Patents

Literature

212results about How to "Good dyeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition for improving wettability of surfaces

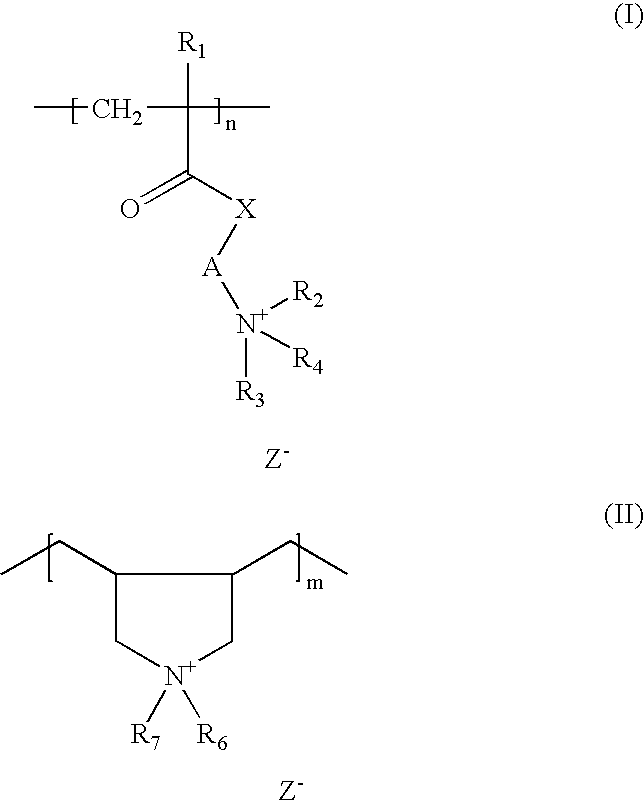

InactiveUS20080033106A1Improve hydrophilicityGood dyeabilityDetergent compounding agentsPolymer scienceNonwoven fabric

The invention is directed to a method for improving the wettability / hydrophilicity of hydrophobic substrates by applying block copolymers to said substrates wherein the block copolymers comprise a quaternary ammonium polymer block and a hydrophobic block. The method of the invention is especially advantageous when used to improve the wettability of non-wovens and in the treatment of hydrophobic surfaces encountered in the home to prevent the buildup of soil residues.

Owner:CIBA SPECIALTY CHEM CORP

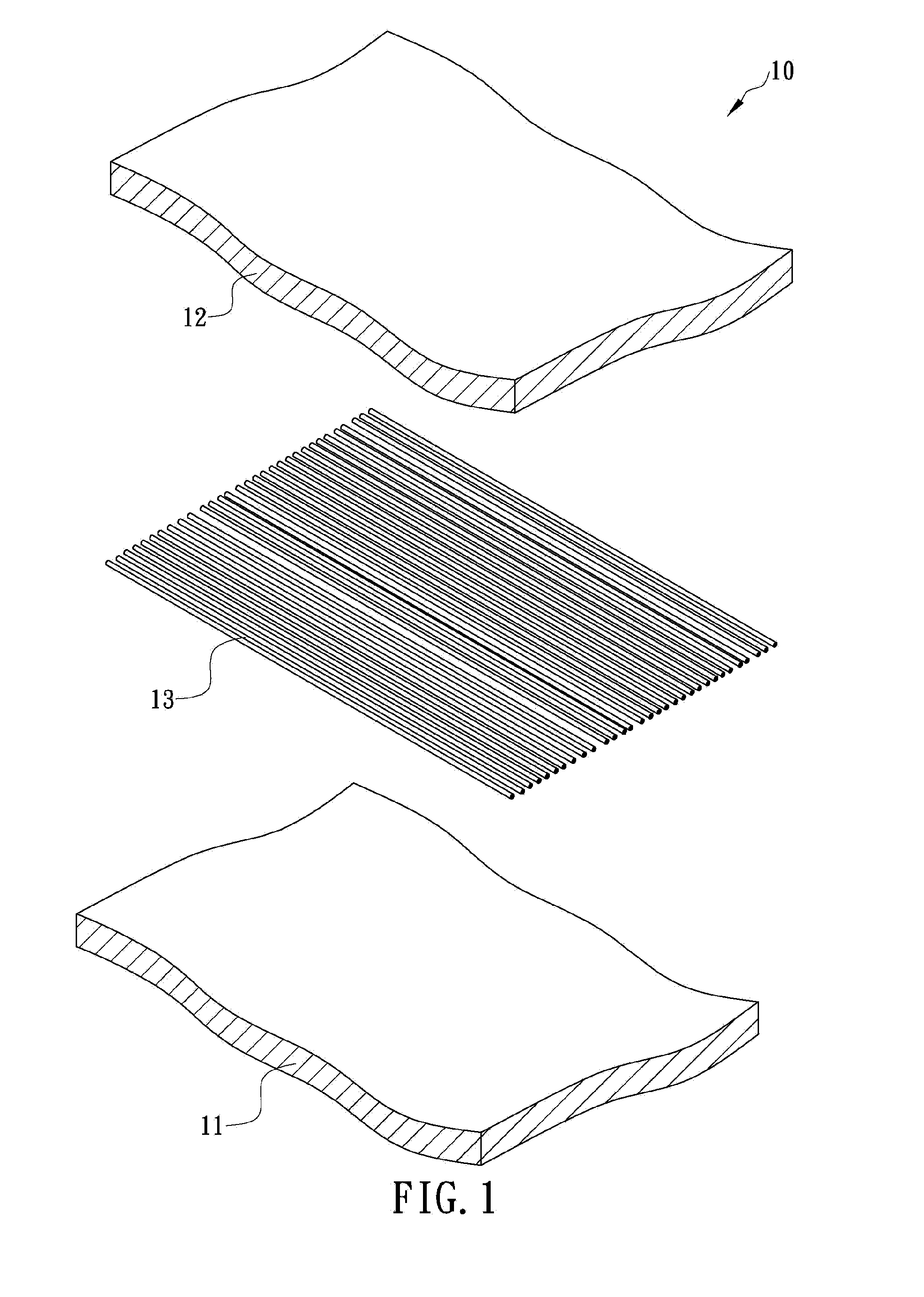

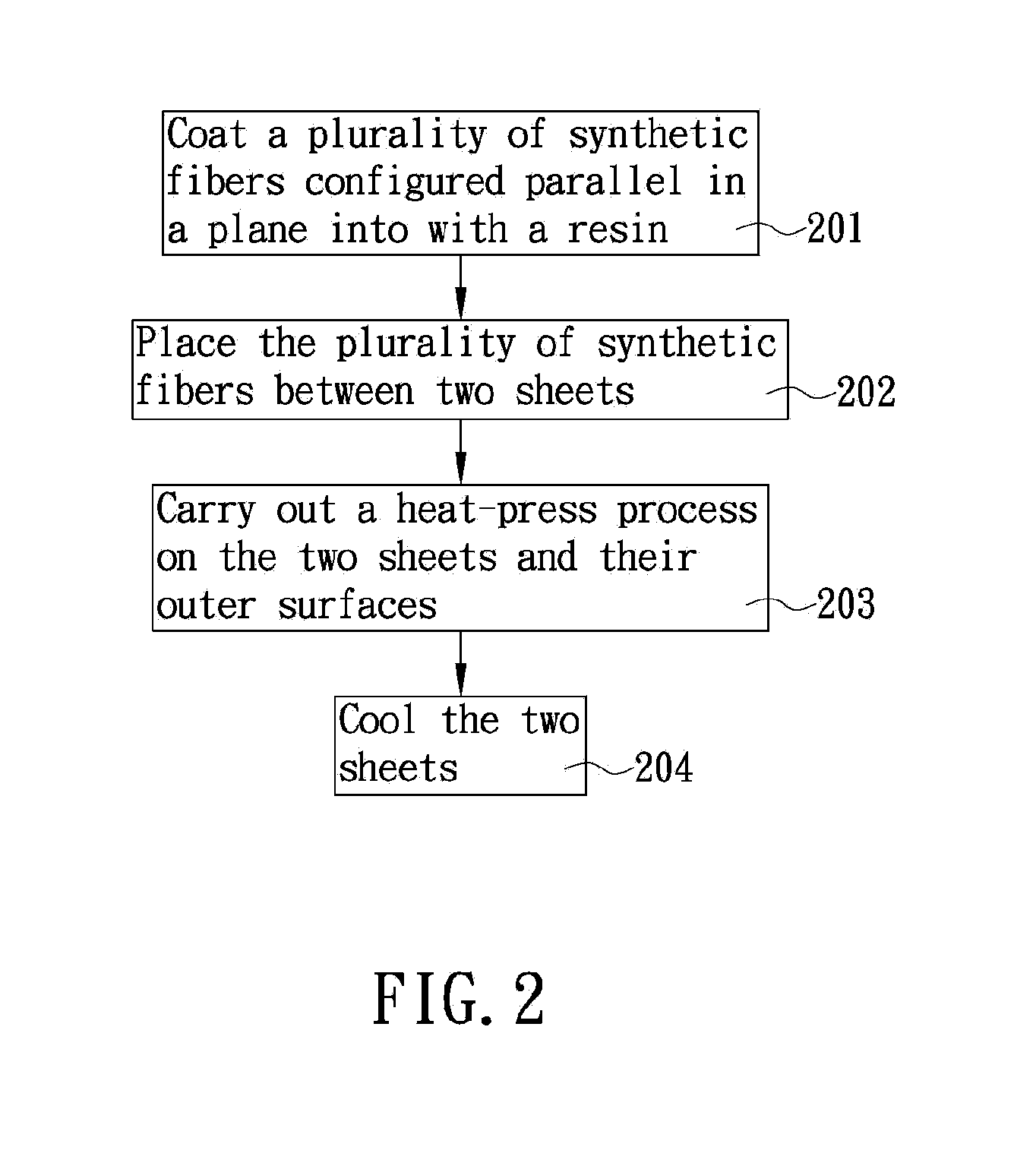

Emulated wood with pores and fibers and fabrication method thereof

ActiveUS20150376840A1Reduce surface polarityImprove compatibilityNatural cellulose pulp/paperPaper after-treatmentPolymer scienceFoaming agent

A method for fabricating emulated wood with pores and fibers, comprising: immersing a plurality of synthetic fibers configured parallel in a plane into a resin so that the resin is coated on the surfaces of the plurality of synthetic fibers and in the gaps between the plurality of synthetic fibers; placing the plurality of synthetic fibers between two sheets, wherein the two sheets are planar sheets made from a uniform composition comprising a thermoplastic elastomer, a foaming agent, and a crosslinking agent; carrying out a heat-press process on the two sheets so that the foaming agent undergoes microcellular foaming and forms dense closed pores in the two sheets, and so that the composition on inner surfaces of the two sheets expands towards the plurality of synthetic fibers and penetrates through the gaps between the plurality of synthetic fibers; and cooling the two sheets to yield an emulated wood board.

