Patents

Literature

523results about How to "Job safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

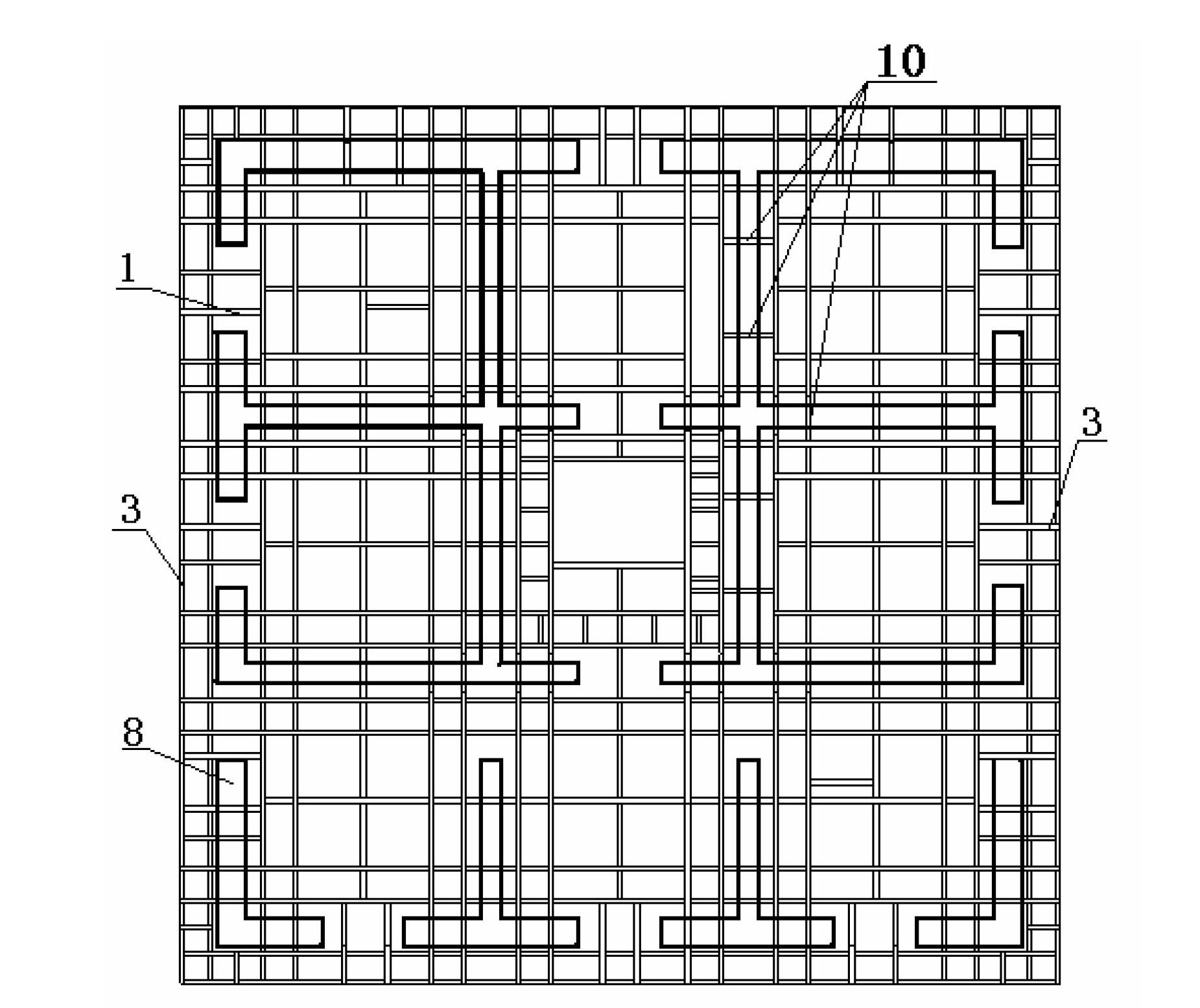

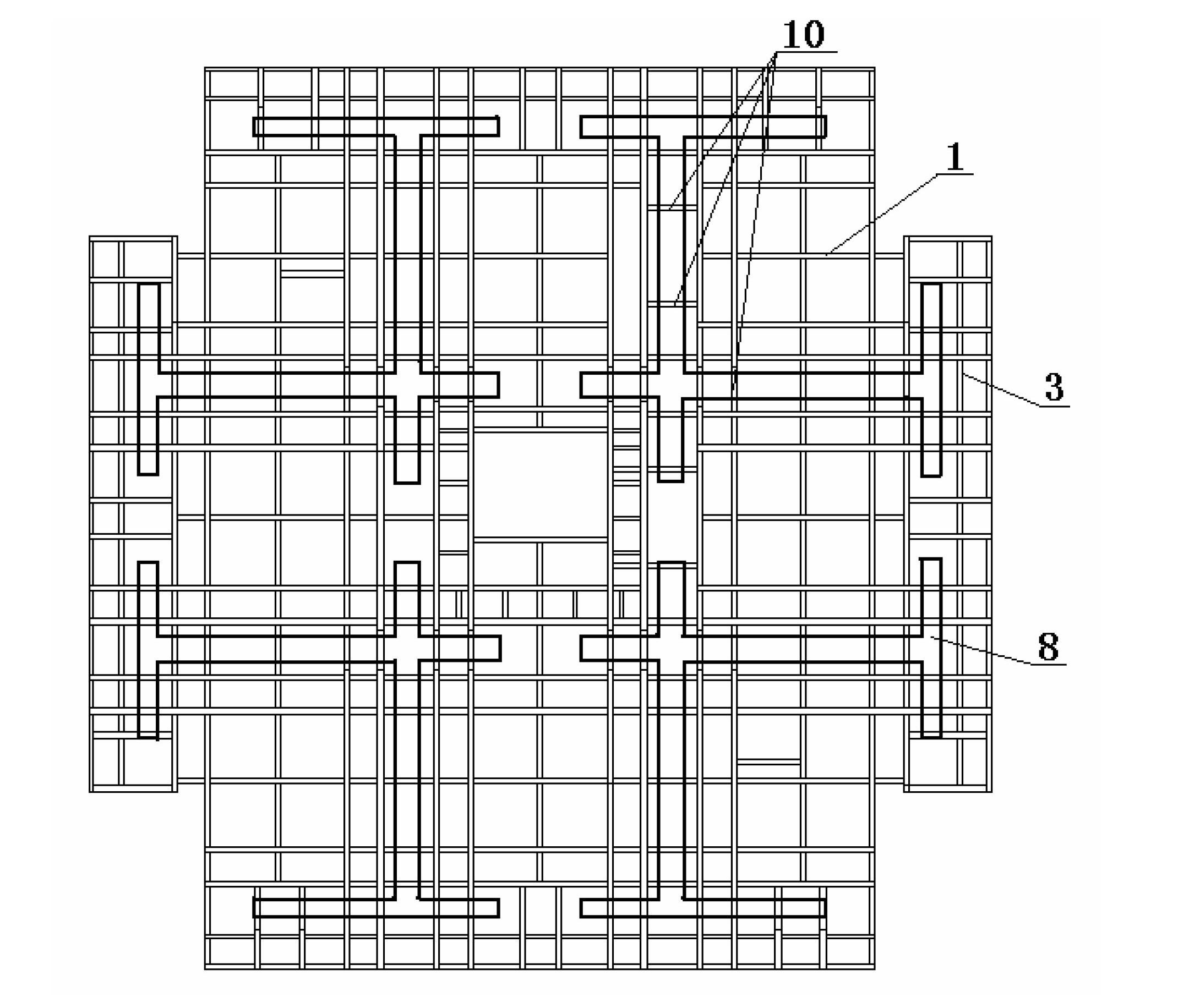

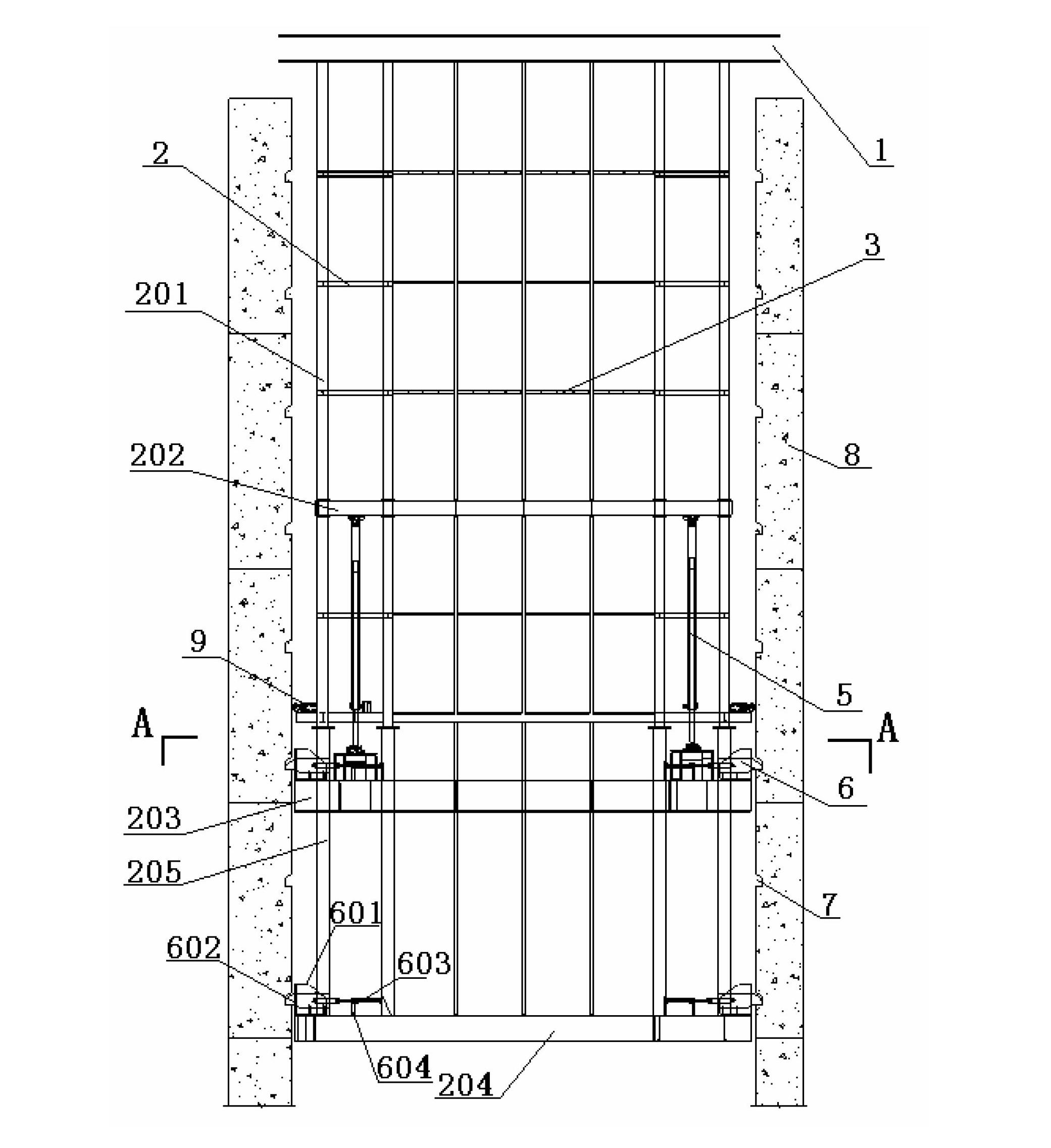

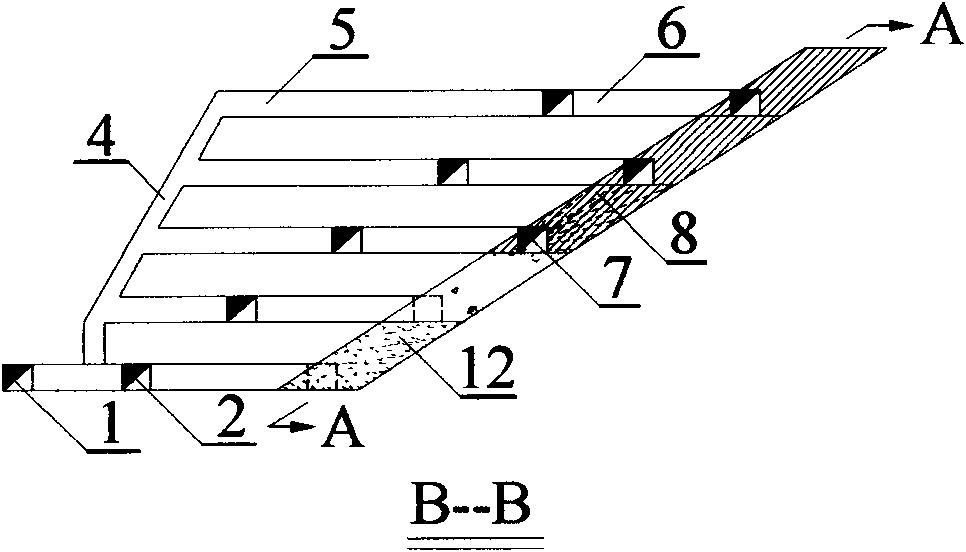

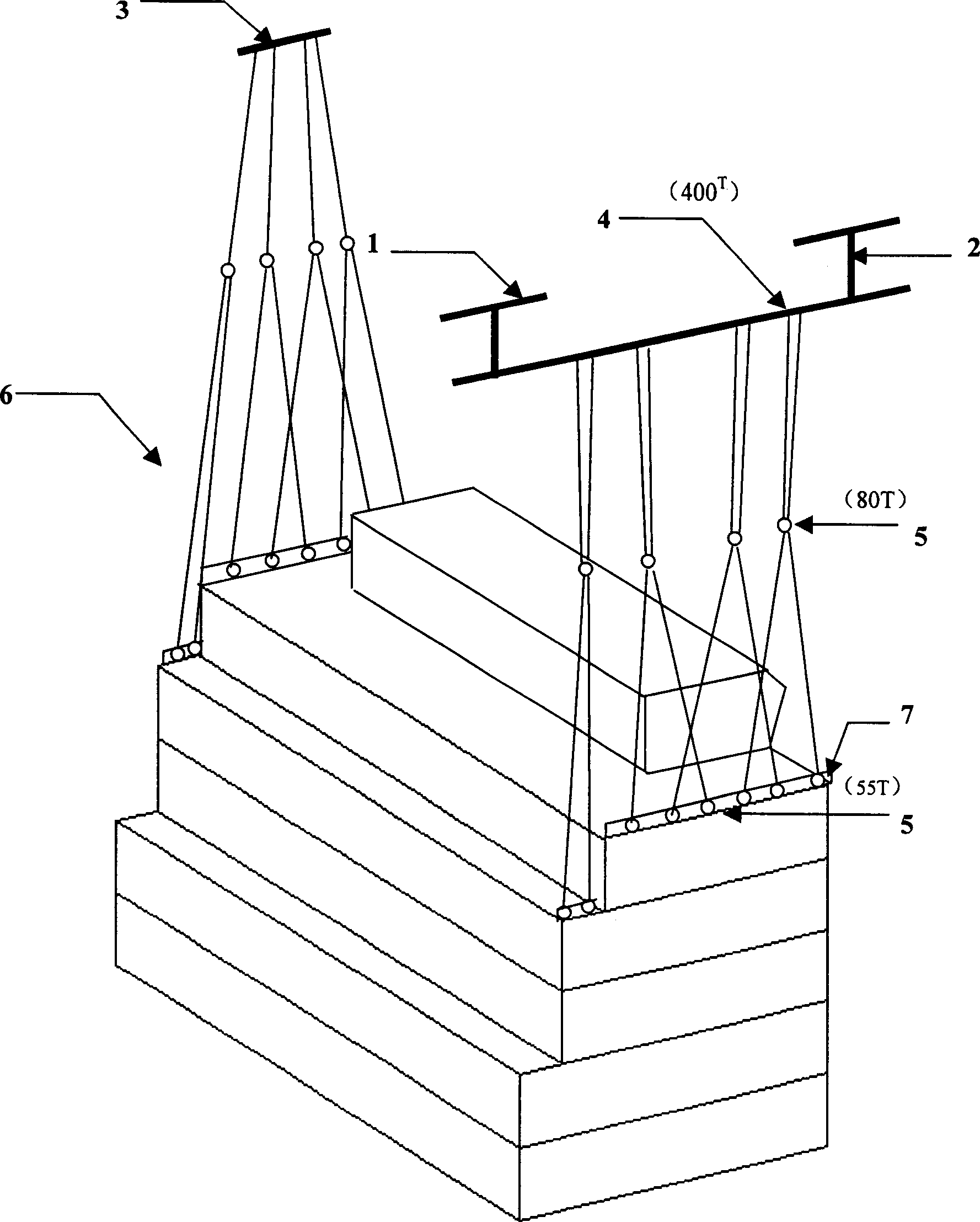

Drum frame supporting power built-in integrated jacking steel platform formwork system and construction method

ActiveCN102661039AEasy maintenanceAvoid the risk of falling objectsForms/shuttering/falseworksBuilding material handlingSteel columnsShear wall

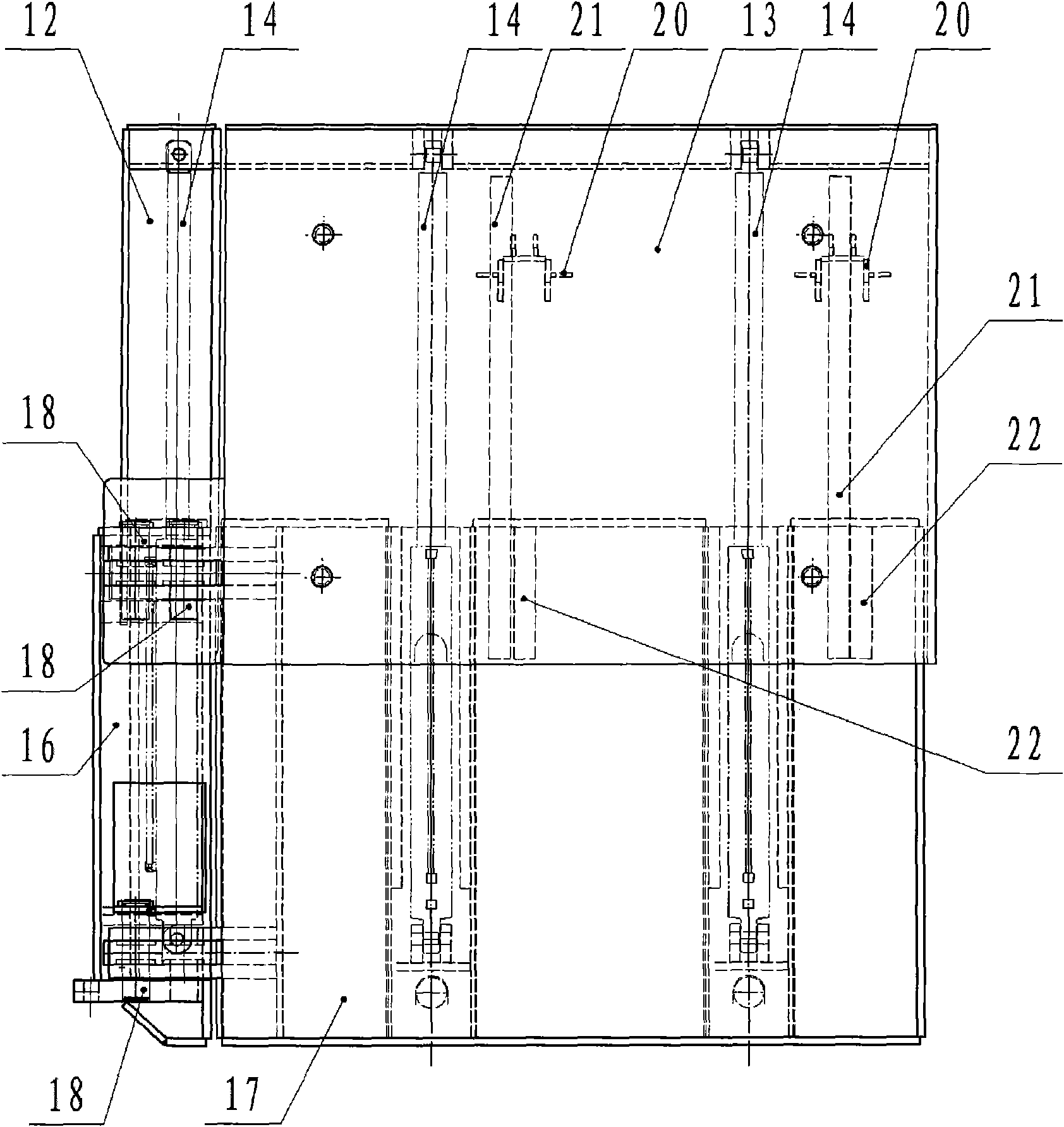

The invention discloses a drum frame supporting power built-in integrated jacking steel platform formwork system, comprising a steel platform, a support system, a suspended scaffold, a template system and a hydraulic jacking power system; the support system comprises a drum frame support and an internal framework support; the drum frame support is located under the steel platform, and comprises a steel platform support, an oil cylinder counter-force beam, a guide roller, a support steel column and a drum frame support beam; the internal framework support is arranged inside the drum frame support and located between the drum frame support beam and the oil cylinder counter-force beam; the hydraulic jacking power system comprises a hydraulic jacking oil cylinder and a power control system thereof; the hydraulic jacking oil cylinder is inverted between the oil cylinder counter-force beam and the internal framework support; telescopic brackets are arranged at the end portions of the internal framework support and the drum frame support beam, respectively; and the telescopic brackets are supported in a preformed hole in a shear wall. The drum frame supporting power built-in integrated jacking steel platform formwork system is capable of realizing the construction operation of a complex core drum, shortening the construction period and ensuring high altitude construction safety, and also capable of improving the green construction level.

Owner:SHANGHAI CONSTRUCTION GROUP +1

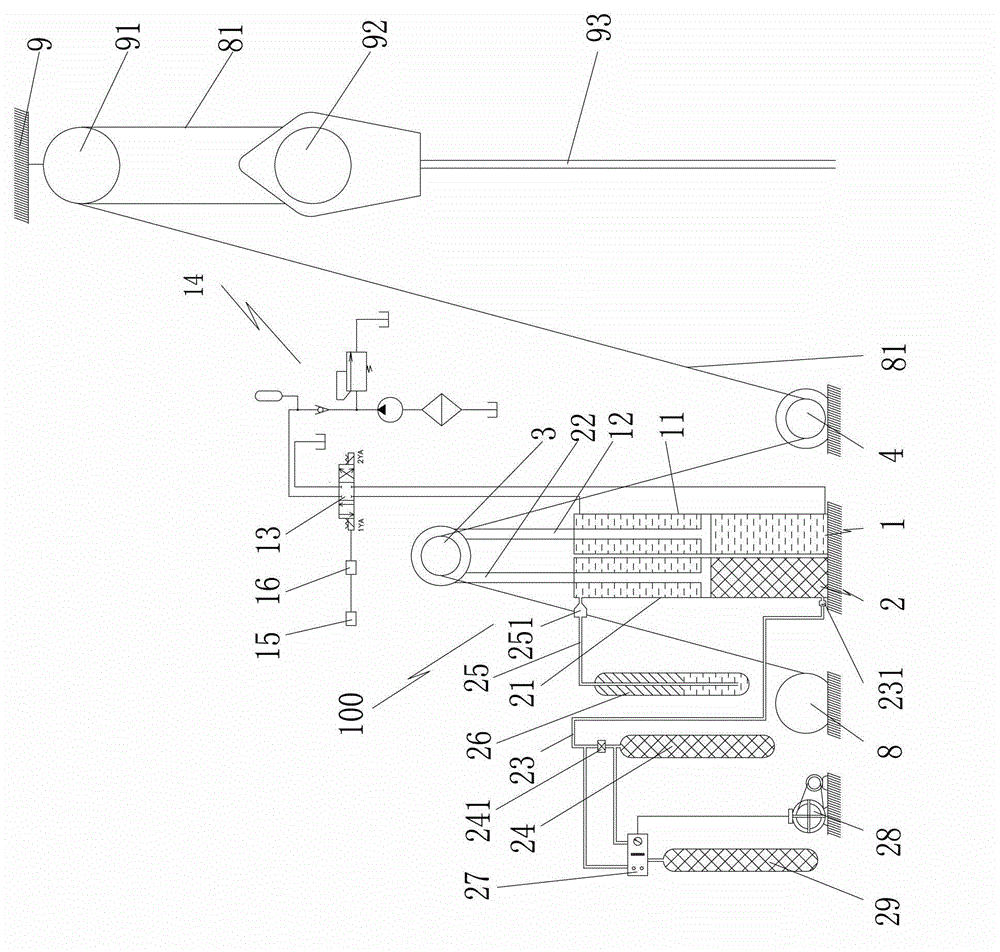

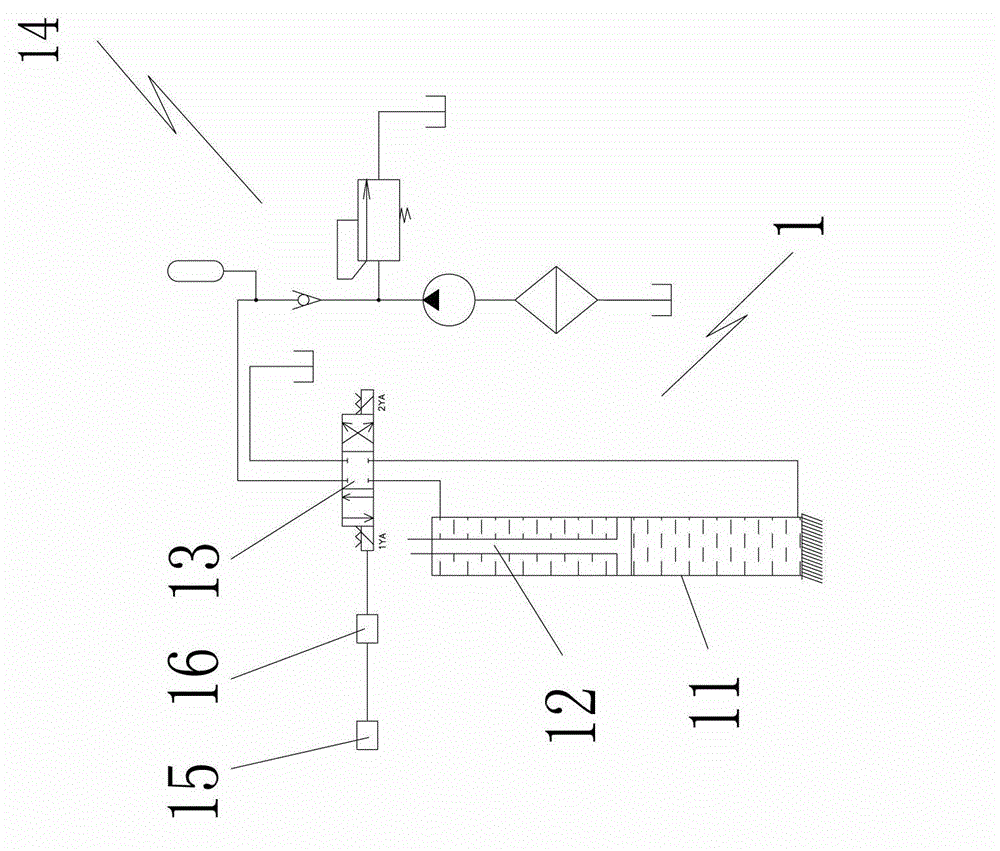

Winch heave compensation device for ocean floating drilling platform

InactiveCN102943636AReduce incidenceImprove safety and reliabilityDrilling rodsDrilling casingsCompensation effectEngineering

