Patents

Literature

544results about How to "Improve weaving efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

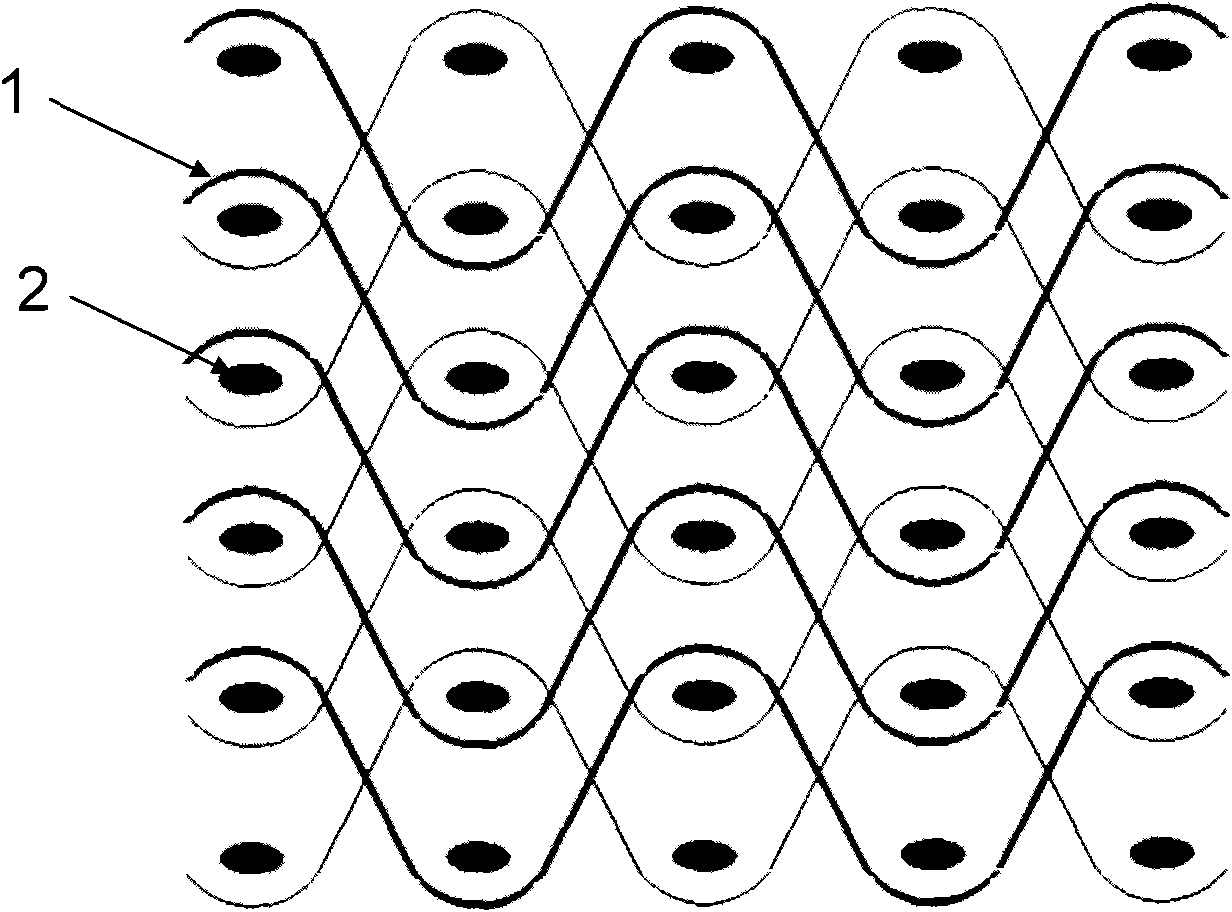

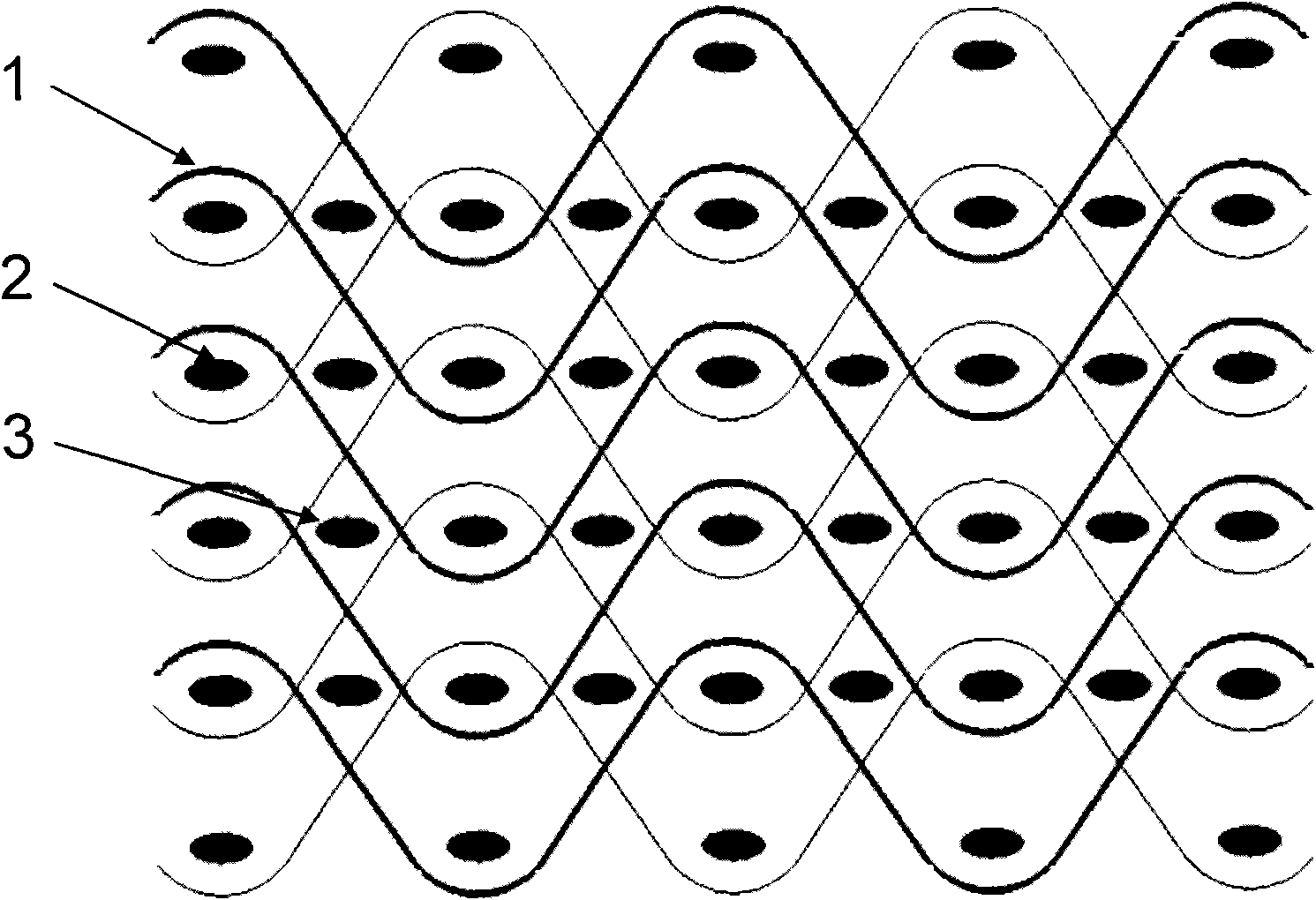

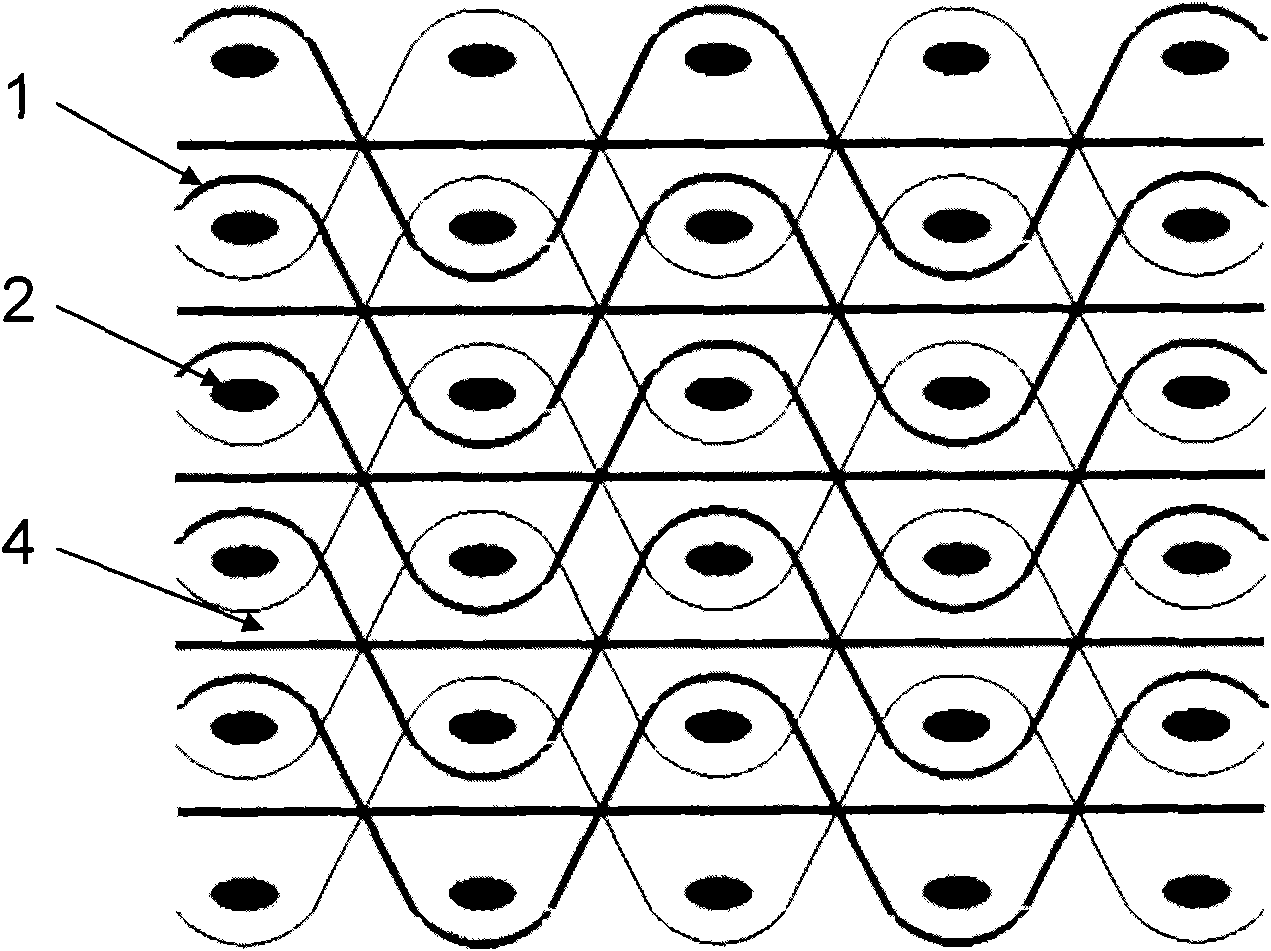

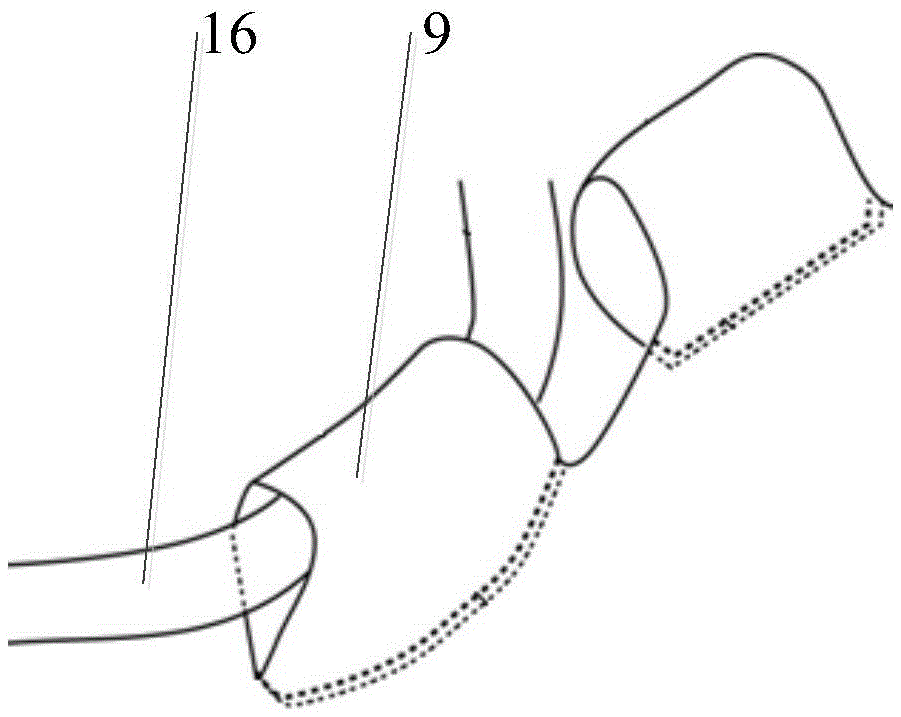

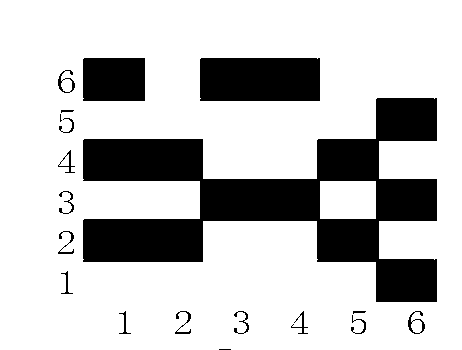

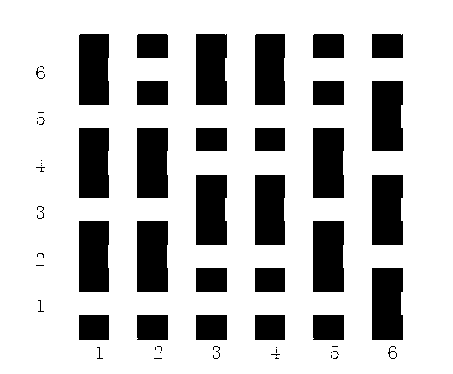

Normal reinforced 2.5D fabric and weaving method thereof

InactiveCN101775683AImprove integrityImprove longitudinal compressive performanceWoven fabricsEngineeringWeft yarn

The invention discloses a normal reinforced 2.5D fabric and a weaving method thereof. The fabric comprises a warp yarn system and a weft yarn system, wherein the warp yarn system and the weft yarn system are interwoven to form a layer-layer-corner interlocking structure. The fabric is characterized by also comprising a normal yarn system, wherein the normal yarn system is perpendicular to the interwoven warp yarn system and weft yarn system, penetrates through the thickness of the fabric, and is held by the adjacent warp yarn and weft yarn, thereby forming the normal reinforced 2.5D fabric. The fabric weaving method is realized in a way that: a technique normal yarn system is added based on the prior weaving method of the 2.5D fabric; and the normal yarn is perpendicularly led between every two adjacent warp yarn rows by a yarn leading device in the weft yarn direction in a certain leading way, penetrates through the thickness direction of the fabric and is held by the adjacent weft yarn rows, thereby weaving the 2.5D fabric. The method comprises the following steps: arranging yarn initially, making a shedding motion, leading in the weft yarn, leading in the normal yarn, making a shedding motion for the second time, leading in the weft yarn for the second time, and repeating the last three steps, thereby obtaining the normal reinforced 2.5D fabric.

Owner:TIANJIN POLYTECHNIC UNIV

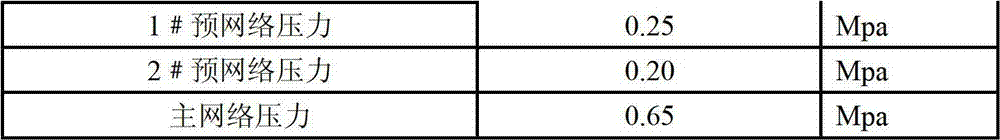

Method for manufacturing nylon/spandex air-textured yarn by false twist texturing machine one-step method

The present invention provides a method for making nylon-polyurethane fiber blended yarn by utilizing false-twist texturing machine and adopting one-step process. Said method includes the following steps: (A), making nylon raw yarn be drawn out from raw yarn frame, and making said nylon raw yarn be fed into first roller by means of first yam-cutting device of false-twist texturing machine, then fed into a texturing hot-box, and passed through a cooling device and a false-twister, then attracted by suction gun; (B), making polyurethane fiber yarn be drawn out from polyurethane fiber roller, and making said polyurethane fiber yarn be passed through second yarn-cutting device and second yarn-detector, then be attracted by suction gun, then combined with nylon yarn; and (C), making the combined two yarns be passed through intermediate roller, air-entanglement jet device, second auxiliary roller and first yarn detector, and be reached to oiling roller, finally passed through winding roller and winding to make formation.

Owner:WUXI HONGYUAN ELECTROMECHANICAL TECH

Method for producing radioresistant worsted fabric

InactiveCN101413172AImprove the finishImprove the accuracy of weft insertionWoven fabricsYarnRadiation resistantWorsted

The invention relates to a production method for a radiation-resistant fine spun fabric, which mainly comprises the following steps: dyeing and recombing wool first, and then combing the wool into colored wool tops, mixing the colored wool tops and metallic short fiber strips in spinning and mixing processes to spin into metallic yarns, and weaving, dyeing and finishing the metallic yarns to produce the radiation-resistant fine spinning fabric. Through spinning and mixing the metallic short fibers, the production method for the fabric makes the metallic fibers distributed in the fabric more evenly and improves radiation-resistant effect; the diameters of the metallic short fibers are softer than that of fine fibers, and so on, so the fabric is softer and more subtle; through the control for the weaving, dyeing and finishing processes, the fabric also has the advantages of high-grade appearance, neat hand feel, fine and pure face and excellent wearing property at the same time of having radiation-resistant function; and the fabric has most popular natural memory fold function at present simultaneously. Therefore, the fabric is suitable for producing male and female fashion coats which can show grace, luxury, romance and grade after being worn.