Owner:MICROCELL COMPOSITE CO LTD

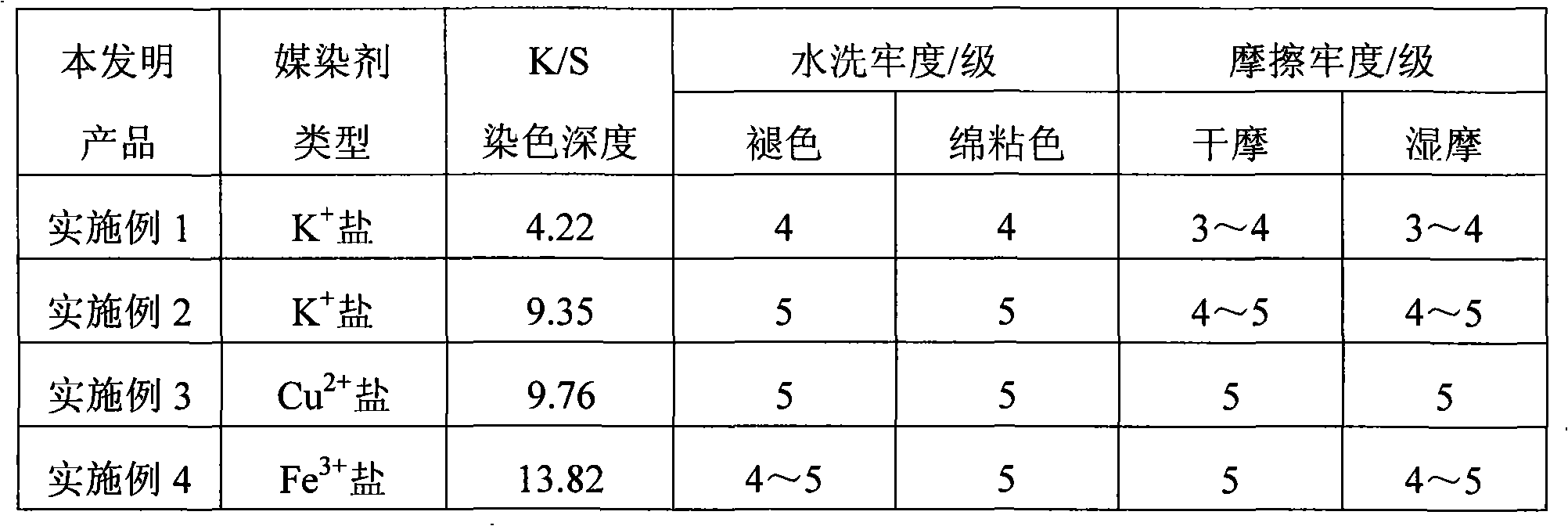

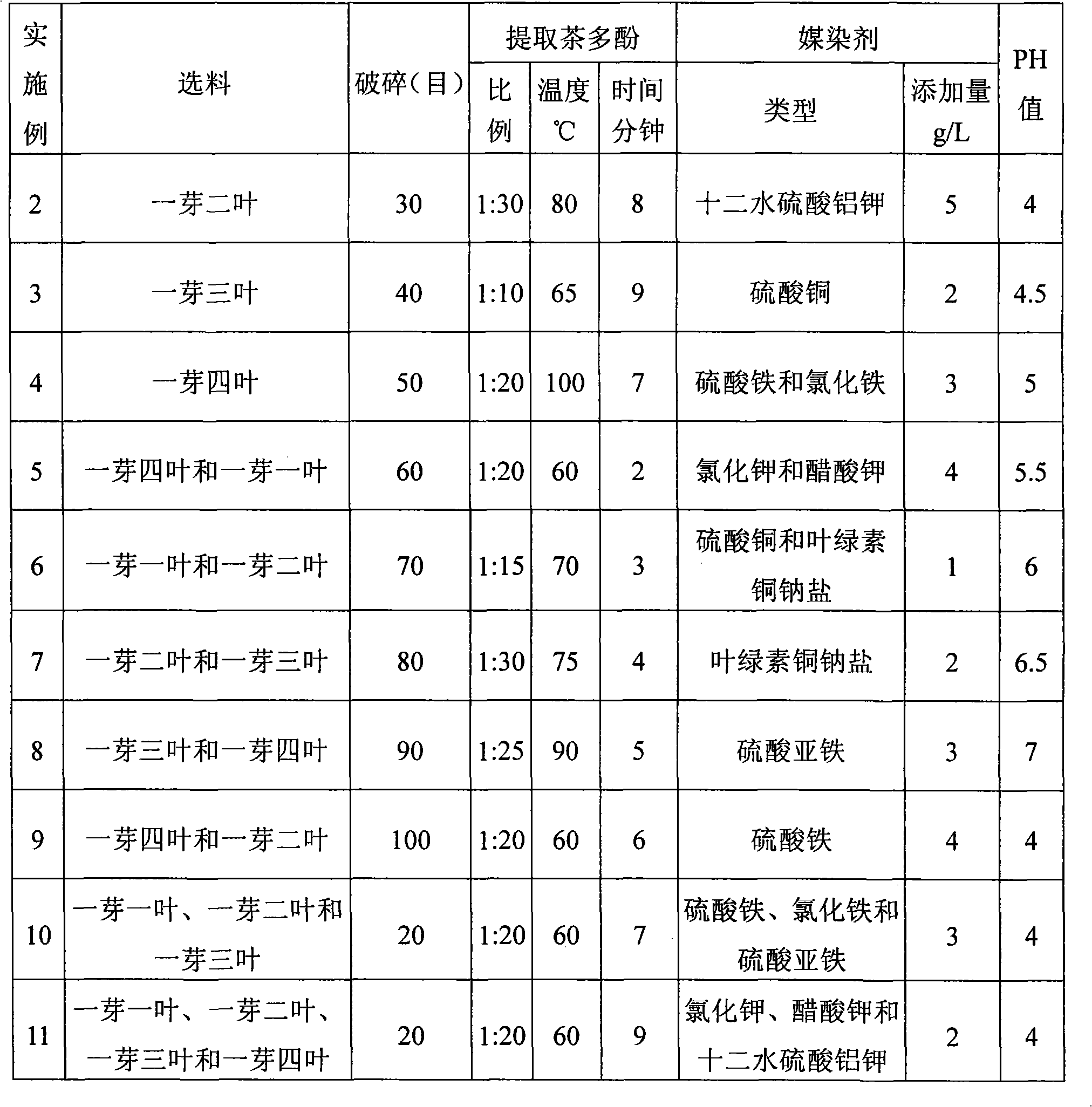

Natural staining agent, preparation thereof and application thereof to silk dyeing

The invention provides a natural coloring agent, which is characterized in that: the fresh tea leaves are used as material to extract tea polyphenol, and then the extraction liquid of the tea polyphenol is added with mordant agent, so as to form the natural coloring agent. As the natural coloring agent has rich color, good dyeing effect, good dyeing fastness (in particular wash fastness), and low production cost, the natural coloring agent has wide application, and strong practicality. The natural coloring agent also provides a preparation method of natural dyeing agent and an application at the aspect of silk fabric dyeing.

Owner:CHONGQING ACAD OF AGRI SCI

Composition for optical material

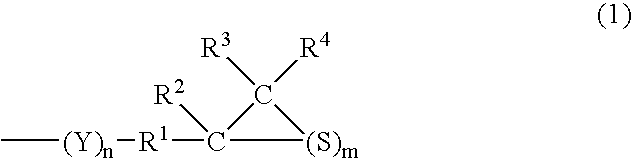

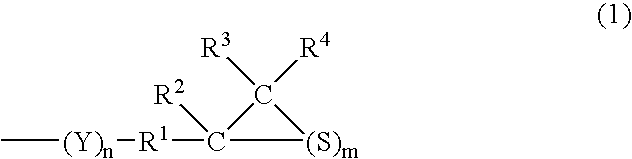

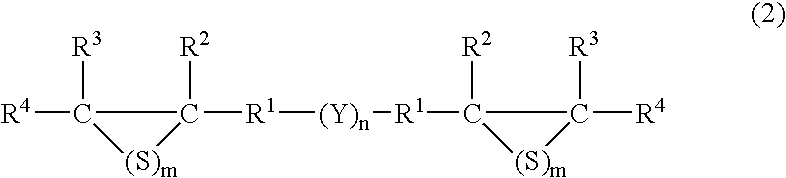

InactiveUS20040122201A1Highly refractoryImprove impact resistanceOptical partsOptical elementsHydrogenSulfur

The present invention relates to a composition for optical materials, comprising (a) a compound having in one molecule at least one structure represented by the following Formula 1: wherein R<1 >is a C0-10 hydrocarbon group, each of R<2>, R<3 >and R<4 >is a C1-10 hydrocarbon group or hydrogen, Y is O, S, Se or Te, m is 1 to 5, and n is 0 to 5; (b) a compound having in one molecule at least one isocyanate group and / or at least one isothiocyanate group; (c) a compound having in one molecule at least one mercapto group; and (d) an inorganic compound having sulfur atom and / or selenium atom, and also relates to an optical material produced by polymerization curing the composition, a production method thereof, and an optical lens comprising the optical material. The present invention provides a high refractive, high Abbe's number optical material having an improved impact resistance.

Owner:MITSUBISHI GAS CHEM CO INC

Powder hair dye composition, use thereof and storage package therefor

InactiveUS20110203604A1Good dyeabilitySuppress increase of oxygen gas pressureCosmetic preparationsHair cosmeticsHair dyesSulfate

A powder hair dye composition containing sodium percarbonate with an active oxygen amount within a range of 12.0 to 15.3% by mass as a component (A), additionally containing a sequestering agent as a component (B) preferably and still additionally the sulfate salt of an oxidation dye as a component (C) more preferably. In accordance with the invention, the dyeability and bleaching ability of the powder hair dye composition can be enhanced, together with the resulting good hair feeling after application; additionally, the increase of oxygen gas pressure in the storage package can be suppressed, and the storage stability of the powder hair dye composition can be retained in a secure fashion.

Owner:HOYU CO LTD

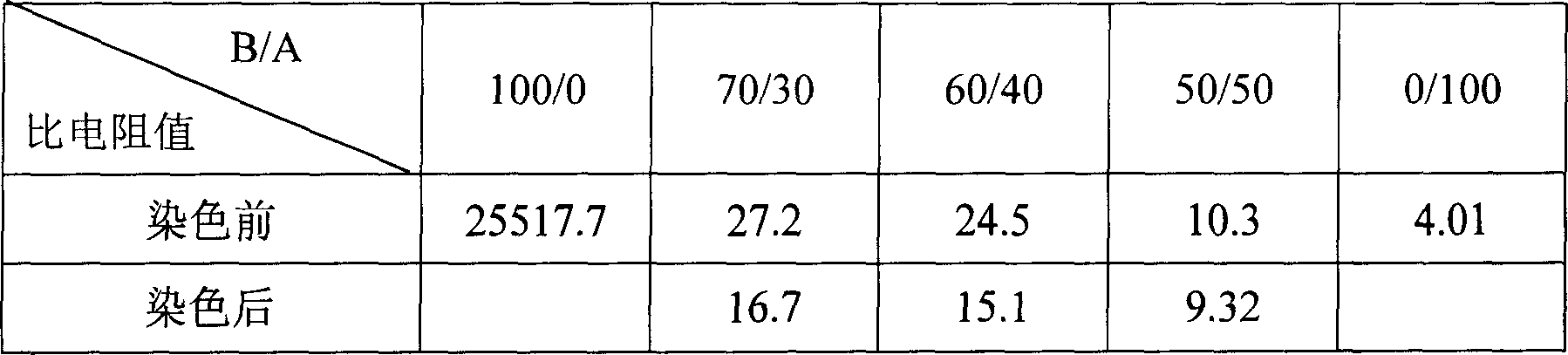

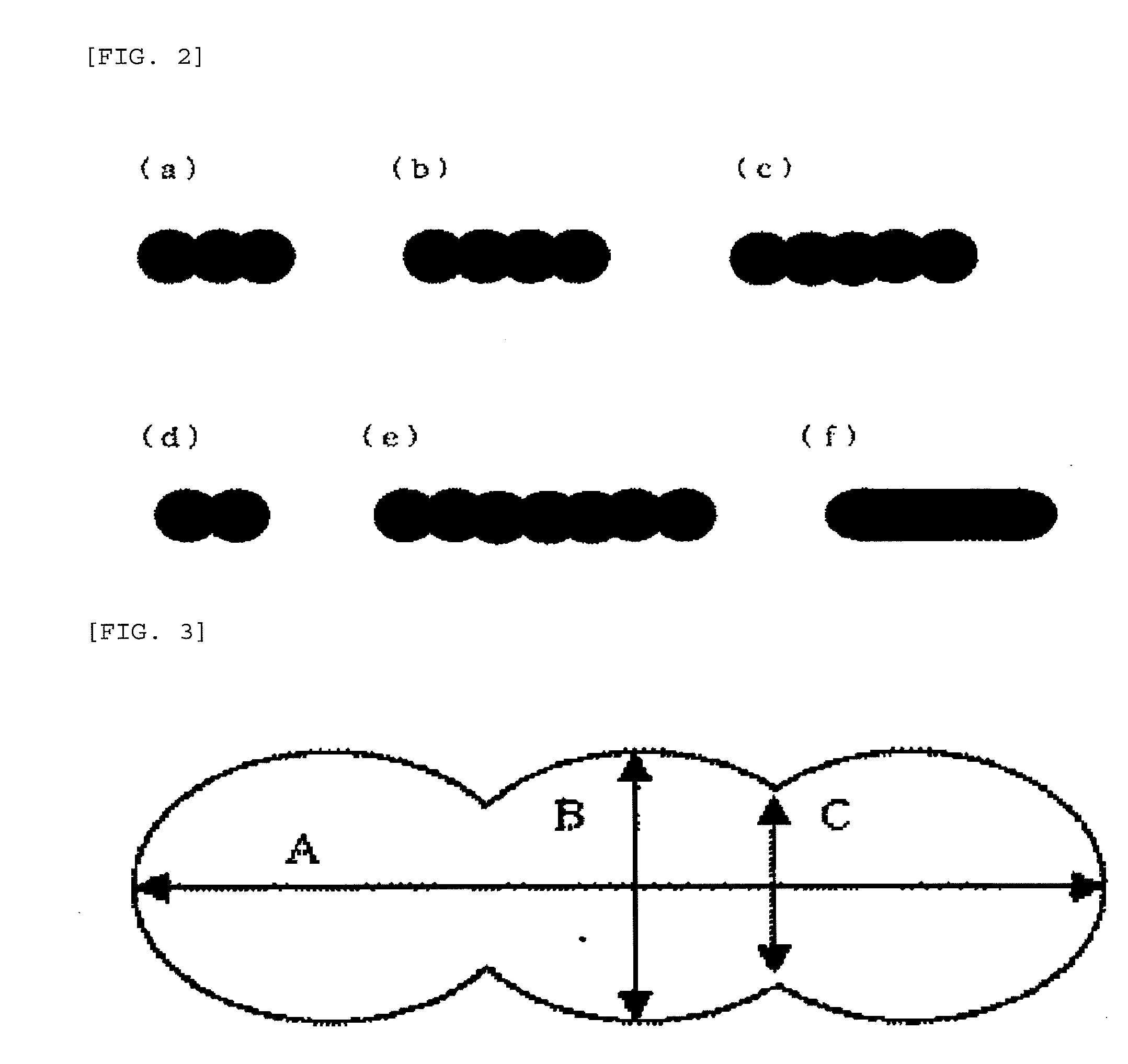

Anti-static, wet absorption and dyeable core-skin composite fiber and its preparing method

InactiveCN1821455AGood hygroscopicityImprove antistatic performanceFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolymer science

The core-skin type composite fiber and its preparation process is disclosed. The core-skin type composite fiber comprises two kinds one polymer material, and includes a core layer of A-B block copolyether ester and a skin layer of melt spun fiber forming polymer in the core / skin ratio of 40 / 60 to 6-96. The fiber may be long or short fiber for woven fabric, knitted fabric and non-woven fabric. The fabric has excellent hydroscopicity, antistatic performance, dry and smooth hand feeling and high color fastness and is suitable for use in underwear, shirt, coat, lining, etc.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Polyol component for polyurethane formation comprising anionic diol and composition

InactiveUS20060182922A1Reduce contentThe degree of freedom becomes largerMonocomponent polyurethanes artificial filamentSynthetic resin layered productsHydrogen atomAdditive ingredient

The present invention provides a polyol component for polyurethane formation comprising an anionic diol (A1); and an anionic diol composition comprising said diol (A1), another active hydrogen atom-containing compound (A2), and / or a compounding ingredient (A3) selected from the group consisting of inert solvents (A31) and additives (A32), with the content of (A2) being not higher than 85 mole % based on the total number of moles of (A1) and (A2).

