Composite anti-splitting continuous sucker rod and preparation device and preparation method

A technology for preparing equipment and sucker rods, which is applied in chemical instruments and methods, drill pipes, earth drilling and production, etc., which can solve the problem of poor wear resistance and pressure resistance of sucker rods, inability to give full play to the advantages of carbon fiber, and anti-torsion performance Poor problems, to achieve the effect of improving the curing degree, avoiding delamination and cracking, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

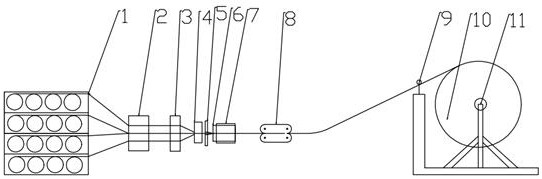

[0044] see Figure 1 to Figure 4 , the present invention provides a technical solution:

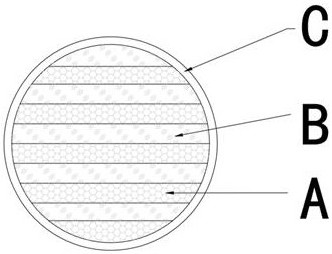

[0045] A composite anti-split continuous sucker rod, comprising a carbon fiber layer A, a glass fiber layer B, and a fabric covering layer C;

[0046] Both the carbon fiber layer and the glass fiber layer are wrapped inside the fabric covering layer; the carbon fiber layer and the glass fiber layer are provided with at least two layers, and the carbon fiber layer and the glass fiber layer are distributed parallel and alternately along the axial direction.

[0047] Further, the cross-section of the carbon fiber layers and glass fiber layers distributed parallel and alternately along the axial direction is circular, and the cross-section ratio is greater than or equal to 98%, and at the same time less than 99%. section ratio.

[0048] Further, the volume ratio of the carbon fiber layer to the glass fiber layer is 1 / 4-3 / 4.

[0049] Further, the cross section of the sucker rod is circular ...

Embodiment 2

[0070] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0071] A composite anti-split continuous sucker rod, comprising a carbon fiber layer A, a glass fiber layer B, and a fabric covering layer C;

[0072] Both the carbon fiber layer and the glass fiber layer are wrapped inside the fabric covering layer; the carbon fiber layer and the glass fiber layer are provided with at least two layers, and the carbon fiber layer and the glass fiber layer are distributed parallel and alternately along the axial direction.

[0073] Further, the cross-section of the carbon fiber layers and glass fiber layers distributed parallel and alternately along the axial direction is circular, and the cross-section accounts for more than 98%.

[0074] Further, the volume ratio of the carbon fiber layer to the glass fiber layer is 1 / 4-3 / 4.

[0075] Further, the cross section of the sucker rod is circular with a diameter of 10-30mm.

[0076] Further, the carbon fiber...

Embodiment 3

[0082] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0083] A composite anti-split continuous sucker rod, comprising a carbon fiber layer A, a glass fiber layer B, and a fabric covering layer C;

[0084] Both the carbon fiber layer and the glass fiber layer are wrapped inside the fabric covering layer; the carbon fiber layer and the glass fiber layer are provided with at least two layers, and the carbon fiber layer and the glass fiber layer are distributed parallel and alternately along the axial direction.

[0085] Further, the cross-section of the carbon fiber layers and glass fiber layers distributed parallel and alternately along the axial direction is circular, and the cross-section accounts for more than 98%.

[0086] Further, the volume ratio of the carbon fiber layer to the glass fiber layer is 1 / 4-3 / 4.

[0087] Further, the cross section of the sucker rod is circular with a diameter of 10-30mm.

[0088] see Figure 1 to Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com