Patents

Literature

1002 results about "Hexamethylenediamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexamethylenediamine is the organic compound with the formula H₂N(CH₂)₆NH₂. The molecule is a diamine, consisting of a hexamethylene hydrocarbon chain terminated with amine functional groups. The colorless solid (yellowish for some commercial samples) has a strong amine odor. About 1 billion kilograms are produced annually.

Semiaromatic polyamide molding compositions and their use

ActiveUS20080274355A1High strengthLow water absorptionPigmenting treatmentNon-fibrous pulp additionHexamethylenediamineAramides

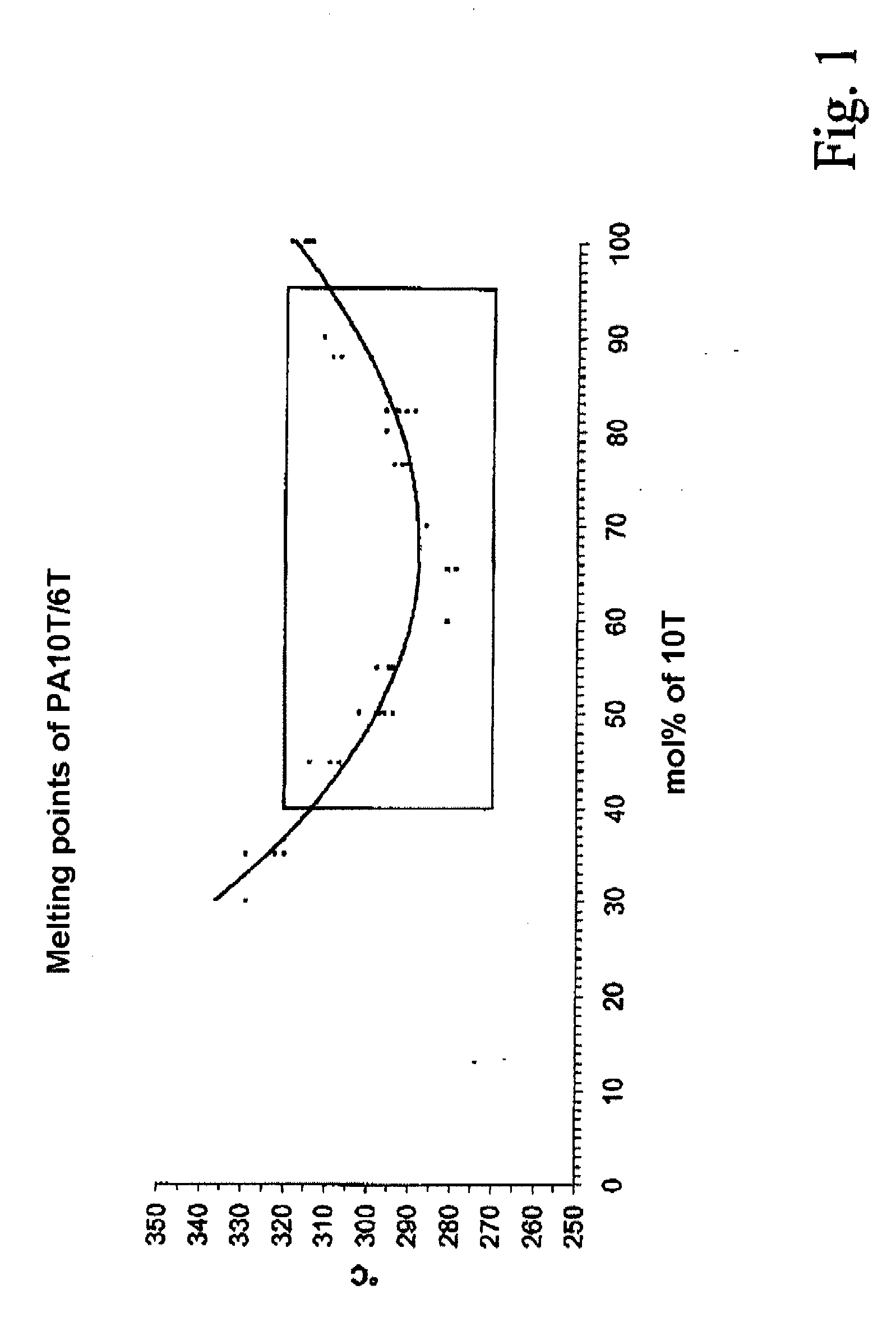

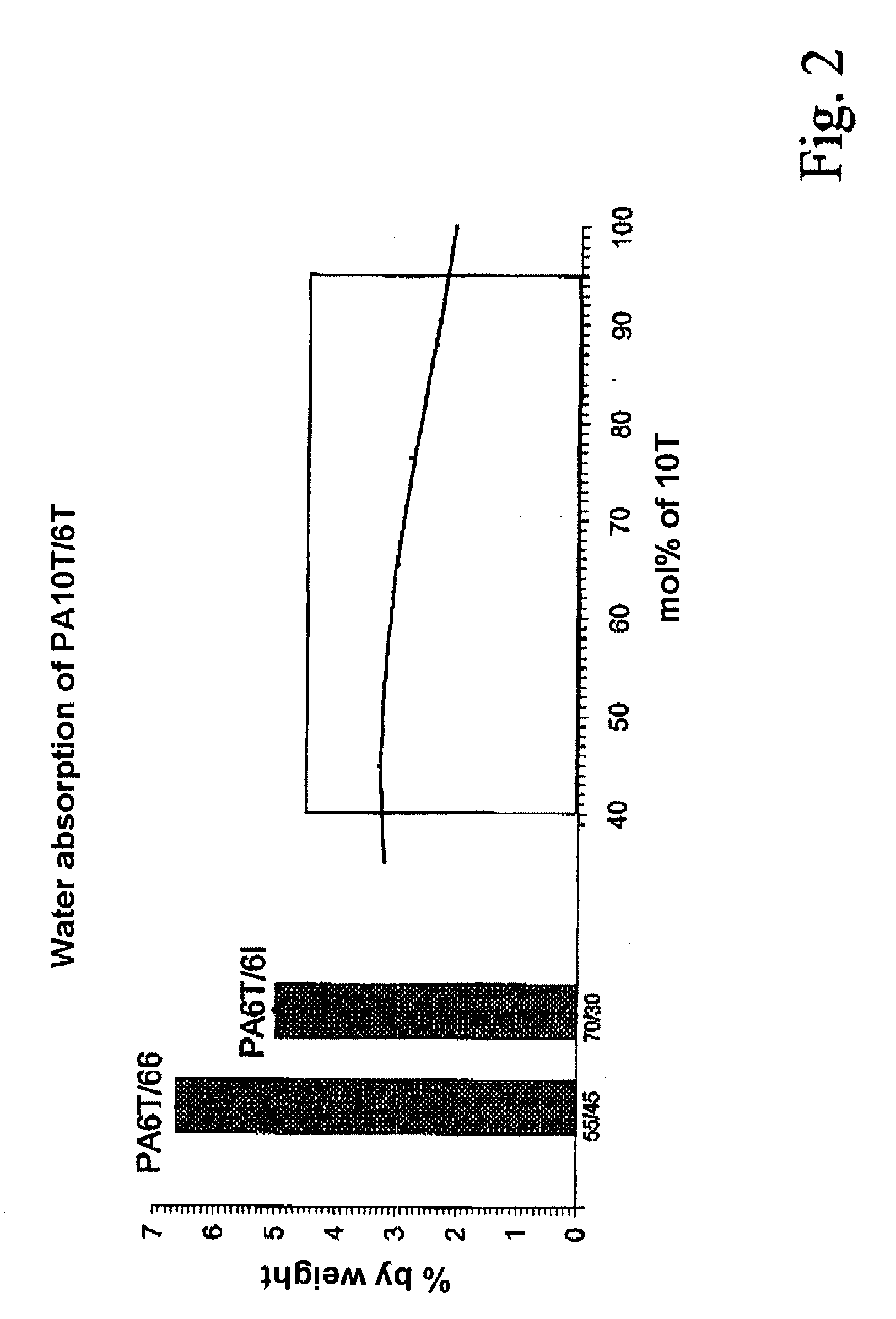

A polyamide molding composition with the following constitution is described:(A) from 30 to 100% by weight of at least one 10T / 6T copolyamide, where this is composed of(A1) from 40 to 95 mol % of 10T units, formed from the monomers 1,10-decanediamine and terephthalic acid(A2) from 5 to 60 mol % of 6T units, formed from the monomers 1,6-hexanediamine and terephthalic acid(B) from 0 to 70% by weight of reinforcing materials and / or fillers(C) from 0 to 50% by weight of additives and / or further polymerswhere the entirety of components A to C is 100%, with the proviso that in component (A) up to 30 mol %, based on the entirety of the dicarboxylic acids, of the terephthalic acid can have been replaced by other aromatic, aliphatic, or cycloaliphatic dicarboxylic acids, and with the proviso that in component (A) up to 30 mol % of 1,10-decanediamine and respectively 1,6-hexanediamine, based on the entirety of the diamines, can have been replaced by other diamines, and with the proviso that not more than 30 mol % in component (A), based on the entirety of the monomers, can have been formed via lactams or amino acids. Uses of this polyamide molding composition are moreover described, as also are processes for the preparation of these polyamide molding compositions.

Owner:EMS PATENT AG

Biaxial tension co-extrusion high-obstruct base material membrane and process for preparing the same

InactiveCN1733397AImprove barrier propertiesImprove qualityTurning toolsHeat deflection temperaturePolyolefin

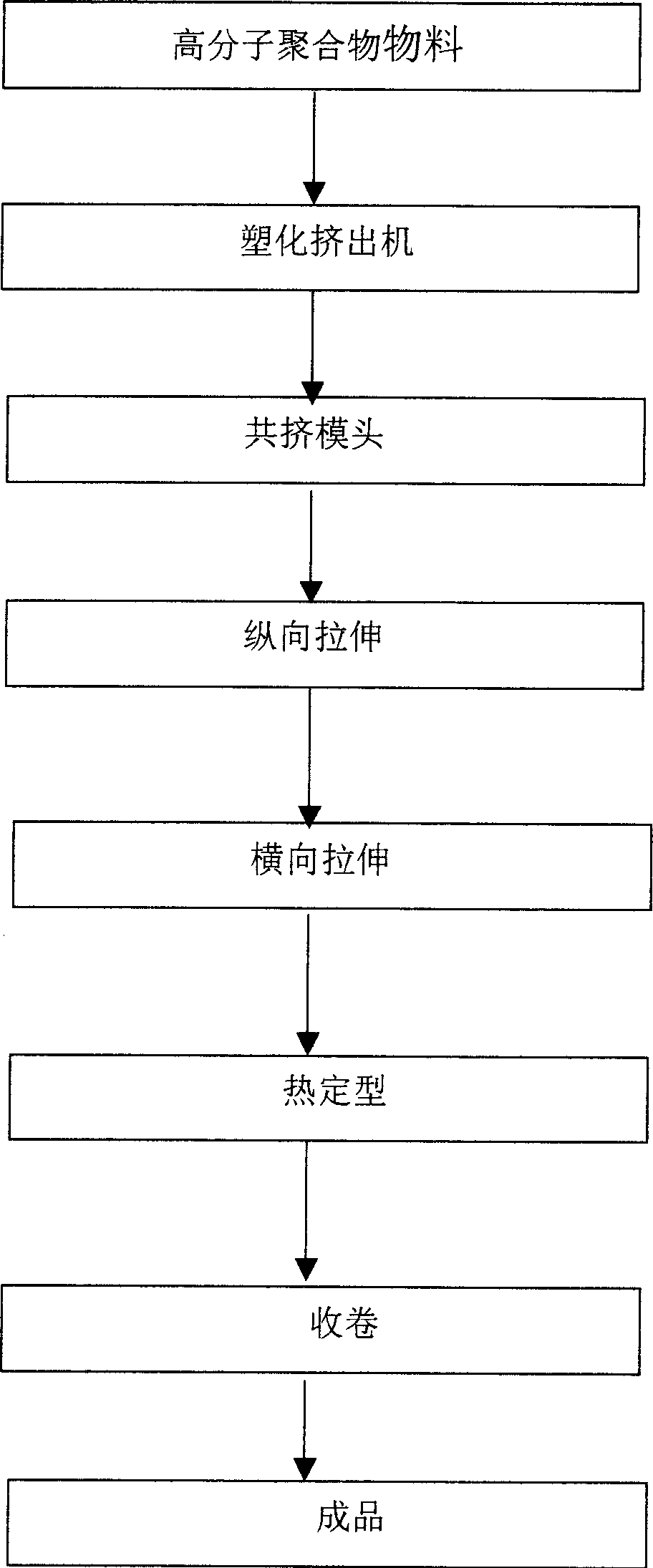

This invention provides biaxial tension coextrude resistive base material membrane and preparation method. Wherein, the membrane comprises at least a resistive layer that is at least one of PA, PVA, PVDC and MAD6, a splice layer belonged to EAA, EEA, ethylenemethacrylic acid copolymerized resin or polyolefin and neolyn resin that can combine the other tow layers, and a heat-sealing layer that is at least one of the polyolefin resin, EVA and PET; besides, there is nano inorganic material in resistive layer and or heat-sealing layer to improve performance. The product fits to package for all kinds goods.

