Patents

Literature

133 results about "Planar inductor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

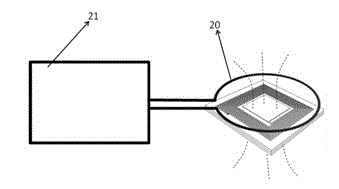

Method and apparatus for wireless power transmission

ActiveUS20080067874A1Sufficient powerSimple and low-cost receivingBatteries circuit arrangementsTransformersElectric power transmissionTransmitted power

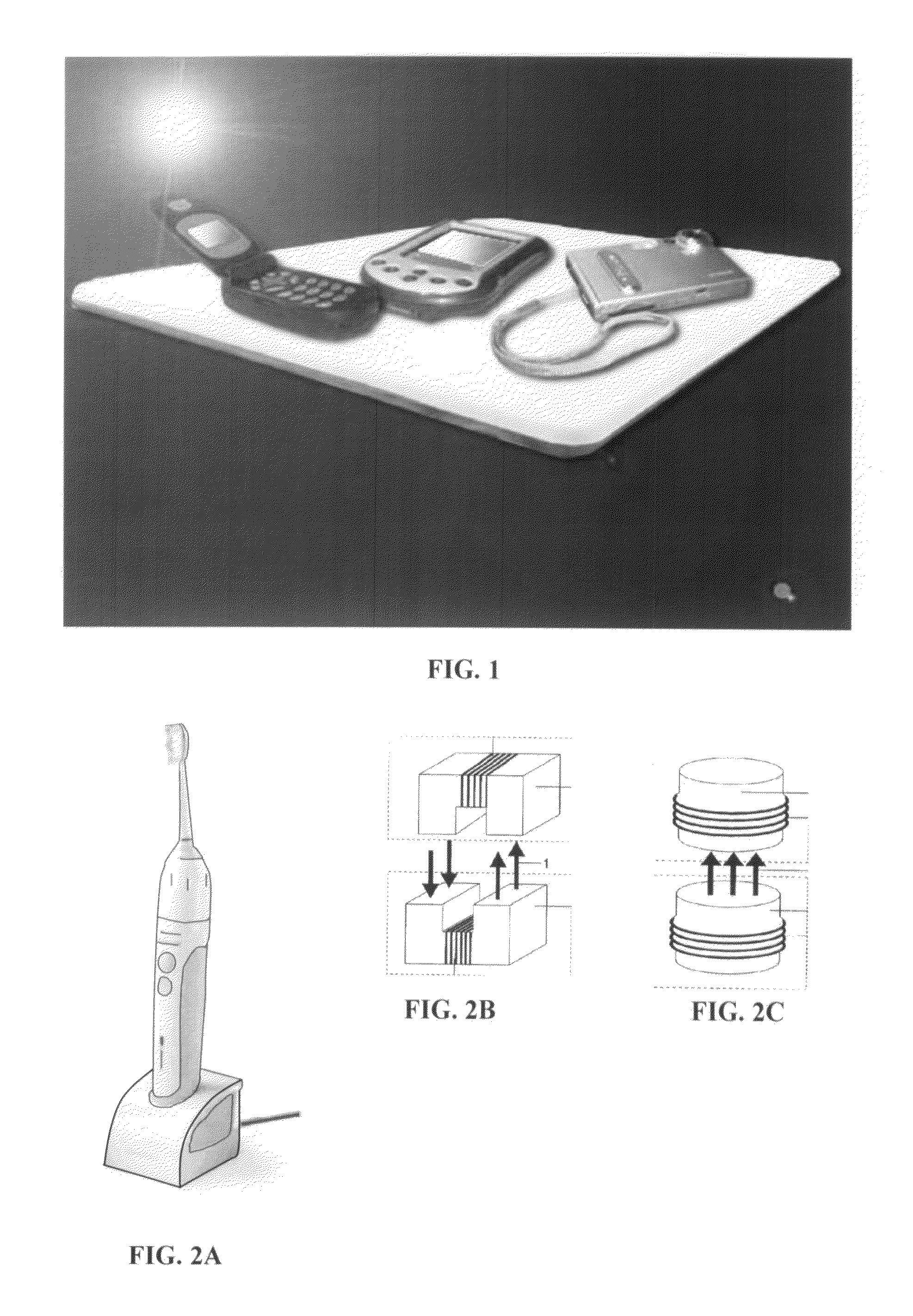

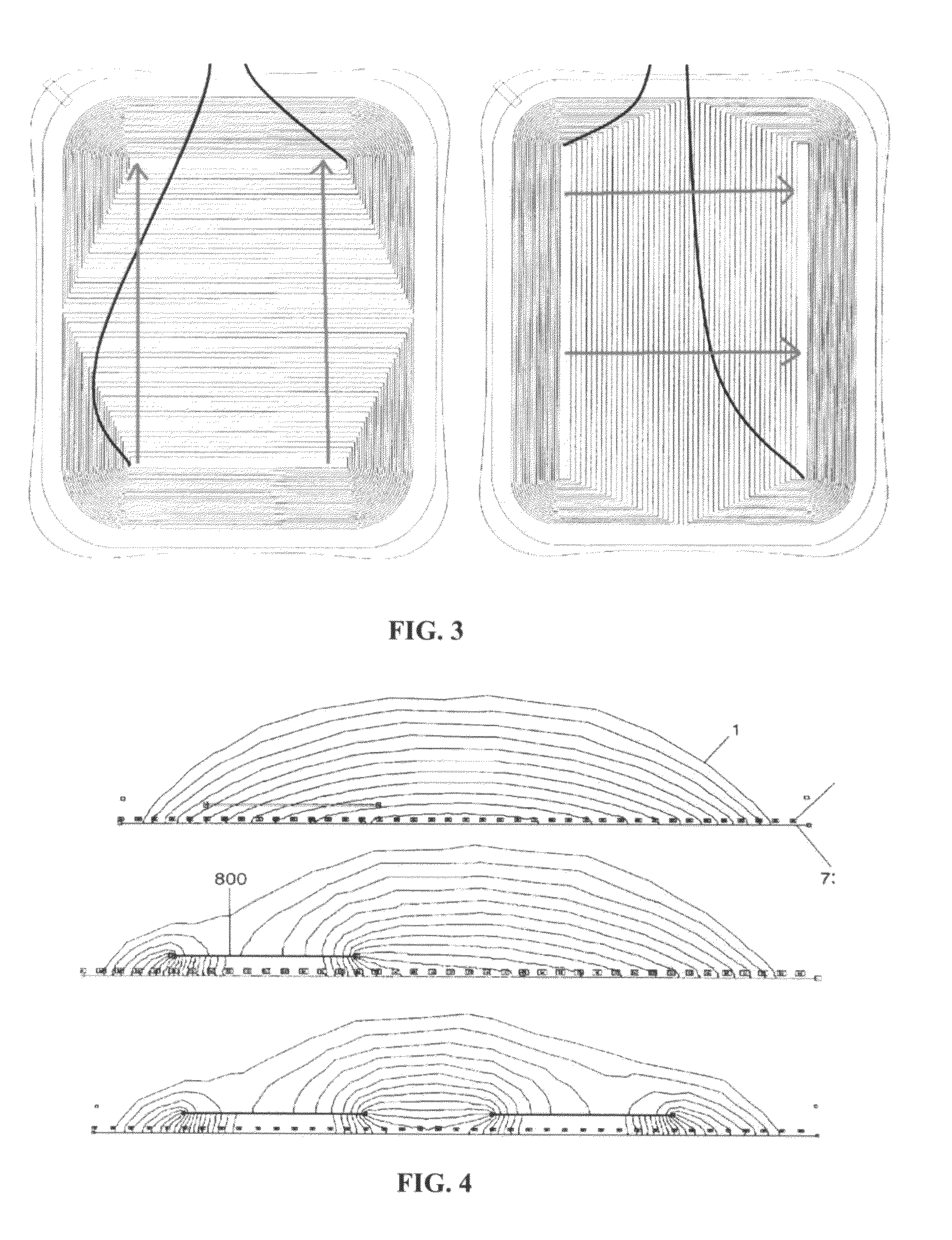

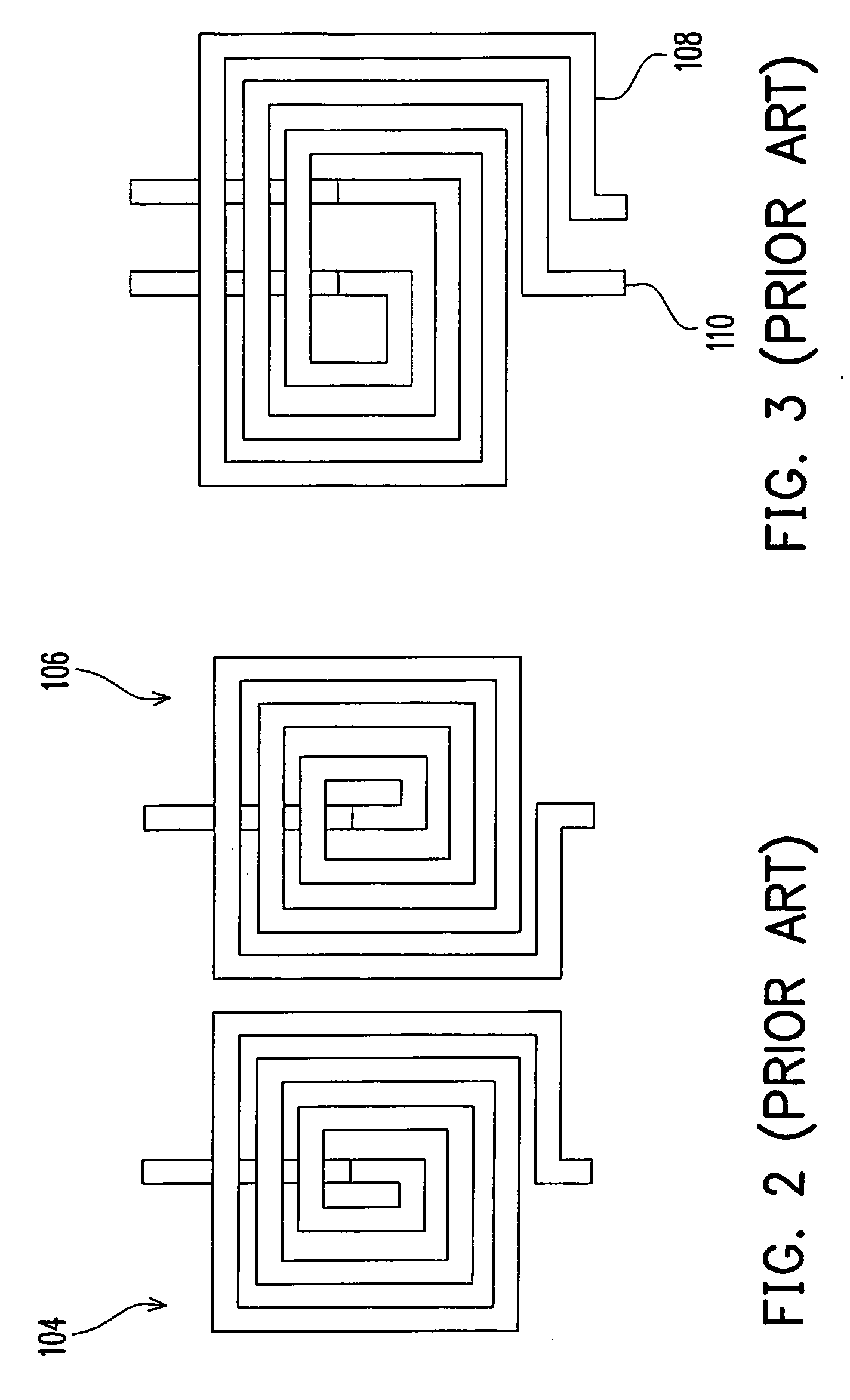

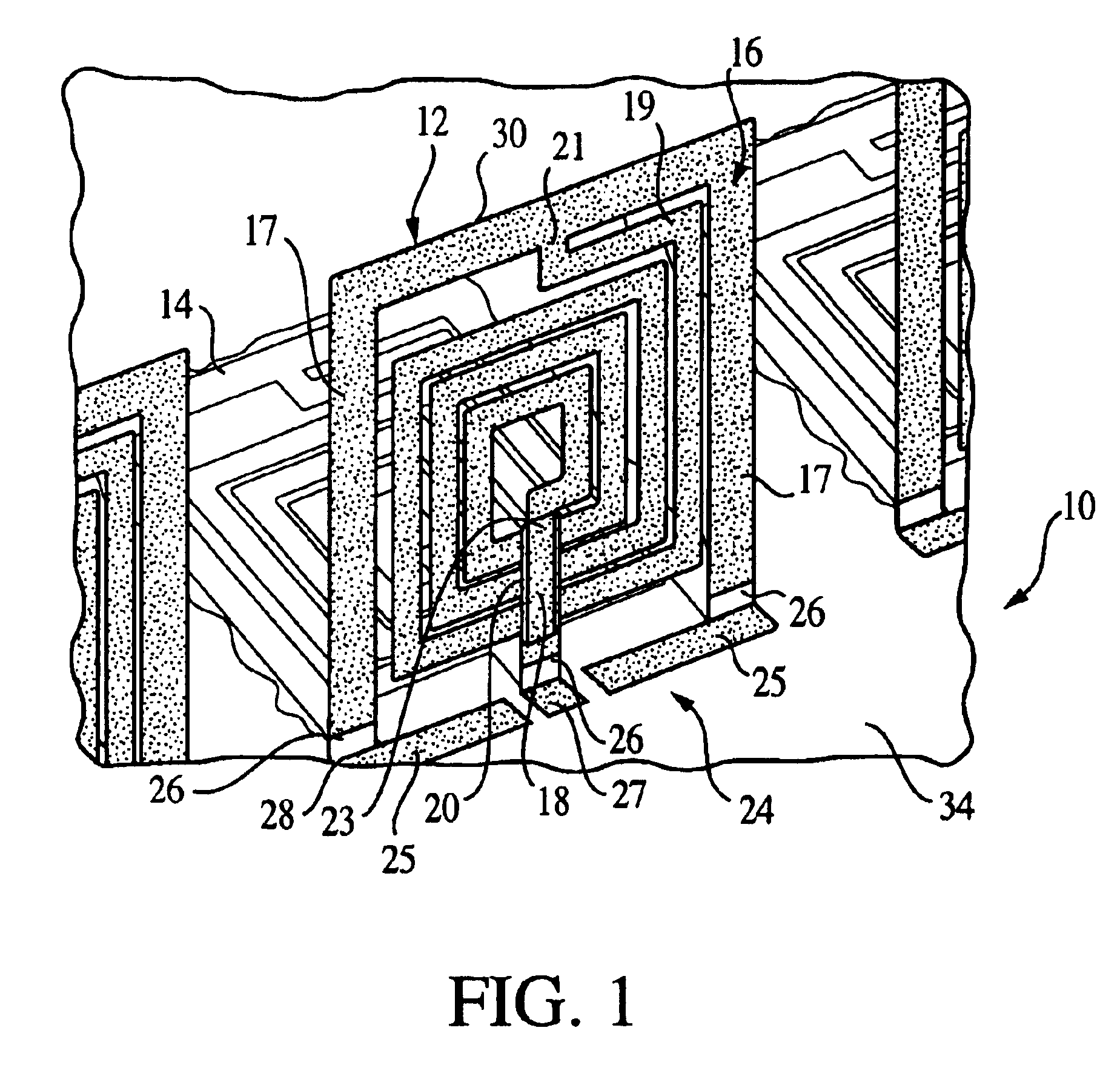

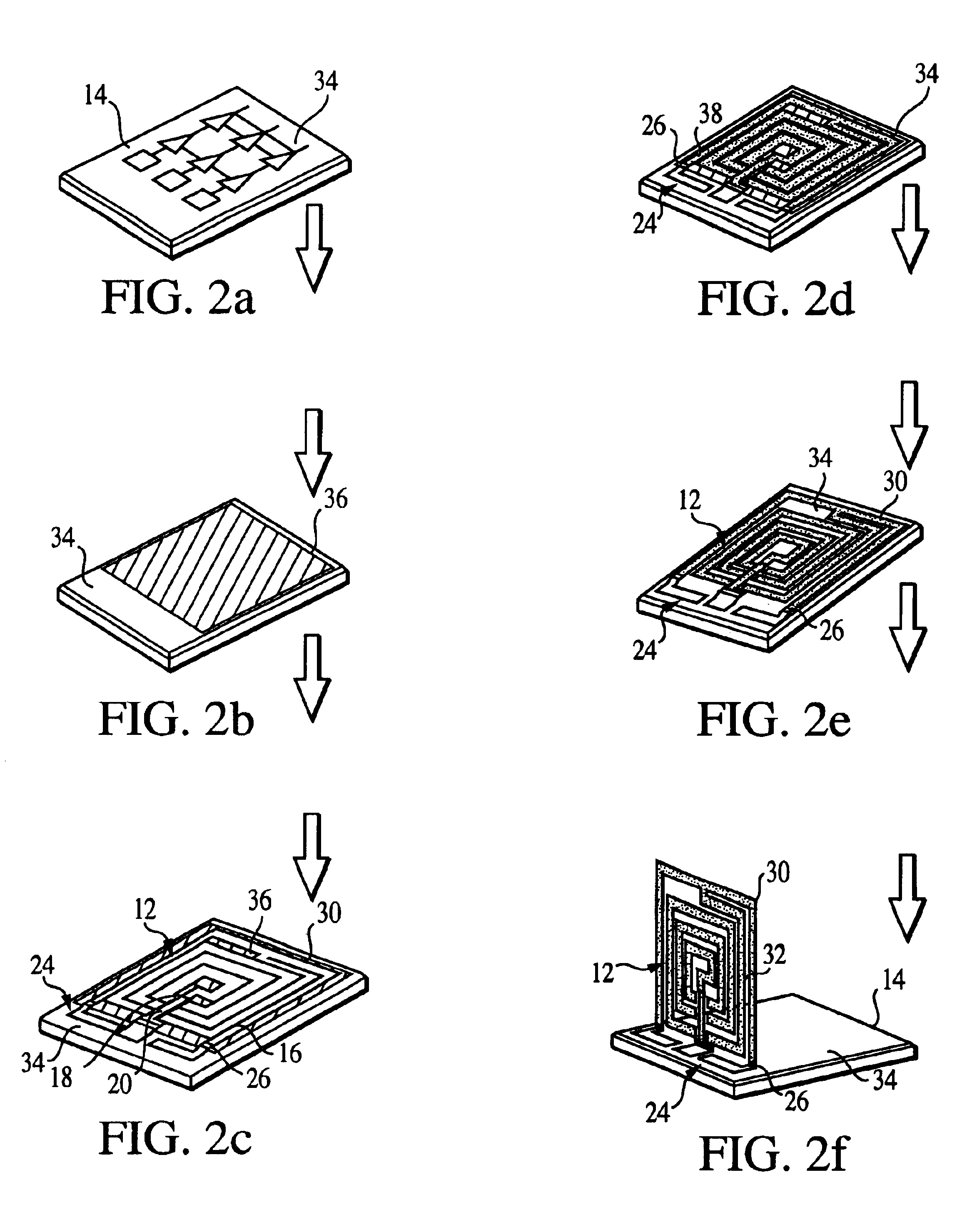

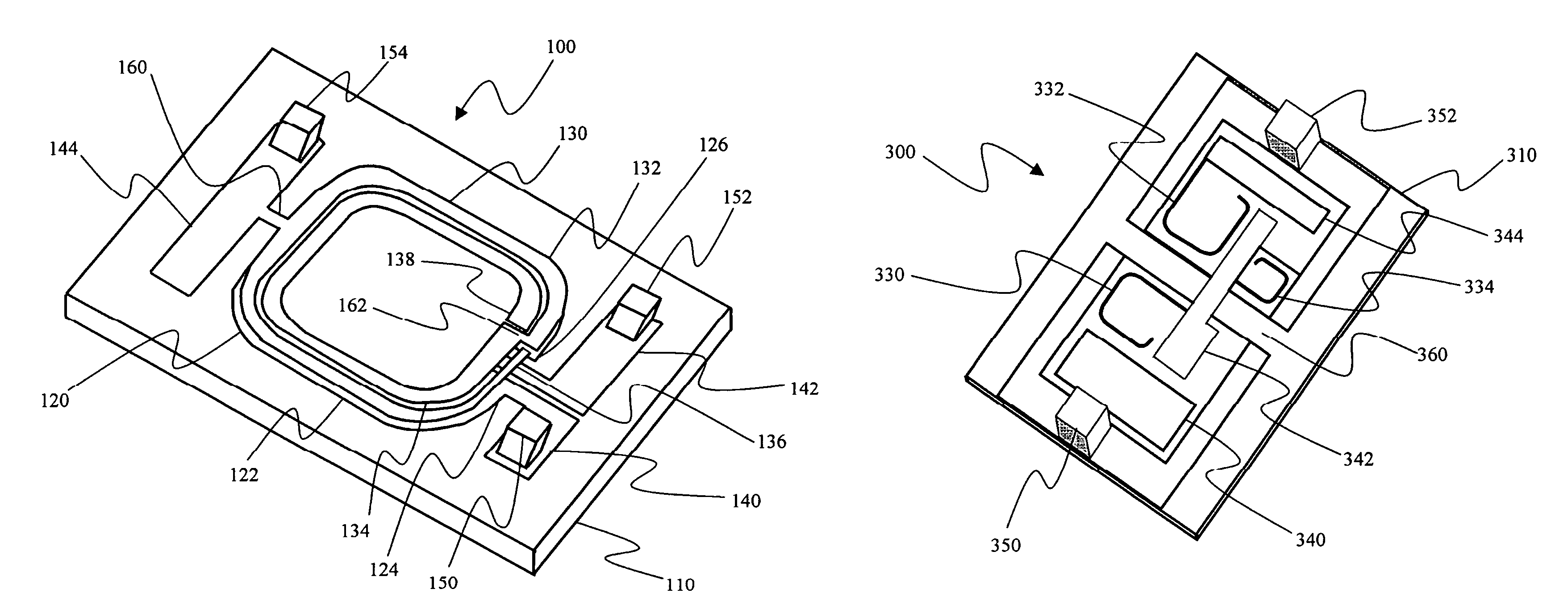

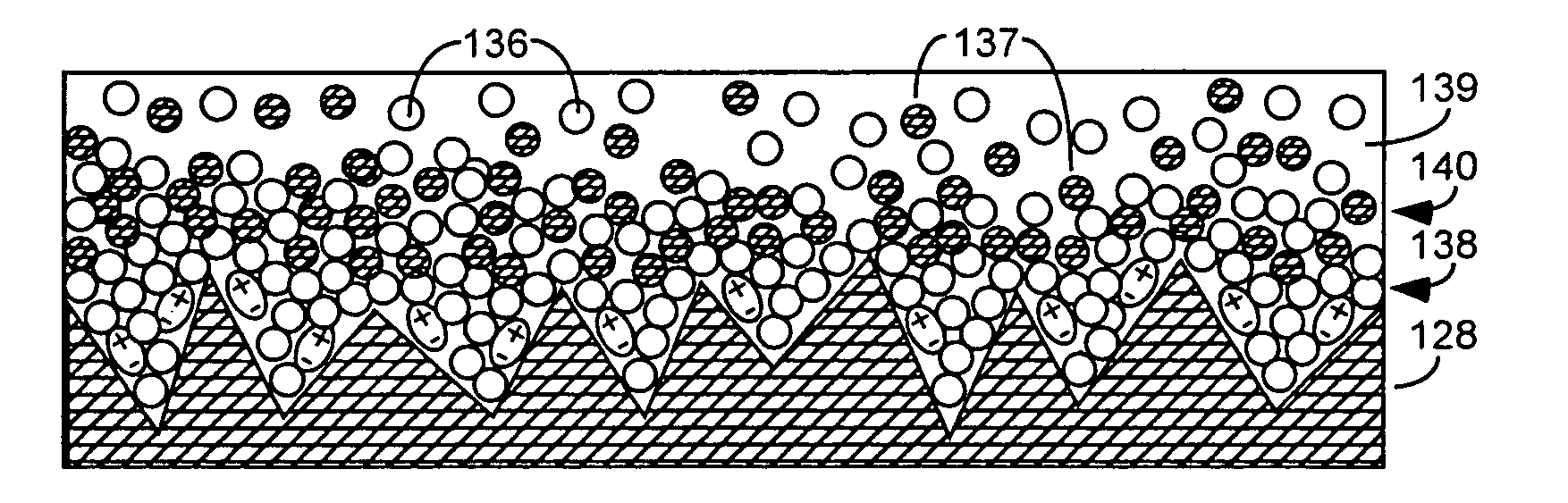

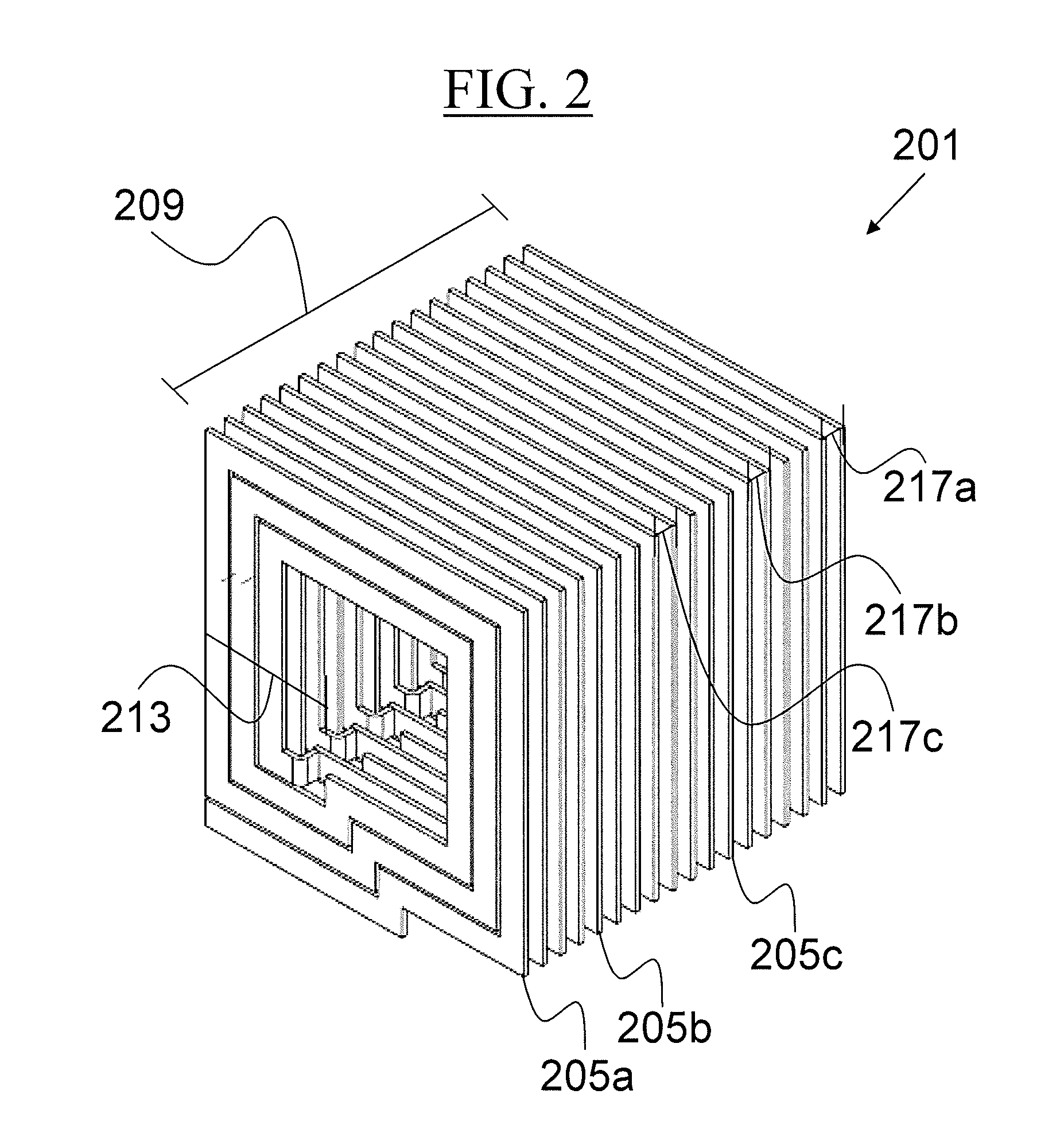

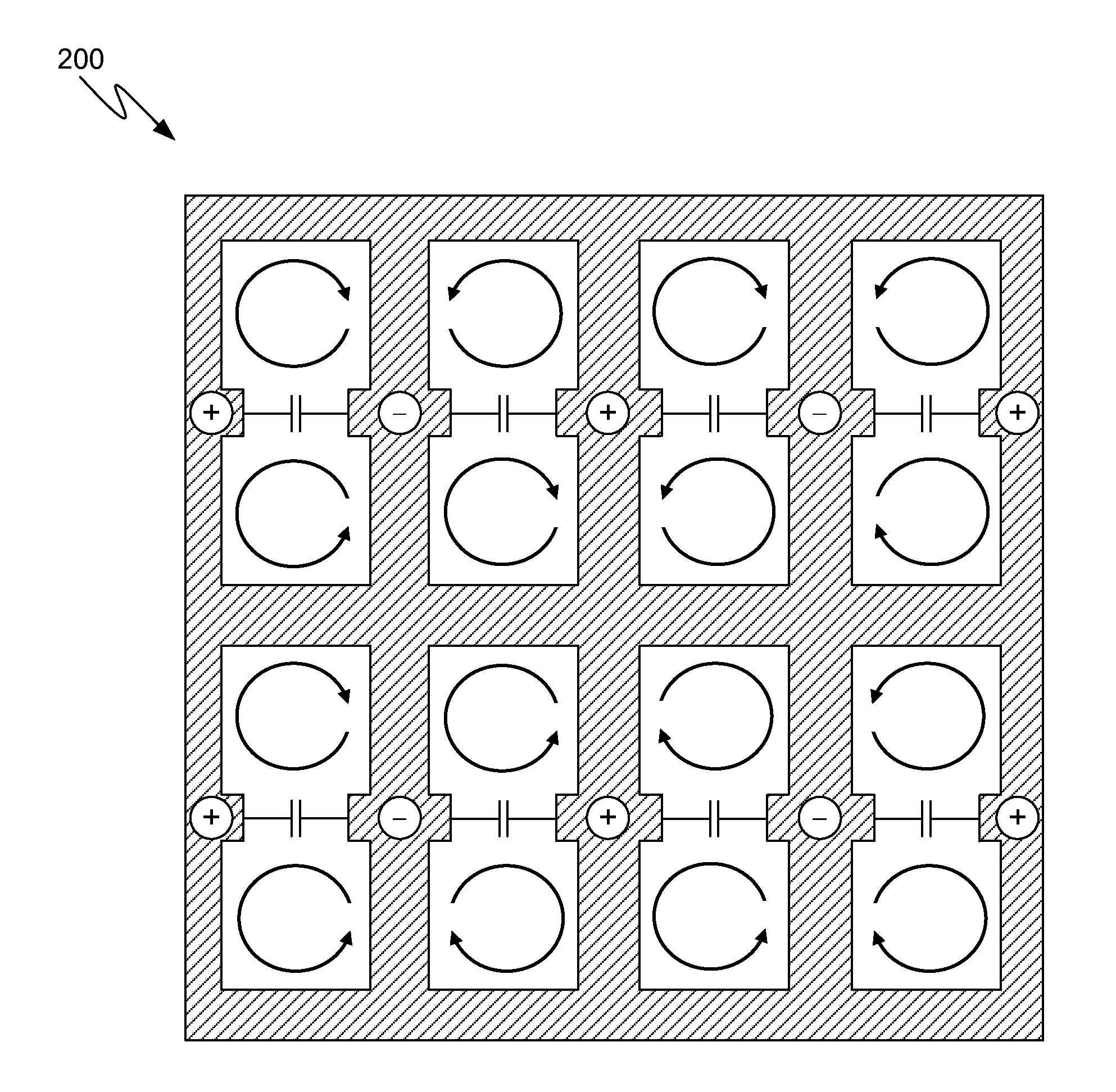

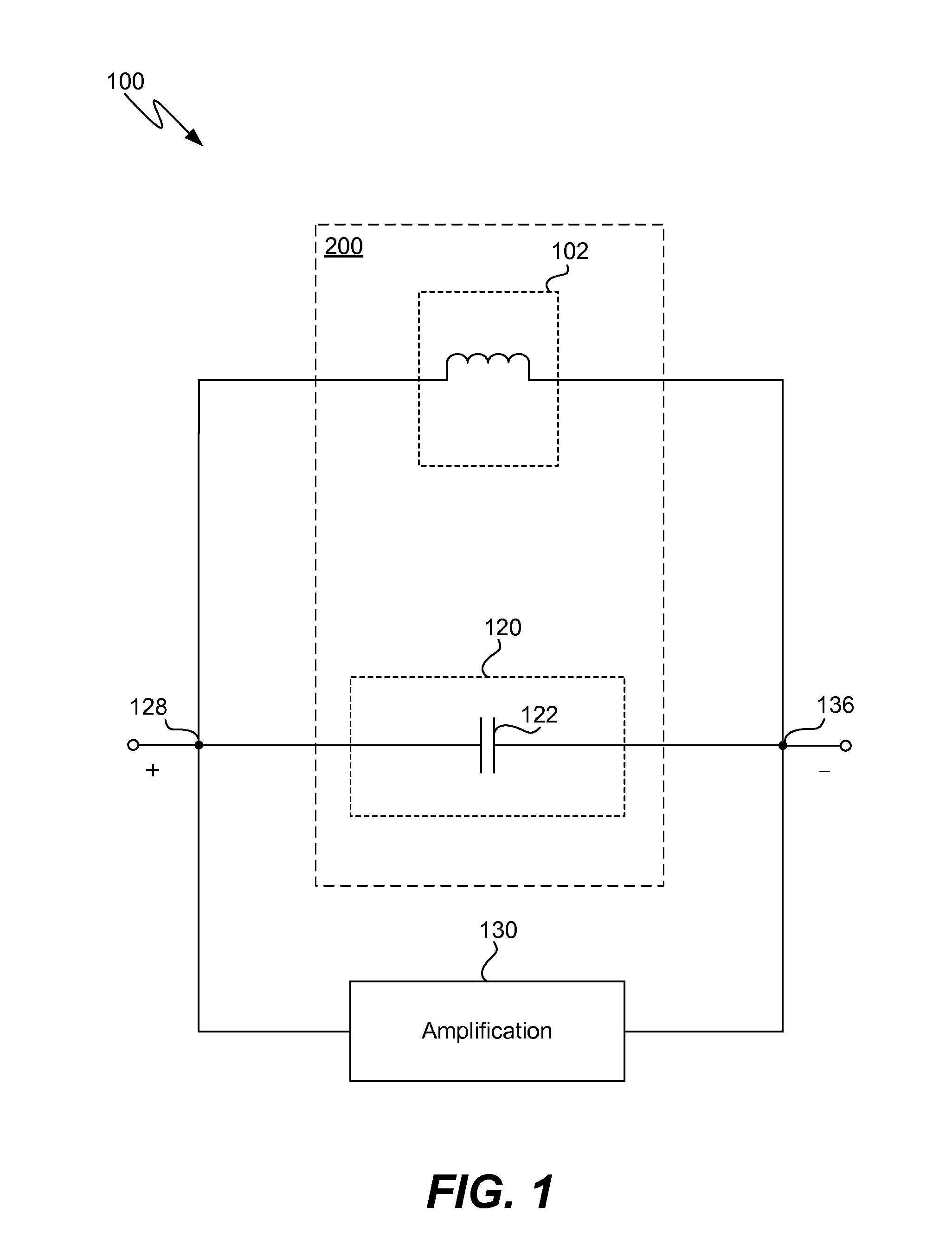

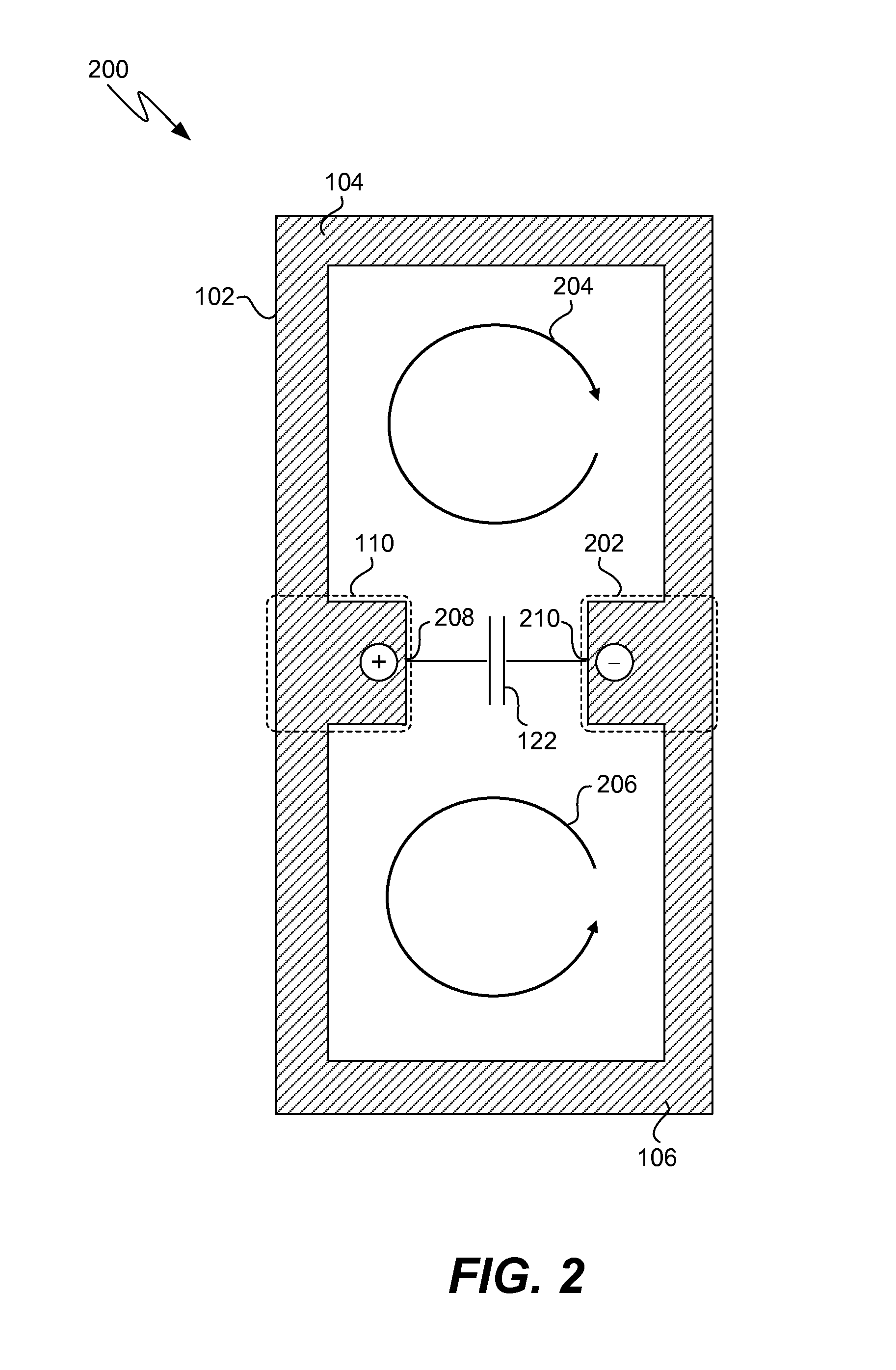

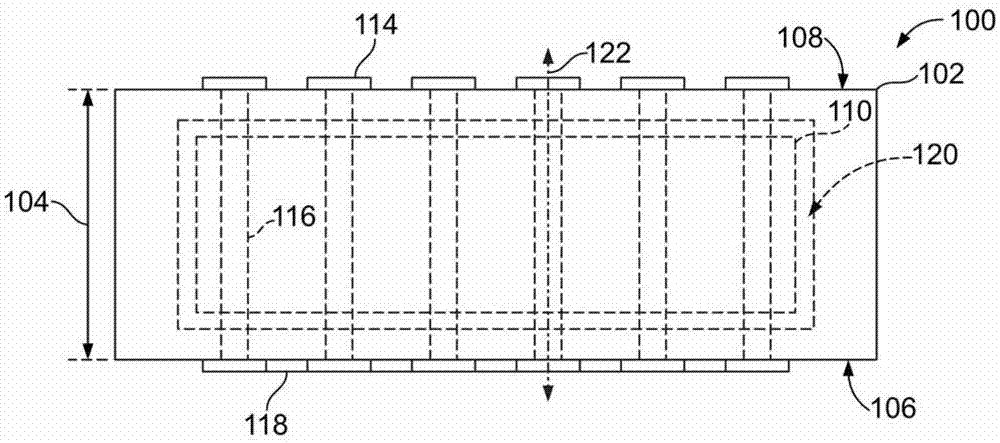

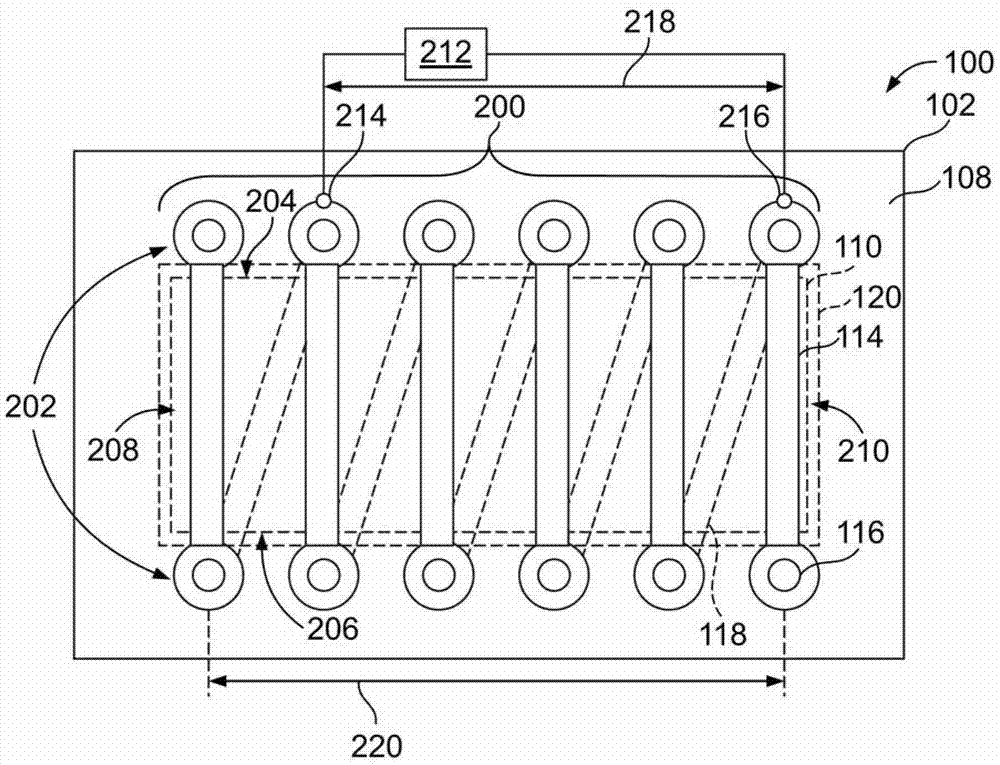

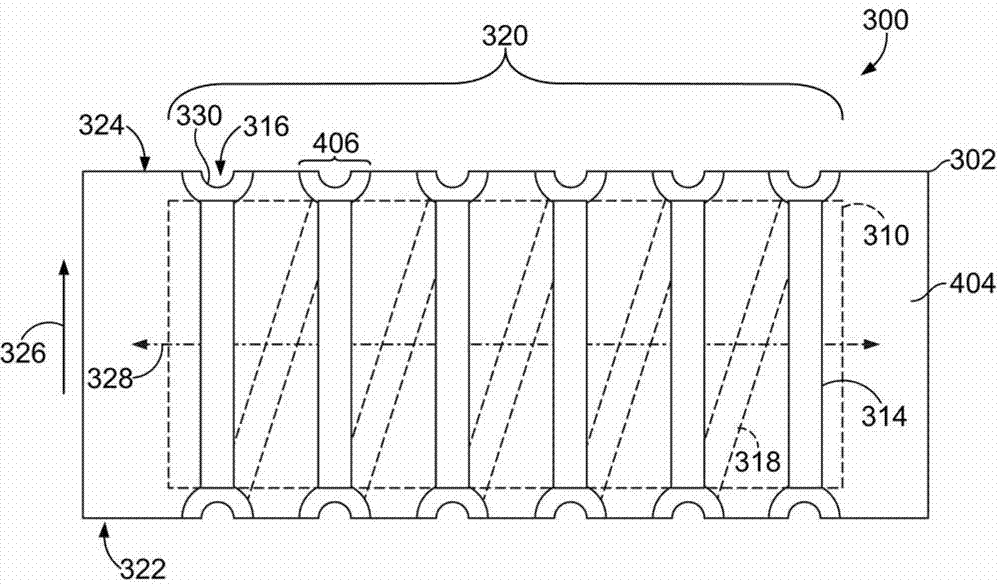

Embodiments of the invention relate to a method and system for transferring power wirelessly to electronic devices. The system can utilize magnetic coupling between two coils at close proximity to transfer sufficient power to charge an electronic device. Embodiments of the invention pertain to an array of spiral coils