Patents

Literature

704 results about "Nickel sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel sulfide is an inorganic compound with the formula NiS. It is a black solid that is produced by treating nickel(II) salts with hydrogen sulfide. Many nickel sulfides are known, including the mineral millerite, which also has the formula NiS. Aside from being useful ores, nickel sulfides are the products of desulfurization reactions, and are sometimes used as catalysts. Nonstoichiometric forms of nickel sulfide are known, e.g., Ni₉S₈ and Ni₃S₂.

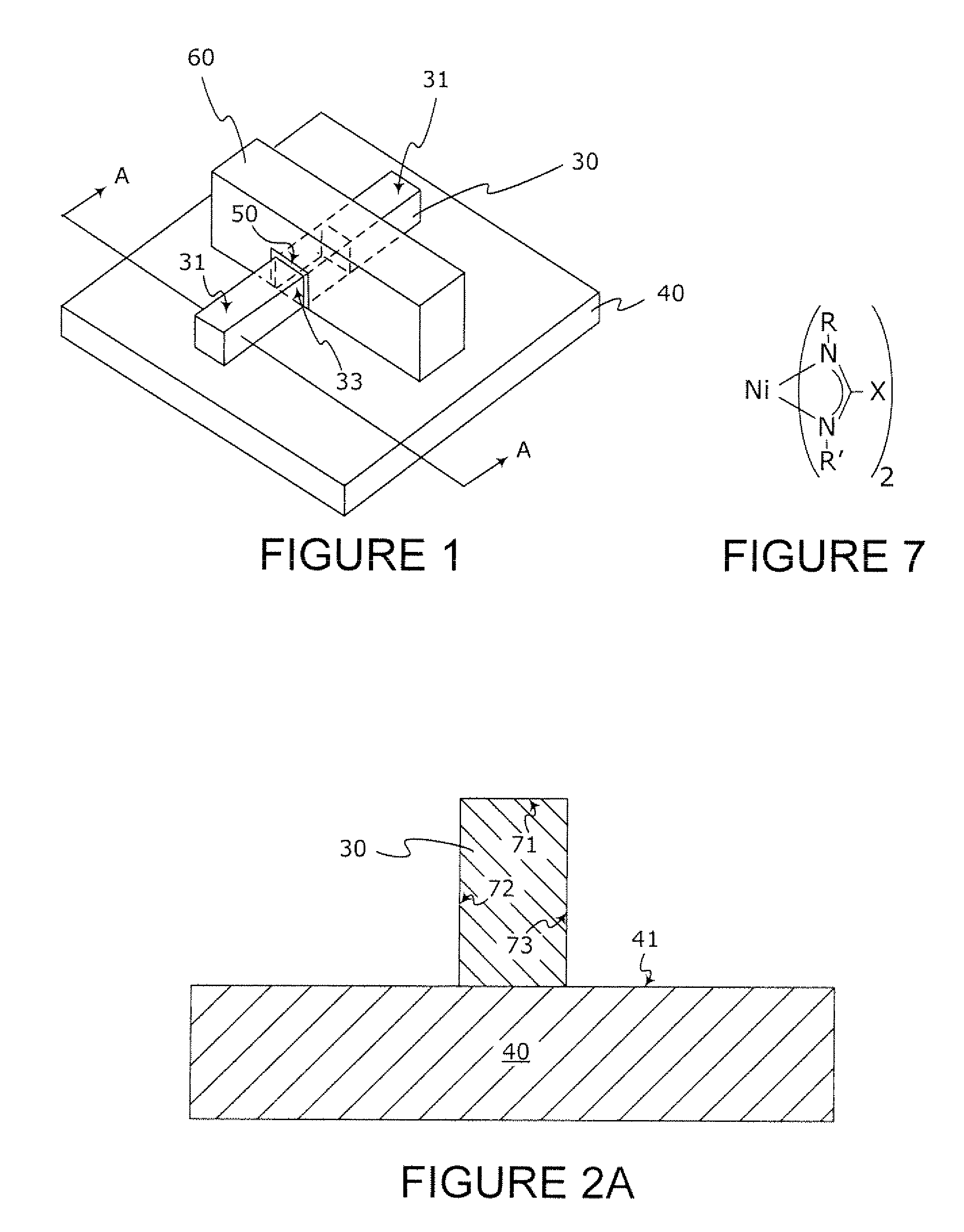

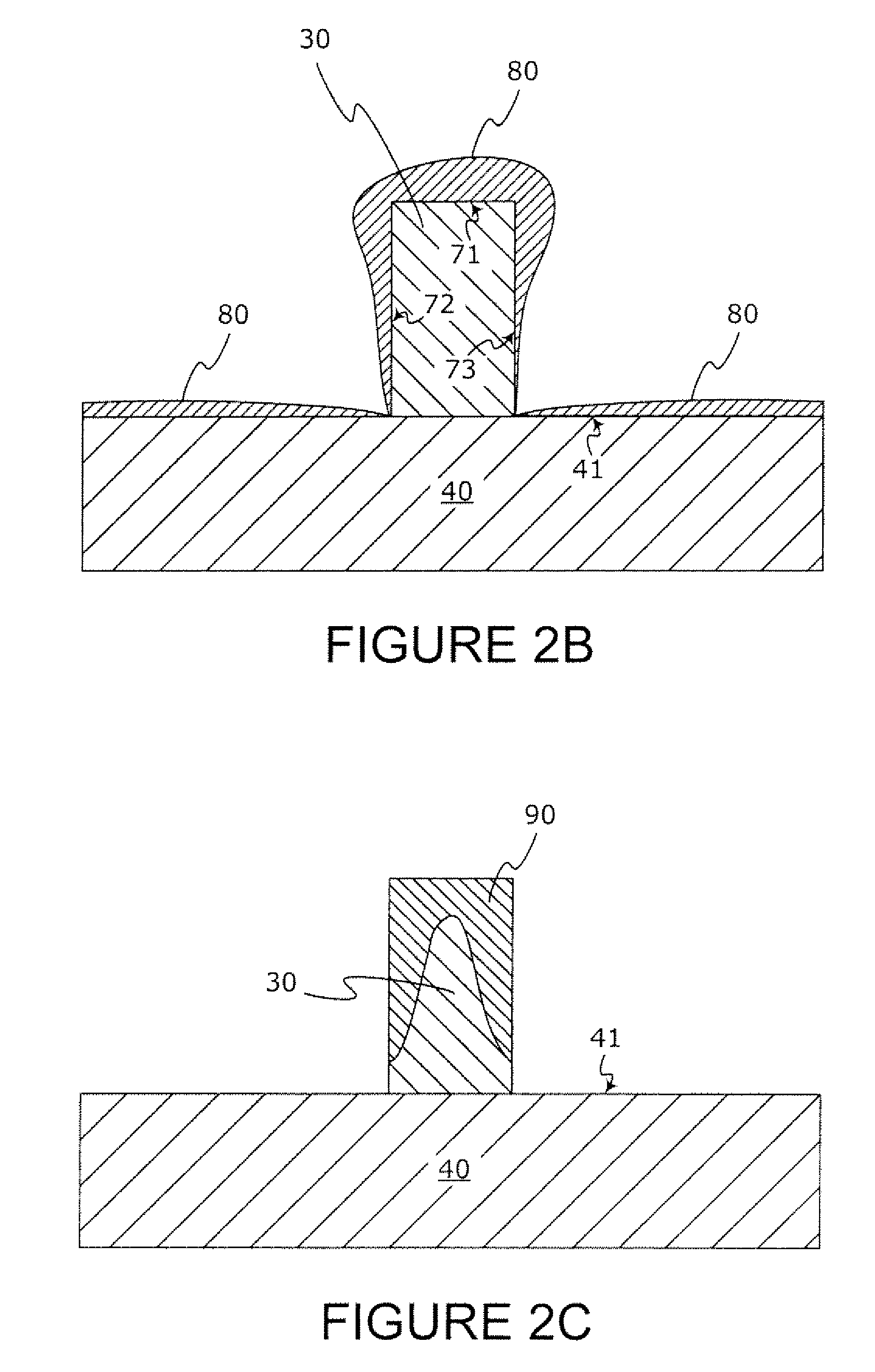

Methods of forming nickel sulfide film on a semiconductor device

InactiveUS20100163937A1Semiconductor/solid-state device detailsSolid-state devicesNickel sulfideSulfur containing

Owner:INTEL CORP

Method for desulfurizing a fuel for use in a fuel cell power plant

A fuel processing system is operable to remove substantially all of the sulfur present in an undiluted hydrocarbon fuel stock supply used to power a fuel cell power plant in a mobile environment, such as an automobile, bus, truck, boat, or the like, or in a stationary environment. The power plant hydrogen fuel source can be gasoline, diesel fuel, naphtha, light hydrocarbon fuels such as butane, propane, natural gas, or other like fuels which contain relatively high levels of organic sulfur compounds such as mercaptans, sulfides, disulfides, and the like. The undiluted hydrocarbon fuel supply is passed through a nickel desulfurizer bed wherein essentially all of the sulfur in the organic sulfur compounds react with the nickel reactant, and are converted to nickel sulfide while the desulfurized organic remnants continue through the remainder of the fuel processing system. The system does not require the addition of steam or a hydrogen source to the fuel stream prior to the desulfurizing step. The system operates at relatively low temperatures and can be used to desulfurize either a liquid or a gaseous fuel stream.

Owner:UNITED TECH CORP

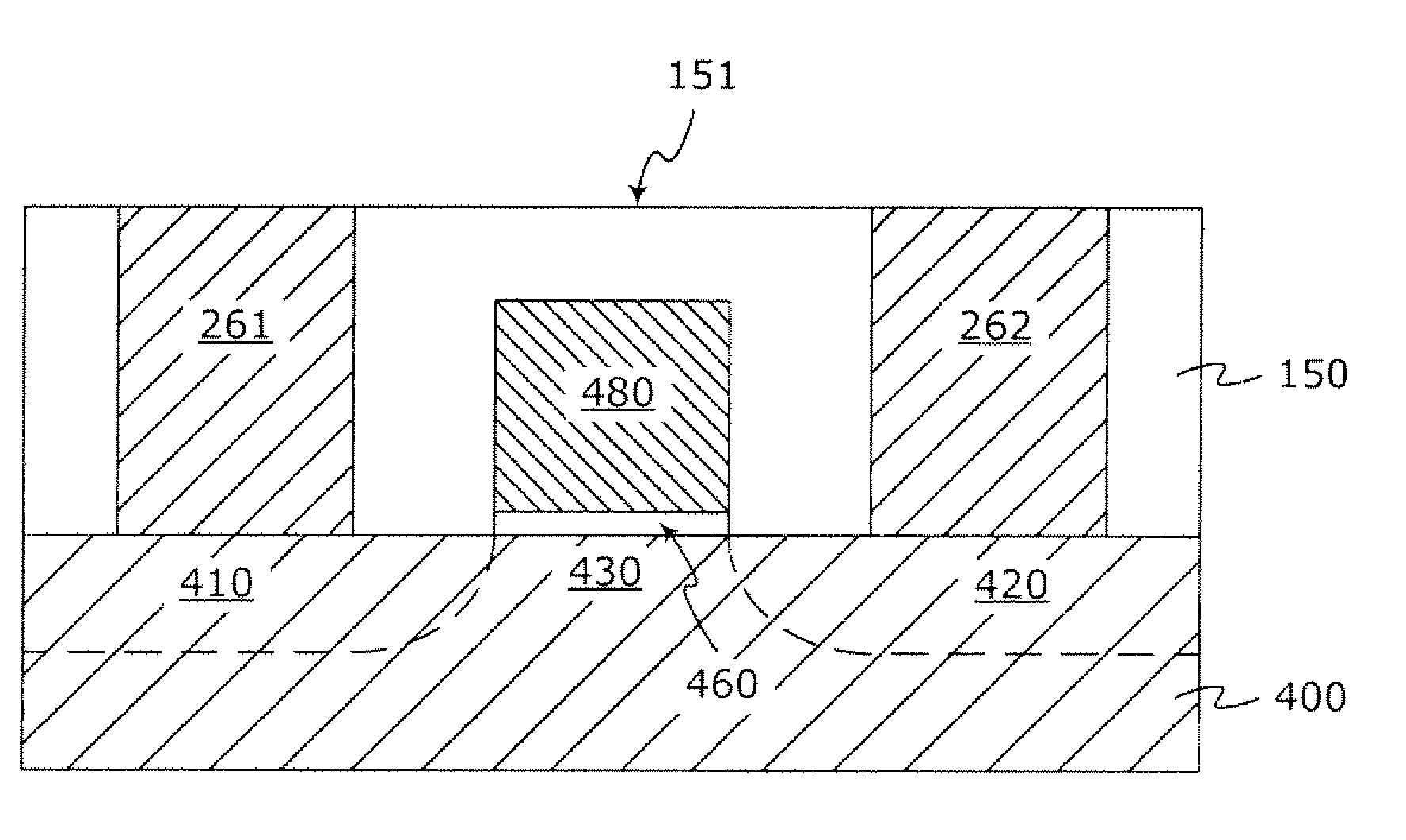

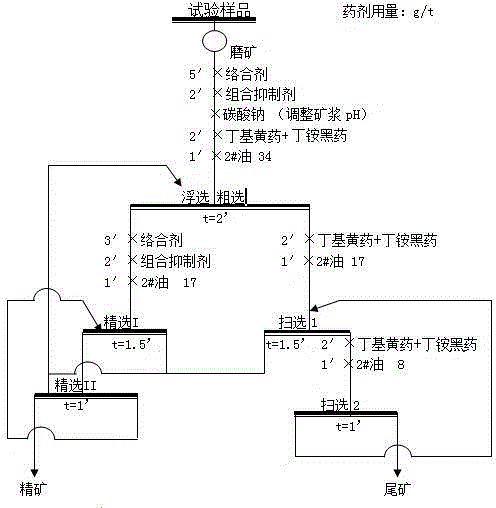

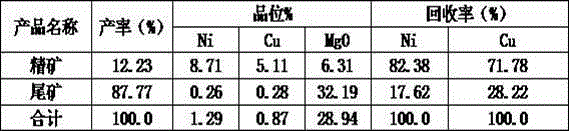

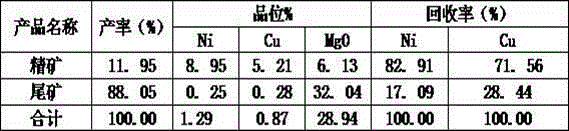

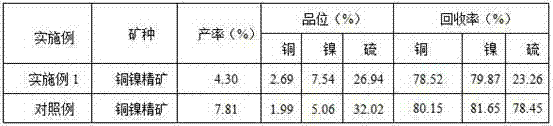

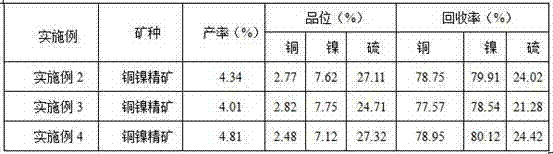

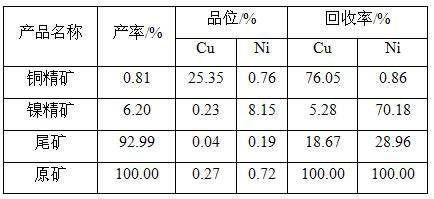

Method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation

The invention relates to a method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation. The method includes steps of firstly adding complexing agent oxalic acid, citric acid, tartaric acid, quadrol and EDTA (ethylene diamine tetraacetic acid), cleaning active ions of copper and nickel on the surface of magnesium-contained gangue mineral such as serpentine, removing flotation activity of sulfide ore collector such as xanthogenate, and adding composition agent to suppress gangue mineral. Ore pulp is treated by complexing agent, the flotation environment is improved, and floatability difference between copper-nickel sulfide mineral and magnesium-contained gangue mineral is increased. By combined inhibitor, serpentine and talc gangue mineral are suppressed, and magnesium-reducing effect is better; nickel recovery rate is increased to some extent as compared with that of actual production. Meanwhile, content of magnesium oxide in concentrate is reduced, and melting cost is lowered.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

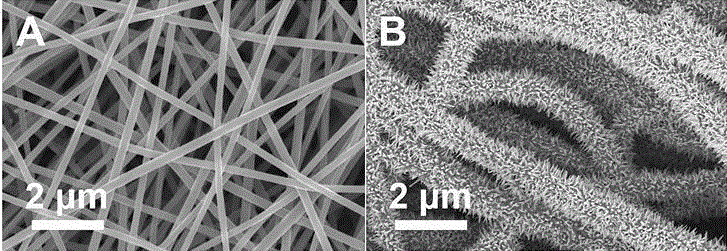

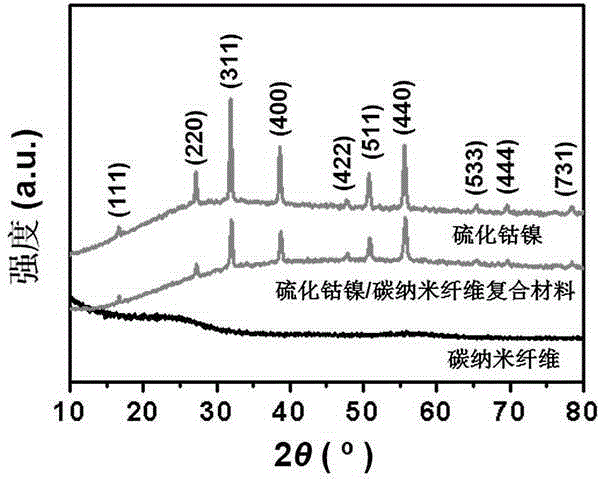

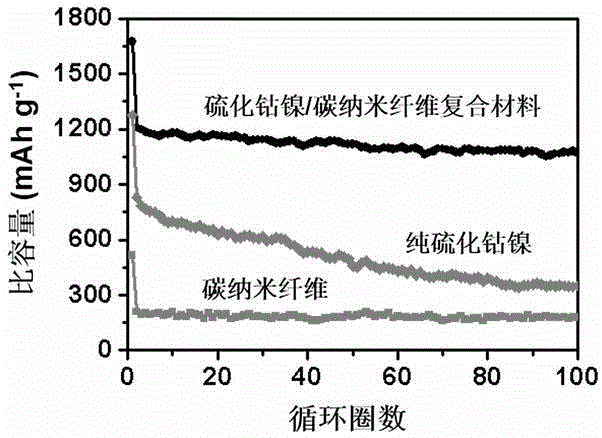

Cobalt-nickel sulfide/carbon nanofiber composite material and preparation method and application thereof

InactiveCN105280896AEasy to makeEasy to operateMaterial nanotechnologyHybrid capacitor electrodesNew energyCarbon nanofiber

The invention belongs to the technical field of transition metal sulfide-carbon materials, and particularly discloses a cobalt-nickel sulfide / carbon nanofiber composite material and a preparation method and an application thereof. The method comprises the following preparation processes: preparing a carbon nanofiber through electrostatic spinning and high-temperature carbonization methods; and carrying out in-situ growth of a cobalt-nickel sulfide nanorod on the carbon nanofiber through a one-step hydrothermal method. The carbon nanofiber prepared by the method has the advantages of stable chemical property, good conductivity, good mechanical property and the like; the final cobalt-nickel sulfide / carbon nanofiber composite material is controllable in morphology; the cobalt-nickel sulfide nanorod uniformly grows on the carbon nanofiber; and a unique base structure and high specific surface area of the carbon nanofiber are fully utilized. The cobalt-nickel sulfide / carbon nanofiber composite material prepared by the method can be used as an ideal high-property electrocatalytic material, and an electrode material for new energy devices of a lithium-ion battery, a super capacitor and the like.