Owner:JIANGSU SUNSHINE +1

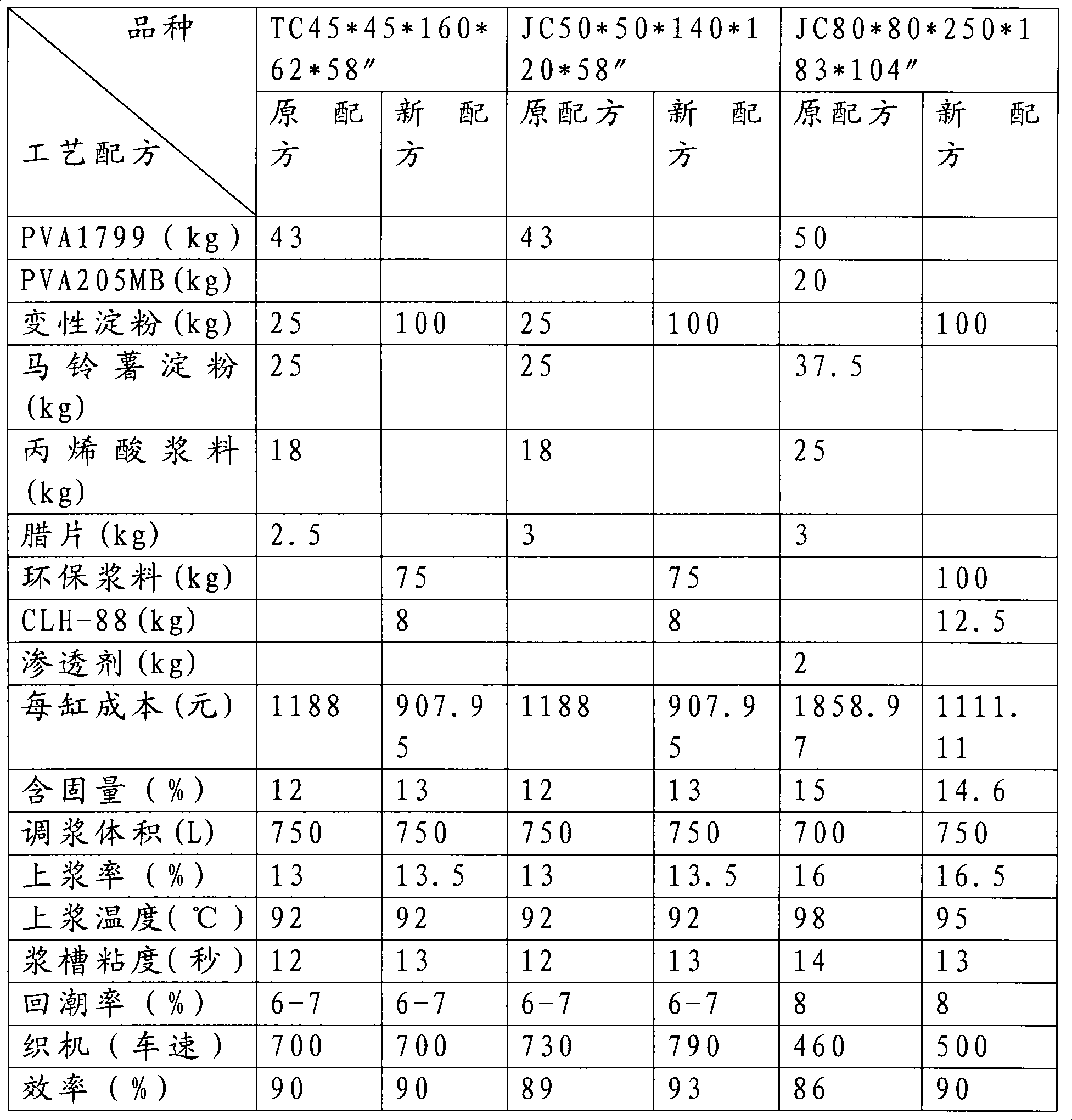

Textile slurry composition replacing for polyvinyl alcohol and preparing method thereof

The invention provides an environment-friendly textile size composition which has simple process and convenient use, and substitutes for polyvinyl alcohol, and a preparation method thereof, which aim at the current status that the sizing of the prior textile fiber warp can not be independent from PVA size and the disadvantages of the prior size. The size composition is prepared by mixing an ultrafine particle inorganic material which accounts for 1 to 10 percent of the total weight, polyacrylic acid size which accounts for 10 to 40 percent of the total weight, and water for the balance. The size composition is matched with modified starch size, can fully substitute for the PVA size during the sizing process of yarns such as pure cotton, polyester cotton, hemp, artificial cotton, and tenel, and meet the manufacturing requirement of high-difficulty varieties.

Owner:青岛常力恒工贸有限公司

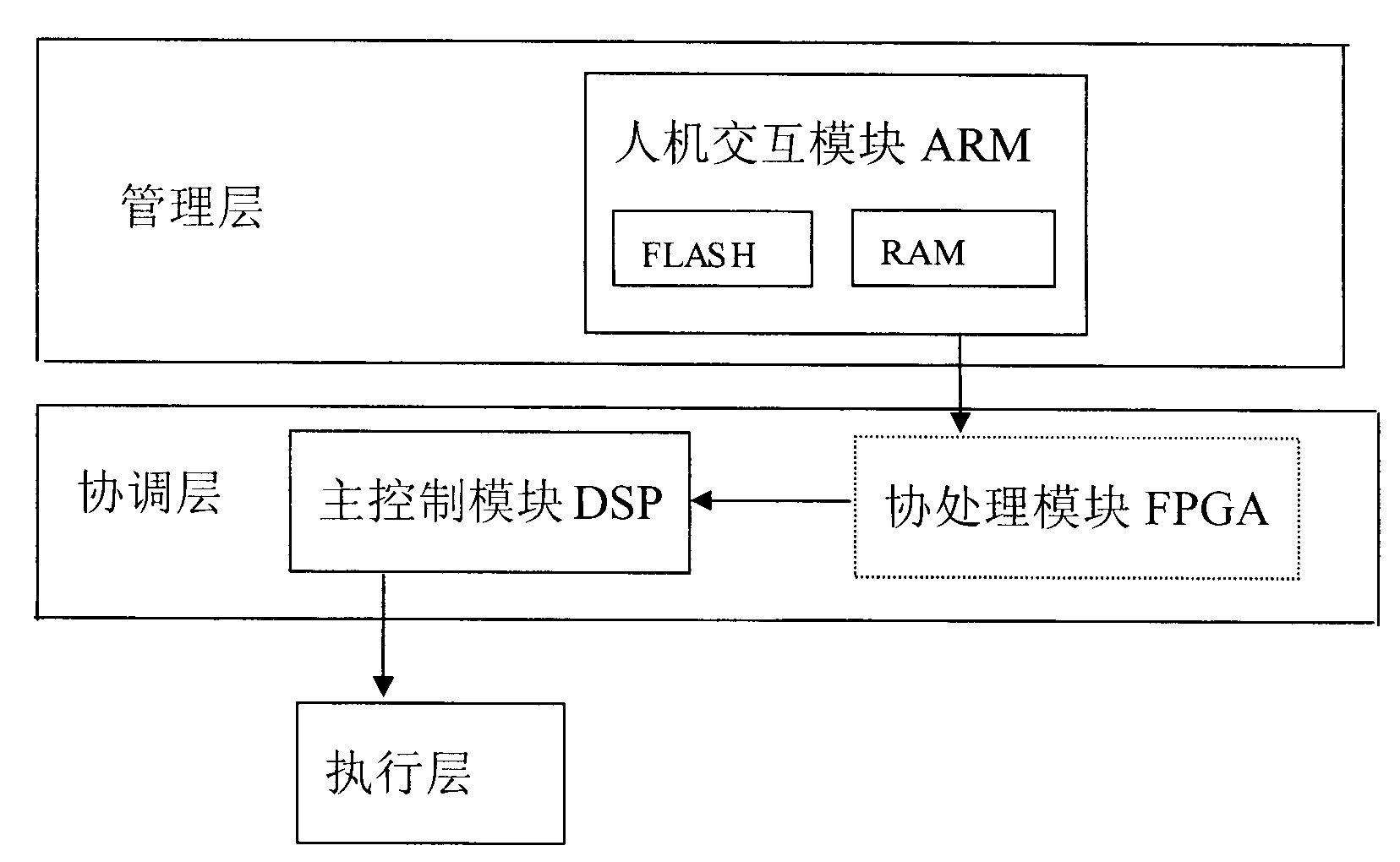

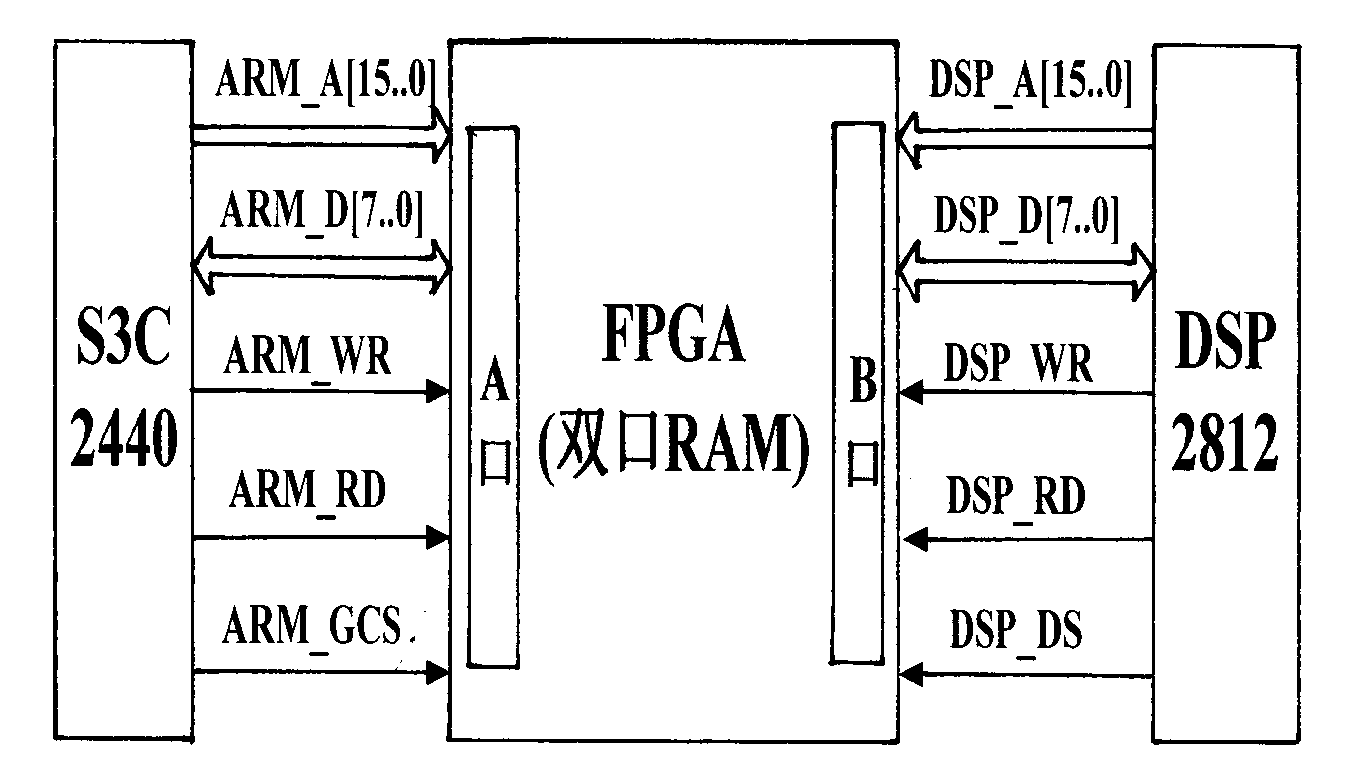

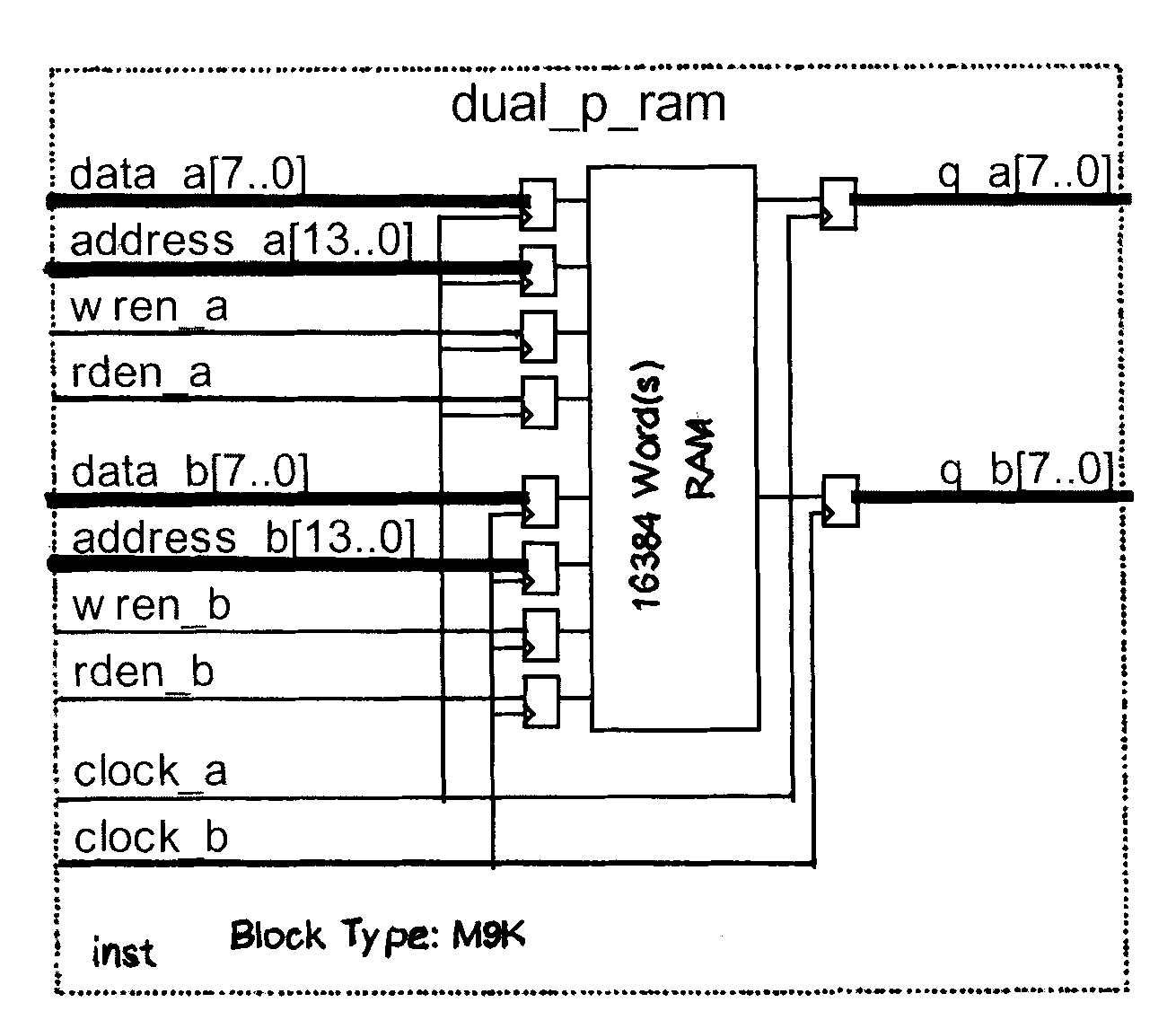

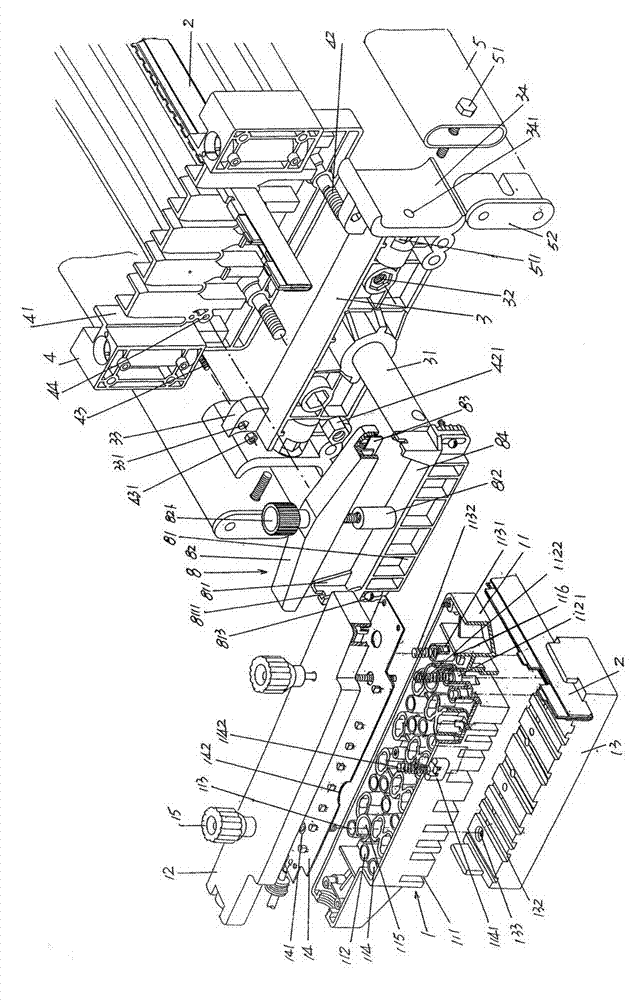

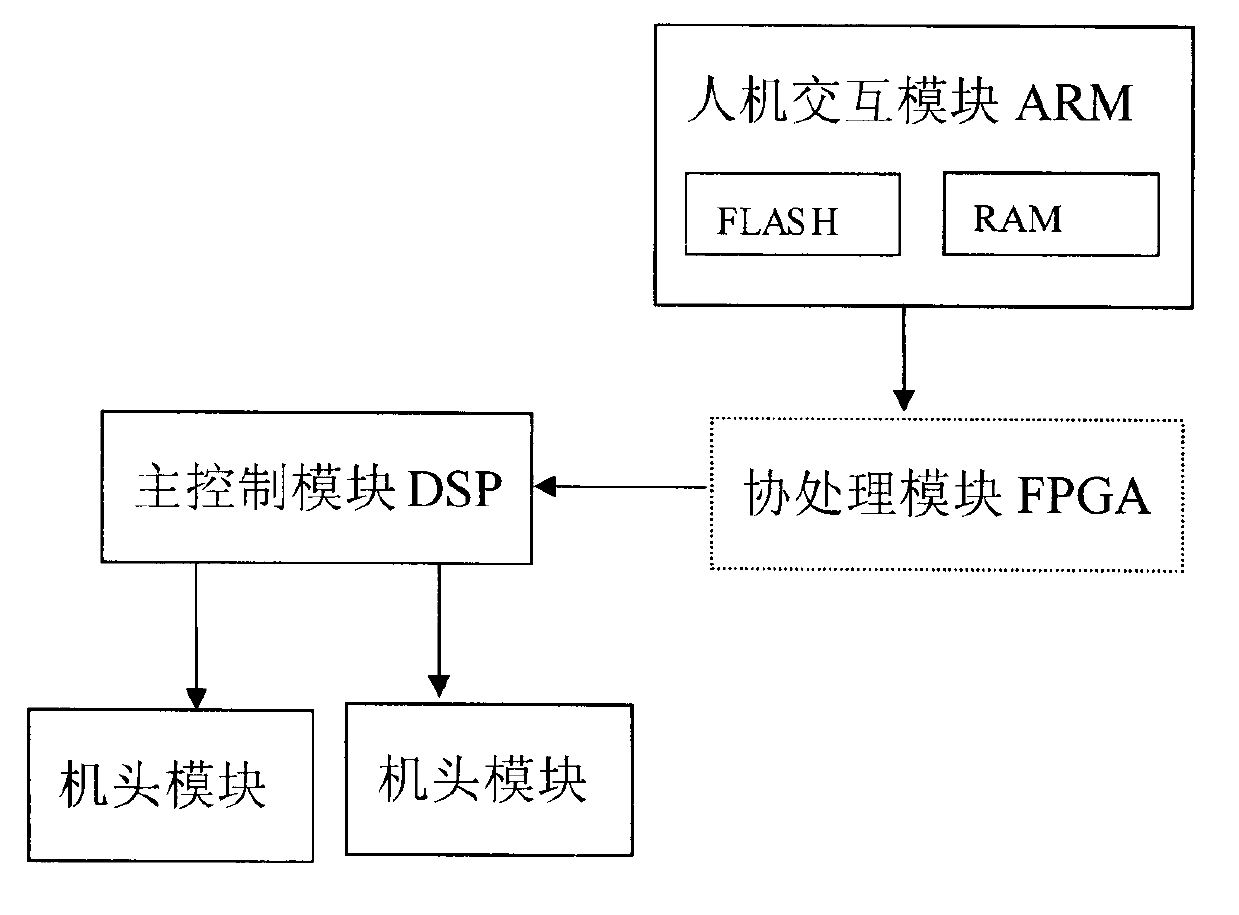

Flat machine numerical control system based on field programmable gate array (FPGA) high-speed communication method

InactiveCN101968642AHighly integratedImprove stabilityNumerical controlControl systemCoordination layer

The invention relates to a flat machine numerical control system based on a field programmable gate array (FPGA) high-speed communication method. The flat machine numerical control system comprises a management layer with an ARM module, a coordination layer with a DSP module and an FPGA module and an execution layer, and is characterized in that a dual-port RAM high-speed communication module is arranged between the ARM module and the FPGA module and is provided with independent valid read / write pins. The invention has the following obvious substantive characteristics: the dual-port RAM high-speed communication module is arranged and is provided with the independent read / write pins, so that signals of each layer are matched and are prevented from holding time and conflicting; and the data communication efficiency between the management layer and the coordination layer is improved by a method of adopting abundant logical resources in the FPGA module to realize dual-port RAM high-speed communication in a software programming mode, thus the weaving efficiency is improved. By adopting the control method of the control system, the communication speed is improved, and the control system has the characteristics of strong anti-interference performance, good generality and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

