Patents

Literature

2037 results about "Melamine resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

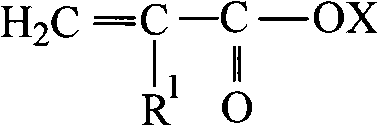

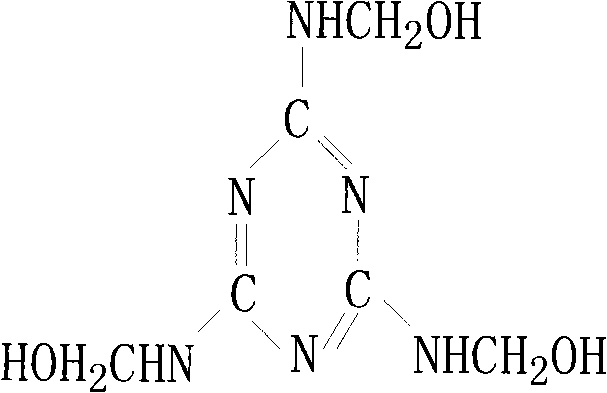

Melamine resin or melamine formaldehyde (also shortened to melamine) is a resin with melamine rings terminated with multiple hydroxyl groups derived from formaldehyde. This thermosetting plastic material is made from melamine and formaldehyde. In its butylated form, it is dissolved in n-butanol and xylene. It is then used to cross-link with alkyd, epoxy, acrylic, and polyester resins, used in surface coatings. There are many types, varying from very slow to very fast curing.

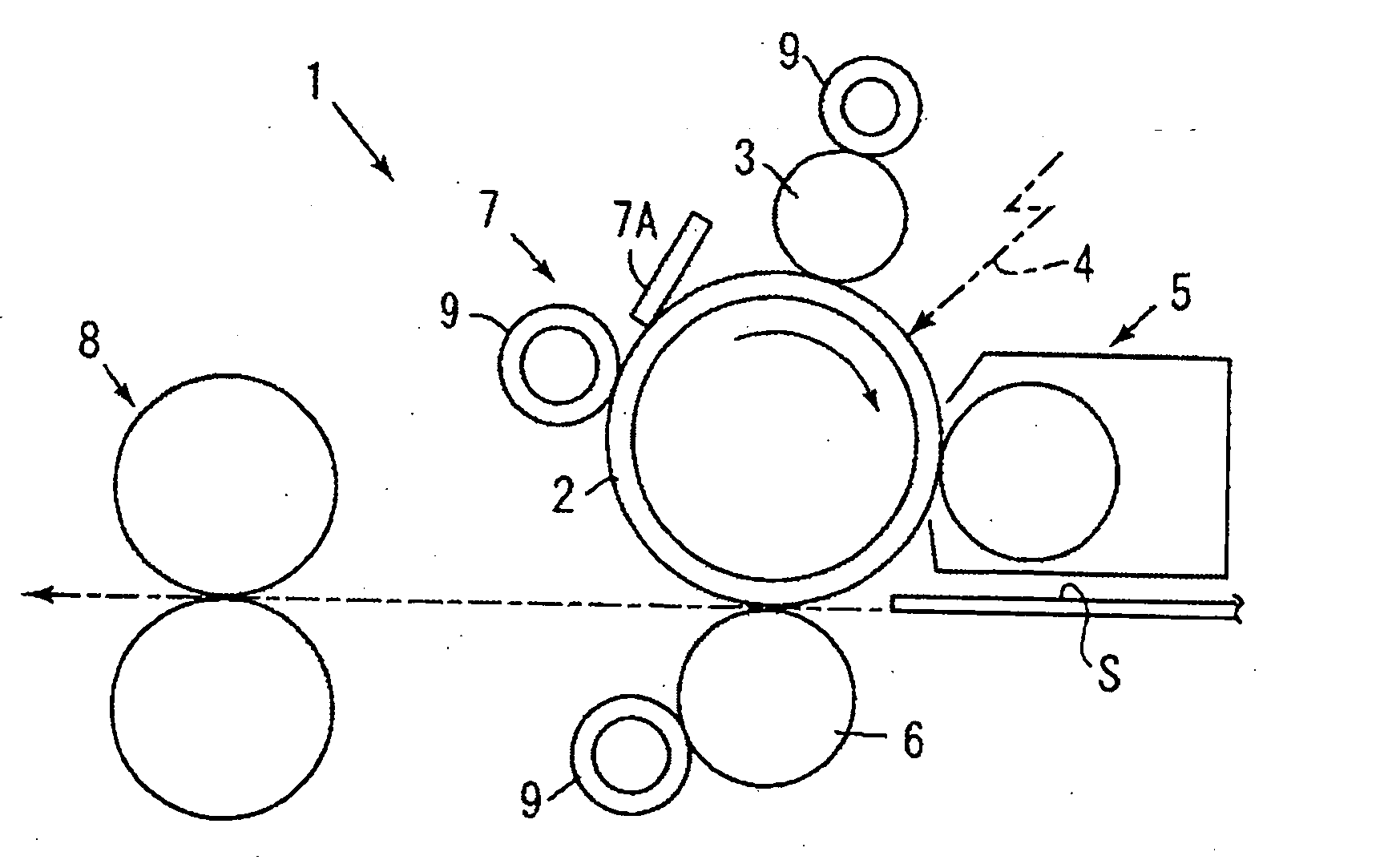

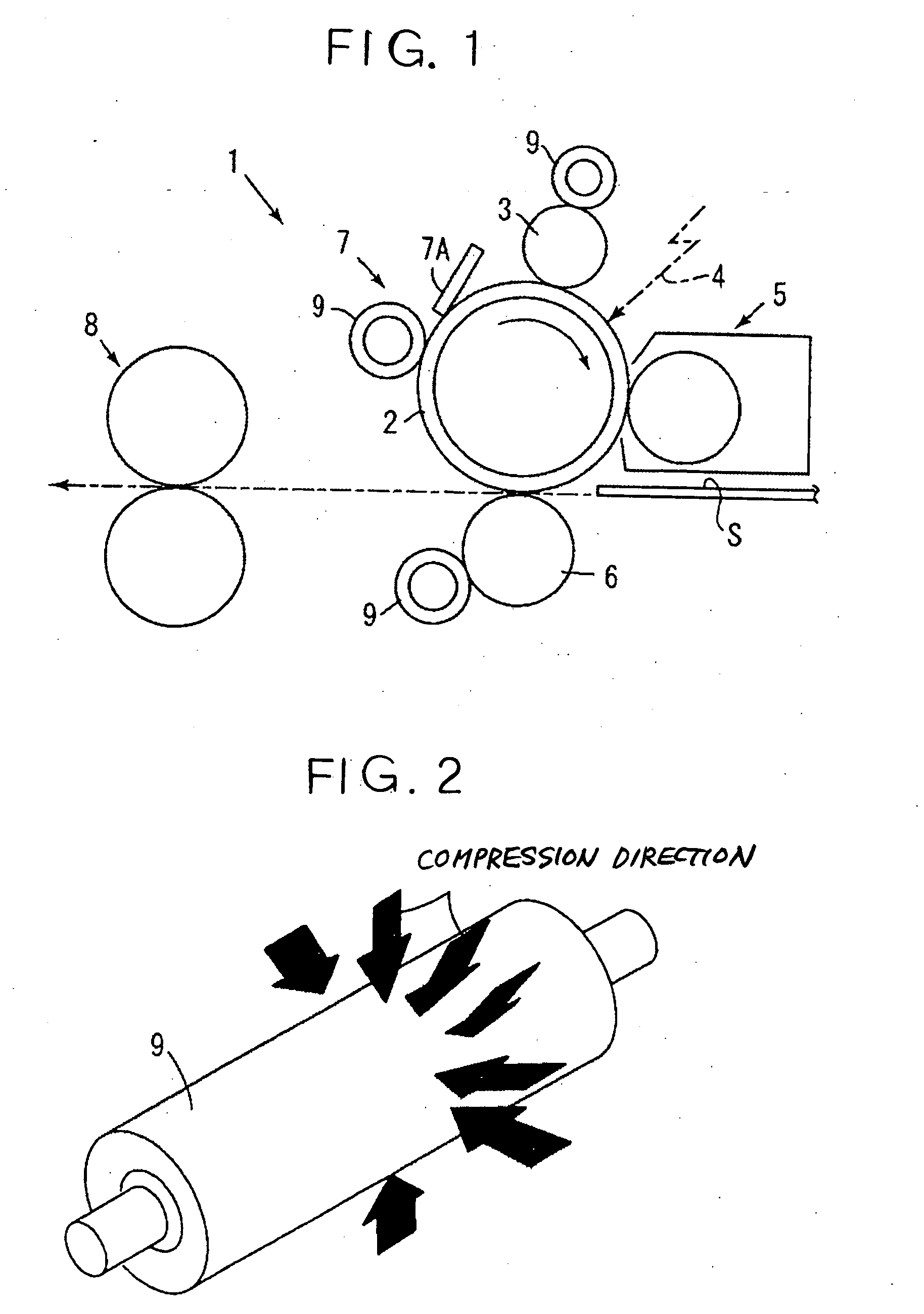

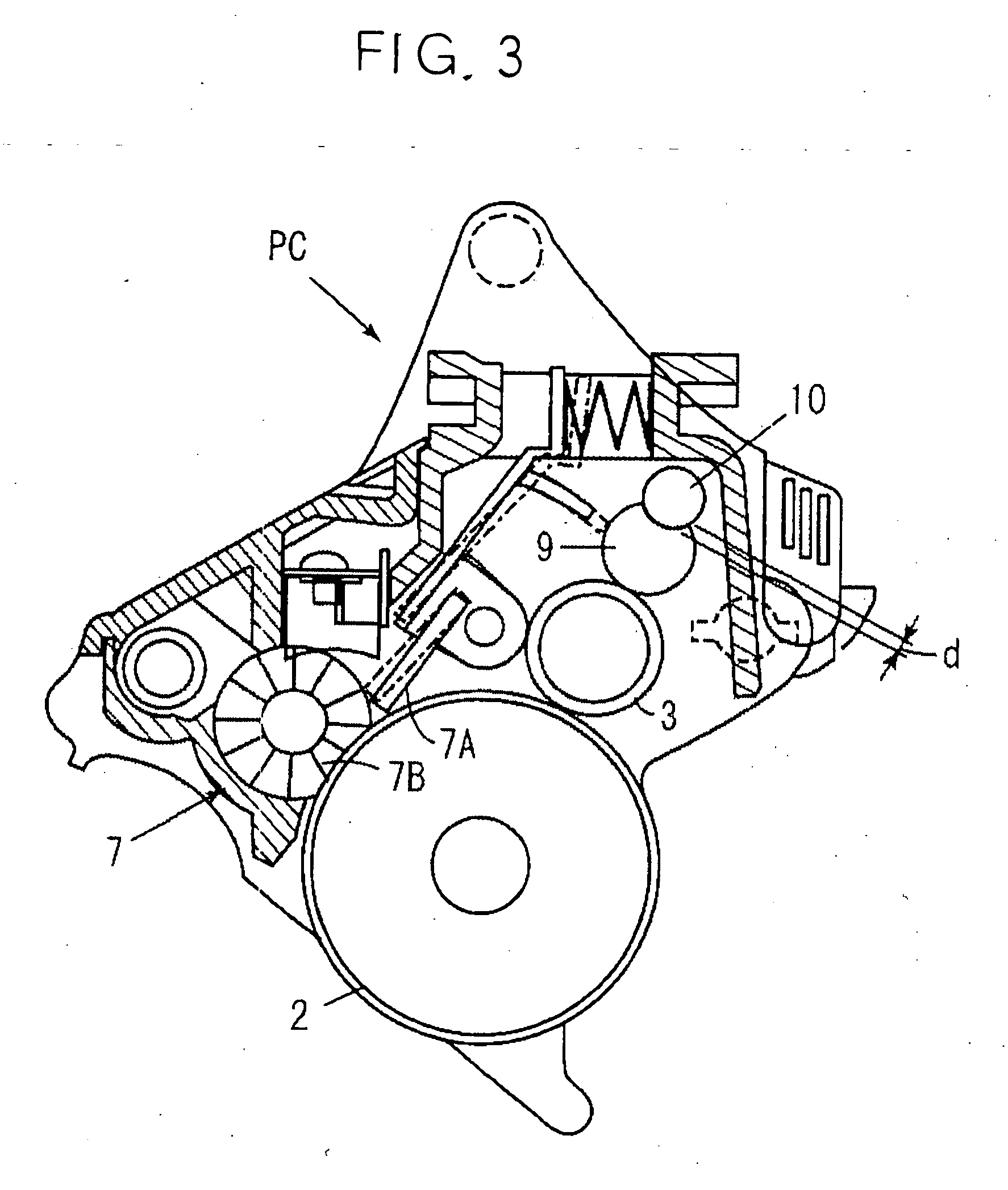

Charged device, cleaning device, process cartridge, toner, and image-forming device that uses these

ActiveUS20050191081A1Increase costReduce image qualityElectrographic process apparatusCorona dischargeForeign matterImaging quality

There is provided a cleaning device for an image-forming device configured so as to be capable of preventing the image quality from deteriorating by being able to prevent the deterioration of the charging state caused by deposits of foreign matter without increasing costs. There is also provided a cleaning member that can make contact with the cleaning target-members. The cleaning member has a portion composed of melamine resin foam for making contact with at least the cleaning target members, and the melamine resin foam has an Asker F hardness of 5 to 25 points and a hardness variation of 5 points or less, and is used on the cleaning target members in a state obtained by heat compression from the original shape. The pressing member is furthermore disposed in contact with the cleaning member.

