Patents

Literature

86results about How to "Gloss stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

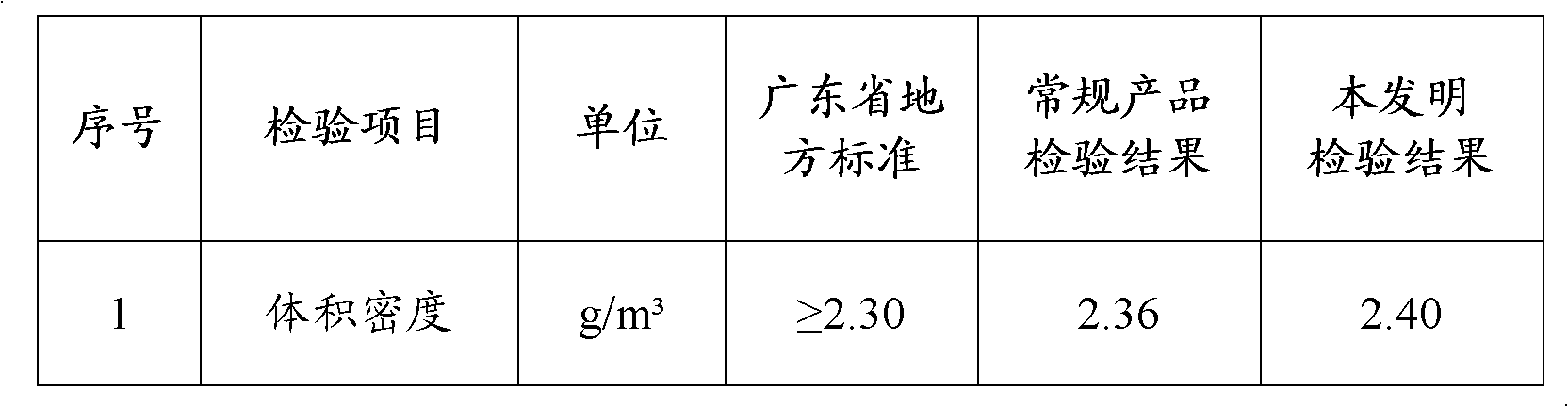

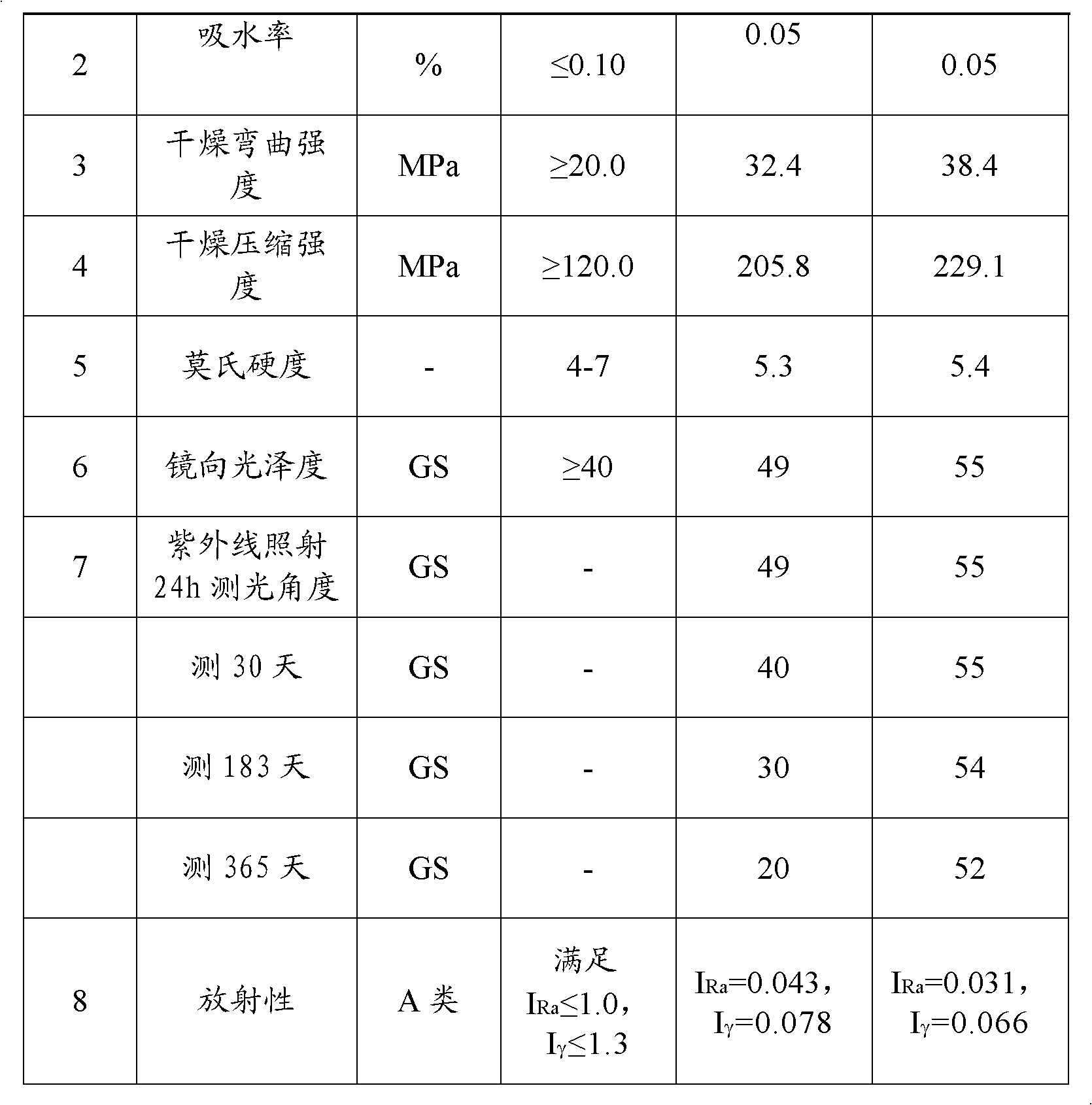

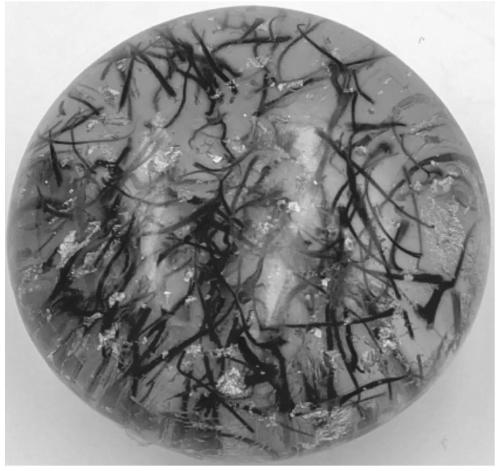

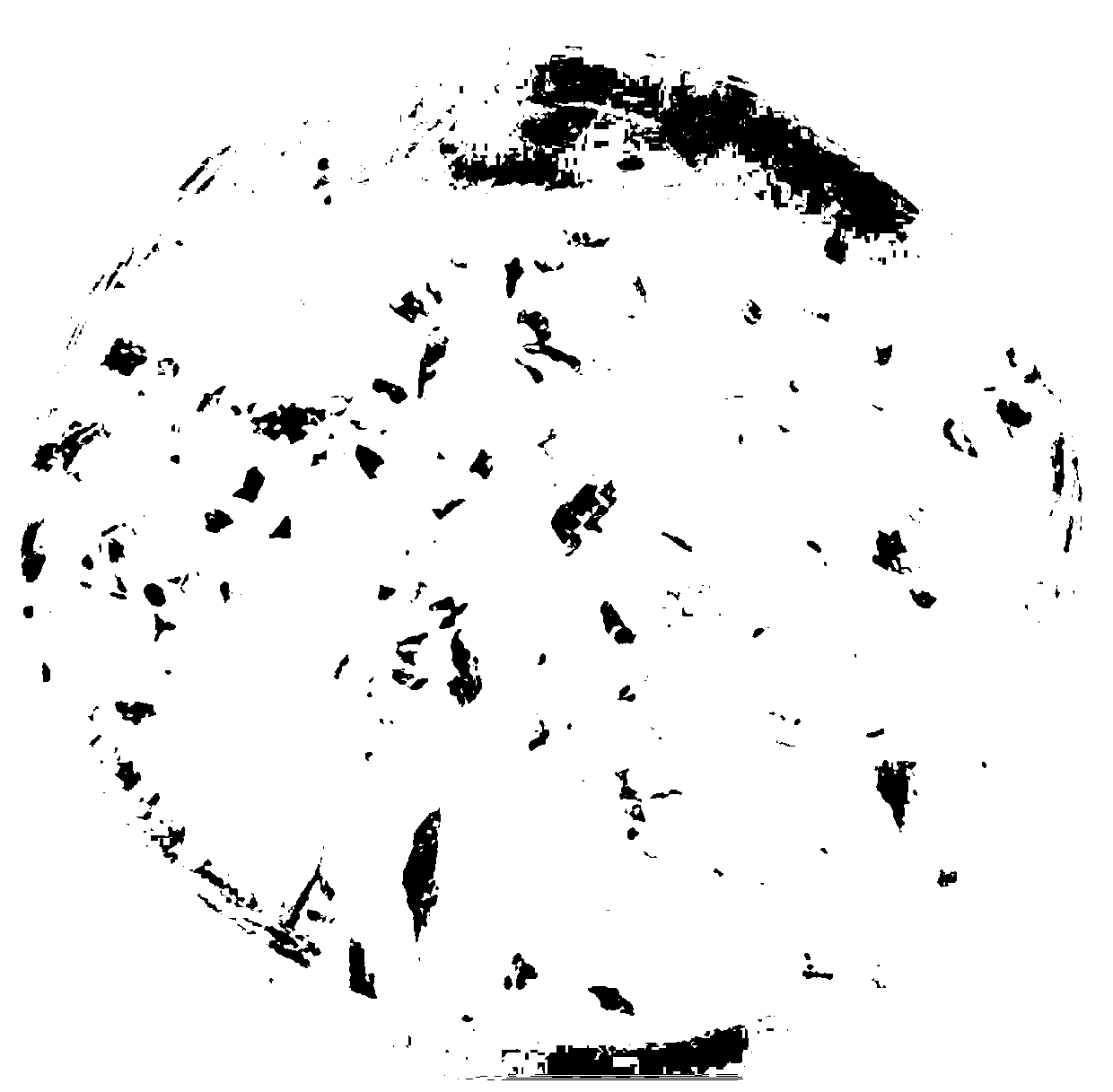

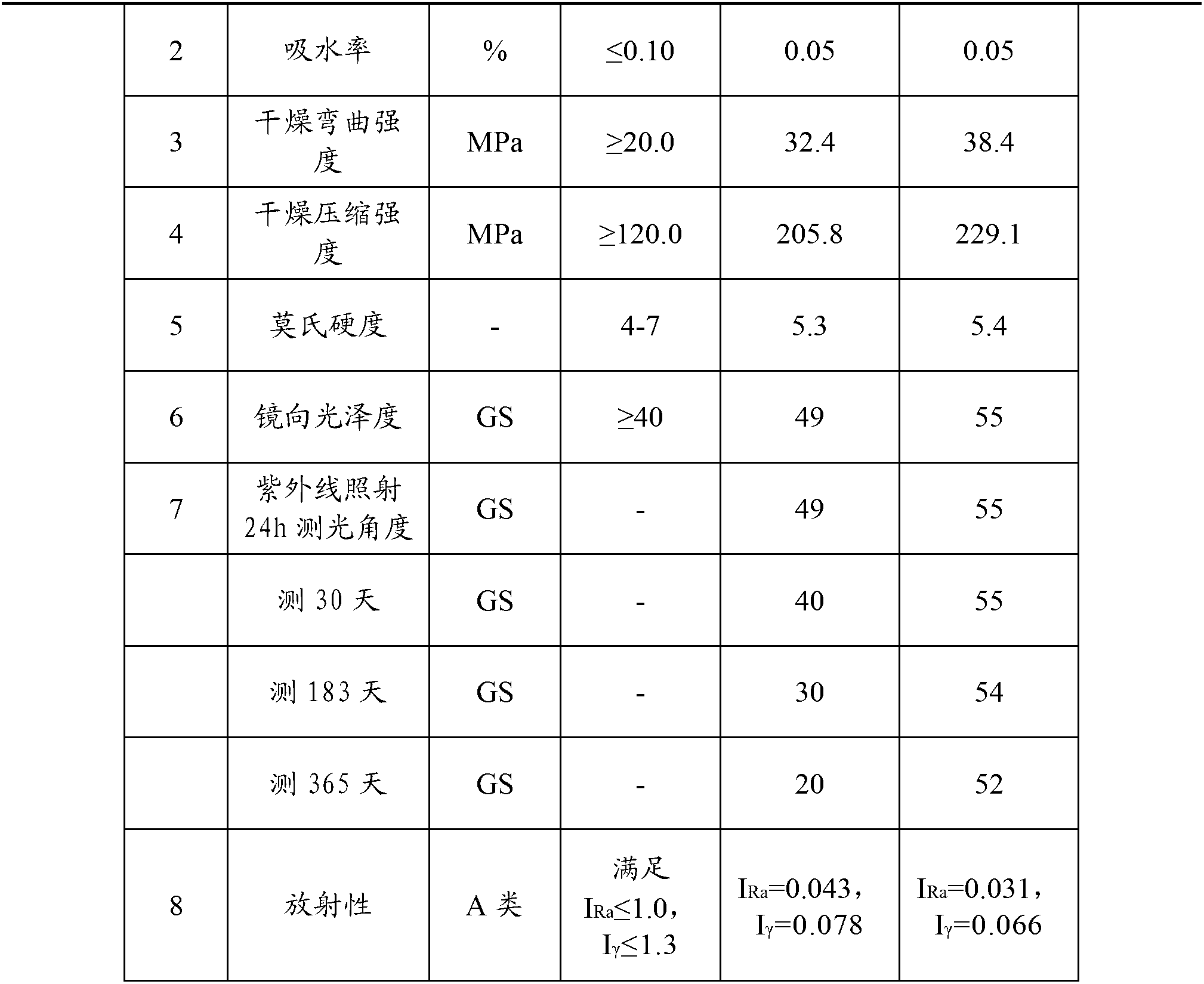

Quartzite material, artificial quartzite plate and manufacturing process thereof

ActiveCN102030497AExcellent physical and chemical propertiesGood anti-light aging performanceArtificial stonePolyresin

The invention discloses an artificial quartzite plate material which comprises the following components in percentage by total mass of quartzite plate: 60-63 percent of quartz sand with the grain size of 5-100 meshes and inorganic silicon materials of waste glass granules, and the like, 28-32 percent of quartzite powder with 320-3000 meshes, 7-9 percent of unsaturated resin and 0.4-0.6 percent ofpigment and a coupling agent as well as other components in percentage by mass of resin: 0.5-1 percent of ultraviolet absorber, 0.5-1 percent of disintegrant and 0.8-1 percent of curing agent. The invention also discloses the quartzite plate prepared from the raw materials and a manufacturing process thereof. In the invention, the quartzite plate is produced by the steps of vibrating and pressurizing the quartz sand, the quartzite powder, the inorganic silicon materials of waste glass granules, and the like and the unsaturated resin under the vacuum state and curing and synthesizing under theintermediate temperature. The quartzite plate overcomes the problem that the traditional artificial stone is aged under strong lights after long-term use outdoors and has favorable physical and chemical properties.

Owner:新云石业(云浮)有限公司

Low temperature curing epoxy low-gloss powder coating and preparation method thereof

InactiveCN101747826ASimple recipeLow curing temperaturePowdery paintsEpoxy resin coatingsPowder coatingEpoxy

The invention discloses a low temperature curing epoxy low-gloss powder coating, which comprises the following components in part by weight: 100 to 200 parts of epoxy resin, 1 to 10 parts of epoxy curing agent, 0 to 50 parts of delustering agent, 0 to 160 parts of inorganic filling and 0 to 10 parts of addition agent. The invention also discloses a method for preparing the powder coating. The low temperature curing epoxy low-gloss powder coating has the characteristics of simple formula, low curing temperature, stable gloss and free adjustment of a coat, good mechanical properties, good chemical resistance and the like.

