Patents

Literature

2529results about How to "Colorful" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

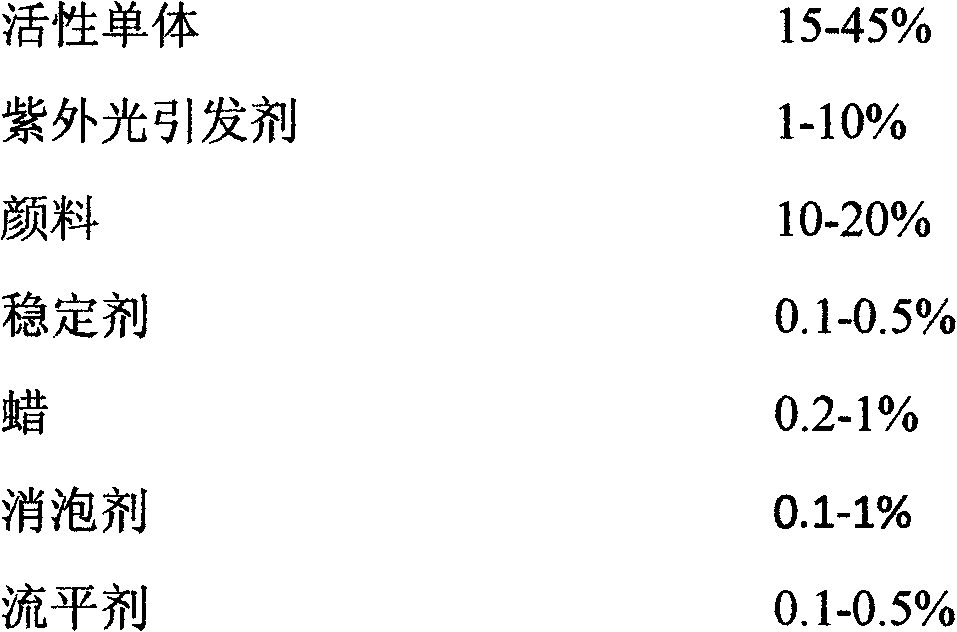

Digital ink jet fabric-treating process

The present invention is digital ink jet fabric treating process, and belongs to the field of textile science and technology. The fabric pre-treating process for digital ink jetting and printing with water thinned pigment ink is suitable for fabric of cotton, hemp, silk, Dacron, polyester and cotton blend, acrylic fiber, etc.; and the treated fabric may be ink jetting printed with water thinned pigment ink in one digital ink jetting printer. After printing and proper heat treatment, may be produced printed product with clear pattern, bright color, and high fastness to resist water washing, friction and sunlight.

Owner:JIANGNAN UNIV

Ultraviolet light curing printing ink for digital printing and dyeing preparation thereof

UV solidified printing ink for digital code printing and dyeing is composed of polyurethane acrylate, prepolymer, activity monomer, dyestuff, light initiator, dispersant agent and other addition agents. The prepolymer has the character of low viscosity and good flexibility. The ink doesn't contain organic solvent and has wide material adaptation, storage stability and softness.