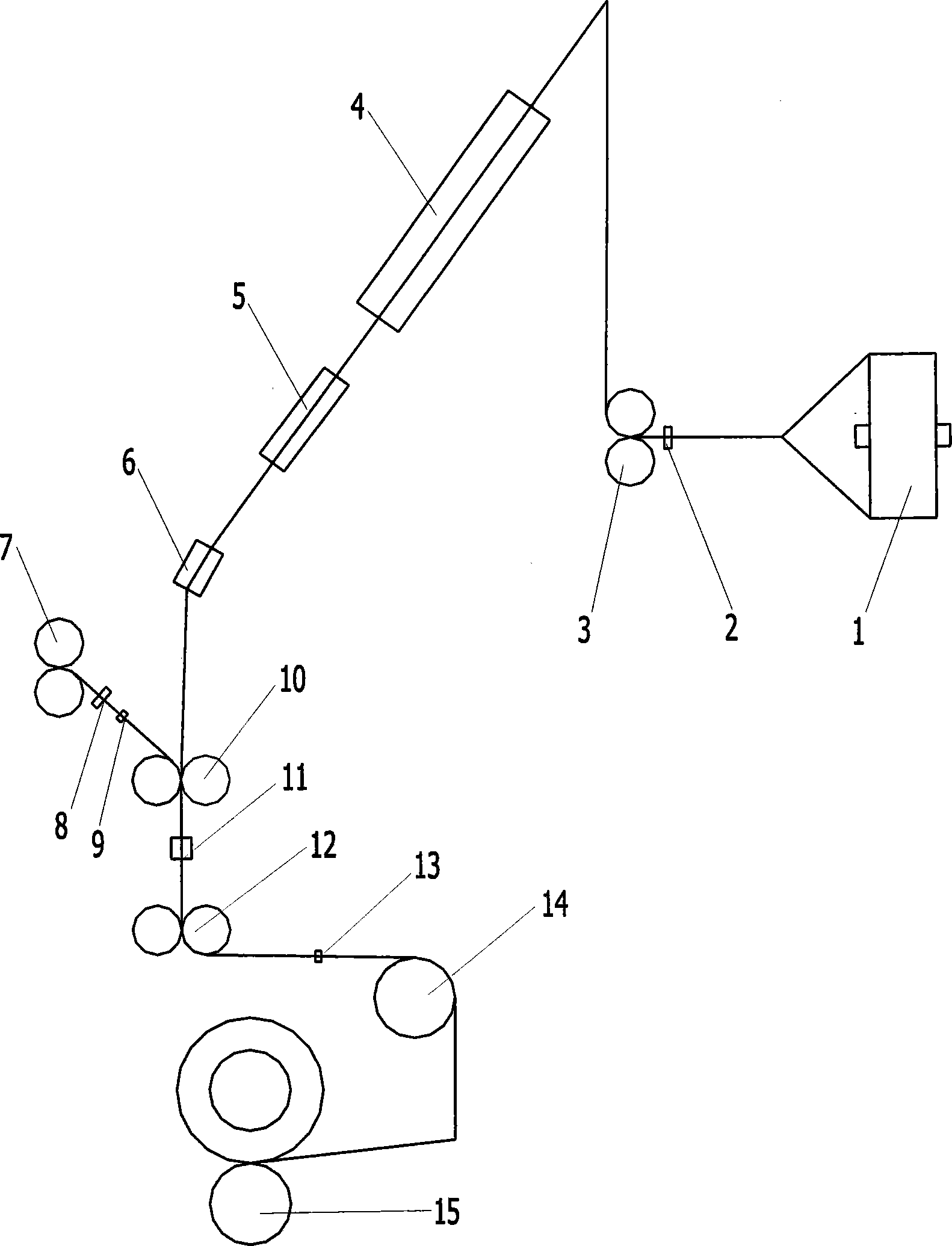

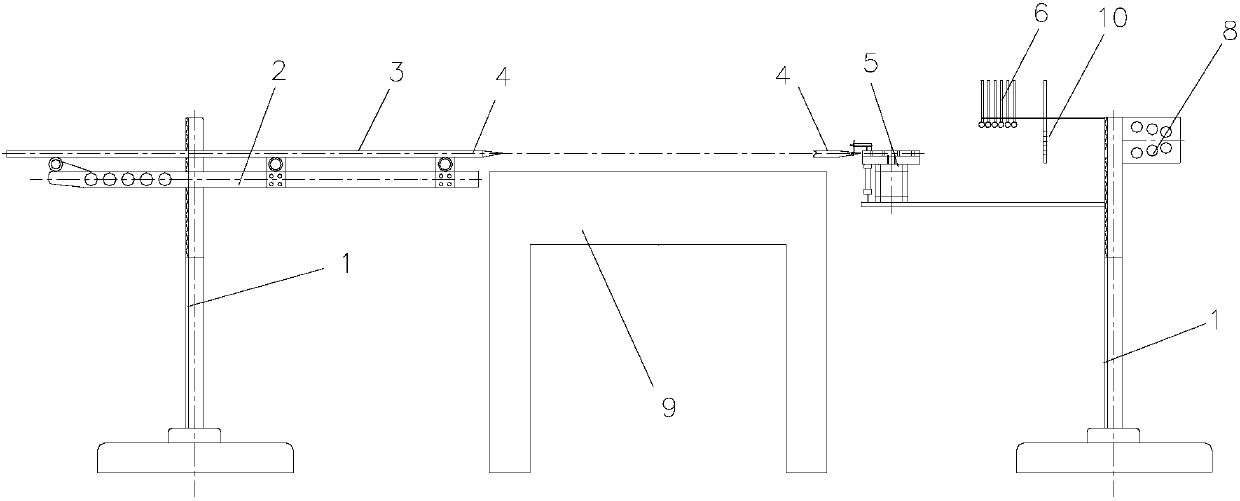

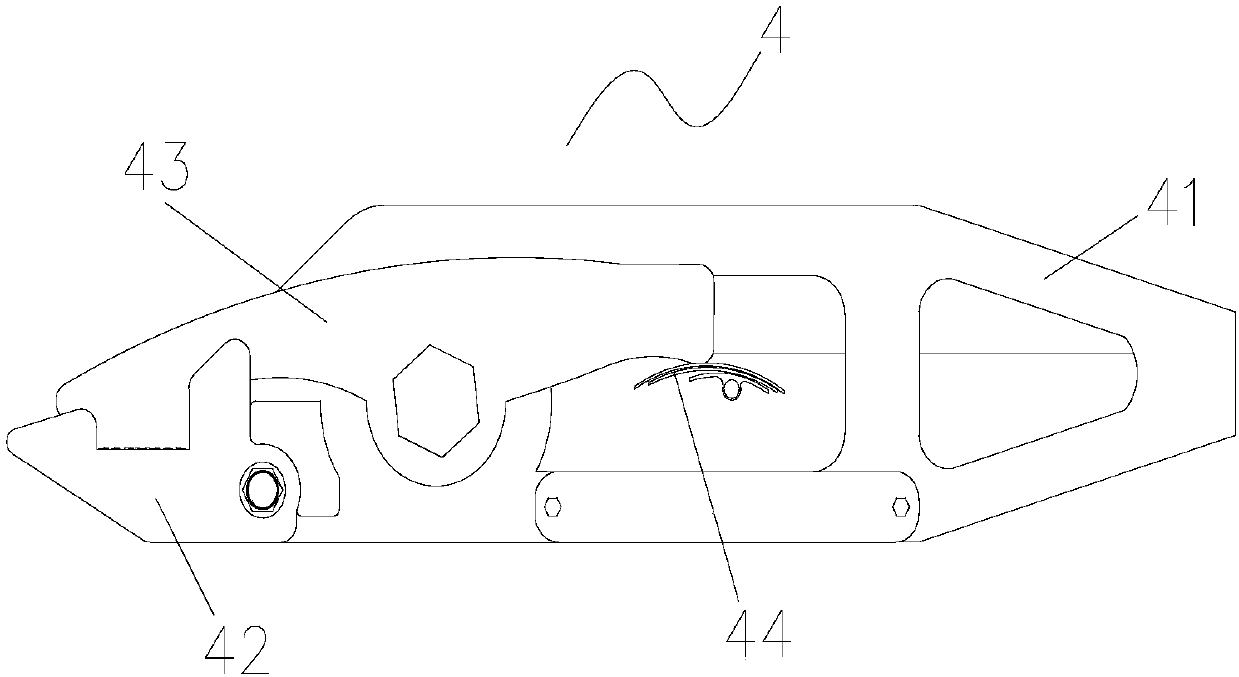

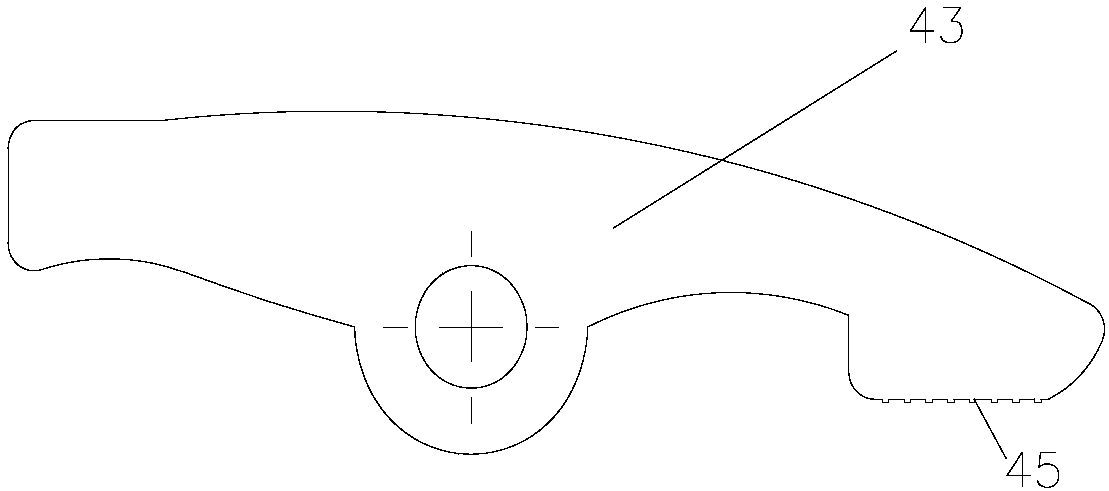

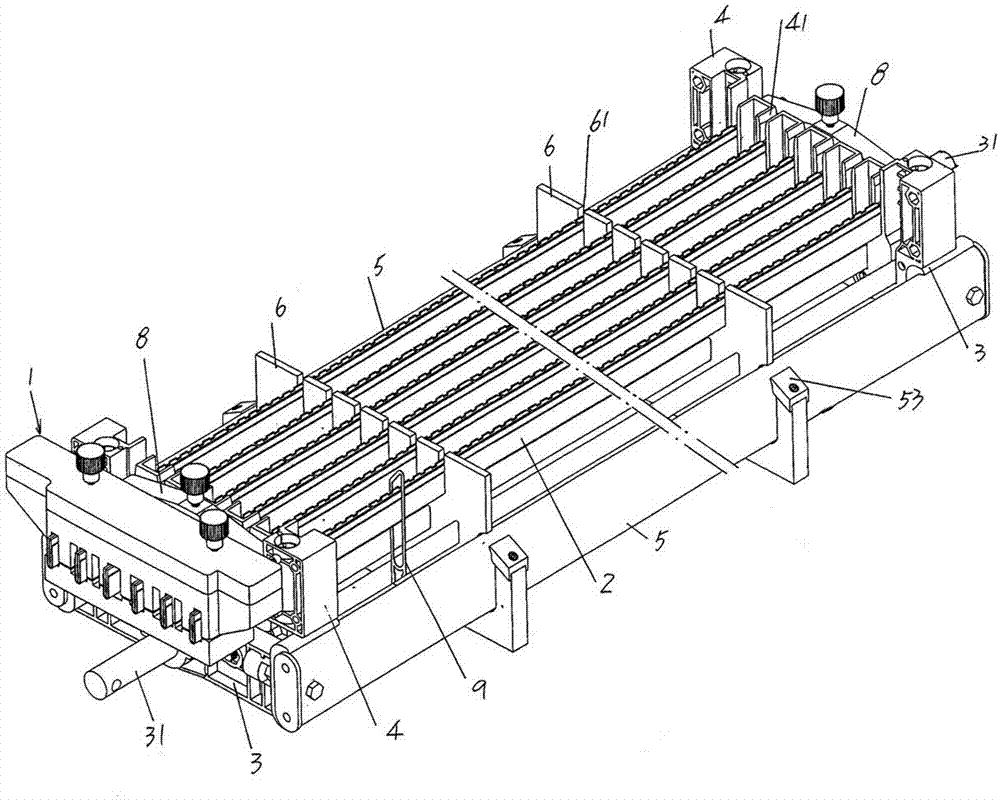

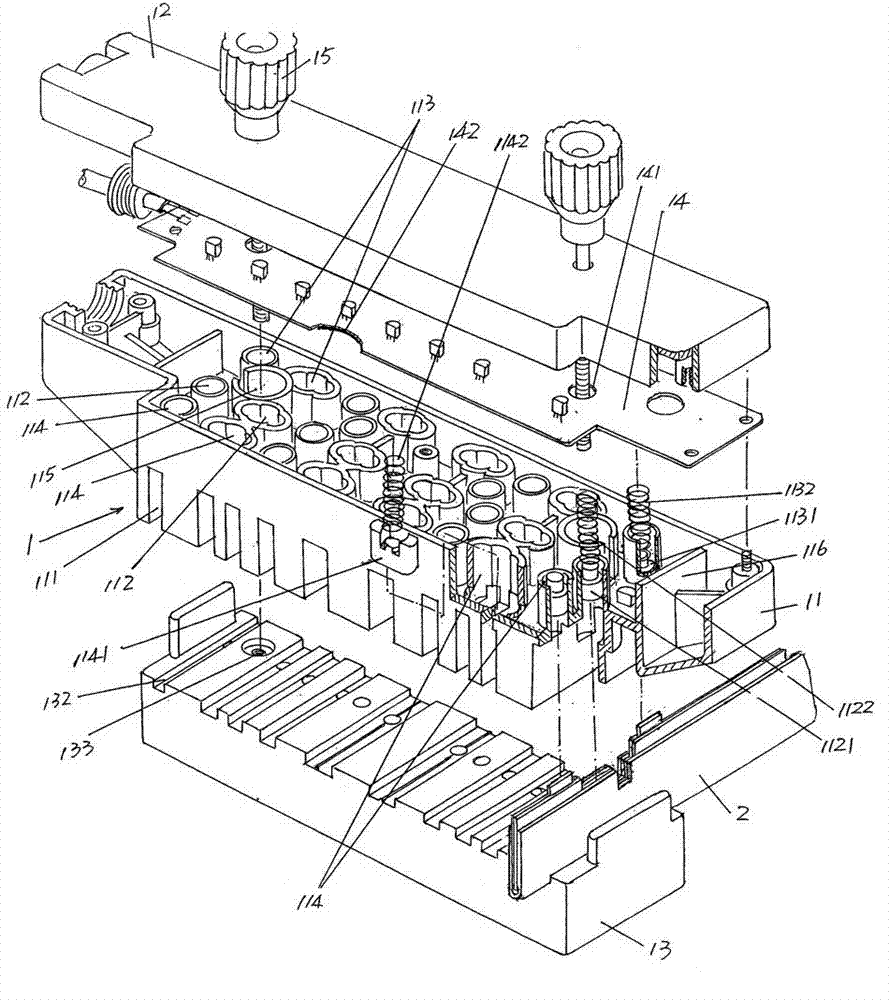

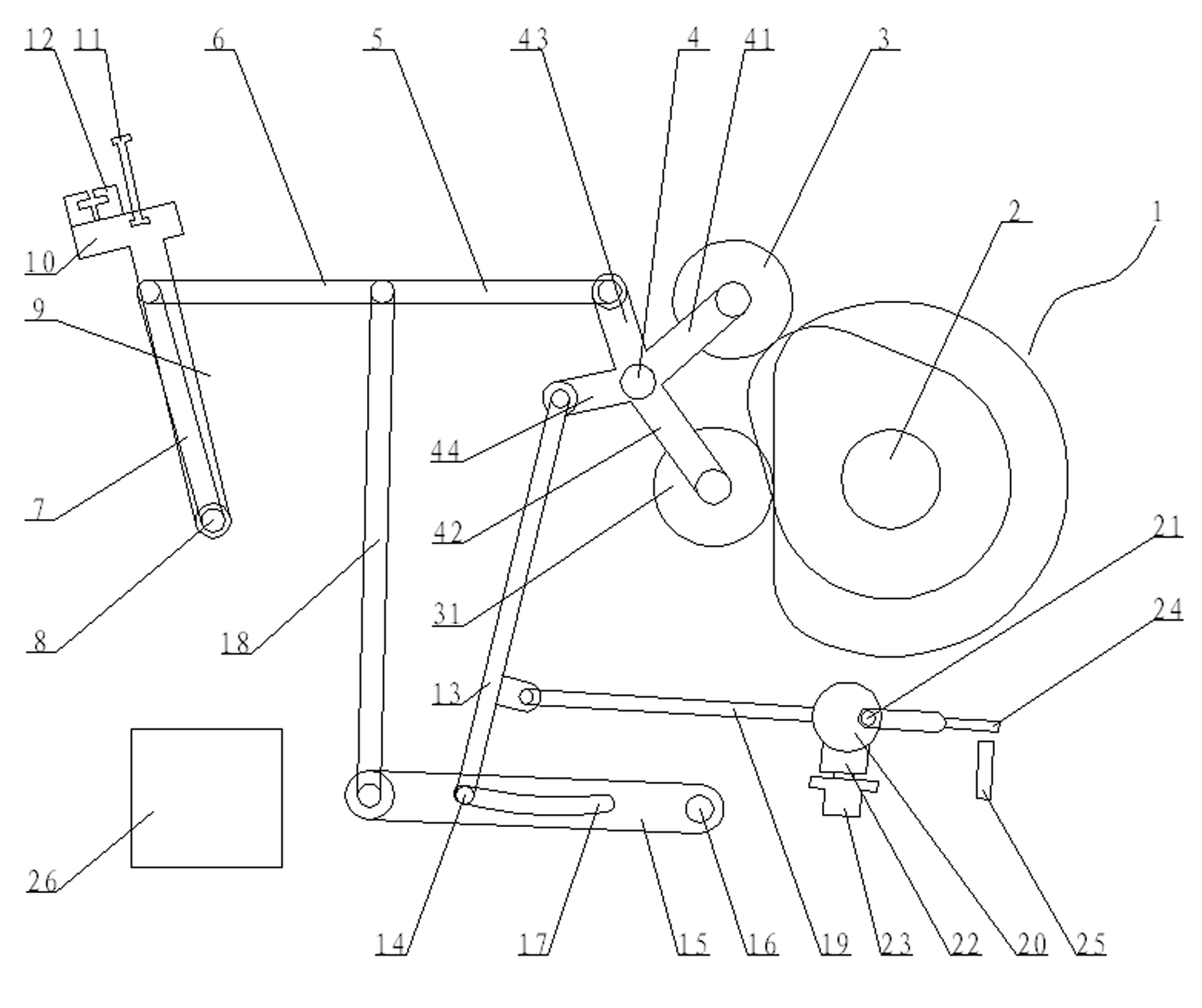

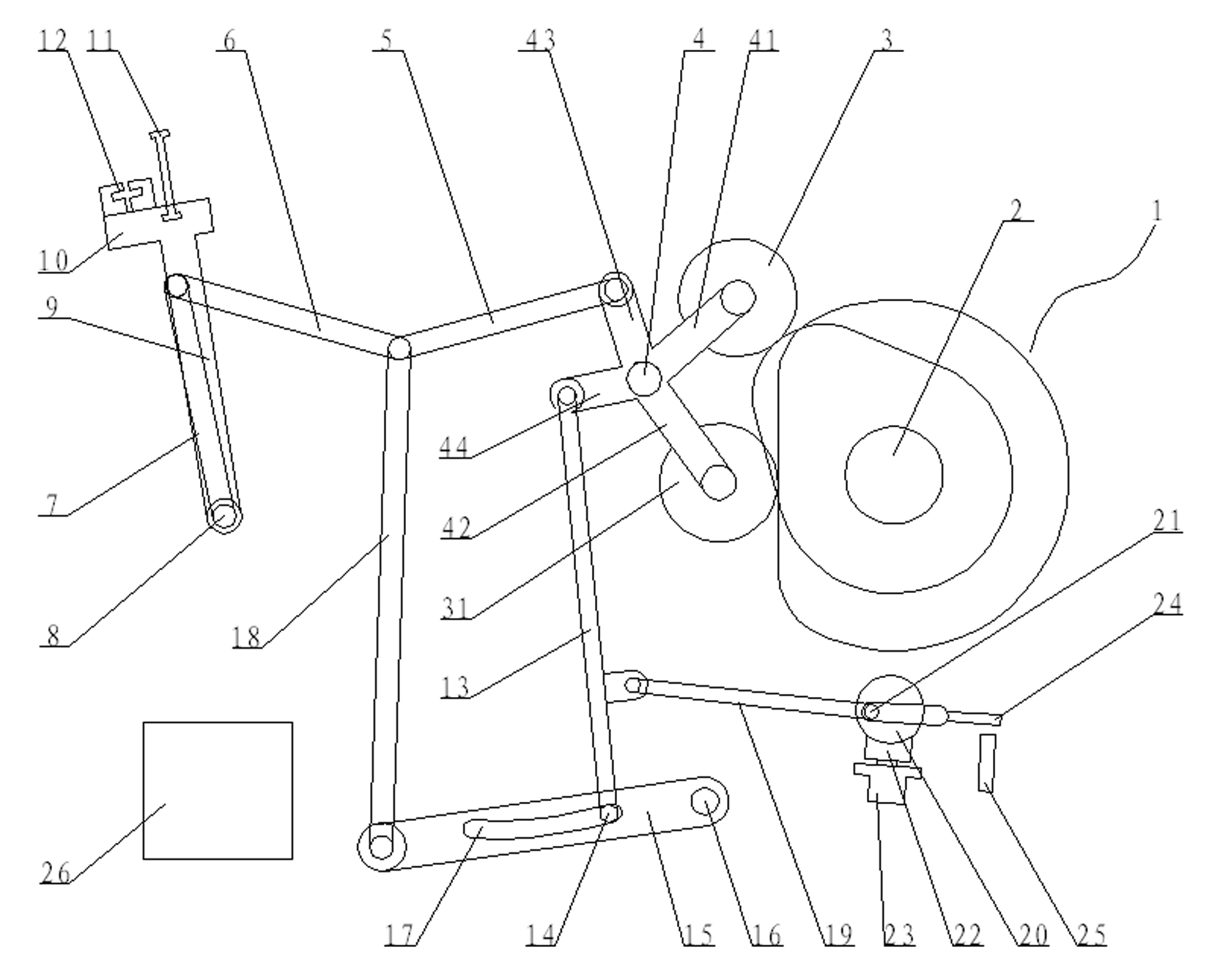

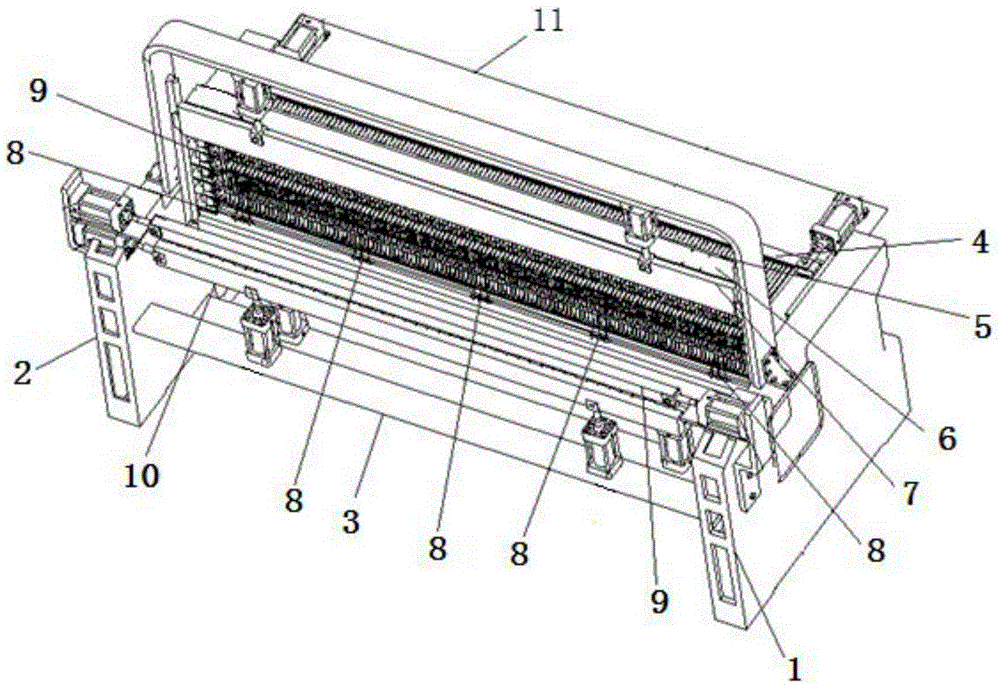

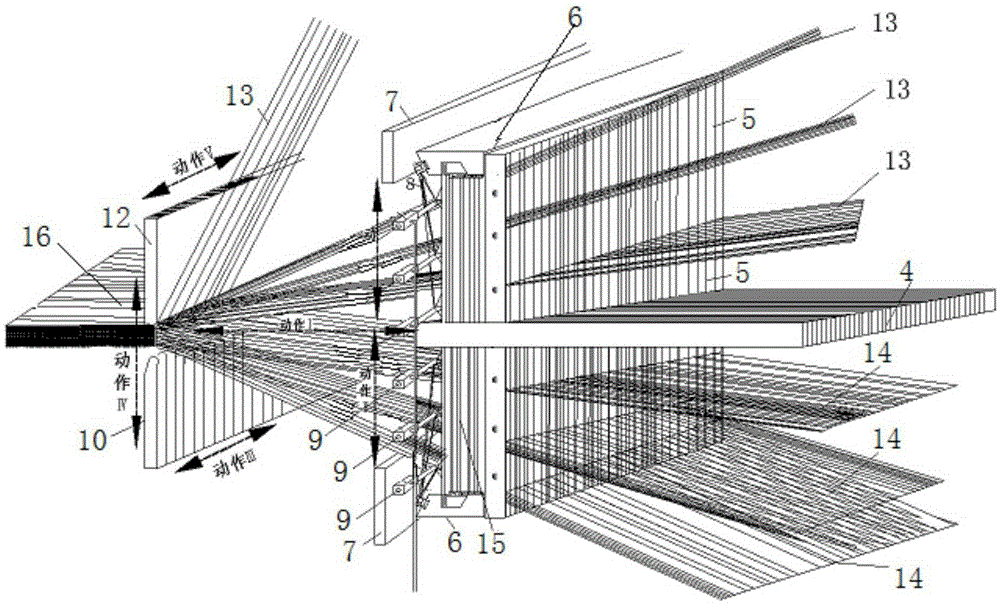

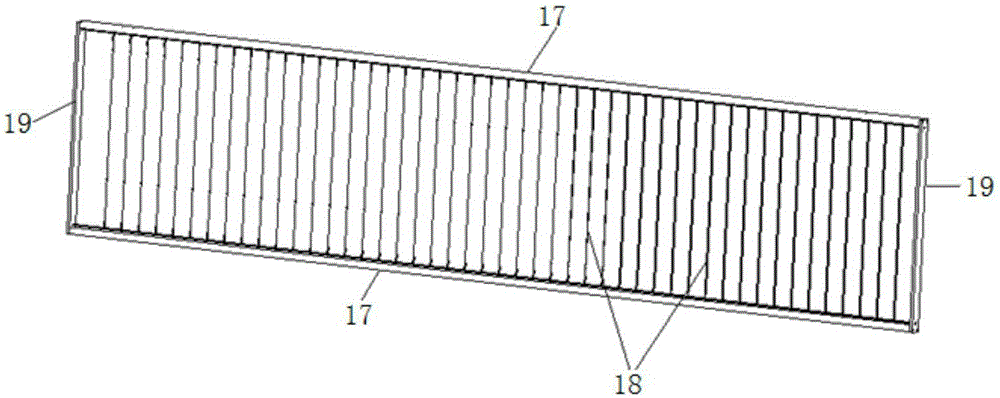

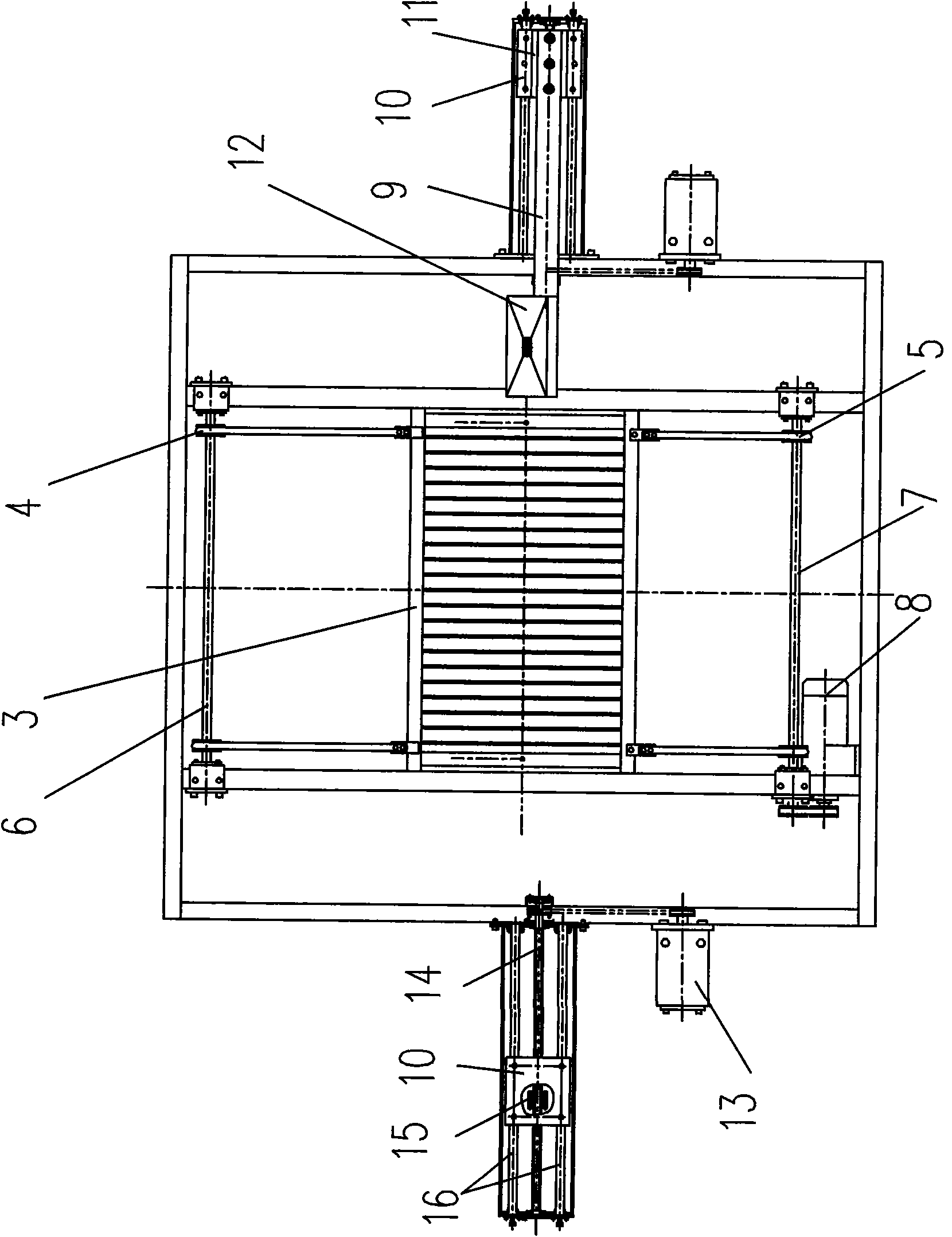

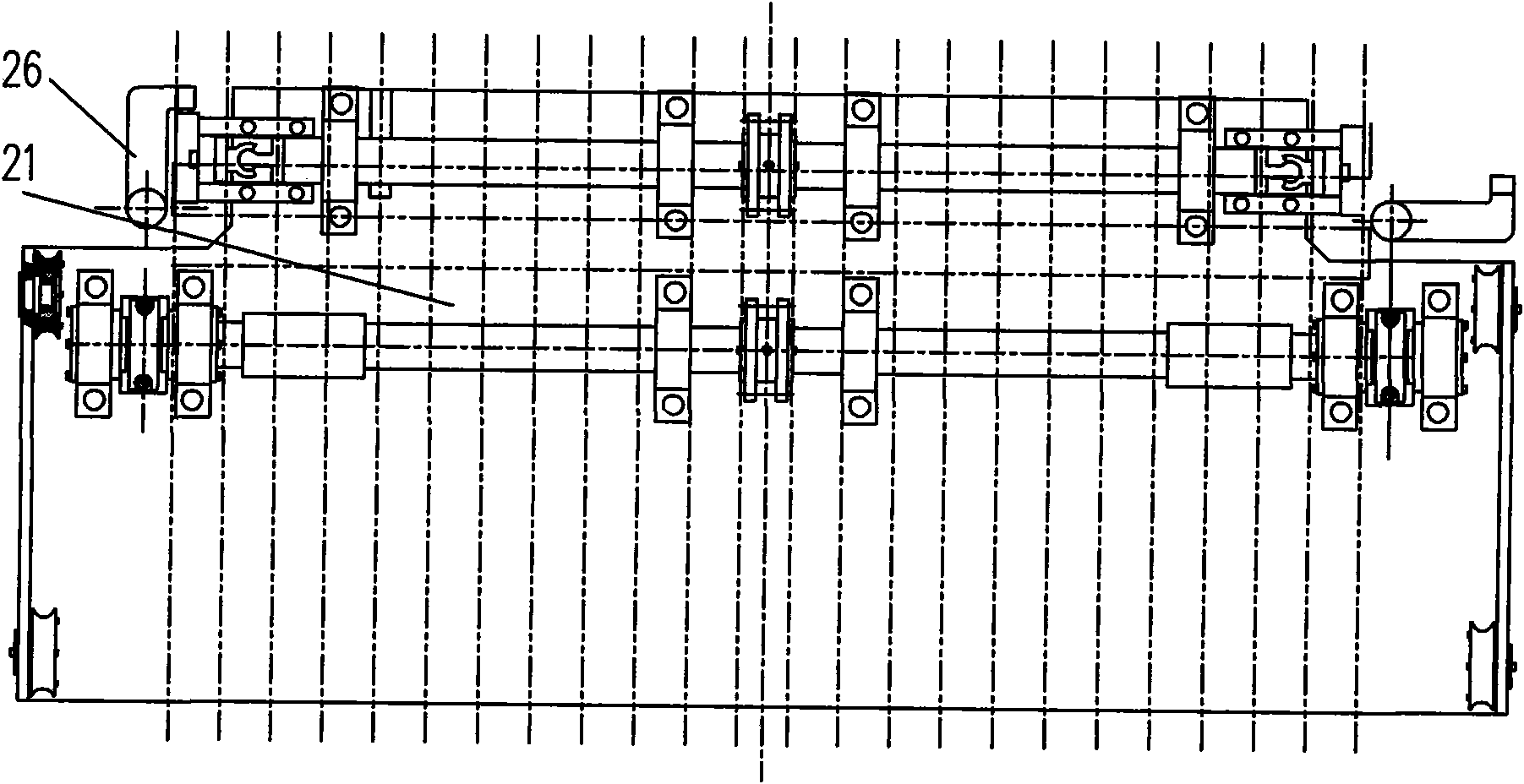

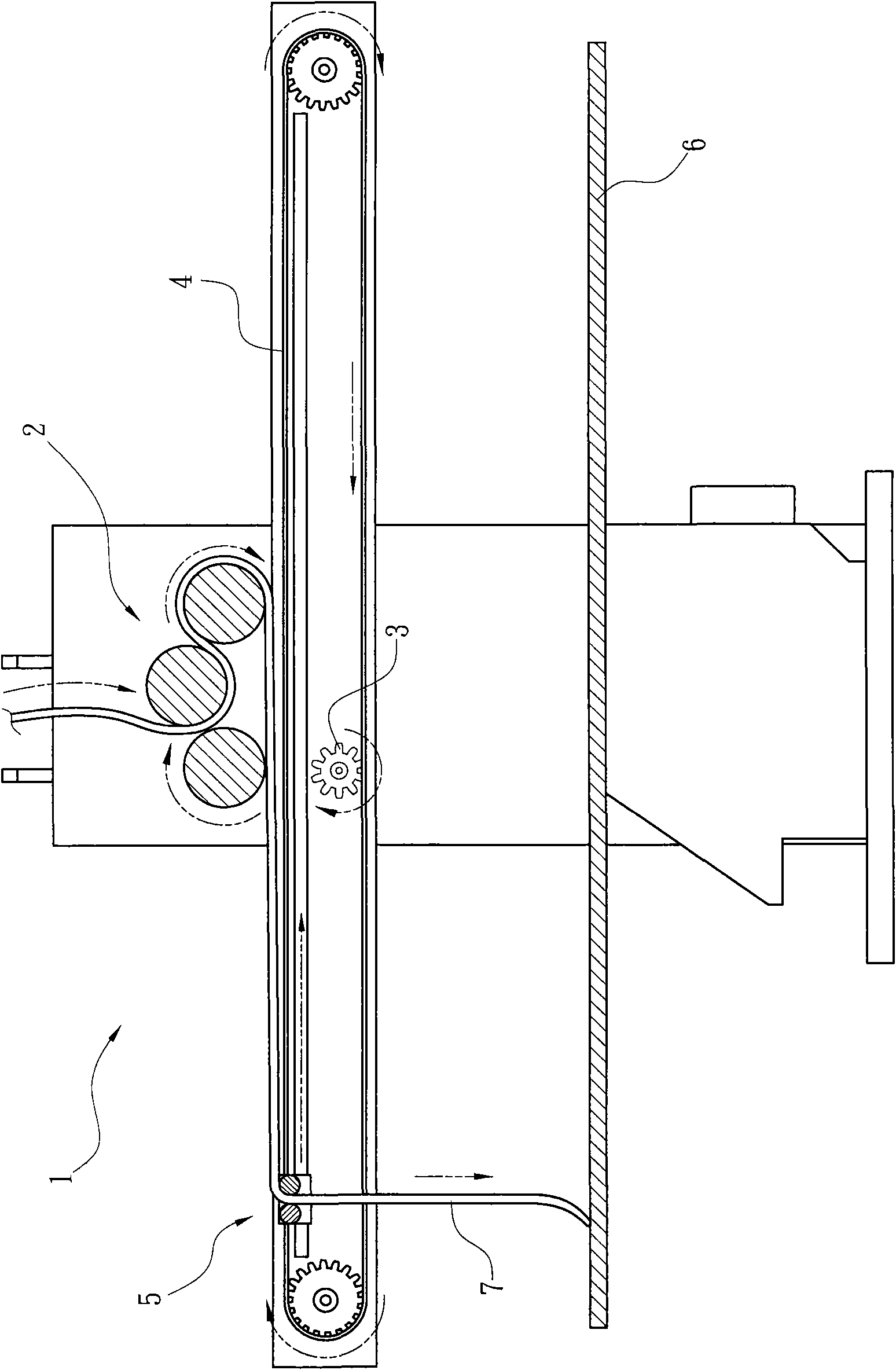

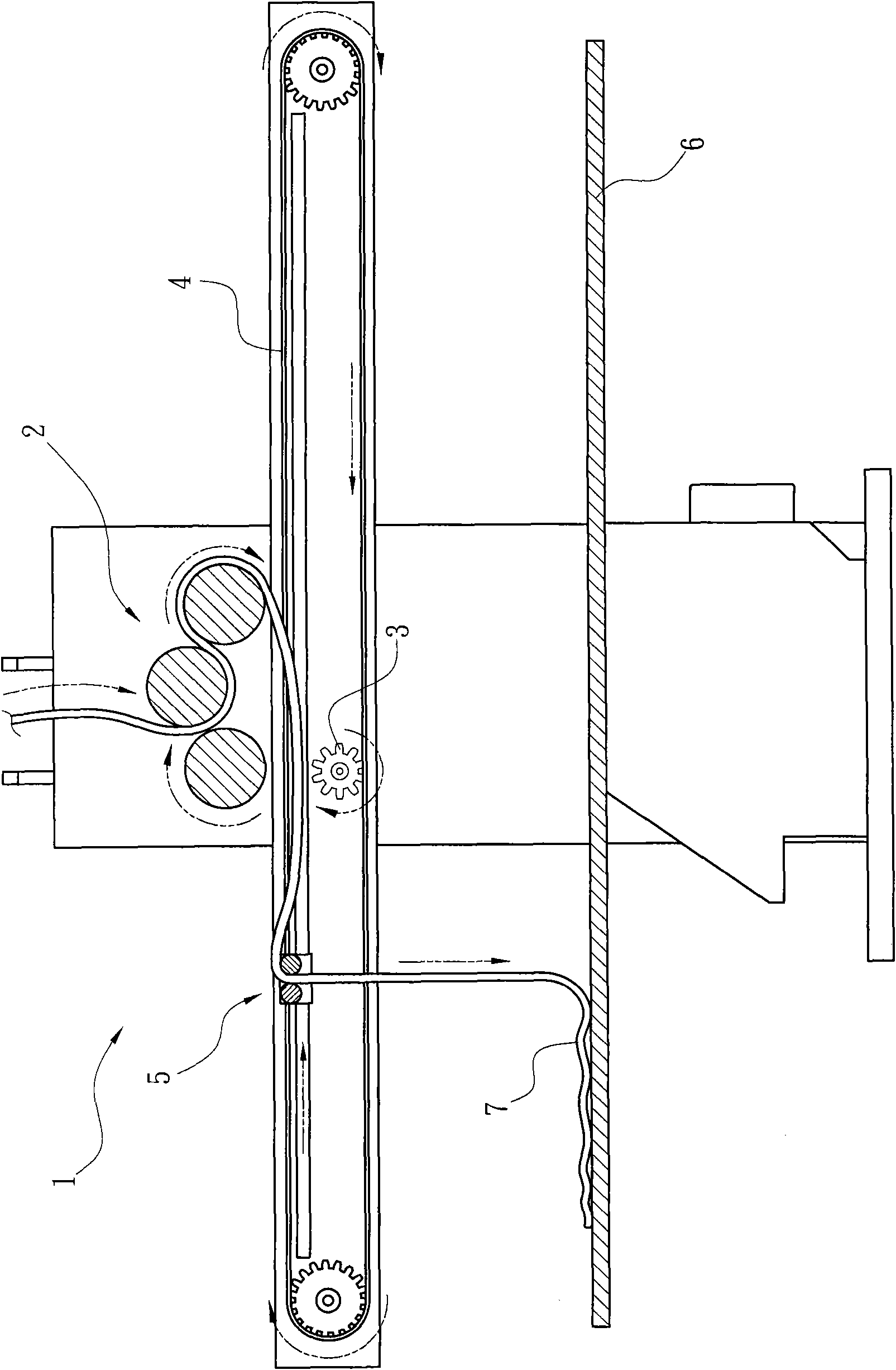

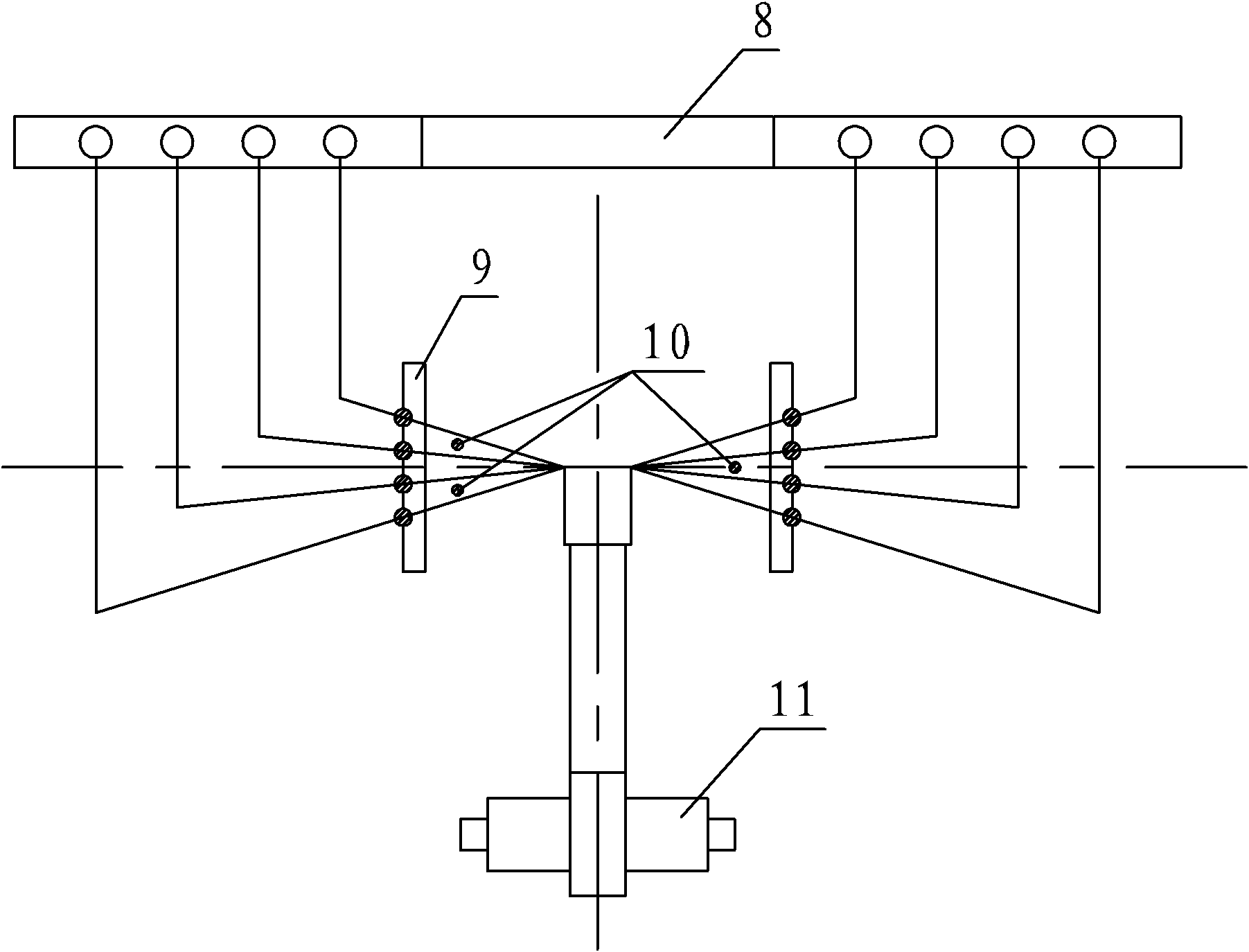

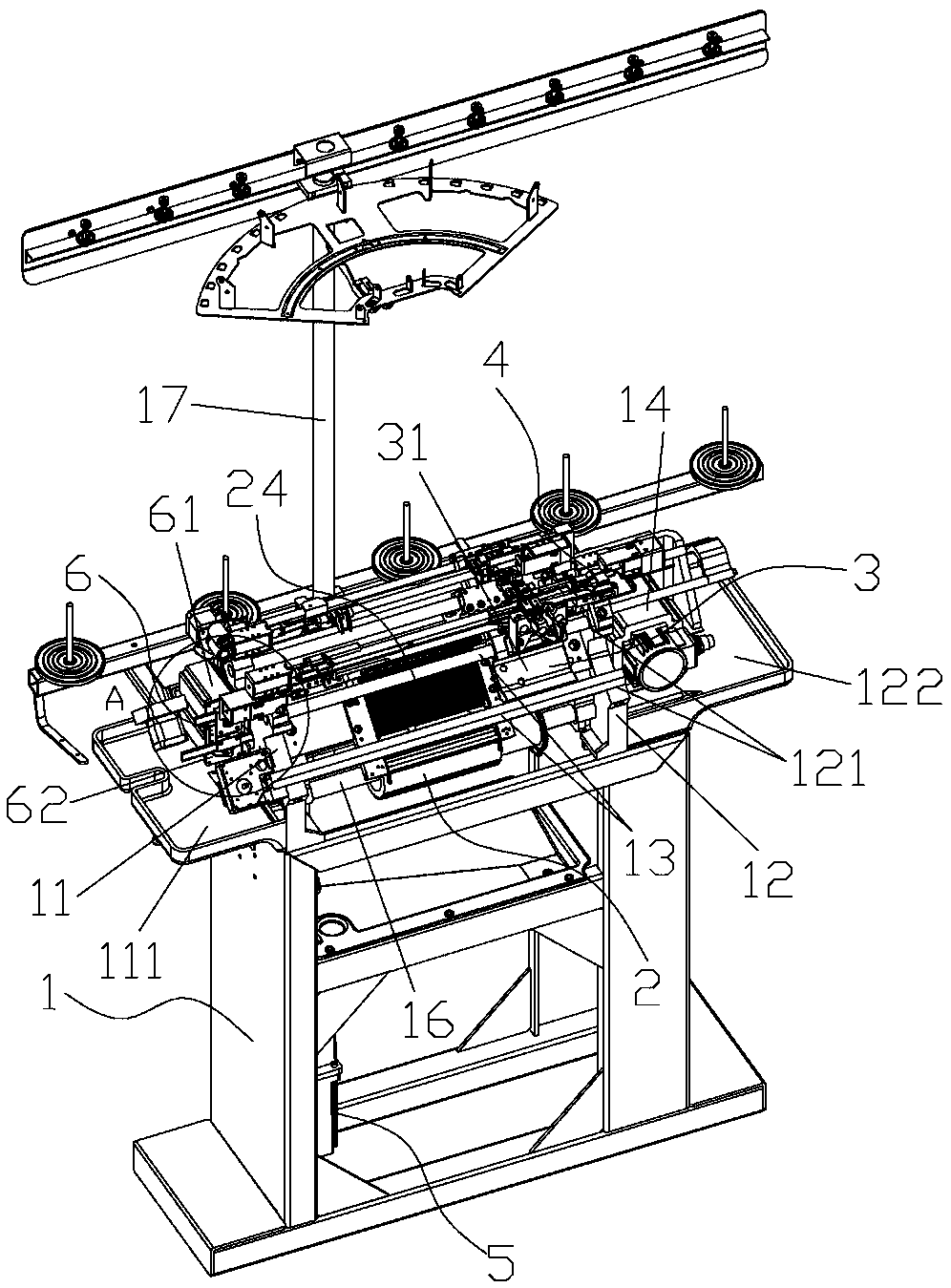

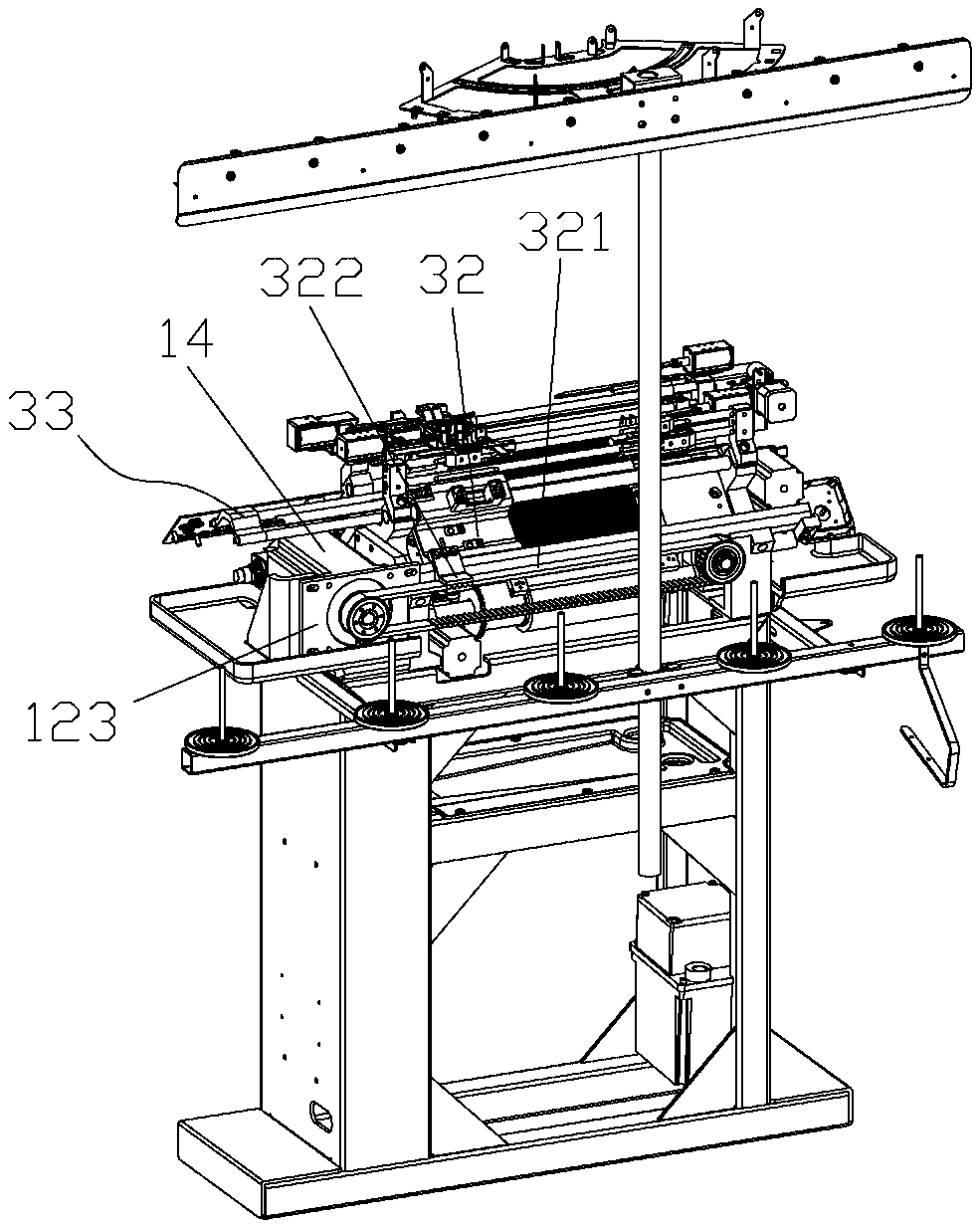

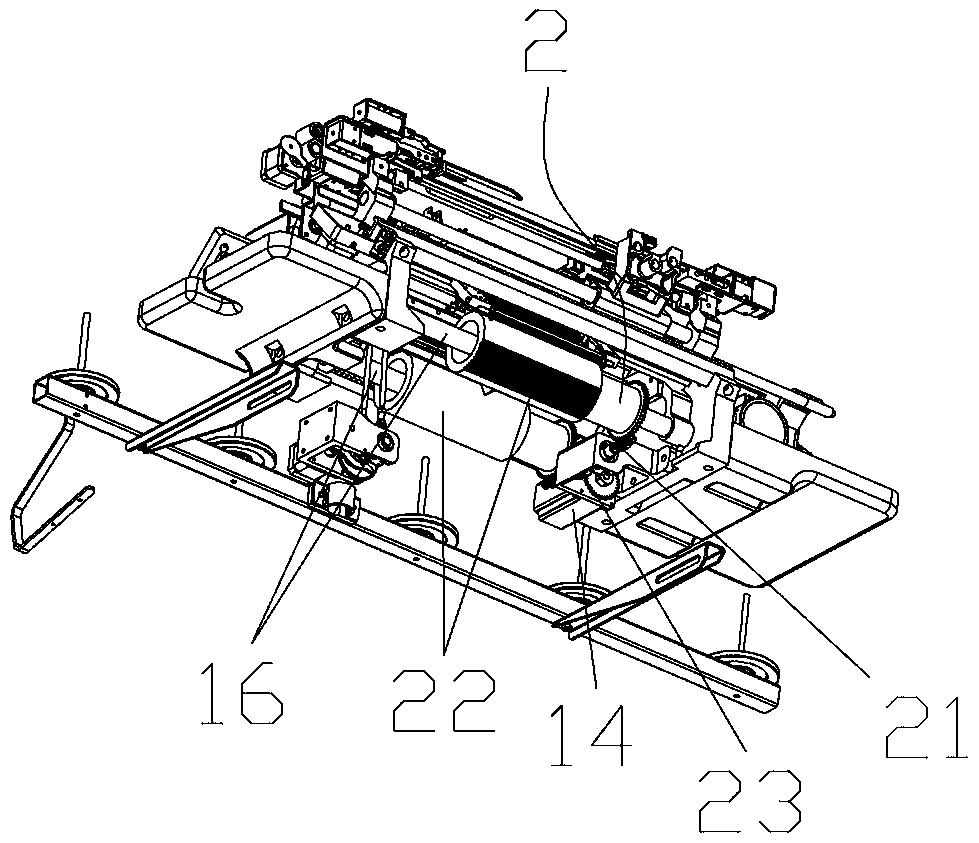

Weft insertion device and method for multilayer braided prefabricated body

ActiveCN108035053AIncrease exerciseImprove weaving efficiencyLoomsBiomedical engineeringInsertion device

The invention discloses a weft insertion device and method for a multilayer braided prefabricated body. The weft insertion device comprises a support, the support comprises a base and a lifting devicearranged on the base, and a yarn storing mechanism, a yarn selecting mechanism, a merging mechanism, a cutting mechanism and a traction mechanism are arranged on the lifting device in sequence in theweft insertion yarn