Owner:FUDAN UNIV

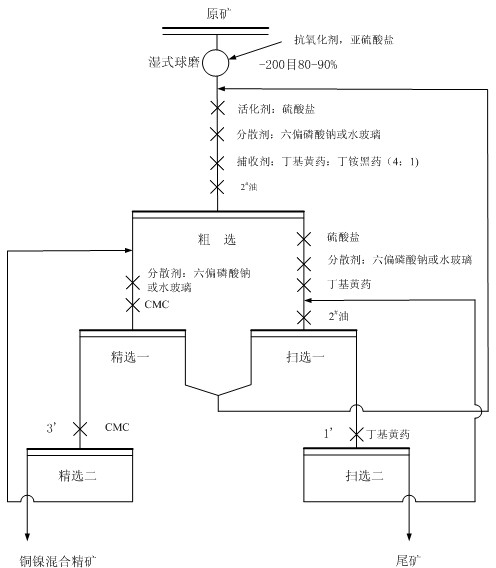

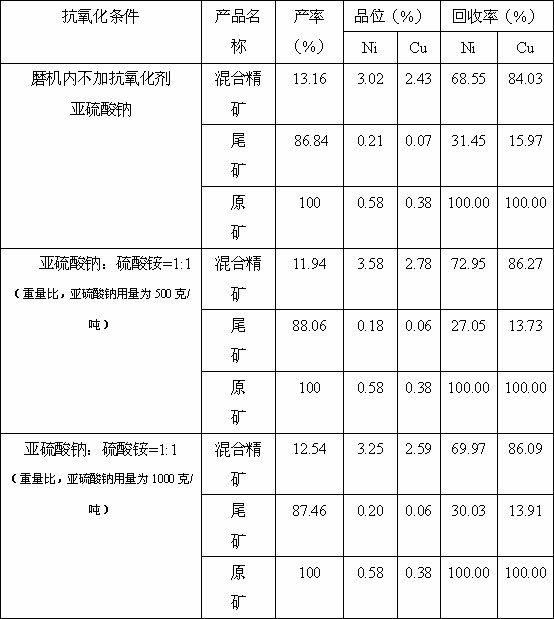

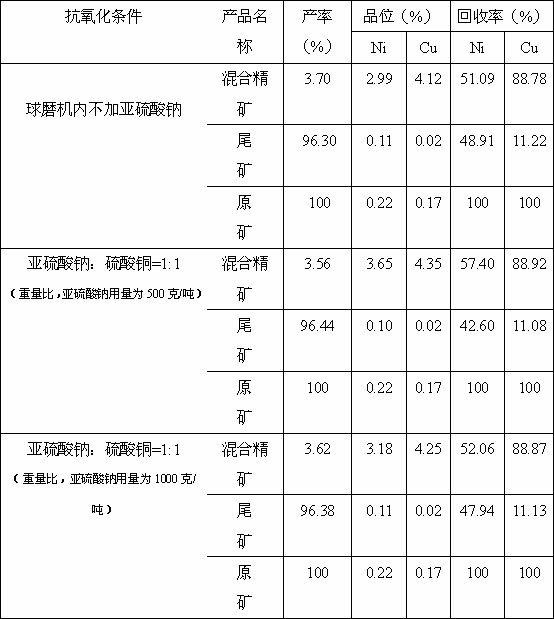

Flotation method for copper-containing nickel sulfide ore

InactiveCN102423728AGuaranteed not to be oxidizedImprove adsorption capacityFlotationAntioxidantPyrite

The invention discloses a flotation method for a copper-containing nickel sulfide ore. In order to solve the problem that nickel-containing sulfide is easily oxidized in the flotation process, the invention provides a flotation method which can ensure that the nickel-containing sulfide is not oxidized and can make a part of oxidized nickel ore activated, namely sulfite serving as an antioxidant of nickel sulfide is added during grinding operation of the copper-containing nickel sulfide ore, and sulfate serving as an activating agent with the same weight as the sulfite is added before flotation operation, so that the using amount of the antioxidant is sufficient, the requirement of preventing or delaying the nickel sulfide from being oxidized is met, and the nickel-containing sulfide such as pentlandite and the like is activated. Compared with the conventional flotation method in which the antioxidant is not added, the anti-oxidation method has the advantages that: the grade of a copper-nickel mixed concentrate can be improved by about 1 percent, the recovery rate of copper can be improved by 0 to 2 percent, and the recovery rate of nickel can be improved by 4 to 6 percent.

Owner:KUNMING UNIV OF SCI & TECH

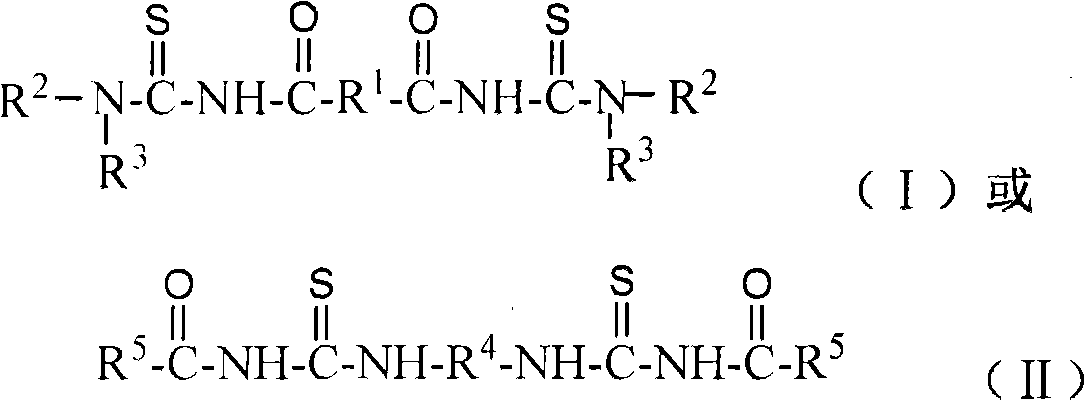

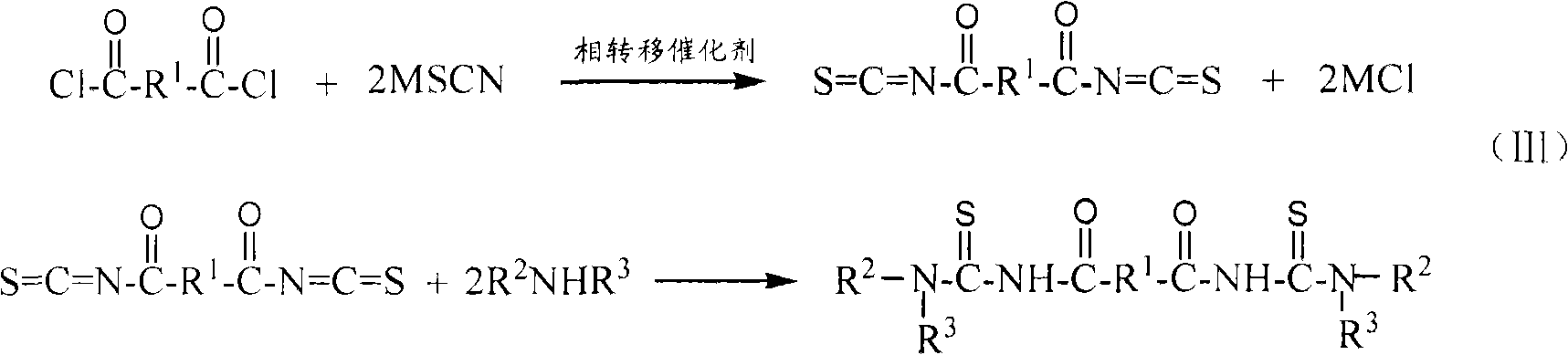

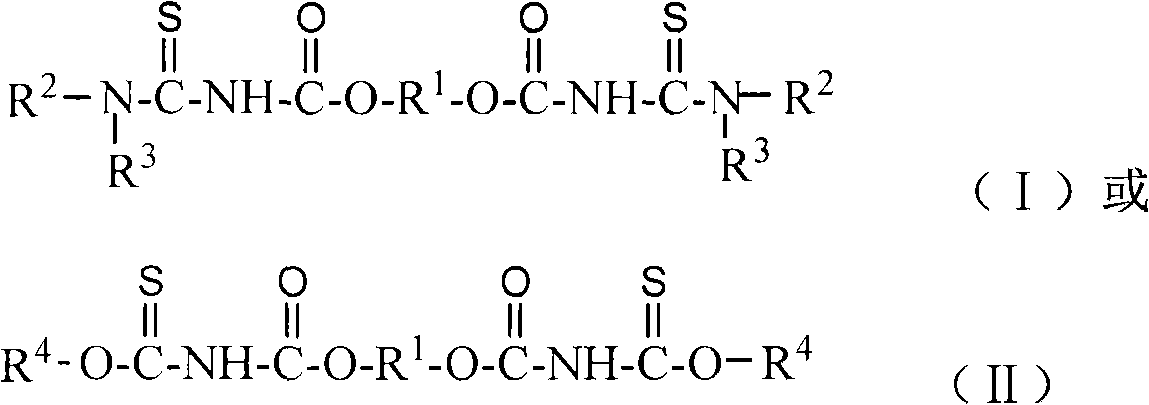

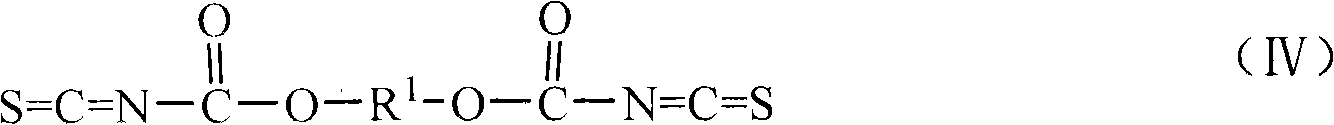

Sulphide ore floation collector and use method of diacyl bis-thiourea and preparation method thereof

InactiveCN101337206AEasy to makeEfficient flotation separationOrganic chemistryFlotationMagmaThiourea

The invention discloses the application processes and the preparation methods of a sulphide ore flotation collector as well as a diacyl bis-thiourea. The invention relates to a novel collector used for high efficiently recycling valuable sulfide minerals from metal sulphide ores; the compositions of the sulphide ore flotation collector include diacyl bis-thiourea surface active agents; the diacyl bis-thiourea compound is shown in the constitutional formula (1) or (2). The collector has strong collecting ability to copper sulphide minerals such as chalcopyrite, etc., lead sulfide minerals or zinc sulfide minerals activated by copper ions, nickel sulfide minerals as well as noble metal minerals such as gold, silver, etc., and has good selectivity to gangue sulphide minerals such as iron pyrites, pyrrhotite, etc., thereby realizing the high efficient flotation separation of the copper sulphide minerals and ferric sulfide minerals when the pH value of ore magma is below 11, reducing the used amount of lime, and improving the comprehensive recovery of copper sulphide ores.