The invention relates to a winch heave compensation device for an ocean floating drilling platform. The device comprises an active compensator and a passive compensator which are arranged on one side of a winch in parallel. The active compensator comprises a first single-rod piston cylinder with a piston rod stretching upwards and a force transducer, wherein two chambers of the first single-rod piston cylinder are connected to a hydraulic system through a three-position four-way magnetic exchange valve, and the force transducer is used for detecting force on a steel wire rope and electrically connected with a force feedback controller which controls exchange actions of the three-position four-way magnetic exchange valve. The passive compensator comprises a second single-rod piston cylinder with a piston rod stretching upwards. Tops of the piston rods of the first piston cylinder and the second piston cylinder are connected onto a movable pulley, a fixed pulley is further arranged on the drilling platform, and the steel wire rope on the winch is connected with a crown block and a traveling block after bypassing the movable pulley and the fixed pulley sequentially. According to the device, the compensation effect that active compensation and passive compensation are mutually synchronous and promoted can be achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

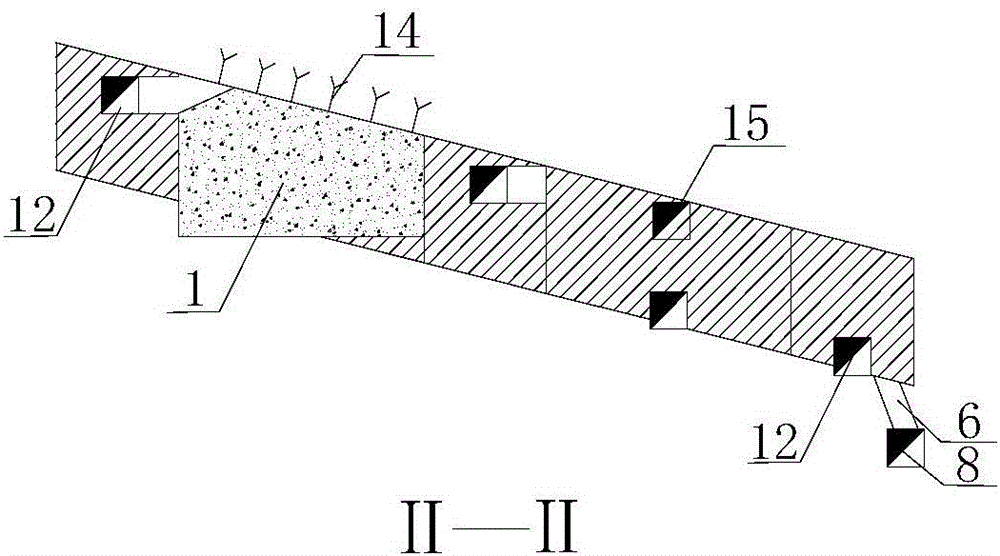

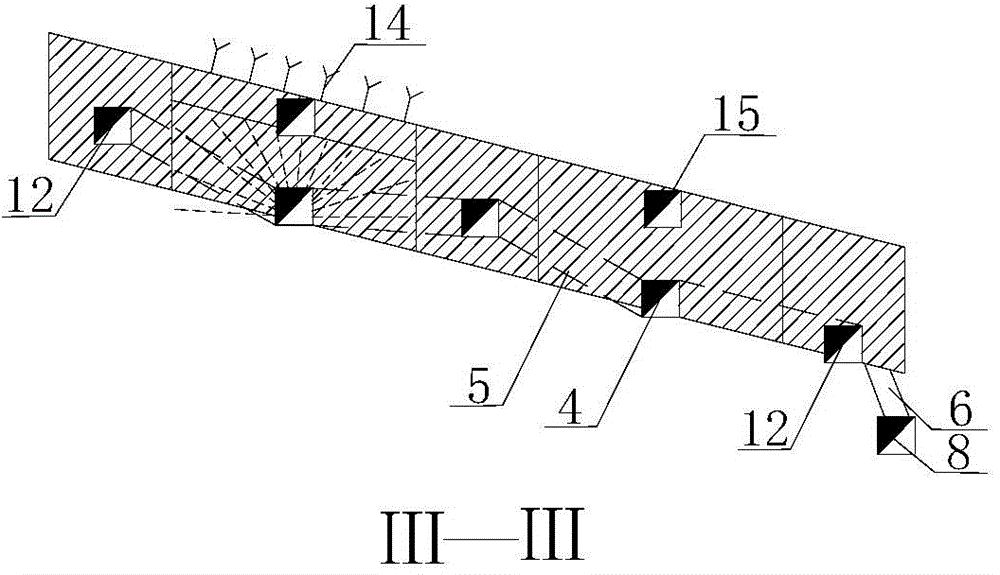

Central outside-vein house pillar type combined crosscut two-end inside-vein continuous segment filling mining method

InactiveCN102953733AHigh degree of mechanizationReduce labor intensityUnderground miningSurface miningVeinEngineering

The invention discloses a central outside-vein house pillar type combined crosscut two-end inside-vein continuous segment filling mining method for medium-thickness inclined crushed phosphorus ores. The method comprises the following steps: dividing an ore into middle segments, dividing each of the middle segments into panels, dividing each of the panels into segments, dividing the center of each of the segments into ore houses and ore pillars, and dividing two ends of each of the segment along an inside-vein drilling ore-removal level non-pillar into recovery units; adopting a hanging side outside-vein trackless mining system which is formed by a panel ramp, a concentrated ore-removal ore-pass, segment levels at the central outside-vein and shifting to inside-vein at two sides, and an connection lane commonly used by the ore houses and the ore pillars; recovering the ore houses in the middle segments, filling close to back, and recovering the ore pillars; and carrying out parallel operations of technologies comprising drilling, exploding, supporting, ore removal, filling and the like of a plurality of the ore houses to realize continuous mining. The method disclosed in the invention has the substantial characteristics of improvement of the recovery safety and the panel productivity, reduction of the resource dilution rate and the mining-cutting ratio, increase of enterprise benefits and the like.

Owner:彭康

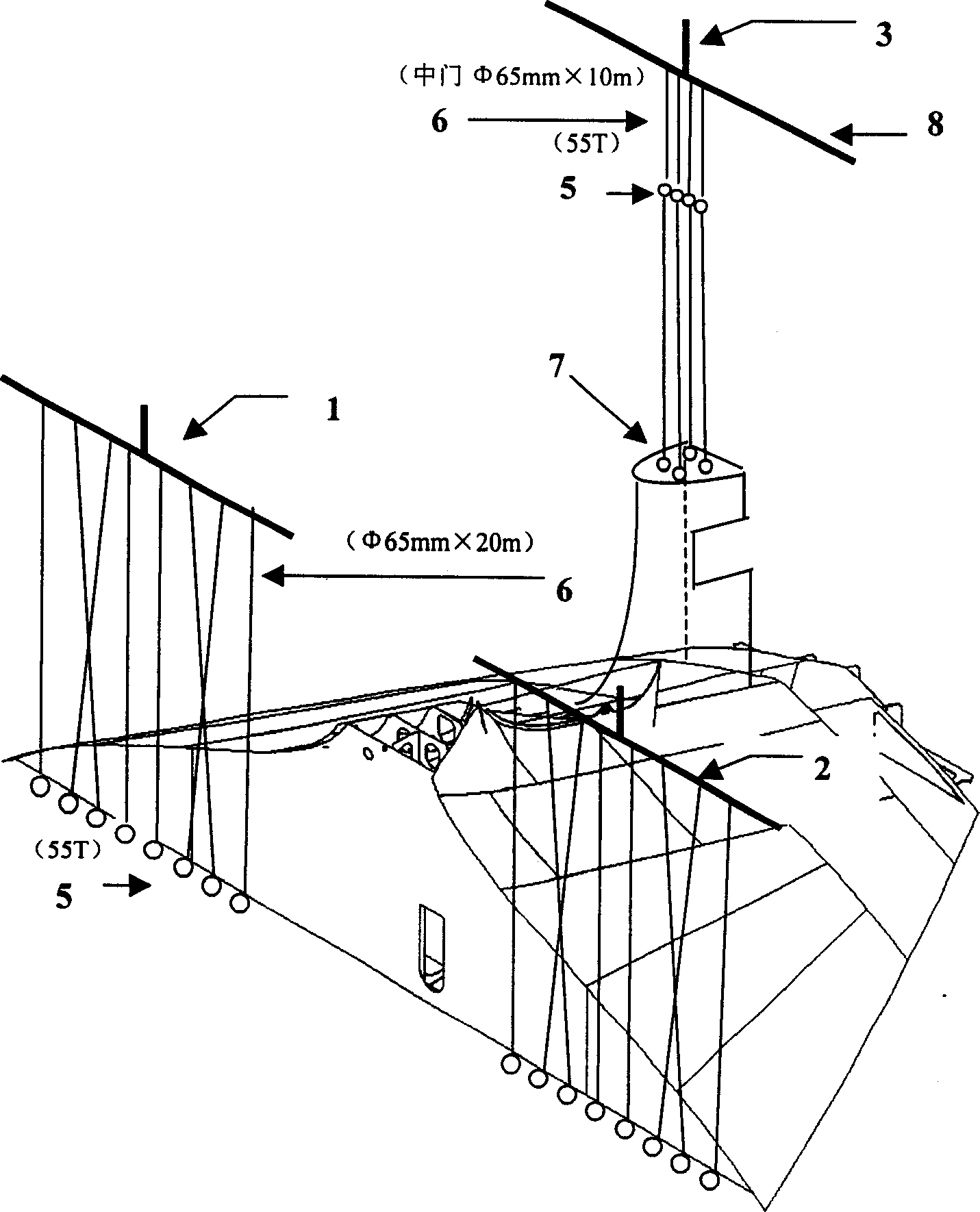

Sectional hoisting method

The invention relates to one sectional hoisting technique, which may be applied to series disperses freighter with 17.5 or 177000 tons, this hoisting technique includes: The district embarkation hoisting technique and the body section embarks the hoisting technique, respectively partitions the hoisting technique carries out the following step: a) determines the partition the actual tonnage; b) hanging establishment and hanging rigging equipment, which includes the selection steel wire's diameter, length, quantity, docking way and unloading gram, the load bearing tonnage and the material with which the suspenders corresponds; c) selects and arranges three gantry cranes hook; d) partitions stands up from failure the total group and the embarkation; e) controls partitions the time which the total group and the embarkation need. This invention partition hoisting technique, the host hung row of small, the hoisting working procedure are few, which causes the hull hoisting process and the tool utilization and the manpower arrangement which obtains the optimization, partitioned one time of arrive rate is high, the error was quite small, 100% guaranteed the hoisting success ratio.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

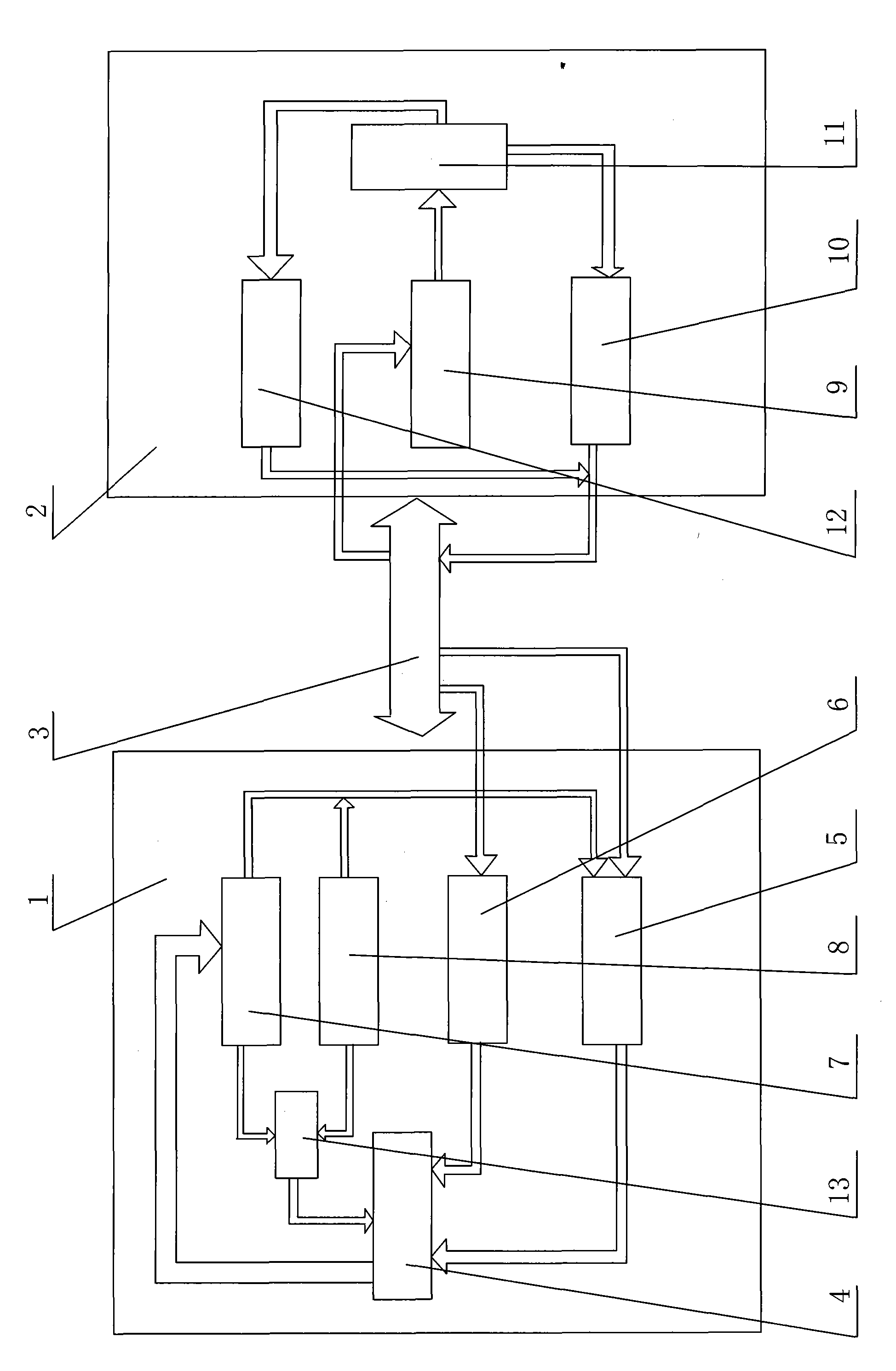

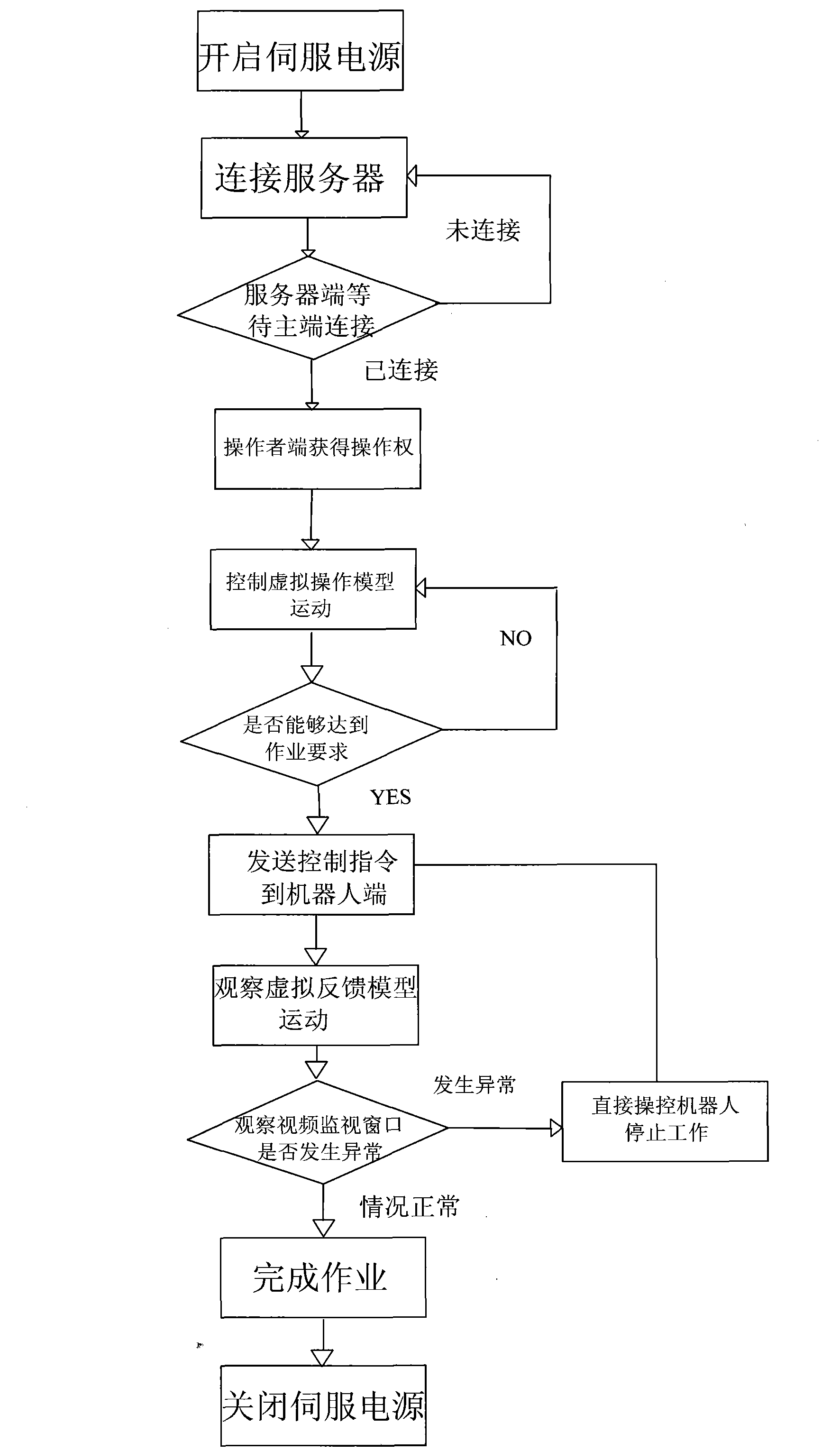

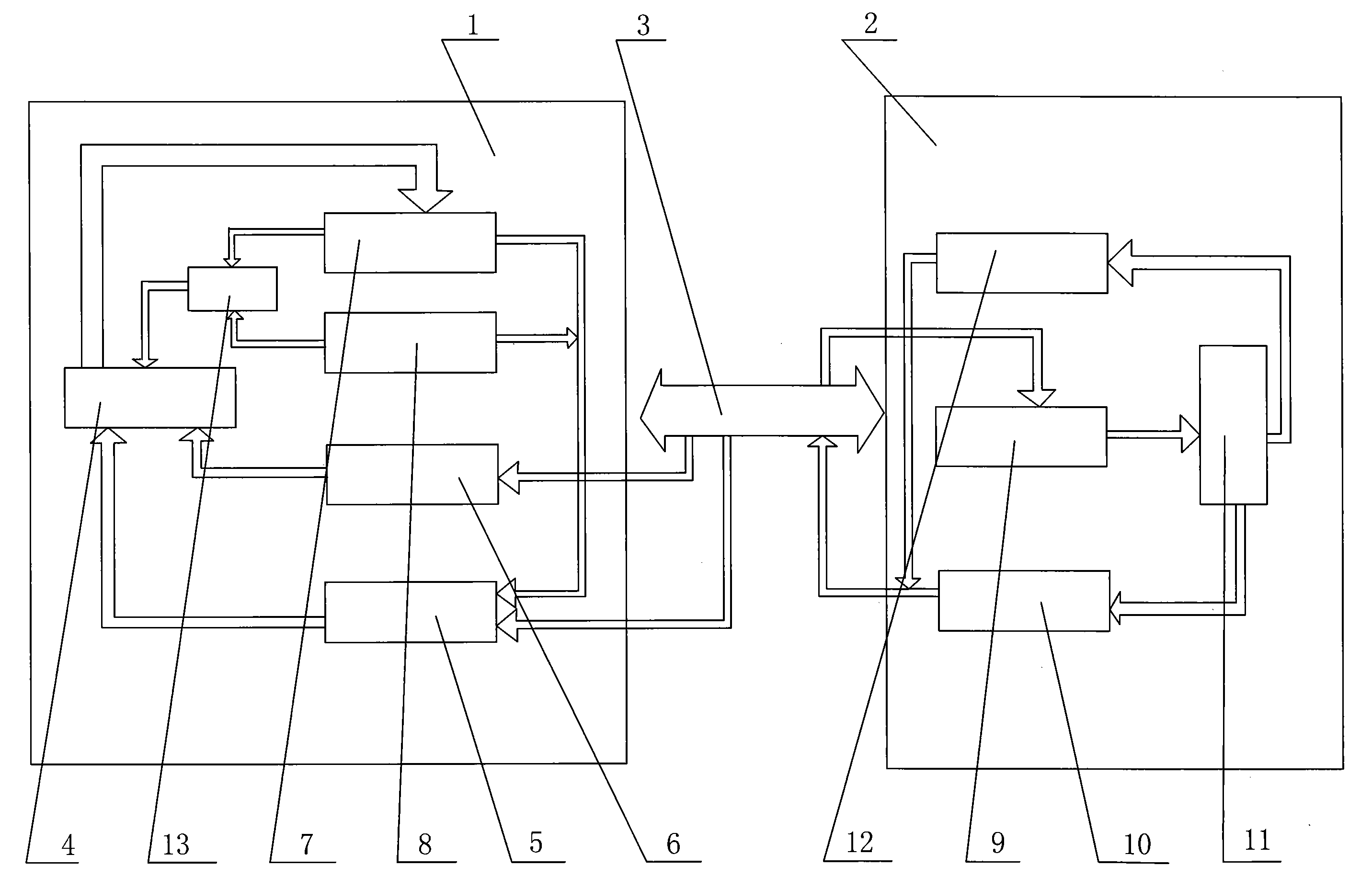

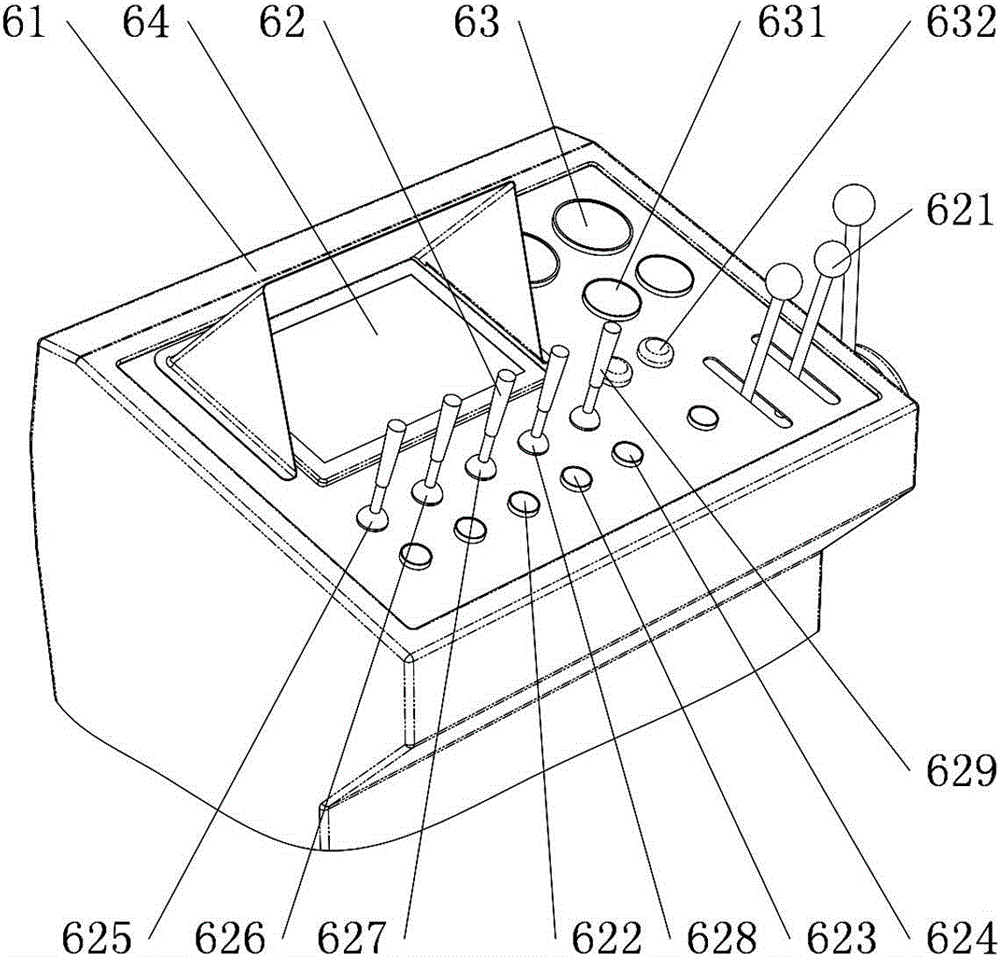

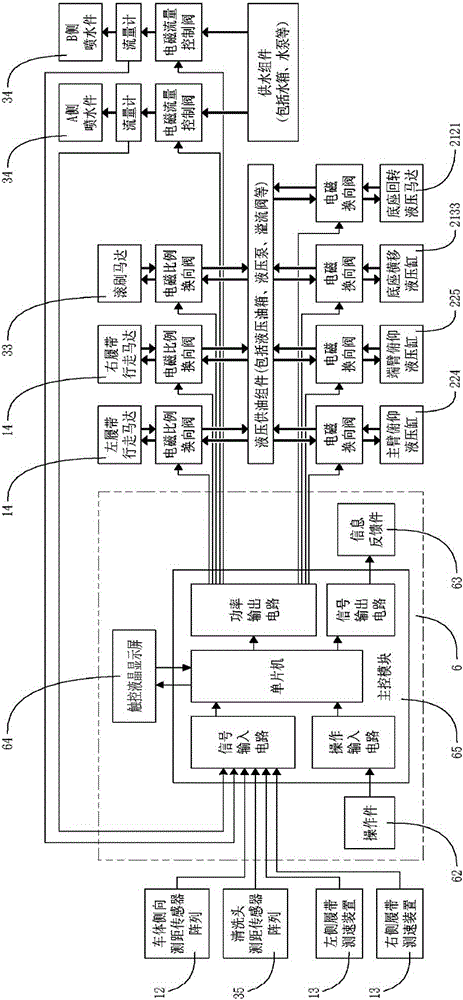

Novel remote operation far-end robot control platform and method

InactiveCN102120325ASports status observationHigh precisionManipulatorVideo monitoringRemote control

The invention discloses a novel remote operation far-end robot control platform and a method. The conventional master-slave type man-machine interaction control system is usually recognized an as effective remote operation method, but the operation quality of the conventional master-slave type man-machine interaction control system is determined by operators, so long time is needed to train the operators, and the operators, who work in large labor intensity, go fatigue easily and cannot complete high-precision operation. In the invention, the control platform comprises a client (1) and a server (2), wherein the client transmits data to the server (3) through a network and comprises man-machine interaction equipment (4) which is connected with a video display(5), a data comparator (6), anda virtual operation model (7) and a virtual feedback model (8), which are connected together, at the same time; and the server comprises a far-end robot control unit (9) which is connected with a far-end robot (10) that is connected with a data acquisition unit (11) and video monitoring equipment (12). The control platform and the method are used for remote control and operation of the robot.

