Patents

Literature

192results about How to "Improve high frequency characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ni-Zn soft magnetic ferrite material and preparation method thereof

The invention discloses a nickel-zinc soft magnetic ferrite material and a preparation method thereof. The material comprises the following compositions in mol percentage: 45 to 50 mol percent of ferric oxide Fe2O3, 20 to 26 mol percent of zinc oxide ZnO, 12 to 17 mol percent of nickel protoxide NiO, 5 to 10 mol percent of copper oxide CuO, and 3 to 10 mol percent of magnesium oxide MgO. The preparation method comprises the following steps: treating raw materials, proportioning, primary ball milling, drying, powdering or screening, preburning, secondary proportioning, secondary ball milling, secondary drying and secondary powdering or screening; the preburning condition is to carry out pre-synthesis in an air furnace at a temperature of between 900 and 980 DEG C, and the sintering temperature is between 1,050 and 1,100 DEG C. The nickel-zinc soft magnetic ferrite material has the characteristics of property of high Q, high frequency, high TC, high Bm and low cost.

Owner:广东肇庆微硕电子有限公司 +1

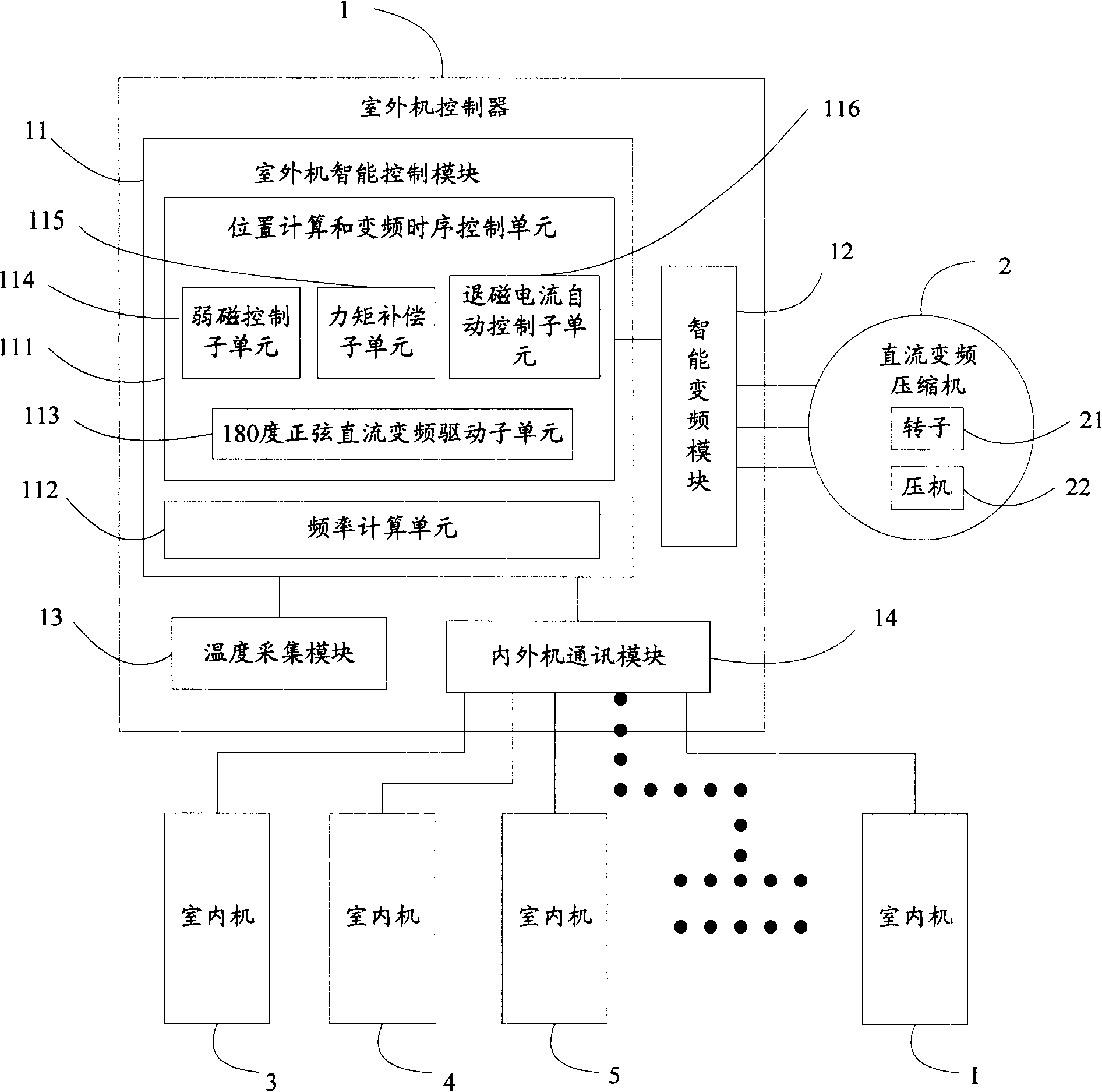

Sine DC frequency conversion multi-split air conditioner control system and its control method

ActiveCN101191651AImprove high frequency characteristicsImprove low frequency characteristicsAC motor controlSpace heating and ventilation safety systemsControl systemFrequency conversion

The present invention discloses a sine DC variable frequency one-driving-multiple air conditioner control system, comprising an outdoor unit controller, at least three indoor units and a DC variable frequency compressor, wherein, the outdoor unit controller further controls an outdoor unit intelligent control module, an intelligent frequency conversion module, an indoor-outdoor unit communication module and a temperature acquisition module; the outdoor unit intelligent control module is used for controlling the drive of the DC variable frequency compressor. The present invention also discloses a sine DC variable frequency one-driving-multiple air conditioner control method, which first calculates the needed frequency of the DC variable frequency compressor, and then calculates the instantaneous position and the velocity information of a DC variable frequency compressor rotor, and finally drives the DC variable frequency compressor. The present invention increases the service efficiency of the compressors of one-driving-multiple air conditioners, improves the high frequency characteristics and low frequency characteristics of air conditioners, and ensures that one-driving-multiple air conditioners save more energy.

Owner:HAIER GRP CORP +1

Core/shell structure containing Fe/SiO2 composite nano particles with high stability and method for making same

InactiveCN1594450ASimple preparation processEasy to controlInorganic pigment treatmentSilicic acidComposite nanoparticles

The invention discloses a core / shell-structure-containing Fe / SiO2 composite nano particles with high stability and its preparing process which comprises, using ferric salt as raw material, organic acid as complexing agent, absolute ethyl alcohol or isopropyl alcohol as dissolvent so as to form uniform non-aqueous gel, charging silicic acid ethyl acetate, evaporating and dehydrating to form gel, preparatory roasting in air to remove the organics, deacidizing at different temperature in H2 atmosphere.

Owner:NANJING UNIV

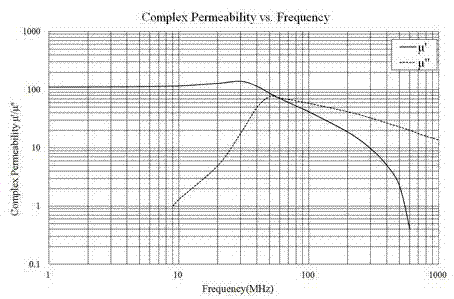

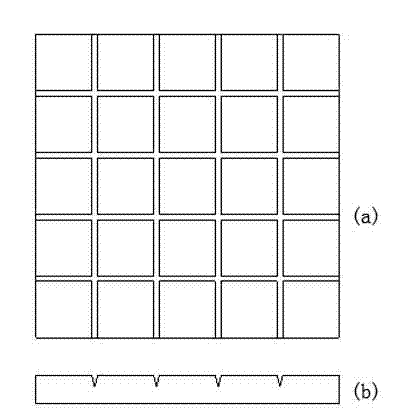

Nickel-zinc ferrite material for wireless signal sensing, sheet core and preparation method thereof

ActiveCN102807361AImprove frequency characteristicsHigh resistivityInorganic material magnetismTransformers/inductances detailsSurface mountingNano sio2

The invention relates to a nickel-zinc ferrite material for wireless signal sensing, a sheet core and a preparation method thereof. The nickel-zinc ferrite material comprises main components which are calculated by the following oxides in mole percent: 48.0-62.5mol% of Fe2O3, 15.3-25.5mol% of NiO, 18.5-23.5mol% of ZnO and 3-10mol% of CuO; and the nickel-zinc ferrite material additionally comprises auxiliary components which are calculated by the following standard substances in weight percent relative to the total weight of the main components: 0.05-0.10wt% of nano CaCO3, 0.30-0.85wt% of nano SiO2, 1.50-2.50wt% of Mn3O4, 0.05-0.35wt% of Co2O3 and 1.00-1.50wt% of Bi2O3. The nickel-zinc ferrite material is prepared by adopting an oxidation method. The sheet core is a reticular sheet, the length is 45-250mm, the width is 45-250mm, the thickness is 0.05-0.3mm, the sheet core is formed by small sheets in a connecting way, the gaps among the small sheets are less than 50mum, and the sheet core is directly molded and then is sintered, or a magnetic bar is molded and then is sliced into small sheets which form the sheet core through an SMT (surface mount device) technology. At frequency of 13.56MHz, the material has the electromagnetic performance that mu' is equal to 125 plus or minus 20% and the mu'' is less than or equal to 4. Therefore, the material can satisfy the requirement of high-frequency low consumption on the ferrite material for wireless signal sensing.

Owner:TDG HLDG CO LTD

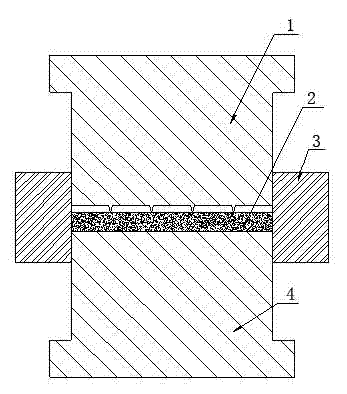

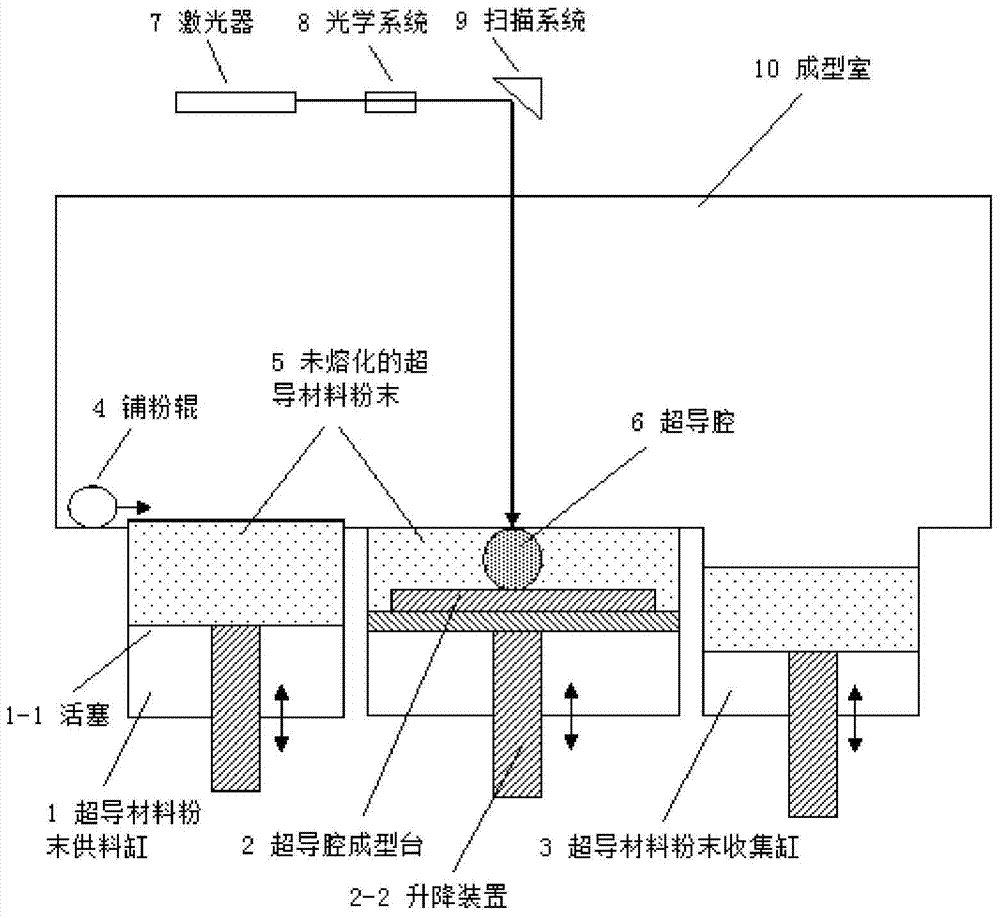

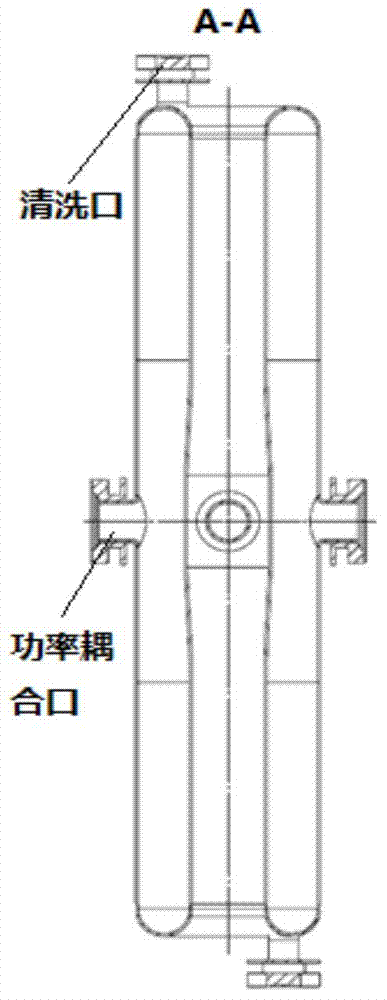

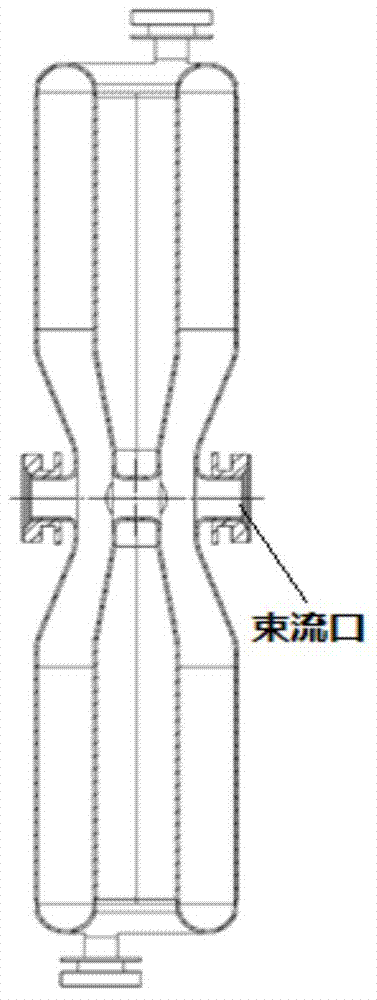

Manufacturing method of superconductor cavity

The invention belongs to the technical field of particle accelerators and particularly relates to manufacture of a radio frequency superconductor cavity. A manufacturing method of the superconductor cavity mainly comprises the following steps: (1) using superconductor materials as raw materials, (2) utilizing CAD software to generate a superconductor cavity model, and adopting layering software to layer the superconductor cavity model, (3) using an atmosphere control system to provide argon for a forming chamber, (4) laying powder of superconductor materials in the step (1) on a forming table of the forming chamber, (5) using a scanning control system to print laser energy onto a powder layer according to the description of a software model of a superconductor cavity slicing layer so as to generate a superconductor material slicing layer entity. The entity is a part of the superconductor cavity. A next slicing layer is processed continually on the first slicing layer entity until the whole superconductor cavity processing process is finished. Finally, mechanical polishing, chemical washing, high-temperature annealing, high-pressure super-pure water washing and super-clean chamber assembly are conducted. The method shortens the development cycle of the superconductor cavity, improves the finished product rate of the development of the superconductor cavity due to the fact that the whole superconductor cavity is free of welding joints, is free of restriction of stamping forming conditions and capable of improving the performance of the superconductor cavity, and reduces product cost due to the fact that surplus superconductor material powder can be used repeatedly.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

