Patents

Literature

388 results about "Melamine foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melamine foam is a foam-like material consisting of a formaldehyde-melamine-sodium bisulfite copolymer. The foam is manufactured by several manufacturers worldwide, most notably by BASF of Germany under the name Basotect. It has been used for over twenty years as insulation for pipes and ductwork, and has a long history as a soundproofing material for studios, sound stages, auditoriums, and the like. The low smoke and flame properties of melamine foam prevent it from being a fire hazard.

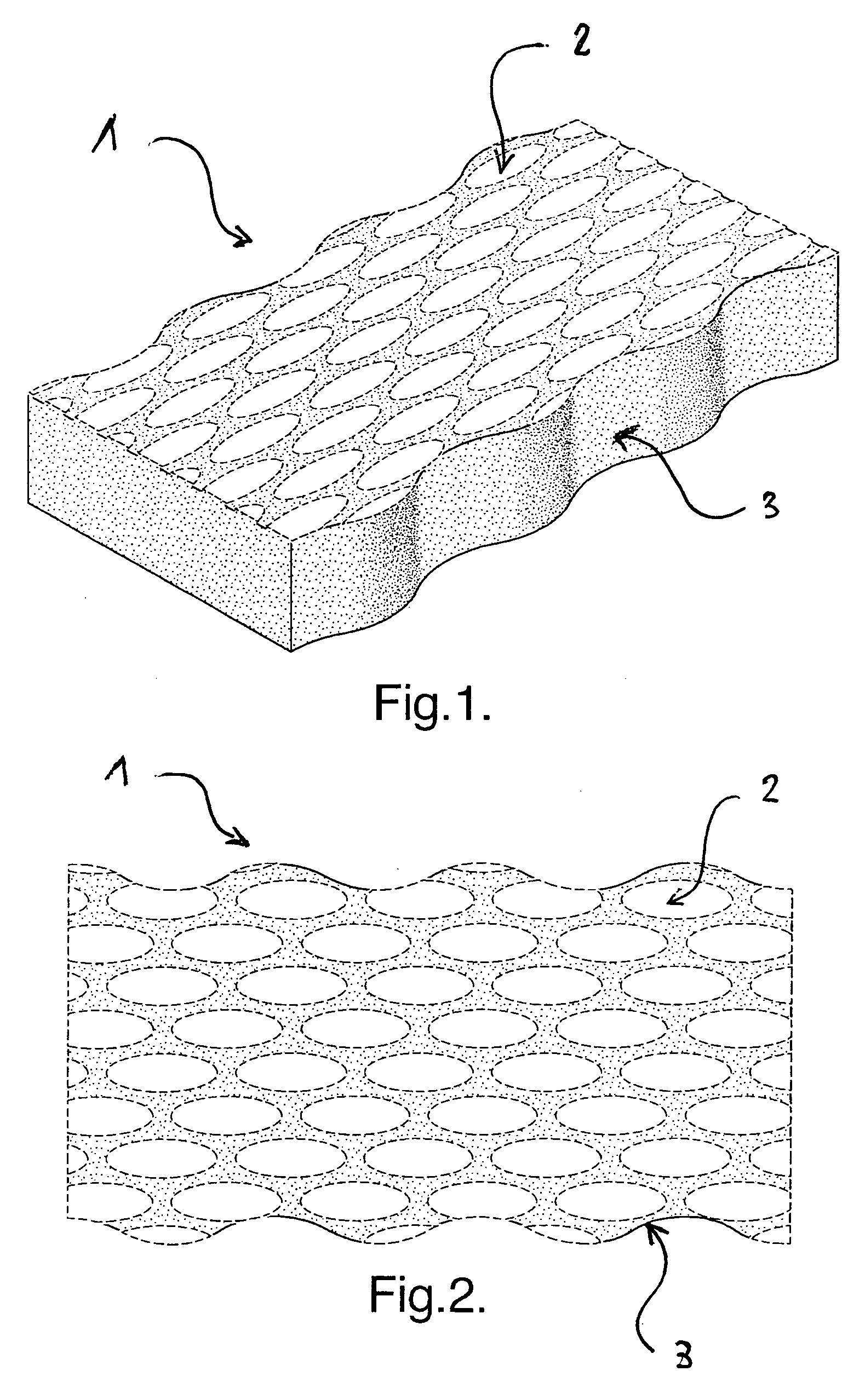

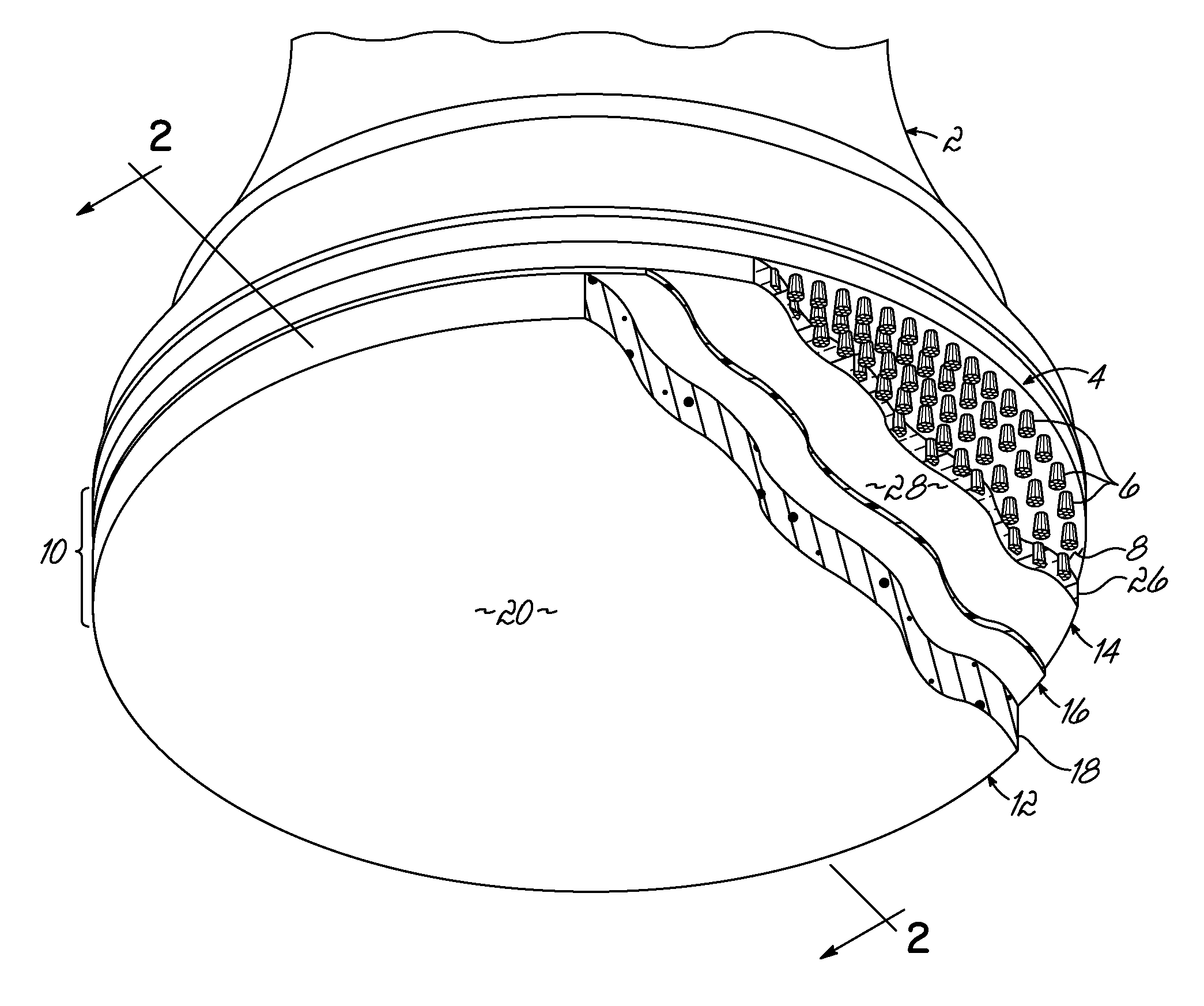

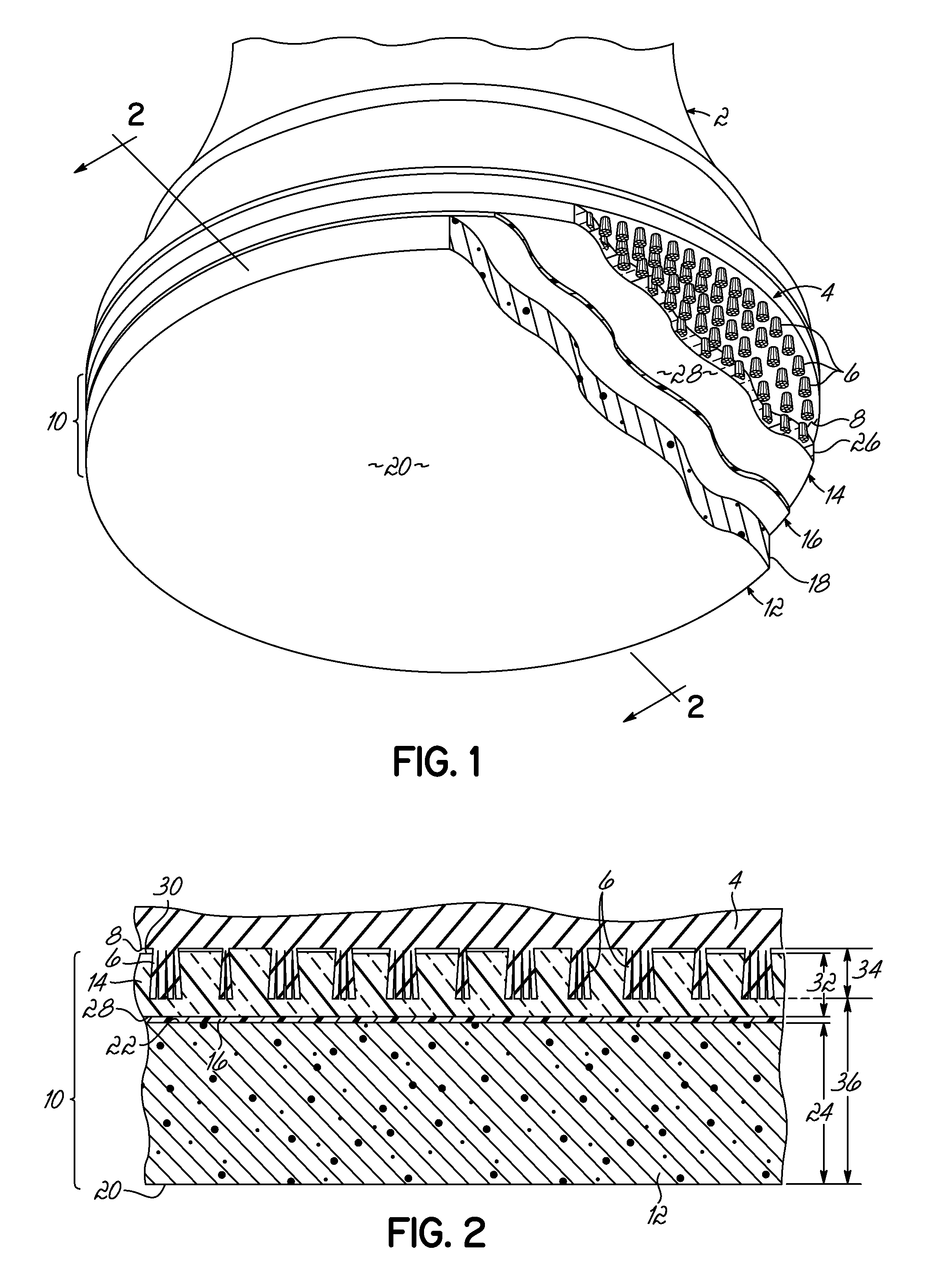

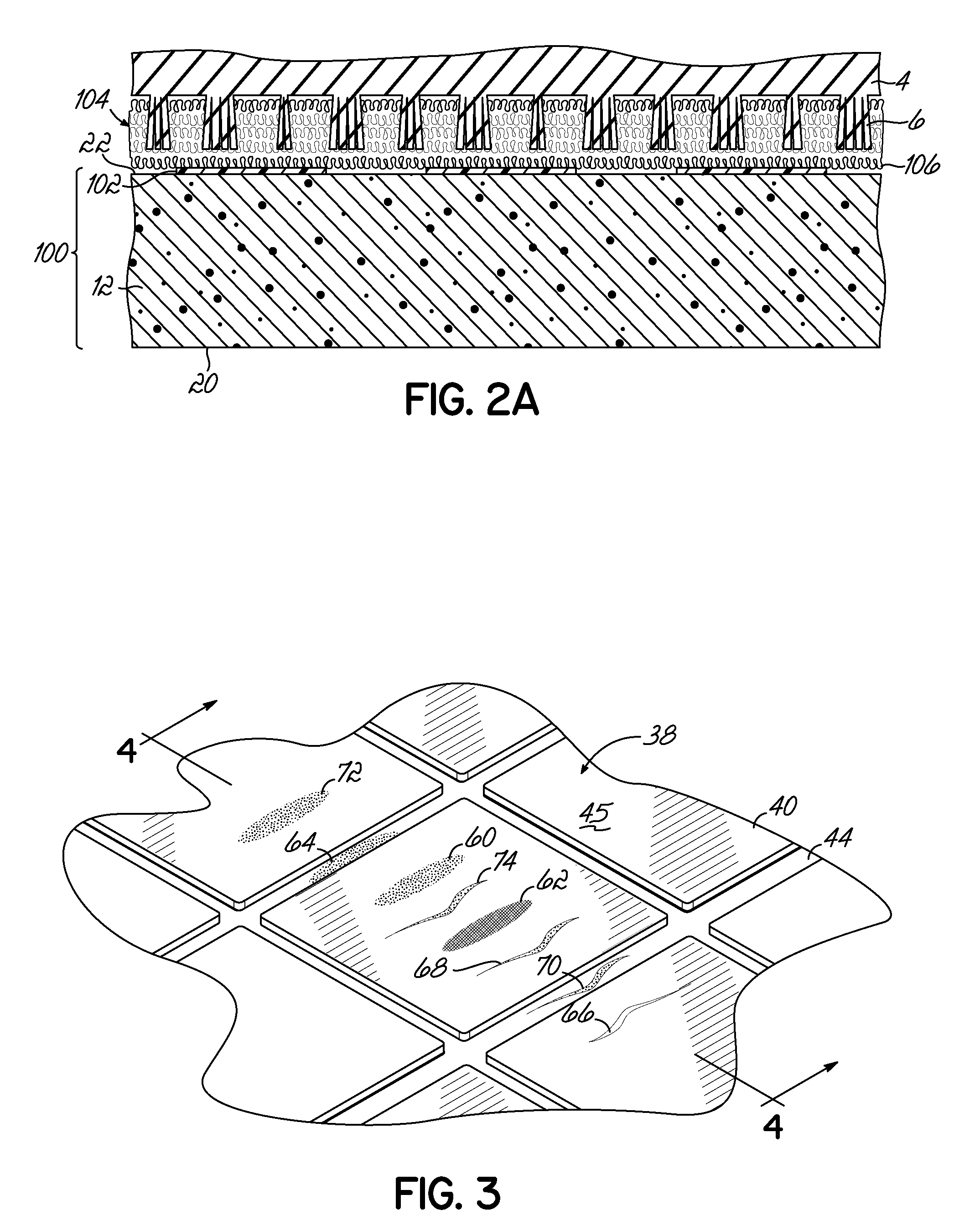

Particulate materials for acoustic texture material

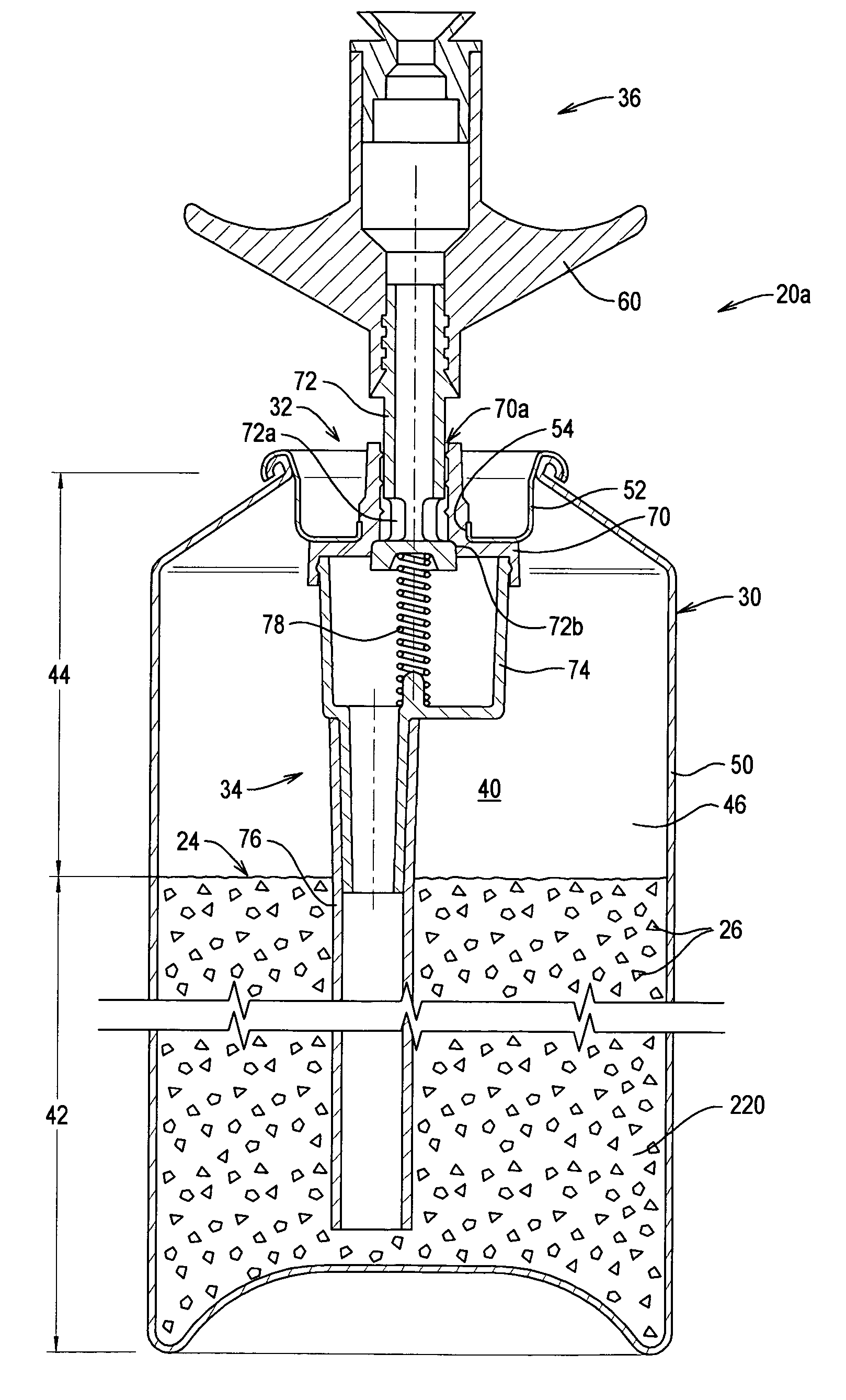

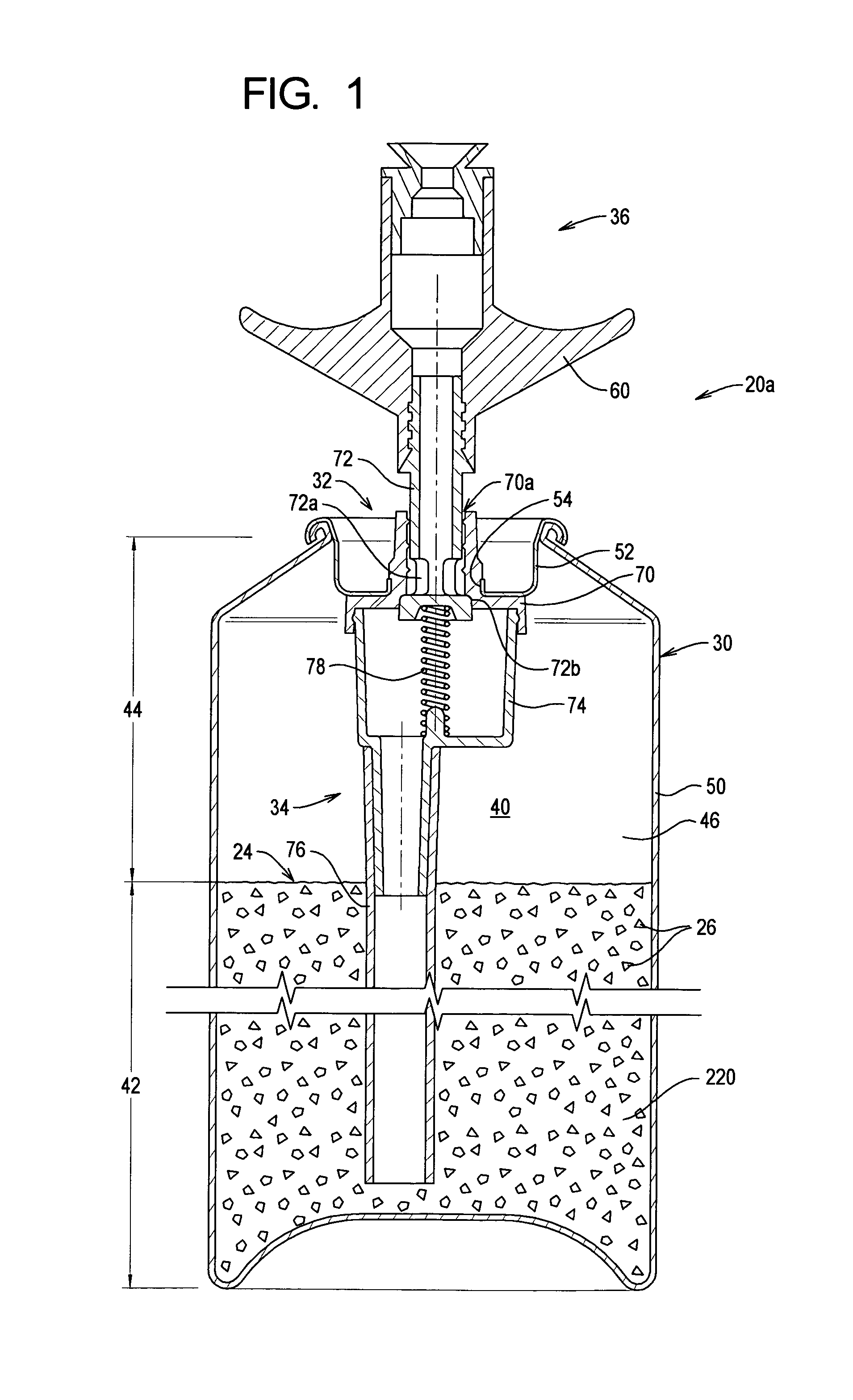

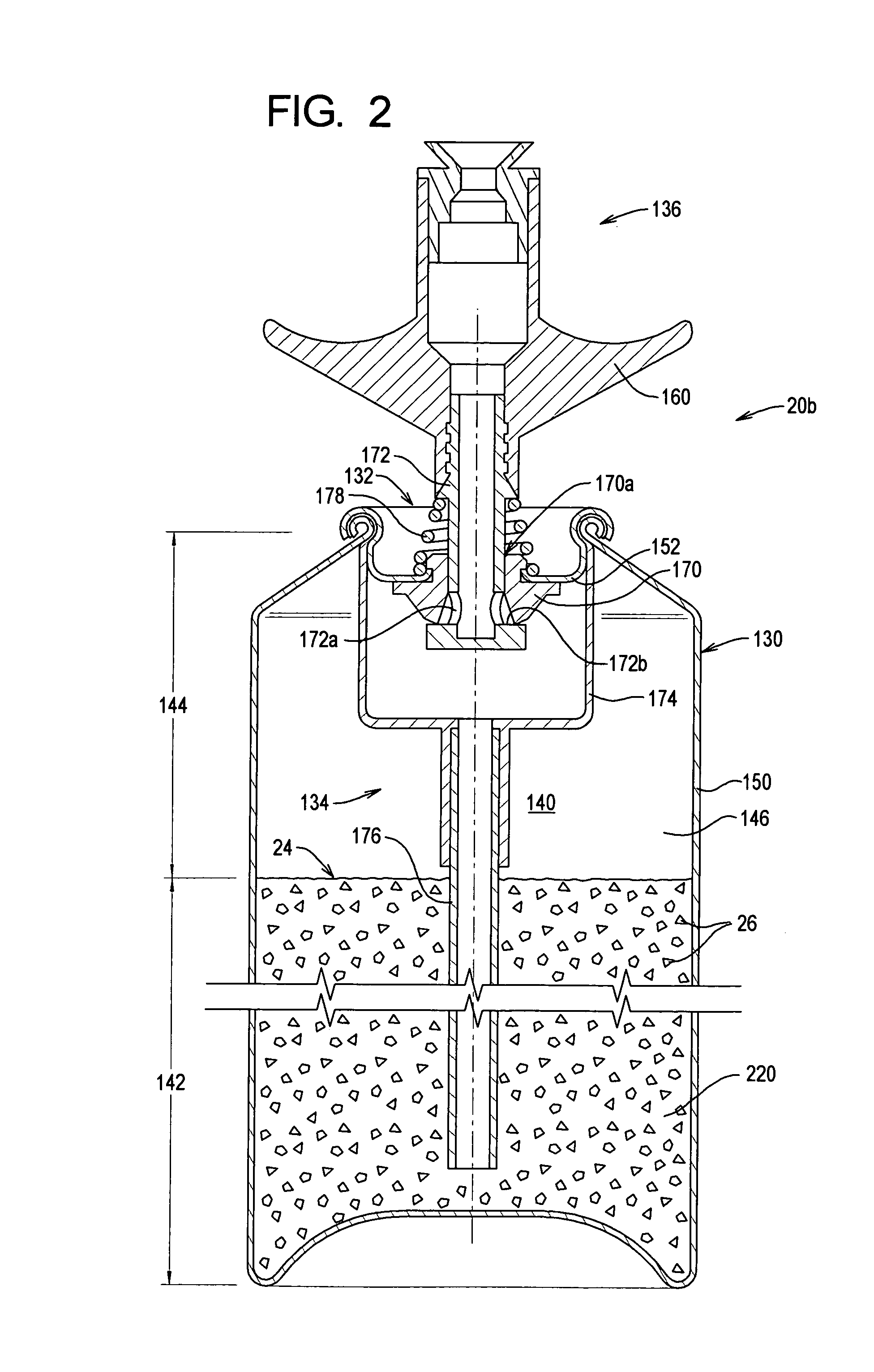

An aerosol texturing system for forming a textured surface on drywall material. The aerosol texturing system comprises an aerosol assembly defining a product chamber and acoustic texture material and propellant material disposed within the product chamber. The aerosol assembly is selectively operable in a first mode in which the product chamber is sealed and in a second mode in which fluid is allowed to flow out of the product chamber along a dispensing passageway. The acoustic texture material comprises a base portion and a particulate portion. The particulate portion comprises at least one particulate material selected from the group consisting of urethane foam and melamine foam. At least a portion of the propellant material exists in a gaseous state such that, when the aerosol assembly is in the second mode, the propellant material forces the acoustic texture material out of the aerosol assembly along the dispensing passageway.

Owner:PPG ARCHITECTURAL FINISHES INC

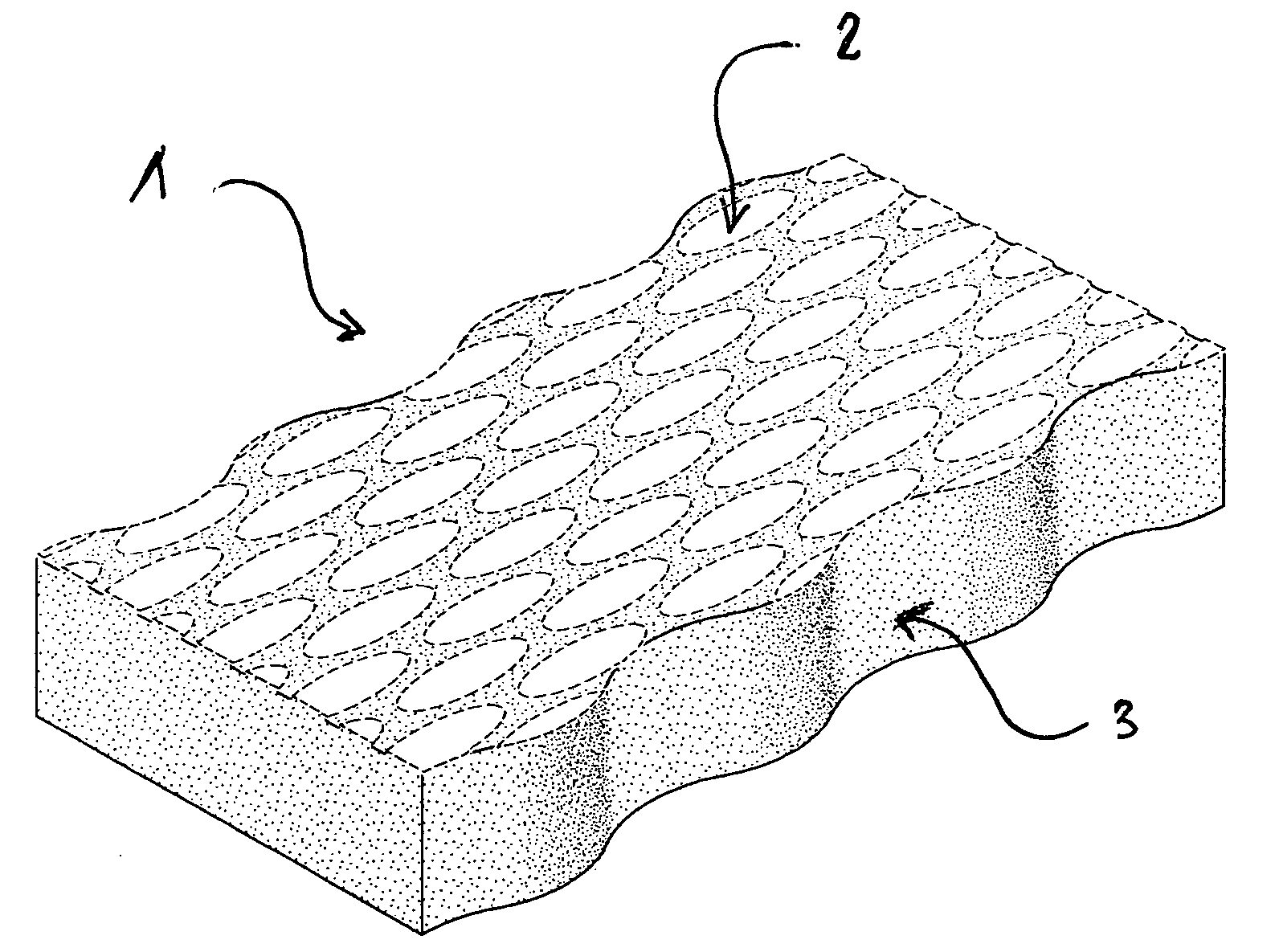

Cleaning implement comprising melamine foam

The present invention relates to a cleaning implement (1) suitable for hard surface cleaning comprising heat-compressed melamine foam, wherein the heat-compressed melamine foam has been heat-compressed at about 250° C. to about 300° C., for about 1 minute to below about 3 minutes.

Owner:THE PROCTER & GAMBLE COMPANY

Liquid hard surface cleaning composition

InactiveUS20100081606A1Not to damageSo as not to damageOrganic detergent compounding agentsSoap detergents with inorganic compounding agentsFiberSurface cleaning

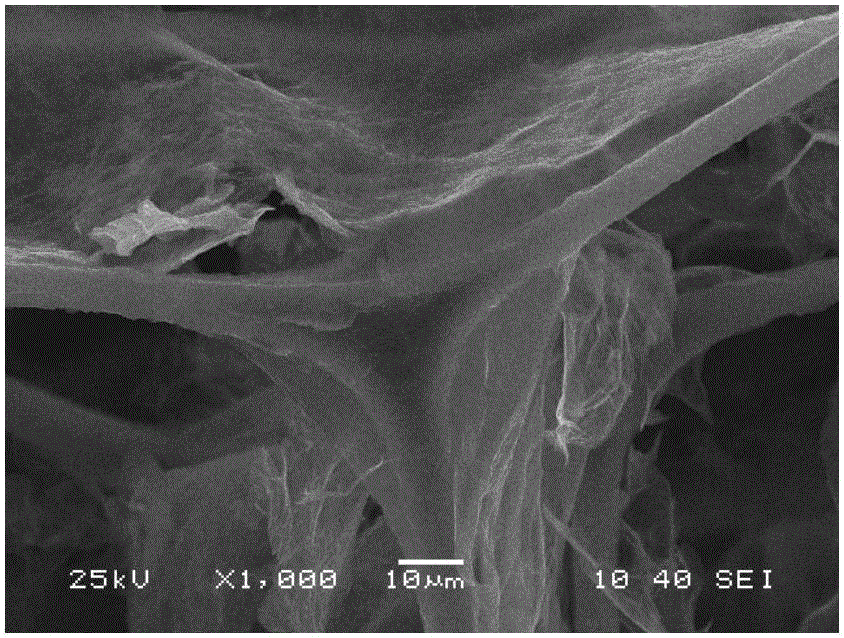

The present invention relates to a liquid hard surface cleaning composition comprising melamine foam fibres and a formaldehyde scavenger.

Owner:THE PROCTER & GAMBLE COMPANY