Owner:GUANGZHOU QINGTIAN INDAL

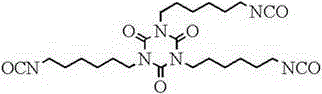

Preparation method of polyurethane trimer curing agent of low free isocyanate monomer

ActiveCN102718944AGood compatibilityRapid curing at room temperatureOrganic chemistryPolyurea/polyurethane coatingsPolymer scienceNitrogen

The invention discloses a preparation method of a polyurethane trimer curing agent of a low free isocyanate monomer, comprising the following steps of: under the protection of nitrogen, firstly putting an isocyanate monomer and an esters solvent into a reaction container to evenly stir, wherein the temperature is kept at 50-90DEG C; dropwise adding diamine into the reaction container under the condition of stirring, wherein the dropwise adding time is 1-1.5 hours; and after dropwise adding, adding a catalyst of which the mass is 0.1-0.5% of that of the isocyanate monomer once, continuing stirring and reacting at the temperature of 70-100DEG C for 3-6hours, when the NCO base content is 20%-25%, immediately adding the polymerization inhibitor of which the mass is 0.1-1% of that of the isocyanate monomer, keeping the temperature for 1-2hours, and discharging in a cooling way. The polyurethane trimer curing agent prepared by the preparation method can be better compatible with the resin, can be quickly solidified under normal temperature, and has the advantages of being higher in mechanical strength, modulus, adhesion, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

