Patents

Literature

618 results about "Carbon fiber reinforced composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon Fiber Reinforced Polymer Composites (CFRP) are lightweight, strong materials used in the manufacturing of numerous products used in our daily life. It is a term used to describe a fiber-reinforced composite material that uses carbon fiber as the primary structural component.

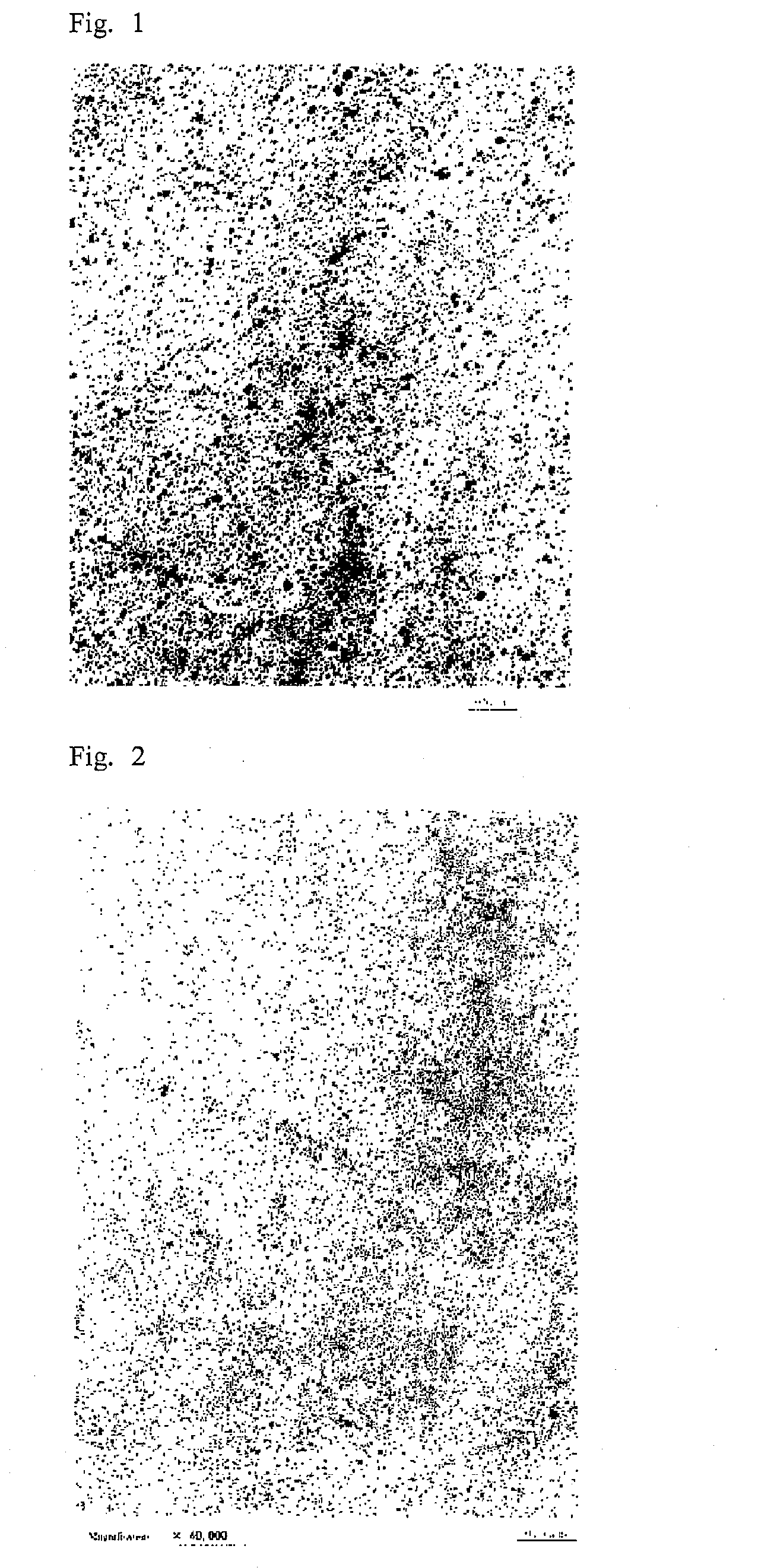

Vapor grown carbon fiber reinforced composite materials and methods of making and using same

ActiveUS7338684B1Low yieldReduce quality problemsMaterial nanotechnologyLiquid surface applicatorsFiberCarbon nanofiber

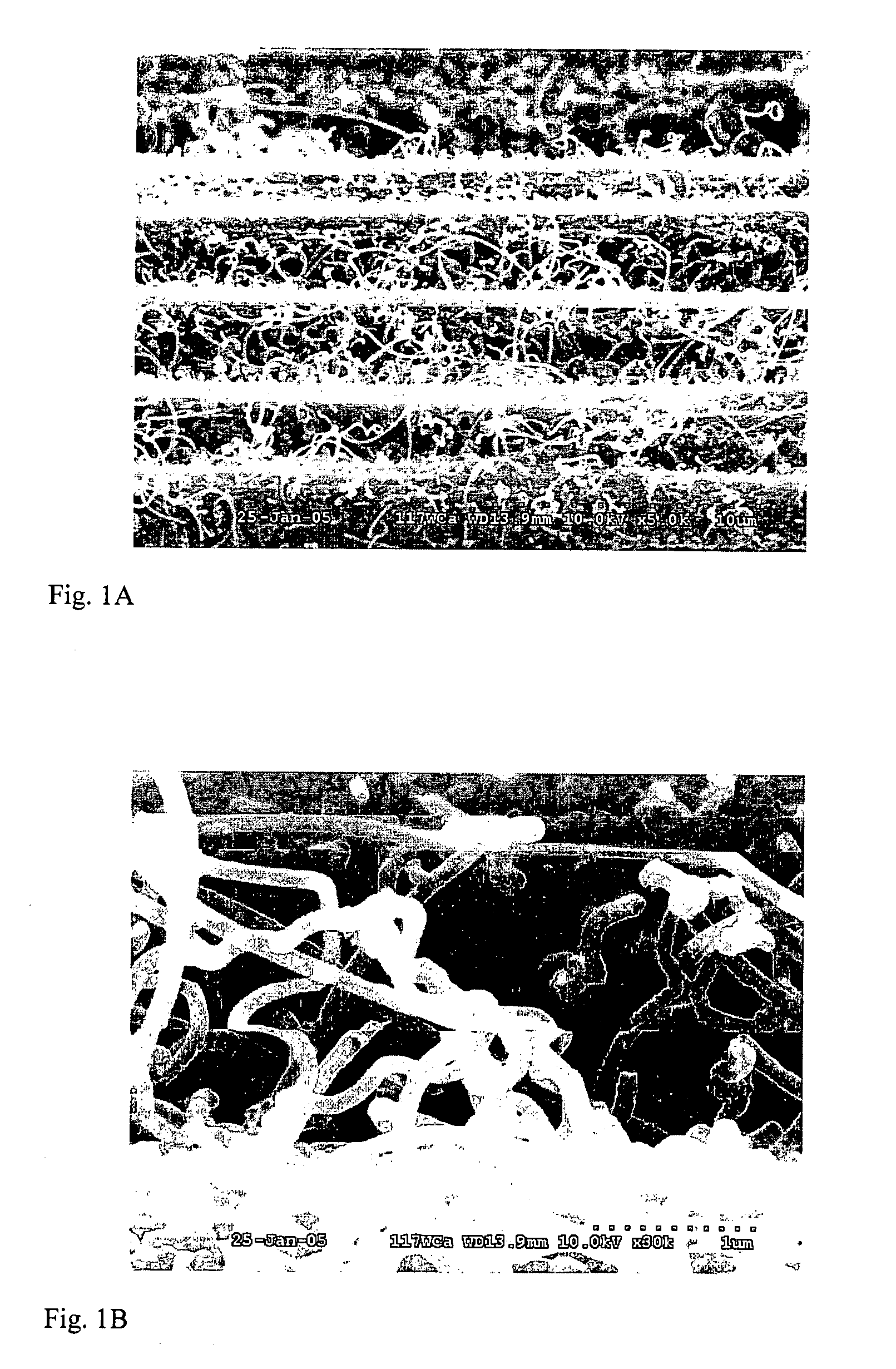

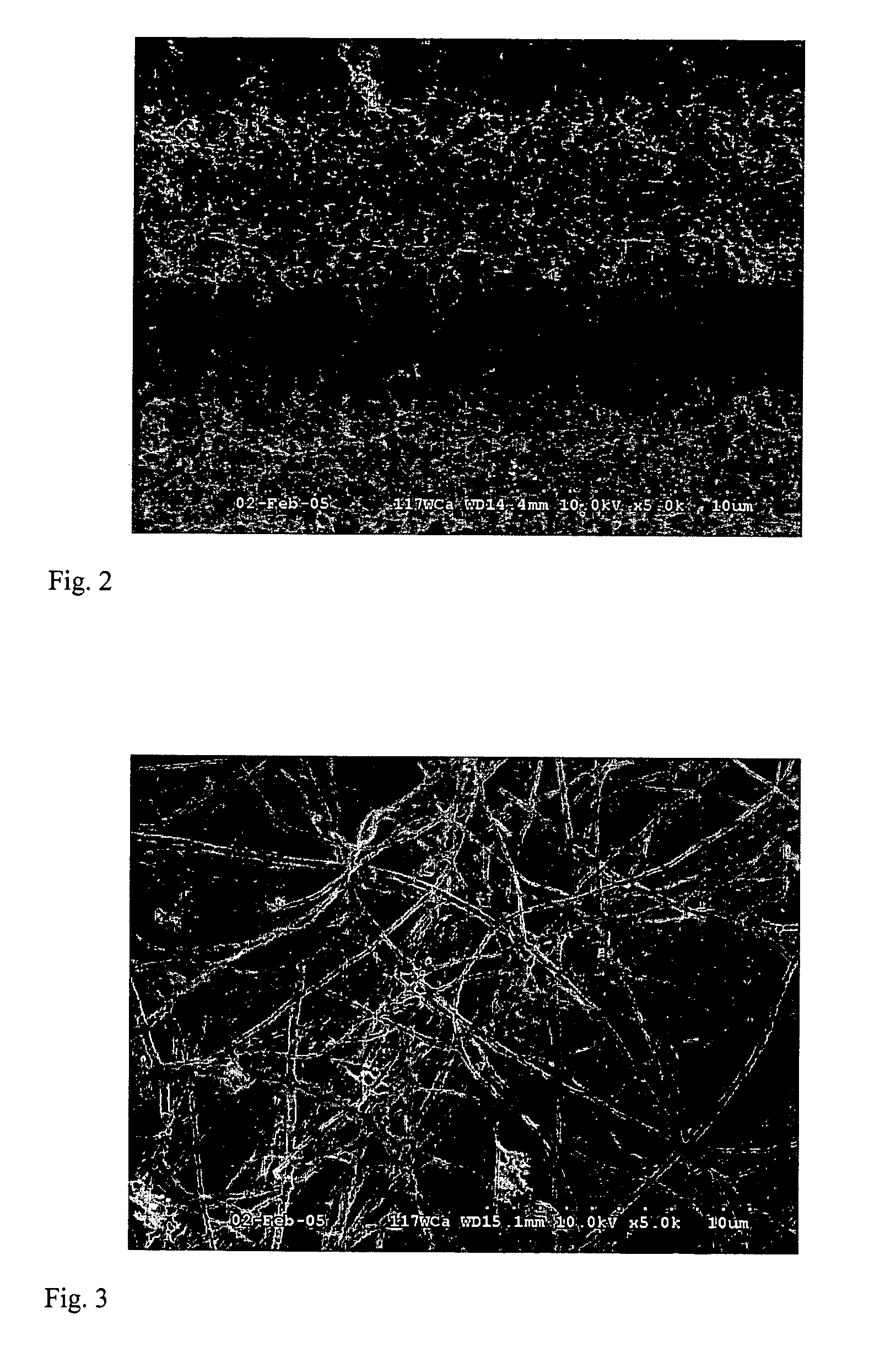

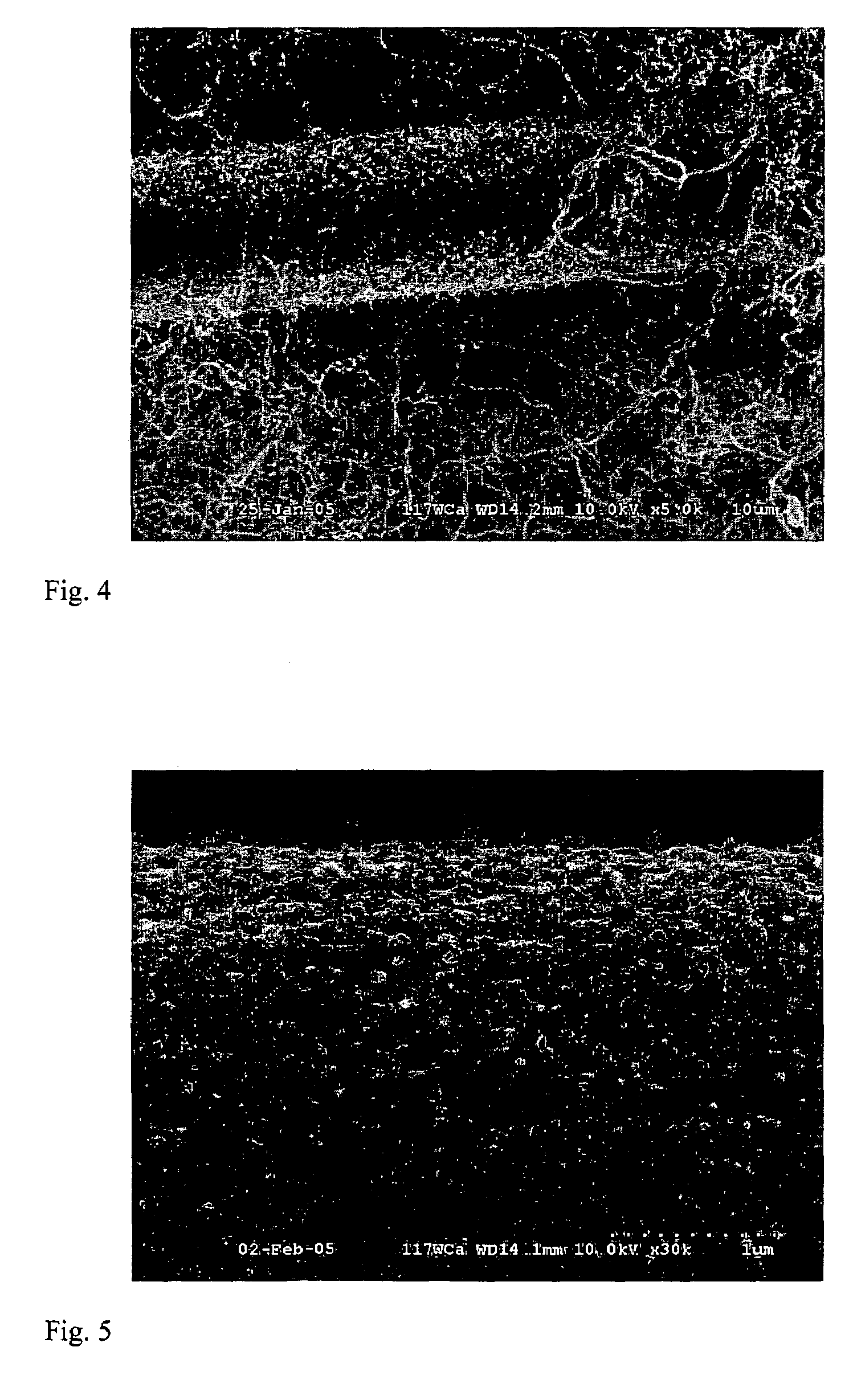

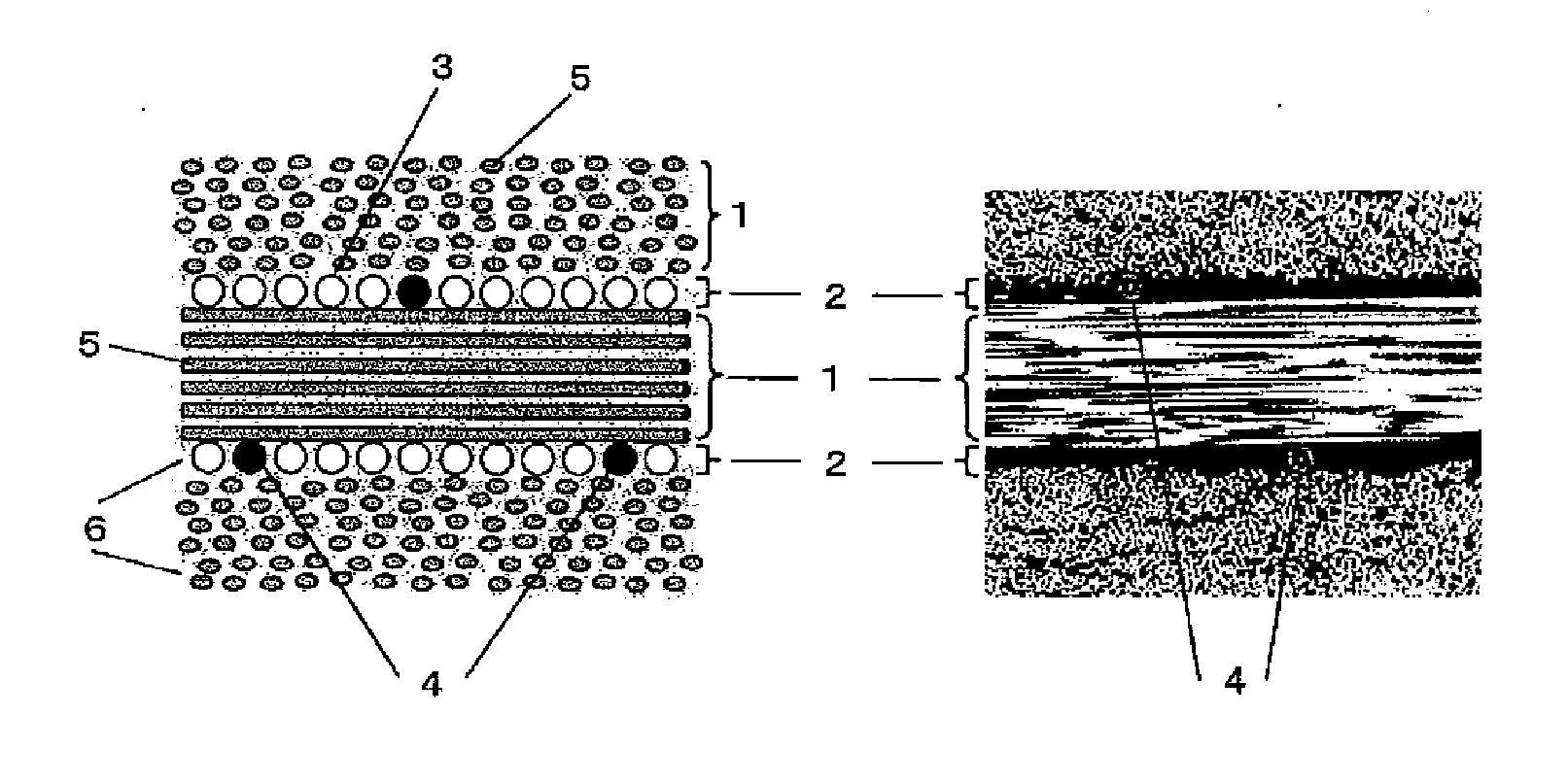

A process for producing-vapor grown carbon fiber (VGCF) reinforced continuous fiber performs for the manufacture of articles with useful mechanical, electrical, and thermal characteristics is disclosed. Continuous fiber preforms are treated with a catalyst or catalyst precursor and processed to yield VGCF produced in situ resulting in a highly entangled mass of VGCF infused with the continuous fiber preform. The resulting continuous fiber preforms are high in volume fraction of VGCF and exhibit high surface area useful for many applications. Furthermore, this invention provides for a continuous fiber preform infused with VGCF so that the carbon nanofibers are always contained within the fiber preform. This eliminates the processing steps for isolated carbon nanofibers reported in other carbon nanofiber composite approaches and therefore greatly reduces risk of environmental release and exposure to carbon nanofibers.

Owner:PERFORMANCE POLYMER SOLUTIONS

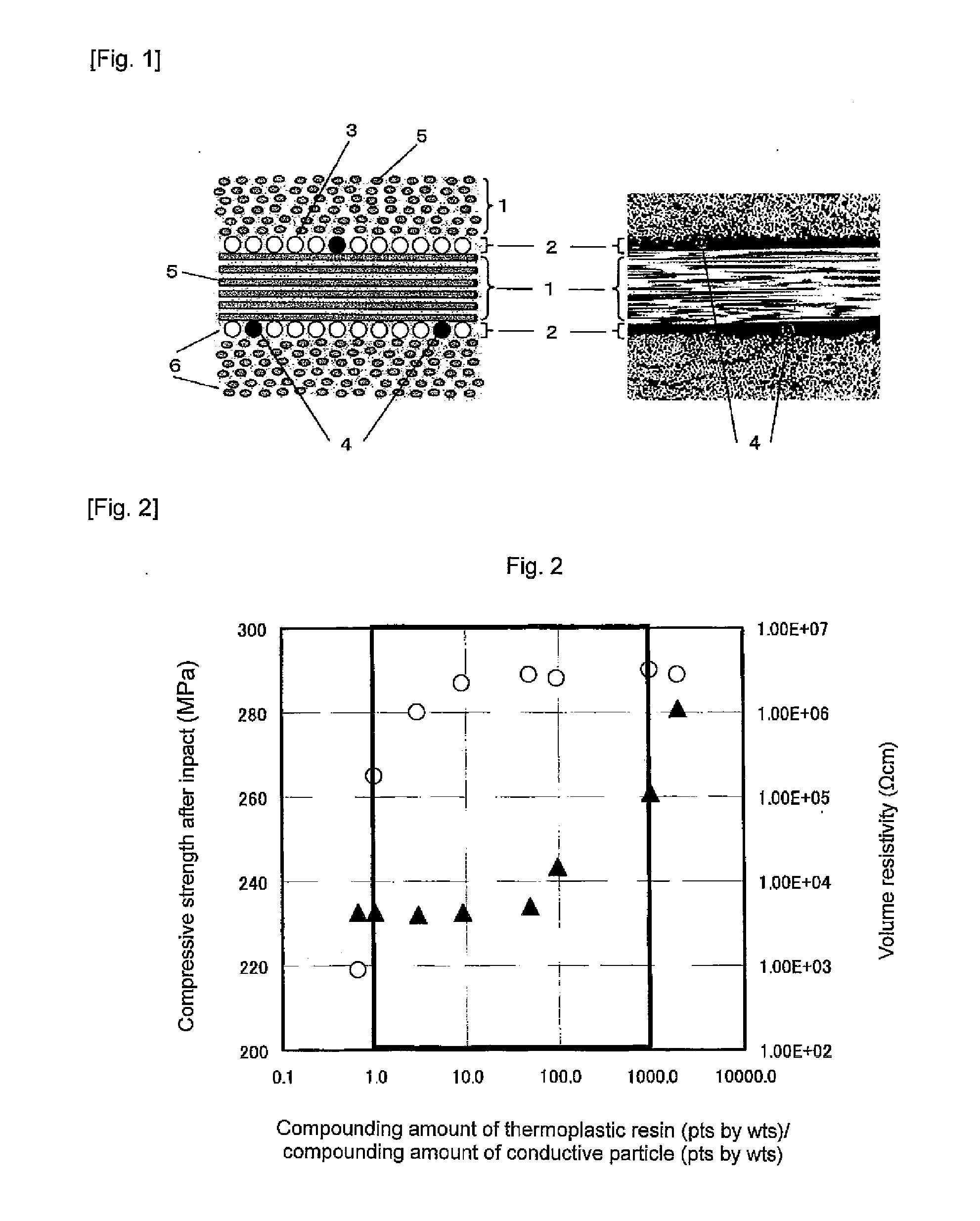

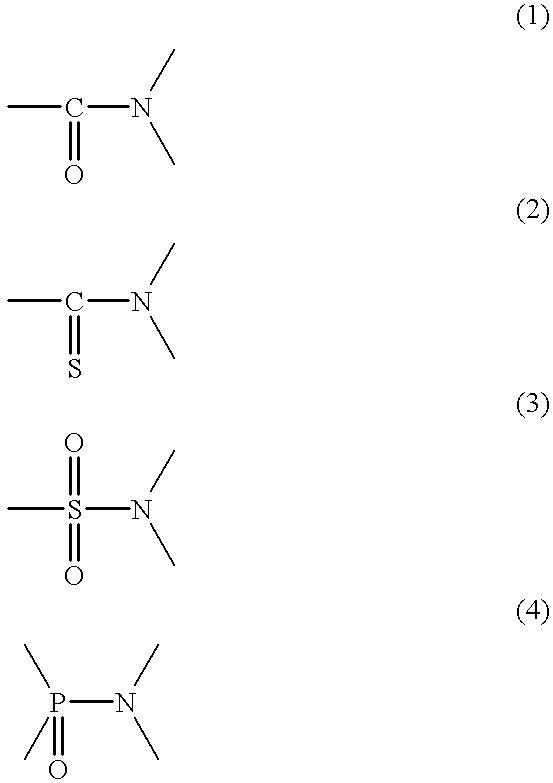

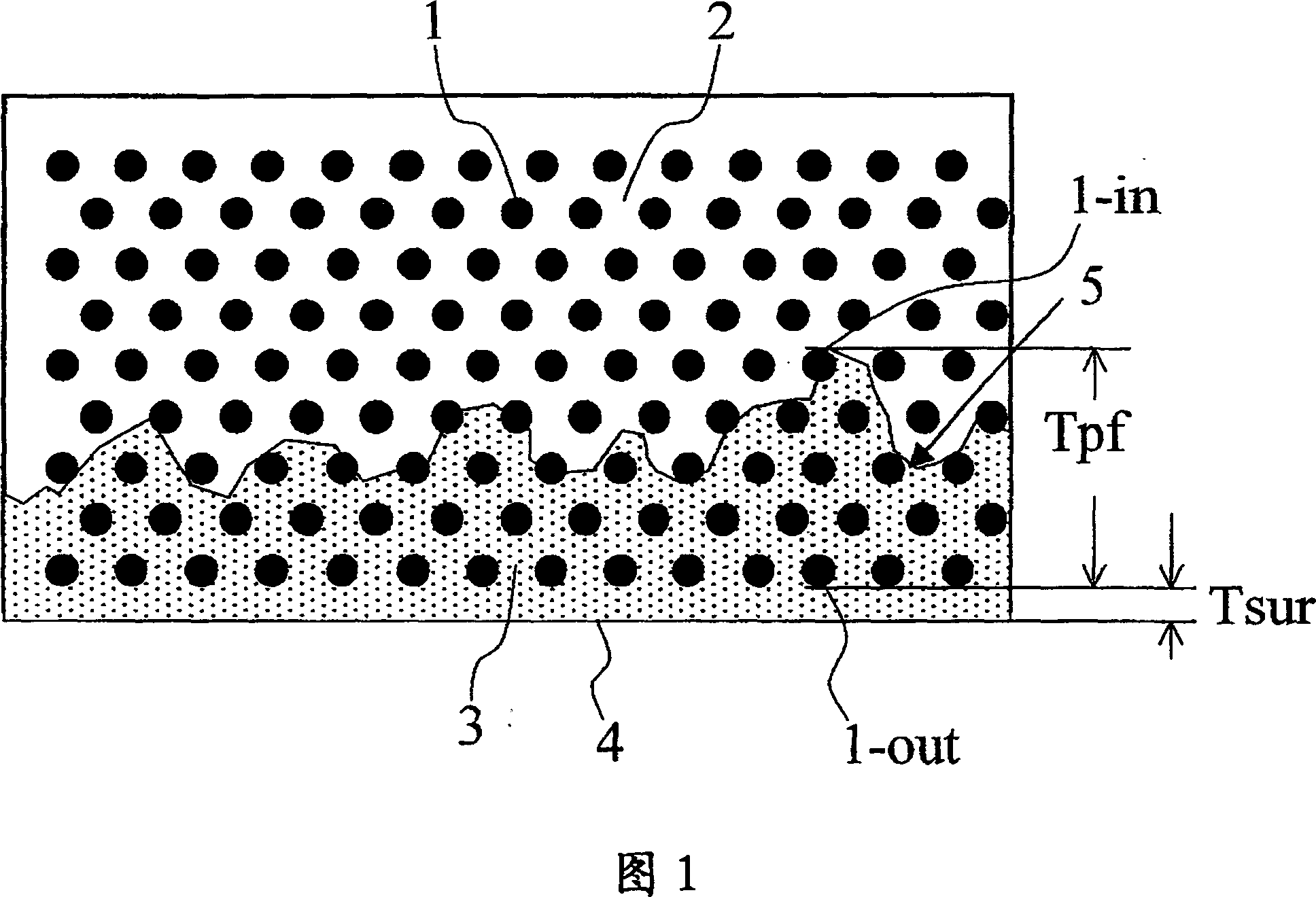

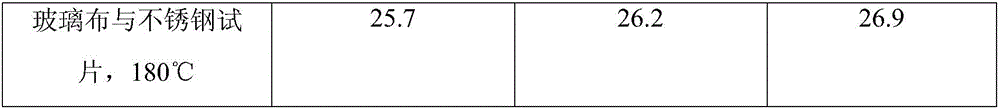

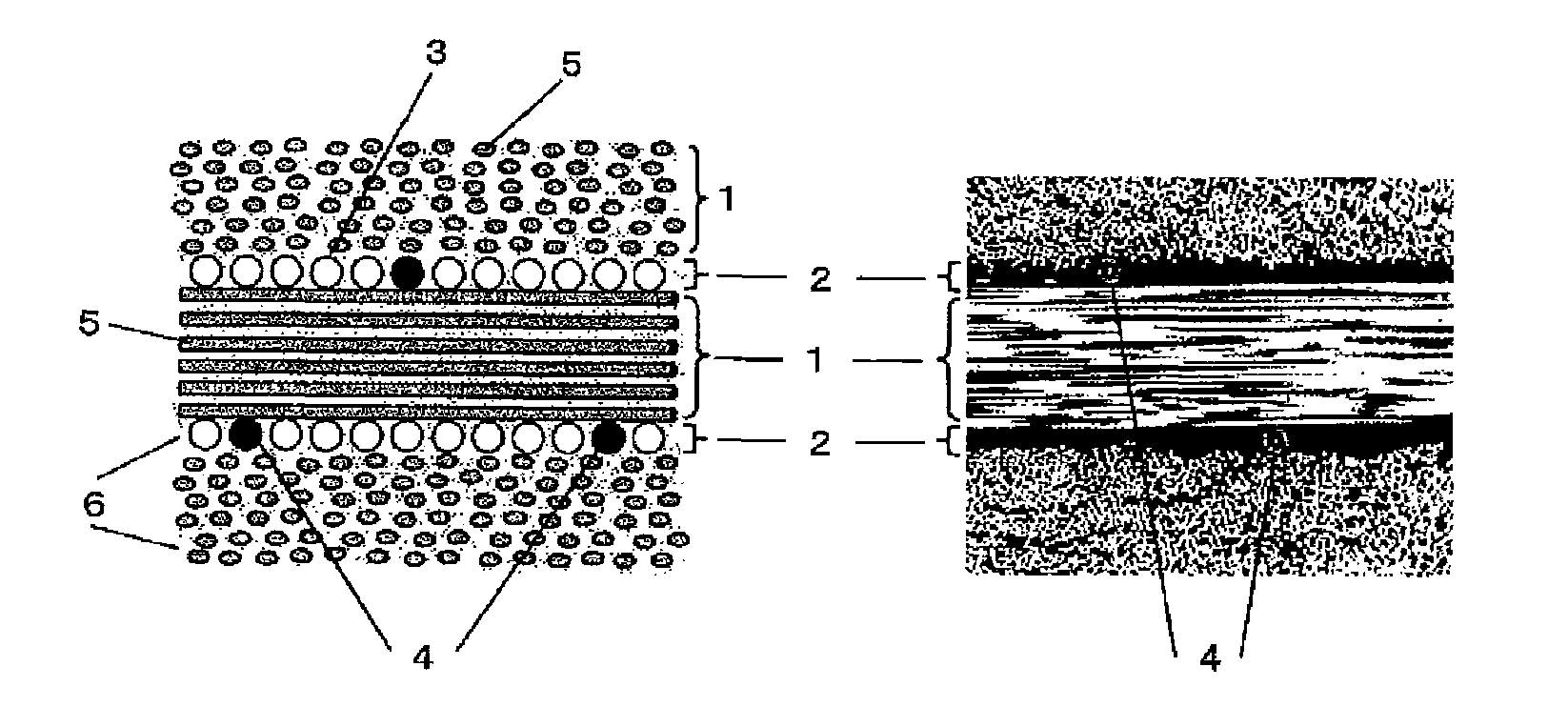

Prepreg and carbon fiber reinforced composite materials

ActiveUS20100178487A1Improve conductivityImprove impact resistanceNon-metal conductorsCarbon fibresCarbon fiber reinforced compositePre-preg