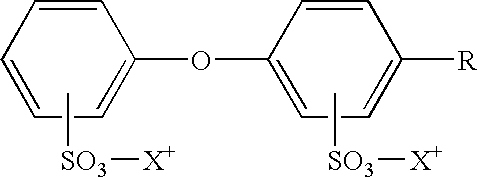

Hydrophobation of melamine foam

Melamine foams exhibiting a very low level of water absorption and low residual formaldehyde are provided. The foams may be prepared by repeatedly soaking a melamine foam with an aqueous polysiloxane emulsion and squeezing out the emulsion, followed by a drying step and then a high-temperature annealing step.

Owner:POLYMER TECH CORP

Method for modifying melamine foam

The invention relates to a method for modifying melamine foam, which comprises the following steps of: adding an emulsifier, a foaming agent, a curing agent and other aids into a base material, namely melamine formaldehyde resin synthesized by melamine and formaldehyde in a low molar ratio, adding melamine and one or more hydramine compounds, and uniformly emulsifying; heating and foaming at certain temperature for a certain period of time through microwaves in a microwave oven; and curing at high temperature, and processing and forming. In the process of foaming through the microwaves, the melamine or the melamine formaldehyde resin and the hydramine compounds can generate a compound capable of improving the performance of foam at high temperature under the action of the microwaves, and the foam is modified at the same time, so that the aim of improving the performance of the melamine foam is fulfilled.

Owner:SICHUAN NEW ENERGY POWER CO LTD

Melamine foam material for pipeline heat insulation and preparation method and use thereof

InactiveCN101423648ALight weightLow thermal conductivityThermal insulationPipe protection by thermal insulationFoaming agentSolid content

The invention provides a melamine foaming material for heat preservation of a pipeline, which consists of a foaming liquid system, wherein the foaming liquid system comprises a high solid content melamine resin, a foaming agent, a curing agent and an emulsifier, and the weight proportion of the high solid content melamine resin to the foaming agent to the curing agent to the emulsifier is 50-250 to 5-30 to 2.5-15 to 1-10. The invention also provides a method for preparing the melamine foaming material and application of the melamine foaming material. The melamine foaming material with adequate thickness is processed according to the shape of the pipeline and sleeved outside the pipeline, and the outside of the melamine foaming material is coated with a reinforced protective layer which is provided with a coating belt for fixation, so that the heat preservation effect of the pipeline can be achieved. The melamine foaming material has the advantages of low thermal conductivity coefficient, softness and moderation, easy machine shaping, simple construction, and firmness and reliability.

