Patents

Literature

49results about How to "Guaranteed physical and mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

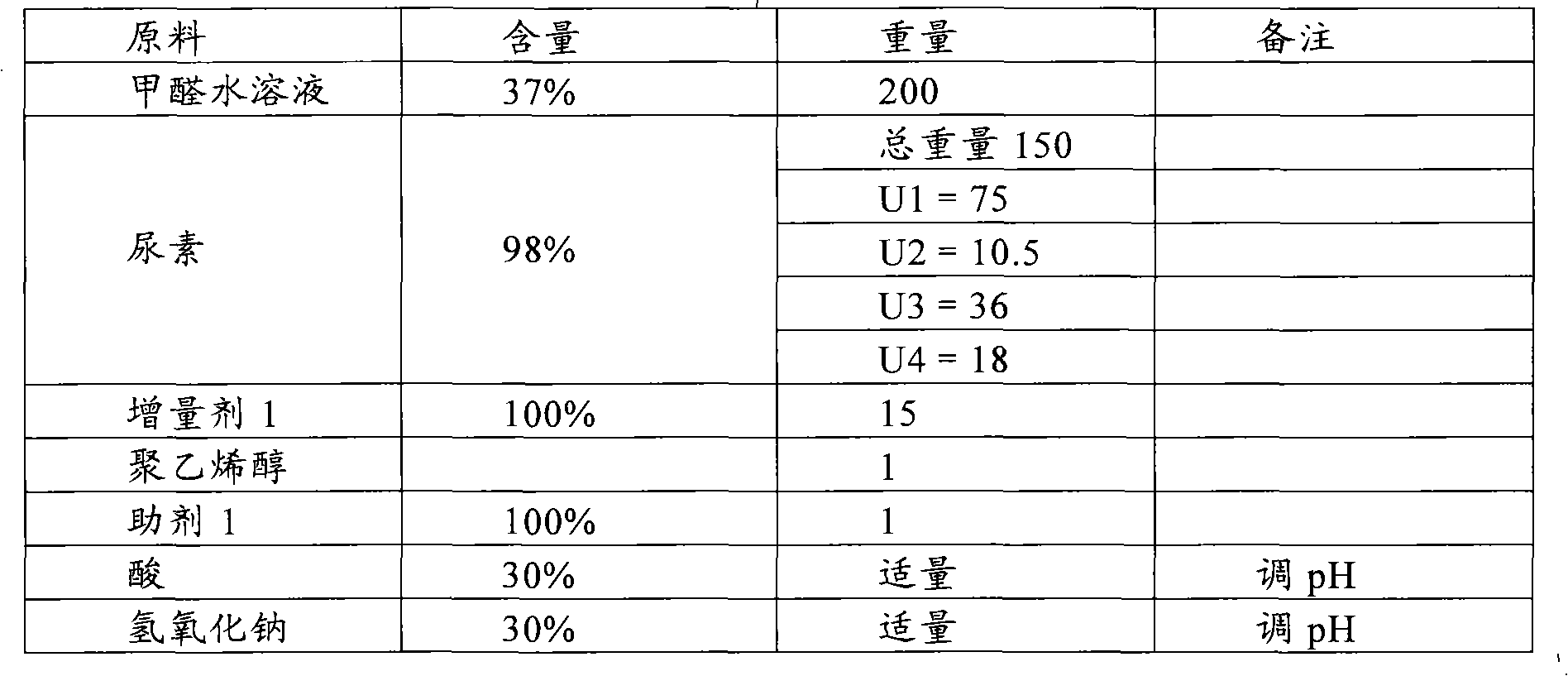

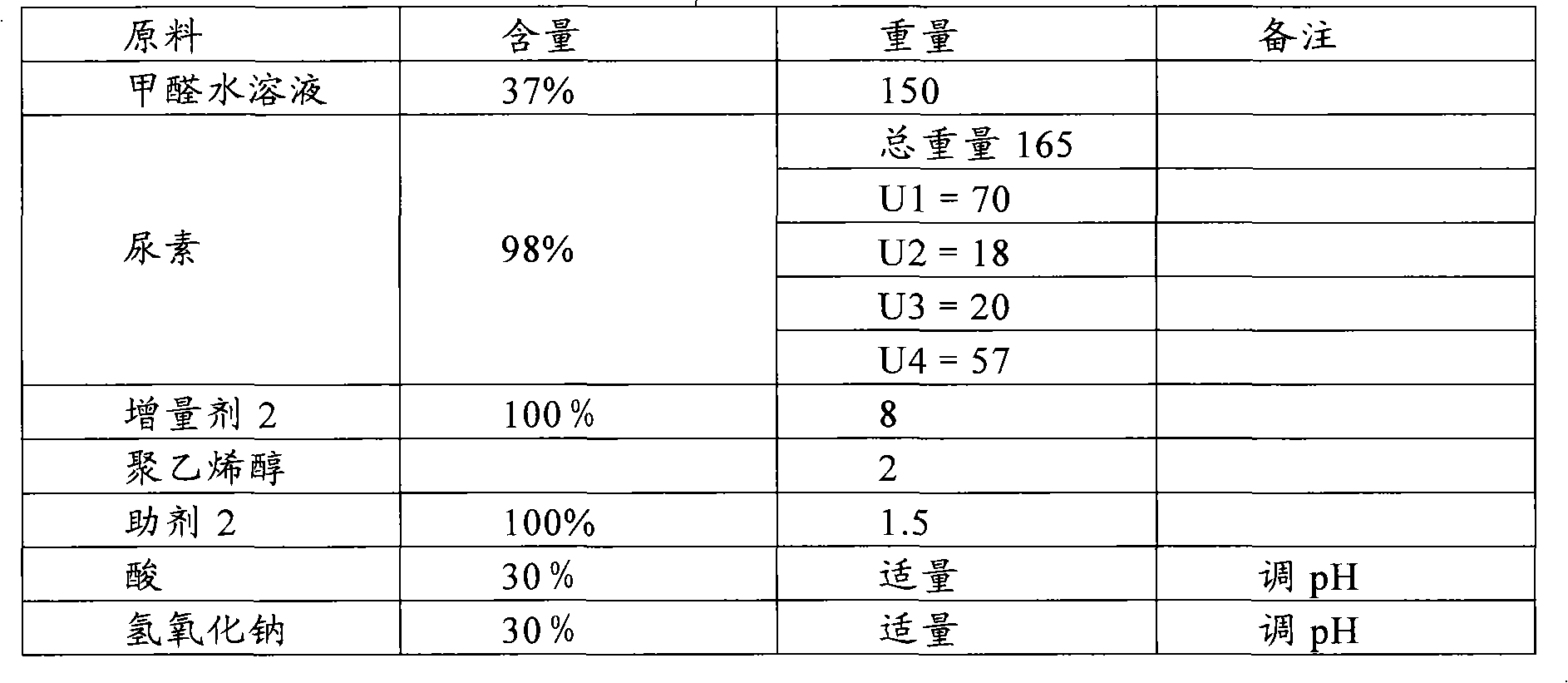

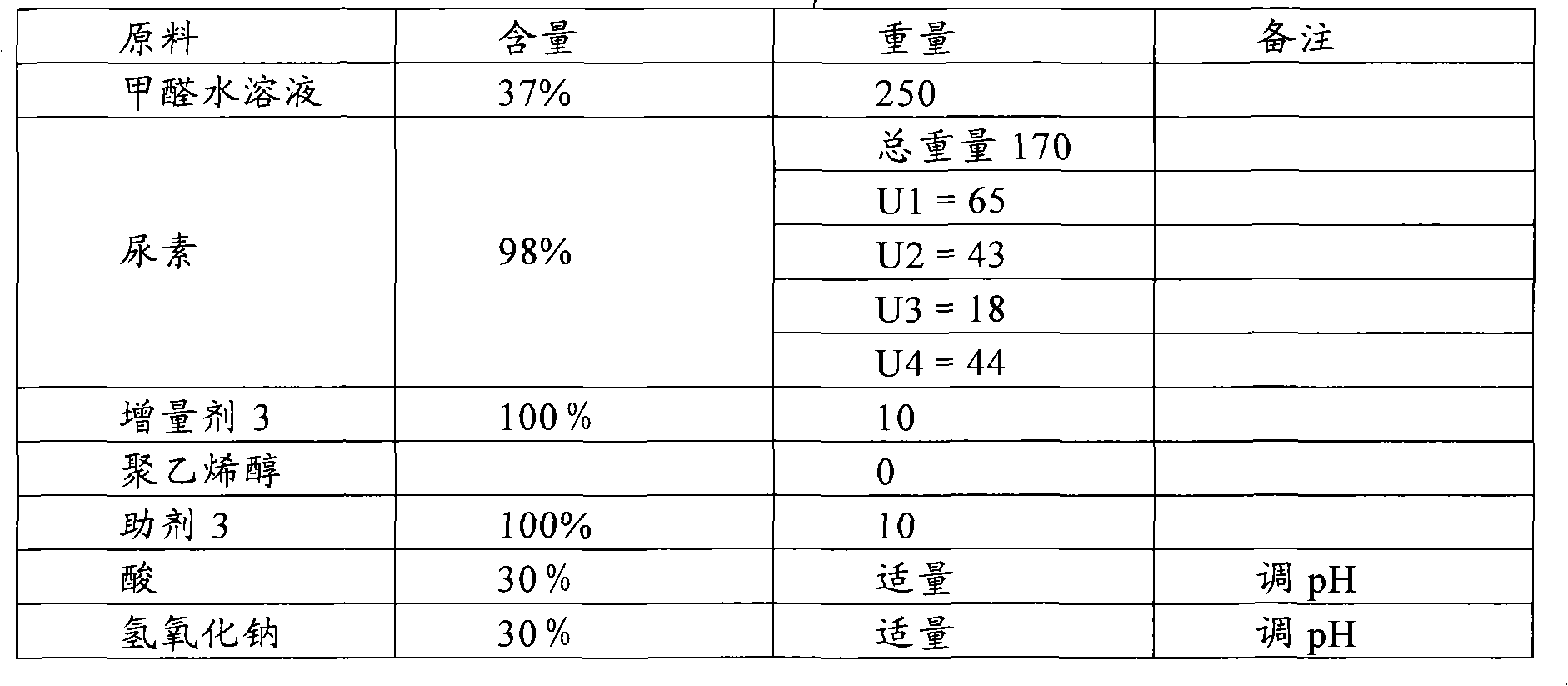

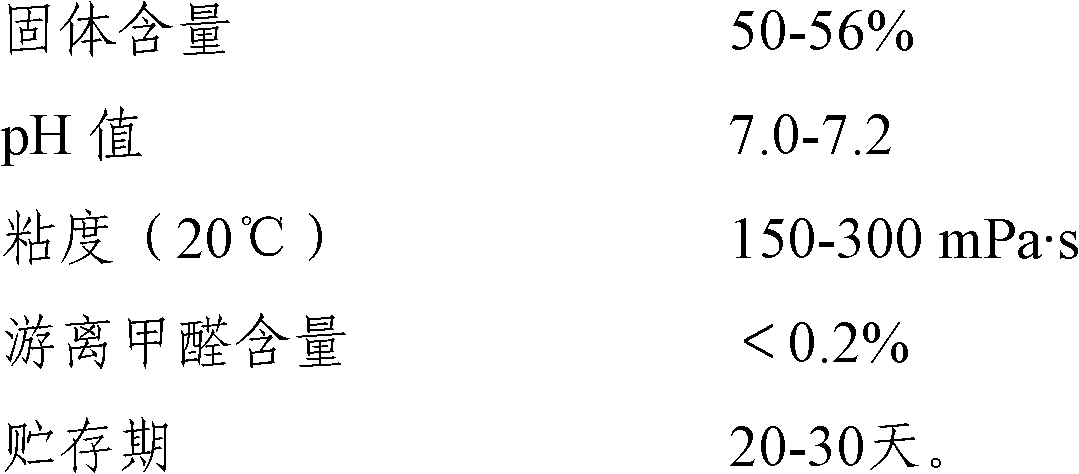

Urea-formaldehyde resin for non-dewatering particleboard and preparation method thereof

ActiveCN102086295AShorten the production cycleLower unit production costAldehyde/ketone condensation polymer adhesivesPolyvinyl alcoholWastewater

The invention relates to urea-formaldehyde resin and a preparation method thereof. The urea-formaldehyde resin comprises the following components in parts by weight: 200 parts of formaldehyde solution, 120-170 parts of urea, 0-2 parts of polyvinyl alcohol, 1-10 parts of additive and 3-20 parts of extender, wherein the concentration of formaldehyde solution is 37%; in the preparation process, ureais added three or four times and the reaction is performed in weakly alkaline medium, weakly acidic medium and neutral medium in turn; and additive and extender are added in the synthesis of urea-formaldehyde resin. The urea-formaldehyde resin can be used in the production of the particleboard without being dewatered, thus the problems of wastewater discharge and environmental pollution can be solved and the production cost of the particleboard can be greatly reduced; and the urea-formaldehyde resin is suitable for various large, medium and small particieboard enterprises.

Owner:江苏露水河人造板有限公司

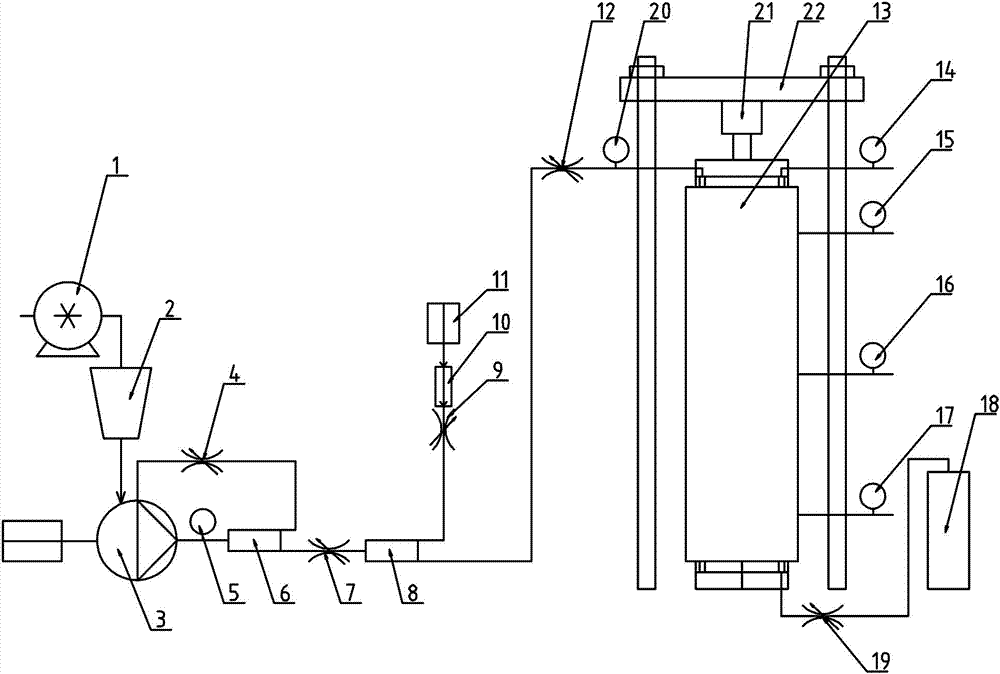

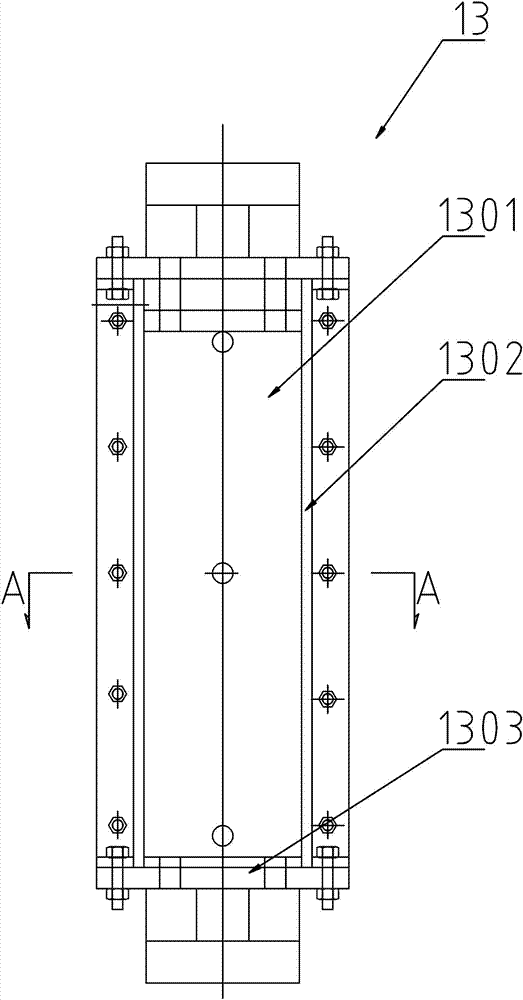

Pressure grouting experiment device

InactiveCN103048439AGuaranteed physical and mechanical propertiesSuitable for useMaterial testing goodsExperimental laboratoryClassical mechanics