Owner:CENT SOUTH UNIV

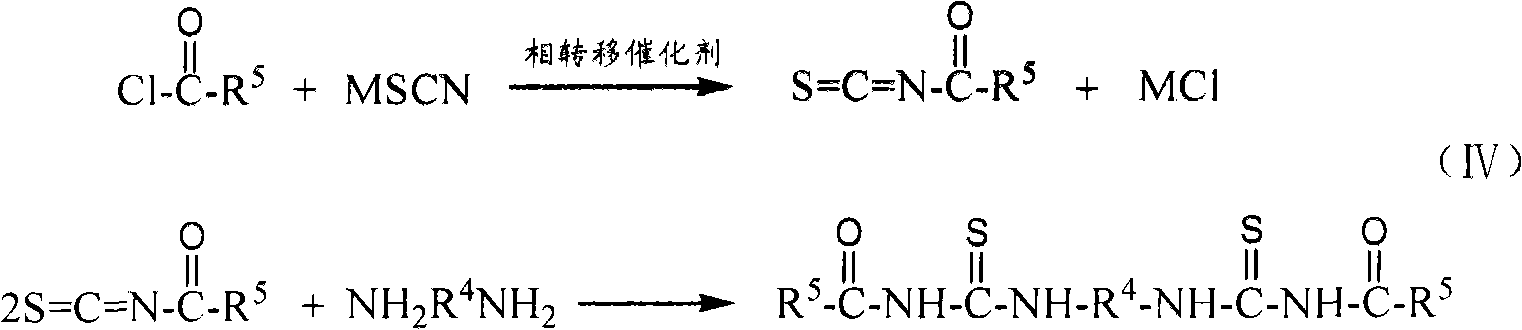

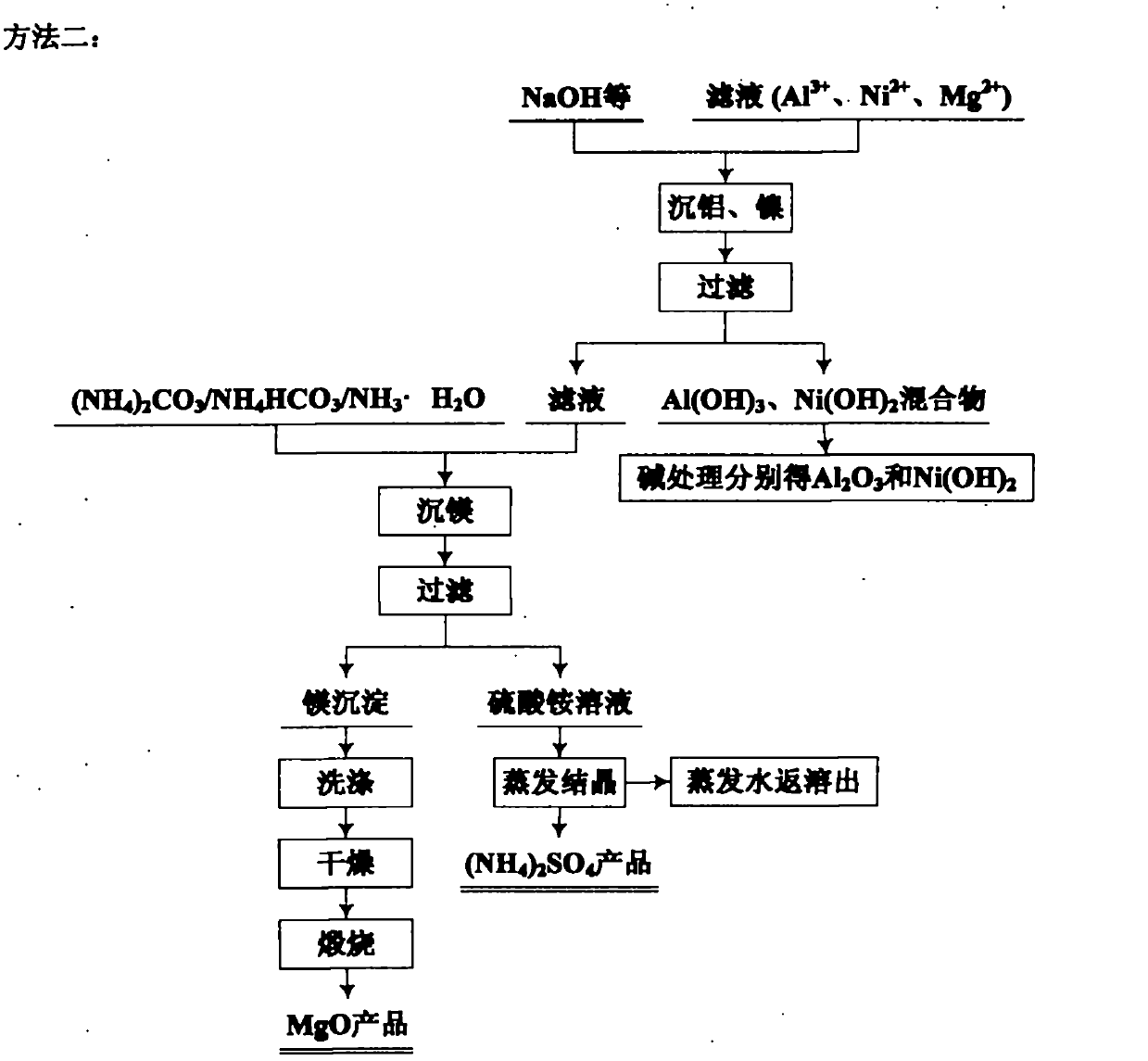

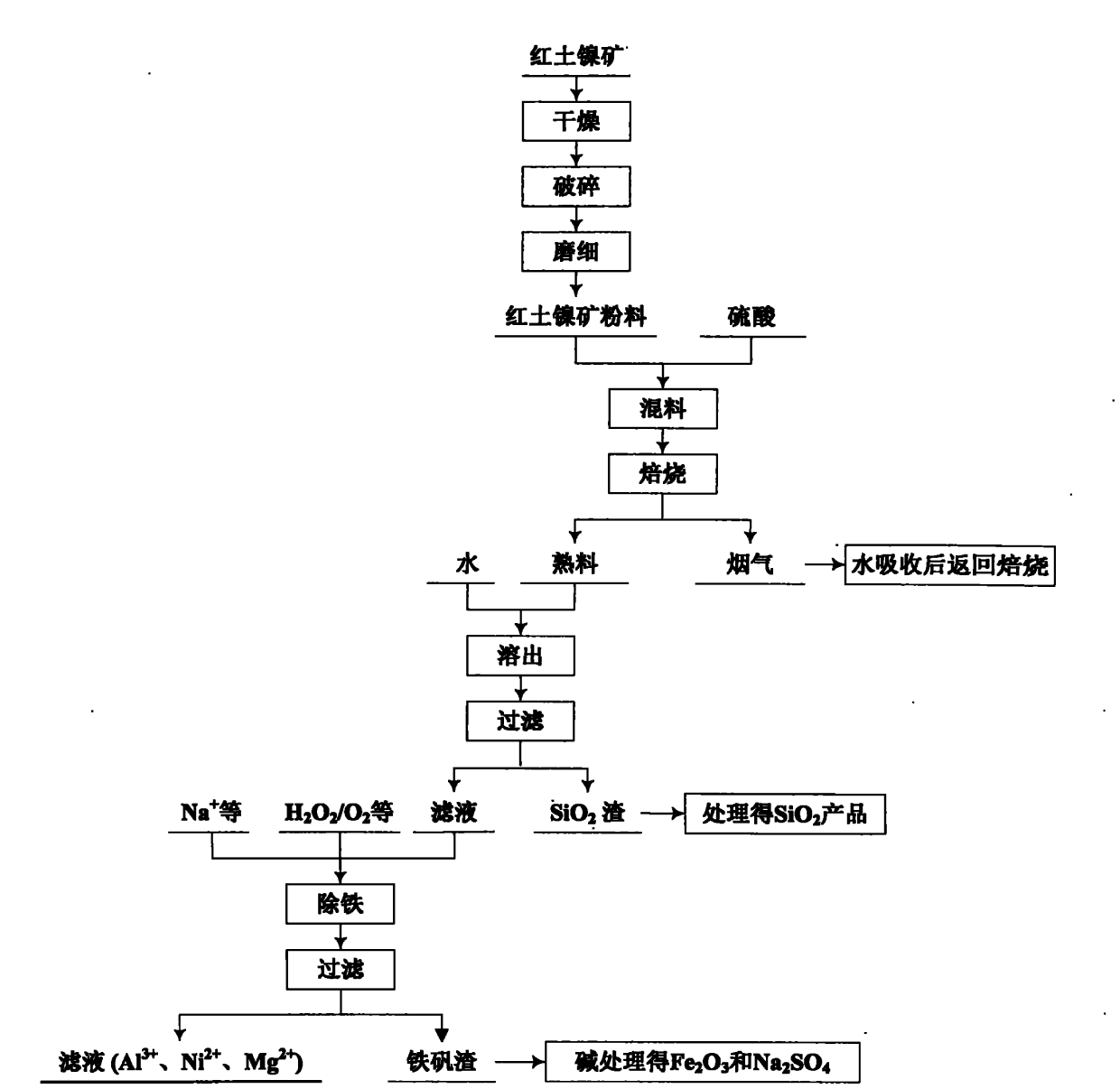

Comprehensive utilization method for laterite-nickel ore

The invention relates to an environmental-friendly comprehensive utilization method for a laterite-nickel ore, which comprises the following steps of: (1) grinding the laterite-nickel ore, mixing with sulfuric acid, roasting, dissolving out roasted clinker and filtering to obtain silicon dioxide and dissolution liquid; (2) deironing the dissolution liquid to obtain liquid No.2 and filter residue (iron compounds), wherein the liquid No.2 comprises aluminum, nickel and magnesium and can be treated by the step (3) or (4); (3) precipitating the aluminum in the liquid No.2 by using alkali, filtering, precipitating the nickel in filtrate by using sodium sulfide, filtering, precipitating the magnesium by using the alkali, and treating filter residue to obtain aluminum oxide, nickel hydroxide, nickel sulfide and magnesium oxide respectively; and (4) precipitating the aluminum and the nickel in the liquid No.2 by using the alkali, treating mixed slag containing the aluminum and the nickel by using the alkali to obtain aluminum hydroxide and nickel hydroxide products, and precipitating the magnesium in filtrate subjected to aluminum and nickel precipitation by using ammonia or ammonium saltto obtain a magnesium oxide product. The method is suitable for treating various laterite-nickel ores, three wastes (waste gas, waste water and waste residue) are not generated, and valuable components magnesium, nickel, iron, aluminum and silicon in the laterite-nickel ore are separated and extracted.

Owner:NORTHEASTERN UNIV

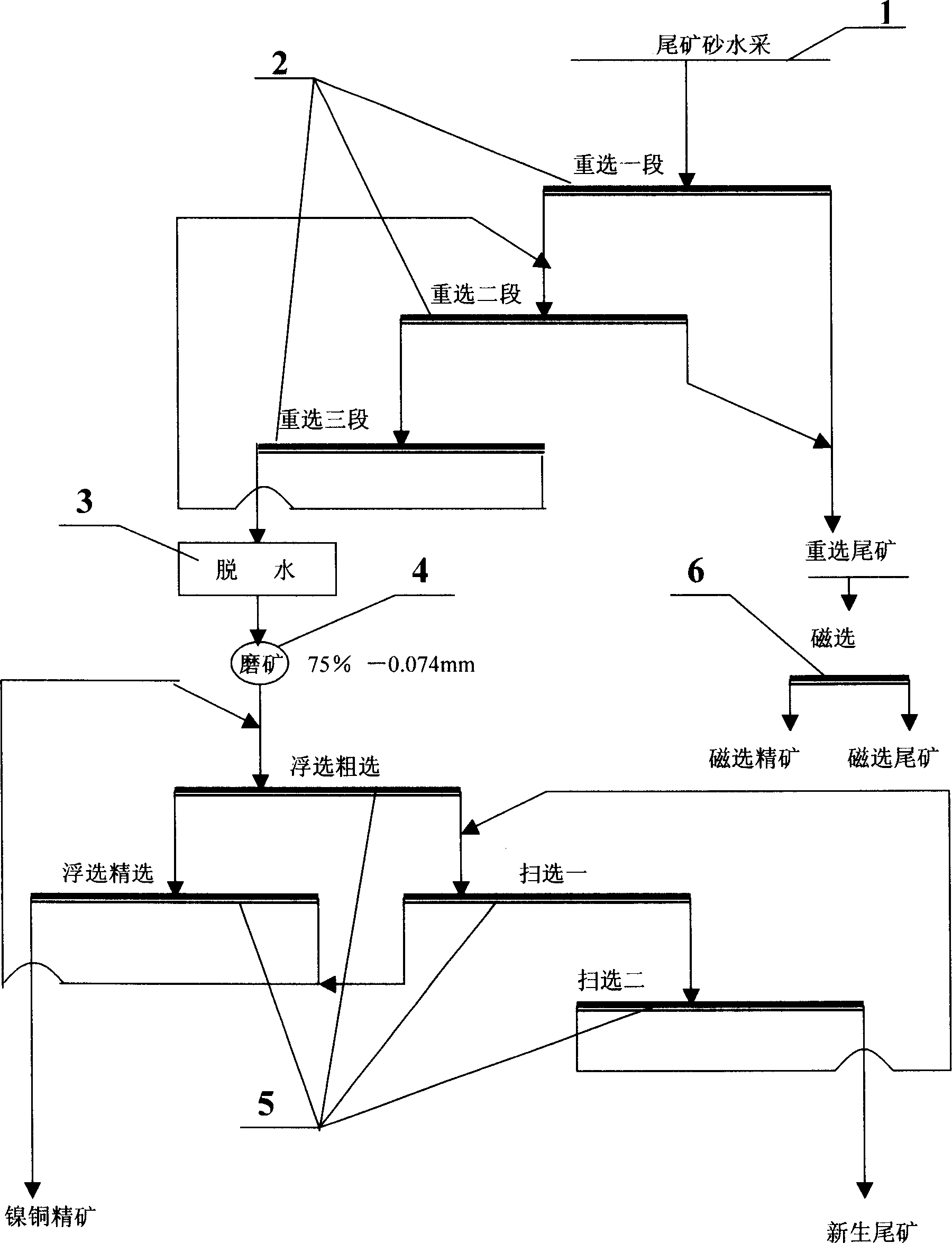

Nickel sulfide, copper tailings comprehensive recovery technology

ActiveCN1651148AAdvanced technologyHigh recovery rateFlotationProcess efficiency improvementSlurryNickel sulfide

A technology for recovering the pickel sulfide-copper sulfide tailings includes water collection of said tailings sand, preparing slurry, three-segment separating, dewatering, grinding, adding the separating chemicals consisting of capture, activator, foamer, regulator and depressent, floatation, and magnetic separating. Its advantages are high productivity and recovery rate, and no secondary pollution.

Owner:JILIN JIEN NICKEL IND

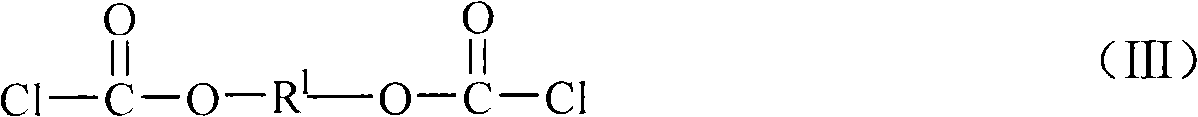

Use of diester isosulfocyanate in sulphide ore floation and preparation method thereof

InactiveCN101337205AEasy to makeStrong harvesting abilityOrganic chemistryFlotationMagmaSulfide minerals

The invention discloses a diester-based 2-thiocyanate ester derivate applied in sulphide flotation, and the preparation method thereof. Diester-based 2-thiourea (the formula one) or diester-based 2-ethionine ester (the formula two) is applied as a novel collector for high efficiently recycling valuable sulfide minerals from metal sulphide ores by floatation. The collector has wide pH range in ore magma, thereby having strong ability to collect copper sulphide minerals such as chalcopyrite, etc., lead sulfide minerals or zinc sulfide minerals activated by copper ions, nickel sulfide minerals as well as noble metal minerals such as gold, silver, etc., and having good selectivity to gangue sulphide minerals such as iron pyrites, pyrrhotite, etc.

Owner:CENT SOUTH UNIV

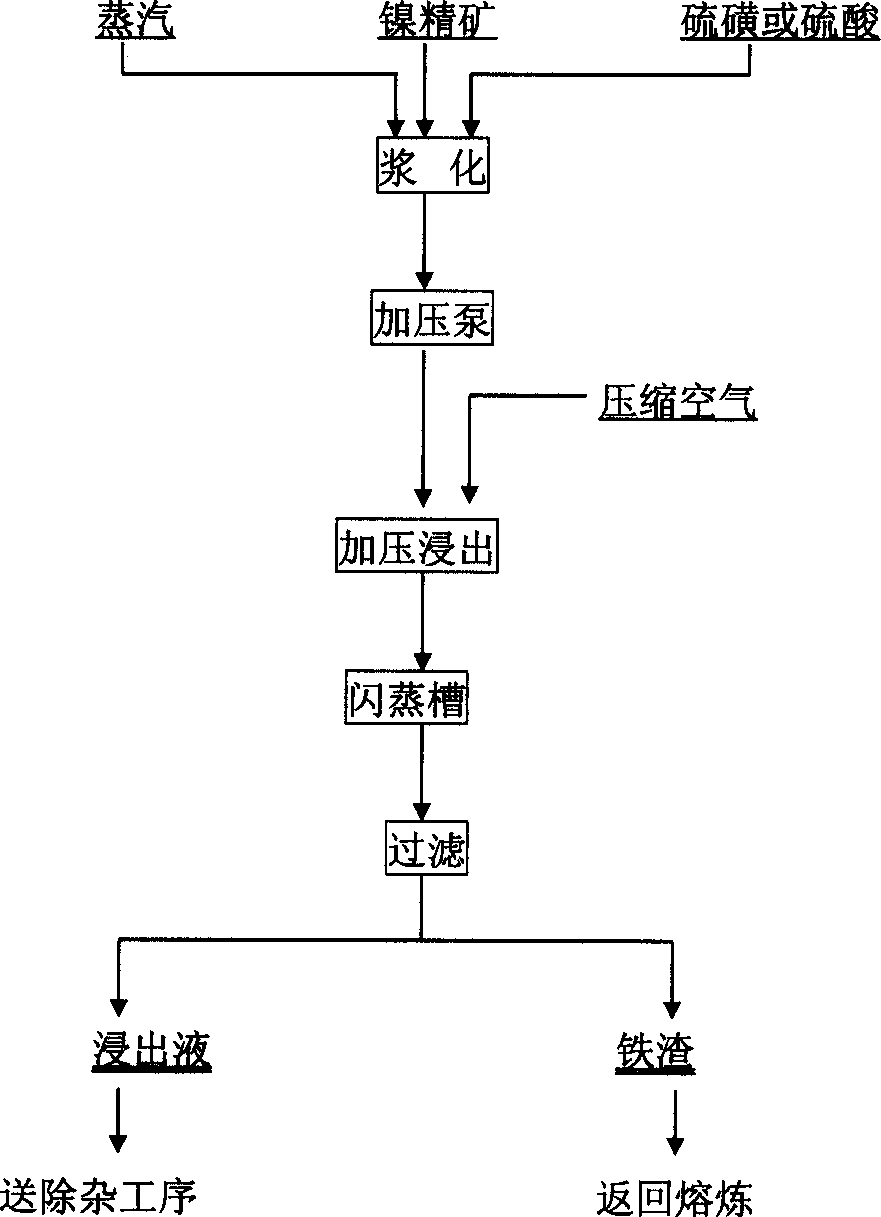

Process for extracting nickel from nickel sulfide material with low copper content

The nickel extracting process of the present invention relates to the one-stage pressurized leaching extraction of nickel from nickel concentrate with low copper content or high sulfur nickel concentrate separated through milling and floating procedure. The process features that under oxygenation and adding sulfur or sulfuric acid, and in 100-180 deg.c and oxygen pressure 50-300 KPa, nickel concentrate is one-step pressurized leached to complete the Ni, Co and Cu leaching process with Fe being fixed in slag. Nickel sulfate solution after liquid-solid separation may be used in production pure nickel sulfate or electrolyte while recovering Co, Cu and other valuable metals. The process is simple and high in production efficiency.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

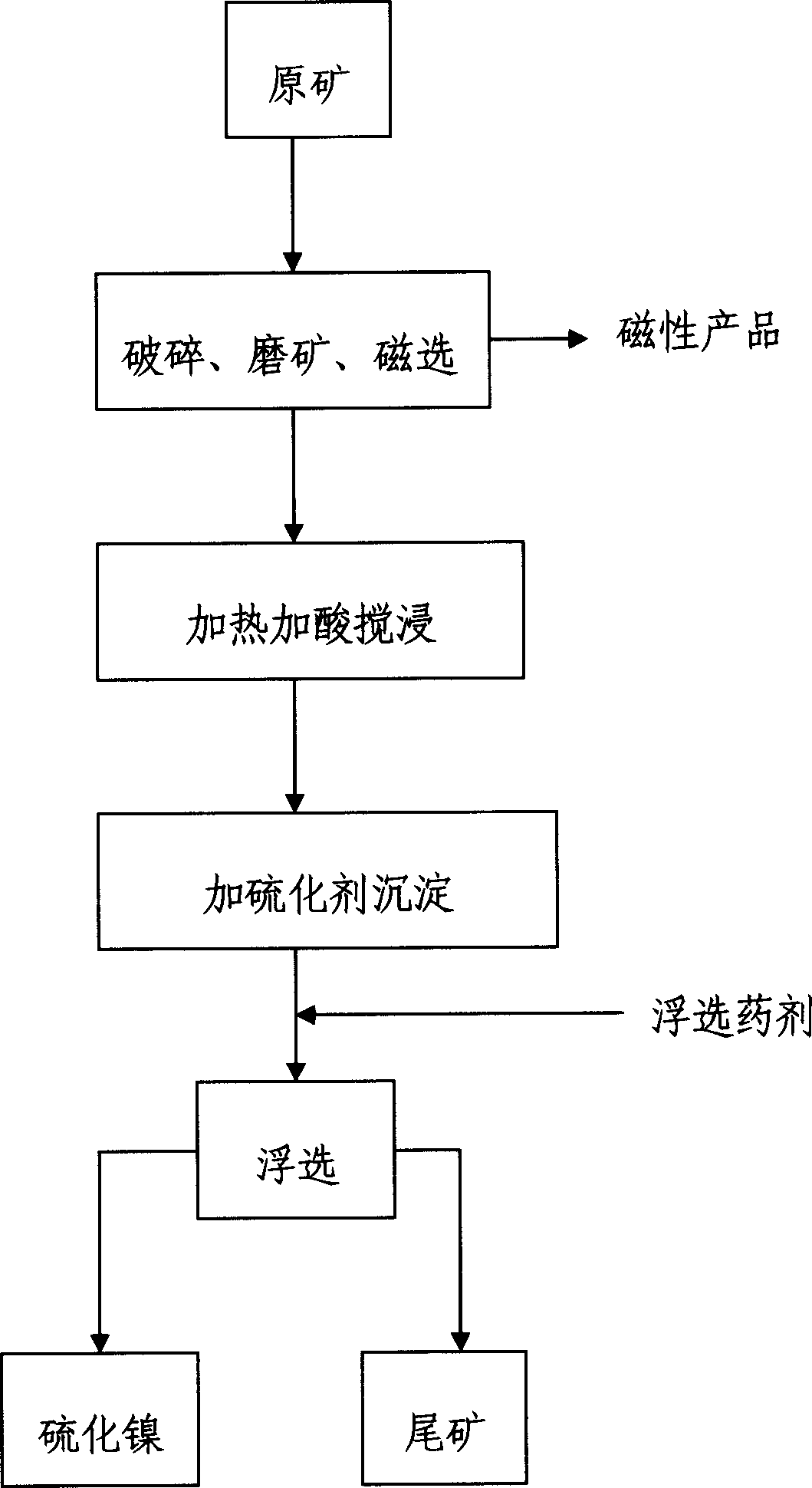

New treating method for nickel oxide ore

InactiveCN1858274AEfficient use ofHigh recovery rateFlotationProcess efficiency improvementChemical reactionNickel sulfide

The new nickel oxide ore treating process has synthesized chemical metallurgy and ore dressing technology. The technological process includes crushing ore, grinding ore into ore pulp, magnetically separating out strong magnetic mineral, heating ore pulp and leaching out with concentrated sulfuric acid, adding sulfurizing agent for chemical reaction to produce nickel sulfide precipitate, and floating out nickel sulfide concentrate. The technological process is simple, low in production cost, high in nickel oxide leaching rate, effective utilization of resource and environment friendship.

