A flexible electrochromic device and method of making the same

A production method and a color-changing technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as poor electrical conductivity, low bendability, and large thickness, and achieve improved electrical conductivity and overall transmittance, The effect of simplifying the structure and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

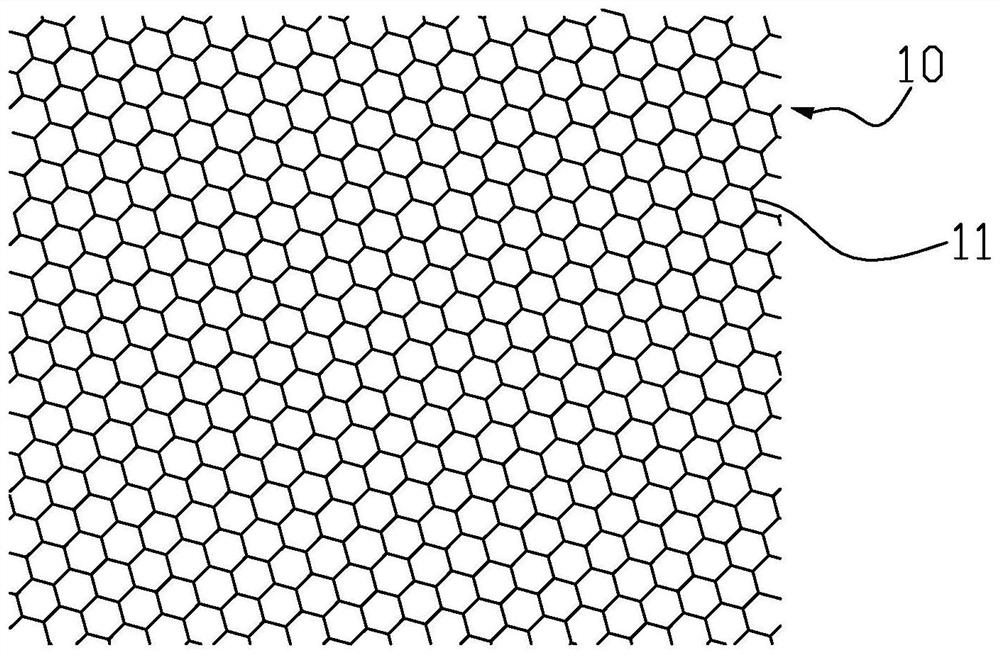

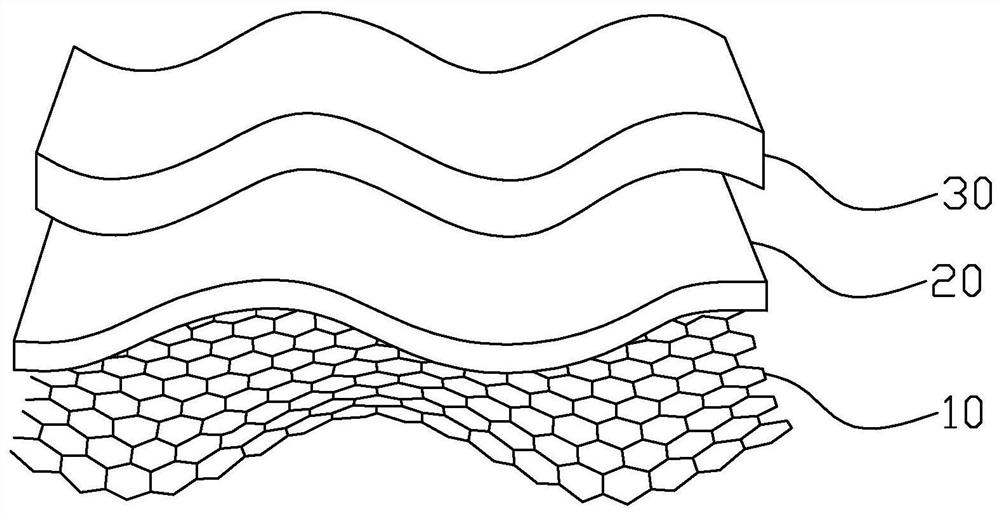

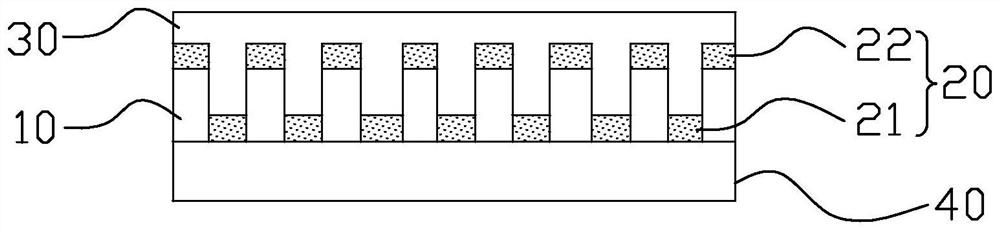

[0032] figure 1 It is a bottom view of the flexible electrochromic device in the first embodiment of the present invention, figure 2 It is a schematic diagram of the exploded structure of the flexible electrochromic device after bending in the first embodiment of the present invention, Figure 3a It is a cross-sectional view of the flexible electrochromic device before being peeled off from the substrate in the first embodiment of the present invention, Figure 3b for figure 1 Cross-sectional view of the medium flexible electrochromic device after being peeled off from the substrate. please combine figure 1 , figure 2 and Figures 3a to 3b , the flexible electrochromic device provided by the first embodiment of the present invention includes a conductive layer 10, a color-changing layer 20 and a conductive gel layer 30. The conductive layer 10 has no substrate 40 and can be freely bent, wherein the color-changing layer 20 is arranged on the conductive layer 20. Above l...

no. 2 example

[0038] Figures 4a to 4gThis is the manufacturing process of the flexible electrochromic device in the second embodiment of the present invention. please combine Figures 4a to 4g , this embodiment provides a manufacturing method of a flexible electrochromic device, which specifically includes the following steps:

[0039] providing a substrate 40;

[0040] The conductive layer 10 having the mesh structure 11 is fabricated on the substrate 40, and the conductive layer 10 remains on the substrate 40;

[0041] Making the color-changing layer 20, and distributing the color-changing layer 20 on the substrate 40 with the conductive layer 10;

[0042] making the conductive gel layer 30, and fixing the conductive gel layer 30 on the substrate 40 after the discoloration layer 20 is distributed;

[0043] The conductive gel layer 30, the color-changing layer 20 and the conductive layer 10 having the mesh structure 11 are peeled off from the substrate 40 to obtain a flexible electroc...

no. 3 example

[0055] Figure 5 It is a bottom view of the flexible electrochromic device in the third embodiment of the present invention. The difference between this embodiment and the first embodiment is that the periodic structure of the conductive layer 10 is a regular quadrilateral.

[0056] please combine Figure 5 , the main body of the conductive layer 10 is a grid structure 11, the grid structure 11 of the conductive layer 10 is a connected graphical structure or a periodic structure, when the grid structure 11 is a connected graphical structure, the graphics can be cartoon characters, Any one or a combination of items, buildings and landscapes; when the grid structure 11 is a connected periodic structure, the periodic structure can be a combination of any one or more of circles, ellipses or polygons . In this embodiment, the conductive layer 10 is a transparent structure, and the material of the conductive layer 10 is any metal material among iron, copper, nickel, aluminum, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com