Owner:DONGHUA UNIV

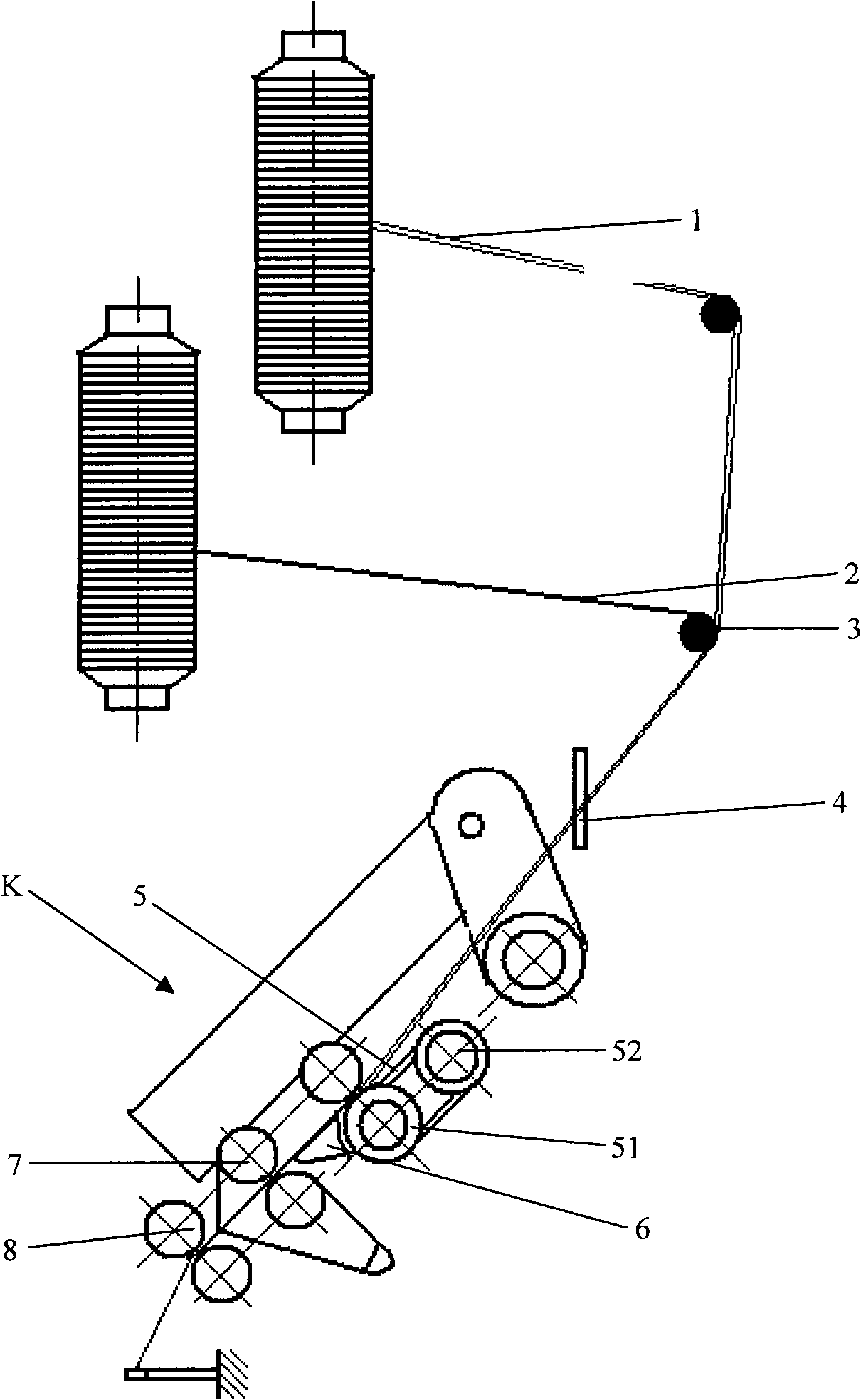

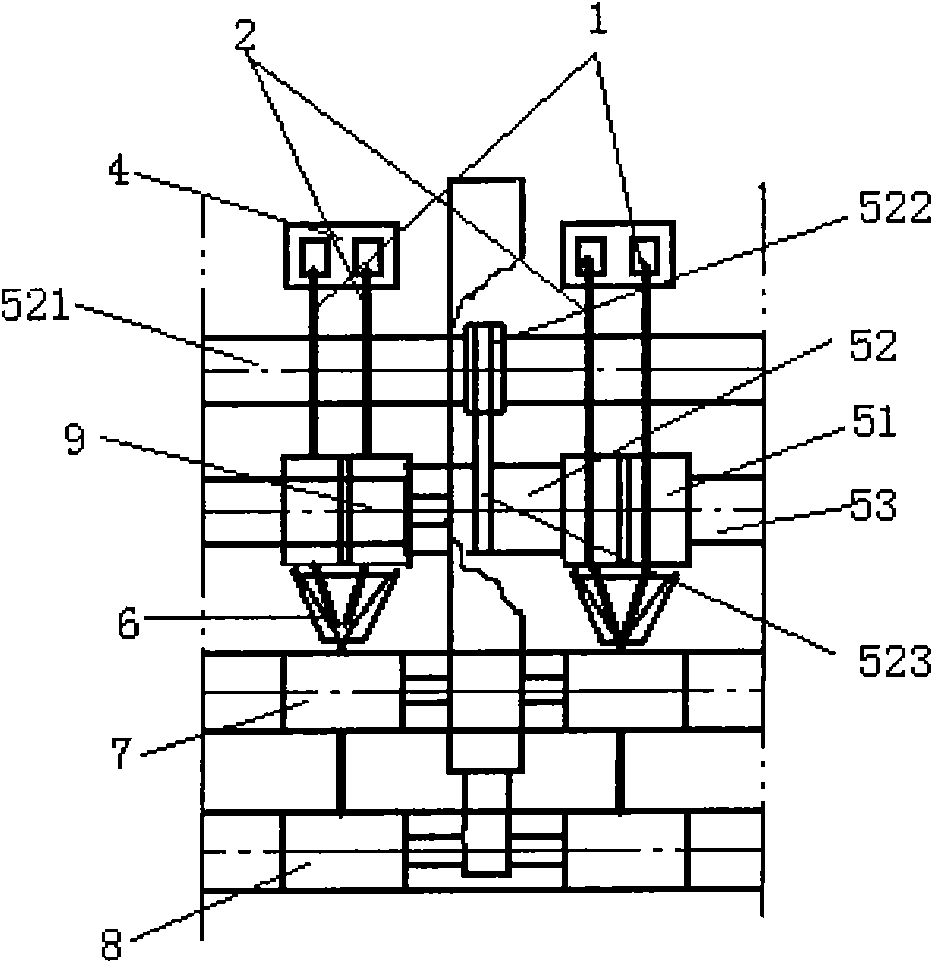

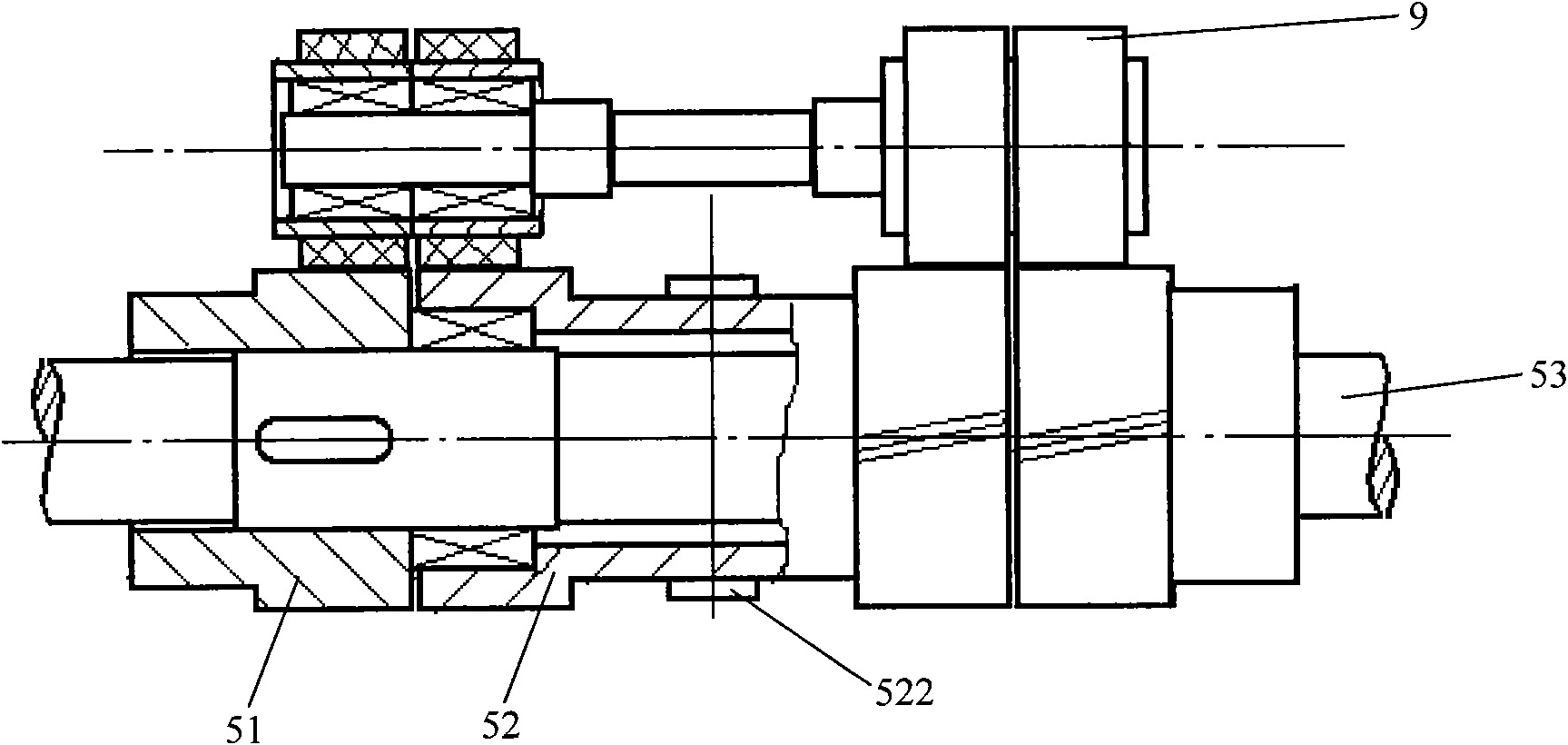

Ring spinning method and device of equi-linear density space dyed yarn

The invention relates to ring spinning method and device of equi-linear density space dyed yarn. The method comprises the following steps of: respectively feeding a fiber strip group (A) with the linear density tex T(A) and a fiber strip group (B) with the linear density tex T(B) into a fixed rear roller and a loop rear roller on a rear roller shaft through yarn guiding rods and grids; and feeding the fiber strip group (A) and the fiber strip group (B) with constant feeding quantity sum into a rear drawing region in any period of time under the process requirement that the feeding speeds of the fiber strip group (A) and the fiber strip group (B) vary with stages by adopting a speed coupling uniform feeding control method. After the strip collection of a strip collector, fiber strips are fed into a middle roller in different drawing ratios, converged in a front drawing region of a spinning machine, drawn and output by a front roller and twisted into equi-linear density space dyed yarn.

Owner:陈伟雄

Dyeing and coating integrated dye dyeing and printing paste-shaped compound and application thereof

ActiveCN105970671AGuaranteed high sublimationGuaranteed wet rubbing fastnessDyeing processDisperse dyeHigh concentration

The invention relates to a textile dyeing and printing technique and specifically relates to a dyeing and coating integrated dye dyeing and printing paste-shaped compound for a hydrophobic textile material and an application thereof. The dye dyeing and printing paste-shaped compound is composed of 1-25% of dyeing and printing concentrated paste, 0.5-10% of thickening agents, 0.05-3% of pH modifiers and 62-98.45% of water. The paste-shaped compound provided by the invention is used for dyeing and printing the hydrophobic textile material and has the advantages of dye dyeing and printing and pigment dyeing and printing; the high sublimation, washing and dry and humid rubbing fastness are ensured while the color is bright and the hand feeling is soft; the generation of high concentration waste water in the traditional disperse dyeing and printing processes is avoided; and therefore, the dyeing and coating integrated dye dyeing and printing paste-shaped compound is a clean and environment-friendly dye dyeing and printing product.

Owner:SHENYANG RES INST OF CHEM IND

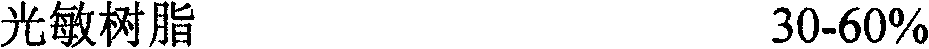

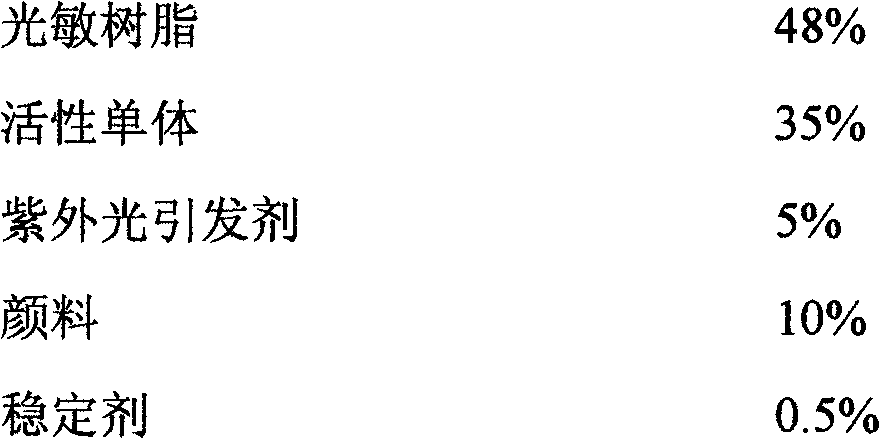

A kind of ultraviolet curing ink and preparation method thereof

The invention relates to an ultraviolet curable ink and a preparation method thereof. The ink comprises 30-60% of light sensitive resins, 15-45% of active monomers, 1-10% of ultraviolet light initiators, 10-20% of pigments and 0.5-2% of auxiliaries by mass and is an ink which is transformed from liquid state to solid state to be cured after binders in the ink are cross-linked under the irradiation of ultraviolet lights with certain wavelengths. The ultraviolet curable ink provided by the invention has the advantages of short light curing time, no need of heating, conservation in energy consumption, no volatile organic solvent VOC (Volatile Organic Compounds) in the ink, no pollution to the atmosphere, smaller effect of temperature variation on system viscosity, high solid content, suitability for multiple production methods and production requirements and excellent comprehensive properties, can be machined and used within a wider temperature range; and very good printing effects of the ultraviolet curable ink on both a hard substrate and a soft substrate can be obtained.

Owner:哈尔滨大东方新材料科技股份有限公司

Colored aluminum pigment with high color depth and preparation method thereof

InactiveCN101445675AGood acid and alkali resistanceColorfulInorganic pigment treatmentMetallic aluminumKetone solvents

The invention relates to a colored aluminum pigment with high color depth and a preparation method thereof. The colored aluminum pigment is obtained by depositing a layer of silicon dioxide on a flaky metallic aluminum sheet substrate and then depositing one or more layers of metal oxide on the surface of the silicon dioxide, and the colored aluminum pigment exists in the form of dry powder. The preparation method comprises the following steps: a. stirring to disperse commercially available aluminum pigment slurry in alcohol, alcohol ether or a ketone solvent; b. regulating the temperature to 30-80 DEG C, respectively adding tetraethoxysilane and aqueous solution to the dispersed aluminum pigment slurry with the mol ratio of the tetraethylorthosilicate to the water ranging from 1:0.5 to 1:20, adding a catalyst such as ethylenediamine solution or aqueous ammonia, and obtaining aqueous aluminum pigment slurry by vacuum filtration and washing after the reaction; and c. cladding the aqueous aluminum pigment slurry obtained in the step b with the hydrated metal oxide on the powdered aluminum surface in a liquid phase. The preparation method help prepare the colored aluminum pigment with diversified colors and high color depth without reducing brightness of the original aluminum pigment slurry.