Owner:RICOH KK

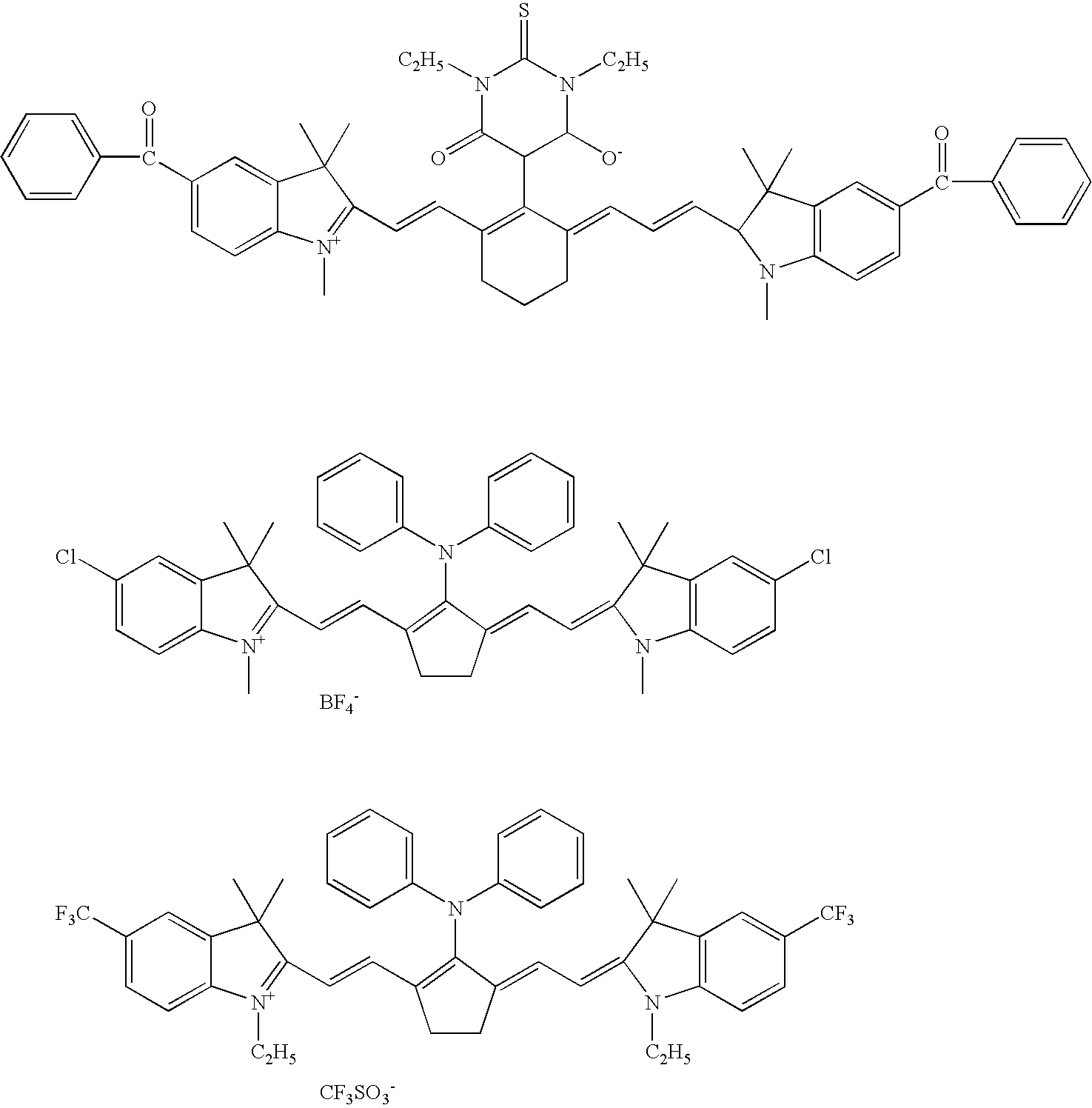

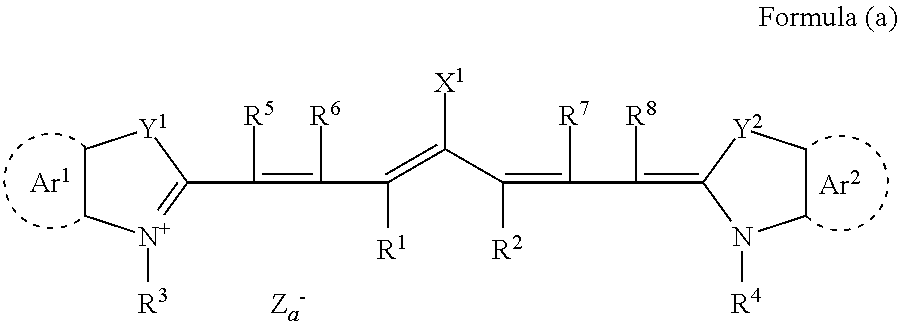

Method for preparing photochromic micro-encapsulation

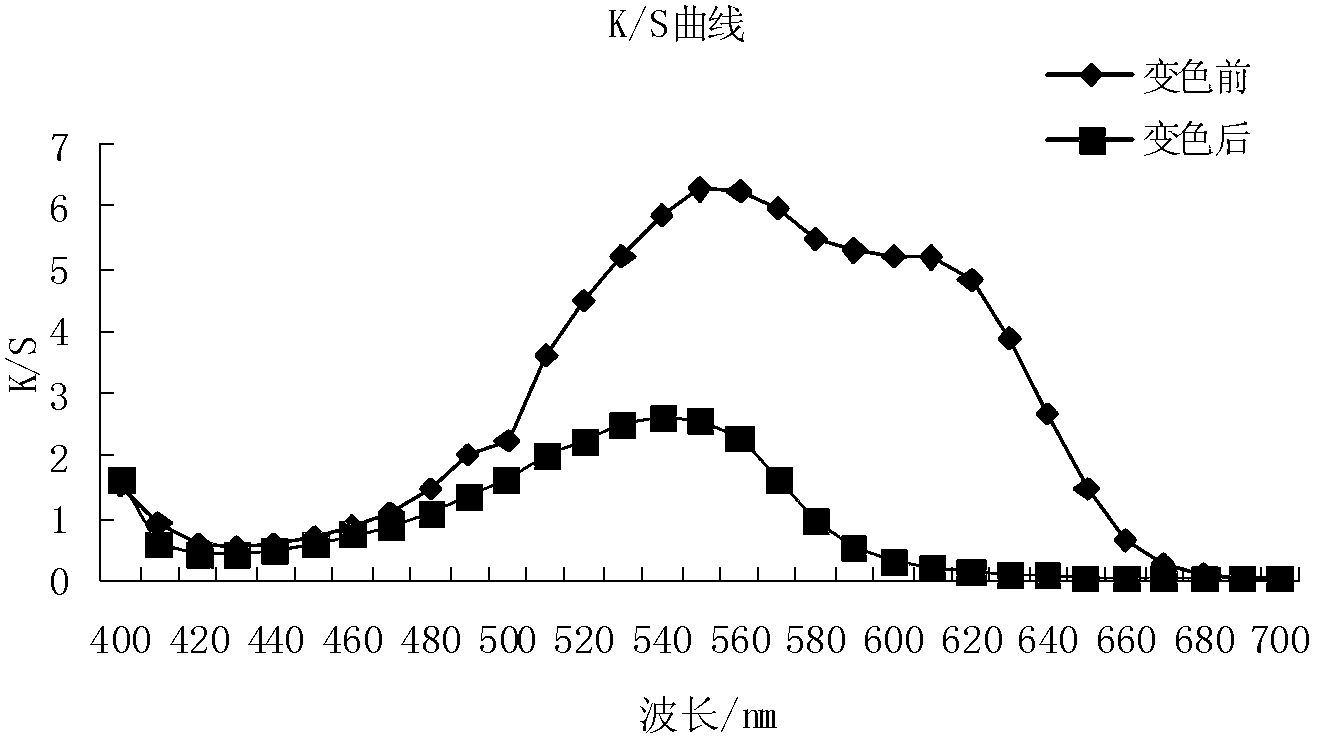

InactiveCN101225296AWith fast and reversible color performanceLess volatileTenebresent compositionsMicroballoon preparationOrganic solventEmulsion

The invention relates to a preparation method for a photochromic micro encapsulant, belonging to technical field of functional macromolecular materials, which comprises following steps: dissolving the photochromic micro encapsulant in organic solvent to obtain photochromic solution; completely dissolving emulsifier, adding the photochromic solution, then emulsion is obtained after the emulsification of mixed solution; adding melamine resin prepolymer in emulsion; adjusting the pH value 3 to 6; adding dispersing agent, then the photochromic micro encapsulant is obtained through cleaning and drying. The preparation method for the photochromic micro encapsulant has the advantages of ability to greatly reduced harm to the health of human body and environmental pollution, simple operation process, improved acid and alkaline resistance and fatigue resistance of chromic material, prolonged service life, good photochromic properties and fast discoloration and decoloration of the prepared micro encapsulant, and wide application prospect in anti-counterfeit and textile field.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