Owner:NO 91872 TROOPS PLA

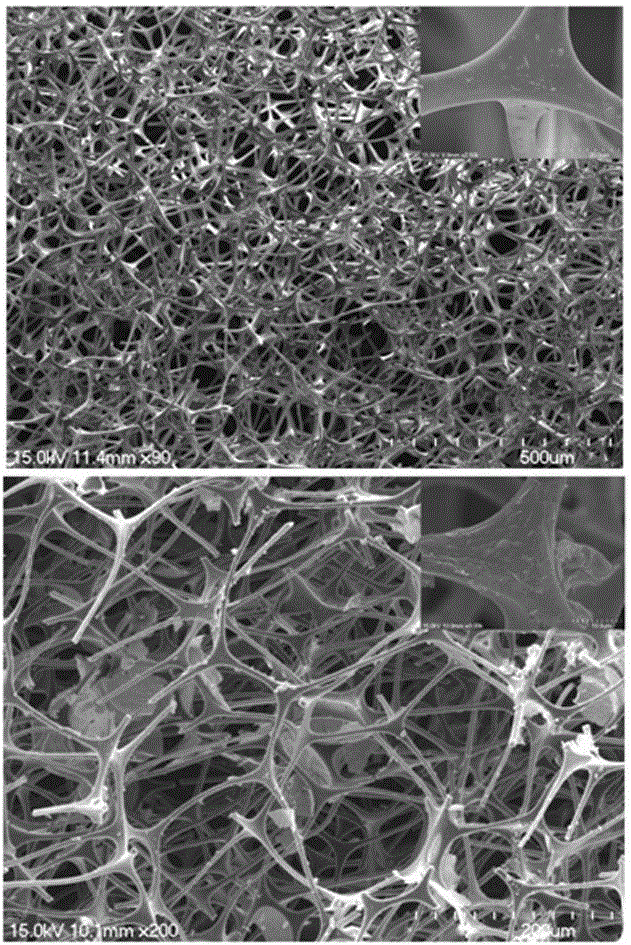

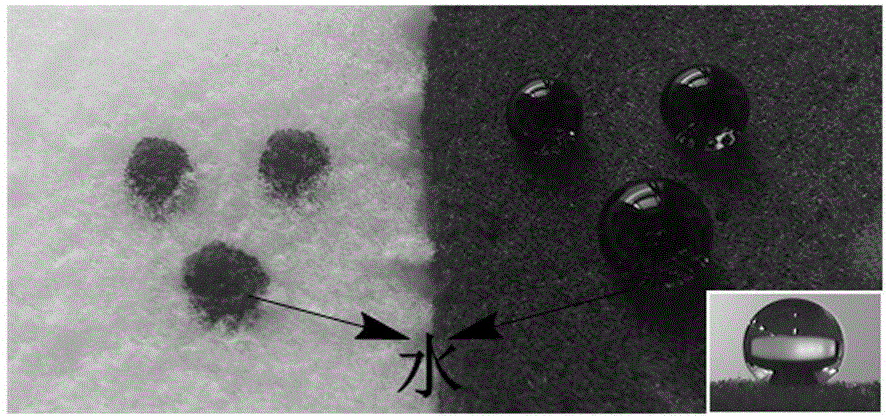

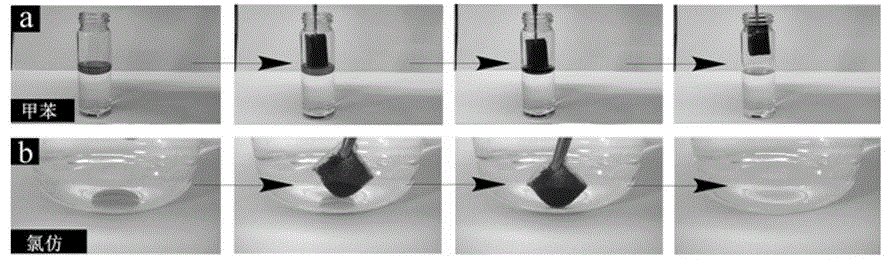

Preparation method of graphene modified super-hydrophobic adsorption material

ActiveCN104607161AHigh adsorption rateOvercome high pricesOther chemical processesLiquid separationSewage treatmentCycle time

The invention discloses a preparation method of a graphene modified super-hydrophobic adsorption material. Hydrophilic melamine foam is modified into super-hydrophobic foam by a surface modification method; furthermore, the modified foam shows the advantages of rapid oil absorption, high adsorption capacity, high cycle times and the like; most importantly, the preparation method is rapid and is easy to operate, and raw materials are cheap, so that the preparation method has favorable application prospect in the aspect of oil and water separation in future sewage treatment.

Owner:SUZHOU UNIV

Liquid hard surface cleaning composition

InactiveUS20100081605A1Not to damageSo as not to damageSoap detergents with inorganic compounding agentsOrganic chemistryFiberSurface cleaning

The present invention relates to a liquid hard surface cleaning composition comprising melamine foam fibres, wherein said compositions has a pH of from about 7 to about 12.

Owner:THE PROCTER & GAMBLE COMPANY

Liquid hard surface cleaning composition

InactiveUS20100081604A1Not to damageSo as not to damageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFiberSurface cleaning

The present invention relates to a liquid hard surface cleaning composition comprising melamine foam fibres, wherein said composition is packaged in a container.

Owner:THE PROCTER & GAMBLE COMPANY

Novel preparation and continuous production method of melamine resin

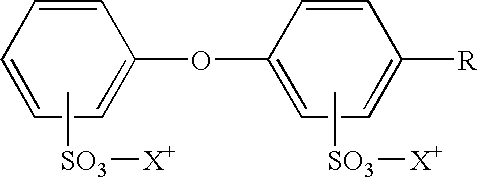

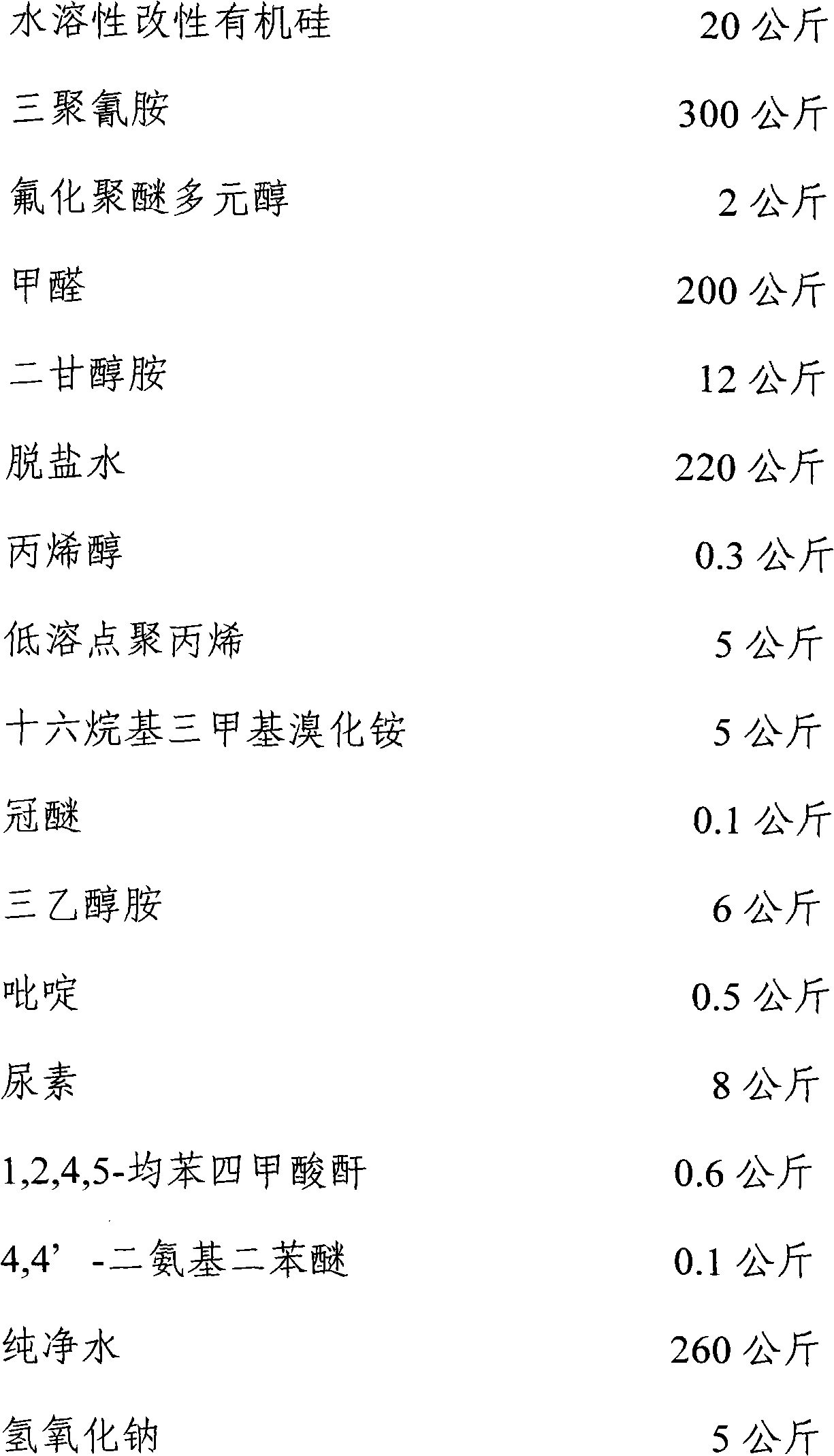

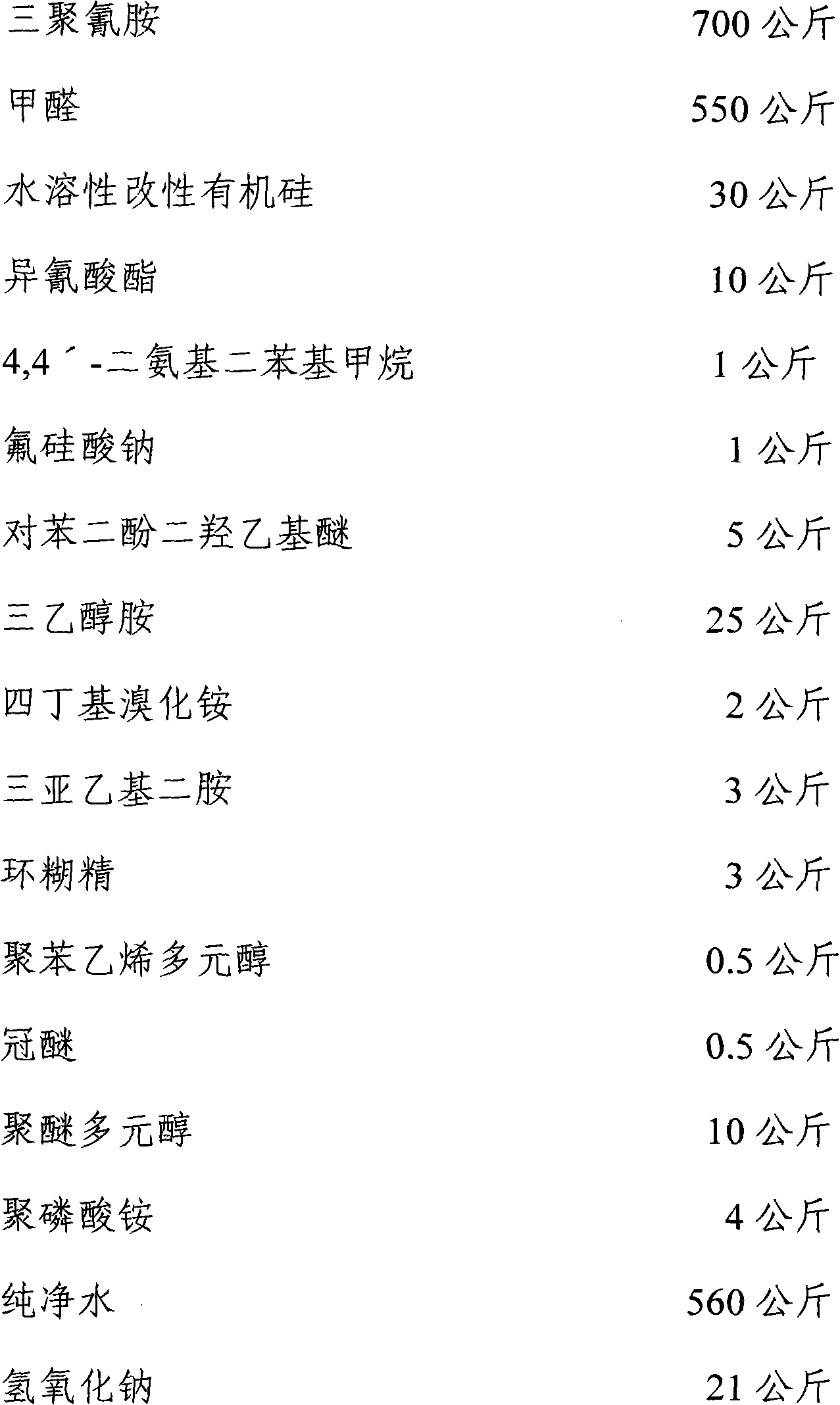

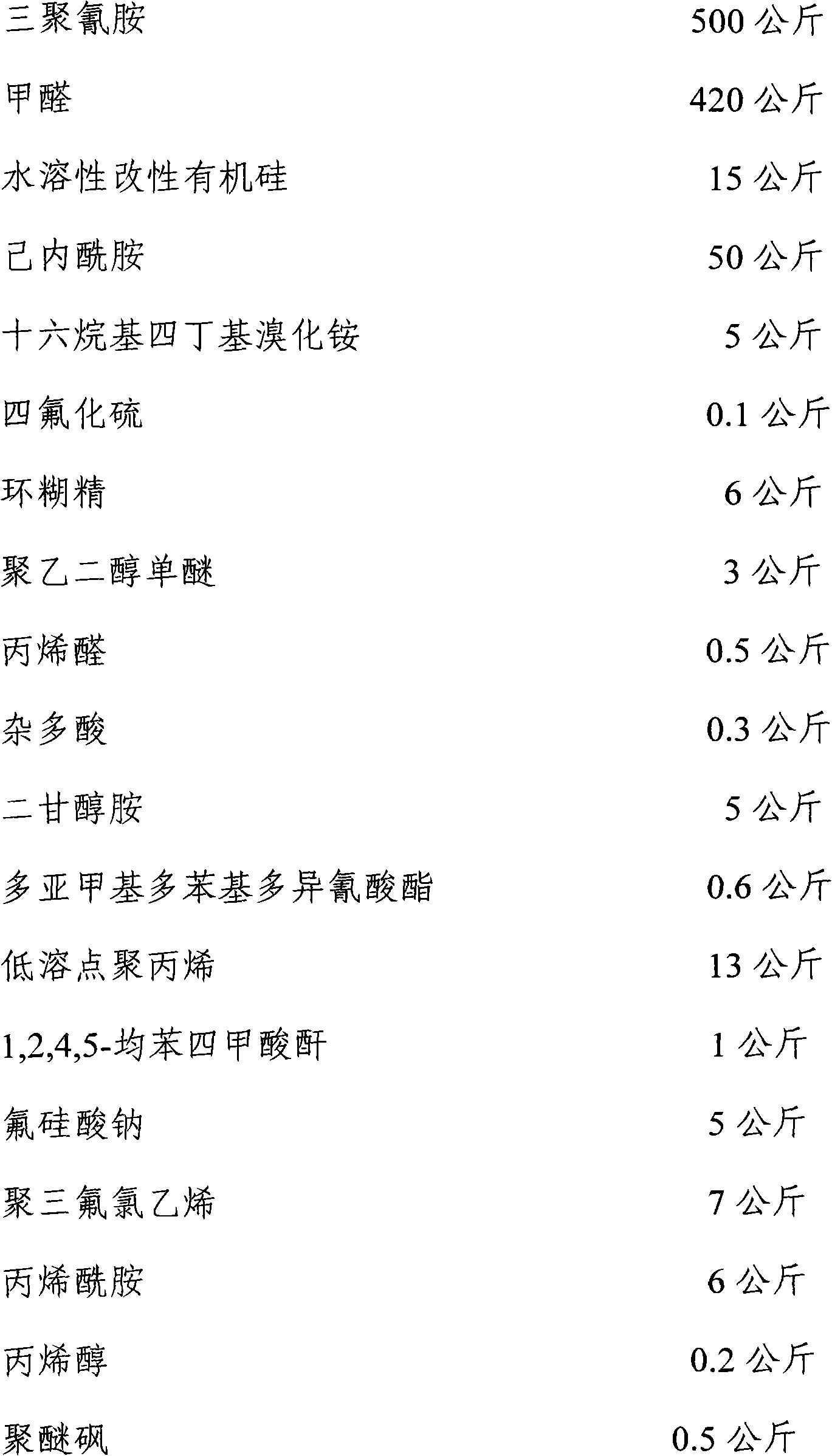

The invention discloses a novel preparation and continuous production method of melamine resin. The melamine resin comprises 0-5 parts of water-soluble modified organic silicon, 0-10 parts of fluorinated polyol, 10-50 parts of melamine, 20-50 parts of formaldehyde, 5-30 parts of modifier, 0.1-5 parts of combined phase transfer catalyst, 10-50 parts of desalted water, and 0-20 parts of sodium hydroxide. The preparation and continuous production method includes the steps of firstly, mixing the materials; secondly, quantitatively conveying for feeding the materials; thirdly, heating for polycondensation; and fourthly, cooling and controlling temperature. The melamine resin produced by the preparation and continuous production method is long in shelf life, high in dispersibility, less prone to caking, stable in performance and the like, and is quite applicable to stable production of melamine resin foamed plastic by an industrial microwave and melamine resin fiber by spinning of a screw machine from melamine resin.

Owner:戴新春

High-temperature-resistance foam enhanced SiO2 aerogel thermal insulation material and preparation method thereof

The invention discloses a high-temperature-resistance foam enhanced SiO2 aerogel thermal insulation material and a preparation method thereof. The high-temperature-resistance foam enhanced SiO2 aerogel thermal insulation material is characterized by being prepared from a carbon foam enhanced body, grid-shaped silicon carbide nanowires and SiO2 aerogel, wherein the grid-shaped silicon carbide nanowires are used for filling and partitioning internal pore spaces of carbon foam, the SiO2 aerogel is used for evenly filling the carbon foam enhanced body, density is 0.05 to 0.15g / cm<3>, porosity is larger than 90%, the foam enhanced body is flexible carbon foam and prepared from tripolycyanamide foam which is pyrolyzed in high temperature, and the diameters of the grid-shaped silicon carbide nanowires are 50 to 20nm. Silicon carbide-carbon compound foam is prepared through chemical vapor deposition, and a normal-pressure drying technology is utilized to prepare the SiO2 aerogel to further obtain the high-temperature-resistance foam enhanced SiO2 aerogel thermal insulation material. The high-temperature-resistance foam enhanced SiO2 aerogel thermal insulation material disclosed by the invention has the following advantages: 1, grid-shaped SiC nanowires can support a carbon framework to improve mechanical property of the compound material; 2, the silicon carbide nanowires reduce foam porosity and reduce thermal conductivity of the material; 3, the compound material has ultralow overall density.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cleaning implement with erodible foam substrate and controlled release system of active agent

ActiveUS20070161533A1Easy to cleanExtended service lifeLayered productsOrganic/inorganic per-compounds compounding agentsParticulatesControlled release

A cleaning implement comprises an erodible foam substrate, such as a melamine foam substrate and a controlled release system comprising an active agent. The controlled release system comprises a component selected from the group consisting of a polymer matrix, a microcapsule, a particulate porous carrier, a complexing agent, a semi-permeable film and a combination thereof and the active agent is selected from the group consisting of a surfactant, a bleaching agent, a limescale reducing agent, a biocide, a solvent and a mixture thereof.