Owner:SANYO CHEM IND LTD

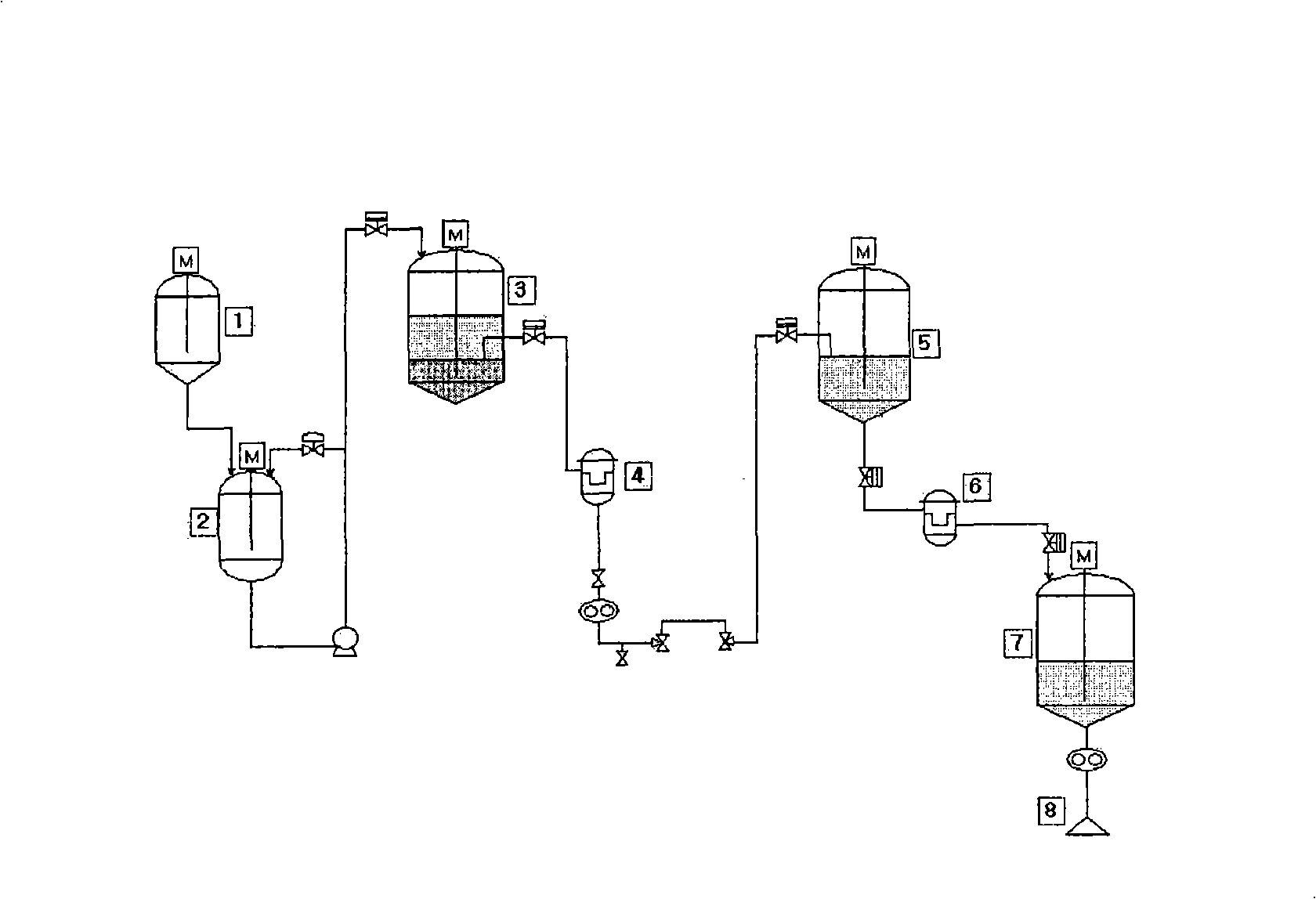

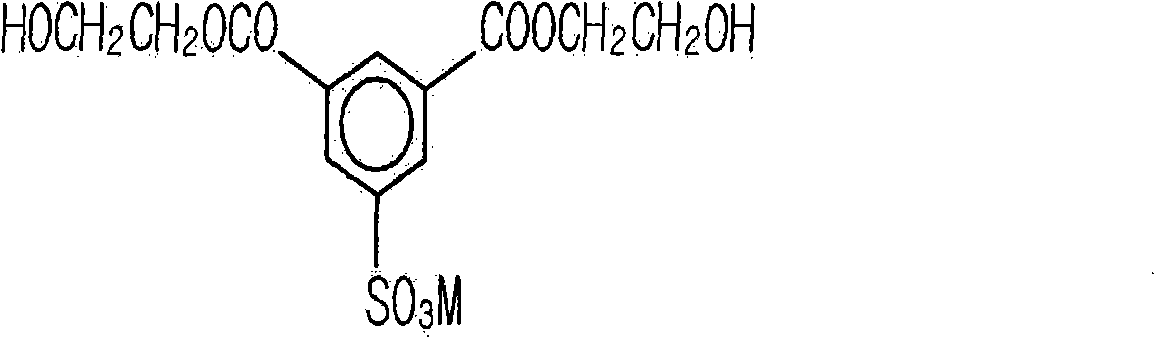

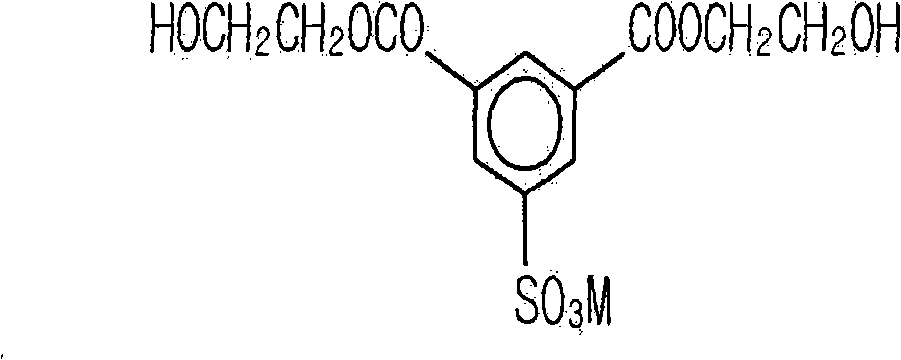

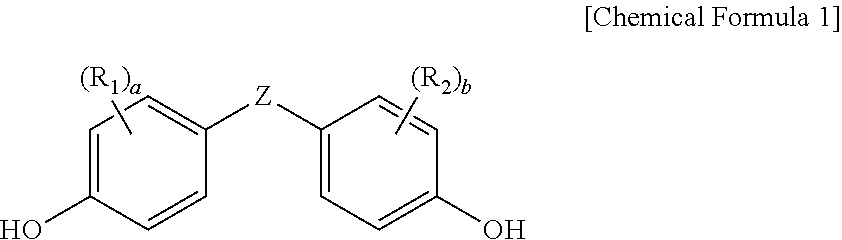

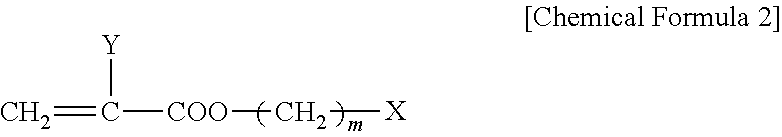

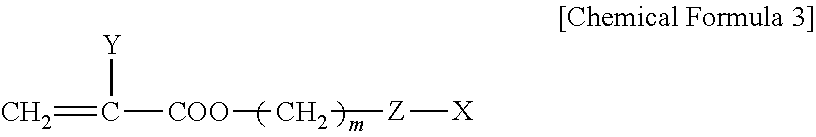

Flame retardant polyesterpolymer able to dye by using cation pigment,its mfg.method and copolymer fiber using the same

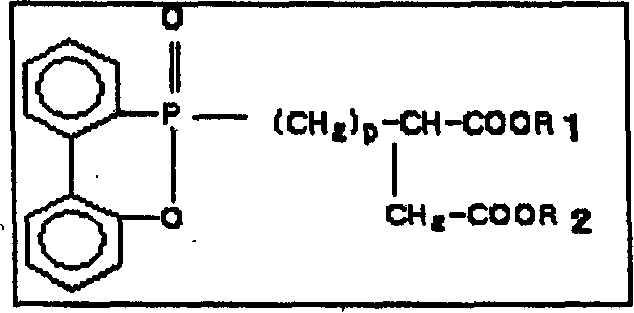

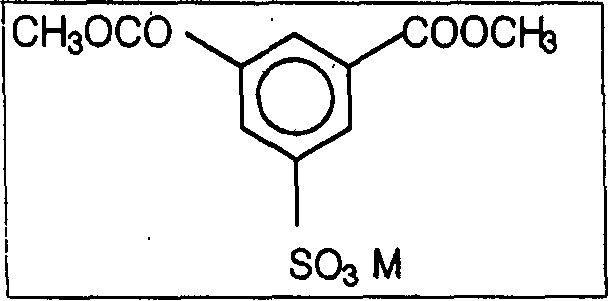

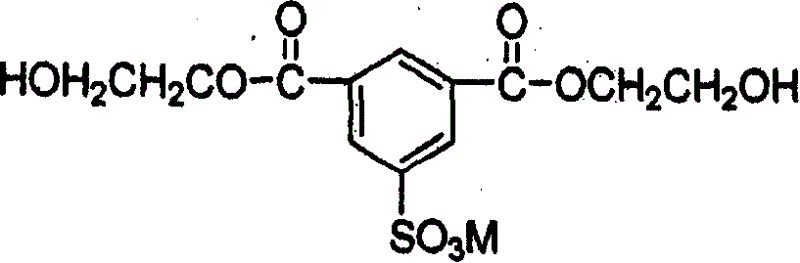

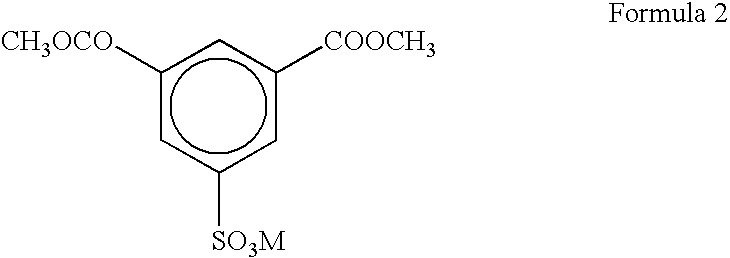

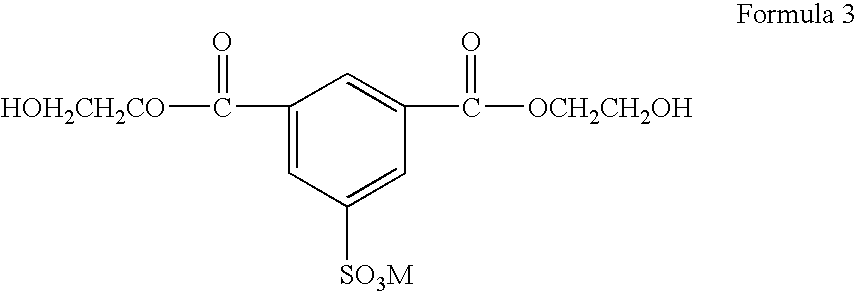

InactiveCN1696173AImprove flame retardant performanceGood dyeabilityFlame-proof filament manufactureMonocomponent copolyesters artificial filamentFiberSulfonate

Disclosed is a flame-retardant polyester polymer dyeable with a cationic dye, a method of producing the same, a copolyester fiber using the same, and fiber products using the copolyester fiber. In the method, after a dimethyl isophthalate component containing metal sulfonate of Formula 2 separately reacts with ethylene glycol so that an extent of the ester interchange reaction is 95% or more to synthesize bis(hydroxyethyl terephthalate) containing metal sulfonate of Formula 3, bis(hydroxyethyl terephthalate) is fed so that a content of bis(hydroxyethyl terephthalate) is 0.01-5 mol % based on a diacid component in a polymer in a course of producing polyester, a phosphorus-based flame retardant of Formula 1 is fed so that a content of a phosphorus atom is 500-40000 ppm based on the polymer, and the mixture is copolymerized. The polyester polymer is dyeable with cationic dye while having excellent flame retardancy, and can be melt-spun like other polymers capable of being melt-spun. The copolyester fiber using the polyester polymer is capable of being processed according to processes through which conventional polyester fibers are processed, and is dyeable with cationic dye while having excellent flame retardancy.