Owner:YUNNAN TIN GROUP HLDG

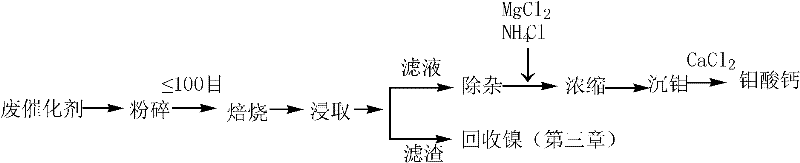

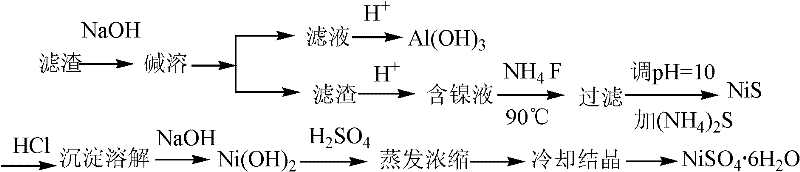

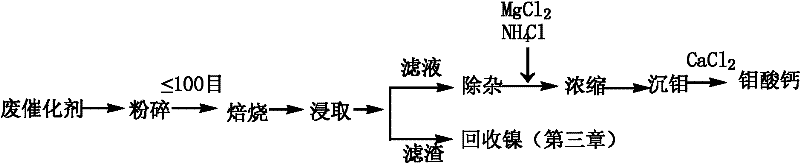

Method for extracting valuable metal from waste hydrogenation catalyst

The invention provides a method for extracting valuable metal from a waste hydrogenation catalyst. In the method, molybdenum is recovered in the form of calcium molybdate, thus the technical problem such as difficult treatment of a large quantity of acid liquor during the process of precipitating molybdenum by using acid is solved, and meanwhile the problem of severe production environmental pollution caused by ammonia water used in the generation process of ammonium molybdate can be avoided. The method comprises the following steps: roasting the waste catalyst at high temperature so as to burn out organic matters, sulfur and carbon; leaching the desulfurized and decarburized catalyst; converting Mo, V and a small amount of Al in the catalyst into water-soluble substances, and respectively processing other metallic oxides which are still remained in solid slags; for the water-soluble part, controlling the temperature and adjusting the PH value so as to remove foreign ions such as AlO2<->, SiO3<2-> and the like in a solution; and for the solid slag part, refining a nickel sulfide precipitate so as to convert the nickel sulfide precipitate into nickel sulfate, cooling and crystallizing to finally obtain nickel sulfate crystal.

Owner:JIANGSU CHUANGXIN PETROCHEM

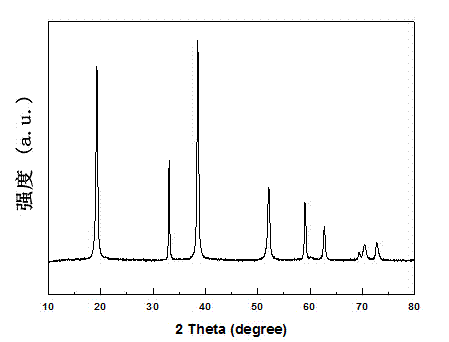

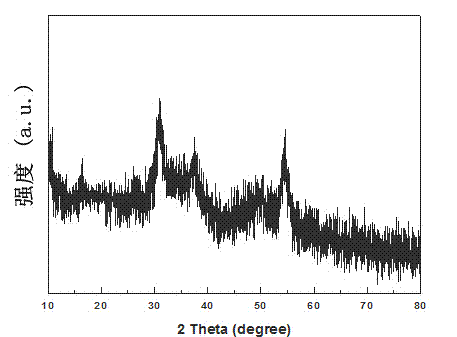

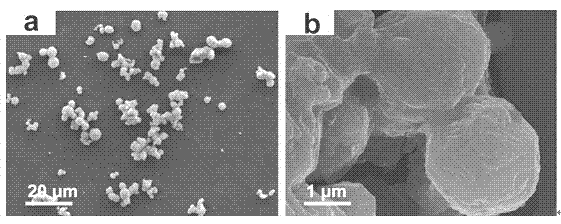

New method for two-step process preparation of nickel sulfide

InactiveCN104261490ASimple production processReaction conditions are easy to controlNickel sulfidesSODIUM SULFIDE NONAHYDRATEHigh pressure

The invention relates to a new method for two-step process preparation of nickel sulfide. The new method comprises the following steps: transferring a water and urea mixed solution of nickel chloride or a water, ammonia water and ethylene glycol mixed solution of nickel chloride into a high-pressure kettle, performing heating reaction at the temperature of 120-160 DEG C for 8-16h, filtering and washing a generated nickel hydroxide precipitate, and drying to prepare a nickel hydroxide precursor; and then dispersing into ethylene glycol, performing ultrasonic dispersion, adding sodium sulfide nonahydrate, transferring into a reactor, performing reflux reaction at the temperature of 160 DEG C for 12-24h, filtering, washing, and performing vacuum drying for 10-12h to prepare nickel sulfide. The new method provided by the invention has the advantages of simple production process, easiness in control of reaction conditions, no need of using a template agent and a surfactant, environmental friendliness and good consistency of the obtained product, is conductive to production of nickel sulfide, and has important practical significance.

Owner:XUZHOU NORMAL UNIVERSITY

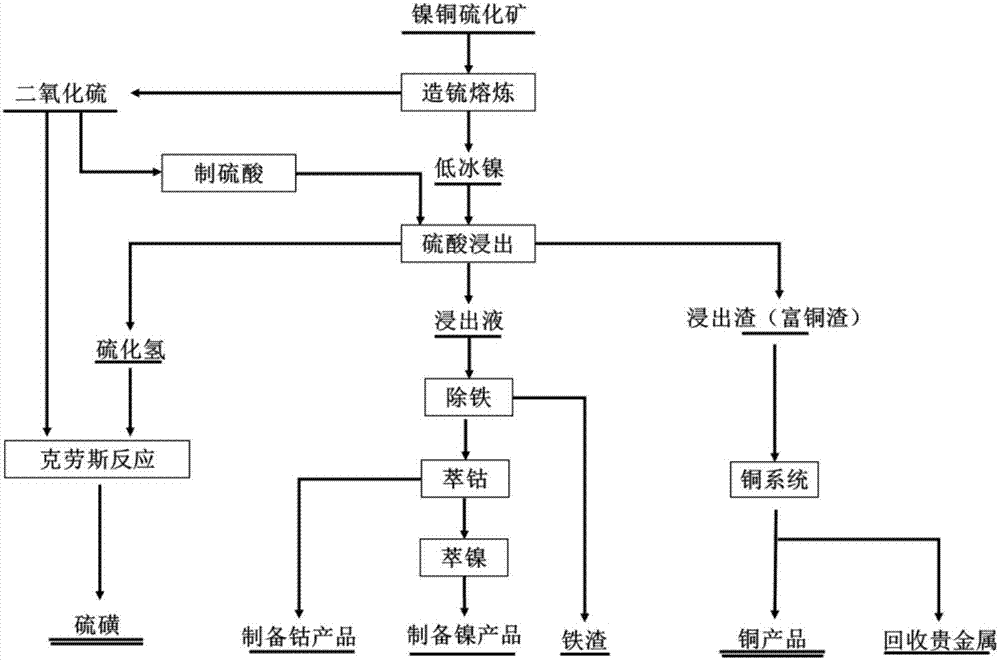

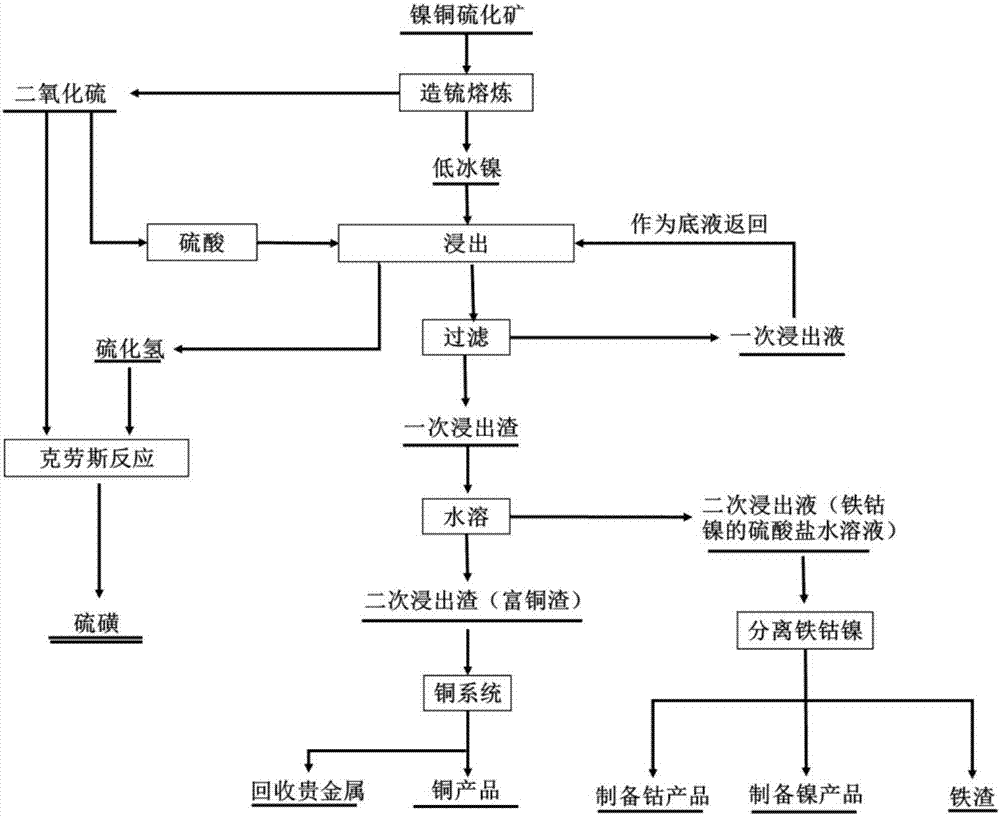

Method for comprehensively utilizing copper-nickel sulfide ores and system thereof

ActiveCN107058730AAvoid lostEfficient recyclingProcess efficiency improvementPregnant leach solutionSelective leaching

The invention provides a method for comprehensively utilizing copper-nickel sulfide ores and a system thereof. The method comprises the steps that (1), low nickel mattes obtained by matte smelting of the copper-nickel sulfide ores is subjected to normal pressure selective leaching directly through sulfuric acid, and hydrogen sulfide gas, leaching liquor and leaching residues are collected separately, wherein the temperature of normal pressure selective leaching is 25-80 DEG C; and (2), the leaching liquor in the step (1) is subjected to iron removal, iron-removed liquor and iron removal residues are collected separately, the iron-removed liquor is used for extracting of nickel and cobalt, the iron removal residues are used for iron making, and / or the leaching residues in the step (1) are sent to a copper smelting system to be smelted to obtain copper and precious metals. According to the method for the comprehensively utilizing the copper-nickel sulfide ores, deep separation of the nickel and the copper can be achieved, the recovery rates of the nickel, the copper, the cobalt and the precious metals are high, and high pure sulfur is output, so that storage is facilitated; and the process is simple, short in procedure, less in energy consumption and low in cost, and large-scale industrial production is easy.