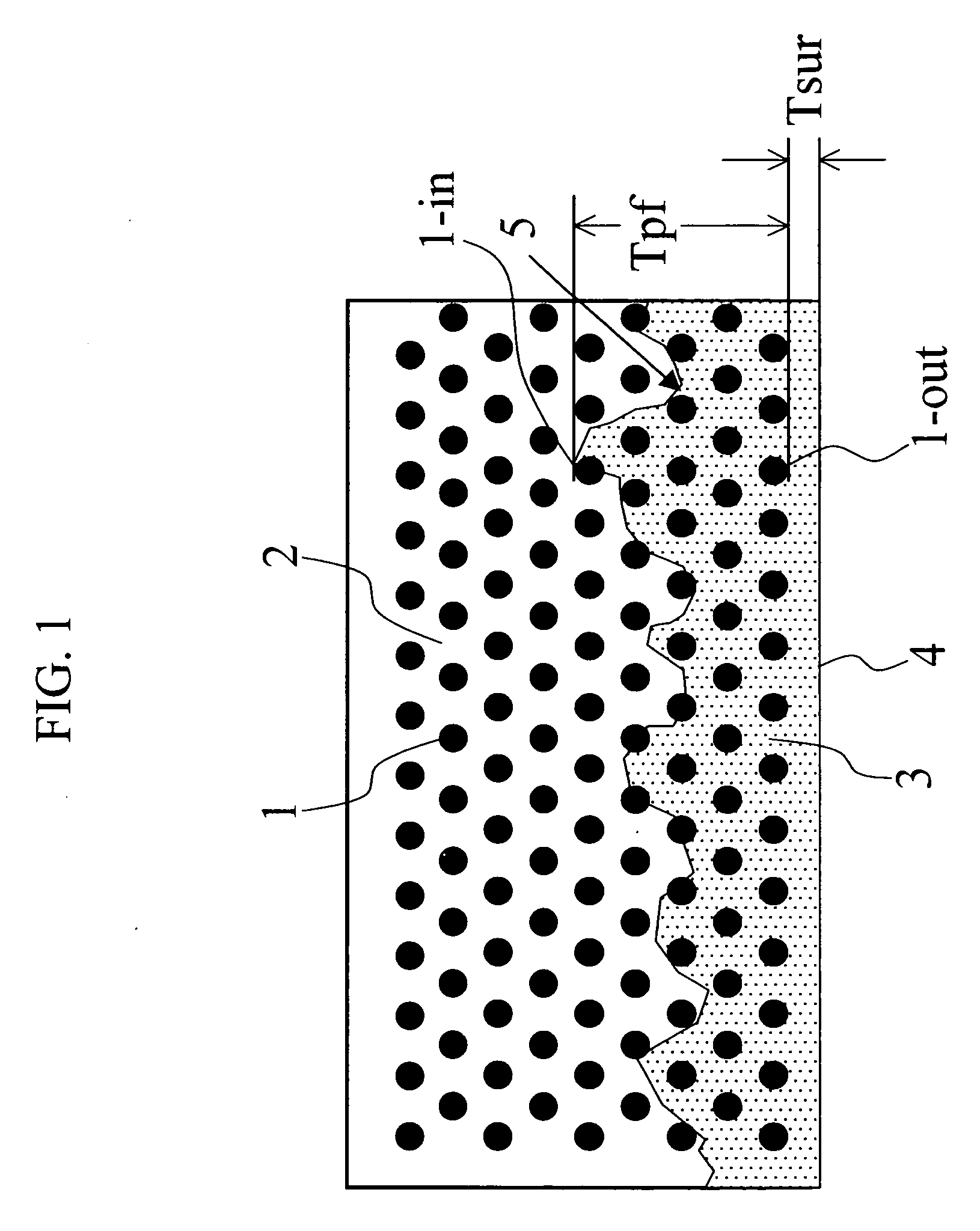

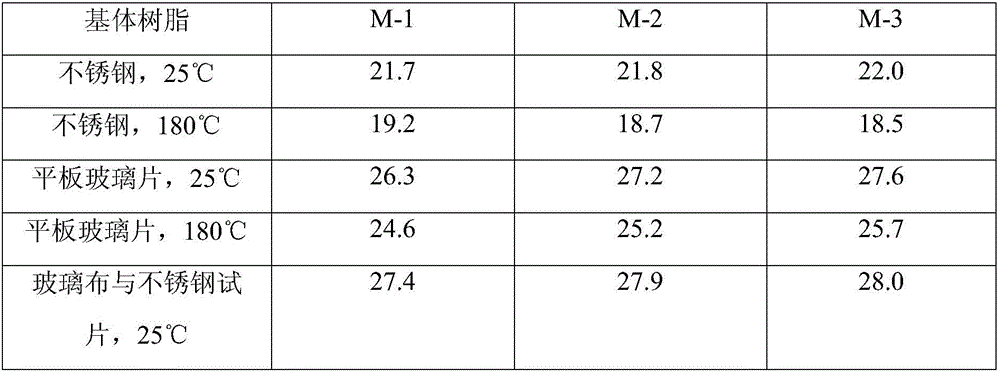

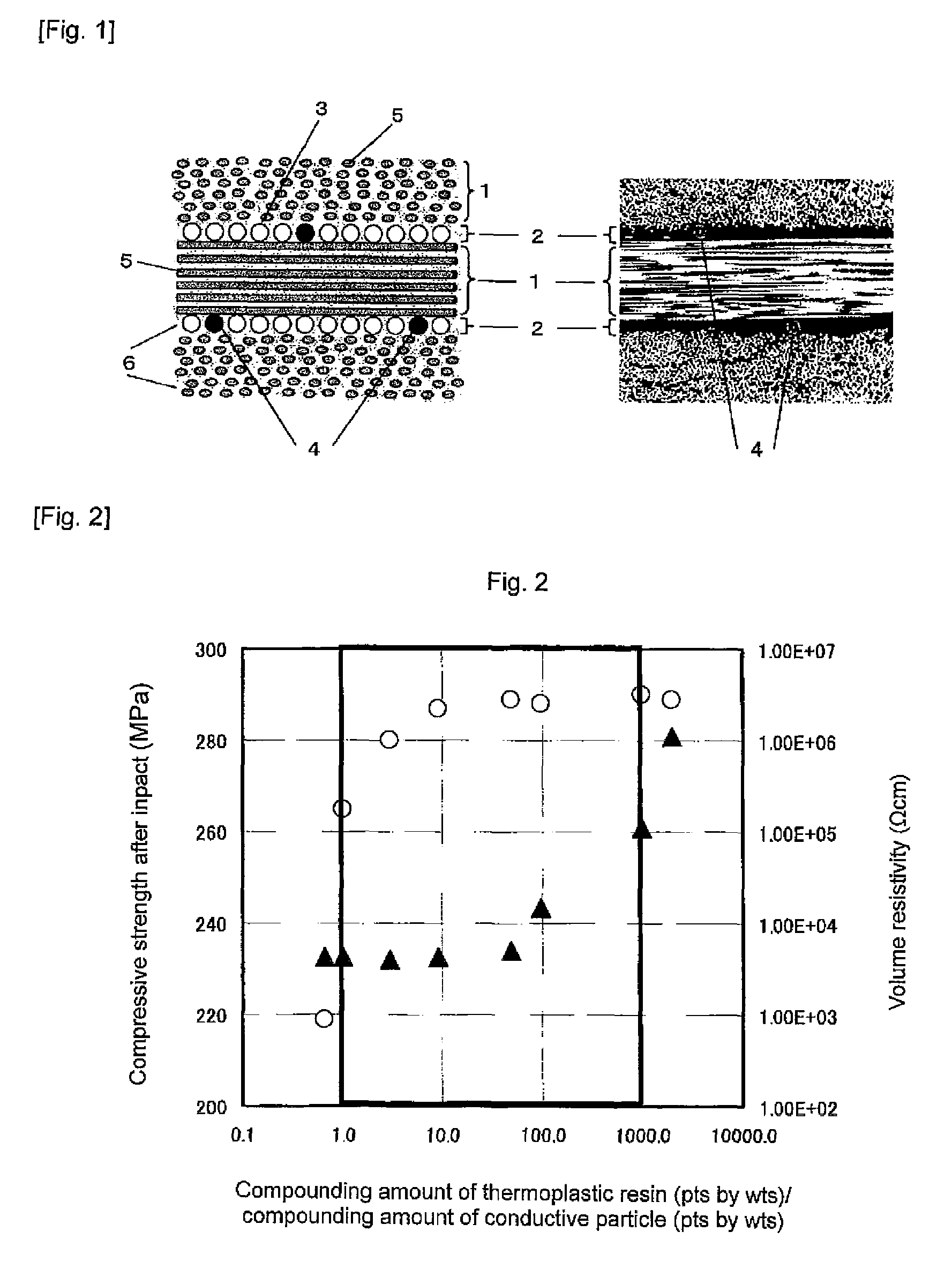

A prepreg containing a carbon fiber [A] and a thermosetting resin [B], and in addition, satisfying at least one of the following (1) and (2).(1) a thermoplastic resin particle or fiber [C] and a conductive particle or fiber [D] are contained, and weight ratio expressed by [compounding amount of [C] (parts by weight)] / [compounding amount of [D] (parts by weight)] is 1 to 1000.(2) a conductive particle or fiber of which thermoplastic resin nucleus or core is coated with a conductive substance [E] is contained.

Owner:TORAY IND INC

Epoxy resin composition for fiber-reinforced composite material, prepreg, and fiber-reinforced composite material

InactiveUS20020007022A1Synthetic resin layered productsThin material handlingInterlaminar shearFiber-reinforced composite

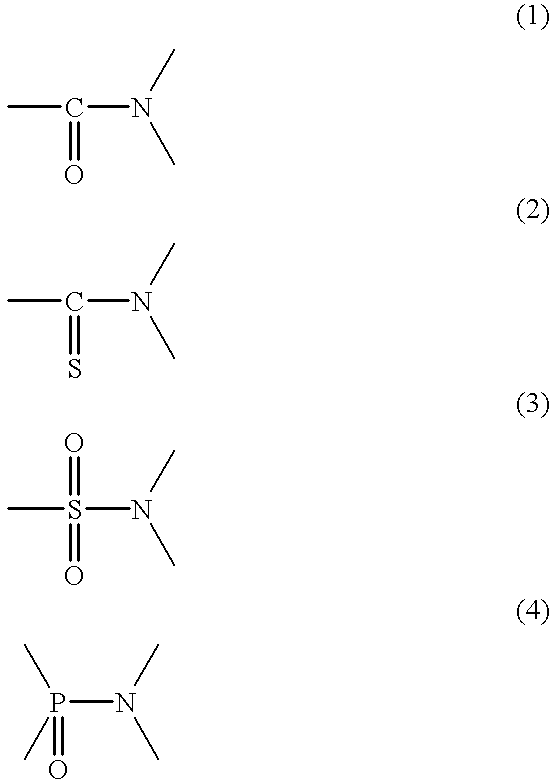

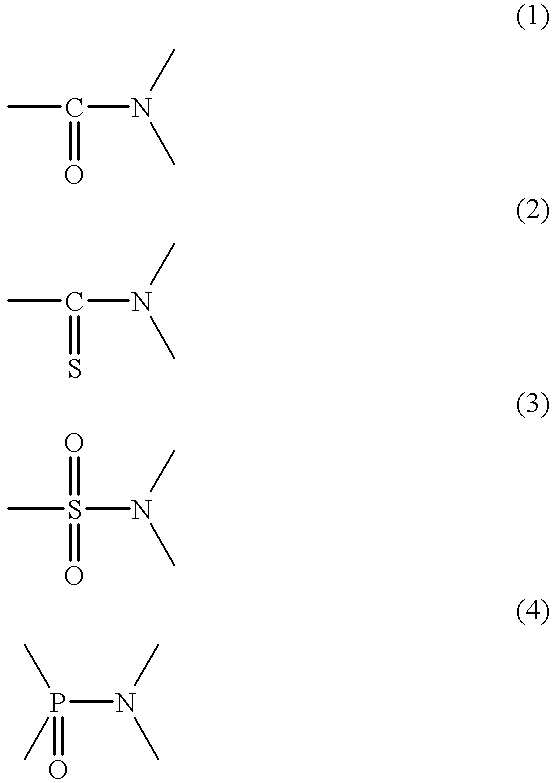

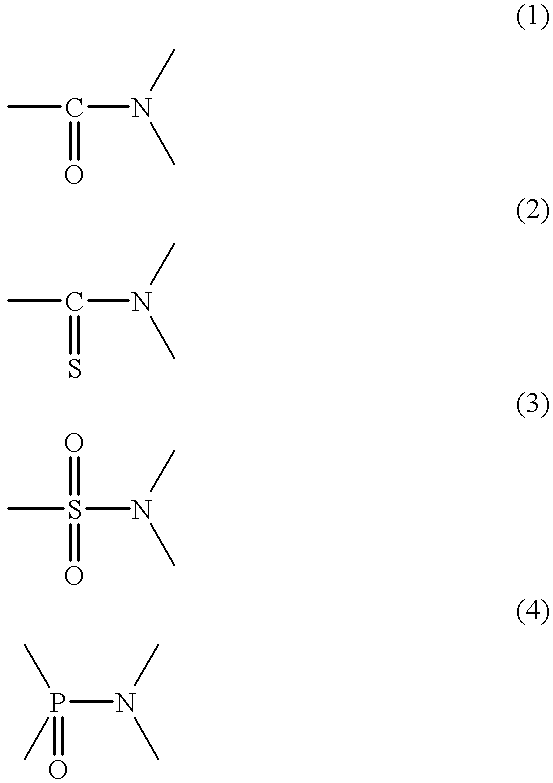

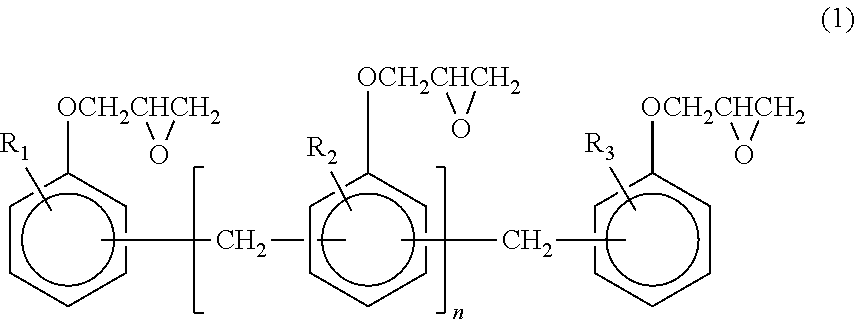

In order to realize the objectives stated above, the thermosetting resin composition for carbon fiber reinforced composite materials of the present invention chiefly comprises the following components. (A) Thermosetting resin (B) Compound containing one functional group which can react with thermosetting resin (A) or its curing agent, and a moiety selected from the following formulae (1) to (4) Furthermore, the present invention also relates to a prepreg formed by impregnating reinforcing fiber with the aforesaid resin composition and to carbon fiber reinforced composite materials comprising reinforcing fiber and a cured aforesaid thermosetting resin composition. In accordance with the present invention, there can be obtained a thermosetting resin composition where the adhesion to reinforcing fiber by the cured material and the elastic modulus of the cured material are excellent, and by using this resin composition there can be obtained carbon fiber reinforced composite materials which are excellent in their 0° compressive strength, 90° tensile strength and interlaminar shear strength, and which also have outstanding impact resistance.

Owner:TORAY IND INC

Surface-modification three-dimensional-network-carbon-fiber-reinforced composite material and preparing method

ActiveCN105818476AMitigating Galvanic CorrosionImprove resilienceLamination ancillary operationsLaminationCarbon nanotubeFiber-reinforced composite

The invention discloses a surface-modification three-dimensional-network-carbon-fiber-reinforced composite material and a preparing method.Three-dimensional carbon fiber frameworks with different bore diameters are prepared as required, and after surface pretreatment, diamond, carbon nanometer tubes and graphene are subjected to chemical vapor deposition; then the mixture and matrix materials are compounded, wherein the matrix materials are metal or polymers; the carbon-fiber-reinforced metal-based or polymer-based composite material with the three-dimensional net-shaped framework structure is obtained.A three-dimensional continuous heat conduction channel is formed in the composite material through the surface-modification three-dimensional net-shaped carbon fibers, and therefore the heat conduction performance of the composite material is greatly improved; meanwhile, according to space distribution of carbon fibers in the matrix material, the mechanical performance of the composite material can also be improved, and the density and the thermal expansion coefficient can be decreased; the thermal expansion coefficient, the mechanical performance and the thermal performance can be further regulated and controlled by adding zero-dimensional particle reinforcement.

Owner:CENT SOUTH UNIV

Carbon fiber reinforced composite and preparation thereof

The invention discloses carbon fiber reinforced thermoplastic resin composite material which is composed of the components according to the percentage by weight: carbon fibers with the surface modified accounting for 5 percent to 50 percent, thermoplastic resin accounting for 44 percent to 75 percent, polytetrafluoroethylene accounting for 5 percent to 15 percent and processing auxiliary agent accounting for 1 percent to 5 percent; the carbon fibers with the surface modified is manufactured by processing the carbon fibers in specially mixed acidic solution under the temperature of 40 DEG C to 80 DEG C for 30 minutes to 120 minutes and dried at the temperature of 80 DEG C to 150 DEG C. The invention also discloses the preparation method of the carbon fiber reinforced thermoplastic resin composite material. The carbon fibers of the carbon fiber reinforced thermoplastic resin composite material provided by the invention are dispersed in a state of 3 mm to 5 mm in a resin matrix, the original high intensity of the carbon fibers is maintained to the maximum, so as to ensure the prepared composite material to have high intensity, high modulus, high heat resistant and high wear resistant performances.