Owner:THE PROCTER & GAMBLE COMPANY

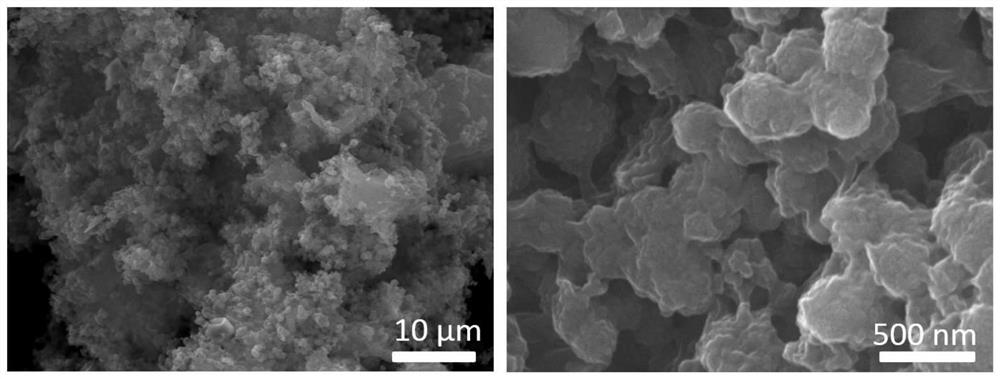

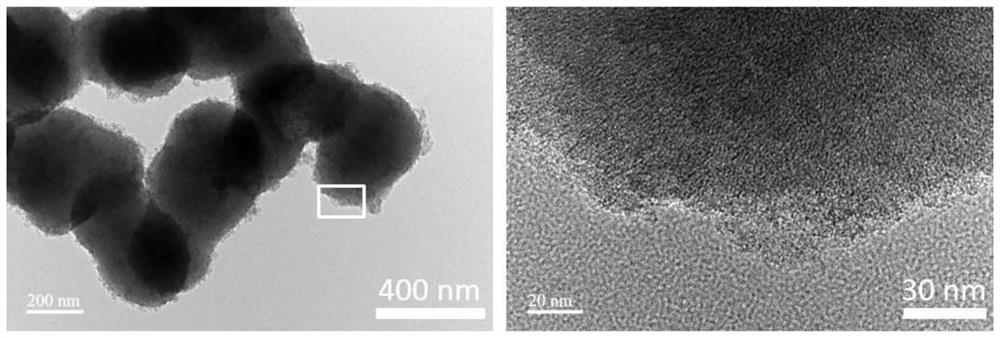

Graphene-melamine foam aerogel and preparation method thereof

InactiveCN106000366AImprove hydrophilicityEasy to operateOther chemical processesWater contaminantsFreeze-dryingVolumetric Mass Density

The invention discloses graphene-melamine foam aerogel and a preparation method thereof. The aerogel is black and blocky, density is 8-15mg / cm<3>, and specific surface area is 100-500m<2> / g. The preparation method comprises the following steps: (1) mixing graphene oxide with deionized water to obtain graphene oxide aqueous solution; (2) mixing the graphene oxide aqueous solution with a reducing agent to obtain mixed solution, then putting melamine foams into the mixed solution, and carrying out constant temperature hydrothermal reaction to obtain graphene-melamine foam hydrogel; and (3) putting the hydrogel into a solvent to be cleaned, and then carrying out freeze drying, so that the graphene-melamine foam aerogel is obtained. The graphene-melamine foam aerogel disclosed by the invention has the advantages that superhydrophilic melamine foams are utilized as a skeleton structure to form graphene aerogel, so that the aerogel can be easily immersed in water and can rapidly adsorb organic pollutants in the water; meanwhile, due to addition of the melamine foams, compression performance of the aerogel is improved, and the aerogel can be recycled.

Owner:JIANGSU UNIV OF SCI & TECH

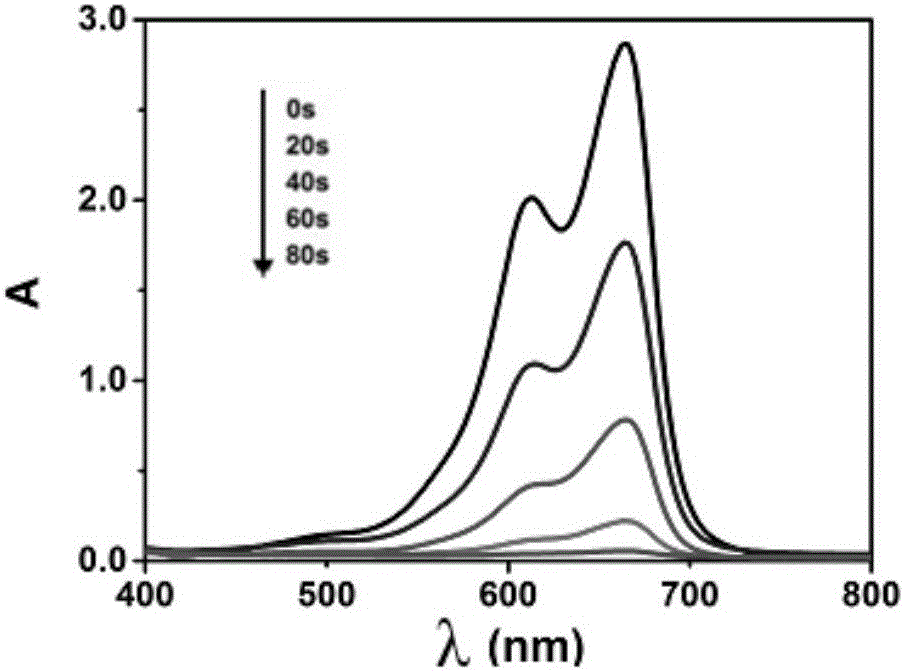

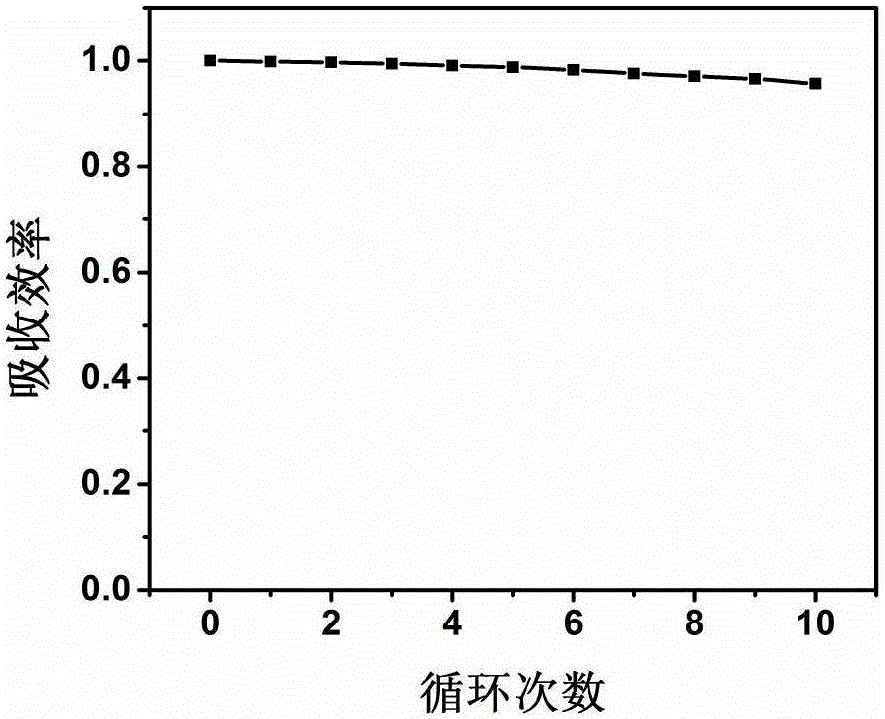

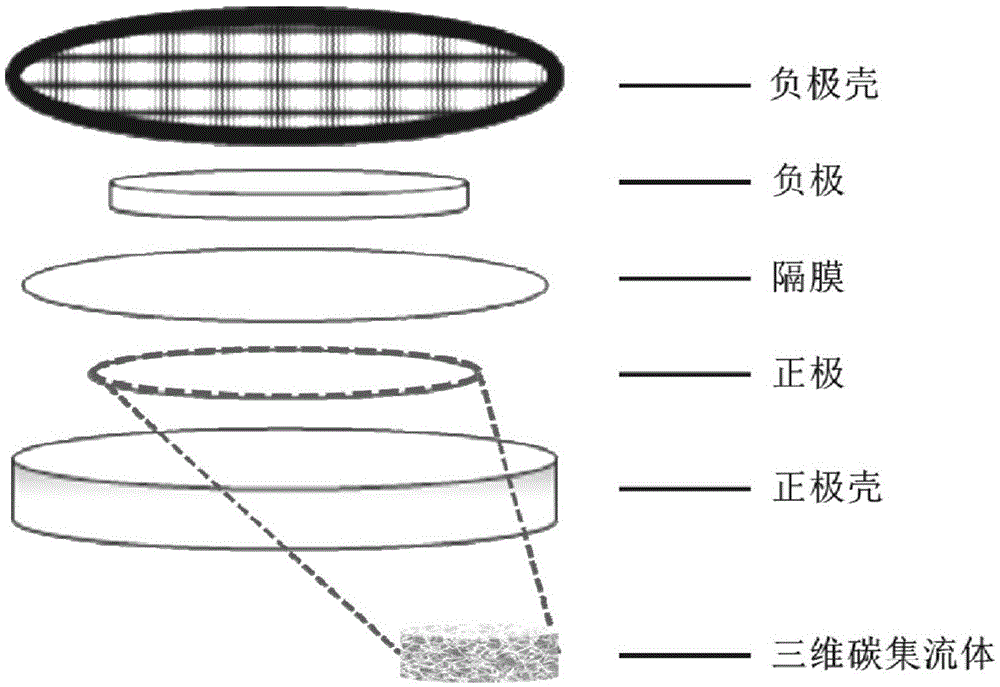

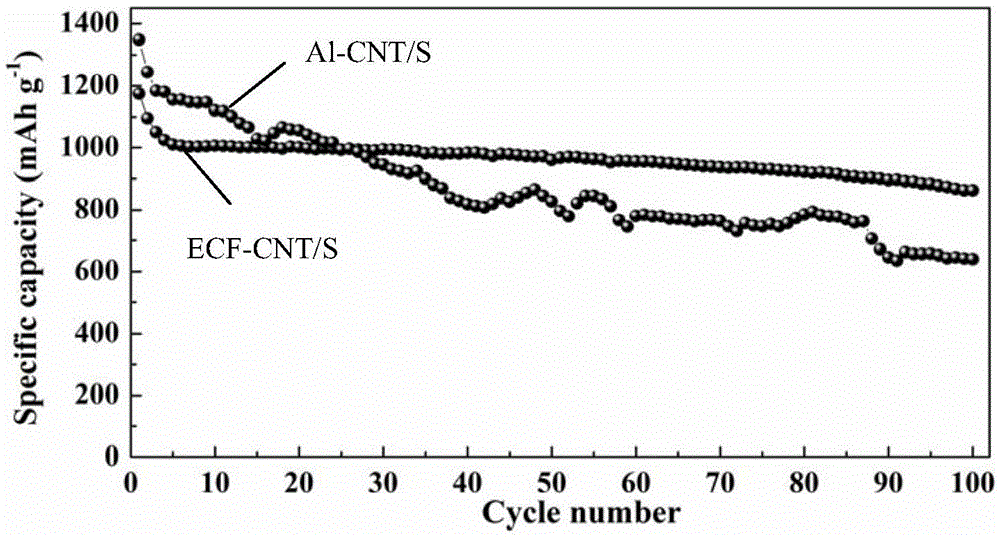

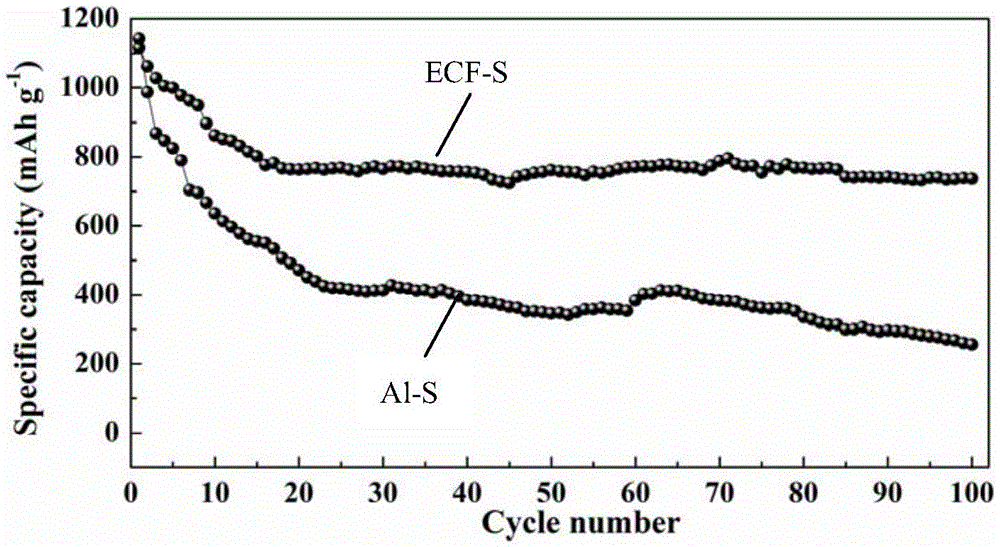

Preparation method and application of lithium-sulfur battery three-dimensional carbon current collector

ActiveCN105489901AImprove cycle stabilityCounteract volume expansionFinal product manufactureElectrode carriers/collectorsCarbonizationSodium–sulfur battery

The invention relates to the field of electrochemical batteries, in particular to a preparation method of a lithium-sulfur battery three-dimensional carbon current collector and application of the lithium-sulfur battery three-dimensional carbon current collector in a lithium-sulfur battery. The preparation method of the lithium-sulfur battery three-dimensional carbon current collector disclosed by the invention comprises the following steps: soaking an organic foam material with an organic solvent for 2-6 h, washing, drying, and preserving the temperature for 2-6 h at the temperature of 700-900 DEG C under the protection of an inert gas so as to obtain the lithium-sulfur battery three-dimensional carbon current collector, wherein the organic foam material is any one of polyurethane foam and melamine foam; and the organic solvent is any one of ethyl alcohol, ethylene glycol, isopropyl alcohol and acetone. According to the preparation method of the lithium-sulfur battery three-dimensional carbon current collector disclosed by the invention, the current collector is prepared through carbonization under a high temperature by adopting the organic foam material, the three-dimensional structure of the current collector can improve the surface sulfur carrying capacity of the current collector and has certain elasticity, and the volume expansion of sulfur in the charging and discharging process can be accommodated.