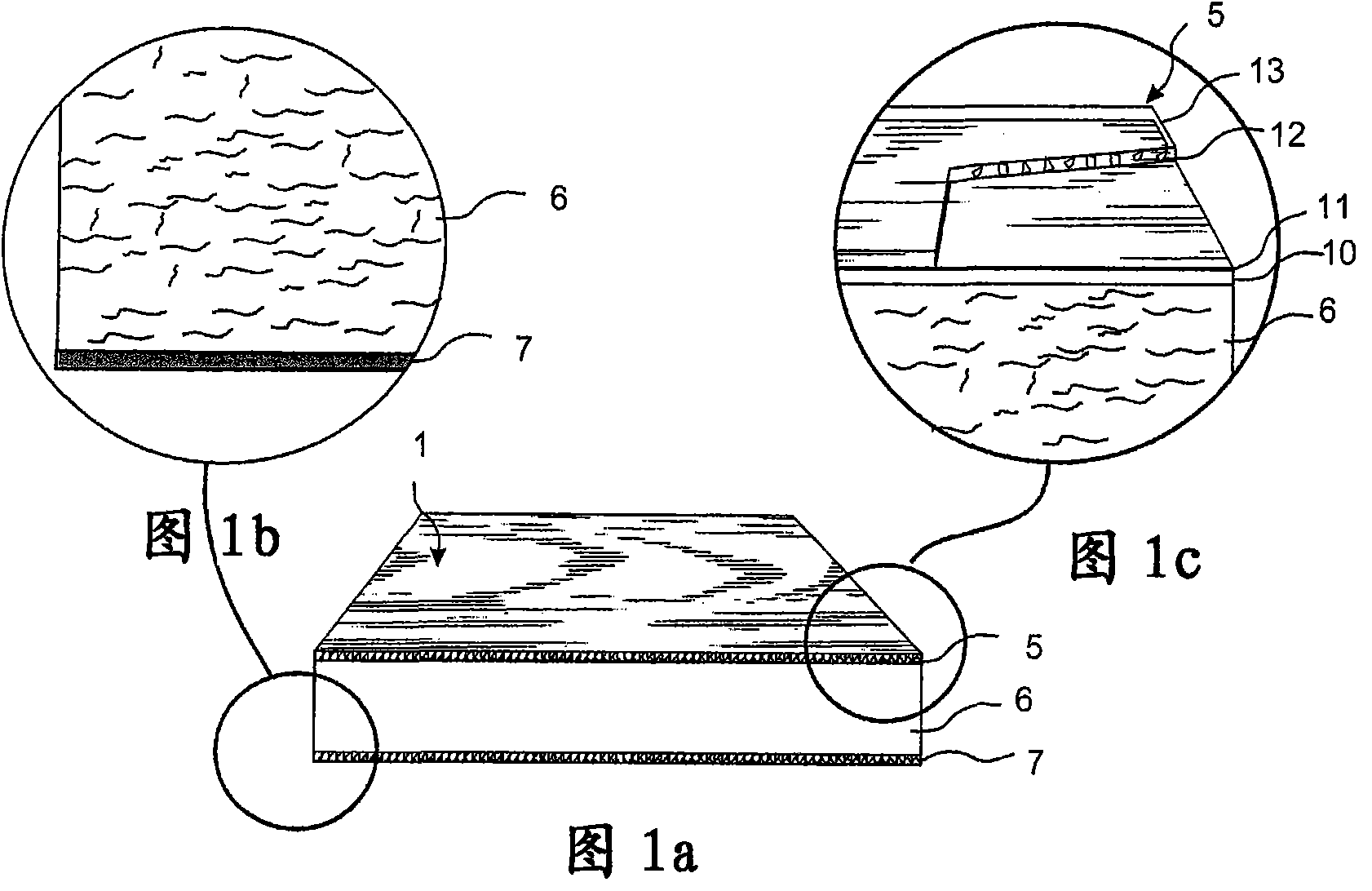

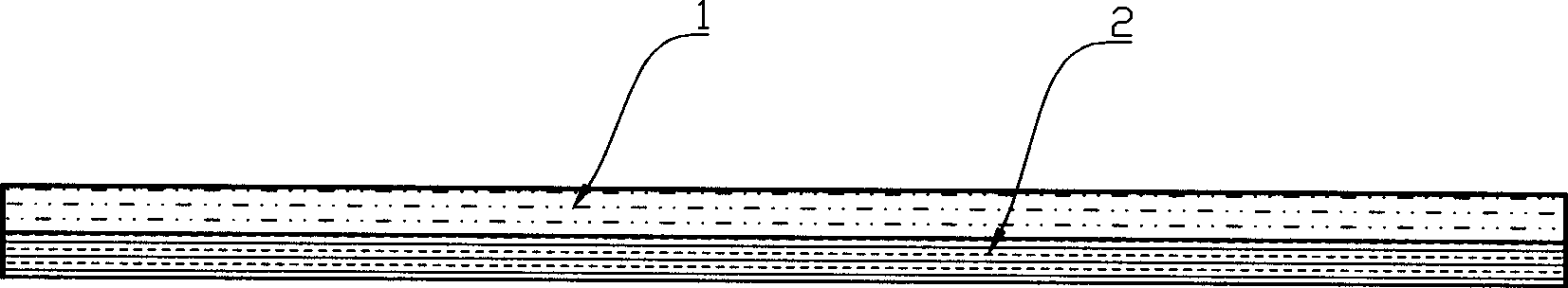

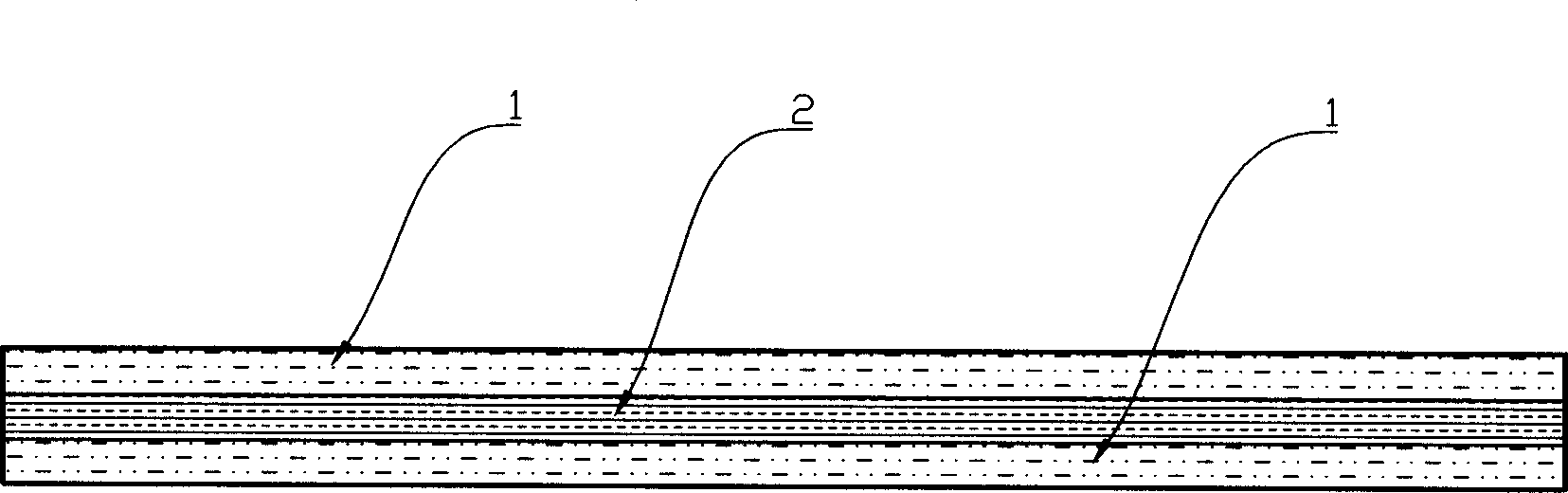

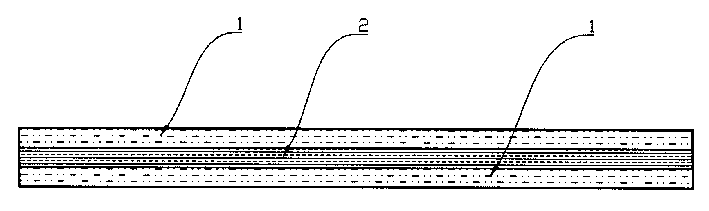

Fibre based panels with a wear resistance surface

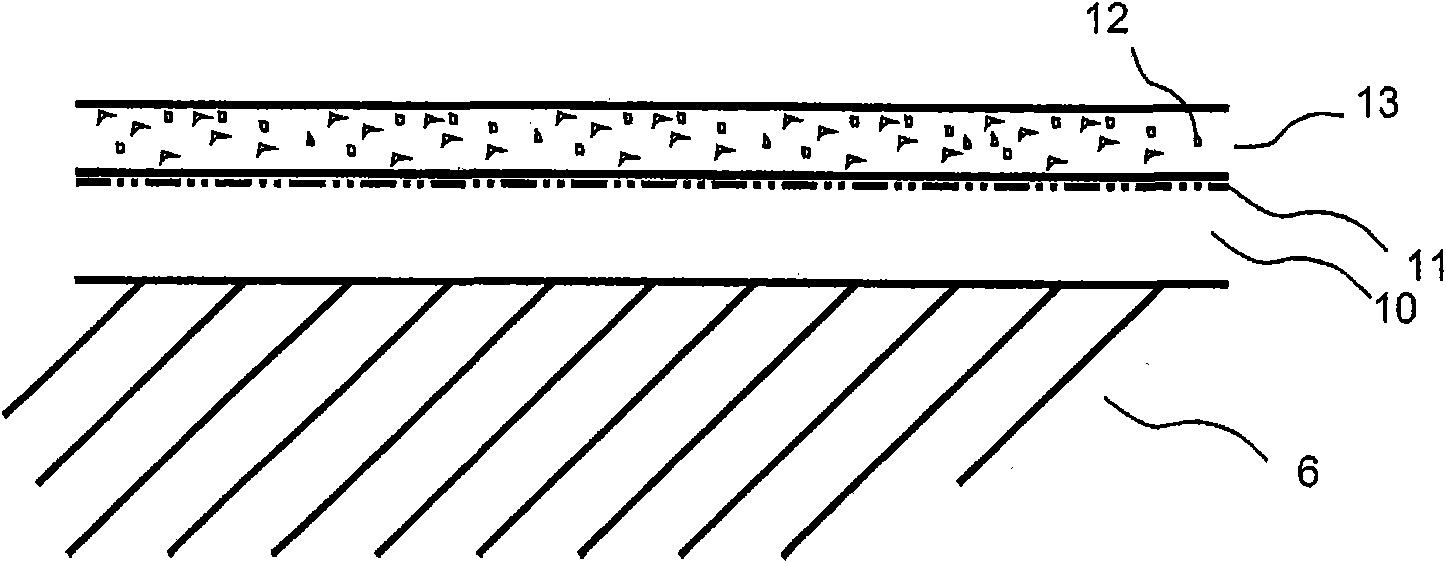

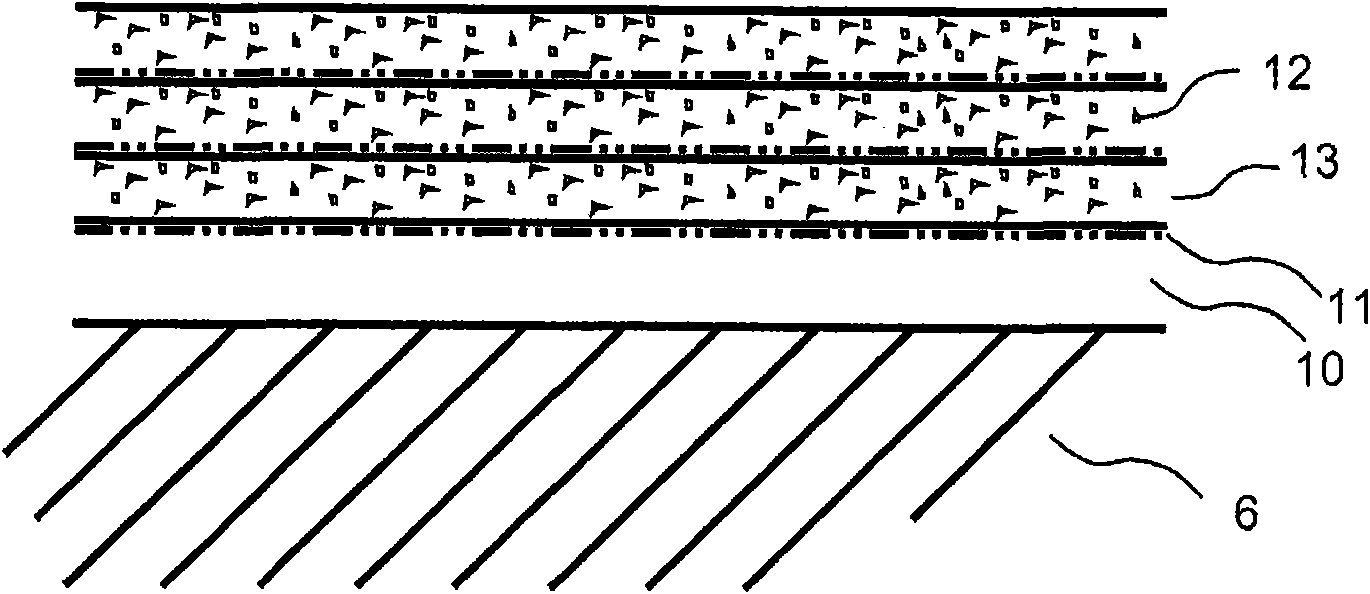

ActiveCN101909836AImprove wear resistanceImprove impact resistanceCovering/liningsSpecial ornamental structuresSurface layerWear resistant

A flooring panel (1) comprising a core (6) and a surface layer (5), the surface layer (5) comprising cork particles (14) or wood fibres (14) comprising lignin resin, melamine resin as binder (19), colour pigments (15), and aluminium oxide as wear resistant particles (12), all components being homogenously mixed, and the core (6) comprising fibres and binder and being provided with a mechanical locking system (4) at its edges and a rear balancing layer (7). Also disclosed is a method of manufacturing said flooring panel by - homogenously mixing the dry particles of the surface layer; - scattering them on an embossed pressure matrix; - applying the core layer as scattered or prefabricated layer on the surface layer; - applying a balancing layer as scattered or prefabricated layer on the core layer; - pre-pressing the panel; - printing and brusching the surface layer; - forming the panel by a further pressing and heating step; - machining the mechanical locking system.

Owner:VÄLINGE INNOVATION AB

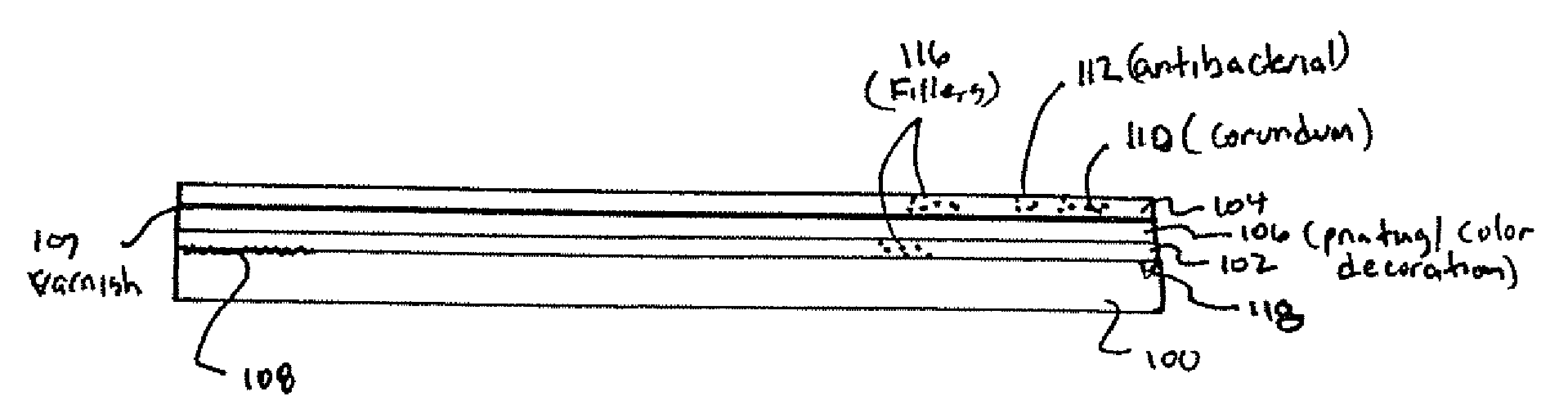

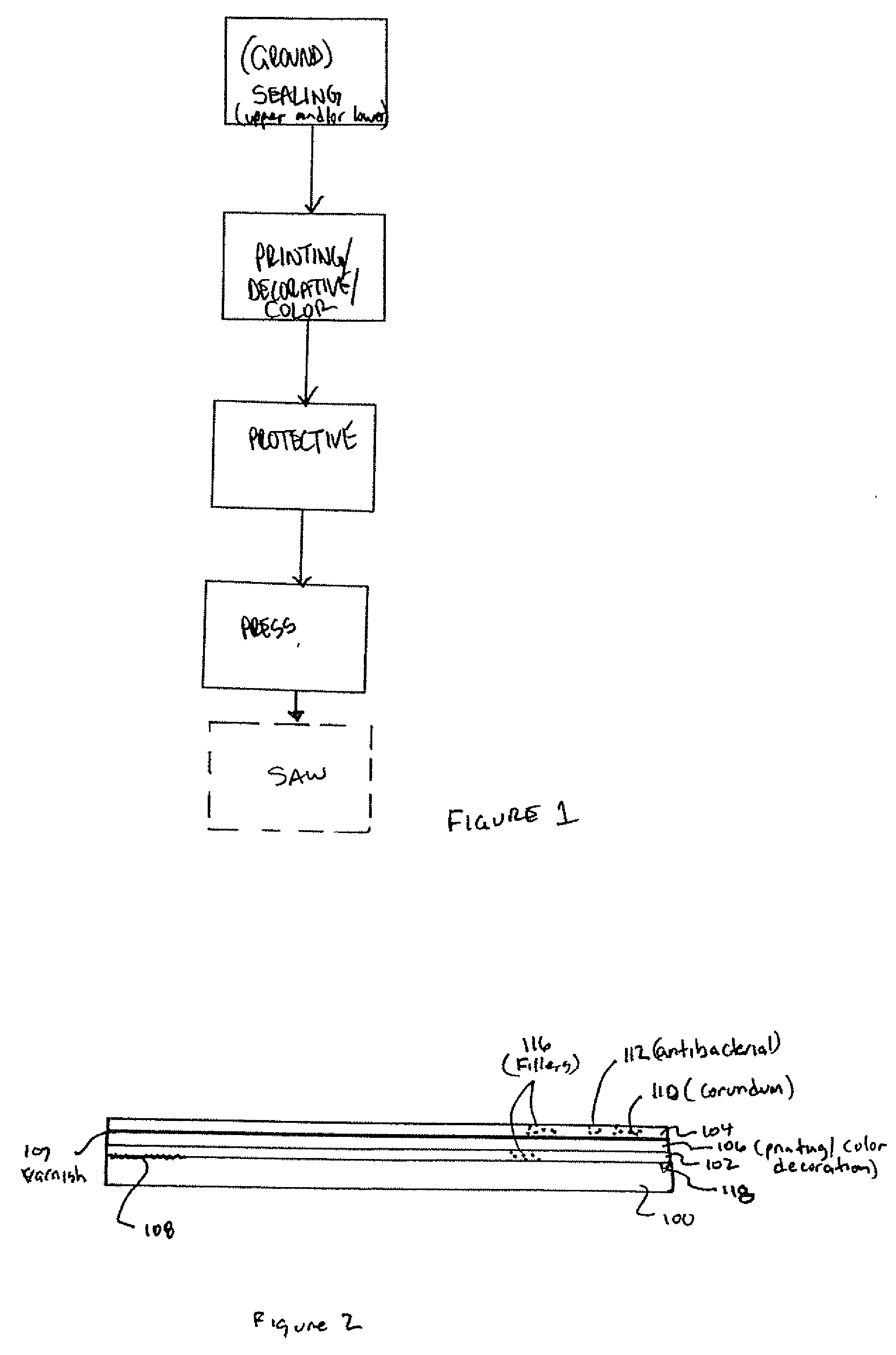

Process for finishing a wooden board and wooden board produced by the process

ActiveUS20060182938A1Synthetic resin layered productsCellulosic plastic layered productsEngineeringMelamine

A process for finishing a wood or wooden board, in particular an MDF or HDF board, with an upper side and an underside. The process includes applying a sealing layer of melamine resin to the upper side of the board and printing a decoration onto the sealing layer. A protective layer is applied of melamine resin to the decoration and the board is pressed under the action of temperature until the protective layer and the sealing layer melt and bond to each other with the inclusion of the decoration printed on.

Owner:FLOORING TECH

Thermo-sensitive discoloration material microcapsule and preparation method thereof

InactiveCN102477290AGood chemical stabilityGood solvent resistanceTenebresent compositionsMicroballoon preparationEmulsionChange color

The invention discloses a thermo-sensitive discoloration material microcapsule and a preparation method thereof. The microcapsule is composed of a core material and a wall material for covering the core material, wherein the core material comprises a thermo-sensitive discoloration compound composed of a chromogenic reagent, a color-developing agent and a solvent; the wall material is a melamine resin pre-polymer; the mass ratio of the thermo-sensitive discoloration compound to the melamine resin pre-polymer is 1:(1-2). The preparation method comprises the following steps of: mixing the chromogenic reagent, the color-developing agent and the solvent to form a thermo-sensitive discoloration solution under the heating condition; adding an emulsifying agent solution into the thermo-sensitive discoloration solution and emulsifying a commixed solution to obtain an emulsion; adjusting the pH value to 3-6 and adding the melamine resin pre-polymer into the emulsion; reacting at a temperature for 60-70 DEG C for 1-1.5 hours and then cooling to 30-40 DEG C; then adding a dispersant; and washing and drying to obtain the thermo-sensitive discoloration microcapsule. According to the method provided by the invention, the influences on human bodies and environments are greatly reduced; the operation is simple, the prepared microcapsule products can fast change color and fade and the effect is obvious, so that the thermo-sensitive discoloration material microcapsule can be widely applied in the fields of anti-counterfeiting textile and printing and the like.