Owner:宁波益德新材料有限公司

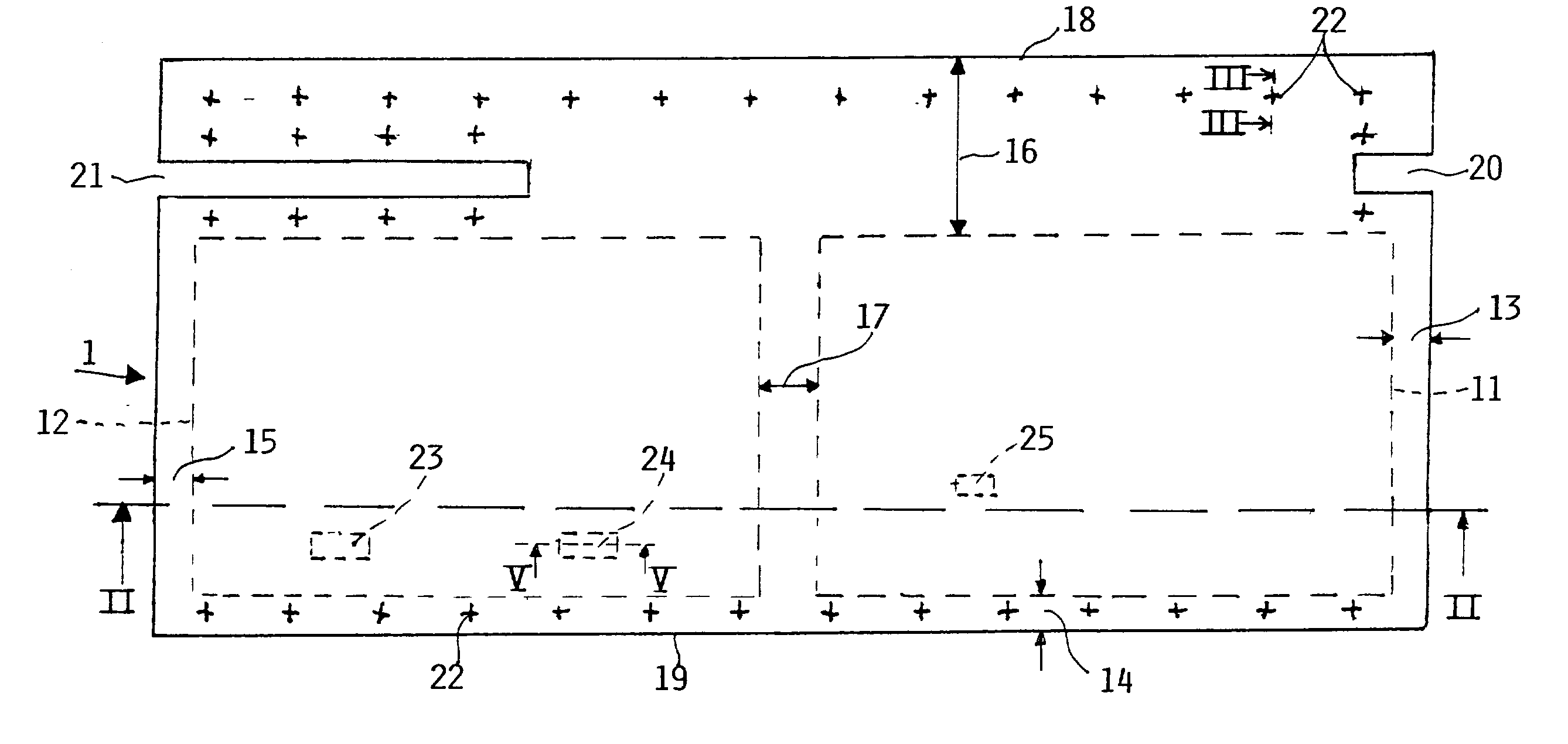

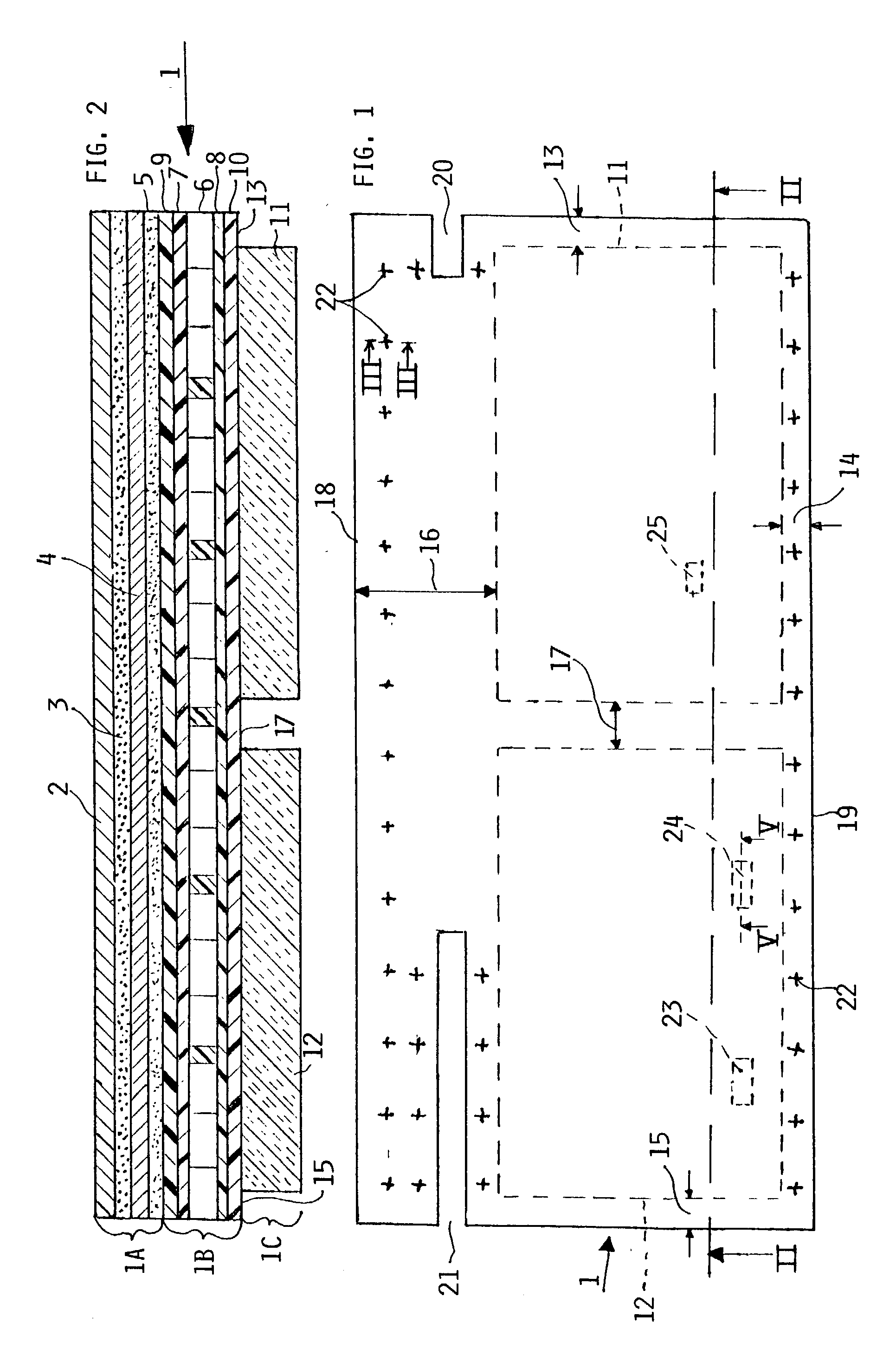

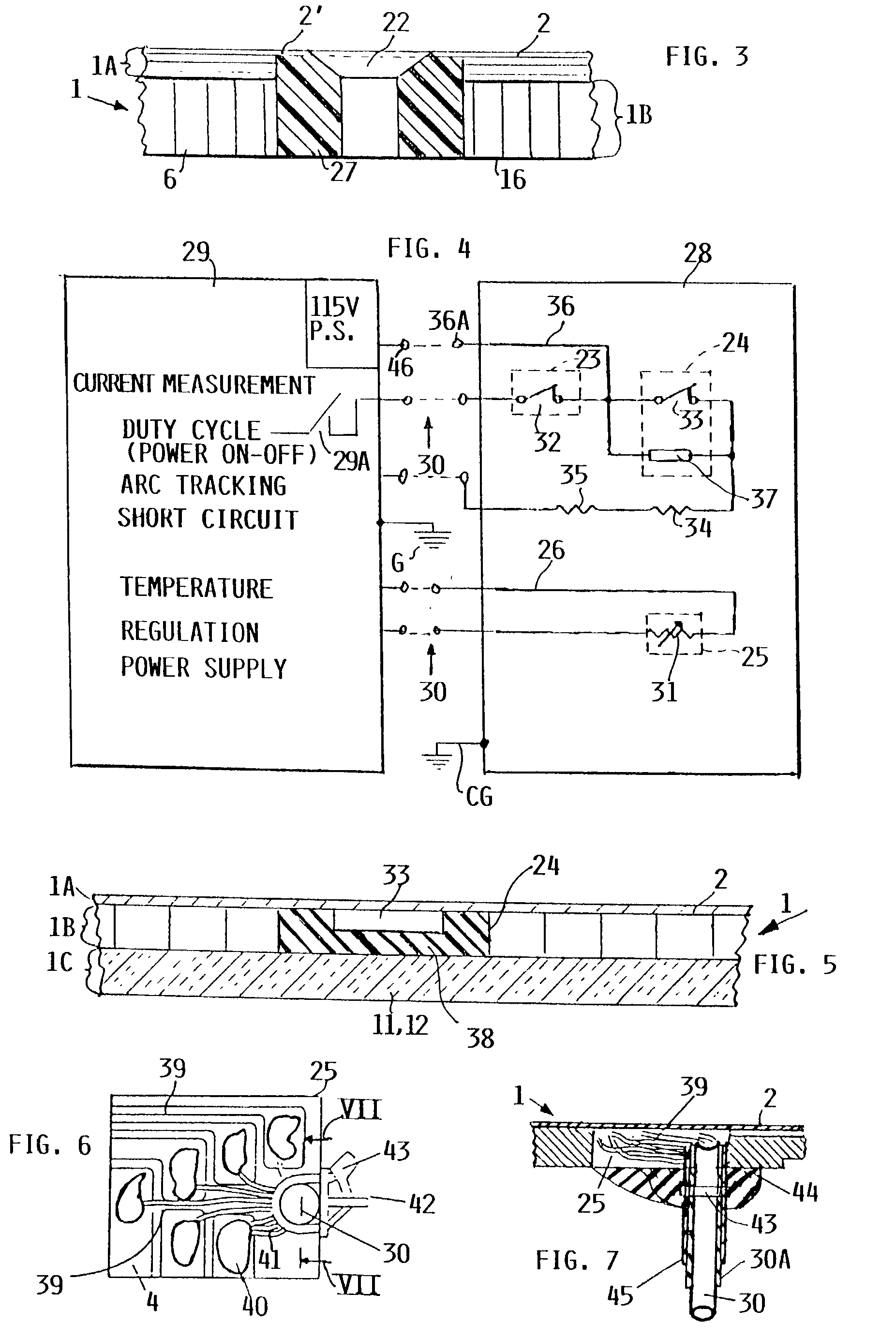

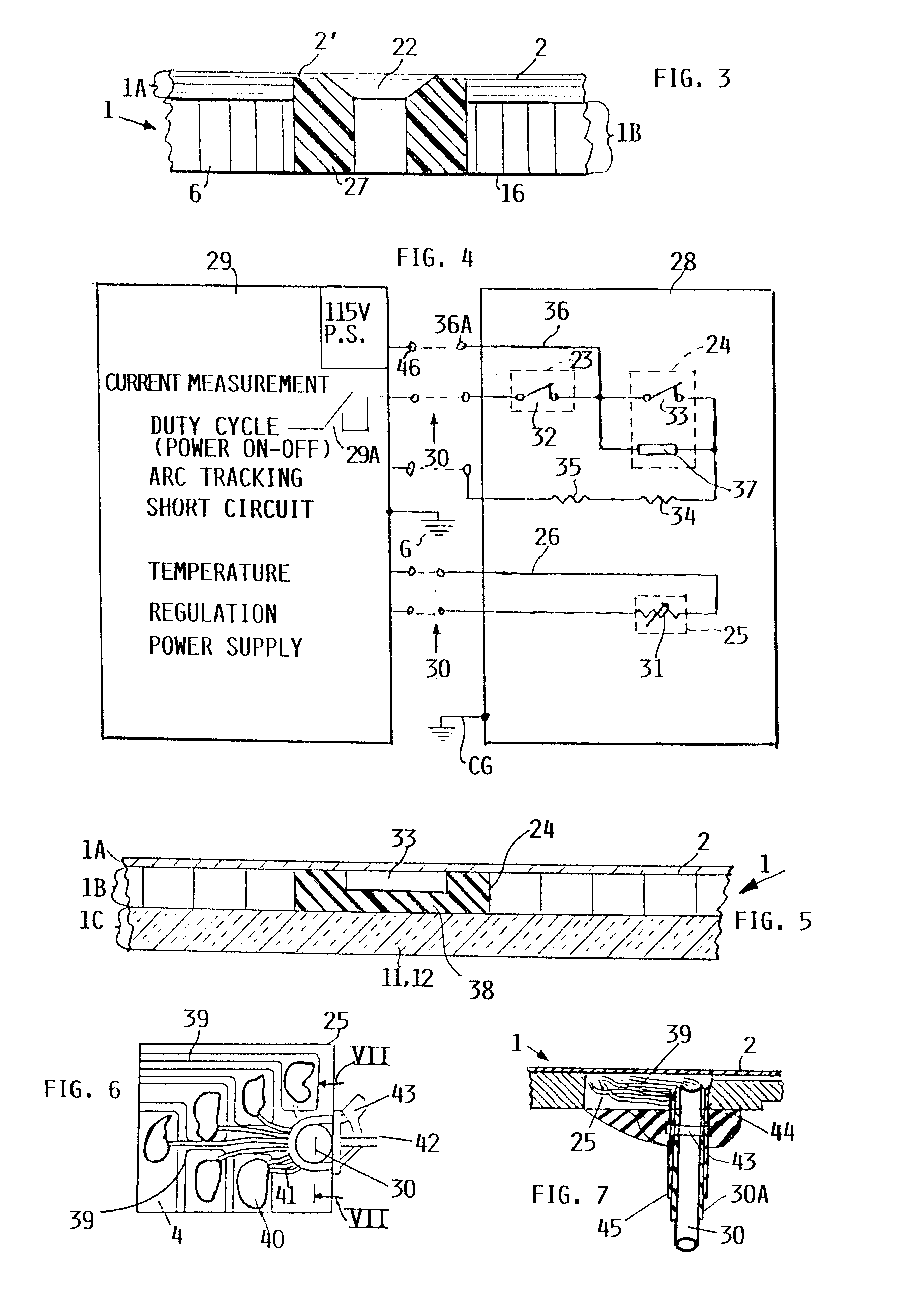

Electrically heated aircraft composite floor panel

InactiveUS20020168184A1Avoid temperature riseReduce consumptionFluid heatersElectric heating systemGlass fiberFiber-reinforced composite

An aircraft floor heating panel is constructed for mechanical strength and to meet special heating requirements next to a door in an aircraft. The panel has a lightweight core. Each surface of the core is first covered with at least one carbon-fiber reinforced composite layer for protection against deterioration. Each carbon fiber layer in turn is covered by a glass fiber reinforced composite layer for mechanical strength. A foil heater is arranged inside the composite panel coextensive with at least a portion of the panel area. A heat distributing metal plate covers the panel as an upper step-on surface. A heat insulating layer is bonded to the panel opposite the heat distributing metal plate. A triple heat control is provided for an increased safety against fire hazards.

Owner:AIRBUS OPERATIONS GMBH

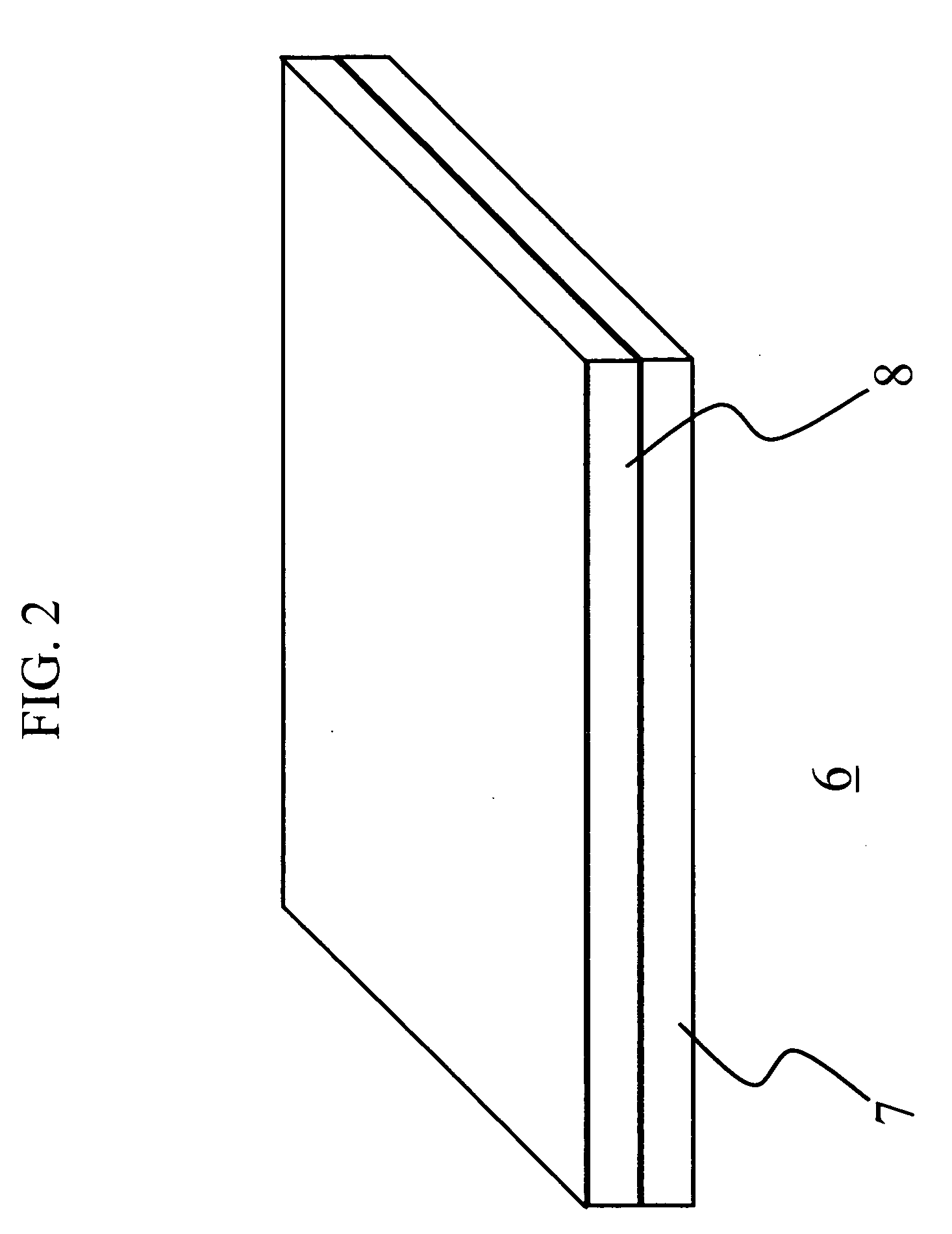

Epoxy Resin Composition for Carbon-Fiber-Reinforced Composite Material, Prepreg, Integrated Molding, Fiber-Reinforced Composite Sheet, and Casing for Electrical/Electronic Equipment

ActiveUS20080166511A1Improve mechanical propertiesLight weightPigmenting treatmentPlastic/resin/waxes insulatorsEpoxyHalogen

The present invention provides a light-weight fiber-reinforced composite material that has excellent flame retardance and mechanical properties and never emits a halogen gas. The present invention also provides a prepreg and en epoxy resin composition suited to obtain the above described fiber-reinforced composite material. The present invention also provides an integrated molding which is produced using the above described fiber-reinforced composite material, thereby suitable for use in electric / electronic casings. The epoxy resin composition is such that it contains the following components [A], [B] and [C]:[A] epoxy resin,[B] amine curing agent, and[C] phosphorus compound,wherein the concentration of the component [C] is 0.2 to 15% by weight in terms of phosphorus atom concentration.

Owner:TORAY IND INC

Composition of epoxy resin, curing agent and reactive compound

A thermosetting resin composition for carbon fiber reinforced composite materials of the present invention chiefly comprises(A)2 thermosetting resin such as epoxy resin and a curing agent, and(B)2 compound containing one functional group which can react with thermosetting resin (A) or its curing agent, and a moiety selected from the following formulae (1) to (4)Furthermore, the present invention also relates to a prepreg formed by impregnating reinforcing fiber with the aforesaid resin composition and to carbon fiber reinforced composite materials comprising reinforcing fiber and a cured aforesaid thermosetting resin composition.

Owner:TORAY IND INC

Method for preparing graphene oxide grafting surface modification carbon fiber

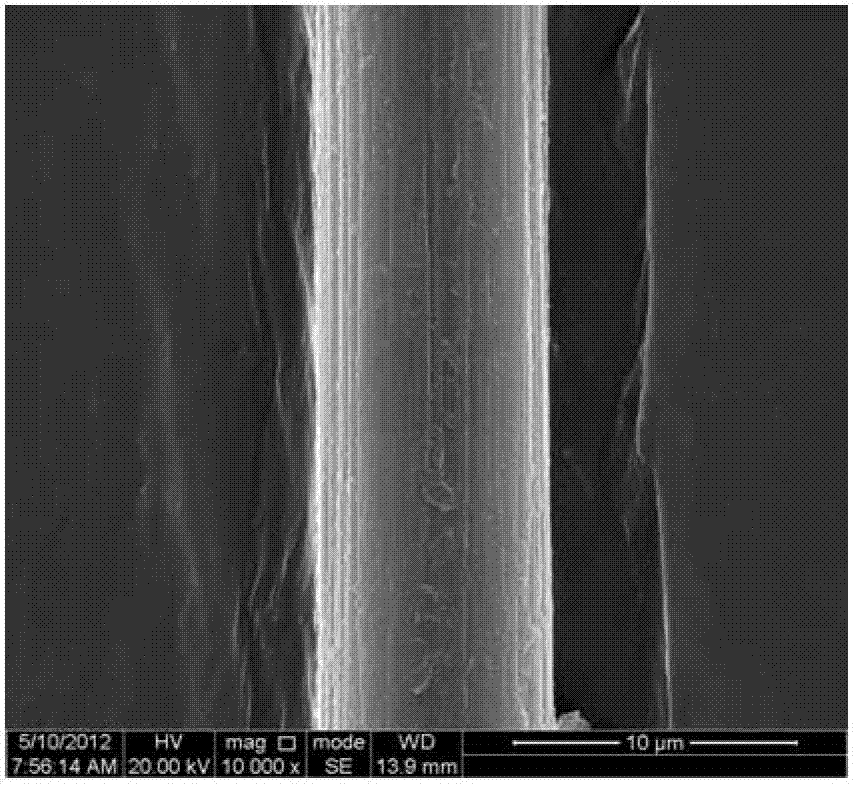

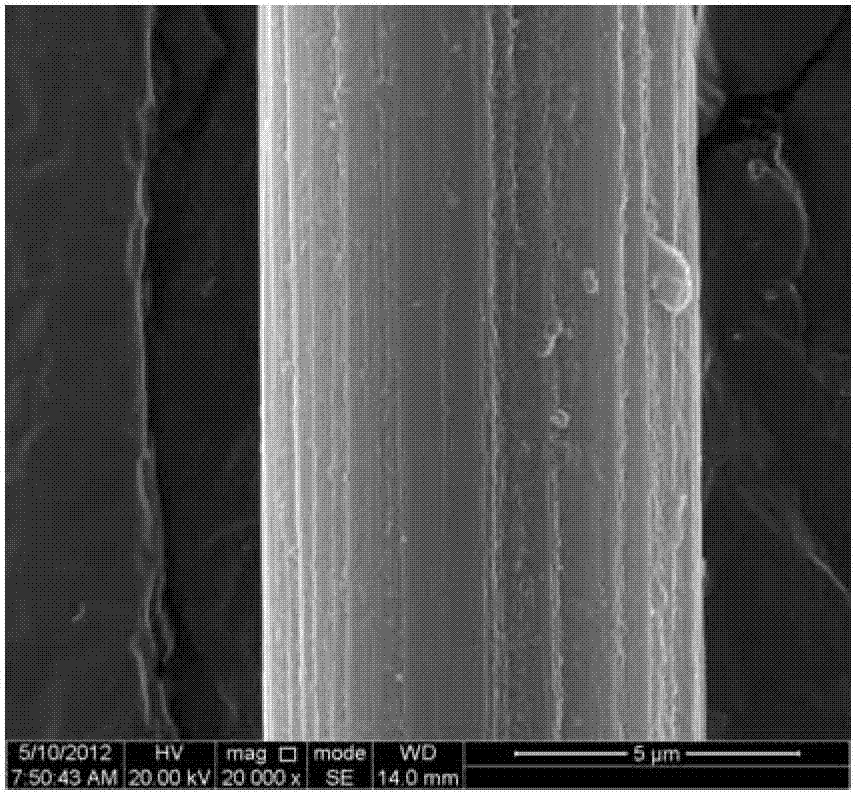

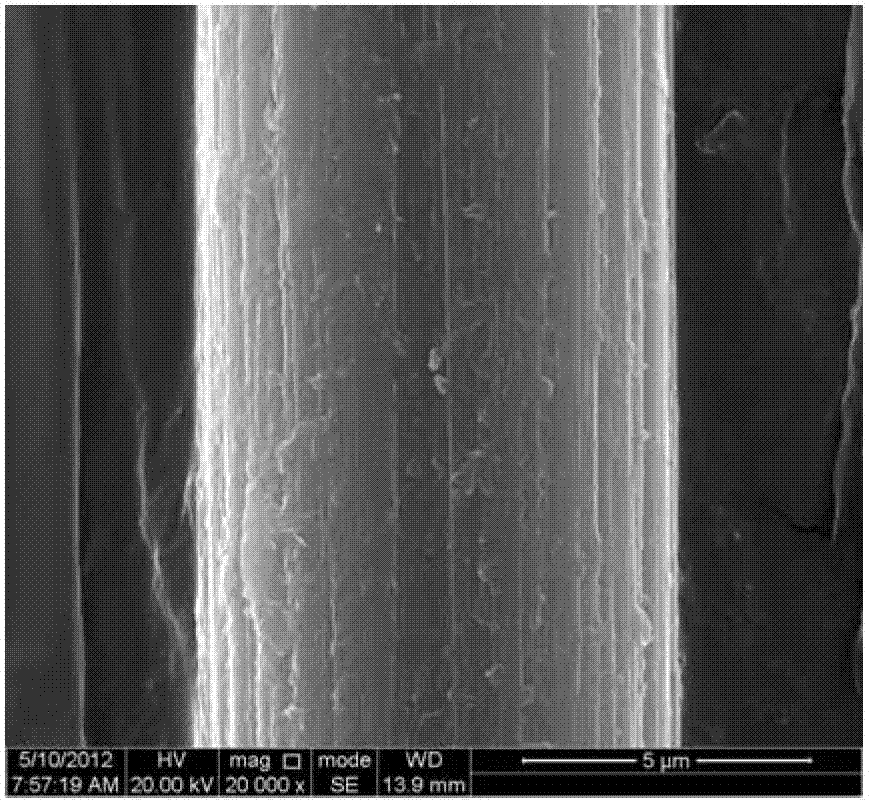

ActiveCN102787488AIncrease roughnessImprove interface performanceCarbon compoundsCarbon fibresCarbon compositesResin matrix

A method for preparing a graphene oxide grafting surface modification carbon fiber relates to a carbon fiber modification method, and is used for solving the technical problems that the existing carbon fiber has low surface activity, reduced surface tension and poor wettability with a resin matrix, and the interlaminar shear strength of a composite material is caused to reduce. The method comprises the steps as follows: 1, graphite oxidization; 2, separation of graphite oxide mother liquor; 3, functionalization of graphite oxide; 4, carbon fiber surface functionalization; and 5, carbon fiber surface graphite oxide treatment. The graphite oxide uniformly covers the carbon fiber surface, the roughness of the carbon fiber surface can be greatly improved, and accordingly, the interfacial properties of a carbon fiber reinforced composite material can be improved by an anchoring action. The interfacial shear strength of the surface grafting graphene oxide carbon fiber / carbon composite material which is prepared through graphene oxide grafting modification can be improved by 25% in comparison with that of the untreated surface grafting graphene oxide carbon fiber / carbon composite material.

Owner:HARBIN INST OF TECH

PCD drill for composite materials

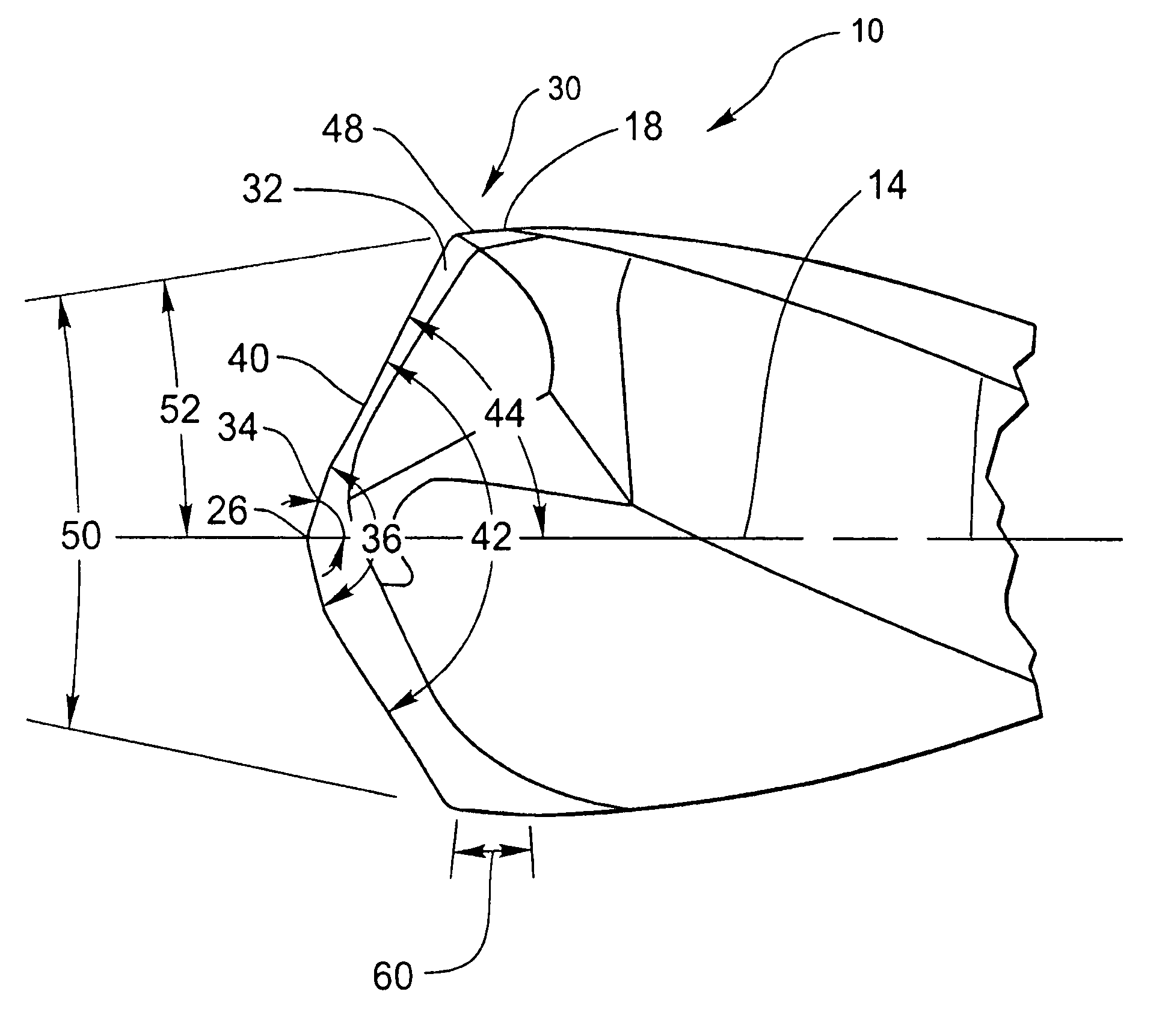

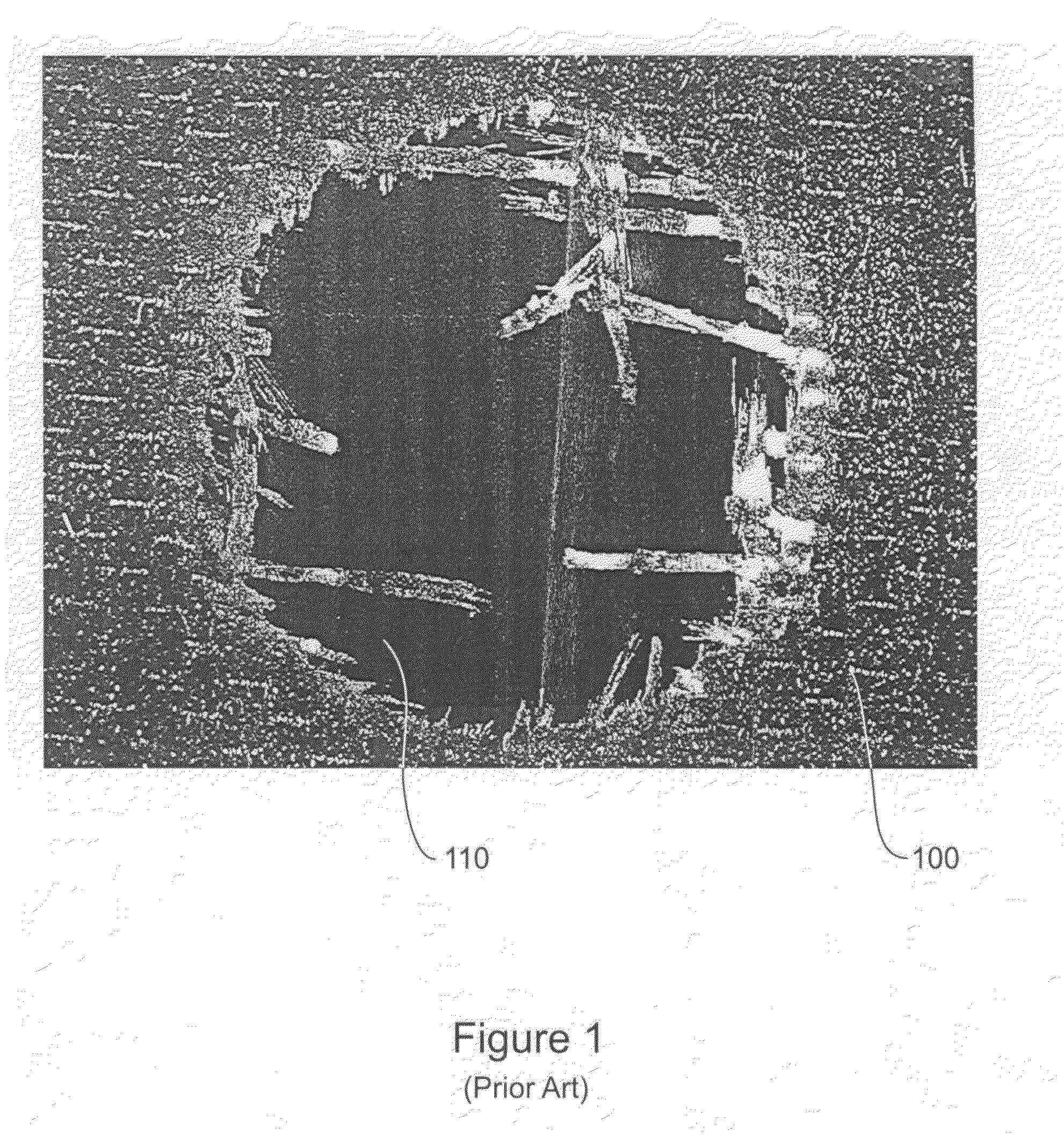

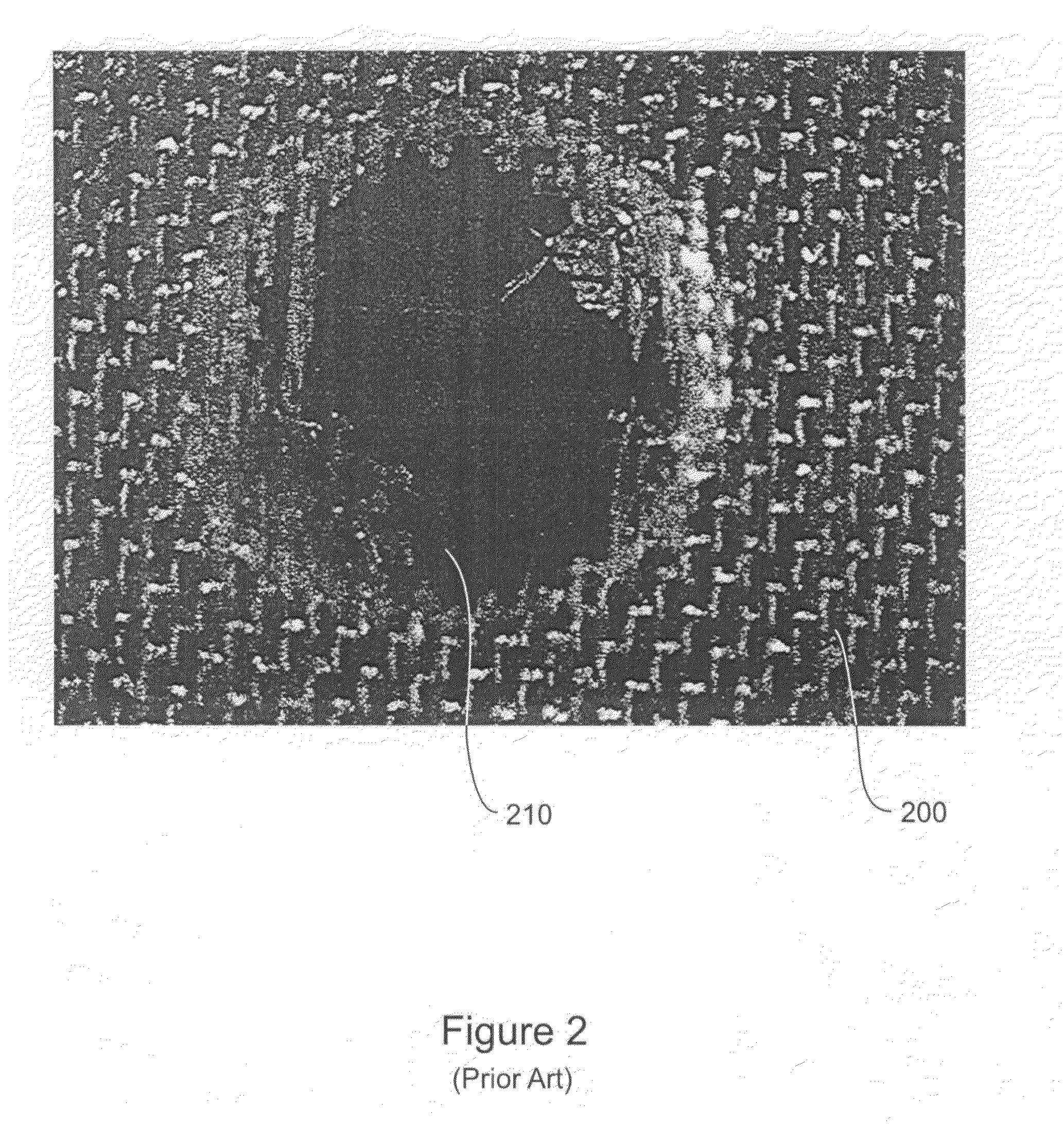

ActiveUS7575401B1Increase chanceMinimal delaminationWood turning toolsTransportation and packagingFiberProduction rate

A PCD drill for producing close tolerance holes in multi layer laminates, such as carbon fiber reinforced composites, with minimum fraying of the fibers on both entrance and exit from the hole is provided. The drills provided include a symmetrical cutting point with a self-centering split point and a high shear second cutting lip positioned at the outer diameter of the drill. The drills of the invention may allow for increased cutting speeds and feeds when used with such advanced composite materials, thus increasing tool productivity and providing increased performance.

