Flexible circuit board, capacitive screen and flexible circuit board processing method

A technology of flexible circuit boards and conductive sheets, which is applied to printed circuit components, electrical digital data processing, and electrical connection printed components, etc. It can solve problems such as poor contact of flexible circuit boards, and achieves avoiding poor contact, simple processing, and simplified processing The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

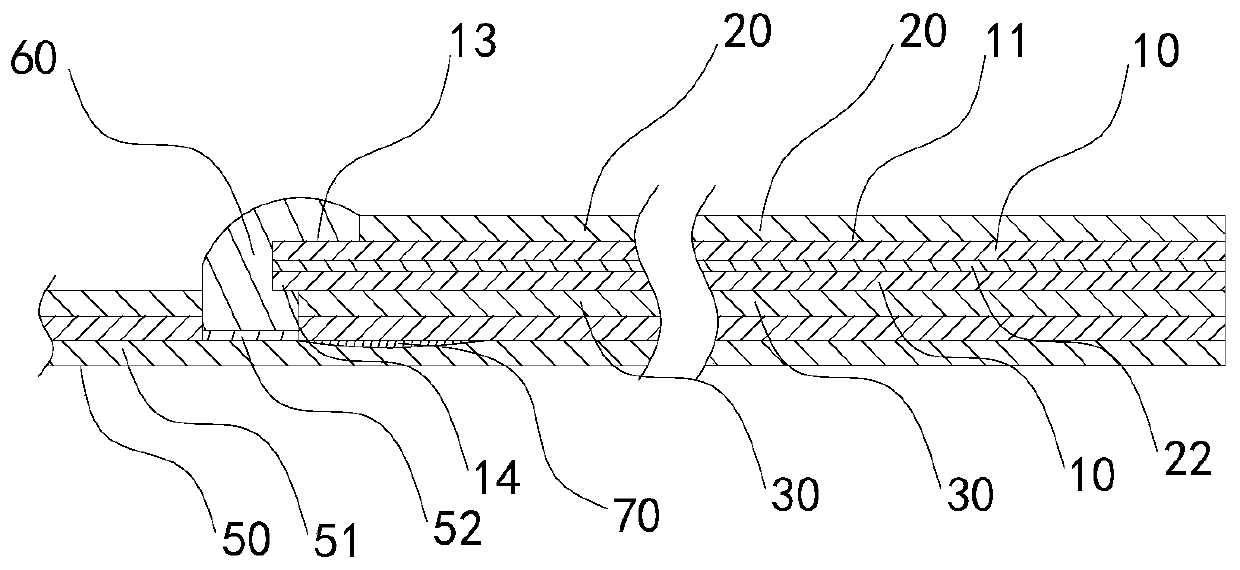

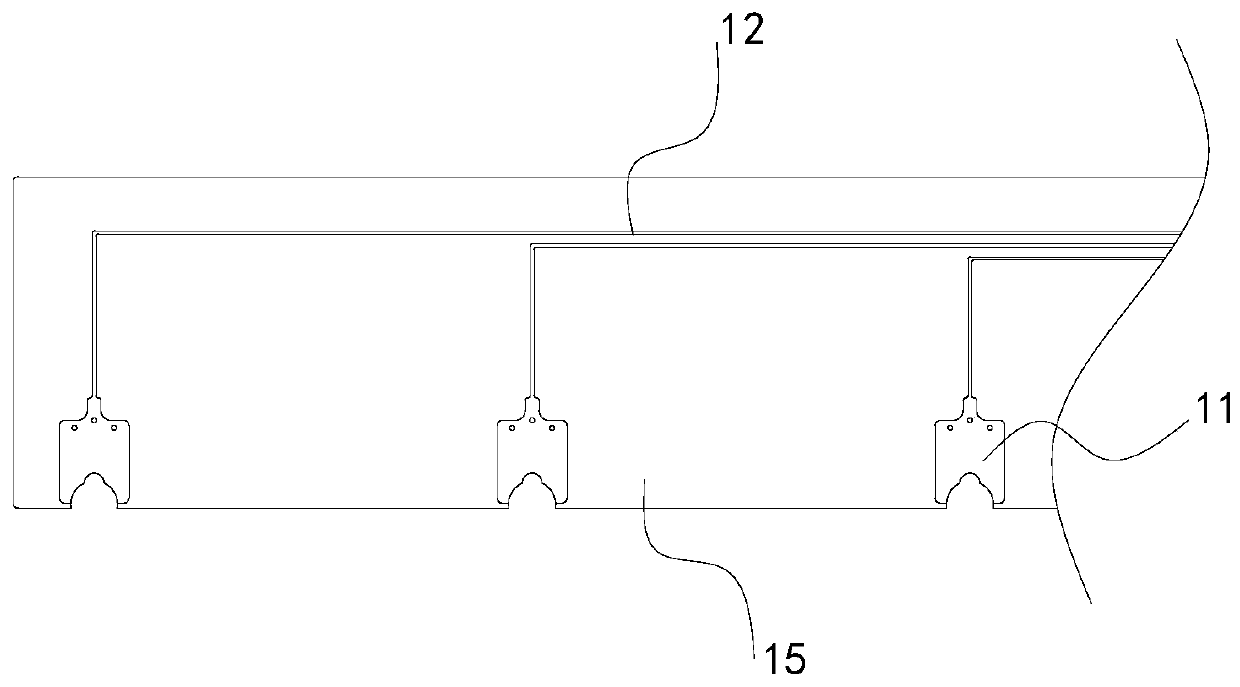

[0064] Such as Figure 1 to Figure 7 As shown, the capacitive screen 50 includes a screen body 51 and a flexible circuit board.

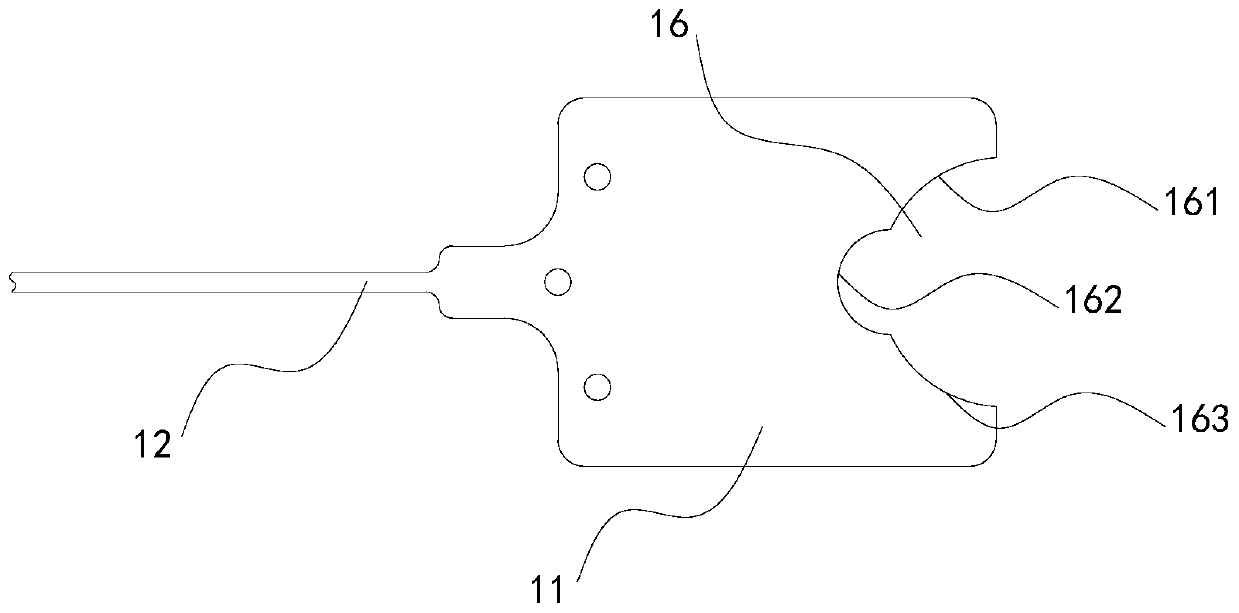

[0065] The flexible circuit board includes: a base layer 22, a conductive layer 10 and a protective layer. The conductive layer 10 is attached to the base layer 22. The protective layer covers the conductive layer 10. The conductive layer 10 has a conductive sheet 11 and a conductive wire 12. The conductive sheet 11 and the conductive wire 12 are electrically connected to each other, the conductive sheet 11 is located at the conductive connection side, and the conductive sheet 11 has a first relief gap 16, and the opening width of the first relief gap 16 gradually decreases from the outside to the inside (this embodiment In an example, the edge of the first abdication 16 is an arc segment).

[0066] There are conductive contacts 52 on the screen body 51, and the back surface of the flexible circuit board is electrically connected to the screen body...

Embodiment 2

[0094] Such as Figure 8 As shown, compared with the first embodiment, this embodiment has the first relief gap 16 whose edge is an arc segment, and there is only one arc segment.

[0095] This embodiment has the following advantages:

[0096] In this embodiment, when processing the conductive sheet 11 , the drill only needs to drill one cut and drill an arc segment to complete the processing of the conductive sheet 11 , and the process of processing the conductive sheet 11 is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com