Car brake pedal arm

A car brake and pedal arm technology, applied in the field of auto parts, can solve the problems of high noise, inability to manufacture large bends, and large plate thickness, etc., to achieve the effect of optimizing car space, improving strength, and increasing bending degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

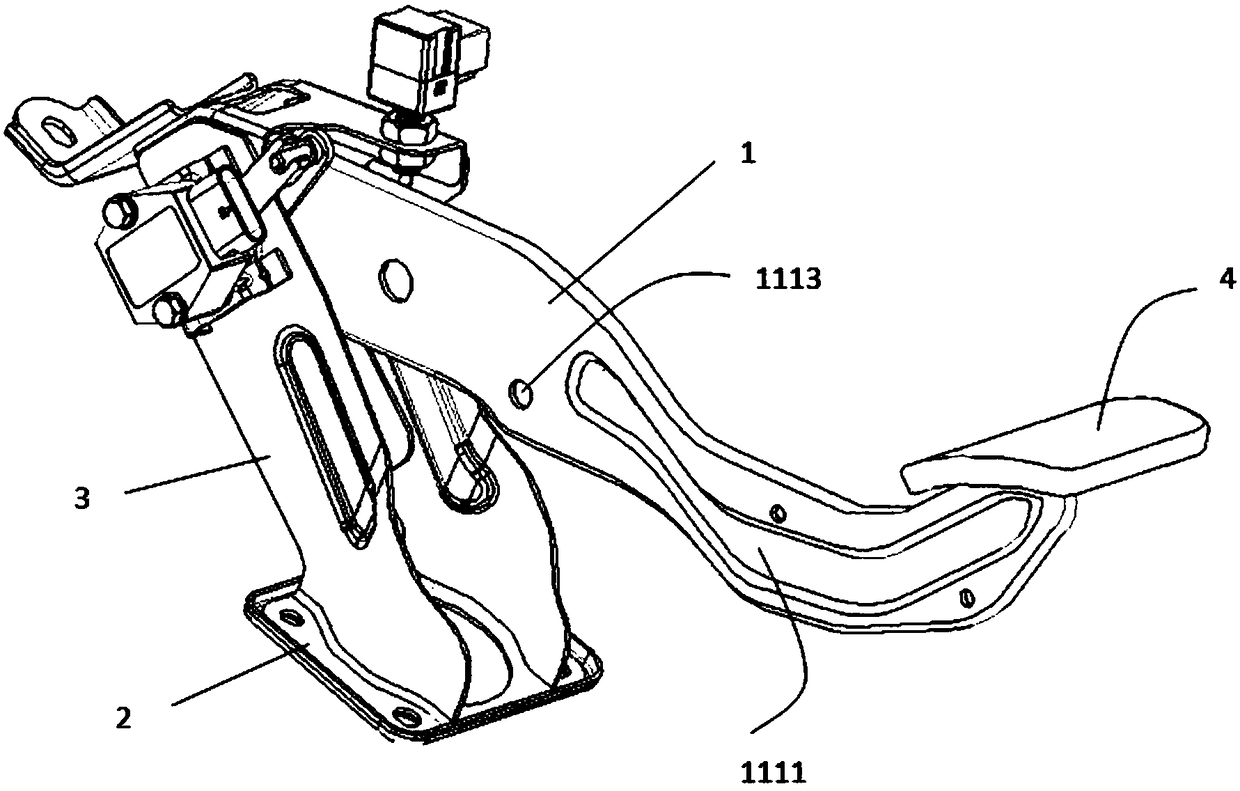

[0020] Such as figure 2 The automobile brake pedal mechanism shown includes a fixed plate 2, a bracket 3 fixedly arranged on the fixed plate 2, and a pedal arm 1 rotatably connected to the bracket, and a pedal sheet 4 is welded at the tail of the pedal arm.