Owner:WENZHOU YOUNGBIO CHEM

Weatherproof color shape bars in aluminium alloy, and manufacturing method

InactiveCN1760497AColorfulModerate costPattern printingSolid state diffusion coatingPolyesterSolid wood

The present invention relates to a superweathering color aluminum alloy section material and its production method. The composition of its base material is AlMg Si0.5-F22 alloy, according to Mg / Si=1.73, in which Mg (0.50-0.75%), Si (0.35-0.50%), Fe (less than 0.3%), Cu(less than 0.1%), Mn (less than 0.1%), Cr (less than 0.1%), Zn (less than 0.1%) and Ti (less than 0.1%); said base material is covered with chromized film whose thickness is 300-1000 mg / sq.m, and the chromized film also is covered with polyester powder coating layer which has imitation woodgrain pattern and whose thickness is 40-120 microns. Its production method includes the following steps: preparing aluminum alloy section base material, making pretreatment and chromizing process, spray-coating super weathering antistatic powder and heat transfer printing imitation woodgrain pattern.

Owner:SHANGHAI ZHENXING ALUMINUM IND

Low temperature ceramic color without lead on glaze, and preparation method

This invention relates to a low-temperature lead-free overglaze pigment, which is composed of lead-free pigment 8-30 wt.%, and lead- and cadmium-free flux 70-92 wt.%. The flux is composed of: SiO2 30-60 wt%, B2O3 5-35 wt.%, Al2O3 1.5-15 wt.%, K2O 1.5-10 wt.%, Na2O 1.5-10 wt.%, Li2O 0-8 wt.%, ZnO 0-15 wt.%, CaO 0-5 wt.%, CoO 0-10 wt.%, BaO 0-5 wt.%, MgO 1-5 wt.%, ZrO2 0-10 wt.%, SnO2 0-10 wt.%, and TiO2 0-5 wt.%. The low-temperature lead-free overglaze pigment has such advantages as no toxic or side effects, compact structure, high chemical stability, low baking temperature, beautiful color, high resistance to acid and base, appropriate thermal expansion coefficient, good luster, good decoration effect, and simple preparation.

Owner:淄博华为颜料有限公司

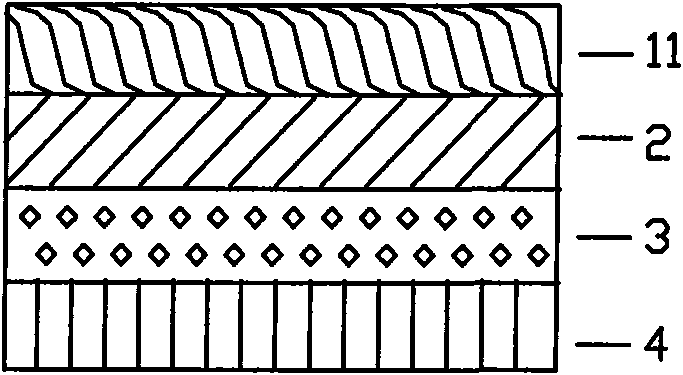

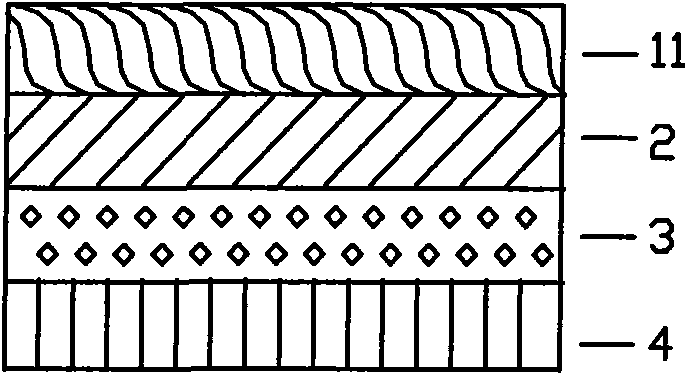

Stained paper for decorating glass inter space, glass mirror face surface and manufacturing process thereof

InactiveCN101497502AExquisite decorationColorfulGlass/slag layered productsTectorial membraneEngineering

The invention provides a stained paper for glass partition or surface decoration of glass or a mirror surface, and provides a method for making the same. The stained paper mainly comprises a protective film layer, an adhesive layer, a base material layer and a process layer. The process layer is arranged on the upper surface of the base material layer which is a transparent plastic film material; the lower bottom of the base material layer is provided with the adhesive layer; the lower bottom of the adhesive layer is provided with the protective film layer; the process layer is prepared based on a UV printing ink process combining with a powder spraying process, a powdering process, a flocking process, a roller hot printing process, or the combination of the processes. A glass wall paper prepared by the method has the advantages of strong decorative effect, high grade, and convenient assembly and replacement, and is a preferably selected replacing product for the complanation of process glass.

Owner:陈威

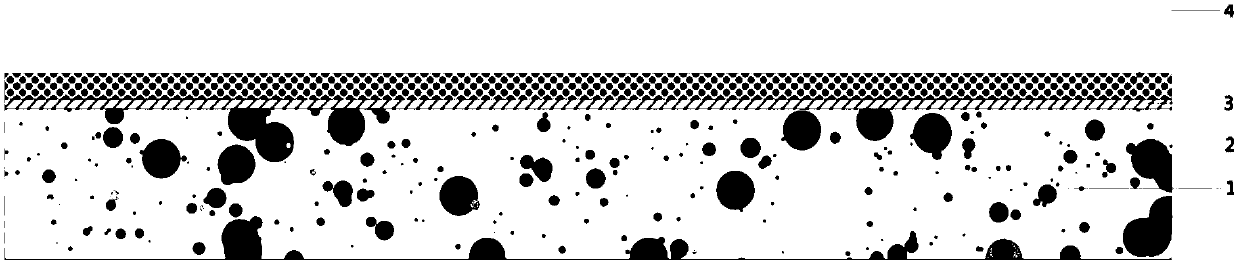

Full-body anti-slip ceramic brick and production method thereof

The invention relates to a full-body anti-slip ceramic brick and a production method thereof. According to the full-body anti-slip ceramic brick, a compound layer brick body is composed of a colored spot green body layer, large-particle colored spots mixed into the colored spot green body layer, a pattern decoration layer on the surface of the green body layer and a dry-particle glaze layer attached to the pattern decoration layer; the production method comprises the following steps: (1) pressing a green body, wherein green body powder is composed of conventional powder and large-particle powder; (2) drying under the conditions that the drying temperature is 80 to 100 DEG C and the drying time is 60 to 80 min; (3) decorating a pattern: before decorating the pattern, not applying any glazelayer or other protection layers on the surface of the blank body, so as to directly realize inkjet printing decoration on the surface of the blank body; (4) applying dry-particle glaze: spraying theglaze through a bell jar; (5) firing under the conditions that the temperature is 1150 to 1160 DEG C and the time is 50 to 60 min.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Inorganic powder texture coating, and its applying method

ActiveCN1757688AEasy constructionUnique texturePowdery paintsCement coatingsInorganic pigmentsMaterials science

A inorganic dry powder paint with good mass sensation is prepared proportionally from cement, color sand, re-dispersed emulsoid powder, hydrophobic agent, inorganic pigment and filler. Its advantages are high adhesion to concrete, high weatherability, good air permeability, and no pollution. Its application method is also disclosed.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Colorized instant noodle formula and preparation method

The invention discloses a colorized instant noodle formula and a preparation method. The formula comprises wheat flour, water, edible oil, edible salt and at least one of coarse grain flour, vegetable juice, fruit juice and edible herb juice; and the preparation method comprises the following steps of: according to the formula, adding water at the temperature of between 20 and 30 DEG C to prepare colorized dough which contains at least one color of yellow, red, green, dark green, purple and black; placing the colorized dough in a sealing mode at the normal temperature for 100 to 140 minutes, and pressing and cutting the colorized dough to strips to obtain the colorized noodles; and curing, shaping, drying, blending and packing the colorized noodles. The colorized instant noodle formula and the preparation method can overcome the defects of lack of nutrient components and single color in the prior art so as to realize abundance in nutrient components and various colors.

Owner:杨军

Heat preserving really stone paint and preparation method thereof

The invention discloses a heat preserving really stone paint and a preparation method thereof. The heat preserving really stone paint is prepared from the following components in parts by weight: 150-200 parts of a silicone acrylic emulsion, 450-500 parts of natural colored sand, 150-200 parts of hollow glass beads, 5-8 parts of hydroxyethyl cellulose, 200-250 parts of tap water and 35-50 parts of an auxiliary. By combining the silicone acrylic emulsion, the natural colored sand and the hollow glass beads, the heat preserving really stone paint disclosed by the invention has stabilities such as excellent weather resistance, tarnish resistance, temperature change resistance and ageing resistance and heat preserving performance as well as color diversification. In addition, the preparation method disclosed by the invention does not need grinding. Only dispersion is needed to prepare a product paint, so that the paint is simple in production process.

Owner:ZHANG ZHOU SAN PAINTS

Stained paper for surface decoration of glass partition, glass and mirror face and manufacture process thereof

InactiveCN101628524ABlock the line of sightSignificant progressDecorative surface effectsPattern printingTectorial membraneQuality level

The invention discloses stained paper for surface decoration of a glass partition, glass and a mirror face, at least comprising a protective film layer, an adhering layer, a substrate layer and an art layer. The stained paper is characterized in that the art layer is arranged on the upper surface of the substrate layer which is a transparent plastic film layer; the bottom surface of the substrate layer is provided with the transparent adhering layer; and the bottom surface of the adhering layer is provided with the protective film layer. The art layer is singly manufactured by a UV ink process, a flocking process, a crystal dispensing process and a flexible-mould relief process, or by combining the flocking process, the crystal dispensing process and the flexible-mould relief process based on the UV ink process or the combination thereof. The glass stained paper prepared by the method has a main characteristic that transparent part and non-transparent part are arranged on a same plane, and has good decoration effect, high quality level as well as convenient installation and change, and is the preferable substitute products of art glass complanation.

