Core/shell structure containing Fe/SiO2 composite nano particles with high stability and method for making same

A technology with composite nanoparticles and high stability, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc. It can solve the problems of high equipment requirements, cumbersome preparation process, spontaneous combustion, etc., and achieve easy process control and high improvement. The effect of frequency characteristics and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

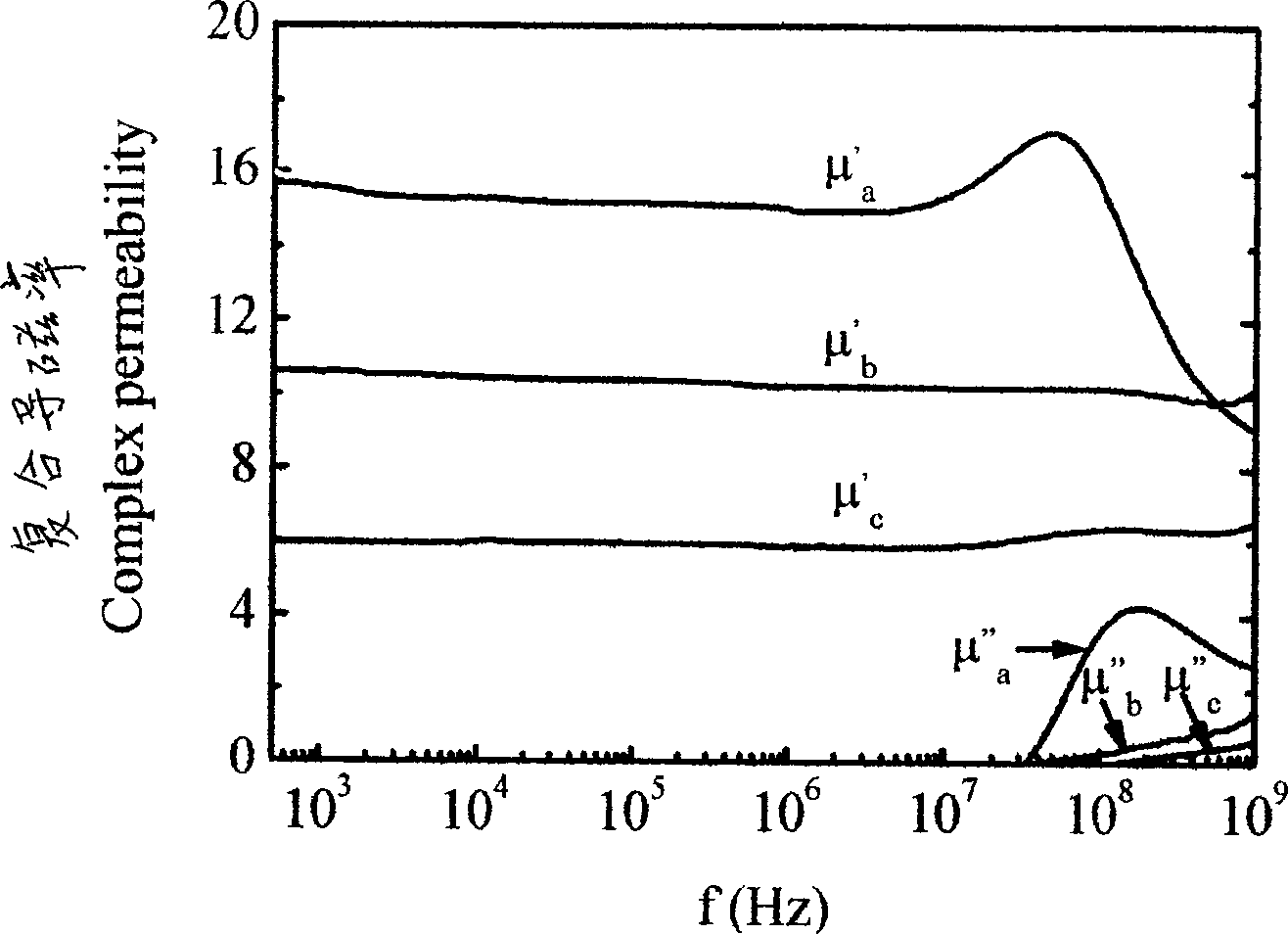

[0014] Example 1: under strong stirring, 0.01mol FeCl 2 4H 2 O and 0.015mol citric acid were dissolved in 100mL of absolute ethanol, and stirred continuously at 60°C for 6 hours to form a uniform transparent sol; add 0.083mL tetraethyl orthosilicate, evaporate and dehydrate at 80°C until a xerogel was formed; Pre-calcined at 450°C for 3 hours, and then reduced in a tube furnace at 800°C for 4 hours in a hydrogen atmosphere. The obtained product has an average particle size of about 5 nanometers and is amorphous SiO 2 The shell, the core is a composite nanoparticle of α-Fe in the cubic crystal phase, and the saturation magnetization is 197Am 2 / kg, coercivity 2.6kA / m. Magnetic spectrum measurements of the product show that at frequencies up to 10 8 Before Hz, μ’ is stable at 16, while μ” is very low. The magnetic spectrum measurement results are shown in figure 1 Curve a.