Owner:PRECORP INC

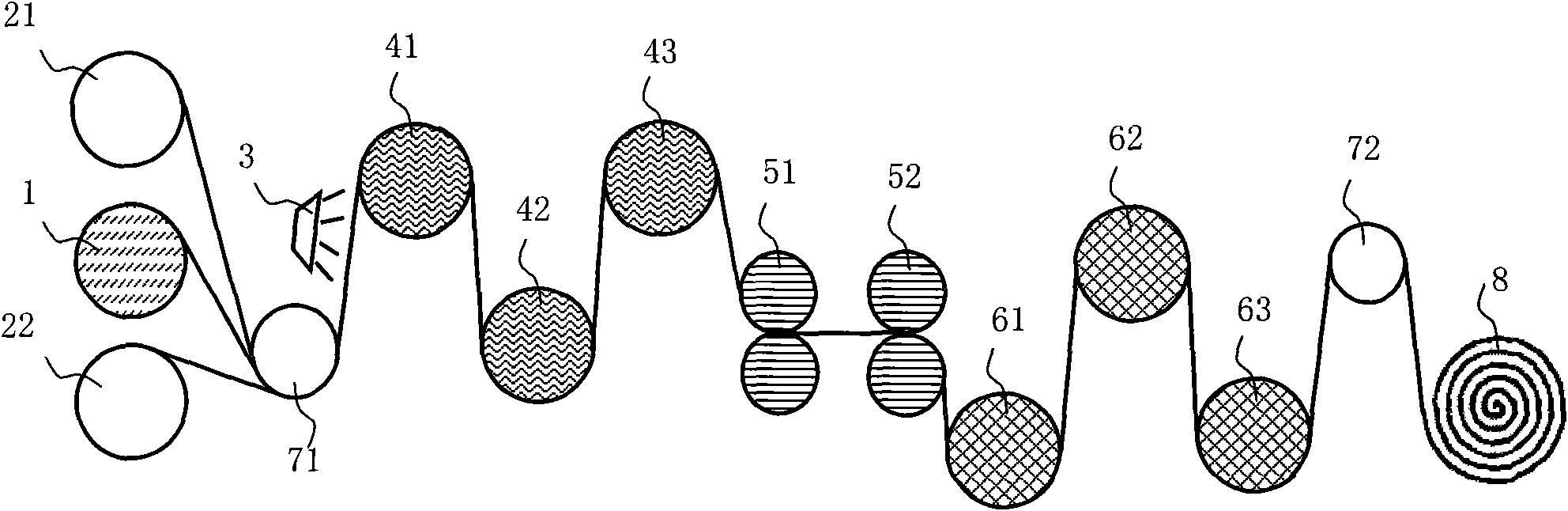

Thermoplastic resin-based carbon fiber composite and preparation method thereof

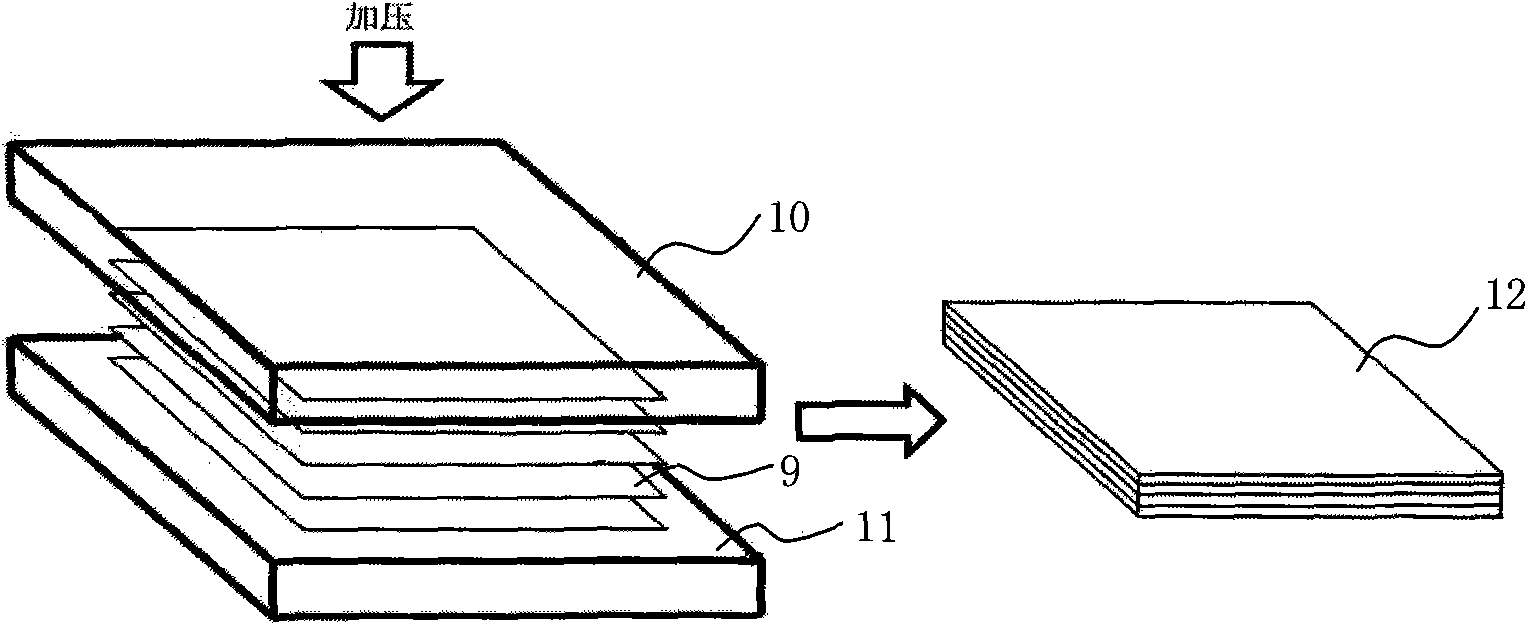

The invention discloses a thermoplastic resin-based carbon fiber composite and a preparation method thereof. The thermoplastic resin-based carbon fiber composite comprises the following components in percentage by volume: 50 to 70 percent of carbon fibers and 30 to 50 percent of thermoplastic resin. In the preparation method, according to rheological properties of the thermoplastic resin, the thermoplastic resin-based carbon fiber composite with good interface binding property is prepared by utilizing hot-roller hot-pressing continuous equipment and adjusting process conditions such as machining temperature, machining pressure, machining time and the like. Compared with the prior art, the thermoplastic resin-based carbon fiber composite has the advantages of simple structure, good interface binding property, high impact resistance and recycling property; and the preparation method can realize the uniform distribution of the carbon fibers and the thermoplastic resin and ensure the carbon fibers are immersed by the thermoplastic resin completely, so that the defect of the conventional method is overcome.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

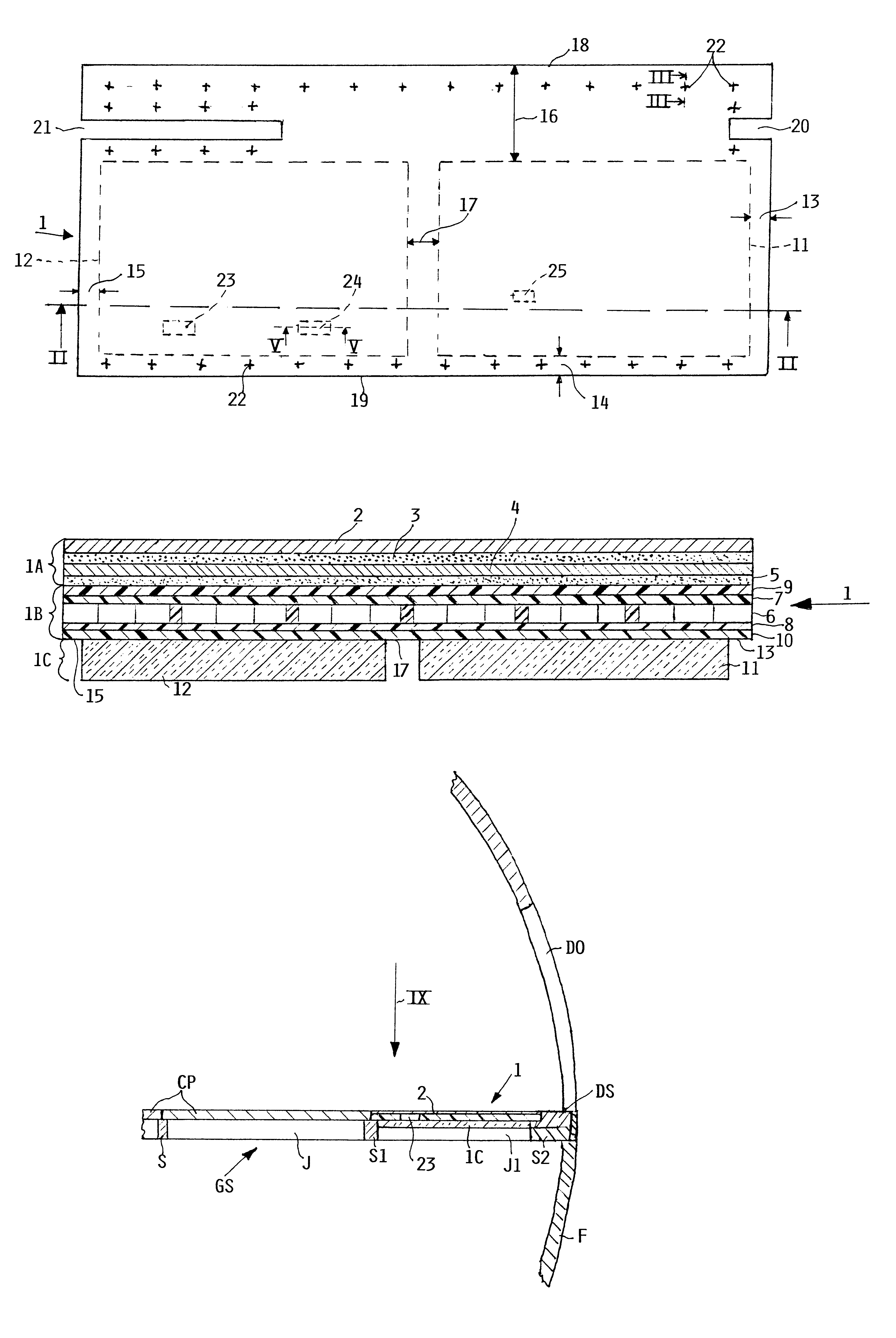

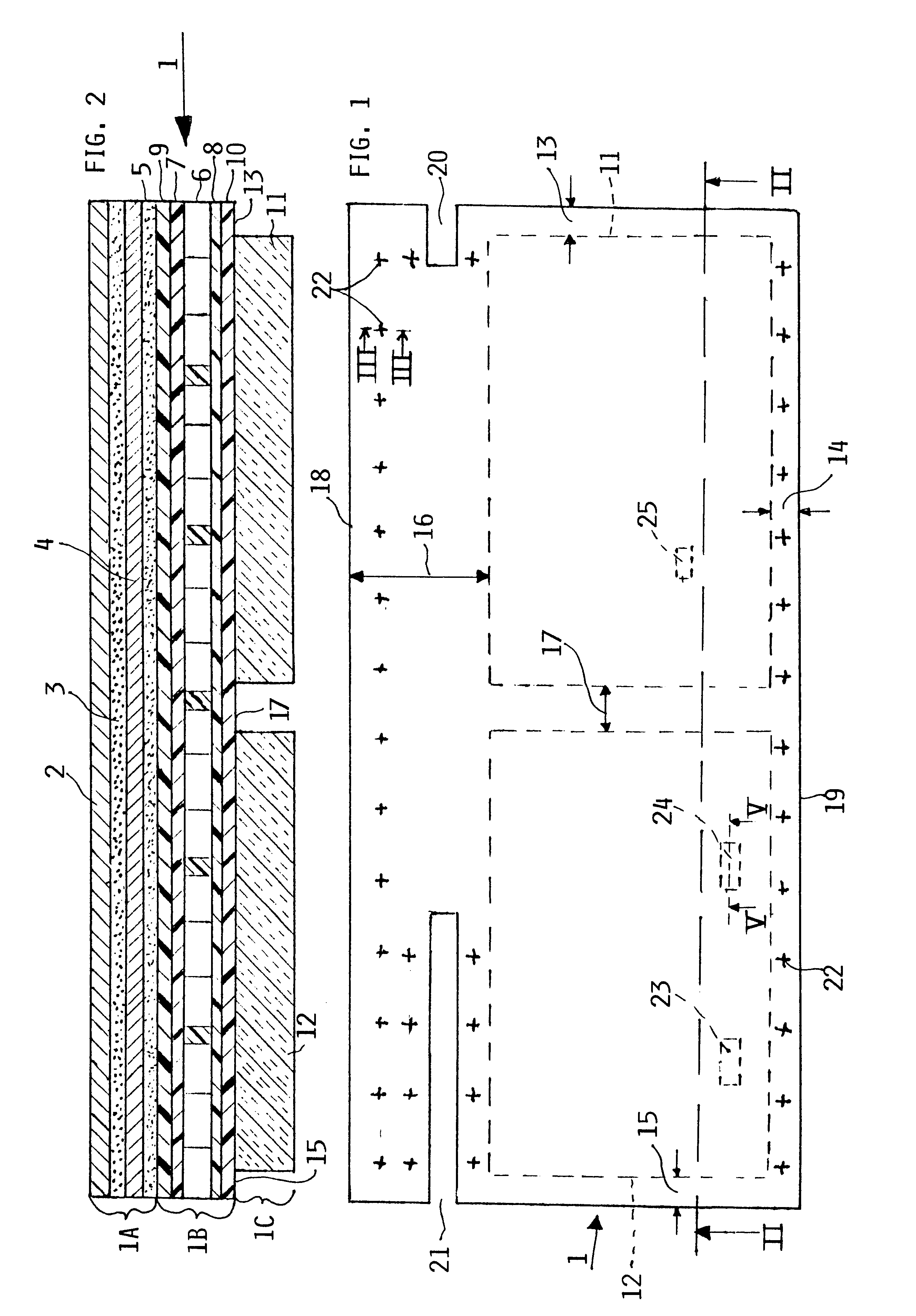

Electrically heated aircraft composite floor panel

InactiveUS6611659B2Reduce consumptionReduce weightFluid heatersElectric heating systemGlass fiberFiber-reinforced composite

An aircraft floor heating panel is constructed for mechanical strength and to meet special heating requirements next to a door in an aircraft. The panel has a lightweight core. Each surface of the core is first covered with at least one carbon-fiber reinforced composite layer for protection against deterioration. Each carbon fiber layer in turn is covered by a glass fiber reinforced composite layer for mechanical strength. A foil heater is arranged inside the composite panel coextensive with at least a portion of the panel area. A heat distributing metal plate covers the panel as an upper step-on surface. A heat insulating layer is bonded to the panel opposite the heat distributing metal plate. A triple heat control is provided for an increased safety against fire hazards.

Owner:AIRBUS OPERATIONS GMBH

Epoxy resin composition for carbon-fiber-reinforced composite material, prepreg, integrated molding, sheet of fiber-reinforced composite material and cabinet for electrical/electronic equipment

ActiveCN1946780AIncrease flame retardancyExcellent mechanical propertiesPigmenting treatmentLayered productsCombustionHalogen

A lightweight fiber-reinforced composite material that exhibits excellent flame resistance and mechanical properties and does not emit any halogen gas at combustion; an epoxy resin composition and prepreg suitable for obtaining the above fiber-reinforced composite material; and an integrated molding suitable to electrical / electronic equipment cabinet, in which use is made of the above fiber-reinforced composite material. There is provided an epoxy resin composition for carbon-fiber-reinforced composite material, comprising: [A] epoxy resin, [B] amine curing agent, and [C] phosphorus compound, the component [C] contained in an amount, in terms of concentration of phosphorus atoms, of 0.2 to 15 wt.%.

Owner:TORAY IND INC

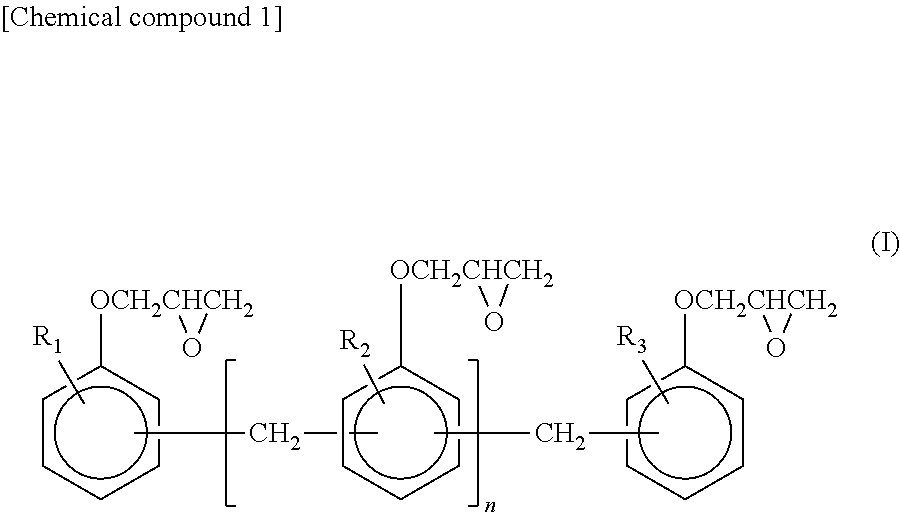

Epoxy resin composition, prepreg, carbon fiber reinforced composite material, and housing for electronic or electrical component

InactiveUS20110319525A1Efficient productionExcellent characteristicsGroup 5/15 element organic compoundsEpoxyPhosphoric Acid Esters

Provided are a carbon fiber reinforced composite material which exhibits excellent flame retardance, fast curing properties, heat resistance, and mechanical characteristics. Also provided are an epoxy resin composition suitable for use in producing said carbon fiber reinforced composite material as well as a prepreg and housing for electronic / electrical components. The epoxy resin composition is characterized by comprising: [A] an epoxy resin containing at least 50 mass % of a compound as represented by general formula (I), [B] an organic nitrogen compound based curing agent, [C] a phosphoric acid ester, and [D] a phosphazene compound. In general formula (I), R1, R2, and R3 are either a hydrogen atom or a methyl group, and n is an integer of 1 or higher.

Owner:TORAY IND INC

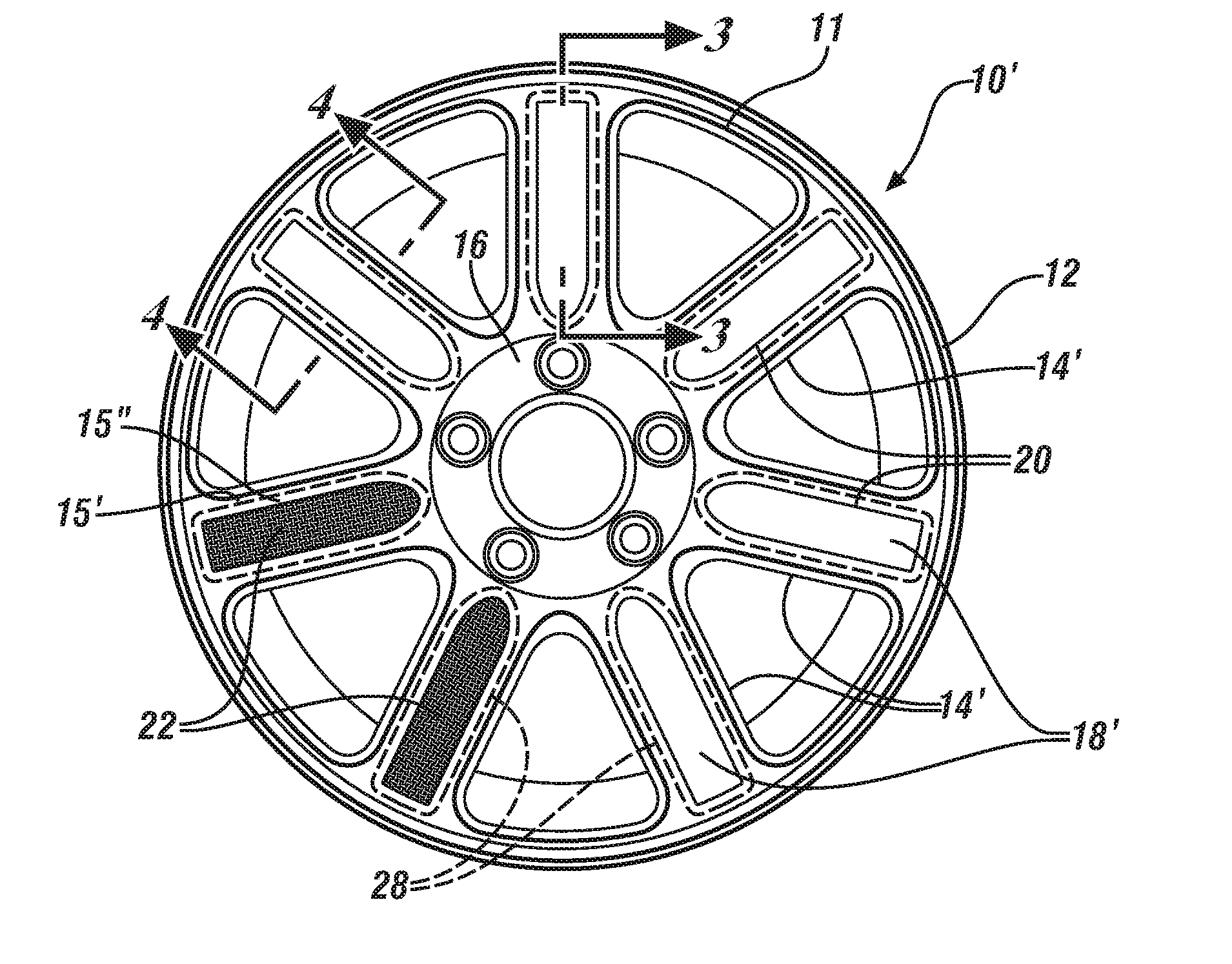

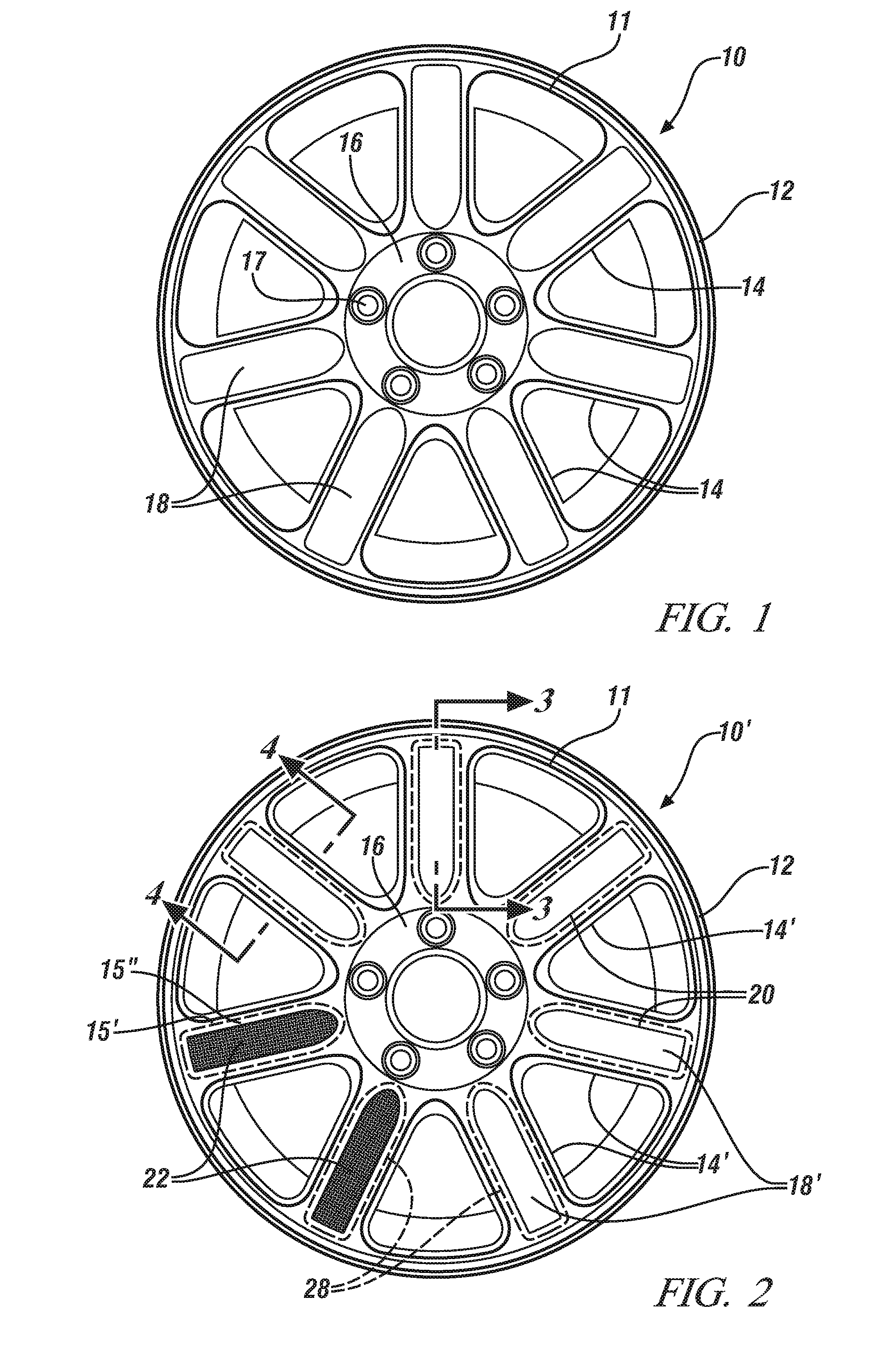

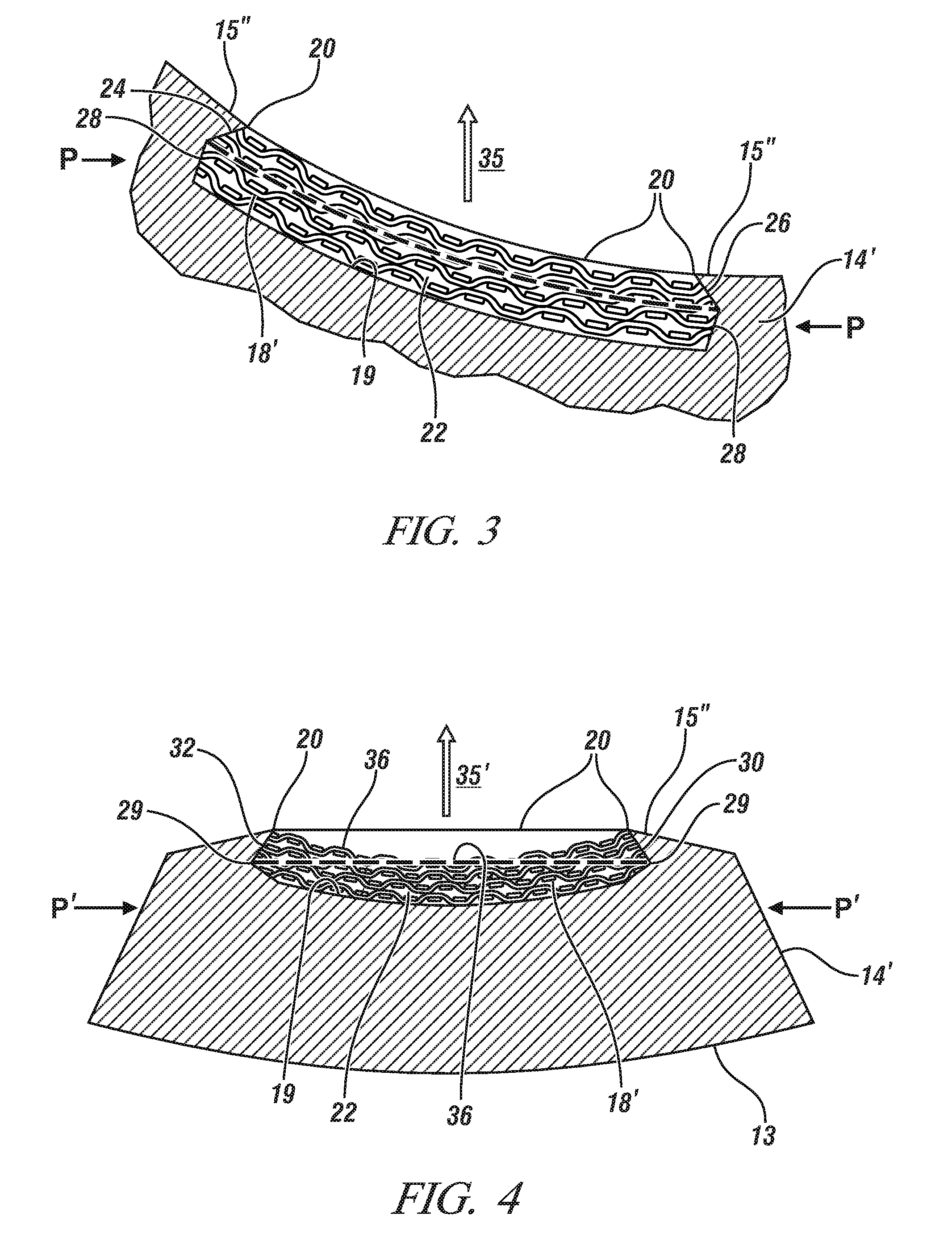

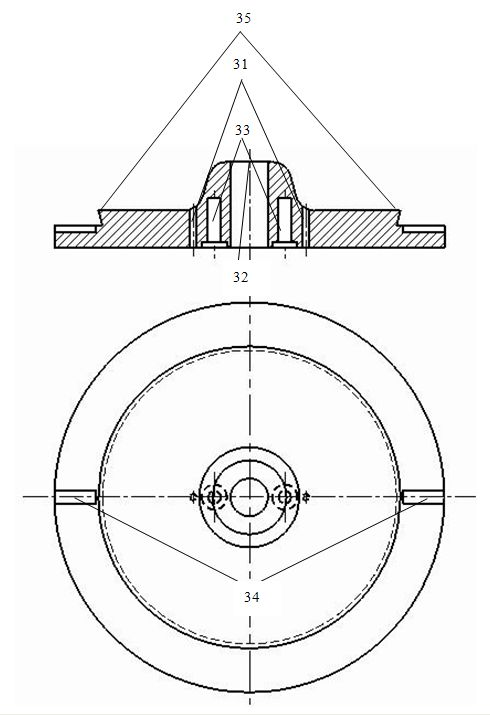

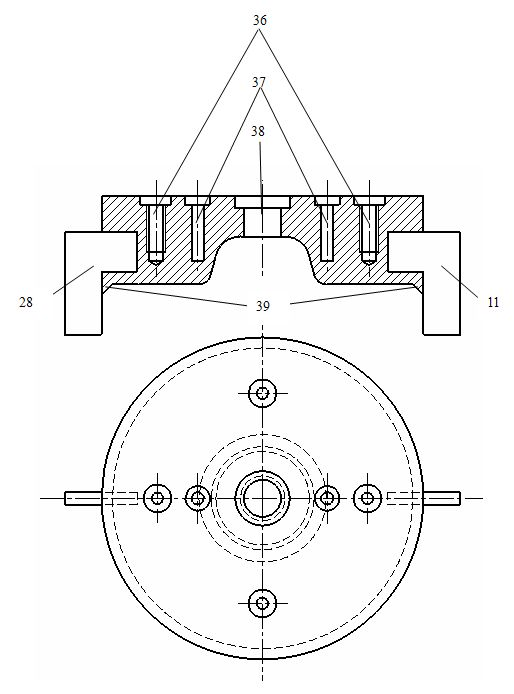

Light-weight vehicle wheels with carbon fiber inserts

ActiveUS20130026816A1Portion is increasedHigh modulusRimsNon-metallic wheel bodyFiberThermal dilatation

Application of carbon fiber reinforced polymer structures to metal vehicle wheels is effective in reducing the mass of the wheel while retaining suitable stiffness in the wheel structure. For maximum effect the reinforced polymer structure and the metal wheel must operate cooperatively. Because of the wide range of operating temperatures experienced by wheels and the large difference in coefficient of thermal expansion between metals and carbon fiber reinforced composites attachment of the polymer structure to the wheel by adhesive alone is problematical. However a wheel with an effective and durable reinforcement may be fabricated by confining, through mechanical interference, the reinforced polymer in a cavity in or on the spoke and by preheating the wheel before curing the polymer.