that can be used to transmit power for transfer to receiver coils. Potential applications of this technology include charging consumer electronic devices (cell phones, laptops, PDAs, etc), developing hermetically sealed devices for extreme environments, and less invasive transcutaneous energy transfer (TET) systems. Various embodiments of the subject system can be referred to as PowerPad system. Embodiments can incorporate one or more of the following: planar inductors, PCB transformers, and very high frequency power supplies. Embodiments of the invention also pertain to planar inductors having characteristics that allow the production of even magnetic field, as well as systems that incorporate such planar inductors.

Owner:QUALCOMM INC

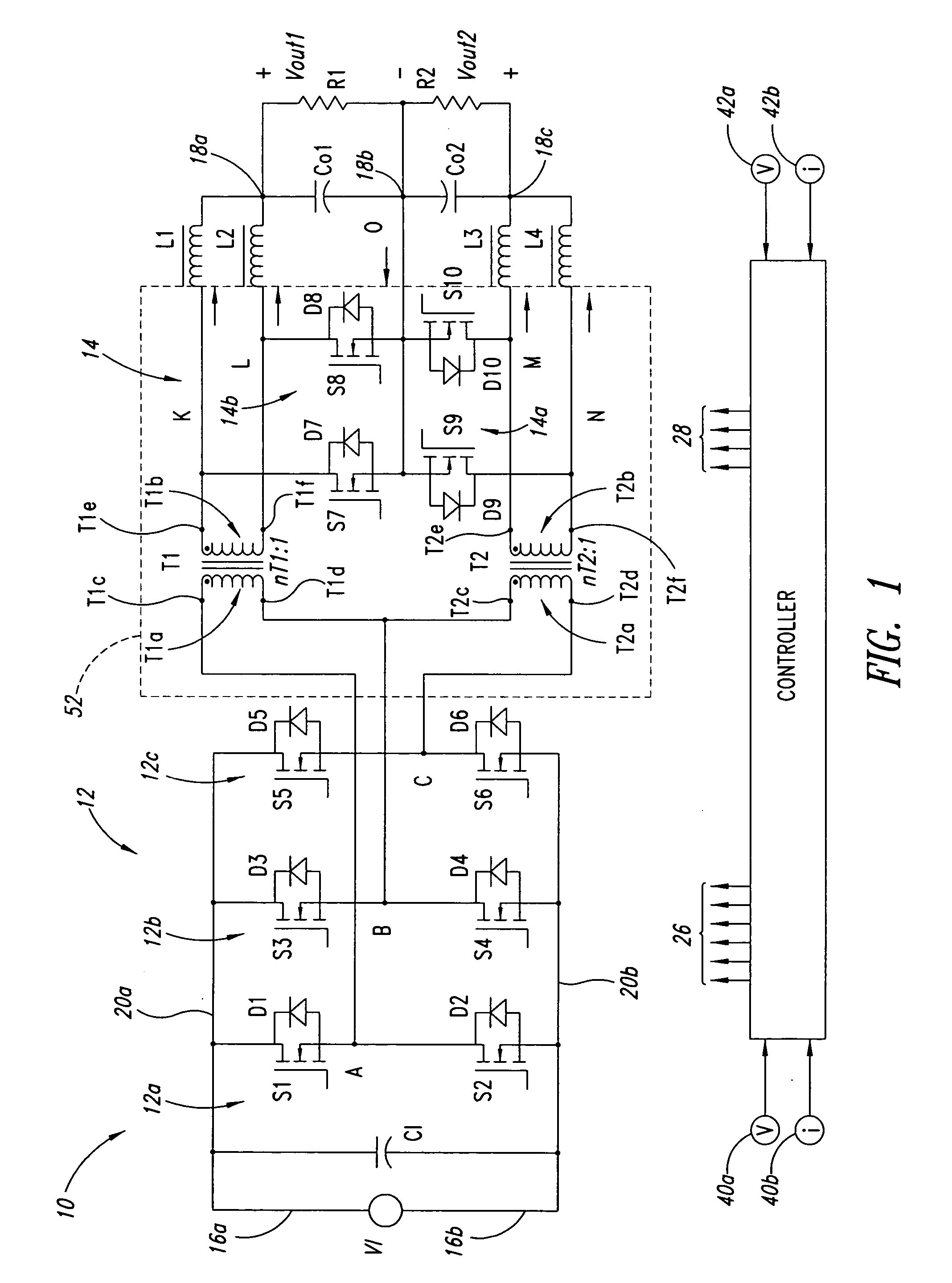

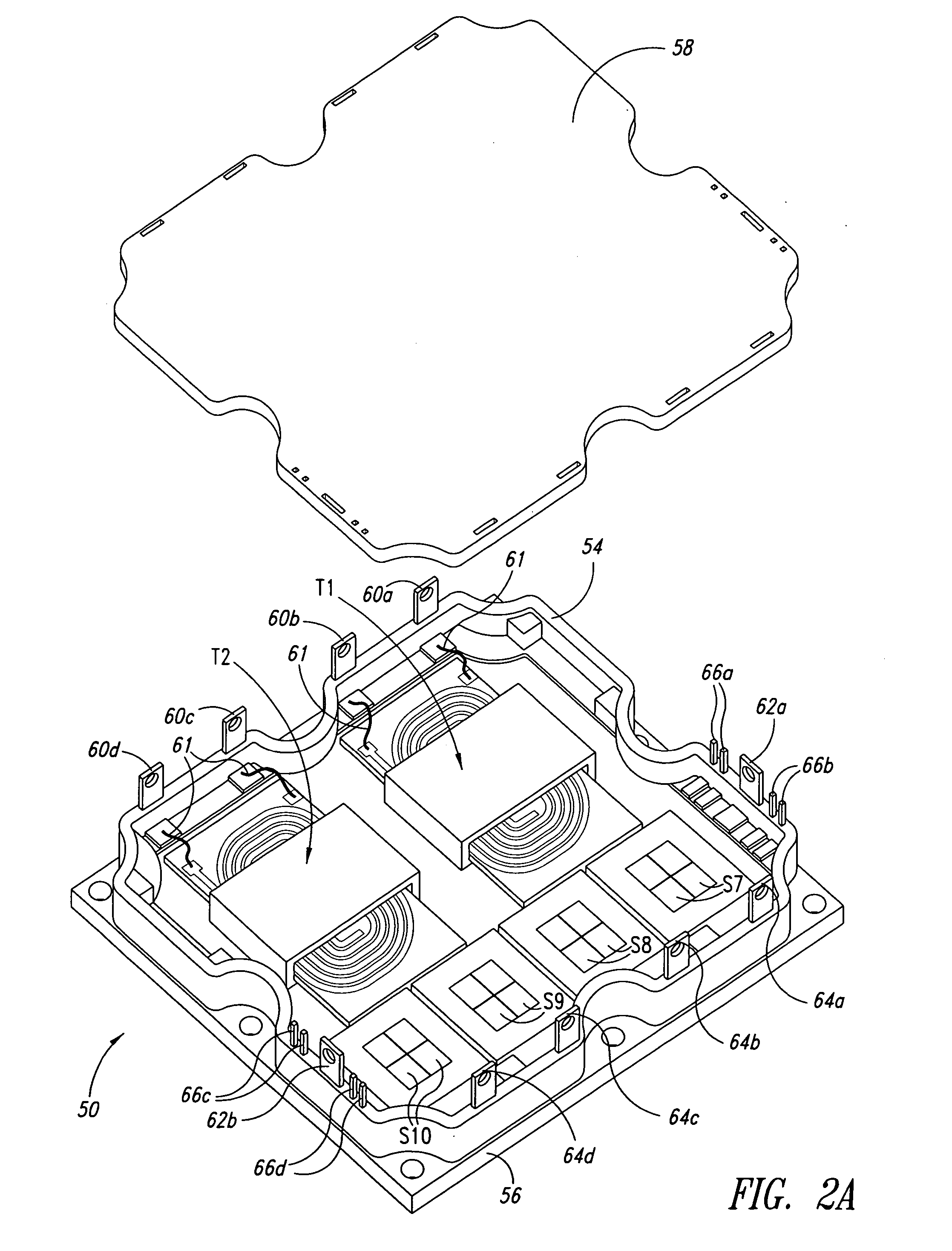

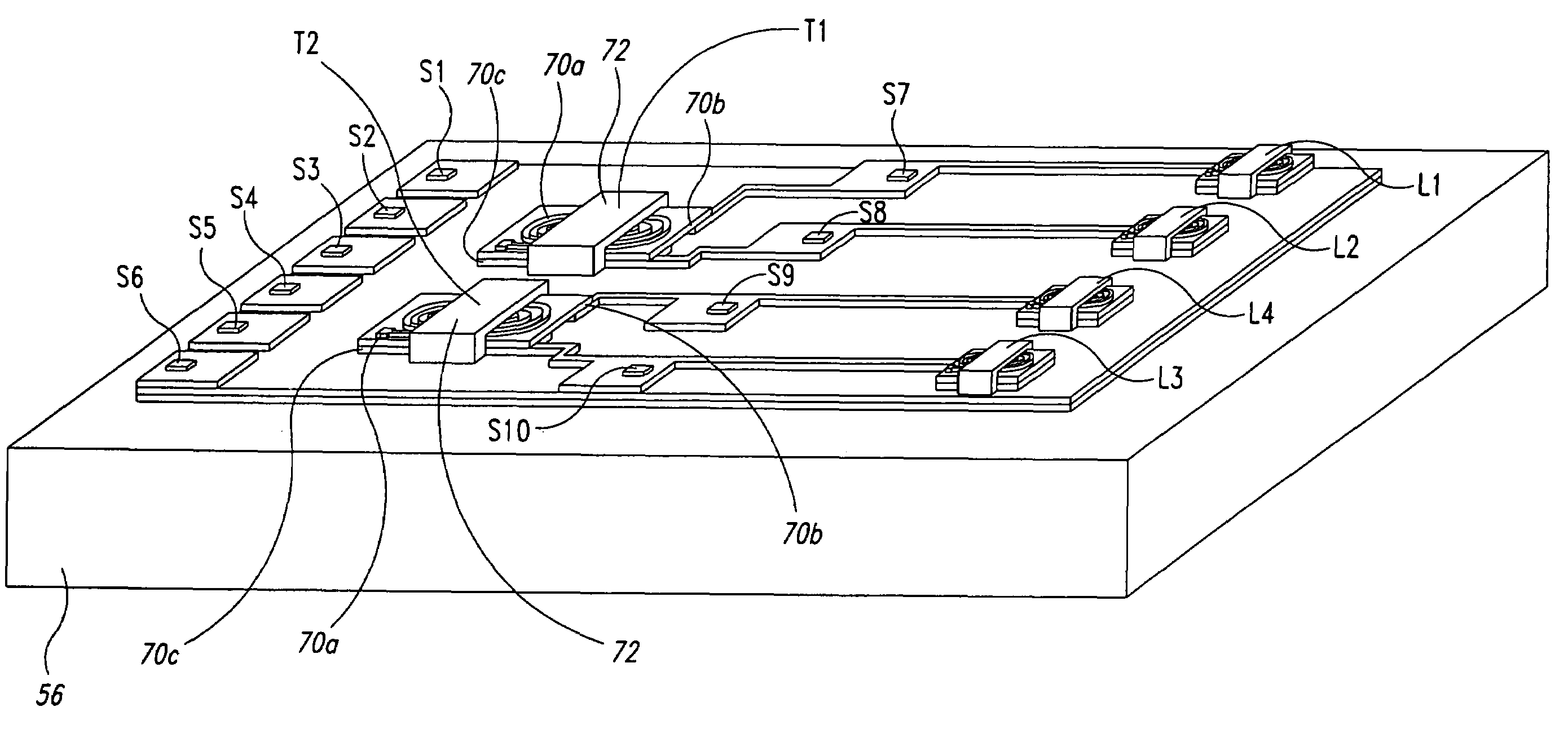

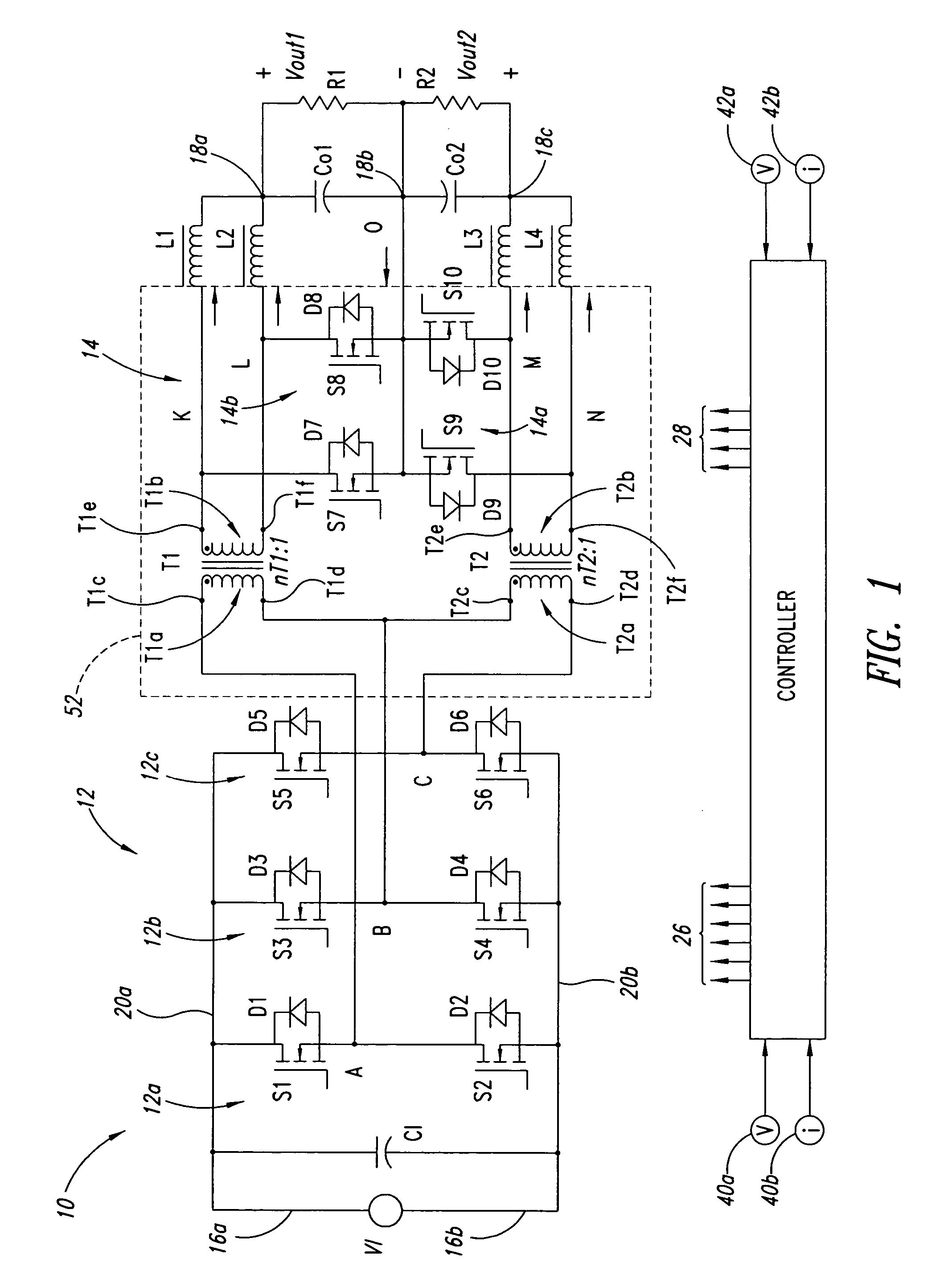

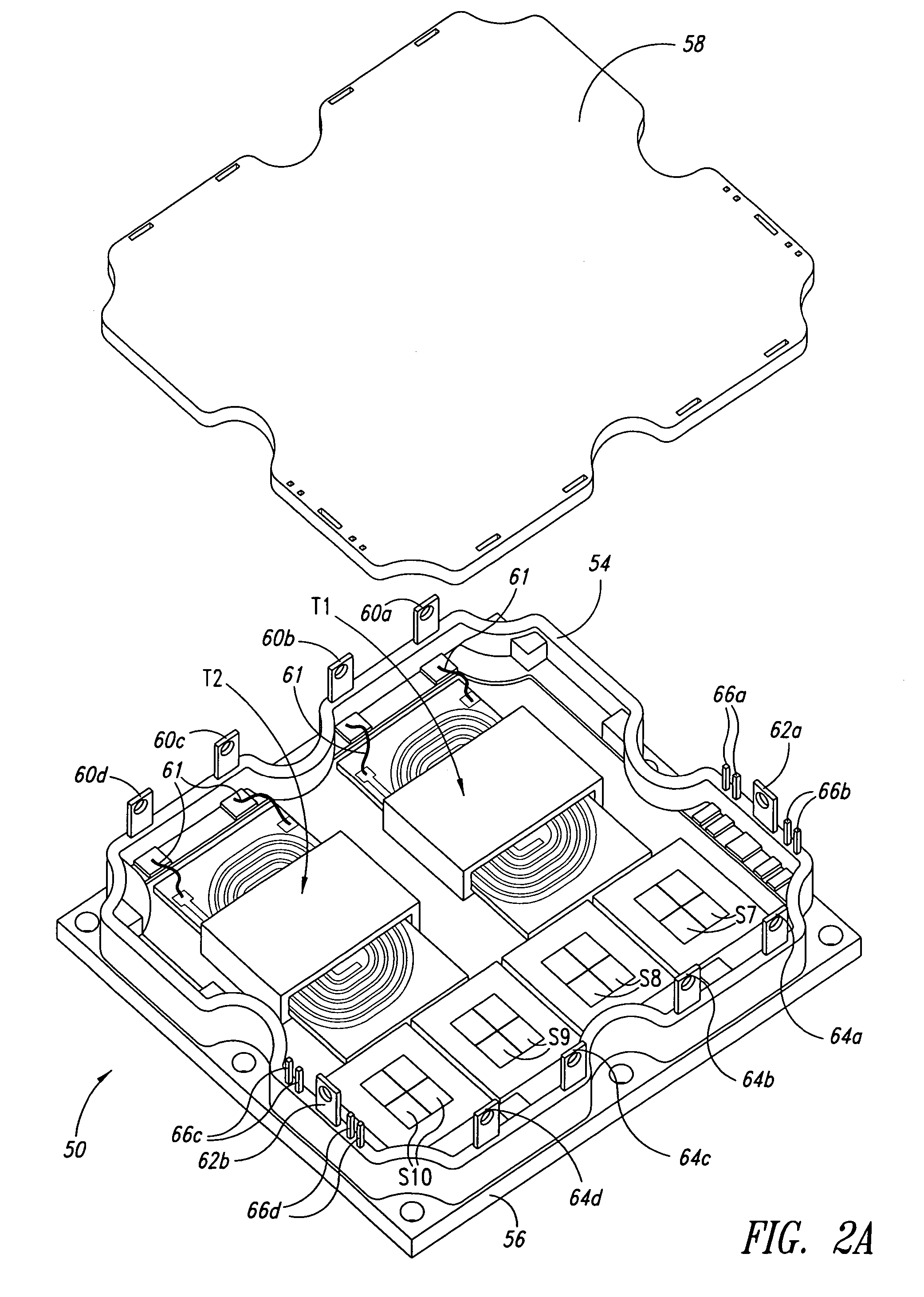

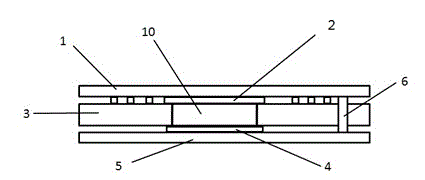

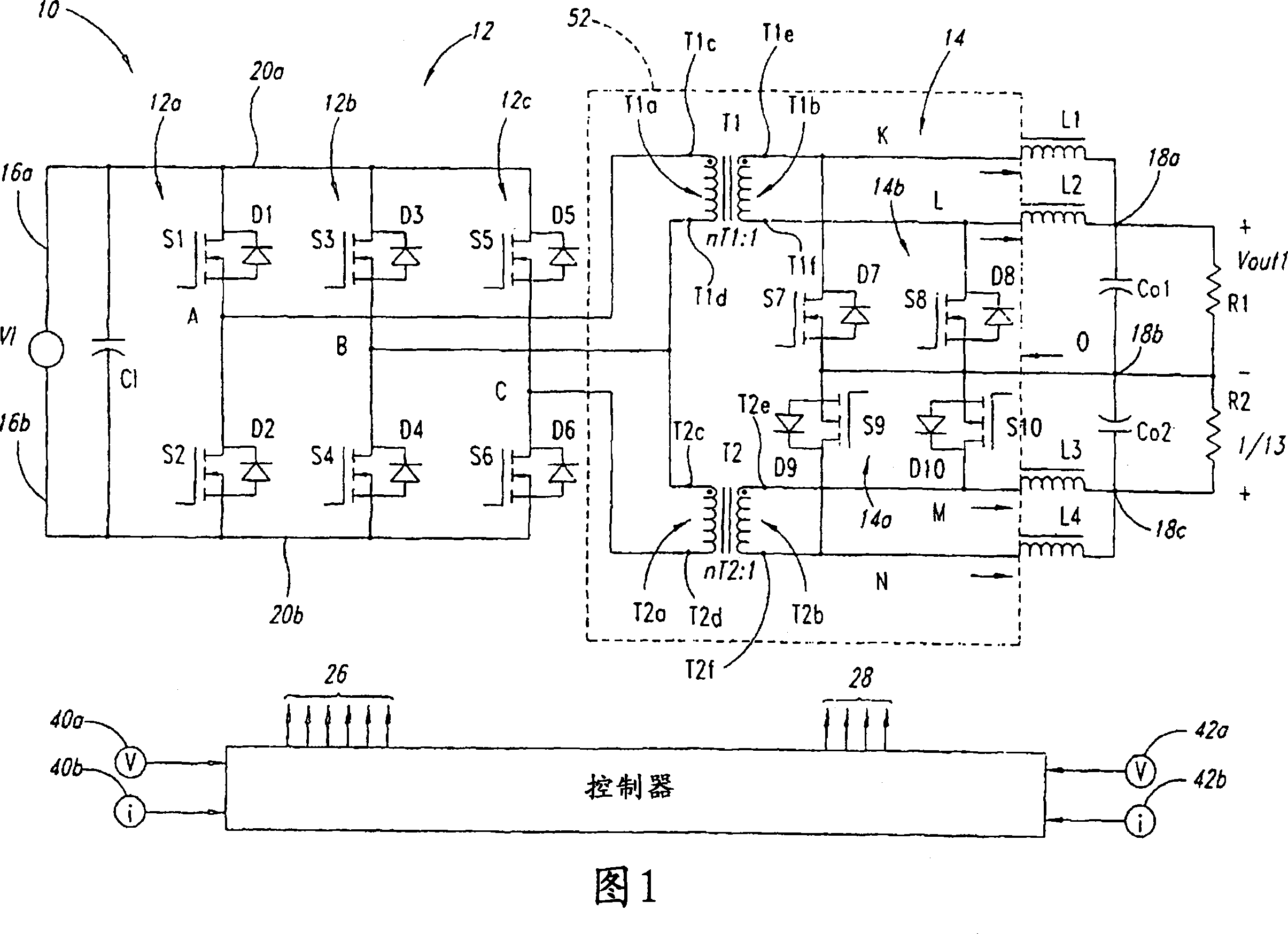

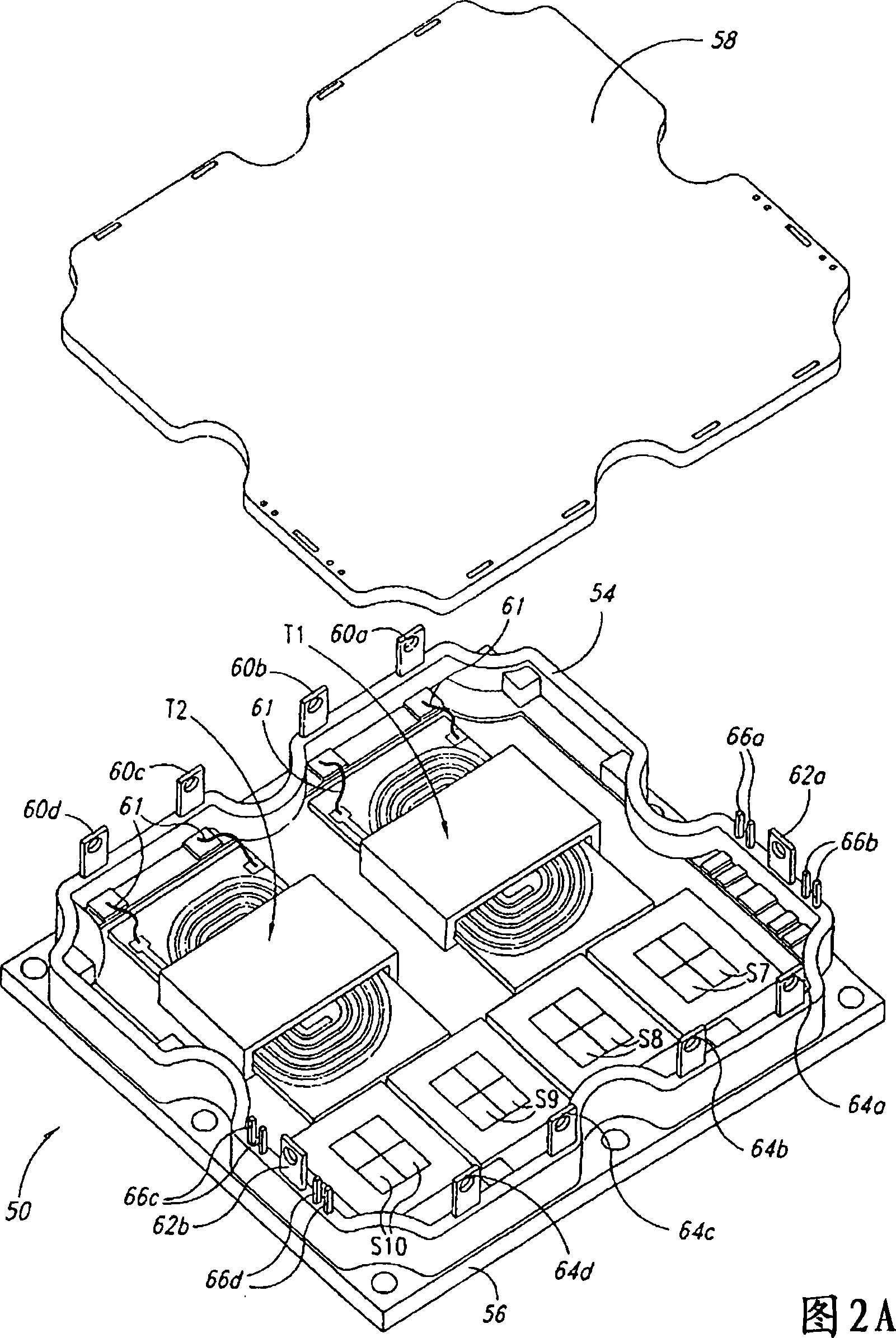

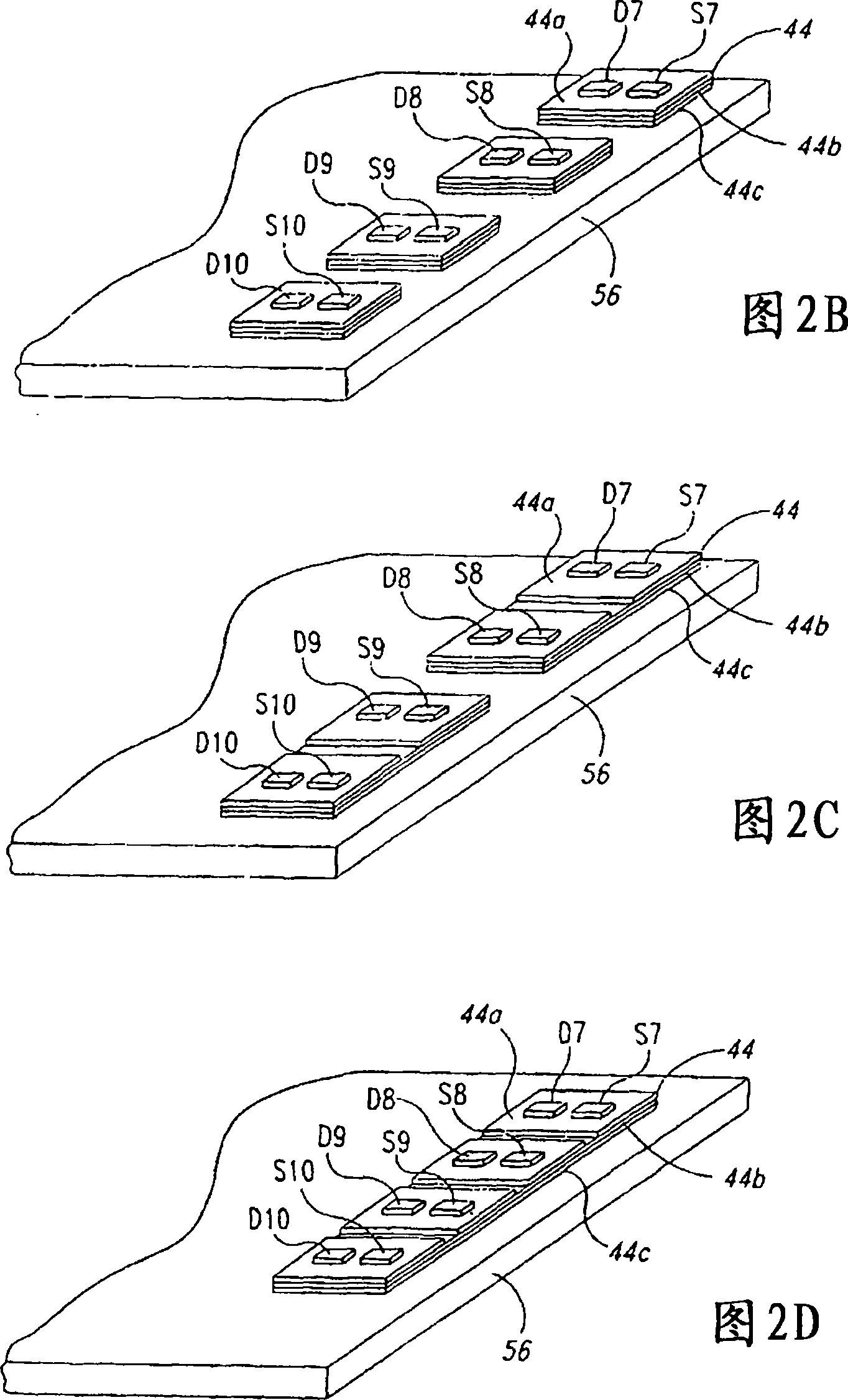

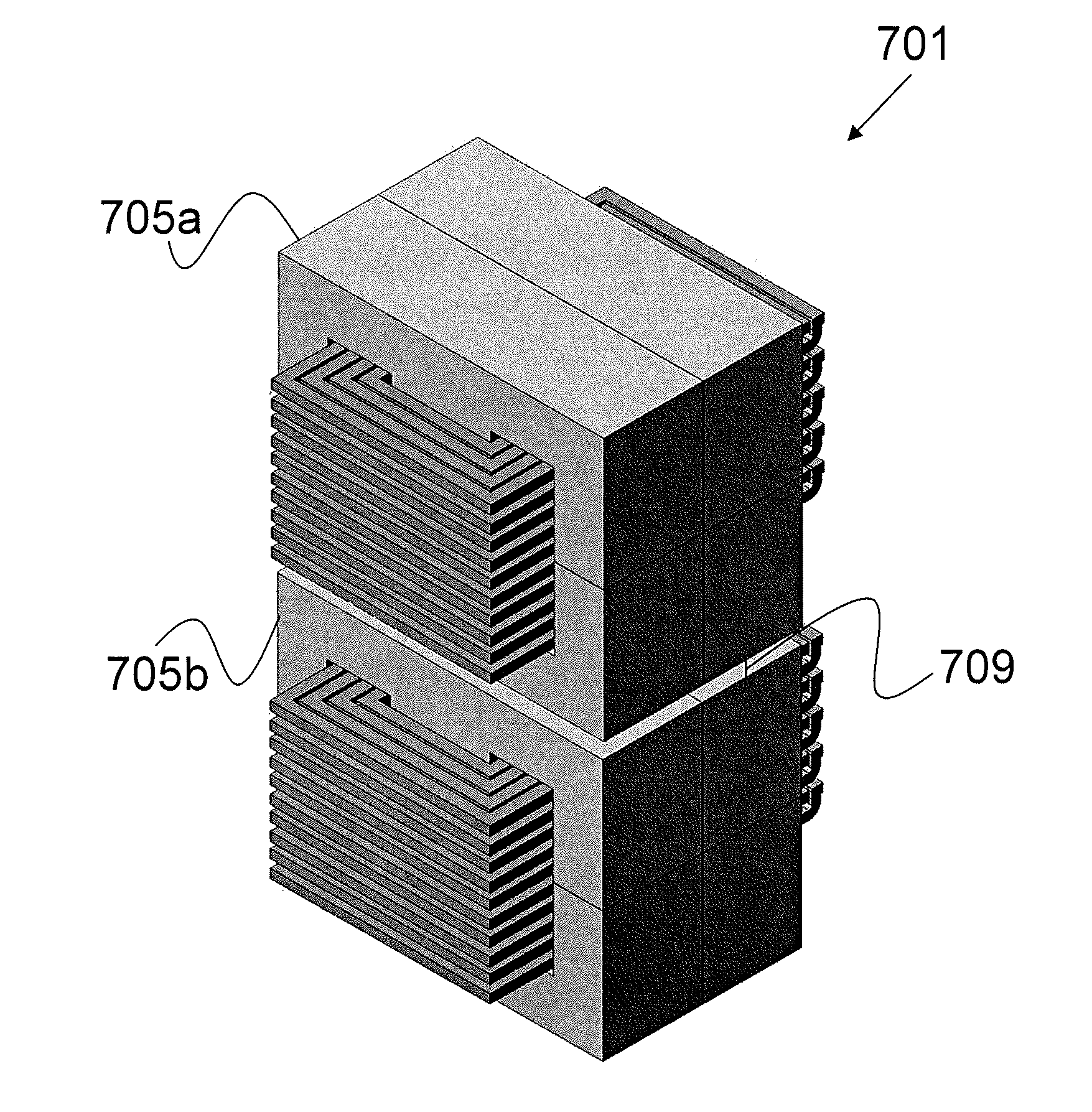

Integration of planar transformer and/or planar inductor with power switches in power converter

