Vibration diaphragm and preparation method thereof

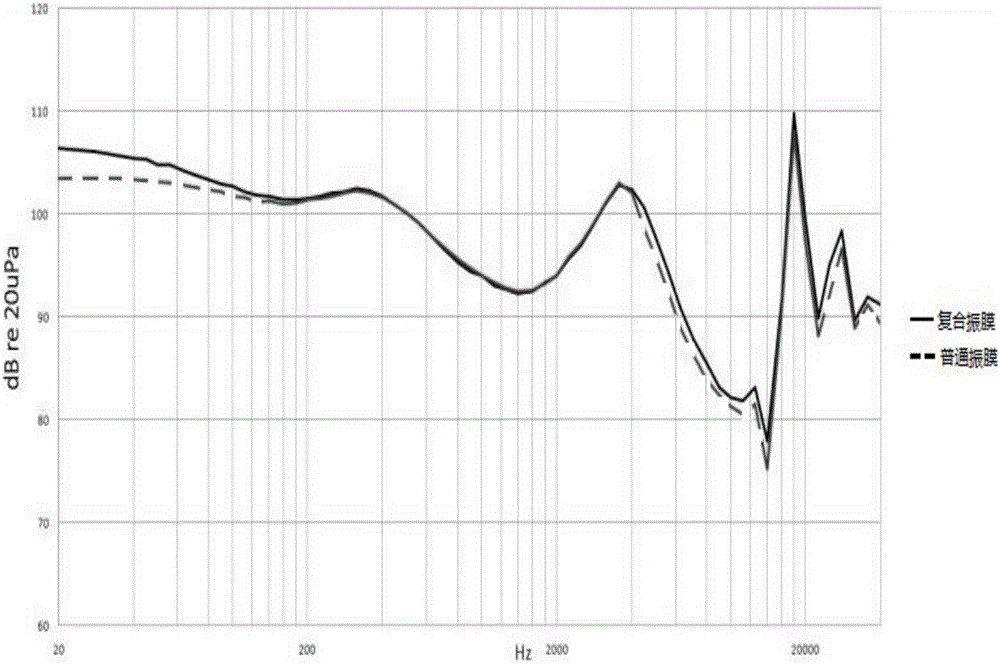

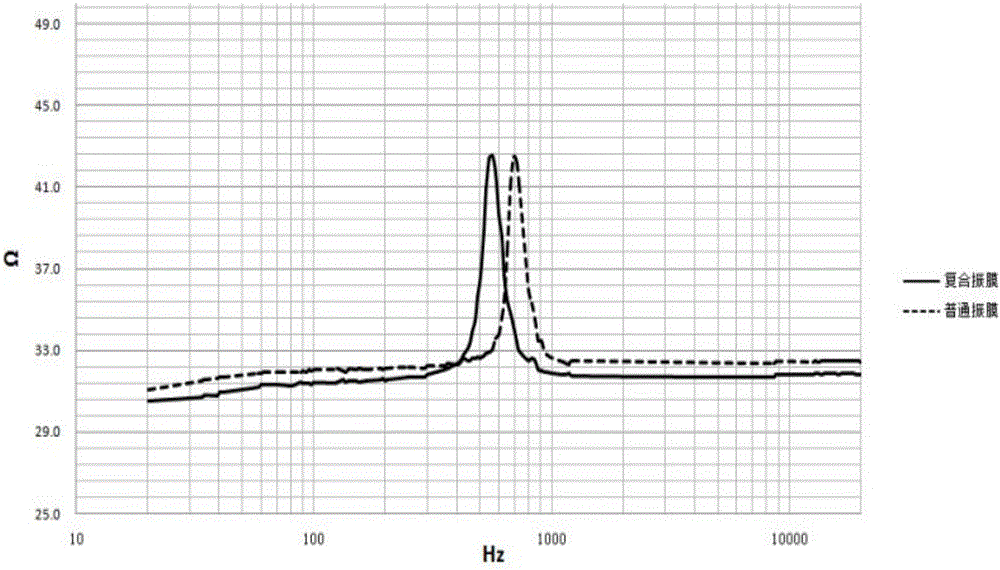

A technology of thin film and mixture, which is applied in the field of diaphragm and its preparation, can solve the problems of easy fracture of graphene, shedding of high and low frequency performance, and not good enough, so as to achieve the effect of not easy to break, improve adhesion, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

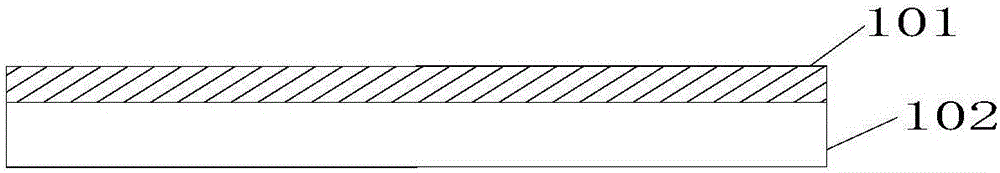

[0034] The present invention provides a kind of preparation method of diaphragm, and this preparation method comprises the following steps:

[0035] S1: Provide a film, glue, graphite powder, and graphene.

[0036] In the step S1, the film provided is made of any one of polyetherimide, polyethylene terephthalate, polyether ether ketone, polyphenylene sulfide, and polyurethane formed film. Polyethylene terephthalate (PET) is preferred.

[0037] The glue is any one of polyurethane, vinyl fluoride, polyacrylate emulsion, vinyl acetate, and ethylene-vinyl acetate, preferably polyurethane.

[0038] S2: Uniformly mixing graphite powder and graphene to form a first mixture, and mixing the first mixture into glue and stirring uniformly to form a second mixture. It can be understood that graphite powder, graphene and glue can be mixed in different proportions. In the present invention, as long as graphite powder and graphene can be completely dispersed in glue, the proportioning is ...

Embodiment 1

[0044] A. Mix graphite powder, graphene and glue, take 1g of graphite powder, 5g of graphene, and 9994g of glue, mix 1g of graphite powder and 5g of graphene evenly, and mix the powder mixed with graphite powder and graphene into 9994g of glue and stirring, so that the graphite powder and graphene are evenly distributed in the glue.

[0045] B. After the graphite powder and graphene are evenly distributed in the glue, the mixture formed by graphite powder, graphene and glue is coated on the surface of the film, and the film coated with the mixture of graphite powder, graphene and glue is dried. Let the colloid solidify and adhere to the surface of the film.

Embodiment 2

[0047] A. Graphite powder, graphene and glue are mixed, take graphite powder 1.5g, graphene 7.5g, glue 9991g, mix 1.5g graphite powder and 7.5g graphene evenly respectively, and the powder after mixing graphite powder and graphene Mix in 9991g of glue and stir to make the graphite powder and graphene evenly distributed in the glue.

[0048] B. After the graphite powder and graphene are evenly distributed in the glue, the mixture formed by graphite powder, graphene and glue is coated on the surface of the film, and the film coated with the mixture of graphite powder, graphene and glue is dried. Let the colloid solidify and adhere to the surface of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com