Patents

Literature

645results about How to "Reduce size requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

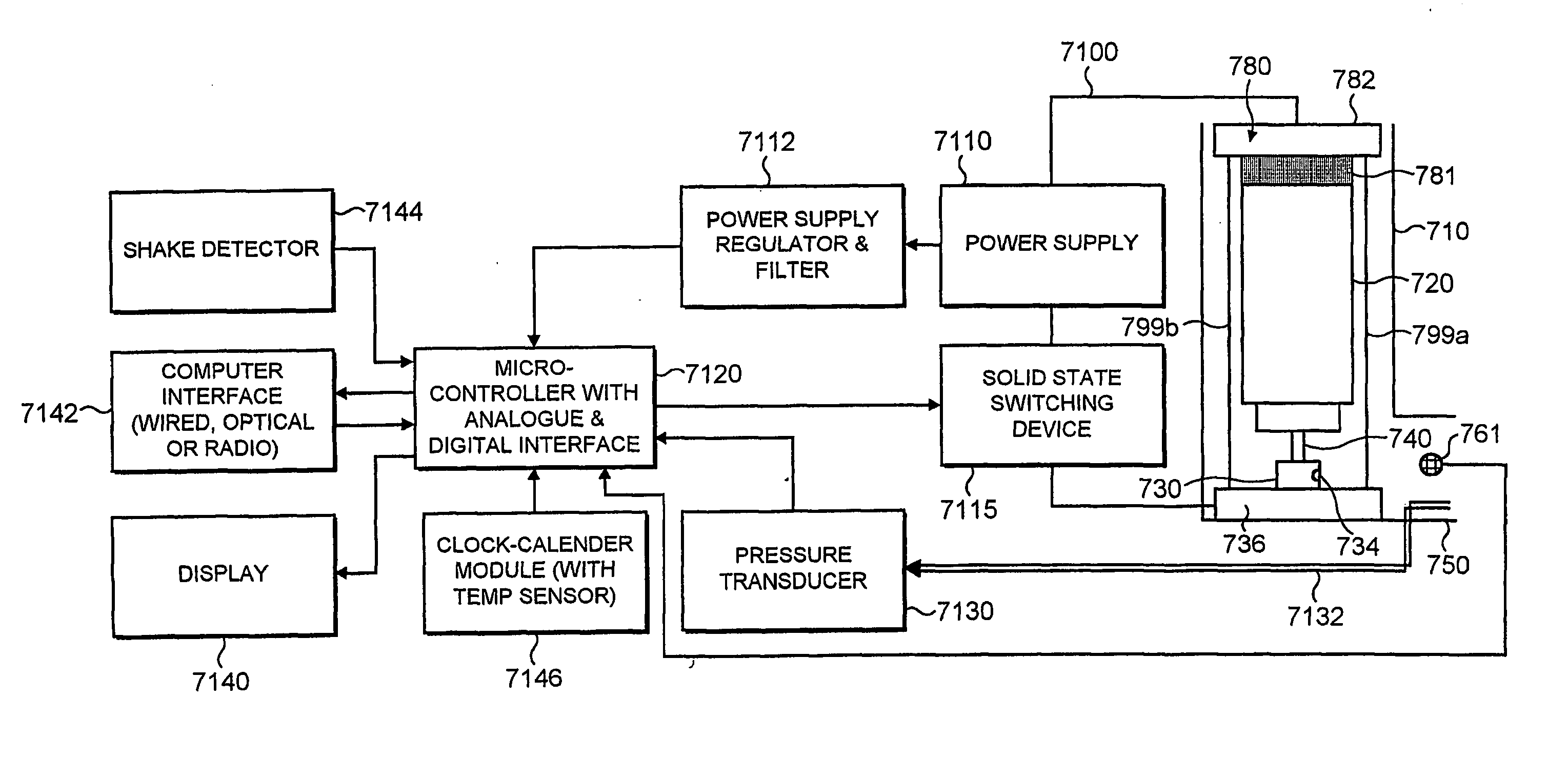

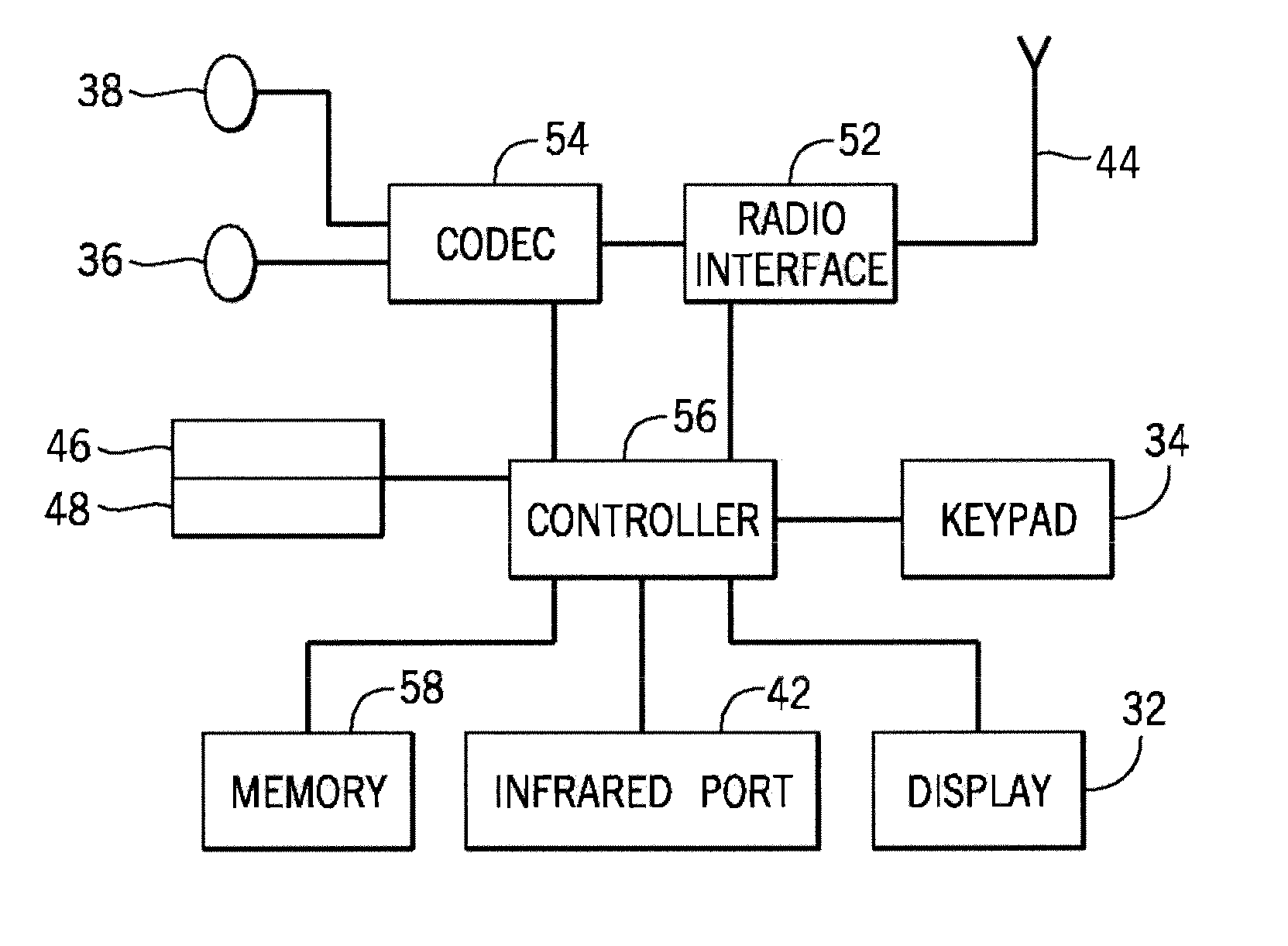

Wireless communication of physiological variables

InactiveUS20060009817A1Simplify the management processEliminate the problemElectrotherapySurgeryCommunication interfaceEngineering

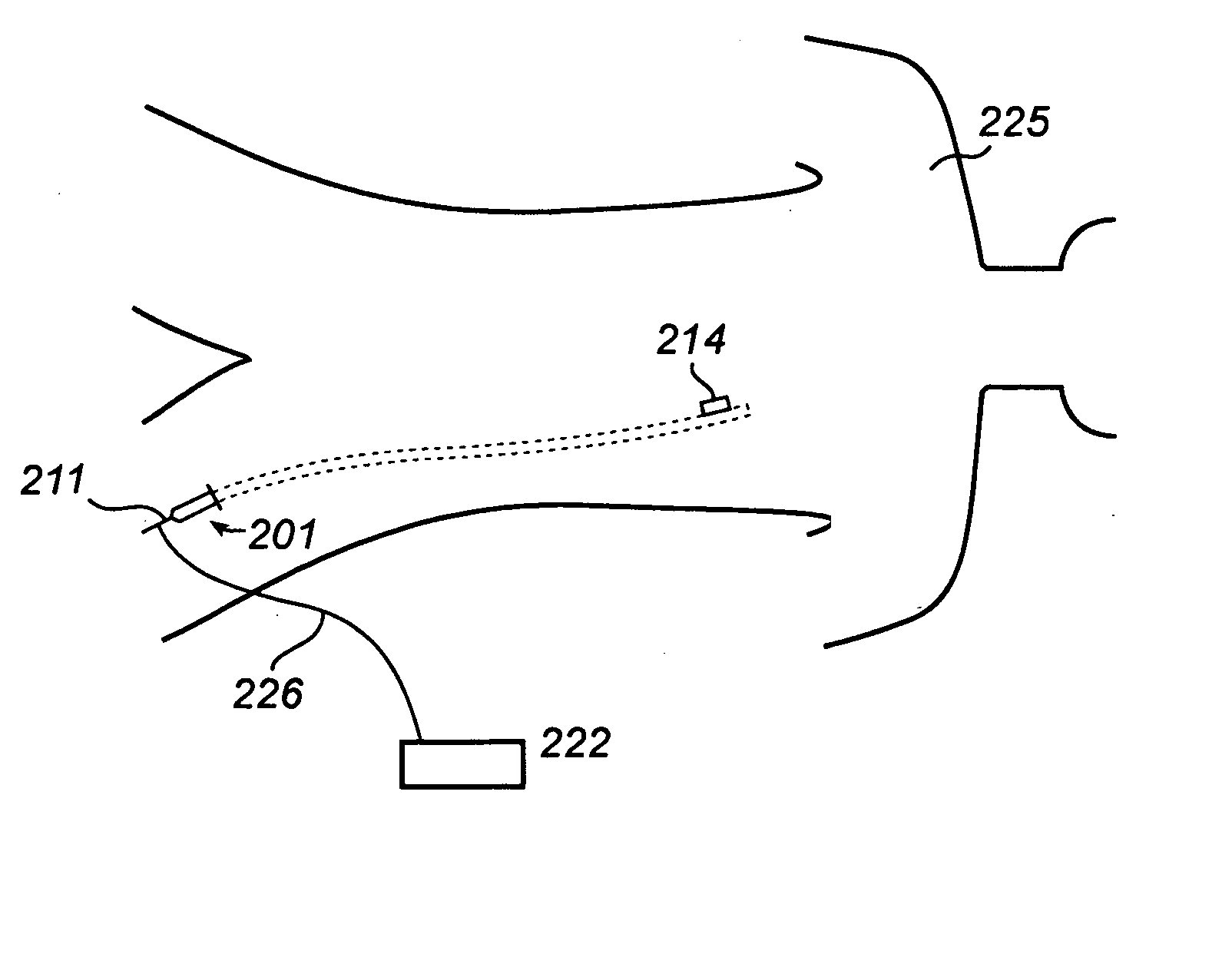

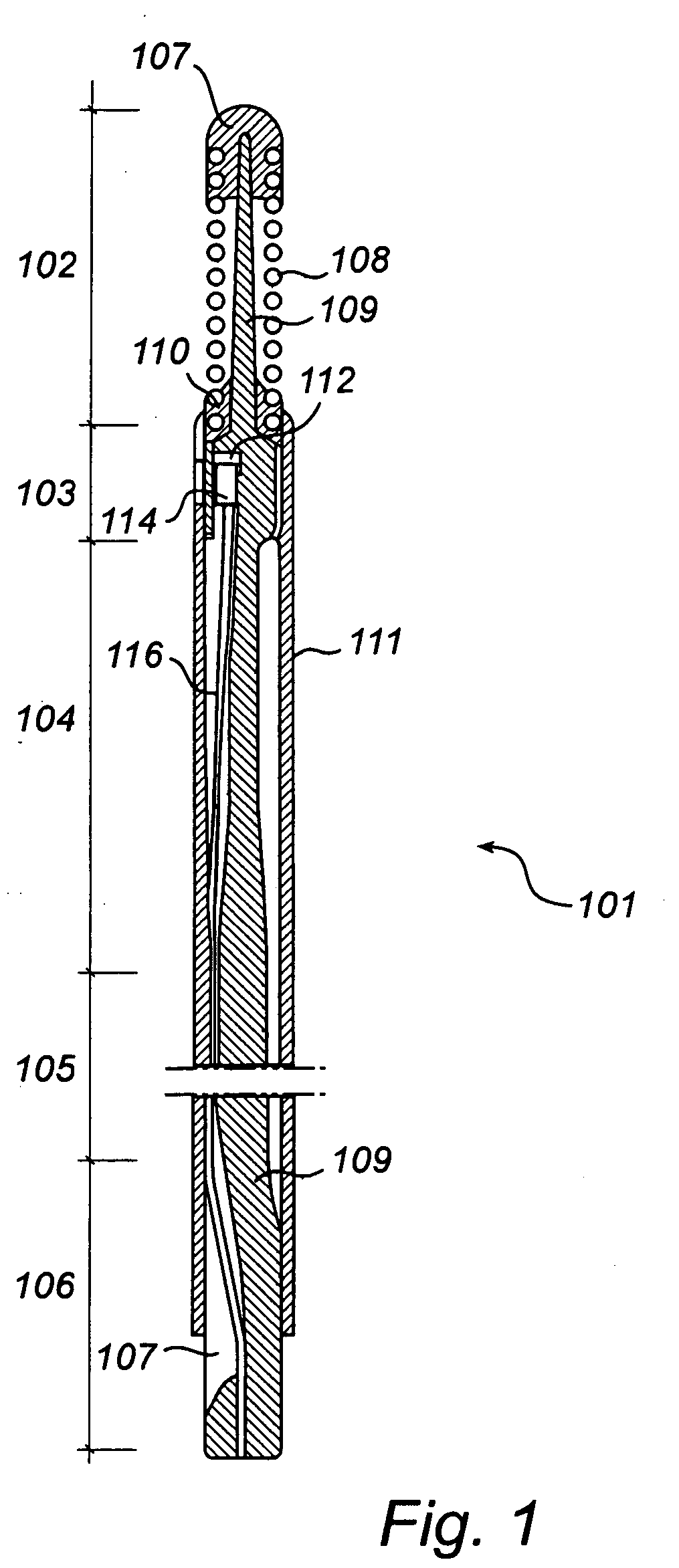

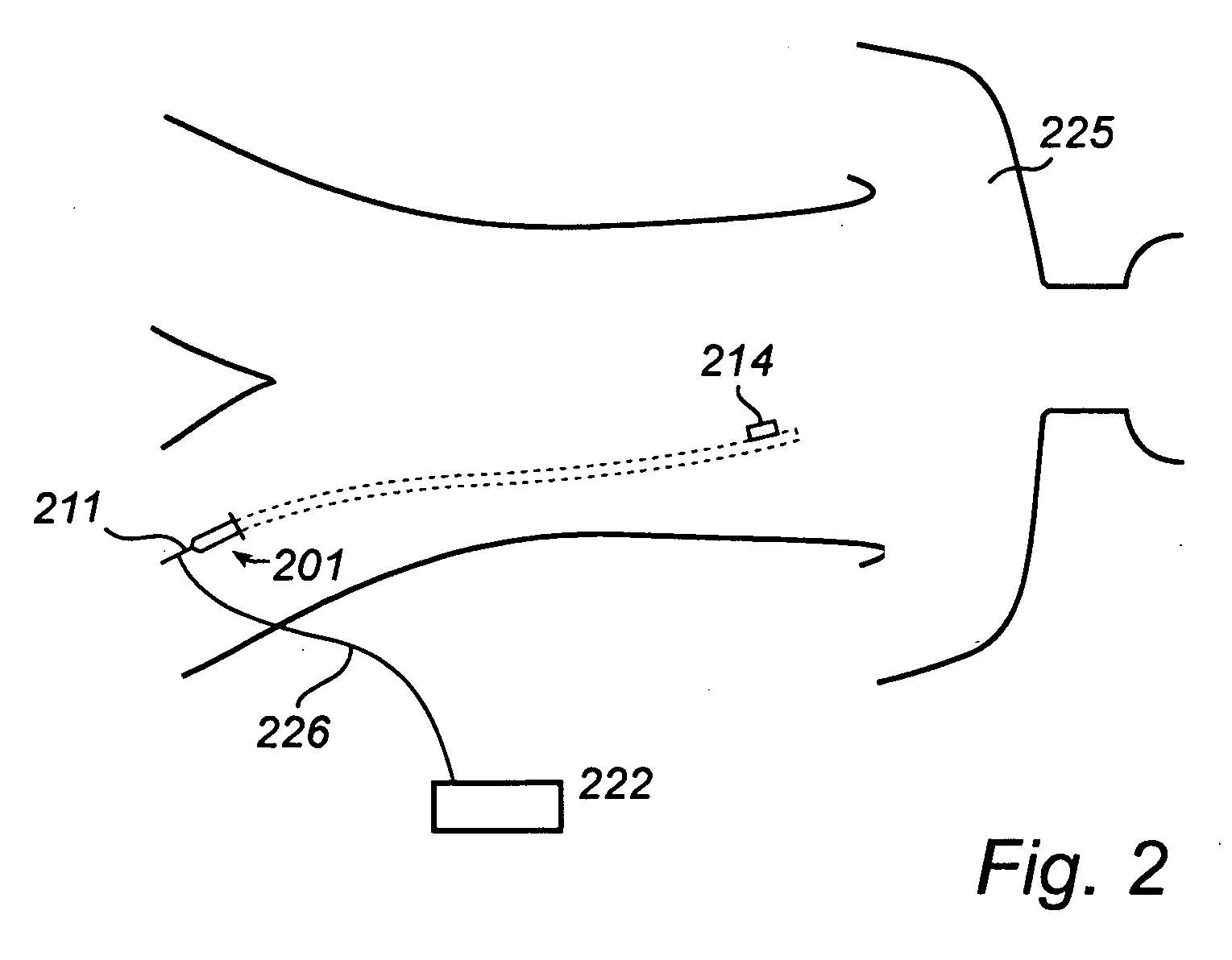

The present invention relates to a system and a method of measuring a physiological variable in a body. A basic idea of the present invention is to measure a physiological variable in a body by means of employing a sensor (314) which is arranged to be disposed in the body for measuring the physiological variable. The sensor must be provided with a supply voltage in order to be operable. Therefore, a control unit (322) disposed outside the body provides this supply voltage to the sensor. The control unit also receives, from the sensor, via a wired connection (311), signals that represent the physiological variables that are measured. The control unit is arranged with a communication interface (401, 701) and a modulator (301) for wireless communication of the measured physiological variables for presentation purposes.