The invention provides a pressure grouting experiment device comprising a slurry supplying device, wherein the slurry supplying device is communicated with a slurry hole of an experiment mould; a lower slurry hole of the experiment mould is communicated with a slurry recycling barrel; a plurality of pipelines are arranged on the outer wall of the experiment mould from top to bottom; each pipeline is provided with a pressure gage; and throttling valves are arranged between the slurry supplying device and the experiment mould and also between the experiment mould and the slurry recycling barrel. According to the pressure grouting experiment device disclosed by the invention, grouting stone bodies with the regular shape can be easily and conveniently obtained through using different moulds, and slurry dispersion radiuses under the different conditions can be obtained. In the testing process, pressure P provided by matching the pressure gages and a flow meter with a jack can relatively and effectively analyze influences of a testing parameter to each physical mechanical property of the stone bodies and the slurry dispersion radiuses. According to the pressure grouting experiment device disclosed by the invention, the grouting amount can be quantized, so that components of the stone bodies are also quantized. The pressure grouting experiment device is small and exquisite, convenient and easy to use, and is particularly suitable for being used in a laboratory.

Owner:CHINA THREE GORGES UNIV

Polyamide/polyester alloy and method for producing the same

InactiveCN101508842AImprove toughnessGuaranteed physical and mechanical propertiesPolyesterPolyethylene glycol

The invention discloses a polyamide / polyester alloy and a preparation method thereof. The polyamide / polyester alloy has the components according to the mixture ratio of parts by weight: 65-87% of poly adipic acid hexanediamine, 5-20% of polyethylene glycol terephthalate, 6-10% of toughener, 1-3% of compatilizer, 0.2-0.6% of antioxidizer and 0.1-5% of other accessory ingredients. Besides having excellent toughness, the polyamide / polyester alloy can maintain other physical mechanical property of the material. The technique for preparing the polyamide / polyester alloy is simple and has low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

Lining model used for shield tunnel longitudinal model test and manufacturing method thereof

PendingCN108776033AEffectively reflect the vertical local effectReliable test resultsStructural/machines measurementModel parametersEngineering

The invention discloses a lining model used for a shield tunnel longitudinal model test and a manufacturing method thereof. The segmental lining model comprises cutting slots and longitudinal connector sheets. The manufacturing method comprises the steps that the model parameters are calculated by drawing up the similarity ratio, trial manufacturing is performed and whether the mechanical parameters meet the requirements is tested, and then pouring of the segmental lining model is performed and splicing is performed. The shield tunnel segmental lining structure stiffness is ensured to be consistent with that of the prototype tunnel structure, and the local stress state of the segmental lining longitudinal connectors can also be reflected so as to have high popularization value.

Owner:SOUTHWEST JIAOTONG UNIV

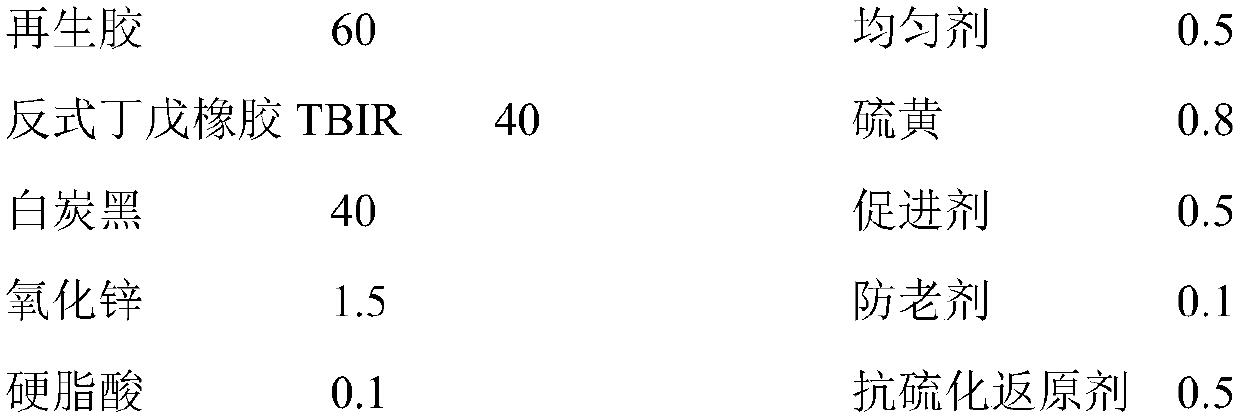

Trans-butadiene-isoprene rubber modified regenerated rubber as well as preparation method and purpose thereof

ActiveCN107814994AGuaranteed physical and mechanical propertiesImproved dynamic fatigue performanceSpecial tyresDispersityPolymer science

The invention relates to regenerated rubber modified by utilizing trans-butadiene-isoprene rubber as well as a preparation method and application thereof. The trans-butadiene-isoprene rubber modifiedregenerated rubber is prepared from the following components in parts by weight: 95 to 50 parts of regenerated rubber, 5 to 50 parts of the trans-butadiene-isoprene rubber TBIR, 2.5 to 50 parts of filling, 1.5 to 4 parts of zinc oxide, 0.1 to 0.6 part of stearic acid, 0 to 5 parts of homogenizing agent, 0.8 to 5 parts of sulfur, 0.5 to 3.5 parts of accelerant, 0.1 to 3 parts of anti-aging agent and 0 to 2.0 parts of anti-reversion agent. According to the preparation method, the regenerated rubber is modified by adopting the trans-butadiene-isoprene rubber TBIR; the dispersity of the filling can be improved; vulcanized rubber is increased by 30 to 70 percent in tensile strength, by 40 to 100 percent in 300-percent stress at definite elongation, by 10 to 20 percent in abrasion performance and by 100 to 700 percent in flexural fatigue performance. The regenerated rubber can be used for a tire tread, a tire side, a tire body, a belted layer and an airtight layer of a tire, a highway pavement and a runway and the dynamic fatigue performance is improved.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD +1

Ferronickel slag magnesium phosphate binding material and application thereof

InactiveCN106630924AHigh yieldGuaranteed physical and mechanical propertiesSolid waste managementPorosityMagnesium phosphate

The invention discloses a ferronickel slag magnesium phosphate binding material and application thereof. The binding material is prepared from 6-12 parts of ferronickel slag, 12-25 parts of dead burned magnesia, 3-12 parts of phosphate and 1-10 parts of retarder. The ferronickel slag magnesium phosphate binding material is used in structural members requiring high strength in early age period and rush-repair work. The ferronickel slag magnesium phosphate binding material has the advantages of achieving rapid hardening and early strengthening, and being high in strength and small in shrinkage deformation, the interior structure is more compact, the porosity is low, and the durability including water tolerance is improved. Moreover, according to the ferronickel slag magnesium phosphate binding material, innocent treatment of the ferronickel slag is achieved, high-efficiency resource utilization of industrial waste residues is promoted, and on the premise that the mechanical properties of the binding material is guaranteed, the consumption of dead burned magnesia is reduced, the consumption of a non-renewable resource, namely magnesite, and energy loss are reduced, the production cost of the magnesium phosphate binding material is decreased, and therefore, economic benefits and environmental benefits are remarkable.

Owner:HOHAI UNIV

Method and device for welding PTFE (Polytetrafluoroethylene) plates

ActiveCN102873860ASolve bonding problemsPhysical and mechanical properties are not lowButt jointEngineering

The invention provides a method and a device for welding PTFE plates. The weld strength and the elongation at break of the welded PTFE plates are not less than 80% of the physical mechanical property of an original plate. The method comprises the following steps: two PTFE plates are in butt joint with each other, and butt-joint areas are heated so as to be melted, then are cooled, and are pressed when being heated, and melts in heating areas can freely flow in the direction vertical to butt-joint seams and parallel to the PTFE plates under the condition of bearing pressure. The device comprises a fixing device used for fixing one PTFE plate, a heating device used for heating the butt-joint areas, a clamping device used for clamping the other PTFE plate, and a pressing device including ropes and pulleys; the ropes are used for hanging balance weights, and are connected with the clamping device through the pulleys; and the balance weights enable the clamped PTFE plate to tightly press the other fixed one in the direction vertical to the butt-joint seams and parallel to the PTFE plates.