Owner:HENAN NORMAL UNIV

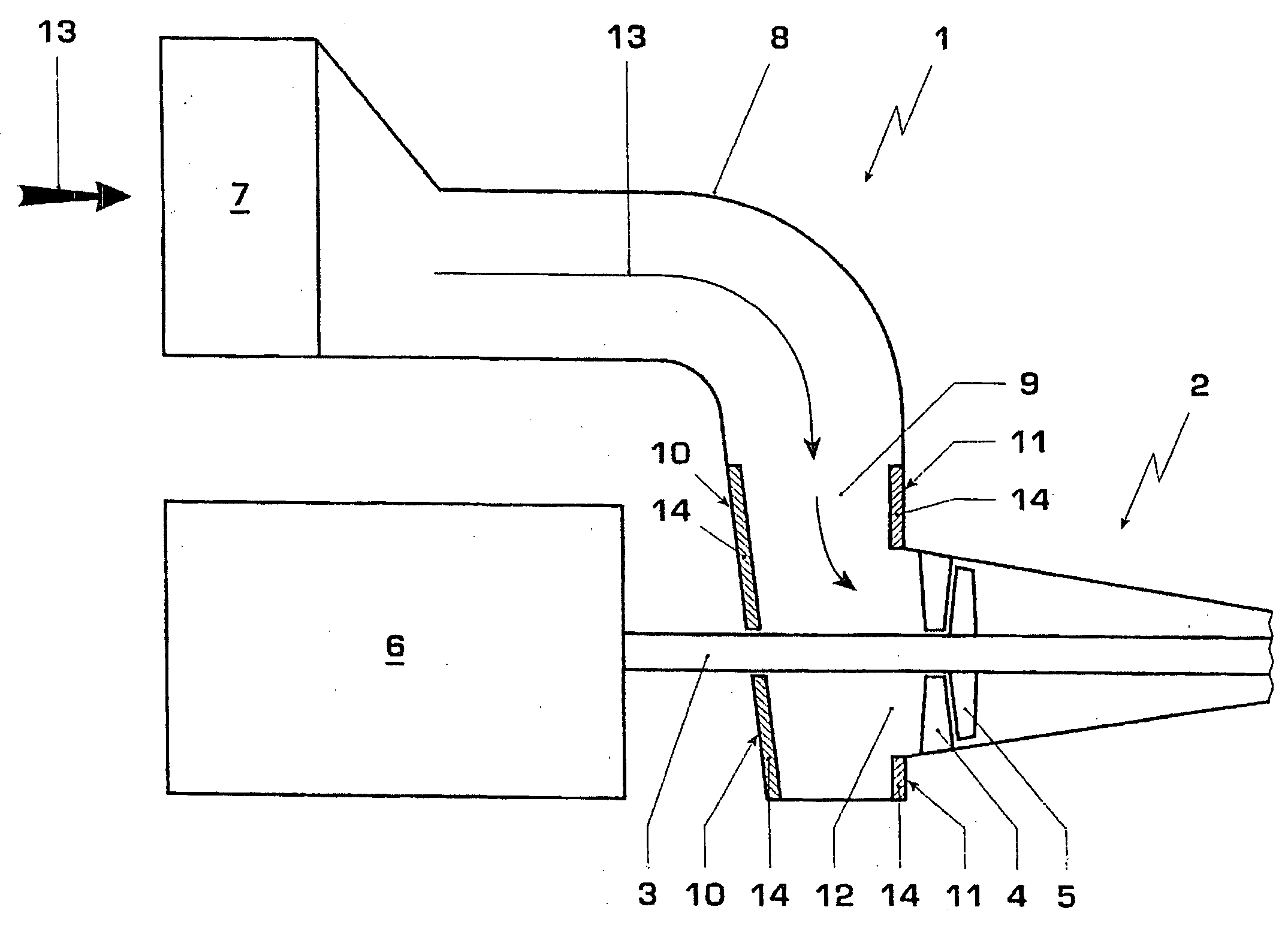

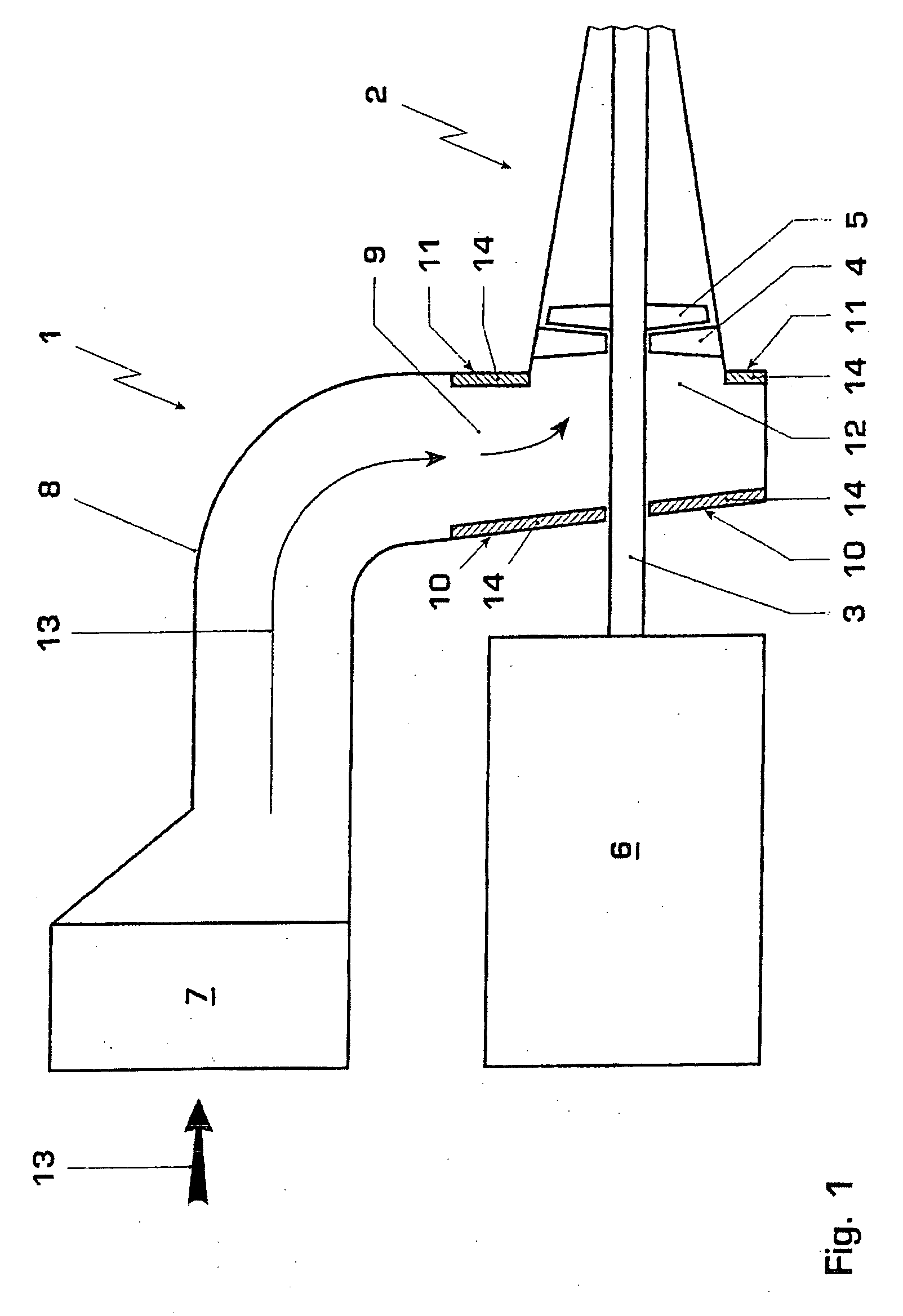

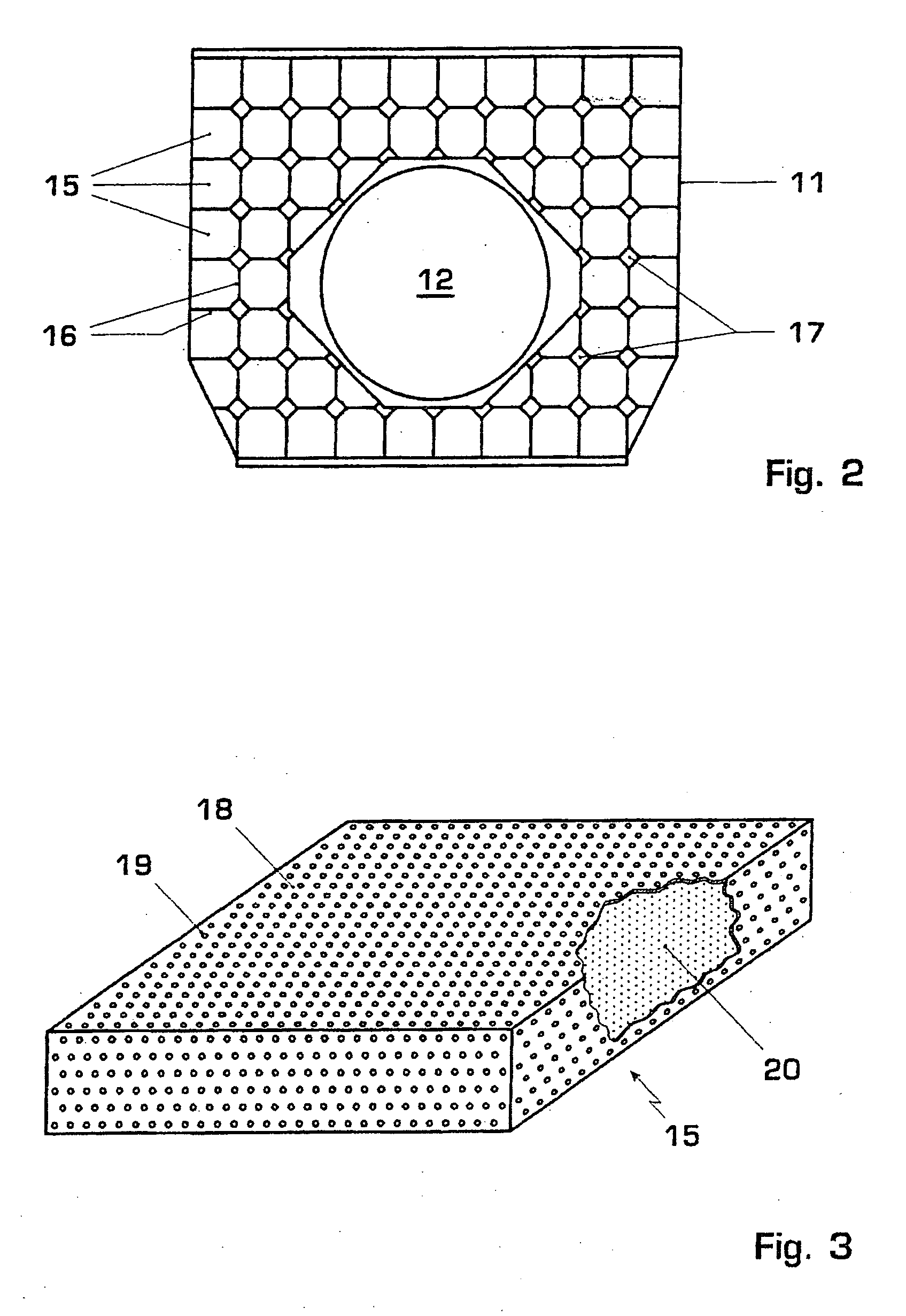

Sound absorber for gas turbine installations

InactiveUS20080202848A1Reliable silencing qualityEfficient silencingPump componentsEngine fuctionsSound AbsorberGas turbines

A device (1) for the feed of air to a compressor (2) of a gas turbine plant has an air inlet duct (8) and an air inlet chamber (9) which adjoins the air inlet duct. For the purpose of damping sound emissions of the compressor (2), a first and second inner wall (10, 11) of the inlet chamber (9) is at least partially lined by means of melamine foam. The invention is characterized by the advantages in that silencing is ensured both with wetness and with chemically aggressive conditions. The silencing device is consequently functionally reliable over an extended operating period.

Owner:ANSALDO ENERGIA IP UK LTD

Production method of ultralow density high-tenacity high-elasticity melamine foams

The invention discloses a production method of ultralow density high-tenacity high-elasticity melamine foams, which comprises the following steps: using melamine formaldehyde resin or modified melamine formaldehyde resin as a base material, and adding an emulsifier, a foaming agent, a curing agent and molecules with an enhanced Marangoni effect; and after uniform emulsification, heating in a microwave oven, curing for a while, and molding. During the microwave foaming process, the addition of the molecules with an enhanced Marangoni effect not only can reduce the use amount of the foaming agent to a large extent, but also can regulate the aperture and the length-diameter ratio of edges of the foams in a large range, so as to greatly improve the various properties of melamine foams.

Owner:QILU UNIV OF TECH

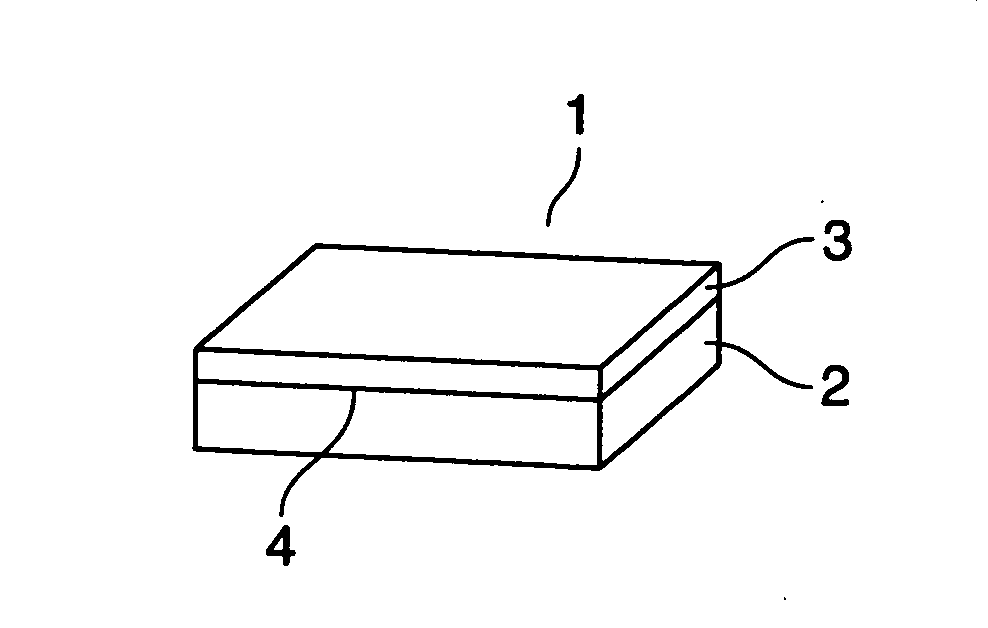

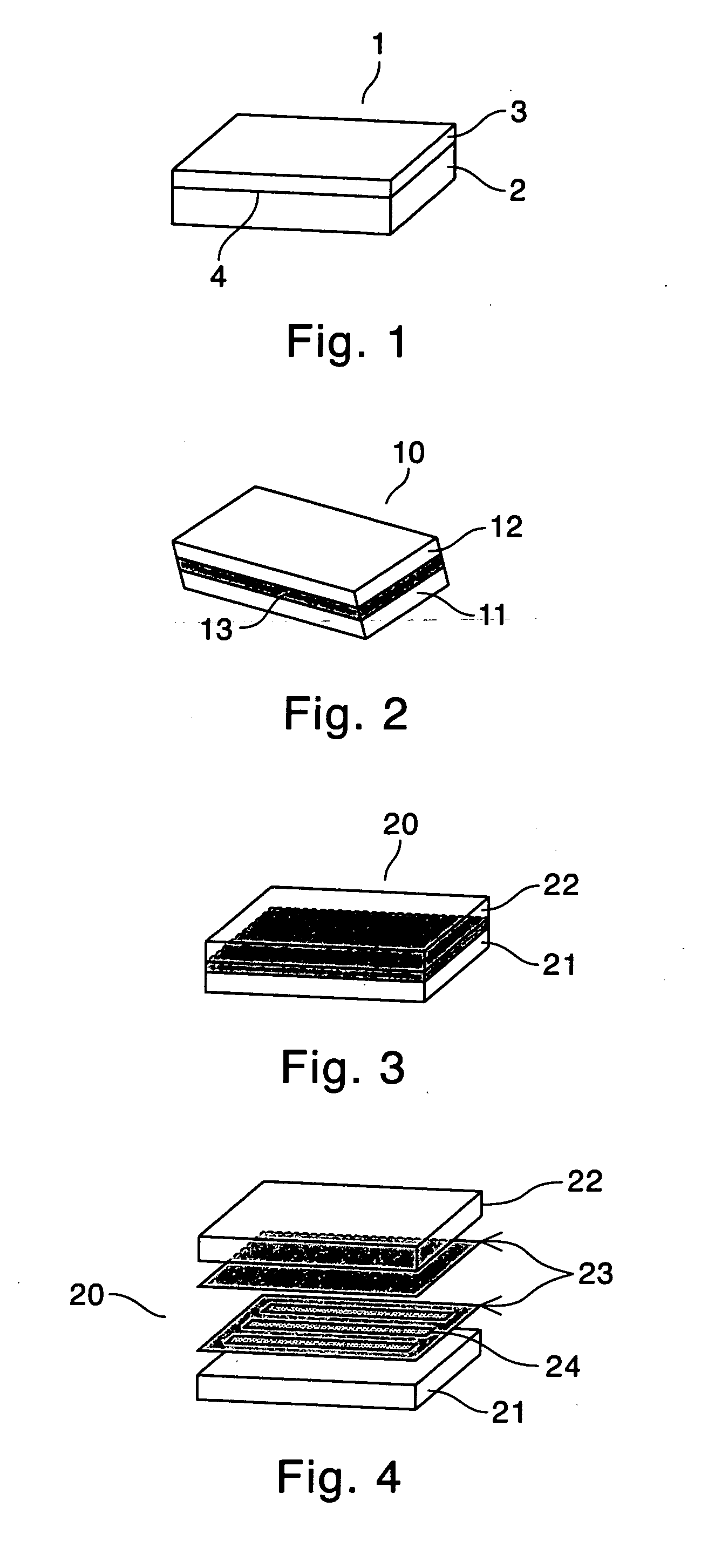

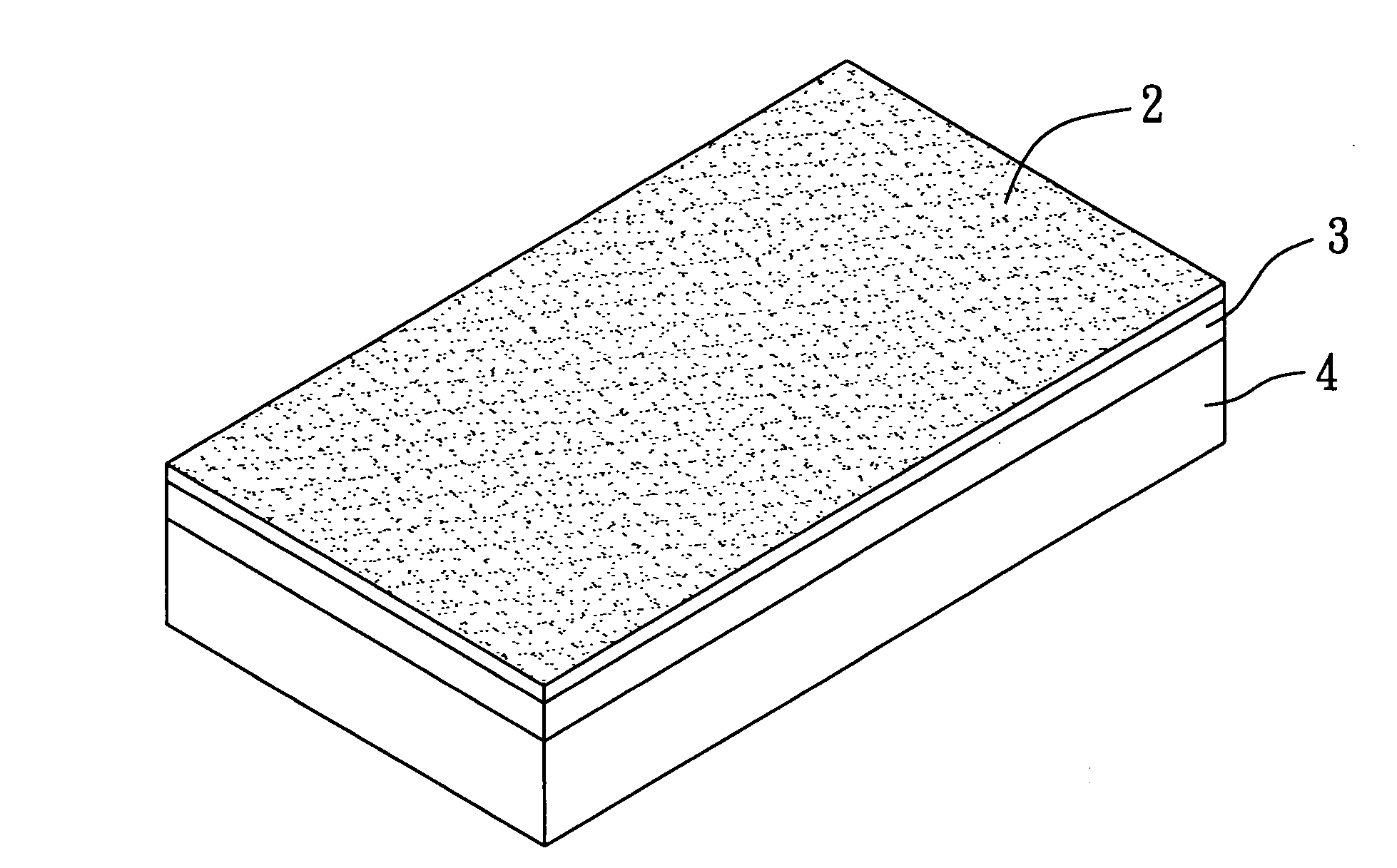

Cleaning implement

InactiveUS7234189B2Sufficient cleaning effectDurableBoard cleaning devicesCarpet cleanersFiberEngineering

A cleaning implement includes a fabric layer made from a splittable conjugate fiber, a sponge wiper layer made of melamine foam, and a reinforcing layer made of a non-melamine foam material and disposed between the fabric and sponge layers. The non-melamine foam material has higher water-absorbing and elastic properties than the melamine foam.

