Preparation method of polymer-grafted graphene

A kind of technology of grafting graphite and polymer, which is applied in the field of preparation of polymer-grafted graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation method of polymer grafted graphene is: adding 1 part by weight of graphene or graphene oxide, 10-1000 parts by weight of solvent, 10-1000 parts by weight of vinyl monomer, and adding 0.01-10 parts by weight under nitrogen Part of the initiator is heated to 55-90° C., reacted for 1.5-60 hours, precipitated, centrifuged, washed, and dried to obtain the product polymer grafted graphene.

[0014] The vinyl monomers are: styrene, sodium styrene sulfonate, methyl methacrylate, butyl methacrylate, hydroxyethyl methacrylate, glycidyl methacrylate, dimethylamino methacrylate Ethyl, diethylaminoethyl methacrylate, tert-butyl methacrylate, 3-(methacryloyloxy)propyltrimethoxysilane, methyl acrylate, butyl acrylate, hydroxyethyl acrylate, glycidyl acrylate , Dimethylaminoethyl acrylate, diethylaminoethyl acrylate, tert-butyl acrylate, acrylamide, N-isopropylacrylamide, methacrylic acid, acrylic acid, 4-vinylpyridine, 2-vinylpyridine, 4 -Vinylpyrrolidone or acrylonitril...