Owner:NANJING COMPTECH COMPOSITES CORP

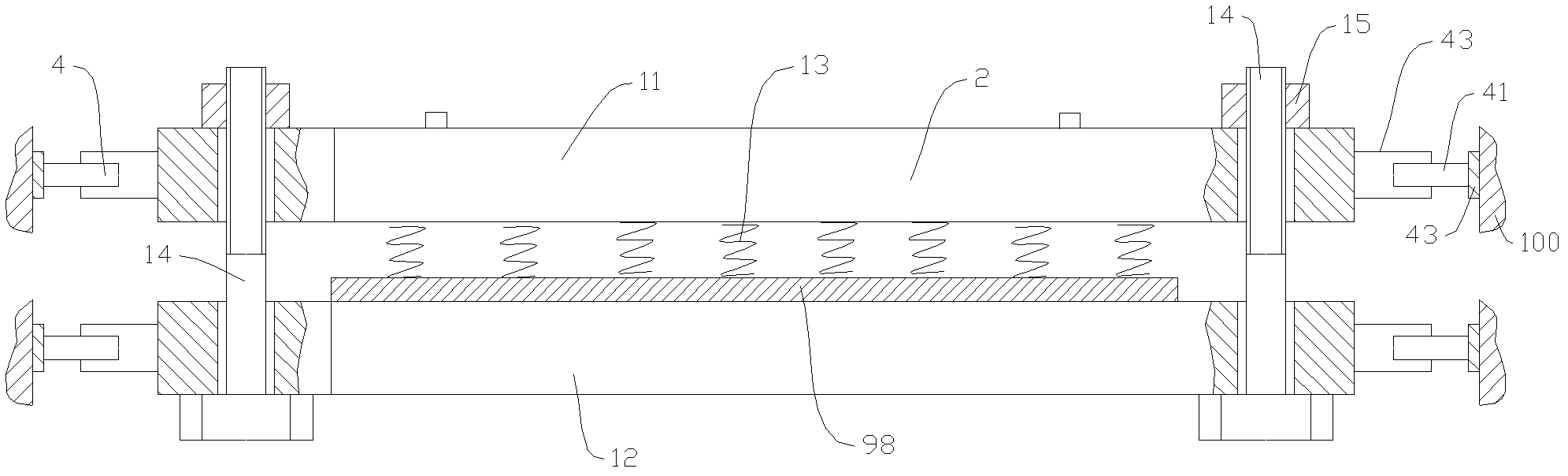

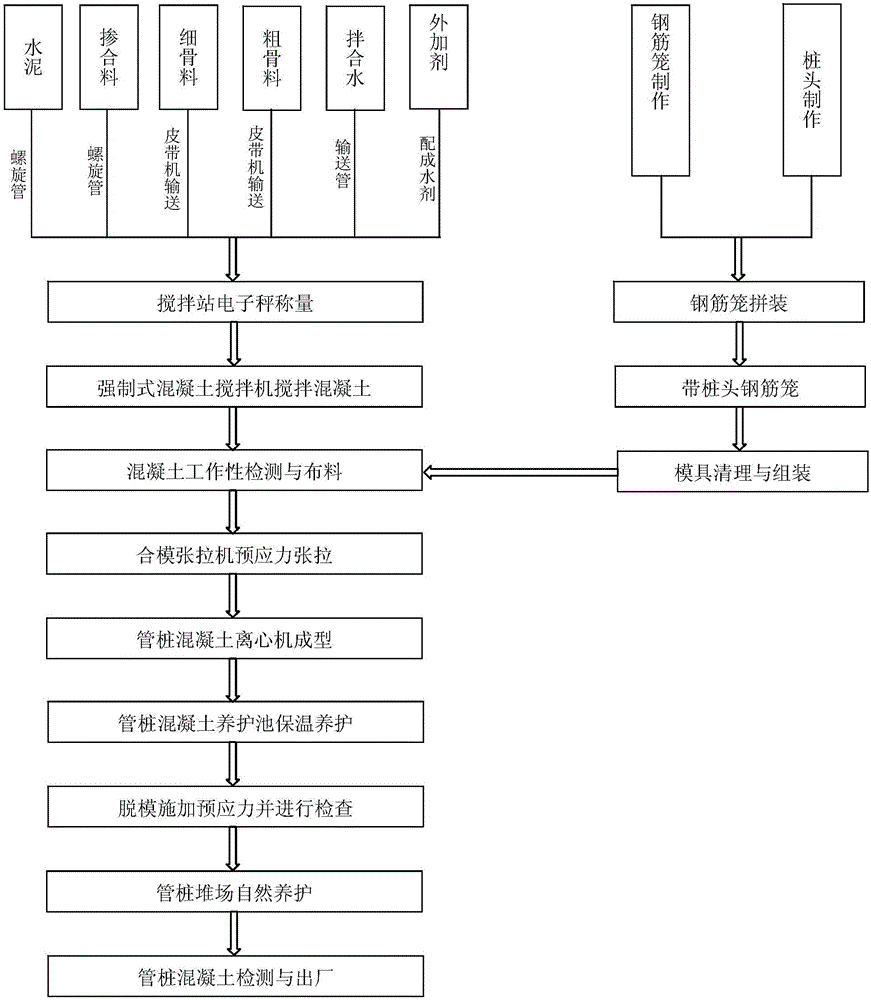

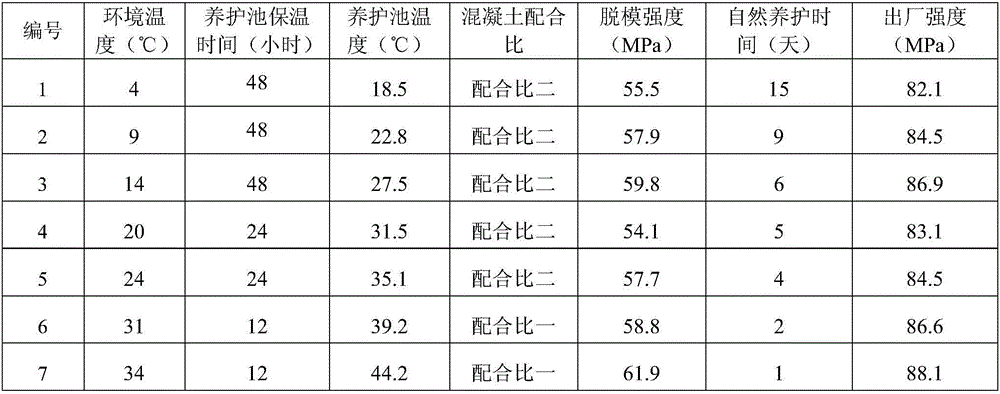

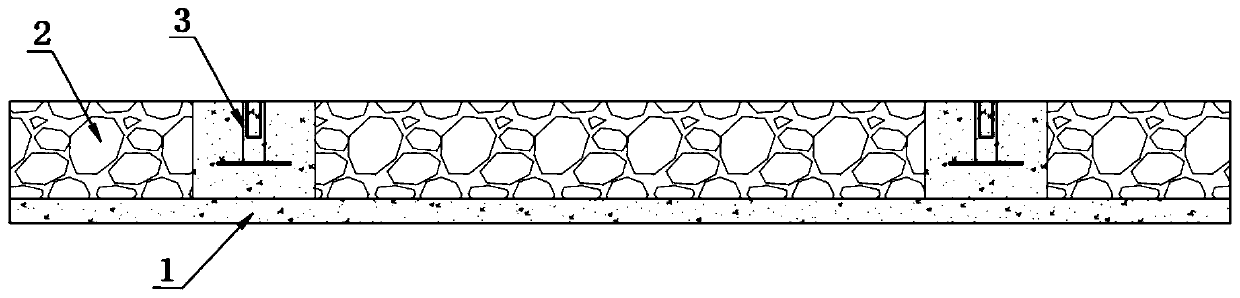

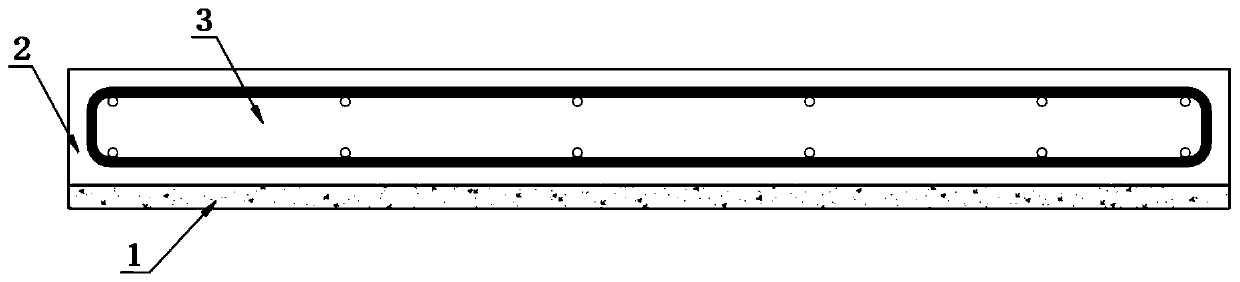

Steaming-free production technology for PHC pipe pile and application of steaming-free production technology

ActiveCN106003396AGuaranteed physical and mechanical propertiesGuaranteed durabilityCeramic shaping apparatusEnergy conservationCivil engineering

The invention belongs to the building technology, relates to a steaming-free production technology for a PHC pipe pile and application of the steaming-free production technology and provides a steaming-free curing method for the pipe pile. The method includes the following steps that firstly, the pipe pile is subjected to insulation curing before demolding; and secondly, the pipe pile obtained after insulation curing in the step (1) is demolded and is subjected to natural curing after being demolded. The invention further provides the application of the above method in the production technology for the PHC pipe pile and the steaming-free production technology for the PHC pipe pile. By means of the steaming-free production technology for the PHC pipe pile and the application of the production technology, the steam curing link is omitted in the pile manufacturing process, the manufacturing difficulty and cost of the pipe pile are lowered, energy is saved, environment friendliness is facilitated, the performance of the manufactured PHC pipe pile meets various requirements of the standard, and very wide application prospects are achieved.

Owner:CCCC THIRD HARBOR ENG +3

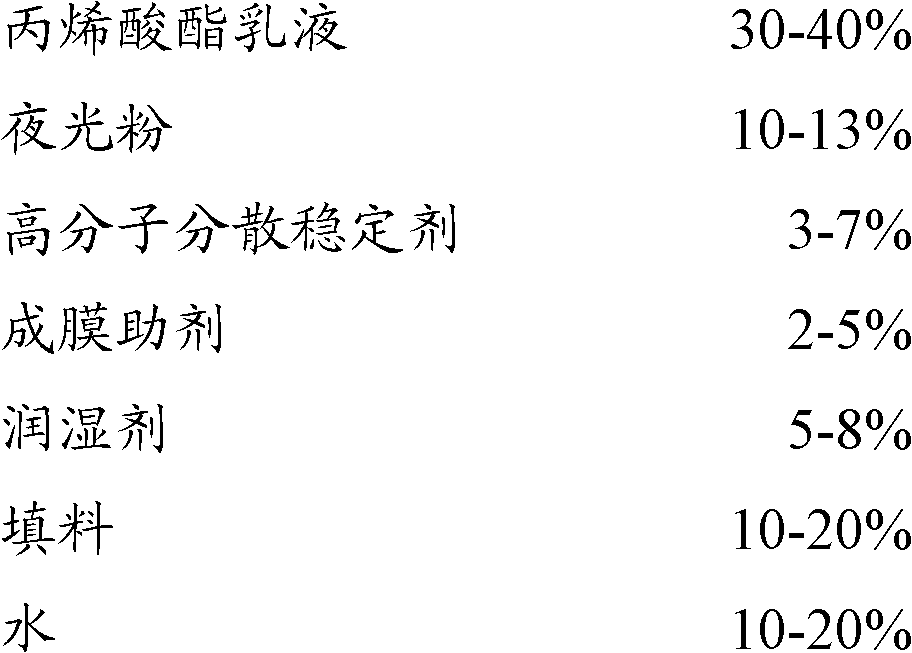

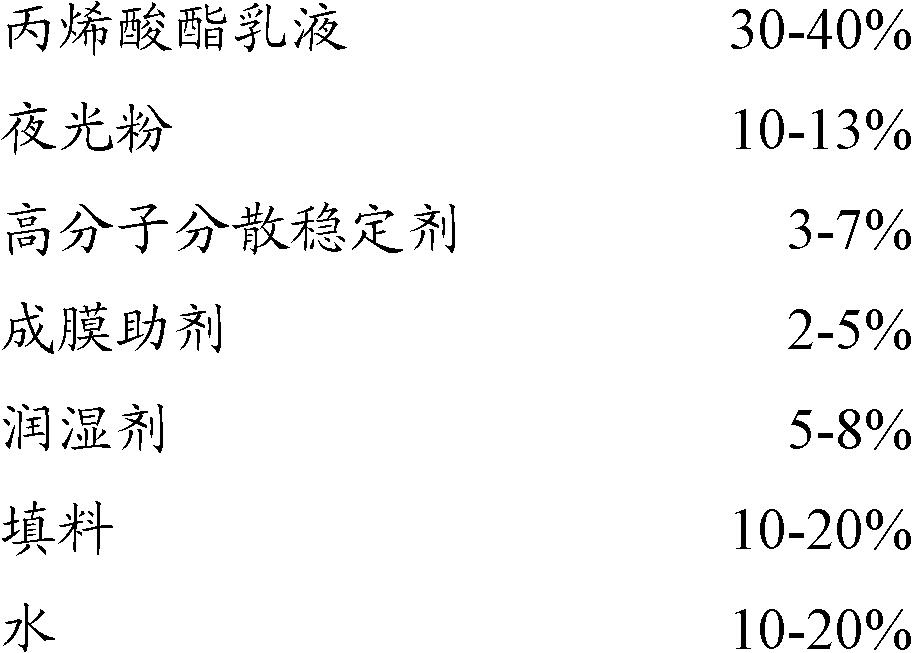

Long-acting type noctilucent propylene decoration pigment

ActiveCN102618124AGloss stableStable mechanical propertiesPigment pastesRare earthMechanical property

The invention provides a long-acting type noctilucent propylene decoration pigment which comprises the following components: 30-40% of acrylate emulsion, 10-13% of noctilucent powder, 3-7% of polyacrylate high polymer dispersion stabilizer, 2-5% of film-forming agent, 5-8% of wetting agent, 10-20% of filler and 10-20% of water. Rare earth luminescent material with long-acting storage luminous effect is added to propylene pigment and an high polymer dispersing agent is added for performing coating treatment, thus overcoming the defect of poor storage stability; the obtained noctilucent propylene decoration pigment can be released for a long time without light attenuation; furthermore, the pigment can be stably stored for a long time, and is long-lasting and stable in gloss and mechanical property.

Owner:贝碧欧美术颜料(昆山)有限公司

Flame-retardant elastic rubber-plastic wave insulation board and preparation method thereof

The invention relates to a flame-retardant elastic rubber-plastic wave thermal insulation material and a preparation method thereof. The flame-retardant elastic rubber-plastic wave thermal insulationmaterial comprises the following raw materials: an ethylene propylene diene monomer, butadiene styrene rubber, high styrene resin, dioctyl sebacate, a vulcanization accelerator, an active agent, an anti-scorching agent, a foaming agent, sulfur, an antioxidant, a light stabilizer and a composite flame retardant. Ethylene-propylene-diene monomer and a composite flame retardant are added; no polar substituent exists in the molecular structure of the ethylene propylene diene monomer; the molecular cohesion is low, a molecular chain can keep flexibility in a relatively wide range, and the flexibility and elasticity of the material are improved; by adding the composite flame retardant, heat can be absorbed to generate a thermal decomposition reaction, the temperature in a condensed phase can bereduced, the thermal decomposition speed of the material can be reduced, and a large number of active hydroxyl free radicals generated in the combustion process can be isolated, so that the flame retardant effect is achieved, and the elasticity and flame retardant property of rubber and plastic products are effectively improved.

Owner:WINCELL INSULATION CO LTD

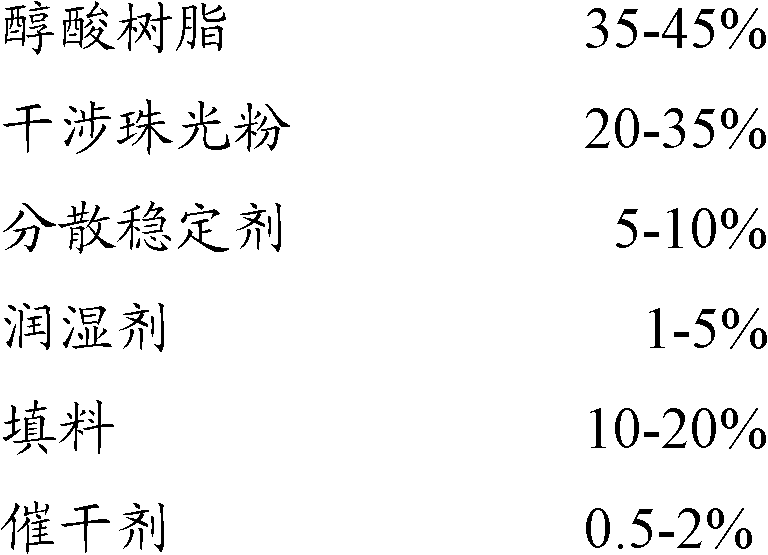

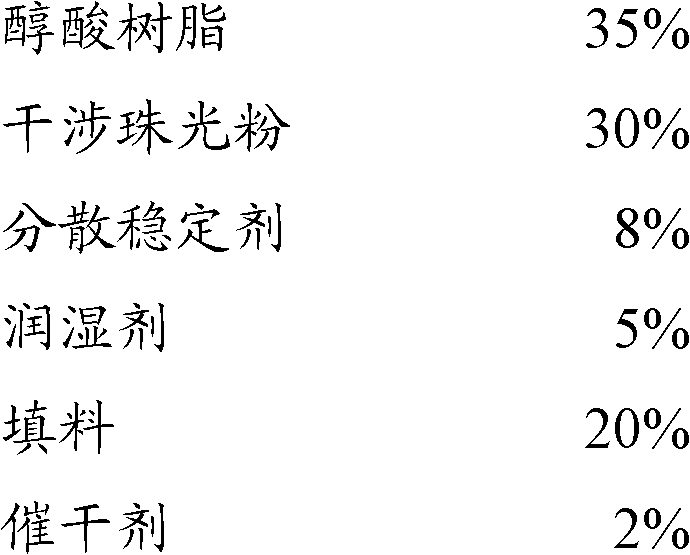

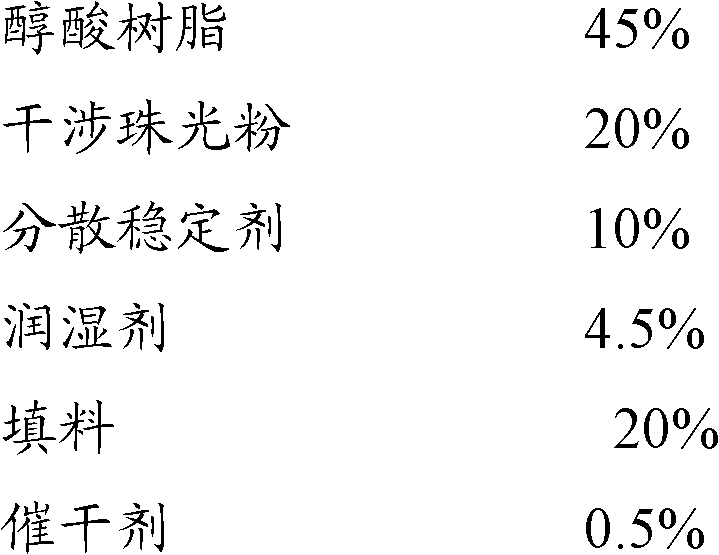

Oil paint with color change interference effect

ActiveCN102618105AGuaranteed physical and mechanical propertiesExcellent anti-delamination effectArtist's paintsPolyester coatingsVegetable oilEngineering

The invention provides oil paint with a color change interference effect, which comprises 35-45% of alkyd resin, 20-35% of interference pearl powder, 5-10% of dispersion stabilizer, 1-5% of wetting agent, 10-20% of filler and 0.5-2% of drier, wherein the percentage content sum of all the components is 100%. By means of using the alkyd resin to substitute for traditional vegetable oil as a film forming carrier, the problems of poor storage stability and easiness in layering oil precipitation of the interference pearl powder in a vegetable oil system are solved, mechanical and physical properties after film forming are guaranteed, and excellent layering preventing effect is generated under the synergy action of modified castor oil dispersion stabilizer.

