Patents

Literature

95 results about "Diethylaminoethyl Methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

/LABORATORY ANIMALS: Acute Exposure/ 1,2-Diethylaminoethyl methacrylate and 2-dimethylaminoethyl methacrylate were strongly irritating to skin of guinea pigs and conjunctiva of rabbits. Diisopropylaminoethyl methacrylate was nonirritating.

Polymeric chelant and coagulant to treat metal-containing wastewater

The present invention is directed to the use of a combination of a polymeric chelant and coagulant to treat metal containing wastewater. More particularly, the invention is directed at removing copper from CMP wastewater. The composition includes a combination of (a) a polymeric chelant derived from a polyamine selected from the group consisting of diethylenetriamine (DETA), triethylenetetraamine (TETA), tertraethylenepentaamine (TEPA), poly[vinylamine], and branched or linear poly[ethylenimine] (PEI); and (b) a water soluble or dispersible copolymer of a tannin and a cationic monomer selected from the group consisting of methyl chloride or dimethyl sulfate quaternary salt of dimethyl aminoethyl acrylate, diethylaminoethyl acrylate, dimethylaminoethyl methacrylate, diethylaminoethyl methacrylate, dimethylaminopropyl methacrylamide, dimethylaminopropyl acrylamide, and diallyl dimethyl ammonium chloride.

Owner:GENERAL ELECTRIC CO

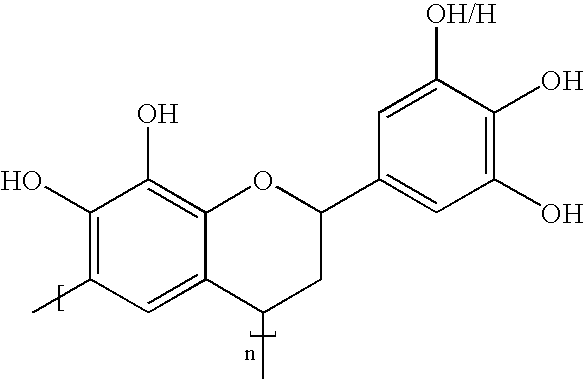

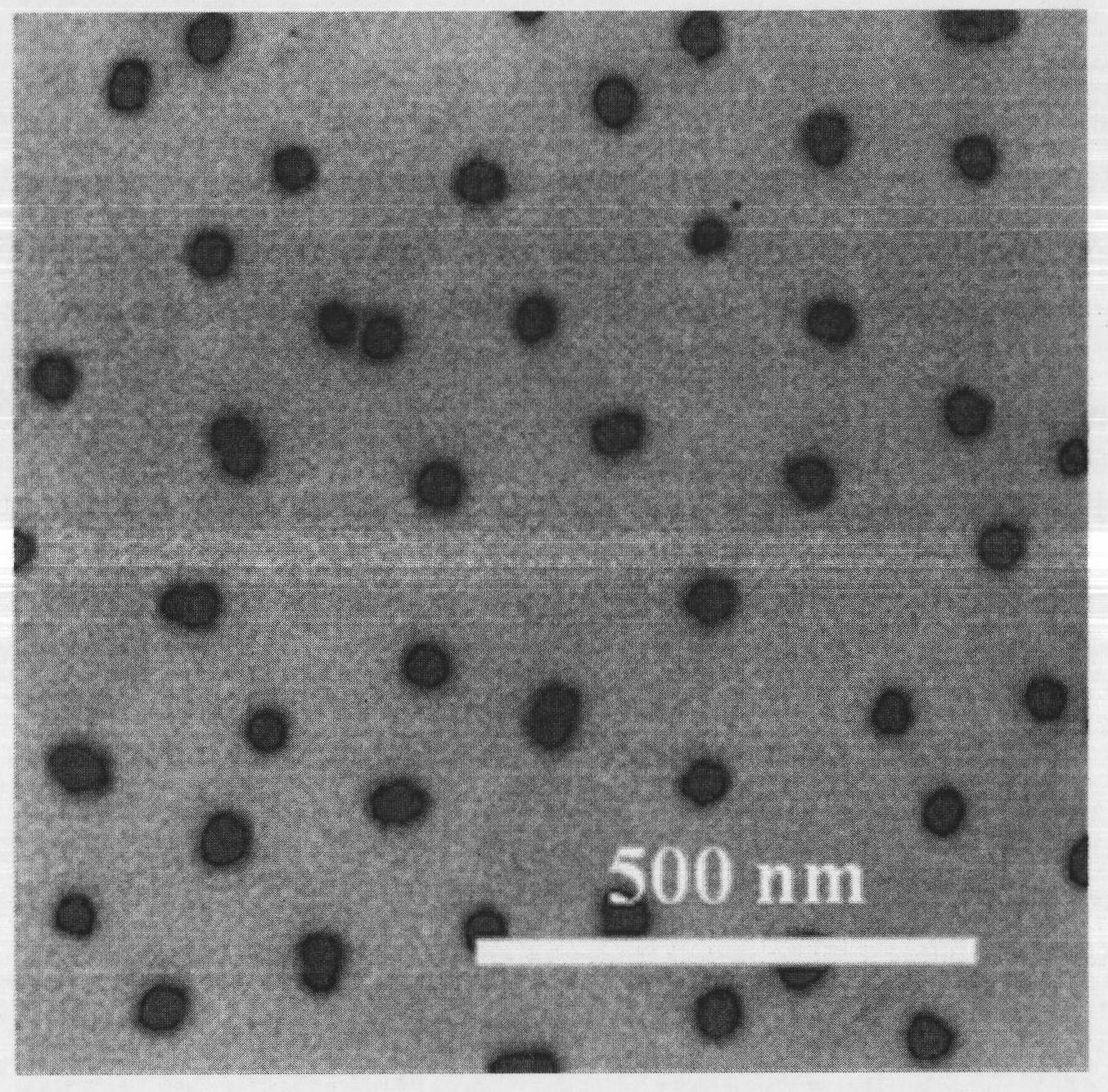

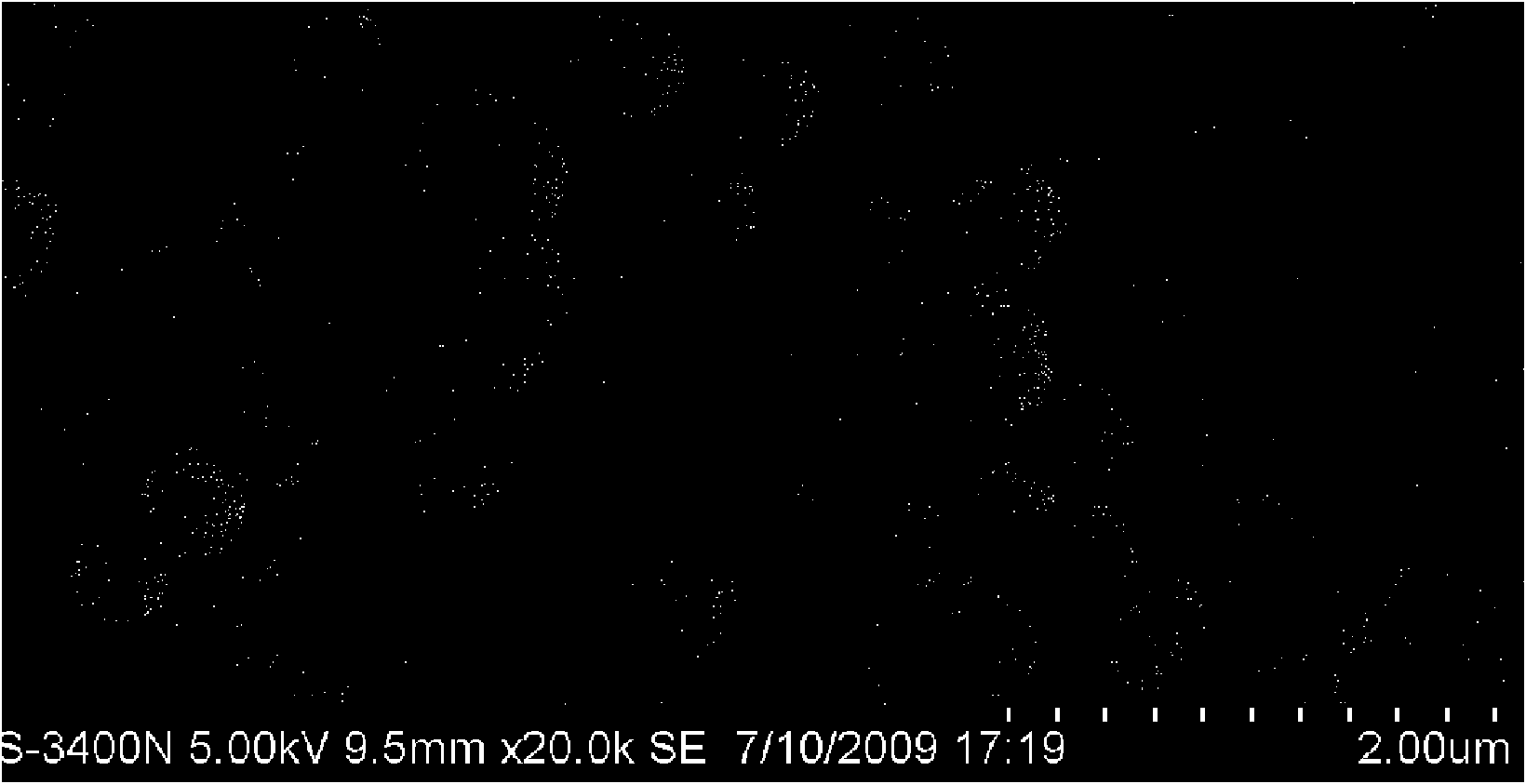

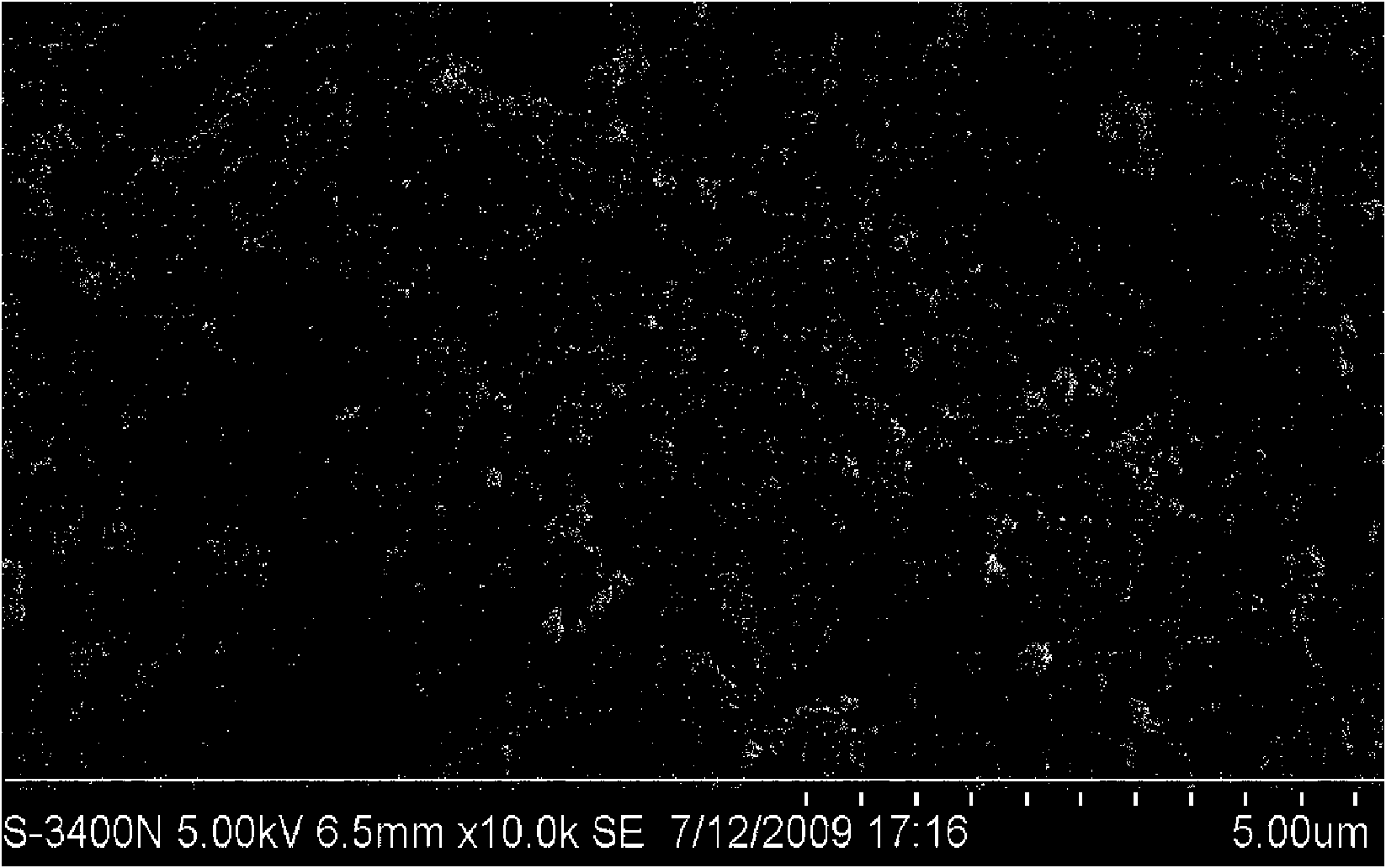

Method for preparing SiO2-poly(dimethylaminoethyl methacrylate) (PDMAEMA) nanoparticles having core-shell structure

ActiveCN101891867AParticle size adjustableNarrow particle size distributionGraft reactionSio2 nanoparticle

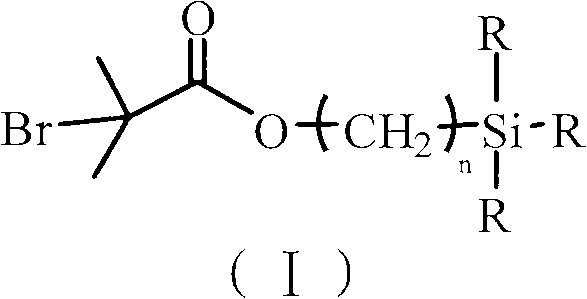

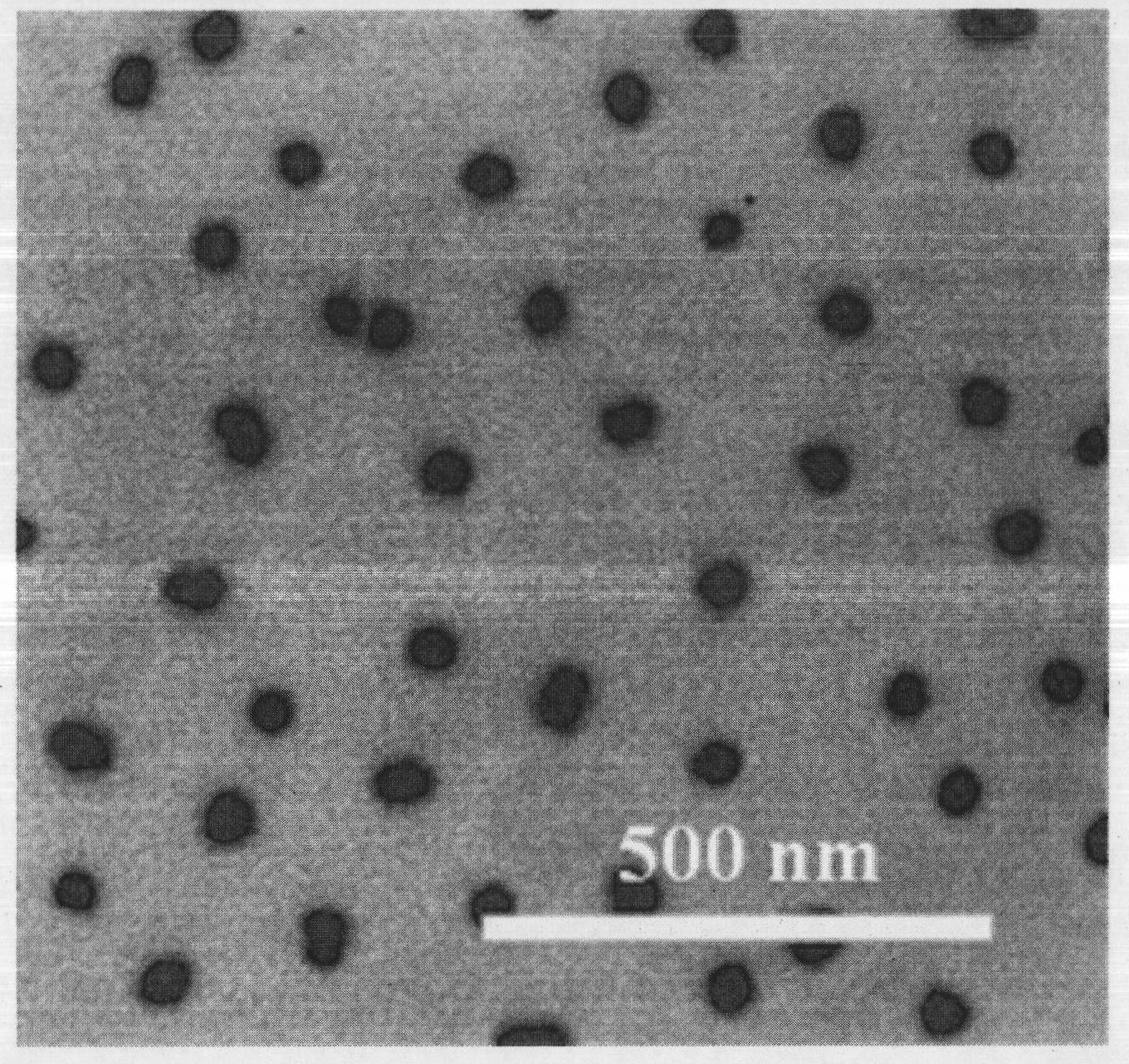

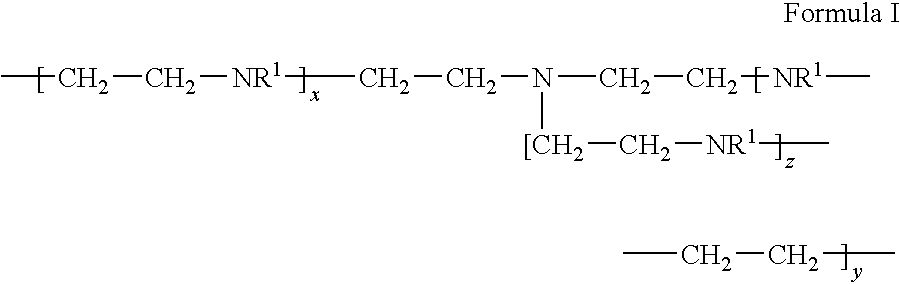

The invention relates to the field of nano technology and discloses a method for preparing SiO2-PDMAEMA nanoparticles having a core-shell structure. The method comprises the following steps of: selecting 2-bromideisobutyryl bromide with a higher initiation activity or a compound represented by a formula (I) as an initiator by using an atom-transfer radical-polymerization method; and during reaction, mixing CuX2 serving as a passivator, a ligand, SiO2 nanoparticles modified by the initiator, a solvent and diethylaminoethyl methacrylate at first and then adding CuX to perform a grafting reaction to obtain the SiO2-PDMAEMA nanoparticles with the core-shell structure. Experiments show that: the prepared SiO2-PDMAEMA nanoparticles have the advantages of controllable particle size, narrow particle size distribution and controllable molecular weight of the polymer PDMAEMA grafted on the surface of SiO2. Moreover, the preparation method provided by the invention has the characteristics of mild reaction conditions, convenience, feasibility and short preparation period and is easy for mass production.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