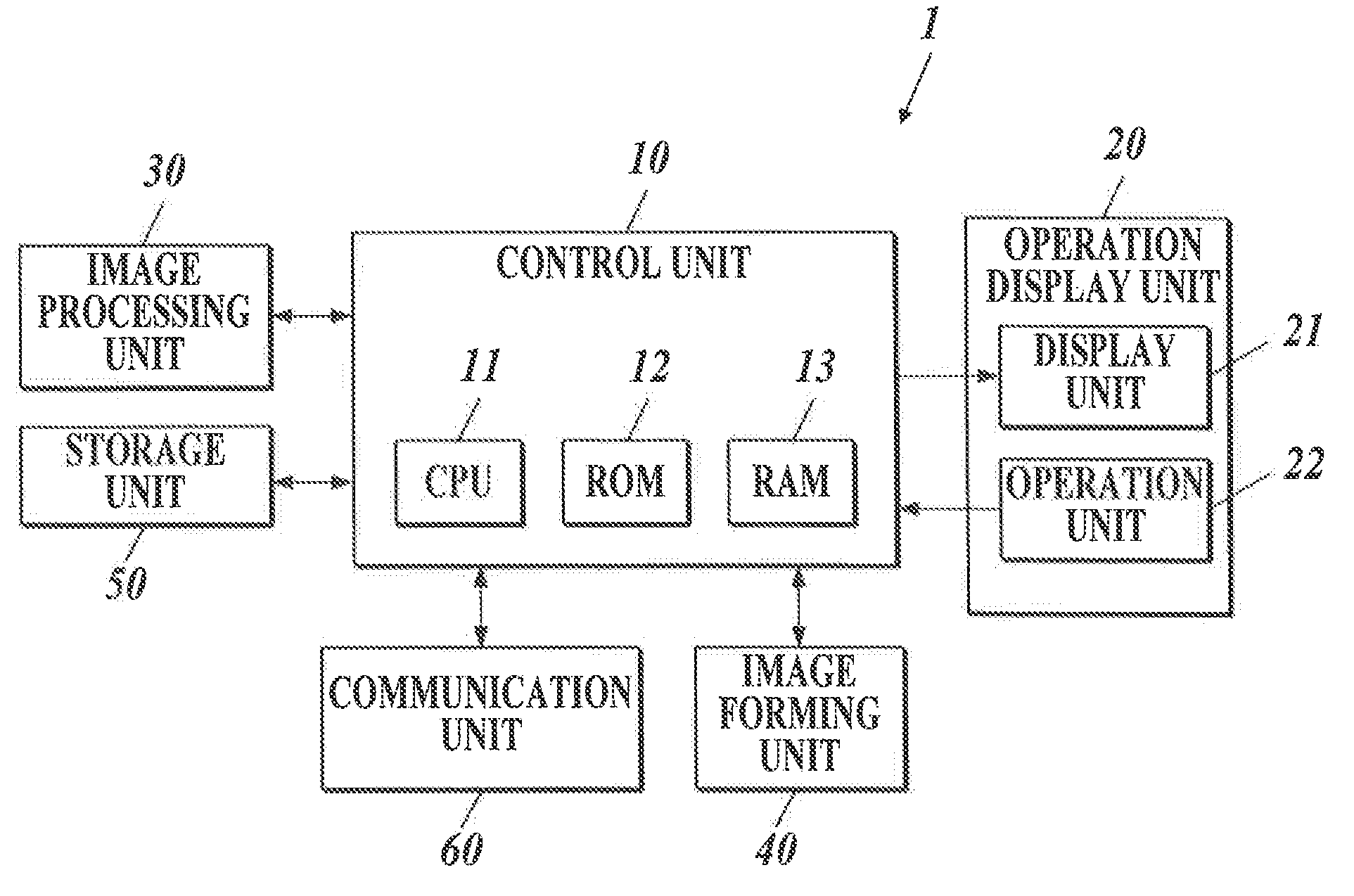

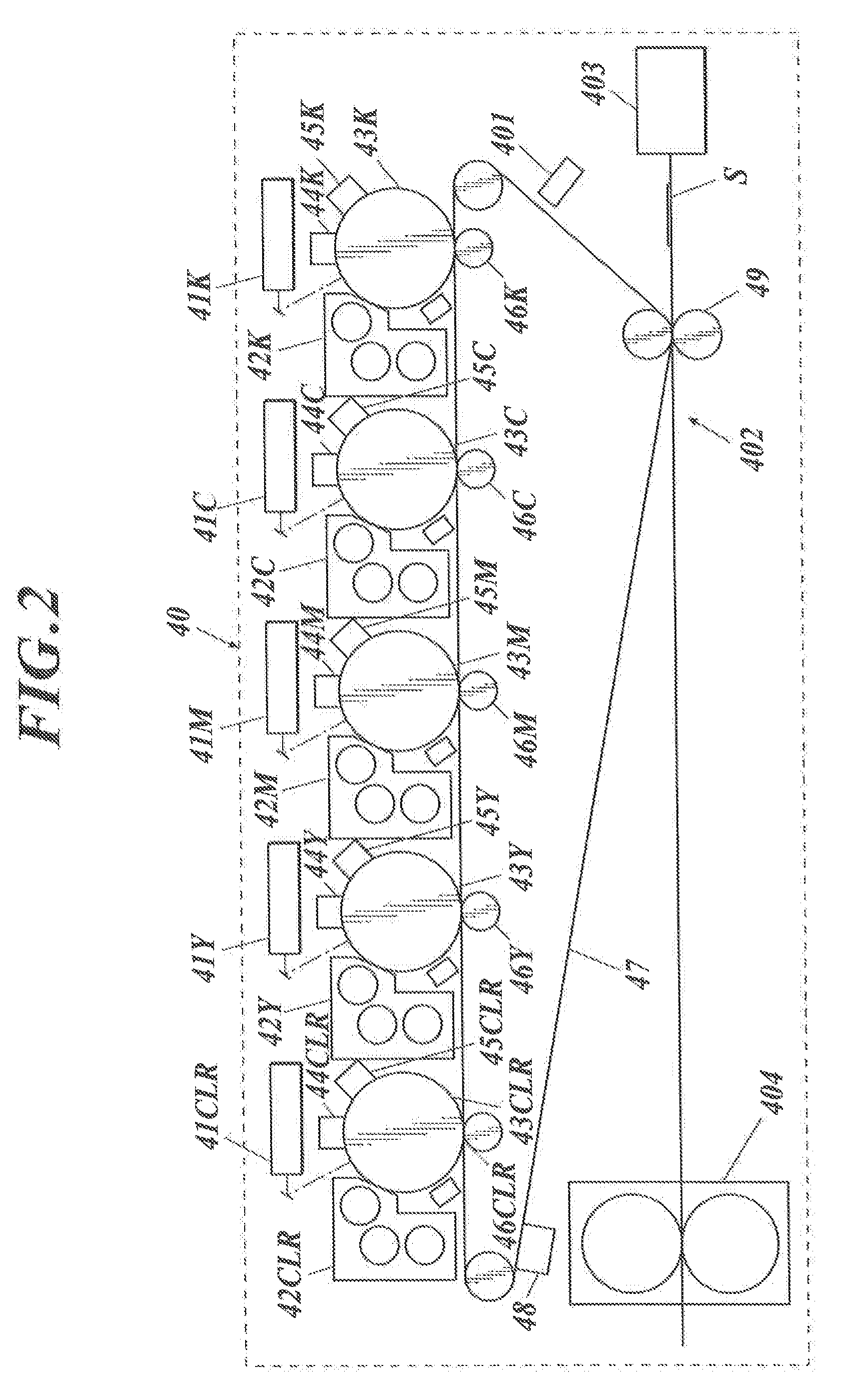

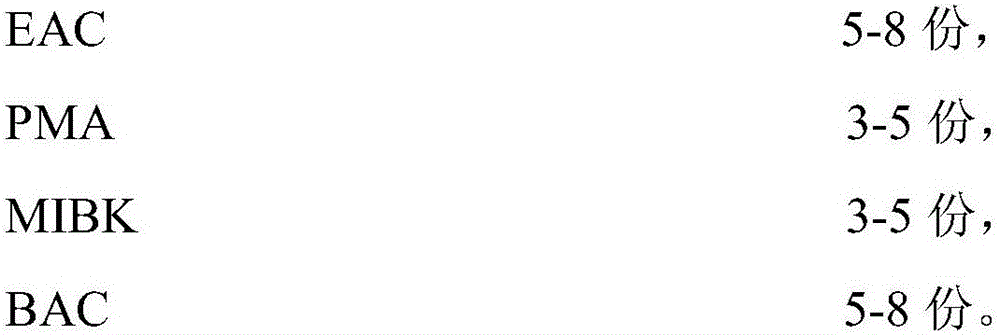

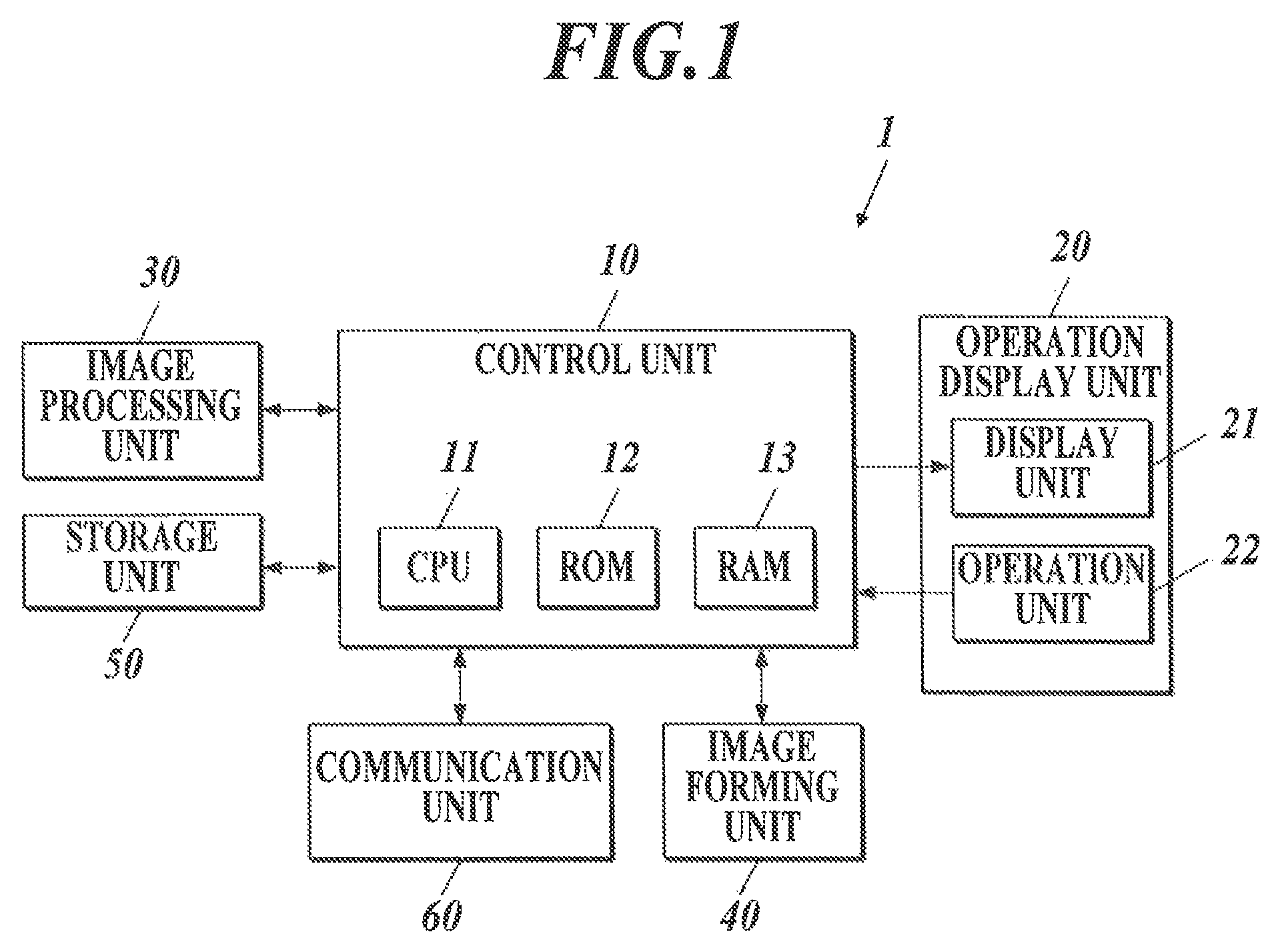

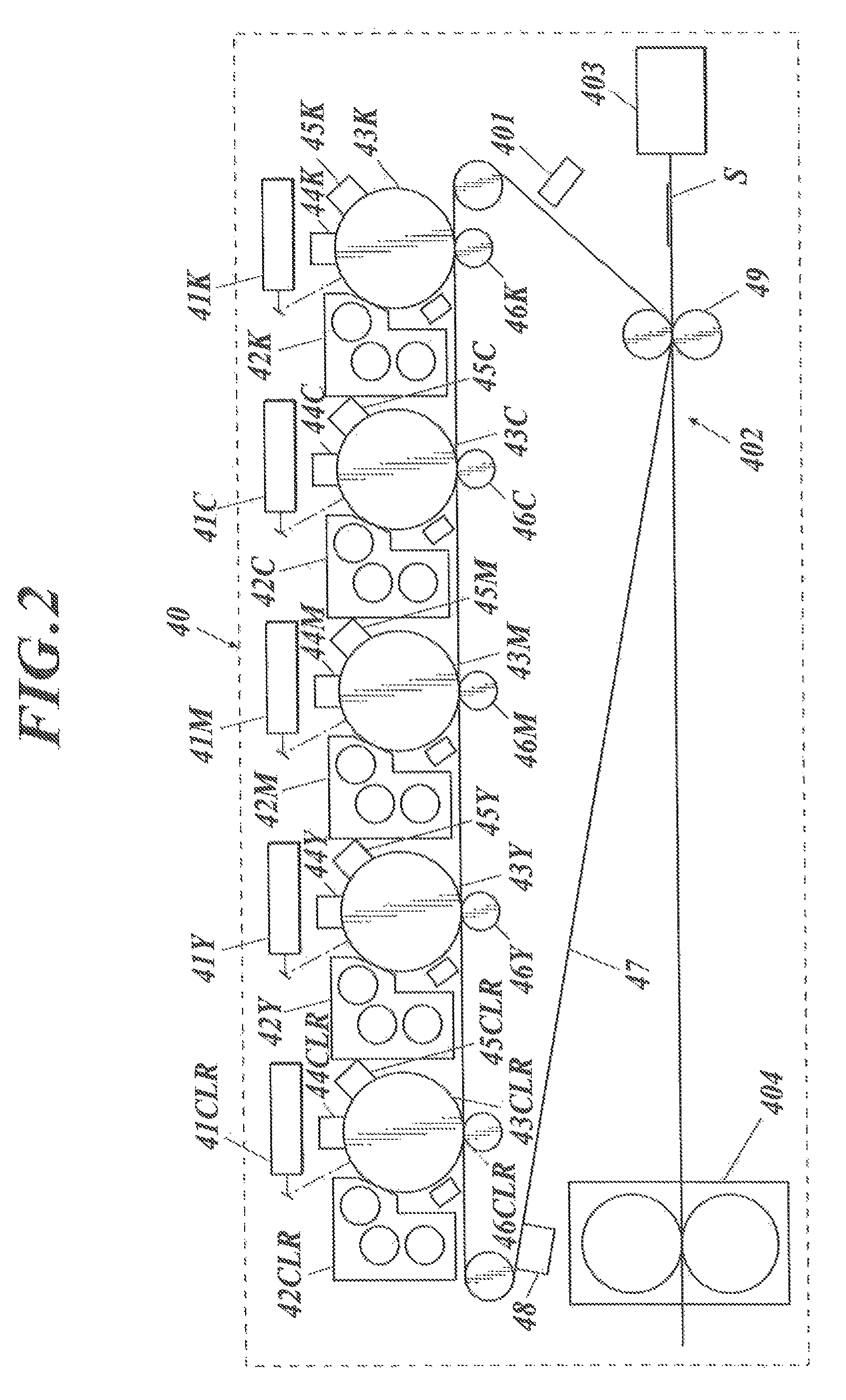

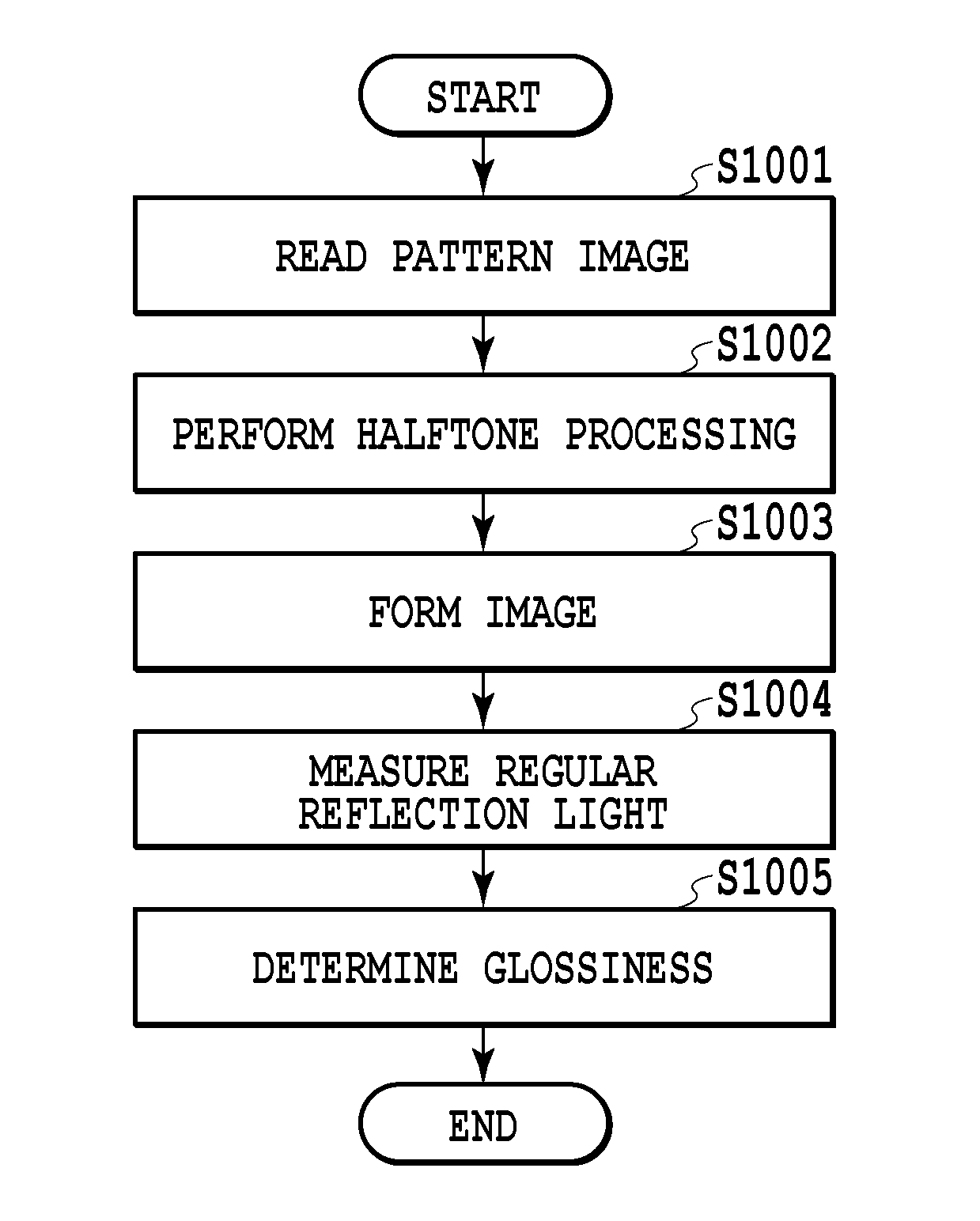

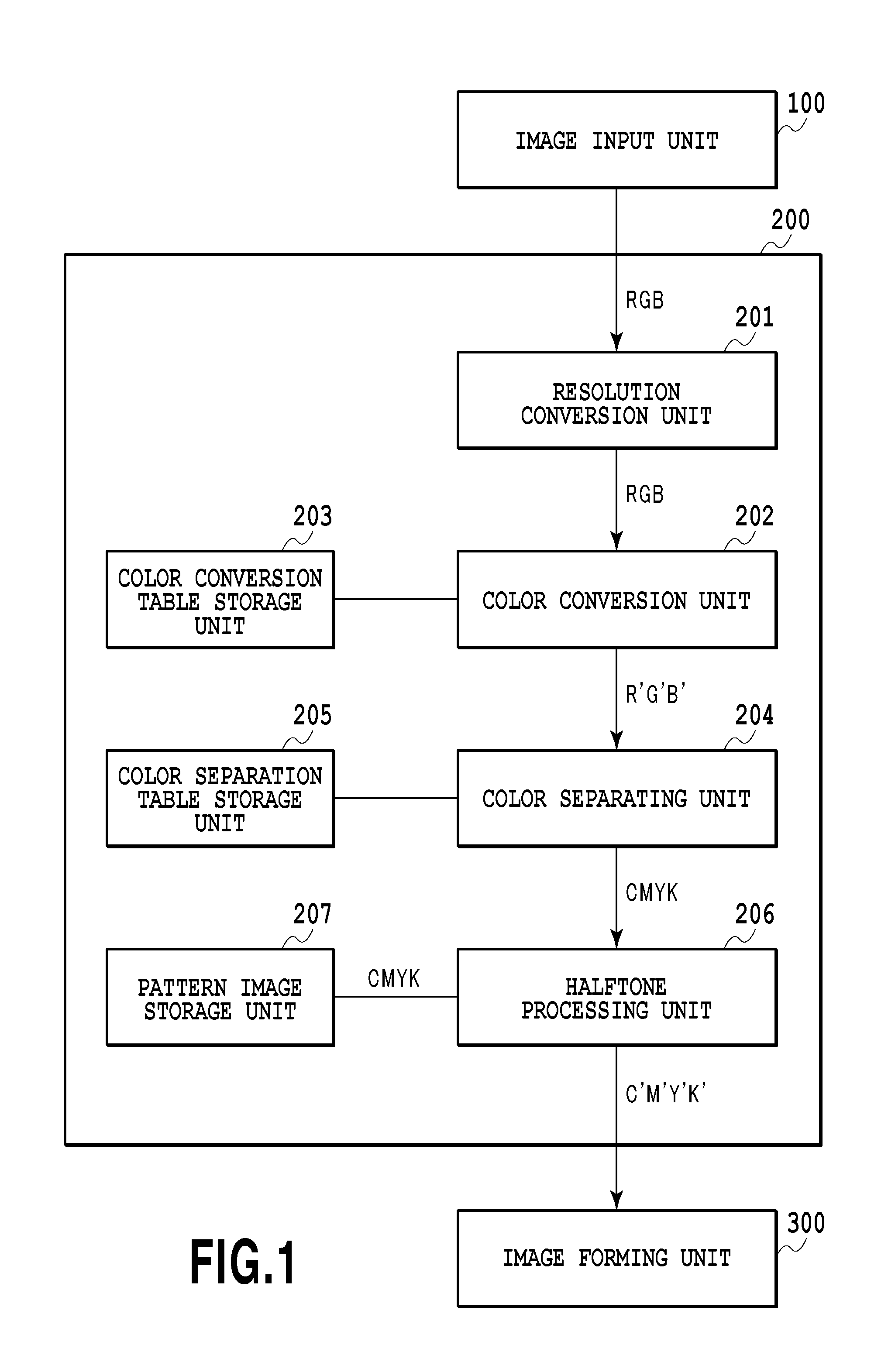

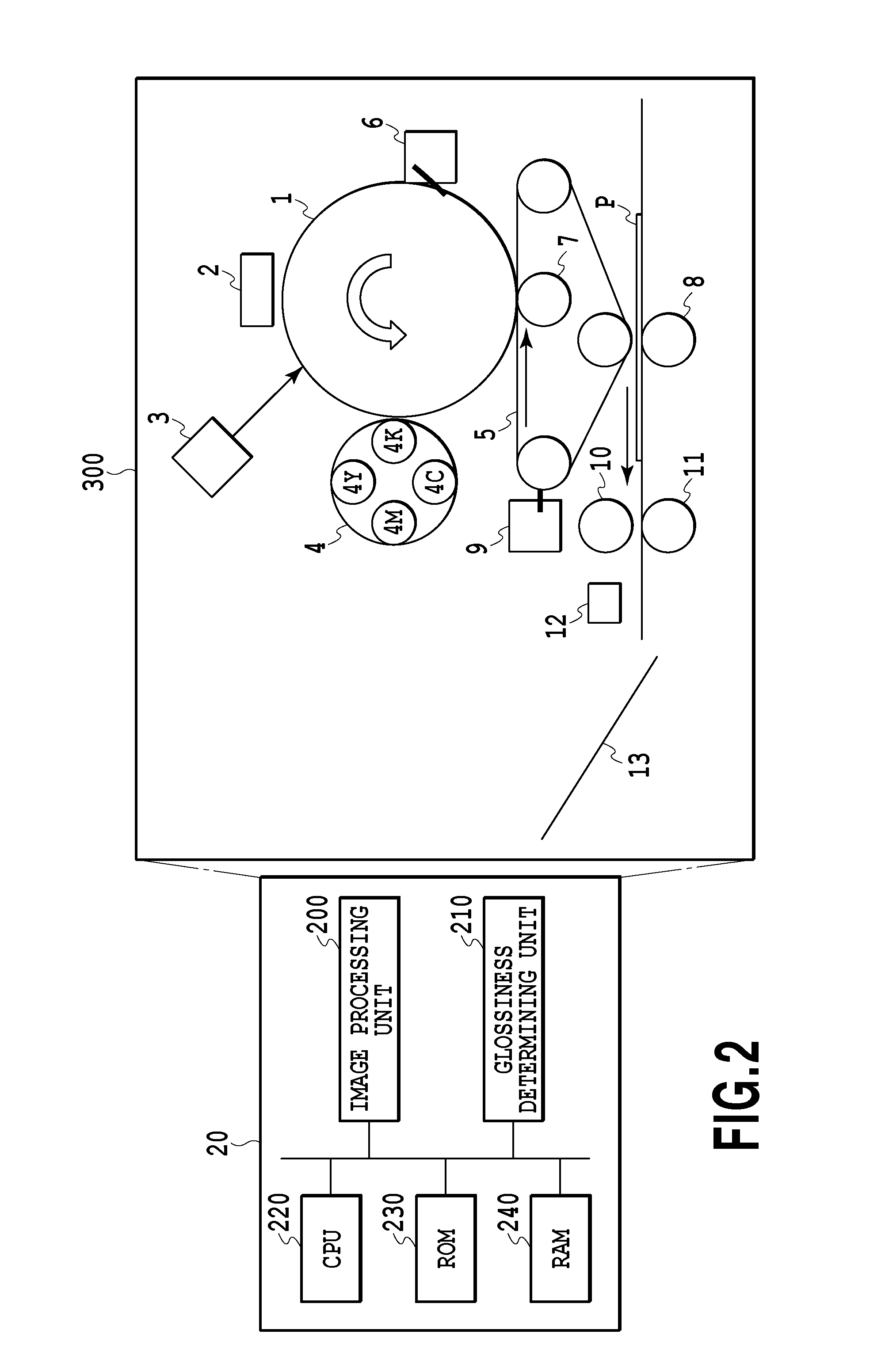

Image forming apparatus and image forming method

ActiveUS20130258367A1Gloss stableUniform glossDigitally marking record carriersDigital computer detailsImaging processingImage formation

An image forming apparatus includes an image forming unit, a storage unit, an image processing unit and a control unit. The image processing unit (i) calculates a summed height of a color toner image formed on a sheet by summing up a height of the color toner image on the basis of input image data, (ii) calculates, on the basis of a target value for glossiness stored in the storage unit, a target total height of the color toner image and a clear toner image to realize the target value for glossiness, and (iii) calculates a height of the clear toner image by subtracting the summed height from the target total height. On the basis of the calculated height of the clear toner image, the control unit adjusts the height of the clear toner image formed on the sheet.

Owner:KONICA MINOLTA BUSINESS TECH INC

Medical coating powder containing nano material

InactiveCN1616105AOvercome the defects that the quality is difficult to guarantee, etc.Simple and fast operationPharmaceutical non-active ingredientsDrageesUltimate tensile strengthMaterials science

The medicinal coating powder containing nanometer material consists of hydromellose 55-65 wt%, copolymer of vinyl pyrrolidone and vinyl acetate 8 wt%, glycerin 15 wt%, Span 8 wt%, coloring agent 2-4 wt%, and nanometer titania 2-10 wt%. The medicinal coating powder containing nanometer material has simple production process, wide application, high performance / cost ratio, no physiological toxicity and many other advantages, and may meet the requirement of coating various solid Chinese medicine preparation.

Owner:GUANGDONG GUOFANG MEDICAL TECH

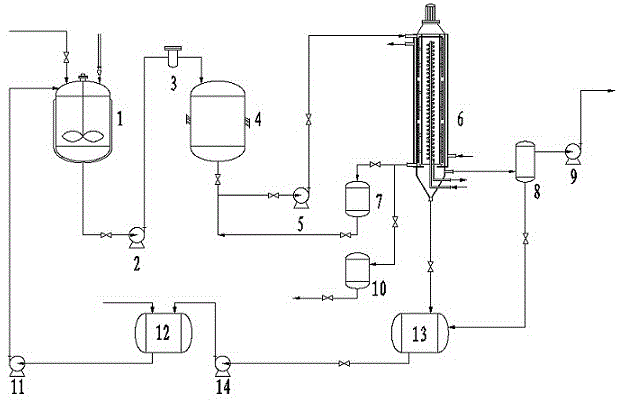

Preparation method of aliphatic diisocyanate tripolymer curing agent

InactiveCN105566239AEvenly loadedSpeed up evaporationOrganic chemistryPolyurea/polyurethane coatingsMonomerPolymerization

The invention discloses a preparation method of an aliphatic diisocyanate tripolymer curing agent. The preparation method is characterized by comprising the following steps of adding aliphatic diisocyanate monomers into a reactor under the protection of inert gas; adding homemade trimerization catalysts for performing self-polymerization to generate aliphatic diisocyanate tripolymers; adding terminating agents to terminate the reaction after the proper conversion rate is reached; filtering and collecting clear filtering liquid to be used as raw products; using a short-process evaporator to perform twice separation on the crude product; recovering and reusing unreacted free monomers, wherein the content of the free monomers in the separated aliphatic diisocyanate tripolymers is reduced to be lower than 0.4 percent. The aliphatic diisocyanate tripolymers prepared by the preparation method can be prepared into super fast-drying paint; good anti-yellowing performance is realized; the aliphatic diisocyanate tripolymers can be widely applied to high-grade paint.

Owner:QINGDAO UNIV OF SCI & TECH +2

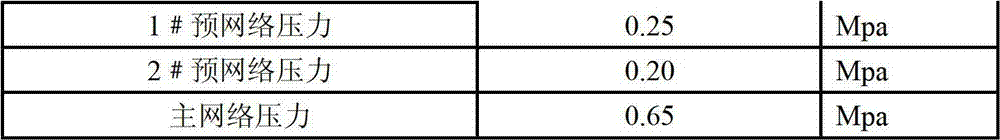

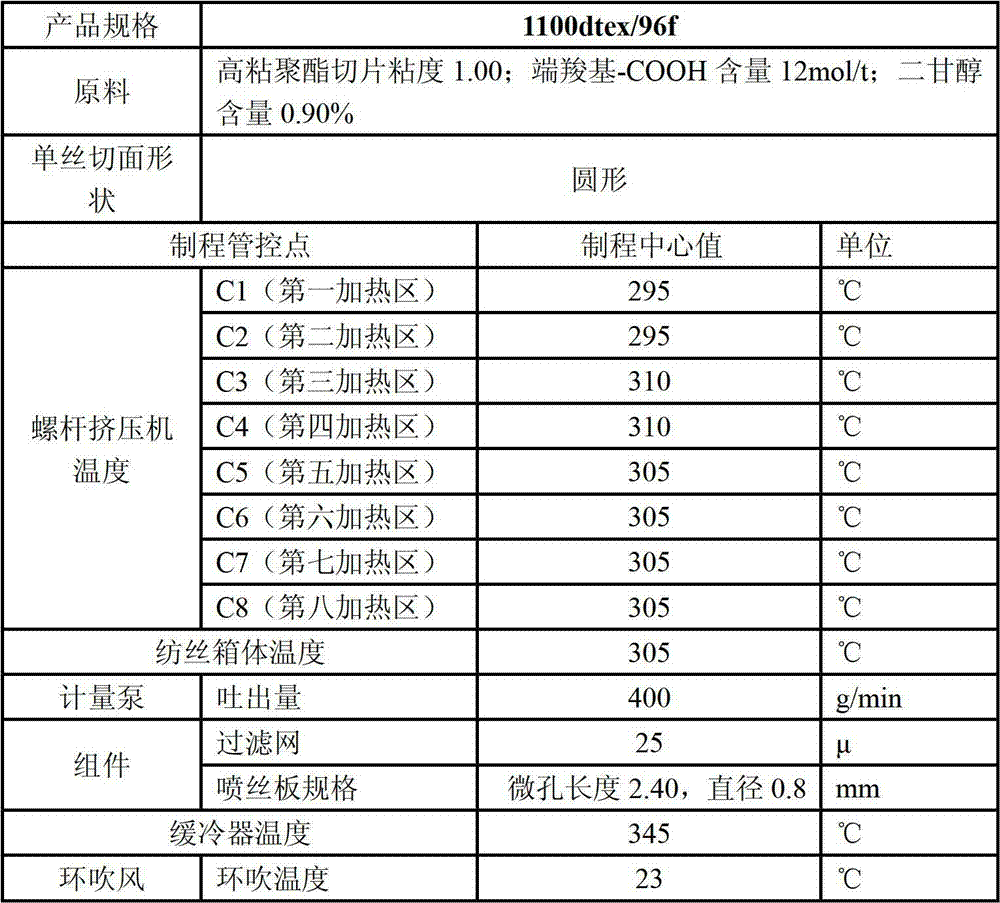

Industrial polyester filament for high-strength ultra-low-elongation safety belt and production method of industrial polyester filament

ActiveCN102808230AImprove weaving efficiencyImprove wear resistanceFilament forming substance formingNew-spun product collectionEngineeringImpurity

The invention relates to an industrial polyester filament for a high-strength ultra-low-elongation safety belt and a production method of the industrial polyester filament. The production method comprises the following steps of: A) high-viscosity polyester chip preparation; B) high-viscosity polyester chip impurity removal; C) melt spinning; and D) drafting, heat setting and winding. The number of the industrial polyester filaments produced by adopting the method is 72-144F, the fineness is 1100-2222dtex, the breaking strength can reach more than 7.80cN / dtex, the fixed-load elongation can reach 4-6 percent under a condition of 11.1KN and the controllable oil content is lower than 0.30-0.60 percent. The industrial polyester filament for the high-strength ultra-low-elongation safety belt and the production method of the industrial polyester filament have the beneficial effects that the breaking strength of the safety belt which is provided by using the obtained industrial polyester filaments can reach 35KN and is much higher than the breaking strength being 28-33KN of the existing safety belt, the physical and mechanical performance is good and the industrial polyester filament is an optimum raw material for producing front-row safety belts; the weaving performance is good, the dyeing uniformity of the safety belt is good due to lower fiber oil content, the gloss is stable, and chromatic aberration and stains do not exist; the waste polyester fibers can be recycled, the energy is saved, the environment is protected and the operating cost is reduced; and the operation is simple to conduct, the process flow is short, the automation level is high and the development space is very great.