Owner:朱春蕾 +4

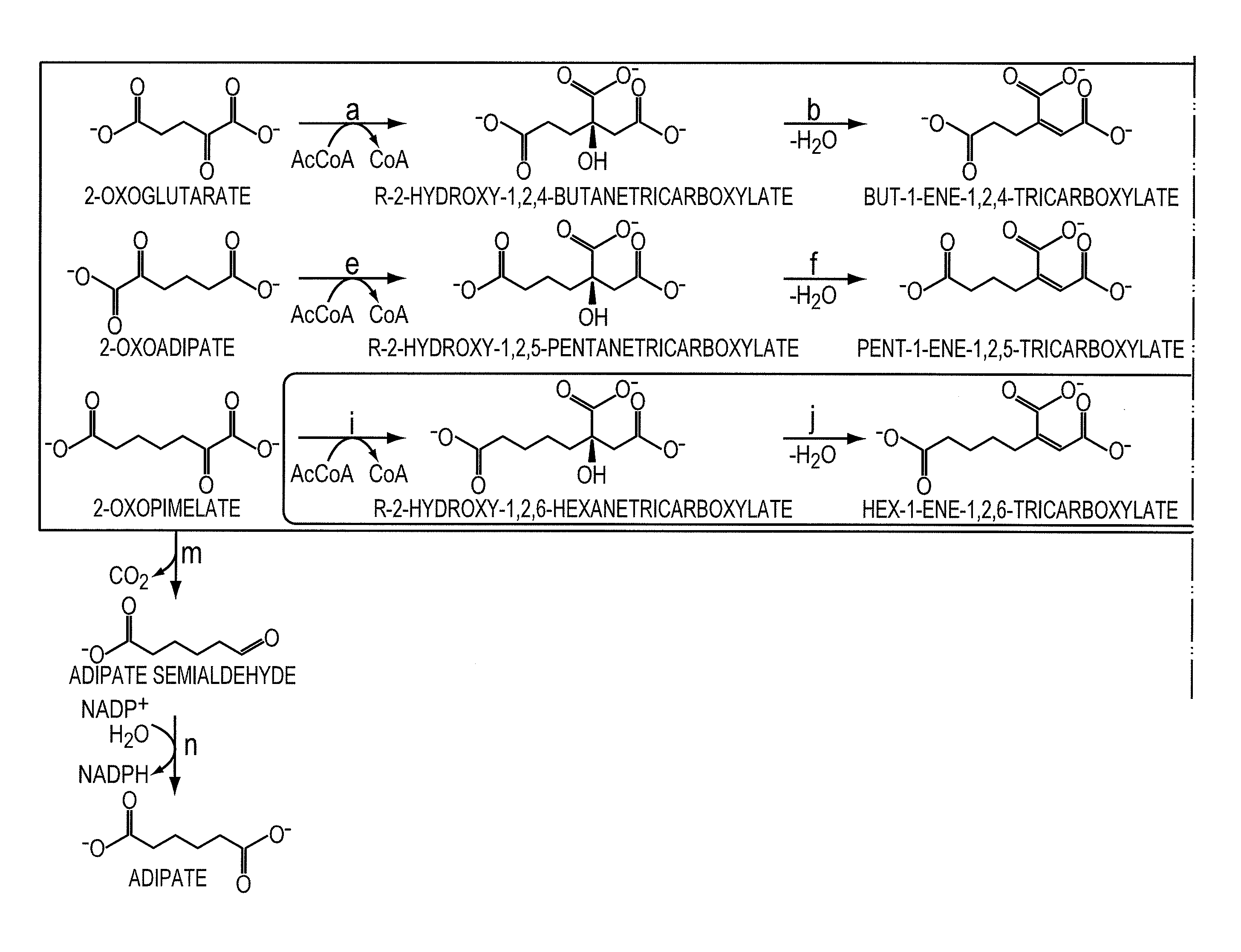

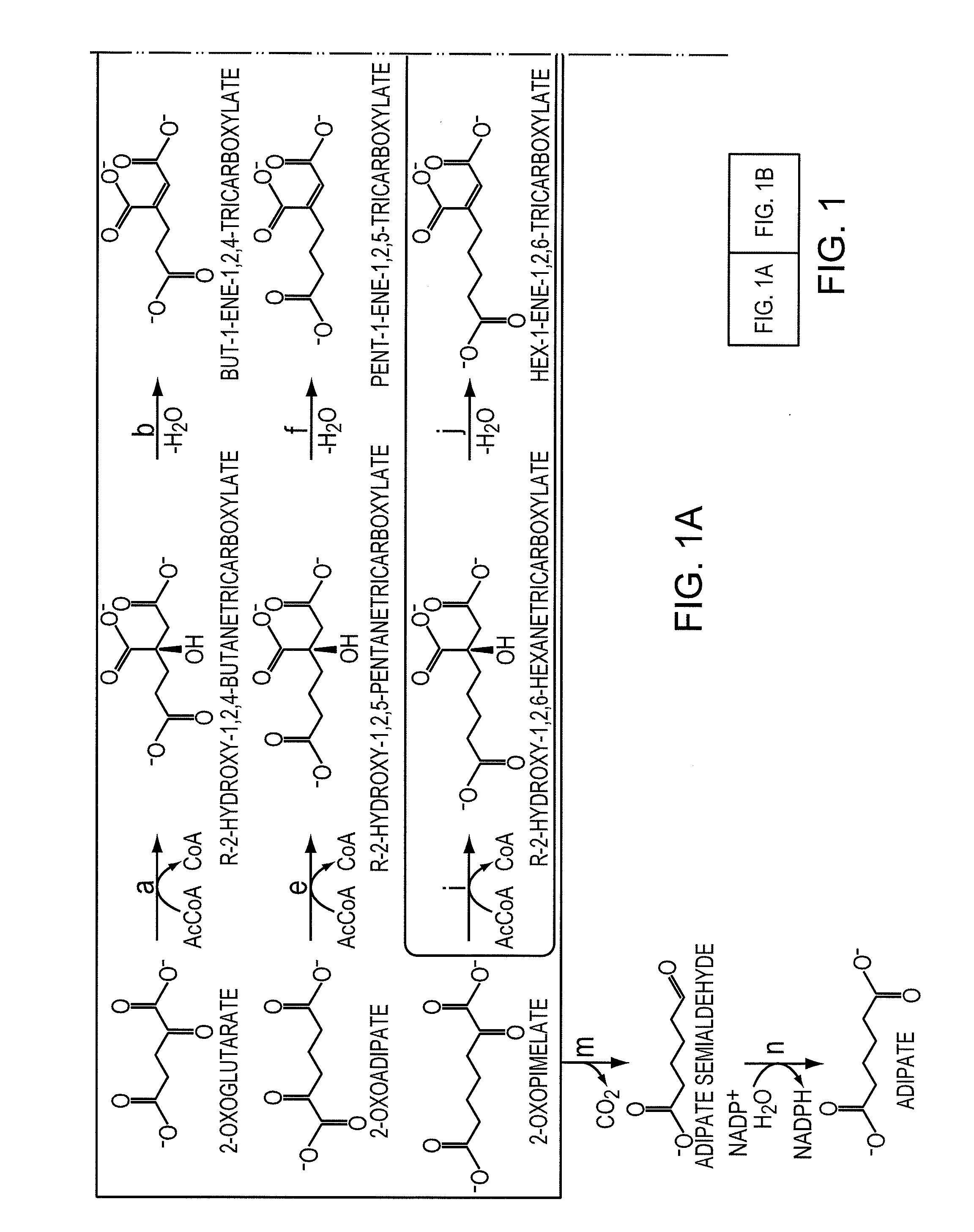

Biological Synthesis of Difunctional Alkanes from Carbohydrate Feedstocks

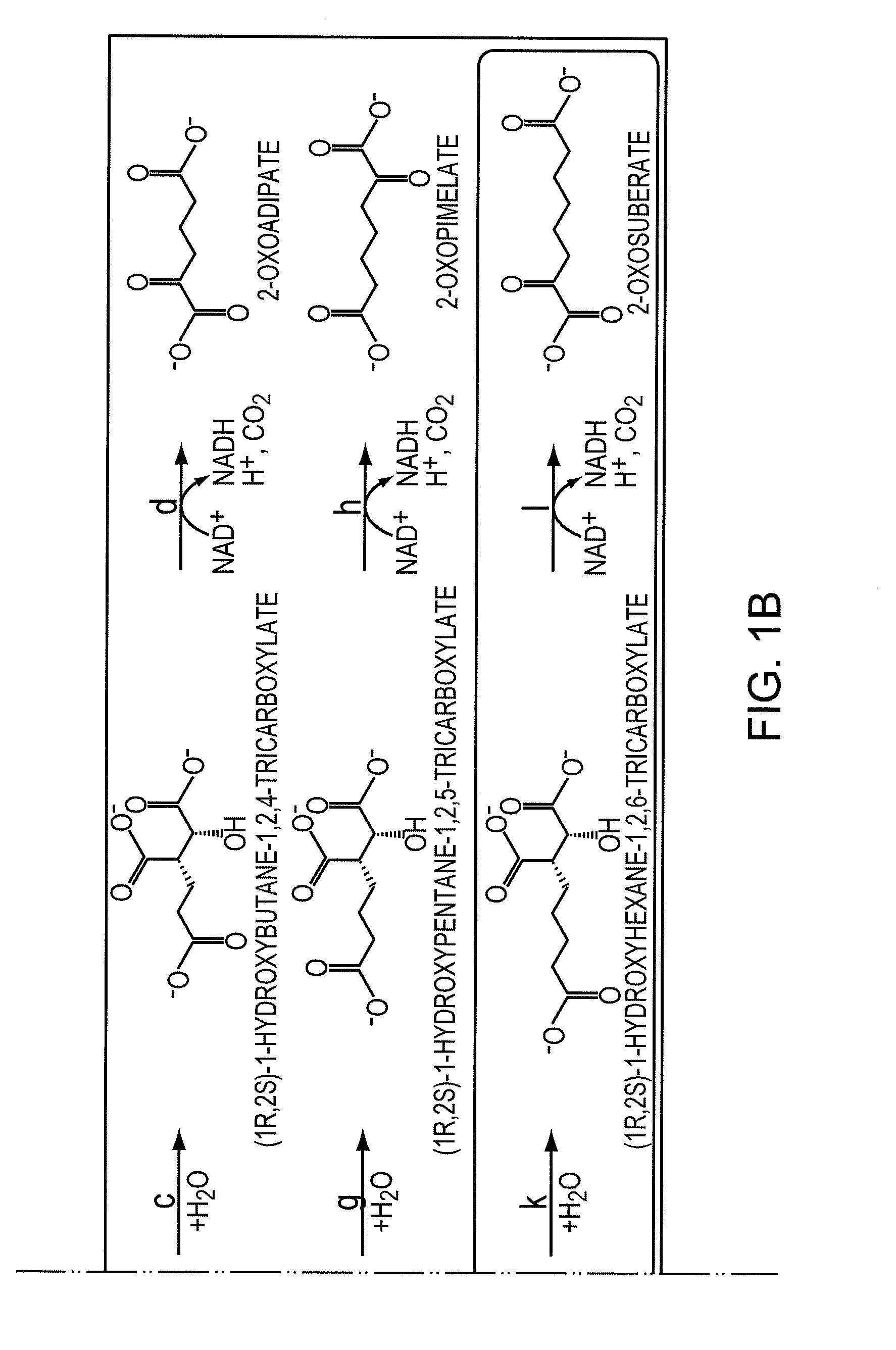

Aspects of the invention relate to methods for the production of difunctional alkanes in host cells. In particular, aspects of the invention describe components of genes associated with the difunctional alkane production from carbohydrate feedstocks in host cells. More specifically, aspects of the invention describe metabolic pathways for the production of adipic acid, aminocaproic acid, caprolactam, and hexamethylenediamine via 2-ketopimelic acid.

Owner:CELEXION

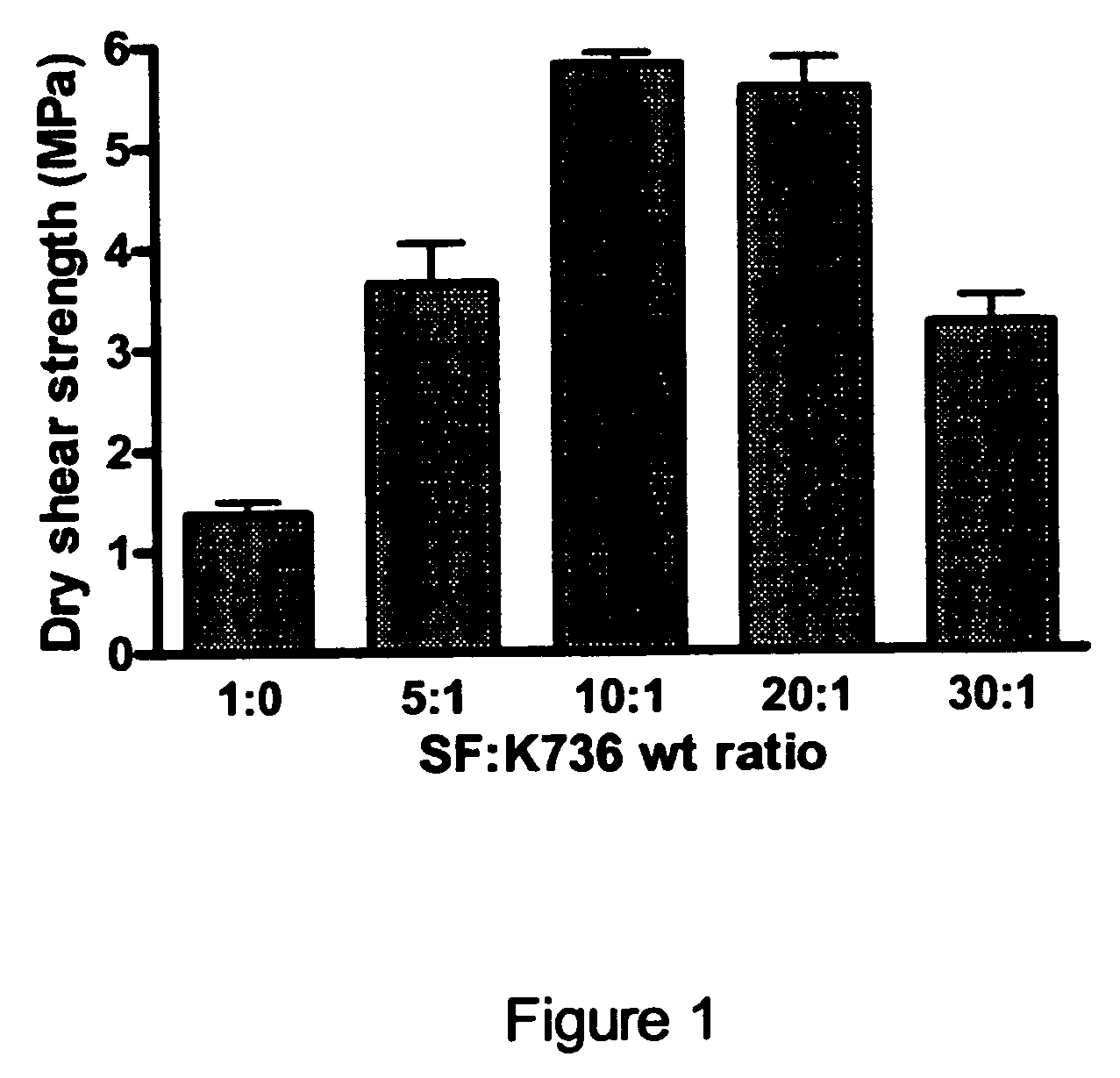

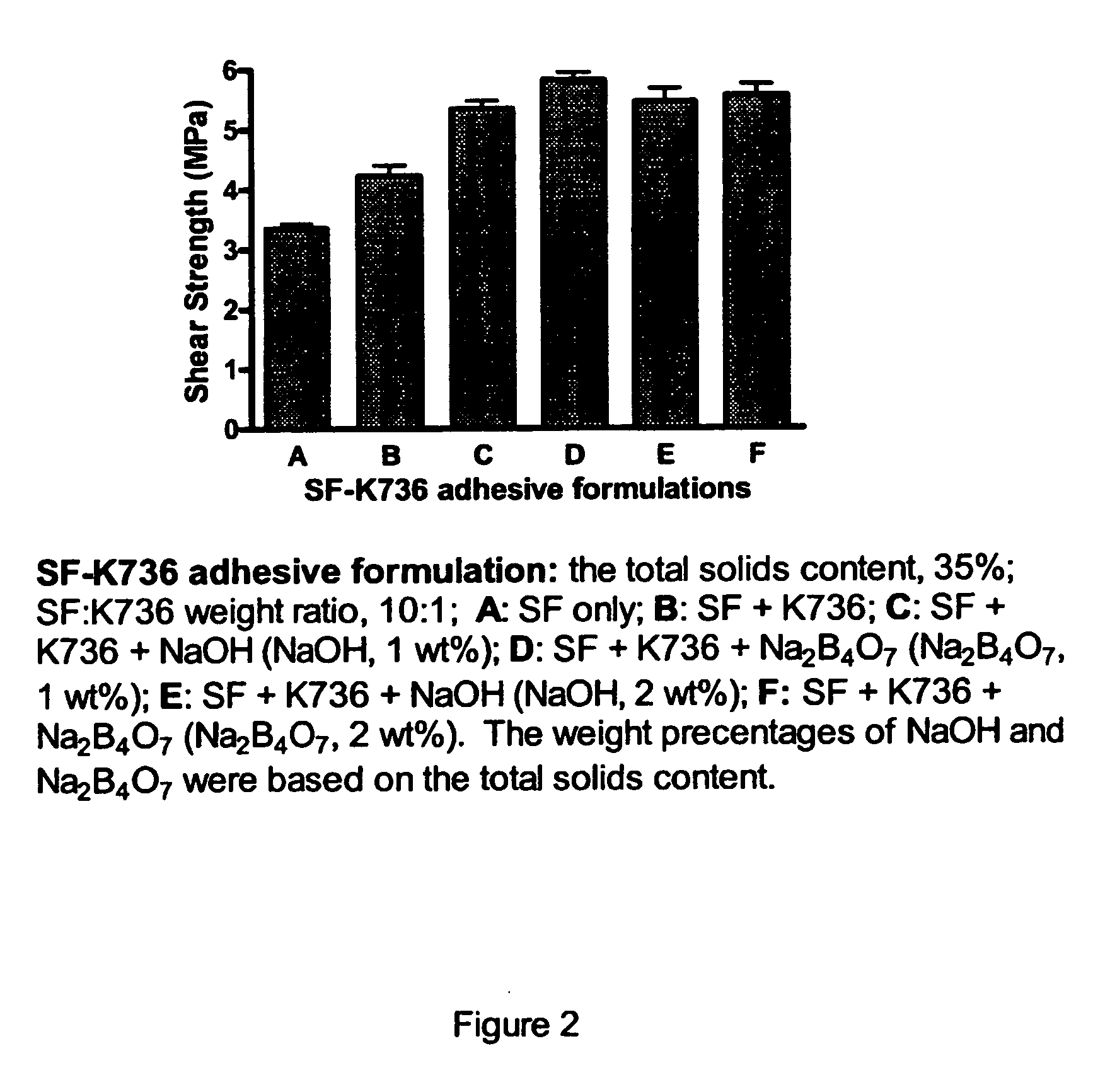

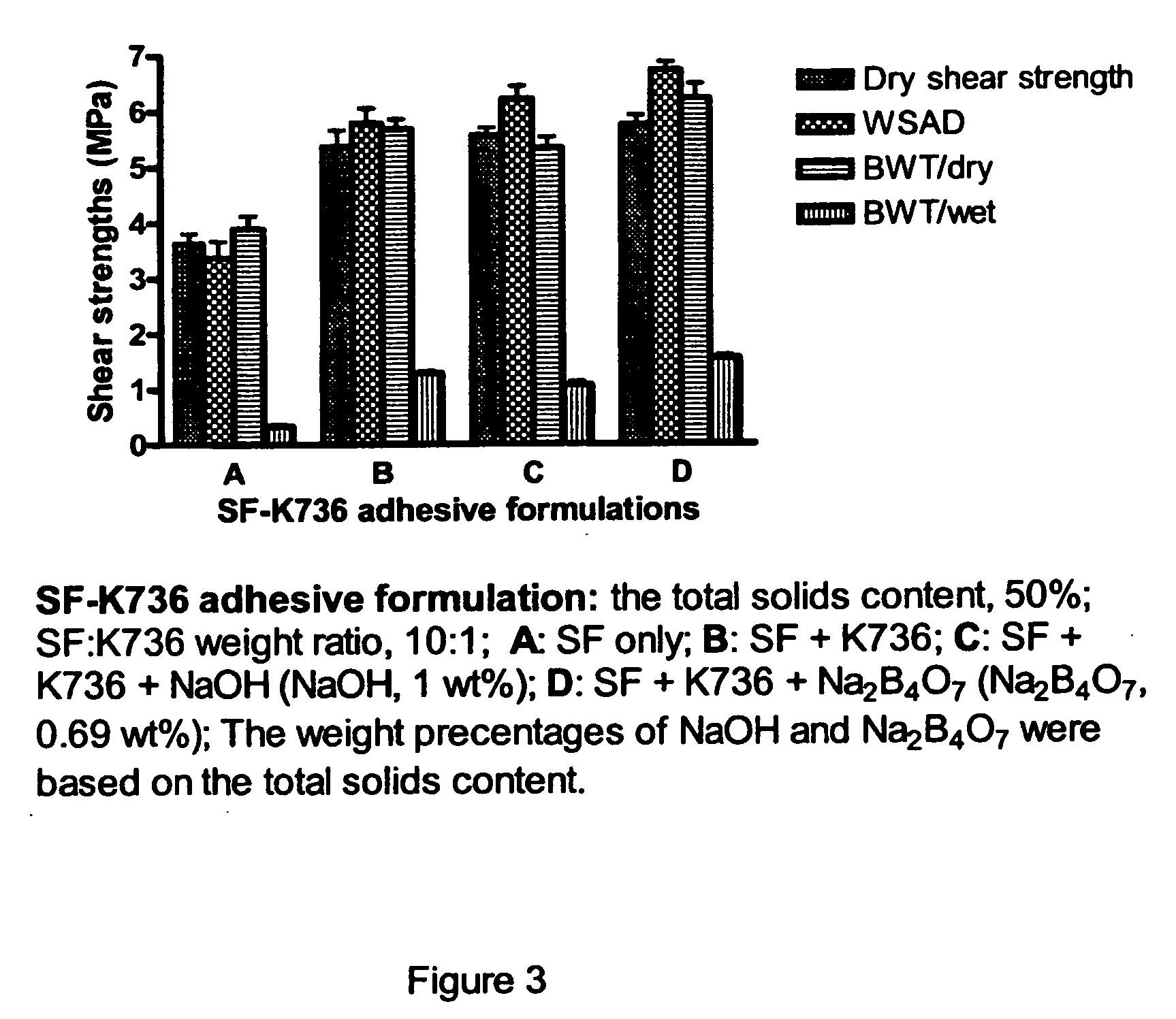

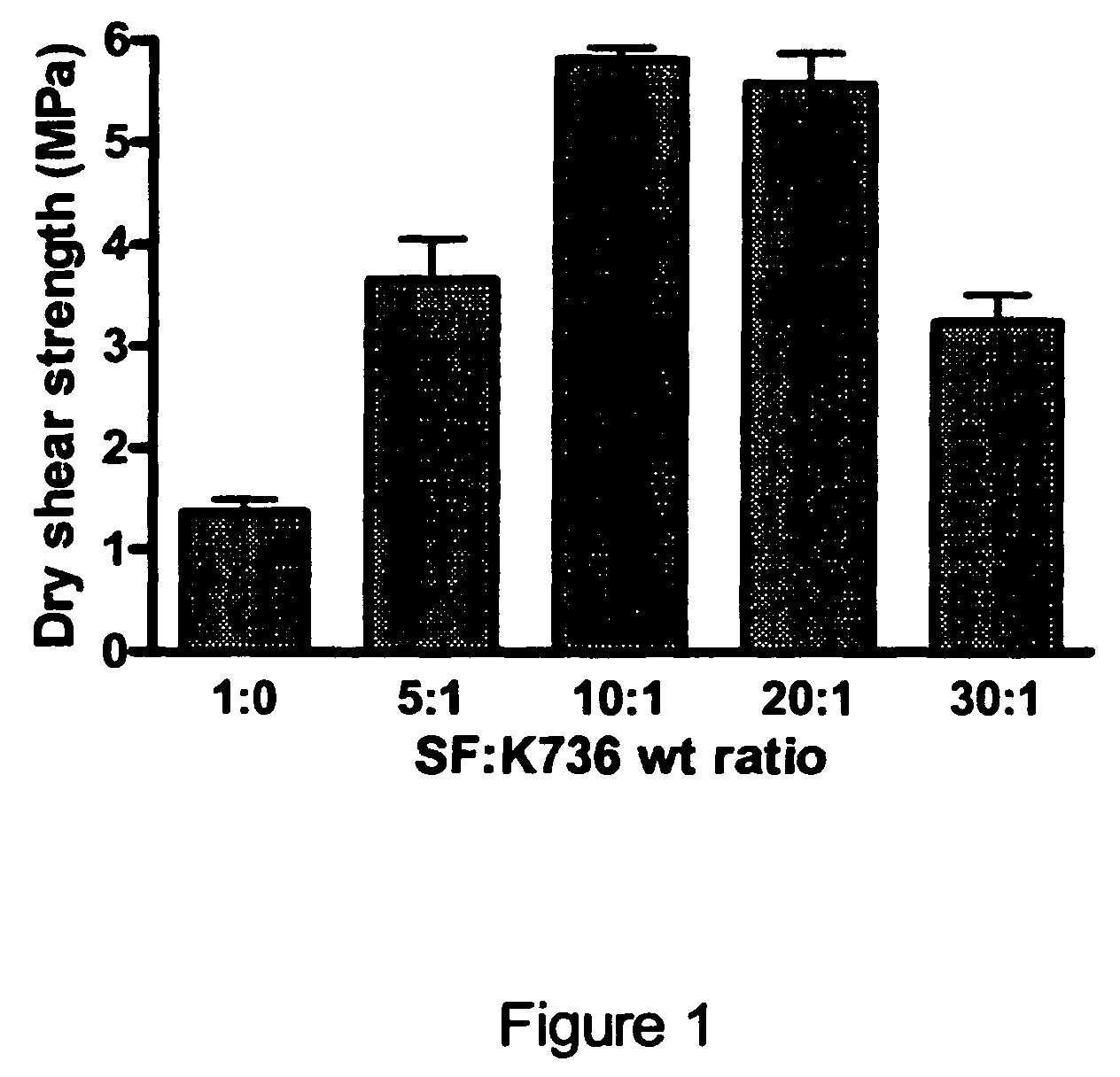

Formaldehyde-Free Adhesives and Lignocellulosic Composites Made from the Adhesives

