Patents

Literature

1065 results about "Compensation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The compensation effect refers to the behavior of a series of closely related chemical reactions (e.g., reactants in different solvents or reactants differing only in a single substituent ), which exhibit a linear relationship between one of the following kinetic or thermodynamic parameters for describing the reactions:

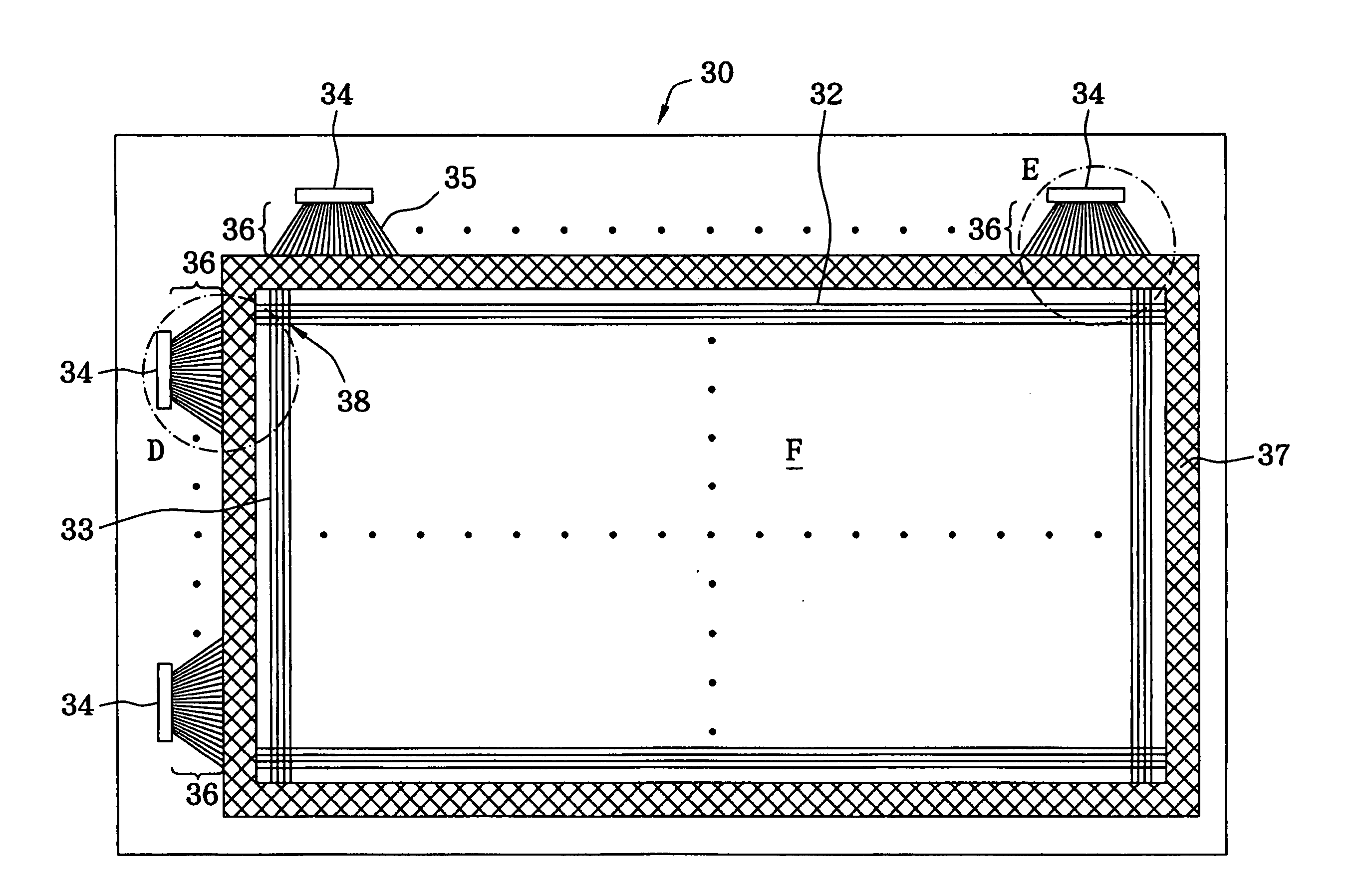

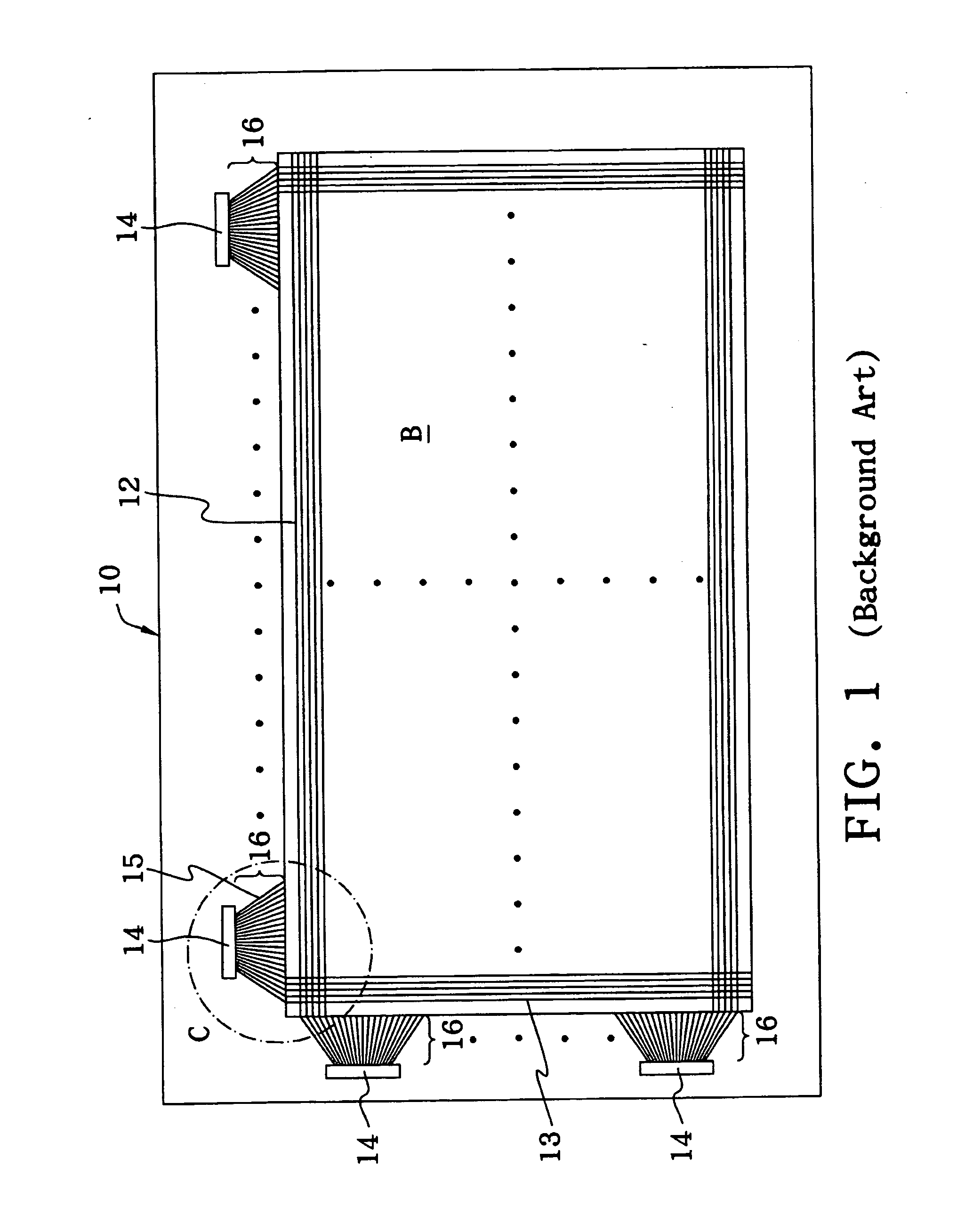

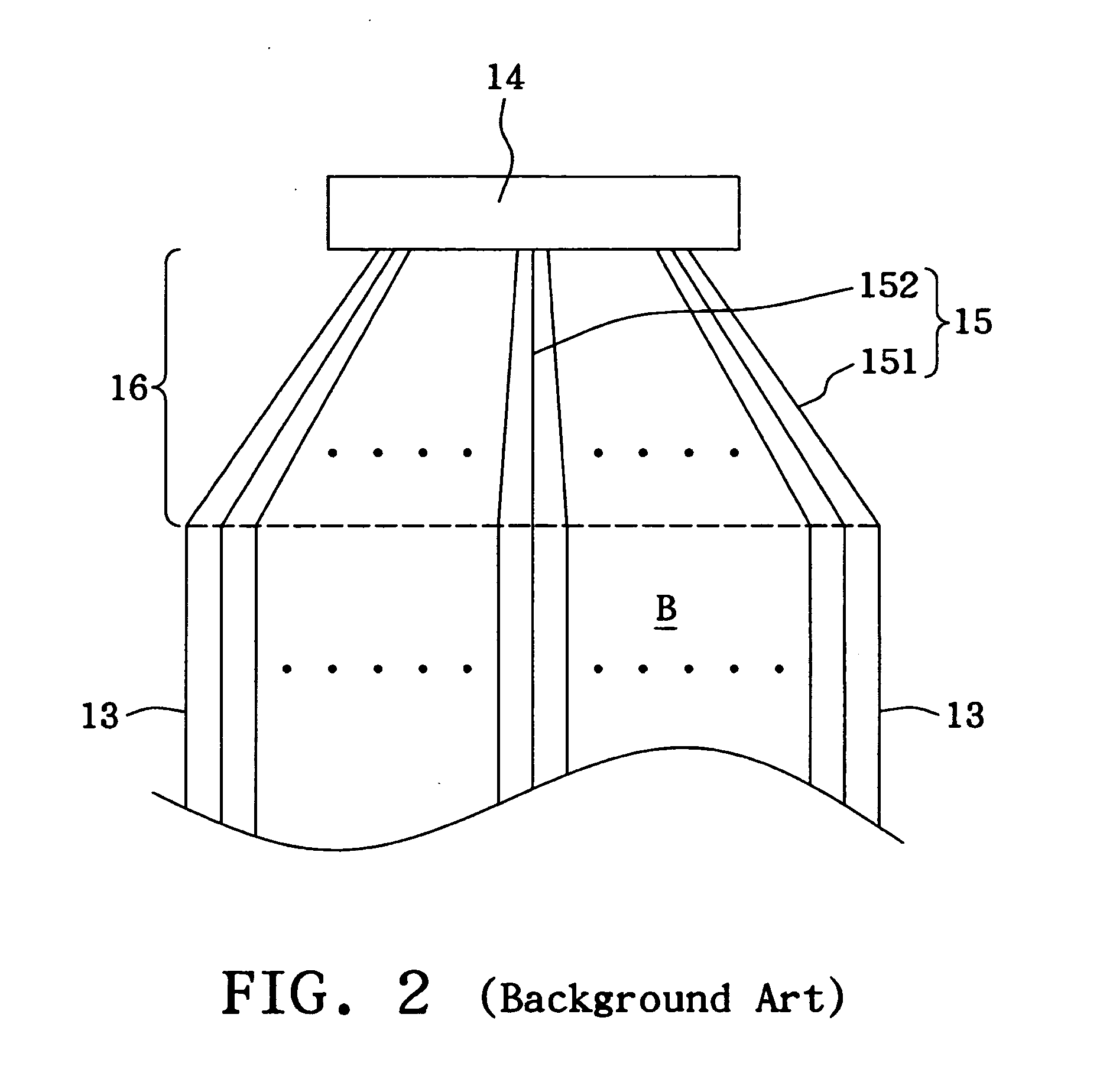

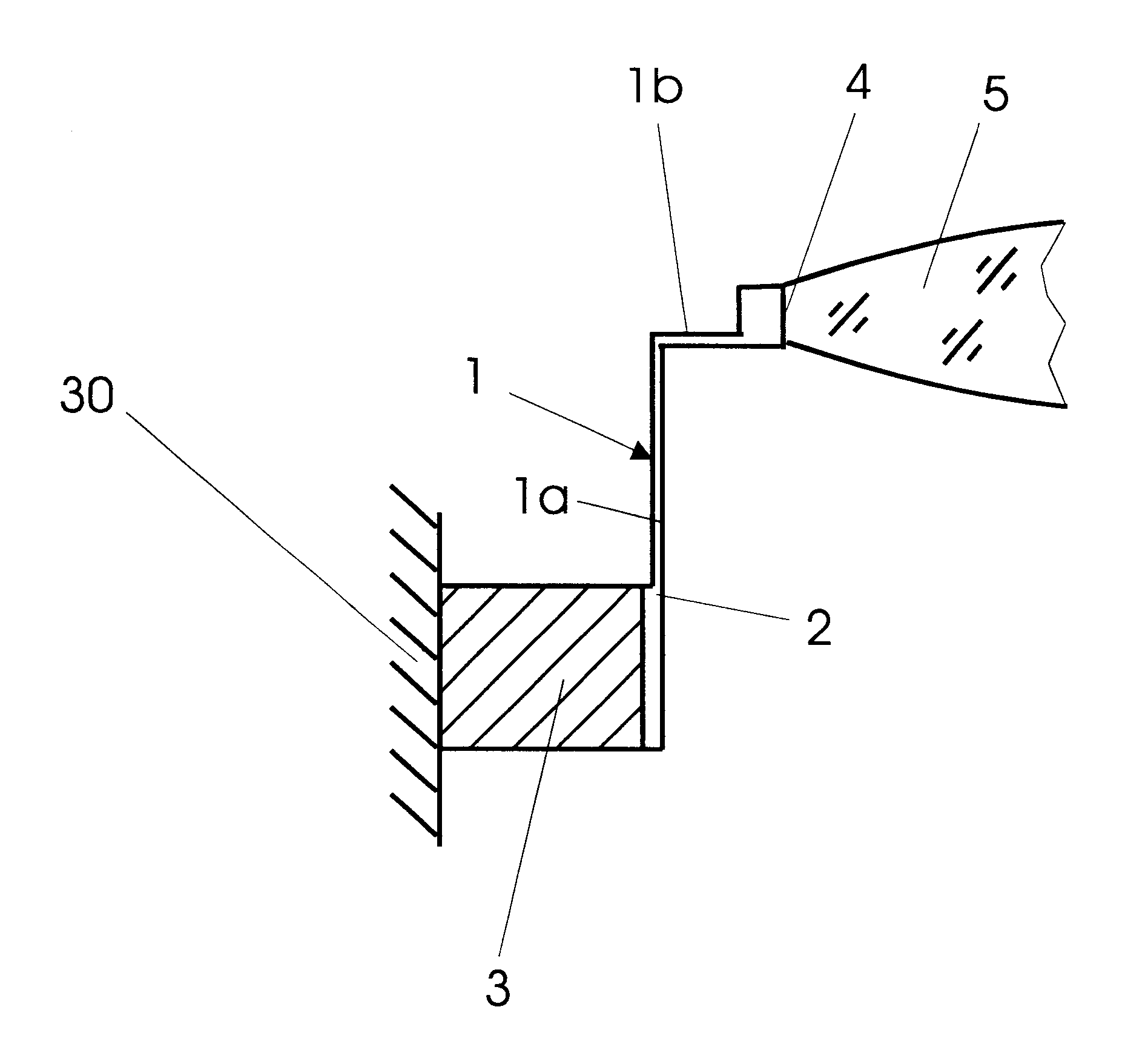

Liquid crystal display panel with reduced flicker

ActiveUS20050018121A1Reduce flickerEliminate flickeringStatic indicating devicesNon-linear opticsElectrical resistance and conductanceLiquid-crystal display

A liquid crystal display panel with reduced flicker comprises an active matrix substrate equipped with a plurality of thin film transistors. The active matrix substrate has an active area that is formed with a plurality of first signal lines and a plurality of second signal lines crossing each other. The active area includes a plurality of pixels arranged in a matrix. There are outer-lead bonding areas around the active area. There are a plurality of pad areas within the outer-lead bonding areas. A plurality of second wires arranged in a fan-out configuration extend from the pad areas and stretch toward the active area. The second wires are connected to their respective first signal lines by their serpentine or zigzag routes resulting in various wire lengths. A frame-like lead overlaps the second wires, and a capacitor exists between each of the second wires and the closed frame-like lead. The induced capacitor and the resistance of the corresponding second wire together result in a compensation effect so as to uniform the time constants of the plurality of first signal lines.

Owner:HANNSTAR DISPLAY CORPORATION

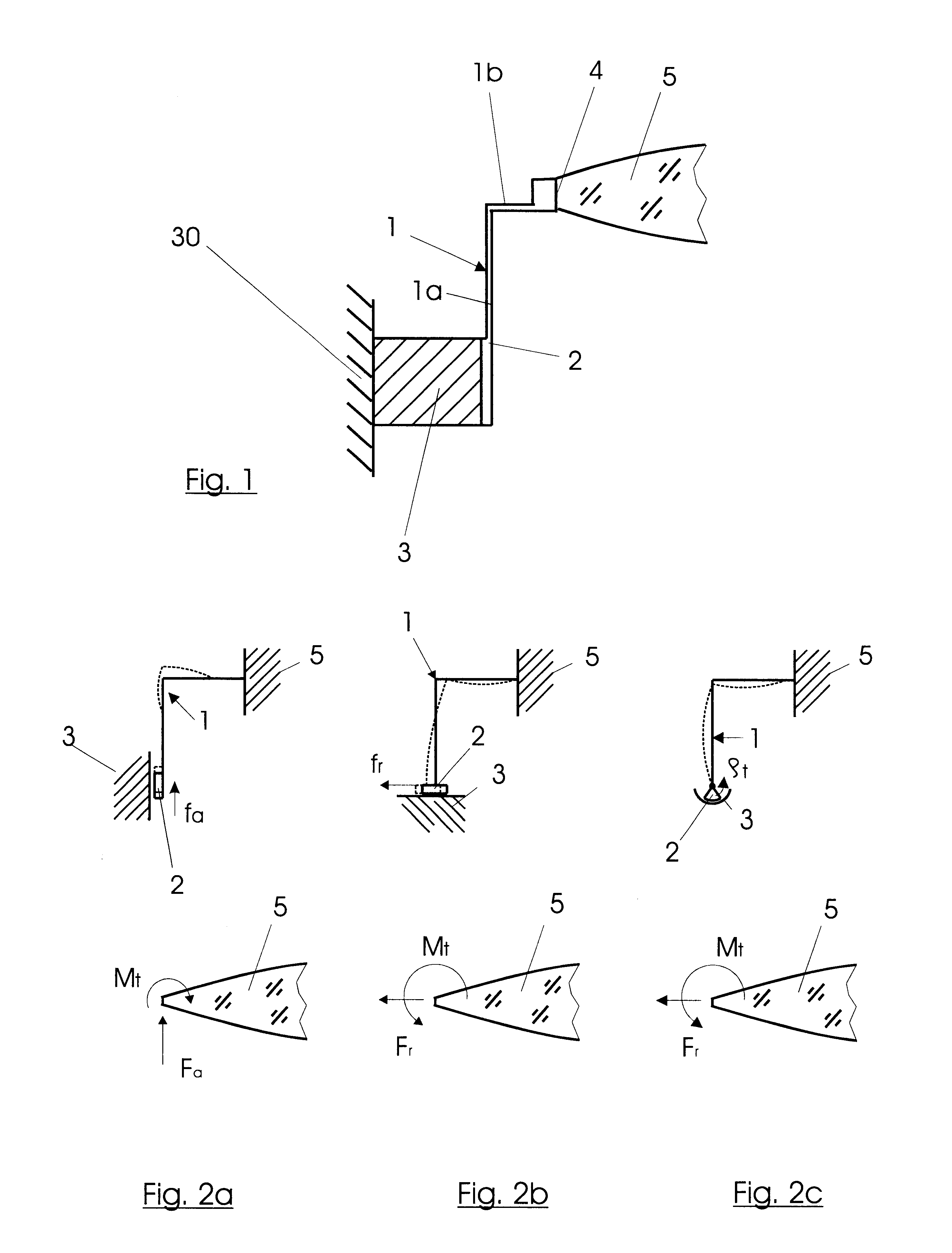

Mounting device for an optical element

InactiveUS6552862B2Deformation MinimizationAcceleration-induced deformations of the optical surface are likewise minimizedSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusIn planeCompensation effect

Owner:CARL ZEISS SMT GMBH

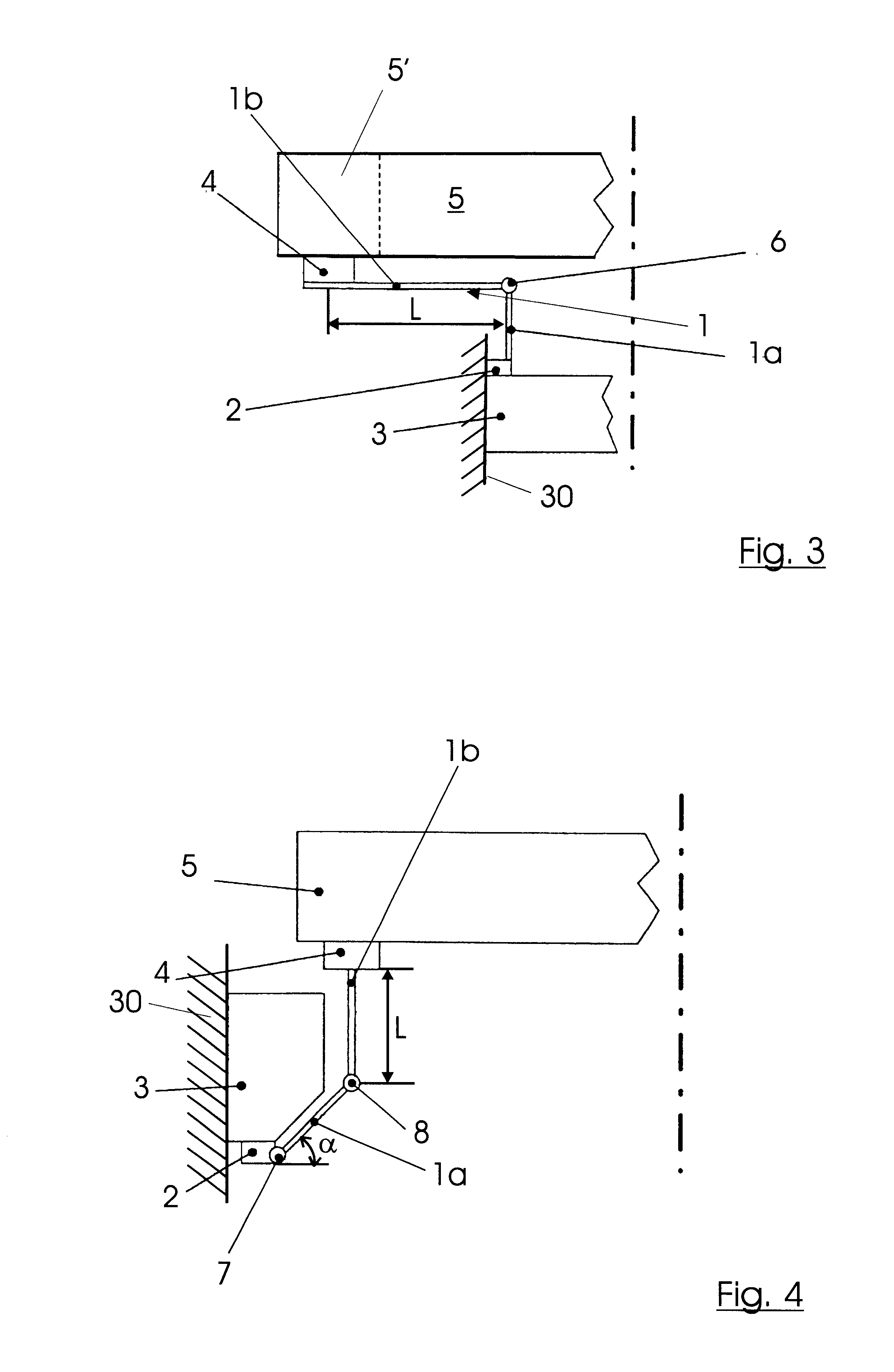

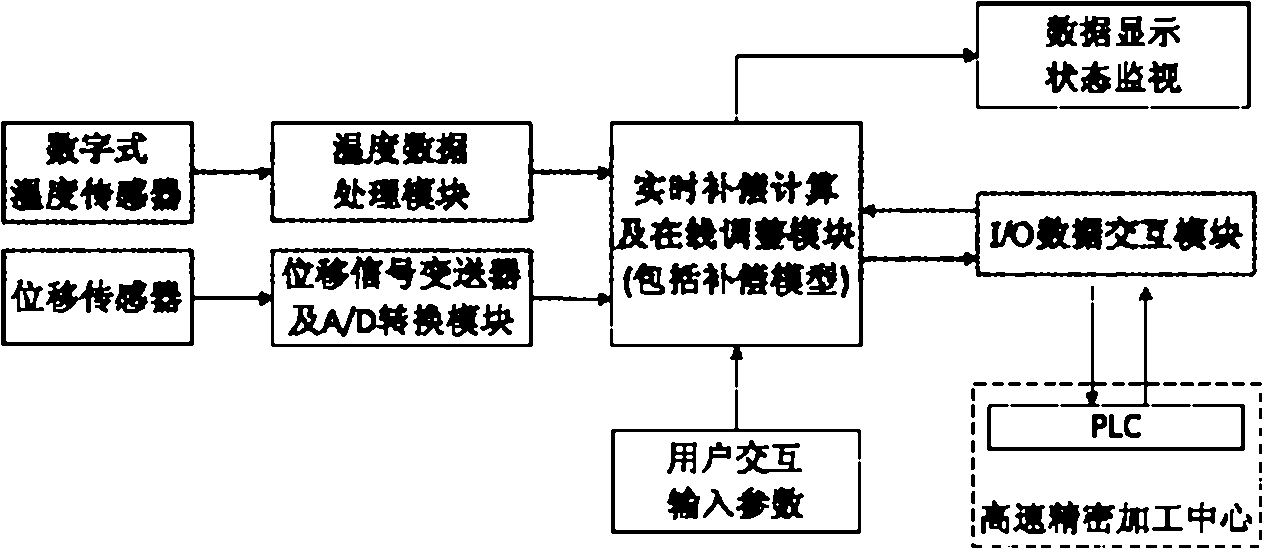

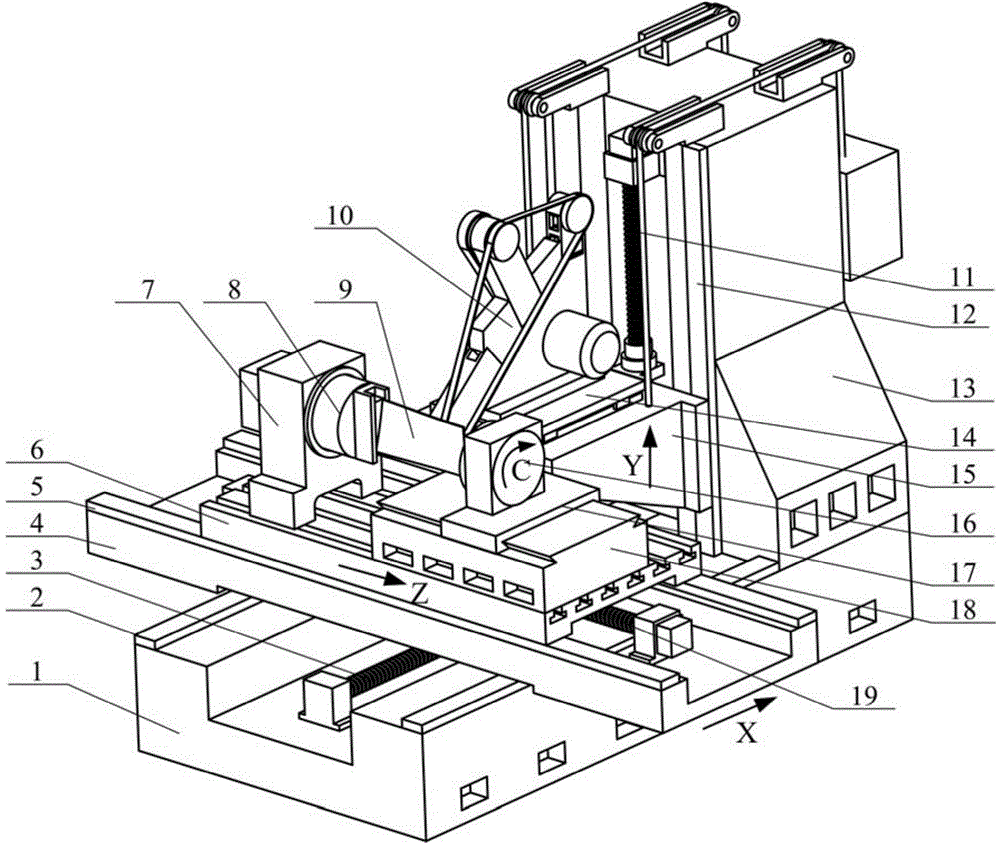

Thermal-error real-time compensation system for high-speed precise machining and compensation method thereof

InactiveCN102122146AReal-time display of tracking effectsGood online monitoring functionProgramme controlComputer controlData displayNumerical control

The invention relates to a thermal-error real-time compensation system for high-speed precise machining and a compensation method thereof in the technical field of numerical control machine processing. The system comprises a digital temperature sensor, a temperature data processing module, a displacement sensor, a displacement signal transmitter, an A / D (Analog / Digital) conversion module, a real-time compensation calculation and online adjustment module, a data display and state monitor module, an I / O (Input / Output) data interaction module and a user interaction module. The invention can realize rapid high-accuracy compensation effect and favorable online monitoring.

