Bright mirror surface and facing artificial plate and manufacturing technique thereof

A wood-based panel and veneer technology, which is applied in the direction of manufacturing tools, papermaking, wood layered products, etc., can solve the problems of limited technical level and unsatisfied consumer needs, etc., and achieve simple process, bright colors, and not easy to collapse edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

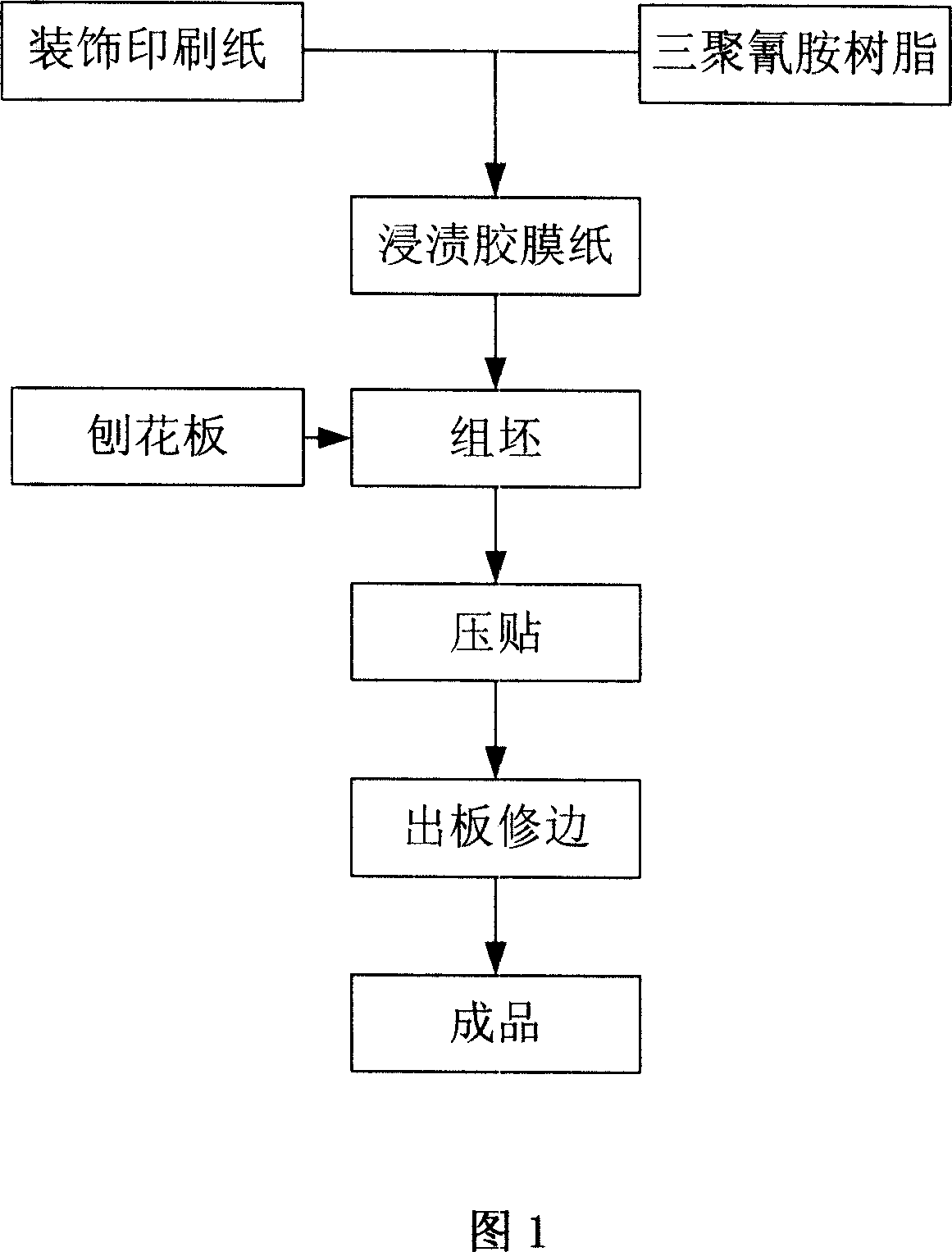

Method used

Image

Examples

Embodiment 1

[0030] First, put 600kg of water, 1000kg of melamine, 900kg of formaldehyde, 100kg of diethylene glycol, 35kg of caprolactone, and 3kg of caustic soda into a 3-ton reactor to prepare melamine resin. In the melamine resin, add 1.5kg of curing agent produced by the German live Shi company.

[0031] Use decorative printing paper with a grammage of 70g / m 2 ; The decorative printing paper is impregnated in melamine resin, and a horizontal two-stage impregnation and drying production line is adopted. The paper is impregnated twice in melamine resin, dried twice, and then cut into melamine-impregnated film paper according to the specifications.

[0032] Assemble the special steel plate and buffer pad into the multi-layer laminating machine, and transport the raw materials to the designated position of the production line; brush off the dust on the surface of the V313 imported waterproof particleboard as the base material; center the particleboard on the operating table and then assem...

Embodiment 2

[0034] First, put 650kg of water, 1000kg of melamine, 1100kg of formaldehyde, 125kg of diethylene glycol, 45kg of caprolactone, and 4.5kg of caustic soda into a 3-ton reactor to prepare melamine resin. In the melamine resin, add 2.25kg of brighteners produced by the German live Shi company.

[0035] Use decorative printing paper with a grammage of 80g / m 2 ; The decorative printing paper is impregnated in melamine resin, and a horizontal two-stage impregnation and drying production line is adopted. The paper is impregnated twice in melamine resin, dried twice, and then cut into melamine-impregnated film paper according to the specifications.

[0036] Assemble the special steel plate and buffer pad into the multi-layer laminating machine, and transport the raw materials to the designated position of the production line; brush off the dust on the surface of the V313 imported waterproof particleboard as the base material; center the particleboard on the operating table and then as...

Embodiment 3

[0038] First, put 700kg of water, 1000kg of melamine, 1300kg of formaldehyde, 150kg of diethylene glycol, 55kg of caprolactone, and 6kg of caustic soda into a 3-ton reactor to prepare melamine resin. Add 1 kg of penetrating agent, 1 kg of release agent and 1 kg of anti-adhesive agent produced by German Huoshi Company to the melamine resin.

[0039] Use decorative printing paper with a grammage of 90g / m 2 ; The decorative printing paper is impregnated in melamine resin, and a horizontal two-stage impregnation and drying production line is adopted. The paper is impregnated twice in melamine resin, dried twice, and then cut into melamine-impregnated film paper according to the specifications.

[0040] Assemble the special steel plate and buffer pad into the multi-layer laminating machine, and transport the raw materials to the designated position of the production line; brush off the dust on the surface of the V313 imported waterproof particleboard as the base material; center th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com