Patents

Literature

3623results about "Workpieces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

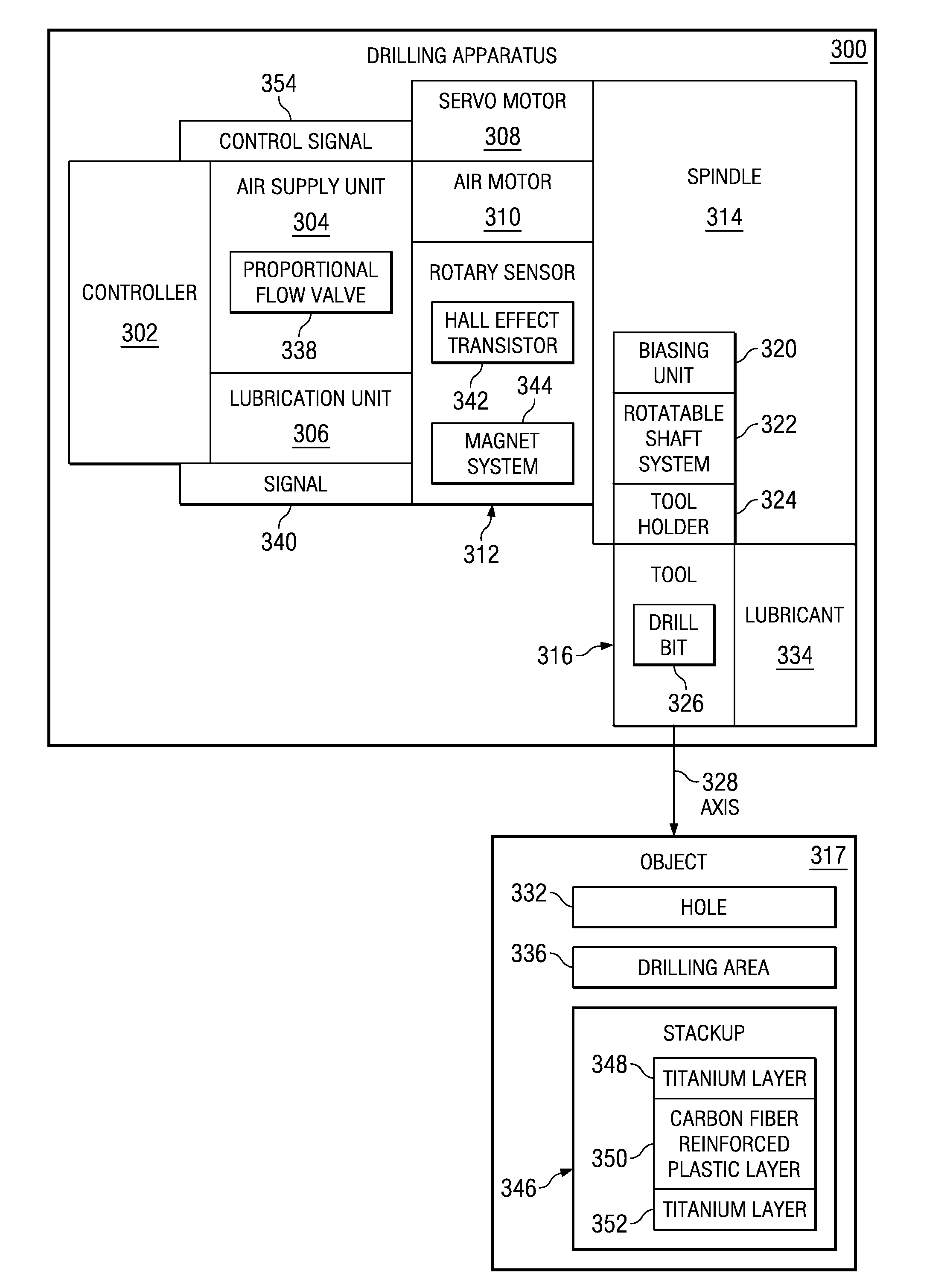

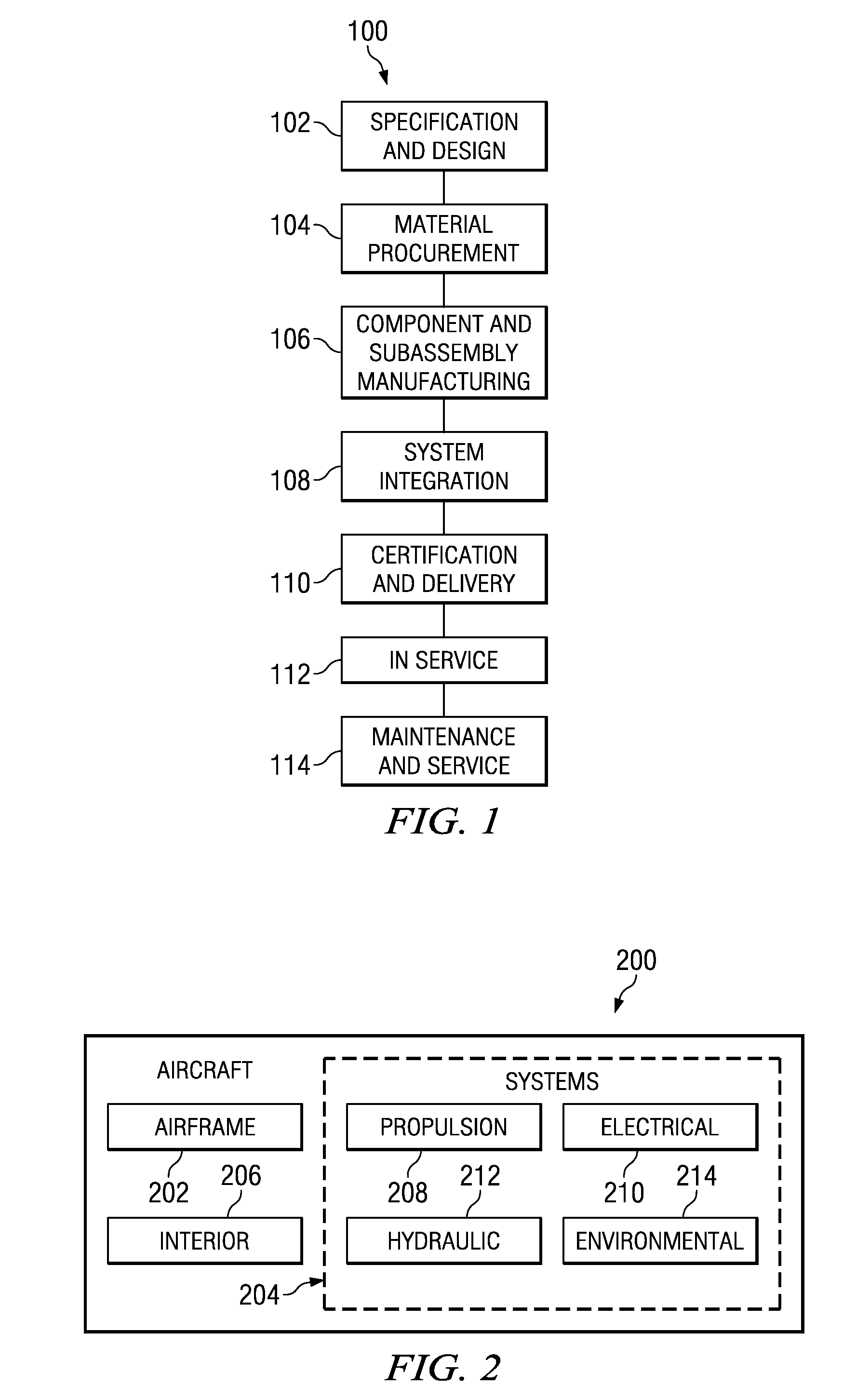

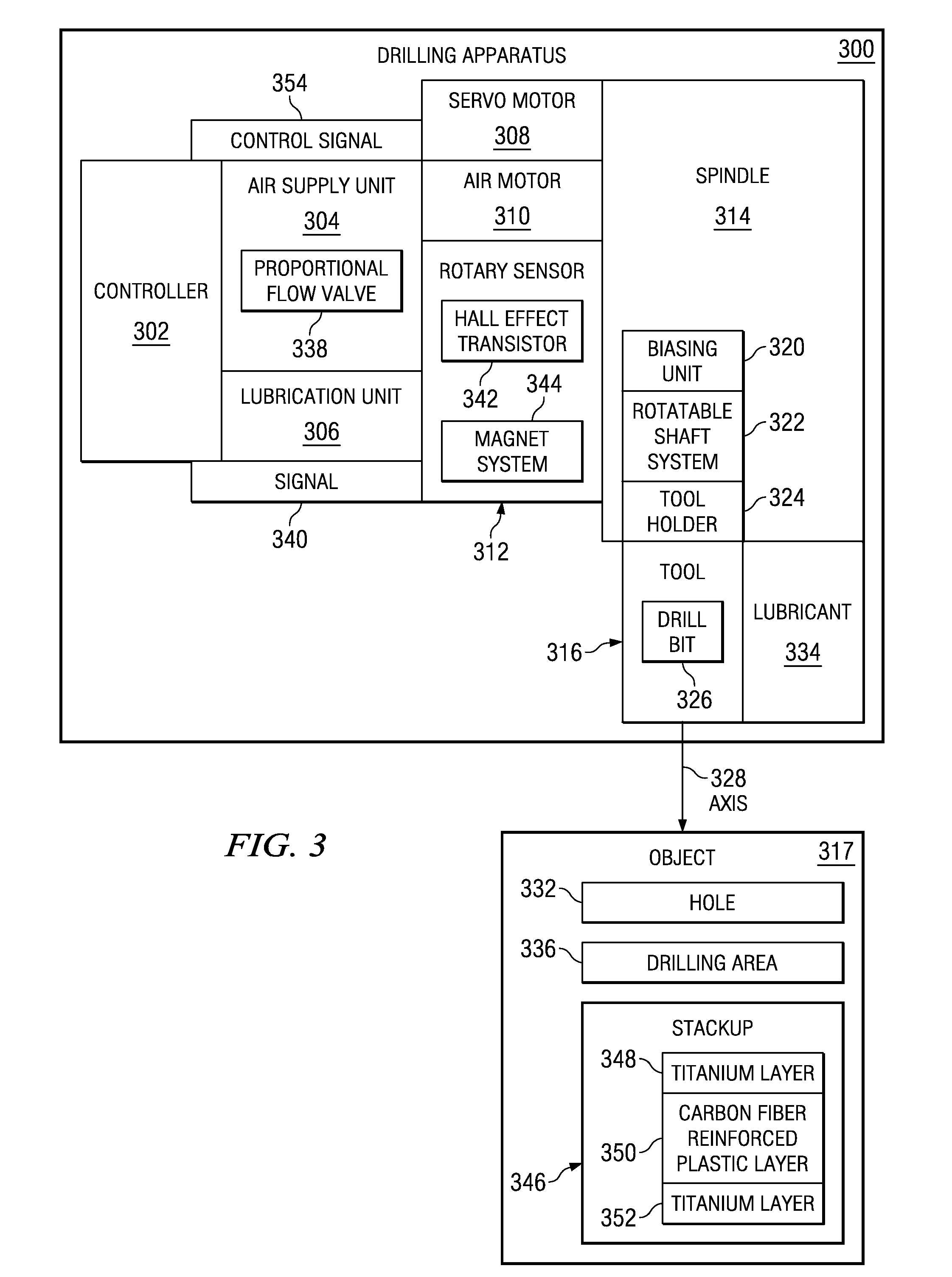

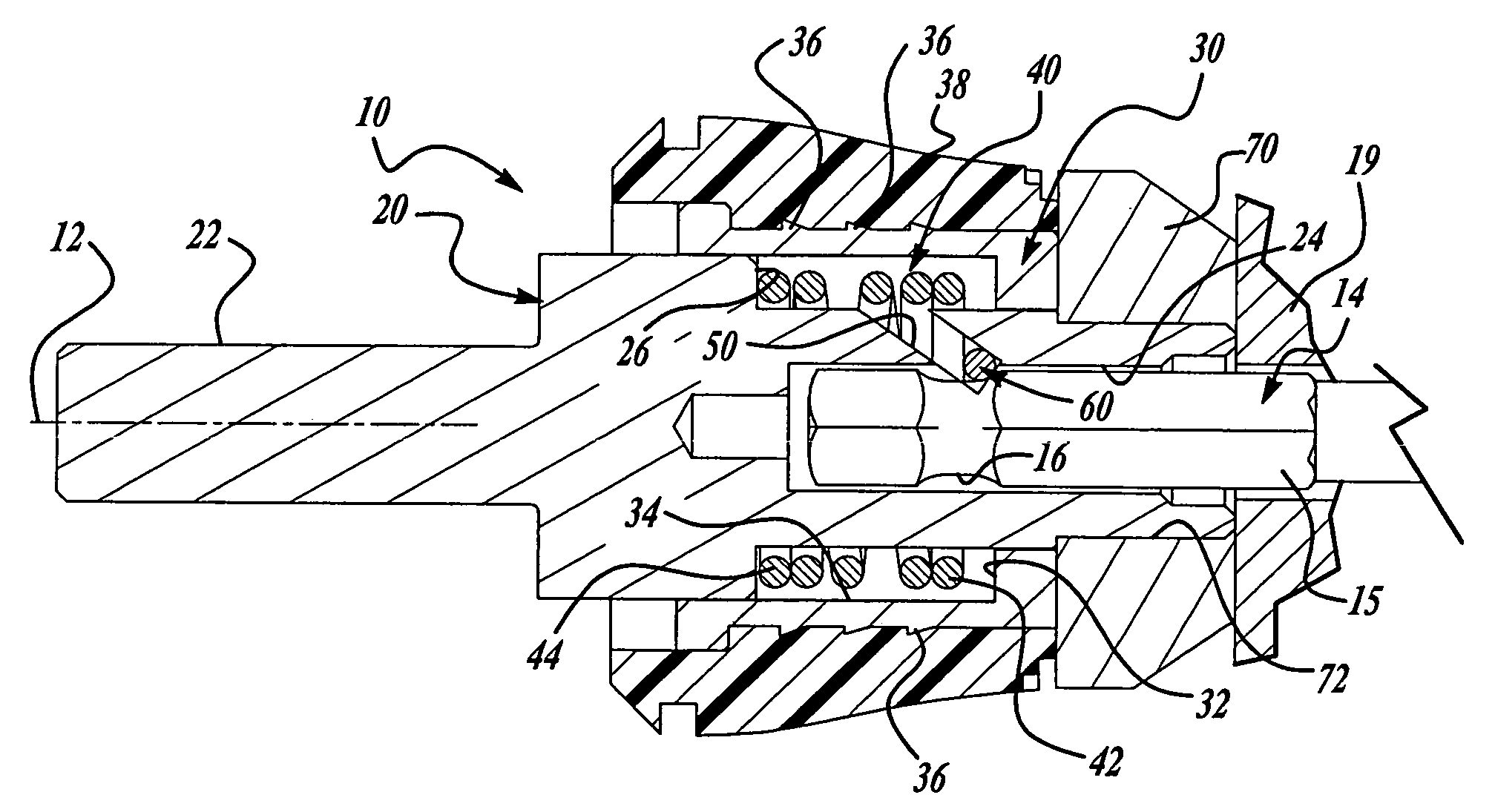

Adaptive positive feed drilling system

An apparatus for a drilling operation. In one advantageous embodiment, the drilling operation includes a motor, a rotary sensor, and a controller connected to the rotary sensor. The rotary sensor may be capable of generating a signal in response to rotary movement of the drill motor. The controller may be capable of monitoring a speed of the air motor from the signal generated by the rotary sensor and may be capable of identifying a change from a current layer in a stackup to a new layer in the stackup using the signal.

Owner:THE BOEING CO

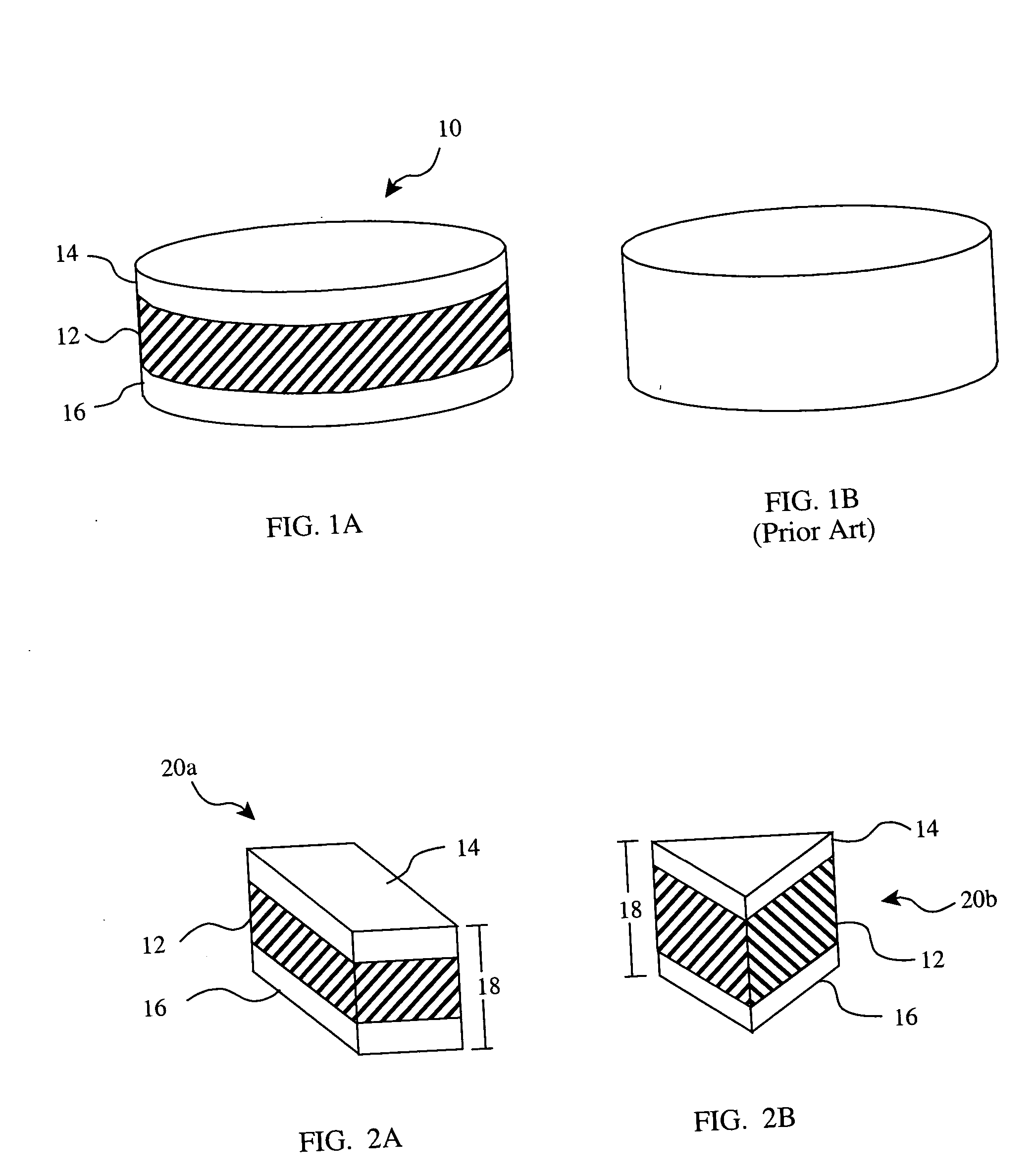

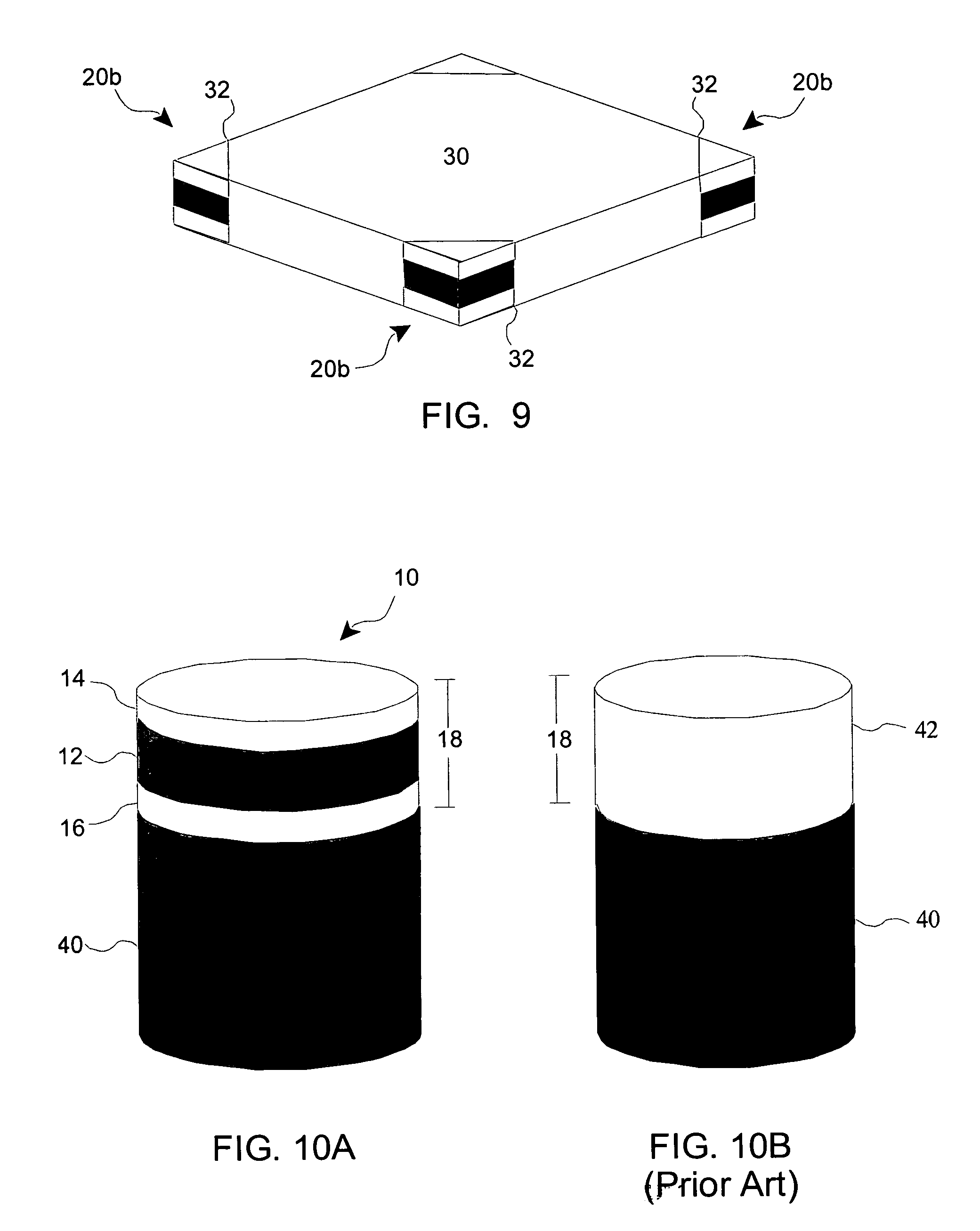

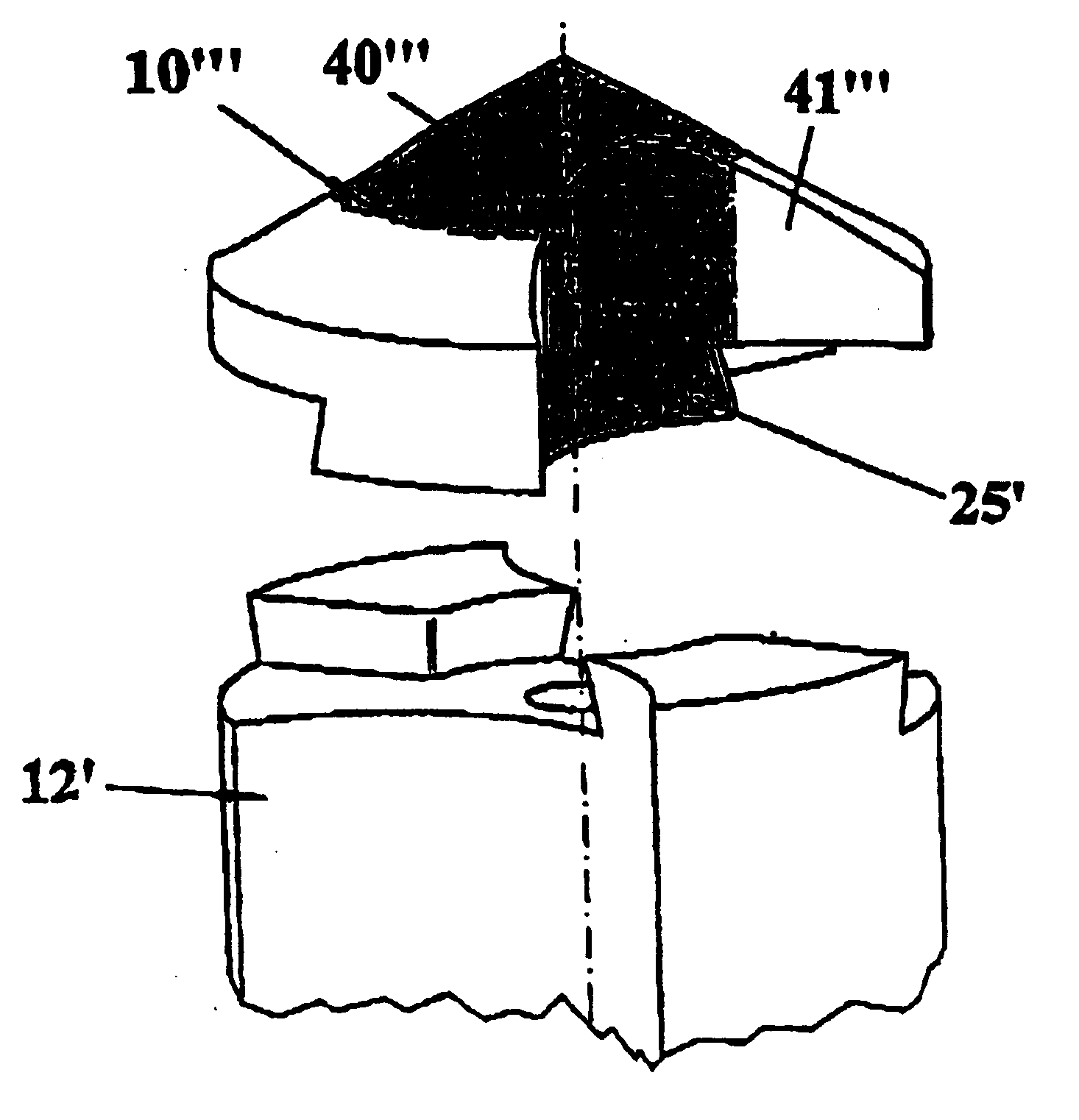

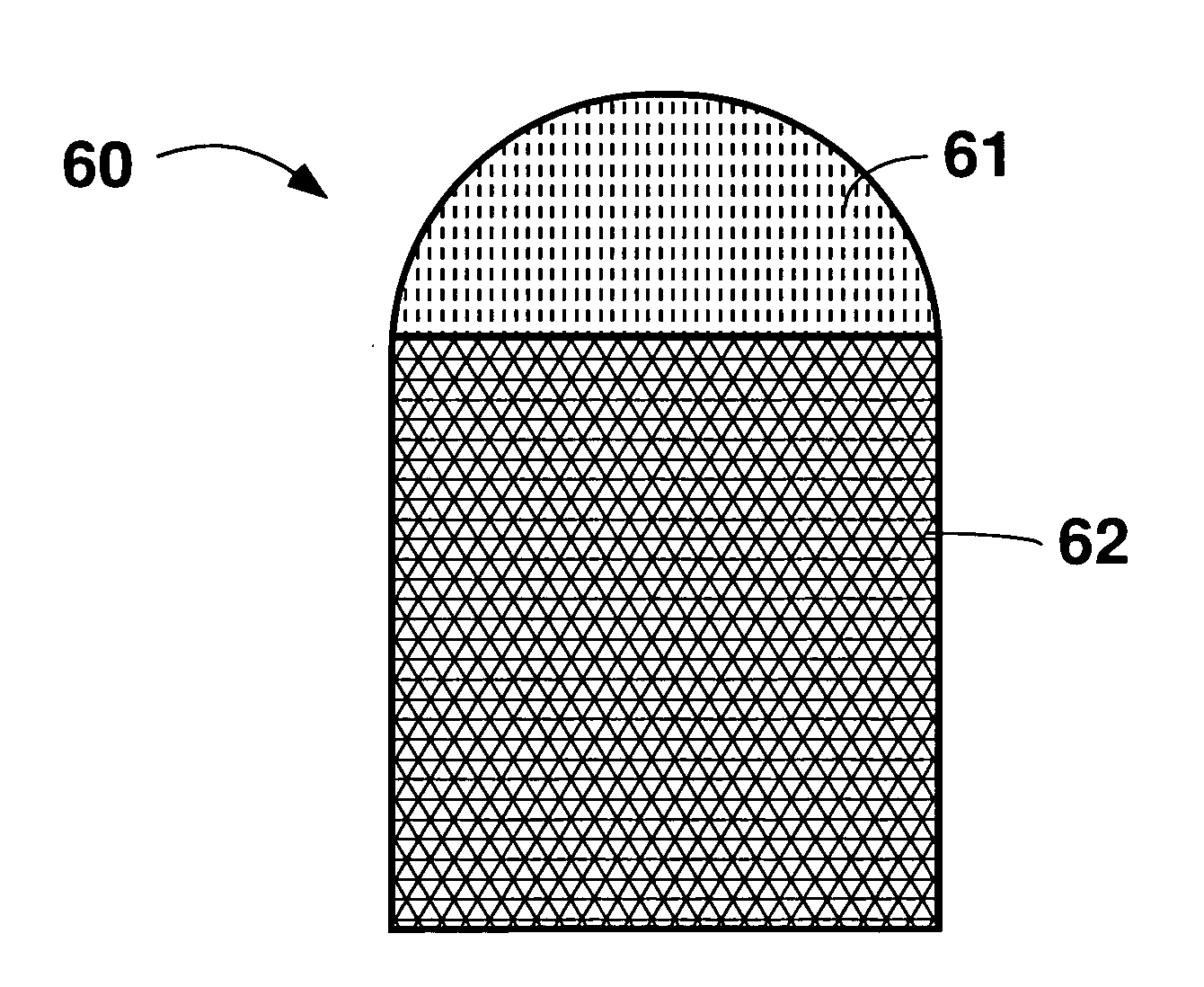

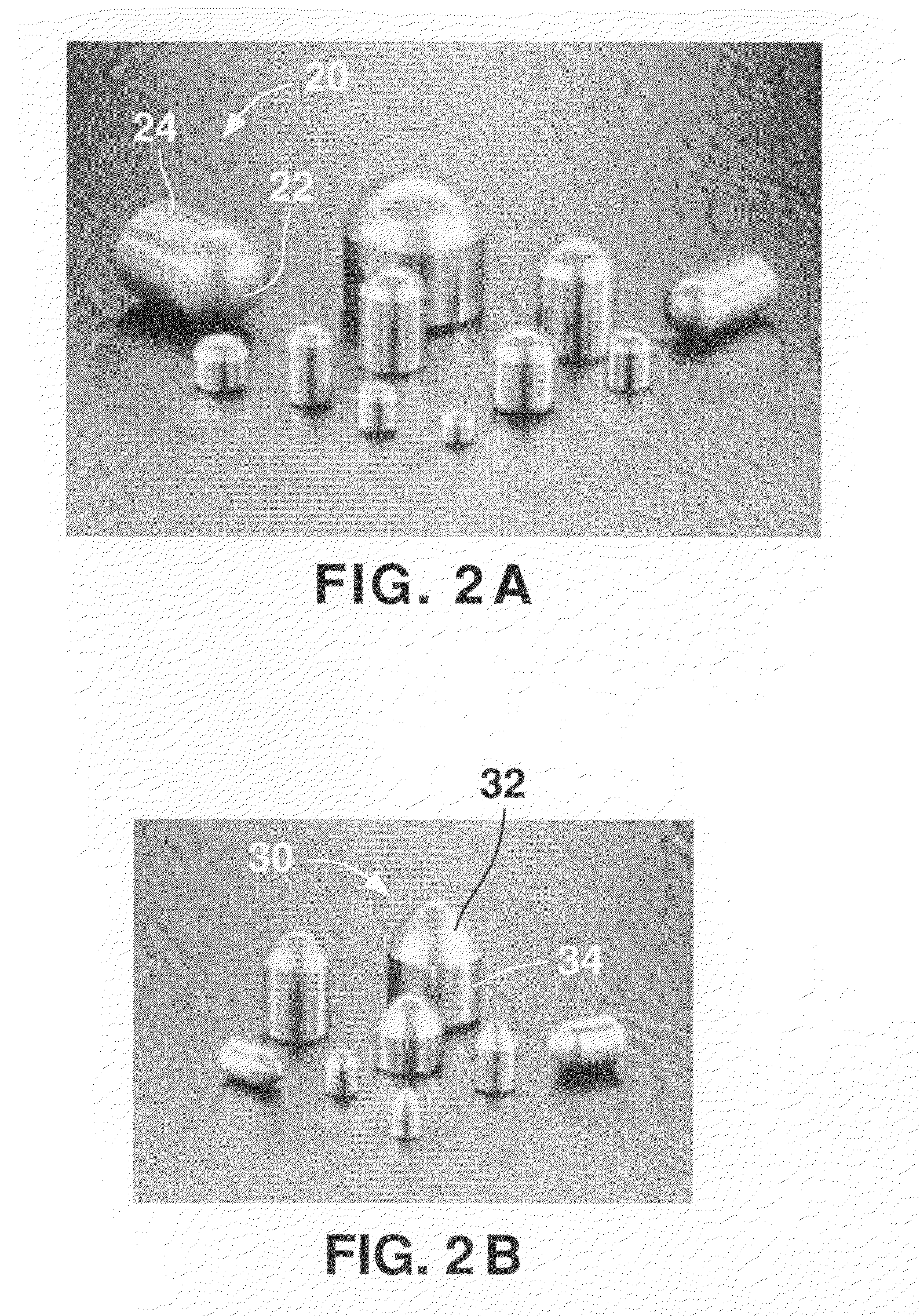

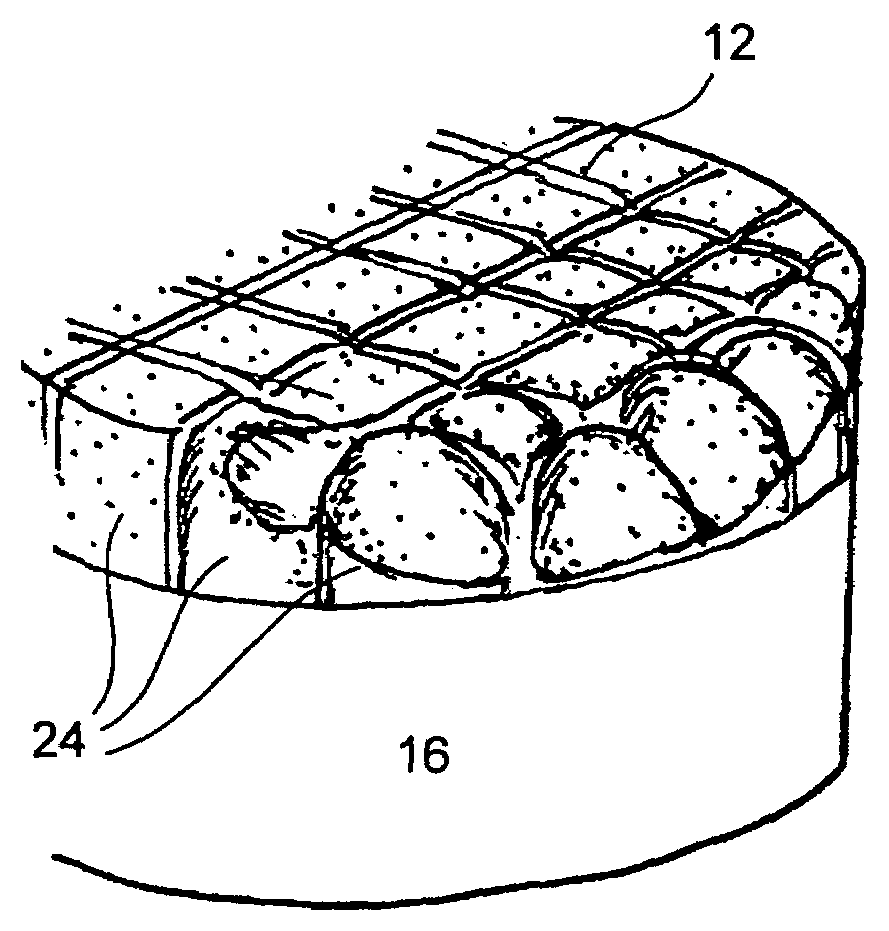

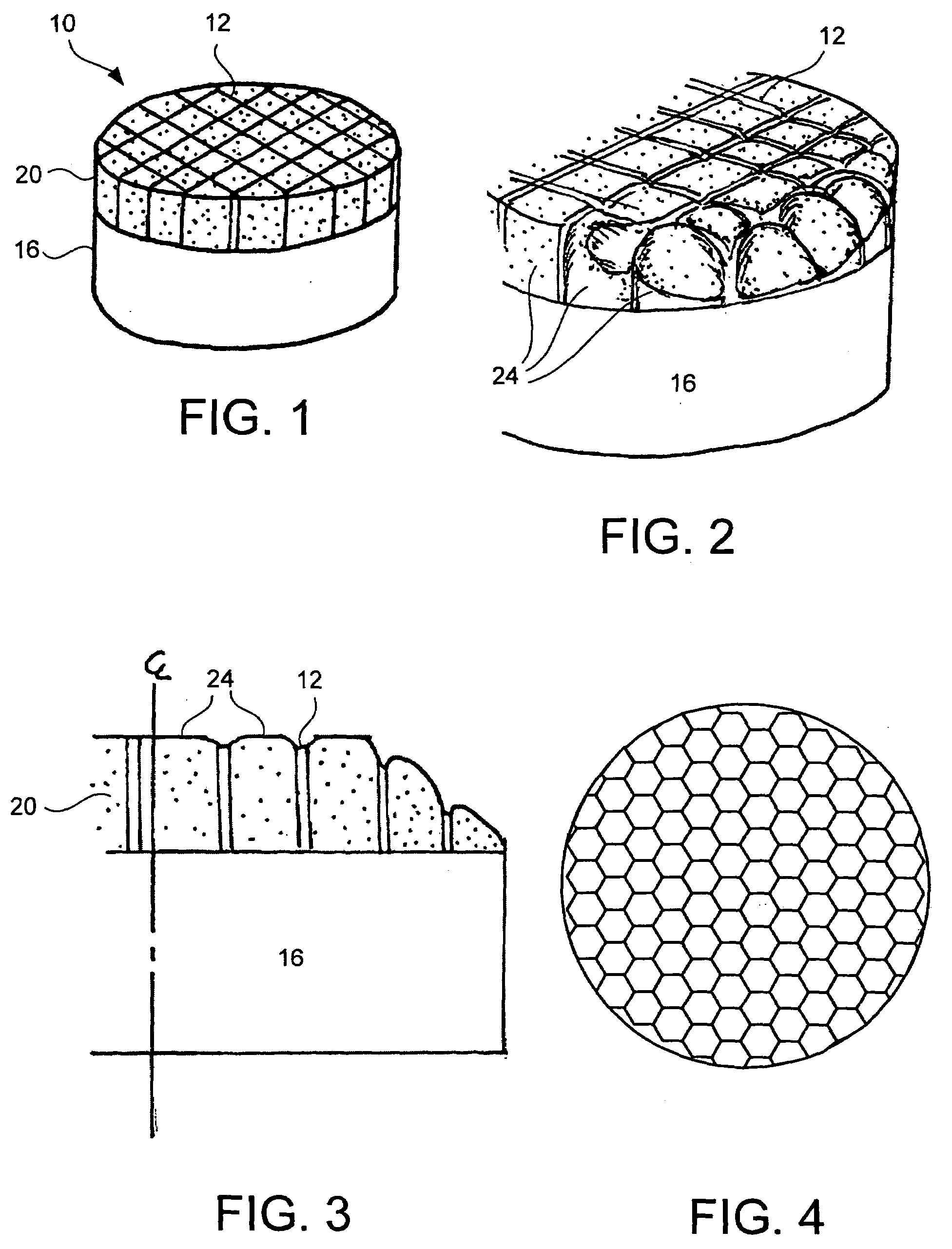

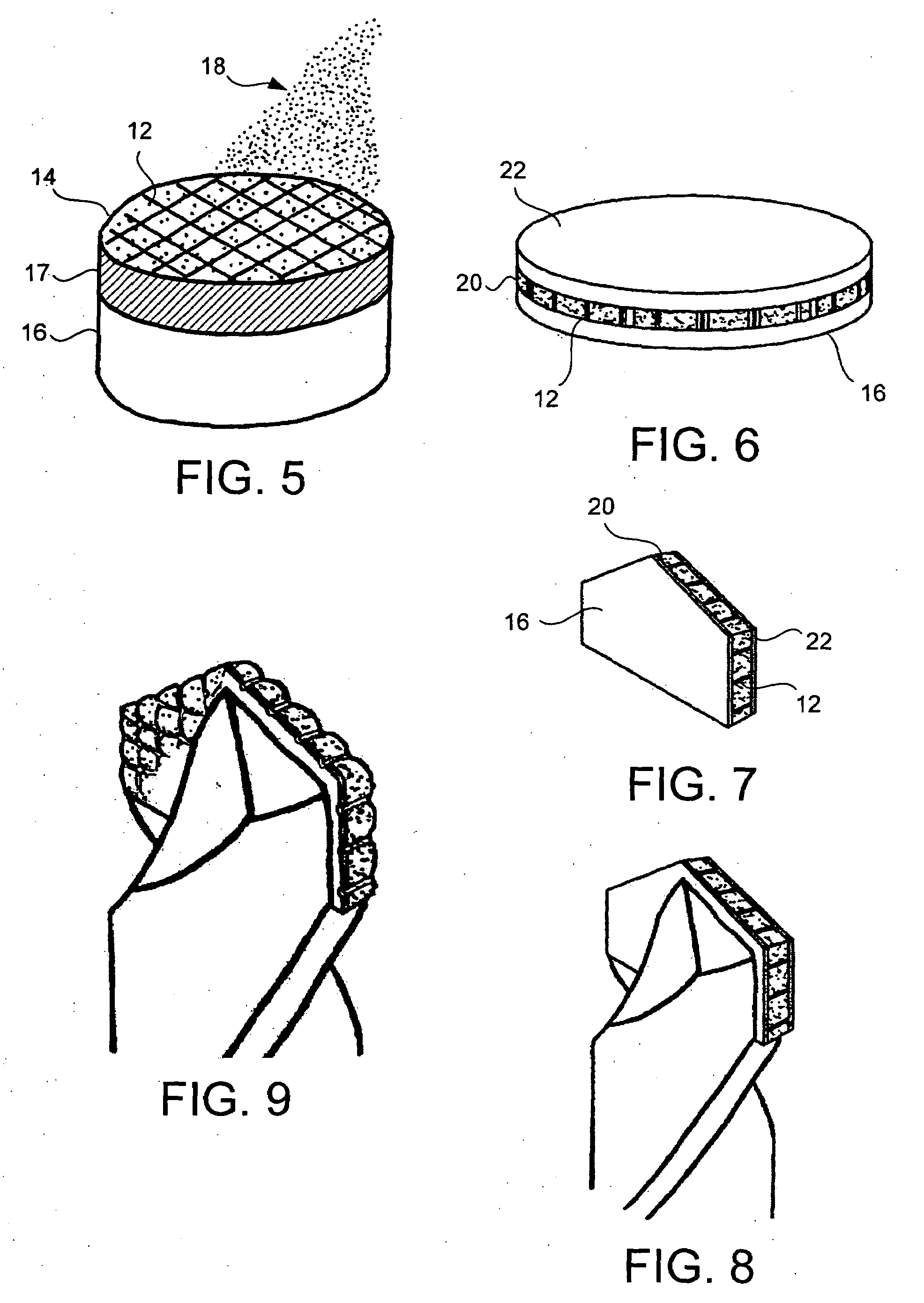

Doubled-sided and multi-layered PCD and PCBN abrasive articles

InactiveUS20050050801A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionHigh pressureMaterials science

