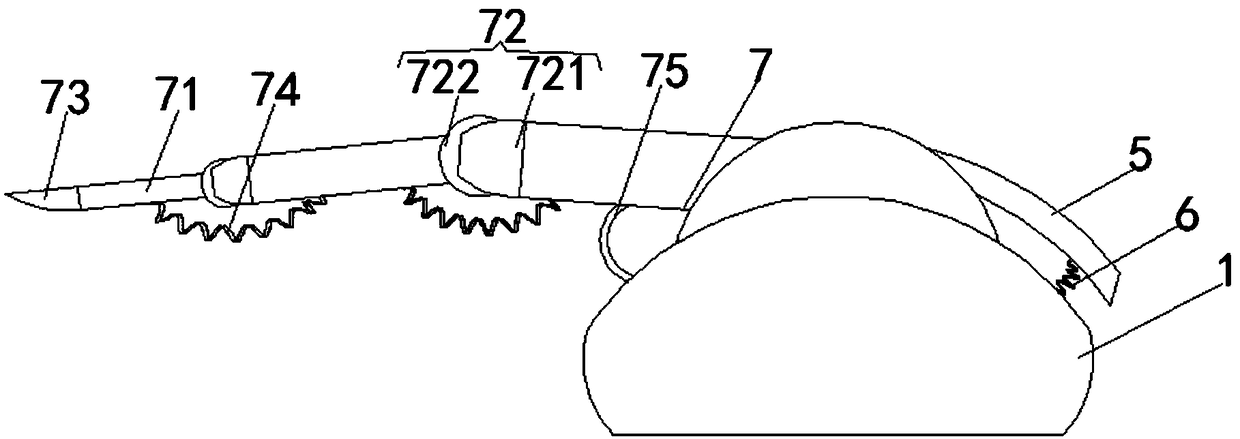

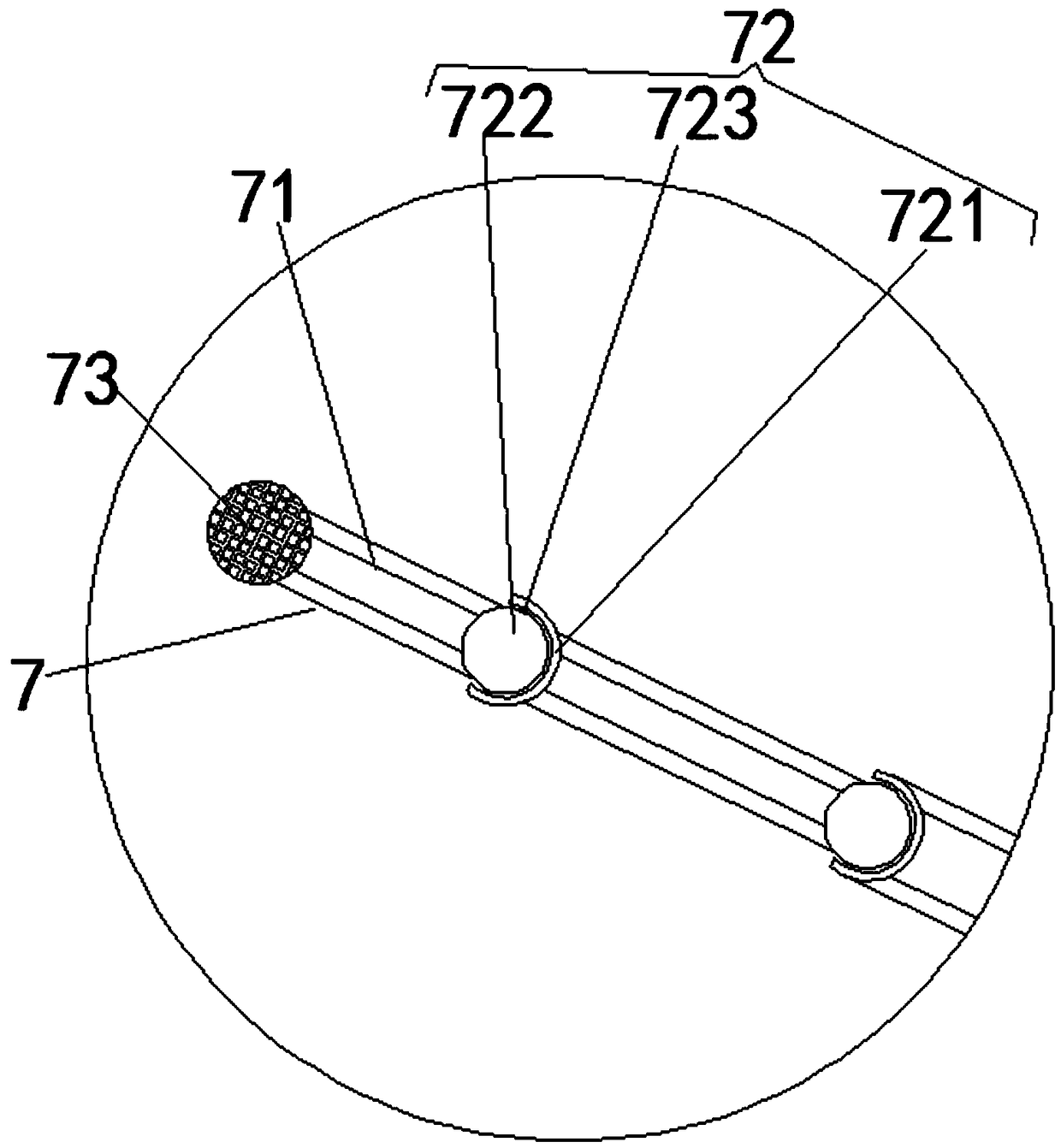

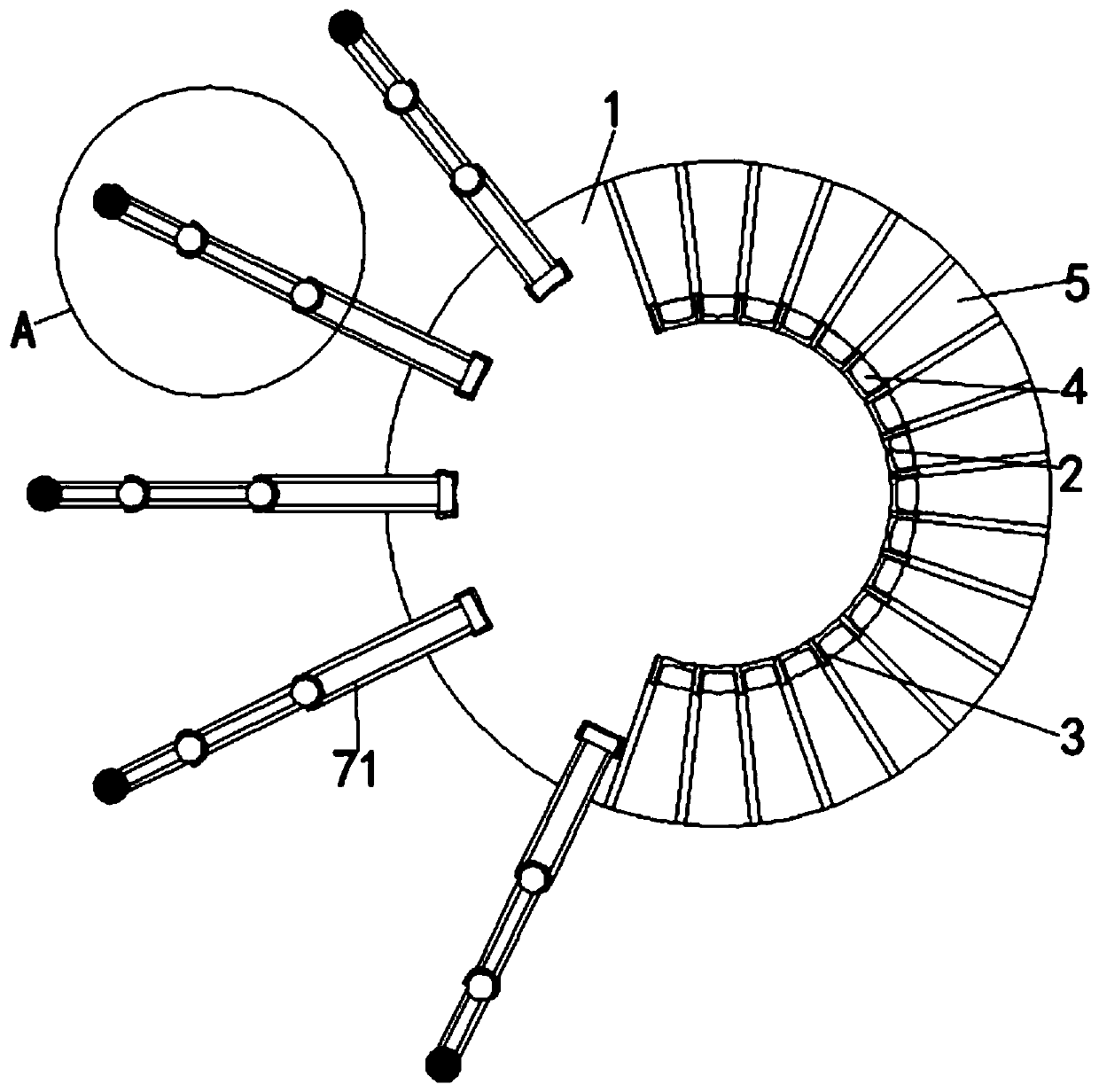

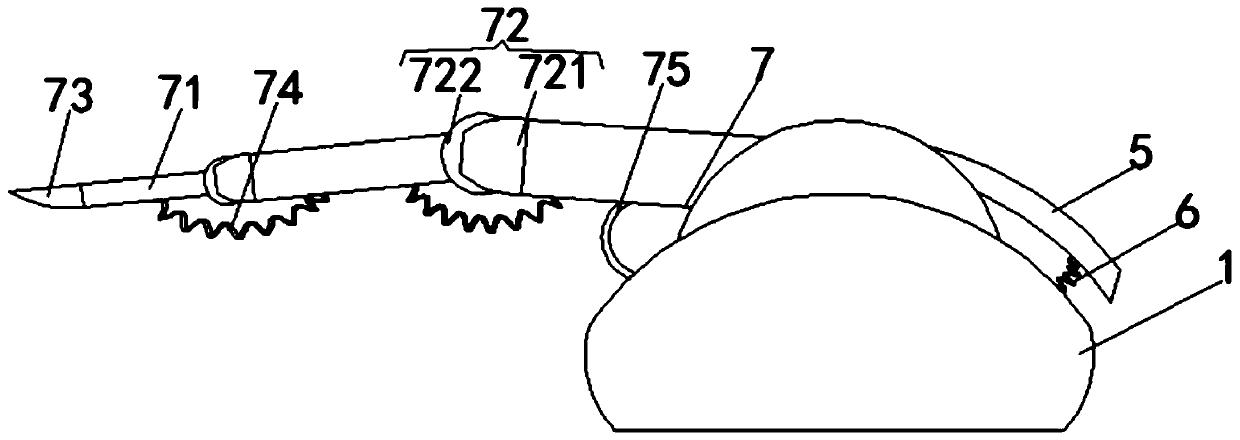

Finger strength exerciser for fracture rehabilitation

InactiveCN108905091AIncrease the degree of bendingAvoid discomfortResilient force resistorsExercise equipmentKnuckle

The invention relates to the technical field of finger exercise equipment, in particular to a finger strength exerciser for fracture rehabilitation to solve the technical problem that after a finger is removed from plaster, flexibility recovery through slow exercise is nor convenient. The finger strength exerciser for fracture rehabilitation comprises a palm block. A half ring groove is formed inthe position on the surface of the palm block and is close to the top two-thirds. Two sides of the inner wall of the half ring groove are connected through arc rods. Rotating sleeves are movably connected with the arc rods in a sleeving mode. One sides of the surfaces of the rotating sleeves are fixedly connected with palm center bent plates. One sides of the inner walls of the palm center bent plates are movably connected with one side of the palm block surface by arc springs. Five fingers are respectively placed onto five finger exercisers, when fingers gradually and slowly bend, the knuckles of tips are first bend. Elastic plates can bend slowly, if the fingers lack strength, the fingers are risen, and the fingers can be activated during the rising process, and therefore flexibility recovery of the fingers can be assisted.

Owner:SHANDONG PROVINCIAL HOSPITAL

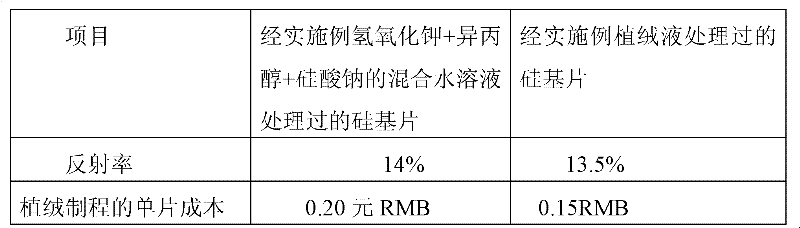

Flocking liquid and preparation method thereof

InactiveCN101844872AThinning Quantity ReductionIncrease the degree of bendingChemical industryAmyl alcohol