Owner:贝碧欧美术颜料(昆山)有限公司

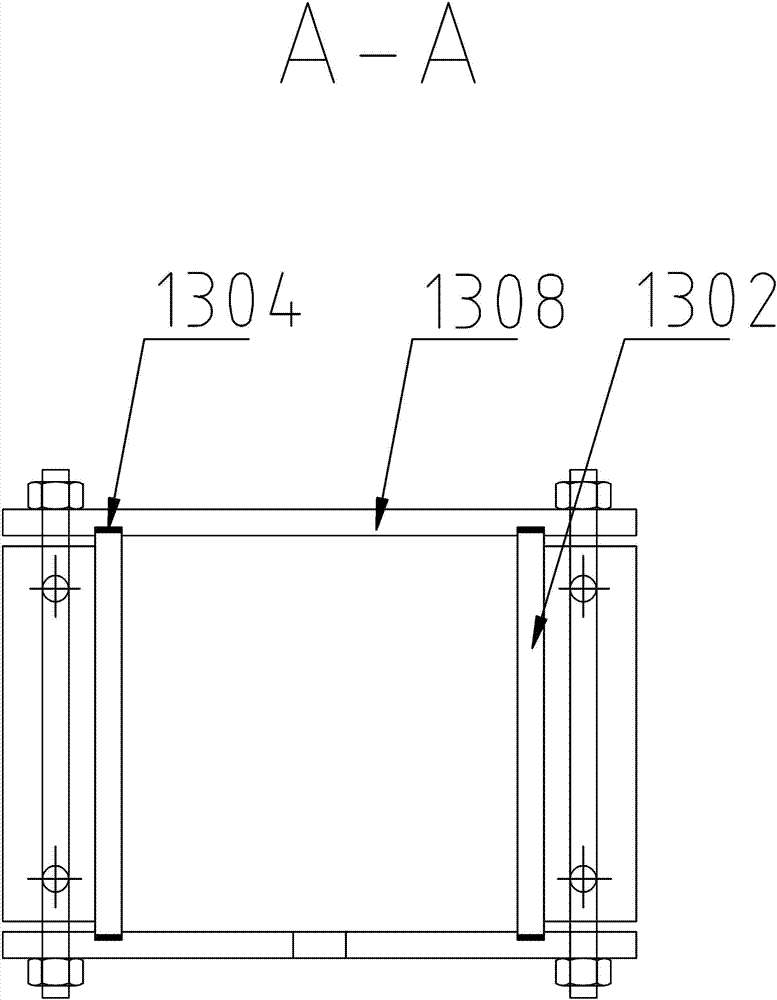

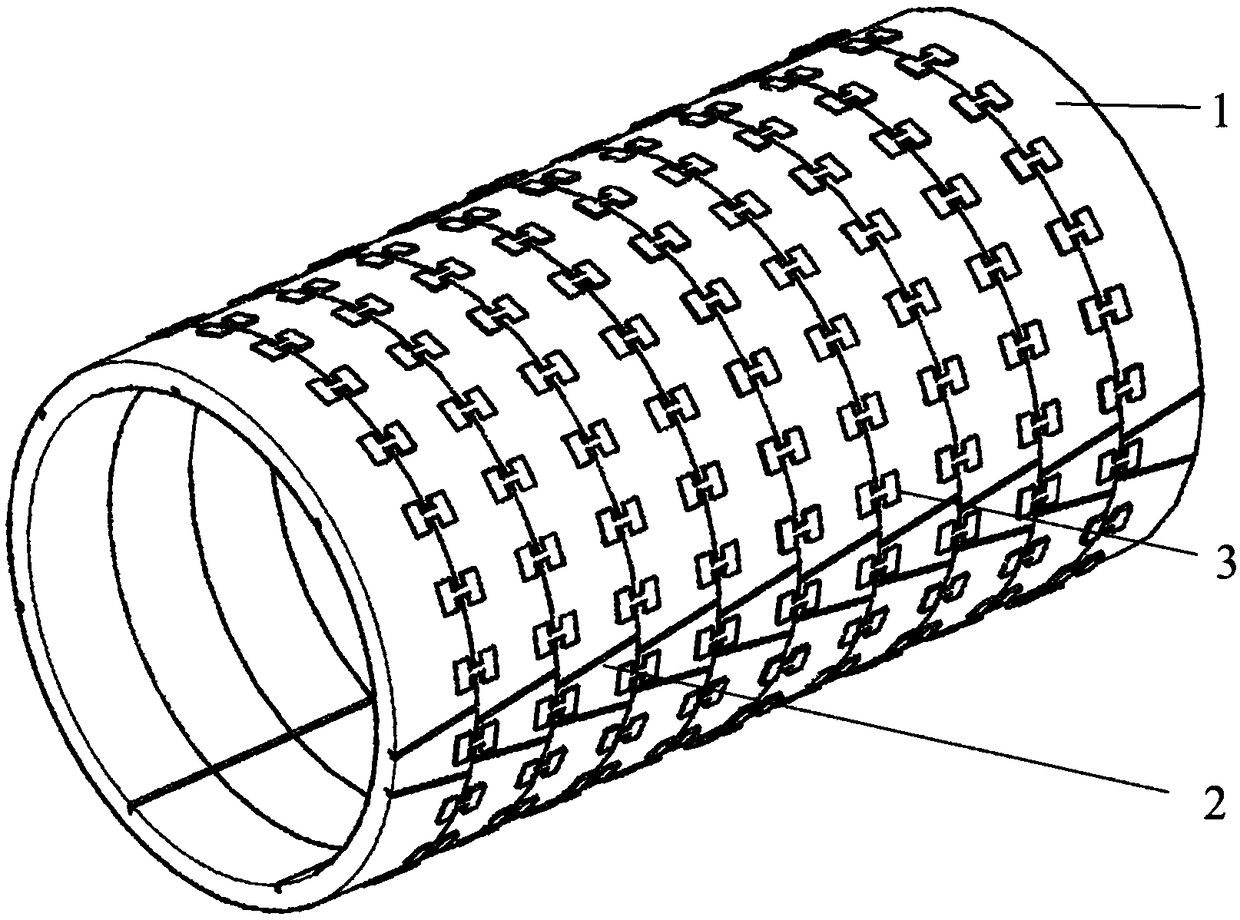

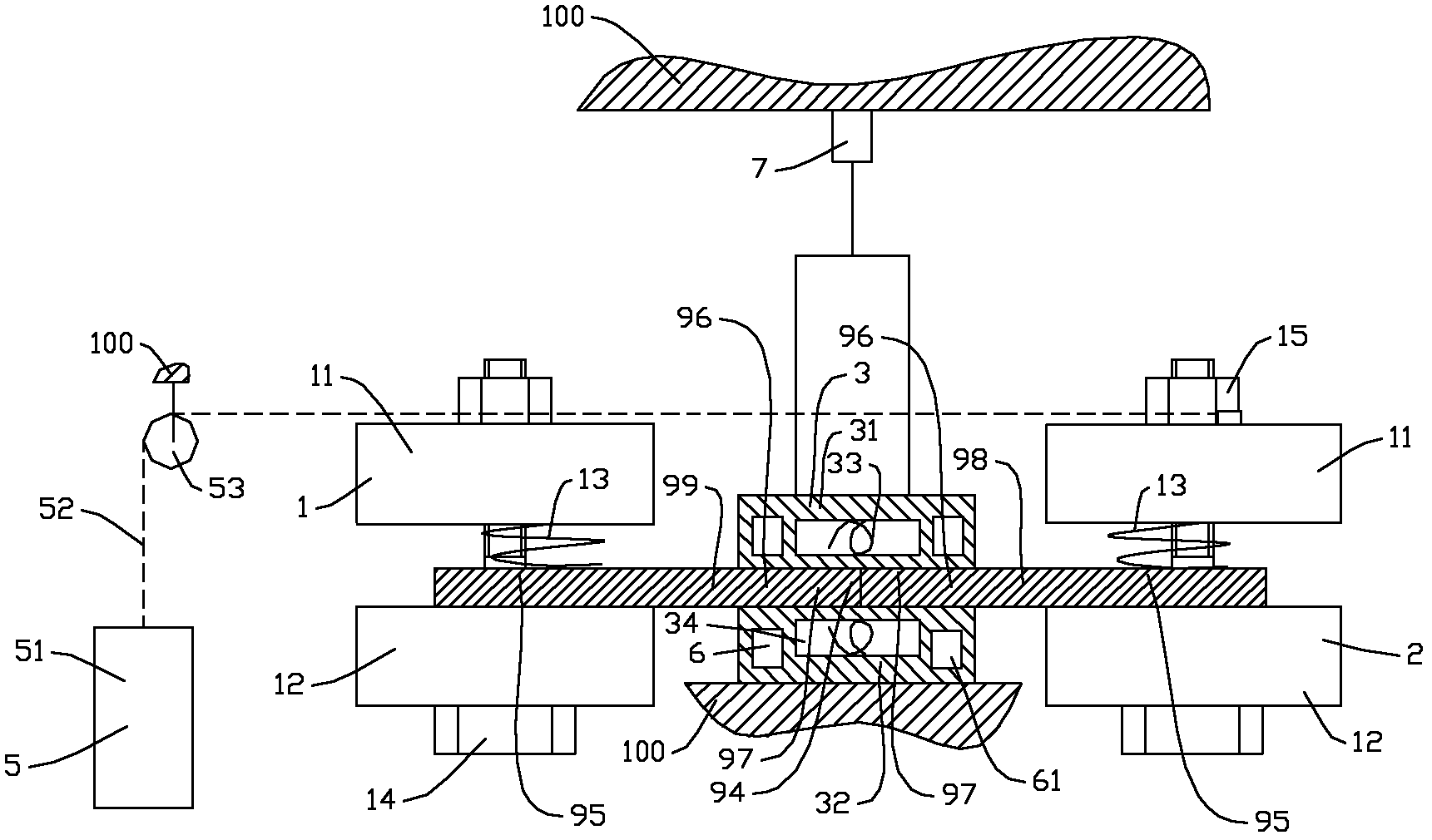

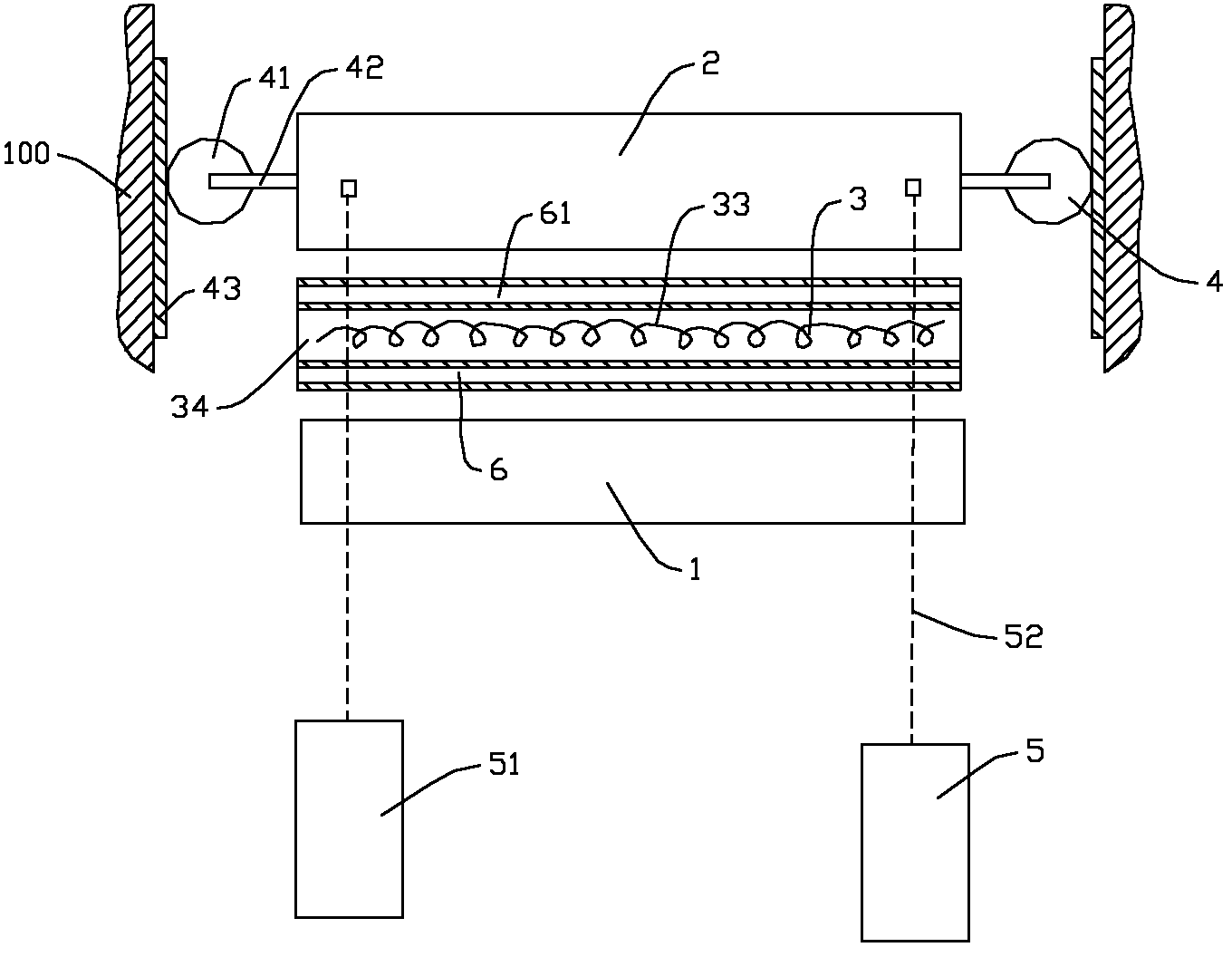

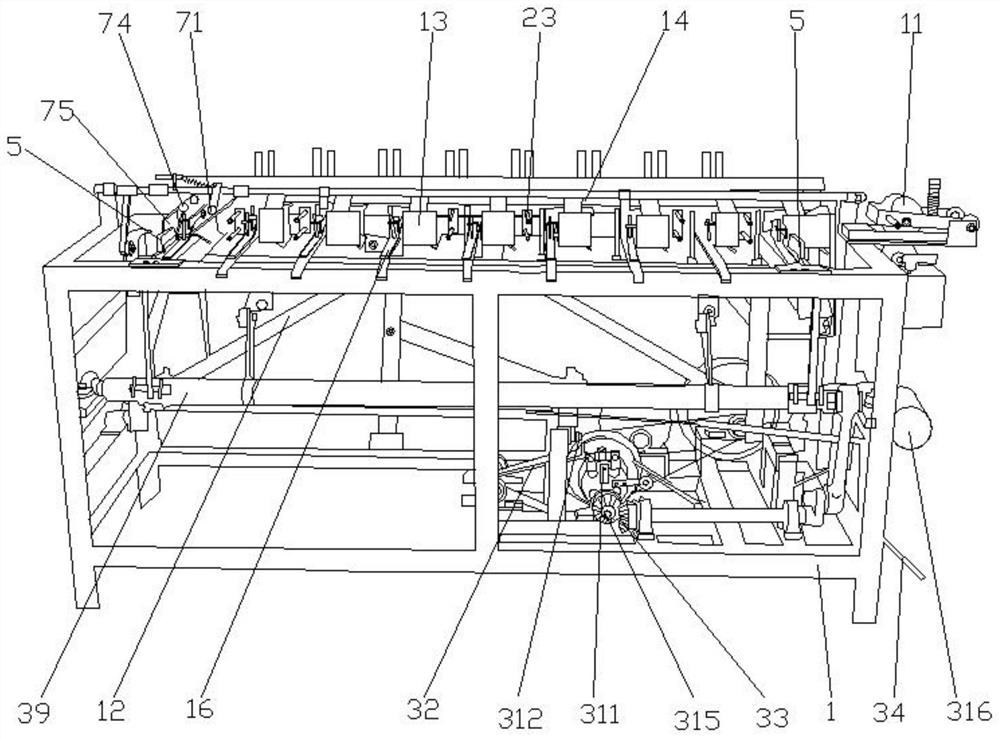

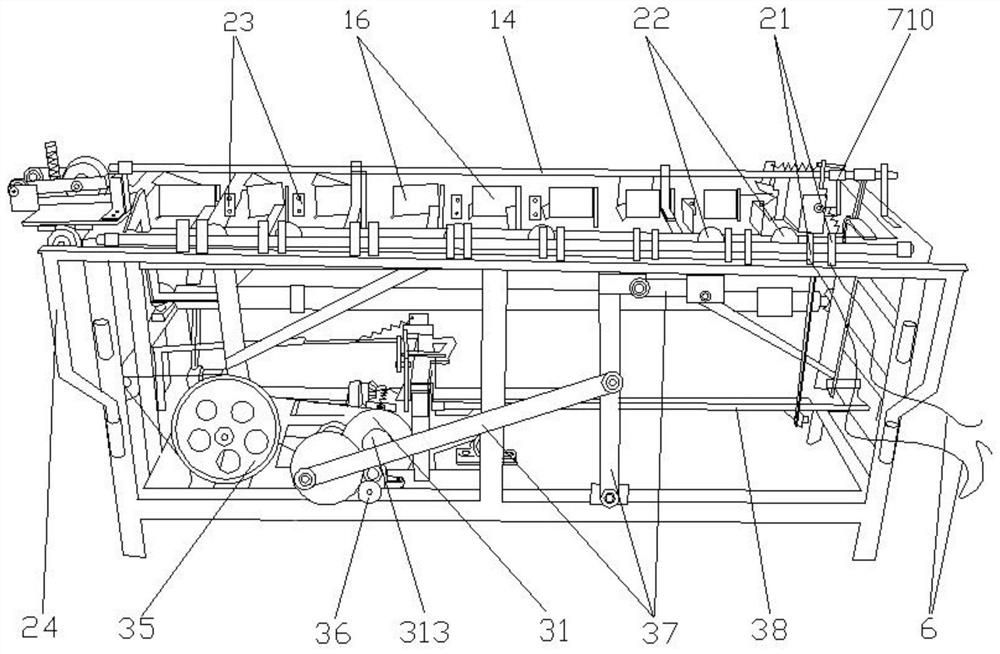

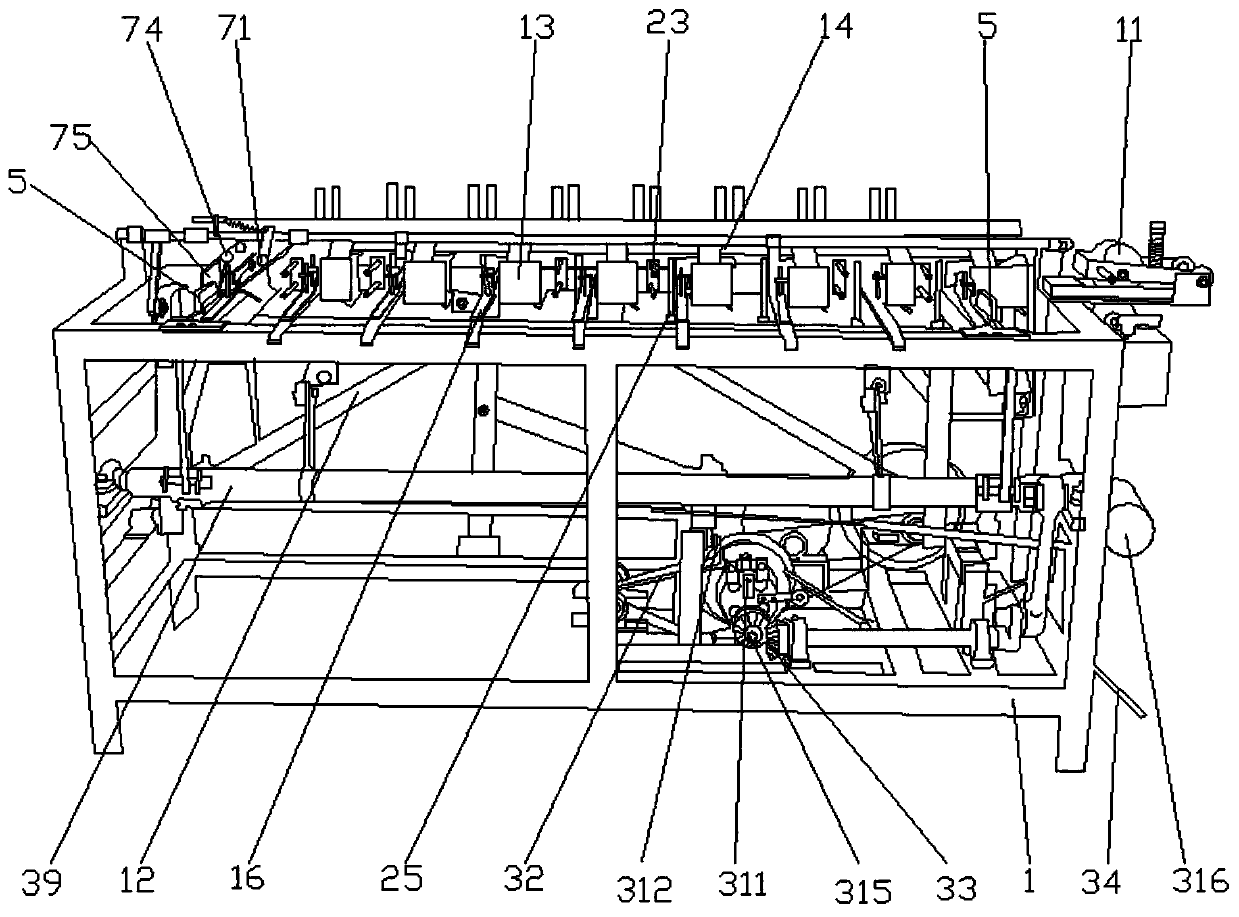

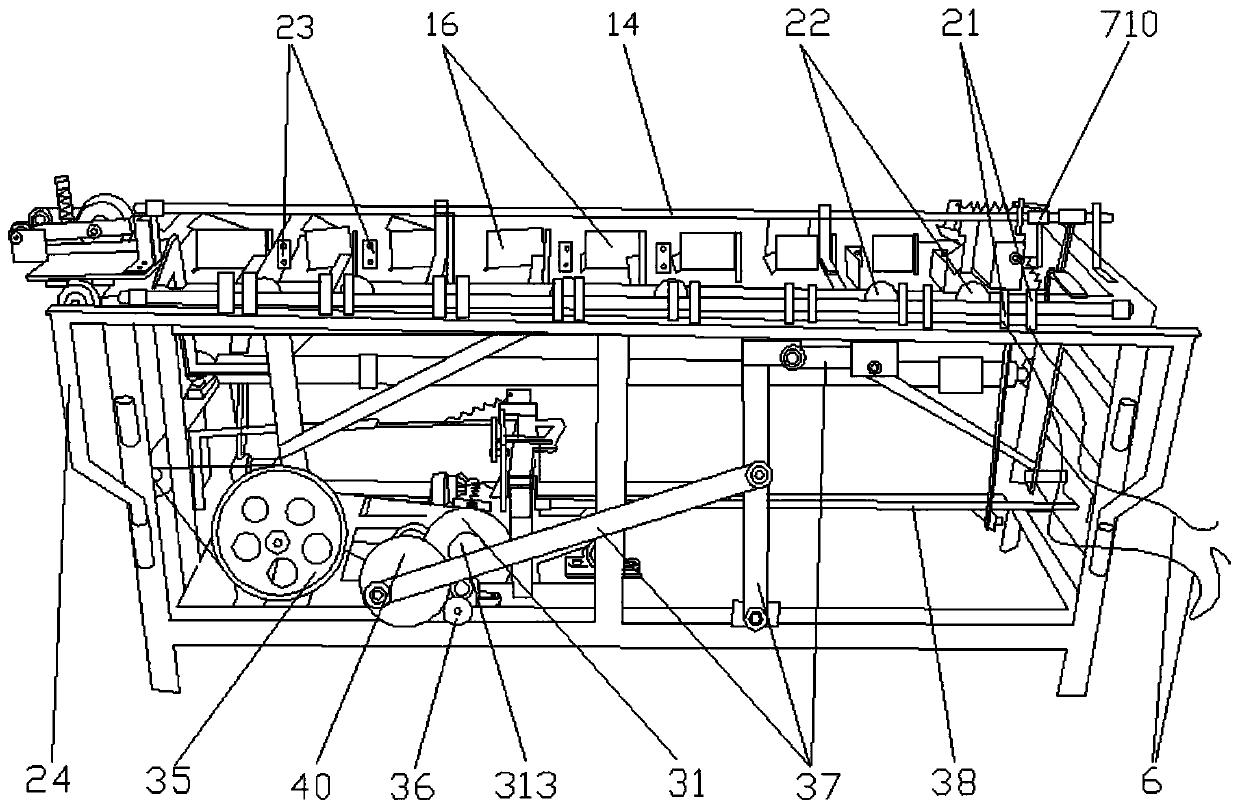

A kind of bamboo bundle fiber integrated veneer weaving machine and veneer weaving method thereof

ActiveCN110253701BEasy to useAdjustable braid tightnessCane mechanical workingReed/straw treatmentFiberWire rod

Owner:INT CENT FOR BAMBOO & RATTAN

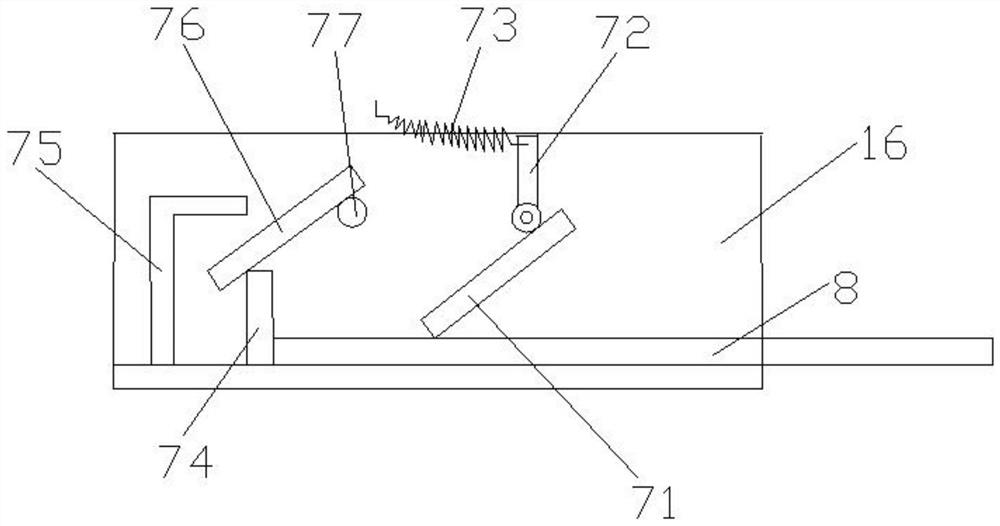

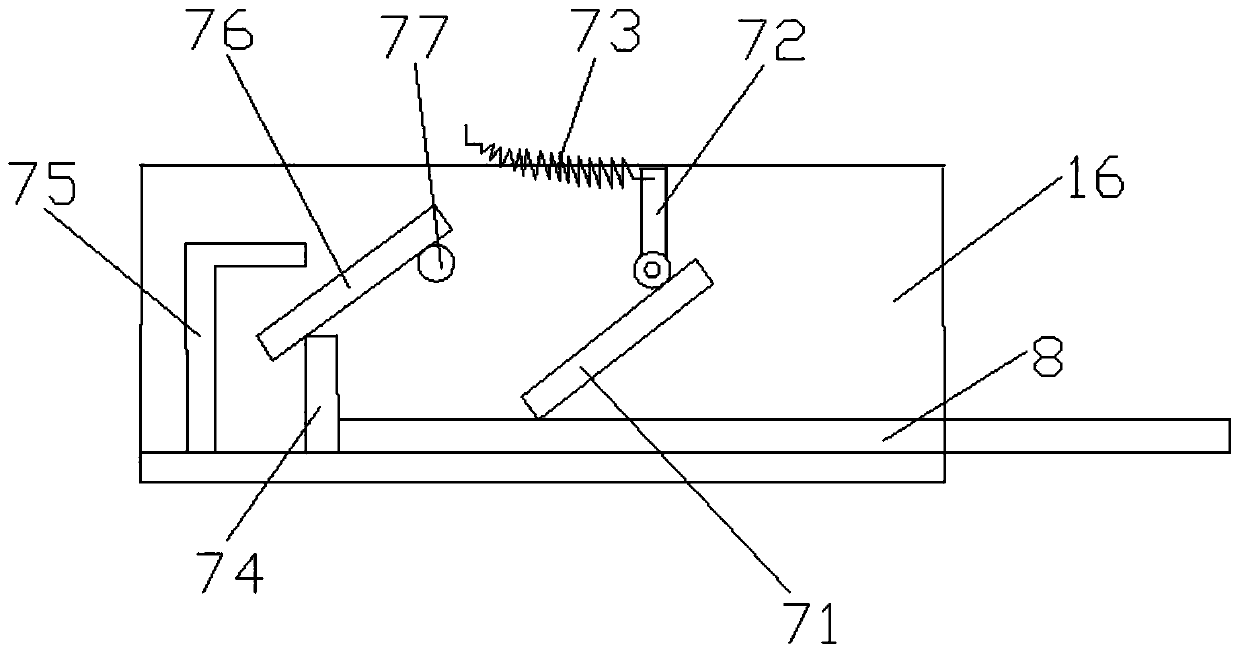

Bamboo bundle fiber entire veneer knitting machine

PendingCN110091395AEasy to useAdjustable braid tightnessCane mechanical workingBio-packagingFiberEngineering

The invention provides a bamboo bundle fiber entire veneer knitting machine. The machine comprises a frame; a feeding mechanism, a knitting mechanism, a transmission mechanism and a mechanical induction triggering mechanism for triggering the transmission mechanism to act after induction of each feeding of bamboo bundle veneers are mounted on the upper surface of the frame; the feeding mechanism and the knitting mechanism are arranged at the top end of the frame; the mechanical induction triggering mechanism is mounted at the tail part of the feeding mechanism; the transmission mechanism is mounted in the inner side position of the frame; and the transmission mechanism drives transmission