Method and equipment for depleting furnace slag of electric melting furnace of side-blowing melting pool

A melting pool smelting and electric furnace technology, applied in the direction of lighting and heating equipment, process efficiency improvement, etc., can solve the problems of nickel content in the waste slag not meeting the requirements, high power, increased power consumption, etc., and achieve good reduction reaction Effects of kinetic conditions, system configuration simplification, and reduction of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

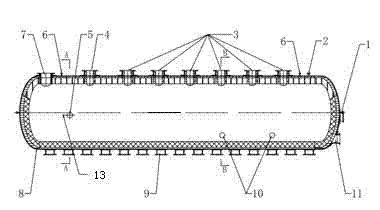

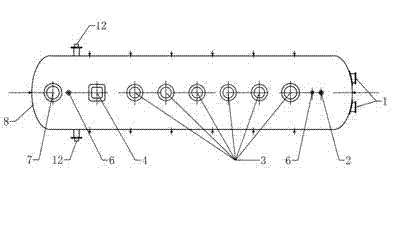

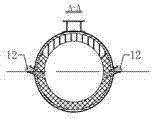

[0029] The oxygen-enriched top-blown nickel smelting system feeds 84 tons of smelting slag (containing Fe 3 o 4 7.5% and 0.9% Ni) to the electric furnace for melting in the side-blowing molten pool. The refractory brick lining of the electric furnace is not easy to fall, and the masonry is convenient; the geometric size of the furnace is conducive to the uniform distribution of the temperature field. The power of the electric furnace is maintained at 8500 kWh per hour, and the furnace temperature is kept at 1330 ° C ~ 1380 ° C. Use a spray gun to inject coal-based reducing agent (68% fixed carbon, 18% volatile matter, 5.5% sulfur, particle size less than 5mm) from the inclined socket of the spray gun Spray into the molten pool in the reduction zone of the electric furnace, the injection rate of the reducing agent is controlled at 25kg / min per gun, and the compressed air volume for transporting the reducing agent is 500Nm 3 / h·Only one gun, the slag is discharged from the sla...

Embodiment 2

[0032] Converting slag (containing Fe 3 o 4 8.2% and 1.6% Ni), sent to the side-blown molten pool smelting electric furnace for dilution treatment, and 21 tons of blowing slag was input per hour. The hearth size of the electric furnace is Φ4×13.5 meters, 3 electrodes, and a spray gun is installed on each side wall of the reduction zone. The power of the electric furnace is maintained at 4600 kWh per hour, and the furnace temperature is kept at 1240 ° C to 1300 ° C. Use a spray gun to inject a coal-based reducing agent (76% fixed carbon, 10% volatile matter, 3.8% sulfur, and a particle size of less than 5mm) from the inclined socket of the spray gun. Spray into the molten pool in the reduction zone of the electric furnace, the injection rate of the reducing agent is controlled at 9kg / min per gun, and the compressed air volume for transporting the reducing agent is 180Nm 3 / h · gun. After being diluted, the slag is discharged intermittently from the slag outlet of the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com