ActiveUS20050270745A1Transformers/inductances coolingSemiconductor/solid-state device detailsEngineeringPlanar inductor

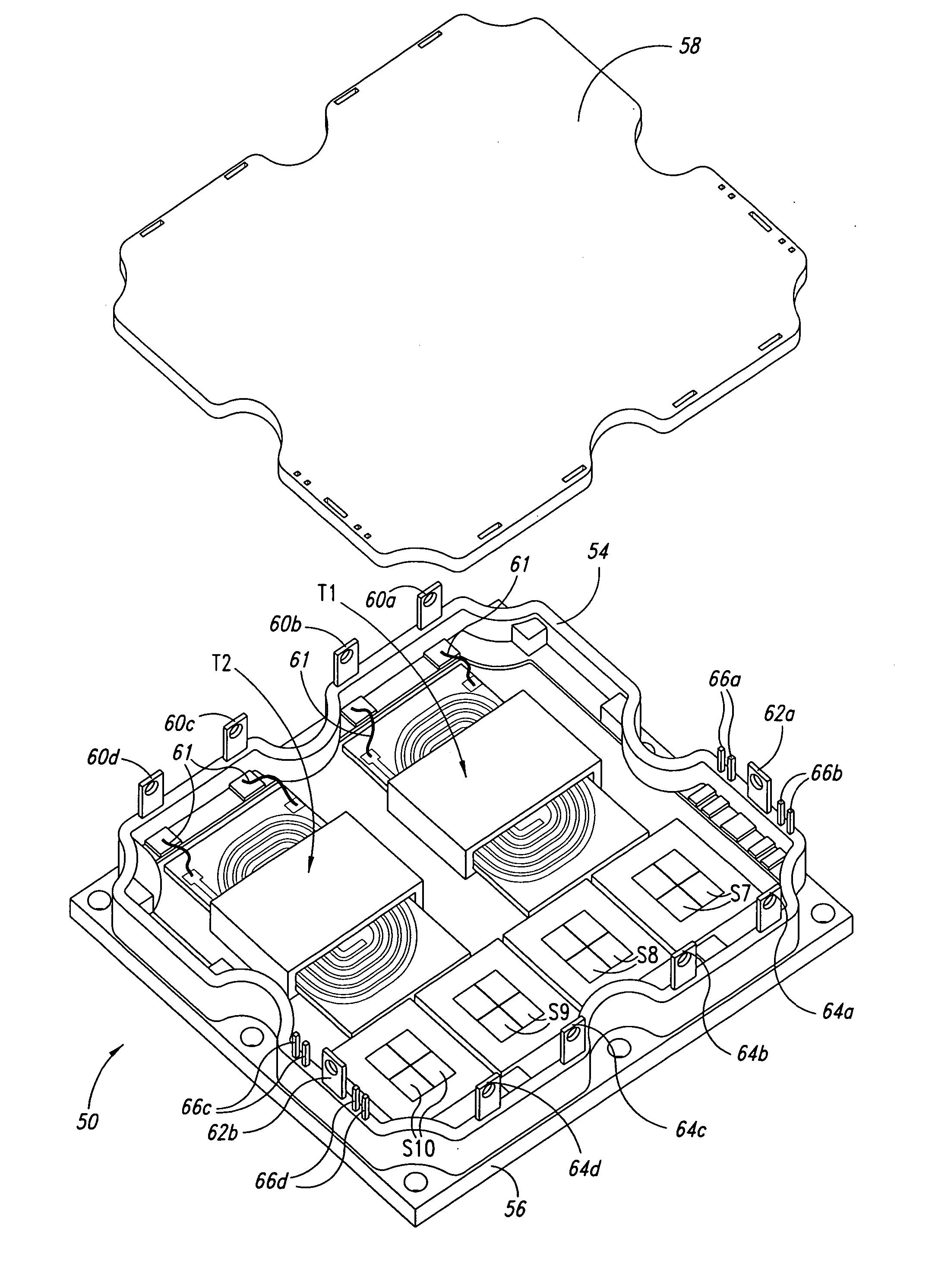

A power converter integrates at least one planar transformer comprising a multi-layer transformer substrate and / or at least one planar inductor comprising a multi-layer inductor substrate with a number of power semiconductor switches physically and thermally coupled to a heat sink via one or more multi-layer switch substrates.

Owner:VITESCO TECH USA LLC

Integration of planar transformer and/or planar inductor with power switches in power converter

ActiveUS7289329B2Transformers/inductances coolingSemiconductor/solid-state device detailsPlanar inductorSemiconductor

Owner:VITESCO TECH USA LLC

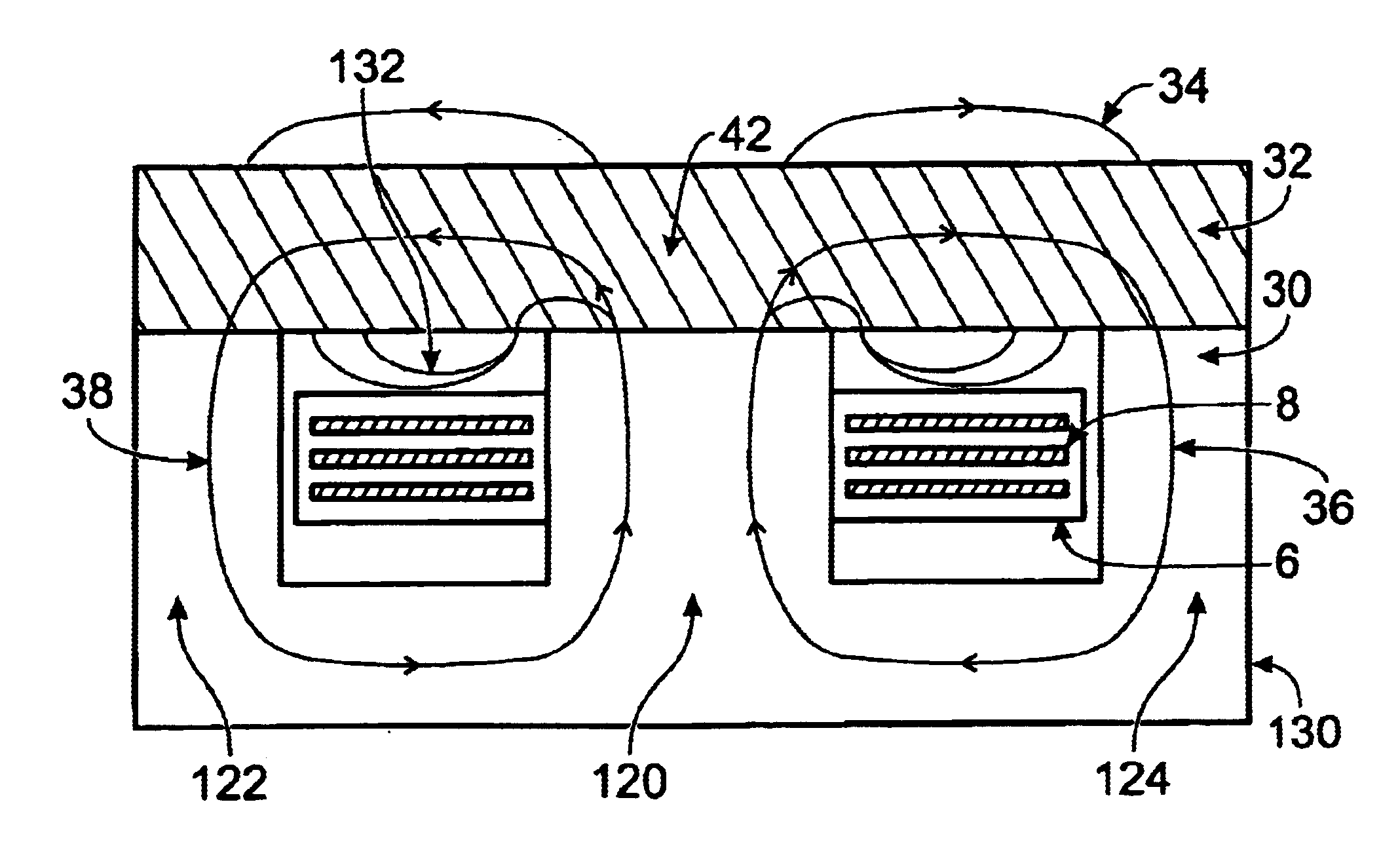

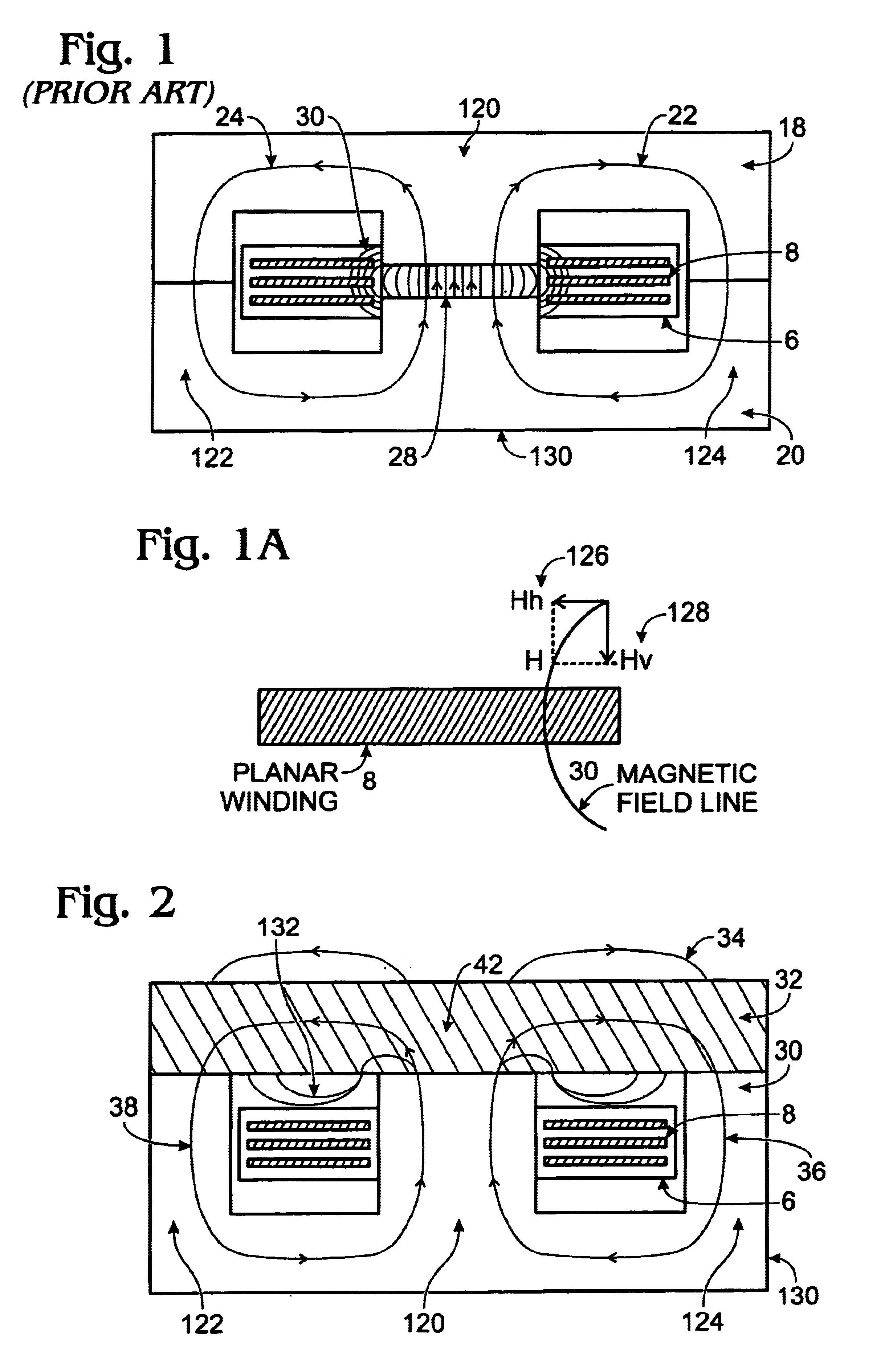

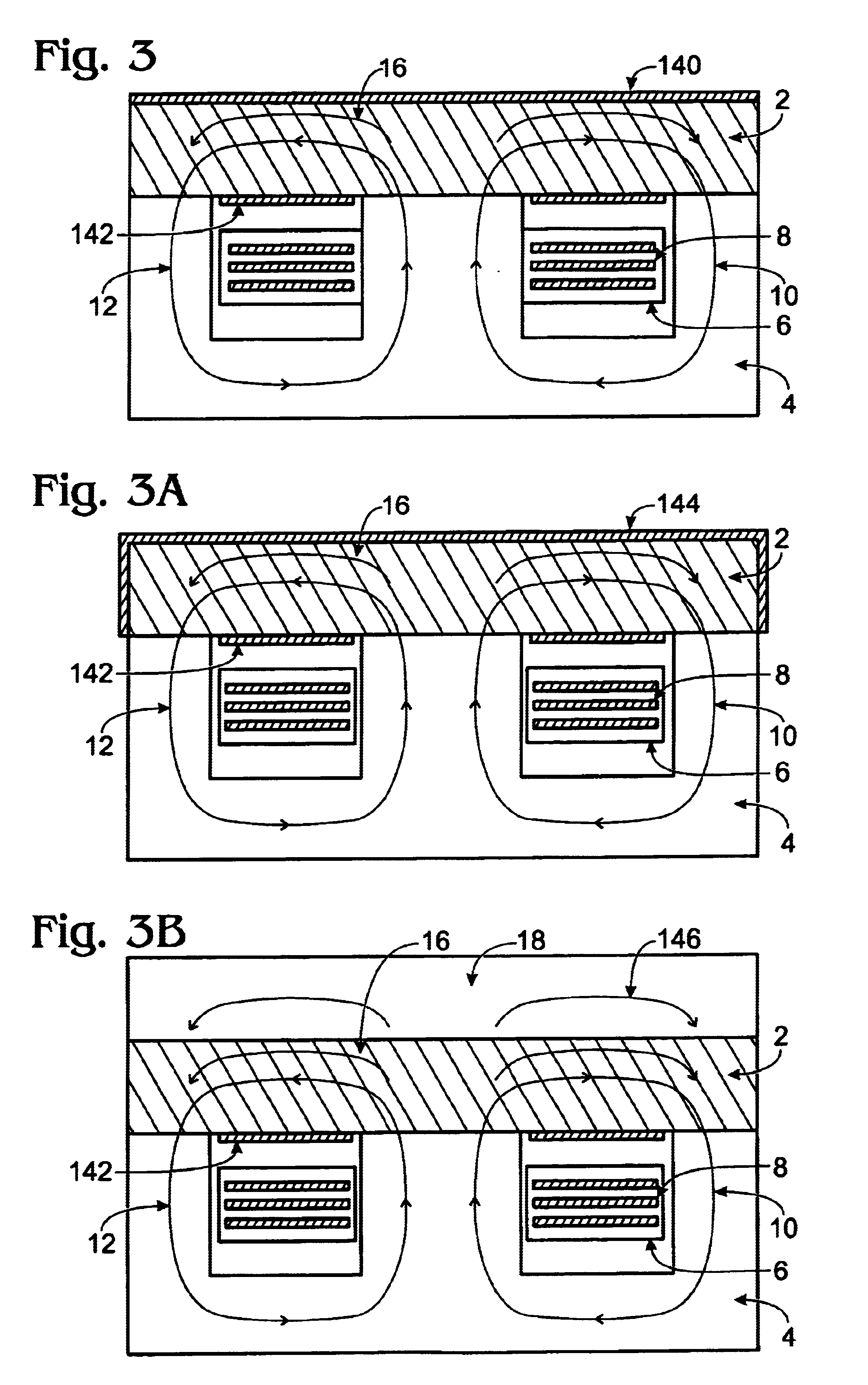

Planar inductive element

InactiveUS6967553B2Reduce the impactReduce impactTransformers/inductances casingsTransformers/inductances magnetic coresEddy currentPlanar inductor

A storage magnetic element, which minimizes the power loss in the planar winding due to the fringe magnetic field associated with a discrete air gap, is presented. The invention describes a construction technique wherein the magnetic core is formed by an E section made of high permeability magnetic material and an I section made by a material capable to store energy due to its distributed gap structure. The I section of the magnetic core in one of the embodiments is covered by an electrically conductive shied to force the magnetic flux into the I section and to minimize the component of the fringe magnetic field perpendicular on the planar winding. In another embodiment of this invention the electrically conductive shield is replaced by a high magnetic permeability material to accomplished the same goal of reducing the magnetic field component perpendicular on the planar winding. In a prefer embodiment of this invention the I section of the magnetic core has a cavity which will accommodate the middle leg of the E section. This construction will force the fringe magnetic field at the edge of the gap to be parallel with the planar winding of the storage magnetic element. In another embodiment of this invention a flat I section is used with the addition of another high permeability magnetic material placed on the I section on top of the winding. This construction will force the fringe magnetic field around the edge of the gap to be parallel with the planar winding. The embodiments of this invention are aimed at reducing the fringe magnetic field perpendicular on the planar winding, lowering the eddy current induced by this field.

Owner:DELTA ENERGY SYST SWITZERLAND

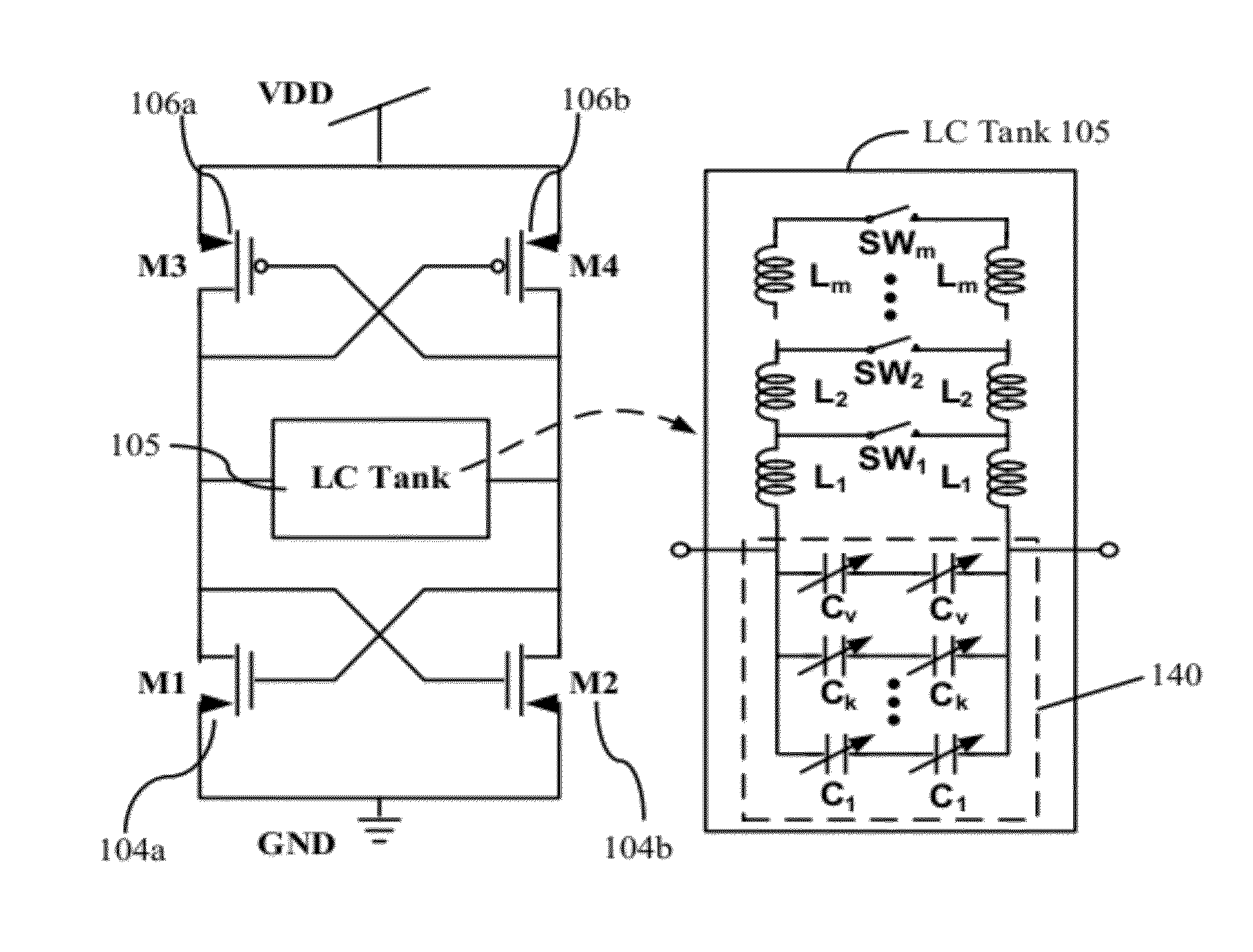

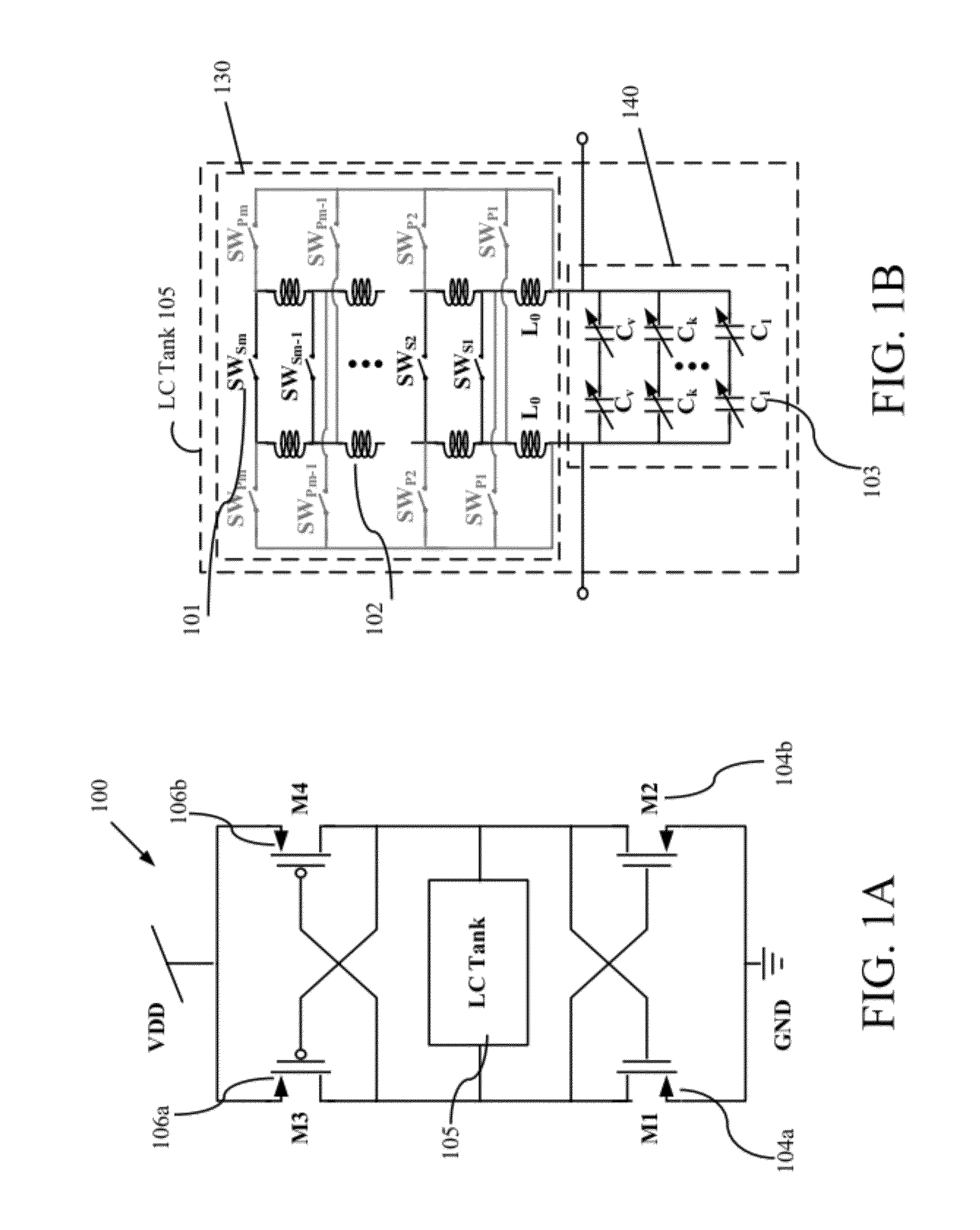

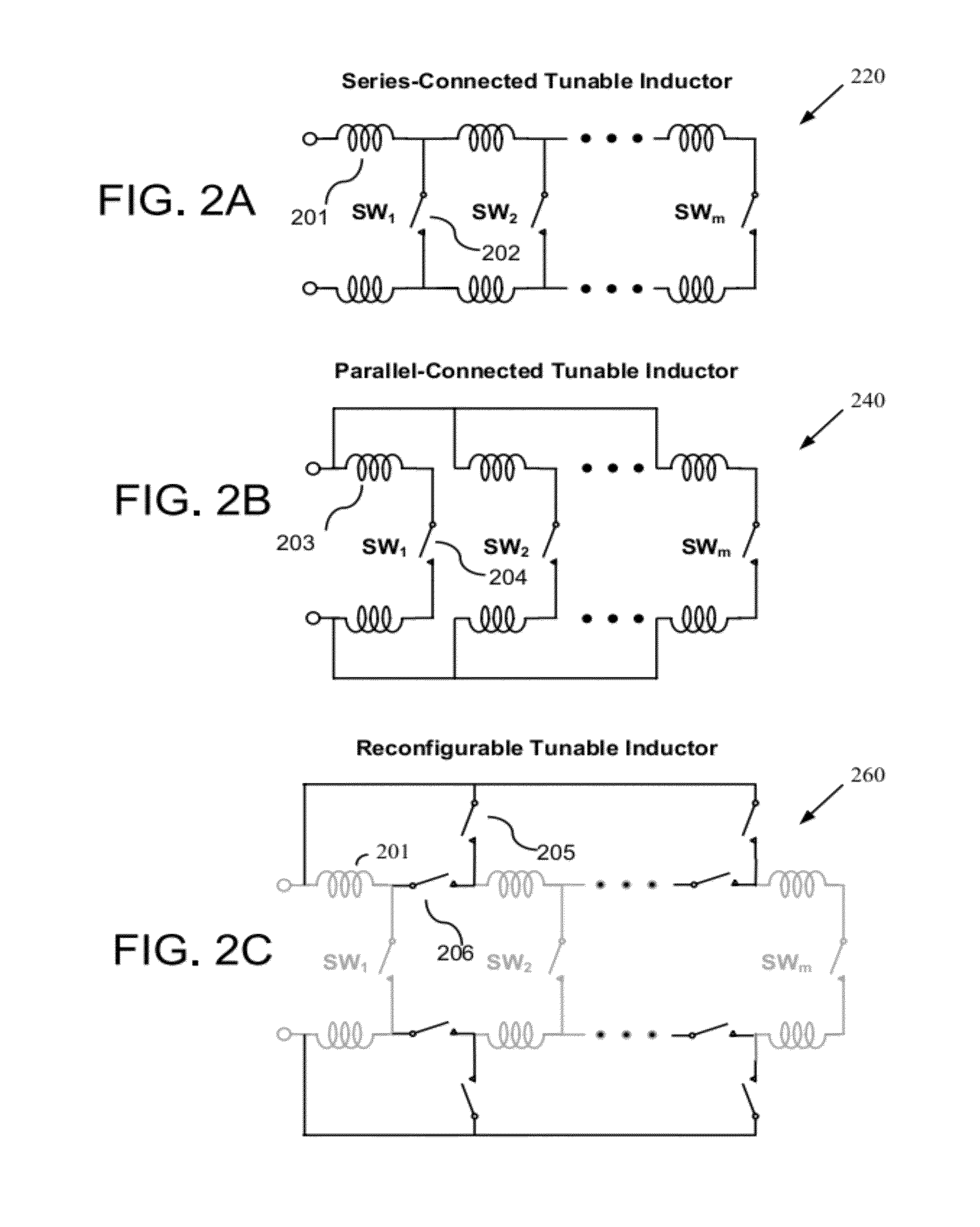

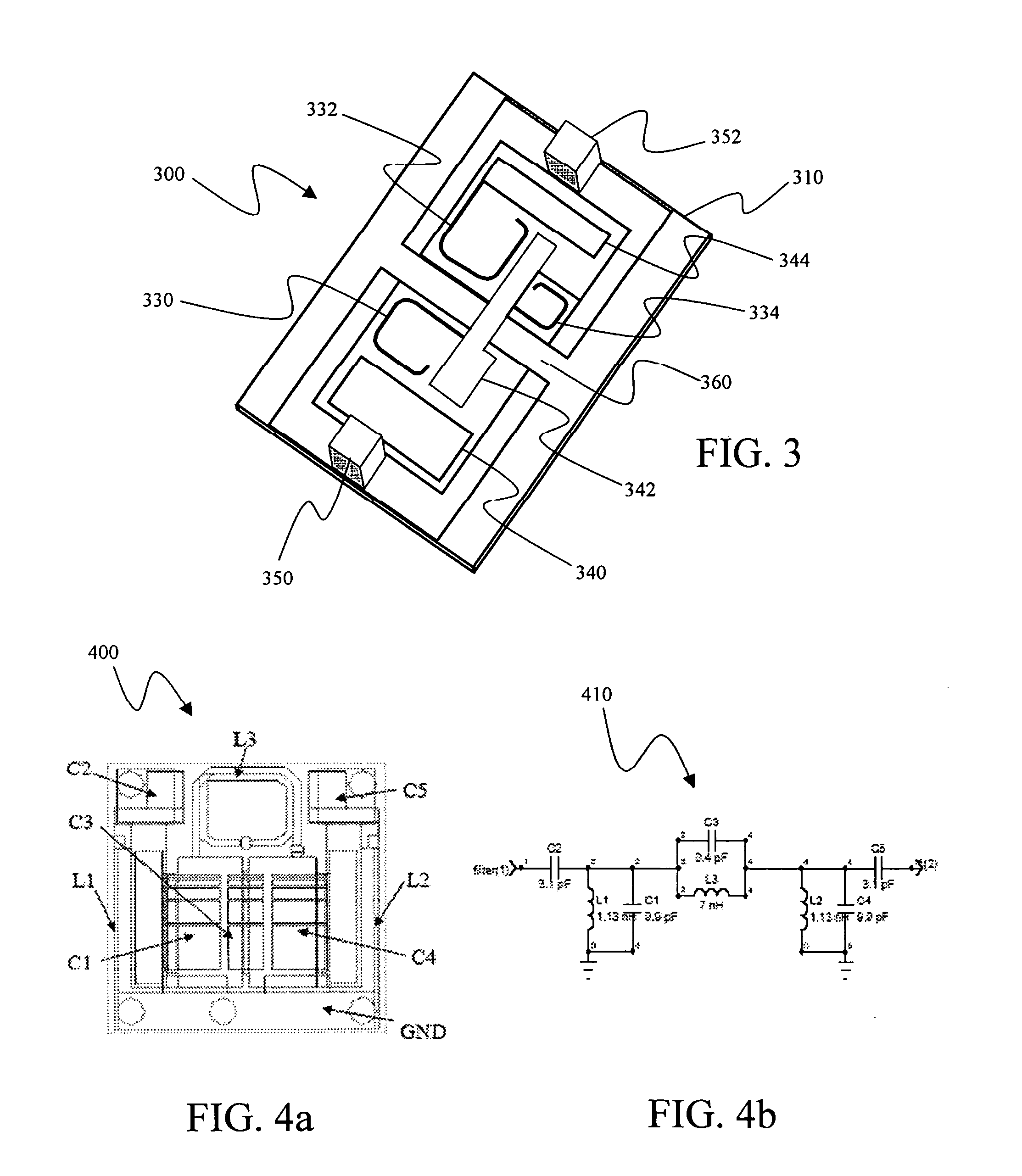

Systems and Methods for Wideband CMOS Voltage-Controlled Oscillators Using Reconfigurable Inductor Arrays

InactiveUS20120286889A1Adjust capacitanceElectric pulse generatorOscillations generatorsUltra-widebandCapacitance

As wireless communication technology evolves, various transceivers become integrated into a single system, which implements a seamless connection to search available frequency bands and to provide wireless connections regardless of their wireless standards. One of the key technologies for seamless implementation is an ultra-wideband local oscillator, which can overcome the restriction of limited tuning range in typical RF local oscillators. Many RF oscillators incorporate LC-tuned oscillators because of their good noise performance while their tuning range is limited by fixed inductance and varied capacitance. The planar inductor fabricated on the CMOS process occupies a large area as well. By replacing the planar inductor with the array of bondwires, and including switches to provide proper impedance for the circuit to generate negative impedance, the tuning range of a CMOS voltage-controlled oscillator (VCO) is extended more than 100%, which number can not be achieved in a convention VCO.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

