Patents

Literature

36results about How to "Increased twisting strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

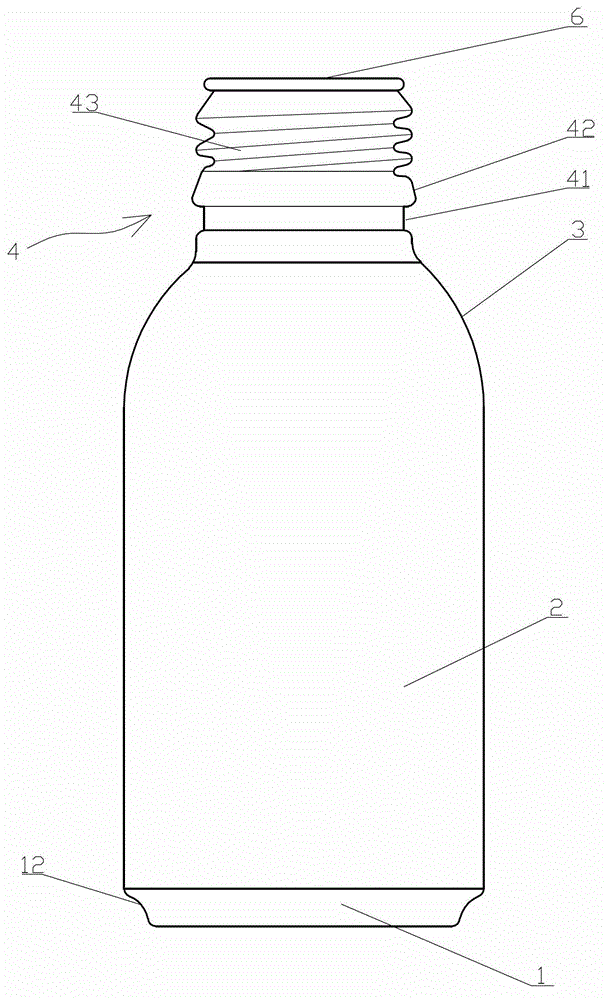

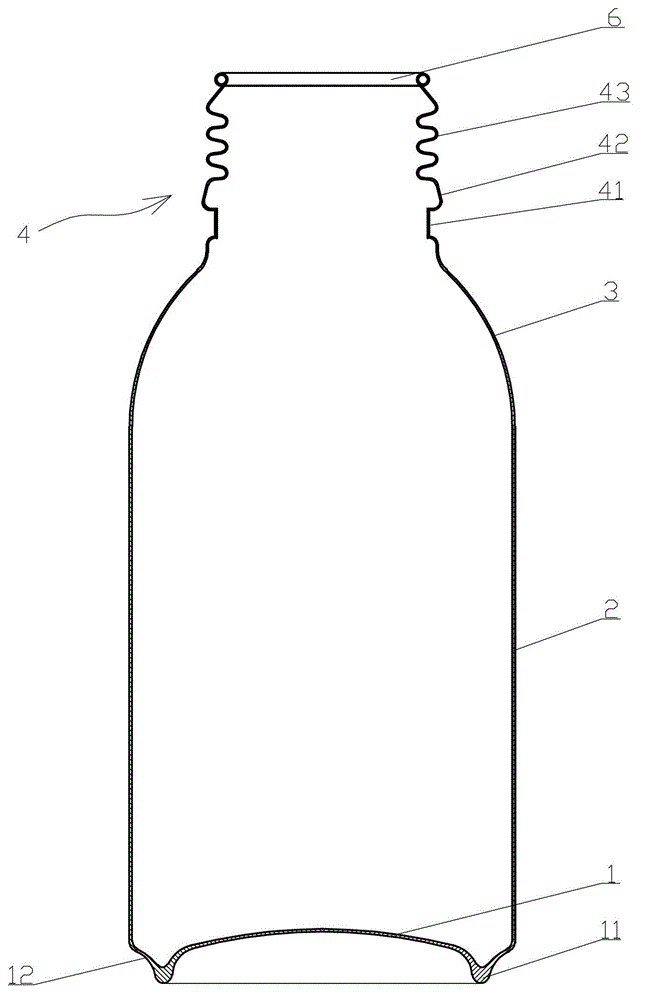

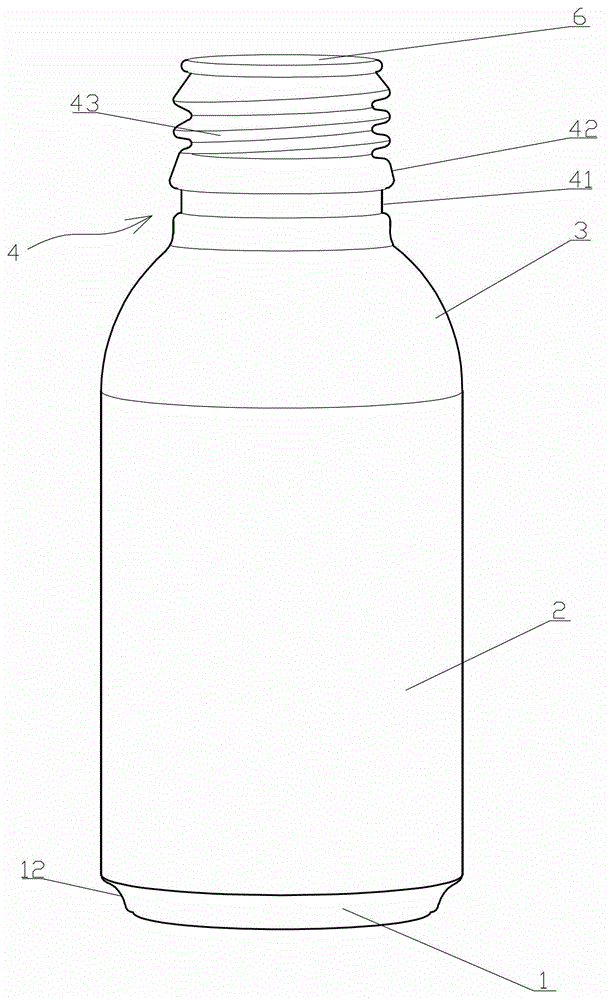

Aluminium screw-on packaging jar and manufacturing method thereof

InactiveCN102910330AImprove stress resistanceSimple processing methodBottlesHollow articlesFlangingAluminium

The invention discloses an aluminium screw-on packaging jar, which comprises a jar bottom. The aluminium screw-on packaging jar has the essential scheme that the jar bottom is provided with a bottom side which is moulded downwards in an extruding manner and is protruded out of the jar bottom downwards; the edge of the bottom side extends upwards to form a jar cylinder; the jar cylinder is shrunk upwards to form a jar shoulder; the jar shoulder is shrunk upwards to form a jar neck; the jar neck is = provided with an annular groove and an inclined bulge loop which is arranged at the upper end of the annular groove to incline upwards; an external thread is arranged at the upper end of the inclined bulge loop of the jar neck; a jar opening with a lip is arranged at the opening end of the jar neck in a flanging manner. The invention further discloses a manufacturing method for the aluminium screw-on packaging jar. The method comprises the following steps: a, cutting; b, stamping; c, stretching the jar cylinder; d, finishing and polishing; f, cleaning; g, protecting; h, necking and moulding; and i, cleaning and leak hunting. The aluminium screw-on packaging jar has advantages of high anti-pressing and anti-twisting strength, simple structure, anti-counterfeiting performance and simplicity in manufacturing.