Owner:陈威

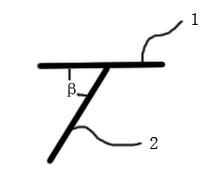

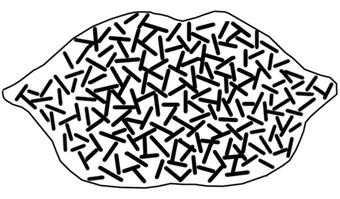

Light-free T-shaped stitch for embroidery and embroidering method

ActiveCN102182023APreserve the characteristics of line lightThere will be no color deviationEmbroidering machines apparatusHand embroideringBiomedical engineeringTextile

The invention discloses a light-free T-shaped stitch for embroidery and an embroidering method. At least three layers of embroidering stitches are embroidered from top to bottom on the front face of an embroidered cloth through an embroidering needle and an embroidering thread, wherein each layer of embroidering stitches is formed by adjacently arranging a group of T-shaped embroidering stitch units with stitches having approximately the same length on the front face of the embroidered cloth; when any T-shaped embroidering stitch unit serves as a standard, the tightly adjacent T-shaped embroidering stitch units around the T-shaped embroidering stitch unit are arranged at angles; the lengths of needle feet of the T-shaped embroidering stitch units in each layer of embroidering stitches aregradually reduced from top to bottom; the stitch of the T-shaped embroidering stitch units consists of first needle feet and second needle feet; the first needle feet and the second needle feet are arranged in a shape of 'T' on the front face of the embroidered cloth; an included angle between the first needle feet and the second needle feet is in a range of between 60 and 90 degrees in the shapeof 'T'; and the ratio of the length of the first needle feet to the length of the second needle feet is in a range of between 1:0.7 and 1:1.3. The problem that faces and limbs of characters reflect light because of inherent thread light and thread textures of silk threads is solved through the T-shaped stitch and the embroidering method, so breakthrough and innovation are made in Suzhou (a province in China) embroidery in the embroidering method for portraits.

Owner:顾金珍

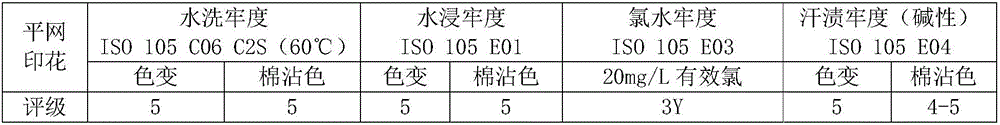

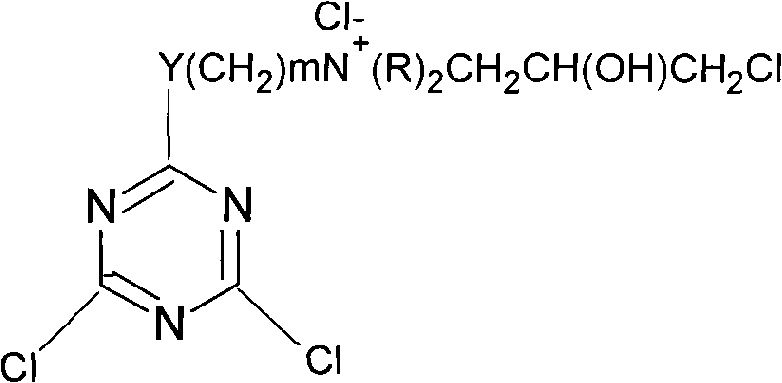

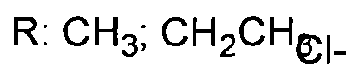

Fabric graft modified full-fixation printing method

InactiveCN101403185AReduced charge repulsionReduce processing burdenDyeing processVegetal fibresSodium bicarbonateWorking fluid

The invention relates to a whole fixation printing method for the graft modification of textiles, and aims at providing the whole fixation printing method that can promote the dye fixation rate from 70 percent to 80 percent to more than 90 percent to 98 percent. The technical proposal is as follows: 1) the pretreatment of a textile, the textile is treated according to the processes of desizing, boiling, smelting and bleaching; 2) the preparation of the graft modification working fluid, the working fluid comprises 0.1 percent to 10 percent of cationic graft agent, 0.1 percent to 20 percent of alkali agent and 0 percent to 1 percent of penetrating agent, and the rest is water; 3) the treatment of the graft modification, the pretreated textile is put into a dyeing machine, and the graft modification working fluid is added; or the pretreated textile is padded with the graft modification working fluid in a padder; the printing formula of the invention comprises 50 grams of protoplasm, 2 grams to 5 grams of urea, 0.5 gram to 8 grams of dye, 1 gram to 2.5 grams of sodium bicarbonate and 0.5 gram to 1.5 grams of reserve salt, and the rest amount of water in every 100 grams according to weight; and 4) the printing technology, the printing is carried out according to the conventional technology. The whole fixation printing method for the graft modification of the textiles is used in the whole fixation printing.

Owner:ZHEJIANG JIAXIN SILK

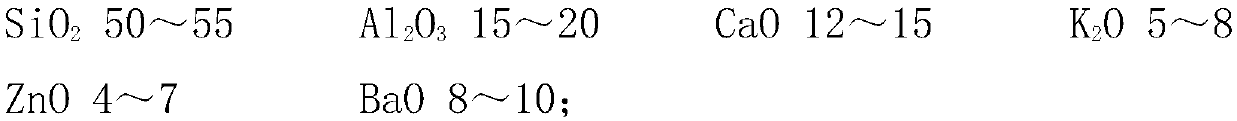

Nucleated glass composite material and process for preparing same

InactiveCN1433985AThe level of artistic aesthetics has improvedReduce manufacturing costGlass compositesSurface layer

The present invention relates to a nucleated glass composite material and its preparation method. Said composite material is formed from surface layer nucleated glass and base material. Its surface layer bucleated glass includes ZnO 10-40% (wt%), SiO2, Al2O3, CaO, MgO, Na2O+K2O, Li2O, BaO and ZrO2, and its base material is ceramic or nucleated glass layer. Said nucleated glass is made up by following steps: preparing surface layer nucleated glass granulated raw material, preparing base material, combining them and making them into semi-finished product, edge grinding, scrapping, coarse grinding, polishing, edge grindnig, chamferring and drying, and the pattern of the obtained nucleated glass copmosite material can be various forms of ball, chrysanthemum flower, slag flow, flower cluster, flowing lines, flame and radiation, etc.

Owner:戴长禄 +1

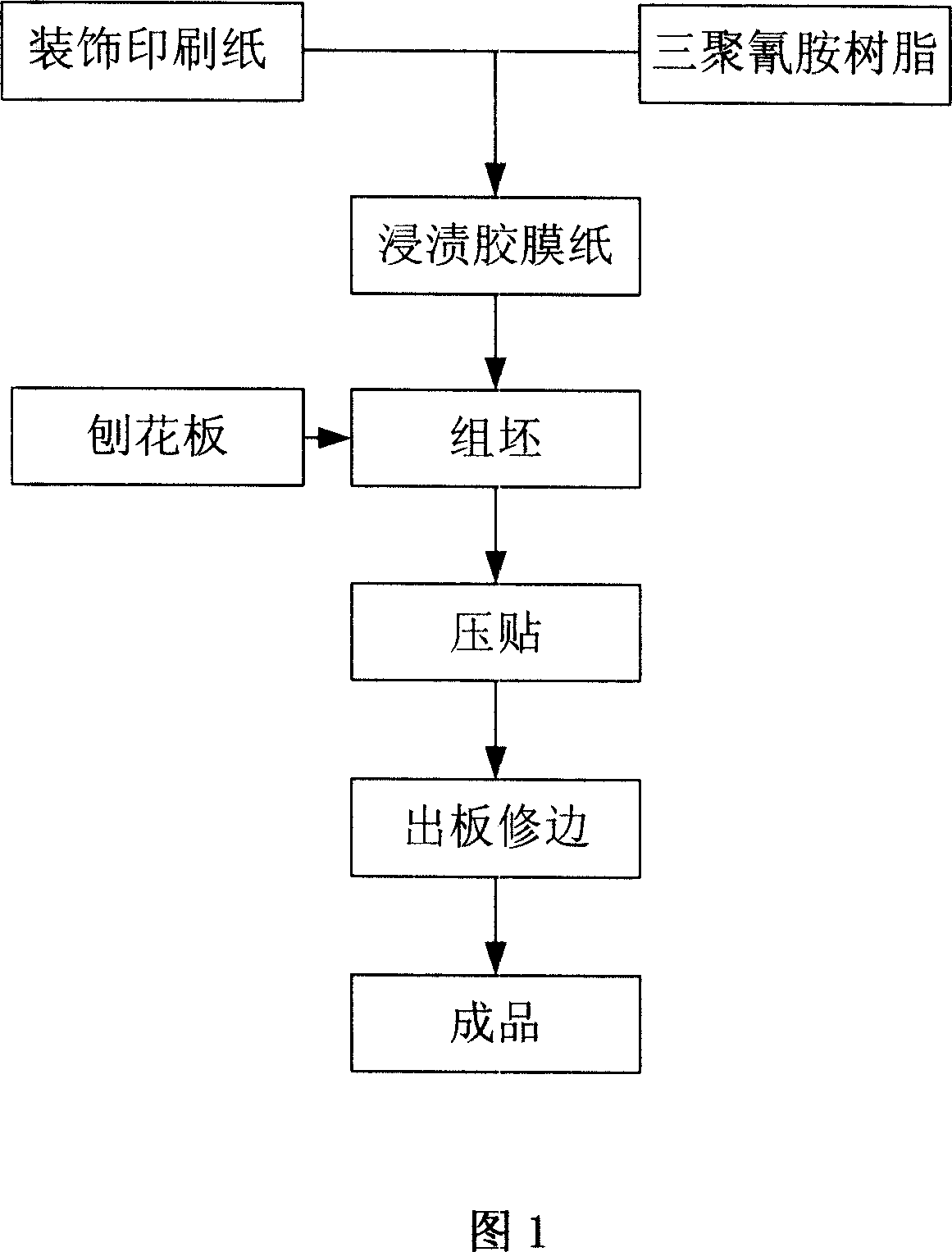

Bright mirror surface and facing artificial plate and manufacturing technique thereof

InactiveCN101011828AIncrease usageOvercoming the deficiency of low brightnessNon-macromolecular organic additionPaper/cardboardDiethylene glycolPulp and paper industry

A melamine impregnated bond paper and chipboard compressed bright surface wood based board is composed of 60-70 portions of water, 100 portions of melamine, 90-130 portions of formaldehyde, diethylene glycol monoethylether 10-15 portions, aminocaprolactam 3.5-5.5 portions and caustic soda 0.3-0.6 portions. Firstly, it wipes off the powder on the surface of the chipboard, aligning them with melamine impregnated bond paper covering the chipboard, increasing the temperature, sending the chipboard and the paper into the compressing machine, ensuring the aligning of the center line of the chipboard and that of the compressing machine, closing the compressing machine, sending out the board, trimming, and getting the bright artificial board. It is bright, with good luster saturation, fine wearing resistance, heat, burning, crack, light and corrosion features.

