Wind wheel vane anti-lightning device for wind generating set and mounting method thereof

A technology for wind turbines and wind rotor blades, which is applied to wind turbine components, wind engines, and wind engines in the same direction as the wind. Requirements and other issues to achieve good lightning effects and increase the area of the protected area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0031] The wind turbine blade lightning protection device of the wind power generating set of the present invention is mainly applicable to such as figure 1 The wind turbine blade 1 shown in the wind power generating set uses carbon fiber reinforced composite material as the main beam.

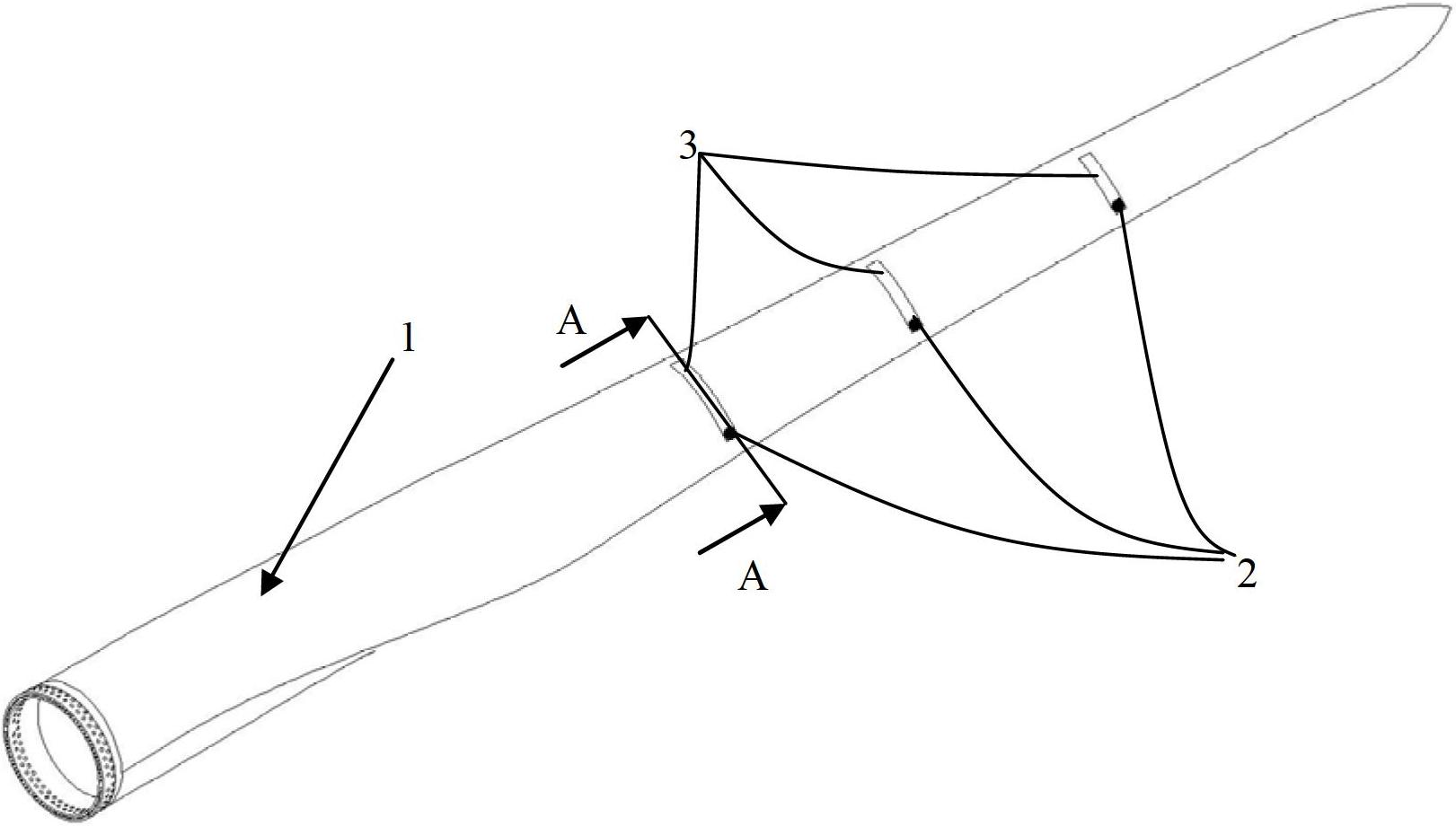

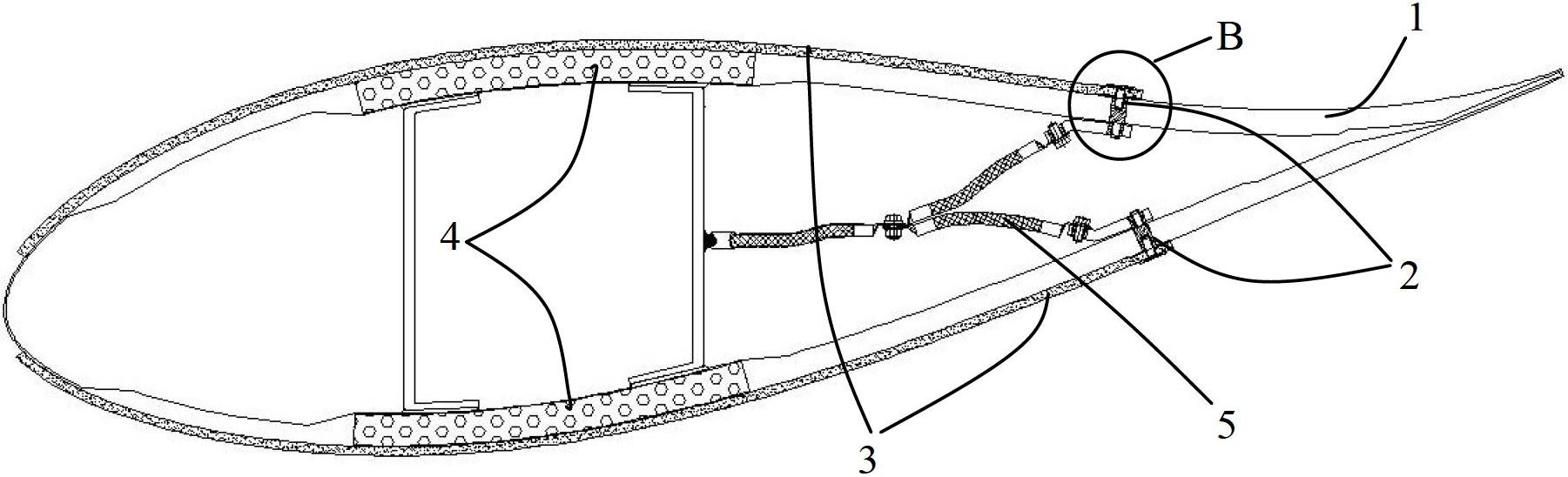

[0032] like figure 2 , 3 , 4, and 5, the wind turbine blade lightning protection device of the wind power generating set of the present invention has a lightning receptor 2 pre-embedded in the wind rotor blade 1 shell of the non-main girder 4 area, and the lightning receptor 2 passes through the wind rotor blade. The wire 5 in the inner cavity of the blade 1 is connected to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com