Owner:GUANGDONG EURO ASIA PACKAGING

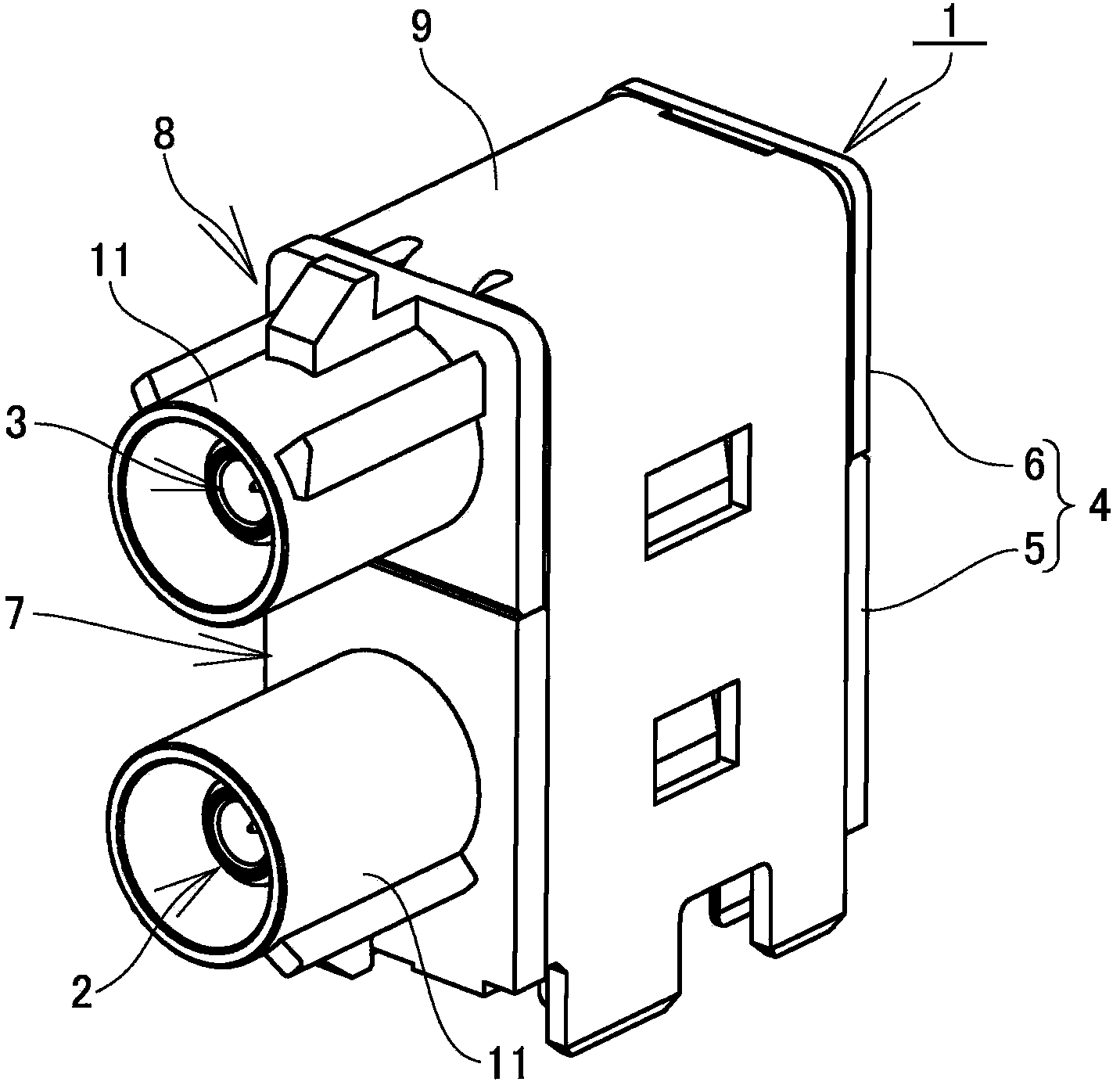

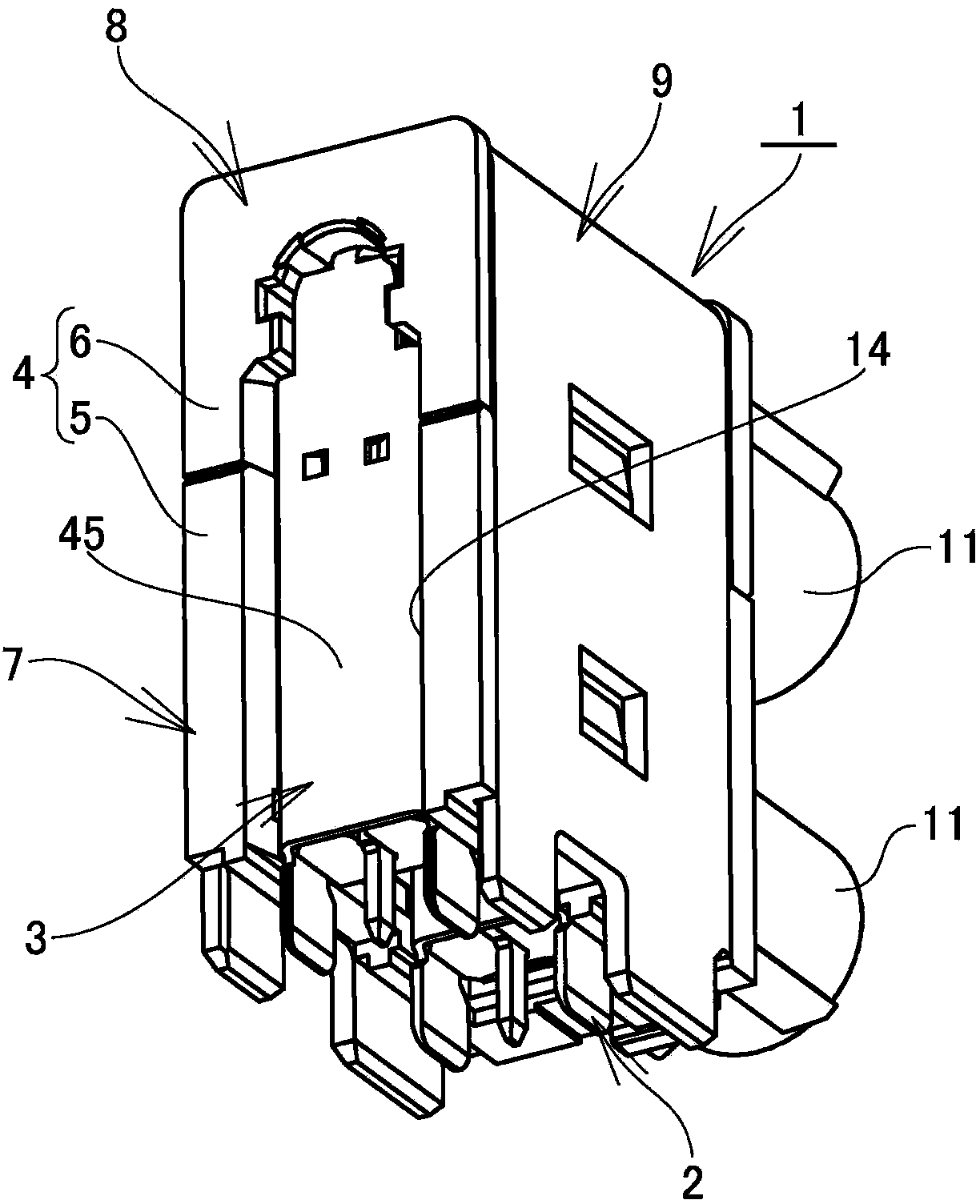

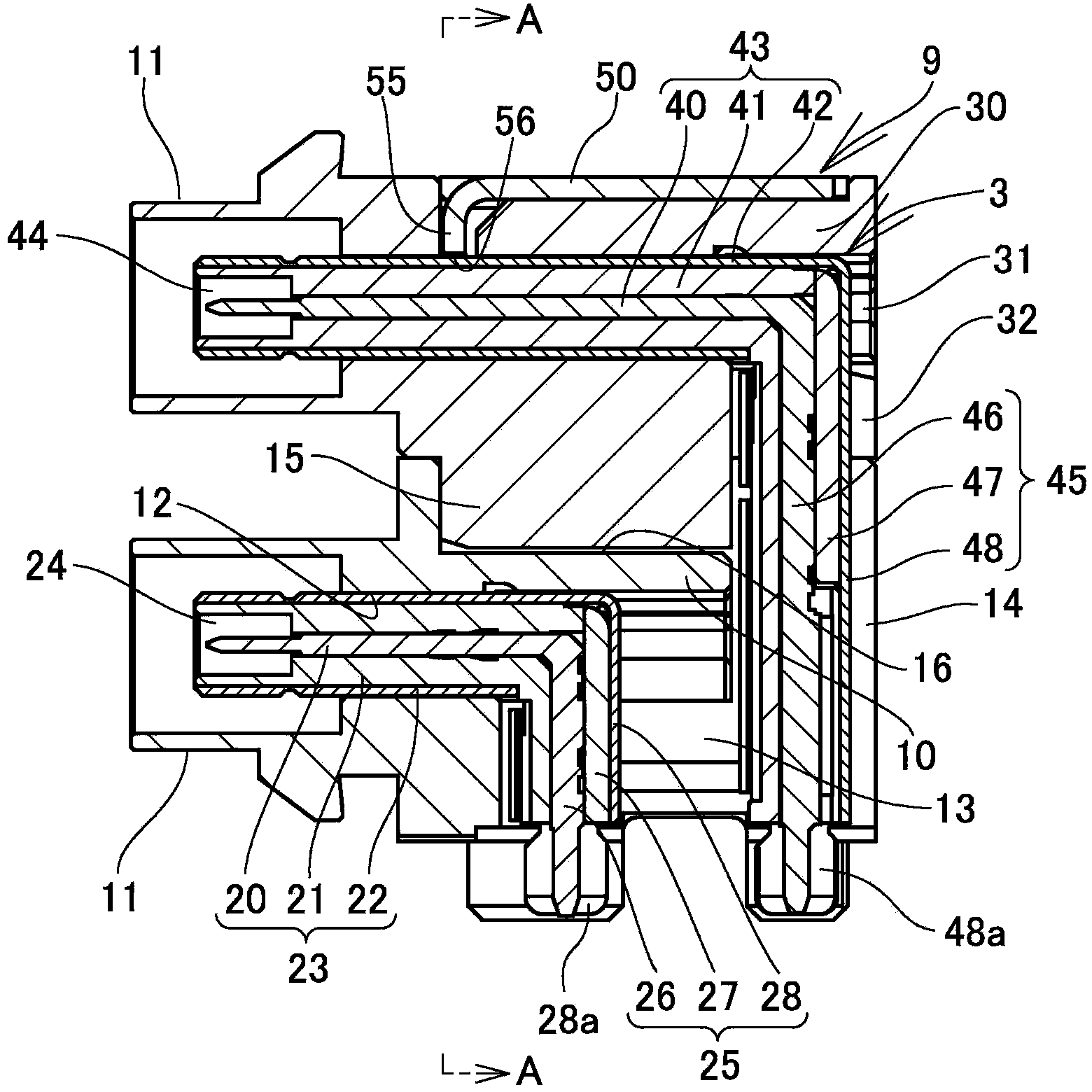

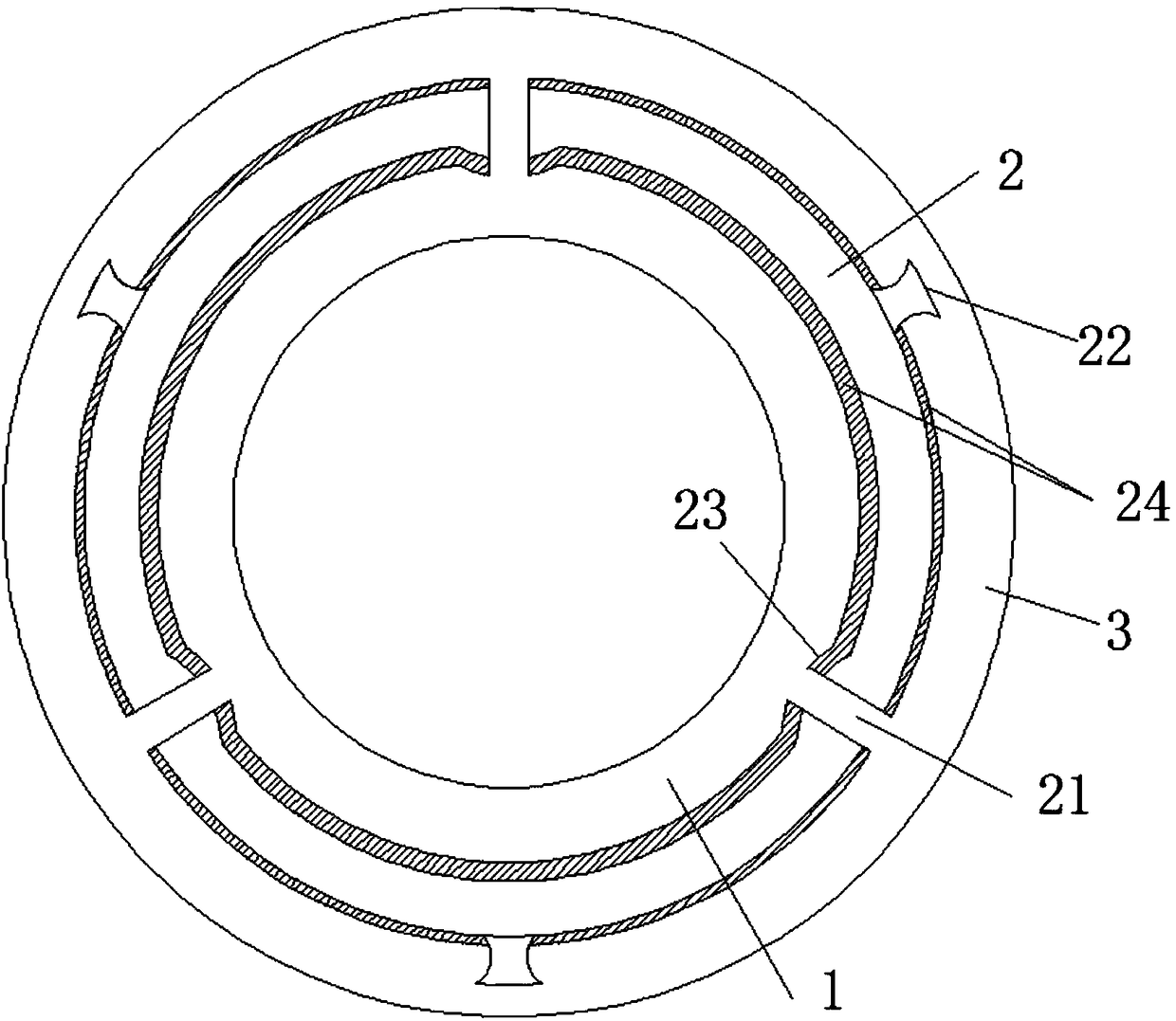

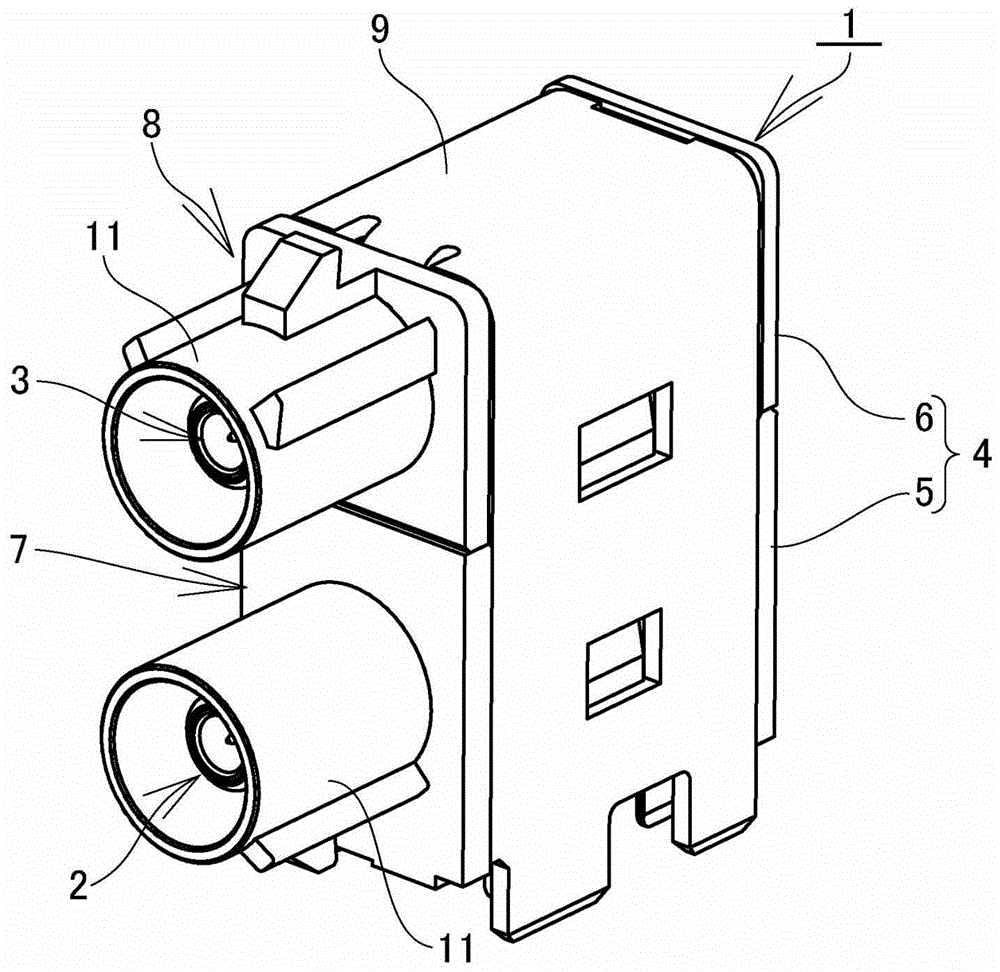

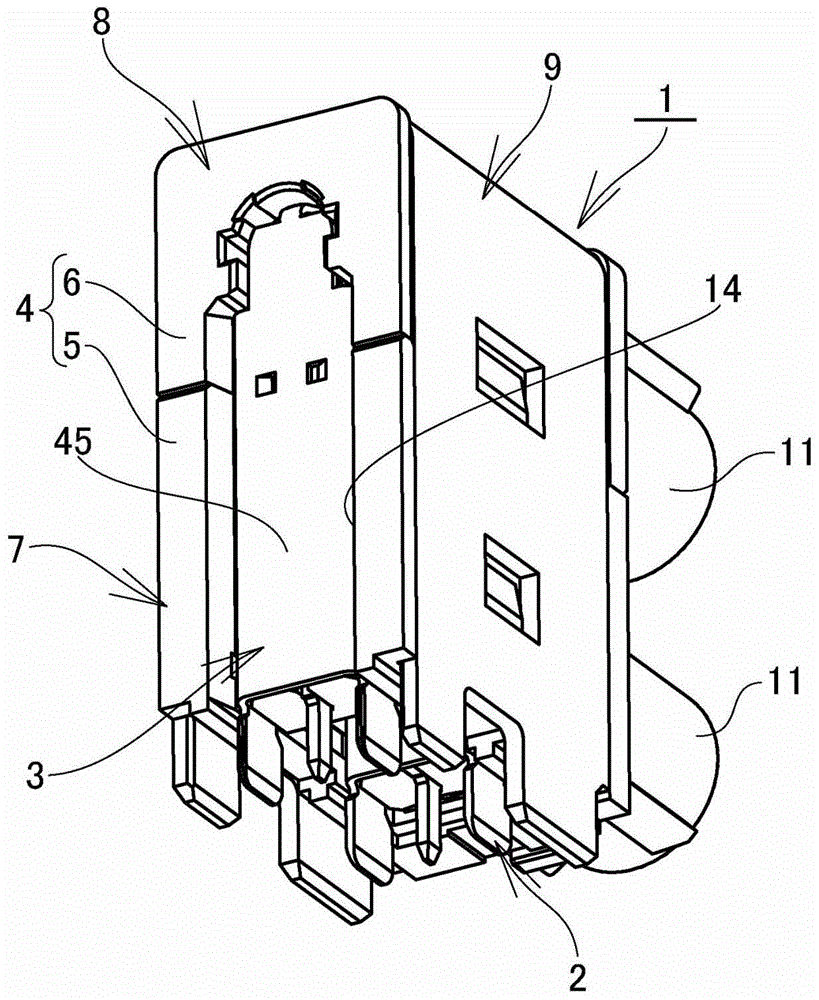

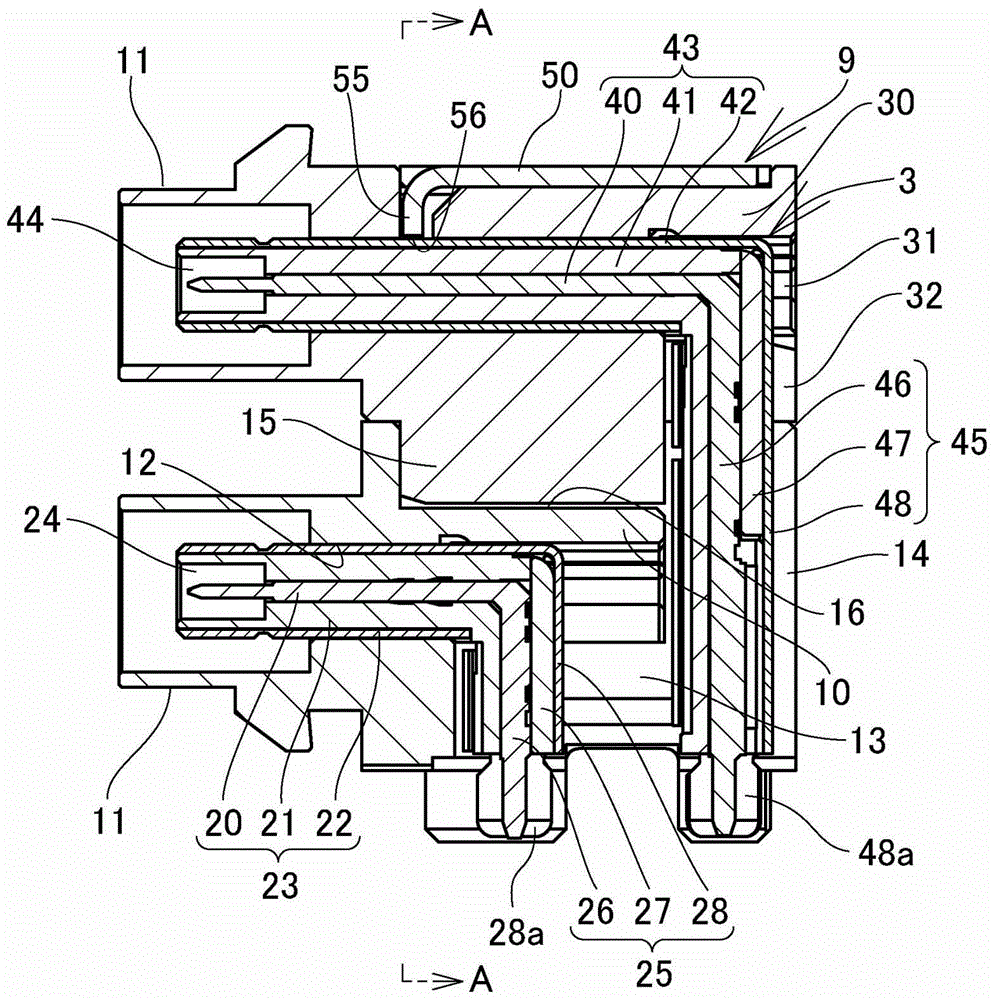

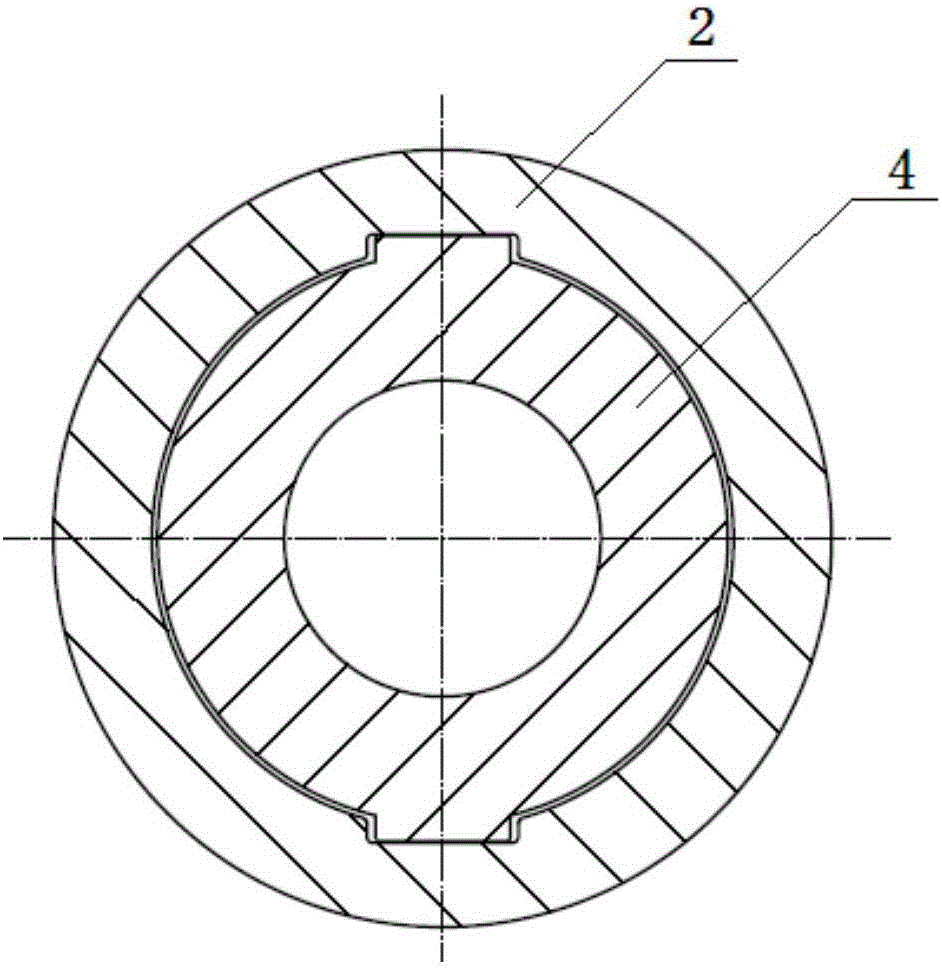

Multi-pole connector

InactiveCN104241880AHigh strengthEasy and efficient assemblyElectrically conductive connectionsIncorrect coupling preventionMechanical engineeringEngineering

The invention provides a multi-pole connector which can correspond with multiple poles of an interface and realizes space saving of an interface part. Furthermore the multi-pole connector can correspond with a multilayer configuration in which a plurality of conductor connecting parts are configured on a mounting substrate in a vertical direction. The multi-pole connector is provided with a plurality of divided connectors (7,8) which are obtained through respectively holding conductors (2,3) on divided housings (5,6) that are divided from the housing (4) and have different shapes. A joint end surface part of one divided housing (5) in the divided housings (5,6) which are adjacent with each other is provided with a key embedding part (16) for insertion of a connecting key (15). Through embedding the connecting key (15) into the key embedding part (16), the connecting key (15) is clamped between the joint end surface parts in a manner of bestriding the joint end surface parts, thereby joining the two divided housings (5,6), thereby connecting the divided connectors (7,8) which are adjacent with each other.

Owner:SMK CO LTD

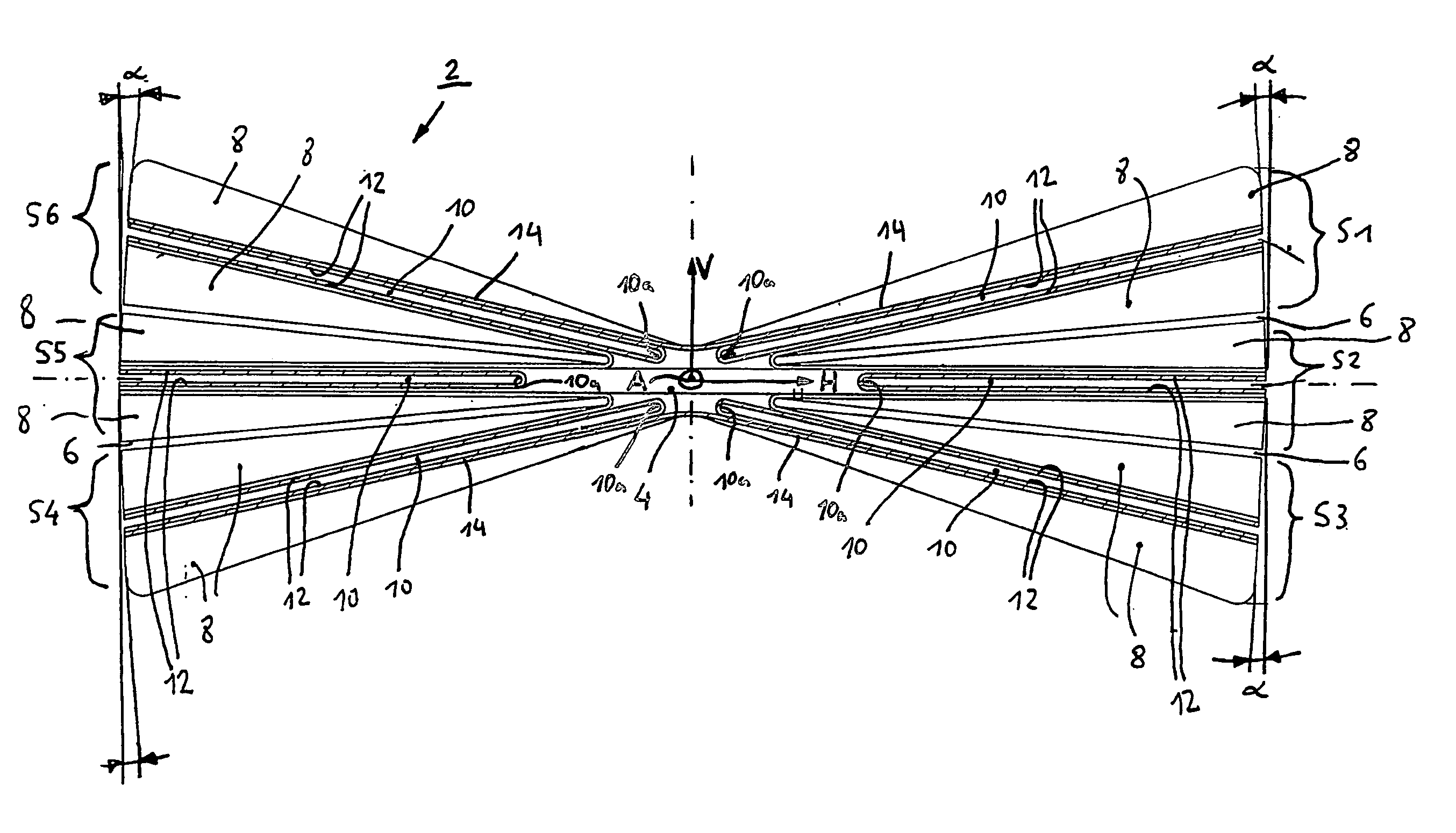

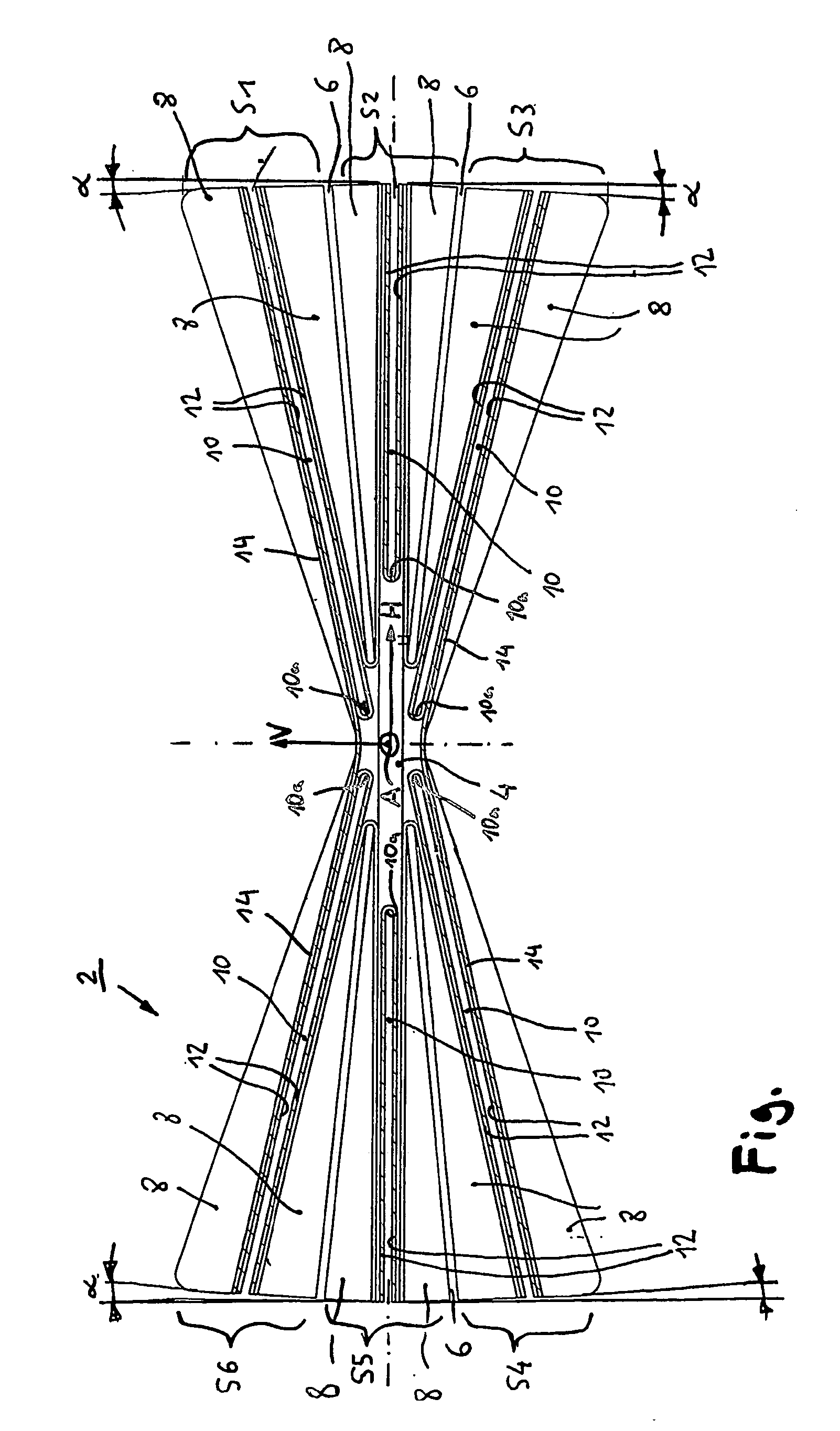

Drilling element for a bearingless rotor

InactiveUS20060193727A1Increase stiffnessLow torsional stiffnessPropellersPump componentsFiberEngineering

A twist element for a bearingless rotor is made mostly of composite fiber material and has a cross section with a substantially symmetric, flattened shape that has approximately the contour of a horizontal, central section of a double cone. In addition, a bearingless rotor having at least one such twist element. and a rotorcraft, particularly a helicopter, having at least one rotor with at least one such twist element are provided.