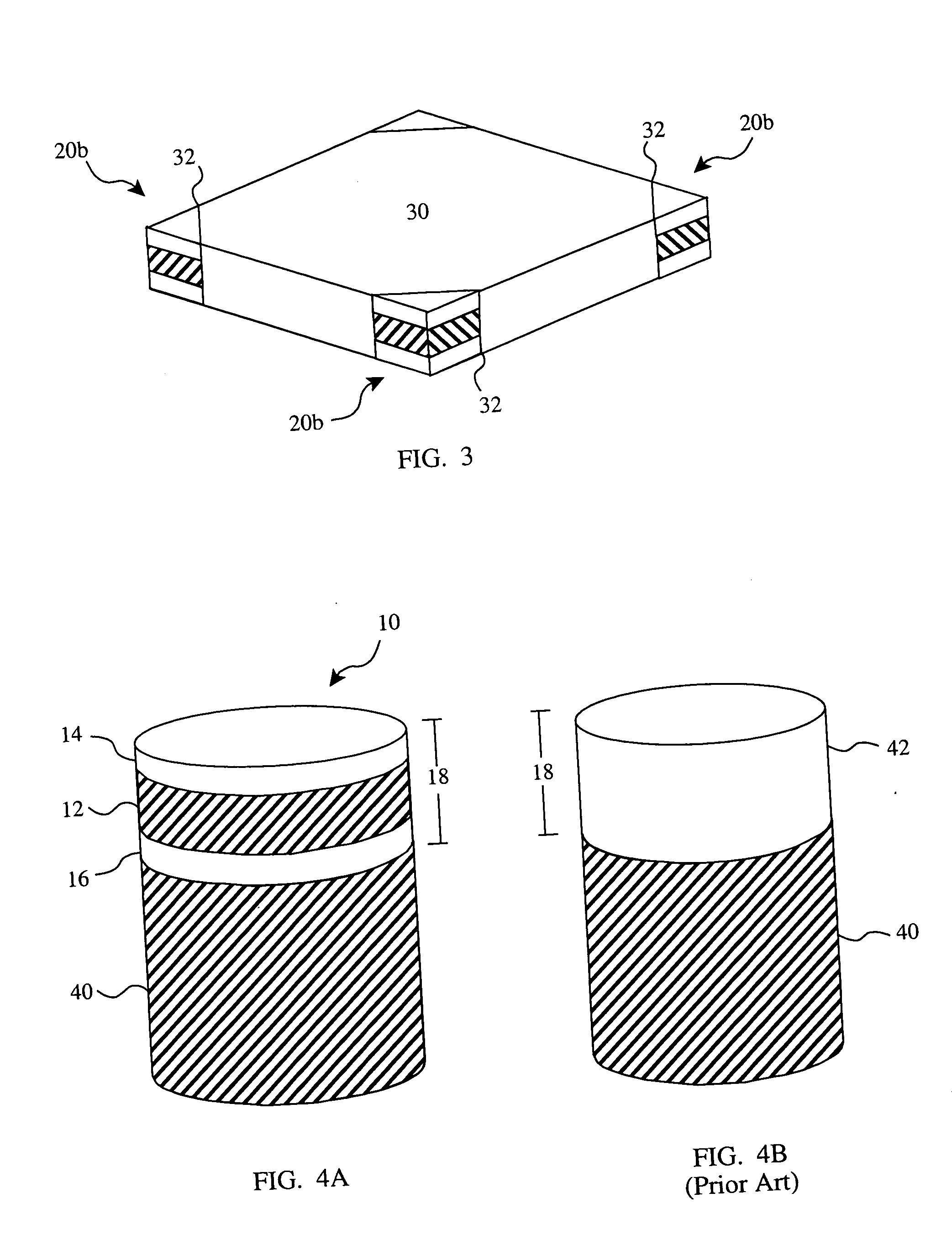

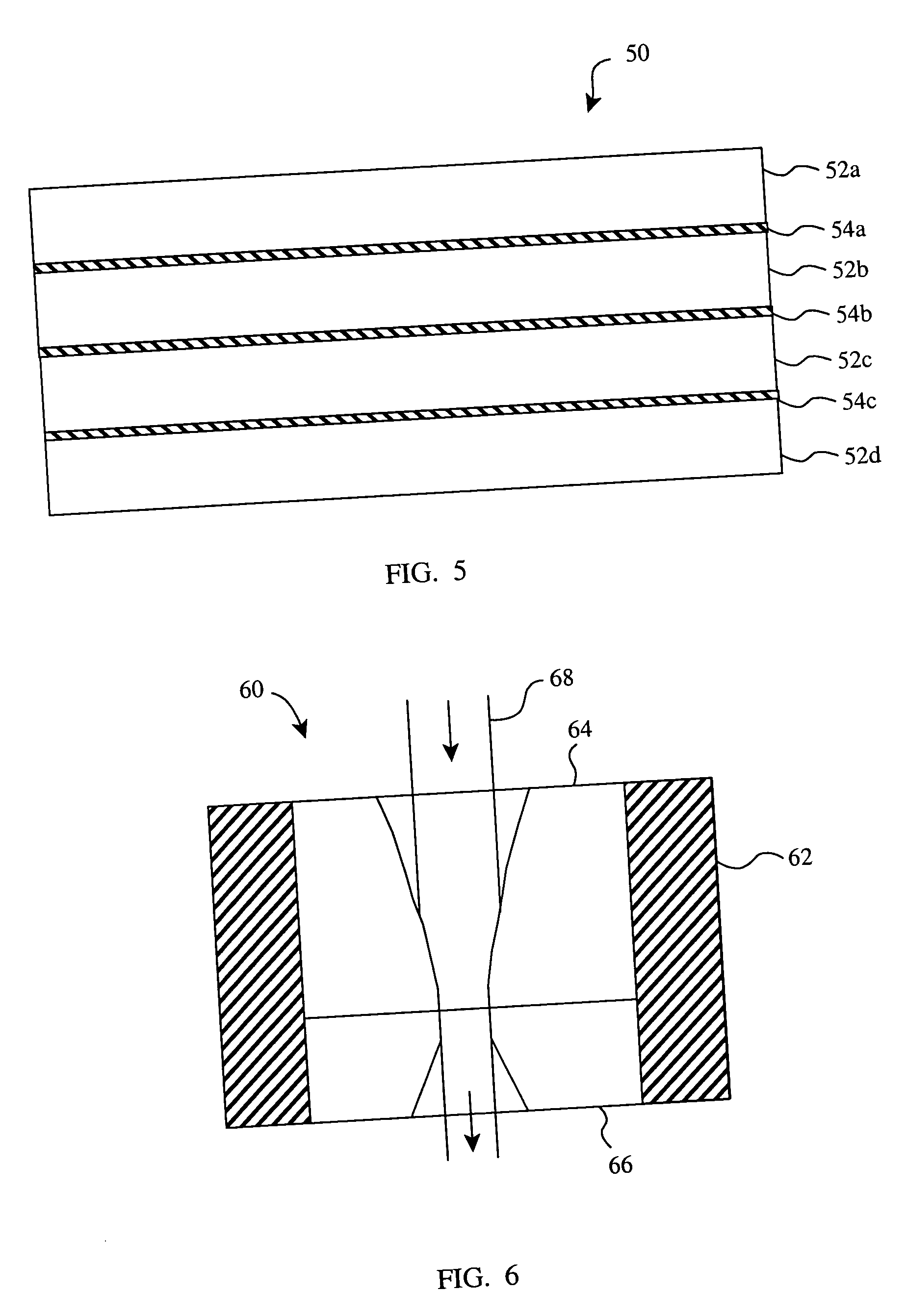

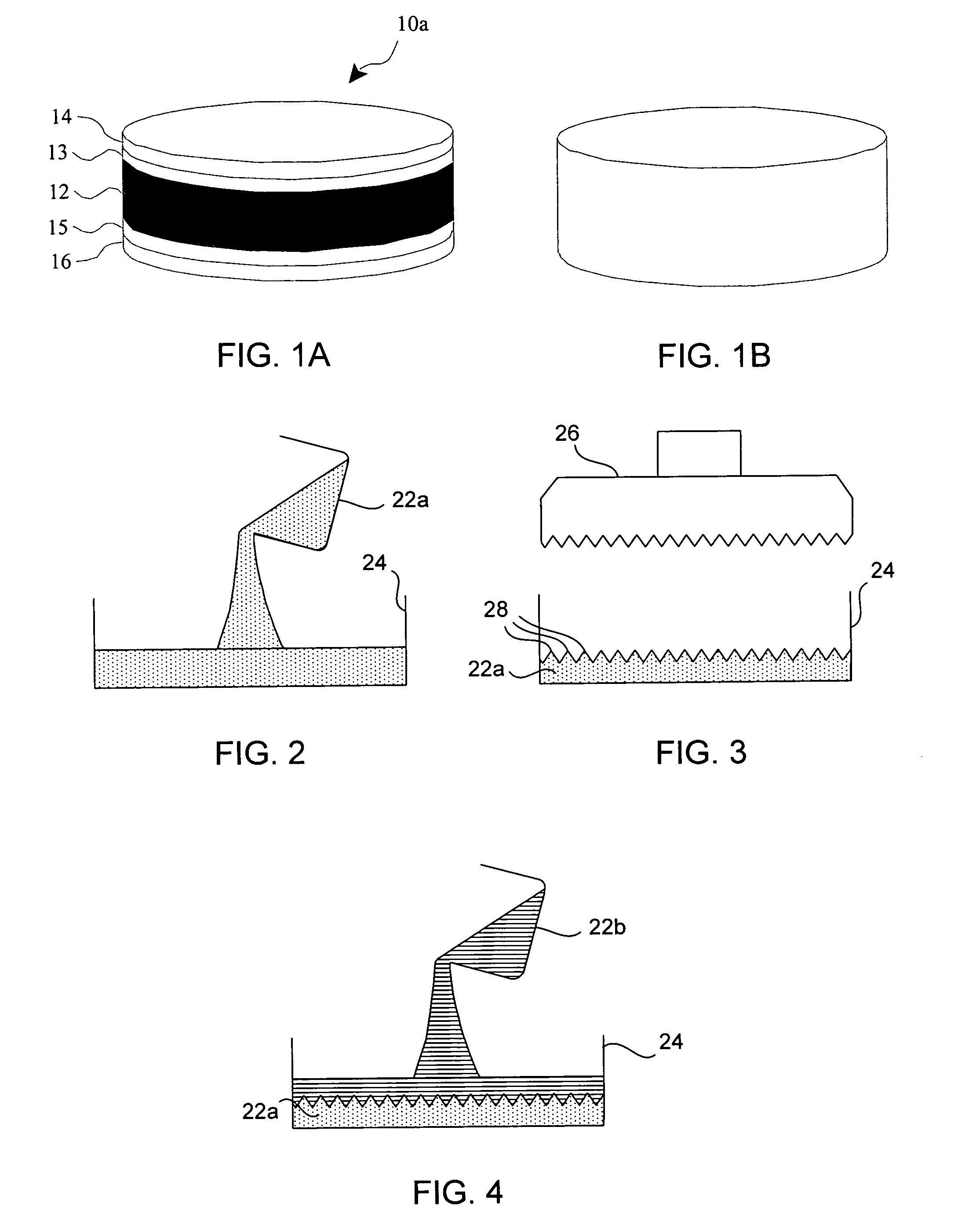

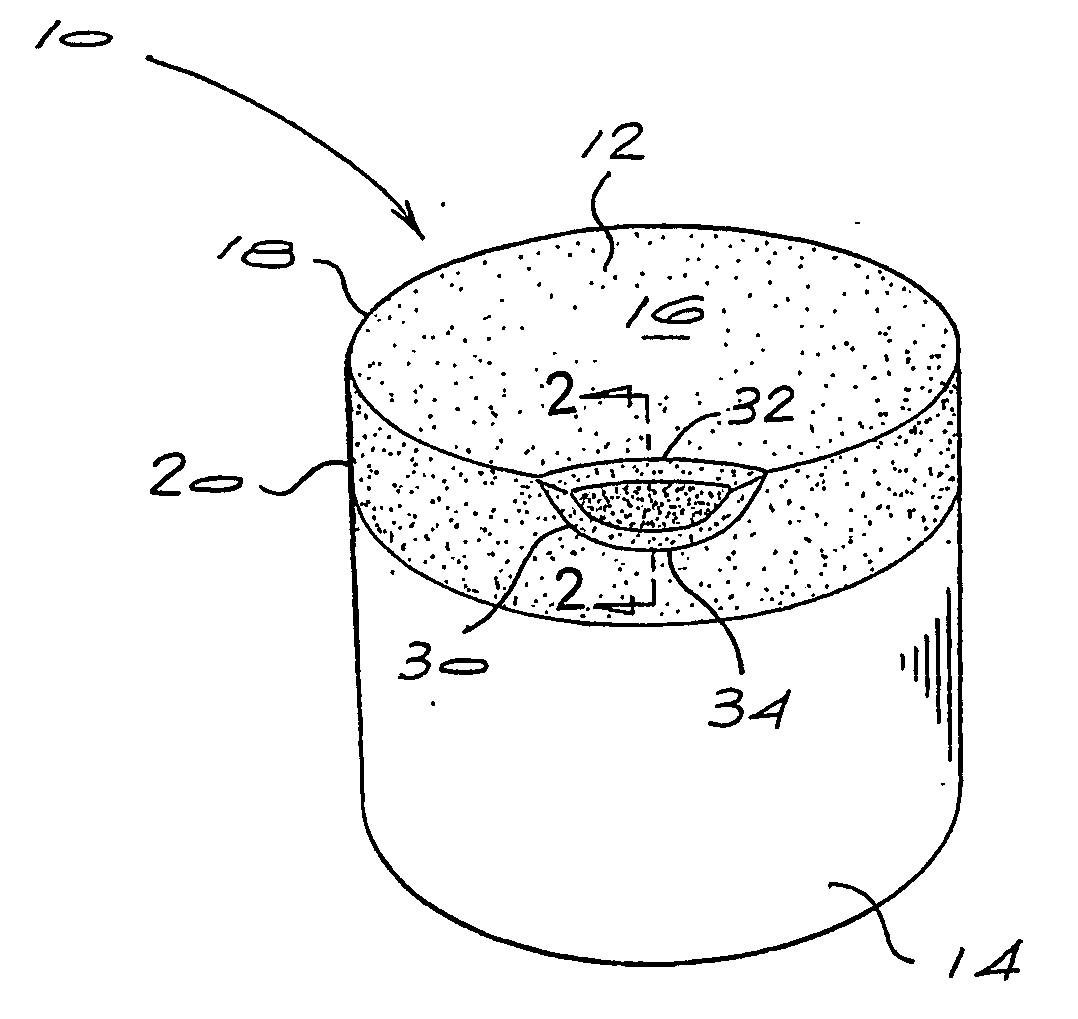

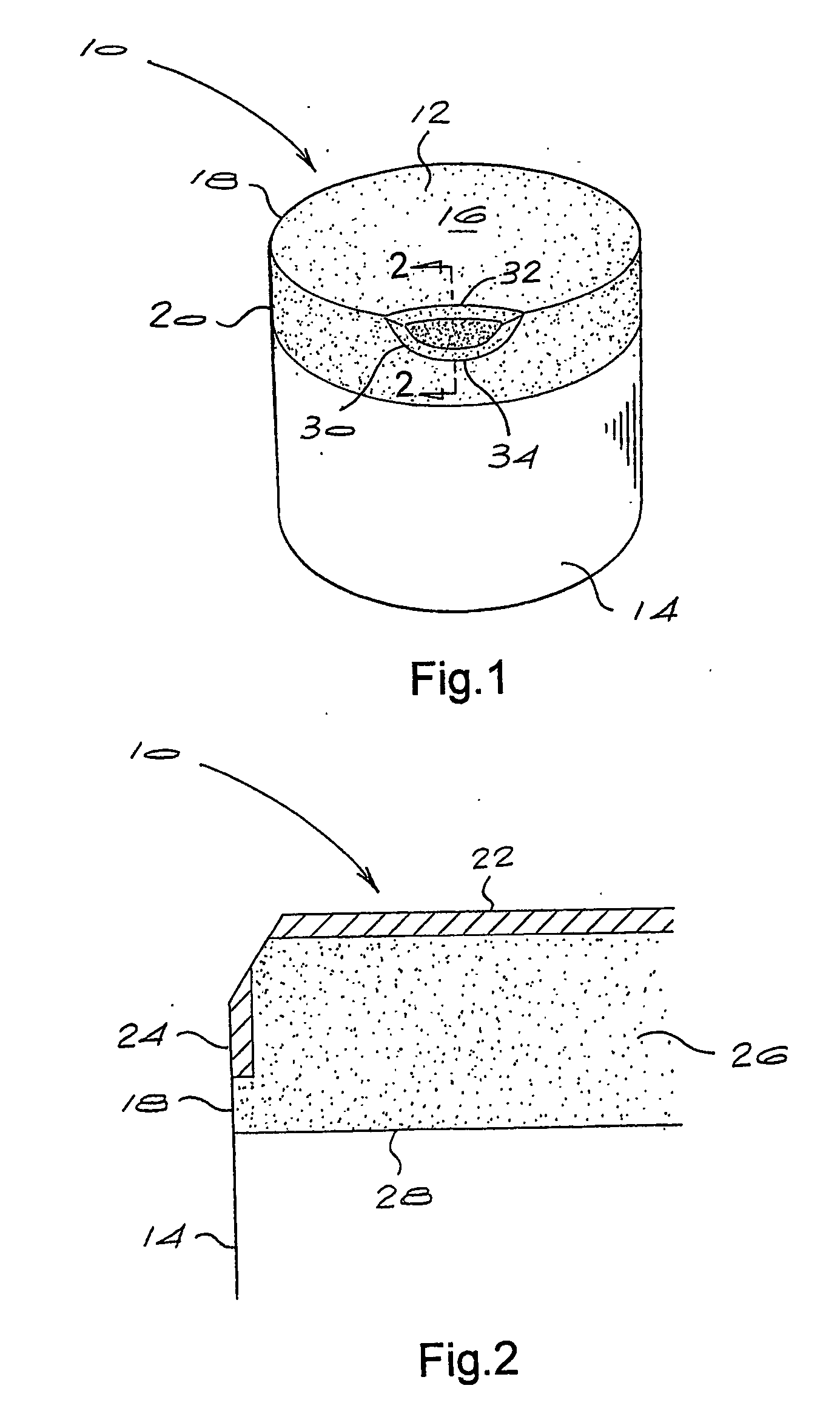

A doubled-sided PCD or PCBN compact as well as a new multi-layered PCD and PCBN can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can include superabrasive particles bonded together by sintering or chemical bonding with an additional metal. Such double-sided PCD and PCBN compacts as well as a new multiple layered PCD and PCBN allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided and / or multiple layered PCD and PCBN compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:CHO HYUN SAM +2

Doubled-sided and multi-layered PCBN and PCD abrasive articles

InactiveUS20050210755A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionWear particleHigh pressure

A doubled-sided PCBN and / or PCD compact can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools, decreased delamination, and increased useful service life. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can be attached to the substrate via an intermediate layer containing superabrasive particles. Such double-sided PCBN and PCD compacts allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided PCBN and PCD compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