Owner:GM GLOBAL TECH OPERATIONS LLC

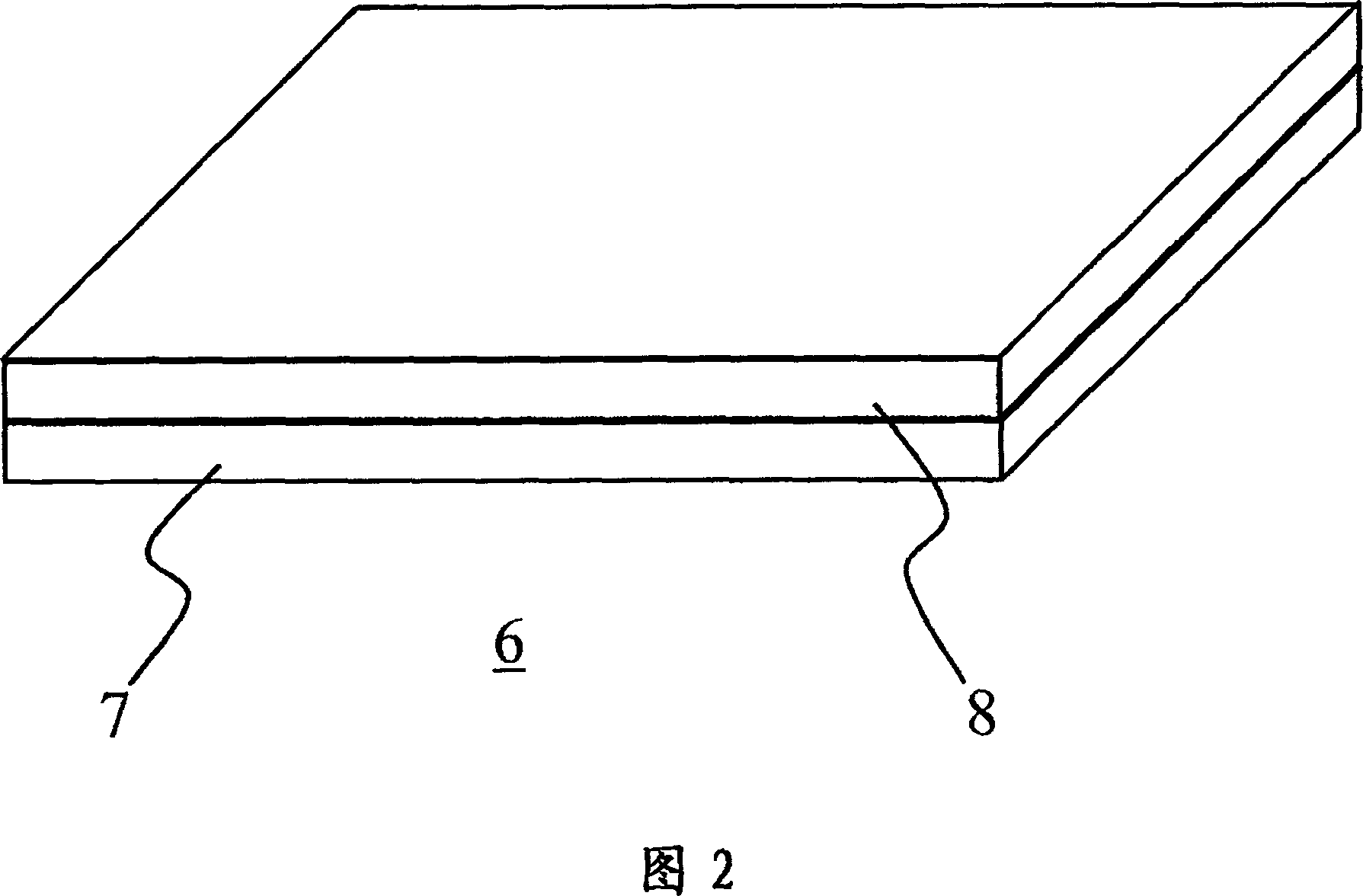

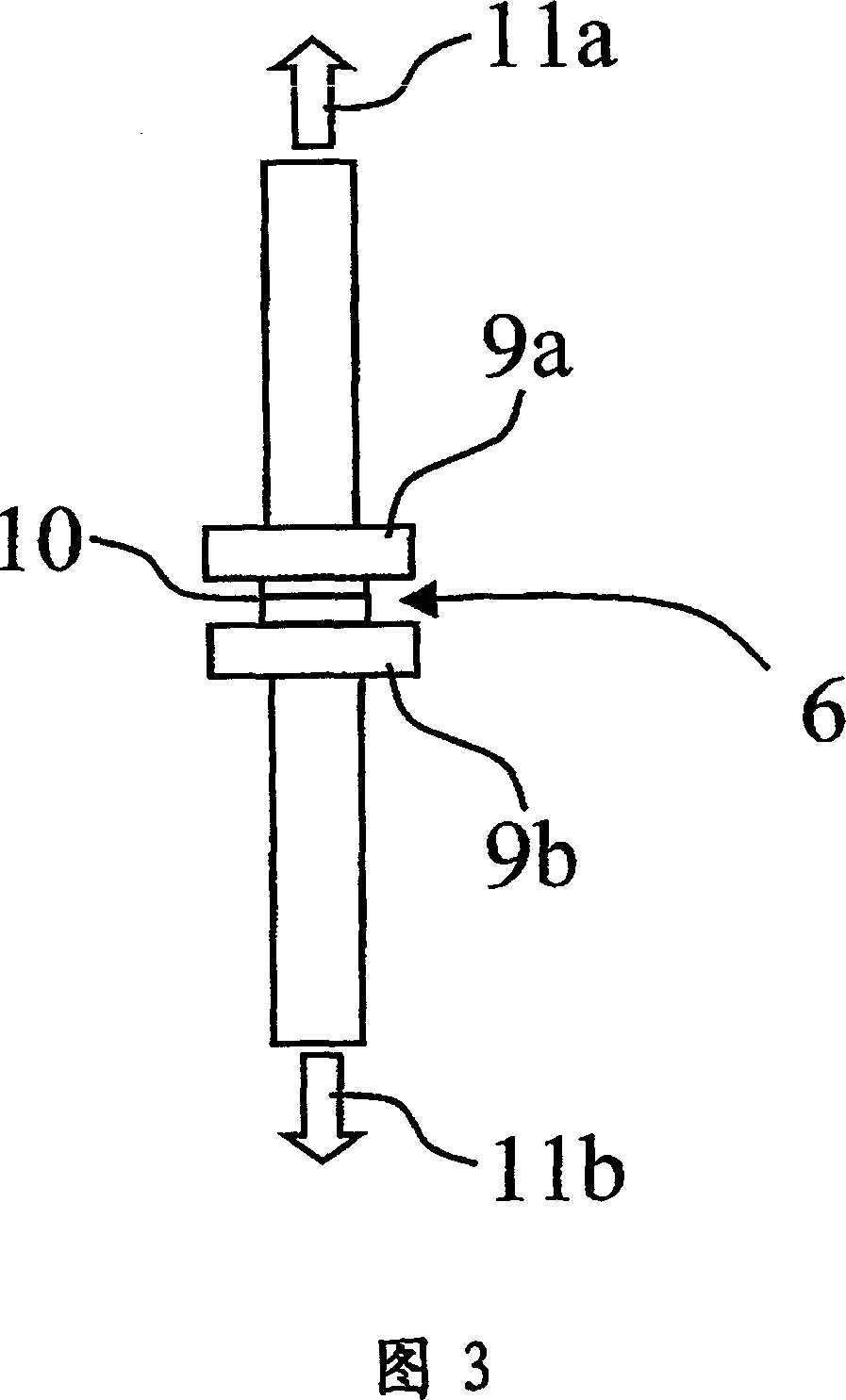

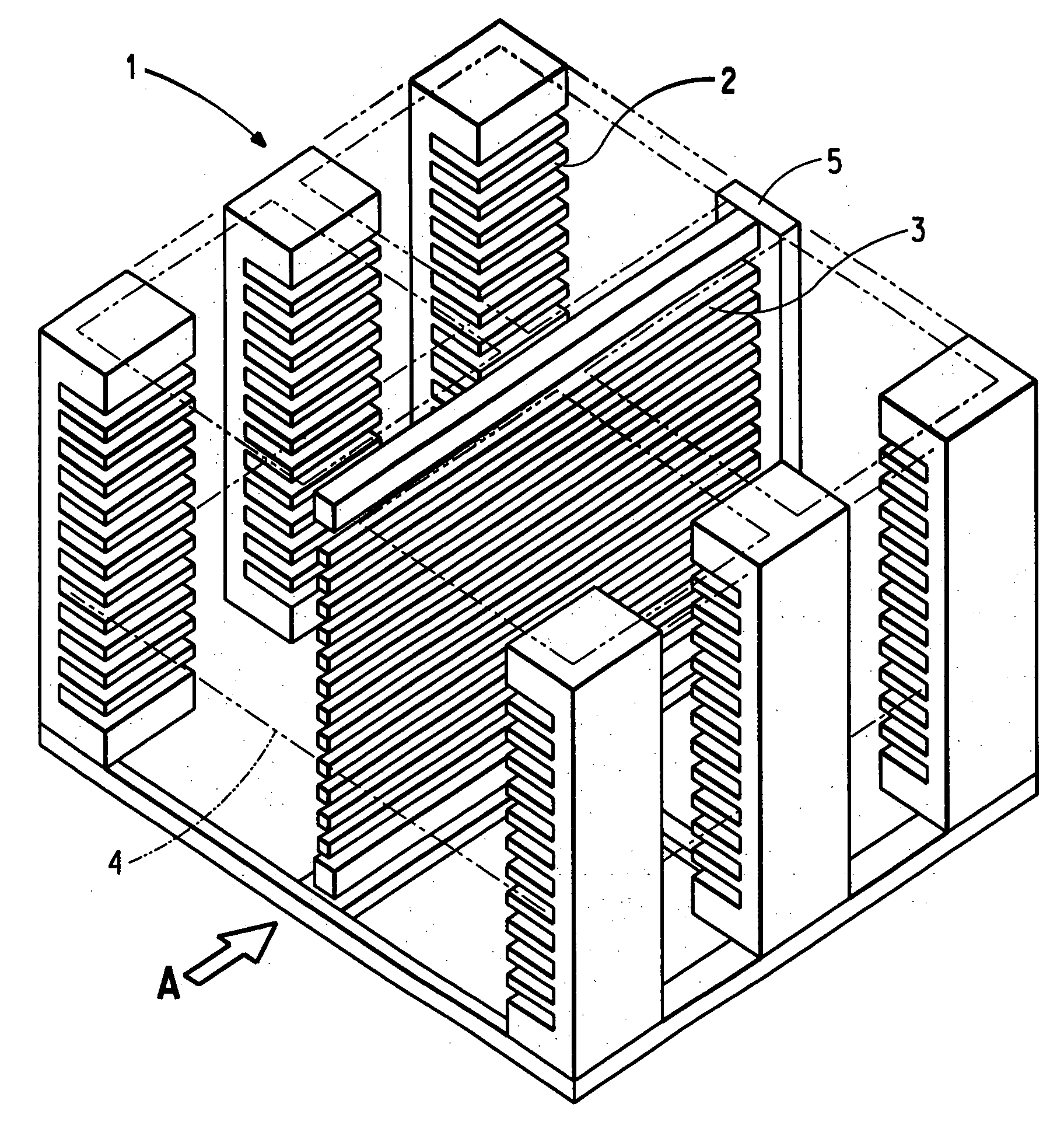

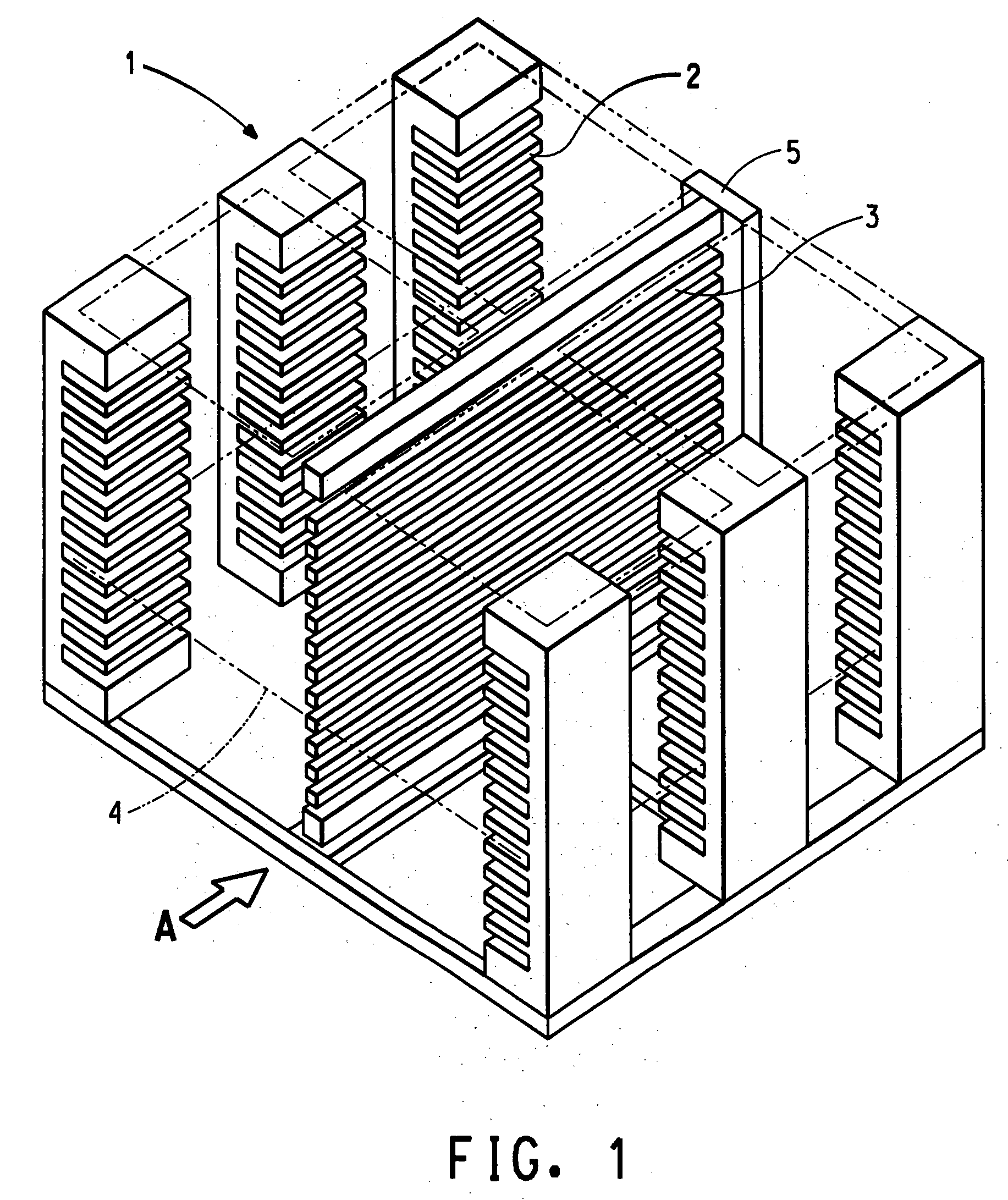

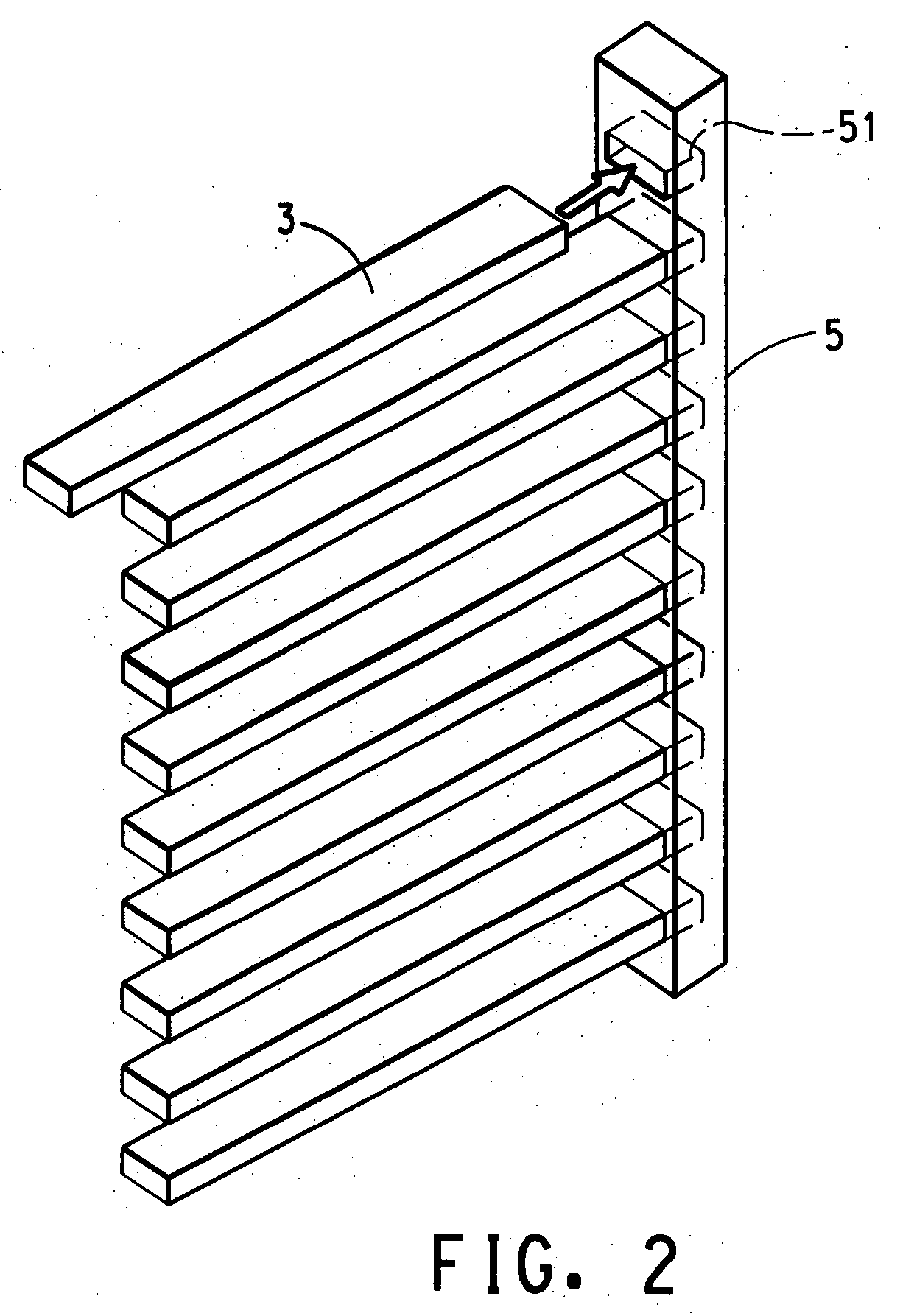

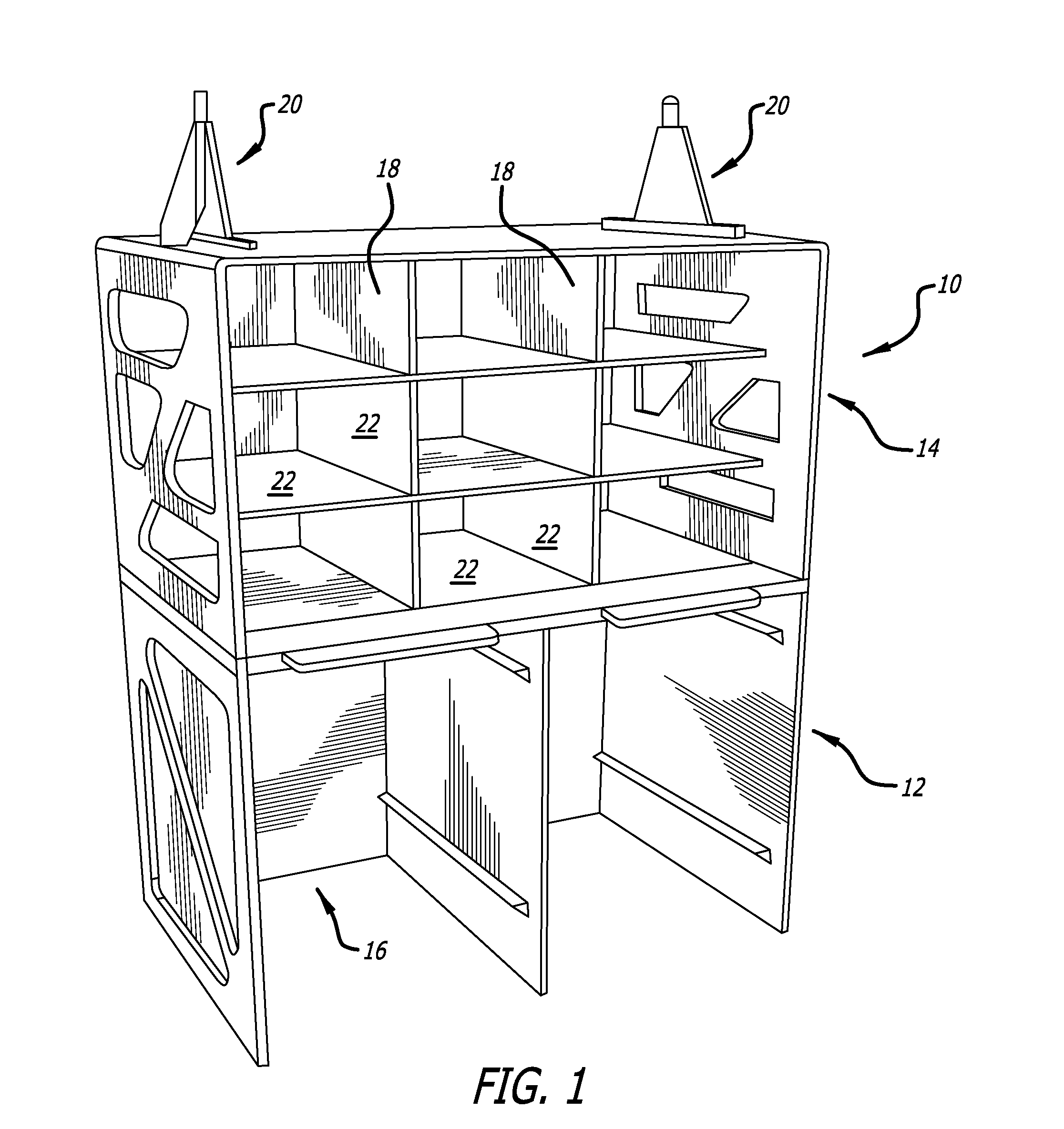

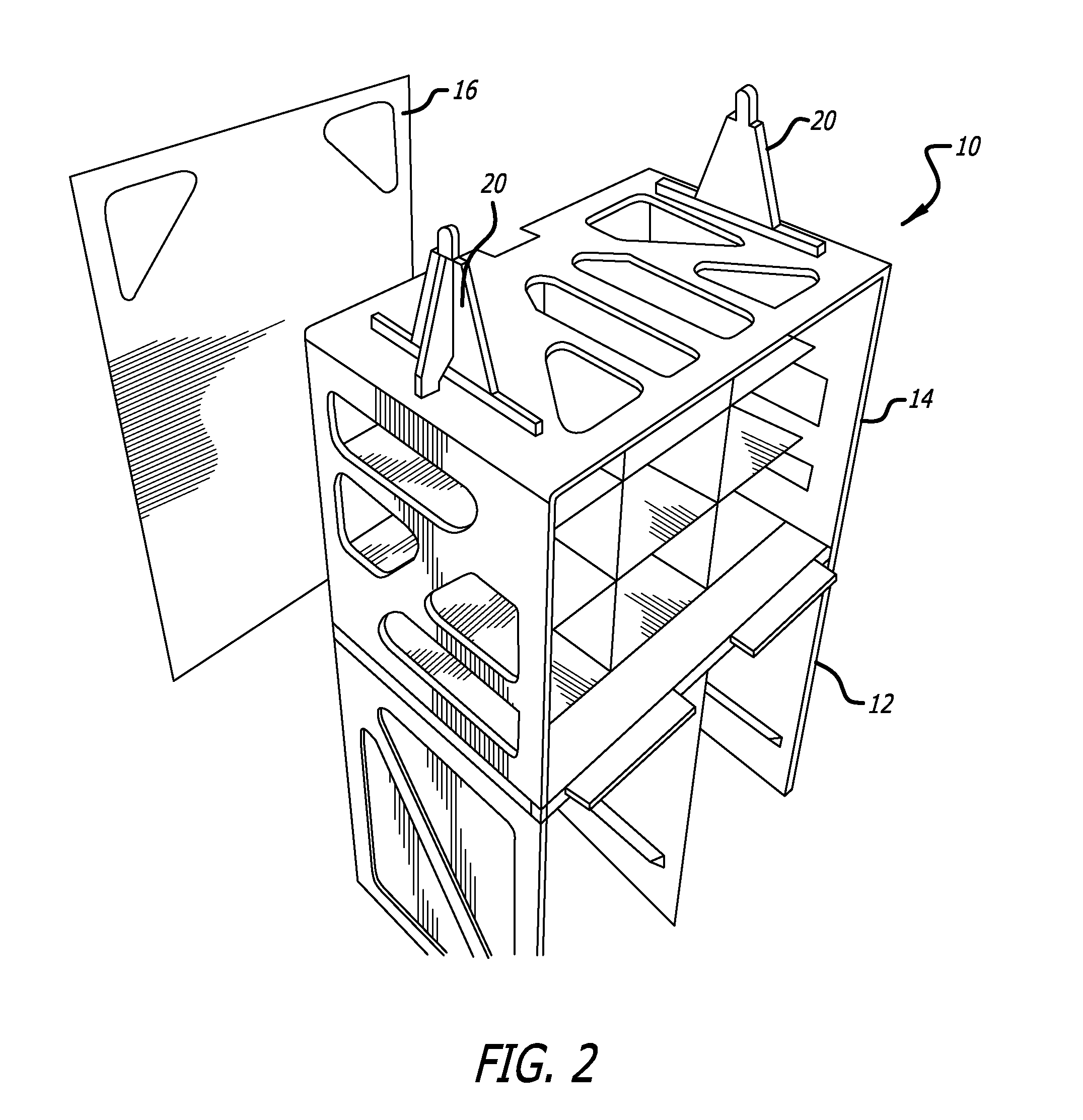

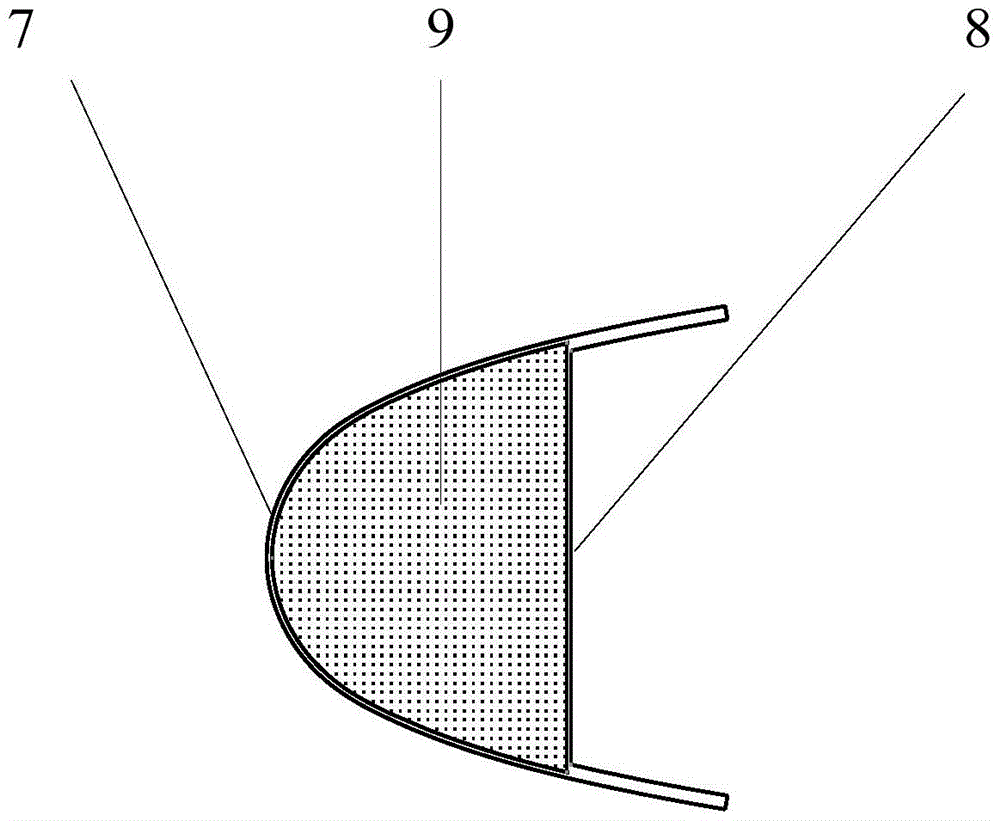

Supporting bar for substrate cassette

InactiveUS20060011507A1Semiconductor/solid-state device manufacturingOther accessoriesFiberCarbon fiber reinforced composite

A plate cassette support bar that suppresses the increase in weight of the plate or substrate cassette that increases in size and lessens substrate or plate cassette vibration at the time of loading / unloading the substrates or plates to improve workability. The substrate or plate cassette has the end support parts that support the ends of the substrates or plates stored on both the right and left side of the substrate loading opening and the support bars that are fixed at the opposite side of the substrate loading opening, that have free ends on the substrate loading opening side, that are allotted in one line or multiple lines in the vertical direction, and that support the substrates to be stored between the above-mentioned end support parts of the cassette, and which stores multiple substrates horizontally in multiple levels in the vertical direction, the above-mentioned support bars are formed by the carbon fiber reinforced composite material containing 30% or more of highly elastic carbon fibers having a tensile modulus of 490-950 GPa, and are formed preferably into the shape of a hollow pipe, or more preferably into the shape of a taper that the tip part side becomes narrower.

