Novel preparation and continuous production method of melamine resin

A melamine and resin technology, applied in the field of melamine resin preparation, can solve the problems of impossible use of resin, easy to thicken and agglomerate, poor stability, etc., and achieve the effect of promoting fusion and collision, not easy to thicken and agglomerate, and stable in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

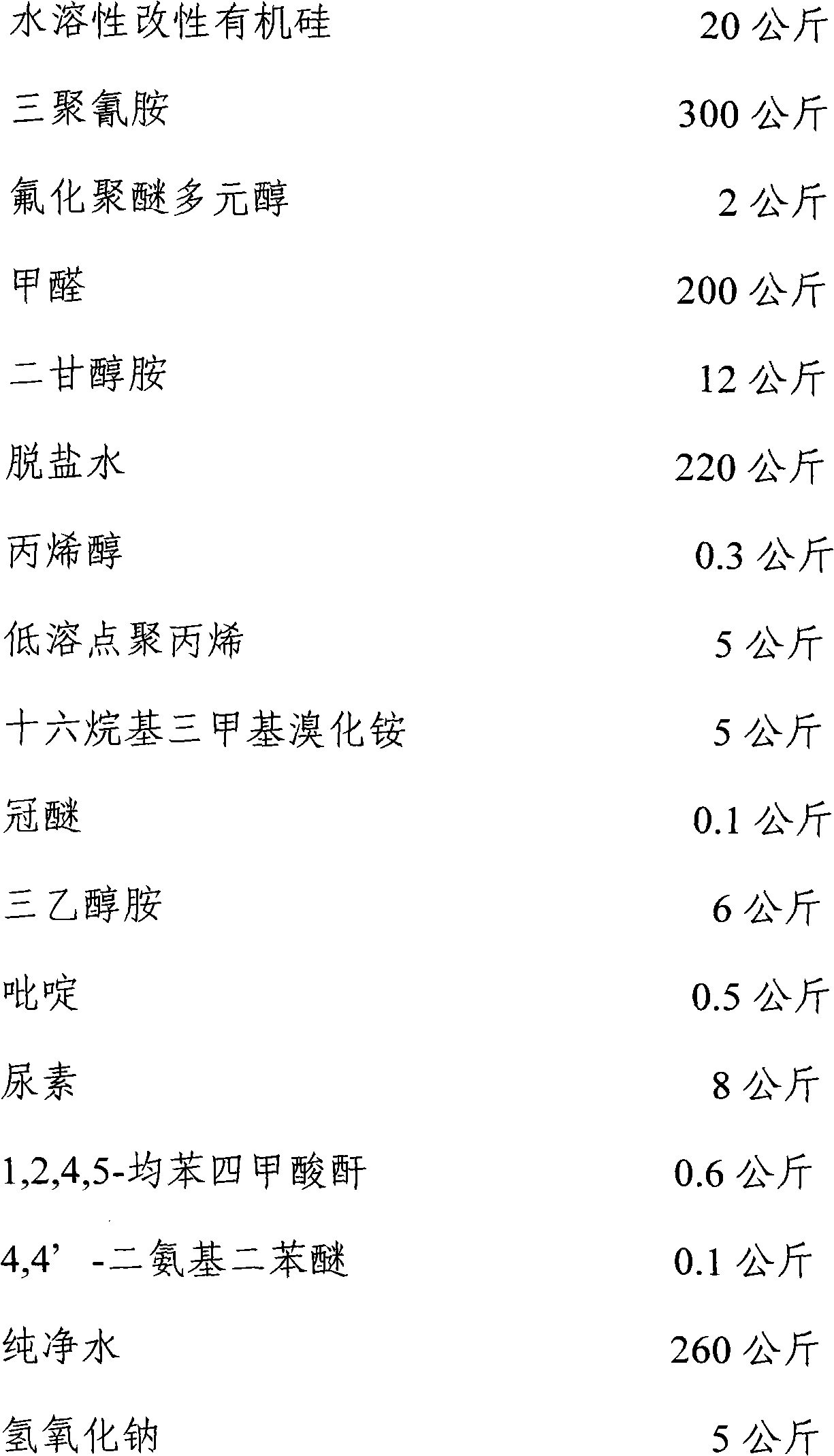

Embodiment 1

[0015]

[0016] Mix the above raw materials, add the raw materials according to the weight ratio into the mixing kettle, and stir evenly. After the feeding is completed, open the mixing tank and stir to 120rpm. The stirring time is 15 minutes, then open the feeding valve of the mixing tank, and use the gear metering pump to quantitatively transport the resin into the heating screw machine. The gear metering pump delivers quantitatively at 2.6 kg per minute. The premixed material is heated to 110°C in the heating screw machine, and the speed of the heating screw machine is set at 160rpm at the same time. Under the action of electric heating in the screw, the reaction material is continuously and stably heated, reacts quickly, and enters the cooling screw machine after 15 minutes. The rotating speed of the cooling screw machine is set at 160 rpm, the temperature of the cooling circulating fluid of the cooling screw machine is -17° C., the melamine resin is cooled to 22° C., an...