Owner:CENT SOUTH UNIV

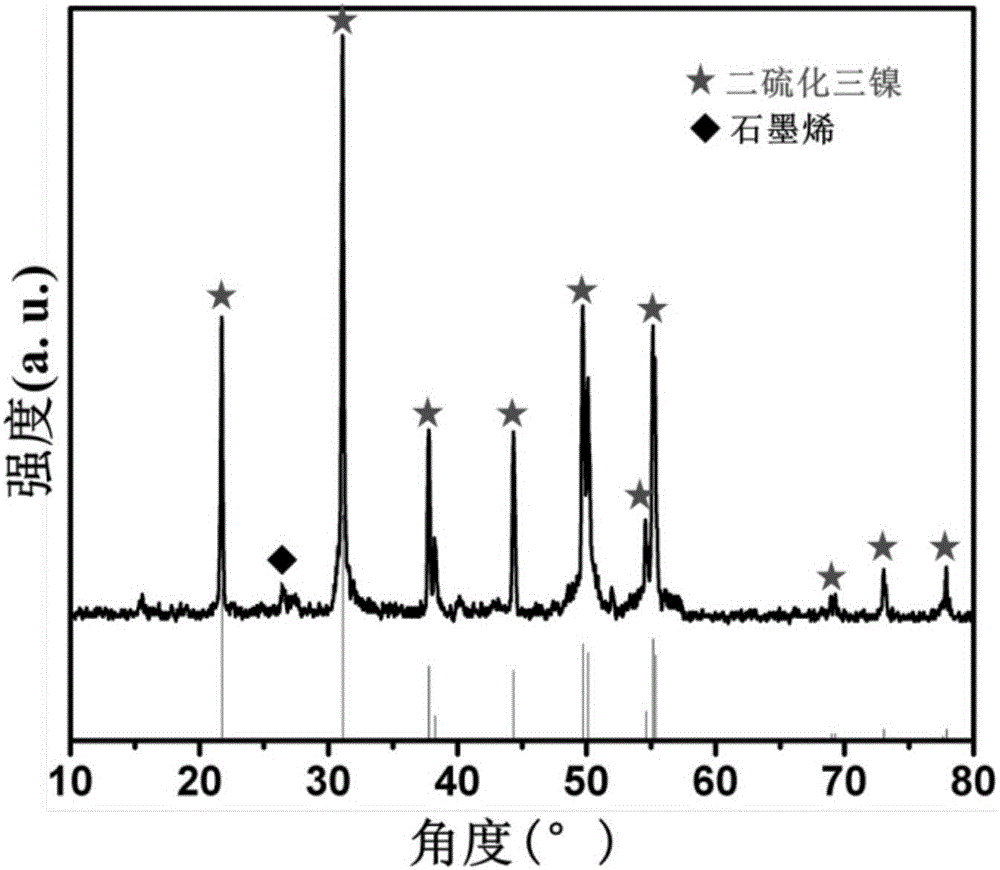

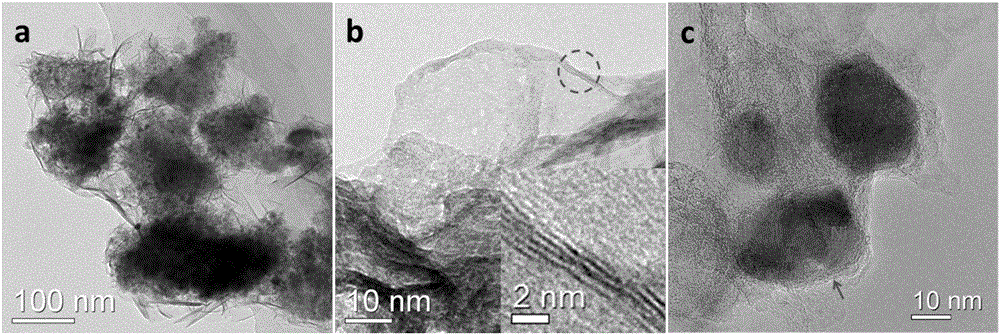

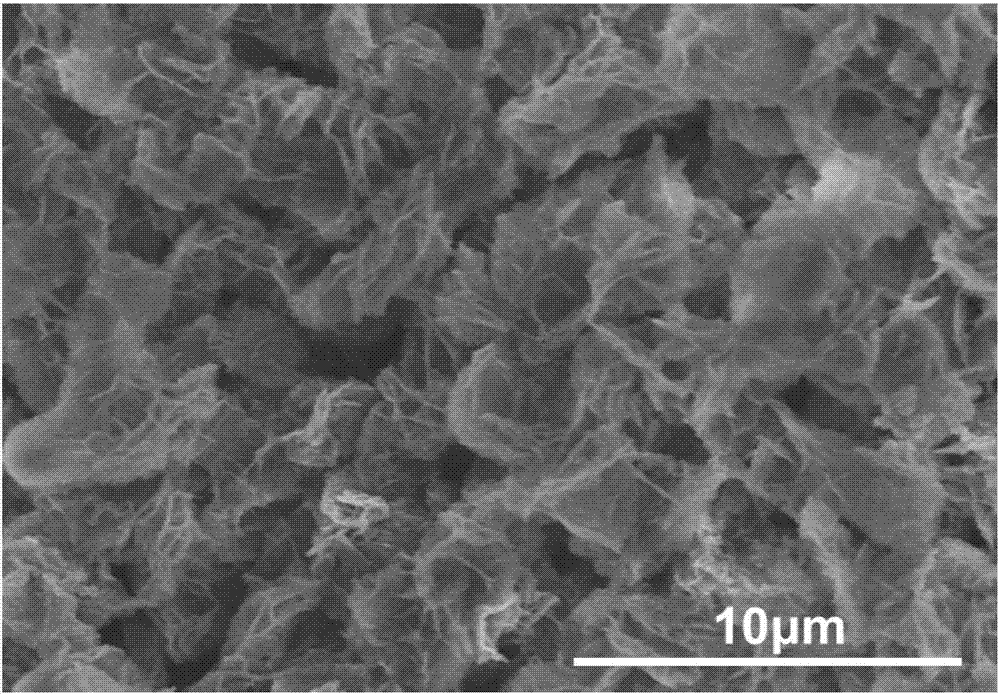

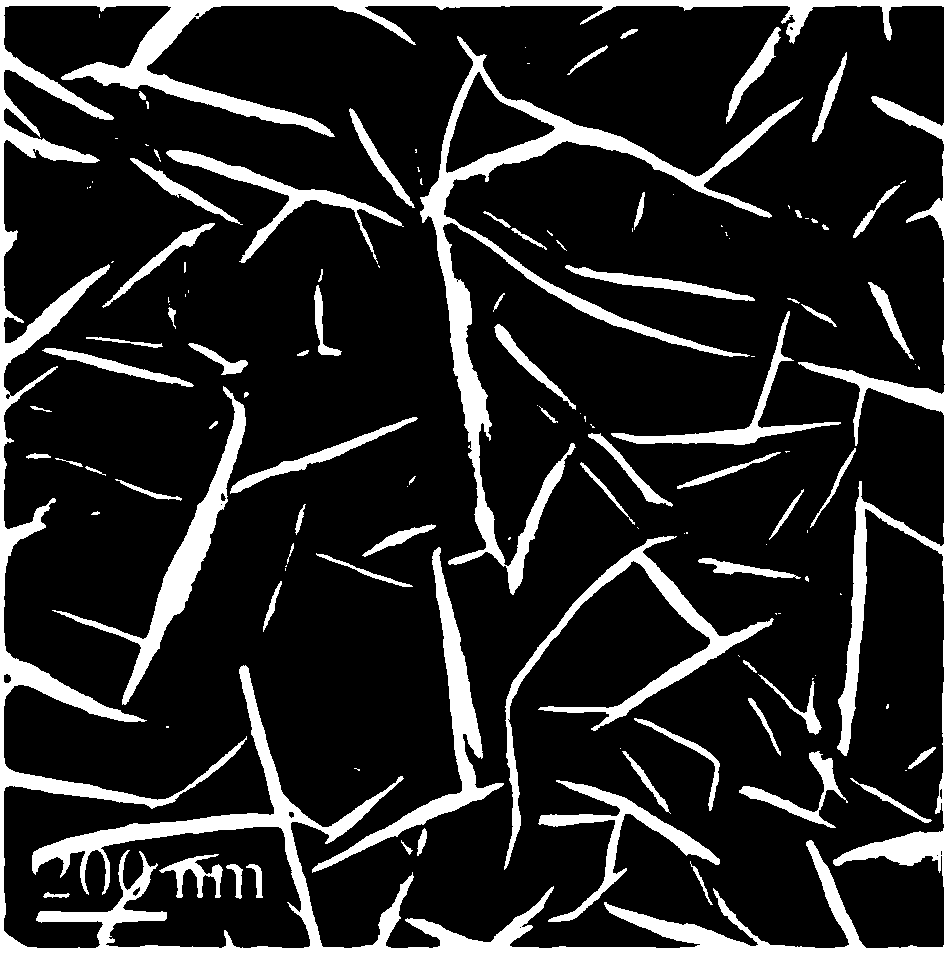

Graphene/nickel sulphide nano composite electrode material and preparation method thereof

InactiveCN104183848AEasy to synthesizeEasy to operateMaterial nanotechnologyCell electrodesSolventNickel sulfide

The invention discloses a graphene / nickel sulphide nano composite electrode material and a preparation method thereof. The graphene / nickel sulphide nano composite electrode material is prepared under the crosslinked action of graphene with graphene oxide as a carrier, nickel acetate as a nickel source and carbon disulphide as a sulphur source. The graphene / nickel sulphide nano composite electrode material comprises graphene nanosheets and nickel sulphide flower-type submicrostructure ingredients in a mass ratio of (5-35%): (95-65%). The preparation method of the graphene / nickel sulphide nano composite electrode material has the advantages that graphene oxide, nickel acetate and carbon disulphide are taken as raw materials and the graphene / nickel sulphide nano composite electrode material is obtained by adopting a one-pot solvothermal method in an organic solvent, and the graphene / nickel sulphide nano composite electrode material has good electrochemical lithium storage property and can serve as a cathode material for a lithium ion battery.

Owner:NANCHANG HANGKONG UNIVERSITY

Phyllosilicate mineral depressor for sulfide ore floatation and preparation method thereof

The invention provides a phyllosilicate mineral depressor for sulfide ore floatation and a preparation method thereof. The phyllosilicate mineral depressor for the sulfide ore floatation is prepared from the following components in part by weight: 0 to 20 parts of modified corn starch, 8 to 30 parts of sodium alginate, 1 to 35 parts of carboxymethyl cellulose or polyanionic cellulose or methylenenapadisilate dinaphthalene sulfonate, and 5 to 55 parts of sodium hexametaphosphate. The preparation method comprises the following steps of: selecting the reagents according to types of depressed minerals; adding the reagents in a high-speed mixing granulator in the set ratio for granulation; and drying the obtained grains to obtain the phyllosilicate mineral depressor for the sulfide ore floatation. The product has the characteristics of small dosage, good depression selectivity, low toxicity, and the like. The specific depressor is mainly applied to depressing phyllosilicate minerals such as talcs, serpentines, chlorites, kaolinites and the like during the sulfide ore floatation, thus the specific depressor is favorable for improving floatation concentrate grade and metal recovery rate, and is particularly suitable for floating talc-containing molybdenites and nickel sulfide ores.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

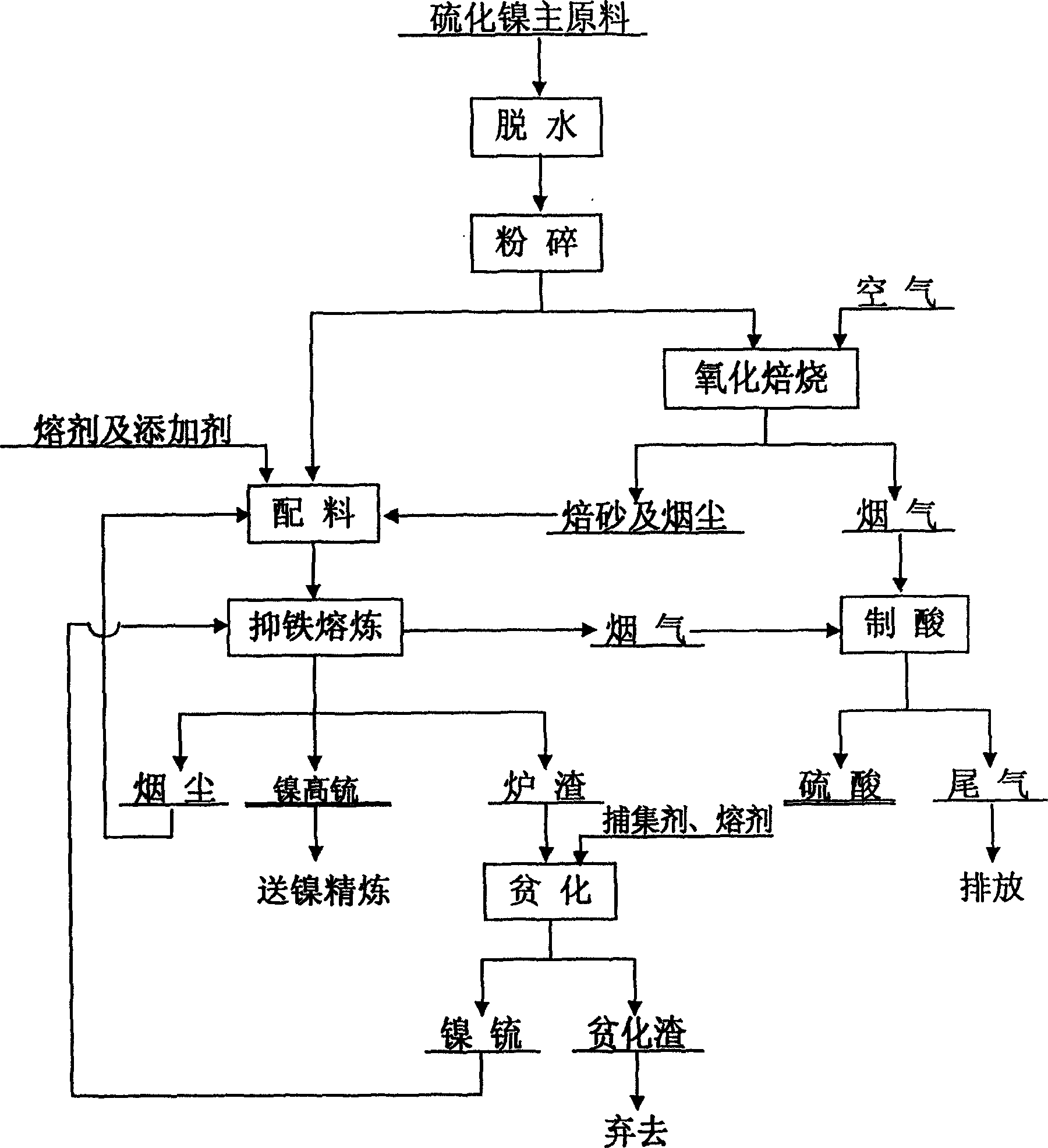

Bessemer matte production method using nickel sulfide materials

InactiveCN1730684AReduce processing costsImprove direct yieldProcess efficiency improvementSlagNickel sulfide

The invention relates to a bessemer matte production method using nickel sulfide materials which comprises, oxidizing and sintering nickel sulfide as main raw material, mixing with fusing agent, fluxing agent and reducing agent, smelting at 1300-1450 deg C, holding the temperature for reacting 30-60min, thus obtaining Bessemer matte product. The 83.0-93.0% of ferrum in the main raw material is inhibited and enters the furnace slag.

Owner:云锡元江镍业有限责任公司

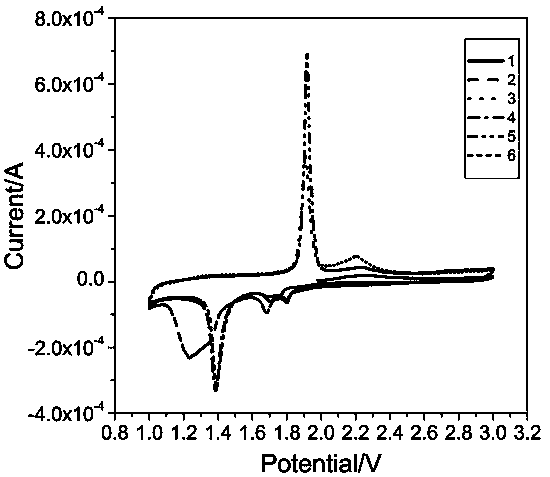

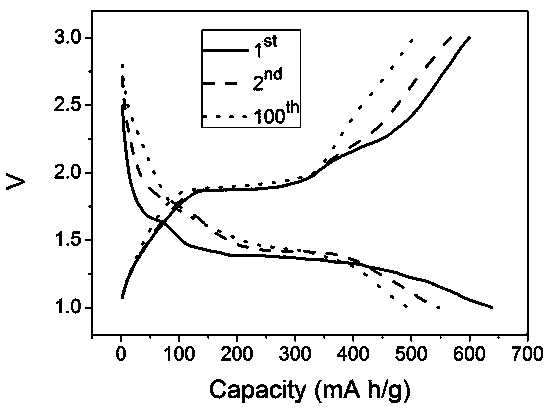

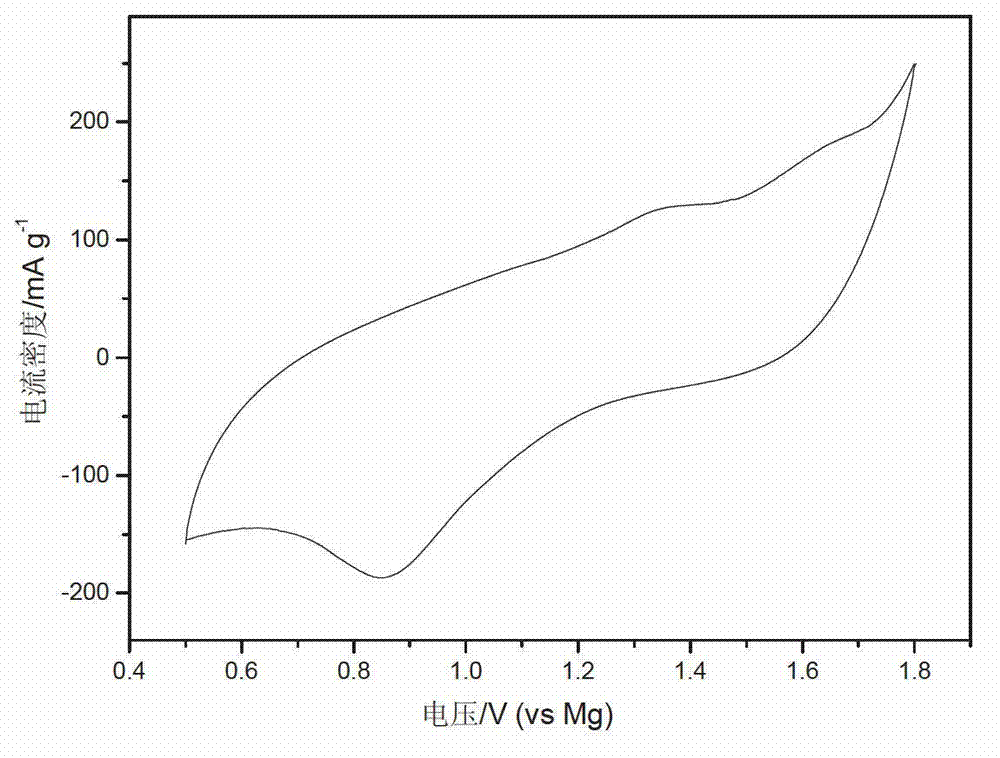

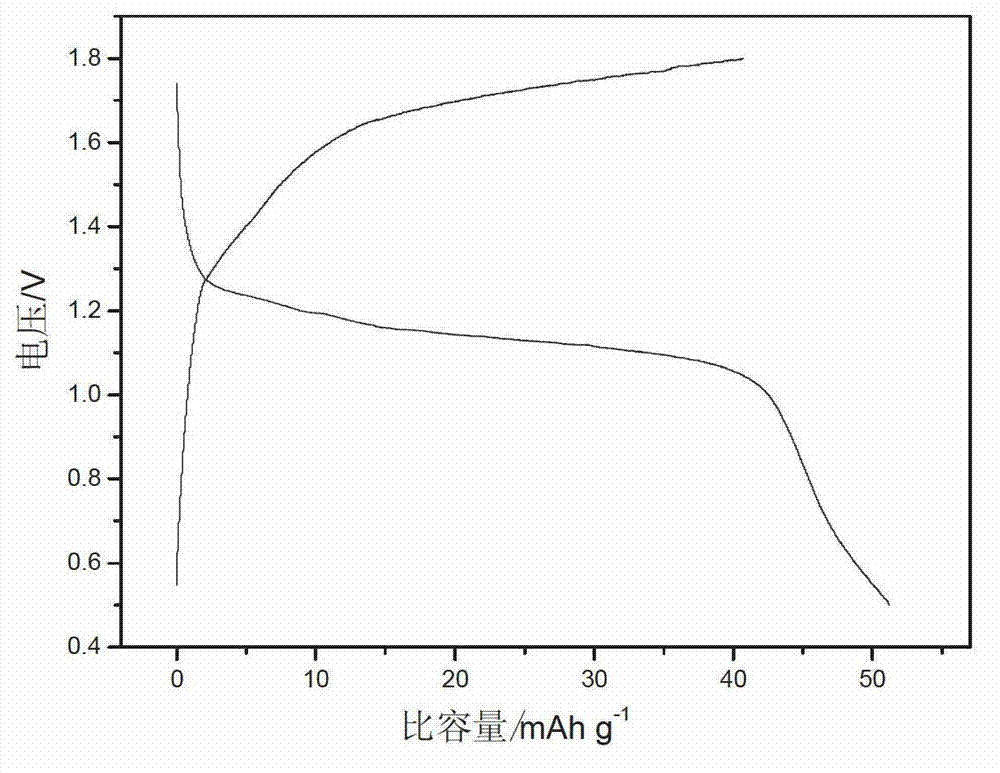

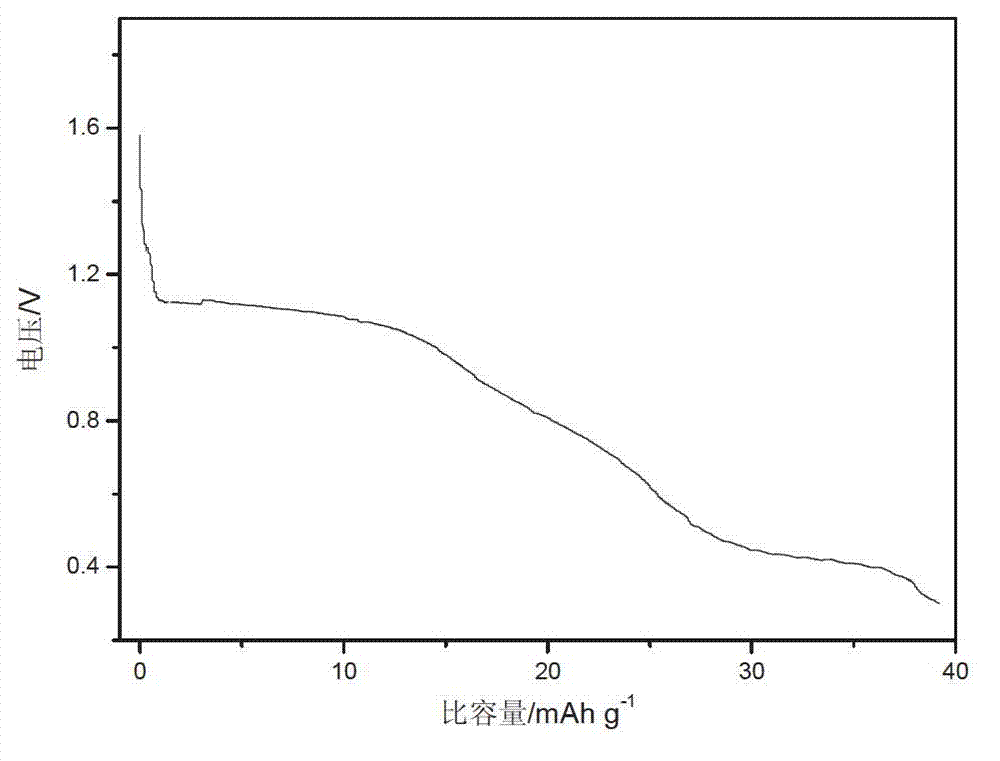

Application method of binary metal sulfides in chargeable magnesium battery

InactiveCN102969501AUnderstand the purposeLearn about featuresCell electrodesFinal product manufactureNickel sulfideCobalt sulfide

The invention discloses an application method of binary metal sulfides in a chargeable magnesium battery. The binary metal sulfides comprise nickel sulfide, manganese sulfide, cobalt sulfide, ferric sulfide, tin sulfide, tungsten sulfide, zinc sulfide, vanadic sulfide and the like. The preparation method for preparing the chargeable magnesium battery with the binary metal sulfides as an anode material specifically comprises the steps of: grinding the binary metal sulfides; adding a conductive agent and a bonding agent into the binary metal sulfides, and agitating uniformly and coating on a current collector; placing the current collector in an oven to dry, punching into a pole piece by a punch, tabletting and placing into a vacuum oven to dry so as to obtain the anode material; and using magnesium as a cathode, adding an electrolyte and assembling the chargeable magnesium battery. The chargeable magnesium battery prepared by the method provided by the invention has the advantages of simpleness in preparation, abundance in materials, low cost, and easiness in mass production. The chargeable magnesium battery has a great advantage as a large energy storing battery and has a good application prospect as a green energy resource.

