Capacitor structure

A capacitor structure and electrode technology, applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problem of insufficient noise attenuation characteristics, achieve high noise suppression effect, and improve high-frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

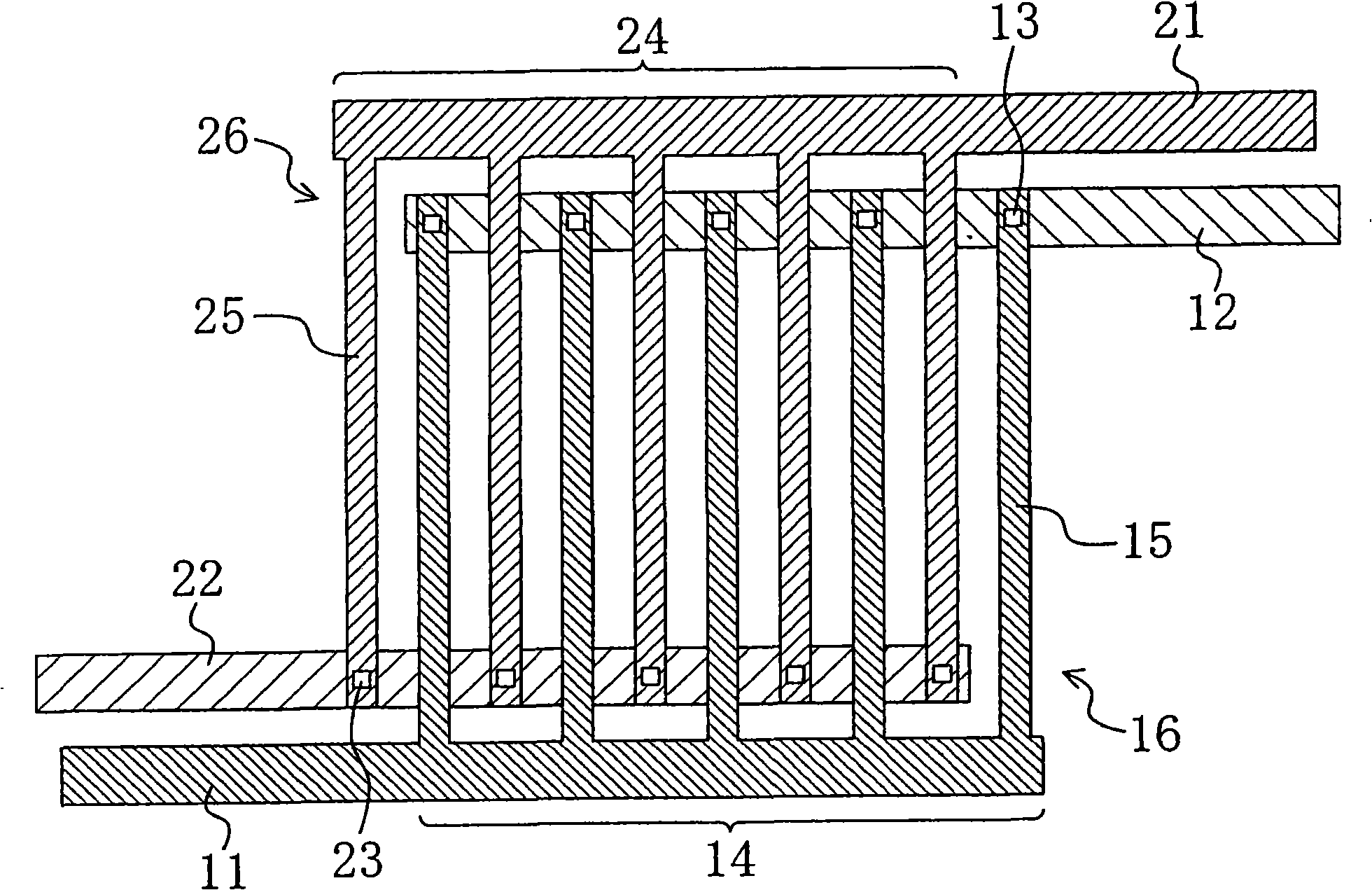

[0027] figure 1 It is a plan view showing the structure of a capacitor formed on an integrated circuit on a semiconductor substrate according to Embodiment 1 of the present invention. figure 1 Among them, 11 and 21 are the first and second electrode wirings formed on the upper wiring layer as the first wiring layer. A first electrode 16 is formed on the first electrode wiring 11 . The first electrode 16 has a plurality of ( figure 1 5 in the middle) tooth portion 15. A second electrode 26 is formed on the second electrode wiring 21 . The second electrode 26 has a plurality of ( figure 1 5 in the middle) tooth portion 25. The first electrode 16 and the second electrode 26 face each other in a state where the tooth portions 15 and 25 are meshed with each other via a dielectric. That is, the first electrodes 16 and the second electrodes 26 have a so-called interdigitated arrangement.