Owner:AIRBUS HELICOPTERS DEUT GMBH

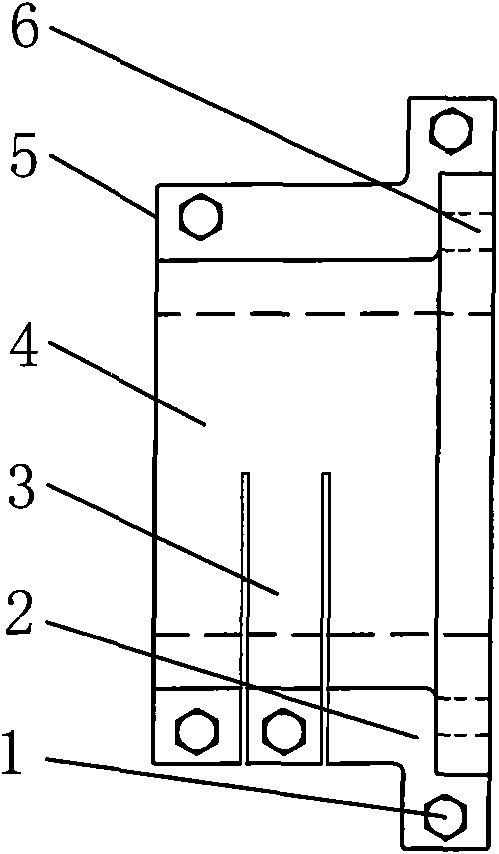

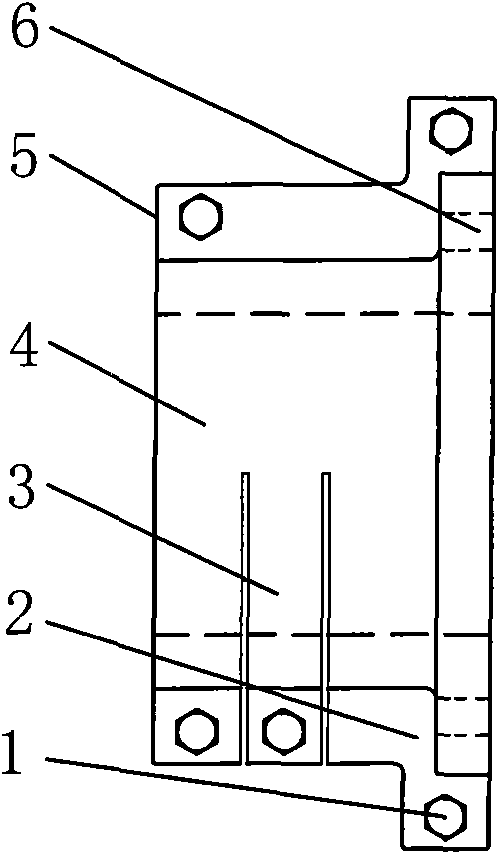

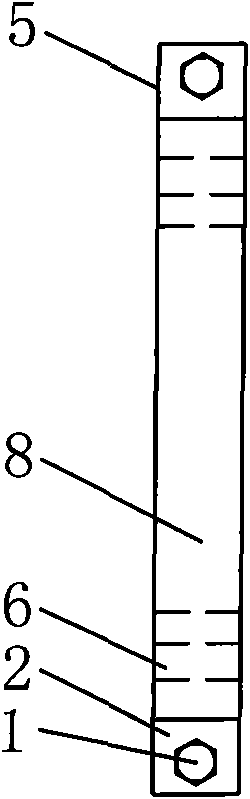

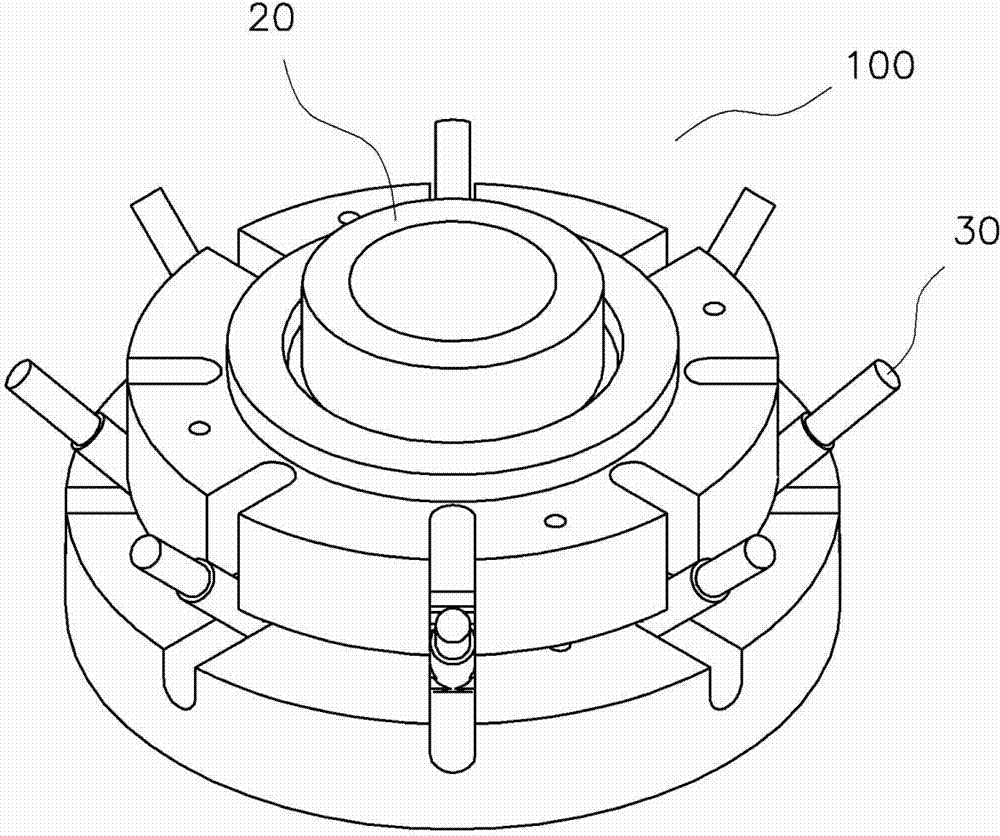

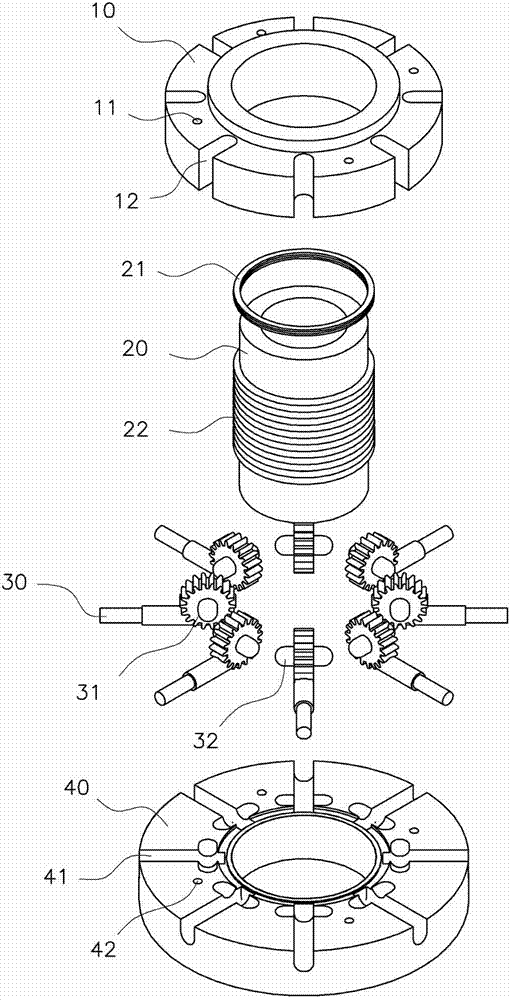

One-step forming process and die of carbon fiber driving shaft

The invention discloses one-step forming process and die of a carbon fiber driving shaft. An inner die is in a disk type structure, is partitioned and cut along a center line, is buckled in a flange type and is connected by a bolt. The inner end of an outer die is in a disk structure; the outside of the outer die is in a sleeve structure; and the outer die is portioned and cut along a center line, is buckled in a flange type and is connected by a bolt. The sleeve part of the outer die is transversely cut along a partition surface on one side to form a compressed clamping strip so as to be convenient for fastening a mandrel. Fastening lug seats are correspondingly arranged on the inner die disk and the outer die disk and are provided with bolt holes. The one-step forming process comprises the steps of 1. preparation of the carbon fiber driving shaft, 2.flange preparation, and 3, ring flange shaping. In the invention, the ring flange processing die has simple structure, is simple, convenient andfeasible for production process and is convenient and quick for processing and using; the one-step forming of the carbon fiber driving shaft and the flange can be realized and the production cost of the die and products can be reduced; the produced carbon fiber driving shaft has high concentricity; the continue track of secondary forming can be eliminated; the torsion strength of the flange of the carbon fiber driving shaft can be enhanced; and the production efficiency and the quality of products can be improved.

Owner:SHANDONG BENO COOLING EQUIP CO LTD

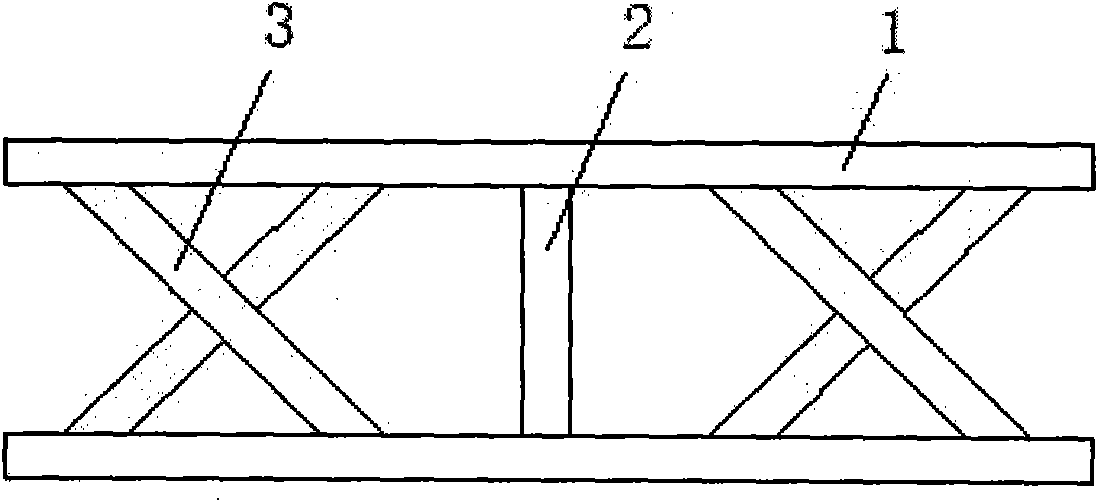

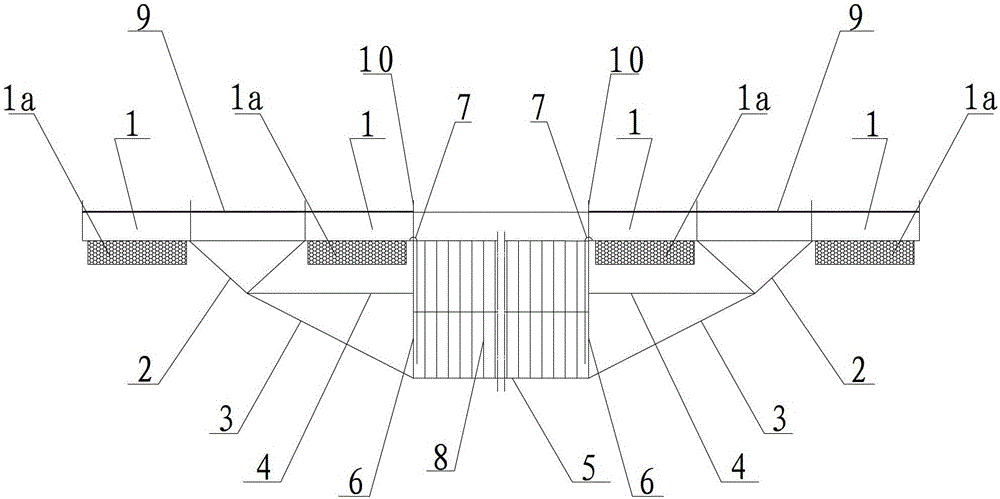

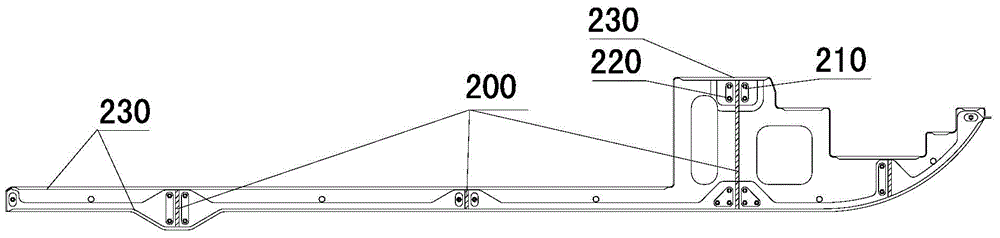

Auxiliary frame structure of concrete mixer truck

InactiveCN103661605AIncreased twisting strengthGuaranteed safety and reliabilityUnderstructuresVehicle frameTruck

The invention discloses an auxiliary frame structure of a concrete mixer truck. The auxiliary frame structure is mainly composed of girders and beams. A middle beam and X beams are connected to the girders. Each X beam is of an X-shaped structure formed by combining the two beams. The auxiliary frame structure has the advantages that the torsion resisting strength of an auxiliary frame of the mixer truck can be effectively improved, and driving safety and reliability of the concrete mixer truck in the mixing process are guaranteed.

Owner:唐雅蓉

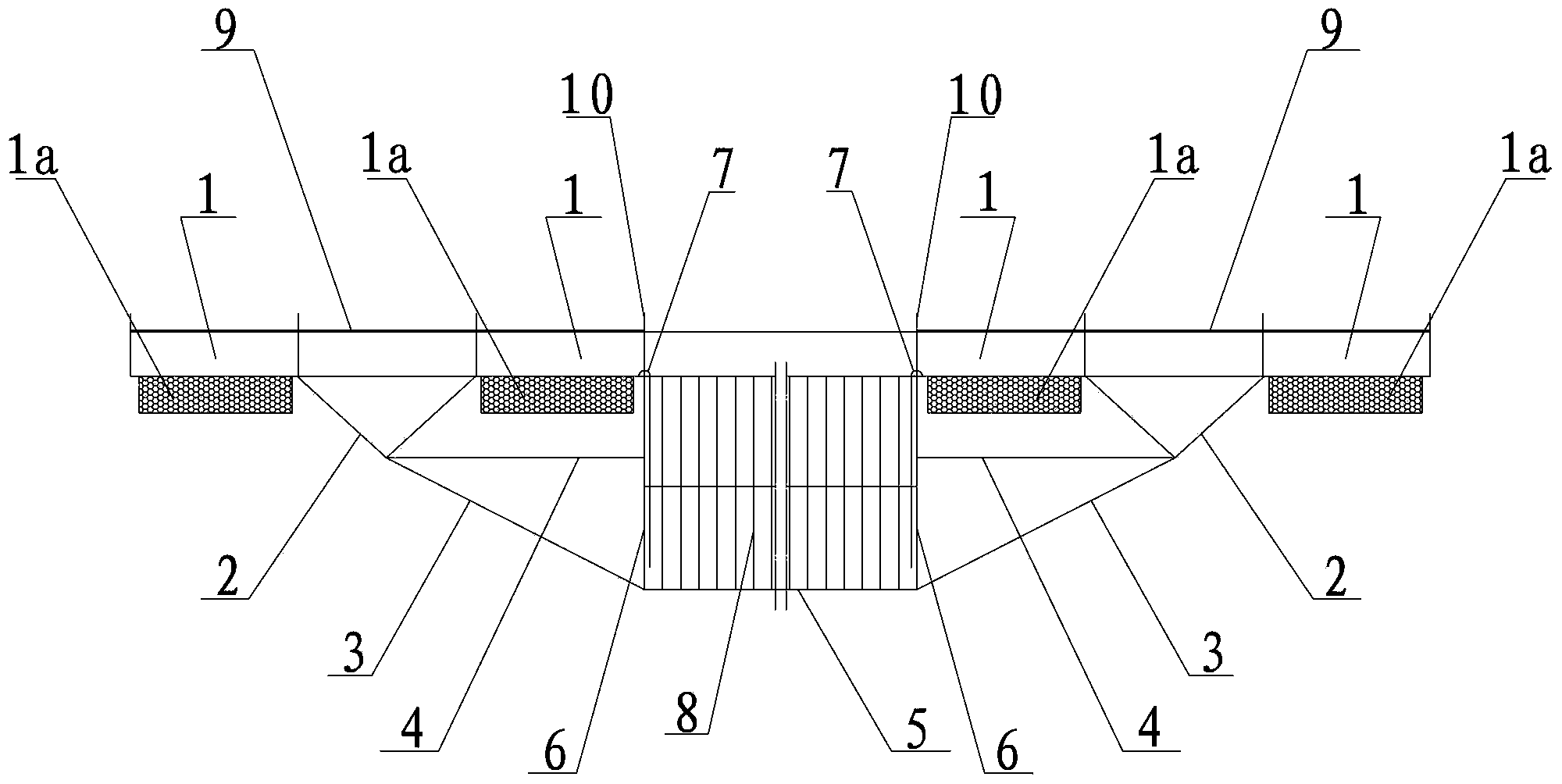

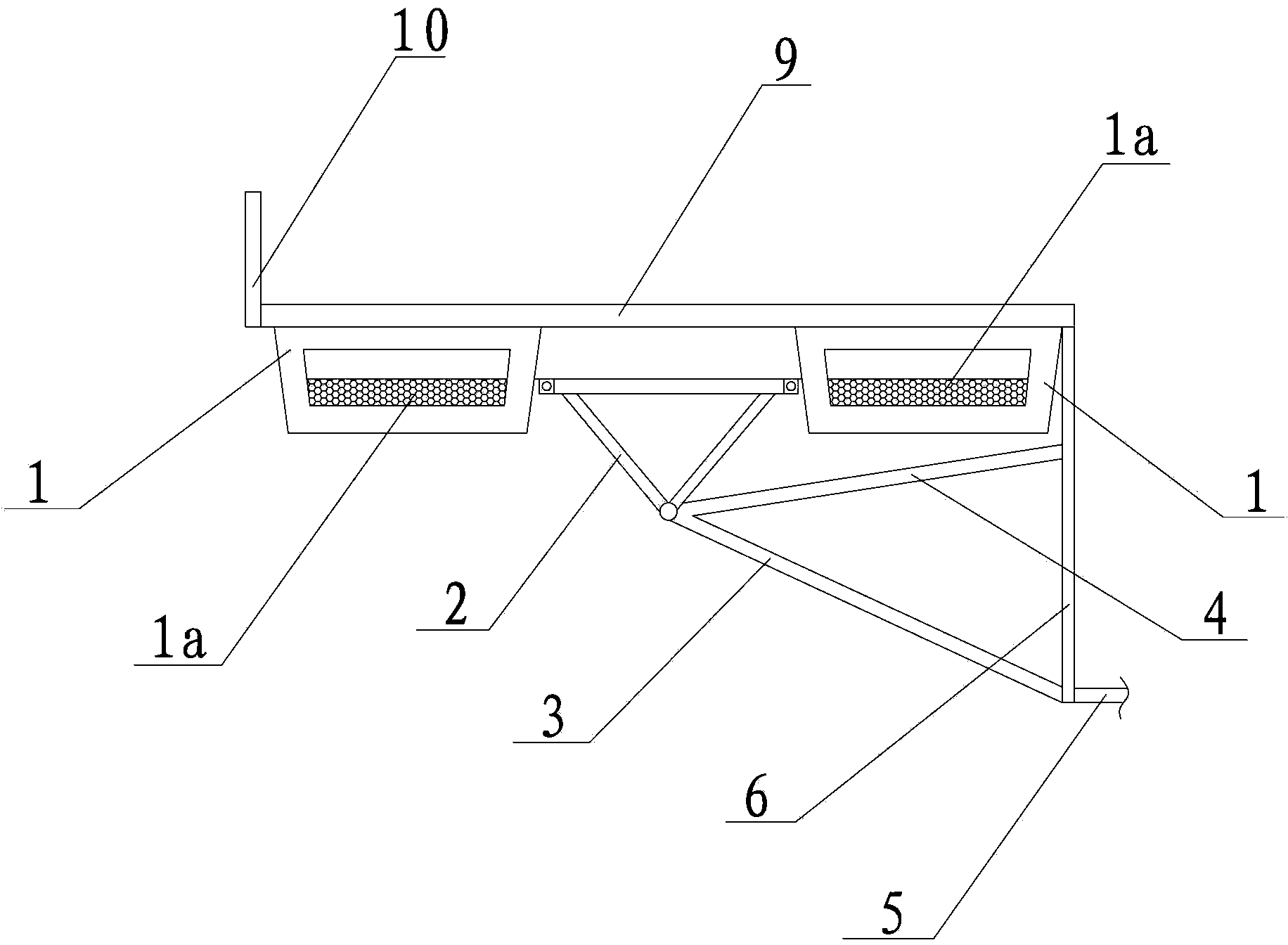

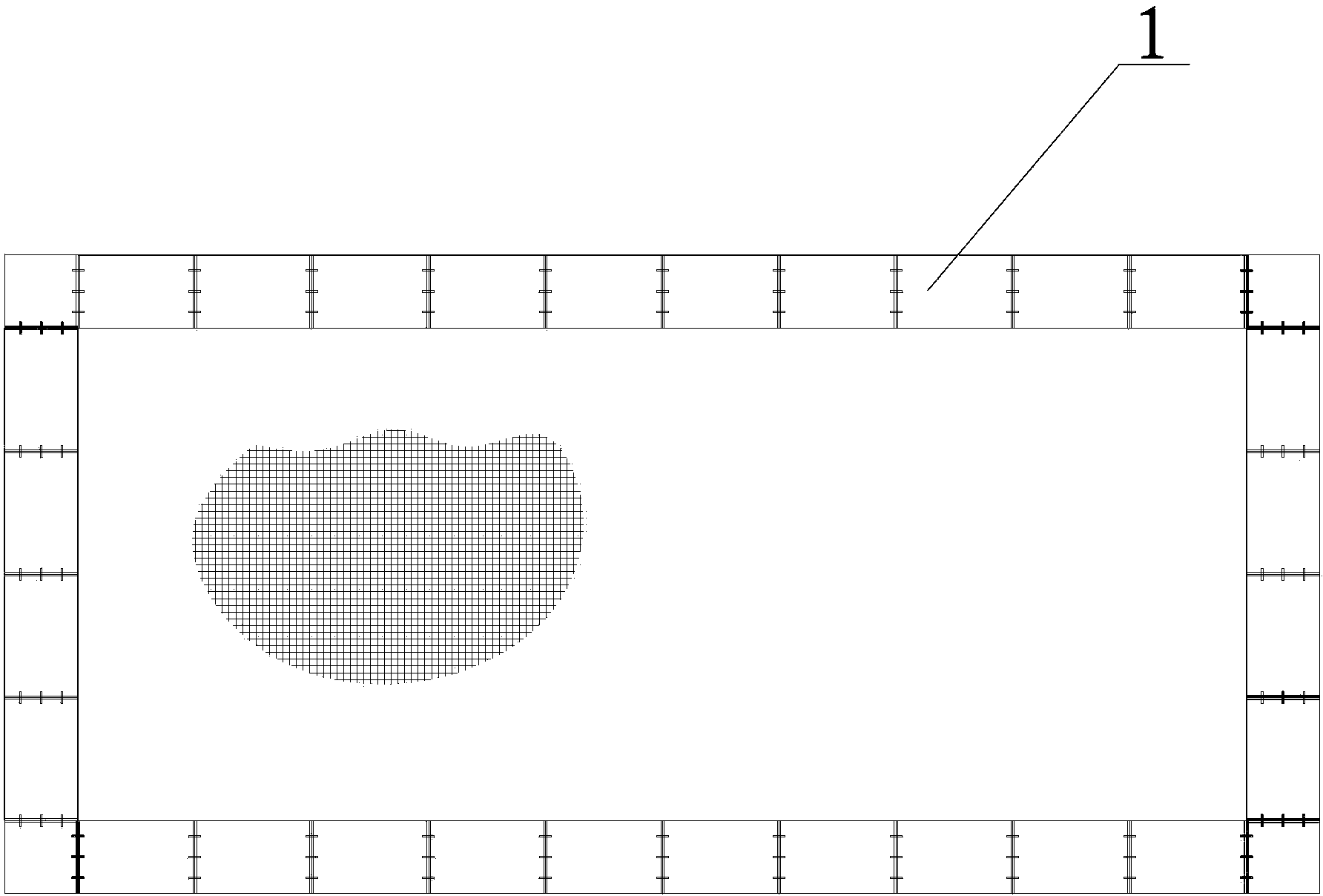

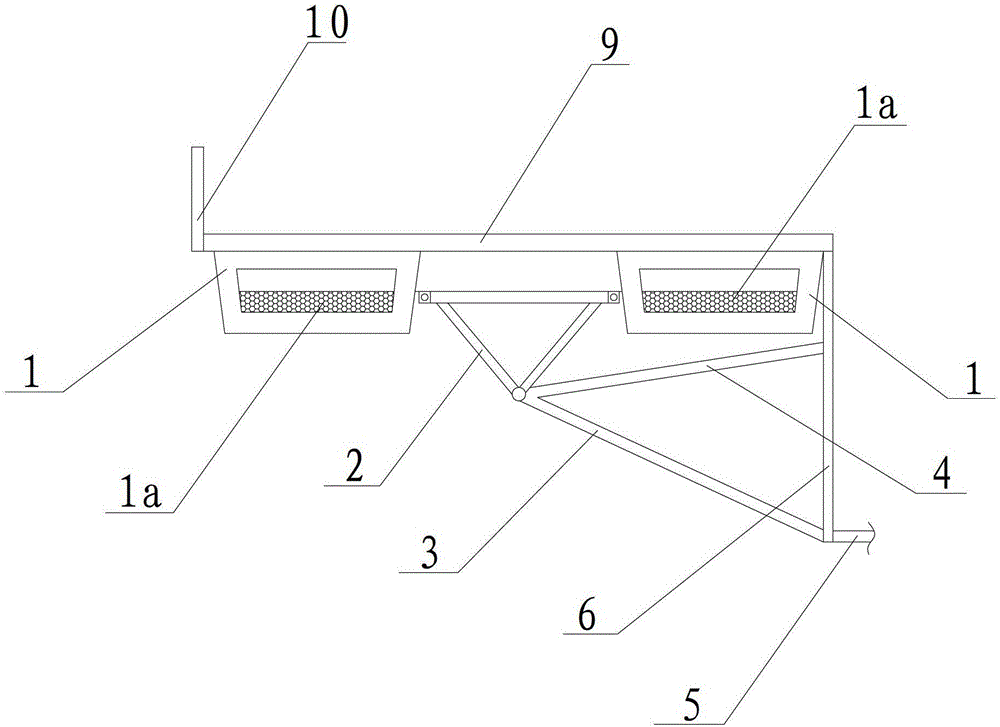

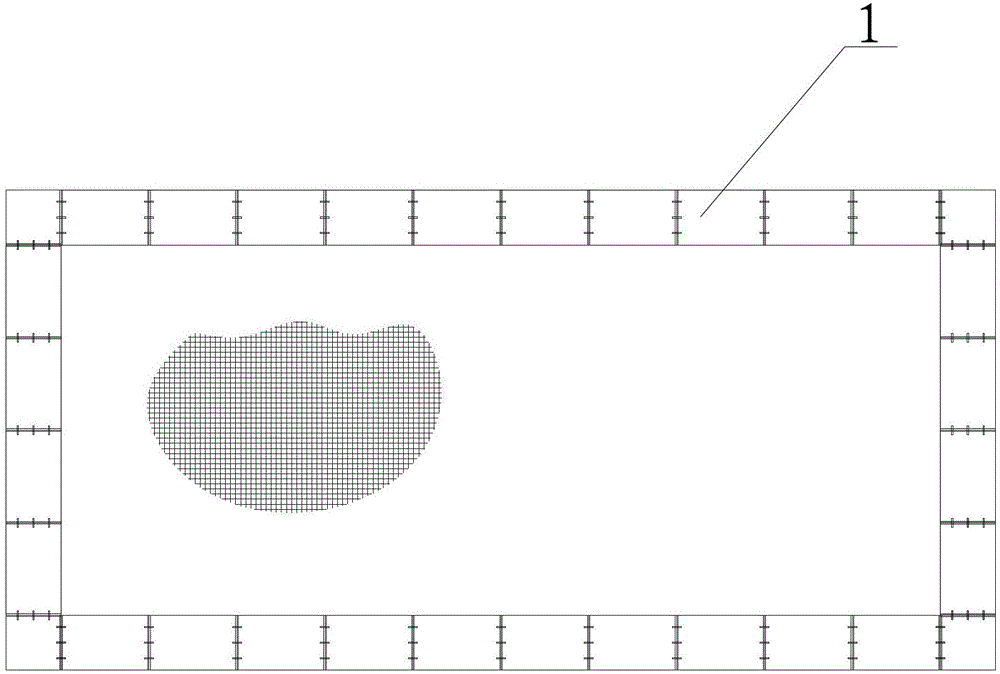

Over-water floating swimming pool

ActiveCN103410350AImprove stabilityIncrease twist strengthGymnasiumFloating buildingsEnvironmentally friendlyMarine engineering

The invention provides an over-water floating swimming pool. The over-water floating swimming pool comprises a swimming pool body, a walkway deck, a railing, floating bodies arranged around the swimming pool body, a first inclined strut, a second inclined strut and a triangular bracket for supporting the floating bodies, wherein the swimming pool body is composed of a pool bottom cross beam, pool bank columns and pool band guardrails. The over-water floating swimming pool has the advantages that the over-water floating swimming pool is good in stability, easy to assemble and convenient to dismount and maintain; the triangular bracket is subjected to preservative treatment, not prone to rusting, durable and environmentally friendly and sanitary; the floating bodies are made of waterproof materials, have good waterproof performances, are low in cost, simple in structure and safe and reliable and have high promotion and application values.