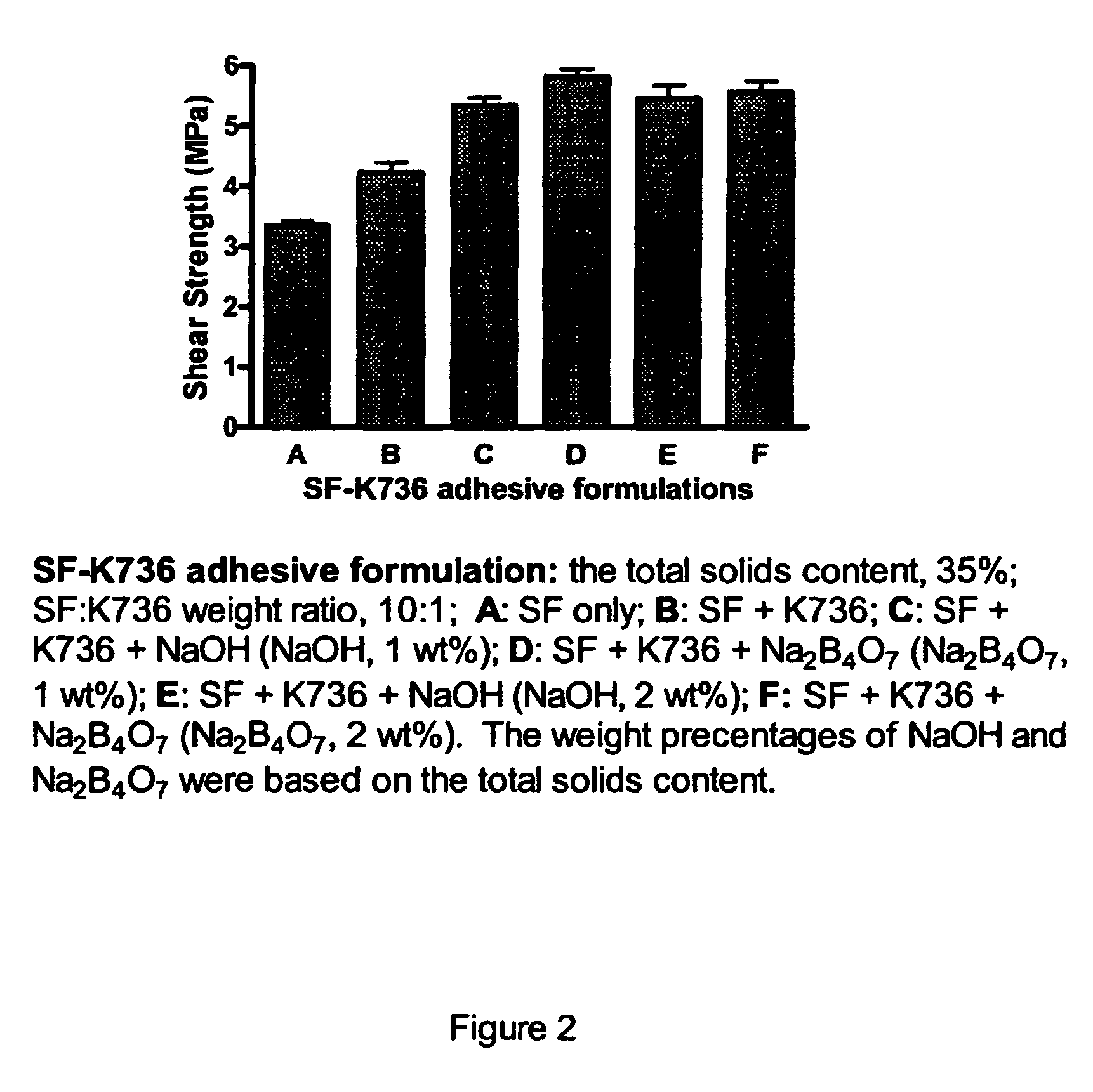

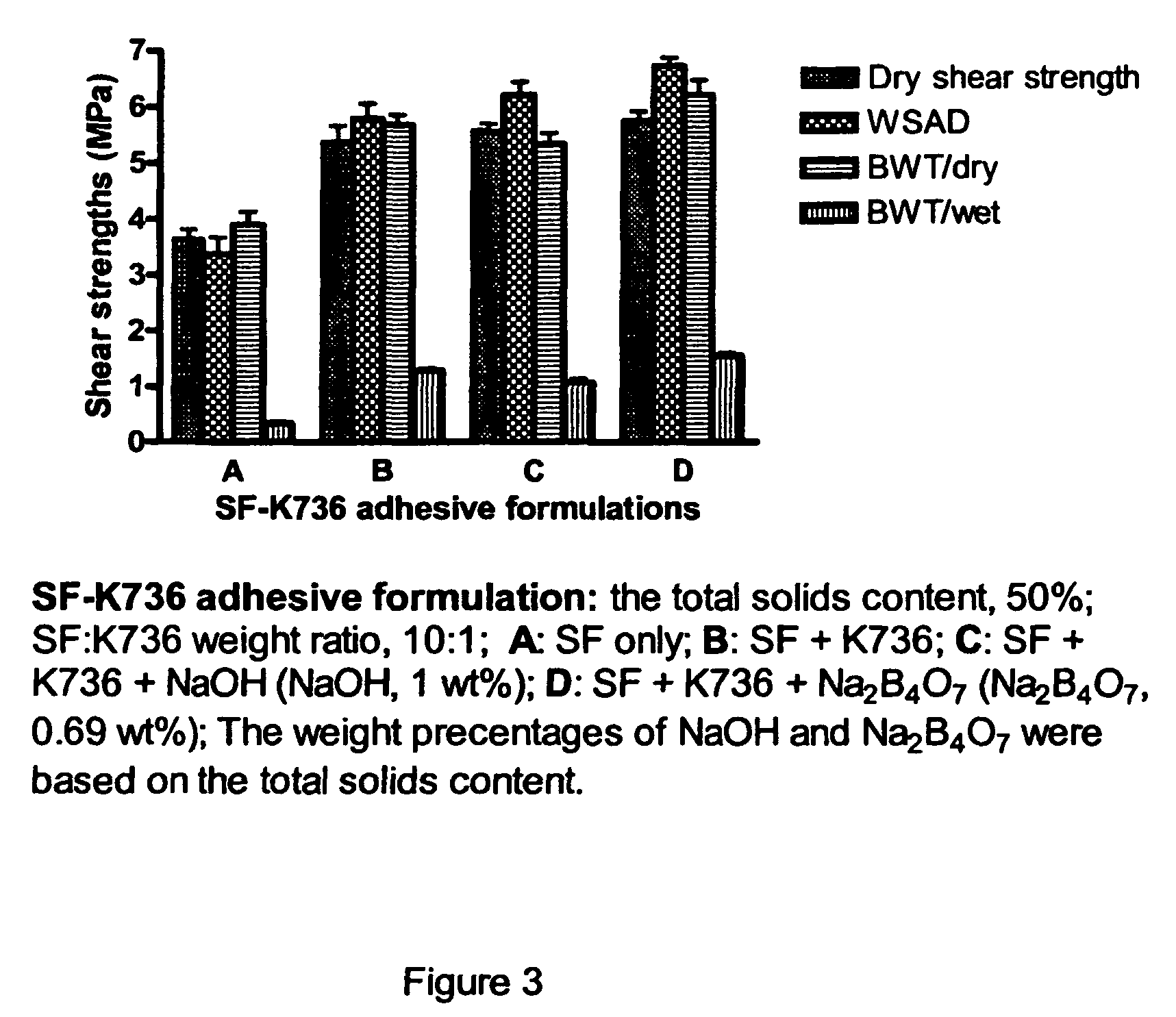

A first variant of an adhesive composition for making a lignocellulosic composite includes soy protein and / or lignin; at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein; and at least one compound selected from a boron compound, a group IA oxide or hydroxide, or a group IIA oxide or hydroxide. A second variant of an adhesive composition includes a first component selected from soy protein and / or lignin; and at least one substantially formaldehyde-free curing agent selected from a reaction product of epichlorohydrin with ethylenediamine, a reaction product of epichlorohydrin with bis-hexamethylenetriamine, or a reaction product of epichlorohydrin with hexamethylenediamine.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

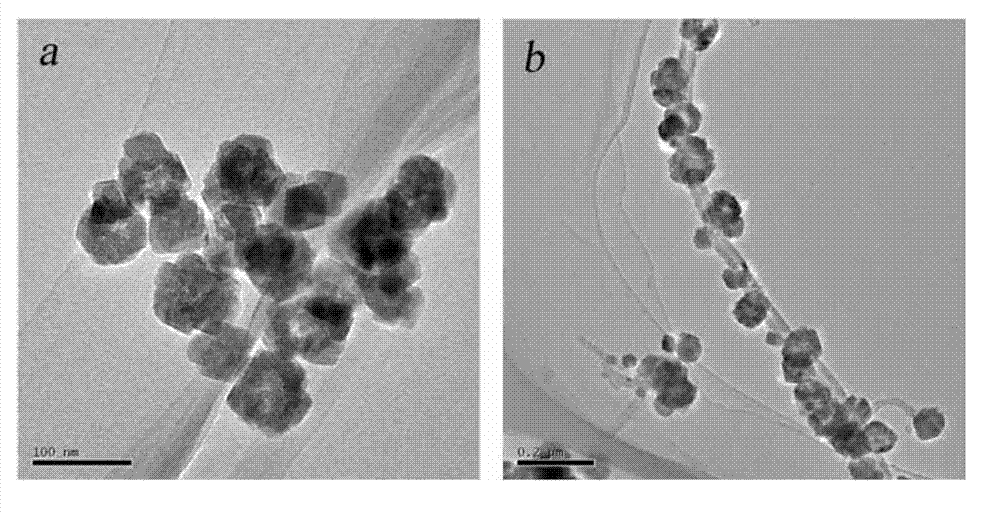

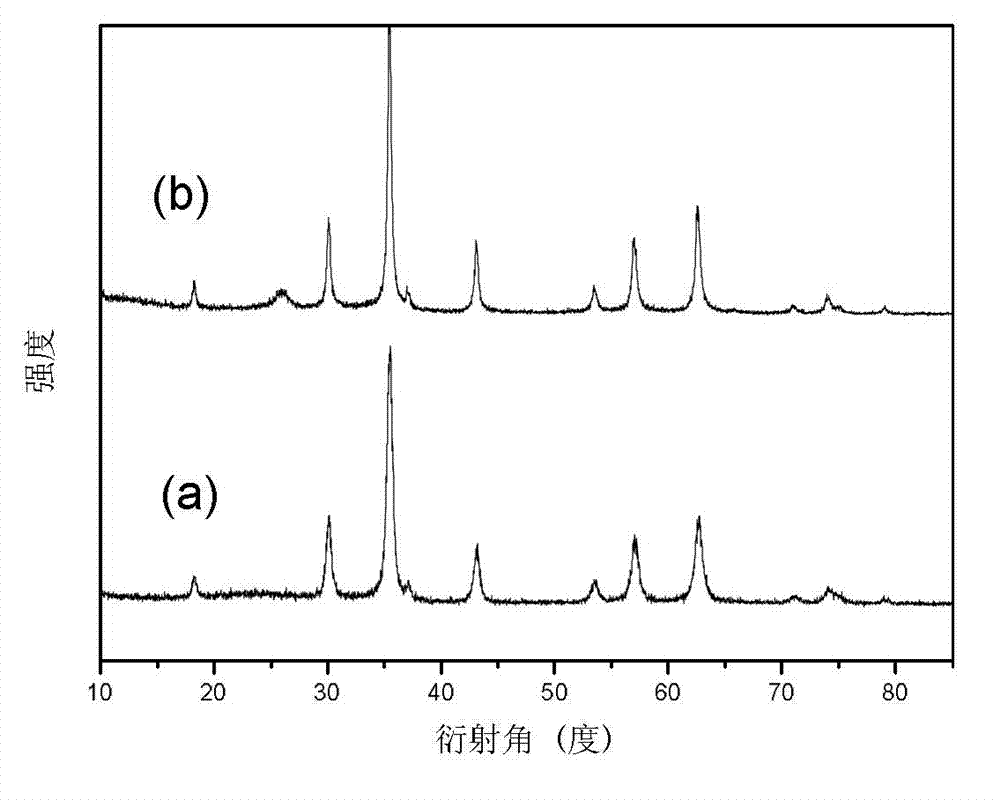

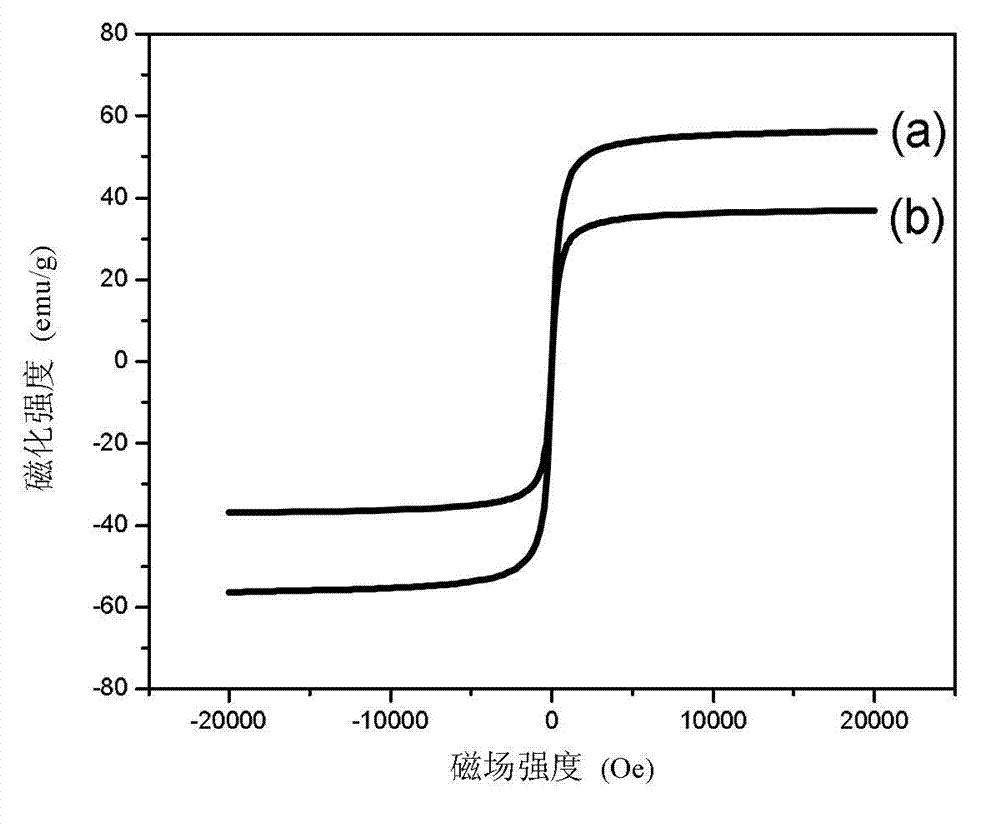

Magnetic carbon nanotube composite material and preparation method and application thereof

InactiveCN103041773AImprove bindingEasy to separateIon-exchange process apparatusComponent separationSorbentHexamethylenediamine

The invention discloses a magnetic carbon nanotube composite material and a preparation method and an application thereof. The preparation method comprises the following steps: adding FeCl3.6H2O to an ethylene glycol solution; then adding anhydrous sodium acetate and polyethylene glycol; adding a carboxylated multiwalled carbon nanotube; performing ultrasonic dispersion; adding hexamethylenediamine or ethanediamine; heating to 200-300 DEG C for reaction for 8-24h; and washing and performing vacuum drying to prepare the amino-modified magnetic Fe3O4-carbon nanotube composite material. The amino-modified magnetic Fe3O4-carbon nanotube composite material prepared by the invention is of nanoscale and superparamagnetism, can be stably dispersed in solutions, and can be quickly separated and enriched through a simple action of a magnetic field. As an adsorbent, the material is large in superficial area and has various active groups on the surface. The material can adsorb pigments from complex substrates through pi-pi electron interaction and hydrophobic effect of the carbon nanotube and can adsorb compounds such as organic acids and phenols through weak anion exchange effect of amino groups on the surfaces of magnetic nanoparticles.