Owner:SHANGHAI JIAO TONG UNIV

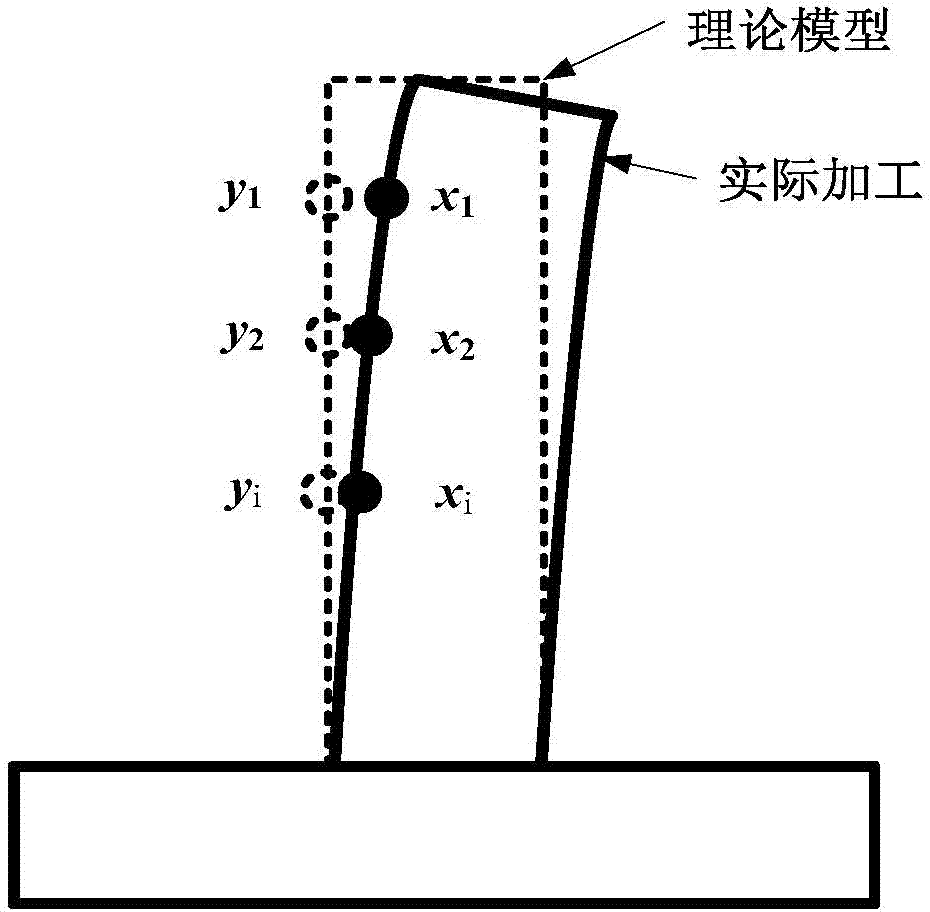

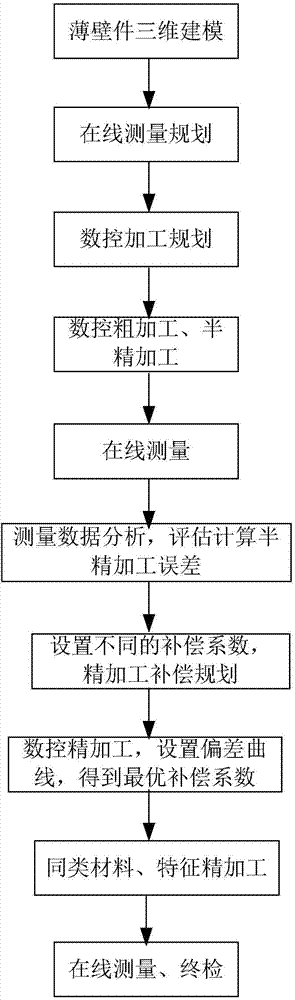

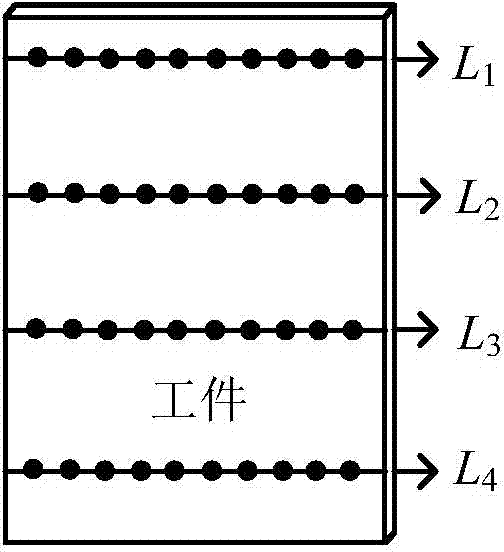

Online milling deformation measurement and complementation machining method for thin-walled part

ActiveCN104759942AAvoid insufficient boundary conditionsGood compensationGeometric CADMachine tool componentsNumerical controlMeasurement point

The invention discloses an online milling deformation measurement and complementation machining method for a thin-walled part. The online milling deformation measurement and complementation machining method for the thin-walled part comprises the steps that 1, a three-dimensional model of the thin-walled part is established, and a numerical control code is obtained; 2, measurement point locations are extracted from the three-dimensional model; 3, based on the model, a measurement path is planned; 4, rough machining and semi-precise machining are conducted on a workpiece blank; 5, online measurement is conducted, and the coordinate values of all the planed measurement point locations are obtained; 6, the obtained coordinate values of the planed measurement point locations are compared with those of the corresponding point locations on the three-dimensional model of the thin-walled part, and the difference between the coordinates of each point location of the actually machined workpiece and those of the corresponding point location on the three-dimensional model is calculated; 7, according to the machining differences, a complementation factor optimal machining path is generated according to the machining differences, precise machining is conducted according to the path, and then the final deformation deviation and the compensation values are obtained. By the adoption of the online milling deformation measurement and complementation machining method, semi-precise machining and precise machining are adopted, the identical machining parameters are adopted by the semi-precise machining and the precise machining, and the best precise machining compensation effect of the thin-walled parts which are made of the same materials and have the same characteristics can be achieved to the greatest extent through only one group of tests.

Owner:HUAZHONG UNIV OF SCI & TECH

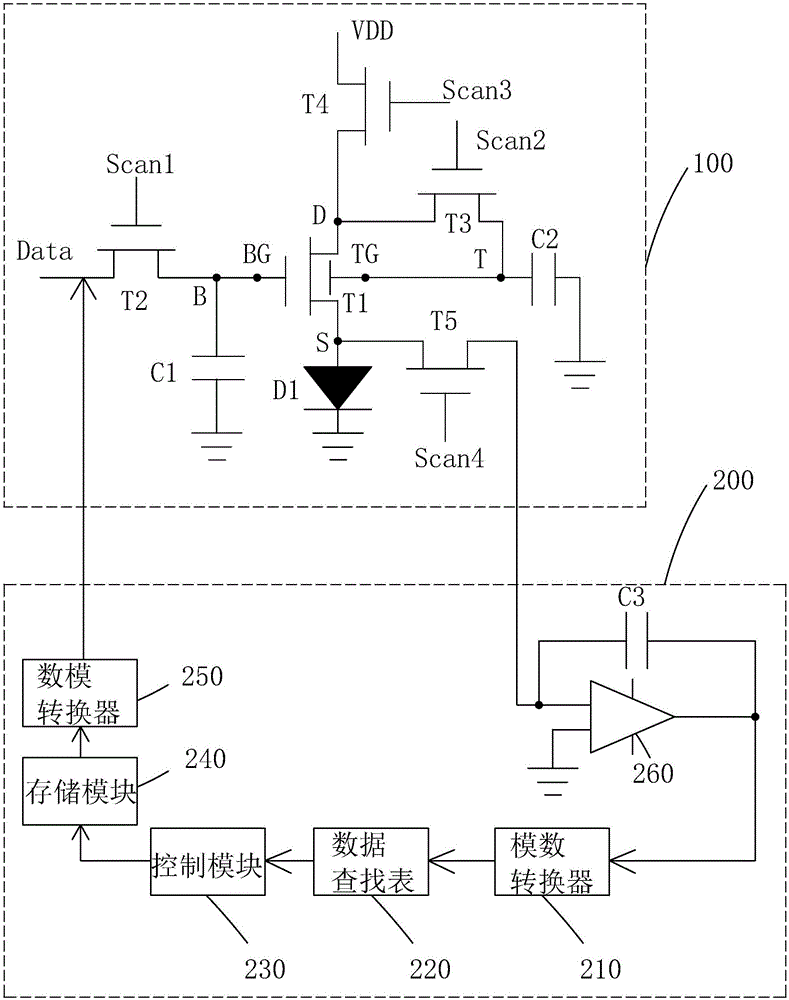

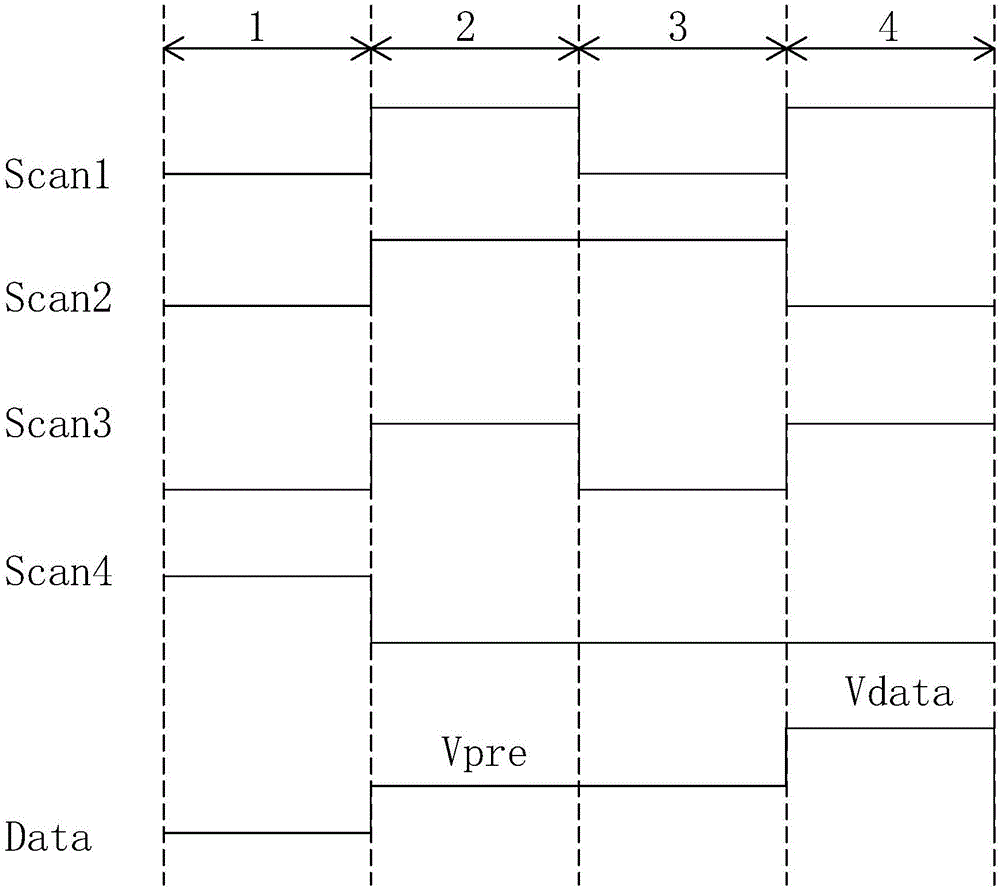

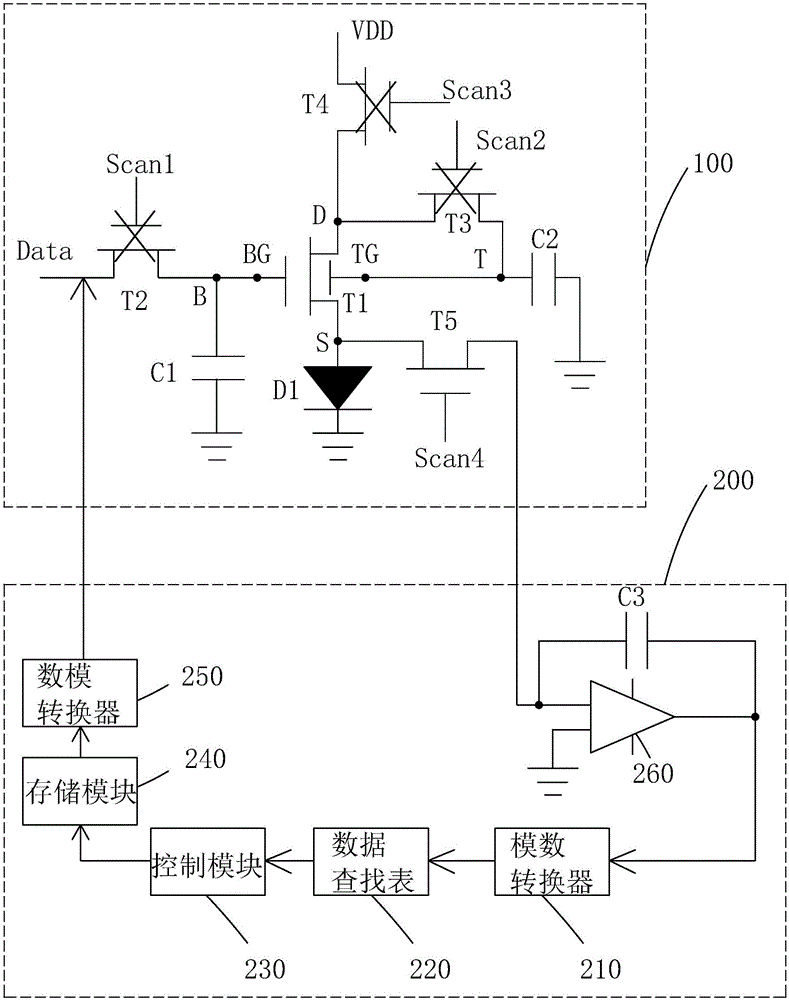

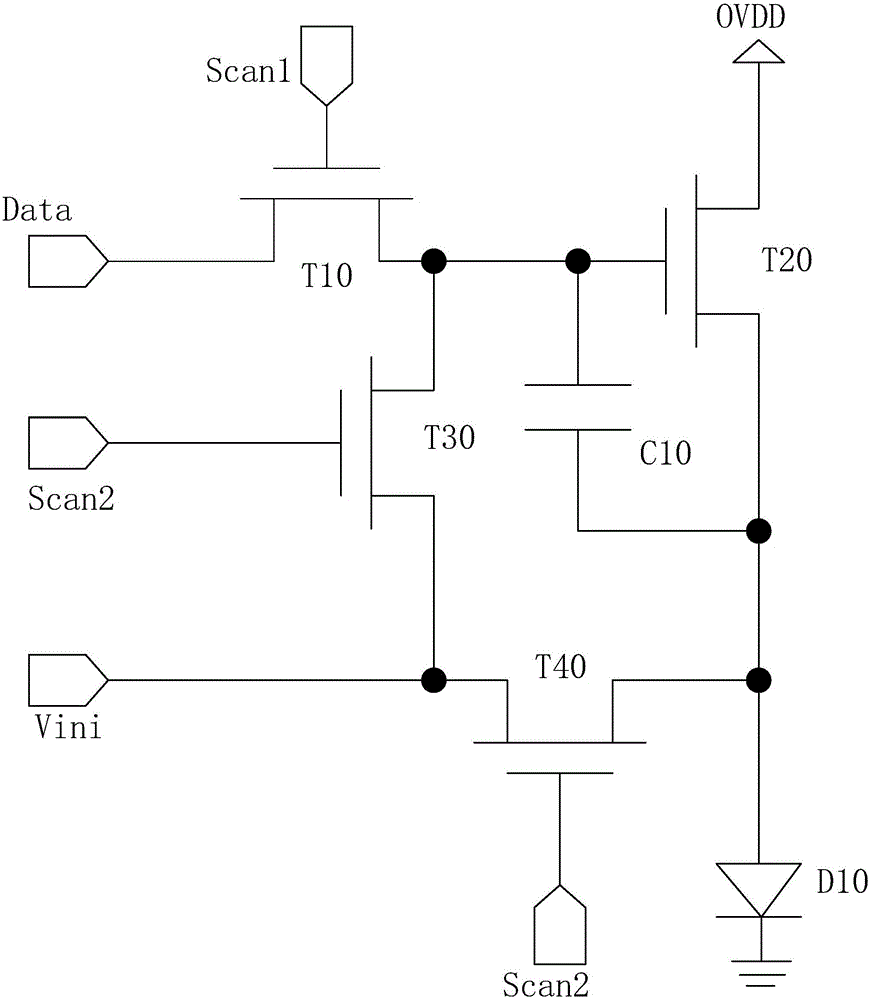

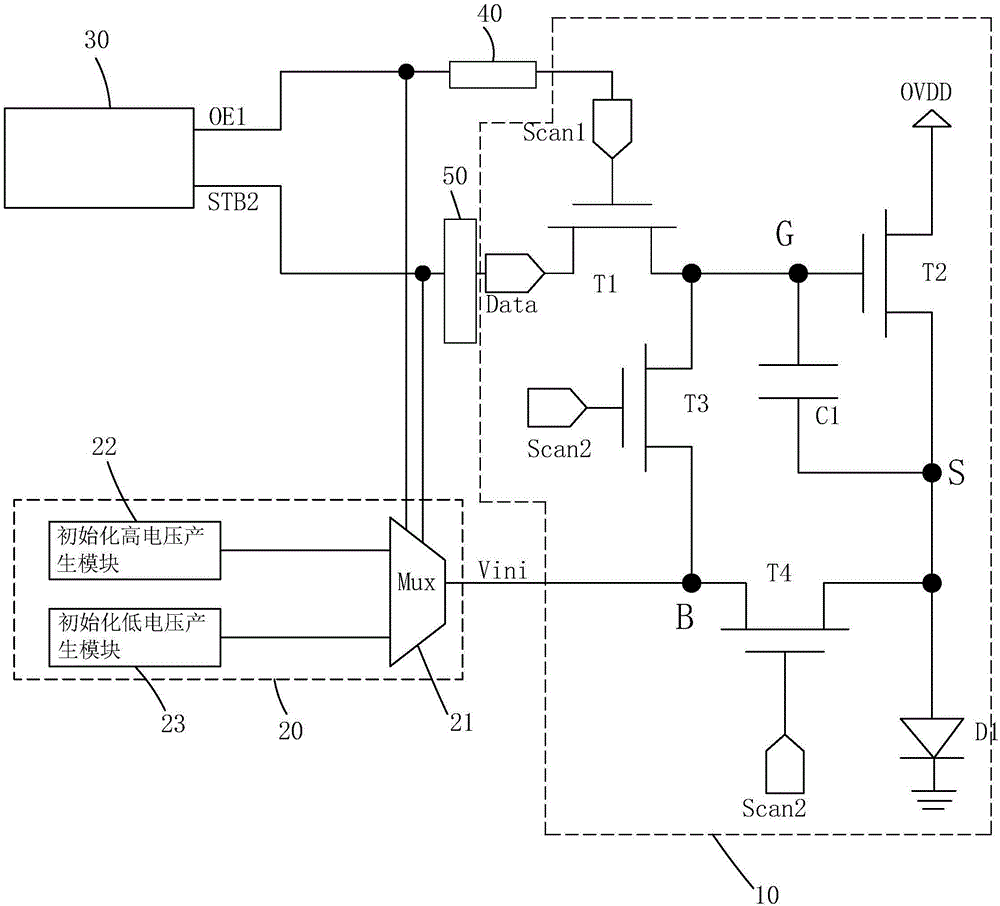

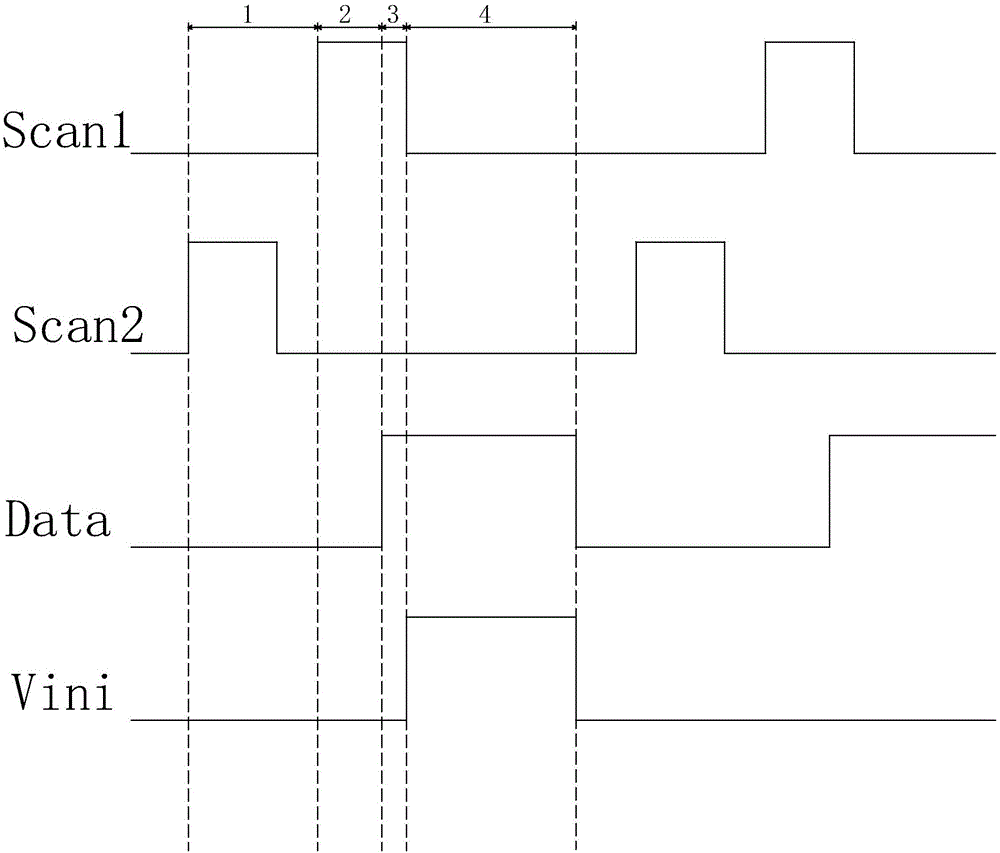

OLED pixel blending compensation circuit and blending compensation method

ActiveCN106504707AUniform luminanceGuaranteed stabilityStatic indicating devicesPower flowCompensation effect

The present invention provides an OLED pixel blending compensation circuit and a blending compensation method. A 5T2C structure is employed and a thin film transistor is driven to compensate the threshold-voltage drift for a pixel internal drive circuit (10) of a bigrid thin film transistor, and an external compensation circuit (200) is employed to compensate the non-uniform brightness of an organic light-emitting diode (D1) caused by aging and declination. Through combination of the rapid internal compensation operation speed and the big external compensation range, the OLED pixel blending compensation circuit and the blending compensation method have better compensation effects, simplify the data signals (Data) and realize the uniform brightness of the panel through the stability of the OLED current.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

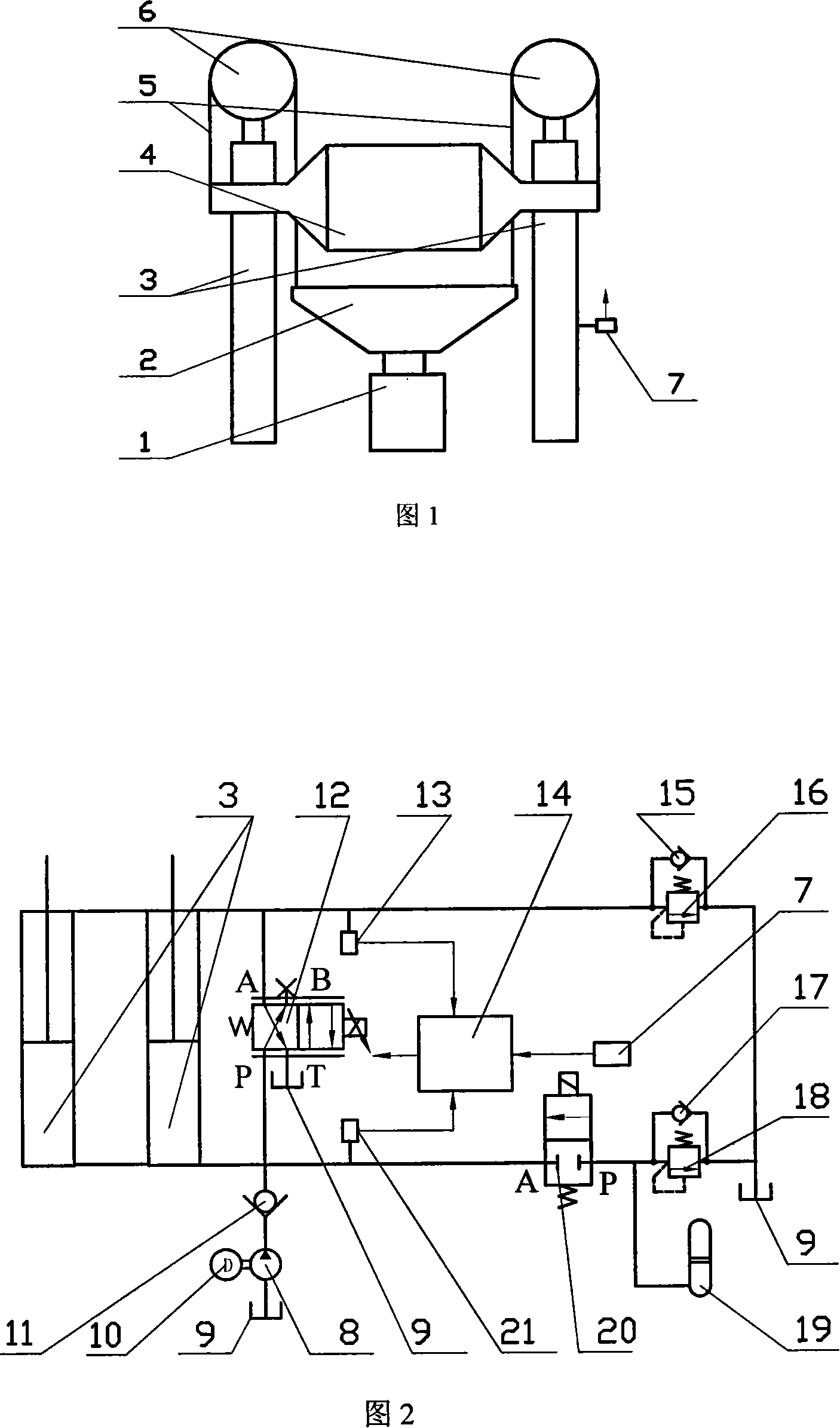

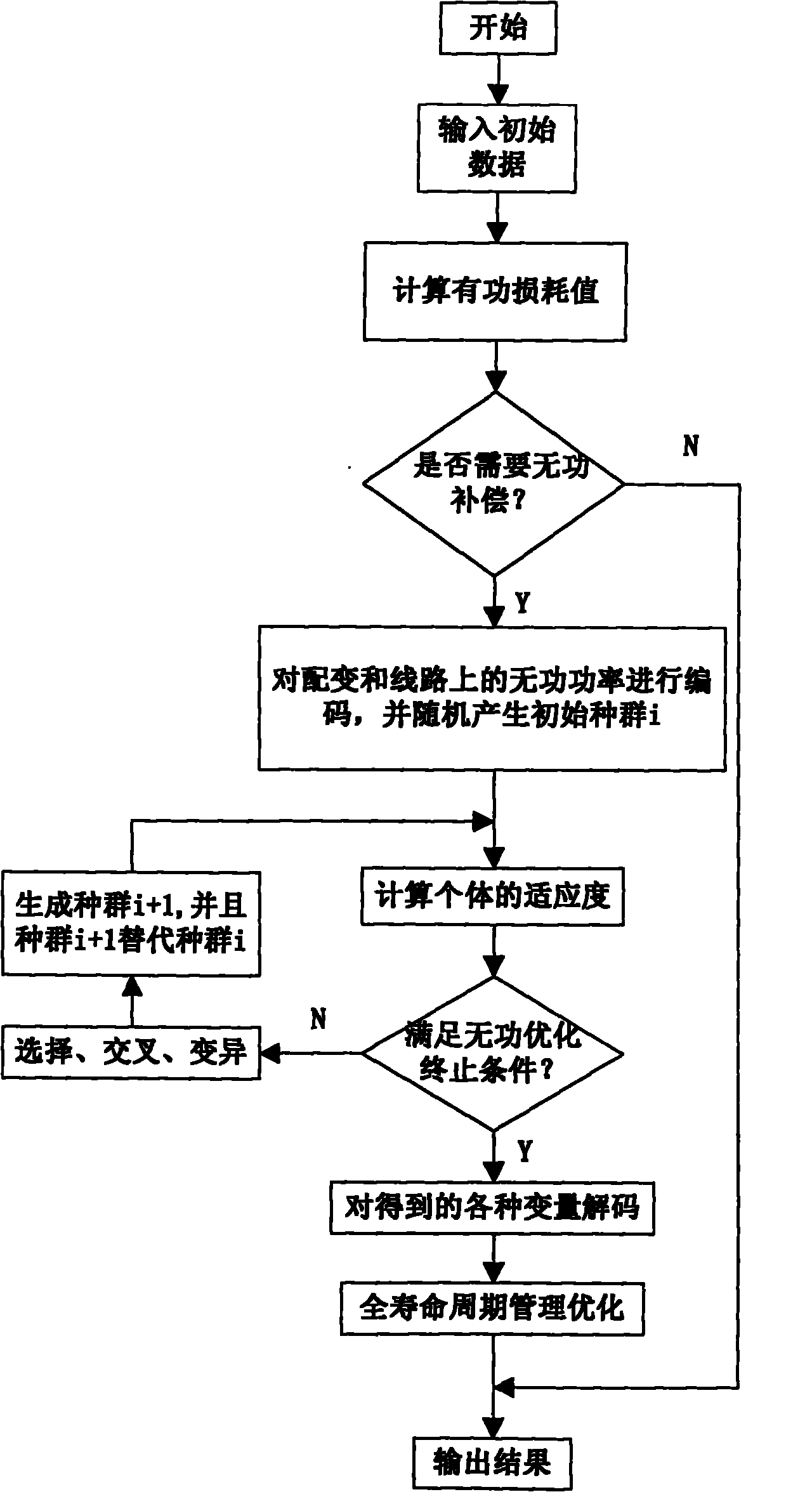

Drilling column heave compensation device of marine floating type drilling platform

InactiveCN101798909ALimit consumptionOvercome dynamic loadDrilling rodsServomotorsHydraulic cylinderCompensation effect

The invention discloses a drilling column heave compensation device of a marine floating type drilling platform. A composite hydraulic cylinder is adopted as a heave compensation hydraulic cylinder in a crown block heave compensation device; the high-pressure hydraulic oil output by a hydraulic pump flows into a rodless cavity of an inner cylinder and a rod cavity of an outer cylinder of the composite compensation hydraulic cylinder by a compensation control valve to provide controllable additional force for a piston rod of the outer cylinder; and the resultant force of the force and the hydraulic force acted by the rodless cavity of the outer cylinder of the compensation hydraulic cylinder provides support force to a crown block. The direction and magnitude of the additional force are controlled according to the platform heave motion, and the compensation effect of a heave compensation system is improved. A control unit transmits a control command to the hydraulic system according to the motion speed of the platform in the vertical direction, wherein the motion speed is obtained by detection, drives a piston of the compensation hydraulic cylinder to push the crown block to move and compensates the heave motion of the platform so that the crown block, a traveling block and a large hook are in a static state in the vertical direction relative to the well bottom in the allowable range.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

