Light extinction composition

A composition and extinction technology, applied in the coating and other directions, can solve the problems of low shrinkage, high volatile organic content, affecting the extinction effect of silica, etc., and achieve the effect of stable gloss and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

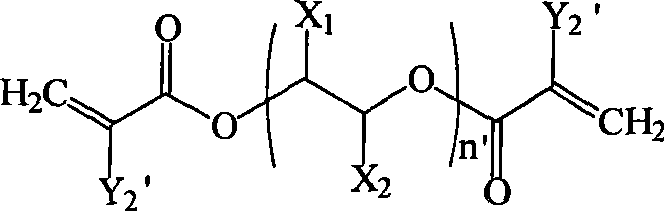

[0040] According to a preferred embodiment of the present invention, the acrylate monomer of the formula (V) has the formula (V 1 ):

[0041]

[0042] where Y 5 'is methyl or isopropyl; Y 4 ' is hydrogen or methyl; m' is an integer selected from 6 to 12.

[0043] The present invention further provides a method for preparing a matting composition, which comprises:

[0044] (a) modifying the clay with a quaternary ammonium cation selected from the group consisting of a quaternary ammonium cation of formula (I), a quaternary ammonium cation of formula (II), or a mixture thereof to produce a modified clay; and

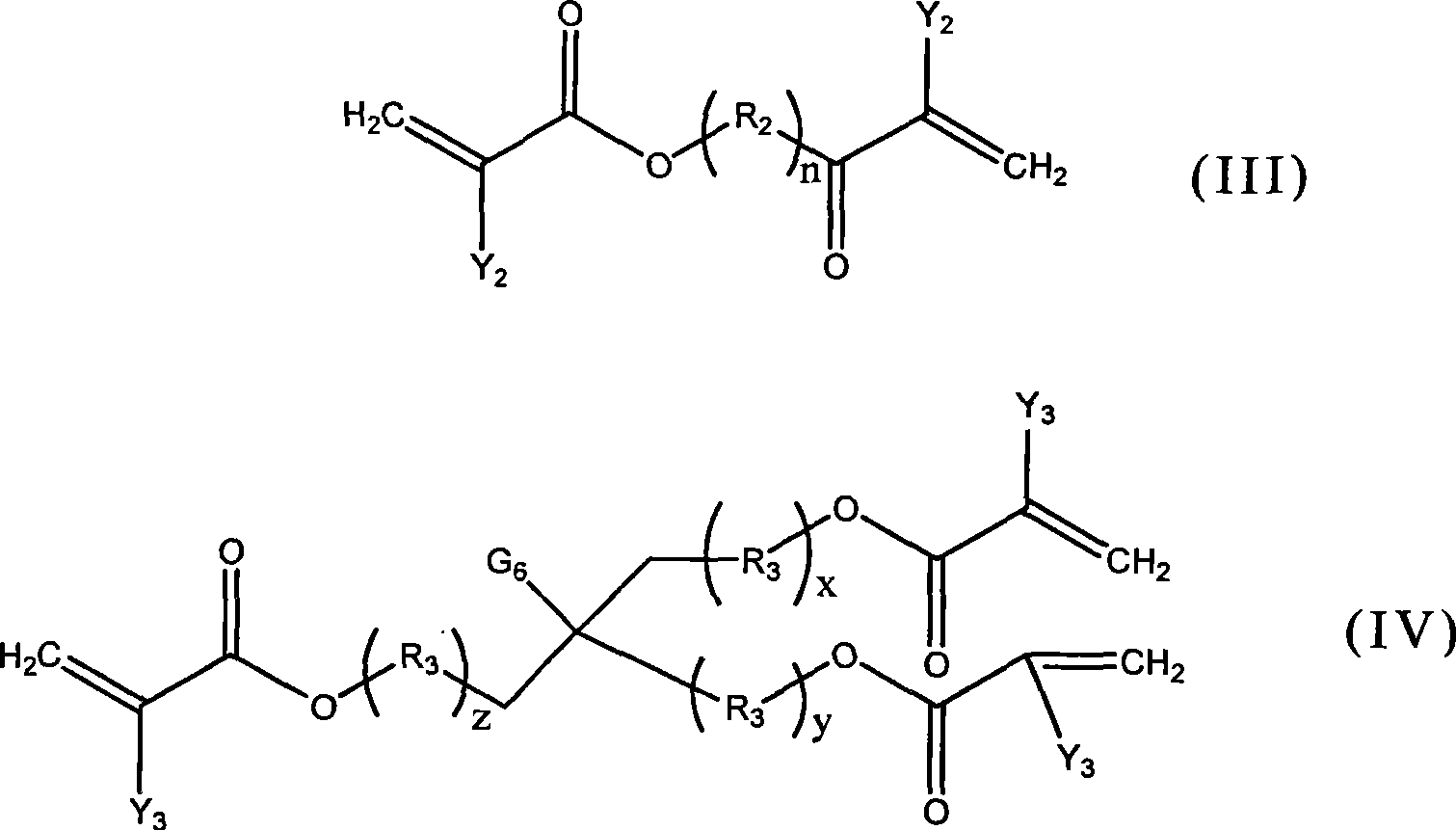

[0045] (b) combining the modified clay prepared in step (a) with at least one acrylate monomer (preferably at least one acrylate monomer selected from formula (III) and formula (IV)) and optionally Another acrylate monomer (preferably the acrylate monomer of formula (V)) that is incompatible with the above-mentioned acrylate monomer is mixed to prepare a matting co...

preparation example

[0050] Preparation of modified clay

[0051] Stir and disperse 20 grams of clay [China Glaze Company, model CN-C34], 8 grams of octadecyltrimethylammonium chloride and 5 grams of methacryloxyethyltrimethylammonium chloride in 100-400ml of ethanol Mix the solution with water (weight ratio 1:1), gradually raise the temperature to 50-85°C, keep it for 8-12 hours, then cool down and filter, and then fully wash with the mixed solution of ethanol and water until it is washed with 0.1M AgNO 3 The solution does not detect Cl - Until it exists, it is vacuum-dried and pulverized and passed through a 200-mesh sieve for subsequent use.