Owner:HARBIN UNIV OF SCI & TECH

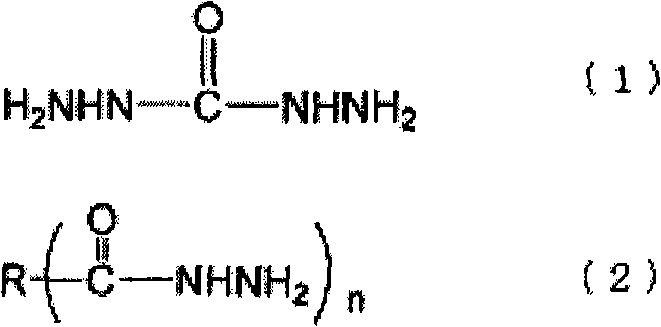

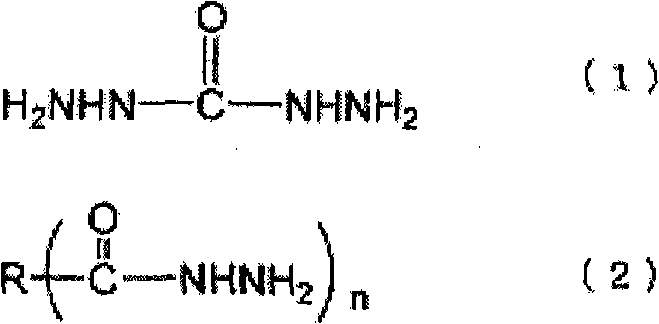

Method for producing metal particle dispersion, conductive ink using metal particle dispersion produced by such method, and conductive coating film

InactiveCN101287566AEffective conductivityImprove performanceConductive layers on insulating-supportsInksDispersion stabilityLiquid medium

Disclosed is a method for producing a metal particle dispersion wherein a metal compound is reduced by using carbodihydrazide represented by the formula (1) below or a polybasic acid polyhydrazide represented by the formula (2) below (wherein R represents an n-valent polybasic acid residue) in a liquid medium. By reducing the metal compound in the presence of a compound having a function preventing discoloration of the metal, there can be obtained a metal particle dispersion having excellent discoloration preventing properties. Metal particles produced by such methods have a uniform particle diameter and are excellent in dispersion stability. By using a conductive resin composition or conductive ink containing a metal particle dispersion obtained by such production methods, there can be formed a conductive coating film, such as a conductive circuit or an electromagnetic shielding layer, having good characteristics.

Owner:TOYO INK SC HOLD CO LTD

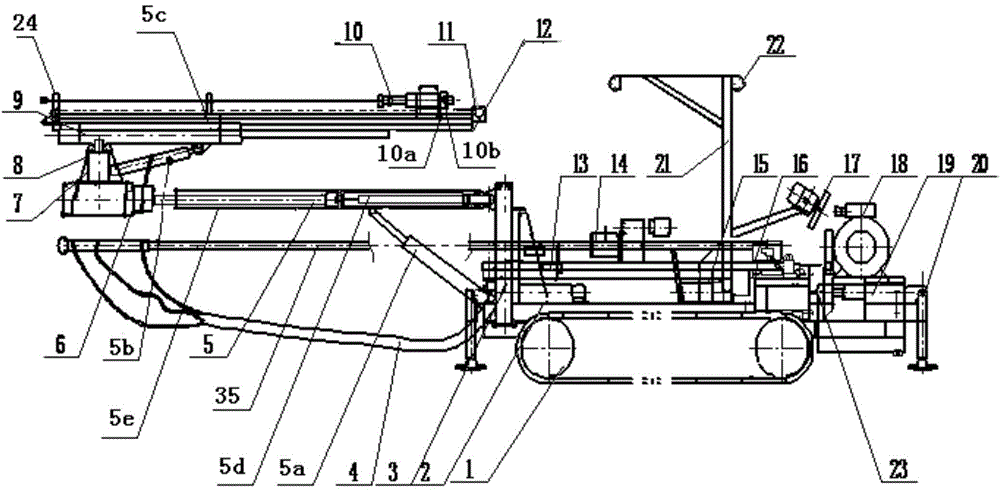

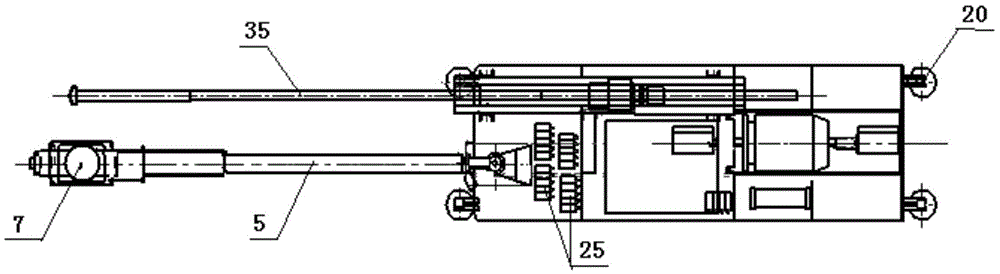

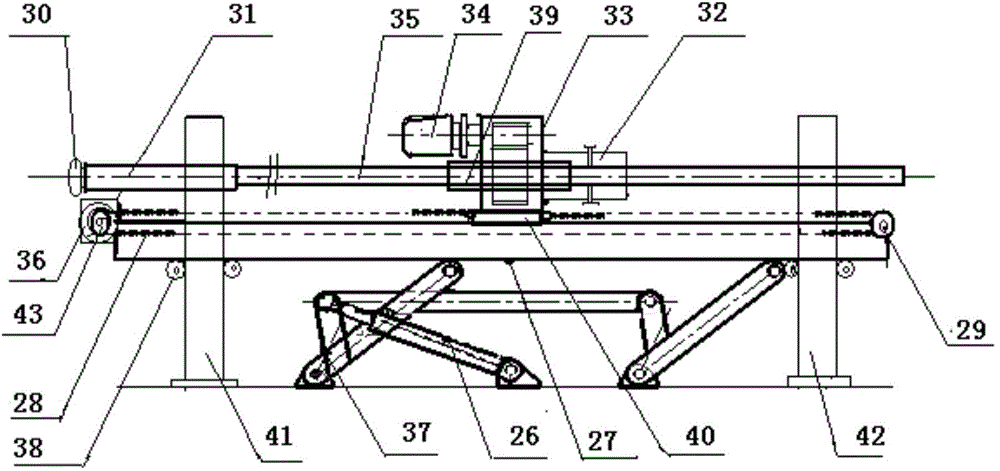

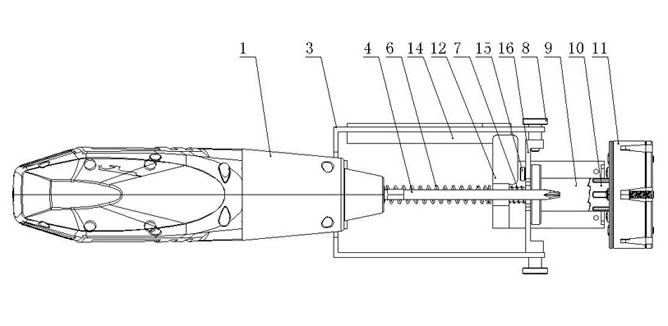

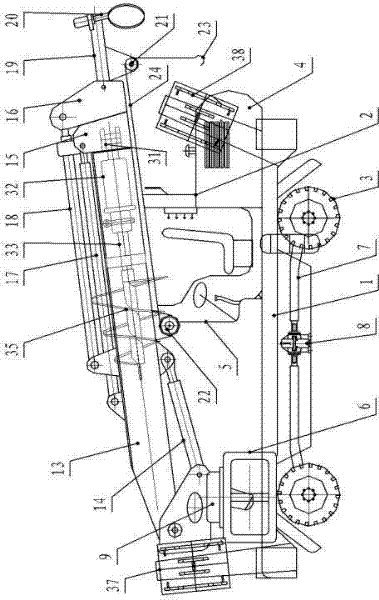

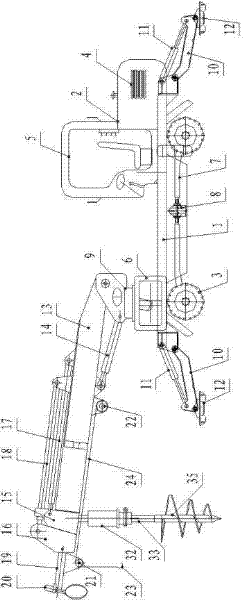

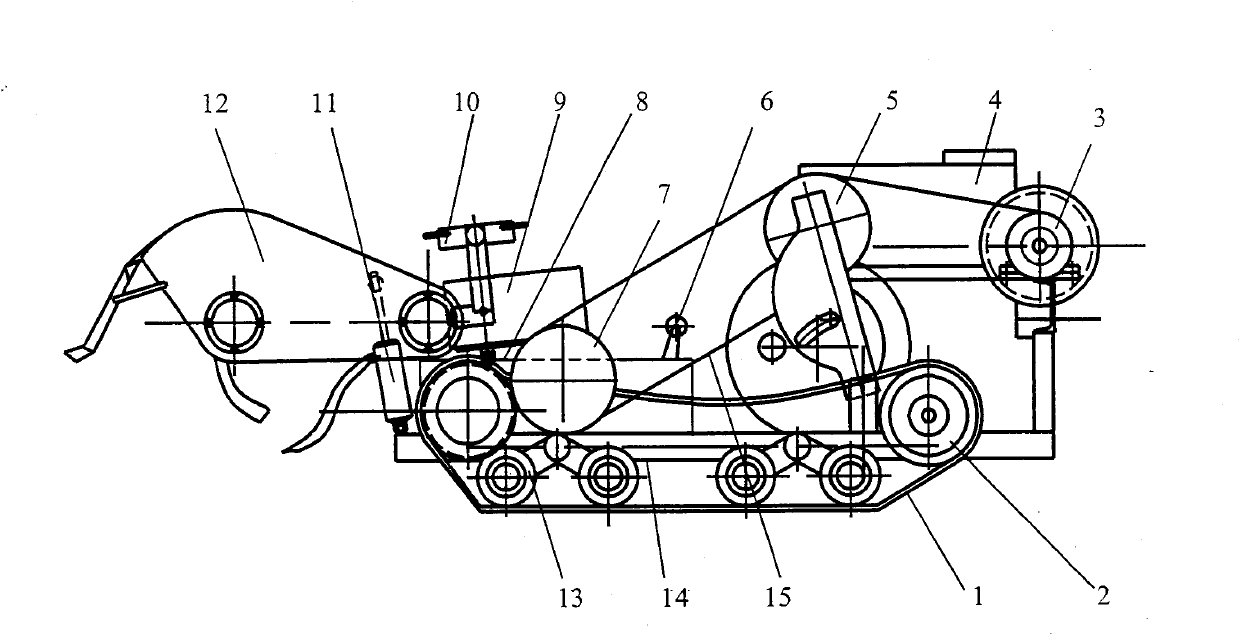

Whole-section quick-drilling drill carriage for parallel cut blasting of large empty holes in roadway

ActiveCN104612586ACompact chassisCompact structureDerricks/mastsDrilling drivesHydraulic motorReducer

The invention discloses a whole-section quick-drilling drill carriage specially used for parallel cut blasting of large empty holes in a roadway. The drill carriage is composed of a walking mechanism, a carriage frame, a hydraulic system, an electrical system and two drilling devices, wherein the first drilling device is used for drilling common blasting holes, and the second drilling device is used for drilling cut holes with the diameter of 100 mm or more. In the operating process of the drill carriage, a hydraulic motor drives a main chain wheel of a crawler-type walking chassis to rotate through a speed reducer; after a carriage body is stabilized, the first drilling device and the second drilling device are manipulated to select hole locations respectively; after the first drilling device and the second drilling device are located, the common blasting holes and the empty holes with the diameter of 100 mm or more can be drilled in rock simultaneously. The drill carriage is suitable for the roadway with the minimum section of 8 square meters and the maximum section of 23 square meters; by the adoption of a building block structural design, the drill carriage is convenient and fast to disassemble and assemble and convenient to transport; as a result, the drill carriage can be used when the length of the roadway under tunneling construction is seven meters or more, and accelerates tunneling mechanization and quick and efficient tunneling modernization.

Owner:SHANDONG UNIV OF SCI & TECH +1

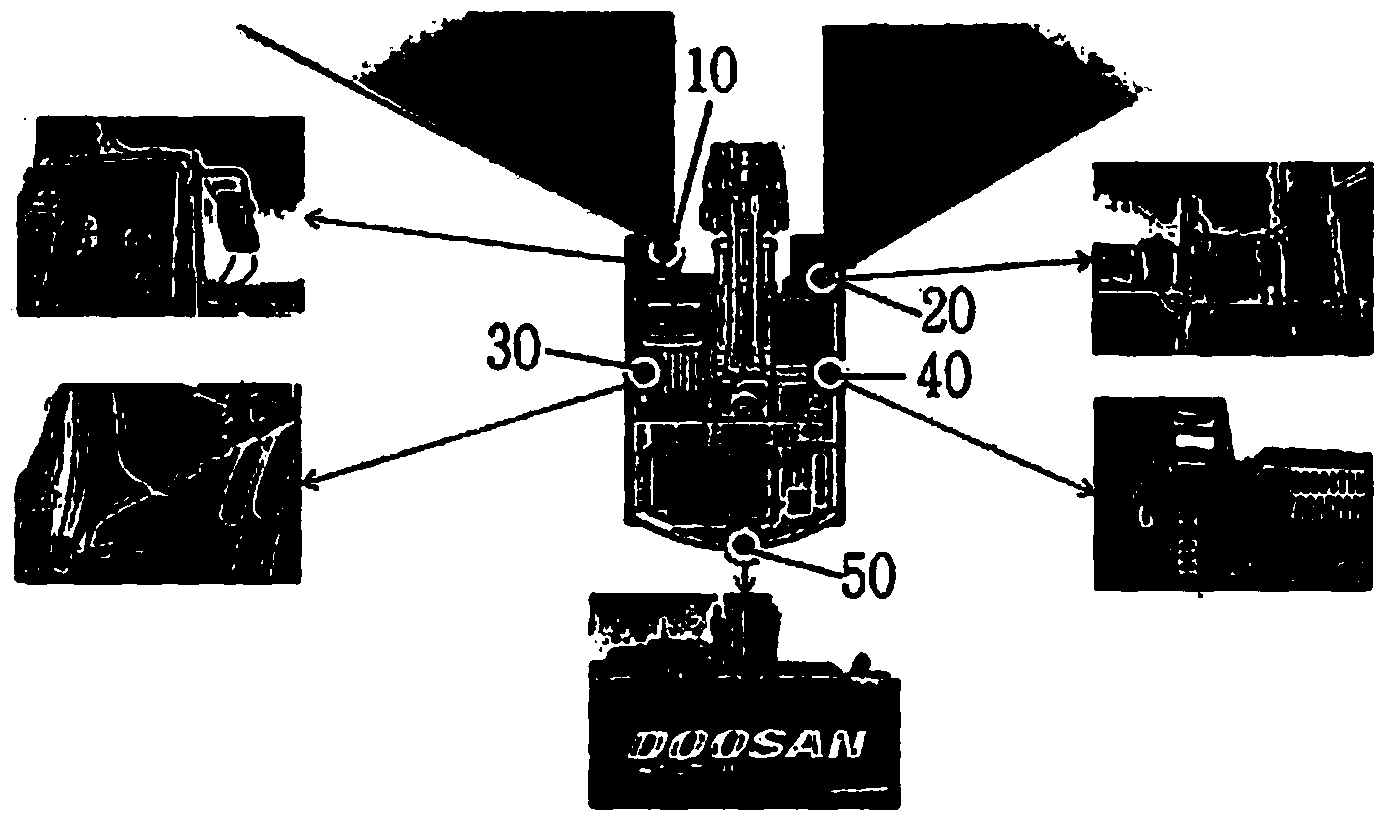

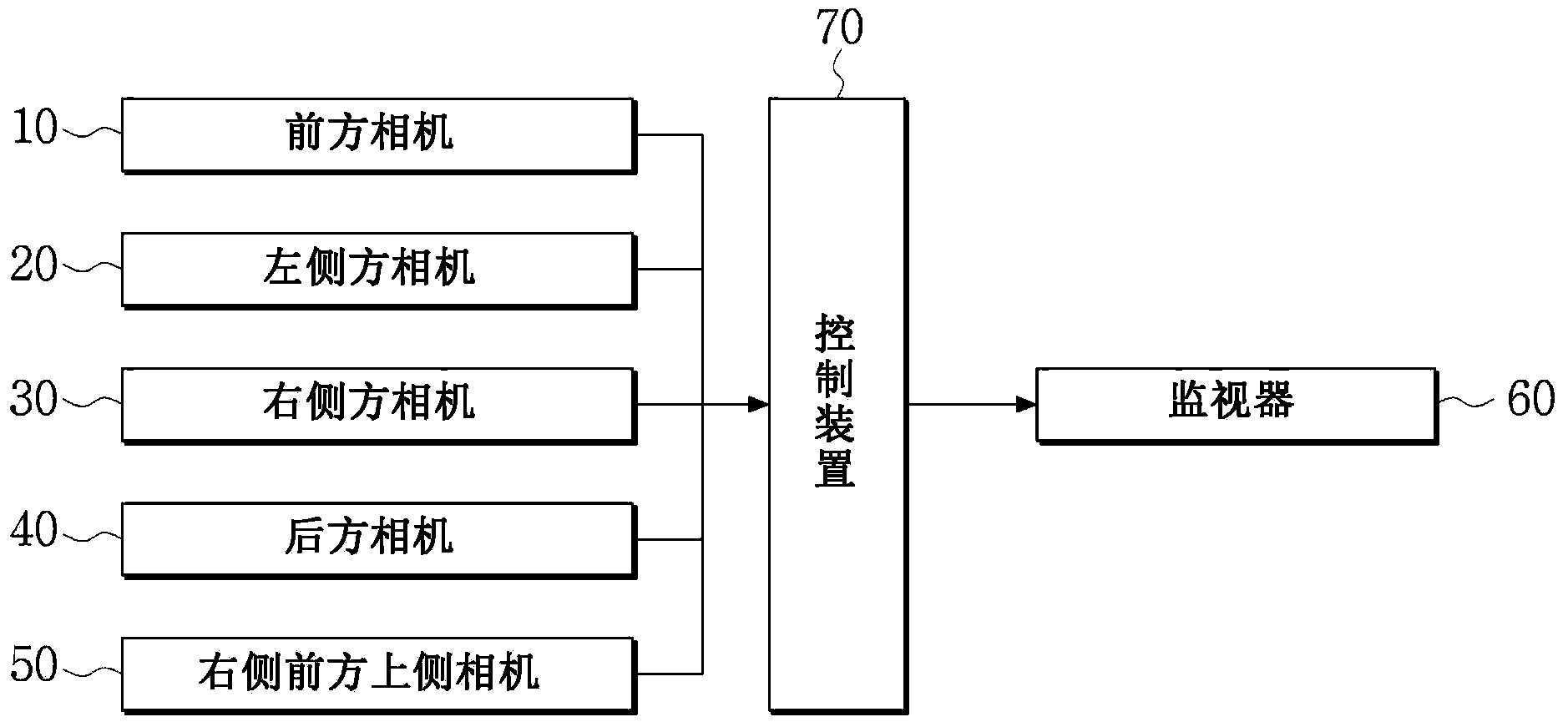

Operational stability enhancing device for construction machinery

ActiveCN103649426AJob safetyAvoid approachingGeometric image transformationSoil-shifting machines/dredgersArchitectural engineeringOperational stability

Provided is an operational stability enhancing device for construction machinery. The operational stability enhancing device for construction machinery according to the present invention comprises: a plurality of cameras that capture images of the vicinity of a construction machine; a plurality of sensors that detect an obstacle located in the vicinity of the construction machine; a monitor that displays the images of the vicinity of the construction machine captured by the plurality of cameras; an electronic hydraulic control valve that controls the output flow rate of the driving unit of the hydraulic system so as to correspond to the operation signal from the user operation unit of the construction machine; and a control unit that displays the captured image of a detected object on the monitor through screen conversion or changes the image for the user to easily recognize the image when the detected object approaches the construction machine in the case where the detected object is detected by the sensor as being in the vicinity of the moving path and where the detected object is a target to avoid.

Owner:DOOSAN INFRACORE CO LTD

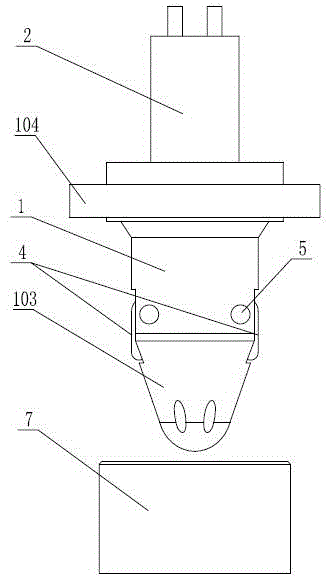

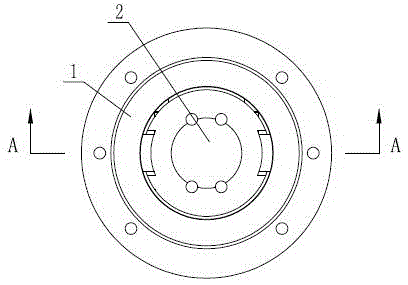

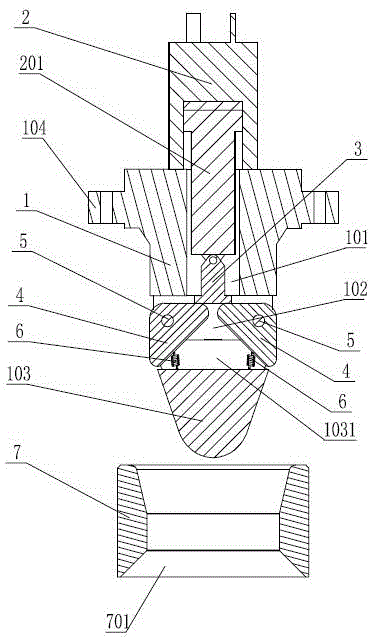

Underwater automatic docking mechanism for ROV

ActiveCN105539782AGuaranteed disengagementSimple structureUnderwater equipmentEngineeringMechanical engineering

The invention relates to an underwater automatic docking mechanism for an ROV(remotely operated vehicle). The underwater automatic docking mechanism comprises a mounting seat, wherein an axial hole and a radial through slot I which are in communication are formed in the mounting seat; an oil cylinder piston rod extends into the axial hole, and a pushing head is hinged to the piston rod; the mounting seat is fixedly connected with a conical guide head with a radial through slot II, and the two radial through slots communicate to form mounting spaces for locking blocks, and the two locking blocks are symmetrically arranged on two sides of the pushing head; the locking blocks are hinged to one side wall of the radial through slot I, the shape of the cross section of each of the locking blocks is triangular, and springs are connected between the locking blocks and the bottom of the radial through slot II; under the action of the springs, the end surfaces of the outer sides of the two locking blocks are at the vertical positions or the lower ends of the two locking blocks are close to the tilted position of the axis of the mounting seat, and the tops of the two locking blocks are in docked connection with the bottom of the pushing head; a docking block is provided with an axial through hole, and an outwards-expanding tapered hole is formed in the lower part of the axial through hole; during docking, the mounting seat extends into the axial through hole, and the locking blocks are driven by the oil cylinder to rotate, until the end surfaces of the outer sides of the locking blocks are in docked connection with the wall surface of the tapered hole. According to the underwater automatic docking mechanism, the automatic docking of the ROV and underwater equipment can be realized.