Owner:CHEN CHI HUNG

Preparation method of semi-hard melamine foam

The invention discloses a preparation method of semi-hard melamine foam. The preparation method comprises the following steps: preparing semi-hard melamine foam plastic dedicated resin from raw materials such as melamine, formaldehyde, modified monomers, and the like, through in-situ synthesis; then adding resin, an emulsifier, a foam stabilizer, a foaming agent, an auxiliary agent, and a curing agent into a special mixing apparatus such as a screw extruder, mixing the components mentioned above to prepare a foaming liquid; and subjecting the foaming liquid to microwave foaming and a high temperature post treatment so as to produce the semi-hard melamine foam.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

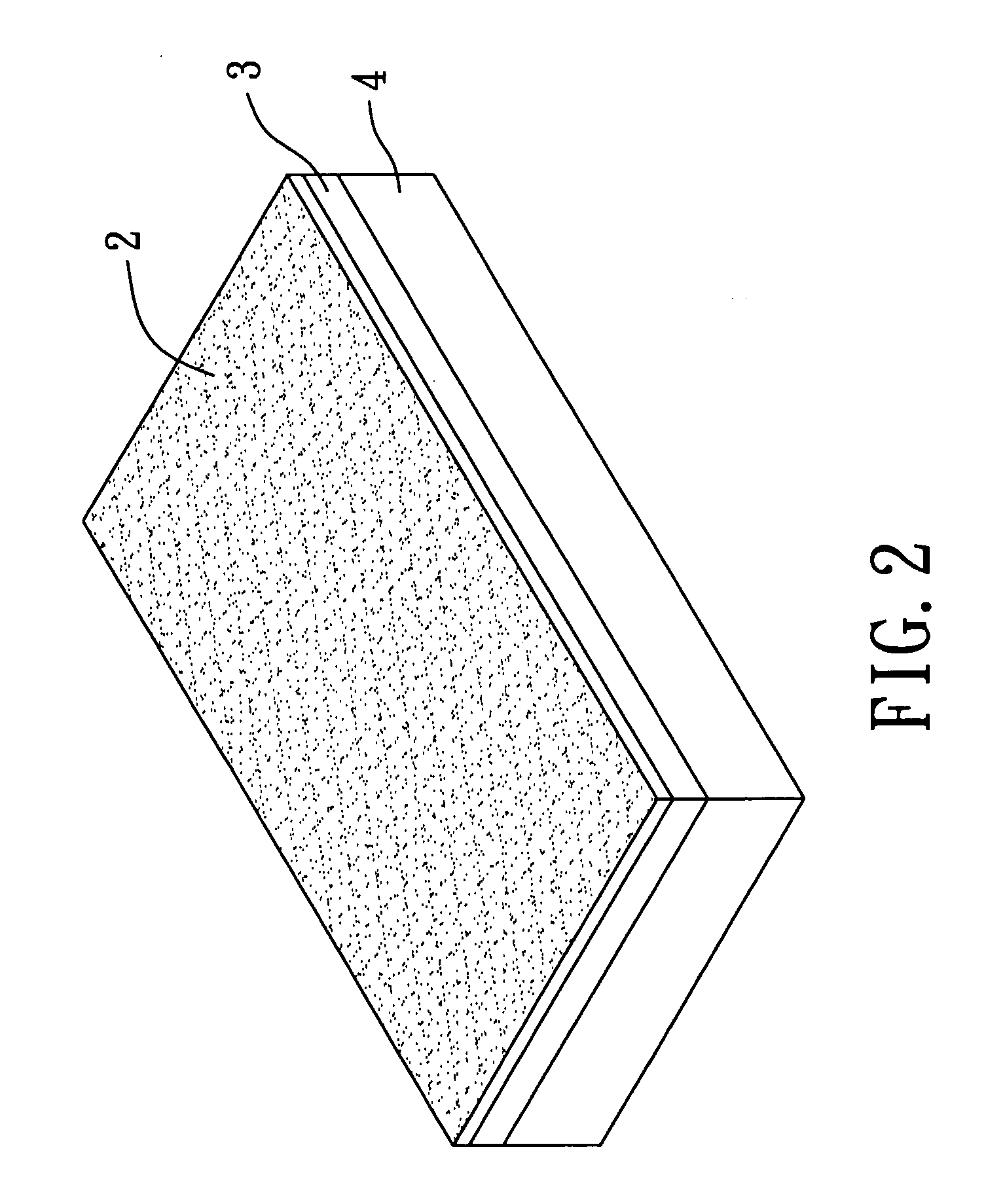

Ultrathin buffer foam tape and production method thereof

ActiveCN105670529AAuto excludeImprove buffering effectFilm/foil adhesivesPolymer scienceSilicone tape

The invention discloses a production method of ultrathin buffer foam tape.The production method includes: preparing PET double-sided tape and ultrathin buffer foam layer base material, and tightly adhering one side of the PET double-sided tape to the ultrathin buffer foam layer; compositing an embossed release material layer on the other side of the PET double-sided tape.A production method of the ultrathin buffer foam layer specifically includes: cutting thick PE foam with high foaming ratio into foam sheets of 0.3-0.5mm, and performing hot-press forming on the foam sheets to obtain the ultrathin buffer foam layer; or performing hot-press forming on PU foam or melamine foam to obtain the ultrathin buffer foam layer, wherein the temperature of the hot-press forming is 180-220 DEG C, the pressure of the hot-press forming is 3-8kg / cm<2>, and the speed of the hot-press forming is 8-20m / minute.The ultrathin buffer foam tape produced by the hot-press process has functions of absorbing shock and sounds and automatically removing bubbles.

Owner:HENGSHAN JIACHENG NEW MATERIAL

Lightweight melamine aerogel felt and preparation method thereof

InactiveCN105859320AAvoid structural damageImprove use valueCeramicwareNetwork structureMechanical stability

The invention provides a lightweight melamine aerogel felt and a preparation method thereof. The lightweight melamine aerogel felt is characterized by comprising, by volume, 99.4 to 99.7% of SiO2 aerogel and 0.3 to 0.6% of melamine foam, wherein the melamine foam is open-cell foam, the unit weight of the foam is 4 to 10 Kg / m<3>, and the SiO2 aerogel penetrates an interlaced three-dimensional network structure formed by pores of the melamine foam in the form of flocculent gel. The preparation method for the aerogel felt comprises the following successive steps: (1) preparing a silica sol system; (2) putting the melamine foam into a die, casting the silica sol system and then carrying out standing and aging; and (3) successively carrying out cleaning and displacement, drying and heat treatment so as to obtain the melamine aerogel felt. The aerogel felt has a light weight, good mechanical stability, a regular shape and a smooth surface and is easy to process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