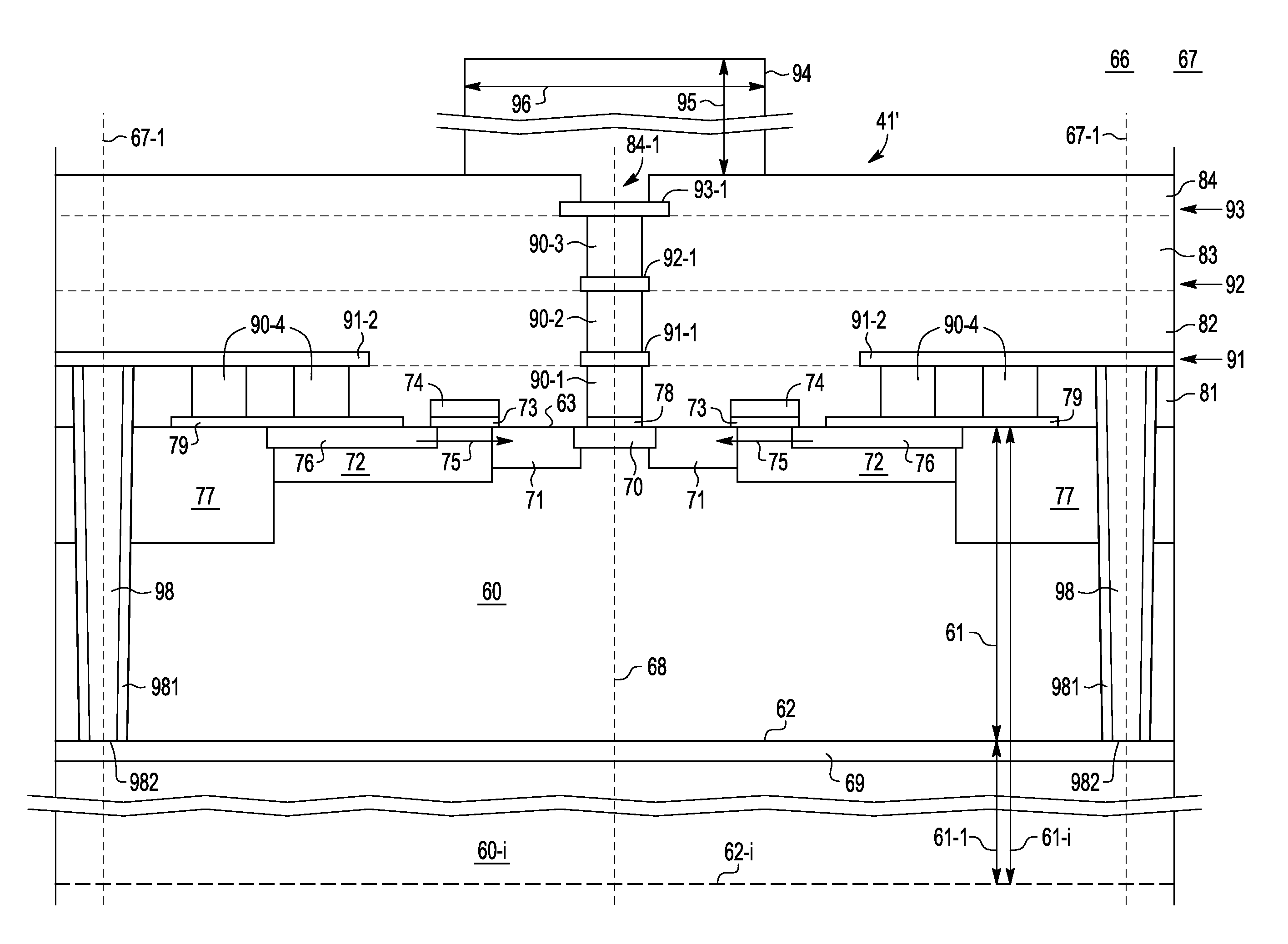

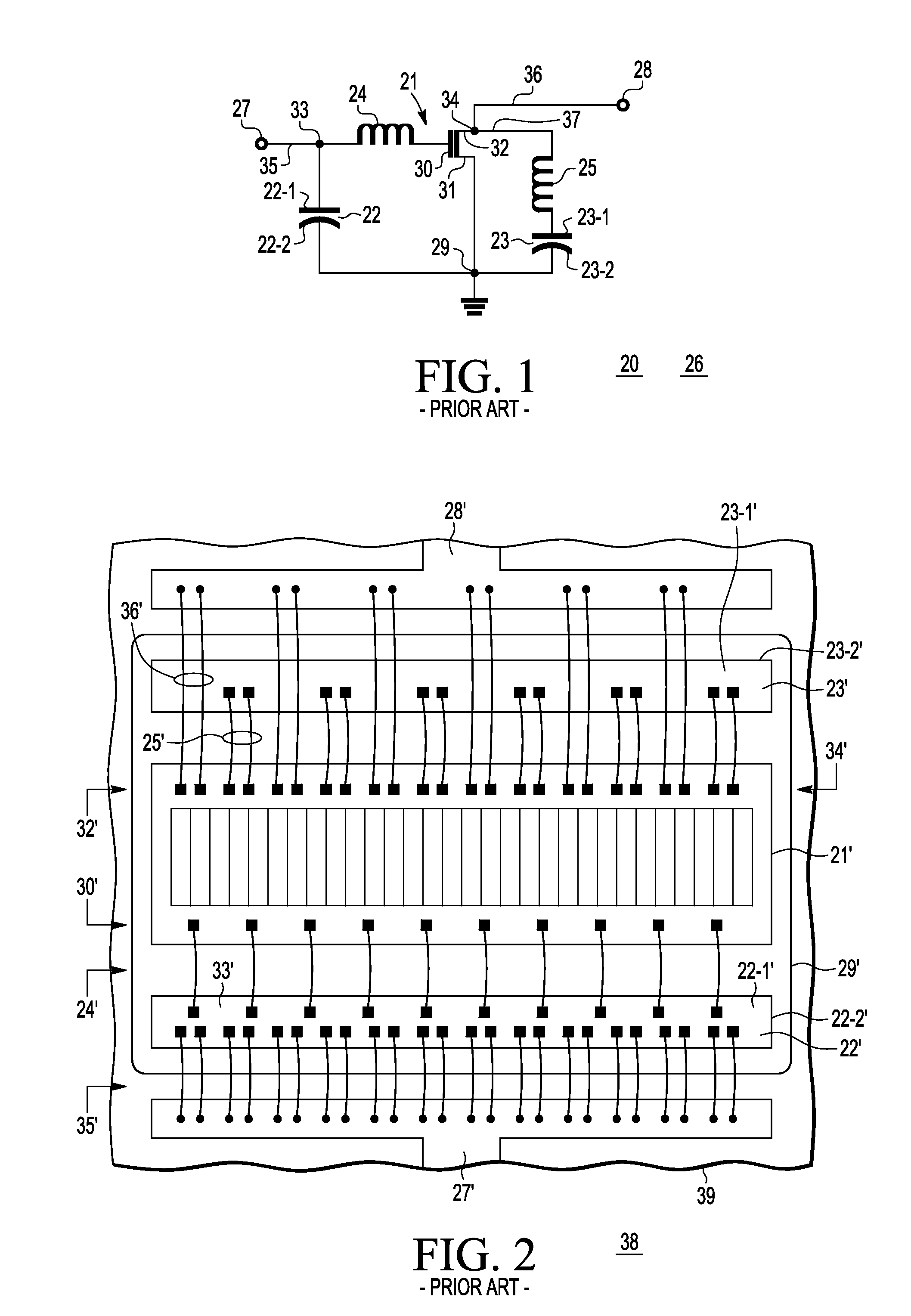

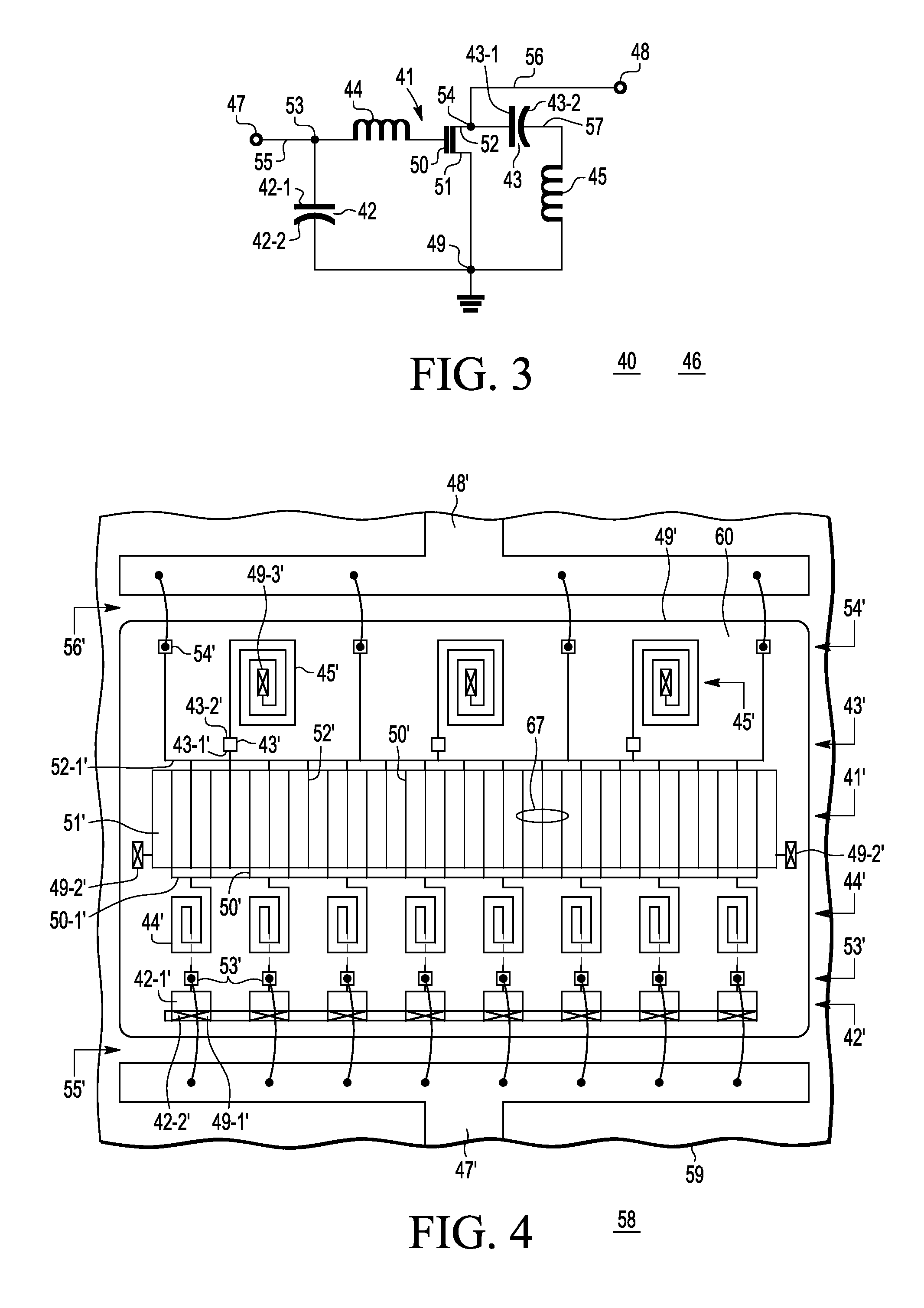

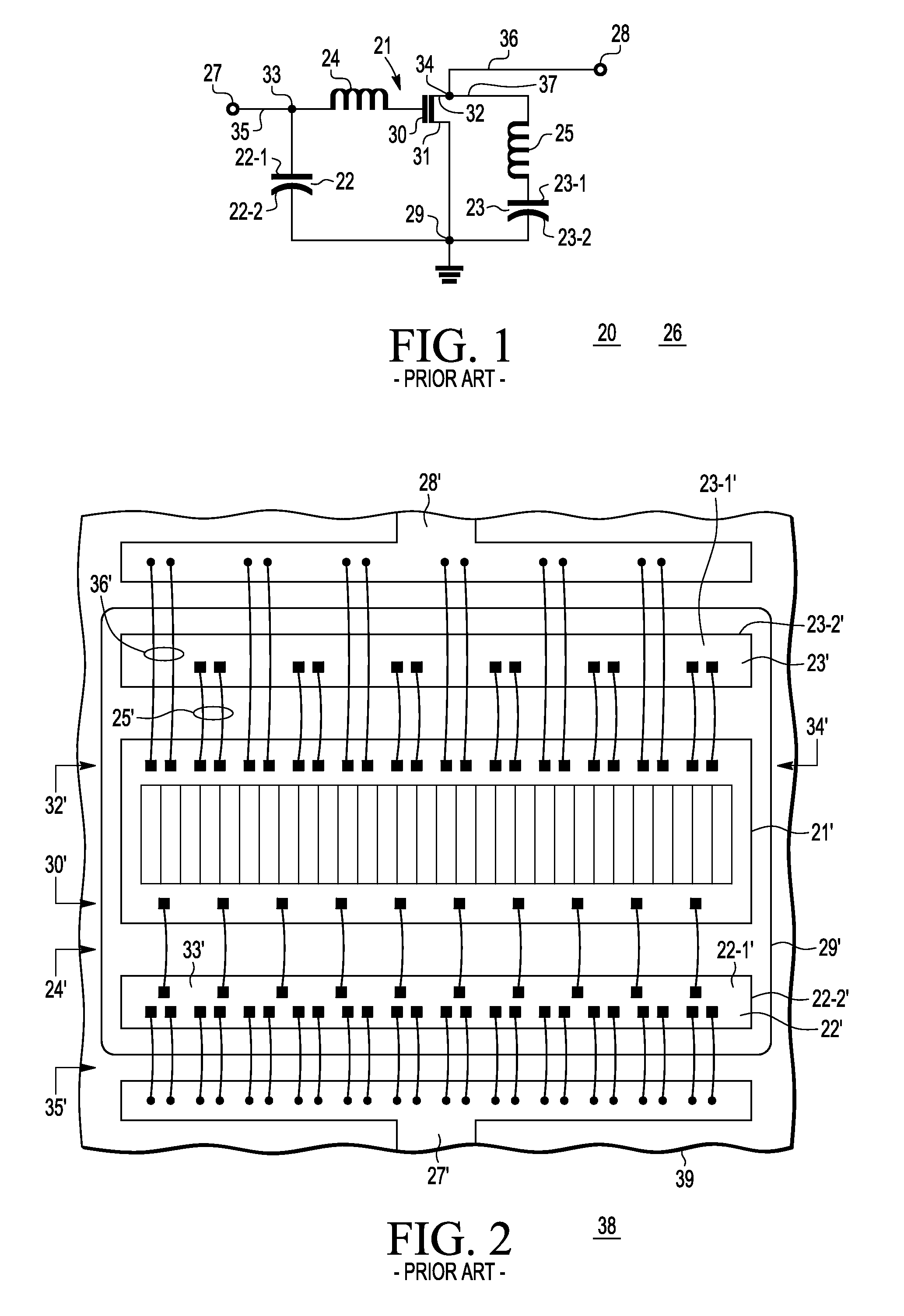

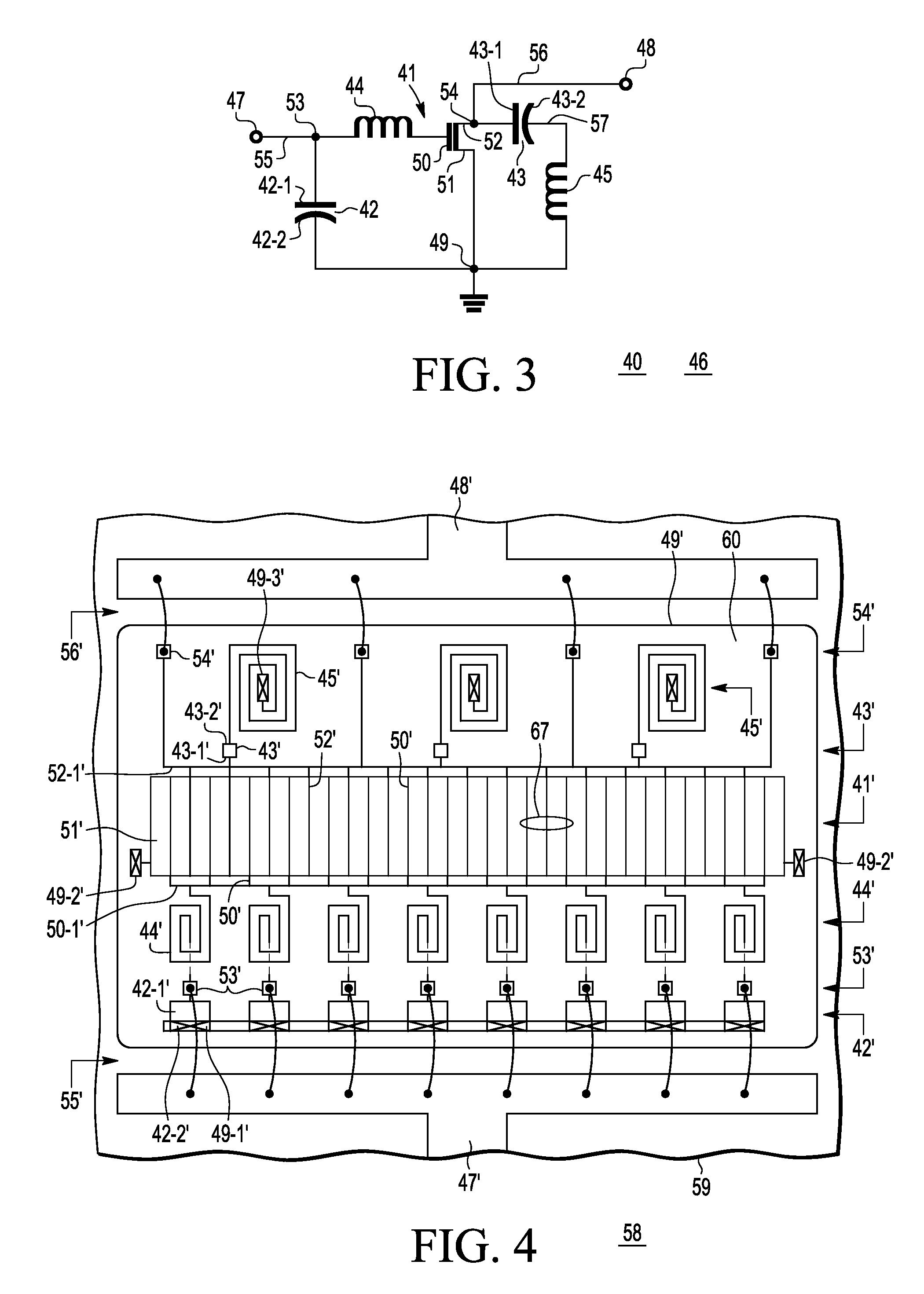

Monolithic microwave integrated circuit

Low Q associated with passive components of monolithic integrated circuits (ICs) when operated at microwave frequencies can be avoided or mitigated using high resistivity (e.g., ≧100 Ohm-cm) semiconductor substrates (60) and lower resistance inductors (44′, 45′) for the IC (46). This eliminates significant in-substrate electromagnetic coupling losses from planar inductors (44, 45) and interconnections (50-1′, 52-1′, 94, 94′, 94″) overlying the substrate (60). The active transistor(s) (41′) are formed in the substrate (60) proximate the front face (63). Planar capacitors (42′, 43′) are also formed over the front face (63) of the substrate (60). Various terminals (42-1′, 42-2′, 43-1, 43-2′,50′, 51′, 52′, 42-1′, 42-2′, etc.) of the transistor(s) (41′), capacitor(s) (42′, 43′) and inductor(s) (44′, 45′) are coupled to a ground plane (69) on the rear face (62) of the substrate (60) using through-substrate-vias (98, 98′) to minimize parasitic resistance. Parasitic resistance associated with the planar inductors (44′, 45′) and heavy current carrying conductors (52-1′) is minimized by placing them on the outer surface of the IC where they can be made substantially thicker and of lower resistance. The result is a monolithic microwave IC (46, 58) previously unobtainable.

Owner:NXP USA INC

Planar-like inductor coupling structure

A planar-like inductor coupling structure includes a first planar inductor embedded in an insulating material layer and a second planar inductor also embedded in the insulating material layer. The first planar inductor and the second planar inductor are substantially at the same height, and have a portion in a horizontal distribution serving as a coupled overlapping region with electric insulation from each other. In addition, the first planar inductor and the second planar inductor may be at different heights.