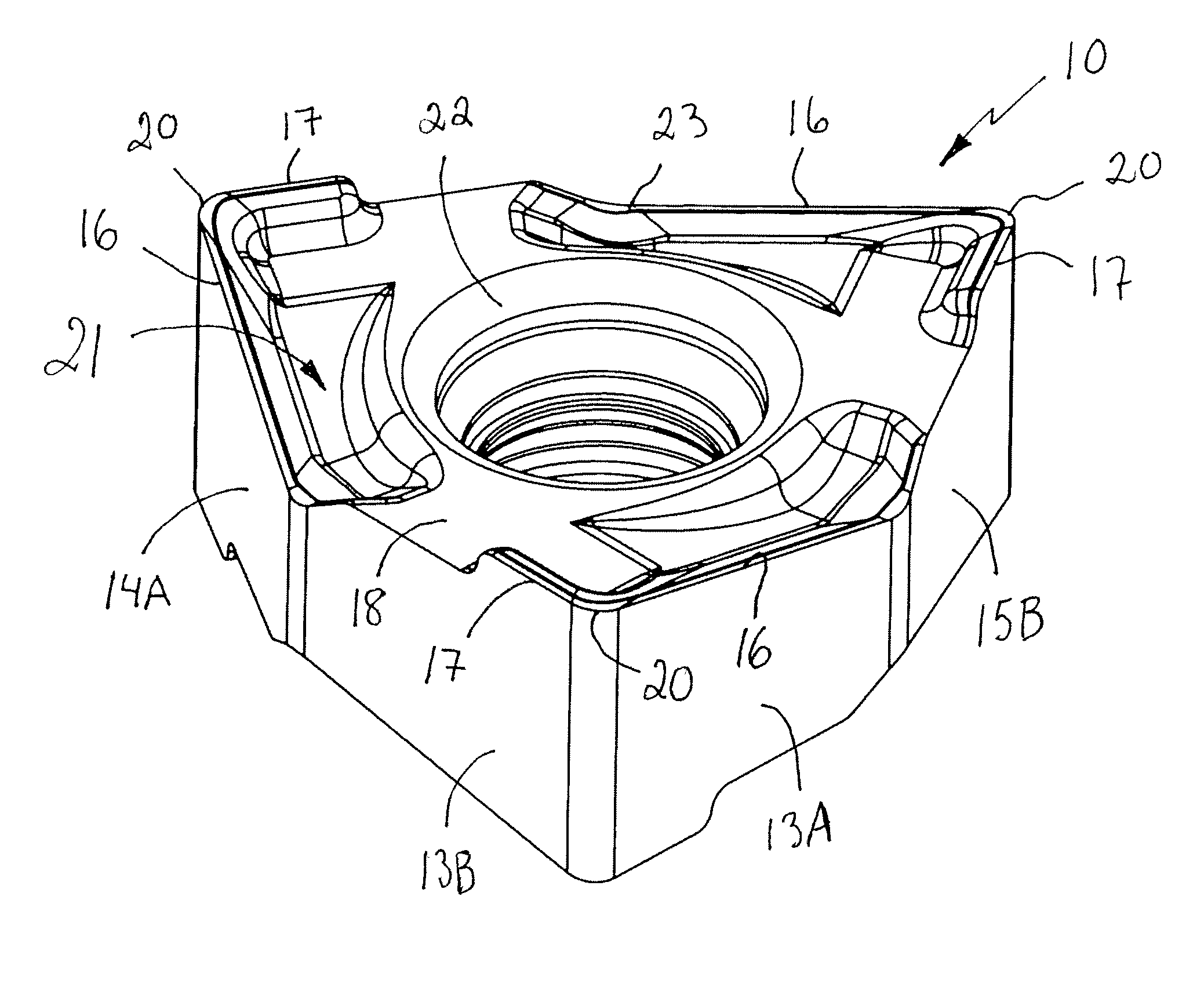

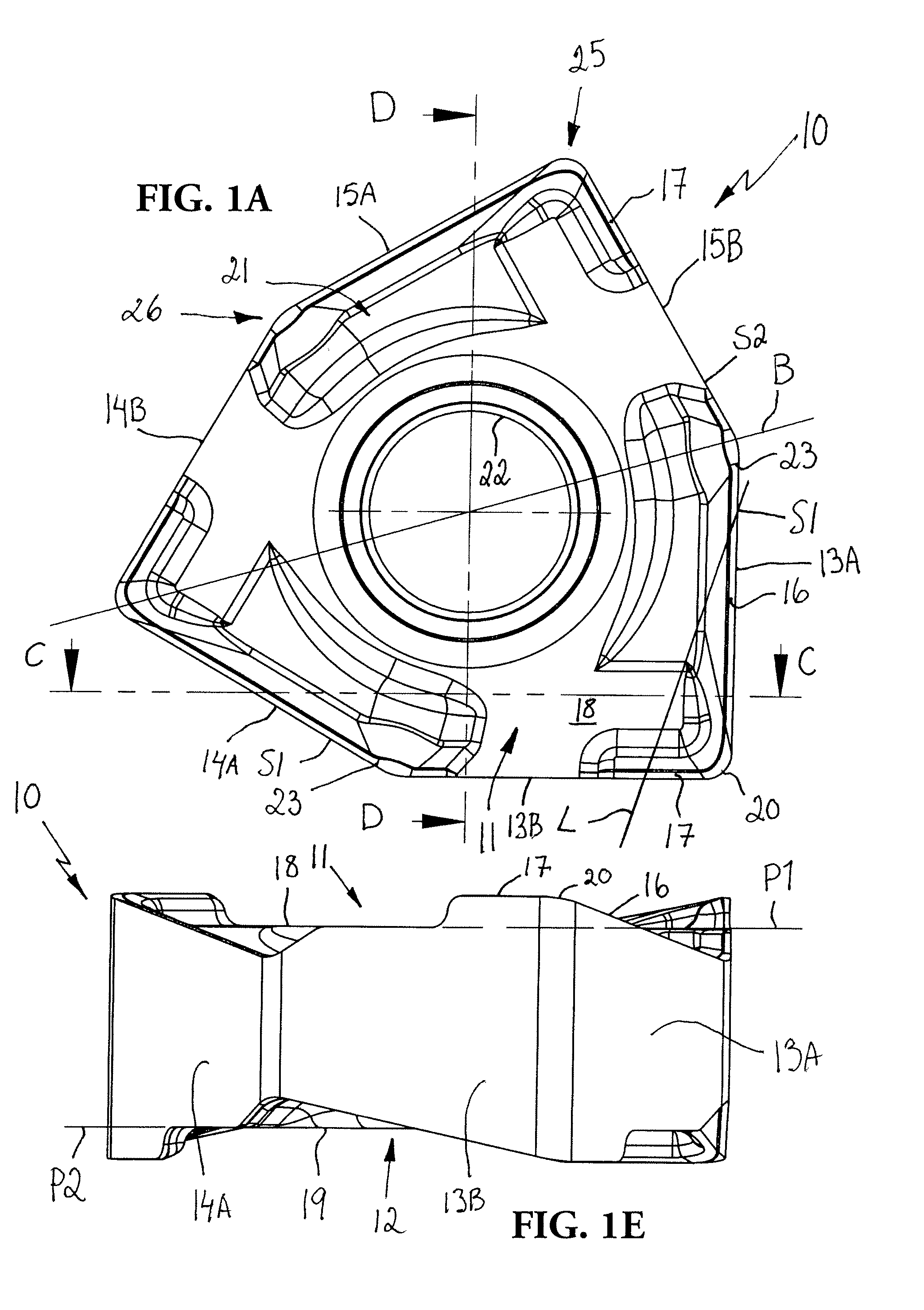

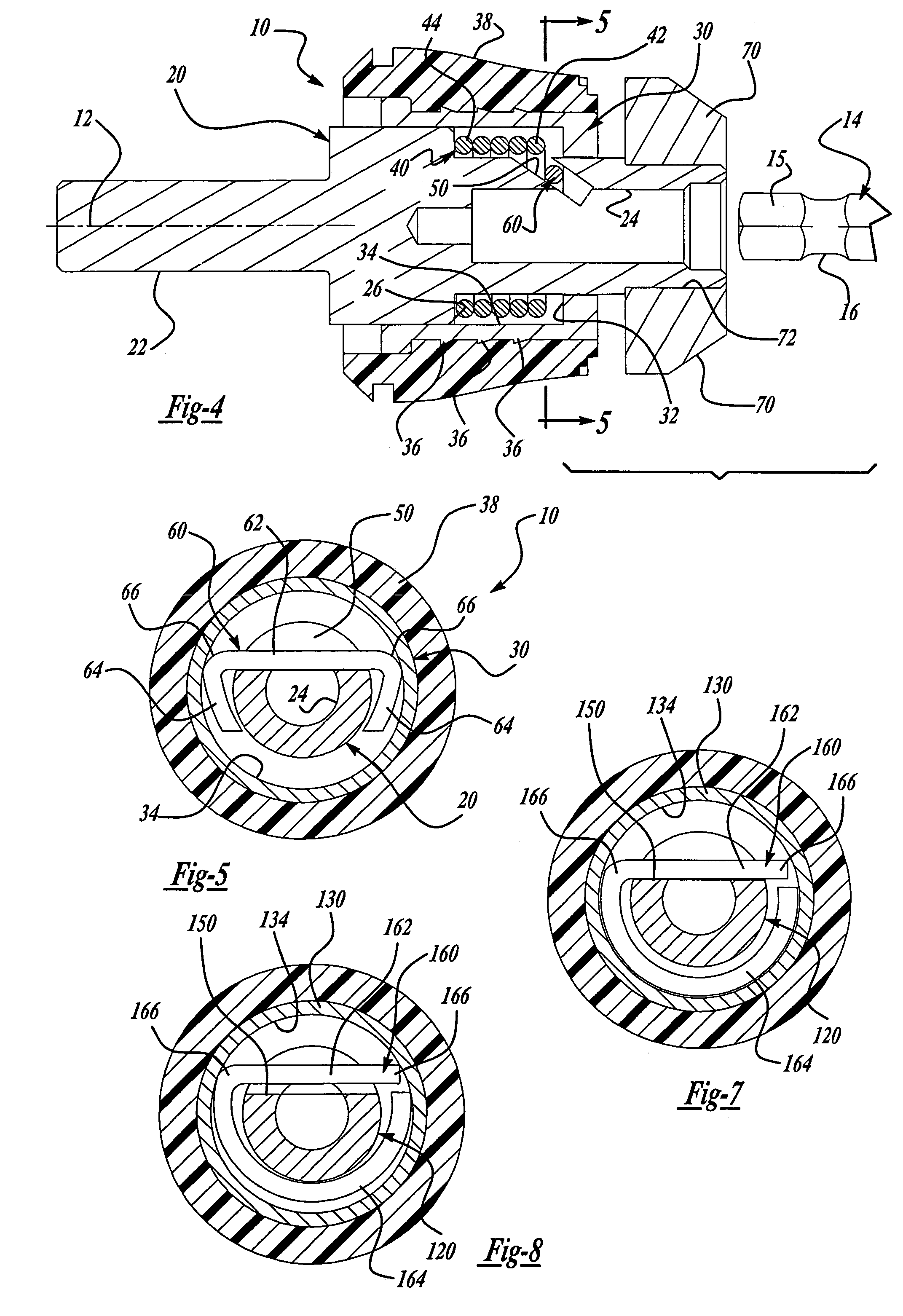

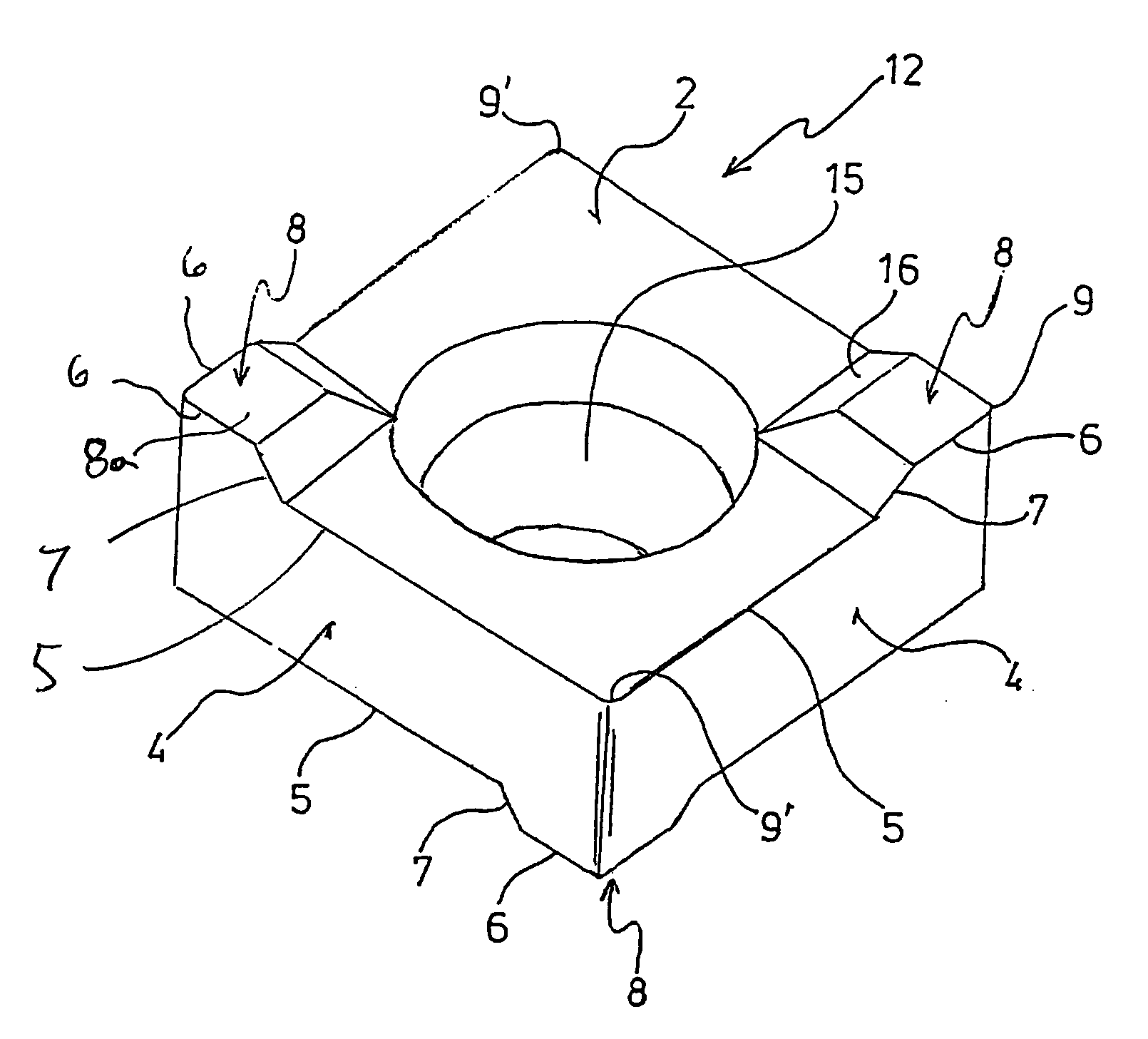

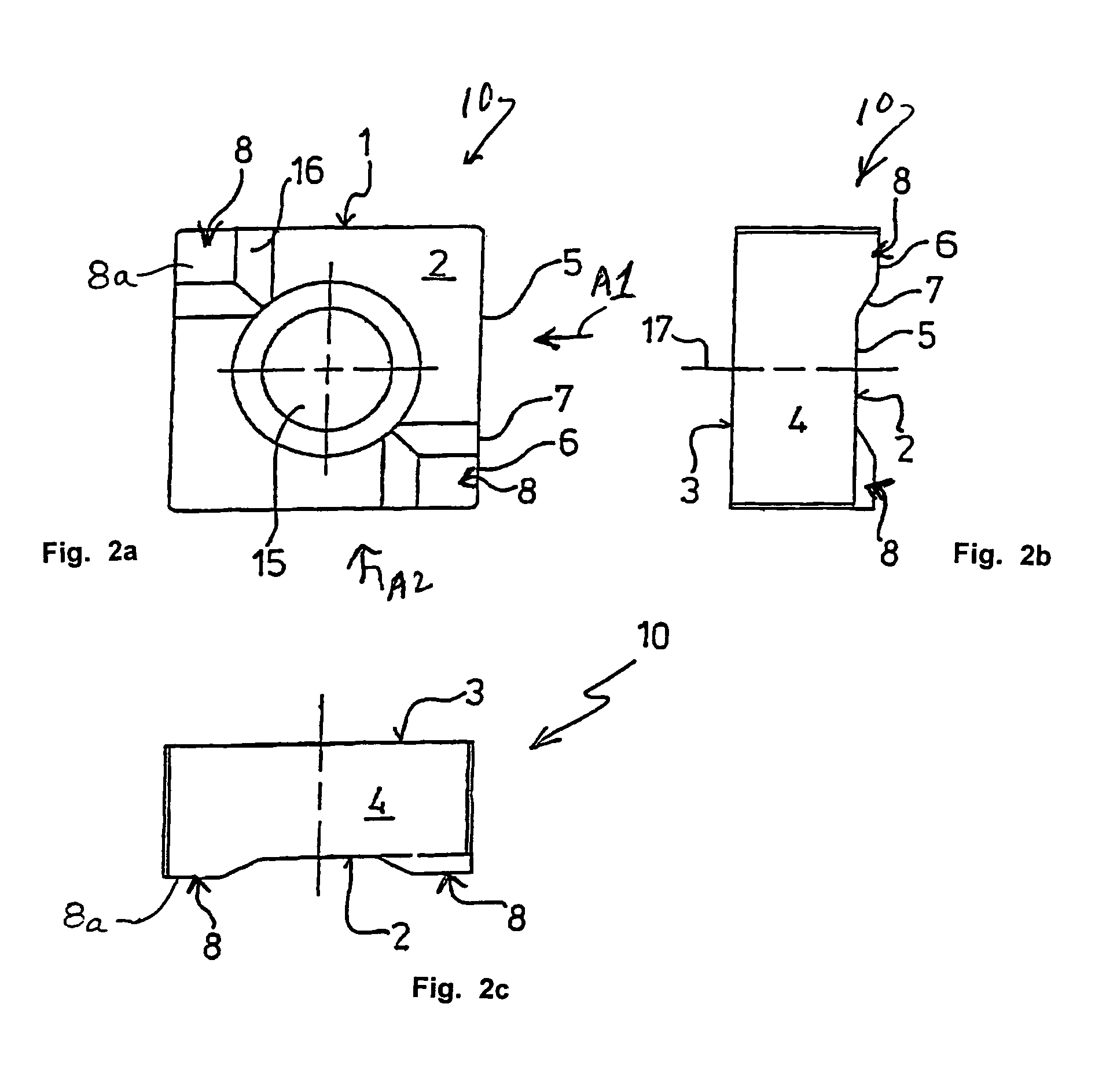

Milling insert and a milling tool

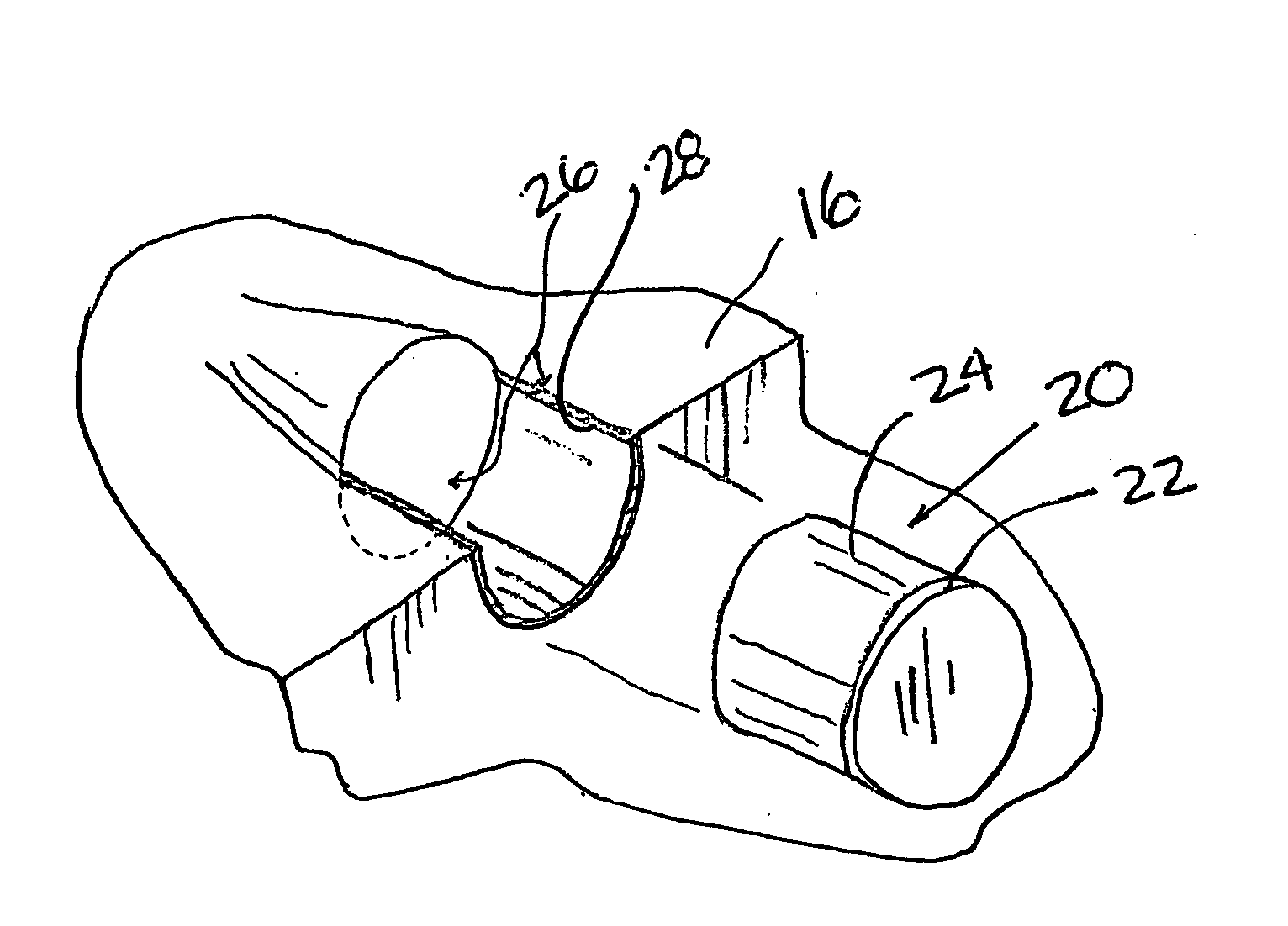

The present invention relates to an indexable milling insert and a milling tool for chip removing machining. The milling insert is intended to be able to mill substantially perpendicular corners in a work piece. The milling insert comprises an upper side, a lower side and edge surfaces extending therebetween. The upper side and the lower side are substantially identical. An imaginary circle inscribed in the milling insert touches the milling insert periphery in four to six points. Lines of intersection between the edge surfaces and the sides form relative to each other substantially perpendicular main cutting edges and minor cutting edges. Each of the sides includes a support surface, each of which being provided in a plane. Each minor cutting edge projects from the plane of the associated support surface. Each major cutting edge intersects the plane of the associated support surface.

Owner:SECO TOOLS AB

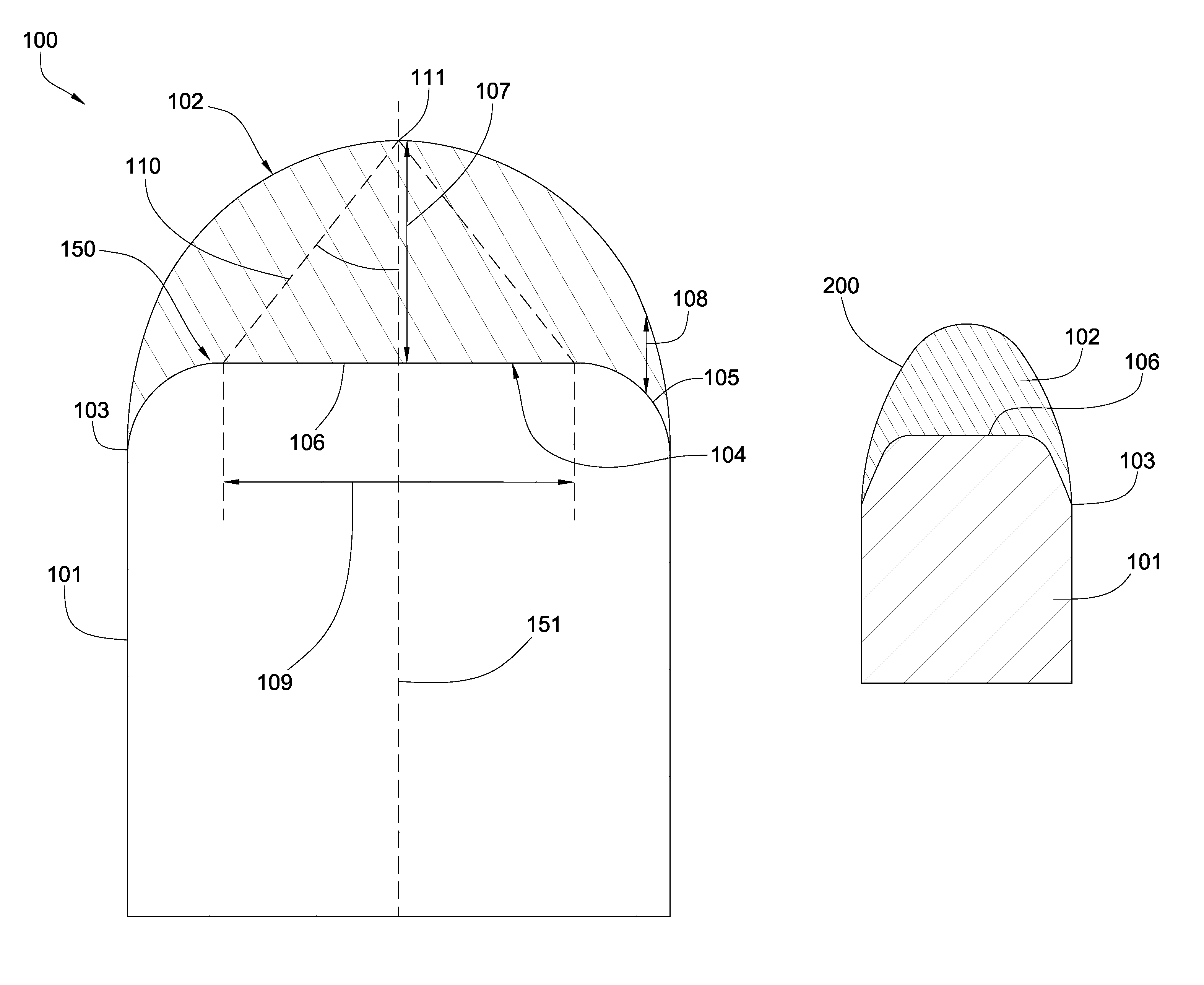

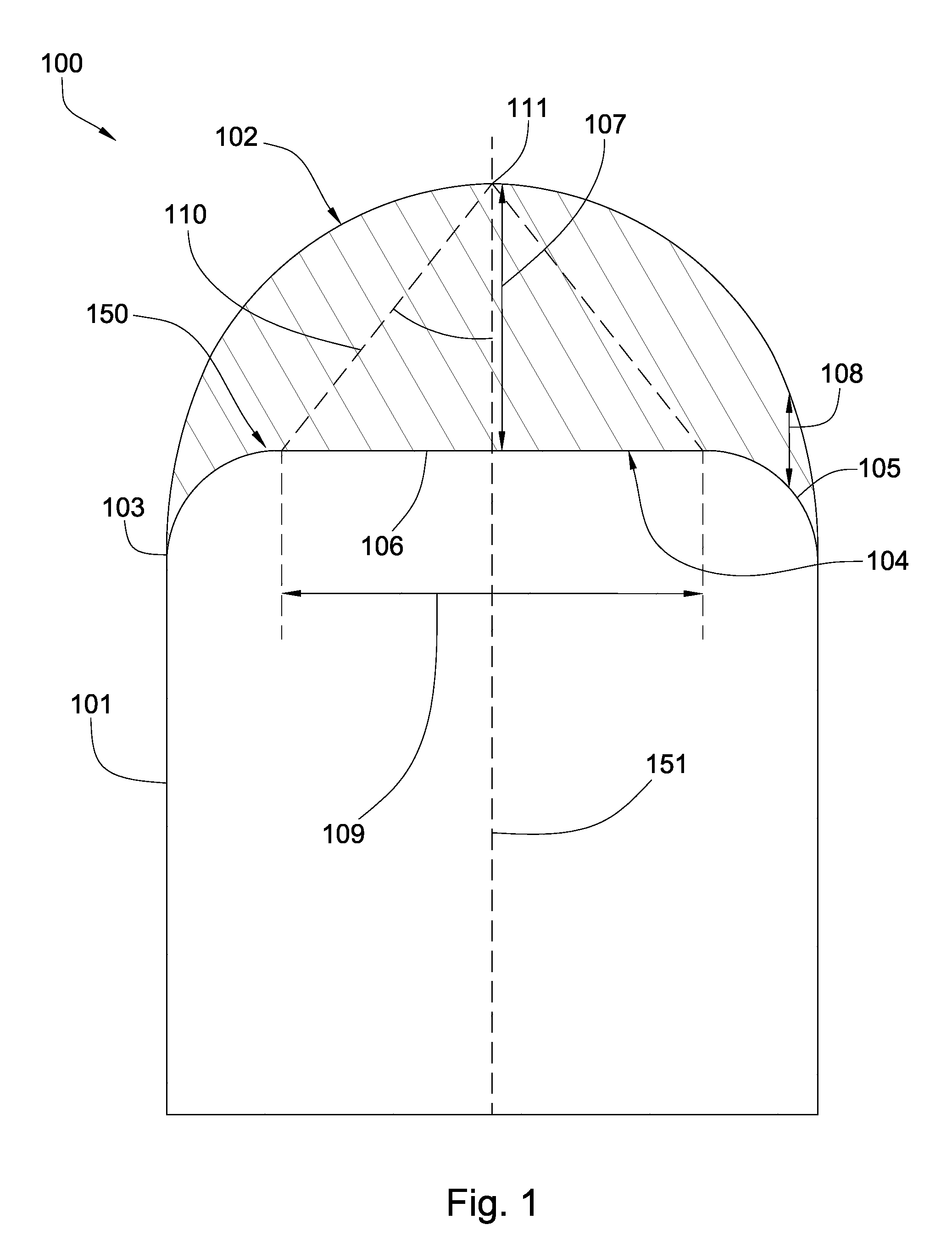

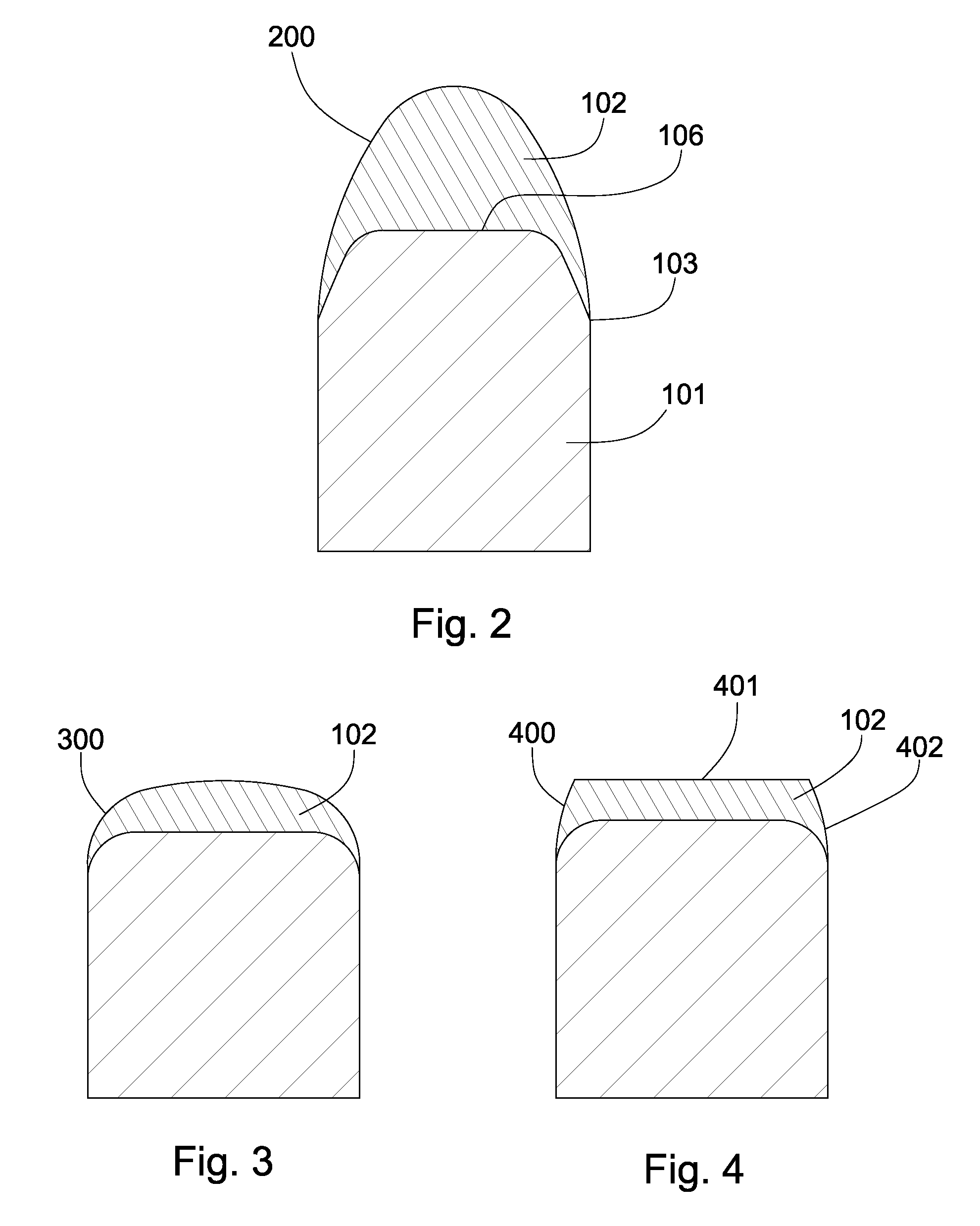

Superhard insert with an interface

In one aspect of the invention, a superhard insert has a carbide substrate bonded to ceramic layer at an interface. The substrate has a generally frusto-conical end at the interface with a tapered portion leading to a flat portion. The central section of the ceramic layer may have a first thickness immediately over the flat portion of the substrate. The peripheral section of the ceramic layer has a second thickness being less than the first thickness covering the tapered portion of the substrate. The ceramic layer may be formed using HPHT technology.

Owner:SCHLUMBERGER TECH CORP

Cutting tool insert

ActiveUS20070039762A1Reducing and preferably eliminating and spalling and chipping typeImproved wear behaviorDrill bitsWorkpiecesLeading edgeMetallurgy

A polycrystalline diamond abrasive cutting element consists generally of a layer of high grade polycrystalline diamond bonded to a cemented carbide substrate. The polycrystalline diamond layer has a working surface and an outer peripheral surface and is characterized by having an annular region or a portion thereof adjacent the peripheral surface that is lean in catalysing material. A region adjacent the working surface is also lean in catalysing material such that in use, as a wear scar develops, both the leading edge and the trailing edge thereof are located in a region lean in catalysing material.

Owner:BAKER HUGHES INC

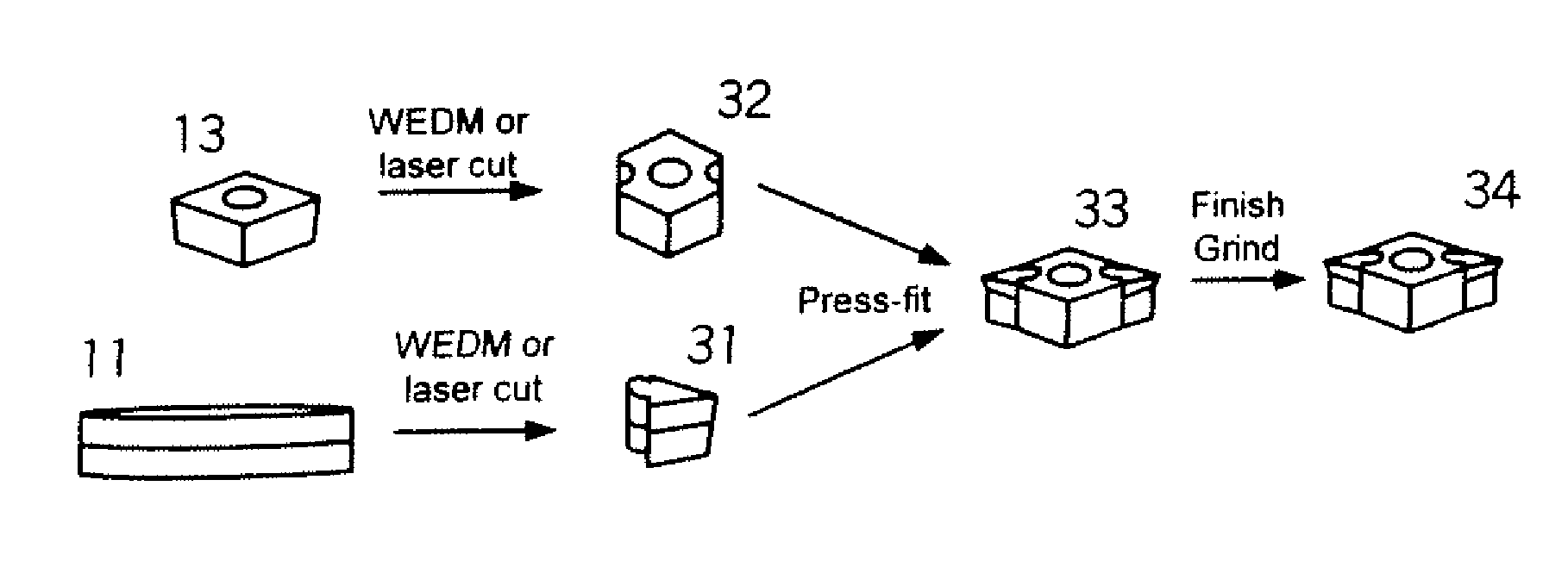

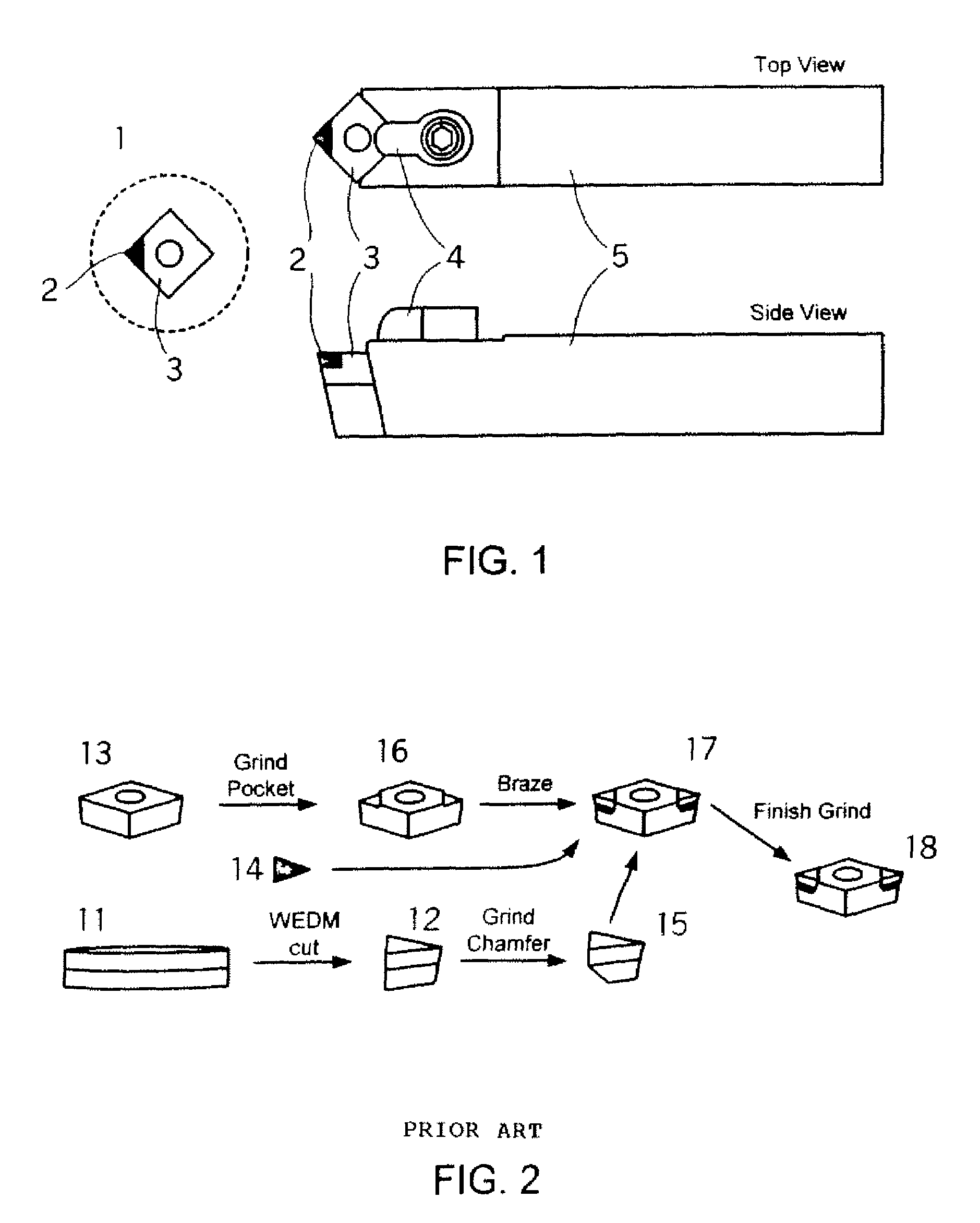

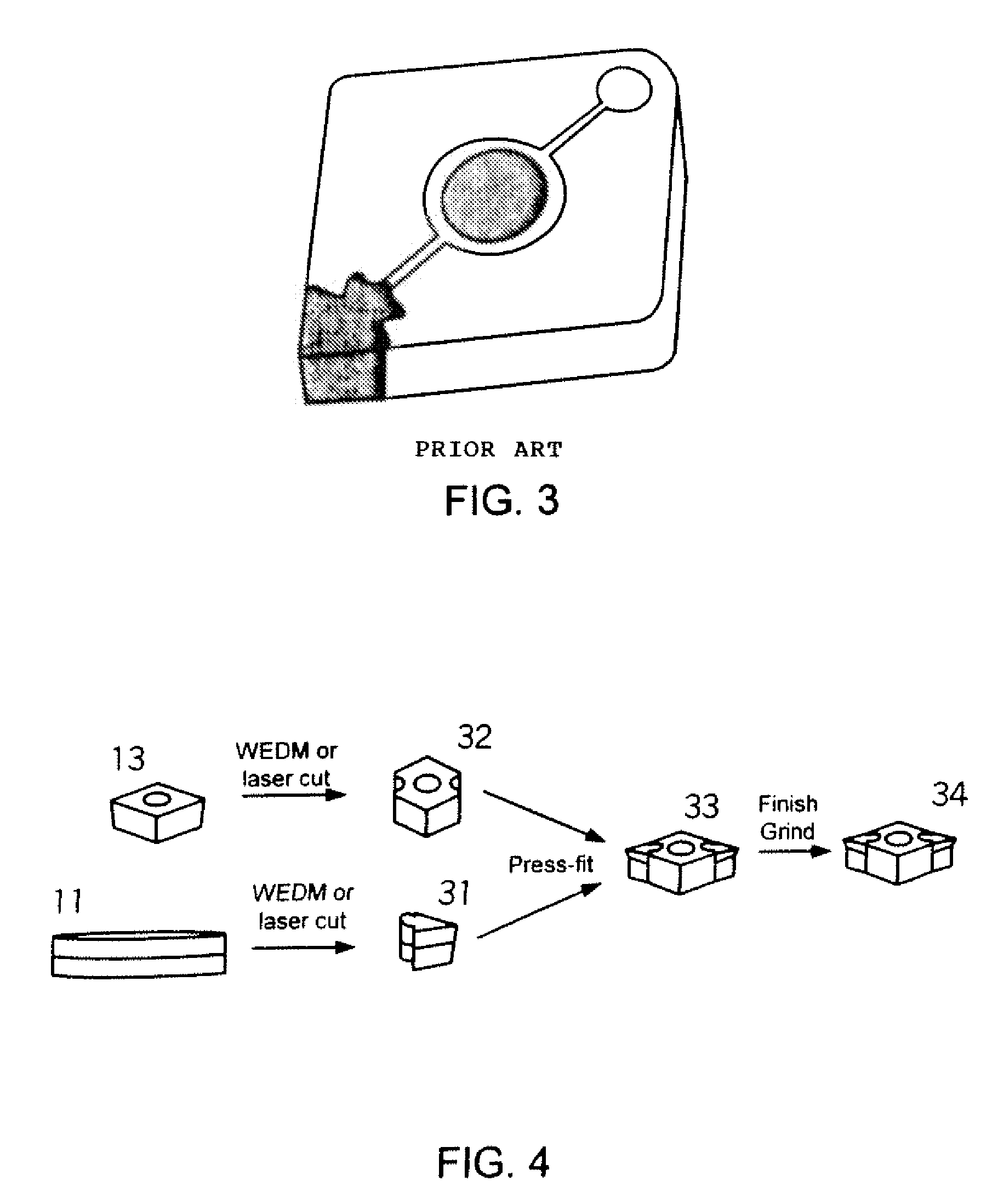

Cutting tool inserts and methods to manufacture

The present invention relates to cutting tool inserts. A cutting tool insert includes an abrasive tip of a hard material, an abrasive or superabrasive material. A cutting tool insert is bonded to an insert body by mechanical force. The mechanical forces are generated through deformation of mating geometric features on the abrasive tip and insert body.

Owner:DIAMOND INNOVATIONS INC

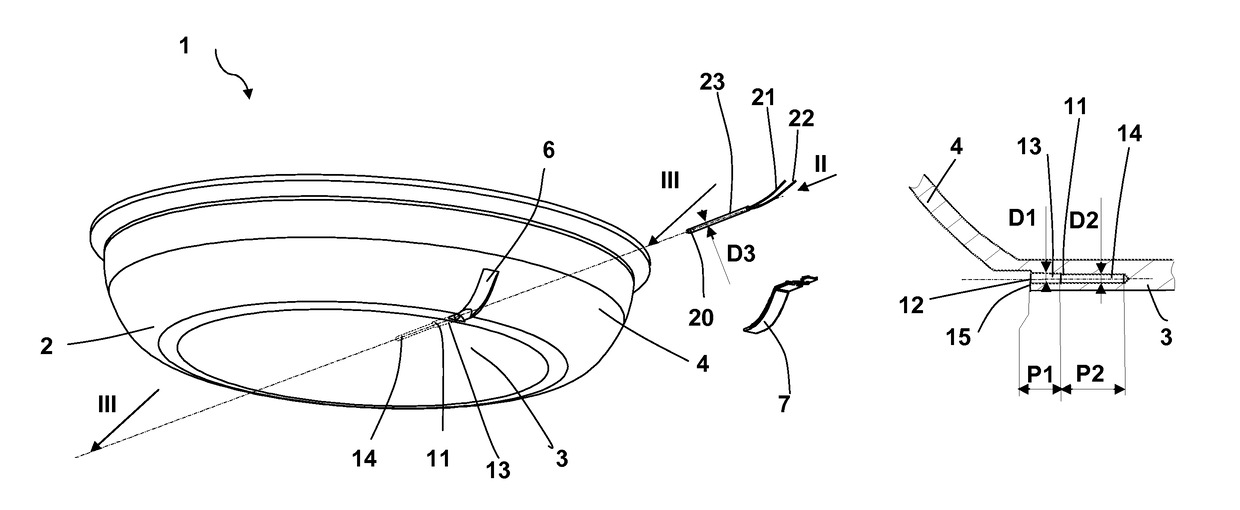

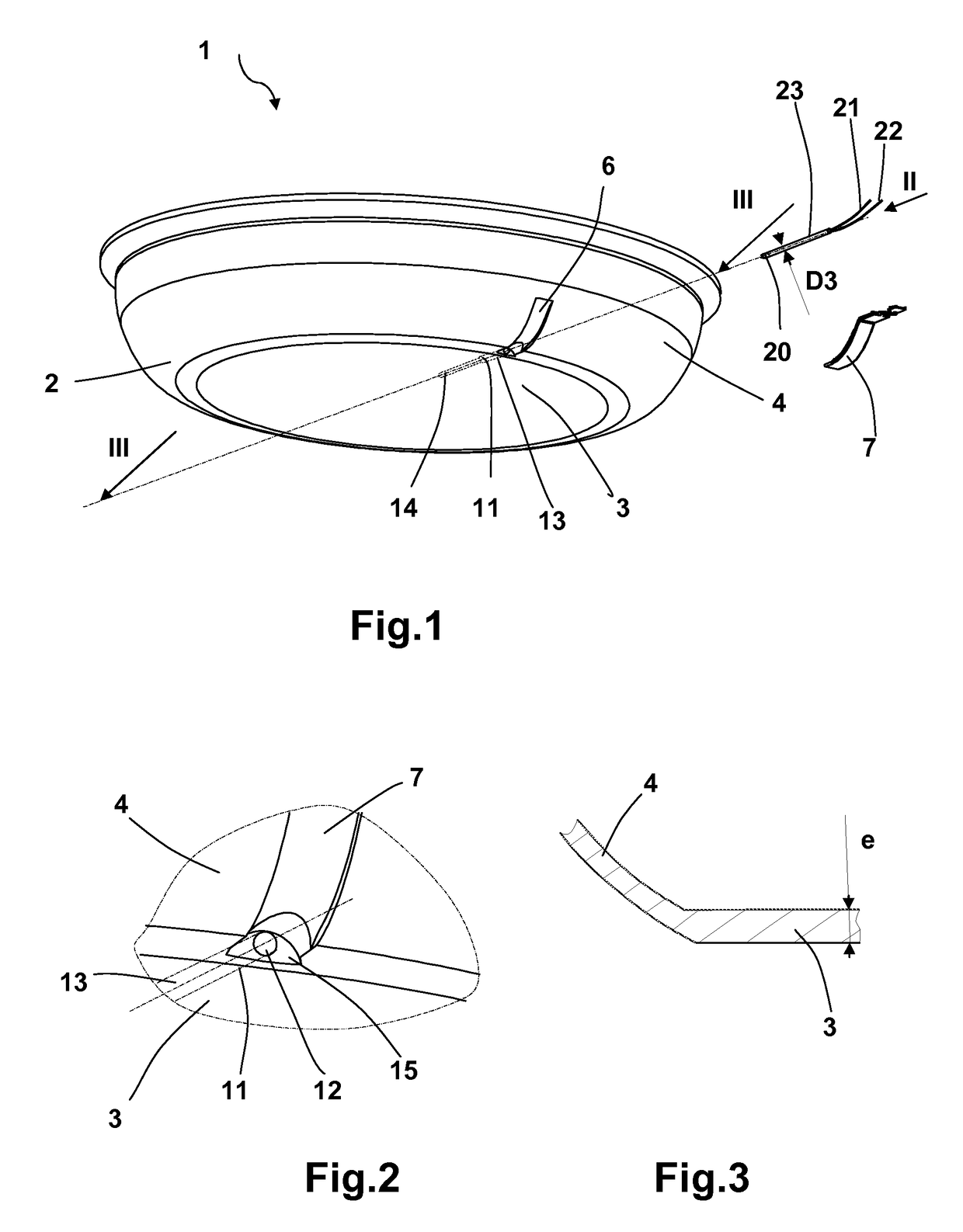

Machining mechanical parts with a hollow cylindrical tool

ActiveUS20060291970A1Simple processAvoid high frequency noiseThread cutting feeding devicesDrilling rodsWood shavingsMechanical components

The present invention relates to a device for machining mechanical parts by means of a hollow cylindrical tool presenting a distal end with a free edge that is shaped to perform machining when said tool is rotated about its axis. In accordance with the invention, the hollow cylindrical tool is fitted internally with a transverse member forming a shaving-breaker, and said hollow cylindrical tool is secured axially to a distal end of a hollow cylindrical spindle, said hollow cylindrical spindle being mounted to rotate about its own axis on a support plate, and being driven externally by rotary drive means mounted on said support plate, and said hollow cylindrical spindle having a proximal end facing and directly adjacent to a hollow cylindrical endpiece secured to said support plate and connected to a suction hose, such that the machining shavings can be evacuated internally by passing successively through the hollow cylindrical tool going round the transverse member forming a shaving-breaker, through the hollow cylindrical spindle, through the hollow cylindrical endpiece, and through the suction hose.