Owner:TIANJIN UNIV

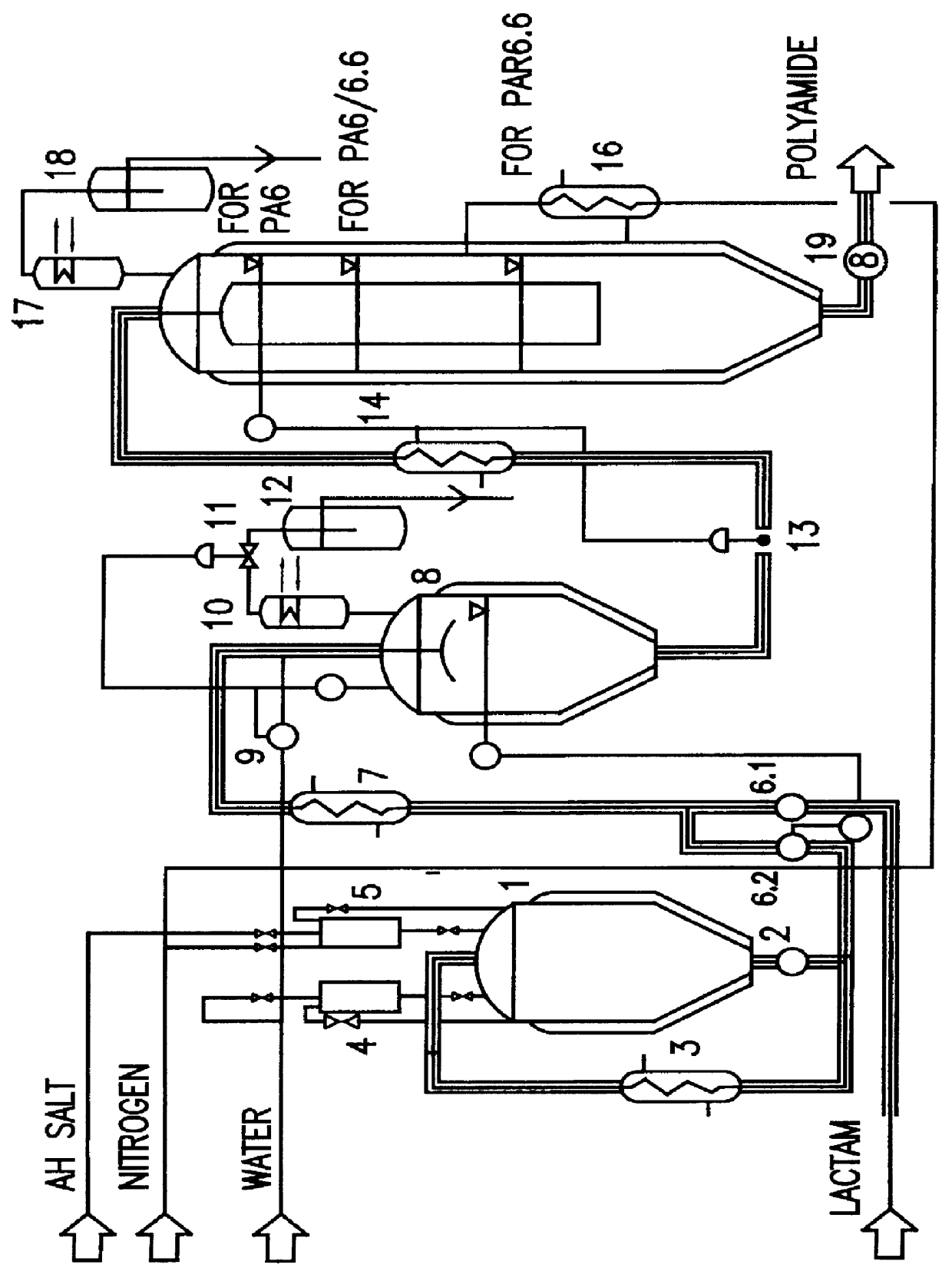

Process and device for the standardized continuous production of polyamides

InactiveUS6136947AHigh viscosityOvercome disadvantagesChemical recyclingHexamethyldiamineHexamethylenediamine

PCT No. PCT / EP96 / 05514 Sec. 371 Date Nov. 13, 1998 Sec. 102(e) Date Nov. 13, 1998 PCT Filed Dec. 10, 1996 PCT Pub. No. WO90 / 21758 PCT Pub. Date Jun. 19, 1997A process and device for the standardised continuous production of polyamide 6, polyamide 6.6 and / or copolyamides from e-caprolactam and / or adipic acidic hexamethylenediamine or adipic acid and hexamethylenediamine uses a combination of known specific processes to design a polymerisation reactor in which product with sufficiently high quality can be produced with the most efficient possible use of the energy applied and in such a way that the initial substances can be used alternately in the individual processing stages: pre-heating of the initial products using a common heat exchanger to 190-300 DEG C.; polymerisation of the initial products in a pressure stage with or without elimination of water and product recycling at 150-280 DEG C. and a pressure of <20 bar, dewatering of the polymer melt in a one to five turn coil under slow pressure reduction; and final condensation of the melt in at least one common vertical reactor at temperatures of between 210 and 285 DEG C.

Owner:POLYMER ENG

Semiaromatic moulding compositions and uses of these

ActiveUS20110123749A1Low process temperatureSufficient compatibilityNon-metal conductorsEnvelopes/bags making machineryLaurolactamPolymer science

A polyamide moulding composition with the following constitution is described:(a) from 40 to 90% by weight of a copolyamide, where this is composed of(a1) 1,6-hexanediamine and 1,10-decanediamine and also(a2) terephthalic acid and at least one other polyamide-forming monomer selected from the group of: dicarboxylic acid having from 8 to 18 carbon atoms, laurolactam, aminolauric acid, and / or mixtures thereof;(b) from 10 to 40% by weight of macromolecular plasticizers, with the proviso that these can have been replaced to some extent by low-molecular-weight plasticizers;(c) from 0 to 20% by weight of additives and / or added substances.Uses of this type of moulding composition are also described, in particular for the production of a fuel line, cooling line, oil line or urea line for the automobile sector, as also are production processes to give mouldings.

Owner:EMS PATENT AG

Catalyst for synthesizing hexamethylenediamine

InactiveCN106807377APromote productionReduce the likelihood of aggregationOrganic compound preparationAmino compound preparationHydrogenHexamethylenediamine

The invention relates to a catalyst for synthesizing hexamethylenediamine. The catalyst is composed of three parts, namely a main active ingredient, aids and a carrier subjected to ammoniated treatment, wherein the main active ingredient is Ni or Co; the aids refer to one or more ofmetals such as Fe, Cu, Ru, Re, K, Zn and B or oxides; and the carrier subjected to ammoniated treatment is selected from SiO2 or Al2O3 subjected to ammoniated treatment. In the total weight of the catalyst, the main active ingredient accounts for 1-40%, and the aids account for 0.1-20%. The catalyst disclosed by the invention has the characteristic that the adopted carrier needs special ammoniated treatment. According to the catalyst disclosed by the invention, an ammonolysis reaction of hexanediol or amino hexanol or a hexanediol / amino hexanol mixture is implemented, the hexamethylenediamine product is synthesized under a hydrogen present condition, and the catalyst has high activity, high selectivity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

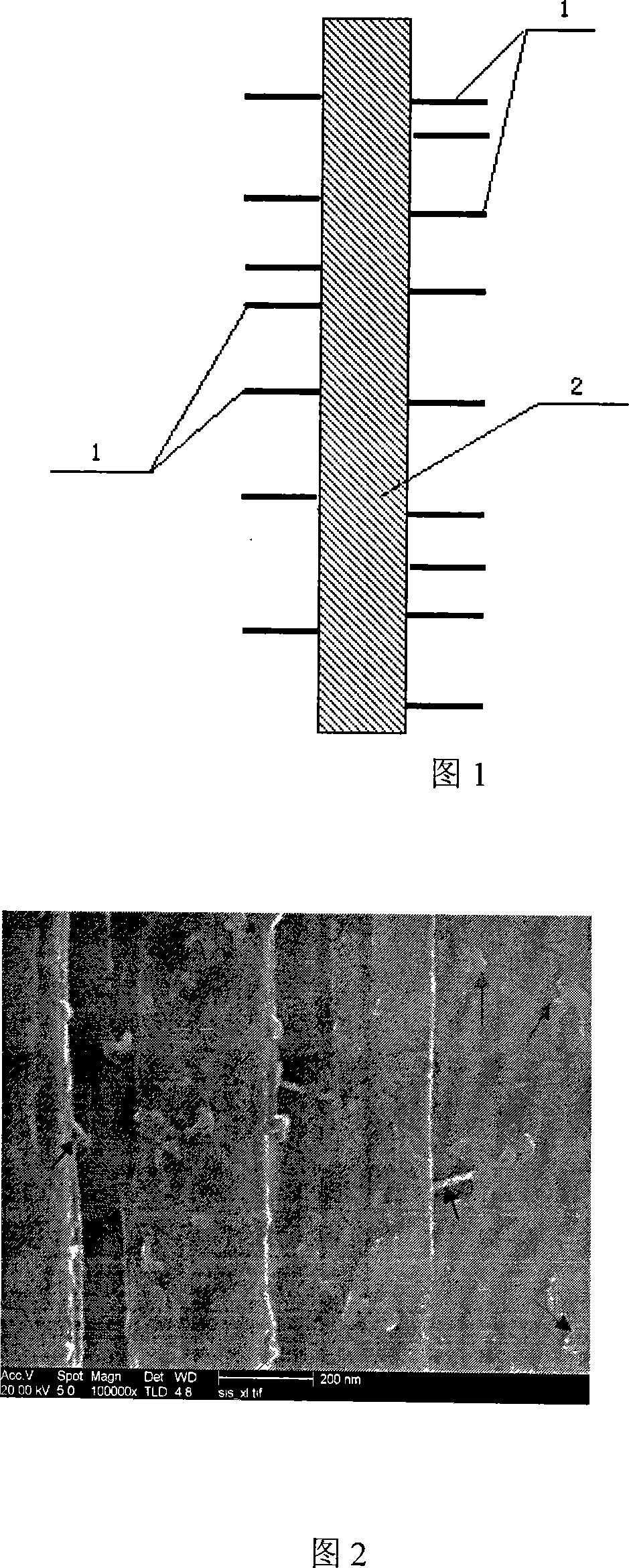

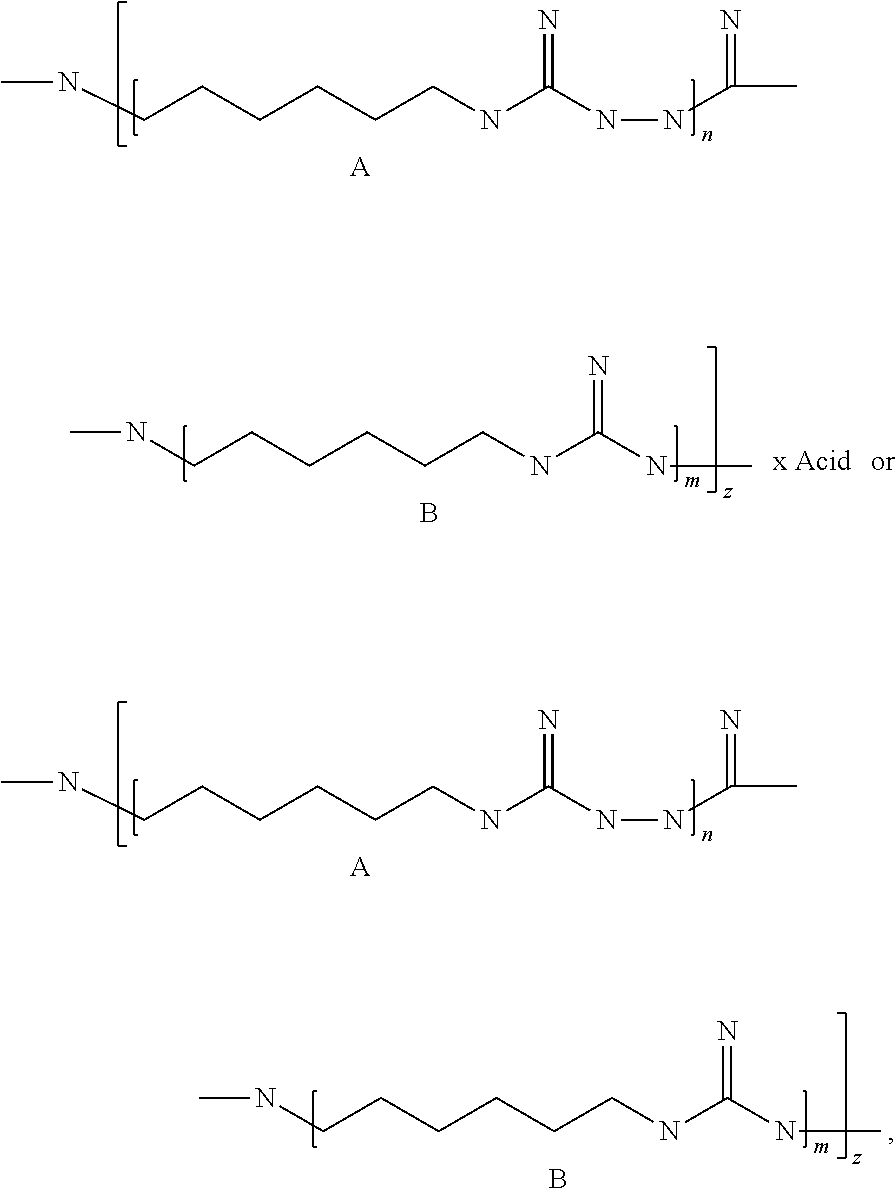

Carbon nano-tube connecting carbon fiber multi-scale reinforcing body and method for producing the same

InactiveCN101173386ATake full advantage of mechanical propertiesRealize chemical bond connectionFibre treatmentArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a multi-scale reinforcement body that carbon nano-tube is connected with carbon fiber and a preparation method aiming at solving the drawbacks of increasing rigidity at the interface, lowering toughness of material and not improving performance of resin base between the fibers and between carbon fiber plywoods after prior carbon fiber treatment is made. The multi-scale reinforcement body of carbon nano-tube connecting carbon fiber is made through combining between a carbon nano-tube decorated by 1, 6 hexamethylenediamine and carbon fiber with acyl chloride functional group on the surface. The preparation method comprises: the carbon nano-tube decorated by 1, 6 hexamethylenediamine and the carbon fiber with acyl chloride functional group on the surface are prepared before put into N,N-dimethylformamide for reaction, thereby getting the multi-scale reinforcement body of carbon nano-tube connecting carbon fiber. The invention has the advantages of big activity on the surface, a plurality of chemical activated functional groups, strong reactive activity, good cohesiveness with the base, improving shearing intensity at the interface for composite material by 127.5% to 144.7% and improving toughness for the base by 34.43% to 48.67%.

Owner:HARBIN INST OF TECH

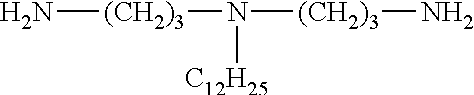

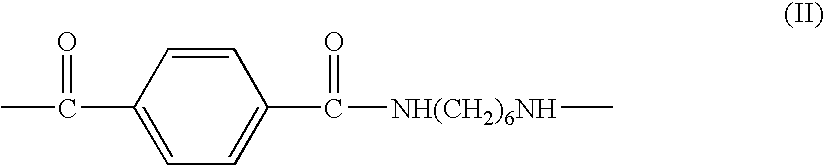

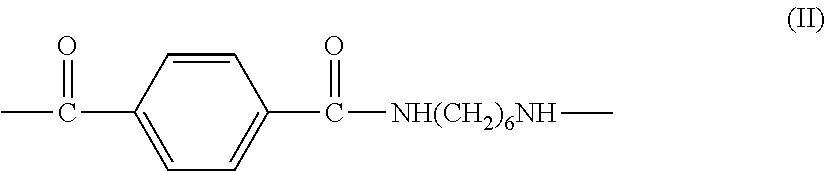

Method for Producing Biocidal Polyguanidine, and Biocidal Polyguanidine

ActiveUS20110269936A1High activityOrganic active ingredientsOrganic chemistryMicroorganismHexamethyldiamine

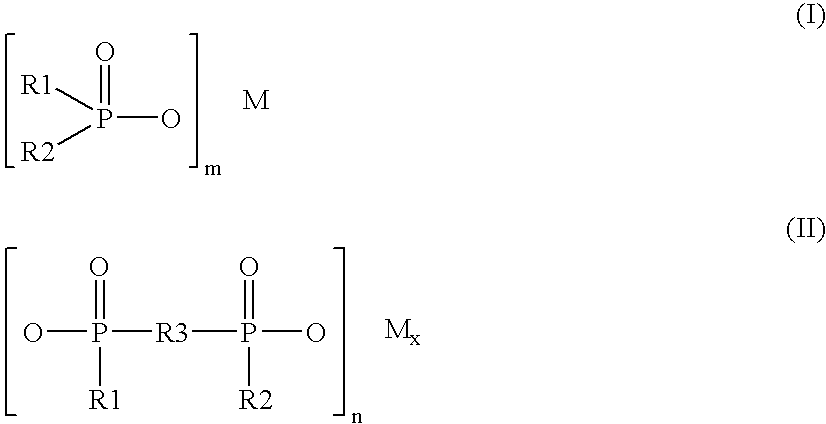

The inventions relate to antiseptic agents and the method for producing thereof and can be used as a broad-spectrum disinfectant in medicine, veterinary medicine, agriculture etc.The method for producing of biocidal polyguanidine that comprises condensation polymerization of hexamethylenediamine with guanine salt additionally uses hydrazine hydrate during the condensation polymerization process, at the following ratio of components, mass %:hexamethylenediamine 20-55guanidine salt 25-65hydrazine hydrate the rest.Biocidal polyguanidine obtained by means of the above-mentioned method, with the following formula:wheren—the number of links A in a single unit of the polymer chain, n=1-3;m—the number of links B in a single unit of the polymer chain, m=2-10;z—the number of single units in the polymer chain, z=4-20;Acid—an acid.The inventions allow obtaining a biocidal polyguanidine with high level of broad-spectrum antimicrobial activity.