Owner:HYOSUNG CORP

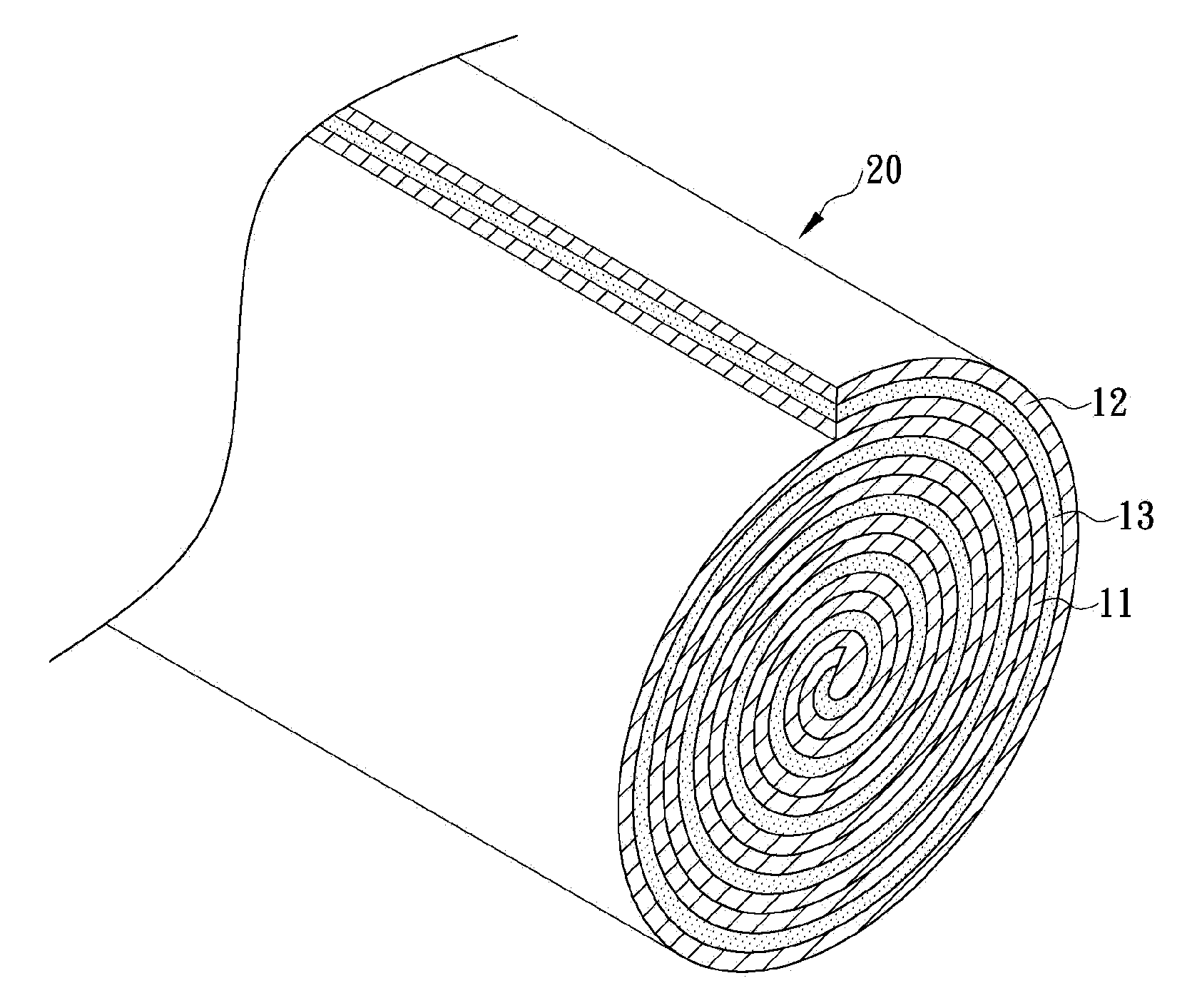

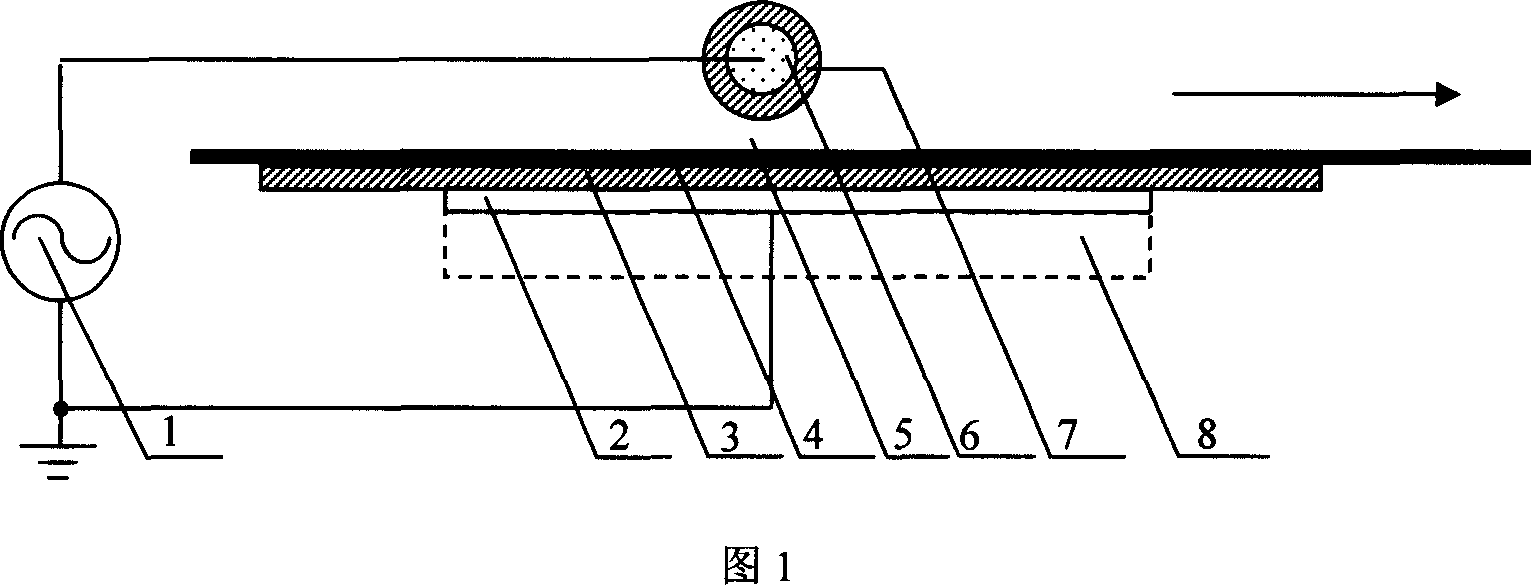

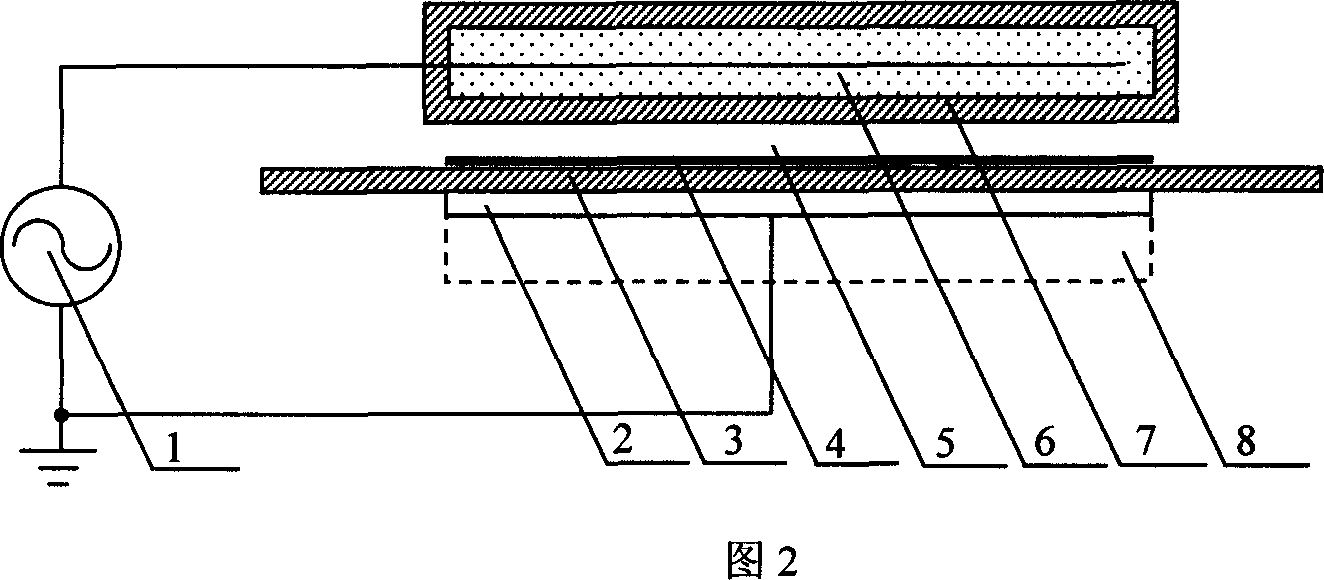

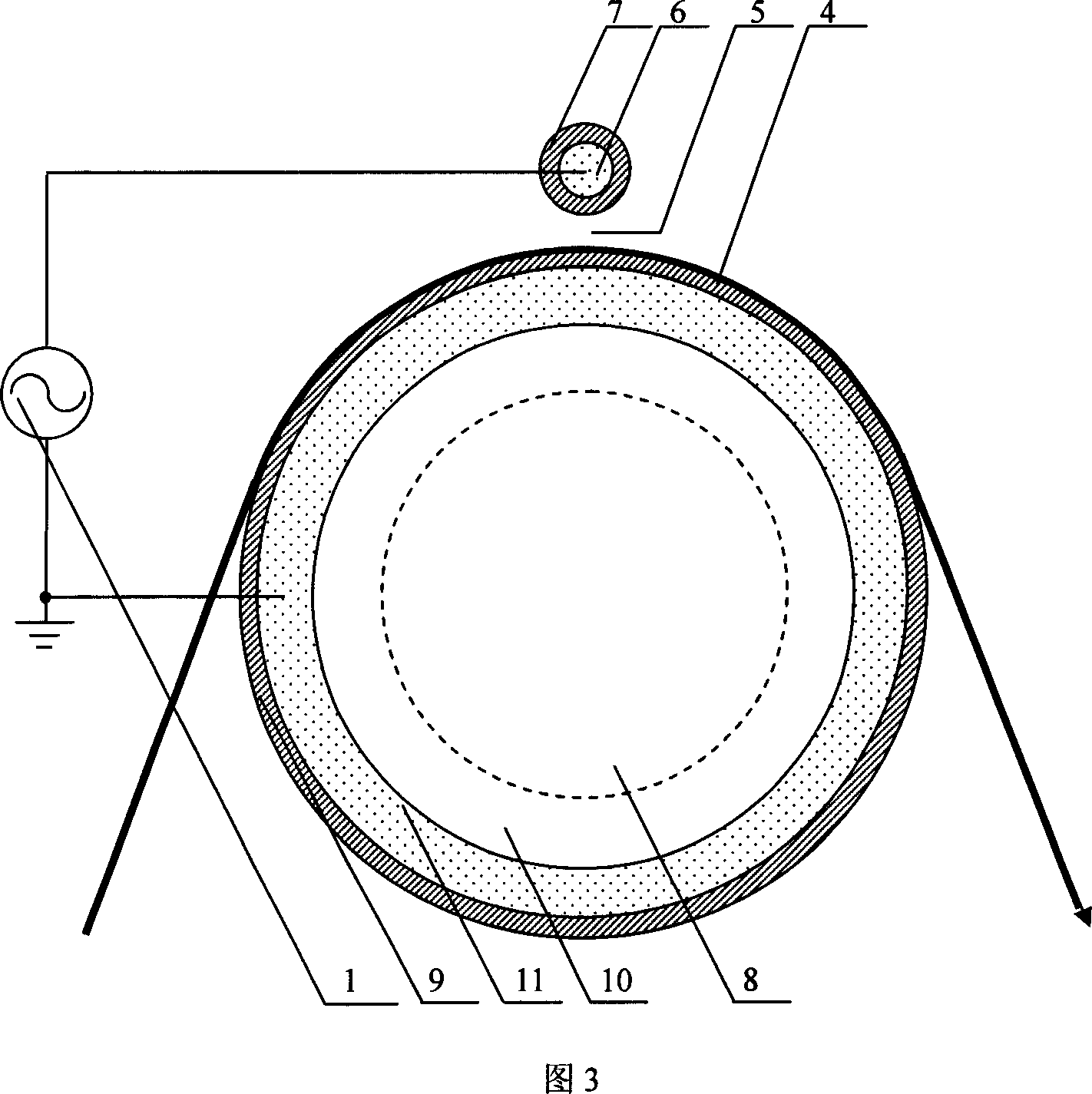

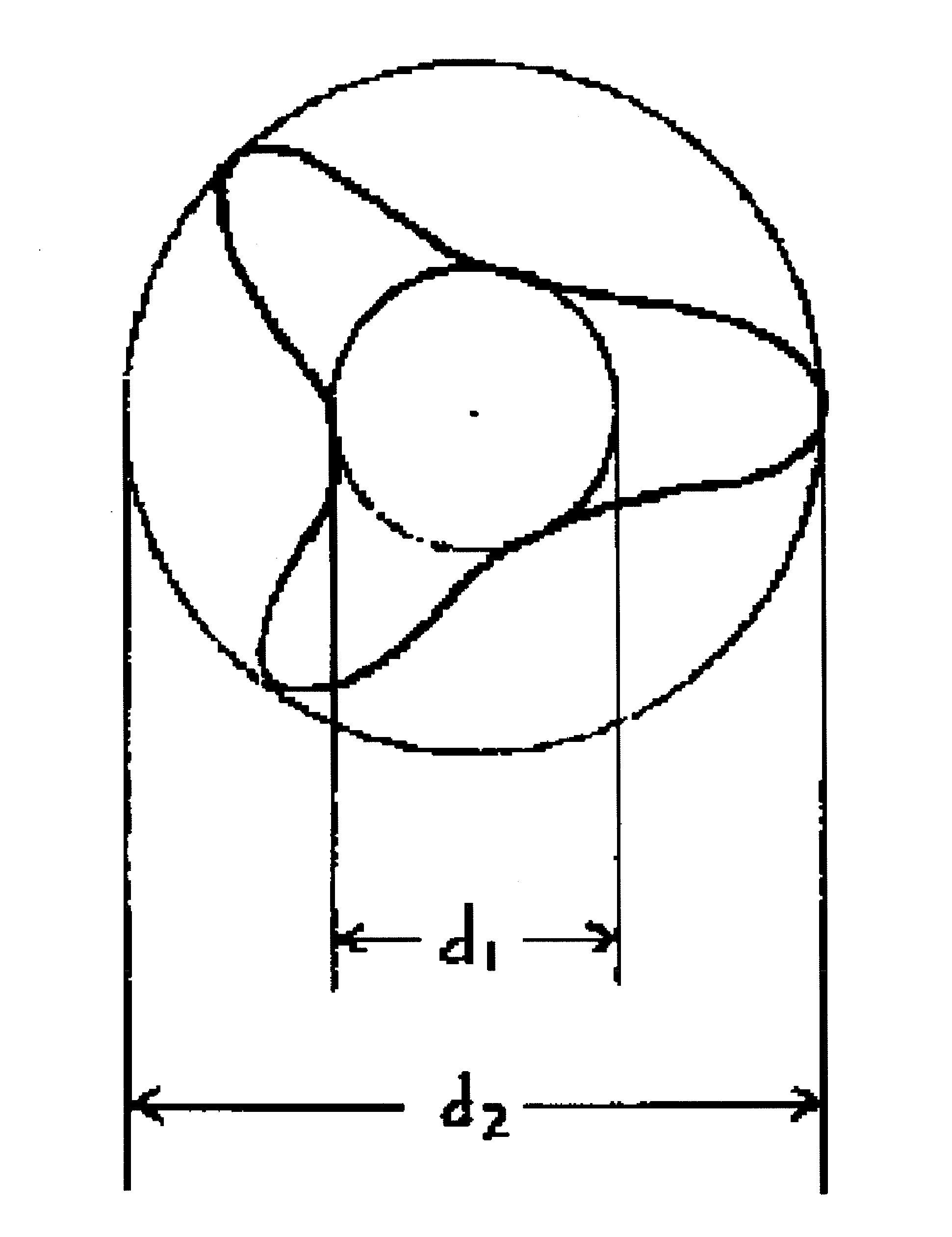

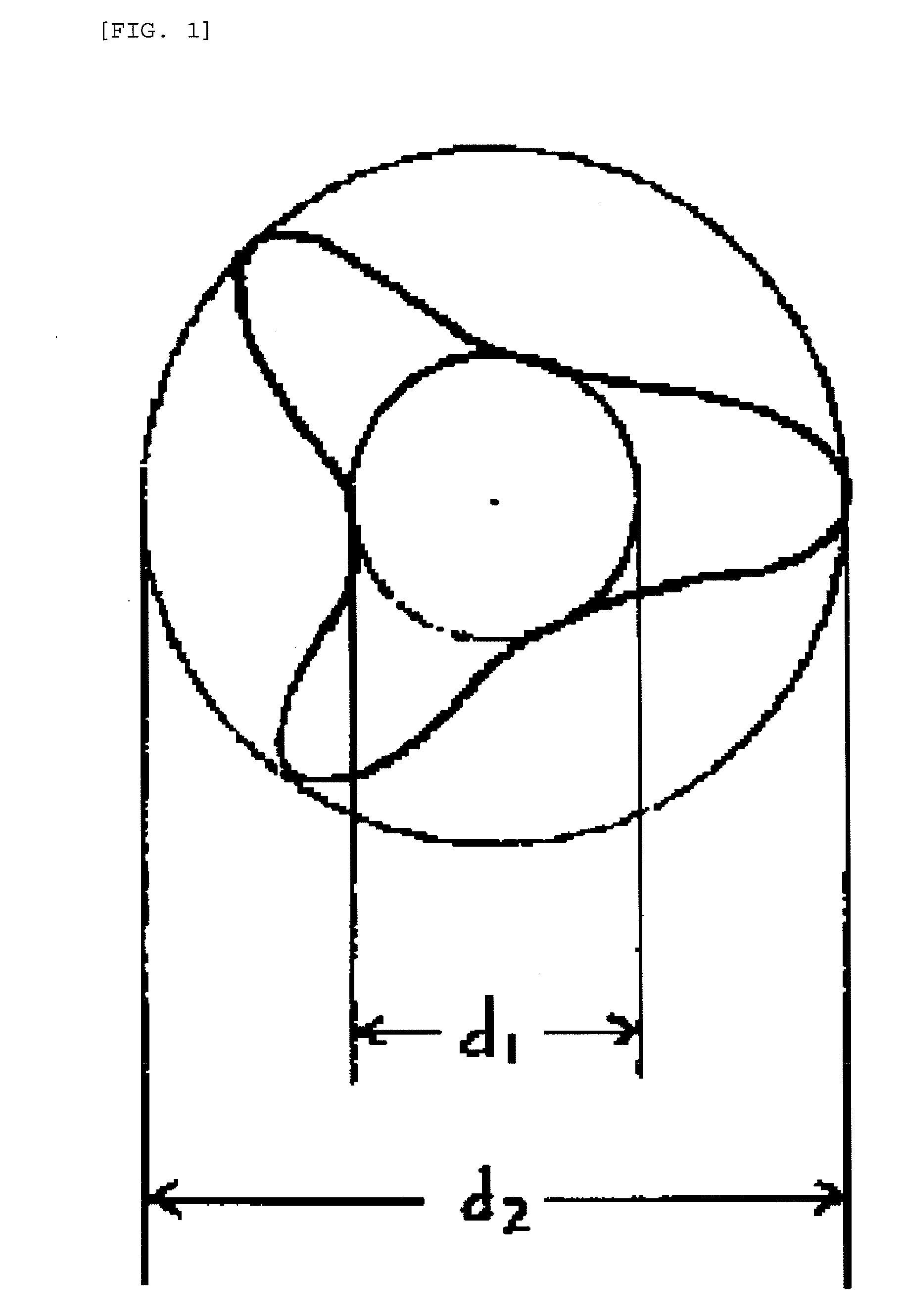

Textile and non-woven cloth plasma surface treating device

ActiveCN1932132AEvenly distributedSimple structurePhysical treatmentHigh frequency powerHigh pressure

The present invention belongs to the field of gas discharge technology, and relates to a plasma surface treatment equipment for textiles and non-woven fabric. Said plasma surface treatment equipment for textiles and non-woven fabric includes high-frequency power supply, high-voltage electrode and grounding electrode. The high-voltage electrode is at least one medium tube whose interior is filled with metal powder and sealed or one metal tube whose exterior is covered with silicone rubber, the high-voltage end of said high-frequency power supply is inserted into the medium tube interior by means of conducting wire, and the grounding electrode is a metal electrode covered with medium plate or a metal rod whose exterior is covered with silicone rubber tube, the grounding end of said high-frequency power supply is connected with metal electrode by means of conducting wire. Said invention can be used for making large-area plasma surface treatment of textiles, non-woven fabric and paper material, etc.

Owner:NANJING SUMAN PLASMA TECH CO LTD

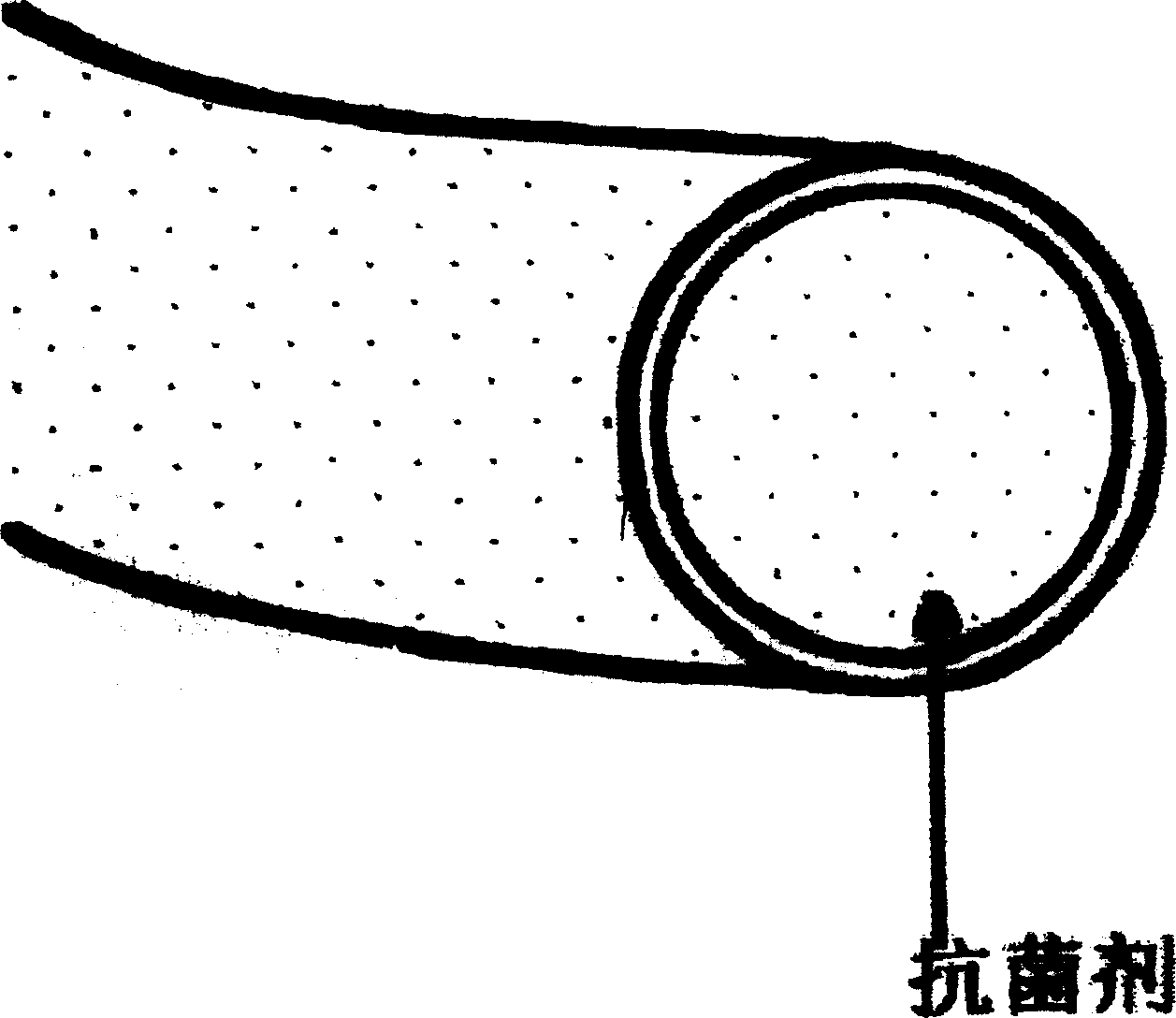

Nanometer silver-series inorganic antibiotic complex functional fiber and its preparation method and application

InactiveCN1721590AGood dyeabilityImprove spinnabilityMonocomponent polyolefin artificial filamentArtifical filament manufacturePolypropyleneNanometre

This invention relates to a nanometer layer silver abio antibiosis compound fiber, wherein the fiber materials are of polypropylene, polythene, polyester or polyamide. In the fiber, the powder and fiber amounts to 0.5-4úÑ evenly scattered inside the fiber or surface layer. This invention relates to a nanometer layer silver abio compound fiber process method and its usage.

Owner:王开利

Printing and dyeing process

ActiveCN103628336ASimple printing and dyeing processEasy to implementLiquid/gas/vapor removalDyeing processEconomic benefitsChloride sodium