Owner:IND TECH RES INST

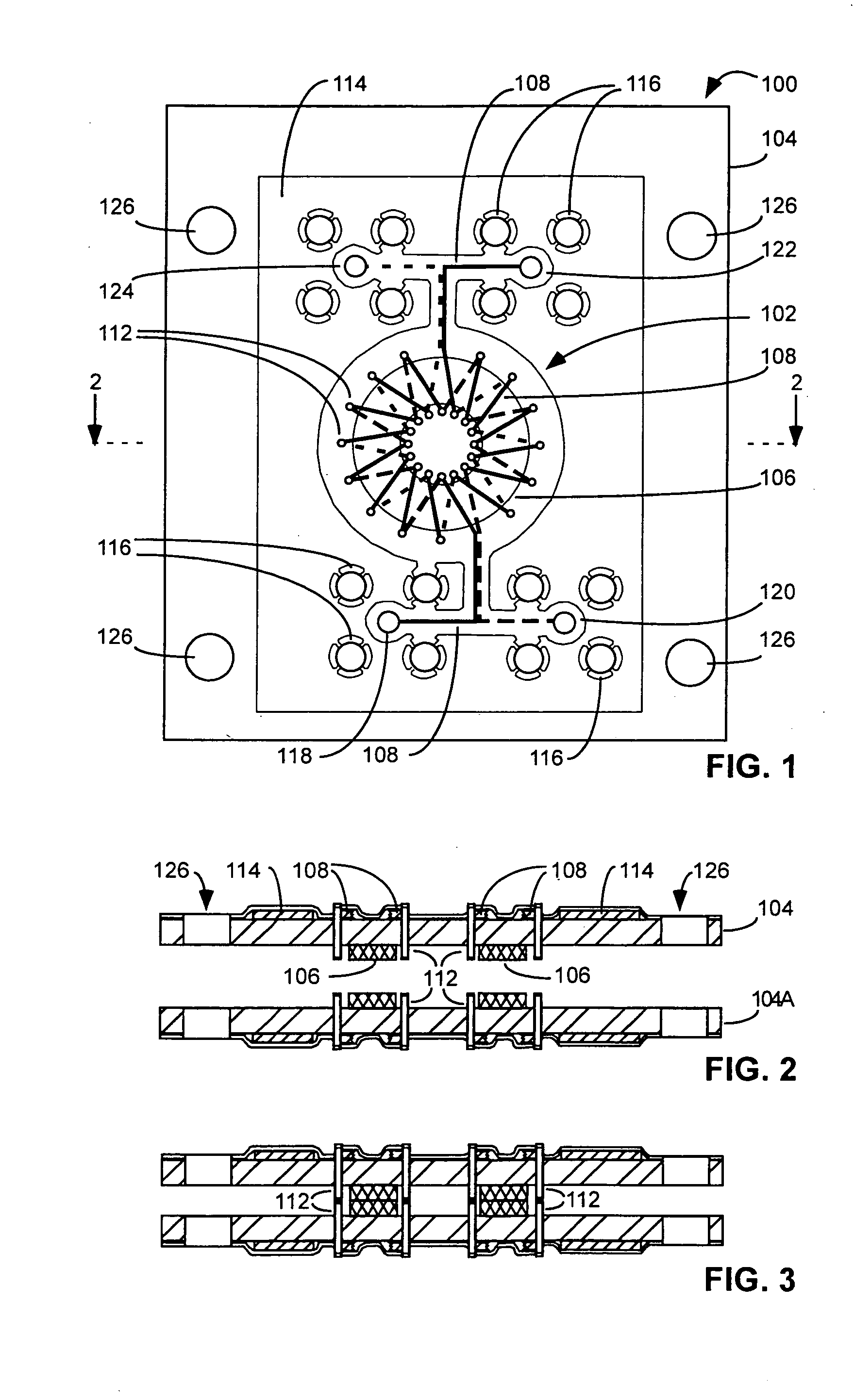

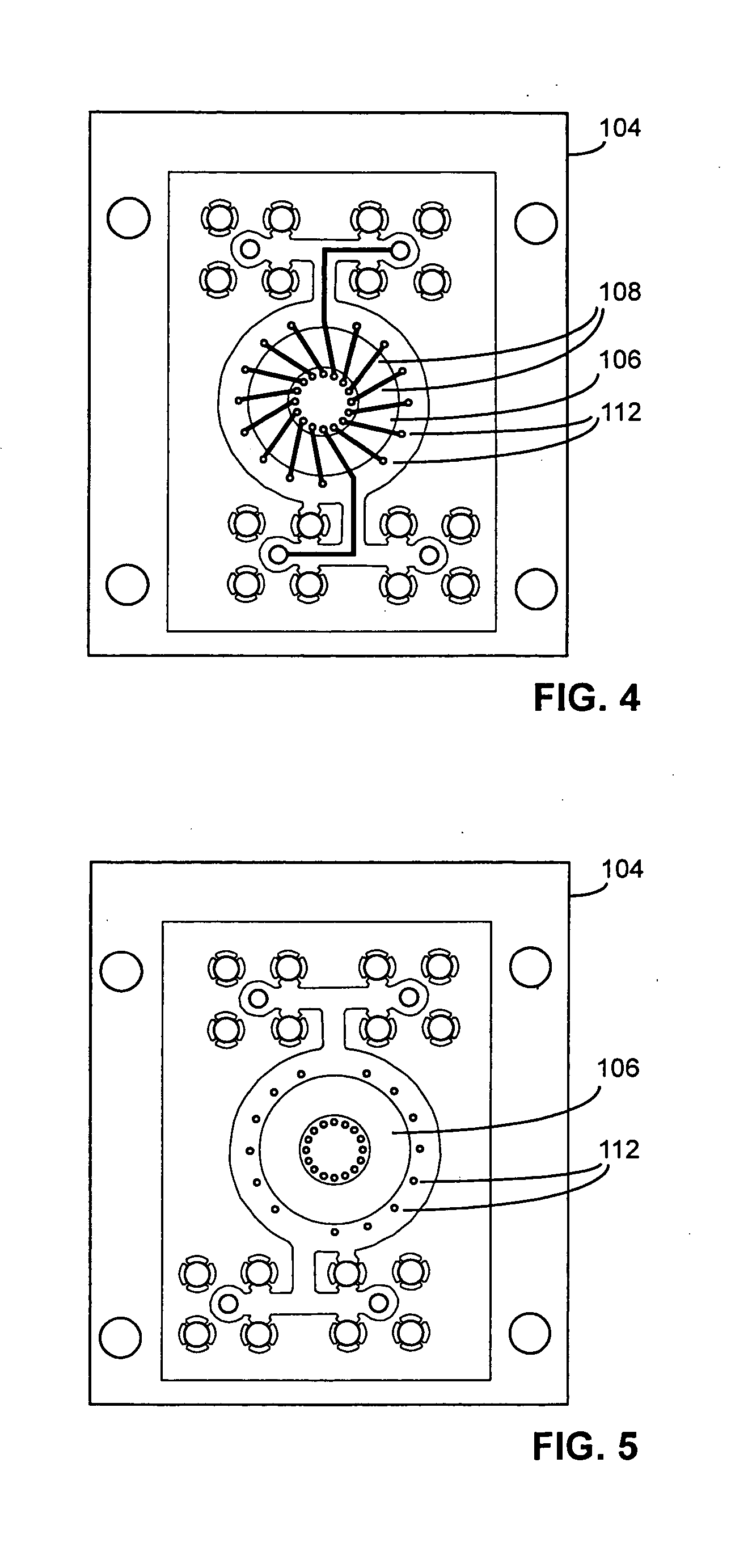

Offset Planar Coil Coaxial Surge Suppressor

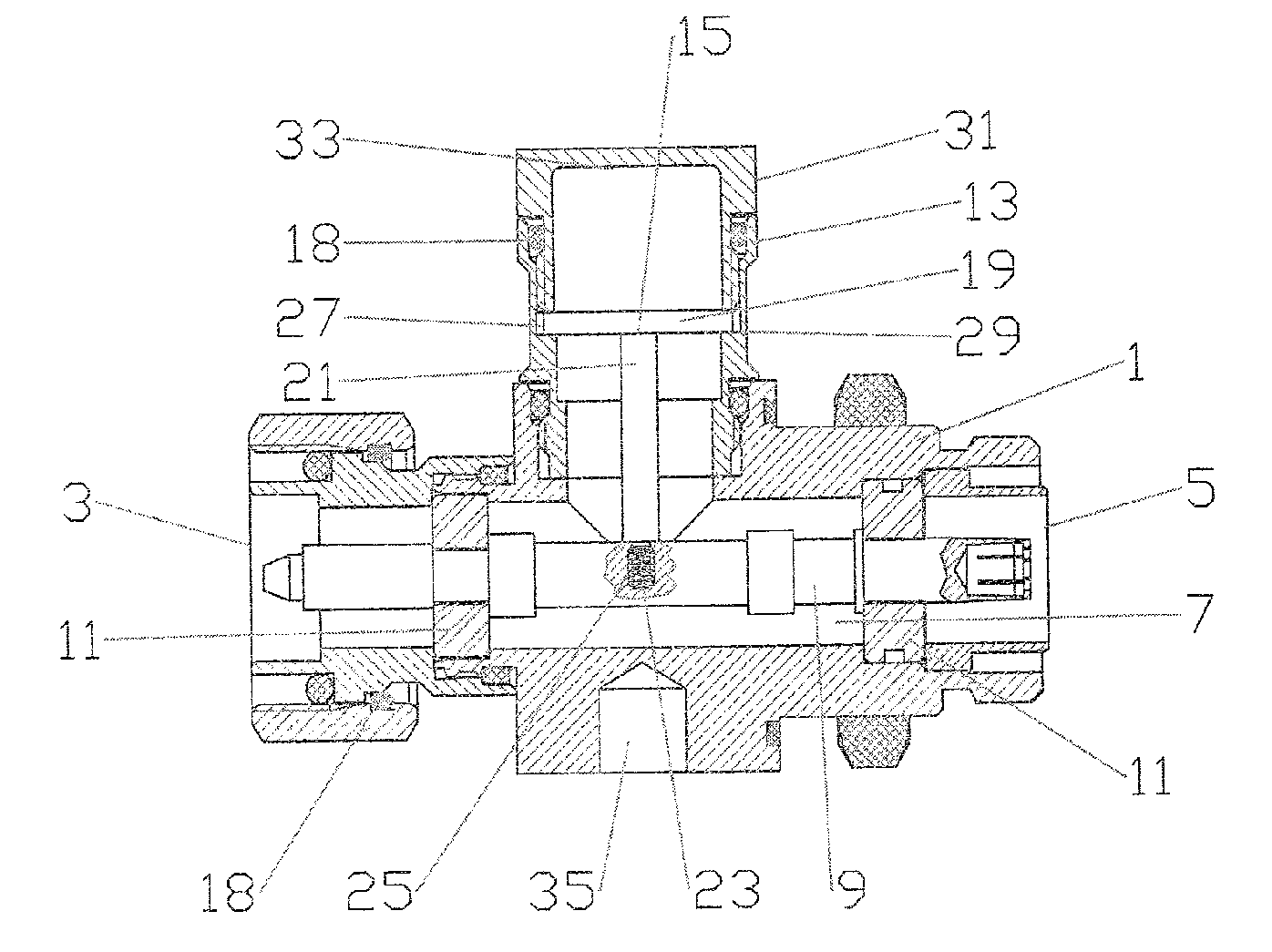

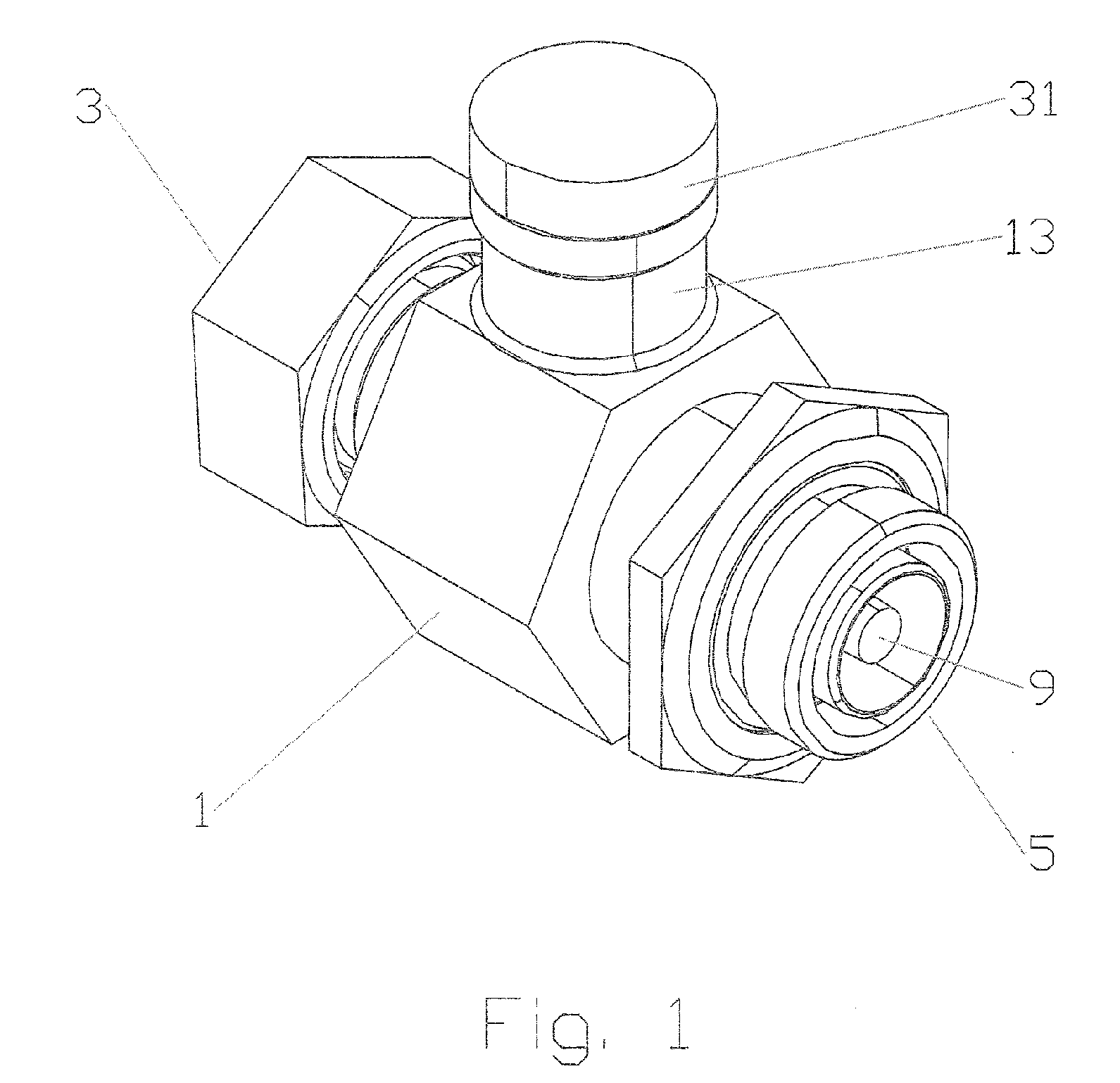

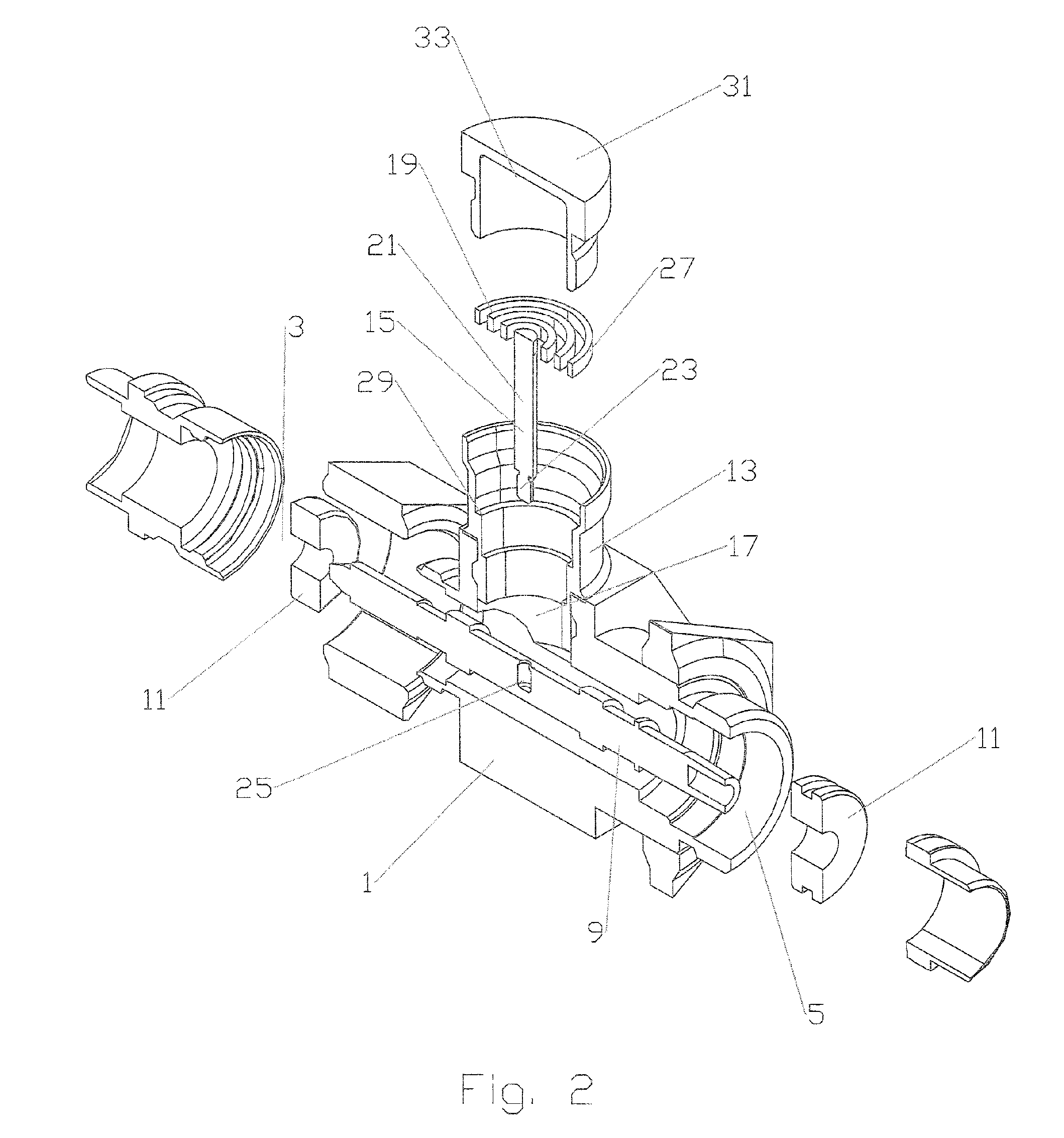

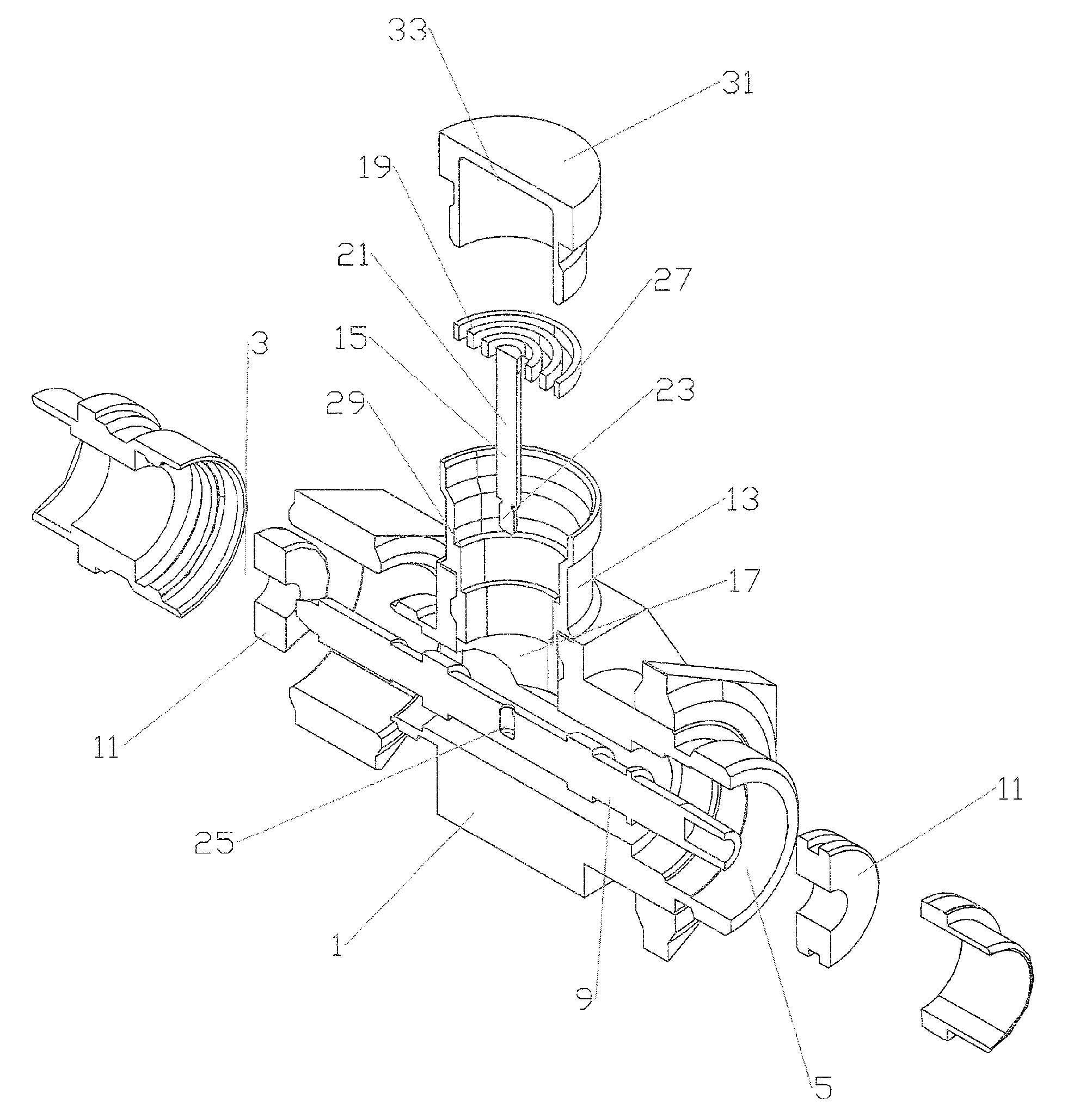

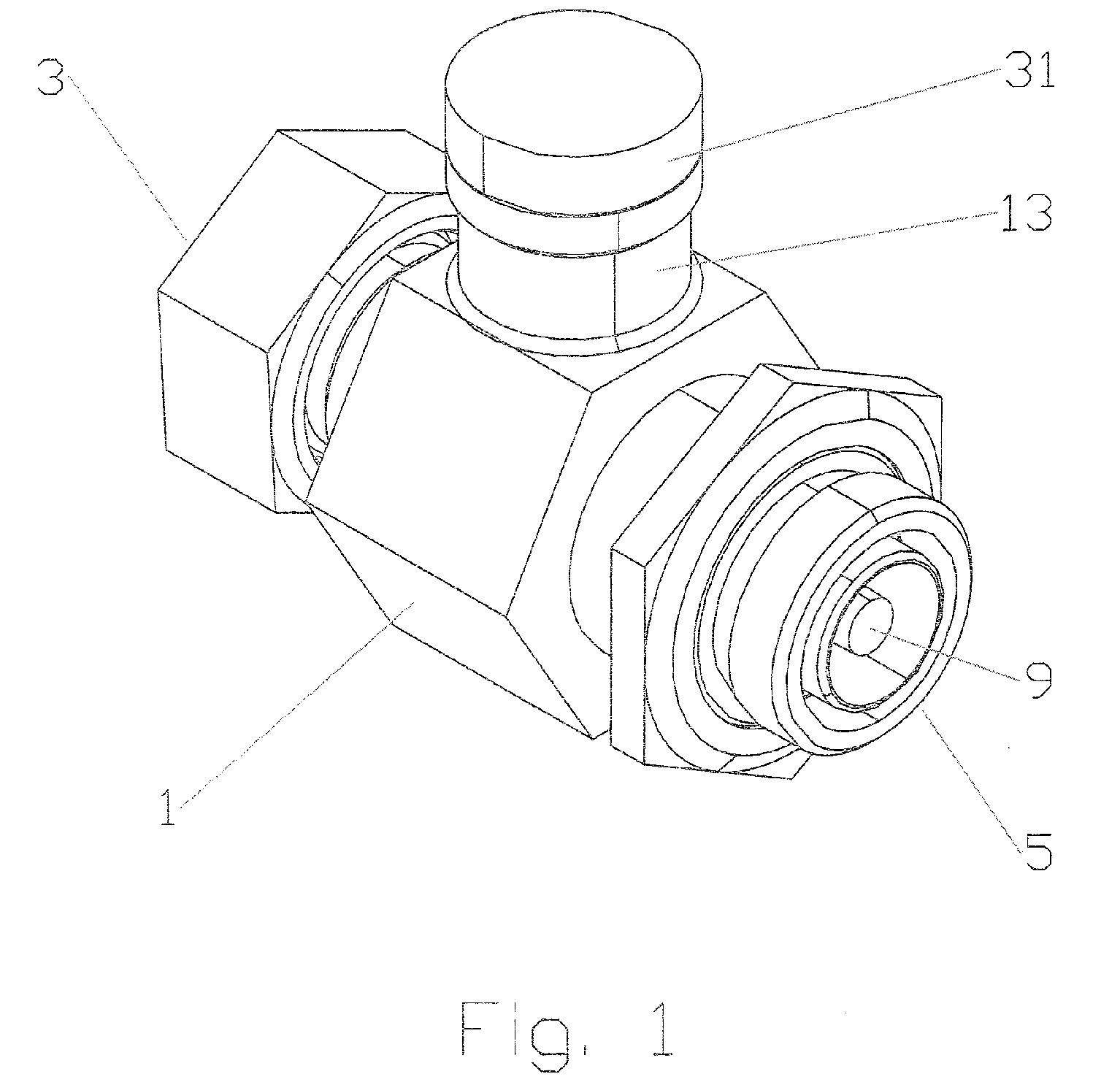

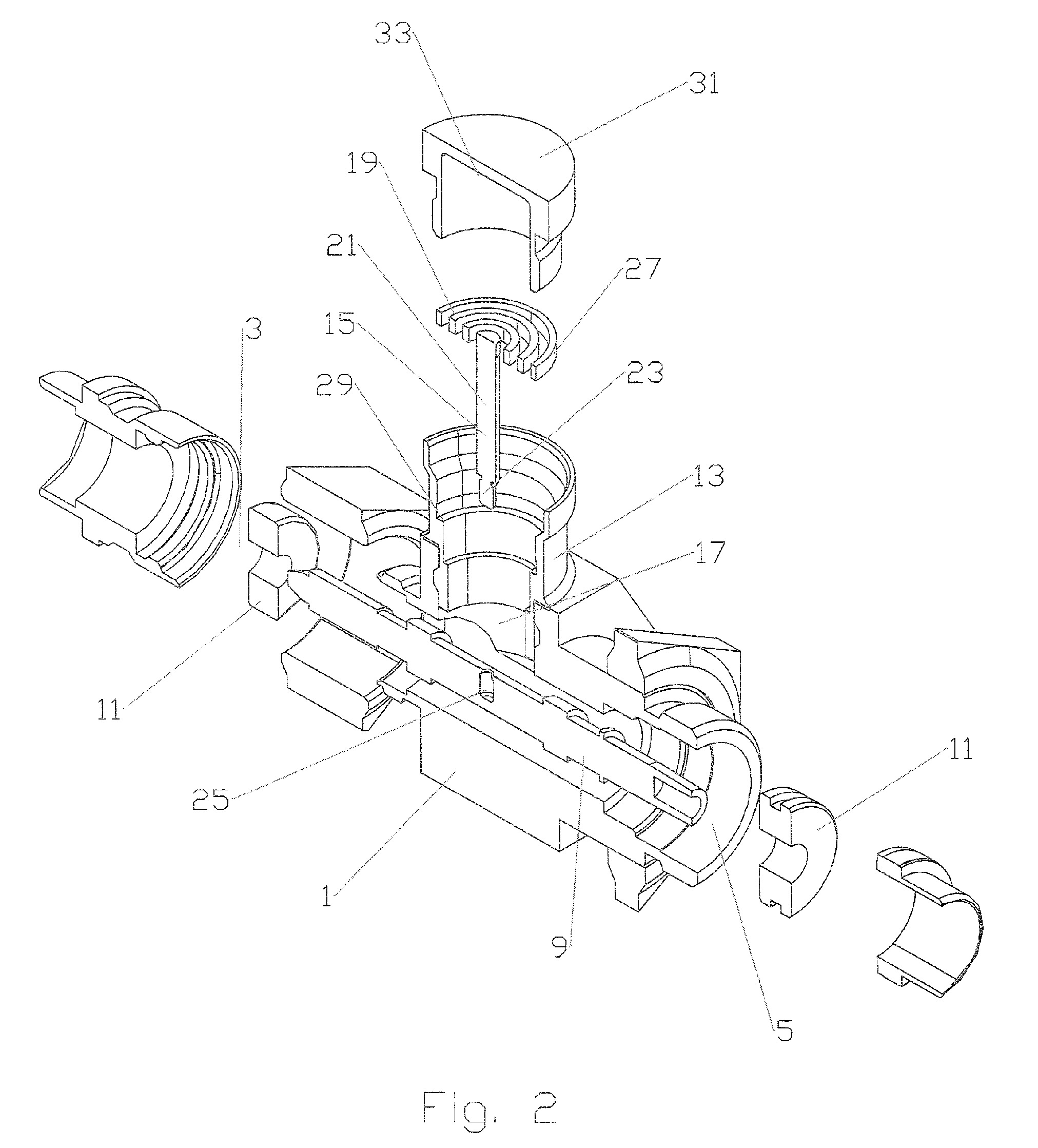

ActiveUS20070053130A1MinimizationSmall component sizeTwo pole connectionsEmergency protective arrangement detailsElectrical conductorSuppressor

An in-line surge suppressor assembly having a body with a side aperture and an inner conductor positioned coaxial within a bore of the body. An insert having a planar inductor coil with a post extending from an origin point of the planar inductor coil is positioned with the post passing through the side aperture and coupled to the inner conductor at a distal end. An outer rim of the planar inductor coil is electrically coupled to the body.

Owner:COMMSCOPE TECH LLC

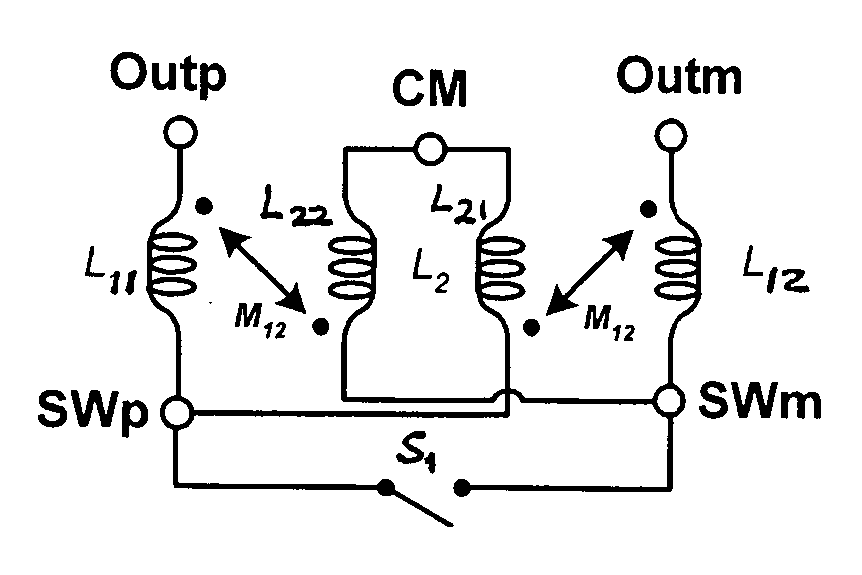

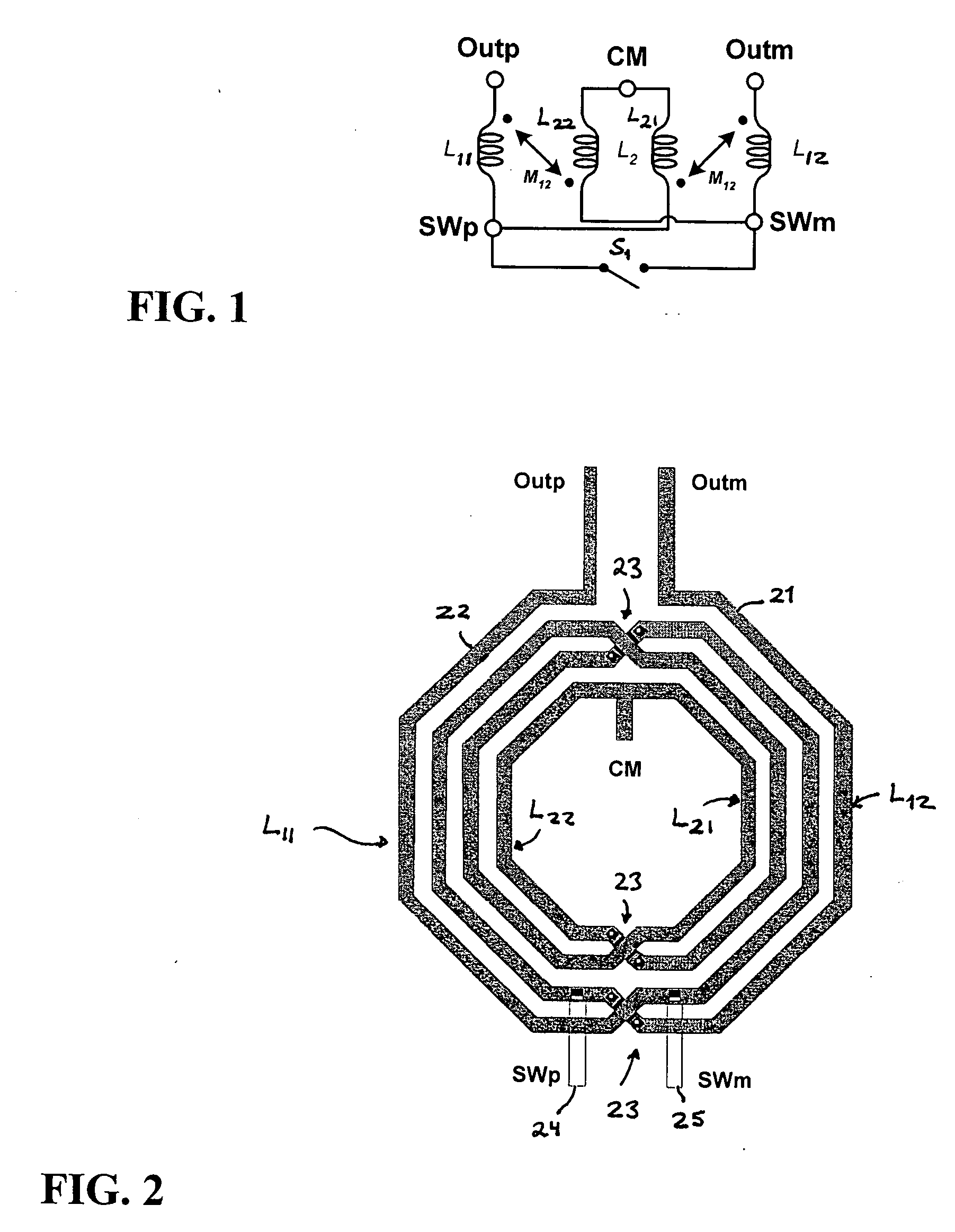

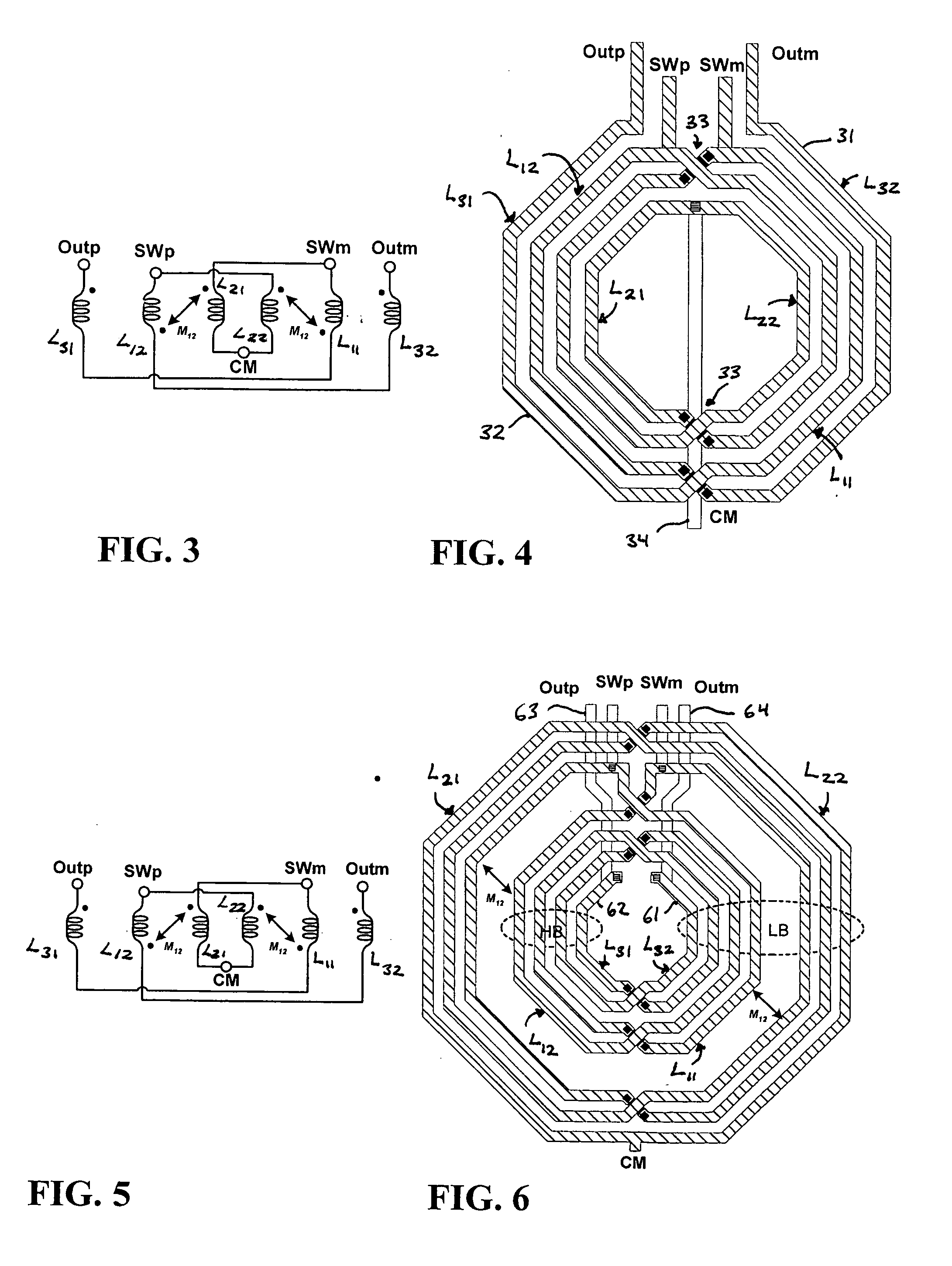

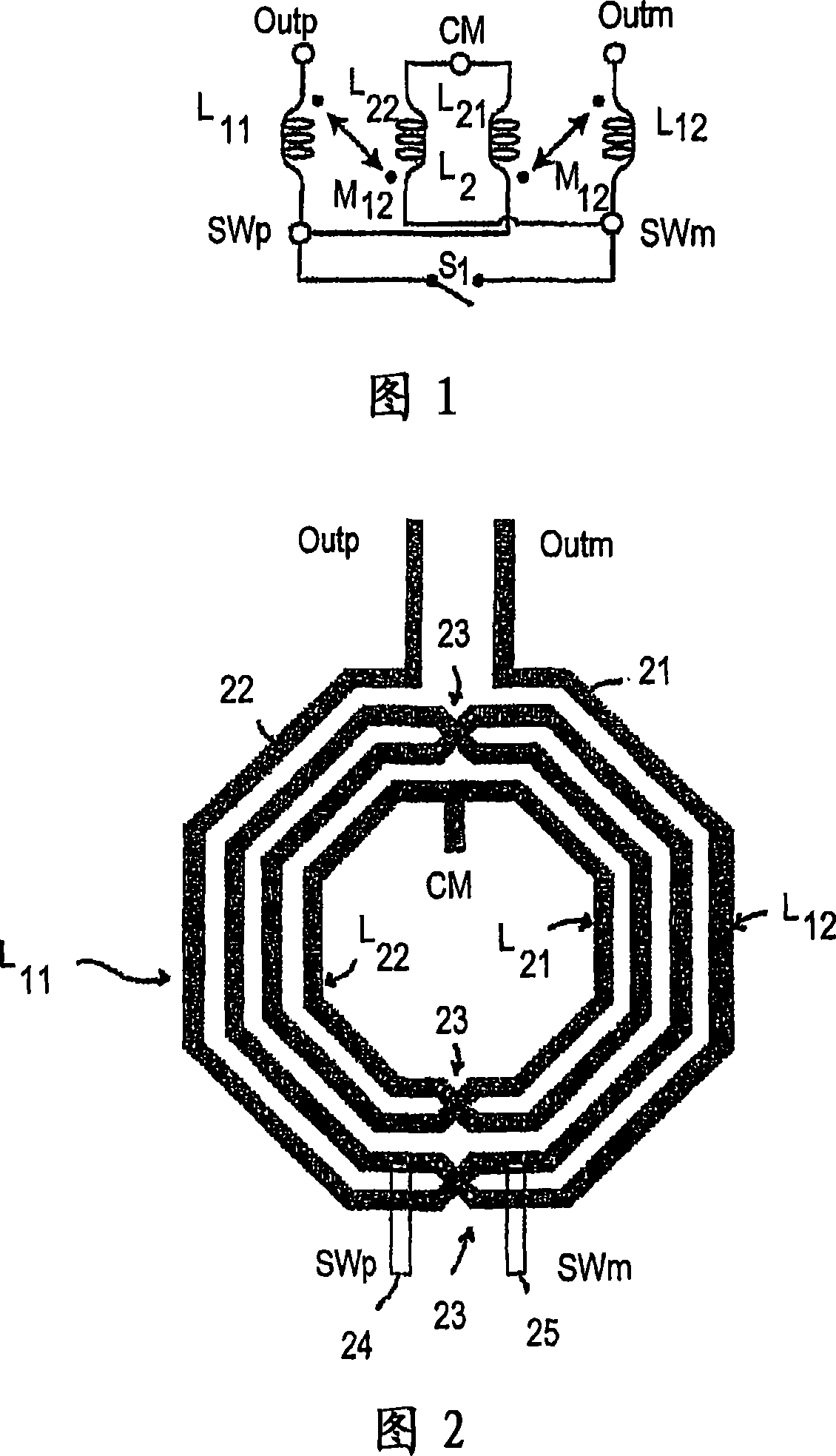

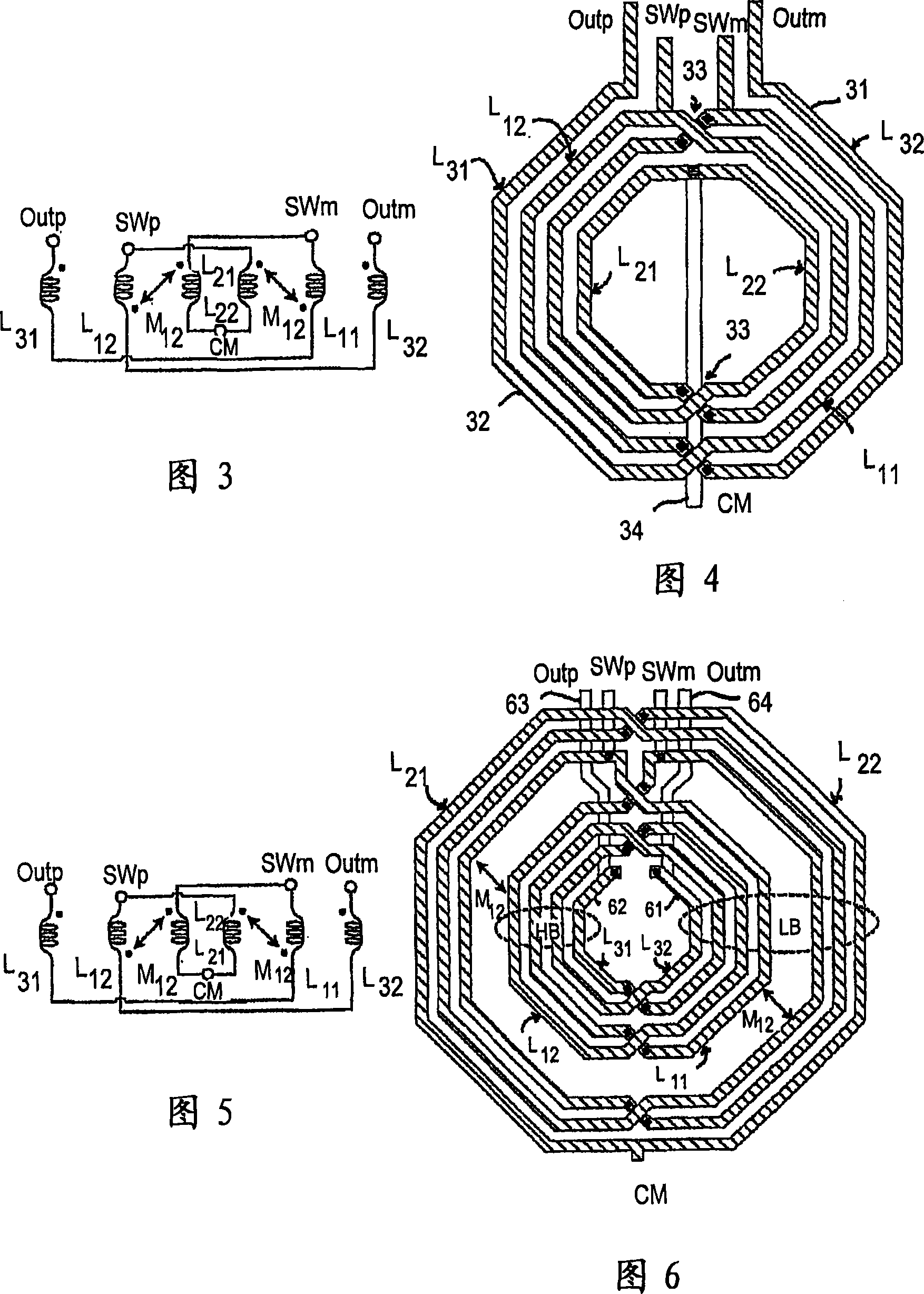

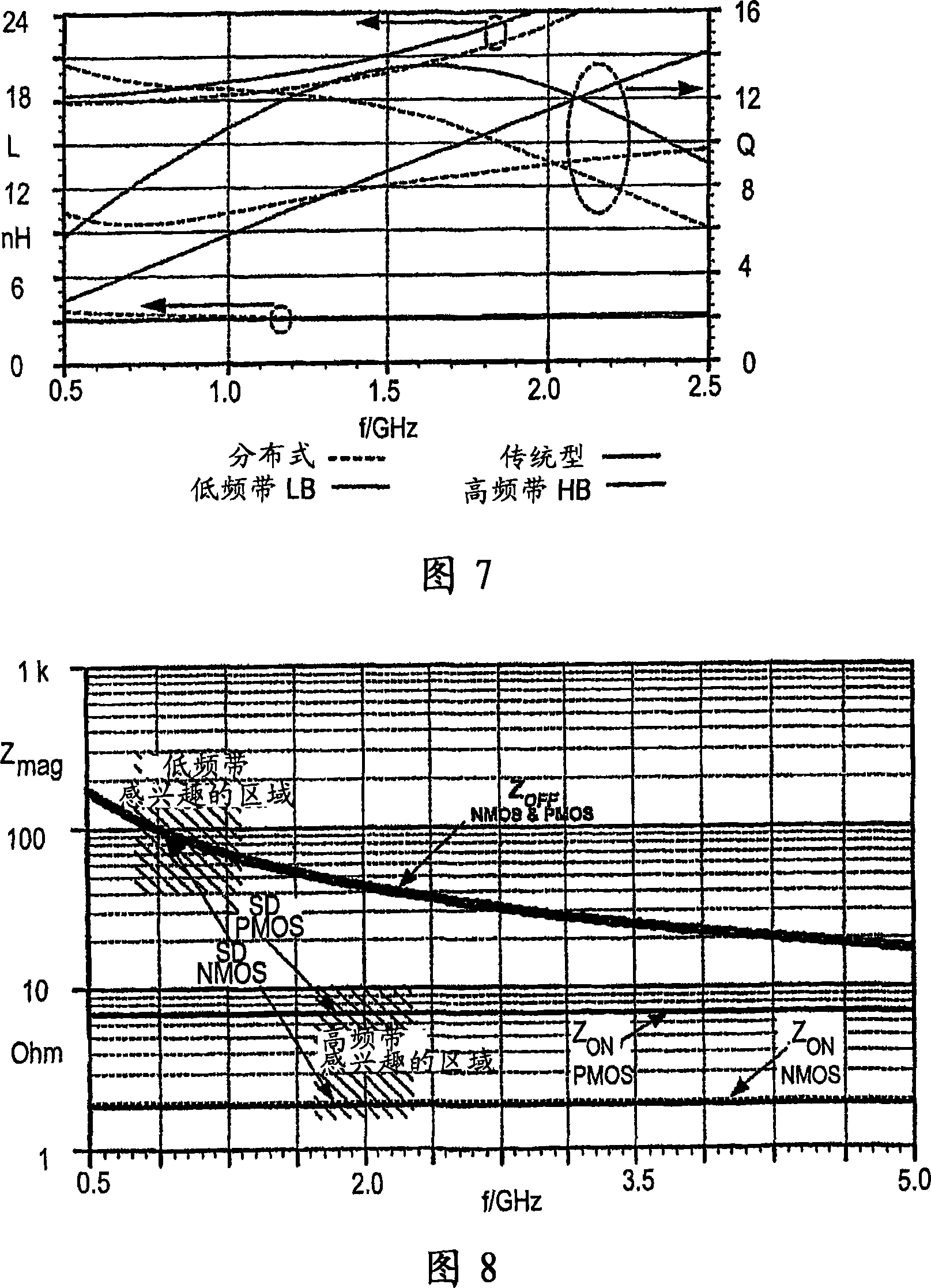

Inductor device for multiband radio frequency operation

InactiveUS20070158782A1Reduce the amount requiredReduction in performanceSolid-state devicesAmplifier with semiconductor-devices/discharge-tubesAudio power amplifierFrequency mixer

The inductance of a monolithic planar inductor is distributed into smaller inductor portions. The smaller inductor portions are provided in a cascode configuration in a manner that causes inductor to function as a differential inductor device. The node between the immediate inductor portions is a common-mode point of the inductor device, which is typically connected to the signal ground. The nodes at the outer ends of the inductor portions are differential outputs, e.g. output nodes of an amplifier device at the interface of the device itself and the following device (e.g. input stage of a mixer). Some of the inductor portions are arranged to be symmetrically bypassed or shortcut in relation to the common point in one or more steps for operation in one or more higher radio frequency band. By means of the switchable symmetric shortcut, a controllable inductance step can be provided. The common-mode signal is affected the same inductance regardless of the controlled condition.

