Electron multiplying charge coupled device (EMCCD) drive circuit based on autotransformer

A technology of autotransformer and drive circuit, which is applied in TV, electrical components, color TV, etc., can solve the problems of small output power, self-excited oscillation output current, influence of distributed parameter circuit, etc., and achieve lower requirements, low power consumption, Effect of Power Consumption Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

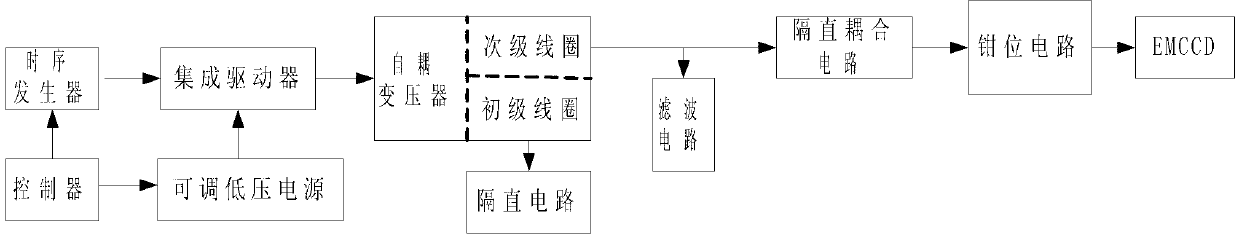

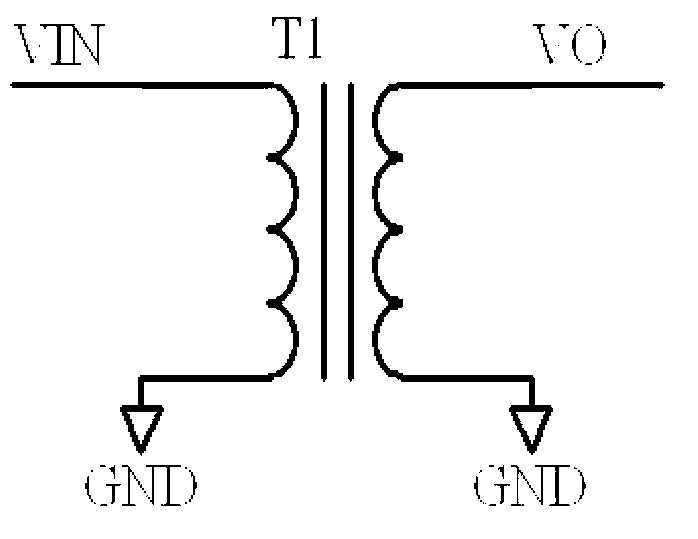

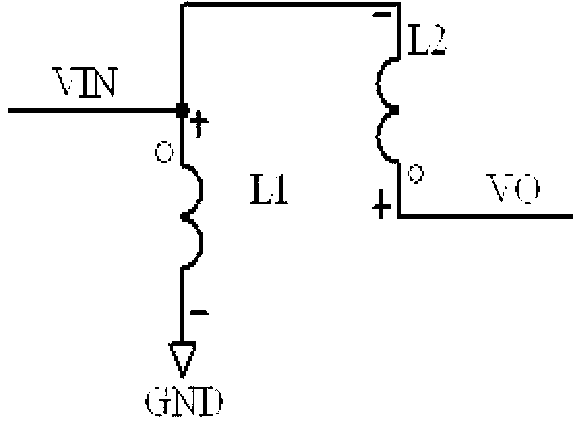

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 4 Describe this embodiment, an EMCCD drive circuit based on an autotransformer, the circuit includes a timing generator, an integrated drive circuit, an autotransformer, a DC blocking coupling circuit, a controller, an adjustable low-voltage power supply, a DC blocking circuit, and a filter circuit and clamping circuit; the controller is connected to the timing generator and the adjustable low-voltage power supply, and through real-time control of the timing generator, the timing generator outputs a high-speed timing signal with a fixed level and a finely adjustable phase, which is sent to the integrated driver; adjustable The low-voltage power supply is connected to the integrated driver to supply power for the integrated driver; the adjustable low-voltage power supply is controlled by the controller, and the amplitude of the output signal of the integrated driver can be changed by changing the output volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com