forward direction. A rapier is used for weft insertion, a tension detection and control mechanism is arranged on a spool, real-time monitoring and compensation on weft yarn tension are achieved, and by means of a yarn selector, automatic selection on yarns of different specifications can be achieved. According to the weft insertion method for the multilayer braided prefabricated body, the adopted device is simple in structure, small in occupied area and convenient to operate; when weft insertion is conducted, the mechanism movement is easy, weft insertion of high-thicknessbraided prefabricated body braiding can be achieved, and the braiding efficiency is significantly improved; meanwhile, online automatic yarn selection and merging can be achieved for the yarns of different specifications, and the braising quality is improved; the multilayer braided prefabricated body is high in structural design; the device and method are suitable for preparing platy prefabricated bodies with complex shapes.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

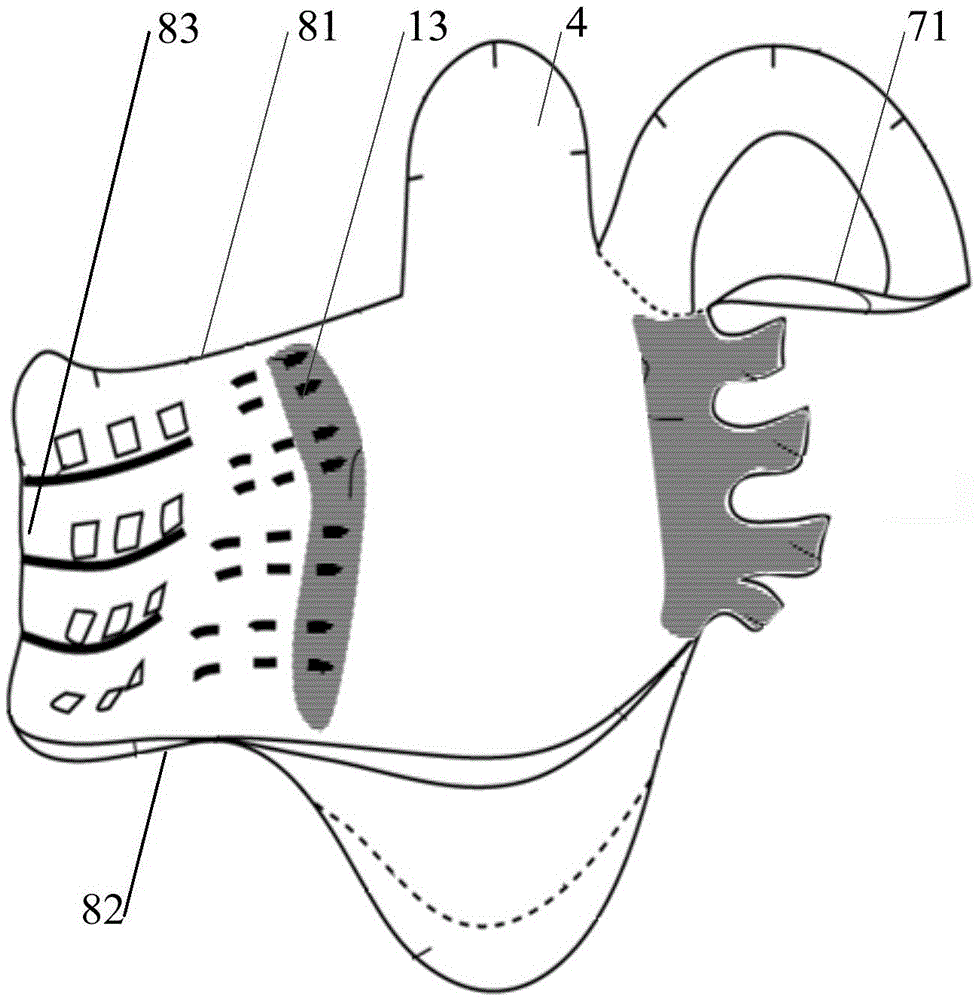

Formed knitted shoe cover, weaving method of formed knitted shoe cover and shoe body adopting formed knitted shoe cover