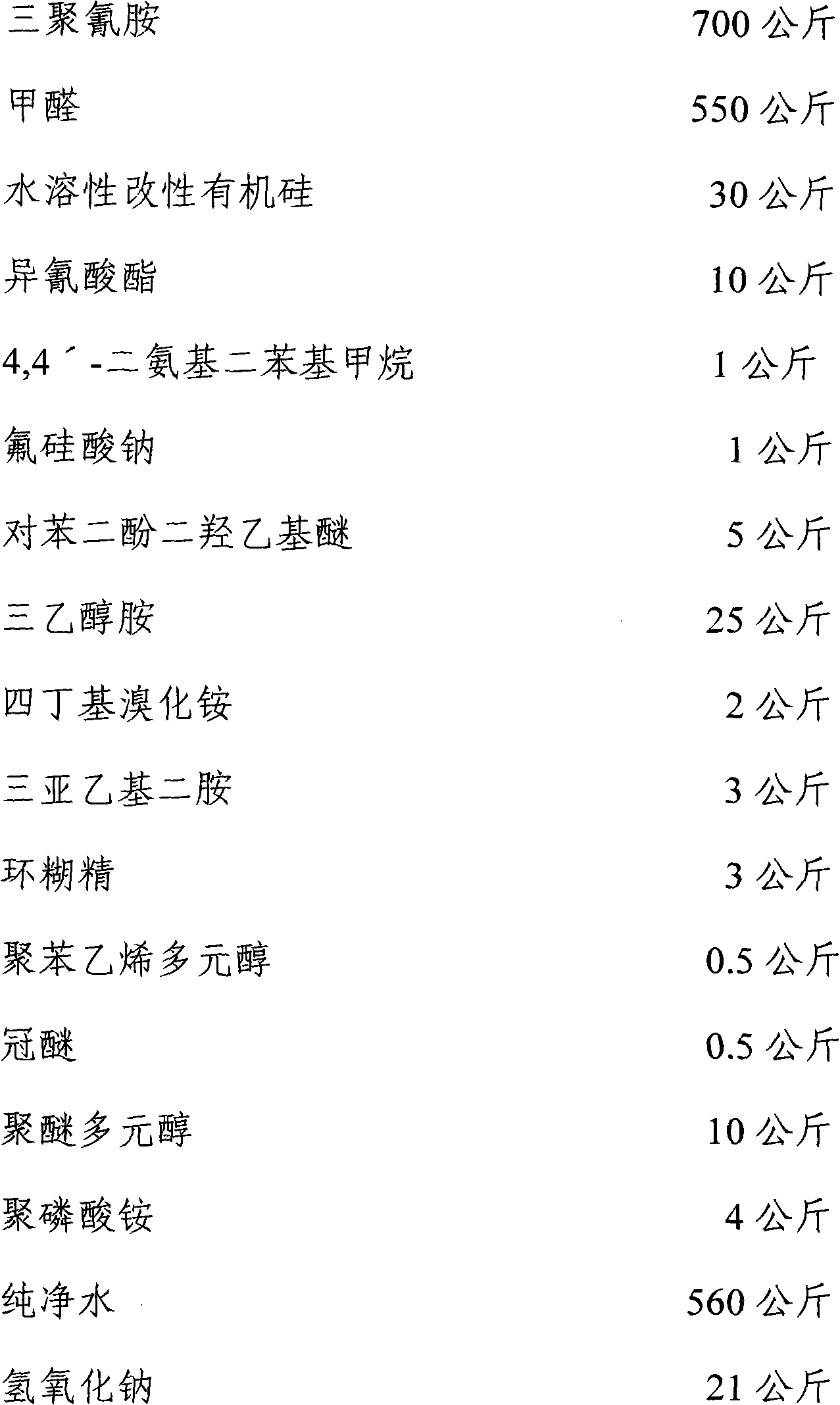

Embodiment 2

[0018]

[0019] Mix the above raw materials, add the raw materials according to the weight ratio into the mixing kettle, and stir evenly. After the feeding is completed, open the mixing tank and stir to 100rpm. The stirring time is 12 minutes, then open the feeding valve of the mixing tank, and use the gear metering pump to quantitatively transport the resin into the heating screw machine. The gear metering pump is quantitatively delivering at 2.2 kg per minute. The premixed material is heated to 106°C in the heating screw machine, and the speed of the heating screw machine is set at 156rpm at the same time. Under the action of electric heating in the screw, the reaction material is continuously and stably heated, reacts quickly, and enters the cooling screw machine after 16 minutes. The rotating speed of the cooling screw machine is set at 130 rpm, the temperature of the cooling circulating fluid of the cooling screw machine is -19° C., the melamine resin is cooled to 30° C...