Owner:TETS VIKTOR VENIAMINOVICH

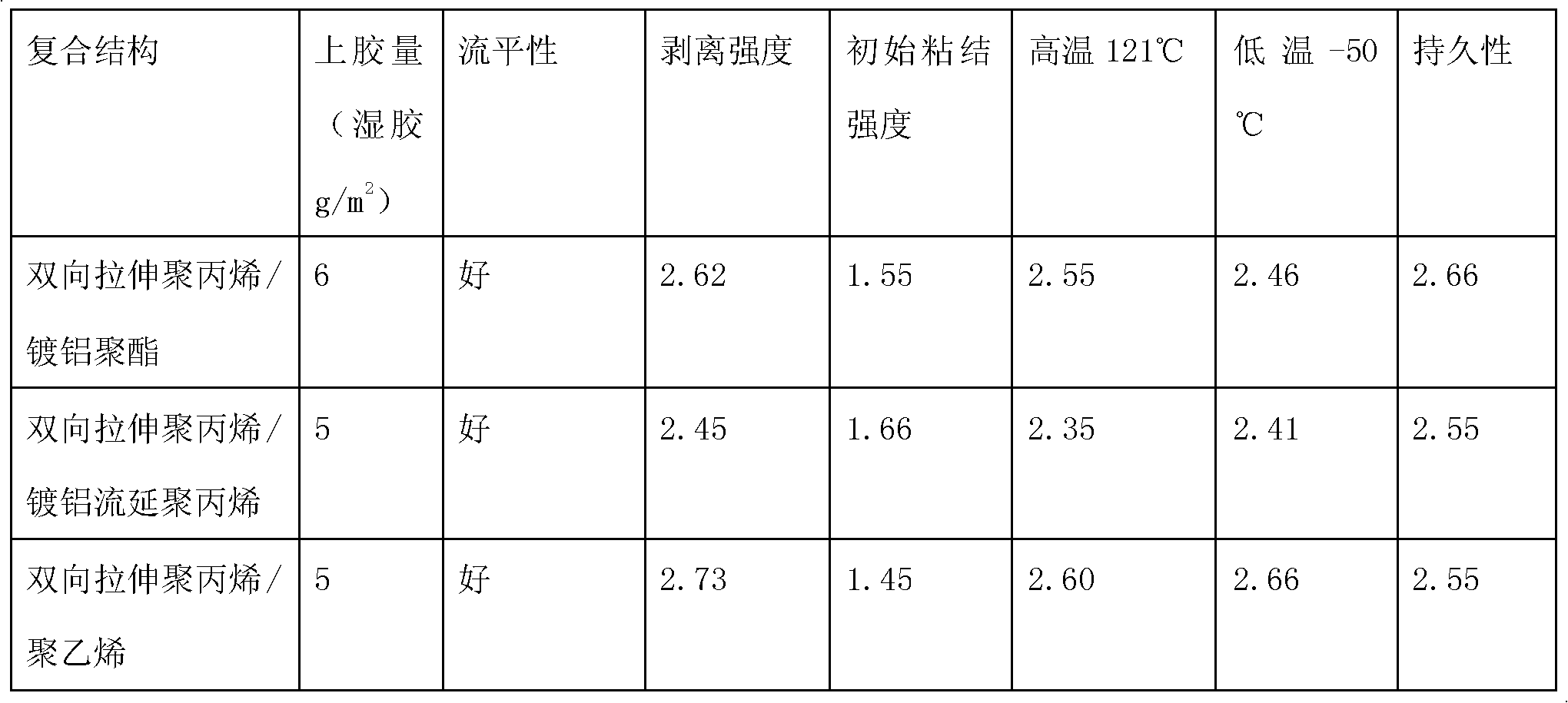

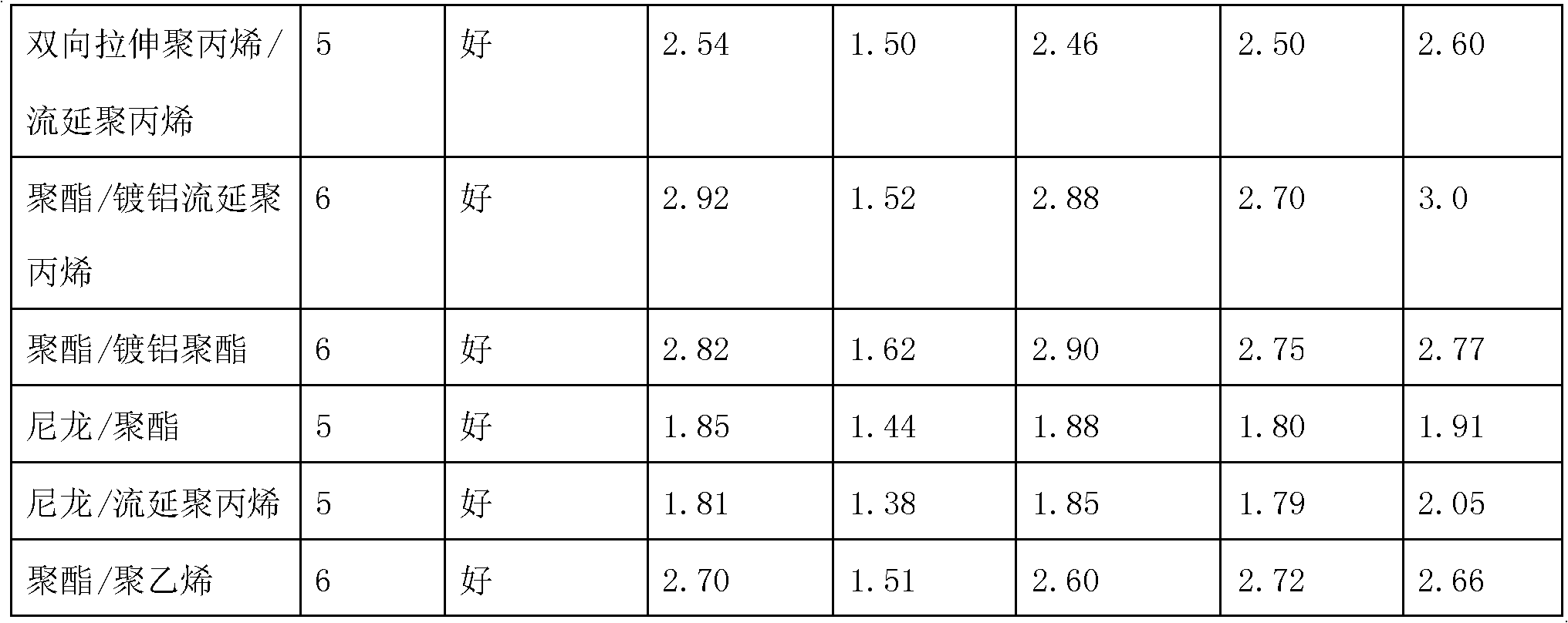

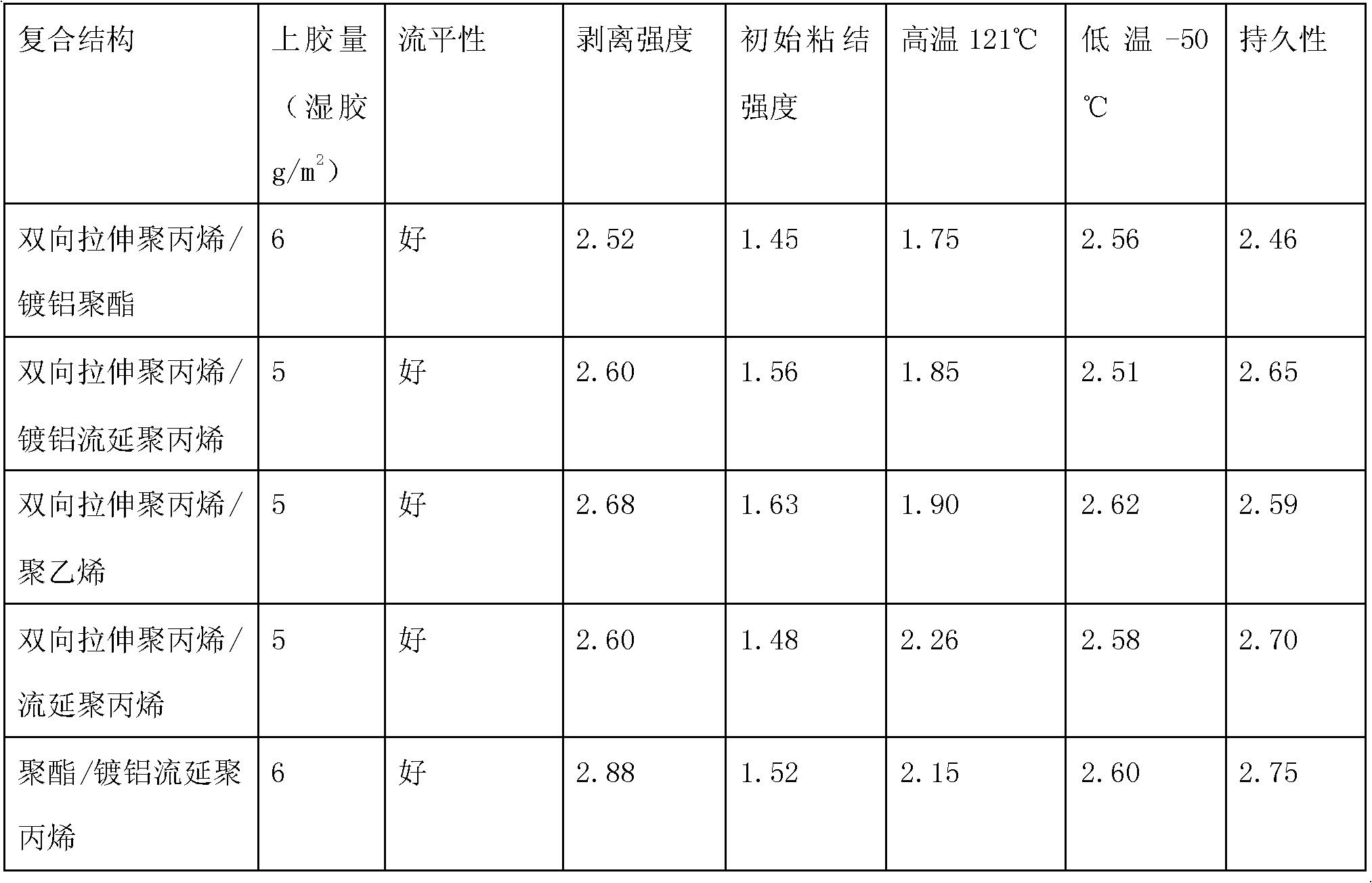

Water-based composite adhesive

InactiveCN102618193AHigh peel strengthGood high and low temperature resistanceEster polymer adhesivesCross-linkWater based

The invention discloses water-based composite adhesive, which contains acrylate emulsion and a cross-linking agent, wherein the weight of the cross-linking agent is 0.1-6 percent of the weight of the acrylate emulsion; the cross-linking agent is any one or a mixture of hexamethylenediamine and adipic acid dihydrazide; and the acrylate emulsion is formed by copolymerizing a terpenes hard monomer, a terpenes soft monomer, a terpenes carboxylic acid monomer, a terpenes functional monomer, a dual-vinyl monomer and a terpenes cross-linking monomer through nuclear shells under an emulsion system. The adhesive is particularly suitable for dry-type composite adhesion between flexible package composite base materials such as a plastic film and a vacuum aluminized film which are processed through corona; has good leveling, fast drying, high transparency, capability of curing at room temperature, high initial strength, excellent peel strength, difficulty in mesh clogging and skinning, wide adaptability and low cost; and can be applied to various machine types, does not contain any organic solvent, can replace solvent adhesive at present completely, and belongs to environment friendly adhesive.

Owner:GUANGDONG RONGYU INDAL

Formaldehyde-free adhesives and lignocellulosic composites made from the adhesives

A first variant of an adhesive composition for making a lignocellulosic composite includes soy protein and / or lignin; at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein; and at least one compound selected from a boron compound, a group IA oxide or hydroxide, or a group IIA oxide or hydroxide. A second variant of an adhesive composition includes a first component selected from soy protein and / or lignin; and at least one substantially formaldehyde-free curing agent selected from a reaction product of epichlorohydrin with ethylenediamine, a reaction product of epichlorohydrin with bis-hexamethylenetriamine, or a reaction product of epichlorohydrin with hexamethylenediamine.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

PTC thermistor and substrate applied therein and manufacturing method thereof

InactiveCN102176360AUniform cross-linked structurePromote absorptionPositive temperature coefficient thermistorsHigh resistanceCross-link

A PCT thermistor comprises a substrate and two tinsel-shaped electrodes which are combined with two surfaces of the substrate. The substrate is made of the following components in weight percentage: 28-55% of high-polymer material; 22-32% of conductive filling material; 13-46% of auxiliary filling material; and 1-5% of auxiliary agent in processing. The high-polymer material is obtained through mixing one or multiple materials selected from: polyethylene, polypropylene, maleic anhydride grafted polyethylene, ethane-vinyl acetate copolymer, ethane-acrylic acid copolymer, polyvinylidene fluoride, polycaprolactam, polyhexamethylene adipamide, polydecamethylene sebacamide and polyundecylamide. The auxiliary agent in processing is one component or a mixture of multiple components selected from: an anti-oxidant, a coupling agent, a cross-linking agent and a sensitized cross-linking agent. The sensitized cross-linking agent is one component or multiple components selected from the unsaturated compounds of multiple functional groups with higher decomposition temperature. The PTC thermistor of the invention has the following advantages: high strength, and high resistance for multiple times of large current impact.

Owner:深圳市长园维安电子有限公司

Adsorbent used for separating formaldehyde from air and preparation method thereof

InactiveCN101642698ALow costLow running costOther chemical processesDispersed particle separationSorbentHexamethylenediamine

The invention discloses an adsorbent used for efficiently separating formaldehyde from air and a preparation method thereof. An adsorbent carrier is active carbon, the surface of which is attached with one or more of -NH, -NH2 and -NH3. The precursor of -NH, -NH2 and -NH3 is one of salvolatile, ammonium bicarbonate, ammonium sulfate, ammonium nitrate, ammonium chloride, ethene diamine, hexamethylenediamine, aniline and urea. The adsorbent can absorb and separate formaldehyde in air when space velocity is 20000-80000h<-1> at room temperature. Especially when the formaldehyde and benzene seriesin the air coexist, the adsorbent not only can absorb and separate formaldehyde but also can absorb and separate the benzene series. Therefore, the adsorbent can be widely applied to the purifying treatment of air in hermetic and semi-hermetic limited spaces, such as building interiors, spacecrafts, submarines, undergrounds and the like.

Owner:BEIHANG UNIV

Method for preparing high temperature nylon

The present invention provides a preparation method of high-temperature nylon, including the following steps: (a) dicarboxylic acid and diamine are used to prepare 6T salt or 6I salt under the temperature of 80 to 110 DEG C and the carbon atomicity n of the obtained paraphthaloyl acidhexamethylene diamine salt or m-phthalic acryl acidhexamethylene diamine salt is 4 to 16; (b) 6T salt or 6I salt obtained in step (a) and 66 salt or hexanolactam are polymerized to obtain primary condensation compound and the characteristic viscosity of the primary condensation compound in dense sulfuric acid is 0.09 to 0.25dl / g under the temperature of 30 DEG C; (c) the primary condensation compound obtained in step (b) is under solid phase condensation and polymerization to obtain the high-temperature nylon under the temperature of not more than 250 DEG C. The method provided by the present invention can increase the polyamide size stability, mechanic performance and heat resistance, reduce the molecular weight distribution of the high-temperature nylon, and prevent the occurrence of amine exchange, thermal degradation, gelation and other side reactions.

Owner:北京瑞宝知春时代印刷技术开发有限公司

Salt resistant polyamide compositions

Polyamides made from 1,6-hexanediamine, and the dicarboxylic acids 1,10-decandioic acid and / or 1,12-dodecanedioic acid, and terephthalic acid in specified proportions are particularly resistant to salt stressed (induced) corrosion cracking. This makes them particularly useful as vehicular parts which may be exposed to salts. Particularly when these polyamides contain tougheners and / or plasticizers they are especially useful for hoses and tubes.

Owner:EI DU PONT DE NEMOURS & CO

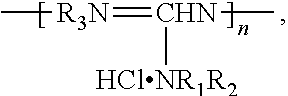

Method for preparing amphiprotic polyacrylamide oil field compression fracture thickening agent