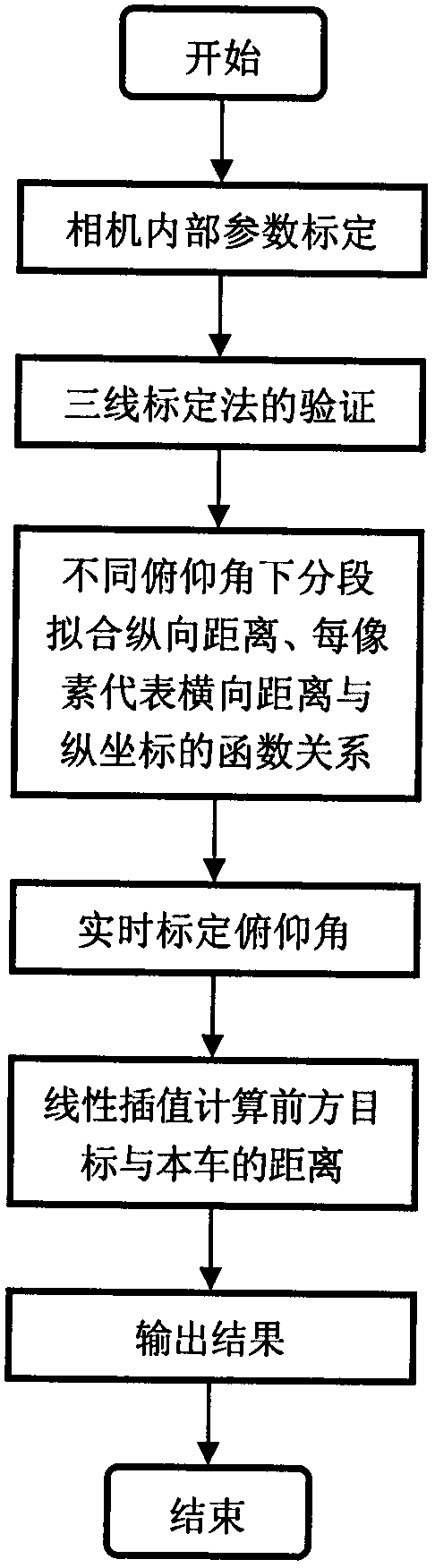

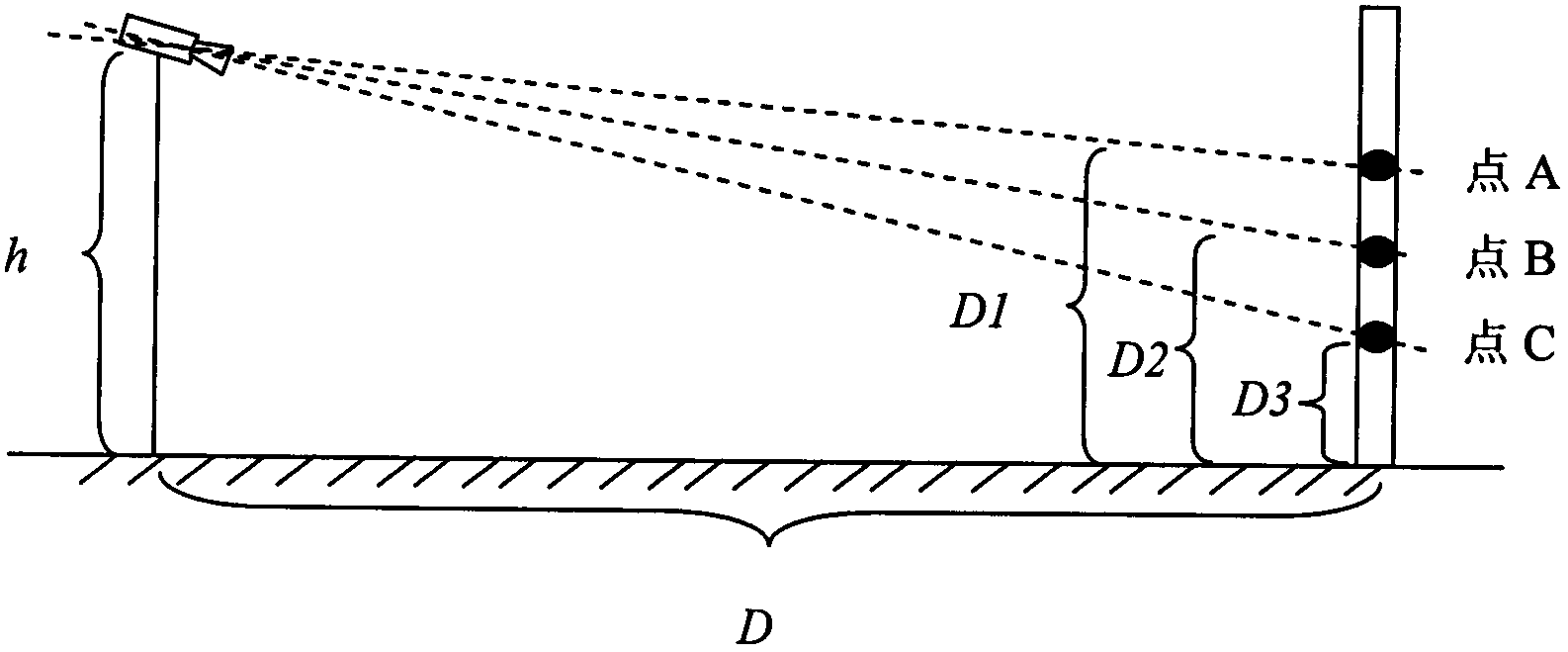

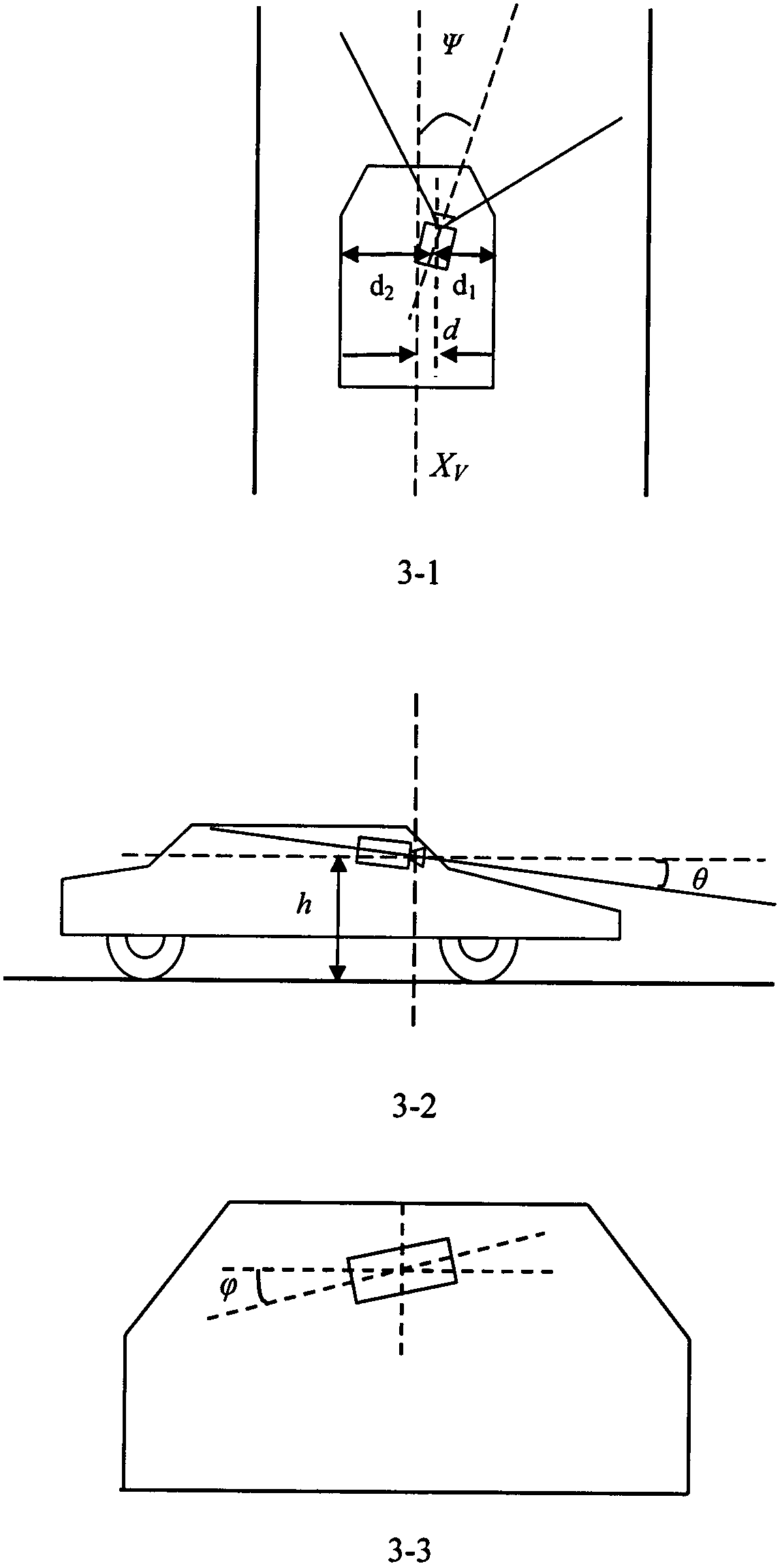

Front vehicle ranging method based on monocular vision

ActiveCN102661733ASimple methodEasy to implementOptical rangefindersPhotogrammetry/videogrammetryCompensation effectEngineering

The invention belongs to the technical field of intelligent transportation and relates to a front vehicle ranging method based on monocular vision. The method includes: adjusting the posture of a vehicular camera, considering the pitch angle variation range due to bumping to adjust the pitch angle of the camera, and using the obtained actual measurement data to segmentally fit the functional relation between an ordinate and an actual longitudinal distance at different pitch angles and the functional relation between the ordinate and an actual transverse distance represented by per horizontal pixel at different pitch angles; and when a vehicle runs, calibrating real-time pitch angle of the camera according to left and right lane lines detected in real time and a three-line calibration method, and then using the linear interpolation method to calculate to obtain the distance between the vehicle and a target vehicle. The front vehicle ranging method based on monocular vision has a real-time dynamic compensation effect on ranging error caused by vehicle bumping and can be used for accurately calculating the distance between the vehicle and the front vehicle.

Owner:TIANJIN POLYTECHNIC UNIV

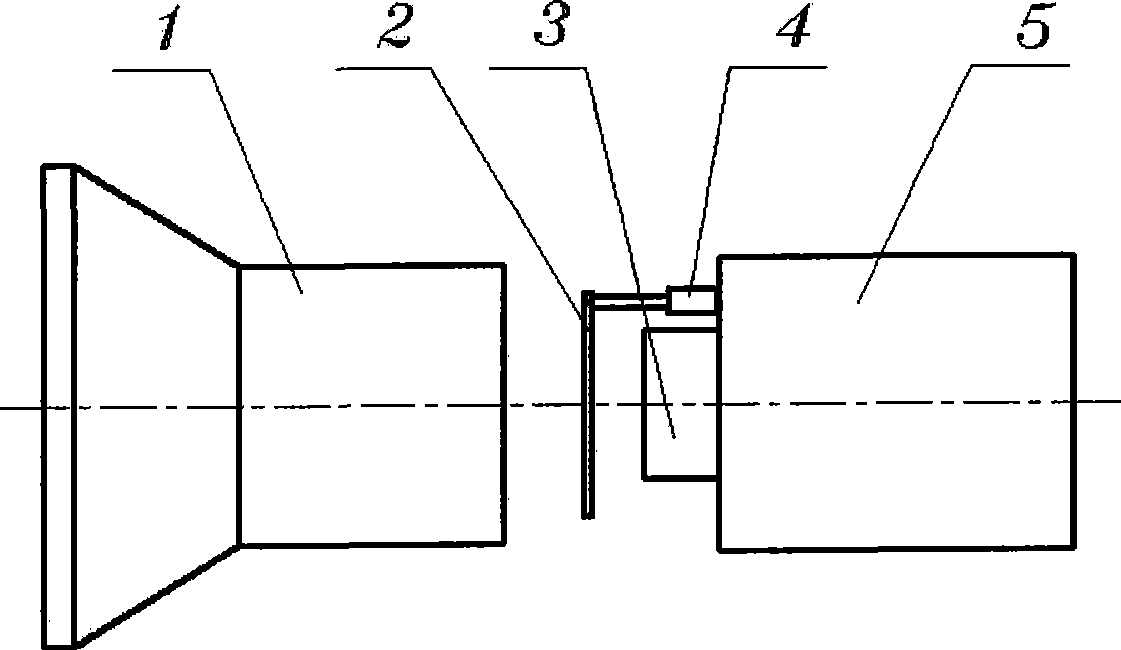

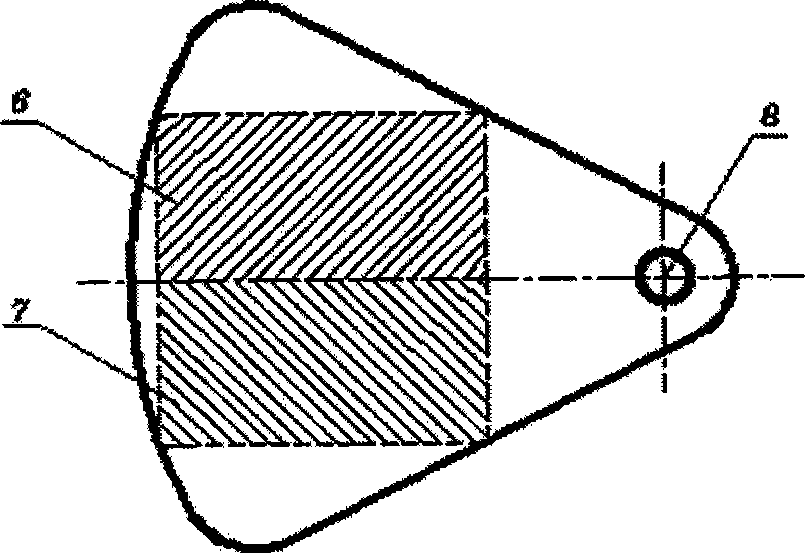

Ununiformity emendation real-time calibration apparatus for staring type thermal imaging system

InactiveCN101470026AImprove image qualityImprove stabilityPyrometry using electric radation detectorsCorrection algorithmTime domain

The invention discloses a non-uniformity collection real-time calibration device for staring type thermal imagers, comprising an infrared lens, an infrared detector and a signal processing control circuit, wherein the signal processing control circuit is connected with the infrared detector, an equivalent high and low temperature reference blackbody retaining strip between the infrared lens and the infrared detector is connected with the rotor of a step motor, the power supply and control port of the step motor are connected with the signal processing control circuit, the equivalent high and low temperature reference blackbody retaining strip is provided with an equivalent high temperature reference blackbody region and an equivalent low temperature reference blackbody region. The non-uniformity collection real-time calibration device can make thermal imagers follow working conditions in actual application to adopt two-point non-uniformity correction algorithm based on temporal recursive to process on-site real-time calibration, thereby obtaining good non-uniformity correction effect and temporal shift compensation effect, thereby improving the imaging quality and stability of staring type thermal imagers, to expand the application range of staring type thermal imagers.

Owner:NANJING UNIV OF SCI & TECH

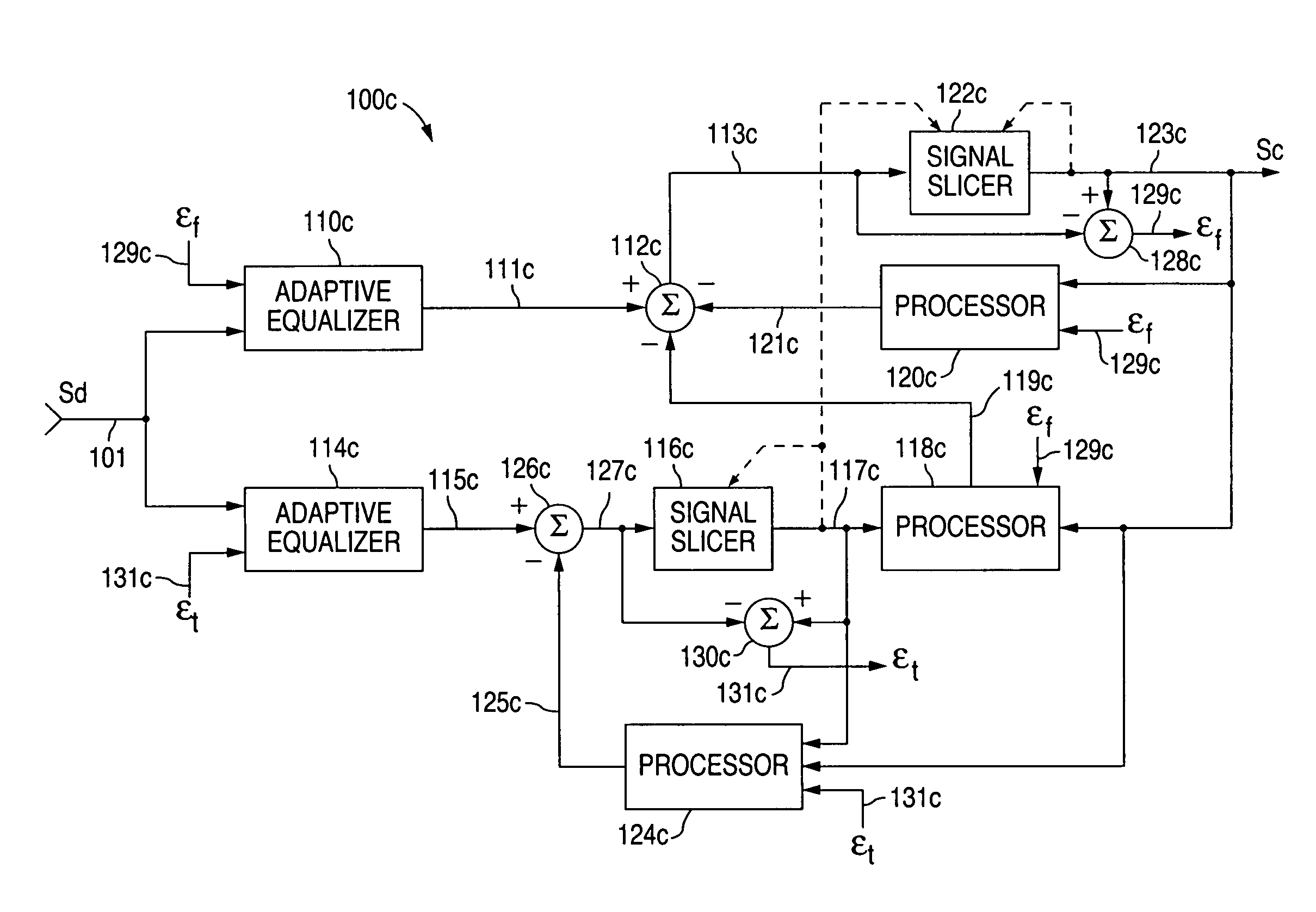

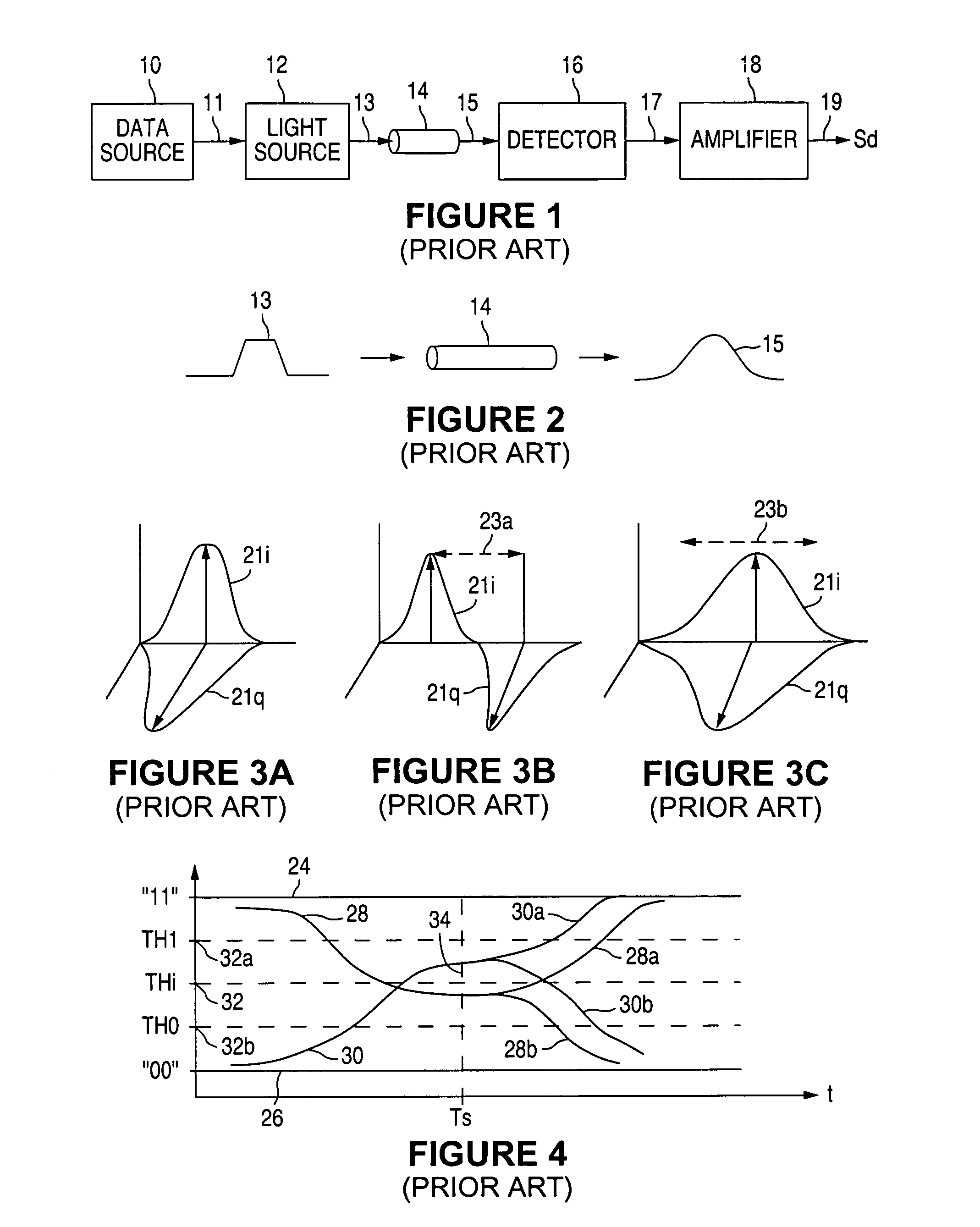

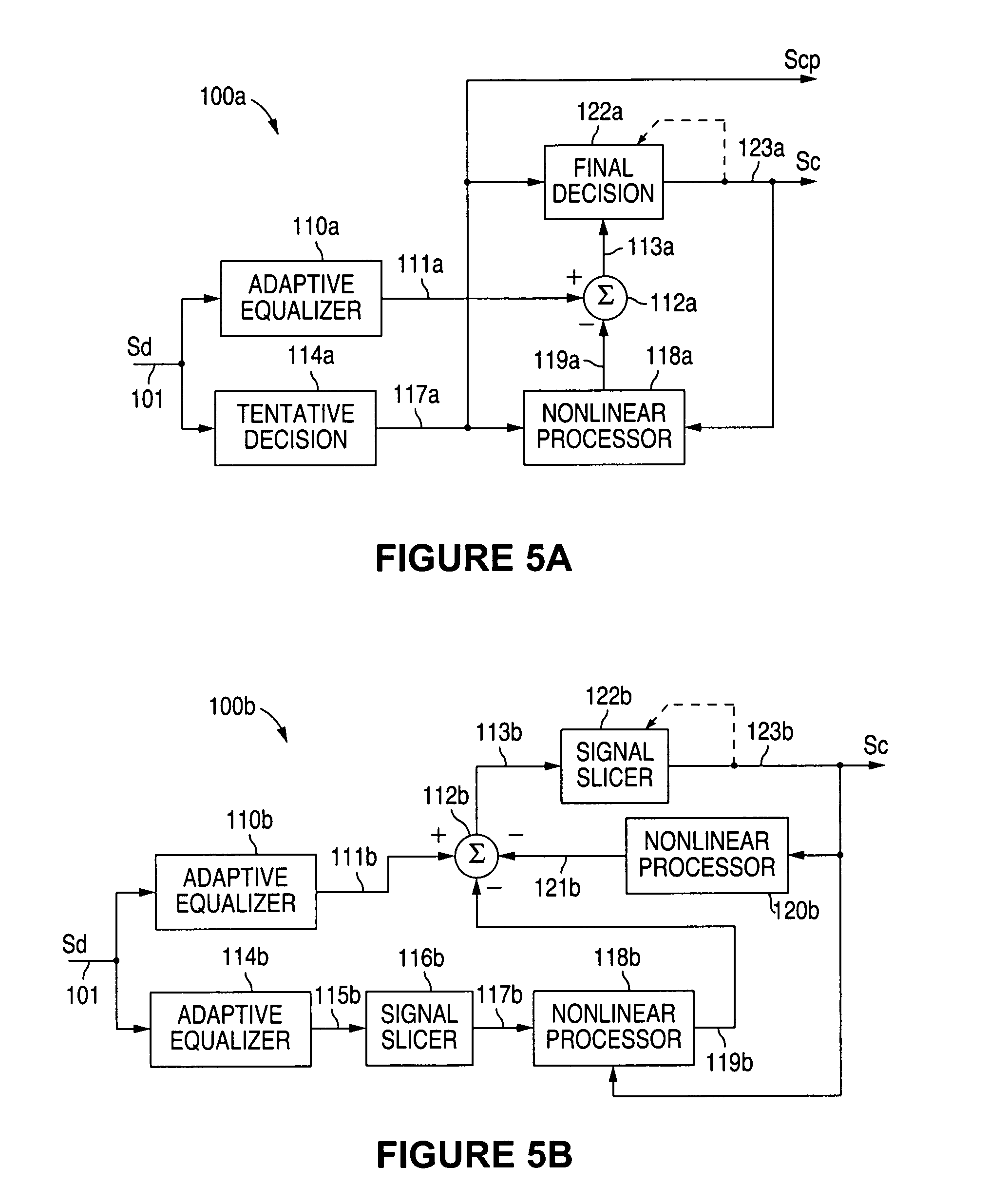

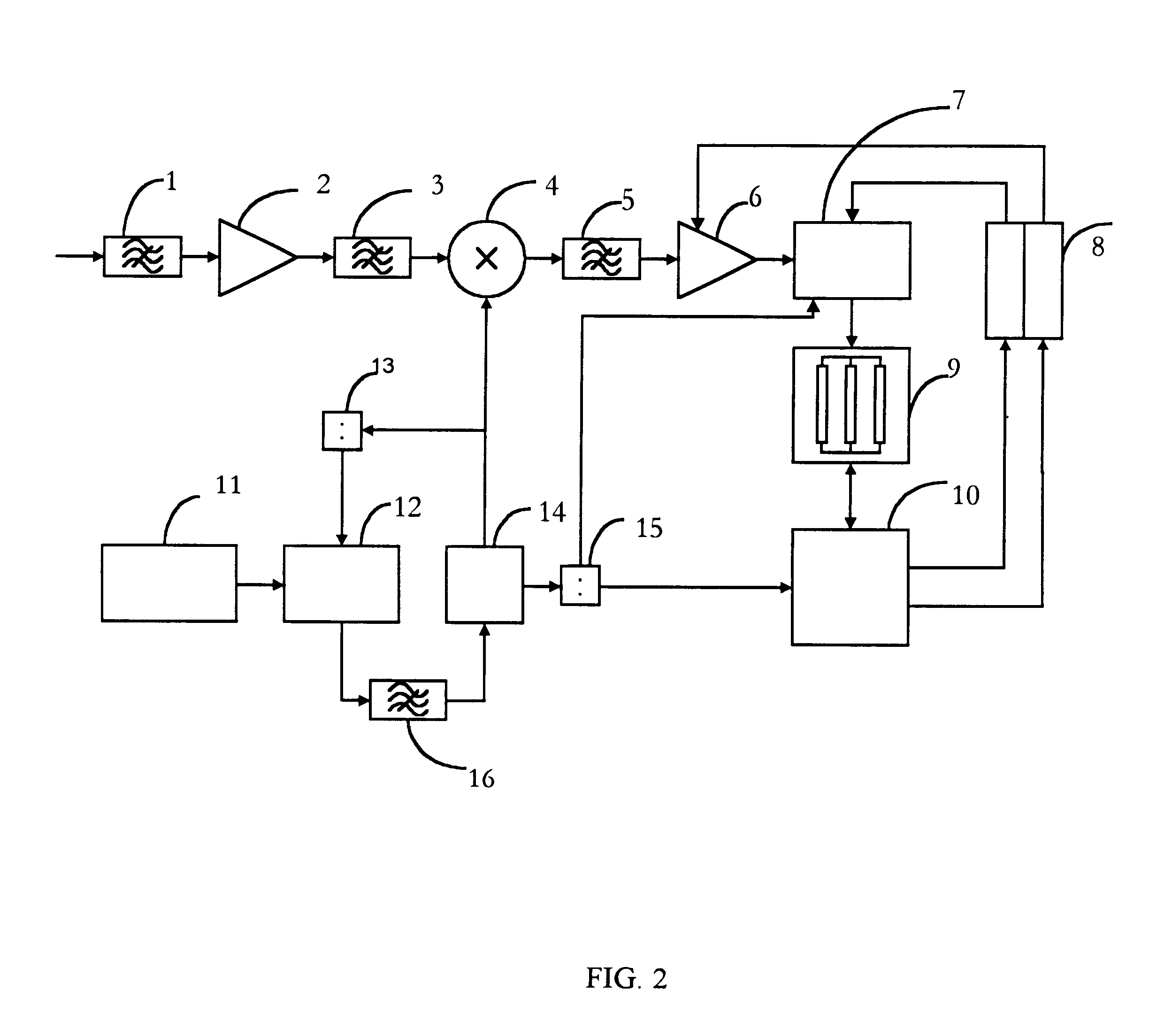

Compensation circuit and method for reducing intersymbol interference products caused by signal transmission via dispersive media

A compensation circuit and method for reducing ISI products within an electrical data signal corresponding to a detected data signal received via a signal transmission medium introduces distinct compensation effects for individual ISI products within the electrical data signal. Distinct data signal components within the detected data signal and corresponding to such ISI products can be selectively and individually compensated, thereby producing a compensated data signal in which each selected one of such individual data signal components is substantially removed. Individual data signal components or selected combinations of data signal components can be compensated as desired.

Owner:MARVELL ASIA PTE LTD

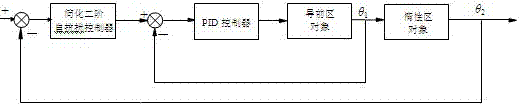

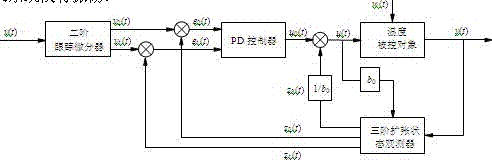

Method for controlling main steam temperature in power plant based on simplified second-order auto disturbance rejection controller

InactiveCN102360176AEasy to adjustRealize decoupling controlControllers with particular characteristicsCompensation effectControl manner

The invention discloses a method for controlling a main steam temperature in a power plant based on a second-order simplified auto disturbance rejection controller. In the method, a cascade control mode is used for forming a cascade steam temperature mediation and control system; in an inner ring, proportion integration differentiation (PID) adjustment is used for eliminating the deviation of an advance timing steam temperature to achieve a coarse tuning effect on an overheating steam temperature; in an outer ring, the simplified second-order auto disturbance rejection controller is used for controlling the outlet temperature of an overheater, so that the defects of large inertia and large delay of a temperature object in an inertia area are fully overcome; and by a disturbance compensation effect of the simplified second-order auto disturbance rejection controller, the disturbance of factors such as loads, flue gas and the like is eliminated, so that the stability of the main steam temperature is ensured. In the method, an algorithm is simple, a parameter is easy to adjust, and a higher response speed, higher steady state accuracy, higher disturbance resistance and higher robustness can be well acquired without dependence on a mathematical model with an accurate main steam temperature in the power plant.