[0028] Further, the tip of each tooth portion 15 of the first electrode 16 is electrical...

Embodiment approach 2

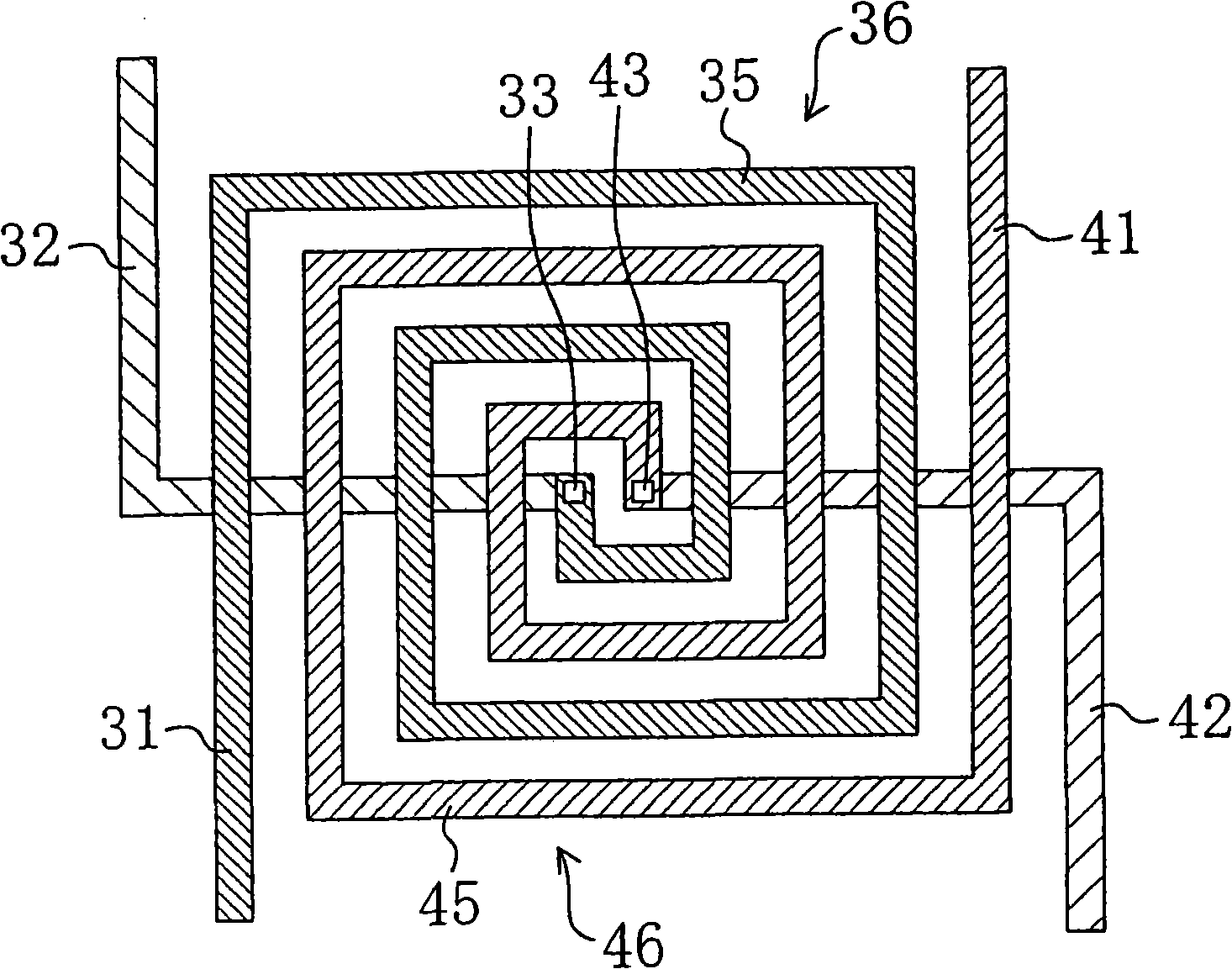

[0035] figure 2 It is a plan view showing a structure of a capacitor formed on an integrated circuit on a semiconductor substrate according to Embodiment 2 of the present invention. figure 2 The shown capacitor structure is to figure 1 In the shown capacitor structure of Embodiment 1, the comb-shaped electrodes are replaced by scroll-shaped electrodes.

[0036] figure 2 Among them, 31, 41 are the first and second electrode wirings formed on the upper wiring layer as the first wiring layer. A first electrode 36 is formed on the first electrode wiring 31 . The first electrode 36 has a scroll portion 35 extending from the first electrode wiring 31 . A second electrode 46 is formed on the second electrode wiring 41 . The second electrode 46 has a scroll portion 45 extending from the second electrode wiring 41 . The first electrode 36 and the second electrode 46 face each other in a state in which the scroll portions 35 , 45 are intertwined with each other via a dielectric...