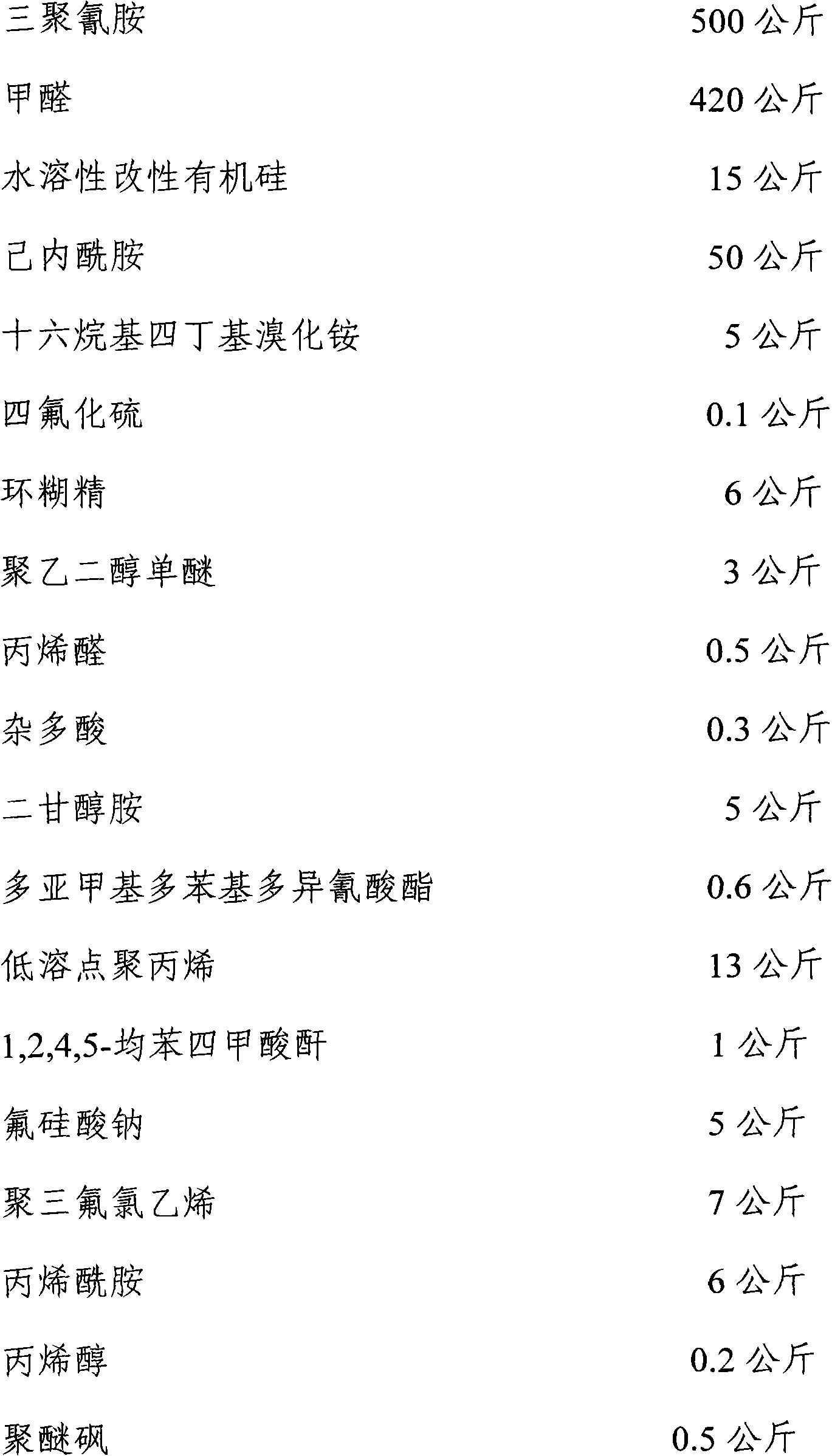

Embodiment 3

[0021]

[0022]

[0023] Mix the above raw materials, add the raw materials according to the weight ratio into the mixing kettle, and stir evenly. After the feeding is completed, open the mixing tank and stir to 109rpm. The stirring time is 14 minutes, then open the feeding valve of the mixing tank, and use the gear metering pump to quantitatively transport the resin into the heating screw machine. The gear metering pump quantitatively delivers 2.9 kg per minute. The premixed material is heated to 90°C in the heating screw machine, and the speed of the heating screw machine is set at 136rpm at the same time. Under the action of electric heating in the screw, the reaction material is continuously and stably heated, reacts quickly, and enters the cooling screw machine after 10 minutes. The rotation speed of the cooling screw machine is set at 110 rpm, the temperature of the cooling circulating fluid of the cooling screw machine is -12° C., the melamine resin is cooled to 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com