The invention discloses a printing and dyeing process which comprises the following steps: (1) preprocessing; (2) dyeing, namely putting a preprocessed fabric into a dyeing solution, heating the dyeing solution to 45-55 DEG C at speed of 1-2 DEG C / min, and keeping the temperature for 20-40 minutes; adding sodium chloride, heating to 60-70 DEG C at the speed of 1-2 DEG C / min, and keeping the temperature for 20-40 minutes; adding sodium carbonate, heating to 80-90 DEG C at speed of 0.2-1 DEG C / min, and keeping the temperature for 20-40 minutes; finally cooling at the speed of 1-2 DEG C / min to finish the dyeing process; (3) post-processing. According to the printing and dyeing process, the dye-uptake rate and the dye-uptake process are adjusted to be optimal through controlling temperature ranges in the dyeing process, so that a printed and dyed product is good in dyeing uniformity and high in color fastness. The printing and dyeing process is simple, can realize large-scale industrialization production and bring good economic benefits to enterprises, and has a wide prospect.

Owner:杭州开源风云信息技术有限公司

Method for carrying out salt-free dyeing on un-scoured and unbleached cotton textile by reactive dyes

The invention relates to a method for carrying out salt-free dyeing on an un-scoured and unbleached cotton textile by reactive dyes and belongs to the technical field of textile printing, dyeing and finishing. According to the method, the un-scoured and unbleached cotton textile is pre-swelled in a pre-swelling liquid which is formed by mixing a high-proportion alcohol-type organic solvent and a small amount of water, and the pre-swelled cotton textile is dyed by a dyeing liquid which is formed by mixing a high-proportion alcohol-type organic solvent, water and dyes, the wettability and the dyeability of the un-scoured and unbleached cotton textile can be effectively enhanced, and the pre-treating work processes of scouring and bleaching the cotton textile are reduced. The method can effectively enhance the dye-uptake rate, the color fixation rate, the dyeing effect and the color fastness of the reactive dyes onto the un-scoured and unbleached cotton textile, can completely meet production requirements, does not need salt, and is simple in technology, high in feasibility and easy for industrialization; the use amount of water is reduced greatly; besides, the alcohol-type organic solvents can be recycled, so that the method is little in pollution, low in cost, clean, energy-saving, safe and environment-friendly.