[0052] Preparation of matting composition A of the present invention

[0053] The modified clay prepared above was mixed with monomer EM222 (dipropylene glycol diacrylate, purchased from Eternal Chemical Co., LTD.), and stirred for 10 to 24 hours to make it uniformly dispersed. The content of modified clay is about 30 wt%, and the content of monomer EM...

Embodiment 13-20

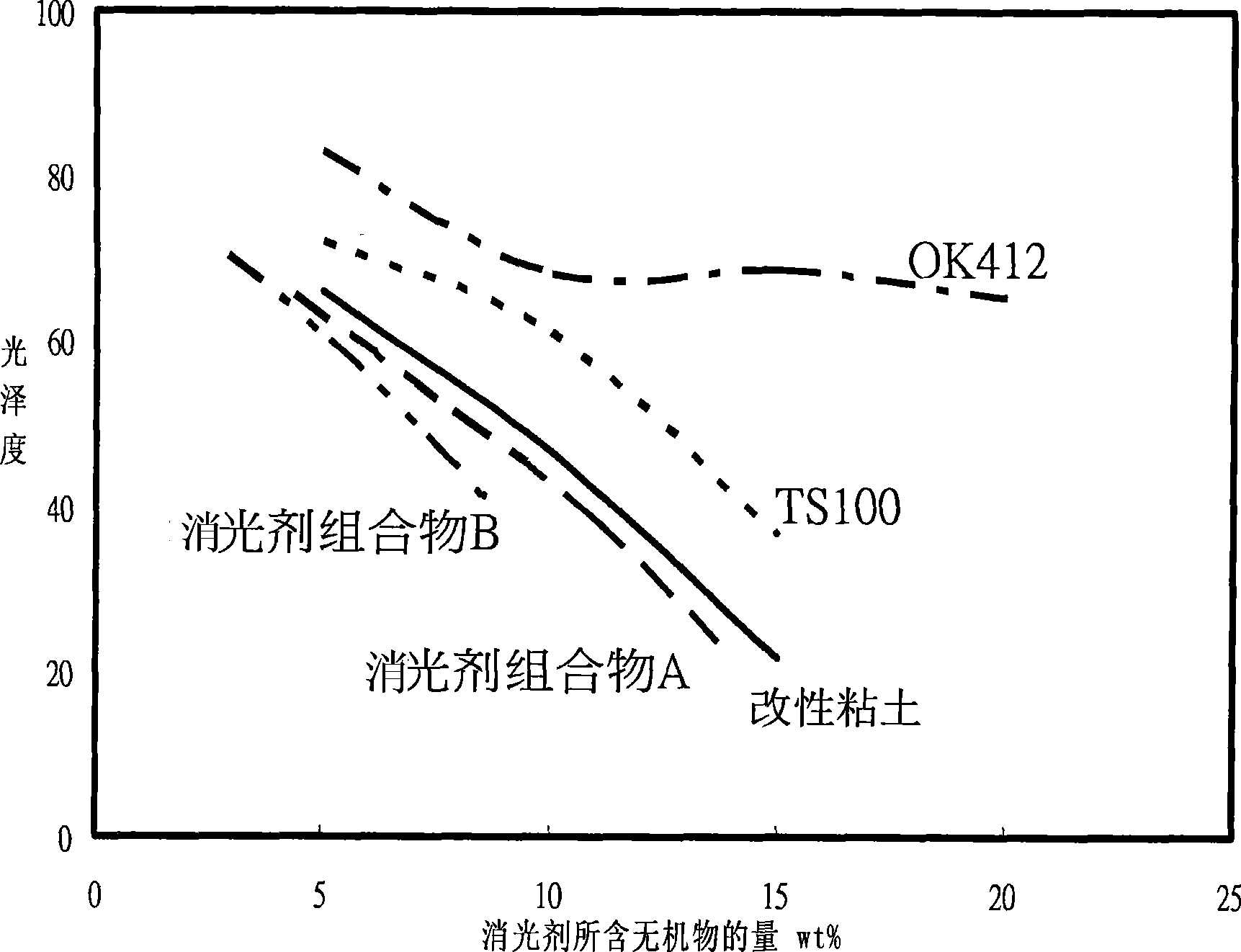

[0066] Mix the matting composition A and matting composition B of the preparation example with the ultraviolet curable resin, disperse evenly and coat it on the cardboard, after the ultraviolet light curing coating, detect its 60 ° gloss, and record the results in Table 2 middle. For comparison with known matting agents, the amount of matting composition A is to make the amount of modified clay (inorganic substance) contained therein reach 1.5, 3, 4.5 and 6 grams; in addition, depending on the content of matting composition A and matting composition B With the increase of monomer amount, increase the amount of photoinitiator Darocur1173 appropriately.

[0067]

[0068]From the results in Table 1 and Table 2, it can be seen that increasing the amount of matting agent can achieve the effect of reducing gloss. Comparing the results of Comparative Examples 1-12 and Examples 13-16, it can be seen that in the known matting agent TS100 or the matting agent method containing only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com