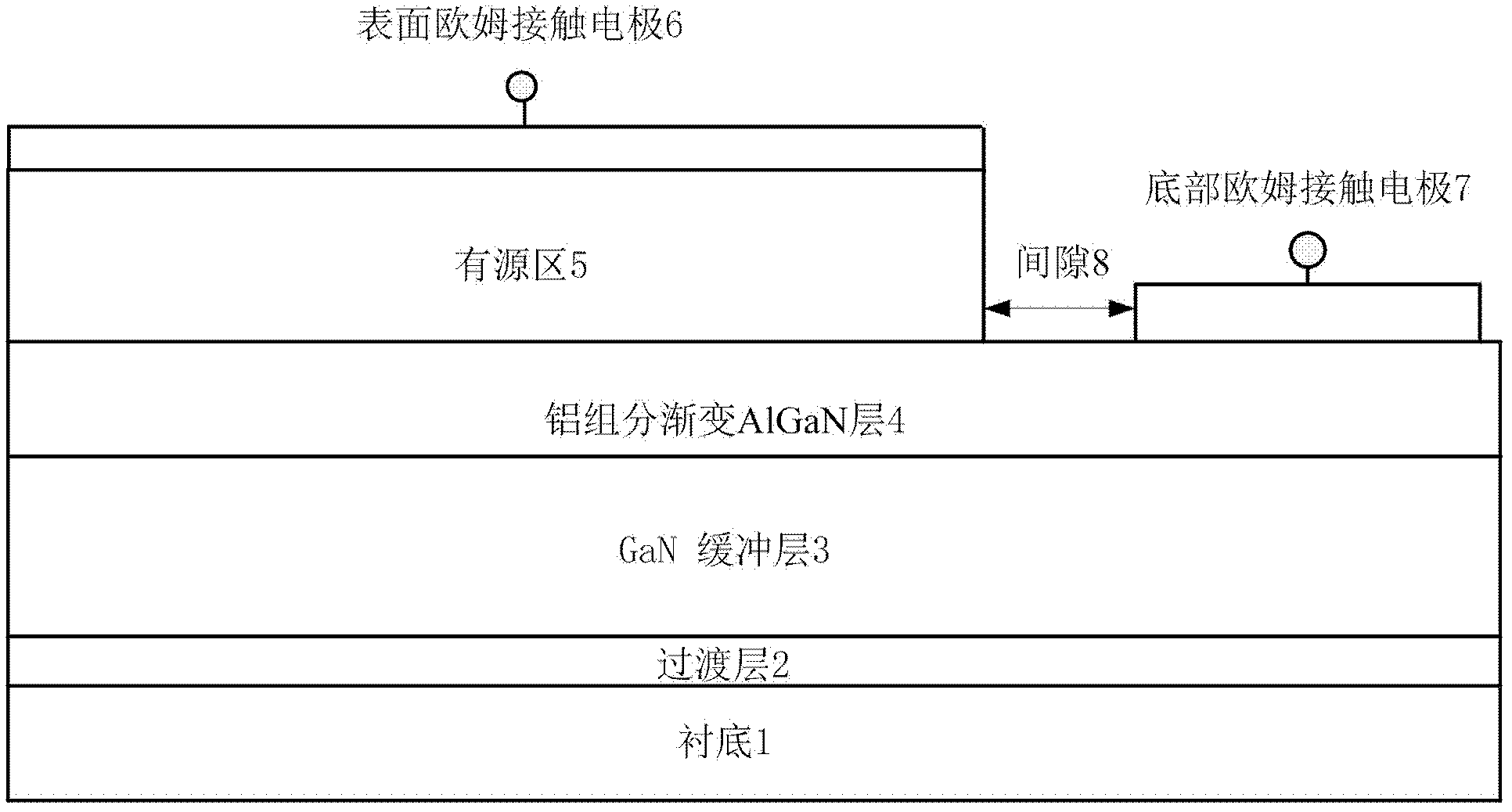

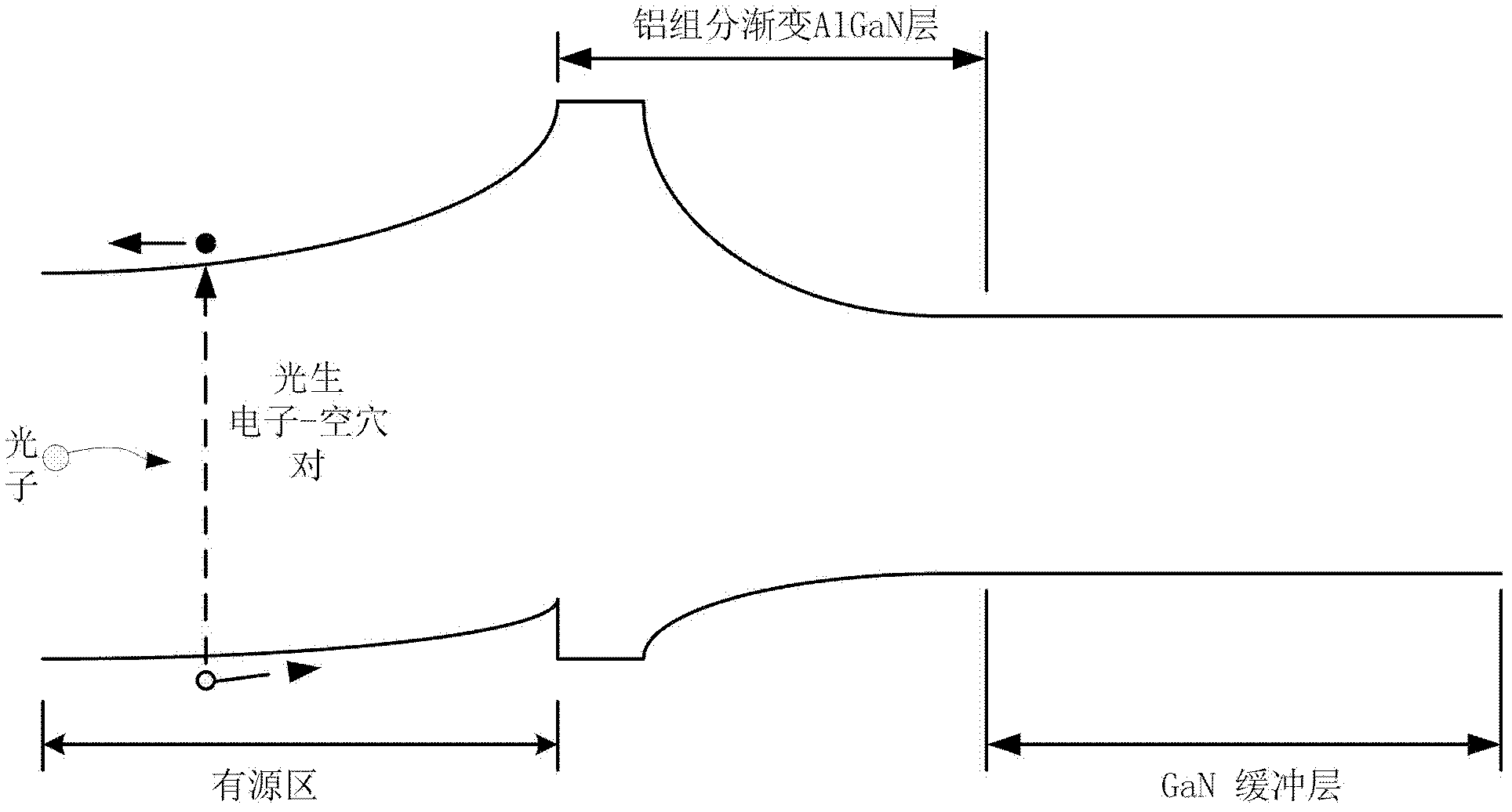

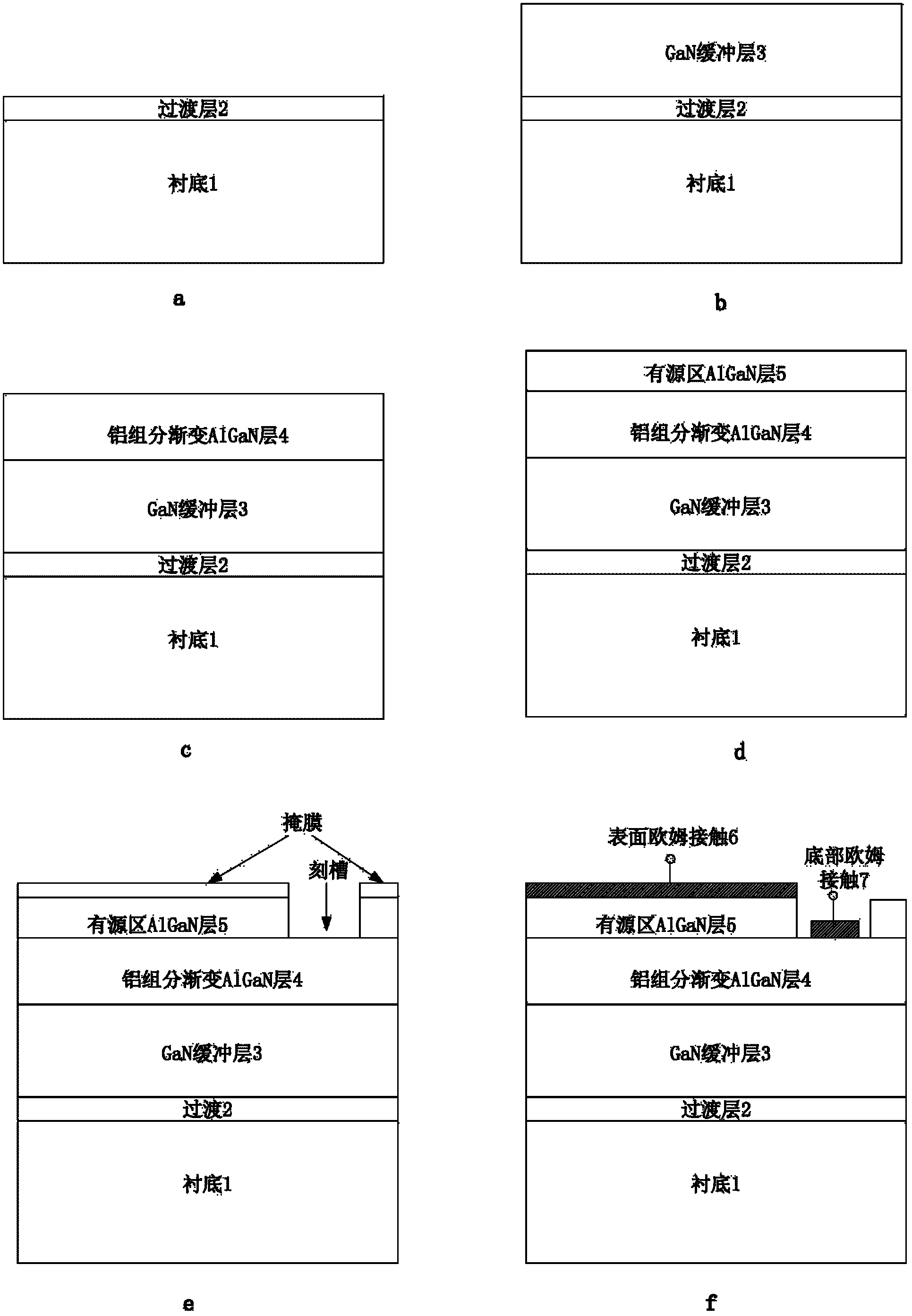

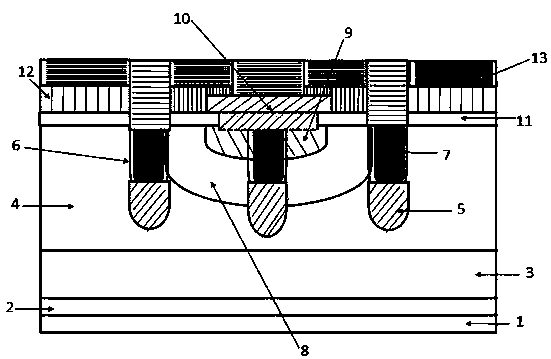

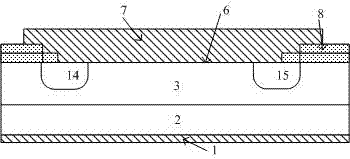

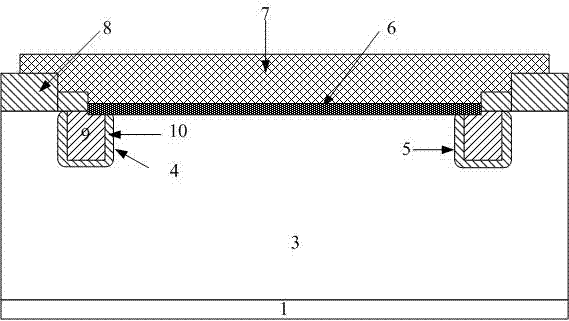

AlGan polarized ultraviolet photoelectric detector and manufacturing method thereof

ActiveCN102214705AAutomatically block interferenceReduce dark currentFinal product manufactureSemiconductor devicesPhotovoltaic detectorsOhmic contact

The invention discloses an AlGan material-based ultraviolet photoelectric detector structure and a manufacturing method thereof, which are mainly used for solving the problem of the dependence on a P-type doping material in the prior art. A detector comprises a substrate (1), a transition layer (2), a GaN buffer layer (3), an aluminum component gradual change AlGaN layer (4) and an active layer (5) from bottom to top, wherein the aluminum component gradual change AlGaN layer (4) is partitioned into an upper layer and a lower layer; the thickness of the lower layer is 20-30 nanometers, and thecontent of an aluminum component increases from 0 percent to 80-100 percent; the thickness of the upper layer is 10-20 nanometer, and the content of the aluminum component is 0-80 percent; the left upper side of the aluminum component gradual change AlGaN layer (4) is covered by the active layer (5); a bottom ohmic contact (7) is deposited on the right upper side of the aluminum component gradualchange AlGaN layer (4); a gap (8) is formed between the ohmic contact and the active region; the active region (5) consists of an AlGaN material with the aluminum component content of 0-80 percent; the thickness of the active region (5) is 50-100 nanometers; and a surface ohmic contact electrode (7) is deposited on the surface of the active region. The detector structure has the advantages of capability of automatically working in a photovoltaic mode, high high-frequency characteristic and small dark current, and can be applied to optical signal detection in ultraviolet wavebands between 226 nanometers and 363 nanometers.

Owner:陕西半导体先导技术中心有限公司

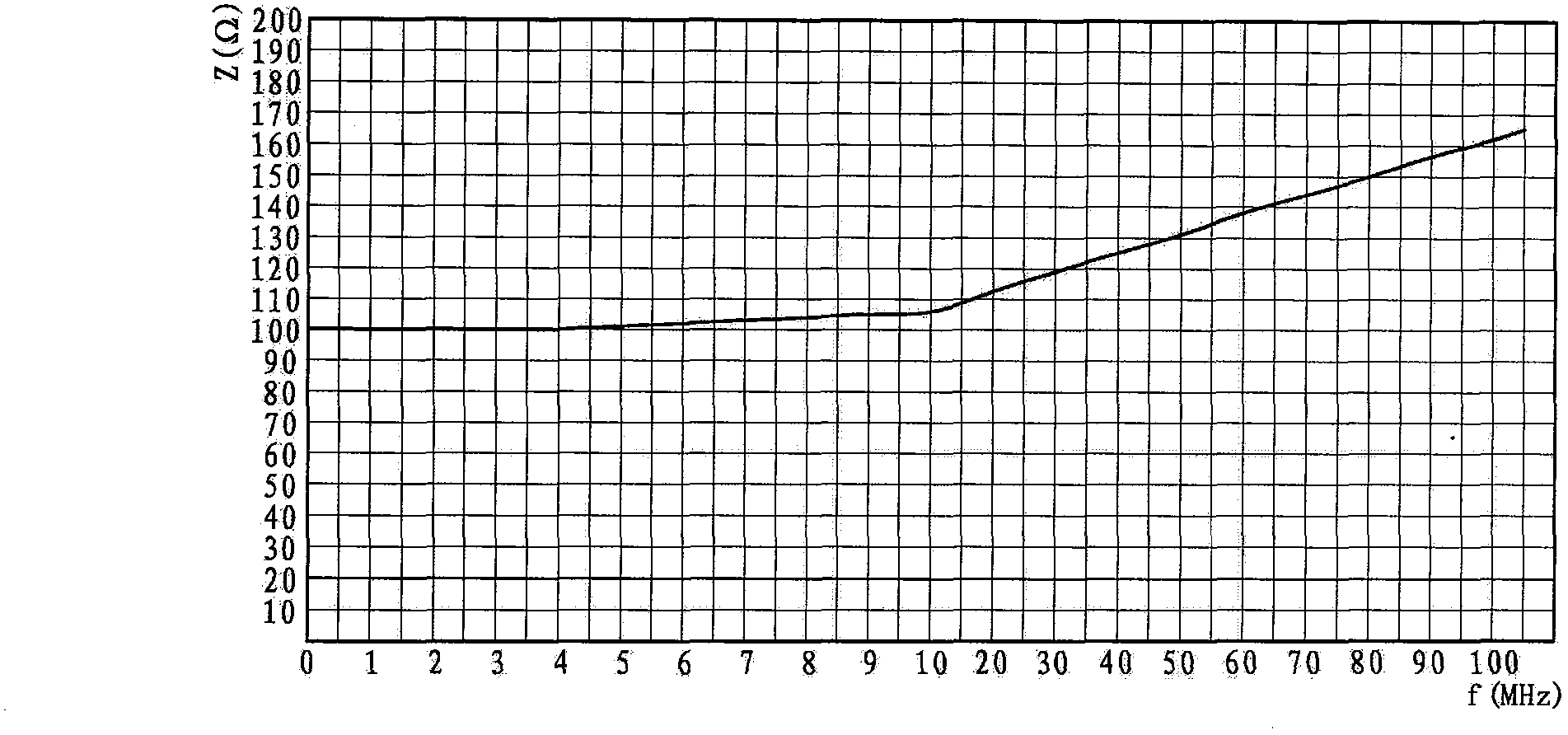

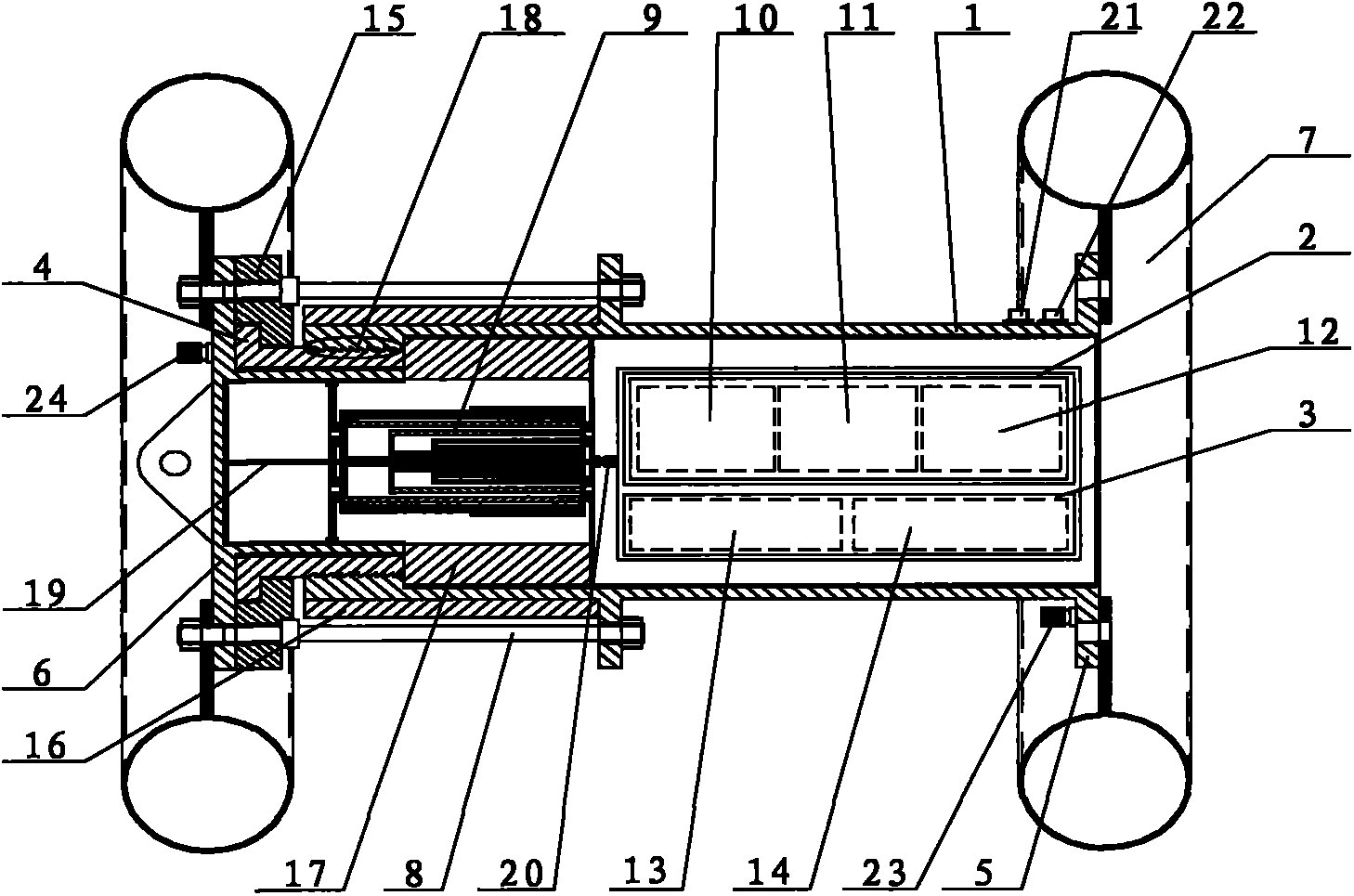

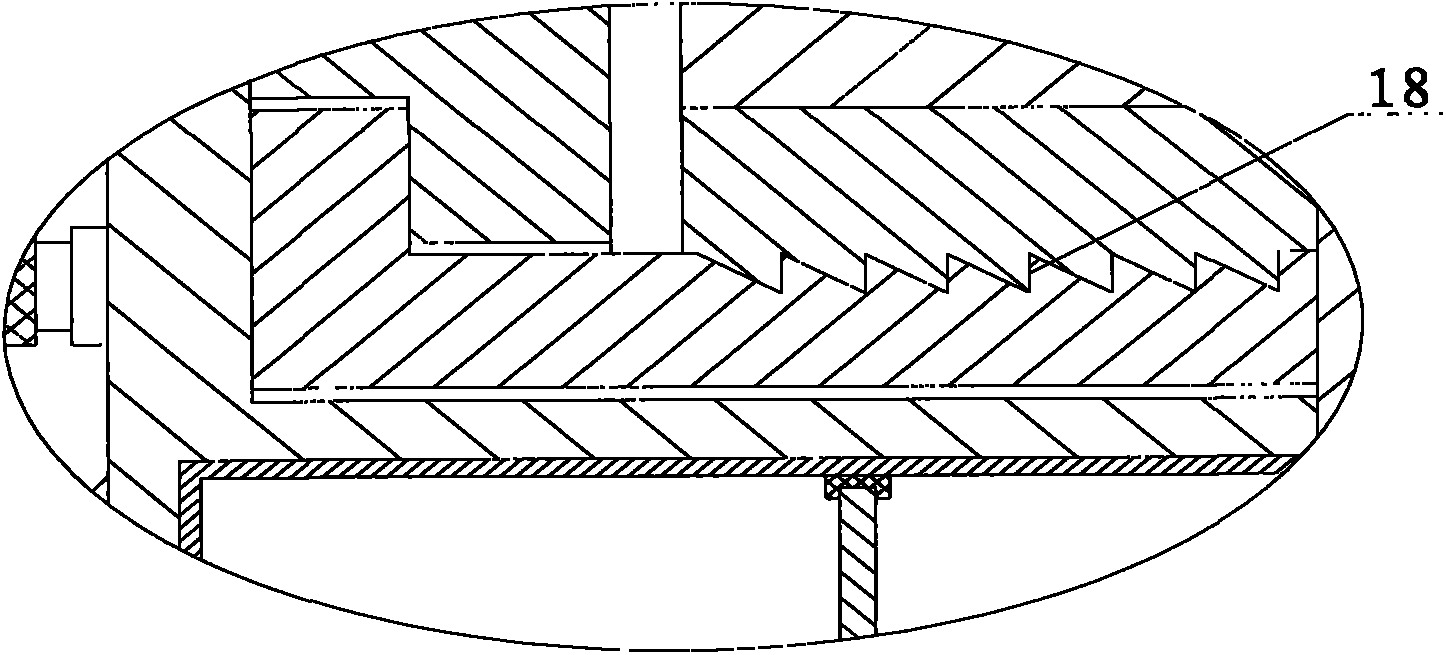

Broadband online measurement sensor for DC extra-high voltage corona current

ActiveCN102662097AReduce coronaImprove high-frequency measurement performanceCurrent/voltage measurementVoltage dividersCapacitanceLow voltage

The invention relates to a broadband online measurement sensor for DC extra-high voltage corona current, which comprises an isolation electrode unit, a signal processing unit and a system power supply unit, wherein the isolation electrode unit comprises an insulated isolation sleeve, a hollow tubular long arm low-voltage electrode and a hollow tubular short arm high-voltage electrode, wherein two ends of the insulated isolation sleeve are respectively in security isolation connection with the high-voltage electrode and the low-voltage electrode in a special way; the signal processing unit consists of a sampling resistor module, a signal acquisition module, a signal conversion module and a signal transmission module; the system power supply unit comprises a storage battery pack and a charging module; and the signal processing unit and the system power supply unit are arranged in the isolation electrode unit, so that the high-accuracy integral measurement sensor can be formed. The broadband online measurement sensor solves the problems of shielding disturbance of a strong electric field between an acquired signal and an acquisition channel as well as surrounding stray capacitance, and realizes the broadband domain online measurement and the multi-point network online measurement of the DC extra-high voltage corona current.

Owner:CHINA ELECTRIC POWER RES INST +2

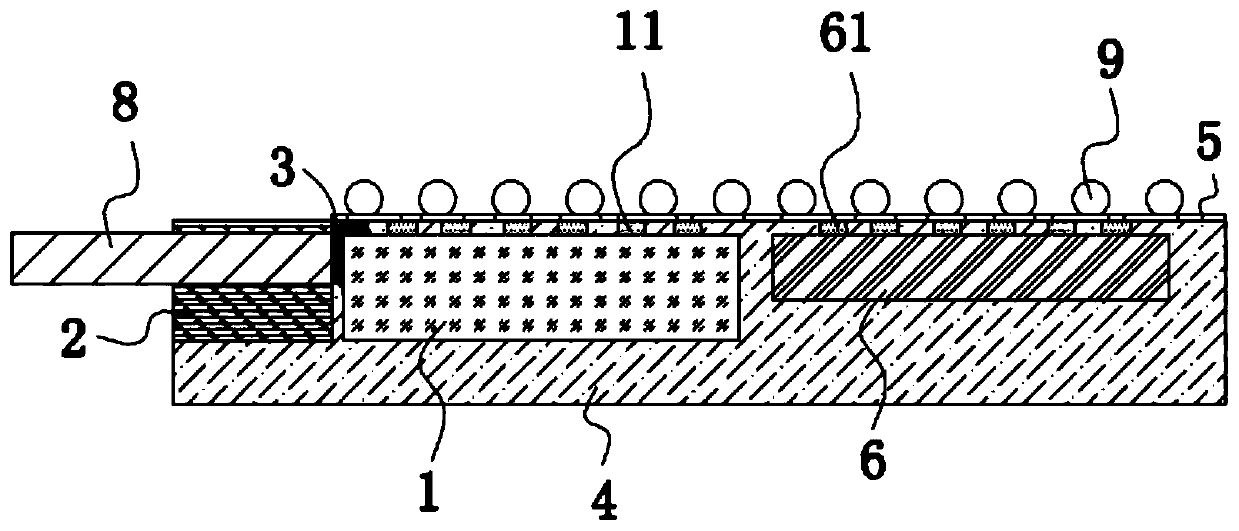

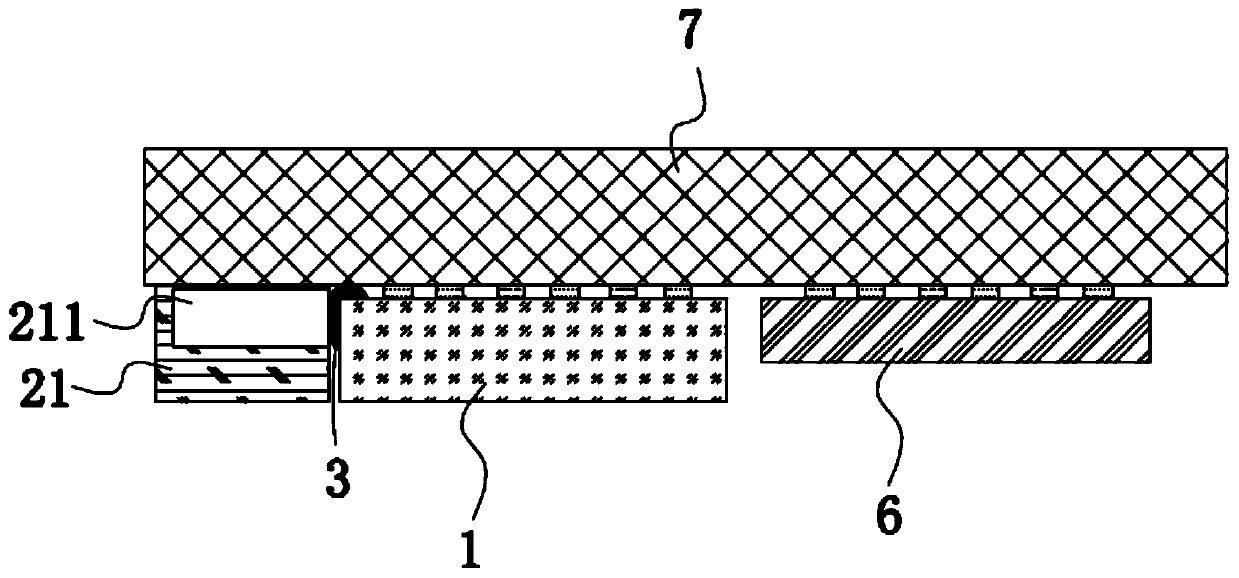

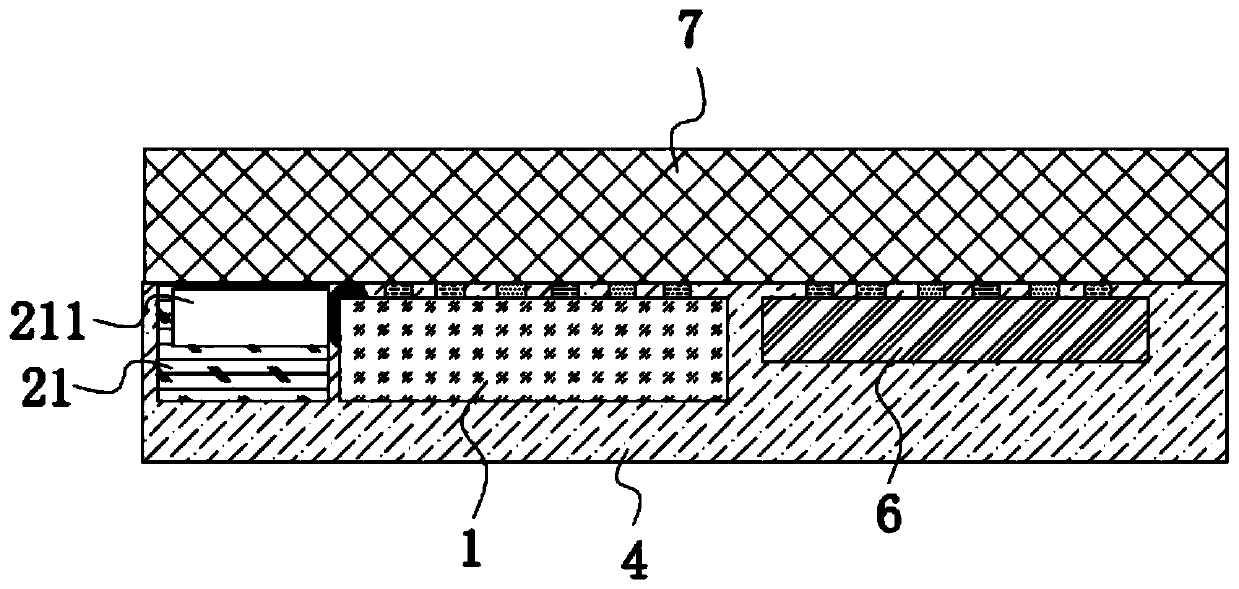

Silicon photonic optical transceiver module

The invention discloses a silicon photonic optical transceiver module. The silicon photonic optical transceiver module comprises a circuit board and an optical component; the circuit board is arrangedin a hollow region, and the hollow region is used for accommodating the optical component; the circuit board is provided with a plurality of first bonding pads along the periphery of the hollow region; a plurality of second bonding pads are arranged at the edge of the optical component; and after the optical component and the circuit board are attached in a reverse mounting mode, the second bonding pads are attached to the corresponding first bonding pads so as to implement electrical connection. The electrical connection is established between the circuit board and the optical component by the first bonding pads and the second bonding pads, an electric signal connection path is short, a stray capacitance is small, high-frequency transmission loss is low, high-frequency characteristics are improved, and the problem of high-frequency inhibition caused by a gold-wire bonding wire currently can be effectively improved. Meanwhile, the optical component and the circuit board are attached in a reverse buckling mode, the design structure is compact, and the size of the silicon photonic optical transceiver module can be effectively reduced.