Owner:ST JUDE MEDICAL COORDINATION CENT

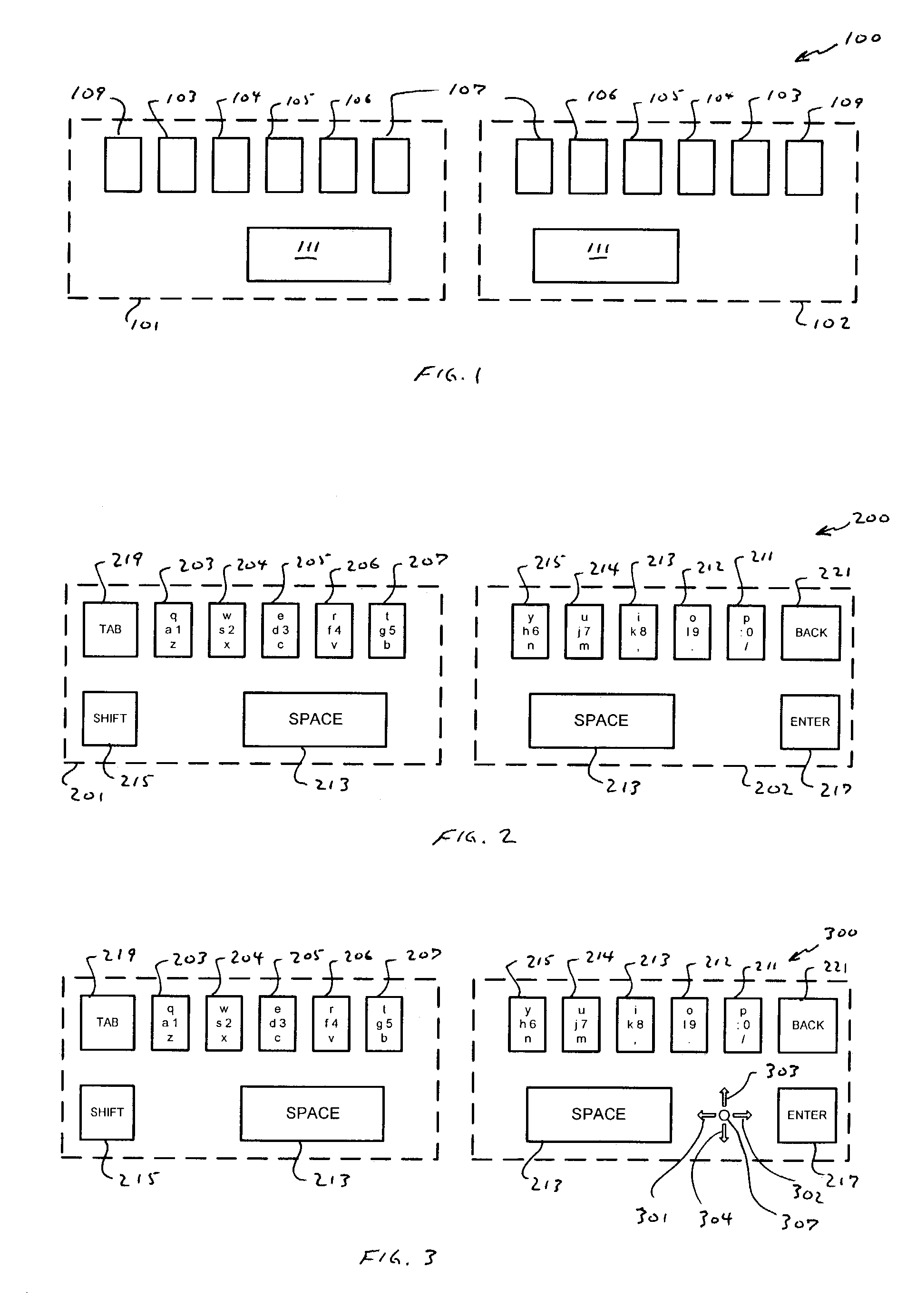

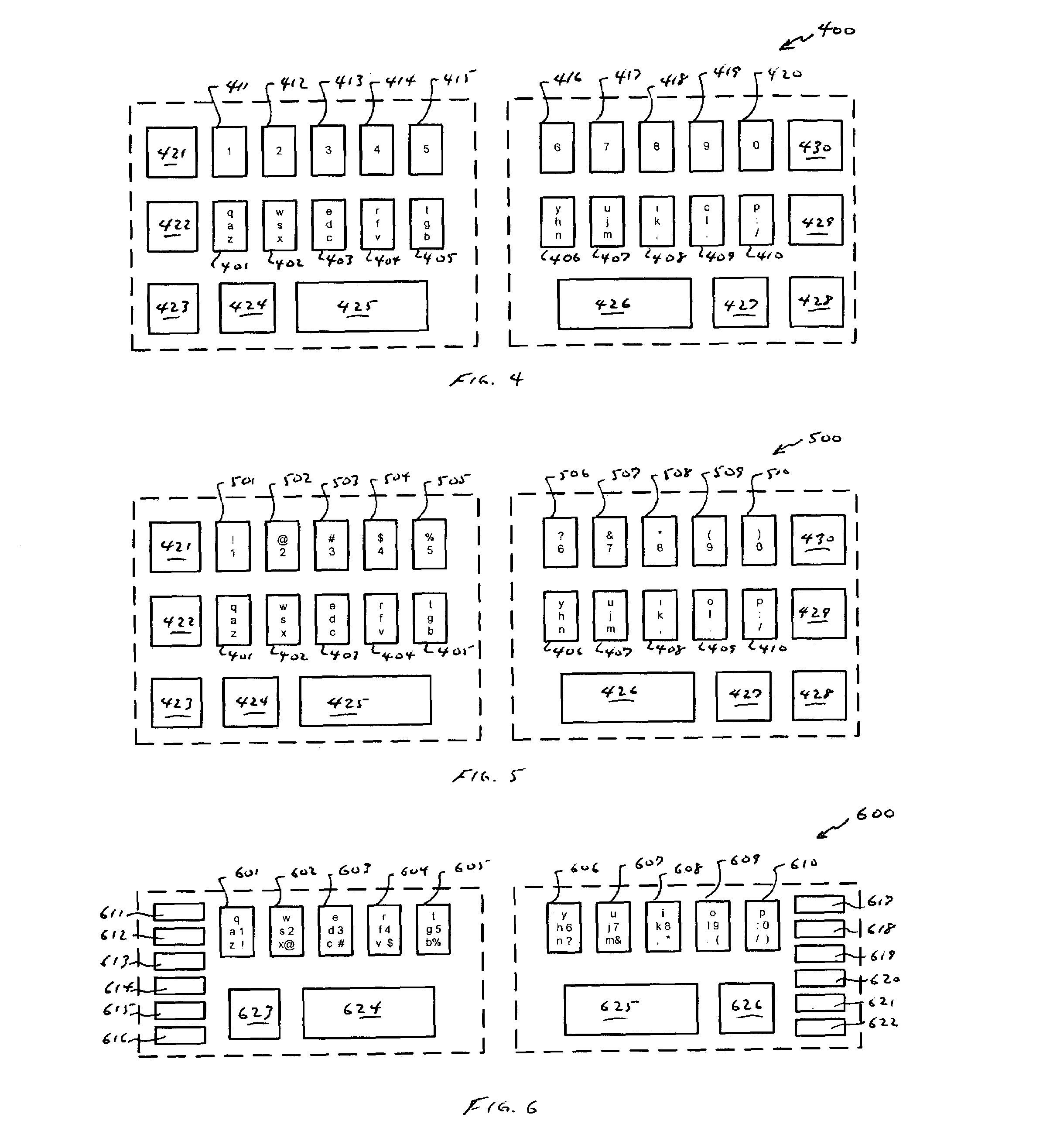

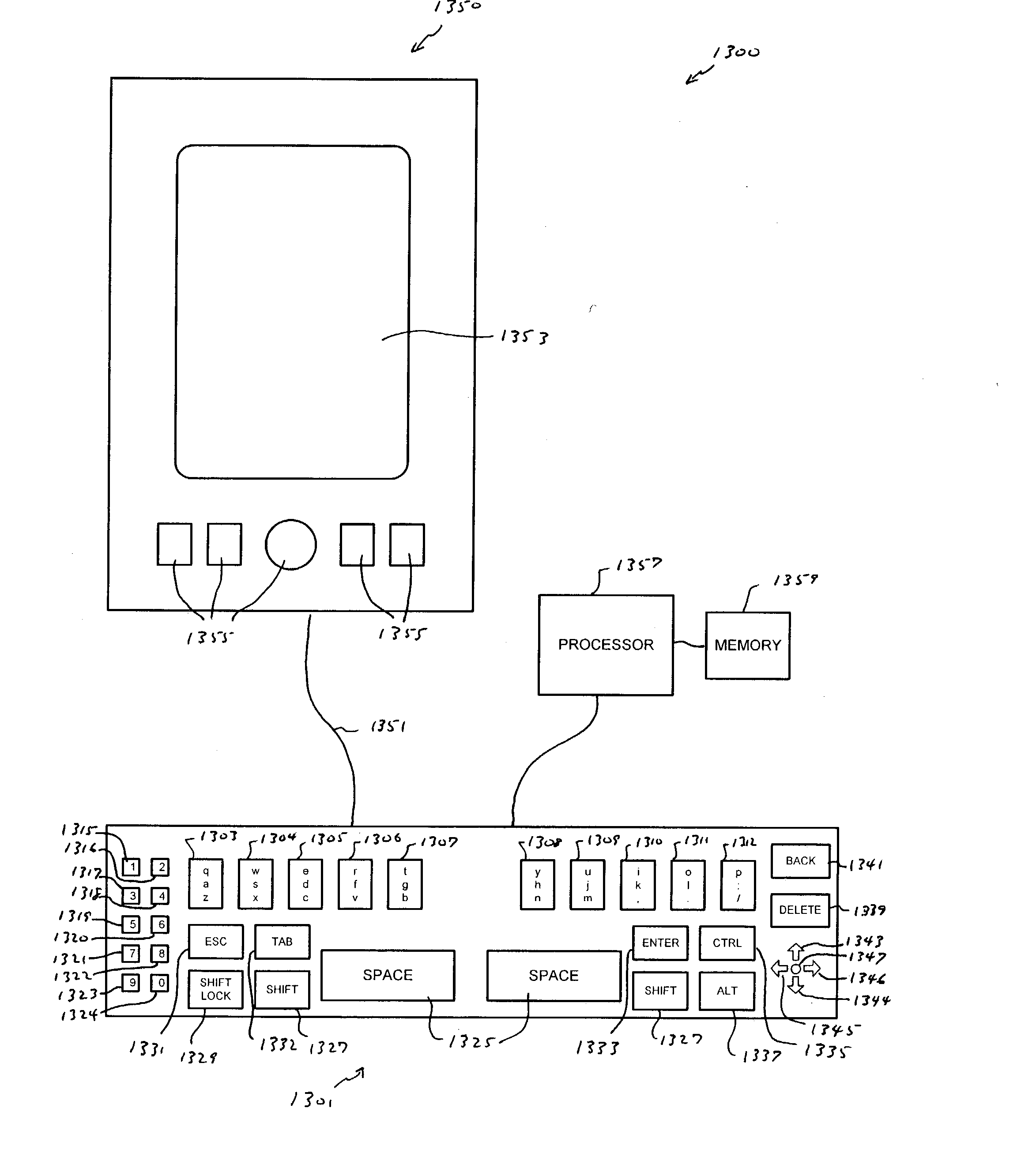

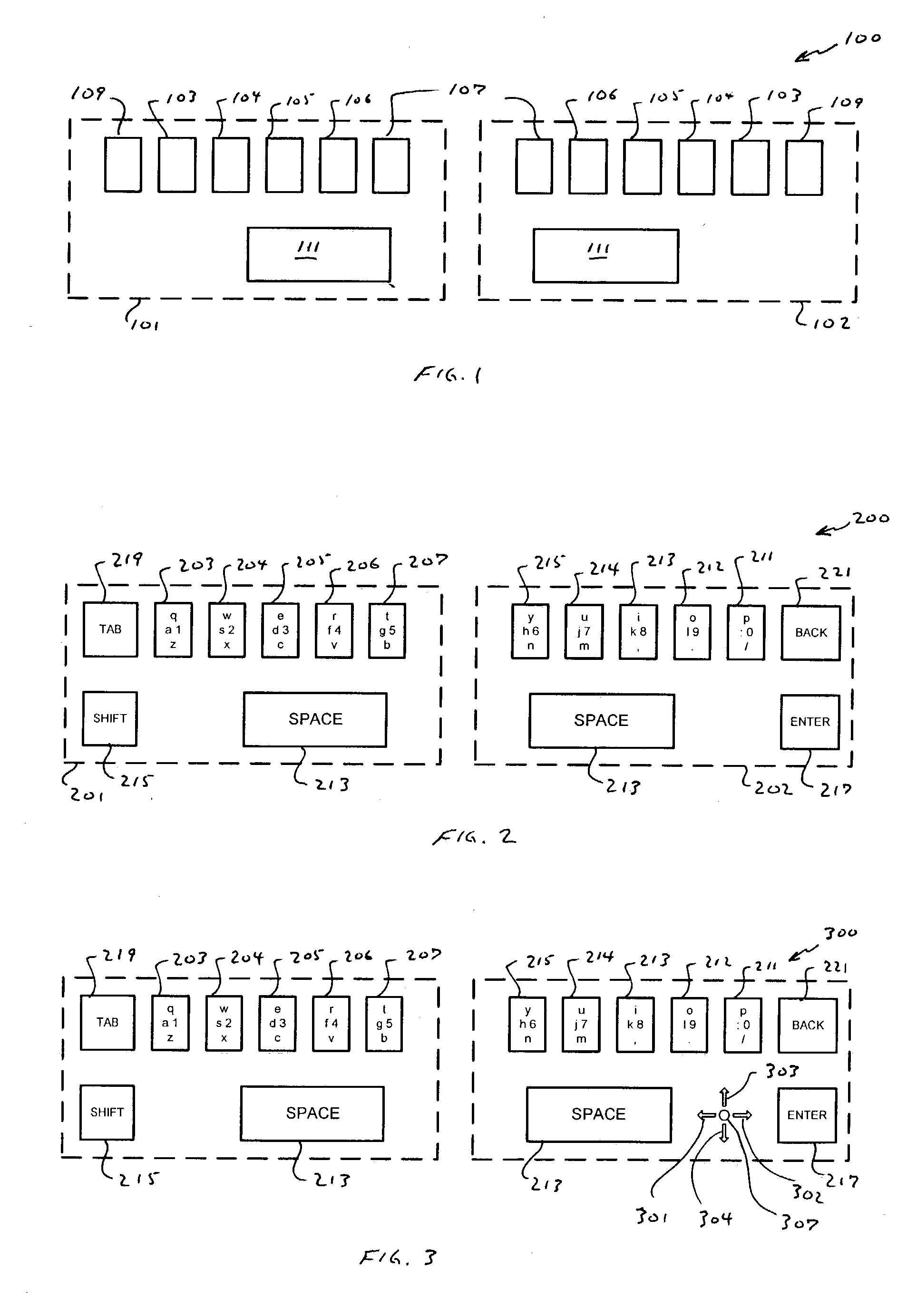

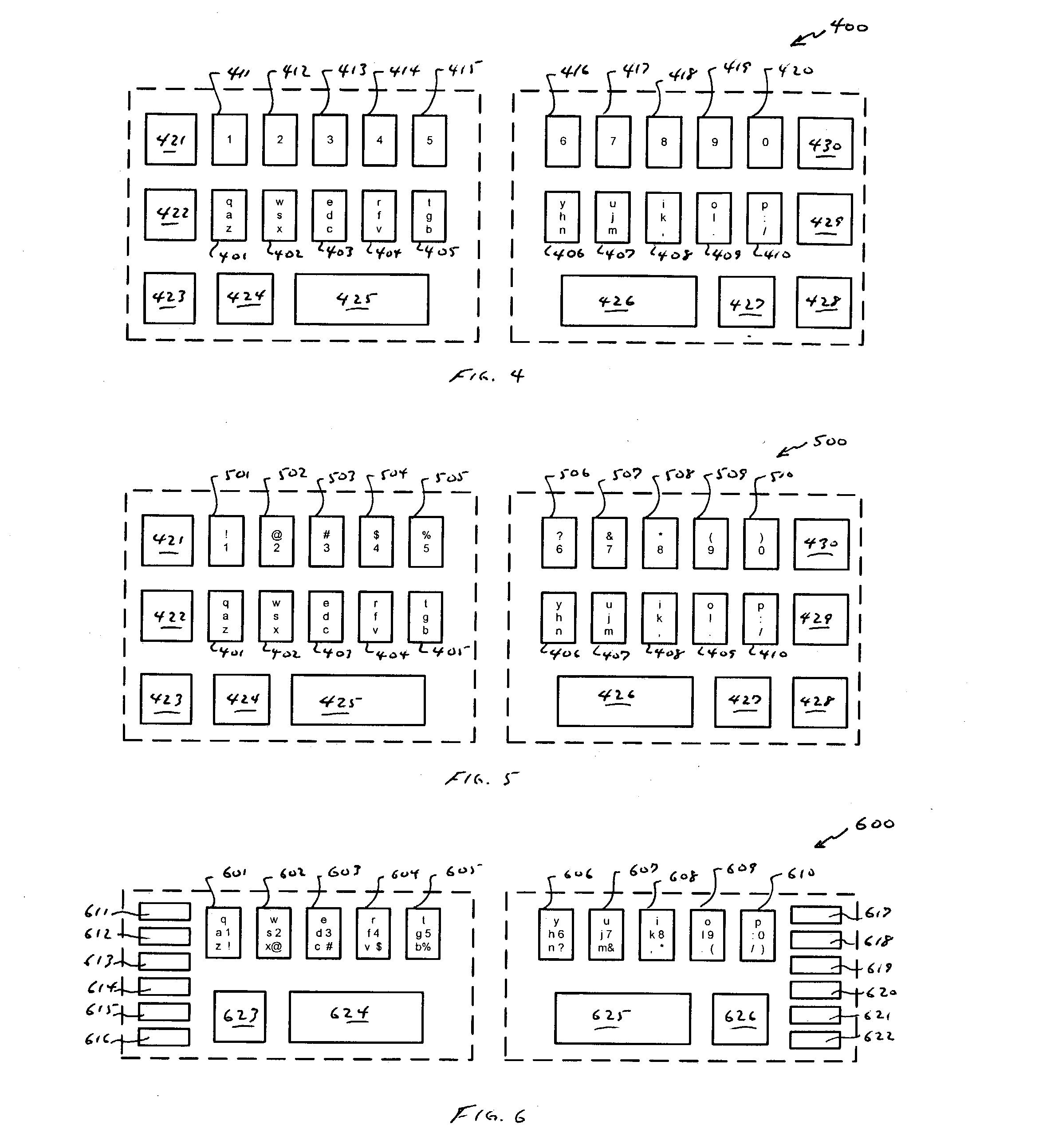

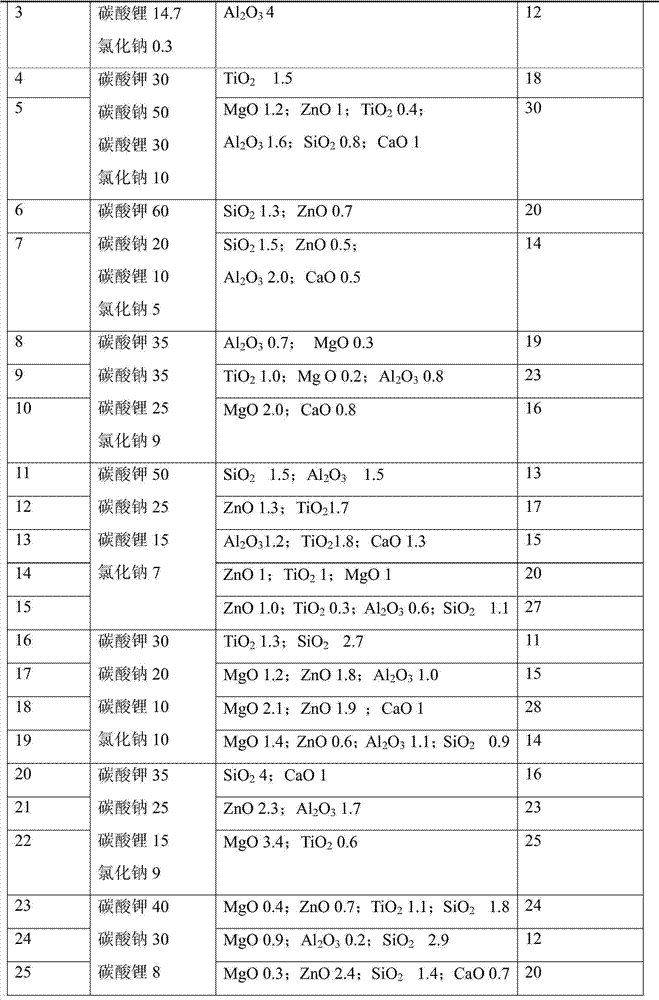

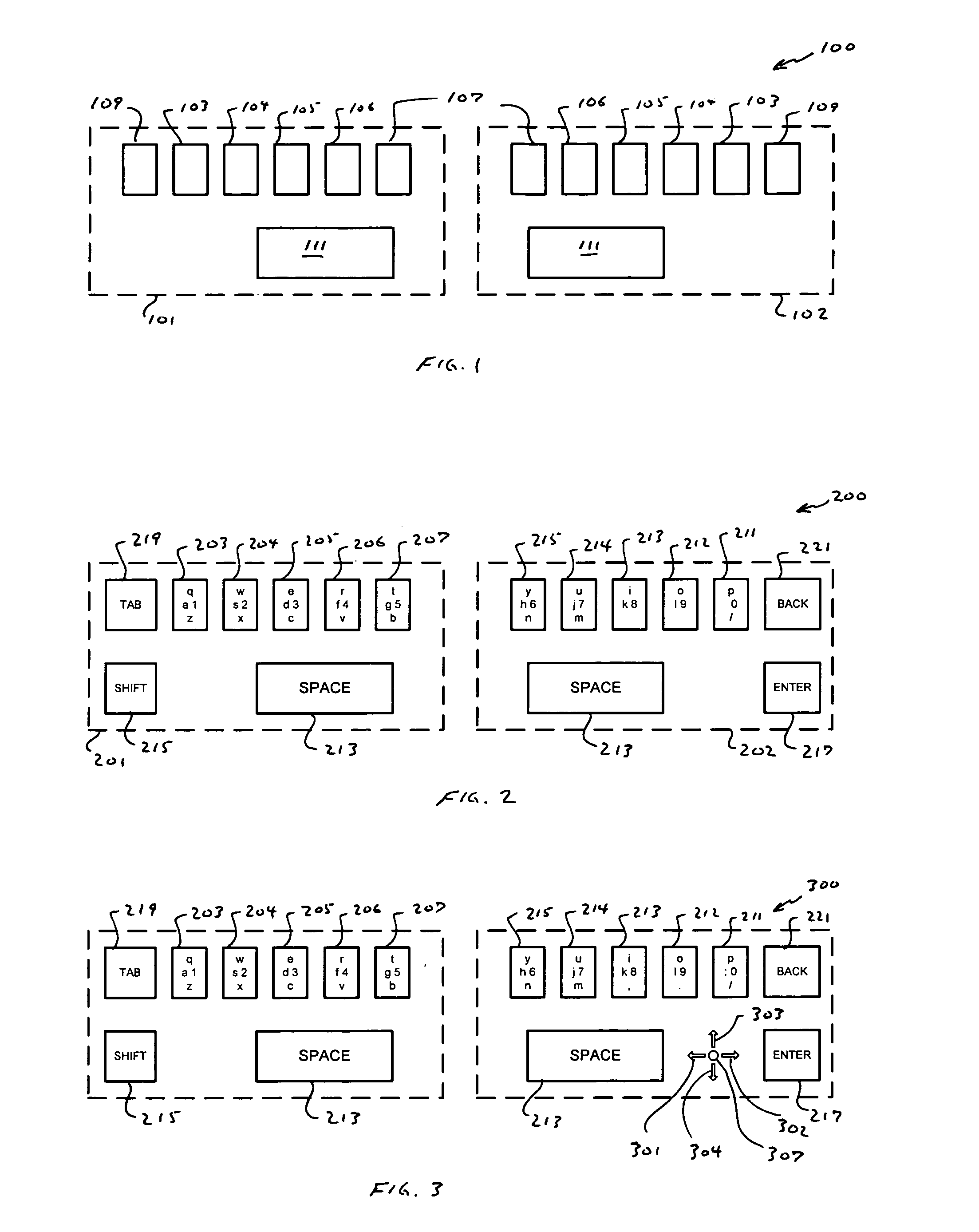

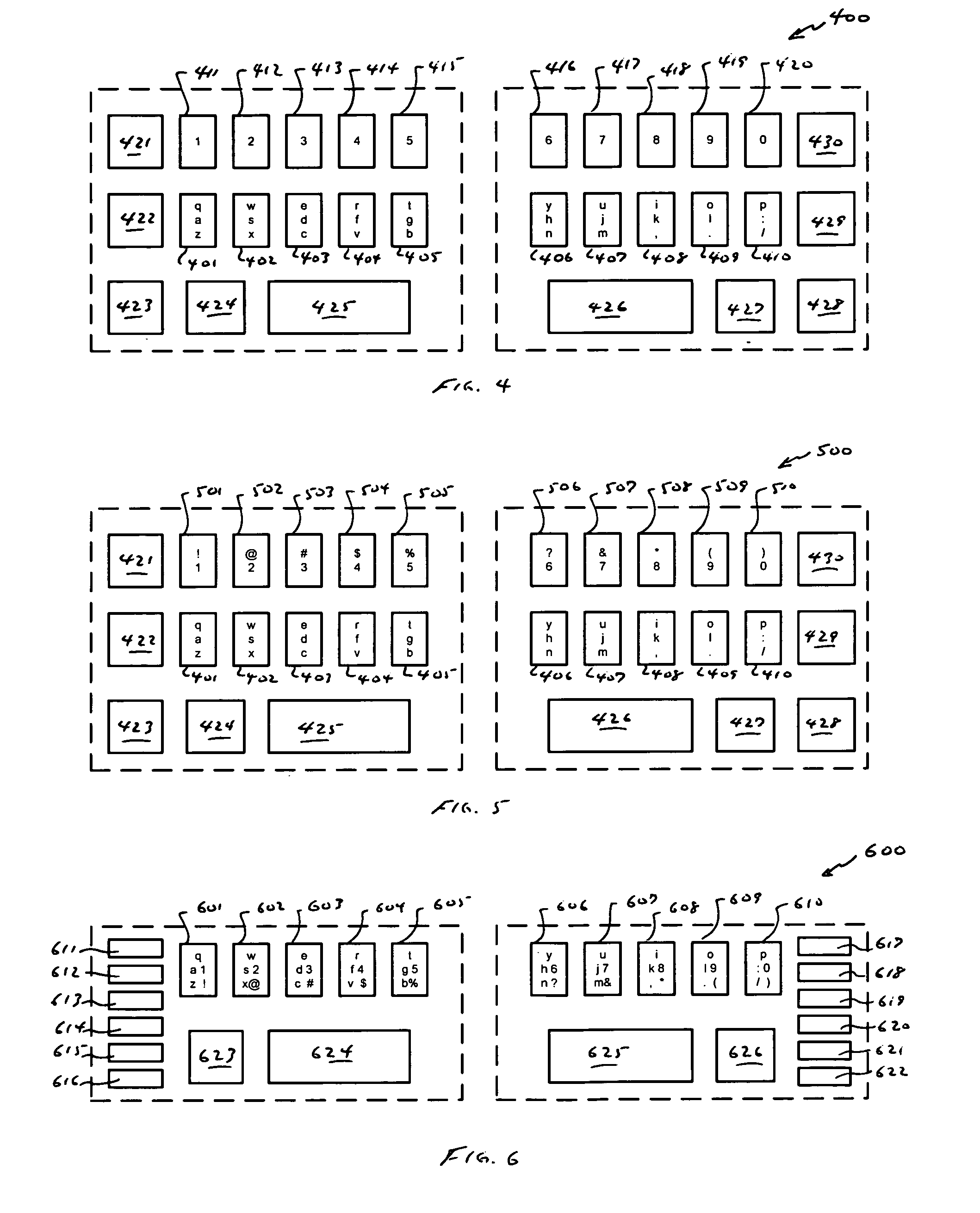

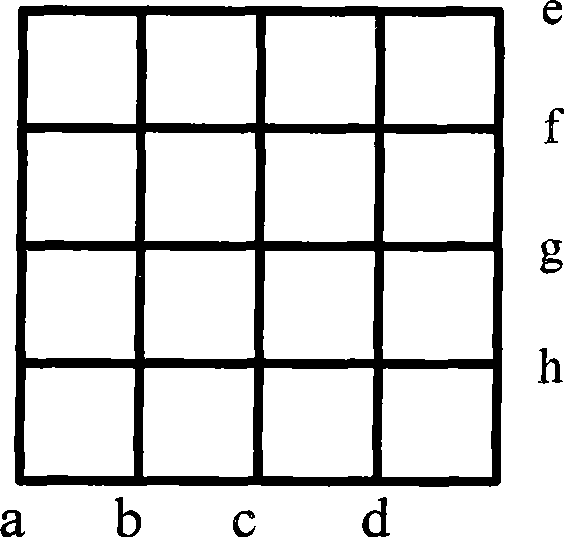

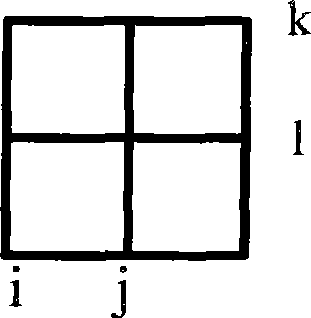

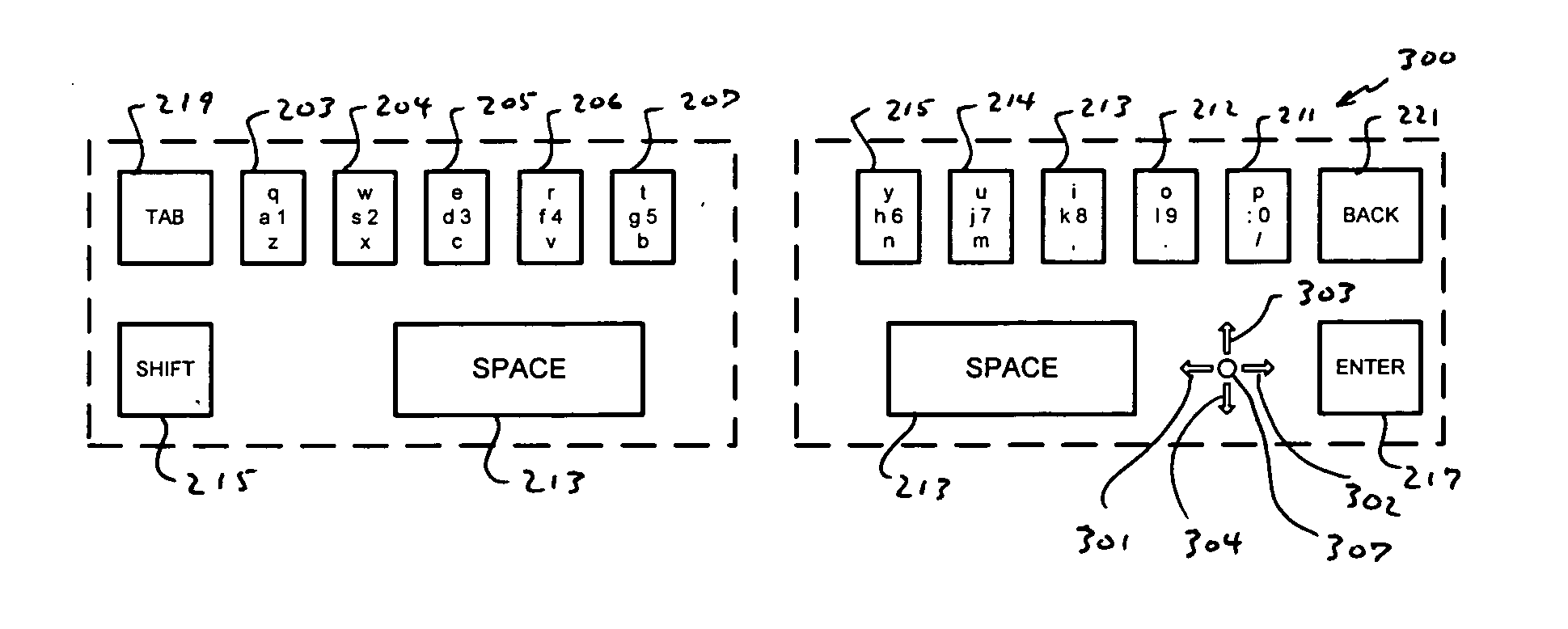

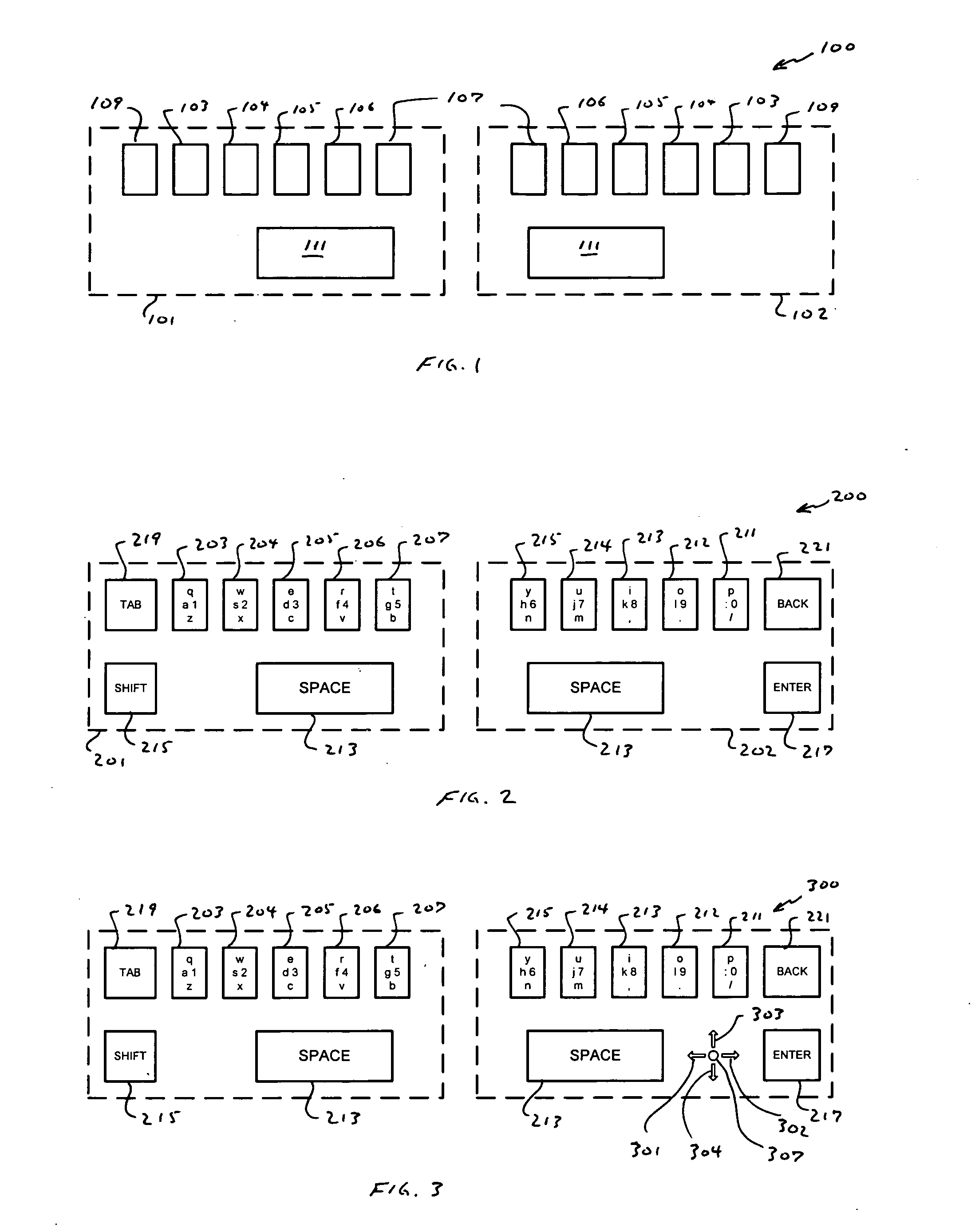

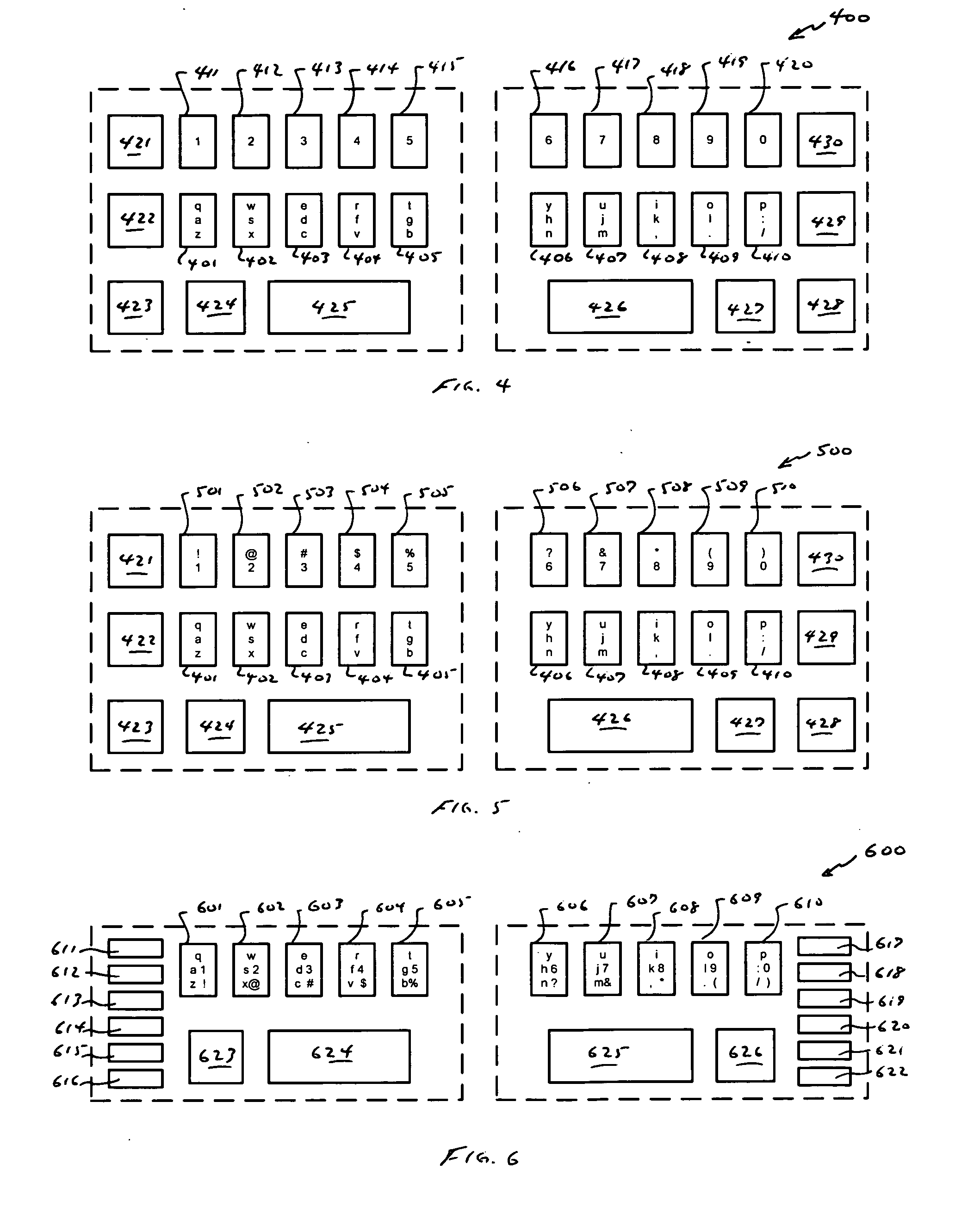

Compressed standardized keyboard

InactiveUS7081837B2Reduce size requirementsSmall sizeInput/output for user-computer interactionInterconnection arrangementsReduced sizeComputer science

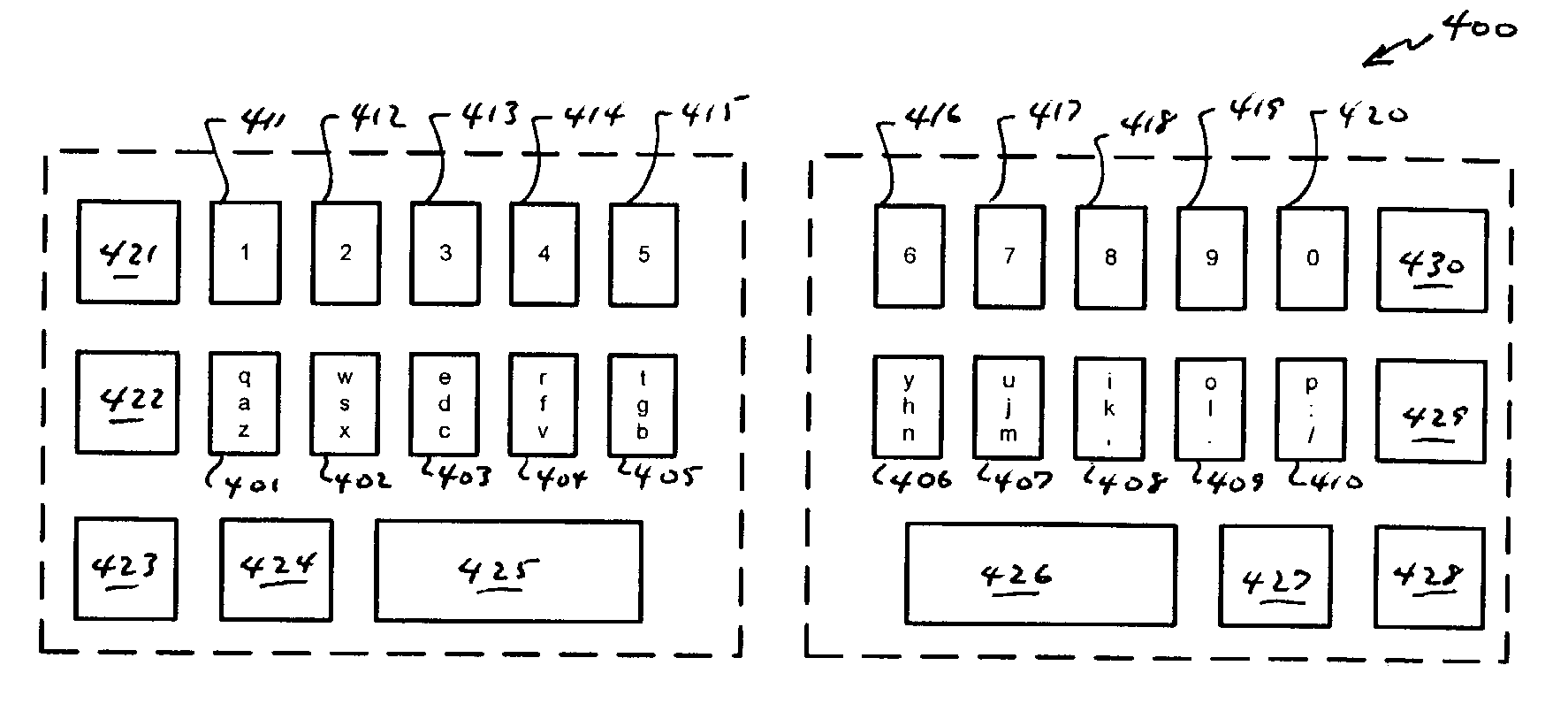

A keyboard of reduced size is provided in which multiple characters are assigned to each of the primary keys. The selection of the characters to be assigned to each specific primary key is based on the touch typing rules associated with a specific standardized keyboard, preferably allowing at least three rows of keys to be reduced to a single row of keys. A disambiguating system is used to interpret which of the characters and / or symbols assigned to a particular key is intended, typically by applying a set of disambiguating rules to generated input sequences.