Owner:NOKIA CORP

Inductor device for multiband radio frequency operation

InactiveCN101253586AOperation steps can be controlledEasy to operateTransformers/inductances coils/windings/connectionsAmplifier with semiconductor-devices/discharge-tubesAudio power amplifierPlanar inductor

Owner:NOKIA CORP

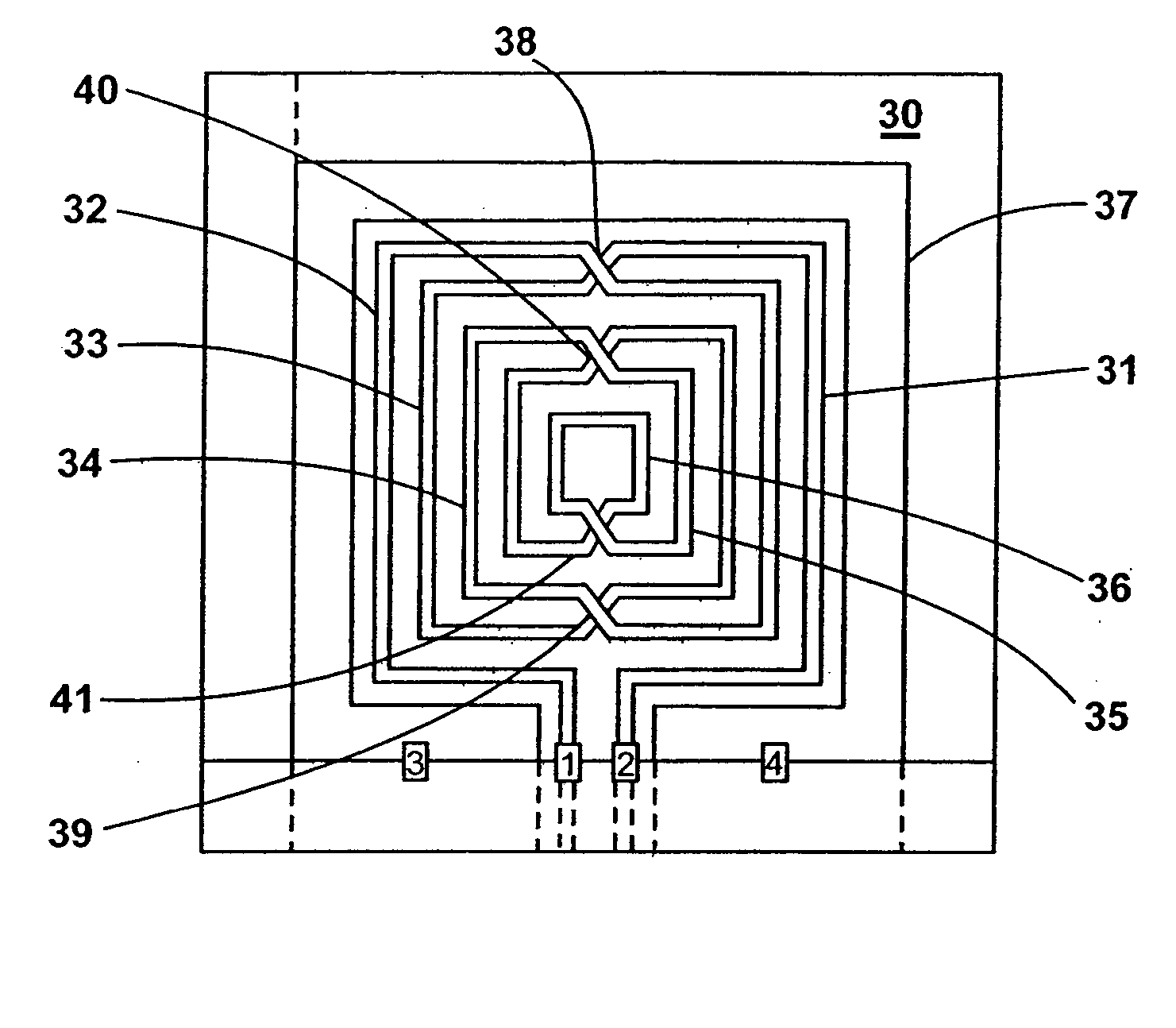

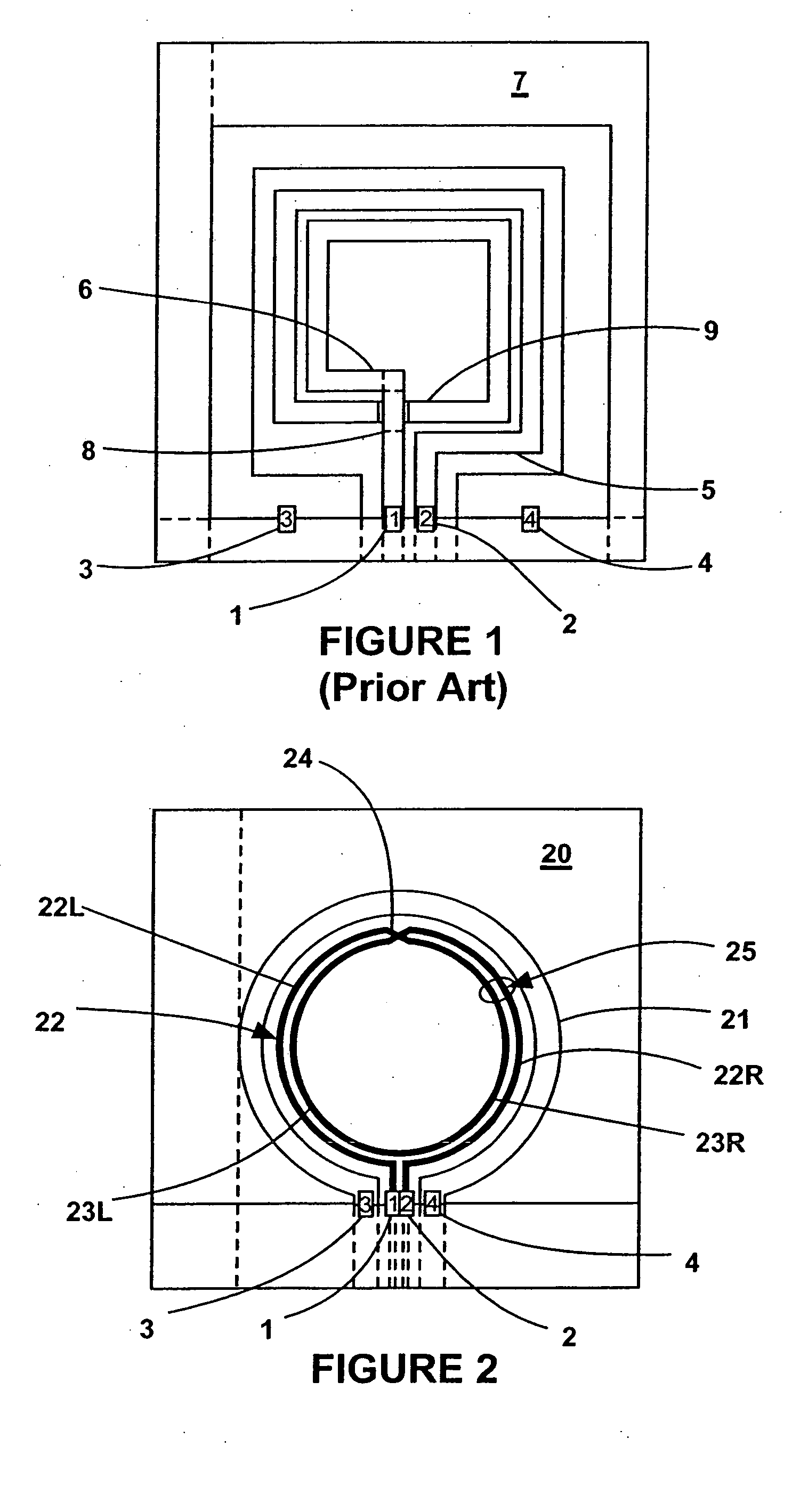

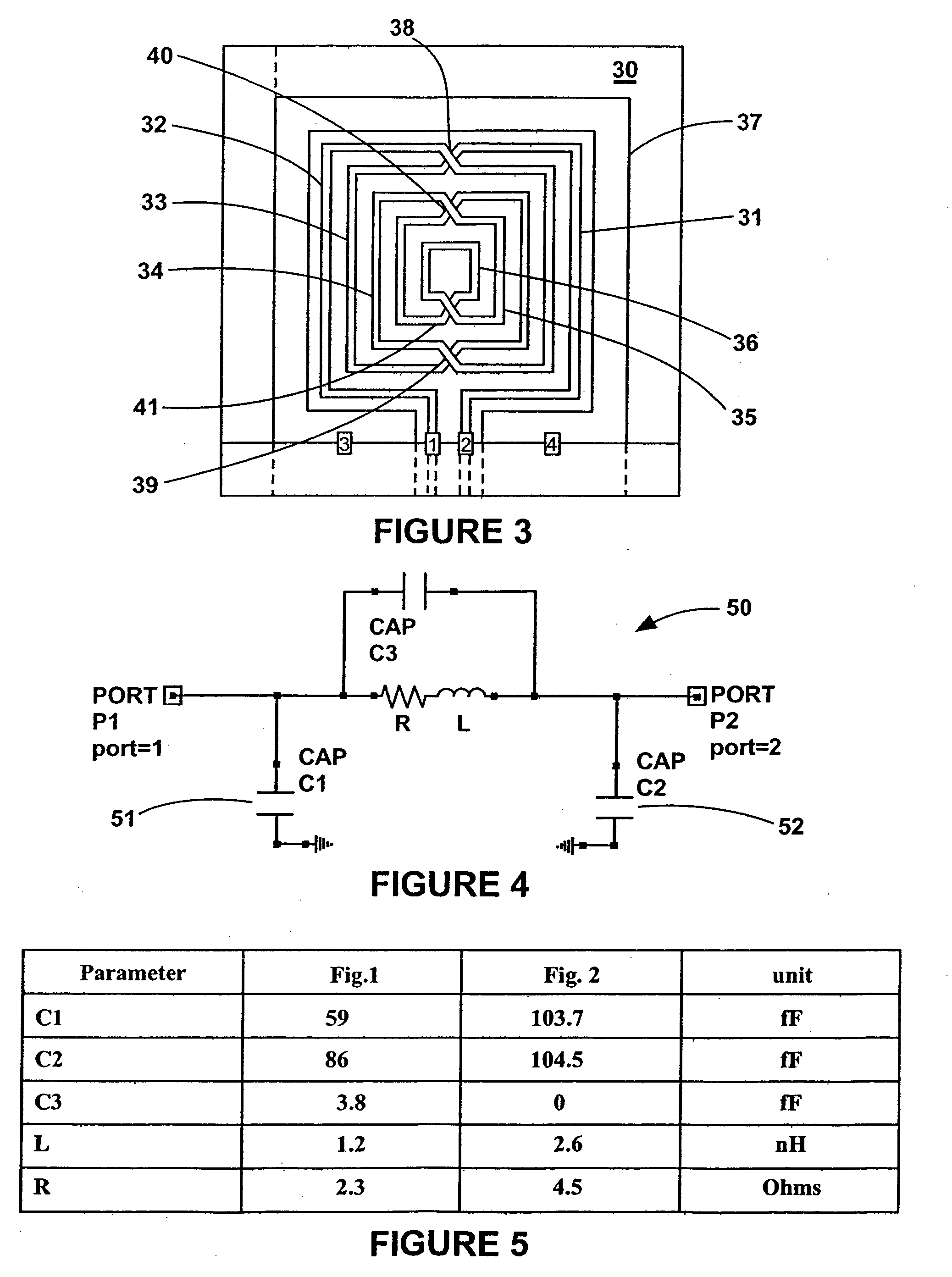

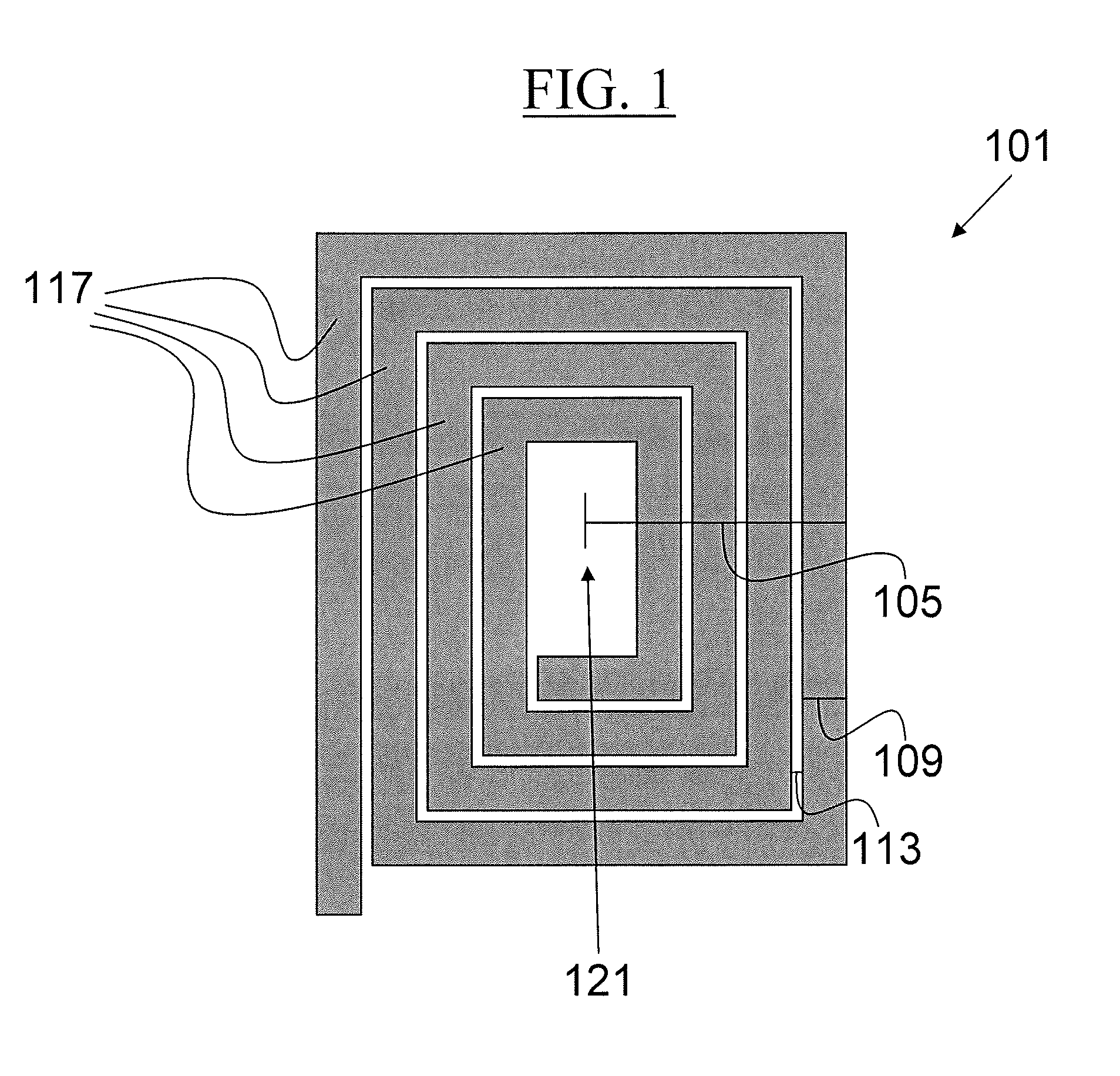

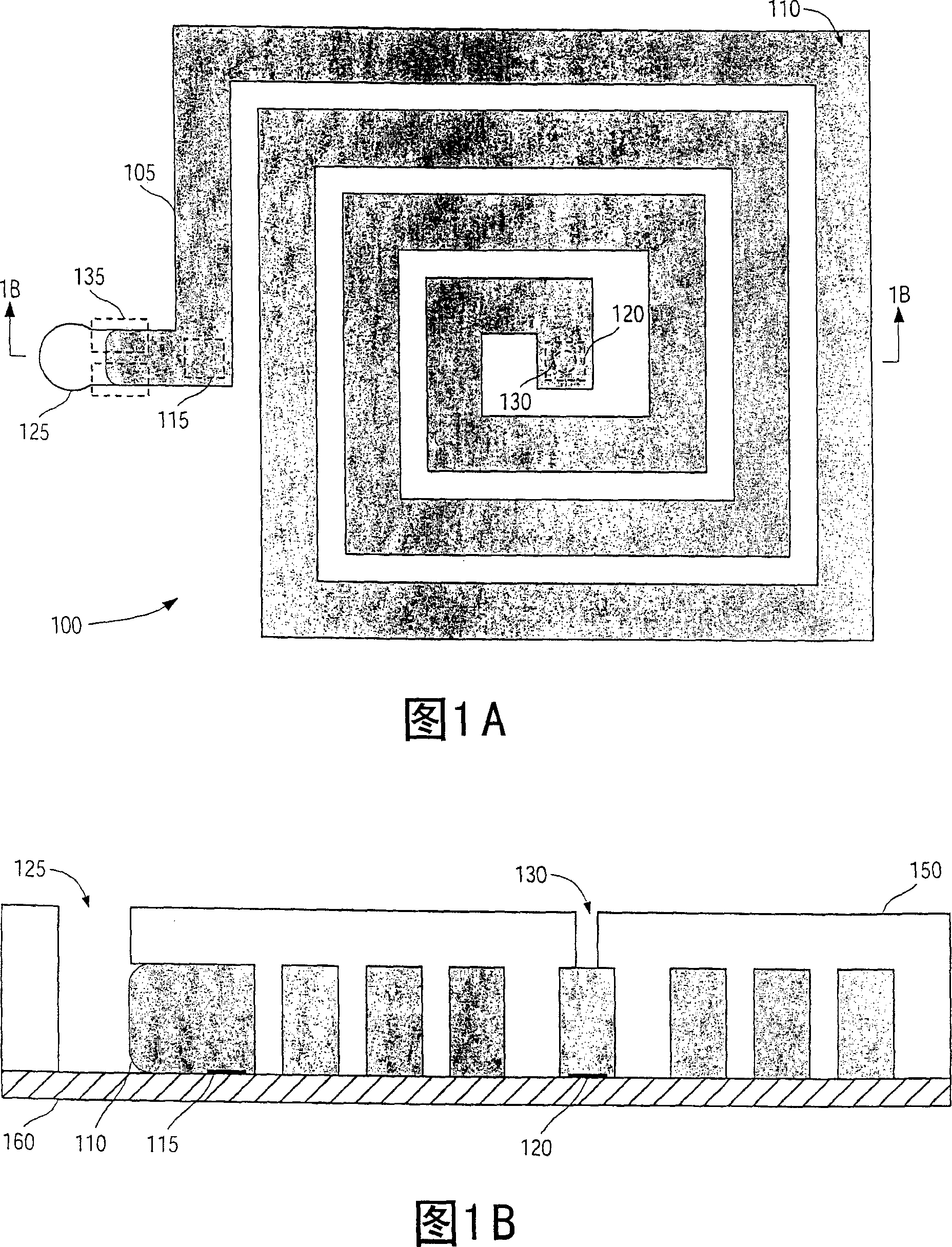

Symmetric planar inductor

InactiveUS20050077992A1Symmetry of the inductor is preservedCapacitive effects caused by conductor crossovers, are substantially minimizedSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorPlanar inductor

A substantially symmetric inductor comprising a plurality of windings, at least one conductor crossover, and a peripheral conductor disposed at the periphery of the plurality of windings, the plurality of windings having a generally symmetric shape, each of the plurality of windings having a center and being of a different size from other ones of the plurality of windings, the peripheral conductor being generally symmetric and having a center, the plurality of windings and the peripheral conductor being substantially concentric, the conductor crossovers being disposed such that the symmetry of the inductor in substantially preserved. A method of winding an inductor such that the inductor is substantially symmetric about a center of the inductor, whereby signal degradation due to asymmetry of the inductor is substantially minimized.

Owner:HRL LAB

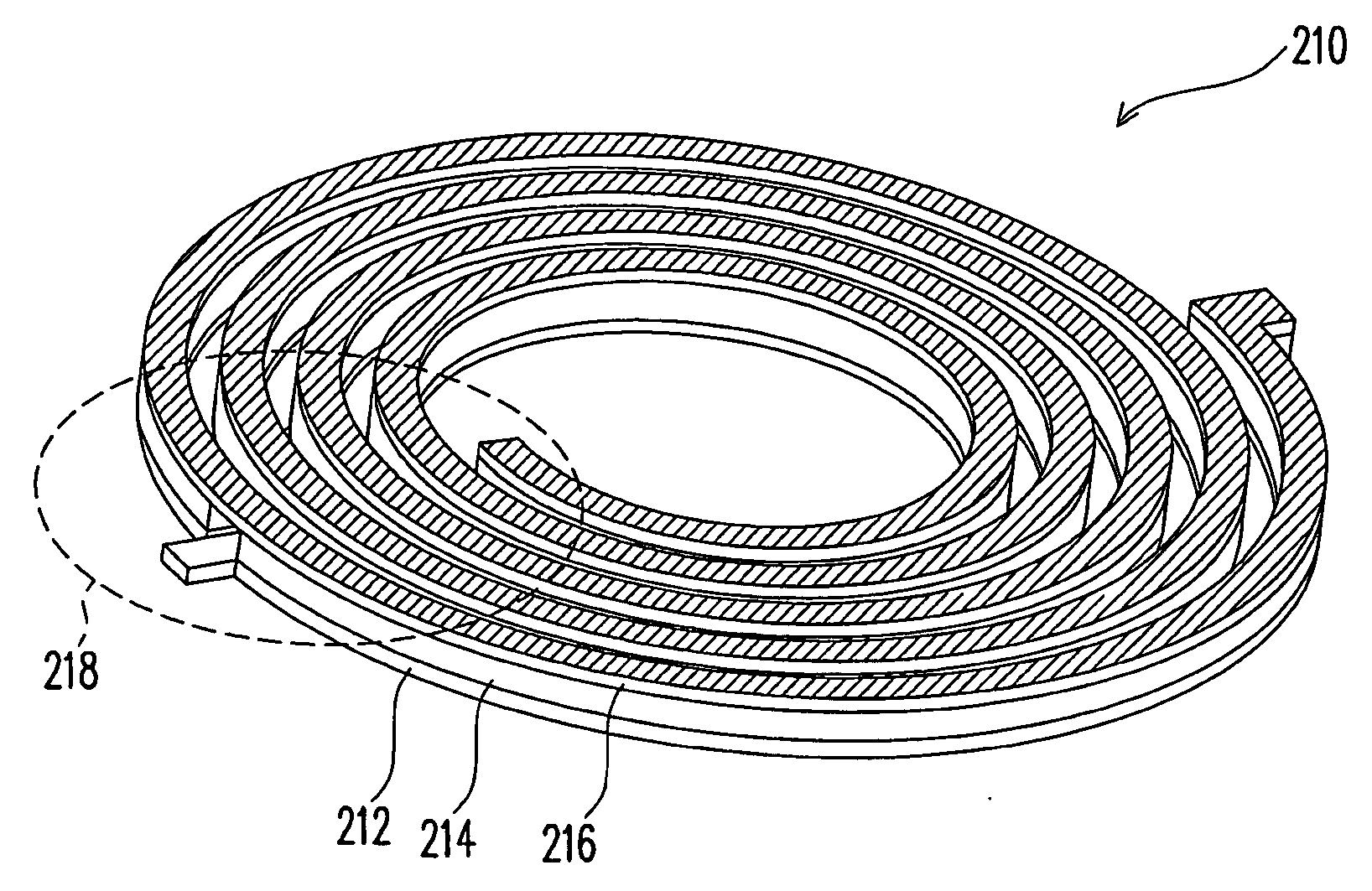

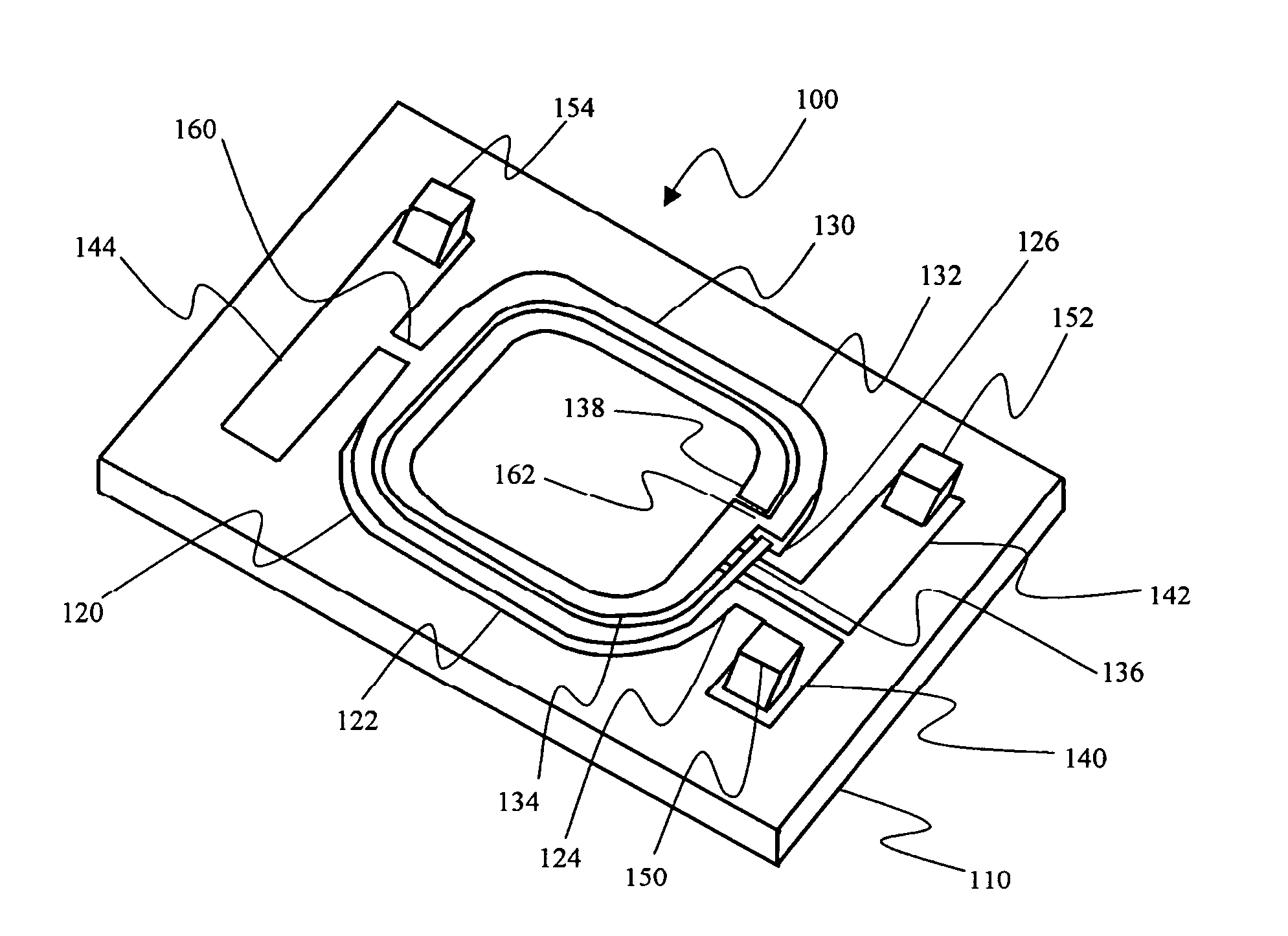

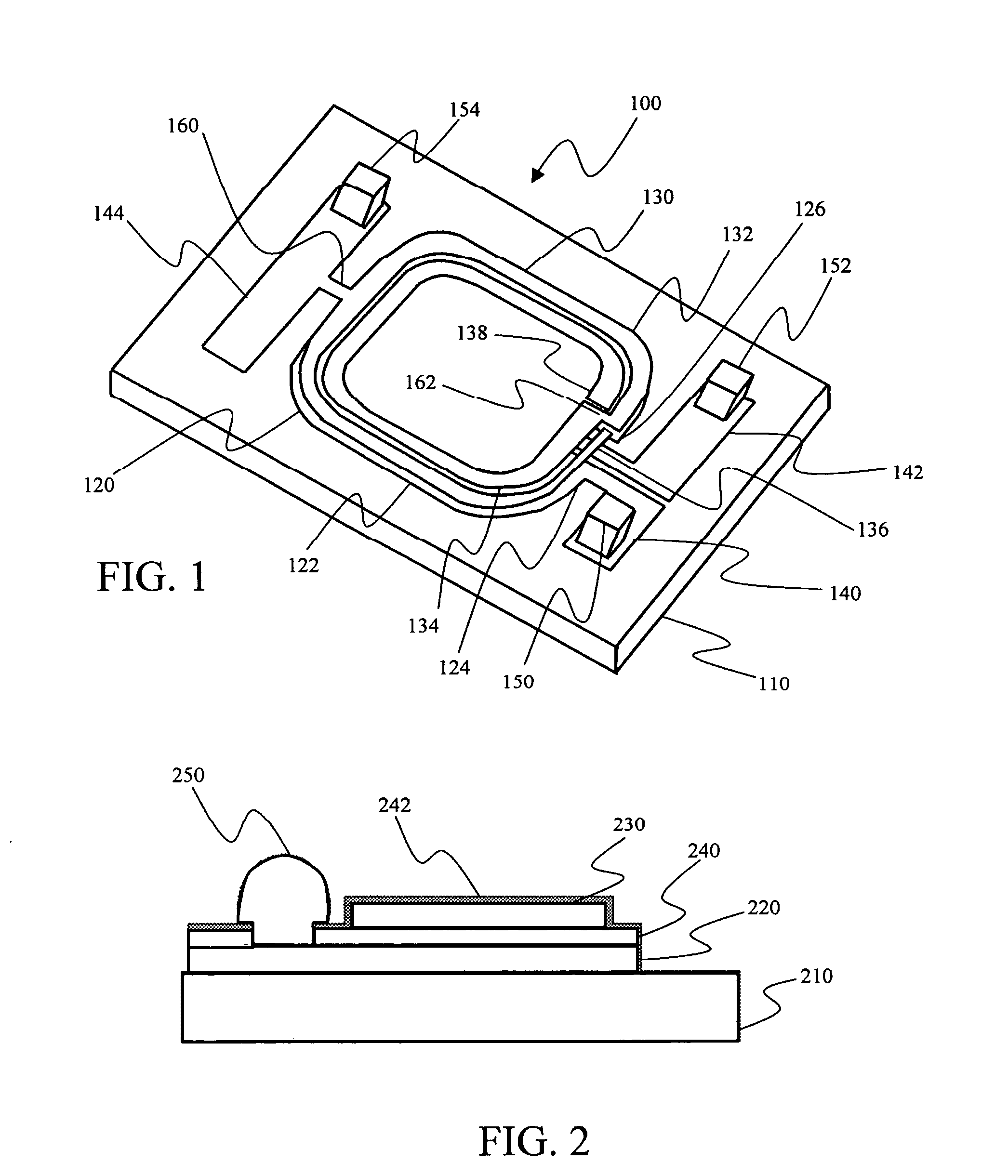

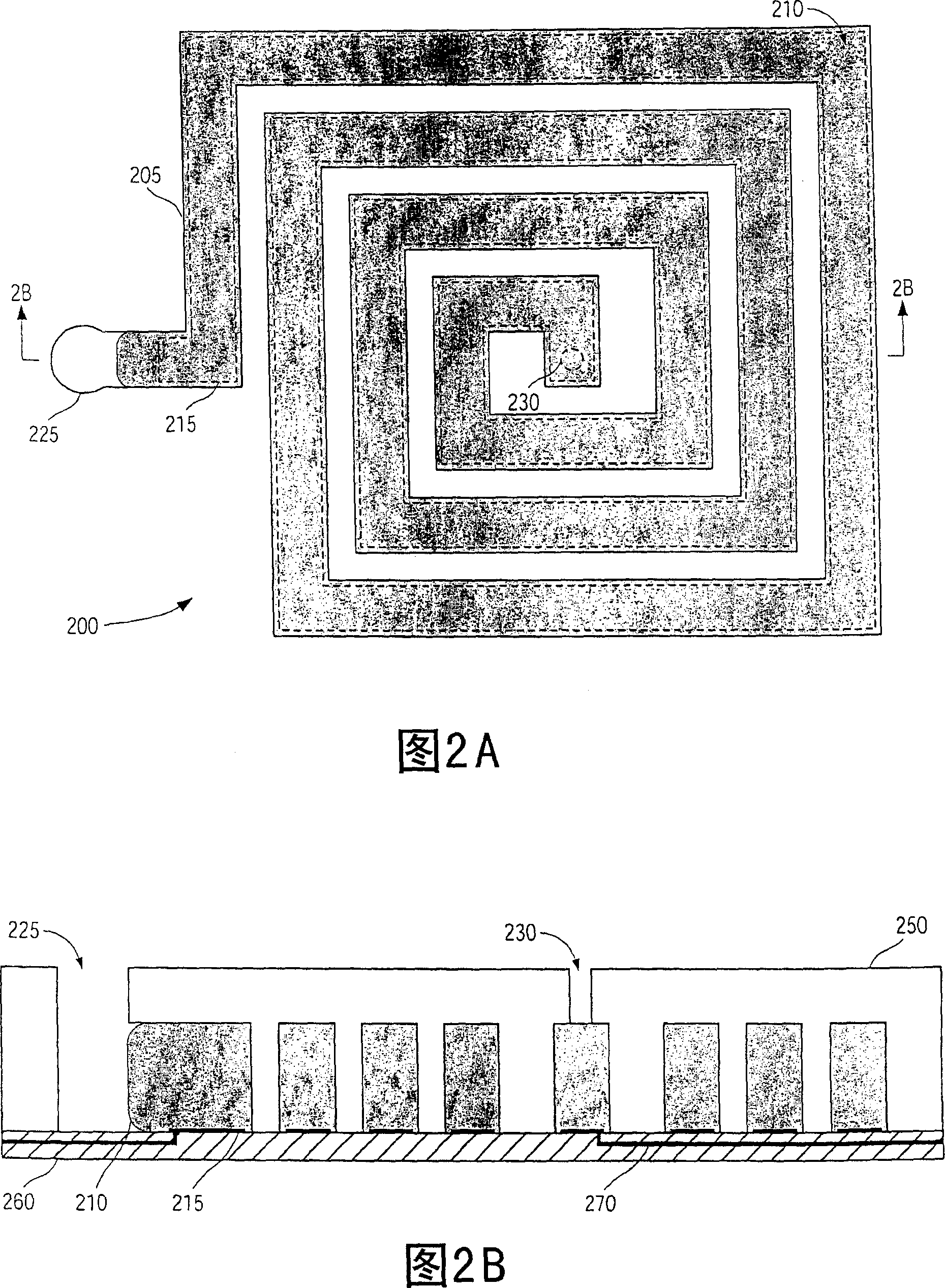

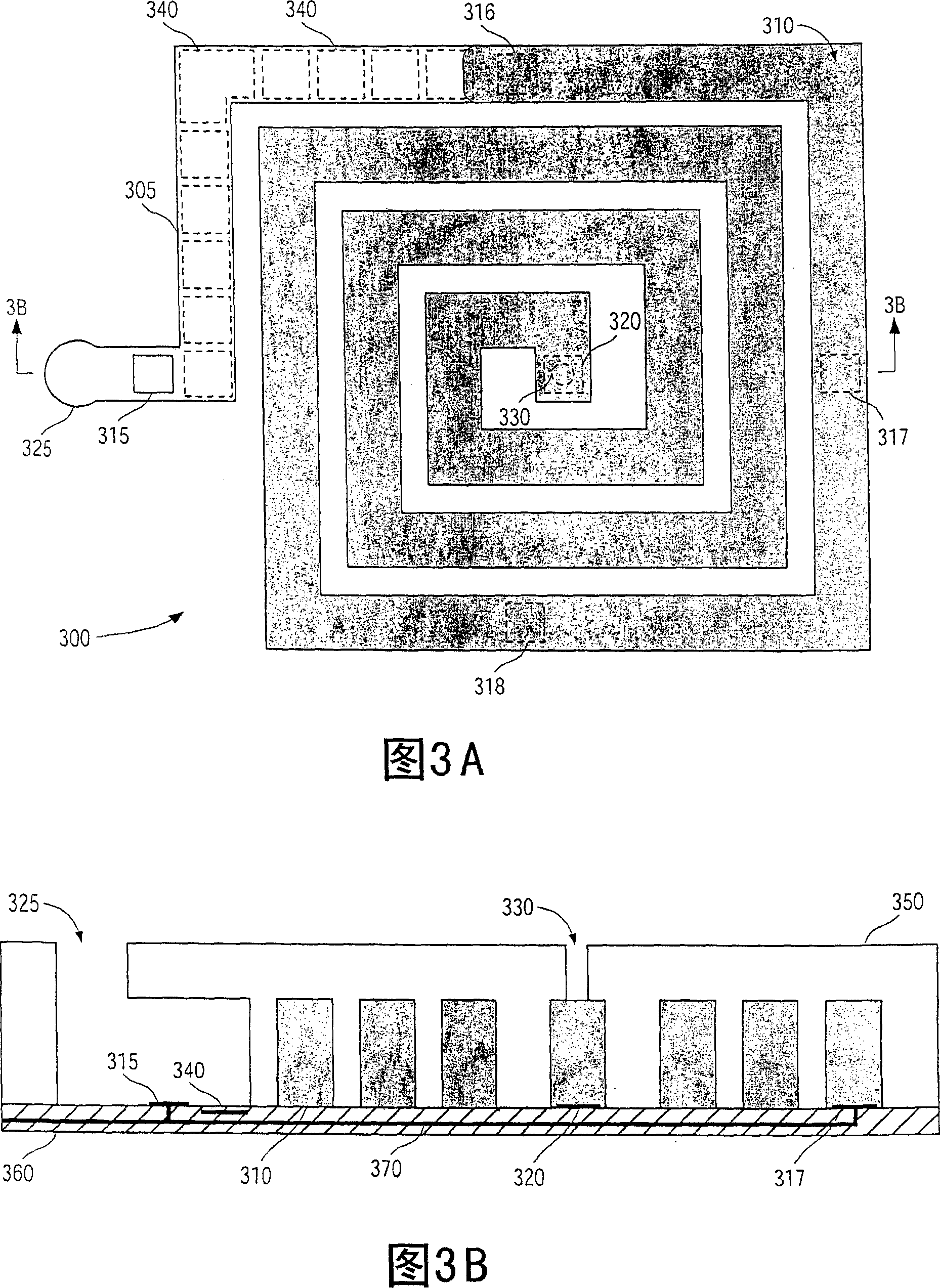

High Q planar inductors and IPD applications

ActiveUS20060158300A1Small sizeImprove operating characteristicsVariable inductances/transformersInductances/transformers/magnets manufactureCouplingPlanar inductor

