Nanometer silver-series inorganic antibiotic complex functional fiber and its preparation method and application

A composite function, inorganic antibacterial technology, applied in the direction of single-component polyolefin rayon, single-component polyamide rayon, etc., can solve the problems of poor washability, low antibacterial rate, and non-durable antibacterial, and achieve dispersion Good resistance, less added amount, long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

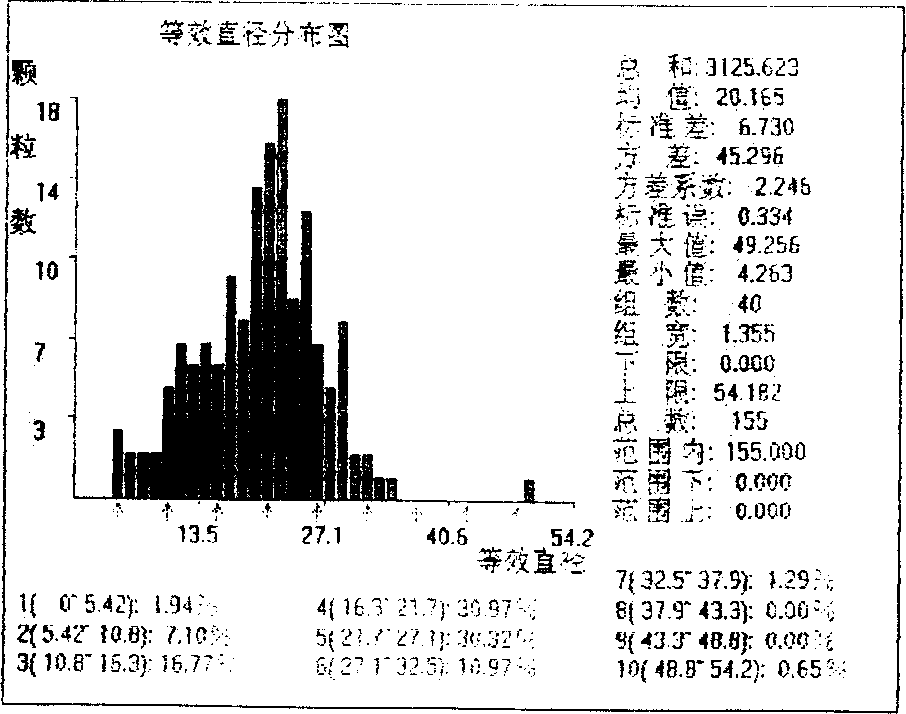

[0014] In order to prepare one ton of polypropylene fiber with 2% nano-silver inorganic antibacterial, anti-mildew, deodorant, and far-infrared composite functions, 980 kg of polypropylene slices and 20 kg of nano-layered silver-based inorganic anti-bacterial, anti-mildew, deodorant, and far-infrared composite functions are required. Powder (powder particle size 4-50nm is the best particle size). The above-mentioned powder and chips are blended and melted to form a polypropylene masterbatch with antibacterial, mildew-proof, deodorant, and far-infrared composite functions, and the prepared antibacterial composite functional masterbatch is added to the corresponding high-speed spinning equipment. Under the conditions of 300) ℃, screw melting pressure (2-6) Mpa and spinning speed (3800-4800) m / min, spinning and winding are carried out to obtain the desired antibacterial composite functional fiber.

[0015] The polypropylene antibacterial composite functional fiber thus obtained c...

specific Embodiment 2

[0016] In order to prepare one ton of 2% nano-silver inorganic antibacterial, anti-mildew, deodorant, and anti-ultraviolet composite functional polyester fibers, 980 kg of polyester slices and 20 kg of nano-layered silver-based inorganic anti-bacterial, anti-mildew, deodorant, and anti-ultraviolet composite functional powder are required body (powder particle size 4-50nm is the best particle size). The above-mentioned powder and chips are blended and melted to form a polyester masterbatch with antibacterial, mildew-proof, deodorant, and anti-ultraviolet composite functions, and the prepared antibacterial composite functional masterbatch is added to the corresponding high-speed spinning equipment. Under the conditions of 300) ℃, screw melting pressure (2-6) Mpa and spinning speed (3800-4800) m / min, spinning and winding are carried out to obtain the desired antibacterial composite functional fiber.

[0017] The obtained polyester antibacterial composite functional fiber can be u...

specific Embodiment 3

[0018] In order to prepare one ton of nano-silver inorganic antibacterial, mildew-proof, deodorant, and far-infrared composite functional polypropylene fiber with a content of 4%, 960 kg of polypropylene slices and 40 kg of nano-layered silver-based inorganic antibacterial, anti-mildew, deodorant, and far-infrared composite functional powder are required body (powder particle size 4-50nm is the best particle size). The above-mentioned powder and chips are blended and melted to form a polypropylene masterbatch with antibacterial, mildew-proof, deodorant, and far-infrared composite functions, and the prepared antibacterial composite functional masterbatch is added to the corresponding high-speed spinning equipment. Under the conditions of 300) ℃, screw melting pressure (2-6) Mpa and spinning speed (3800-4800) m / min, spinning and winding are carried out to obtain the desired antibacterial composite functional fiber.

[0019] The obtained polypropylene antibacterial composite func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com