Owner:BOLLMAN TAYLOR

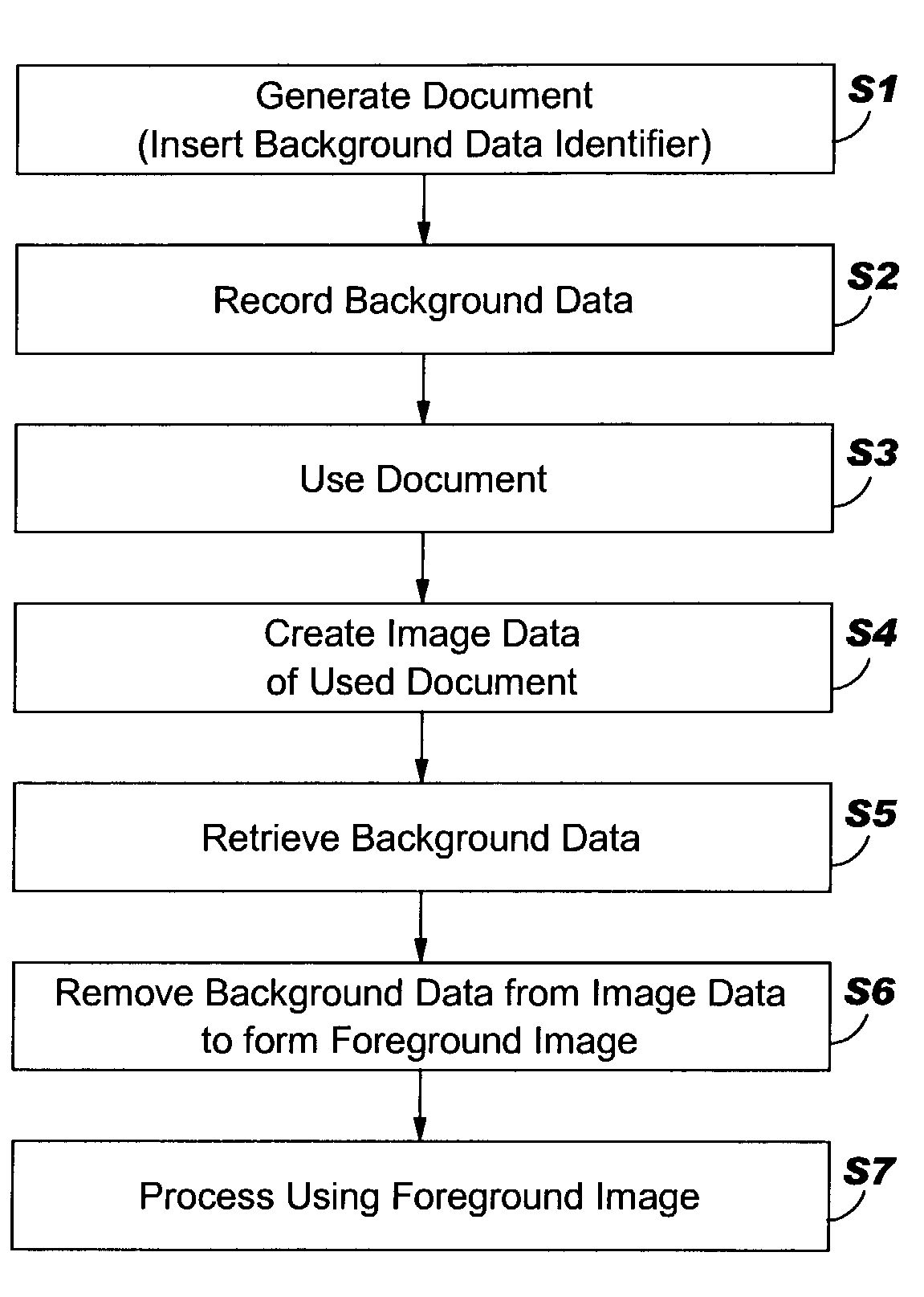

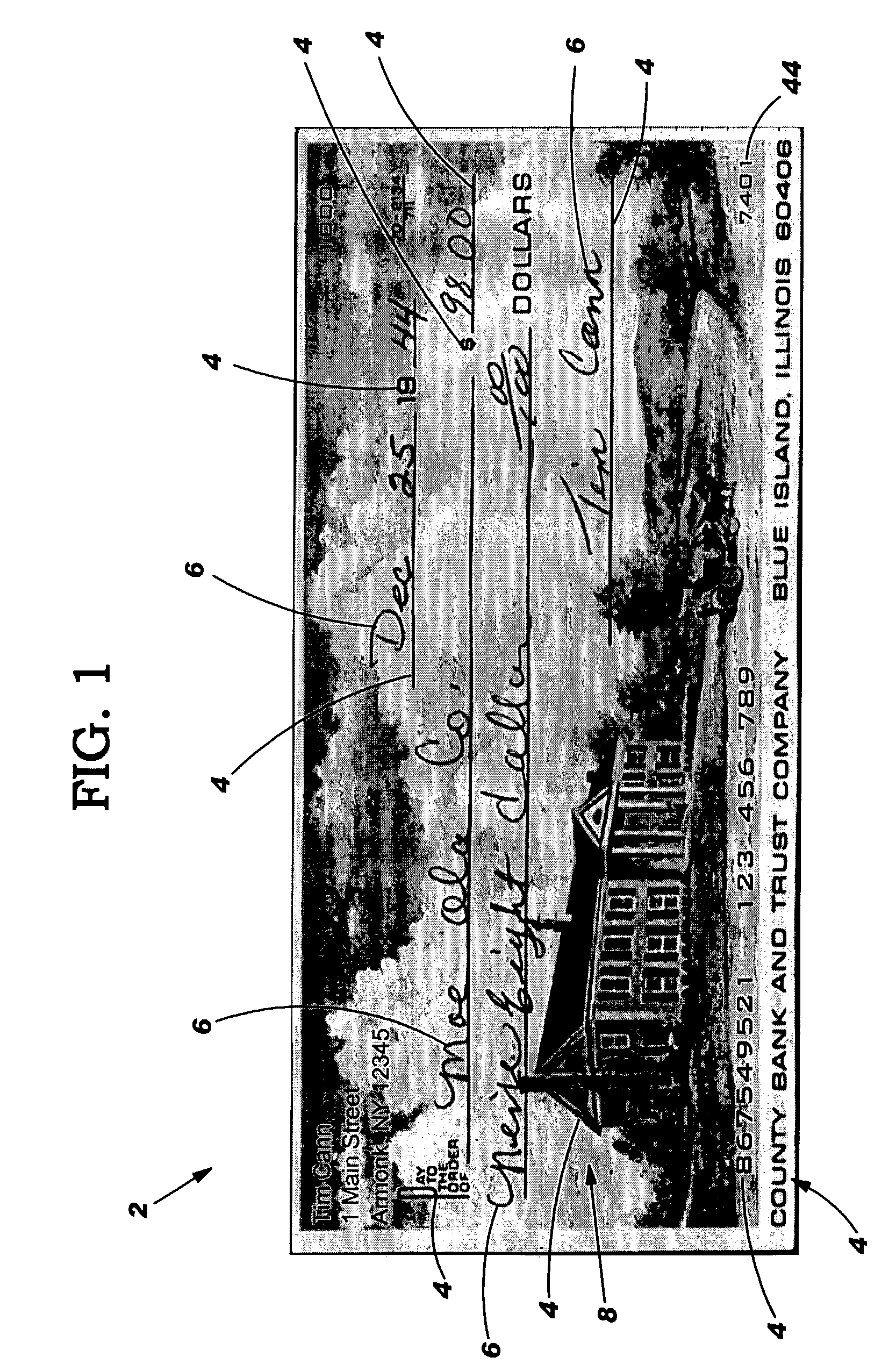

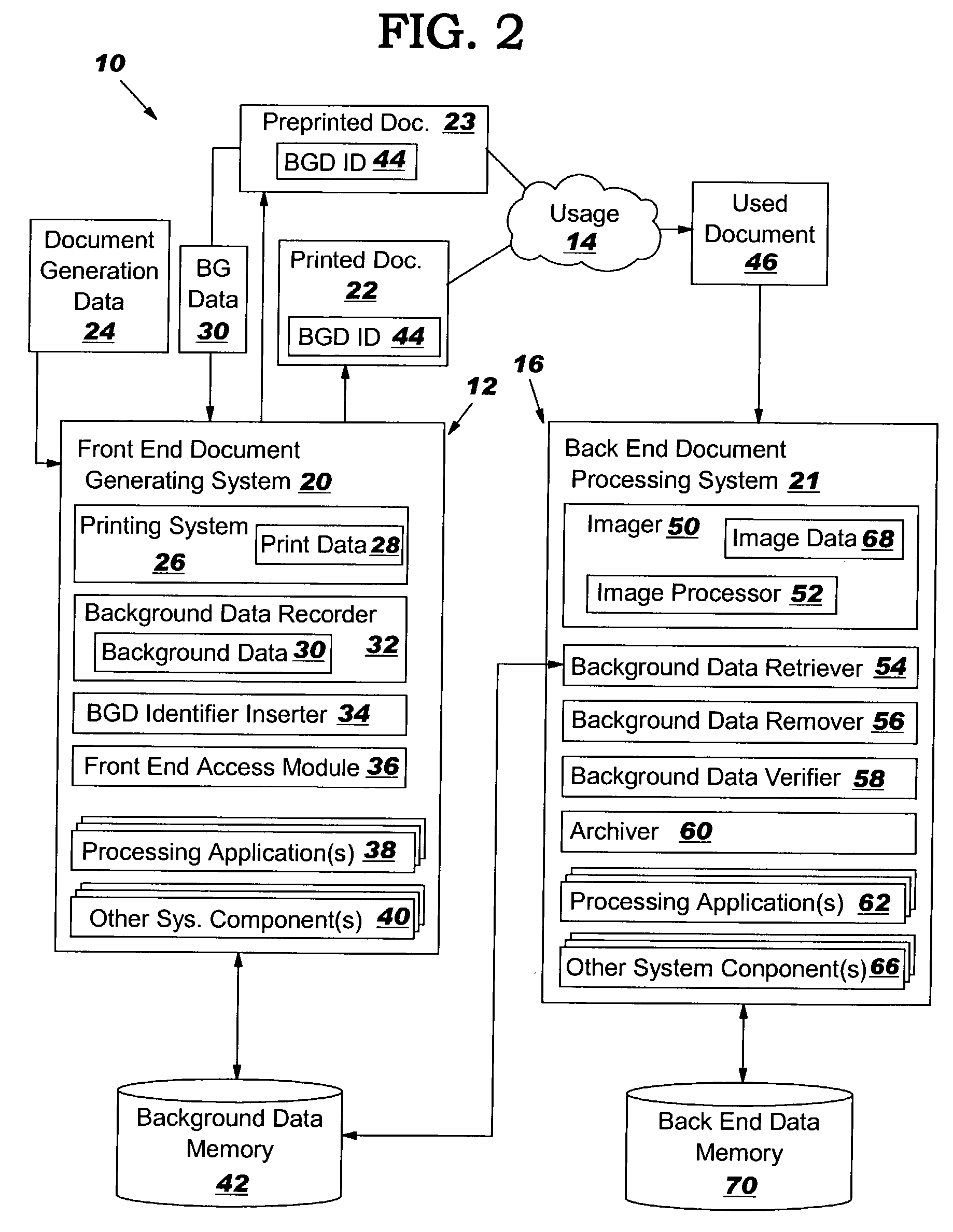

Background data recording and use with document processing

InactiveUS7312902B2Improve accuracyReduce size requirementsElectric signal transmission systemsDigital data processing detailsData recordingDocumentation

Systems, methods and program products for recording a document's background data during front-end generation of the document, and inserting a background data identifier on the document. In addition, the invention provides for use of the background data for document processing. For example, the invention provides for removal of the background data from scanner image data of the document to create a foreground image. The foreground image can be used to conduct processing relative to the document such as archiving, fraud detection and other processing. Background data recordation and removal during back-end processing results in improved archive accuracy, lowered storage size requirements, and reduced transmission costs. In addition, background data recordation allows referencing of a single background by a large number of documents.

Owner:RICOH KK

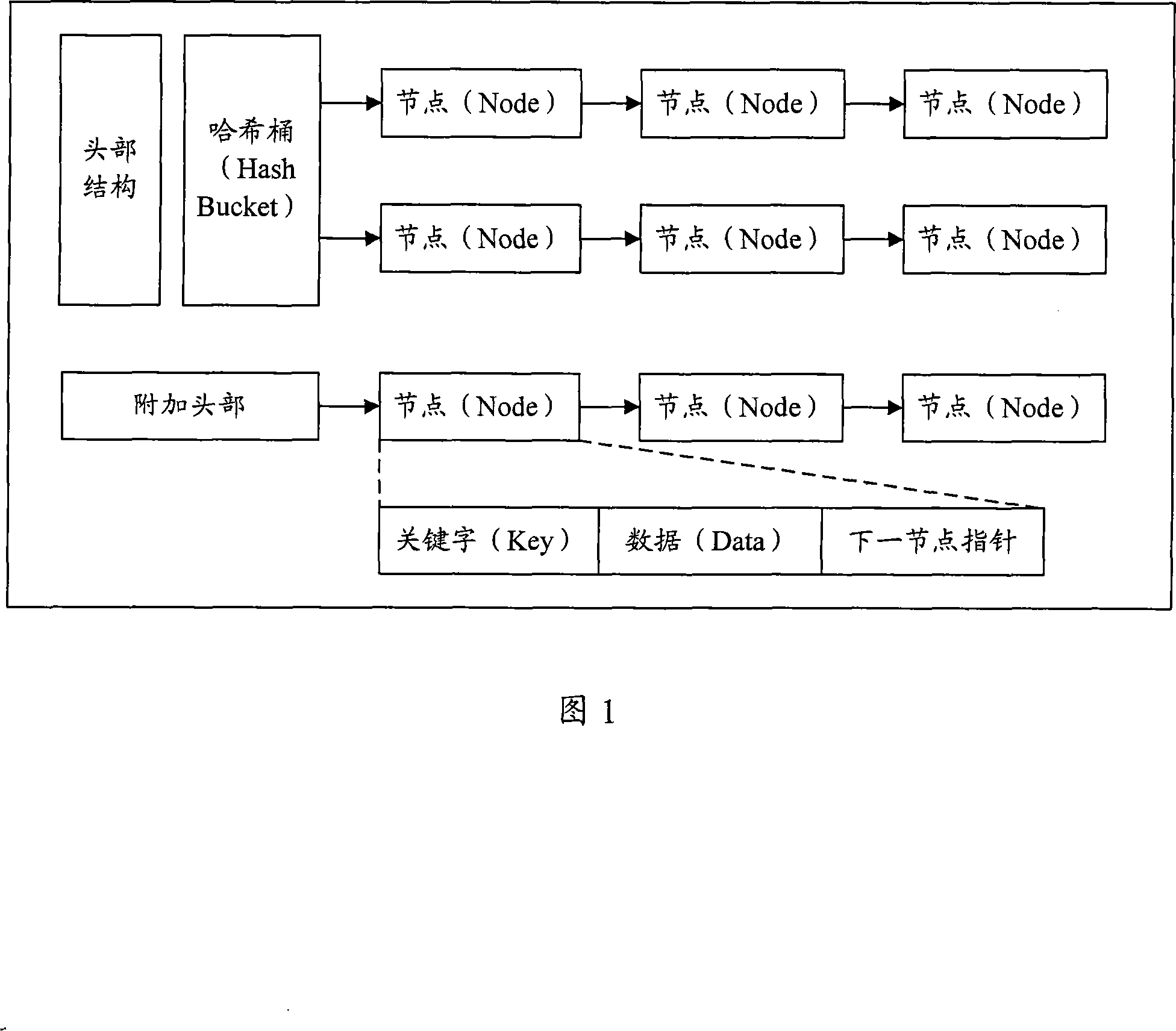

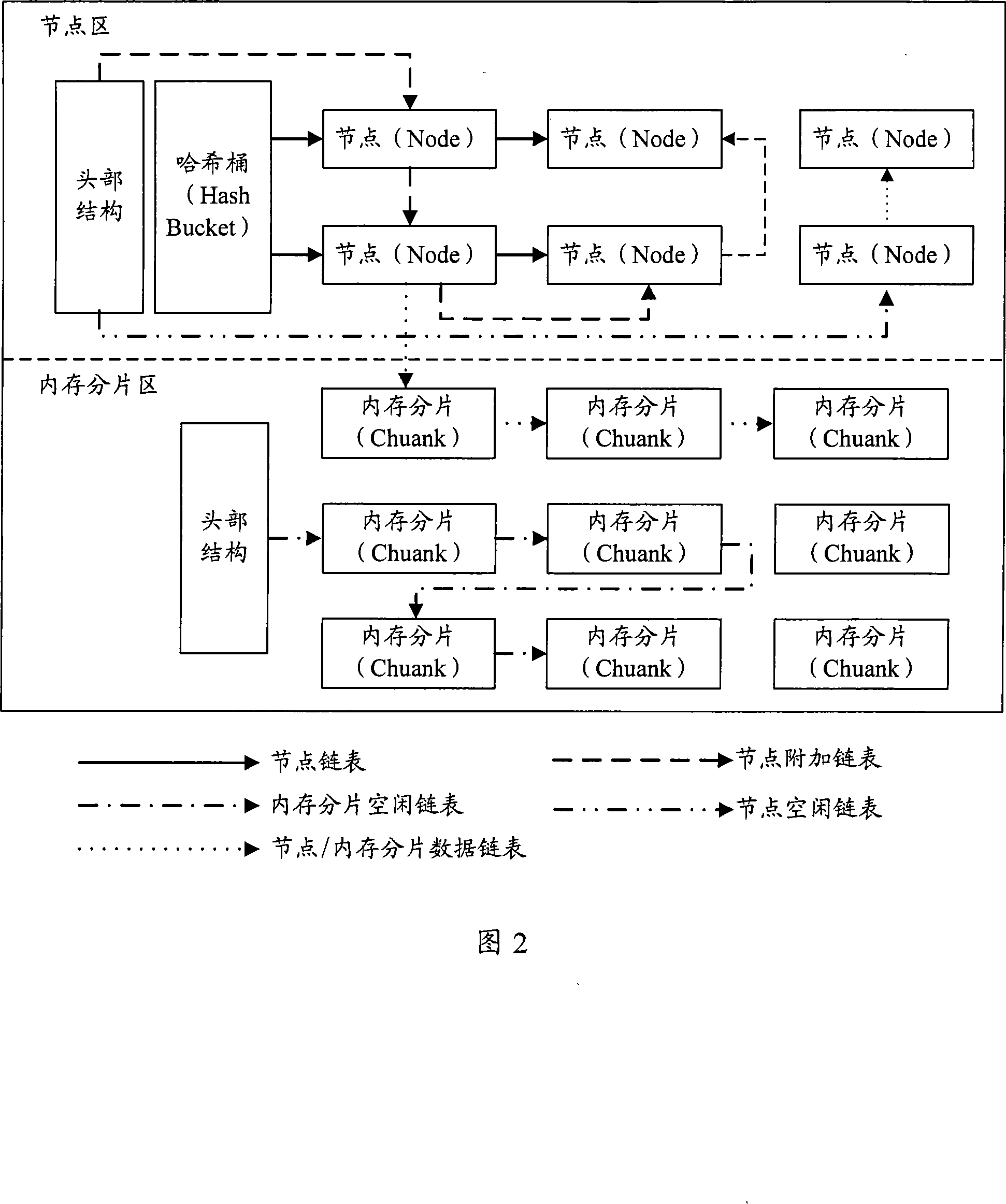

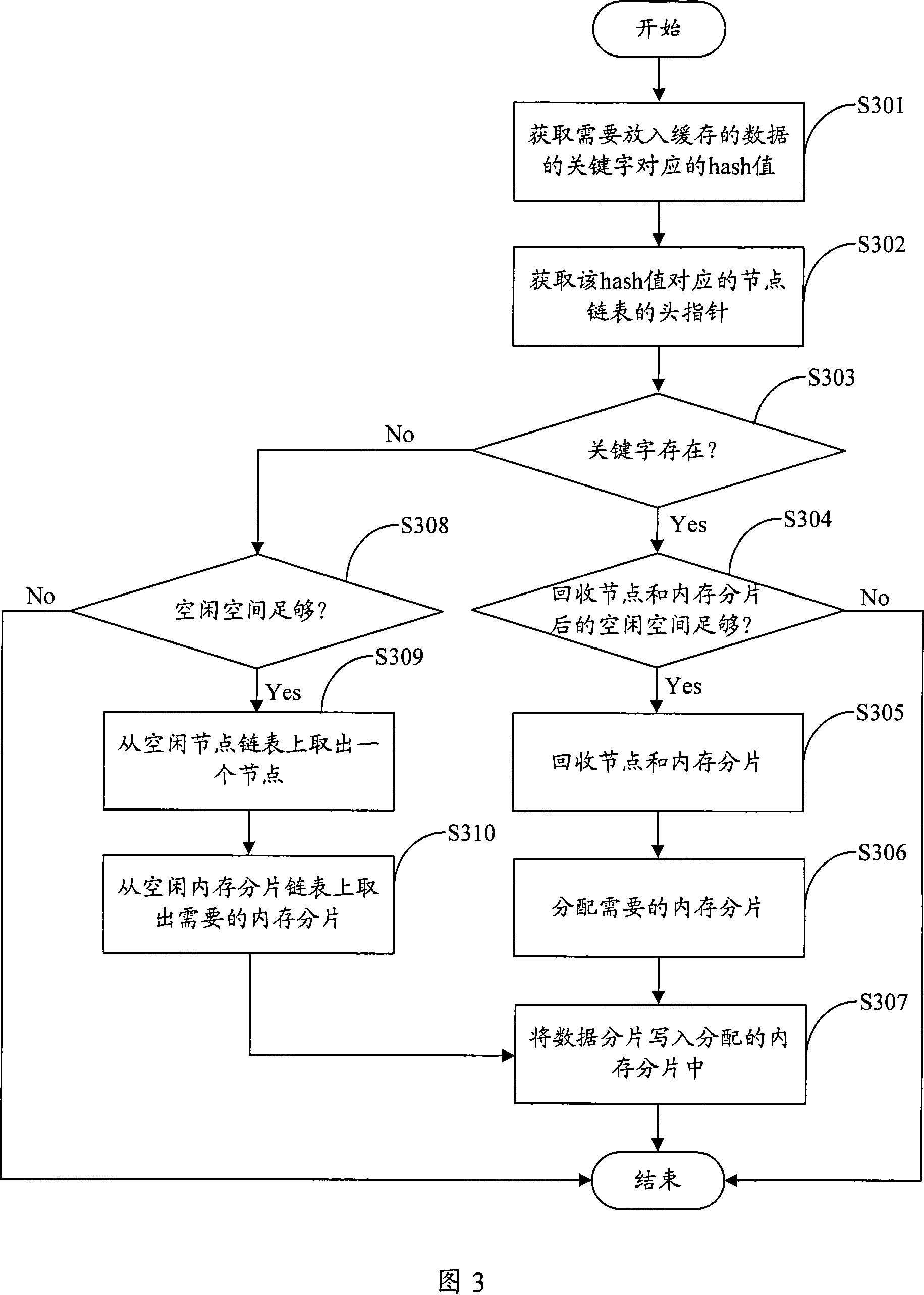

Data cache processing method, system and data cache device

ActiveCN101122885AImprove versatilityReduce wasteMemory adressing/allocation/relocationSpecial data processing applicationsLow demandOperating system

The present invention, which applies to the data cache field, provides a data cache process method, method and device. The method includes the following steps: configure a node in a cache and a corresponding memory slice; the node is used for storing the index information of the data and pointing to a pointer of the corresponding memory slice which is used to store the data written into the cache; according to the configured node and corresponding memory slice, cache the data. The present invention has a low demand on a data size, a good generality and requires no prior knowledge of single storage data size and distribution, thus not only enhancing generality of the cache, but also reducing memory waste as well as improving memory usage rate.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

Collapsible container

InactiveUS6431406B1Improve efficiencyReduce size requirementsDispensing apparatusBottlesEngineeringMechanical engineering

A collapsible container is disclosed having a top portion and base portion joined by a midsection of undulating walls of accordion style which allows for the axial compression and expansion of the container. A U-shaped handle is also disclosed which provides for grasping of the container, provides axial stability when the container is in its fully expanded form, secures the container in its fully collapsed form, and protects the container's closure mechanism.