Owner:GUANGXUN SCI & TECH WUHAN

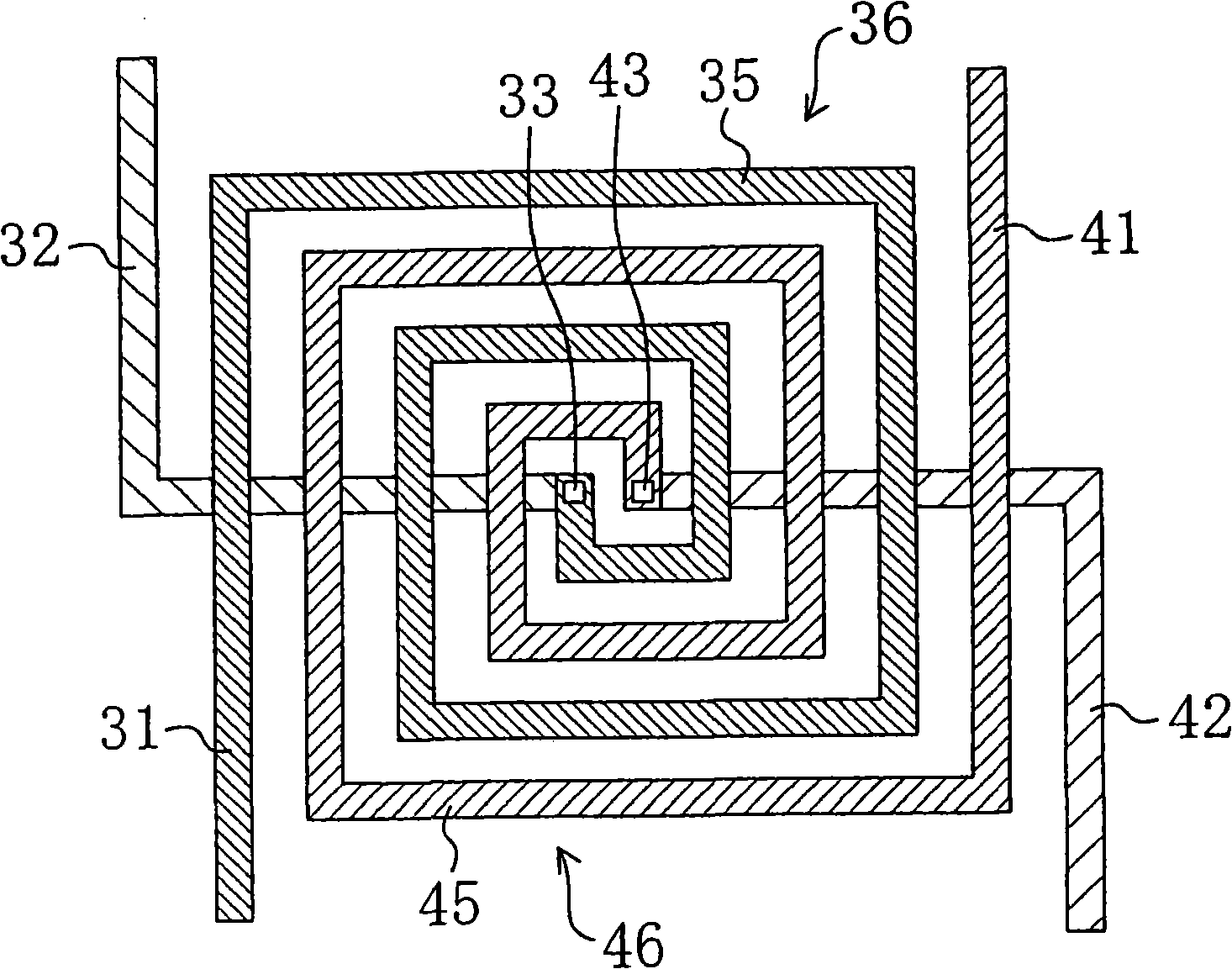

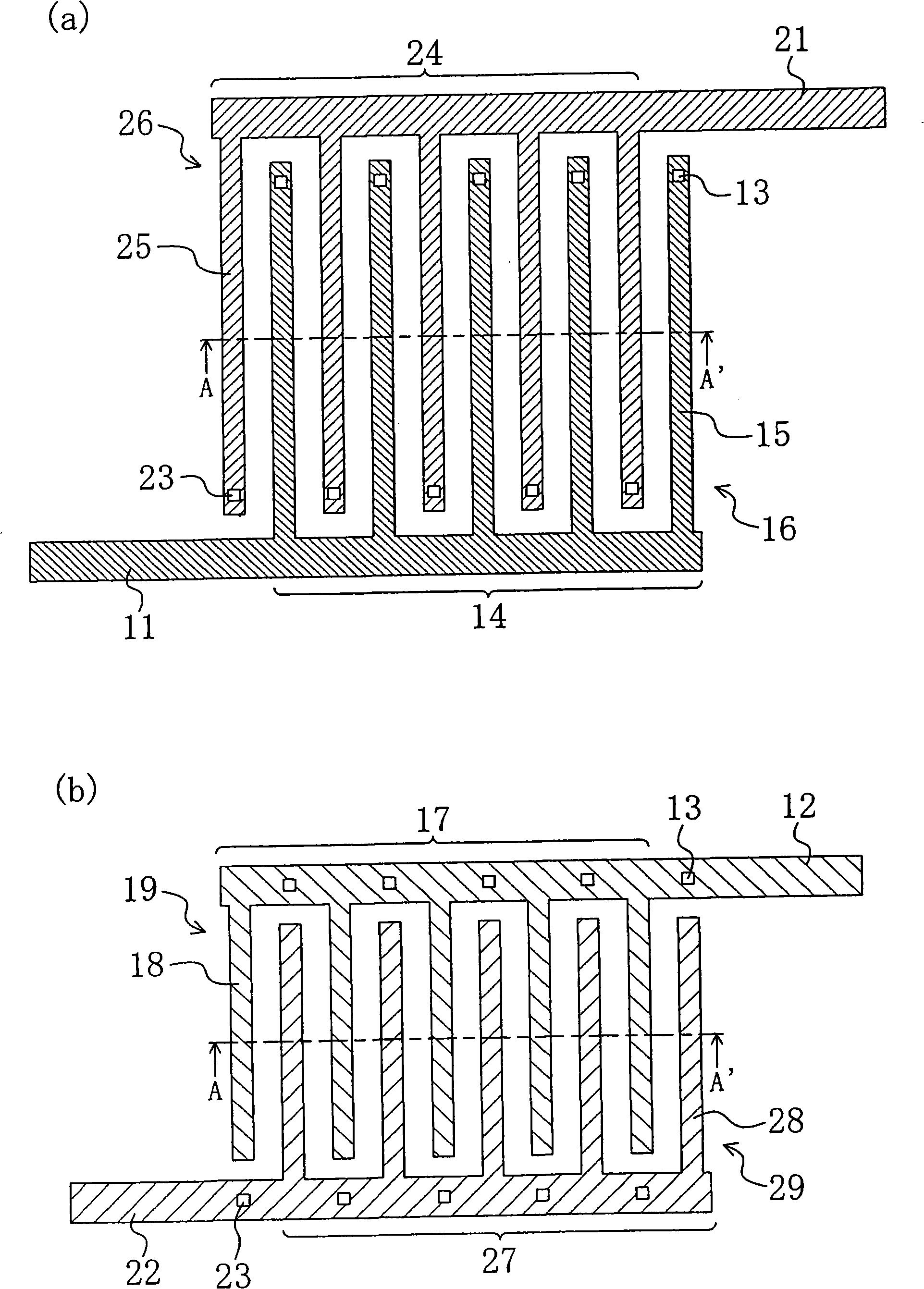

Planar magnetic inductor and method for manufacturing the same

InactiveCN1801412AImprove the inductanceImprove high frequency characteristicsLiquid applicationPrinted circuit manufactureInductorInductance

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

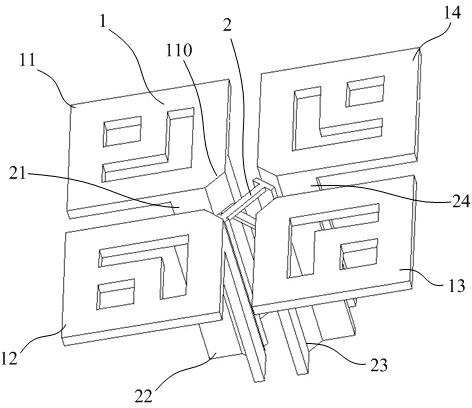

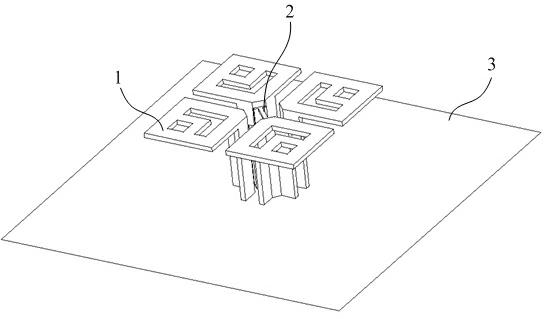

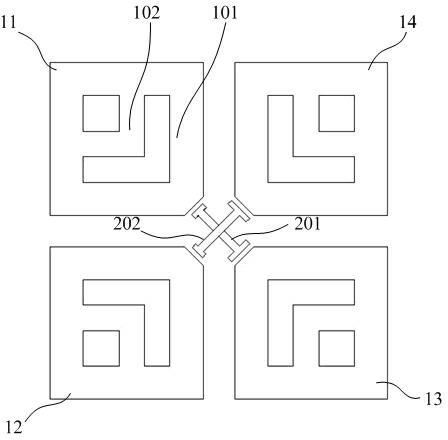

Broadband dual polarization radiation unit

InactiveCN102496777ASimple structureReduce consistencyAntenna supports/mountingsRadiating elements structural formsElectricityBroadband

The invention discloses a broadband dual polarization radiation unit comprising a radiator and balance feeder equipment. The radiator includes four radiation fins and four support bars. The four radiation fins, which are on a same plane, are arranged in an array with two rows and two columns and are distributed in a mode in which two and two are symmetrical, so that two pairs of dipoles of orthogonal polarization are formed. Each of the radiation fins consists of an outer ring frame and an inner ring frame, wherein the outer ring frame and the inner ring frame are at a same plane; the inner ring frame is nested inside the outer ring frame is connected with the outer ring frame. And the four support bars are respectively connected with the four radiation fins in one-to-one correspondence mode; and corresponded tangential angles are formed on all the radiation fins at connection points. Besides, the balance feeder equipment is arranged in the central portion of the radiator and is used for carrying out feeding on the two pairs of dipoles. According to the invention, the provided broadband dual polarization radiation unit has advantages of wide frequency band, stable broadband characteristic and simple structure.

Owner:GCI SCI & TECH +1

Low-voltage formation aluminum foil manufacturing method suitable for high-frequency low-impedance electrolytic condenser aqueous electrolyte

ActiveCN103366964AReduce lossReduce the impedance valueElectrolytic capacitorsElectrolysisMetallurgy

The invention aims to provide a low-voltage formation aluminum foil manufacturing method suitable for high-frequency low-impedance electrolytic condenser aqueous electrolyte. The low-pressure formation aluminum foil is long in service life, good in high-frequency property and small in impedance value. The aluminum electrolytic condenser is strong in high-temperature resistance, and has a high-temperature (105 DEG C) load service life of 6000 hours or more, thus effectively solving the difficult problems of short service life, low stability and poor ripple current resisting capacity of the aluminum electrolytic condenser in the prior art.

Owner:广西梧州华锋电子铝箔有限公司

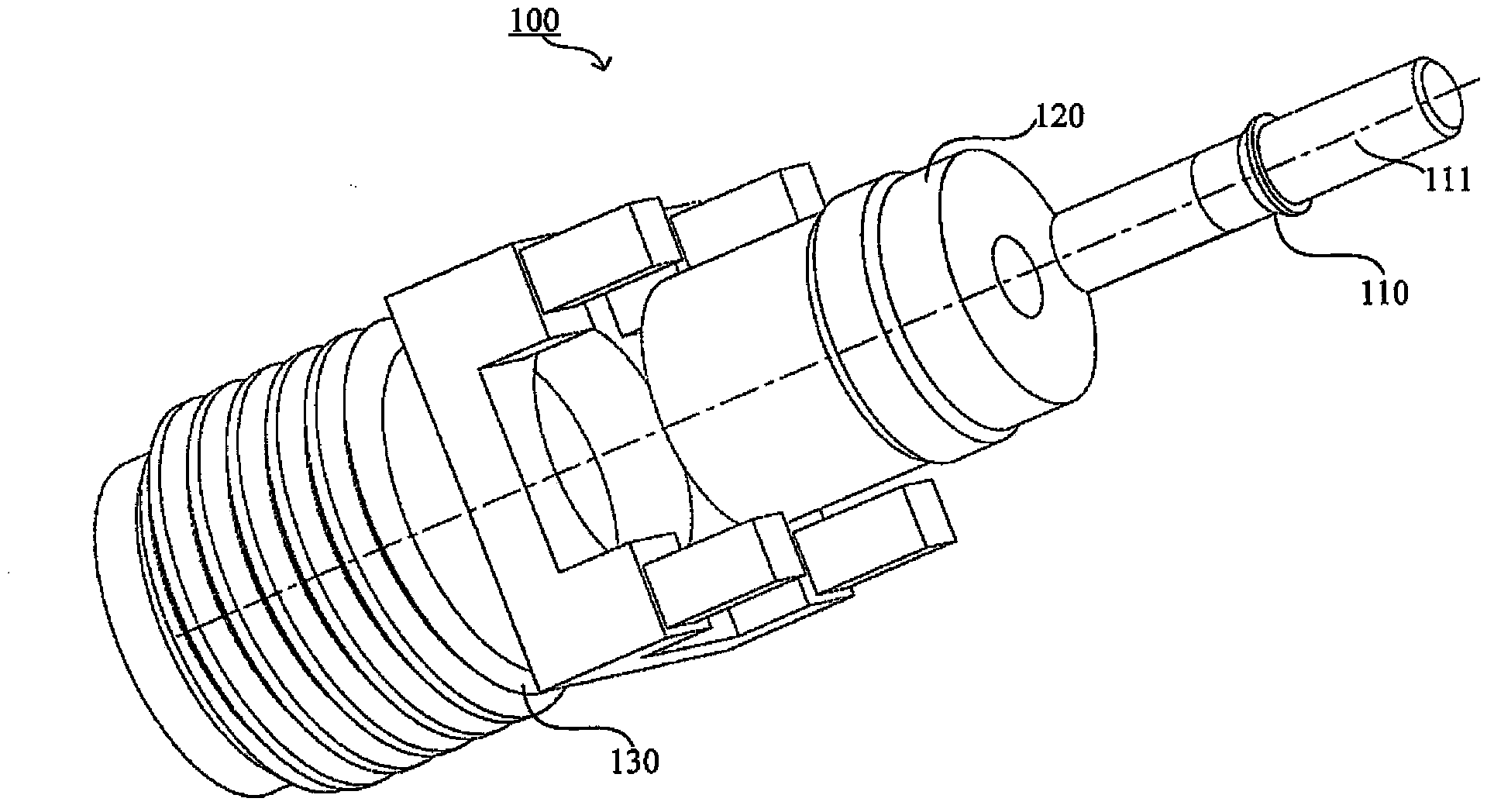

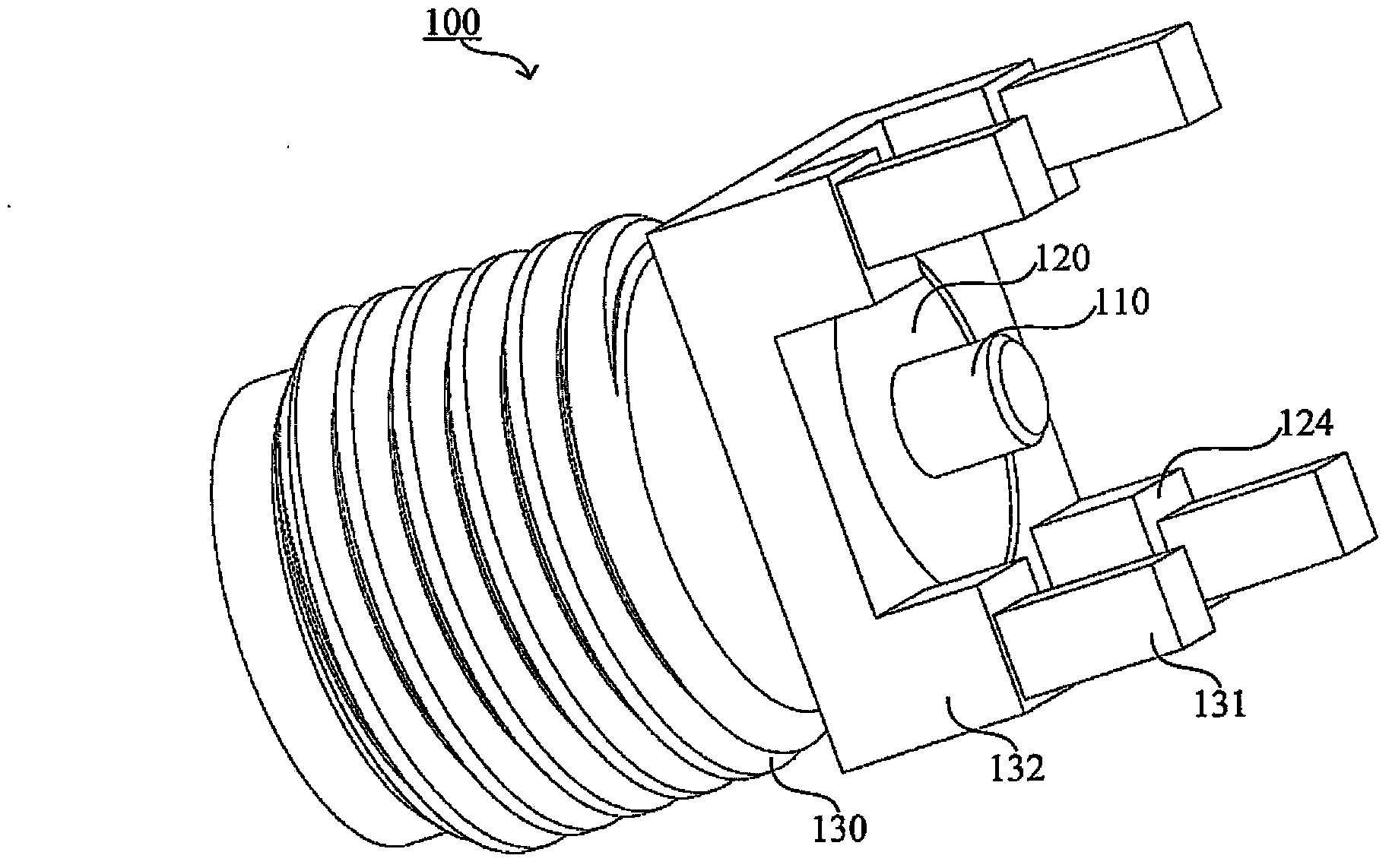

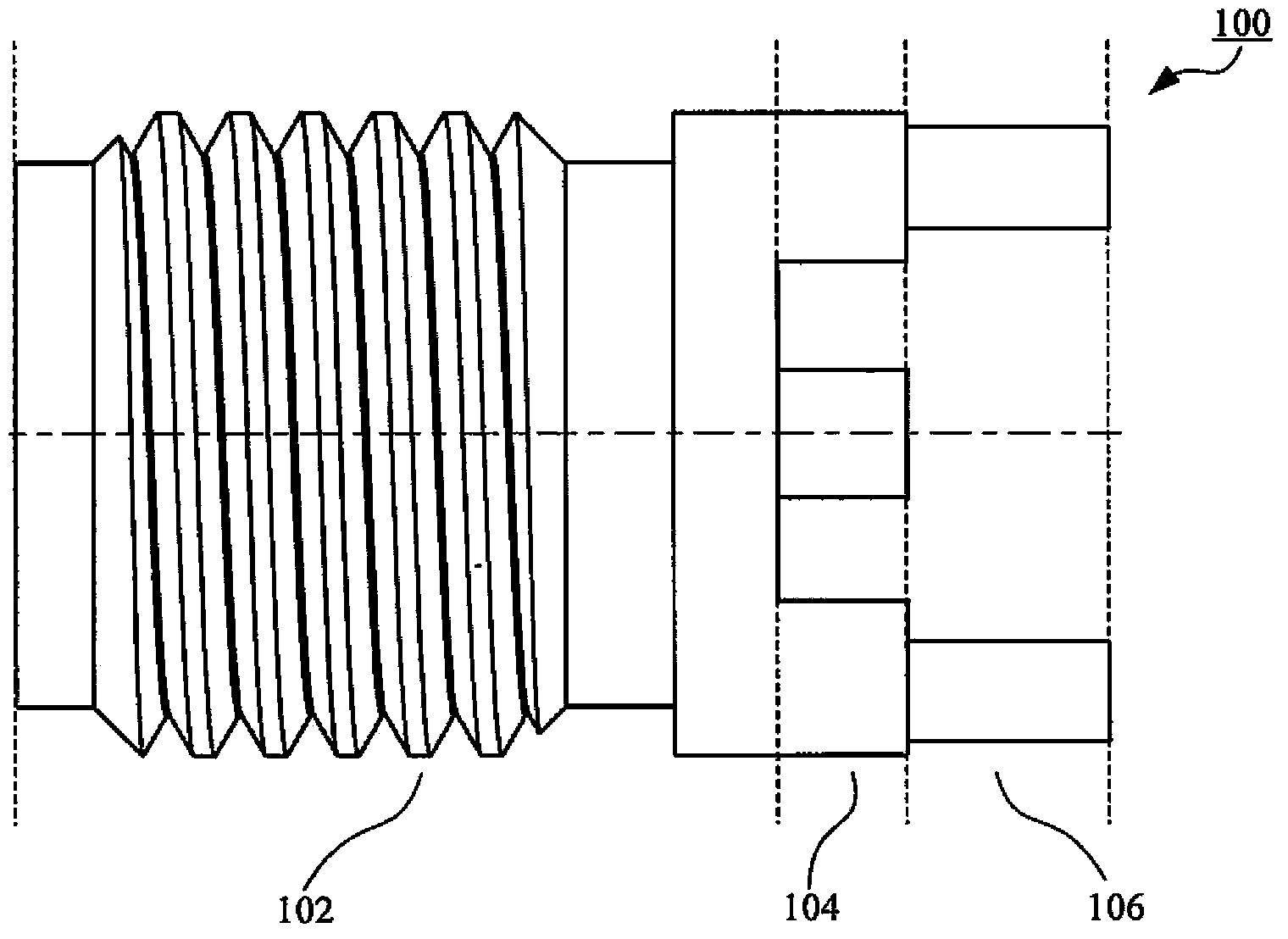

Radio-frequency connector

InactiveCN103579871AImprove impedance continuityImprove shielding effectTwo-part coupling devicesFixed connectionsSurface mountingEngineering

The invention proposes a connector (400) for surface mounting to a circuit substrate, the connector comprises an insulator (420), a center conductor (410) centrically mounted to the insulator and a shielding shell (430) externally mounted on the insulator, the shielding shell comprises a first portion for connecting the shielding shell with a connector and a second portion for surface mounting the connector to the circuit substrate, the second portion includes a body (432) and a plurality of solder legs (431) formed on the body, wherein the body comprises a shielding portion (434) surrounding an extending portion of the center conductor and at least one opening (433) configured to communicate inner space between the center conductor and the shielding portion with outside space of the connector when the RF connector is soldered to the circuit substrate.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +1

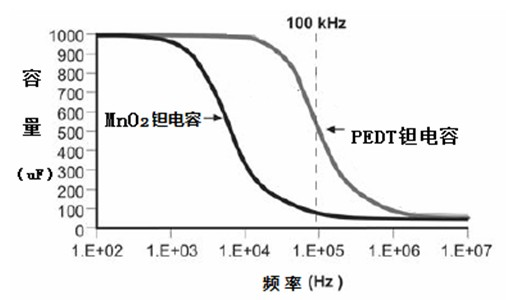

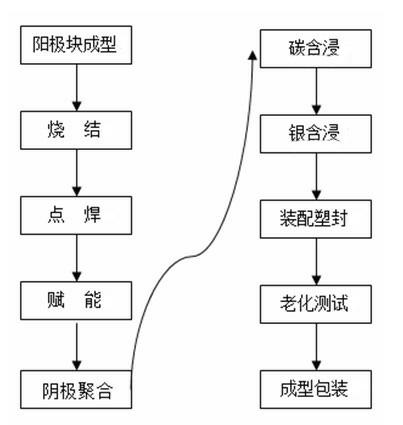

A two-step method for manufacturing pedt cathode chip tantalum electrolytic capacitors

The invention discloses a method for manufacturing a polymer ethylenedioxythiophene (PEDT) cathode plate type tantalum electrolytic capacitor by a two-step method. The cathode plate type tantalum electrolytic capacitor is manufactured by adopting the two-step method. The two-step method is a method which comprises the following steps of: impregnating an oxidizing agent at the first time, impregnating a monomer at the second time, and polymerizing the oxidizing agent and the monomer to prepare PEDT so as to manufacture the cathode plate type tantalum electrolysis capacitor, wherein the whole process is performed under normal temperature. The manufacturing method comprises the following steps of: A, adding a certain amount of adhesive agent into tantalum powder, and stamping and molding themixture, sintering the treated mixture at high temperature to volatilize the adhesive agent and effectively adhere the tantalum powder so as to form a multi-hole tantalum anode plate, and applying direct-current voltage in acidic solution, so that the surface of the tantalum powder is oxidized to generate an amorphous dielectric layer Ta2O5; B, repeatedly immersing the anode plate with the dielectric layer in the oxidizing agent and monomer solution for reaction so as to form a conducting polymer PEDT layer with a certain thickness, namely a cathode; and C, immersing the anode block with the PEDT layer in graphite and silver slurry respectively, curing respectively at high temperature, and performing assembly, plastic package, aging test and labeling to package a capacitor product.