Owner:中国船舶重工集团公司第七〇二研究所

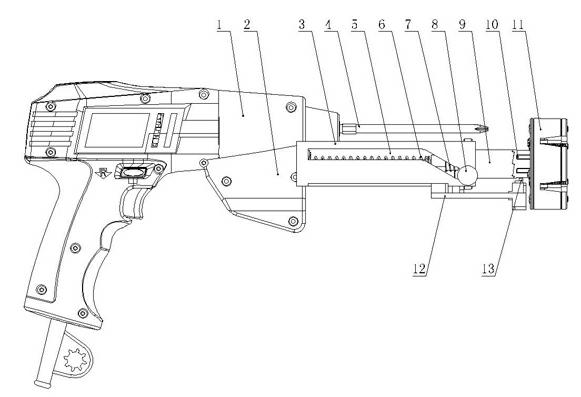

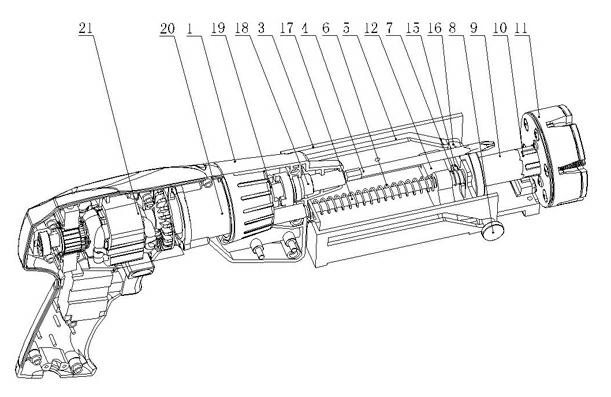

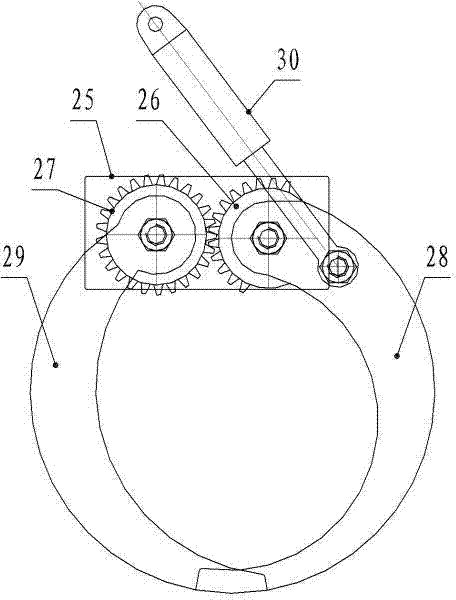

Automatic feed electric screwdriver

ActiveCN102328290AJob safetyLess prone to personal injury accidentsSpannersWrenchesMechanical engineeringEngineering

The invention creatively discloses an automatic feed electric screwdriver which comprises a machine body (1), a screwdriver (4) and a fixed seat (2), wherein a sliding groove frame (3) is fixedly arranged on the fixed seat (2), a reset guide rod (17) which is parallel to the screwdriver (4) and can perform linear movement is arranged on the sliding groove frame (3), a reset spring (6), a screw disk positioning mechanism, a one-way ratchet component and a screw disk component (11) are sequentially arranged on the reset guide rod (17), the one-way ratchet component comprises a connecting seat (16), an upper ratchet (9) and a lower ratchet (10) which are sequentially sheathed on a limit sleeve (22), the limit sleeve (22) is sheathed on the reset guide rod (17), a connecting seat (16) is arranged on sliding grooves (5) on the two sides of the sliding groove frame (3), the connecting seat (16) is connected with the upper ratchet (9), the upper and lower ratchets (9, 10) are mutually meshed, and the screw disk component (11) is fixed on the lower ratchet (10). After the structure is adopted, the automatic feed electric screwdriver has the advantages of being simple and reasonable in structure, convenient to operate and use, fast in mounting speed, high in working efficiency and capable of operating with single hand and the like.

Owner:ZHENGYANG IND & INVESTMENT CO LTD

Deep hole underwater installation and locating method of steel pipe column in weak watery stratum

ActiveCN101824919AReduce construction costsJob safetyArtificial islandsUnderwater structuresUnderwaterEarth surface

The invention discloses a deep hole underwater installation and locating method of a steel pipe column in a weak watery stratum, concretely comprising the following construction steps of firstly, pouring concrete with a design height in the steel pipe column, and installing and locating a screw jack at the bottom of the steel pipe column; secondly, measuring and paying off on the construction ground surface, and drilling by a drill; thirdly, installing a drilling pile reinforcement cage in a hole; fourthly, installing a location platform on the construction ground surface; fifthly, hoisting the steel pipe column and putting the steel pipe column in a drilling pile hole; sixthly, locating the top part of the steel pipe column by the ground surface location platform; seventhly, locating and measuring the verticality of the steel pipe column by a laser plummet; eighthly, locating the bottom of the steel pipe column by the screw jack; ninthly, pouring drilling pile concrete underwater to the design burying height of the steel pipe column; and tenthly, pouring steel pipe column internal concrete to the top of a steel tube after the drilling pile internal concrete achieves the design strength of 70 percent. The method has the advantages of simple operation, high construction efficiency, low construction cost, high and controllable installation accuracy and little safety risk.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

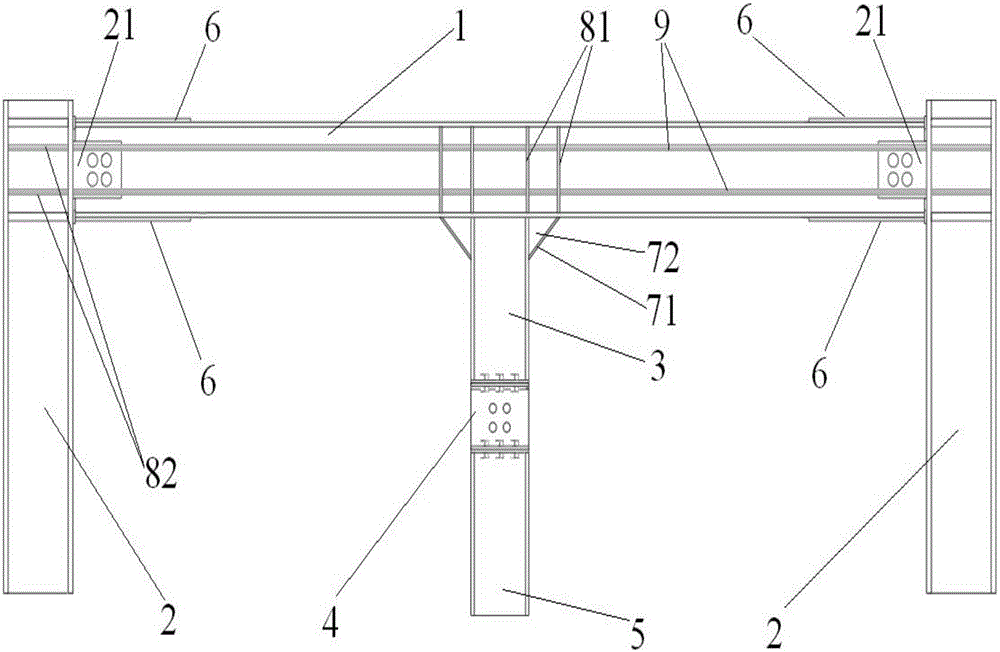

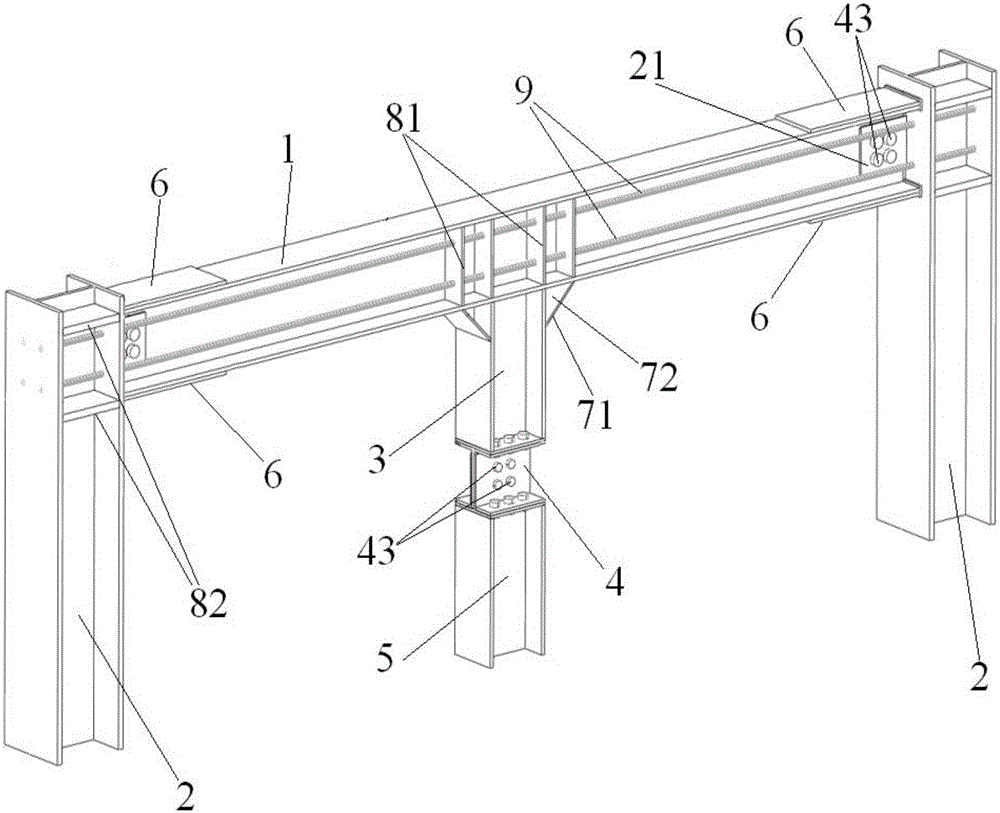

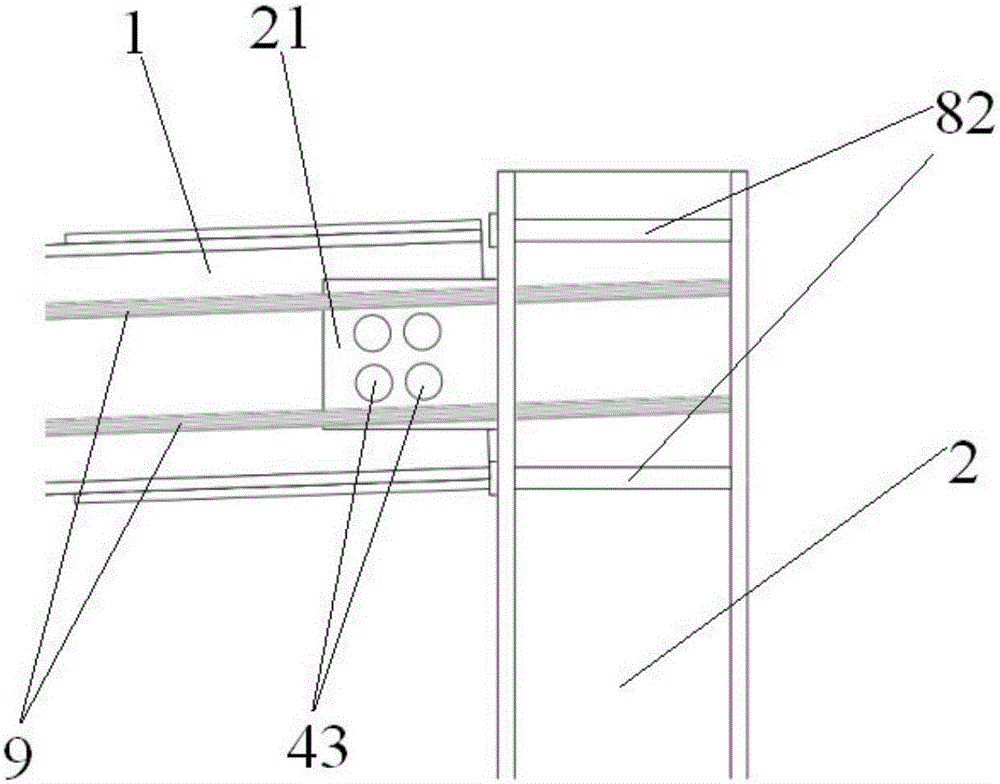

Prestressed assembled middle column steel frame recoverable in function

The invention relates to the technical field of steel structures in building industry and discloses a prestressed assembled middle column steel frame recoverable in function. The prestressed assembled middle column steel frame comprises a frame beam, two frame columns, an upper middle column, a friction energy-consuming device and a lower middle column, the frame beam is arranged horizontally, the frame columns are vertically arranged at two ends of the frame beam, the frame columns are movably connected with the frame beam, the upper middle column is vertically arranged below the frame beam, the top of the upper middle column is fixedly connected with the frame beam, and the upper middle column, the friction energy-consuming device and the lower middle column are sequentially connected from top to bottom. Rigidity of the whole steel frame can be enhanced; energy dissipation of the steel frame can be improved through the friction energy-consuming device, so that overall deformation degree of the prestressed assembled middle column steel frame is lowered greatly, in other words, inter-layer displacement angle response is reduced, stability of a whole building is improved, designing requirements are met, and safety in operation can be guaranteed.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

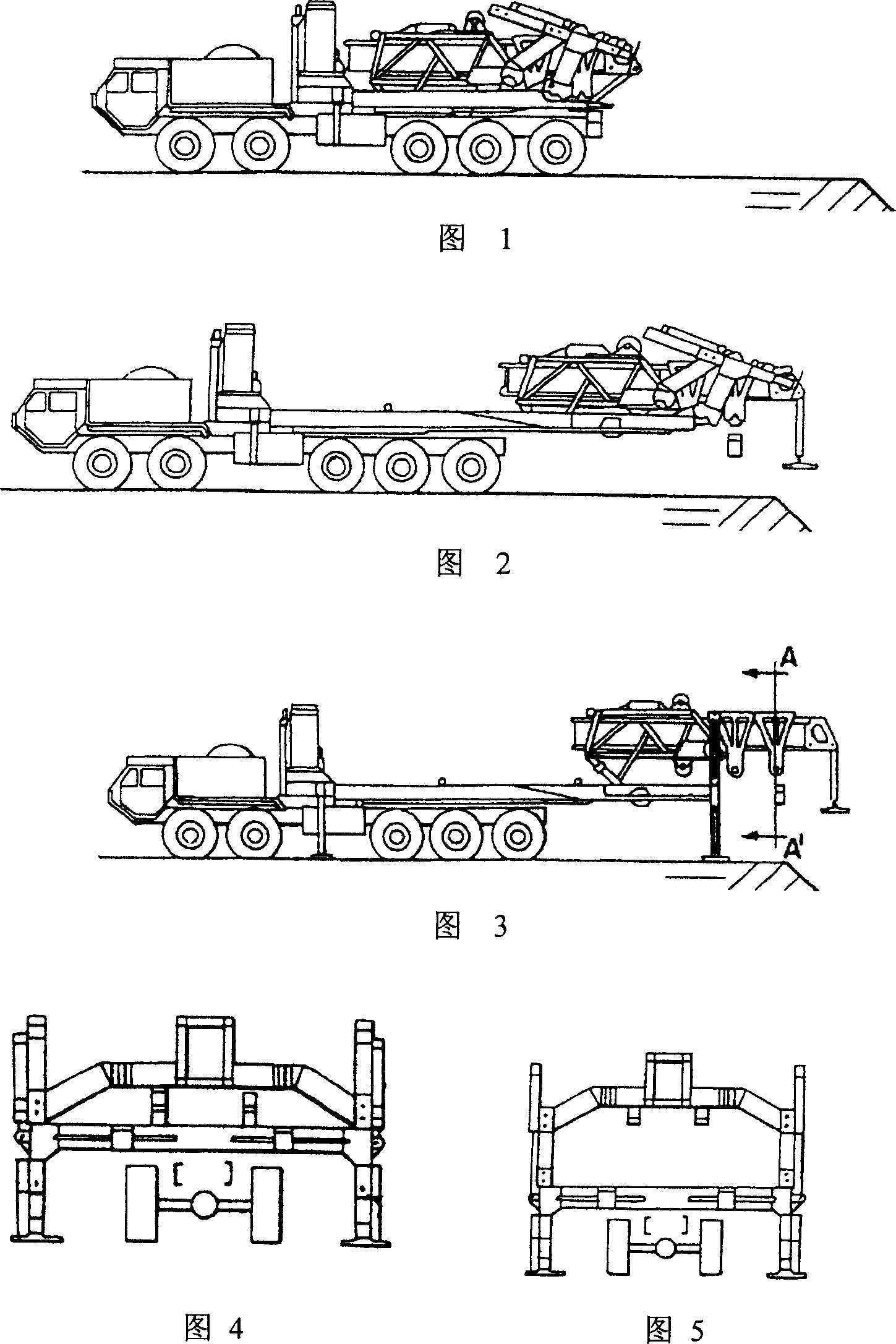

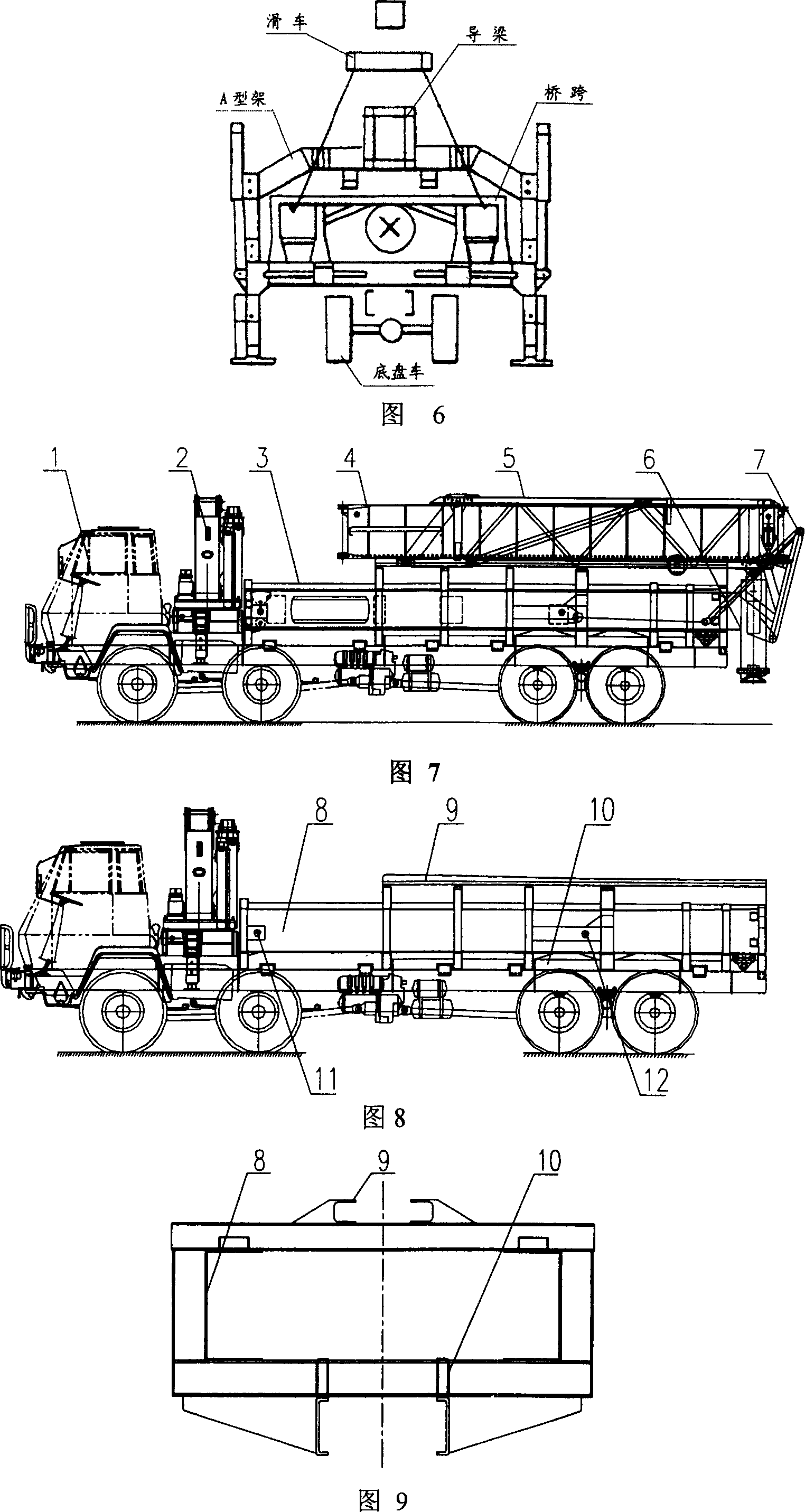

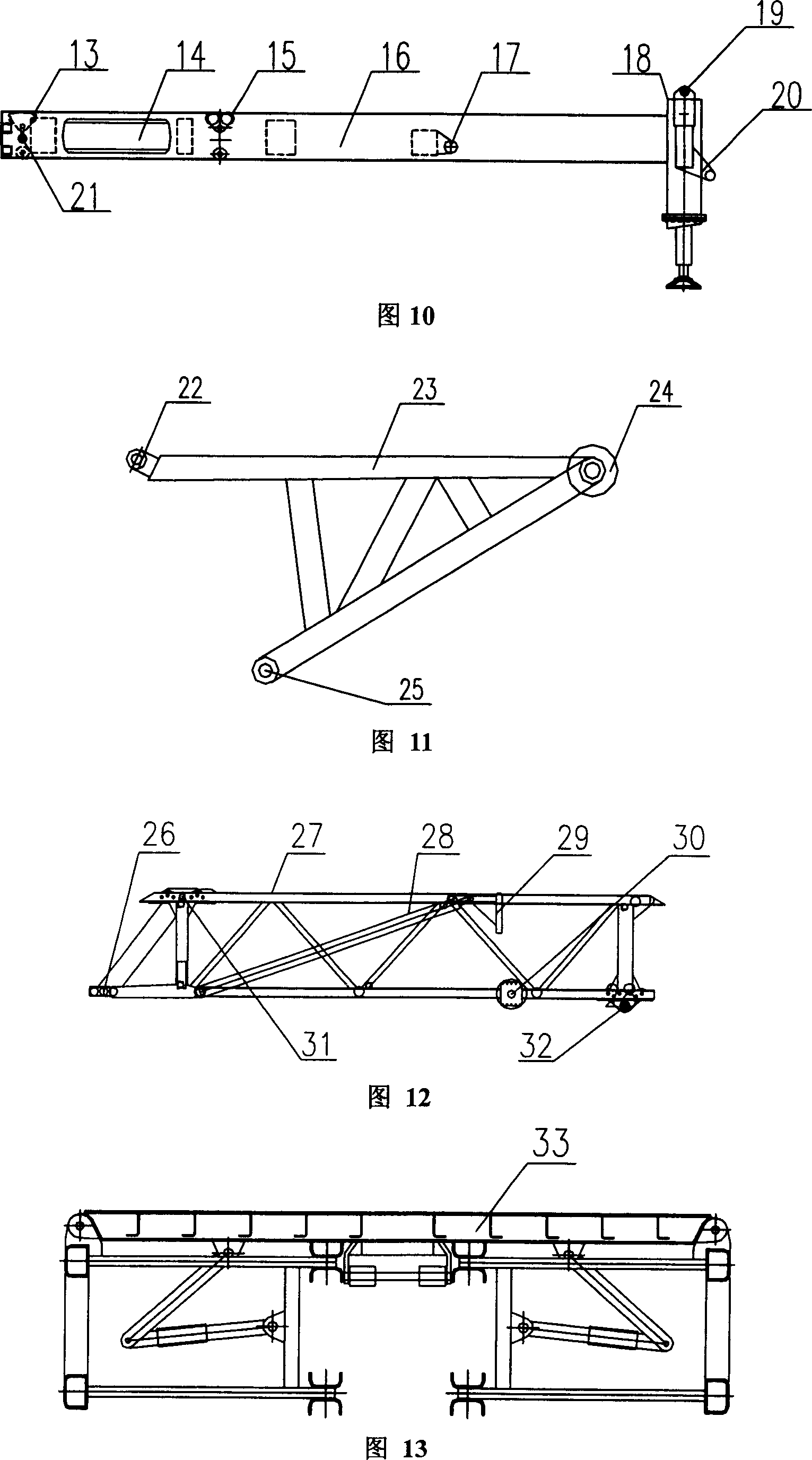

Longspan bridge erecting apparatus and erecting method thereof

InactiveCN100999895ASingle functionImprove reliabilityPortable bridgeBridge erection/assemblyArm foldingLong span

The long span bridge erecting apparatus and process belongs to the field of traffic technology, and is especially suitable for constructing military long span bridge in wartime. The long span bridge erecting apparatus consists of chassis, arm folding crane, erecting platform, leading-in girder unit, leading-in girder sheath, movable stand, chassis frame and bridge section. The long span bridge erecting apparatus has lowered erecting height, convenient transportation, composite structure and high reliability. The present invention has short construction period, low operation plane and relatively simple construction and other advantages.