Owner:WUHAN TEXTILE UNIV +1

Polylactic acid composition

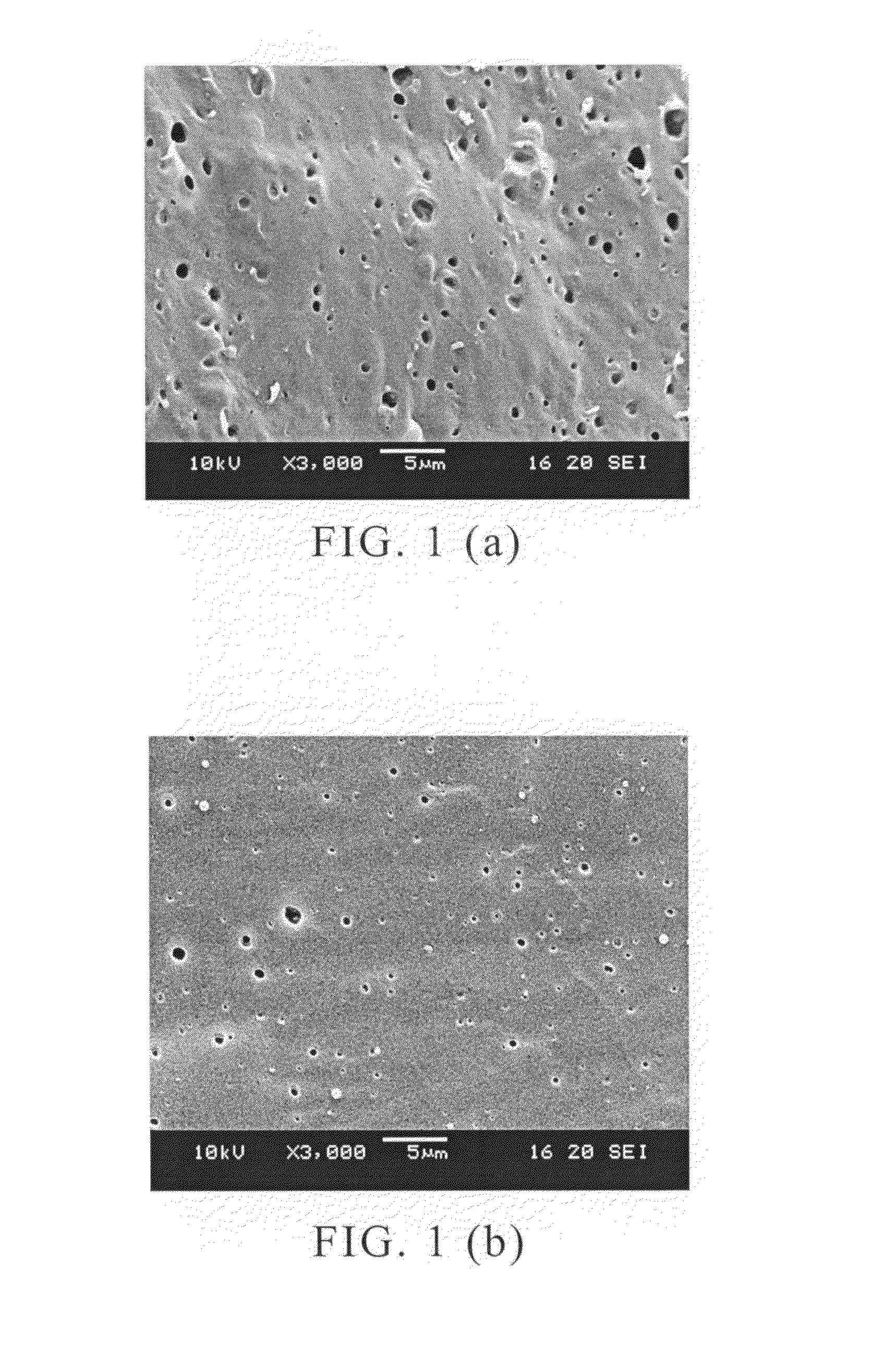

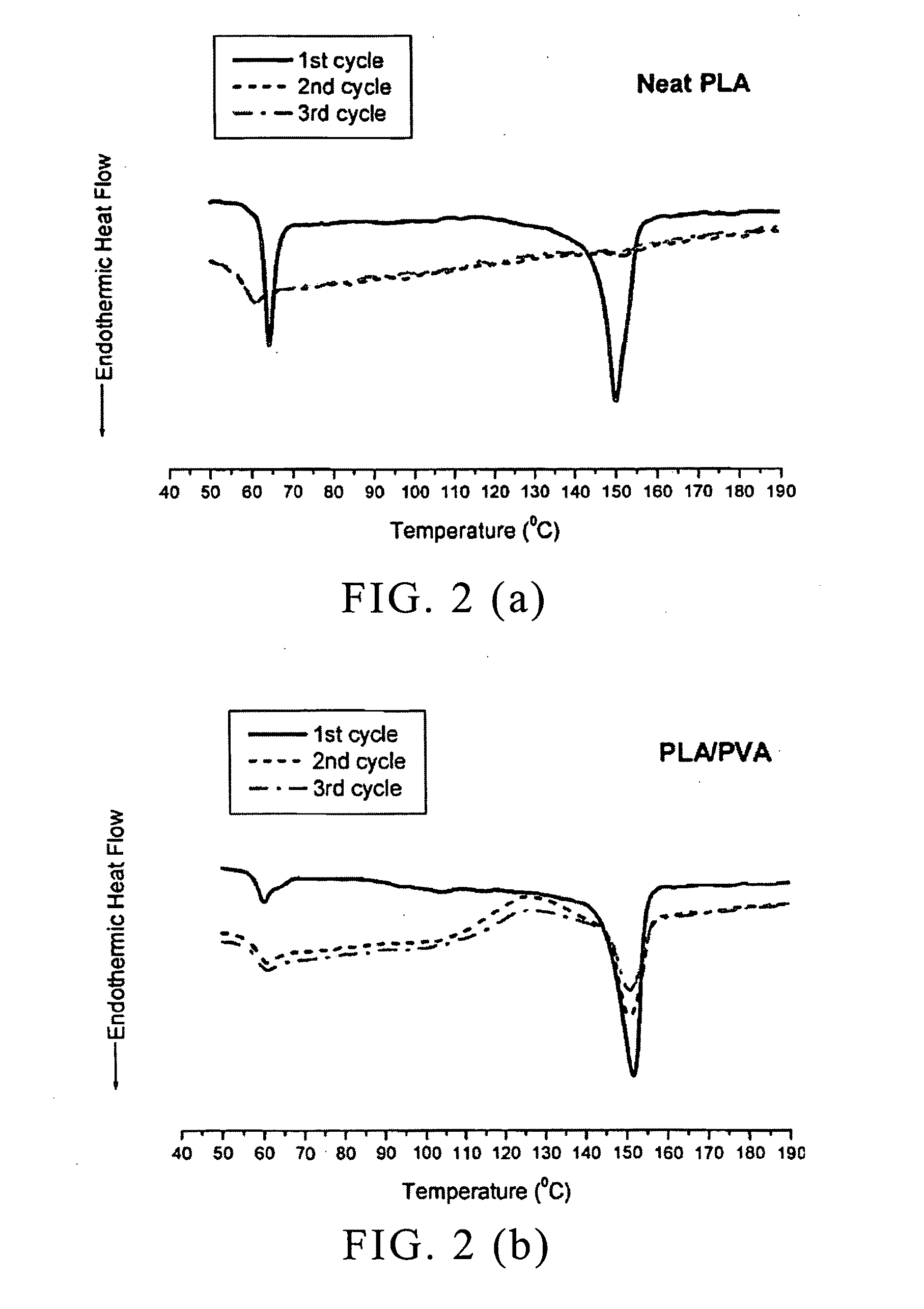

InactiveUS20090312493A1Good physical propertyStable strengthDyeing processMonocomponent polyesters artificial filamentMelt blowingPolymer chemistry

The present invention relates to a polylactic acid composition, which comprises a polylactic acid, a polyvinyl alcohol, and a grafted polylactic acid. In the present invention, the polylactic acid composition has an improved dyeing property, physical strength, crystal stability, and so forth. Hence, the composition of the present invention can be manufactured into textile fabrics having good strength by melt blowing or reeling.

Owner:TATUNG COMPANY +1

Marijuana second hard fibre processing method

InactiveCN101245492ASimple methodEasy to implementCarding machinesMechanical treatmentChemistryHigh pressure

A processing method of a secondary category hemp crude fiber relates to a spinning treatment method of secondary category hemp crude fiber (that is, falling matters of hemp skin and stems separation). The existing method adopts an alkali cooking method, which can not get ideal effect, and the others comprise alkali and sodium sulfide method, while the discharged wastewater can pollute environment. The technique of the invention comprises pre-gluing treatment, chemical ungluing treatment and after-gluing treatment. The chemical ungluing treatment adopts softener to do softening treatment and to cultivate, and then carding is carried out and the process is finished. After being treated by the method of the invention, the hemp crude fiber of secondary category has great improvement in spinning property and dyeing property with perfect effect, which not only improves economic value of the secondary category crude fiber, but also has no pollution to environment for the produced wastewater is easy to be purified; therefore, the processing method of secondary category hemp crude fiber is an ideal treating method.

Owner:YINGKOU XINYI TEXTILE

Normal pressure cationic dyeable polyester and fiber

InactiveUS20100275568A1Improve dyeing effectHigh strengthFilament/thread formingMonocomponent copolyesters artificial filamentPolyesterPhosphonium salt

It is a problem of the present invention to provide a normal pressure cationic dyeable polyester being cationic dyeable under normal pressure, and having high strength. The problem can be solved by a normal pressure cationic dyeable polyester, characterized by being a copolymerized polyester having a main repeating unit including ethylene terephthalate, and including, in an acid component forming the copolymerized polyester, a metal salt of sulfoisophthalic acid (A) and a compound (B) which is a phosphonium salt of sulfoisophthalic acid or the like in such a state as to simultaneously satisfy the two mathematical expressions. Preferably, the glass transition temperature of the copolymerized polyester is within the range of 70 to 85° C., and the intrinsic viscosity of the copolymerized polyester is within the range of 0.55 to 1.00 dL / g. Further, by melt spinning the copolymerized polyester, it is possible to provide a polyester fiber.

Owner:TEJIN FIBERS LTD

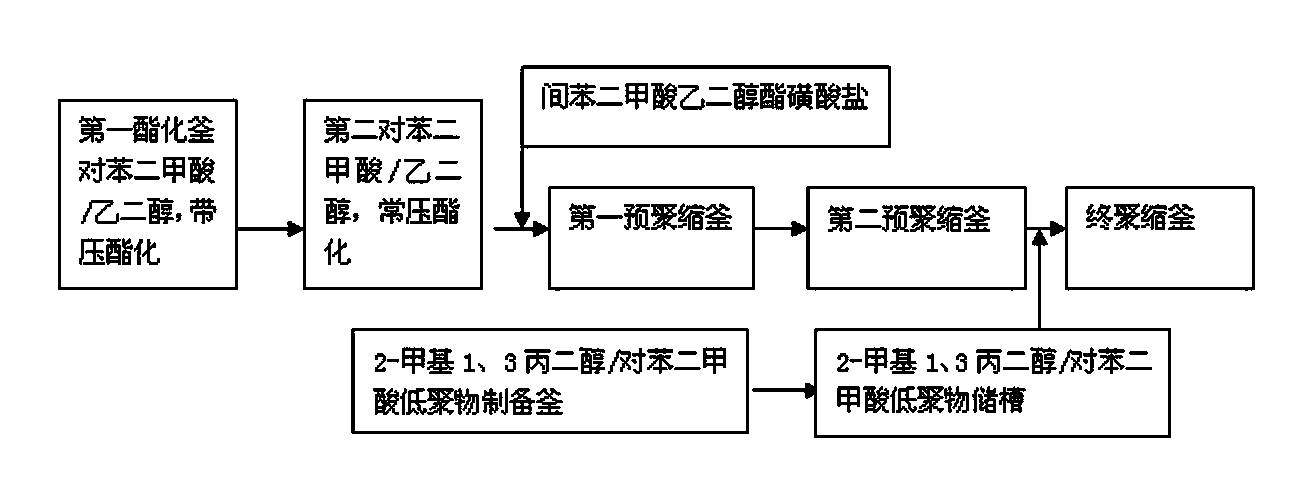

Atmospheric cationic dye dyeable copolyester polymer, manufacturing method thereof, and atmospheric cationic dye dyeable copolyester fiber using the same

InactiveCN101298493ALower glass transition temperatureGood dyeabilityMonocomponent copolyesters artificial filamentDyeing processFiberSulfonate

The invention discloses atmospheric cationic dye dyeable copolyester polymer, a manufacturing method thereof and atmospheric cationic dye dyeable copolyester fibers using the same, particularly the invention provides atmospheric cationic dye dyeable copolyester polymer, a manufacturing method thereof and atmospheric cationic dye dyeable copolyester fibers using the same, wherein copolyester polymer includes dyadic fatty acid of 1-2 mol% accounting for diprotic acid and m-phthalic acid bis hydroxyl ethyl ester with metal sulfonate of 1.0-2.0 mol% accounting for diprotic acid.

Owner:HYOSUNG CORP

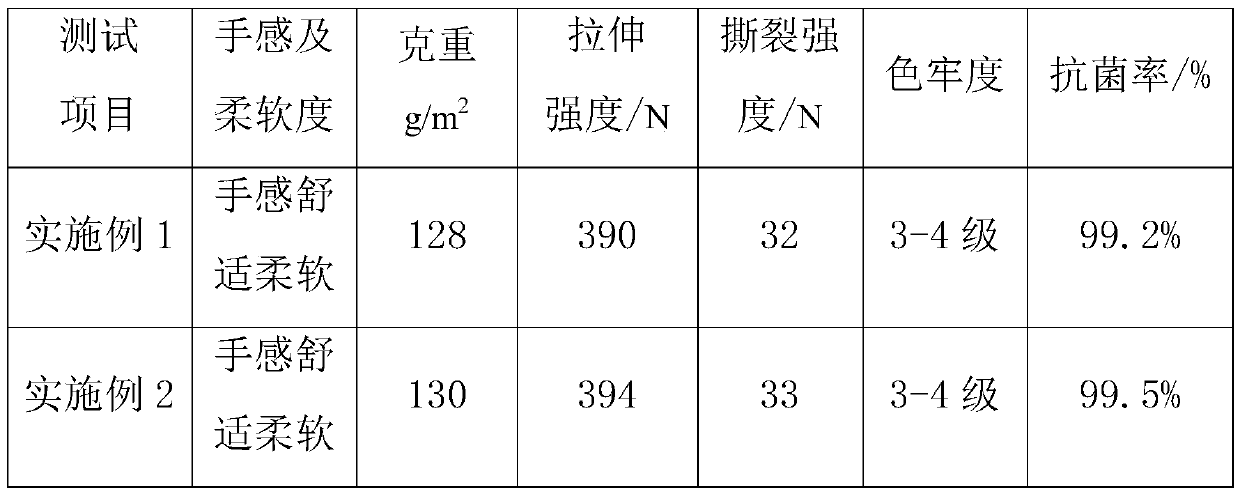

Graphene antibacterial fabric and preparation method thereof

InactiveCN110106603AHighly dispersed bindingImprove antibacterial propertiesElectroconductive/antistatic filament manufactureCarbon fibresYarnPre treatment

The invention discloses a graphene antibacterial fabric. The fabric comprises, by weight, 80-140 parts of graphene composite fibers, 10-15 parts of bamboo charcoal fibers, 6-12 parts of PTT, 30-50 parts of cotton and 8-12 parts of an antibacterial agent, wherein the graphene composite fibers comprise 0.6-1.5 parts of graphene and 79.4-138.5 parts of a fiber matrix. A preparation method of the graphene composite fibers includes the following steps of S1, pretreatment; S2, dry mixing, S3, blending and granulating; S4, melt spinning; S5, drawing and shaping, and then the graphene composite fibersare obtained. A preparation method of the graphene antibacterial fabric comprises the following steps of S1, yarn blending, S2, mercerizing; S3, warping and weaving; S4, fabric weaving; S5, antibacterial finishing; S6, post-treatment including dyeing and finishing, washing, shaping and pre-shrinking. The graphene antibacterial fabric has the advantages of being comfortable, soft, breathable, cool, durable in antibacterial performance and high in efficiency.

Owner:南通尚坊布业有限公司

Production method of high wet modulus bamboo pulp viscose glue fiber

ActiveCN101736408AImprove wet modulusImprove stabilityArtificial filaments from viscoseWet spinning methodsBreaking strengthHigh humidity

The invention discloses a production method of high wet modulus bamboo pulp viscose glue fiber, which adopts the steps of dipping, squeezing, smashing, maturing, yellowing, spinning, drawing, refining, drying and the like to prepare high wet modulus bamboo pulp viscose glue fiber. The high wet modulus bamboo pulp viscose glue fiber prepared with the method of the invention has dry breaking strength of 3.2-3.8 CN / dtex, wet breaking strength of 2.0-2.4 CN / dtex and wet modulus of 0.60-0.65 CN / dtex, has the characteristics of high humidity modulus, better purity, favourable affinity for dyestuff, non-fibrillation, non-fibrillar structure and the like, reduces expansion, reduces water retention capacity and improves alkali stability. Prepared fabric has silky luster and draping property, is extremely soft, has excellent dyeability and vivid luster and can keep bright and colorful after being cleaned several times.