Owner:ZHUZHOU HONGDA ELECTRONICS

Capacitor structure

InactiveCN101276812ASuppresses characteristic deteriorationImprove high frequency characteristicsSemiconductor/solid-state device detailsSolid-state devicesDielectricInductance

The capacitor structure includes a first electrode having a plurality of teeth protruding in a comb shape from an electrode base of a first electrode line and a second electrode having a plurality of teeth protruding in a comb shape from an electrode base of a second electrode line, both formed in a first wiring layer. The first and second electrodes face each other with their teeth interdigitated with each other via a dielectric. At least one of the teeth of the first electrode is electrically connected with a third electrode line formed in a second wiring layer.

Owner:コラボイノベーションズインコーポレイテッド

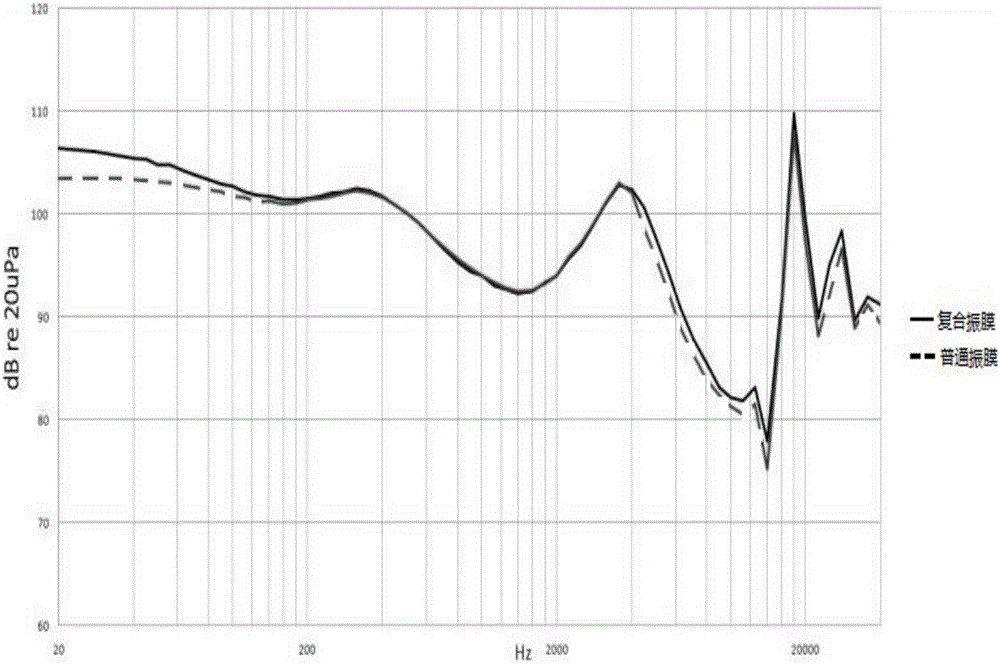

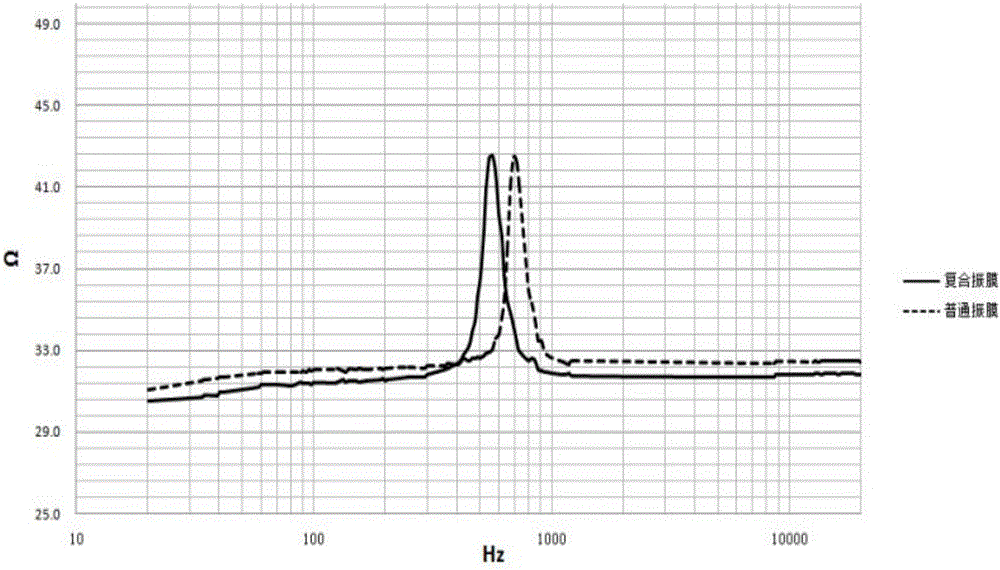

Vibration diaphragm and preparation method thereof

ActiveCN106162450AImprove high frequency characteristicsImprove stabilityPolymeric diaphragmsPolyurea/polyurethane coatingsPolyetherimidePolyethylene glycol

The invention relates to vibration diaphragm and a preparation method thereof. The vibration diaphragm comprises a base layer which is thin film made of any one material of polyetherimide, polyethylene glycol terephthalate, polyetheretherketone, polyphenylene sulfide and polyurethane; and a strengthened layer which is formed by drying and curing a mixture of graphene, graphite powder and glue, wherein the weight ratio of the graphene, graphite powder and glue in the strengthened layer is (1-2):(5-10):(9994-9988), and the strengthened layer is adhered on the surface of the base layer. The preparation method comprises the steps of providing the thin film, glue, graphite powder and graphene, evenly mixing the graphite powder and the graphene to form a first mixture, mixing the first mixture in the glue, evenly mixing to form a second mixture; and evenly coating the second mixture on the surface of the thin film and carrying out drying, thereby curing the second mixture on the surface of the thin film to obtain the final vibration diaphragm. According to the vibration diaphragm and the preparation method, the adhesion of the vibration diaphragm is high, the resonant frequency f <0> is reduced, the high frequency sound pressure is increased, and the high and low frequency characteristics are completed.

Owner:CHANGZHOU AMT

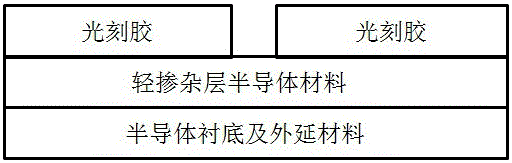

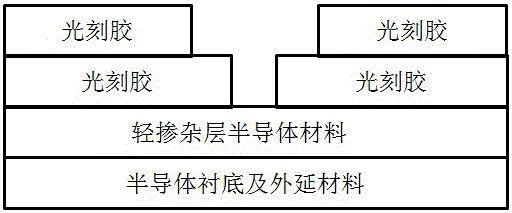

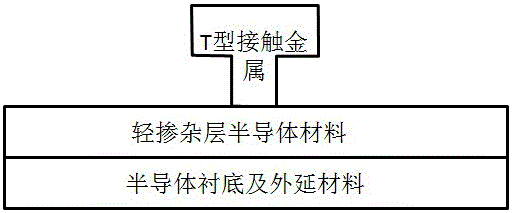

Method of making Schottky diode T-type anode contact air bridge electrode

ActiveCN106683992AImprove high frequency characteristicsSmall anode parasitic capacitanceSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsEtching

The invention relates to a method of making a Schottky diode T-type anode contact air bridge electrode, comprising the following steps: making a diameter-A anode contact hole in a lightly doped semiconductor material by means of photo-etching; making a diameter-B anode contact hole in the diameter-A anode contact hole in an overlay manner; forming T-type anode contact metal through an evaporative stripping process; forming air bridge lower glue by means of photo-etching; forming air bridge upper glue by means of photo-etching; forming air bridge metal through an evaporative stripping process; and connecting the T-type anode contact metal with an anode electrode plate, thus completing the making of a Schottky diode T-type anode contact air bridge electrode. The advantage is that by using the method of making a T-type anode air bridge electrode, the parasite capacitance of anode electrodes can be reduced effectively, and the cutoff frequency of Schottky diodes can be improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Method for modified silicon iron boron soft magnetic powder core with magnetic conductivity of 90

ActiveCN103500643AImprove noise defectsImprove high frequency characteristicsInorganic material magnetismInductances/transformers/magnets manufactureSilicon ironMaterials science

The invention belongs to the field of metal soft magnetic material manufacturing, and particularly relates to a method for manufacturing a modified silicon iron boron soft magnetic powder core with magnetic conductivity of 90. The method comprises the first step of embrittlement treatment, the second step of crushing, the third step of screening and matching, the fourth step of passivating treatment and insulation covering, the fifth step of modifying agent adding, the sixth step of compression moulding and the seventh step of annealing treatment and spraying. According to the method, the noise defect of the silicon iron boron soft magnetic powder core can be overcome, and the high-frequency performance of the silicon iron boron soft magnetic powder core can be improved.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

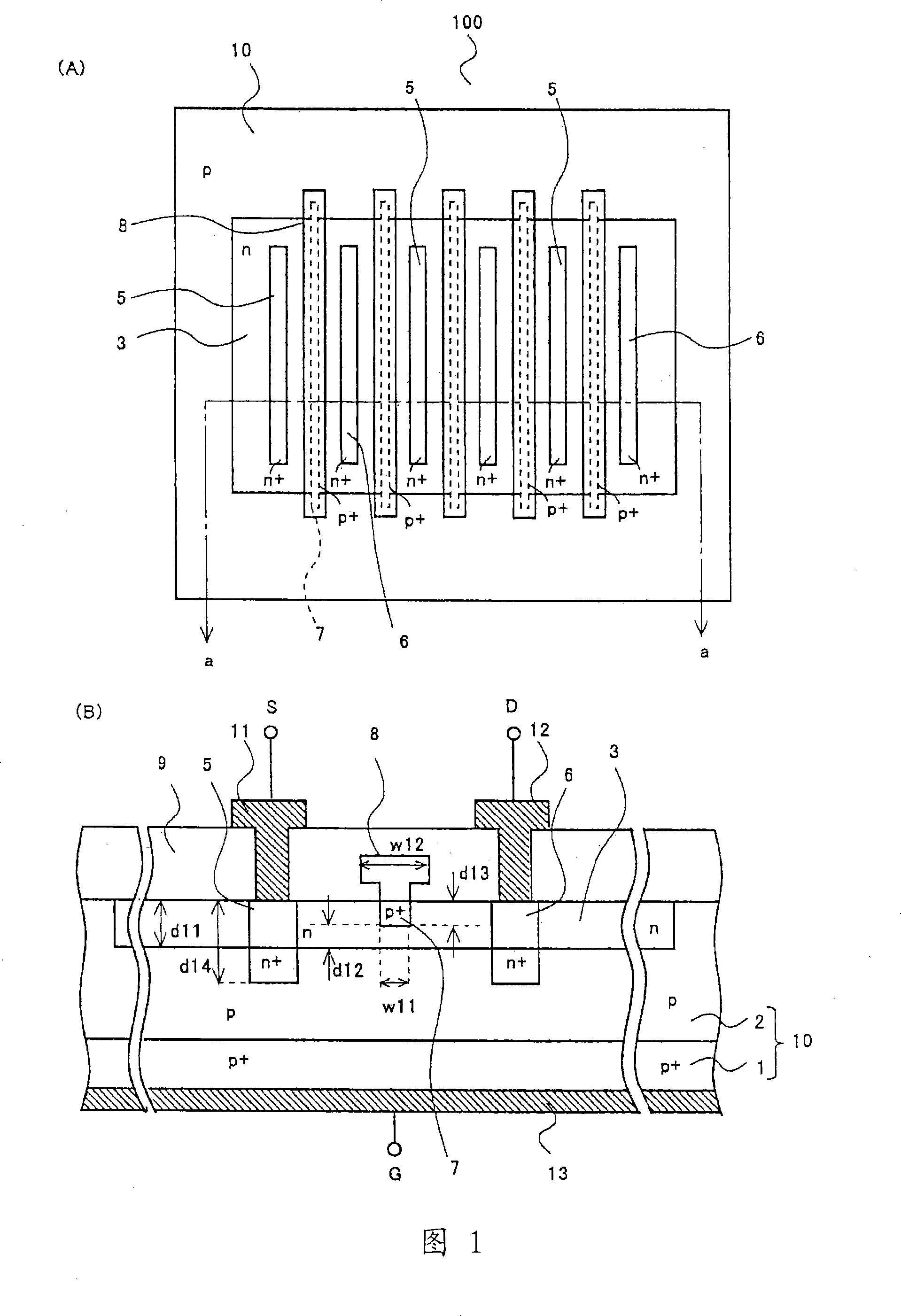

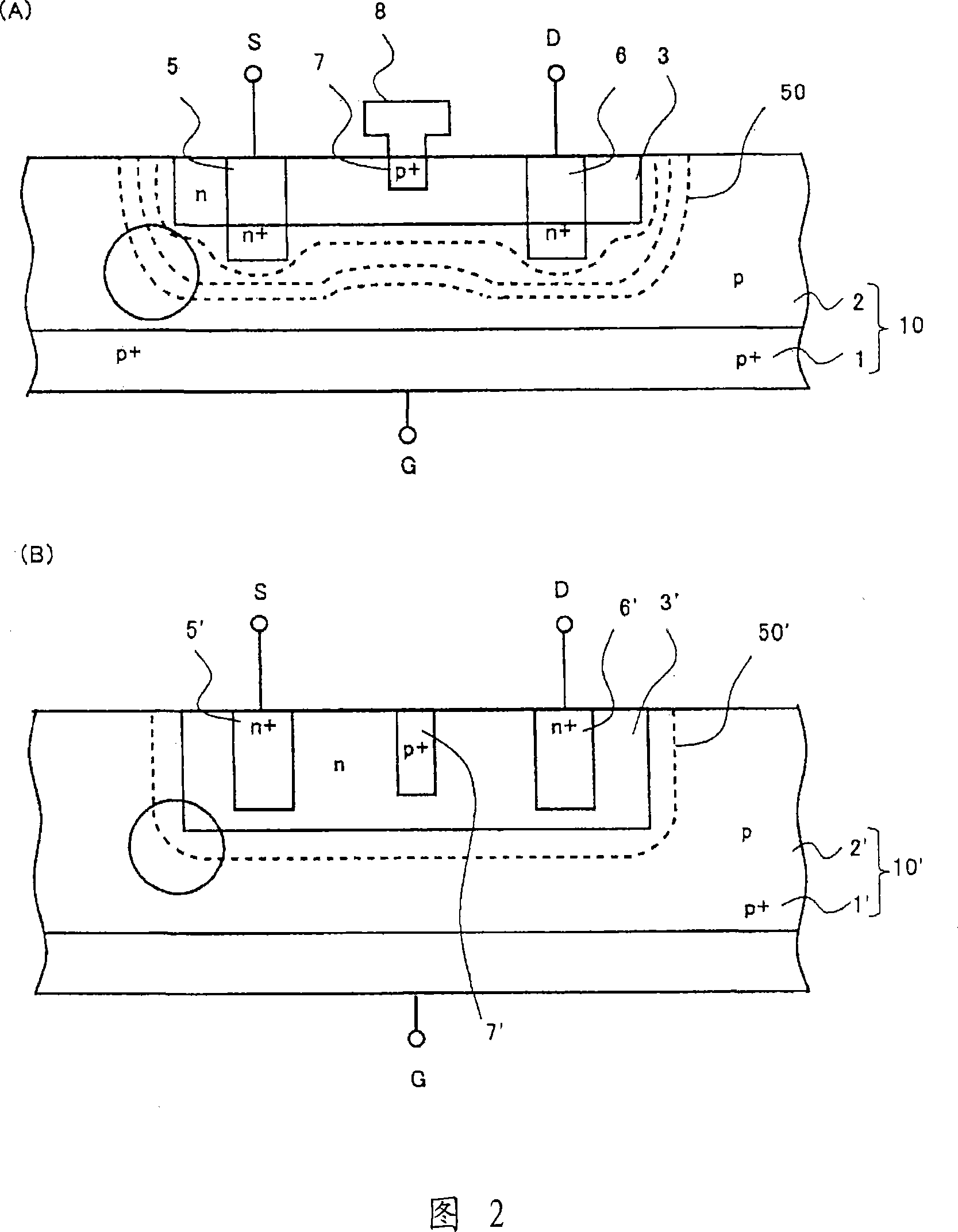

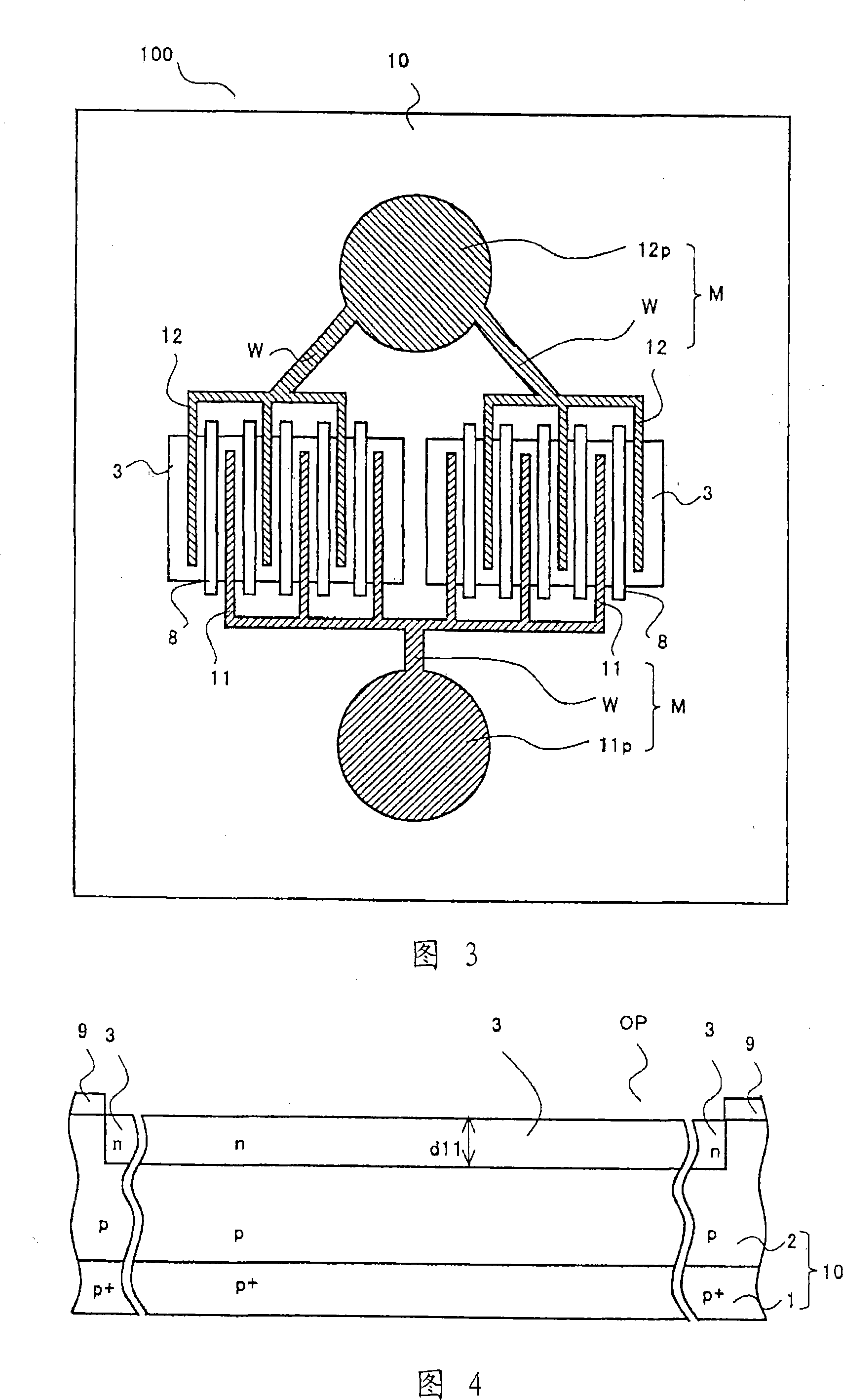

Junction field effect tube and method of manufacturing the same

InactiveCN101170136ALow pn junction areaImprove high frequency characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceInternal resistance

Owner:SANYO ELECTRIC CO LTD +1

Method for producing laminate

InactiveCN1798647AImprove adhesionHeat resistance with high adhesionPrinted circuit manufactureFlat articlesLiquid crystallineMetal foil

A method for producing a laminate, wherein a film comprised of a liquid-crystalline polymer film forming an optically anisotropic molten phase and a metal foil are piled and are passed between pressing rolls, to adhere said film to said metal foil by pressing with heating, which comprises using, as at least one roll of said pressing rolls, a coated roll having a metal roll and, provided on the surface thereof, a coating layer of a resin such as a fluororubber or a polyimide having a thickness of 0.02 to 5 mm, or comprises passing the above polymer film and metal foil between metal pressing rolls together with a heat-resistant film piled on the surface contacting with the metal roll of the polymer film or the metal foil. The method allows the production of a laminate of a liquid-crystalline film and a metal foil exhibiting satisfactory adhesion between them and being excellent in heat resistance, with good productivity.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