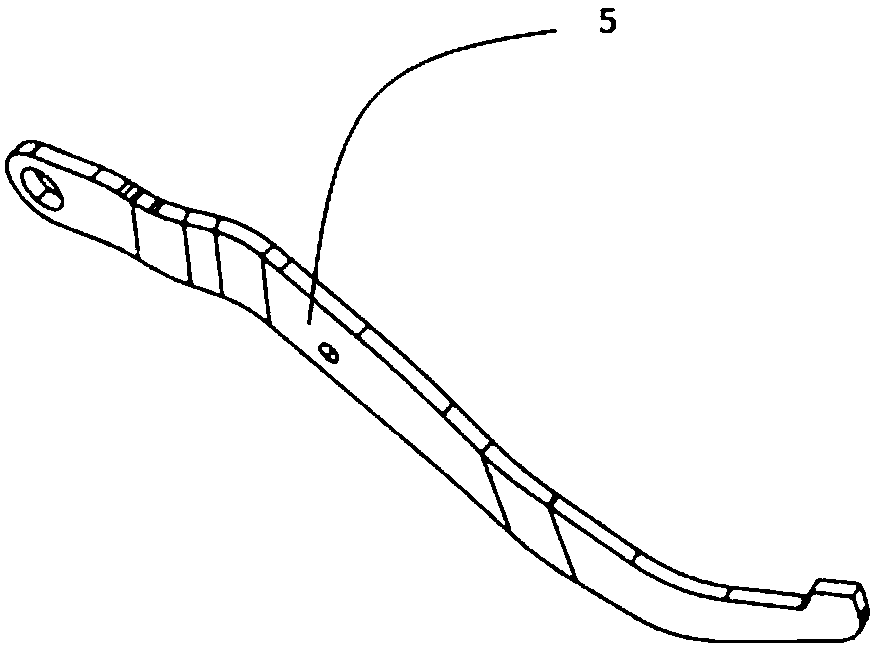

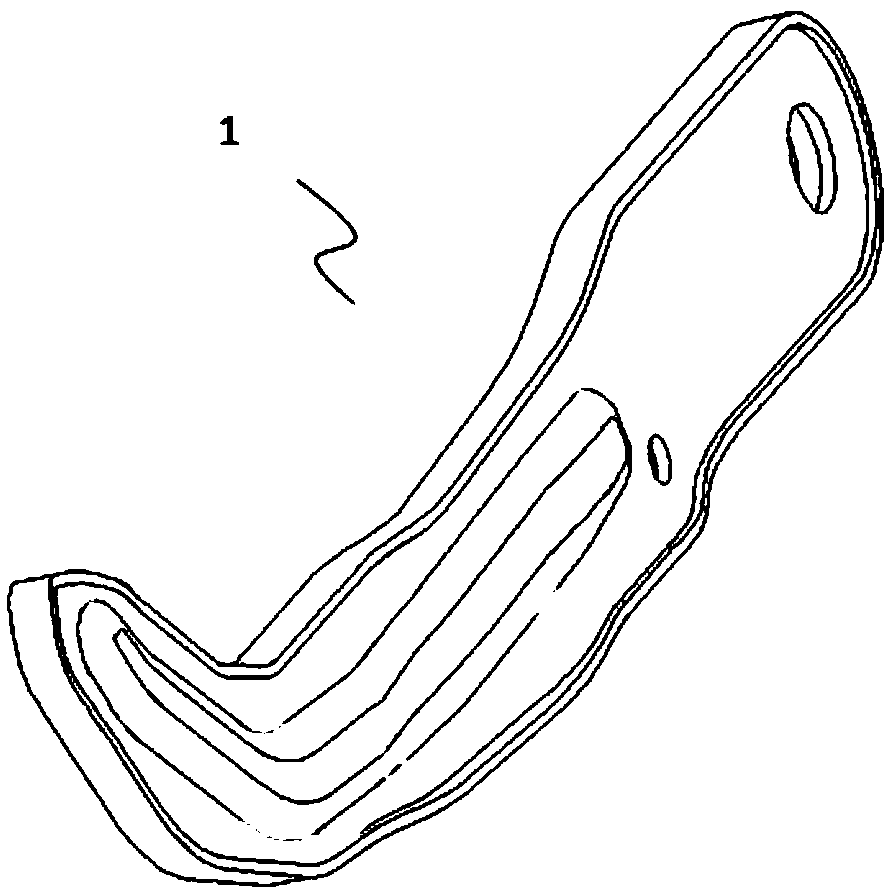

[0021] Such as Figure 3 to Figure 5 The shown automobile brake pedal arm 1 includes a pedal arm body 11, the pedal arm body includes a base plate 111 and a flange 112 arranged on the edge of the base plate, the base plate and the flange form a cavity, and the cavity is set There is a reinforcing plate 12 whose shape is adapted to the shape of the bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com