Owner:SHANDONG ELECTRIC POWER SCHOOL

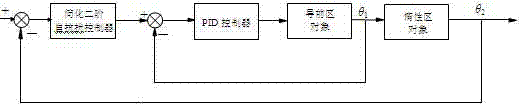

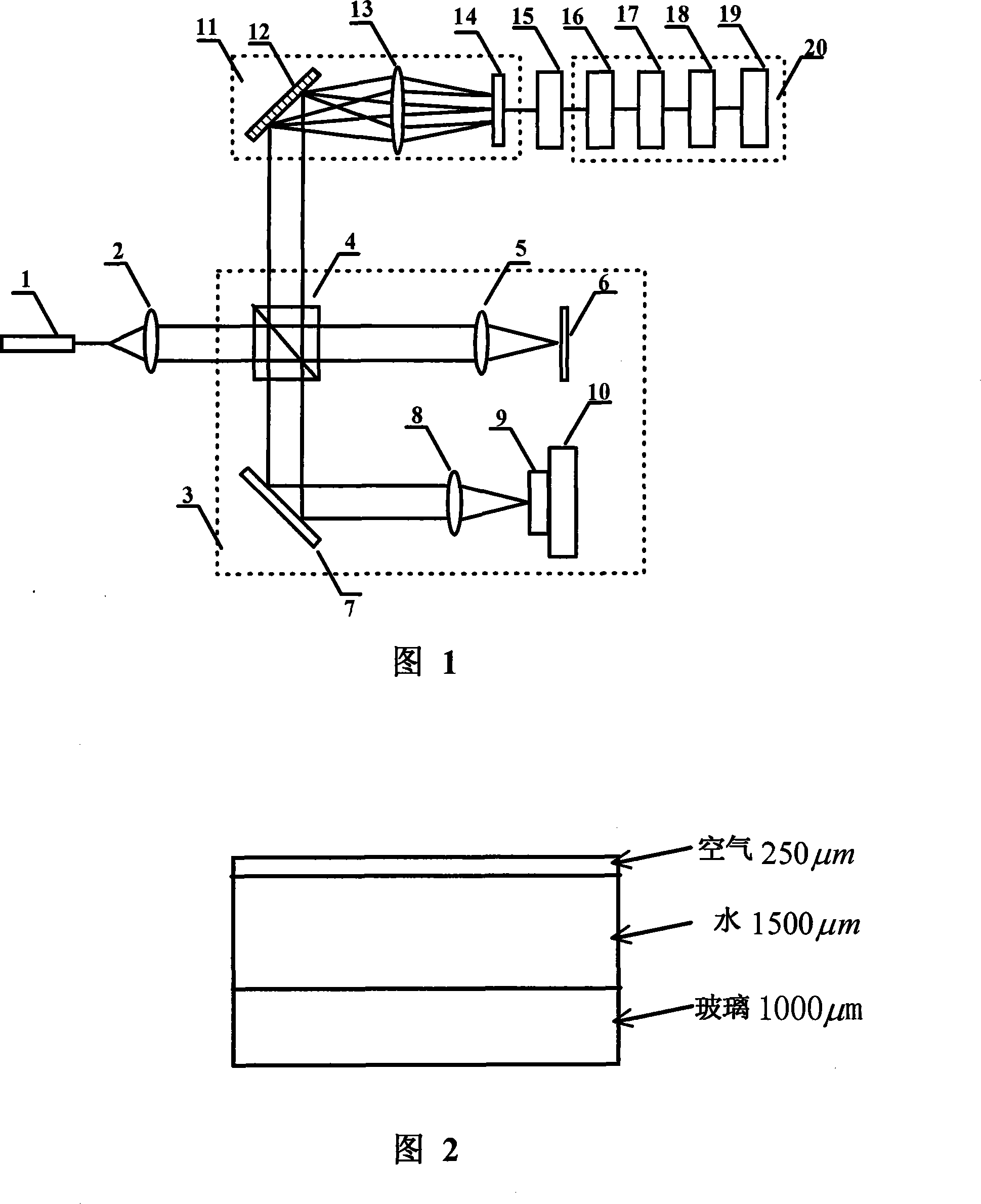

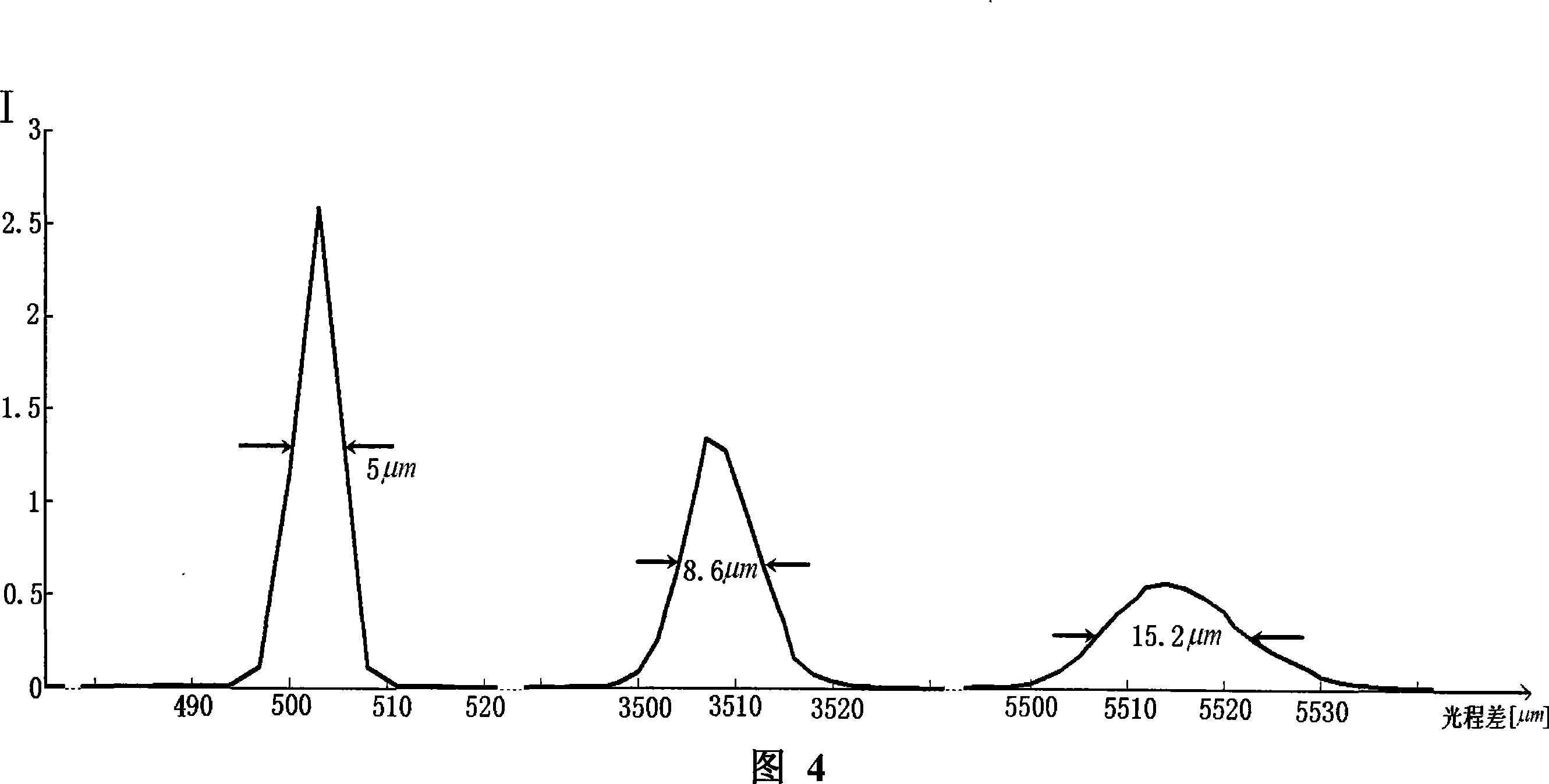

Method for the tomography of high resolution optics coherence

ActiveCN101181153AIncrease vertical resolutionAccurate Compensation EffectPhase-affecting property measurementsDiagnostic recording/measuringCompensation effectTomography

The invention relates to a high-resolution optical coherence tomography method, which adopts depth resolution dispersion compensation to more accurately compensate the dispersion in a compensation circuit and a sample, so as to eliminate the widening effect of the dispersion. The invention has the advantages that the dispersion compensation can be implemented without learning the materials and the structure information of the sample in advance, and the invention can not only compensate the dispersion mismatching of the two arms of an interference device, but can also compensate the internal dispersion of the sample; furthermore, the invention can adopt the corresponding dispersion coefficient to carry out the compensate against the different depth of the internal part of the sample, so as to achieve the best compensation effect and obtain optical coherence tomography images with high-resolution.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

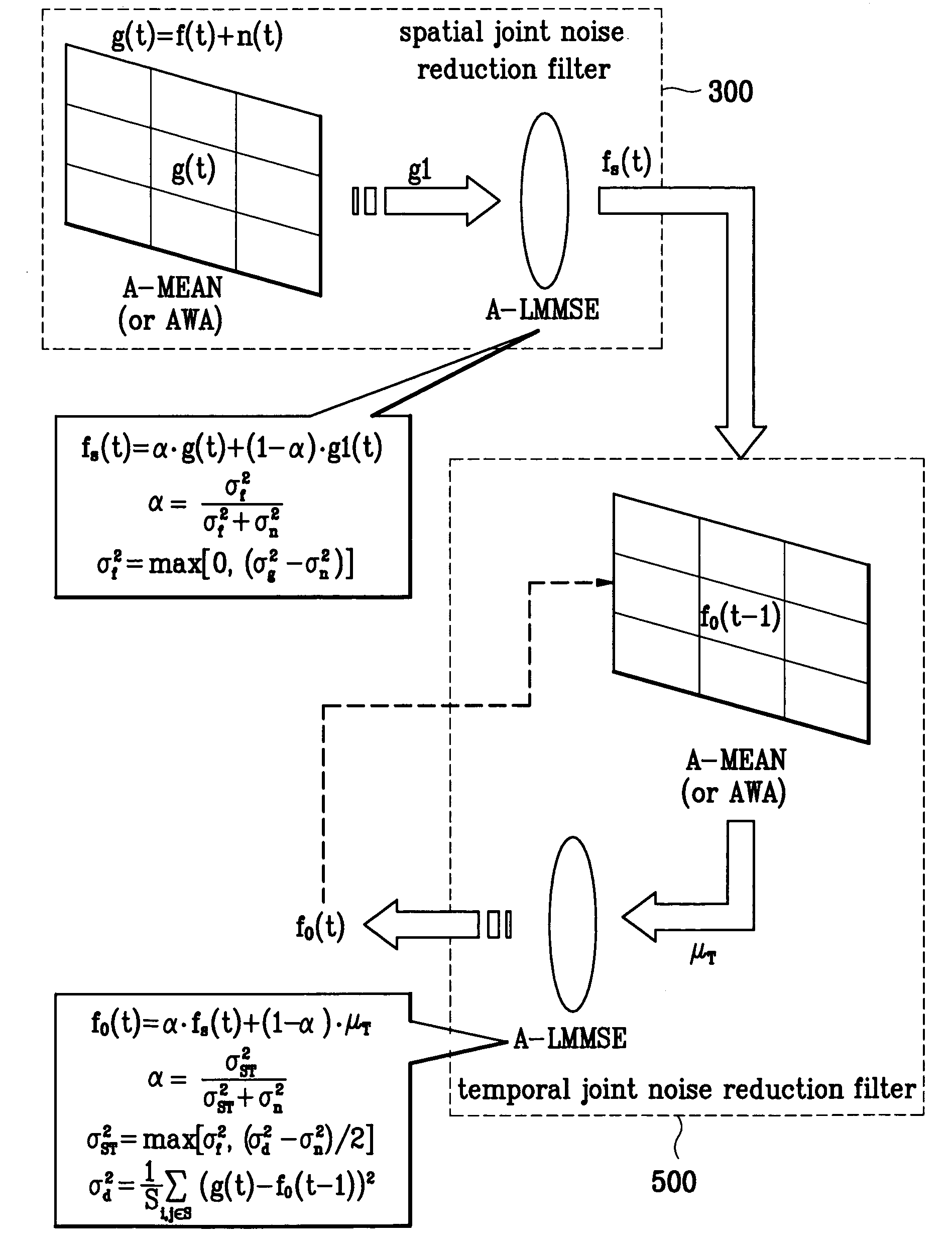

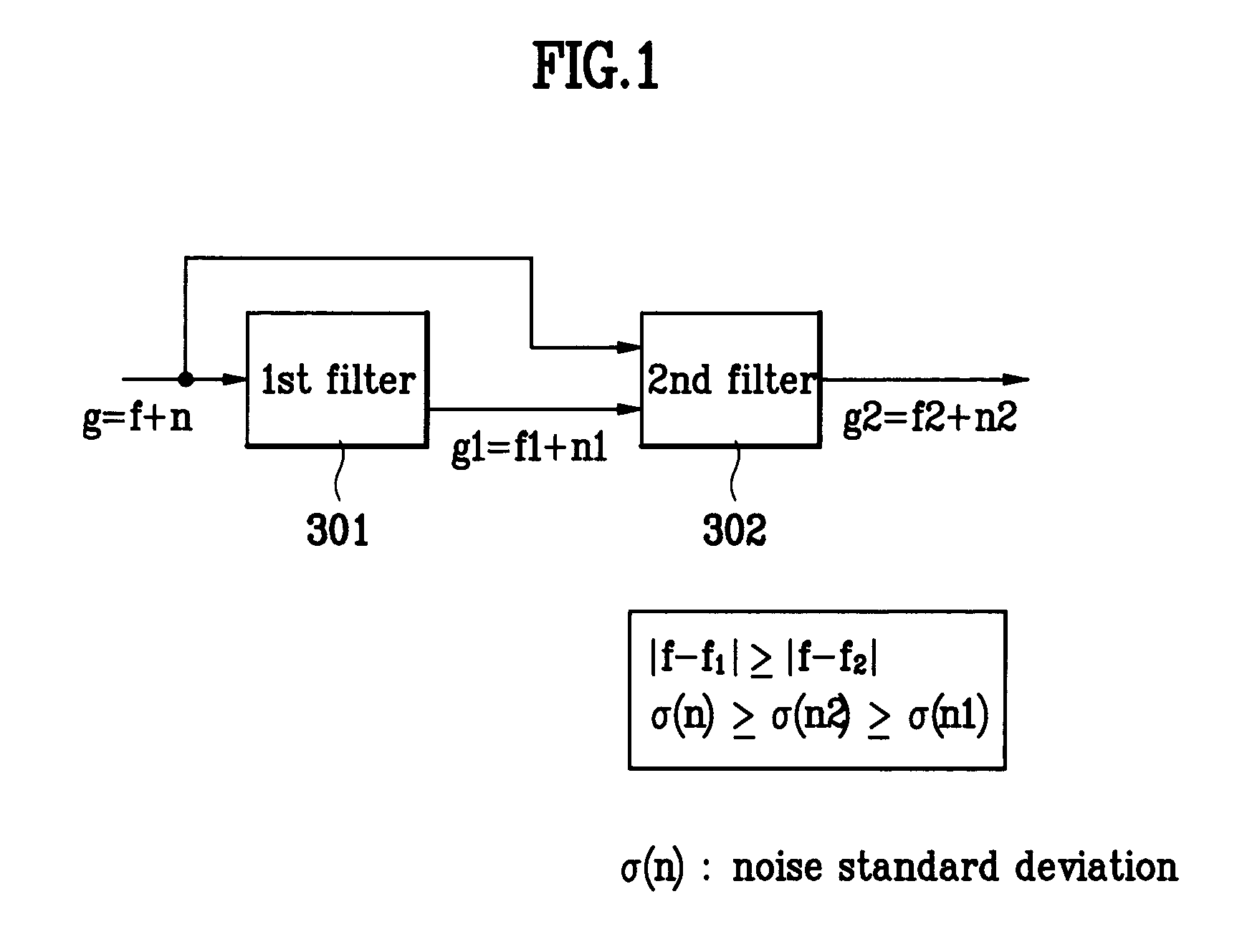

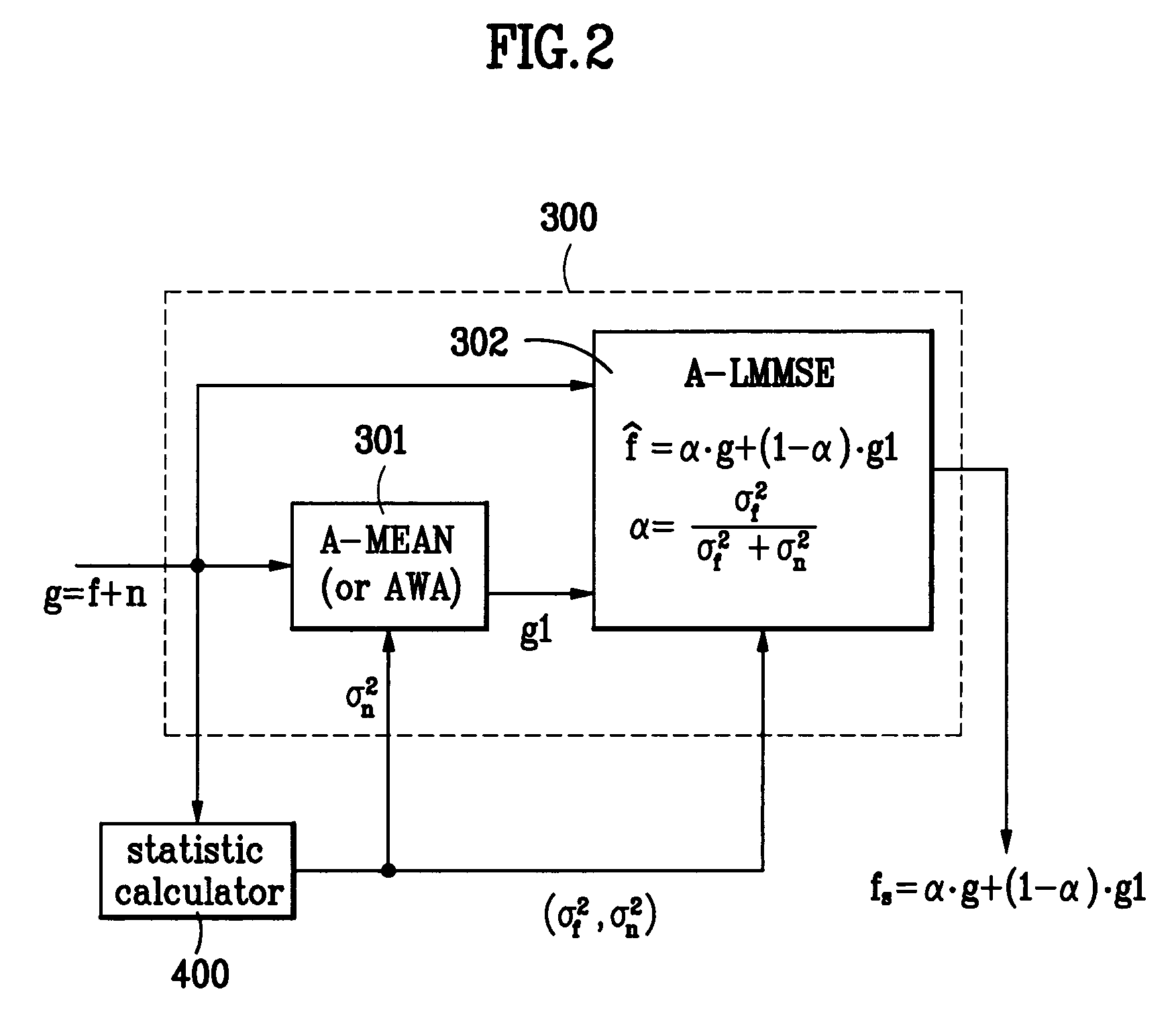

Spatio-temporal joint filter for noise reduction

InactiveUS6999634B2Reduce noiseEliminates temporal flickerImage enhancementTelevision system detailsCompensation effectEngineering

A spatio-temporal joint filter and a spatial joint filter for noise reduction are disclosed. The spatio-temporal joint filter includes a spatial joint filter including the first and second sub filters having different characteristics and includes a temporal joint filter. When the present invention is adequately used, an edge / detail region of an image is well preserved, an aggressive noise reduction is performed on a flat region, and the temporal flicker problems are eliminated. Additionally, it has an intrinsic motion compensation effect by using the spatio-temporal correlation between the adjacent frames.

Owner:LG ELECTRONICS INC

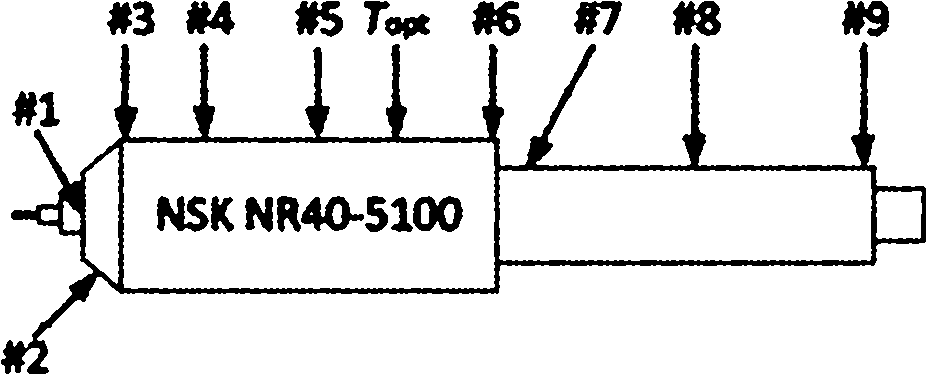

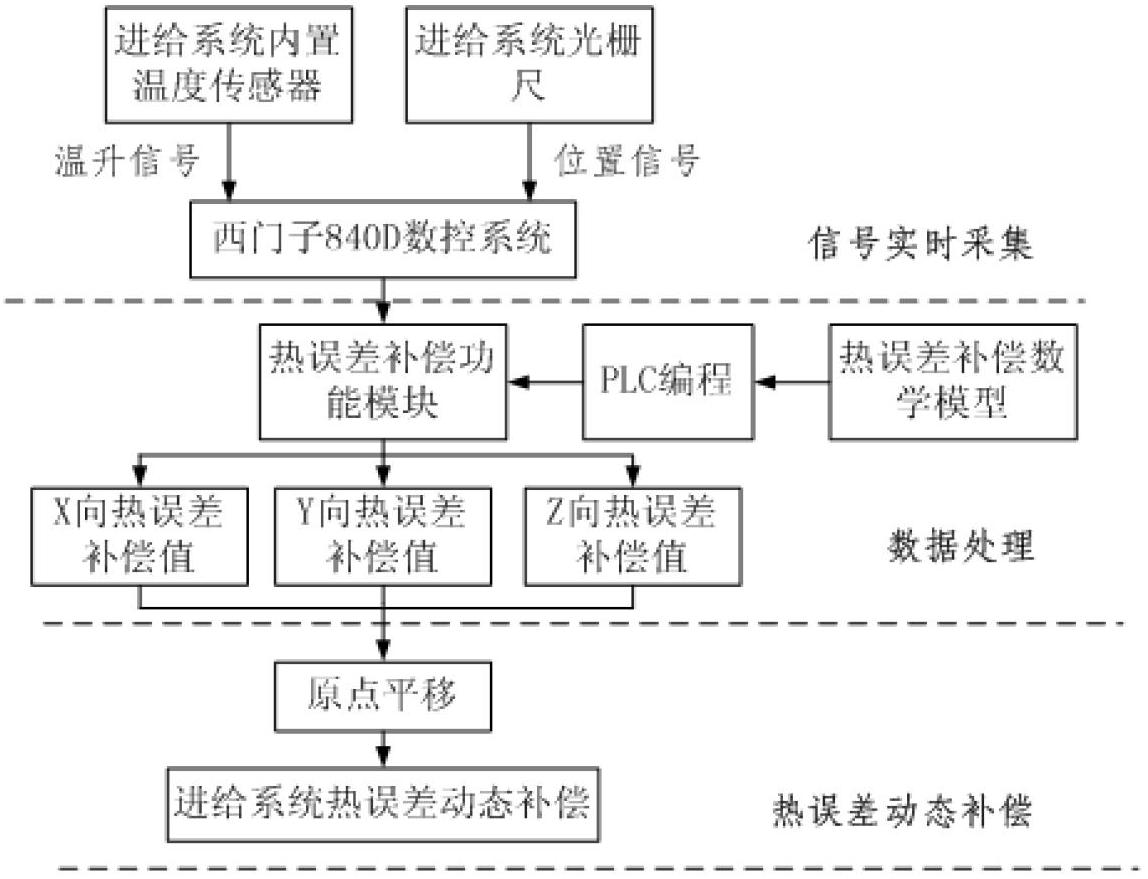

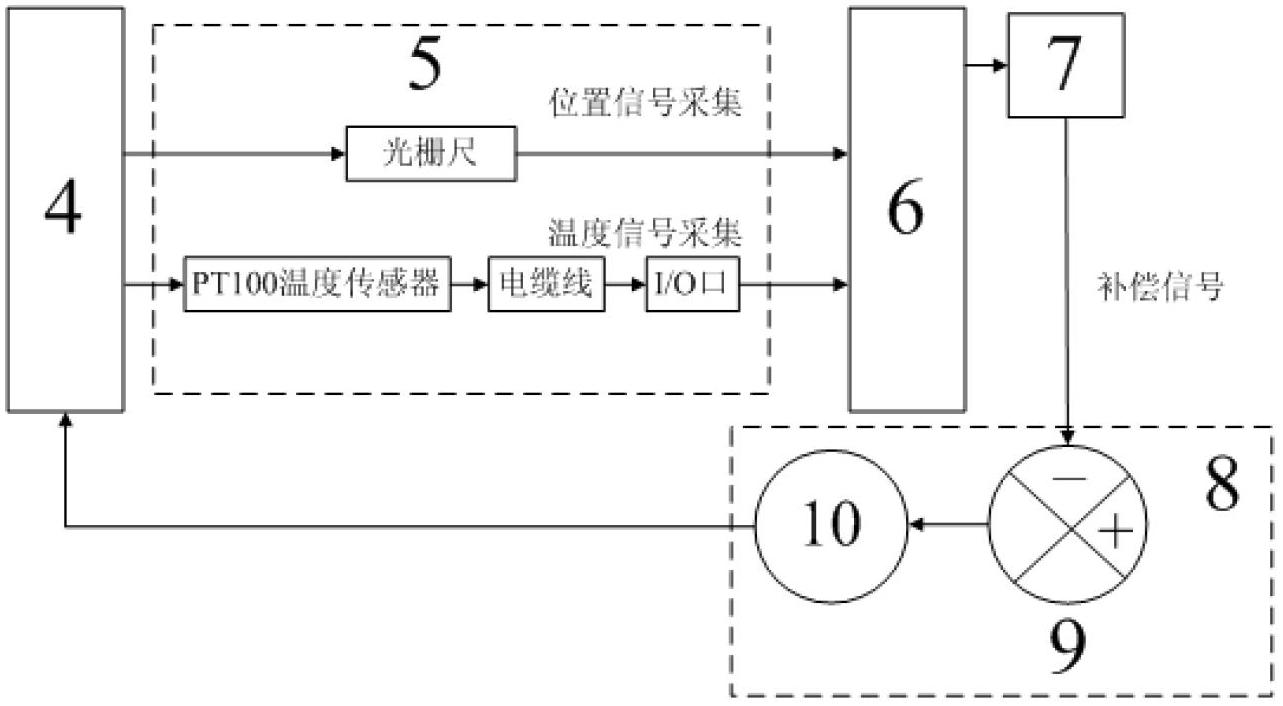

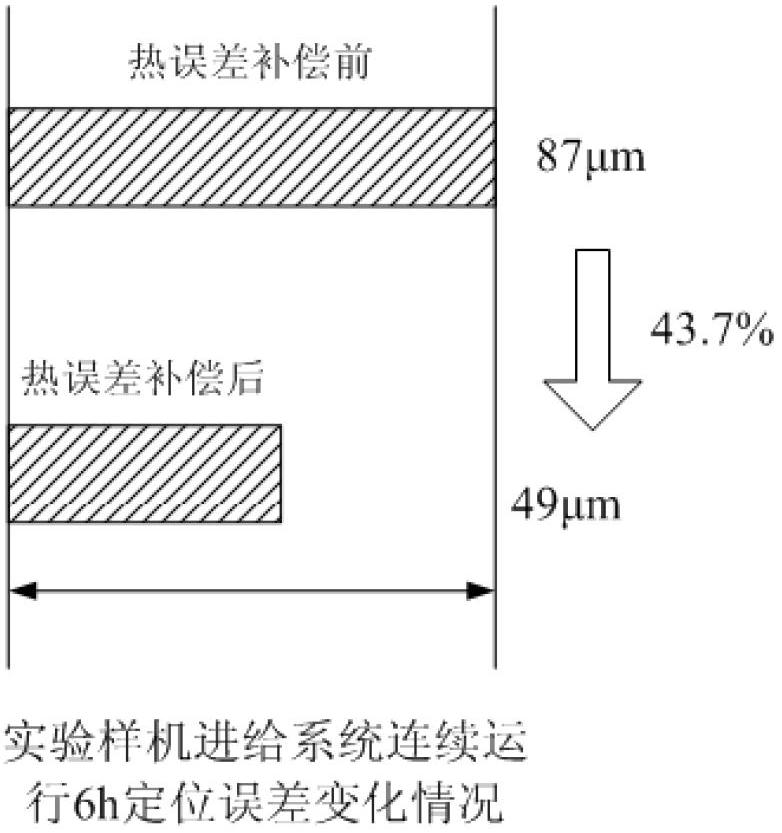

Full working stroke thermal error compensation method of numerically-controlled machine tool feeding system and implementation system thereof

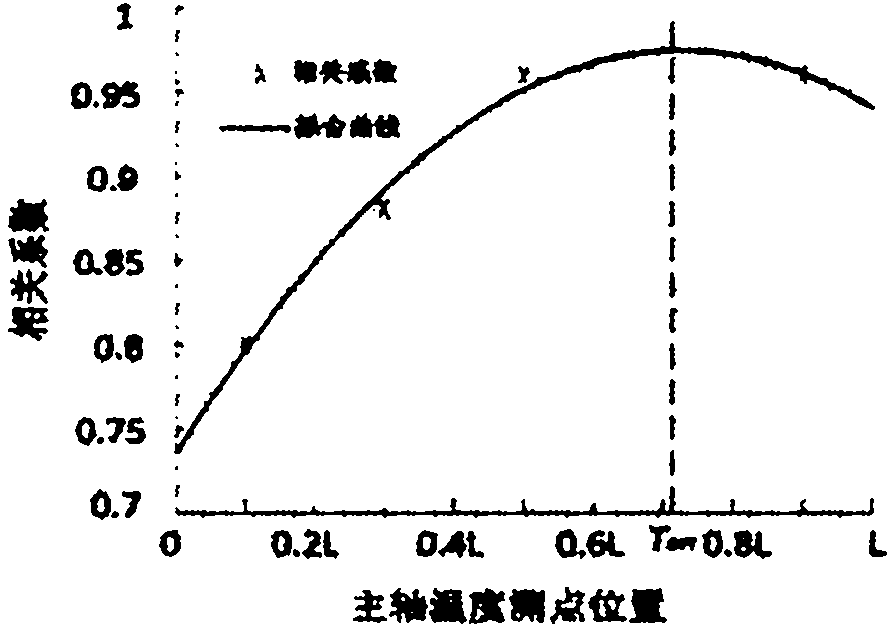

InactiveCN102672527AInfluence of machining accuracyImprove machining accuracyAutomatic control devicesFeeding apparatusNumerical controlCompensation effect

The invention discloses a full working stroke thermal error compensation method of a numerically-controlled machine tool feeding system and an implementation system thereof. Reduction of whole machine machining accuracy is mainly caused by thermal errors of the numerically-controlled machine tool feeding system, and a whole set of the technical scheme for measuring, analyzing and compensating the feeding system is provided. Application techniques of thermal error measurement, thermal key point identification, thermal error compensation modeling and thermal error on-line compensation of the numerically-controlled machine tool feeding system under typical working conditions are surveyed. On that basis, a thermal error on-line compensation system of the numerically-controlled machine tool feeding system is constructed. Taking an X-direction high-speed feeding system of a Longmen numerical control machining center in a certain model as an example, measurement, analysis and modeling compensation of the thermal errors are carried out respectively, and compensation effects are obvious. The full working stroke thermal error compensation method can be used for solving the thermal error compensation problem of the numerically-controlled machine tool feeding system and provides technical supports for machining accuracy and stability of a numerically-controlled machine tool.