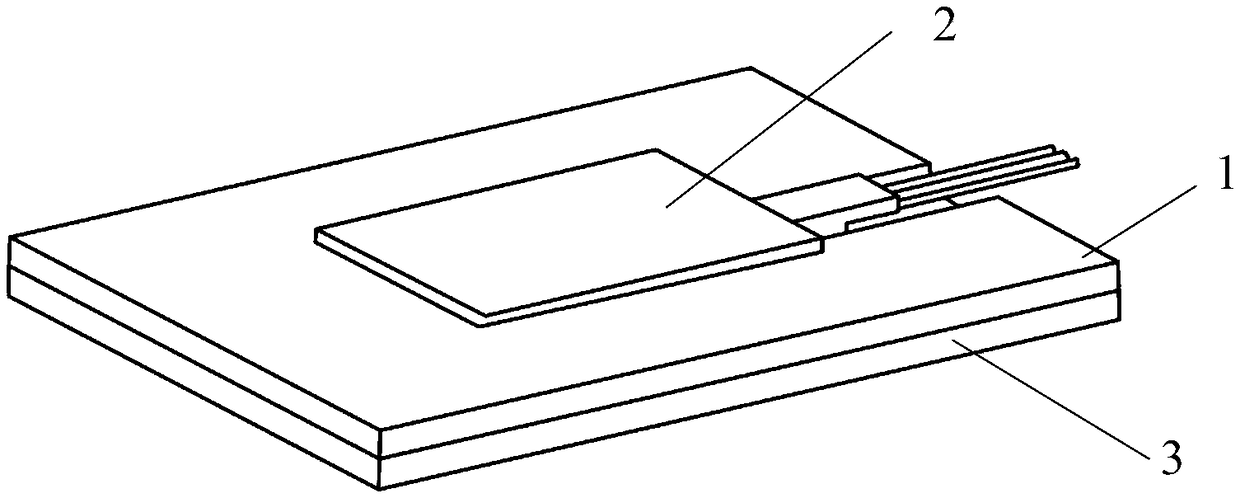

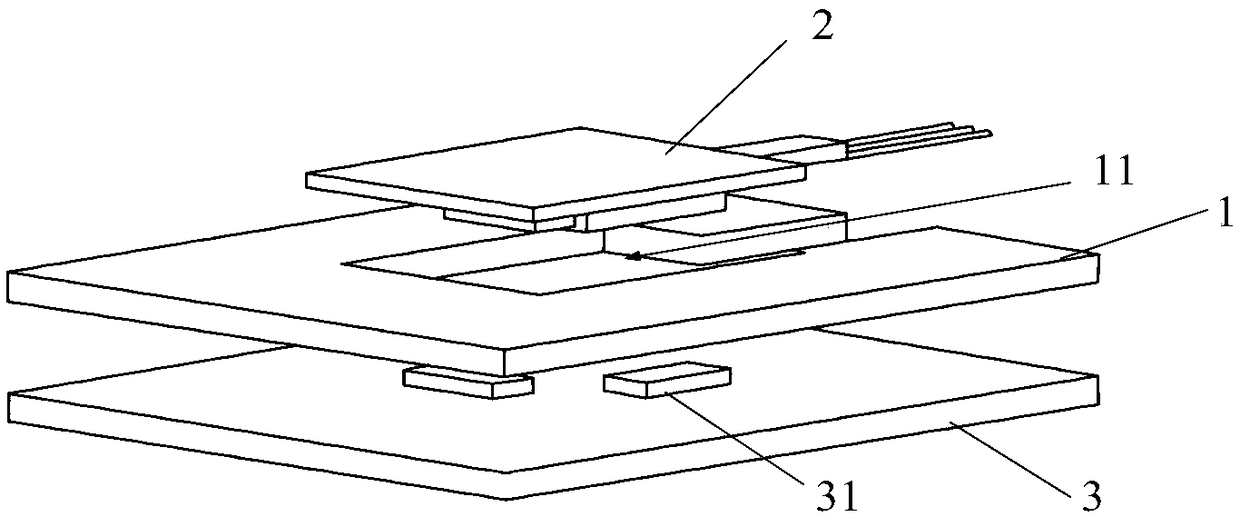

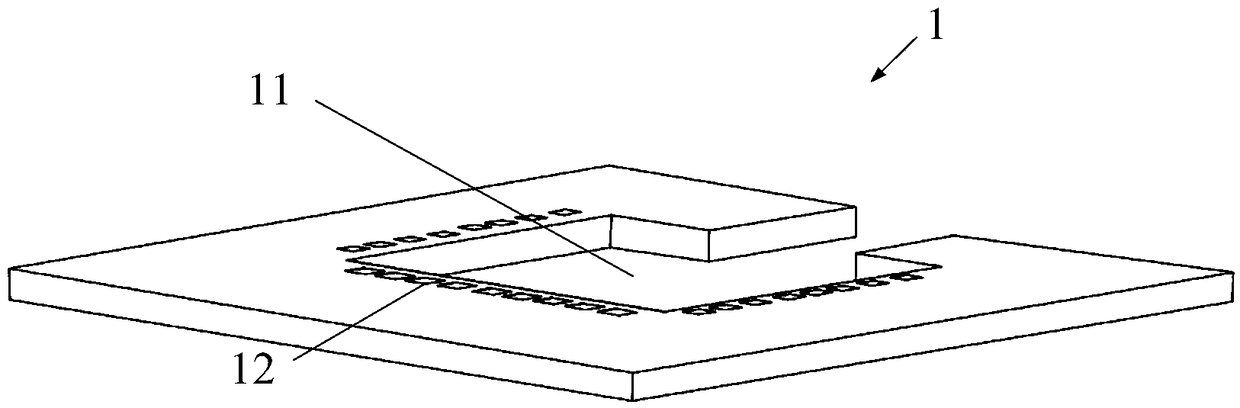

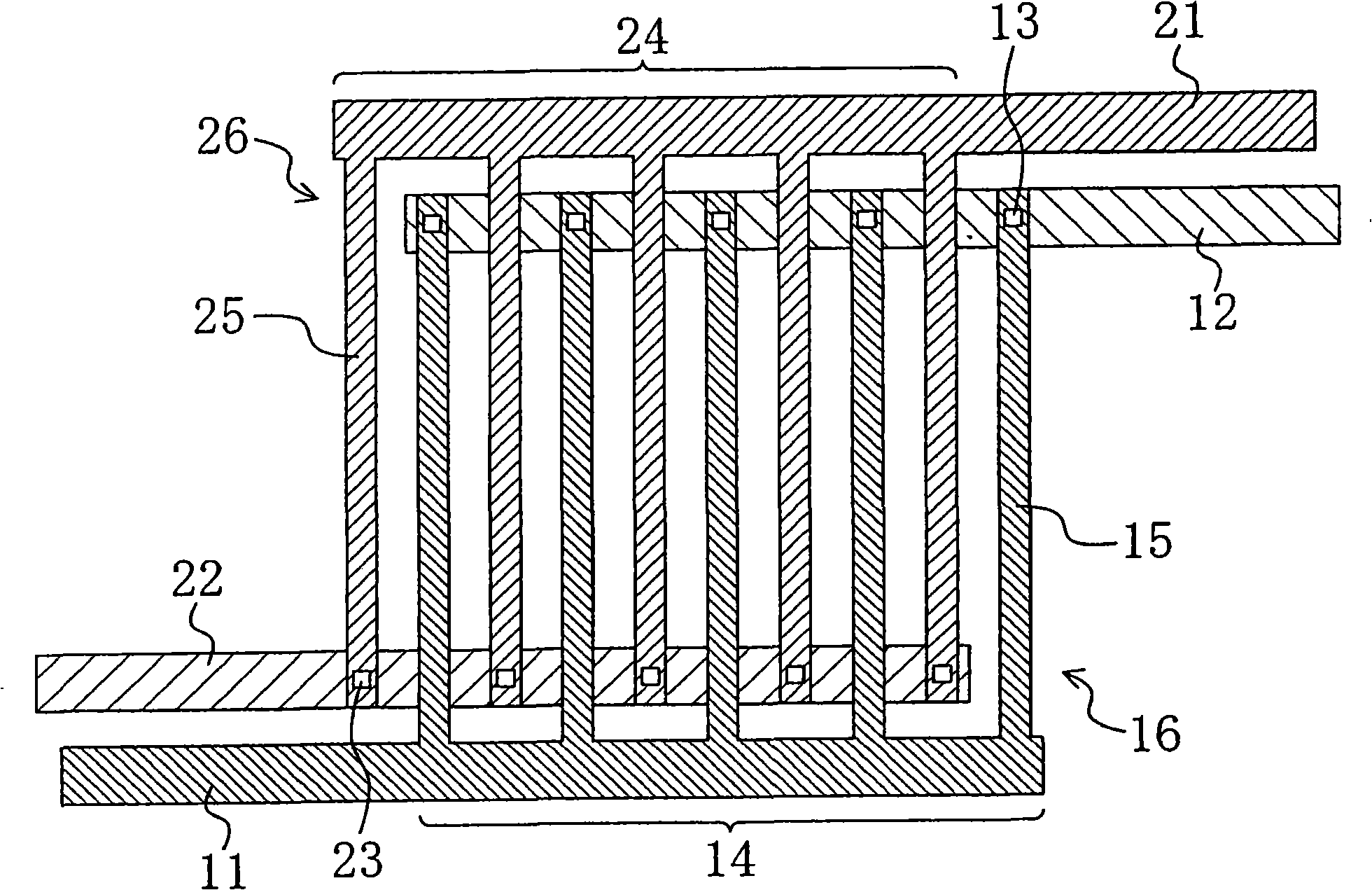

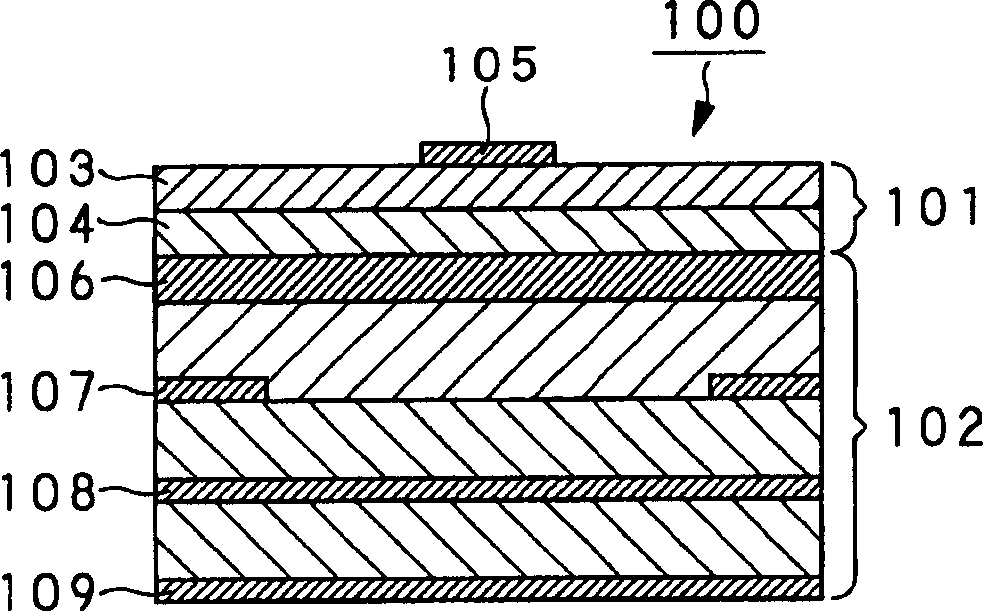

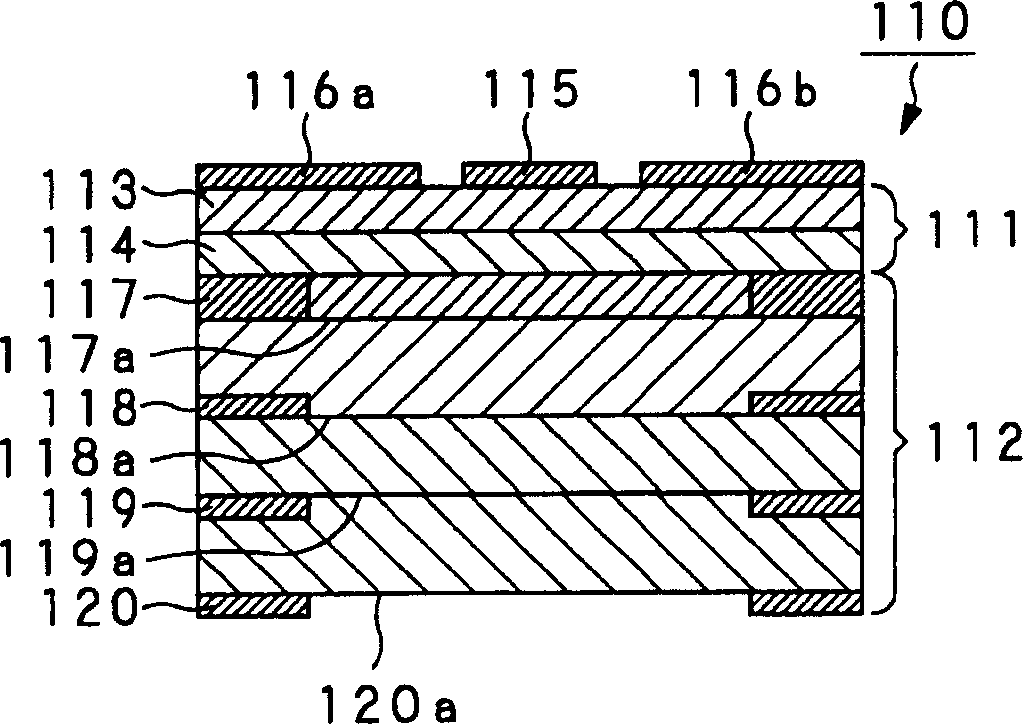

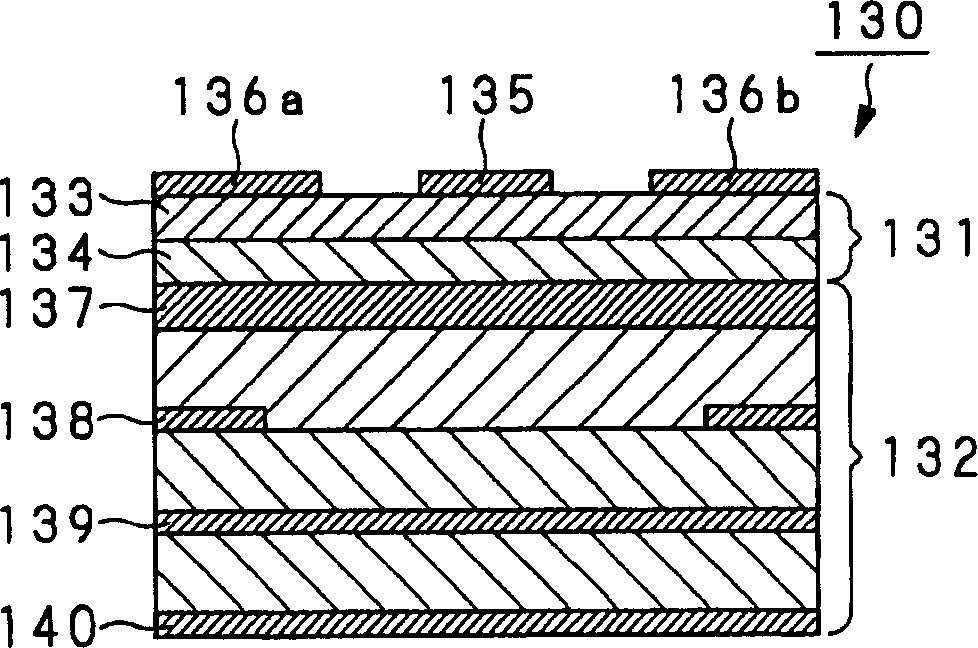

High frequency module

InactiveCN1507671ALow costReduce uneven thicknessCross-talk/noise/interference reductionSemiconductor/solid-state device detailsSemiconductor chipEngineering

The present invention provides a high frequency module having a base substrate unit ( 2 ) which has its uppermost layer planarized to form a buildup-forming surface ( 16 ), a high frequency circuit unit ( 3 ) having multiple wiring layers which are formed on the base substrate unit ( 2 ), each of which layers has a wiring pattern and film elements formed on a dielectric insulating layer thereof, whose uppermost wiring layer ( 17 ) has plural lands ( 22 ) and ground patterns ( 20 ) formed thereon together with the wiring pattern and inductor elements ( 19 ), and a semiconductor chip ( 4 ) mounted on the wiring layer ( 17 ) of the high frequency circuit unit ( 3 ). Transmission lines ( 24 ) to connect the inductor elements ( 19 ) and lands ( 22 ) which are formed on the wiring layer ( 17 ) are directed within hollowed pattern regions ( 20 c) formed at the ground pattern ( 20 ) to constitute coplanar type transmission lines.

Owner:SONY CORP

Fabrication method of field-effect transistor and field-effect transistor fabricated by employing fabrication method

ActiveCN105742500ASimplify processing stepsImprove high frequency characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingFiberMicro nano

The invention discloses a method for fabricating a field-effect transistor by employing an electric fluid direct-writing process. The method comprises the following steps of (1) fabricating an organic semiconductor thin film on a substrate; (2) fabricating linear fibers in parallel on the substrate with the semiconductor thin film by using the electric fluid direct-writing process; (3) fabricating parallel dielectric fibers perpendicular to the linear fibers by electric fluid direct writing; (4) vacuum-depositing metal on the substrate; and (5) applying conductive sliver paste onto the two ends of the dielectric fibers, and leading out a grid electrode. The invention also discloses a corresponding product. According to the method, a transistor channel is obtained by means of the dielectric micro-nano fibers, the length side of the channel is equivalent to the diameter sizes of the fibers and can reach sub-micron even nanoscale, and meanwhile, the fibers are also an insulation layer of the transistor; and moreover, through one-time metal vacuum deposition, a source, a drain and a grid of the field-effect transistor can be simultaneously formed. By the method, the fabrication process step of the transistor is greatly simplified, and meanwhile, the fabrication cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

New bonding and assembling process for slow wave circuit of microwave tube and its bonding agent cleaning system

InactiveCN1805680AImprove high frequency characteristicsEven contactWork holdersCleaning using liquidsInterference fitMicrowave tube

The invention relates to a microwave slow-wave circuit adhere installment technique, which also discloses relative cleaning system of said adhesive. The inventive microwave slow-wave circuit can improve the high-frequency property of microwave tube. The inventive cleaning system can clear the adhesive and save the consumed solvent, with simple structure, continuous operation, and high safety. The inventive technique comprises: first sticking three ceramic clamping rods with adhesive on the integration of screw line and core rod in 120 degree; then abrading the outer round of integration; pushing the integration and the microwave tube in interference fit with special device into the tube case; and removing the adhesive.

Owner:NANJING UNIV OF TECH

Electrostatic shielding effect transistor and design method thereof

ActiveCN104009087AImprove high frequency characteristicsReduce dynamic lossSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

The invention discloses an electrostatic shielding effect transistor. The electrostatic shielding effect transistor comprise a collector, groove-type grids, a base region, an oxidization layer, a polycrystalline silicon layer and emitters. The collector comprises a leading-out end, an N+ substrate, an N+ conductive material layer and an N- conductive material layer. The groove-type grids are arranged on the N- conductive material layer, B ions of certain concentration are injected into the bottom of a groove to serve as P+ regions, and the base region injected with the B ions is arranged between the grids. The oxidization layer is arranged on the grids and the base region, the emitters are formed on the base region and the oxidization layer, the polycrystalline silicon layer is deposited on the oxidization layer and the polycrystalline silicon layer forms an emitting region below the emitters after high-temperature diffusion. The electrostatic shielding effect transistor is provided with the emitters and the base region which are super shallow in junction and small in size, and therefore, the emitter current crowding effect and the base region flow extruding effect of the device can be greatly improved. Due to the super small junction depth of the structure and the base region of the device, the hole extraction speed is increased and the high frequency property of the device is improved.