of the feeding mechanism and the knitting mechanism. The machine solves the problems of incapability of performing the veneer entire treatment on bamboo bundle units for bamboo recombination in the bamboo bundle fiber entire veneer knitting, inconvenience for adjustment of the knitting elasticity of bamboo bundle entire veneers and inapplicability to knitting of the bamboo bundle units with different thicknesses.

Owner:INT CENT FOR BAMBOO & RATTAN

Antibacterial acid-resistant plastic glove material

InactiveCN106467642AIncrease elasticityGuaranteed physical and mechanical propertiesPolymer scienceMechanical property

The invention provides an antibacterial acid-resistant plastic glove material, belonging to the technical field of plastics. The antibacterial acid-resistant plastic glove material is prepared from, by weight, 40 to 45 parts of PVC powder, 20 to 25 parts of synthetic resin, 0.2 to 0.8 part of nanometer silver-loaded antiseptic, 10 to 15 parts of liquid nitrile rubber, 10 to 15 parts of epoxy natural rubber, 3 to 8 parts of a plasticizer, 0.5 to 2.8 parts of a stabilizing agent and 0.6 to 0.8 part of a catalyst. A plastic glove prepared from the material has good elasticity; the formula of the raw materials is simple and reasonable; and the prepared has good physical properties, wear resistance and acid resistance, can guarantee physical and mechanical properties of the plastic glove, is low in energy consumption and cost, high in production efficiency, good in antibacterial effect and long in service life.