Owner:吴根水

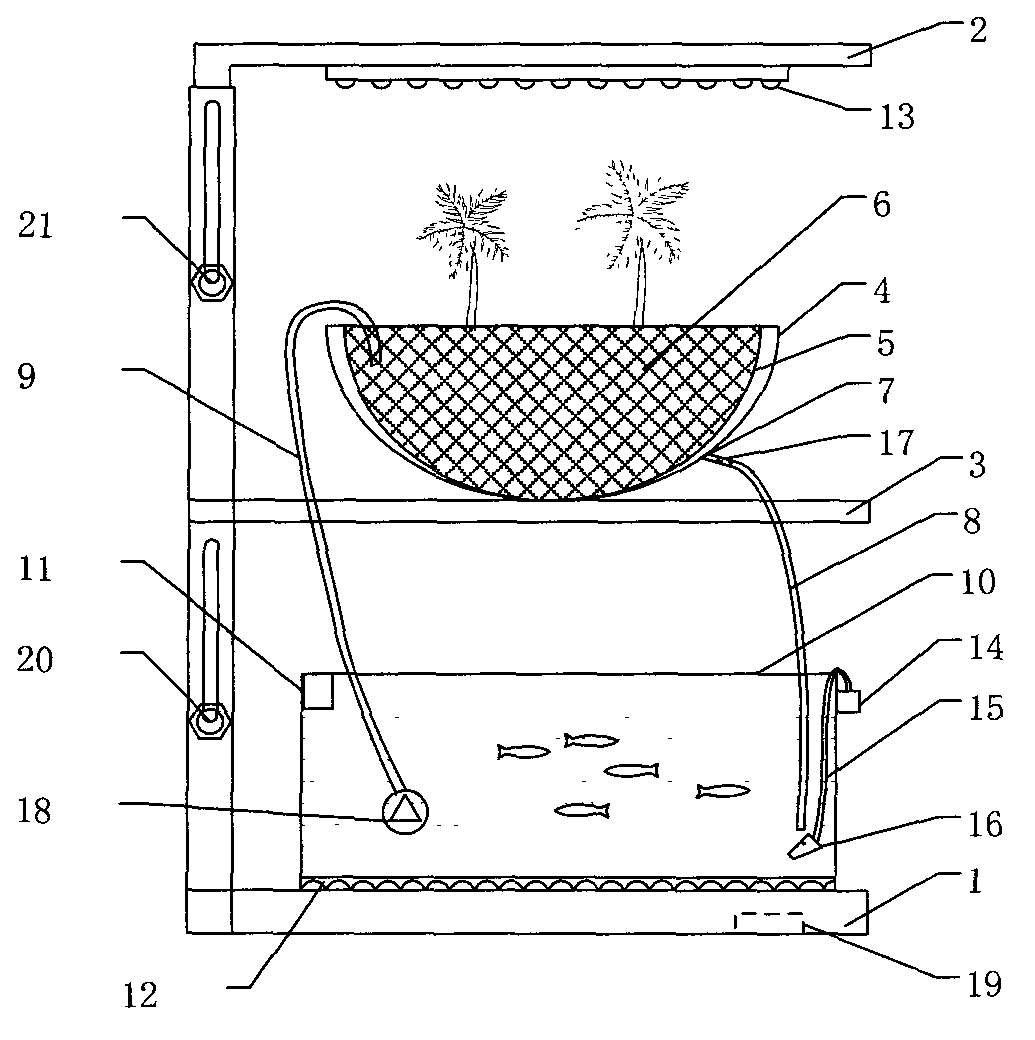

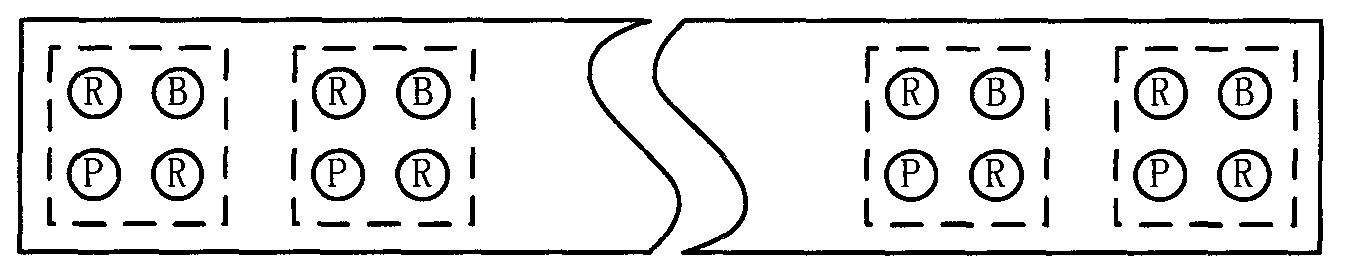

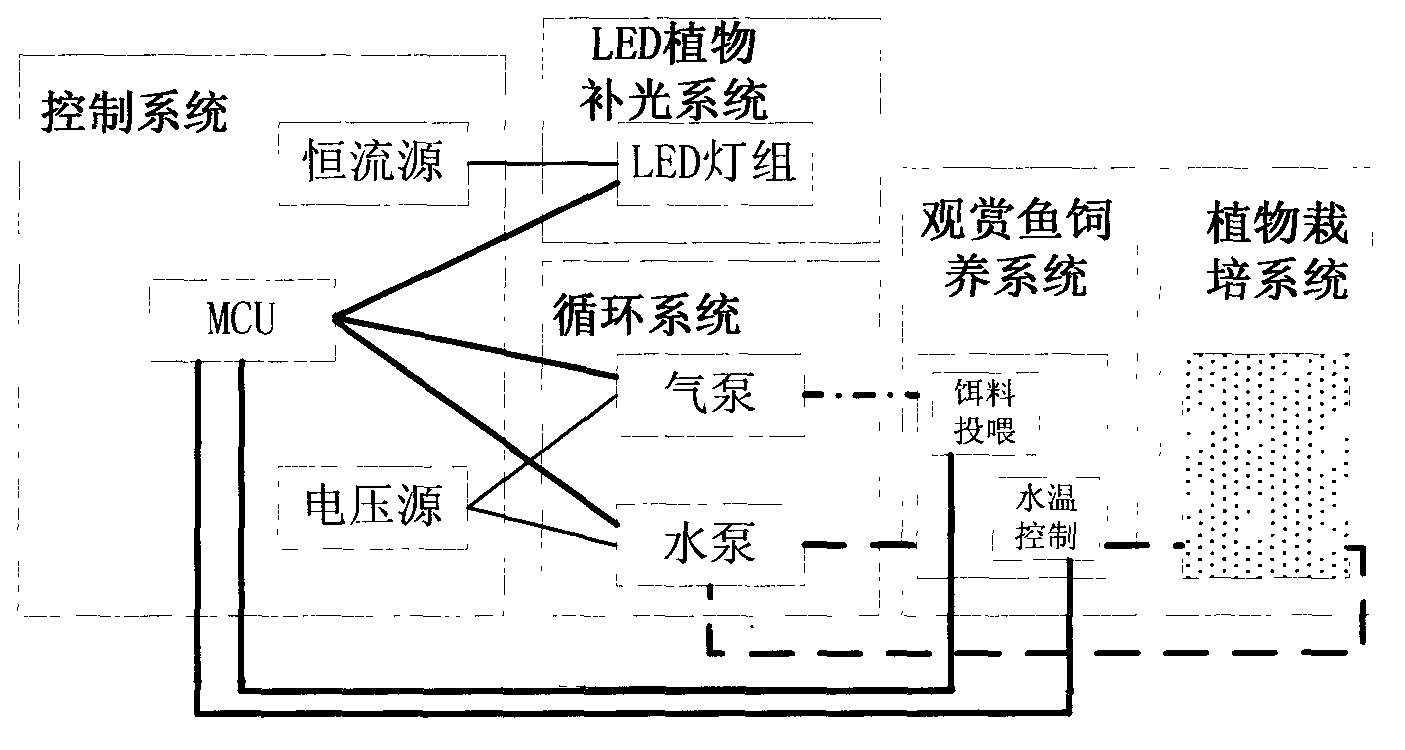

Intelligent LED (Light-Emitting Diode) light supplementing indoor circulating economical planting and breeding system

InactiveCN103070062AAchieve recyclingRegulate humidityPisciculture and aquariaAgriculture gas emission reductionAir cycleControl system

The invention discloses an intelligent LED (Light-Emitting Diode) light supplementing indoor circulating economical planting and breeding system, which is characterized by comprising a plant culturing system, an aquarium fish breeding system, an LED plant light supplementing system, an air circulating system, a water circulating system and a control system, wherein the plant culturing system is connected with the aquarium fish breeding system through the water circulating system; plants are irrigated by using fish breeding water, and excrements of fishes are purified by using the plants, so that circular utilization of water and nutrients is realized; the LED plant light supplementing system is connected with the plant culturing system, so that illumination adjustment and supplement are performed on the plants, and healthy growth of the plants is facilitated; and the aquarium fish breeding system is connected with the air circulating system, so that air with a certain flow amount is pumped into a fish tank periodically, and the oxygen content in water is ensured. According to the economical planting and breeding system, a complete indoor economical planting and breeding system is constructed, and the entire system is simple in structure and low in cost; and meanwhile, the economical planting and breeding system has the effects of purifying indoor air, adjusting indoor air humidity and beautifying indoor environment.