The invention belongs to the technical field of chemical industry, and relates to flocking liquid, in particular to flocking liquid applied in a flocking process of a process for manufacturing a solar cell; and meanwhile, the invention also discloses a preparation method for the flocking liquid. In order to solve the problems that etching liquid used in the conventional flocking process for manufacturing the solar cell contains low-boiling-point and easily volatile chemical substances such as isopropanol and the like and the chemical substances cause instability between batches of the flocking process during use and frequently produce a large amount of spotted plates to seriously affect the appearance and power generation efficiency of cell plates, the invention provides the flocking liquid. The flocking liquid comprises alkali capable of reacting with silicon, aqueous solution of silicate and mixture of amyl acid and amyl alcohol, wherein the mass ratio of the amyl acid to the amyl alcohol in the mixture of the amyl acid and the amyl alcohol is 3:1-2:1.

Owner:上海长悦涂料有限公司

A kind of manipulator mold and using method

The invention discloses a mold for a manipulator and a method for using it. Through the cooperation of a lower mold, an upper mold and a sealing mold, the manufacture of the manipulator is completed, pouring through the manipulator, and through the cooperation of the upper mold and the lower mold, pouring or injection molding of liquid silica gel and TPU , TPE and other plastic rubber materials to make the manipulator; the manipulator is sealed, and the surface of the poured manipulator is sealed through the sealing mold to complete the production of the manipulator. The manipulator produced can quickly pick strawberries and other agricultural products through cooperation. In the process, it will not damage the surface of strawberries, raspberries, cherry tomatoes and other agricultural products.