Owner:SICHUAN UNIV

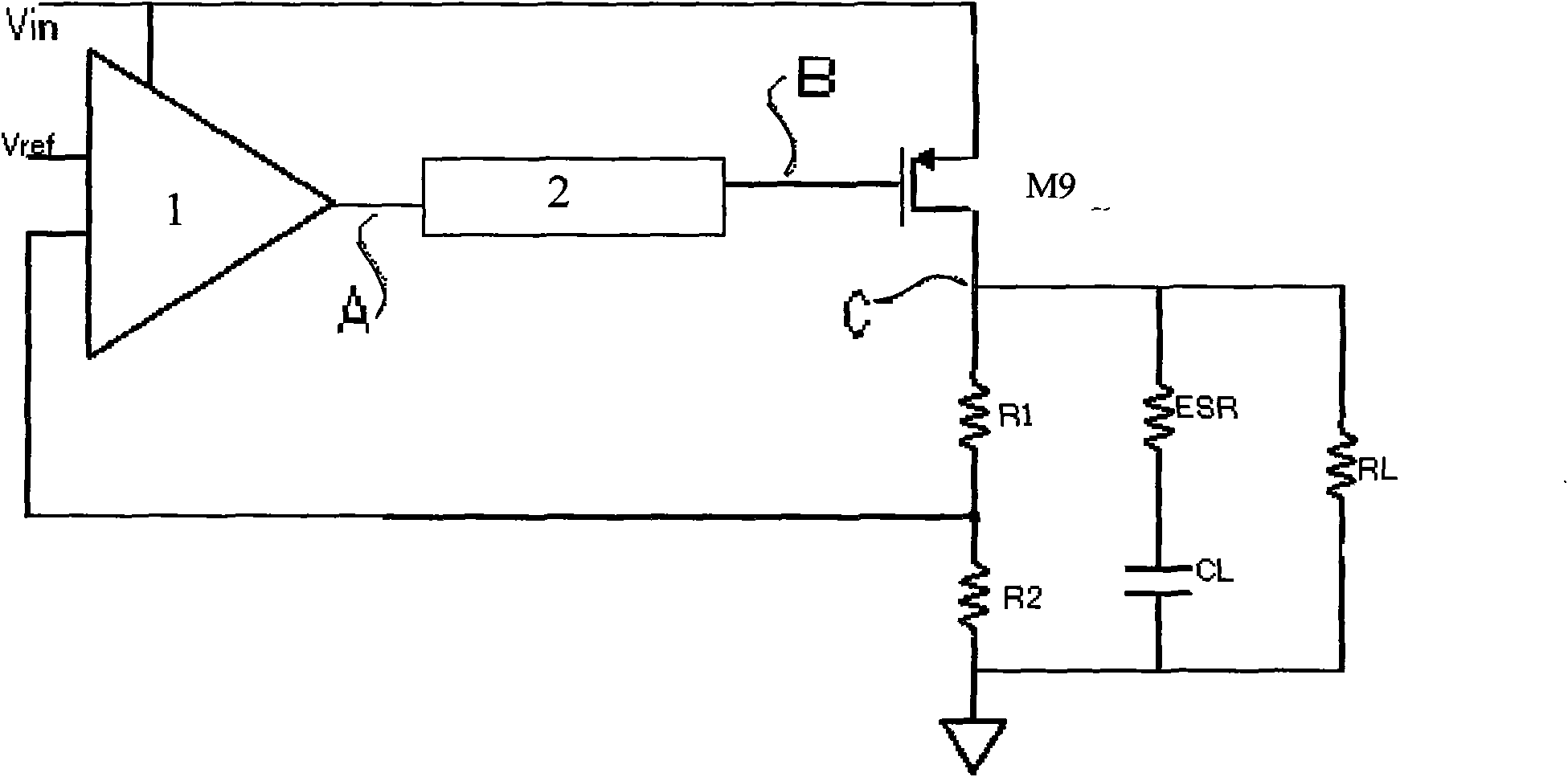

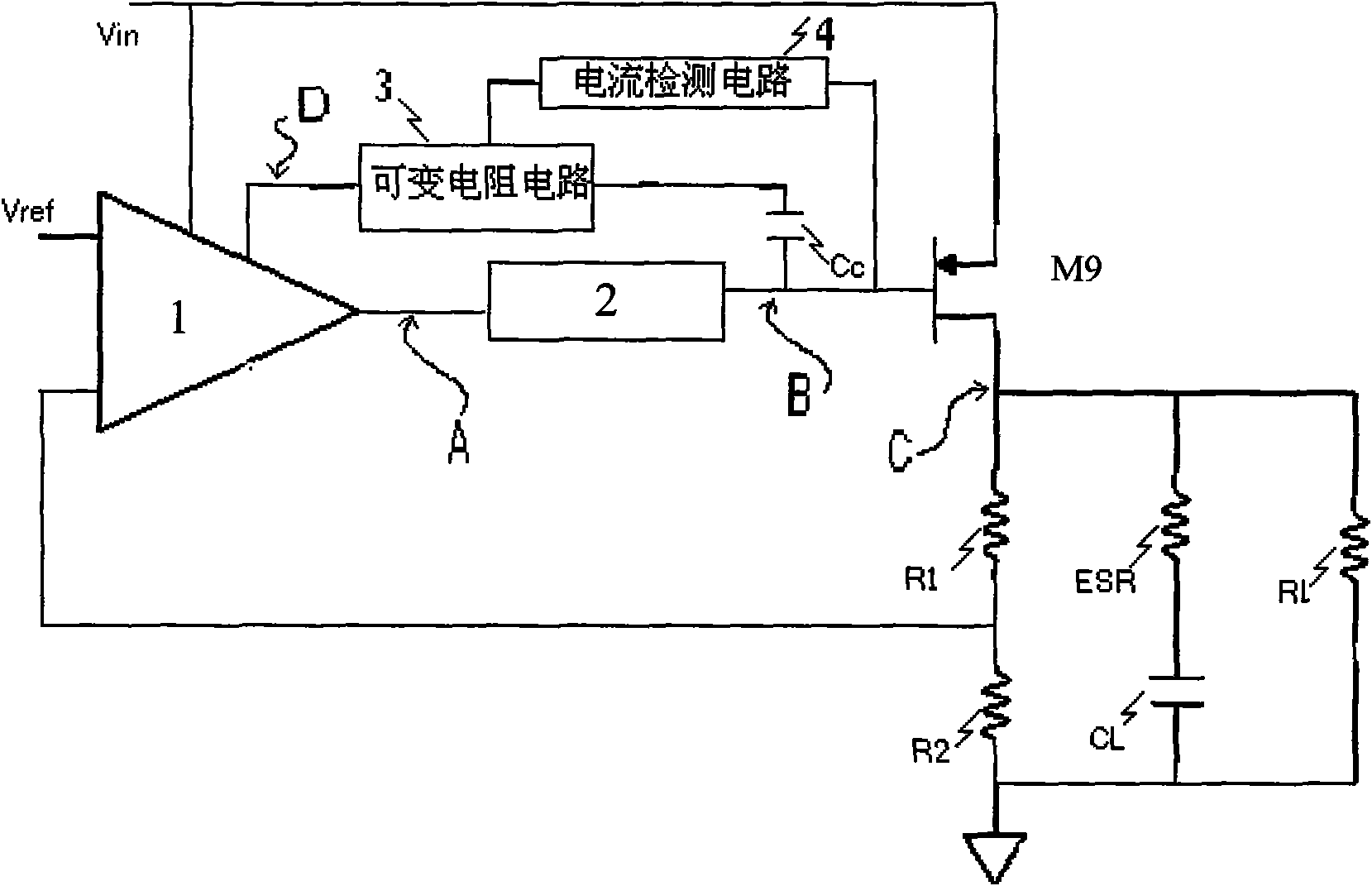

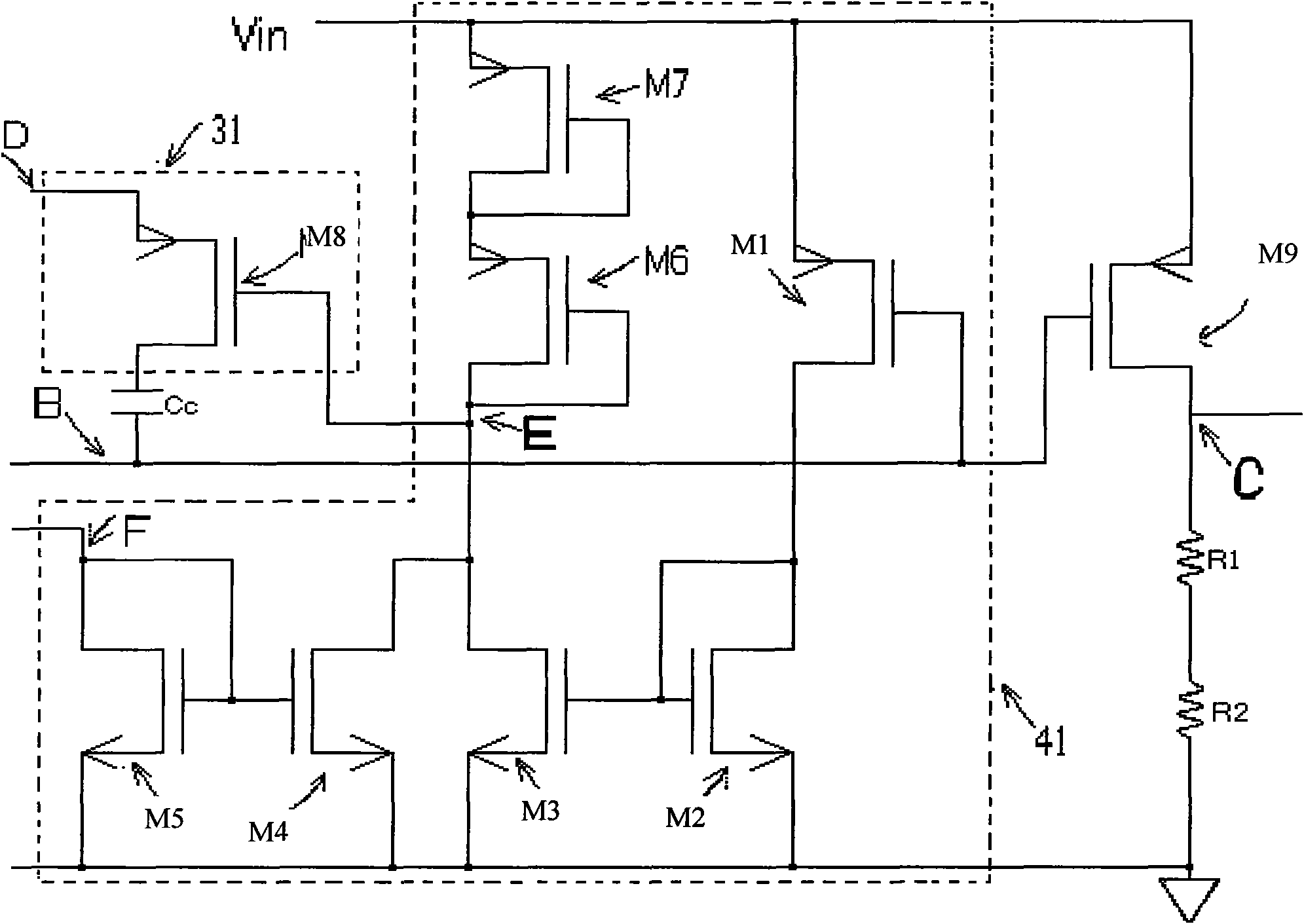

Self-adaption zero-frequency compensation circuit in low-voltage difference linear voltage regulator

ActiveCN101957628ALower resistanceFix stability issuesElectric variable regulationCapacitanceLow voltage

The invention relates to a self-adaption zero-frequency compensation circuit in a low-voltage difference linear voltage regulator. The output end of a transconductance amplifier is connected with a voltage regulation pipe by a voltage bumper, a current detection circuit is connected with the voltage bumper and the common end of the voltage regulation pipe, and the other end is connected with a variable-resistance circuit connected with the compensation end of the transconductance amplifier. In the invention, when a load is higher and current is lower, the current detection circuit can detect the load and the current and the load and the current act on the variable-resistance circuit at the moment to ensure that the resistance is enlarged, and the zero position is also relatively lower; on the contrary, when the load is reduced and the current is enlarged, the resistance value of the variable-resistance circuit is reduced, and the zero position is higher. Therefore, the self-adaption zero can change along with the change of a pole so that the compensation circuit takes the effect of compensation and effectively ensures the stable state of system operation. The compensation circuit successfully solves the problem of poor stability of a low-voltage difference linear voltage regulator so that a load capacitance equivalent series resistance is not really important to the influence on system stability, transient response and ripple waves.

Owner:江西芯世达微电子有限公司

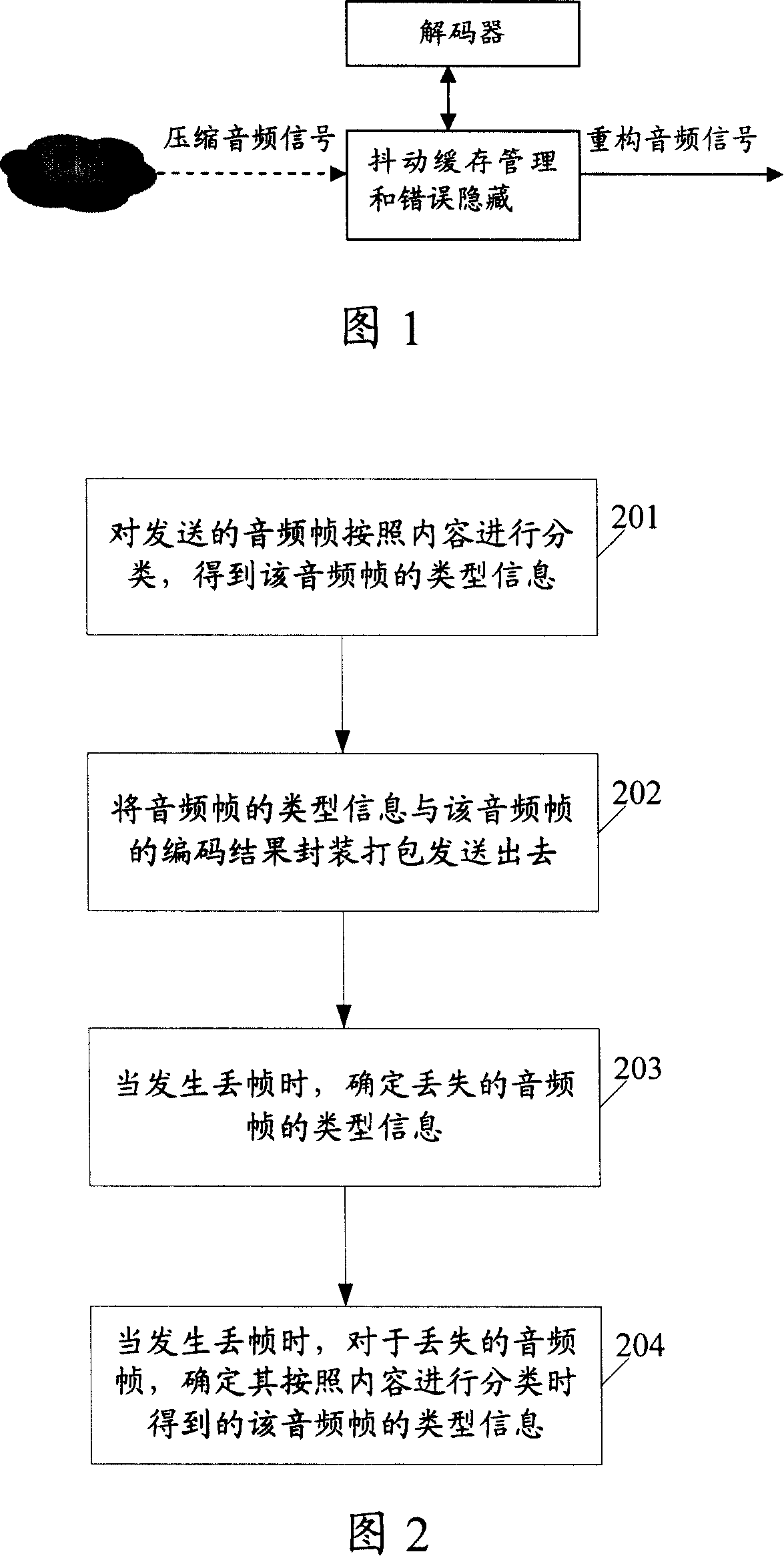

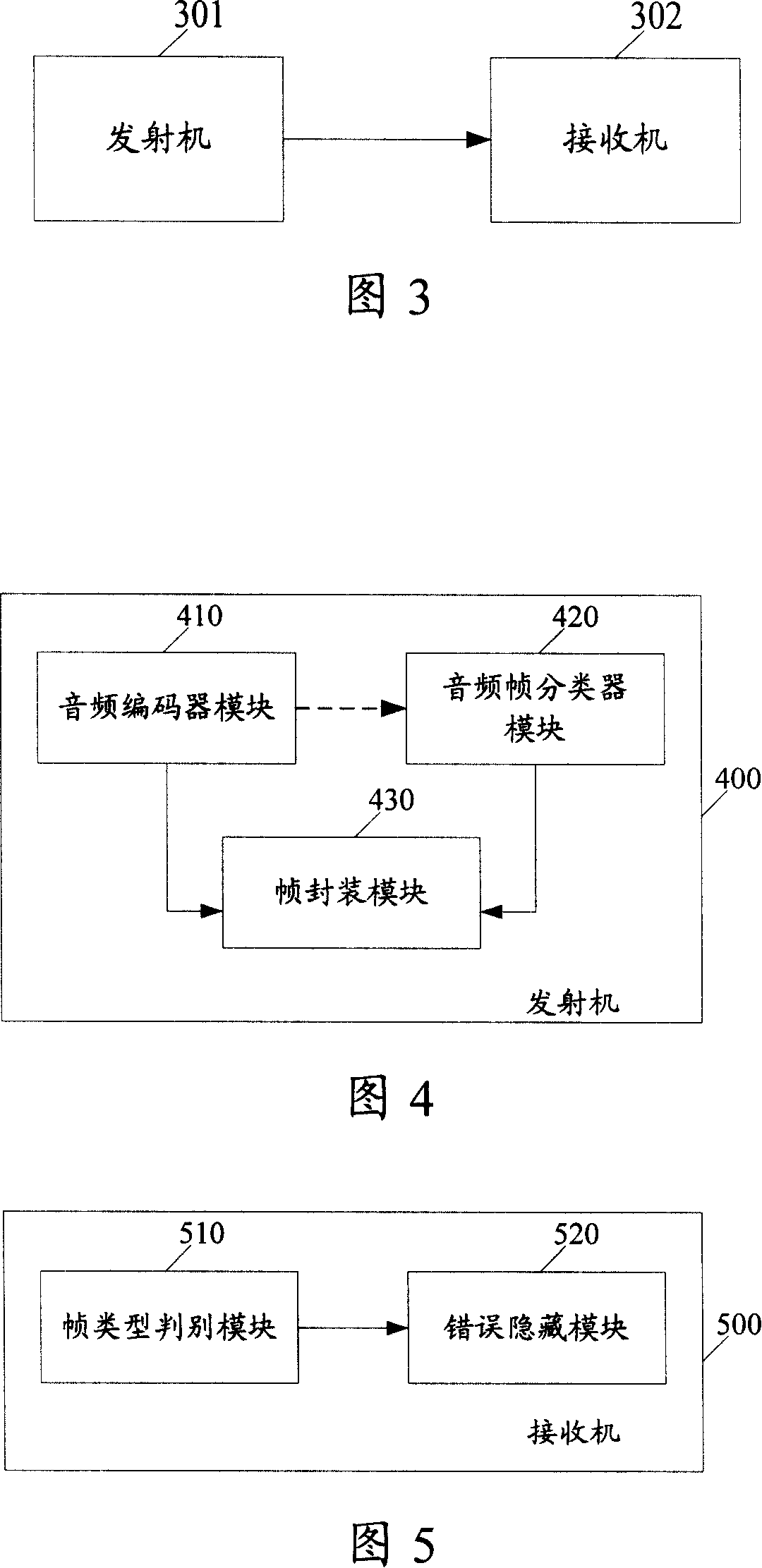

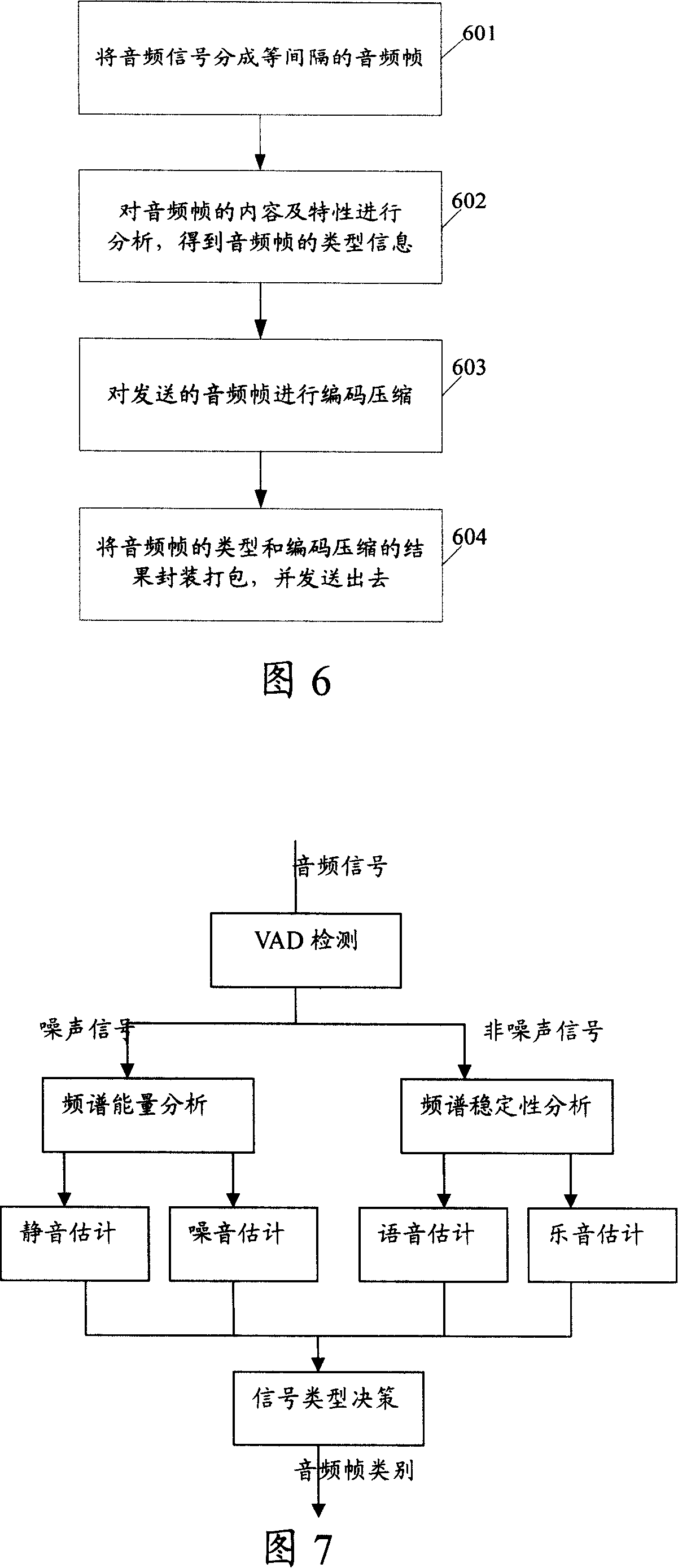

Method, device and system for hiding audio stream error

InactiveCN101155140AGood subjective hearingImprove resolvabilityError preventionSpeech analysisCompensation effectError concealment

The invention discloses a method of hiding the error of audio stream. The said method comprises: a. sorting the transmitting audio frame in term of content to obtain the type information of the said audio frame; b. packaging the type information of the said audio frame and the coding result of the said audio frame and sending them; c. determining that the type information of the lost audio frame is obtained in term of content when the frame is lost; d. reconstructing the audio frame using the corresponding error recovering strategy based on the type information of lost audio frame. The said way of hiding the error make the reconstruction of lost frame with stronger pertinence; the audio frame is self-adapting reconstructed to obtain better compensation effect. The invention also discloses a sending and receiving method of hiding the error of audio stream. The invention also discloses a transmitter, receiver and system of hiding the error of audio stream.

Owner:HUAWEI TECH CO LTD

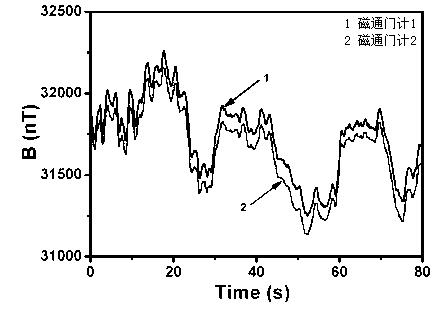

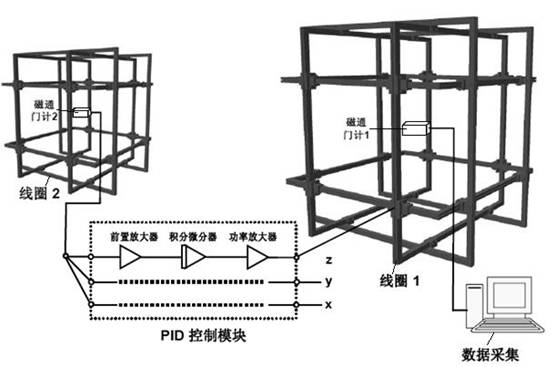

Magnetic-field dynamic compensation system and methods based on spatial correlation

ActiveCN101893693AEliminate the effects ofEasy to buildMagnetic measurementsHelmholtz coilCompensation effect

The invention relates to a magnetic-field dynamic compensation system and methods based on spatial correlation, wherein the system can realize the dynamic compensation of environment magnetic fields at the directions of three axles through a large set and a small set of Helmholtz coil racks and two fluxgate meters based on the spatial correlation of a PID (Proportion Integration Differentiation) negative feedback electronic circuit and the fluctuation of the environment magnetic fields. The invention further discloses three methods using the system, including (1) a proportioning type magnetic-field dynamic compensation method, (2) a series type integral magnetic-field dynamic compensation method, and (3) a parallel integral type magnetic-field dynamic compensation method. The system of the invention is easy to construct, has low cost and simple operation, and can achieve excellent dynamic compensation effect, and simultaneously, the methods can maximally eliminate the affects of the fluxgate meters to other magnetic detectors at the centers of coils, and have great application prospect in extremely-low field nuclear magnetic resonance, imaging thereof and other biological magnetic researches based on an SQUID (Superconducting Quantum Interference Device).