The invention discloses a formed knitted shoe cover, a weaving method of the formed knitted shoe cover and a shoe body adopting the formed knitted shoe cover. The weaving method comprises: by local weaving, obtaining a shoe rear waist and a shoe midsole, and extending to weave a shoe midsole middle part and a shoe midsole front part so as to form a heelpiece and the shoe midsole which are stereoscopically formed at a time; extending towards both sides of the shoe midsole middle part from the position of the shoe midsole middle part to form a shoe inner waist and a shoe outer waist; at one side of the shoe midsole front part and towards the direction far away from the shoe rear waist, forming a shoe endshield by local weaving; finally, carrying out point alignment and sewing on the edge of the shoe cover so as to obtain the knitted shoe cover stereoscopically formed at a time. In the weaving process, the shoe rear waist, a shoe midsole rear part, the shoe midsole middle part and the shoe midsole front part are formed and woven at a time, both the left and right sides of the shoe midsole middle part extend to be woven to obtain the shoe inner waist and the shoe outer waist, the shoe endshield is woven at the position of the shoe midsole front part, and finally, an alignment point at each position on the shoe cover is aligned and sewn so as to obtain the shoe cover stereoscopically formed at a time. The process of splicing each position of the shoe cover is simplified, so that the weaving process is optimized, and weaving efficiency is improved.