Owner:邹煜 +7

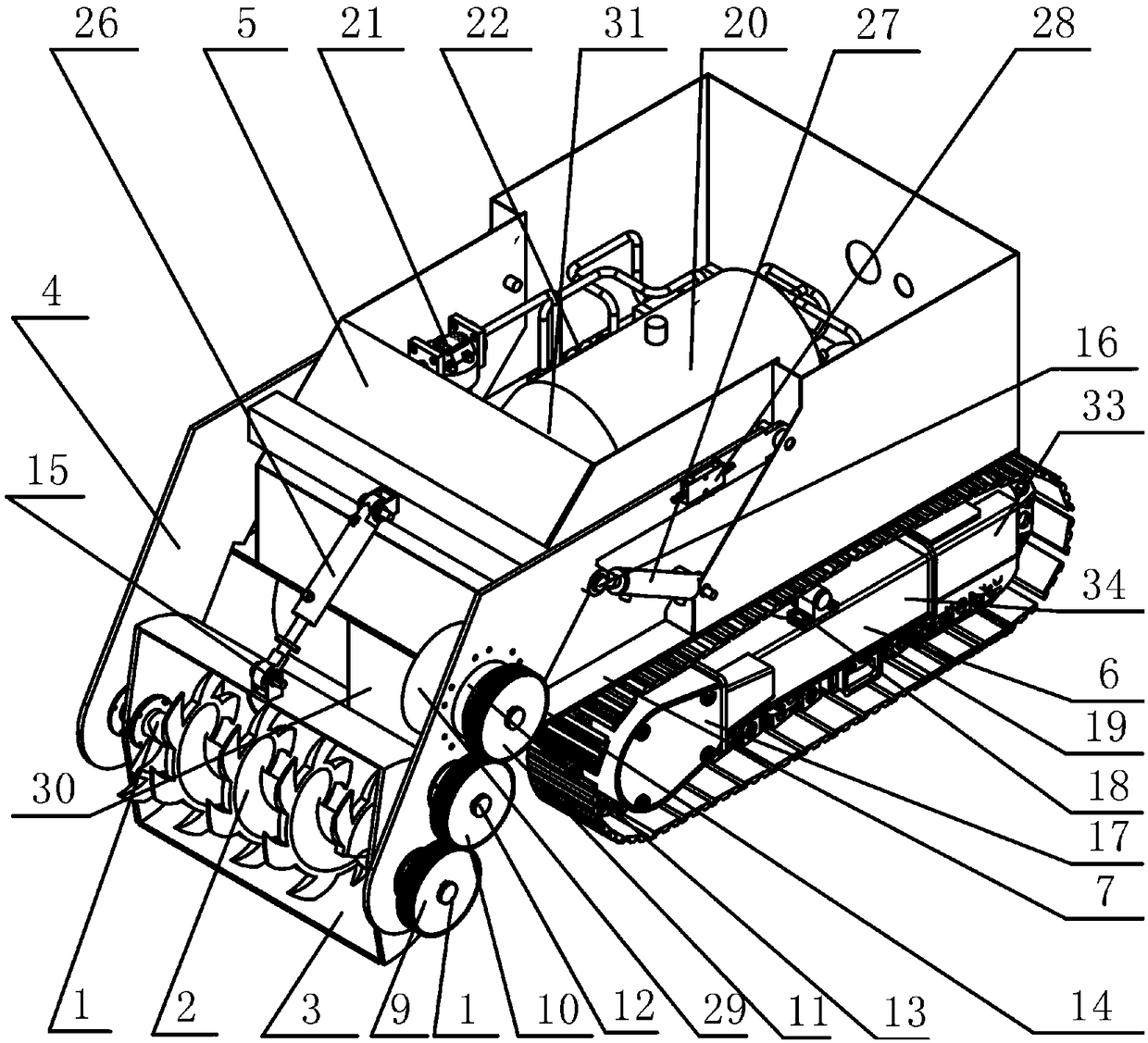

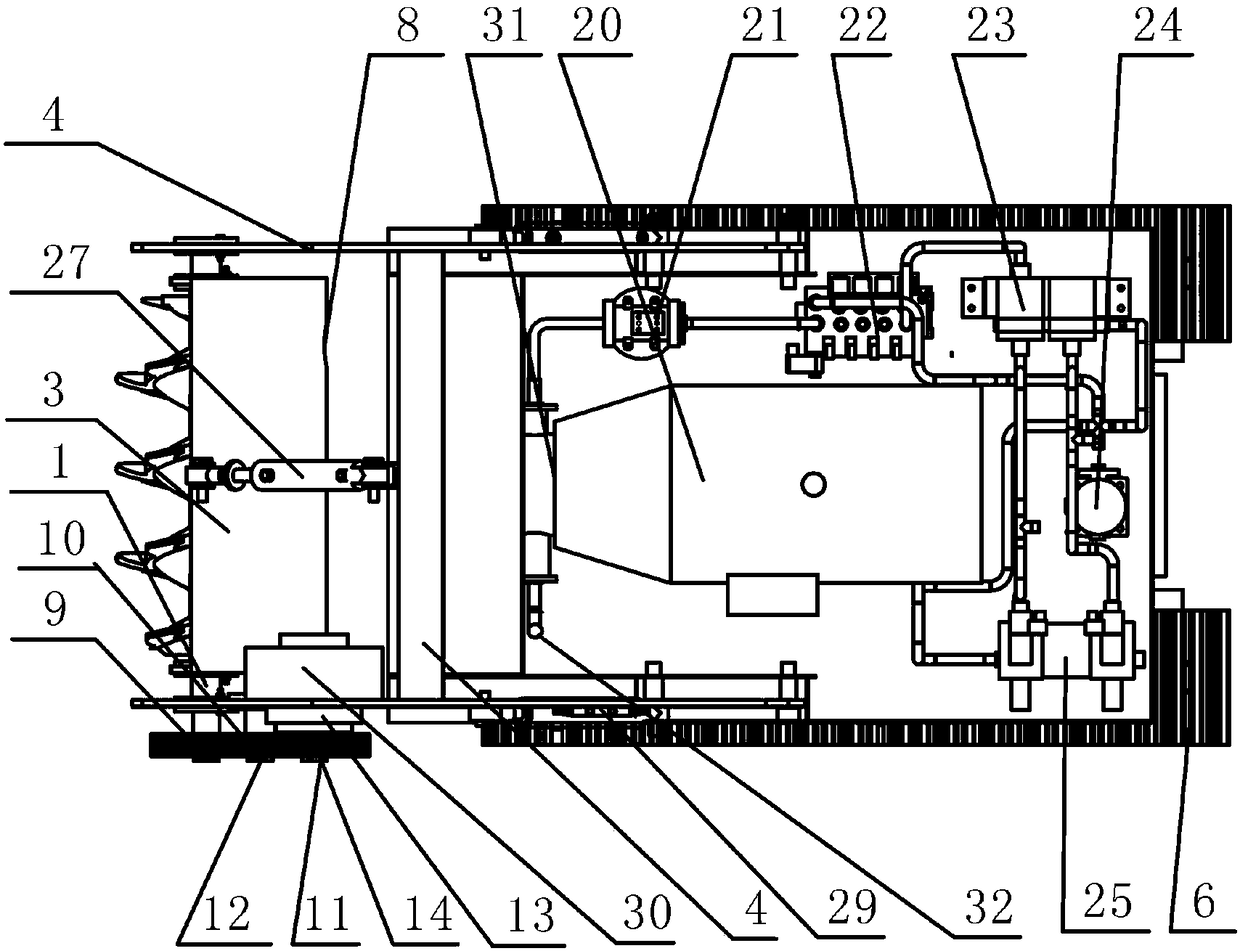

Crawler belt type dredging robot

InactiveCN108166606ASolve the current situation of difficult dredgingPowerfulSewer systemsHydraulic cylinderSynchronous motor

The invention discloses a crawler belt type dredging robot, and belongs to the technical field of environmental protection equipment. The crawler belt type dredging robot includes a dredging reamer device, a turnover mechanism, a double-arm pushing mechanism, a dredging robot body and a hydraulic system. An overturning hydraulic cylinder drives a bucket to turn over downward, the turn-over angle of the overturning hydraulic cylinder is set to be 35 degrees, and it is ensured that after dredging, residual sludge of the bucket can smoothly fall down. Big connection beams are connected with a left walking crawler belt and a right walking crawler belt respectively, at the same time, a base is provided for four supporting square steels, the speed of a walking motor is controlled by controllingthe displacement of a valve element of a load-sensitive proportional multi-way valve, a synchronous motor ensures synchronous advancing of the crawler belts, two-way electromagnetic throttles ensure left turning and right turning of the walking motor, and thus the walking crawler belts can stably walk. The robot is simple and reliable in structure, at the same time, sludge is conveyed efficiently,the dredging efficiency is largely improved, the robot can be suitable for dredging tasks of drainage pipelines large in pipe diameter and box culverts, and the problem that at present, the dredgingprocesses of existing drainage pipelines large in pipe diameter and existing box culverts are difficult is solved.

Owner:BEIJING UNIV OF TECH

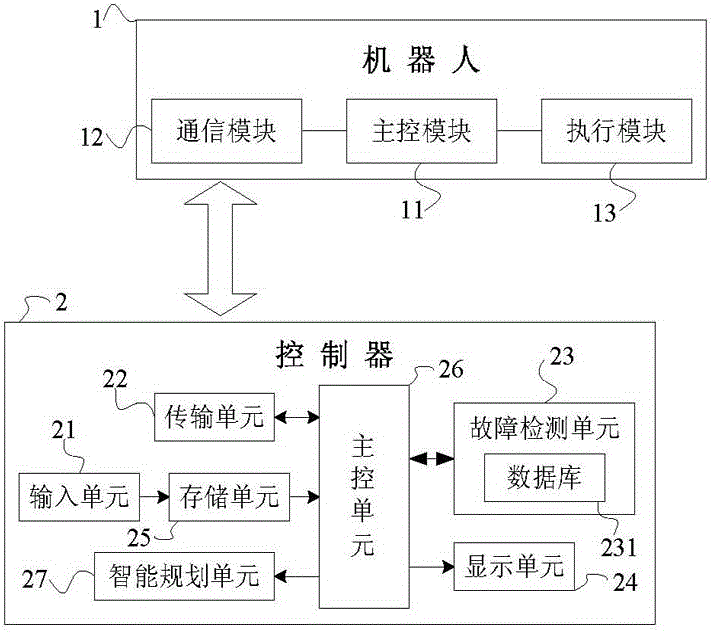

Industrial robot control system

InactiveCN104950723AFlexible controlImprove intelligenceProgramme control in sequence/logic controllersHandwritingControl manner

The invention discloses an industrial robot control system. The industrial robot control system comprises a robot and a controller, wherein the robot and the controller are separated from each other; the robot comprises a main control module, a communication module and an execution module; the controller comprises an input unit, a transmission unit, a fault detection unit, a display unit, a storage unit, a main control unit and an intelligent planning unit. According to the industrial robot control system provided by the invention, a control mode is flexible, and the intelligent degree is high; an input mode comprises a key-press input mode, a handwriting input mode and a voice input mode; the fault detection unit can be used for detecting the performance and the state of the robot online, and the operation accuracy and the operation safety of the robot are ensured; the intelligent planning unit is used for applying an artificial intelligence technology to track planning of the robot, the working mode of a traditional industrial robot that the working is inflexible, the operation just can be carried out according to an established procedure, and a response to the change of an environment cannot be carried out can be changed, an optimal track can be autonomously planned, and the service life of the robot can be prolonged.

Owner:南京采薇且歌信息科技有限公司

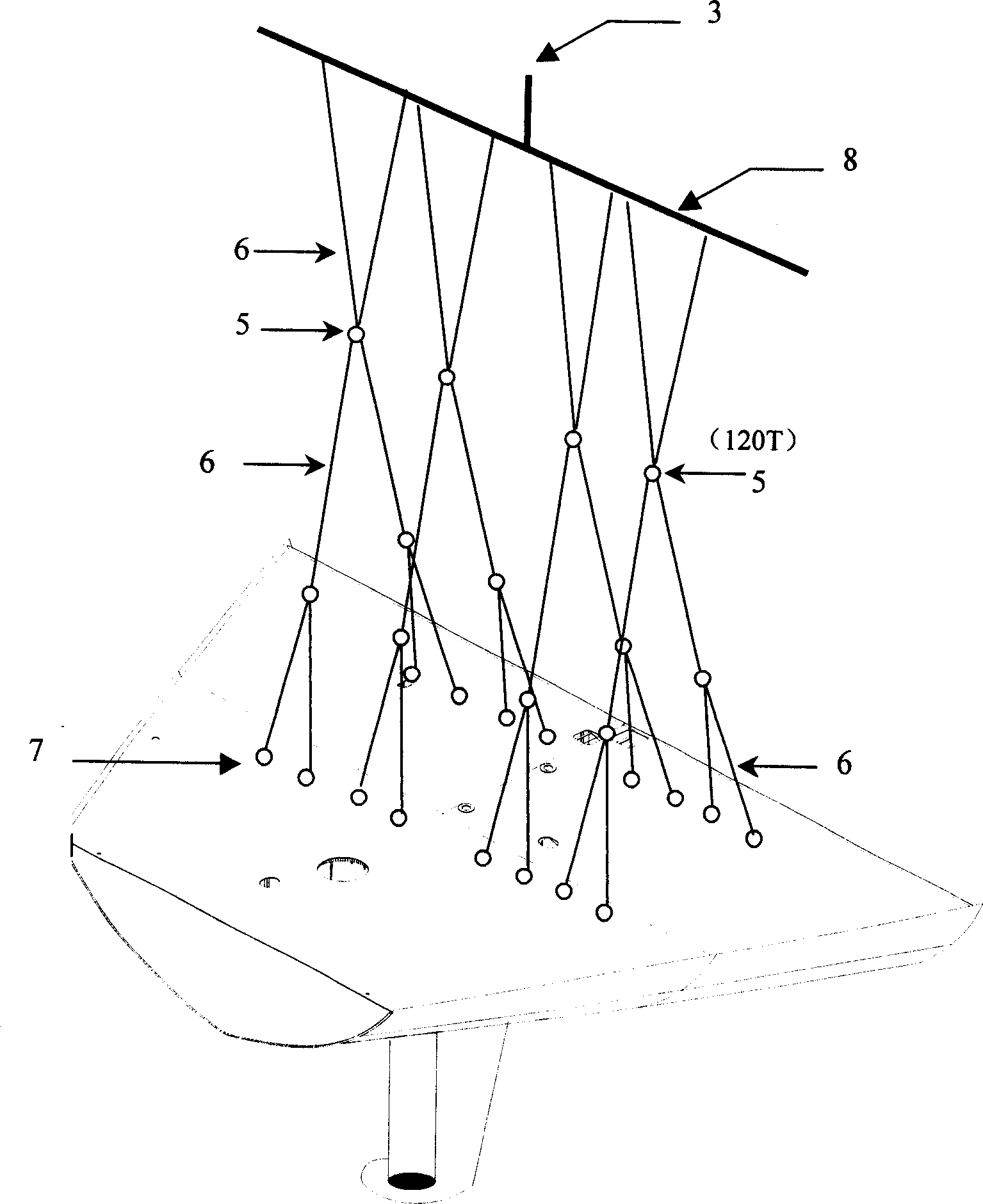

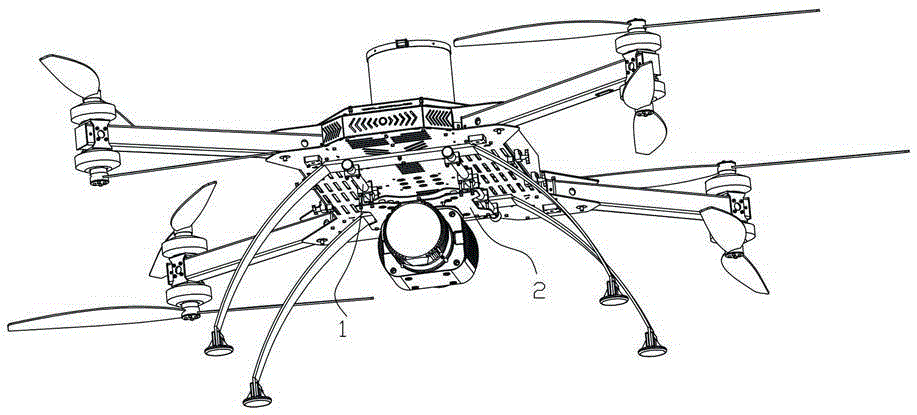

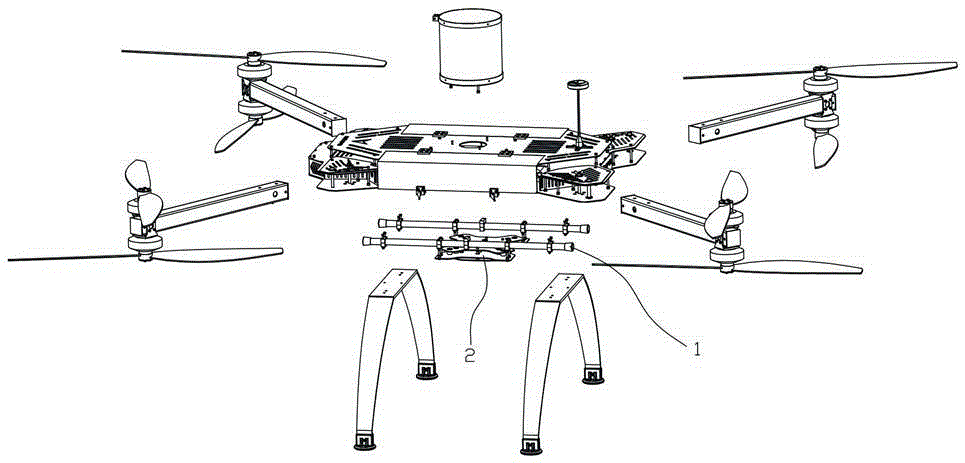

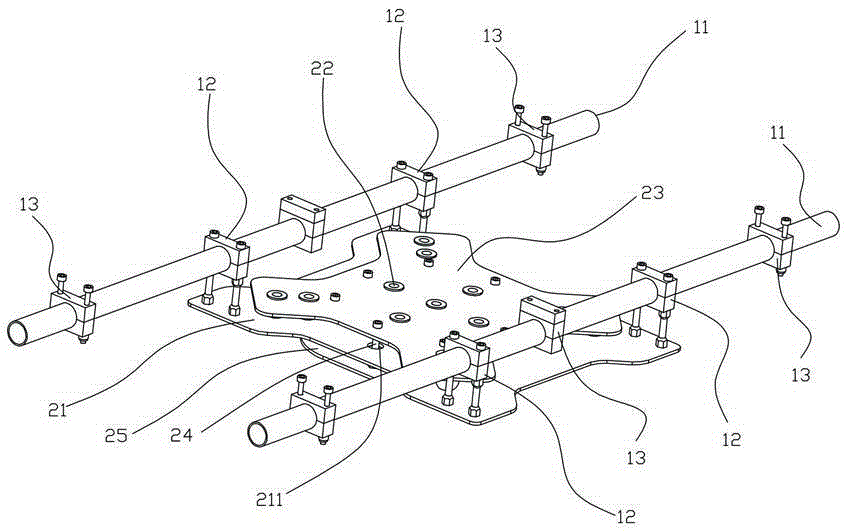

Mounting platform of unmanned airplane

ActiveCN105270644ABest flying performanceTake off smoothlyAircraft componentsJet aeroplaneGravity center

The invention discloses a mounting platform of an unmanned airplane. The mounting platform comprises a gravity center adjustment assembly and a hanging assembly for hanging articles. The gravity center adjustment assembly is connected with a fuselage. The hanging assembly is hung onto the gravity center adjustment assembly. The gravity center adjustment assembly is provided with a plurality of first hanging parts for adjusting the horizontal position of the hanging assembly. The mounting platform is simple in structure and can be applied to the unmanned airplane, wherein the gravity center thereof can be quickly adjusted. Therefore, different articles can be hung onto the hanging assembly. Meanwhile, the mounting platform is good in damping and shock-filtering effect and is particularly suitable for the hanging of heavy articles.

Owner:HUNAN AIRTOPS INTELLIGENT TECH CO LTD

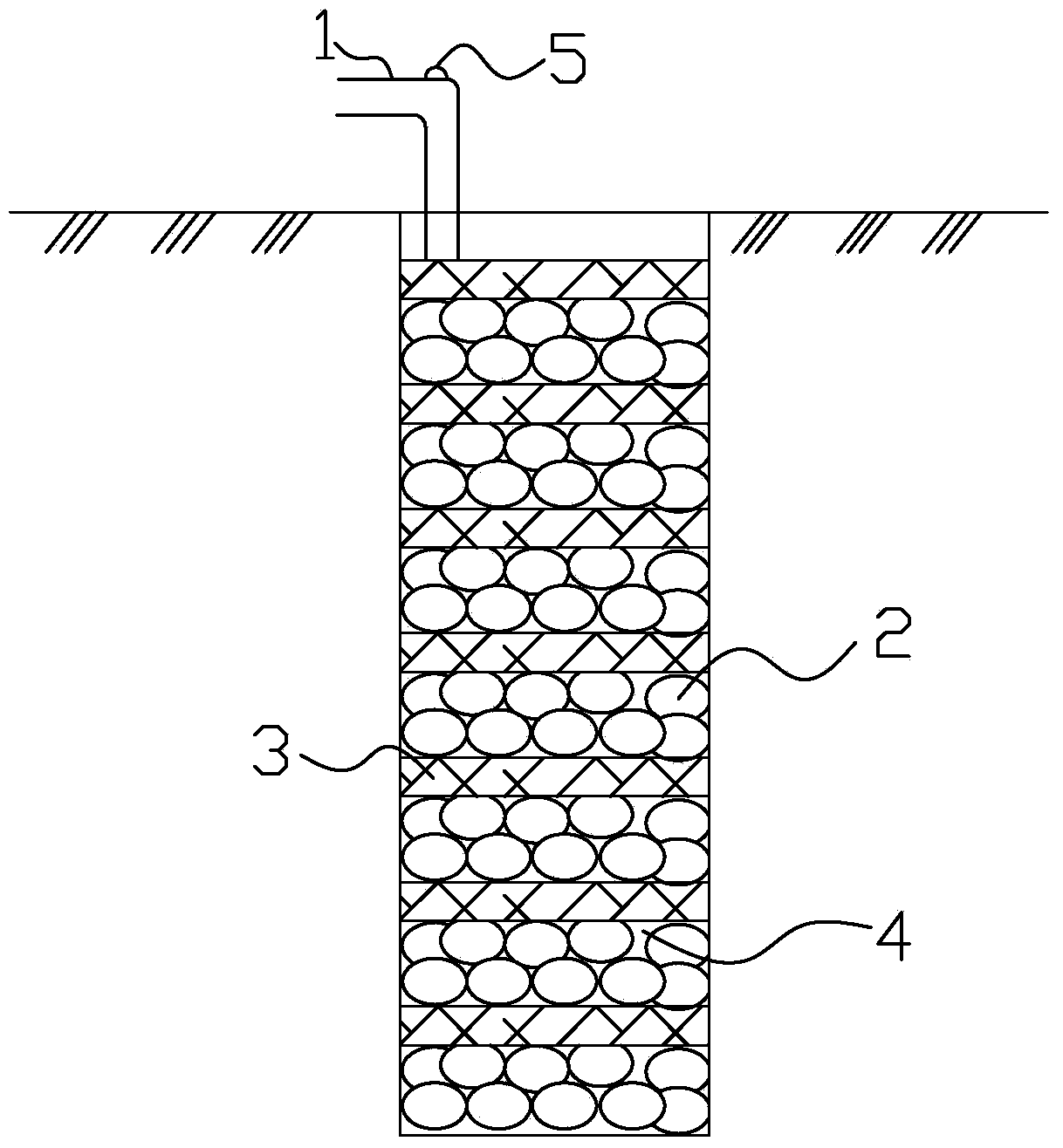

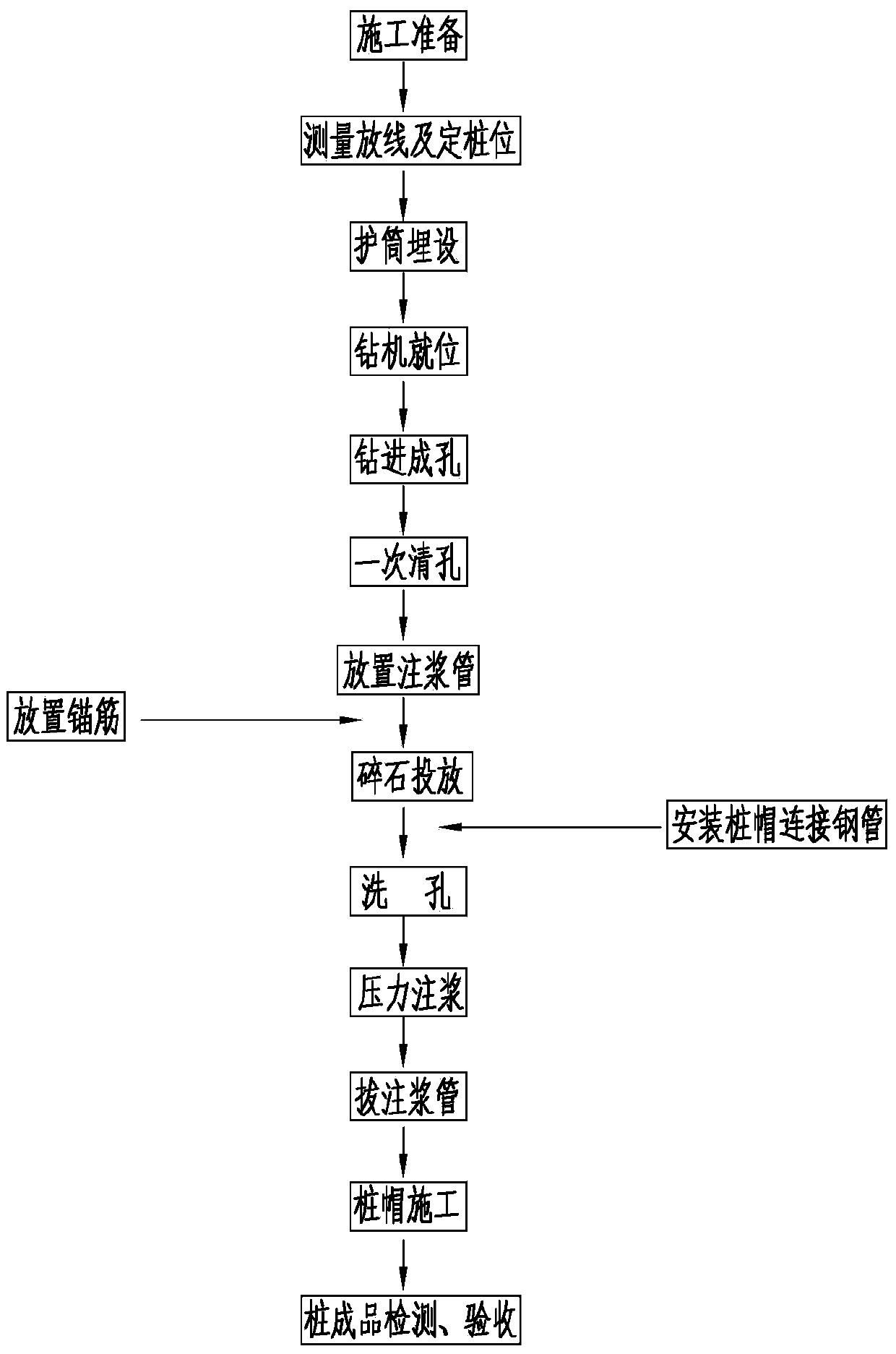

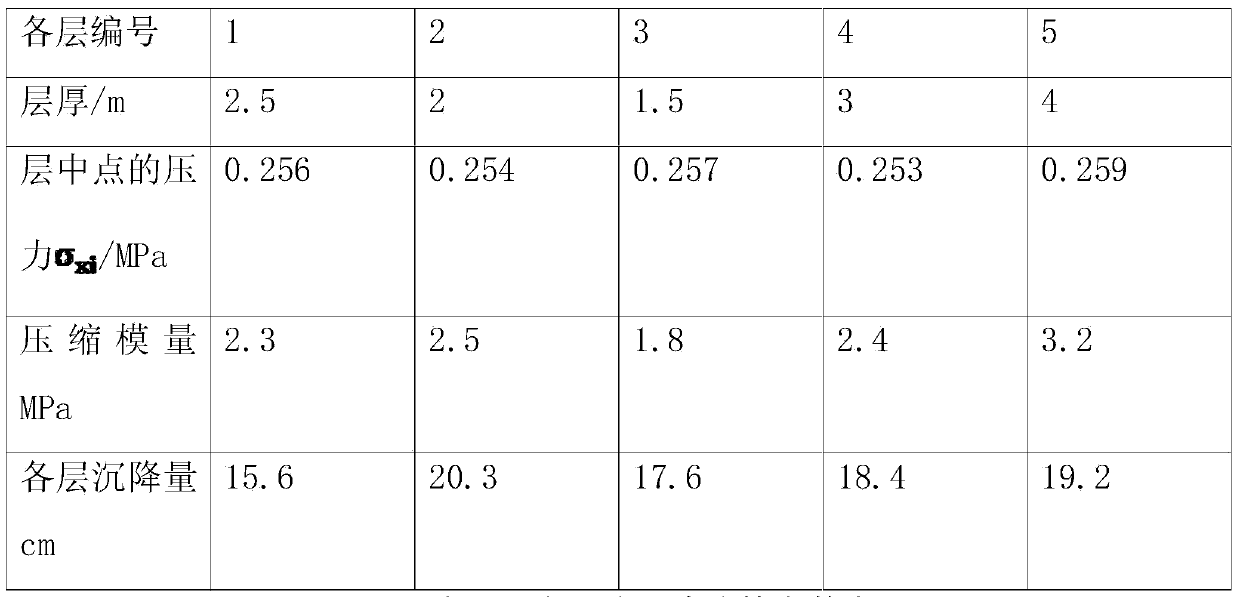

Construction method of gravel grouting pile

The invention discloses a construction method of a gravel grouting pile. The construction method comprises the following steps: (1) preparing for construction, (2) conducting measurement, paying off and positioning of the pile, (3) embedding a protective canister, (4) placing a drilling machine in place, (5) forming a hole by drilling, (6) cleaning the hole at a time, (7) placing a grouting pipe, (8) placing an anchor bar, (9) putting gravels in the hole, (10) installing a pile cap connecting steel pipe, (11) cleaning the hole, (12) conducting pressure grouting, (13) pulling the grouting pipe out, (14) constructing a pile cap, and (15) conducting detection and acceptance inspection on the finished pile. According to the construction method of the gravel grouting pile, the construction speed is high, the construction period is shortened, and compared with soft foundation treatment such as a prestressed pipe pile and a Y-type pile, the engineering investment is saved; the labor intensity is low, the construction is safe, and the construction method can be widely popularized and used; the gravel pile formed by cement and gravels is high in integrality and stability. The engineering drilling machine is adopted in a soft foundation to drill the hole in a rotating and cycling mode to form the pile, the disturbance to the foundation and the surrounding buildings is small, ground depression is controlled, and the construction method is small in vibration and low in noise during the construction and has good social benefits.