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

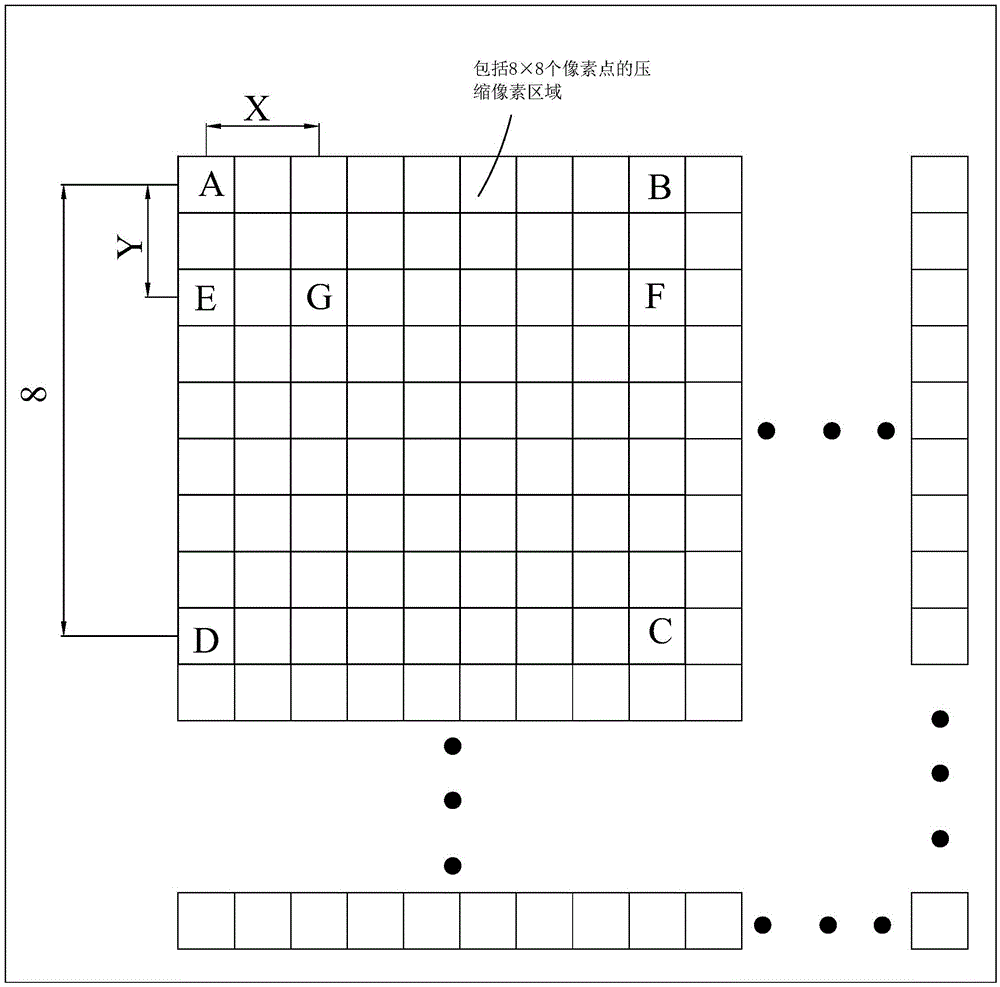

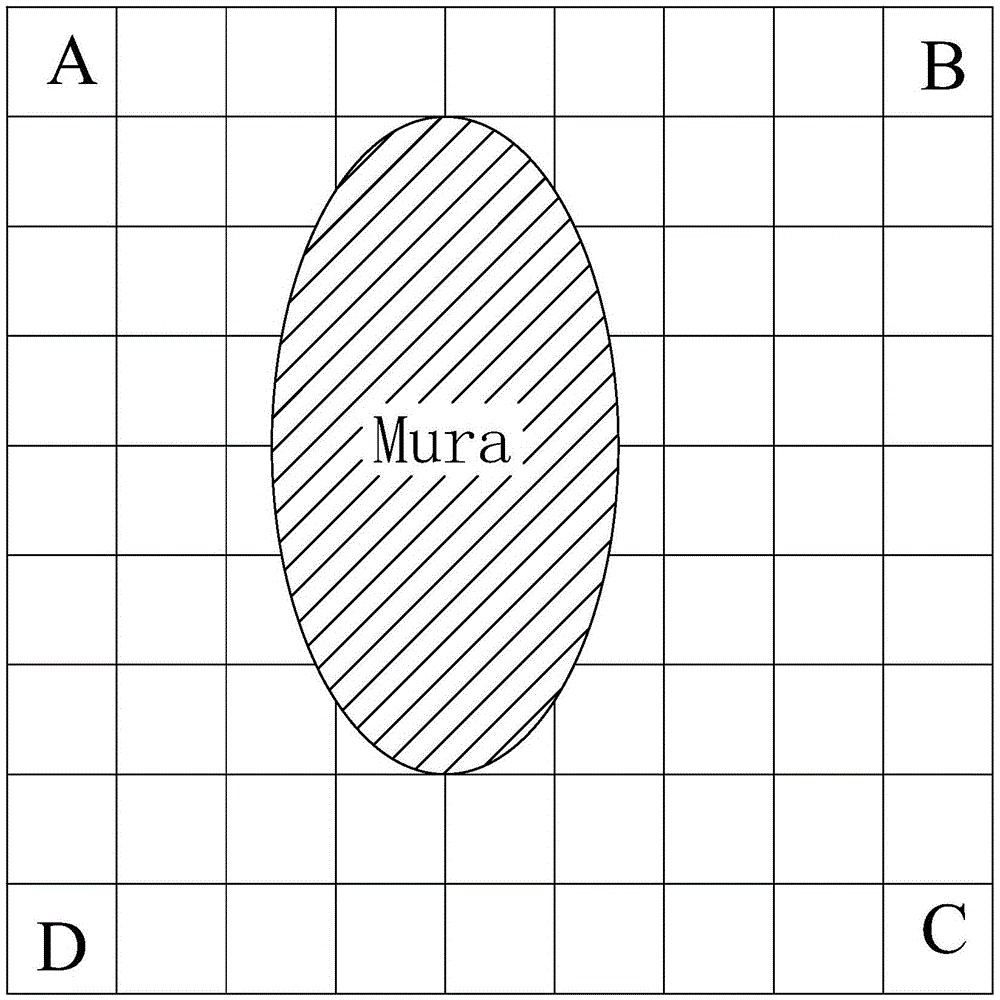

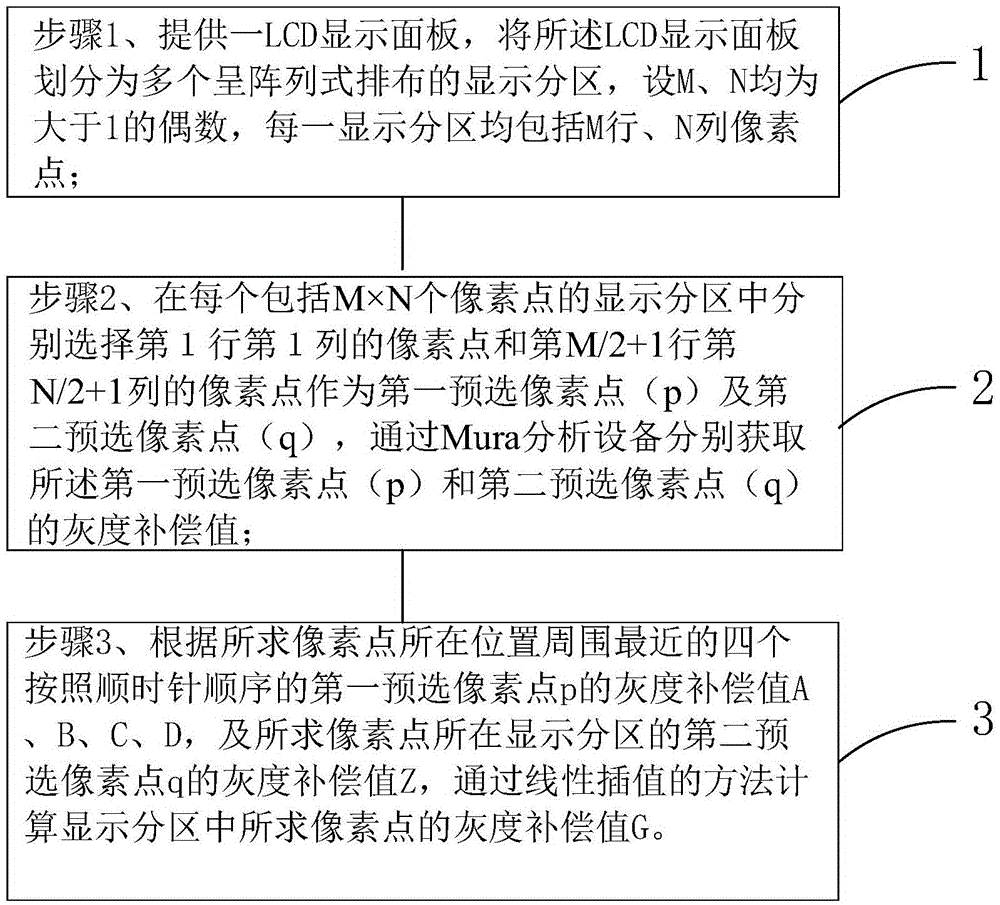

Mura phenomenon compensation method

ActiveCN105632443AGood compensationCompensation effectStatic indicating devicesCompensation effectComputer science

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

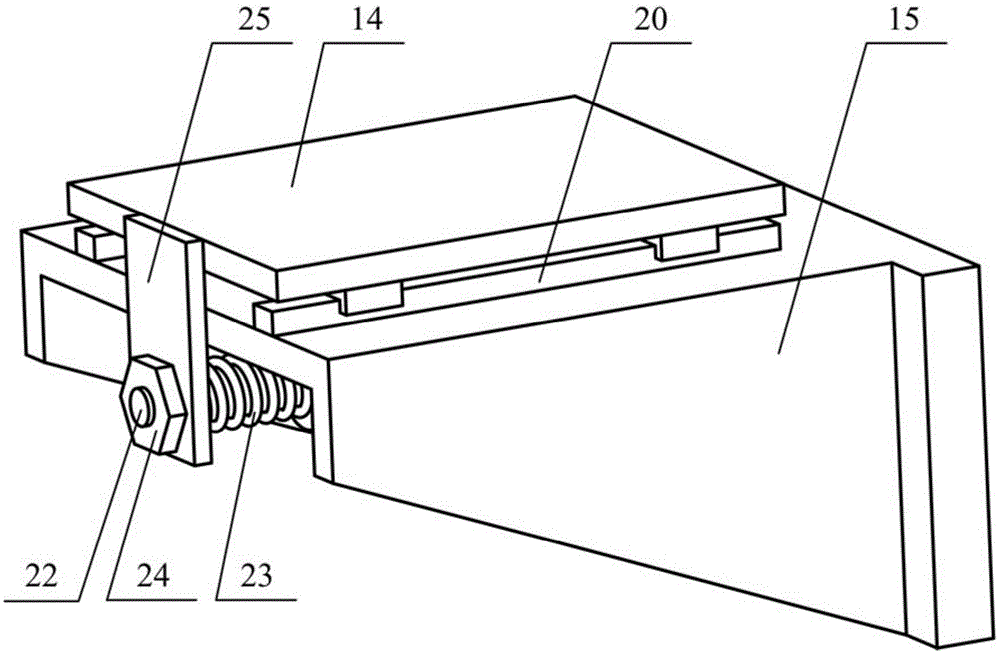

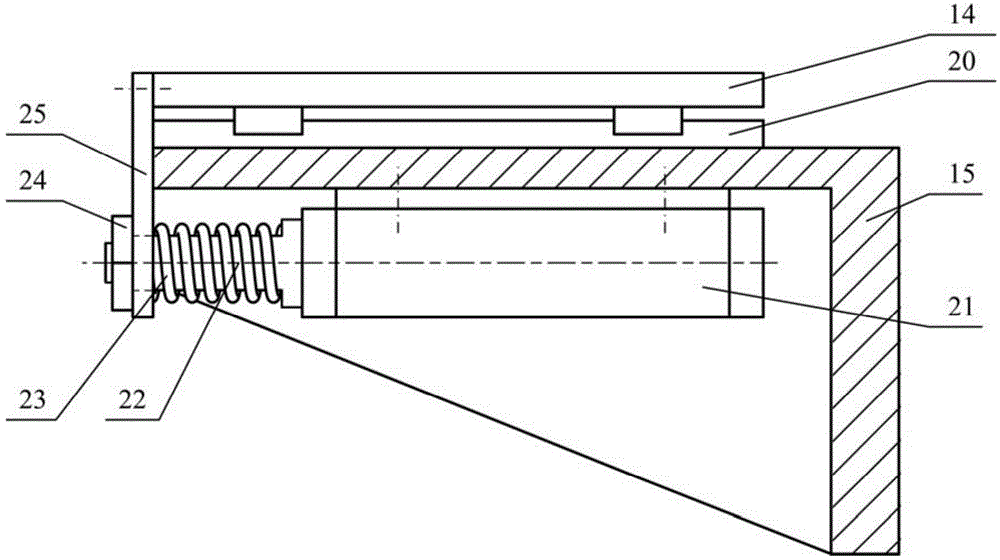

Self-adaption profile modification blade abrasive belt polishing machine tool

ActiveCN104440474ARealize the effect of polishing contact pressure compensationReduce performance pressureGrinding drivesBelt grinding machinesContact pressureCompensation effect

The invention discloses a self-adaption profile modification blade abrasive belt polishing machine tool, comprising a machine tool body, an X-axis carriage, an X-axis carriage, a C-axis rotary table, a Y-axis sliding block, an abrasive belt polishing head component, an air cylinder, and the like, wherein a pressure compensation element is in series connection between the abrasive belt polishing head component and the air cylinder to cooperate with the air cylinder to form a polishing contact pressure. During machining, the polishing machine tool performs interpolation feed according to an ideal polishing track; due to the existence of a blade profile error (or waveness), the polishing contact point deviates from the ideal polishing track in a pressure shaft direction, and the acting pressure of the pressure compensation element changes along with the deviation, so as to realize the polishing contact pressure compensation; the pressure compensation element can utilize a constant-pressure type gas bearing with oppositely arranged air cushions, and realizes the polishing contact pressure compensation effect by utilizing a pressure balance function to the oppositely arranged air cushions. The self-adaption profile modification blade abrasive belt polishing machine tool has the advantages that the response speed of pressure compensation is increased, the self-adaption modification on the profile error (or waveness) during blade polishing machining is realized, and the profile precision is improved.

Owner:XI AN JIAOTONG UNIV

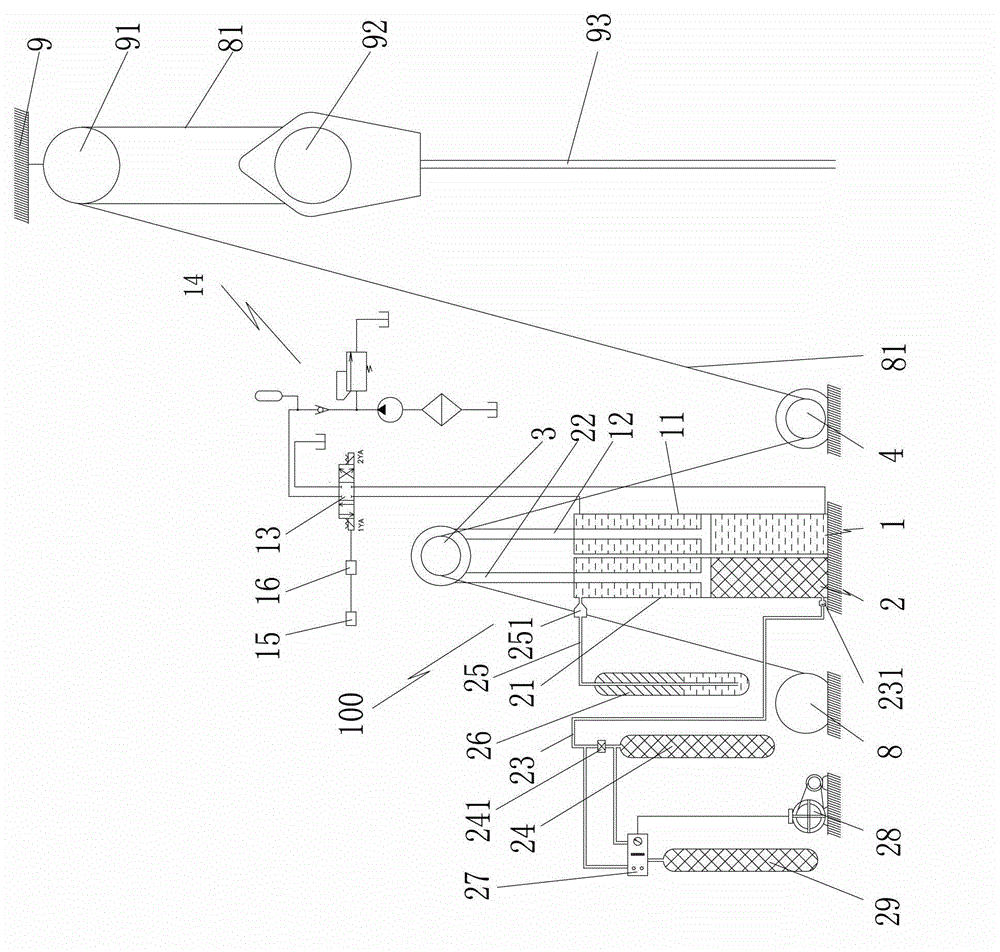

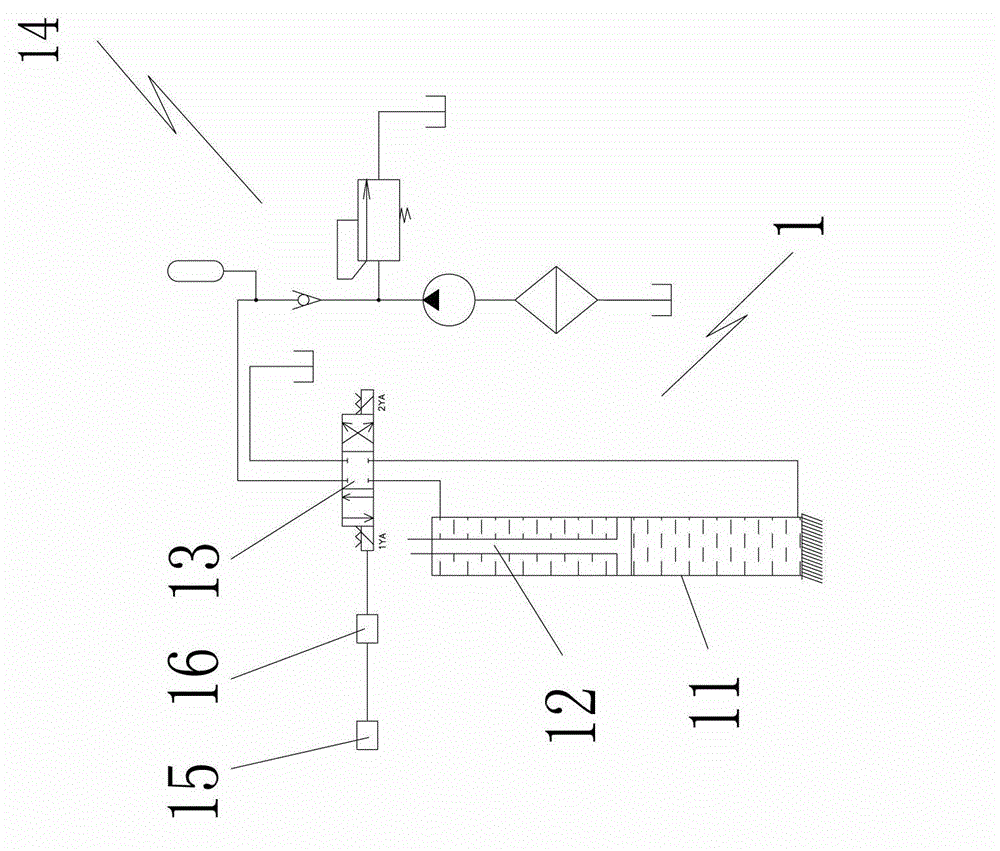

Winch heave compensation device for ocean floating drilling platform

InactiveCN102943636AReduce incidenceImprove safety and reliabilityDrilling rodsDrilling casingsCompensation effectEngineering

The invention relates to a winch heave compensation device for an ocean floating drilling platform. The device comprises an active compensator and a passive compensator which are arranged on one side of a winch in parallel. The active compensator comprises a first single-rod piston cylinder with a piston rod stretching upwards and a force transducer, wherein two chambers of the first single-rod piston cylinder are connected to a hydraulic system through a three-position four-way magnetic exchange valve, and the force transducer is used for detecting force on a steel wire rope and electrically connected with a force feedback controller which controls exchange actions of the three-position four-way magnetic exchange valve. The passive compensator comprises a second single-rod piston cylinder with a piston rod stretching upwards. Tops of the piston rods of the first piston cylinder and the second piston cylinder are connected onto a movable pulley, a fixed pulley is further arranged on the drilling platform, and the steel wire rope on the winch is connected with a crown block and a traveling block after bypassing the movable pulley and the fixed pulley sequentially. According to the device, the compensation effect that active compensation and passive compensation are mutually synchronous and promoted can be achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Drilling column heave compensator for floating drill platform in the sea

InactiveCN101130949ALimit consumptionImprove the compensation effectArtificial islandsUnderwater structuresCompensation effectEngineering

The present invention discloses one kind of heave compensation system for drill stem of marine floating drilling platform. High pressure hydraulic oil is led from the energy accumulator through a compensation control valve to the compensating hydraulic cylinder, so as to provide one additional force controlled based on the heave motion of the platform for raised compensation effect. The control unit detects the vertical motion of the platform to control the hydraulic system for compensating the heave motion of the platform by means of the steel cable or chain to make the crossbeam and rotary hook in vertically quiescent state relative to the well bottom. The present invention is superior to traditional passive heave compensation system, and has high reaction speed, high compensation precision, low power consumption and low operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

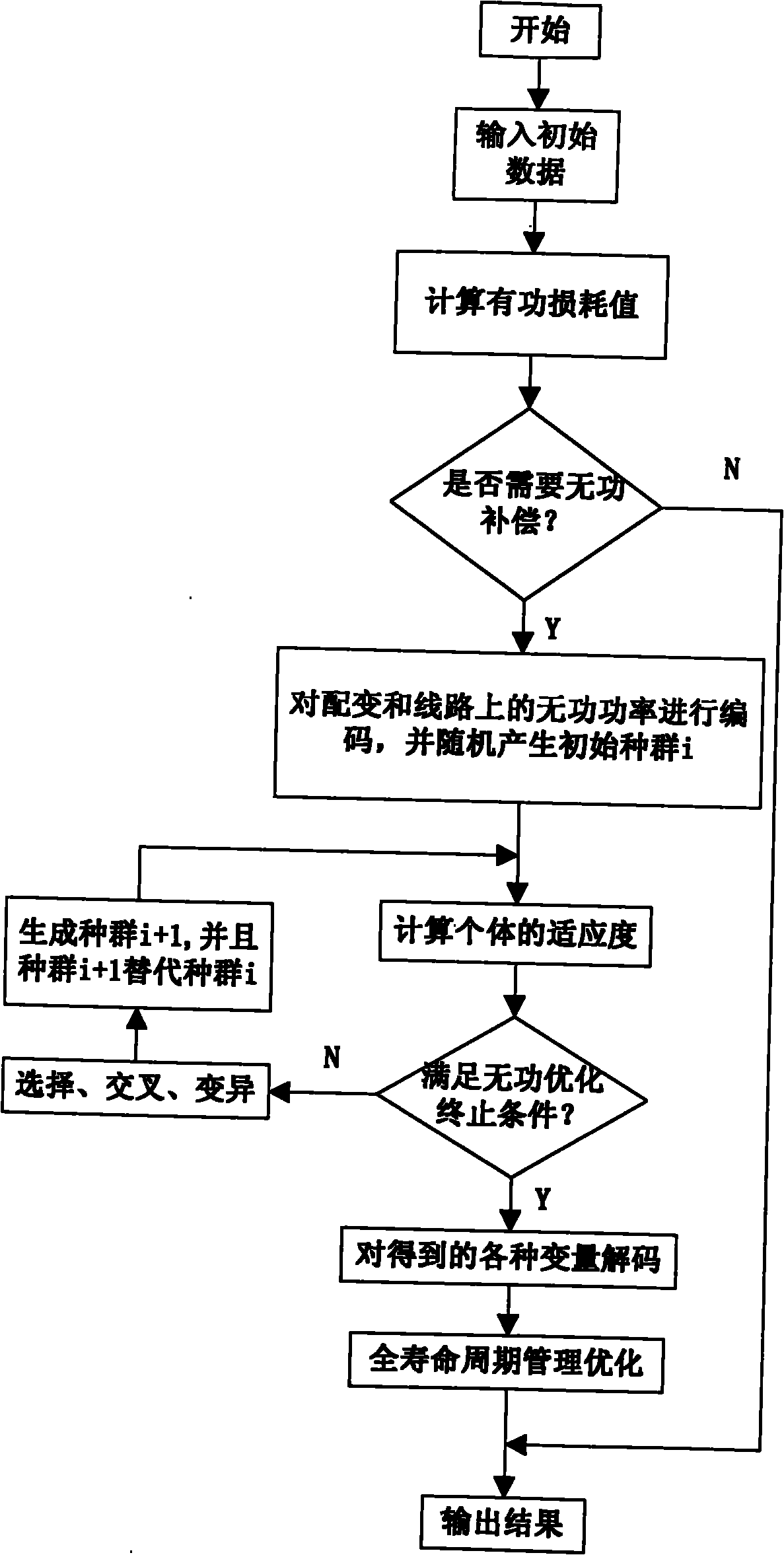

10 kv-distribution network reactive power compensation optimization method in power system

ActiveCN102055196ALow costIncrease profitEnergy industryReactive power adjustment/elimination/compensationPower compensationDistribution transformer

The invention discloses a 10 kv-distribution network reactive power compensation optimization method in a power system. The method comprises the following process steps of: firstly, determining the structure and the actual load condition of a distribution network and obtaining a topological structure of the distribution network by modeling the structure, such as the connection mode of lines, the number of distribution transformers, and the quantity and the positions of reactive compensation devices before compensating, of the distribution network; secondly, inputting original data; thirdly, calculating parameters before reactive power compensation; fourthly, taking the minimal network loss as a target, optimizing the reactive power compensation capacity and the position of the 10 kv-distribution network by a genetic algorithm; fifthly, selecting optimization calculation of configuration capacity based on life cycle management; sixthly, finishing an optimization process and outputting an optimization result; and finally, checking and ratifying a compensation effect by performing load flow calculation before and after optimizing the configuration, and regulating the scheme based on the checked and ratified compensation effect. The method has the advantages that: the cost of power supply enterprises can be optimized when reactive power compensation is provided; the utilization rate of equipment is improved; and the economic benefit of the power supply enterprises is improved.

Owner:南京软核科技有限公司 +1

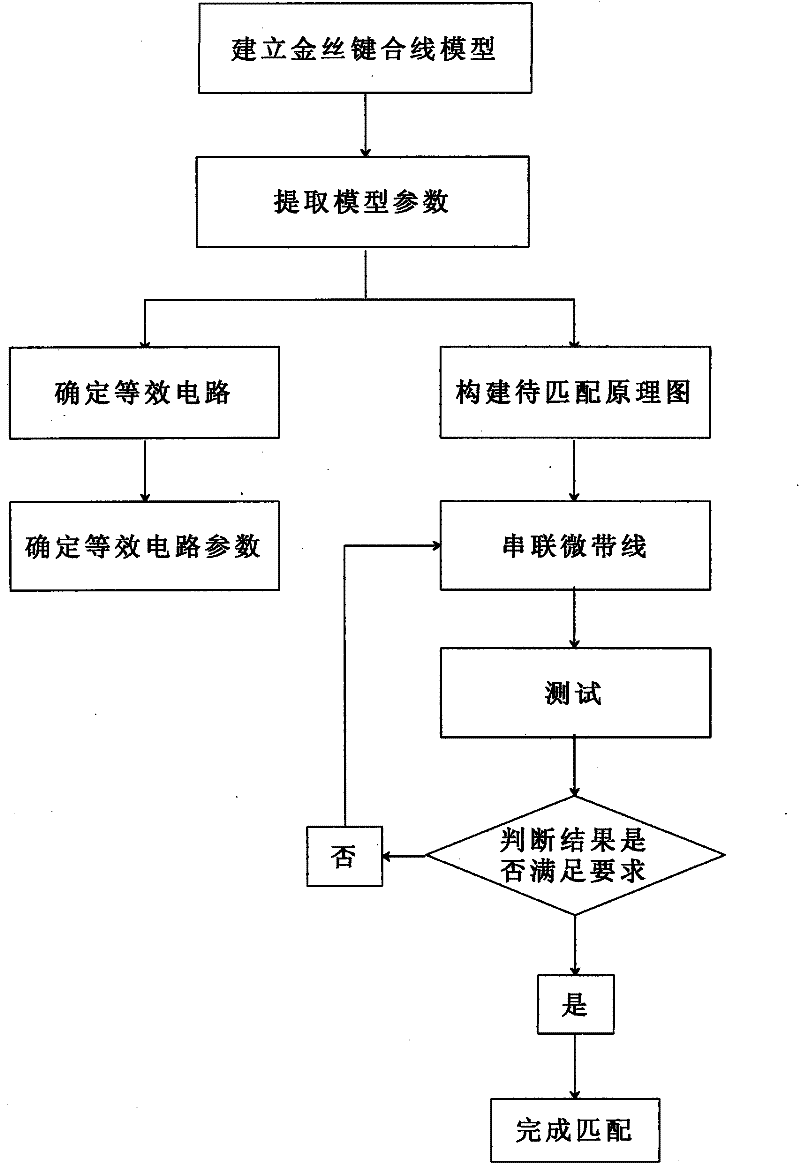

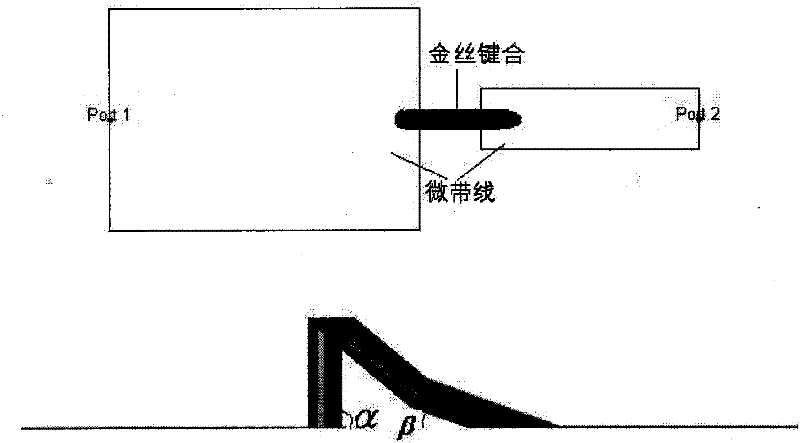

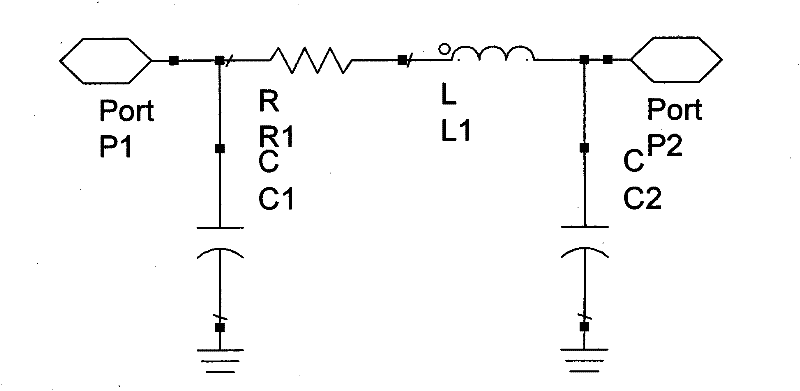

Impedance matching method for gold bonding wire

InactiveCN102393863AOvercoming the lack of cumbersome designThe design idea is simpleSpecial data processing applicationsSmith chartCompensation effect

The invention discloses an impedance matching method for a gold bonding wire. The method comprises the following steps: establishing a gold bonding wire model; extracting model parameters in a circuit application frequency band; causing the gold bonding wire model to be equivalent to a TT-shaped low-pass filter network; fitting equivalent network parameters by using the extracted model parameters; and introducing the extracted model parameters into a to-be-matched schematic diagram and adding a Smith chart matching control. In the Smith chart, 2-4 sections of micro-strip wires are serially connected so as to establish a matching network; a load impedance is converted into an actual impedance by first to second sections; the actual impedance is converted into a source impedance by a third section which is a Lambda / 4 converting wire, thereby achieving impedance matching; and a fourth section is a gradual changing wire used for transition. The impedance matching method has the advantagesof simple design concept, easiness in application, capability of saving a circuit board space, small frequency limitation, wide frequency band width and excellent compensation effect. The impedance matching method is used for interconnecting monolithic microwave integrated circuits, coplanar waveguides, microwave transmission lines or RF (Radio Frequency) grounding sides.