Owner:ORIENTAL IND SUZHOU

Method of yarn-bundle-shape continuous back-flow silkete

InactiveCN101525826AImprove labor productivityWater saving is obviousMercerising of yarns/threads/filamentsYarnSewage

The invention relates to a method of yarn bundle-shape continuous back-flow silkete, which includes the following steps: 200 to 1000 billet yarns are combined into a yarn bundle, and 1 to 36 yarn bundles are arranged for parallel running; the 1 to 36 yarn bundles continuously run on a silkete machine set and sequentially pass through an immersing and rolling alkali tank 1, a ventilating drum 1, an immersing and rolling alkali tank 2, a ventilating drum 2, an alkali-removing steam box, an alkali-removing eluting tank, a water scrubbing tank 1 and a water scrubbing tank 2 to fall into a yarn container in a wet-yarn type. The method of yarn-bundle-shape continuous back-flow silkete realizes the continuous production of yarn silkete, reduces sewage discharging amount, has the yarn-bundle running of the yarn, high production efficiency, uniform silkete quality and high yarn utilizing rate, enables the yarn silkete to be the normal preprocessing technology, and is helpful for improving the product grade of yarn dyed fabric and knitted fabric.

Owner:DONGHUA UNIV

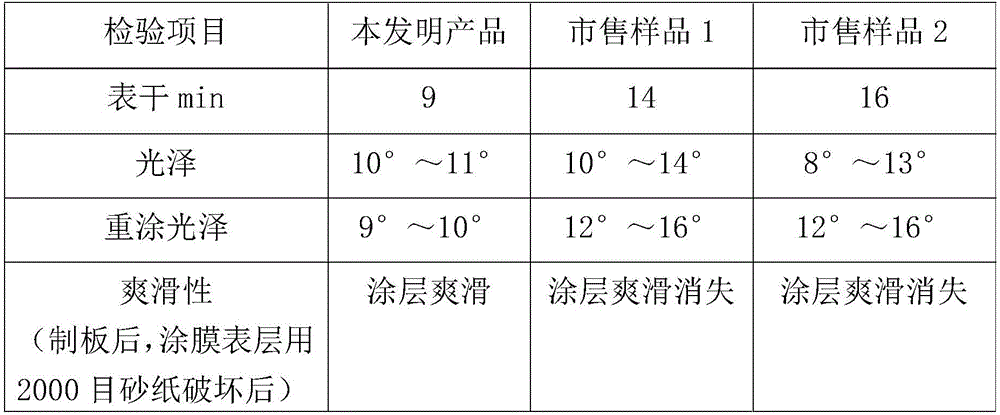

High abrasion-resistance ultraviolet (UV) matte coating capable of recoating, preparation method thereof and appliance

ActiveCN105419621AGood construction performanceTo solve the requirement of high wear resistancePolyurea/polyurethane coatingsWaxAcrylic resin

The invention provides a high abrasion-resistance ultraviolet (UV) matte coating capable of recoating. The coating is characterized by being prepared from, by mass, 30%-50% of prepolymer, 20%-40% of matte prepolymer, 1%-10% of thermoplastic acrylic resin, 1%-8% of photoinitiator, 1%-15% of flatting wax, 1%-10% of pearl powder, 0-10% of transparent color paste, 0.1-1% of flatting agent, 0-1% of dispersant and 10%-20% of solvent. The high abrasion-resistance UV matte coating capable of recoating is excellent in construction performance, excellent in hardness and adhesive force and excellent in abrasive resistance by matching and adjusting the types and contents of different polymers in the formula.

Owner:JIANGMEN LING YUN PAINT CO LTD

Waterborne UV-curable matt paint

InactiveCN106675275AHigh hardnessTo achieve the surface effectPolyurea/polyurethane coatingsWater basedSilicon dioxide

The invention discloses waterborne UV-curable matt paint for furniture. Raw materials of the paint are composed of the following ingredients (by weight): 30-50% of a polyurethane acrylate emulsion, 20-40% of a self-drying acrylate emulsion, 5-10% of purified water, 5-10% of water-based color paste, 1-5% of white carbon black fumed silica, 3-5% of a photoinitiator and 1-3% of an auxiliary agent. According to a common paint preparation method used by a technicist in the field, the above materials are made into a spraying waterborne UV-curable matt paint. The paint is automatically sprayed by equipment or manually onto a base material. Therefore, VOC emission can be greatly reduced and production efficiency can be enhanced. By infrared curing and then UV light curing, excellent leveling property can be obtained, and surface effect of PU paint and hardness and scratch resistance of UV can be achieved.

Owner:HUIZHOU CHANGRUNFA PAINT

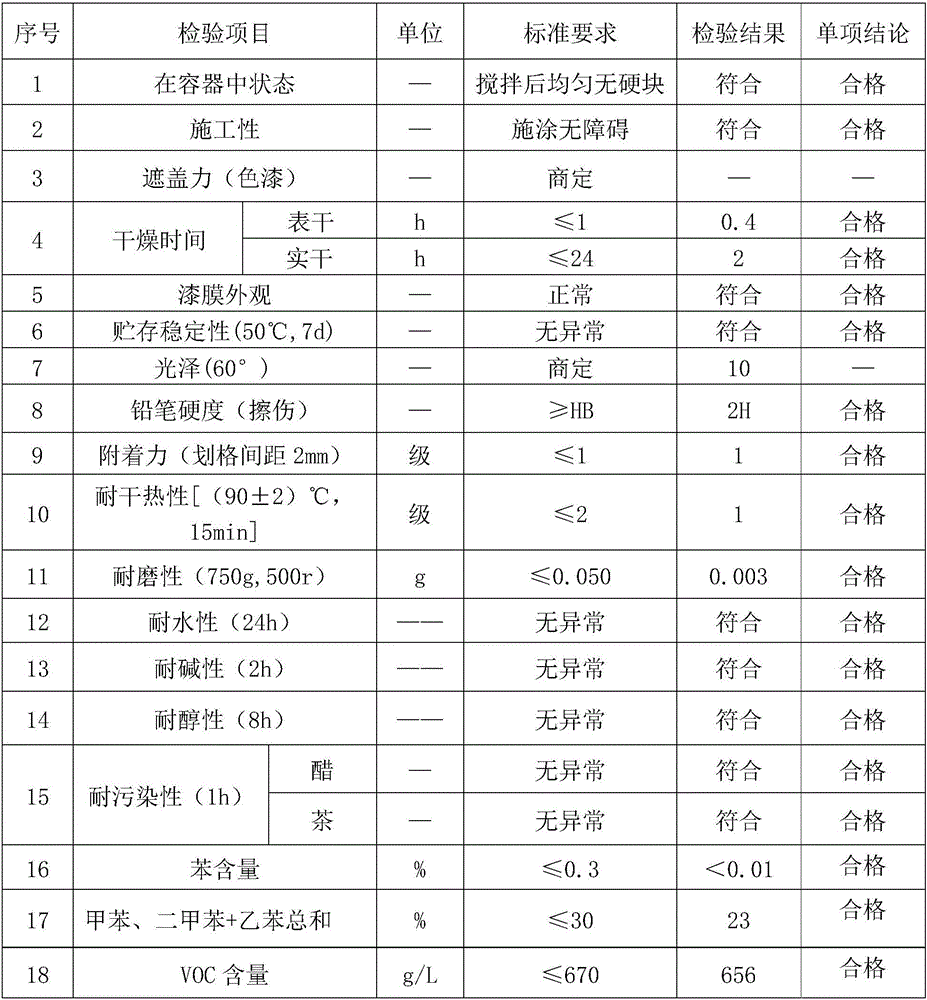

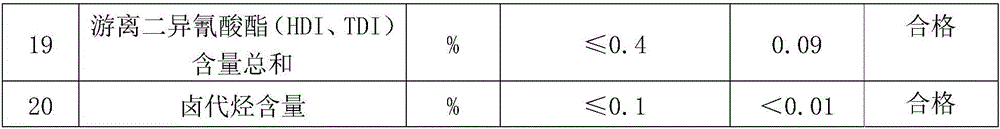

PU matte white finish stable in gloss and permanently smooth and preparation method thereof

The invention provides PU matte white finish stable in gloss and permanently smooth and a preparation method thereof. The PU matte white finish is prepared in the steps that white paste with the solid content being 60%, short oil alkyd resin, PE matting wax slurry, 6900-20X anti-sediment wax, anti-sediment slurry, wetting dispersant, a flatting agent, a defoaming agent, MIBK, vinyl chloride-vinyl acetate resin solution with the solid content being 20%, ED-30 matt powder, polytetrafluoroethylene wax powder and the like are prepared from a first component; a 1451 light trimer curing agent, a TDI additive product curing agent, an HDI trimer curing agent, MIBK, MEK and n-butyl acetate are prepared into a second component; methylbenzene, n-butyl acetate, acetic ether, MEK and propylene glycol methyl ether acetate are prepared into a third component; the first component, the second component and the third component are evenly mixed according to the proportion. Detection and trial prove that a paint film obtained after the PU matte white finish is sprayed is good in leveling property and high in sagging resistance, dazzled does not happen if the white finish is coated thin, the white finish can be kept permanently smooth, gloss is stable, and the PU matte white finish is suitable for coating of high-furniture and other wood products.

Owner:GUANGDONG BADESE CHEM

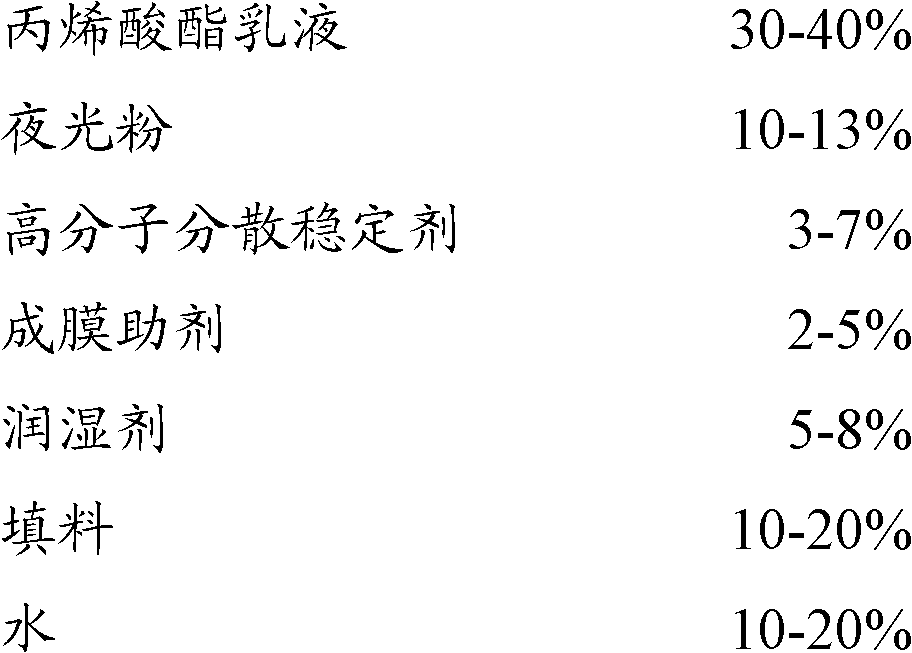

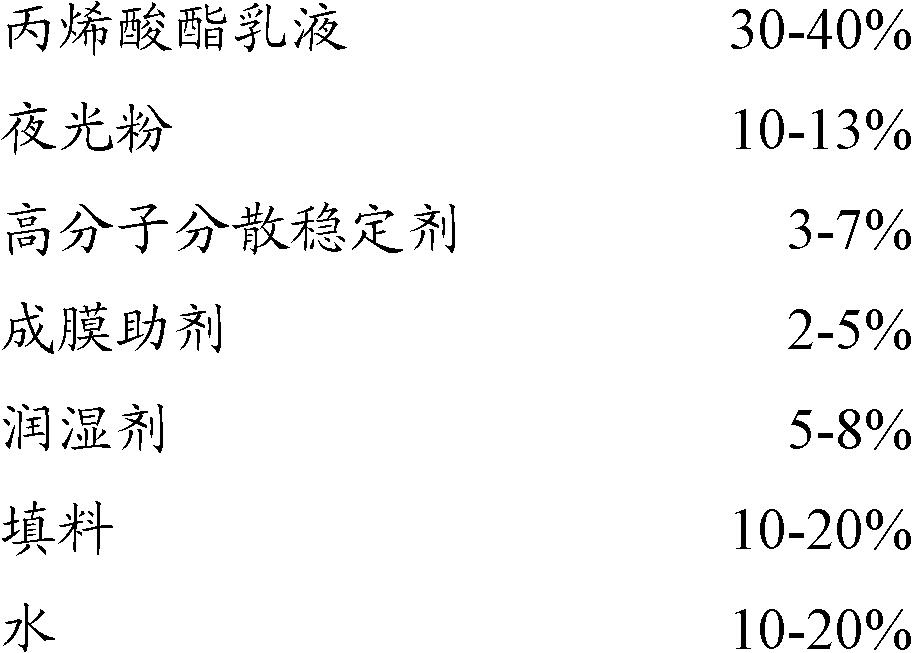

Long-acting type noctilucent propylene decoration pigment

ActiveCN102618124AGloss stableStable mechanical propertiesPigment pastesRare earthMechanical property

The invention provides a long-acting type noctilucent propylene decoration pigment which comprises the following components: 30-40% of acrylate emulsion, 10-13% of noctilucent powder, 3-7% of polyacrylate high polymer dispersion stabilizer, 2-5% of film-forming agent, 5-8% of wetting agent, 10-20% of filler and 10-20% of water. Rare earth luminescent material with long-acting storage luminous effect is added to propylene pigment and an high polymer dispersing agent is added for performing coating treatment, thus overcoming the defect of poor storage stability; the obtained noctilucent propylene decoration pigment can be released for a long time without light attenuation; furthermore, the pigment can be stably stored for a long time, and is long-lasting and stable in gloss and mechanical property.