Owner:李国佺

floating swimming pool

ActiveCN103410350BImprove stabilityIncreased twisting strengthGymnasiumFloating buildingsMarine engineeringEnvironmentally friendly

The invention provides an over-water floating swimming pool. The over-water floating swimming pool comprises a swimming pool body, a walkway deck, a railing, floating bodies arranged around the swimming pool body, a first inclined strut, a second inclined strut and a triangular bracket for supporting the floating bodies, wherein the swimming pool body is composed of a pool bottom cross beam, pool bank columns and pool band guardrails. The over-water floating swimming pool has the advantages that the over-water floating swimming pool is good in stability, easy to assemble and convenient to dismount and maintain; the triangular bracket is subjected to preservative treatment, not prone to rusting, durable and environmentally friendly and sanitary; the floating bodies are made of waterproof materials, have good waterproof performances, are low in cost, simple in structure and safe and reliable and have high promotion and application values.

Owner:李国佺

Steel-plastic composite steady-state pipe

PendingCN108468875AHigh strengthIncreased twisting strengthRigid pipesPipe layerUltimate tensile strength

The invention discloses a steel-plastic composite steady-state pipe which comprises a plastic inner layer, a steel pipe layer and a plastic outer layer. The steel pipe layer is arranged between the plastic inner layer and the plastic outer layer, the surface of the steel pipe layer is provided with an organic passive film layer, the inner wall of the steel pipe layer is provided with protrusions which are arranged in the axial direction of the pipeline, the protrusions are provided with through holes, and reinforcing ribs are arranged on the steel pipe layer in the axial direction of the pipeline. According to the steel-plastic composite steady-state pipe, the strength of the composite pipeline can be effectively improved, and meanwhile the distortion resistance strength of the pipeline can be improved.

Owner:谭连平

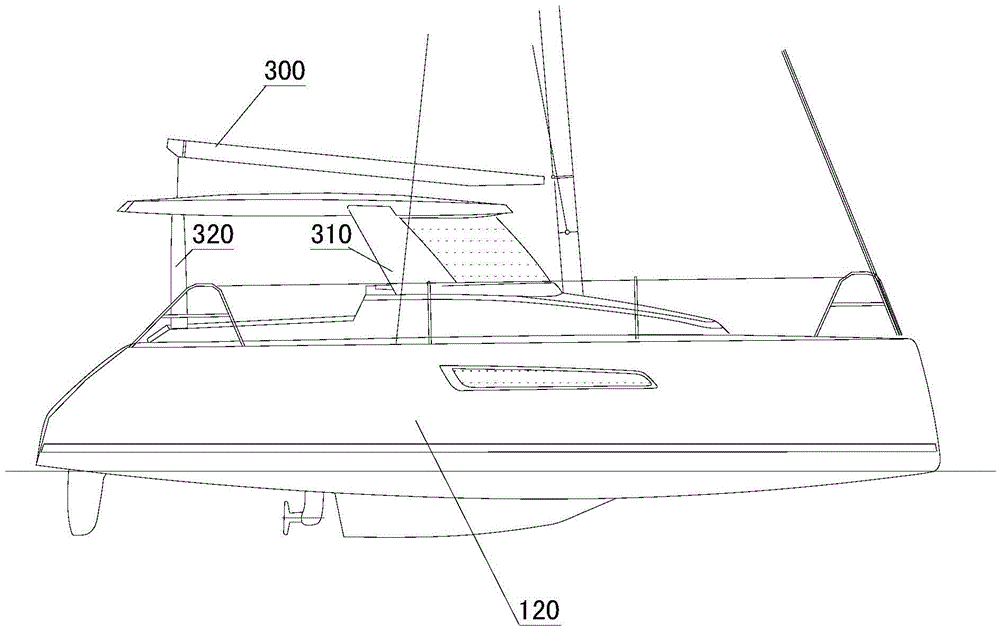

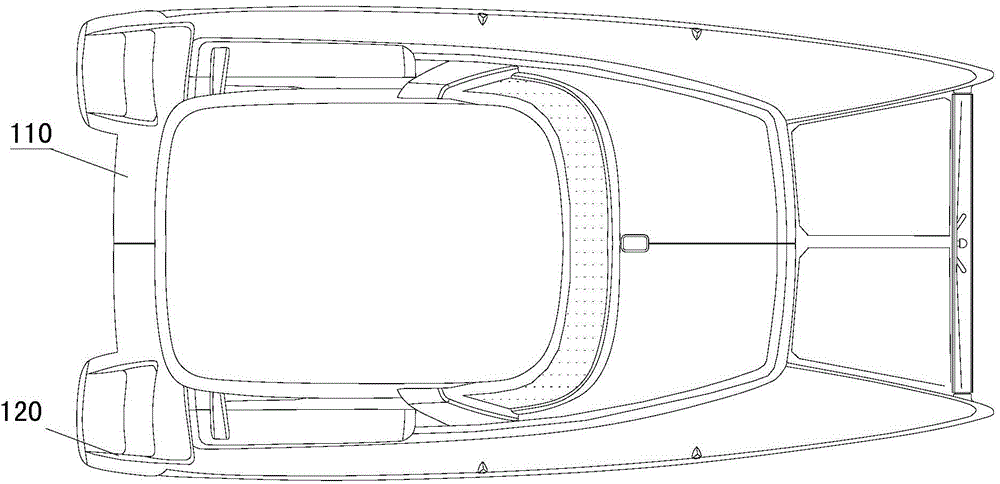

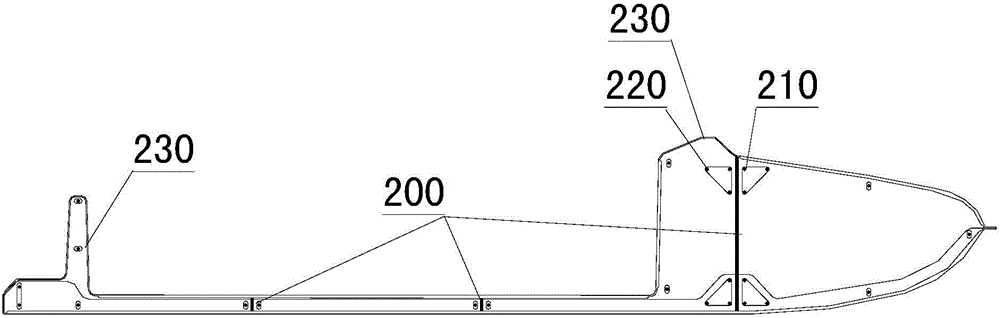

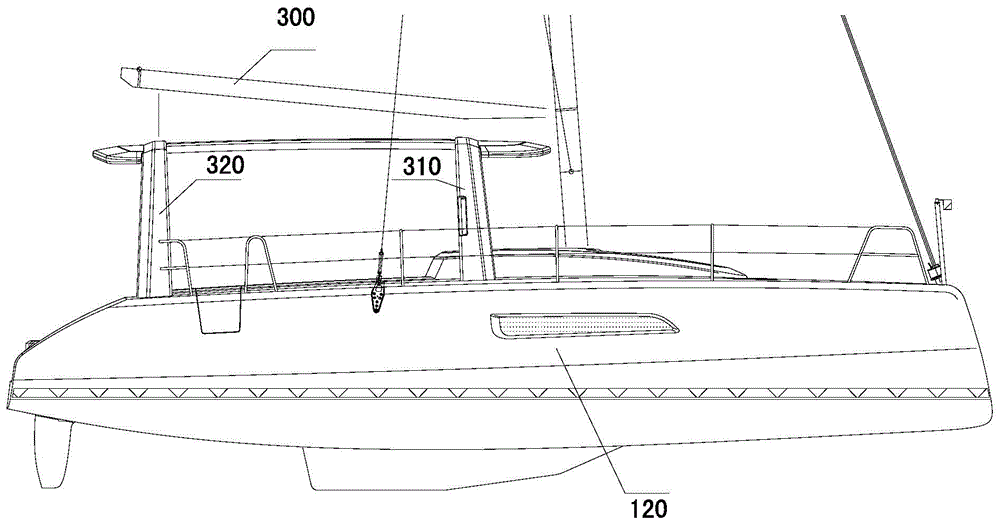

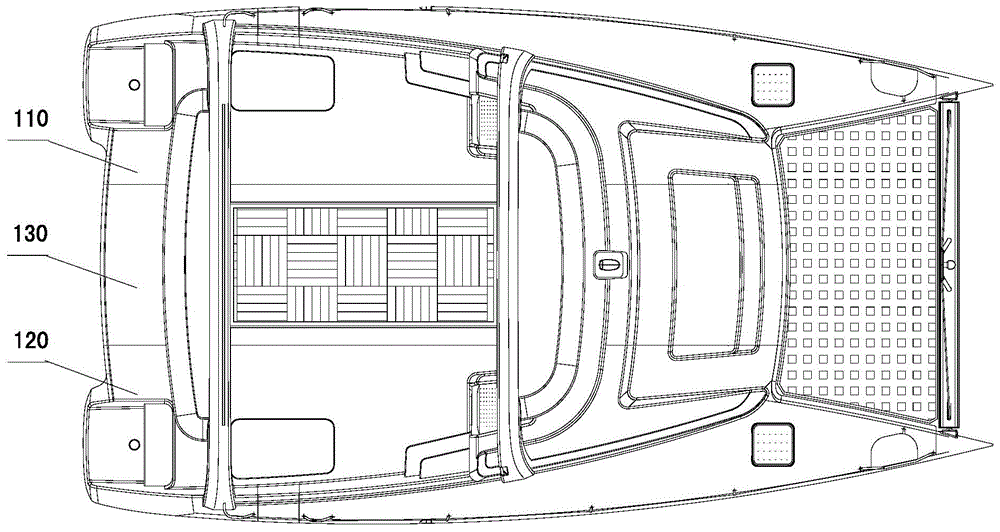

Modular two-body ship

InactiveCN104943815AAvoid torsional deformationEven by forceHydrodynamic/hydrostatic featuresMarine engineeringEngineering

The invention provides a modular two-body ship. A ship body is formed by connecting two split ship bodies. The split ship bodies are the left main ship body and the right main ship body. A ship body connection piece and reinforcing rib plates are arranged between the split ship bodies. A ceiling is arranged above the split ship bodies. The left side of the ceiling is connected with the left main ship body. The right side of the ceiling is connected with the right main ship body. According to the modular two-body ship, the ship body of the two-body sailing ship is designed to be of a two-body structure, all the split ship bodies can be arranged in a 400-foot high container respectively to be transported, and site mounting and combining can be conducted after the ship bodies reach the destination. The middles of the connection positions of all the split ship bodies are provided with the reinforcing rib plates, all the split ship bodies correspond to one another one by one, balance stress of ship body connection points is guaranteed, and the ship bodies can be prevented from being twisted and deformed. The upper portions of the ship bodies are provided with the ceiling, four stand columns of the ceiling are adopted to be connected with the split ship bodies, the whole ship body forms a rectangular pipe again, and the torsional strength is enhanced.

Owner:上海珐伊复合材料科技有限公司

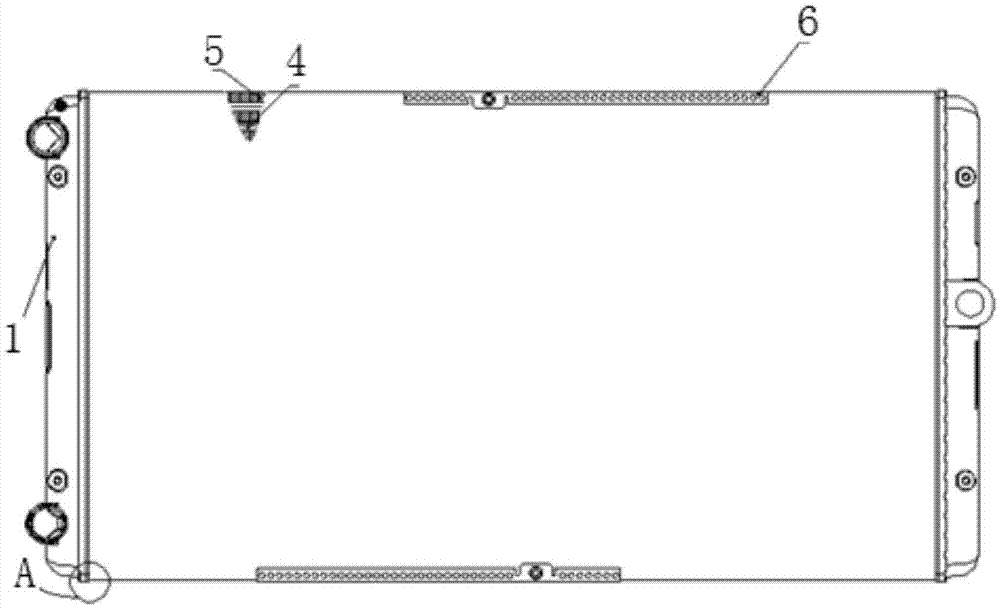

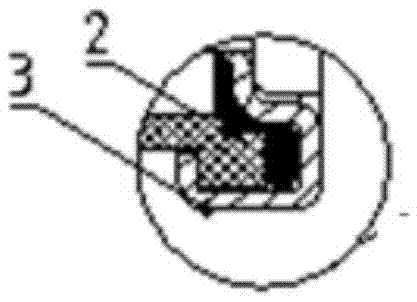

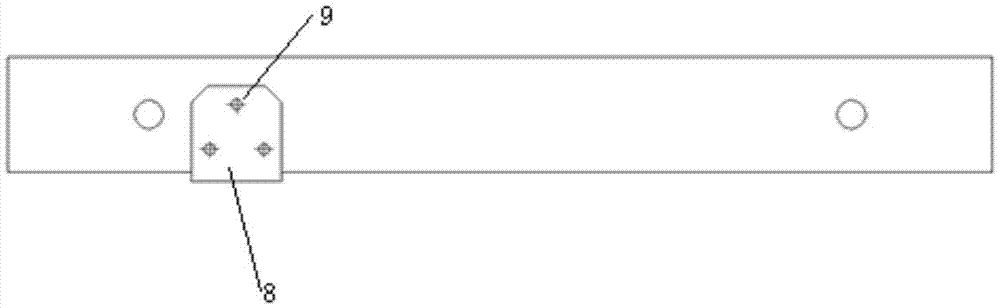

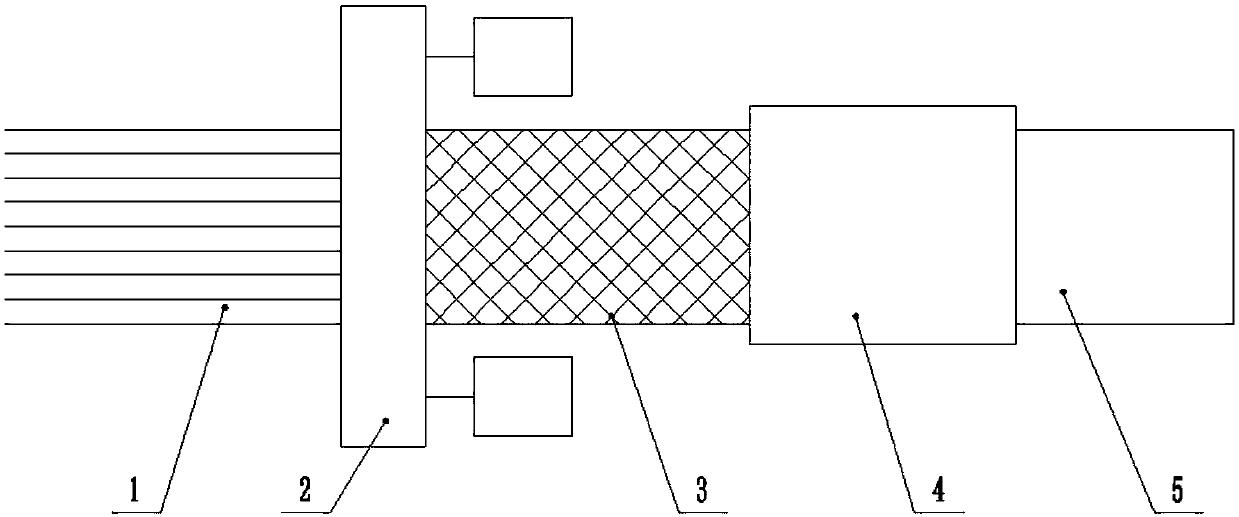

Automotive radiator high in firmness and low in leakage rate

InactiveCN106917665AReduce return rateLow costMachines/enginesEngine cooling apparatusRear quarterEngineering

The invention relates to an automotive radiator high in firmness and low in leakage rate. The automotive radiator comprises a water chamber (1), a main sheet (3), a radiating tube (4) and side plates (6). The main sheet (3) is connected with the water chamber (1), the radiating tube (4) and the side plates (6). The side plates (6) are provided with corresponding threaded mounting holes (61). Compared with the prior art, the side plates are provided with the corresponding threaded mounting holes, a fan can be installed directly, an original support structure is omitted, there is no need to manually rivet a support onto the side plates, and therefore the loosening hidden danger in riveting is eliminated, and the reject rate of radiator products is greatly lowered; only a set of mold is required for one-time forming, and thus mold cost and manual riveting cost are reduced; and one face of a radiating tube sealing gasket makes contact with the main sheet and is provided with convex ribs, the contact sealing effect is good and the leakage rate is low.

Owner:SHANGHAI DELANG AUTO RADIATOR MFG

multi-pole connector

InactiveCN104241880BHigh strengthEasy and efficient assemblyElectrically conductive connectionsIncorrect coupling preventionEngineeringMechanical engineering

Owner:SMK CO LTD

One-step forming process and die of carbon fiber driving shaft

The invention discloses one-step forming process and die of a carbon fiber driving shaft. An inner die is in a disk type structure, is partitioned and cut along a center line, is buckled in a flange type and is connected by a bolt. The inner end of an outer die is in a disk structure; the outside of the outer die is in a sleeve structure; and the outer die is portioned and cut along a center line, is buckled in a flange type and is connected by a bolt. The sleeve part of the outer die is transversely cut along a partition surface on one side to form a compressed clamping strip so as to be convenient for fastening a mandrel. Fastening lug seats are correspondingly arranged on the inner die disk and the outer die disk and are provided with bolt holes. The one-step forming process comprises the steps of preparation of the carbon fiber driving shaft, flange preparation and ring flange shaping. In the invention, the ring flange processing die has simple structure, is simple, convenient and feasible for production process and is convenient and quick for processing and using; the one-step forming of the carbon fiber driving shaft and the flange can be realized and the production cost of the die and products can be reduced; the produced carbon fiber driving shaft has high concentricity; the continue track of secondary forming can be eliminated; the torsion strength of the flange of the carbon fiber driving shaft can be enhanced; and the production efficiency and the quality of products can be improved.