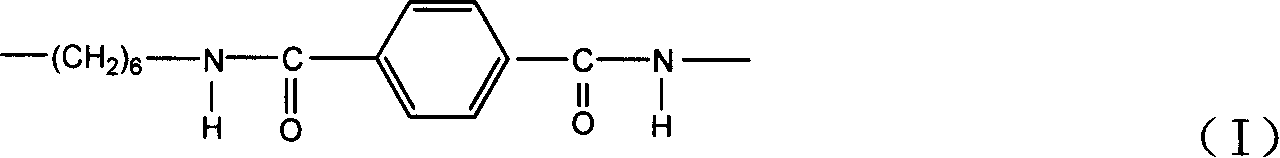

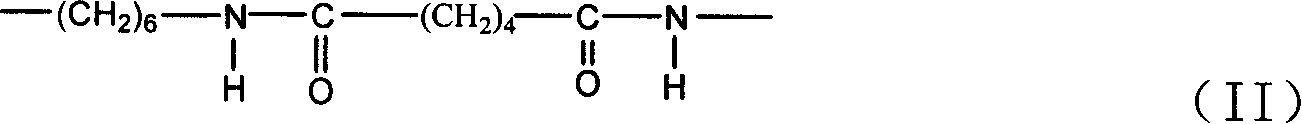

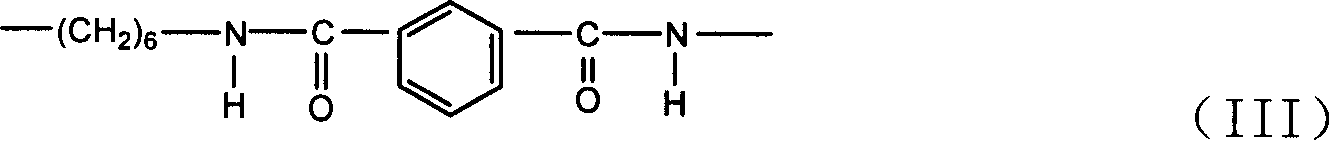

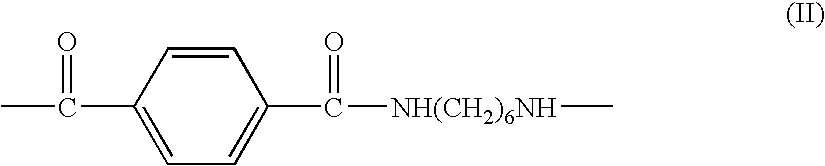

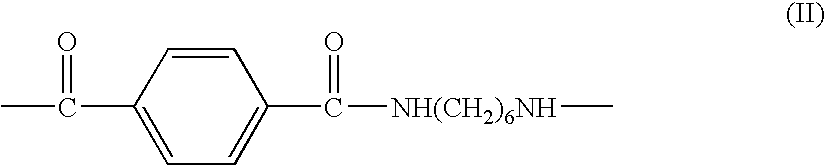

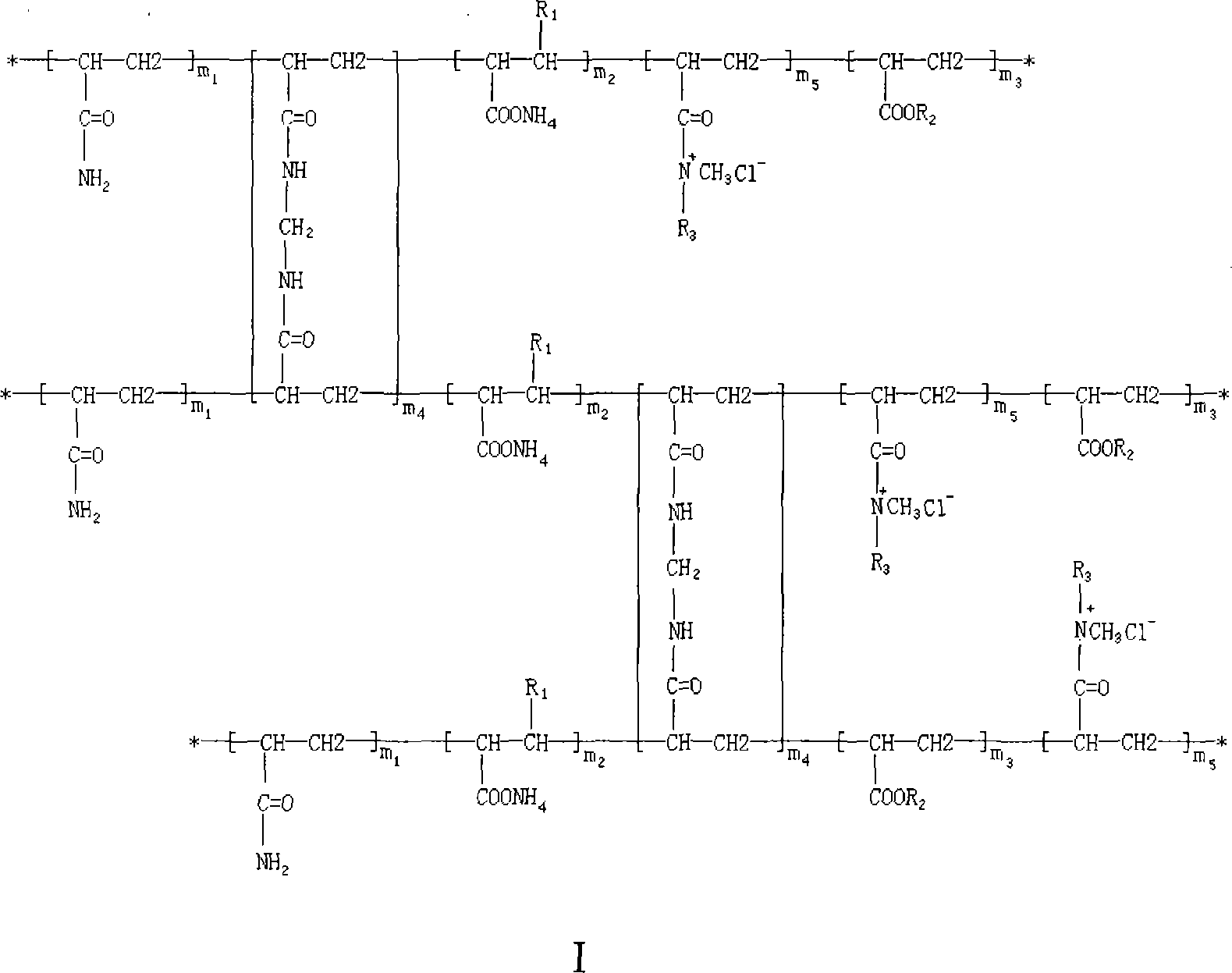

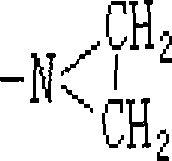

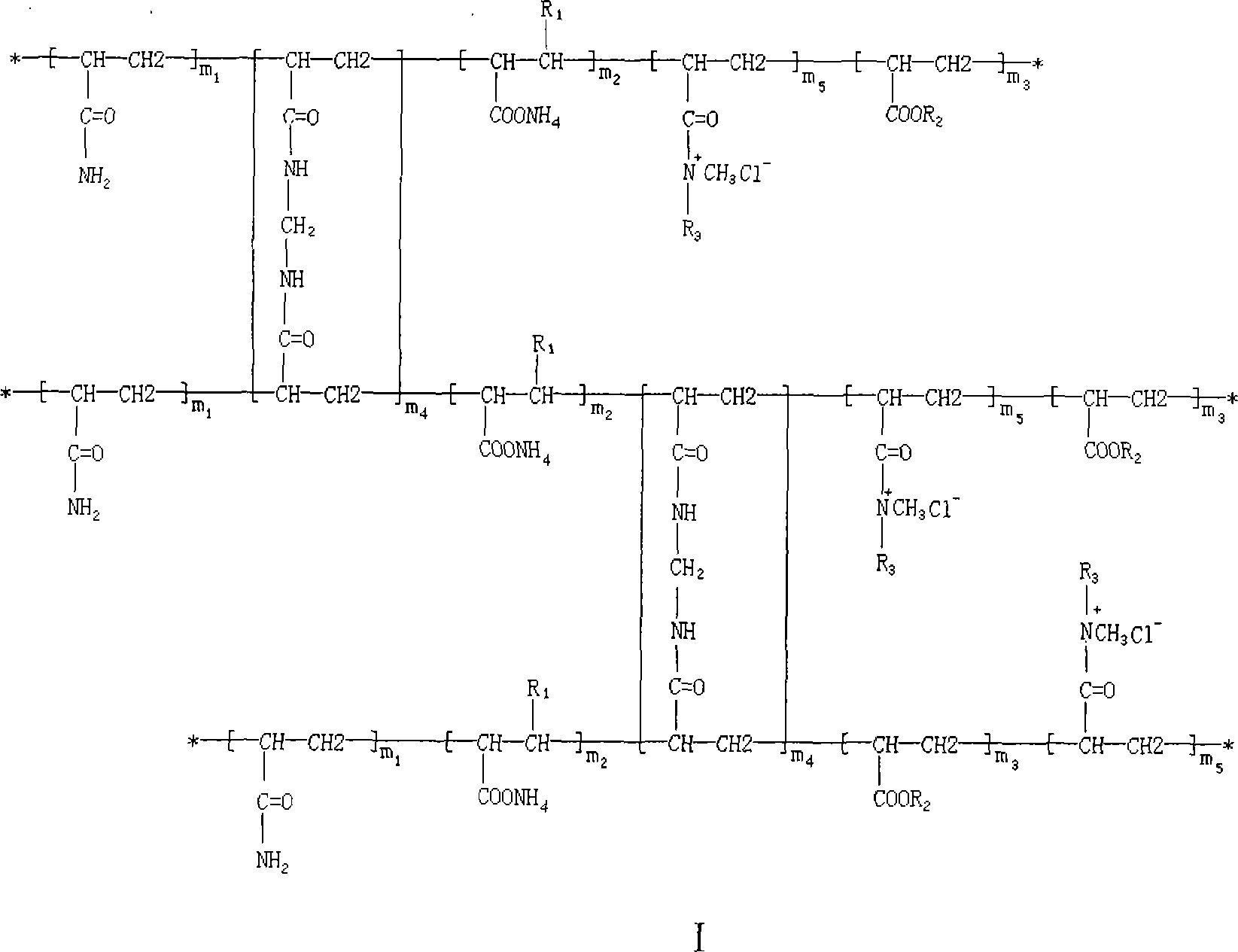

InactiveCN101235283AExcellent thickening and viscosifying efficiencyAggregation is controllableDrilling compositionCross-linkStructural formula

An amphiprotic polyacrylamide oil field fracturing gelatinizer and a preparation process are disclosed. The gelatinizer has the structural formula which is showed by I, wherein R1 is H or CH3, R2 is C1-C4 alkyl, R3 is C2-C14 alkyl, m1, m2 and m5 are integers from 2 to 10, m3 is an integer from 0 to 100, and m4 is the integer from 0 to 1. The preparation process comprises using the compound of dehydration sorbic alcohol fatty acid ester, nonyl phenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether non-ionic emulsifier as emulsifier, using acrylamide, acroleic acid or methacrylic acid, methyl alkyl pi-allyl ammonium chloride, N, N -methylene bisacrylamide as monomer, obtaining even and stable invert emulsion through conducting invert emulsion system polymerization reaction for water, oil, alcohol, amine sulphurate and ethanedioic acid hexamethylene diamine, and conducting cross-linking through utilizing Cr3+, Zr4+ and Ti4+, -CHO, or the structural formula II as cross linking agent to obtain gelatinizer gel.

Owner:HUBEI UNIV

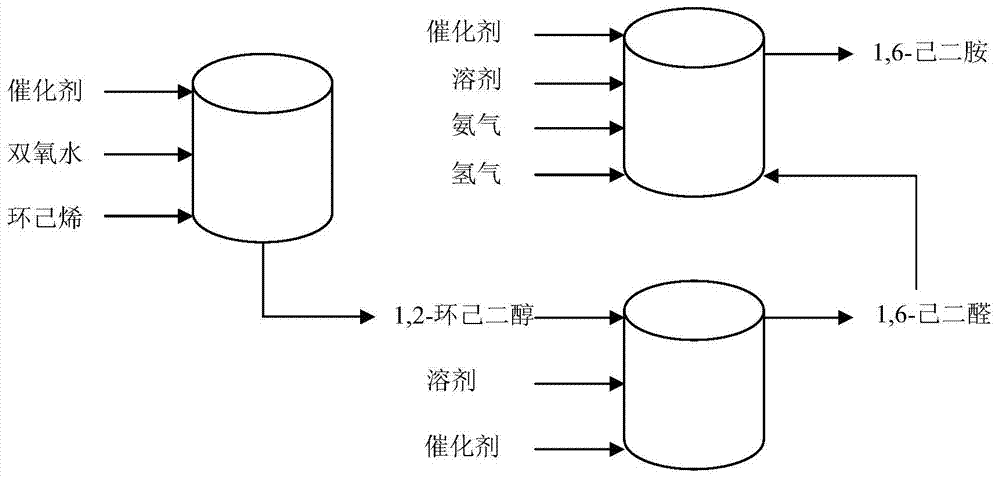

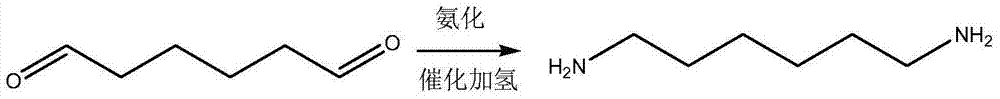

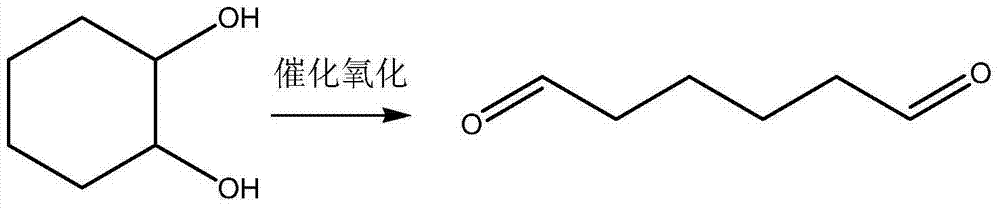

Preparation method of hexamethylenediamine

ActiveCN104262168AEasy to separateHigh catalytic activityPreparation by reductive alkylationHexamethylenediamineEnergy consumption

The invention discloses a preparation method of hexamethylenediamine. The method is used for preparing 1, 6-hexamethylenediamine by virtue of carrying out ammoniation and catalytic hydrogenation on 1, 6-adipaldehyde. The method is simple in process, low in cost, high in yield, low in energy consumption and free from industrial three wastes.

Owner:BEIJING RISUN TECH CO LTD

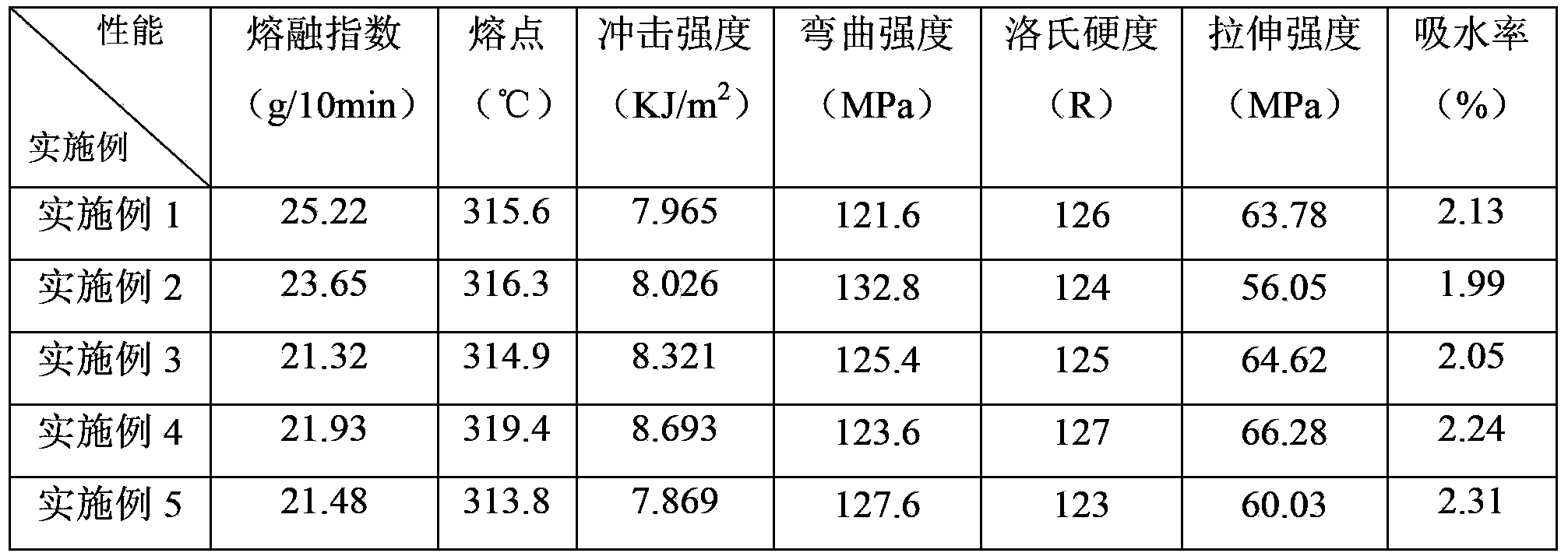

High-temperature-resistant nylon PA66T material and preparation method thereof

The invention belongs to the field of polymer synthesis, and relates to a high-temperature-resistant nylon PA66T material and a preparation method thereof. The nylon PA66T material is prepared from the following components in mole number: 11.00-12.32 moles of aromatic binary acid, 9.00-9.90 moles of hexane diacid, 19.20-21.34 moles of hexamethylenediamine, 0.035-0.05 mole of a nucleating agent, 0.015-0.03 mole of a catalyst and 250-300 mole of deionized water. The high-temperature-resistant nylon PA66T material provided by the invention has the advantages of light weight, high temperature resistance, high mechanical strength, superior size stability and the like, and is suitable to be applied in a high-temperature environment; and meanwhile, the high-temperature-resistant nylon PA66T material is simple in the synthesis process, is moderate in viscosity, and is suitable for industrial popularization and subsequent machine shaping.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for preparing magnetic lignin adsorbent

InactiveCN104475044ARich sourcesEfficient removalOther chemical processesAlkali metal oxides/hydroxidesEthylenediamineEpoxy

The invention belongs to the technical field of water treatment, and particularly relates to an adsorbent for removing metal ions and a dye. The method is characterized in that lignin is adopted as a base body; epoxy chloropropane is adopted as a cross-linking agent; ferroferric oxide is adopted as a magnetic source; and diethylenetriamine, hexamethylenediamine, ethylenediamine and the like are adopted as aminating reagents. Compared with a traditional lignin adsorbent, the method has the characteristics that the adsorbent is easy to separate, can be repeatedly used, is beneficial to environmental protection and the like.

Owner:JIANGNAN UNIV

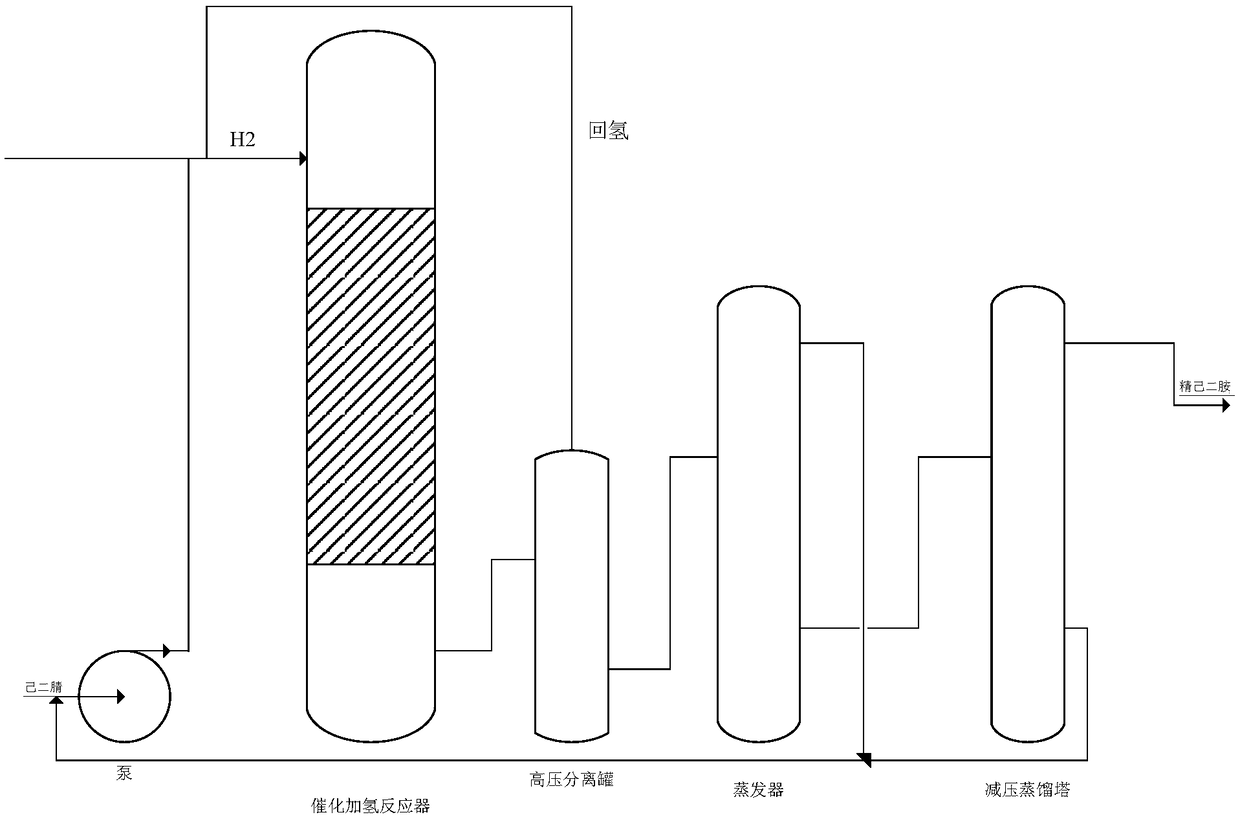

Method for preparing hexamethylene diamine by direct hydrogenation of adiponitrile under alkali-free conditions

InactiveCN108084035AOrganic compound preparationCatalyst activation/preparationAlkali freeHexamethylenediamine

The invention discloses a method for preparing hexamethylene diamine by direct hydrogenation of adiponitrile under alkali-free conditions. The method comprises the steps of using an alkaline earth metal oxide or rare earth metal oxide prepared by a coprecipitation method for modifying an aluminium trioxide-supported metallic nickel catalyst under a condition of no need of adding alkali or ammoniawater, directly hydrogenating an adiponitrile ethanol solution at a temperature of 60 to 200 DEG C, under pressure of 3 to 8 MPa, and obtaining high-qualityhexamethylene diamine through vacuum distillation of a resulting product. The method is suitable for using in batch tank reactors and also in continuous fixed bed reactors.