Embodiment 1

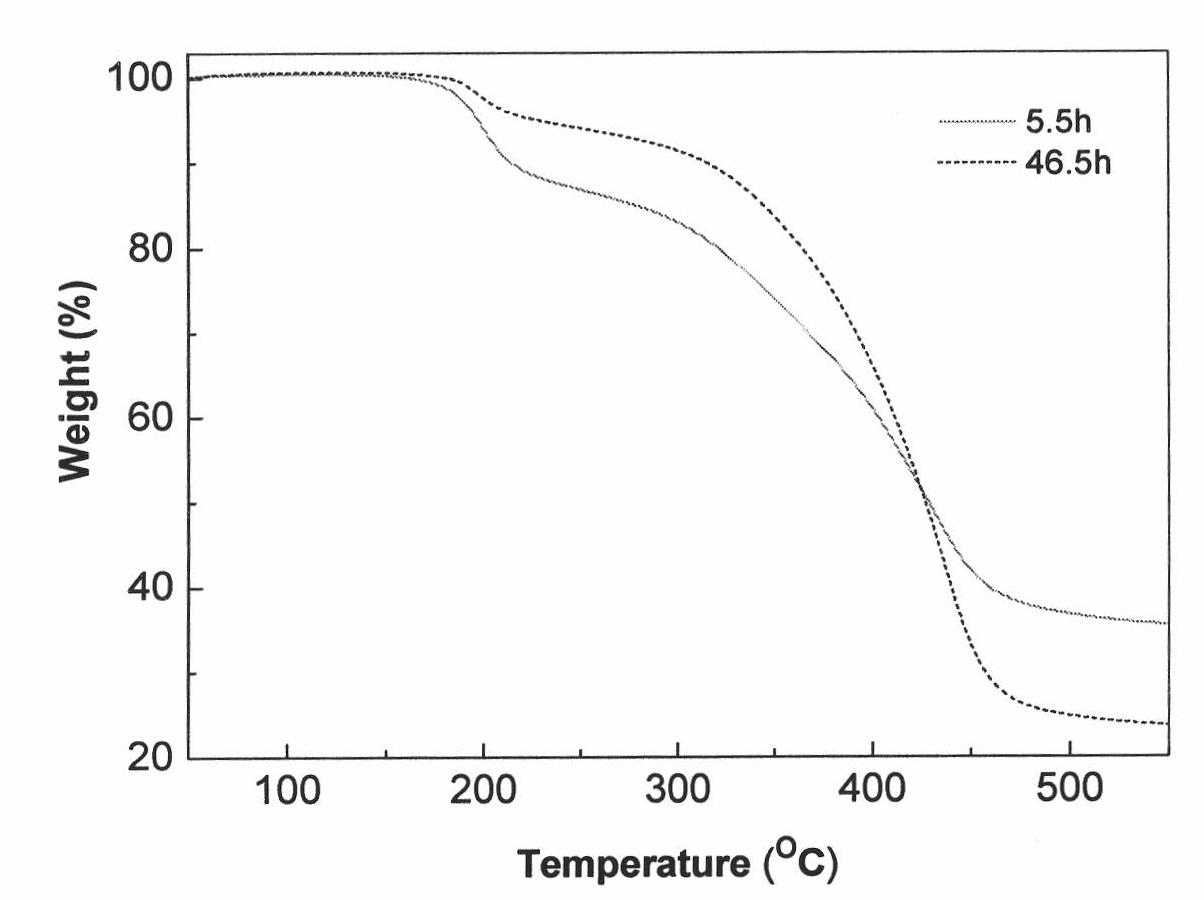

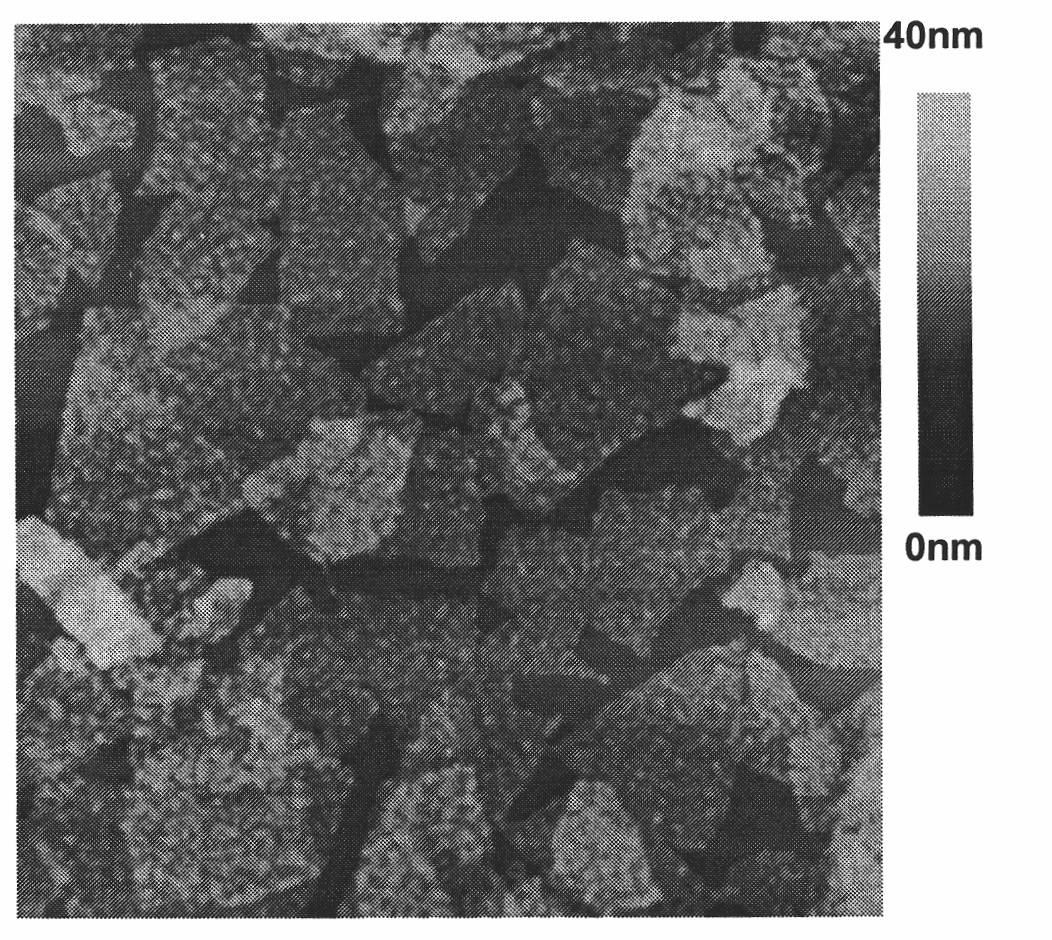

[0019] Add 50.0mg of graphene oxide to the reaction flask, add 40mL of N,N-dimethylformamide (DMF) and 7.1g of glycidyl methacrylate, stir for 30min under nitrogen protection, and then add 41.0mg of azobisiso Nitrile, then heated to 65°C, reacted for 48h, precipitated, centrifuged, washed, and dried to obtain polymer grafted graphene with a polymer grafting amount of 77%. The thermal weight loss curve is as follows figure 1 Shown; its atomic force microscope image is as figure 2 As shown, multiple monodisperse polymer-grafted graphene sheets can be seen.

Embodiment 2

[0021] Using the same reaction steps as in Example 1, the reaction time was 5.5 hours, and the polymer grafted graphene with a polymer grafting amount of 64% was obtained. The thermal weight loss curve is as follows figure 1 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com