Owner:SHANDONG BENO COOLING EQUIP CO LTD

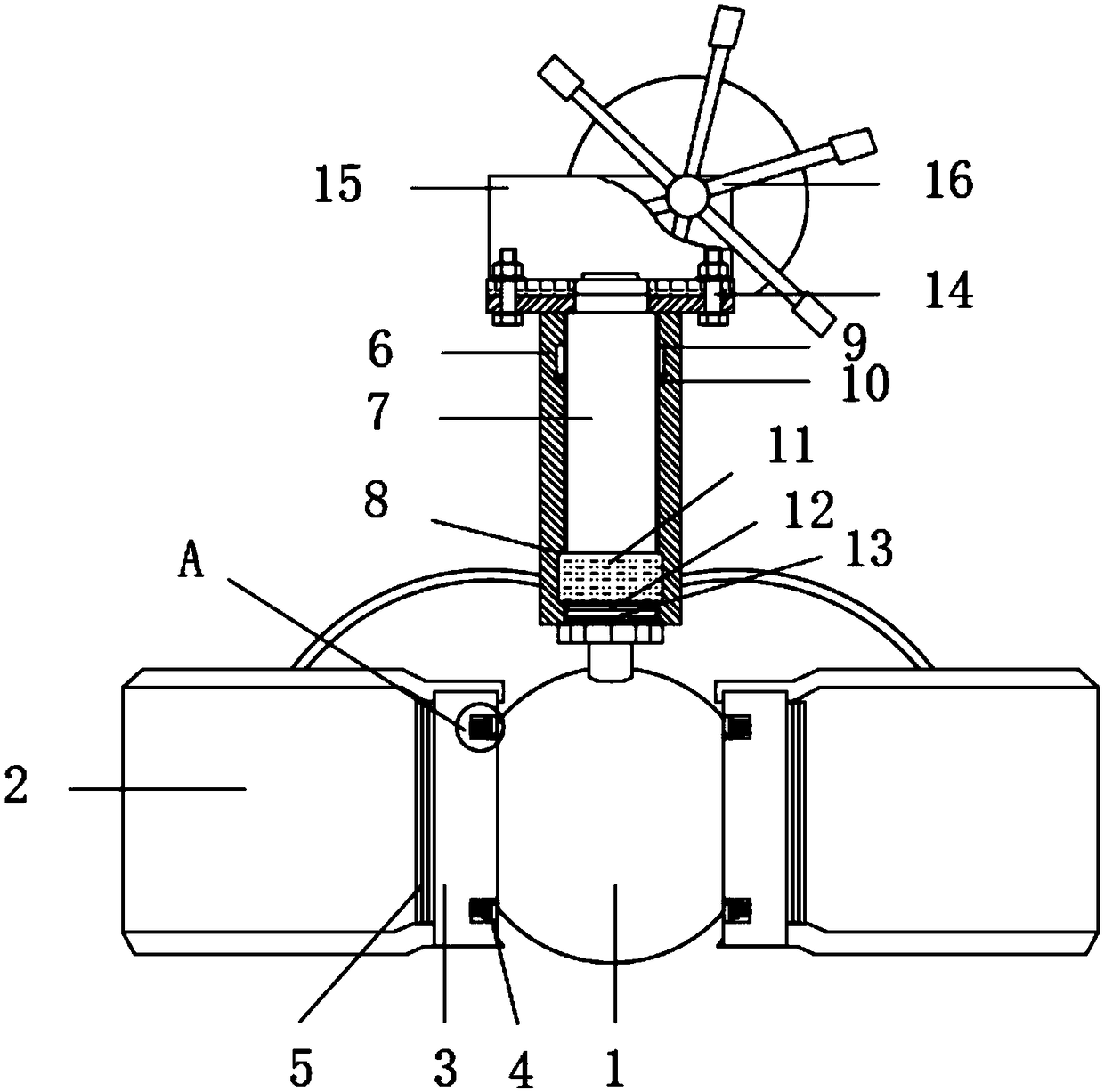

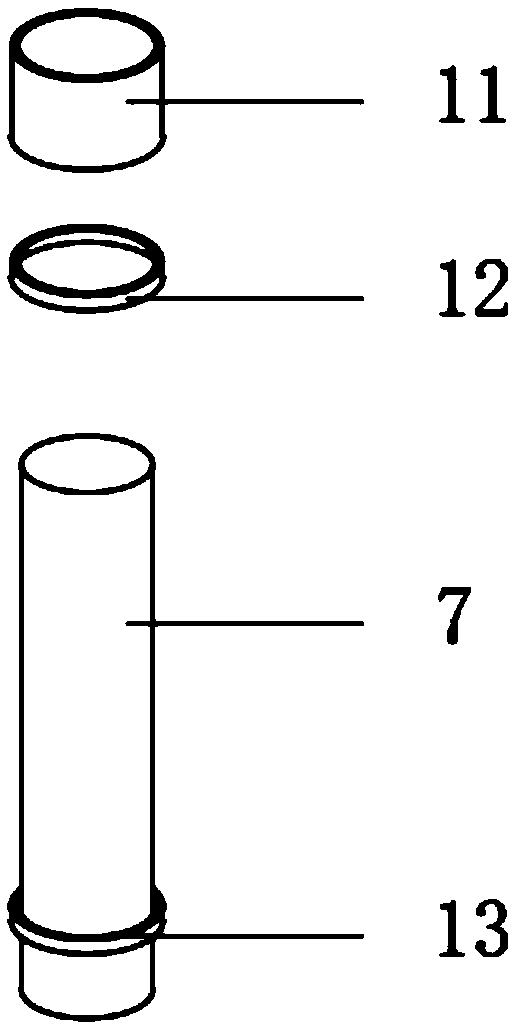

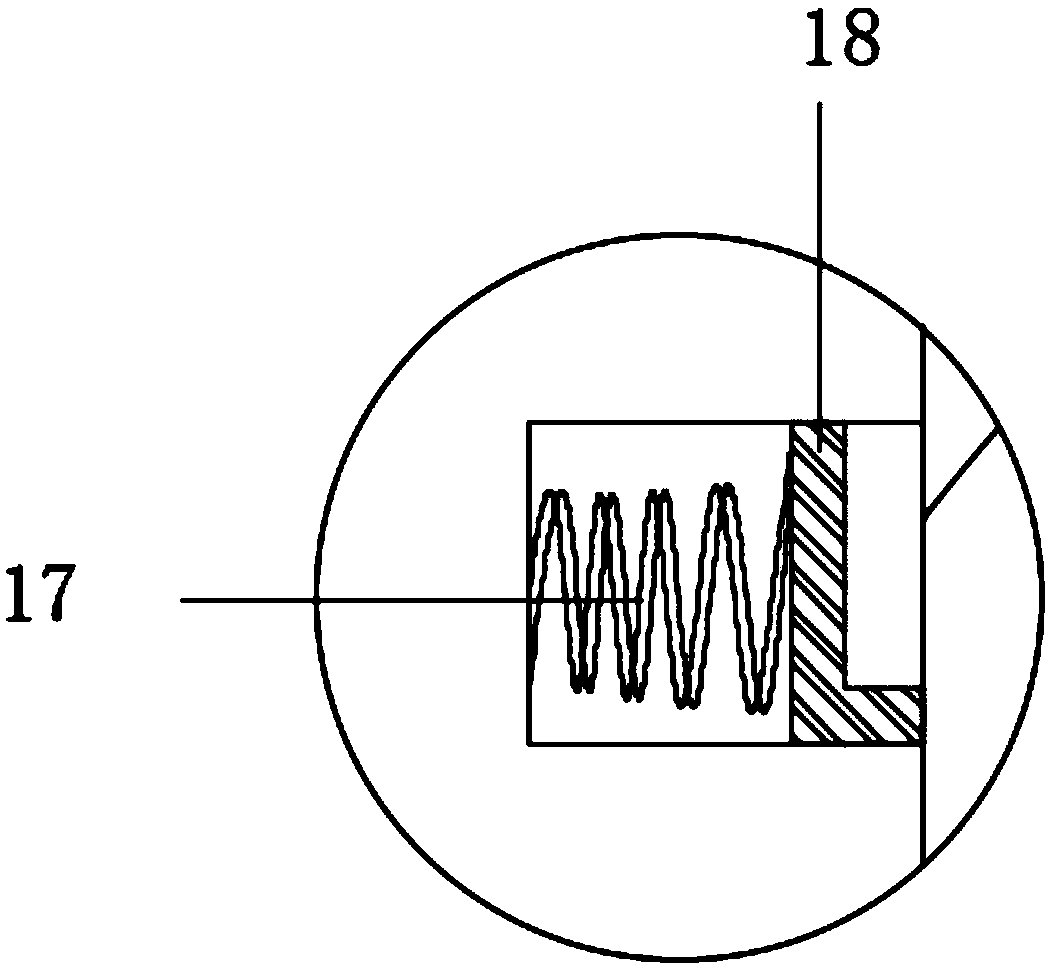

Thermal ball valve resistant to leakage

PendingCN108799540AGreatly use efficiencyIncreased twisting strengthSpindle sealingsPlug valvesFiberCarbon fibers

The invention discloses a thermal ball valve resistant to leakage. The thermal ball valve resistant to leakage comprises a sphere. Floating valve seats are connected with the two sides of the sphere.Buffer limiting mechanisms are connected with both the upper end and the lower end of the side, close to the sphere, of each floating valve seat. According to the thermal ball valve resistant to leakage, a valve rod is made of 20Cr13 stainless steel, the valve rod is high in torsional strength and smooth in machined surface, and a lubricating sealing effect is improved; the valve rod is installedfrom the lower part of the interior of a valve rod connecting sleeve, pressure is pushed towards the valve rod by using a thrust washer support made of a low-friction material, and therefore the valverod only plays a role in transmitting torque without generating load; meanwhile, because the valve seats are composed of carbon fiber reinforced polytetrafluoroethylene and springs, self lubrication,friction resistance and resistance to temperature as high as 200 DEG C are achieved; an O-shaped sealing ring is made of VITON fluororubber, and thereby being good in temperature resistance, resistant to friction and high in corrosion resistance; and a first sealing ring is assembled at a low temperature, and thereby being high in adaptive capacity of changes of pressure and temperature, and no leakage is likely to happen within the marked range of pressure and temperature.

Owner:JIANGSU CHENGGONG VALVE TECH

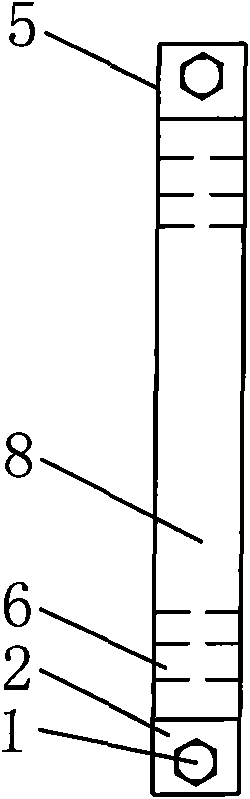

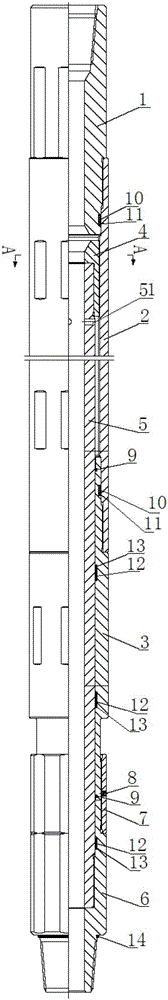

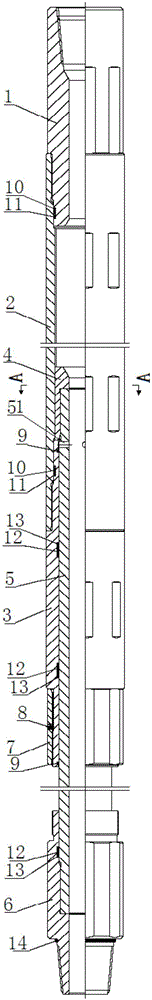

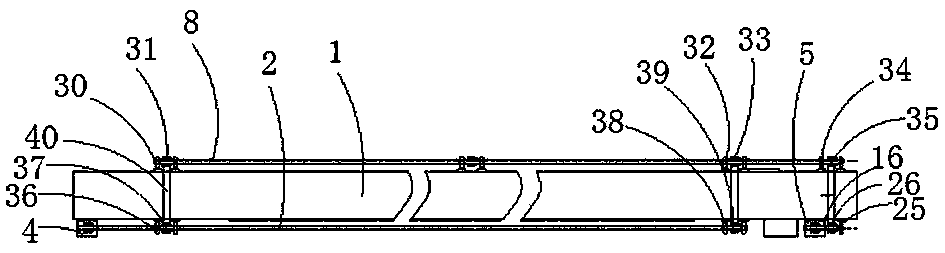

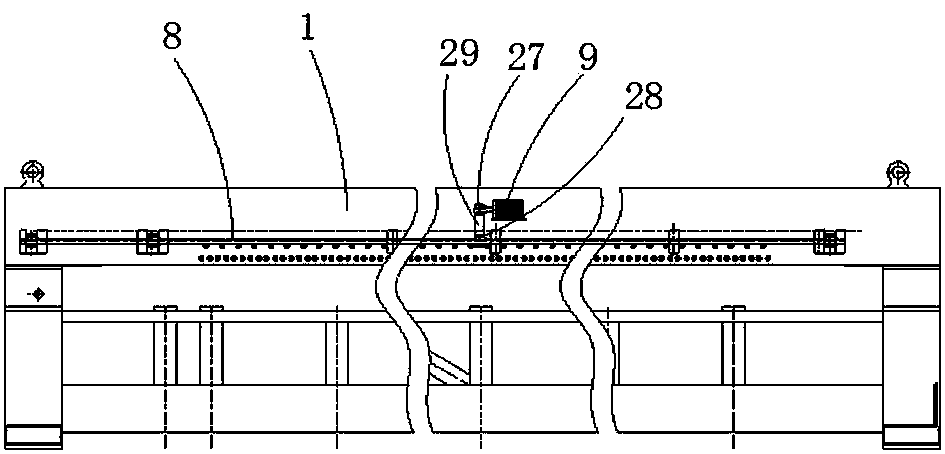

Telescopic pipe suitable for floating platform testing

InactiveCN106401499ASimple structureIncrease twist strengthDrilling rodsDrilling casingsFloating platformEngineering

The invention relates to a telescopic pipe suitable for floating platform testing. The telescopic pipe is characterized by comprising an outer cylinder string and a core shaft string located in the outer cylinder string; the outer cylinder string comprises an upper connector, a spline outer cylinder and a sealing short joint, wherein inner threads are arranged at the upper end and the lower end of the spline outer cylinder correspondingly, the lower end of the upper connector is connected with the upper end of the spline outer cylinder through an outer thread in a matched manner, and the upper end of the sealing short joint is connected with the lower end of the spline outer cylinder through an outer thread in a matched manner; the core shaft string comprises a spline short joint, a torsion core shaft and a lower connector, wherein outer threads are arranged at the upper end and the lower end of the torsion core shaft correspondingly, the lower end of the spline short joint is connected with the upper end of the torsion core shaft through the corresponding inner thread in a matched manner, the upper end of the lower connector is connected with the lower end of the torsion core shaft through the corresponding inner thread in a matched manner; and the spline short joint is arranged on the inner side of the spline outer cylinder in the manner that the spline short joint can slide and cannot rotate.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Modular three-body ship

InactiveCN104943816AAvoid torsional deformationEven by forceHydrodynamic/hydrostatic featuresMarine engineeringTorsional strength

The invention provides a modular three-body ship. A ship body is formed by connecting three split ship bodies. The split ship bodies are the left main ship body, the right main ship body and the middle deck ship body. Split ship body connection pieces are arranged among the split ship bodies. Reinforcing rib plates are arranged between the middle deck ship body and the right main ship body, and the reinforcing rib plates are provided with the ship body connection pieces. The ceiling is arranged above the split ship bodies. The left side of the ceiling is connected with the left main ship body, and the right side of the ceiling is connected with the right main ship body. According to the modular three-body ship, the ship body of the sailing ship is designed to be of a three-body structure, all the split ship bodies are arranged in a 40-foot high container to be transported, and site mounting and combining can be conducted after the split ship bodies reach the destination. The middles of the connection positions of all the split ship bodies are provided with the reinforcing rib plates, all the split ship bodies correspond to one another one by one, balance stress of ship body connection points is guaranteed, and the ship bodies can be prevented from being twisted and deformed as well. The upper portions of the ship bodies are provided with the ceiling. Four stand columns of the ceiling are connected with the split ship bodies, the whole ship body forms a rectangular pipe again, and the torsional strength is enhanced.