Owner:PRUETT NICOLAS ROGER

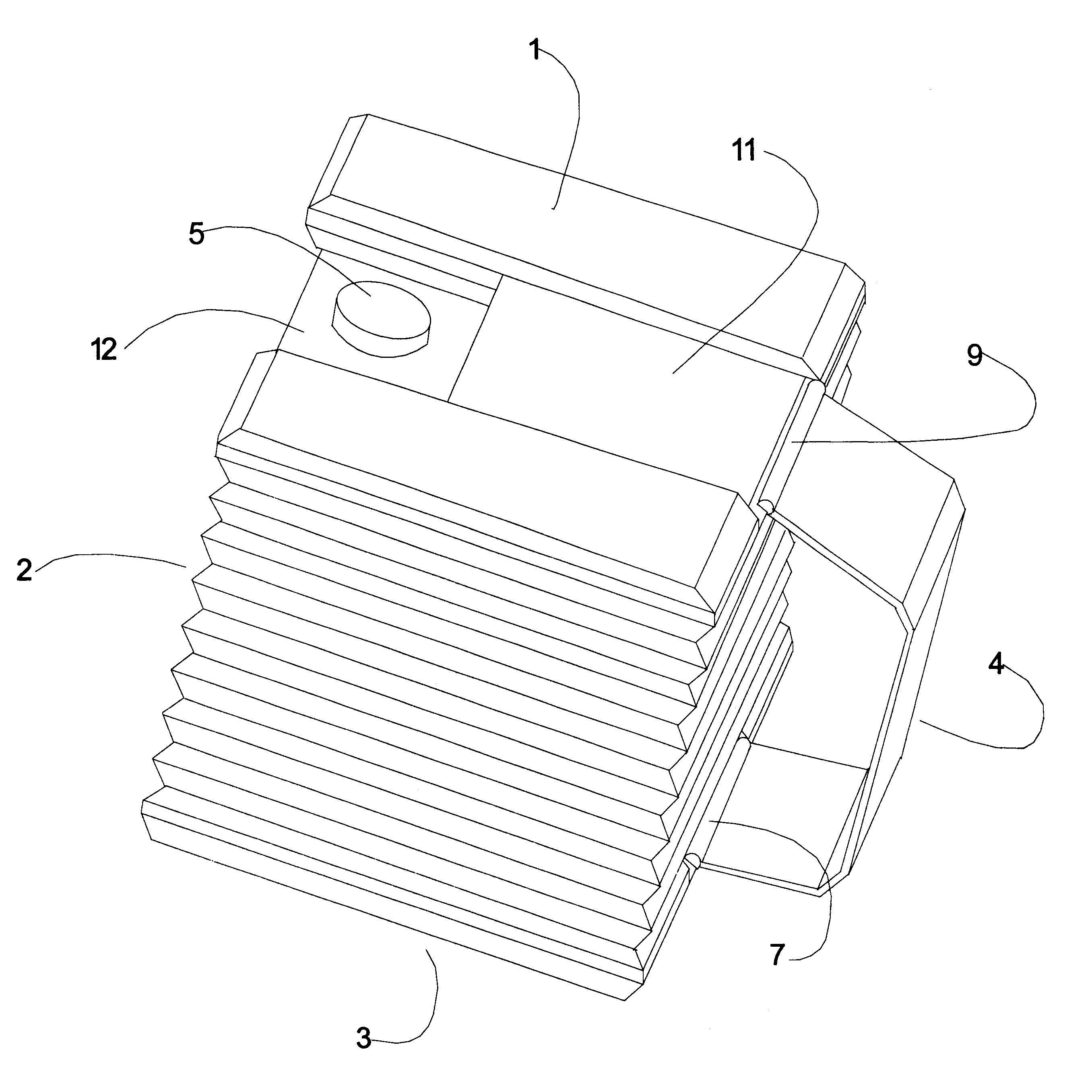

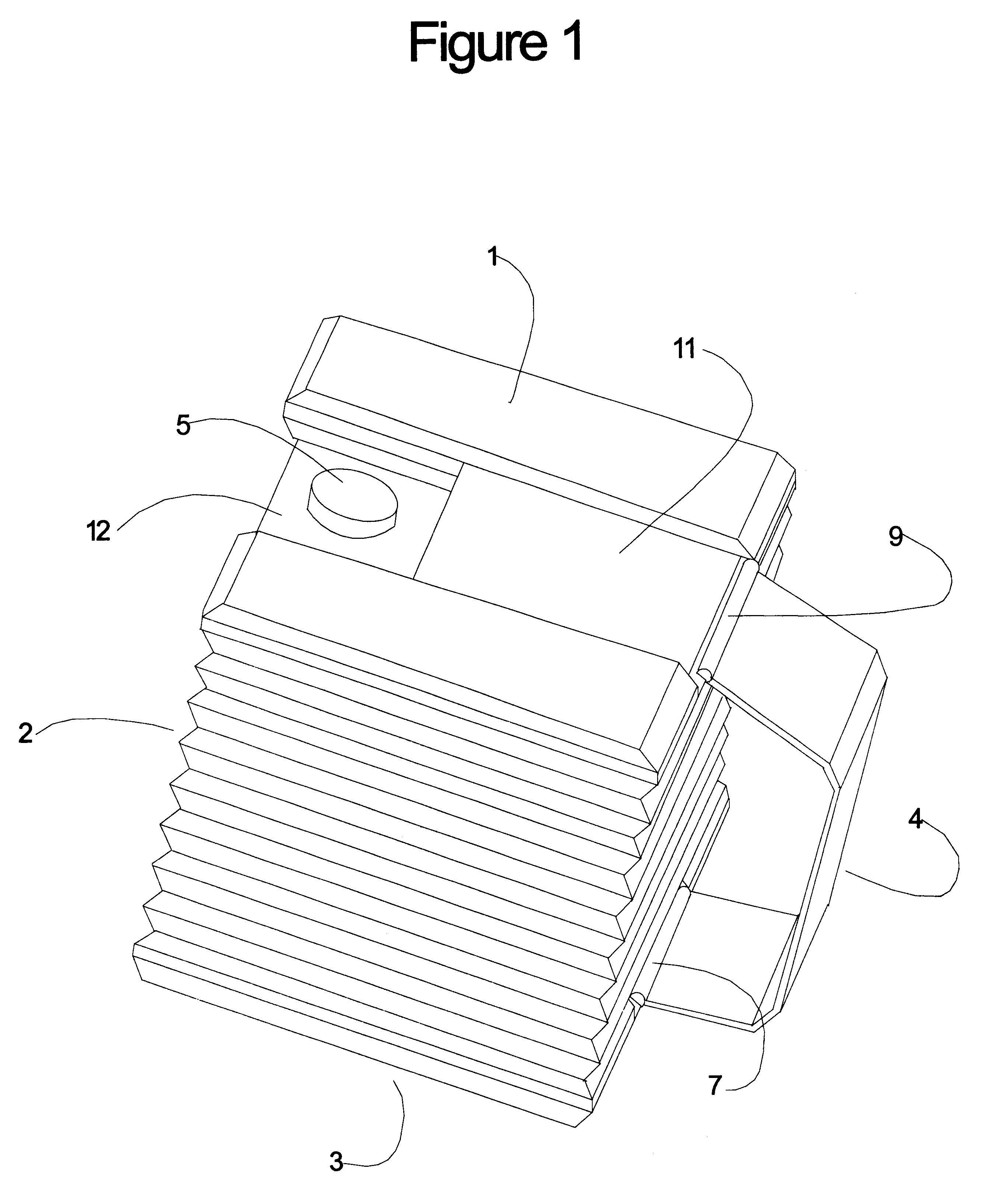

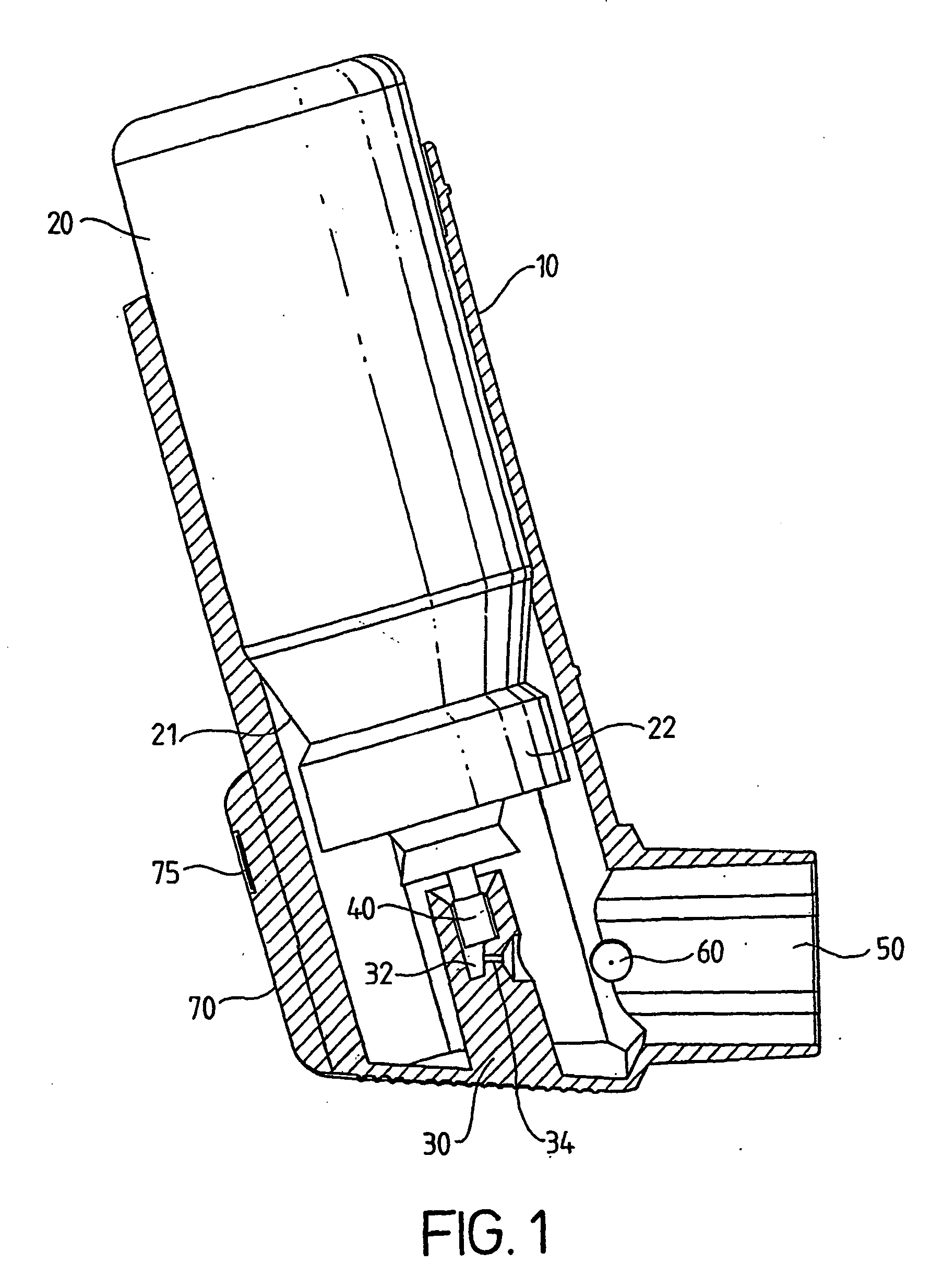

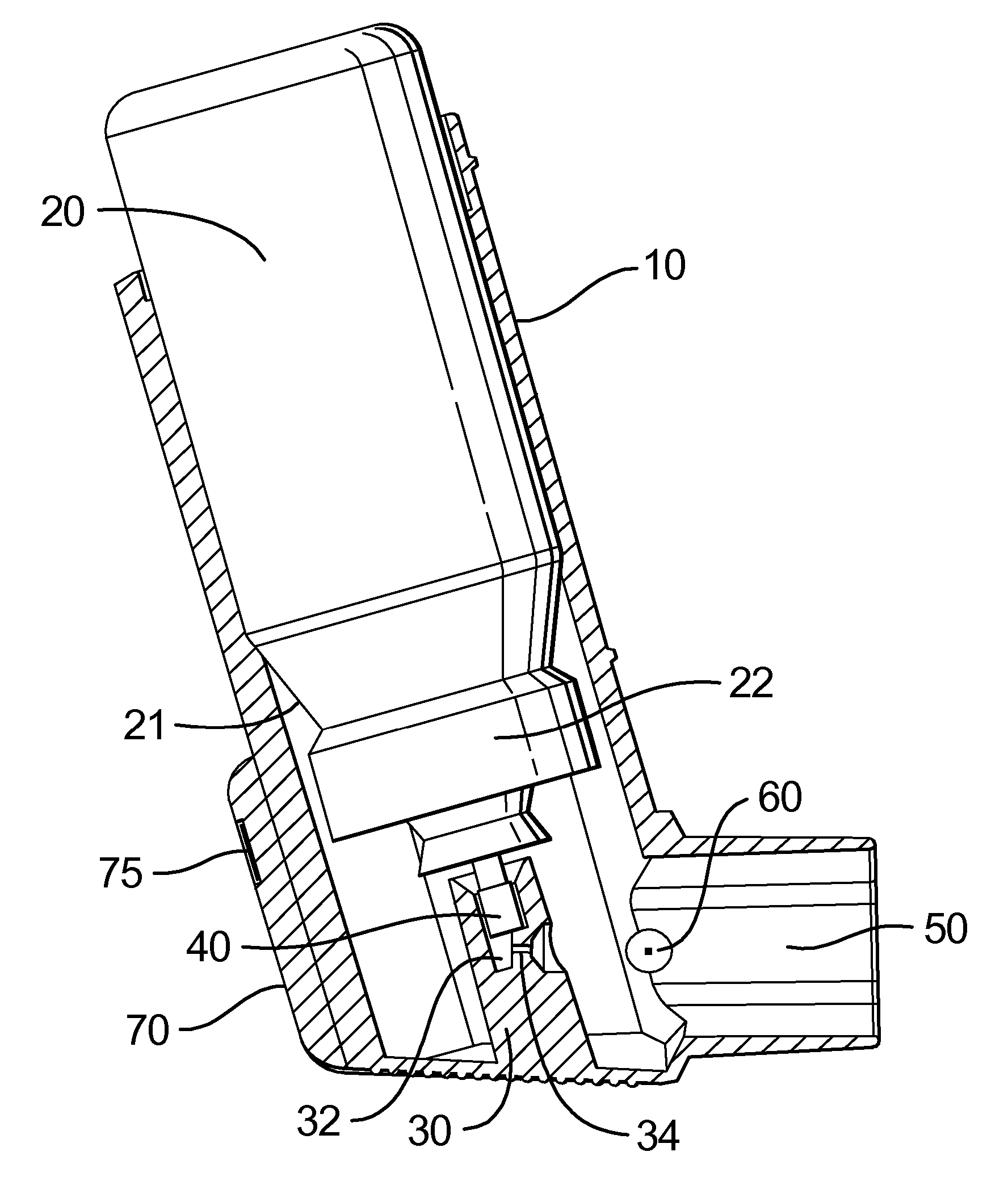

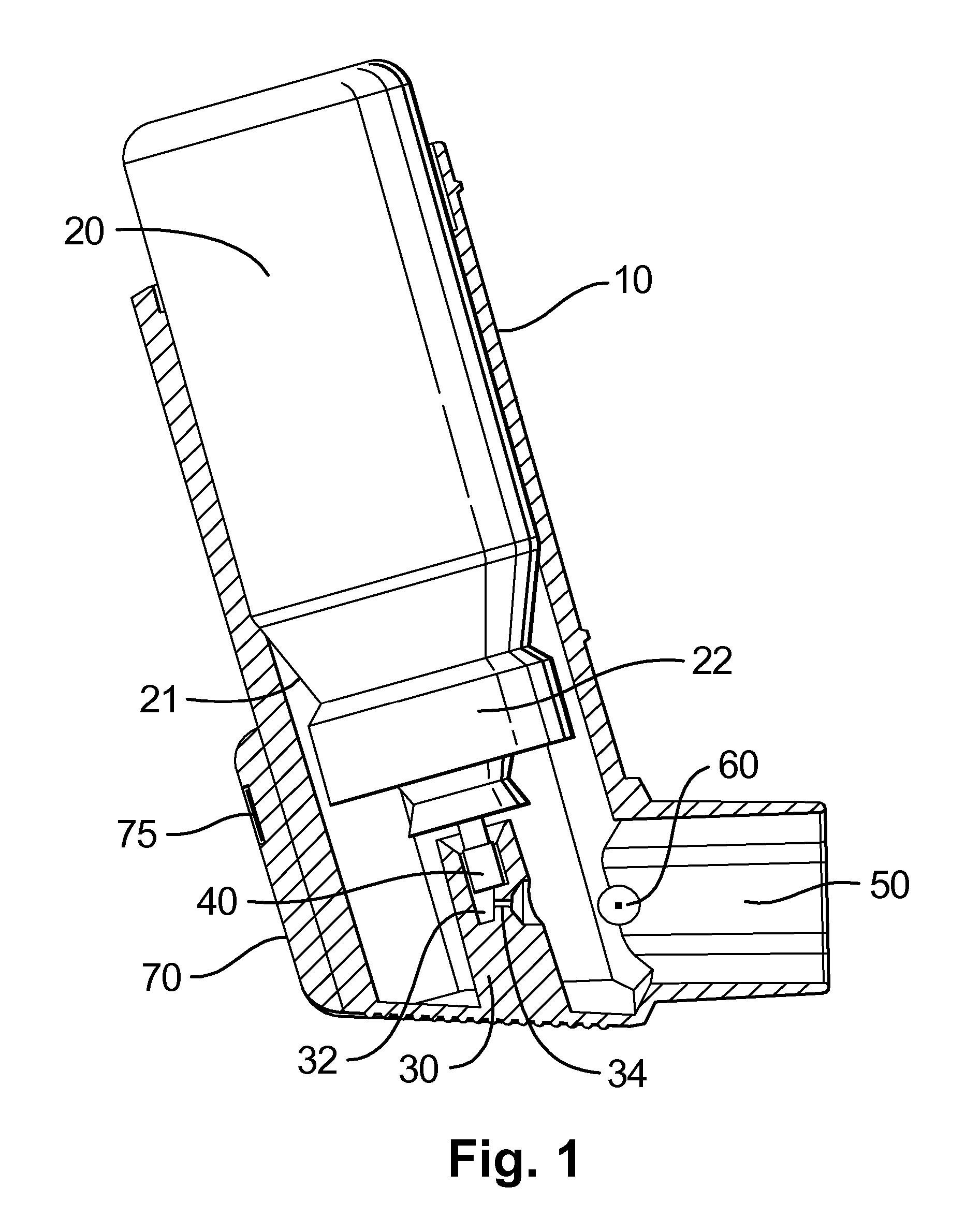

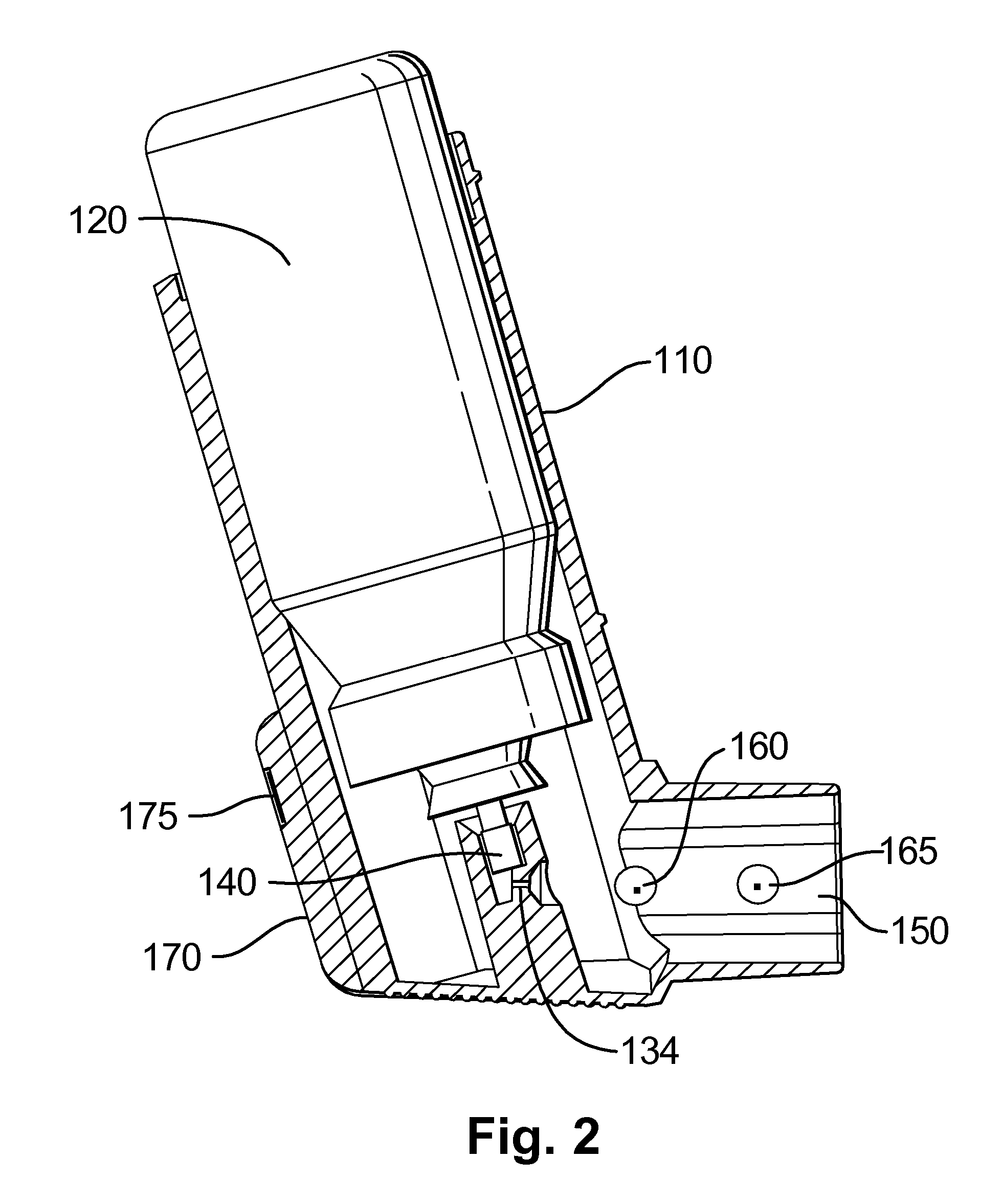

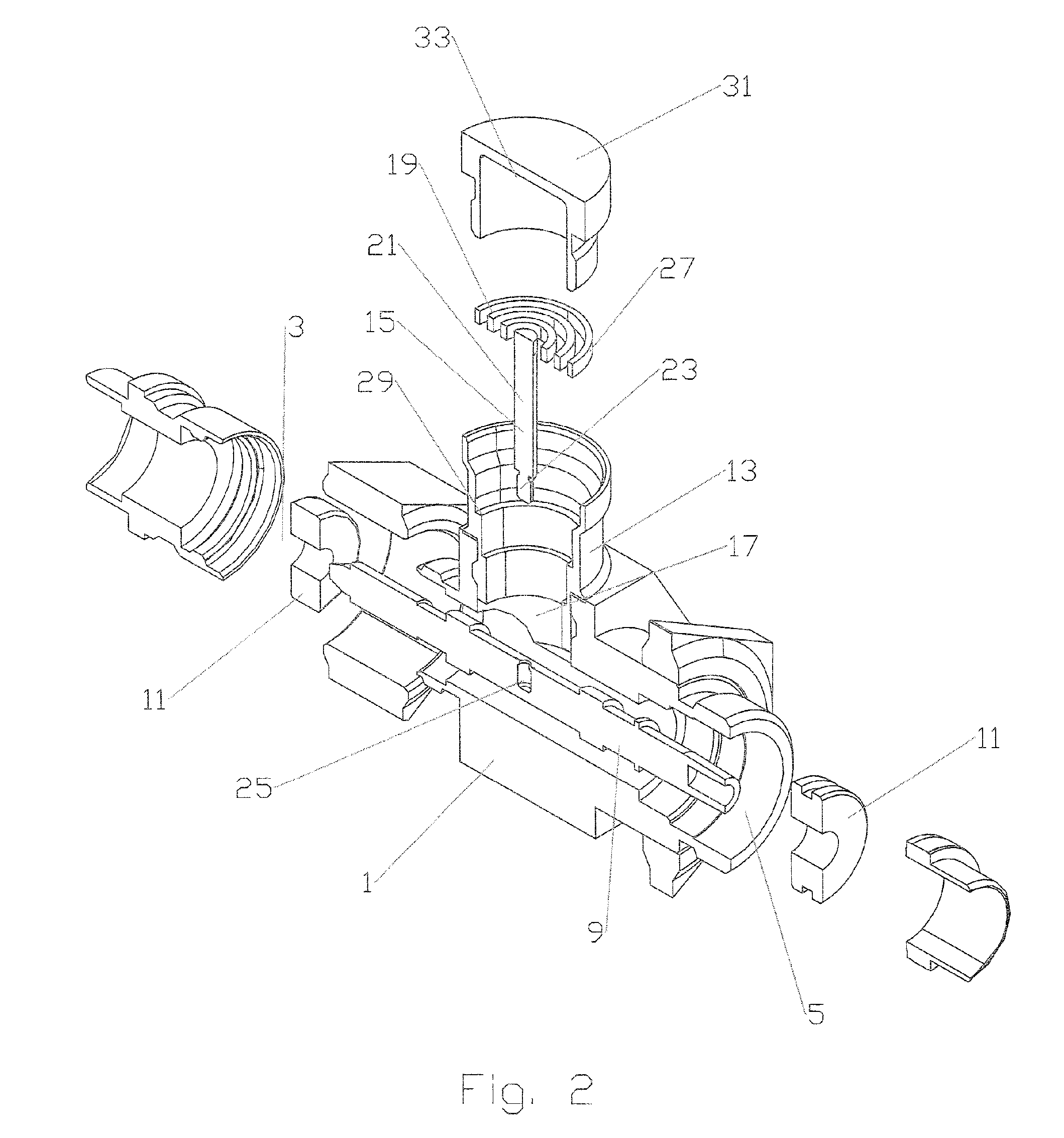

Medicament dispenser

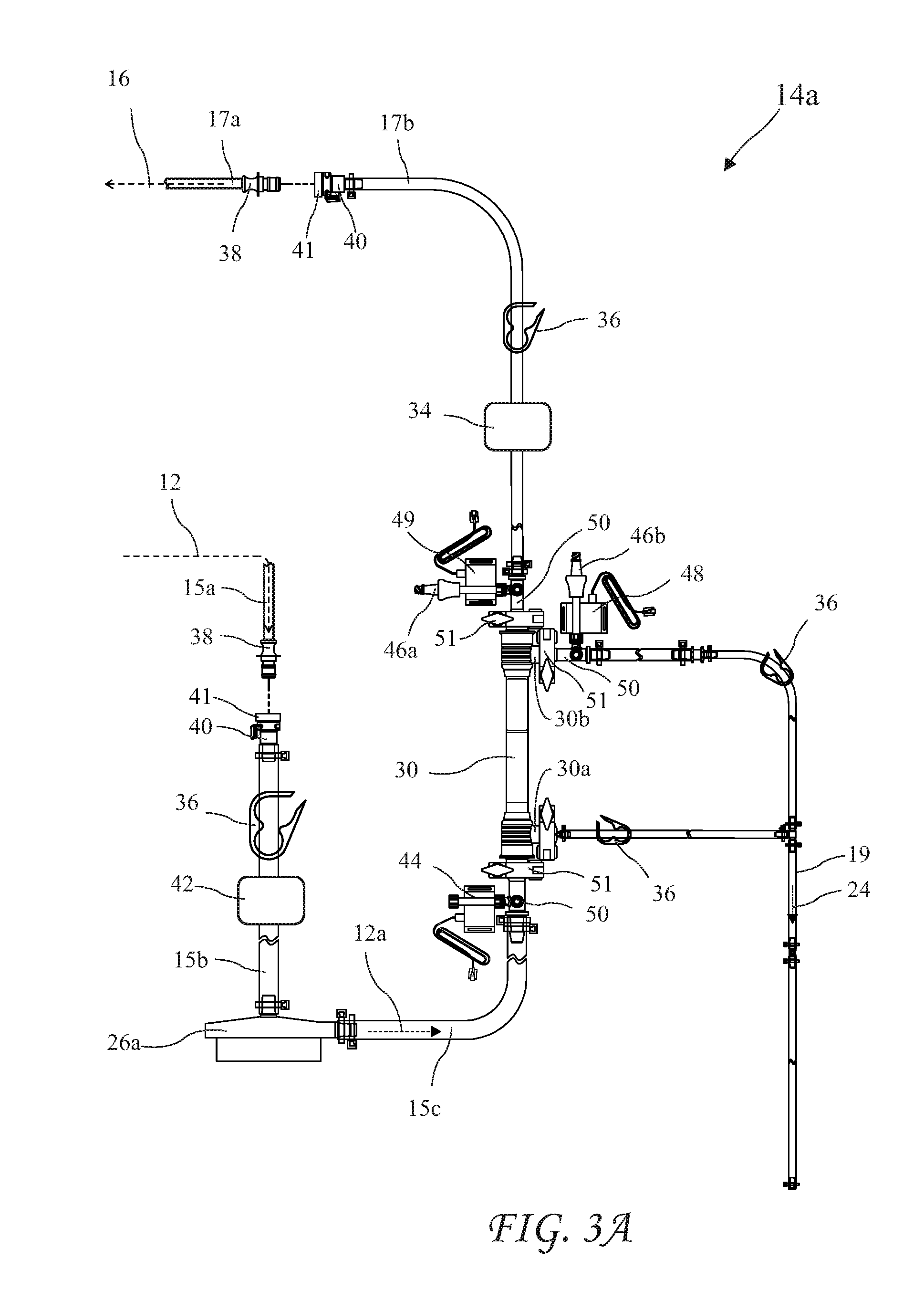

InactiveUS20050076904A1Not easy to make mistakesAvoid overall overheatingMedical devicesFire rescueMedication DispenserDrug release

A medicament dispenser comprising: (i) a housing having an outlet; (ii) a medicament container locatable within said housing; (iii) an electronic dose counter associated with said outlet, wherein said dose counter comprises a first sensor for directly detecting a medicament release dispensible from said medicament container through said outlet is disclosed.

Owner:GLAXO GROUP LTD

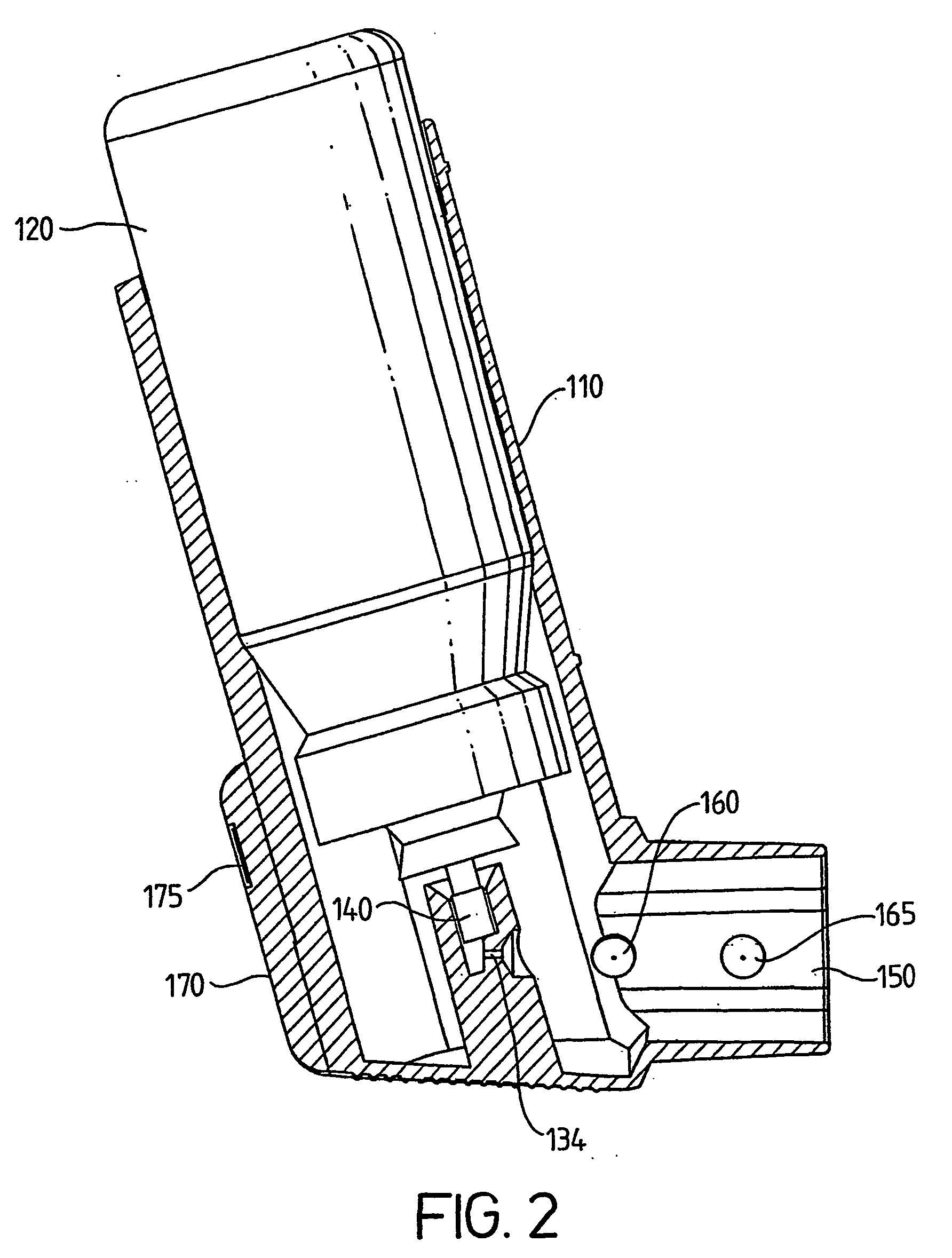

Medicament dispenser

InactiveUS20080017193A1Not easy to make mistakesAvoid overall overheatingMedical devicesMedical atomisersMedication DispenserDrug release

A medicament dispenser comprising: (i) a housing having an outlet; (ii) a medicament container locatable within said housing; (iii) an electronic dose counter associated with said outlet, wherein said dose counter comprises a first sensor for directly detecting a medicament release dispensible from said medicament container through said outlet is disclosed.

Owner:GLAXO GRP LTD

Compressed standardized keyboard

InactiveUS20040239533A1Small sizeRealized benefitsInput/output for user-computer interactionInterconnection arrangementsReduced sizeComputer science

A keyboard of reduced size is provided in which multiple characters are assigned to each of the primary keys. The selection of the characters to be assigned to each specific primary key is based on the touch typing rules associated with a specific standardized keyboard, preferably allowing at least three rows of keys to be reduced to a single row of keys. A disambiguating system is used to interpret which of the characters and / or symbols assigned to a particular key is intended, typically by applying a set of disambiguating rules to generated input sequences.

Owner:BOLLMAN TAYLOR

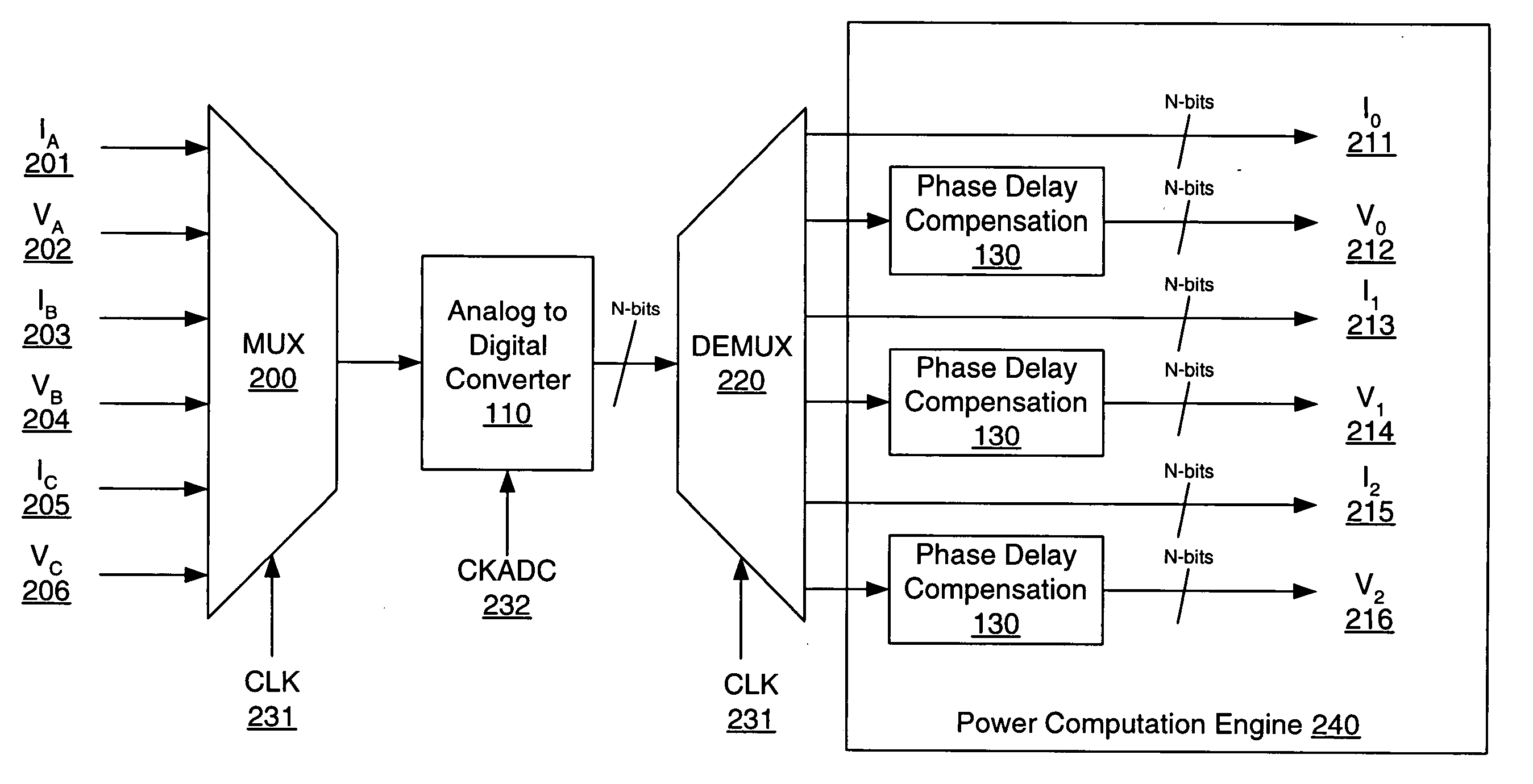

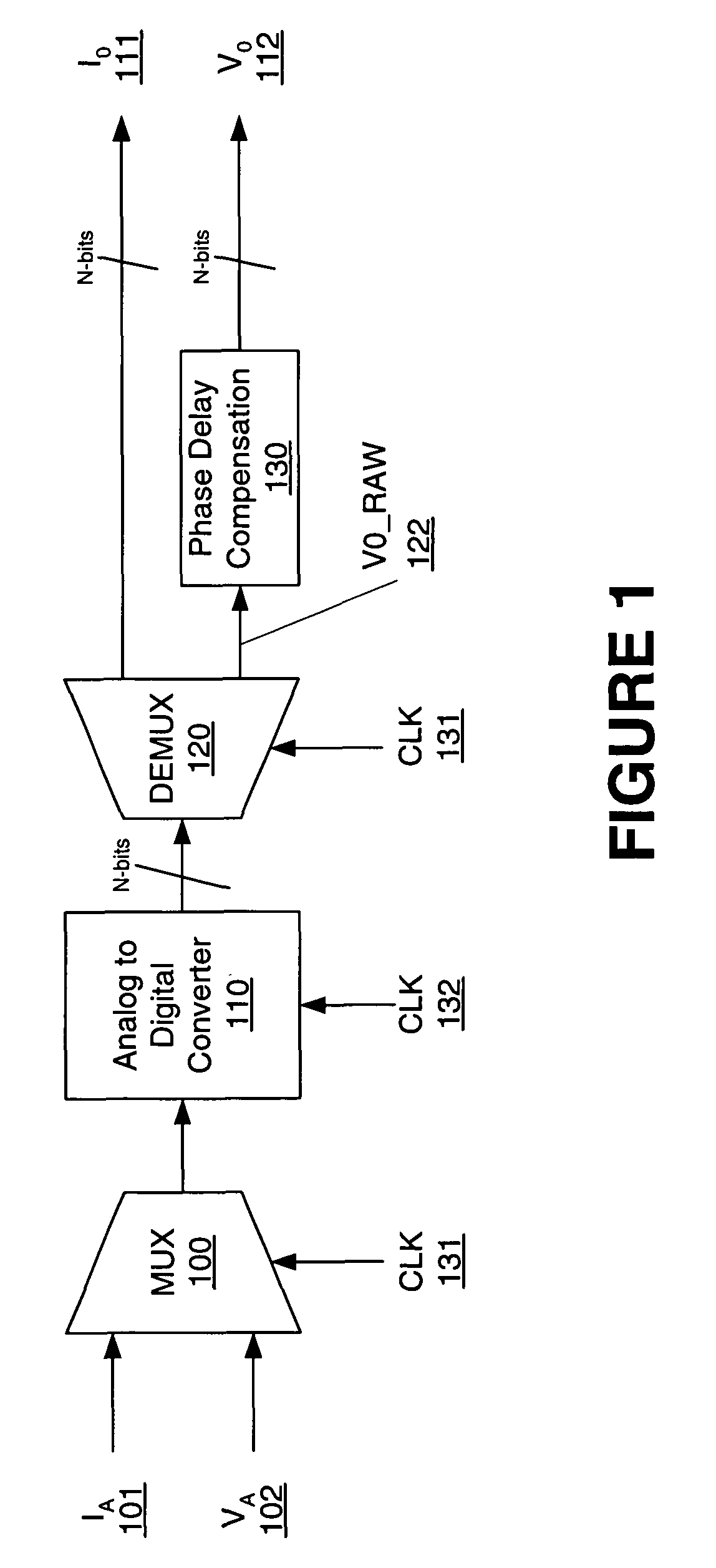

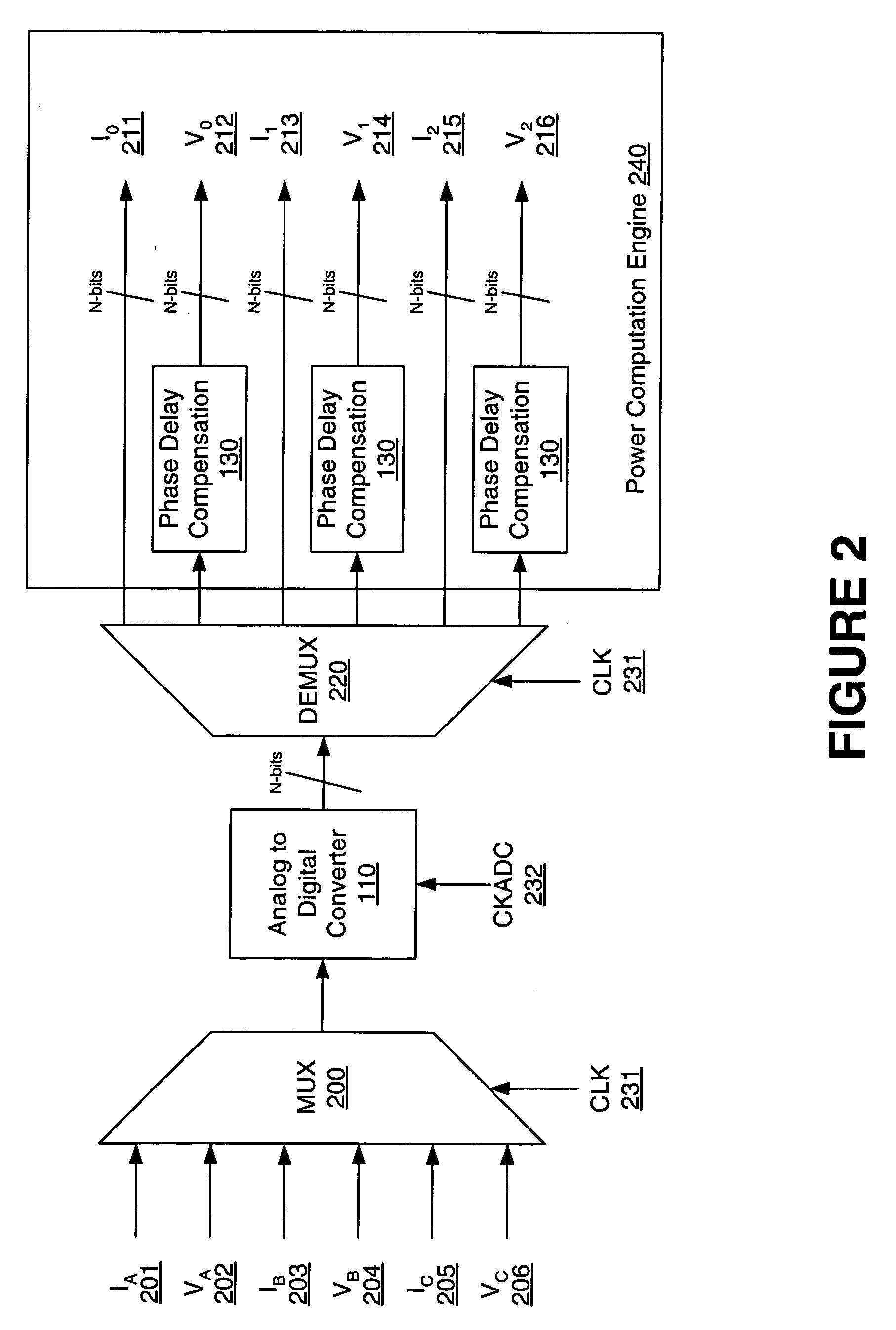

Method and apparatus of obtaining power computation parameters

ActiveUS20040032357A1Reducing power computation errorReduced conversion timeElectric signal transmission systemsPower measurement by digital techniqueMultiplexerAnalog signal

A method and apparatus for obtaining power computation parameters is presented. Accurate computation of power requires multiplying voltage and current at the same instant of time and integrating the results over time. The present invention provides a method of using a single Analog to Digital Converter to convert both voltage and current for all the phases of any electrical system and then digitally compensating for the phase error caused by the non-simultaneous sampling of the current and voltage signals. The compensating filter could be implemented as a simple interpolator, an all-pass filter, or a combination of both. A single multiplexer is used to select which signal is processed by the Analog to Digital Converter. By scheduling and converting the voltage and analog signals one at a time, potential for crosstalk is significantly reduced, power requirement is reduced, and die size requirement is reduced.