Owner:DALIAN UNIV OF TECH

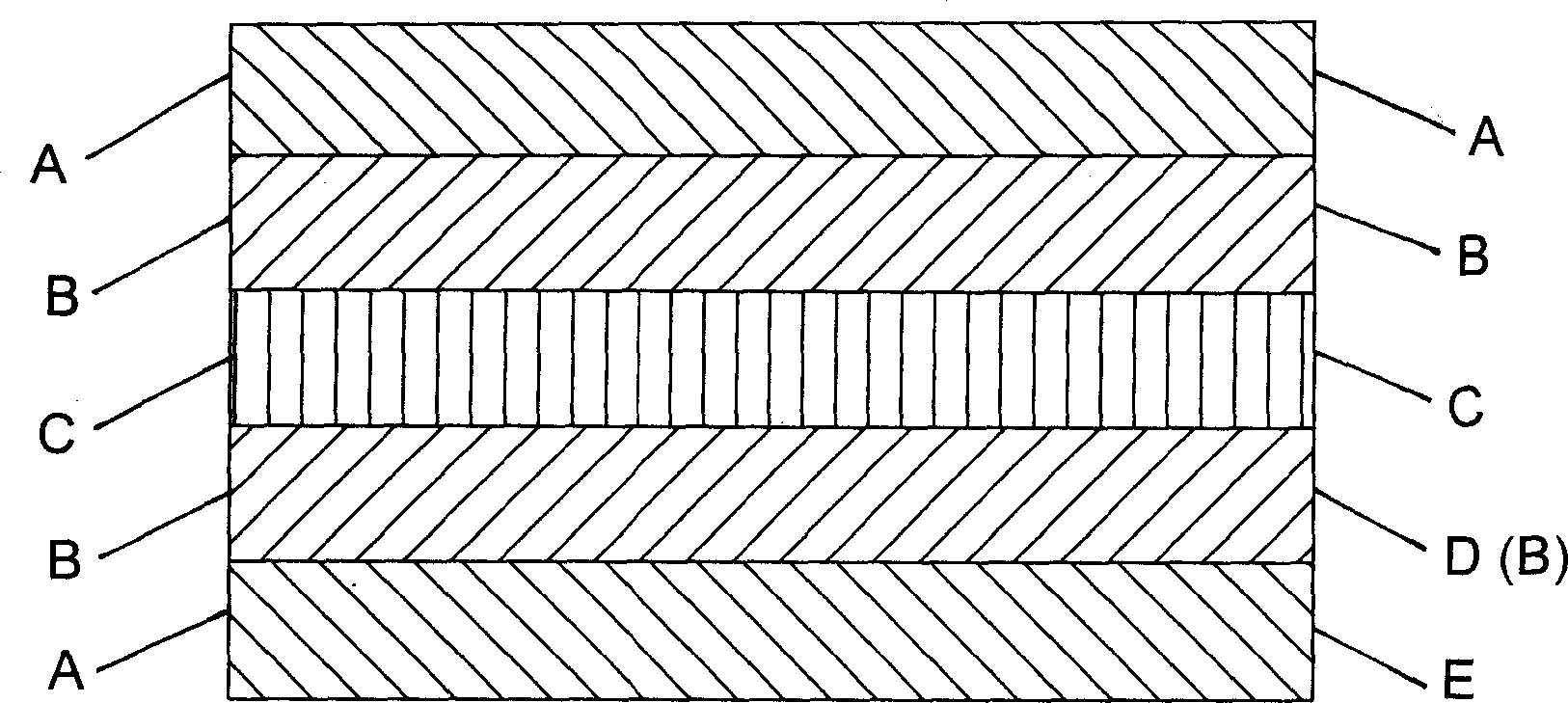

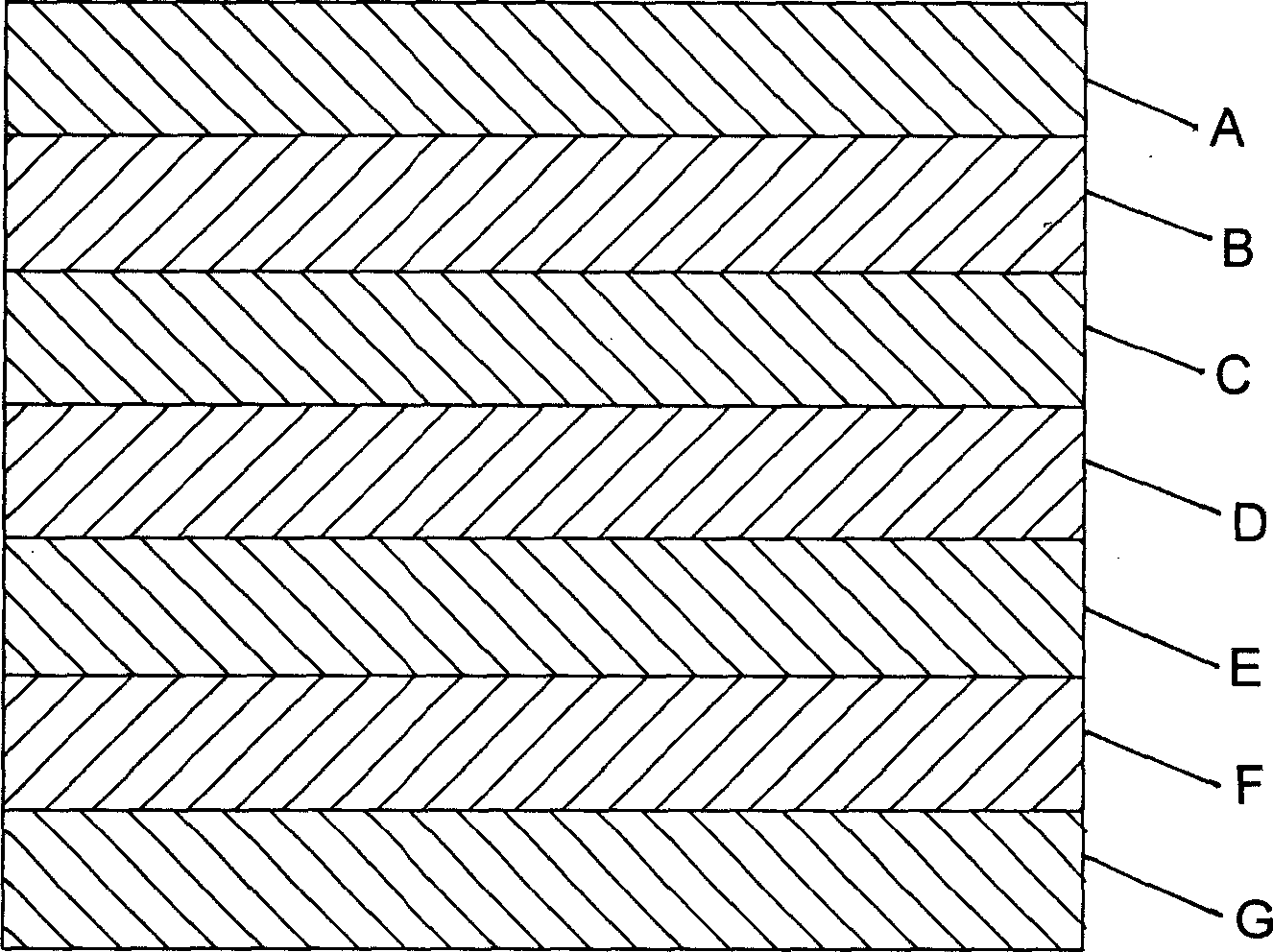

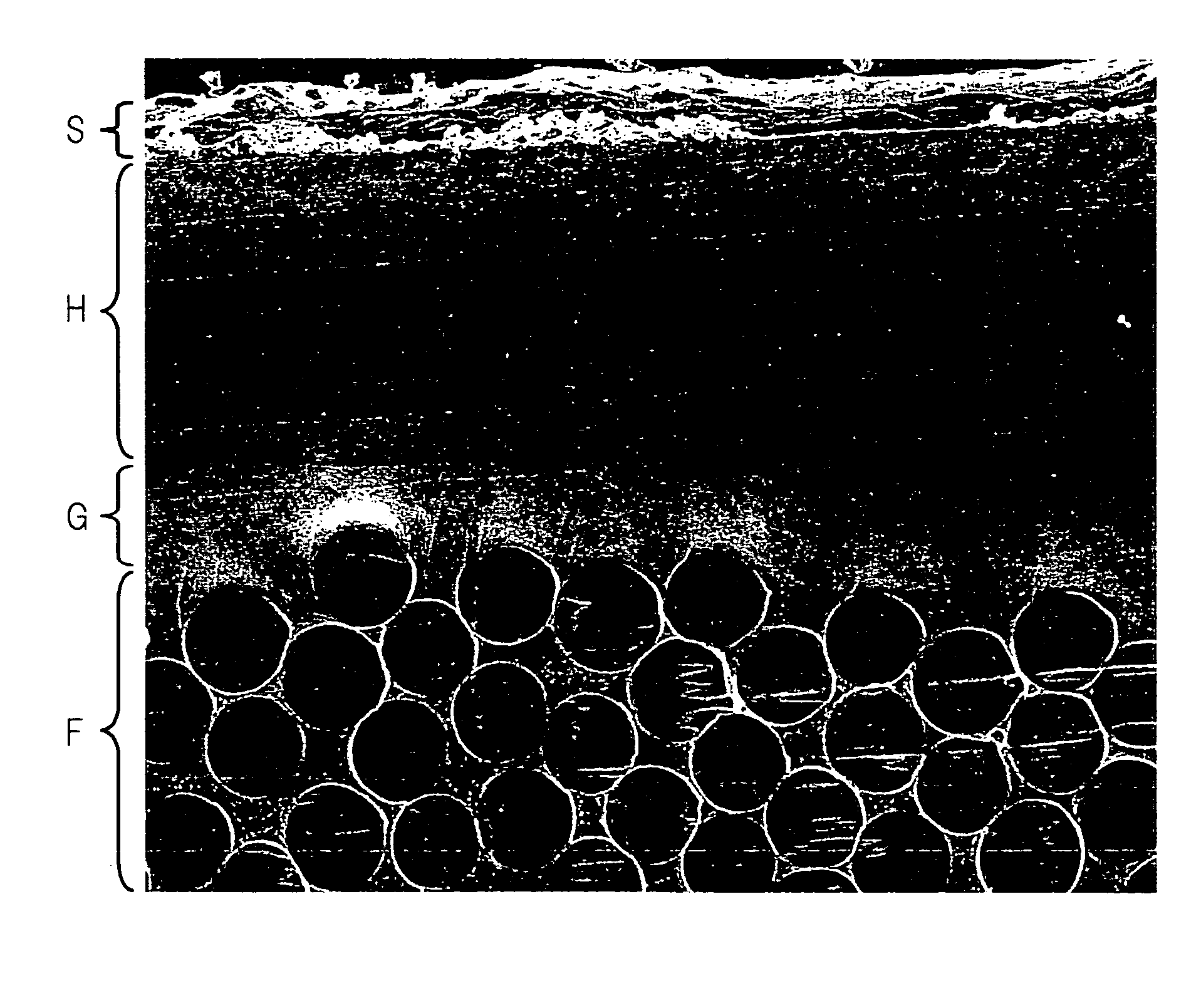

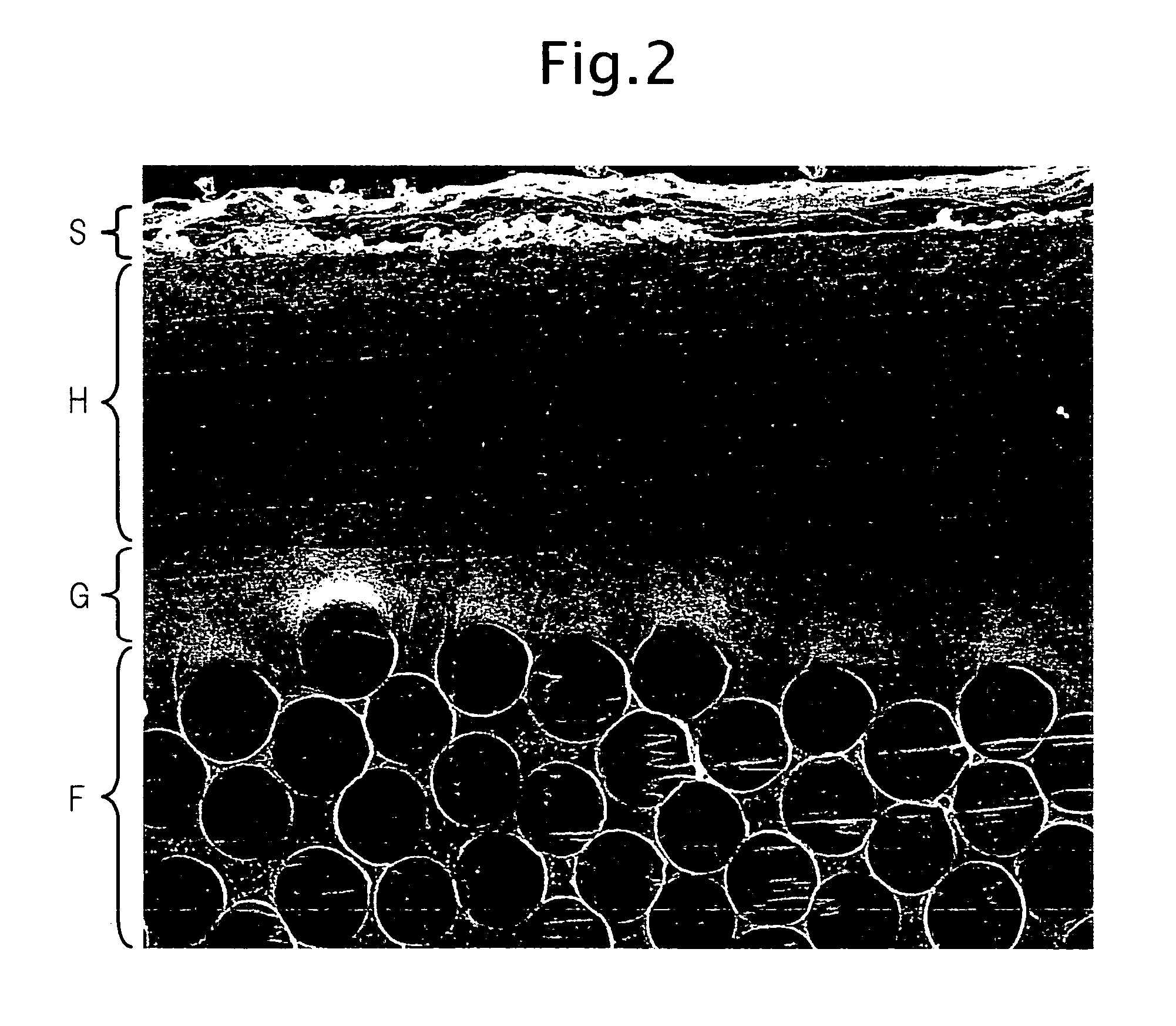

Composite having two or more layers, including an EVOH layer

InactiveUS20060141188A1Solve the lack of resistanceSynthetic resin layered productsFlexible pipesLaurolactamHexamethylenediamine

The present invention provides a layered composite, which includes the following layers: (I) a layer I composition including: (a) from 0 to 80 part by weight of at least one polyamide selected from the group including PA6, PA66, PA6 / 66 and mixtures thereof; (b) from 0 to 100 parts by weight of at least one polyamine-polyamide copolymer that includes the following monomer units: (α) from 0.5 to 25% by weight, based on the weight of the polyamine-polyamide copolymer, of at least one polyamine having at least 4 nitrogen atoms and having a number-average molar mass Mn of at least 146 g / mol, and (β) at least one polyamide-forming monomer selected from the group including lactam, ω-aminocarboxylic acid, equimolar combination of diamine and dicarboxylic acid, and mixtures thereof; and (c) from 0 to 80 parts by weight of at least one polyamide selected from the group including PA11, PA12, PA612, PA1012, PA1212 and wherein, in the layer I, a total of the parts by weight of (a), (b) and (c) is 100; wherein within an entirety of (a) and (b), at least 20 parts by weight of the entirety include monomer units selected from the group including caprolactam, combination of hexamethylenediamine / adipic acid, and mixtures thereof; and wherein within an entirety of (b) and (c), at least 20 parts by weight of the entirety include monomer units selected from the group including ω-aminoundecanoic acid, laurolactam, combination of hexamethylenediamine / 1,12-dodecanedioic acid, combination of 1,10-decanediamine / 1,12-dodecanedioic acid, combination of 1,12-dodecanediamine / 1,12-dodecanedioic acid, and mixtures thereof; and (II) a layer II composition which includes at least one ethylene-vinyl alcohol copolymer.

Owner:EVONIK OPERATIONS GMBH

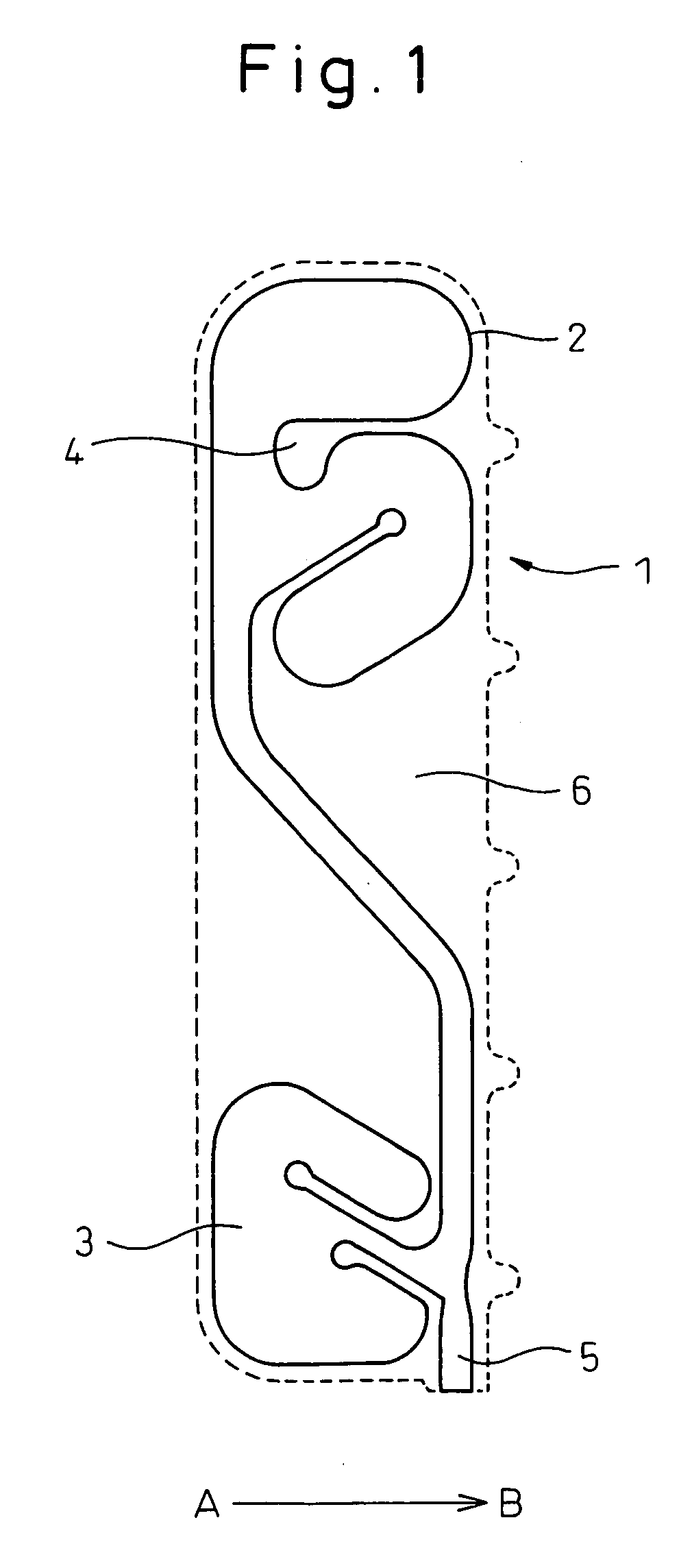

Hollow Weave Fabric for an Air Bag and Method of Producing the Same

InactiveUS20080042414A1Excellent in internal pressure retentionReduce weightLoomsFibre treatmentFiberPolymer science

A hollow weave fabric for an air bag in which the periphery of a double-layer hollow weave portion is formed with a seam zone, wherein the warp yarn and the weft yarn forming the base fabric are each a poly(hexamethylene adipamide) fiber having a total size of 150 to 500 dtex, the double-layer hollow weave portion has a fabric weight of 120 to 350 g / m2 on one side, and the fabric shows a logarithmic decrement of 0.01 to 0.10.