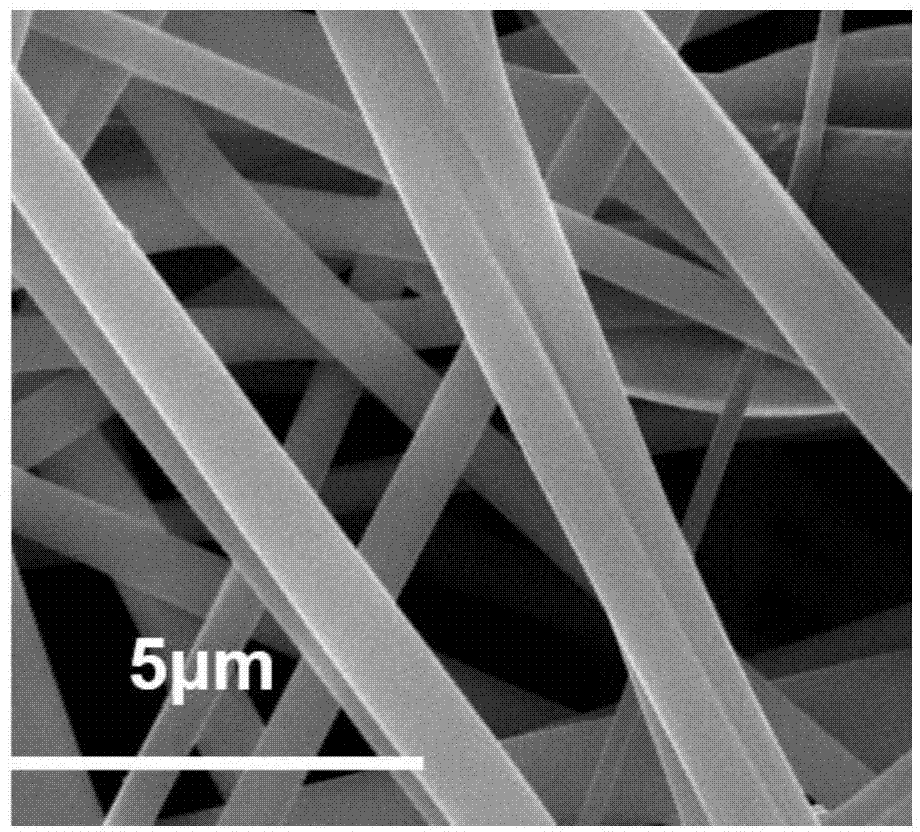

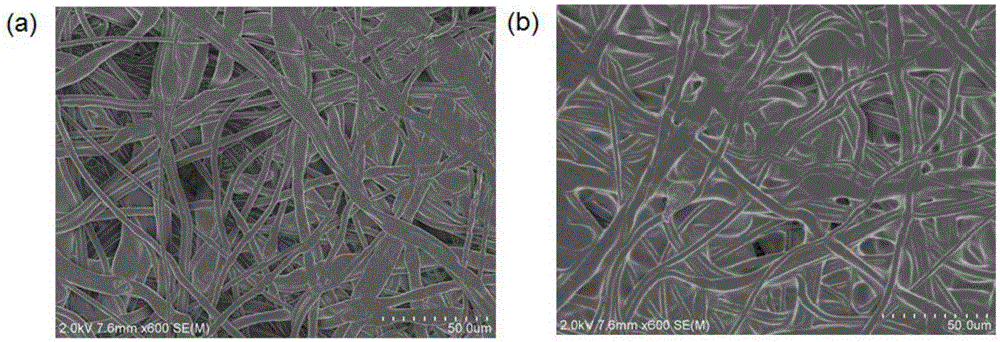

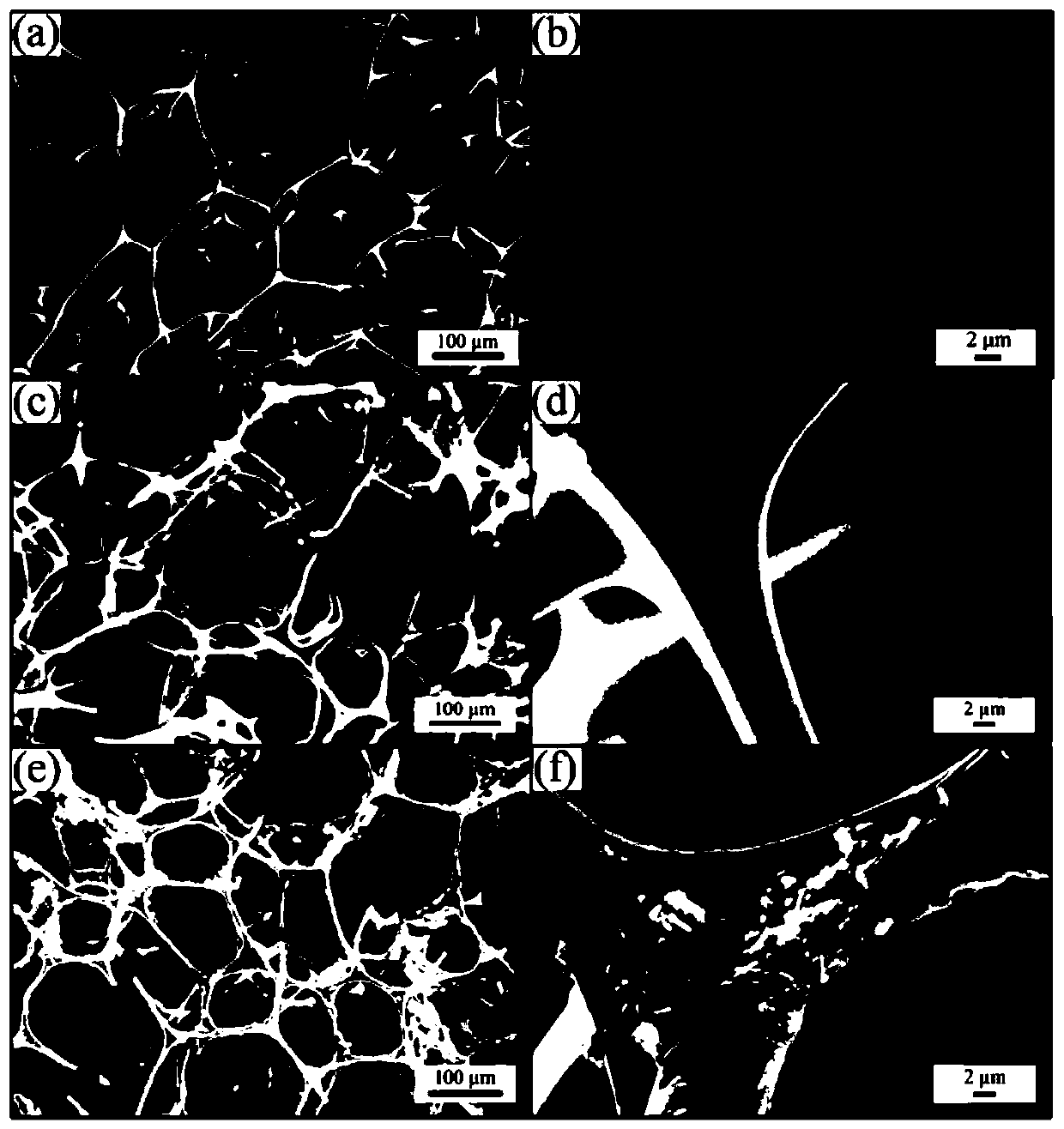

Oil water separation nanofiber membrane with CO2 stimulus response as well as preparation method and application thereof

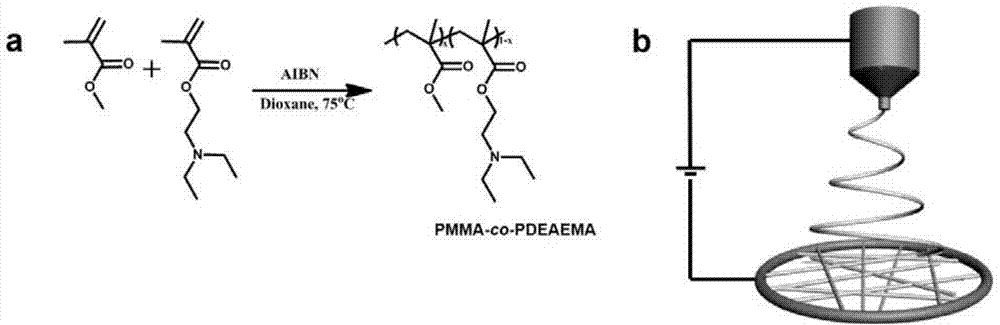

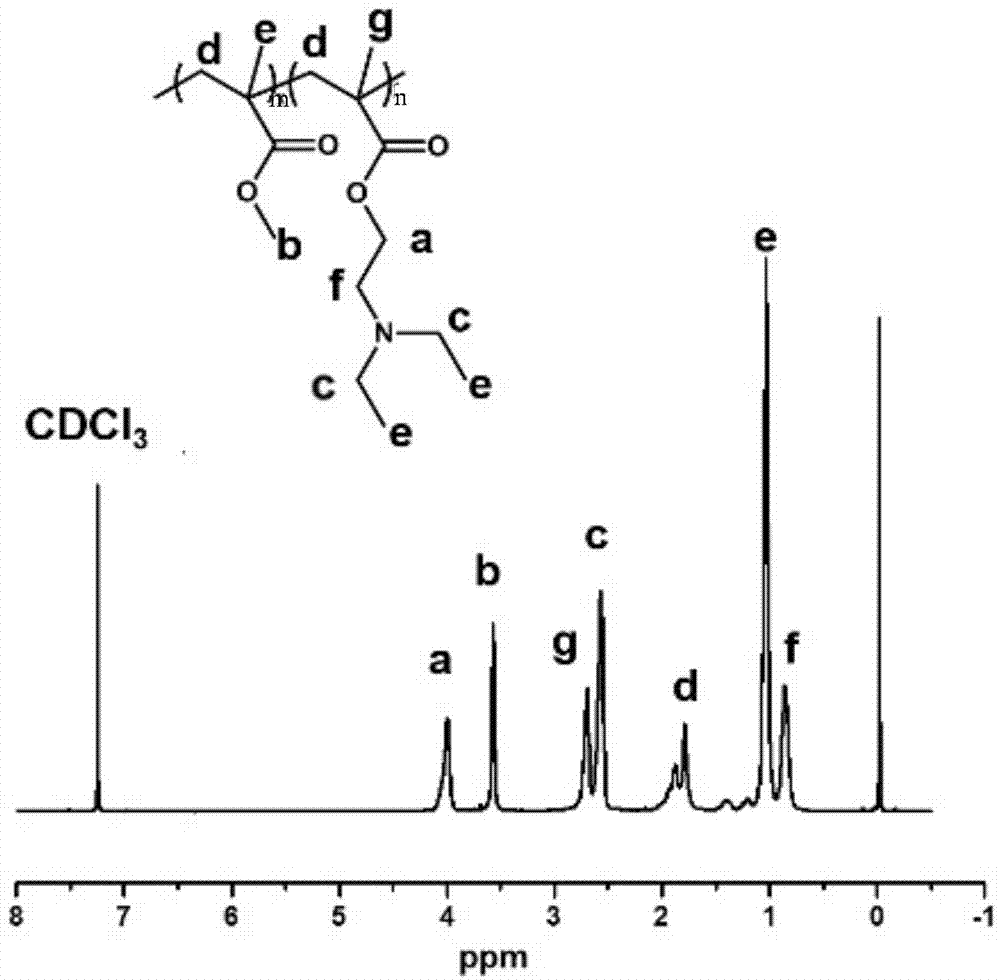

ActiveCN104841293ALipophilic and hydrophobicSimple and fast operationSemi-permeable membranesLiquid separationPolymethyl methacrylateNanofiber

The invention discloses an oil water separation nanofiber membrane with CO2 stimulus response as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing a random copolymer and a solvent to obtain spinning solution, wherein the random copolymer is polymethyl methacrylate-2-Diethylaminoethyl Methacrylate; (2) performing electrostatic spinning on the spinning solution to obtain nanofibers, and interweaving and arranging the nanofibers to obtain the nanofiber membrane. The oil water separation nanofiber membrane is applied to oil water separation. The nanofiber membrane prepared by utilizing an electrostatic spinning technology has a CO2 stimulus response function, can selectively perform oil water separation, is low in cost, simple and convenient to operate, clean and environment-friendly, and has better separation effects for various oil-water mixed systems.

Owner:TSINGHUA UNIV

Fabric coloring agent

The invention discloses a fabric coloring agent. The fabric coloring agent is prepared from the following constituents in parts by weight: 2-3 parts of sodium pyrophosphate, 1-2 parts of dibutyl phthalate, 4-5 parts of calcium sulphate, 6-7 parts of magnesium sulfate, 1-2 parts of aluminium oxide powder, 3-4 parts of iron blue, 4-5 parts of dinitrosopentatetramine, 4-5 parts of dimethyl formamide, 5-6 parts of diethylaminoethyl methacrylate, 3-4 parts of tert-butyl peroxybenzoate, 8-9 parts of an initiator, 8-9 parts of hexamethoxymethylmelamine, 8-9 parts of water, and 1-2 parts of glycerol. The fabric coloring agent disclosed by the invention is easy to color and low in possibility of color fading.

Owner:江苏金牛华尔车服饰有限公司

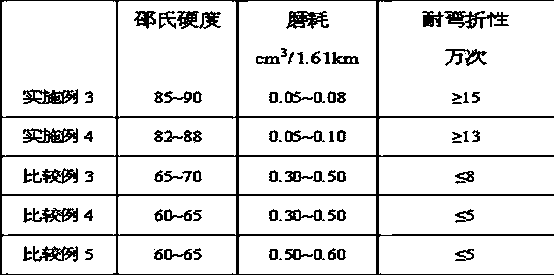

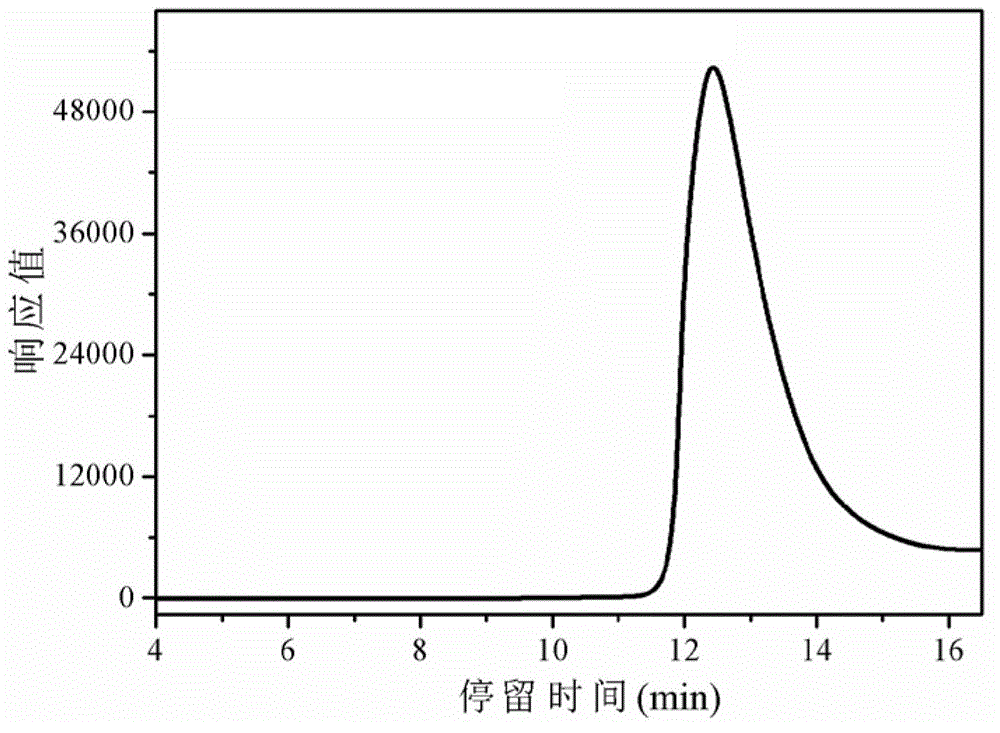

Polyurethane elastomer and sole made from same

ActiveCN104072716AIncrease elasticityHigh strengthSolesSynthetic resin layered productsPolyesterPolyurethane elastomer

The invention relates to a polyurethane elastomer. The polyurethane elastomer is formed by uniformly mixing the following ingredients in parts by weight: 20-22 parts of diisocyanate, 8-10 parts of polyester polyol, 5-6 parts of 1,4-butanediol, 1.8-2.0 parts of hydroxy-terminated butadiene, 1.2-1.5 parts of diethylaminoethyl methacrylate, 0.20-0.25 part of triethylenediamine, 0.40-0.50 parts of water, and 0.25-0.30 parts of foam stabilizer, and injecting the mixture a preheated pre-shaped die for reaction and curing. The polyurethane elastomer provided by the invention has micropore structures, has relatively high elasticity and strength compared with a conventional foamed plastic, is relatively low in density, and is excellent in bendability resistance and aging resistance.

Owner:ZHEJIANG AOKANG SHOES

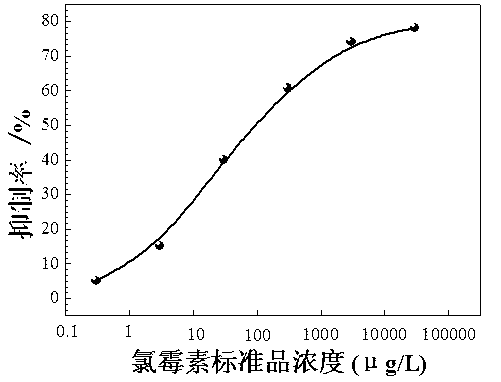

Process for producing chloromycetin molecular engram solid phase extraction small column

InactiveCN1811409AWith dynamic "memory" functionImprove efficiencyComponent separationOther chemical processesCross-linkFunctional monomer

The present invention relates to a preparation method of chloromycetin molecular engram solid-phase extraction small column, belonging to the field of biological engineering technology. Said method includes the following steps: using template molecule chloromycetin, functional monomer N-N-diethylaminoethyl methacrylate and cross-linking agent ethylene glycol dimethacrylate according to the mole ratio of 1:2-8:25 and making them undergo the process of suspension polymerization to obtain chloromycetin molecular engram polymer microsphere; weighing said chloromycetin molecular engram polymer microsphere and filling it into polyprophylene solid-pase extraction small column so as to obtain the invented chloromycetin molecular engram solid-phase extraction small column.