Owner:ROMER INC

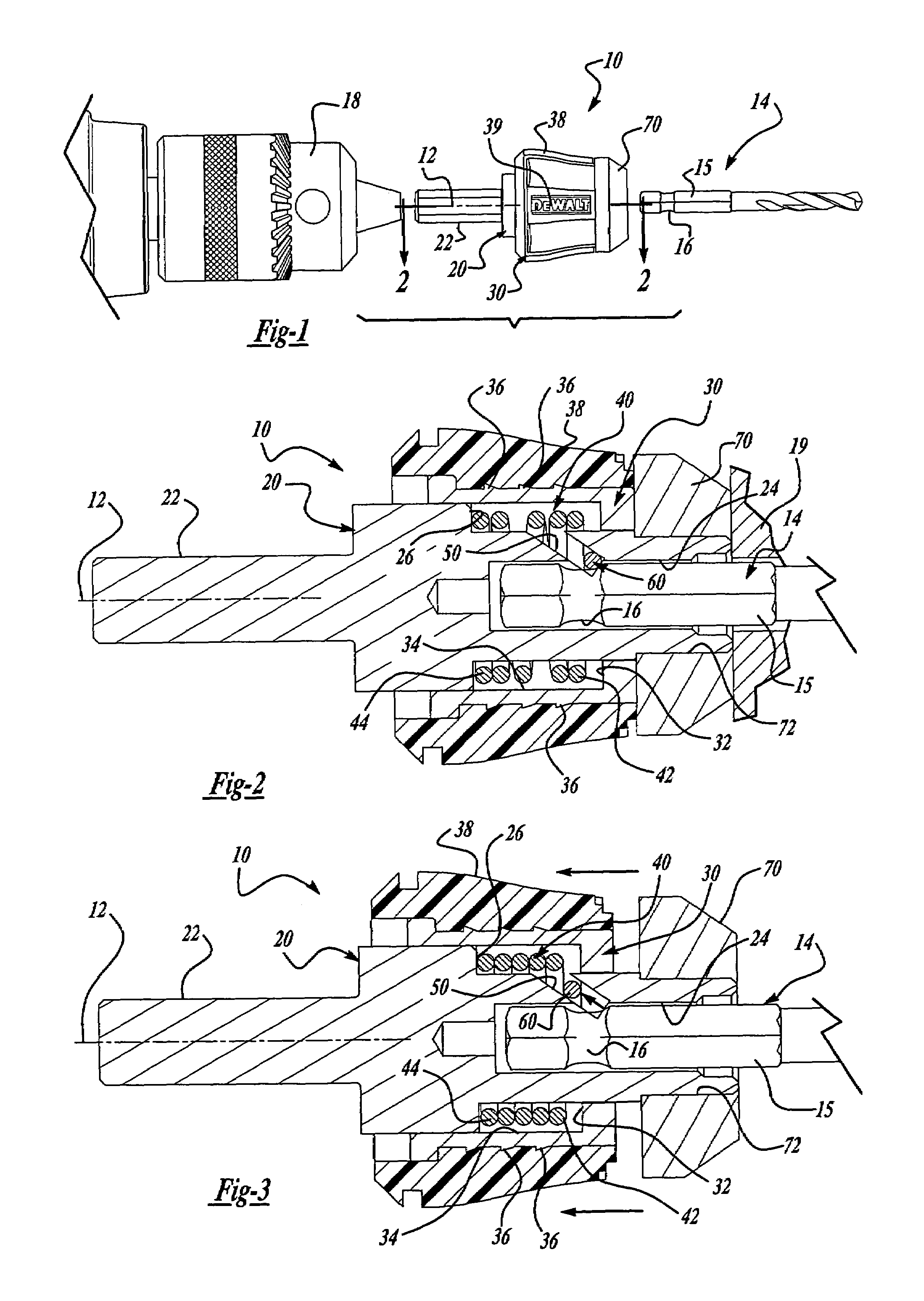

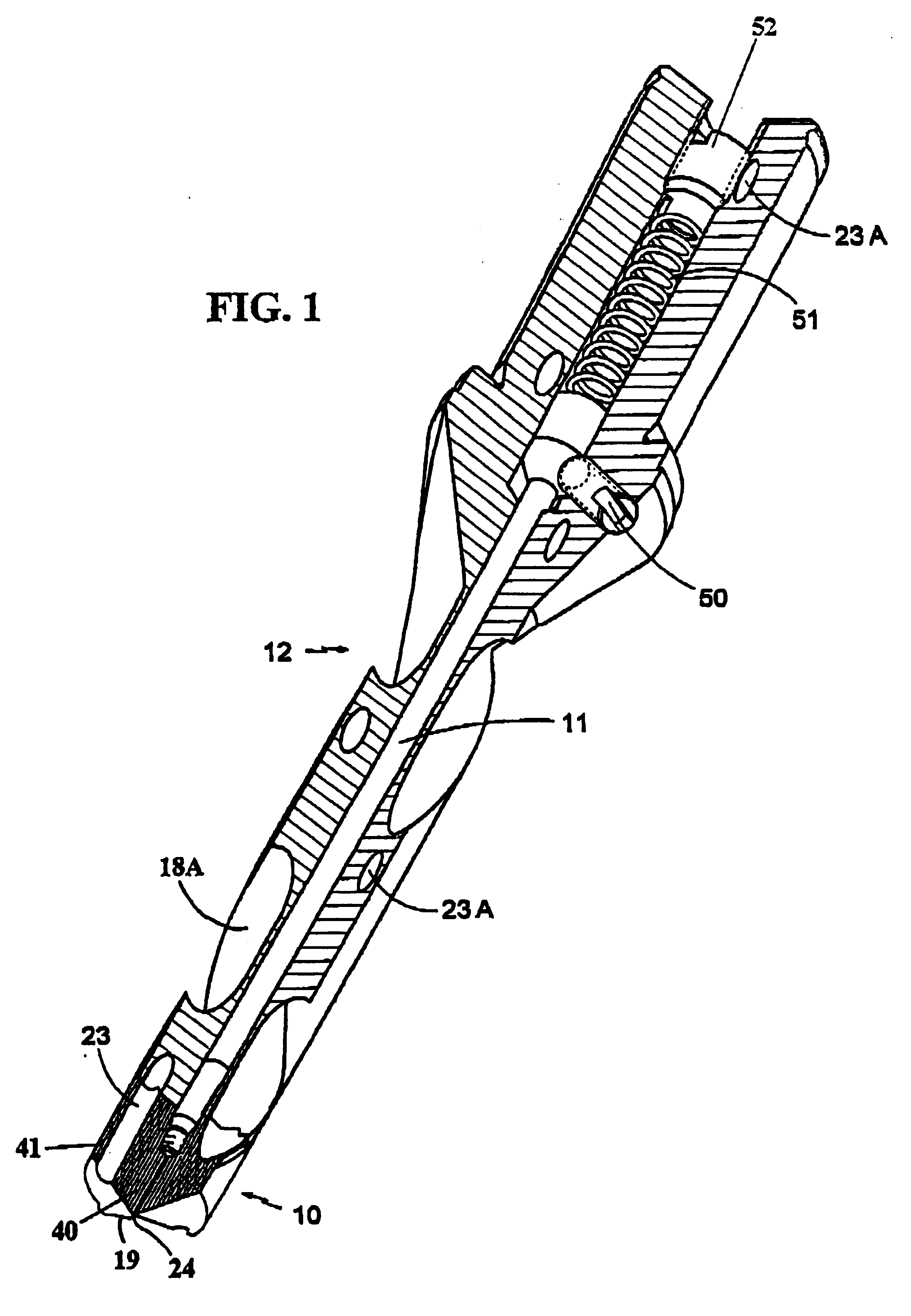

Quick-acting tool bit holder

InactiveUS7086813B1Minimize off-axis “ cocking ”Prevent over-retractionThread cutting machinesTransportation and packagingTool bitCoil spring

A “snap-in” bit chuck assembly for a rotary hand or powered tool, includes an elongated body having a hex shank at its rearward end, an elongated retraction collar slidably disposed on the body, and an outer retaining collar fixed to the forward end of the body. The body has a coaxial hex socket formed therein to allow a reversible tool to be inserted thereinto. A slot is formed in the body, between the outer surface of the body and the internal hex socket. A coil spring surrounds the body, inside the retraction collar, and normally biases the retraction collar forwardly and biases a retaining clip toward the bottom of the angular slot. The retaining clip slides outwardly in the angular slot, against the bias of the coil spring, as the reversible tool is inserted, where a recess on the reversible tool is engaged and retained by the clip. The tool is removed by sliding the retraction collar rearwardly, to compress the coil spring and allow the retaining clip to retract back up the slot. The clip is directly engaged by the coil spring and has two legs extending about the body so that the clip is self-retaining. The clip legs extend around the body such that the retraction force on the coil spring is directed through the center of the coil spring to keep it coaxially aligned with the body.

Owner:BLACK & DECKER INC

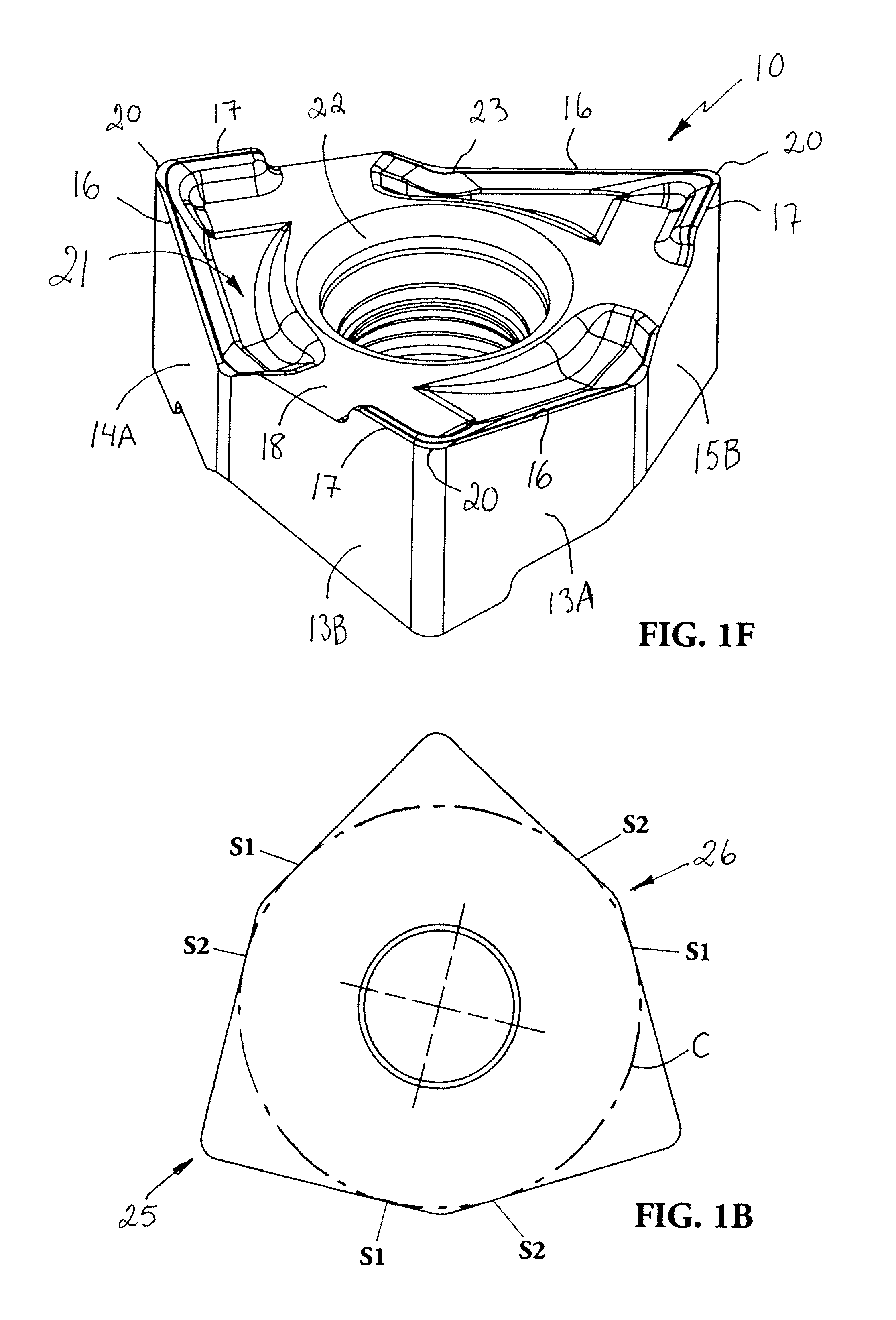

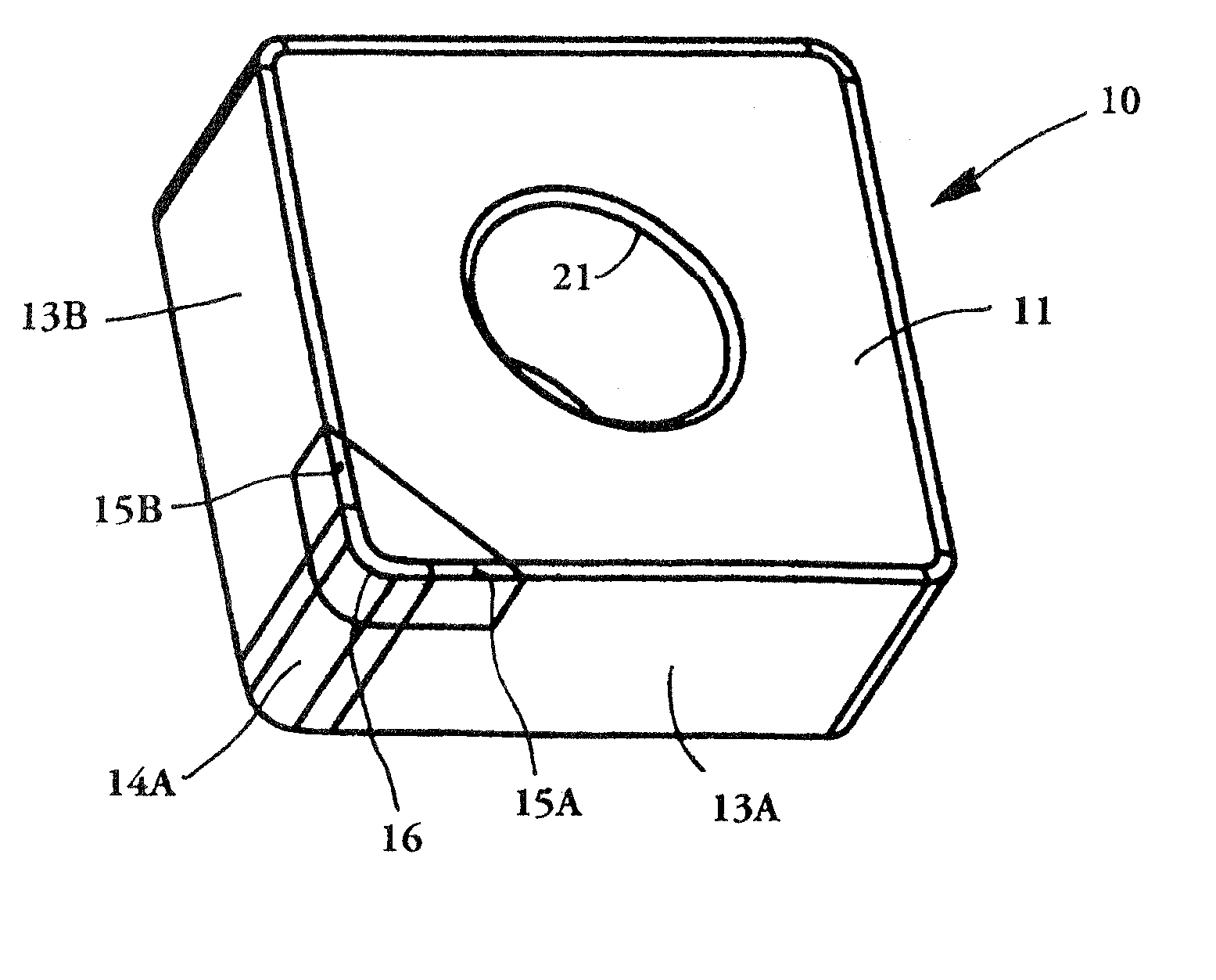

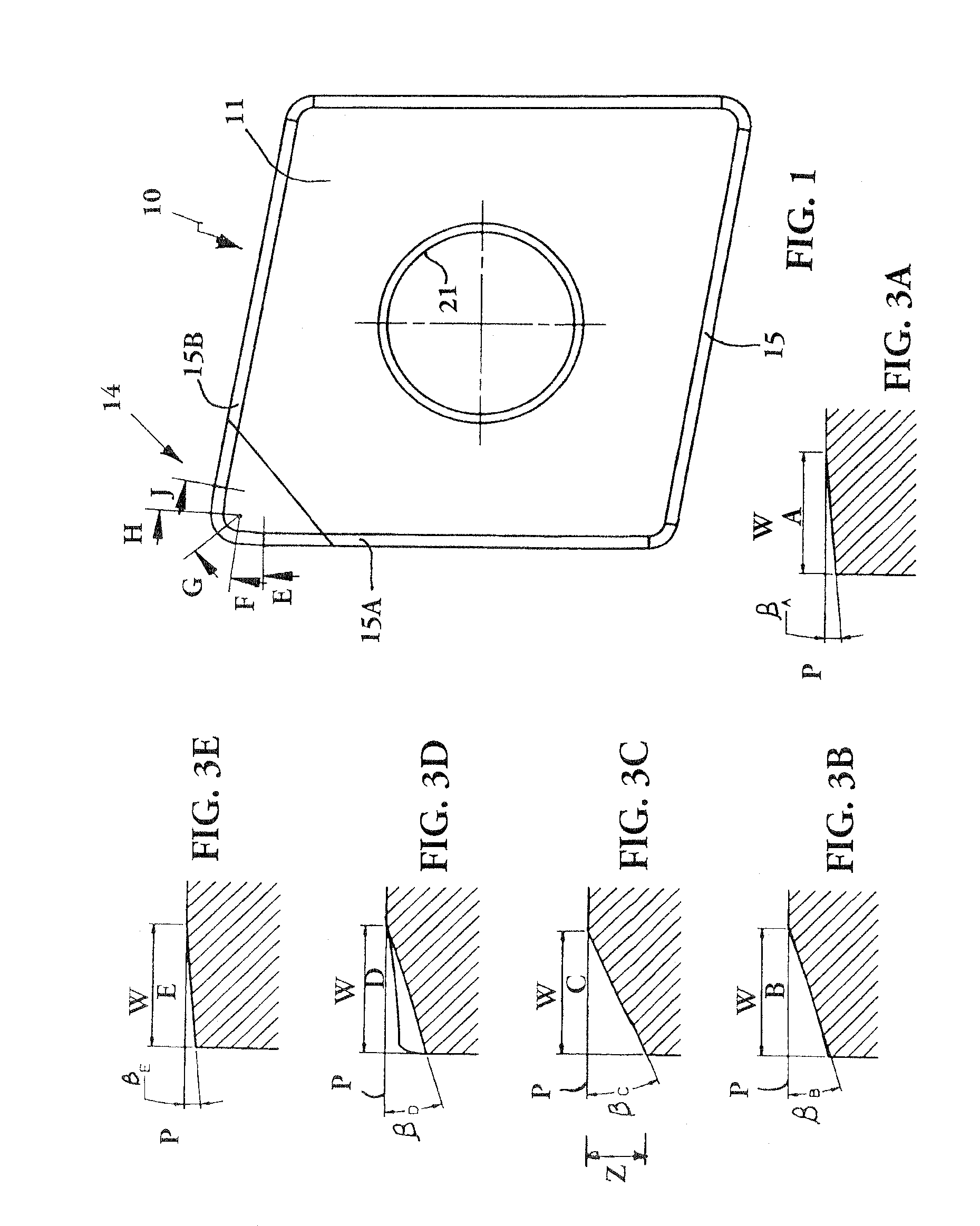

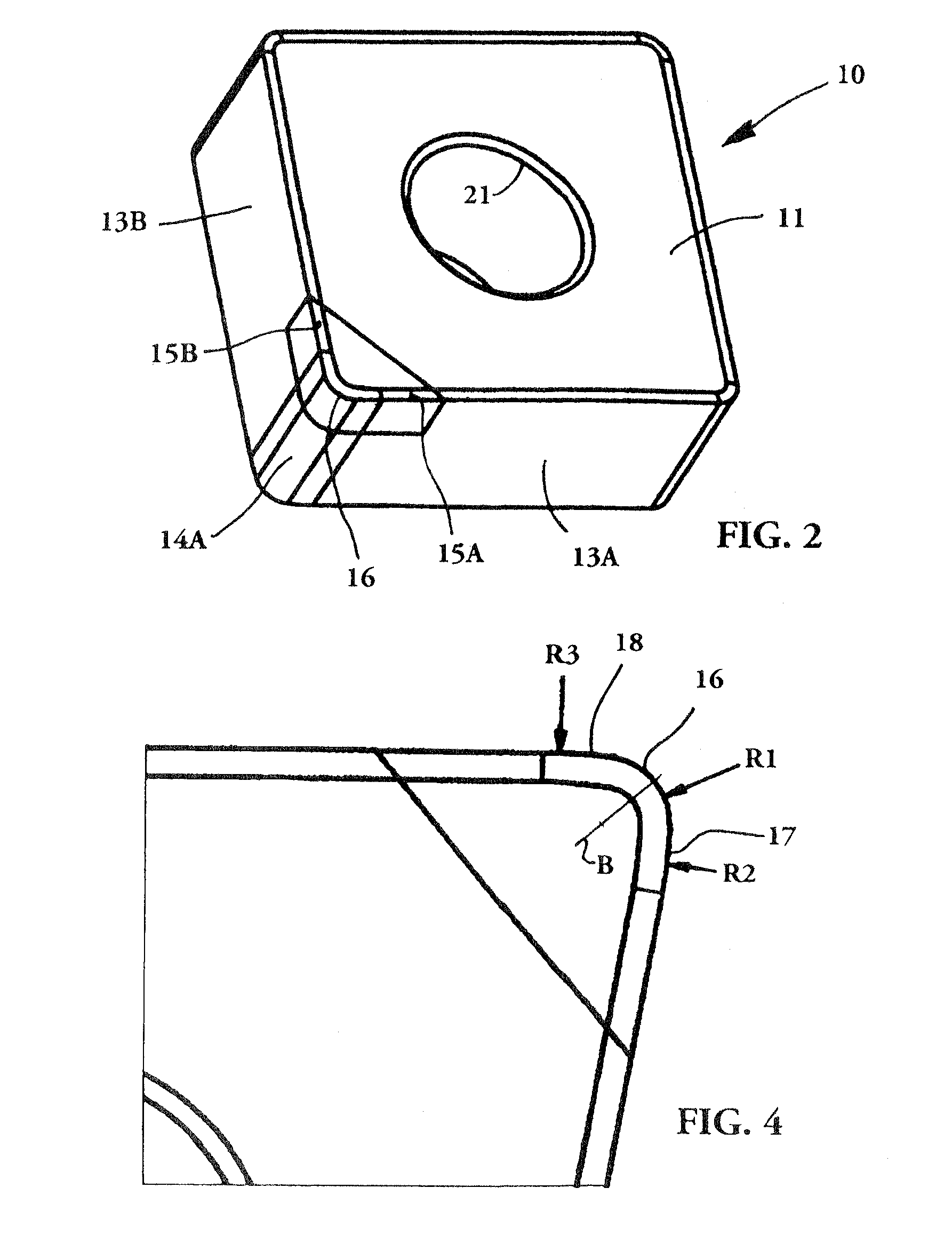

A cutting insert

ActiveUS20060228179A1Improve finenessLittle changeCutting insertsWorkpiecesEngineeringMechanical engineering

The present invention relates to a metal cutting insert that is primarily intended for turning operations. The cutting insert comprises an upper surface, a lower surface substantially parallel with said upper surface, and at least three side surfaces extending between said upper and lower surfaces. A transition between two adjacent side surfaces forms a rounded nose radius surface at a cutting insert corner. The cutting insert includes a peripheral land bridging the upper and side surfaces at least at the corner portion at a chamfer angle. An intersection of the land and the nose radius surface forms a nose cutting edge. The nose cutting edge is defined by at least one radius. The cutting corner includes at least one curved wiper edge. The chamfer angle in a cross-section at the nose cutting edge is larger than the chamfer angle in a cross-section a distance away from the nose cutting edge.