Owner:贝碧欧美术颜料(昆山)有限公司

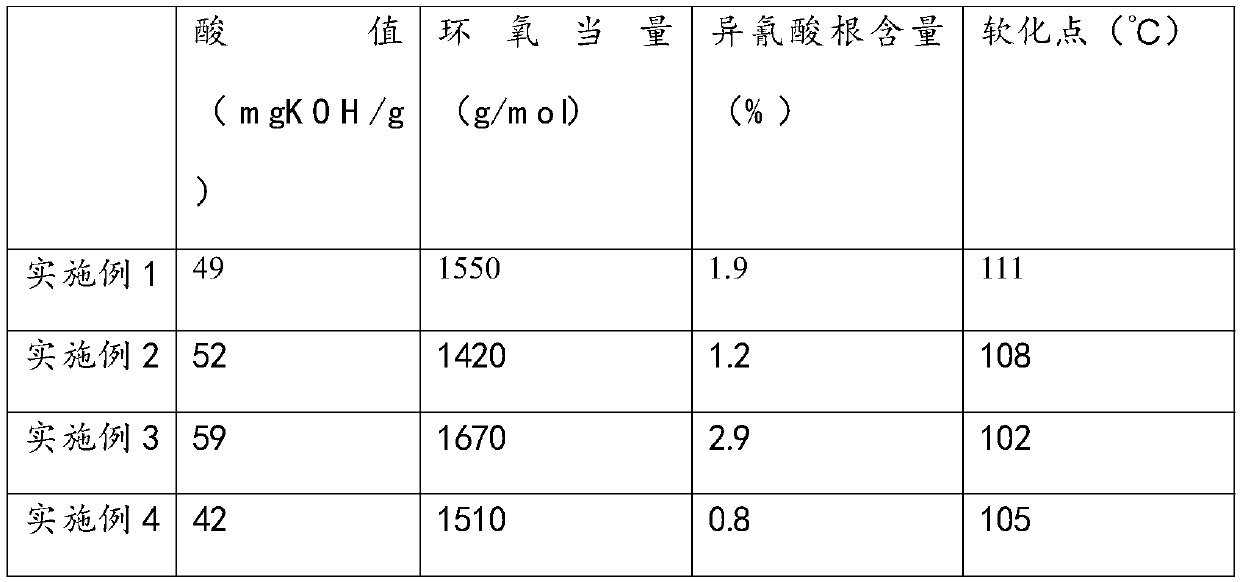

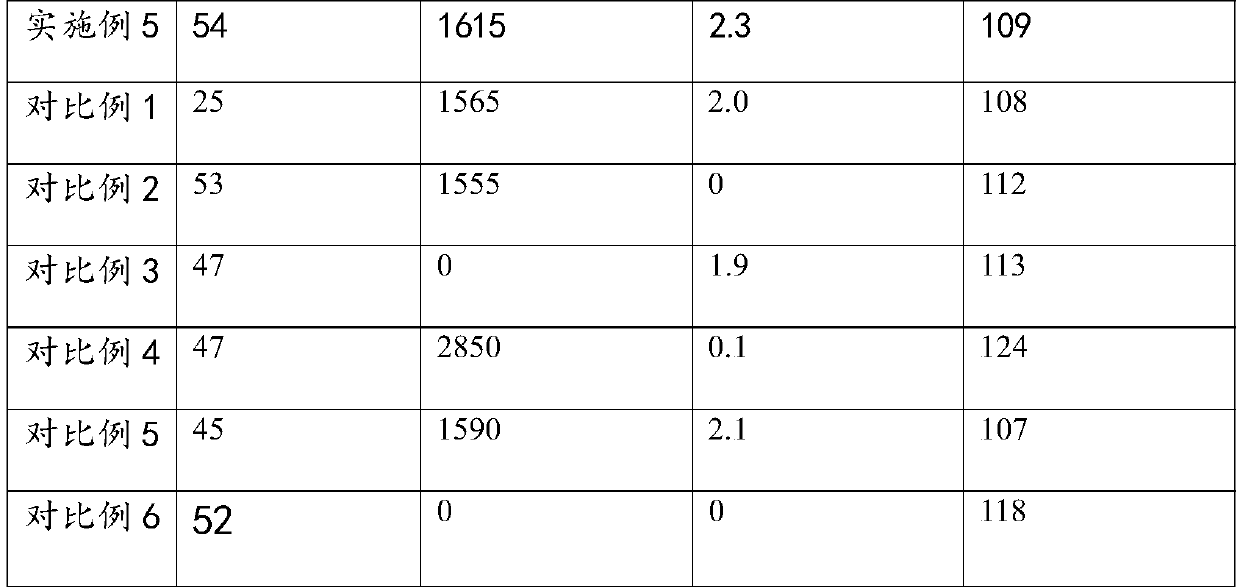

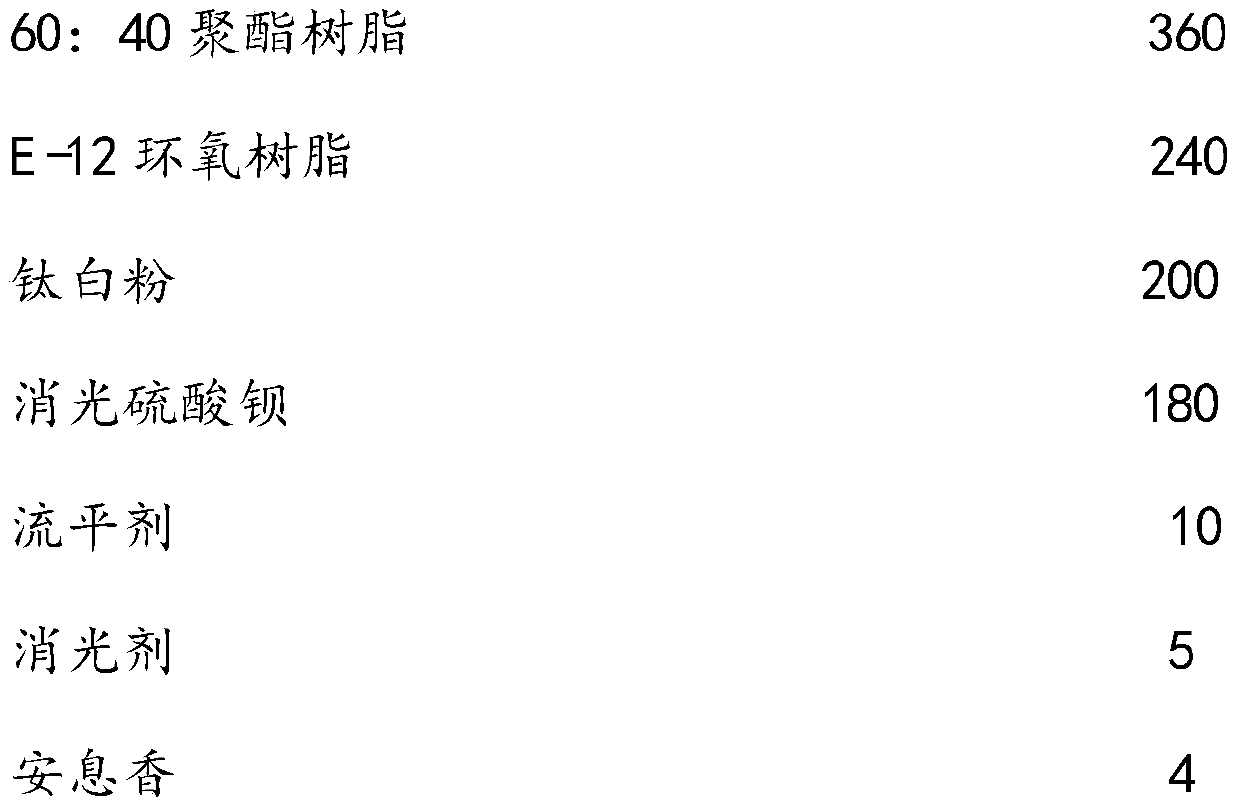

60/40 low-gloss polyester resin for powdery coating, and three-kettle combined preparation method thereof

ActiveCN110655644AGloss stableAvoid the problem of uneven physical mixingPolyurea/polyurethane coatingsPowdery paintsEpoxyPolymer science

The invention belongs to the technical field of coatings, particularly relates to a 60 / 40 low-gloss polyester resin for a powdery coating, and further relates to a three-kettle combined preparation method of the polyester resin. The main raw materials of the polyester resin mainly comprise ethyl 2,2'-dipyridine-4,4'-dicarboxylate, terephthalic acid, trimesic acid, 3-nitrophthalic anhydride, adipicacid, neopentyl glycol, 3,7-dimethyl-1,7-octanediol, 1,4-di(hydroxymethyl)cyclohexane, pentaerythritol, diethylene glycol, toluene diisocynate and diglycidyl terephthalate. Three polyester products with different end group structures are respectively prepared by combining three kettles, and then are uniformly melt-blended lately to obtain the uniformly-dispersed mixed 60 / 40 polyester resin product. The powdery coating is prepared from the finally obtained polyester resin, is matched with a small amount of a delustering agent, and then is cured with an E-12 epoxy resin to stably obtain a filmwith the gloss of below 10%.

Owner:黄山市向荣新材料有限公司

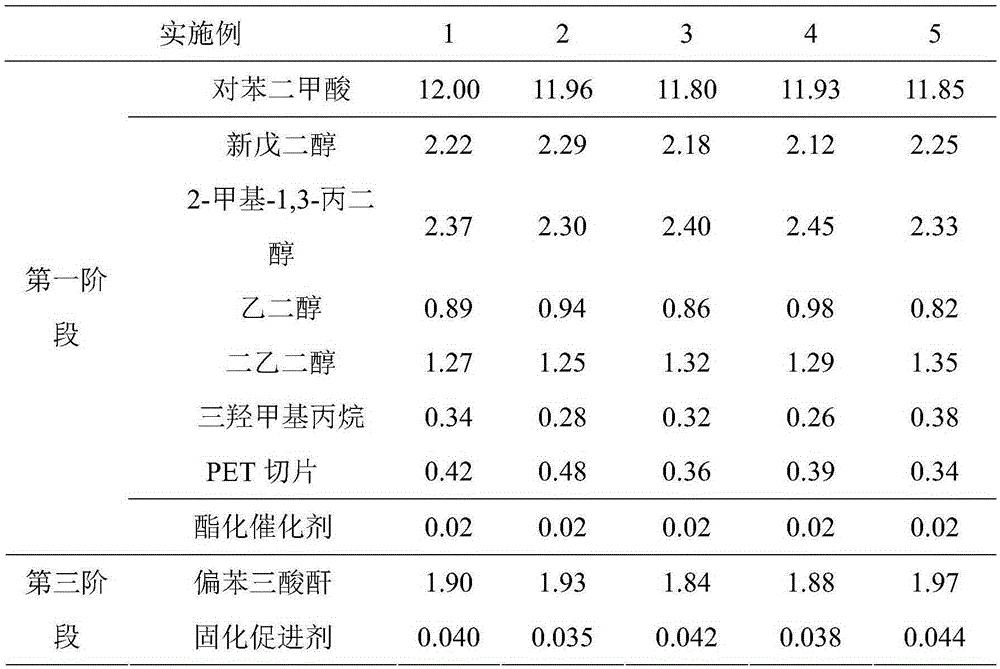

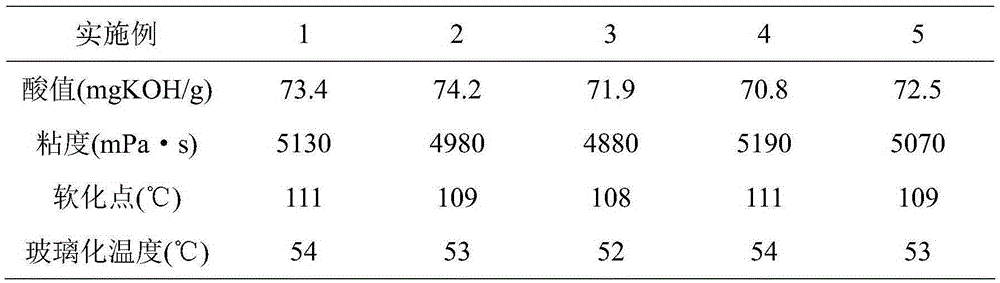

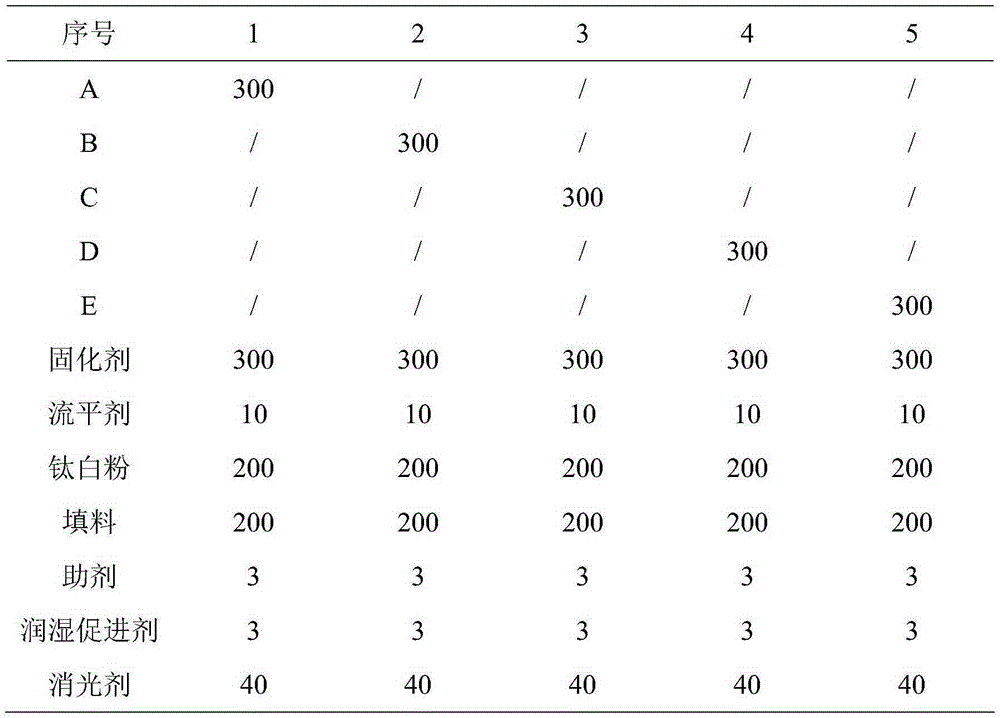

Mixed polyester resin and preparation method and powder coating thereof

ActiveCN105254863AExcellent overall performance of the coatingGloss stablePowdery paintsPolyester coatingsChemistryHybrid type

The invention discloses a mixed polyester resin and a preparation method and a powder coating thereof. The raw components of the resin and the parts by weight thereof are as follows: 8.75 to 9.5 parts of alcohol, 11.5 to 12.5 parts of acid, 0.25 to 0.5 part of PET (polyester) chips, 0.02 part of esterification catalyst, 1.8 to 2.0 parts of trimellitic anhydride and 0.03 to 0.05 part of curing accelerator. The invention utilizes renewable resource degradation to produce the polyester resin, so the mixed polyester resin is economic and environment-friendly; the comprehensive property of coatings is good, the mixed polyester resin can be perfectly applied in the flatting powder coating, the gloss is stable, leveling is excellent, and the panel is clear and full.

Owner:ANHUI SHENJIAN NEW MATERIALS

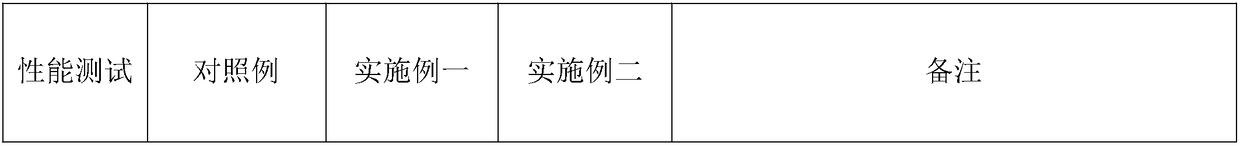

Flatting modification technology of edge band surface UV curable varnish

InactiveCN108285542AGloss stableImprove qualityPolyurea/polyurethane coatingsEpoxy resin coatingsUV curingUltraviolet lights

The invention discloses a flatting modification technology of edge band surface UV curable varnish. The flatting modification technology comprises the following steps that the UV curable varnish is printed on the surfaces of base materials; N2 is introduced into curing equipment to exhaust air; the base materials pass through short-wave and long-wave UV curing equipment at certain speed in sequence. In an existing edge band surface low-glossiness modification method, a flatting agent is added into the UV curable varnish so that the flatting agent can be distributed on the surface of the paintfilm formed by the UV curable varnish after the paint film is cured and shrunken, reflection of incident rays is reduced to achieve the flatting effect, however, the glossiness of the formed paint film is not uniform, and the uniform flatting pain film cannot be formed. Besides, the addition of the flatting agent easily lowers the curing speed, the surface hardness and the wear resistance of the curable varnish, the touch feeling of the paint film is not obvious, and the requirement of a client for high-quality low-glossiness paint film cannot be met. By means of the flatting modification technology of the edge band surface UV curable varnish, low-transmission ultraviolet light and long-wave ultraviolet light are adopted in sequence to irradiate the UV curable varnish, the paint film withwrinkling skin layers is formed, and the problems are effectively solved that the flatting paint film is instable in glossiness, and low in hardness and wear resistance.