Owner:SHANGHAI JIAO TONG UNIV

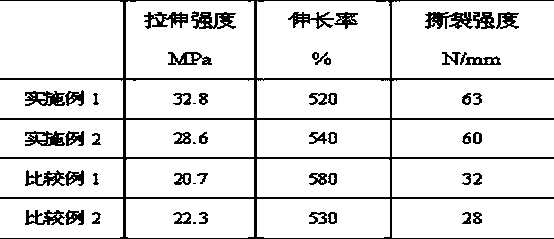

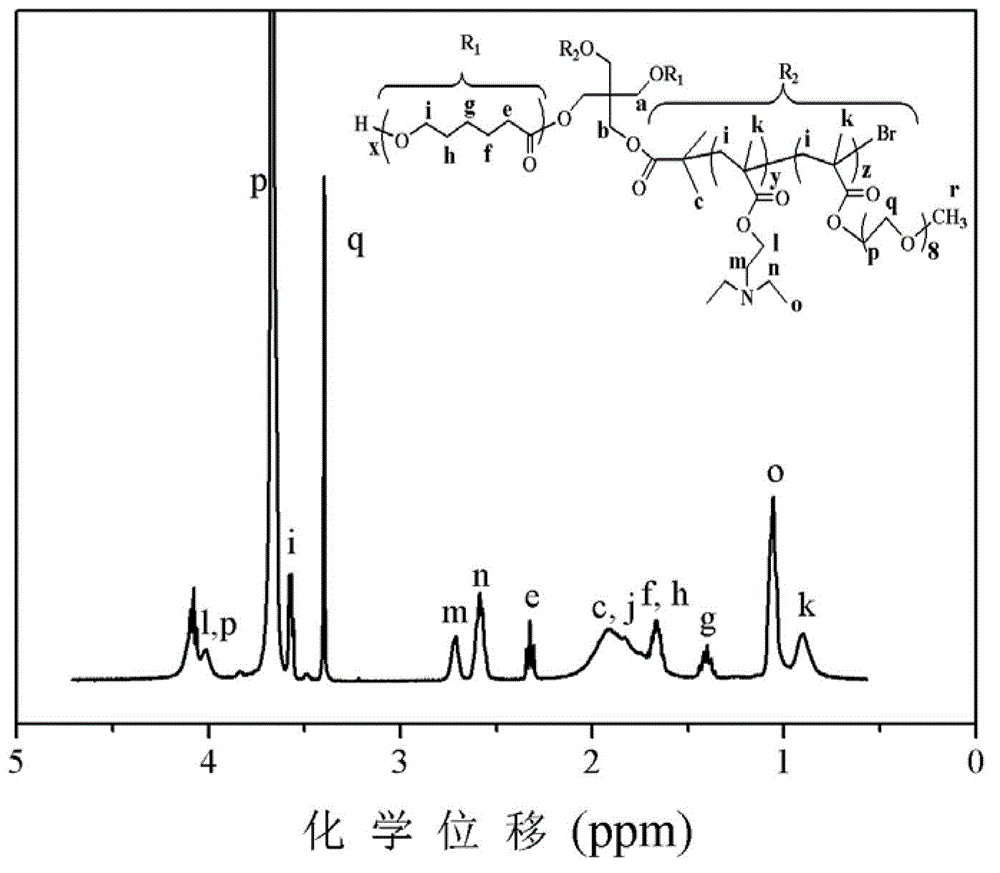

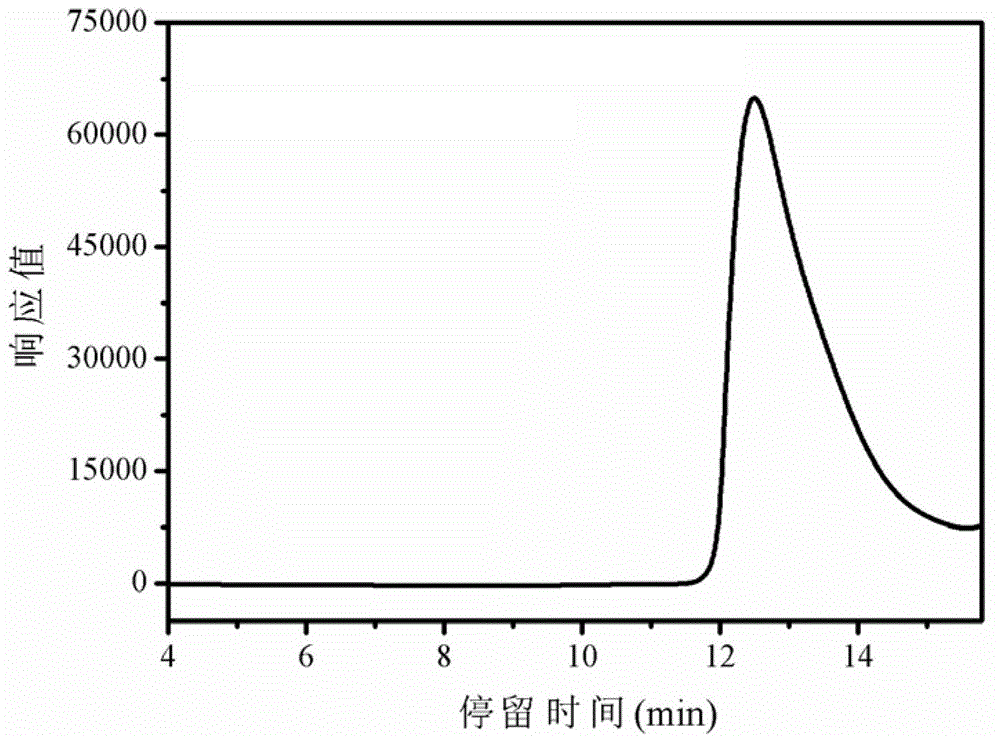

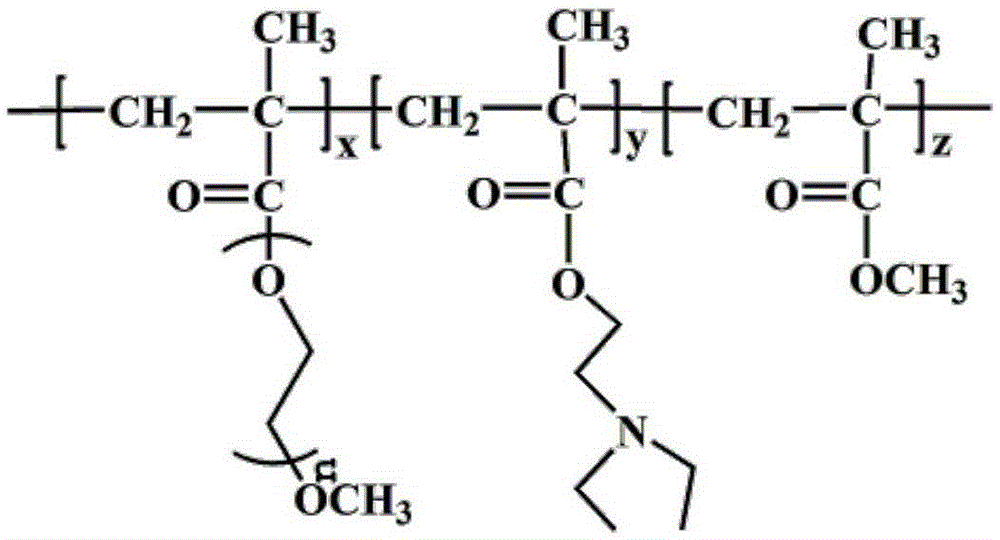

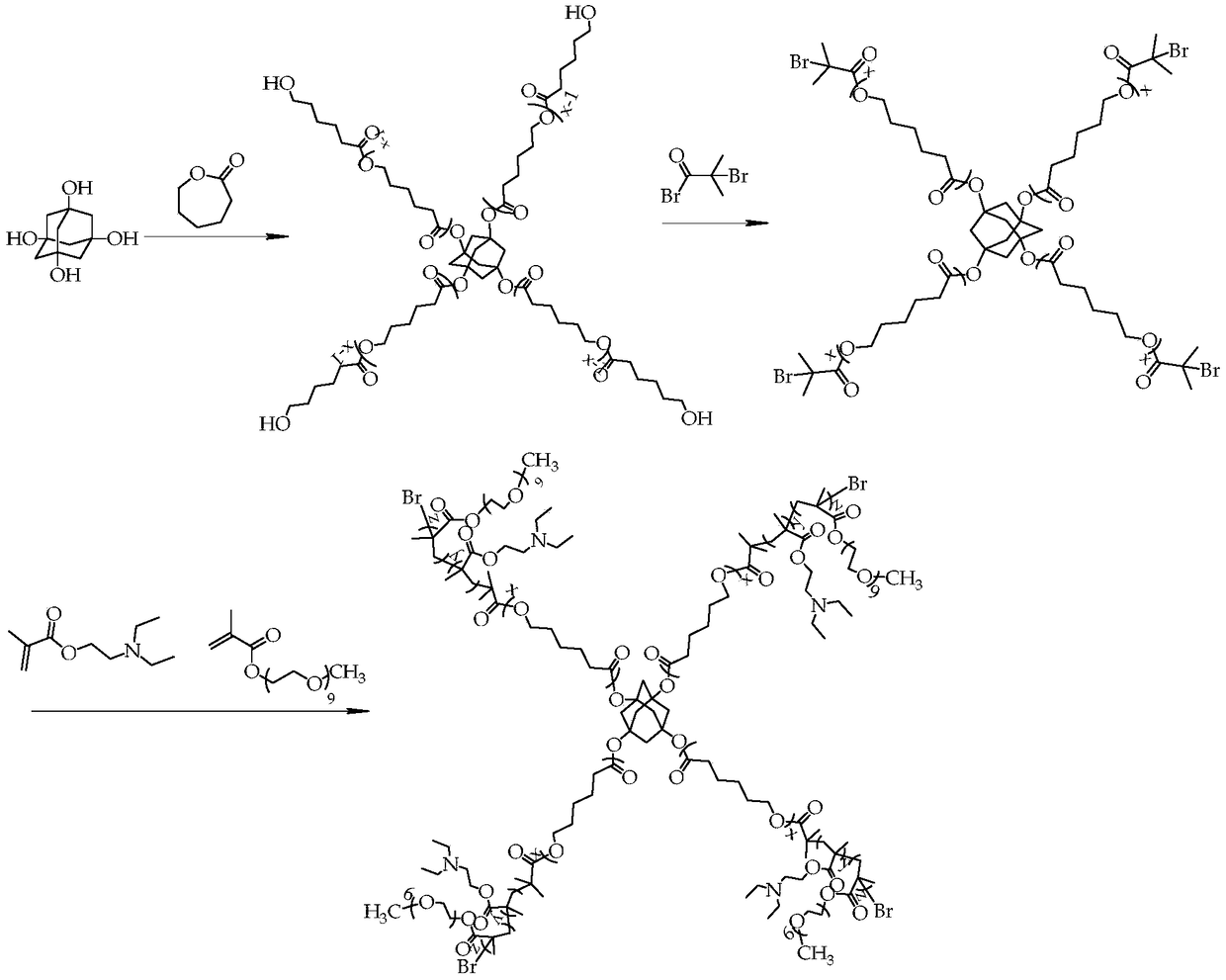

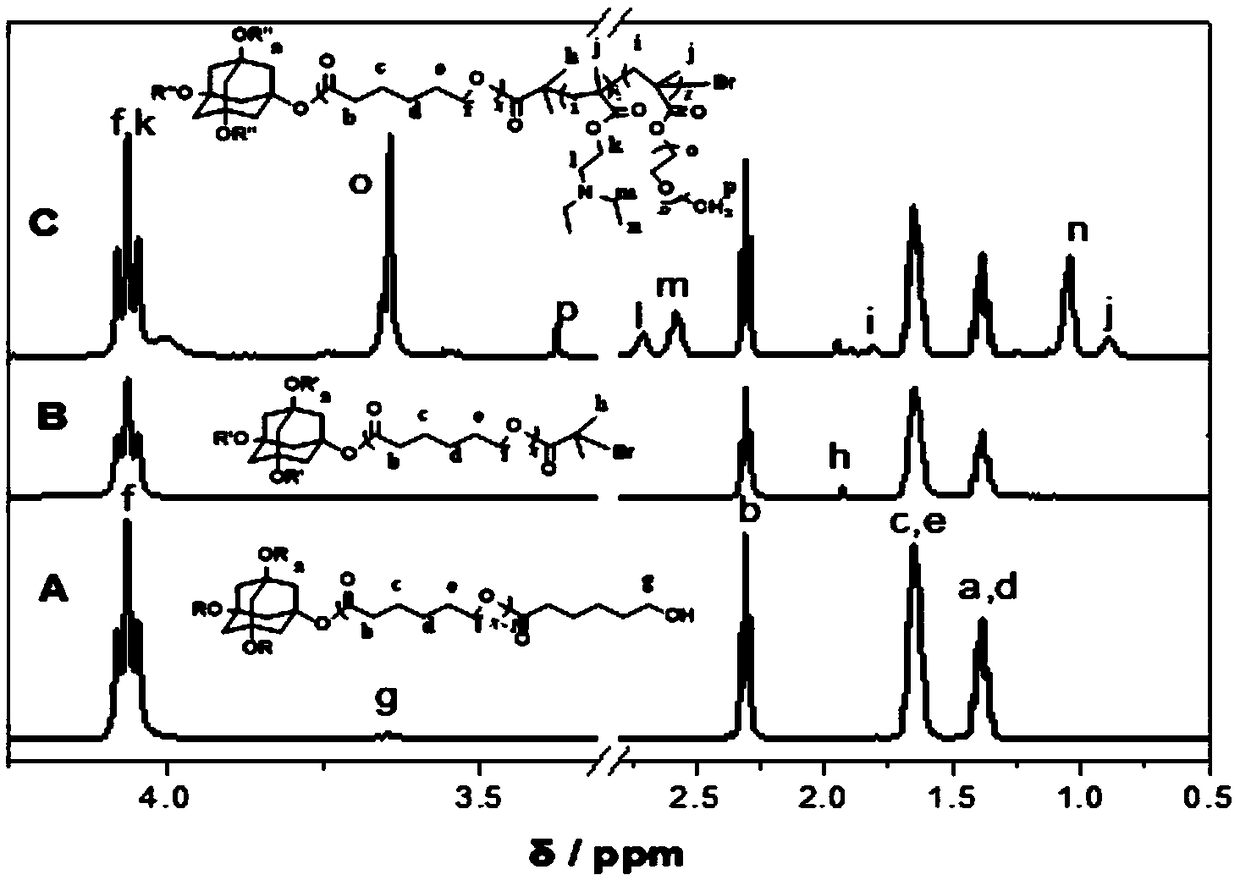

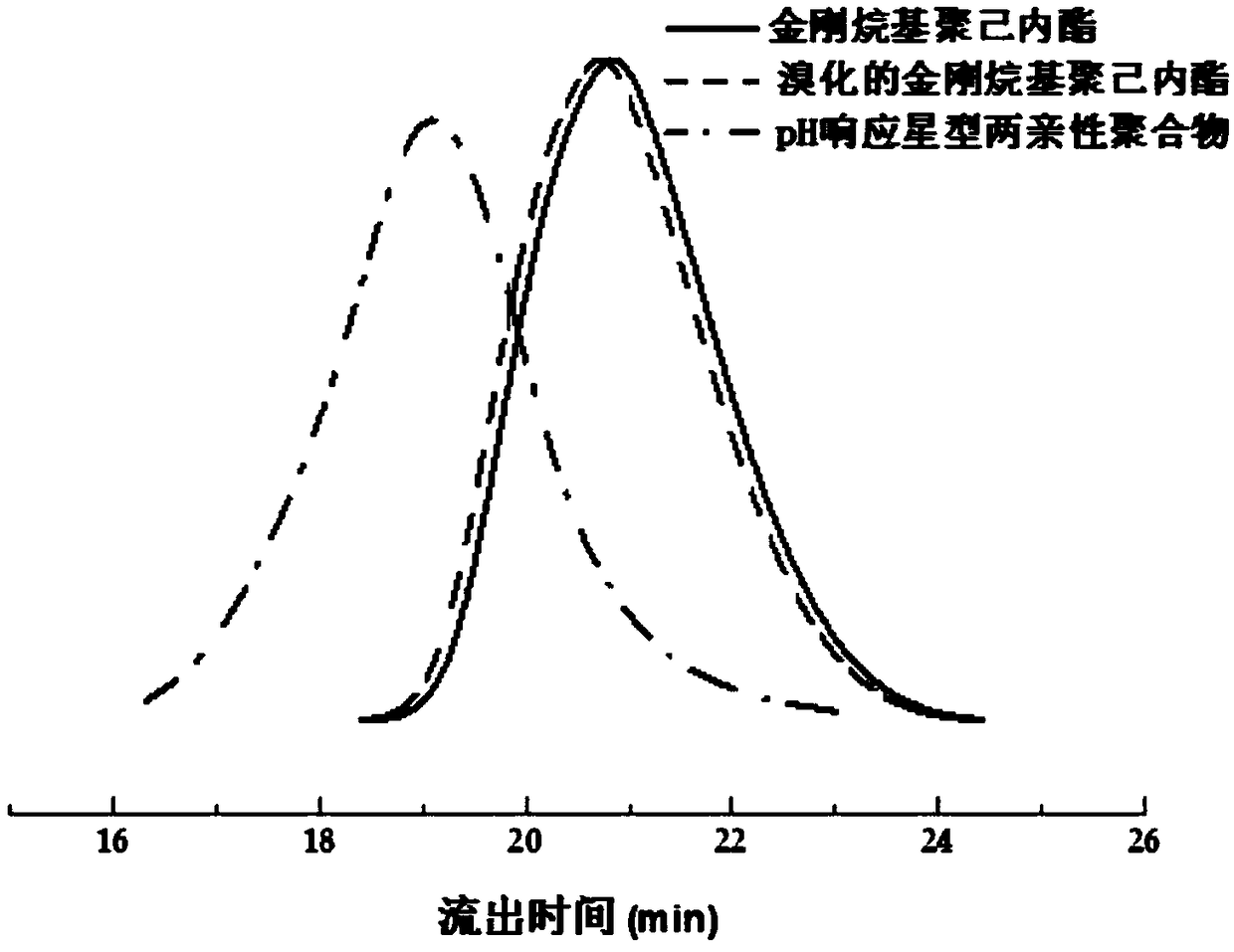

Amphiphilic pH-responsive 4/6 heteroarm star-shaped copolymer and preparation method thereof

ActiveCN103333301AEasy to operateMild reaction conditionsPharmaceutical non-active ingredientsWater insolubleDistillation

The invention belongs to the technical field of high molecular polymer materials for biomedicine, and discloses an amphiphilic pH-responsive 4 / 6 heteroarm star-shaped copolymer of which the number-average molecular weight is 30000-54000g / mol. The invention also discloses a preparation method of the amphiphilic pH-responsive 4 / 6 heteroarm star-shaped copolymer, which comprises the following steps: mixing epsilon-caprolactone, stannous octoate and low molecular initiator, reacting at 110-140 DEG C for 24-48 hours, performing reduced pressure distillation, precipitating, filtering, and drying to obtain polycaprolactone high molecular initiator; dissolving the polycaprolactone high molecular initiator, 2-diethylaminoethyl methacrylate, hexamethyltriethylenetetramine and copper bromide in toluene, stirring, then adding stannous octoate, and reacting at 60-90 DEG C for 5-12 hours; and adding methoxy polyoxyethylene methacrylate, continuously polymerizing for 5-12 hours, removing a catalyst, filtering, and performing posttreatment on the filtrate to obtain the amphiphilic pH-responsive 4 / 6 heteroarm star-shaped copolymer. The amphiphilic pH-responsive 4 / 6 heteroarm star-shaped copolymer is used for preparation of a micelle system for carrying water insoluble medicaments.

