Online milling deformation measurement and complementation machining method for thin-walled part

A technology of thin-walled parts and processing methods, which is applied in the direction of machine tool parts, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of not obvious compensation processing effect, reduction of processing efficiency, interruption of processing process, etc., and achieve good deformation suppression effect, avoiding insufficient boundary conditions, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

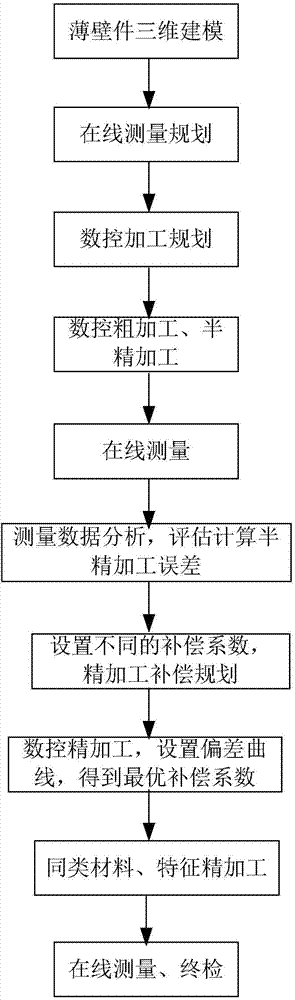

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

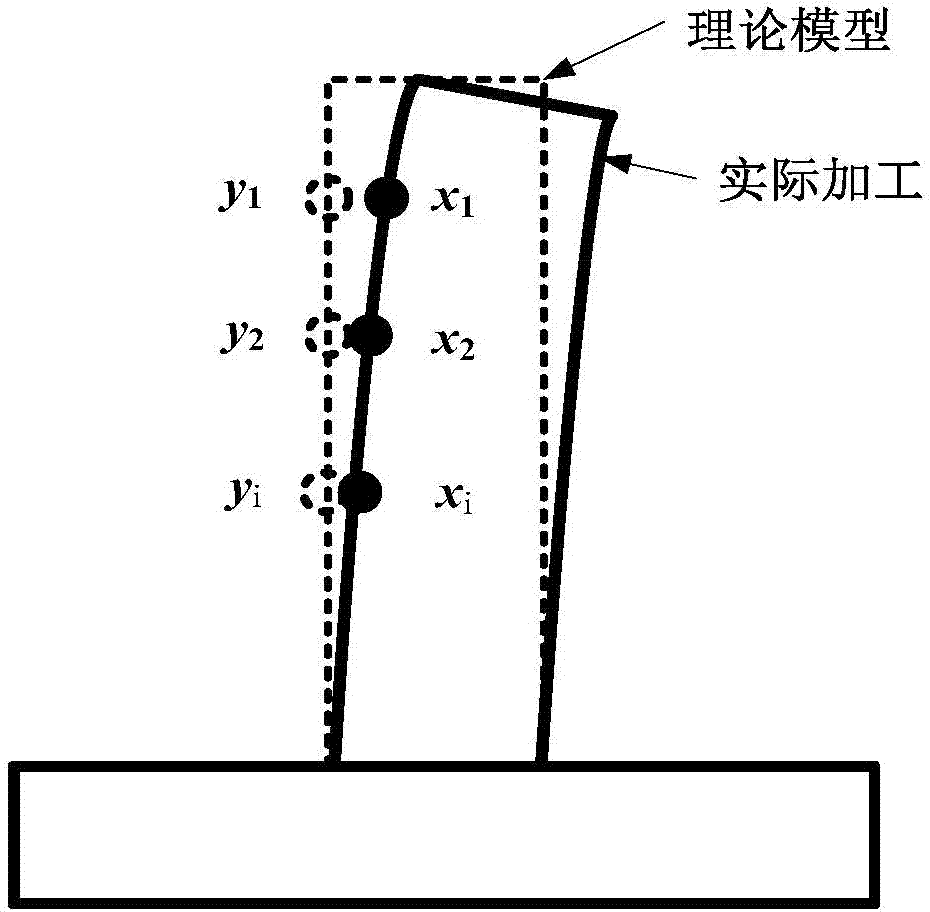

[0032] An embodiment of the present invention is attached figure 2 The thin-walled cantilever structure shown is taken as an example, but the thin-walled part processed by the method of the present invention is not limited to the above-mentioned structure and its specific size. In fact, the method of the present invention is applicable to any specific thin-walled parts.

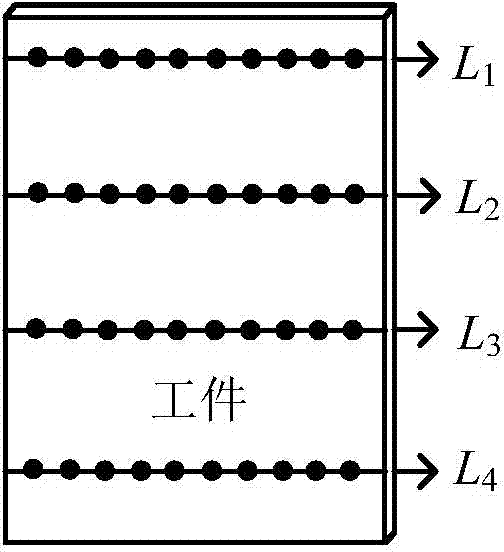

[0033] The thin-walled cantilever structure corresponding to this embodiment has a structural size of about 30mm in height, 0.7mm in thickness, and 40mm in width. The thin-walled blank material is titanium alloy TC4, and the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com