Owner:CHINA JILIANG UNIV

Nourishing life-prolonging noodles

InactiveCN104171903AColorfulEnhance interestFood ingredient functionsFood preparationPolygonum odoratumBearded tooth

The invention discloses nourishing life-prolonging noodles which consist of the following components in parts by mass: 85-97 parts of basic powder, 2-11 parts of health powder, 0.2-0.4 part of enhancement powder and 0.2-6 parts of nutritional powder, wherein the basic powder is one or a combination of more of wheat powder, oat powder, buckwheat flour, purple sweet potato powder, soybean meal, black bean meal, black rice powder, sesame powder, red rice powder and red small bean powder; the health powder consists of corn stigma powder, konjak powder, hericium erinaceus powder, lily powder, sealwort powder, arrowroot, polygonatum odoratum powder and medlar powder; the enhancement powder is peanut protein powder or egg albumen powder; the nutritional powder is one or more of tomato powder or juice, carrot powder or juice, pumpkin powder or juice, strawberry powder or juice, orange powder or juice, hami melon powder or juice, yaw powder, castanea mollissina powder, walnut powder and lotus seed powder. The nourishing life-prolonging noodles supply comprehensive nutritional components; if people eat the product for a long time, the effects of delaying aging, stimulating the appetite, purging the gut, reducing the three highs, tonifying qi, benefiting the kidney, beautifying, resisting cancers and the like are achieved.

Owner:吕甲旺

Outdoor ceramic permeable brick and preparation method thereof

InactiveCN101182185ASolve the defects left in the river and seaPurifying airCeramic materials productionClaywaresBrickMetallurgy

The invention relates to an outdoor ceramic permeable brick and a preparation method thereof. The ceramic permeable brick is made from the components with the following weight content of 90-95wt percent ceramic wastes which are broken into particles that are larger than 0 and smaller than 200 order and 5-10wt percent of adhesive which is bentonite. The ceramic waste particles include mixed particles which are screened from the broken ceramic waste particles. The mixed particles include particles of 0-8 order, the content of which is larger than zero and smaller than 5 percent; particles of 8-30 order, the content of which is 85-90 percent; particles of 30-100 order, the content of which is 5-15 percent. The preparation method includes: firstly, breaking the ceramic waste materials into the particles of 8-30 order; secondly, adding adhesive and water in proportion in the particle ceramic waste materials to obtain a mixture; thirdly, filling the mixture slurry in a die to press into a water permeable brick shape under the 90-110pa / mm<2> pressure of a press machine; fourthly, firing at the temperature of 1160-1220 DEG C.

Owner:福建省晋江协隆陶瓷有限公司

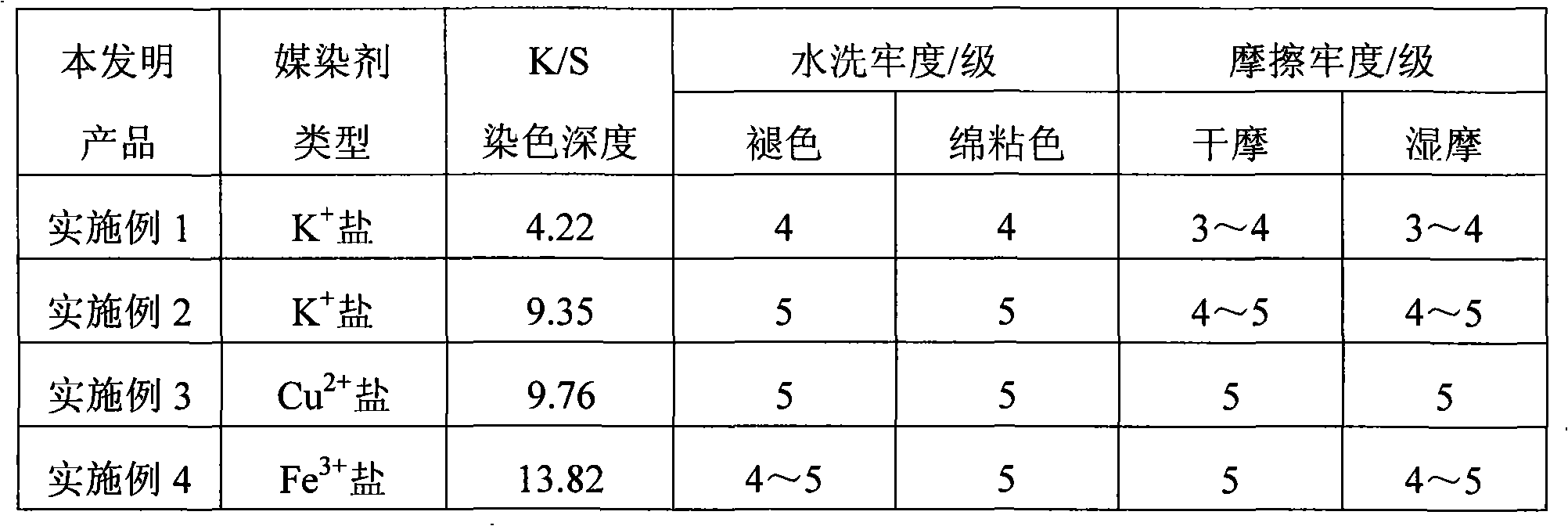

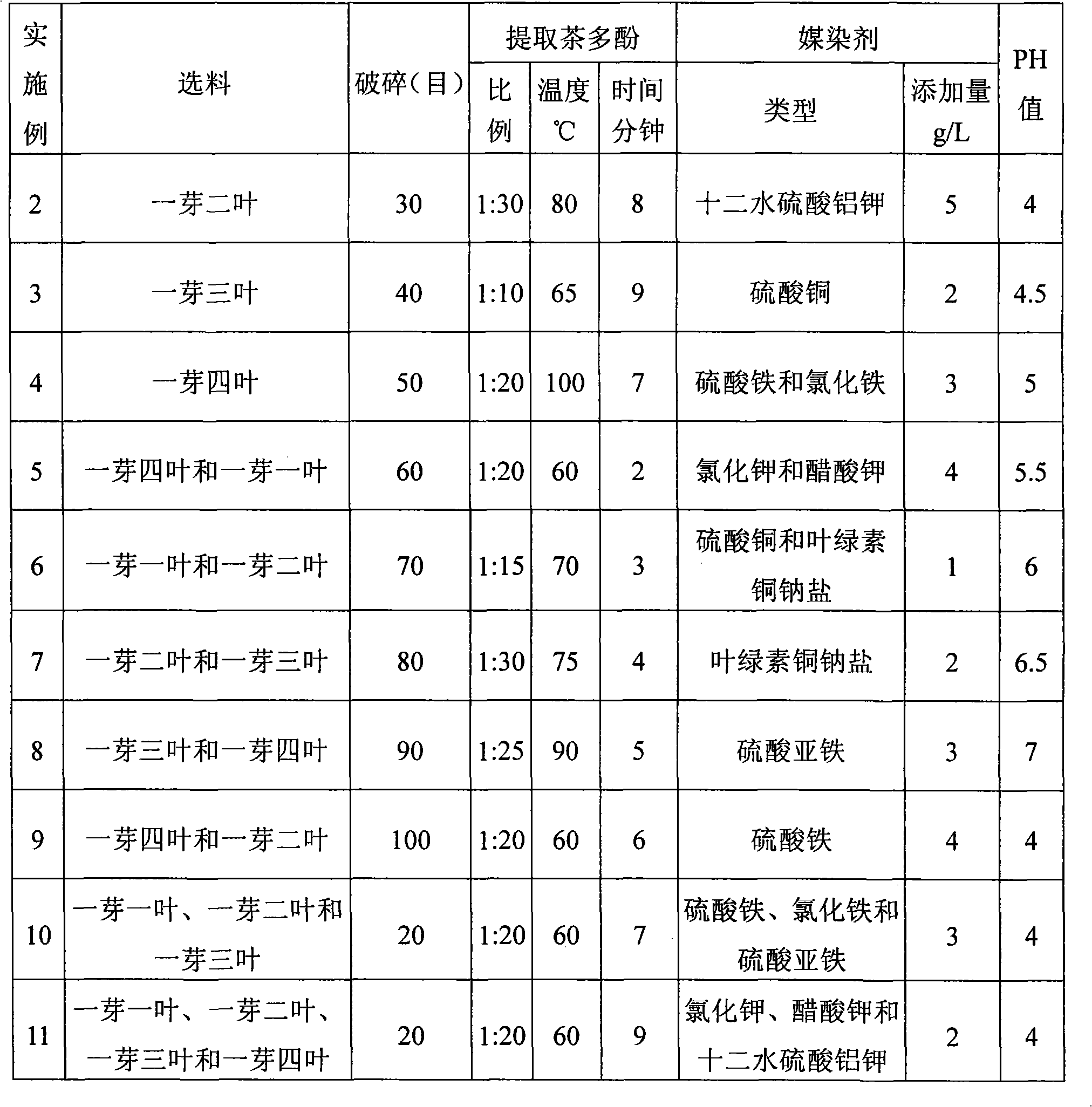

Natural staining agent, preparation thereof and application thereof to silk dyeing

The invention provides a natural coloring agent, which is characterized in that: the fresh tea leaves are used as material to extract tea polyphenol, and then the extraction liquid of the tea polyphenol is added with mordant agent, so as to form the natural coloring agent. As the natural coloring agent has rich color, good dyeing effect, good dyeing fastness (in particular wash fastness), and low production cost, the natural coloring agent has wide application, and strong practicality. The natural coloring agent also provides a preparation method of natural dyeing agent and an application at the aspect of silk fabric dyeing.