Owner:SILERGY SEMICON HONG KONG LTD

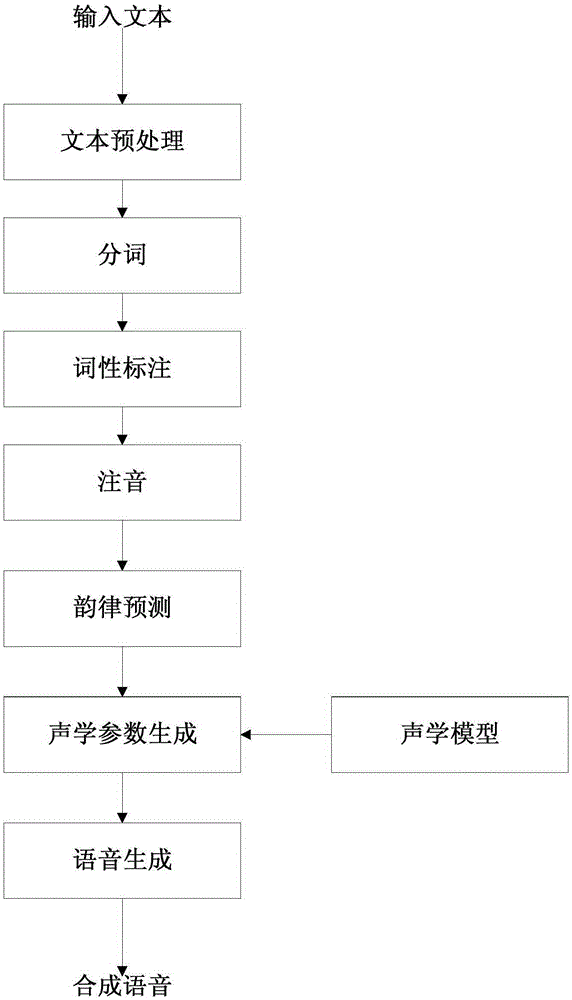

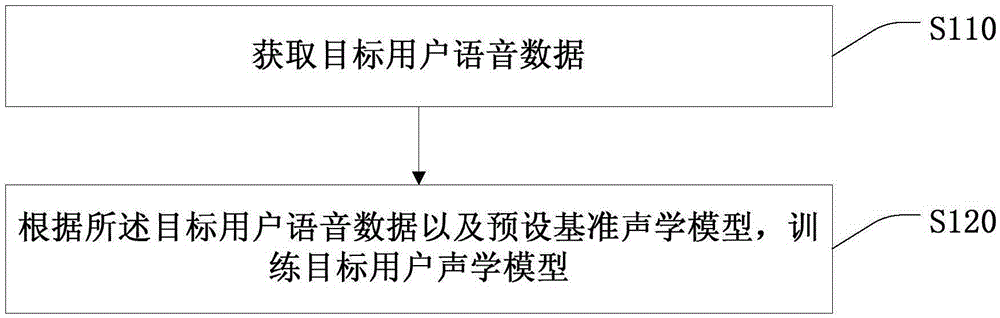

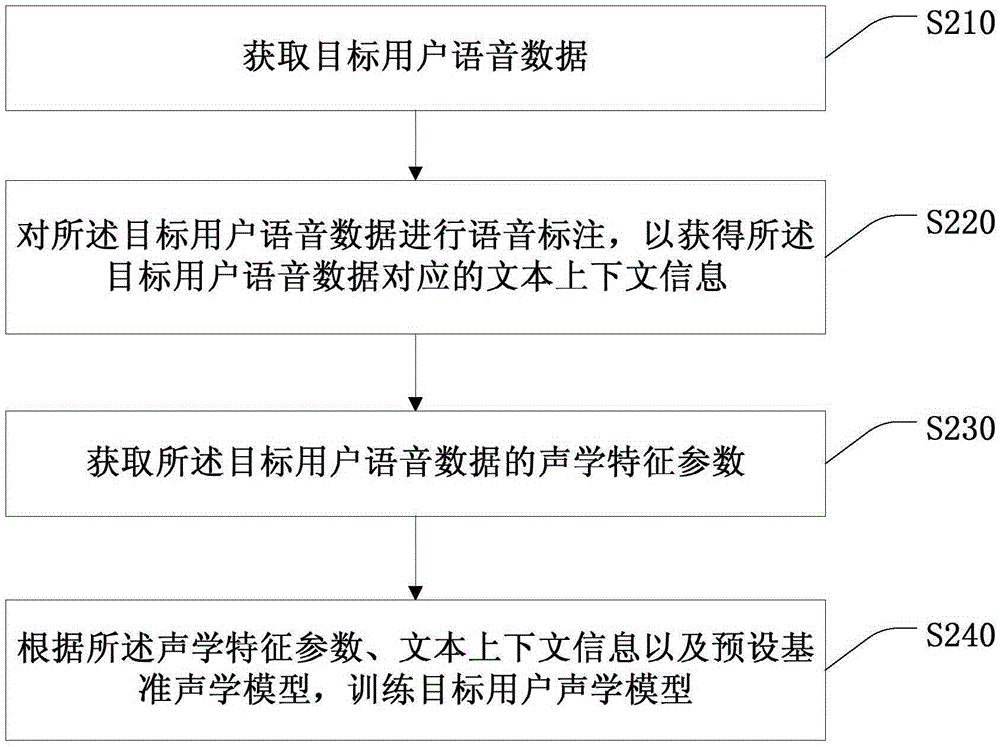

Voice synthesis method and apparatus

InactiveCN105261355AImprove experienceReduce size requirementsSpeech synthesisPersonalizationSynthesis methods

The invention discloses a voice synthesis method and apparatus. The voice synthesis method comprises: obtaining target user voice data; and according to the target user voice data and a preset reference acoustic model, training a target user acoustic model. The voice synthesis apparatus includes a target user voice data obtaining module and a target user acoustic model training module; the target user voice data obtaining module is used for obtaining target user voice data; and the target user acoustic model training module is used for training a target user acoustic model based on the target user voice data and a preset reference acoustic model. According to the invention, the scale requirement of the user recording data can be reduced during the individual voice synthesis process.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

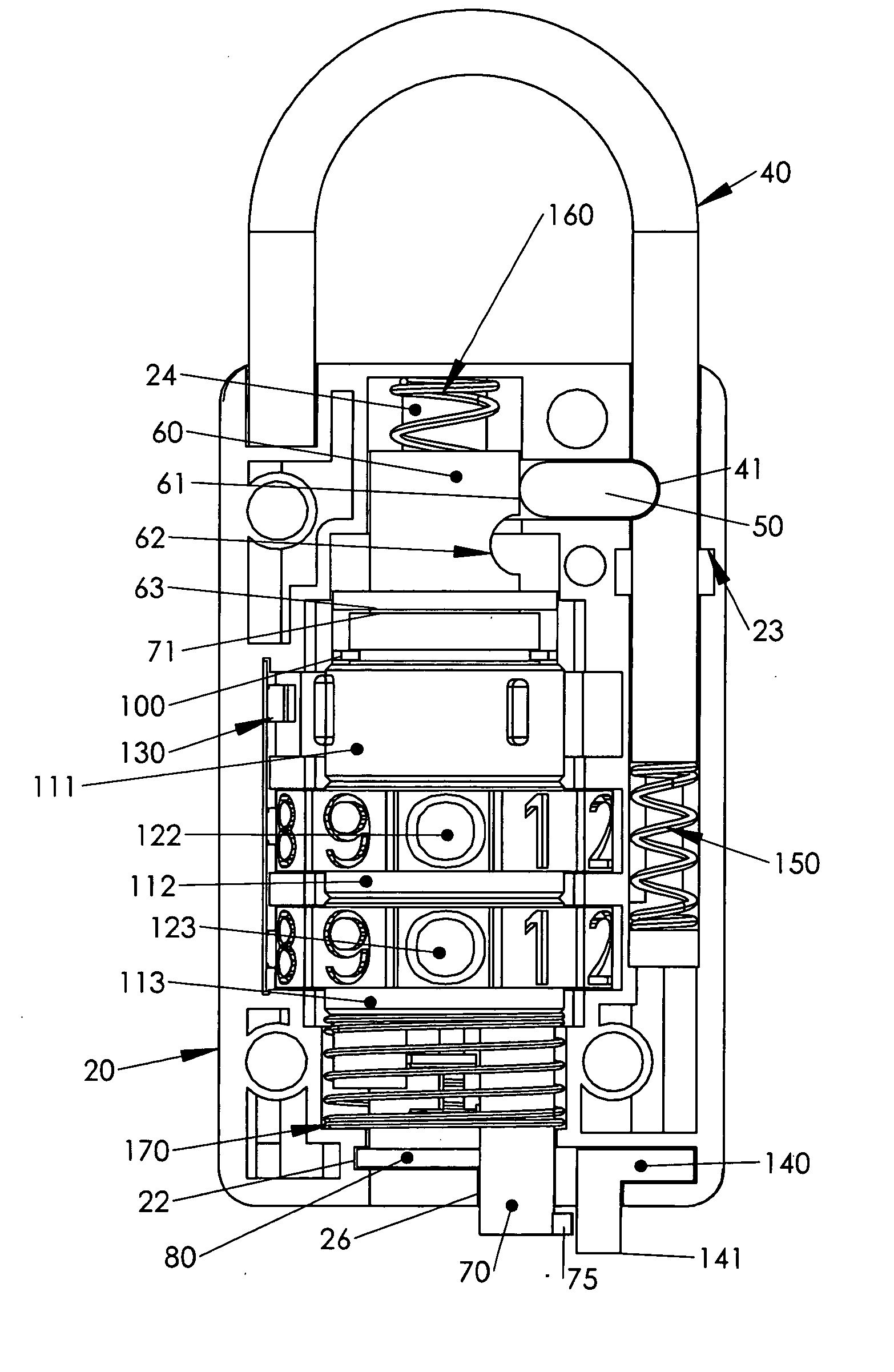

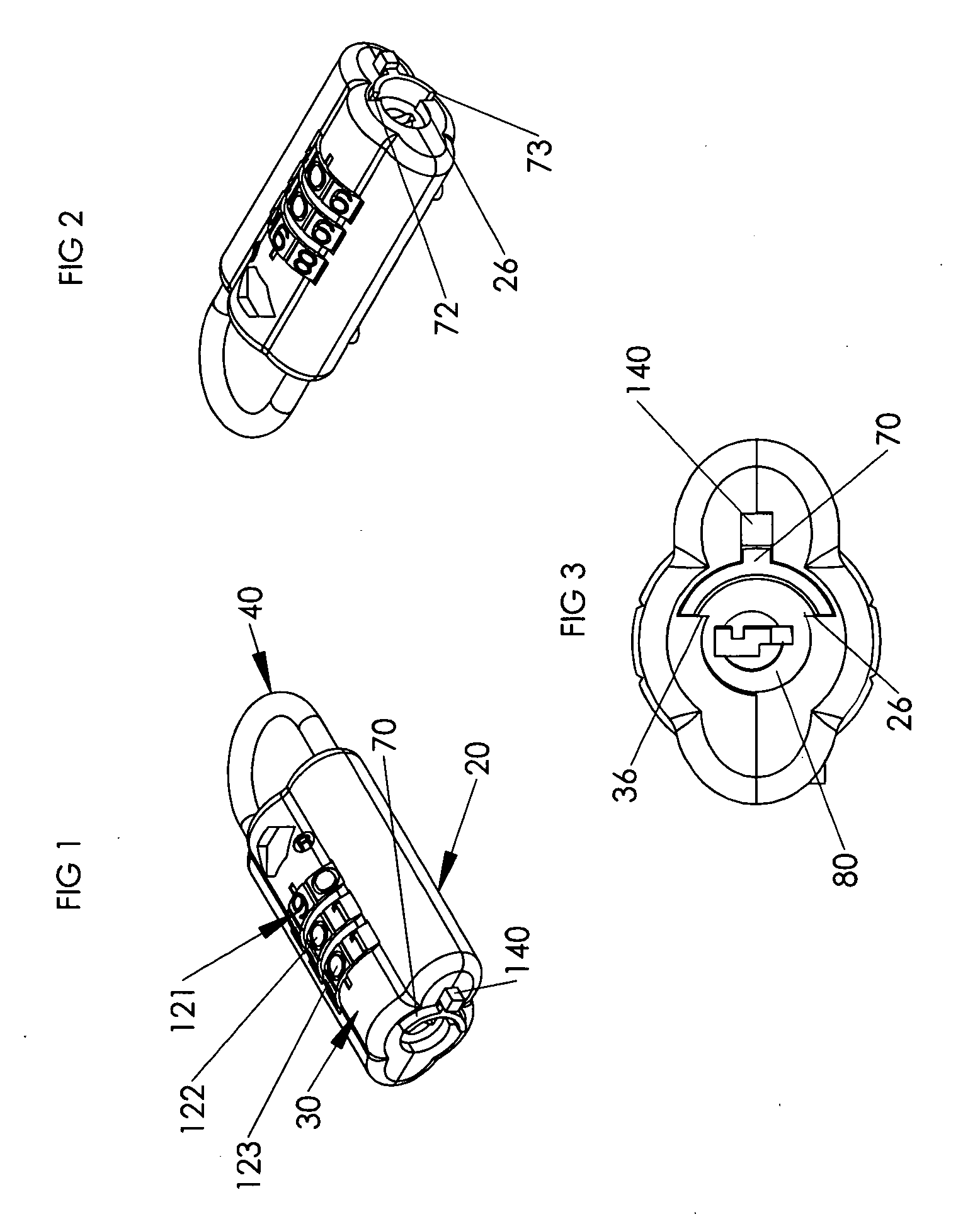

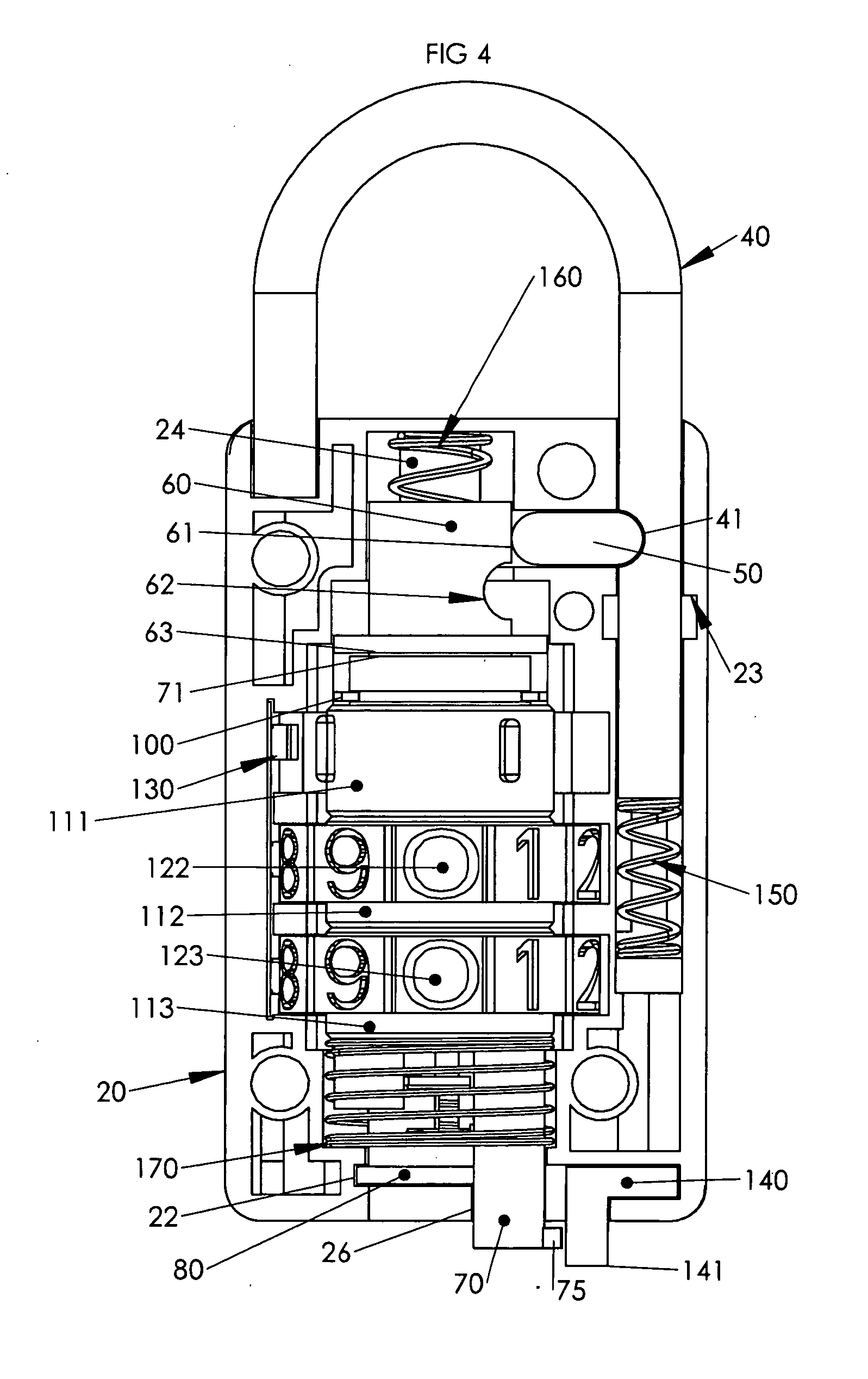

High security, dual-mode padlock construction

ActiveUS20090113947A1Reduce componentsReduce size requirementsPadlocksPuzzle locksDual modeArchitectural engineering

By employing a deadbolt construction for virtually eliminating the ability of the shackle to be removed from the housing by the application of excessive force, an effective, easily produced, padlock is achieved which also incorporates two separate and independent locking systems formed in a single padlock. In the present invention, a single housing and a single shackle assembly are employed and are constructed for enabling the shackle to be released from locked engagement with the housing either a rotatable dial combination construction or a key activated tumbler construction. Furthermore, the rotatable combination defining dials, which controls the release of the shackle using the preset combination, are coaxially aligned, peripherally surrounding the key controlled tumbler / cylinder. As a result, a compact construction is realized, as well as an efficient and effective release construction which is shared by both the combination controlled section as well as the key controlled section.

Owner:SUN LOCK COMPANY LIMITED -THE-

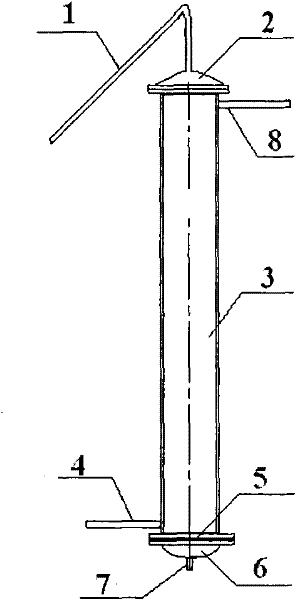

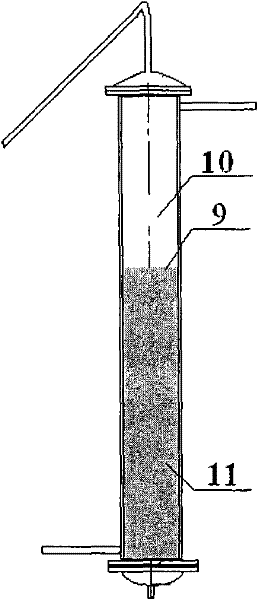

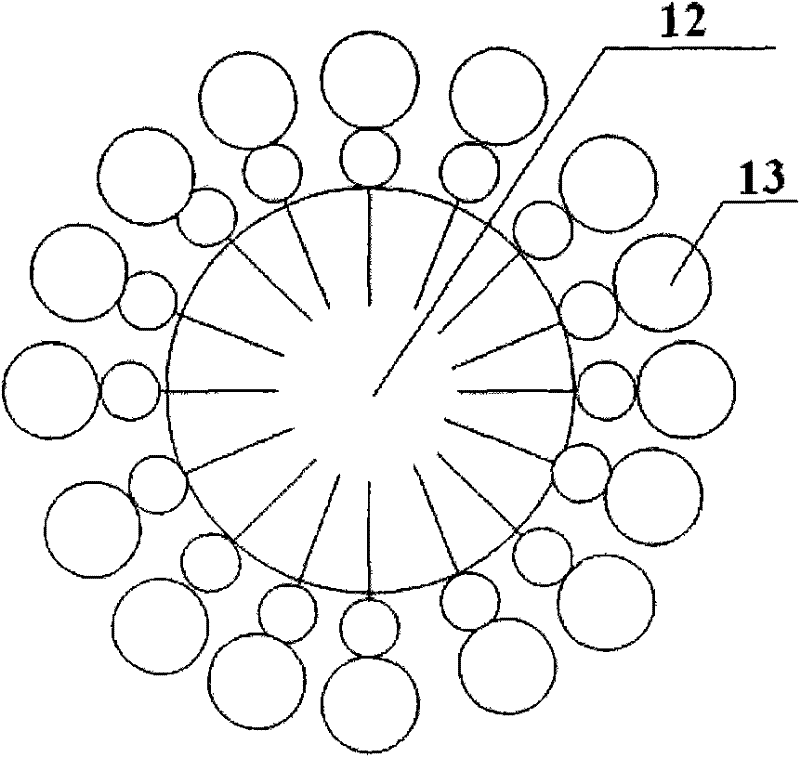

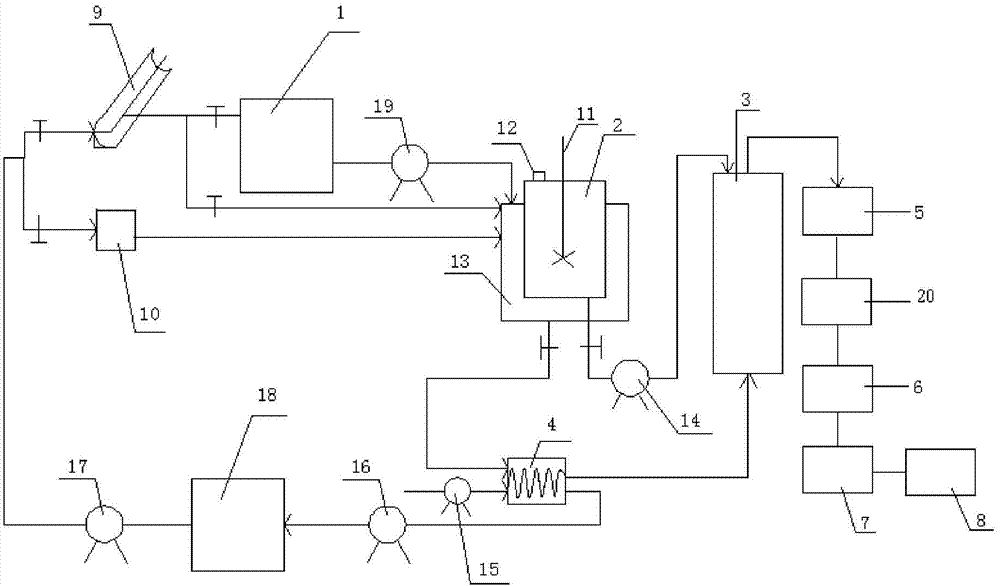

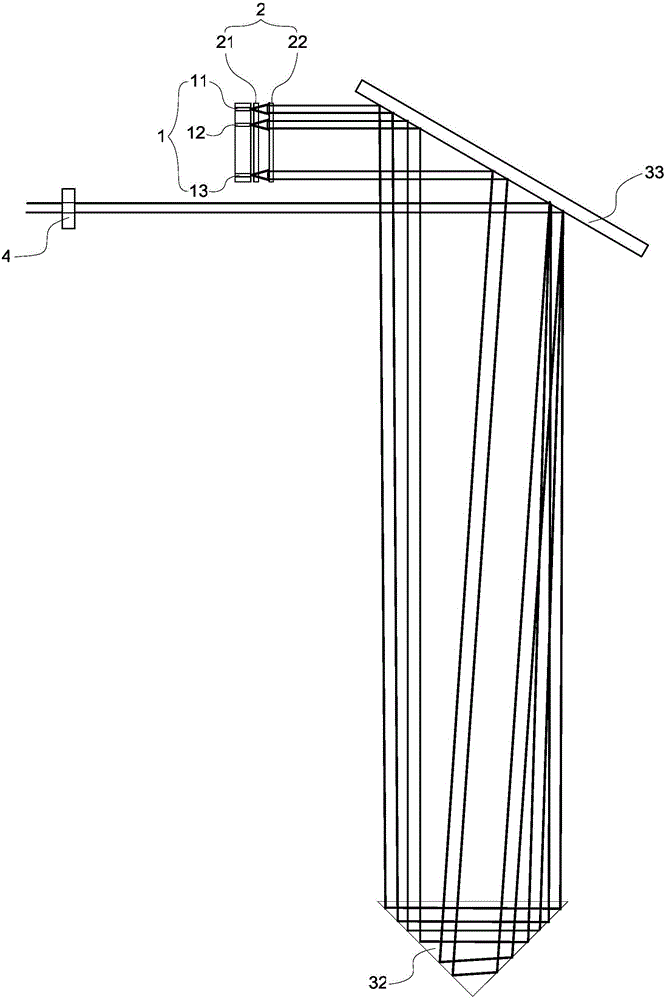

Method, device and system for separating microalgae

ActiveCN102127509AReduce moisture contentSimple structureUnicellular algaeMicroorganism based processesSURFACTANT BLENDChemistry

The invention relates to a method, a device and a system for separating microalgae, in particular to a method for separating the microalgae from microalgae suspension. The method comprises the following steps of: a) providing algae-containing suspension; b) adding a surfactant or solution of the surfactant into the suspension to dissolve or disperse the surfactant; c) filling bubbles from the bottom of the suspension in which the surfactant is dissolved to ensure that the bubbles are contacted with the microalgae in the rising process; d) ensuring that the microalgae are adsorbed on the bubbles to form aggregate which comprises the bubbles and the algae; e) floating the aggregate to the surface of the suspension to form a foam layer; and f) collecting the foam layer formed by the aggregate. The method, the device and the system have low equipment requirements, are economic and are favorable for scale-up production and industrial application.

Owner:ENN SCI & TECH DEV

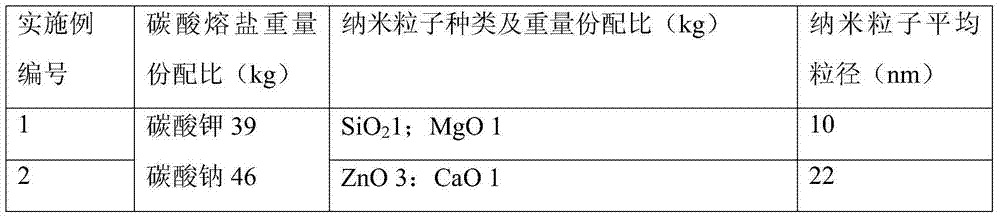

Molten nano-carbonate heat transfer and accumulation medium, and preparation method and application thereof

ActiveCN103923619AHigh safe use upper limit temperatureReduce volume shrinkage ratioHeat-exchange elementsHeat stabilityNanoparticles dispersion

The invention provides a molten nano-carbonate heat transfer and accumulation medium, and a preparation method and an application thereof, and belongs to the technical field of heat storage and transmission. The molten nano-carbonate heat transfer and accumulation medium contains a molten carbonate system formed by potassium carbonate, sodium carbonate, lithium carbonate and sodium chloride, nanoparticles are added into the molten carbonate system, and the nanoparticles are metal oxide and / or nonmetal oxide; and the nanoparticles are dispersed into the molten carbonate system, and the molten nano-carbonate heat transfer and accumulation medium is formed through compounding. The melting point of molten nano-carbonate is low, so the molten nano-carbonate heat transfer and accumulation medium has an upper limit use temperature of 800DEG C, has a good heat stability and a high heat conductivity, and is very suitable for the heat accumulation and transfer systems of industrial energy accumulation and solar photo-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

Compressed standardized keyboard

InactiveUS7310053B2Reduce size requirementsSmall sizeInput/output for user-computer interactionOperation facilitationReduced sizeComputer science

Owner:BOLLMAN TAYLOR

Offset Planar Coil Coaxial Surge Suppressor

ActiveUS20070053130A1MinimizationSmall component sizeTwo pole connectionsEmergency protective arrangement detailsElectrical conductorSuppressor

An in-line surge suppressor assembly having a body with a side aperture and an inner conductor positioned coaxial within a bore of the body. An insert having a planar inductor coil with a post extending from an origin point of the planar inductor coil is positioned with the post passing through the side aperture and coupled to the inner conductor at a distal end. An outer rim of the planar inductor coil is electrically coupled to the body.