Owner:DONGGUAN HUALI INDUSTRIES CO LTD

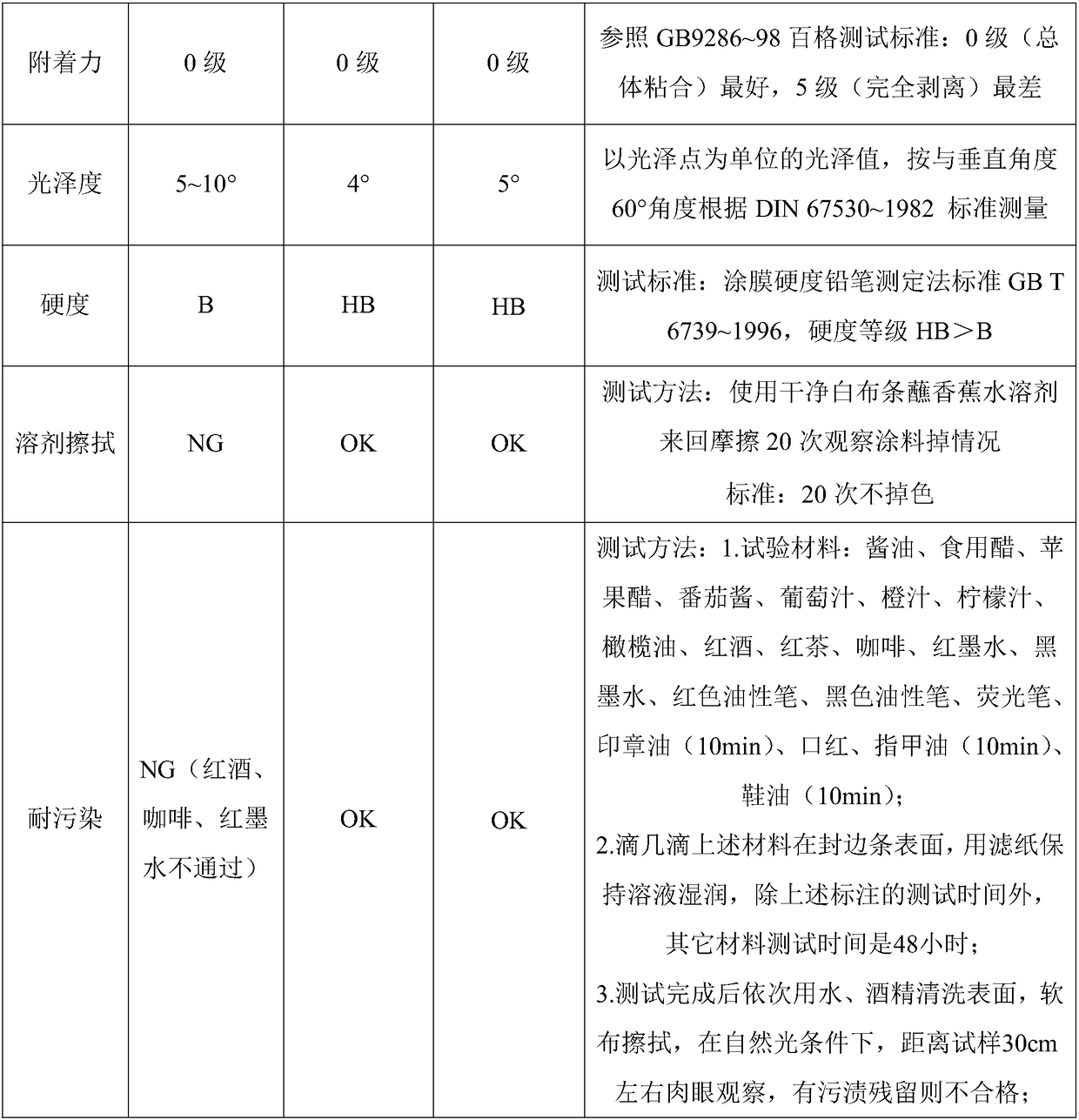

Special antimicrobial-function environment-friendly matte finish paint for children and preparation method thereof

ActiveCN104087140AImprove performanceGood quality coatingAntifouling/underwater paintsPaints with biocidesEnvironmental resistancePhysical well being

The invention particularly relates to a special antimicrobial-function environment-friendly matte finish paint for children and a preparation method thereof. A main paint of the finish paint is prepared from the following raw materials in parts by weight: 40-70 parts of synthetic fatty acid resin, 10-20 parts of coconut oil modified alkyd resin, 10-30 parts of aldehyde ketone resin solution with the solid content of 60-80%, 0.1-1 part of defoamer, 0.5-2 parts of leveling agent, 0.2-1 part of humectant, 1-9 parts of matting agent, 0.5-2 parts of wax powder, 0.5-1 part of high-oxidation-state nano silver ion solution, 0.1-0.3 part of drier and 5-15 parts of environment-friendly mixed solvent. The paint is environment-friendly and healthy, avoids the generation of substances which are harmful to good health of children, can form an antibacterial-function coating on the surface of the coated substance, and prevents secondary pollution. Besides, the paint can be directly used on a wood substrate, can not generate the phenomena of shrinkage and sinking of the paint film, and has the advantages of favorable hardness, favorable wear resistance and the like.

Owner:SKSHU PAINT

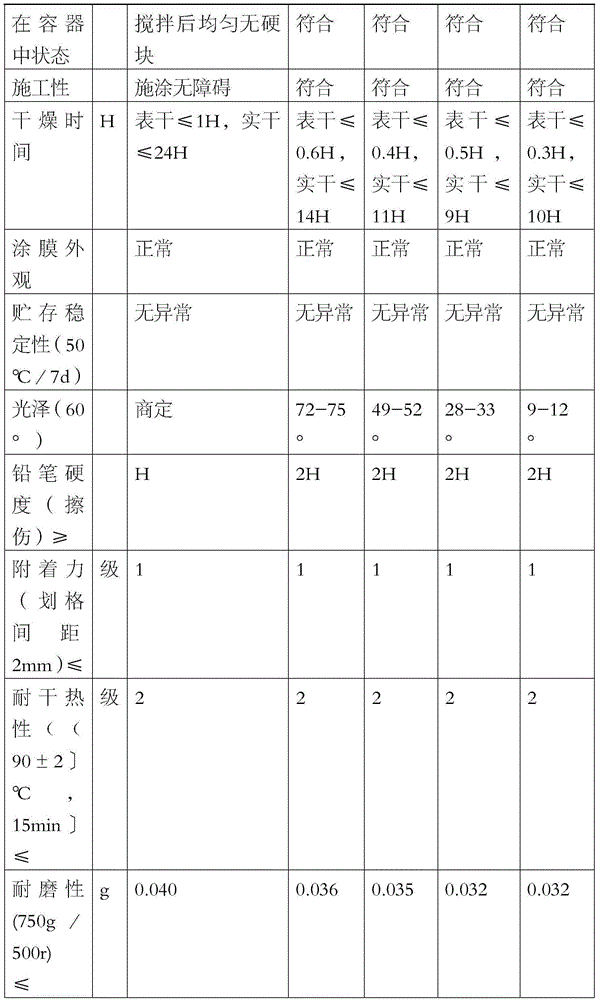

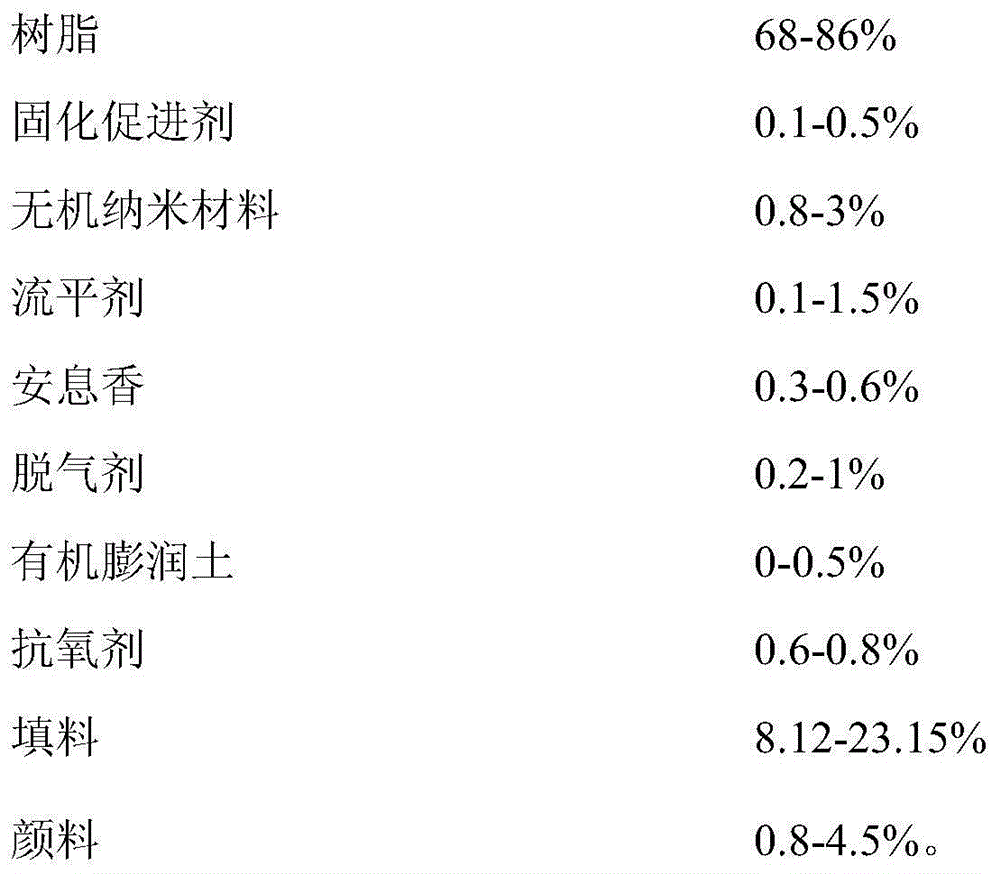

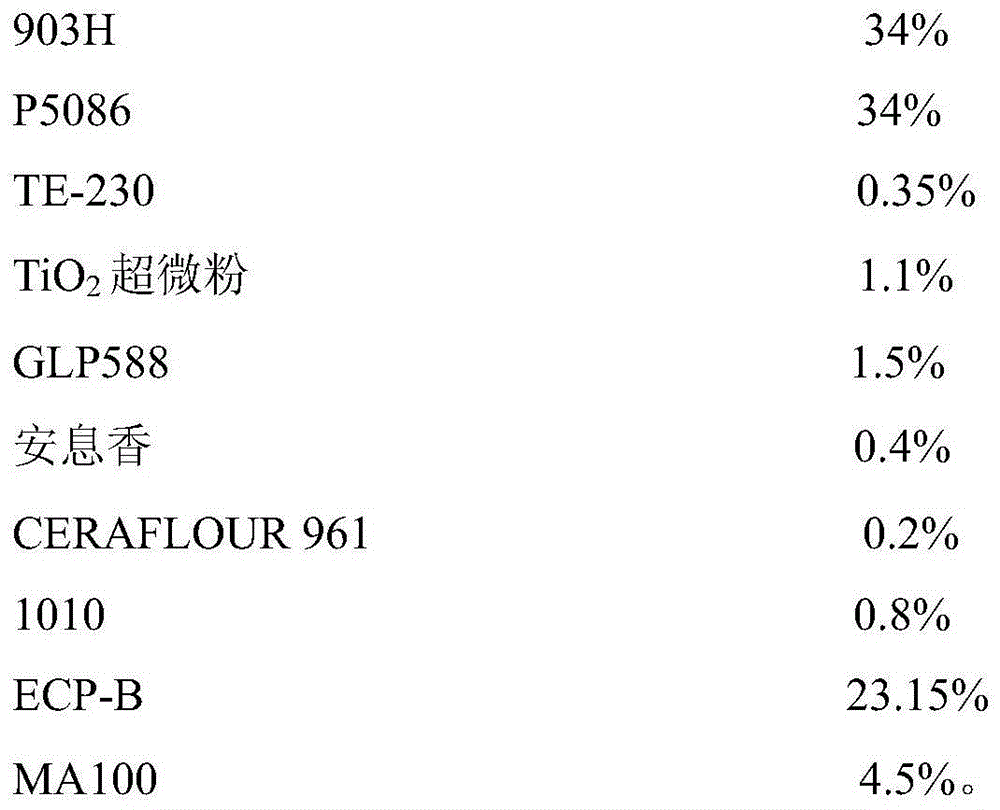

High-performance corona-resistant powder coating for varnished wire and preparation method and application thereof

PendingCN104946088AGloss stableSimple recipeEpoxy resin coatingsPolyester coatingsAntioxidantMechanical property

The invention belongs to the technical field of powder coating, and particularly relates to a high-performance corona-resistant powder coating for a varnished wire and a preparation method and application thereof. The high-performance corona-resistant powder coating for the varnished wire is made of the following raw materials of 68 to 86 % of resin, 0.1 to 0.5 % of solidification promoting agent, 0.8 to 3 % of inorganic nano-materials, 0.1 to 1.5 % of flatting agent, 0.3 to 0.6 % of benzoin, 0.2 to 1 % of degassing agent, 0 to 0.5 % of organic bentonite, 0.6 to 0.8 % of antioxidant, 8.12 to 23.15 % of filler and 0.8 to 4.5 % of pigment. The high-performance corona-resistant powder coating for the varnished wire has the advantages of being simple in formula, stable in coating gloss, good in oil resistance and adhesive force, good in outdoor durability and the like, the mechanical property of the high-performance corona-resistant powder coating for the varnished wire is better than that of a traditional paint-type varnished wire, and the high-performance corona-resistant powder coating for the varnished wire is environmentally friendly and free from pollution.

Owner:山东朗法博粉末涂装科技有限公司

Safe and environment-friendly semi-matte varnish for automobile interior trim part and preparation method thereof

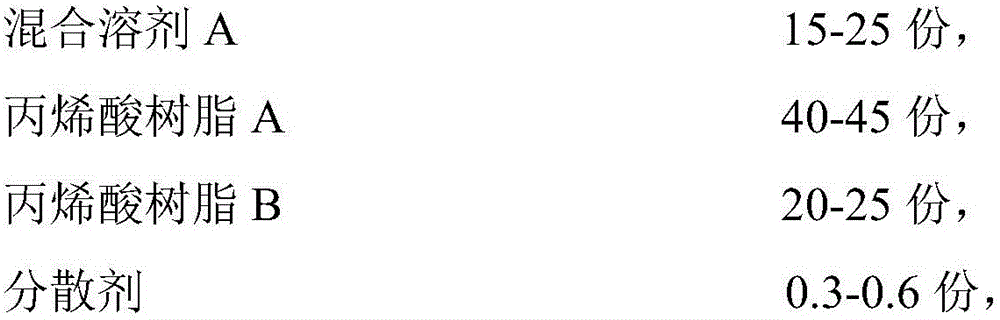

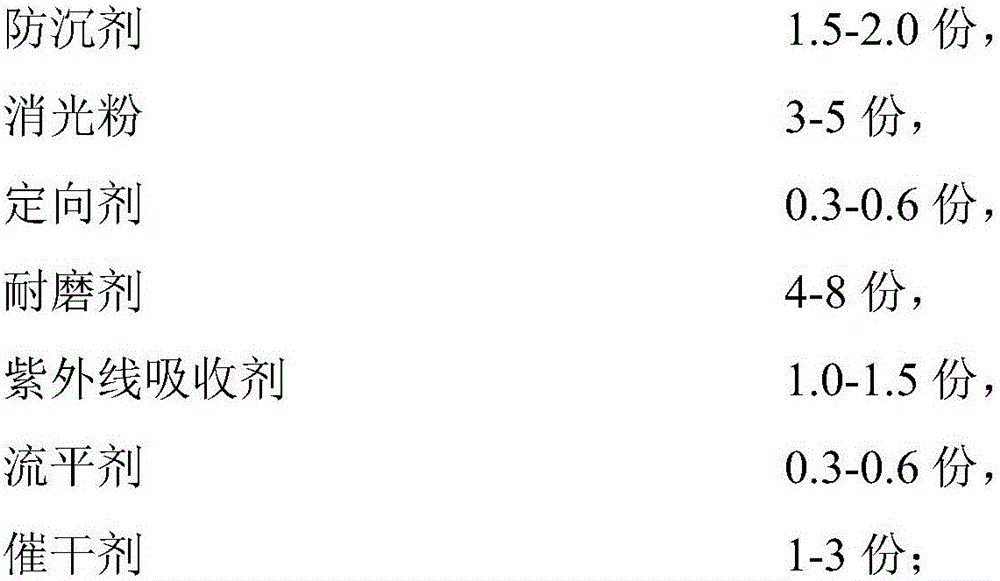

The invention relates to safe and environment-friendly semi-matte varnish for an automobile interior trim part and a preparation method thereof. The varnish comprises the following ingredients in parts by weight: 200 to 300 parts of a precursor solution A and 80 to 120 parts of a precursor solution B, wherein the precursor solution A comprises the following ingredients in parts by weight: 15 to 25 parts of a mixed solvent A, 40 to 45 parts of acrylic resin A, 20 to 25 parts of acrylic resin B, 0.3 to 0.6 part of dispersing agents, 1.5 to 2.0 parts of anti-settling agents, 3 to 5 parts of extinction powder, 0.3 to 0.6 part of orientation agents, 4 to 8 parts of wear-resistant agents, 1.0 to 1.5 parts of ultraviolet light absorbers, 0.3 to 0.6 part of flatting agents and 1 to 3 parts of drier; the precursor solution B comprises the following ingredients in parts by weight: 45 to 55 parts of curing agents and 45 to 55 parts of a solvent B. During the preparation, mixing, stirring and grinding are performed to obtain the precursor solution A; then, the precursor solution B is prepared through mixing and stirring; then, the precursor solution A and the precursor solution B are mixed. Compared with the prior art, the safe and environment-friendly semi-matte varnish has the advantages that the scratch resistance, wear resistance and chemical corrosion resistance are realized; the luster is stable; the comfort durability and decoration attractive appearance are realized; safety and environment-friendly effects are realized; the production and the use are easy.

Owner:DONGLAI COATING TECH SHANGHAI

Composite board and surface finish method thereof

InactiveCN103372527AHigh hardnessEnvironmental performancePretreated surfacesCoatingsWater basedCoated surface

The invention provides a composite board and a surface finish method thereof, and belongs to the technical field of composite boards. The problem that an existing composite board surface finish technology cannot meet requirements on environmental protection, hardness and glossiness simultaneously is solved. The surface finish method of the composite board includes the steps: (1) spraying low-temperature cured powder on the composite board, and then baking and curing; (2) spraying water-based radiation cured coatings on the composite board, and then baking prior to curing. The finish method is environmentally friendly and free of pollution, and an obtained coating is high in surface hardness (can be more than 2H) and has optional stable glossiness (can be more than 95 degrees or less than 15 degrees). The surface of the composite board is finished via the method.