Owner:SHENZHEN SHENGYUAN SEMICON

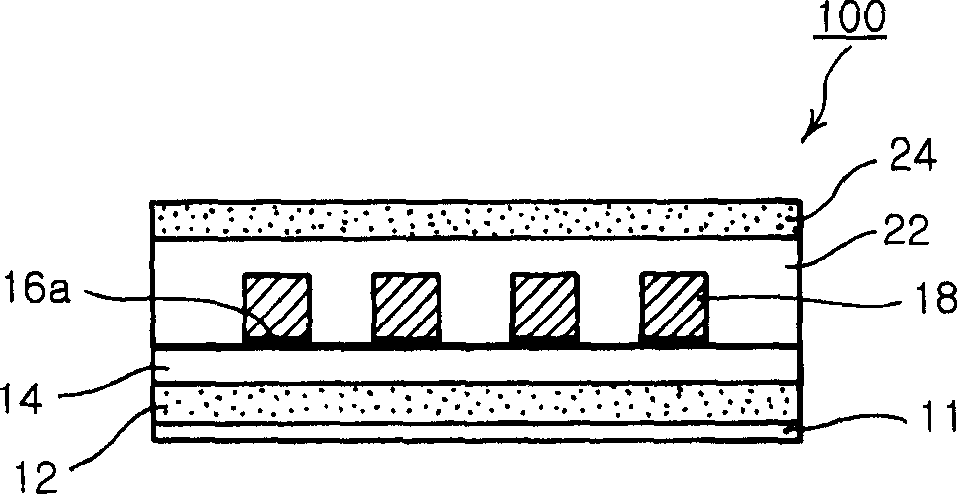

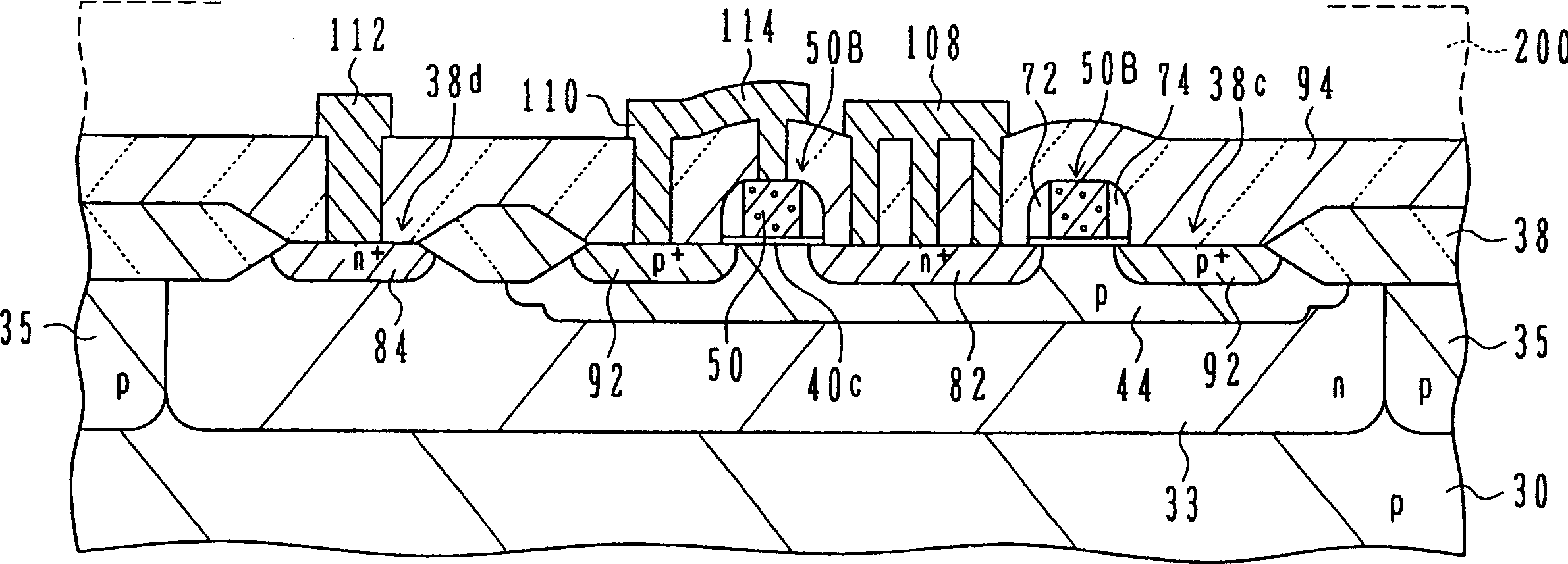

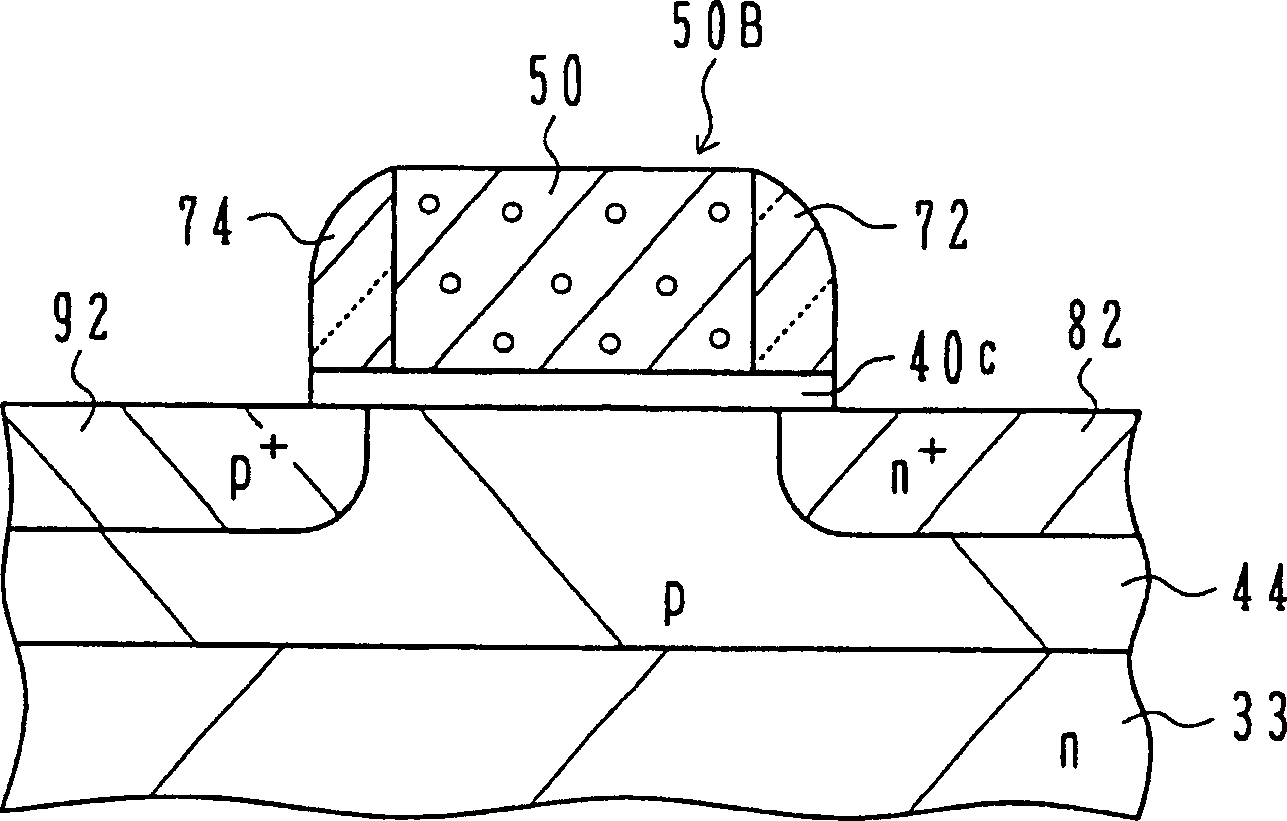

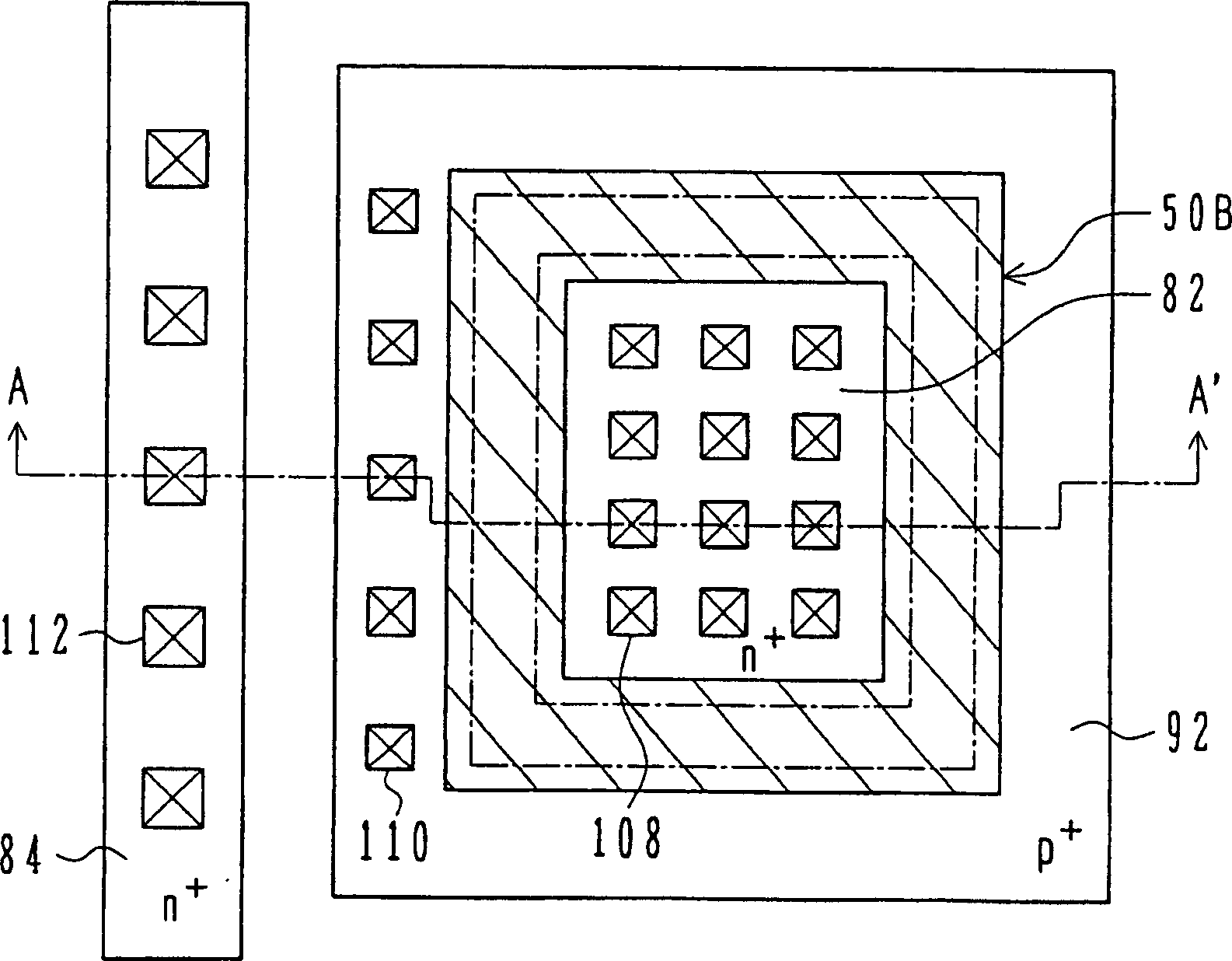

Semiconductor device including bipolar junction transistor with protected emitter-base junction

InactiveCN1677690AReduce leakage currentLower base resistanceTransistorSolid-state devicesCMOSSemiconductor

A method of manufacturing a CMOS-BJT semiconductor device comprises the steps of: forming a collector region of a first conductivity type and a first well of the first conductivity type, simultaneously in a semiconductor substrate; forming a second well of a second conductivity type opposite to said first conductivity type, in the semiconductor substrate; forming a base region of the second conductivity type in the collector region; forming first and second insulated gate structure on said first and second wells, and a junction protection structure having same constituent elements as said insulated gate structures on said base region; and forming second source / drain regions of the first conductivity type in said second well, and an emitter region of the first conductivity type in the base region, simultaneously, with an emitter-base junction reaching the principal surface below said junction protection structure.

Owner:YAMAHA CORP

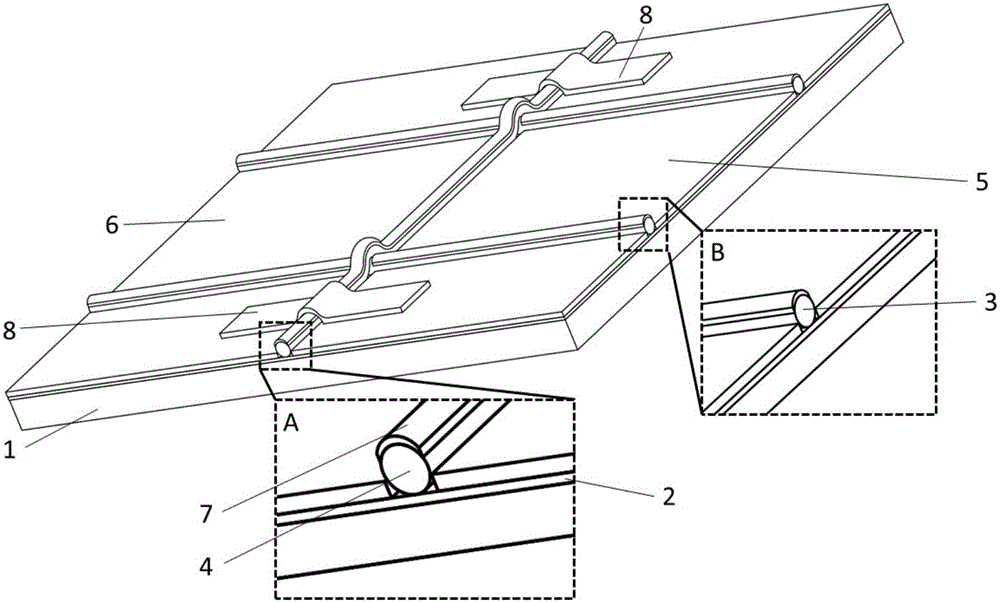

Edge coupling photoelectric device packaging structure and preparation method thereof

PendingCN110673279AHigh precisionSimple structureCoupling light guidesOptical couplingMaterials science

The invention belongs to the field of photoelectric devices and relates to an edge coupling photoelectric device packaging structure. The edge coupling photoelectric device packaging structure comprises an optical chip, an optical coupling structure block and a transparent resin protection structure block; the edge coupling structure is arranged on the optical chip; the optical coupling structureblock abuts against the side coupling structure; a through hole used for fixing an optical fiber is formed in the optical coupling structure block; the transparent resin protection structure block isarranged between the optical chip and the optical coupling structure block and is used for covering the coupling surface of the optical chip so as to ensure normal light transmission; and the opticalchip, the coupling structure block and the transparent protection resin are all located in a packaging layer. In the use process of the edge coupling photoelectric device packaging structure, it justneeds to directly insert the optical fiber into the through hole so as to be fixed, so that high-precision alignment between the optical fiber and the optical chip can be achieved. The edge couplingphotoelectric device packaging structure has the advantages of passive alignment, simple structure, high precision and easiness in assembling process and mass production.

Owner:NAT CENT FOR ADVANCED PACKAGING

Schottky diode and manufacturing method thereof

InactiveCN103094358AImprove reverse breakdown voltageImprove high frequency characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorIsolation layer

The invention relates to a semi-conductor device, in particular to a novel channel schottky rectifier tube. The rectifier tube comprises a first semi-conductor layer, a first metal electrode arranged below the first semi-conductor layer, a first channel, a second channel, isolation layers, a barrier metal layer, an oxide layer, and a second metal electrode, wherein the first channel and the second channel are arranged in the first semi-conductor layer and are mutually separated, the isolation layers are located in the channels, the barrier metal layer is arranged above the first semi-conductor layer and between the first channel and the second channel, the oxide layer is arranged above the first semi-conductor layer outside the barrier metal layer, and the second metal electrode is arranged above the first semi-conductor layer. The depths of the channels are 2um-7um. By means of arrangement of the channels, reverse breakdown voltage of a schottky diode is improved.

Owner:BYD CO LTD

Solid electrolytic capacitor and manufacturing method of the same

InactiveCN101055804AUniform thicknessImprove the installation effectSolid electrolytic capacitorsCapacitor housing/encapsulationCathode rayAluminum electrolytic capacitor

A solid electrolytic capacitor includes a capacitor element, an anode terminal, a cathode terminal, and an outer casing resin. The anode and cathode terminals constitute parts of the mounting surface, and are drawn immediately below the capacitor element. The anode terminal and the cathode terminal are electrically coupled with an anode leader of the capacitor element and a cathode layer, respectively. The outer casing resin covers the capacitor element, and exposes the anode and cathode terminals on the mounting surface. At least one recess is provided on a mounting surface side of at least one of the anode and cathode terminals having a larger area projected onto the mounting surface.

Owner:PANASONIC CORP

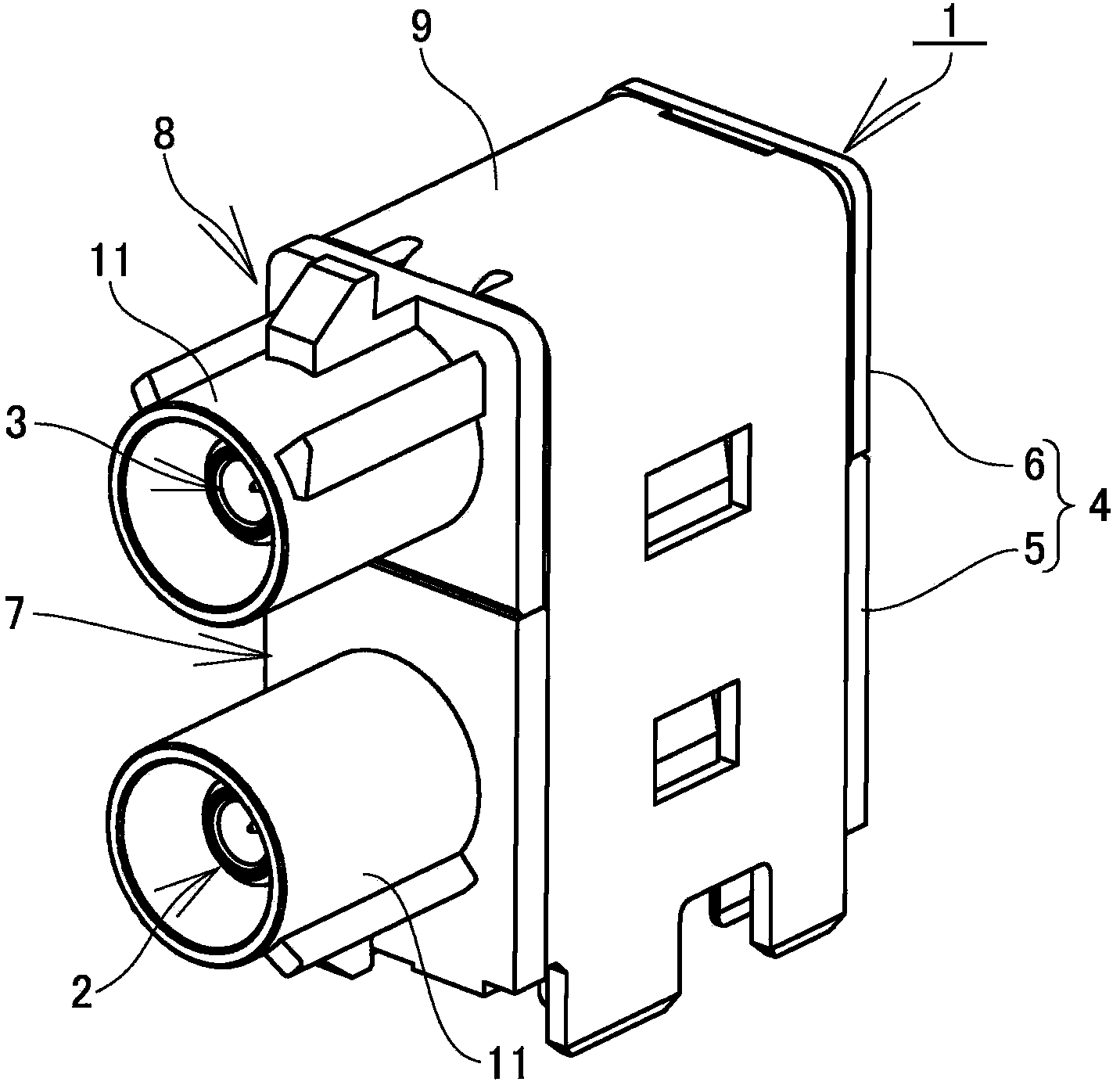

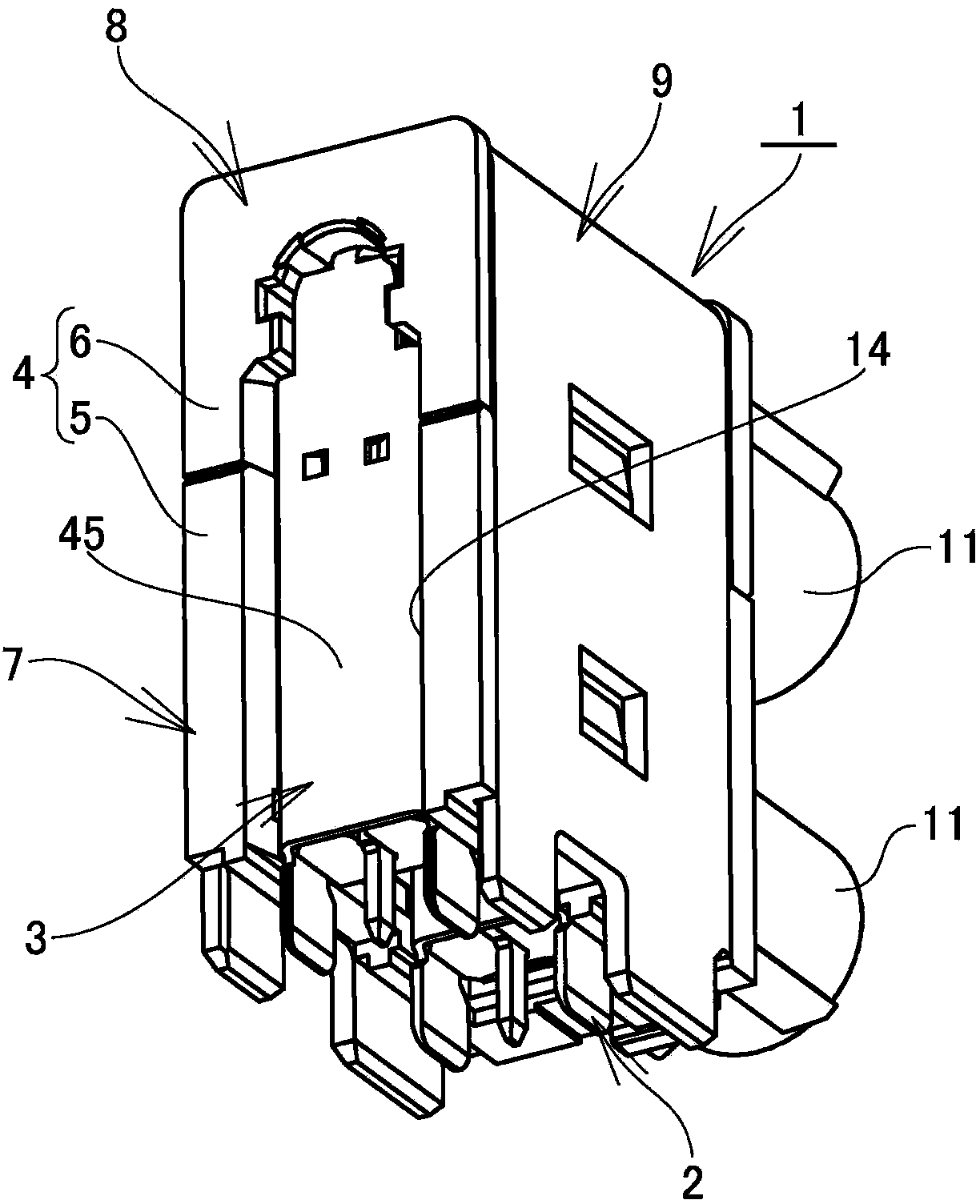

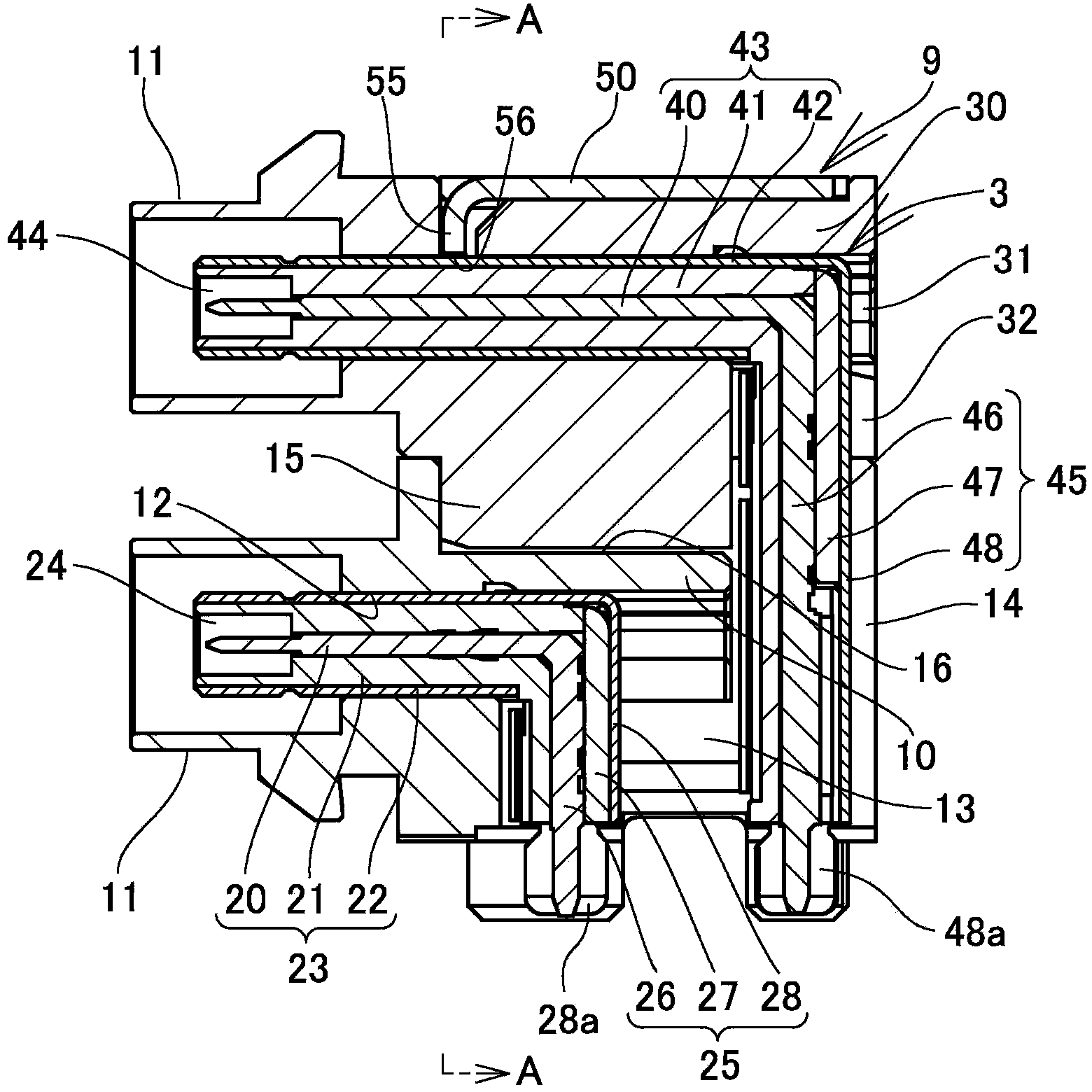

Multi-pole connector

InactiveCN104241880AHigh strengthEasy and efficient assemblyElectrically conductive connectionsIncorrect coupling preventionMechanical engineeringEngineering

The invention provides a multi-pole connector which can correspond with multiple poles of an interface and realizes space saving of an interface part. Furthermore the multi-pole connector can correspond with a multilayer configuration in which a plurality of conductor connecting parts are configured on a mounting substrate in a vertical direction. The multi-pole connector is provided with a plurality of divided connectors (7,8) which are obtained through respectively holding conductors (2,3) on divided housings (5,6) that are divided from the housing (4) and have different shapes. A joint end surface part of one divided housing (5) in the divided housings (5,6) which are adjacent with each other is provided with a key embedding part (16) for insertion of a connecting key (15). Through embedding the connecting key (15) into the key embedding part (16), the connecting key (15) is clamped between the joint end surface parts in a manner of bestriding the joint end surface parts, thereby joining the two divided housings (5,6), thereby connecting the divided connectors (7,8) which are adjacent with each other.