Owner:COMMSCOPE TECH LLC

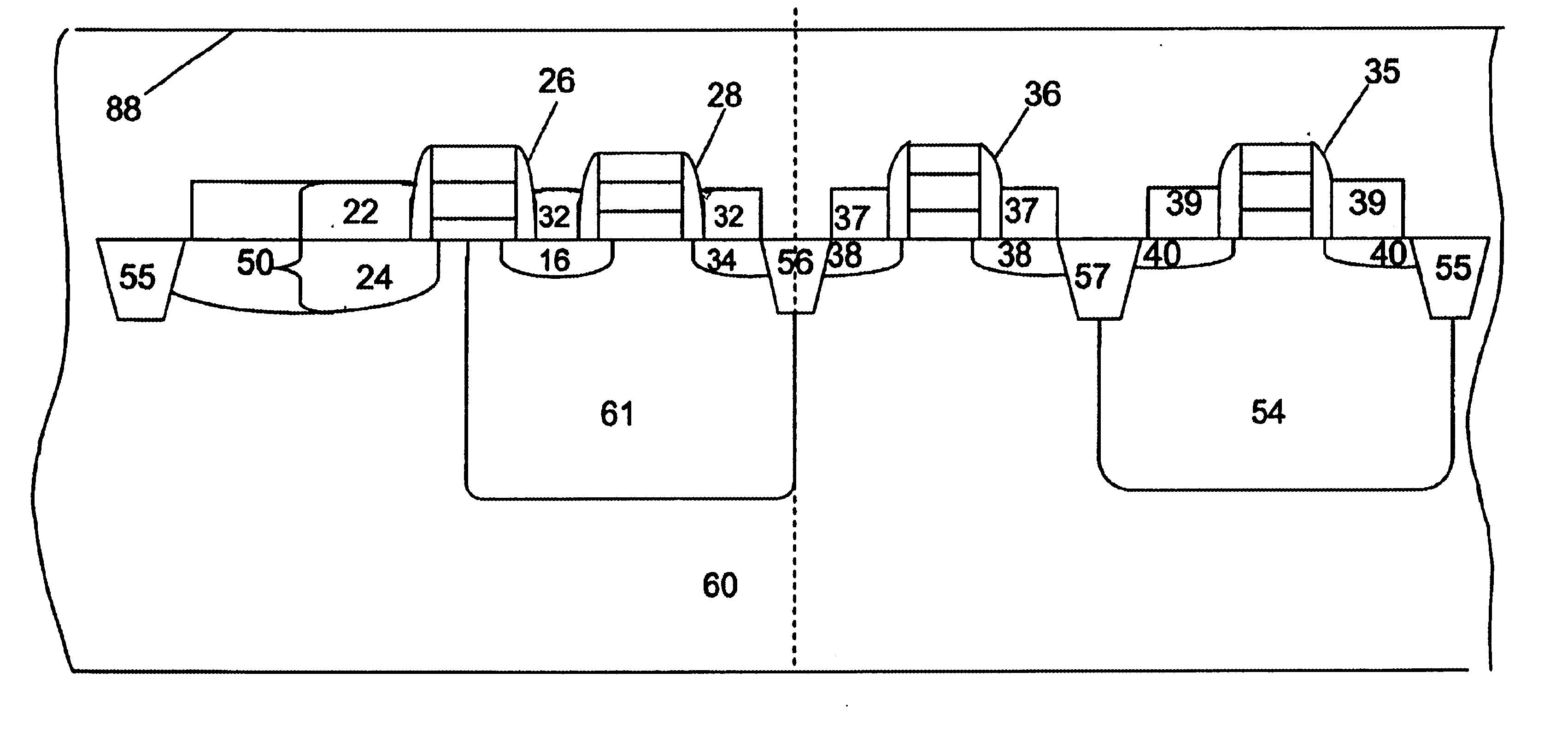

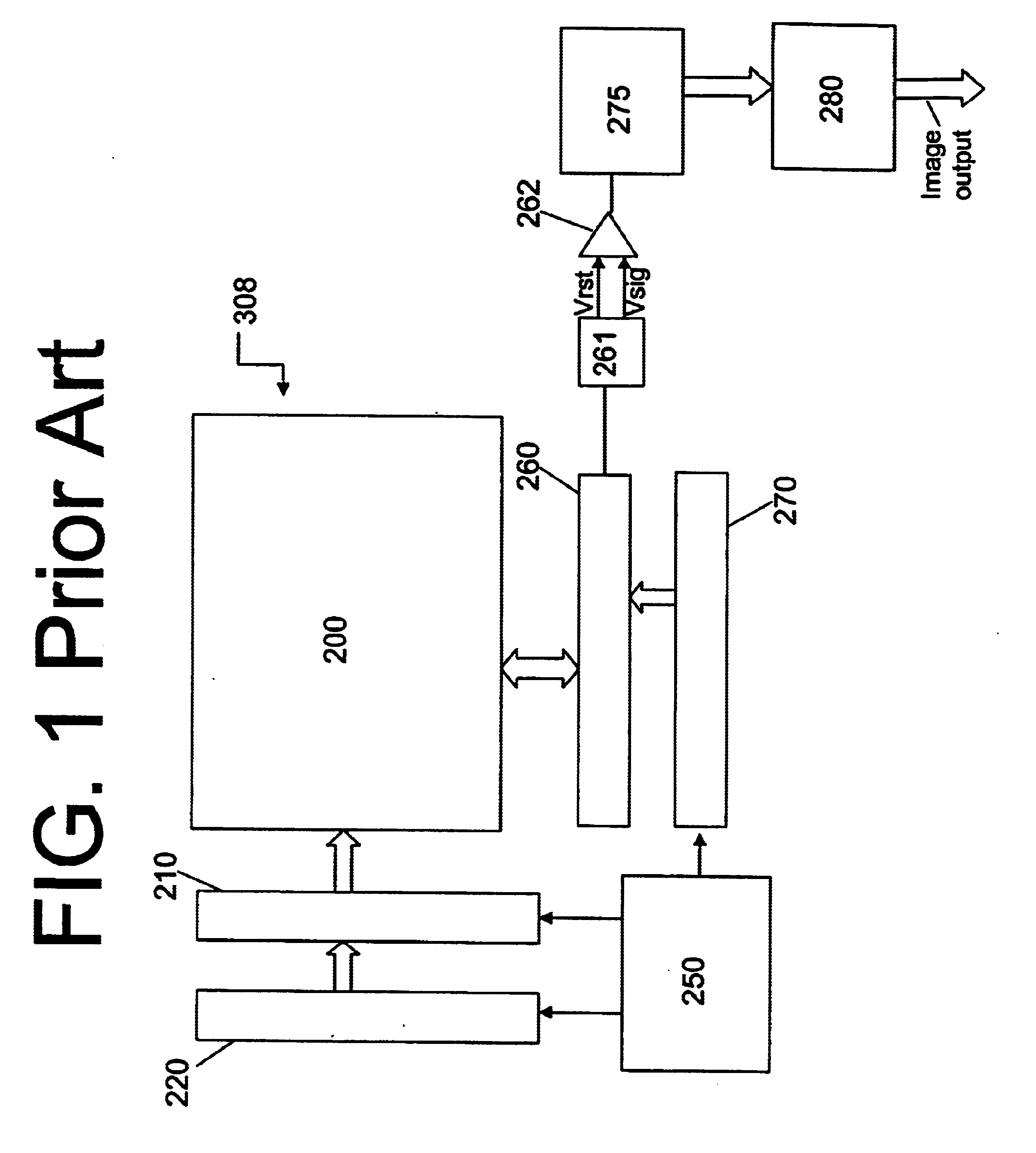

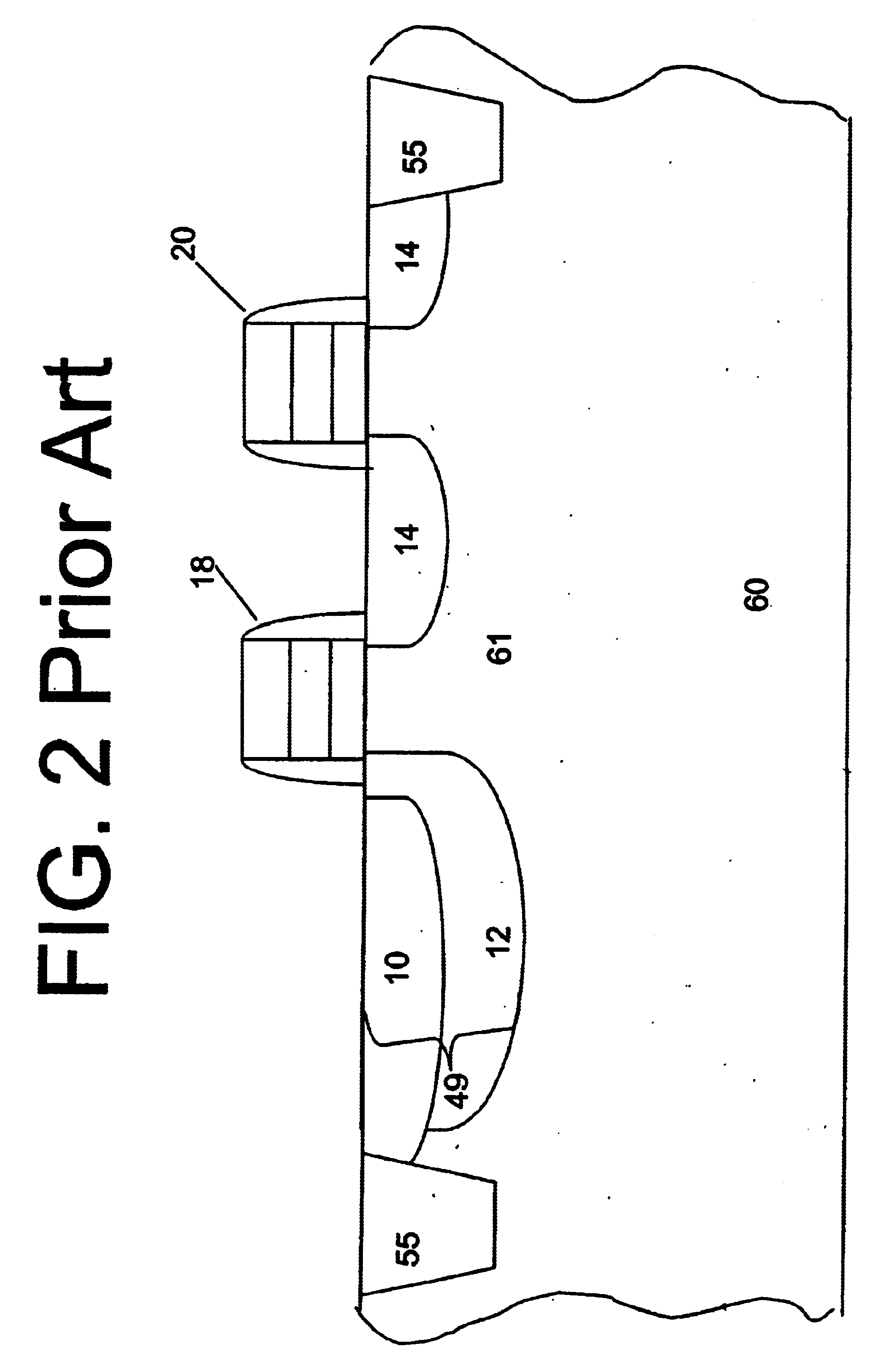

Elevated photodiode in an image sensor

InactiveUS6847051B2Reduce size requirementsReducing imageTransistorSolid-state devicesPhotodiodeComputer science

The invention provides an elevated photodiode for image sensors and methods of formation of the photodiode. Elevated photodiodes permit a decrease in size requirement for pixel sensor cells while reducing leakage, image lag and barrier problems typically associated with conventional photodiodes.

Owner:APTINA IMAGING CORP

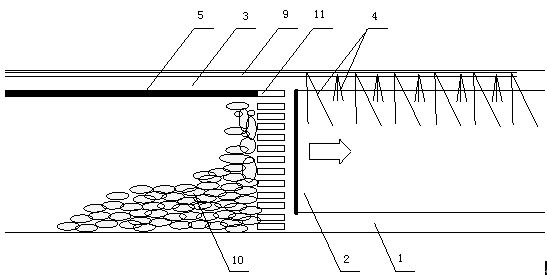

Co-extraction method for pillar-less coal and gas of advanced entry-retaining construction extraction engineering

InactiveCN102635392AImprove reliabilityExtended extraction timeUnderground miningSurface miningEngineeringMechanical engineering

The invention relates to a co-extraction method for pillar-less coal and gas of advanced entry-retaining construction extraction engineering. The co-extraction method comprises the following steps: firstly, pre-constructing a drill hole on a front directional coal layer of a coal extraction working surface; confirming positions of top and bottom plate of the coal layer in a wedge-shape vertical crack area; before starting a gob-side entry retaining process, drilling gas extraction drill holes on the top plate, bottom plate and two sides of gob-side in front of the coal extraction working surface, and then forward pushing the coal extraction working surface to cross the gas extraction drill holes; while forward pushing, finishing the gob-side entry retaining behind the coal extraction working surface; and sealing the gas extraction drill holes on the top plate, bottom plate and two sides of gob-side when a flow value of to-be-extracted gas pressure is greatly reduced. The drilling construction in the retaining entry is unnecessary, the demand on the size of the cross section of the retaining entry is reduced, the demand on restraining volume of the cross section is reduced and the time for efficiently extracting gas is prolonged.

Owner:CHINA UNIV OF MINING & TECH

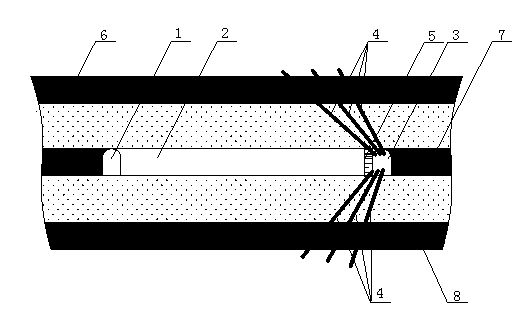

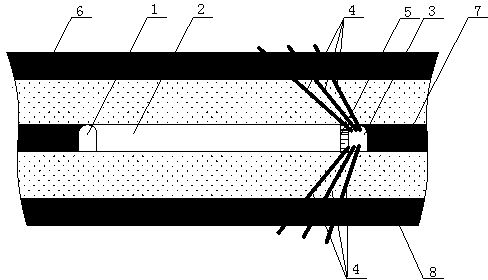

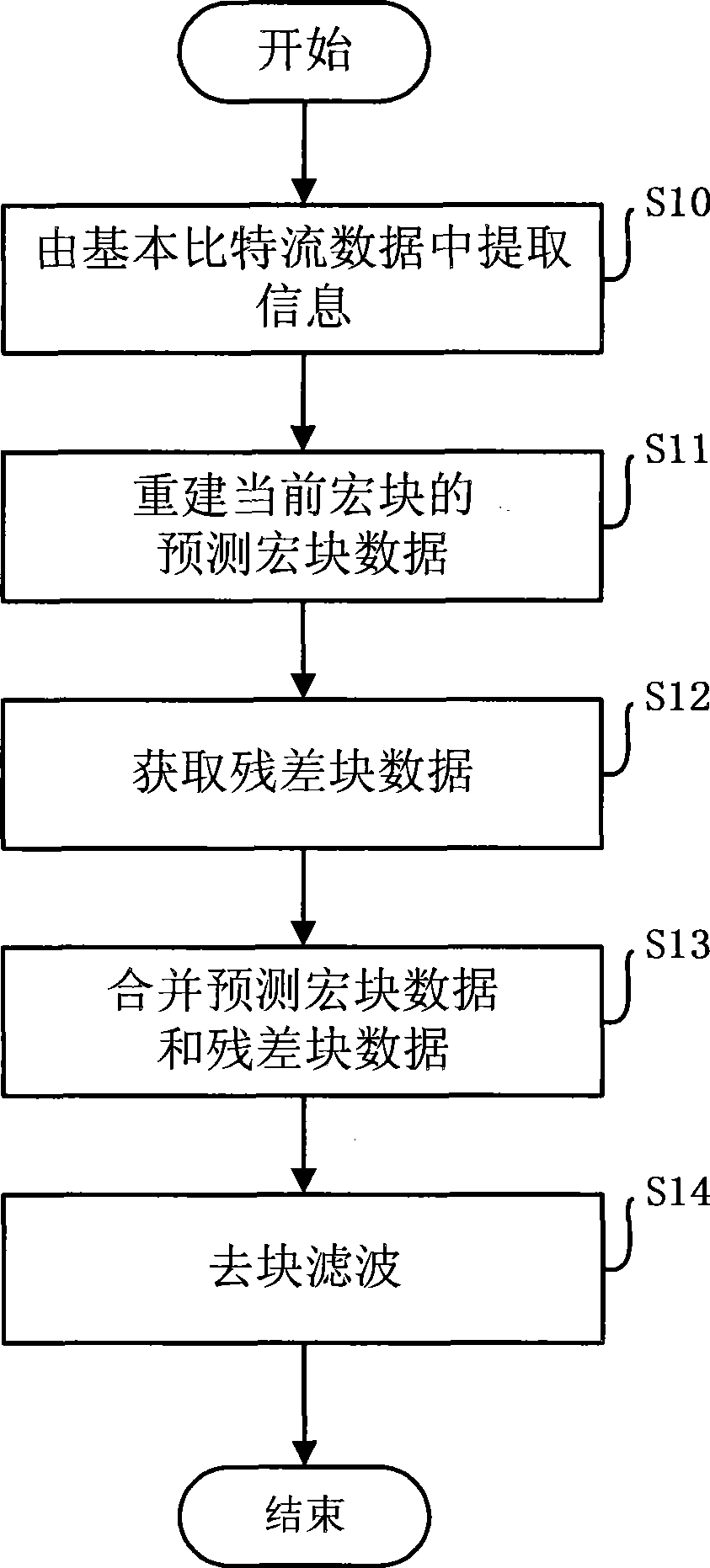

Decode method and apparatus for de-block effect filtering based on boundary strength factor

InactiveCN101472176AReduce size requirementsReduce delays and other issuesTelevision systemsDigital video signal modificationDecoding methodsBlock effect

The invention provides a decoding method based on edge intensity factors for conducting the de-blocking filter in the video compression processing, wherein, the acquisition of edge intensity factors is finished before the acquisition of the predication macro-block data and the residual block data. The method has the advantages that the current macro-block information can be released from a memory area in advance, and the needed information for the reference to macro blocks share the information existed in other storage area, so that the on-chip memory space in the decoding device is not exclusively occupied, and the memory space is in no need of being externally connected. Therefore, the demand on the memory device is reduced, the problems, such as the delay caused by the repeated memory, and the like are reduced, and the system efficiency is improved.

Owner:CHIPNUTS TECH INC

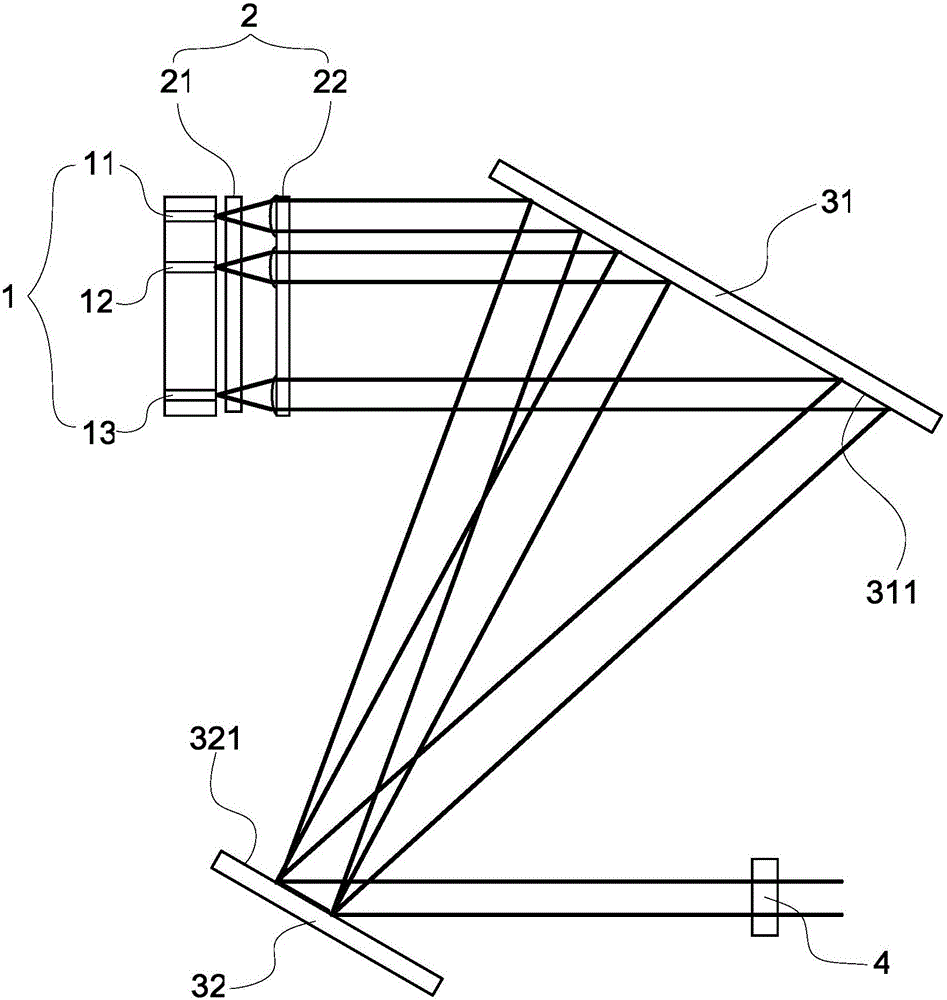

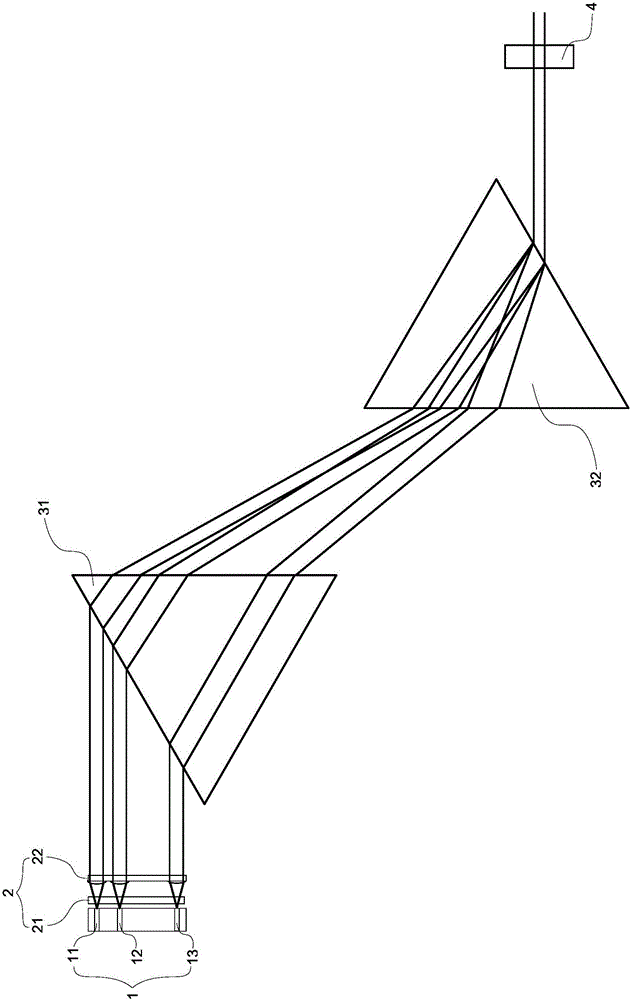

Laser array beam combining device

InactiveCN105811245AReduce size requirementsQuality improvementLaser optical resonator constructionSemiconductor laser arrangementsLaser arrayLight beam

The invention discloses a laser array beam combining device, which comprises a laser gain medium array, a shaping optical system, a dispersing optical component and a partial reflecting optical component, wherein the laser gain medium array comprises at least two laser gain elements; each laser gain element can generate a laser beam with a certain spectrum width; the shaping optical system is used for collimating each laser beam generated by the laser gain medium array to obtain a group of parallel collimated laser beam arrays; the dispersing optical component is used for carrying out at least two diffraction or refraction on the incident collimated laser beam arrays and then combining the beams for outputting; and the partial reflecting optical component is used for receiving the combined laser beams and ejecting the laser beams.

Owner:II VI SUWTECH INC

Shale gas horizontal well proppant in-crack shielding and temporary plugging staged fracturing process

ActiveCN106223922ASolve complex problems such as inability to downloadStable and reliable perforationFluid removalPressure riseSand blasting

The invention discloses a shale gas horizontal well proppant in-crack shielding and temporary plugging staged fracturing process. The process includes following steps: lowering a continuous oil pipe and a sand blasting perforation tool a layer section needing fracturing modification, performing multi-cluster perforation, and lifting up the continuous oil pipe and the perforation tool; setting highest safe pumping pressure on the ground, and conducting main fracturing to promote a reservoir to generate a size crack; after injection liquid quantity reaches 1600-1800m3, pumping a proppant section plug for temporary plugging; after the section plug used for sand filling enters a stratum hole, lowering injection displacement until a sand plug completely enters a stratum; if shaft pressure rises to the highest safe pumping pressure set on the ground, showing that shielding and plugging are successful; lowering the continuous oil pipe for multi-cluster perforation and main fracturing of the next section until fracturing of all sections is completed. Multi-cluster sand blasting perforation of the continuous oil pipe is combined with in-crack sand filling temporary plugging staged fracturing, so that the complex problems that a mechanical bridge plug and a perforation tool cannot be lowered due to casing deformation and hole shrinkage and the like can be solved effectively.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

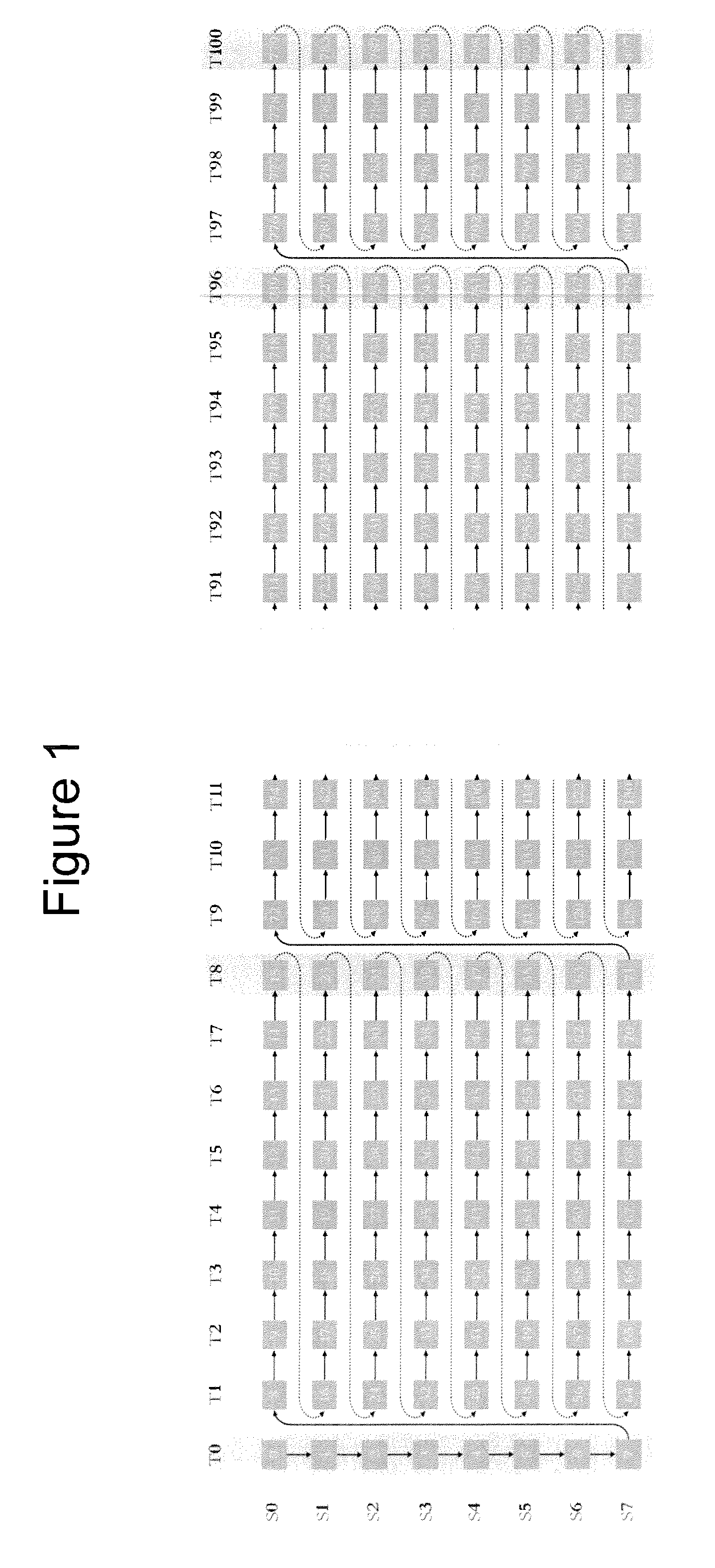

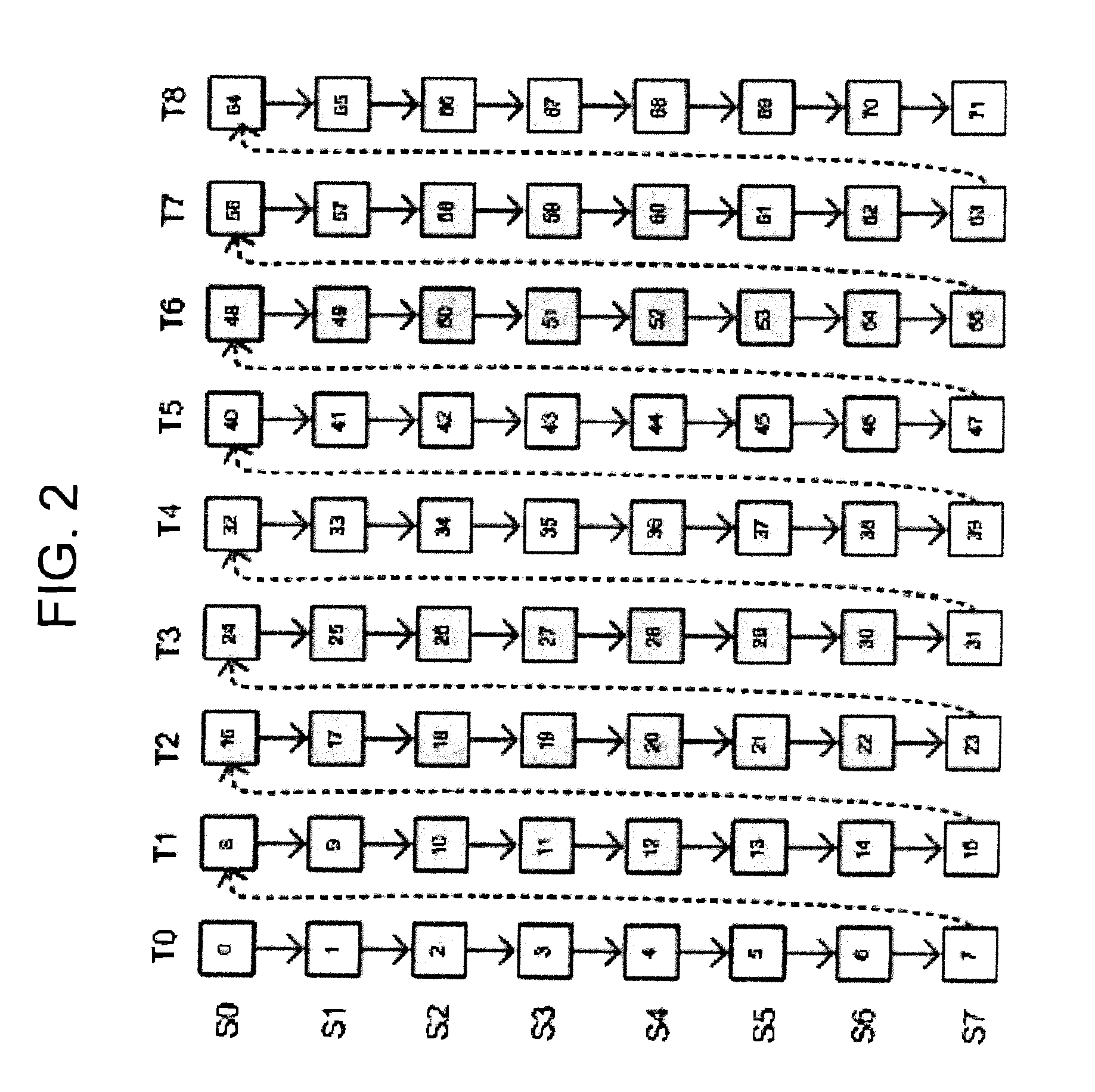

System and method for implementing low-complexity multi-view video coding

ActiveUS20080095234A1Reduce complexityReduce size requirementsColor television with pulse code modulationPulse modulation television signal transmissionVideo bitstreamVideo encoding

A system and method for implementing low complexity multi-view video coding. According to various embodiments, single-loop decoding is applied to multi-view video coding. For N coded views, where only M of the N views are to be displayed, only those M views are required to be fully decoded and stored to a decoded picture buffer (DPB) when needed. Pictures of other views are only partially decoded or simply parsed and do not have to be stored into the DPB. Various embodiments also provide for an encoder that encodes multi-view video bitstreams in accordance with the single-loop decoding concept, as well as a decoder that utilizes single-loop decoding to decode and output on a subset of the encoded views from a multi-view bitstream.