Owner:BEIJING CTA TEX CHEM

Planographic printing plate precursor and pile of planographic printing plate precursors

ActiveUS8105751B2Desorption of the fine particles is preventedHigh affinityPhotosensitive materialsSemiconductor/solid-state device manufacturingEpoxyPolystyrene

Owner:FUJIFILM CORP

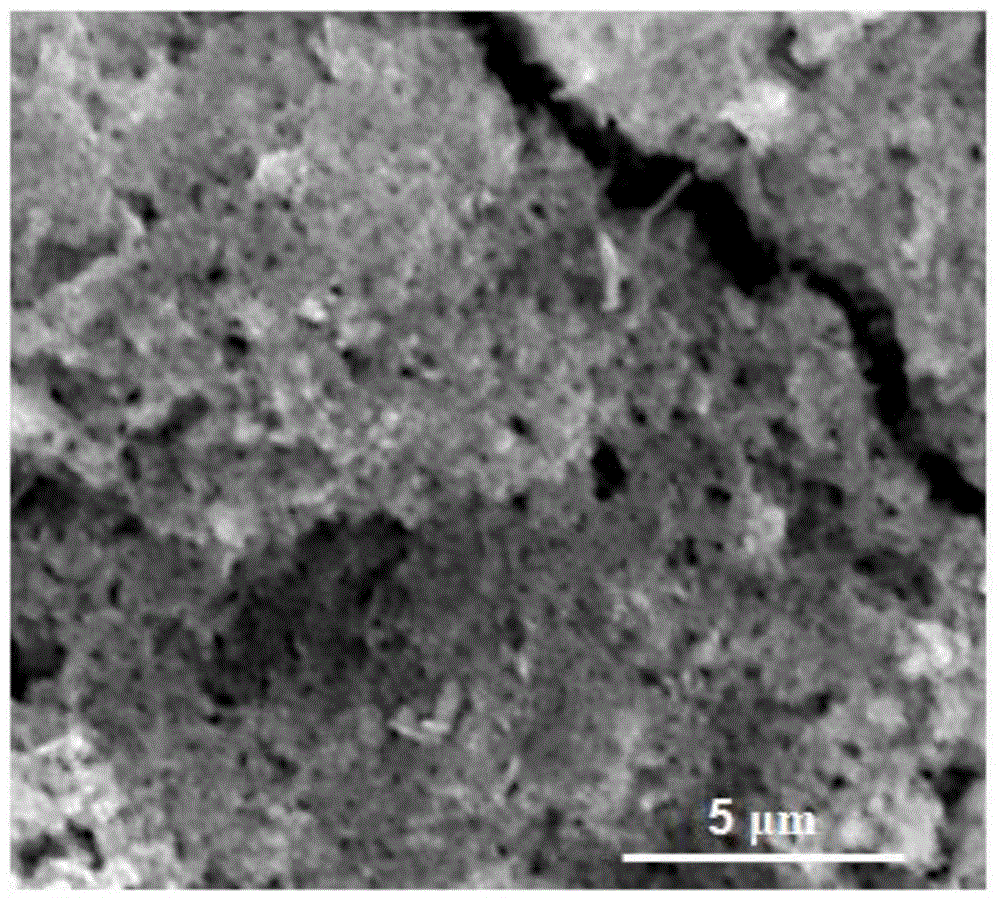

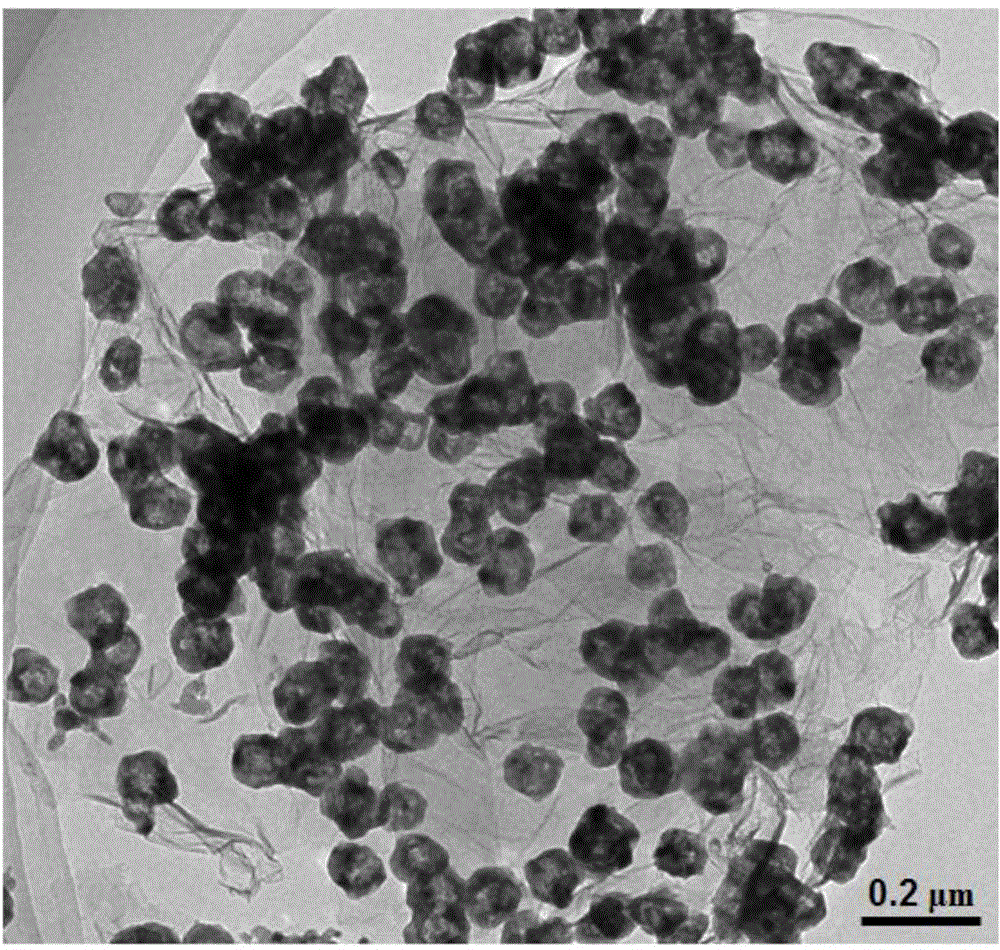

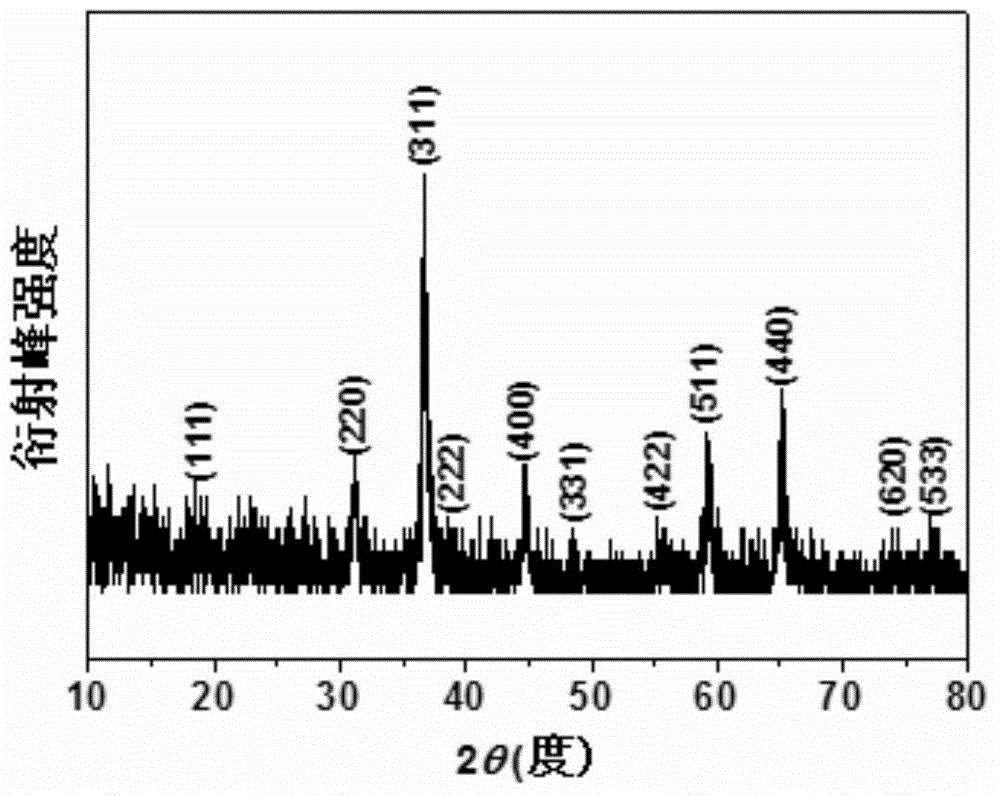

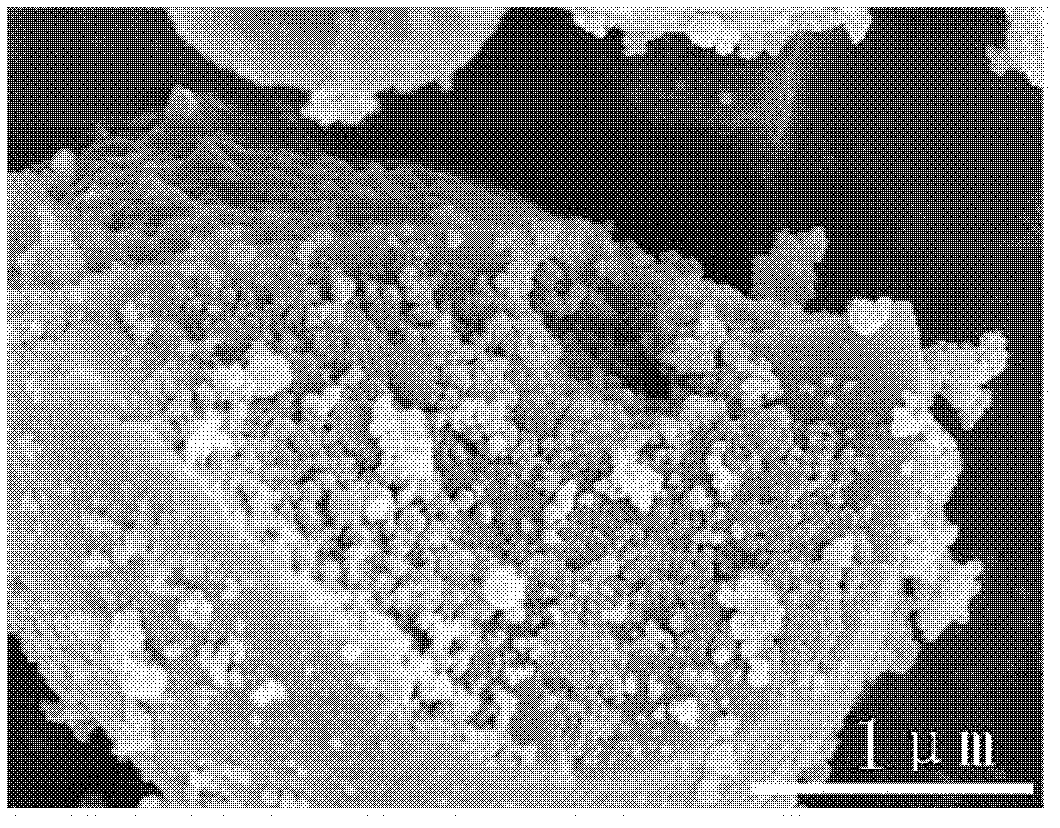

Nitrogen-doped graphene and Co3O4 hollow nanosphere composite material as well as preparation method and application of composite material

ActiveCN104681823AImprove conductivityLarge specific surface areaMaterial nanotechnologyPhysical/chemical process catalystsDoped grapheneNitrogen doped graphene

The invention relates to a novel composite material, and particularly relates to a preparation method and application of a nitrogen-doped graphene and cobaltosic oxide hollow nanosphere composite material. The novel composite material comprises a doped graphene substrate and cobaltosic oxide hollow nanospheres which is attached to the surface of the doped graphene substrate. Melamine resin is taken as a cross-linking reagent for integrating graphite oxide with Co<2+> into a single coordination precursor. The preparation method comprises the following steps: in a pyrolysis process of the precursor, taking the melamine resin as a new nitrogen source to uniformly dope the graphene with nitrogen, fixing cobalt oxide which is generated in situ, and finally preparing the nitrogen-doped graphene / Co3O4 hollow nanosphere composite material with a sandwich structure. The composite material has a graded porous structure, is high in specific surface area, more in active sties, good in electron conductivity and ion conductivity, and good in application prospect in the field of new energy resources and catalysis.

Owner:CHINA WEST NORMAL UNIVERSITY

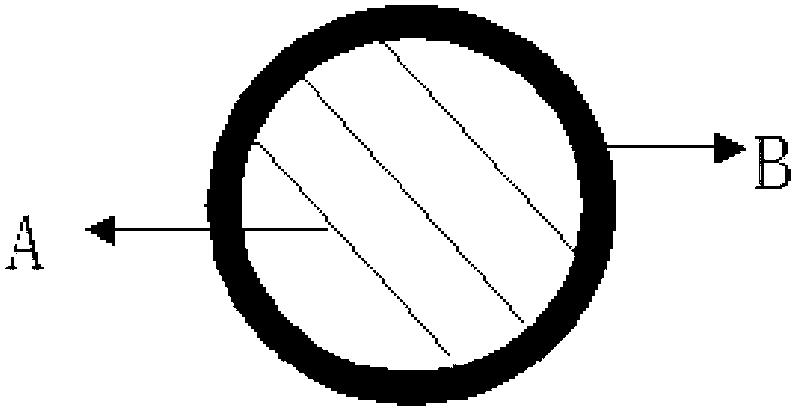

Double layer capacitor and its manufacturing method

InactiveUS6341057B1Optimisation of viscosityIncrease capacitanceHybrid capacitor electrodesLiquid electrolytic capacitorsConductive coatingEngineering

A double layer capacitor and a method for producing the same wherein the double layer capacitor comprises a conductive coating based on binders of the melamine resin type such that the conductive coating is present at the interfaces between the current collectors and the electrodes. The double layer capacitor thus produced has good mechanical and chemical integrity and flexibility and is suitable for use in combination with batteries.

Owner:DANIONICS INTERNATIONAL AS

High-brightness wear-resistant decorative sticky membrane paper and preparation method thereof

ActiveCN103147346AHigh glossPollution resistantNon-fibrous pulp additionPaper coatingWear resistantHardness

The invention belongs to the technical field of building and ornament materials, relates to sticky membrane paper, and in particular relates to high-brightness wear-resistant decorative sticky membrane paper and a preparation method thereof. The preparation method of the high-brightness wear-resistant decorative sticky membrane paper comprises the steps: firstly placing the decorative paper in urea formaldehyde resin solution for steeping in a steeping area, then spraying a melamine resin solution and wear-resistant material mixed liquor in a spraying area, coating melamine resin solution in a coating area, and drying to obtain the high-brightness wear-resistant decorative sticky membrane paper. For the traditional laminate flooring, wear-resistant paper and decorative paper are attached to the surface of a floor substrate, the high-brightness wear-resistant decorative sticky membrane paper is prepared by evenly coating the urea formaldehyde resin solution on the surface of the decorative paper, spraying the melamine resin and wear-resistant material mixed solution and coating the melamine resin solution through the steeping, spraying and coating techniques, the wear-resistant paper and the decorative paper are combined into one, one procedure is reduced in the attaching process of the floor, the cost can be lowered, the equipment loss can be lightened, the surface of the product has the characteristics of being large in hardness, wear-resistant, high in brightness, high in clearness and the like.