Owner:伍明

Image forming apparatus and image forming method

ActiveUS8804194B2Gloss stableUniform glossDigitally marking record carriersDigital computer detailsImaging processingImage formation

Owner:KONICA MINOLTA BUSINESS TECH INC

Saffron amino acid soap and preparation method thereof

ActiveCN109810812APromote blood circulationRegulate liver and kidney functionSurface-active non-soap compounds and soap mixture detergentsSkin careSODIUM COCOYL GLUTAMATECorrosion

The invention relates to a saffron amino acid soap and a preparation method thereof. According to the saffron amino acid soap of the invention, sodium cocoyl glutamate is used as a substrate, variousplant extracts are added and mixed after heating, demoulding is performed, and the saffron amino acid soap with efficacy of repairing, moisturizing, beautifying, diminishing inflammation and resistingaging is obtained. Saffron, gold foil, and an amino acid soap are well integrated, and effective ingredients in the saffron are evenly dissolved in a soap base, so that the effective ingredients of the saffron are effectively brought into full play, the efficacy of the saffron is greatly improved, the reaction efficiency is high, the reaction time is short, the reaction is complete, and the dissolution rate of crocin is high; with the addition of the gold foil, stable gloss, oxidation resistance, moisture resistance, corrosion resistance and mildew resistance of the soap are achieved; after long time use, metabolism of the skin is promoted, the skin is smooth and exquisite and maintains vitality of youth; the expiration date of the saffron amino acid soap of the invention is prolonged.

Owner:上海邑埠国际贸易有限公司

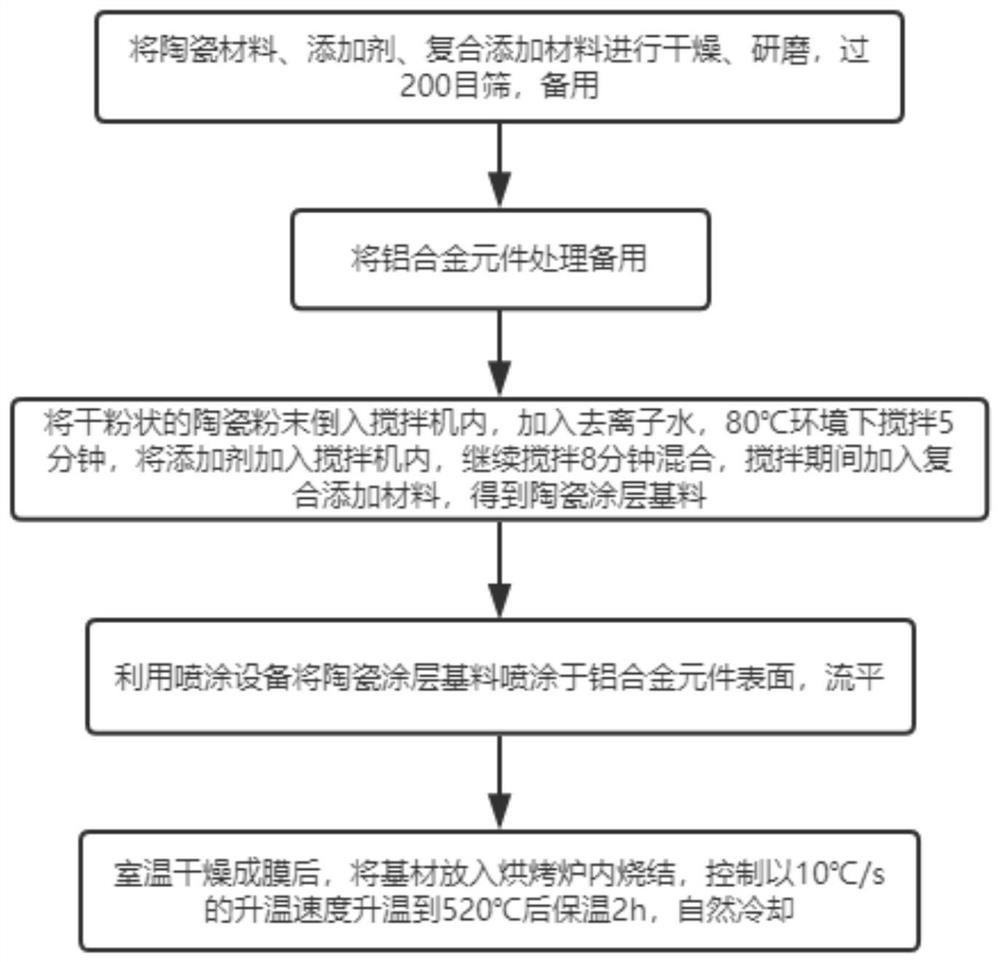

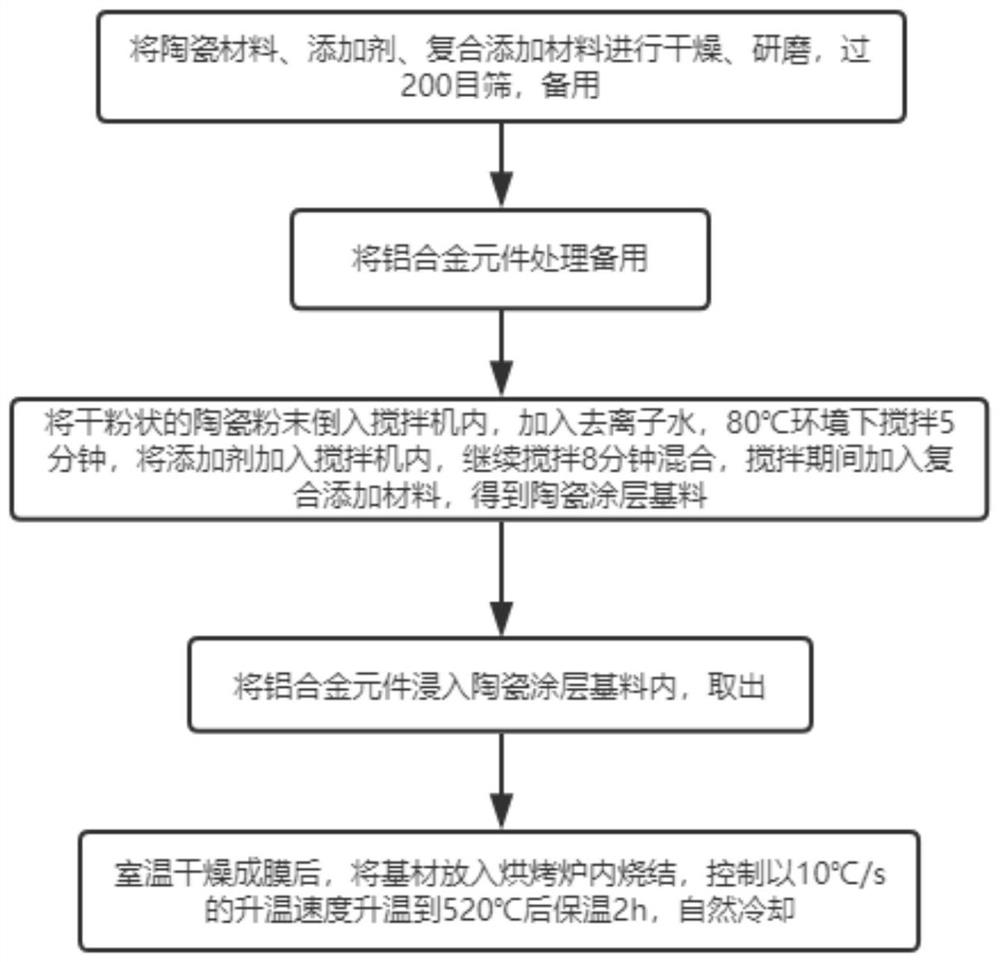

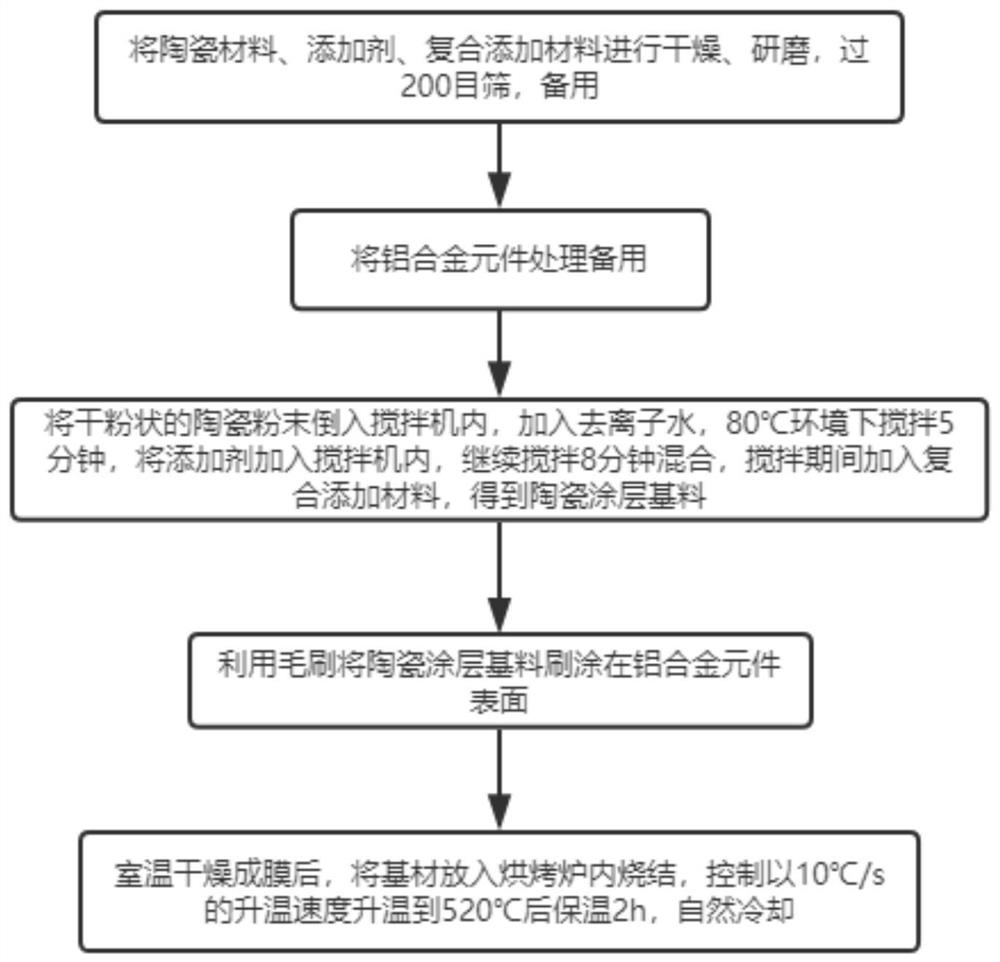

Preparation method of corrosion-resistant and wear-resistant modified ceramic coating on aluminum alloy surface

InactiveCN111647886AEvenly dispersedImprove bindingHeat inorganic powder coatingAl powderCeramic coating

The invention discloses a preparation method of a corrosion-resistant and wear-resistant modified ceramic coating on aluminum alloy surface, relates to the technical field of aluminum alloy surface treatment, and aims to solve the problem of cracks in the coating cooling to room temperature. The preparation method particularly comprises the steps that ceramic materials, additives and composite additives are dried, ground and passed through a 200-mesh sieve for use; aluminum alloy components are processed for use; and dry ceramic powder is poured into a mixer, and deionized water is added. According to the preparation method, the deionized water is used as carrier liquid, the additives are used as binders, and various metal inorganic oxides are added, fully stirred and milled to obtain a uniformly dispersed ceramic coating. The composite additives, aluminum powder and the like are added and further oxidized in the heat treatment process, and can produce volume expansion to compensate for the volume shrinkage of the ceramic coating during a sintering process. The coating can be densified to have a toughening effect, and the adhesion of the coating on the aluminum alloy surface is improved.

Owner:沈永成

Preparation method of scratching-resistant matte varnish

The invention relates to a preparation method of scratching-resistant matte varnish, and belongs to the technical field of paint preparation. The preparation method comprises the steps that gamma-glycidoxy propyl trimethoxy silane and diethoxydimethylsilane serve as the raw materials, a reaction is conducted under the acidic condition, and highly transparent epoxy-modified organic silicone resin is obtained; silicon dioxide is treated with a silane agent, treated silicon dioxide and a light stabilizer are subjected to a grafting reaction, and modified silicon dioxide is obtained; silicon carbide and talcum powder are subjected to ball milling and then activated through a surfactant, and a scratching-resistant agent is obtained; the scratching-resistant agent, modified silicon dioxide, epoxy-modified organic silicone resin and the like are subjected to high-speed stirring, and an emulsion is obtained; auxiliaries are added for stirring finally, and the scratching-resistant matte varnish is obtained. The scratching-resistant matte varnish prepared through the preparation method is high in hardness which is not smaller than 2 HB and not prone to be scratched, and the service life of the scratching-resistant matte varnish is greatly prolonged; the glossiness is kept to range from 4 gloss to 6 gloss, the glossiness is stable, the hand feeling is good, and the scratching-resistant matte varnish is suitable for the field of solid wood furniture decoration.

Owner:董晓

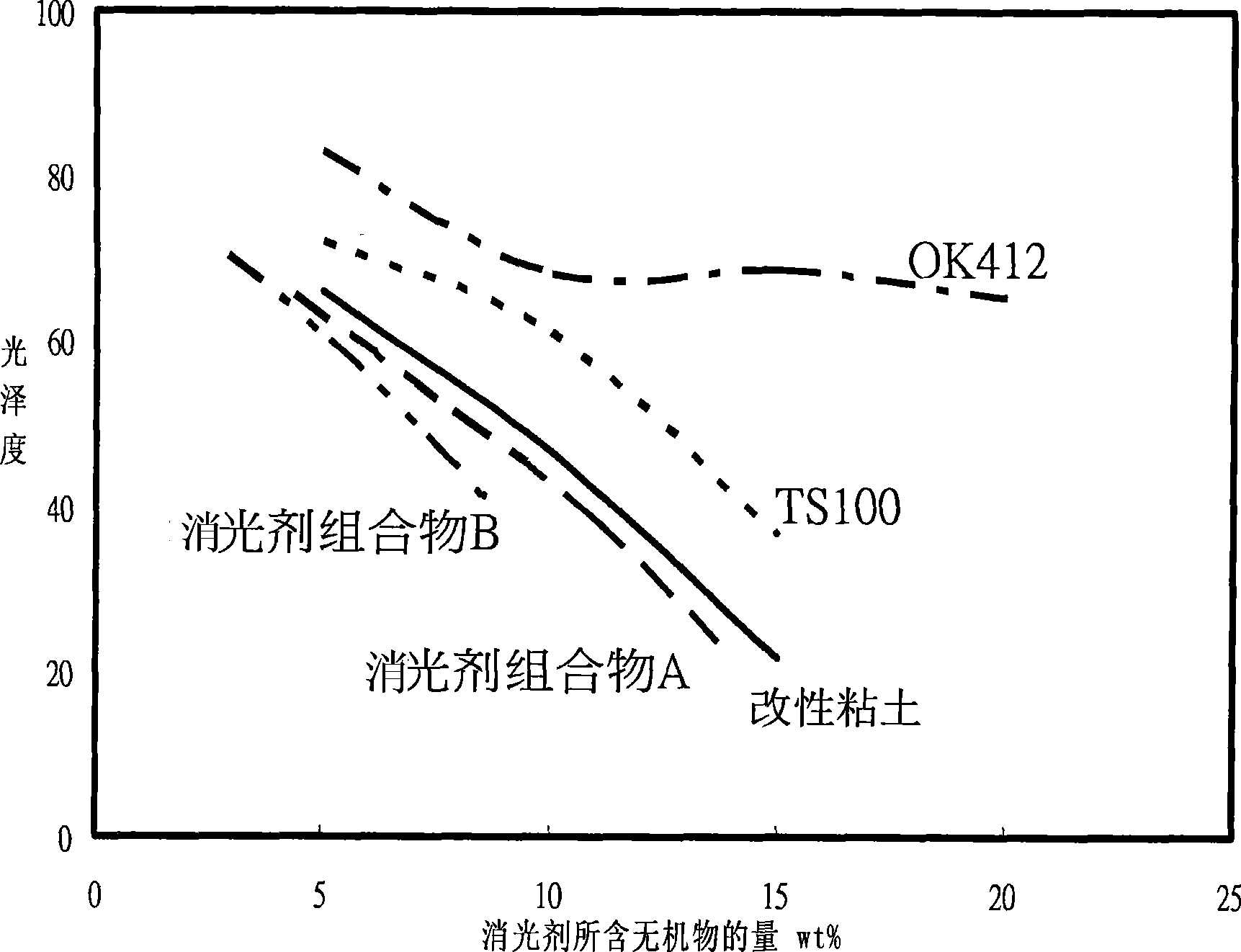

Light extinction composition

The invention provides an extinction composition, which comprises modified clay and at least one acrylic ester monomer, wherein the content of the modified clay accounts for at least 0.5 percent of the total weight of the extinction composition. The extinction composition can be used for radiation curing coatings, and has the characteristics of convenient operation, stable glossiness and the like.

