Chinlon 6 section for bromochlorodifluoromethane (BCF) carpet yarn and preparation method thereof

A carpet yarn and slicing technology, which is applied in the manufacture of rayon, single-component polyamide rayon, chemical characteristics of fibers, etc., can solve the problems of increasing production cost, short residence time, reducing production efficiency, etc., and achieves improved thermal stability. stability, increase stability, reduce effects of preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

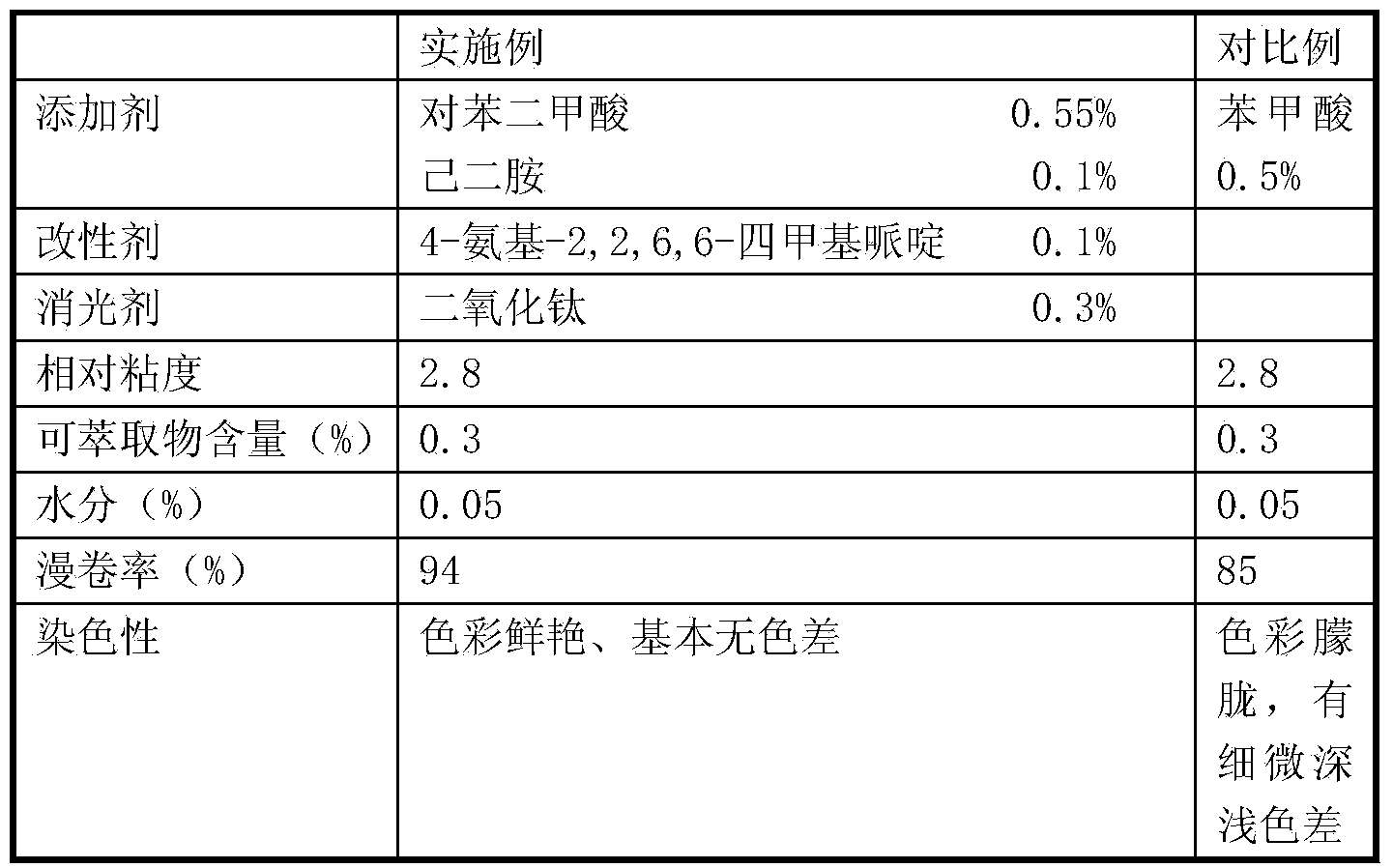

[0026] The present invention is a nylon 6 slice used for BCF carpet yarn, which is made of the following raw materials in weight ratio: 99-100% caprolactam, 0.02-1% additive A, 0.02-1% additive B, modified 0.05-0.6% of neutralizing agent, 0-0.5% of matting agent; the sum of the weight percentages of each component is 100%. The preparation method of the slice has the following steps:

[0027] 1) Solution preparation of additive A

[0028] Dissolve additive A in 100-80% molten caprolactam or caprolactam aqueous solution, stir and disperse to make 2-30% molecular weight modifier dispersion;

[0029] 2) Solution preparation of additive B

[0030] Dissolve additive B in 100-80% molten caprolactam or caprolactam aqueous solution, stir and disperse to make 1-30% molecular weight modifier dispersion;

[0031] 3) Preparation of modifier solution

[0032] Dissolve the modifier in 100-50% caprolactam or caprolactam aqueous solution, stir and disperse to make a 2-50% modifier solution ...