Owner:NOKIA TECHNOLOGLES OY

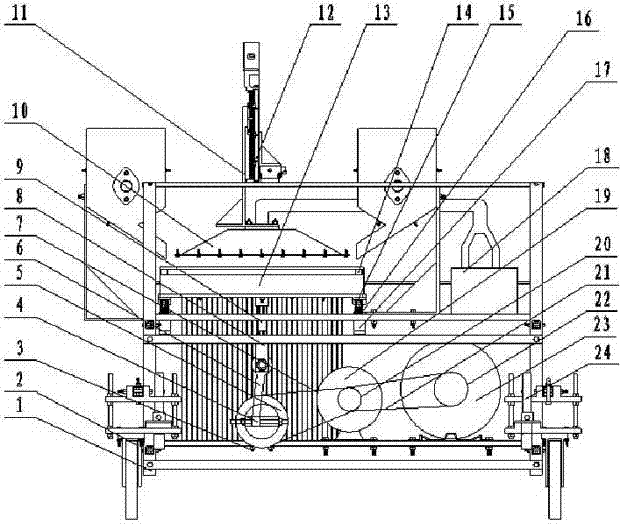

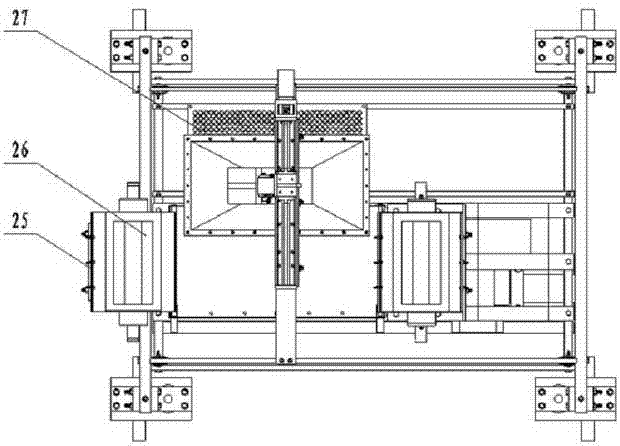

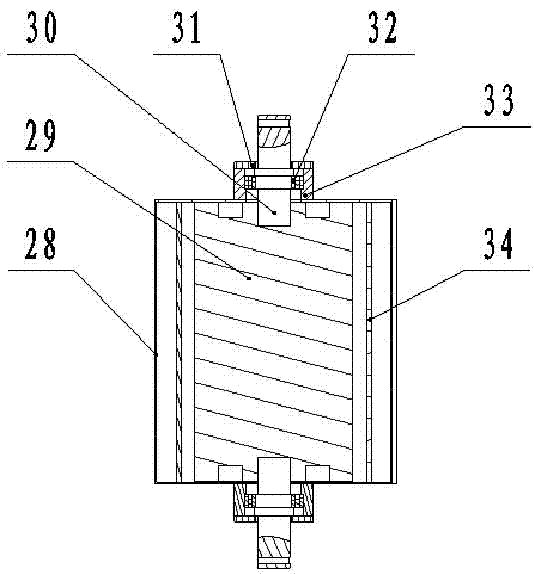

Air-sucking vibration plate type precision seeder for field seedling raising

InactiveCN102550180AImprove seeding uniformity and work efficiencyReduce seedling costSeed depositing seeder partsRegular seed deposition machinesManipulatorBiology

The invention discloses an air-sucking vibration plate type precision seeder for field seedling raising, which relates to the field of agricultural precision seeding and is mainly used for the field precision seedling raising and seeding with the planting density of 1-2 seeds / hole. The precision seeder comprises a machine frame of the seeder, a power source, an air pressure source, a vibration seed plate mechanism, a 2-degree-of-freedom manipulator, a leveling device, a quantitative seed feeding bin, a chuck, a seed guide pipe, a power generation device, a control unit and the like. The vibration seed plate mechanism and the air pressure source are mounted on the machine frame of the seeder, and a small-sized gasoline engine is adopted to supply power. According to the air-sucking vibration plate type precision seeder, the field precision seedling raising and seeding with the planting density of 1-2 seeds / hole is realized, the seeding efficiency and uniformity are effectively improved, the seedling raising cost is reduced, and further, the requirement on the size of seeds is not high, and seeds are not damaged.

Owner:JIANGSU UNIV

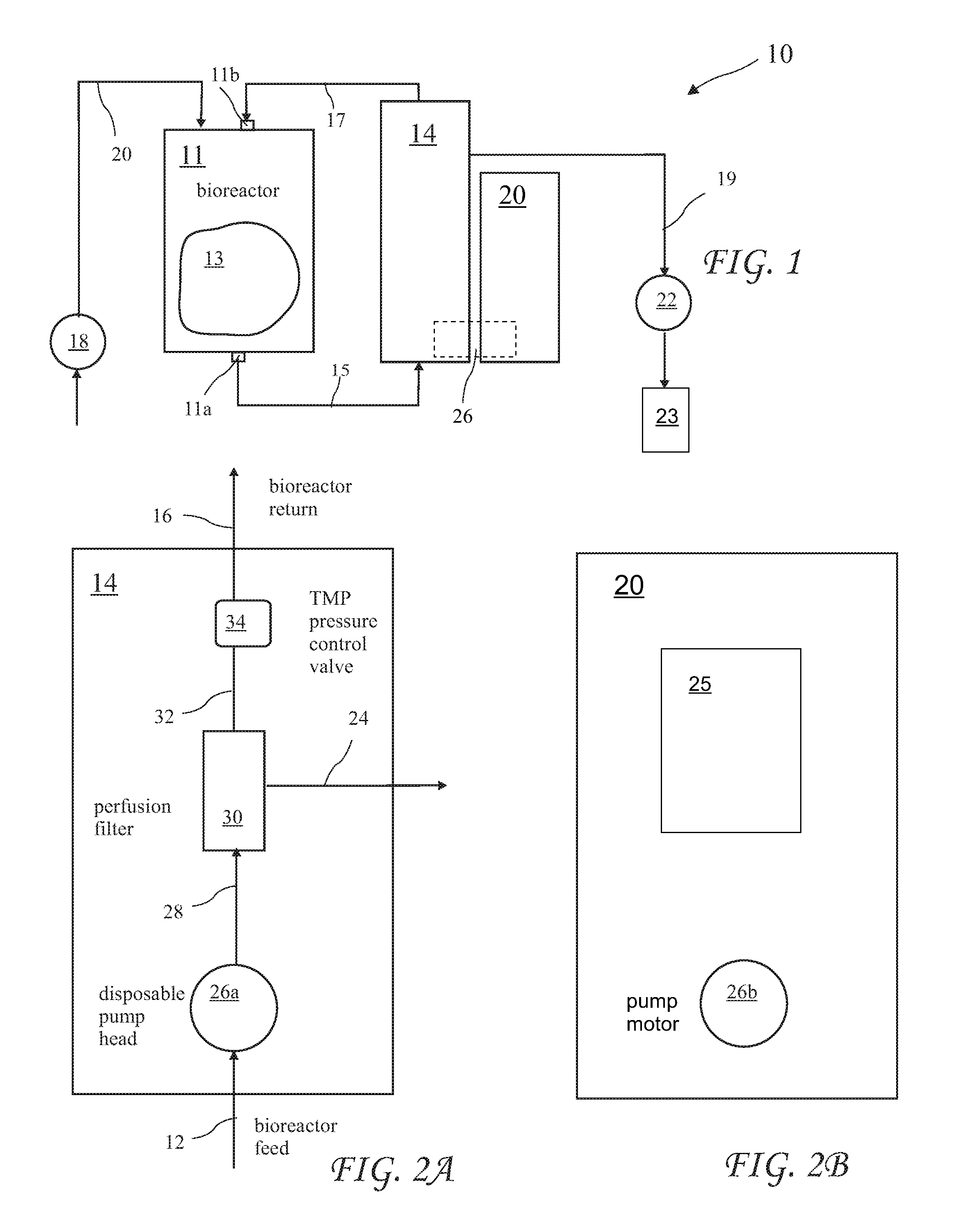

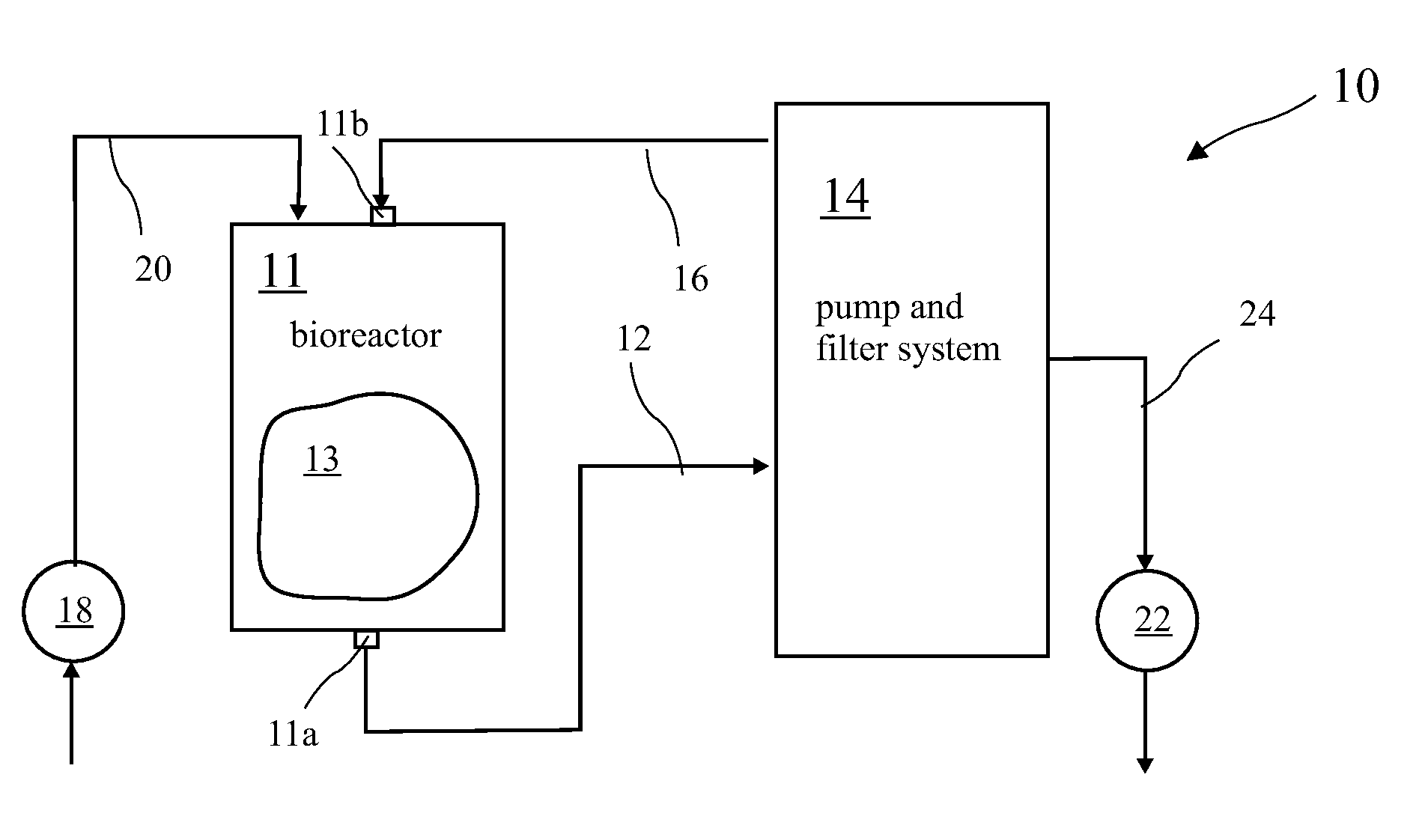

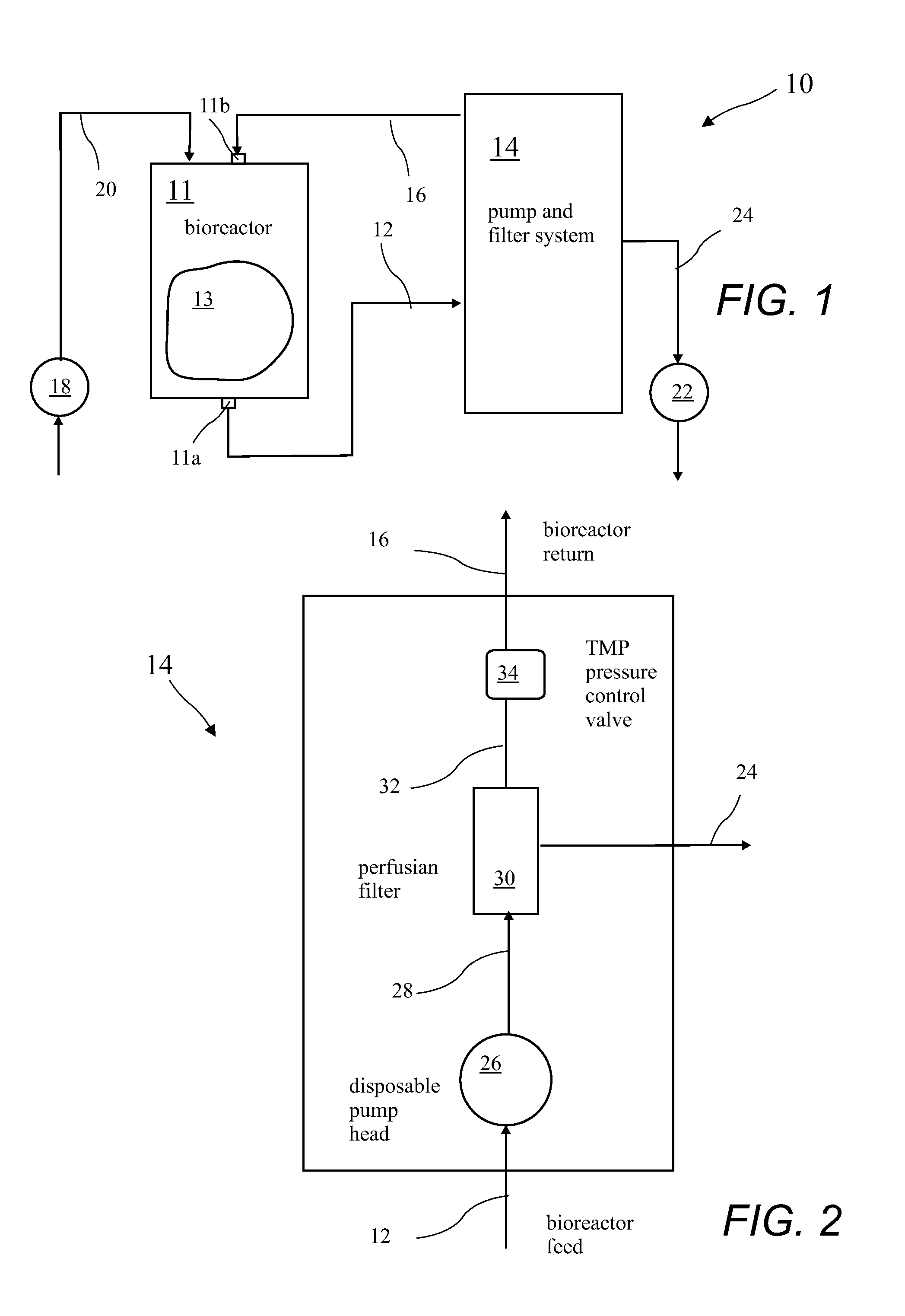

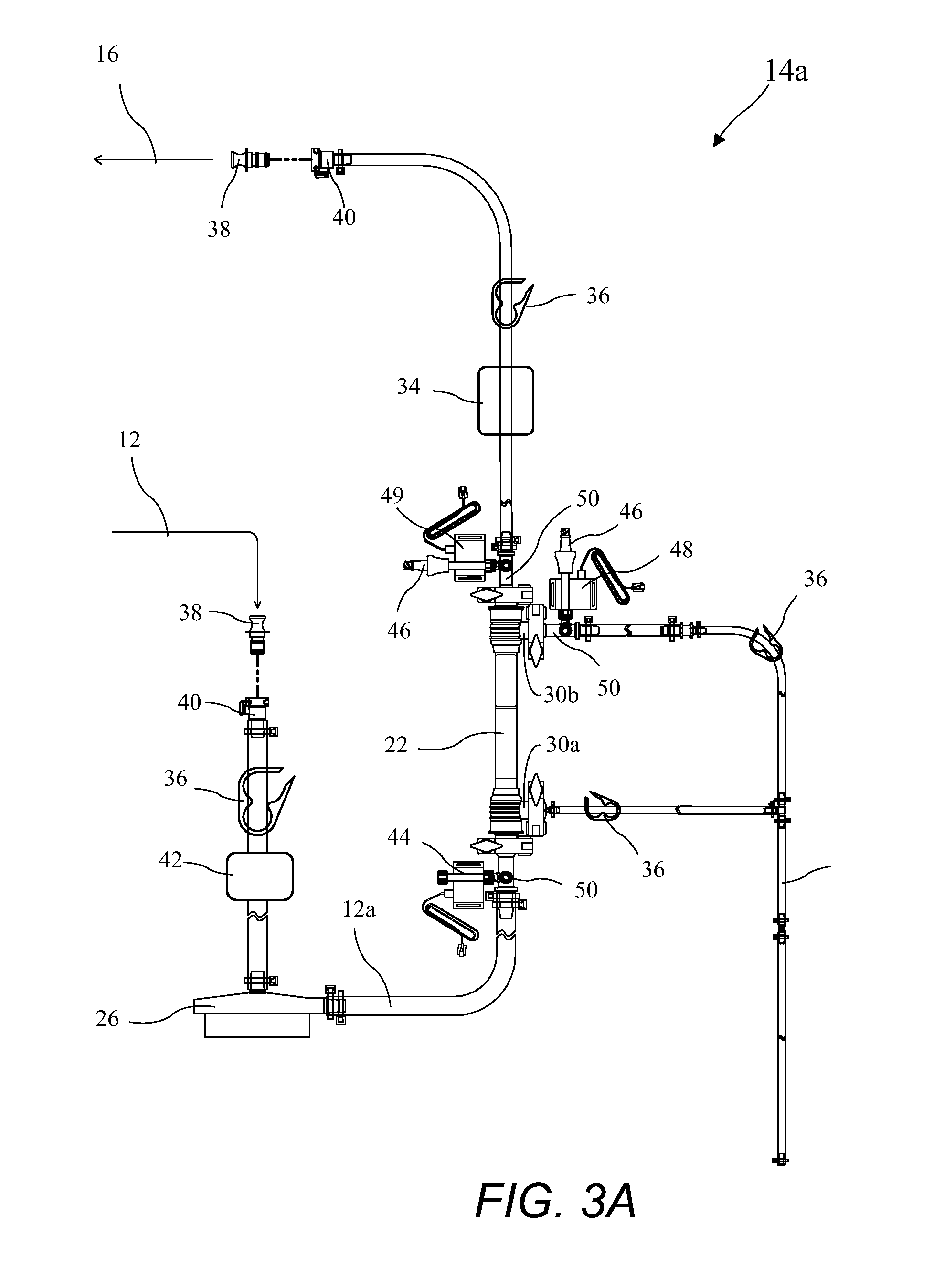

Method for Proliferation of Cells Within a Bioreactor Using a Disposable Pumphead and Filter Assembly

ActiveUS20160222337A1Improve cell productionSimple and quick attachmentBioreactor/fermenter combinationsMembranesHollow fibreCell separation

A method for promoting biological activity uses a filter system to increase cell production of a fed batch bioreactor. The filter system cycles bioreactor fluid through a hollow fiber tangential flow filter which separates metabolic wastes (as well as proteins) from cells produced in bioreactor and returned to fed batch bioreactor, improving cell production in the fed batch bioreactor. The filter system includes a disposable pump and filter, and a reusable control system. The pump is a low shear gamma stable pump gently cycling bioreactor fluid through the filter with minimal damage to the cells produced in the bioreactor. The pumphead and hollow fiber tangential flow filter are disposable. The pump motor is part of the control system and is reusable. The pumphead and filter are provided as an assembled and pre-sterilized unit allowing simple and quick attachment to the fed batch bioreactor, and simple and quick disposal.

Owner:REPLIGEN CORP

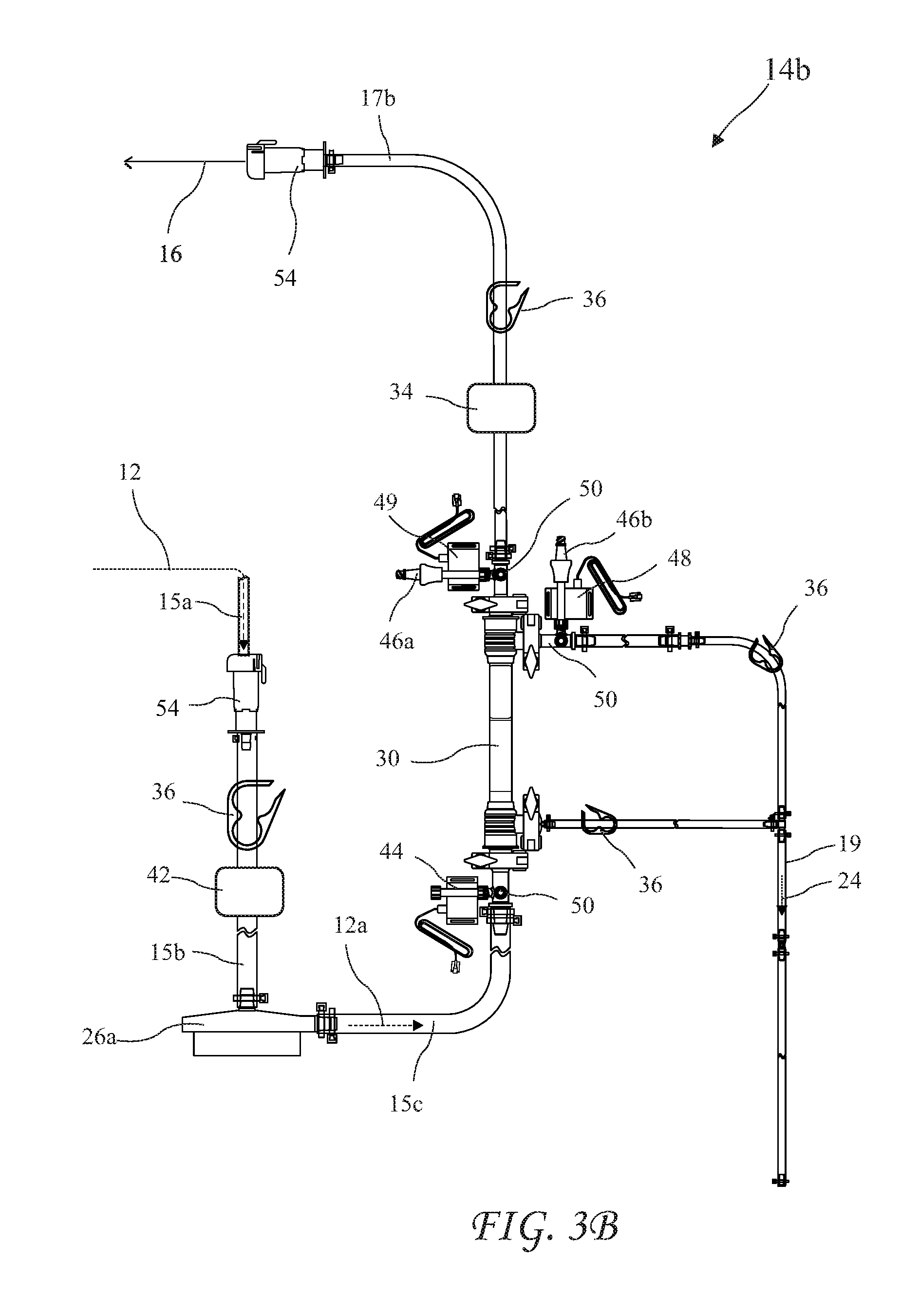

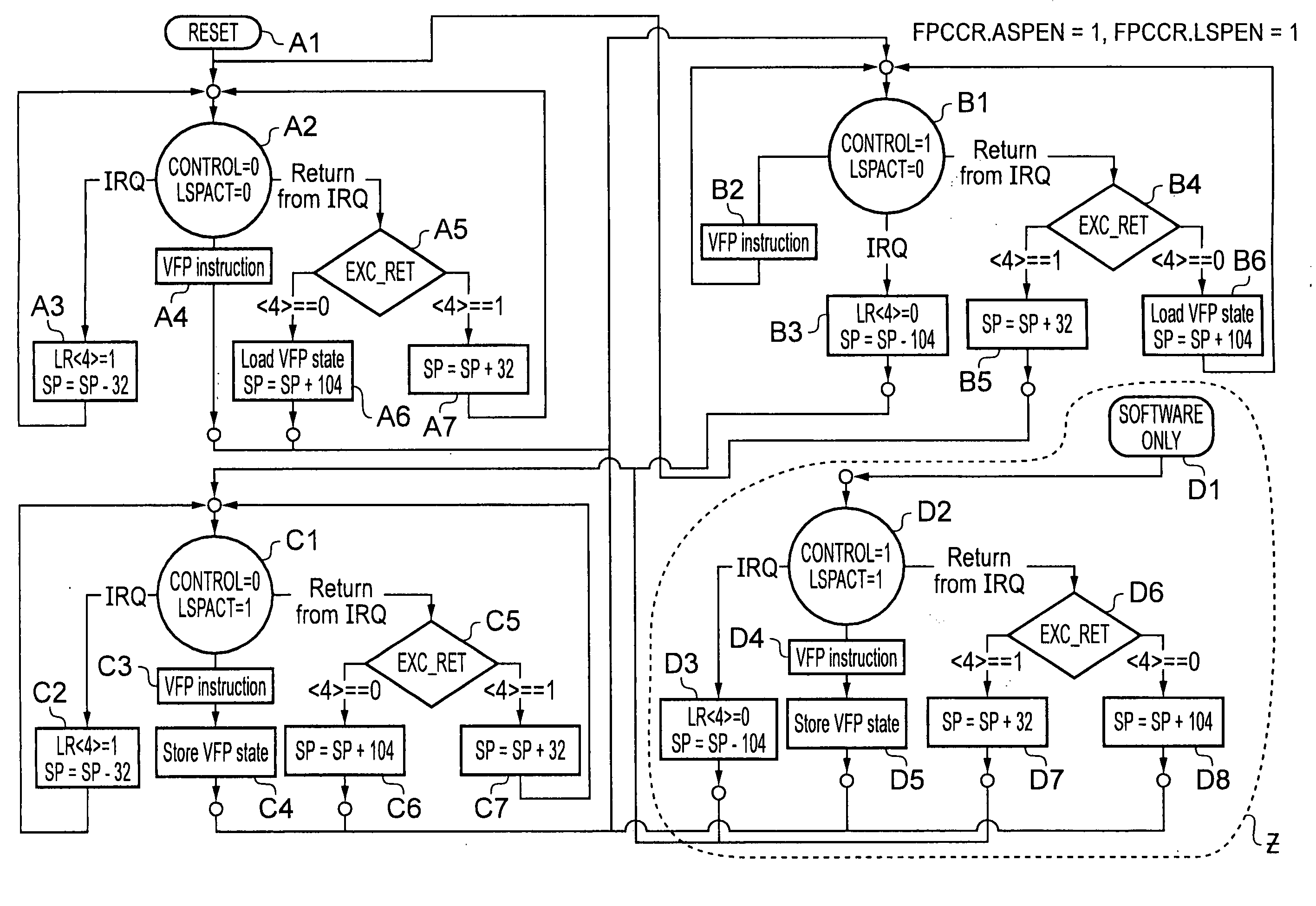

Data processing apparatus and method

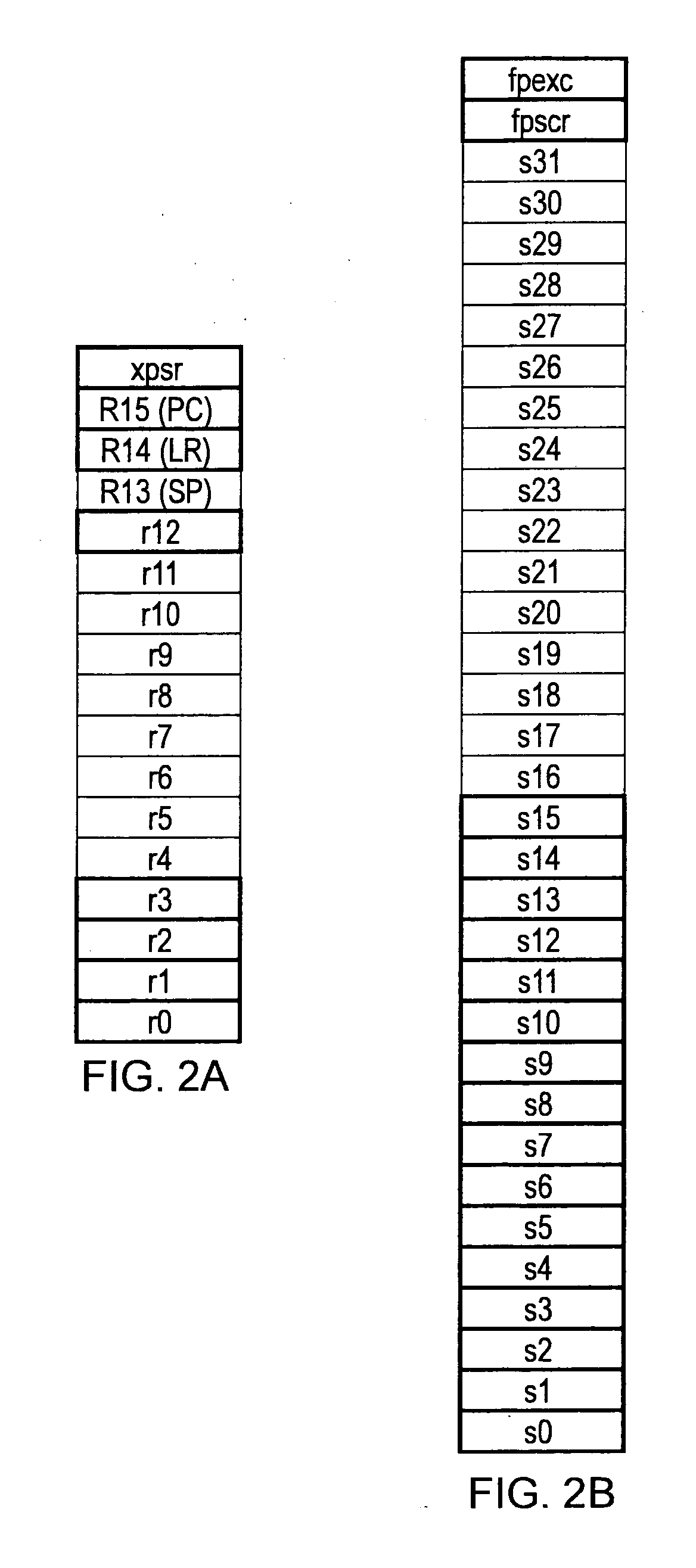

ActiveUS20100325397A1Improve timelinessReduce processRegister arrangementsDigital computer detailsProcessor registerParallel computing

A data processing apparatus is described which comprises processing circuitry responsive to data processing instructions to execute integer data processing operations and floating point data processing operations, a first set of integer registers useable by the processing circuitry in executing the integer data processing operations, and a second set of floating point registers useable by the processing circuitry in executing the floating point data processing operations. The processing circuitry is responsive to an interrupt request to perform one of an integer state preservation function in which at least a subset of only the integer registers are copied to a stack memory, and a floating point state preservation function in which at least a subset of both the integer registers and the floating point registers are copied to the stack memory, the one of said integer state preservation function and the floating point state preservation function being selected by the processing circuitry in dependence on state information. In this way, it is possible to reduce the memory size requirement through reduced stack sizes, and to reduce the number of memory accesses required compared with the basic solution of always preserving floating point registers. As a result, power usage and interrupt latency can be reduced.

Owner:ARM LTD

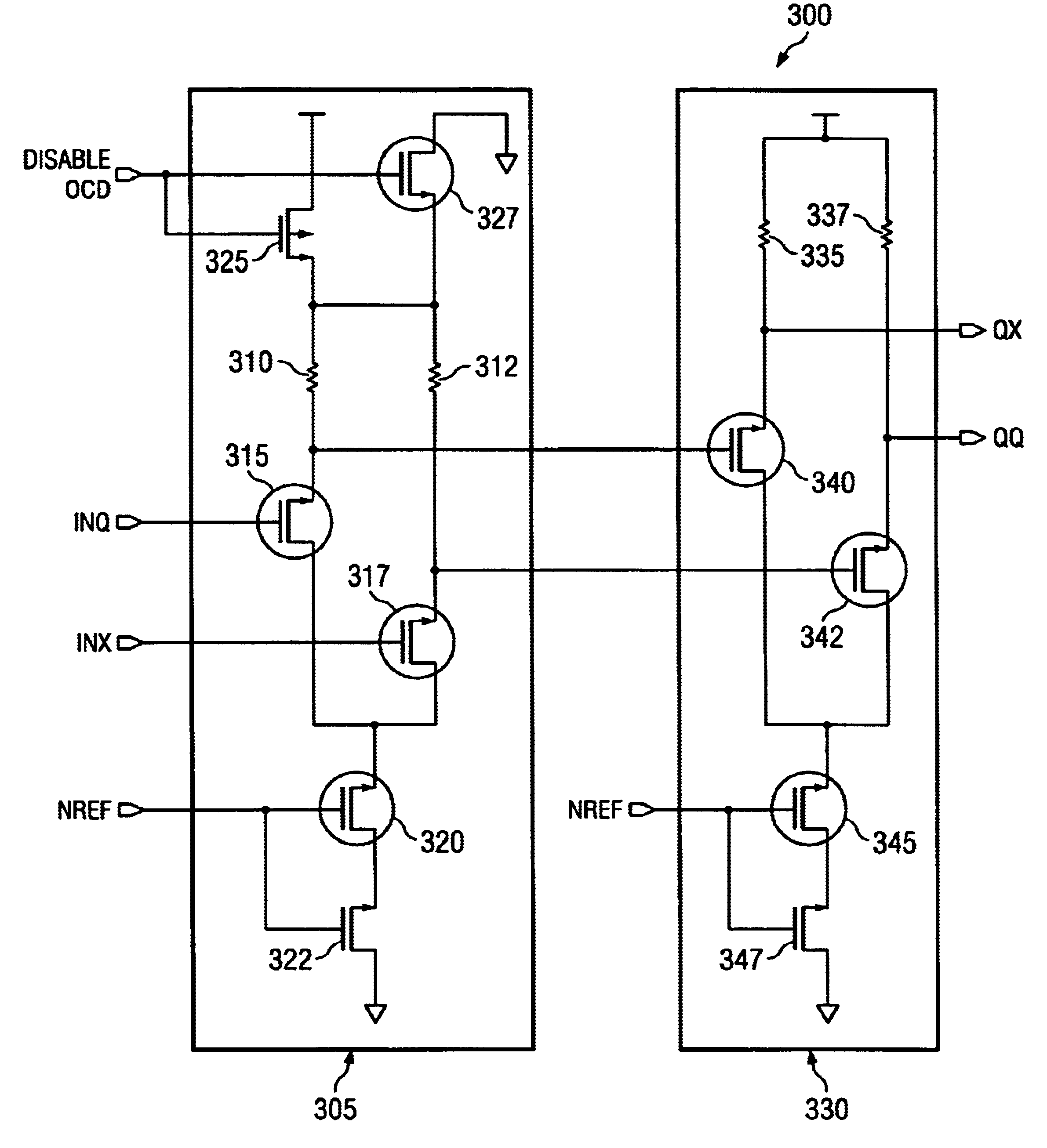

CML (current mode logic) OCD (off chip driver)-ODT (on die termination) circuit for bidirectional data transmission

InactiveUS6847225B2Easy to routeEasy to placeReliability increasing modificationsBaseband system detailsSignal onControl circuit

An apparatus for use as both an off chip driver (OCD) and an on die termination (ODT) circuits. A preferred embodiment comprises a control circuit (for example, control circuit 305) coupled to a dual function OCD / ODT circuit (for example, OCD / ODT circuit 330) with an enable line coupled to the control circuit. The control circuit may be used to selectively choose OCD and ODT functionality based on a value on the enable line. With the control circuit choosing OCD, the dual function OCD / ODT circuit functions as an OCD circuit, placing signals provided through the control circuit onto a transmission line. With the control circuit choosing ODT, the dual function OCD / ODT circuit becomes terminating resistors for incoming signals on a transmission line. The use of a single circuit for both OCD and ODT functions can save both integrated circuit real-estate and implementation costs due to a reduction in use of circuit elements.