Owner:SECO TOOLS AB

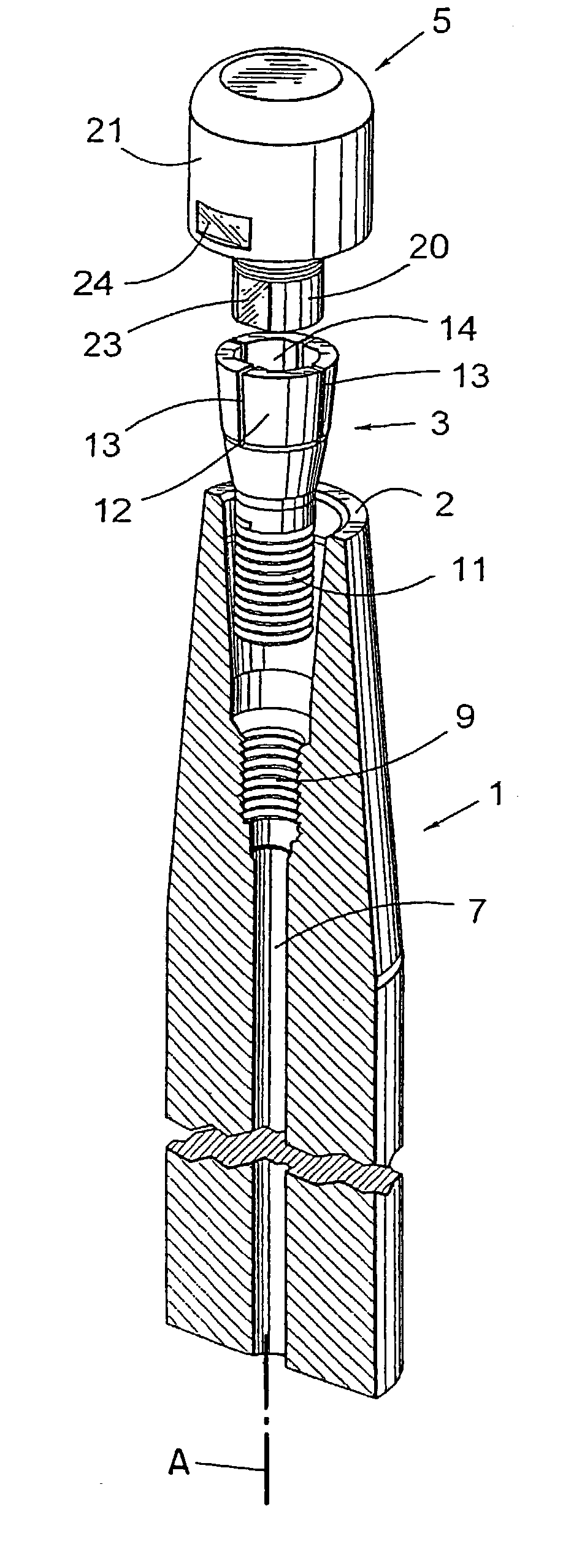

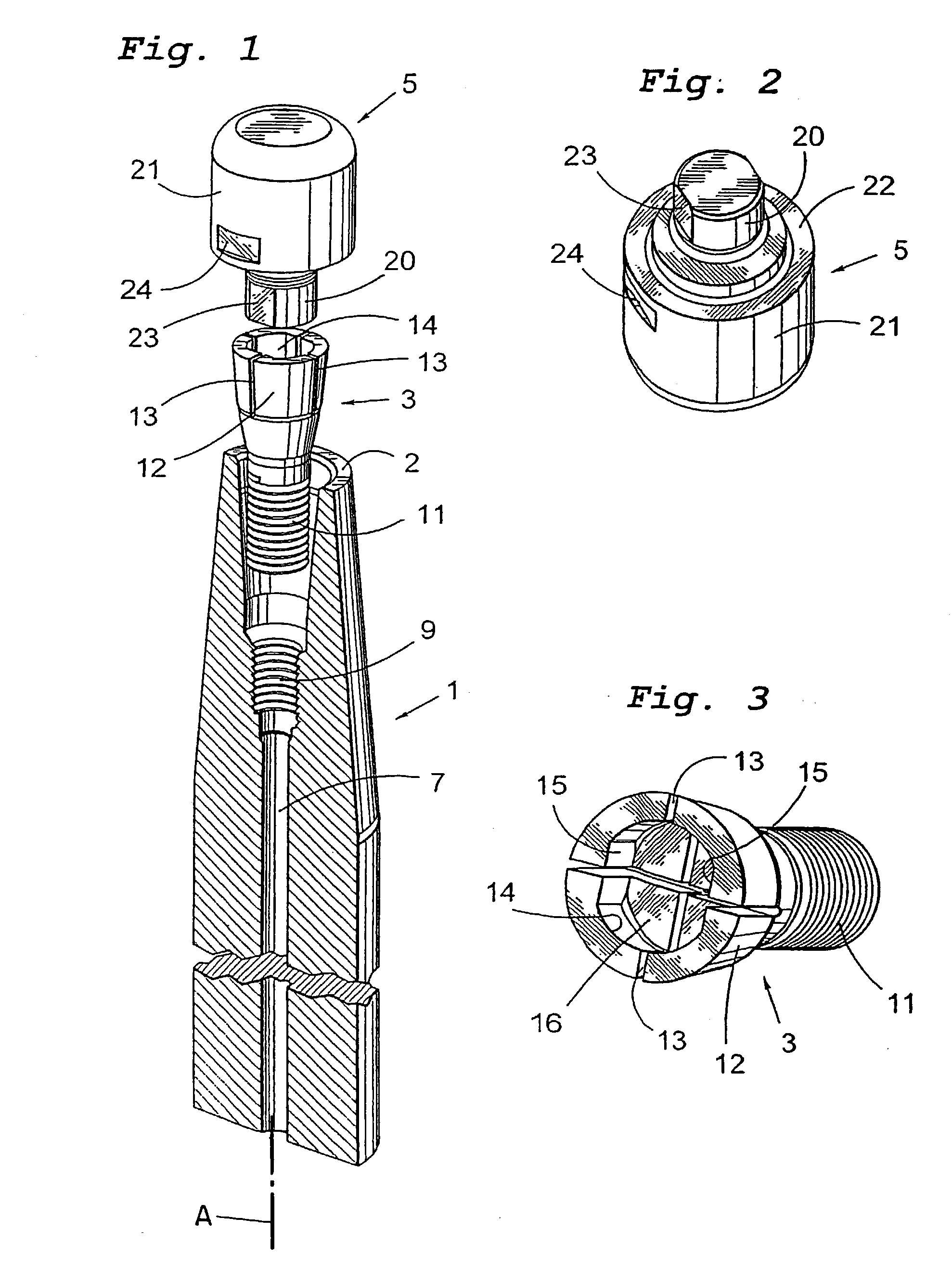

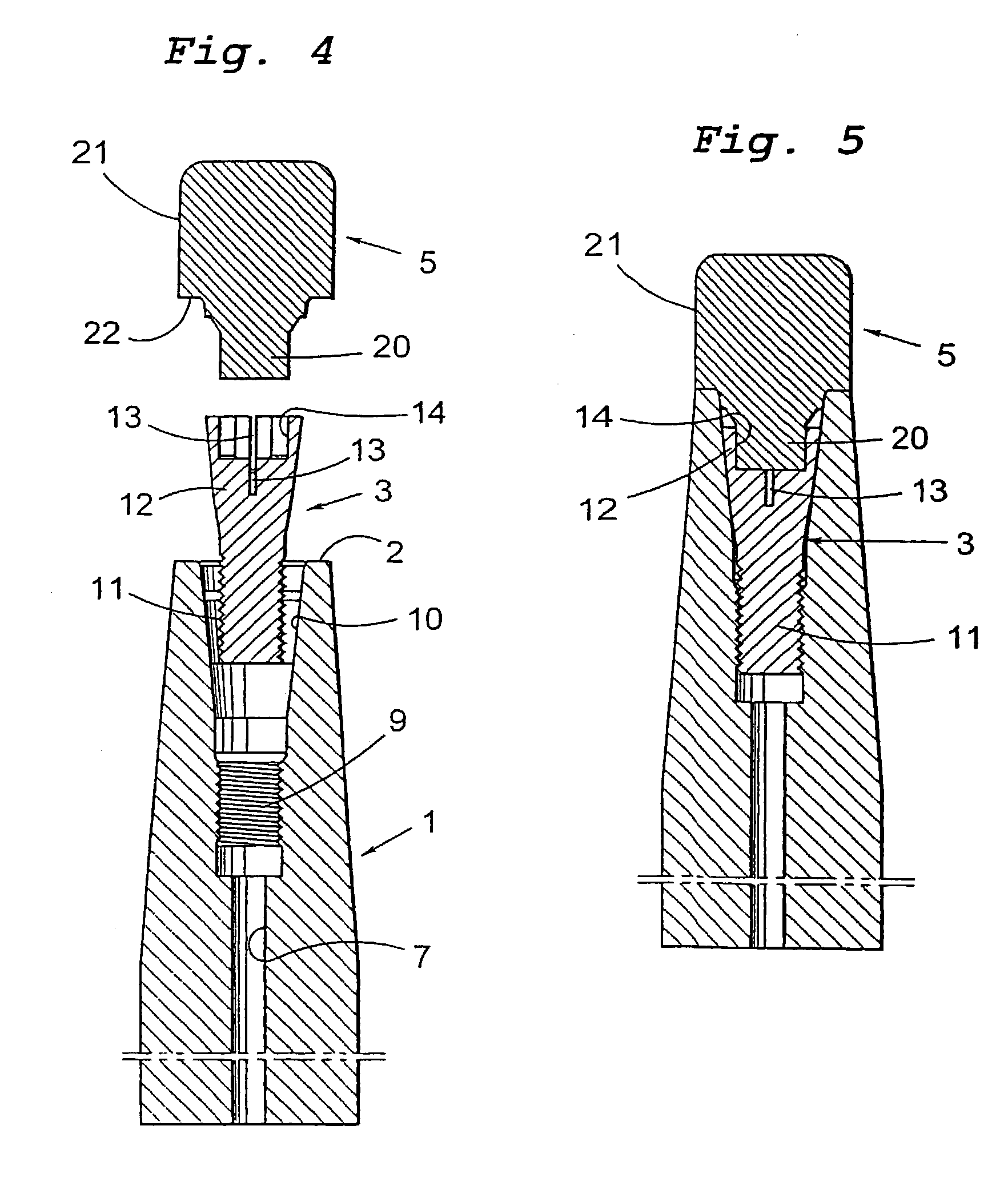

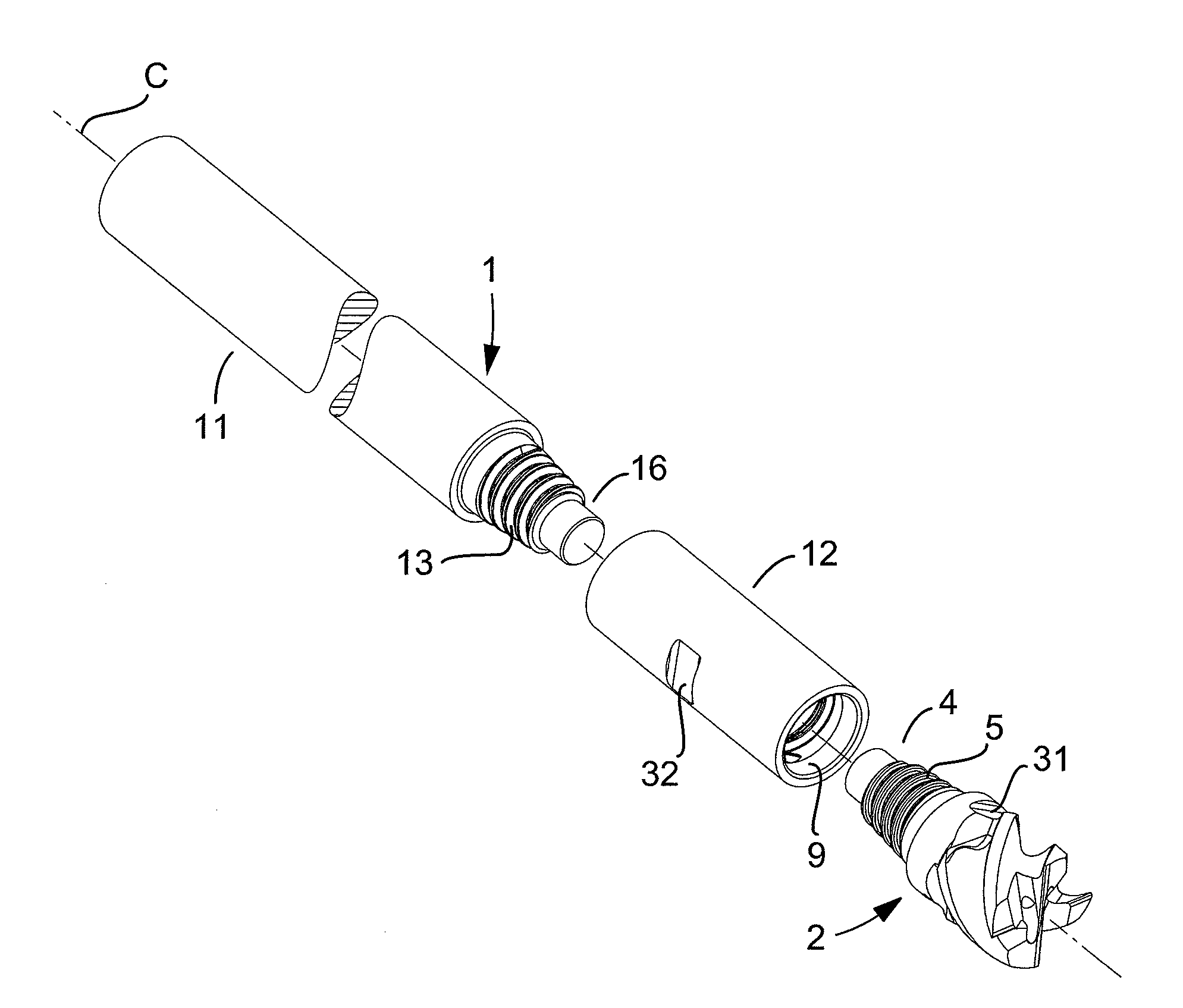

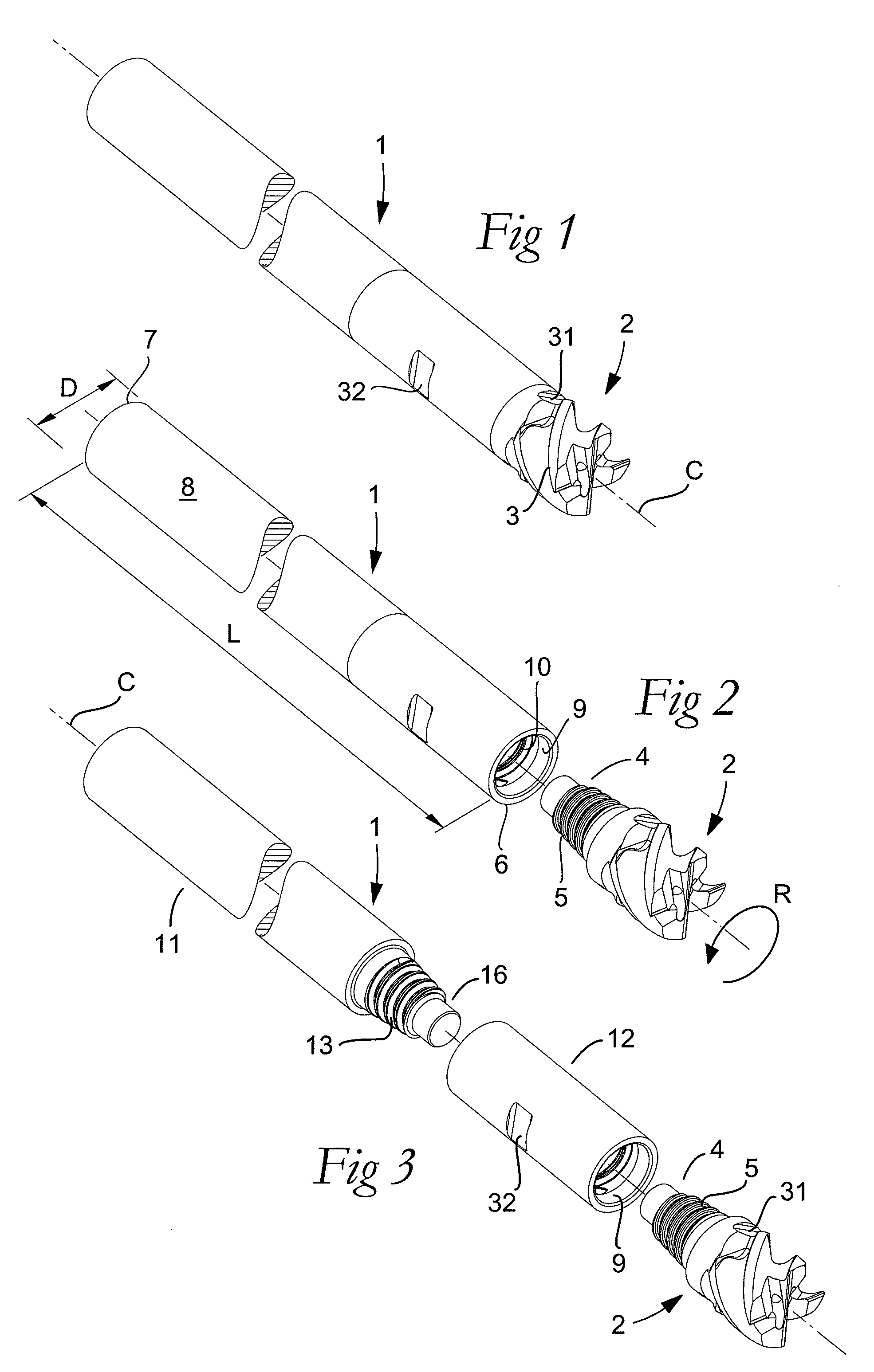

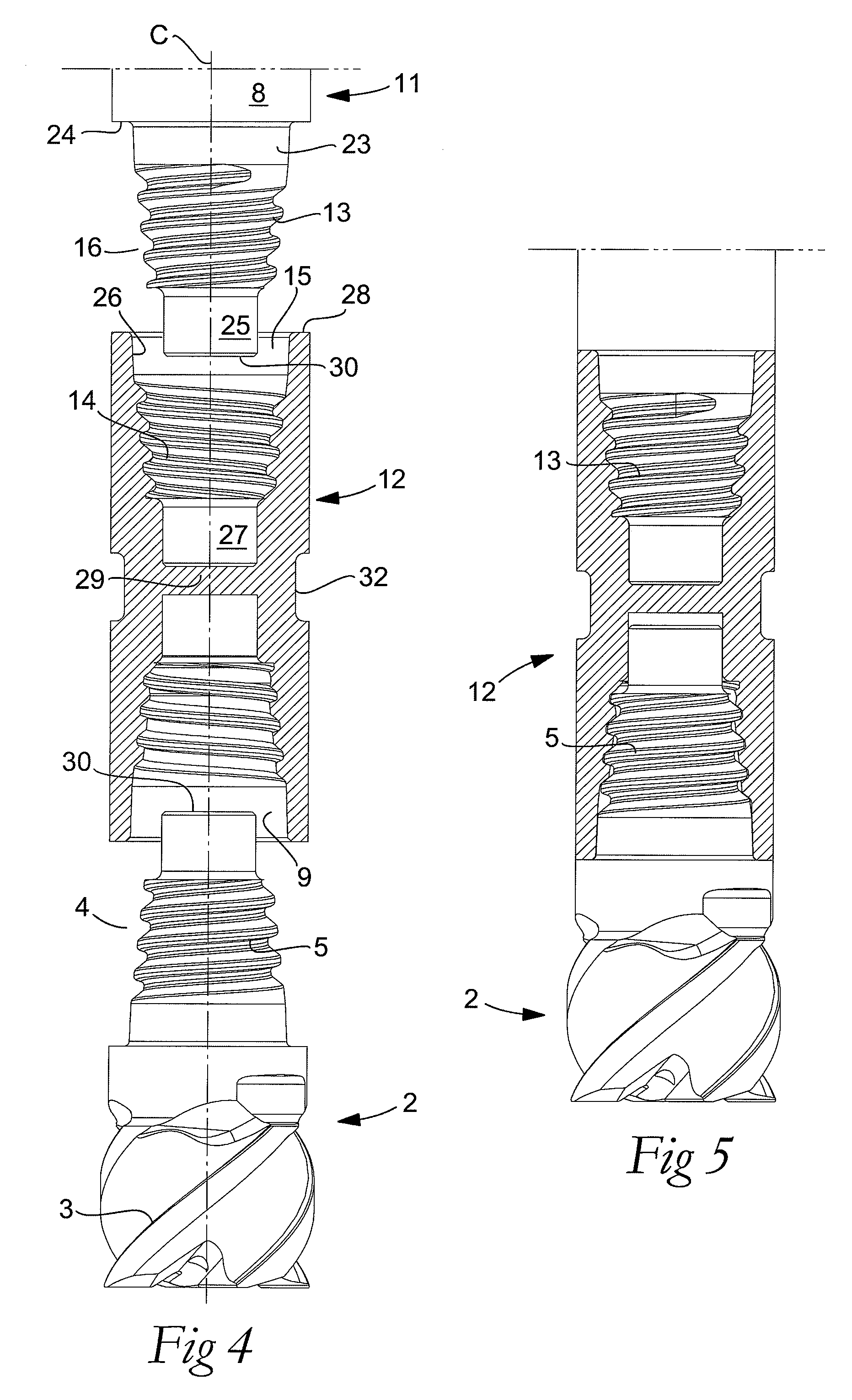

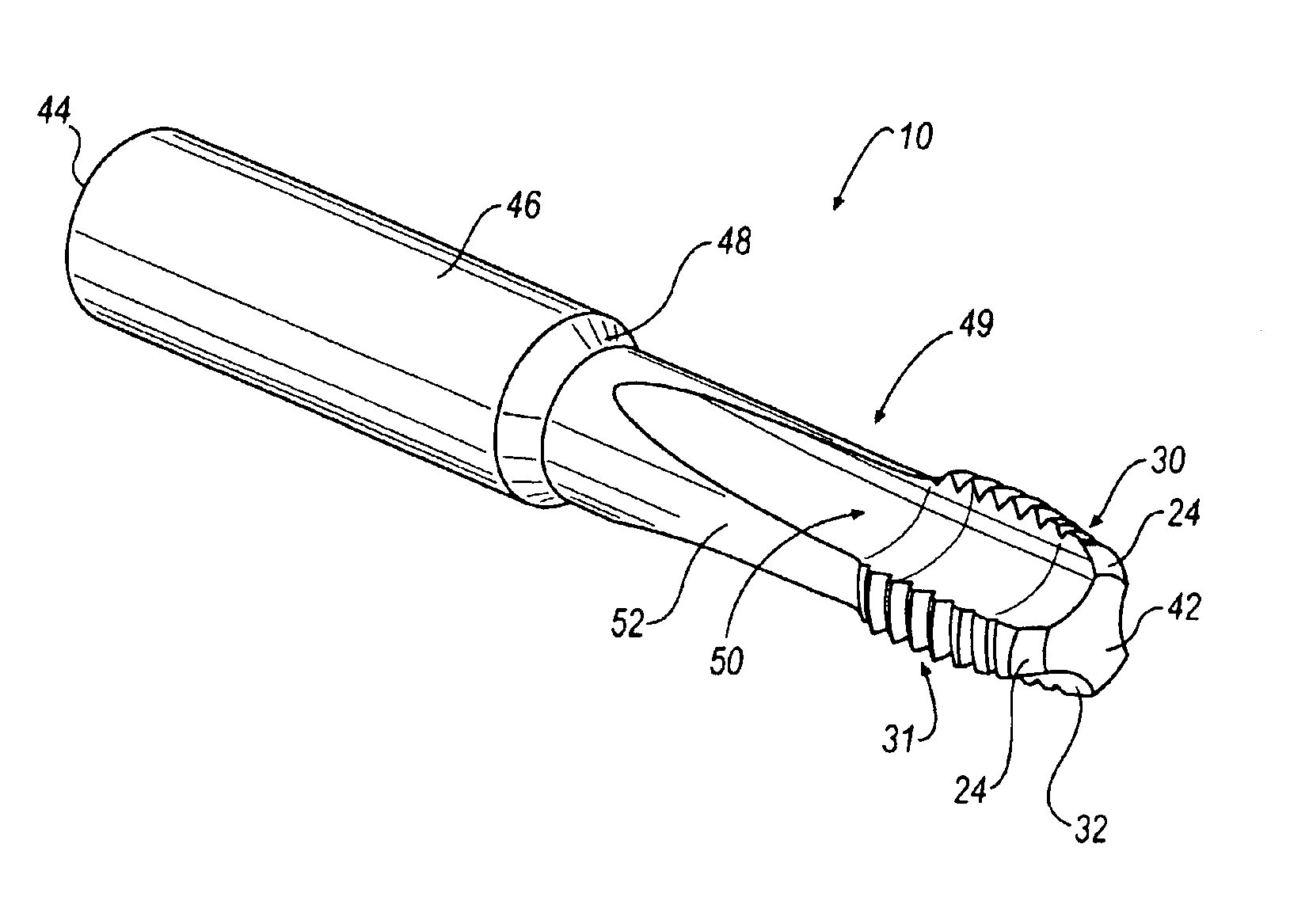

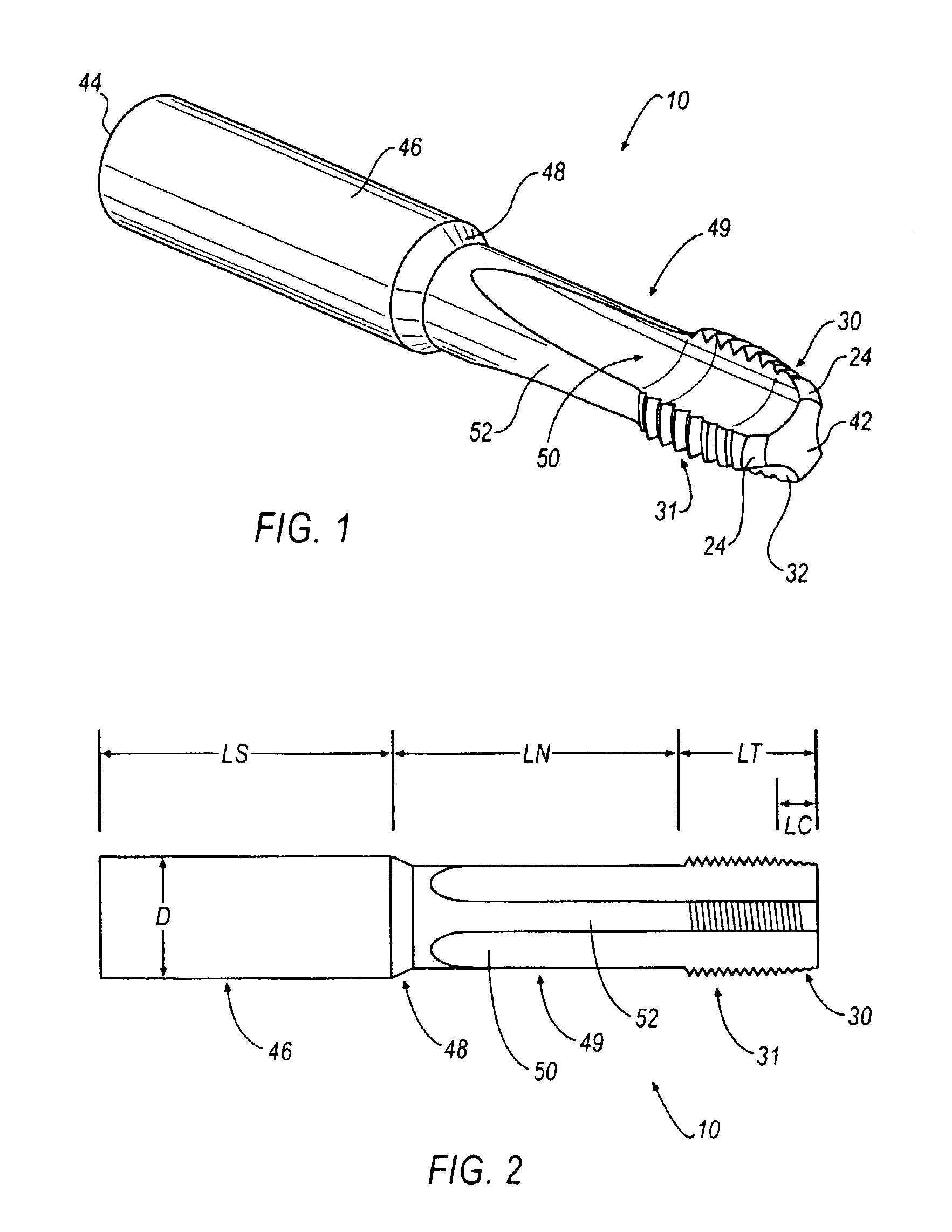

Tool for rotary chip removal, a tool tip and a method for manufacturing a tool tip

InactiveUS6551035B1Eliminate the problemWood turning toolsTransportation and packagingCouplingScrew thread

A rotary chip-removing tool includes a rotary tool body and a tool tip fastened on a front end thereof. The tool tip is formed of an injection molded body which has an integral cutting edge at its front end, and a coupling structure at its rear end. The coupling structure can be in the form of a threaded hole, or a rearward projection, for coupling the tool tip against the tool body. The tool tip is formed of first and second materials. The first material forms at least part of the cutting edge, and the second material forms the coupling structure. The first material is more brittle than the second material, and the second material is tougher than the first material.

Owner:SECO TOOLS AB

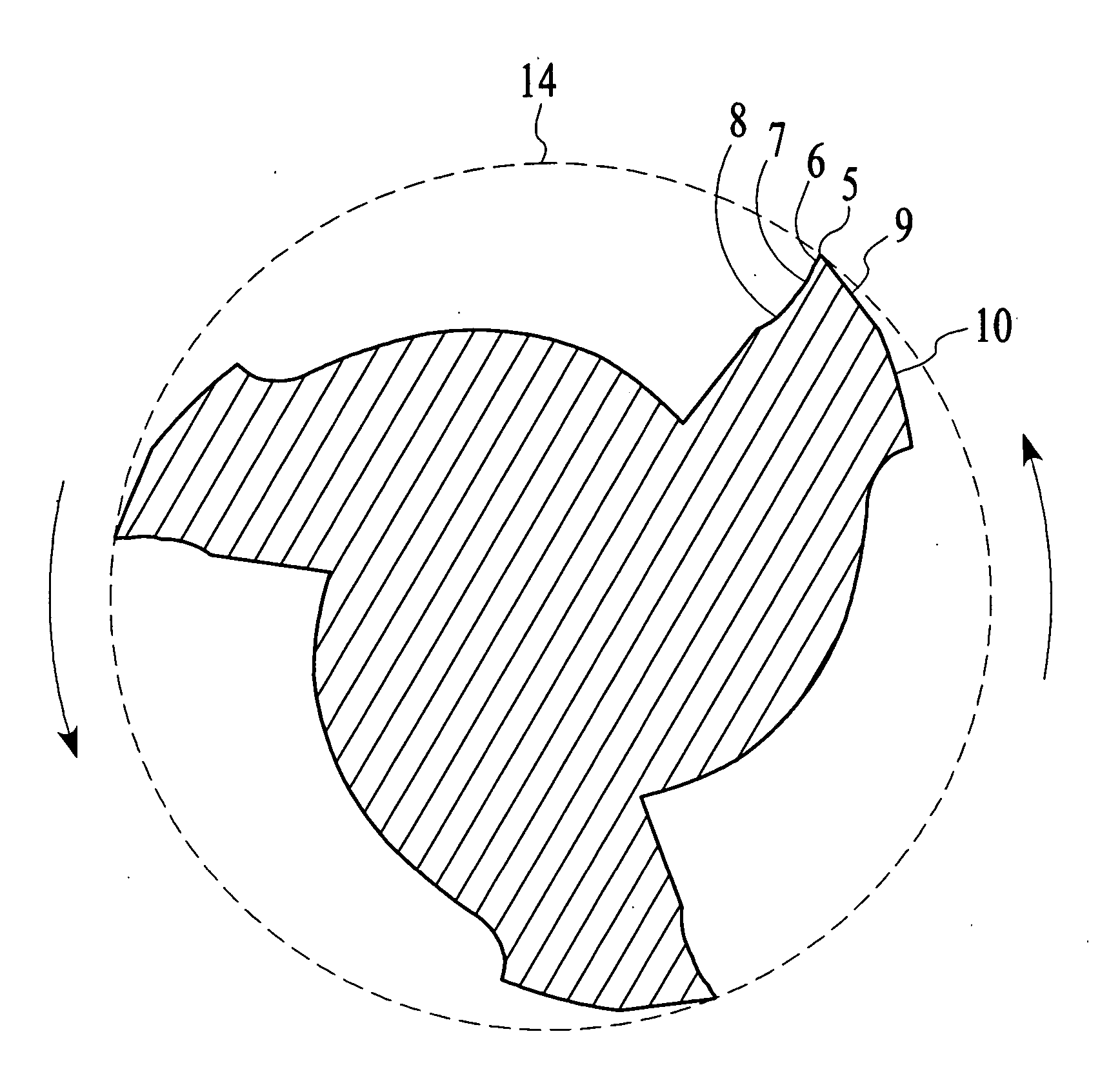

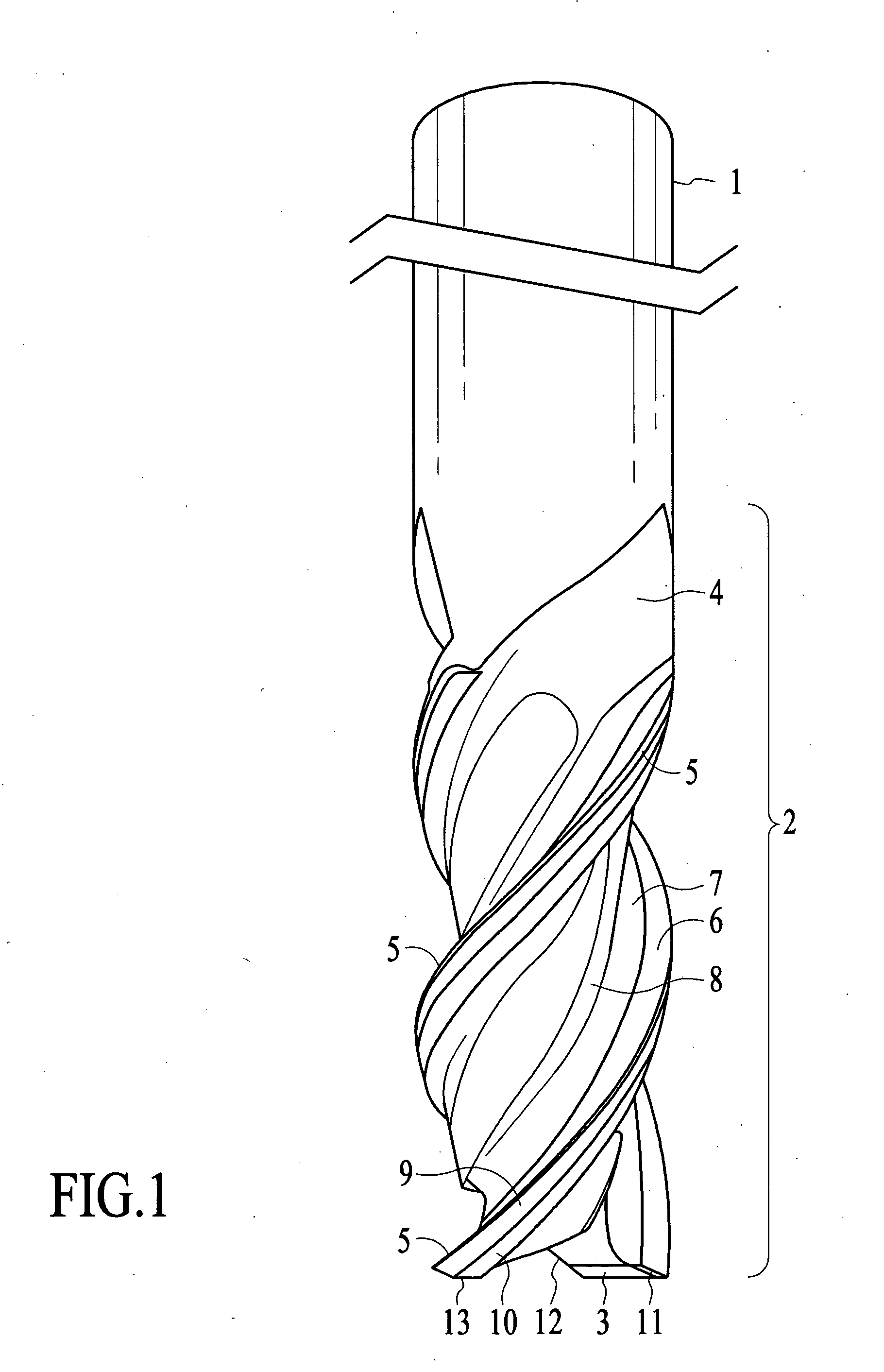

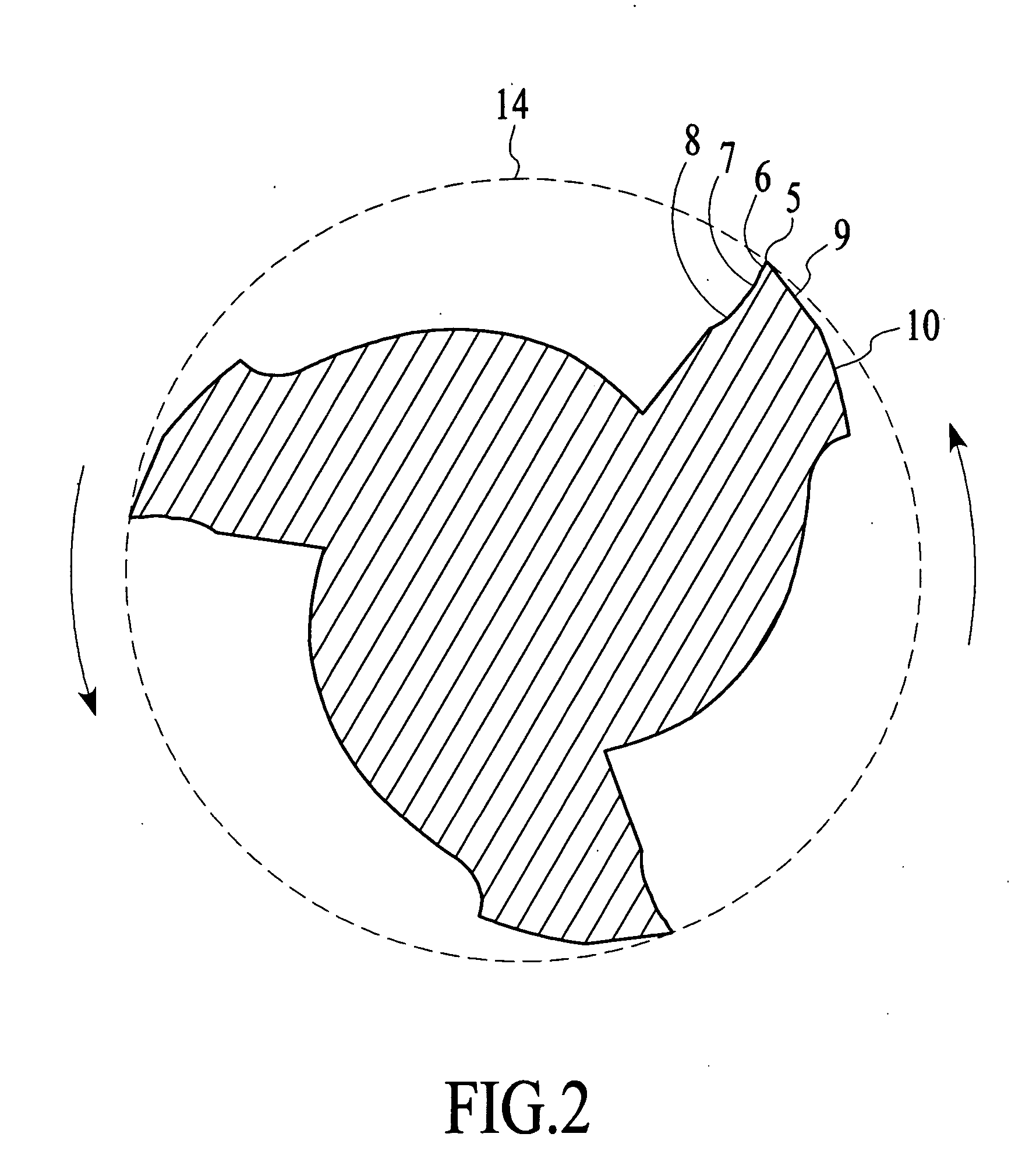

End mill

InactiveUS20060067797A1Aggressive and deep cutLess forceMilling cuttersWorkpiecesUltra fineEngineering

An end mill with a peripheral margin which increases in width from the terminal end of the tool to the shank portion of the tool. The end mill also has a tooth face made up of three tooth-face walls The depth of the tool face gradually decreases from the terminal end to the shank portion of the tool. The end mill also has an end cutting face which includes a flat, narrow land at the outmost region of the end cutting end. The end mill has chip breakers with rounded peripheral corners. The end mill can be made up of ultra-fine micro grain tungsten carbide with a cobalt content which varies throughout the length of the tool.

Owner:CALAMIA GUY ALLEN

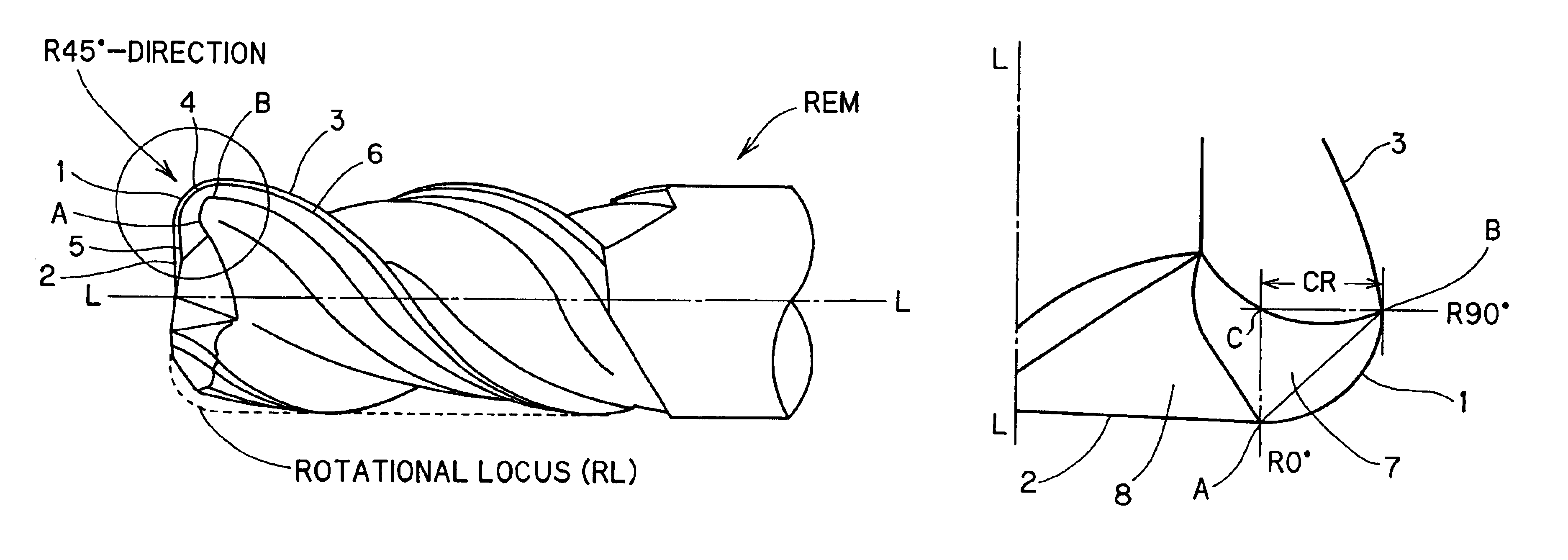

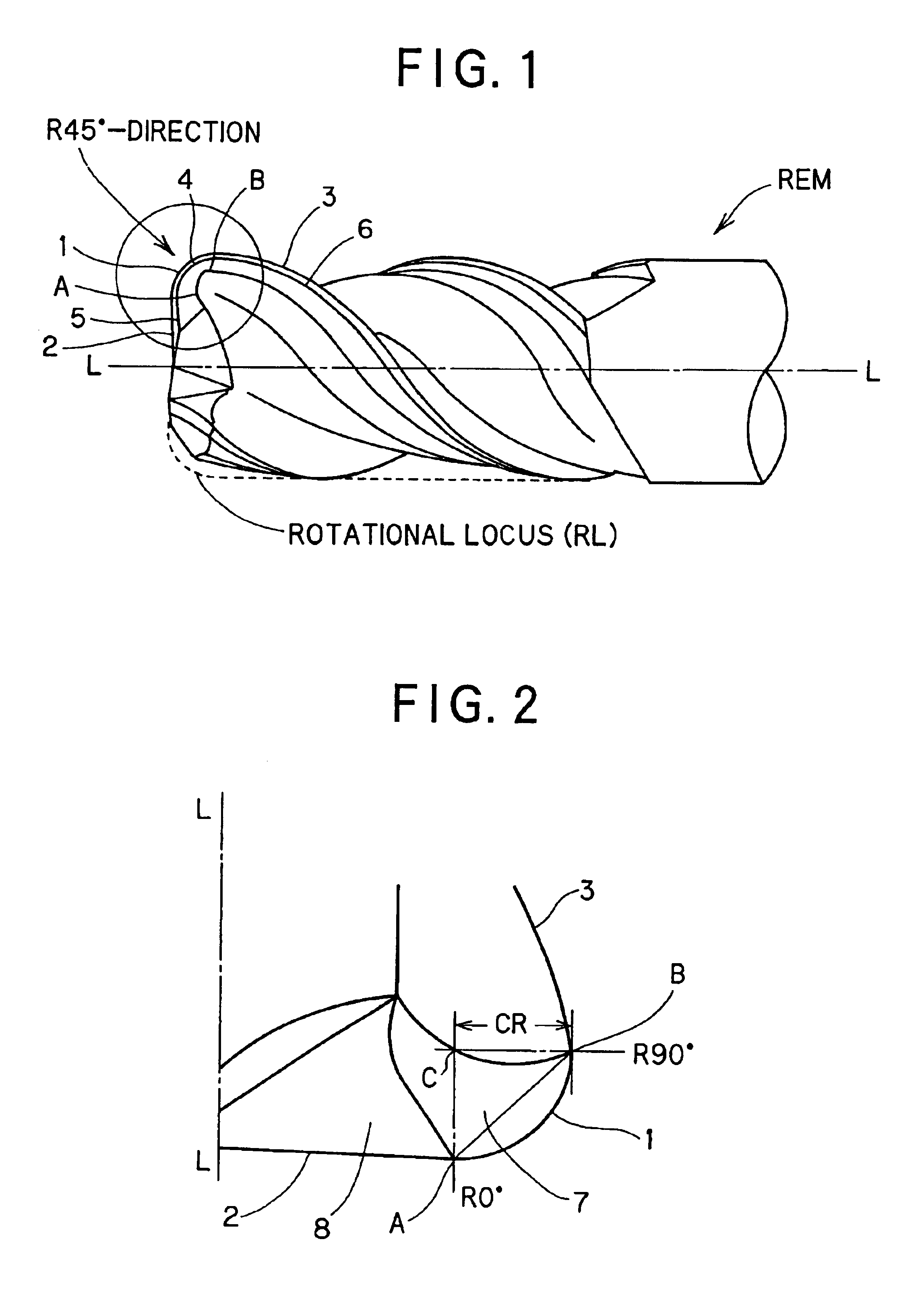

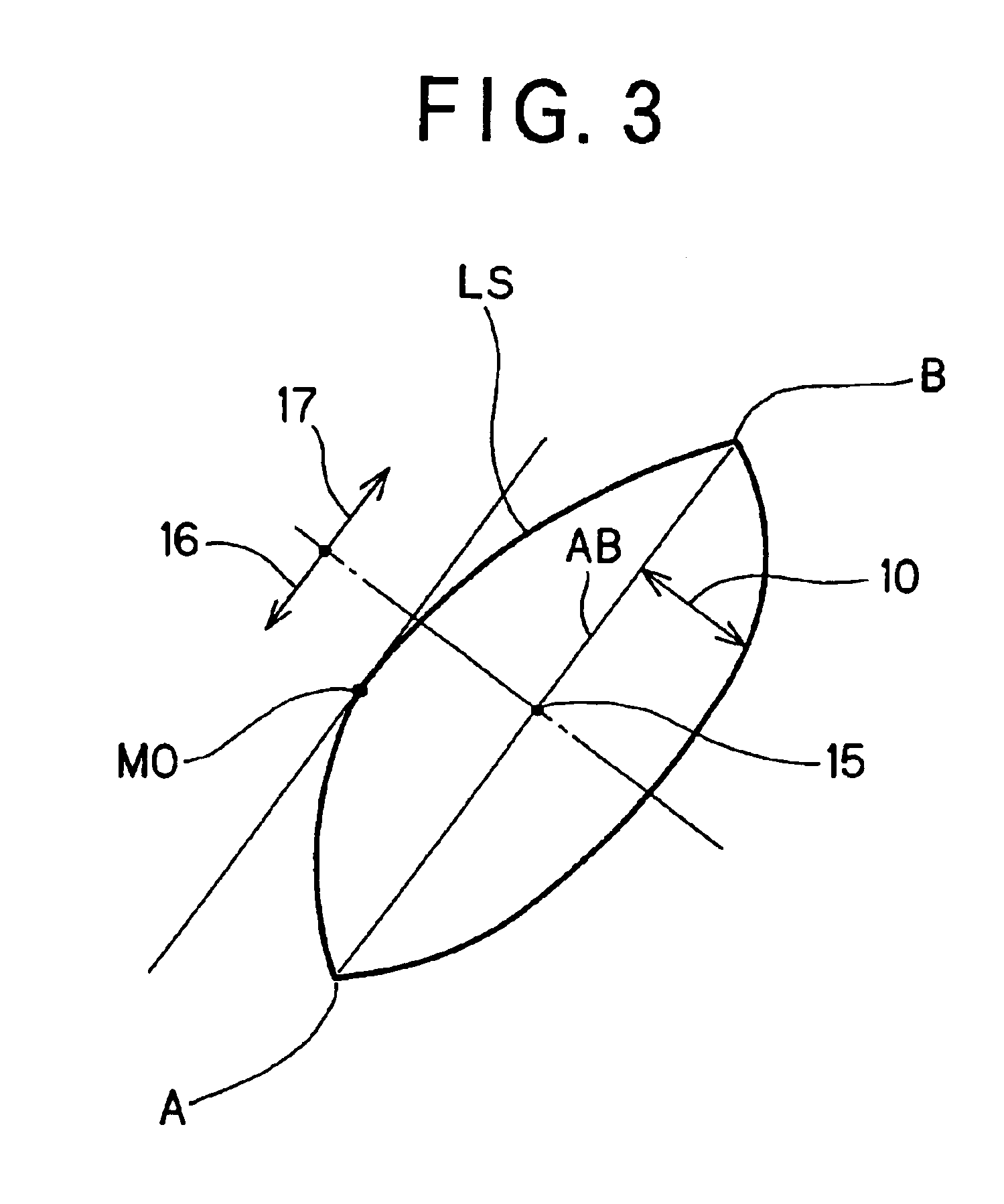

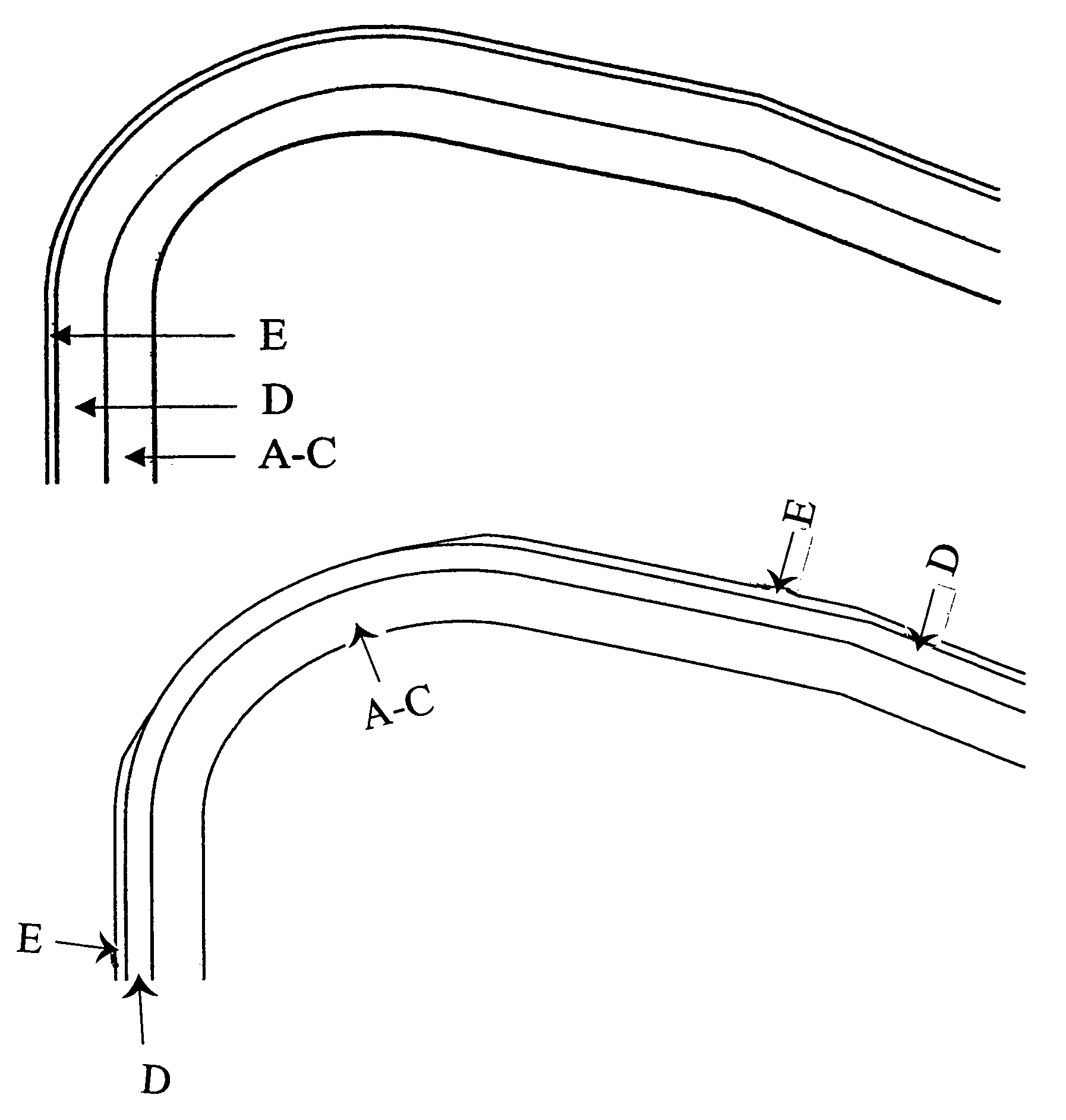

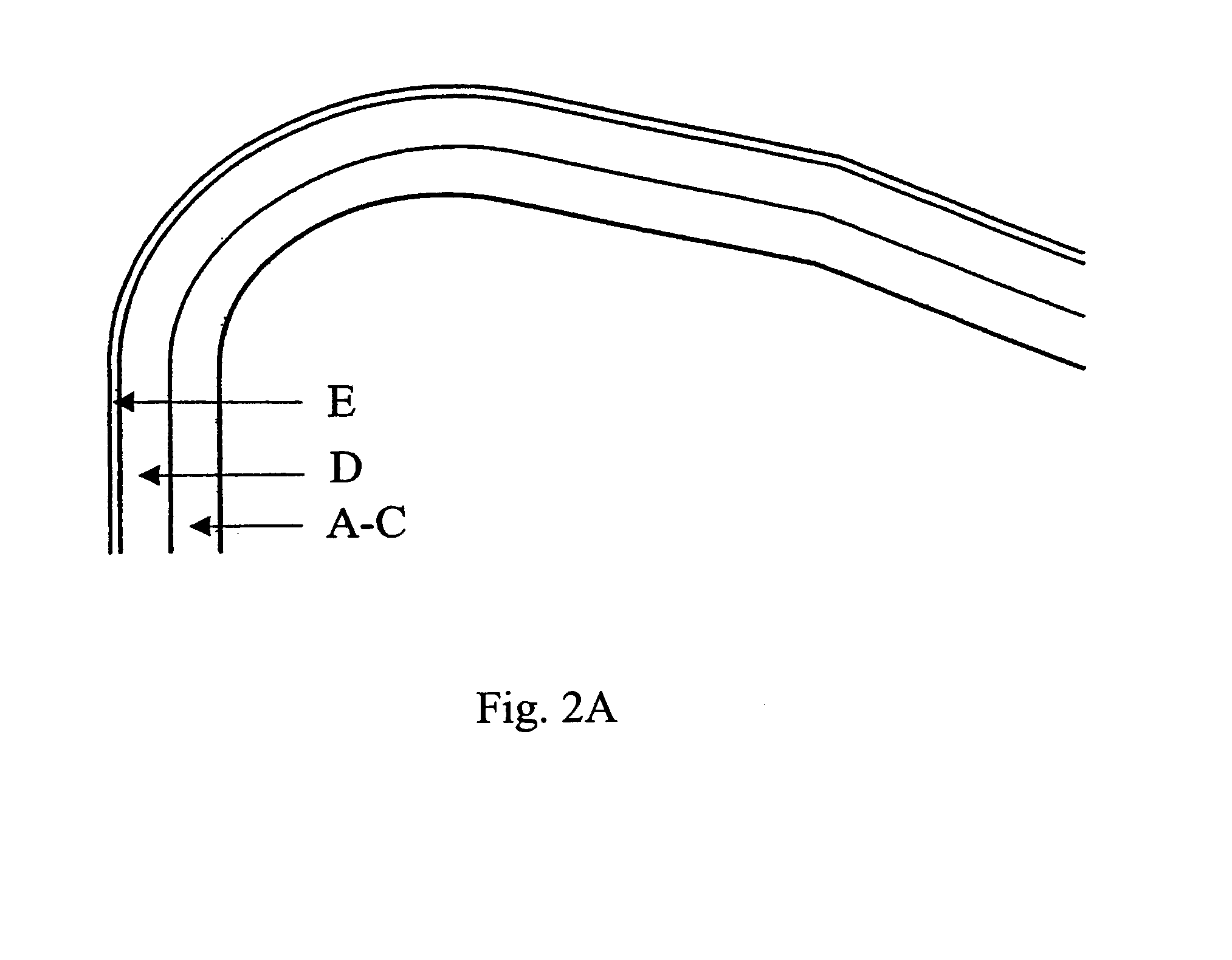

Radius end mill having radius edge enhanced in resistance to chipping and fracture

InactiveUS6846135B2Suppress chipping and fractureHigh-feed cuttingMilling cuttersWorkpiecesEngineeringCurve line

In a radius end mill having a bottom edge formed on the end face thereof, a radius edge designed in a substantially quarter arc shape and formed at a corner portion thereof, and an outer peripheral edge formed spirally on the side surface thereof, the bottom edge and the radius edge being continuously connected to each other at a connecting point A while the radius edge is continuously connected to each other at a connecting point B, when a view taken along a plane that passes through the connecting points A and B and crosses a rake face of the radius edge is represented by an R cross-sectional view, the rake face of the radius edge is designed to have a convex curved line extending from the connecting point A to the connecting point B in the R cross-sectional view.