Owner:DARE WOOD BASED PANEL GRP

High temperature resistant type phase-change material micro-capsule and preparation thereof

InactiveCN101376800AImprove thermal stabilityLow thermal weight lossHeat-exchange elementsMicroballoon preparationMelamine formaldehydeHeat resistance

The invention relates to a high-temperature resistant phase-change material microcapsule and a preparation method thereof which belong to the technical field of compound materials. The invention needs to solve the technical problem of providing a high-temperature resistant phase-change material microcapsule in the field of melt spinning; the components thereof counted according to weight portions include 100 portions of core phase-change material, 7 to 12 portions of dispersant, 2 to 5 portions of emulsifying agent as well as a wall material prepared by 0.3 to 0.6 portion of modified monomer and 30 to 50 portions of melamine resin. The preparation method of the high-temperature resistant phase-change material microcapsule includes the emulsification of the core, the preparation of the prepolymer of the wall material, the preparation of the microcapsule and the removing of free formaldehyde. The high-temperature resistant phase-change material microcapsule has higher heat stability, heat-resistance as well as uniform grain sizes and can meet the requirements of spinning fibers. The preparation technique is simple, is conveniently operated, can save energies and is environmental friendly; the product is easy for industrialization production and has a better market prospect.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

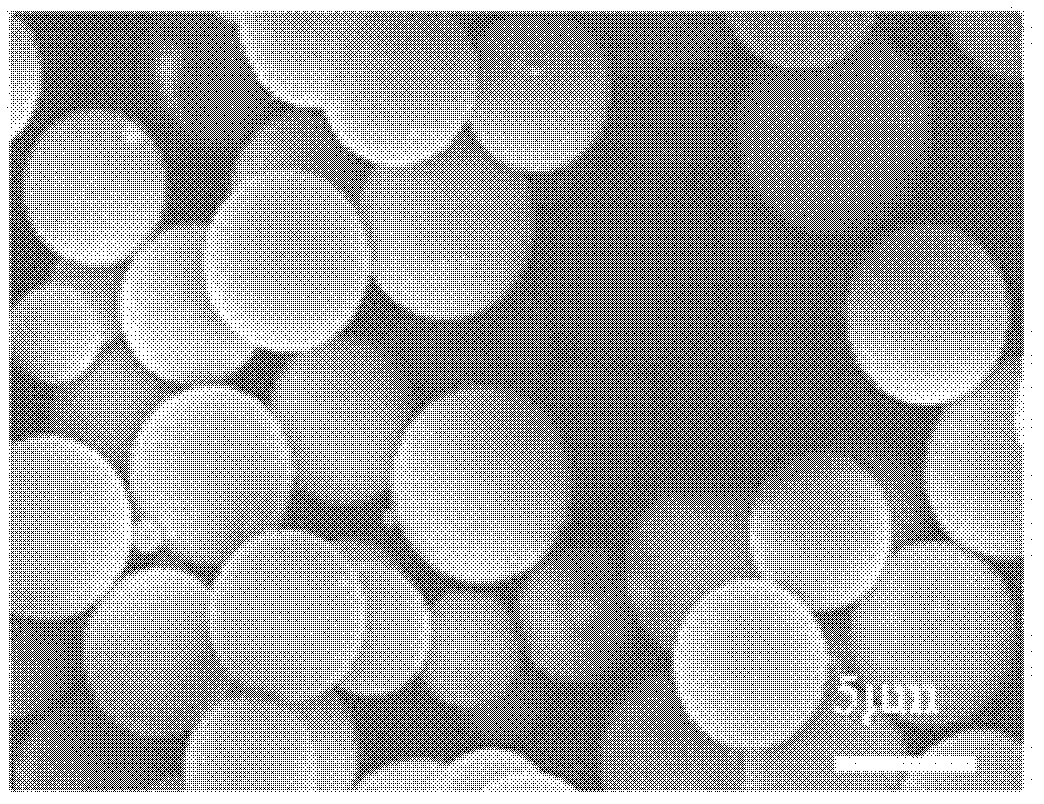

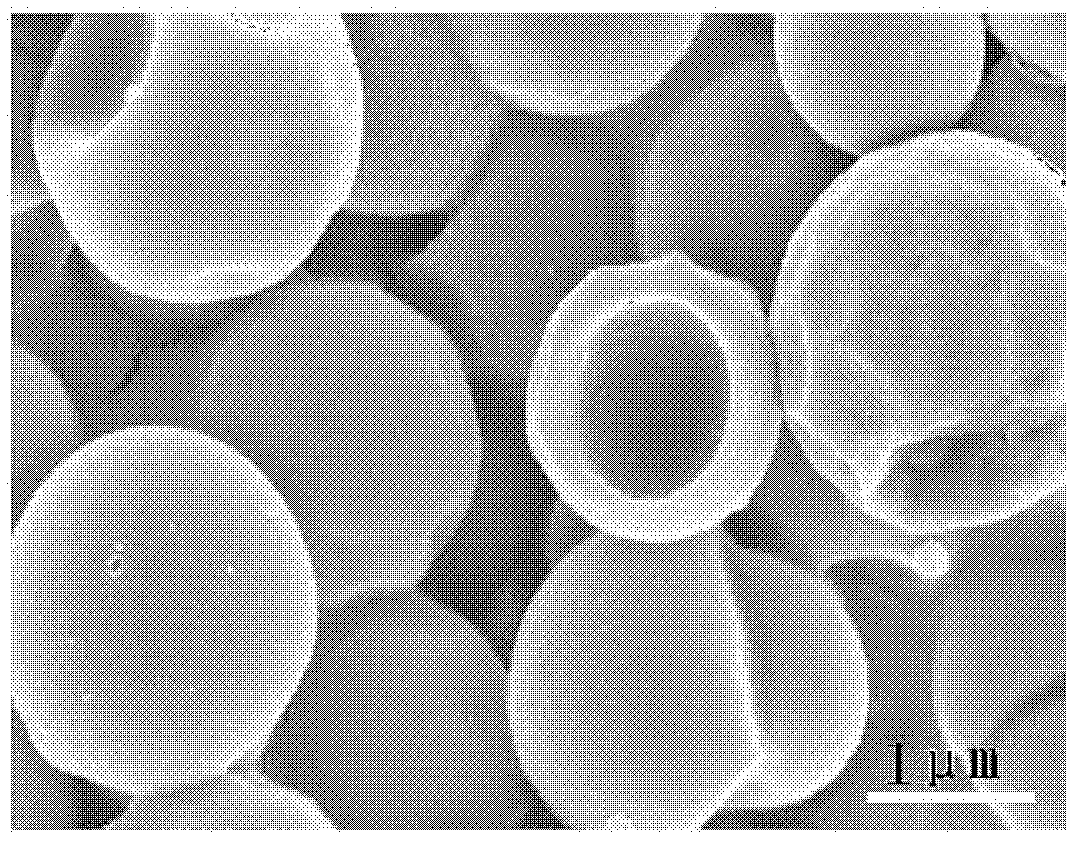

Method for preparing nitrogenous graphitized hollow carbon microspheres

InactiveCN102637533AEasy to makeLow costCarbon compoundsElectrolytic capacitorsSynthesis methodsMicrosphere

The invention relates to a method for preparing nitrogenous graphitized hollow carbon microspheres, which relates to a method for preparing hollow carbon microspheres. The method disclosed by the invention aims to solve the technical problem that in the existing method for preparing nitrogenous graphitized hollow carbon microspheres, because a template agent is utilized, the preparation process is complicated, and the cost is increased. The method comprises the following steps: adding melamine powder and a formaldehyde solution into deionized water, and after heating for reaction, obtaining reaction liquid; then, transferring the reaction liquid into a reaction kettle, and after carrying out hydrothermal reaction on the reaction liquid, obtaining melamine resin microspheres; and putting the melamine resin microspheres into a quartz tube type furnace, and heating the melamine resin microspheres so as to split the melamine resin microspheres, thereby obtaining nitrogenous graphitized hollow carbon microspheres. The average diameter of the nitrogenous graphitized hollow carbon microspheres is 1-5 microns; and by using the method, no template agent and no catalyst are required to be added in the preparation process, the preparation process in a synthesis method is simple, the cost is low, and microspheres are easy to be performed mass production and can be used as electrode materials or carrier materials of active substances of electrodes in the fields of electrochemical super capacitors, lithium ion batteries, fuel cells and the like.

Owner:HEILONGJIANG UNIV

Thermosensitive discoloring energy-storage material and preparation method thereof

InactiveCN102827597AOvercoming the Liquid Leakage Problem of Phase ChangesOvercome the defect of high discoloration temperatureHeat-exchange elementsTenebresent compositionsMelamineStorage material

The invention discloses a thermosensitive discoloring energy-storage material and a preparation method of the thermosensitive discoloring energy-storage material, belonging to the field of functional composite materials. The invention aims at solving the technical problem of forming a thermosensitive discoloring energy-storage microcapsule by using crystal violet lactone as a leuco body, using bisphenol A as a color developing agent, and using the compound of tetradecanol and hexadecanol as a solvent; mixing the leuco body, the color developing agent, the solvent and an appropriate amount of dispersant cationic dyes to form a core material; using a melamine resin formed by formaldehyde-melamine as a wall material; and covering the core material by the wall material. The thermosensitive discoloring energy-storage material disclosed by the invention can not only reversibly discolor along with the change of temperature, but also absorb and dissipate energy; and the thermosensitive discoloring energy-storage material is compact in structure, uniform in particle size and long in service life, and can be widely used in the fields of civil textiles, industry cloths, construction and building materials, printing, anti-faking and the like.

Owner:TIANJIN POLYTECHNIC UNIV

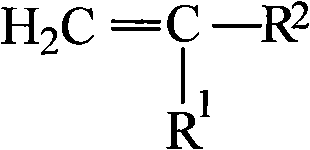

Heat-storage and heat-preservation microcapsules and preparation method and application thereof

ActiveCN102002343AImprove processing resistanceImprove wear resistanceFibre treatmentHeat-exchange elementsTemperature controlIn situ polymerization

The invention relates to phase-change energy-storage microcapsules and a preparation method and application thereof, in particular to heat-storage and heat-preservation microcapsules by taking a core material as a phase-change energy-storage material, and a preparation method and application thereof. Each microcapsule consists of a core, an internal nuclear shell and an external nuclear shell, wherein the core material is an organic phase-change material; the internal nuclear shell takes vinyl monomers as polymerizing monomers and packs the core through interfacial polymerization; and the external nuclear shell takes etherified melamine resin prepolymers as polymerizing monomers and packs the internal nuclear shell through in-situ polymerization. The heat-storage and heat-preservation microcapsules have thermosetting properties of microcapsule walls, high processing resistance, high abrasive resistance and high durability. The heat-storage and heat-preservation microcapsules can be used for heat-preservation finishing of textiles and building heat-preservation materials and can ensure the higher phase change energy of the organic phase-change materials of the cores of the heat-storage and heat-preservation microcapsules, the organic phase-change materials cannot flow or shift after phase change, so that a temperature control function can be enduringly kept.

Owner:溧阳常大技术转移中心有限公司

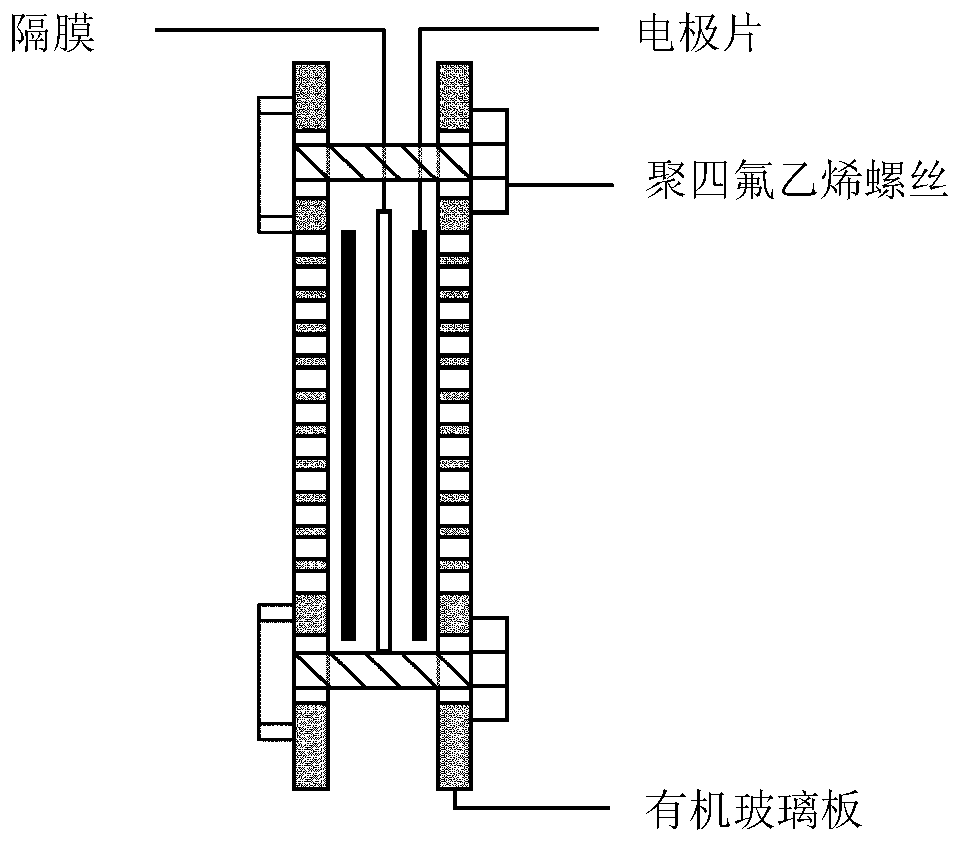

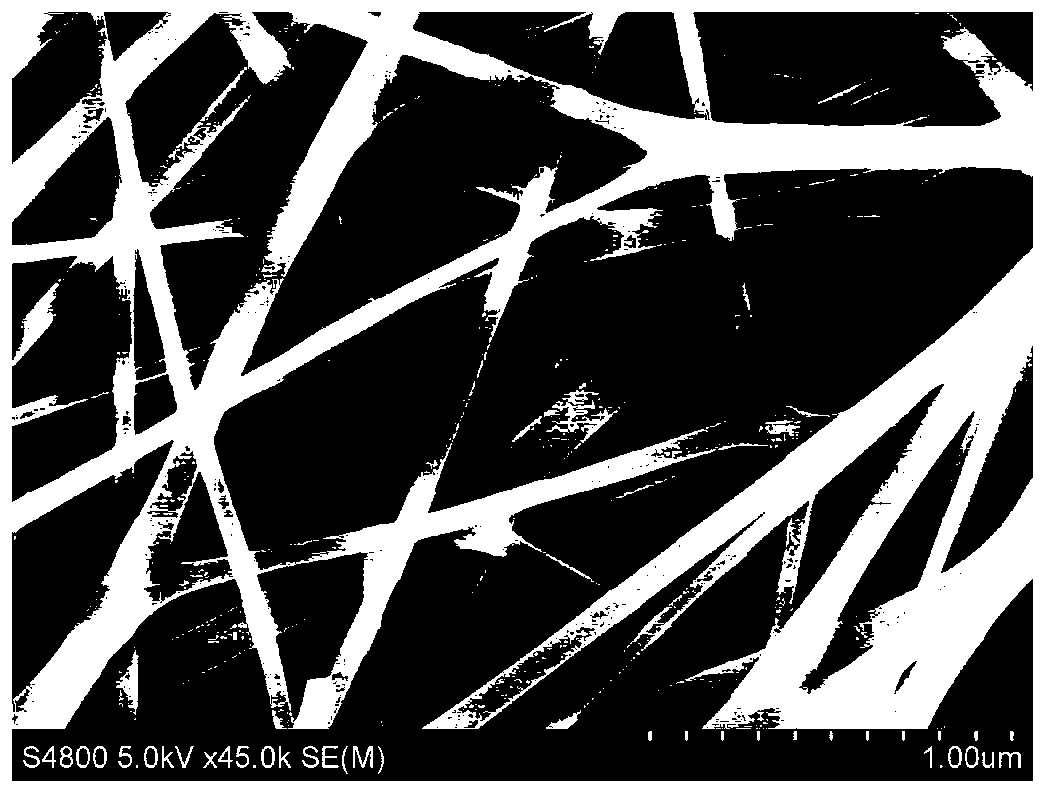

Method for preparing porous nitrogen-contained carbon fiber electrode material from melamine resin/polyvinyl alcohol aqueous solution through high-pressure static spinning technology