Owner:刘泳

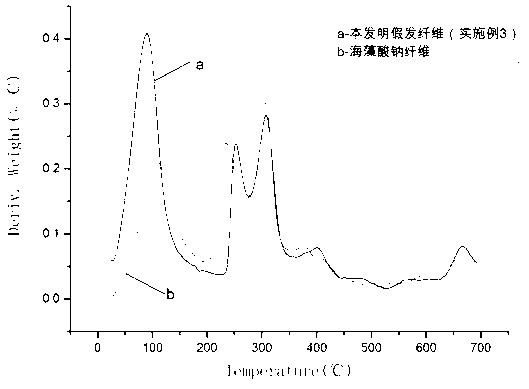

Preparation method of synthetic wig fiber

ActiveCN102926025AAbundant resourcesLow priceConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentFiberProtein solution

The invention discloses a preparation method of a synthetic wig fiber. The method is used for preparing the synthetic wig fiber with euphausia superba meat protein and sodium alginate served as raw materials by blended spinning. The preparation method comprises steps as follows: dissolving euphausia superba powder in an alkaline solution, separating, and purifying to obtain an euphausia superba meat protein solution; then mixing a protein solution and a sodium alginate solution based on a certain ratio, spinning, and solidifying to form; washing by water, and stretching; then dipping by a mixed aqueous solution of sodium dihydrogen phosphate and etherified silicone soil; and finally parching and sizing, so as to obtain the synthetic wig fiber based on the euphausia superba meat protein and the sodium alginate. The synthetic wig fiber prepared by the method disclosed by the invention is excellent in performance, has simulated and vivid effects, and can be widely applied to a wig-weaving field and a decorative art field.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Extra-fine mulberry silk crepe satin plain production method

InactiveCN103710814AUnique luster and flavorGood dyeabilitySilk reelingDyeing processComposite materialColour fastness

The invention discloses an extra-fine mulberry silk crepe satin plain production method. The extra-fine mulberry silk crepe satin plain production method includes inducing four-molter into three-molter through the drug called 'chaoxisu' to produce high-quality extra-fine silkworm cocoons with the filament number of 1 denier, drying the silkworm cocoons into dried cocoons by a hot-air re-drying process at a low temperature in a long time, cooking the cocoons by a steam cooking process at a low temperature in a short time, reeling extra-fine raw silk in the specification of 9 / 11 denier from ten cocoons quantitatively, twisting and doubling four pieces of extra-fine raw silk in the specification of 9 / 11 denier into warp and weft respectively to knit an extra-fine mulberry silk fabric, preparing red, yellow and blue acid dyes respectively by taking the paste PS-14 as a medium, painting the dye pastes on the degummed and whitened fabric according to the color-separation drawing plates, thereby producing the crepe satin plain with various patterns. The crepe satin plain produced by the method has the advantages of unique luster, crease resistance, good dyeability, high color fastness, bright color and high economic value, is capable of leading to the improvement of the conventional silk industry, and meets diversified requirements of domestic and foreign markets.

Owner:ZHEJIANG UNIV

Polycarbonate Resin Composition with Mar Resistance and Scratch Resistance

InactiveUS20130158161A1Excellent impact strengthGood heat resistanceAntifouling/underwater paintsPaints with biocidesPolytetramethylene terephthalatePolycarbonate

A polycarbonate resin composition includes 100 parts by weight of a base resin composition including about 30 to about 50 wt. % of a polycarbonate resin (A), about 20 to about 40 wt. % of a modified acrylic copolymer (B), about 5 to about 10 wt. % of a rubber modified aromatic vinyl graft copolymer (C), and about 10 to about 30 wt % of polybutylene terephthalate resin (D); and about 1 to about 8 parts by weight of a siloxane-co-polyester (E).

Owner:CHEIL IND INC

Composite fiber of polyacrylonitrile-sodium alginate, and jpreparation method

InactiveCN1696361AImprove human affinityGood dyeabilityAlginate artificial filamentsConjugated synthetic polymer artificial filamentsSolventItching

The invention discloses a polyacrylonitrile-sodium alginate composite fibre. The said fibre is formed from sodium alginate and polyacrylonitrile, the sodium alginate content is 1-20% and the polyacrylonitrile content is 80-99%. Said invention also provides the concrete steps of its production method, and the invented composite fibre can raise human body substantivity of polyacrylonitrile fibre, can make polyacrylonitrile fibre have the special effect of resisting bacteria and relieving itching, raise its dyeability and reduce its pilling property.

Owner:DONGHUA UNIV

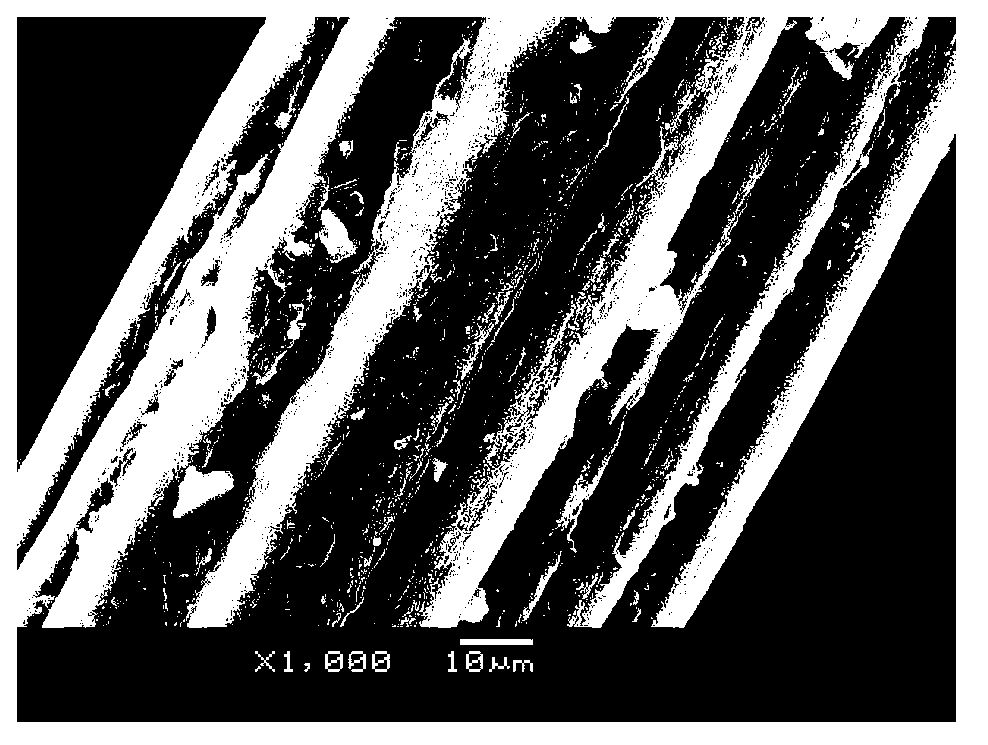

Polyester composite fiber with intelligent surface, and preparation method and application thereof

InactiveCN109385893ASpecial surface structureImprove hydrophilicity and hydrophobicityPhysical treatmentLiquid repellent fibresOil waterPolyester composite

The invention discloses a polyester composite fiber with an intelligent surface, and a preparation method and application thereof. The polyester composite fiber comprises a polyester fiber matrix andparticles covering the polyester fiber matrix, wherein the particles and the polyester fiber matrix are chemically bonded; preferably, the particles are polymer particles; more preferably, the particles are polymer particles with environmental response; thus, covering of the surface of the polyester fiber matrix with the particles can improve the hydrophilicity and hydrophobicity of the fiber andendows the fiber with certain environmental response. The preparation method comprises the following steps: preparing the polyester fiber matrix having reactive groups on the surface at first; then preparing the particles having reactive functional groups; and finally, mixing the polyester fiber matrix and the particles for a reaction so as to obtain the polyester composite fiber. The polyester composite fiber of the invention can be used for smart textiles, non-woven fabrics, porous films, composite materials and oil-water separators, preferably for smart textiles and oil-water separators.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

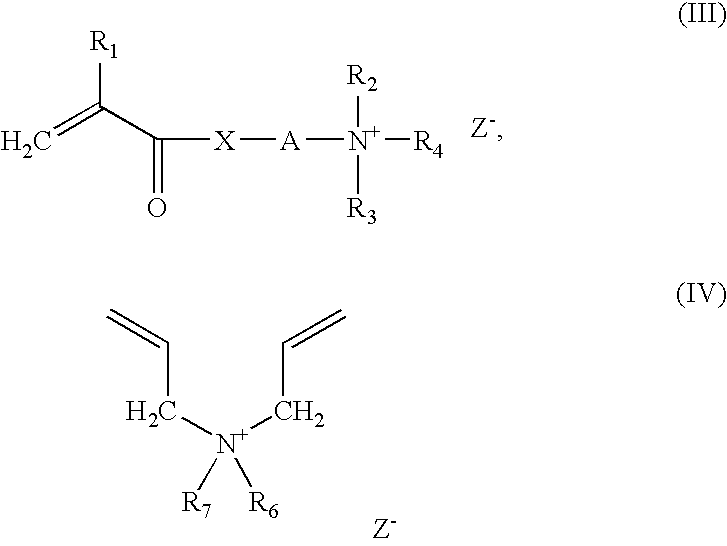

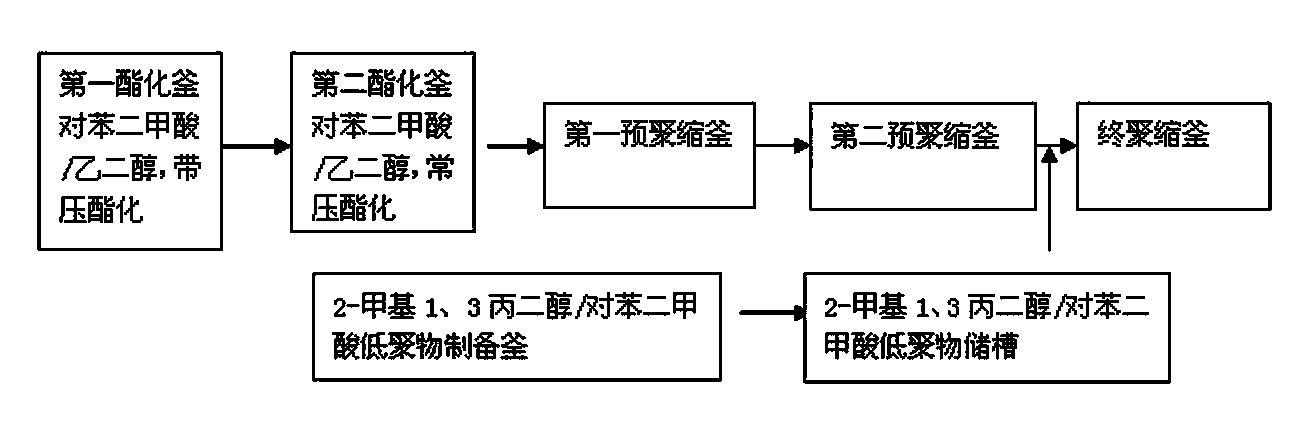

1, 2-propylene glycol modified polyethylene terephthalate

A 1, 2-propylene glycol modified polyethylene terephthalate is characterized in that a 1, 2-propylene glycol part is used to replace ethylene glycol to synthesize a 1, 2-propylene glycol modified PETcopolymer, the combination of a toluene sulfonic acid and a tert-butyl oxide titanium compound is used as a catalyst, a prepolymer is formed by carrying out esterification on a terephthalic acid and the ethylene glycol under the condition of pressurization, and then a polyester with high molecular weight and good color is obtained by conducting condensation polymerization on the prepolymer under the condition of high temperature and vacuum.

Owner:WUJIANG YINGXIANG CHEM FIBER

PA6-56 copolymerized material and preparation method thereof

The invention relates to the field of polymer materials, and discloses a PA6-56 copolymerized material and a preparation method thereof. The PA6-56 copolymerized material is prepared through blend polymerization of liquid caprolactam and a water solution of pentamethylene diamine adipate, wherein the molar ratio of the liquid caprolactam to the pentamethylene diamine adipate is 7:3-9:1. The methodcomprises the following steps: mixing the liquid caprolactam, the water solution of the pentamethylene diamine adipate and other reaction raw materials according to a certain proportion, carrying outstirring in a reactor under the protection condition of inert gas, and carrying out a polycondensation reaction at a temperature of 150-300 DEG C, so as to obtain the PA6-56 copolymer material. According to the invention, PA6 monomer caprolactam is mainly copolymerized with PA56 monomer pentamethylene diamine adipate to prepare the PA6-56 copolymer material, and the material not only has the advantages of high strength, wear resistance, acid and alkali resistance of PA6, but also has better hygroscopicity and dyeability, so that better wearing comfort and more abundant color are provided to the textiles.

Owner:浙江恒逸锦纶有限公司

Environment-friendly hair-care hair dye and preparation method thereof

ActiveCN102824283ANeutralize damageGood dyeabilityCosmetic preparationsHair cosmeticsPolyphenolHair care

The invention provides an environment-friendly hair-care hair dye which consists of three agents A, B and C. The agent A comprises the following components: L-cysteine, Na2CO3, triethanolamine, sodium carboxy methyl cellulose, glycerin and water; the agent B comprises the following components; metal salt, the sodium carboxy methyl cellulose, a surfactant, an odorant and the water; and the agent Ccomprises the following components: pigment, the sodium carboxy methyl cellulose, the surfactant, citric acid, fragrance and the water. The hair dye uses the plant pigment such as tea polyphenol and the like as a dye, has easily obtained raw materials, is low in cost, has no toxicity, is easy to color and also has a hair care effect.