Owner:SOUTH CHINA UNIV OF TECH

Stain not easy to fade

ActiveCN103711004AImprove bindingNot easy to fadeDyeing processTrimethylolpropaneDibutyltin dilaurate

The invention discloses a stain not easy to fade, which is prepared from the following raw materials in parts by weight: 20-30 parts of dibutyl phthalate, 40-50 parts of diphenyl ether tetracarboxylic dianhydride, 20-30 parts of dimethylformamide, 20-40 parts of diethylaminoethyl methacrylate, 20-50 parts of dibutyltin dilaurate, 10-20 parts of calcium sulfate, 20-50 parts of triethanolamine, 50-60 parts of hydroxymethyl cellulose, 10-20 parts of iron blue, 20-30 parts of trimethylolpropane, 20-25 parts of hexamethoxy methyl melamine, 10-20 parts of an initiator, 10-20 parts of a surfactant, and 50-80 parts of water. The soaping fastness of the stain disclosed by the invention is grade 4.5-5.0, the strain is strong in combination and not easy to fade, the K / S value is as high as 8.215, and the dyeing performance is good.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

Preparation method and application of molecular imprinting polymer microspheres for Chlorsulfuron

ActiveCN101649021ALarge specific surface areaImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesCross-linkMonosulfuron

The present invention provides a preparing method and application of molecular imprinting polymer microspheres for Chlorsulfuron, relating to a preparing method and the application of molecular imprinting polymer microspheres and solving the problems that molecular imprinting polymer particles obtained in the prior method are irregular and can only absorb one substance. The preparation method comprises the steps as follows: dissolving diethylaminoethyl methacrylate and Chlorsulfuron in a solvent, adding a cross-linking agent and an initiating agent, carrying out ultrasonic processing, leadingin nitrogen, sealing, heating, cooling and centrifugating , washing dry sediments by an acetic acid and methanol solution, and then washing by methanol and drying to obtain the molecular imprinting polymer microspheres for Chlorsulfuron. The obtained molecular imprinting polymer microspheres for Chlorsulfuron are used for detecting the trace amount of Chlorsulfuron herbicides, thifensulfuron methyl herbicides and monosulfuron herbicides. The molecular imprinting polymer microspheres for Chlorsulfuron prepared by the method have the advantages of regular shape, even size and absorbability of Chlorsulfuron, monosulfuron and thifensulfuron methyl.

Owner:BEIJING PURKINJE GENERAL INSTR

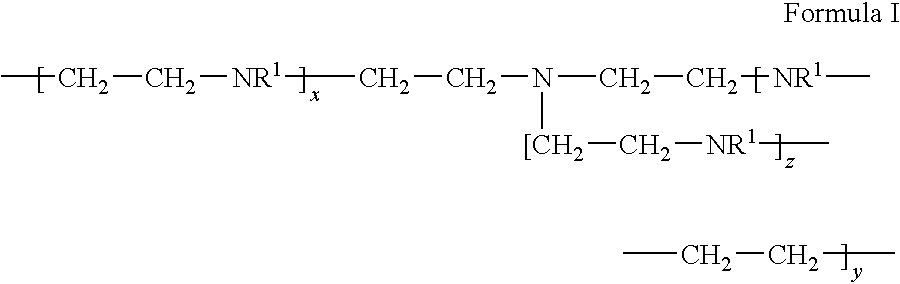

Polymer, preparation method and poly-N-isopropylacrylamide europium complex micelle

InactiveCN105085845AEasy to prepareRaw materials are easy to getPharmaceutical non-active ingredientsPolymer sciencePoly(N-isopropylacrylamide)

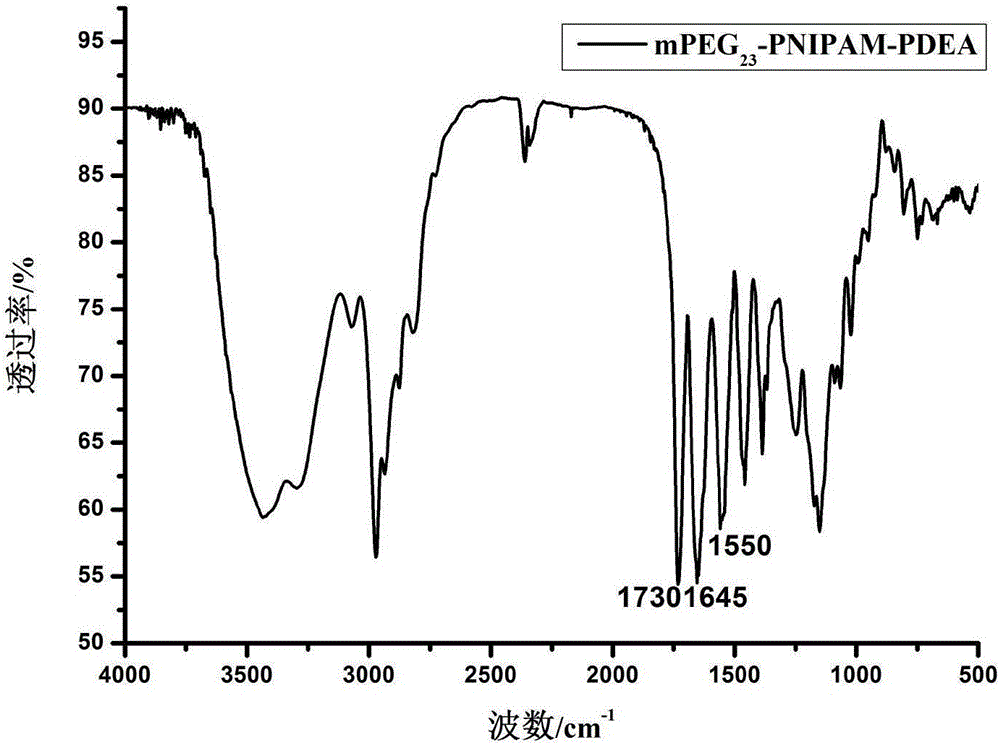

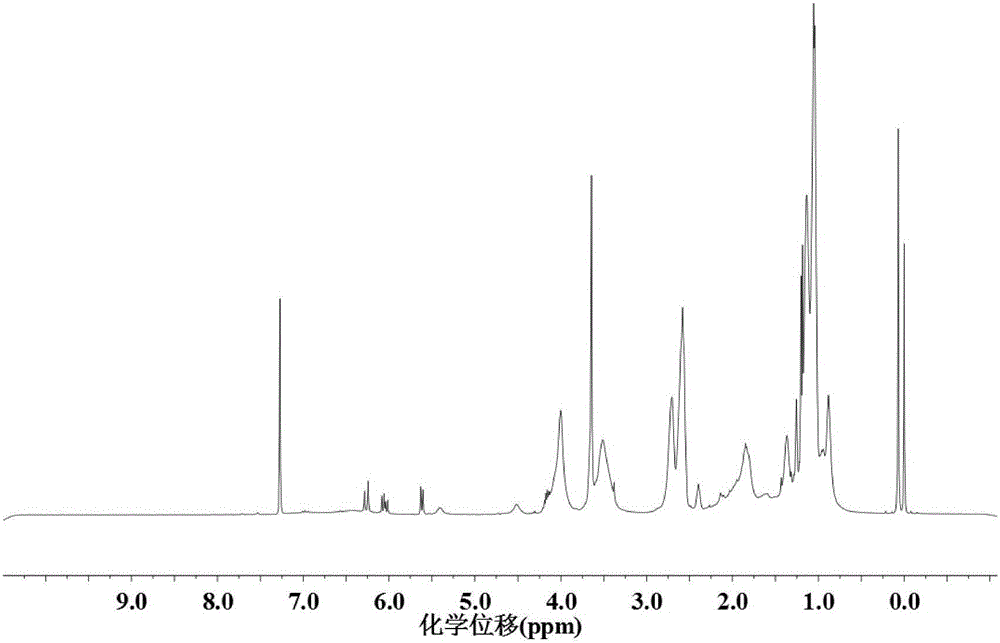

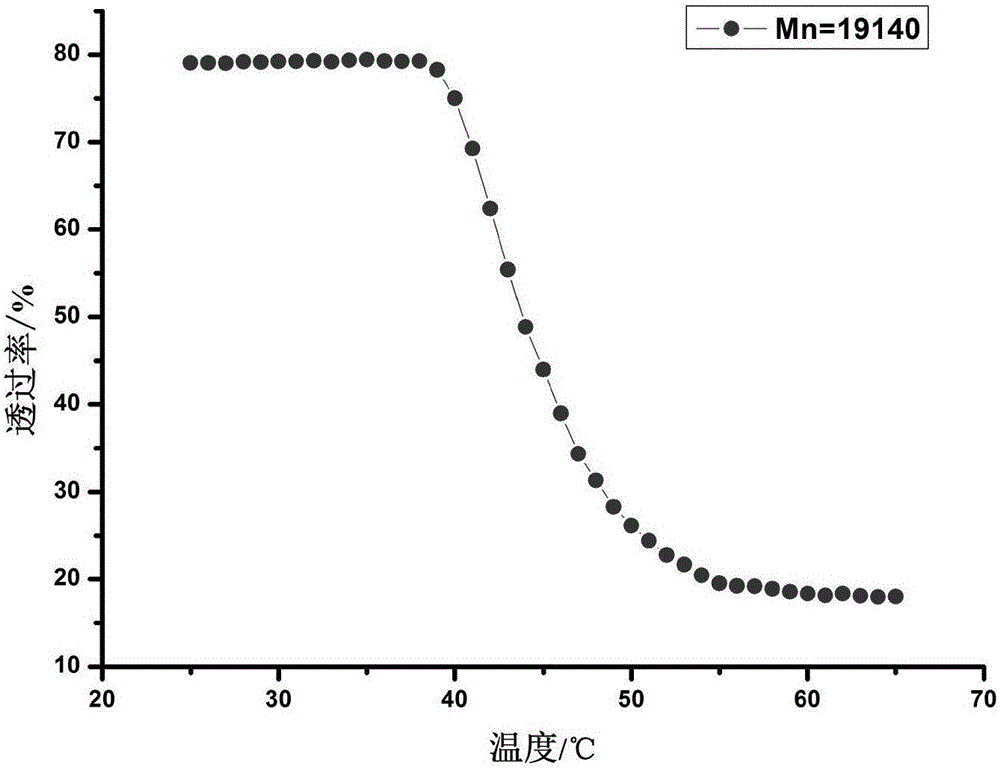

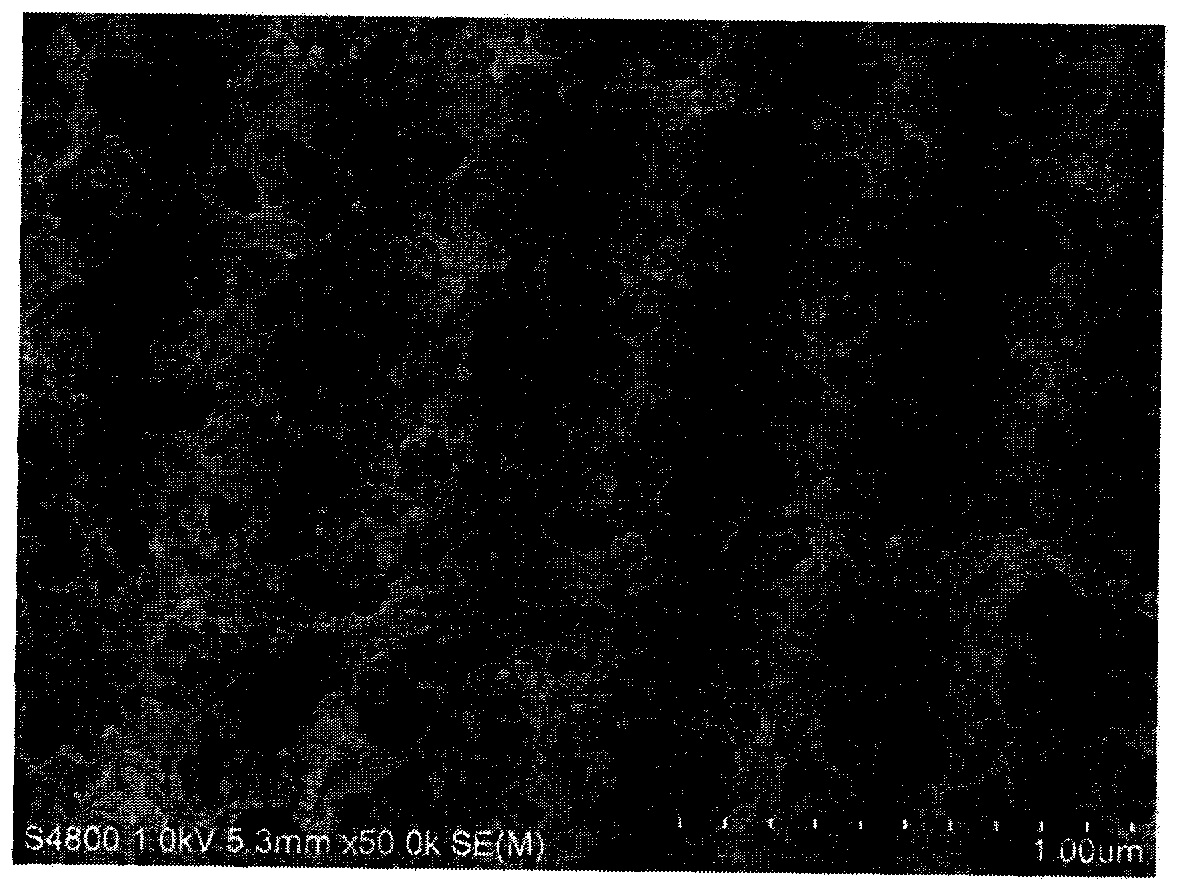

The invention provides a polymer, a preparation method and a poly-N-isopropylacrylamide europium complex micelle, and belongs to the field of europoium complexes. The polymer is methoxypolyethylene glycol-poly-N-isopropylacrylamide-polymethylacrylic acid N,N-diethylaminoethyl, the structural formula is shown as the formula I, and the abbreviate formula is mPEG23-PNIPAM-PDEA, wherein mPEG23 is methoxypolyethylene glycol, PNIPAM is poly-N-isopropylacrylamide, and PDEA is polymethylacrylic acid N,N-diethylaminoethyl. The structural formula of the europium complex micelle is shown as the formula II. Due to the fact that the polymer (mPEG23-PNIPAM-PDEA) has good thermosensitivity and pH sensibility, the polymer can be used as a chemical conveying carrier after being prepared into the europium complex micelle.

Owner:CHANGCHUN UNIV OF SCI & TECH

Modified polypropylene hollow fiber filter membrane for environmental detection and preparation method of modified polypropylene hollow fiber filter membrane

InactiveCN107174976AKeep hydrophilicImprove pollutionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceP-Aminophenol

The invention discloses a modified polypropylene hollow fiber filter membrane for environmental detection. The modified polypropylene hollow fiber filter membrane for environmental detection comprises a polypropylene hollow fiber membrane and a coating which coats the surface of the polypropylene hollow fiber membrane, wherein the polypropylene hollow fiber membrane comprises the following raw materials: polypropylene granules, glyceryl triacetate, poly(ethylene glycol) methyl ether methacrylate, p-aminophenol, aminocyclohexanol, and a film coalescence aid; and the coating comprises the following raw materials: diethylaminoethyl methacrylate, dopamine hydrochloride, poly-hydroxy phytic acid, taurine and trishydroxymethylaminomethane. The invention further discloses a preparation method of the modified polypropylene hollow fiber filter membrane for environmental detection. By reasonable blending of the components of the polypropylene hollow fiber filter membrane and the components of the coating and technical procedures, while the hydrophilic performance of the polypropylene hollow fiber filter membrane is guaranteed, the antifouling property and the stability are improved, the binding force of the coating and the polypropylene hollow fiber filter membrane is further increased, and the service life of the filter membrane is prolonged.

Owner:安徽众诚环境检测有限公司

Preparation method for rebaudiodside A molecularly-imprinted polymer

ActiveCN104098739AEasy to identifyHigh adsorption selectivityOther chemical processesAlkali metal oxides/hydroxidesCross-linkFunctional monomer

The invention relates to the field of food separation technology, specifically to a preparation method for a rebaudiodside A molecularly-imprinted polymer. According to the invention, rebaudiodside A is used as a template molecule, diethylaminoethyl methacrylate is used as a functional monomer, ethylene glycol dimethacrylate is used as a cross-linking agent, a mixed solvent of N,N'-dimethyl formamide and tetrahydrofuran is used as a pore forming agent, azodiisobutyronitrile is used as an initiator, and the rebaudiodside A molecularly-imprinted polymer is prepared through dispersion and uniform mixing of the above-mentioned substances, introduction of nitrogen for removal of oxygen, thermal-initiation polymerization, Soxhlet extraction and drying. The invention has the following beneficial effects: the prepared molecularly-imprinted polymer has good adsorption selectivity and great adsorption capacity on rebaudiodside A in a water-containing mobile phase and can be used as an adsorption and separation material for separating and purifying rebaudiodside A in stevia rebaudiana extract.