Owner:NINGBO SHENGHONG CONSTR ENG

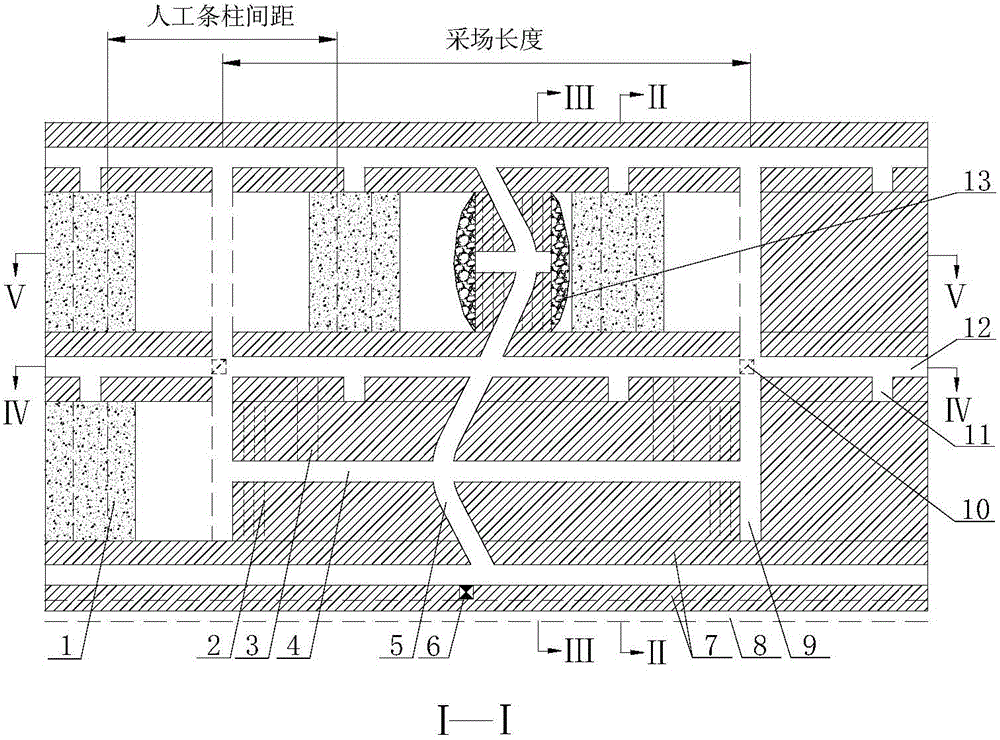

Mining method with adjustable and controllable structure size of gentle dip medium-thickness ore body strip column reconstructed stope

ActiveCN104632220AReduce climbing angleReduce lossesUnderground miningSurface miningLoss rateEngineering

The invention discloses a mining method with an adjustable and controllable structure size of a gentle dip medium-thickness ore body strip column reconstructed stope. The work of a recovery process is safe by adopting an advanced top cutting anchor rod support roof; efficient recovery of ores is realized by middle-deep hole ore break down, retreating type recovery and ore removal of a carry scraper; a studding is not formed along the inclined direction of an ore body and thus the loss rate of ores is reduced; and a goaf roof is supported by a waste stone slip casting glue structured artificial strip column so that the effective management on ground pressure of the stope is realized. The mining method with the adjustable and controllable structure size of the gentle dip medium-thickness ore body strip column reconstructed stope, disclosed by the invention, has the advantages that the working is safe, the production efficiency is high, the loss rate of the ores is relatively low, and few filling raw materials are needed.

Owner:CENT SOUTH UNIV

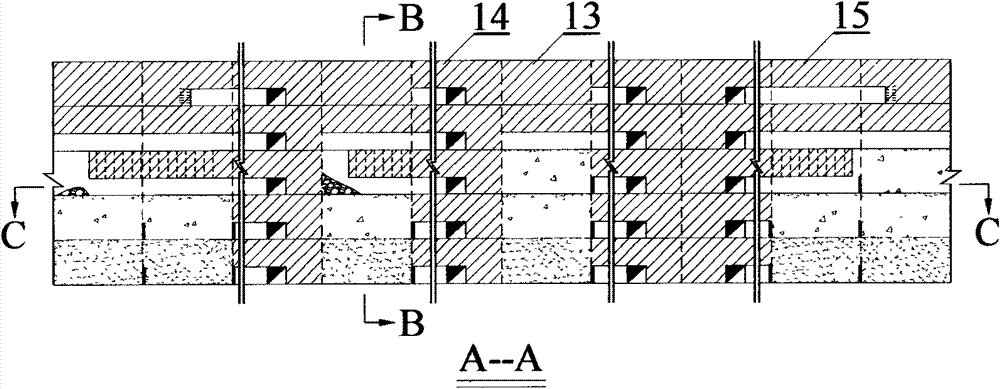

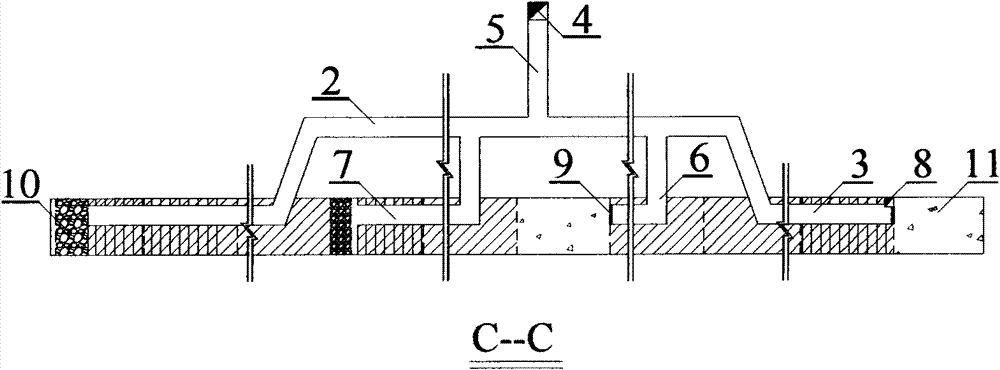

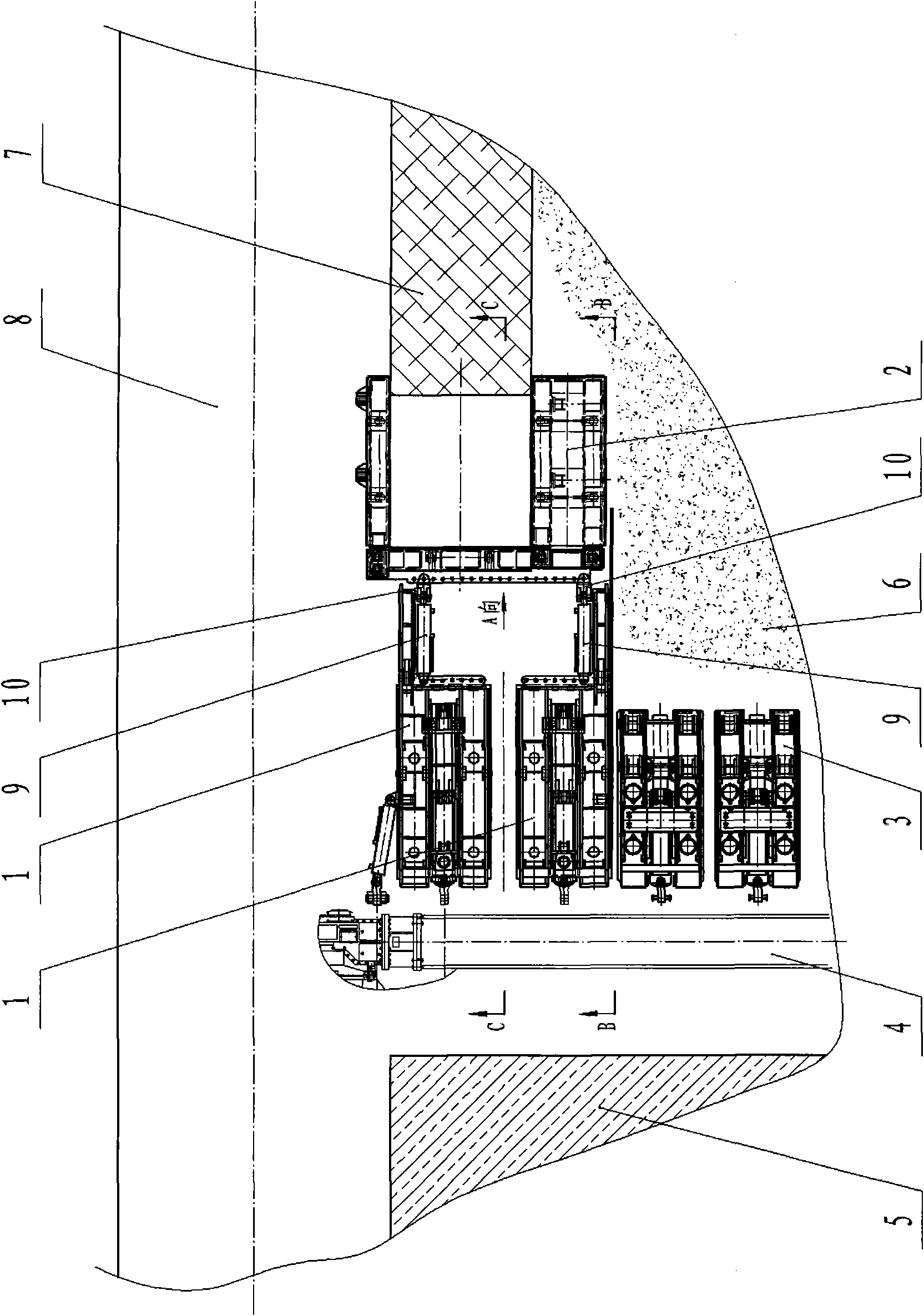

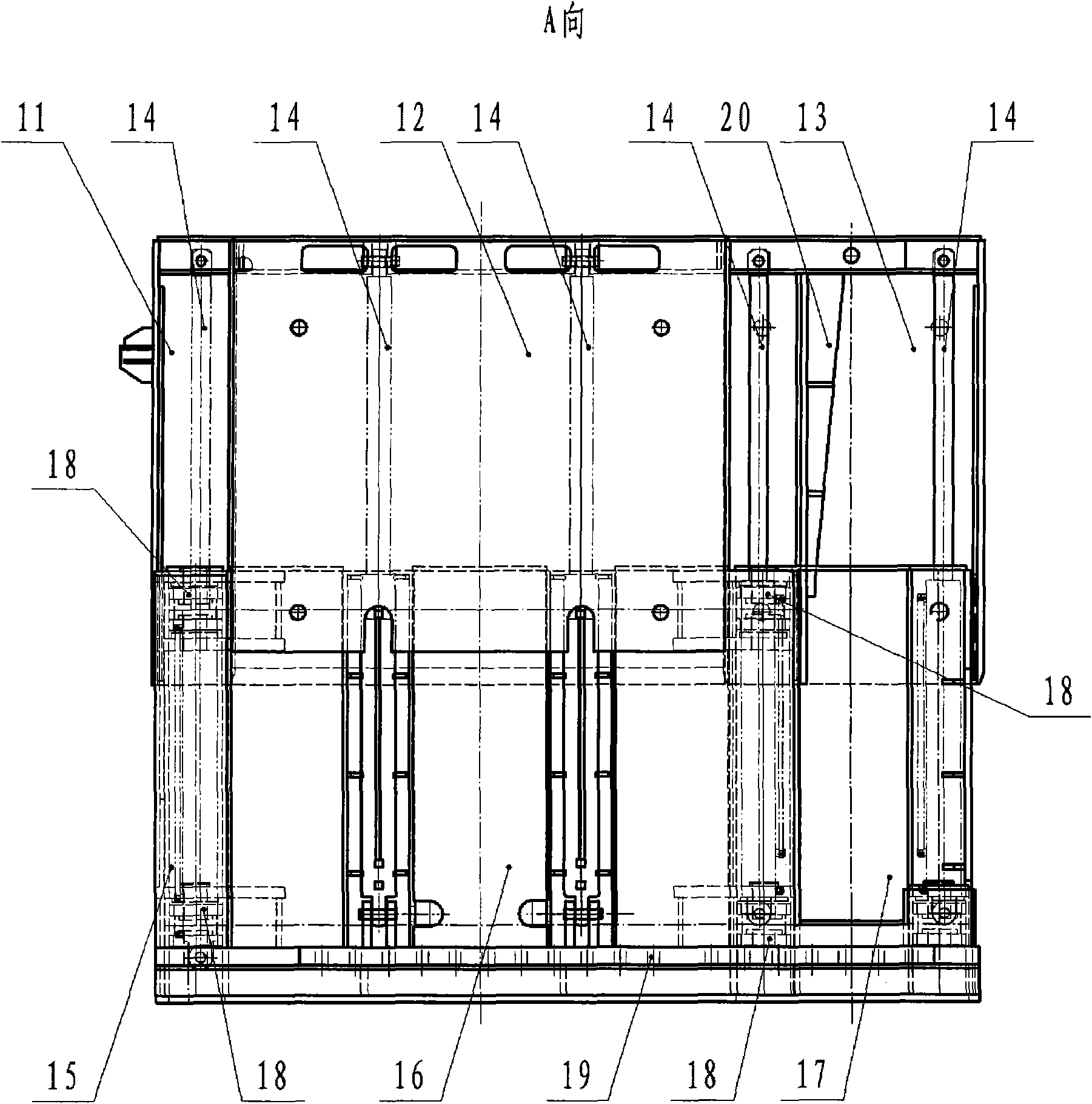

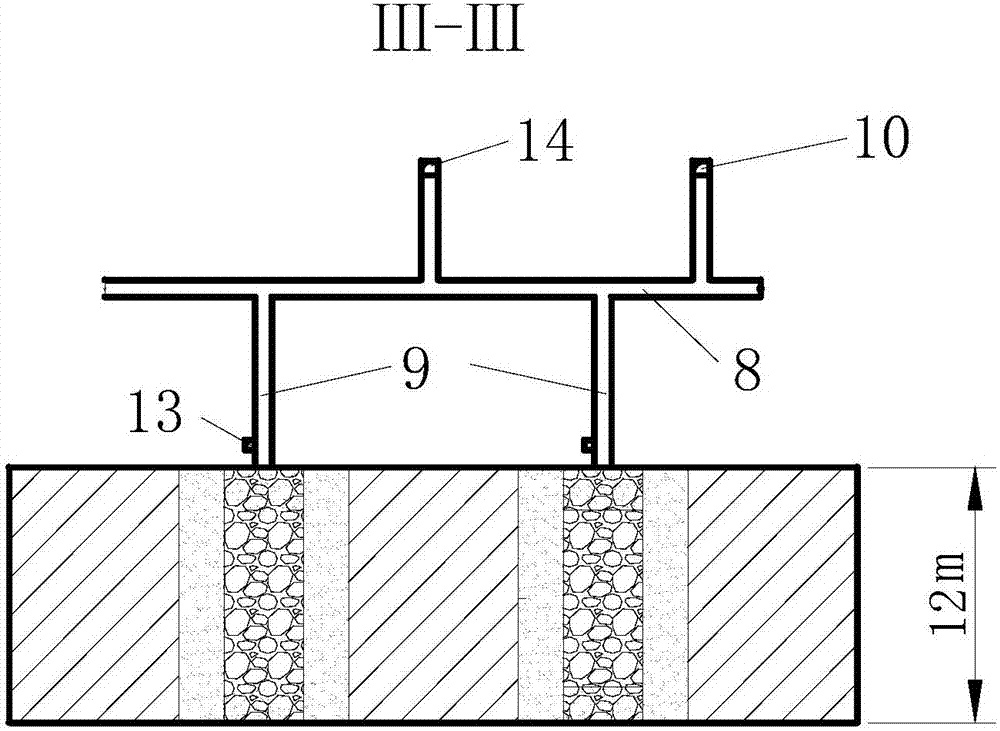

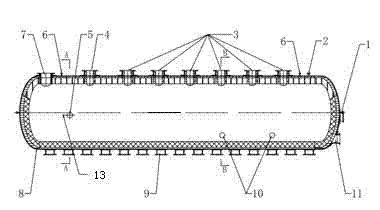

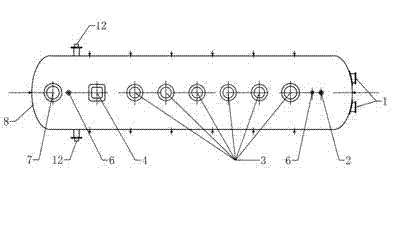

Gob-side entry retaining work mould base

ActiveCN101560883AAchieve miningReasonable structural designMaterial fill-upMine roof supportsHydraulic cylinderBand shape

The invention discloses a gob-side entry retaining work mould base, which effectively conquers the defect that template integrity is low in prior suspension equipment. The mould base comprises coal mining equipment, a baffle support frame and a filling mould box, wherein, the coal mining equipment is paved along work surface; the baffle support frame consists of a top beam and a bottom base, is connected with a four bar linkage mechanism and is supported by a hydraulic vertical column; and the filling mould box is arranged right ahead along a gob entry retaining filling wall body. The technical point is as follows: the bottom base of the baffle support frame is connected with the filling mould box by a hydraulic cylinder and a connecting head; the baffle support frame is provided with an upper baffle and a lower baffle by the rear part of one side of the gob; the tail end of the top beam is joggled with the end part of the rear top beam; and the bottom part of the top beam is joggled with the rear part of the bottom base by the hydraulic vertical column. The invention has reasonable design, safe and convenient operation, leads a mould setting device and a mould moving device not only to be internally independent but also to match with the coal mining equipment so as to carry out normal coal mining and roof support parallel job, obviously improves integrity and the degree of mechanization, and can form a strip-shaped regular wall body at the isolated gob near the entry.