Embodiment approach 3

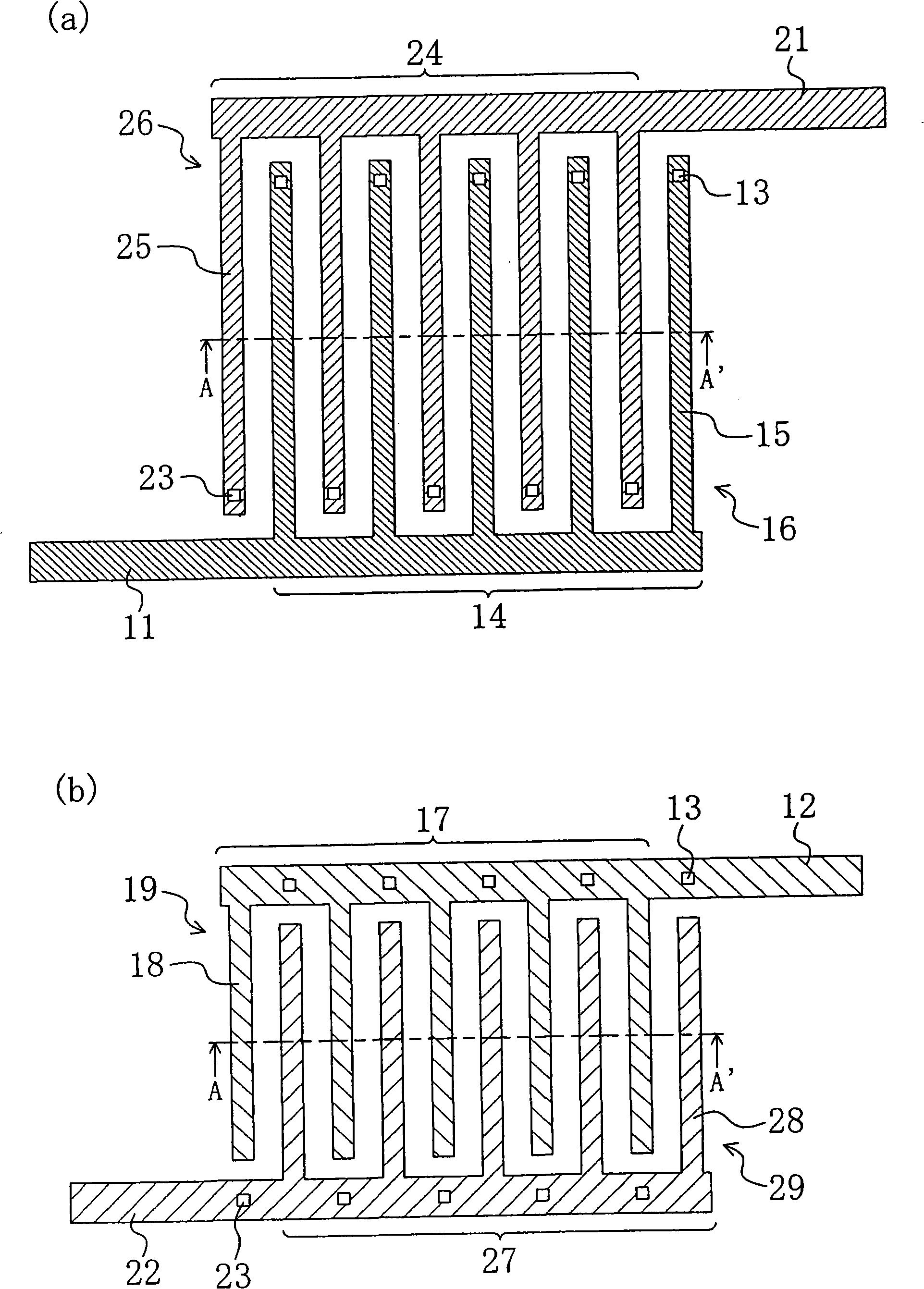

[0044] image 3 It is a plan view showing a capacitor structure formed on an integrated circuit on a semiconductor substrate according to Embodiment 3 of the present invention, in which (a) shows a planar structure of an upper wiring layer, and (b) shows a planar structure of a lower wiring layer. and also, Figure 4 yes image 3 The cross-sectional view of the line A-A'.

[0045] image 3 and Figure 4 The capacitor structure with figure 1 The capacitor structure is the basic configuration, and furthermore, a capacitor is formed by opposing electrodes in the lower wiring layer and between the upper and lower wiring layers.

[0046] Such as image 3 As shown, a first electrode 16 and a second electrode 26 are formed on the upper wiring layer. The first electrode 16 has a plurality of teeth 15 protruding from the electrode base 14 of the first electrode wiring 11 in a comb shape, and the second electrode 26 has a plurality of teeth protruding from the electrode base 24 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com