Owner:JIANGNAN UNIV

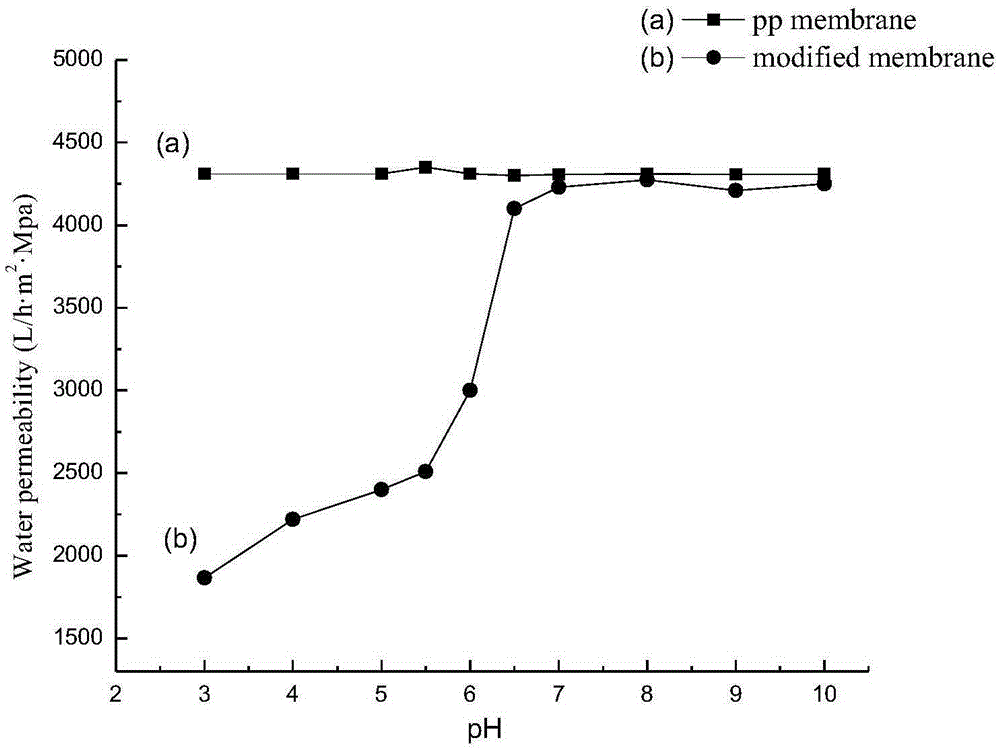

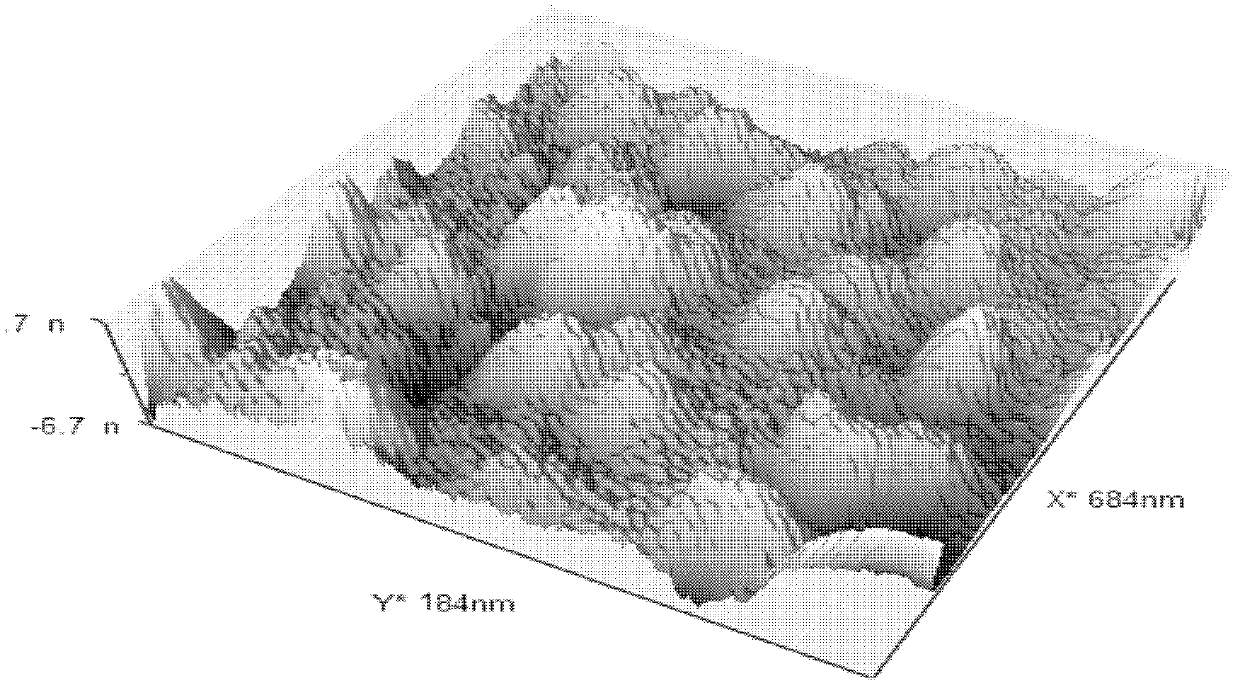

Responsiveness-based copolymer modified polypropylene (PP) micro-filtration membrane

The invention provides a responsiveness-based copolymer modified PP micro-filtration membrane, belonging to the field of functional polymer materials. According to the invention, polyethylene glycol methacrylate (PEGMA), diethylaminoethyl methacrylate (DEAEMA) and methyl methacrylate (MMA) are used as copolymerization monomers and undergo free radical polymerization to synthesize responsive three-component random copolymer P (PEGMA-co-DEAEMA-co-MMA); the responsiveness of the PP micro-filtration membrane is modified by using a surface entrapment method, and the wettability and surface morphology of the membrane can be regulated and controlled by changing the concentration and variety of a modification agent, treating temperature, etc.; and the amounts of water permeation of the PP micro-filtration membrane under different pH value conditions before and after modification. The responsive PP micro-filtration membrane with controllable surface morphology and performance obtained in the invention is expected to be used as an intelligent responsive material in the fields like tissue engineering and oil-water separation materials.

Owner:JIANGNAN UNIV

Preparation method of 96-well enzyme label plate chloramphenicol molecularly imprinted polymer film

The invention discloses a preparation method of a 96-well enzyme label plate chloramphenicol molecularly imprinted polymer film. The preparation method comprises the following steps of a, dissolving chloramphenicol as a template molecule, N,N-diethylaminoethyl methacrylate as a functional monomer and ethylene glycol dimethacrylate as a cross-linking agent in tetrahydrofuran as a pore forming agent according to a mole ratio of 1: 4: 0.2, and carrying out ultrasonic treatment for 30min, wherein a use amount ratio of tetrahydrofuran to chloramphenicol is 5ml / 0.25mmol, b, adding azodiisobutyronitrile as an initiator into the mixture, and carrying out ultrasonic treatment for 15min, wherein a use amount ratio of azodiisobutyronitrile to chloramphenicol is 5mg / 0.25mmol, c, dropwisely adding the solution obtained by the step b on a 96-well enzyme label plate, putting the 96-well enzyme label plate into a sealing bag, filling nitrogen into the sealing bag, carrying out sealing, and carrying out ultraviolet lamp irradiation to initiate polymerization lasting for 6h, d, putting the 96-well enzyme label plate into a methanol-acetic acid mixed solution having a volume ratio of 3: 1, and carrying out ultrasonic elution for 48h, and e, drying the 96-well enzyme label plate at a temperature of 50 DEG C for 2h to obtain the chloramphenicol molecularly imprinted polymer film.

Owner:DALIAN OCEAN UNIV +1

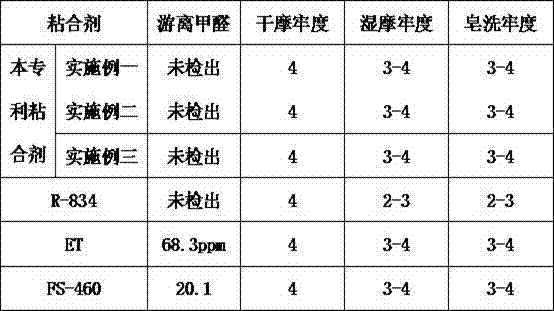

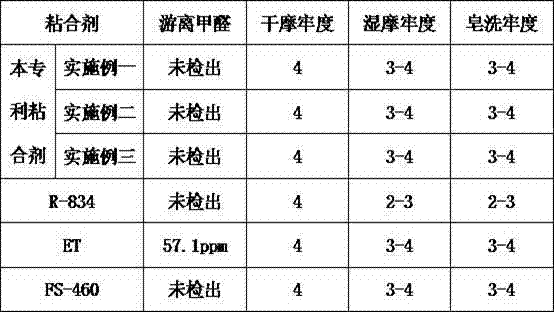

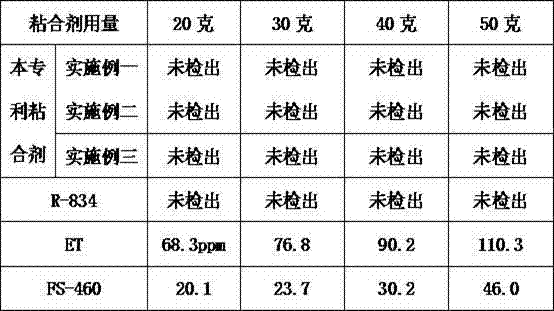

Binder used for pigment printing of textiles and preparation method thereof

InactiveCN102504090AHigh fastnessImprove film water resistanceDyeing processTextile printerPolymer science

The invention discloses a binder used for pigment printing of textiles and a preparation method thereof. The binder is prepared by seed emulsion polymerization of fatty alcohol polyoxyethylene ether sodium sulfate, diethylaminoethyl methacrylate, methacryloyloxy ethyl acetoacetate, sodium lauryl sulfate, acrylic acid, acrylic ester, ammonium persulfate and deionized water. The binder is free of formaldehyde or alkylphenol polyoxyethylene and has soft hand-feeling and good soaping fastness.

Owner:LIAONING FIXED STAR FINE CHEM

Water-soluble acrylic resin coating and preparation method thereof

InactiveCN104073117AThe appearance of the coating film is smooth and smoothWidely producedCoatingsPolymer science(Hydroxyethyl)methacrylate

The invention discloses a water-soluble acrylic resin coating and a preparation method thereof. The preparation method comprises the following steps of weighting hydroxyethyl methacrylate, chlorinated polyethylene, methyl methacrylate, butyl methacrylate, monobutyl maleate, butyl acrylate, styrene, diethylaminoethyl methacrylate, azobisisobutyronitrile, methylbenzene, a crosslinking agent, hexahydrophthalic anhydride, methanol 1 and a plasticizer; adding hydroxyethyl methacrylate, chlorinated polyethylene, methyl methacrylate and butyl methacrylate into a reaction kettle; stirring while heating; then, adding styrene, methanol and azobisisobutyronitrile; recovering methanol; adding monobutyl maleate and methylbenzene; adding the rest raw materials, and grinding to obtain the water-soluble acrylic resin coating. The water-soluble acrylic resin coating has the viscosity of 60-80s, the adhesive force of 1-2 grades and the hardness of 0.55-0.75; the impact strength is 45-65kg / cm, the tack-free time is 30-50min, and the solid drying time is 4-6h; a coated film has no bubbling and winkling phenomena after being soaked in a saturated calcium hydroxide solution for 7-14d and has no falling and bubbling phenomena after being soaked in water for 15-30d; the water-soluble acrylic resin coating has the flexibility of 2-4mm and can be widely produced and used for continuously replacing the traditional material.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

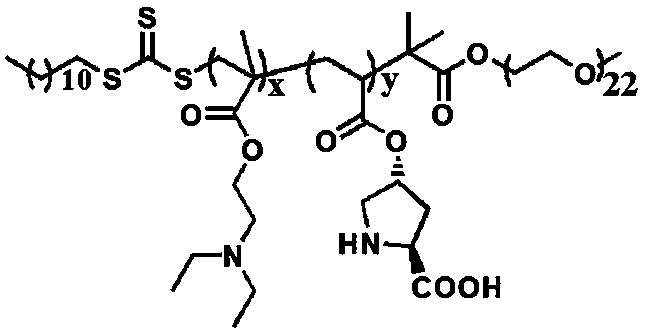

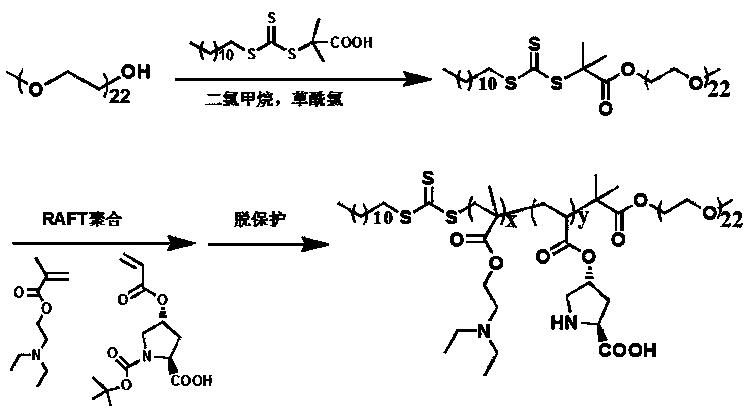

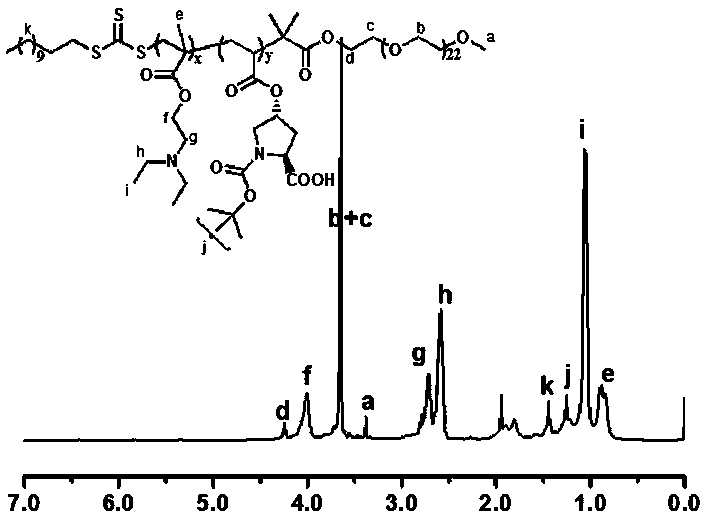

pH responsive block polymer immobilized with L-proline, and applications thereof

ActiveCN108164665AAchieve separationCompact spaceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReversible addition−fragmentation chain-transfer polymerizationMonomer

The invention belongs to the field of high molecular catalyst and synthesis thereof, and more specifically relates to a pH responsive block polymer immobilized with L-proline, and applications thereof. According to a preparation method of the pH responsive block polymer immobilized with L-proline, synthesized methoxyl polyethylene glycol trithiocarbonate PEG-DDMAT is taken as a large molecular chain transferring agent, reversible addition fragmentation chain transfer polymerization method is adopted to realize copolymerization of amino group protected functionalized L-proline Boc-ProIA, and pHresponsive monomer diethylaminoethyl methacrylate DEAEMA; and at last amino deprotection of an obtained polymer is carried out so as to obtain the pH responsive block polymer PEG-b-P(DEAEMA-co-ProIA)immobilized with L-proline. The pH responsive block polymer immobilized with L-proline is used for direct catalysis of asymmetric Aldol reaction in a water phase.

Owner:TAIYUAN UNIV OF TECH

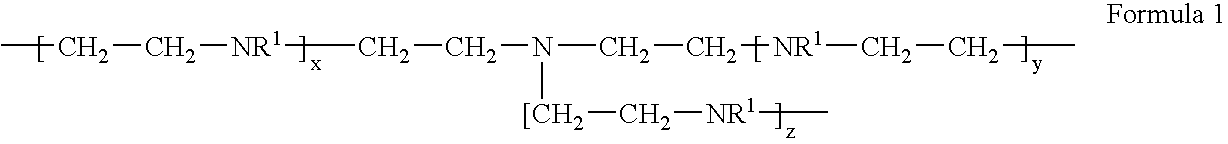

Polymeric chelant and coagulant to treat metal-containing wastewater

InactiveUS7722841B2Solvent extractionSolid sorbent liquid separationWater dispersibleDiethylenetriamine

The present invention is directed to the use of a combination of a polymeric chelant and coagulant to treat metal containing wastewater. More particularly, the invention is directed at removing copper from CMP wastewater. The composition includes a combination of (a) a polymeric chelant derived from a polyamine selected from the group consisting of diethylenetriamine (DETA), triethylenetetraamine (TETA), tertraethylenepentaamine (TEPA), poly[vinylamine], and branched or linear poly[ethylenimine] (PEI); and (b) a water soluble or dispersible copolymer of a tannin and a cationic monomer selected from the group consisting of methyl chloride or dimethyl sulfate quaternary salt of dimethyl aminoethyl acrylate, diethylaminoethyl acrylate, dimethylaminoethyl methacrylate, diethylaminoethyl methacrylate, dimethylaminopropyl methacrylamide, dimethylaminopropyl acrylamide, and diallyl dimethyl ammonium chloride.