Owner:NEW TECH KNITTING CO LTD

Warp stopping frame

The invention relates to a warp stopping frame and belongs to a shuttleless loom accessory. The warp stopping frame comprises a warp stopping bar junction box, a group of warp stopping bars, a pair of warp stopping bar supporting plate fixing seats, a pair of warp stopping bar supporting plates, a pair of warp frames and a group of warp stopping bar middle supporting plates; the warp stopping bar junction box comprises a box body, a box cover, a box seat and a circuit board, and the group of warp stopping bars comprises an iron clad, a broken warp display protection mechanism and an insulation coating pieces. The warp stopping frame is characterized in that power supply negative pole contact matching notches are opened at the positions on the insulation coating pieces, the positions on the insulation coating pieces correspond to positions between a power supply positive pole contact plate and a signal output contact plate, an upper edge of the iron clad, which corresponds to the positions of the power supply negative pole contact matching notches, is higher than an upper edge of a thin insulation sheet, one end of a power supply negative pole contact is electrically contacted with the iron clad at the position of the power supply negative pole contact matching notches, the other end of the power supply negative pole contact is electrically contacted with one end of a power supply negative pole electric conduction spring, and the other end of the power supply negative pole electric conduction spring is electrically connected with a contact point of a power supply negative pole on the circuit board. By means of the warp stopping frame, reliability of the warp stopping bar junction box responding to warp breaking signals is guaranteed, machine halt time is shortened, and weaving efficiencies are improved.

Owner:CHANGSHU CHANG XIN TEXTILE EQUIP

Kuralon fiber finely woven fabric and preparation method thereof

A kuralon fiber finely woven fabric is characterized by comprising the following components by weight percent: 70-80% of wool or wool and other fibers and 20-30% of kuralon fiber; and the preparation method comprises the following steps: 1) selecting raw materials; 2) recombing; 3) spinning; 4) weaving; and 5) dyeing and finishing. The kuralon fiber finely woven fabric produced by the method of the invention has bulky and soft hand feeling and the hollowness is up to 20-30%. The selection of kuralon is reasonable, the mixing method ensures that the kuralon fiber finely woven fabric can be smoothly spun, the spinnability is good, the fiber is easy to draw, the evenness is good, the fault is less, the weaving efficiency is high, and the characteristics that the fabric is hollow and the hand feeling is bulky and soft, of the kuralon fiber finely woven fabric can be better embodied after finishing.

Owner:JIANGSU DANMAO TEXTILE

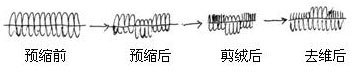

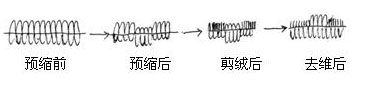

Method for processing blanched untwisted relief towels

ActiveCN102121156ASolve the problem that embossed towels cannot be producedImprove weaving efficiencyPile loops cuttingDomestic applicationsEngineeringWater soluble

The invention discloses a method for processing blanched untwisted relief towels. The method comprises the following steps: doubling and twisting high temperature water soluble vinylon yarns at the temperature being higher than 90 DEG C with the common cotton yarns to prepare untwisted water soluble yarns; arranging the obtained untwisted water soluble yarns and the common yarns at intervals in a ratio of 1:1 and warping the yarns to prepare wool warp beams and interweaving the wool warp beams with ground warp and weft yarns to form jacquard patterns; ensuring the untwisted parts to shrink and the parts needing to be sheared to protrude through squeezing, moistening and high temperature roller blanching; after drying, shearing the raised parts needing to be sheared on a shearing machine; dissolving out the water soluble yarns on the untwisted yarns with high temperature water at the temperature being higher than 90 DEG C to ensure the untwisted yarns to be untwisted and pop; and after washing, carrying out water removal, softening and drying to ensure the untwisted yarns to be fluffy and raised. Through changing the preshrinking method, the problem that the relief towels can not be produced with the high temperature water soluble untwisted yarns is solved and the effects of low cost, high weaving efficiency, strong third dimension of the relieves and high yield can be achieved.

Owner:NANTONG DADONG

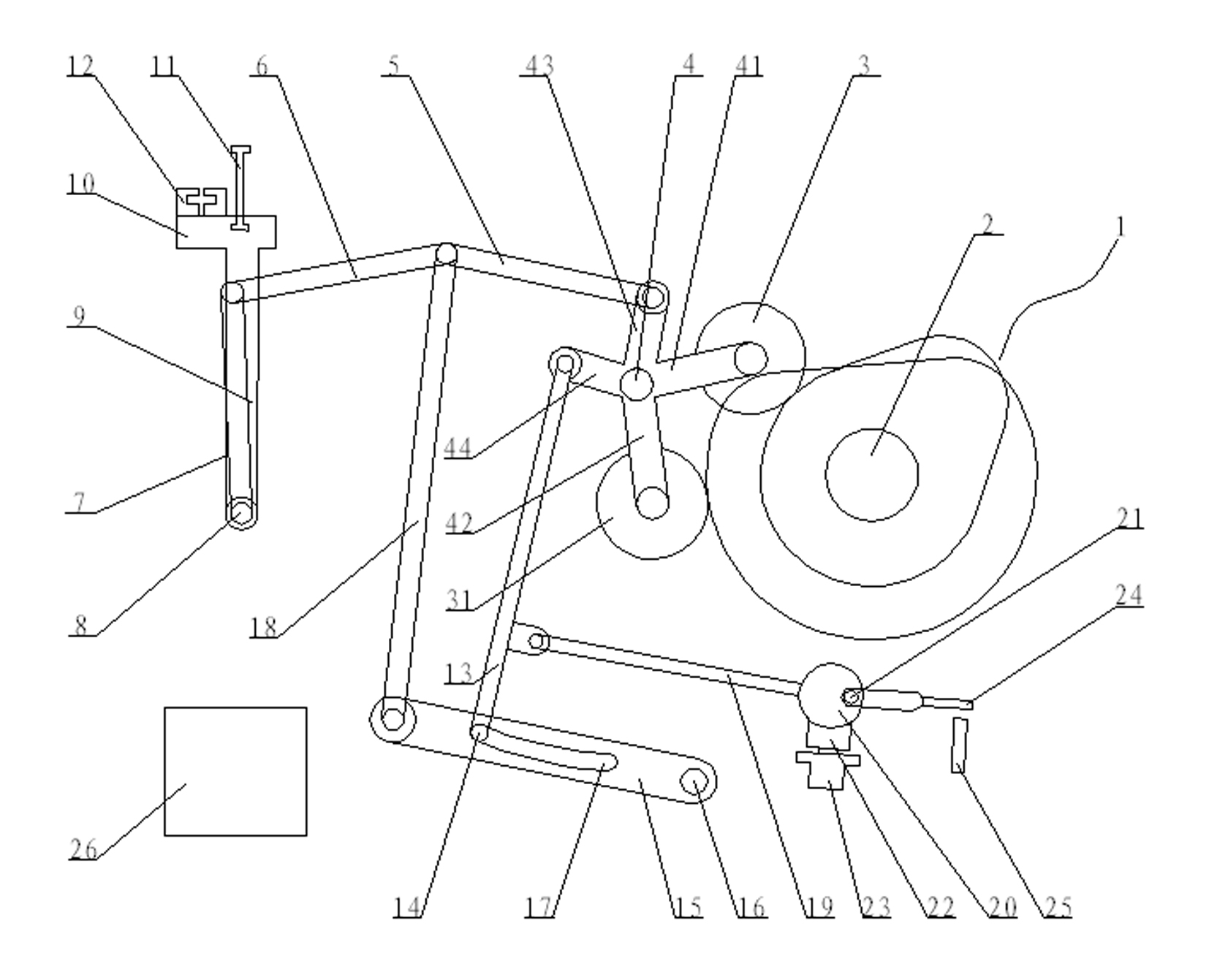

Novel numerical control reed-moving fluff conjugate cam beating-up mechanism

InactiveCN102011253ASolve the accuracy problemTransmission length shortenedLoomsRelative displacementHinge joint

The invention relates to a novel numerical control reed-moving fluff conjugate cam beating-up mechanism. The beating-up mechanism comprises a conjugate cam group, a pendulum shaft assembly, a beating-up drive link and a sley beating-up part, wherein the conjugate cam group is hinged with the beating-up drive link through the pendulum shaft assembly in a movable manner to drive the sley beating-up part; the beating-up drive link consists of more than two stages of drive links which are hinged mutually; the hinged joint of each two stages of drive links are movably hinged with a positioning link which can move up and down; and the positioning link is connected with a numerical control regulating mechanism to regulate the rising and falling of the positioning link and ensure that the straight line drive effective total length between the both ends of the beating-up drive link can be controlled by changing the angle between each two stages of drive links. The invention provides the novel numerical control reed-moving fluff conjugate cam beating-up mechanism which is suitable for high speed, has the advantages of compact structure, low cost and high weaving efficiency, is easy to repair and can weave products with different pile heights; and the mechanism can control the relative displacement of each weft of reed to control the pile height of each weft and weave different hair types with 3-7 wefts such as wavy hair and zigzag hair.

Owner:王勇

Softener for thick salix integra and preparation method of softener

ActiveCN103659979AImprove toughnessSmoothReed/straw treatmentWood impregnation detailsEthylenediamineBetaine

A softener for thick salix integra is made from raw materials in parts by weight as follows: 5-7 parts of ethylenediamine, 4-5 parts of tartaric acid, 4-5 parts of coco-betaine, 1-2 parts of decyl polyglucoside, 4-5 parts of ammonium dihydrogen phosphate, 10-12 parts of dandelion, 4-6 parts of chrysanthemum, 10-12 parts of coptis chinensis, 3-4 parts of camphor tree bark, 6-8 parts of povidone iodine,3-4 parts of an assistant and 100 parts of water. According to the softener, the ethylenediamine, the tartaric acid and multiple surfactants are used, so that the softener is high in permeation speed, high in softening speed and even in softening; the salix integra is good in toughness and touches smooth, and the weaving efficiency can be improved; and Chinese herbal medicines such as the camphor tree bark and the like as well as the povidone iodine are used, so that salix integra is smooth in surface, mould-proof and free of worms. The softener is applicable to softening of the thicker salix integra.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

