Natural staining agent, preparation thereof and application thereof to silk dyeing

A natural dyeing agent and mordant technology, applied in the field of natural dyeing agent and its preparation, can solve the problems of poor color fastness to washing, high production cost, difficulty in popularization and application, etc., achieve good dyeing effect, strong practicability, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: a kind of natural dyeing agent, it is characterized in that it is that the tea polyphenol in fresh tea leaf is extracted with fresh tea leaf as raw material, then adds mordant to make in tea polyphenol extraction liquid again.

[0040] Its concrete preparation steps are as follows:

[0041] Material selection: Fresh leaves of tea trees from April to October are used, free from rot, inclusions, and sand. The standard for fresh leaves is one bud and one leaf;

[0042] Raw material cleaning: the cleaning water must meet the GB5749 standard, and the water should be washed repeatedly until the water is clear;

[0043] Crushing: use a hammer cutter to break into particles of about 20 mesh;

[0044] Extraction: adopt stainless steel extraction tank to extract by microwave heating, microwave heating frequency is 2400~2500MHz, heating extraction temperature is 60 ℃, extraction time is 9 minutes; The dosage ratio of fresh tea leaves and water (hereinafter referred...

Embodiment 2~ Embodiment 11

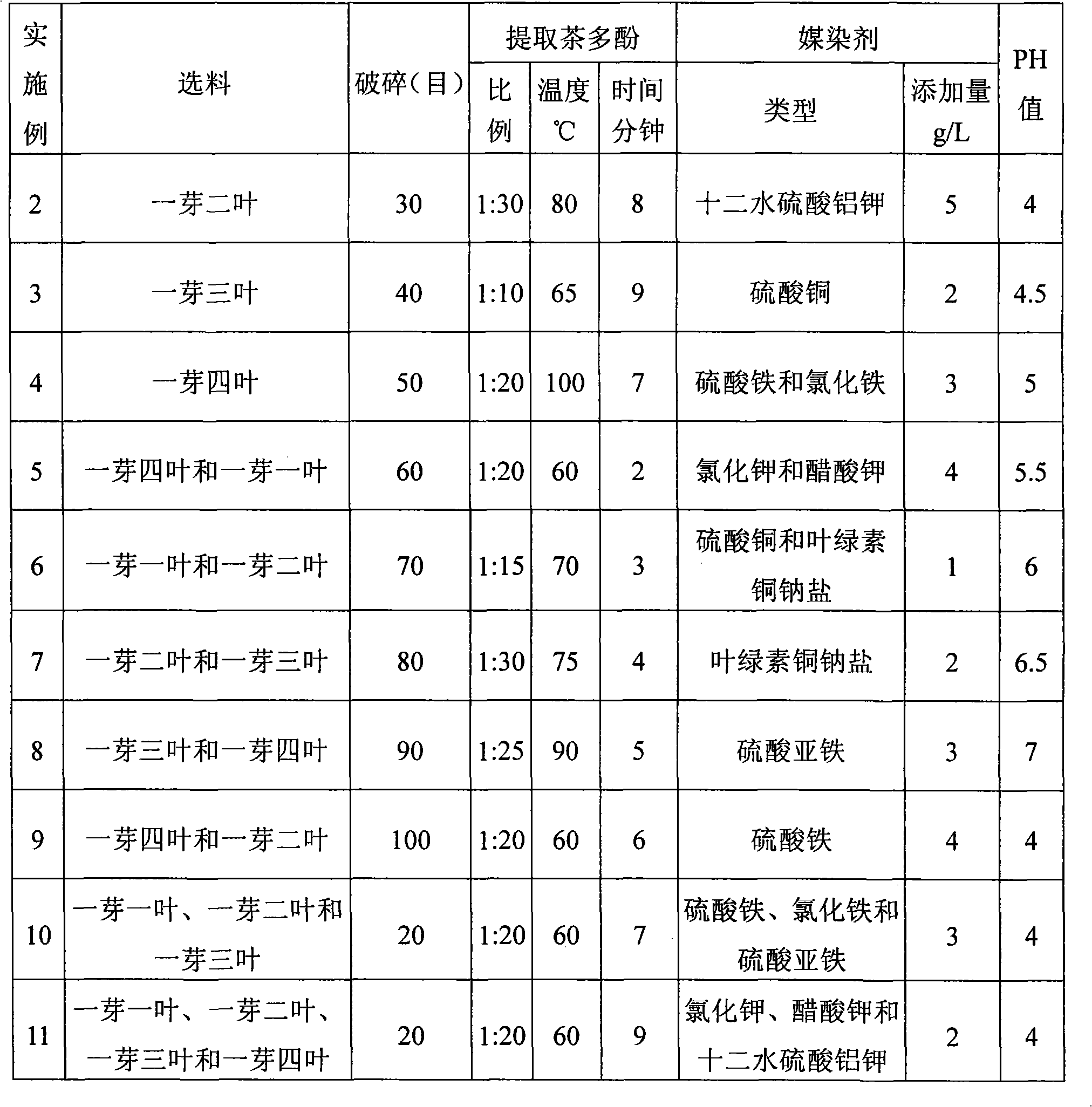

[0050] Repeat the steps described in Example 1, wherein the various process parameters involved are shown in Table 8, and the rest are the same as in Example 1.

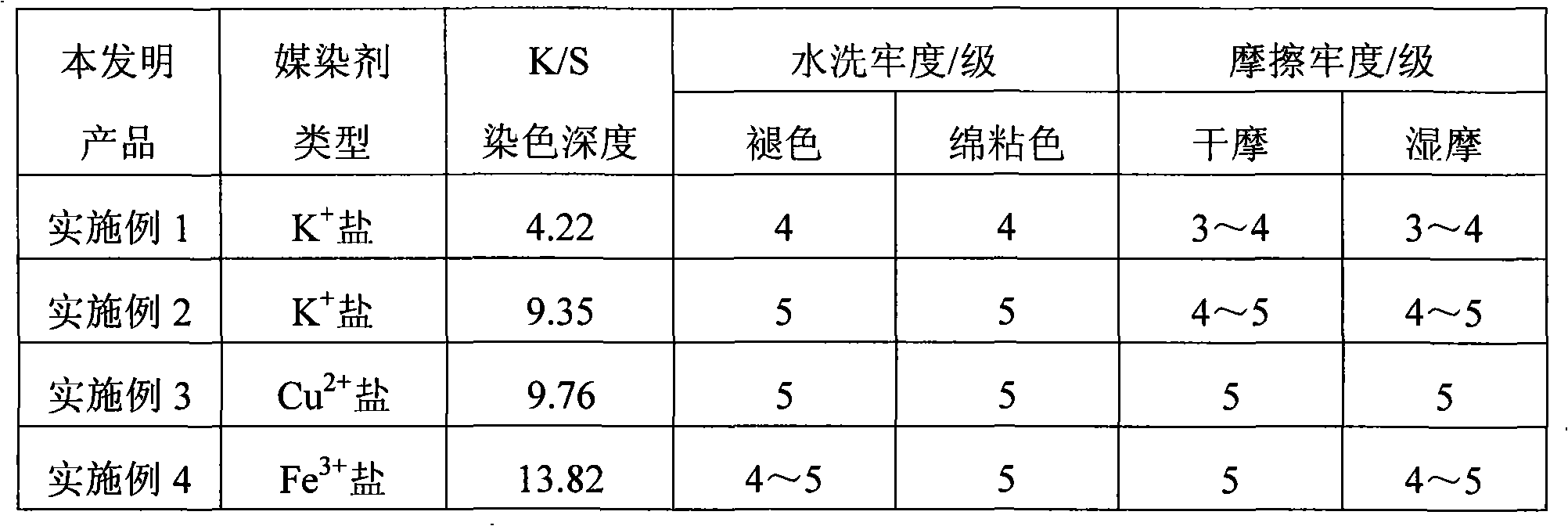

[0051] The dyeing effects of the products of Examples 2 to 4 applied to gray fabrics of natural silk fabrics are shown in Table 1 above.

[0052] Table 8: Various process parameters in Embodiment 2 to Embodiment 11 of the present invention

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com