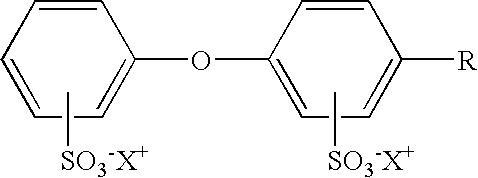

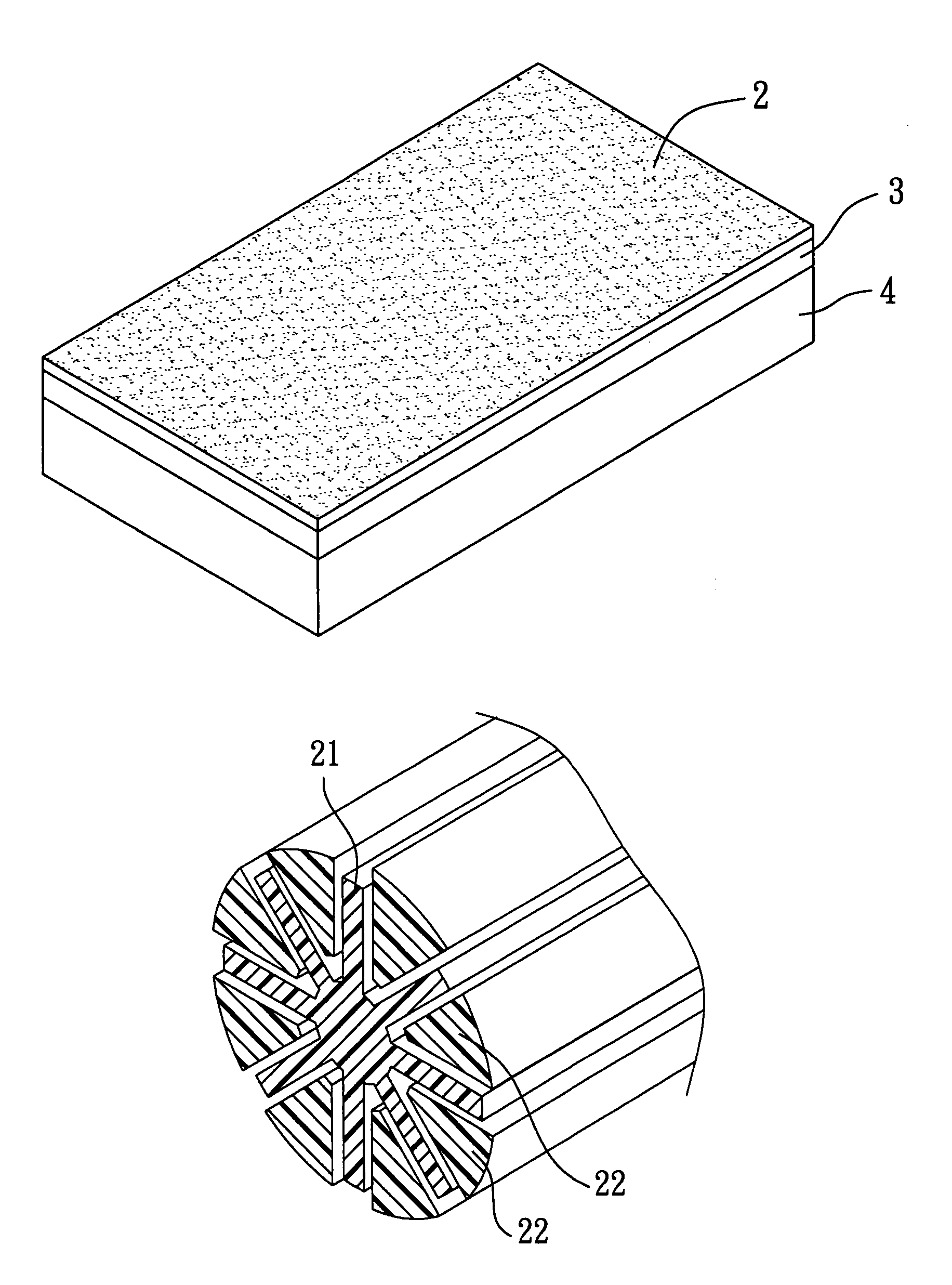

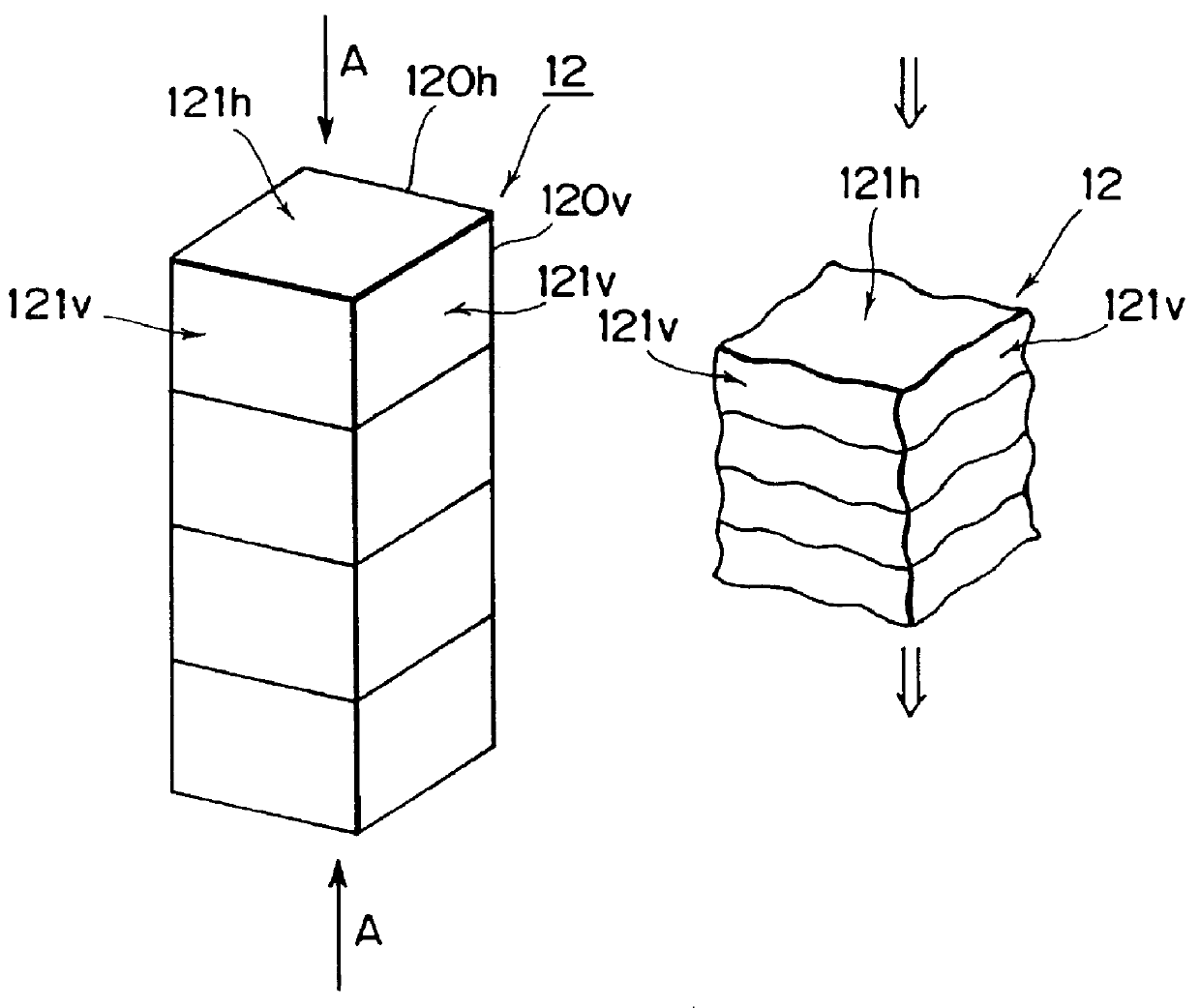

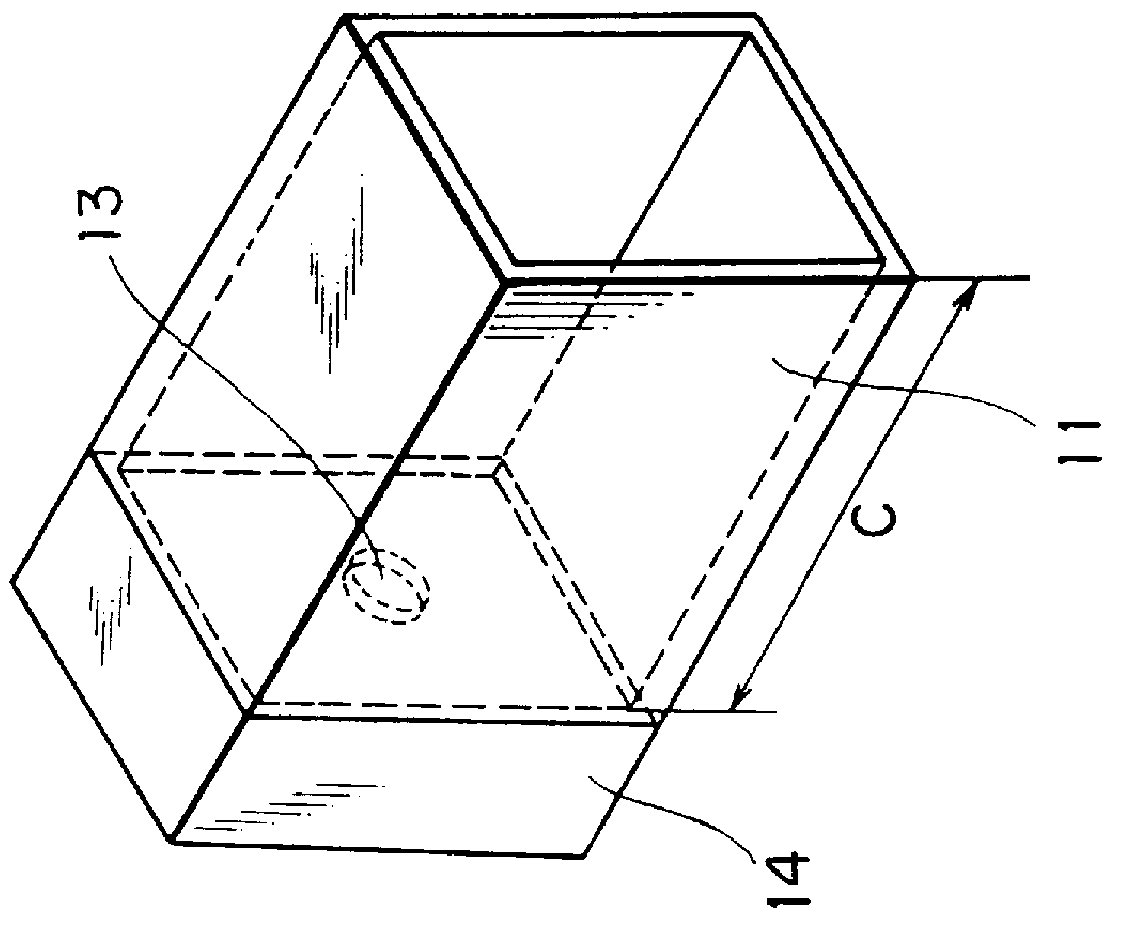

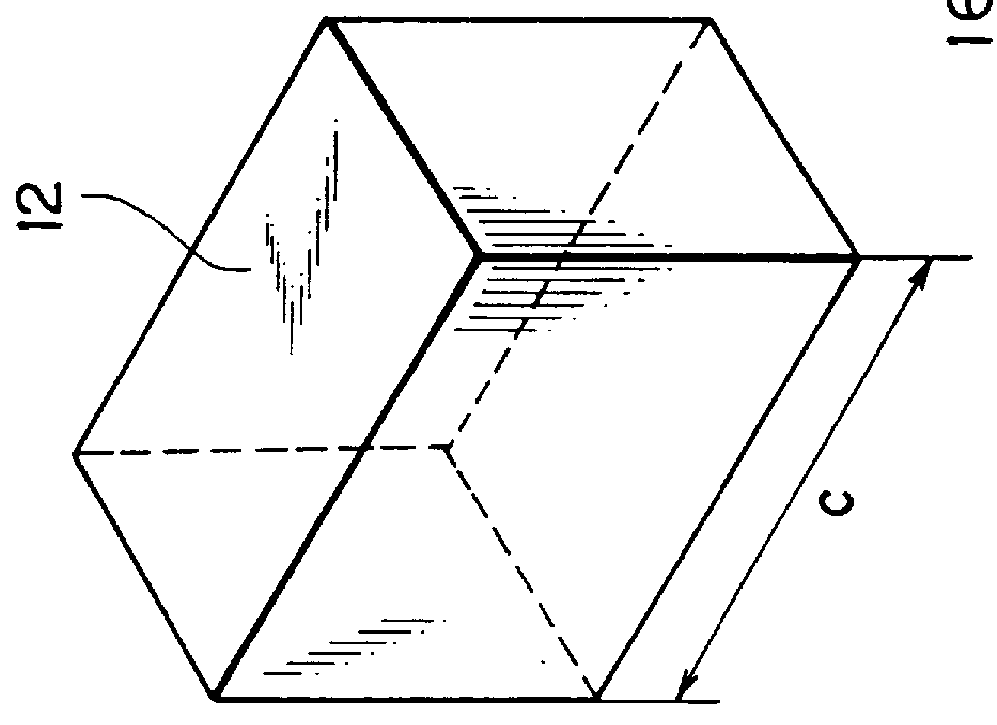

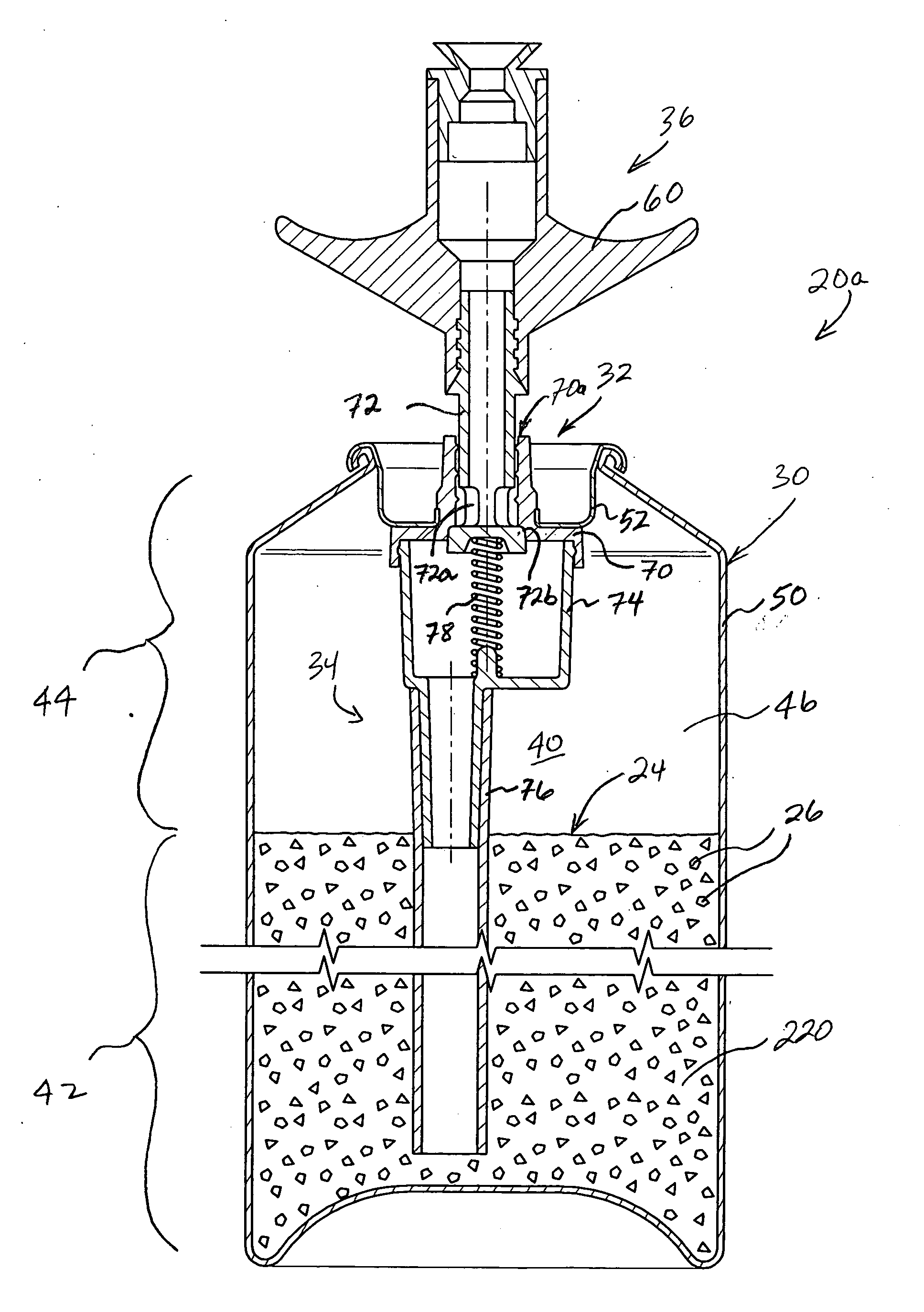

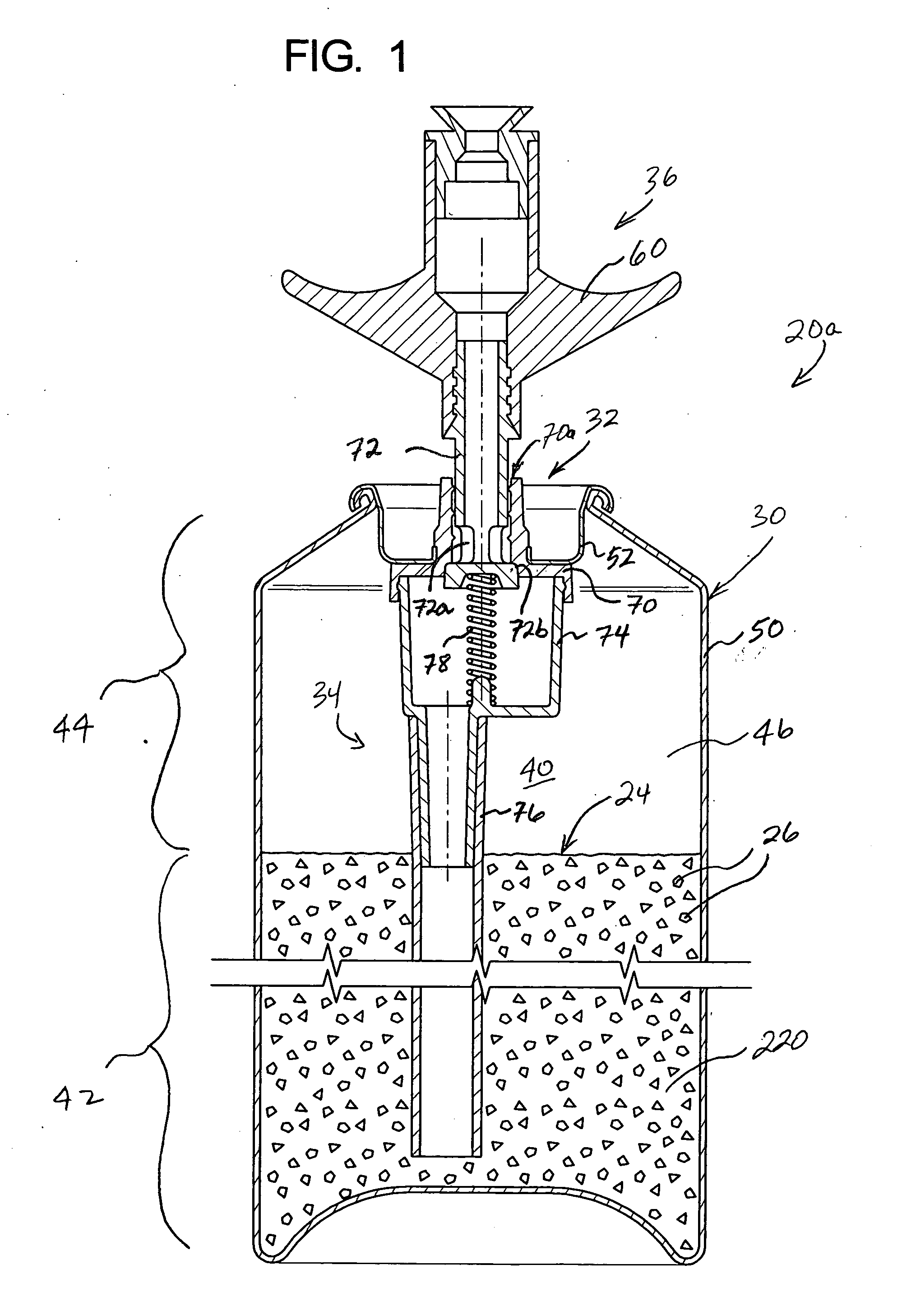

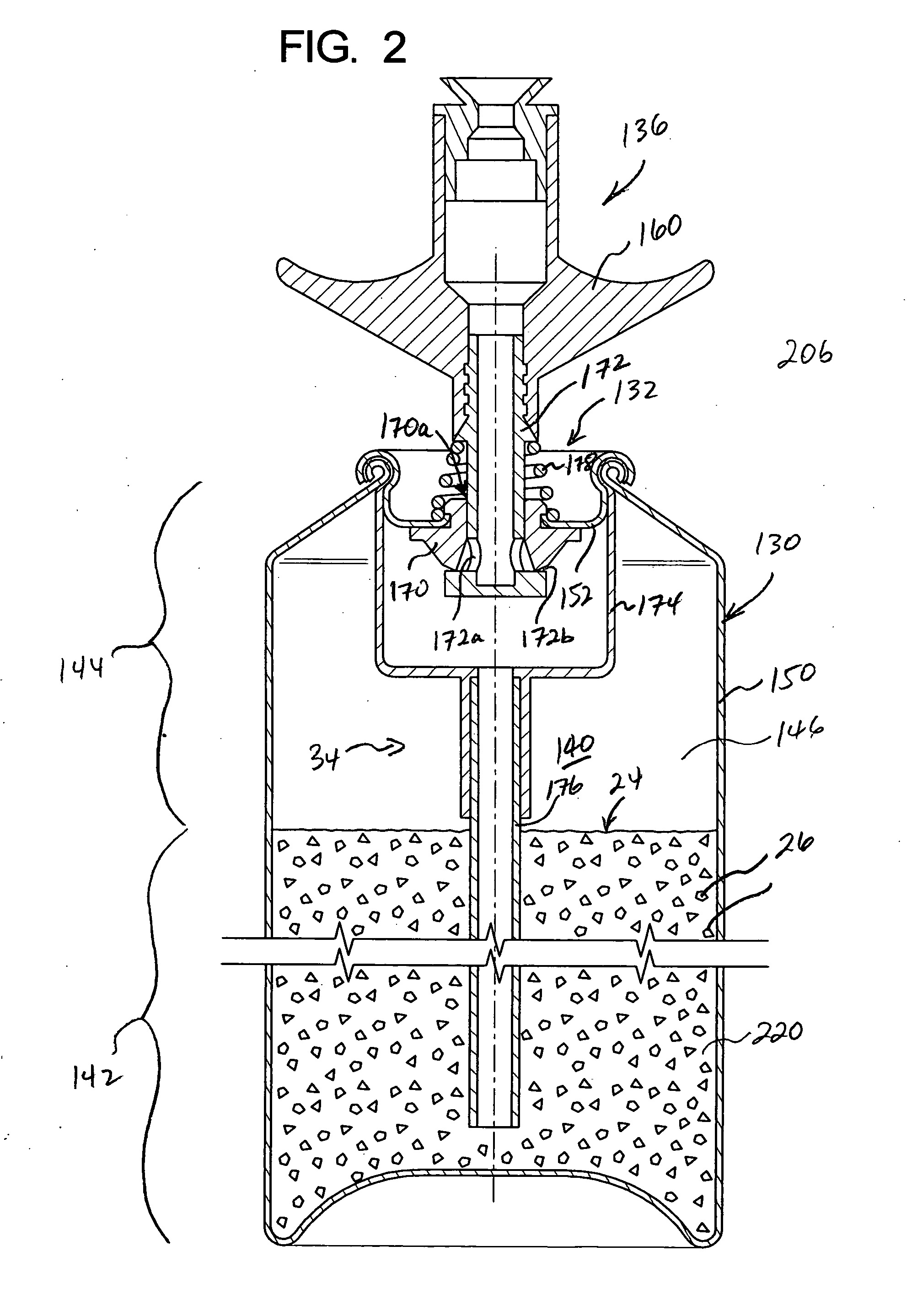

Ink tank, head cartridge and ink jet printing apparatus

A length of a melamine foamed block to be accommodated in an ink tank housing as measured in the longitudinal direction is dimensioned to be larger than a length of the ink tank housing as measured in the longitudinal direction. Thus, while the foamed block is accommodated in the ink tank housing, it is compressed in the direction orienting toward an ink feeding port from which ink is fed to a printing head, i.e., in the ink feeding direction. Consequently, the ink retaining force induced by the capillary force is not intensified in the compressing direction of the melamine foamed block, resulting in an ink feeding capability of the printing head being improved. On the contrary, the ink retaining force effective at a right angle relative to the compressing direction of the melamine foamed block is intensified.

Owner:CANON KK

Cleaning implement

ActiveUS20070157405A1Easy to controlImprove distributionBoard cleaning devicesCarpet cleanersChemistryMelamine foam

The present invention envisages a cleaning implement comprising a melamine foam preferably having a thickness of at least about 5 mm and a perfume source, processes for making them and methods for using them.

Owner:THE PROCTER & GAMBLE COMPANY

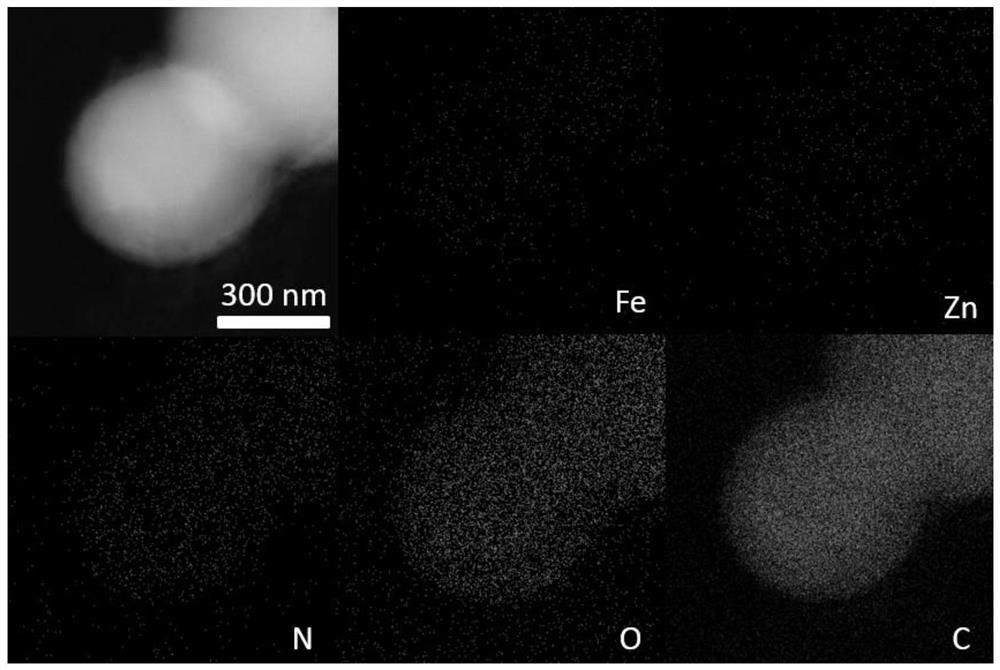

Preparation method of zinc-based bimetallic-nitrogen-doped carbon material and application of zinc-based bimetallic-nitrogen-doped carbon material in electrode catalyst

InactiveCN111864222AHigh yieldGood electrocatalytic stabilityFuel and primary cellsCell electrodesPtru catalystCarbonization

The invention belongs to the technical field of hybrid material preparation and relates to a preparation method of a zinc-based bimetallic-nitrogen-doped carbon material. The method comprises the steps of dissolving a metal chloride, zinc chloride and a carbon source molecule in water to form a mixed solution according to a mass ratio of 5-15: 5-15: 1; by taking melamine foam as a framework and anitrogen source, performing fully soaking, taking-out and drying to obtain a precursor; heating the precursor to 800-1000 DEG C in an inert gas atmosphere at a heating rate of 5-10 DEG C / min, annealing for 1-2 hours, and cooling to room temperature to obtain a carbonized product; and crushing, washing with acid, water and alcohol, and drying to obtain the material. According to the preparation method, the melamine foam is used as the framework and the nitrogen source, so that the uniform doping of heteroatoms and the increase of the specific surface area are facilitated, zinc chloride assistedannealing can be used for pore forming and zinc doping of the carbon-based material, and the synergistic improvement of the specific surface area of the carbon-based material and the density of zinc-nitrogen active sites is facilitated. Compared with commercial Pt / C, the prepared material has higher ORR electrocatalytic activity and stability.

