Multi-layer module superposition wax mold structure and method for efficiently preparing single crystal blade by using same

A technology of single crystal blades and wax molds, applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve problems such as deterioration of temperature field distribution, uneven lateral temperature field, and bending of isotherms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a single crystal blade, comprising the following steps:

[0041] Provide the multi-layer module superimposed wax mold structure described in the above technical solution;

[0042]The multi-layer module superimposed wax mold structure is successively coated, sanded, dewaxed and roasted to obtain a mold shell;

[0043] The molten alloy liquid is poured into the mold shell, so that the molten alloy liquid is directional solidified from bottom to top, and the single crystal blade is obtained after shelling.

[0044] The present invention provides the multi-layer module superimposed wax mold structure described in the above technical solution. In the present invention, a pneumatic wax pressing machine is preferably used to obtain the multi-layer modular superimposed wax mold structure described in the above technical solution. In the present invention, the temperature of the wax cylinder during the pressing is pref...

Embodiment 1

[0054] The first step, the structural design and preparation of the wax model:

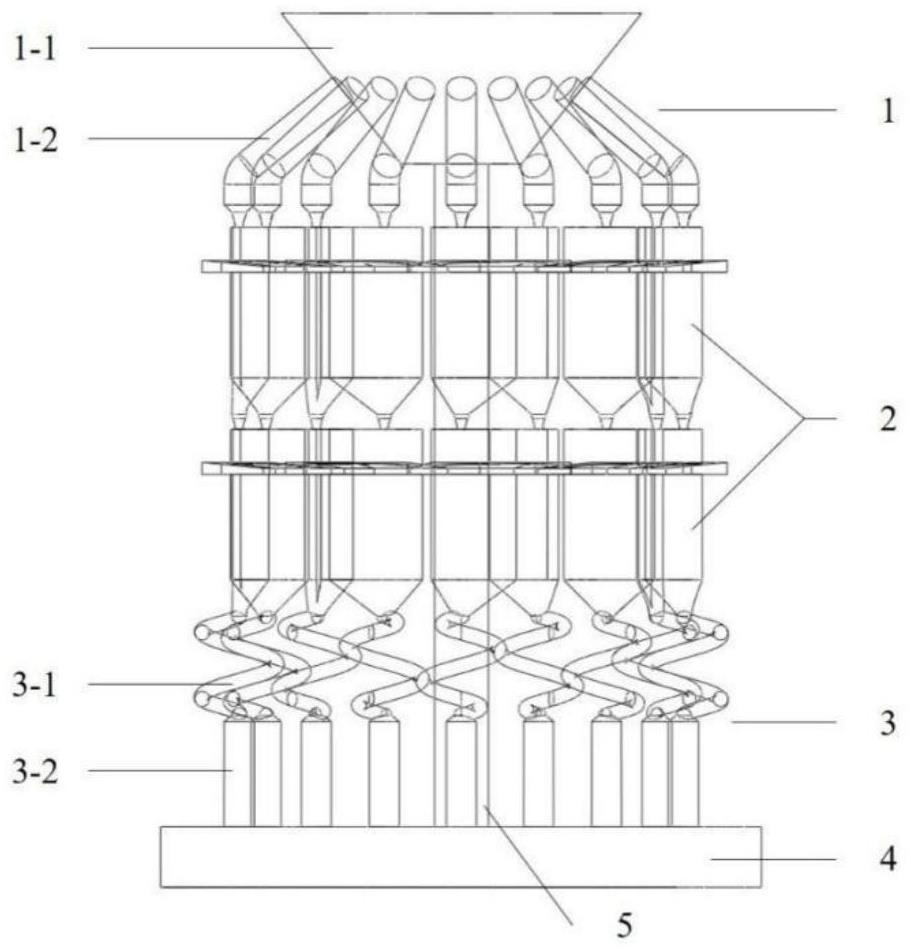

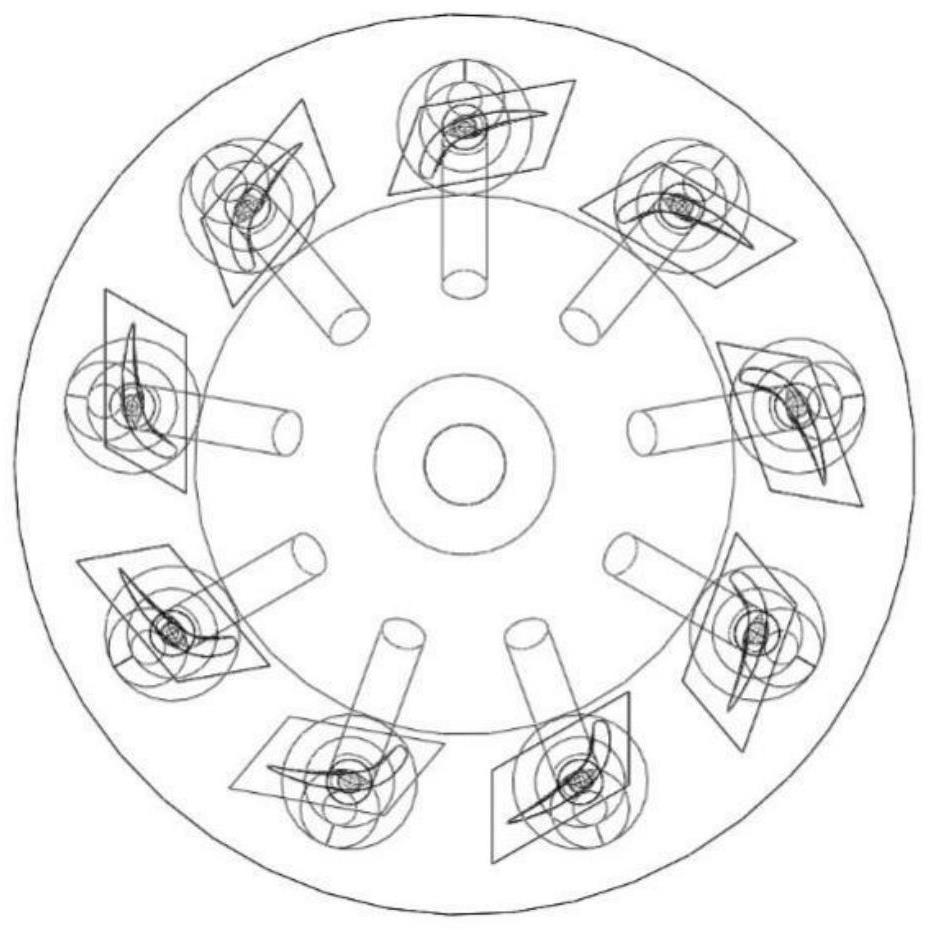

[0055] The double-layer module superimposed wax mold structure adopted in this embodiment is as follows: Figures 1 to 2 shown.

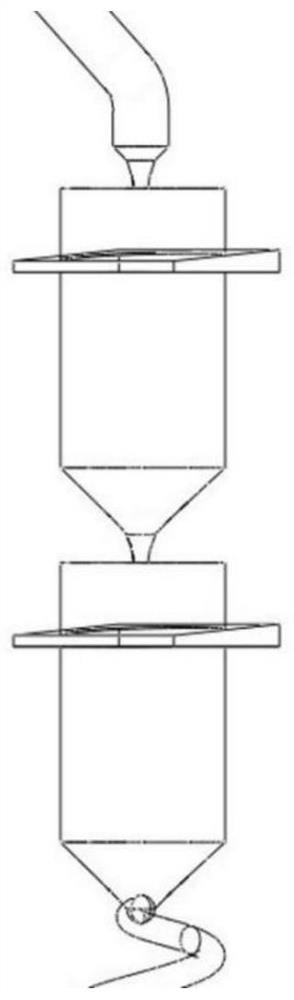

[0056] a. The design of the double-layer module superimposed wax mold structure and the wax mold pressing: the double-layer module superimposed wax mold structure consists of the casting system wax mold 1, blade wax mold 2, crystal selector wax mold 3, and chill plate wax The mold 4 and the central pillar wax mold 5 are composed of five parts; the pouring system wax mold 1 is composed of a sprue cup wax mold 1-1 and a number of inclined sprue wax molds 1-2 evenly distributed around it. The separator wax mold 3 is composed of the upper spiral section wax mold 3-1 and the lower seeding section wax mold 3-2; the wax mold of the above structure is pressed out by a pneumatic wax press; the temperature of the wax tank when the wax mold is pressed At 75℃, the nozzle temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com