Owner:SMK CO LTD

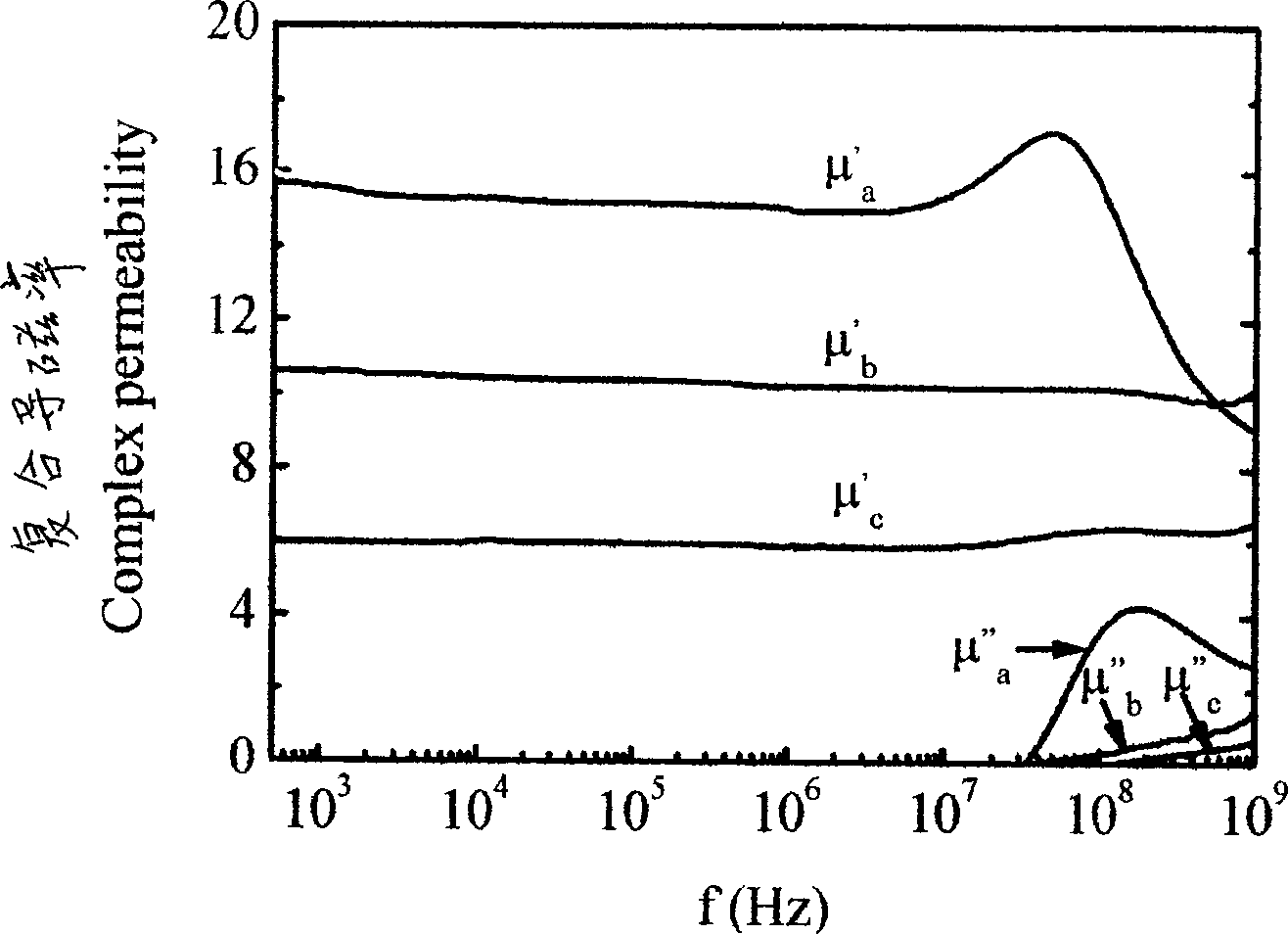

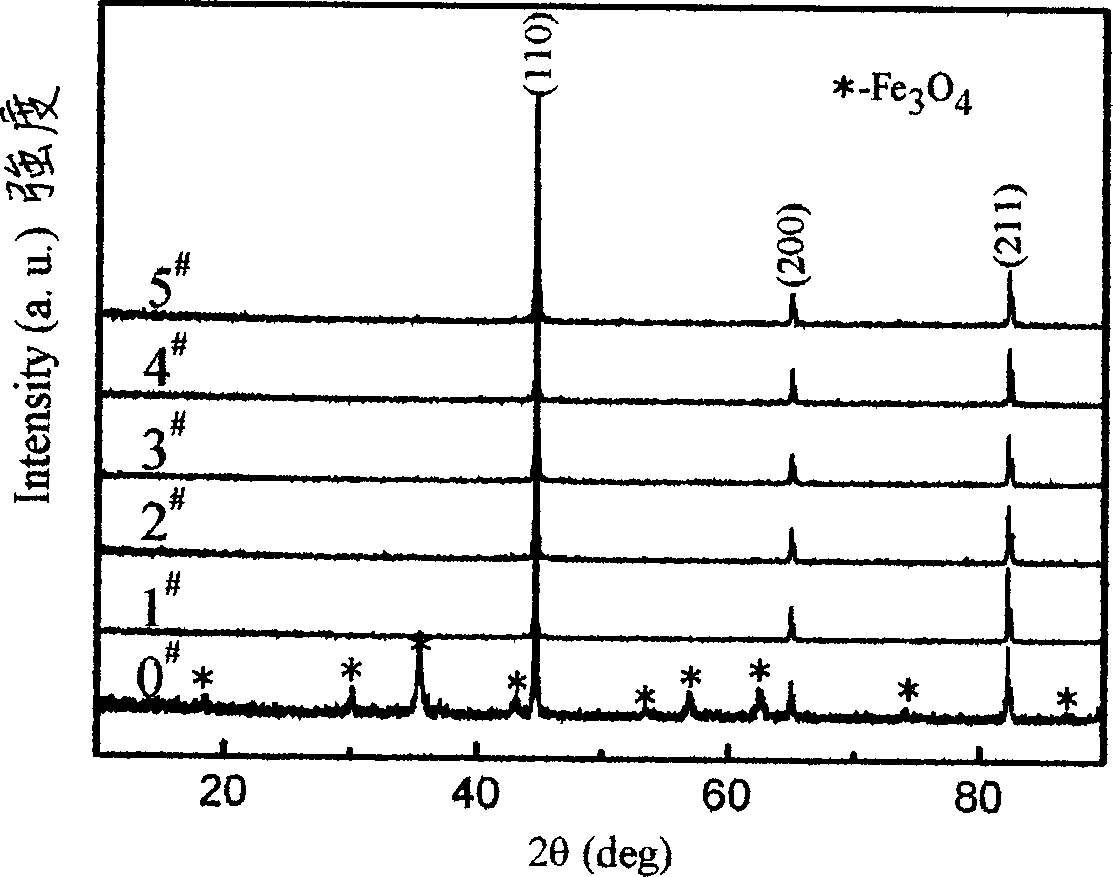

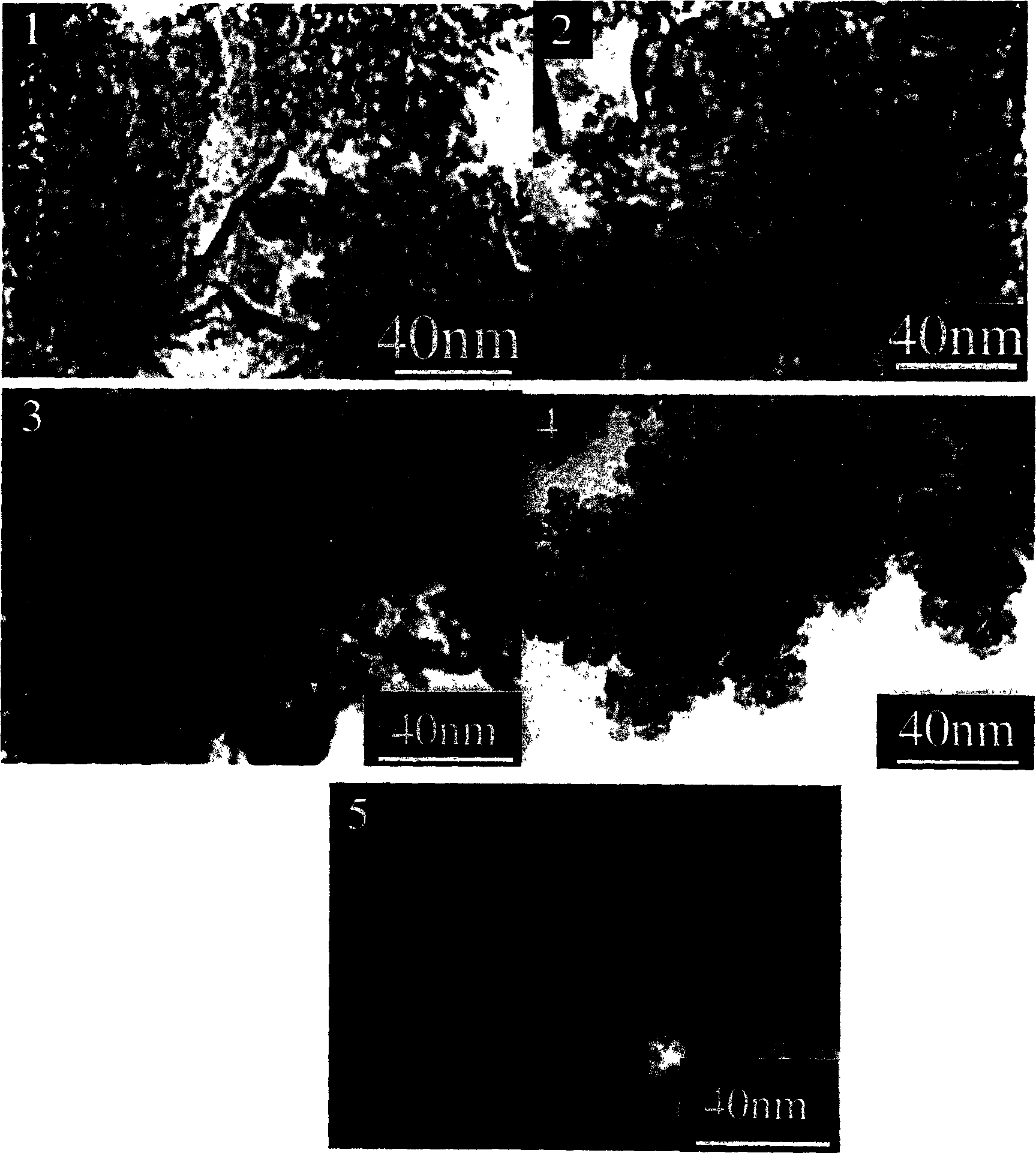

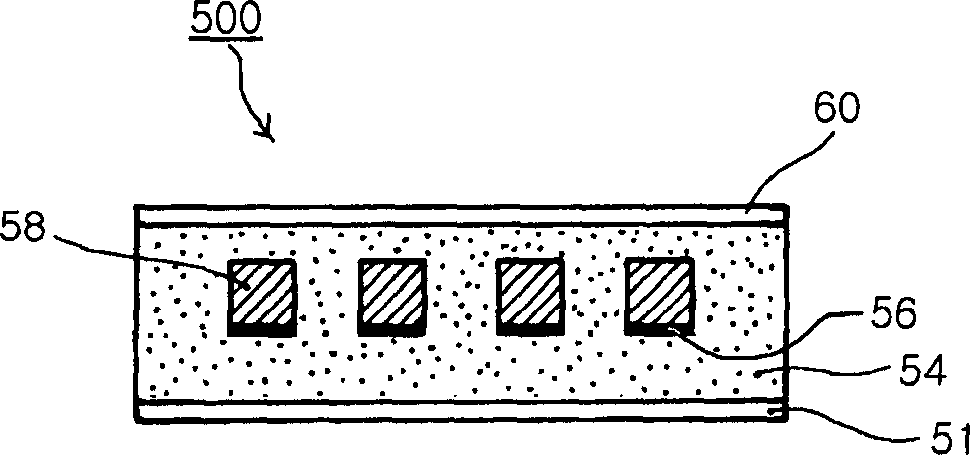

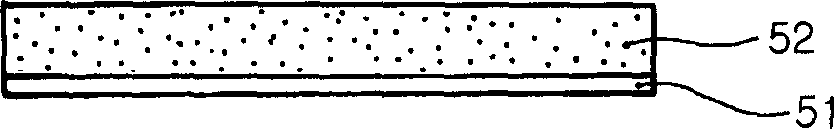

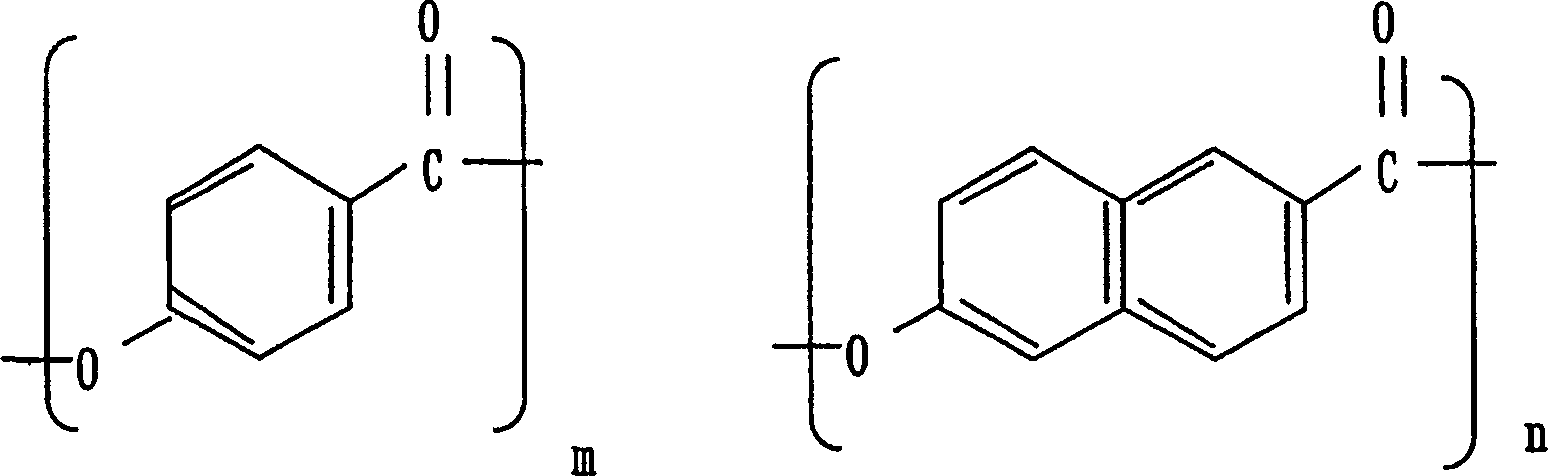

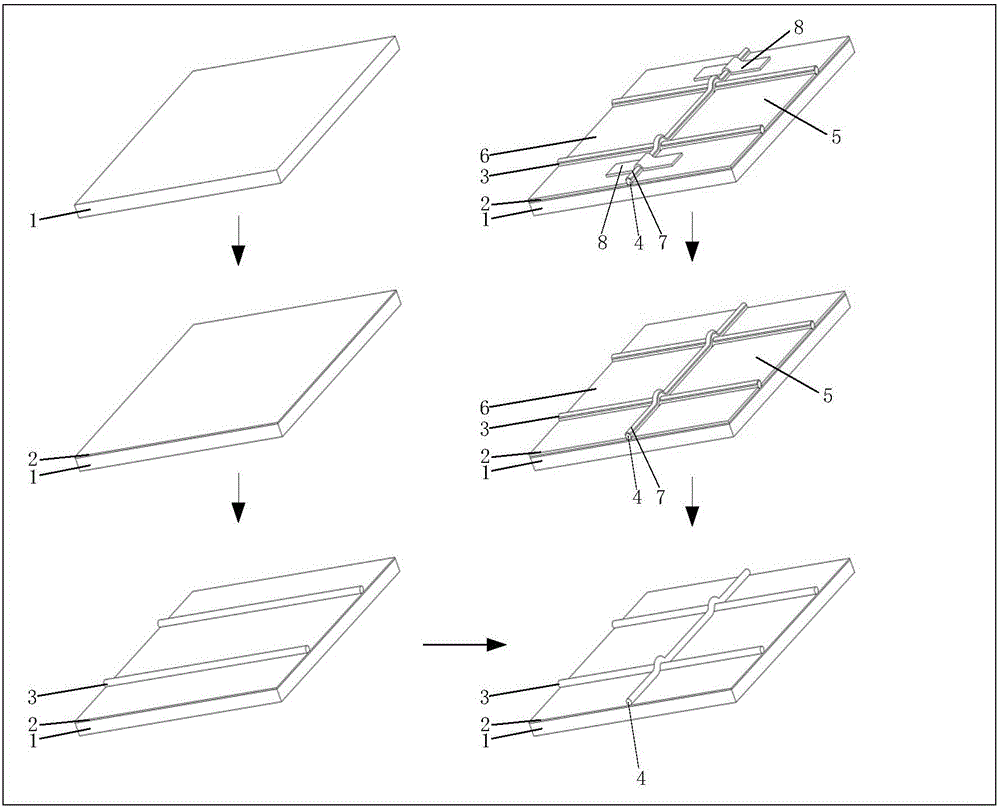

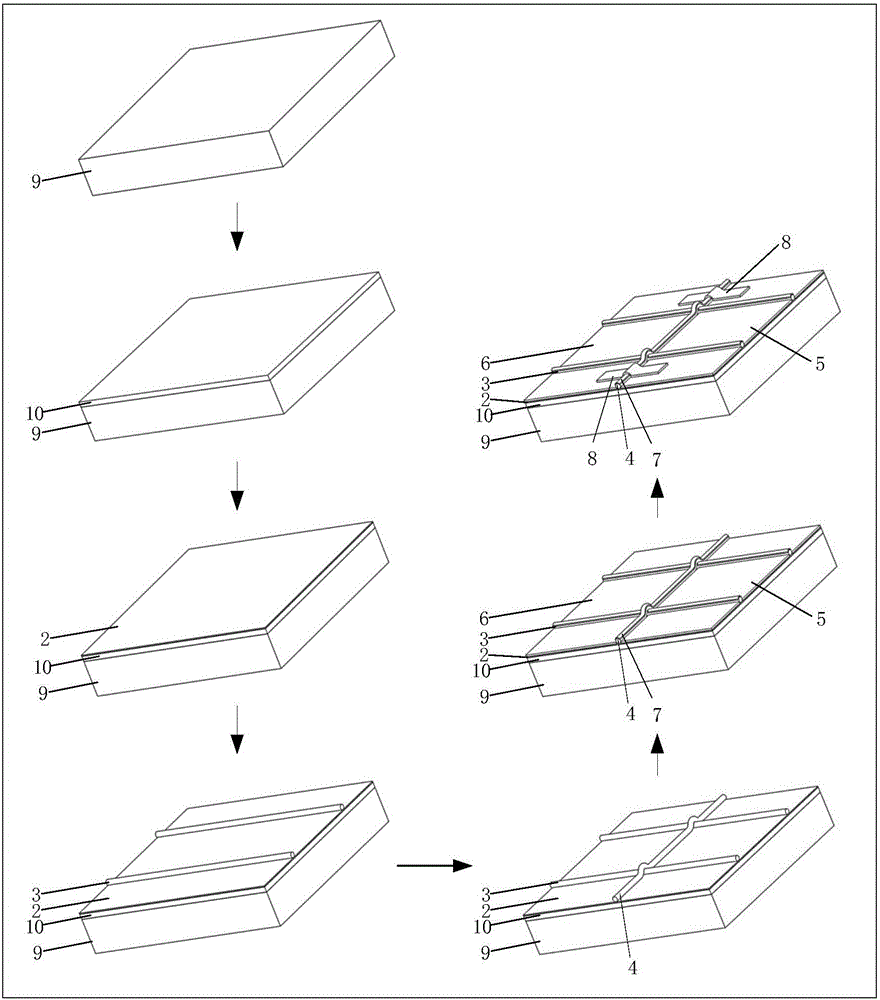

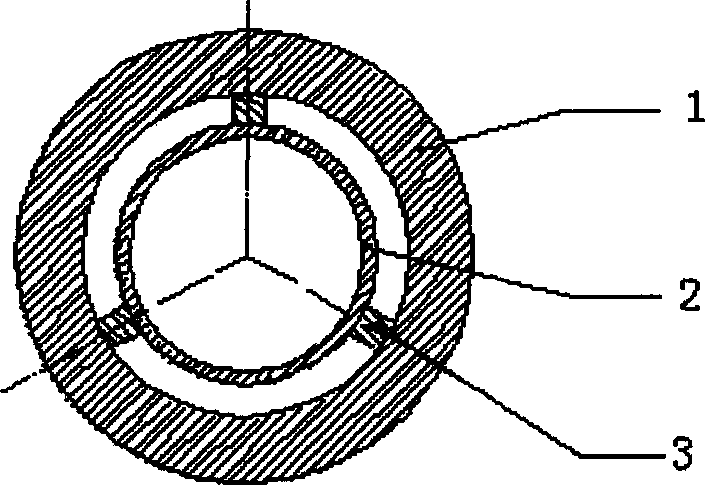

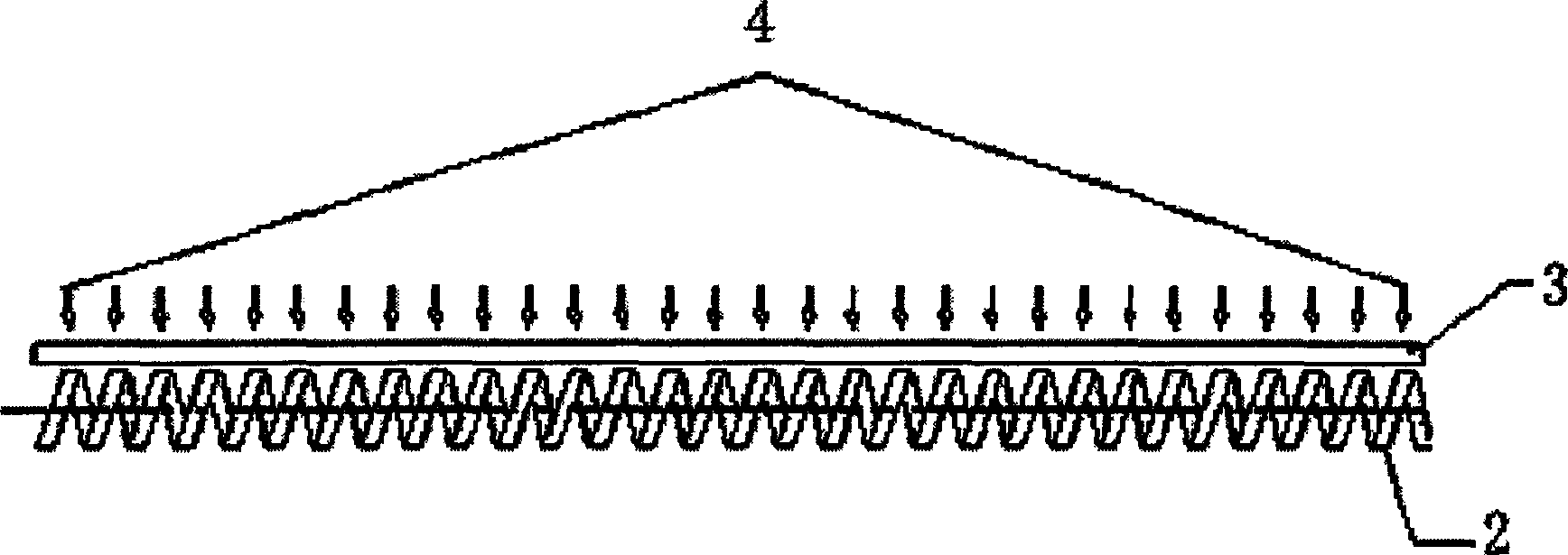

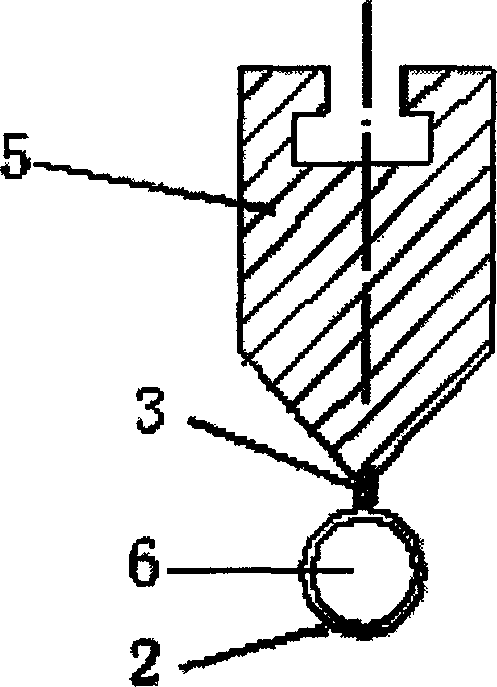

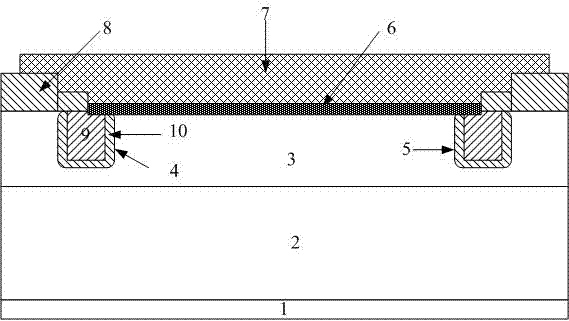

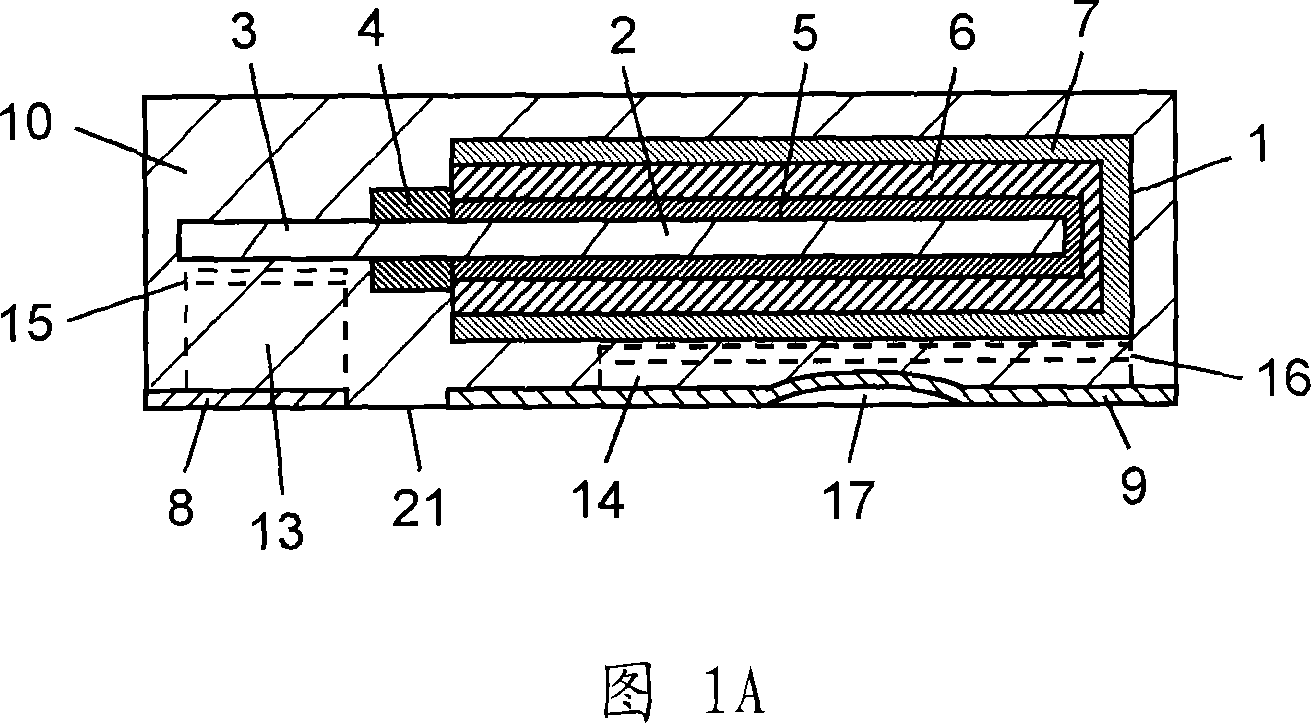

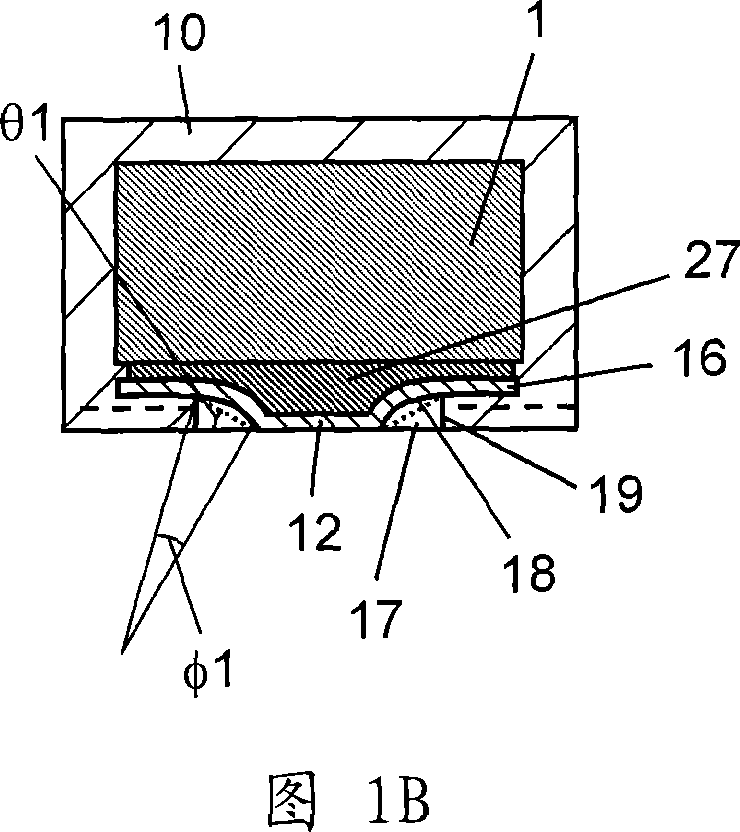

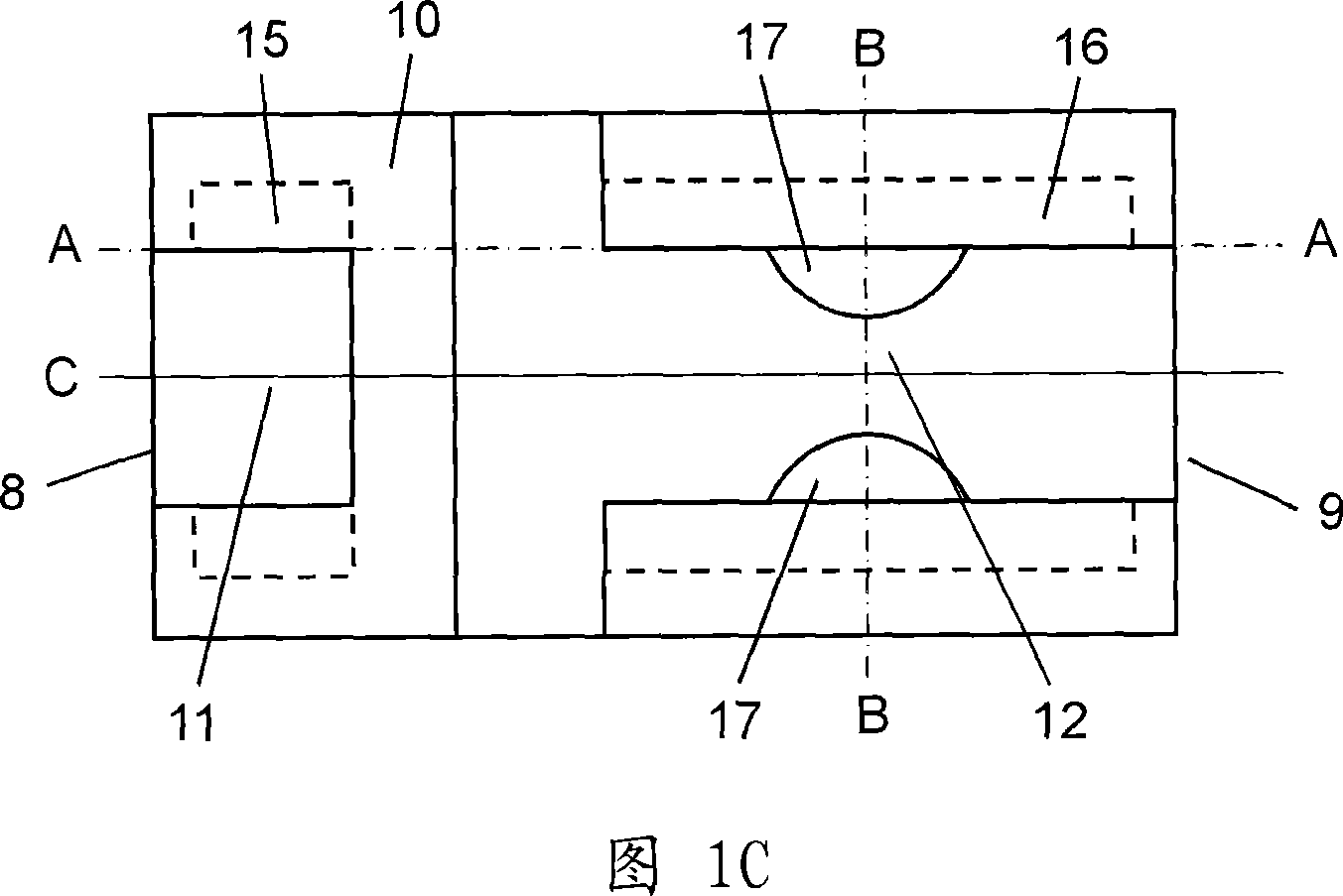

Fe/(SiO-[2]ú½C) core-shell composite nanometer particle with high stability and method for preparing same

InactiveCN1632888AAdjustable thicknessSimple preparation processIndividual molecule manipulationInorganic material magnetismIron saltsSilicic acid

It is a compound nanometer particles of Fe / (SiO#-[2]+C) nucleus or shell with high stability. The process method comprises the following steps: to use iron salt as material and citric acid or other organic acid and organic amine as bonding agent and non-water ethanol as solve agent to form even non-water glue; to join silicic acid ethyl acetate and after vaporizing and condense to form solid glue; to pre-sinter in the air to remove the organic material; to deoxidize in H#-[2] and different temperatures to get the particles.

Owner:NANJING UNIV

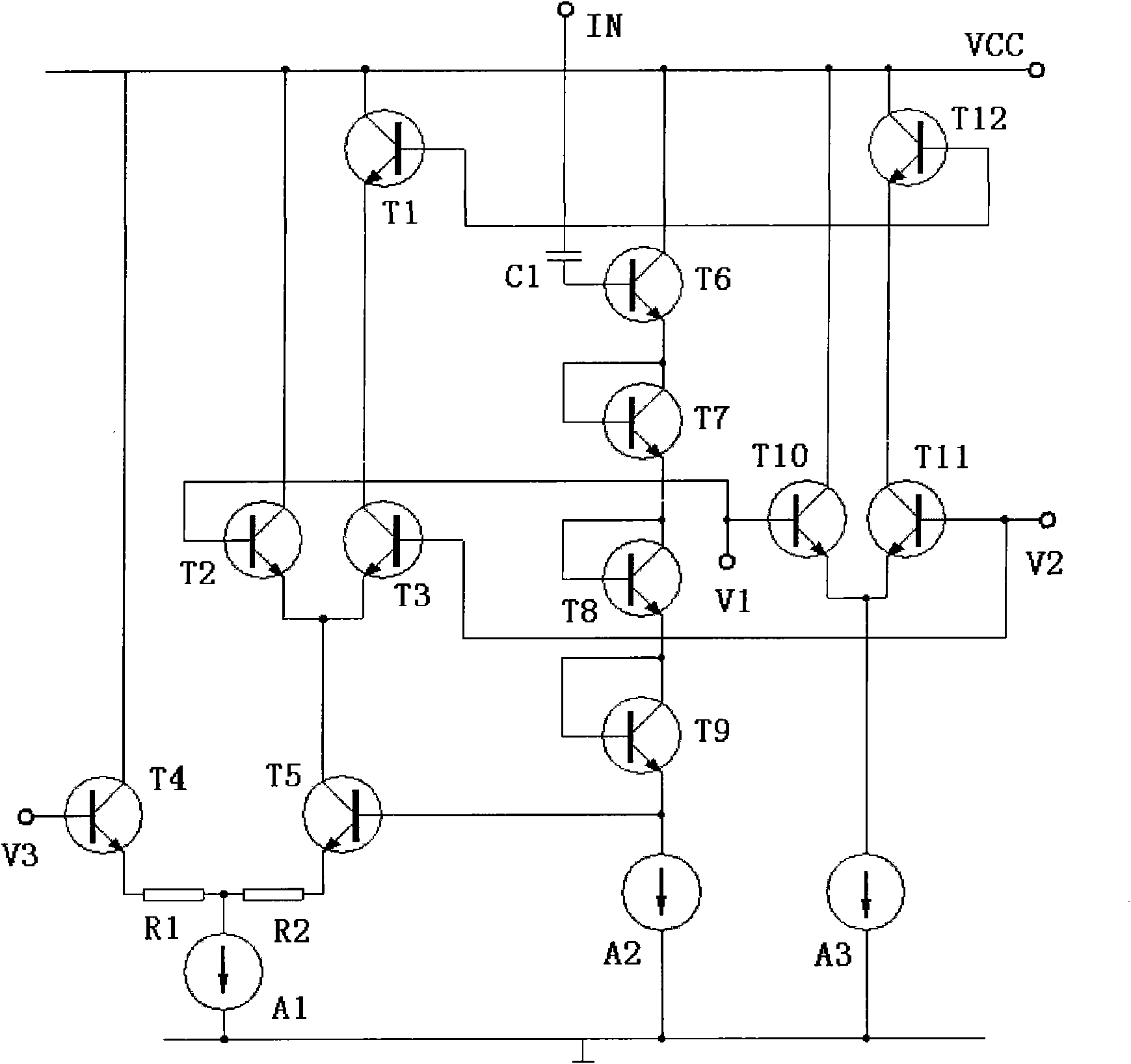

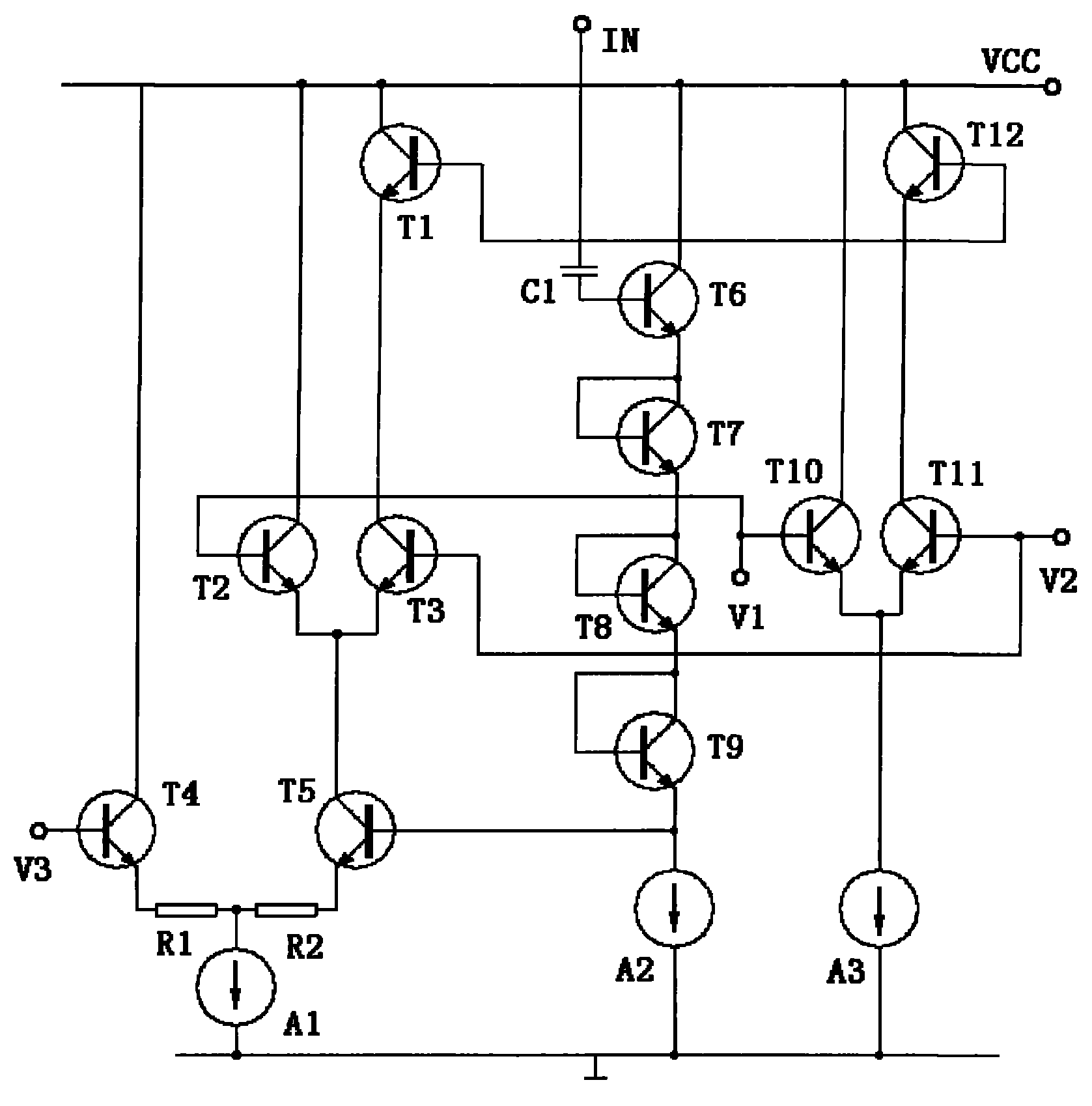

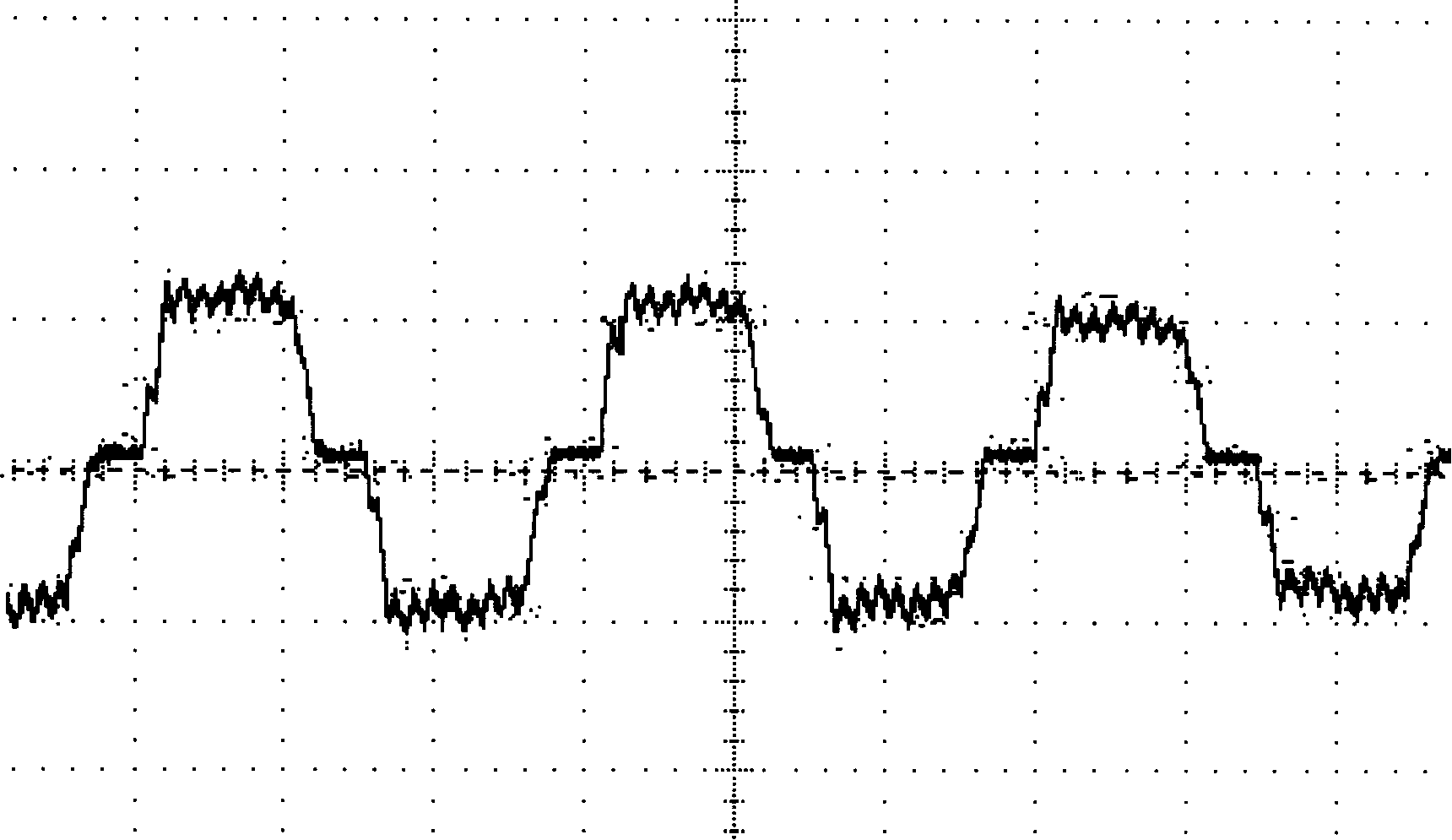

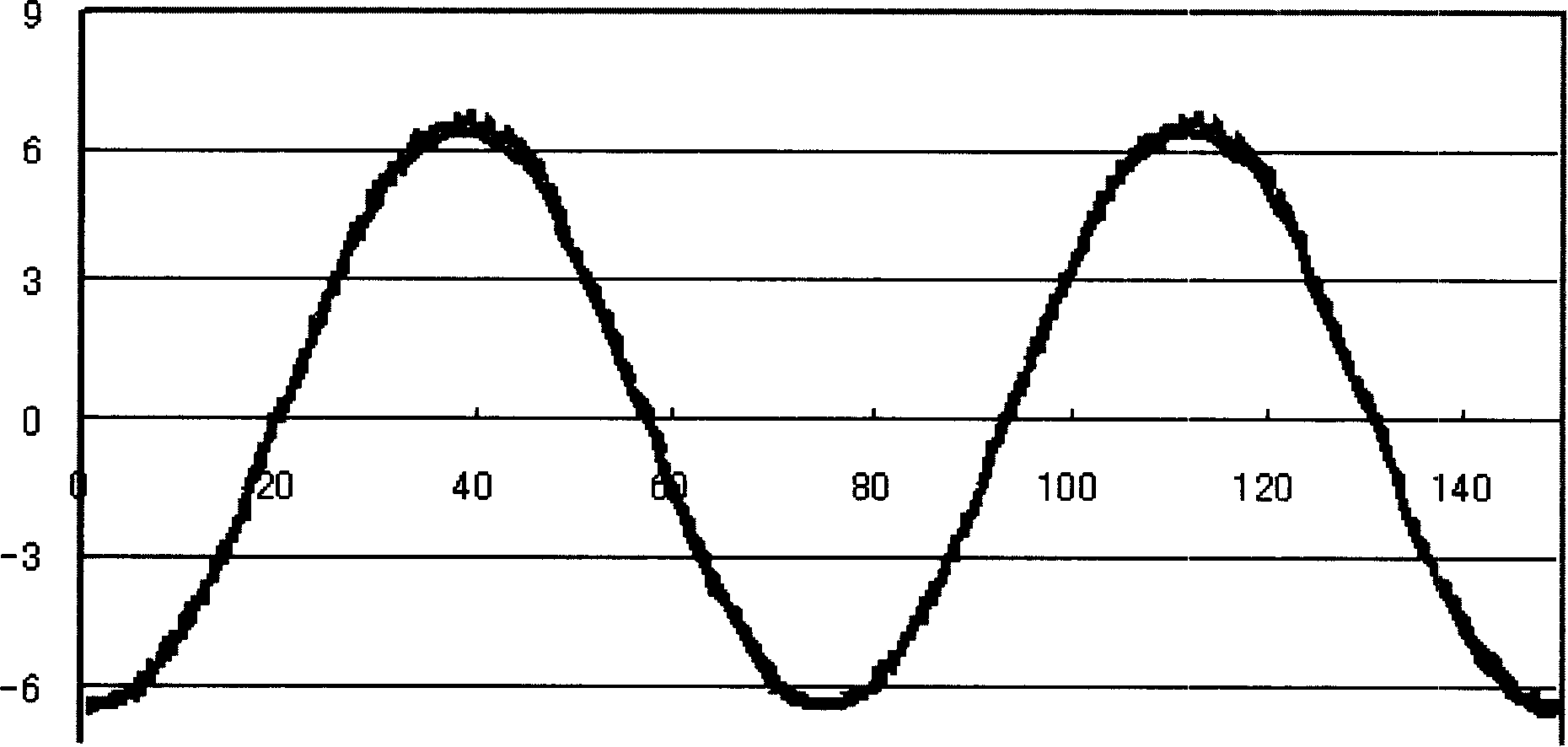

Active high-pass wave filter amplification circuit