Owner:仲芳

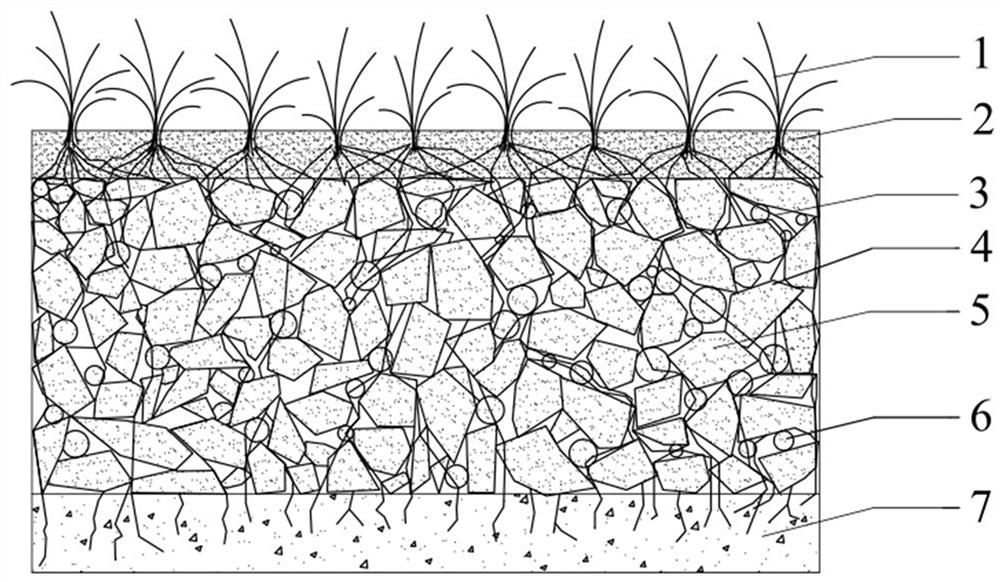

Ecological concrete containing nutritional base material particles and preparation method thereof

PendingCN114538845ASlow down the rate of lossNutrient Release SustainedSuperphosphatesSolid waste managementFertilizerNutrition

The invention discloses ecological concrete containing nutritional base material particles and a preparation method of the ecological concrete. The ecological concrete comprises the following raw materials in parts by weight: 0-15 parts of fine aggregate; 50 to 85 parts of coarse aggregate; 5-35 parts of nutritional base material particles; 15 to 25 parts of cement; 0-8 parts of fly ash; 0.3 to 0.5 part of a water reducing agent; 4 to 10 parts of water; nutrition base material particles are doped into the ecological concrete, the strength and the erosion resistance of the ecological concrete can be improved under the condition that the porosity among ecological concrete aggregates is small, meanwhile, the ecological concrete has the good fertilizer efficiency slow release performance, the good water retention and soil moisture preservation capacity and the suitable internal alkaline environment, and the ecological concrete has the good water retention and soil moisture preservation performance. The purposes of long-term plant attachment growth and ecological environment improvement in a small-pore environment are achieved.

Owner:CHINA THREE GORGES UNIV

Wear-resistant heatproof material used for plastic runway

The invention relates to a wear-resistant heatproof material used for plastic runway, which belongs to the technical field of plastic cement. The wear-resistant heatproof material comprises the following components in parts by weight: 20-25 parts of natural rubber, 36-56 parts of ultrahigh molecular weight polyethylene, 20-25 parts of glass fiber, 40-50 parts of white carbon black, 0.5-1.5 parts of a stabilizing agent, 0.5-0.8 parts of a fluorescent agent, 1-3 parts of an antioxidant, 0.5-1 part of a dispersant, and 2-4 parts of a vulcanizing agent. The raw materials formula is simple and reasonable, and the physical properties of the product are good. A preparation method has the advantages of simple and reasonable process, low energy consumption and high production efficiency, the wear-resistant heatproof material has wear resistant and heatproof characteristics, can effectively guarantee the physical and mechanical capability of the plastic runway, and has the advantages of low cost and long usage life.

Owner:仲芳

Preparation method for preparing multi-element synergic flame-retarding polymer polyalcohol of polyurethane and application

InactiveCN105175710AGuaranteed physical and mechanical propertiesImprove flame retardant performanceHigh polymerTetrabromophthalic anhydride

The invention discloses a preparation method for preparing multi-element synergic flame-retarding polymer polyalcohol of polyurethane and application and belongs to the technical field of high polymer chemistry, reaction type fire retardants and building heat-preservation materials. The multi-element synergic flame-retarding polyalcohol is prepared by taking phosphorus pentoxide, water, epoxy chloropropane, isocyanuric acid, melamine and tetrabromophthalic anhydride to react. The multi-element synergic flame-retarding polymer polyalcohol is used for preparing a flame-retarding polyurethane foam material.

Owner:UNIV OF JINAN

Corrosion-resistant antioxidative plastic pipeline

InactiveCN106467629AGuaranteed physical and mechanical propertiesImprove impact resistanceAdditive ingredientAntioxidant

A corrosion-resistant antioxidative plastic pipeline belongs to the technical field of plastics. The corrosion-resistant antioxidative plastic pipeline is prepared from the following ingredients (by weight): 30-40 parts of ABS plastic, 40-45 parts of high density polyethylene, 2-3 parts of an antioxidant, 0.8-1.2 parts of a stabilizer, 30-40 parts of nano-alumina powder, 2-6 parts of an anti-corrosive agent, 20-25 parts of thermoplastic resin, 1-2 parts of a dispersant and 1-2 parts of an anti-ageing agent. The raw material formula of the plastic pipeline is simple and reasonable, and the product has good physical properties. A preparation method of the product is simple and reasonable; energy consumption is low; production efficiency is high; the product has wear resistance, heat resistance, corrosion resistance and oxidation resistance; physical mechanical properties of the plastic pipeline can be effectively guaranteed; and the product has good impact resistance, is low-cost and has long service life.

Owner:仲芳

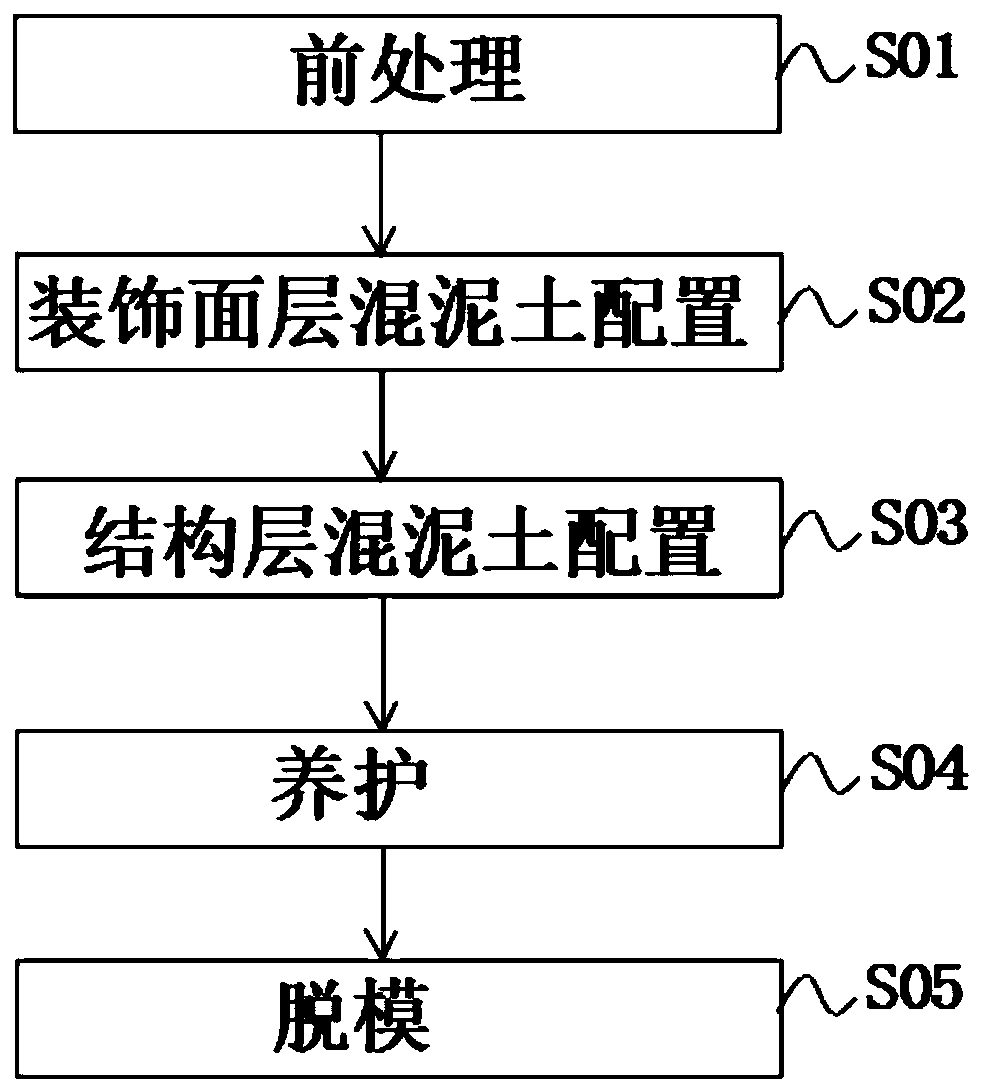

Preparation method of lightweight concrete decorative member

InactiveCN111302828AGuaranteed decorative effectGuaranteed durabilityCeramicwareBuilding energySludge

The invention discloses a preparation method of a lightweight concrete decorative member, and relates to the technical field of lightweight concrete decorative members. The method comprises the following steps: S01, pretreatment; S02, decorative surface layer concrete preparing; S03, concrete configuration of structural layer; S04, curing; and S05, demolding: demolding the cured concrete decorative member to complete the preparation. According to the invention, the inner layer is a ceramsite concrete structure layer, and ceramsite concrete is used as a structural layer, so that the weight of the wall body is greatly reduced, the on-site construction workload is reduced, the labor cost is reduced, resources and energy are saved, and the influence on the environment is greatly reduced; and the lightweight aggregate raw material added into the decorative member is mainly formed by sintering sludge and pot clay, so that waste utilization is achieved, the material source is wide, and the building energy consumption is greatly reduced.

