Winch heave compensation device for ocean floating drilling platform

A drilling platform and heave compensation technology, which is applied to drilling equipment, drill pipes, drill pipes, etc., can solve problems such as difficulty in ensuring safety and reliability, high energy consumption, and difficult installation, achieving considerable economic benefits, reducing operating costs, The effect of installing a low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

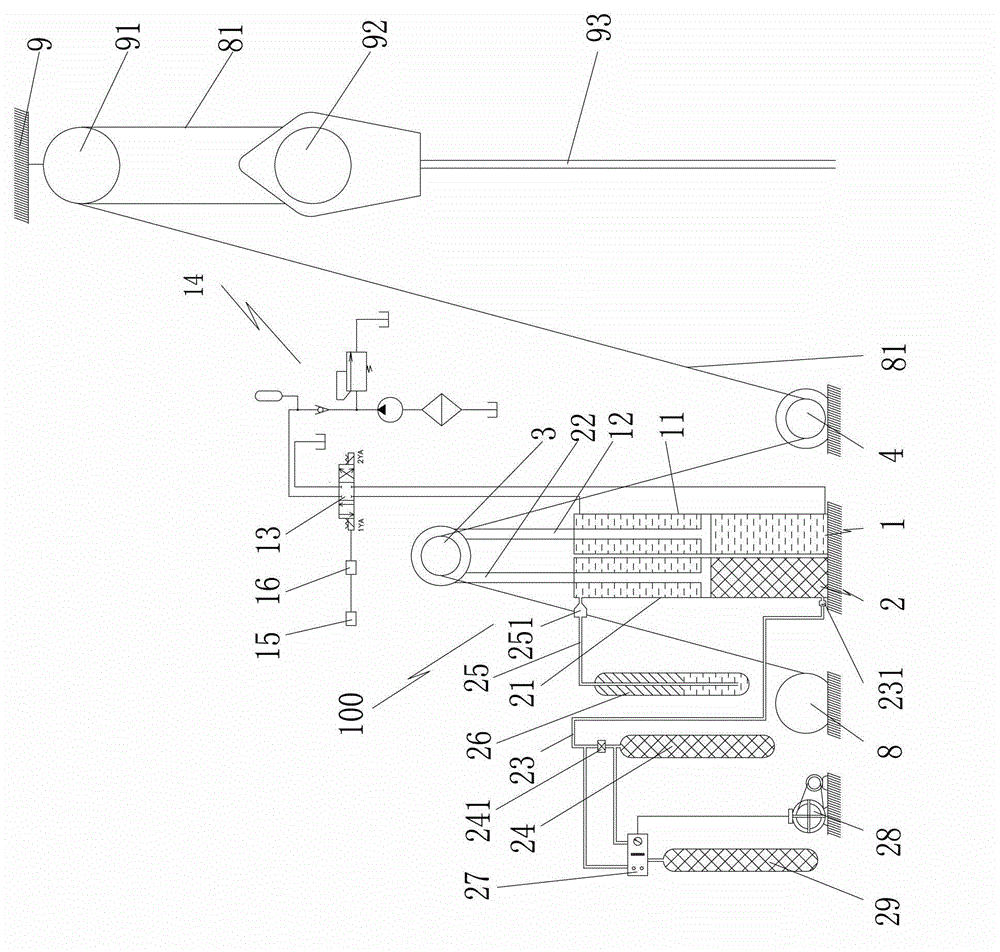

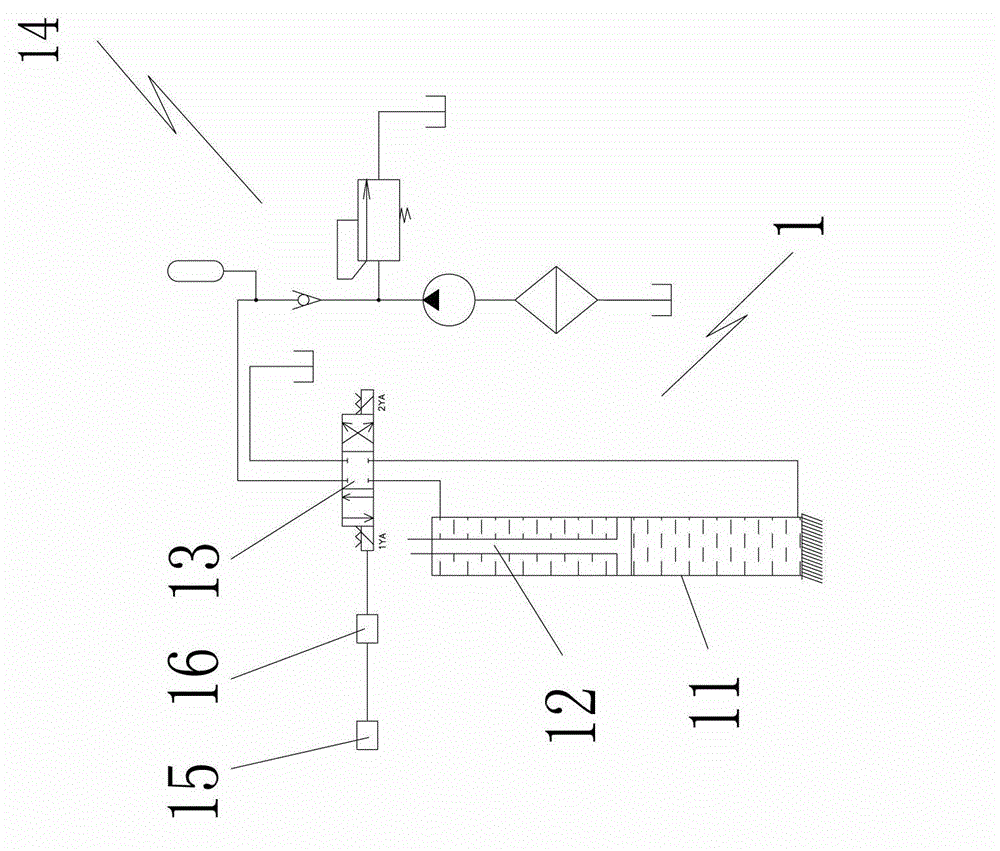

[0019] Such as figure 1 , figure 2 As shown, the present invention proposes a drawworks heave compensation device 100 for an offshore floating drilling platform. The drilling platform is provided with a drawworks 8 and a derrick 9, and the derrick 9 is provided with a crown block 91, a traveling block 92 and a drill pipe 93. The travel block 92 and the crown block 91 are connected through the wire rope 81 on the winch 8; the winch heave compensation device 100 includes an active compensator 1 and a passive compensator 2 arranged on one side of the winch 8 and arranged side by side; the active compensator 1 includes a first single-rod piston cylinder 11 with a piston rod 12 protruding upwards. The two chambers of the first singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com