Owner:JIANGSU UNIV

Foamy carbon based heat-insulation composite material with light weight and high strength

ActiveCN106904973AImprove antioxidant capacityImprove mechanical propertiesCeramicwareChemical vapor depositionMechanical property

The invention provides a foamy carbon based heat-insulation composite material with light weight and high strength. The foamy carbon based heat-insulation composite material with light weight and high strength is characterized by comprising a base material foamy carbon, an SiC coating and reticulated SiC nanowires, wherein a foamy carbon skeleton is coated with the SiC coating; three-dimensional pores are filled with the reticulated SiC nanowires, porosity is 90%-95%, average pore diameter is 50 nm-500 nm, apparent density is 0.05-0.2 g / cm<3>, and compressive strength is 5-15 MPa. Foamy carbon is flexible foamy carbon and is prepared from melamine foam through high-temperature pyrolysis, the porosity is 99% or higher, and the average pore diameter is 20-50 mu m; the thickness of the SiC coating is 0.5-1 mu m, the diameter of the SiC nanowires is 50-300 nm, the average length is 30-50 mu m, and all the SiC nanowires are prepared with a chemical vapor deposition method. The light foamy carbon based heat-insulation composite material with high strength has the advantages as follows: 1, the foamy carbon skeleton is coated with SiC, so that oxidation resistance of the composite material is improved; 2, the foamy carbon skeleton is coated with SiC, and mechanical properties of the composite material are improved accordingly; 3, internal pores of foam are segmented by the SiC nanowires, the internal pore diameter is reduced, and the heat conductivity of the composite material is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

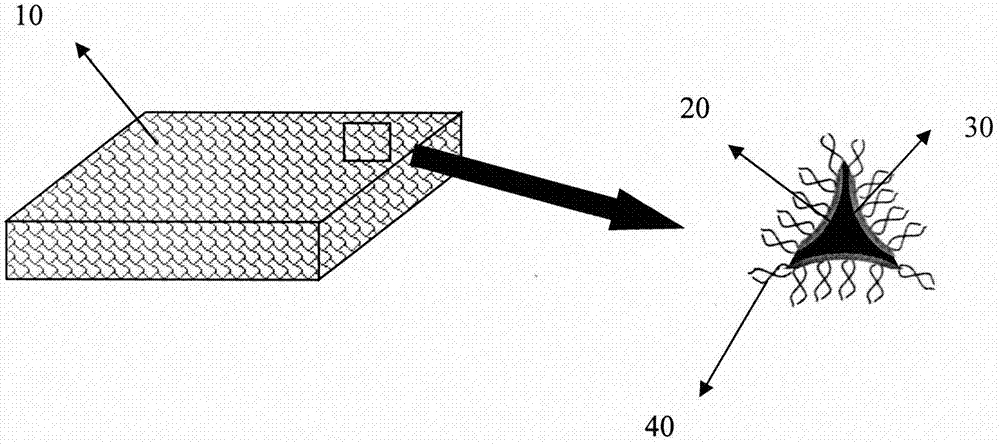

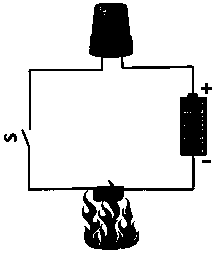

Resistance type fire detection/early-warning sensor and application

ActiveCN108109317AEasy to prepareCheap and easy to getFire alarm electric actuationFire riskLow voltage

The invention relates to the field of functional materials. In order to solve the deficiencies and defects of the traditional infrared fire alarms and smoke alarms in the using process at present, theinvention provides a novel resistance type fire detection / early-warning sensor, which is formed by connecting a low-voltage power supply, a warning lamp, a fire early-warning composite material and aplurality of lead wires in sequence, wherein the fire early-warning composite material is prepared from, by weight, 25-45 parts of melamine foam, 8-40 parts of graphene oxide and 15-67 parts of silicon-containing additive. The process is simple and efficient, and the raw material is low in cost. The invention further provides an application of the resistance type fire detection / early-warning sensor. The resistance type fire detection / early-warning sensor is used for monitoring and preventing various types of combustible materials in a high fire risk region, reducing or even avoiding the occurrence of fires and loss caused by the fires.

Owner:HANGZHOU NORMAL UNIVERSITY

Cleaning implement

InactiveUS20070017053A1Clean enoughSufficient cleaning effectBoard cleaning devicesCarpet cleanersFiberEngineering

A cleaning implement includes a fabric layer made from a splittable conjugate fiber, a sponge wiper layer made of melamine foam, and a reinforcing layer made of a non-melamine foam material and disposed between the fabric and sponge layers. The non-melamine foam material has higher water-absorbing and elastic properties than the melamine foam.

Owner:CHEN CHI HUNG

Particulate materials for acoustic texture material

An aerosol texturing system for forming a textured surface on drywall material. The aerosol texturing system comprises an aerosol assembly defining a product chamber and acoustic texture material and propellant material disposed within the product chamber. The aerosol assembly is selectively operable in a first mode in which the product chamber is sealed and in a second mode in which fluid is allowed to flow out of the product chamber along a dispensing passageway. The acoustic texture material comprises a base portion and a particulate portion. The particulate portion comprises at least one particulate material selected from the group consisting of urethane foam and melamine foam. At least a portion of the propellant material exists in a gaseous state such that, when the aerosol assembly is in the second mode, the propellant material forces the acoustic texture material out of the aerosol assembly along the dispensing passageway.

Owner:PPG ARCHITECTURAL FINISHES INC

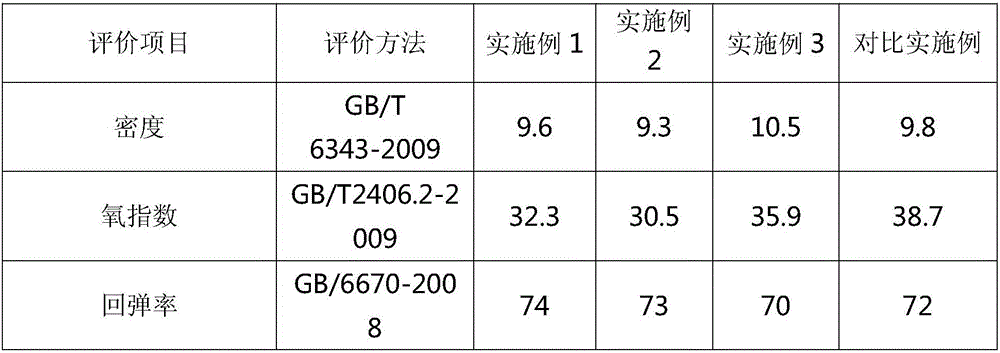

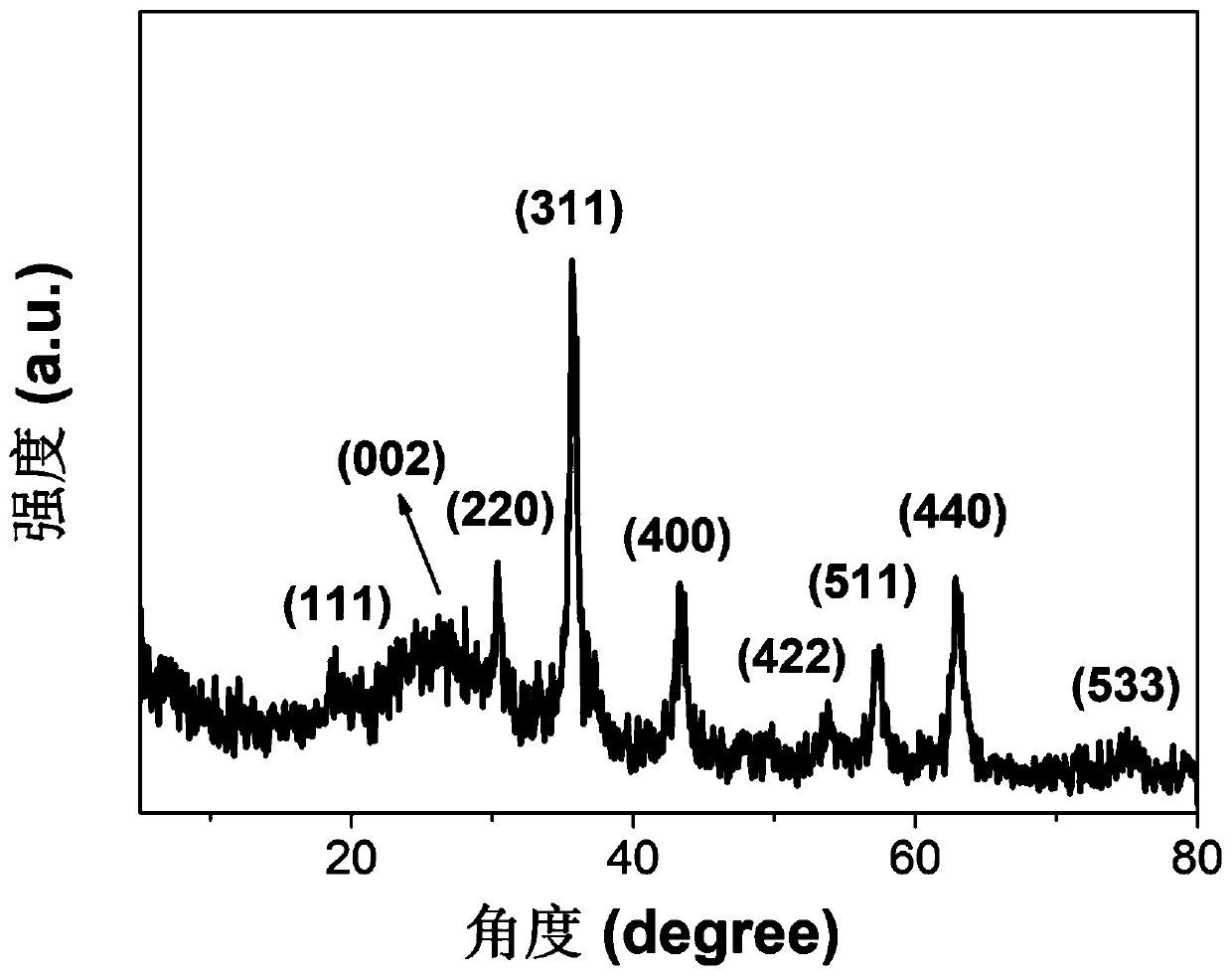

Novel high-resilience load-bearing foam material and preparation method thereof

The invention discloses a novel high-resilience load-bearing foam material. The novel high-resilience load-bearing foam material is prepared from raw materials as follows: expandable melamino-formaldehyde resin, elastomer rubber or resin, a surfactant, a nucleating agent, a foaming agent and a vulcanizing agent. The invention further discloses a preparation method of the novel high-resilience load-bearing foam material. The preparation method comprises the following steps: the expandable melamino-formaldehyde resin is prepared; the elastomer rubber or resin, the surfactant, the vulcanizing agent and the nucleating agent are added, and an expandable melamino-formaldehyde resin-elastomer emulsion is prepared; the foaming agent and an acid catalyst are added, and a foaming solution is prepared; micorwave foaming and crosslinking are performed; high-temperature drying and curing are performed; quenching is performed at the normal temperature, and the novel high-resilience load-bearing foam material is obtained. The novel high-resilience load-bearing foam material has good flame retardancy, thermal stability, shock resistance and flexibility, high resilience and high indentation ratio, high porosity, high elasticity and better compression set resistance and repeated indentation fatigue performance than common melamine foam and touches fine.

Owner:成都美讷敏新材料科技有限公司

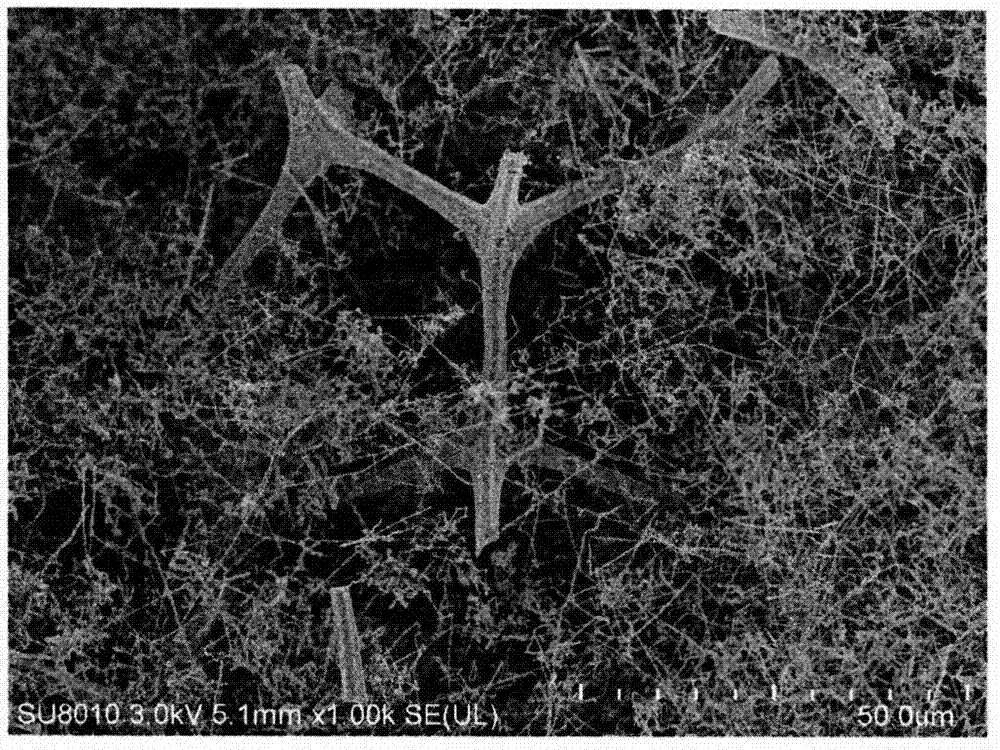

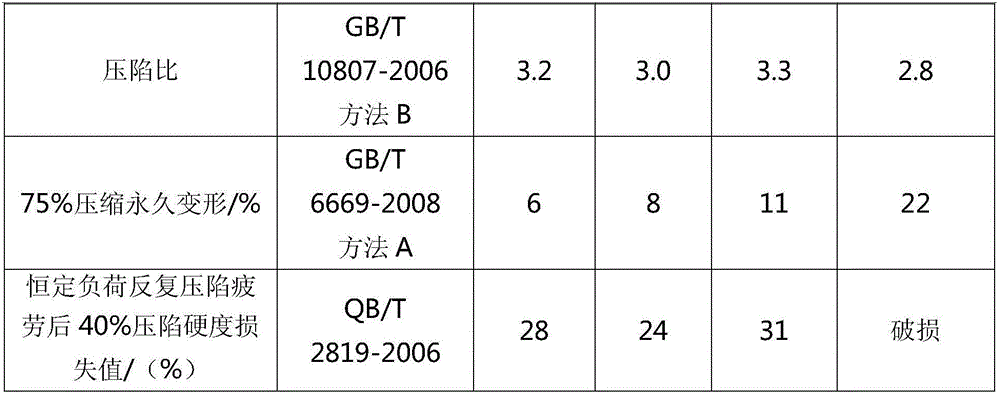

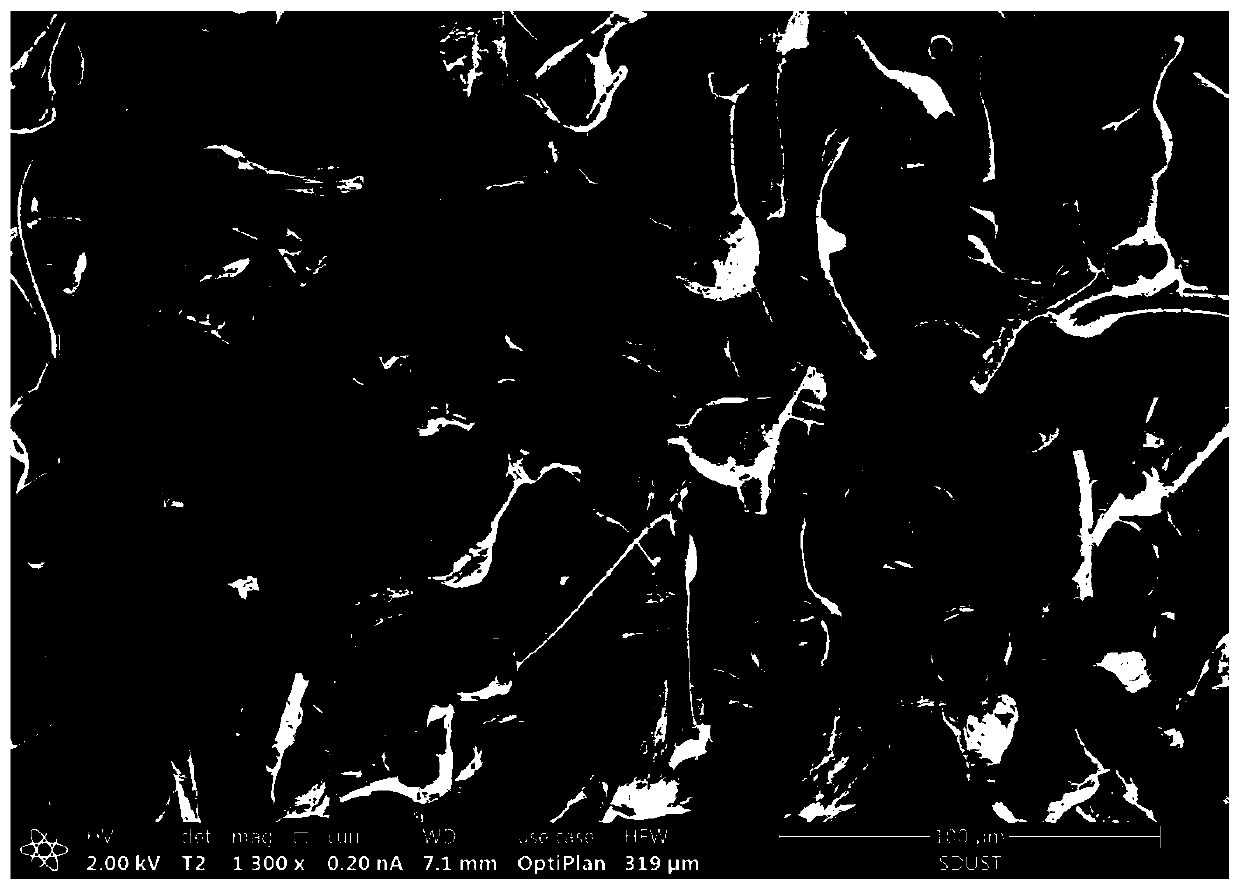

Iron oxide-nitrogen doped carbon micro-tube composite wave-absorbing material and preparation method thereof

ActiveCN110790316AOvercome the disadvantages of cumbersome operationOvercome the disadvantage of high densityOther chemical processesCarbon nanotubesNitrogen dopedMetal salts

The invention discloses an iron oxide-nitrogen doped carbon micro-tube composite wave-absorbing material and a preparation method thereof. The preparation method comprises the following steps that S1)metal salt containing M ions and iron ions is dissolved in deionized water, and ultrasonic treatment is conducted after uniform stirring, with the M ions being one or more of Cu<2+>, Ni<2+>, Co<2+>,Mn<2+>, Zn<2+> and Fe<2+>; S2) melamine foam is placed in the metal salt solution in the step S1, and the melamine foam ultrasonically adsorbs the metal salt solution; and S3) the melamine foam adsorbing the metal salt is naturally dried, then put into a tubular furnace, and calcined in a mixed atmosphere containing inert gas and oxygen. The iron oxide-nitrogen doped carbon micro-tube composite wave-absorbing material prepared has excellent wave-absorbing performance, and has a good application prospect in the field of electromagnetic wave absorbing materials.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com