Owner:CHONGQING ACAD OF AGRI SCI

Method for applying metal wire-imitated coating film on surface of engineering plastics

ActiveCN102166565AAnti-corrosionWear-resistantCoatingsSpecial surfacesWater savingEngineering plastic

The invention provides a method for applying a metal wire-imitated coating film on the surface of engineering plastics, and relates to a surface treatment method of the engineering plastics. The method for applying the metal wire-imitated coating film on the surface of engineering plastics can improve the function and the quality of a plastic metalized product, can simplify the technology, can reduce the production cost, and is water-saving and environment-friendly without needing any water liquid in the whole technological process. The method comprises the steps of adding dye into plastic master batch, and coloring; cleaning and activating a plastic blank in a drying way; spraying a color coat onto the plastic blank; performing the wire drawing to a work piece so as to obtain the surface with wire drawing veins; cleaning and activating the work piece in a drying way; and spraying finishing paint to the work piece with the wire drawing veins so as to apply the metal wire-imitated coating film on the surface of the engineering plastics.

Owner:XIAMEN RUNNER IND CORP

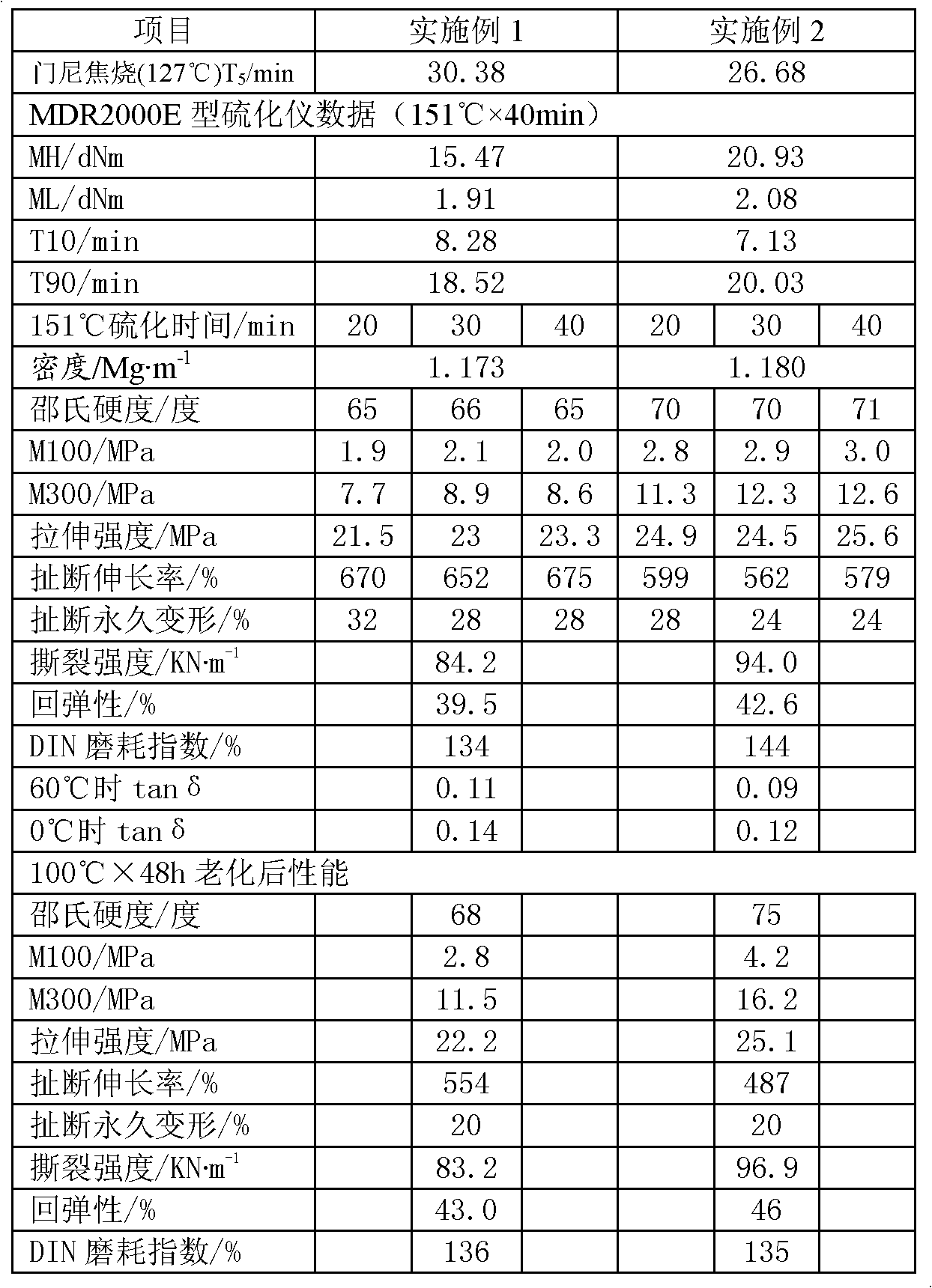

Rubber composition for color truck radial tire tread

The invention discloses a rubber composition for a color truck radial tire tread. The rubber composition comprises, by weight, 100 parts of a rubber matrix, 5-8 parts of an active agent, 40-80 parts of white carbon black, 4-8 parts of a silane coupling agent, 4-10 parts of light color rubber oil, 1.5-3.5 parts of an accelerator, 4-8 parts of an anti-aging agent, 1-2 parts of a vulcanizing agent, 5-8 parts of an antistatic agent, and 3-6 parts of a coloring agent, wherein the rubber matrix comprises a natural rubber and rare earth polybutadiene rubber, or comprises a natural rubber, rare earthpolybutadiene rubber and styrene butadiene rubber, the white carbon black is the high dispersible precipitated white carbon black, the accelerator is the combination of an accelerator CBS and an accelerator DPG, the anti-aging agent is the combination of three components of a non-polluting type light color antiozidant, a non-polluting type light color antioxidant and an anti-aging agent RD, the vulcanizing agent is sulfur, and the antistatic agent is a polyether antistatic agent. With the rubber composition of the present invention, the tensile strength of the prepared tread is 25 MPa, and the elongation at break is more than 500%. The rubber composition of the present invention is mainly used for the color truck radial tire tread.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

Colour asphalt and its preparation method

The present invention discloses a color asphalt and its preparation method. Its composite includes petroleum asphalt 90# 40-44%, petroleum resin 120# 26-30%, petroleum resin 90# 3-5%, extractive oil 4-6%, xylene 2-4%, santobrite salt 5-7%, 99% chromium 2-4%, iron oxide 30# 3-5%, rosen 3-4% and titanium oxide 1-3% and proper quantity of pigment. Said invention adopts the following processes: reduced pressure distillation for extracting asphaltene, splitting by splitter tower, adding resin material, titanium and pigment, then making high-temp. synthesis. It is a new type builidng material, can be used for laying pavement, etc.

Owner:周英久

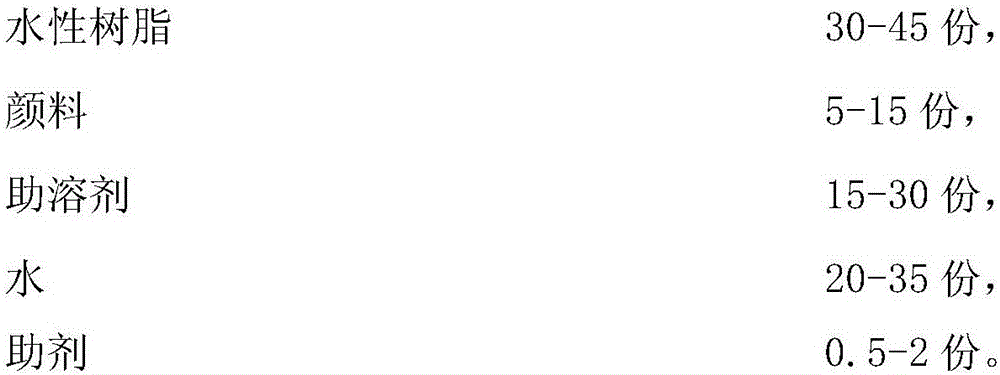

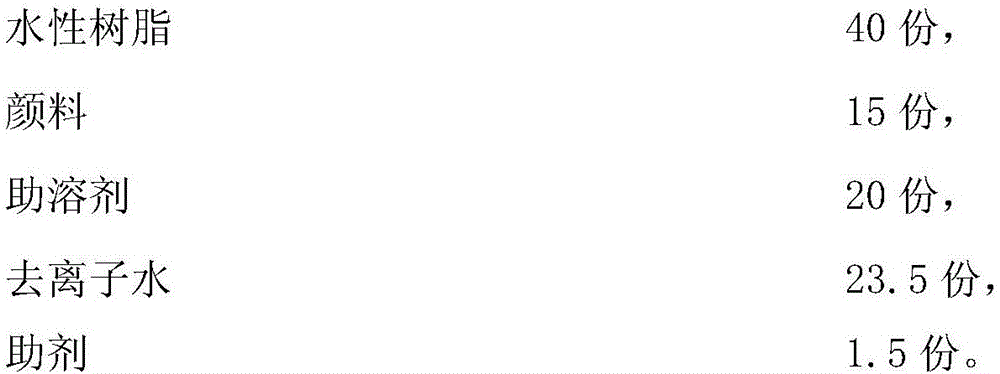

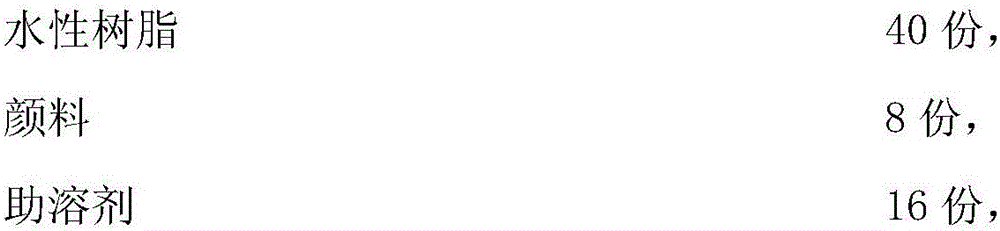

Environmentally-friendly aqueous spray paint and preparation method thereof

InactiveCN105907201AImprove atomization effectHigh ejection ratePolyurea/polyurethane coatingsEnvironmental resistanceHardness