[0015] Similar results to the above were obtained using ferric chloride, ferric nitrate.

Embodiment 2

[0016] Example 2: under strong stirring, 0.01mol FeCl 2 4H 2 O and 0.015mol citric acid were dissolved in 100mL of absolute ethanol, and stirred continuously at 60°C for 6 hours to form a uniform transparent sol; add 0.34mL tetraethyl orthosilicate, and evaporate and dehydrate at 80°C until a xerogel was formed; Pre-calcined at 450°C for 3 hours, and then reduced in a tube furnace at 800°C for 4 hours in a hydrogen atmosphere. The obtained product has an average particle size of about 5 nanometers and is amorphous SiO 2 The shell, the core is a composite nanoparticle of α-Fe in the cubic crystal phase, and the saturation magnetization is 168Am 2 / kg, coercivity 3.8kA / m. The magnetic spectrum measurement results of the product show that μ’ is basically constant in the entire measurement frequency range, and the loss μ” is very low, almost approaching 0. The magnetic spectrum measurement results are shown in figure 1 Curve c.

Embodiment 3

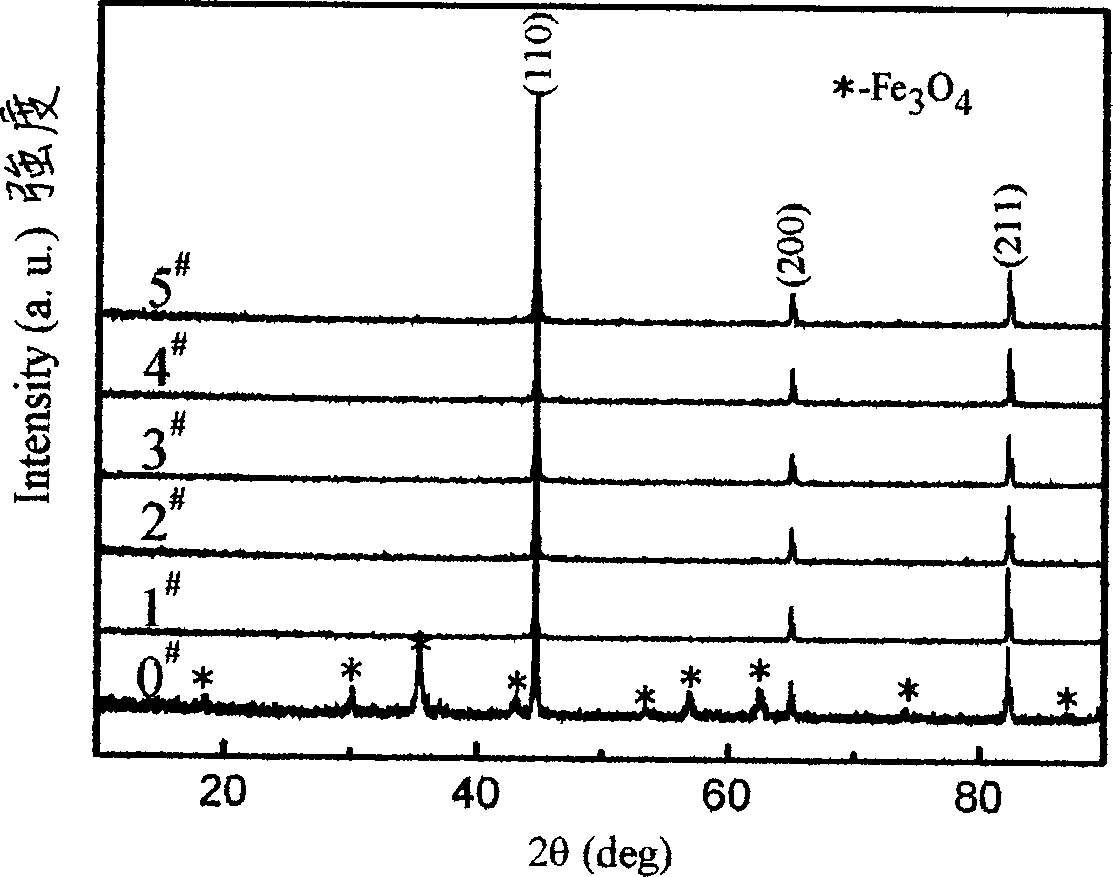