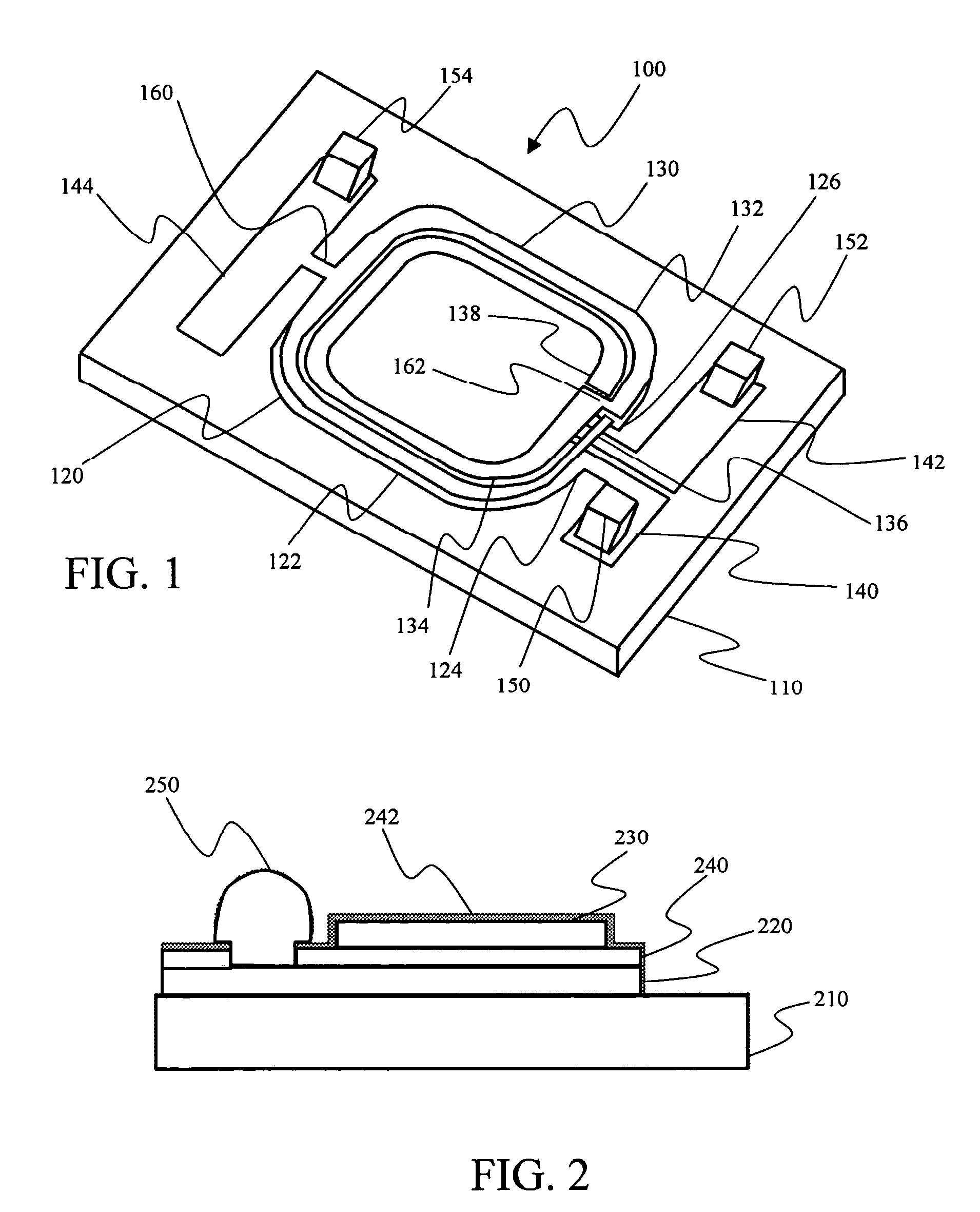

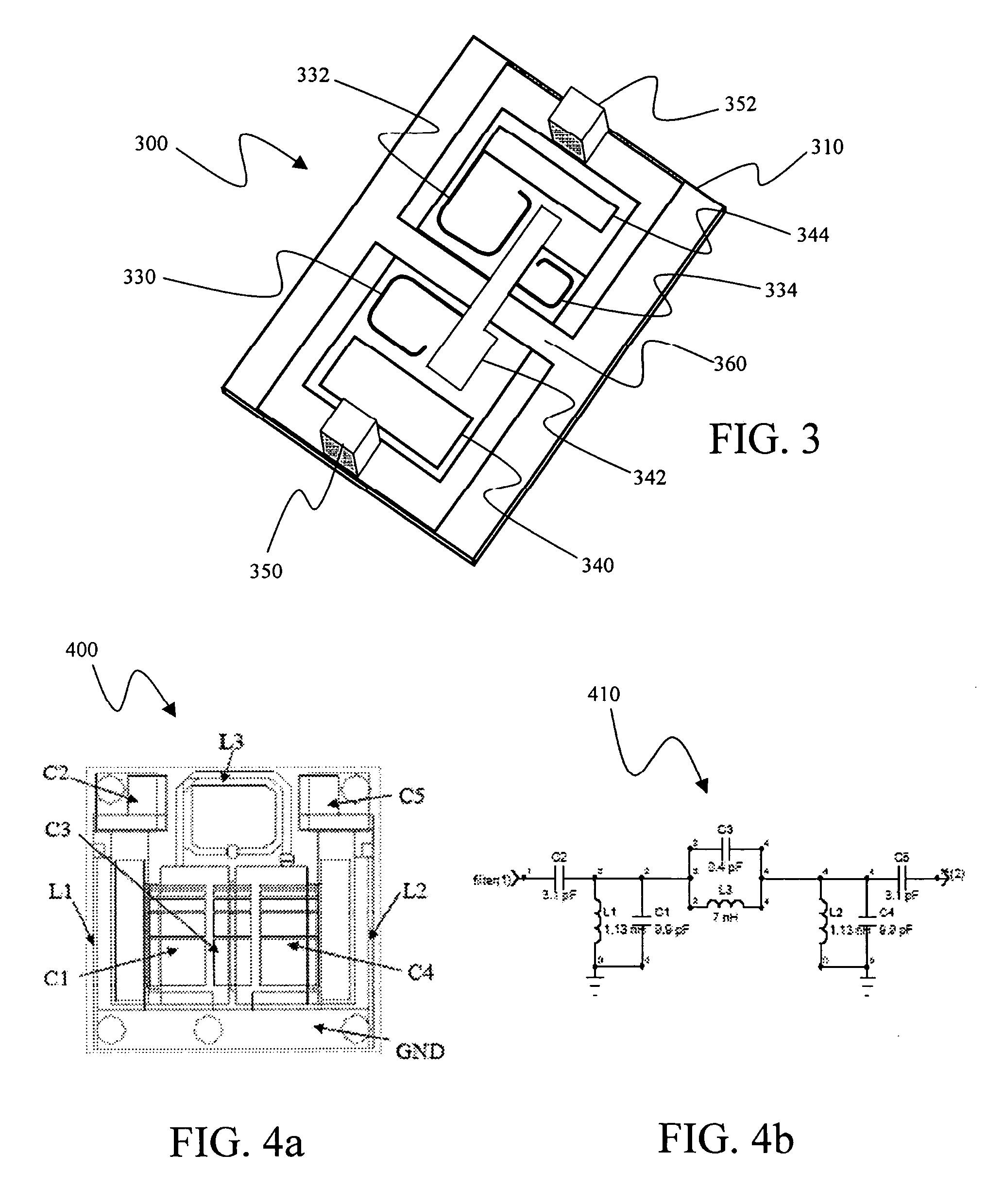

Disclosed is methodology and apparatus for producing a planar inductor having a high quality (Q) factor. The inductor is formed by providing a first, relatively wide coil turn, and at least a pair of relatively more narrow second coil turns, displaced in a different plane from that occupied by the first coil turn. The configuration of such coil turns produces a high value of mutual coupling among the coil turns, resulting in an inductor having a high quality (Q) factor.

Owner:KYOCERA AVX COMPONENTS CORP

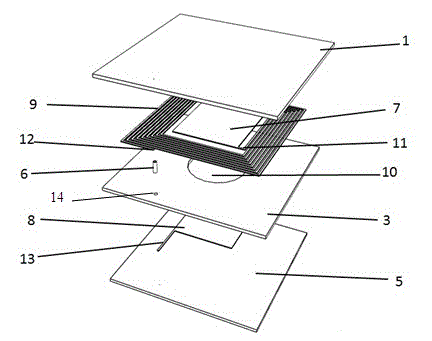

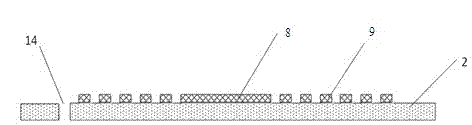

Flexible-substrate-based passive wireless pressure sensor with self-packaging function

InactiveCN103148977AProtection capacitorProtection inductanceFluid pressure measurement using capacitance variationCapacitanceEngineering

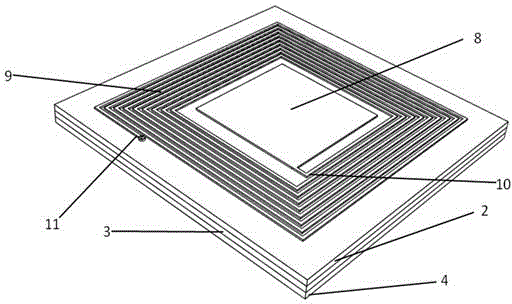

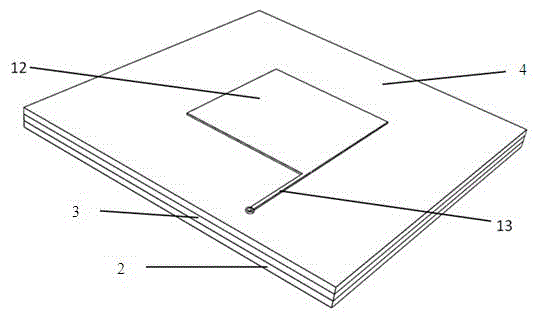

The invention discloses a flexible-substrate-based passive wireless pressure sensor with a self-packaging function. The pressure sensor comprises an upper flexible substrate, an upper metal layer, a middle flexible substrate, a lower metal layer and a lower flexible substrate, which are sequentially arranged from top to bottom and fixedly connected. An electric through hole and a cavity are formed in the middle flexible substrate. The upper metal layer comprises a planar inductance coil and a capacitor upper polar plate positioned on the middle part of the planar inductance coil. An inner connector of the planar inductance coil is connected with the capacitor upper polar plate. The lower metal layer comprises a capacitor lower polar plate opposite to the upper plate capacitor and an interconnecting wire connected with the capacitor upper polar plate. The sizes of the capacitor upper polar plate and capacitor lower polar plate are the same. An outer connector of the planar inductance coil of the upper metal layer is connected with the interconnecting wire of the lower metal layer through a conductive medium column in the electric through hole. The cavity of the middle flexible substrate is positioned between the capacitor upper polar plate and capacitor lower polar plate. The pressure sensor has the high performance of self packaging, non-contact, high sensitivity and high quality factor.

Owner:SOUTHEAST UNIV

Integration of planar transformer and/or planar inductor with power switches in power converter

A power converter integrates at least one planar transformer (T1, T2) comprising a multi-layer transformer substrate and / or at least one planar inductor comprising a multi-layer inductor substrate with a number of power semiconductor switches (S7-S10) physically and thermally coupled to a heat sink via one or more multi-layer switch substrates.

Owner:SIEMENS VDO AUTOMOTIVE CORP

Passive wireless pressure sensor preparation method based on flexible substrate

InactiveCN103091003AMass productionSimple processForce measurementCapacitive pressure sensorEngineering

The invention discloses a passive wireless pressure sensor preparation method based on a flexible substrate. The preparation method comprises the following steps: 10) preparing an upper flexible substrate: electroplating an upper metal layer on the upper surface of the flexible substrate, forming a capacitance upper plate and a planar inductor coil on the upper metal layer in a photoetching mode, and drilling a hole to form an upper through hole, 20) preparing a middle flexible substrate: drilling holes in the flexible substrate to form a hollow cavity and a middle through hole, 30) preparing a lower flexible substrate: electroplating a lower metal layer on the lower surface of the flexible substrate, and drilling a hole to form a lower through hole, 40) manufacturing a capacitor: using a laminating technique to enable the upper flexible substrate, the middle flexible substrate and the lower flexible substrate to be connected fixedly to manufacture the capacitor of a pressure sensor and 50) manufacturing the pressure sensor: electroplating the upper through hole, the middle through hole and the lower through hole to form a guide line to manufacture the passive wireless pressure sensor. The passive wireless pressure sensor preparation method based on the flexible substrate can be used for the mass production of capacitive pressure sensors, and is simple in technology and high in consistency and reliability.

Owner:SOUTHEAST UNIV

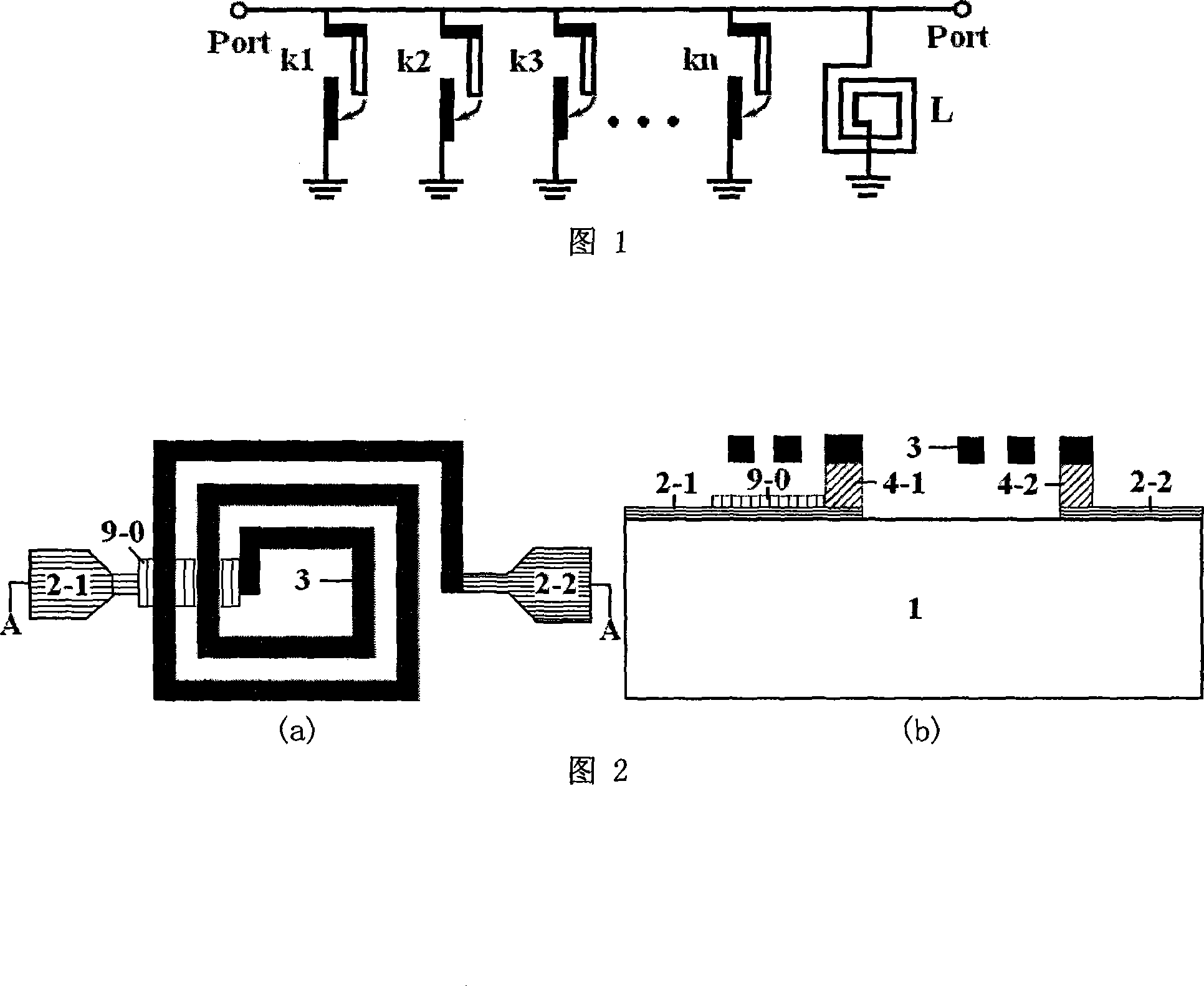

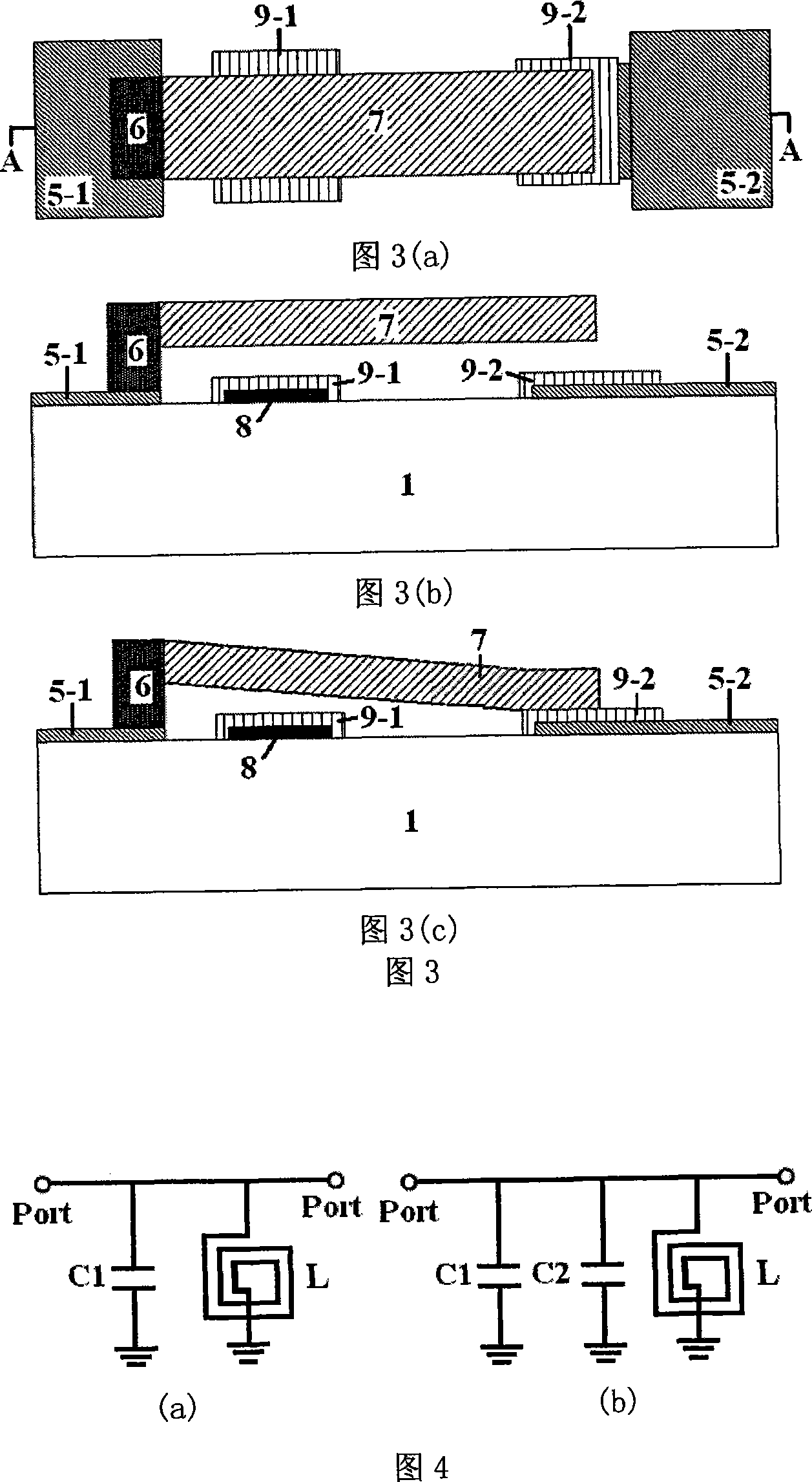

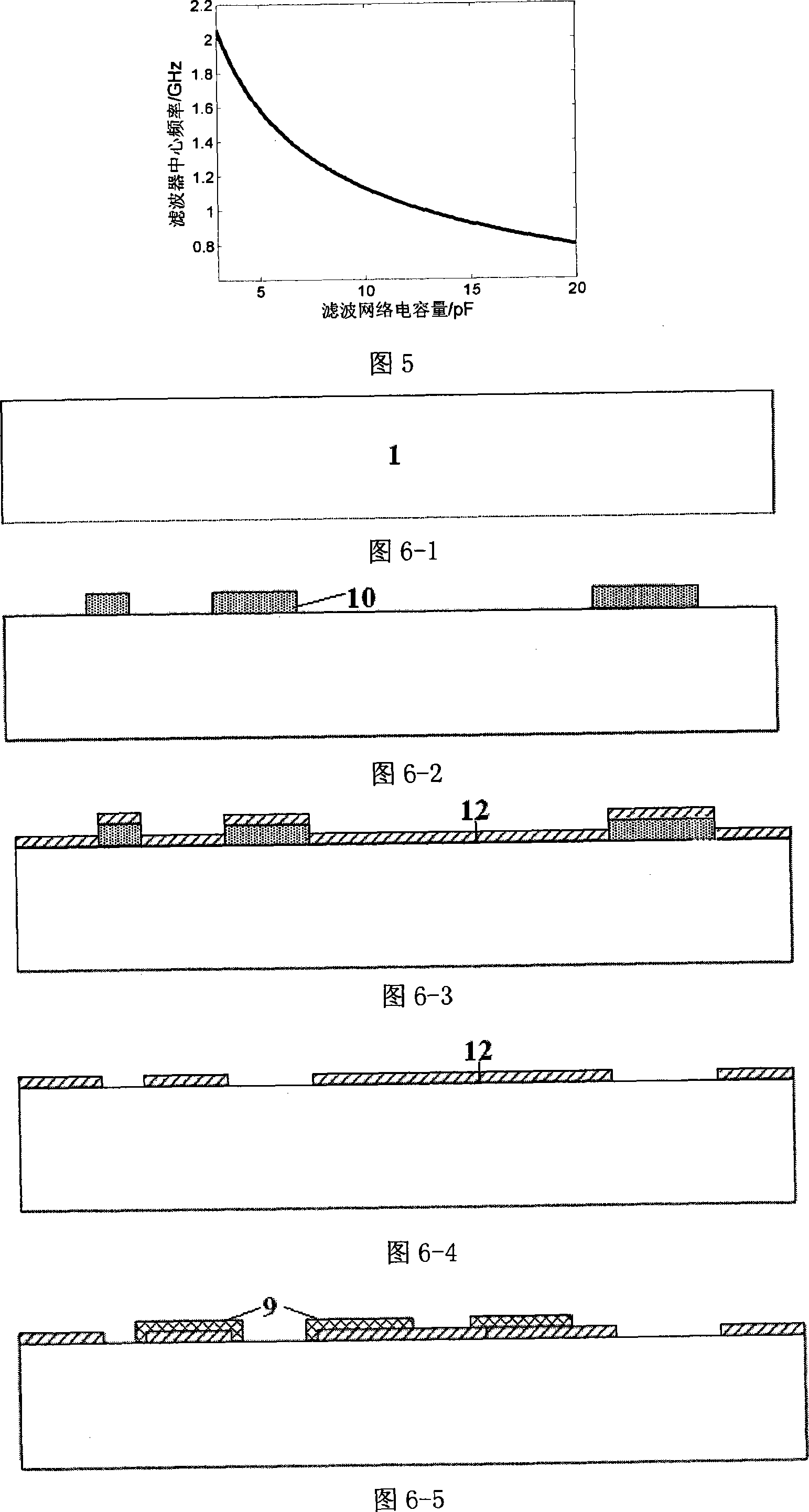

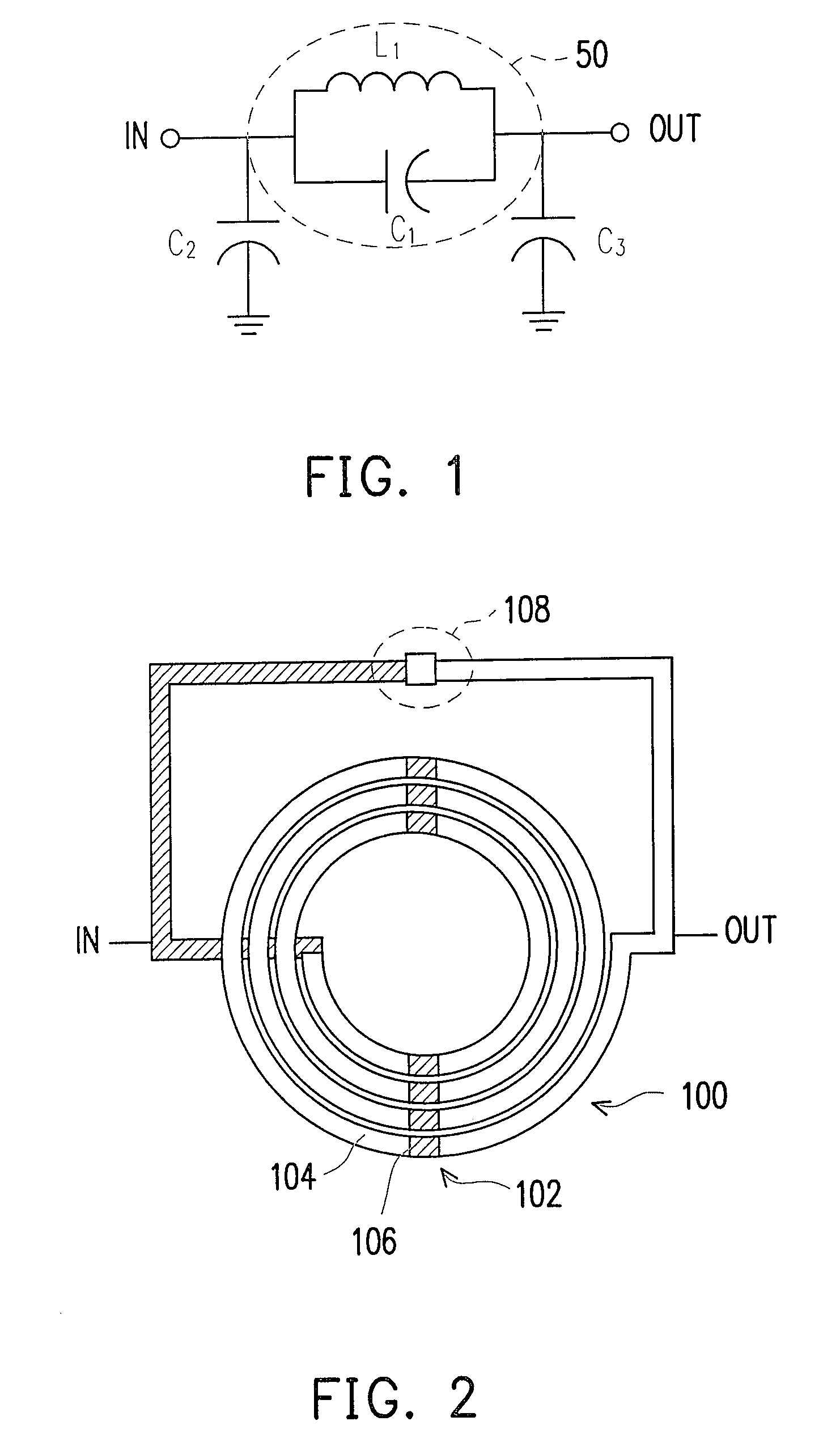

Microelectronic mechanical variable bandpass filter and process for producing the same

InactiveCN101141120AMeet application requirementsLarge adjustment rangeMultiple-port networksDecorative surface effectsBandpass filteringCapacitance

The invention discloses a micro-electronic mechanical tunable band pass filter that consists of a group of micro-electronic mechanical capacitance serial switch and an planar inductor(L), the amount of the capacitance that is connected to the wave filter capacitance is regulated by the on and off of the micro-electronic capacitance serial switch(kn) so as to regulate the central frequency point of the wave filter. The planar inductor(L) applies the GaAs liner(1) as the liner, the two sides of the upper surface of the GaAs liner are provided with a transmission line, the inductive choke(3) is connected with the transmission line through a connecting support pole and is suspended at the silicon nitride media layer(9-0) and the transmission line(2-2); the micro-electric capacitance type serial switch applies the GaAs liner as the liner, the upper surface of the GaAs liner is provided with transmission line(5) and a pull down electrode(8). One part of the transmission line and the pulldown electrode are provided with a layer of SiN media layer(9), an anchor area(6) that is connected with one end of the switch gird(7) is arranged on the transmission line so as to suspend the switch gird above the SiN media layer.

Owner:SOUTHEAST UNIV

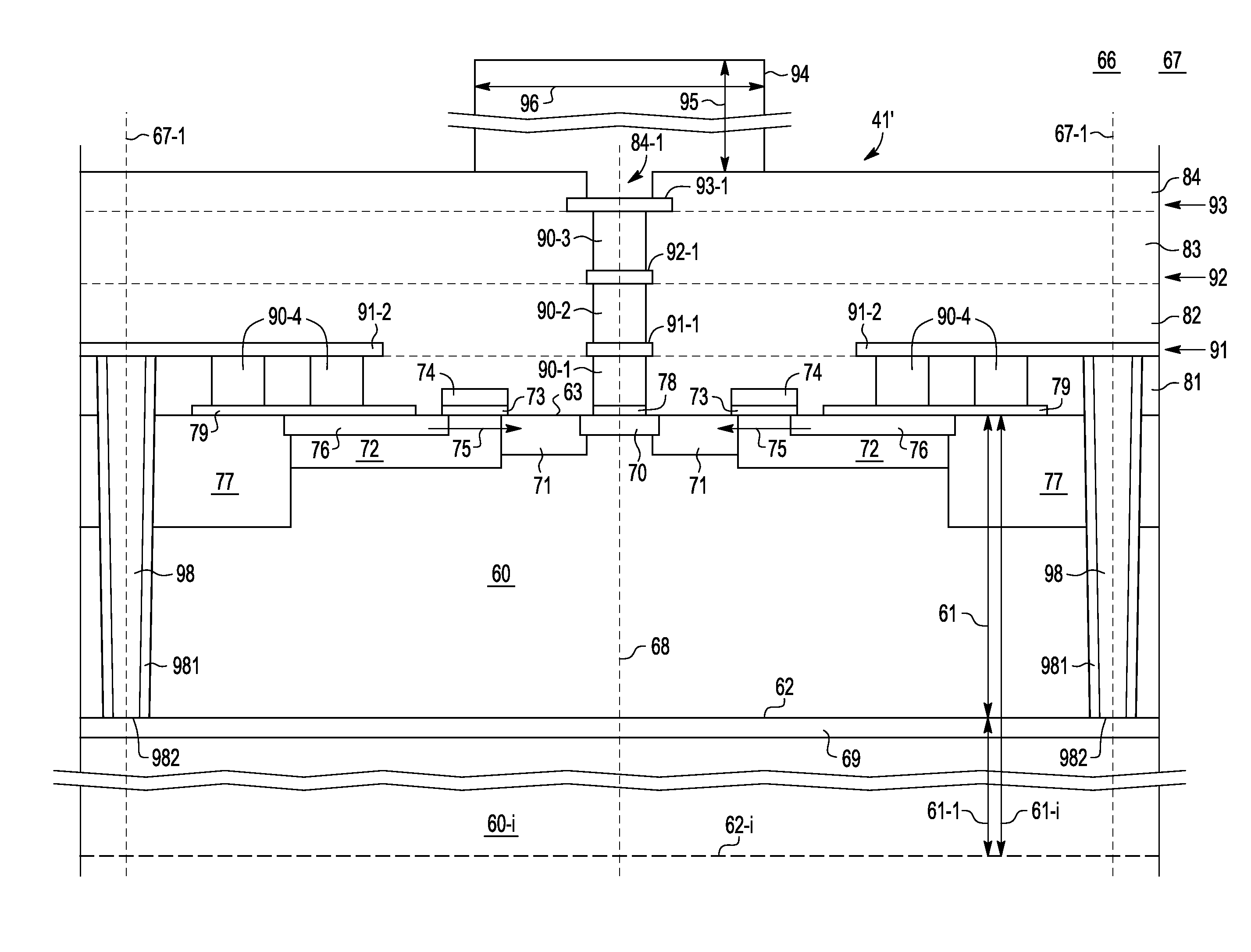

Monolithic microwave integrated circuit

Low Q associated with passive components of monolithic integrated circuits (ICs) when operated at microwave frequencies can be avoided or mitigated using high resistivity (e.g., ≧100 Ohm-cm) semiconductor substrates (60) and lower resistance inductors (44′, 45′) for the IC (46). This eliminates significant in-substrate electromagnetic coupling losses from planar inductors (44, 45) and interconnections (50-1′, 52-1′, 94, 94′, 94″) overlying the substrate (60). The active transistor(s) (41′) are formed in the substrate (60) proximate the front face (63). Planar capacitors (42′, 43′) are also formed over the front face (63) of the substrate (60). Various terminals (42-1′, 42-2′, 43-1, 43-2′,50′, 51′, 52′, 42-1′, 42-2′, etc.) of the transistor(s) (41′), capacitor(s) (42′, 43′) and inductor(s) (44′, 45′) are coupled to a ground plane (69) on the rear face (62) of the substrate (60) using through-substrate-vias (98, 98′) to minimize parasitic resistance. Parasitic resistance associated with the planar inductors (44′, 45′) and heavy current carrying conductors (52-1′) is minimized by placing them on the outer surface of the IC where they can be made substantially thicker and of lower resistance. The result is a monolithic microwave IC (46, 58) previously unobtainable.