The invention provides an environmentally-friendly aqueous spray paint liquid, a propellent, an aerosol coated environmentally-friendly aqueous spray paint and a preparation method of the paint. The liquid comprises, by weight, 30-45 parts of aqueous resin, 5-15 parts of a pigment, 15-30 parts of a cosolvent, 20-35 parts of water and 0.5-2 parts of an assistant. The environmentally-friendly aqueous spray paint liquid adopts an aqueous resin system, so a whole paint film has a good hydrophobic and oleophobic effect, and improvement of the quality of spray paint products is facilitated; water is used to substitute parts of a solvent, so the VOC is reduced, and environmental protection is realized; and the produced environmentally-friendly aqueous spray paint has good sprayability and a high spray rate, and a film formed by the paint has high fullness, excellent hardness, adhesion, glossiness, flexibility and impact resistance, and has abundant and gorgeous colors, excellent decorative effect, good ageing resistance, and extremely good antirust and protection functions.

Owner:中山市润宜汽车用品有限公司

Preparation method of red photonic crystal structured colored glaze

The invention discloses a preparation method of red photonic crystal structured colored glaze, which belongs to the technical field of ceramic glaze preparation. The preparation method comprises the following steps: 1) preparing anhydrous ethanol, ammonia water, water and ethyl orthosilicate in percentage by volume, and after the anhydrous ethanol, the ammonia water and the water are fully and uniformly mixed firstly, adding the ethyl orthosilicate into the obtained mixture, and stirring to have reaction to obtain SiO2 microsphere suspension liquid; 2) centrifuging the SiO2 microsphere suspension liquid, taking precipitates, and washing and drying the precipitates so as to obtain monodisperse SiO2 microspheres; 3) adding the monodisperse SiO2 microspheres into the anhydrous ethanol, carrying out ultrasonic dispersion so as to obtain a SiO2 microsphere emulsion; and 4) putting a ceramic substrate vertically into the SiO2 microsphere emulsion, carrying out vacuum drying until the anhydrous ethanol in the SiO2 microsphere emulsion is completely volatilized, and finally preparing a red photonic crystal structured colored glaze on the surface of the ceramic substrate. Because no pigment or coloring oxide is introduced, the method has the advantages of energy saving and environmental protection, has a broad application prospect, and can be applied to the preparation of red glaze for artistic ceramics, antique ceramics, floor and wall tiles and other ceramics.

Owner:SHAANXI UNIV OF SCI & TECH

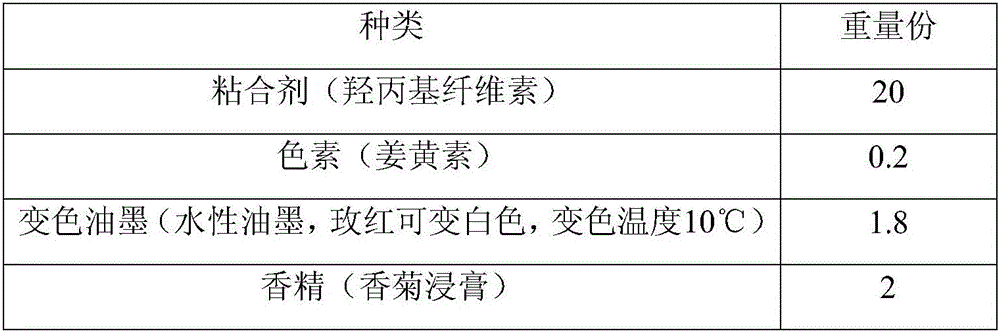

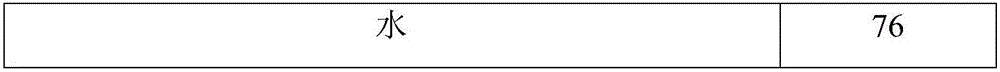

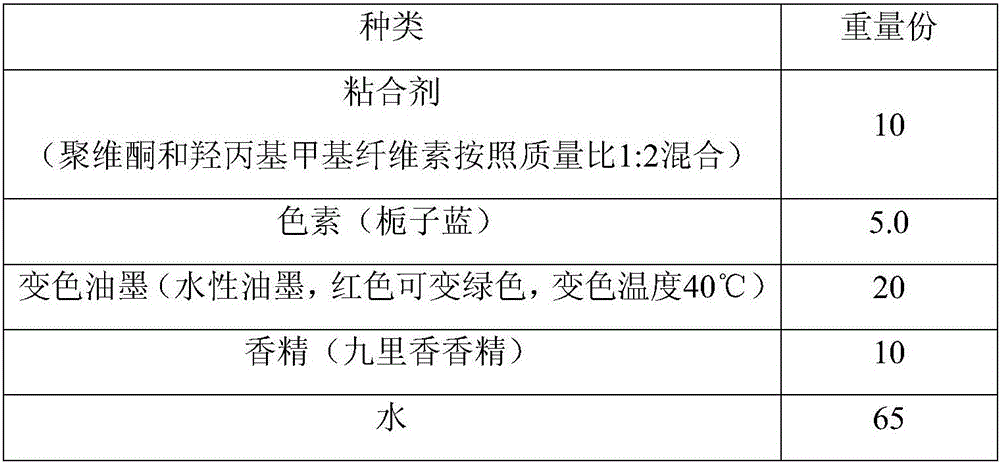

Variable color fragrance bead for tobacco and preparation method of the fragrance bead

The invention provides a variable color fragrance bead for tobacco and a preparation method of the fragrance bead. The fragrance bead is prepared by the following steps: firstly solid mixed powder material is placed in a centrifugal coating granulator, and an adhesive solution is sprinkled as a slurry material, the powder material is rotated in the centrifuge and forms mother cores, then the mother cores are still placed in the centrifugal coating granulator, a variable color fragrance adhesive solution is sprinkled as a slurry material, the solid mixed powder material is added during the process of sprinkling, enlargement and preparation of granules is continued and the granule size increases, and the granules form variable color fragrance beads for tobacco. The solid powder material is formed by evenly mixing natural plant powder, starch, chitosan and microcrystalline cellulose. The variable color fragrance adhesive solution is formed by mixing adhesives, pigments, essence, variable color printing ink and water. The method can provide tobacco with fragrance which can improve the smoking quality, and a customer can see color change of the beads directly during smoking, so that the customer can have both vision and taste experience.

Owner:HUBEI CHINA TOBACCO IND

Method for manufacturing Chinese hemp multi-component covering type two-sided knit fabric

ActiveCN101498074ANatural antibacterialNatural UV resistanceWeft knittingWarp knittingYarnUltraviolet

The invention relates to a manufacture method of a hemp, polycomponent, covering and double-knitted fabric, which comprises the following steps: (1), weaving 30 percent of hemp, 35 percent of terylene and 35 percent of cotton by weight percentages into hemp blended yarn with a yarn number of 40 and then weaving the hemp blended yarn with moisture-bsorbing and rapidly-drying terylene yarn into a fabric under the condition that the weight ratio of the hemp blended yarn to the moisture-bsorbing and rapidly-drying terylene yarn is 55-65 to 35-45; (2) bleaching and heating a solution at a speed of 2 DEG C / min to a temperature of 98 DEG C under the condition that a bath ratio is 1 to 12, bleaching the solution at the temperature for 30 minutes, cooling the solution at a speed of 2 DEG C / min to 25 DEG C and washing the solution for 20 minutes; (3) dyeing; and (4) post-treatment technology. The invention has the advantages that hemp fibers have wide prospects after being applied to fabrics because the hemp has natural superior characteristics of antibacterium, ultraviolet ray resistance, moisture absorbable and breathable properties, and the like, the fabric adopts the blended yarn of the hemp, the cotton and the terylene to weaken the rigidity of the blended yarn, and the hemp fabric solves the problem of scratchiness and has bright colors and high color fastness.

Owner:北京铜牛集团有限公司

Crystal color ceramic, crystal color glass, composite material for crystal color illuminating layer and technical method thereof

The invention discloses a crystal colorized ceramic and crystal colorized glass, substantially composite materials and process method of crystal colorized decorative layer, which comprises the following weight materials: dry-powder glaze 6-60, bond 15-50, additive 0-70, glass micro-ball 20-90; in the invention the surfaces of the ceramic and glass product adopt the crystal colorized materials and then are ornamented with patterns, and then sintered for a plurality of times at 400-860 DEG C so as to form a crystal colorized decorative layer. The product has the advantages of brocade-like straight light, wool-like side light, light-shift color-change, and special optical effect with strong solid feeling.

Owner:邓念东 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com