Owner:SHENYANG TIAN AN TECH CO LTD

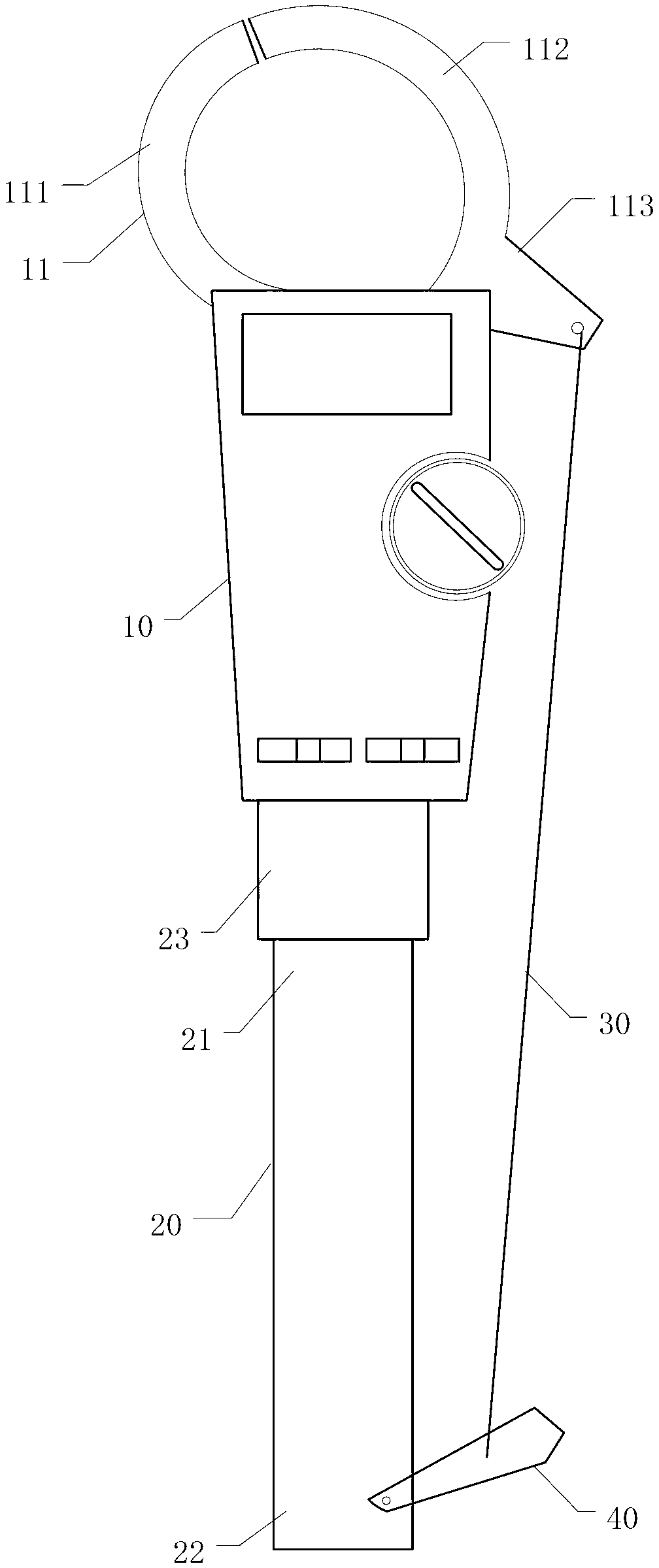

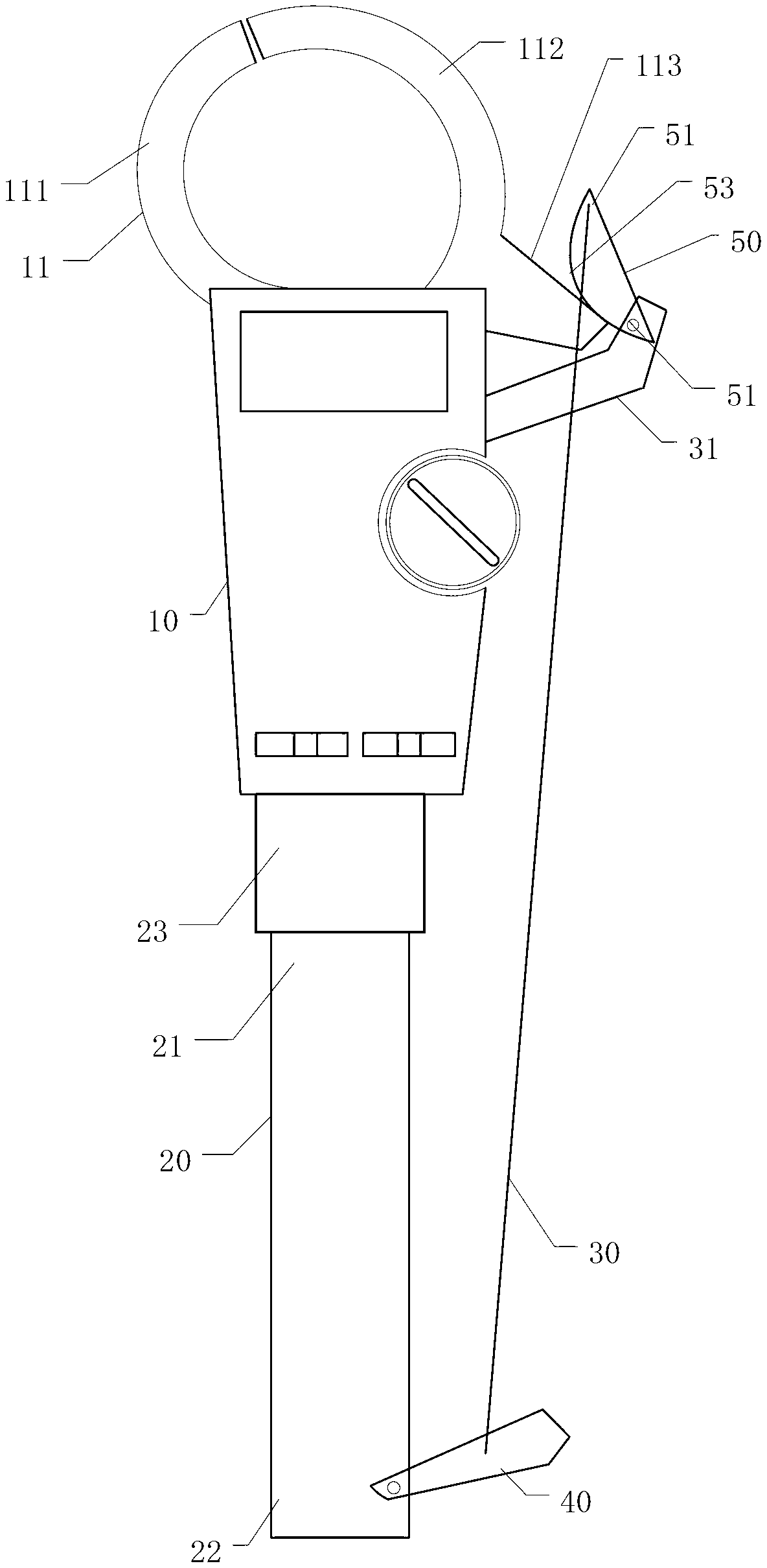

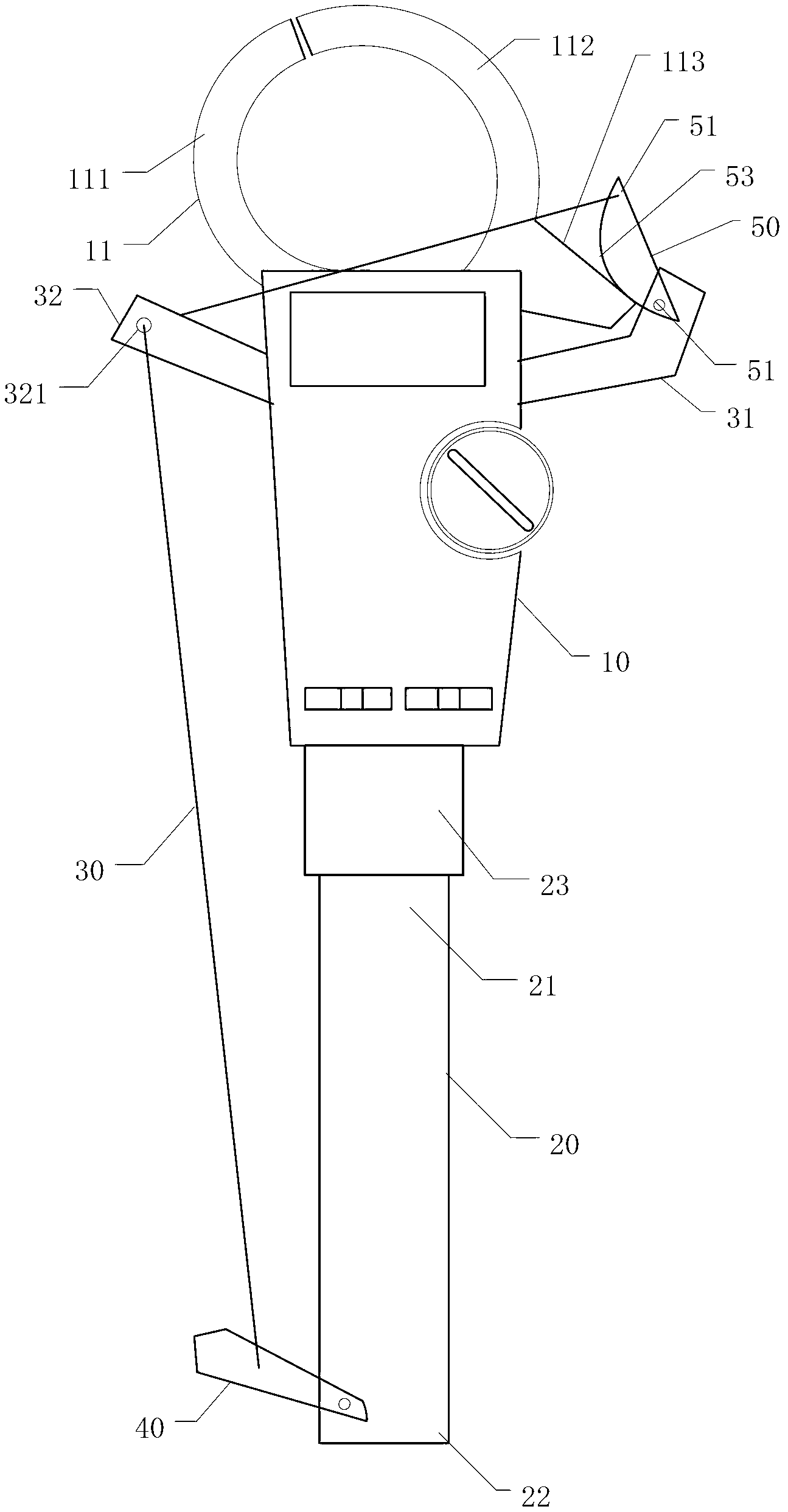

Current measuring device

The invention discloses a current measuring device. The current measuring device comprises a clip-on ammeter, an insulating handle and a pull wire, wherein the clip-on ammeter is provided with a tongs head, the tongs head comprises a fixed bayonet and a moving bayonet, and the moving bayonet is provided with a clamping piece used for opening the tongs head; the upper end of the insulating handle is hinged to the clip-on ammeter; the head end of the pull wire is connected with the clamping piece and used for pulling or pressing the clamping piece to open the tongs head. The current measuring device can make the clip-on ammeter close to overhead electrical equipment by the utilization of an insulating rod to perform measurement, a measurement worker does not need to be close to the overhead electrical equipment for measurement, and the current measuring device is more convenient and safe to use in operation.

Owner:STATE GRID CORP OF CHINA +1

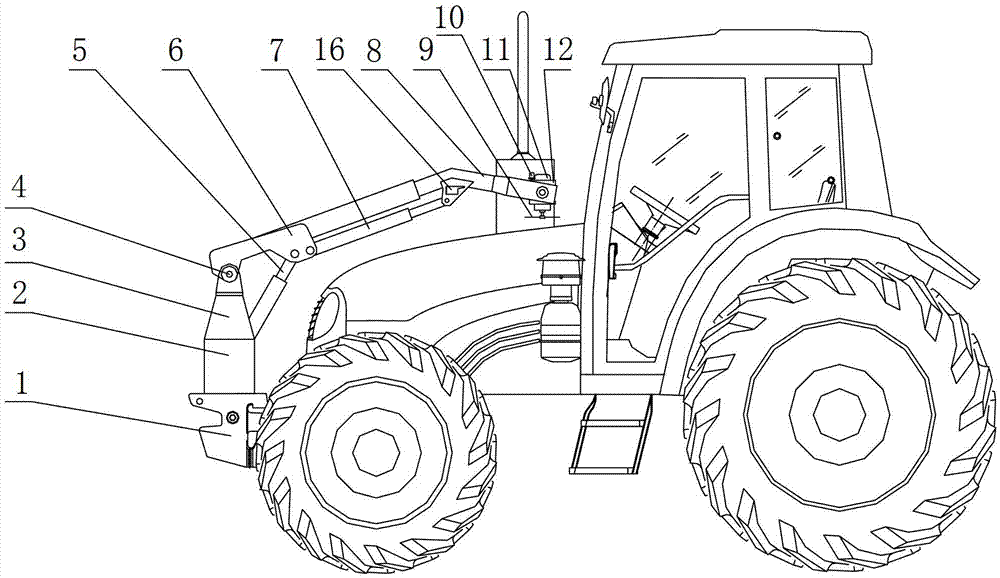

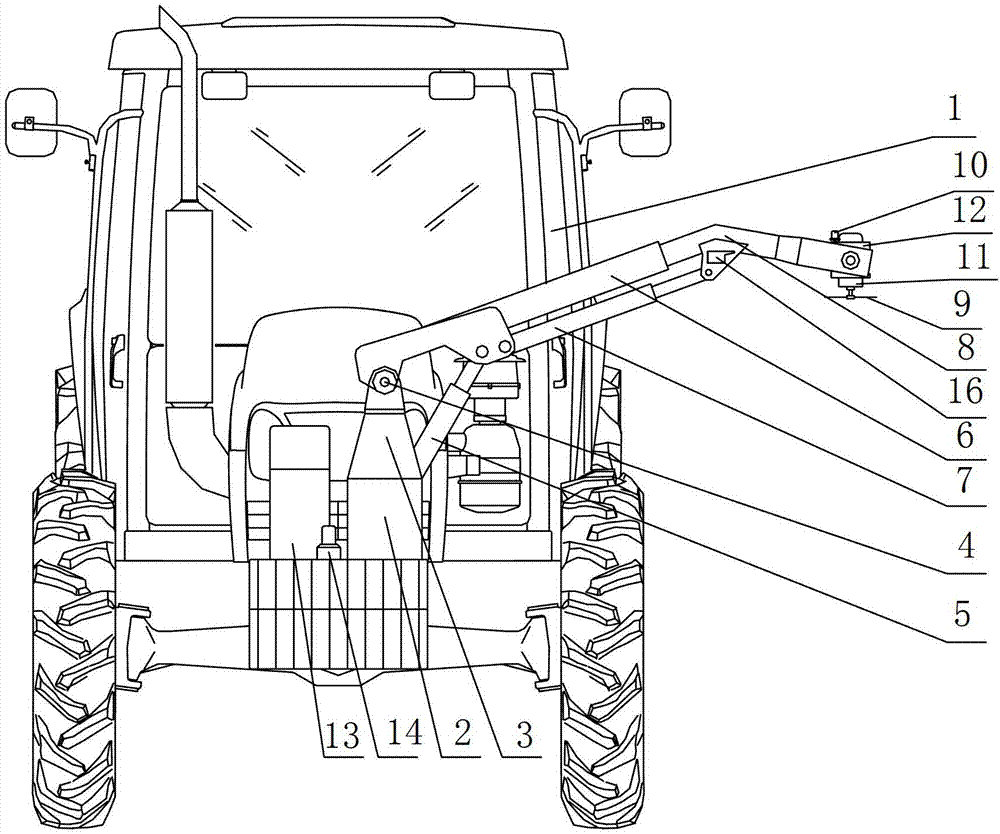

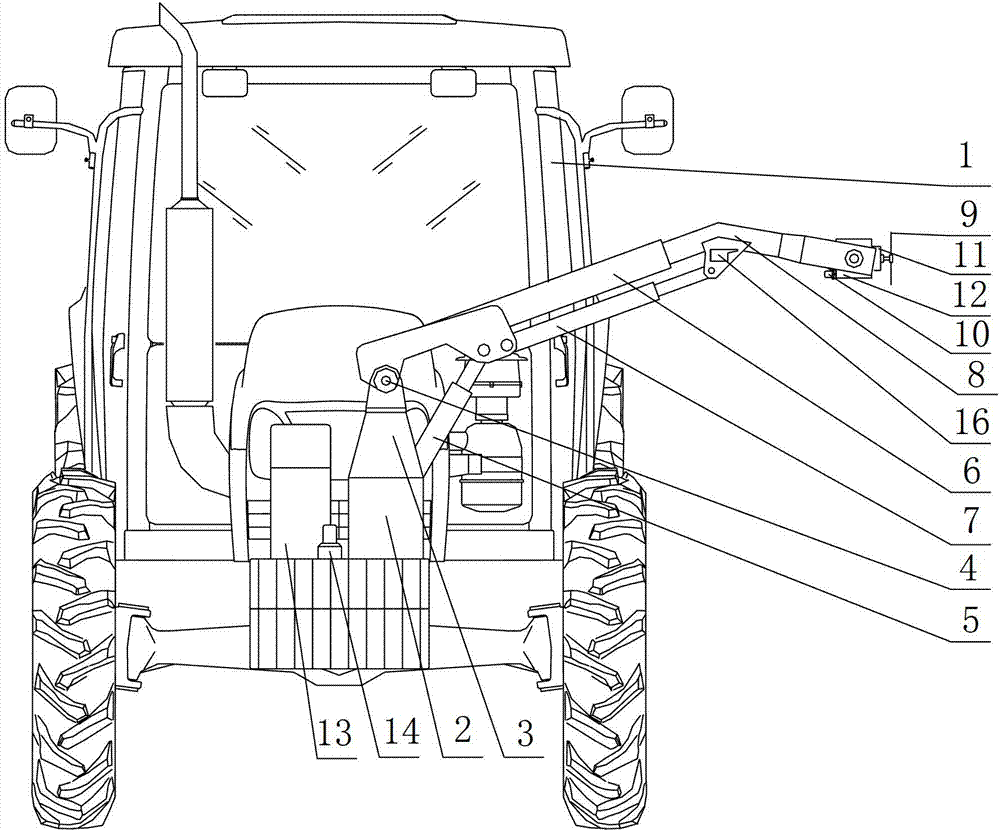

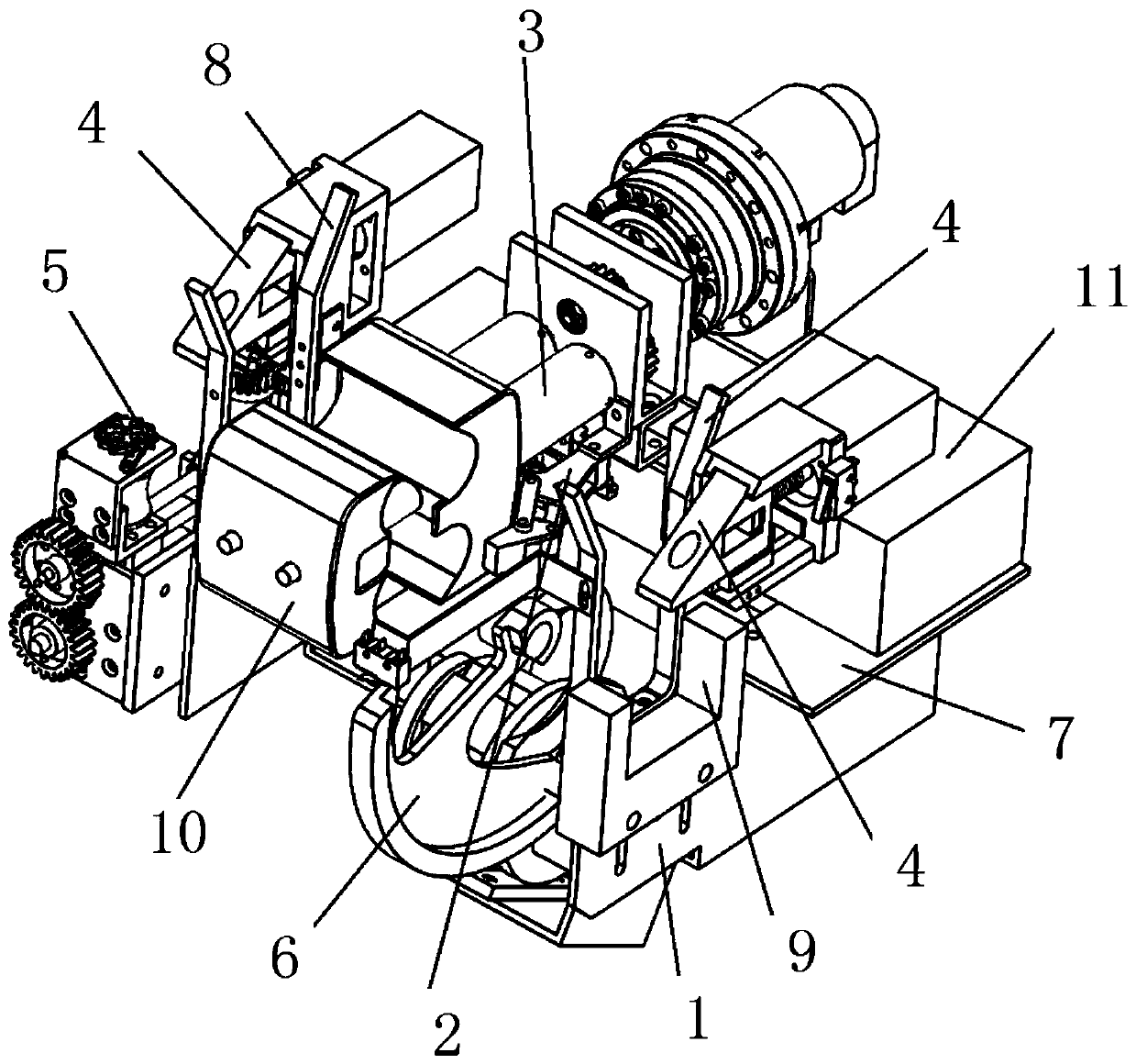

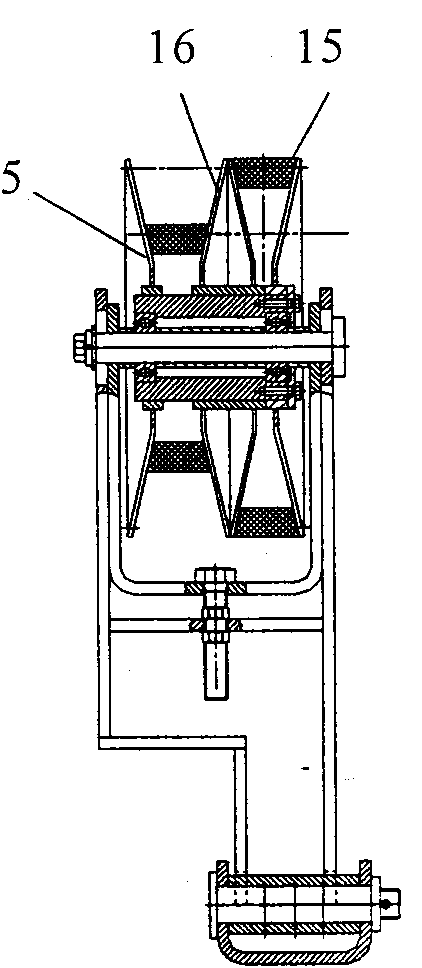

Vehicle-borne dwarf closely-planted jujube trimmer

InactiveCN102823445AIncrease profitSimple structureCuttersCutting implementsControl systemEngineering

The invention discloses a vehicle-borne dwarf closely-planted jujube trimmer which comprises a bearing vehicle and a jujube trimming device which is installed on the bearing vehicle; and the jujube trimming device comprises a rotary base which is horizontally installed in front of the base of the bearing vehicle and can horizontally rotate, a mechanical arm which is installed on the rotary base and can stretch back and forth and move up and down, a cutter mounting rack which is installed at the front end part of the mechanical arm in a hinge manner, a cutter which continuously rotates under the drive of a cutter drive mechanism, a base drive device which drives the rotary base and a mechanical arm drive device which drives the mechanical arm, and the cutter drive mechanism, the base drive device, the mechanical arm drive device and a cutter mounting rack drive mechanism are all controlled by a control system. The vehicle-borne dwarf closely-planted jujube trimmer has the advantages of simple structure, convenience in operation, high operation efficiency, good use effect and high practicable value, and can be used for overcoming the problems that the existing jujube trimming device is not convenient to use and operate, is labor-wasting and time-wasting, has low automation degree and the like.

Owner:CHANGAN UNIV

Power distribution network electrified automatic wiring tool set and robot

ActiveCN110071406AImplement automatic connectionReduce labor intensityUnstripped conductor connection apparatusClip conductor connectionLine BreakDistribution grid

The invention relates to the technical field of wiring devices, in particular to a power distribution network electrified automatic wiring tool set and a robot. The automatic wiring tool set comprisesa frame body, a clamping mechanism, a wire clamp tightening mechanism, main line fixing mechanisms, a branch line fixing mechanism, a line breaking mechanism, a controller and induction mechanisms, wherein the clamping mechanism is fixedly arranged on the frame body and is used for clamping a wiring mechanism and has a clamping end for clamping the wiring mechanism; the wire clamp tightening mechanism is arranged on a supporting frame corresponding to the clamping mechanism, and is used for driving the wiring mechanism to act to enable main lines and a branch line to be connected; the main line fixing mechanisms and a branch line fixing mechanism are arranged on the frame body corresponding to the wiring mechanism separately and are used for fixing the main lines and the branch line; theline breaking mechanism is arranged on the frame body corresponding to the wiring mechanism, and is used for cutting off redundant branch lines; the controller is connected with driving mechanisms onthe clamping mechanism, the wire clamp tightening mechanism, the main line fixing mechanisms, the branch line fixing mechanism and the line breaking mechanism separately; by controlling the driving mechanisms, the actions of the clamping mechanism, the wire clamp tightening mechanism, the main line fixing mechanisms and the branch line fixing mechanism can be controlled; and the induction mechanisms are in signal connection with the controller.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

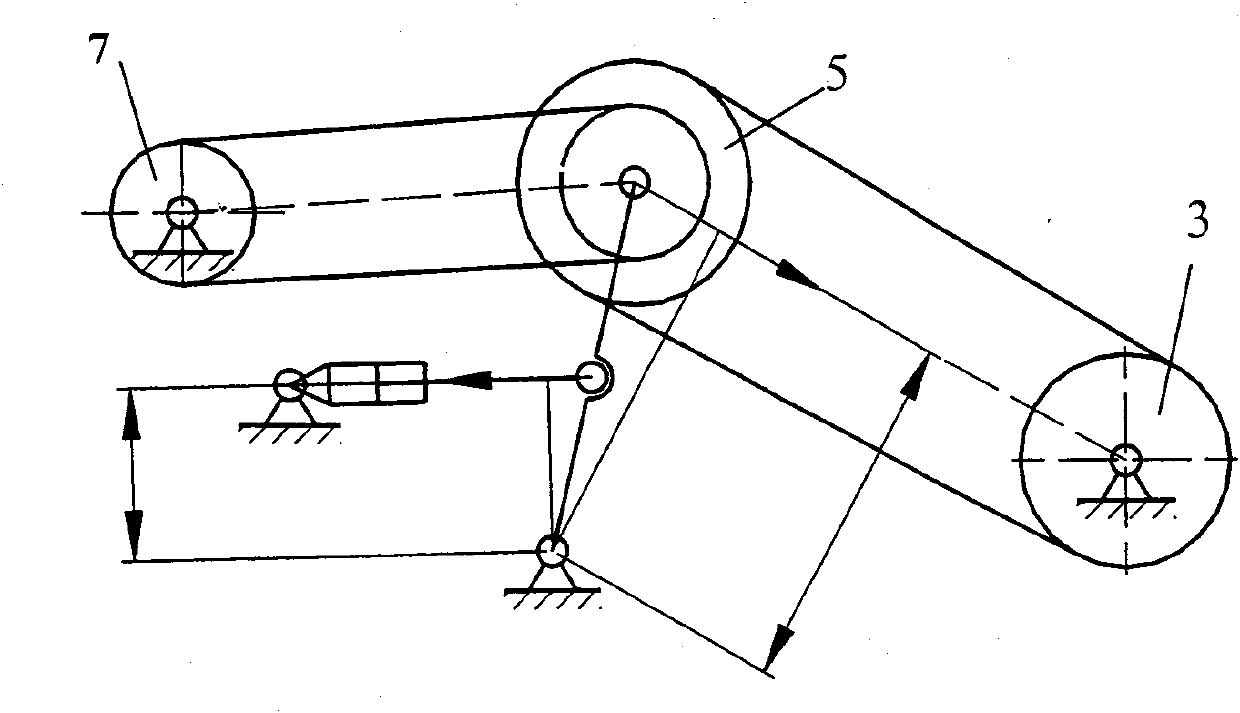

Linear hoisting device of goose-neck jib lorry-mounted crane and control method of linear hoisting device