Owner:NXP USA INC

Raised on-chip inductor and method of manufacturing same

InactiveUS6922127B2Less susceptibleSmall footprintSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsPlanar inductorMagnetic layer

A raised on-chip planar inductor. An inductor is fabricated on a substrate. The inductor, except for an anchoring extremity, is lifted from the substrate, preferably by application of a magnetic field to a magnetic layer formed on the inductor. The lifting of the inductor deforms a plastic bending region. After the magnetic field is removed, the inductor remains raised with respect to the substrate.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Passive wireless pressure and temperature integrated sensor based on LTCC and preparation method of integrated sensor

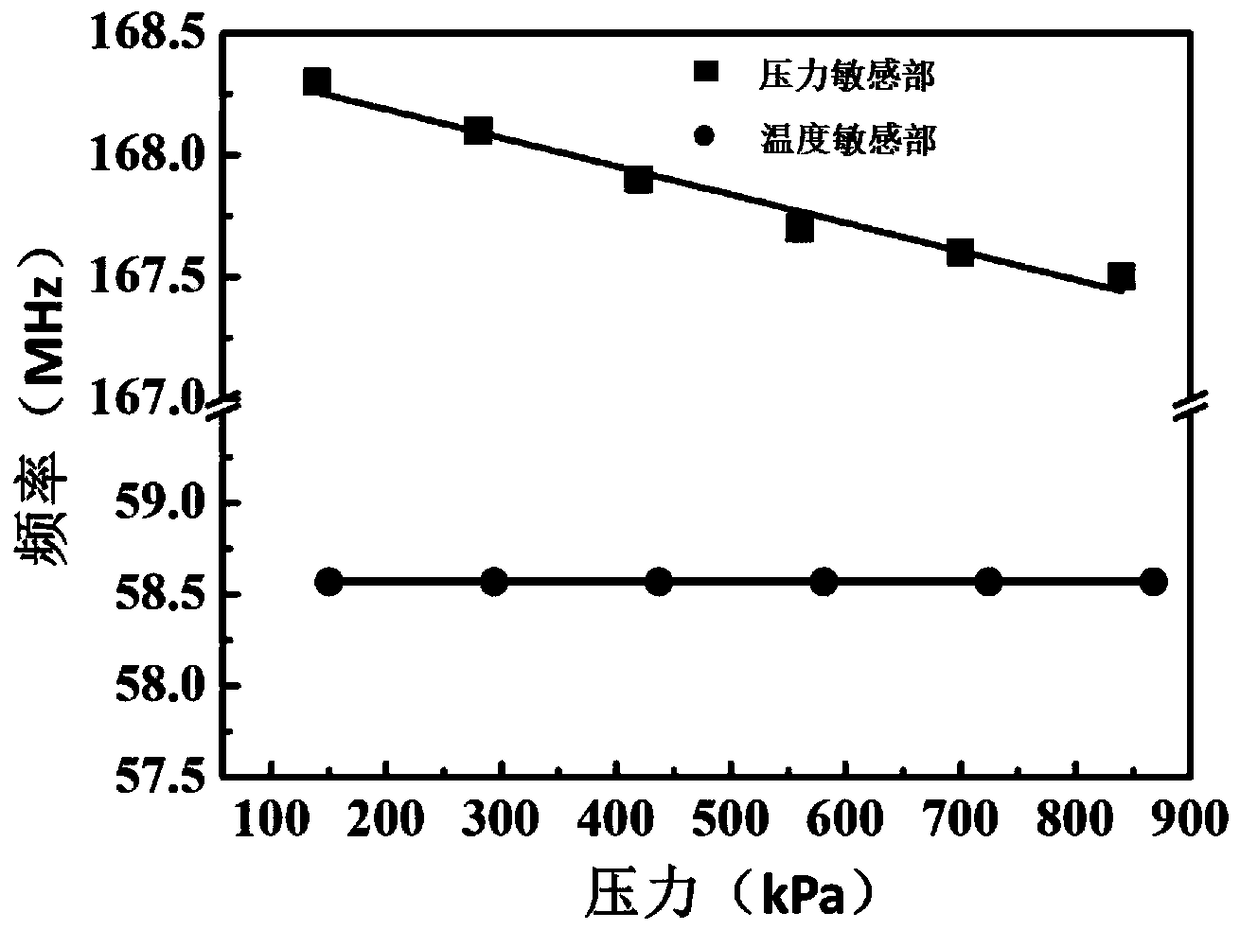

ActiveCN108507621AAchieve Wireless ResponseHigh sensitivityMeasurement devicesCapacitanceSignal response

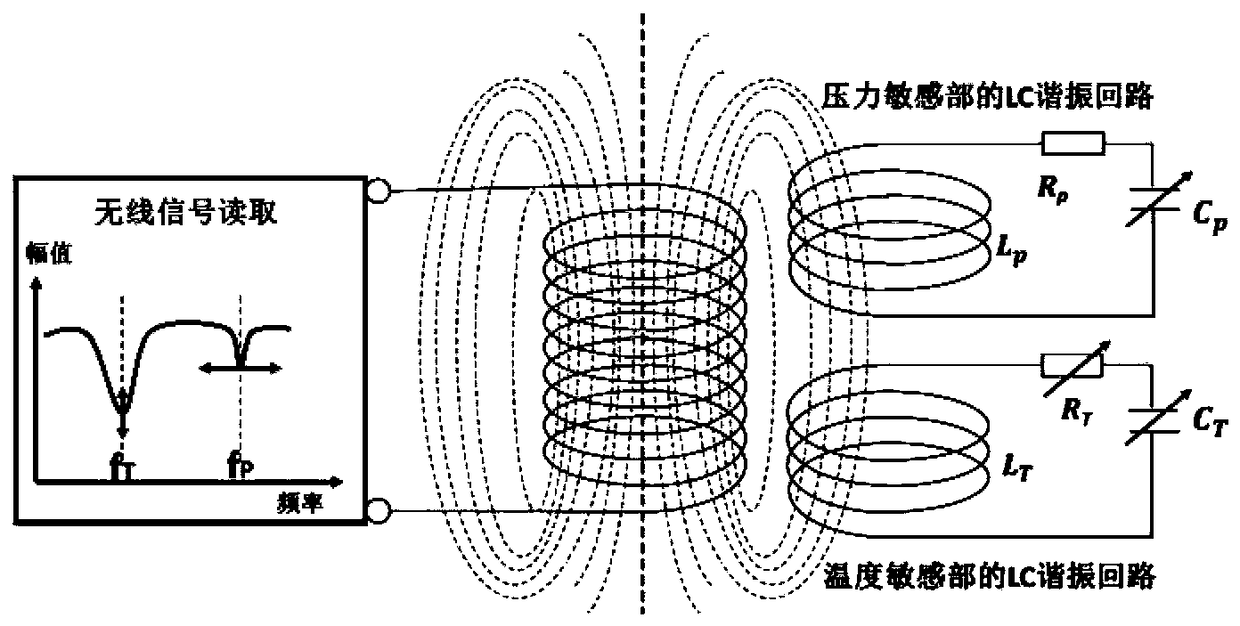

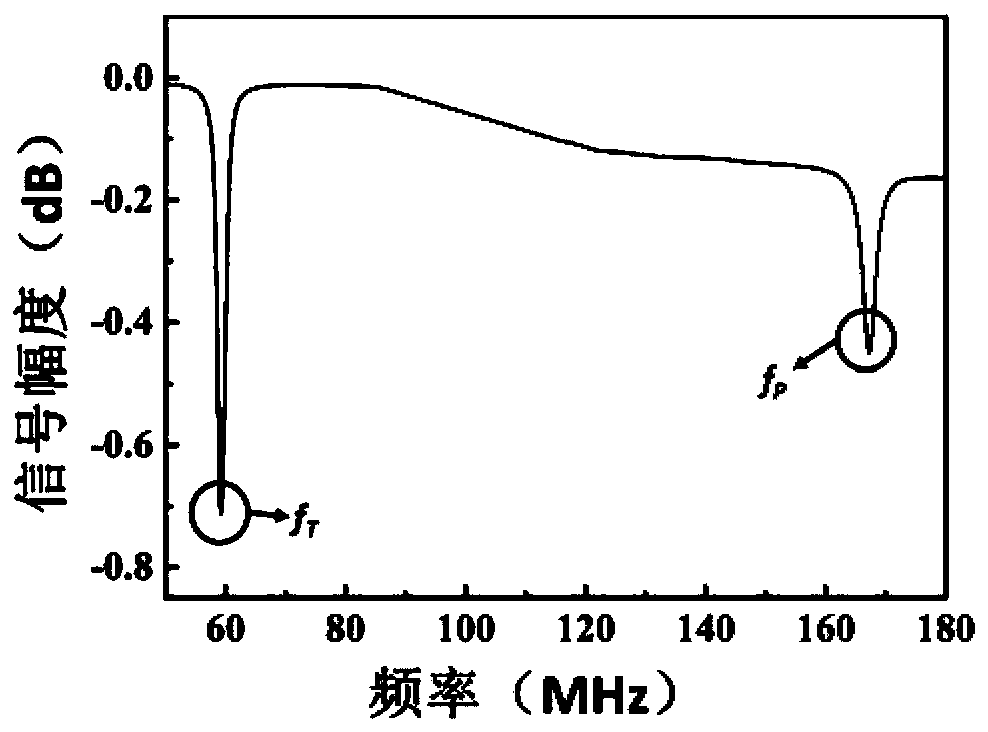

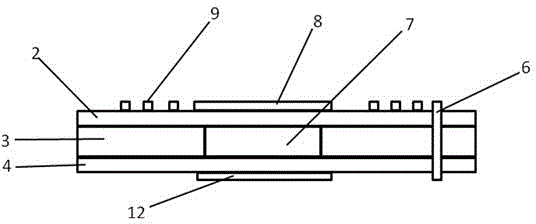

The invention provides a passive wireless pressure and temperature integrated sensor based on LTCC and a preparation method of the integrated sensor and solves the problem that existing sensor measurement parameters and signal response are single. The sensor has a wireless pressure sensitive part and a wireless temperature sensitive part which are stacked mutually; the wireless pressure sensitivepart comprises four layers of LTCC base plates, namely, a middle layer, a first layer with cavity, a second layer with cavity and a bottom layer, the first layer with cavity and the second layer withcavity are located above and below the middle layer and have corresponding cavities, the bottom layer is located below the second layer with cavity, a planar inductor and a cavity parallel plate capacitor first electrode are formed on the upper surface of the middle layer, a cavity parallel plate capacitor second electrode is formed on the upper surface of the bottom layer, and the two electrodescorrespond to the cavities of the first layer with cavity and the second layer with cavity; the temperature sensitive part comprises a base layer which is formed by an LTCC base plate, and a planer thermosensitive inductor and a planer interdigitated capacitor are formed on one surface of the base layer; the pressure sensitive part and the temperature sensitive part form two LC resonance circuitswith different resonant frequencies.

Owner:ZHEJIANG SIRAMIC TECH CO LTD

Passive wireless pressure sensor based on flexible substrates

InactiveCN103148970AReduce lossImprove quality factor Q valueForce measurementCapacitancePlanar inductor

The invention discloses a passive wireless pressure sensor based on flexible substrates. The passive wireless pressure sensor comprises an upper metal layer, an upper flexible substrate, a middle flexible substrate, a lower flexible substrate and a lower metal layer, wherein interlinked electrical through holes are formed in the upper flexible substrate, the middle flexible substrate and the lower flexible substrate; a cavity is formed on the middle flexible substrate; the upper metal layer comprises a planar inductance coil and a capacitive upper electrode plate which is arranged on the middle part of the planar inductance coil; an inner-side connecting head of the planar inductance coil is connected with the capacitive upper electrode plate; the lower metal layer comprises a capacitive lower electrode plate and an interconnecting wire, wherein the dimension of the capacitive lower electrode plate is the same as that of the capacitive upper electrode plate, the position of the capacitive lower electrode plate is opposite to that of the capacitive upper electrode plate, and the interconnecting wire is connected with the capacitive lower electrode plate; an outer-side connecting head of the planar inductance coil of the upper metal layer is connected with the interconnecting wire of the lower metal layer by a conductive medium column which is arranged in the electrical through holes; and the cavity of the middle flexible substrate is arranged between the capacitive upper electrode plate and the capacitive lower electrode plate. The pressure sensor has the excellent performances of non-contact, high flexibility, high quality factor and low power consumption.

Owner:SOUTHEAST UNIV

High Q planar inductors and IPD applications

ActiveUS7714688B2Small sizeImprove operating characteristicsVariable inductances/transformersInductances/transformers/magnets manufactureCouplingPlanar inductor

Disclosed is methodology and apparatus for producing a planar inductor having a high quality (Q) factor. The inductor is formed by providing a first, relatively wide coil turn, and at least a pair of relatively more narrow second coil turns, displaced in a different plane from that occupied by the first coil turn. The configuration of such coil turns produces a high value of mutual coupling among the coil turns, resulting in an inductor having a high quality (Q) factor.

Owner:KYOCERA AVX COMPONENTS CORP

Method of manufacturing planar inductors

InactiveUS20050005424A1Transformers/inductances coils/windings/connectionsSolid-state devicesTransformerEngineering

Method of forming a ferromagnetic layer on at least one surface of a dielectric material that may be serve as an inductive core on a printed circuit board or a multichip module. Conductive leads can form two separate coils around the core to form a transformer, and a planar conducing sheet can be placed on or between one or more of the dielectric layers as magnetic shielding. The core can be formed at least in part by electroless plating, and electroplating can be used to add a thicker layer of less conductive ferromagnetic material. Ferromagnetic layers are formed by dipping the dielectric surface in a solution containing catalytic metal particles having a slight dipole, and placing the surface in a metal salt to cause a layer containing metal to be electrolessly plated upon the dielectric. Surface roughening techniques can be used before the dipping to help attract the catalytic particles.

Owner:CUSTOM ONE DESIGN

High power inductor and ignition transformer using planar magnetics

InactiveUS20130063234A1Large windingTransformers/inductances coolingCoils manufactureTransformerPlanar inductor

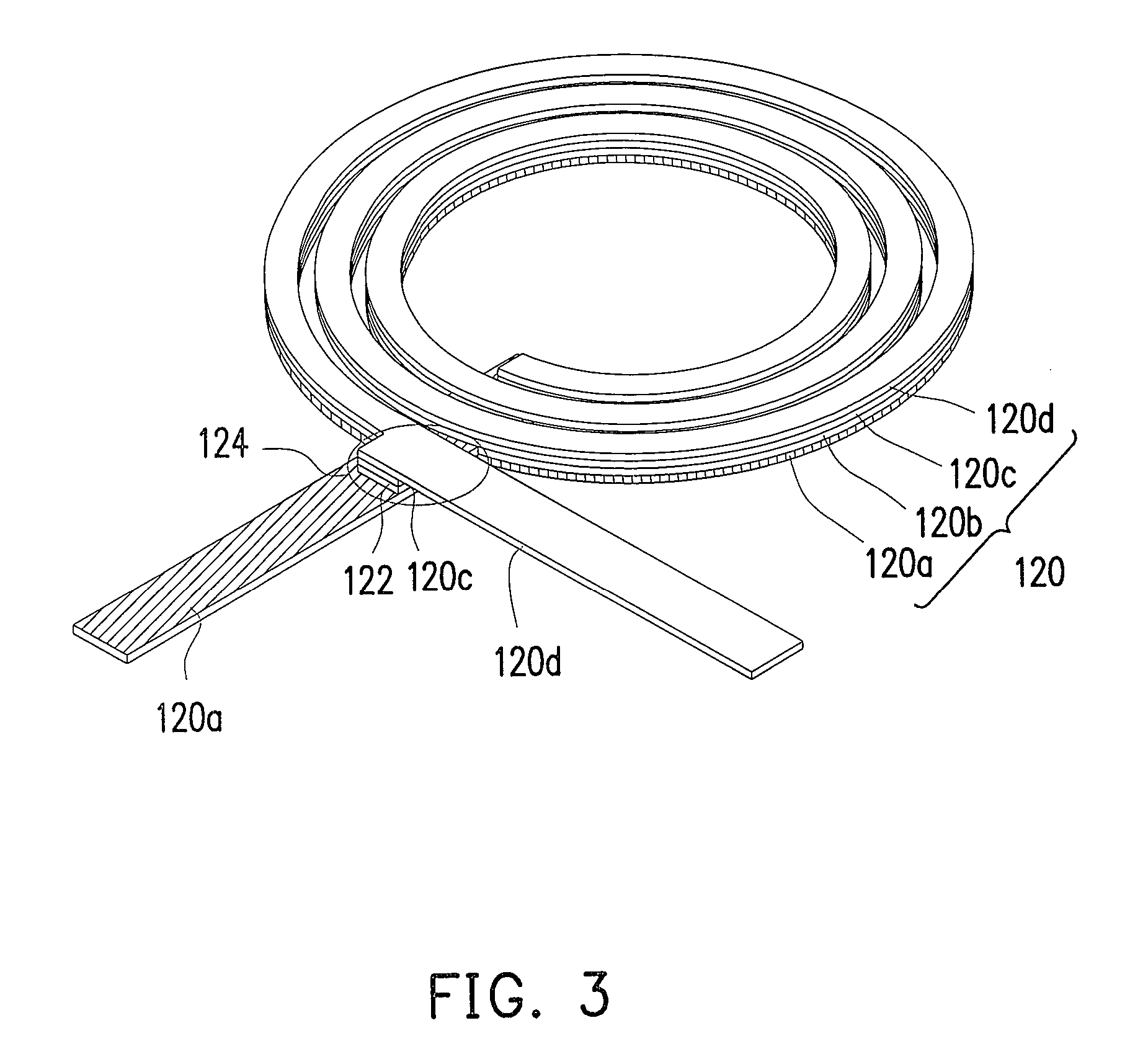

Described are methods and systems for using a planar inductor that includes a magnetically conductive core, a first planar coil and a second planar coil. The first and second planar coils are attached to a first bridge, located about the core, and are composed of a conductive material. The first and second planar coils have at least one thermally conductive surface exposed to cooling fluid. The first planar coil, the first bridge and the second planar coil are formed from a first unitary section of conductive material. The second planar coil is positioned relative to the first planar coil in a spaced relationship, which is defined by a thickness of the first bridge. An upper surface of the first planar coil is oriented toward a lower surface of the second planar coil to define a first cooling channel between the first planar coil and the second planar coil.

Owner:HYPERTHERM INC

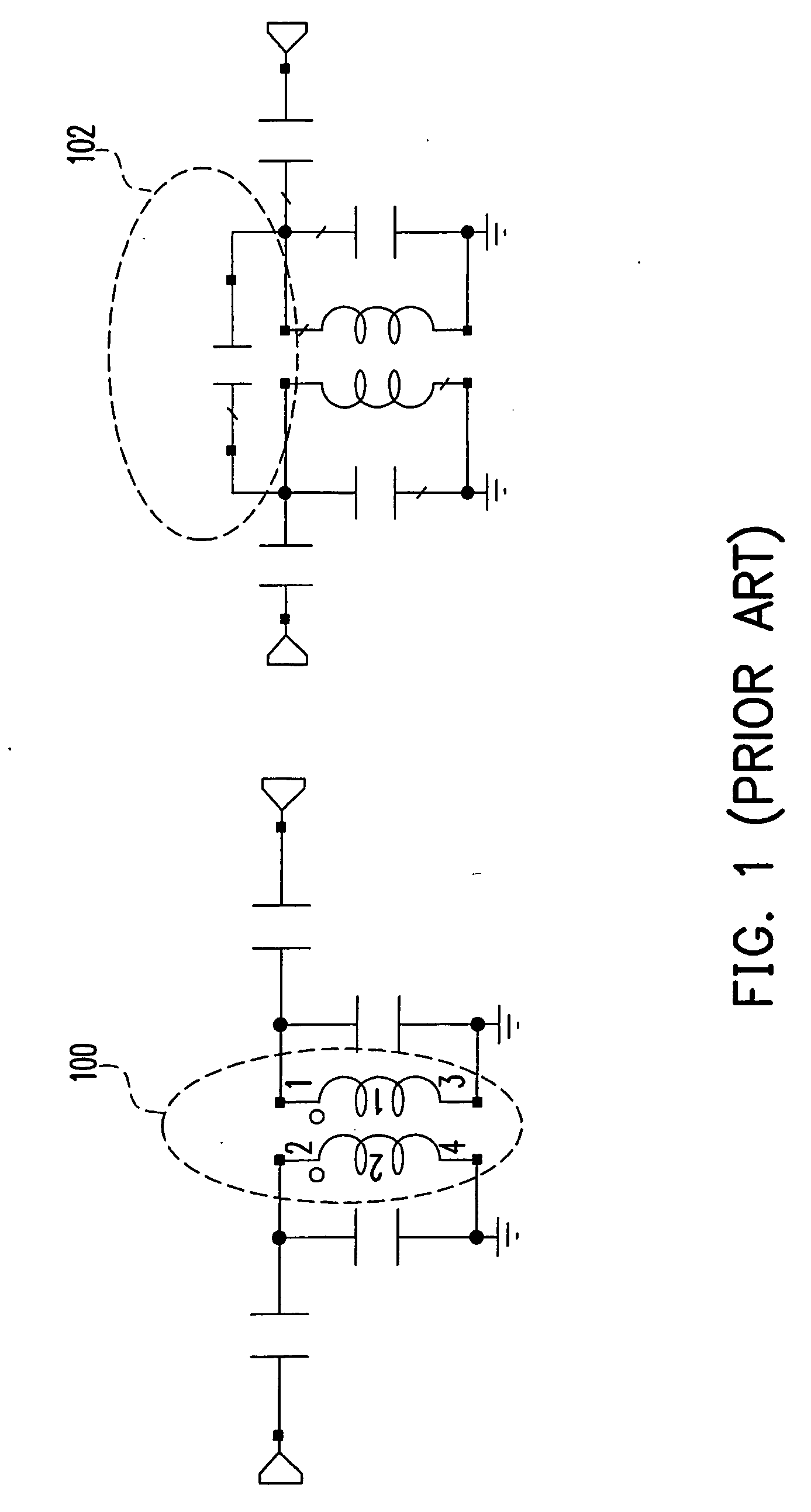

Mutual Inductance Circuits

ActiveUS20130082793A1Transformers/inductances coils/windings/connectionsOscillations generatorsPower flowPlanar inductor

An apparatus includes a first conductive loop coupled to conduct a first current and a second conductive loop coupled in parallel with the first conductive loop and further coupled to conduct a second current. A first conductive portion forms a part of the first conductive loop and the second conductive loop. The first conductive portion is coupled to conduct the first current and the second current. In at least one embodiment of the apparatus, the first conductive loop and the second conductive loop are planar inductors formed in a conductive layer on a substrate of an integrated circuit.

Owner:SILICON LAB INC

Inductor and manufacturing method thereof

PendingCN107768069AReduce distributed capacitanceReduce areaTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresHigh densityMold filling

The invention discloses an inductor and a manufacturing method thereof. The manufacturing method of the inductor comprises the following steps of S1, magnetic core manufacturing: pressing pelleting magnetic powder into a high-density block body; then, cutting the high-density block body into a magnetic core structure; sintering the magnetic core structure into a compact state, wherein a magnetic core comprises a middle post and two swinging blades; S2, coil winding: winding a coil on the middle post; after the winding, enabling the cross section of the coil to be parallel to the long and highplane of the inductor, wherein the two leading-out ends of the coil are positioned at two sides of the middle post and are positioned on the same plane; S3, compression molding: filling the bottom ofa mold with a layer of pelleting magnetic powder for prepressing compaction; then, implanting the magnetic core wound with the coil in the step 2 into the mold; after the implantation, fully filling the mold with the pelleting magnetic powder for compression molding; S4, semi-finished product heat treatment; S5, end electrode manufacturing. The inductor and the manufacturing method thereof have the advantage that on the basis of obtaining the inductor with great induction quantity, higher self-resonant frequency is realized.

Owner:SHENZHEN SUNLORD ELECTRONICS

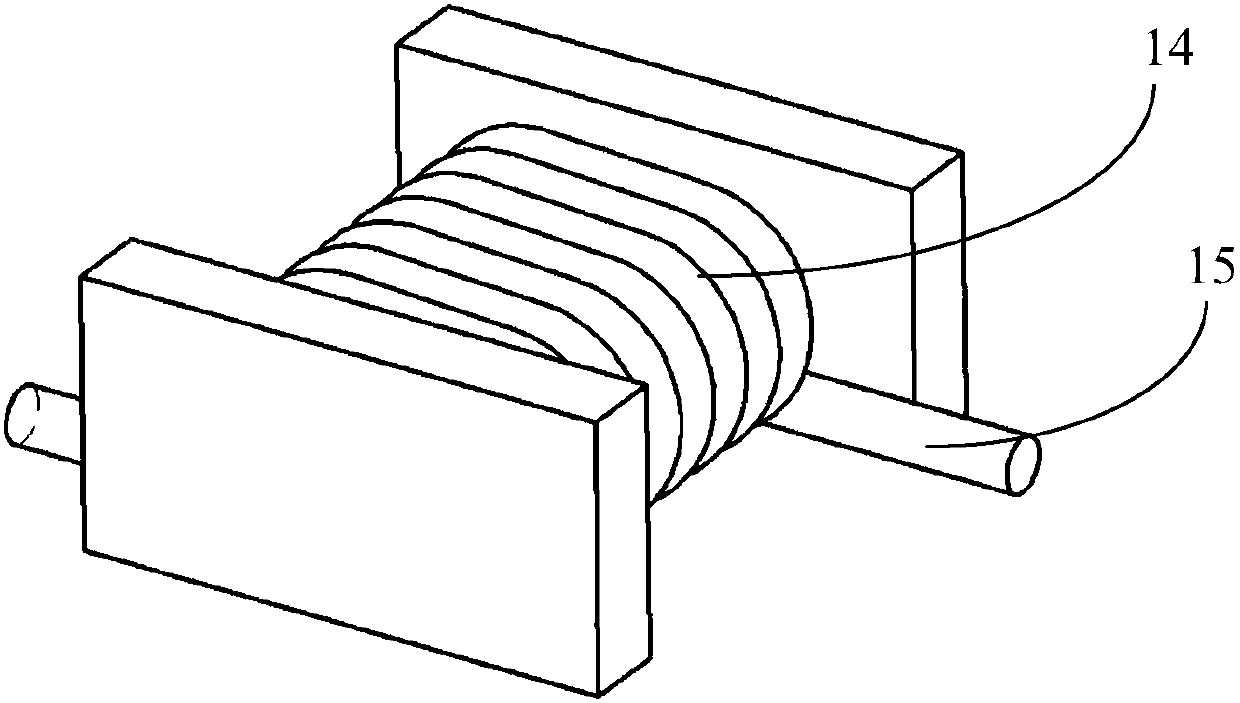

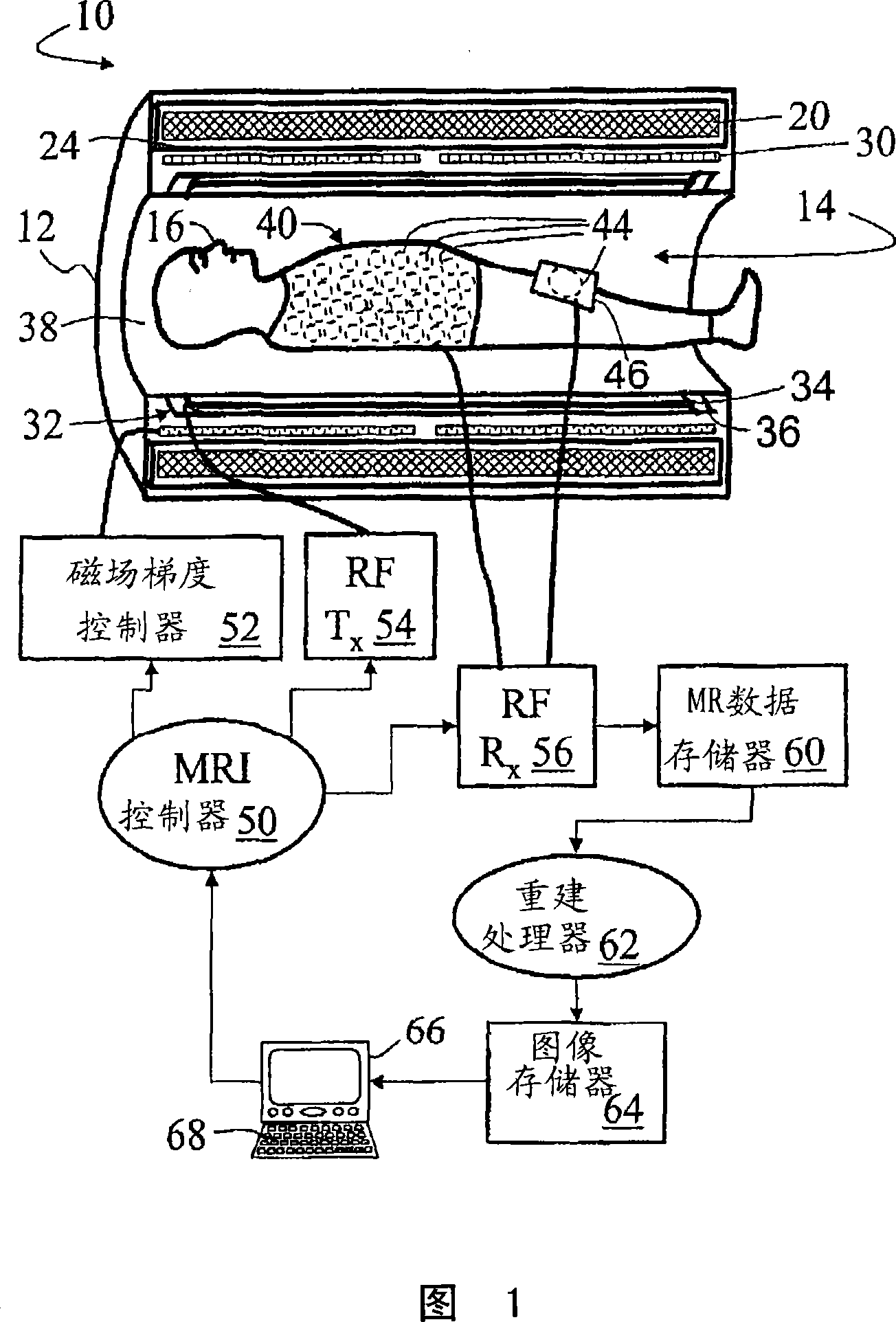

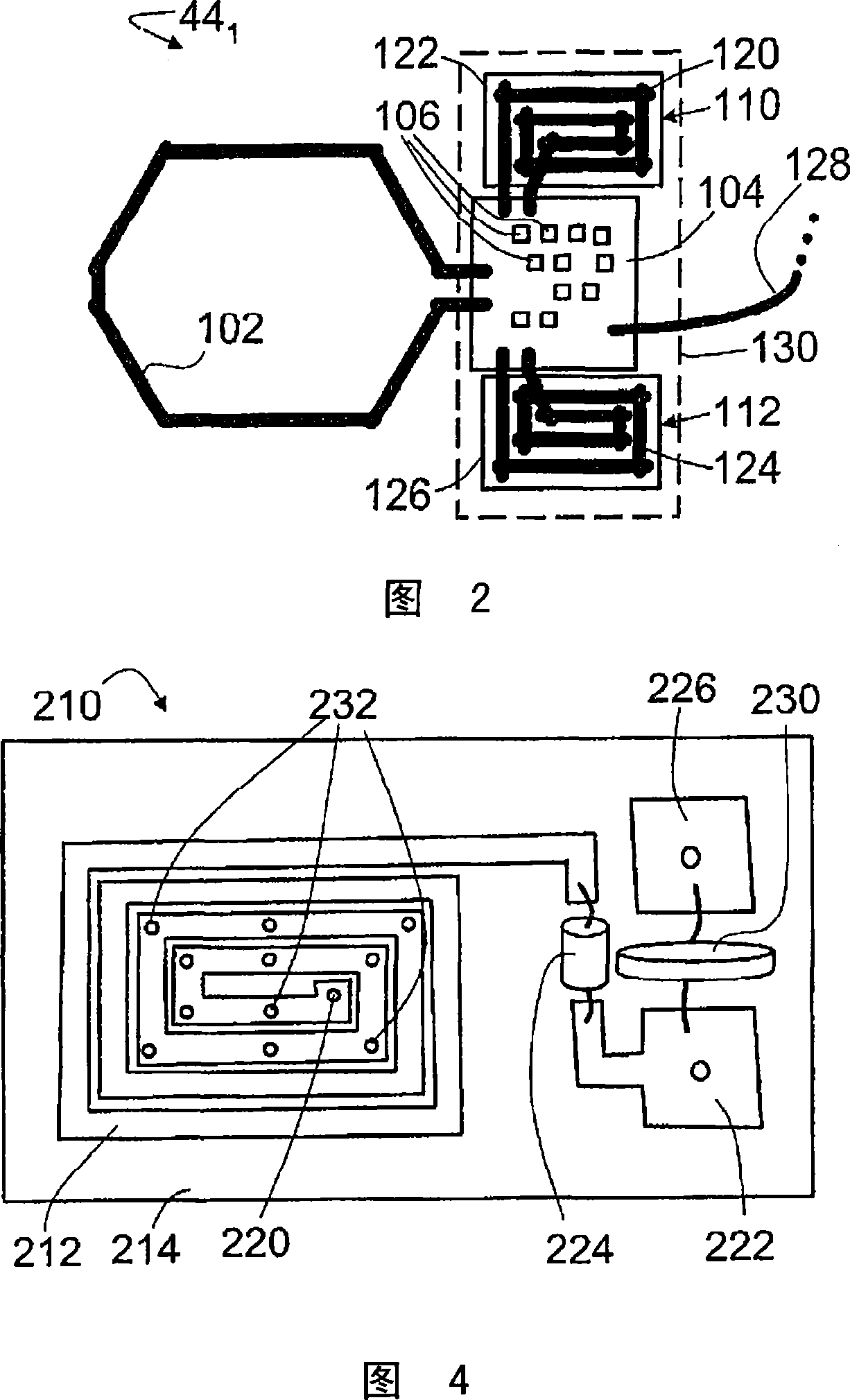

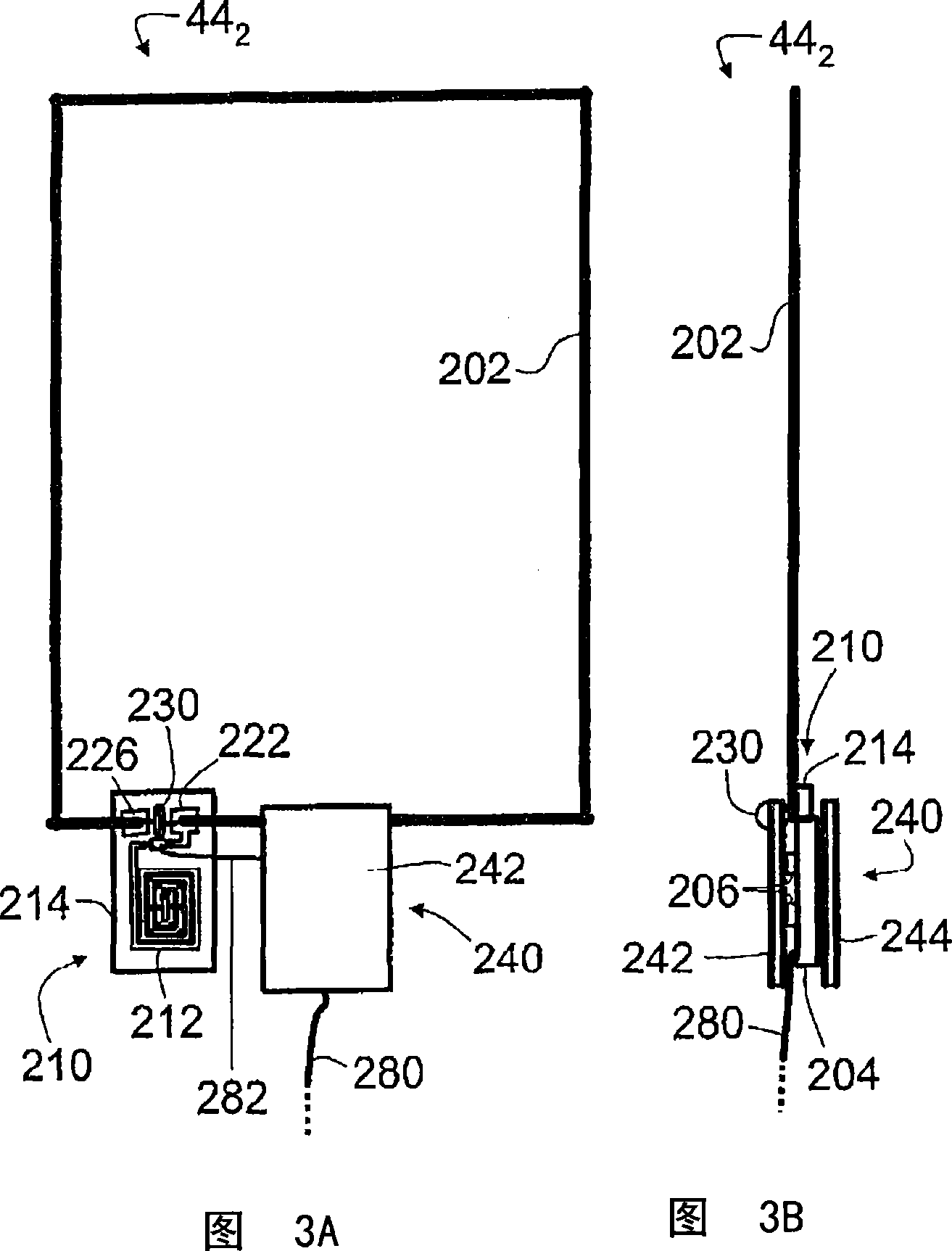

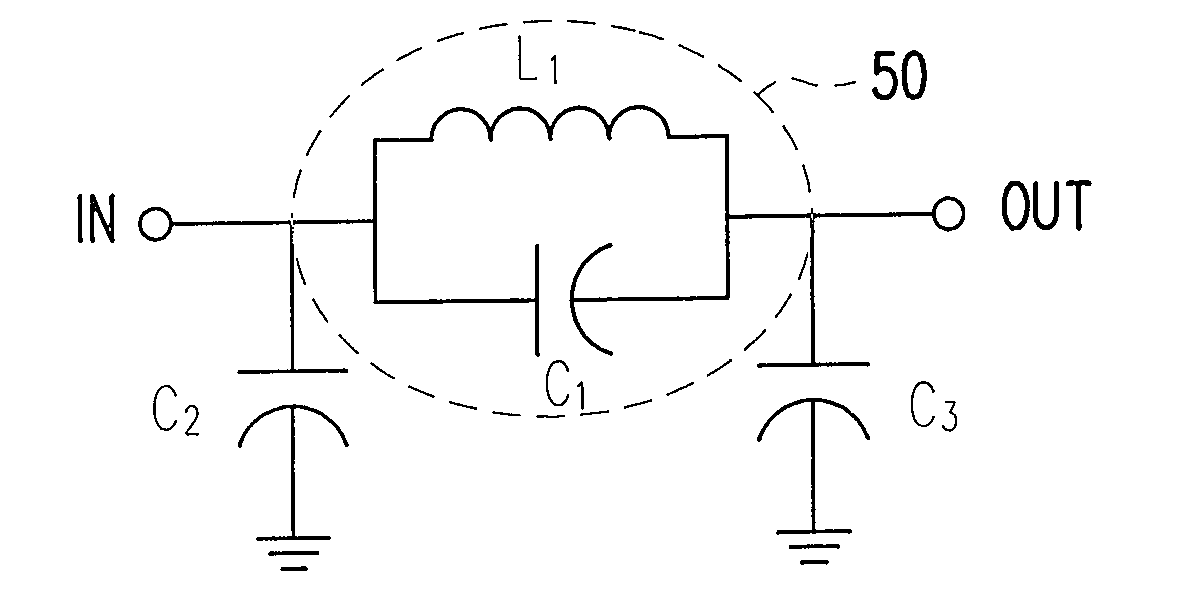

Magnetic resonance receive coils with compact inductive components

InactiveCN101023369AReduction of stray magnetic fieldsEasy to manufactureMeasurements using magnetic resonanceElectricityFrequency filtering

A low profile radio frequency coil (32, 44, 441, 442, 443) for use in a magnetic resonance imaging system includes a low profile antenna (34, 102, 202, 302) that is configured to resonate at about a magnetic resonance frequency of the magnetic resonance imaging system. A generally planar inductor (110, 112, 210, 240, 310) is electrically connected or coupled with the low profile antenna. The generally planar inductor provides selected frequency filtering of a radio frequency signal received by or transmitted by the low profile antenna.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Circuit device having inductor and capacitor in parallel connection

ActiveUS20090237178A1Reduce decreaseReduce connecting wiresMultiple-port networksResonatorsPlanar inductorDielectric layer

A circuit device having an inductor and a capacitor in parallel connection includes a planar inductor embedded in an insulating material layer, wherein the planar inductor has a winding wire portion, a first connection terminal and a second connection terminal. The first connection terminal and the second connection terminal are located at different elevations and have an overlapping region. A capacitor dielectric layer is located within the overlapping region between the first connection terminal and the second connection terminal, and the capacitor dielectric layer and the first connection terminal and the second connection terminal together form a capacitor.

Owner:IND TECH RES INST

Planar inductor using liquid metal mems technology

InactiveCN1971776ASemiconductor/solid-state device detailsSolid-state devicesElectrical conductorLiquid state

Owner:AGILENT TECH INC

Planar inductor devices

InactiveCN103026431ATransformers/inductances coils/windings/connectionsFixed transformersPlanar inductorElectric current

A planar inductor device (1000) comprises a ferrite body (1016) and a conductive pathway (1002). The ferrite body extends around an opening (1014) in the ferrite body. The conductive pathway includes an input section (1004), a current-splitting section (1016), a coil section (1008), a current-combining section (1010), and an output section (1012) connected with each other, the input section extending toward the opening in the ferrite body. The current- splitting section includes a plurality of conductive coils (1018) joined with the conductive pathway and electrically disposed parallel to each other. The coil section includes the conductive coils helically wrapped around the ferrite body. The current-combining section includes the conductive coils joined with each other, and the output section includes the joined conductive coils extending out of the ferrite body.

Owner:TE CONNECTIVITY CORP

Offset planar coil coaxial surge suppressor

ActiveUS7349191B2MinimizationSmall component sizeTwo pole connectionsEmergency protective arrangement detailsElectrical conductorSuppressor

An in-line surge suppressor assembly having a body with a side aperture and an inner conductor positioned coaxial within a bore of the body. An insert having a planar inductor coil with a post extending from an origin point of the planar inductor coil is positioned with the post passing through the side aperture and coupled to the inner conductor at a distal end. An outer rim of the planar inductor coil is electrically coupled to the body.

Owner:COMMSCOPE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com