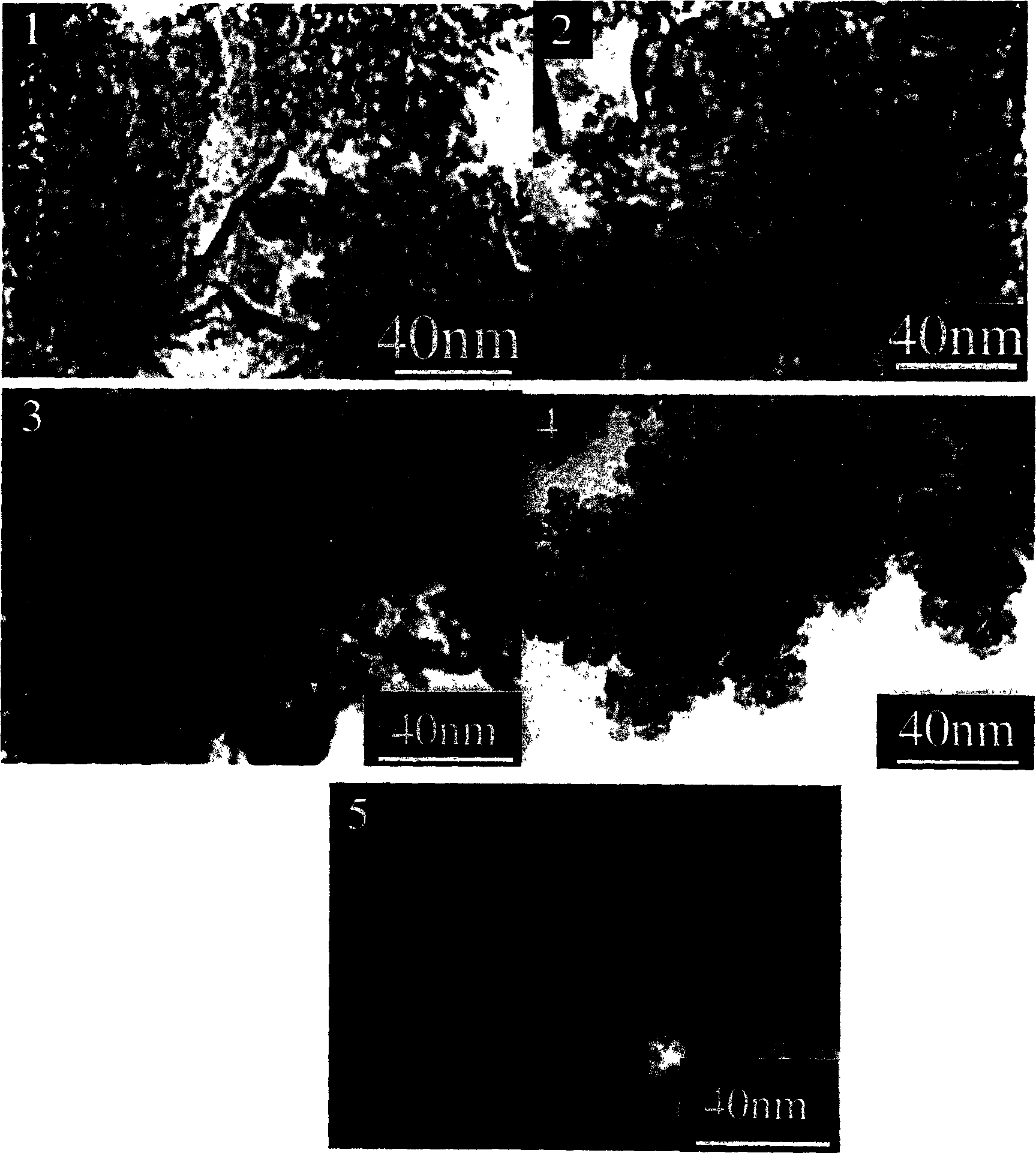

[0017] Example 3: under strong stirring, 0.01mol FeCl 2 4H 2 O and 0.015mol citric acid were dissolved in 100mL of absolute ethanol, and stirred continuously at 60°C for 6 hours to form a uniform transparent sol; add 0.167mL tetraethyl orthosilicate, evaporate and dehydrate at 75-80°C until a xerogel is formed; xerogel Pre-calcined at 450°C in air for 3 hours, and then placed in a tube furnace in a hydrogen atmosphere for reduction at different temperatures (400-800°C) for 4 hours. When the reduction temperature is 400°C, the resulting product contains a large amount of unreduced Fe 3 o 4 ; The product obtained at a reduction temperature above 500°C has amorphous SiO 2 The shell, the core is a composite nanoparticle of α-Fe in the cubic crystal phase, and the XRD spectra of the samples obtained by different reduction temperatures are shown in figure 2 ; The reduction temperature has little effect on the particle size of the product, see the TEM photo image 3 ; The magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com