Embodiment 1

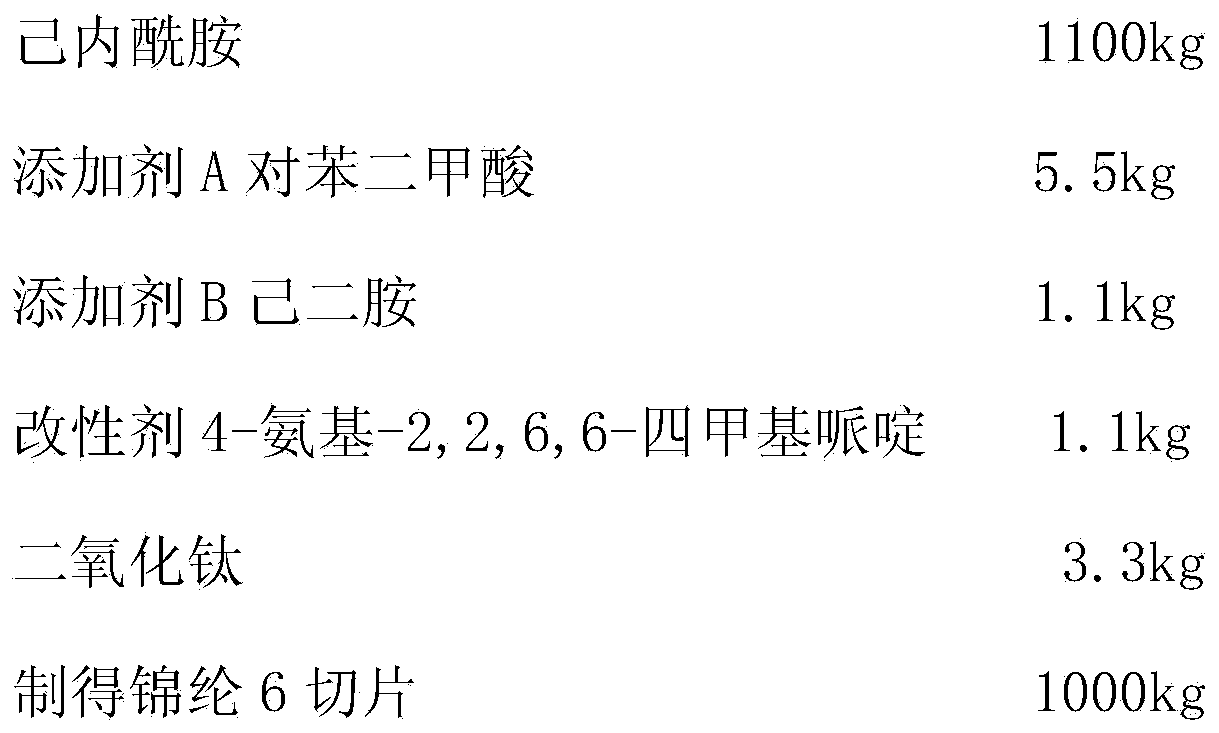

[0043] The weight of each component of the raw material used in the present embodiment nylon 6 slice is:

[0044]

[0045] Has the following steps:

[0046] 1) Solution preparation of additive A

[0047] Dissolve 5.5kg of terephthalic acid in 94.5kg of 80% caprolactam aqueous solution, stir and disperse to make a 5% solution by weight;

[0048] 2) Solution preparation of additive B

[0049] Dissolve 1.1 kg of hexamethylenediamine in 18.9 kg of 80% caprolactam aqueous solution, stir and disperse to make a 5% solution by weight;

[0050] 3) Preparation of modifier solution

[0051] Dissolve 1.1kg of 4-amino-2,2,6,6-tetramethylpiperidine in 9.9kg of molten caprolactam, stir and disperse to make a 10% solution by weight;

[0052] 4) Preparation of titanium dioxide dispersion

[0053]The composition of titanium dioxide, liquid caprolactam and water is prepared according to the ratio of 3.3kg:10kg, then stirred at 10-50°C for 0.5-5 hours, circulated and filtered, and then pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com