Owner:HITACHI TOOL ENG LTD

Integral carbide goldfish scale milling cutter

InactiveCN101623778AExtended service lifeImprove processing efficiencyMilling cuttersWorkpiecesGlass fiberFiber

The invention discloses an integral carbide goldfish scale milling cutter used for milling and processing composite materials such as carbon fiber, glass fiber and the like. The milling cutter of the invention comprises a milling cutter blade and a milling handle, wherein the cutting blade on the milling cutter blade is a cutting unit formed by left and right-handed rotation symmetrical staggered spiral grooves, and the number of the left spiral groove is two more than that of the right spiral groove; the length of the cutting blade of each cutting unit is 0.05-0.1mm, and the width of the rear cutter surface of the cutting blade along the cylinder surface is 0-0.01mm; the anterior angle of the cutting blade is 10-15 degrees, the front cutter surface is a straight line on a normal plane; the relief angle of the cutting blade is 20-25 degrees; the depth of the spiral cutter groove is 7-8% of the diameter of the cutter. The invention has the advantages that the cutting blade of the integral carbide goldfish scale milling cutter is composed of a plurality of cutting units and is sharp, which greatly lowers cutting resistance and realizes high speed cutting so as to obtain the effect of using milling for replacing abrading, so that the processing efficiency and the surface quality of the composite materials can be improved, and the service life of the milling cutter can be prolonged.

Owner:SHENYANG AIRCRAFT CORP

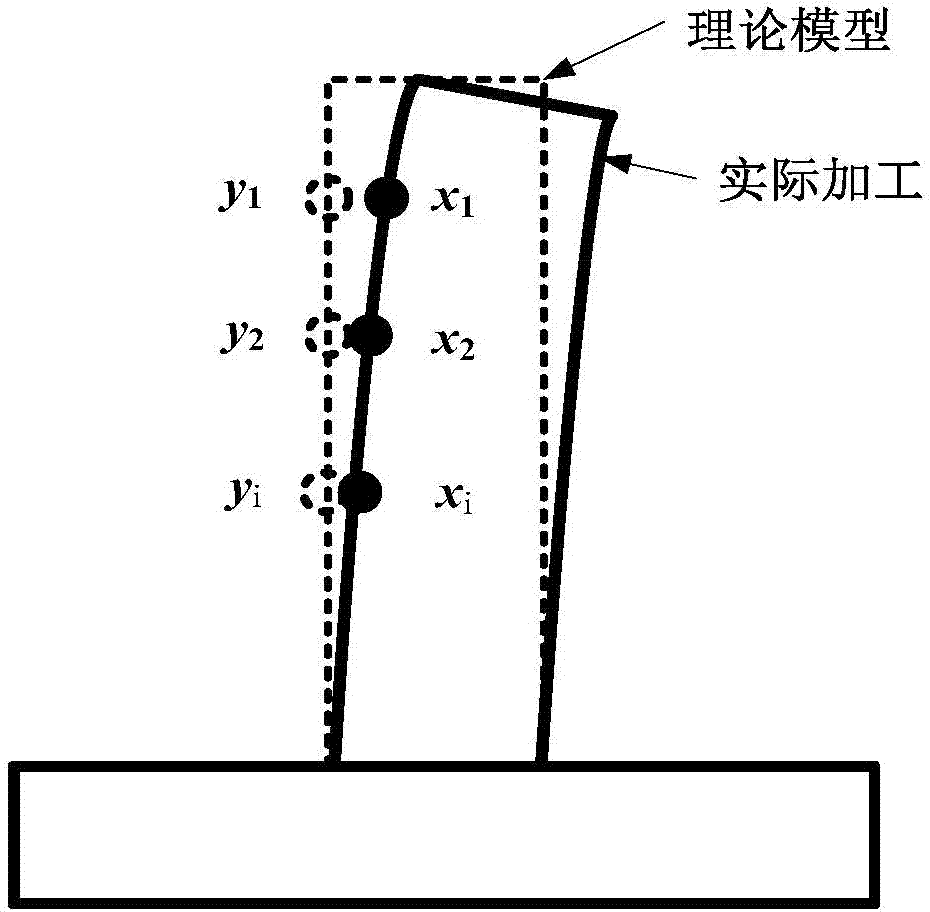

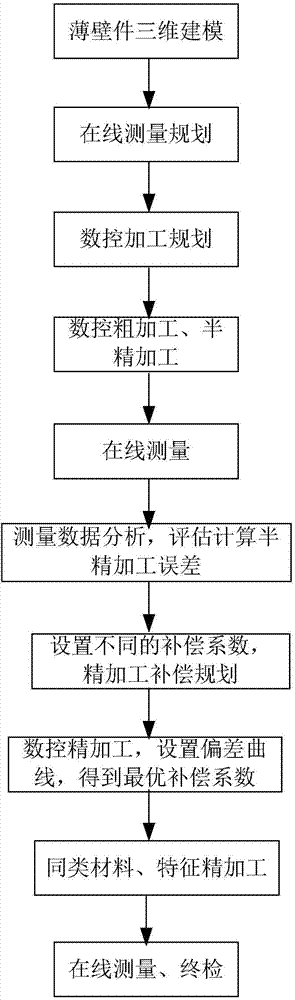

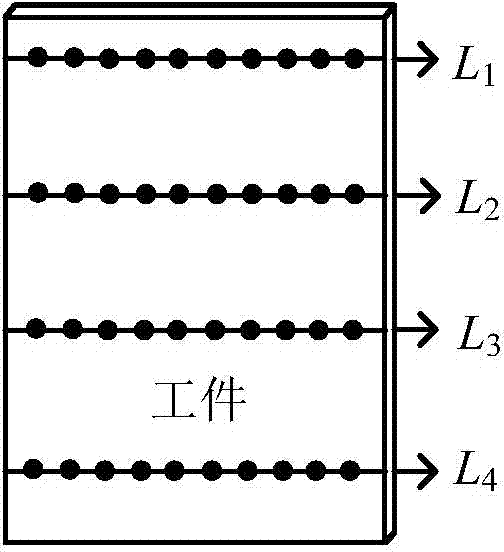

Online milling deformation measurement and complementation machining method for thin-walled part

ActiveCN104759942AAvoid insufficient boundary conditionsGood compensationGeometric CADMachine tool componentsNumerical controlMeasurement point

The invention discloses an online milling deformation measurement and complementation machining method for a thin-walled part. The online milling deformation measurement and complementation machining method for the thin-walled part comprises the steps that 1, a three-dimensional model of the thin-walled part is established, and a numerical control code is obtained; 2, measurement point locations are extracted from the three-dimensional model; 3, based on the model, a measurement path is planned; 4, rough machining and semi-precise machining are conducted on a workpiece blank; 5, online measurement is conducted, and the coordinate values of all the planed measurement point locations are obtained; 6, the obtained coordinate values of the planed measurement point locations are compared with those of the corresponding point locations on the three-dimensional model of the thin-walled part, and the difference between the coordinates of each point location of the actually machined workpiece and those of the corresponding point location on the three-dimensional model is calculated; 7, according to the machining differences, a complementation factor optimal machining path is generated according to the machining differences, precise machining is conducted according to the path, and then the final deformation deviation and the compensation values are obtained. By the adoption of the online milling deformation measurement and complementation machining method, semi-precise machining and precise machining are adopted, the identical machining parameters are adopted by the semi-precise machining and the precise machining, and the best precise machining compensation effect of the thin-walled parts which are made of the same materials and have the same characteristics can be achieved to the greatest extent through only one group of tests.

Owner:HUAZHONG UNIV OF SCI & TECH

Rotary tool and cutting part comprised in the tool

InactiveUS20030210963A1Acceptable toleranceTransportation and packagingMilling cuttersInterference fitMilling cutter

A rotary tool for chip removing machining, for example a milling cutter or a drill, includes a shaft, a holder, and a cutting part. The shaft has a conical seating arranged in its front end. The holder has a slightly conical recess, whose cross-sectional dimension decreases toward the open end of the recess. The cutting part has a slightly conical pin designed to be received in the recess and has a cross-sectional dimension which increases in the direction of the free end of the pin. The recess is formed by a wall which is elastically flexible in a radial direction. When the holder is drawn axially into the seating, the wall is flexed radially inwardly, causing the conical surface of the recess to tightly grip the conical surface of the pin and create an interference fit of the pin in the recess.

Owner:SANDVIK AB

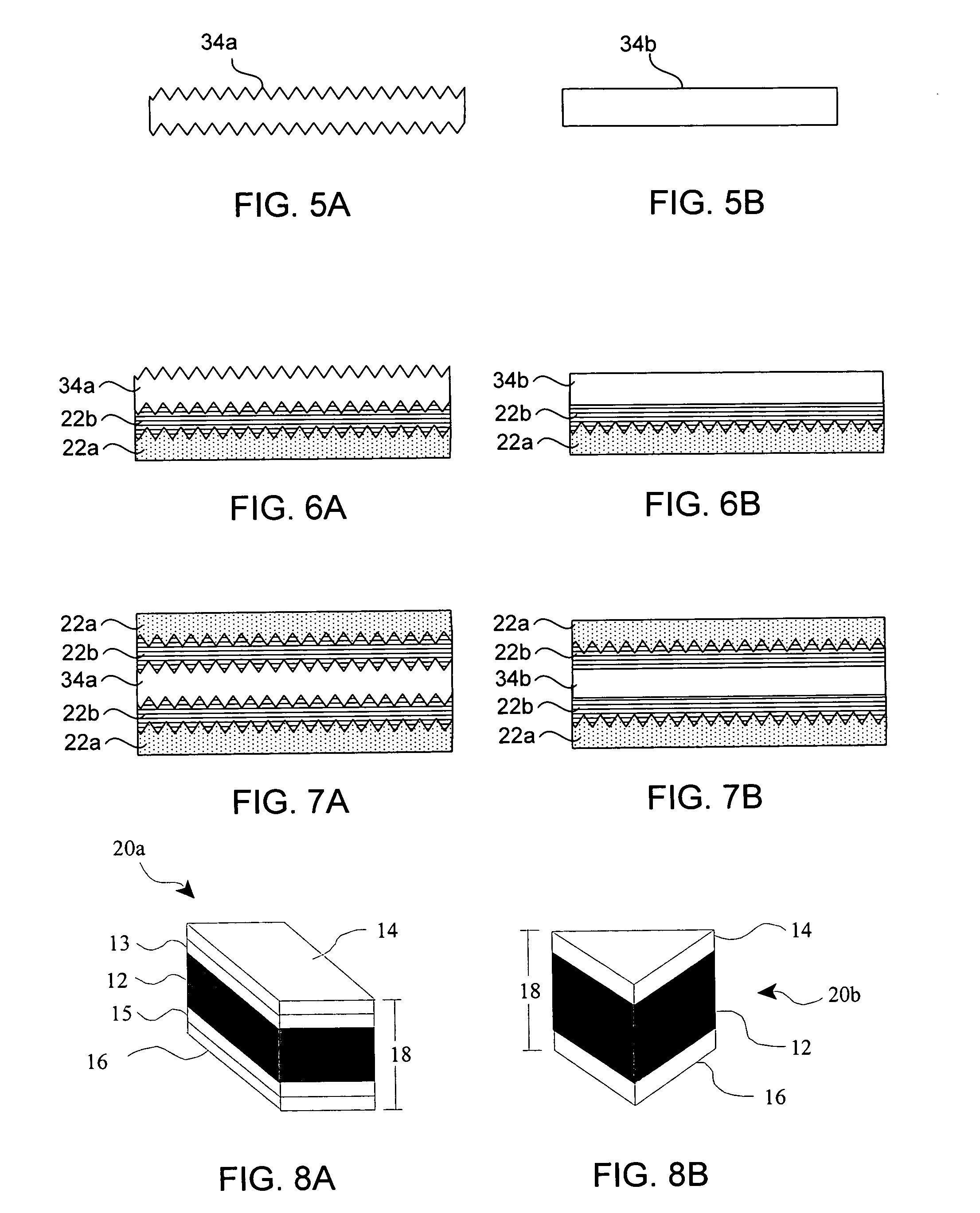

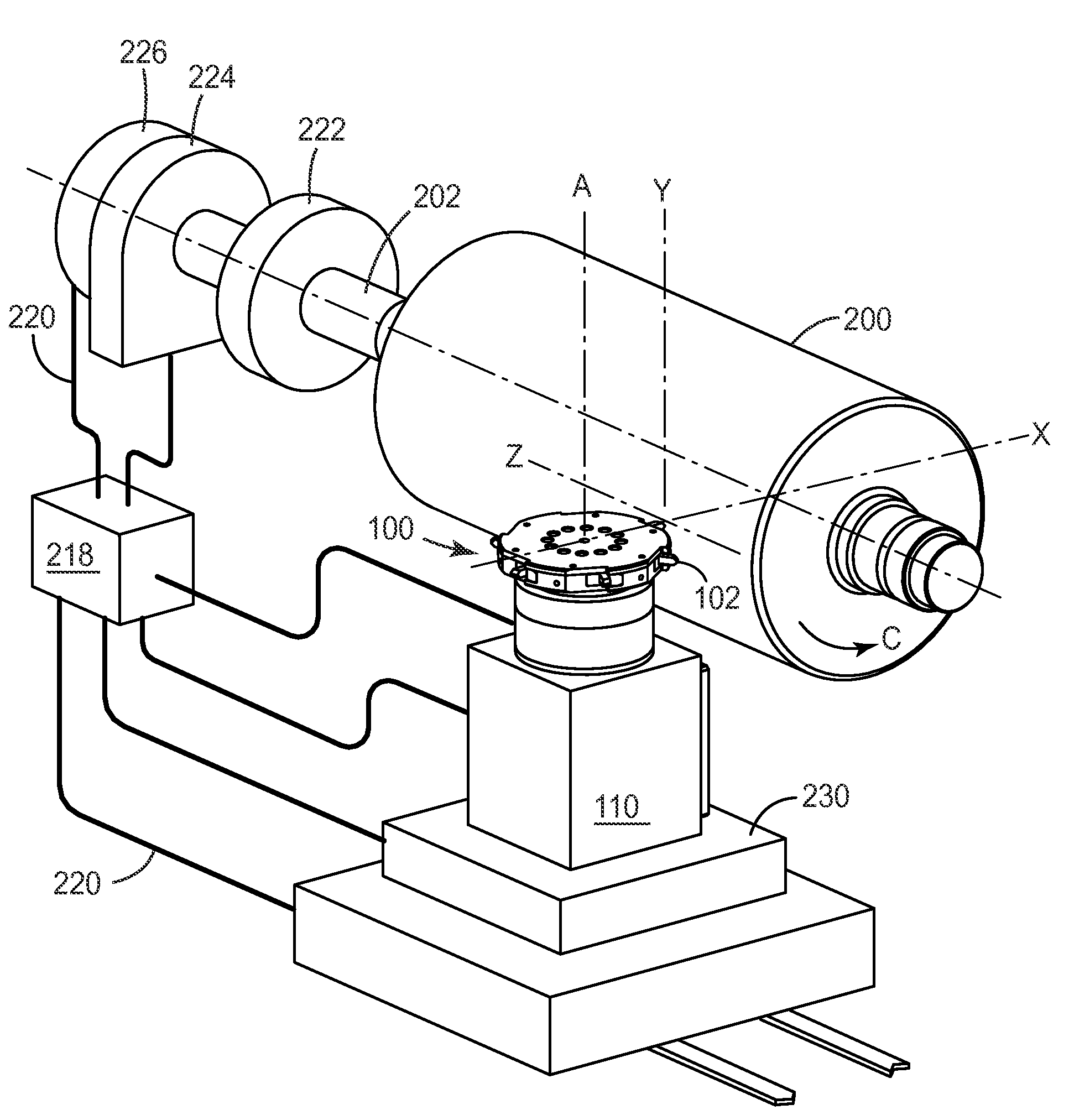

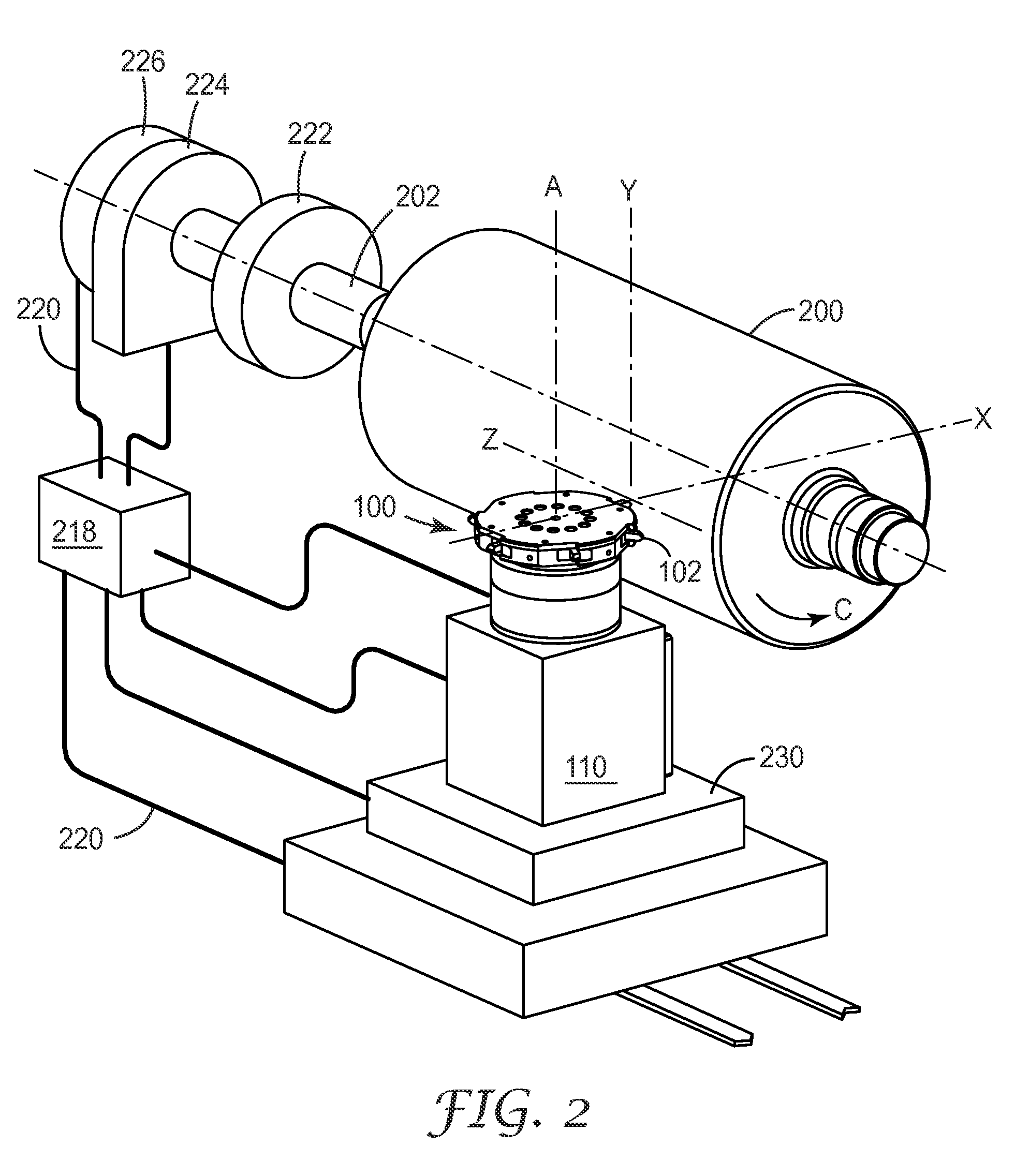

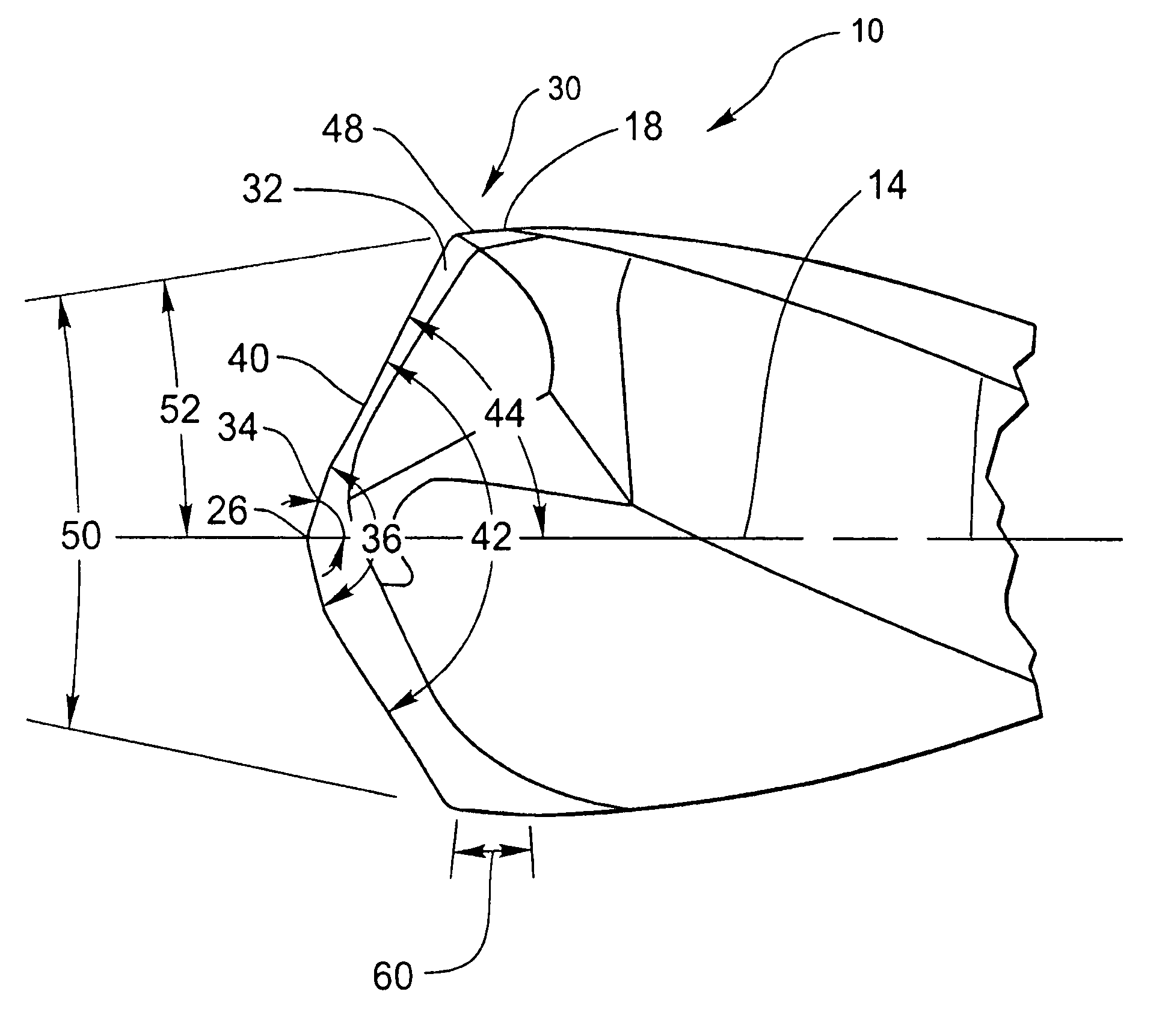

Fly-cutting system and method, and related tooling and articles

Methods of fly-cutting a workpiece are disclosed, and in methods in which the position of a fly-cutting head or its associated cutting element is known as a function of time. Also disclosed are methods of forming features, such as grooves or groove segments, in a workpiece such as a cylindrical roll. The features may be provided according to one or more disclosed patterns. Articles made using tools machined in the manner described are also provided, such as polymeric film or sheeting that exhibit certain beneficial properties.

Owner:3M INNOVATIVE PROPERTIES CO

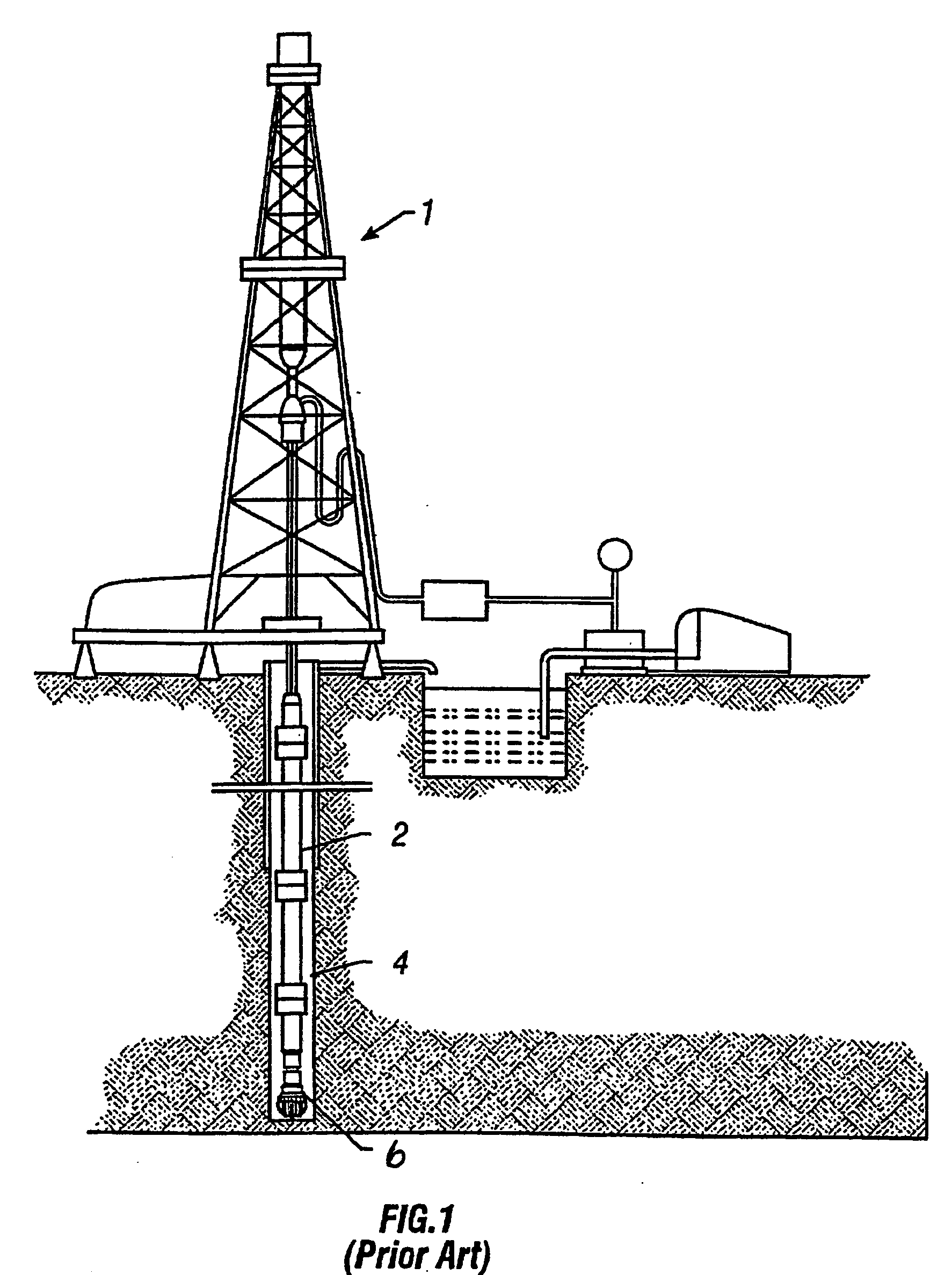

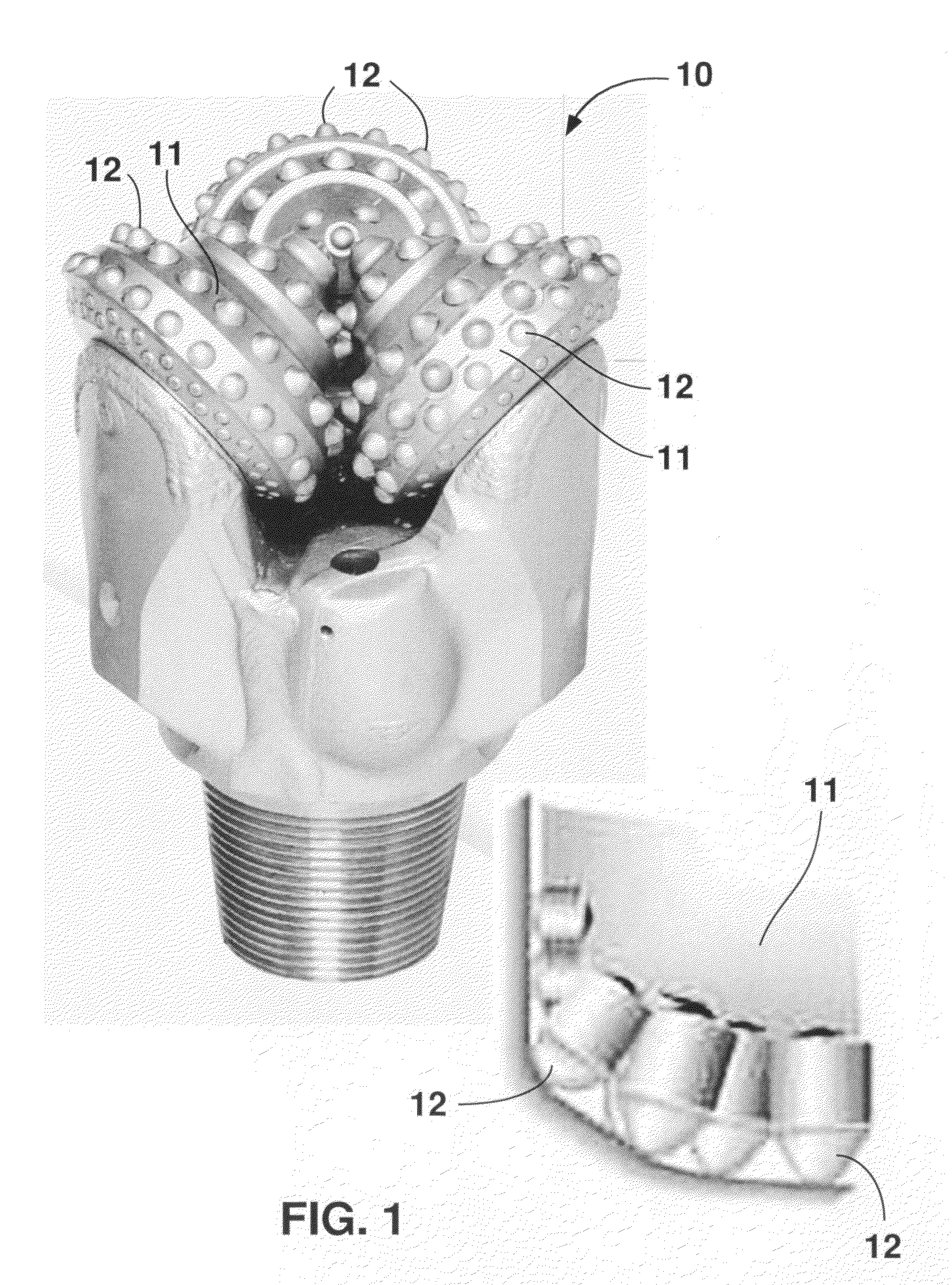

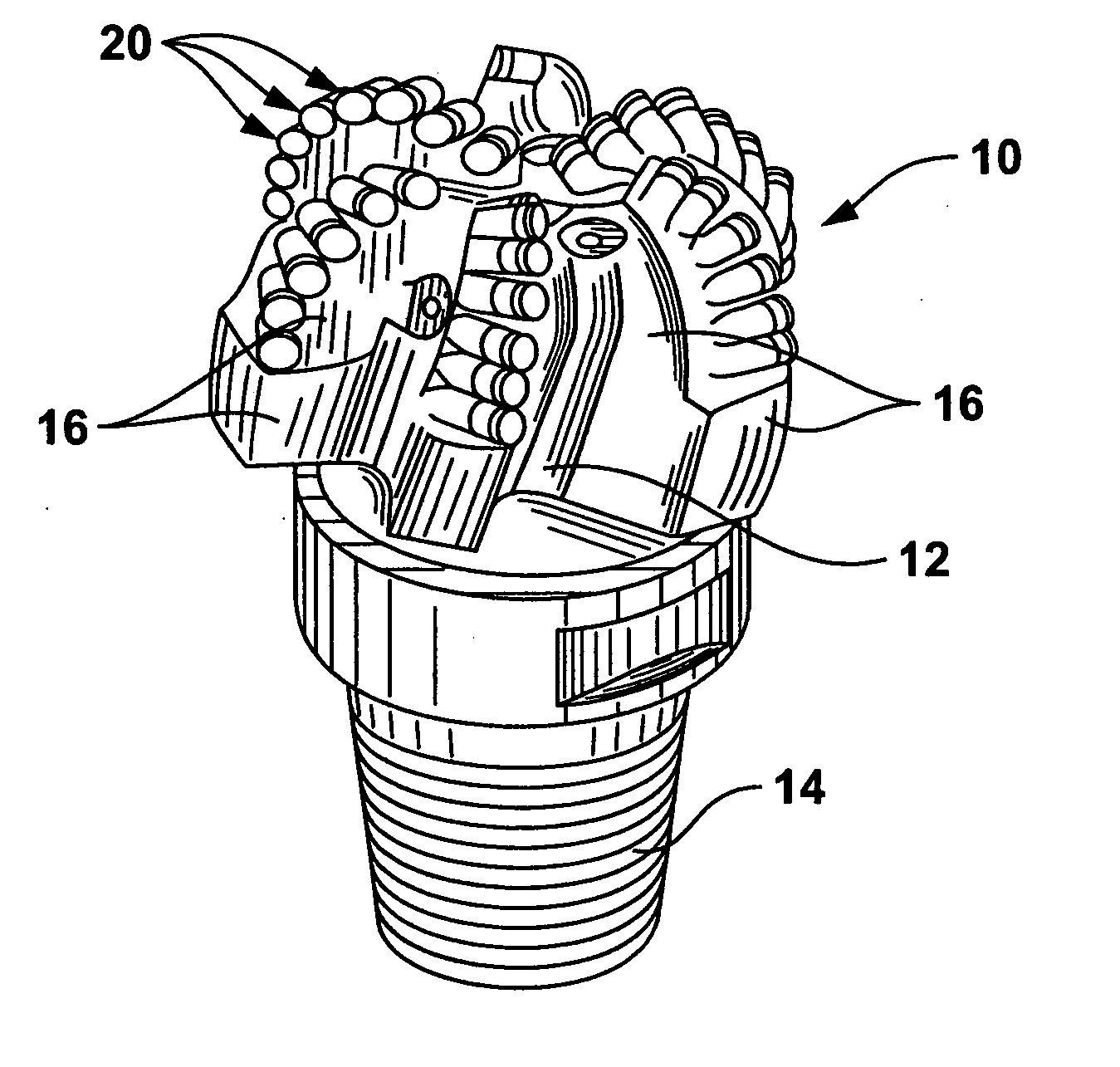

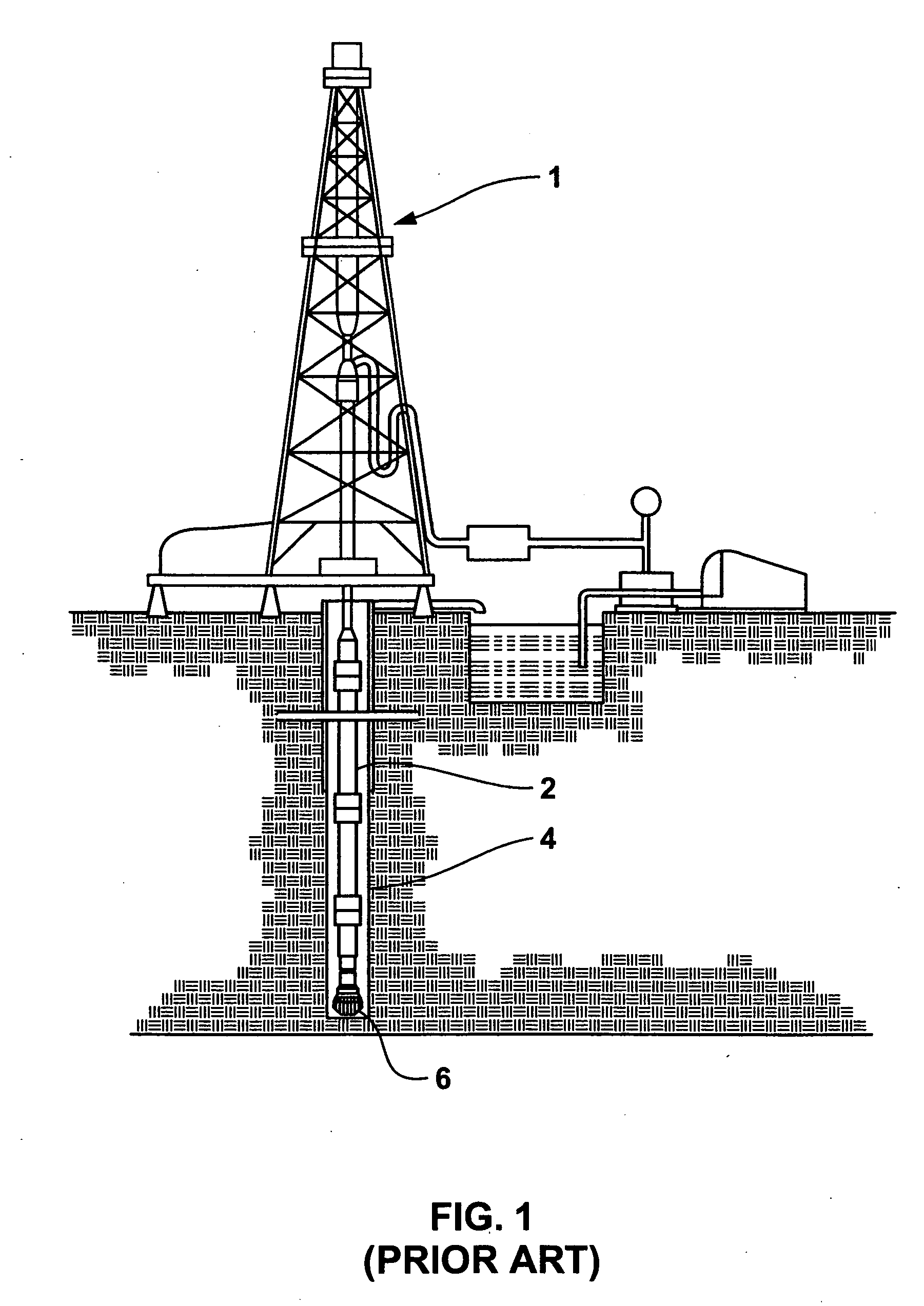

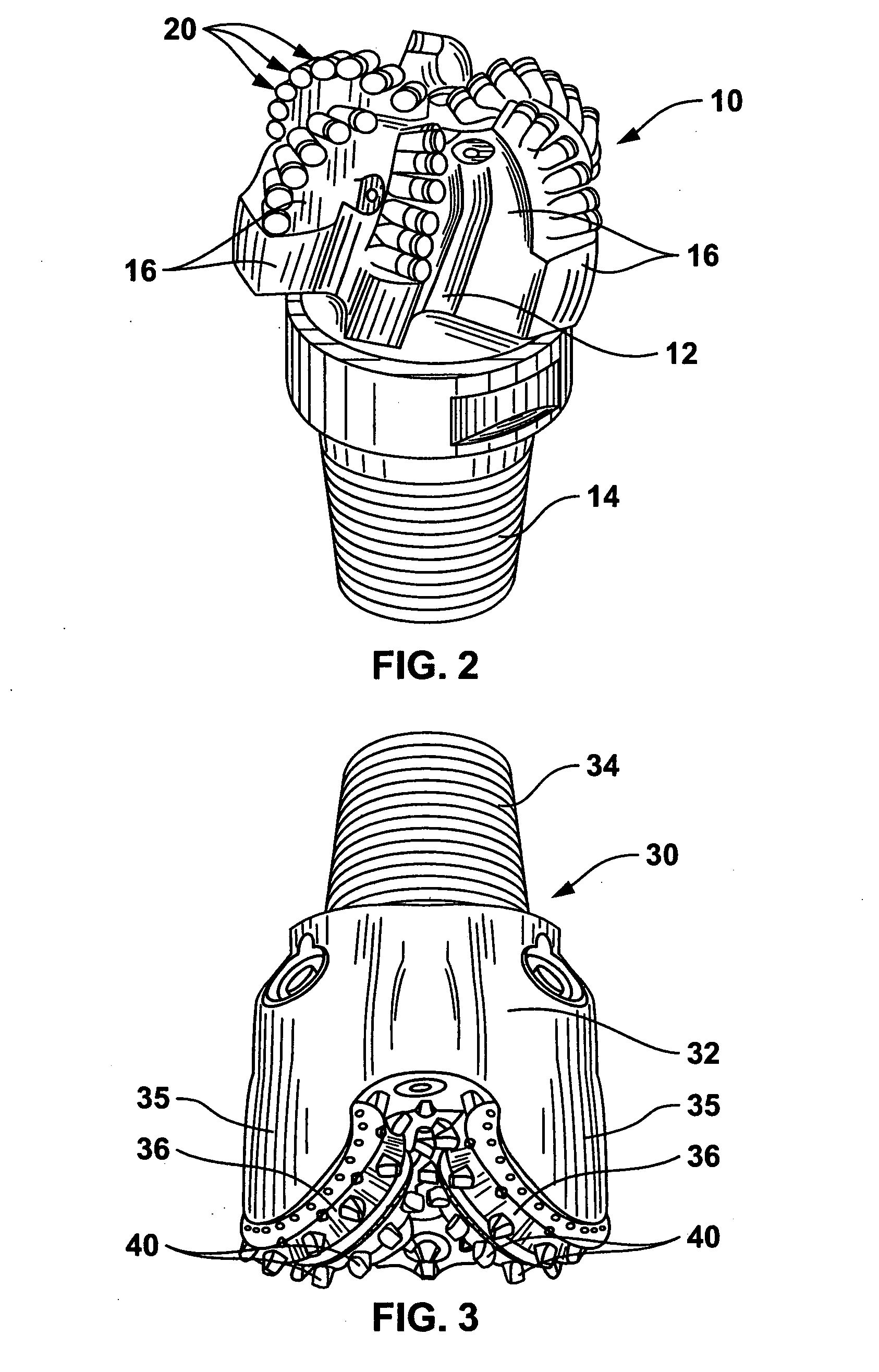

Braze alloy for drilling applications

A down hole cutting tool includes a cutting element support structure. The cutting element support structure has at least one cavity formed therein. A cutting element is disposed in the cavity. Braze alloy is also disposed in the cavity between the cutting element and the cutting element support structure. The braze alloy comprises between about 0.5% and about 10% by weight of at least one selected from the group of gallium (Ga), indium (In), thallium (Tl). Methods for building a down hole tool using the braze alloy are also disclosed.