Owner:ZHEJIANG SCI-TECH UNIV

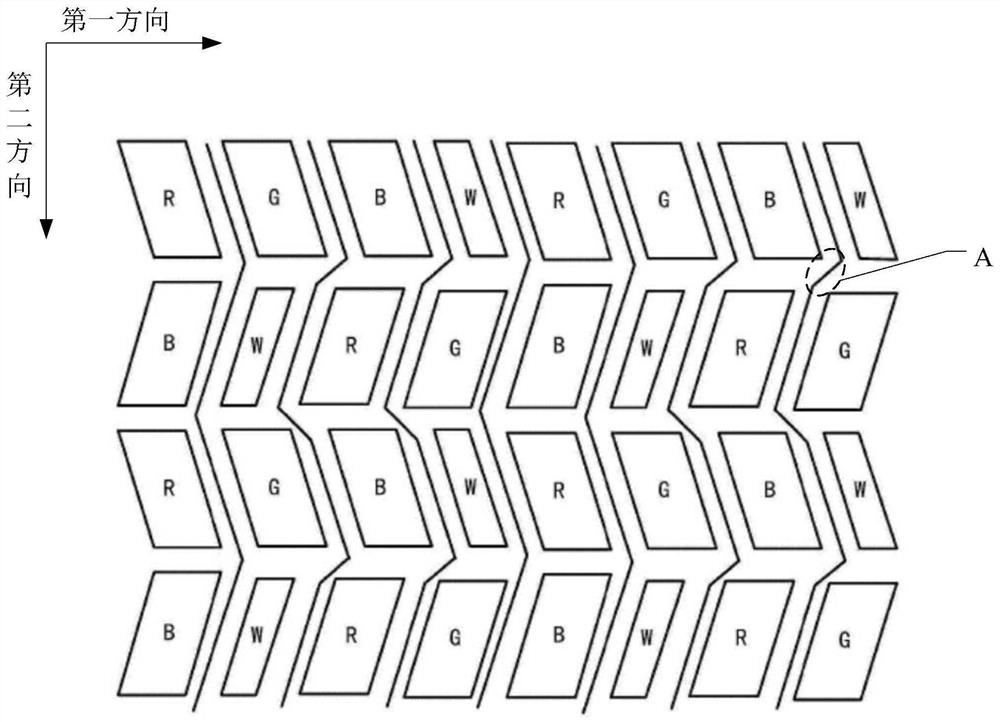

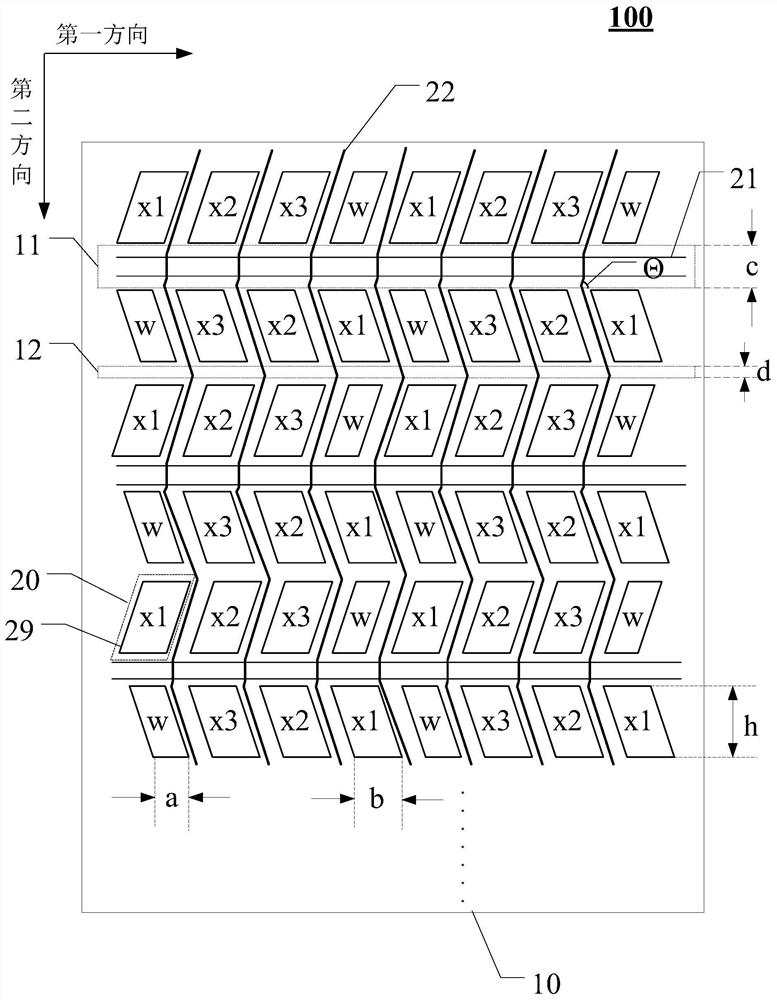

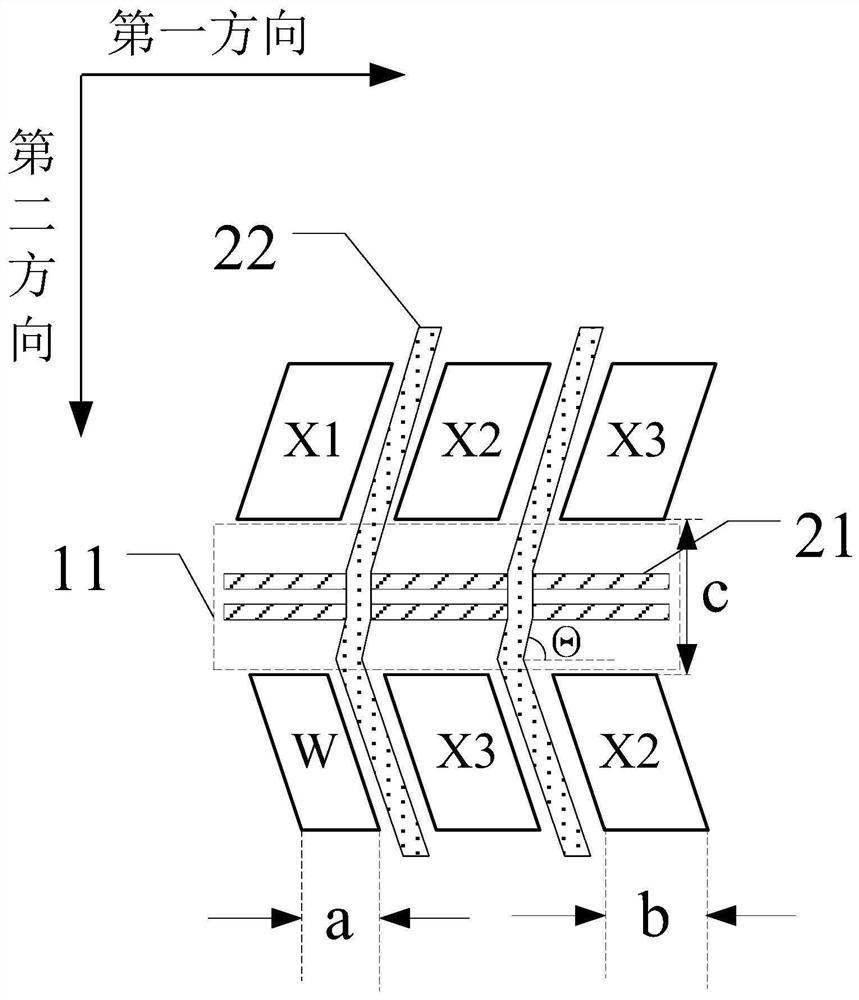

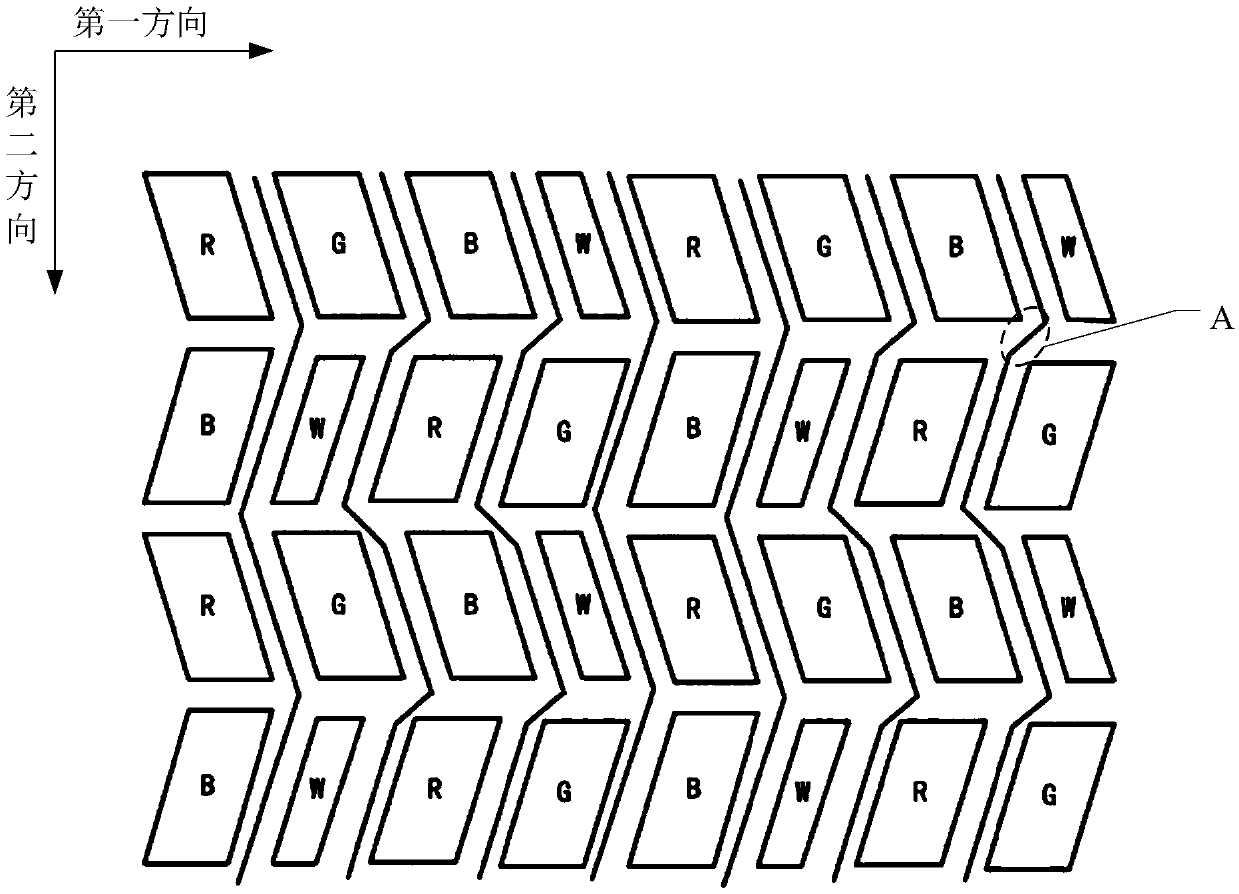

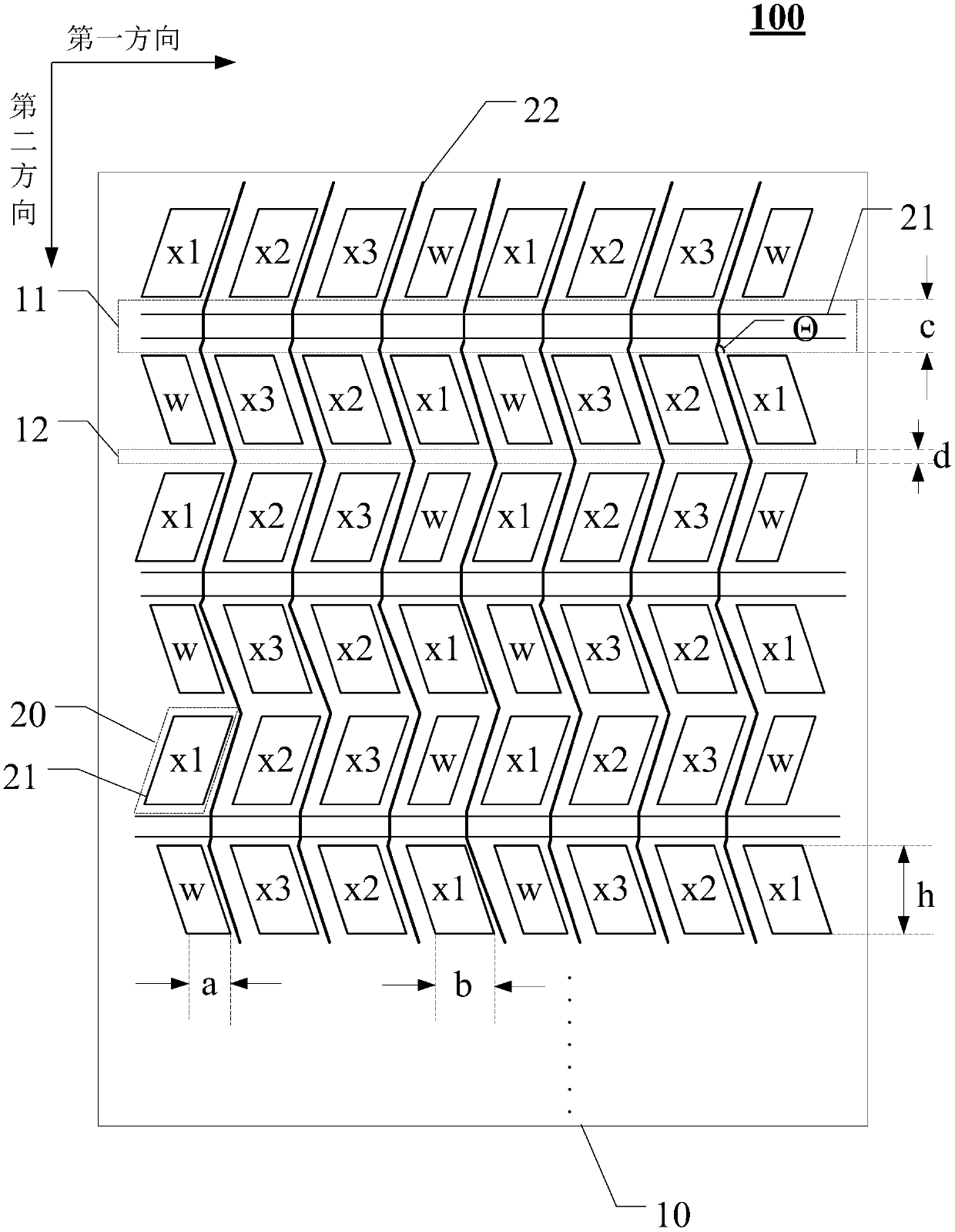

Display panel and display device

ActiveCN109637370BImprove display reliabilityIncrease widthNon-linear opticsIdentification meansComputer hardwareComputer graphics (images)

The invention discloses a display panel and a display device, the display panel comprises a scanning line extending in a first direction and a data line extending in a second direction; sub-pixel units, wherein each sub-pixel unit comprises a sub-pixel opening, the sub-pixel opening comprises a white sub-pixel opening, a first sub-pixel opening, a second sub-pixel opening and a third sub-pixel opening; in the first direction, the widths of the first sub-pixel opening, second sub-pixel opening and third sub-pixel opening are equal, and the width a of the white sub-pixel opening is smaller thanthe width b of the first sub-pixel opening; in the second direction, at least part of adjacent two rows of sub-pixel openings are provided with a first interval with a width of c, at least part of adjacent two rows of sub-pixel openings are provided with a second interval, two scanning lines are arranged in the first interval, and no scanning lines are arranged in the second interval; in the firstinterval, the angles between the data line and the scanning lines include an acute angle theta, wherein theta>=arctanc / (b / a). Thereby reducing the risk of disconnection of the data line is facilitated.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Mobile phone connector convenient to disassemble and assemble

ActiveCN112260023AEasy to disassembleEasy to installBatteries circuit arrangementsCouplings bases/casesEmbedded systemMobile phone

The invention discloses a mobile phone connector convenient to disassemble and assemble, and particularly relates to the technical field of connectors. The mobile phone connector comprises data linesand a shell, the two sides of the shell are fixedly connected with two groups of data lines, and the top end of the shell is fixedly connected with a supporting structure. By arranging a first connector, a second connector, a third connector and a fourth connector, when a traditional mobile phone connecting base is used for charging connection of a mobile phone, only one connector can be used on the connecting base, therefore the application range of the connecting base is small; four different connectors, i.e. the first connector, the second connector, the third connector and the fourth connector are installed on the connecting base, charging connection can be conducted on an existing mobile phone interface on the market, the first connector can be directly connected with a mobile phone through a data line, the mobile phone does not need to be fixed, The use effect of the connecting base is further improved through the multiple connectors and two sets of connecting modes, and the application range of the connecting base is widened.

Owner:深圳市宇文发电子科技有限公司

A flexible electrochromic device and method of making the same