Owner:上海君道住宅工业有限公司

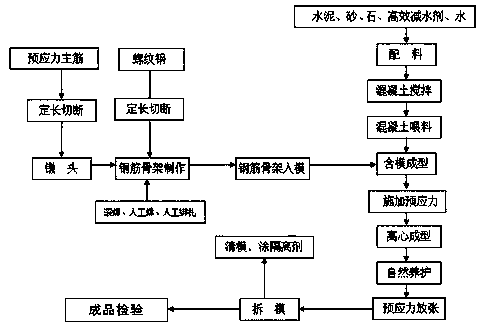

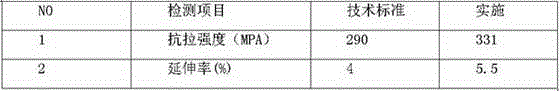

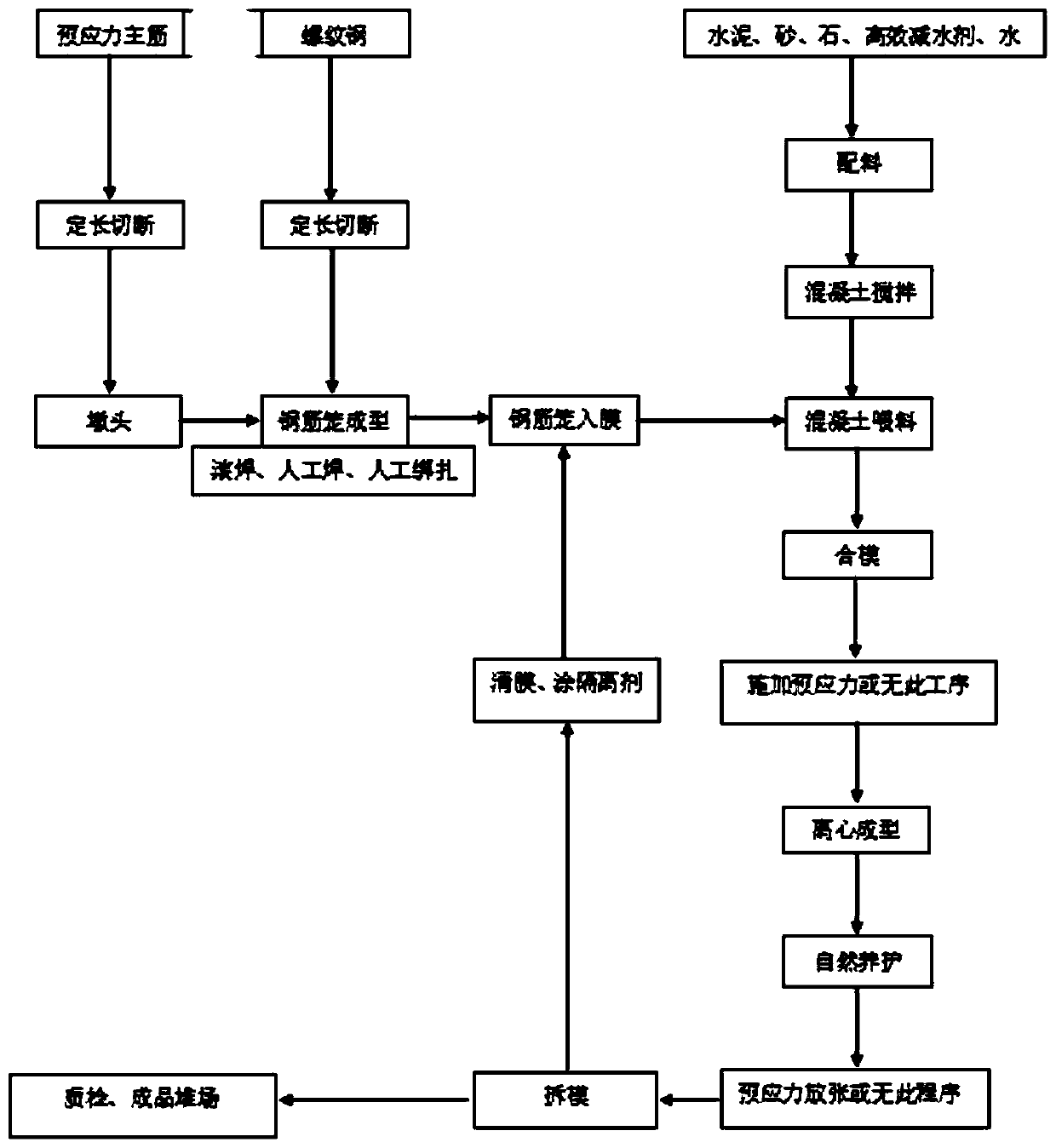

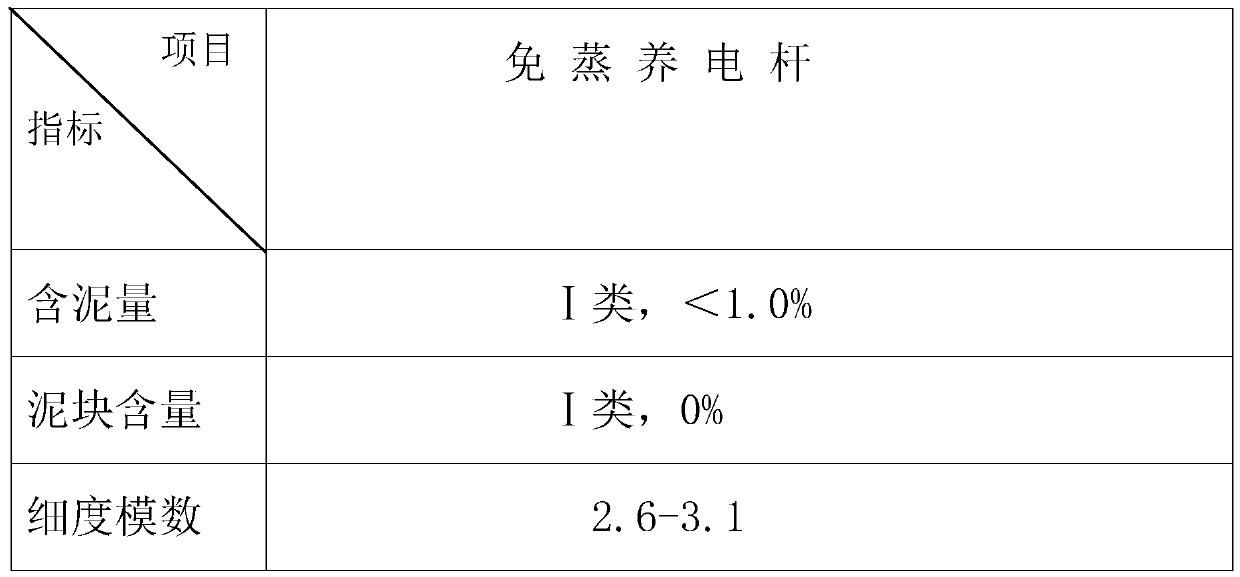

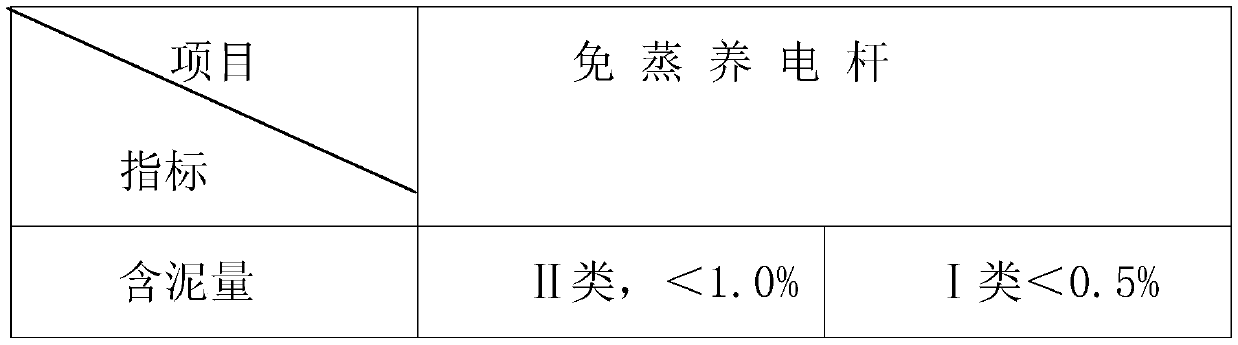

Manufacturing technology for autoclaving-free pole

InactiveCN108908685AImprove qualityGuaranteed physical and mechanical propertiesShaping reinforcementsManufacturing technologySuperplasticizer

The invention provides a manufacturing technology for an autoclaving-free pole. The specific machining technology comprises the following steps that one, prestressed steel bars and screw-thread steelare machined; two, a steel bar framework is manufactured; three, a concrete mixture is manufactured; four, mold closing and formation of the autoclaving-free pole are conducted; five, natural curing is conducted; six, mold removing is conducted; and seven, finished product inspection is conducted. The manufacturing technology for the autoclaving-free pole has the beneficial effects that by means of improvement of raw material quality, optimization of mixing proportion and adoption of an efficient water reducing agent, a large amount of energy consumption is saved on the premise that physical and mechanical properties, durability and production time of the pole are guaranteed; a cost ranging from 30 rmb to 60 rmb can be saved by each pole; production cost is reduced greatly; the history ofhigh energy consumption of the pole is changed completely; a novel breakthrough of the pole is achieved; the concrete of the autoclaving-free pole is high in durability such as chloride corrosion resistance property, freezing resistance and the like and high in latter strength; a strength loss of 17% of steam curing is avoided; the autoclaving-free pole is artistic in appearance; a non-pulp-pouring technology is adopted; meanwhile, numerous troubles of the remaining pulp are avoided; and the manufacturing technology is environmentally friendly.

Owner:泰州桓通管业有限公司

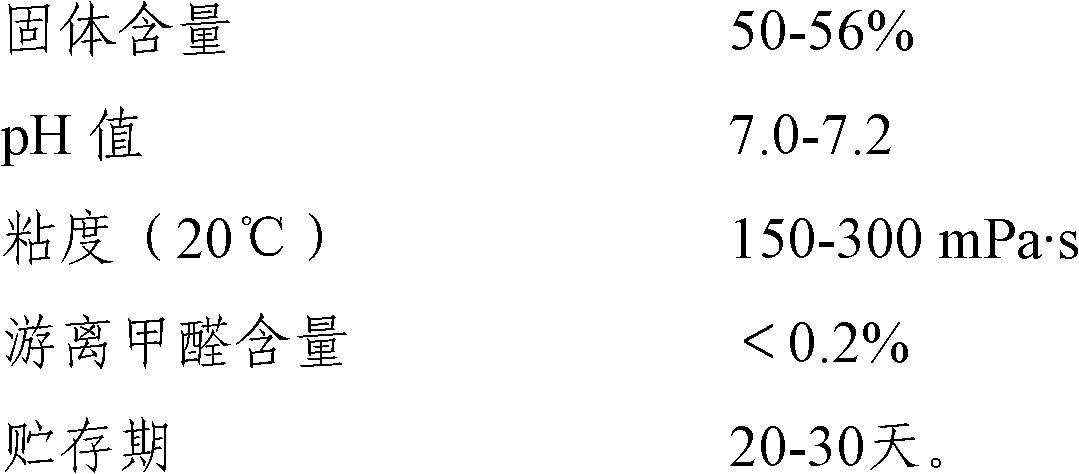

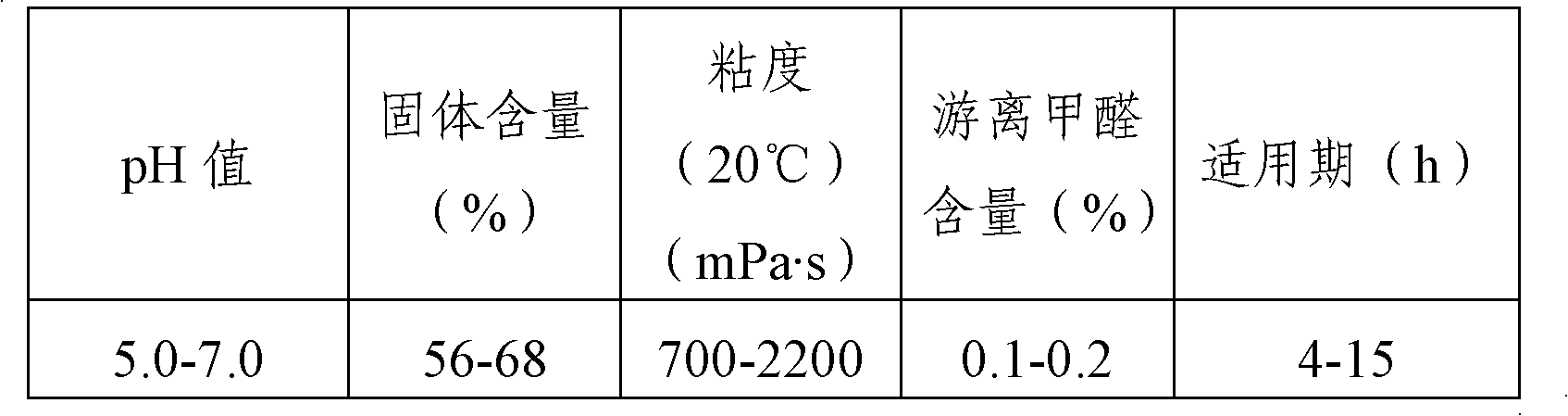

Method for lowering adhesive consumption of melamine-modified urea resin wood adhesive

InactiveCN103965819AGuaranteed physical and mechanical propertiesReduce the amount of sizingAldehyde/ketone condensation polymer adhesivesFiberPolymer science

The invention belongs to the field of wood adhesives and particularly relates to a method for lowering adhesive consumption of melamine-modified urea resin wood adhesive. The method comprises steps of preparing adhesive, mixing adhesive, applying adhesive and thermally pressing. The method is characterized in that adhesive consumption of the melamine-modified urea resin wood adhesive is lowered by a diluting method, wherein the diluting method comprises the steps of adding water to dilute, and is used for gluing of a high-density fiber board and a shaving board. The melamine-modified urea resin wood adhesive contains over 5% by weight of melamine and is good in water solubility. The diluting process can be completed in an adhesive-preparing rear stage or an adhesive mixing stage, wherein water adding amount is 0.1-2 times the weight of the adhesive, and then high-speed stirring is carried out. The method disclosed by the invention has the advantages that the adhesive consumption is lowered by 9%-18%, formaldehyde emission is over E1, and physical and mechanical performances of the board are also ensured, and is simple and convenient to use.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Additive agent of urea-formaldehyde resin adhesive and preparation method thereof

InactiveCN102321439BSolve the problem of size reductionGood preloading effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesResin adhesiveMechanical property

The invention provides an additive agent of urea-formaldehyde resin adhesive and a preparation method thereof. The additive agent of the urea-formaldehyde resin adhesive is prepared from the following components in parts by weight: 100 parts of modified starch, 1-5 parts of polymer compound, 300-500 parts of desulfurization gypsum, and 0.1-2 parts of swelling agent which are mixed uniformly to obtain the additive agent. The additive agent of the urea-formaldehyde resin can replace flour to be added into urea-formaldehyde resin, the adhesive is endowed with favorable prepressing when artificial plates are prepared, the high production efficiency of the artificial plates is ensured, simultaneously the formaldehyde emission of the artificial plates can be reduced effectively, the problem of volume reduction in the process of preparing the urea-formaldehyde resin adhesive is solved, and the physical mechanical property of the artificial plates is improved.

Owner:BEIJING FORESTRY UNIVERSITY

A fast-growing material surface enhancement manufacturing method and its profile

ActiveCN102626941BOvercoming deformation and corrosion resistanceExtended service lifeDrying using combination processesWood compressionMoistureHeat treated

The invention relates to a fast-growing wood surface reinforcing manufacturing method and sections manufactured thereby, belonging to the field of functional improvement on wood and wood processing. The technical scheme comprises the following steps of (1) drying step: drying fast-growing wood till a moisture content of 5-12%; (2) carbonizing step: carbonizing the fast-growing wood; (3) surface reinforcing step: compacting and reinforcing the surface of the fast-growing wood; and (4) thermally processing and fixing step: thermally processing and fixing the fast-growing wood at the temperature of 180-220 DEG C. The problems are solved that in the conventional technical scheme, the production process is complicated, the production cost is high, the wood yield is low, obtained sections are poor in texture and color and luster and poor in product stability, and the like; compared with the prior art, the fast-growing wood surface reinforcing manufacturing method has the advantages of simple process, no addition of any chemical in the production process, environment-friendly production, high production efficiency, capability of realizing large-scale flow-line production, low wood loss, high wood yield, low production cost and the like; and the obtained fast-growing wood surface-reinforced sections have the advantages of hard surfaces and soft middle parts or bottoms, high size stability, high corrosion resistance, clear texture, plump color and luster, good decorative effect and the like.

Owner:福建秦朝木业科技有限公司

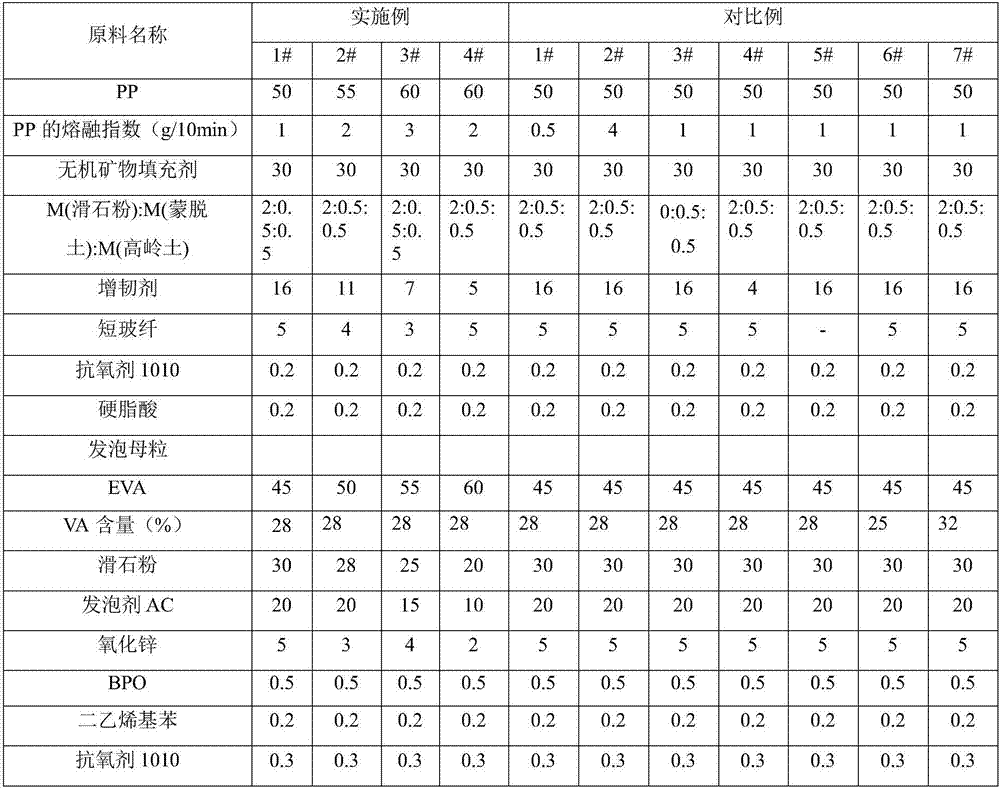

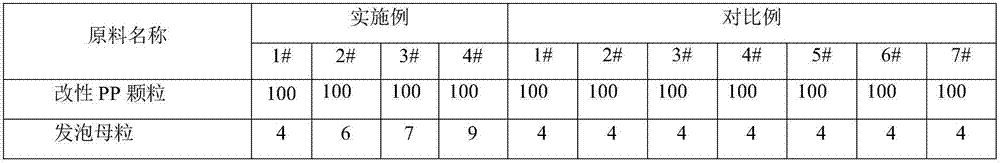

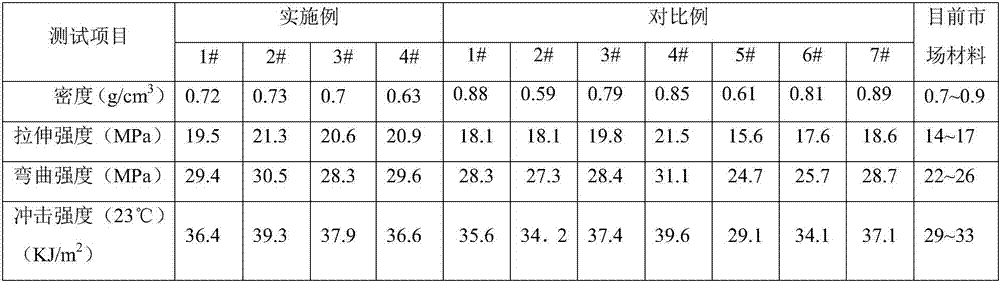

Modified PP foaming enhanced material and preparation method thereof

InactiveCN107141599AGuaranteed physical and mechanical propertiesSolve the problem that is not conducive to foamingPolypropyleneFlexural strength

The invention belongs to the technical field of macromolecular material modification, and in particular relates to a modified PP (polypropylene) foaming enhanced material and a preparation method thereof. The modified PP foaming enhanced material consists of modified PP particles and foamed masterbatches, wherein the modified PP particles consist of PP, an inorganic mineral filling agent, a toughening agent, short glass fibers, an antioxidant 1010 and a surfactant; and the foamed masterbatches consist of EVA, talcum powder, a foaming agent, a foaming promoter, a crosslinking agent, an assistant crosslinking agent and an antioxidant 1010. The PP is enhanced and modified and then is subjected to chemical foaming, so that the prepared PP foamed material has low density, also has excellent tensile strength, bending strength and impact strength, can be used for replacing parts such as a door plate and an instrument desk on an automobile prepared by non-foamed PP at present, and can achieve the aims of reducing weight, insulating heat, reducing noise and the like.