InactiveCN101997514ALarge dynamic rangeImprove high frequency characteristicsDifferential amplifiersFrequency selective two-port networksCurrent sourceHigh-pass filter

The invention discloses an active high-pass wave filter amplification circuit, which relates to an amplification circuit, in particular to an improved structure of the active high-pass wave filter amplification circuit. The invention provides the active high-pass wave filter amplification circuit with good high-frequency characteristic. The active high-pass wave filter amplification circuit comprises a triode, a current source, a resistor and a capacitor.

Owner:曾立帅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Fe/(SiO-[2]ú½C) core-shell composite nanometer particle with high stability and method for preparing same Fe/(SiO-[2]ú½C) core-shell composite nanometer particle with high stability and method for preparing same](https://images-eureka.patsnap.com/patent_img/77a1ef64-fc06-4164-a5f1-b835fb77cbeb/A20041006550900071.PNG)

![Fe/(SiO-[2]ú½C) core-shell composite nanometer particle with high stability and method for preparing same Fe/(SiO-[2]ú½C) core-shell composite nanometer particle with high stability and method for preparing same](https://images-eureka.patsnap.com/patent_img/77a1ef64-fc06-4164-a5f1-b835fb77cbeb/A20041006550900072.PNG)

![Fe/(SiO-[2]ú½C) core-shell composite nanometer particle with high stability and method for preparing same Fe/(SiO-[2]ú½C) core-shell composite nanometer particle with high stability and method for preparing same](https://images-eureka.patsnap.com/patent_img/77a1ef64-fc06-4164-a5f1-b835fb77cbeb/A20041006550900081.PNG)