The invention provides a flexible electrochromic device and a manufacturing method thereof. The flexible electrochromic device includes a conductive layer, a color-changing layer and a conductive gel layer. The conductive layer has no substrate and can be freely bent, and the color-changing layer is arranged above the conductive layer. , the conductive gel layer is arranged above the color-changing layer. The present invention provides a flexible electrochromic device and a manufacturing method thereof. On the one hand, by using a grid structure without a substrate as a conductive layer, the thickness of the flexible electrochromic device is lower than that of the existing electrochromic device, and the improvement is improved. The conductivity and overall transmittance of the electrochromic device are improved, and the manufacturing cost is reduced; on the other hand, the present invention adopts a grid structure without a substrate as the conductive layer, and cooperates with the conductive gel layer, which can achieve far higher than the existing The degree of bending of the electrochromic device. In addition, the conductive gel layer itself has stickiness and can be adhered to the surface of most objects, thus realizing the applicability of the electrochromic device.

Owner:SVG TECH GRP CO LTD +1

Display panel and display device

ActiveCN109637370AReduce bendingReduce the possibility of disconnectionIdentification meansAcute angleData lines

The invention discloses a display panel and a display device, the display panel comprises a scanning line extending in a first direction and a data line extending in a second direction; sub-pixel units, wherein each sub-pixel unit comprises a sub-pixel opening, the sub-pixel opening comprises a white sub-pixel opening, a first sub-pixel opening, a second sub-pixel opening and a third sub-pixel opening; in the first direction, the widths of the first sub-pixel opening, second sub-pixel opening and third sub-pixel opening are equal, and the width a of the white sub-pixel opening is smaller thanthe width b of the first sub-pixel opening; in the second direction, at least part of adjacent two rows of sub-pixel openings are provided with a first interval with a width of c, at least part of adjacent two rows of sub-pixel openings are provided with a second interval, two scanning lines are arranged in the first interval, and no scanning lines are arranged in the second interval; in the firstinterval, the angles between the data line and the scanning lines include an acute angle theta, wherein theta>=arctanc / (b / a). Thereby reducing the risk of disconnection of the data line is facilitated.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Preparation method of flocking liquid

InactiveCN101844872BThinning Quantity ReductionIncrease the degree of bendingChemical industryAmyl alcohol

The invention belongs to the technical field of chemical industry, and relates to flocking liquid, in particular to flocking liquid applied in a flocking process of a process for manufacturing a solar cell; and meanwhile, the invention also discloses a preparation method for the flocking liquid. In order to solve the problems that etching liquid used in the conventional flocking process for manufacturing the solar cell contains low-boiling-point and easily volatile chemical substances such as isopropanol and the like and the chemical substances cause instability between batches of the flocking process during use and frequently produce a large amount of spotted plates to seriously affect the appearance and power generation efficiency of cell plates, the invention provides the flocking liquid. The flocking liquid comprises alkali capable of reacting with silicon, aqueous solution of silicate and mixture of amyl acid and amyl alcohol, wherein the mass ratio of the amyl acid to the amyl alcohol in the mixture of the amyl acid and the amyl alcohol is 3:1-2:1.