Owner:XIDIAN UNIV

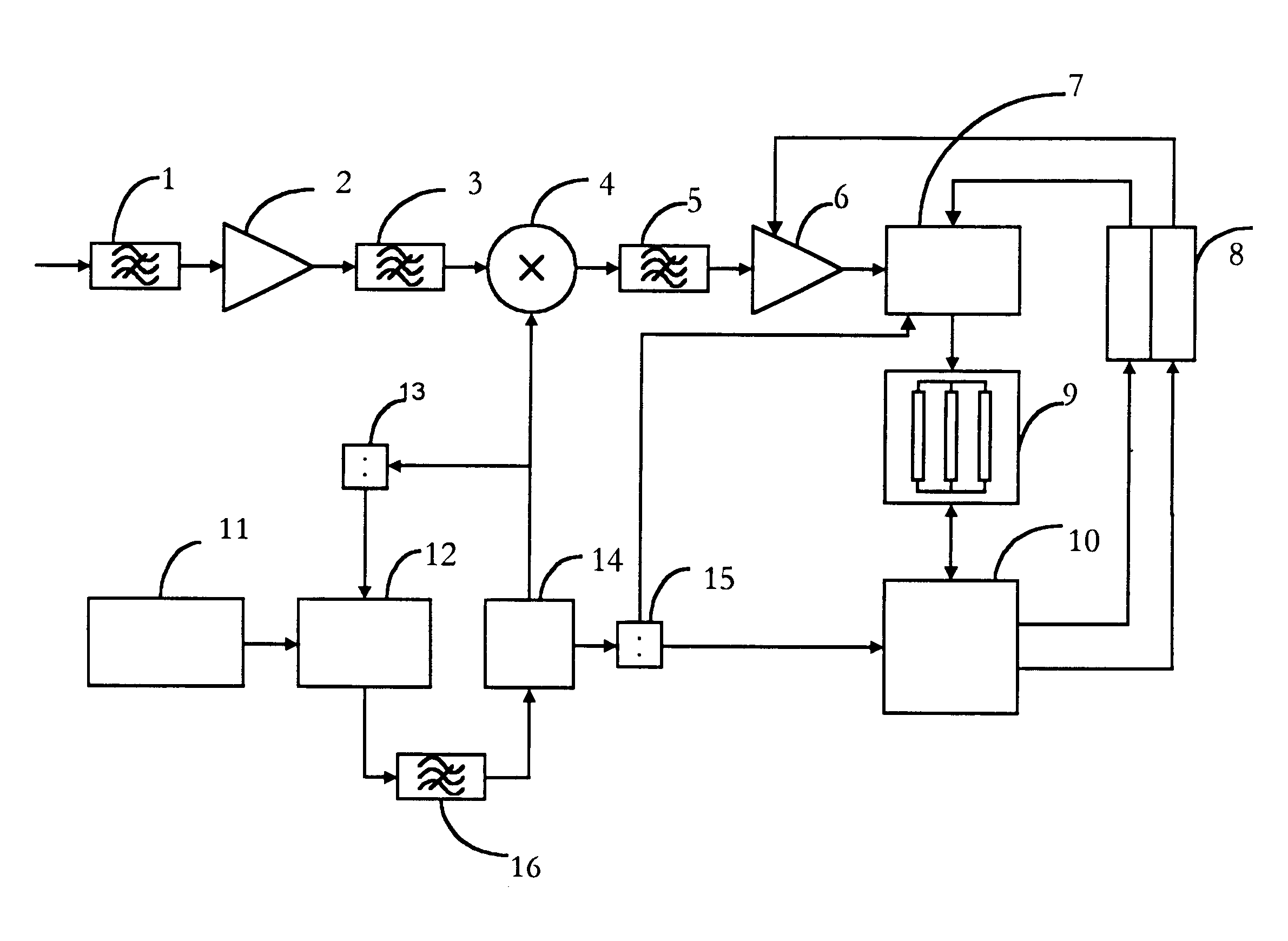

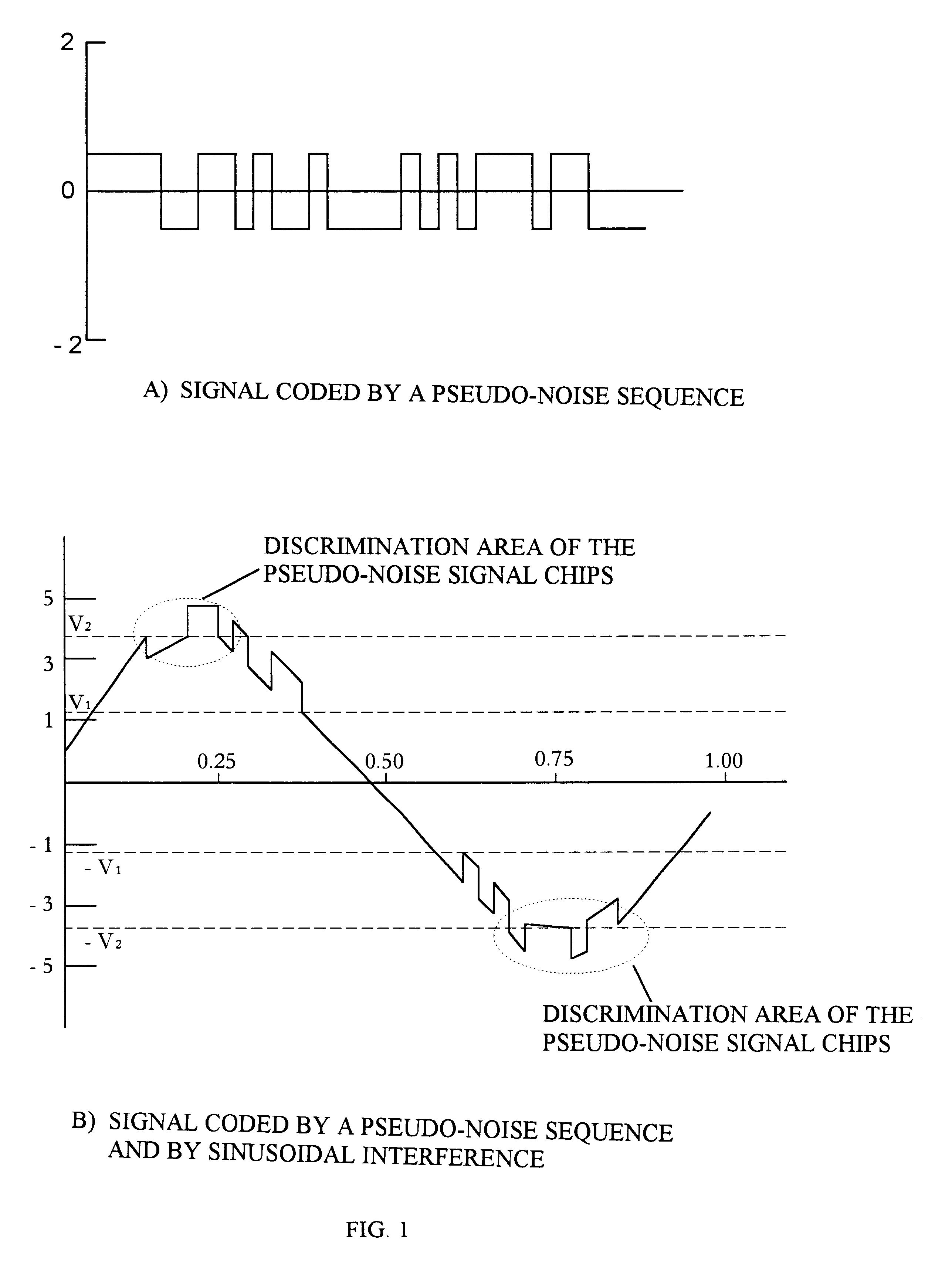

Multiple-channel digital receiver for global positioning system

InactiveUS6816539B1Easy to quantifyInhibition is effectiveBeacon systemsSatellite radio beaconingControl signalCompensation effect

The invention relates to systems for receiving a digital radio signal and, more particularly, to receivers of radio signals, coded with a pseudo-noise sequence, which are used in global positioning system GPS (USA) and GLONASS (Russia), allowing a compensation effect for the narrow-band interference by using a device, controlled by the processor, with an automatic gain control, multilevel analog-to-digital converter, and additional correlation channel for detection of sinusoidal interference consisting of the digital generator having quadrature mixers and accumulators. Information from output of the of accumulators is read by a processor, in which is detected the presence (or absence) of interference, and the amplitude is evaluated. Therefore, the processor generates control signal directing amplification in the device using an automatic gain control.

Owner:SAMSUNG ELECTRONICS CO LTD

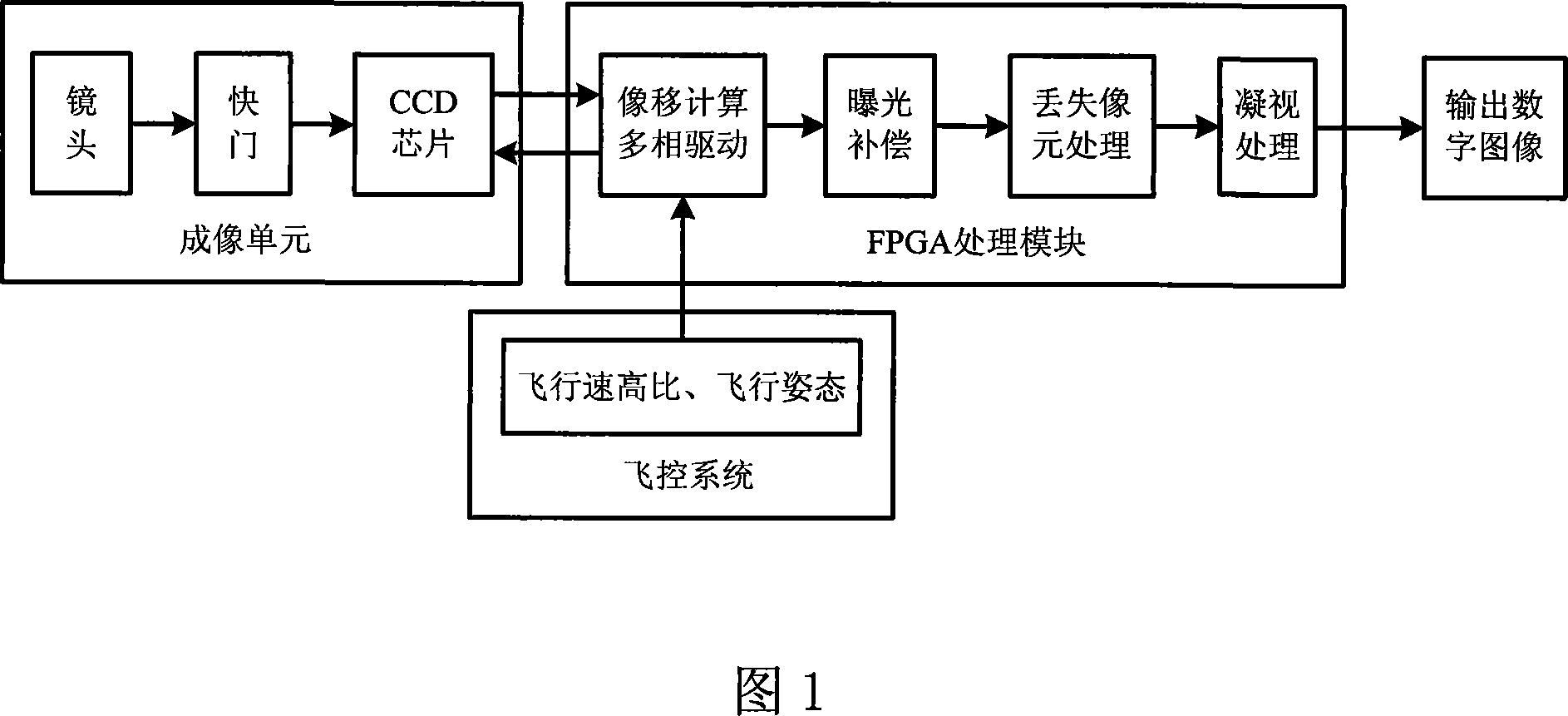

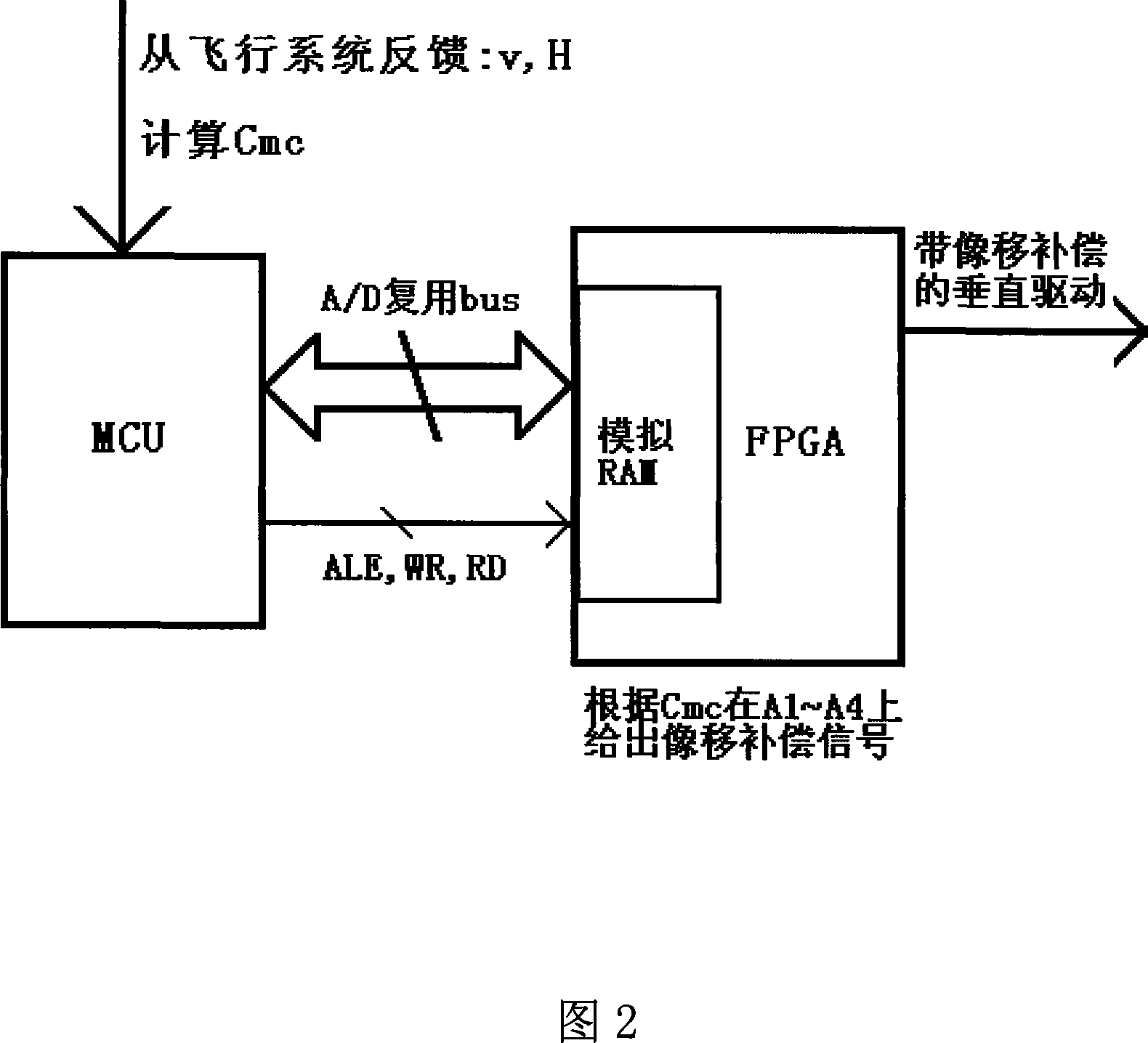

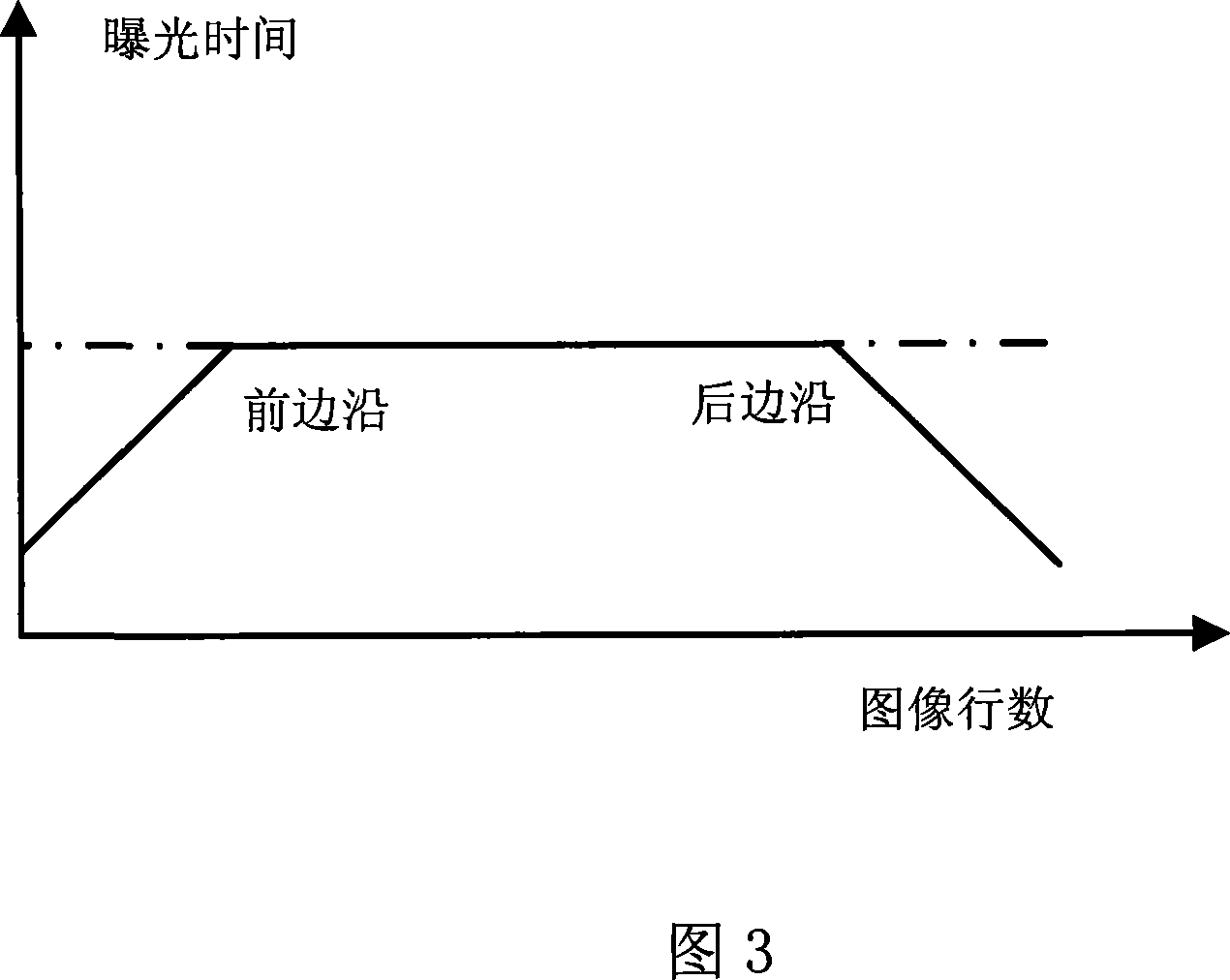

Aviation total-frame transfer type matrix CCD camera image shift compensation method

InactiveCN101078622AReduce development costsSimple structurePicture taking arrangementsAviationElectricity

The invention discloses an image motion compensation method for aviation full-frame transferring area CCD camera, accomplishing image motion compensation in aviation photography by combining mechanical shutter and electric shutter and the pure-electricity image motion compensation method of changing CCD line frequency driving according to aircraft speed-altitude ratio. Compared with common mechanical compensation technology, studying cost and complicated degree of area aviation camera are decreased greatly. In image motion compensation, flight altitude, exposure jitter and staring model so on are considered fully to strengthen compensation effect. Because compensation circuit adopts multi-phase driving method electric compensation accuracy can achieve sub-pixel level and improve image definition furthermore.

Owner:BEIJING LUSTER LIGHTTECH

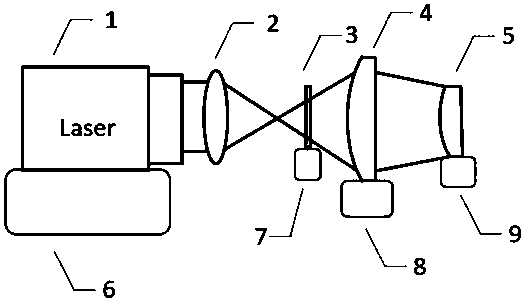

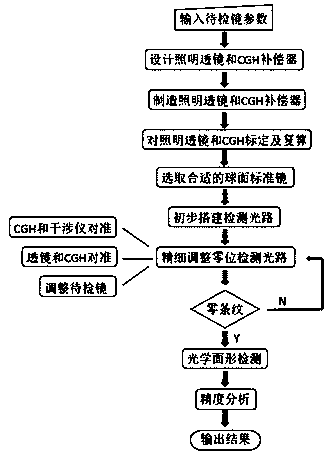

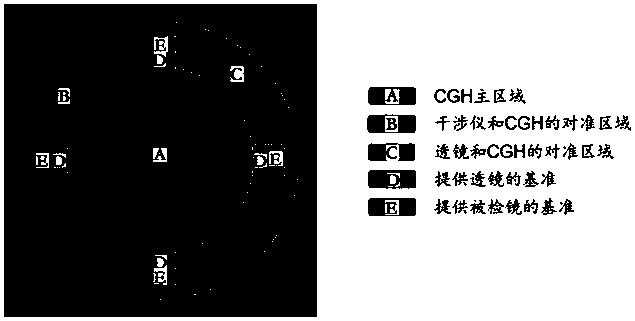

Convex aspheric surface reflector surface shape detection device and method

ActiveCN107796329ASmall caliberRealize high-precision detectionUsing optical meansCompensation effectPhase difference

The present invention discloses a convex aspheric surface reflector surface shape detection device and method which can detect a convex aspheric surface reflector of a large caliber (the caliber is more than 200 mm) by using a CGH compensator of a small size on the condition of guaranteeing the detection precision. The device of the present invention converges the light beams via a lens, so that the caliber of the adopted CGH compensator is very small, and the CGH compensator can realize the high-precision detection of the surface shape of the convex aspheric surface reflector of the large caliber within a high-precision processing size range. The method of the present invention is characterized by combining the phase difference compensation effect of the CGH compensator to the wavefrontsand the convergence effect of the lens to the light beams and using the CGH compensator of the small size to detect the convex aspheric surface reflector of the large caliber, solves the problems thata conventional CGH compensation detection method only can detect the surface shape of the convex aspheric surface reflector of the small caliber, and can detect the convex aspheric surface reflectorsof various curved surface types by being compared with the conventional convex aspheric surface reflector surface shape detection method.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

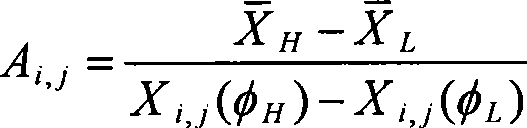

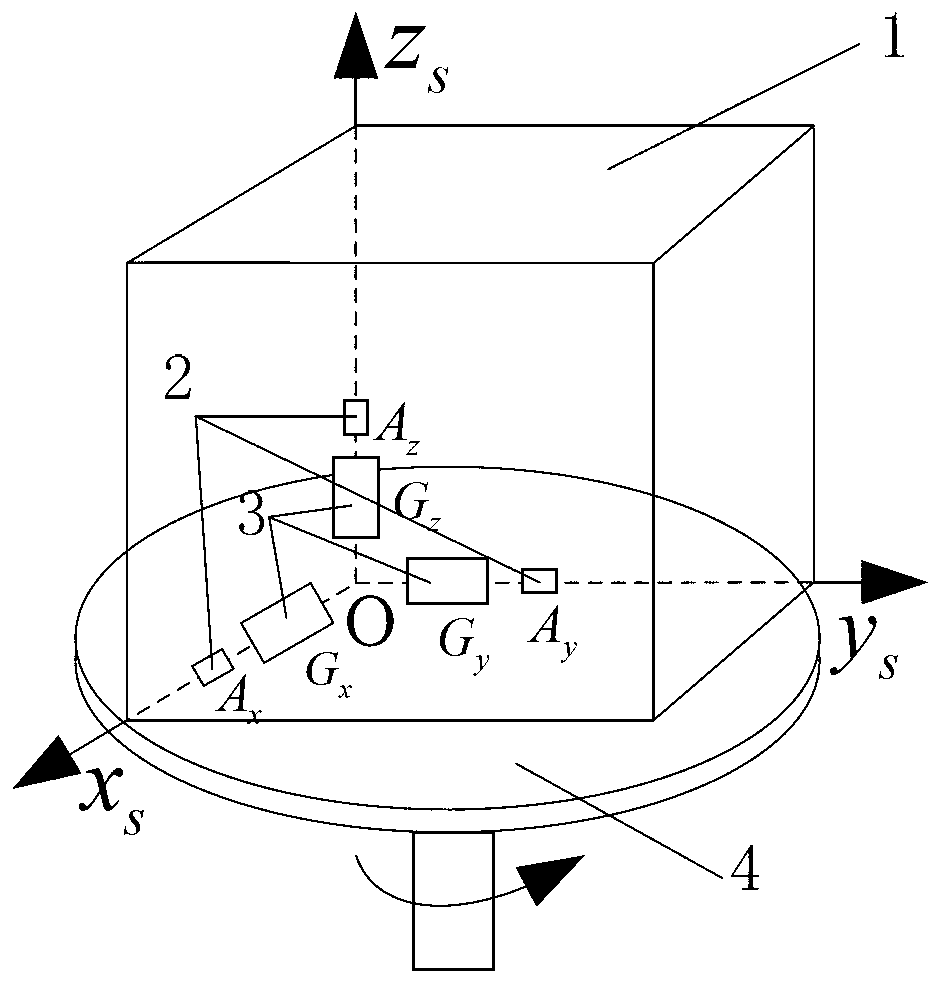

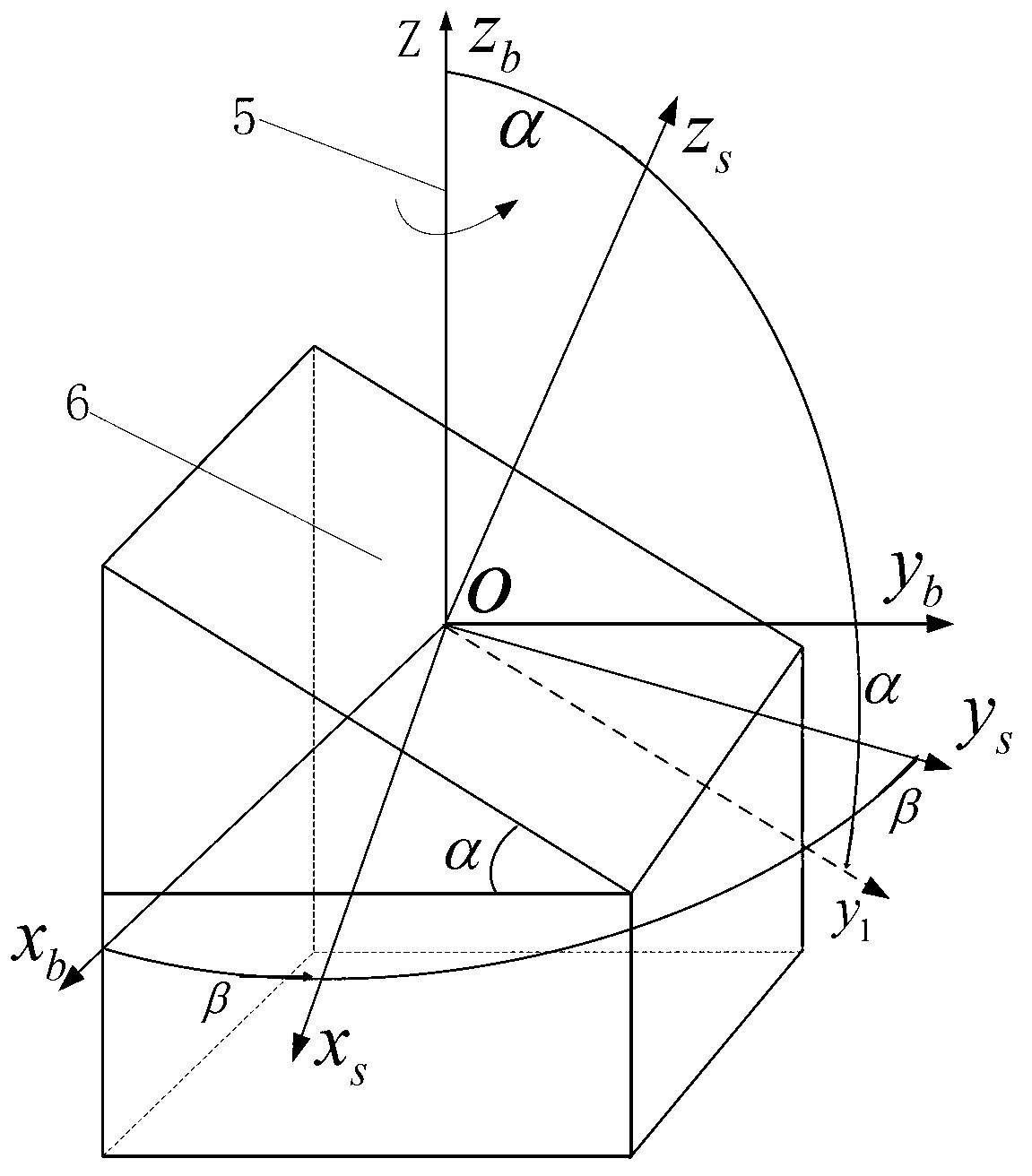

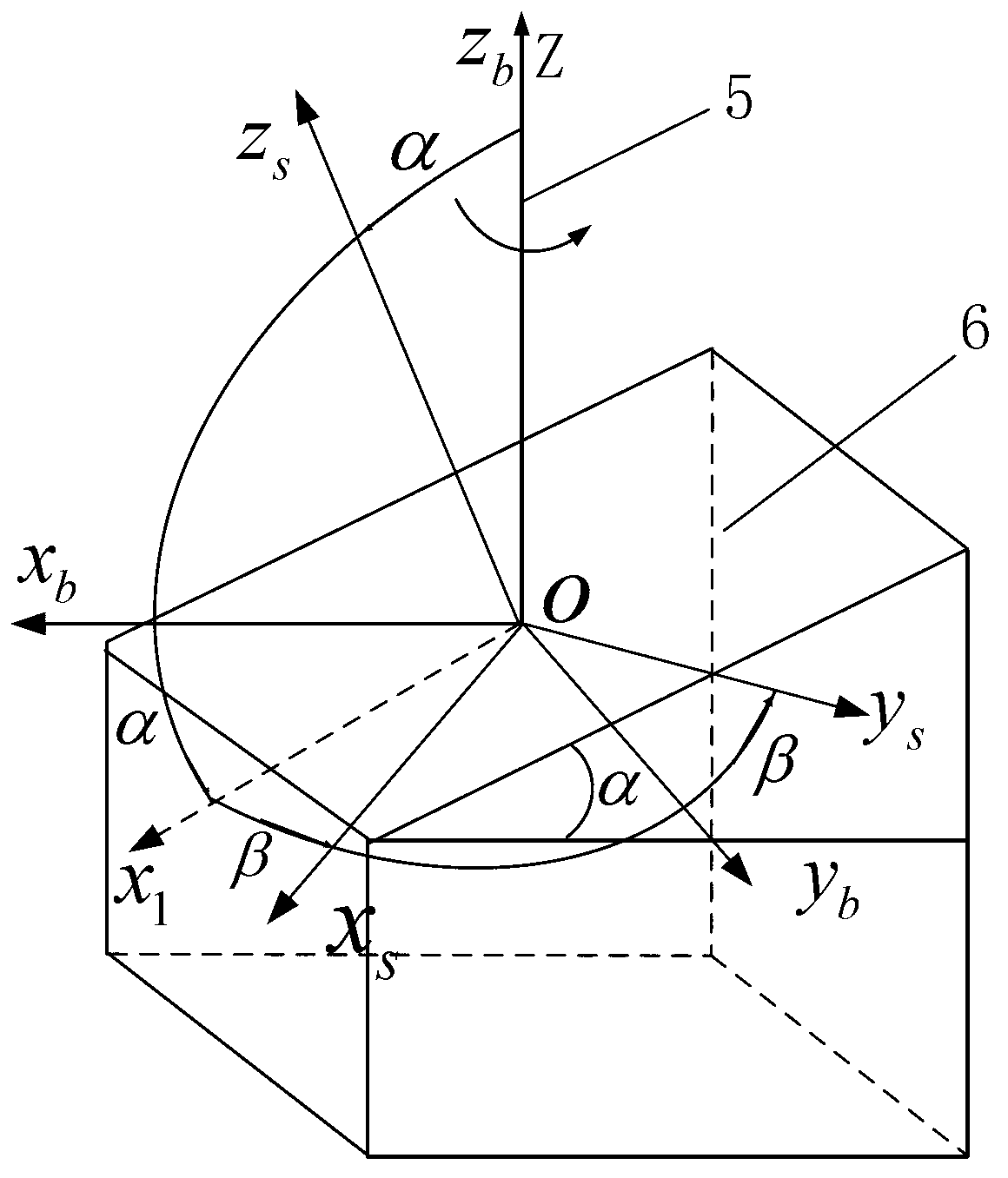

Single-shaft rotary type inertial navigation system and special error self-compensation method thereof

ActiveCN103292809AReduce warranty maintenance costsImprove the compensation effectNavigation by speed/acceleration measurementsAccelerometerGyroscope

The invention relates to a single-shaft rotary type inertial navigation system. The invention further relates to a special error self-compensation method of the single-shaft rotary type inertial navigation system. The single-shaft rotary type inertial navigation system comprises an indexing mechanism and a single-shaft rotary type inertial navigation system inertial measurement unit, wherein the single-shaft rotary type inertial navigation system inertial measurement unit is mounted on an inertial measurement unit mounting plane; the inertial measurement unit mounting plane and the indexing mechanism are connected together; coordinate axes of the single-shaft rotary type inertial navigation system inertial measurement unit are vertical to each other two by two; each coordinate axis is provided with a gyroscope and an accelerometer. According to the single-shaft rotary type inertial navigation system disclosed by the invention, real-time drifting estimation is implemented by adopting a manner of realizing an adjustable inclined angle of an IMU (Inertial Measurement Unit) mounting plane; the inclined angle can be dynamically readjusted at intervals, so as to further improve the compensation effect of the system; a previous process of recalibrating in a laboratory with a high-precision inertial navigation testing rotary table can be finished in field in a use process, and the guarantee and maintenance costs of an operation period of the inertial navigation system are greatly reduced.