InactiveCN102797111AReduce pollutionLow costElectrolytic capacitorsHollow filament manufactureFiberCarbon fibers

The invention provides a method for preparing a porous nitrogen-contained carbon fiber electrode material from a melamine resin / polyvinyl alcohol aqueous solution through a high-pressure static spinning technology, relates to a preparation method of a supercapacitor electrode material, and solves the problems of poor pore-forming effect, complex operation, high cost and heavy pollution of current porous nitrogen-contained carbon fiber electrode material. The preparation method comprises the steps as follows: 1, adding a pore-forming agent into the mixed liquor of the polyvinyl alcohol aqueous solution and the melamine resin aqueous solution to prepare a basic spinning solution; 2, preparing a melamine resin / polyvinyl alcohol composite fiber film through the high-pressure static spinning technology; and 3, carbonizing the composite fiber film prepared in step 2 and foam nickel wrapped with a piece of graphite paper so as to obtain the porous nitrogen-contained carbon fiber electrode material. According to the method, the pore-forming agent is added to the basic spinning solution so that the preparation of the porous nitrogen-contained carbon fiber electrode material and the pore forming can be synchronously accomplished; and the method has the advantages of good pore-forming effect, simplicity in operation, low cost and little pollution and is applied to producing the porous nitrogen-contained carbon fiber electrode material.

Owner:HEILONGJIANG UNIV

Method for forming coated film and intermediate coating material

InactiveUS6863929B2Easy to separateSmall sizeElectric shock equipmentsPretreated surfacesPolyolAlcohol

A method for forming a coated film comprising the steps of sequentially applying an intermediate coating material, a base coating material and a clear coating material on a substrate on which an electrodeposition coated film has been formed; and simultaneously curing the applied three layers by baking, wherein the intermediate coating material comprises: (a) 40 to 56% by weight of an urethane modified polyester resin, the urethane modified polyester resin being obtainable by polyaddition of: a hydroxyl group containing polyester resin which is obtainable by polycondensation of an acid ingredient including not less than 80% by mole of isophthalic acid with a polyhydric alcohol ingredient, with an aliphatic diisocyanate compound; (b) 10 to 30% by weight of a melamine resin; (c) 15 to 30% by weight of a blocked isocyanate compound; (d) 4 to 15% by weight of a nonaqueous dispersion resin having core-shell structure; and (e) 0.4 to 2 parts by weight of a flake-like pigment. The resulting layered coated film is superior in aesthetic appearance and chipping resistance even formed in the three-coating and one-baking method.

Owner:MAZDA MOTOR CORP +1

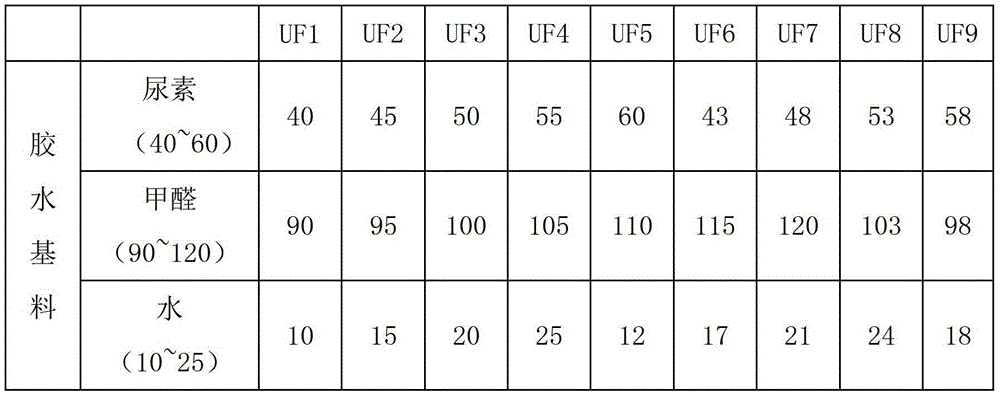

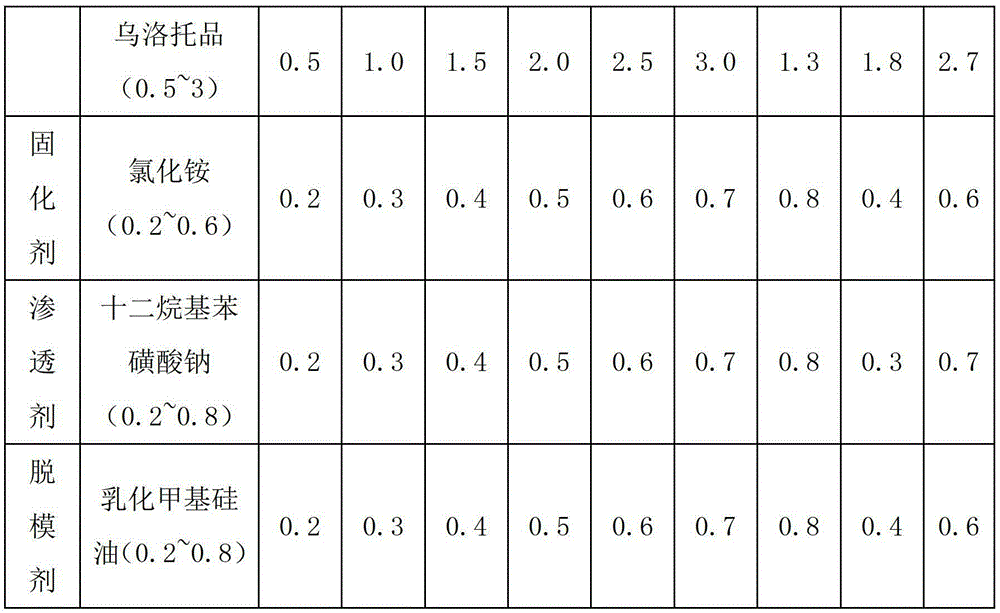

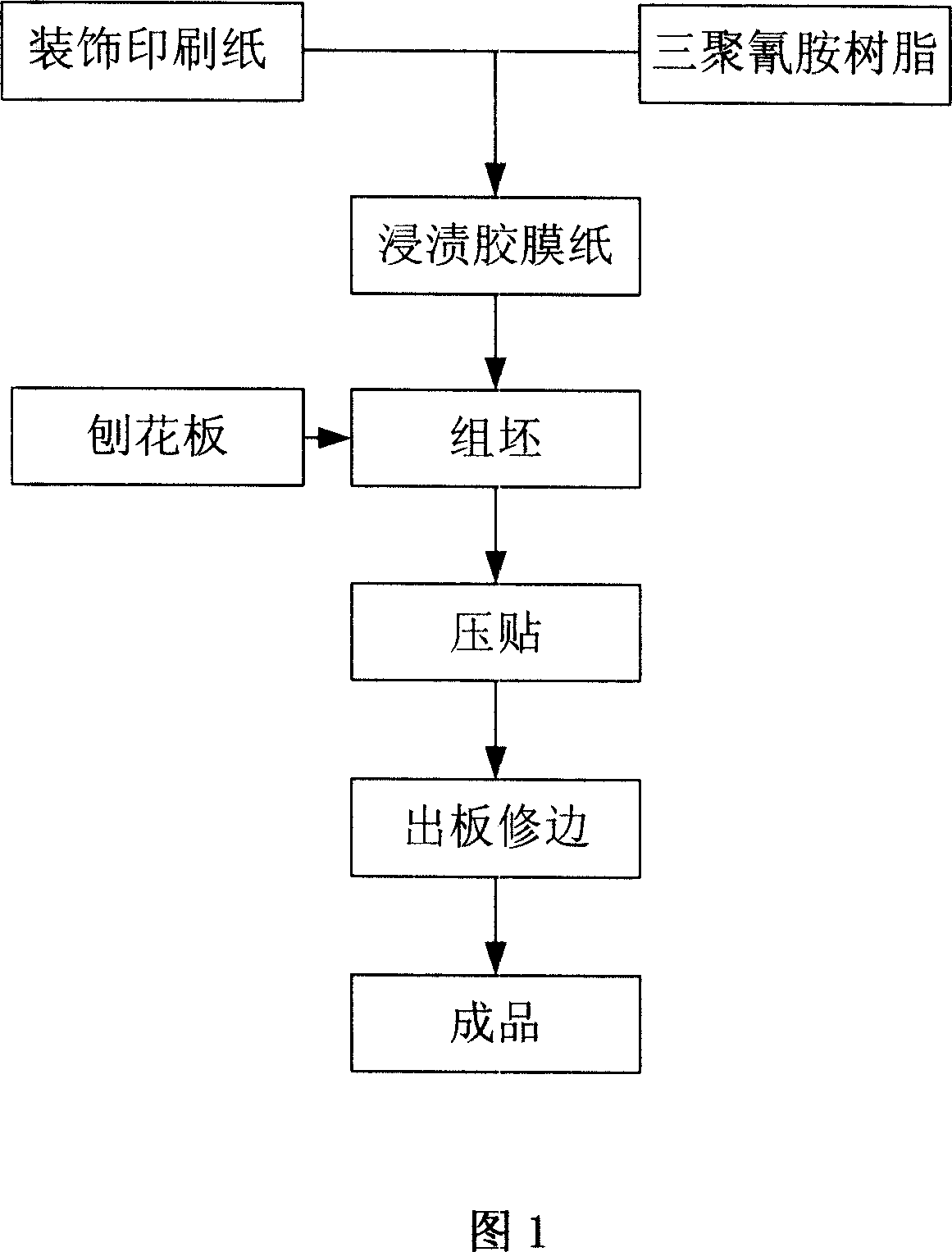

Melamine decorative veneer and preparation method thereof

ActiveCN101439524AImprove the finishHigh glossWood veneer joiningWood layered productsAdhesiveHeat resistance

The invention discloses a melamine veneer and a preparation method thereof, and belongs to the technical field of decorating materials. The melamine veneer is composed of a substrate and melamine impregnated paper. The melamine impregnated paper is obtained by impregnating paper in a melamine resign adhesive and processing the impregnated paper. The melamine resin adhesive has better activity as the formula thereof is determined by repeated tests. The melamine veneer has a simple processing technology, which causes the melamine resin adhesive to be more evenly and thoroughly immersed into decorating paper. The veneer formed by pressing has a plurality of advantages of the traditional melamine veneer such as high hardness, good abrasion resistance and good heat resistance, good chemical resistance, smooth and clean surface, easy maintenance and cleaning and the like, and further has the advantage of high luminance.

Owner:QUANYOU FURNITURE

Bright mirror surface and facing artificial plate and manufacturing technique thereof

InactiveCN101011828AIncrease usageOvercoming the deficiency of low brightnessNon-macromolecular organic additionPaper/cardboardDiethylene glycolPulp and paper industry

A melamine impregnated bond paper and chipboard compressed bright surface wood based board is composed of 60-70 portions of water, 100 portions of melamine, 90-130 portions of formaldehyde, diethylene glycol monoethylether 10-15 portions, aminocaprolactam 3.5-5.5 portions and caustic soda 0.3-0.6 portions. Firstly, it wipes off the powder on the surface of the chipboard, aligning them with melamine impregnated bond paper covering the chipboard, increasing the temperature, sending the chipboard and the paper into the compressing machine, ensuring the aligning of the center line of the chipboard and that of the compressing machine, closing the compressing machine, sending out the board, trimming, and getting the bright artificial board. It is bright, with good luster saturation, fine wearing resistance, heat, burning, crack, light and corrosion features.

Owner:吴根水

Epoxy resin composition and electronic part

InactiveUS6905768B2Improve flame retardant performanceExcellent heat resistance and thermal impact resistance and solder crackingOther chemical processesGroup 5/15 element organic compoundsEpoxyThermal impact

The epoxy resin of the invention comprises (A) an epoxy resin, (B) at least one member selected from the group consisting of a phenolic hydroxyl group-containing compound, a urea resin and a melamine resin, (C) a crosslinked phenoxyphosphazene compound, and (D) an inorganic filler powder, the amount of component (C) being in the range of 0.01 to 30 wt. % based on the total amount of components (A), (B) and (C), and the amount of component (D) being in the range of 60 to 98 wt. % based on the total amount of components (A), (B), (C) and (D). The epoxy resin composition of the invention and a molded product are halogen-free and antimony-free and are excellent in flame retardancy. When an element for an electronic part such as LSI and VLSI is encapsulated by the epoxy resin composition of the invention, the obtained electronic part is outstanding in heat resistance, moisture resistance, thermal impact resistance and like properties.

Owner:OTSUKA CHEM CO LTD

Method for preparing HMMM resin

InactiveCN101333198AImprove performanceGood cross-linking effectOrganic chemistryHexa(methoxymethyl)melamineOrganic acid

The invention discloses a preparation method for hexakis (methoxymethyl) melamine resin, namely, in the first step; 92% polyformaldehyde, melamine and methanol are reacted in alkaline environment through hydroxymethylation to generate the intermediate product hexamethylolmelamine crystals; in the second step, the intermediate product and methanol are reacted with organic acid through etherification to prepare the hexakis (methoxymethyl) melamine resin. The method of the invention is non-polluting, odorless and easy to operate. The hexakis (methoxymethyl) melamine resin produced through the method of the invention is stable and non-crystalline, which is used in coiled materials and baking varnish, with very good cross-linking effect.

Owner:ZHANGJIAGANG SHUNCHANG CHEM

Organic additives for the preparation of cementitious compositions with improved constancy of color

Described herein is the use of a combination of organic additives that is particularly advantageous for the preparation of cementitious compositions having a high conservation of the degree of white, which contain in mass a photocatalyst that is able to oxidize, in the presence of light, air and ambient humidity, pollutant substances present in the environment, the said photocatalyst being, in particular, titanium dioxide prevalently in the form of anatase.The above combination of additives comprises the following: a melamine resin; a cellulose ether; a polymer chosen from among an ethylene polymer, an acrylic polymer, and a terpolymer comprising as co-monomers at least one ester of acrylic acid with an alcohol and at least one ester of vinyl alcohol with a carboxylic acid, or alternatively, an acrylic, styrene or butadiene latex; and a chemically modified starch.