Owner:EI DU PONT DE NEMOURS & CO +1

Carbon fiber reinforced composite material and preparation technology thereof

The invention provides a carbon fiber reinforced composite material and a preparation technology thereof. Carbon fiber braided fabric is pretreated in a composite pretreatment solution with the concentration of 50 to 60 percent, wherein the composite pretreatment solution comprises 5 to 20 percent of oxydol and one or more of the following components: 50 to 70 percent of nitric acid, 30 to 50 percent sodium nitrate, ferric chloride, potassium permanganate, and acidic potassium dichromate; the carbon fiber braided fabric is pre-tightened in a adjustable and controllable stretching mechanism byadopting a compression moulding forming method, and then is fixed on a mould through a positioning device and coated with thermosetting resin powder with a required thickness; according to the performance indexes of the carbon fiber reinforced composite material to be manufactured, the carbon fiber braided fabric and the thermosetting resin powder with the required thickness are laid in a matrix position in the mould lay by lay until to designed layer number and thickness are achieved; and then heating and compression molding are carried. Through the surface treatment to the carbon fiber withthe specially prepared composite solution, the compatibility of carbon fiber and thermoset material is greatly improved, and the adhesion property of the carbon fiber and matrix resin is improved. Through the adoption of compression moulding forming, the forming technology is simple, the production is flexible, the production cycle is short, the equipment investment is small, and the cost is low.

Owner:DANYANG DANJIN AVIATION MATERIAL TECH

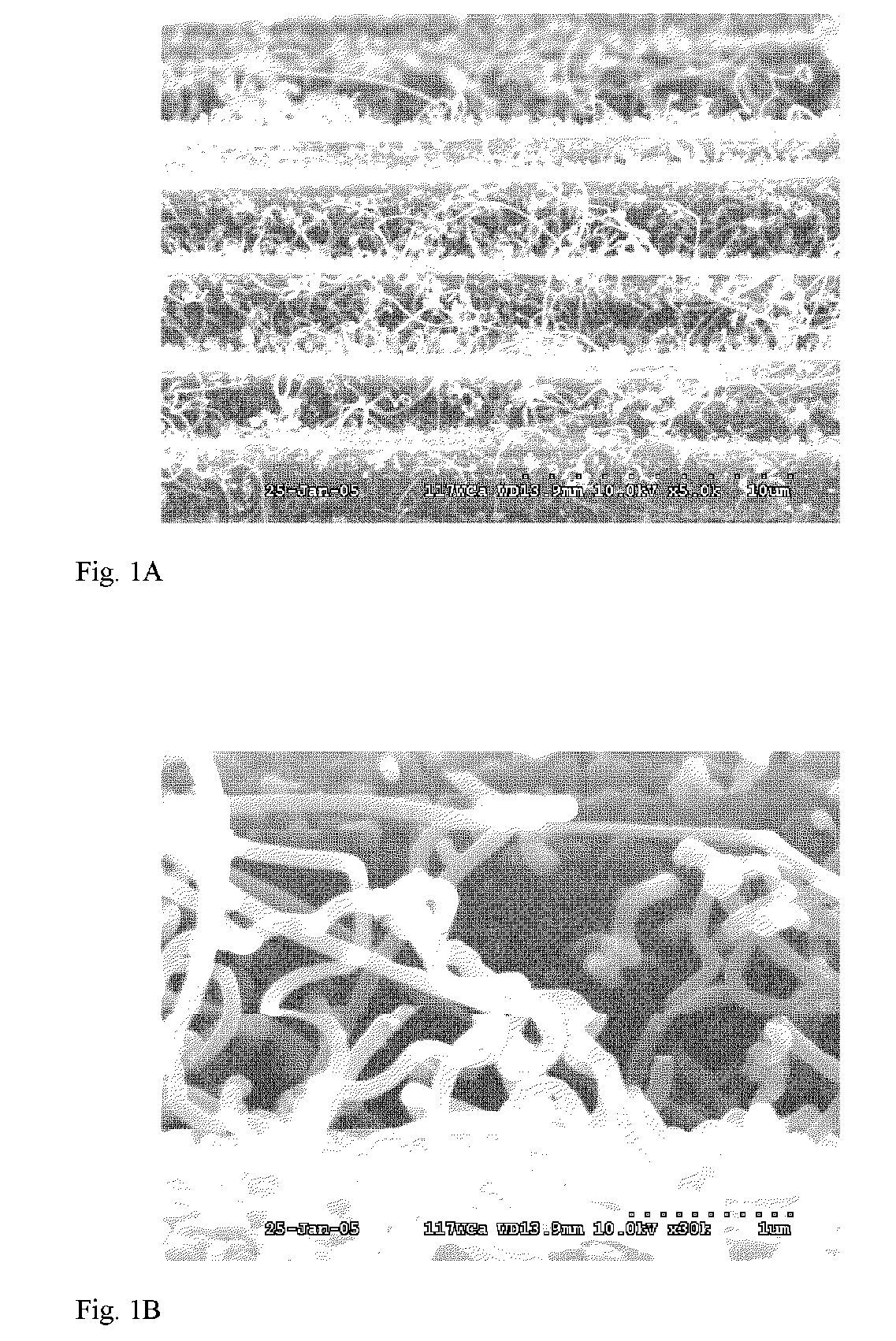

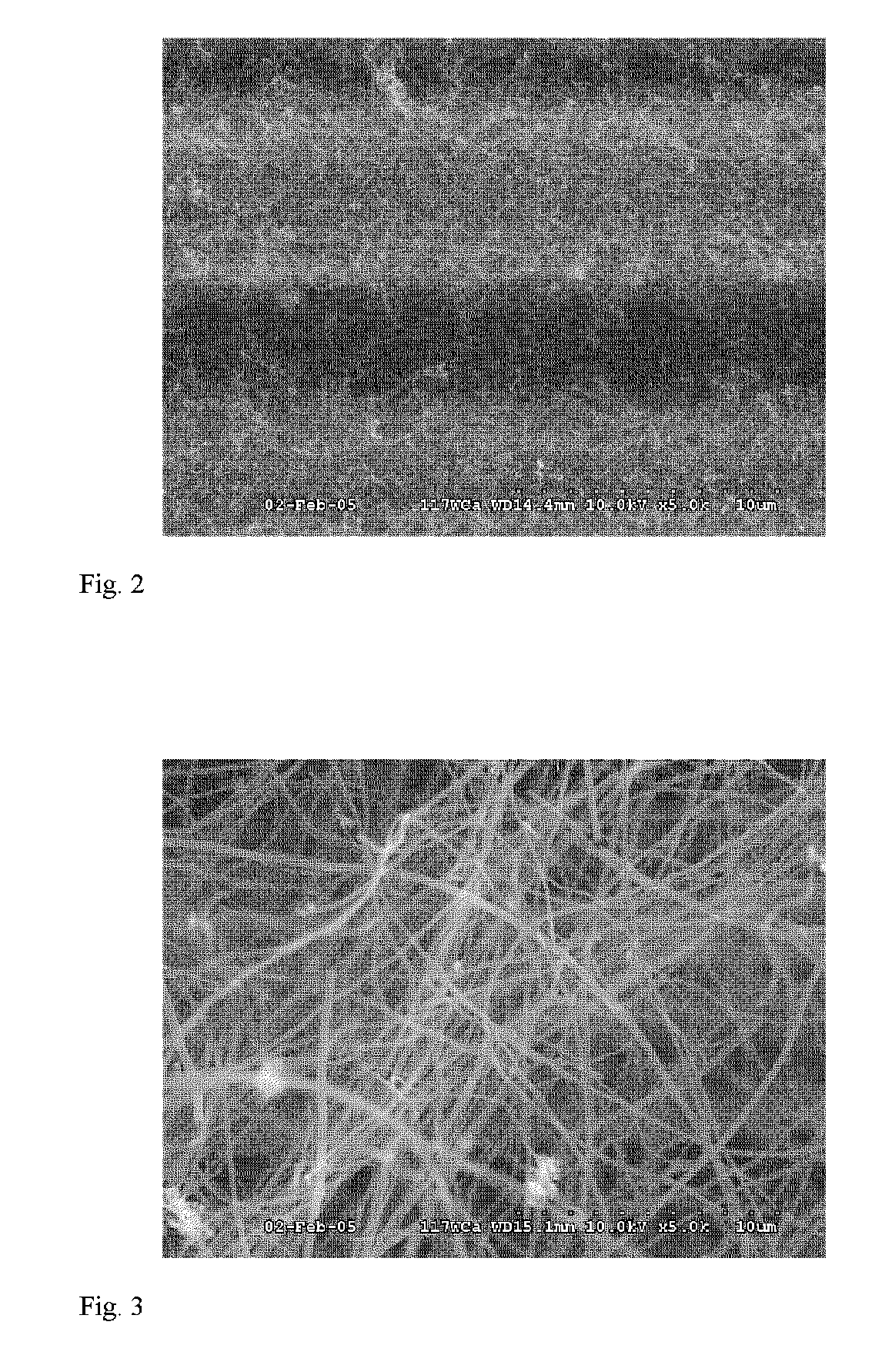

Vapor grown carbon fiber reinforced composite materials and methods of making and using same

InactiveUS20080182108A1Low levelLow yieldMaterial nanotechnologyLiquid surface applicatorsFiberGas phase

This invention provides vapor grown carbon fiber (VGCF) reinforced continuous fiber performs for the manufacture of articles with useful mechanical, electrical, and thermal characteristics. Continuous fiber preforms are treated with a catalyst or catalyst precursor and processed to yield VGCF produced in situ resulting in a highly entangled mass of VGCF infused with the continuous fiber preform. The resulting continuous fiber preforms are high in volume fraction of VGCF and exhibit high surface area useful for many applications. Furthermore, this invention provides for a continuous fiber preform infused with VGCF so that the carbon nanofibers are always contained within the fiber preform. This eliminates the processing steps for isolated carbon nanofibers reported in other carbon nanofiber composite approaches and therefore greatly reduces risk of environmental release and exposure to carbon nanofibers.

Owner:PERFORMANCE POLYMER SOLUTIONS

YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and preparation method thereof

The invention relates to a YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and a preparation method thereof. The matrix resin is composed of YASI, an epoxy resin, 3-aminopropyl trialkoxysilane, an imide oligomer and a curing agent. The preparation method comprises the following steps: (1) preparing the imide oligomer; and (2) adding the YASI and epoxy resin into a reaction kettle, stirring and mixing to react, adding the imide oligomer, continuing stirring to react, adding the 3-aminopropyl trialkoxysilane, stirring to react, adding the curing agent, and uniformly stirring and mixing. The resin can be widely used for bonding metals (such as steel, copper, aluminum and the like) and substrates (ceramic, glass, resin-base composite materials and the like), and preparing glass fibers, aramid fibers and carbon-fiber-reinforced polymer composite materials, and thus, has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

Prepreg and carbon fiber reinforced composite materials

ActiveUS7931958B2Improve conductivityIncrease resistanceCarbon fibresSynthetic resin layered productsFiberCarbon fiber reinforced composite

A prepreg containing a carbon fiber [A] and a thermosetting resin [B], and in addition, satisfying at least one of the following (1) and (2).(1) a thermoplastic resin particle or fiber [C] and a conductive particle or fiber [D] are contained, and weight ratio expressed by [compounding amount of [C] (parts by weight)] / [compounding amount of [D] (parts by weight)] is 1 to 1000.(2) a conductive particle or fiber of which thermoplastic resin nucleus or core is coated with a conductive substance [E] is contained.

Owner:TORAY IND INC

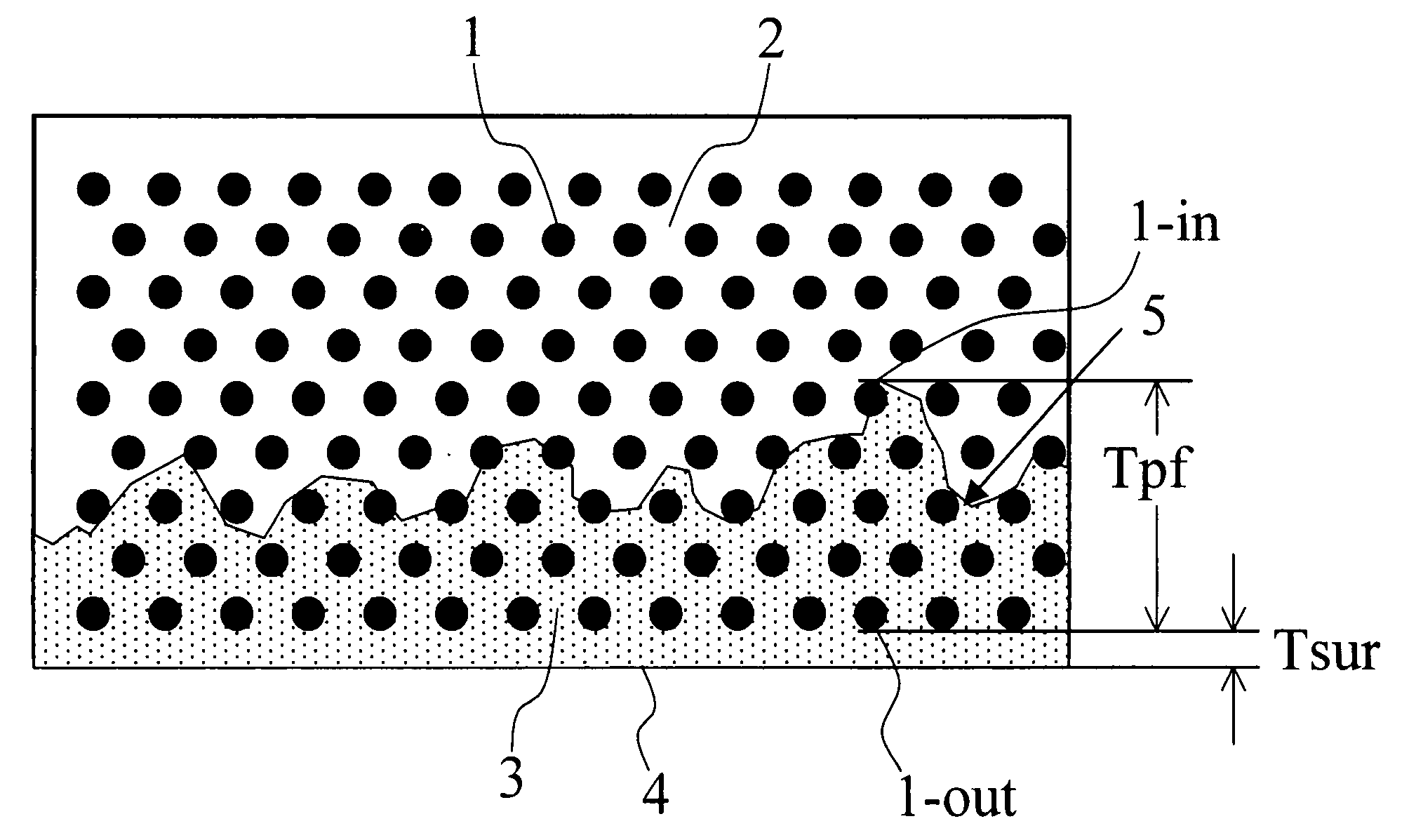

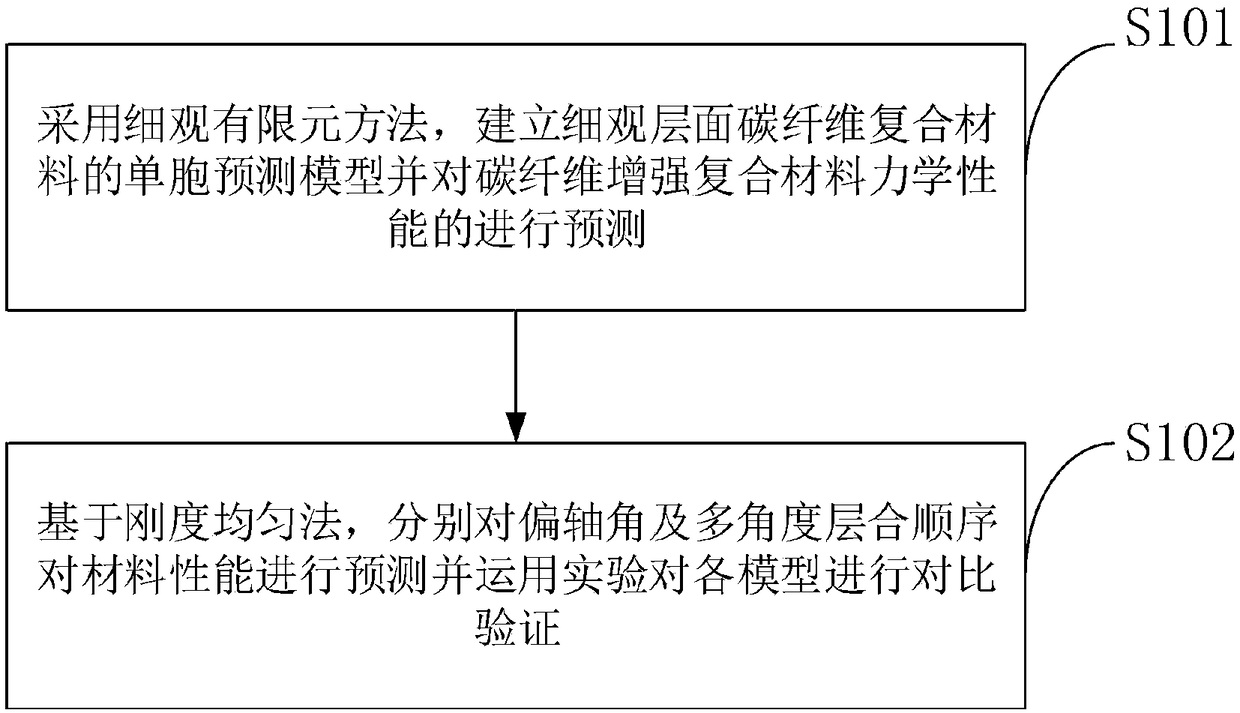

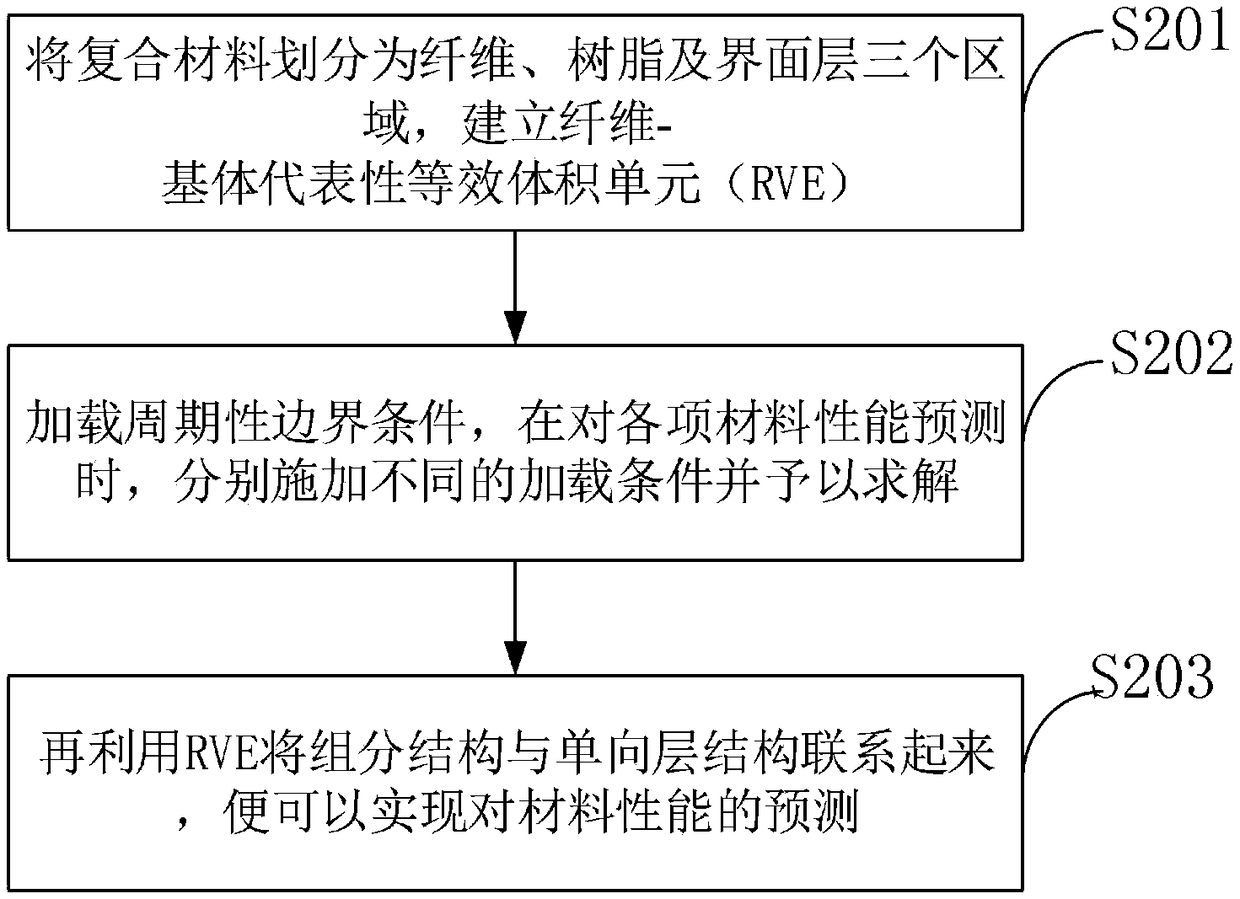

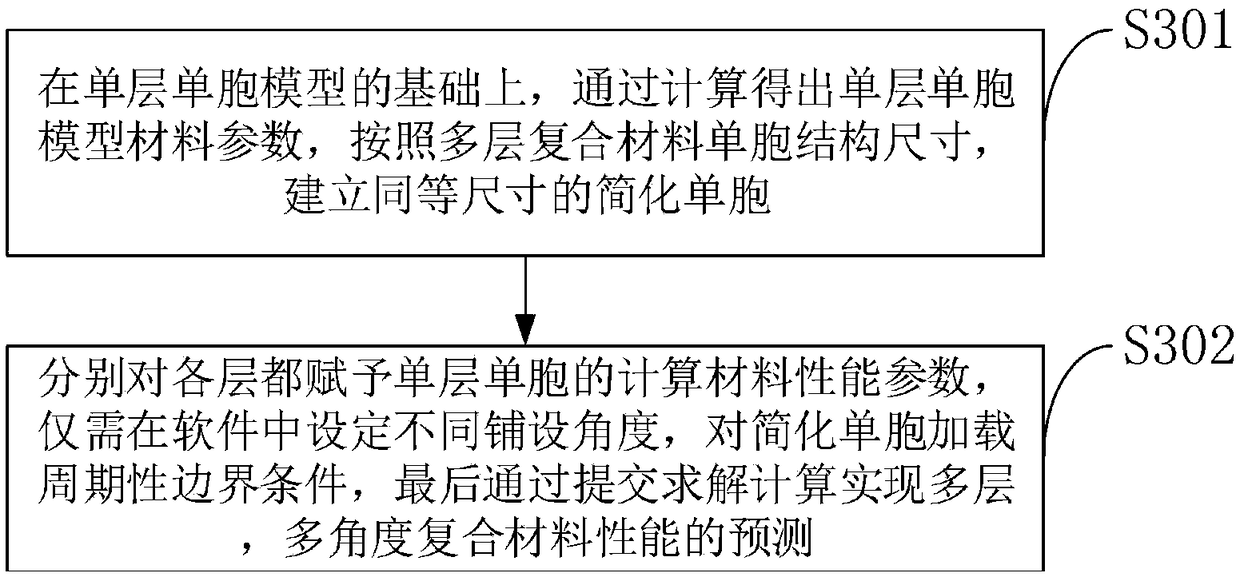

Carbon fiber reinforced composite material mechanical performance prediction method based on cross-scale simulation

ActiveCN109241650AImprove mechanical propertiesSustainable transportationDesign optimisation/simulationPredictive methodsFinite element method

The invention belongs to the technical field of composite material prediction, and discloses a carbon fiber reinforced composite material mechanical performance prediction method based on cross-scalesimulation. The prediction method comprises the following steps: adopting a meso-finite element method, establishing a single cell prediction model of a meso-level carbon fiber composite material andpredicting the mechanical performance of the carbon fiber reinforced composite material; Based on the stiffness homogeneity method, predicting the off-axis angle and multi-angle lamination sequence and verifying the models by experiments. The invention provides a method for predicting the mechanical properties of the composite material, and the experimental results are consistent with the theoretical model.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

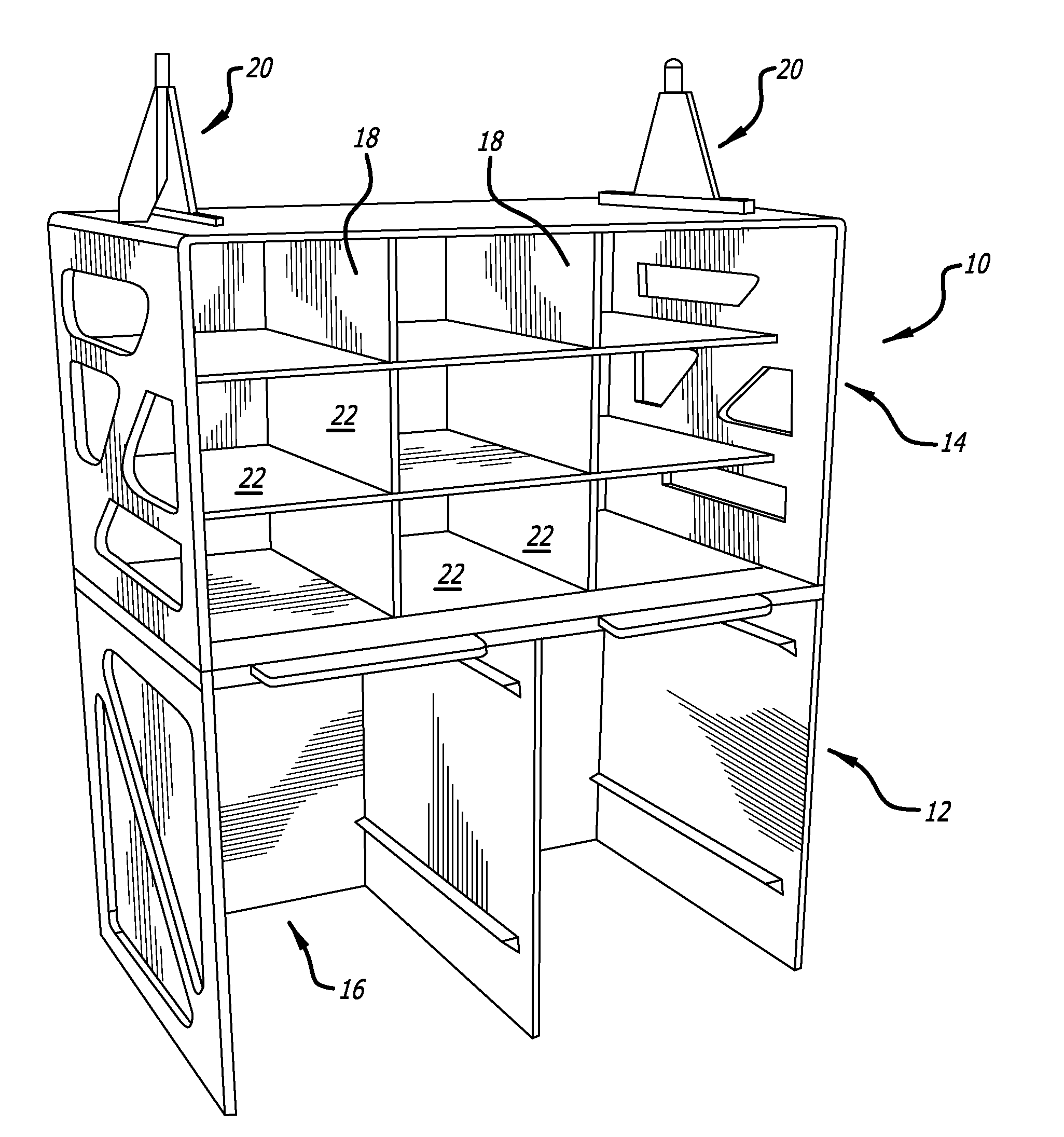

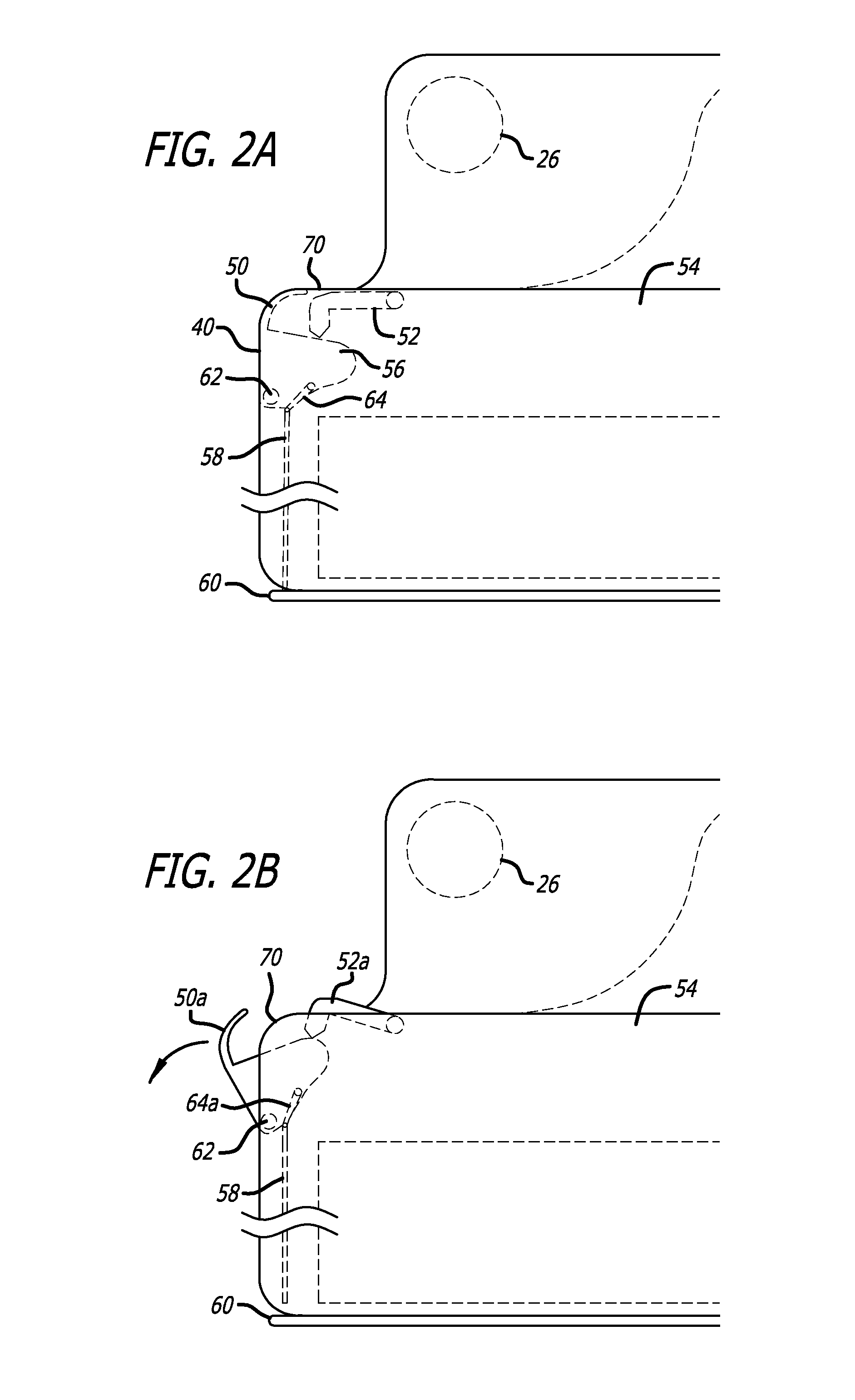

Aircraft galley monument structure

ActiveUS20130256249A1Reduced activityMeet cutting requirementsGalleysWeight reductionFiberManufacturing technology

An improved monument structure combining an integrated construction system with carbon fiber reinforced composites to form an exoskeleton chassis that significantly reduces the build times, manufacturing skill level requirements, post processing activities, and overall weight of a given aircraft monument.