Owner:SMITH INT INC +1

Articles Having Improved Resistance to Thermal Cracking

An article includes a working portion including cemented carbide, and a heat sink portion in thermal communication with the working portion. The heat sink portion includes a heat sink material having a thermal conductivity greater than a thermal conductivity of the cemented carbide. Also disclosed are methods of making an article including a working portion comprising cemented carbide, and a heat sink portion in thermal communication with the working portion and including a heat sink material having a thermal conductivity that is greater than a thermal conductivity of the cemented carbide. The heat sink portion conducts heat from the working portion.

Owner:KENNAMETAL INC

Tool for chip removing machining as well as a basic body therefore

InactiveUS7713004B2Easy to processImprove accuracyTool workpiece connectionTransportation and packagingCouplingAxial force

A tool for chip removing machining, including a long narrow basic body having an envelope surface which is concentric with a center axis, and two opposite ends, and a replaceable loose top which is connected to the basic body via a first coupling that includes a first seating formed in one end of the basic body and a first male element formed in one end of the loose top. The basic body includes a primary part body made of a first material having a first modulus of elasticity, and a secondary part body which includes the first seating and is made of a second material having a second modulus of elasticity which is lower than the first modulus of elasticity. The two part bodies of the basic body are interconnected via a second coupling which includes a second seating in the secondary part body as well as a second male element that is formed on the primary part body and has one or more precision machined flank surfaces that are arranged to apply, together with one or more co-operating and precision machined flank surfaces of the second seating, joining axial forces to the part bodies by turning the part bodies in relation to each other.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

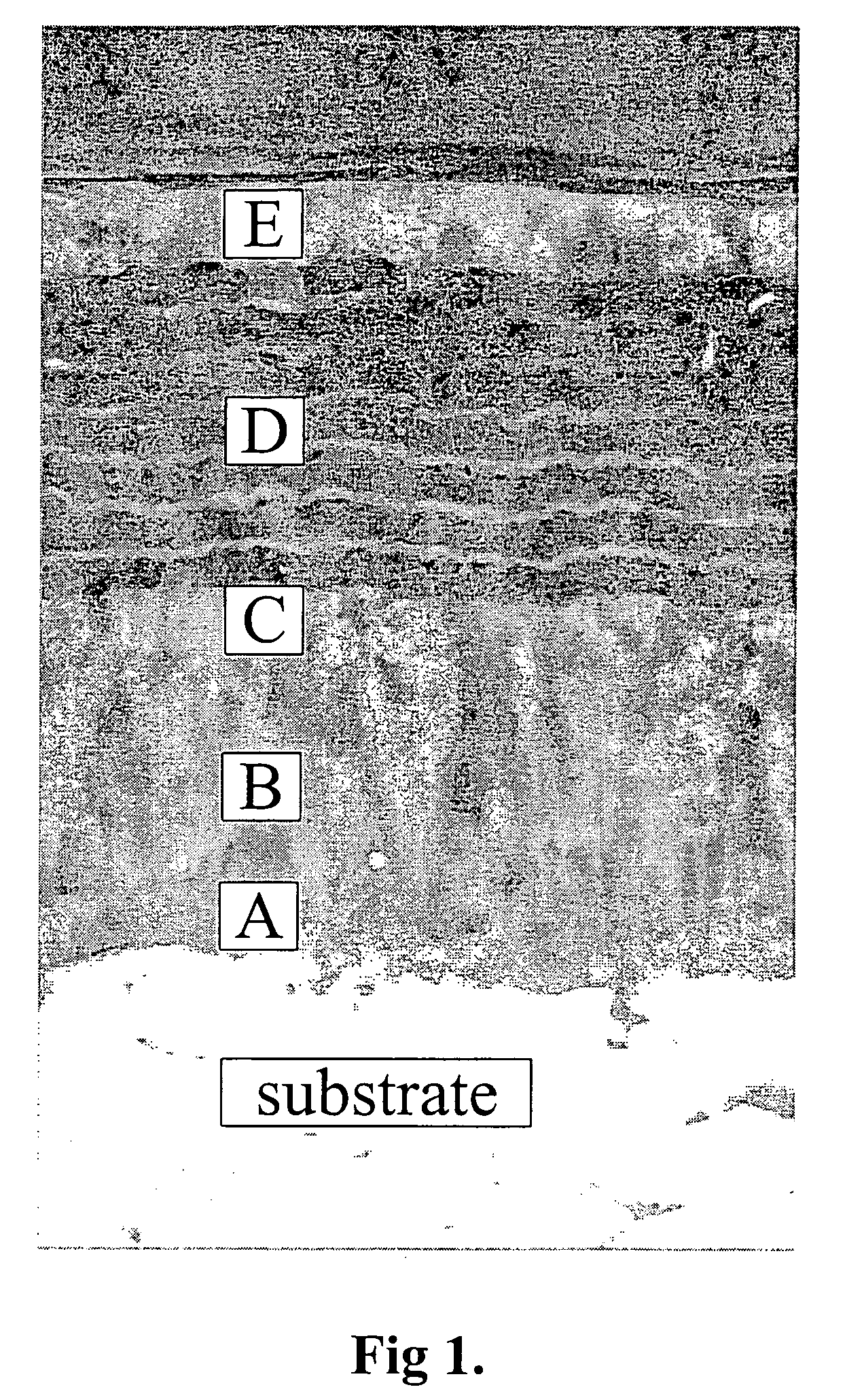

Coated cemented carbide insert

ActiveUS7153562B2Eliminate deficienciesImprove performancePigmenting treatmentCutting insertsAlloyCemented carbide

The present invention relates to a cutting tool insert particularly for turning of steel comprising a cemented carbide body, a coating with a post treatment witha first, innermost layer system of one or several layers of TiCxNyOz with x+y+z≦1 with a total thickness of 0.7–4.5 μma second multilayer system consisting of a totally 5–31 alternating Al2O3 and TiCxNyOz (x+y+z≦1), preferably κ-Al2O3 and TiN, the Al2O3-layers having an individual layer thickness of <0.5 μm and the TiCxNyOz-layers 0.01–0.2 μm with a total thickness of the multilayer of 1.0–4.0 μm. The multilayer is exposed along the edge line and into the rake and flank face, at least 0.02 mm, from the edge line on the rake face, preferably the contact length of the chip at most 0.9 mm, and 0.02–0.20 mm on the flank face.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

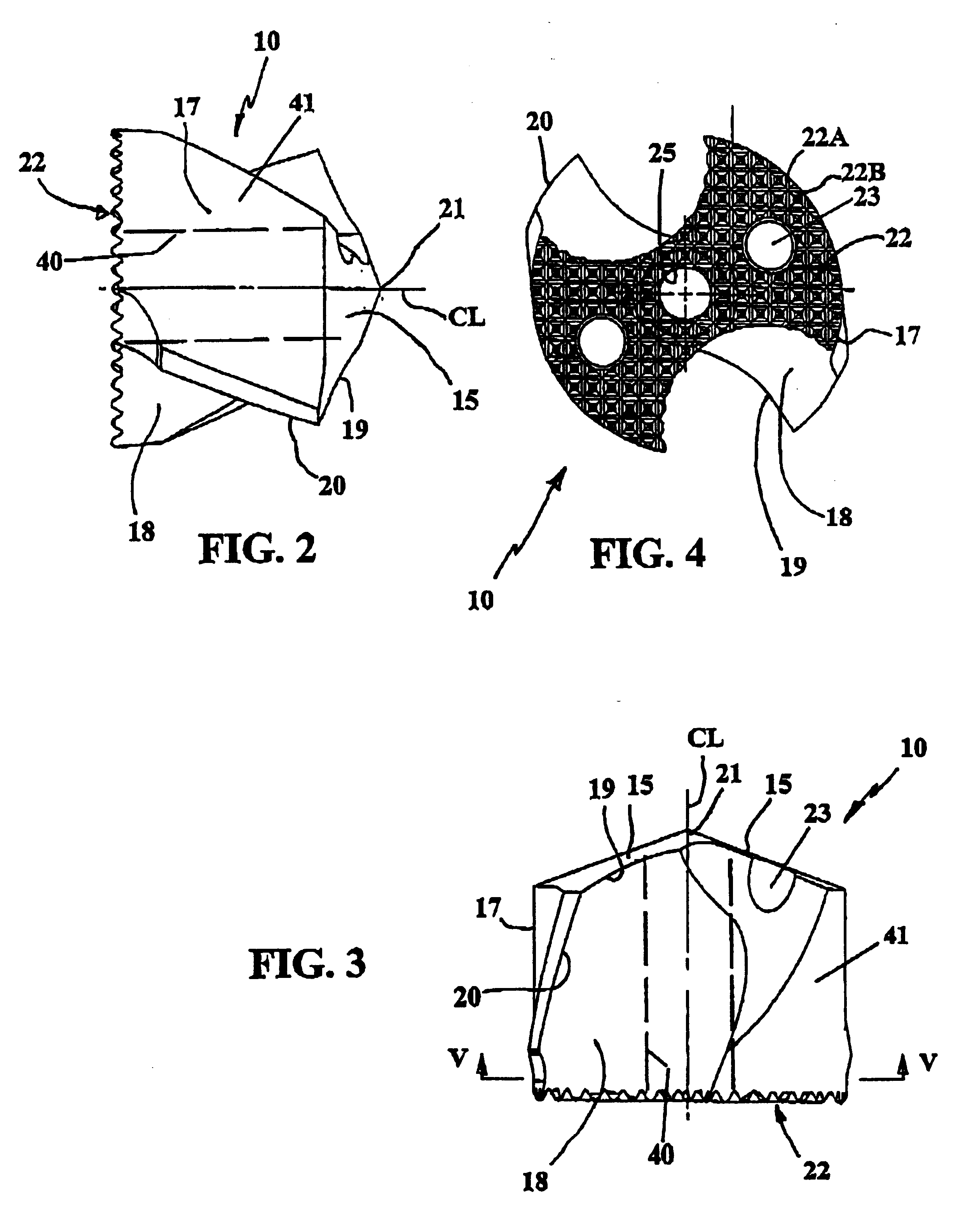

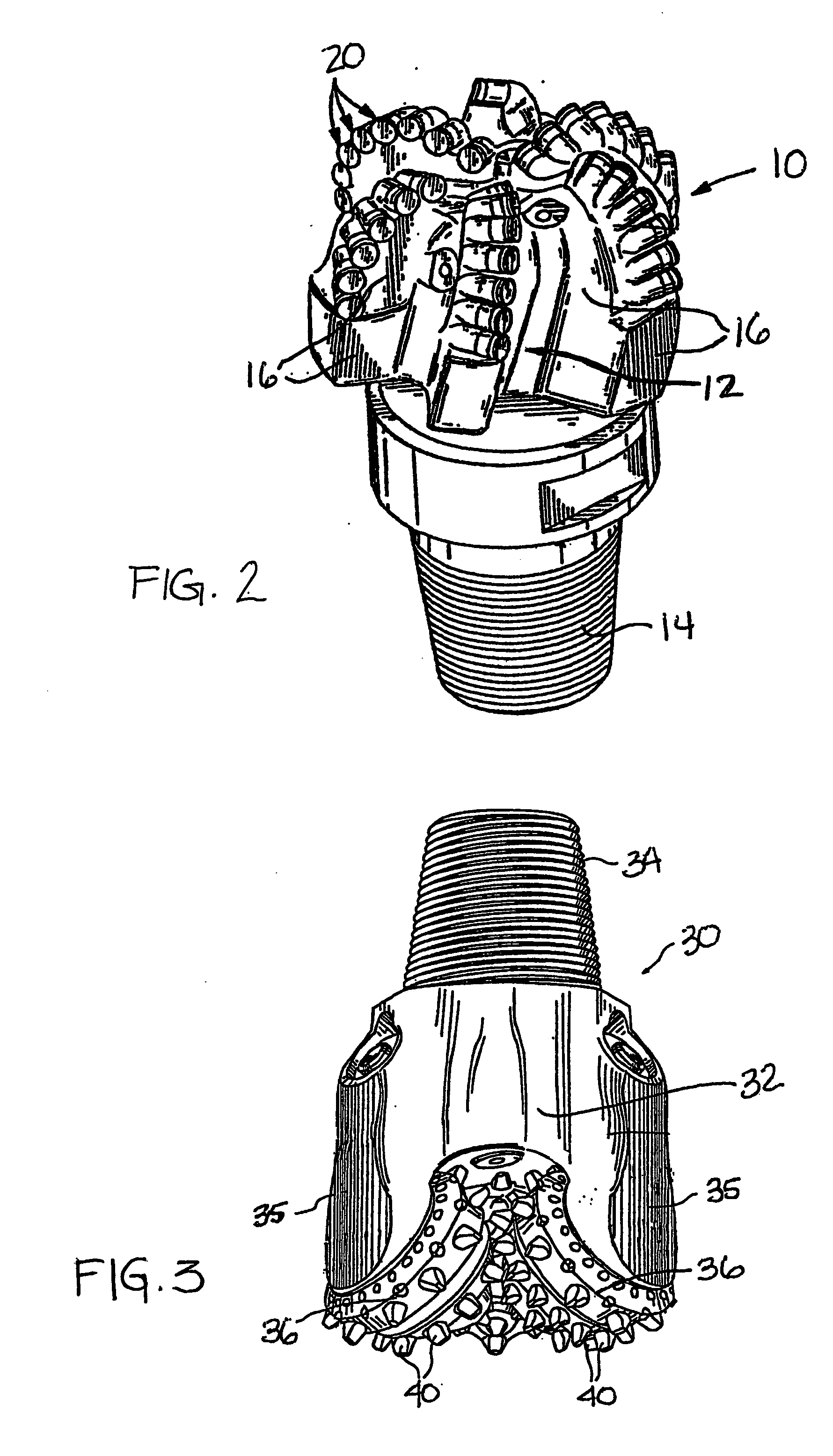

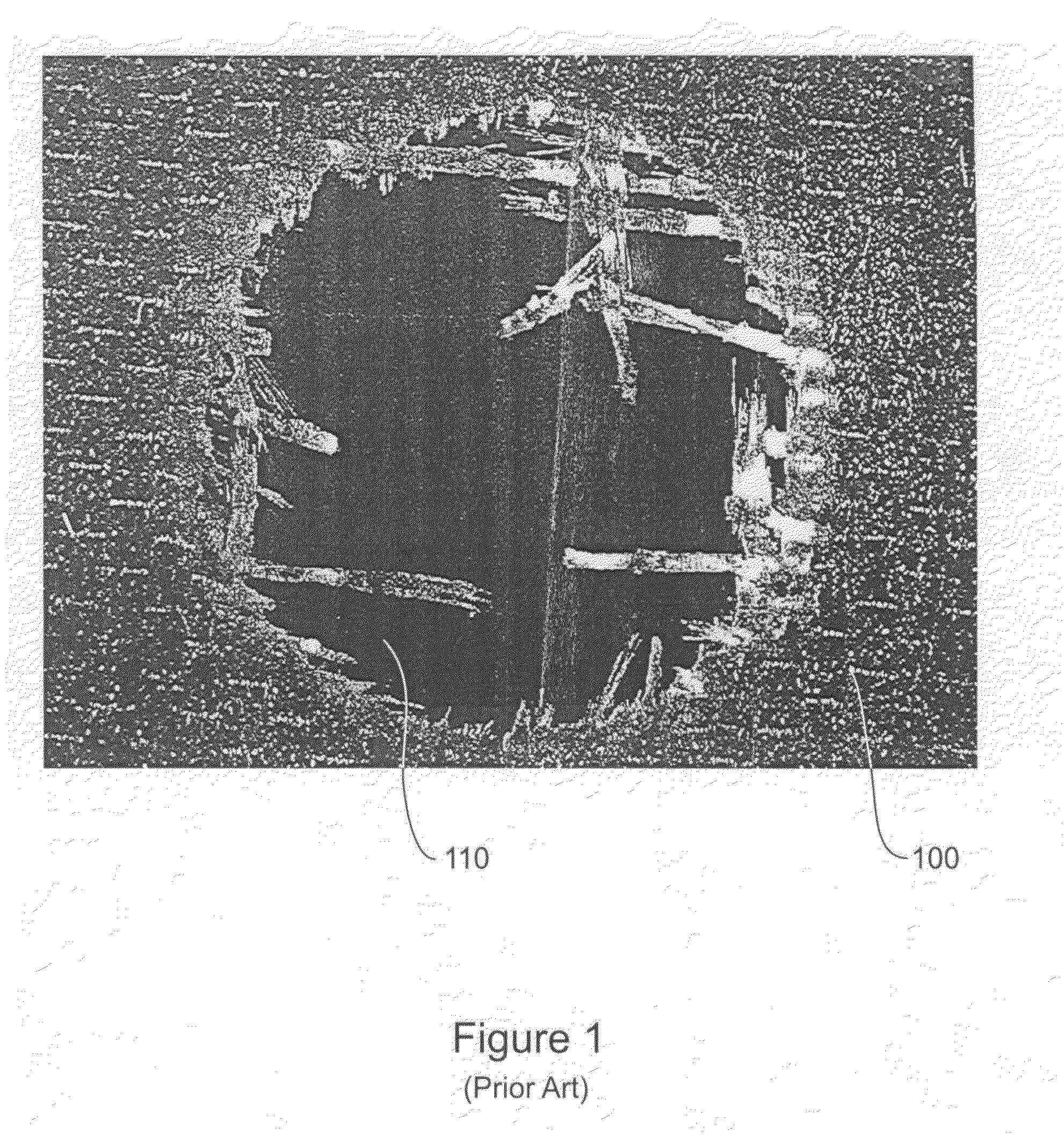

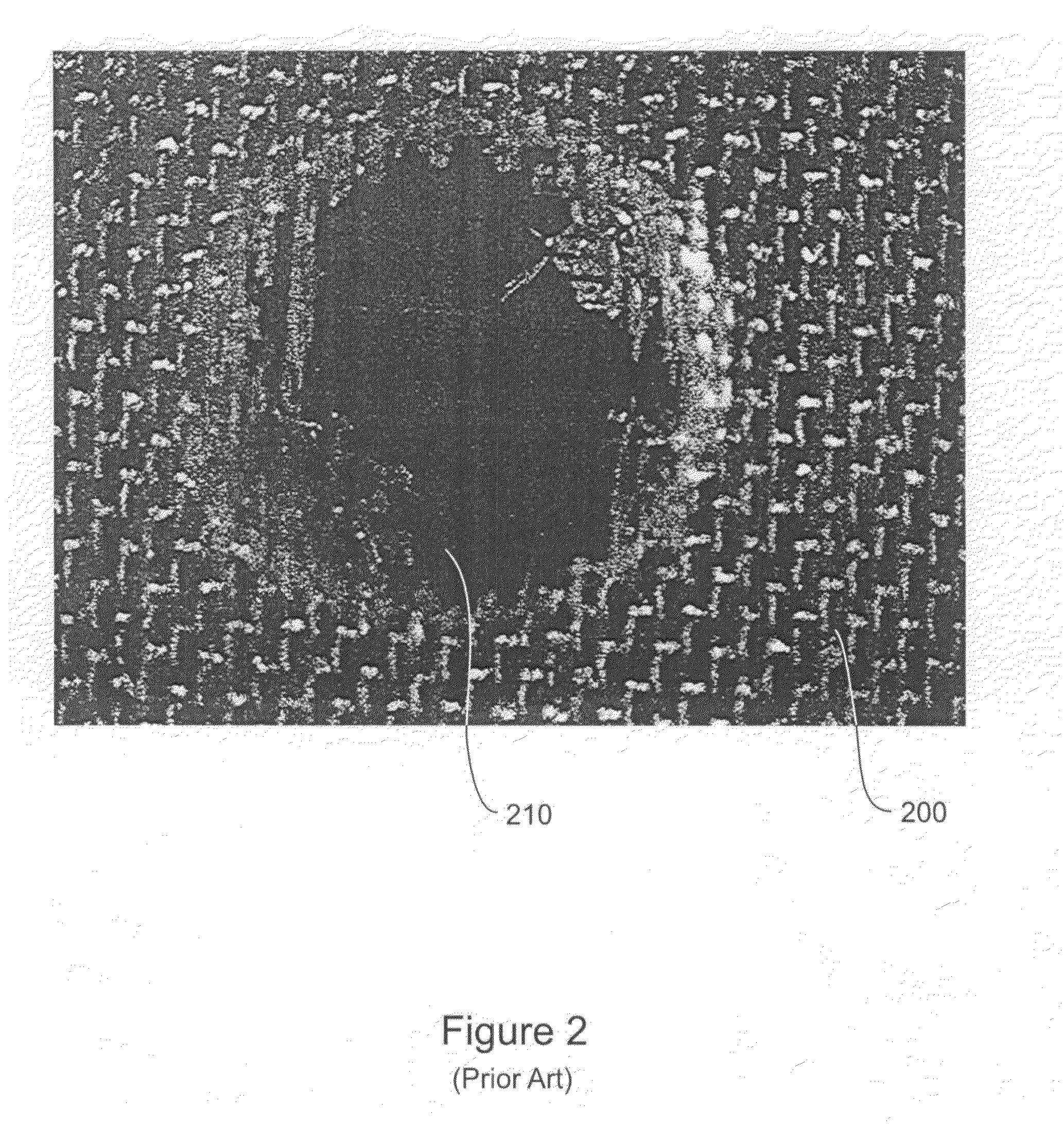

PCD drill for composite materials

ActiveUS7575401B1Increase chanceMinimal delaminationWood turning toolsTransportation and packagingFiberProduction rate

A PCD drill for producing close tolerance holes in multi layer laminates, such as carbon fiber reinforced composites, with minimum fraying of the fibers on both entrance and exit from the hole is provided. The drills provided include a symmetrical cutting point with a self-centering split point and a high shear second cutting lip positioned at the outer diameter of the drill. The drills of the invention may allow for increased cutting speeds and feeds when used with such advanced composite materials, thus increasing tool productivity and providing increased performance.

Owner:PRECORP INC

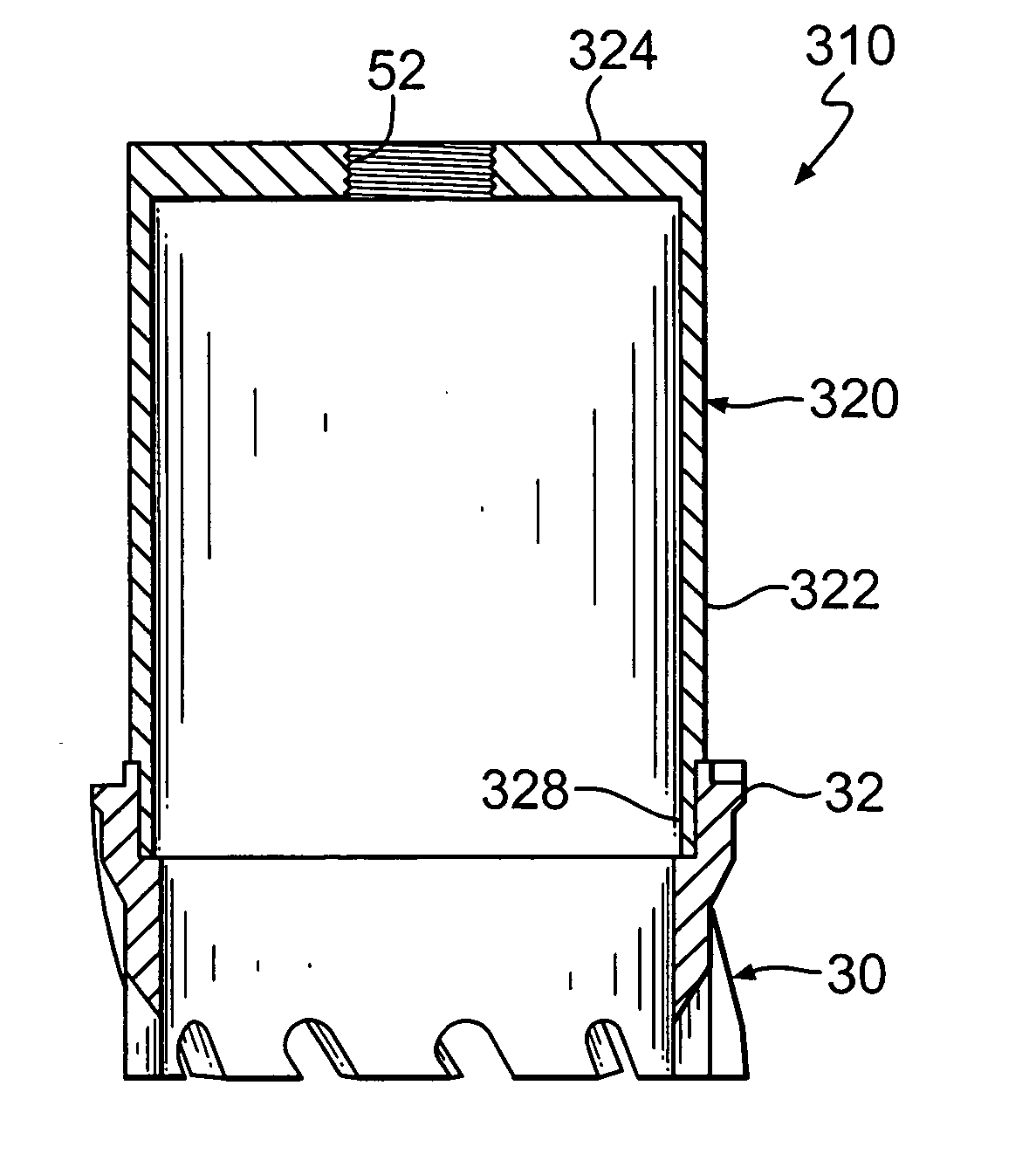

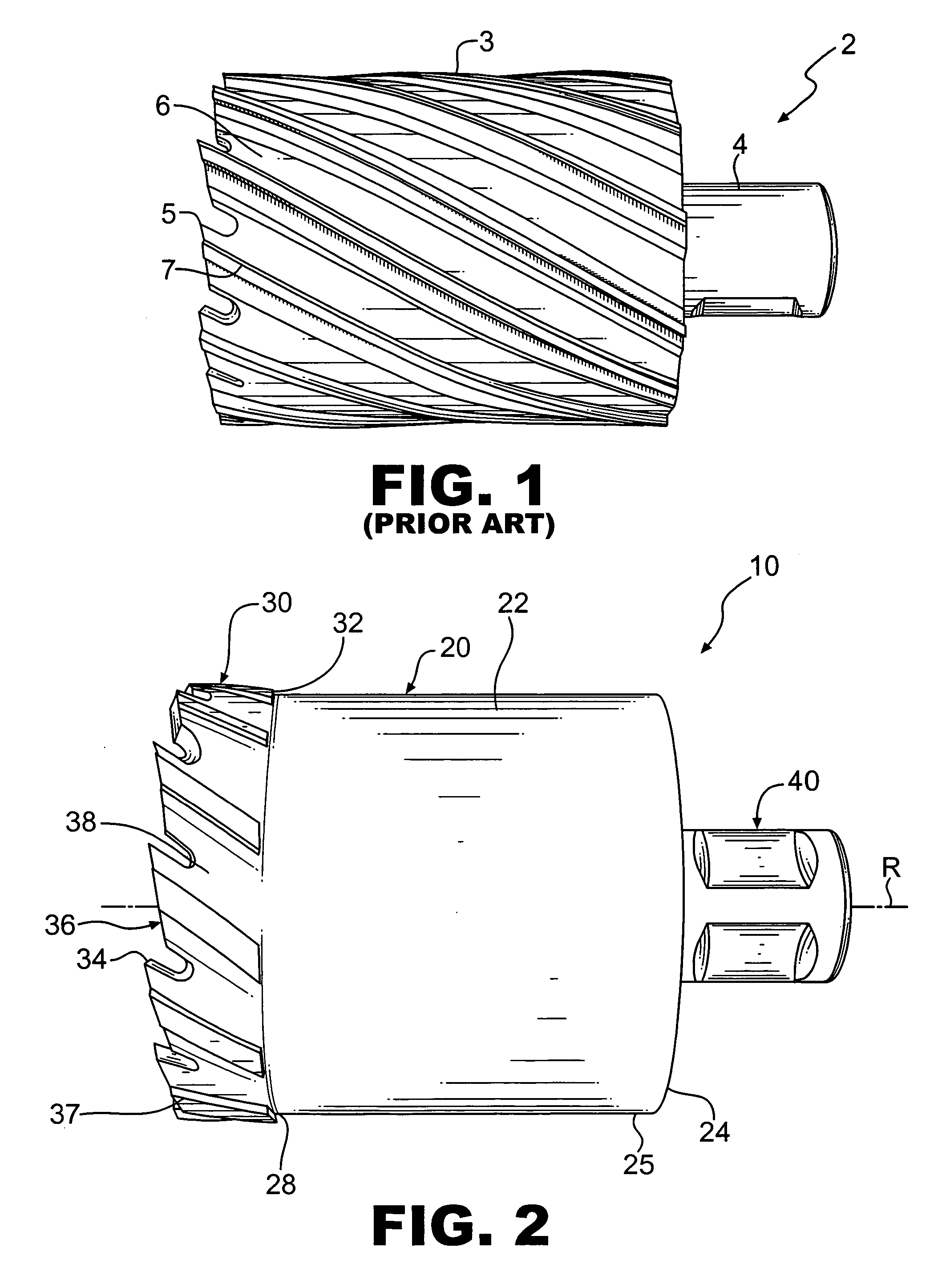

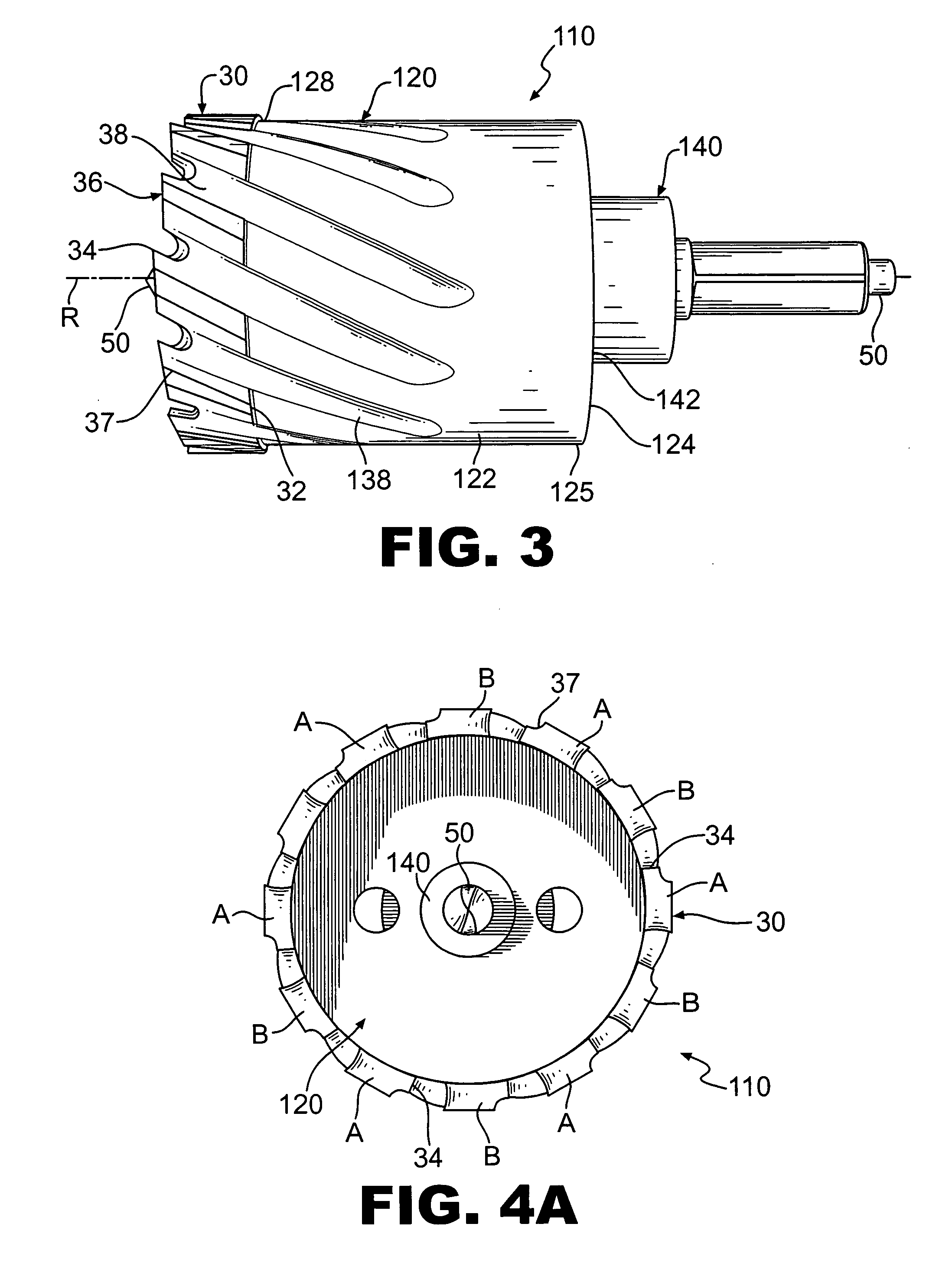

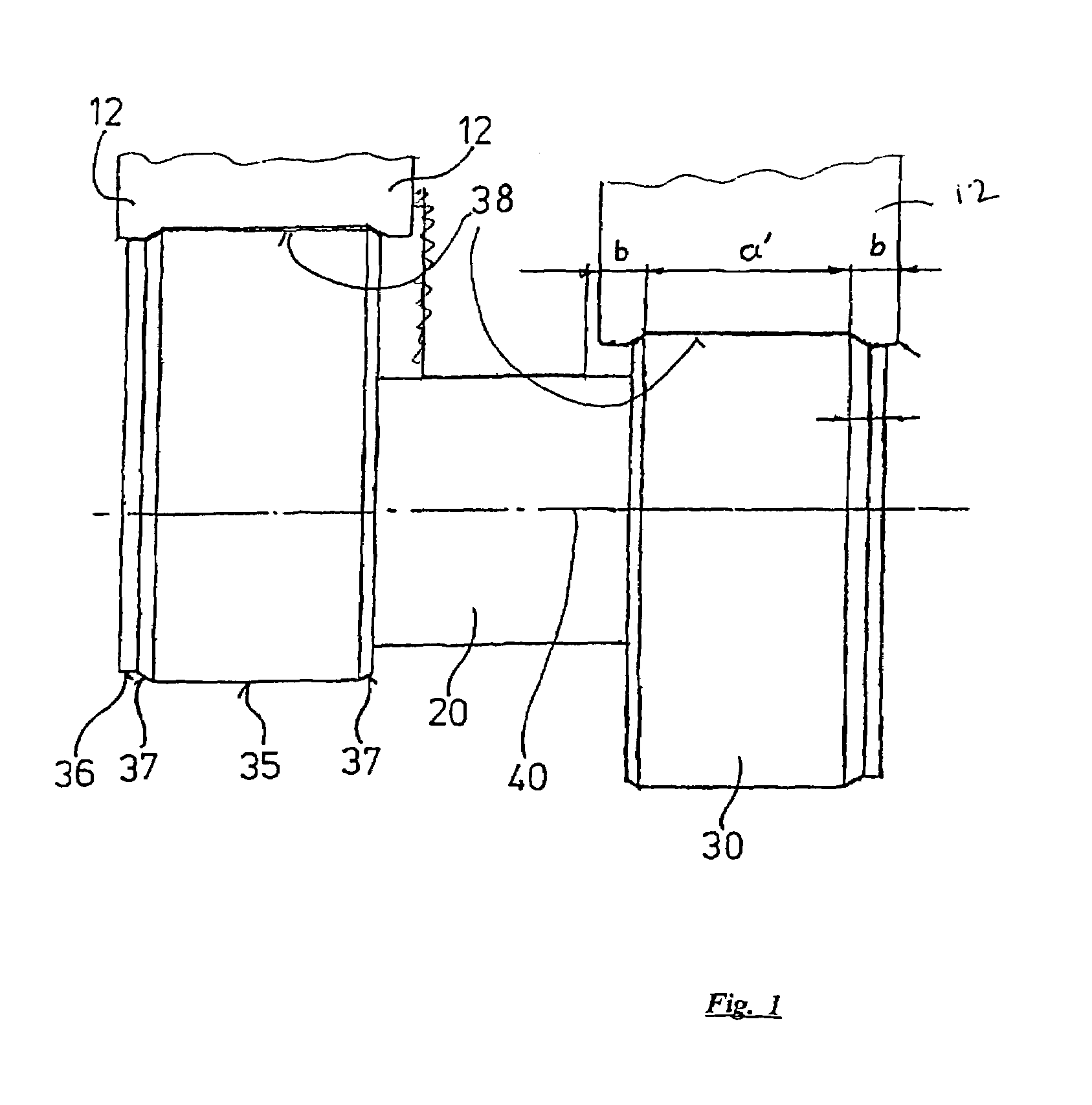

Hole cutter and method for producing

InactiveUS20050105981A1Low costOvercome disadvantagesTool workpiece connectionTransportation and packagingHole sawAnnular cutter

A hole cutter machine tool combines the characteristics and properties of a low-cost hole saw with the speed and performance of an annular cutter. The hole cutter comprises a cutter ring portion similar to an end portion of existing annular cutters with a carrier portion similar to the cup of a hole saw. In one embodiment the hole cutter has a threaded aperture which enables use with a standard hole saw arbor or with a replaceable arbor having an annular cutter shank. An embodiment of the method of making the hole saw includes a joining process in which the cutter ring is simultaneously attached to the carrier portion and heat treated.