Owner:ITALCEMENTI

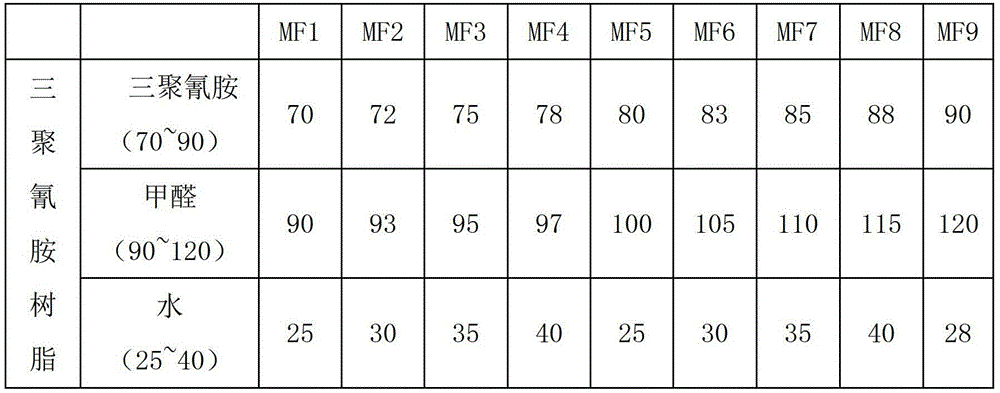

Modified melamine resin and production method thereof

The invention discloses a modified melamine resin and a production method thereof. The modified melamine resin comprises the following components in part by weight: 500 to 600 parts of formaldehyde, 5 to 9 parts of polyvinyl alcohol, 25 to 35 parts of methenamine, 70 to 80 parts of melamine, 180 to 250 parts of carbamide, 50 to 300 parts of methanol or ethanol, and 20 to 80 parts of polyethylene glycol or diethylene glycol. Due to the addition of raw materials of high aliphatic chain, the modified melamine resin and the production method thereof further prolong the storage life of the melamine resin, can meet the production requirements of enterprises on the long storage life, save production cost, improve working efficiency and save energy consumption.

Owner:SHENZHEN NEWCCESS IND

Composite modified soybean protein adhesive as well as production method and application thereof

InactiveCN101857792AImprove wettabilityNo pollution in the processProtein adhesivesWood veneer joiningCross-linkAlkaline water

The invention discloses a composite modified soybean protein adhesive as well as a production method and application thereof. The composite modified soybean protein adhesive comprises the following components: an alkaline water solution of surfactant, soybean protein products, a modifier, a cross-linking agent and fillers. In the invention, soybean protein molecules are modified by using a composite modifying method of degradation-crosslinking, the wetting property of the adhesive on wood surfaces is improved through degradation, and intermolecular cohesive forces of the solidified adhesive are improved through crosslinking. The composite modified soybean protein adhesive is water adhesive, which is nontoxic and pollution-free and has excellent glue joint strength and water resistant property, and can be used as the adhesive for processing man-made planks instead of traditional phenolic resin adhesives, urea-formaldehyde resin adhesives and melamine-formaldehyde resin adhesives.

Owner:SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

Chemical-resistant porous film

InactiveCN1856533AGood chemical resistanceGood characterMembranesSemi-permeable membranesEpoxyCellulose acetate

A chemical-resistant porous film comprising a porous film substrate coated with a chemical-resistant polymeric compound, characterized in that the film has a multiplicity of micropores communicating with each other, the micropores having an average pore diameter of 0.01 to 10 mum. As the chemical-resistant polymeric compound, use can be made of, for example, a phenolic resin, a urea resin, a melamine resin, a benzoguanamine resin, a polyimide resin, an epoxy resin, a benzoxazine resin, a polypropylene resin, a polyurethane resin, a fluorinated resin, an alkyd resin, a cellulose acetate resin, a phthalic acid resin, a maleic acid resin, a silicon resin or the like.

Owner:DAICEL CORP

Dispersing dye microcapsule dyeing method

The present invention relates to a disperse microcapsule dyeing method. It adopts the disperse dyes microcapsule using di-or polyisocyanate compound or melamine resin prepolymer and ethylene monomer as microcapsule wall material to implement high-temp. high-pressure open-width dyeing, high-temp. high-pressure ropd dyeing, thermosol dyeing or multiple transfer printing treatment of polyester fabrics. The present invention has no need of dispersing agent, high-temp. level dyeing agent and other dyeing adjuvant.

Owner:SHANGHAI WOODGE TEXTILE TECH

Two-component urethane resin adhesive for polymer lithium ion battery flexible package film

InactiveCN102329594ANot easy to peel offPeeling does not affectPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterStrong acids

The invention provides a two-component urethane resin adhesive for a polymer lithium ion battery flexible package film, and aims to provide an adhesive which has the advantages of high bonding strength, stripping resistance, excellent barrier property, impact resistance, high bonding compatibility with a nonmetallic film or an aluminum foil, resistance to swelling, dissolving, permeation and absorption of electrolyte organic solvents and high-volatility substances, resistance to strong acid and strong alkali and difficulty in breaking a molecular chain after becoming dry and hard. The two-component urethane resin adhesive consists of components, wherein a first component (A) is an emulsion waterborne Poly Urethane (PU) performed polymer which is obtained by compounding polyester and isocyanate / benzene ring-containing polyether in the mass ratio 75 / 25-55 / 45 and adding an aid for reacting; a second component (B) is a composition consisting of glycidyl ether epoxy resin with the epoxy resin 0.25-0.45 and a melamine-formaldehyde resin additional crosslinking agent; the weight ratio of the first component to the second component is 10 / 1-10 / 2; and a certain amount of additional crosslinking agent is added into a PU emulsion in a certain mass ratio.

Owner:刘继福

Melamine foam material for pipeline heat insulation and preparation method and use thereof

InactiveCN101423648ALight weightLow thermal conductivityThermal insulationPipe protection by thermal insulationFoaming agentSolid content

The invention provides a melamine foaming material for heat preservation of a pipeline, which consists of a foaming liquid system, wherein the foaming liquid system comprises a high solid content melamine resin, a foaming agent, a curing agent and an emulsifier, and the weight proportion of the high solid content melamine resin to the foaming agent to the curing agent to the emulsifier is 50-250 to 5-30 to 2.5-15 to 1-10. The invention also provides a method for preparing the melamine foaming material and application of the melamine foaming material. The melamine foaming material with adequate thickness is processed according to the shape of the pipeline and sleeved outside the pipeline, and the outside of the melamine foaming material is coated with a reinforced protective layer which is provided with a coating belt for fixation, so that the heat preservation effect of the pipeline can be achieved. The melamine foaming material has the advantages of low thermal conductivity coefficient, softness and moderation, easy machine shaping, simple construction, and firmness and reliability.

Owner:NO 91872 TROOPS PLA

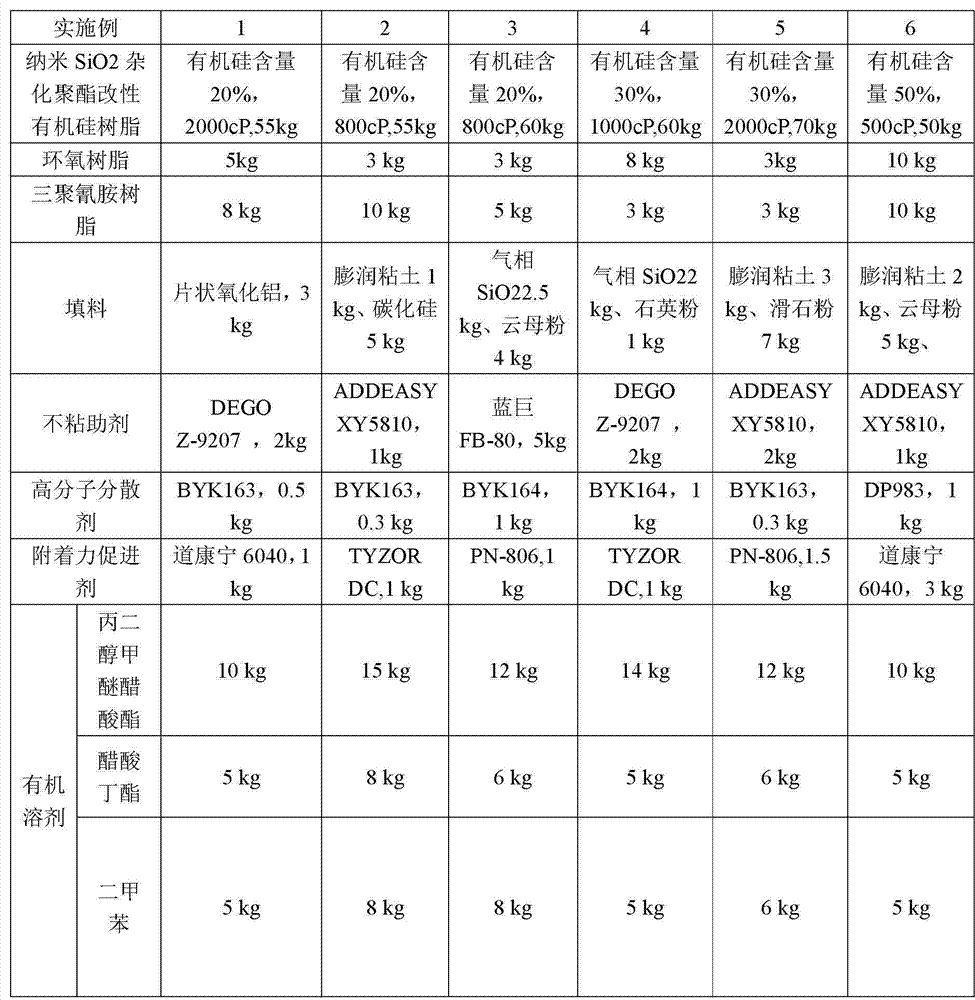

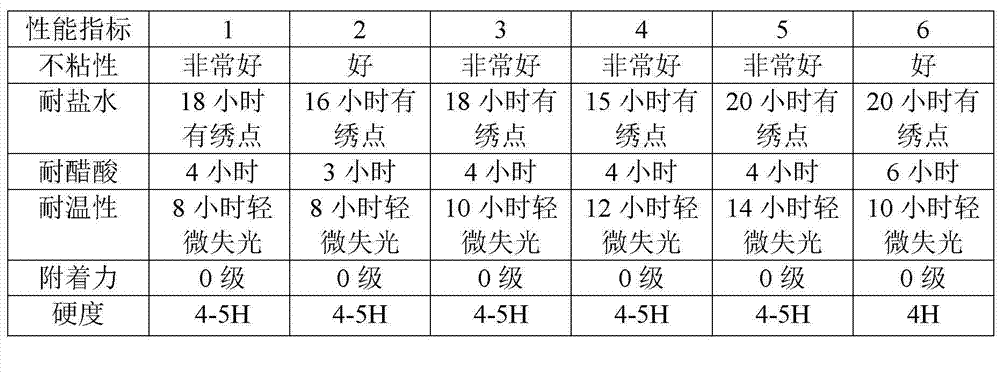

Nanometer SiO2 hybrid polyester modified organosilicon non-stick paint and coating method thereof

ActiveCN103205203ASolve defects that are not suitable for application on ferrous substratesGood non-stickPretreated surfacesEpoxy resin coatingsPolyesterEpoxy

The invention relates to a nanometer SiO2 hybrid polyester modified organosilicon non-stick paint. The non-stick paint is prepared mainly by mixing the following components by weight: 50 to 70 parts of a nanometer SiO2 hybrid polyester modified organosilicon resin, 3 to 10 parts of an epoxy resin, 3 to 10 parts of a melamine resin, 3 to 10 parts of a filling material, 20 to 30 parts of an organic solvent, 1 to 5 parts of a non-stick auxiliary agent, 0.3 to 1 part of a polymeric dispersant and 1 to 3 parts of an adhesion promoter. A coating prepared through coating of the non-stick paint has the characteristics of good non-stick performance, good temperature tolerance, excellent chemical resistance, corrosion resistance, high hardness and the like, is especially applicable to non-stick coatings for ferrous baking equipment and a cake mould and accords with relevant FDA and LFGB standards for food contact materials. According to the invention, the technical defect of a high sintering temperature (normally, higher than 380 DEG C) of a conventional fluoro paint is overcome; and the non-stick paint provided by the invention only needs a sintering temperature of about 280 DEG C, so a phosphating film on the surface of a ferrous substrate is protected, resistance to chemical corrosion is improved, and energy saving and environmental protection are realized.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