Owner:上海珐伊复合材料科技有限公司

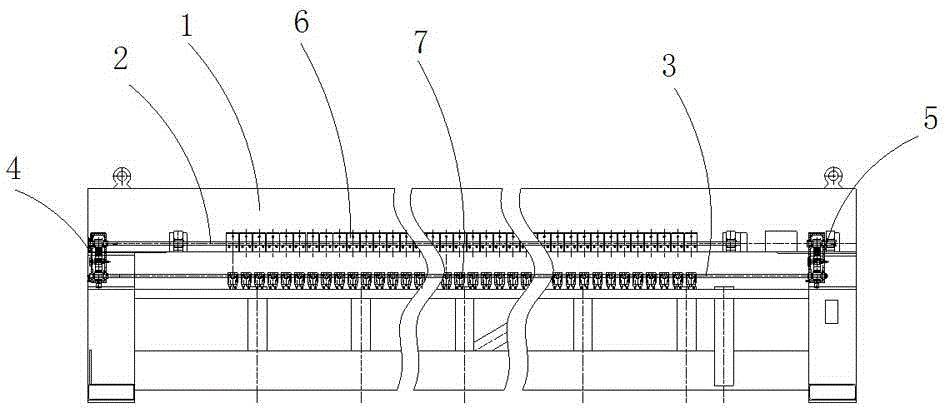

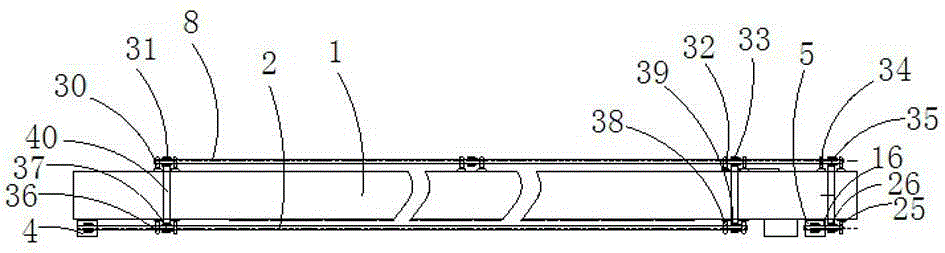

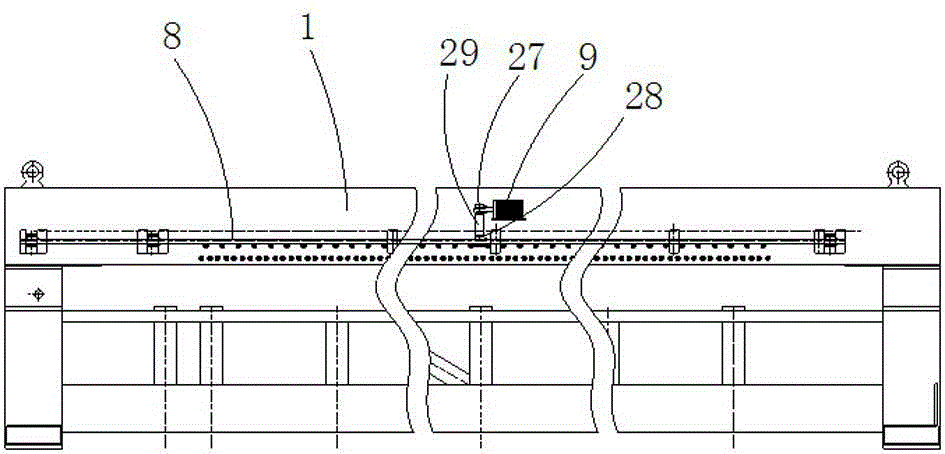

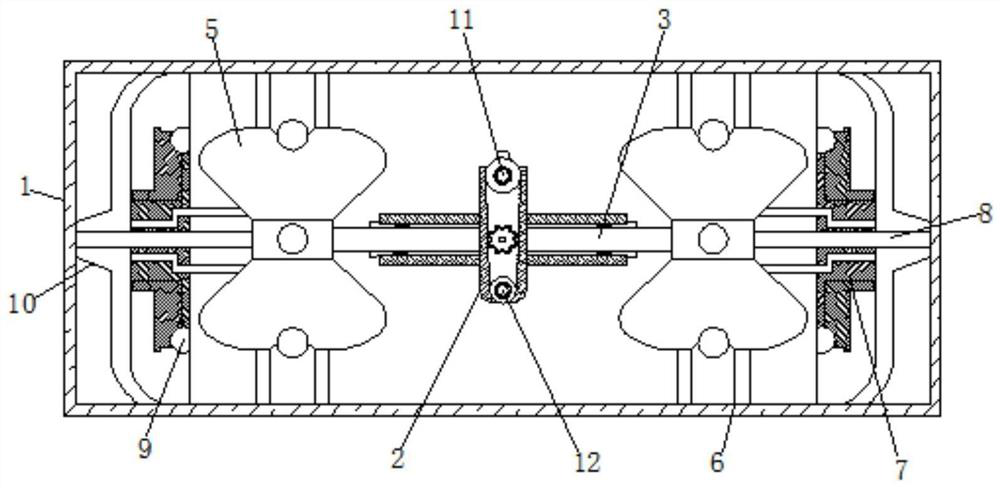

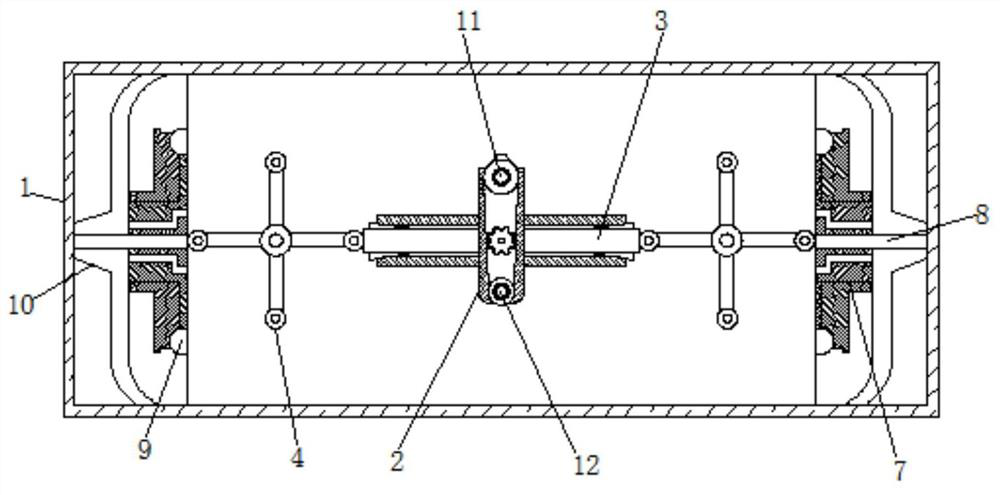

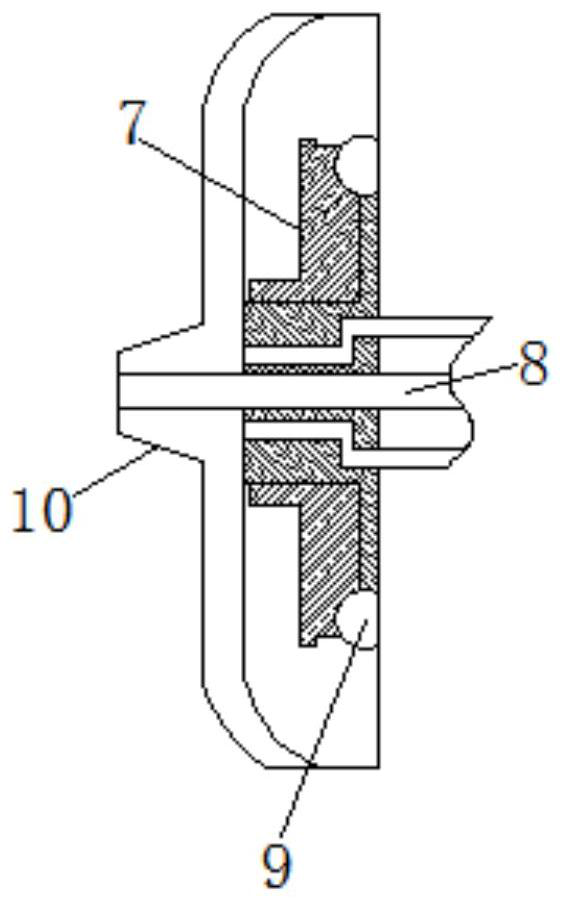

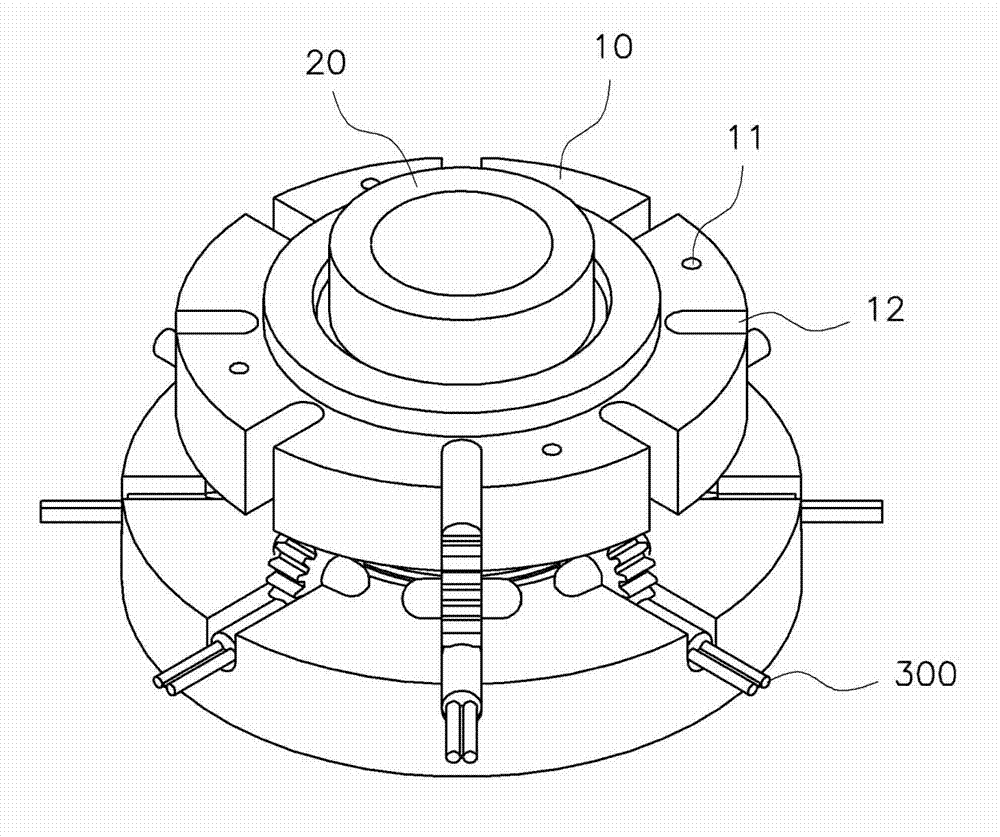

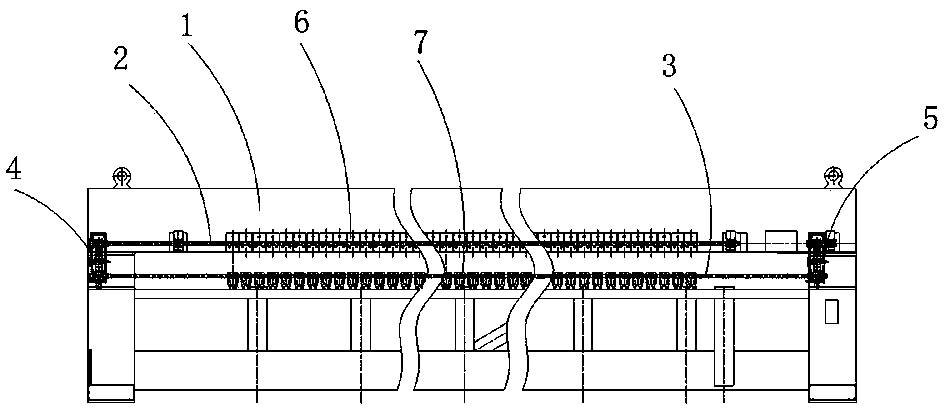

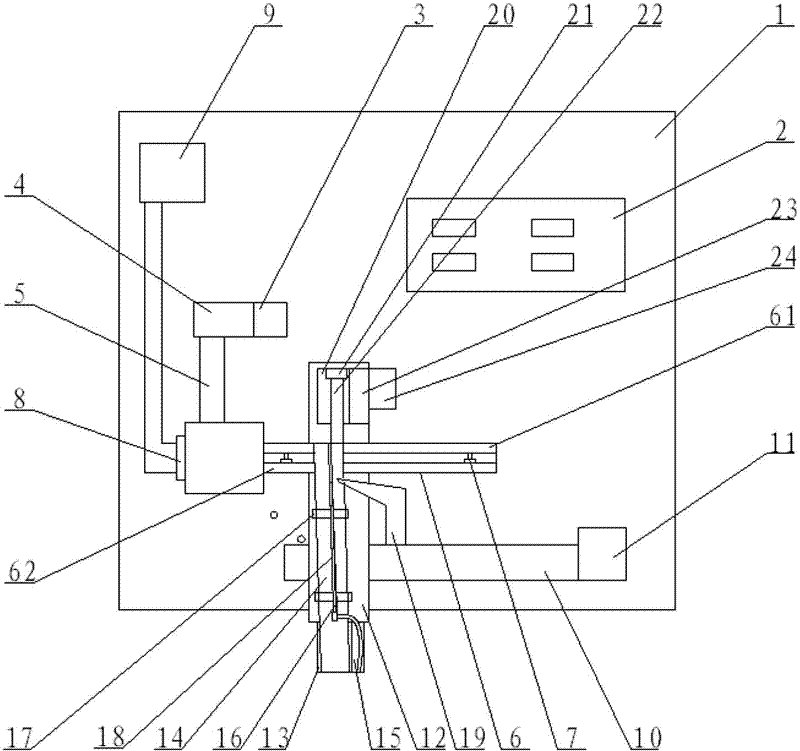

Two-way main shaft transmission mechanism for embroidery machine

ActiveCN102864598ACompact structureIncreased twisting strengthEmbroidering machines apparatusMechanical engineeringSynchronism

The invention relates to a transmission mechanism, in particular to a two-way main shaft transmission mechanism for an embroidery machine. The two-way main shaft transmission mechanism is used for the embroidery machine, and comprises a crossbeam, wherein a left-side transmission mechanism is arranged at the left side end of the crossbeam, and a right-side transmission mechanism is arranged at the right side end of the crossbeam; the left-side transmission mechanism drives the right-side transmission mechanism. The two-way main shaft transmission mechanism for the embroidery machine is simple and compact in structure and high in synchronism, and the warping strength is improved.

Owner:HANGZHOU JINGWEI ELECTRONICS MECHANICAL MFG

A device for increasing softness and strength of yarn

ActiveCN110485005BIncreased twisting strengthTo achieve the effect of local coolingTextiles and paperYarnClassical mechanics

The invention relates to the technical field of twining of yarn, and discloses a device for improving the softness and strength of the yarn. The device comprises a shell, a yarn tensioning pillar is movably connected to the interior of the shell, a ventilation pipeline is hinged to the surface of the yarn tensioning pillar, and yarn winding pillars are movably connected to the two sides of the ventilation pipeline; air blowing ports are movably connected to the interiors of the yarn winding pillars, cooling pipelines are fixedly connected to the two sides of each air blowing port, a yarn outlet nozzle is movably connected to the side, away from the ventilation pipeline, of each yarn winding pillar, and a yarn guiding port is fixedly connected to the interior of each yarn outlet nozzle. Theyarn tensioning pillar is also driven to rotate, and conducts primary twisting on the yarn entering the yarn tensioning pillar from the right side, and then the yarn temporarily winds the yarn tensioning pillar, and afterwards, breaks away from the yarn tensioning pillar and winds the yarn winding pillars to be subjected to secondary twisting; the yarn winding the yarn winding pillars finally flows out of the yarn guiding ports in the yarn outlet nozzles, and then the yarn outlet nozzles are driven by rotation balls to rotate for third-time twisting. By means of the device, the effect of improving the twisting strength is achieved.

Owner:浙江晨宇针织有限公司

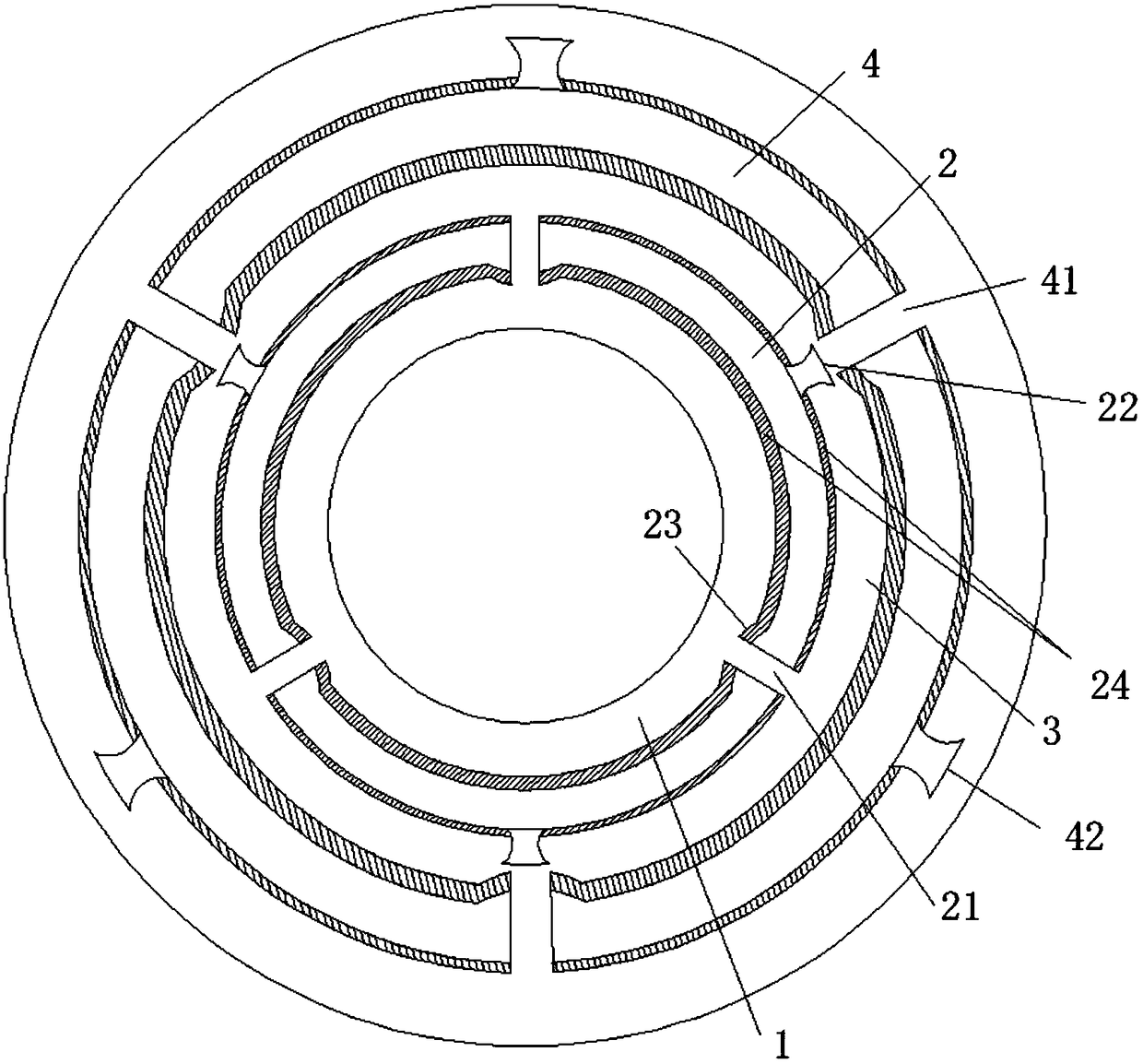

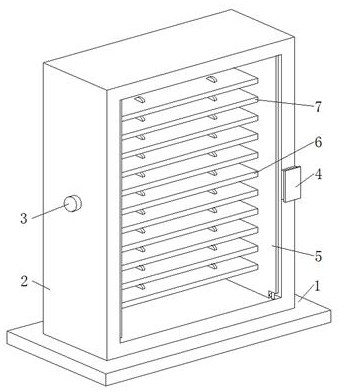

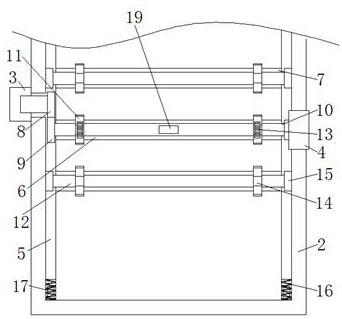

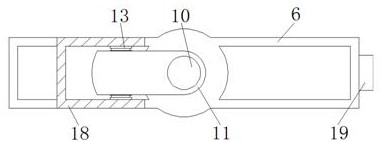

Hollow built-in magnetic assembly for controlling overturning angle of shutter roller

PendingCN112196442AAvoid damageImprove practicalityBuilding braking devicesLight protection screensMagnetic tension forceWindow shutter

The invention discloses a hollow built-in magnetic assembly for controlling an overturning angle of a shutter roller. The magnetic assembly comprises a base, wherein a window frame is fixedly installed at the upper end of the base, a servo motor is fixedly installed at the left end of the window frame, a control screen is fixedly installed at the front end of the window frame, a protective interlayer is fixedly installed at the inner end of the window frame, a central window lattice is fixedly installed at the inner end of the protective interlayer, driven window lattices are fixedly installedat the positions, located at the inner end of the protective interlayer, of the outer side of the central window lattice, and the driven window lattices are distributed on the outer side of the central window lattice at equal intervals. The hollow built-in magnetic assembly for controlling the overturning angle of the shutter roller is installed in a built-in mode, damage to exposed parts is reduced, practicability is high, magnetic force can be used for driving a driven roller to rotate in a following mode, angle overturning of a shutter is completed, manual operation is not needed, convenience is high, the overturning angle of the shutter can be proper according to the external illumination degree, the automation degree is high, the service life is long, and the safety is good.

Owner:无锡市四方达节能材料有限公司

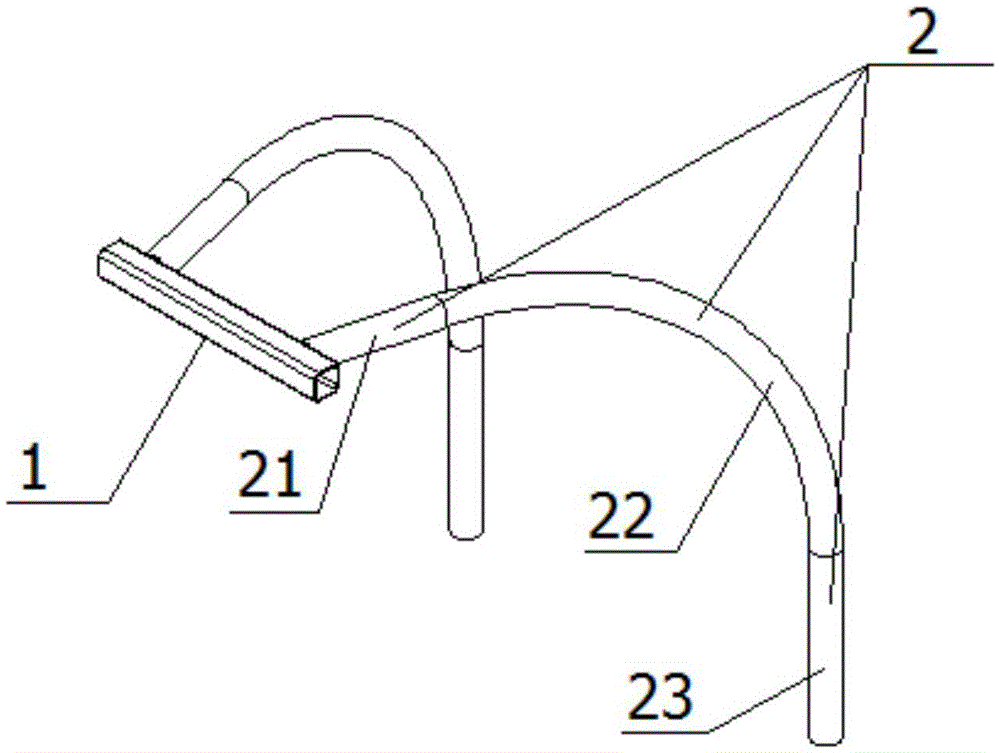

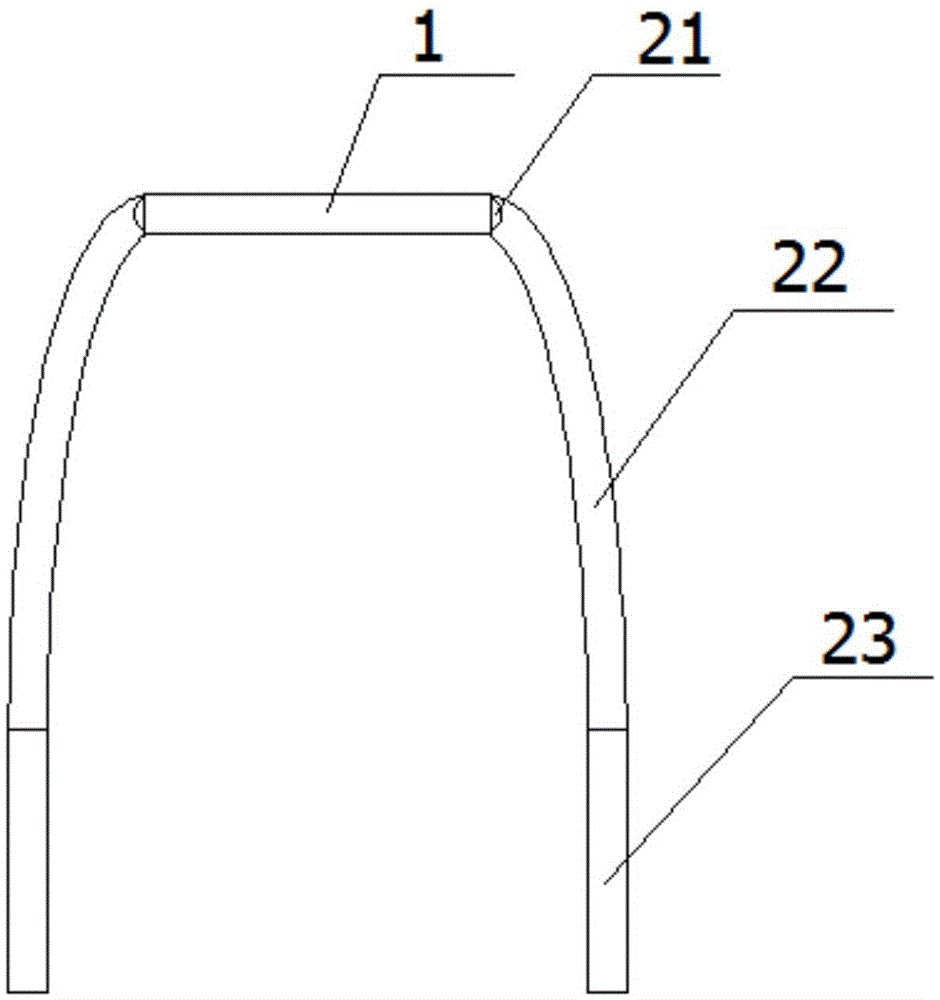

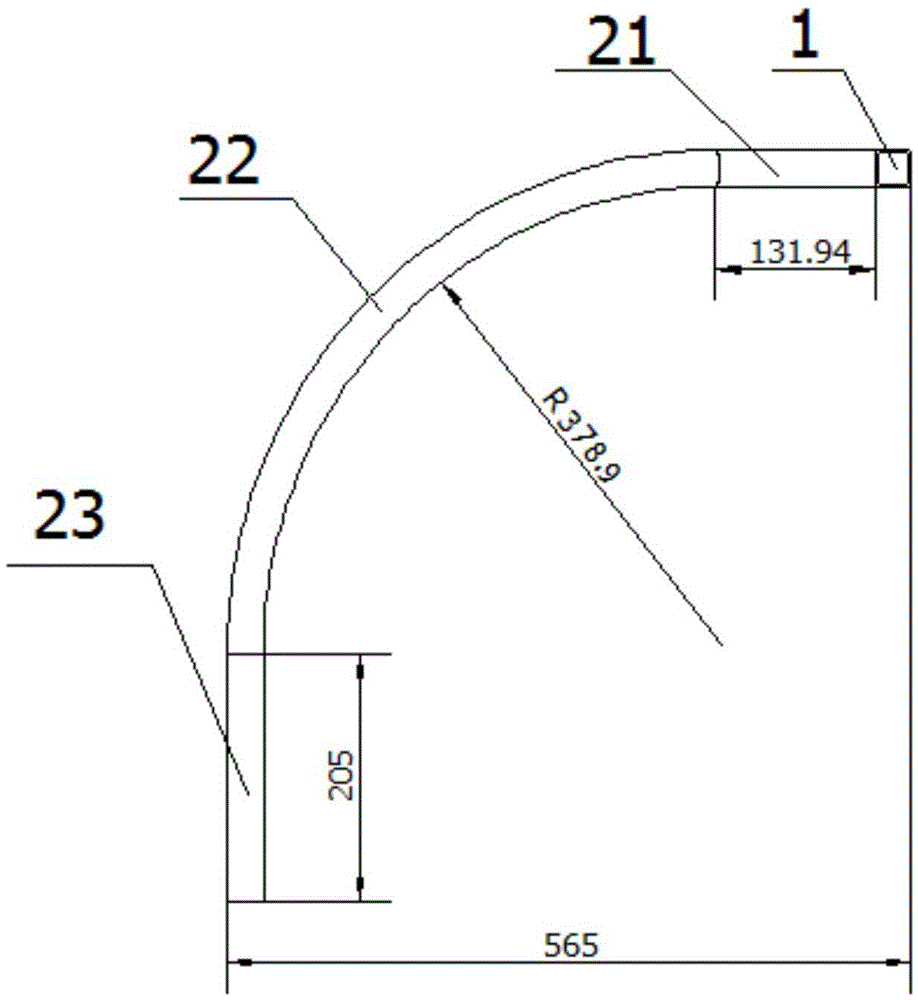

Steering wheel frame

InactiveCN105536248ASimple structureEasy to connectCosmonautic condition simulationsVideo gamesEngineeringSteering wheel

The invention belongs to the field of direction adjusting and changing devices, and particularly relates to a steering wheel frame. The steering wheel frame comprises a handle and two connecting rods connected with wheels. The handle is a hollow square pipe, and the two ends of the handle are connected with the two connecting rods respectively. The connecting rods comprise horizontal sections connected with the handle, transition sections and vertical sections connected with the wheels, the two ends of the transition sections are connected with the horizontal sections and the vertical sections respectively, and the transition sections are of arc bending structures. The steering wheel frame has the advantages that the structure is simple, and connecting and manufacturing are convenient; as each connecting rod is divided into three sections, and the transition sections of the arc bending structures are adopted, when the connecting rods drive the wheels to rotate to adjust the direction, stress can be buffered, it is avoided that the connecting rods are broken, the service life of the connecting rods is prolonged, and as the handle is the hollow square pipe, operation is light when the handle is turned.

Owner:CHONGQING HUANMAN TECH

Tent and control device of tent connecting rod

InactiveCN102852379AIncrease elasticityIncreased twisting strengthTents/canopiesConnectionsTorsional strengthMotor control

A tent is safely unfolded or folded when used and requires less time to unfold or fold and can be pitched automatically as well as manually to solve the problems of the prior art. In the tent, a worm gear and worm wheels are combined and tent connecting rods are attached to the worm wheels, respectively, so that when the worm wheels are moved, the tent connecting rods are moved to fold or unfold the tent. The worm wheel can be manually moved within the tent or the worm wheel can be automatically operated by providing a motor controlled through a remove controller so that the tent connecting rods can be unfolded or folded. In the tent, a central cavity part of a worm wheel body may be used as an air vent, and used as a passage for a smoke outlet from a heater in the winter. When the tent for four seasons is unfolded, the cross section of the tent connecting rods is in the shape of a peanut, and the tent provided has an improved flexibility and torsional strength and is beautiful when in use.