Owner:M K MORSE COMPANY THE

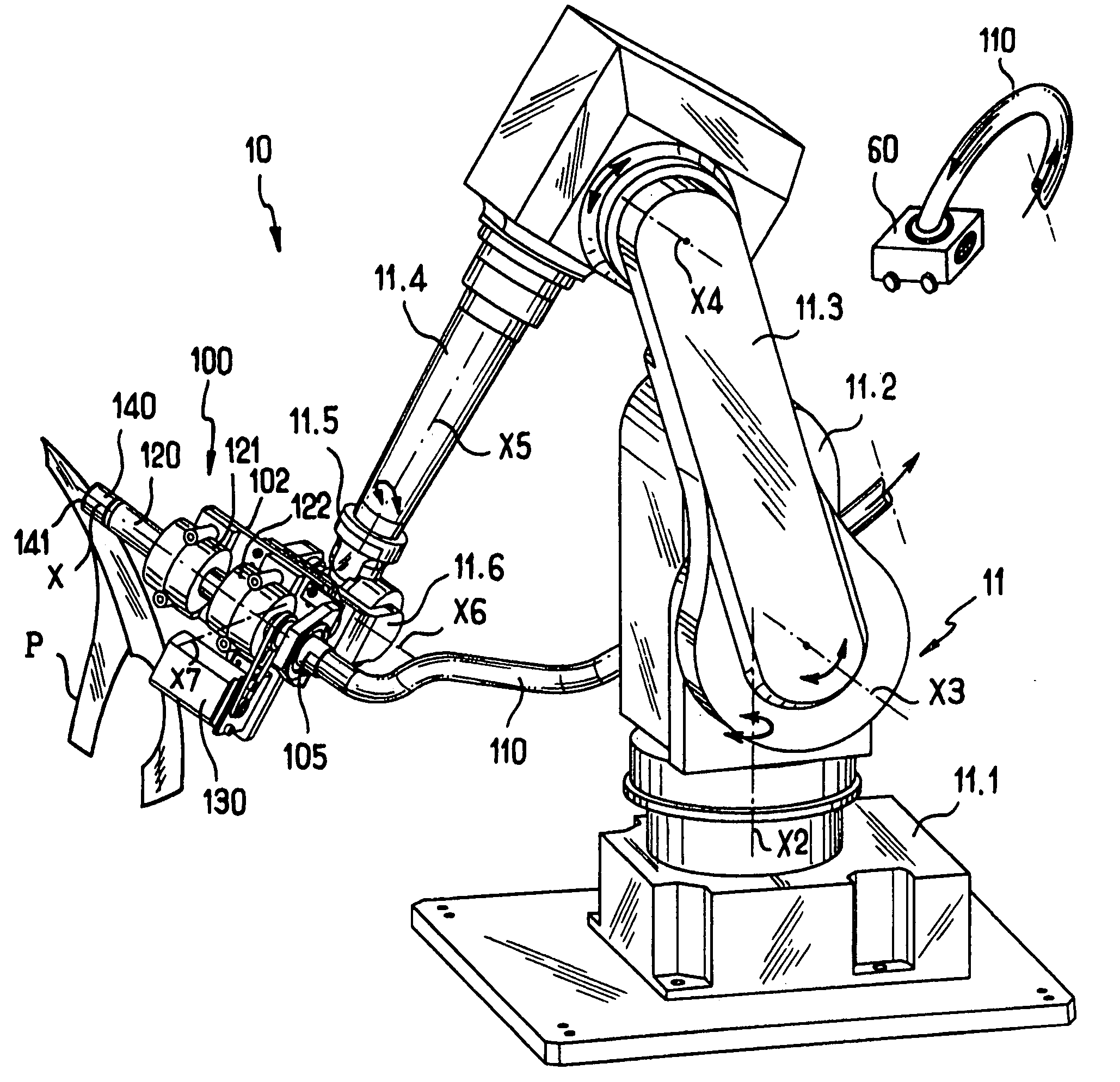

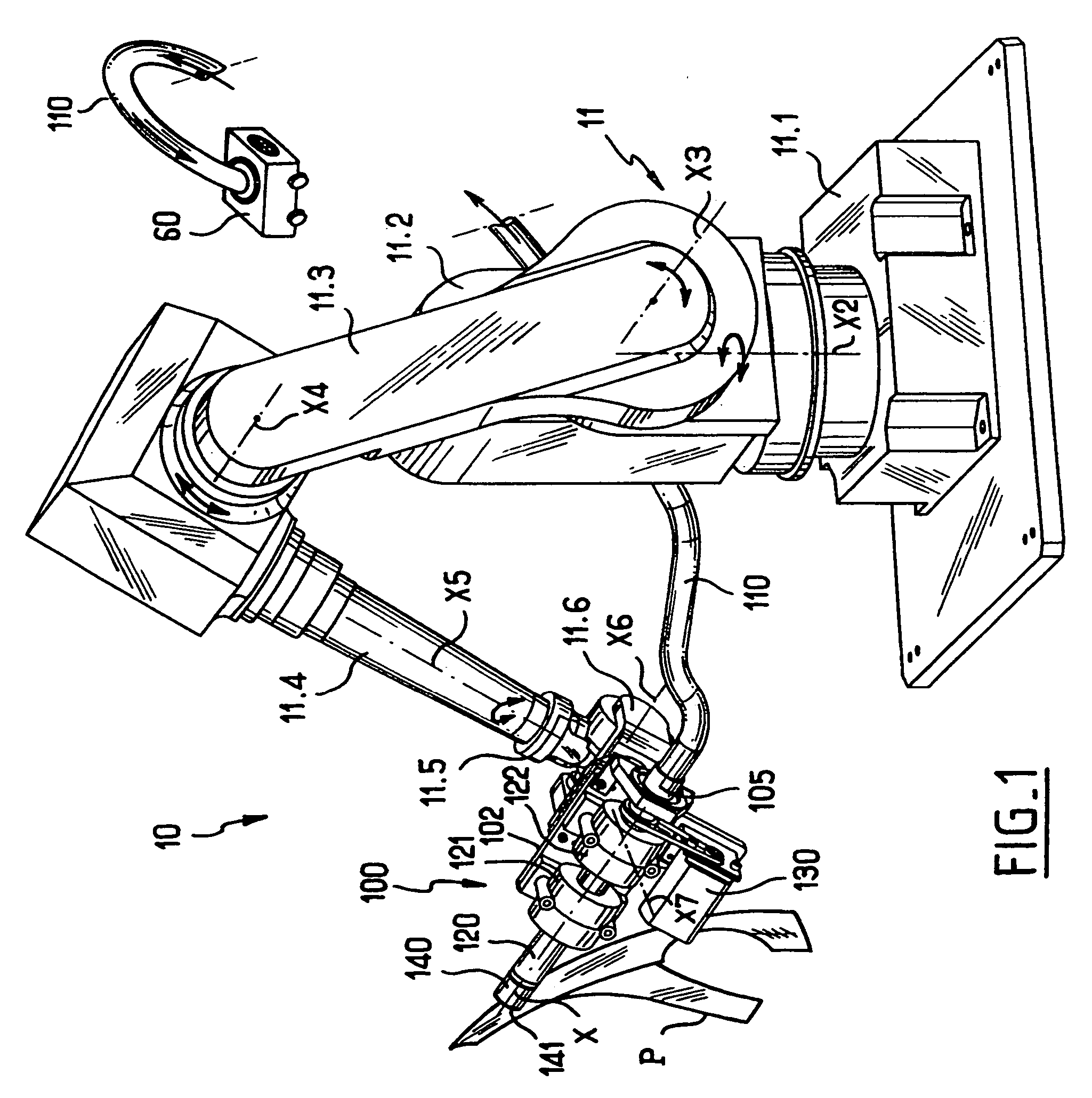

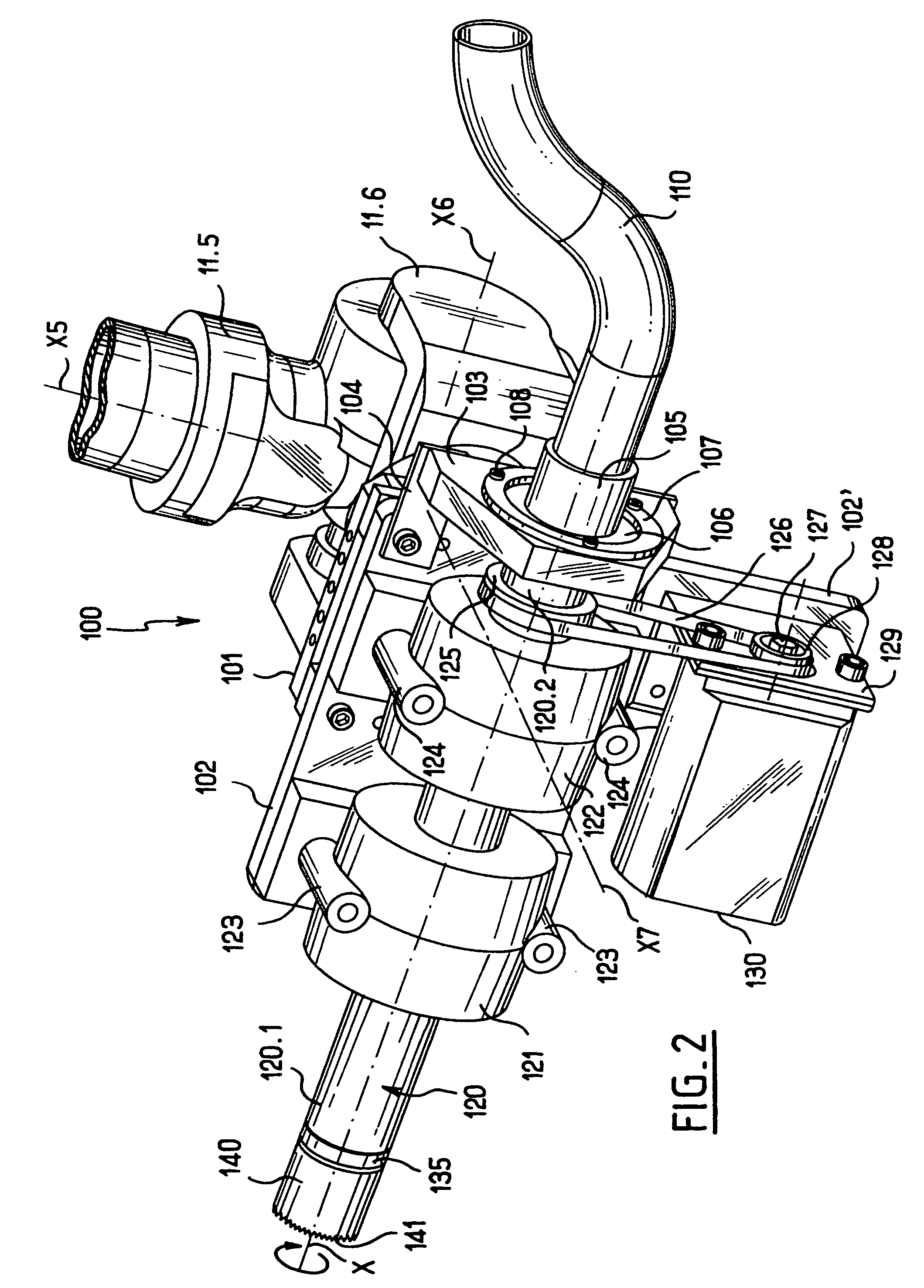

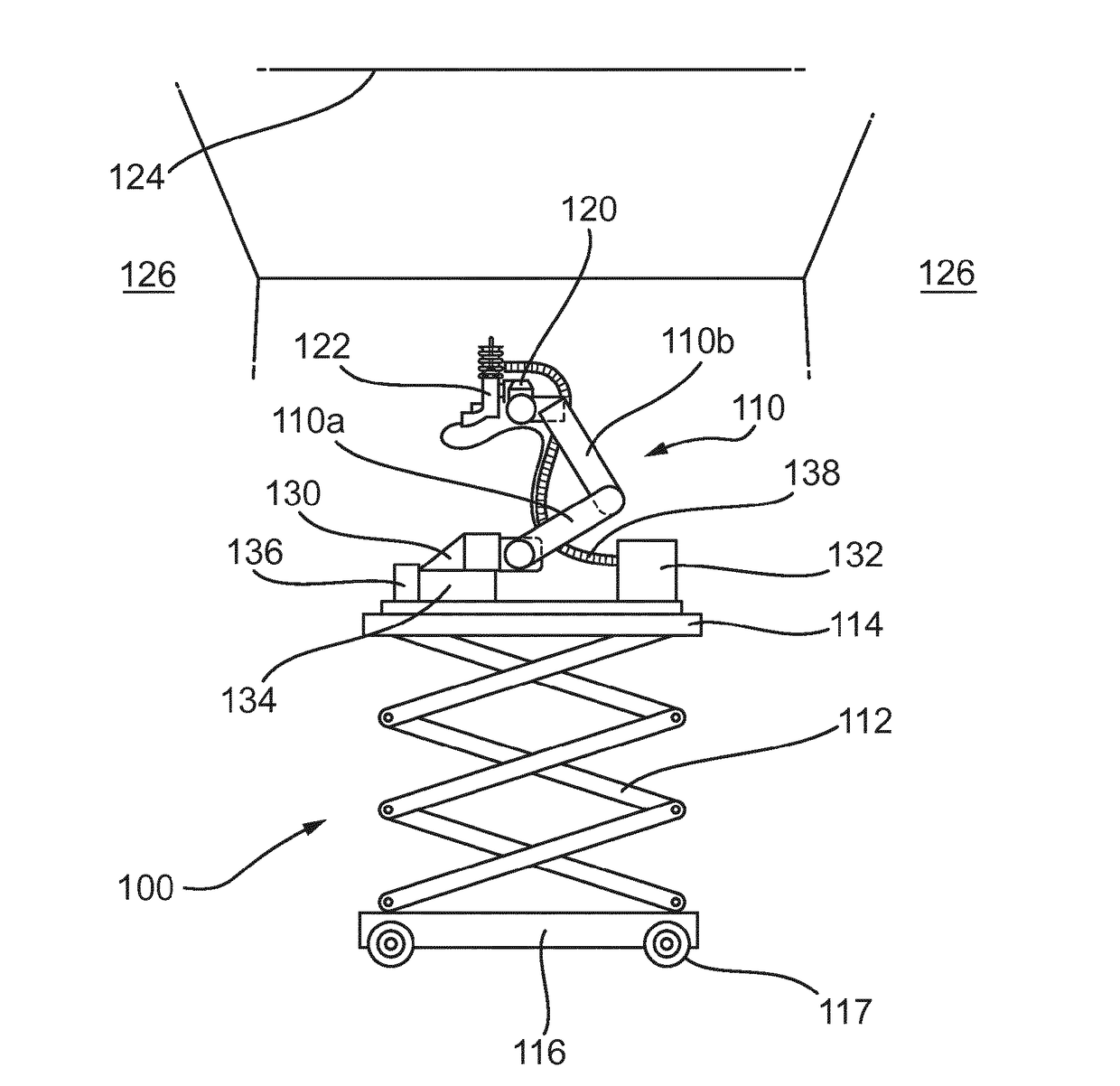

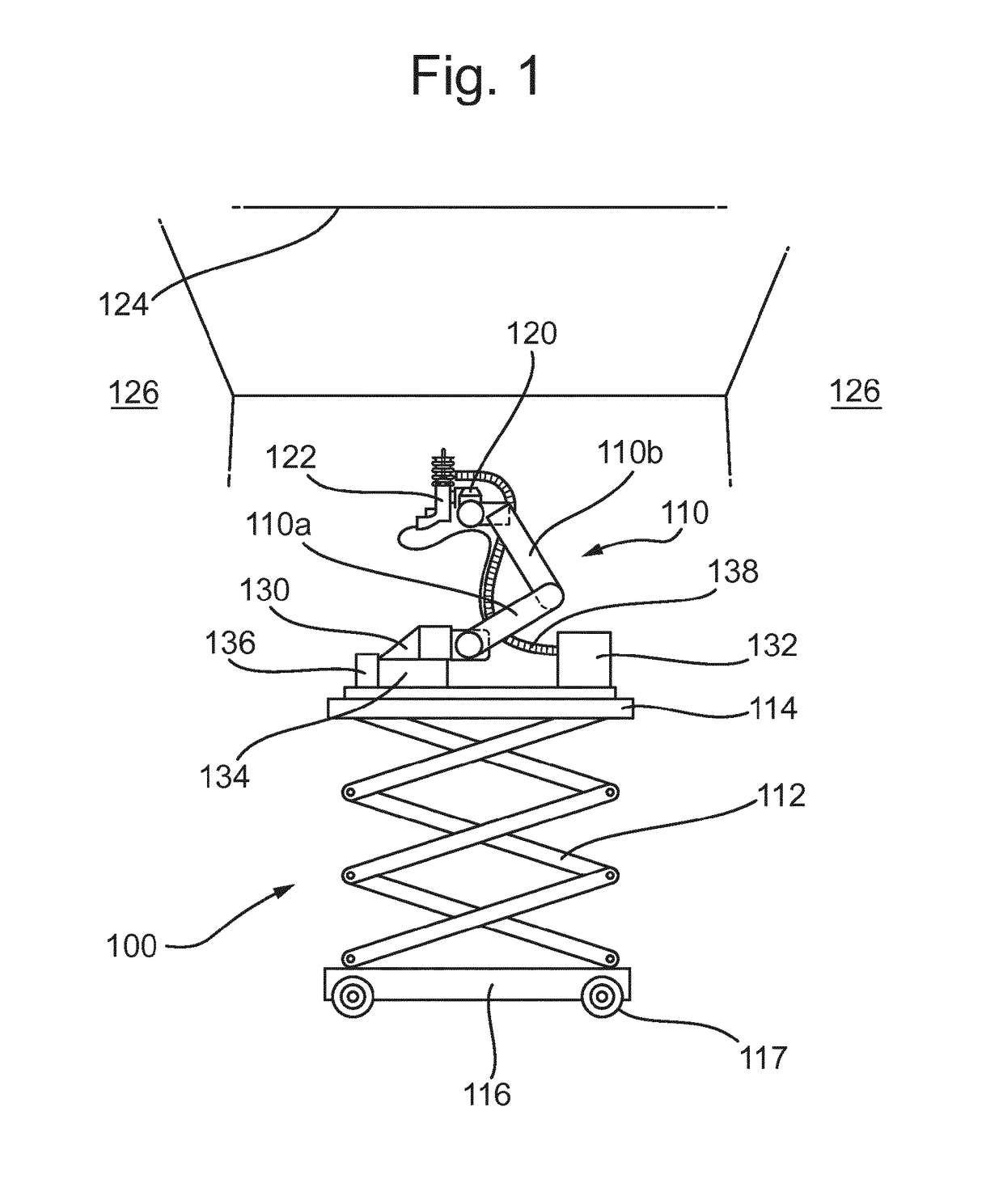

Mobile robotic drilling apparatus and method for drilling ceilings and walls

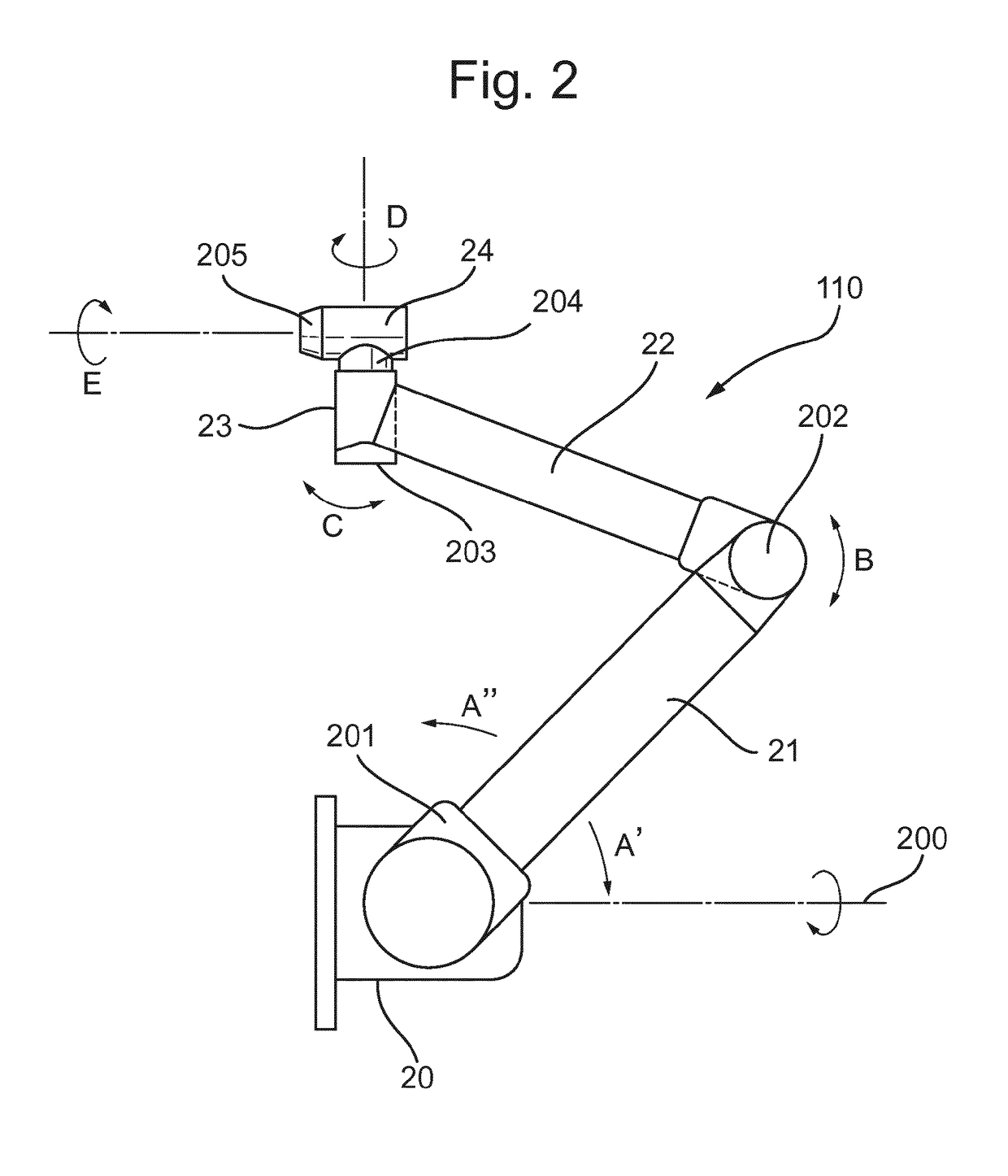

PendingUS20180326507A1Precise drillingDelay in reachingProgramme-controlled manipulatorWorkpiecesThree-dimensional spaceRobotic arm

A robotic drilling apparatus is described which has been adapted for drilling holes in ceilings and walls on a construction site. The apparatus (100) comprises a robotic arm (110) mounted to a substructure (112), the substructure comprising a lifting mechanism arranged to lift the robotic arm to a working position, wherein the robotic arm has a base end (110a) and a movable end (110b), the base end being mounted to an upper surface (114) of the lifting mechanism and the movable end being capable of movement with respect to the base end in a three dimensional space, wherein the robotic drilling apparatus further comprises a mount (120) provided on the movable end for holding a drilling device (122) and a control unit (134) for controlling the operation of the robotic arm. The lifting mechanism preferably comprises a scissor-jack lifting platform. The robotic arm (110) and any support structure (134) for the robotic arm weighs less than 43 kg, and preferably individually weigh less than 23 kg.

Owner:HILTI CORPOARATION

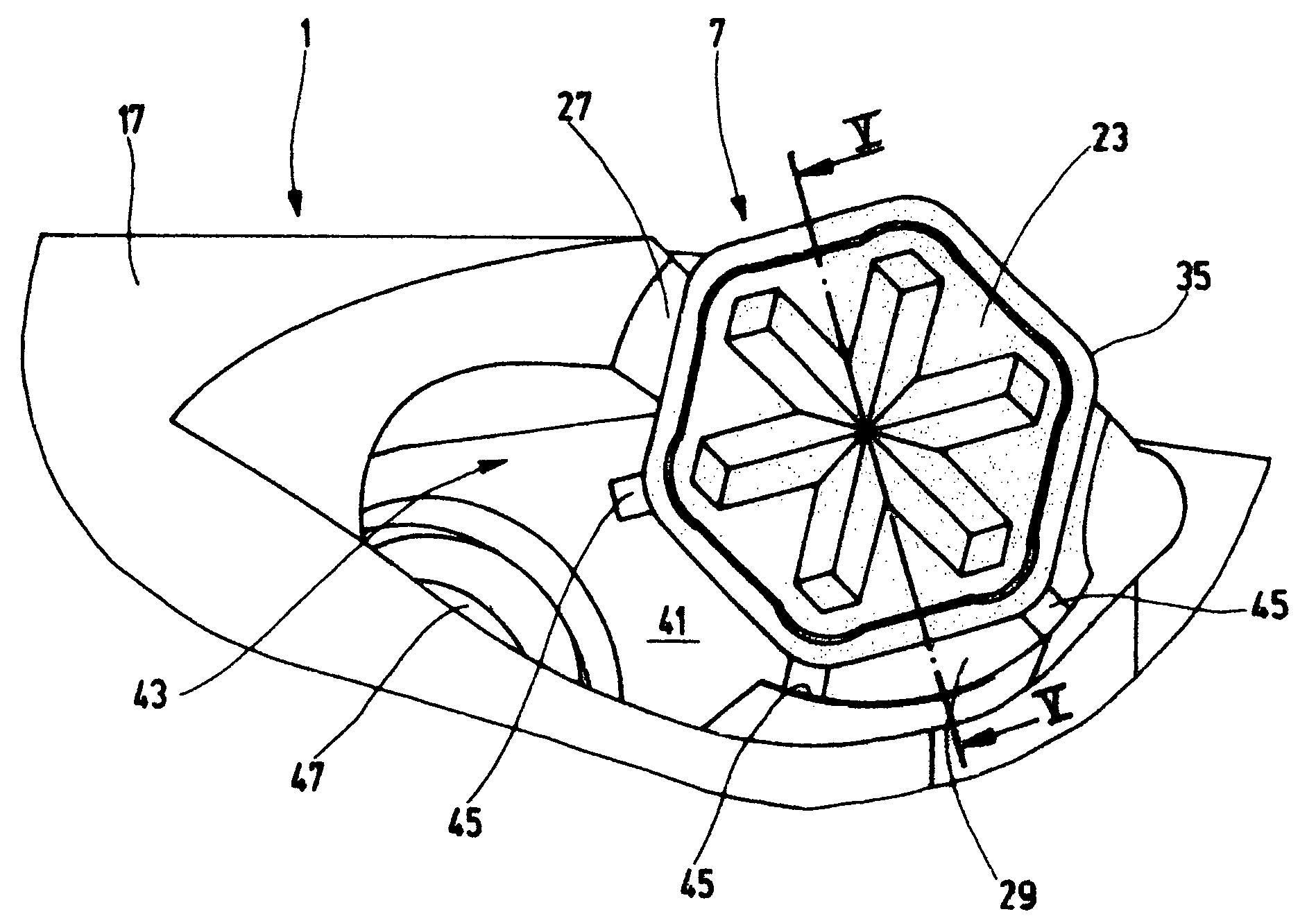

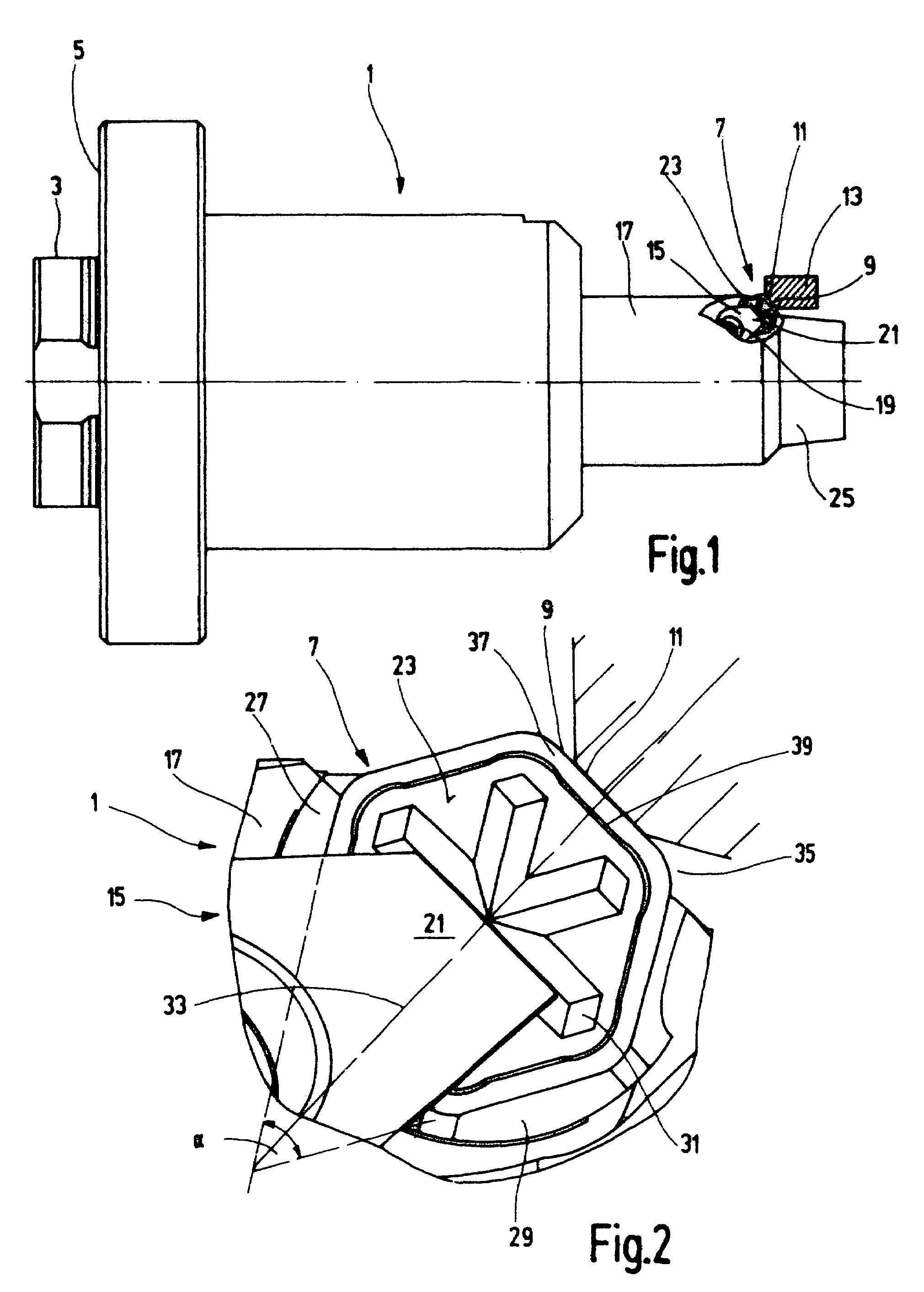

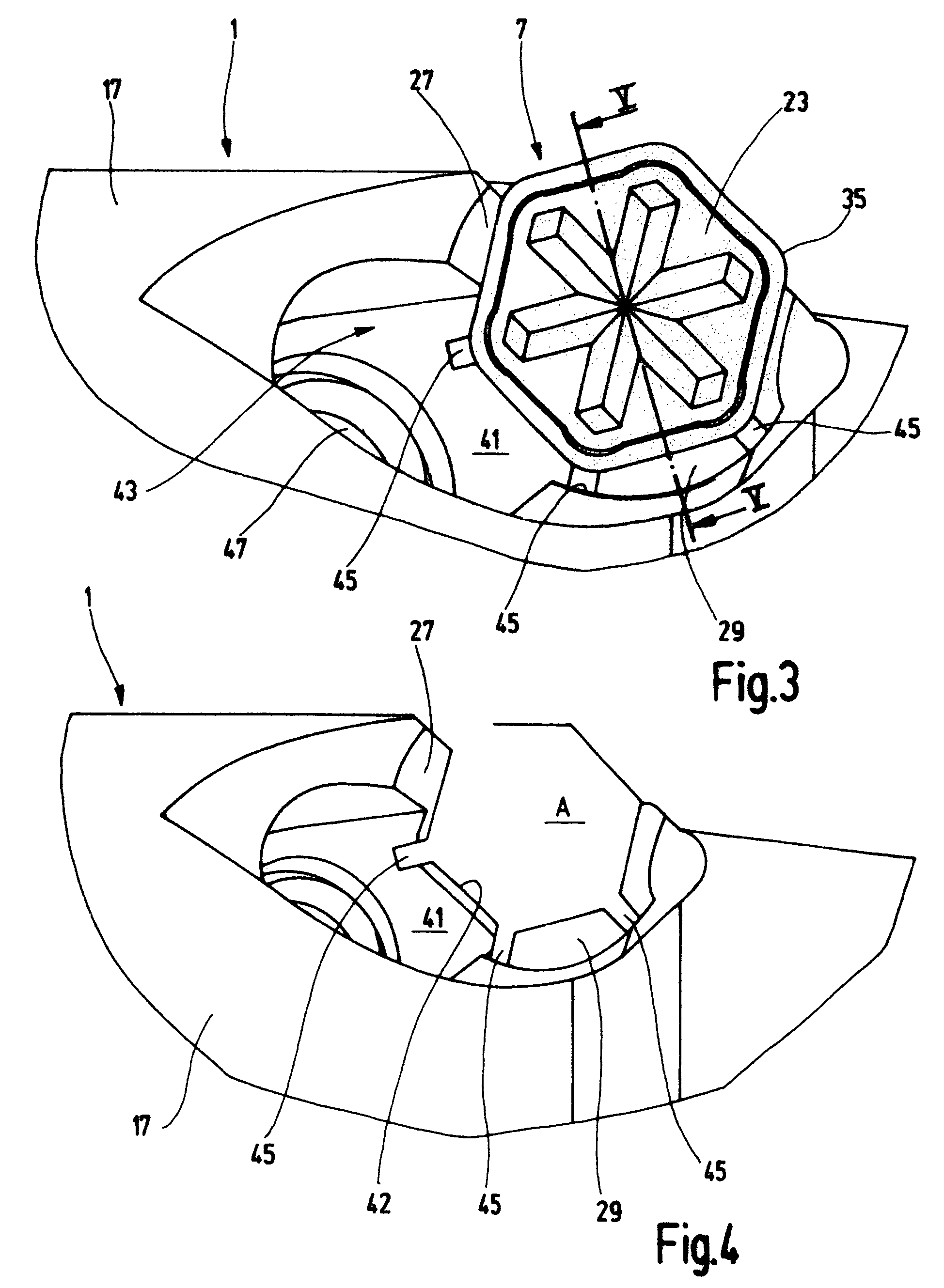

Tool for the metal cutting machining of valve seats

InactiveUS7530769B2Less-expensive solutionSimple methodThread cutting toolsTransportation and packagingCylinder headEngineering

A tool for metal-cutting machining of a surface of an opening particularly of a valve seat in a cylinder head of an internal combustion engines. The tool has a cutter tip with at least one geometrically defined cutting edge. The cutter tip rests on two supporting regions in the tool which are arranged at an angle α, and an angle-bisecting line runs essentially perpendicularly with respect to the active cutting edge which then is removing chips from the valve seat. A claw holds the cutting tip to the tool end. Coolant and lubricant are supplied through an outlet from the claw.

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

Braze alloy

A braze alloy is described which includes indium and / or thallium as alloying elements. For example, between about 0.5% and about 10% by weight of indium (In) and / or thallium (Tl) can be added to a braze alloy to reduce the braze temperature without substantially effecting braze strength. Braze alloys that are alloyed to including indium (In) and / or thallium (Tl) can be use in brazing cutting elements to drilling tools. These alloying elements may also be added to braze alloys used for other applications to reduce braze temperature.

Owner:KEMBAIYAN KUMAR T

Precision cemented carbide threading tap

InactiveUS7147413B2Improve accuracyIncrease speedThread cutting toolsWood turning toolsEngineeringCemented carbide

A precision cemented carbide threading tap is designed for use in precision tool holders in synchronous high speed tapping. The precision tap includes a fully cylindrical shank without the aid of squares, flats or other notches. The precision tap further includes a threaded body portion and a threaded cutting chamfer portion. The threaded body portion and the threaded cutting chamfer portion of the precision tap are concentric to the cylindrical shank of the tap within a runout of 10 microns. The precision cemented carbide threading tap improves the accuracy, life and speed by which internal screw threads are produced.

Owner:KENNAMETAL INC +1

Polycrystalline superabrasive composite tools and methods of forming the same

ActiveUS20080023230A1Wide applicationProperty is limitedPigmenting treatmentDrill bitsCarbideHigh pressure

A polycrystalline superabrasive composite tool can be produced using high pressure high temperature processes allowing for increased thermal resistance, wear resistance and toughness of abrasive tools, and additionally allowing for increased effective thickness of abrasive tools. A polycrystalline superabrasive compact can include a support substrate and a superabrasive polycrystalline layer having a diffusion bridge embedded therein that includes a carbide former. Additionally, a working layer can be attached adjacent to the superabrasive polycrystalline layer and opposite the support substrate to form a drill bit sandwich segment. The diffusion bridge matrix of the present invention allows for a new welding phase at each interface between the superabrasive polycrystalline layer and support substrate and between the polycrystalline layer and the metal working layer, thus eliminating delamination failure at the interfaces. The superabrasive polycrystalline layer can include superabrasive particles of varying particle sizes such that the final composite tool is tailored for specific abrading characteristics. The polycrystalline superabrasive composite tools can be incorporated for use in machining, drilling, grinding, cutting, polishing and similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

Cutting insert and cutting insert holder therefor

A milling cutter for machining camshafts includes a rotary disc and an annular row of cutting bits mounted in pockets formed in the disc. Each cutting bit includes a top surface having a pair of diagonally spaced raised portions. Cutting edges are formed where the top surface and the raised portions intersect side surfaces of the bit. The pockets are arranged along an edge of the disc where a cylindrical outer periphery of the disc intersects an end face of the disc. Each pocket is configured with an internal cavity for receiving a raised portion of an inactive cutting portion of the respective bit.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com