Owner:SHANGHAI JIAO TONG UNIV

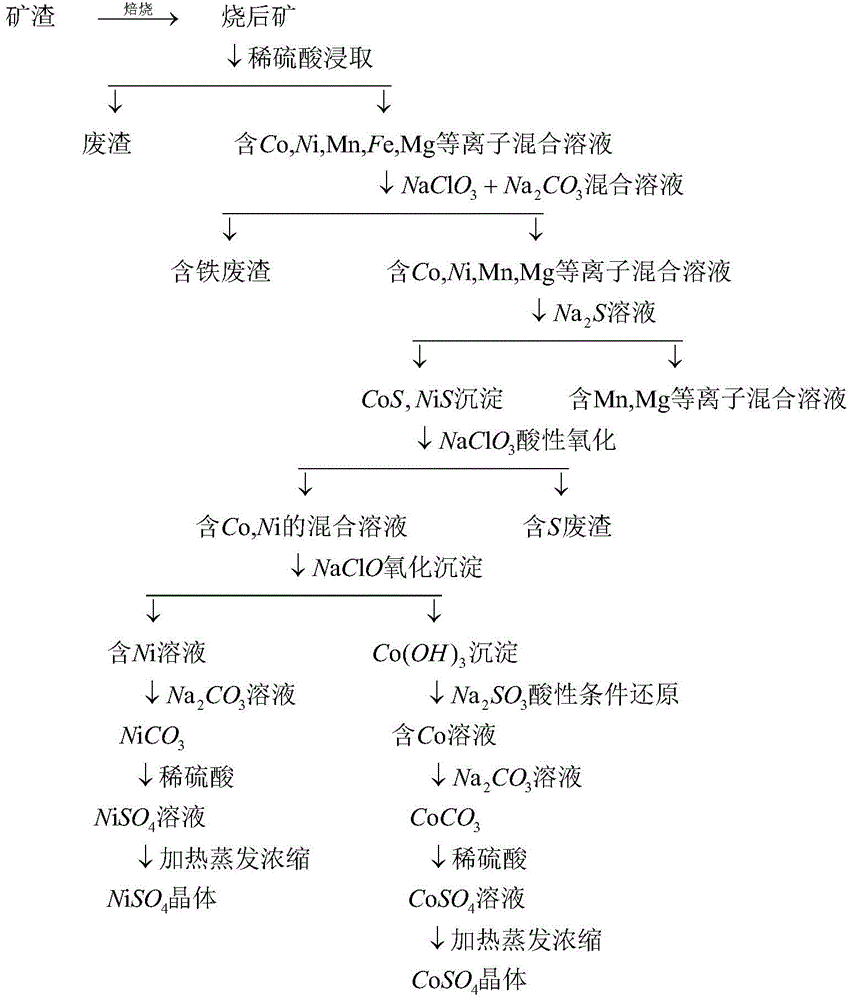

Process method for extracting cobalt and nickel from manganese waste slag

The invention discloses a process method for extracting cobalt and nickel from manganese waste slag, belonging to the field of comprehensive utilization of resources. The process method comprises the steps of carrying out oxidizing roasting and acid leaching, removing iron by virtue of oxidation hydrolysis, separating cobalt, nickel and manganese by virtue of precipitation, carrying out oxidizing and acid dissolving on cobalt sulfide and nickel sulfide, and separating cobalt and nickel by virtue of oxidizing hydrolysis. According to the method, the problem of high energy consumption, high pollution and high cost in traditional complex cobalt and nickel extraction industries are solved; the method is applicable to industries for extracting cobalt and nickel from mineral slag, and metals such as cobalt and nickel can be directly separated from the manganese waste slag by virtue of a simple process having the characteristics of high efficiency, low pollution, low cost and short period. According to the process method iron is removed by virtue of an oxidizing hydrolysis method, so that the iron removal efficiency is high, the loss ratio of valuable components is low, the operability is strong, and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

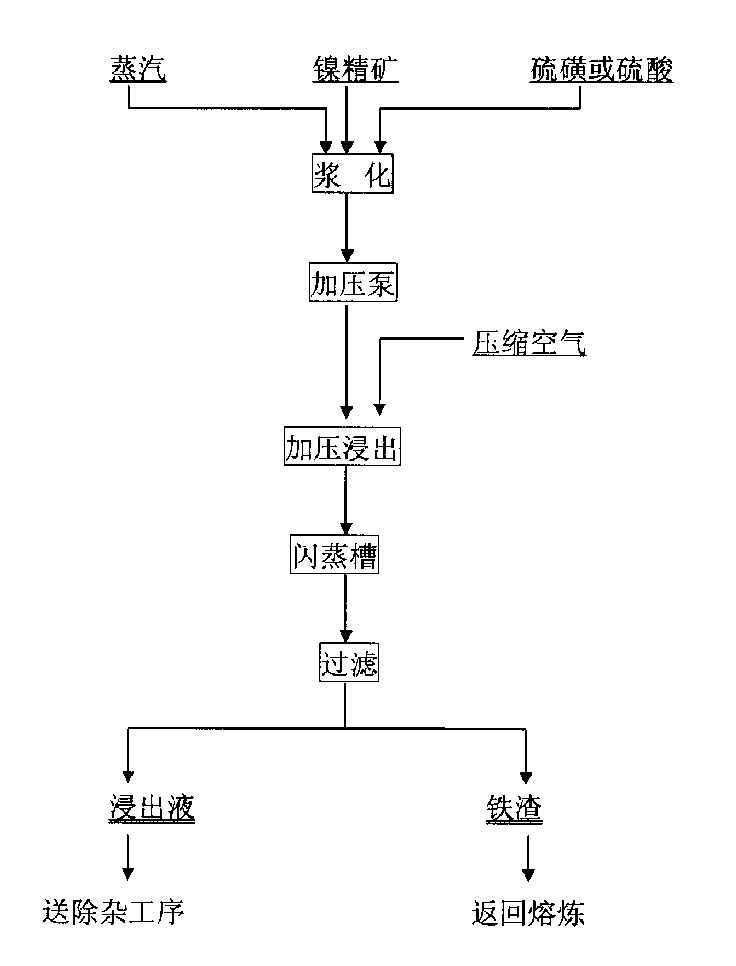

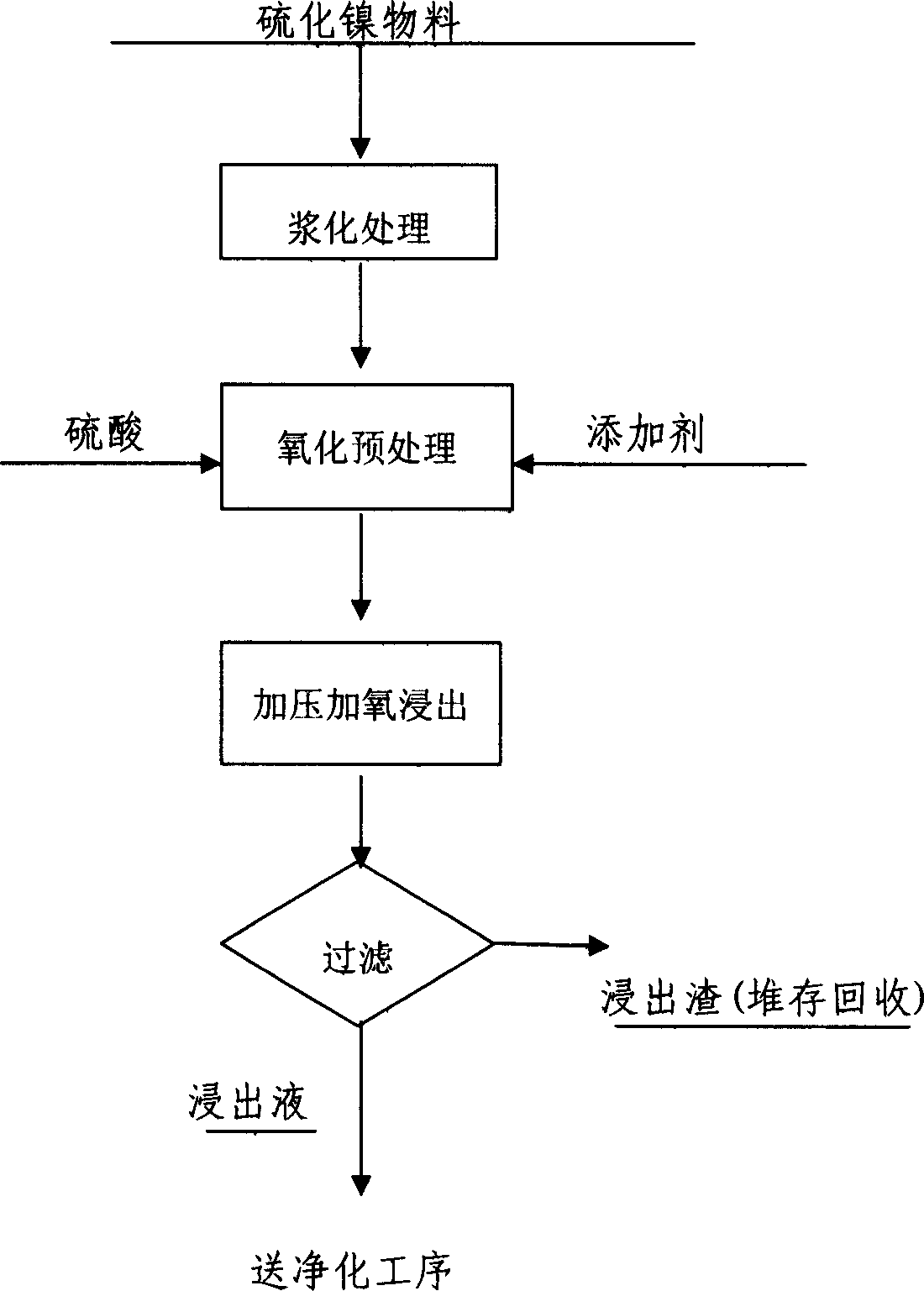

Wet treatment method of iron containing nickel sulfide material

The invention relates to a wet treatment method extracting nickel from iron containing nickel sulfide material. Its features are after slurring and oxidizing pretreatment to the iron containing nickel sulfide material; adopting pressurizing, adding oxygen, and additive method to effectively lixiviate nickel cobalt and restrain iron, reduce purifying deferrization reagent consumption and iron slag, reduce nickel losing, use sodium hydroxide to sink nickel after leaching solution, use sulphuric acid to dissolve nickel hydroxides, and gaining bright nickel sulphate solution after extracting and reclaiming cobalt. The nickel sulfate solution is produced out nickel sulfate by condensing crystallizing, or electricity nickel products by electro deposit, and both of them are according with GB.

Owner:云锡元江镍业有限责任公司

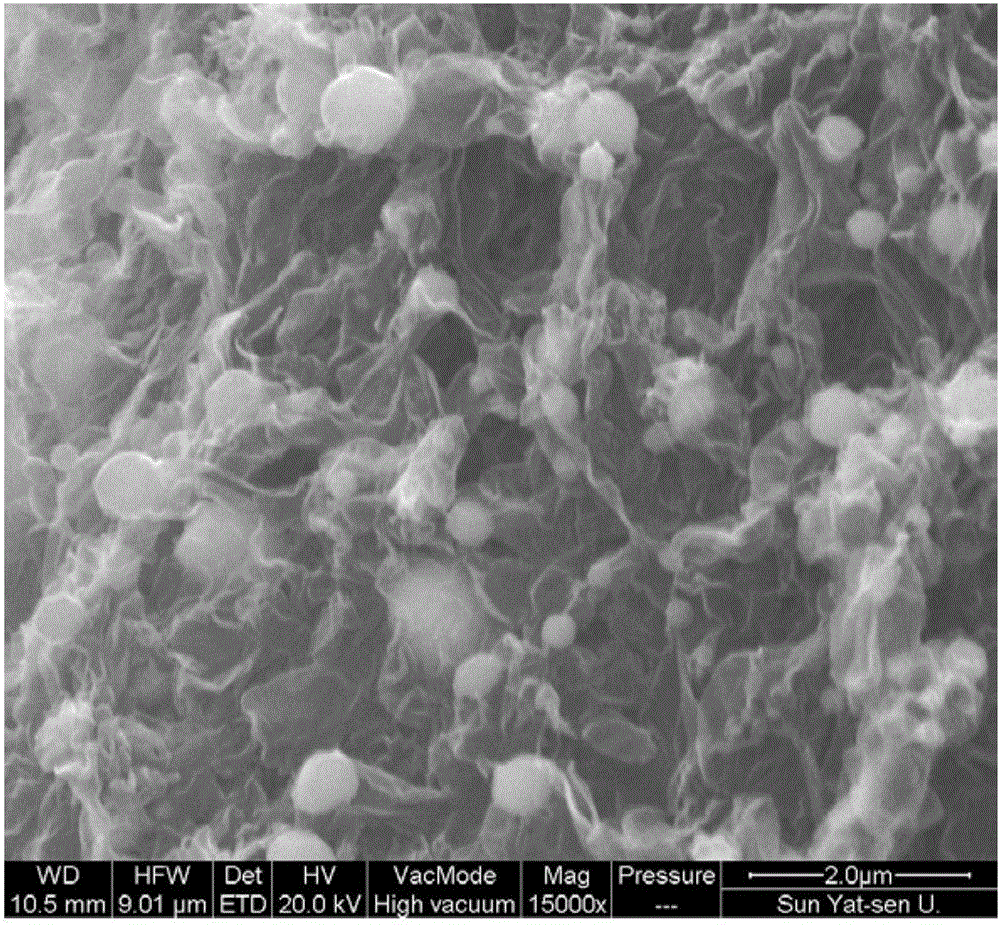

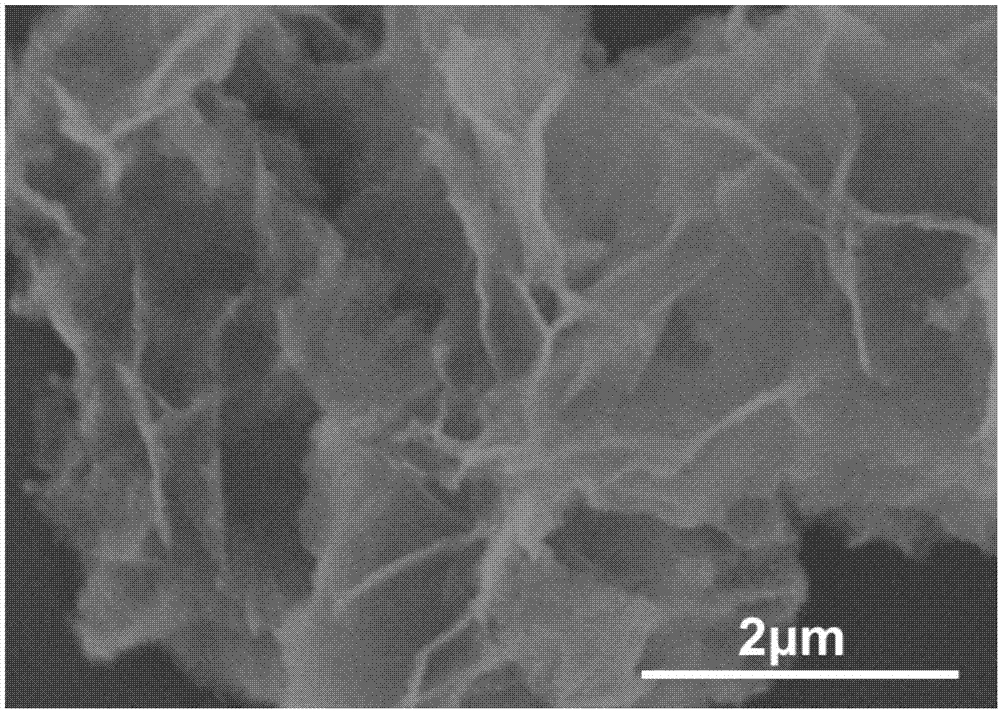

Preparation method for nitrogen-doped graphene-coated nickel sulfide composite electrode material

ActiveCN105895882AEnhanced interactionEasy transferCell electrodesSecondary cellsCyclic processNitrogen doped graphene

The invention discloses a preparation method for a nitrogen-doped graphene-coated nickel sulfide composite electrode material. The preparation method comprises the steps of (1) immersing resin containing nitrogen and sulfur into an acid solution to be stirred, cleaned, dried and smashed; (2) paving the mixture on a material boat, and covering with a nickel-based material; and (3) moving the mixture into a high-temperature furnace, carrying out heating treatment under an inert gas protection condition, and then cooling after the reaction is completed to obtain the composite electrode material. According to the preparation method, a gaseous carbon source, a sulfur source and a nitrogen source are generated from the resin containing both nitrogen and sulfur through thermal decomposition; then nickel sulfide nanoparticles and a graphene composite material are grown on the foamed nickel directly and synchronously; the nitrogen-doped graphene which is grown on the surfaces of the nickel sulfide nanoparticles is catalyzed by the nickel sulfide nanoparticles, so that the interaction between the graphene and the nickel sulfide nanoparticles is reinforced, the agglomeration of the nickel sulfide nanoparticles is effectively restrained and the volume expansion of the nickel sulfide nanoparticles in the cycling process is relieved; meanwhile, the nitrogen-doped graphene can promote ion and electron transport; and in addition, the composite electrode material is less in steps, simple in reaction conditions and apparatus, low in cost, and convenient to realize mass production in practical applications.