Owner:上海长悦涂料有限公司

Finger strength exerciser for fracture rehabilitation and exercising method

ActiveCN110935142AEasy to fixRestore flexibilityResilient force resistorsPhysical medicine and rehabilitationFinger joint

The invention relates to the technical field of finger exercise equipment, in particular to a finger strength exerciser for fracture rehabilitation and an exercise method. Aiming to solve the technical problem that the flexibility is inconvenient to recover through slow exercise after a finger takes off gypsum, the invention provides a finger strength exerciser for fracture rehabilitation. The exerciser comprises a palm block, a semi-ring groove is formed in the surface of the palm block and close to the two-thirds position of the top; the two sides of the inner wall of the semi-ring groove are connected through arc-shaped rods, rotating sleeves movably sleeve the arc-shaped rods, palm center bent plates are fixedly connected to one sides of the surfaces of the rotating sleeves, and one sides of the inner walls of the palm center bent plates are movably connected with the palm block. According to the invention, the five fingers are placed on the five finger exercisers respectively; when the fingers are gradually and slowly bent, the finger joints at the tail ends are firstly bent, the elastic pieces can be slowly bent; if the fingers exert insufficient force, the fingers can be lifted up, the fingers can be moved in the lifting process, and therefore, the fingers can be assisted in recovering flexibility.

Owner:文汉

Monocrystal silicon wafer flocking process liquid and preparation method thereof

InactiveCN102154710AImprove conversion efficiencyEliminate piebaldAfter-treatment detailsElectrical batteryPotassium silicate

The invention discloses monocrystal silicon wafer flocking process liquid and a preparation method thereof. The monocrystal silicon wafer flocking process liquid contains the following raw materials in parts by weight: 62-86 parts of industrial pure water, 5-15 parts of electronic-grade potassium hydroxide, 5-15 parts of CP-grade high-radix loop materials and 4-8 parts of electronic-grade sodium silicate. The preparation method of the monocrystal silicon wafer flocking process comprises the following steps: adding 10-30 parts of industrial pure water and 5-15 parts of electronic-grade potassium hydroxide or sodium hydroxide or the mixture of the two into a reactor, stirring and dissolving; adding 5-15 parts of CP-grade high-radix loop materials, stirring and dissolving; adding 4-8 parts of electronic-grade sodium silicate or potassium silicate or the mixture of the two, stirring and dissolving; adding 32-76 parts of hot pure water of 50-80 DEG C, stirring; and naturally cooling and packaging. The monocrystal silicon wafer flocking process liquid adopted the technical scheme has the advantages of removing monocrystal silicon wafer piebald, improving conversion efficiency of batteryplates, lowering production cost of flocking surface and improving quality stability of the flocking surface.

Owner:YANGZHOU HANYUAN NEW MATERIAL TECH

A high-precision guide rail correction device

ActiveCN111251053BIncrease the degree of bendingGood conditionMaintainance and safety accessoriesStructural engineeringHorizontal orientation

Owner:深圳市强华科技发展有限公司

A small double-deck parking device with no avoidance in side orientation

Owner:SICHUAN UNIV

A high-speed cam bending machine

InactiveCN111036743BPrevent deformationHigh degree of automationMetal-working feeding devicesPositioning devicesElectric machineryStructural engineering

The invention discloses a high-speed cam bending machine, which includes a carrier plate, a geared motor and a control device. The carrier plate is provided with a first through hole and a first guide groove. The output shaft of the geared motor passes through the first through hole and The bending cam is set, the output shaft of the deceleration motor is detachably connected to the bending cam, the deceleration motor is fixedly connected to the back of the carrier plate, the carrier plate is provided with a first guide rail, and the first guide rail is provided with There is a second guide groove corresponding to the first guide groove, a first slider and a second slider are arranged on the first guide rail, a second through hole is arranged on the first slider, and the back of the carrier board is An encoder is provided, the first slider and the second slider are respectively provided with a first clamp and a second clamp, the input shaft of the encoder is fixedly connected with the first clamp, and the encoder slides with the carrier plate connection; the high-speed cam bending machine has high working efficiency.