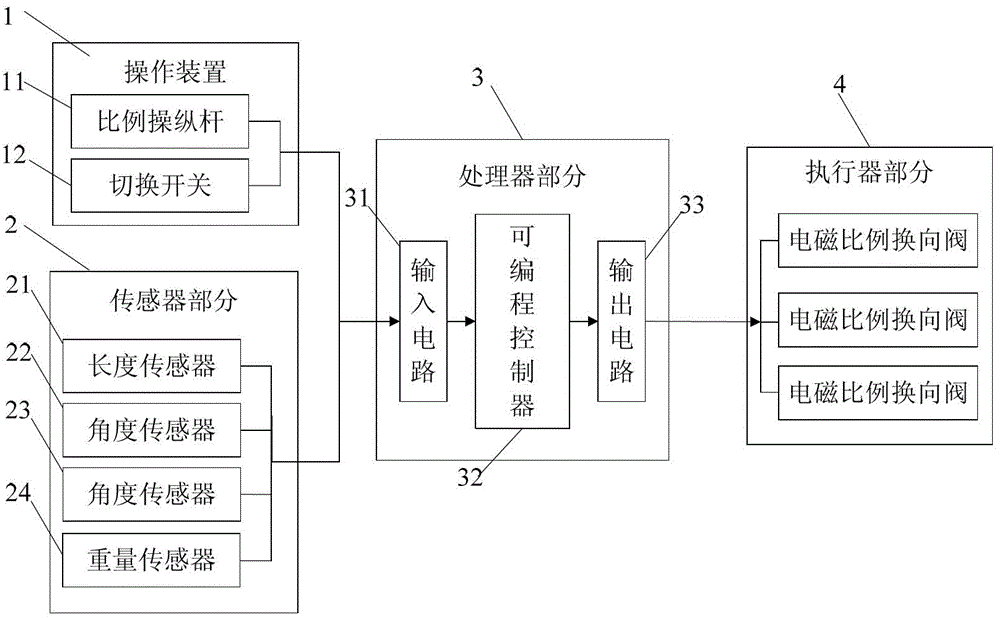

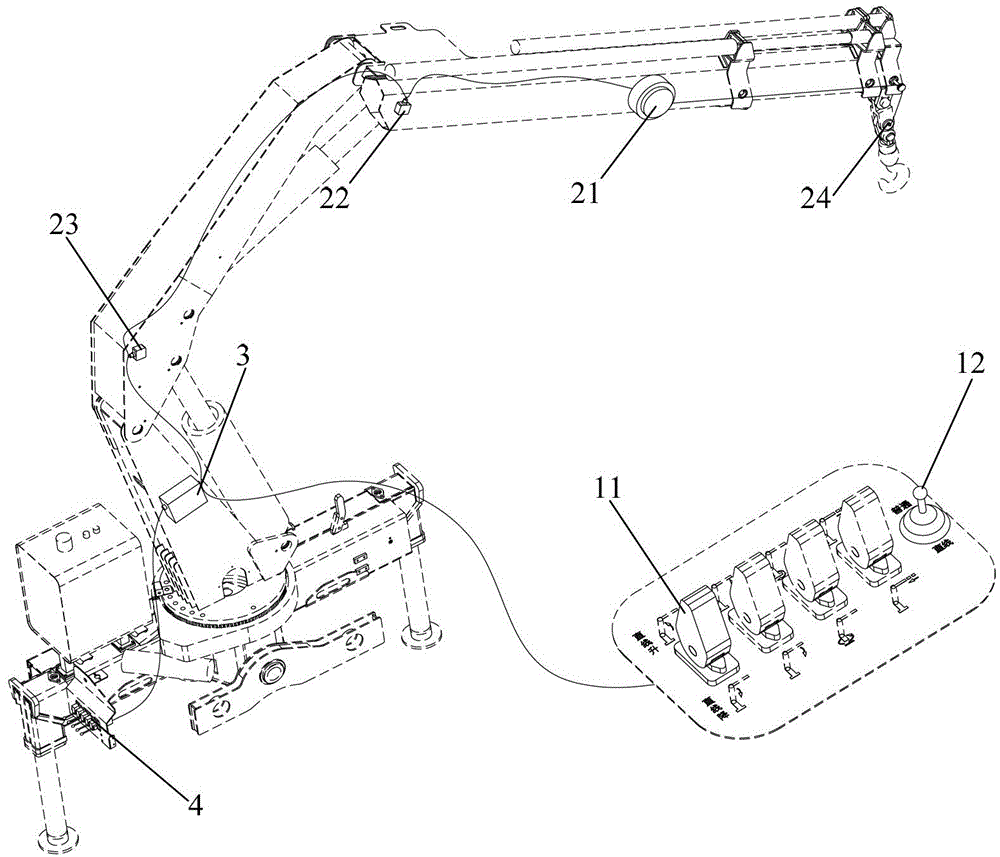

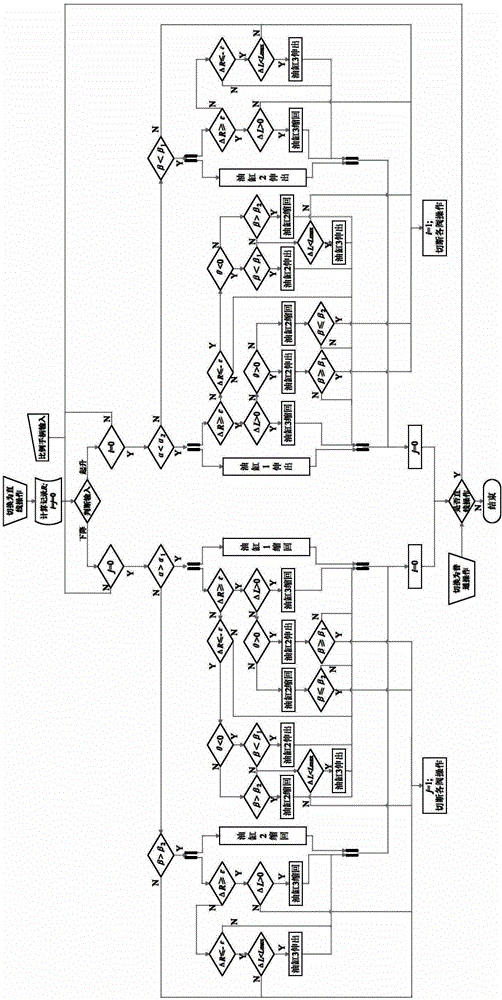

ActiveCN102910534AThe operation process is stableSave spaceLoad-engaging elementsCranesLimiterWire rope

The invention discloses a linear hoisting device of a goose-neck jib lorry-mounted crane. The linear hoisting device comprises an operating device, a sensor part, a processor part and an actuator part, wherein the operating device, the sensor part and the actuator part are connected with the processor part respectively. A steel wire rope of a crane with an extra hoisting mechanism easily swings under the action of wind load when the steel wire rope is lengthen, on the contrary in the prior art. By the linear hoisting device, relative positions of a hoisting load and a hoisting hook are kept basically unchanged, so that the operation process is safer and more stable. In addition, the linear hoisting device is more space-saving than the manner of adding the extra hoisting mechanism, an angle sensor, a length sensor, a controller and the like adopted by the linear hoisting device are applicable to a crane moment limiter, no extra parts are needed, and accordingly device cost is saved effectively.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

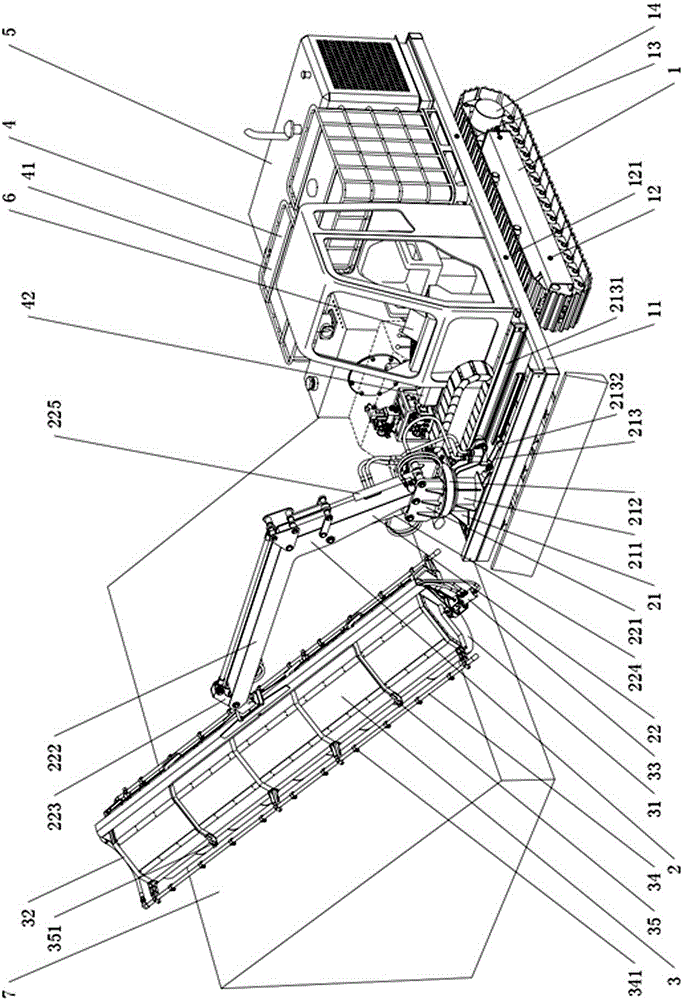

Photovoltaic array washing vehicle and photovoltaic array washing method thereof

ActiveCN105195488AUniform cleaning effectReduce consumptionSolar heating energyFlexible article cleaningComputer moduleEngineering

The invention discloses a photovoltaic array washing vehicle. The photovoltaic array washing vehicle comprises a proceeding chassis, a washing head supporting and positioning unit, a washing head unit, a water supply unit, an operation control unit and a vehicle body pose information collection device used for obtaining pose information of a vehicle body relative to the photovoltaic array, wherein a motion control component of a proceeding chassis steering system driving part is controlled by a main control module of the operation control unit; the washing head supporting and positioning unit comprises a movable base located at the head of the vehicle and a working arm set mounted on the movable base; the movable base comprises a rotation device and a transverse moving device; the working arm group comprises a main arm and an end arm capable of respectively pitching; the washing head unit comprises a washing brush, a water spraying part and a distance measuring sensor used for measuring the surface position and pose of a photovoltaic array board relative to the washing head unit; the main control module of the operation control unit takes a computer as the core of control. The invention also provides a method for washing the photovoltaic array by using the washing vehicle. The washing process is intelligent, efficient, flexible and safe, and is simple to operate, excellent in washing effect and low in usage cost.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

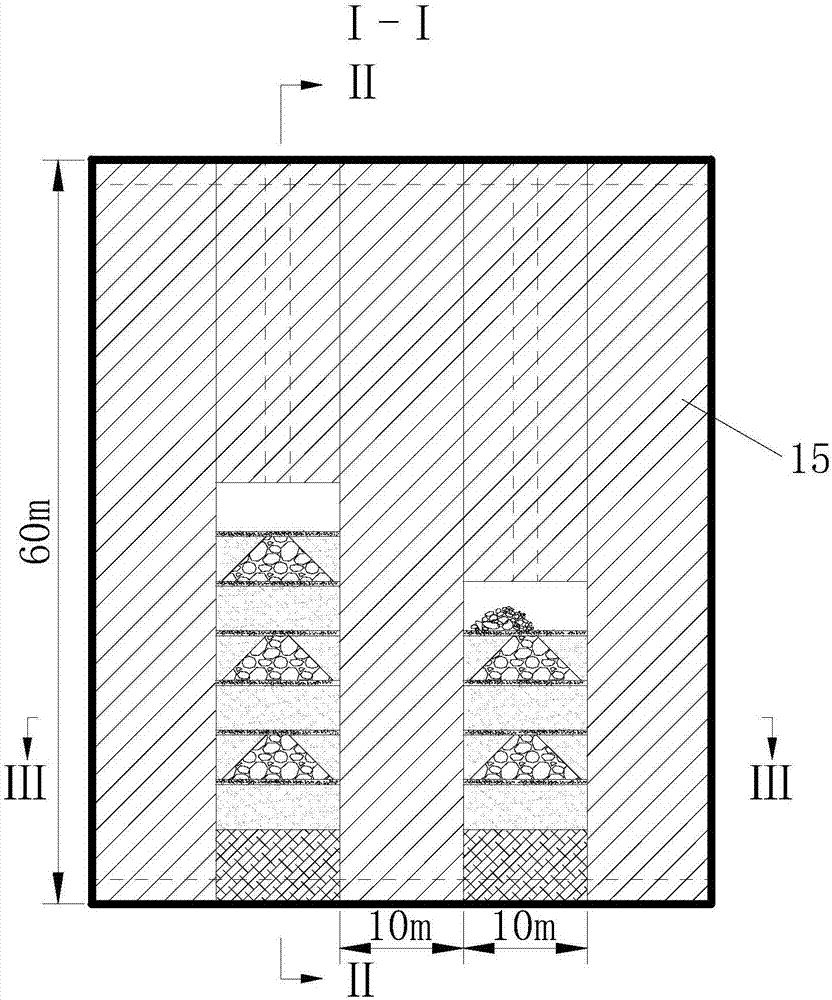

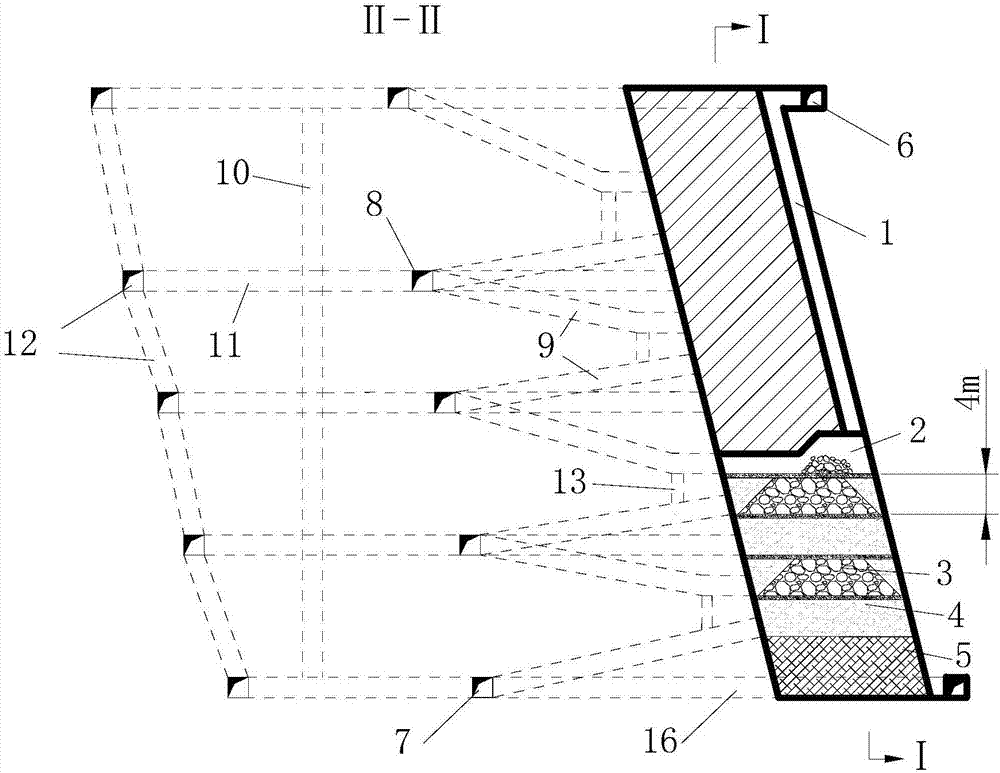

Mechanized upward-slicing wedging mixed filling mining method

ActiveCN106894817AIncrease profitGuaranteed StrengthUnderground miningSurface miningMining engineeringUltimate tensile strength

The invention discloses a mechanized upward-slicing wedging mixed filling mining method. When mining is conducted through the upward horizontal slicing filling process, upward stoping and filling are conducted with each slice being 3-4 m, and slices from bottom to top are alternately subjected to full tail sand cementing filling and waste stone wedging mixed filling. During wedging mixed filling, waste stone is stacked upward to form a quadrangular frustum pyramid. The laying range of the bottom waste stone is arranged according to the size of a stope, and certain spacing is kept with an adjacent stope. Tail sand cementing filling is still conducted on the two sides of a waste stone pile, and making contact with upper and lower layered tail sand cementing filling bodies is conducted, the whole strength of a mixed filling body is guaranteed, and dilution caused by caving of an ore body or surrounding rock at the time of being unstable is stopped. When the upward horizontal slicing filling process is adopted, the strength of the filling body can be guaranteed, and a large quantity of the downhole waste stone can be consumed, so that the waste stone is not out of a pit, and accordingly the cementing filling material is saved, and the filling cost is reduced effectively.

Owner:CENT SOUTH UNIV

Method and equipment for depleting furnace slag of electric melting furnace of side-blowing melting pool

InactiveCN102735047AThere will be no vicious blast furnace accidentsJob safetyLighting and heating apparatusProcess efficiency improvementSulfoniumMolten slag

The invention discloses a method and equipment for depleting the furnace slag of an electric melting furnace of a side-blowing melting pool. The method comprises the following steps of: putting molten slag produced in the nickel melting process or blown slag produced in the process of blowing low-nickel sulfonium into high-nickel sulfonium into a reduction zone of the electric melting furnace of the side-blowing melting pool, controlling the temperature of the furnace to be in a range of 1300 DEG C-1400 DEG C, and injecting a reducing agent into an inclined inserting port of a spraying gun of the electric furnace. By adopting the method in the invention, slag-type optimization of the furnace slag containing nickel, transformation from nickel chemically dissolving in the slag into sulfonium I and separation of the slag and the sulfonium are finished in the electric melting furnace of the side-blowing melting pool. The invention has the advantages that reducing and slag making reaction of magnetic iron oxide, sulfonium making reaction and slag-sulfonium settlement and separation are finished at different zones in one side-blowing electric furnace; the nickel content in the waste slag is low; and the foaming of the furnace slag is avoided and the operation process is smooth and safe.

Owner:KUNMING UNIV OF SCI & TECH +1

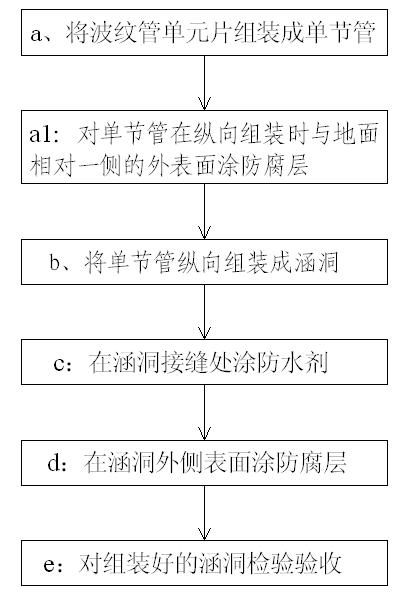

Method for quickly assembling assembled corrugated culvert

The invention discloses a method for quickly assembling an assembled corrugated culvert. The method comprises the following steps: a. assembling the corrugated pipe unit pieces into single pipes; b. longitudinally assembling the single pipes into the culvert; c. coating waterproofing agent on the joint of the culvert; d. coating waterproofing agent on the outside of the culvert; e. inspecting and accepting the assembled culvert. The method has the following beneficial effects: the corrugated pipe unit pieces in the step a are placed on assembling equipment to be assembled, with the axes being horizontal, and when the corrugated pipe unit pieces are assembled on the assembling equipment, the operators stand to operate, so the operation labor intensity is low and the efficiency is high; in the step b, the roller type prong forklift is adopted to transport the single pipes, so the equipment utilization ratio is high and the single pipes are fast and convenient to transport, meanwhile, dislocation adjustment is carried out on the roller type prong forklift, so the adjustment speed is high and the electroplated anticorrosive coating of the corrugated pipe can not be damaged, and bolted connection is carried out on the lifting working platform of the forklift and the crawling ladders at the two sides, so the operation is safe and the efficiency is high; and the waterproofing agent and a preservative are coated on the culvert, so the quality of the culvert can be ensured, and finally the culvert is inspected and accepted, so the quality of the culvertcan be further ensured.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 17TH BUREAU GRP

Multi-function line pole machine

ActiveCN102296876AReduce labor intensityImprove construction efficiencyTowersTransfer caseNatural disaster

The invention discloses a multifunctional stringing pole-erecting machine which comprises a power operation vehicle with a walking chassis, wherein the lower part of the walking chassis is provided with walking wheels, the rear part of the walking chassis is provided with a power mechanism and a driving control chamber, the front part of the walking chassis is provided with a rotary support, the power mechanism is in transmission connection with the walking wheels through a transmission shaft under the walking chassis and a transfer case, the power mechanism is in hydraulic transmission connection with the rotary support, a rotary base is arranged on the rotary support, a pole lifting device is rotatably connected to the rotary base, the lower part of the pole lifting device is provided with a drilling mechanism, and the front end and the rear end of the walking chassis are respectively provided with a foldable front support leg and a foldable rear support leg. The multifunction stringing pole-erecting machine is a power grid stringing construction mechanical device integrating drilling and pole erecting, is integrally of an electrohydraulic control mode, is especially suitable for emergence rush repair when a power grid suffers from natural disasters, and is more suitable for environment with larger pole-erecting operation density in rugged and narrow places and places into which construction vehicles can not enter.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

Minitype remote-control chain-type tractor

InactiveCN102017831AReduce labor intensityImprove adhesionAgricultural machinesTransmission systemsTransmitted powerAgricultural engineering

The invention discloses a minitype remote-control chain-type tractor. A belt variable speed case is arranged between an engine and a gear box, wherein the engine transmits power to the belt variable speed case by a main clutch and drives two drive sprockets of a crawler by two steering clutches; the main clutch, the middle driving wheel of the belt variable speed case, the steering clutches, agricultural implement lifting and an engine revolving speed control accelerator are all driven by a small hydrocylinder; the small hydrocylinder is controlled by solenoid directional valves, and each solenoid directional valve is provided with a radio frequency remote control receiver and a remote control unit for remotely controlling or manually controlling. The minitype remote-control chain-type tractor can pass through fruit trees and under crowns, can conveniently finish operation items of weeding, loosening the soil, fertilizing and the like and is especially suitable to use in low orchards and greenhouses with thick planting.

Owner:山西卓里集团有限公司

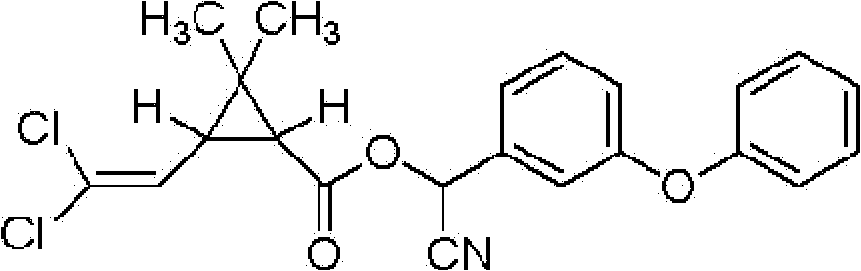

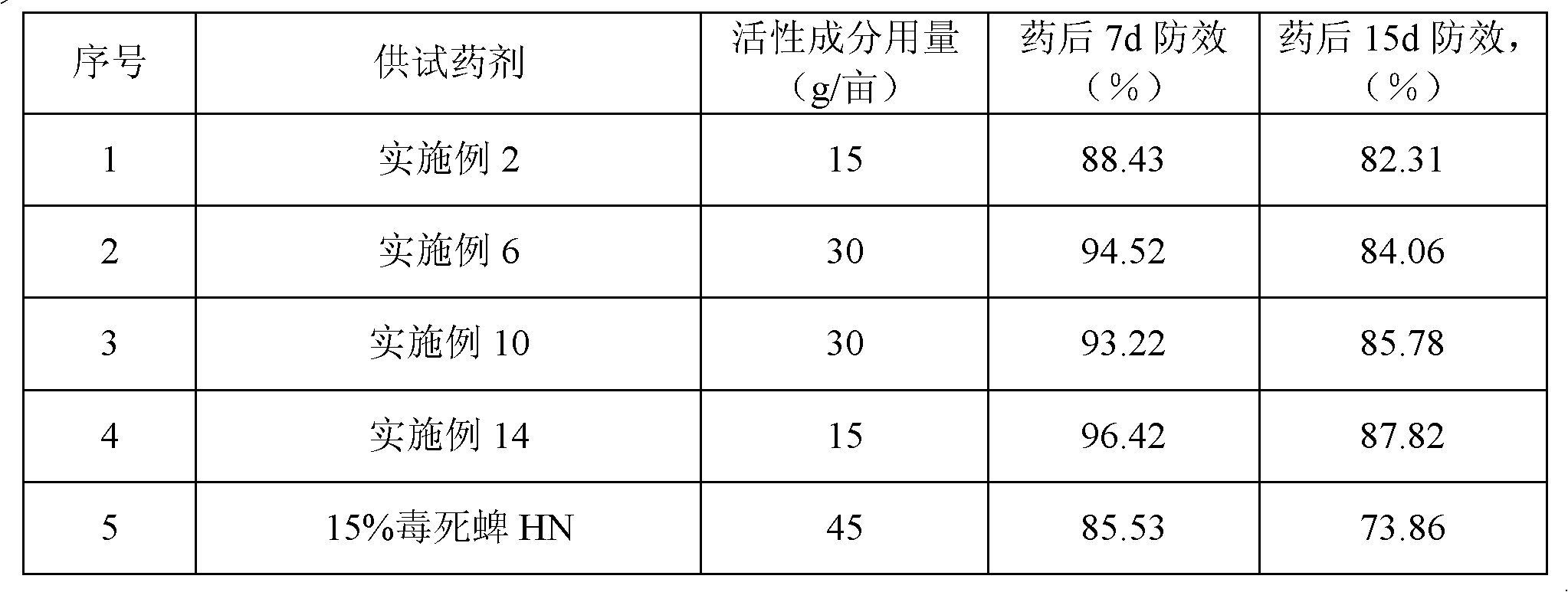

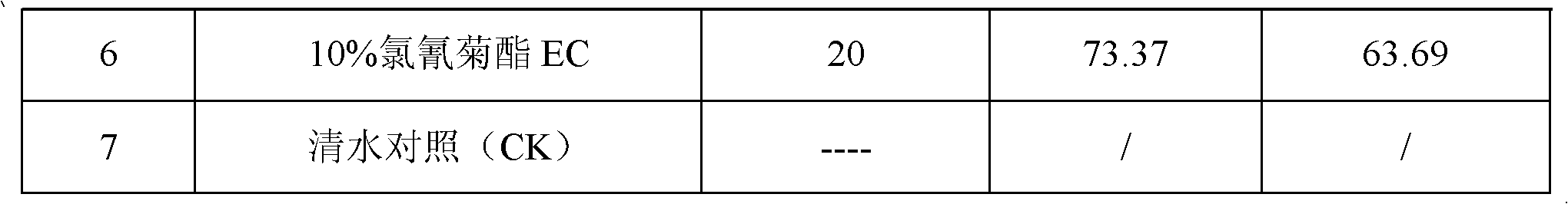

Hot fogging concentrate containing cypermethrin

InactiveCN102630698AReduce total usageImprove the effect of prevention and controlBiocideAnimal repellantsCypermethrinChlorpyrifos

The invention discloses a hot fogging concentrate containing cypermethrin, which is prepared by using cypermethrin or the mixture of cypermethrin and an active component II as the effective constituent, and adding accessory ingredient and solvent, wherein the active component II is any one of chlorpyrifos, dimethoate and nitenpyram. By using the cypermethrin as the effective constituent, the hot fogging concentrate comprises the following components by weight percent: 1.6-30% of cypermethrin, 1-20% of accessory ingredient and the balance of solvent. By using any one of the cypermethrin and the active component II as the effective constituent, the hot fogging concentrate comprises the following components by weight percent: 0.1-20% of cypermethrin, 0.1-40% of active component II, 1-20% of accessory ingredient and the balance of solvent. The hot fogging concentrate disclosed by the invention is applicable to a hot fogging machine for preventing insect pests on sugarcane, corn, tobacco, fruit trees and forests. The hot fogging concentrate has the advantages of high working efficiency, strong knock-down activity, synergetic effect, good preventing effect, simpleness in operation, water and labor saving, safety, environmental friendliness, and the like.

Owner:GAUNGXI TIANYUAN BIOCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com