Owner:WOOGYO

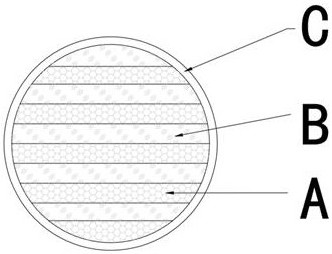

Composite anti-splitting continuous sucker rod and preparation device and preparation method

PendingCN113914784AIncreased torsional strengthEven by forceDrilling rodsSynthetic resin layered productsGlass fiberCarbon fibers

The invention discloses a composite anti-splitting continuous sucker rod and a preparation device and a preparation method. The composite anti-splitting continuous sucker rod comprises carbon fiber layers, glass fiber layers and a fabric coating layer; the carbon fiber layers and the glass fiber layers are coated in the fabric coating layer; and at least two carbon fiber layers and at least two glass fiber layers are provided, and are alternately distributed in parallel in the axial direction. Further, the sections of the carbon fiber layers and the glass fiber layers alternately distributed in parallel in the axial direction are circular. The multilayer parallel structure can fully exert the advantages of carbon fibers, so that the overall shearing strength of a rod body is improved, and the torsion resistance of the rod body is improved. Porous preforming and single-hole preforming mechanisms in preforming mechanisms realize axial uniform and parallel alternate distribution of the carbon fibers and high-modulus glass fibers. The composite anti-splitting continuous sucker rod is once molded through a pultrusion process, so that the product quality stability can be greatly improved, the production efficiency is high, the interlayer strength is high, and the layering cracking condition is prevented.

Owner:CHINA PETROLEUM & CHEM CORP +1

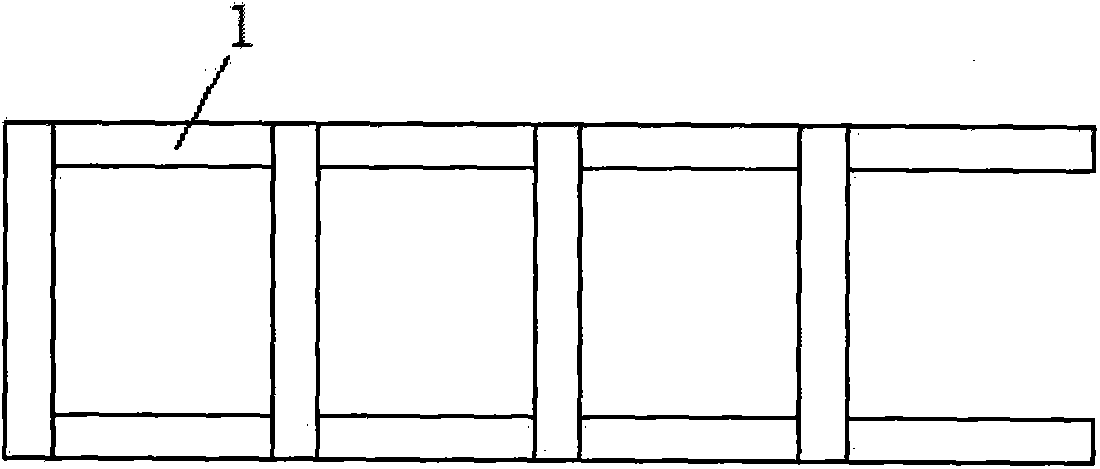

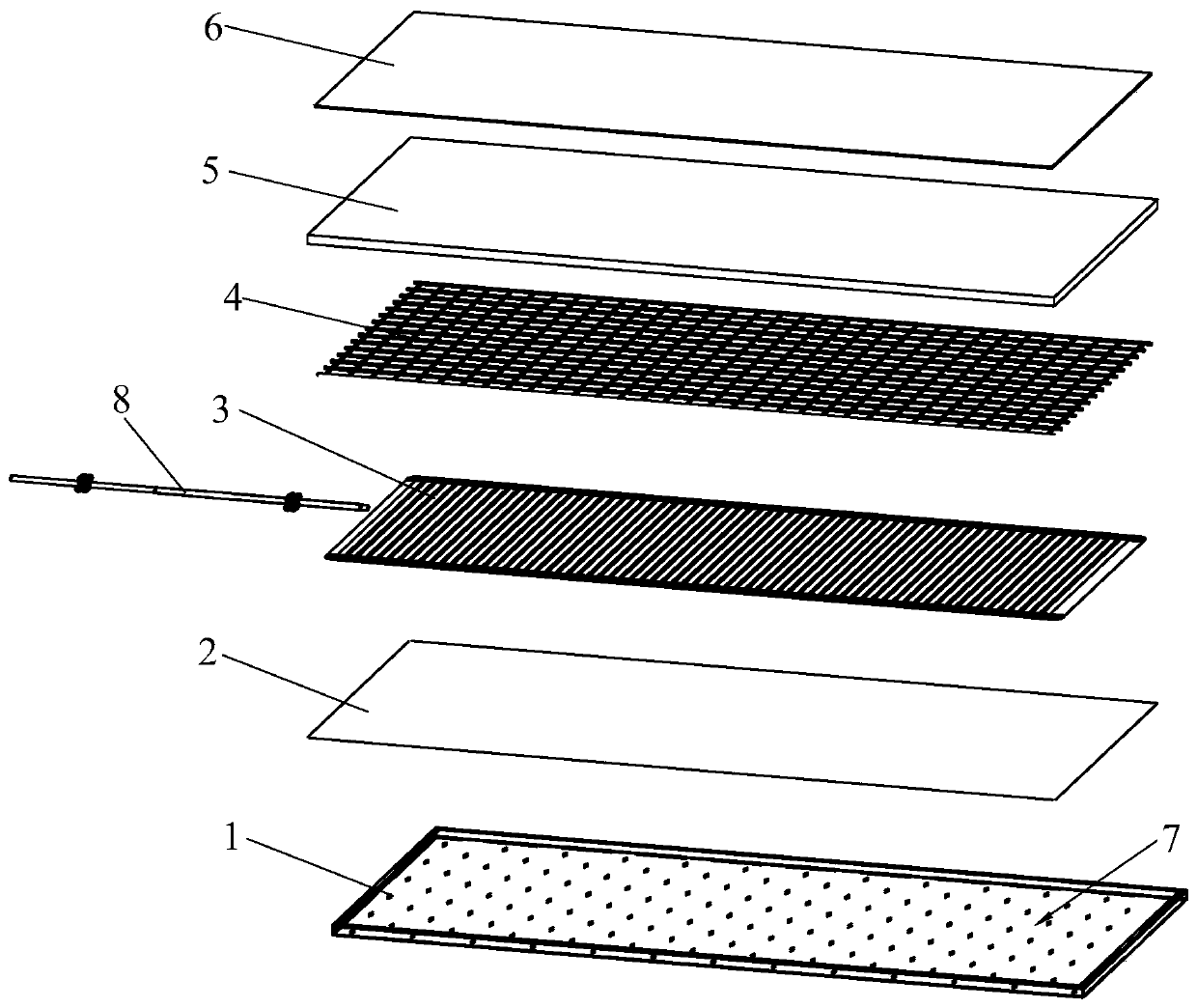

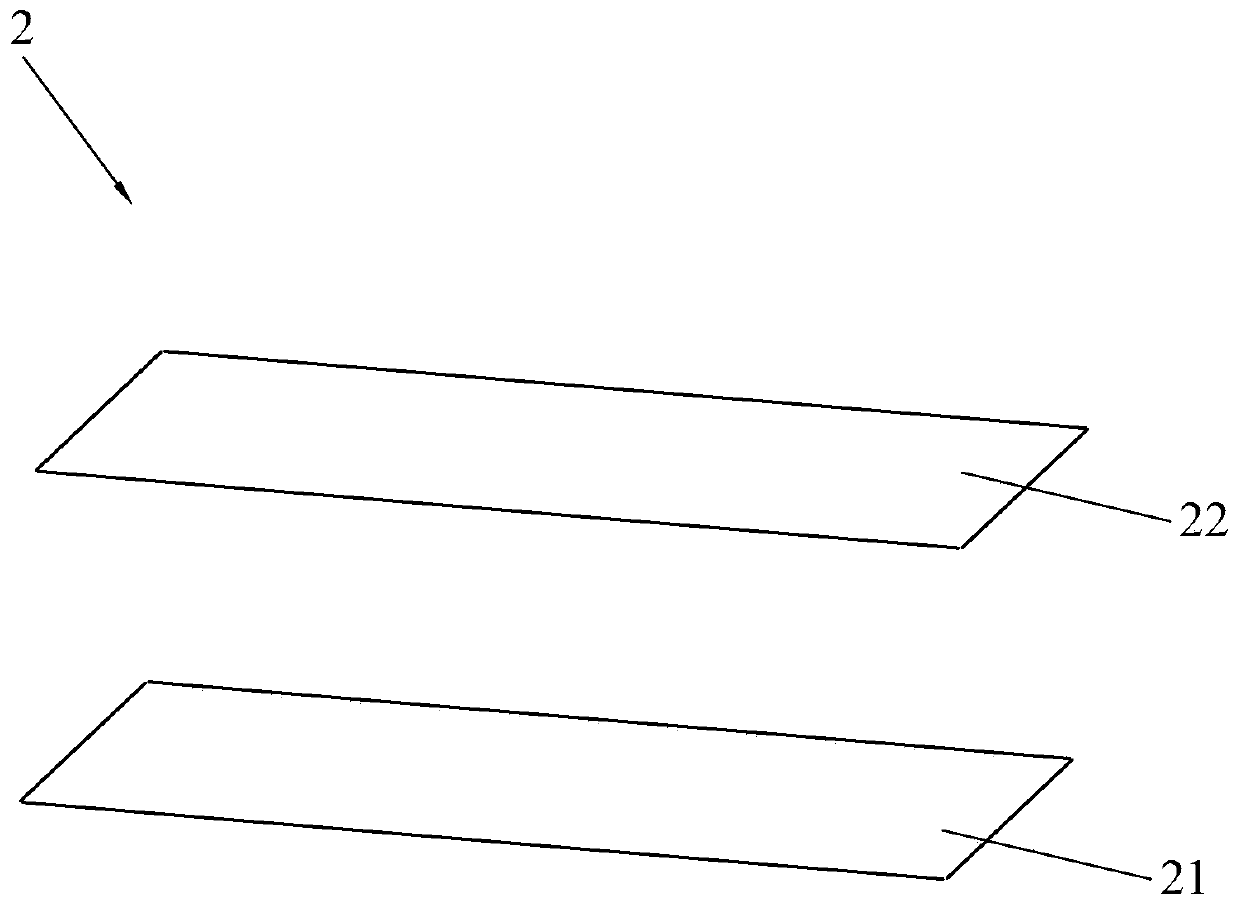

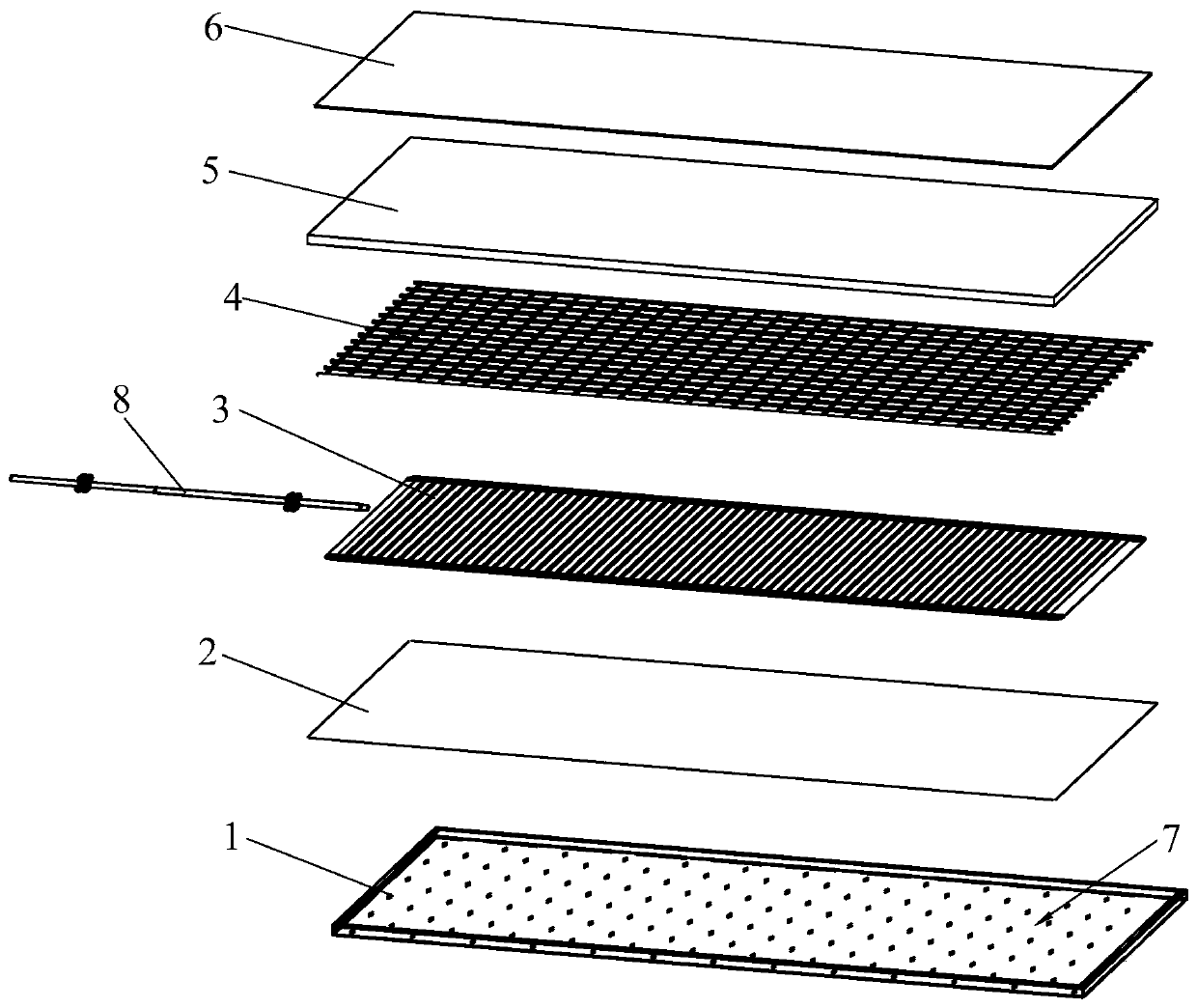

Ground heating film buckle plate module

PendingCN109714839ASafe and keep workingPlay a role in heat preservationLighting and heating apparatusElectric heating systemCapacitancePower flow

The invention discloses a ground heating film buckle plate module. The module comprises a lower housing, a distributed capacitive current absorbing layer, an electric heating film, an anti-twisting structure layer, a polyurethane heat-preservation flame-retardant layer and an upper cover, wherein the upper cover and the lower housing are fixedly combined into a body, and an accommodation cavity isformed between the upper cover and the lower housing. The distributed capacitive current absorbing layer, the electric heating film, the anti-twisting structure layer and the polyurethane heat-preservation flame-retardant layer are sequentially stacked in the accommodation cavity from bottom to top. The module can lead a leakage current, generated by the electric heating film to a ground distributed capacitor, back to a loop, thereby improving the reliability of the product. The arrangement of the polyurethane heat-preservation flame-retardant layer enables the ground heating film buckle plate module to achieve the heat preservation effect, so that a special heat preservation material layer does not need to be laid in the actual construction process, the construction efficiency is improved, and the laying effect is also ensured. In addition, the ground heating film buckle plate module is easy to produce, is safe to use and is convenient to store, transport and install on site.

Owner:广东暖丰电热科技有限公司

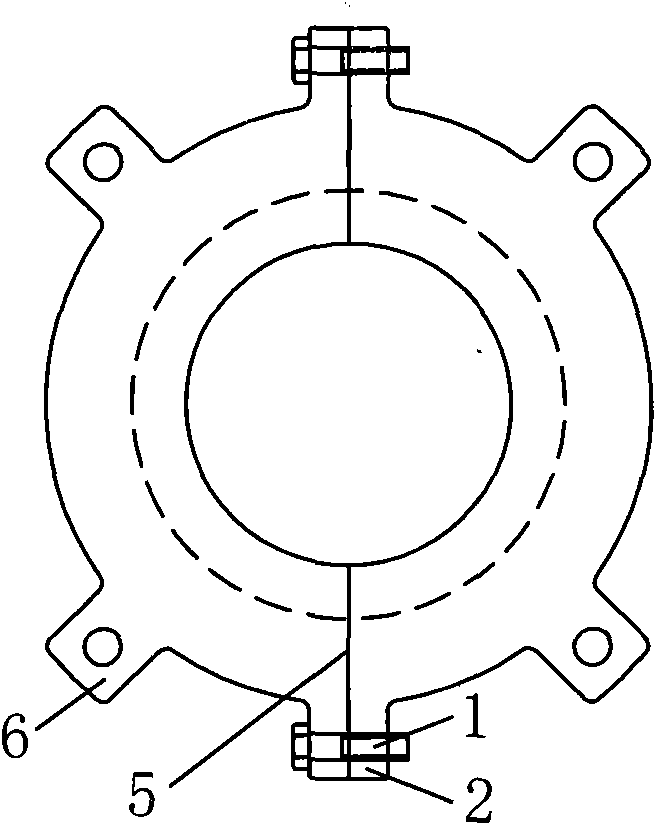

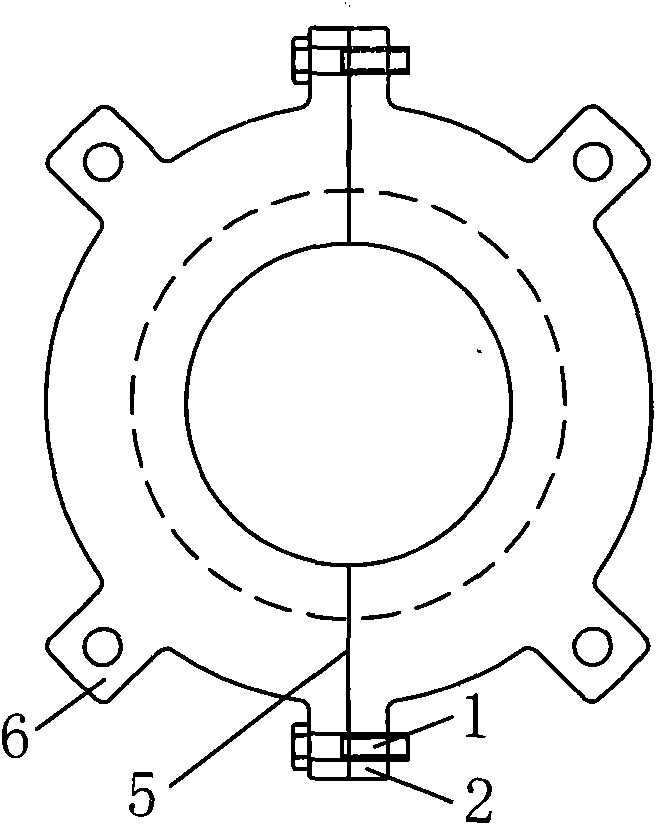

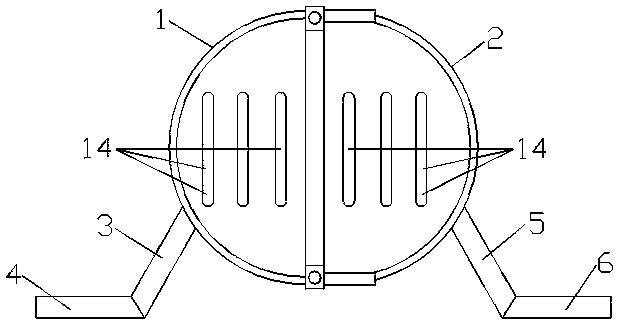

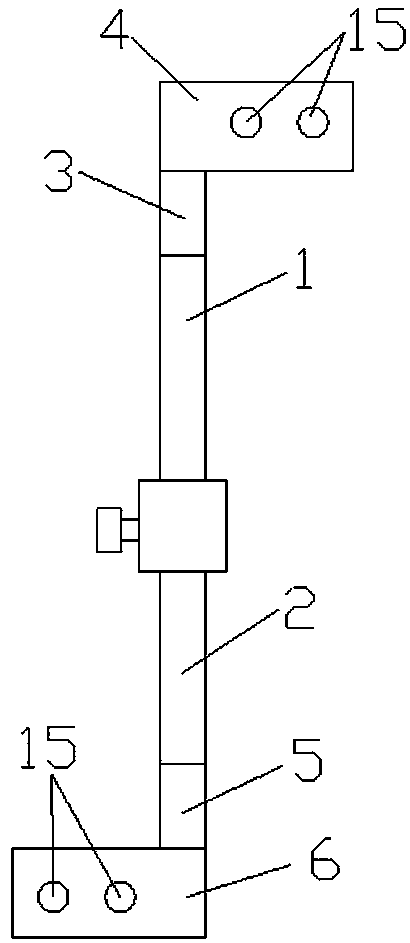

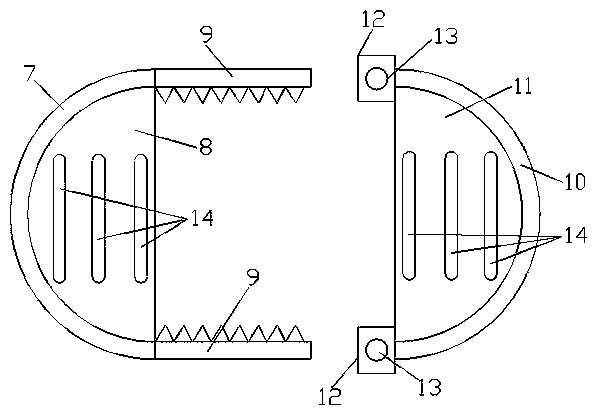

A bidirectional torsional brake bracket

InactiveCN109050509ASimple structureIncreased twisting strengthBraking componentsPulp and paper industryTorsion strength

The invention relates to the technical field of brake brackets, in particular to a bidirectional torsional brake bracket. The bracket has a first semicircular bracket and a second semicircular bracketdisposed oppositely, the two ends of the first semicircular bracket are fixedly connected with the two ends of the second semicircular bracket, One side of the first semicircular bracket is fixed with a first mounting plate through a first connecting arm, and one side of the second semicircular bracket is fixed with a second mounting plate through a second connecting arm. The first mounting plateand the second mounting plate are respectively fixed and arranged on both sides of the forming surfaces of the first semicircular bracket and the second semicircular bracket. The bidirectional anti-torsion brake bracket has simple structure, and the anti-torsion strength of the brake bracket can be improved by adopting the bidirectional fixing, and the use range of the brake bracket can be greatly improved by adopting the adjusting structure, the stable use of the automobile brake can be ensured, the safety of the automobile in the driving process can be improved, and the brake bracket is convenient to be widely popularized and used.

Owner:长兴微羽智能科技股份有限公司

Two-way main shaft transmission mechanism for embroidery machine

ActiveCN102864598BCompact structureIncreased twisting strengthEmbroidering machines apparatusEngineeringMechanical engineering

The invention relates to a transmission mechanism, in particular to a two-way main shaft transmission mechanism for an embroidery machine. The two-way main shaft transmission mechanism is used for the embroidery machine, and comprises a crossbeam, wherein a left-side transmission mechanism is arranged at the left side end of the crossbeam, and a right-side transmission mechanism is arranged at the right side end of the crossbeam; the left-side transmission mechanism drives the right-side transmission mechanism. The two-way main shaft transmission mechanism for the embroidery machine is simple and compact in structure and high in synchronism, and the warping strength is improved.