Owner:哈尔滨工程大学科技园发展有限公司 +1

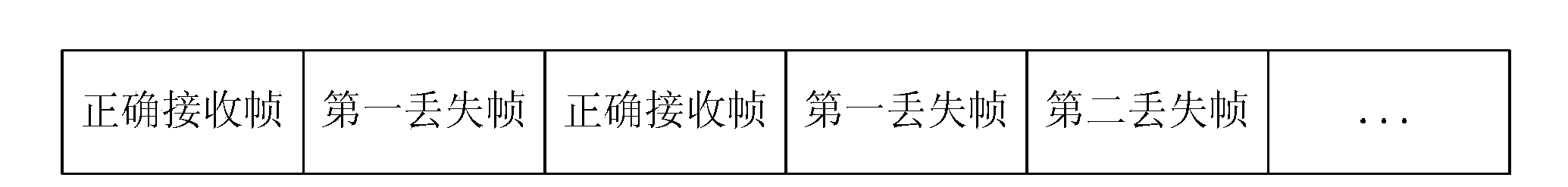

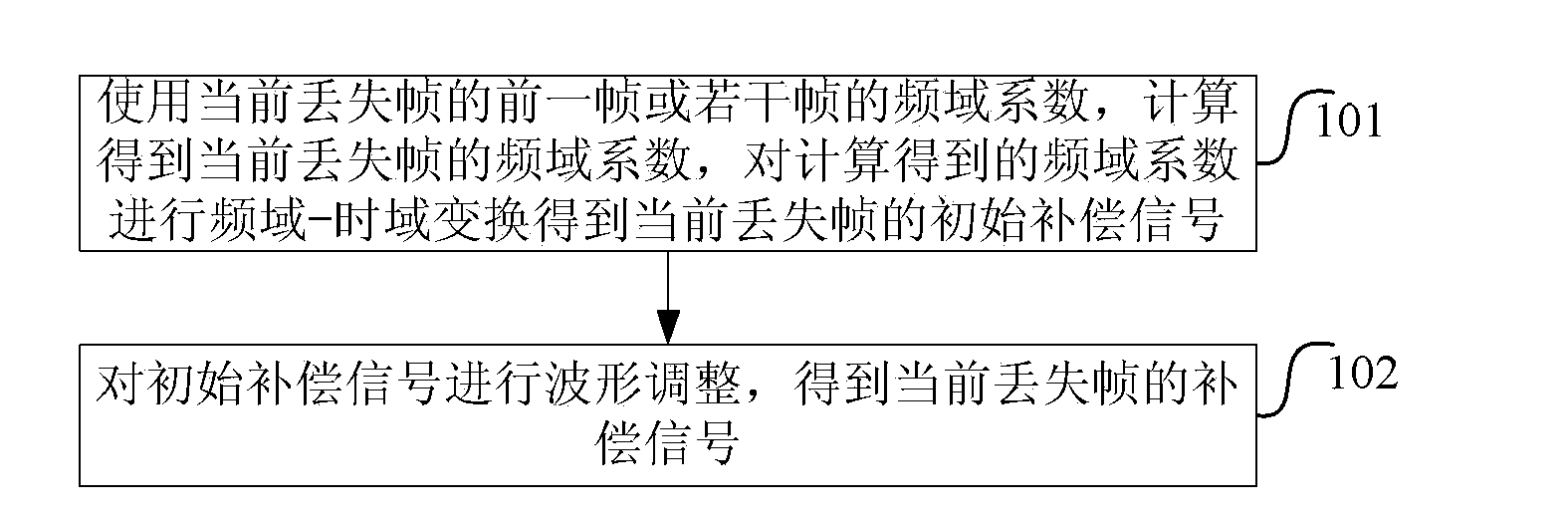

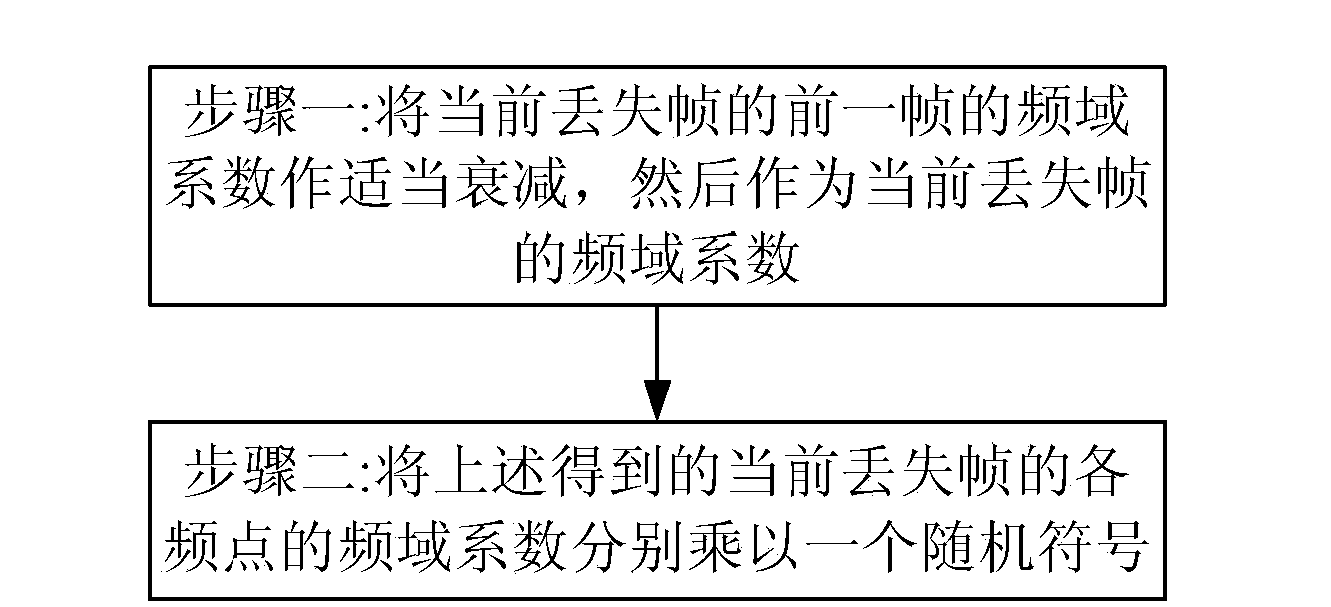

Frame loss compensation method and frame loss compensation device for transform domain

ActiveCN103854649AGood frame loss compensationReduce operational complexitySpeech analysisTime domainCompensation effect

The invention discloses a frame loss compensation method and a frame loss compensation device for a transform domain. The method comprises the following steps: the frequency-domain coefficient of a current lost frame is calculated by using the frequency-domain coefficient of a previous frame or frequency-domain coefficients of multiple previous frames of the current lost frame, and frequency domain-time domain transform is performed to obtain an initial compensation signal; and waveform regulation is performed to obtain a compensation signal so as to reduce the operation complexity and achieve a better compensation effect. Or, for all or part of frequency points of the current lost frame, extrapolation is performed on phases and amplitudes of corresponding frequency points of multiple previous frames to obtain phases and amplitudes of corresponding frequency points of the current lost frame and to further obtain frequency-domain coefficients of the corresponding frequency points, and frequency domain-time domain transform is performed to obtain a compensation signal, thus greatly improving the tone frame compensation effect. The method can be selected through a judging algorithm to compensate the current lost frame to achieve a better compensation effect. A voice signal frame and a music signal frame are processed in a differentiated mode, and a good compensation effect can be achieved in a variety of scenarios. Through gain adjustment, the compensation energy is stabilized and the compensation noise is reduced.

Owner:ZTE CORP

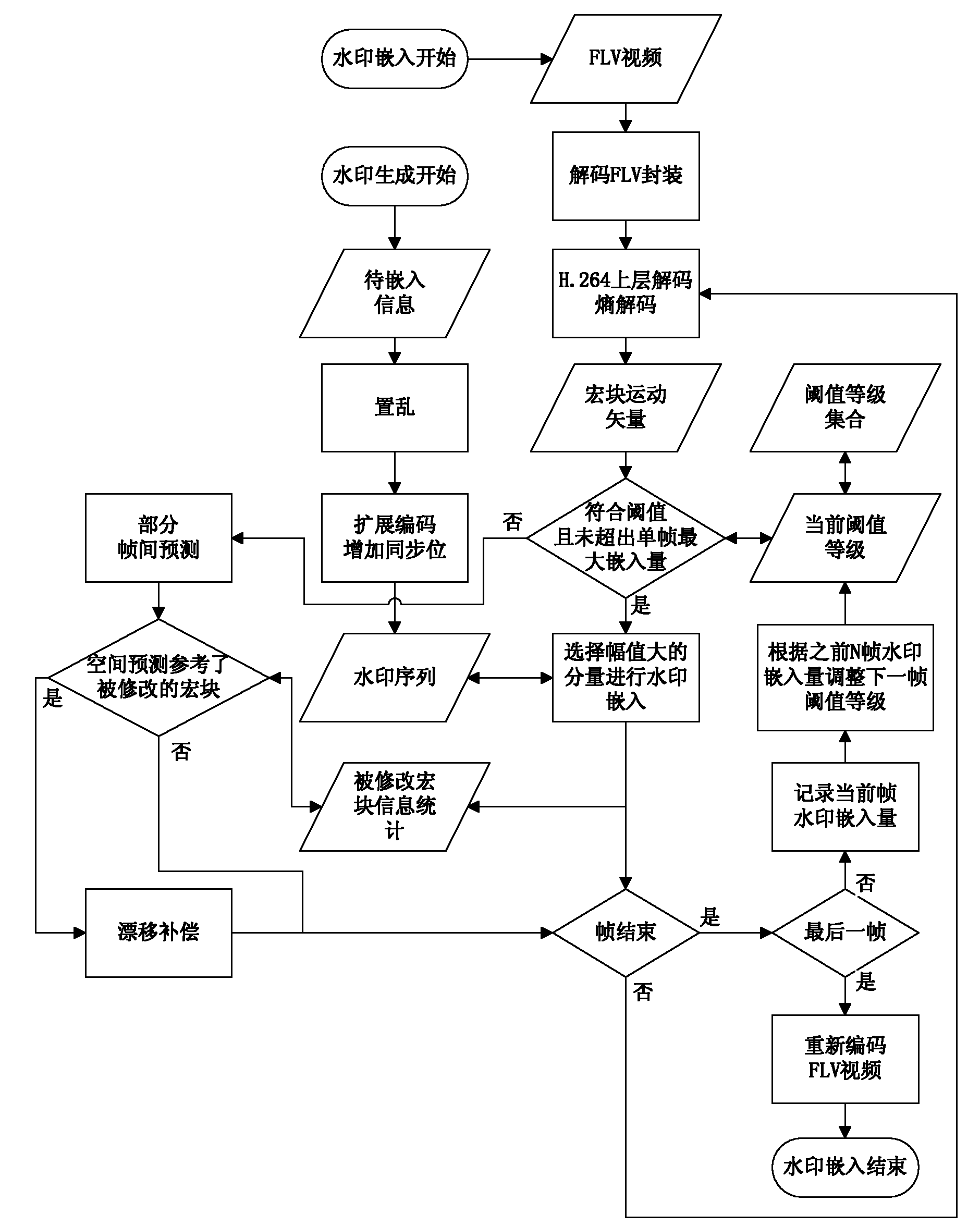

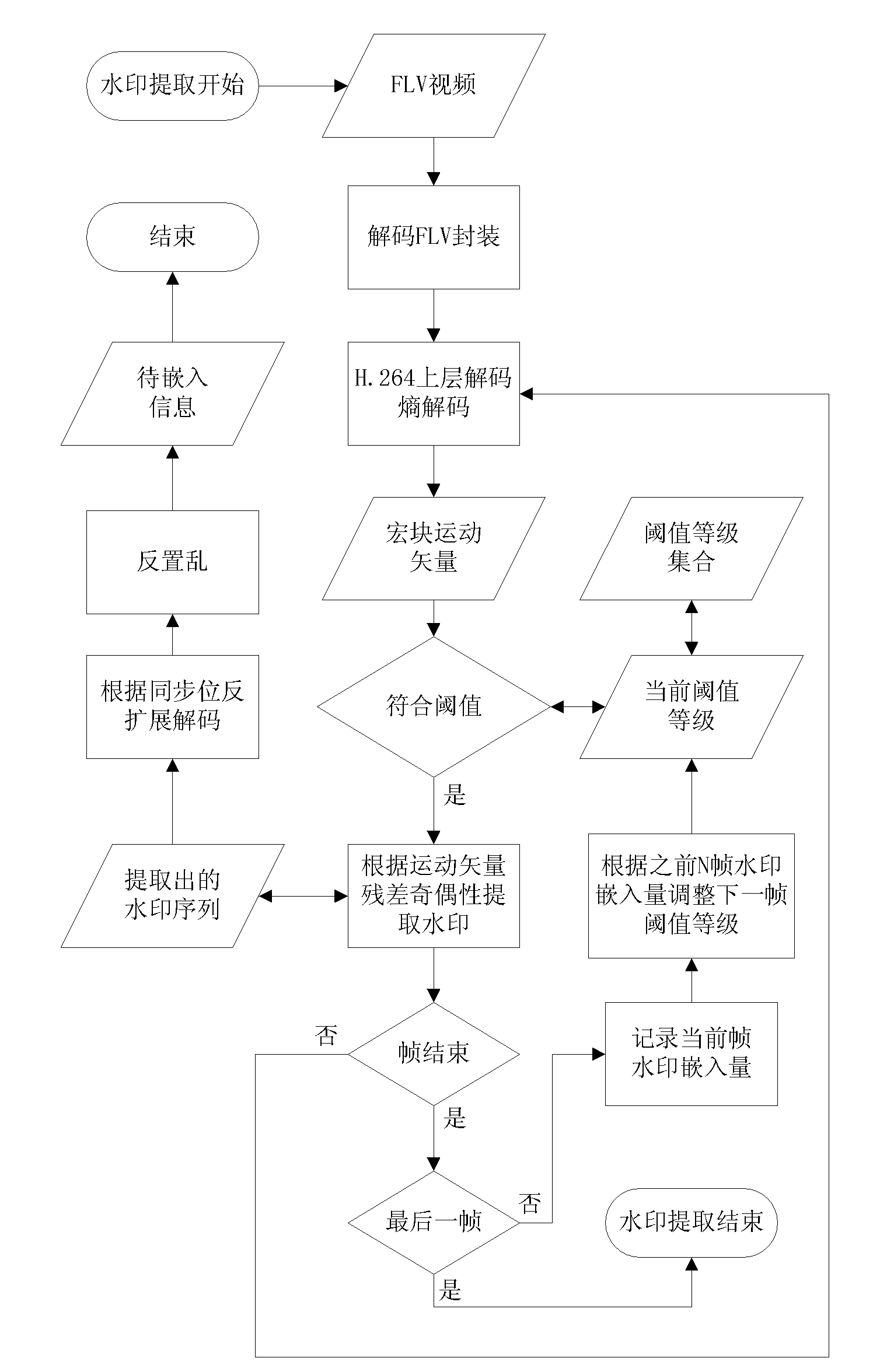

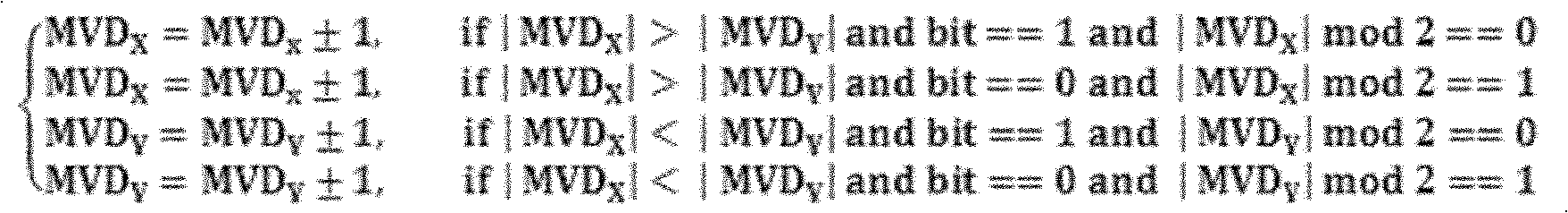

Adaptive H.264 compressed domain video watermark embedding and extracting method

ActiveCN101951520AImprove extraction efficiencyGuaranteed real-timeTelevision systemsImage data processing detailsCompensation effectMotion vector

The invention relates to an adaptive H.264 compressed domain video watermark embedding and extracting method in the technical field of information security, which can realize the real-time operation of video information hiding. The threshold value of a motion vector is adaptively adjusted according to watermark embedding amount statistical data of an adjacent frame, so that watermark capacity is ensured and the requirement of embedding a one-time watermark among a few frames is met; and error diffusion caused by modifying the motion vector is accurately positioned in a partial interframe prediction mode, so that good drift and distortion compensation effects can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

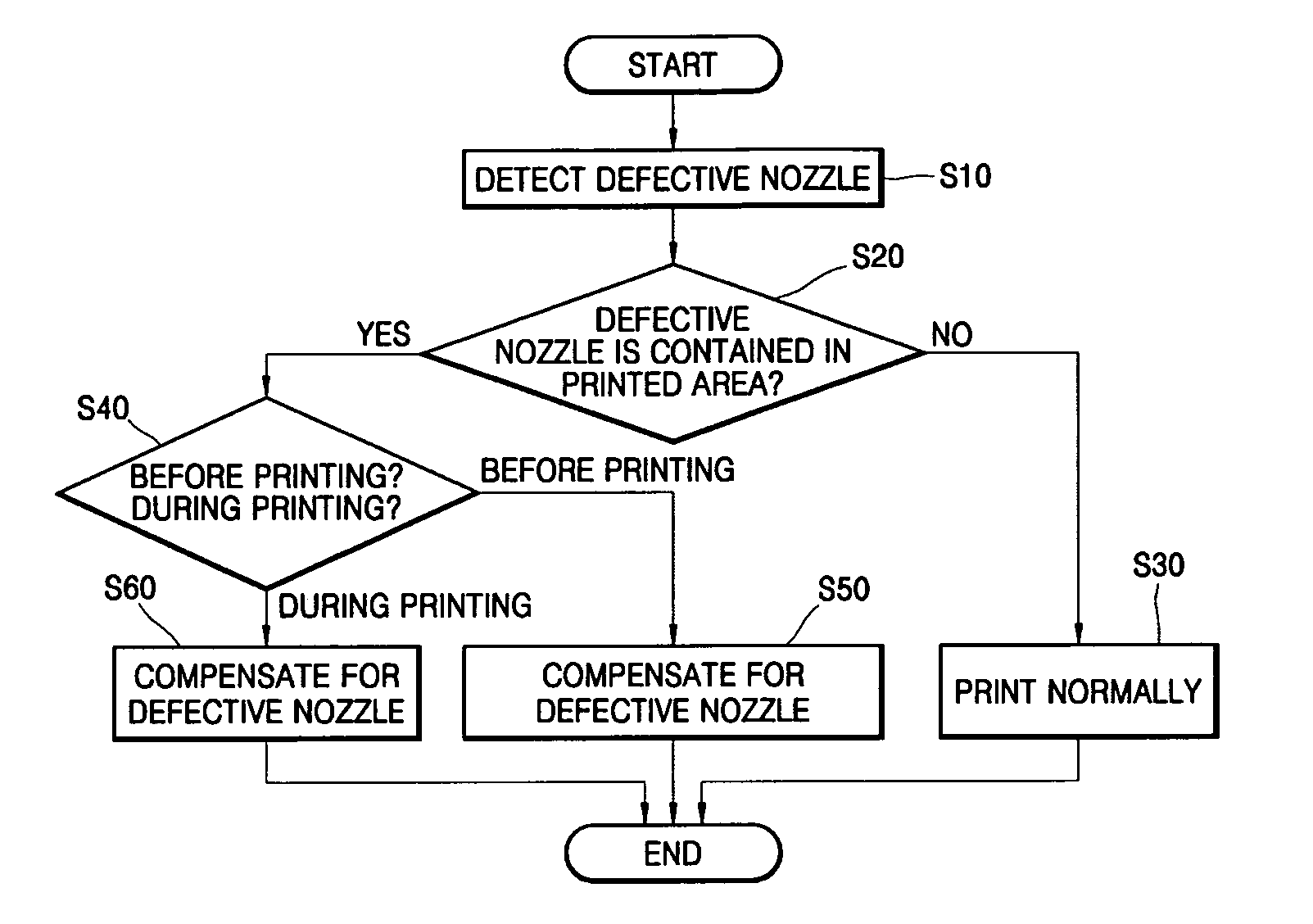

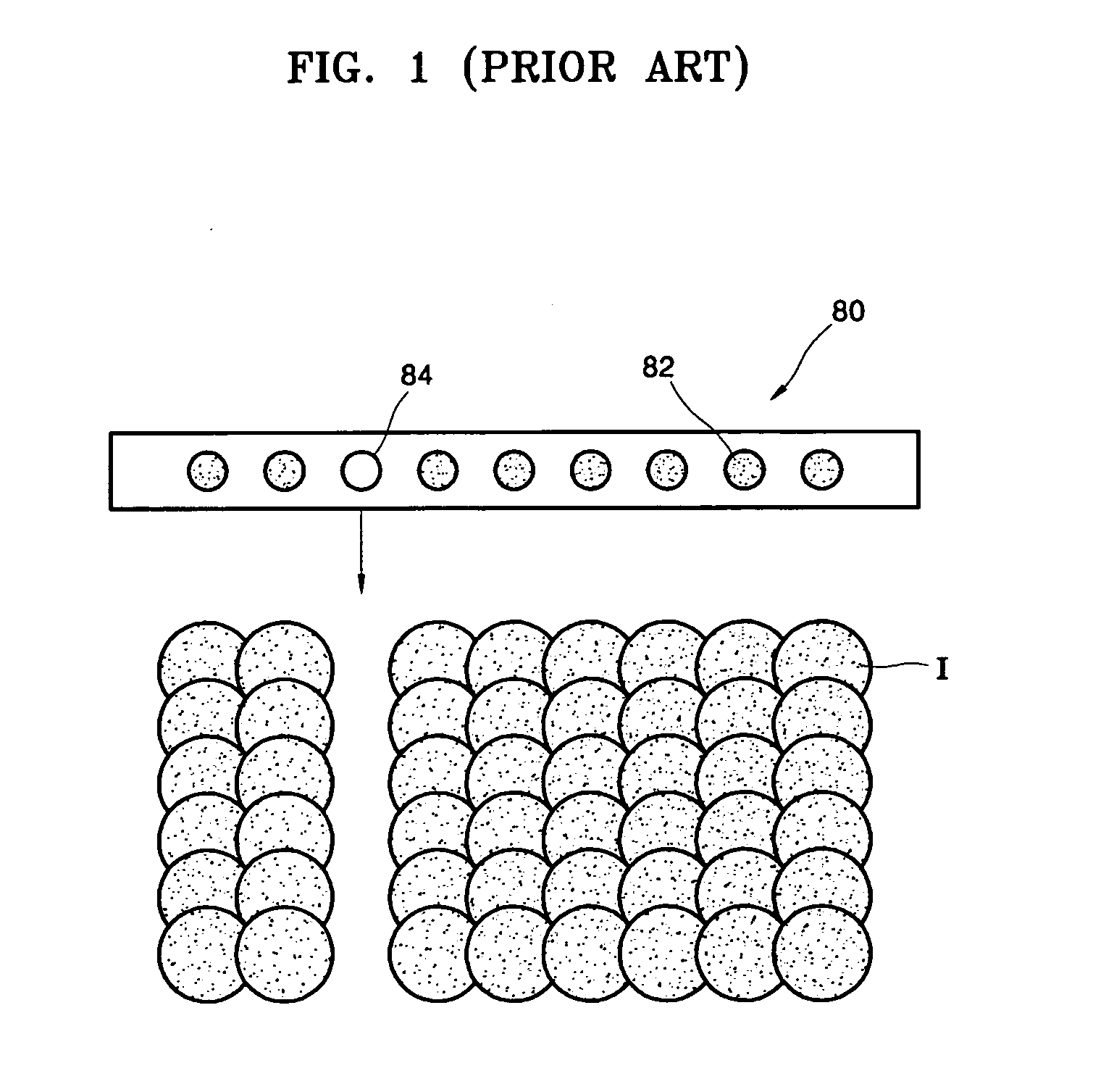

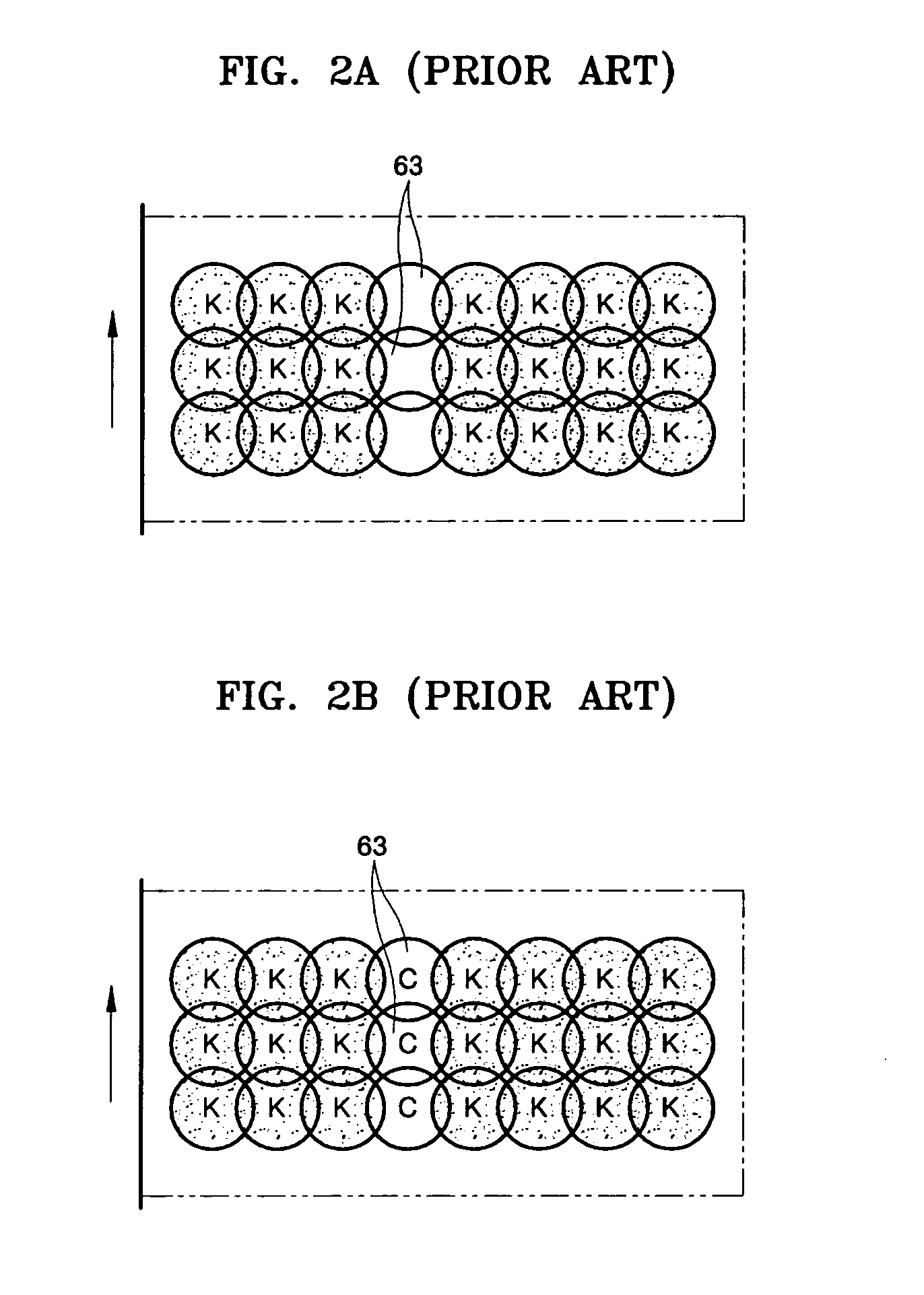

Method of compensating for a defective nozzle in an ink-jet image forming apparatus

A method of compensating for a defective nozzle in an ink-jet image forming apparatus. The method includes detecting a defective nozzle in a nozzle unit, and if the defective nozzle is detected, and compensating for the defective nozzle by using a compensating nozzle unit to eject a colorless ink droplet. The method can compensate for a printing defect, such as a white line which can be easily noticed by a user, using colorless ink droplets. In addition, the method can compensate for a defective nozzle that ejects color ink as well as a defective nozzle that ejects black ink. Also, the method can improve a compensation effect by adjusting a size or an arrangement of the compensating nozzle unit.

Owner:SAMSUNG ELECTRONICS CO LTD

AMOLED pixel driving system and AMOLED pixel driving method

ActiveCN106548753AImprove stabilityStable currentStatic indicating devicesDriver circuitCompensation effect

The invention provides an AMOLED pixel driving system and an AMOLED pixel driving method. The AMOLED pixel driving system comprises a 4T1C (four thin-film transistors and one capacitor) pixel driving circuit and an initial voltage power supply module electrically connected with the pixel driving circuit. The initial voltage power supply module provides a high-level initial signal for the pixel driving circuit in the light emitting stage. The threshold voltage of a driving thin-film transistor can be compensated effectively, and the current flowing through an organic light emitting diode can be stabilized. Moreover, the leakage currents of the gate and the source of the driving thin-film transistor in the light emitting stage can be reduced, and the stability of compensation data in the light emitting stage and the threshold voltage compensation effect can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com