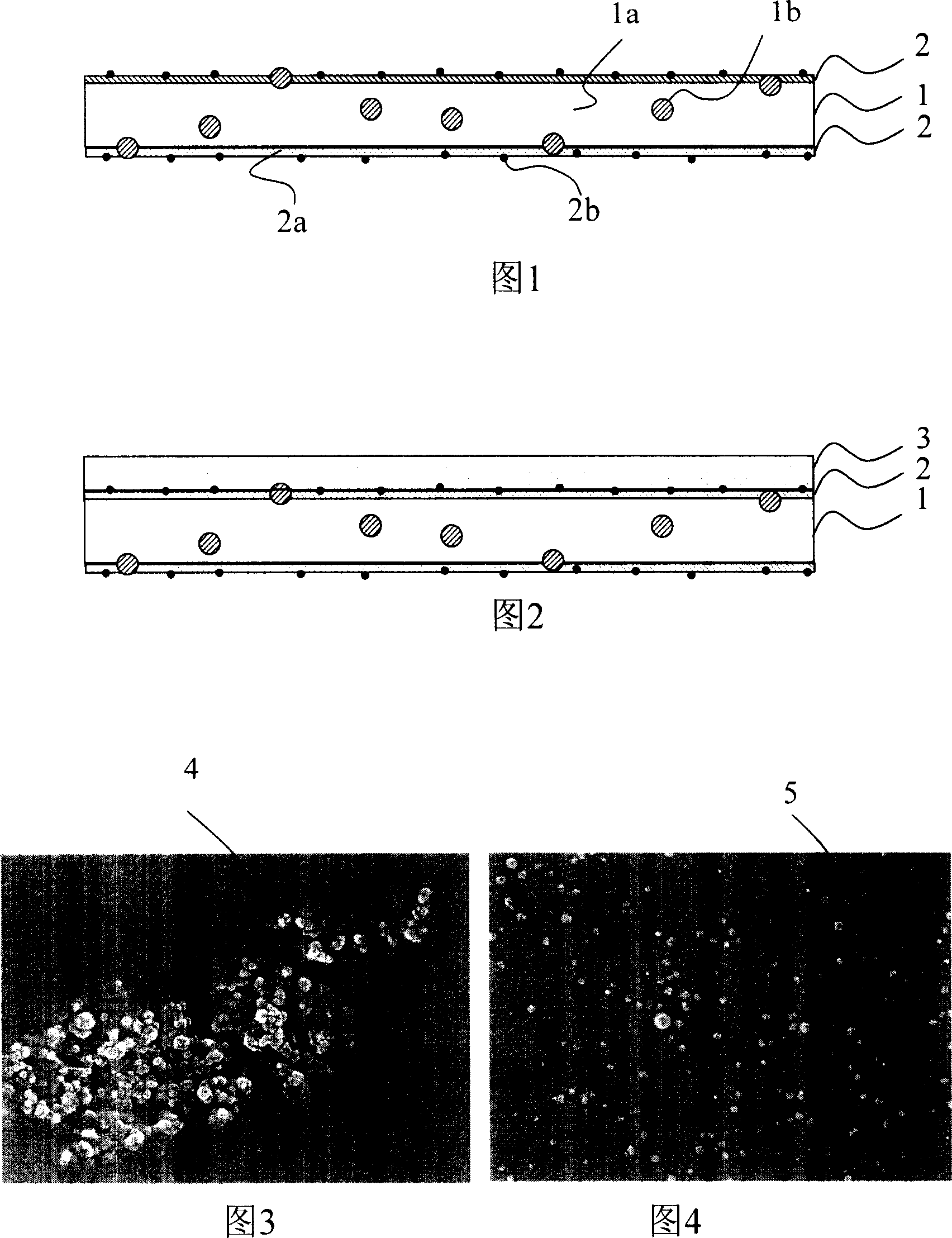

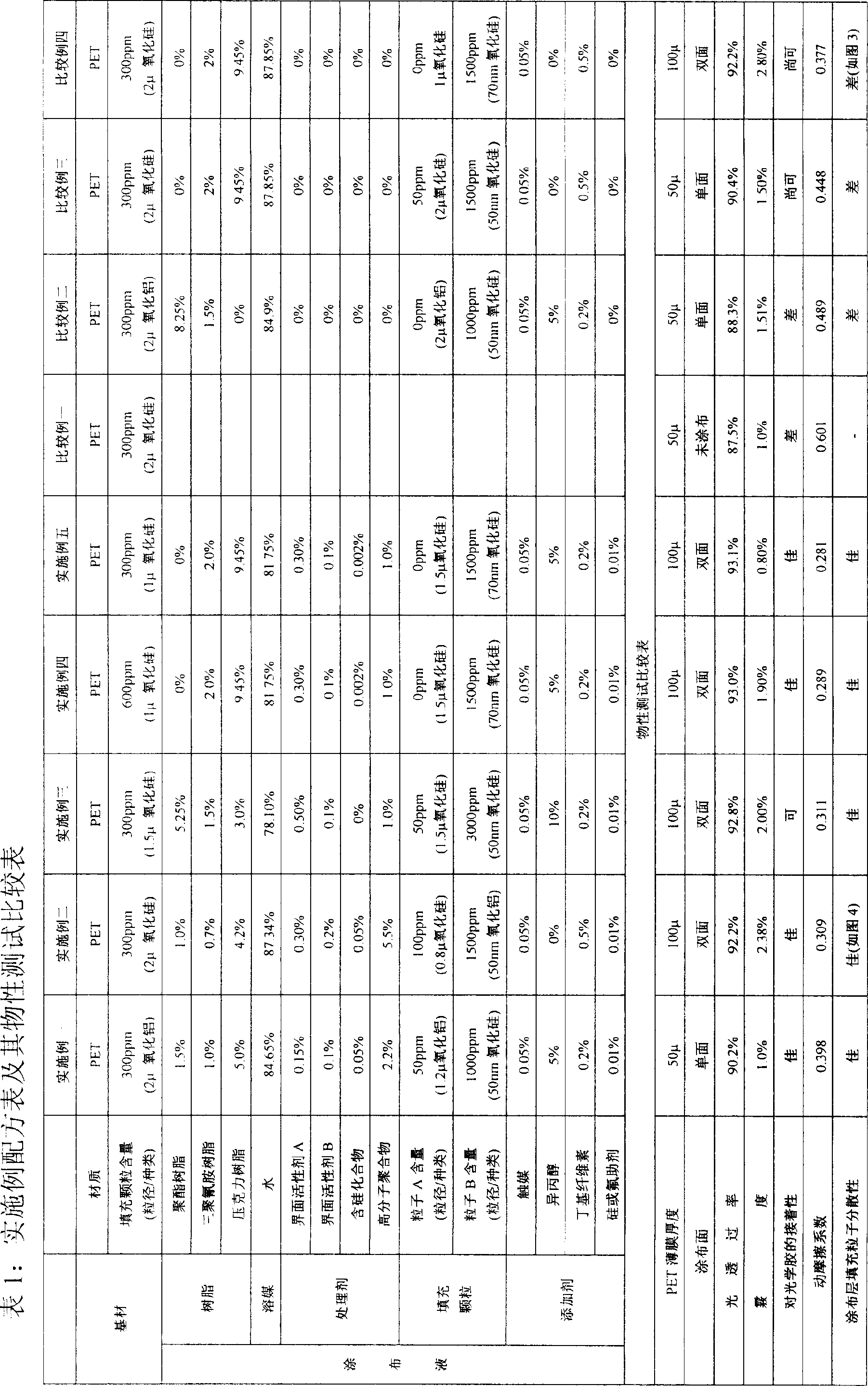

Aqueous applying liquid composition for optical polyester film

The water soluble coating fluid for optical polyester film includes resin 2-40 wt%, modified stuffing fluid 0.05-30 wt% and additives 0.05-10 wt%. It forms the coating comprising component A of polyester resin 20-50 wt%, component B of melamine resin or modified melamine resin 10-40 wt% and component C of acrylate or methacrylate resin 20-80 wt%. The polyester film with coating of the water soluble coating fluid has high transparency, excellent adhesion property, high lubricating property, etc and is suitable for optical use.

Owner:NANYA PLASTICS CORP

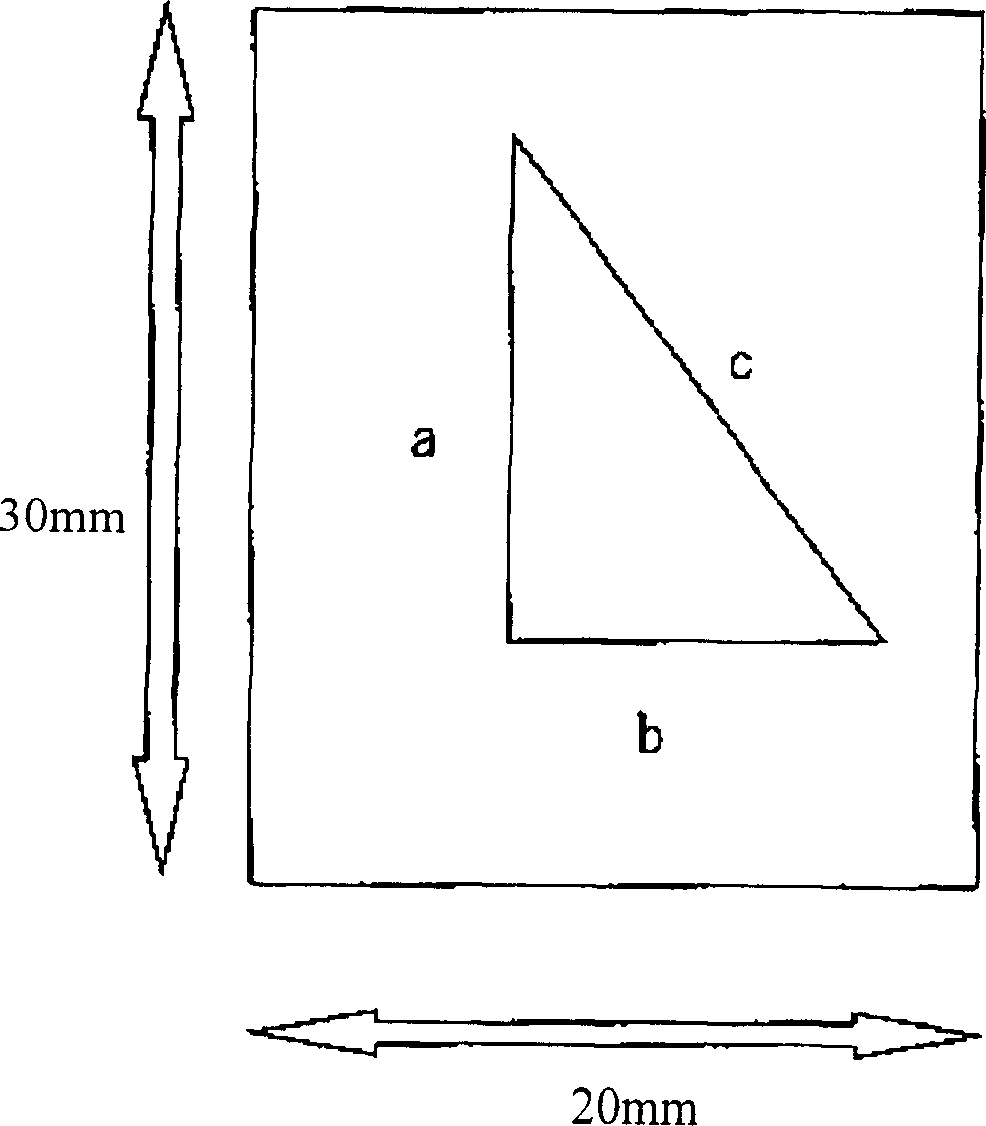

Antibacterial fire-proofing board and manufacturing method thereof

InactiveCN1454776AWill not cause secondary pollutionNovel ideaSynthetic resin layered productsBiochemical engineeringMelamine formaldehyde resin

The present invention discloses an antibacterial fire-proofing plate and its production method, which comprises a fire-proofing layer using phenolic-resin impregnated paper as base material. The antibacterial layer is adhered on the single side of the fire-proofing layer or its two sides. The said antibacterial layer uses the melamine resin impregnated decorative paper with bacteriocide as base material, and the bacteriocide is silver ion and zinc ion, and on the surface of antibacterial layer decorative paper the pattern can be printed to be used as decorative layer. Its production method includes preparation of fire-proofing and antibacterial resin, impregnation of fire-proofing layer and antibacterial layer and drying, heating fire-proofing and antibacterial layer group blank and press-forming steps.

Owner:马青

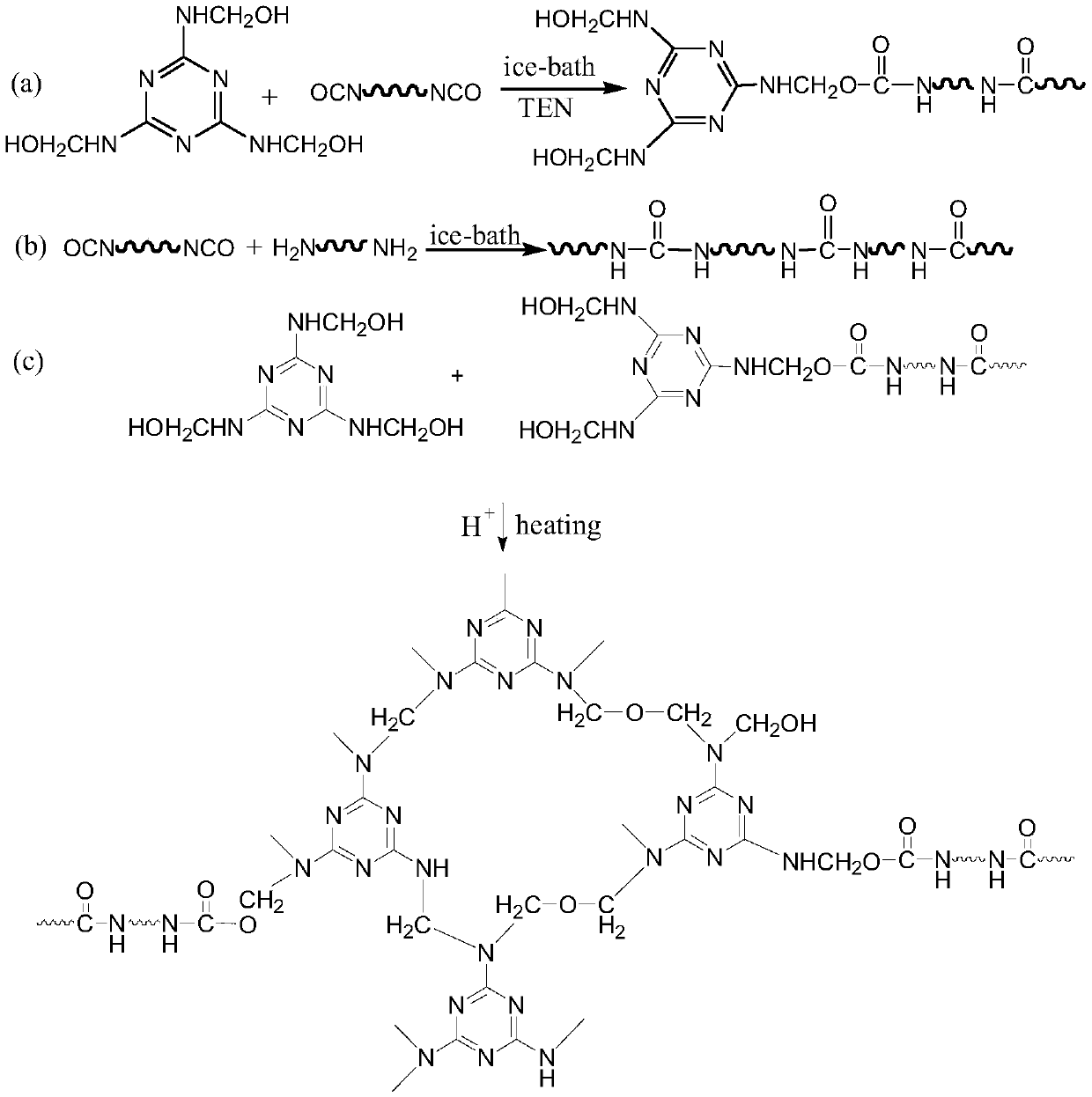

Melamine resin and polyurea resin double-shell microcapsule and preparing method and application thereof

ActiveCN105498652AGood encapsulation effectGood mechanical propertiesMicroballoon preparationMicrocapsule preparationWater bathsLow speed

The invention discloses a melamine resin and polyurea resin double-shell microcapsule and a preparing method and application thereof. The preparing method includes the steps that a melamine prepolymer, a chain extender and an emulsifying agent are added into a reactor by the mass ratio of 100:5:20-100:10:30, and stirred at a low speed at the room temperature until the melamine prepolymer, the chain extender and the emulsifying agent are completely dissolved, the pH value is adjusted to be one to six, a curing agent and core material homogeneous phase mixture is added, an emulsifying machine is used for emulsifying and stirring under the ice-bath condition, and emulsification is conducted continuously; the temperature of a water bath is raised to be 40 DEG C or above, a turbulent stirring paddle is used for stirring, a reaction continues to be conducted, the pH value is adjusted to be larger than or equal to six, and the reaction is stopped to obtain the double-shell microcapsule with the particle size of 0.1-300 micrometers, wherein an outer shell is made of melamine resin, and an inner shell is made of polyurea resin. A core material is protected by two shell materials, storage stability of the microcapsule can be improved, and the water mass content of the double-shell microcapsule is smaller than or equal to 5%; the critical stress is 0-900 mN, and the mechanical property is good.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com