Owner:章华化妆品科技有限公司

Flame-retardant polyester polymer dyeable with cationic dye, method of producing the same, and copolyester fiber using the same

InactiveUS20060052574A1Excellent dyeability and flame retardancyExcellent mechanical property and processabilityCosmetic preparationsHair cosmeticsChemistryFire retardant

Disclosed is a flame-retardant polyester polymer dyeable with a cationic dye, a method of producing the same, a copolyester fiber using the same, and fiber products using the copolyester fiber. In the method, after a dimethyl isophthalate component containing metal sulfonate of Formula 2 separately reacts with ethylene glycol so that an extent of the ester interchange reaction is 95% or more to synthesize bis(hydroxyethyl terephthalate) containing metal sulfonate of Formula 3, bis(hydroxyethyl terephthalate) is fed so that a content of bis(hydroxyethyl terephthalate) is 0.01-5 mol % based on a diacid component in a polymer in a course of producing polyester, a phosphorus-based flame retardant of Formula 1 is fed so that a content of a phosphorus atom is 500-40000 ppm based on the polymer, and the mixture is copolymerized. The polyester polymer is dyeable with cationic dye while having excellent flame retardancy, and can be melt-spun like other polymers capable of being melt-spun. The copolyester fiber using the polyester polymer is capable of being processed according to processes through which conventional polyester fibers are processed, and is dyeable with cationic dye while having excellent flame retardancy.

Owner:HYOSUNG CORP

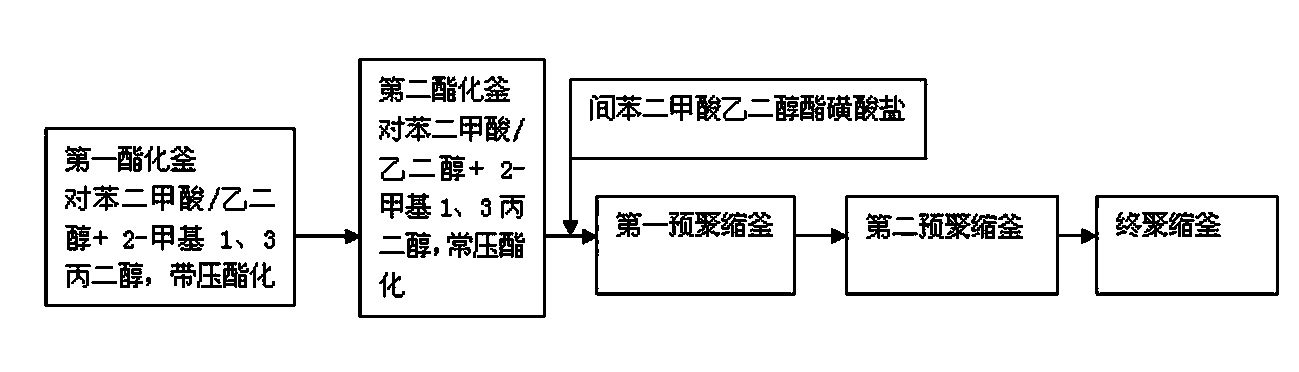

Preparation technologies of modified copolyester chip and fiber

ActiveCN103665350AEasy to replaceGood dyeabilityMonocomponent copolyesters artificial filamentCopolyesterOligoester

The invention discloses a preparation technology of a modified copolyester chip. The technology comprises the following steps: (1) mixing terephthalic acid with ethylene glycol, adding a catalyst, and carrying out esterification reaction under the conditions that the pressure is 0.20-0.35MPA and the temperature is 230-250 DEG C; (2) carrying out condensation polymerization on a mixture obtained after the esterification reaction is ended, so as to obtain a low polymer of ethylene glycol / terephthalic acid; (3) esterifying liquid aliphatic dibasic alcohol and terephthalic acid, so as to obtain a low polymer of liquid aliphatic dibasic alcohol / terephthalic acid, and adding the low polymer to the low polymer of ethylene glycol / terephthalic acid, so as to prepare the modified copolyester chip which can be dyed by a disperse dye at normal temperature and normal pressure. Meanwhile, the invention also discloses another preparation technology of the modified copolyester chip. In addition, the invention also discloses a preparation technology of a modified copolyester fiber. By adopting the preparation technologies, the condition that the copolyester is stable in components, stable in product performance, good in rebound resilience of fiber textile, vivid in color, soft in handle, and pilling-resistant is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

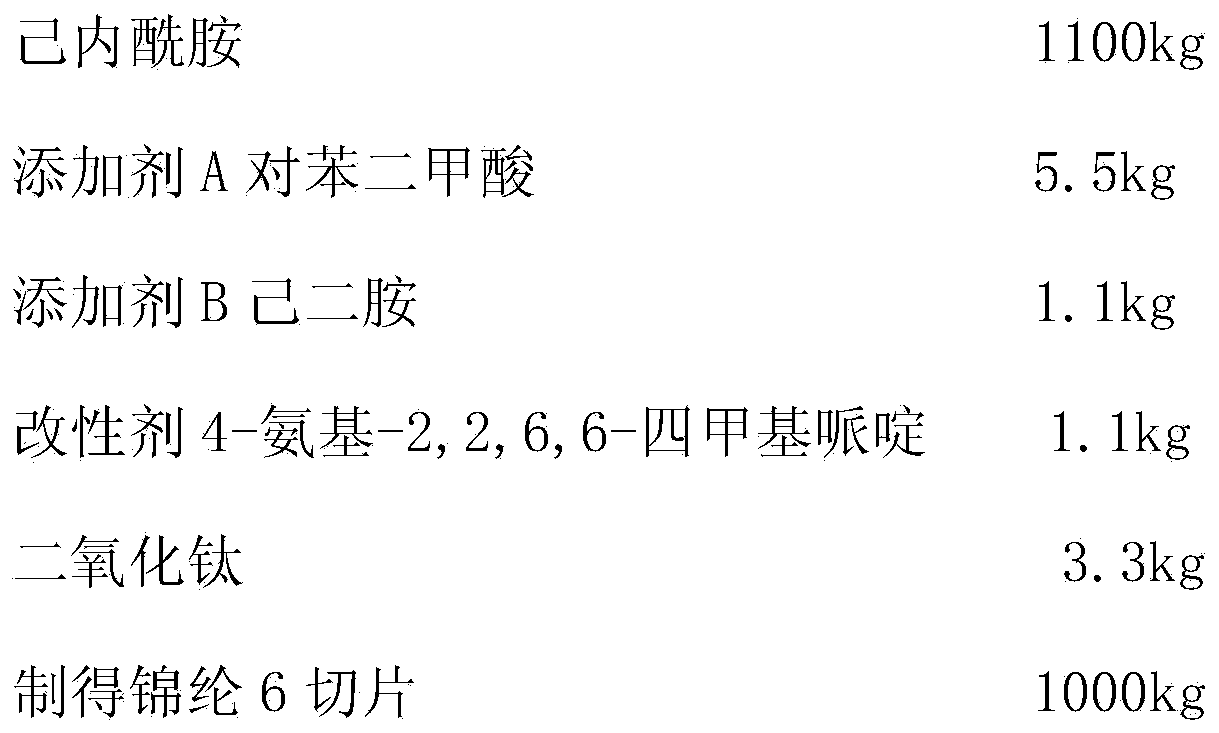

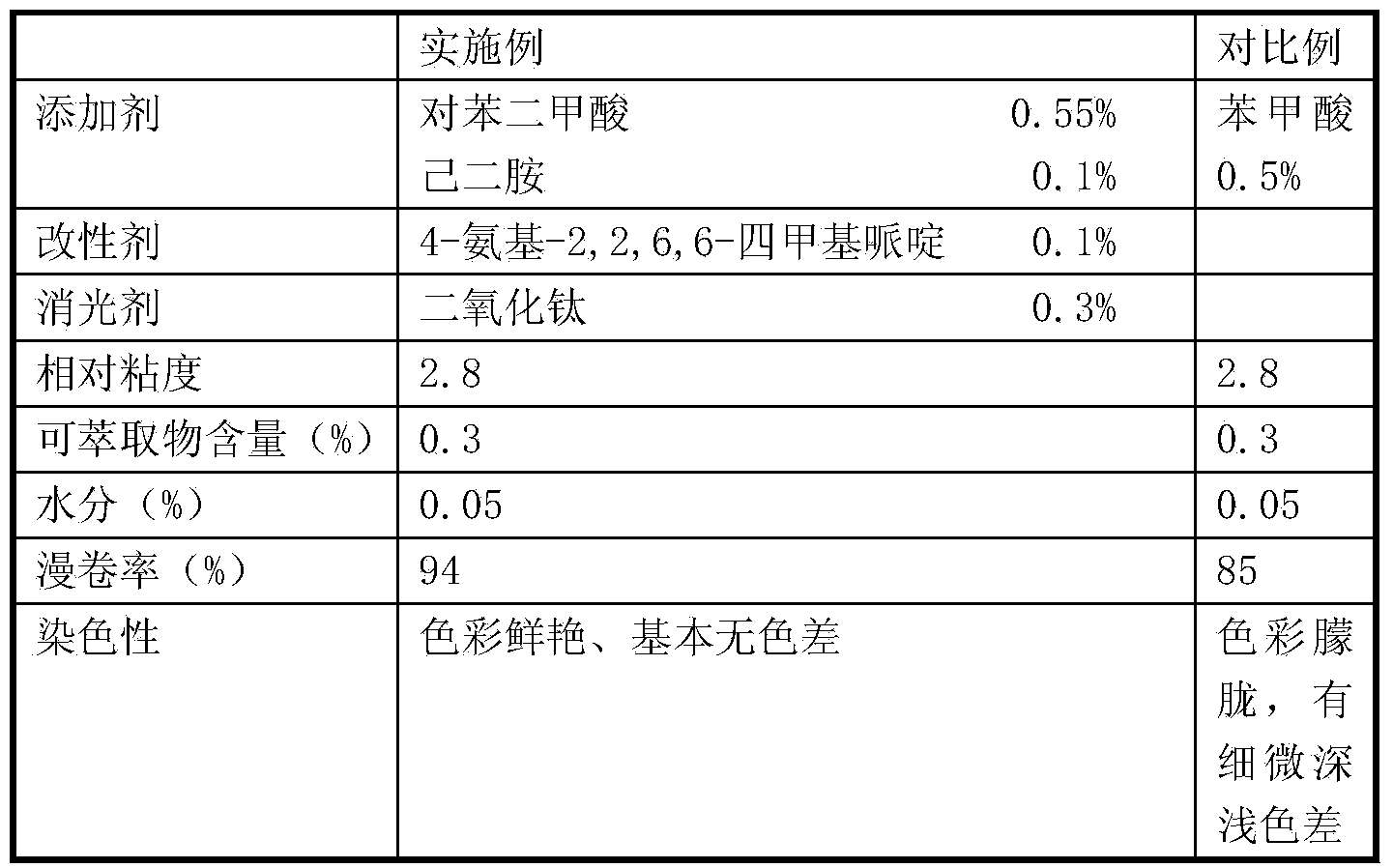

Chinlon 6 section for bromochlorodifluoromethane (BCF) carpet yarn and preparation method thereof

InactiveCN103408749AImprove stabilityImprove photostabilityArtifical filament manufactureMonocomponent polyamides artificial filamentYarnPolymer science

The invention discloses a chinlon 6 section for a bromochlorodifluoromethane (BCF) carpet yarn and a preparation method thereof. The chinlon 6 section is prepared from the following raw materials in percentage by weight: 99-100% of caprolactam, 0.02-1% of additive A, 0.02-1% of additive B, 0.05-0.6% of modifierand 0-0.5% of delustering agent; and the sum of the weight percents of all components is 100%. The preparation method of the section comprises the following steps: 1) preparation of solution of the additive A; 2) preparation of solution of the additive B; 3) preparation of modifier solution; 4) preparation of delustering agent dispersion liquid; 5) continuous polymerization; 6) extraction; and 7) drying. Compared with of the traditional section, the chinlon 6 section manufactured by the invention has the advantages the heat stability, the light stability and the dyeability are improved; the preparation step in a spinning process is reduced; the spinning stability, and the dyeability and the light stability of the BCF carpet yarn are improved; and the chinlon 6 section is especially suitable for production of the BCF carpet yarn.

Owner:JIANGSU HAIYANG CHEM FIBERS

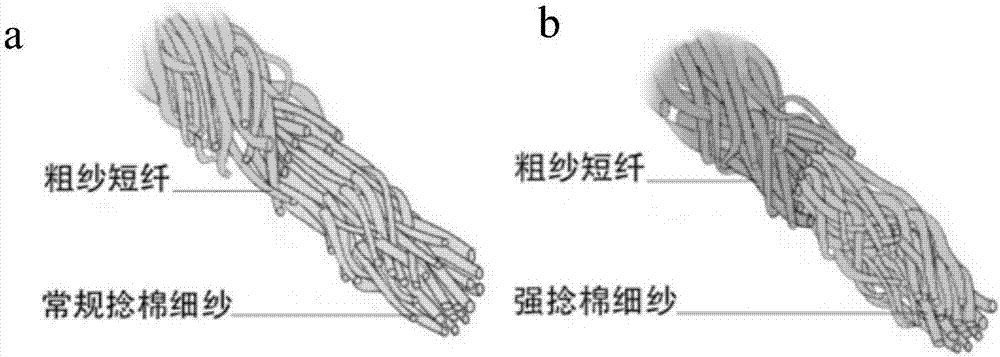

Sirofil pure cotton elastic yarn and manufacturing and application thereof

InactiveCN106917174AComfortable to wearEasy to dressMercerising of yarns/threads/filamentsYarnYarnFiber

The invention relates to a sirofil pure cotton elastic yarn and manufacturing and applications thereof. The pure cotton elastic yarns form a pure cotton coating structure by roving which forms a coating layer and spun yarns which forms a core layer through a sirofil spinning technology. The sirofil pure cotton elastic yarn is obtained by twisting and spinning roving and spun yarns in the same direction on a sirofil spinning frame, and finishing. Pure cotton fibers which do not have elasticity originally have natural elasticity after certain processing procedures and treatment, and the sirofil pure cotton elastic yarns replace conventional spandex elastic core-spun yarns used in an elastic jean fabric, so that technical problems of exposed cores, difficult weaving, and difficult control of breadth caused by using stretch yarns are prevented. The sirofil pure cotton elastic yarns are beneficial for enhancing stiff and smooth property of the elastic jean fabric and do not reduce fabric hand feeling. The invention provides a new yarn raw material for a conventional low-medium elastic jean fabric.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com