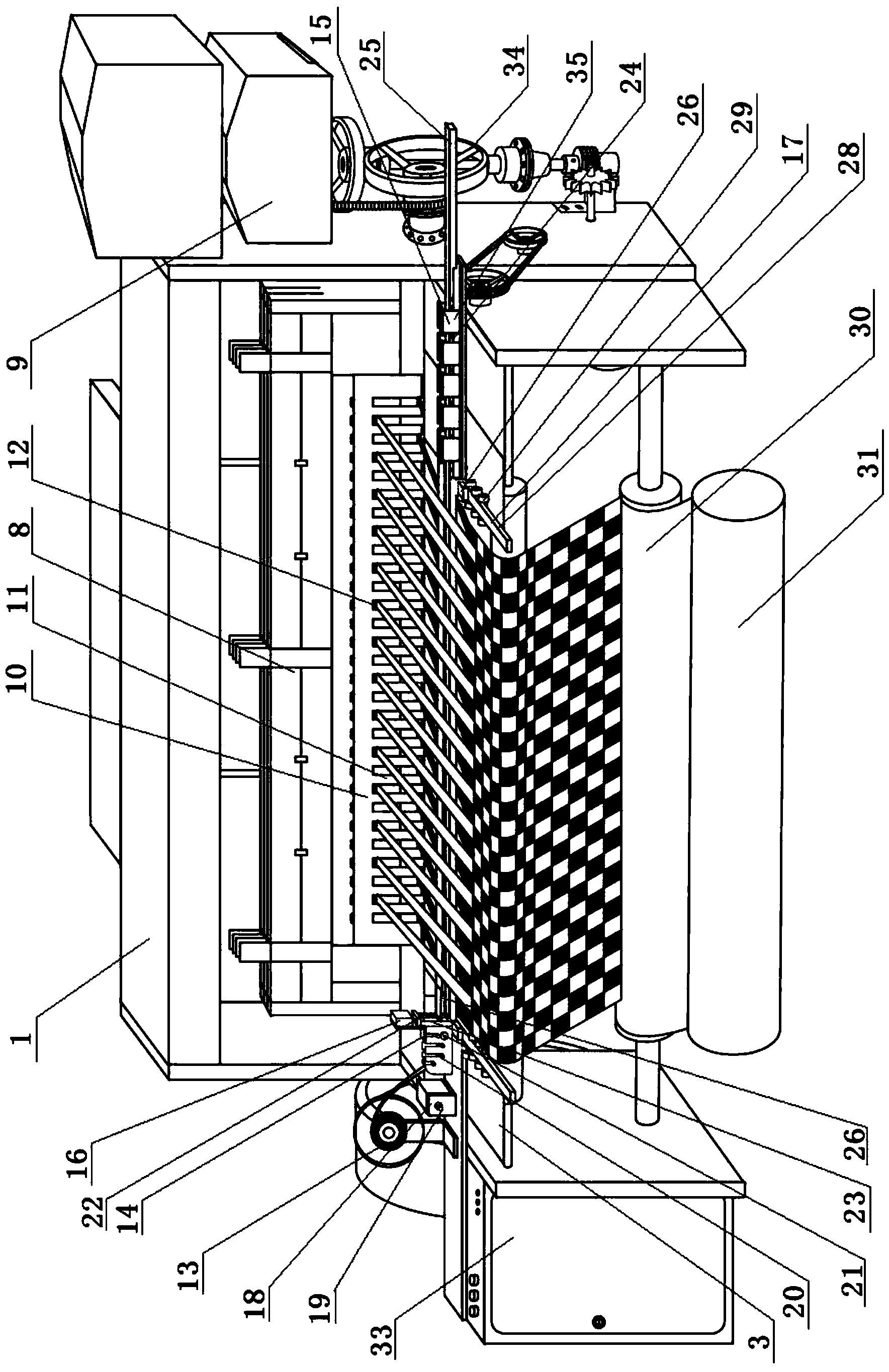

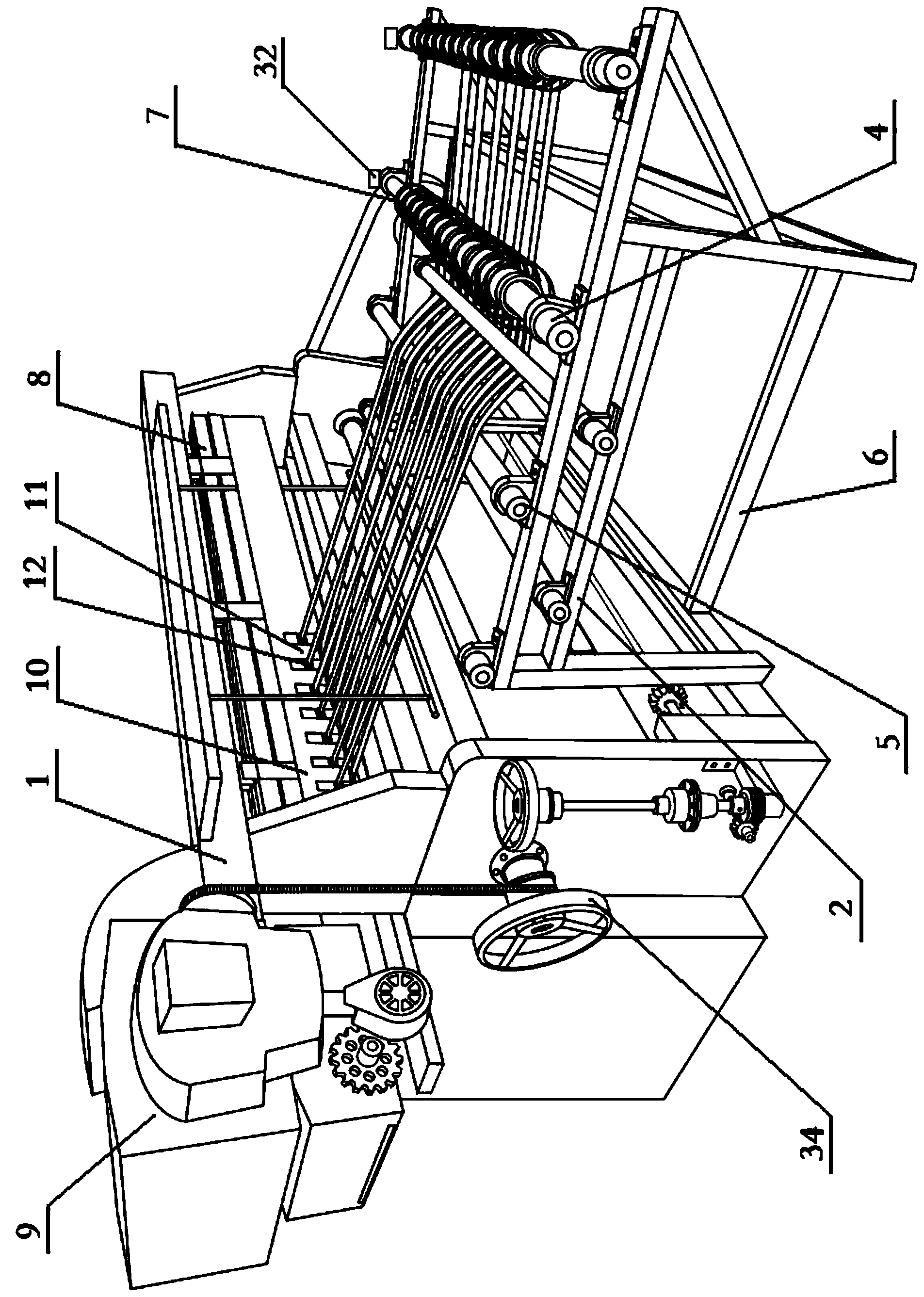

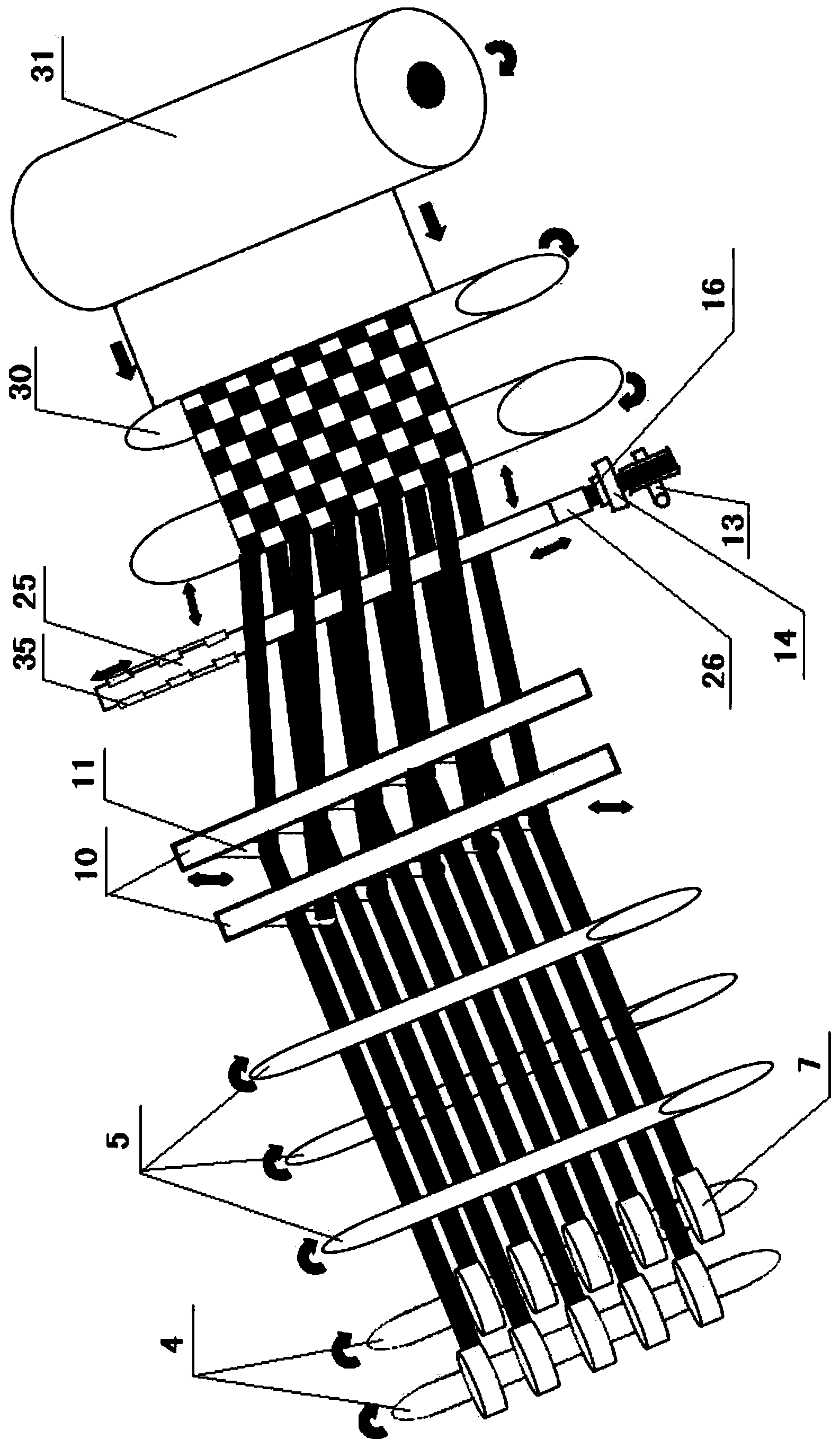

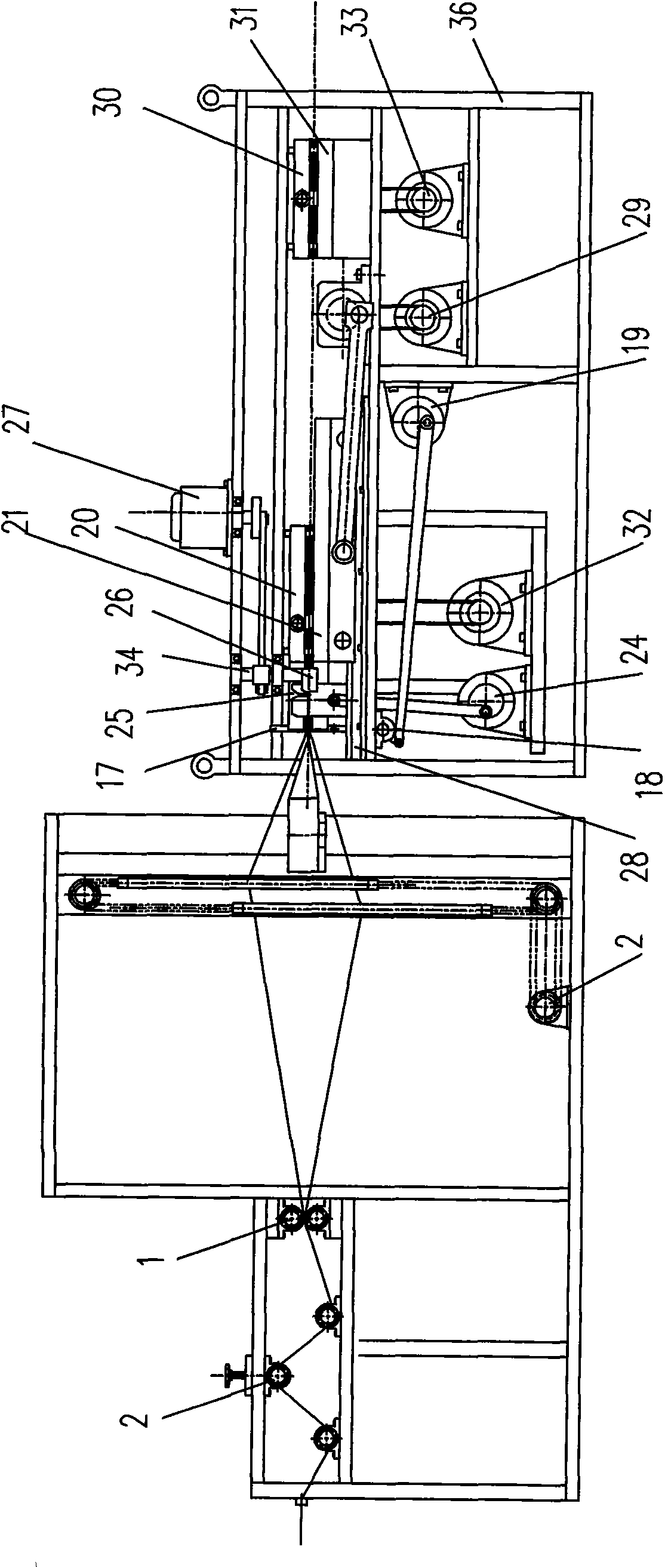

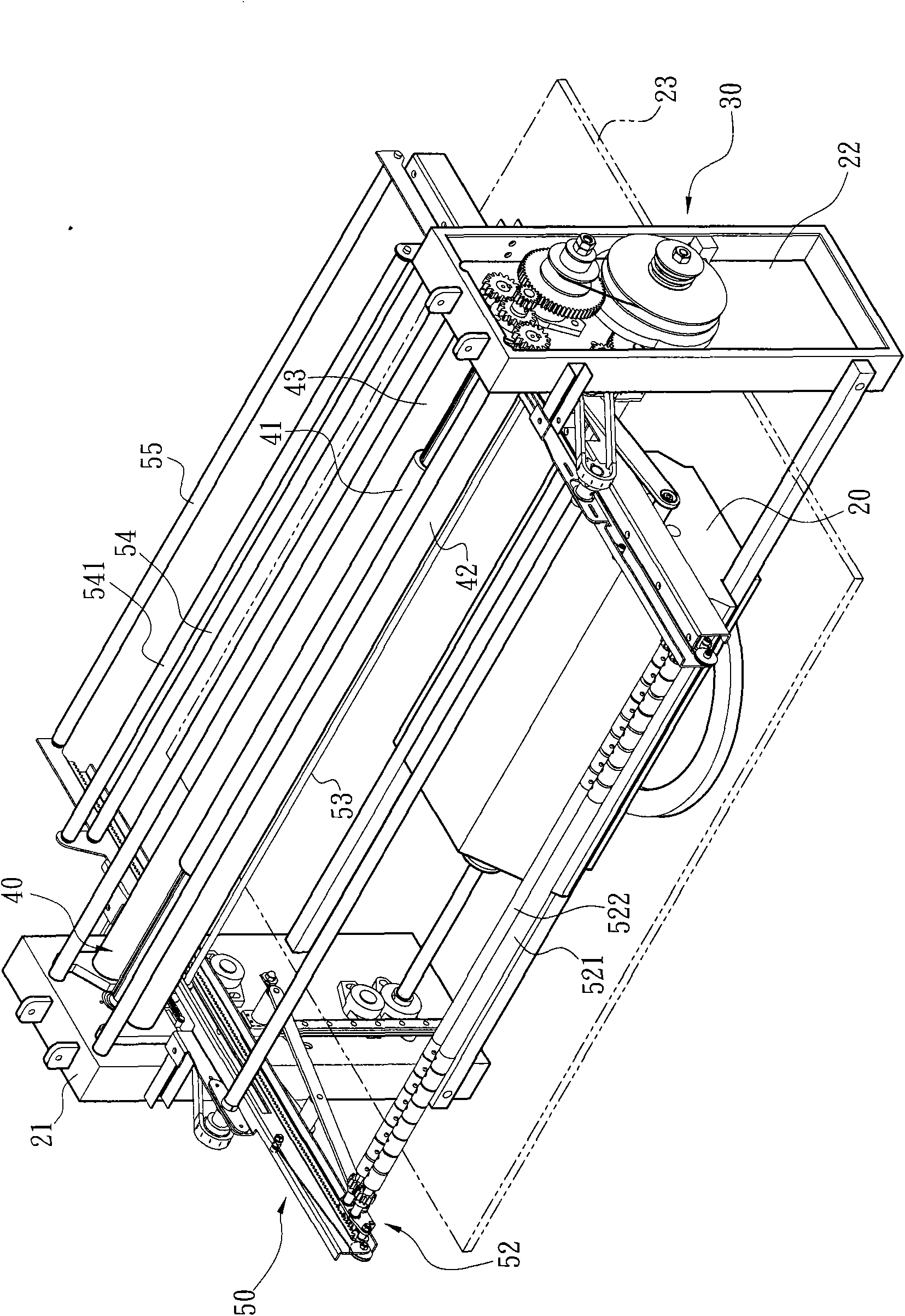

Broad-width carbon-fiber knitting machine and method for producing carbon-fiber gridding cloth by using same

ActiveCN103628224AImprove weaving efficiencySolve the problem that weaving needs pure handmadeLoomsWoven fabricsFiberCarbon fibers

The invention aims to study out special production equipment for knitting carbon-fiber gridding cloth through broad-width carbon fibers and a method for producing the carbon-fiber gridding cloth through the special production equipment. The invention has the technical scheme that a broad-width carbon-fiber knitting machine comprises a knitting-machine main body, a warp conveying device and a knitting table, wherein the warp conveying device is formed by a bottom supporting frame, a plurality of warp driving shafts and a plurality of traction driving shafts, a warp lifting and pulling device and an electric control box which are used for separating broad-width carbon-fiber tow bands up and down at intervals are also arranged on the knitting-machine main body, and a weft frame, a weft releasing device, a weft towing device, a weft cut-off device and a weft translating device are arranged on the knitting table. The invention also discloses the method for producing the carbon-fiber gridding cloth by using the broad-width carbon-fiber knitting machine. The invention has the beneficial effects that by adopting the knitting machine disclosed by the invention, the gridding-cloth knitting efficiency of the carbon-fiber tow bands after fiber expansion can be effectively improved, and the difficult problem that the carbon-fiber tow bands after fiber expansion need to be purely manually knitted is solved.