Owner:常州碳润新材料科技有限公司

Cast AlSi7Mg alloy and modification and refinement method thereof

The invention relates to a cast AlSi7Mg alloy, which is prepared from the following raw materials in parts by weight: 600 parts of AlSi7Mg, 0.48 to 1.2 parts of modifier and 0.09 to 0.27 parts of refiner. According to the cast AlSi7Mg alloy disclosed by the invention, by modifying and refining molten aluminum before pouring an AlSi7Mg casting, physical performance of the AlSi7Mg casting reaches the optimum state, product stability is greatly increased, and the AlSi7Mg casting has superior performance of high strength, high ductility, good metallographic structure and the like. The invention also provides a modification and refinement method for the cast AlSi7Mg alloy.

Owner:HEBEI SHENGYUE RAILWAY ELECTRIFICATION EQUIP

Non-steam-curing production process for telegraph pole

PendingCN110342876ATake advantage ofAchieving a breakthrough in new technologyShaping reinforcementsPre stressRebar

The invention discloses a non-steam-curing production process for a telegraph pole. The production process is as follows: material and equipment preparation, prestressed steel processing, steel reinforcement framework production, concrete preparation, material layout, mold closing, centrifugal molding, hoisting, pool entering, curing and demolding. The non-steam-curing production process has the beneficial effects that WPC-600 polycarboxylate serving as a high-performance water reducer is adopted, so that the physical and mechanical properties of the telegraph pole are guaranteed; two ends areplugged without mortar discharging, so that a great deal of cement mortar does not run off; wastes are sufficiently utilized, and top diameters are plugged, so that the manpower is saved, pollution is thoroughly solved, and the novel process breakthrough of the telegraph pole is realized; prestressed tensioning is adopted, and the tensioning sequence is realized by adopting a symmetric and mutually-staggered tensioning method, so that the phenomena of bending, cracking and prestressed reinforcement breaking of the telegraph pole due to overhigh eccentric pressure generated in a tensioning process are avoided; and due to the adoption of the centrifugal molding, centrifugal sudden increment is overcome, the internal delamination is reduced, and the compactness of a non-steam-cured telegraphpole can be favorably improved.

Owner:临沂通泰电线杆有限公司

Polyamide/polyester alloy and method for producing the same

InactiveCN101508842BImprove toughnessGuaranteed physical and mechanical propertiesPolyesterPolyethylene glycol

The invention discloses a polyamide / polyester alloy and a preparation method thereof. The polyamide / polyester alloy has the components according to the mixture ratio of parts by weight: 65-87% of poly adipic acid hexanediamine, 5-20% of polyethylene glycol terephthalate, 6-10% of toughener, 1-3% of compatilizer, 0.2-0.6% of antioxidizer and 0.1-5% of other accessory ingredients. Besides having excellent toughness, the polyamide / polyester alloy can maintain other physical mechanical property of the material. The technique for preparing the polyamide / polyester alloy is simple and has low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

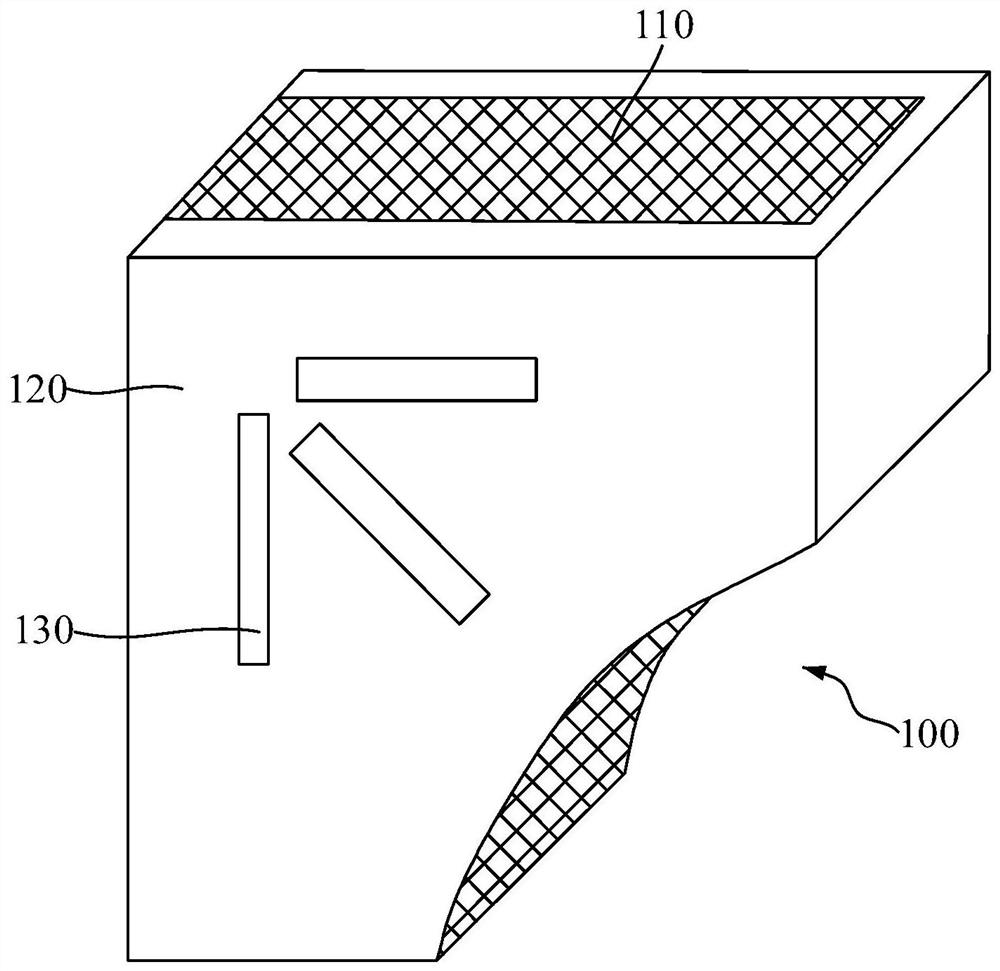

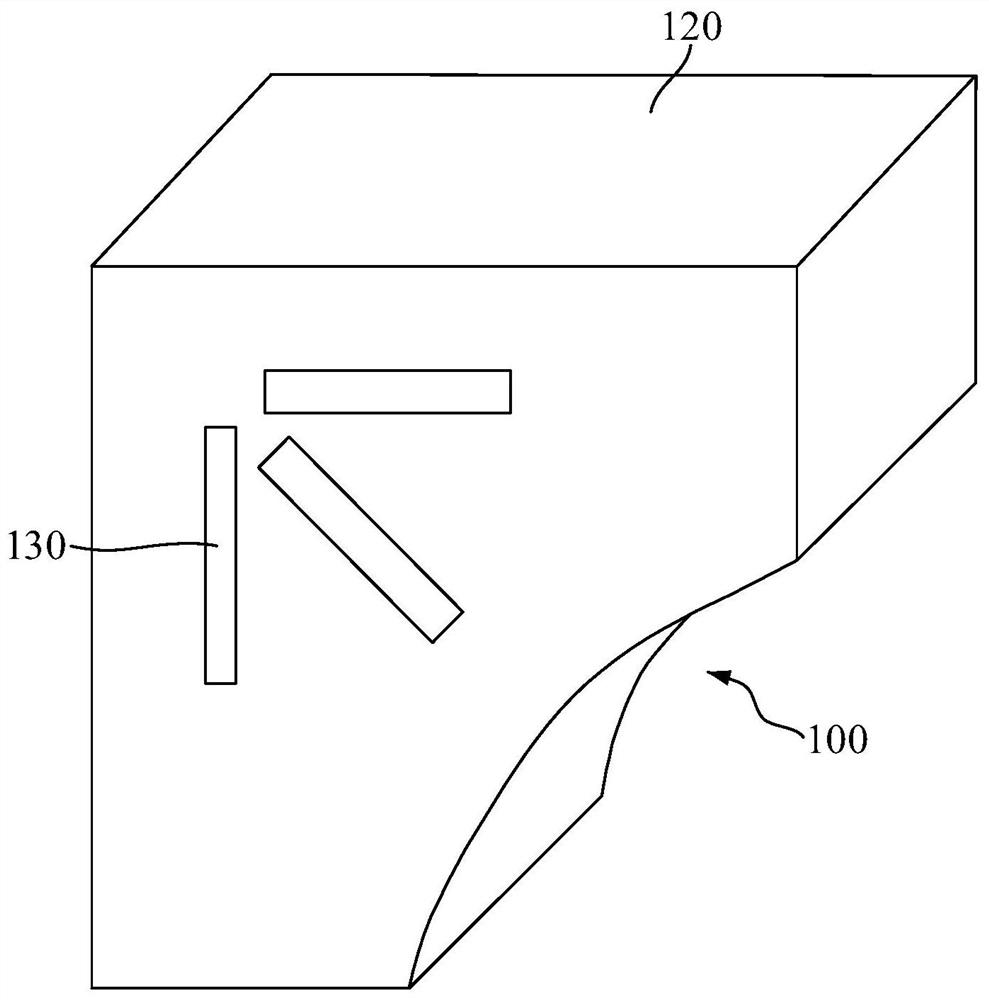

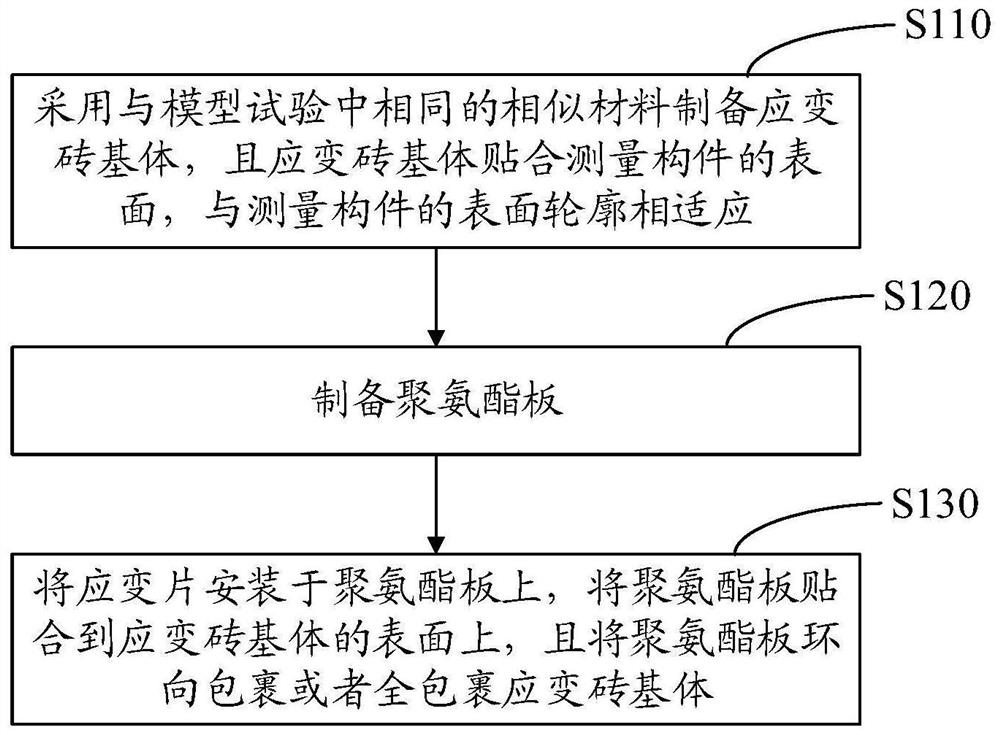

Strain brick and preparation method thereof

ActiveCN111811938AGuaranteed StrengthAvoid breakingPreparing sample for investigationMaterial strength using tensile/compressive forcesBrickEngineering

The invention discloses a strain brick suitable for a model test and a preparation method thereof. The strain brick comprises a strain brick matrix, a polyurethane plate and a strain gauge. A base material of the strain brick is a similar material in a model test, the similar material is poured on the surface of a measurement component, and after a certain strength is reached, a strain brick basebody is generated through cutting and can be perfectly attached to the surface of a complex measurement component. The cut polyurethane plates are pasted on the surface of the base body one by one, and the base body can be partially or completely wrapped according to test requirements. Finally, the strain gauges are installed on the polyurethane plate, and manufacturing of the strain brick is completed. The strain brick is attached to the surface of the complex measurement component to accurately measure the pressure of the component surface; the polyurethane plate partially wraps the strain brick base body so that the strength of the strain brick can be guaranteed, the influence of strain brick embedding on a model test can be reduced, the test error is reduced, and the measurement precision is improved.

Owner:CHONGQING UNIV

A kind of powder metallurgy friction material for railway passenger car and preparation method thereof

ActiveCN110253016BGuaranteed physical and mechanical propertiesInhibition of segregationOther chemical processesTransportation and packagingManganeseTitanium carbide

The invention discloses a powder metallurgy friction material for railway passenger cars and a preparation method thereof, which comprises the following components by mass: 40-60 parts of copper powder, 8-20 parts of iron powder, 4-11 parts of tin powder, chromium alloy 3-8 parts of nickel powder, 3-4 parts of nickel powder, 1-3 parts of molybdenum alloy powder, 0.5-3 parts of phosphorus-iron alloy powder, 0.5-3 parts of manganese powder, 2-5 parts of titanium carbide, 2-5 parts of mullite , 1-3 parts of chromium oxide, 9-25 parts of graphite, and 1-4 parts of molybdenum disulfide. Copper powder, iron powder, tin powder, chromium alloy powder, nickel powder, manganese powder, molybdenum alloy powder and ferrophosphorus powder are mechanically alloyed, then the remaining components and binder are added for mixing; the mixture is cold pressed After forming, it can be degummed and then sintered without pressure at high temperature. The invention not only reduces the production cost of pressure sintering and restricts requirements on equipment and tooling, but also improves the continuous production efficiency and the stability of friction material performance.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

A method for reducing sizing amount of melamine-modified urea-formaldehyde resin wood adhesive

InactiveCN103965819BGuaranteed physical and mechanical propertiesReduce the amount of sizingAldehyde/ketone condensation polymer adhesivesPolymer scienceAqueous solubility

The invention belongs to the field of wood adhesives, and particularly relates to a method for reducing the sizing amount of melamine-modified urea-formaldehyde resin wood adhesives, which includes the steps of making glue, adjusting glue, sizing glue and hot pressing, and is characterized in that the method is diluted Reduce the sizing amount of the melamine modified urea-formaldehyde resin wood adhesive; the dilution method is to add water to dilute, which is used for gluing of medium and high density fiberboards and particleboards. The melamine-modified urea-formaldehyde resin adhesive of the present invention has a melamine content of more than 5% (by weight) and good water solubility. The dilution process can be completed in the late stage of glue production or in the stage of glue mixing. The amount of water added is 0.1~2 times the weight of the adhesive, and then stirred at high speed. The invention has the advantages of being able to reduce the amount of sizing by 9-18%, the amount of formaldehyde emission above E1, the method is simple, the use is convenient, the cost is saved, and the physical and mechanical properties of the board are guaranteed at the same time.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com