Owner:HANGZHOU JINGWEI ELECTRONICS MECHANICAL MFG

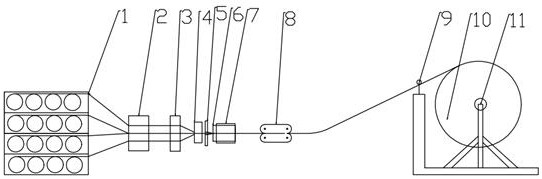

Non-woven air filter element air inlet pipe winding machine and winding process thereof

ActiveCN102219132BExtended service lifeEasy to recycleLiquid surface applicatorsFilament handlingYarnWinding machine

The invention relates to a non-woven air filter element air inlet pipe winding machine and a winding process thereof. The winding machine comprises an electric control box, a winding and rotating device, a feeding and walking device and a glue applicator that are all arranged on a frame; the feeding and walking device is connected with a non-woven roll and a nylon yarn roll; the electric control box is used for controlling the winding and rotating device to rotate; the electric control box is used for controlling the feeding and walking device to walk along the direction of the winding and rotating device and convey non-woven long strips and nylon yarns to the winding and rotating device to rotate and wind the non-woven long strips and the nylon yarns from inside to outside; and the glue applicator is used for applying glue to the non-woven long strips that are wound on the winding and rotating device synchronously. According to the winding machine disclosed by the invention, the non-woven long strips and the hard nylon yarns are adopted to be wound on a core rod uniformly, separately and obliquely, and are formed by bonding through applying glue; and the winding machine has the advantages of simple and compact structure, convenience for operation, simple process, short forming period, capability of satisfying a certain rigidity requirement that butting joint of an automobile engine and an air filter requires random bending under different assembling work conditions, long service life, recycling availability and no waste pollution.

Owner:JIANGSU XINGCHENXING AUTO ACCESSORIES

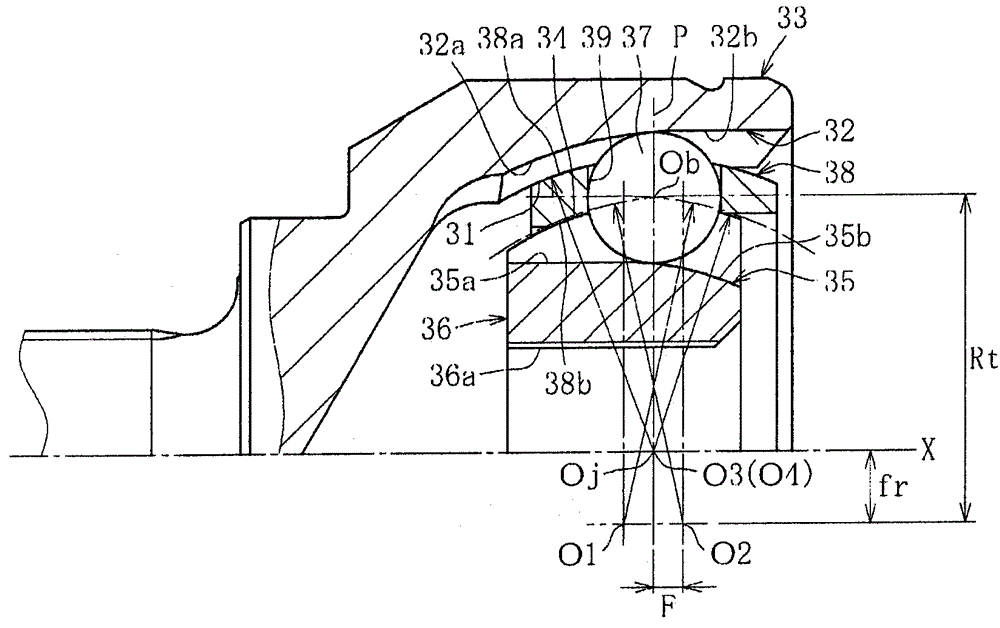

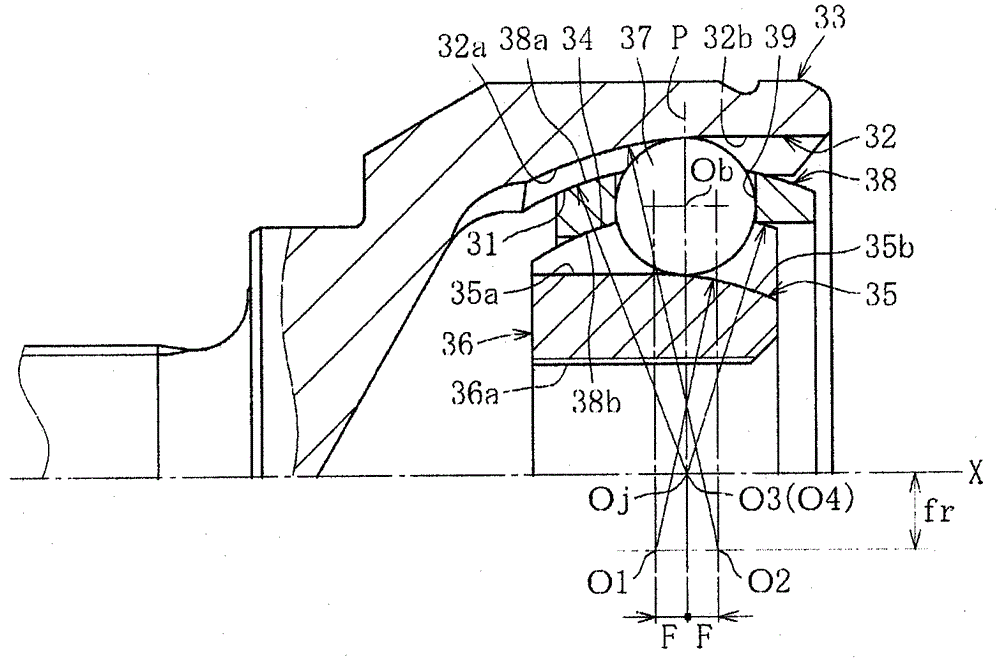

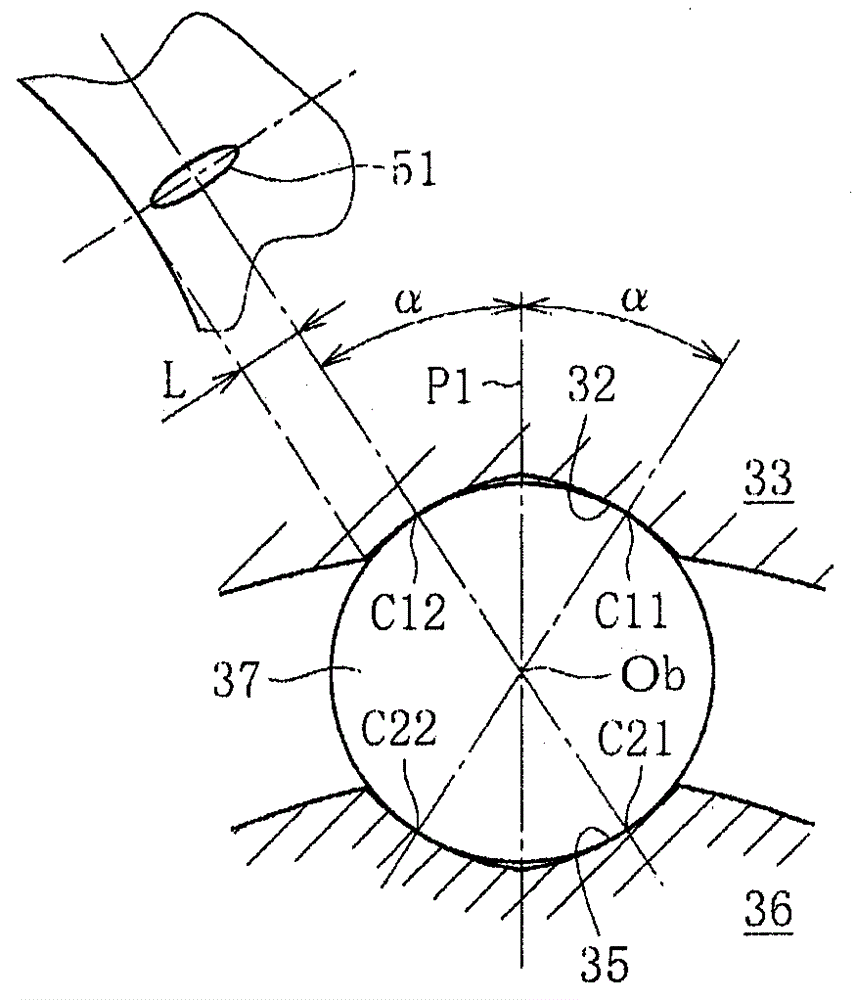

Fixed Constant Velocity Universal Joint

Owner:NTN CORP

Fiber reinforced plate strengthening process for wind blade girder manufacturing

InactiveCN109094048ARealize force sharingImprove performanceDomestic articlesFiber bundleEngineering

The invention discloses a fiber reinforced plate strengthening process for wind blade girder manufacturing. Transverse fiber bundles are uniformly enwound at a fiber plate. The fiber plate comprises longitudinal fiber bundles pulled in the horizontal technology direction and resin attached to the surfaces of the longitudinal fiber bundles. Transverse fiber bundles are arranged at the longitudinalfiber bundles. The longitudinal fiber bundles provided with the transverse fiber bundles penetrate through a pultrusion solidification mold to form the fiber plate. The fiber reinforced plate strengthening process for wind blade girder manufacturing aims to overcome defects in the prior art. The fiber reinforced plate strengthening process for wind blade girder manufacturing having no fracturing and being high in strength and in fiber plate transverse load bearing force is provided. The transverse fiber bundle technology is added on the basis of existing longitudinal fiber bundles, and the problems of an existing fiber plate that fracturing is liable to occur after application and the fiber plate is low in transverse load bearing force are solved.

Owner:南京诺尔泰复合材料设备制造有限公司

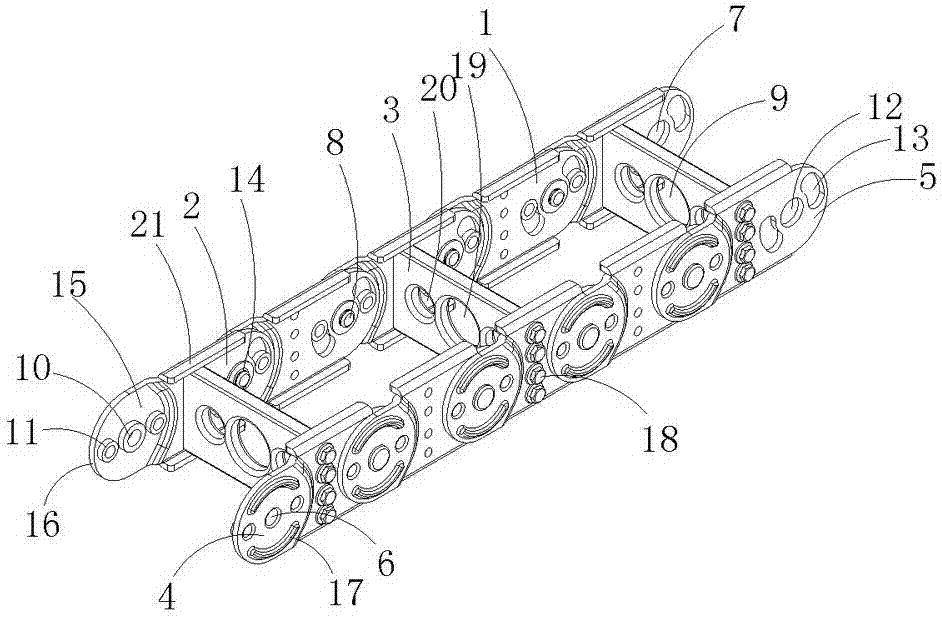

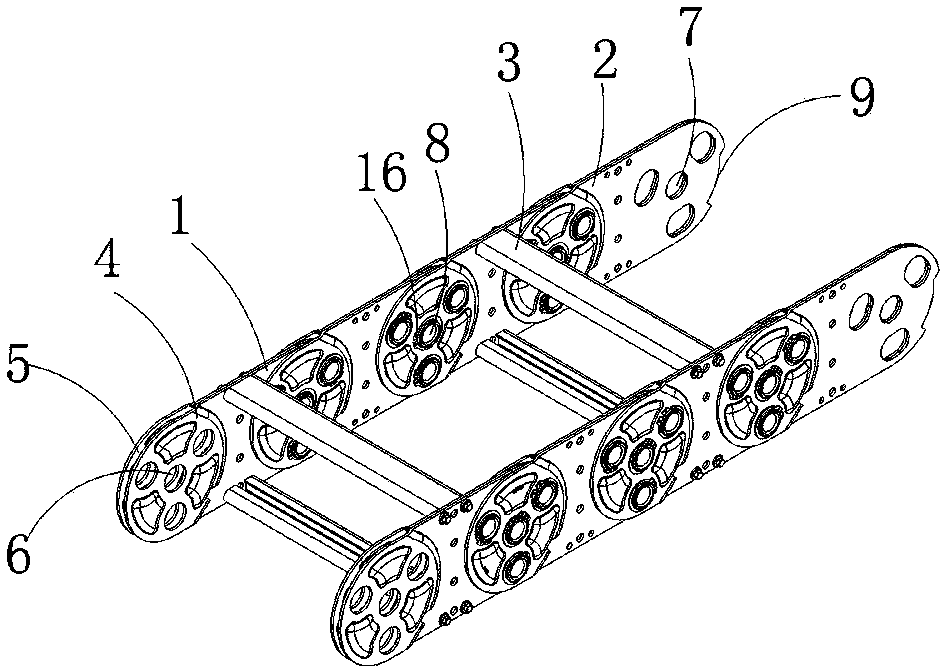

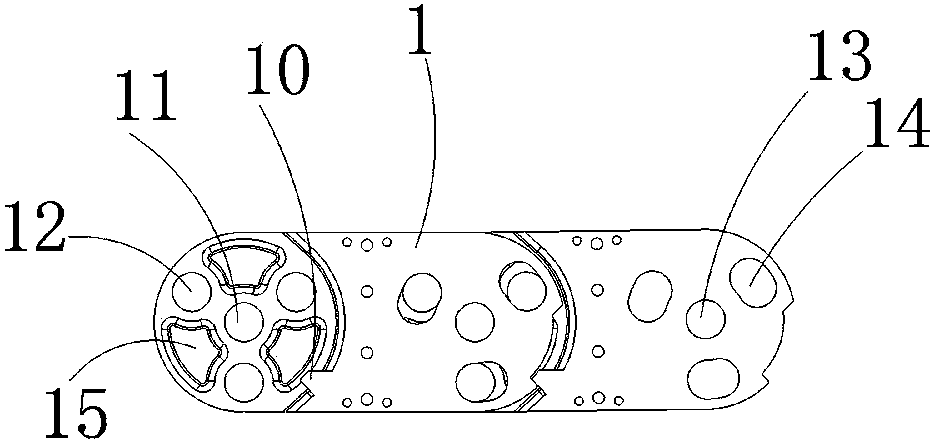

An easy-to-assemble drag chain with high twist resistance and its preparation method

ActiveCN103423377BCompact structureImprove aerial performanceHauling chainsHoisting chainsEngineeringChain link

The invention relates to a drag chain, in particular to an easy-to-assemble drag chain with high anti-twisting strength and a preparation method thereof. The drag chain consists of a chain links which are distributed continuously in sequence, wherein each chain link comprises a pair of symmetrically distributed chain plates; the chain plates are positioned through a supporting plate; the head of each chain plate is provided with a head connecting end; the tail part of each chain plate is provided with a tail connecting end; the head connecting end is provided with a positioning boss; the tail connecting end is provided with a positioning hole; the head connecting end of one chain link is fixedly matched with the tail connecting end of another chain link; the positioning boss and the positioning hole are fixed through a positioning pin; each chain plate consists of a single piece of chain plate; a cable through hole is formed in the supporting plate. The preparation method comprises the following steps: blanking and forming, forming and heating, cooling, deburring, machining the positioning boss and the positioning hole, and electroplating. The easy-to-assemble drag chain with high anti-twisting strength and the preparation method thereof have the advantages of compact structure and capabilities of improving the aerial property, increasing the bearing capacity and enhancing the anti-twisting strength.

Owner:杭州云顶精密制造有限公司

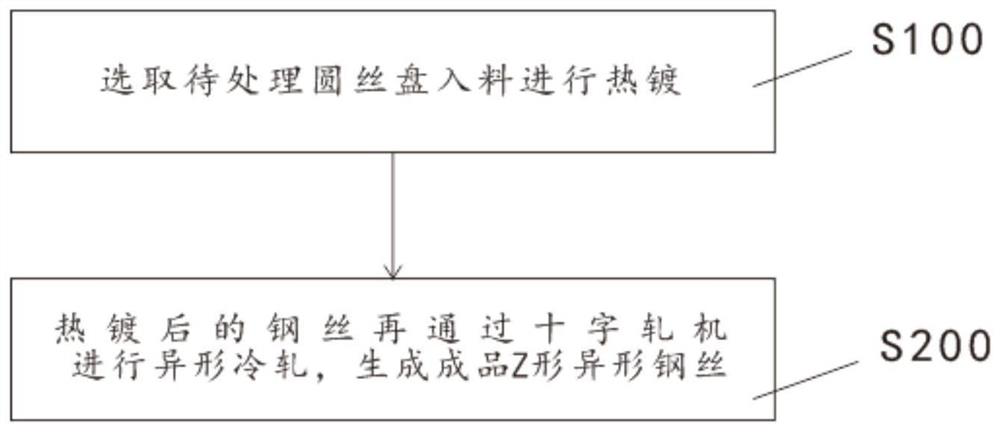

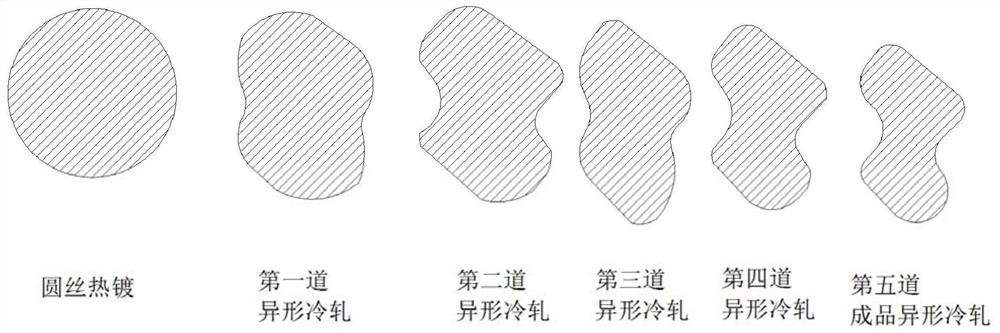

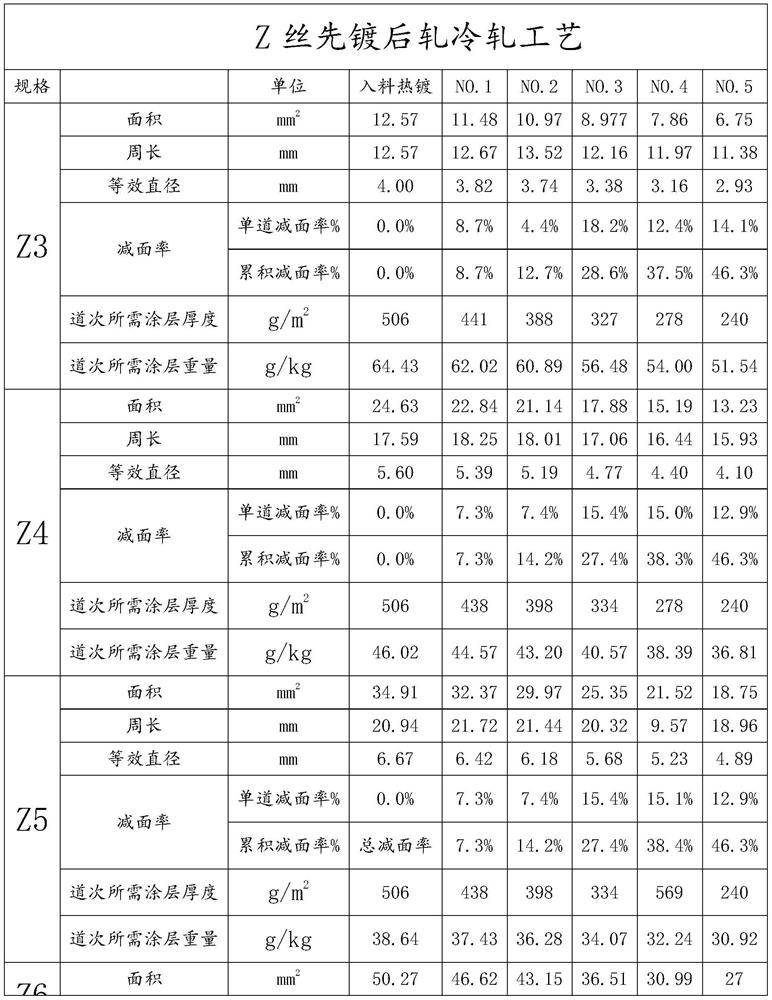

Z-shaped special-shaped steel wire production method

InactiveCN112453099ALittle impact on mechanical propertiesReduce brittlenessHot-dipping/immersion processesMetal rolling arrangementsFlexural strengthUltimate tensile strength

The invention relates to the technical field of steel wire production, in particular to a Z-shaped special-shaped steel wire production method. The Z-shaped special-shaped steel wire production methodcomprises the following steps of selecting a to-be-treated round wire coil for feeding, and being subjected to hot dipping; carrying out special-shaped cold rolling by utilizing a cross-shaped rolling mill to generate a finished Z-shaped special-shaped steel wire. Compared with the prior art, according to the Z-shaped special-shaped steel wire production method, the round wire coil raw material steel wire is subjected to hot dipping and then is subjected to special-shaped cold rolling by the cross-shaped rolling mill, so that the influence of thermal stress generated by hot dipping on the mechanical property of the Z-shaped special-shaped steel wire and the brittleness of the finished Z-shaped special-shaped steel wire are reduced, the hardness of a hot-dip coating of the finished Z-shaped special-shaped steel wire and the bending strength, the twisting strength, the corrosion resistance and the wear resistance of the finished Z-shaped special-shaped steel wire are improved, and therefore the finished Z-shaped special-shaped steel wire is smooth in surface and convenient to twist and process.

Owner:梓兰特线(厦门)科技有限公司

Drag chain capable of protecting cable and production method of drag chain

InactiveCN103423378ACompact structureImprove aerial performanceHauling chainsHoisting chainsEngineeringChain link

The invention relates to a drag chain, in particular to a drag chain capable of protecting cables and a production method of the drag chain. The drag chain consists of chain links which are sequentially and continuously distributed. Each chain link comprises a pair of symmetrically distributed link plates. The link plates are positioned through supporting plates. Link sleeves are arranged at the heads of the link plates. Link sleeve chambers are arranged in the link sleeves. Front positioning pin holes are formed in the link sleeves. Rear positioning pin holes which are distributed corresponding to the front positioning pin holes are formed in the tails of the link plates. The tail of one link is inserted into the link sleeve chamber of another link. Rear limiting notches are arranged on the outer side walls of the tails of the links. Front limiting raised blocks which are adjustably clamped with the rear limiting notches are arranged in the link sleeve chambers. The production method comprises the steps of cutting and formation, heating, cooling, burr removal, pin hole and fixing hole processing, and electroplating. The drag chain capable of protecting cables and the production method thereof have the advantages that the structure is compact, the overhead performance is promoted, the bearing capacity is increased and the torsion strength is enhanced.

Owner:杭州云顶精密制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com