Owner:山东郓城骏通专用车有限公司

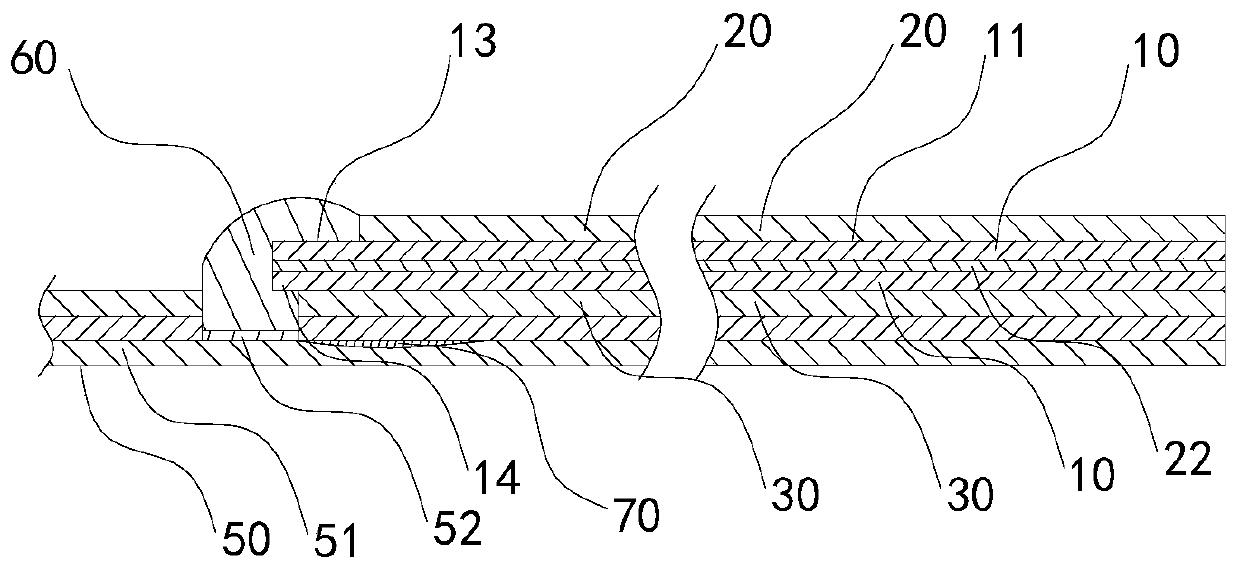

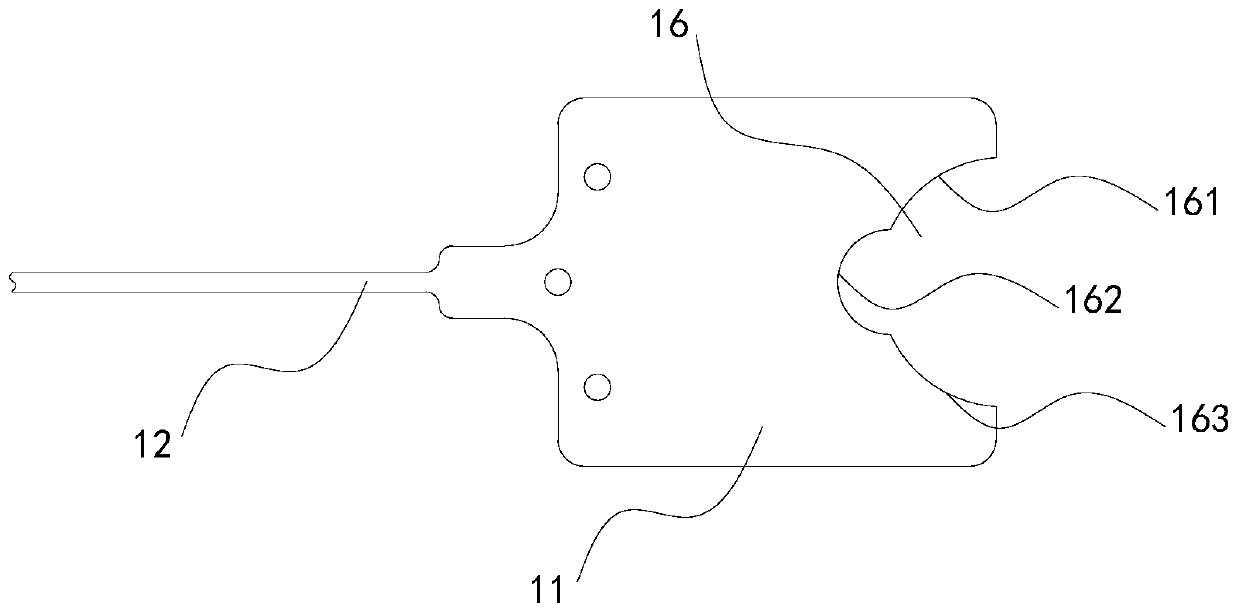

Flexible circuit board, capacitive screen and flexible circuit board processing method

ActiveCN109757031BIncrease contactAvoid breakingElectrical connection printed elementsInput/output processes for data processingCapacitanceFlexible circuits

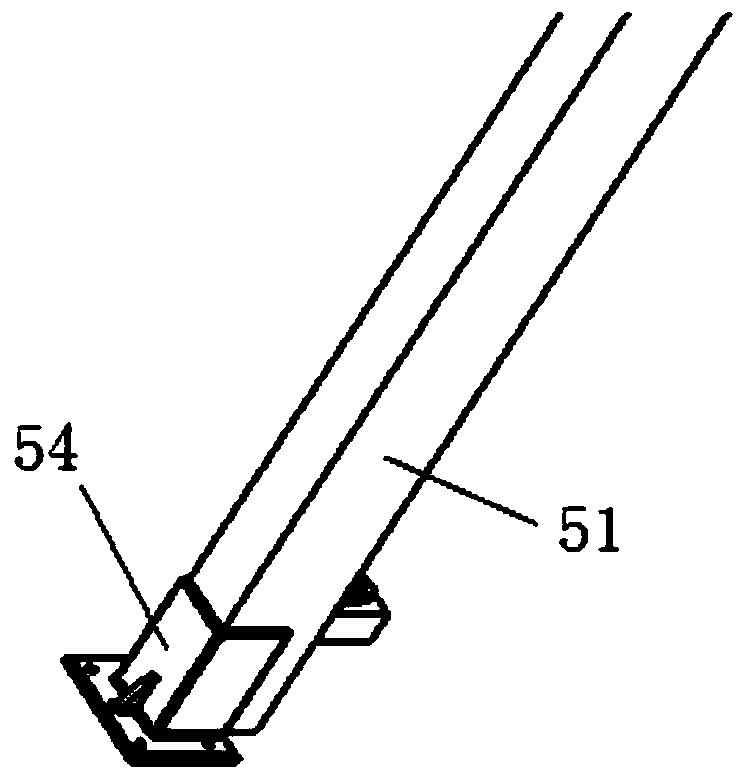

Disclosed are a flexible circuit board, a capacitance screen (50), and a method for machining the flexible circuit board. The flexible circuit board comprises a base layer (22), and a conductive layer (10), wherein the conductive layer (10) is attached to the base layer (22); the conductive layer (10) is at least provided with a conductive sheet (11) and a conductive wire (12); the conductive sheet (11) and the conductive wire (12) are mutually electrically connected; the conductive sheet (11) is located at a conductive connection side, and a first avoidance notch (16) is provided on the conductive sheet (11); and the opening width of the first avoidance notch (16) gradually reduces from the outside to the inside. The conductive connection structure is stable; the problems of poor contact and binding an open circuit in the flexible circuit board can be solved; process flow time for machining the conductive sheet is short; and a drilling operation is easily carried out, and the structure is more stable and reliable.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

A mobile phone connector that is easy to assemble and disassemble

ActiveCN112260023BEasy to disassembleEasy to installBatteries circuit arrangementsCouplings bases/casesEmbedded systemMobile phone

The invention discloses a mobile phone connector that is easy to assemble and disassemble, and specifically relates to the technical field of connectors, including a data line and a housing, two sets of data lines are fixedly connected to both sides of the housing, and the top end of the housing is fixed Connected with support structure. The present invention is provided with a first joint, a second joint, a third joint and a fourth joint. When the traditional mobile phone connection base is used for charging and connecting the mobile phone, only one type of joint can be used on the connection base, so that the connection base is suitable for use. The range is small, and now four different connectors are installed on the connection base, the first connector, the second connector, the third connector and the fourth connector, which can be used for charging connections to the existing mobile phone interfaces on the market, of which the first connector The mobile phone can be directly connected with the data cable without fixing the mobile phone. Multiple connectors and two sets of connection methods further enhance the use effect of the connecting seat and increase the applicable range of the connecting seat.

Owner:深圳市宇文发电子科技有限公司

Bending device for plastic processing and capable of achieving double-face bending

The invention discloses a bending device for plastic processing and capable of achieving double-face bending. According to the technical scheme, the bending device is characterized in that a double-face bending mechanism and an effect improving mechanism are arranged on a machine shell, a first driving part, a fixing plate and a first clamping part are arranged in the double-face bending mechanism, and a first transmission part is arranged on the fixing plate; and the first transmission part is movably connected with the first clamping part through a transmission strip plate, the effect improving mechanism comprises a second driving part and a second clamping part, and the second driving part is fixedly connected with the second clamping part through a second rotating shaft. The bending device is provided with the double-face bending mechanism, double-face bending is carried out on rubber through the double-face bending mechanism, the bending effect can be improved, bending experiments can be carried out on the two faces of the rubber, and therefore more complete experimental data are obtained; and the bending degree is increased or decreased in the rubber bending process through the effect improving mechanism, so that the bending effect is improved, and the efficiency of a bending experiment is improved.