Owner:GUANGXI UNIV

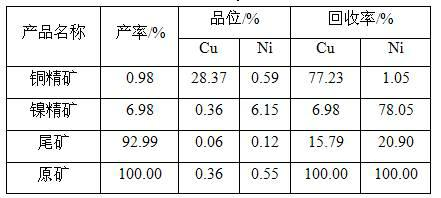

Pyrrhotite flotation inhibitor, preparation and application thereof as well as mineral processing method for copper-nickel sulfide

The invention provides an inhibitor for pyrrhotite flotation. The inhibitor comprises sodium carbonate, sodium pyrosulfite and triethylene tetramine, pyrrhotite in pulp can be effectively and selectively inhibited, meanwhile basically no affect is brought to the flotation of pentlandite and copper pyrite, and the inhibitor is particularly suitable for the flotation and separation of minerals difficult to select such as high content of pyrrhotite and low quality of cooper-nickel; and the invention further provides a preparation method and an application method of the inhibitor for pyrrhotite flotation, the operations are extremely simple and convenient, and excellent industrial prospect is provided.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

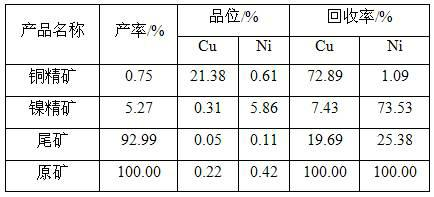

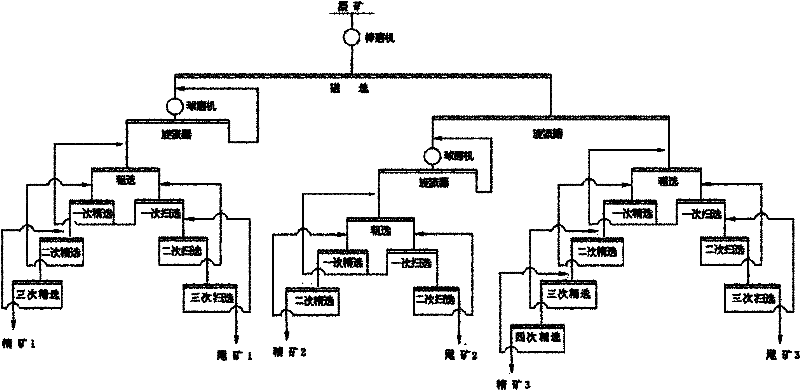

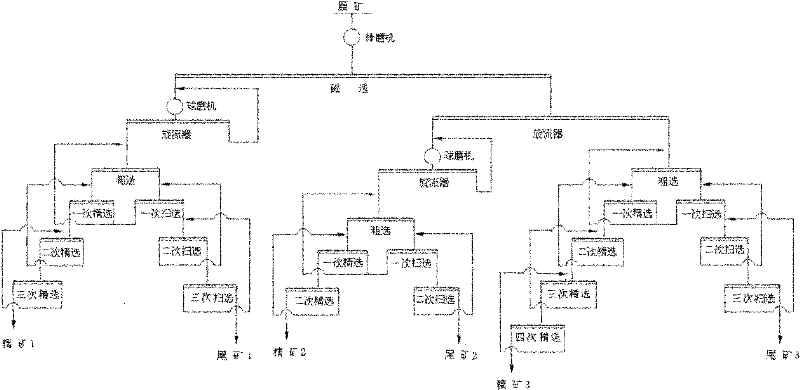

Beneficiation method for copper nickel sulfide ore

The invention relates to a beneficiation method for copper nickel sulfide ore. The beneficiation method is characterized in that a beneficiation process of the method comprises the following steps of: grinding crude copper nickel ore; preferably floating copper mineral from the ground crude ore; performing copper selection on the obtained rough copper concentrate I for five times to obtain copperconcentrate and five selected copper middlings; performing copper scavenging on copper tailing I twice to obtain copper tailing II and two scavenged copper middlings; performing rough selection of nickel mineral on the obtained copper tailing II to obtain rough nickel concentrate and nickel tailing I; performing nickel selection on the obtained rough nickel concentrate for three times to obtain the nickel concentrate and three selected nickel middlings; performing nickel scavenging on the obtained nickel tailing I twice to obtain the nickel tailing and two scavenged nickel middlings; and sequentially returning the two scavenged nickel middlings to the previous layer respectively. By the method, the copper and the nickel have high adaptability to the sequential preferred floatation and separation process, so that the copper and nickel mineral embedded into complex low-grade fine particles can be recovered, the preferred floatation and separation of the copper and nickel mineral can be realized, the quality and the recovery rate of the copper and nickel concentrate are obviously improved, and the method is simple in operation and high in controllability, and has strong adaptability to the ore.

Owner:西部矿业集团科技发展有限公司

Method and system for recovering main associated elements from copper-nickel sulfide ore

ActiveCN107012324AAchieve deep separationImprove efficiencyProcess efficiency improvementSlagNickel sulfide

The invention provides a method and system for recovering main associated elements from copper-nickel sulfide ore. The method comprises the following steps: 1, continuously adding low-grade nickel matte and a leaching reaction solution into a reaction base solution, carrying out selective leaching, and collecting hydrogen sulfide gas, a first leaching solution and a first leaching residue, wherein the leaching reaction liquid is sulfuric acid with the mass fraction being 60-95%; 2, adding water into the first leaching residue for dissolving the first leaching slag, and collecting a second leaching solution and a second leaching residue; and 3, removing iron from the second leaching solution, collecting an iron-removed solution used for extracting nickel and cobalt and an iron-removed residue used for iron making, and / or sending the second leaching residue to a copper smelting device for smelting to obtain copper and noble metal. According to the method, deep separation of the nickel and the copper can be realized, and recovery of the nickel, the copper, the cobalt, the noble metal and sulfur can be effectively realized. The method is simple in process, short in flow and high in efficiency, is a clean and efficient element recovery process and is easy for large-scale industrial production.

Owner:CENT SOUTH UNIV

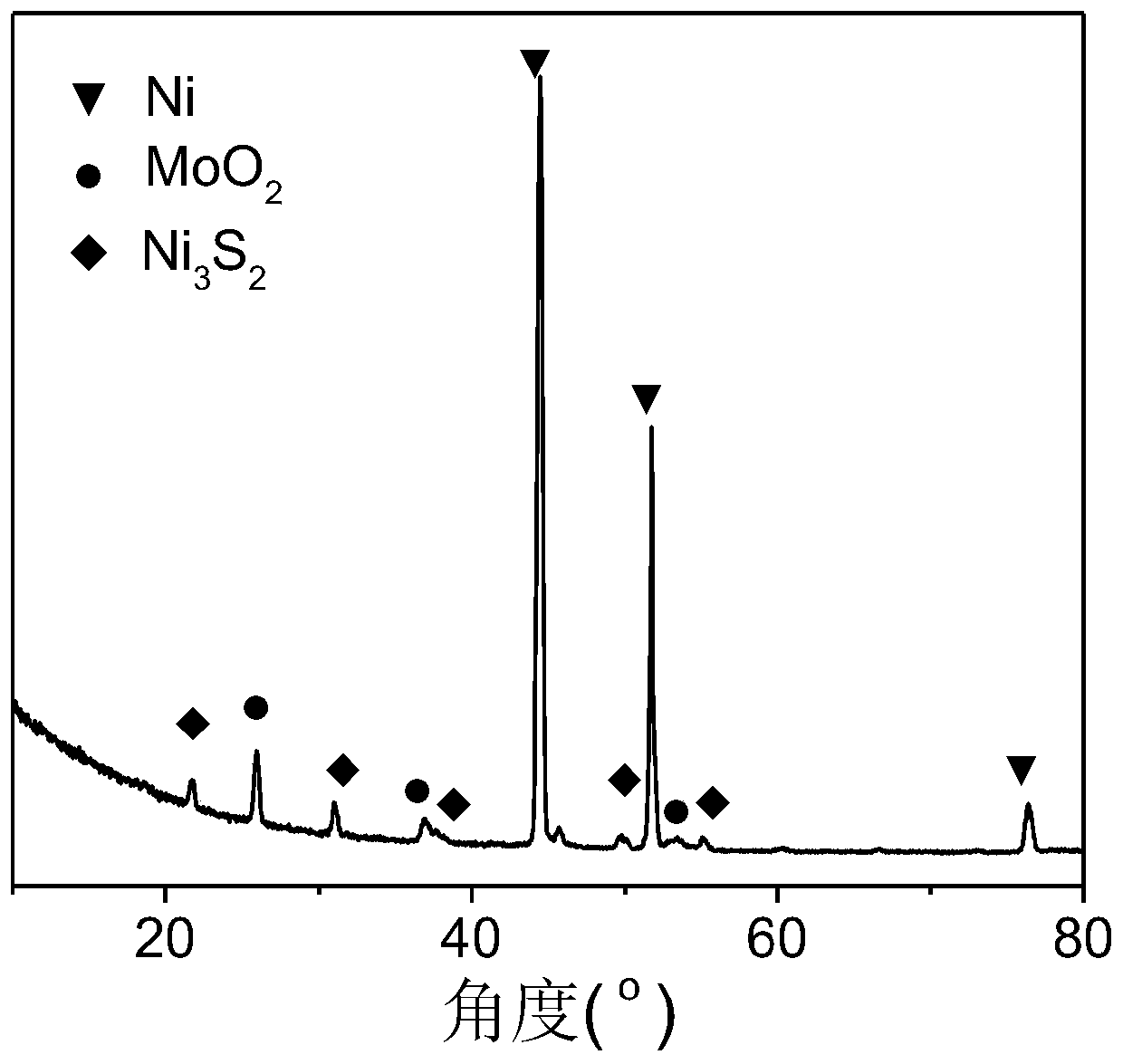

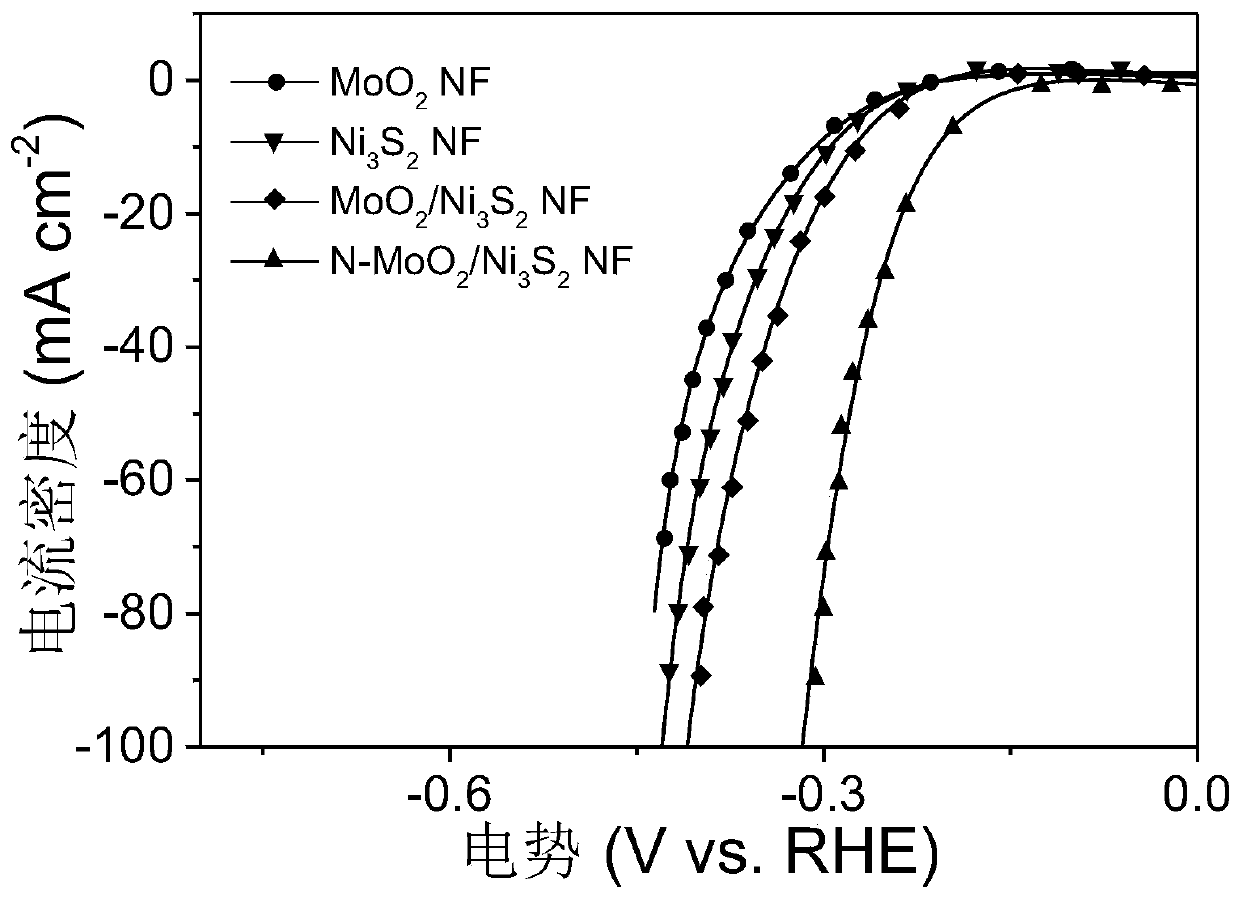

Three-dimensional nitrogen-doped transition metal oxide/nickel sulfide composite catalyst and preparation method and application thereof

ActiveCN110201697AOptimize electronic structureImprove electrocatalytic activityPhysical/chemical process catalystsElectrodesNickel sulfideCalcination

The invention discloses a three-dimensional nitrogen-doped transition metal oxide / nickel sulfide composite catalyst. The catalyst includes nickel foam, nitrogen-doped transition metal oxide and nickelsulfide, wherein the nickel foam serves as a substrate, and the nitrogen-doped transition metal oxide grows on the nickel foam in situ. The invention further discloses a preparation method of the three-dimensional nitrogen-doped transition metal oxide / nickel sulfide composite catalyst. The method includes the following steps that the nickel foam substrate is impregnated in an ammonium tetrathiomolybdate solution and dried after impregnation, and an ammonium tetrathiomolybdate contained nickel foam precursor is obtained; the nickel foam precursor is subjected to vacuum high-temperature calcination, and the molybdenum dioxide / nickel sulfide composite catalyst is obtained; the molybdenum dioxide / nickel sulfide composite materials are subjected to thermal ammoniation, and the three-dimensional nitrogen-doped transition metal oxide / nickel sulfide composite catalyst is obtained. The invention further provides the application of the composite catalyst as a cathode catalyst material in an electrolytic water cathode HER reaction, the composite catalyst shows excellent electrocatalytic performance in alkaline electrolyte and has good stability, and the possibility of hydrogen energy development and utilization is further improved.

Owner:ZHEJIANG UNIV

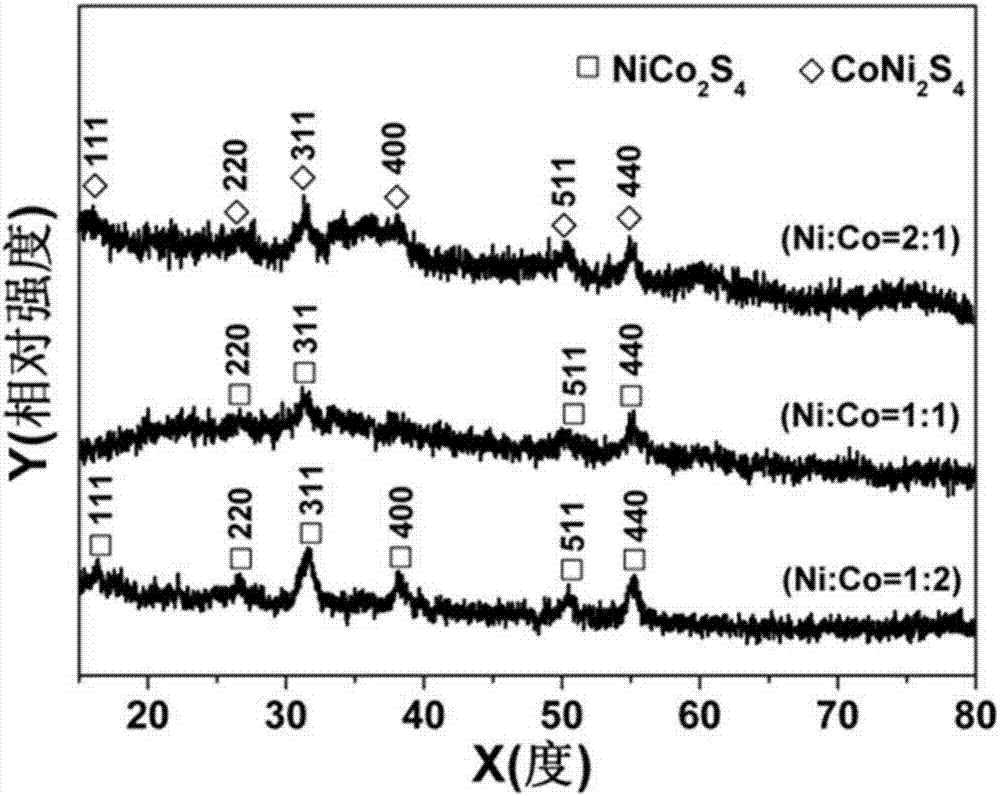

Simple preparation method of cobalt nickel sulfide nanosheet serving as supercapacitor electrode material

The invention relates to a simple preparation method of a cobalt nickel sulfide nanosheet serving as a supercapacitor electrode material by adoption of a simple two-step solvothermal technique. The simple preparation method of the cobalt nickel sulfide nanosheet serving as the supercapacitor electrode material includes: adopting transition metal salt cobalt nitrate, nickel nitrate and anhydrous sodium acetate as reaction raw materials, and respectively adopting polyethylene glycol, ethylene glycol and ethyl alcohol as solvents and taking TAA (thioacetamide) as a sulfur source to prepare the cobalt nickel sulfide nanosheet according to a two-step solvothermal method. The cobalt nickel sulfide nanosheet prepared according to the method has advantages of high repeatability, simplicity in synthesis process, easiness in control and high yield. The laminar structure is beneficial to surface quick action of electrolyte ions and electrodes, efficient charging and discharging are benefited, and a high specific capacity can be provided.

