A high-precision guide rail correction device

A correction device and high-precision technology, applied in metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve problems such as unbalanced force correction accuracy, reduce processing cost and processing difficulty, and achieve accurate detection accuracy , the effect of slowing down the movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

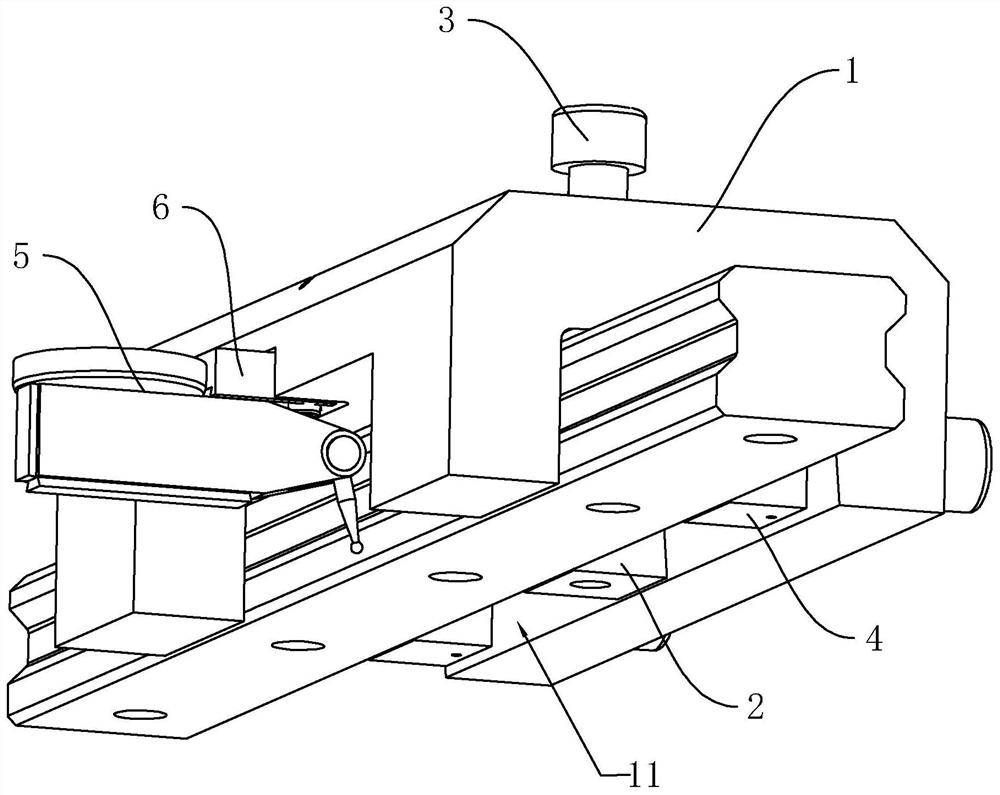

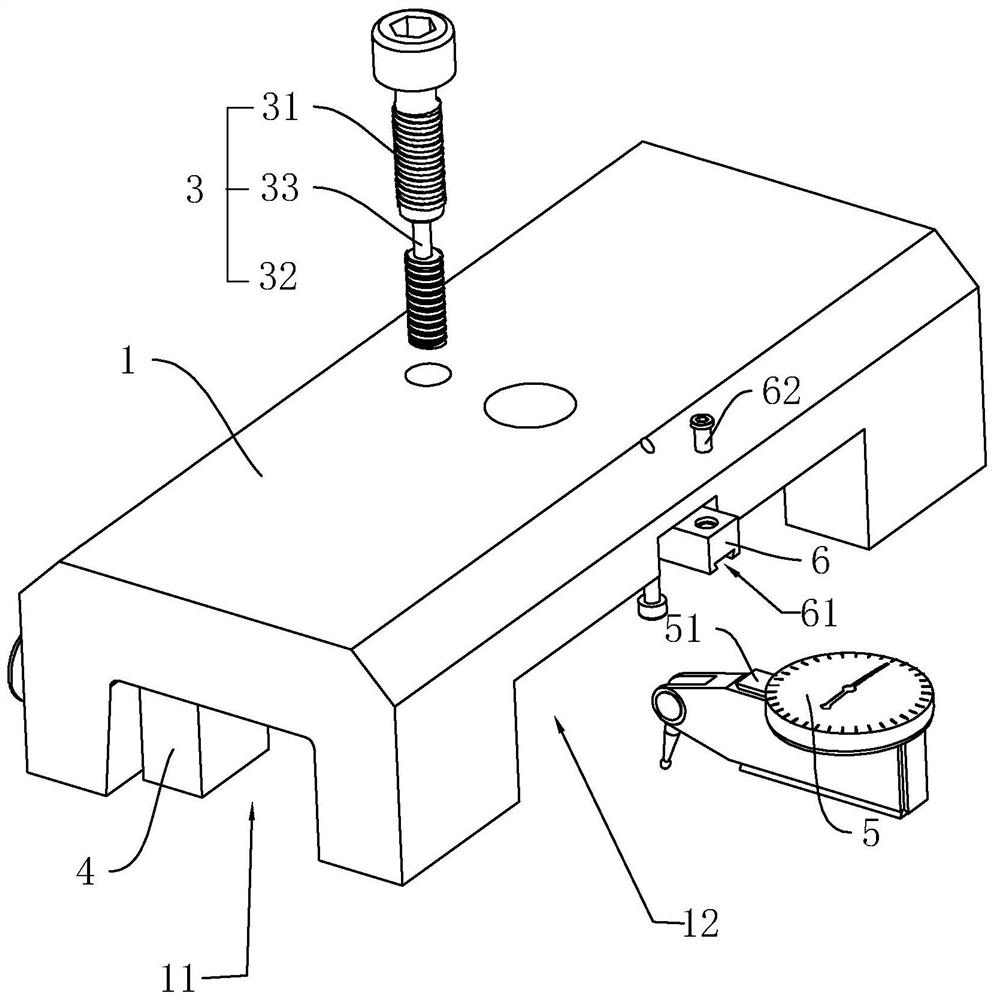

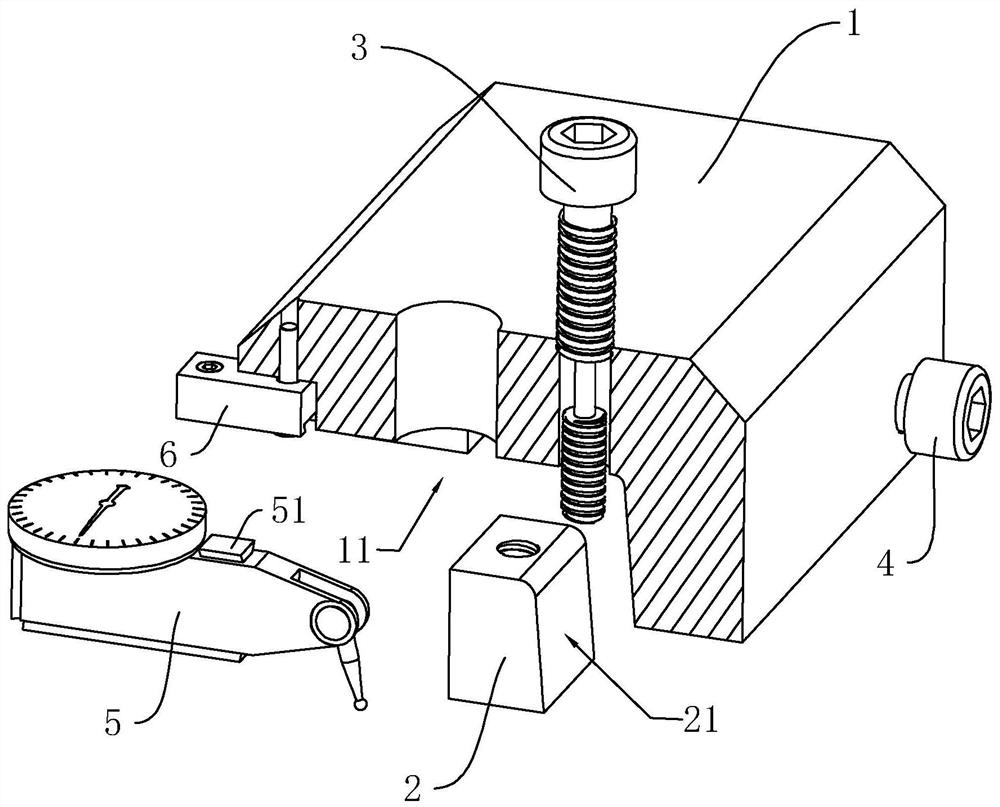

[0035] refer to figure 1 , is a high-precision guide rail correction device disclosed in the present invention, including a base 1, wherein the base 1 is provided with a correction groove 11 for accommodating and resisting the guide rail along its length direction, and the setting of the correction groove 11 makes the base 1 in an inverted U shape type settings. In order to facilitate the guide rail to enter the correction groove 11, the groove width of the correction groove 11 is larger than the width of the guide rail, and the inner wall of one side of the correction groove 11 is vertically slidably connected with the correction block 2, and the two sides of the correction block 2 are connected with the side wall of the guide rail and the correction groove respectively. 11 The side wall is in conflict. The side wall of the correction groove 11 away from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com