Owner:深圳市辉鹏达科技有限公司

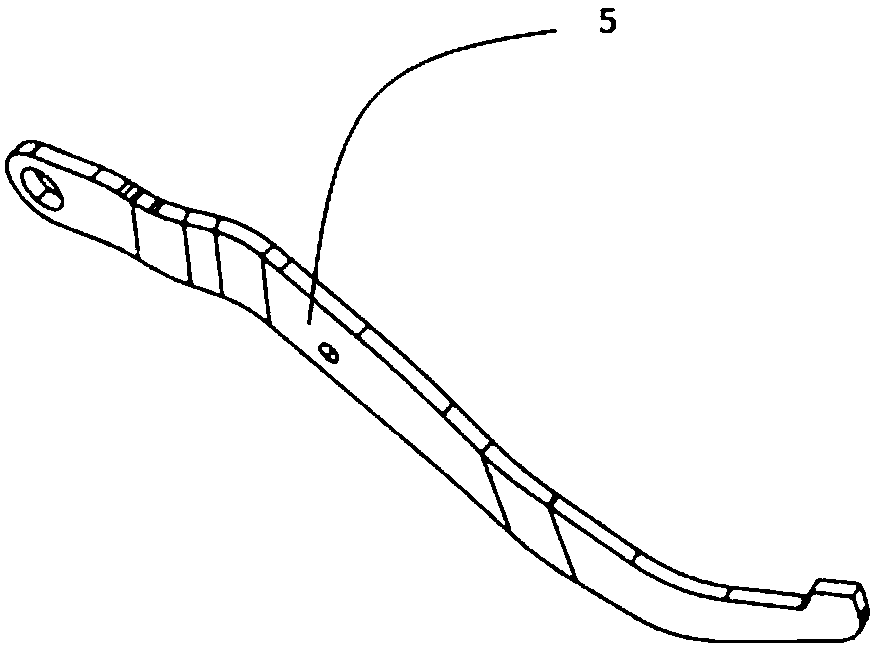

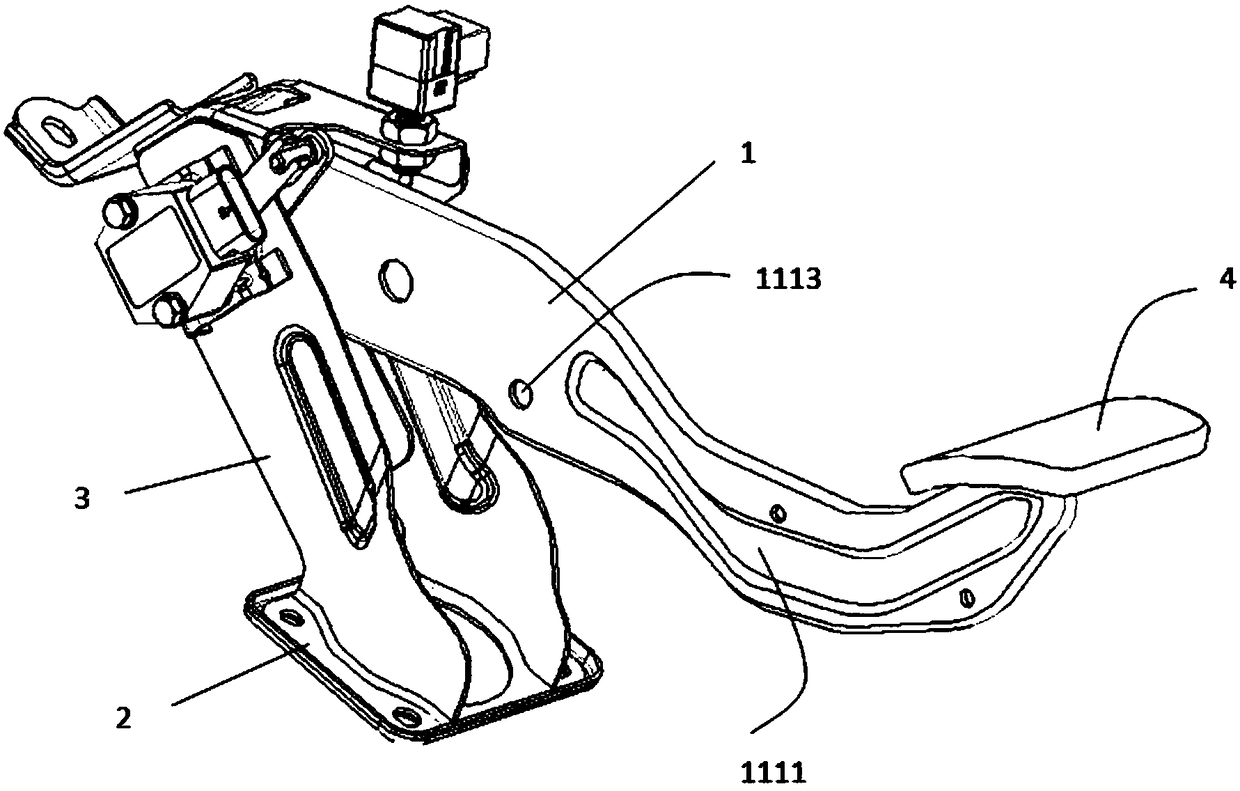

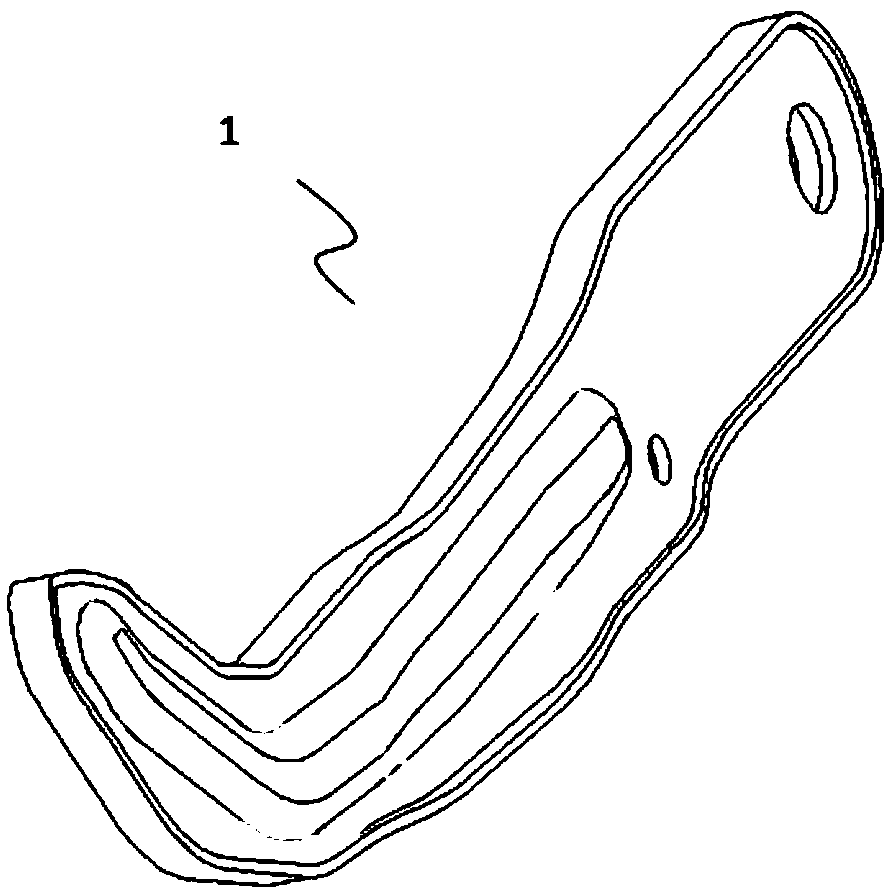

Car brake pedal arm

PendingCN108238021AHigh strengthMeet the intensityFoot actuated initiationsFlangeAutomotive engineering

The invention provides a car brake pedal arm which comprises a pedal arm body. The pedal arm body comprises a bottom plate and a flange arranged at the edge of the bottom plate. A cavity is formed bythe bottom plate and the flange and internally provided with a reinforcing plate. The reinforcing plate is matched with the bottom plate in shape. According to the car brake pedal arm, the structure is simple, the strength of the car brake pedal arm is greatly improved, and the car space is optimized.

Owner:重庆鹏得基业汽车部件有限公司

Monocrystal silicon wafer flocking process liquid and preparation method thereof

InactiveCN102154710BImprove conversion efficiencyEliminate piebaldAfter-treatment detailsPotassium silicatePotassium hydroxide

The invention discloses monocrystal silicon wafer flocking process liquid and a preparation method thereof. The monocrystal silicon wafer flocking process liquid contains the following raw materials in parts by weight: 62-86 parts of industrial pure water, 5-15 parts of electronic-grade potassium hydroxide, 5-15 parts of CP-grade high-radix loop materials and 4-8 parts of electronic-grade sodium silicate. The preparation method of the monocrystal silicon wafer flocking process comprises the following steps: adding 10-30 parts of industrial pure water and 5-15 parts of electronic-grade potassium hydroxide or sodium hydroxide or the mixture of the two into a reactor, stirring and dissolving; adding 5-15 parts of CP-grade high-radix loop materials, stirring and dissolving; adding 4-8 parts of electronic-grade sodium silicate or potassium silicate or the mixture of the two, stirring and dissolving; adding 32-76 parts of hot pure water of 50-80 DEG C, stirring; and naturally cooling and packaging. The monocrystal silicon wafer flocking process liquid adopted the technical scheme has the advantages of removing monocrystal silicon wafer piebald, improving conversion efficiency of battery plates, lowering production cost of flocking surface and improving quality stability of the flocking surface.

Owner:YANGZHOU HANYUAN NEW MATERIAL TECH

A touch display substrate, a preparation method thereof, and a touch display device

ActiveCN109343735BReduce thicknessImprove production efficiencyNon-linear opticsInput/output processes for data processingDisplay devicePhotoresist

Embodiments of the present invention provide a touch display substrate, a method for manufacturing the same, and a touch display device, which relate to the technical field of touch display and can solve the problem of a large thickness of the touch display device. A touch display substrate includes: a base substrate, a color photoresist pattern disposed on the base substrate, and a black matrix pattern for spacing the color photoresist patterns; further comprising: a touch layer, the touch The layer includes a plurality of first touch electrodes arranged in sequence along a first direction and a plurality of second touch electrodes arranged in sequence along a second direction; wherein the first touch electrodes and the second touch electrodes intersect are arranged, and the intersecting positions are insulated from each other by the black matrix pattern. Used to reduce the thickness of the touch display device.

