Multi-pole connector

A connector and multi-pole technology, applied in the direction of connection, conductive connection, and parts of connection devices, can solve the problems of shape change, complicated wiring, labor and time consumption, etc., and achieve high strength, efficient assembly, and easy assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

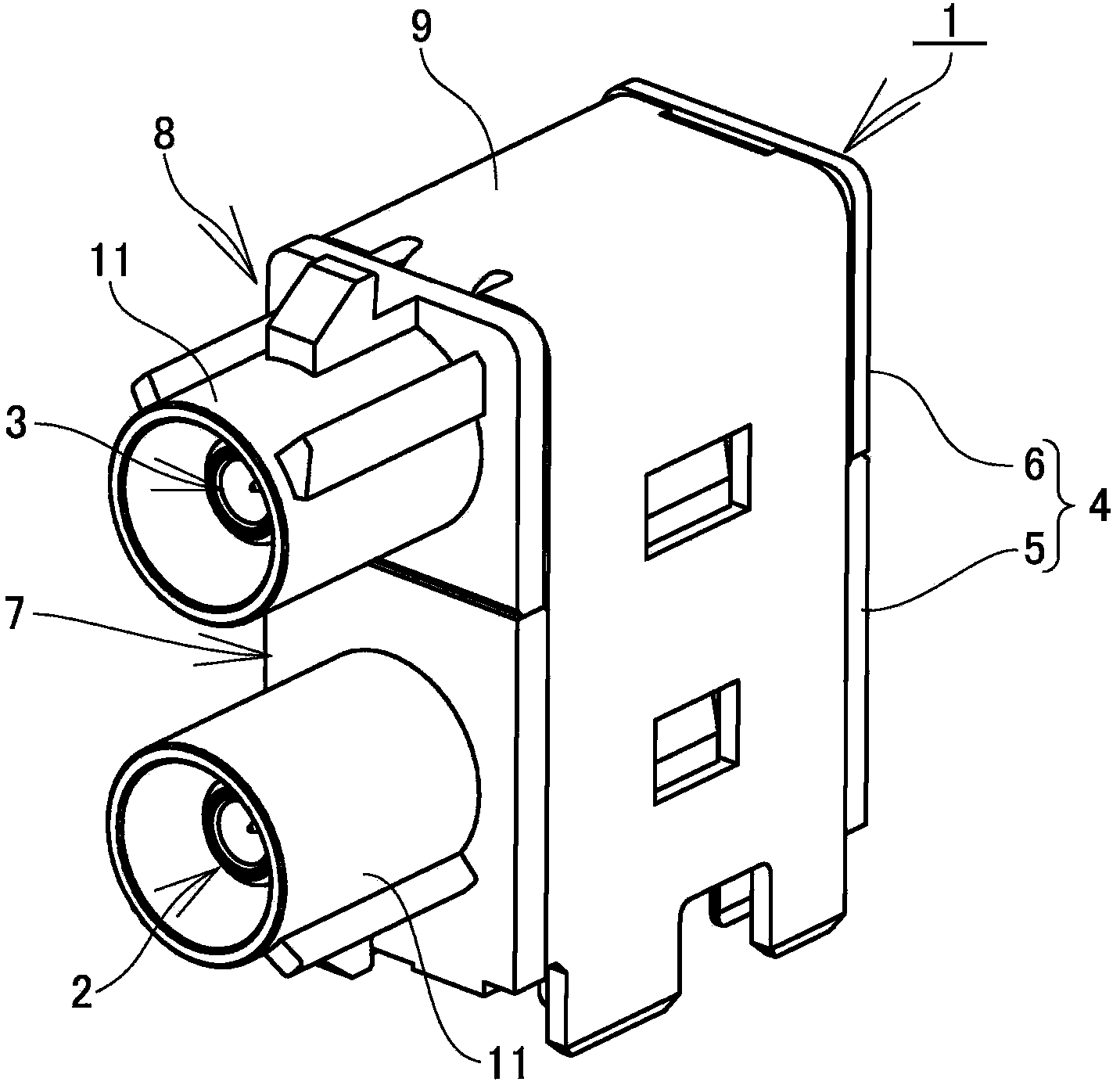

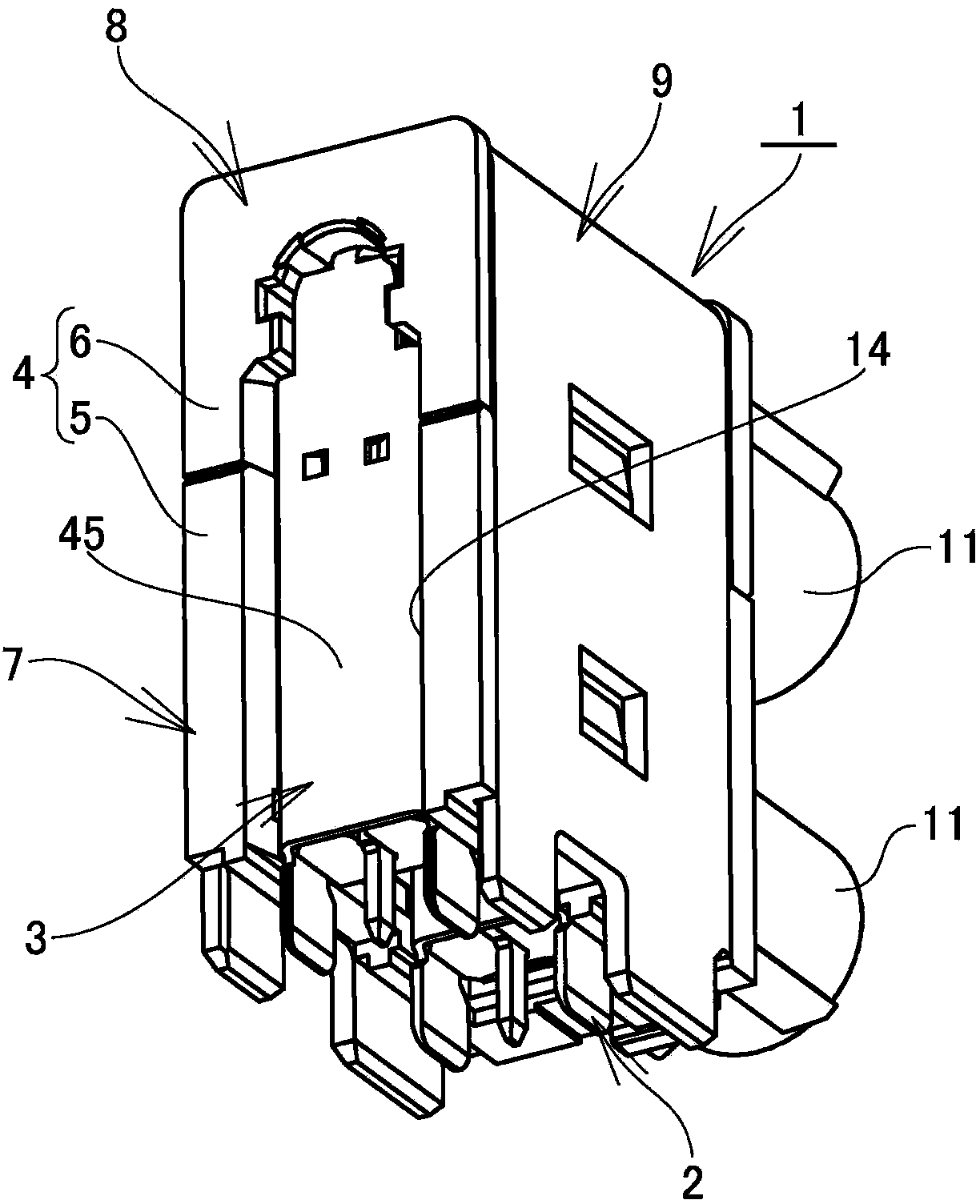

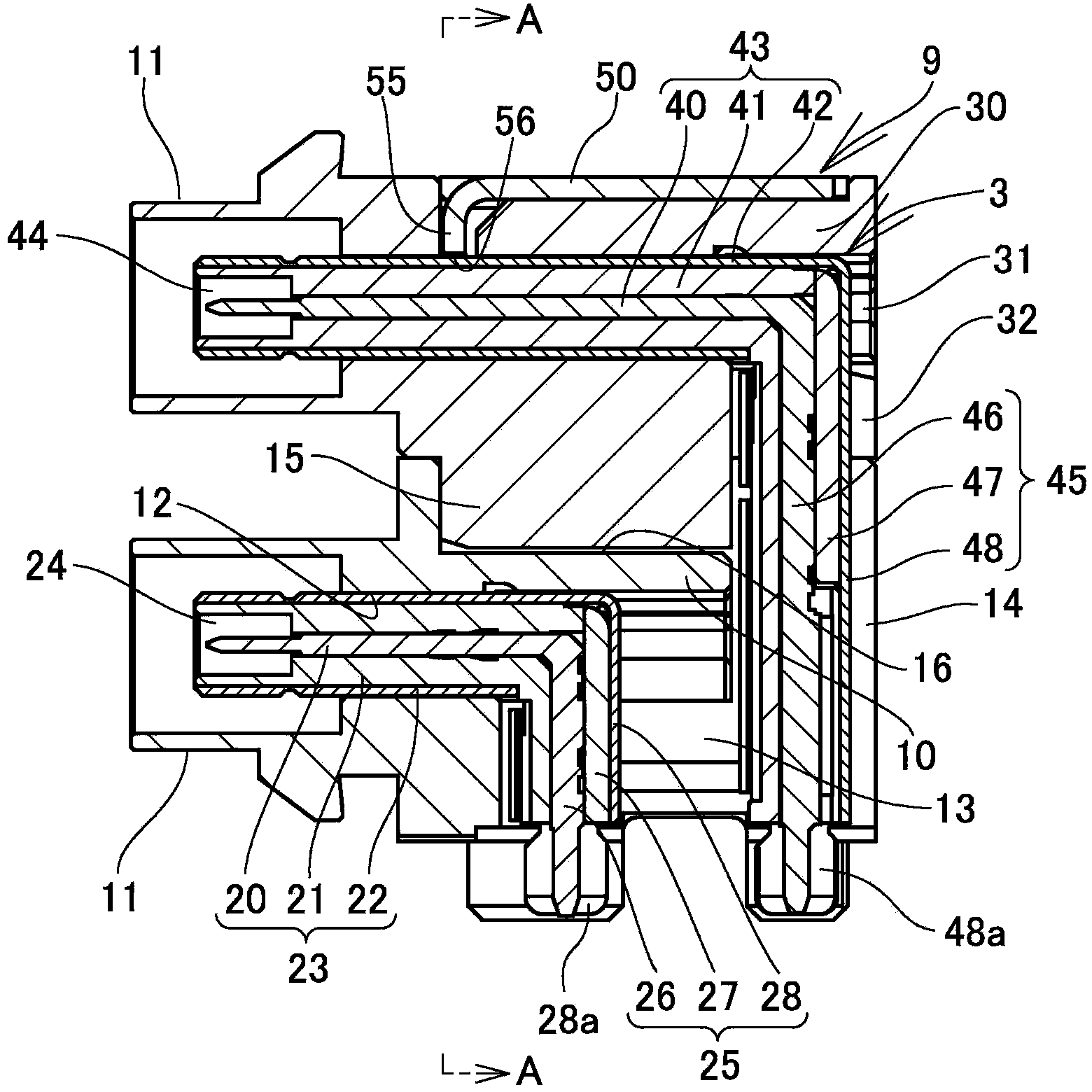

[0052] Next, based on Figure 1 to Figure 15 The illustrated embodiment illustrates the implementation of the multi-pole connector of the present invention.

[0053] This embodiment is described by taking the bipolar coaxial connector arranged in the upper and lower layers as an example, and the symbol 1 in the figure is a multi-pole connector.

[0054] In addition, in this embodiment, the vertical direction relative to the surface of the substrate on which the multipolar connector 1 is mounted (hereinafter referred to as the mounting substrate) is referred to as the up-down direction, and the substrate side is described as the bottom. The connection direction between the connector 1 and the connector on the opposite side is referred to as the front-rear direction when the surfaces are parallel, and the opposite side is described as the front.

[0055] Such as Figure 1 to Figure 5 As shown, the multi-pole connector 1 is the following multi-pole coaxial connector, which is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com