Inductor and manufacturing method thereof

A manufacturing method and technology of inductors, which are used in the manufacture of inductors, fixed inductors, inductors/transformers/magnets, etc., can solve the problems of limited self-resonant frequency increase, impact on product application, and blocked application range, and reduce Distributed capacitance, the effect of increasing self-resonant frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for manufacturing an inductor, the steps of which are described in detail as follows:

[0026] 1) Core production

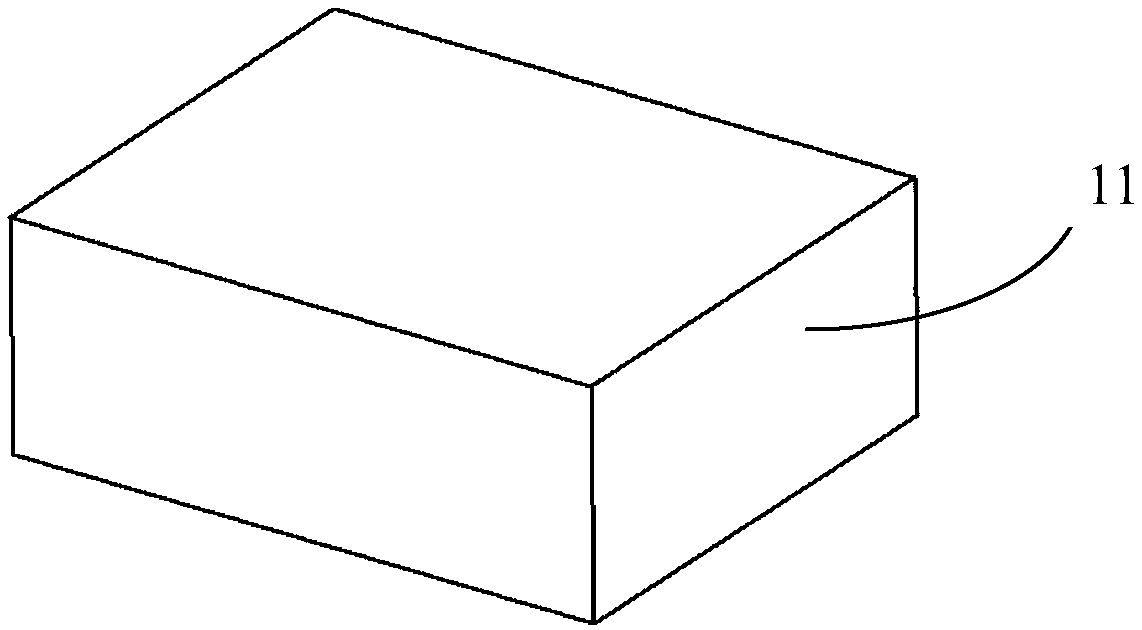

[0027] Preparation of granulated magnetic powder: the granulated magnetic powder includes magnetic powder and resin, and the mass of the resin accounts for 2%wt-5%wt of the mass of the magnetic powder. The magnetic powder can be iron alloy magnetic powder, ferrite magnetic powder or metal magnetic powder. By controlling the ratio within the range, the granulated magnetic powder can be suitable for the compression molding process. The granulated magnetic powder is pressed under a certain pressure to obtain a magnetic block 11, such as Figure 1A and 2A shown.