Owner:GENERAL ELECTRIC CO

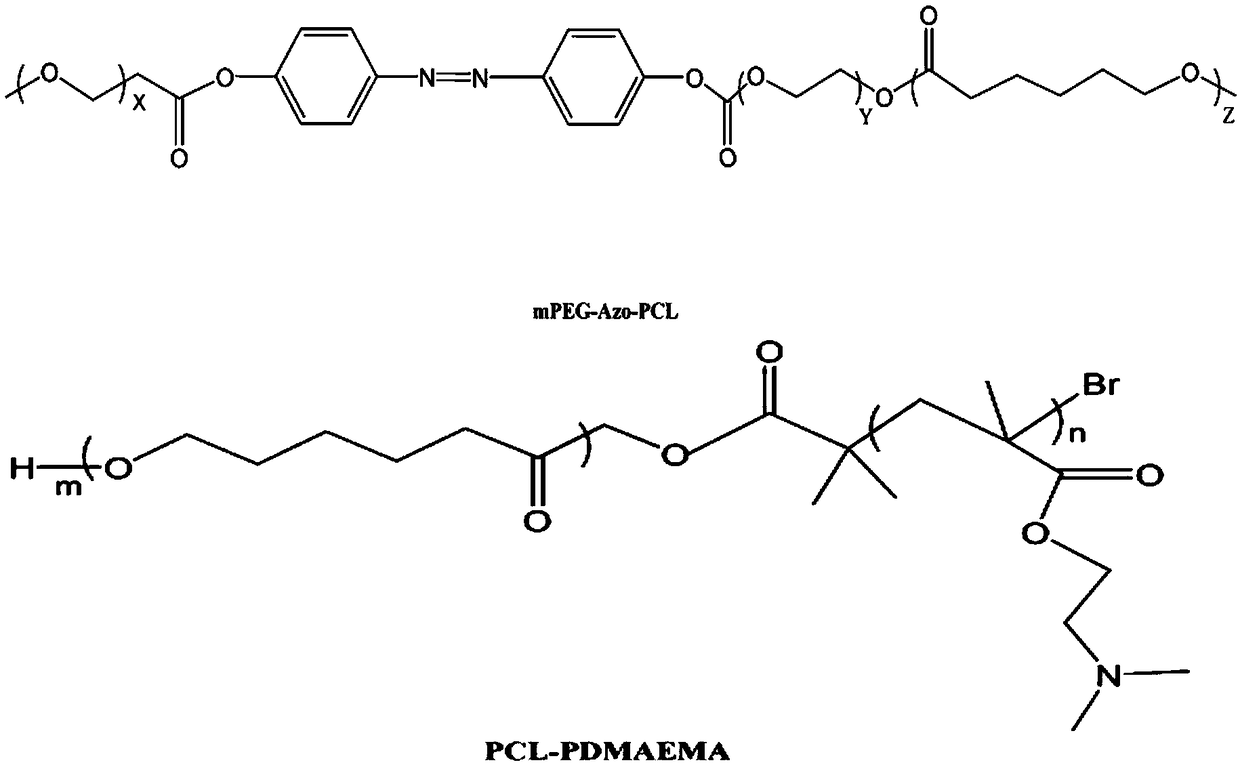

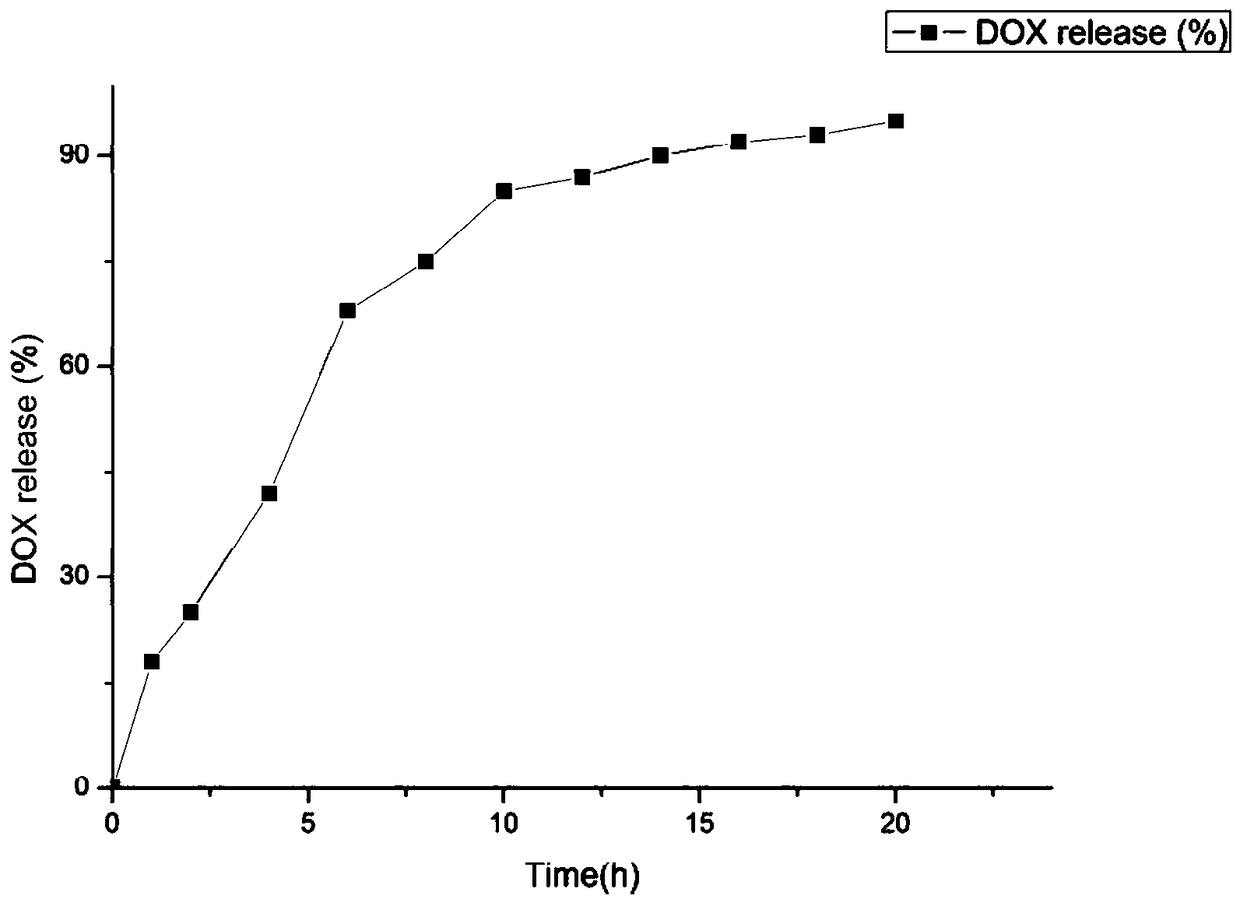

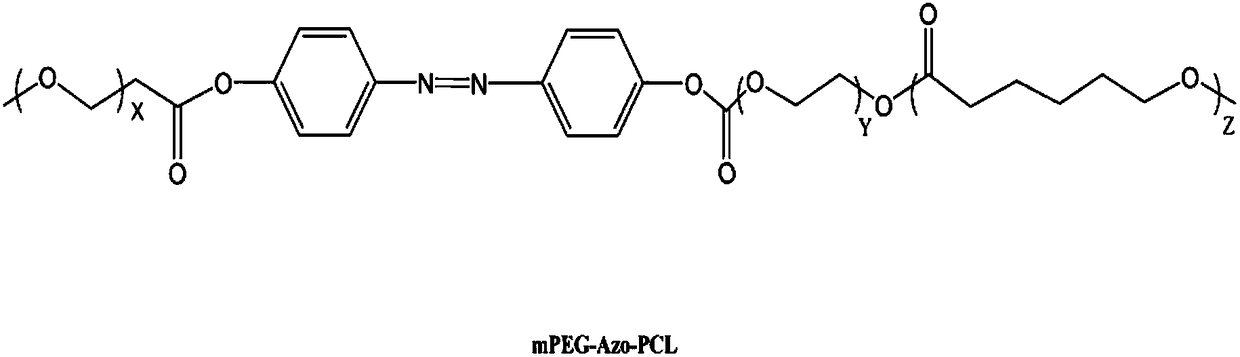

Mixed micelle with hypoxia and pH double responsiveness and preparation method of mixed micelle

The invention belongs to the fields of biological materials and nano materials, and relates to a mixed micelle with hypoxia and pH double responsiveness and a preparation method of the mixed micelle.The method comprises the following specific steps: a product of an esterification reaction of carboxylated monomethoxypolyethylene glycol and p-hydroxyazobenzene is used as a macroinitiator to initiate atom transfer radical polymerization of a cyclocaprolactone monomer; ring-opening polymerization cyclohexanolide is used as a macroinitiator to initiate atom transfer radical polymerization of a N,N-diethylaminoethyl methacrylate monomer; and two block copolymers are used to prepare the mixed micelle by a solvent evaporation method according to a certain charge ratio. The mixed micelle preparedby the method provided by the invention has the hypoxia and pH dual responsiveness, and broad application prospects in biomedical applications, drug carriers, targeted therapies and the like; and thepreparation method provided by the invention is simple and easy to implement, the raw materials can be industrially produced, and the method has very good promotion and application value.

Owner:TONGJI UNIV

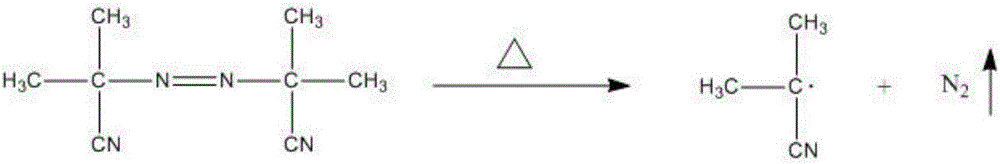

Preparation method of diethylaminoethyl methacrylate

InactiveCN102381996AImprove efficiencyReduce generationOrganic compound preparationChemical industryCatalytic effectAzeotropic distillation

The invention discloses a preparation method of diethylaminoethyl methacrylate, which comprises the following steps that: methyl methacrylate and 2-ethyl aminoethanol are used as raw materials and are reacted in the presence of a catalyst and a polymerization inhibitor by adopting a reactive distillation ester exchange process, and methanol generated by the reaction is timely removed by azeotropic distillation; the obtained reaction product containing diethylaminoethyl methacrylate is distilled under reduced pressure conditions; after excess methyl methacrylate is removed, the catalyst and the polymerization inhibitor are removed to obtain a diethylaminoethyl methacrylate product; and the catalyst is one of lead oxides and / or one of metal titanates, and the polymerization inhibitor is a compound polymerization inhibitor. The preparation method has the advantages of good catalytic effect, short reaction time, high reaction efficiency, good polymerization inhibition, high efficiency of a reaction kettle, high product quality and yield and the like.

Owner:里光

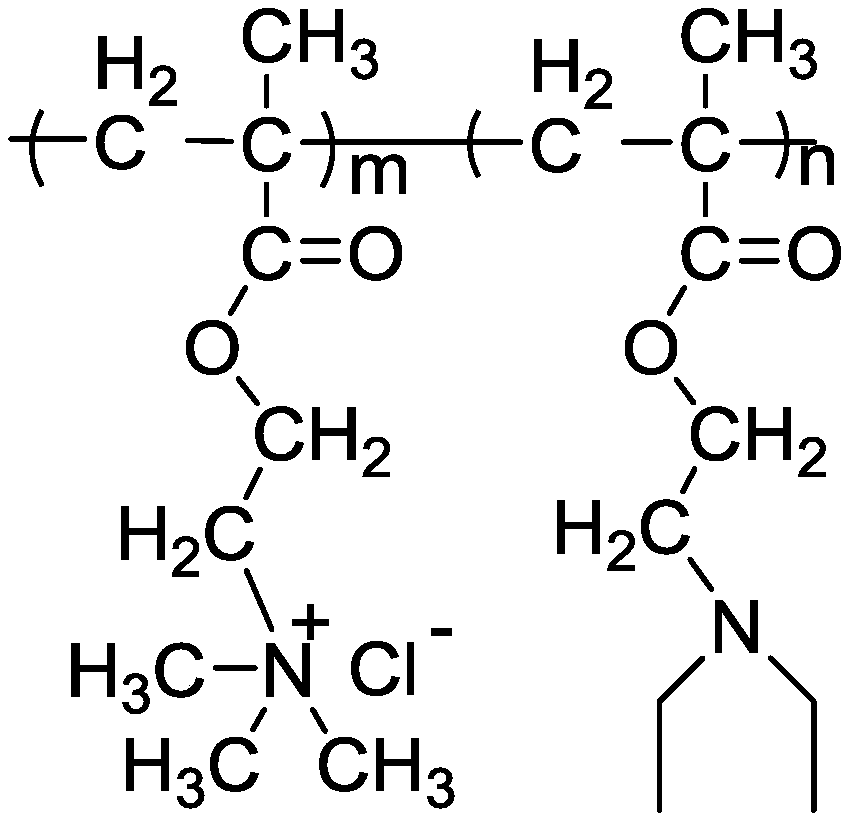

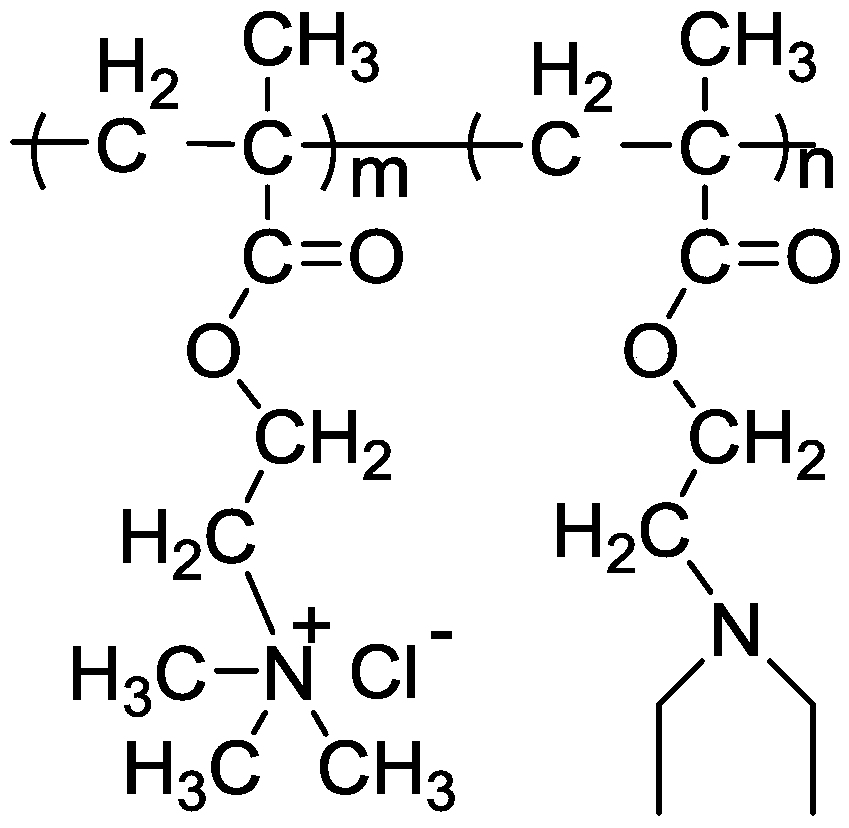

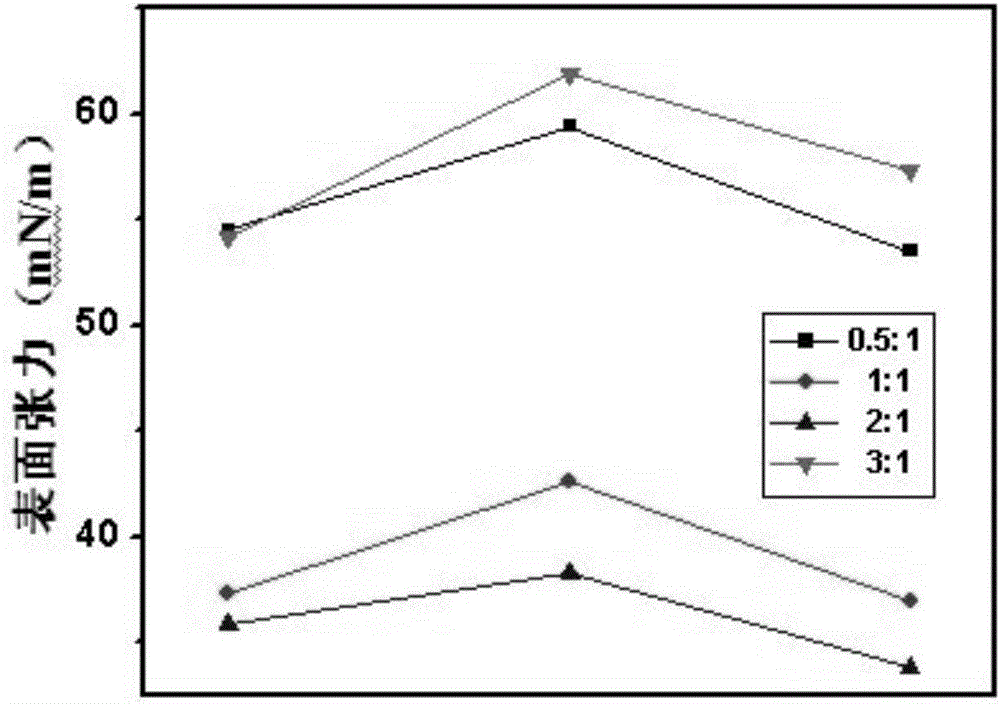

PH-responsive heavy oil emulsifier and preparation method thereof

InactiveCN110229268AWide variety of sourcesLow costPipeline systemsHydrophilic monomerReduction rate

The invention discloses a pH-responsive heavy oil emulsifier and a preparation method thereof, and belongs to the technical field of heavy oil viscosity reduction in petroleum exploitation. The preparation method comprises the following steps: adding a hydrophilic monomer methacrylatoethyl trimethyl ammonium chloride and a pH-responsive monomer 2-diethylaminoethyl methacrylate into a flask at a molar ratio of 1:(1-9) to make the total concentration of the monomers be 10-30%, introducing nitrogen for 30 min, adding 0.1-0.5% of an initiator, and carrying out a reaction at a temperature of 50-70DEG C for 4-8 h to prepare the pH-responsive heavy oil emulsifier. The heavy oil emulsifier has good surface activity under an alkaline condition, and makes the viscosity reduction rate of heavy oil reach 90% or more; and when the obtained emulsion is adjusted to be acidic, the emulsifier loses the surface activity, and the heavy oil emulsion automatically demulsifies. The above viscosity reducingagent solves the problem of difficulty in treatment of the heavy oil after emulsification and viscosity reduction, has the advantages of simplicity in preparation, cheap and easily available raw materials and high viscosity reduction rate, and has a broad application prospect in the field of heavy oil viscosity reduction.

Owner:SOUTHWEST PETROLEUM UNIV

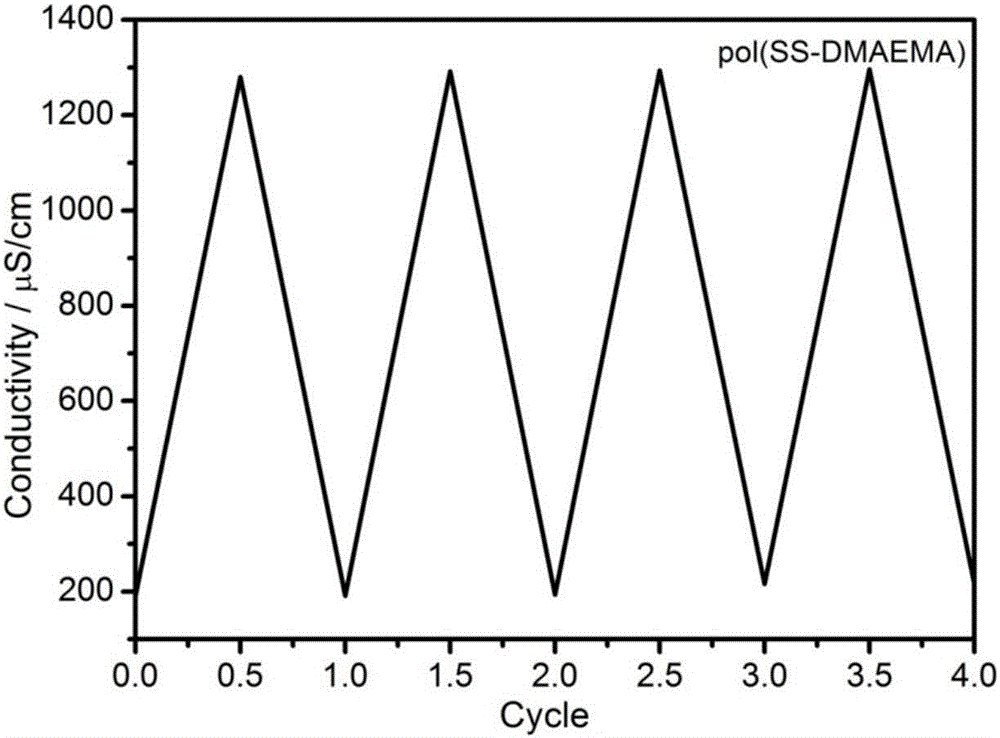

Polymer surfactant with efficient carbon dioxide responsiveness and preparation method

The invention provides a polymer surfactant with efficient carbon dioxide responsiveness and a preparation method, and belongs to the field of preparation of surfactants. The preparation method comprises the steps as follows: DMAEMA (2-(dimethylamino)ethyl methacrylate) and sodium ethanesulfonate are mixed in water, APS (ammonium persulphate) is added, the mixture reacts for 4 hours at 80 DEG C, a reaction solution is extracted, subjected to impurity removal and vacuum solvent removal and dried at 50 DEG C, and the polymer surfactant with efficient carbon dioxide responsiveness is obtained. The polymer surfactant and the preparation method have the advantages that the preparation method is simple, the cost is low, a material has good stability, the prepared polymer surfactant has excellent carbon dioxide responsiveness, and the polymer surfactant can be applied to development of low-quality petroleum resources such as heavy oil and the like.