Owner:POLARIS INNOVATIONS LTD

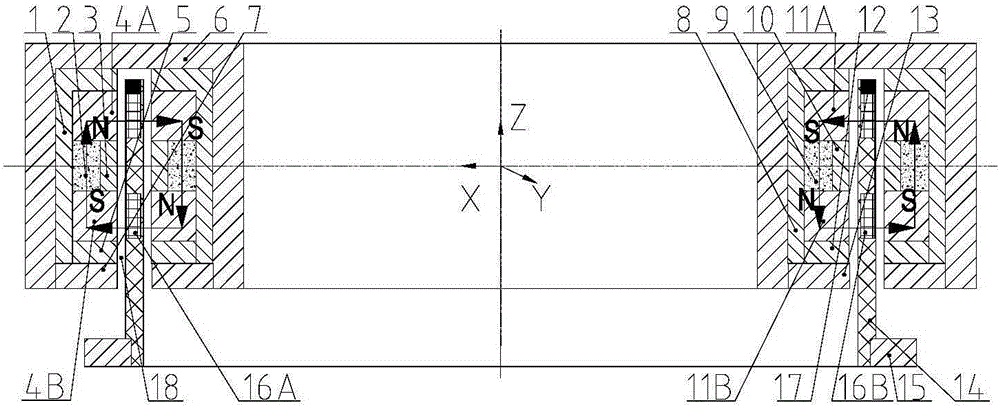

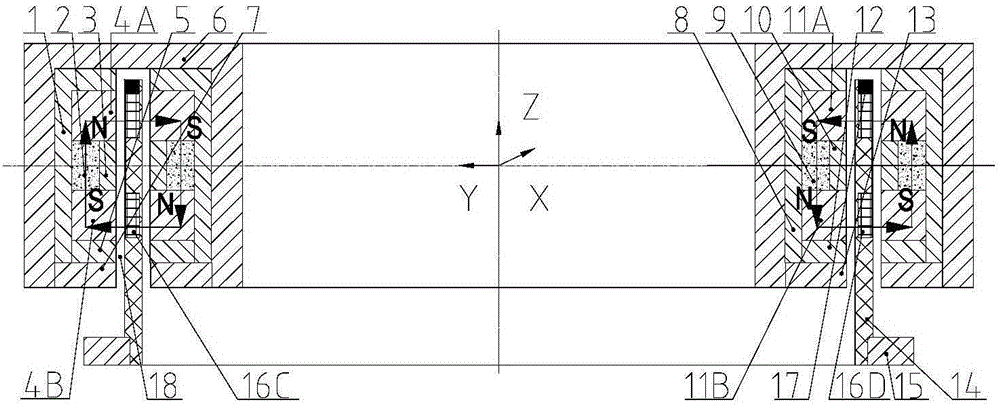

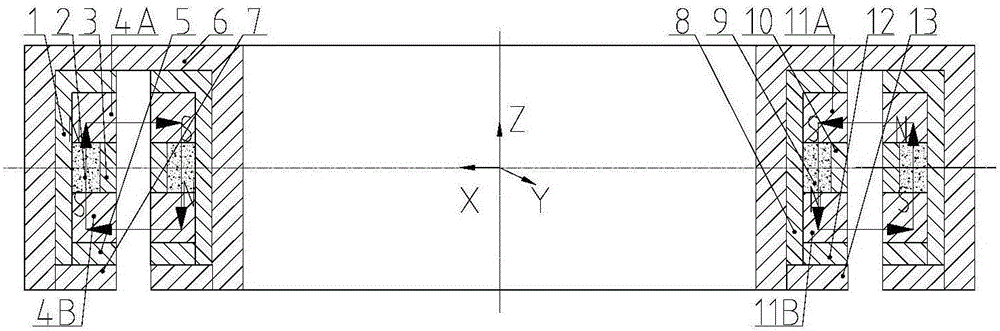

Lorentz force type magnetic bearing capable of realizing double permanent magnet deflection

ActiveCN106090010AReduce lapsReduced dimensional accuracyMagnetic bearingsMagnetic bearingMagnetic poles

The invention discloses a Lorentz force type magnetic bearing capable of realizing double permanent magnet deflection. The bearing comprises a rotor system and a stator system, wherein the rotor system mainly comprises an outer mounting sleeve, outer magnetic steel, an outer magnetism isolating ring, an outer upper magnetism conducting ring, an outer lower magnetism conducting ring, an outer lower magnetism conducting ring lock nut, a turntable, an outer assembly lock nut, an inner mounting sleeve, inner magnetic steel, an inner magnetism isolating ring, an inner upper magnetism conducting ring, an inner lower magnetism conducting ring, an inner lower magnetism conducting ring lock nut and an inner assembly lock nut; the stator system mainly comprises a stator framework, an aluminum substrate, a winding and epoxy resin glue. The magnetic steel axial magnetization scheme is adopted, the number of magnetic steel turns is reduced, the gap flux density fluctuation caused by uneven magnetomotive force of the magnetic steel is reduced, the paramagnetic effect is realized by the aid of the magnetism conducting rings, the gap flux density fluctuation caused by assembly of the outer magnetic steel and the inner magnetic steel is further reduced, and high-precision deflection control torque can be realized. Besides, a magnetism conducting material is used as a magnetic pole material, precision machining of a magnetic pole surface is facilitated, and requirements for size precision and surface roughness of the magnetic steel are reduced.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Compressed standardized keyboard

InactiveUS20060028358A1Small sizeSpace minimizationInput/output for user-computer interactionOperation facilitationReduced sizeComputer science

A keyboard of reduced size is provided in which multiple characters are assigned to each of the primary keys. The selection of the characters to be assigned to each specific primary key is based on the touch typing rules associated with a specific standardized keyboard, preferably allowing at least three rows of keys to be reduced to a single row of keys. A disambiguating system is used to interpret which of the characters and / or symbols assigned to a particular key is intended, typically by applying a set of disambiguating rules to generated input sequences.

Owner:BOLLMAN TAYLOR

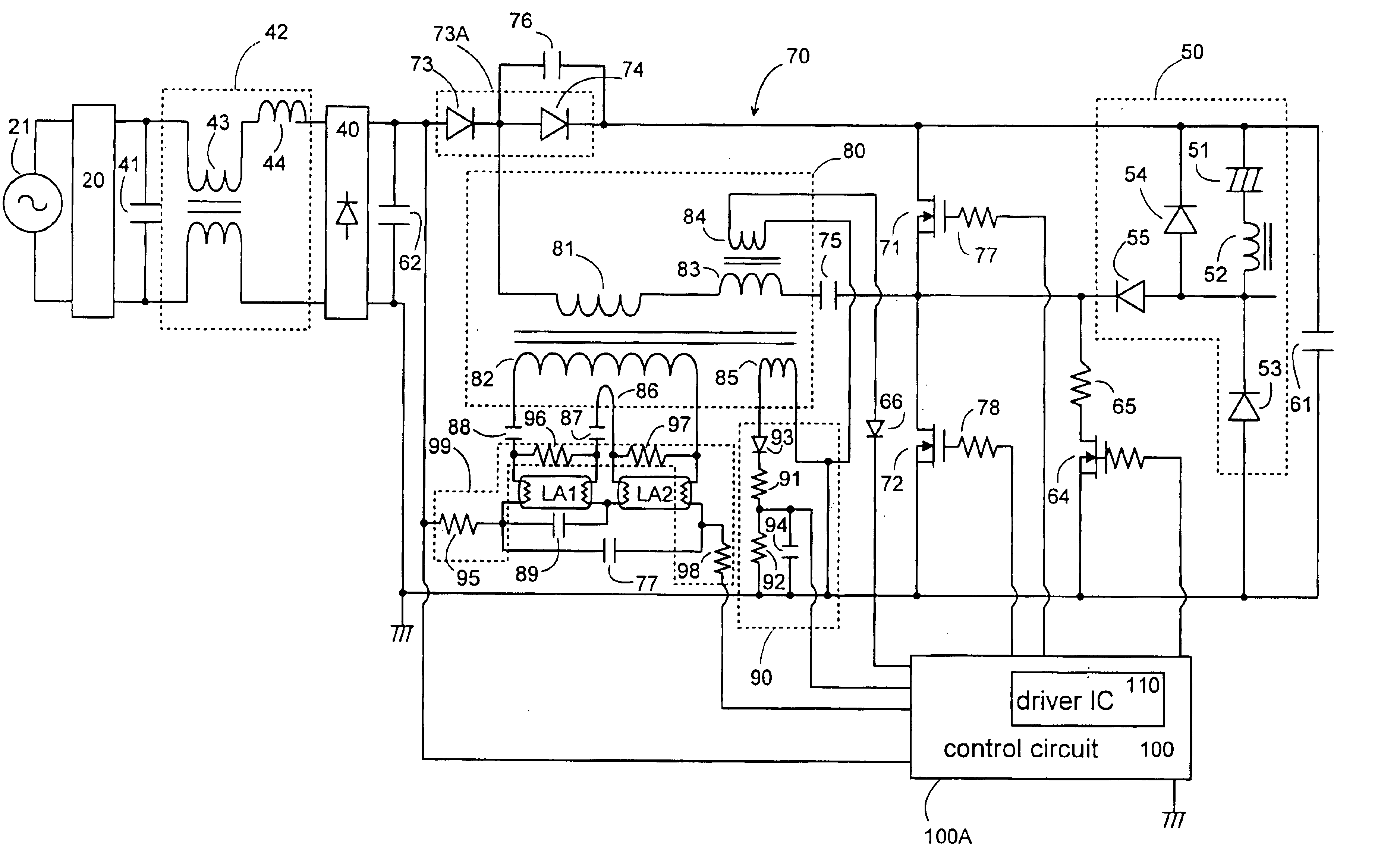

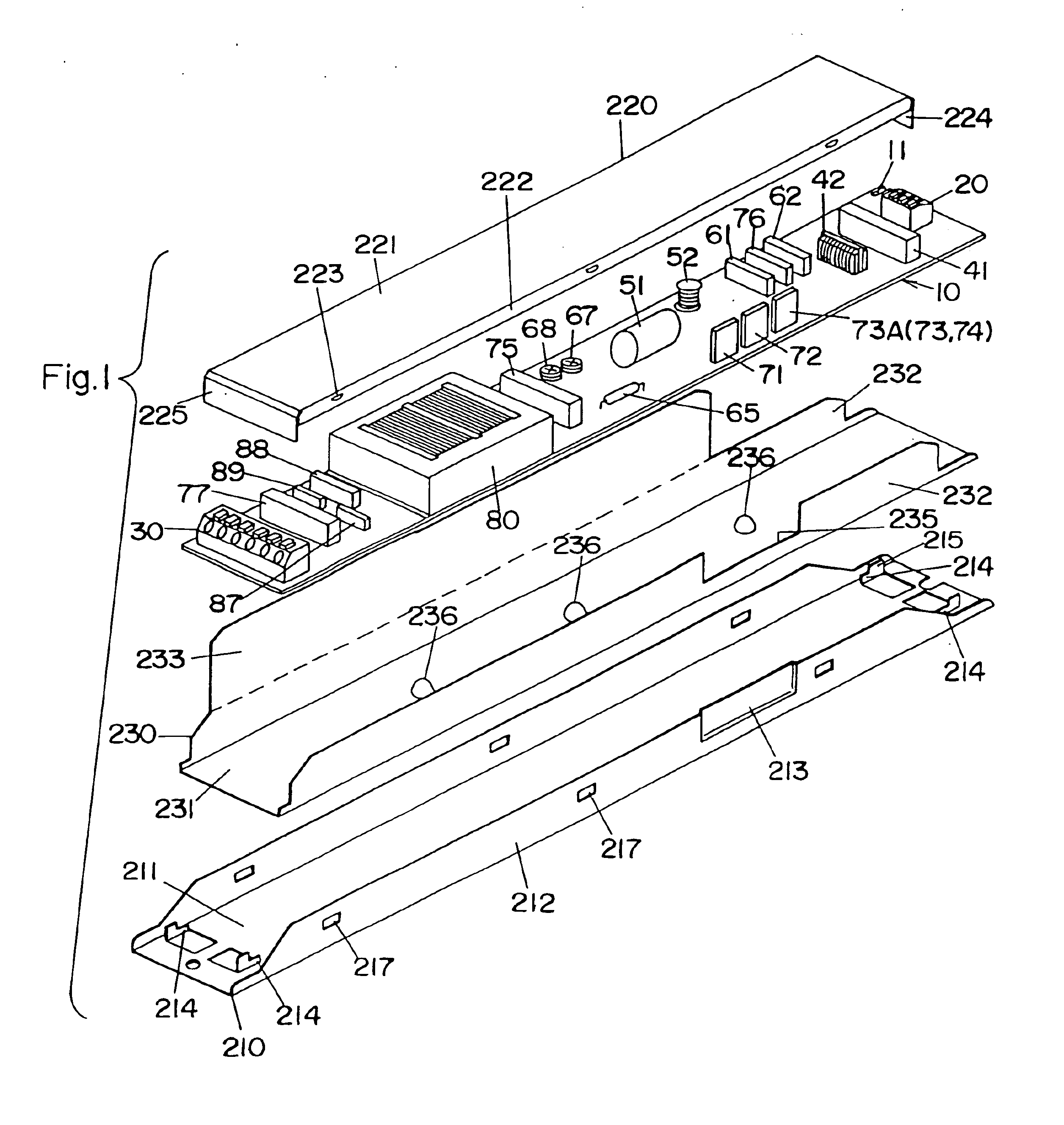

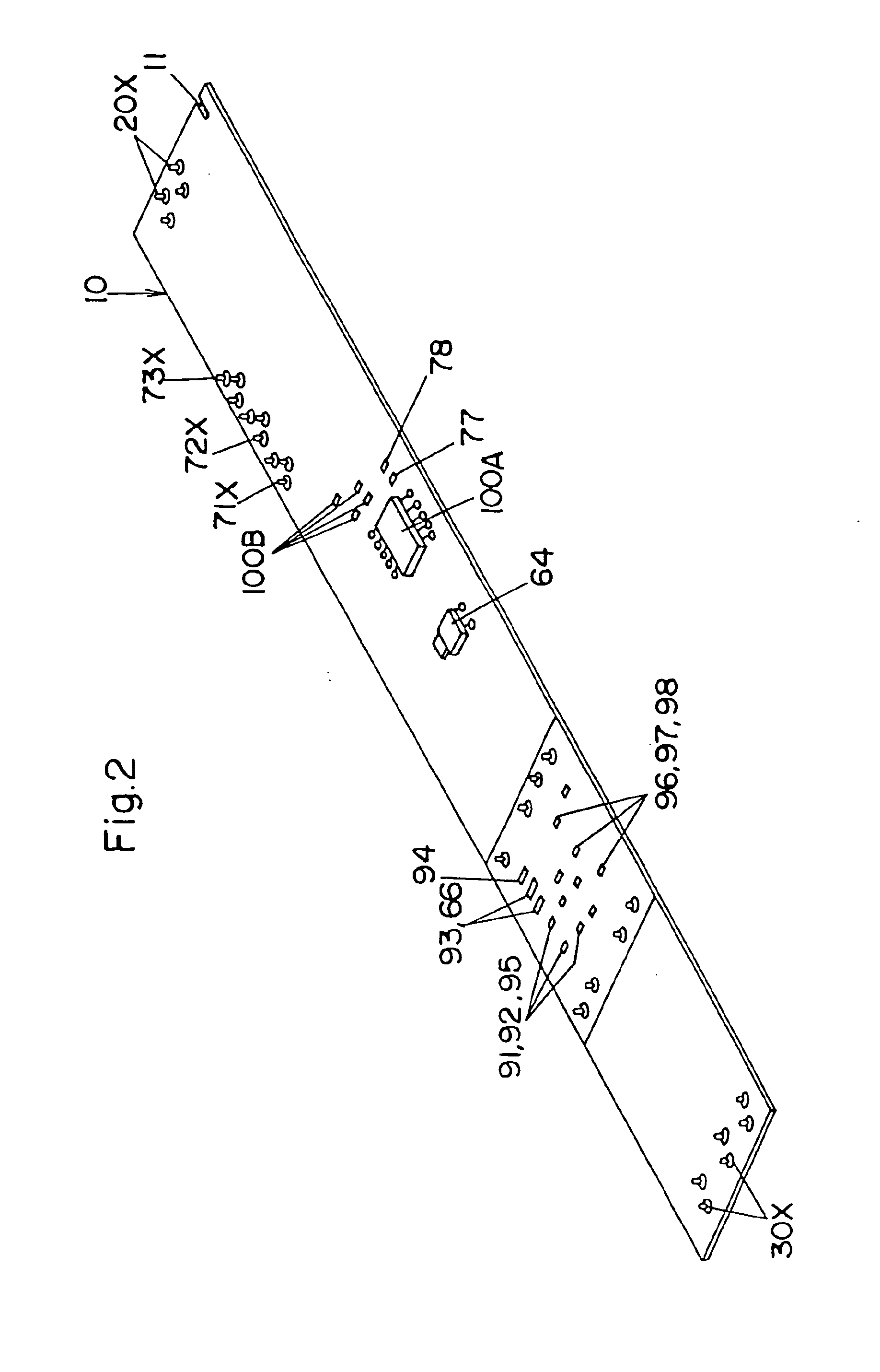

Electronic ballast for a discharge lamp

InactiveUS6943502B2Versatile in functionReduce in quantityPrinted circuit assemblingFinal product manufactureGas-discharge lampOutput transformer

An electronic ballast for a discharge lamp has a compact arrangement of electric parts. The ballast includes an AC-DC converter and an inverter giving a high frequency output voltage for operating the lamp. The inverter includes switching elements, a control circuit, and an output transformer for connection with the lamp. A single circuit board mounts the electric parts forming the converter and the inverter. The circuit board is accommodated within a tubular casing together with a dielectric sheet which is provided for insulating the circuit board as well as the electric parts from the casing. The output transformer is mounted on a top surface of the circuit board together with some of the other electric parts. The ballast includes chip components forming a detection circuit for lamp condition, and the circuit board mounts the chip components on a bottom surface at a location immediately opposite of the output transformer.

Owner:MATSUSHITA ELECTRIC WORKS LTD

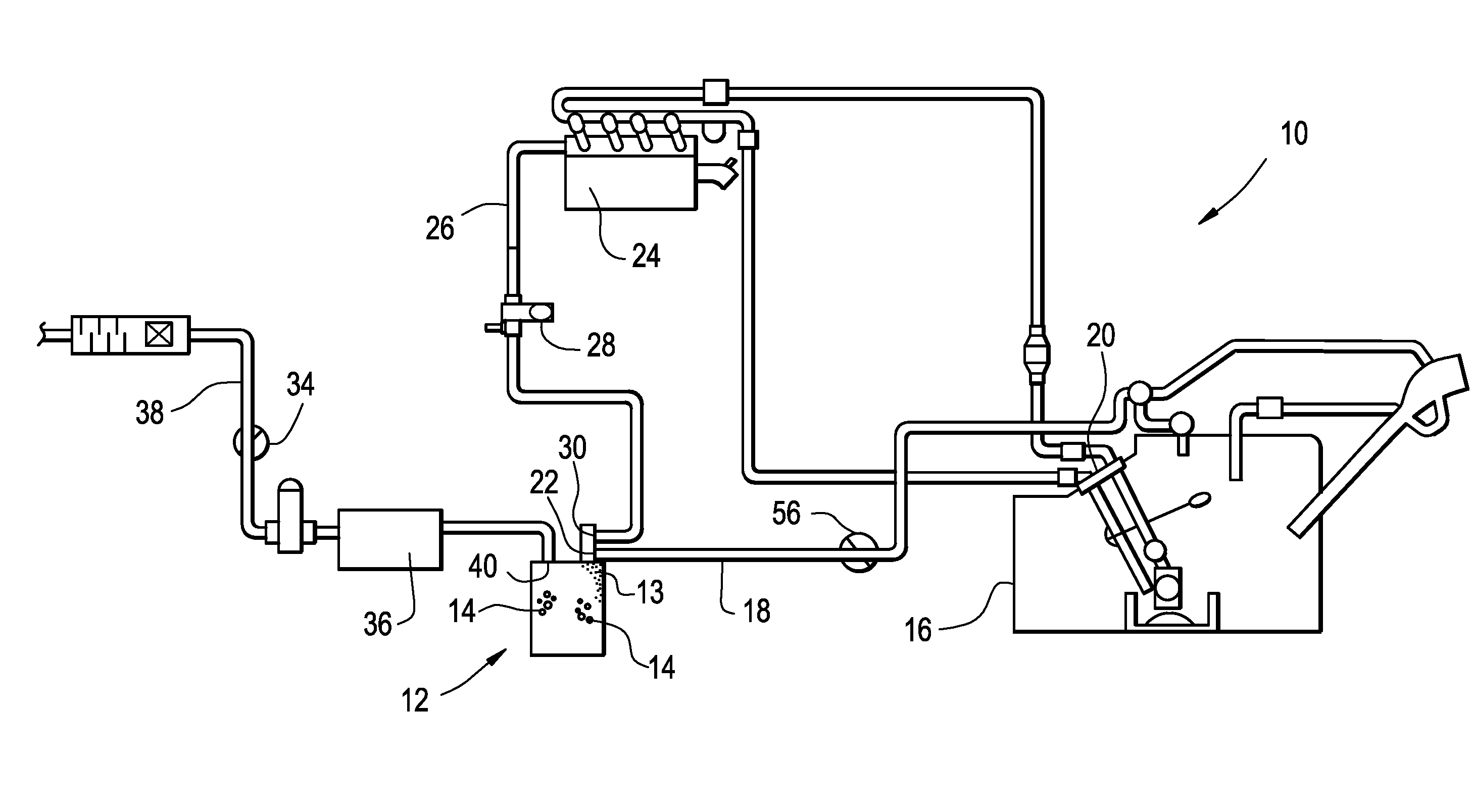

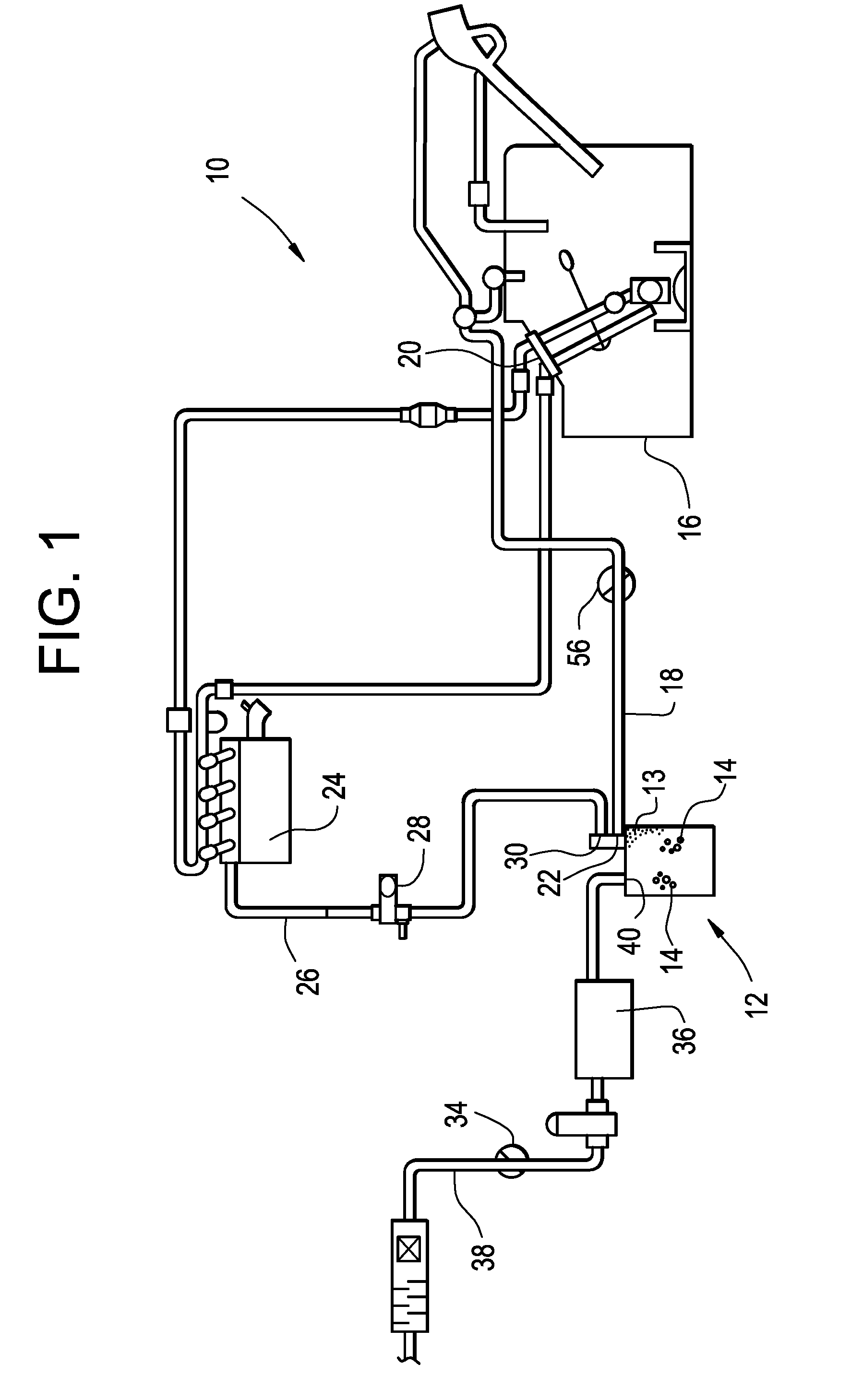

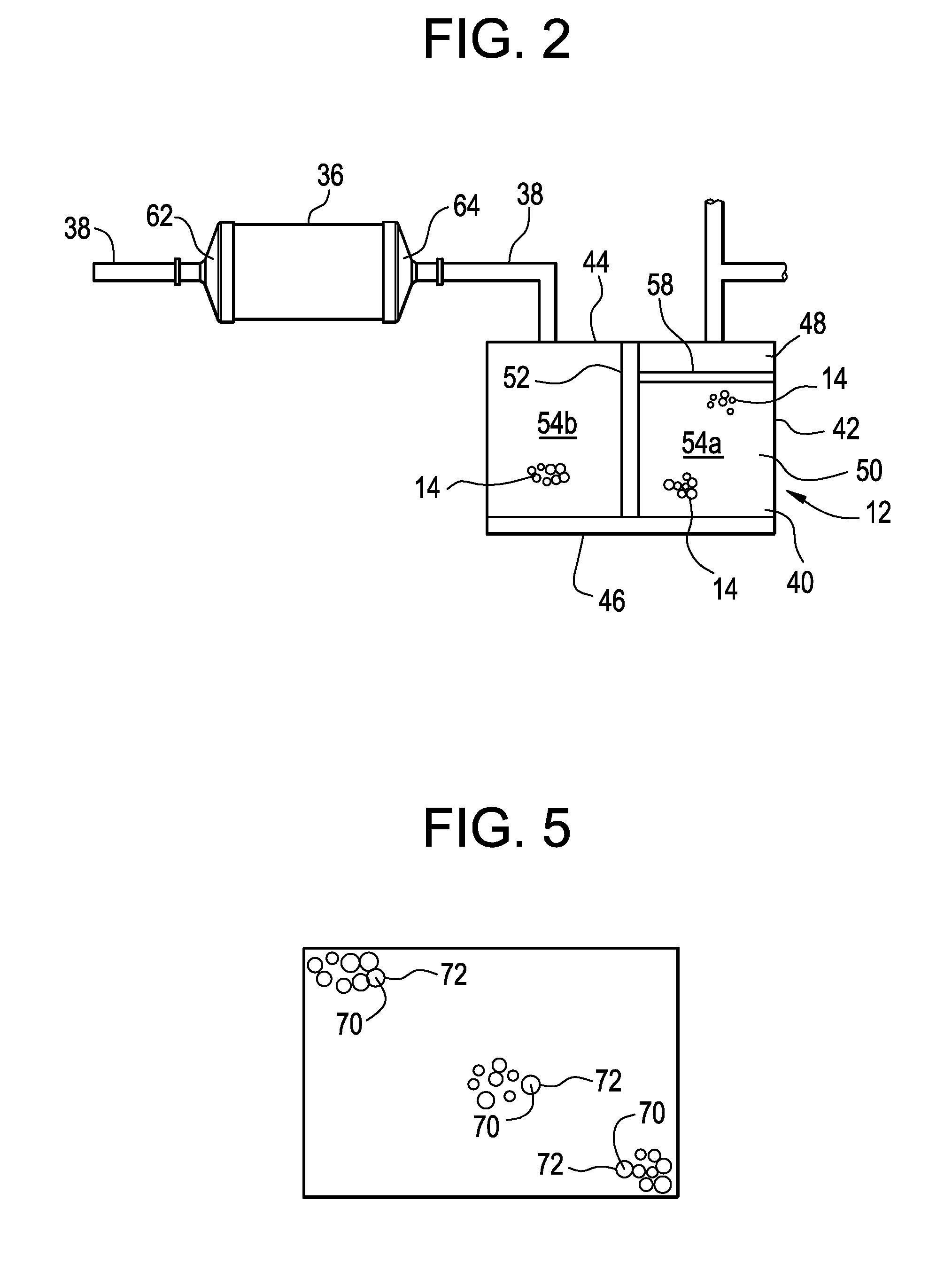

Automotive fuel system for substantially reducing hydrocarbon emissions into the atmosphere, and method

InactiveUS20080308075A1Emission reductionImprove efficiencyNon-fuel substance addition to fuelMachines/enginesAtmospheric airSorbent

An evaporative emissions system is used in an automotive evaporative emission system including a fuel tank coupled to an automotive engine to control emission of fuel vapors to the atmosphere. The system includes an evaporative emissions canister comprising a first molded housing having a circumferential side member, a top member and a bottom member; a hydrocarbon-adsorbing material disposed therein so as to provide a vapor adsorbent chamber for adsorbing hydrocarbon fuel vapor flowing therethrough; and an auxiliary housing containing a carbon-coated reticulated material, the reticulated housing located in the fresh air line of the evaporative emissions canister for preventing fuel vapor molecules from passing through the carbon-coated reticulated material while allowing the air molecules to pass therethrough. A method is provided for preventing or reducing hydrocarbon emissions to the atmosphere.

Owner:FLUID ROUTING SOLUTIONS

Bioreactor Tangential Flow Perfusion Filter System

InactiveUS20140093952A1Increase capacityReduce shearBioreactor/fermenter combinationsBiological substance pretreatmentsHollow fibreFiber

A bioreactor hollow fiber perfusion system increases the capacity of standard fed batch bioreactors. The bioreactor hollow fiber perfusion system cycles bioreactor mass through a hollow fiber tangential flow filter which separates the metabolic wastes (as well as proteins) from the biomass material allowing the reactions in the bioreactor to continue when compared to a fed batch bioreactor. The bioreactor hollow fiber perfusion system preferably includes a low shear gamma stable disposable pumphead responsible for biomass re-cycling and can be easy installed or replaced without the risk of contamination.

Owner:SERWAY DAVID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com