Owner:BE AEROSPACE INCORPORATED

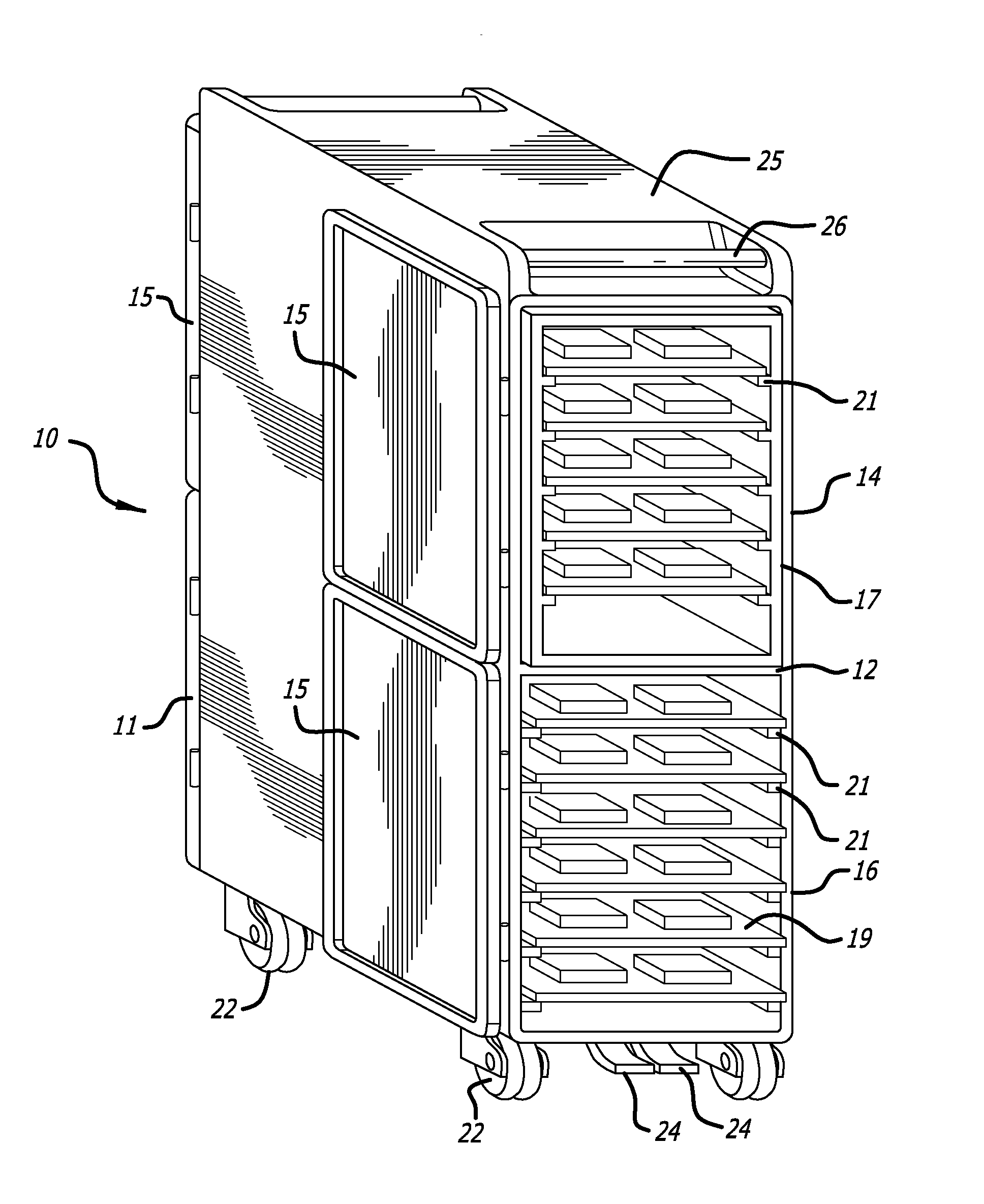

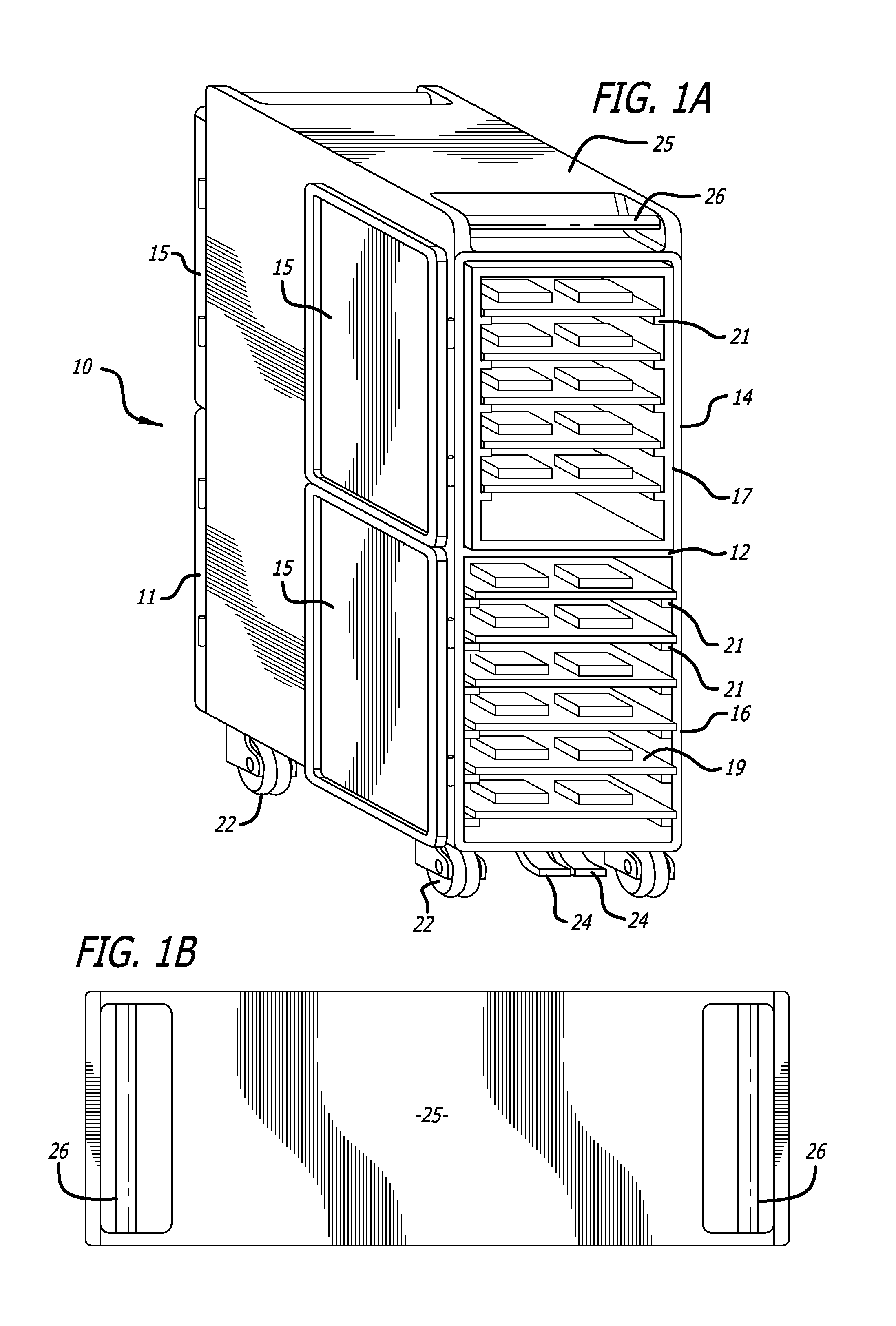

Meal cart for an aircraft galley

ActiveUS20140021690A1Function increasePrevent lateral movementSledgesWeight reductionFiberJet aeroplane

A service cart for an aircraft is disclosed with a housing of carbon fiber reinforced composites forming a multi-compartment carrier, the carrier adapted to hold four standard airline meal carriers. The cart includes at least a pair of cap doors at opposite ends of the cart, each cap door pivoting approximately 270 degrees to bear against a side of the cart, and a plurality of guides on inner walls of the multi-compartment for retaining the standard airline meal carriers. To prevent the doors of the cart from inadvertently opening, the cart also may include a redundant paddle latch system for each door.

Owner:BE AEROSPACE INCORPORATED

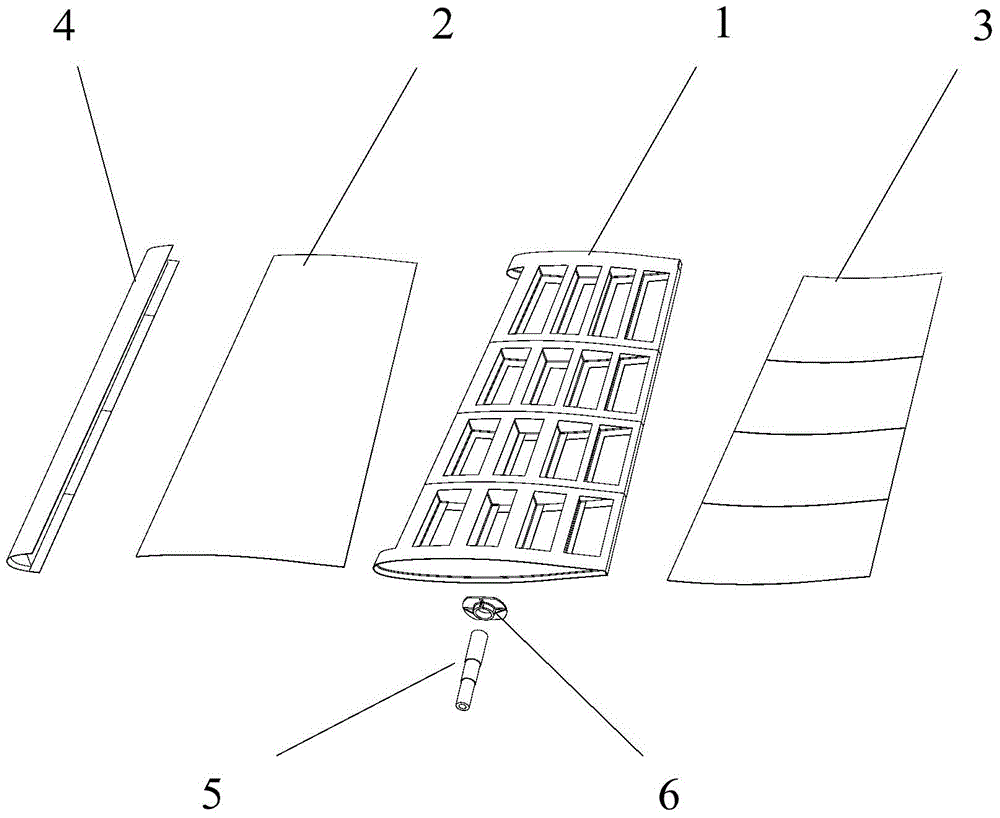

Composite material integrated control surface structure with progressive decrease in rigidity and processing method thereof

ActiveCN105035359AExcellent chatter characteristicsReduce structural weightCosmonautic vehiclesCosmonautic partsFiberEngineering

The invention discloses a composite material integrated control surface structure with progressive decrease in rigidity and a processing method thereof, wherein a design solution of a carbon fiber composite material integrated control surface structure is adopted; besides a control shaft and accessories thereof, the rest of the structure is carbon fiber reinforcedcomposite material; advanced optimization design technology is adopted; through several iterative calculations, the structure size design is optimized; the weight of the control surfacestructure is lightest; the rigidity of the optimized control surface structure is on the decrease progressively along an axial direction, that is, the thickness size of an internal skeleton web is on the decrease progressively towardswing tips and two sides; and the skin thickness is not the same and is on the decrease progressively towards the wing tips, thus the structure weight is further reduced; the control surface modal frequency is increased; and the control surface vibration property is improved.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

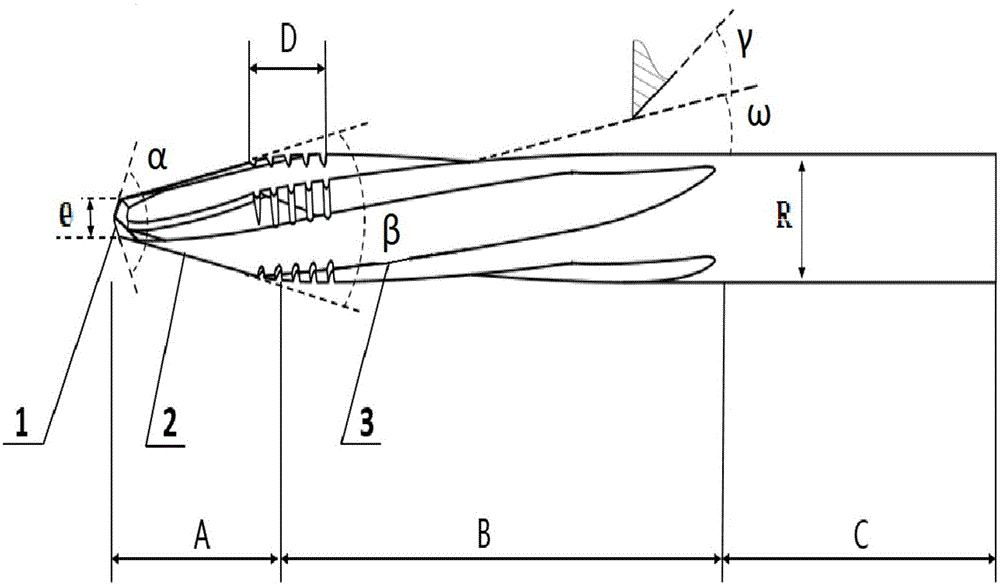

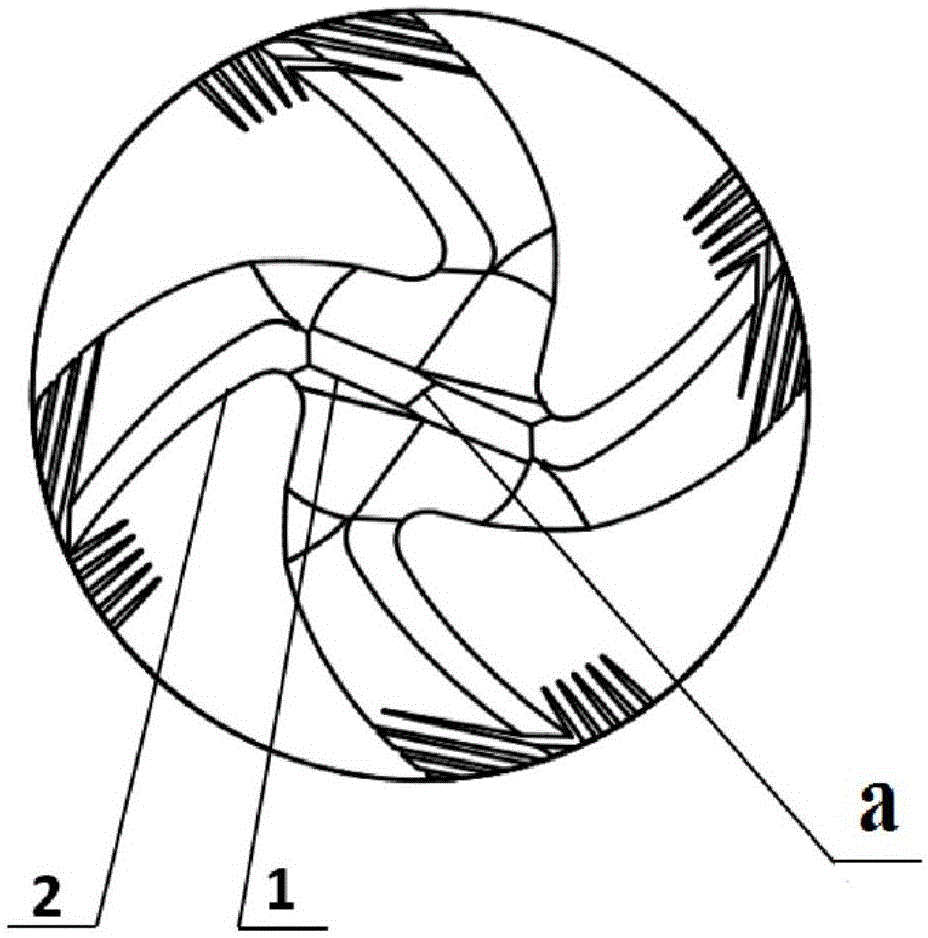

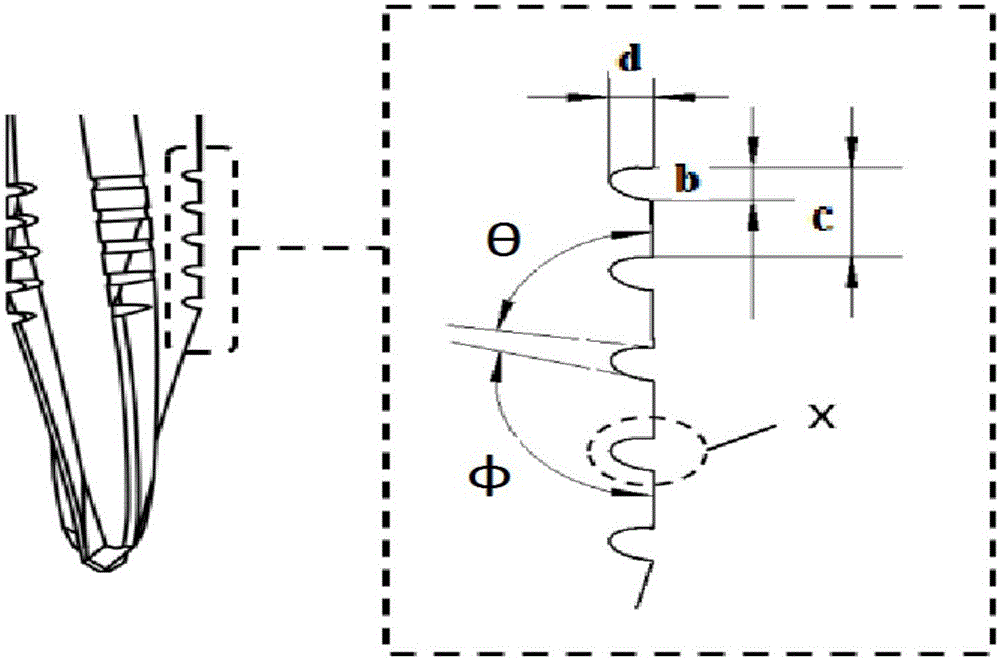

High-efficiency special drilling head for drilling holes in carbon fiber composite material

ActiveCN104999118AHigh dimensional accuracyReduce axial forceTransportation and packagingWorkpiecesCarbon fiber reinforced compositeIntegrated processing

The invention belongs to the technical field of drilling and cutting tools in mechanical processing, and relates to a high-efficiency special drilling head for drilling holes in a carbon fiber composite material. A cutter is the multiple-cutting-edge cutter with double vertex angles and a micro tooth structure and particularly suitable for the one-time high-quality high-efficiency processing of the high-performance carbon fiber reinforced composite material. The drilling head consists of a main cutting region, an assistant cutting region and a cutter handle, wherein a micro tooth cutting region is arranged at a connecting position of the main cutting region and the assistant cutting region; the main cutting region consists of a first main cutting edge and a second main cutting edge; in the assistant cutting region, a left-hand thread is formed in an assistant cutting edge; the micro tooth cutting region consists of a plurality of micro teeth. According to the high-efficiency special drilling head disclosed by the invention, the double vertex angles and the micro tooth structure are utilized, so that a function of integrated processing of drilling-expanding-reaming is realized, the axial force of the drilling and the cutting is reduced, layered defects are overcome, the holes with high size accuracy are obtained, the service life of the drilling head is prolonged, the situation that the cutter is frequently replaced is avoided, and the processing efficiency is improved.

Owner:DALIAN UNIV OF TECH

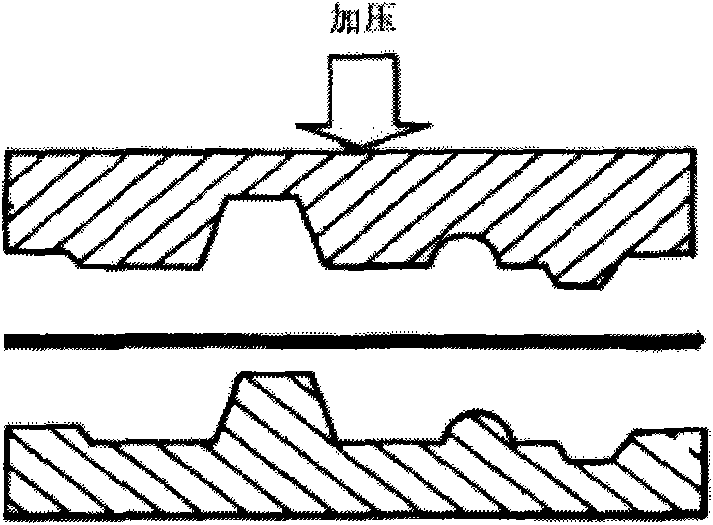

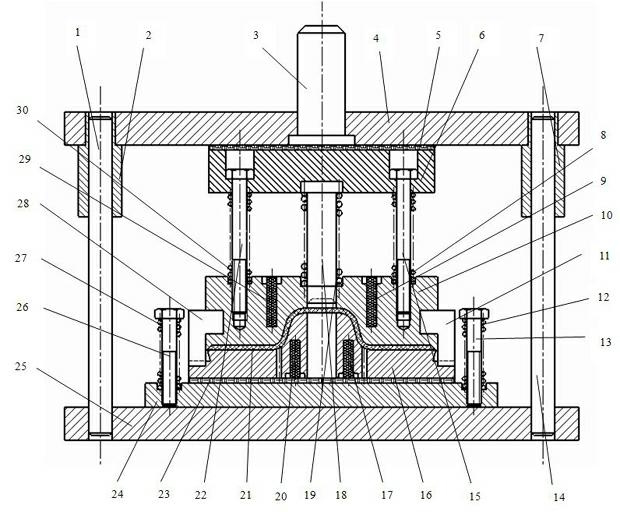

Device and method for manufacturing carbon fiber reinforced composite construction member

The invention discloses a device and method for manufacturing a carbon fiber reinforced composite construction member, belonging to the fields of composite molding and processing. In the invention, through wet-state blanking technologies such as trimming, punching, parting off and the like after resin penetration molding and before solidifying, an outer contour and an inner bore are processed while the carbon fiber reinforced composite construction member is molded; and therefore, the device and method for manufacturing the carbon fiber reinforced composite have the advantages of effectively reducing or avoiding the follow-up milling and drilling processing requirements on a carbon fiber reinforced composite workpiece which is difficult to process in the conventional molding process, improving the molding efficiency and the workpiece surface quality and reducing the device requirements and the manufacturing cost, and is particularly suitable for the manufacturing of large size carbon fiber reinforced composite construction members.

Owner:JIANGSU UNIV

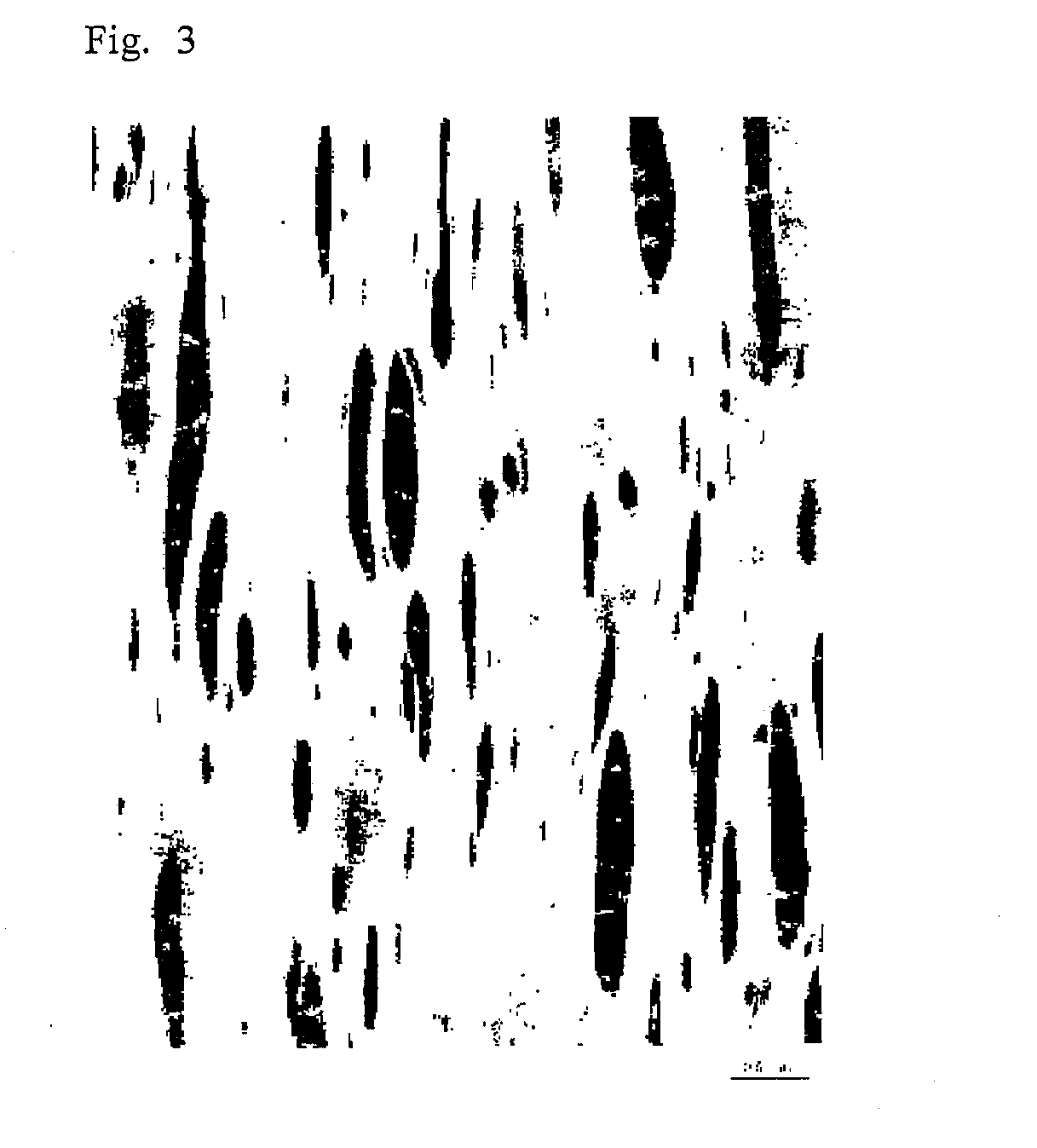

Carbon fiber reinforced composite materials

InactiveUS20120295504A1Improve interface adhesionImprove mechanical propertiesSynthetic resin layered productsLaminationMolten statePolymer science

The invention provides a carbon fiber-reinforced composite material including reinforcing fibers which are continuous carbon fibers in the form of a unidirectional (UD) material, a woven fabric, or a knitted fabric, and a matrix resin including a modified polyolefin resin, thereby achieving better adhesion and mechanical strength. The matrix resin forms a polyphase structure having a sea-island structure which has an average island (independent phase) diameter of not greater than 0.5 μm. The composite material includes as a matrix resin a modified polyolefin resin obtained by, for example, graft-modifying a polyolefin resin with a monomer that contains an ethylenic double bond and a polar group in the same molecule; and includes as reinforcing fibers continuous carbon fibers. For example, the fiber-reinforced composite material is obtained by stacking the modified polyolefin resin and carbon fibers in a mold with a predetermined shape, and impregnating the carbon fibers with the modified polyolefin resin in a molten state under pressure, followed by cooling and curing.