Owner:ETERNAL MATERIALS CO LTD

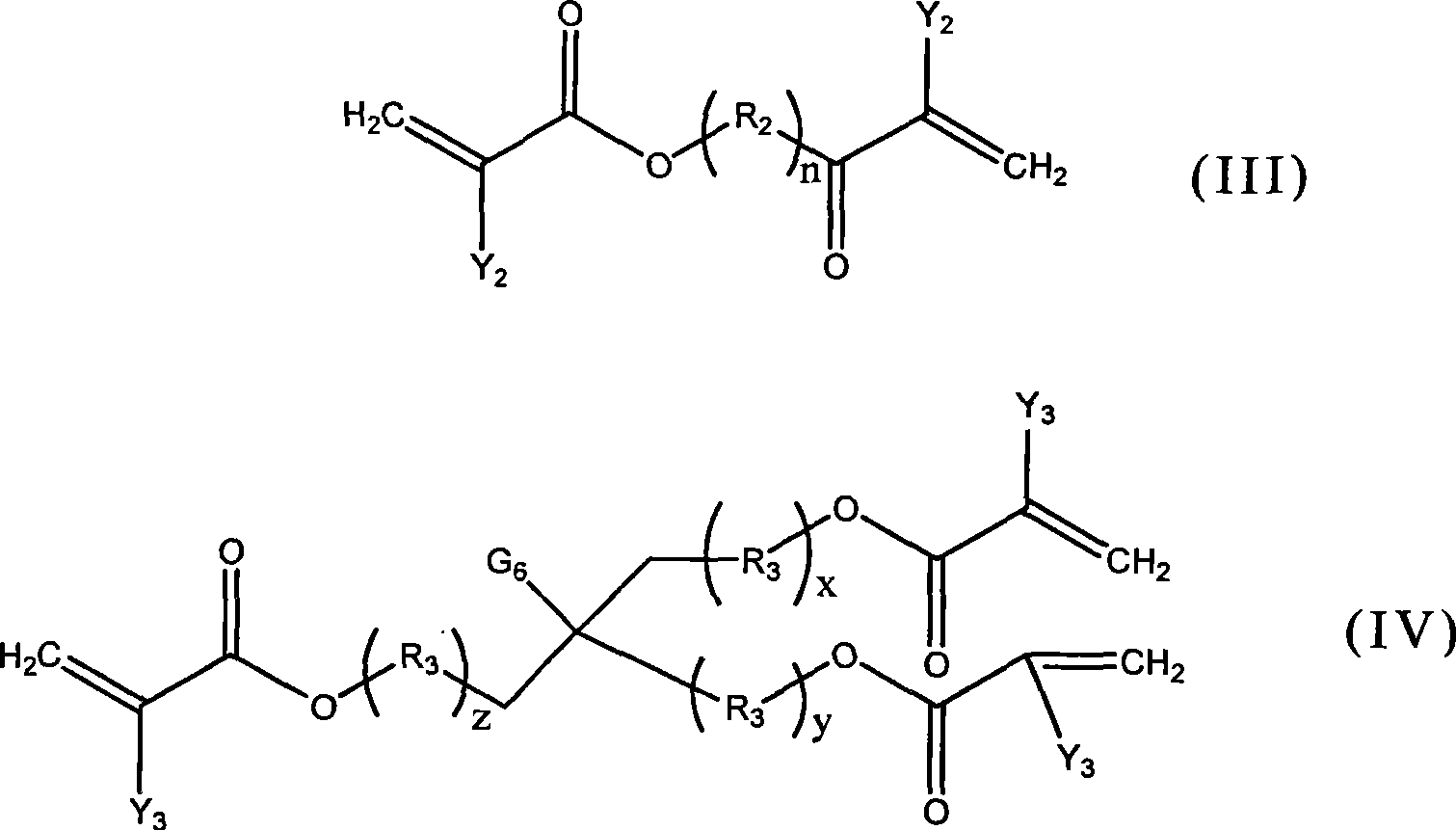

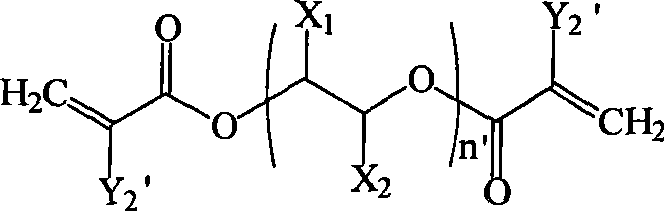

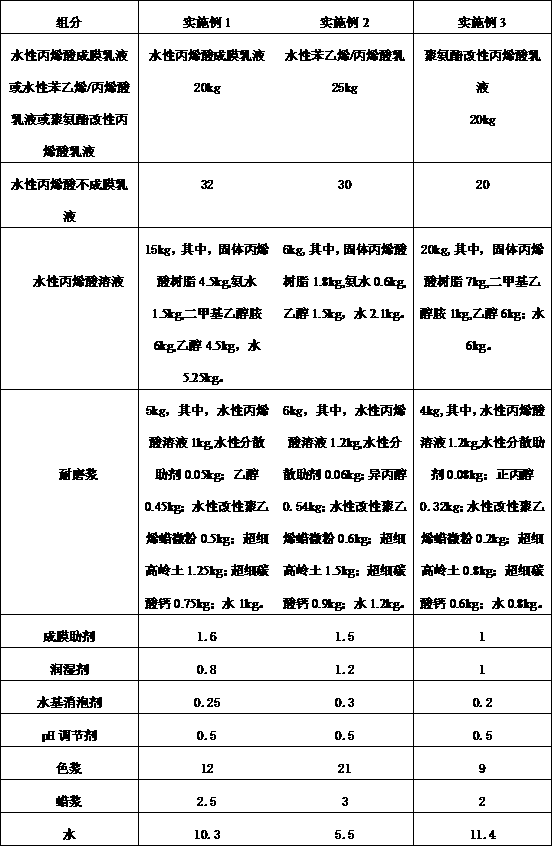

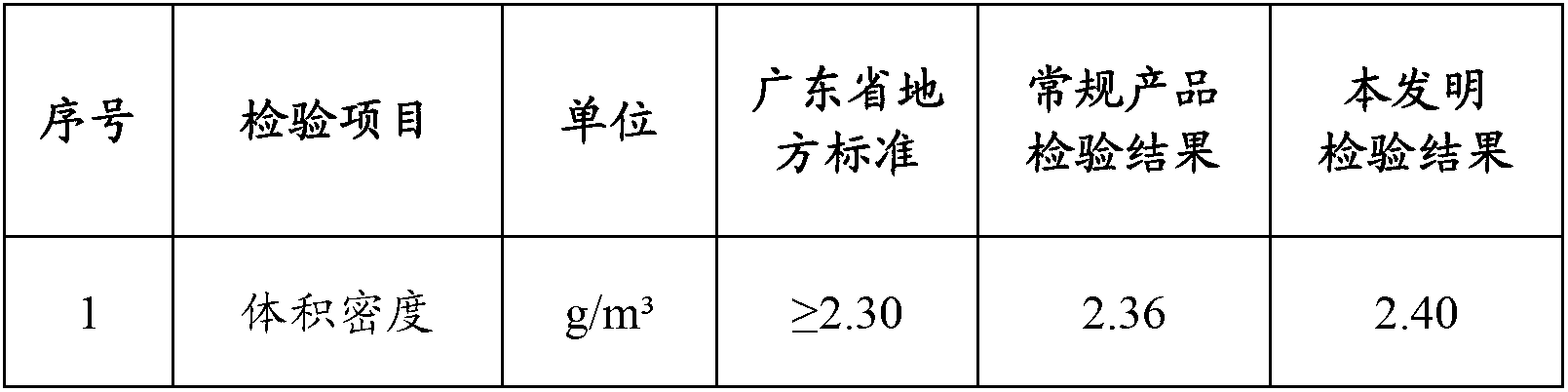

Overprint varnish-free high wear resistance aluminum foil lined paper water-based ink and preparation method thereof

This invention relates to the field of inks, and discloses an overprint varnish-free high wear resistance aluminum foil lined paper water-based ink. The overprint varnish-free high wear resistance aluminum foil lined paper water-based ink comprises 20-25 wt% of an aqueous acrylic film-forming emulsion or an aqueous styrene / acrylic emulsion or a polyurethane modified acrylic emulsion, 20-35 wt% ofan aqueous acrylic non-film forming emulsion, 2-25 wt% of an aqueous acrylic solution, 0.2-2 wt% of a wetting agent, 0.1-0.5 wt% of a defoamer, 0.4-0.6 wt% of a pH adjuster, 10-25 wt% of a color paste, 4-10 wt% of a wax paste, 4-10 wt% of a wear-resistant slurry, 5-15 wt% of water and 0.1-2 wt% of a film forming aid, wherein the wear-resistant slurry comprises 20-30 wt% of an aqueous acrylic solution, 20-25 wt% of water, 5-10 wt% of a water-modified modified polyethylene wax micro-powder, 1-2 wt% of an aqueous dispersion aid, 8-9 wt% of a cosolvent, 20-25 wt% of ultrafine kaolin and 10-15 wt%of ultrafine calcium carbonate. The ink has the adhesion of prime coating, also has the heatproof, waterproof, anti-slip, wear-resistant and scratch-resistant properties of a varnish, is convenient touse, and can simplify aluminum foil pre-coating, monochrome printing and three-time overprint varnish printing into one-time inking printing, so two printing processes are saved, and energy saving and environmental protection are achieved.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

Artificial quartzite plate and manufacturing process thereof

The invention discloses an artificial quartzite plate material which comprises the following components in percentage by total mass of quartzite plate: 60-63 percent of quartz sand with the grain size of 5-100 meshes and inorganic silicon materials of waste glass granules, and the like, 28-32 percent of quartzite powder with 320-3000 meshes, 7-9 percent of unsaturated resin and 0.4-0.6 percent ofpigment and a coupling agent as well as other components in percentage by mass of resin: 0.5-1 percent of ultraviolet absorber, 0.5-1 percent of disintegrant and 0.8-1 percent of curing agent. The invention also discloses the quartzite plate prepared from the raw materials and a manufacturing process thereof. In the invention, the quartzite plate is produced by the steps of vibrating and pressurizing the quartz sand, the quartzite powder, the inorganic silicon materials of waste glass granules, and the like and the unsaturated resin under the vacuum state and curing and synthesizing under theintermediate temperature. The quartzite plate overcomes the problem that the traditional artificial stone is aged under strong lights after long-term use outdoors and has favorable physical and chemical properties.

Owner:新云石业(云浮)有限公司

Easy-toning single-coating elastic coating and preparation method thereof

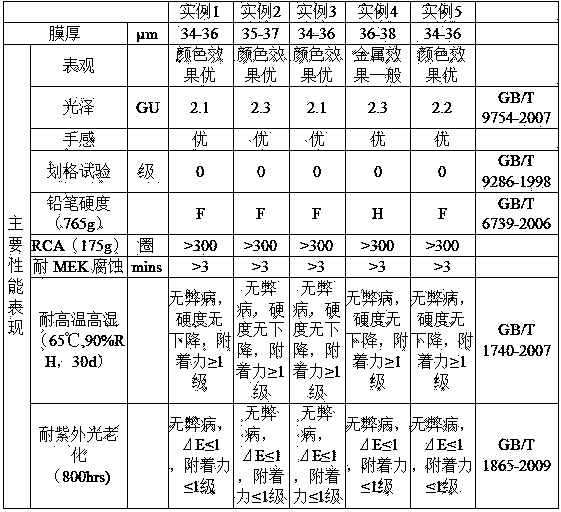

The invention discloses an easy-toning single-coating elastic coating. The coating is prepared from a component A and a component B, wherein the component A comprises a transparent base material and color paste. A method for preparing the coating comprises the following steps: base material preparation, namely uniformly stirring various components until the fineness is less than or equal to 20mu m and the black matrix glossiness bias is less than or equal to 0.1GU, regulating viscosity, filtering and defoaming; color paste preparation, namely uniformly stirring various components until the fineness is less than or equal to 20mu m and the black matrix glossiness bias is less than or equal to 0.1GU, regulating the viscosity, filtering and defoaming; component A preparation, namely uniformly mixing pearlescent pigment or aluminum powder, the base material and the color paste, regulating viscosity, and filtering; and component B preparation, namely uniformly stirring various components until the fineness is less than or equal to 20mu m and the black matrix glossiness bias is less than equal to 0.1GU, regulating viscosity, filtering and defoaming. The coating prepared by the method has comprehensive excellent performance.

Owner:QINGYUAN MEINUOKE NEW MATERIAL

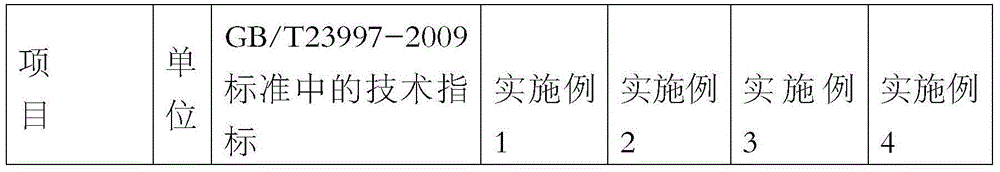

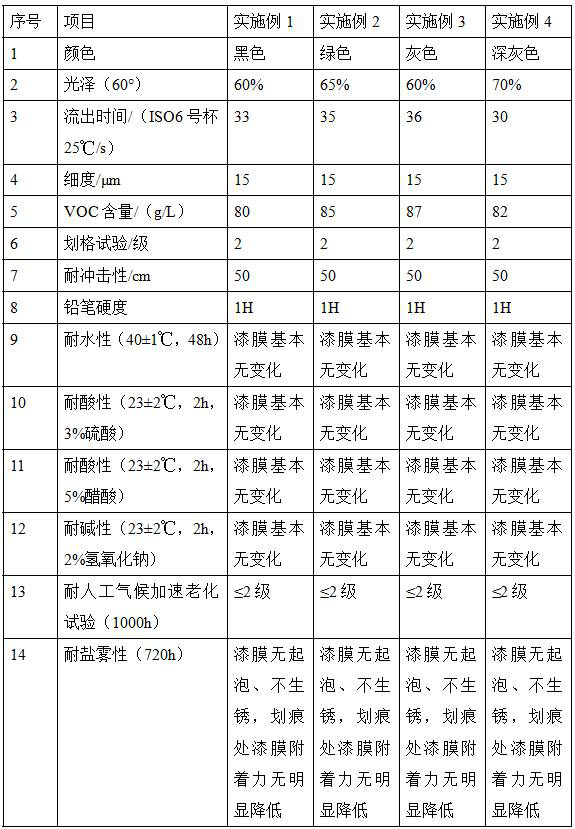

Multicolor low-gloss water-based paint primer-finish composition for passenger train

ActiveCN113201272AGloss stableLong lastingPretreated surfacesAnti-corrosive paintsWeather resistanceAcrylic resin

The invention discloses a multicolor low-gloss water-based paint primer-finish paint composition for a passenger train. The multicolor low-gloss water-based paint primer-finish paint composition comprises a water-based acrylic polyurethane finish and a water-based epoxy primer, wherein the water-based acrylic polyurethane finish adopts hydroxyl-containing water-based acrylic resin, self-extinction water-based polyurethane resin and a hydrophilic polyisocyanate curing agent as film-forming substances and employs pigment and water-based organic color paste to compositely adjust the color of the paint; and the waterborne epoxy primer provides adhesive force with a metal substrate. The obtained water-based paint composition has the characteristics of low VOC, environmental friendliness, non-combustibility, non-explosion, safety and reliability; and a composite paint film formed by matching the water-based acrylic polyurethane finish and the water-based epoxy primer has the advantages of rich and diversified colors, low gloss, high hardness, good water resistance, good corrosion resistance and good weather resistance, and the comprehensive performance of the composite paint film meets the technical requirements of Q / CR 581-2017 on a solid-color finish-primer composite coating.

Owner:SHANXI HUABAO NEW MATERIALS CO LTD +1

Image forming apparatus, image forming method, and medium

InactiveUS20140301745A1Gloss stableImprove accuracyElectrographic process apparatusImage formationDiffuse reflection

There is provided an image forming apparatus for forming an image using coloring materials of a plurality of colors. The image forming apparatus includes a regular reflection light measuring unit configured to measure regular reflection light of an image formed by a coloring material of a color with which a difference in diffused reflection light between a non-image part and an image part on a recording medium is relatively small compared to a difference in specular reflection light of the coloring materials of the plurality of colors at an angle by which a quantity of received light to be measured by a light receiving unit becomes stable in a case where distance between the light receiving unit and a measurement surface varies and a glossiness determining unit configured to determine glossiness based on the intensity of regular reflection light measured by the regular reflection light measuring unit.

Owner:CANON KK

Antistatic matte non-silicon release film and preparation method thereof

PendingCN113563621AAvoid the risks of transferringGloss stableFilm/foil adhesive release linersPolyester coatingsPolymer scienceAcrylic resin

The invention discloses an antistatic matte non-silicon release film and a preparation method thereof. The release film comprises matte PET, a priming coat, an antistatic layer and a non-silicon release layer distributed from bottom to top; the priming coat layer comprises polyvinyl butyral; the antistatic layer comprises the following components in parts by weight: 500-1000 parts of a mixed solvent, 100 parts of a polythiophene solution, 3-20 parts of N, N-dimethylformamide, 0-10 parts of ascorbic acid and 0-5 parts of an amino acid carboxylic acid chelating agent; and the non-silicon release layer is prepared from the following components in parts by weight: 500 to 1000 parts of methylbenzene, 50 to 500 parts of ketone solvent, 0 to 300 parts of amino modified acrylic resin, 0 to 300 parts of hydroxyl saturated polyester resin and 5 to 50 parts of curing agent.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com