Owner:ASAHI KASEI CHEM CORP

Salt resistant polyamide compositions

Polyamides made from 1,6-hexanediamine, and the dicarboxylic acids 1,10-decandioic acid, 1,12-dodecanedioic acid, or 1,14-tetradecanedioic acid and terephthalic acid in specified proportions are particularly resistant to salt stressed (induced) corrosion cracking. This makes them particularly useful as vehicular parts which may be exposed to salts. Particularly when these polyamides contain tougheners and / or plasticizers they are especially useful for hoses and tubes.

Owner:EI DU PONT DE NEMOURS & CO

Method for preparing hexamethylene diamine by starchy material

InactiveCN101628875ALow costSave resourcesOrganic compound preparationAmino compound preparationHexamethylenediaminePetrochemical

The invention discloses a method for preparing hexamethylene diamine by utilizing starchy material, particularly taking common corn starch as raw material to prepare glucose through saccharification, and preparing sorbitol through the hydrogenation of glucose; through high-pressure hydrogenation, the sorbitol is cracked, rectified and separated to obtain 1,6-hexanediol, and finally by amination and dehydration the hexamethylene diamine is obtained. The invention has the advantages of low raw material cost, novel preparation route, unique technical conditions, more moderate reaction condition compared with other cracking process, and easy control. Compared with traditional petrochemical method, the petrochemical product--hexamethylene diamine which is prepared by adopting starchy material in the biochemical engineering process is able to reduce cost, decrease pollution, regenerate raw material and save huge amounts of oil resources.

Owner:郸城财鑫糖业有限责任公司

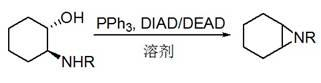

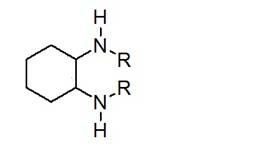

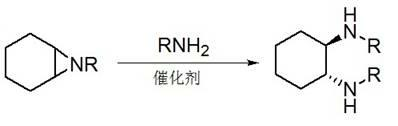

Method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine

InactiveCN102531918ASimple and fast operationMild reaction conditionsOrganic compound preparationAmino compound preparationDiisopropyl azodicarboxylateHexamethylenediamine

The invention discloses a method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine, belonging to the field of chemistry. The method comprises the following steps of: carrying out an airtight or reflux reaction on cyclohexene oxide and an aqueous solution of alkylamine for reacting at 80-120 DEG C for 1.5-5h to obtain 2-alkyl-amino cyclohexanol, dropwise adding DEAD (Diethyl Azodicarboxylate) or DIAD (Diisopropyl Azodicarboxylate) to triphenylphosphine, 2-alkyl-amino cyclohexanol and a solvent under an ice bath for reacting for 5-20h at room temperature to obtain N-alkyl-7-azabicyclo[4, 1, 0]heptane, adding a catalyst to the N-alkyl-7-azabicyclo[4, 1, 0]heptane and the aqueous solution of alkylamine at 100-120 DEG C to carry out the airtight or reflux reaction to obtain trans-N,N'-dialkyl-1,2 cyclohexanamine, dissolving the trans-N,N'-dialkyl-1,2 cyclohexanamine in an alcoholic solvent, and adding a tartaric acid type resolving agent with the equivalent weight of 0.5 to the alcoholic solvent to resolve so as to obtain the enantiomorphous pure symmetric trans-dialkyl cyclohexylamine.

Owner:ANYANG INST OF TECH

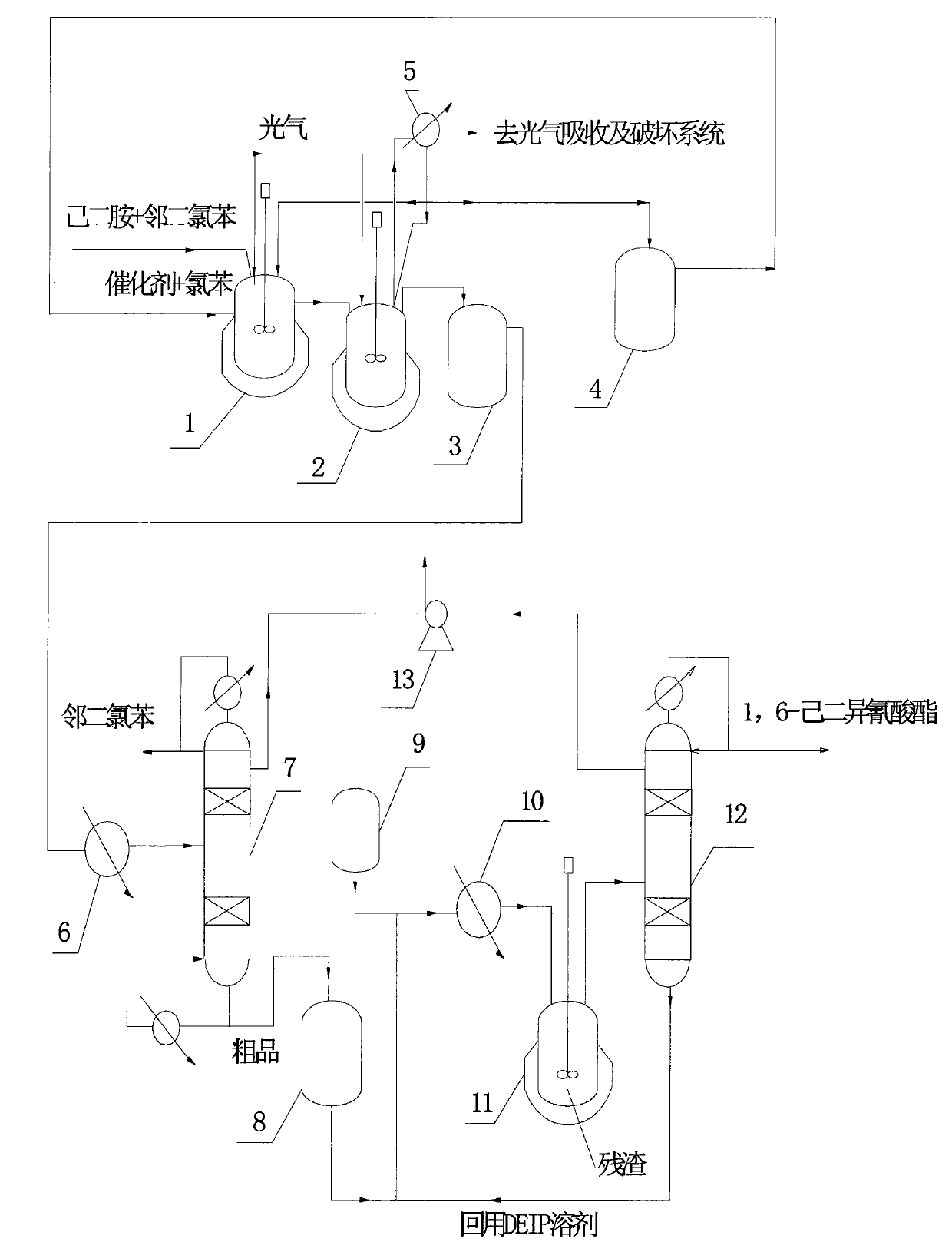

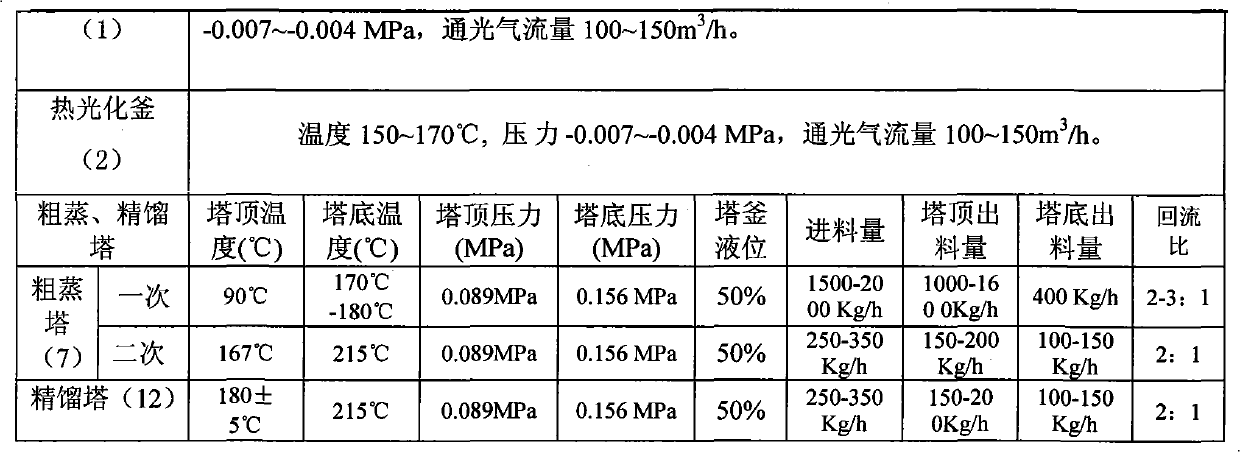

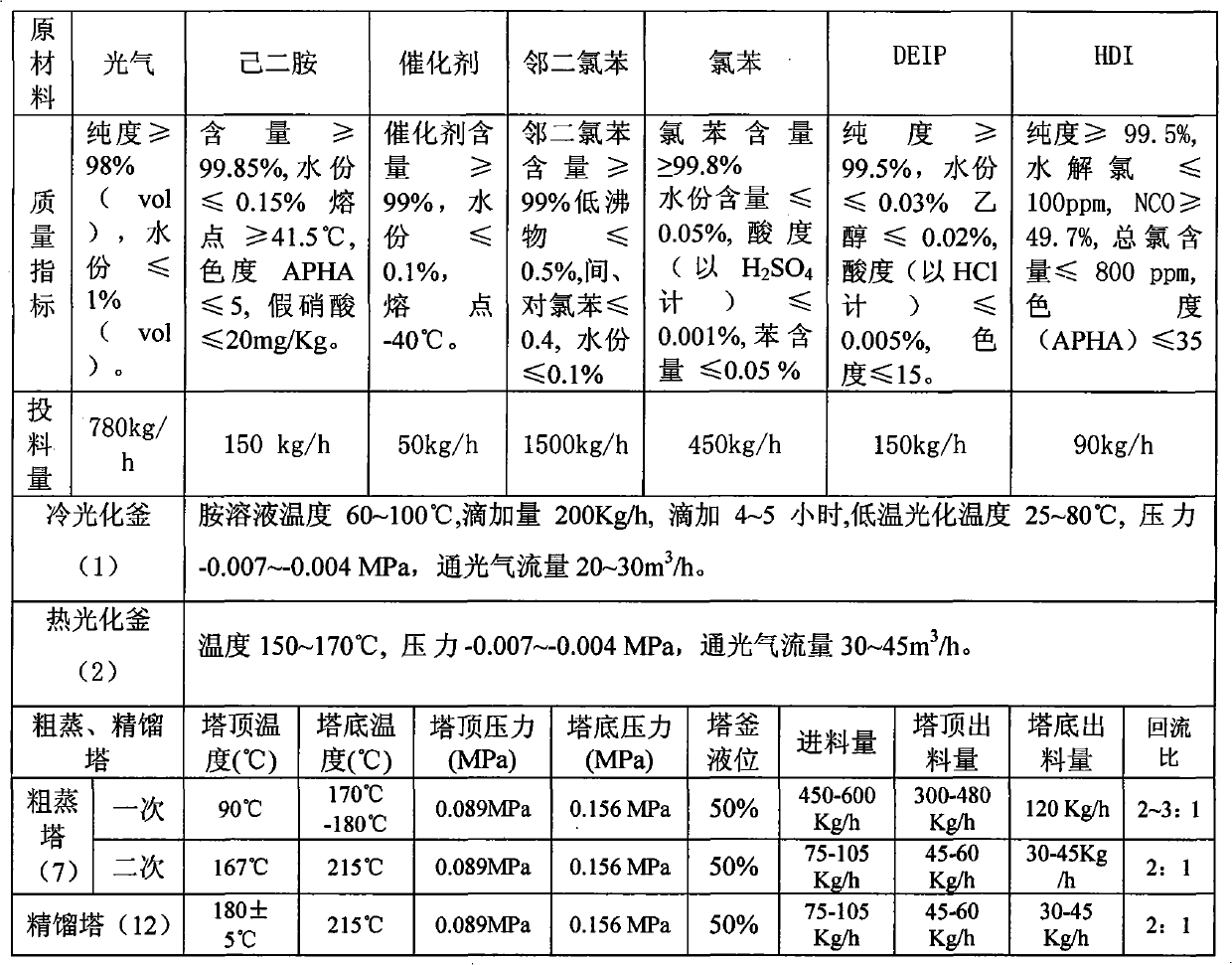

Method for continuously preparing 1,6-hexamethylene diisocyanate

InactiveCN101928235AOrganic compound preparationIsocyanic acid derivatives purification/separationChlorobenzeneBurn treatment

The invention relates to a method for preparing crude 1,6-hexamethylene diisocyanate through the phosgene method and separating pure 1,6-hexamethylene diisocyanate through rectification. The method uses o-dichlorobenzene and chlorobenzene as solvents and comprises the following steps: using hexanediamine and excessive phosgene to perform the two-step reaction of low temperature photochemical reaction and high temperature photochemical reaction under the action of catalyst and generate 1,6-hexamethylene diisocyanate (HDI), removing o-dichlorobenzene through distillation for reuse, continuously distilling to remove by-product chlorinated isocyanate, further mixing with DEIP solvent in a certain ratio through compulsory stirring, heating to perform flash evaporation and rectification, preparing the 1,6-hexamethylene diisocyanate product and DEIP through separation and purification, and regularly discharging the slagged tarry macromolecular compound to perform burning treatment.

Owner:甘肃银光聚银化工有限公司

Method for preparing cyclic carbonate by reacting normal pressure carbon dioxide with epoxide

InactiveCN104496959ALower requirementImprove securityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSalicylaldehydePtru catalyst

The invention relates to a method for preparing cyclic carbonate by reacting normal pressure carbon dioxide with epoxide. Propylene carbonate or ethylene carbonate is prepared by reaction under normal pressure carbon dioxide by taking epoxypropane or ethylene oxide as a substrate, corresponding propylene carbonate or ethylene carbonate as a solvent and Salen-Zn and tetraethyl ammonium bromide as a dual component catalyst, wherein the Salen-Zn is bissalicylaldehyde ethylenediamine-Zn, salicyladehyde cyclohexanediamine-Zn or bis-salicylaldehyde o-phenylenediamine-Zn. The method provided by the invention has the advantages that the catalyst is convenient to prepare, low in cost and less in use level; by using the product as the solvent, posttreatment is convenient; the method is low in reaction pressure, great in rate, safe to operate and suitable for scaled industrial production.

Owner:NANKAI UNIV

Metallic bearing water-based detergent and rinsing agent used together with the same, and method for producing the same

InactiveCN101195790AAvoid corrosionImprove rust resistanceOrganic detergent compounding agentsNon-ionic surface-active compoundsWater basedPhosphoric Acid Esters

The invention relates to metal bearing water-based cleaning agent, rinsing agent matched with the water-based cleaning agent, and the preparation method thereof. Petroleum sodium sulfonate, triethanol amine oleate, fatty alcohol-polyoxyethylene ether, emulgator, and cocoanut oil diethanolamine phosphoric acid ester are mixed with tiethanolamine and ethanolamine according to the weight percentage, are stirred uniformly at room temperature, then are mixed with other raw materials and water, then antibubbling agent AF9020 is added, and therefore the brown yellow and transparent concentrated cleaning agent is formed; nitrous acid dicyclohexylamine, oleic acid triethanolamine and petroleum sodium sulfonate are respectively dissolved into the mixed solvent of tiethanolamine and mono ethanolamine, then benzotriazole is dissolved into water to mix the two solvent, to form the brown yellow and transparent concentrated rinsing agent; the cleaning agent and the rinsing agent are mixed into 5 percent treatment fluid and 1 percent of treatment fluid, then the treatment fluid is cleaned for 30 seconds to 1 minute under ultrasonic wave, rinsed for 30 seconds, and then hot air seasoning, drying and 48 h rust preventing are performed. The invention can replace gasoline cleaning agent, kerosene cleaning agent, and universal water-based cleaning agent, the used raw material is easy to be acquired, the production cost is low, and the invention without parkerizing process can effectively prevent the environmental pollution.

Owner:白马轴承技术(洛阳)有限公司

Polyamide/polyester alloy and method for producing the same

InactiveCN101508842AImprove toughnessGuaranteed physical and mechanical propertiesPolyesterPolyethylene glycol

The invention discloses a polyamide / polyester alloy and a preparation method thereof. The polyamide / polyester alloy has the components according to the mixture ratio of parts by weight: 65-87% of poly adipic acid hexanediamine, 5-20% of polyethylene glycol terephthalate, 6-10% of toughener, 1-3% of compatilizer, 0.2-0.6% of antioxidizer and 0.1-5% of other accessory ingredients. Besides having excellent toughness, the polyamide / polyester alloy can maintain other physical mechanical property of the material. The technique for preparing the polyamide / polyester alloy is simple and has low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com