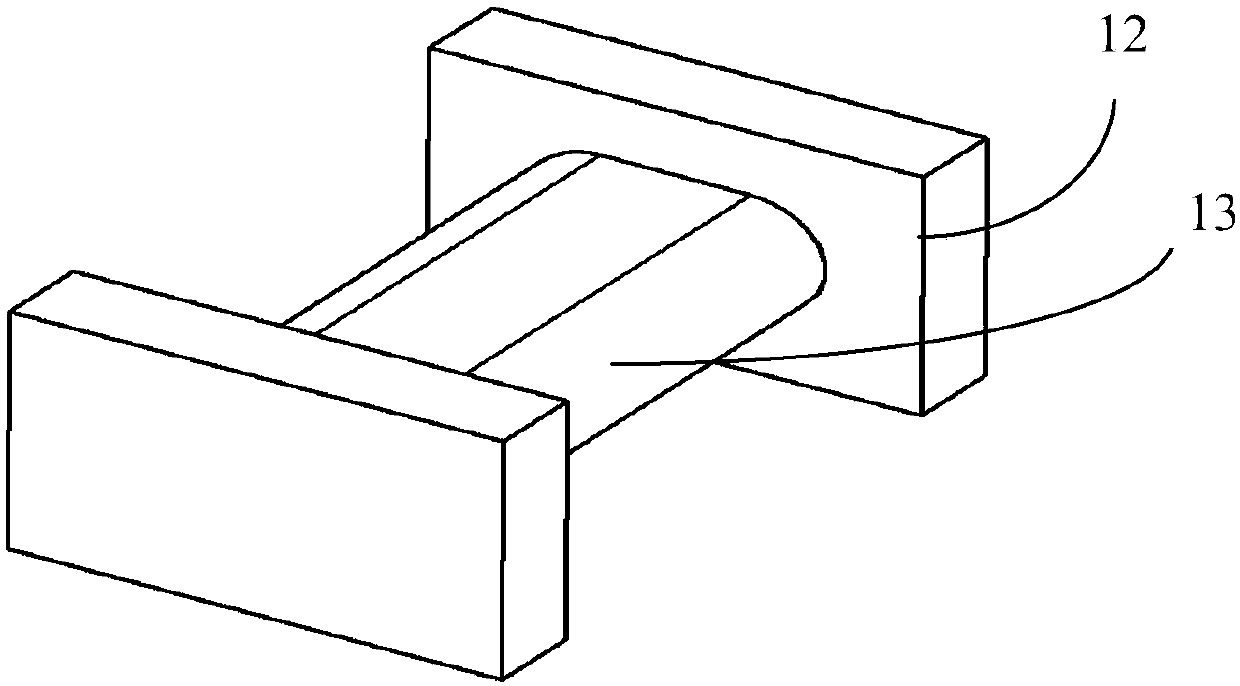

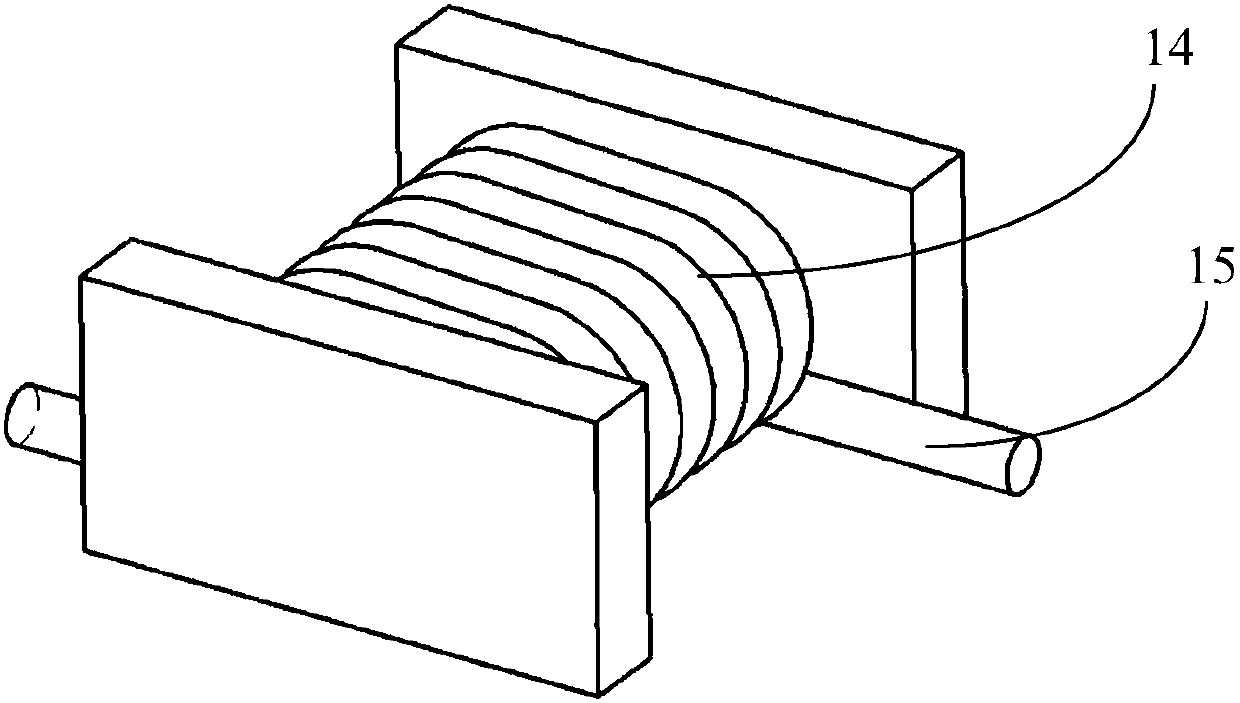

[0028] The obtained magnetic block 11 is cut into a magnetic core structure, which can be any magnetic core structure such as a dumbbell shape or an I-shape. In this example, if Figure 1B As shown, the magnetic block 11 is cut into a dumbbell-shaped magnetic co...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that the coil 24 is wound with a flat wire, thereby having greater space utilization and the area of the lead-out ends 27, 28, such as Figure 5 shown. The preparation process of this example is the same as that of Example 1, and will not be repeated here. In this embodiment, flat wires are used for winding, so that the damage to the flat wires during molding is less, and the risk of open and short circuit of the device is reduced. In the inductor prepared in this example, the coil has a vertical structure. Compared with the ordinary horizontal structure, the self-resonance frequency can be effectively increased, and as the size of the inductance device is gradually thinned, the increase ratio of the self-resonance frequency has a tendency to gradually increase. , suitable for the miniaturization and thinning of inductive devices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com