Owner:TSINGHUA UNIV

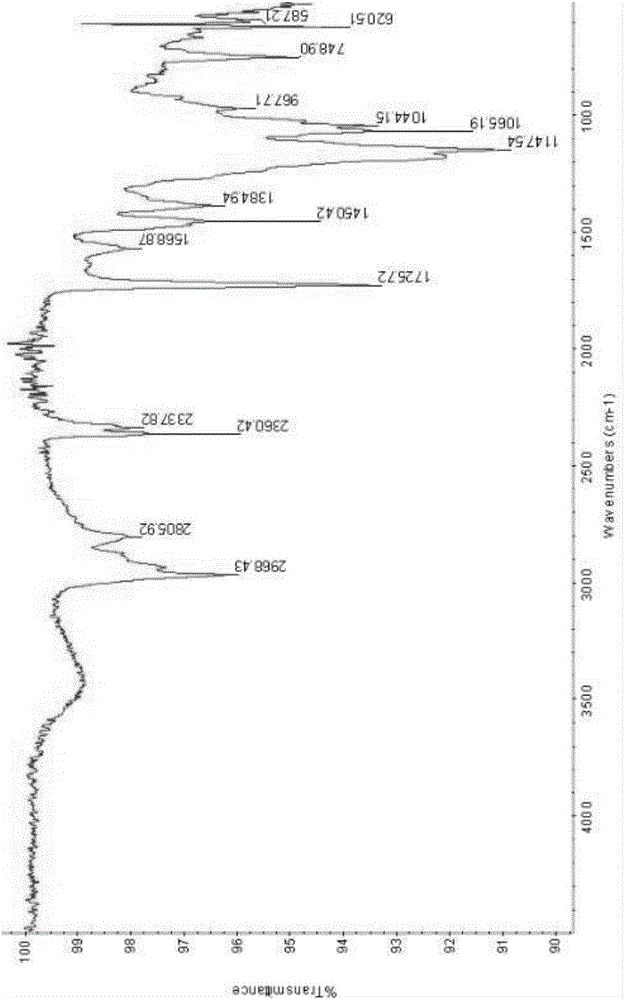

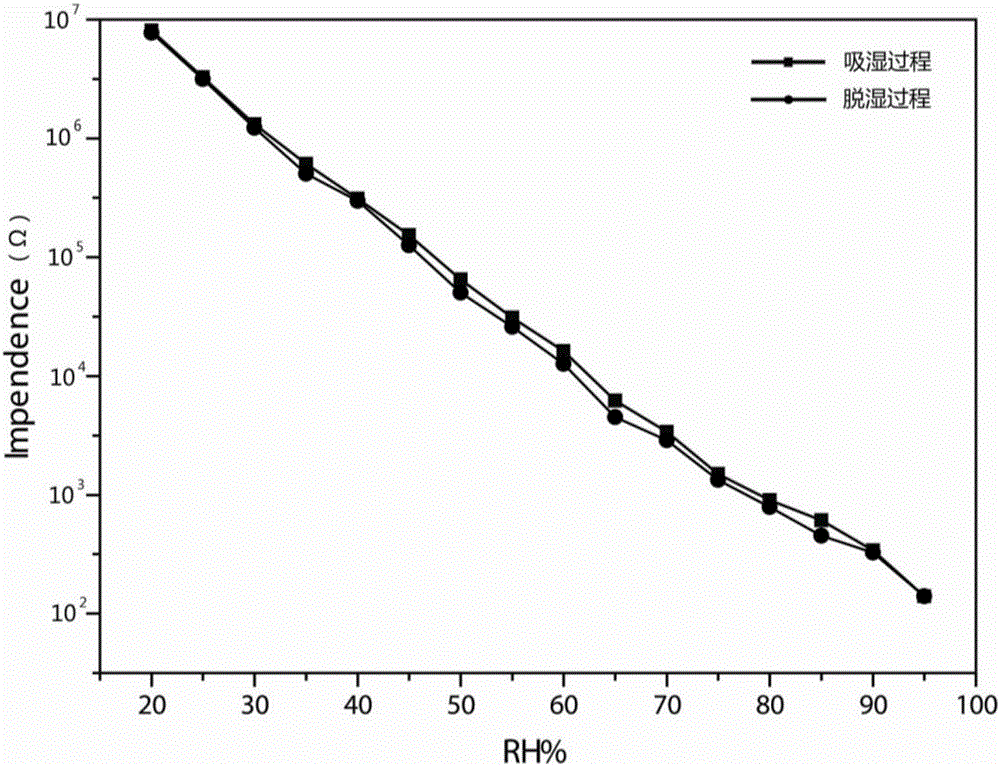

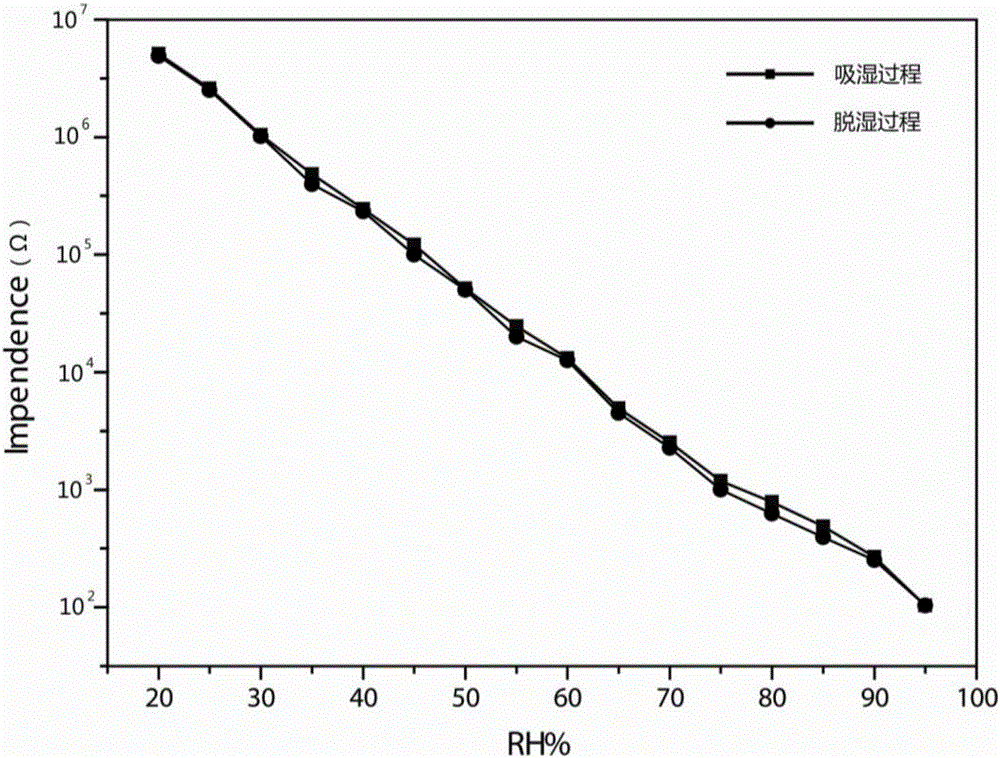

Resistive macromolecule humidity-sensitive material and preparation method thereof

ActiveCN106366242AImprove water resistanceExcellent high humidity resistanceCoatingsMaterial resistanceDiethylaminoethyl MethacrylateChemistry

The invention discloses a resistive macromolecule humidity-sensitive material. A component A, a component B, a component C and a component D react to generate the humidity-sensitive material in a polymerization manner, the component A is one of acryloyloxyethyl trimethyl ammonium chloride, methylacryloyl propyl trimethyl ammonium chloride, methylacrylylethyl trimethyl ammonium chloride; the component B is one of N-methyl allyl amine, acrylamide, dimethylallylamine, dimethylaminoethyl methacrylate, diethyl-amino-ethylmethacrylate and dimethylaminoethyl acrylate; the component C is one of methyl methacrylate, butyl methacrylate, methyl acrylate, butyl acrylate, styrene and ethenylmethyl benzene; the component D is one of sodium p-styrenesulfonate and lithium acrylate. The resistive macromolecule humidity-sensitive material is good in high-humidity resistance and long-term stability.

Owner:GUANGZHOU AOSONG ELECTRONIC CO LTD

Environment-friendly low-temperature setting print adhesive and preparation method thereof

The invention discloses an environment-friendly low-temperature setting print adhesive. The adhesive is prepared from the following raw materials in parts by weight: 30-45 percent of urethane acrylate, 2-3 parts of sodium alcohol ether sulphate, 10-12 parts of diethylaminoethyl methacrylate, 14-16 parts of acetoacetoxy ethyl methacrylate, 6-8 parts of poly(butyl acrylate), 12-14 parts of fatty acid polyglycol ester, 6-8 parts of butyl glycidyl ether, 9-12 parts of polyether glycol, 1-2 parts of tartaric acid, 1-2 parts of ammonium persulphate, 4-5 parts of auxiliary agent and 70-80 parts of water. The adhesive can be set at low temperature, and is environment-friendly, formaldehyde-free, low in viscosity, easy to print, strong in adhesion, water-resistant and corrosion-resistant, has the characteristics of low probability of adhesion to screens, stable patterns, good fastness, easiness in control and easiness and convenience in operation when used for printing, and can be used for garment materials, such as labor protection clothes which are worn and washed frequently and keeping lasting patterns.

Owner:HEFEI JUHE RADIAL CHEM TECH

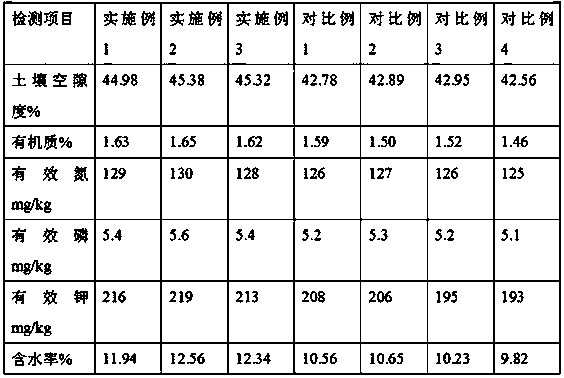

Soil water-retaining agent and preparation method thereof

InactiveCN109181707AHydrophilicGuaranteed long-term preservationOrganic fertilisersSoil conditioning compositionsCellular respirationArbuscular mycorrhizal fungi

The invention discloses a soil water-retaining agent and a preparation method thereof, which belong to the field of crops production. The method adopts chitosan as a first layer network structure, sodium ethylene sulfonate, 2-diethylaminoethyl methacrylate and the like are added to a network structure, the moisture can be better locked, the respiratory action of microorganisms in the soil is always present, and can assist the water-retaining agent for long-term moisture preservation; in the first layer network structure, arbuscular mycorrhizal fungi and cyanobacteria are simultaneously added and mixed, a microbial respiratory responsive additive and carbon dioxide are acted, soil activity is activated, the microbe growth is stimulated, and nutrient can be provided; zeolite is modified by cetyl pyridine bromide, the water-absorption activity is increased, and moisture adsorption quantity is increased, at the same time, the mechanical properties of the gel are enhanced and not lost by the impact of external force, and the water retention performance is stably exerted. The soil water-retaining agent solves the problems of insufficient nutrition to farmland and short water-retention time efficiency of the current water-retaining agents.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

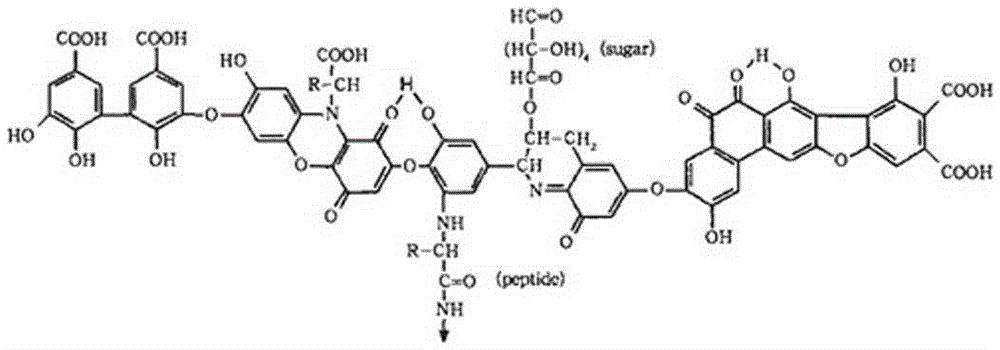

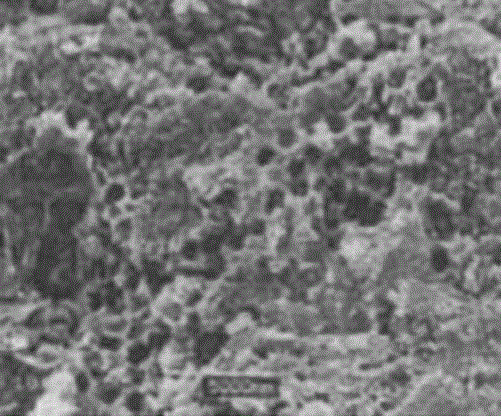

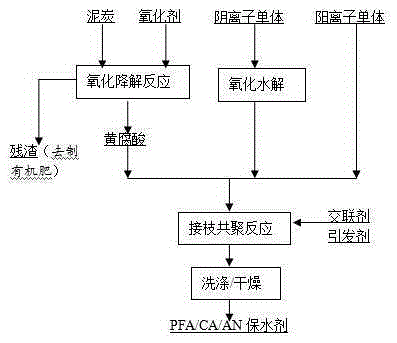

Oxidized peat fulvic acid composite water retaining agent and preparation method thereof

InactiveCN105384882AReduce energy consumptionImprove responseAgriculture tools and machinesBuilding constructionsMeth-Ethyl group

An oxidized peat fulvic acid composite water retaining agent is prepared from, by mass, 50-60 parts of oxidized peat fulvic acid, 15-25 parts of cationic compound monomers, 8-15 parts of anionic compound monomers, 0.1-0.8 part of a cross-linking agent and 0.4-3.8 parts of initiator. The oxidized peat fulvic acid is prepared from, by mass, 1 part of oxidized peat, 0.05-0.20 part of an oxidizing agent and 2.95-8 parts of industrial pure water. The cationic compound monomer is one of (3-methacrylamidipropyl) trimethyl ammonium chloride, methyl acrylyl ethyl trimethyl ammonium iodide, (3-acrylamidopropyl)trimethyl ammonium chloride, dimethylaminoethyl methacrylate, N,N-dimethylaminoethyl acrylate and 2-diethylaminoethyl methacrylate. The cross-linking agent is composed of, by mass, 5-8 parts of N,N-methylene bisacrylamide and 0.5-3 parts of glycerine or ethylene glycol diglycidyl ether or dimethylol urea. The initiator is prepared from, by mass, 5 parts of ammonium persulfate and 1-4 parts of potassium sulfite.

Owner:SHANXI AGRI UNIV

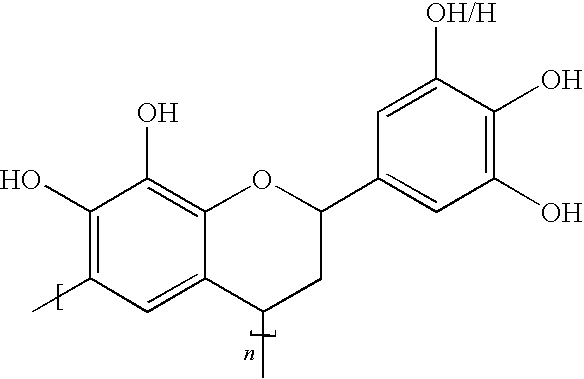

PH response type star-like amphiphilic polymer and preparation method thereof

InactiveCN108610462AGood biocompatibilityPromote degradationChemical structureBiocompatibility Testing

The invention belongs to the technical field of high-molecular polymer materials for biological medicines, and particularly relates to a pH response type star-like amphiphilic polymer and a preparation method thereof. The invention provides the pH response type star-like amphiphilic polymer of a chemical structure of formula (I) as shown in the specification, in the formula, adamantane which is non-toxic and odor-free, good in biocompatibility and unique in spatial configuration is adopted as a core of the pH response type star-like amphiphilic polymer, polycaprolactone which is good in biocompatibility and biodegradability is adopted as a hydrophobic block, a poly-alkaline type polymer, namely polymethylacrylic acid lignocaine ethyl ester, is adopted as a pH response block, and polymethylacrylic acid methoxy polyethylene glycol ester is adopted as a hydrophilic block. The invention further provides a preparation method of the pH response type star-like amphiphilic polymer. The preparation method is simple to operate, gentle in reaction condition, easy in product purification process and controllable in structure. The pH response type star-like amphiphilic polymer has a molecular weight distribution coefficient less than 1.3, and a product yield as high as 85% or greater.

Owner:GUANGDONG UNIV OF TECH

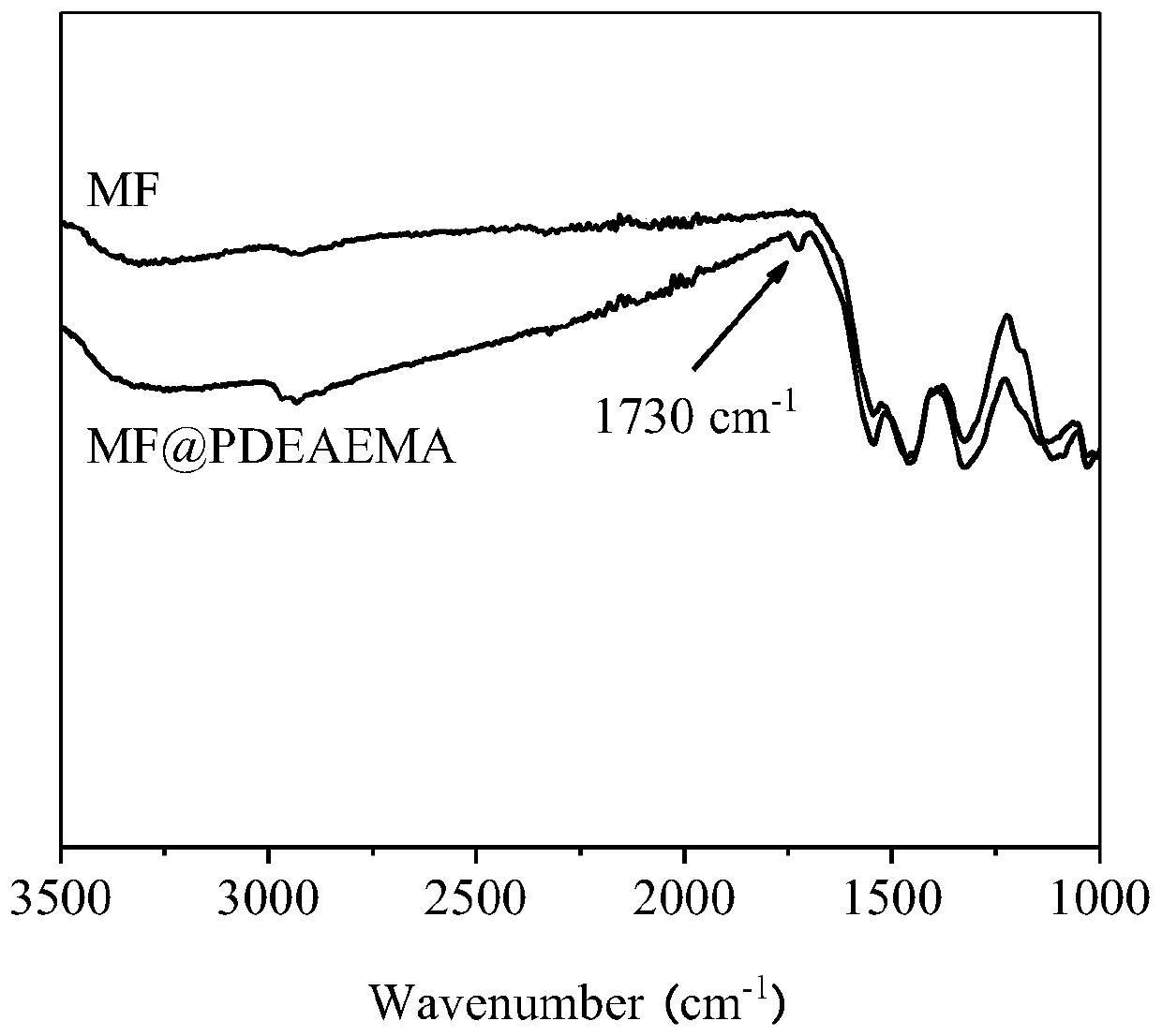

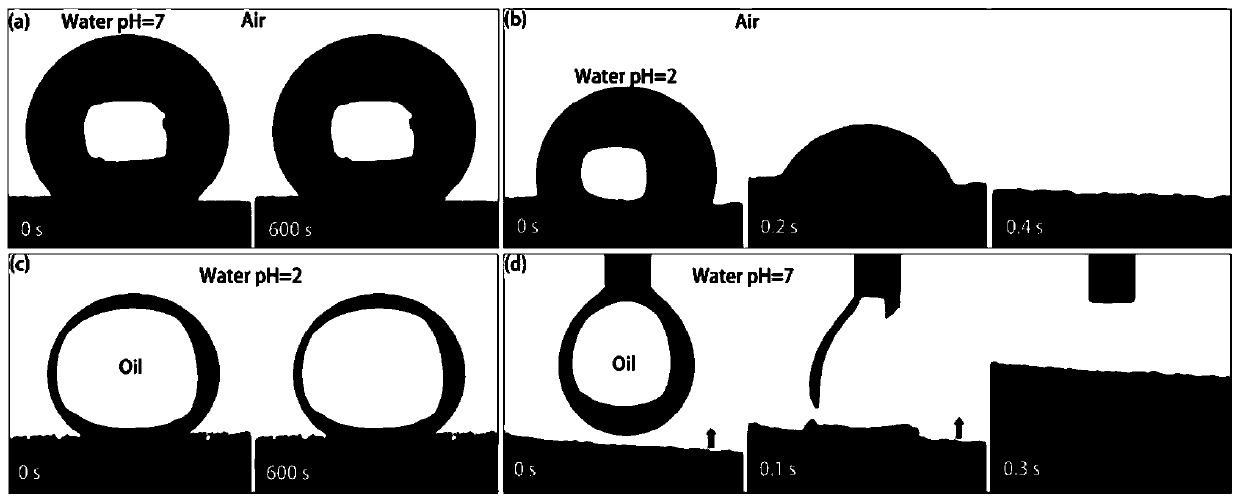

Preparation method of intelligent pH response type melamine foam oil-water separation material