Owner:BOE TECH GRP CO LTD +1

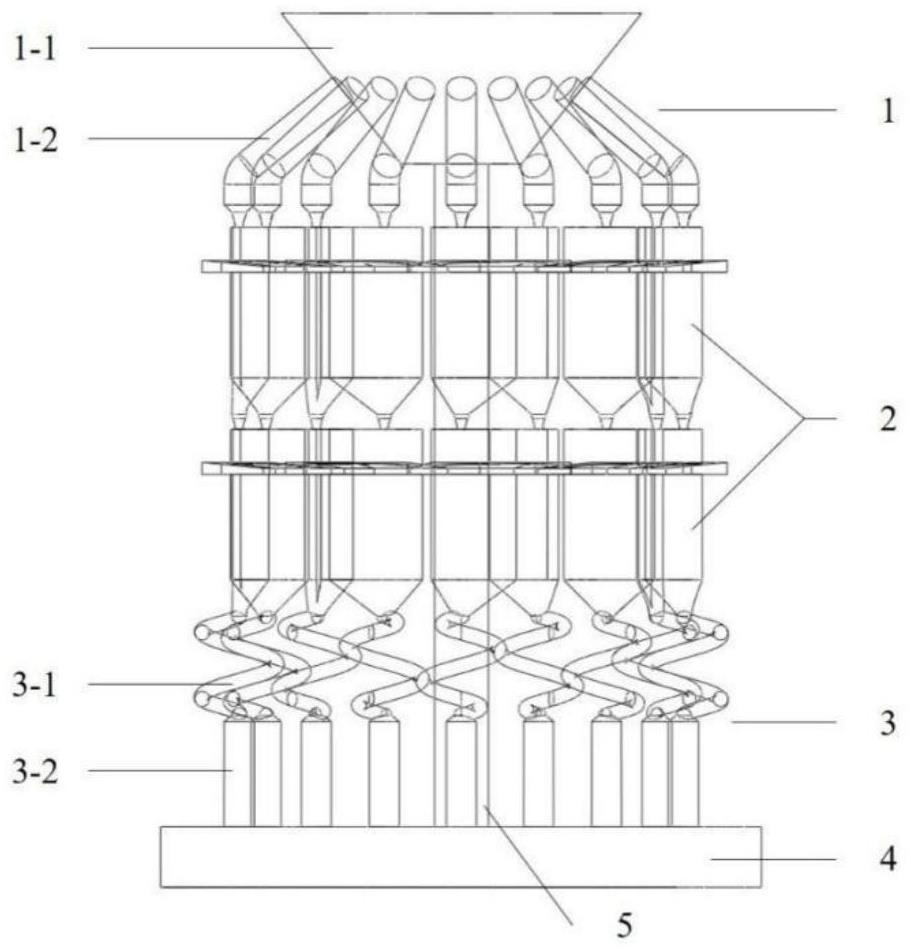

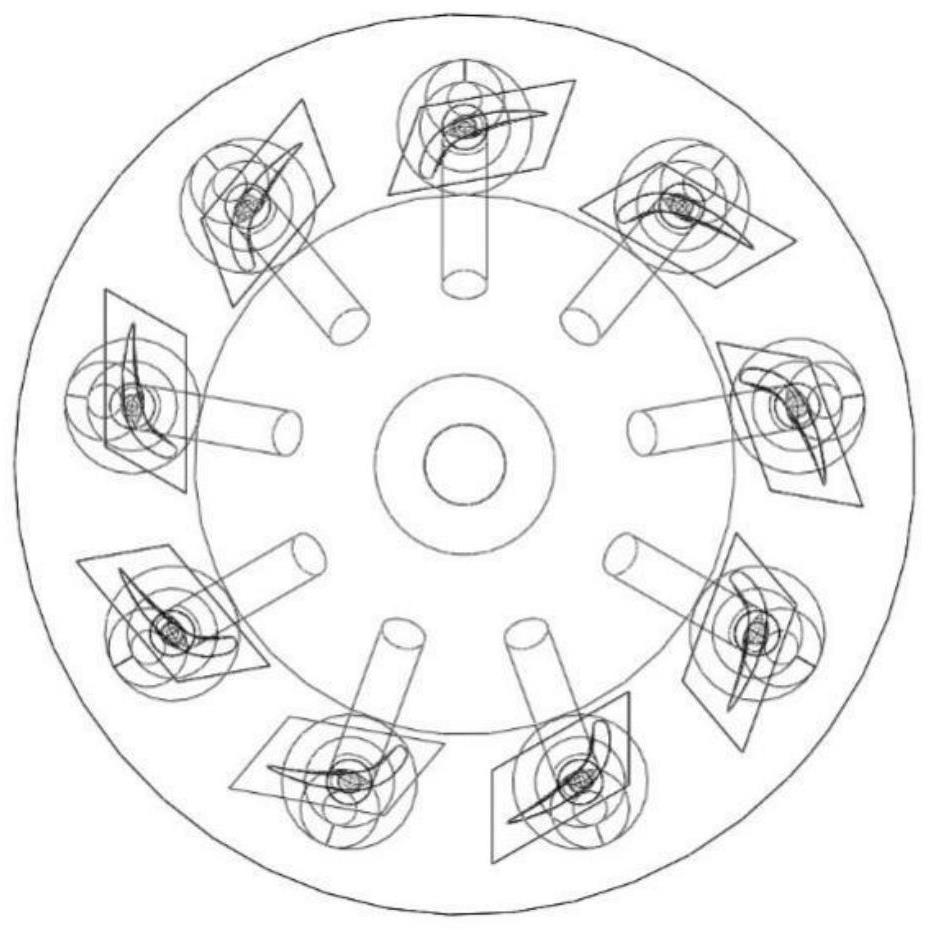

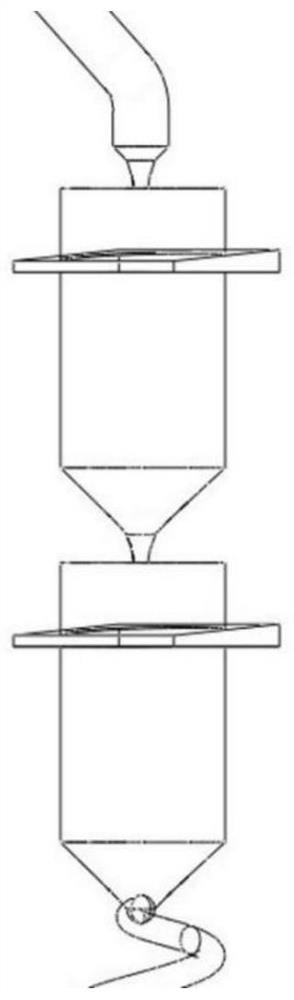

Multi-layer module superposition wax mold structure and method for efficiently preparing single crystal blade by using same

PendingCN114799047AReduce defectsImprove pass rateFoundry mouldsFoundry coresThermodynamicsEngineering

The invention provides a multi-layer module stacking wax mold structure and a method for efficiently preparing a single crystal blade through the multi-layer module stacking wax mold structure, and relates to the technical field of aero-engine blade precision casting. The invention provides a multi-layer module stacking wax mold structure. The multi-layer module stacking wax mold structure comprises a pouring system wax mold, a blade wax mold, a crystal selector wax mold and a chilling plate wax mold which are sequentially connected from top to bottom. The blade wax mould comprises a plurality of layers of blade wax moulds which are sequentially connected from top to bottom. Under the condition of ensuring the same production capacity of the blade, the module diameter is effectively reduced, and the size requirements on the chilling plate and the directional solidification furnace cavity are reduced; the temperature field distribution in the directional solidification process is obviously improved by reducing the diameter of the module, the uniformity of a transverse temperature field is improved, the isotherm bending degree is reduced, and the front edge temperature gradient of a solid-liquid interface is improved; the defects of the single crystal blade are obviously reduced, the tendency of mixed crystal generation at the transition section and the platform is reduced, and the qualified rate of mass production of the single crystal blade is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Display panel, preparation method thereof and display device

PendingCN112951870AIncrease the degree of bendingThe degree of bending reachesSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention discloses a display panel, a preparation method thereof and a display device. The display panel comprises an array substrate and a plurality of light emitting diodes located on one side of the array substrate. The array substrate at least comprises a first groove structure, and the first groove structure is located on at least one side of the light emitting diode in the direction parallel to the plane where the array substrate is located; the display panel further comprises at least one kind of protection glue, the at least one kind of protection glue comprises a first kind of protection glue, the first groove structure is filled with the first kind of protection glue, and at least one of the at least one kind of protection glue covers the light emitting diode. According to the technical scheme provided by the embodiment of the invention, the bending performance of the display panel can be ensured, and meanwhile, the structure, which is easily damaged due to bending, in the display panel can be effectively protected.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com