Owner:KANEKA CORP

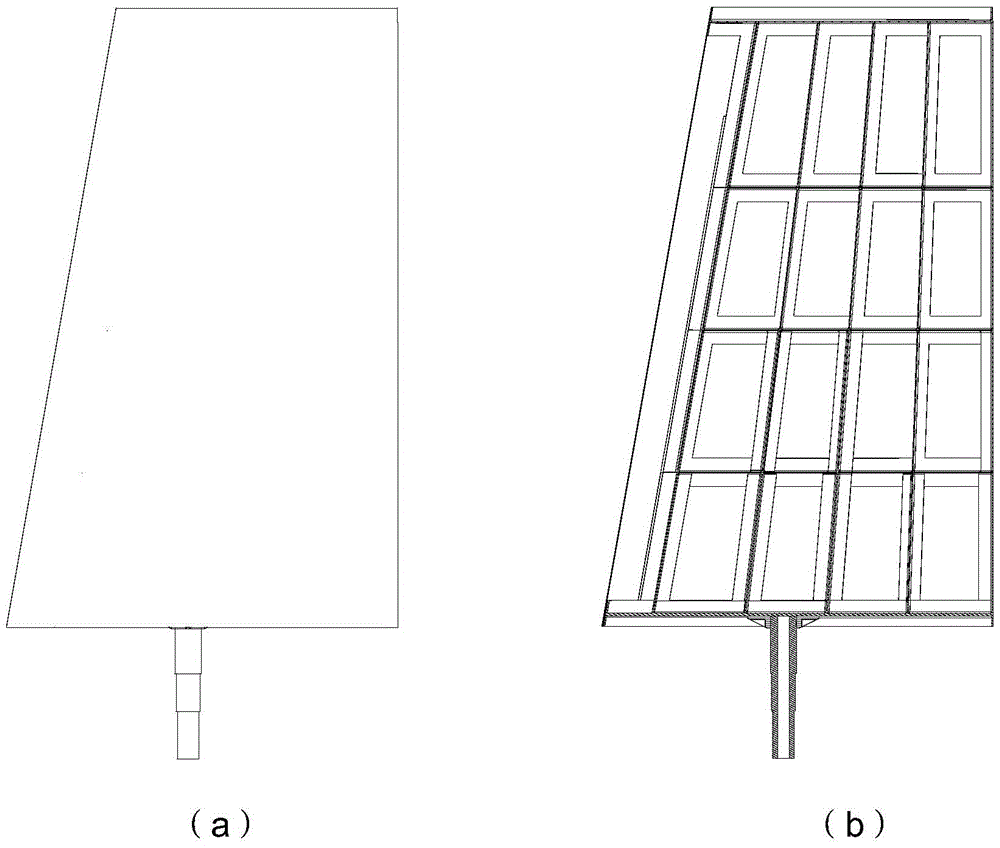

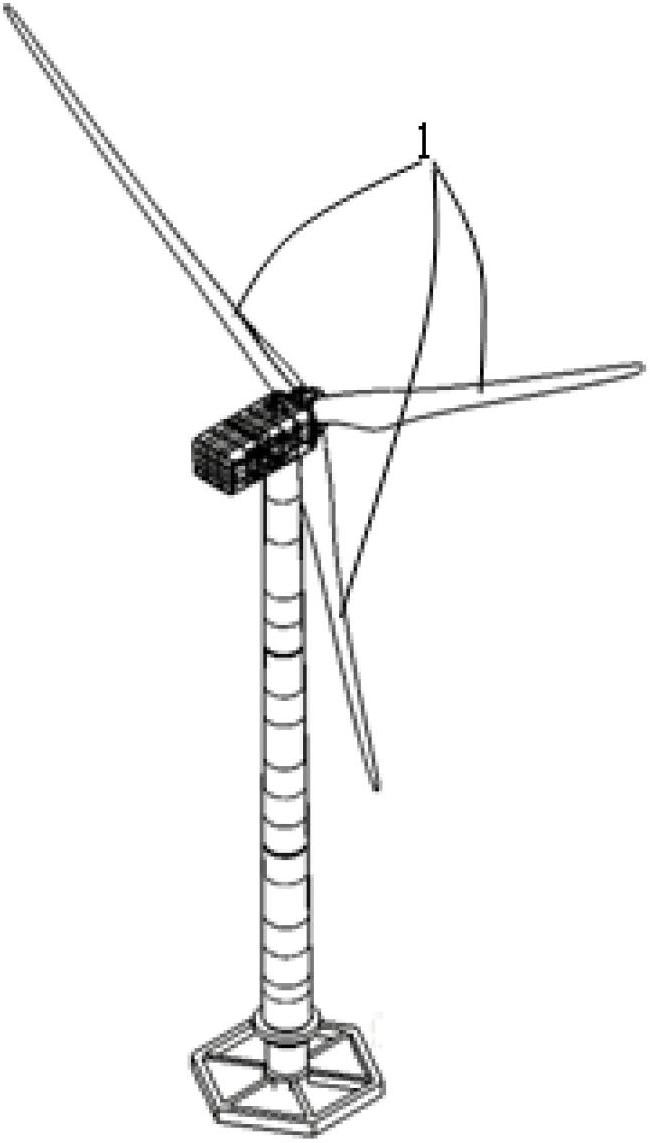

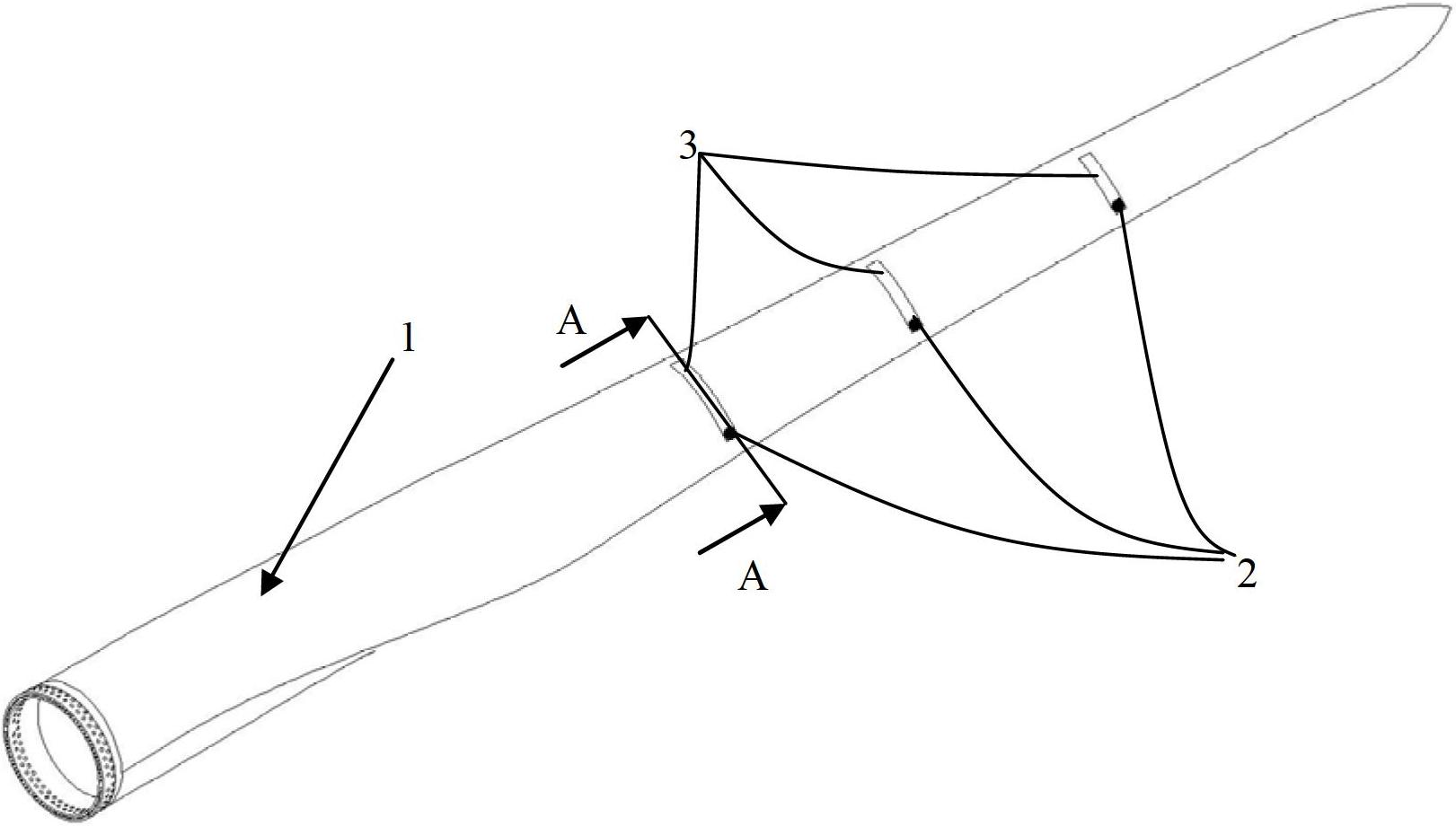

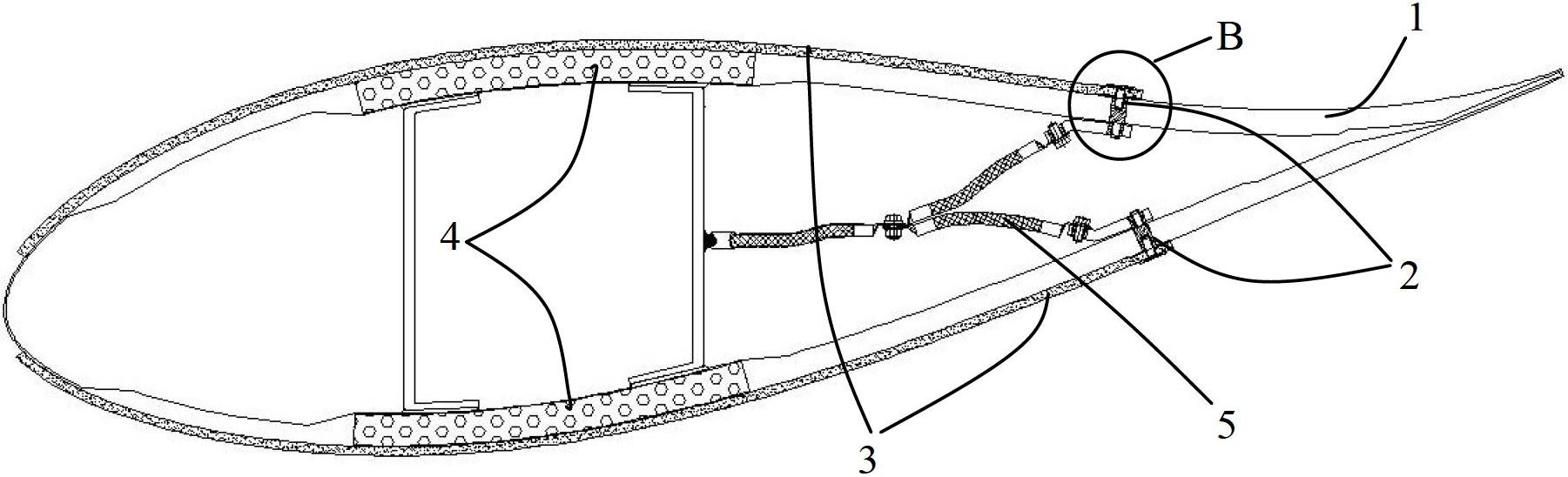

Wind wheel vane anti-lightning device for wind generating set and mounting method thereof

InactiveCN102661240AIncrease the size of the protected areaGood lightning effectInstallation of lighting conductorsMachines/enginesAgricultural engineeringCarbon fiber reinforced composite

The invention discloses a wind wheel vane anti-lightning device for a wind generating set and a mounting method of the anti-lightning device. A main beam of the wind wheel vane adopts carbon fiber reinforced composite material, an air-termination system is embedded in a wind wheel vane casing of the non-main-beam area, and the air-termination system is grounded through a conducting wire in a wind wheel vane inner cavity; a conductive shunting strip is fixed on the outer surface of the wind wheel vane and is connected with the air-termination system by a nut. According to the wind wheel vane anti-lightning device, the conductive shunting strip is arranged on the outer surface of the wind wheel vane, the area of the protection zone of the wind wheel vane anti-lightning device can be improved, the air termination effect is good, and the wind wheel vane anti-lightning device is applicable to the wind generating set of which the main beam of the wind wheel vane is made of the carbon fiber reinforced composite material.

Owner:GUODIAN UNITED POWER TECH

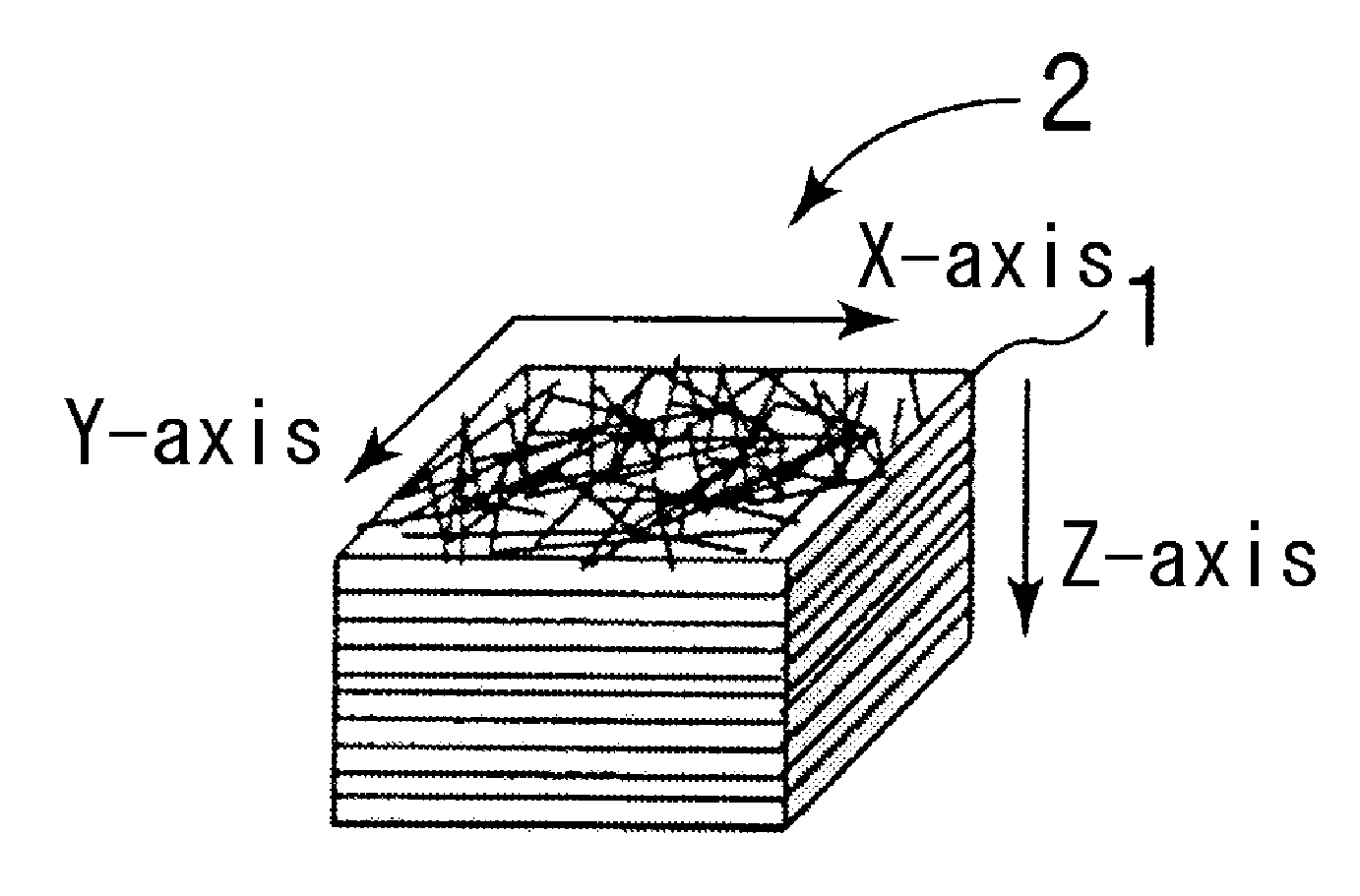

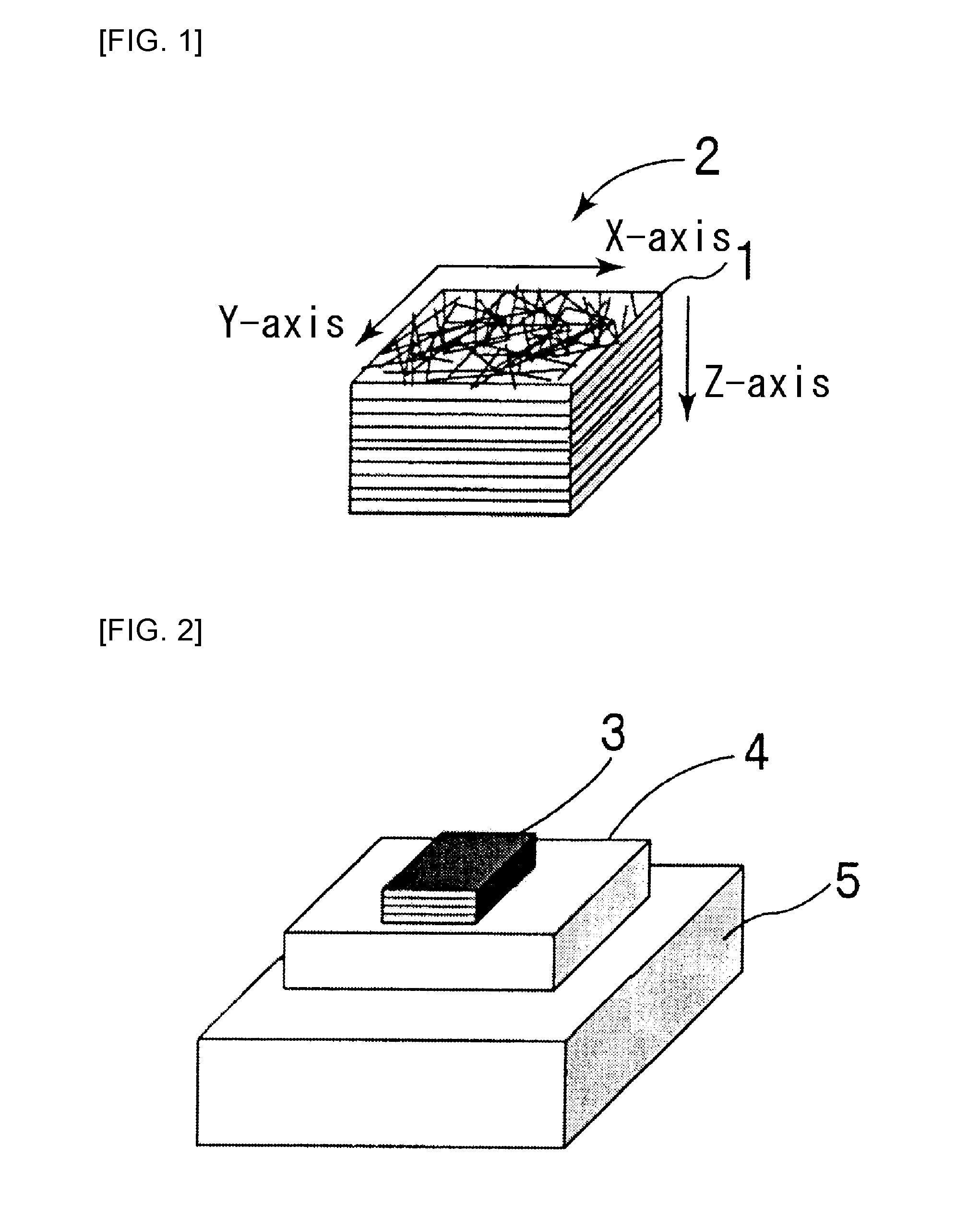

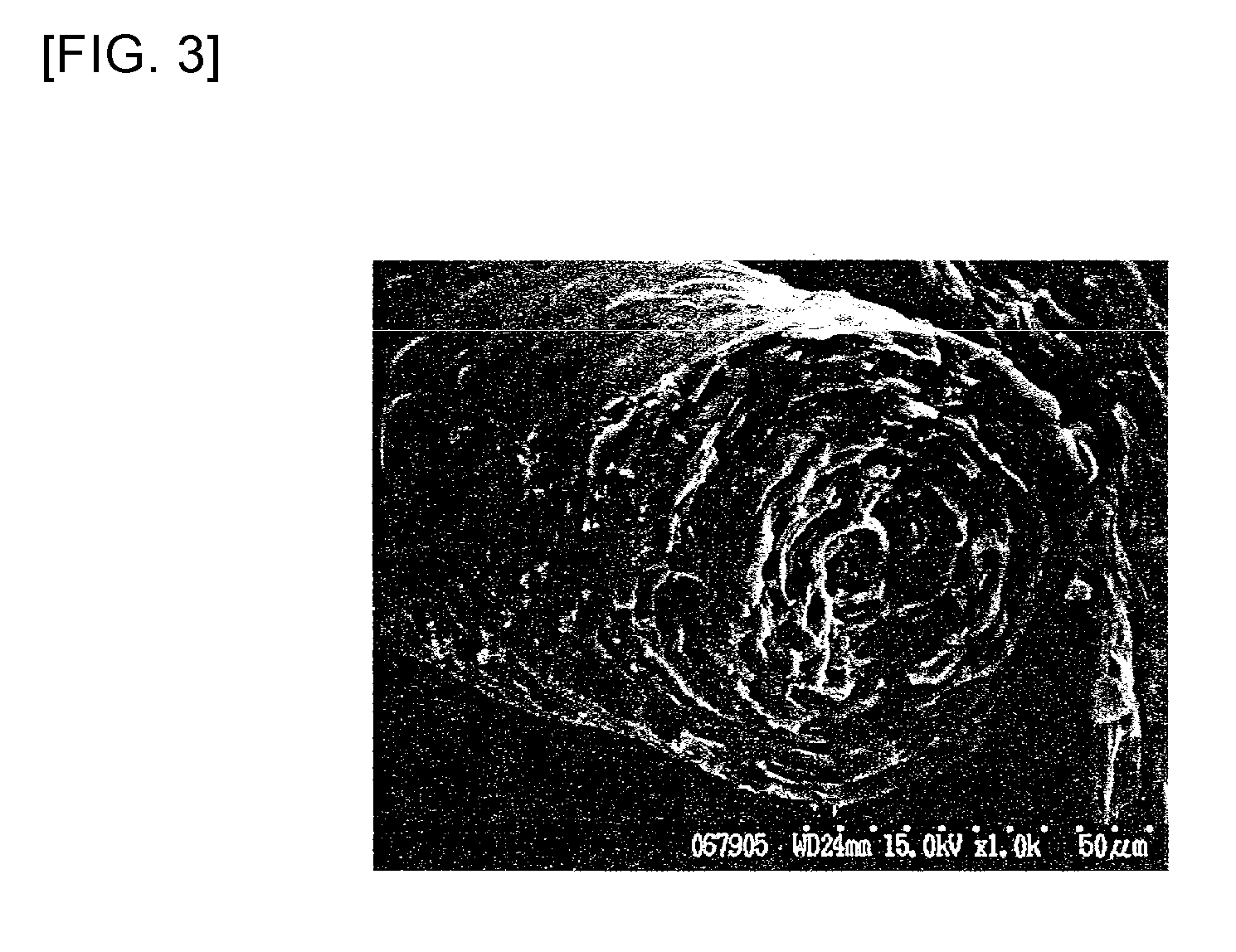

Carbon fiber carbon composite molded body, carbon fiber-reinforced carbon composite material and manufacturing method thereof

InactiveUS20110030940A1Improve thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesCarbon compositesPyrolytic carbon

To obtain a carbon fiber-reinforced carbon composite material exhibiting excellent thermal conductivity in every direction in the plane containing the X and Y axes. A carbon fiber-carbon composite formed body in which a number of sheet-like dispersions containing pitch-based carbon fibers dispersed therein randomly in the plane containing the X and Y axes are laminated into a carbon fiber laminate, and pyrolytic carbon is deposited on the surfaces of the carbon fibers of the carbon fiber laminate to coat around the carbon fibers, whereby the carbon fiber laminate is filled with the pyrolytic carbon, and a carbon fiber-reinforced carbon composite material obtained using the carbon fiber-carbon composite formed body.

Owner:TOYO TANSO KK

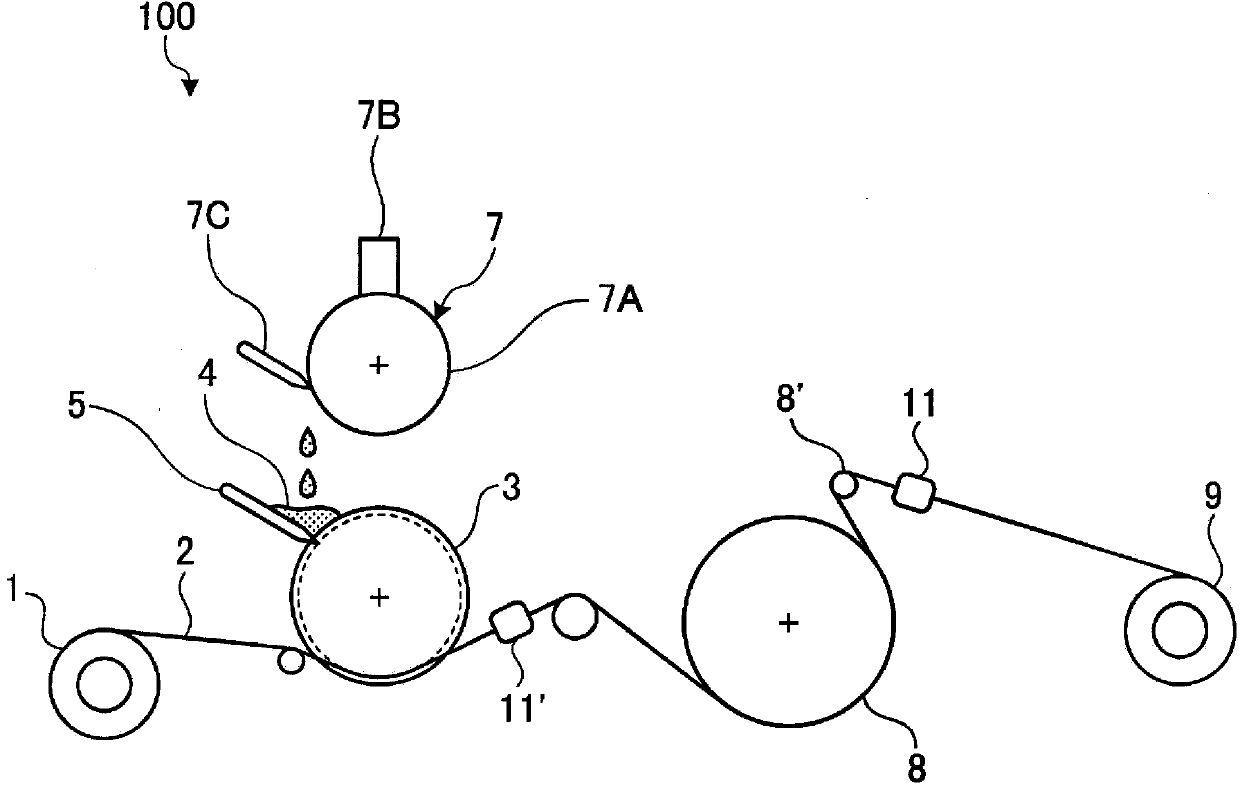

Carbon fiber molding material, molding material, and carbon fiber-strengthening composite material

InactiveCN103975003AGood adhesionCovalent bond formation promotionFibre typesWoven fabricsFiberPolymer science

A carbon fiber molding material is provided that exhibits excellent interfacial adhesion between the carbon fibers and a thermosetting resin, and that yields a molded product exhibiting excellent mechanical properties. The carbon fiber molding material is either (Z) a prepreg containing sizing agent-coated carbon fibers and a thermosetting resin, or (Y) a material for forming woven fabric or braided cords that employs sizing agent-coated carbon fibers. The sizing agent is characterized by containing the following components (A) and (B): component (A) is an epoxy compound having two or more epoxy groups, or two or more functional groups; component (B) is a compound containing one or more of the group consisting of a tertiary amine compound, a tertiary amine salt, a quaternary ammonium salt, a quaternary phosphonium salt, and a phosphine compound. The sizing agent is obtained by blending 0.1-25 parts by mass of the compound (B) with 100 parts by mass of the compound (A).

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com