InactiveCN111013199AIncrease Separation ThroughputWith switchable wettabilityNon-miscible liquid separationPtru catalystEthyl ester

The invention belongs to the technical field of oil absorption materials and environmental protection, and particularly relates to a preparation method of an intelligent pH response type melamine foamoil-water separation material. The preparation method comprises the following steps: firstly, carrying out silanization modification on melamine foam by adopting aminopropyltrimethoxysilane; and withcopper sulfate as a catalyst, carrying out a copper amine oxidation-reduction reaction in an aqueous solution to generate free radicals which initiate graft polymerization of diethylaminoethyl methacrylate so as to prepare the pH-responsive melamine foam oil-water separation material. According to the invention, the melamine foam with high internal porosity and large absorption capacity is selected as a matrix, and free radical graft polymerization is initiated through a simple copper-ammonium oxidation-reduction two-step method to prepare the oil-water separation foam material containing a pH response layer; the material has switchable wettability in different pH environments; and foam modification process is simple, and industrial production is easy to realize.

Owner:CHANGZHOU UNIV

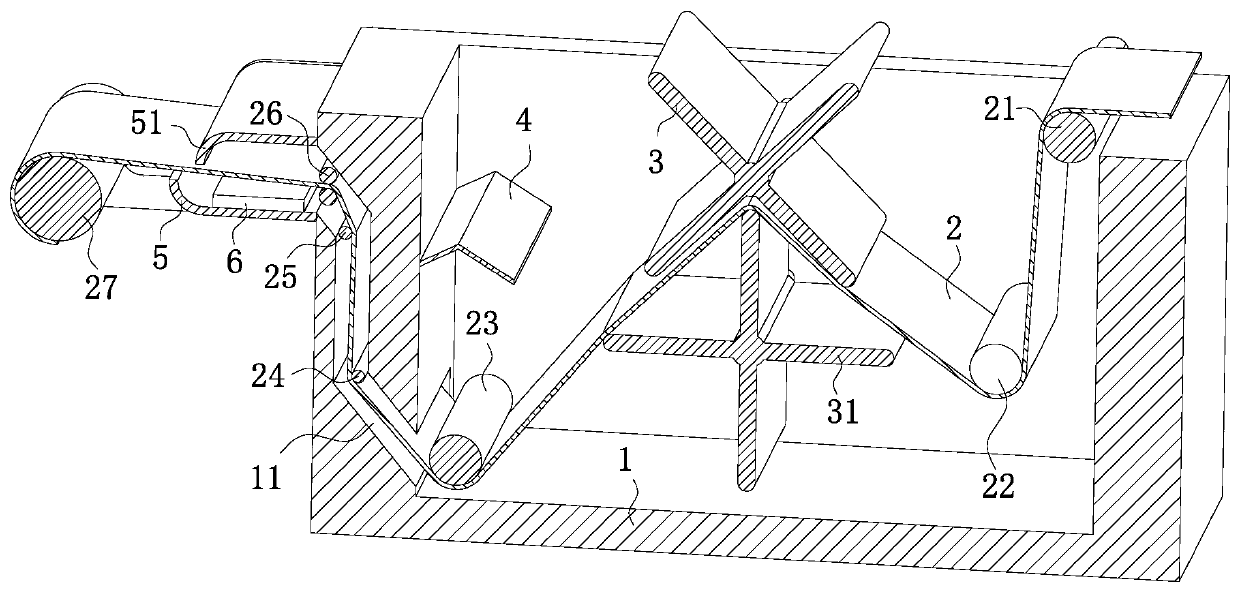

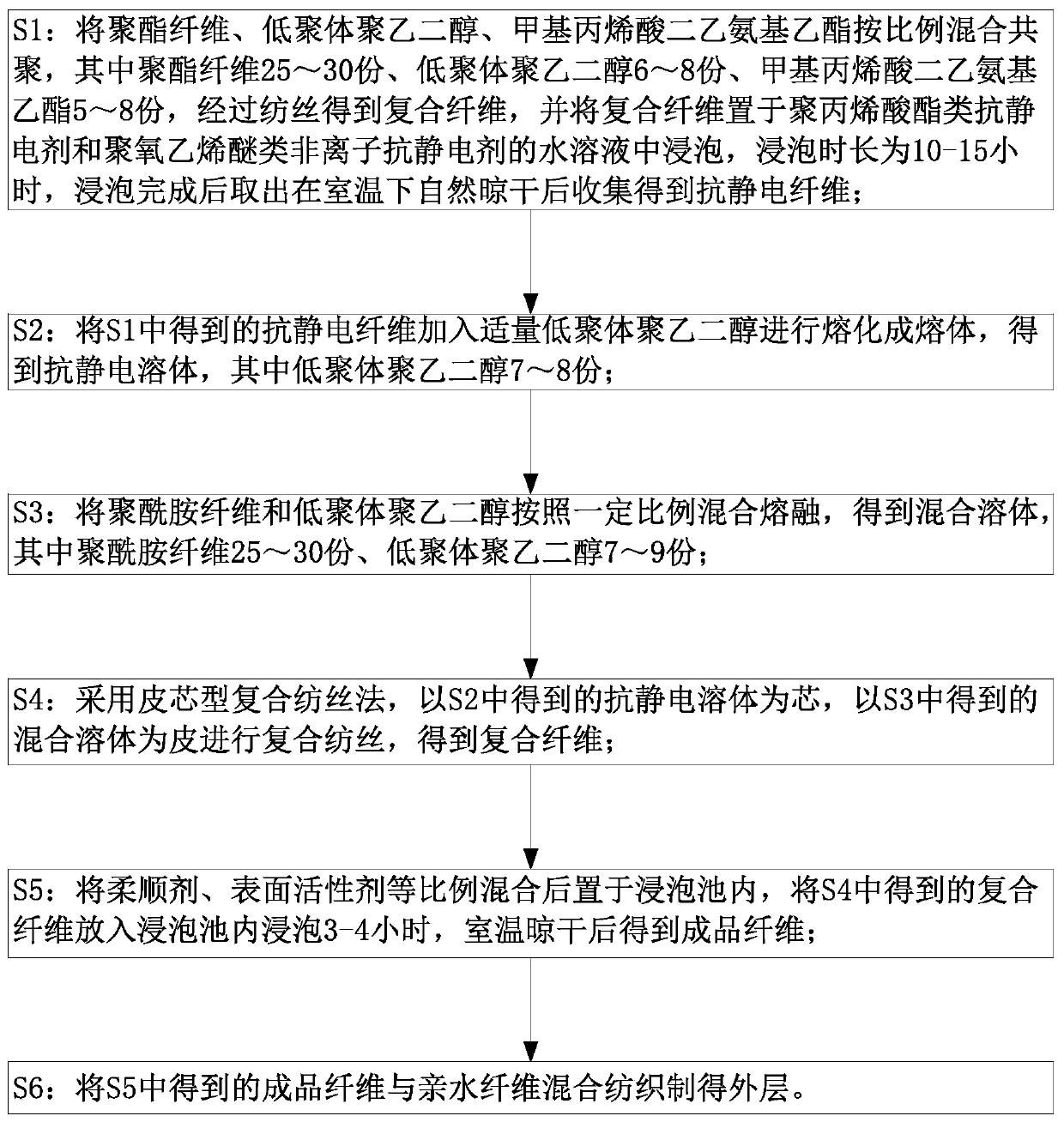

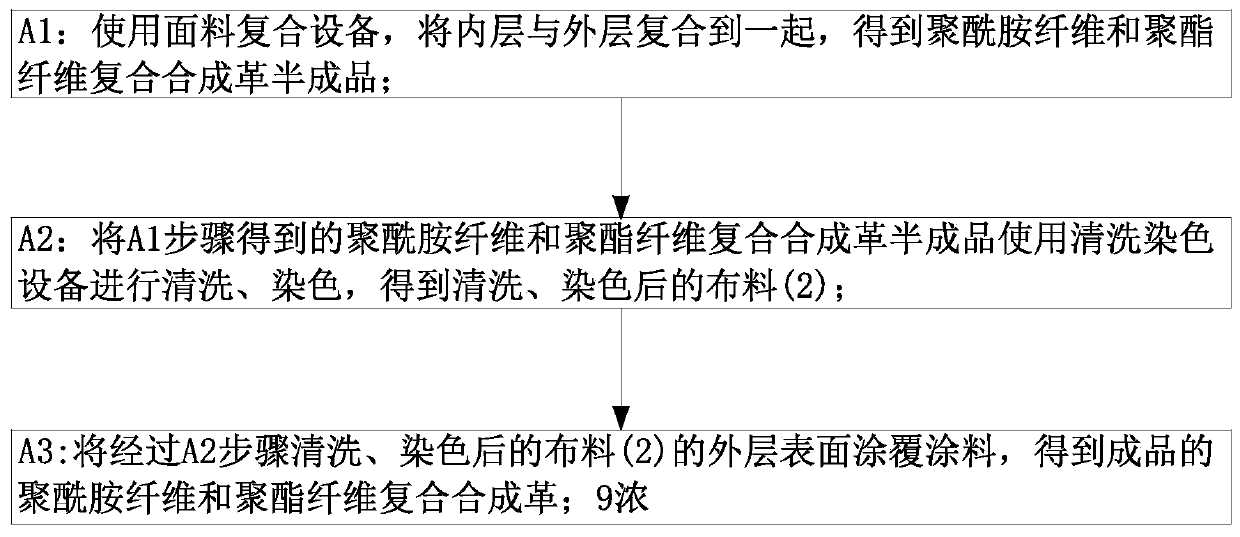

Polyamide fiber and polyester fiber compounded synthetic leather and processing process

PendingCN111593576AAvoid pollutionReduce or eliminate prone to static electricityFibre typesSynthetic resin layered productsPolymer scienceSpinning

The invention belongs to the technical field of synthetic leather production, and particularly relates to a polyamide fiber and polyester fiber compounded synthetic leather and a processing process. The preparation process of an outer layer comprises the following steps that S1, polyester fiber, oligomer polyethylene glycol and diethylaminoethyl methacrylate are blend spun to obtain composite fibers, the composite fibers are treated with an antistatic agent, and antistatic fibers are obtained; S2, oligomer polyethylene glycol is added to the antistatic fibers, fusion is carried out, and antistatic melt is obtained; S3, polyamide fibers and the oligomer polyethylene glycol are mixed and fused to obtain mixed melt; S4, the antistatic melt is adopted as a core, the mixed is obtained as a skin, composite spinning is carried out, and composite fibers are obtained; S5, the composite fibers are treated with a softener and a surface active agent, and finished fibers are obtained; and S6, the finished fibers and hydrophilic fibers are blend spun, and an outer layer is obtained. The synthetic leather has the advantages of being good in wear resistance, high in breaking strength, good in elasticity, good in moisture rate, good in antistatic performance and the like.

Owner:董欠欠

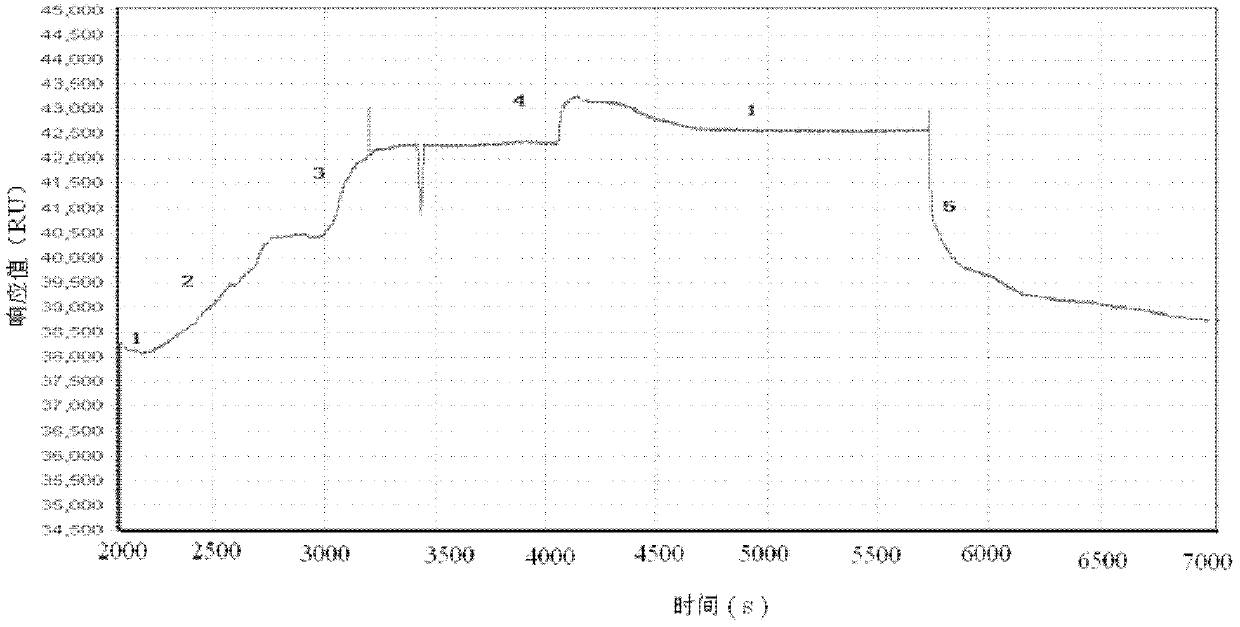

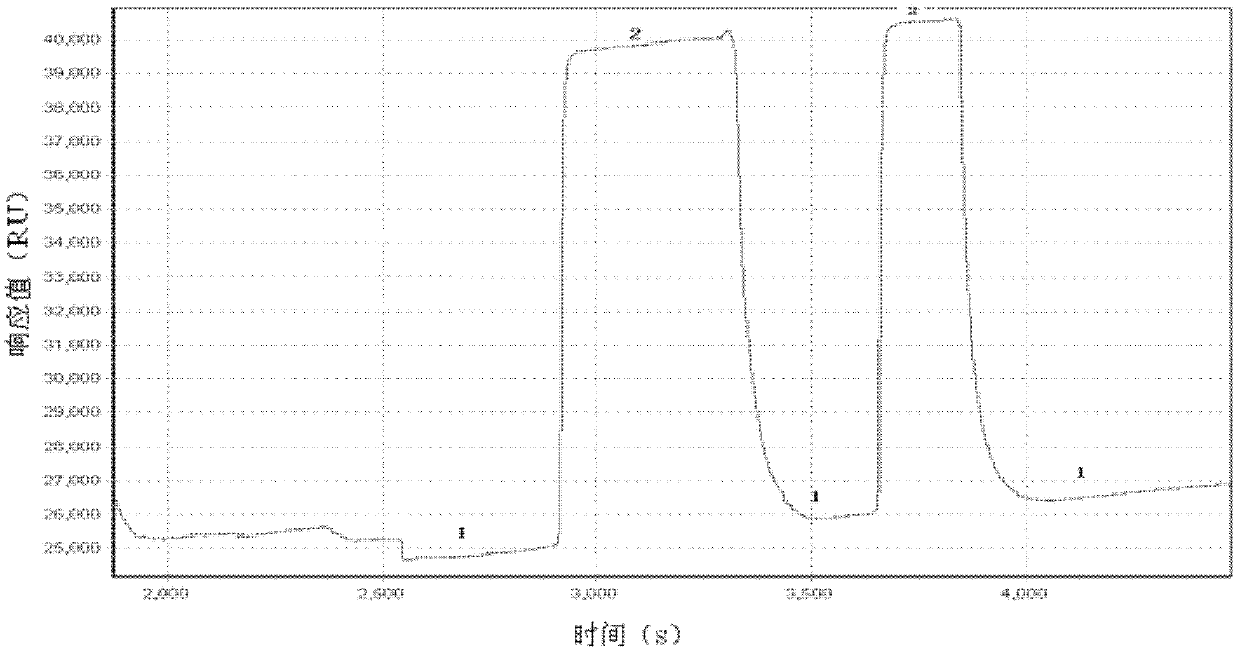

Method for preparing chlorsulfuron molecular imprinting SPR (surface palsmon resonance) sensor chip

InactiveCN102608069AGood saveEasy to storePhase-affecting property measurementsMicrospherePolyvinyl chloride

The invention discloses a method for preparing a chlorsulfuron molecular imprinting SPR (surface palsmon resonance) sensor chip, and relates to a method for preparing an SPR sensor chip. The invention aims at solving the technical problem of poor sensitivity of a chip prepared by the existing molecular imprinting polymer membrane. The method comprises the following steps: depositing chrome and gold on a glass sheet and washing to obtain a chip substrate; adding chlorsulfuron, N,N-diethylaminoethyl methacrylate, trihydroxymethylpropyl trimethylacrylate and 2,2'-azobis(2-methylpropionitrile) into acetonitrile to perform a reaction, removing the chlorsulfuron template in reaction products, and drying to obtain chlorsulfuron molecular imprinting polymer nanospheres; adding chlorsulfuron molecular imprinting polymer nanospheres, polyvinyl chloride and dibutyl phthalate into tetrahydrofuran and mixing evenly to obtain a coating liquid; and coating the coating liquid onto the chip substrate to obtain the chlorsulfuron molecular imprinting SPR sensor chip. The detection limit of the chip to chlorsulfuron can reach 20ng / mL, can detect trace amount of chlorsulfuron and be can used in the technical fields of sensing and separation.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com