Simple preparation method of cobalt nickel sulfide nanosheet serving as supercapacitor electrode material

A supercapacitor, cobalt-nickel sulfide technology, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., to achieve the effects of high repeatability, easy control, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of convenient preparation method for supercapacitor electrode material cobalt-nickel sulfide nano-sheet, the method for preparing cobalt-nickel sulfide nano-sheet comprises the following steps:

[0020] (1) Weigh 1.455g of Co(NO 3 ) 2 , 1.454g of Ni(NO 3 ) 2 ·6H 2 O. 1.6406g of NaAC was dissolved in a mixed solution of 20ml of polyethylene glycol and 20ml of ethylene glycol, dispersed by ultrasonic to form a homogeneous solution, stirred for 30 minutes, put the above mixed solution into a 40mL reaction kettle, and reacted at 200°C After 14 hours, the suspension was taken, washed by centrifugation, and vacuum-dried at 60°C for 12 hours to obtain a cobalt-nickel nanosheet precursor (Ni:Co=1:1);

[0021] (2) Weigh 60mg of the cobalt-nickel precursor (Ni:Co=1:1) obtained in step (1) and redisperse it in 40ml of absolute ethanol, add 120mg of thioacetamide (TAA), and transfer it to the reaction kettle after ultrasonic dispersion , reacted at 150°C for 1 hour, too...

Embodiment 2

[0026] (1) Weigh 2.9103g of Co(NO 3 ) 2 , 1.4543g of Ni(NO 3 ) 2 ·6H 2 O. 2.4609g of NaAC was dissolved in a mixed solution of 20ml polyethylene glycol and 20ml ethylene glycol, dispersed by ultrasonic to form a homogeneous solution, stirred for 30 minutes, put the above mixed solution into a 40mL reaction kettle, and reacted at 180°C After 16 hours, the suspension was taken, washed by centrifugation, and vacuum-dried at 60° C. for 12 hours to obtain a cobalt-nickel nanosheet precursor (Ni:Co=1:2).

[0027] (2) Weigh 60mg of the cobalt-nickel precursor (Ni:Co=1:1) obtained in step (1) and redisperse it in 40ml of absolute ethanol, add 120mg of thioacetamide (TAA), and transfer it to the reaction kettle after ultrasonic dispersion , reacted at 130°C-150°C for 1-2 hours, took the suspension, washed it by centrifugation, and dried it in vacuum at 60°C for 12 hours.

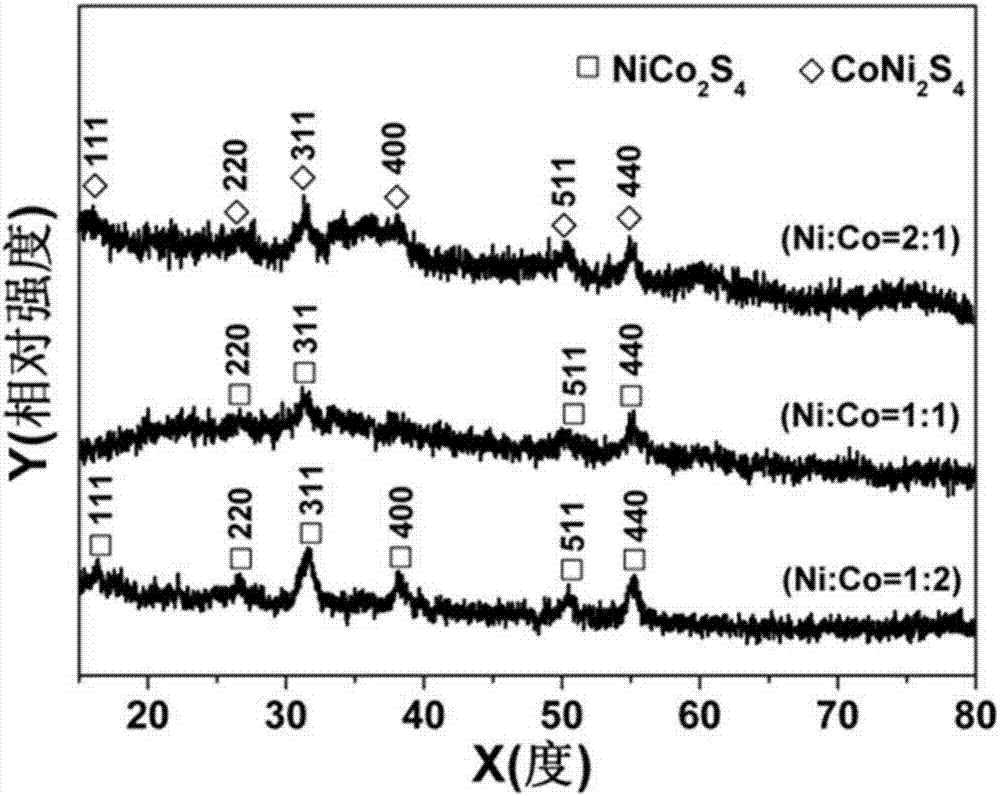

[0028] For the XRD test result in this instance shows: as figure 1 As shown in , the abscissa X is the diffr...

Embodiment 3

[0031] (1) Weigh 1.455g of Co(NO 3 ) 2 , 2.908g of Ni(NO 3 ) 2 , 2.4609g of NaAC was dissolved in a mixed solution of 20ml of polyethylene glycol and 20ml of ethylene glycol, dispersed by ultrasonic to form a homogeneous solution, stirred for 30 minutes, put the above mixed solution into a 40mL reaction kettle, and reacted at 200°C for 15 Hours later, the suspension was taken, washed by centrifugation, and vacuum-dried at 60° C. for 12 hours to obtain a cobalt-nickel nanosheet precursor (Ni:Co=2:1).

[0032] (2) Weigh 60 mg of the cobalt-nickel nanosheet precursor (Ni:Co=1:1) obtained in step (1) and redisperse it in 40 ml of absolute ethanol, add 120 mg of thioacetamide (TAA), and transfer it to In the reaction kettle, react at 130°C-150°C for 1-2 hours, take the suspension, wash it by centrifugation, and dry it in vacuum at 60°C for 12 hours. The sample is labeled cobalt nickel sulfide nanosheet (Ni:Co=2:1).

[0033] For the XRD test result in this instance shows: as fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com