Owner:东营睿港管道工程有限责任公司

New efficient separation process of low-grade copper nickel sulfide ore

InactiveCN102205266ARaise the gradeEliminate the effects ofWet separationNickel sulfideMaterials science

The invention relates to the technical field of ore separation, in particular to a new efficient separation process of low-grade copper nickel sulfide ore. The process comprises the following steps of: grinding the low-grade copper nickel sulfide ore, and performing magnetic separation and pre-enrichment; performing ore grinding flotation on the magnetic separation ore concentrate after the magnetic separation and the pre-enrichment, and adding 25 to 100g / t of ethyl xanthogenate or butyl xanthogenate or dithiophosphate BA to obtain high-grade copper nickel ore concentrate; grading the magnetic separation tailings after the magnetic separation and the pre-enrichment, and performing ore grinding flotation on the coarse product after grading, and adding 25 to 100g / t of ethyl xanthogenate or butyl xanthogenate or dithiophosphate BA to obtain a qualified ore concentrate product; and performing ore grinding flotation on the fine product after grading, adding 25 to 100g / t of ethyl xanthogenate or butyl xanthogenate or dithiophosphate BA, and adding a hyper-dispersant to obtain a qualified ore concentrate product, wherein the nickel grade of the obtained qualified ore concentrate product is 5 to 10 percent.

Owner:NORTHEASTERN UNIV +1

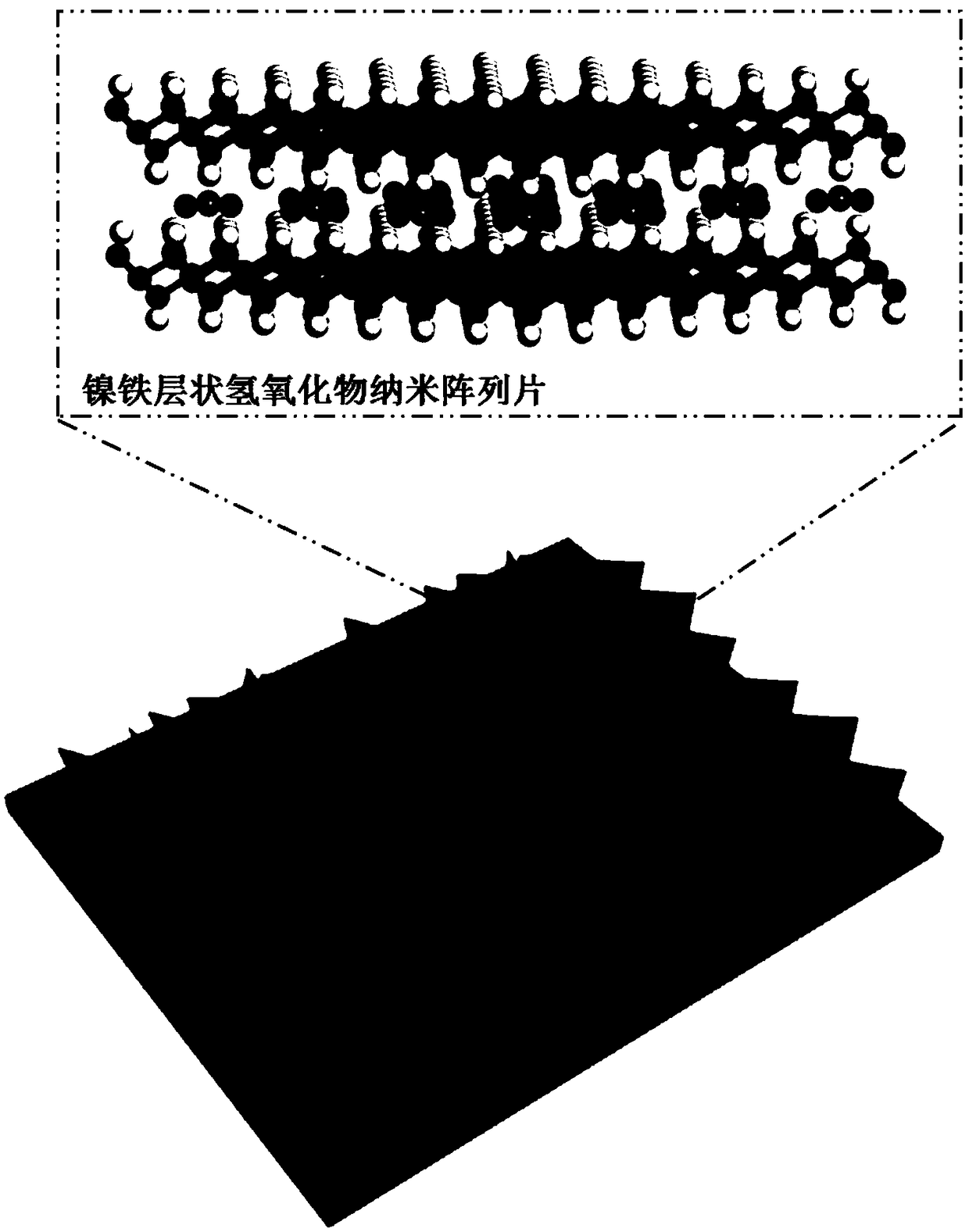

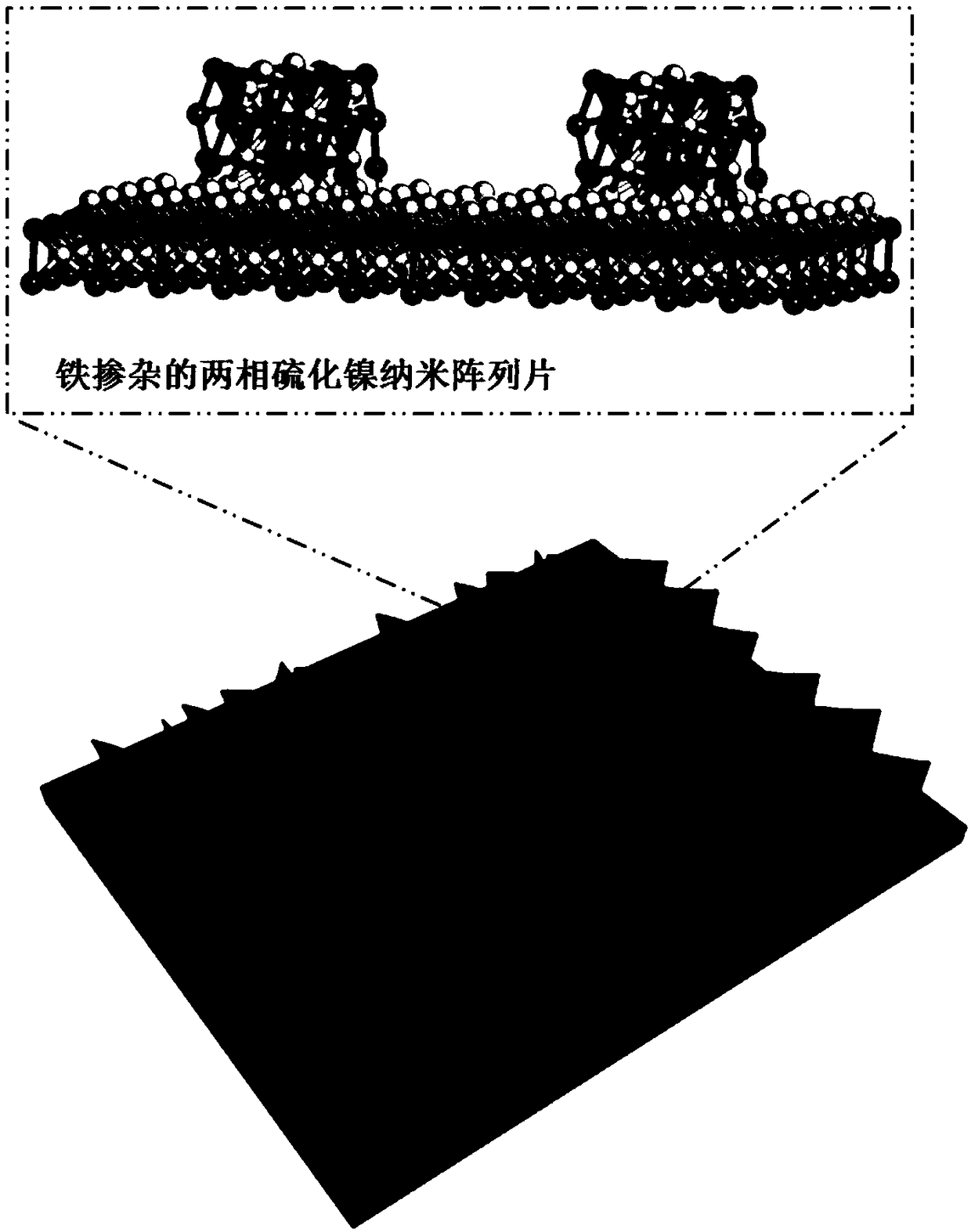

Fe-doped two-phase nickel sulfide nano array material, as well as preparation method and application thereof

ActiveCN108396329AImprove performanceIncrease contactMaterial nanotechnologyElectrodesElectrolysisOxygen

The invention discloses a Fe-doped two-phase nickel sulfide nano array material which comprises a conductive substrate material and a Fe-doped two-phase nickel sulfide nano array structure material growing on the conductive substrate material. The invention further discloses a preparation method of the Fe-doped two-phase nickel sulfide nano array material and application of the Fe-doped two-phasenickel sulfide nano array material in an anode material for oxygen evolution with electrolytic water.

Owner:深圳海氢科技有限公司

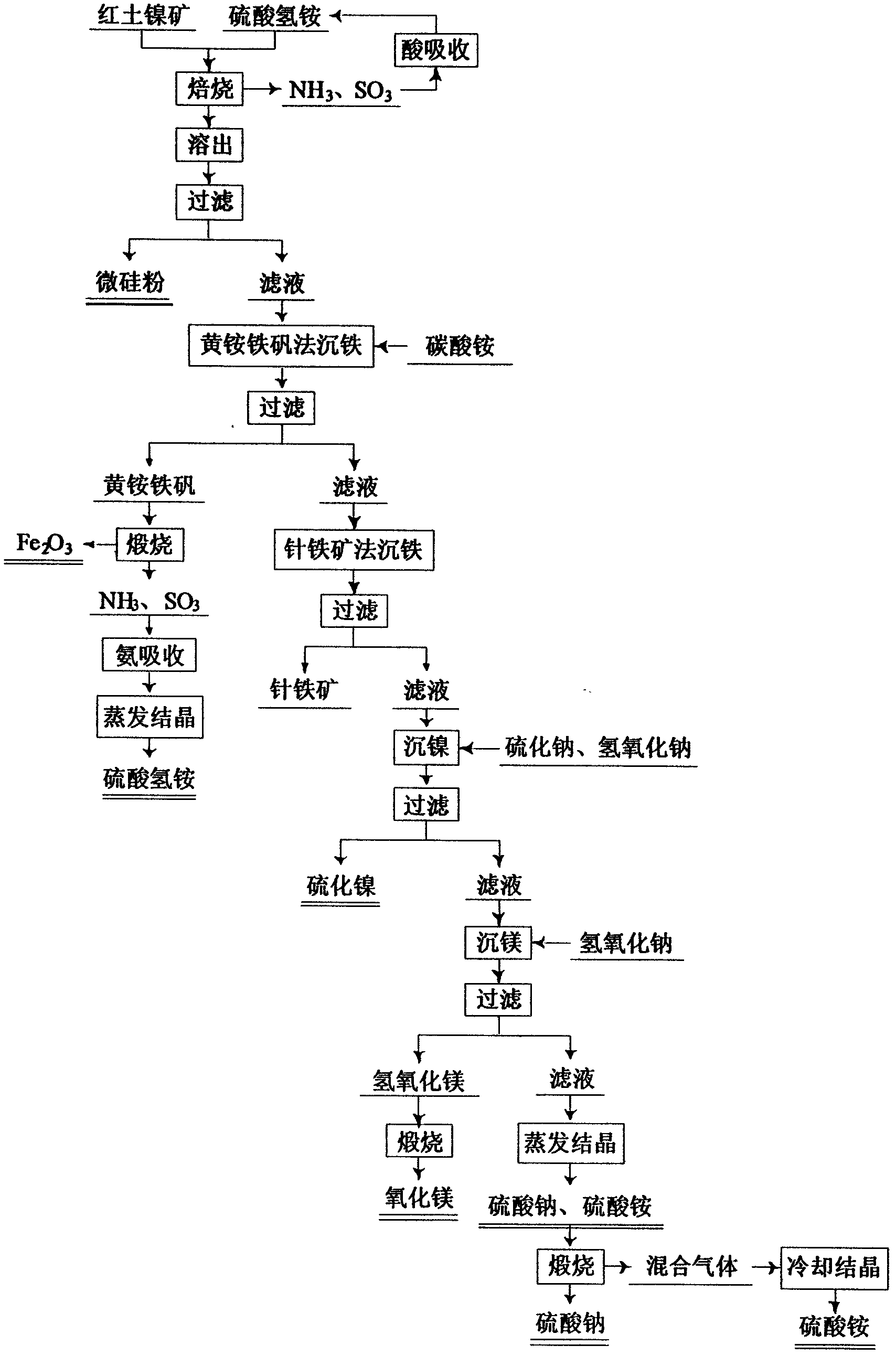

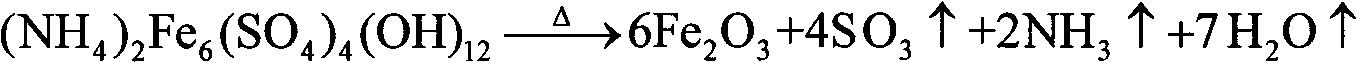

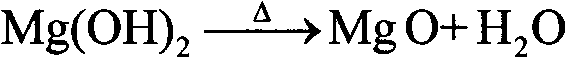

Method for comprehensive utilization of laterite nickel ore

A method for comprehensive utilization of laterite nickel ore comprises the following steps: (1) pulverizing laterite nickel ore, grinding, mixing with ammonium bisulfate, and roasting; (2) dissolving and filtering the roasted clinker to obtain a filtrate, depositing iron by an ihleite method, and depositing iron by a goethite method; (3) performing nickel deposition of the filtrate obtained after iron deposition by sodium sulfide, preparing a nickel sulfide product; (4) performing magnesium deposition of the filtrate obtained after nickel deposition by sodium hydroxide to obtain magnesium hydroxide; (5) washing, drying and calcining magnesium hydroxide to prepare a magnesium oxide product; (6) using the roasted clinker dissolved slag as a microsilica fume product directly, wherein the main component of the slag is silica; (7) calcining ammonium jarosite to obtain an iron oxide product.

Owner:NORTHEASTERN UNIV

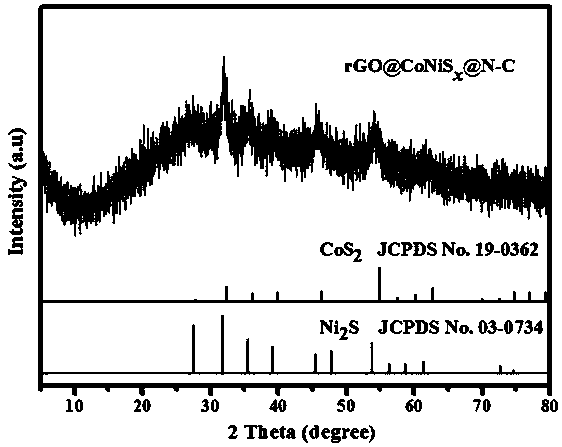

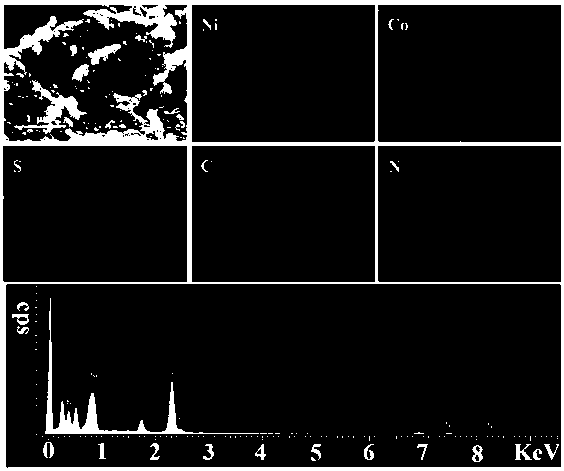

N-doped carbon-coated cobalt-nickel sulfide/graphene composite electrode material

InactiveCN108075128ASimple preparation processImprove controllabilityHybrid capacitor electrodesCell electrodesCapacitanceThiourea

The invention discloses an N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material and a preparation method thereof, belonging to the field of preparation of an electrode material for super capacitors. The preparation method comprises the following processes: adding graphene oxide (GO) into an ethylene glycol solution, and performing ultrasonic dispersion to enable the GOto be uniformly dispersed in the ethylene glycol solution; adding polyvinylpyrrolidone (PVP), cobaltous acetate tetrahydrate and nickel acetate into a GO dispersion solution prepared above, after ultrasonic dispersion and dissolution, transferring to a round bottom flask to perform oil bath reaction and performing centrifugal washing and drying; enabling a product, which is dried via centrifugalwashing after oil bath, to calcine with thiourea to obtain the N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material. According to the prepared electrode material, N-dopedcarbon is coated outside cobalt-nickel sulfide particles which have uniform sizes in microstructure, the electrode material is uniformly loaded on the substrate of graphene, and meanwhile, the electrode material has relatively high specific capacitance, excellent rate capability and cycling stability.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com