Owner:BEIJING ONLYTOP HIGH TECH MATERIALS

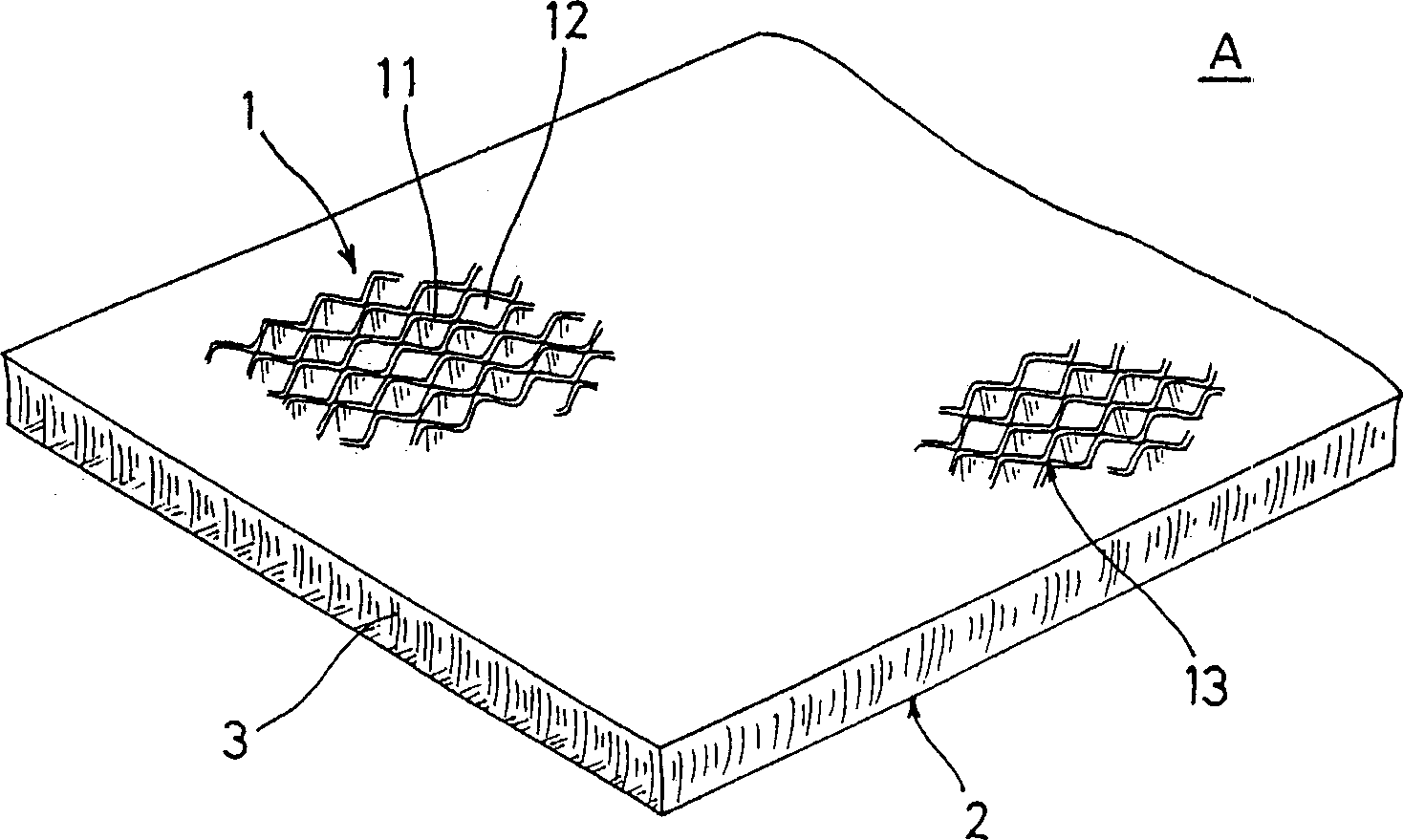

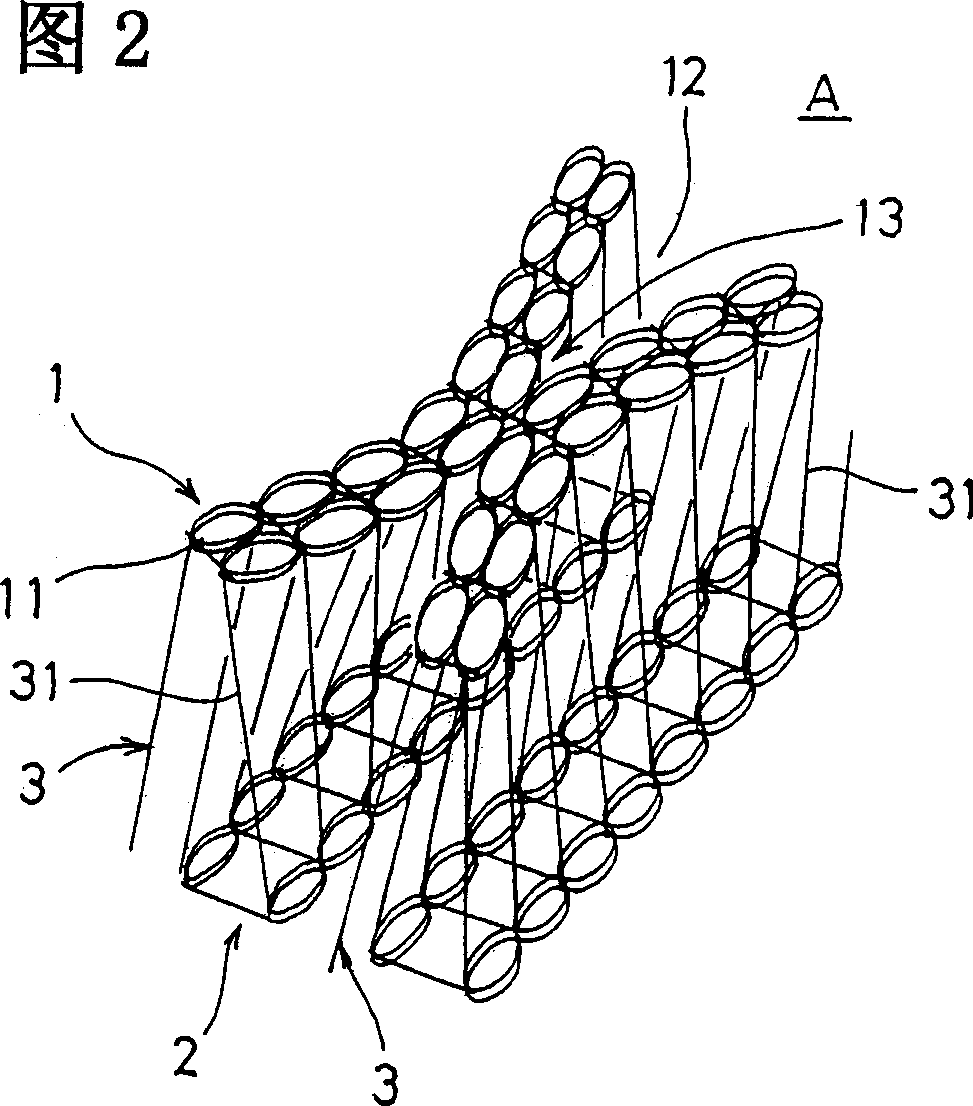

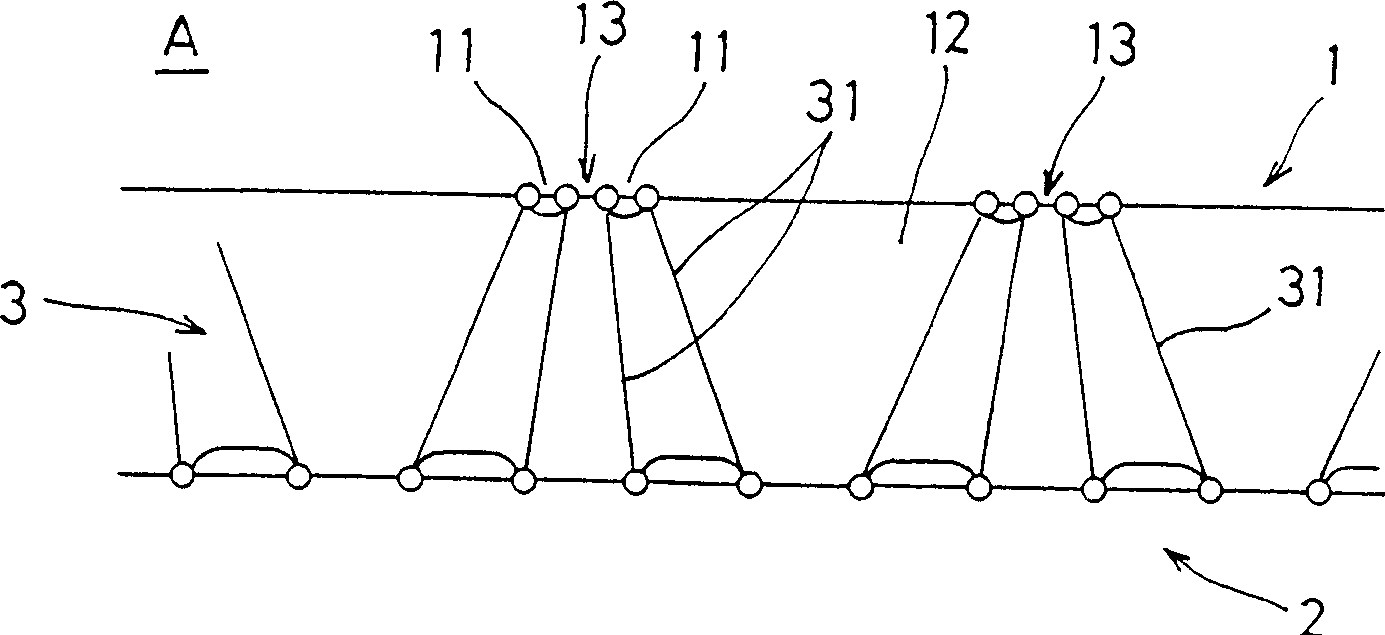

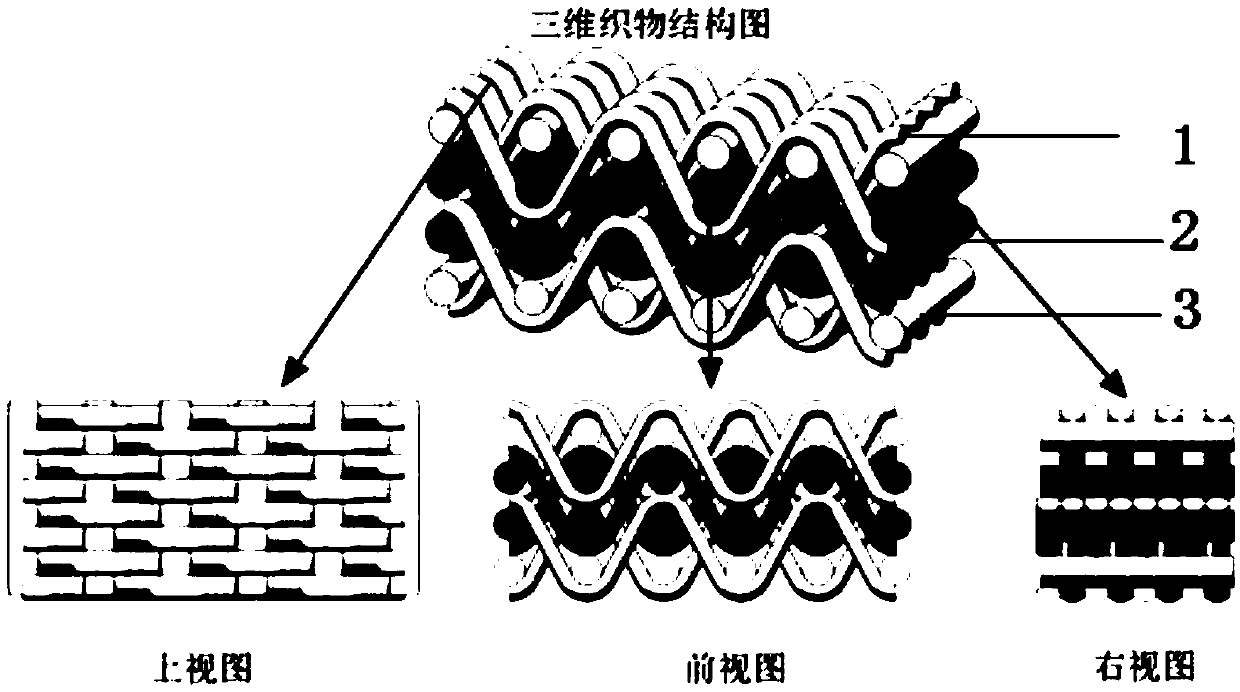

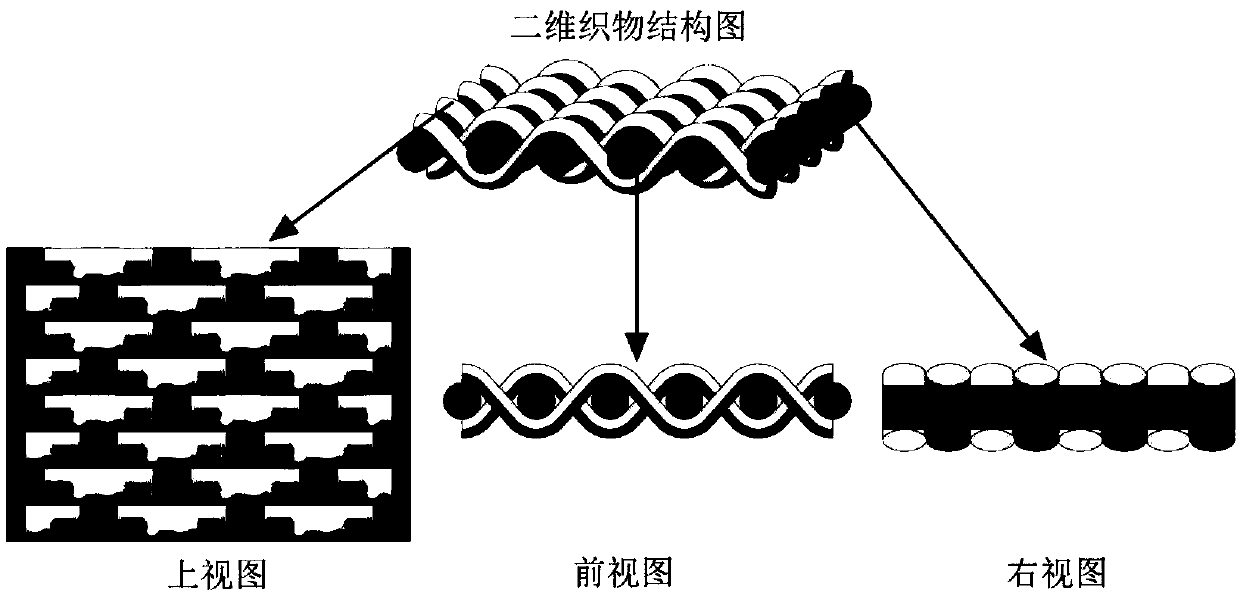

Double knitted fabric

InactiveCN1404539AGood touchImprove appearance qualityOrnamental textile articlesWarp knittingEngineeringLinearity

The invention is aimed to provide a three-dimensional marquisette-like knitted fabric that is good in air retainability, air and water conductibility, light transmittance, as well as dimensional stability and shape retainability in the knitting and knitting-width directions, and in linearity; and has unevenness and slippage preventing property on its surface, thus being suitable in various uses. To this end, a three-dimensional marquisette-like structure is made as follows. A double-web knitted fabric is made by warp knitting, and is preferably comprised of the front and back mesh webs (1, 2) and connecting yarns (3) passed between the mesh webs alternately. At least one of the mesh webs (1, 2) has a marquisette-like construction formed by the rows of chain stitches (11, 21) and inlay yarn (5). In addition, connecting yarns (3) for connecting the mesh webs (1, 2) is shifted knitting-width-wise by at least one wale to be passed as slanted at every required course position corresponding to the marquisette-like construction of at least one of the mesh webs.

Owner:ASAHI DOKEN

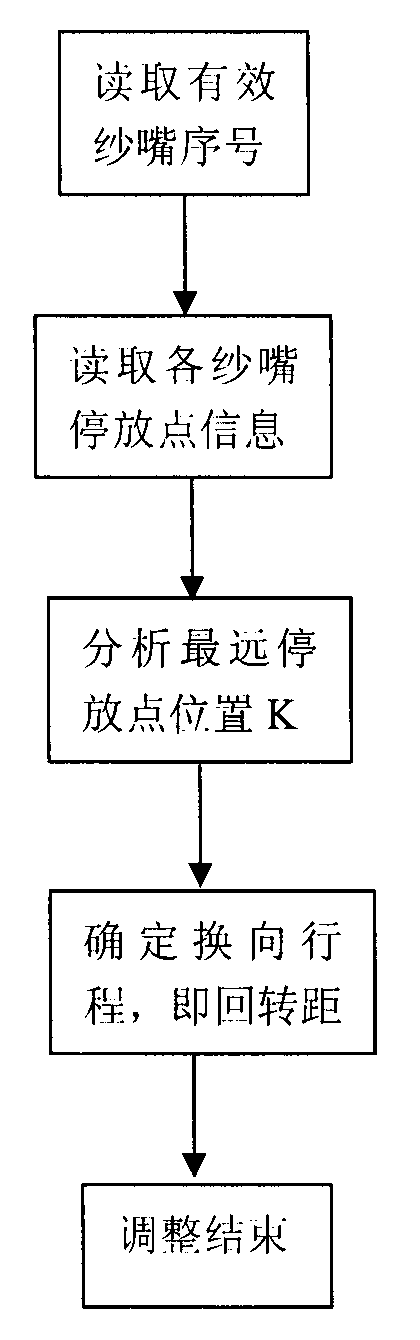

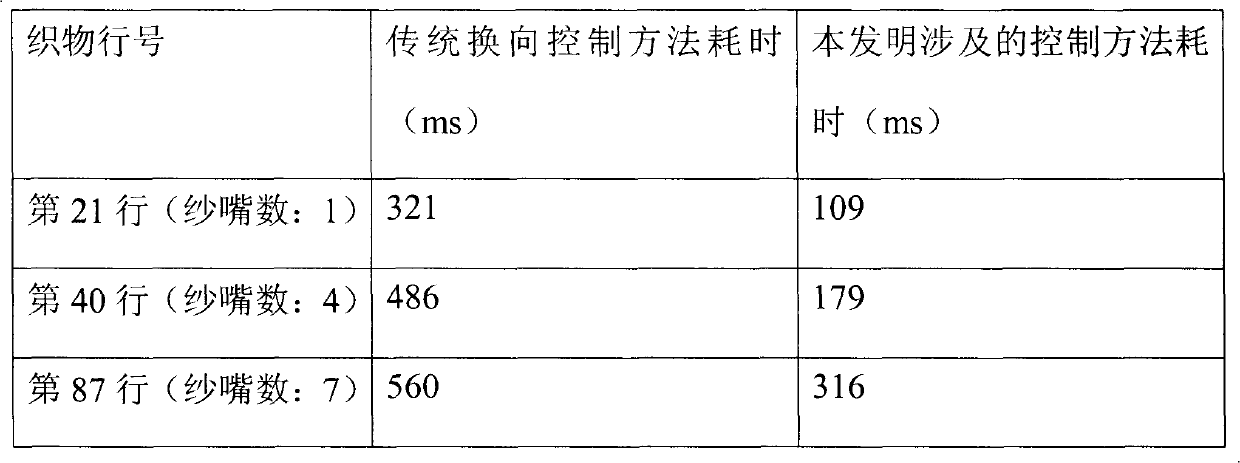

Flat knitting machine nose high speed reversing control method and control system thereof

InactiveCN101950164AAvoid wasting commutation timeImprove commutation efficiencyProgramme controlWeft knittingReverse timeControl layer

The invention relates to a flat knitting machine nose reversing control method and a control system thereof. The method includes the following steps: 1, data is read; 2, reversing action is executed; 3, back torque is adaptively adjusted; 4, reversing is started; 5 reversing is finished. The control system comprises a main control layer, a human-machine interaction layer and a nose driving layer which are in communication connection with the main control layer as well as a main control module in the main control layer and an assistant processing module which is in communication connection with the main control module; wherein the assistant processing module is in communication connected with a storage module in the human-machine interaction layer, and the main control module is also in communication connection with a nose module and a machine body module which are arranged in the nose driving layer. The invention has the substantial characteristics that: each module in the control system is configured, reversing back torque is calculated in real time, namely the back torque is adaptively adjusted, the nose is controlled to reverse according to concrete real-time back torque, the phenomenon that reversing time is wasted in back torque with preset parameter is avoided, and reversing efficiency is improved, thus improving knitting efficiency.

Owner:ZHEJIANG SCI-TECH UNIV +1

A mildew-resistant willow rattan softener and a preparing method thereof

InactiveCN104085007AReduce corrosionSoften evenlyWood treatment detailsWood impregnation detailsSodium bicarbonateHouttuynia

A mildew-resistant willow rattan softener is disclosed. The softener is prepared from following raw materials by weight in part: 12-15 of glycerol, 4-7 of sodium hexametaphosphate, 5-7 of sodium bicarbonate, 6-7 of sodium citrate, 3-4 of wild chrysanthemum flower, 5-7 of the tuber of stemona, 2-4 of cordate houttuynia, 4-5 of povidone-iodine, 3-4 of auxiliary agents and 100 of water. The softener adopts a weak acid and a weak base, and is low in surface corrosion, uniform in softening and good in toughness. By using the glycerol and the sodium hexametaphosphate, surfaces of rattans are smooth and the weaving efficiency is increased. By using the tuber of stemona and other Chinese herbal medicines, mildew and damage by worms can be prevented.

Owner:ANHUI HUAYU CRAFTS GRP

Elastic worsted fabric with contact coldness sense and preparation method thereof

InactiveCN102534949AIncrease elasticityFeel coolWoven fabricsYarnWorstedPolytrimethylene terephthalate

The invention relates to an elastic worsted fabric with a contact coldness sense and a preparation method thereof. The fabric comprises polytrimethylene terephthalate (PTT) fibers with a contact coldness sense effect, wherein the PTT fibers are prepared by spinning PTT slices which contain mineral powder with the contact coldness sense and are taken as raw materials, or prepared by taking PTT slices as raw materials and adding mineral powder with the contact coldness sense effect in the spinning process; the PTT fibers have high heat conductivity, can quickly absorb heat on the surface of skin, and are not stuffy when external temperature is high, and the coolness and comfort of the worsted fabric can be kept all the time; and the PTT fibers have high spinnability, evenness and weaving efficiency and a few yarn faults and are easy to draw, and the elasticity of the worsted fabric with the contact coldness sense is better reflected through after finishing.

Owner:JIANGSU DANMAO TEXTILE

Preparation method of high-quality wool heavy-twist and anti-wrinkle fabric

ActiveCN104397910AAvoid damageUniform dyeingLiquid/gas/vapor removalDyeing processEngineeringDesign methods

The invention provides a preparation method of high-quality wool heavy-twist and anti-wrinkle fabric. The high-quality wool heavy-twist and anti-wrinkle fabric is prepared by interweaving warps and wefts, wherein the warps and the wefts are respectively prepared by blending raw materials by weight percent, and the raw materials comprise 75% of 16.0 mu m Australasian wool and 25% of mulberry silk. The preparation method adopts an innovative easily-caring and anti-wrinkle fabric design method and an after-finishing technology; the prepared fabric is smooth in hand feeling, good in elasticity, excellent in draping property and good in wearability, and reaches the requirement of easy care, thus being very suitable for making a high-quality non-lining or semi-lining business and casual suit.

Owner:江苏纺谷科技有限公司

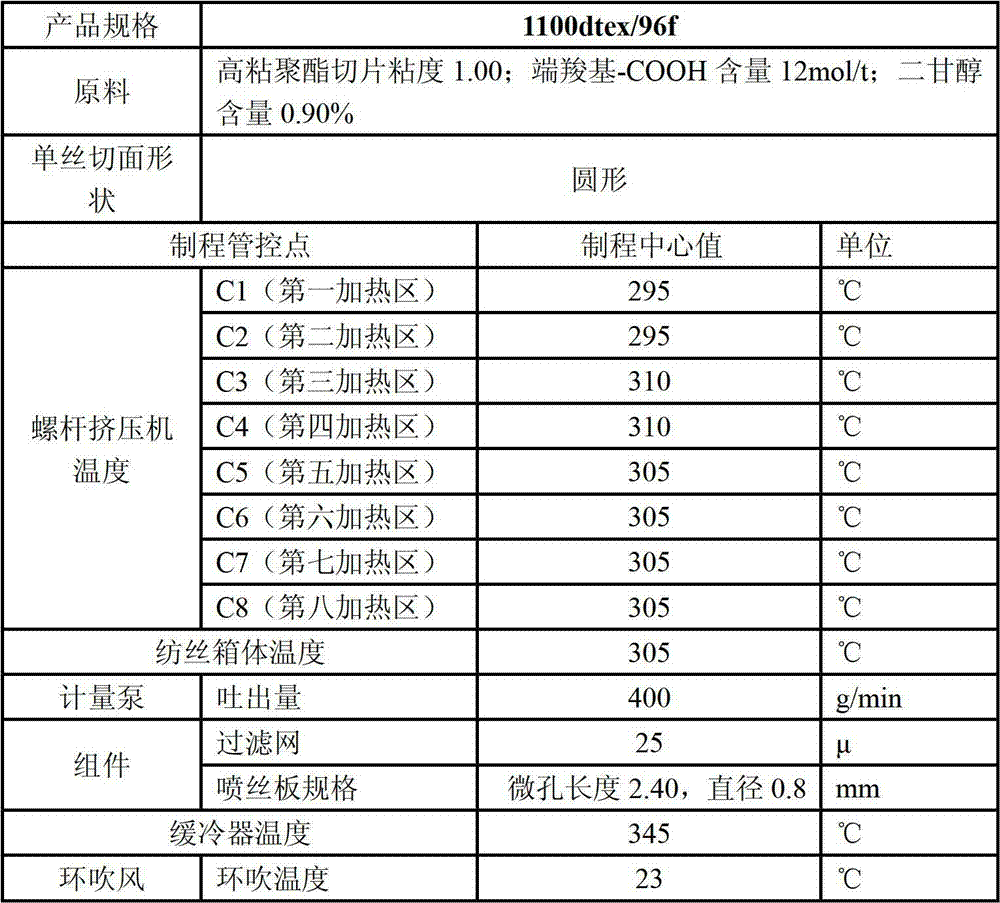

Industrial polyester filament for high-strength ultra-low-elongation safety belt and production method of industrial polyester filament

ActiveCN102808230AImprove weaving efficiencyImprove wear resistanceFilament forming substance formingNew-spun product collectionEngineeringImpurity

The invention relates to an industrial polyester filament for a high-strength ultra-low-elongation safety belt and a production method of the industrial polyester filament. The production method comprises the following steps of: A) high-viscosity polyester chip preparation; B) high-viscosity polyester chip impurity removal; C) melt spinning; and D) drafting, heat setting and winding. The number of the industrial polyester filaments produced by adopting the method is 72-144F, the fineness is 1100-2222dtex, the breaking strength can reach more than 7.80cN / dtex, the fixed-load elongation can reach 4-6 percent under a condition of 11.1KN and the controllable oil content is lower than 0.30-0.60 percent. The industrial polyester filament for the high-strength ultra-low-elongation safety belt and the production method of the industrial polyester filament have the beneficial effects that the breaking strength of the safety belt which is provided by using the obtained industrial polyester filaments can reach 35KN and is much higher than the breaking strength being 28-33KN of the existing safety belt, the physical and mechanical performance is good and the industrial polyester filament is an optimum raw material for producing front-row safety belts; the weaving performance is good, the dyeing uniformity of the safety belt is good due to lower fiber oil content, the gloss is stable, and chromatic aberration and stains do not exist; the waste polyester fibers can be recycled, the energy is saved, the environment is protected and the operating cost is reduced; and the operation is simple to conduct, the process flow is short, the automation level is high and the development space is very great.

Owner:ORIENTAL IND SUZHOU

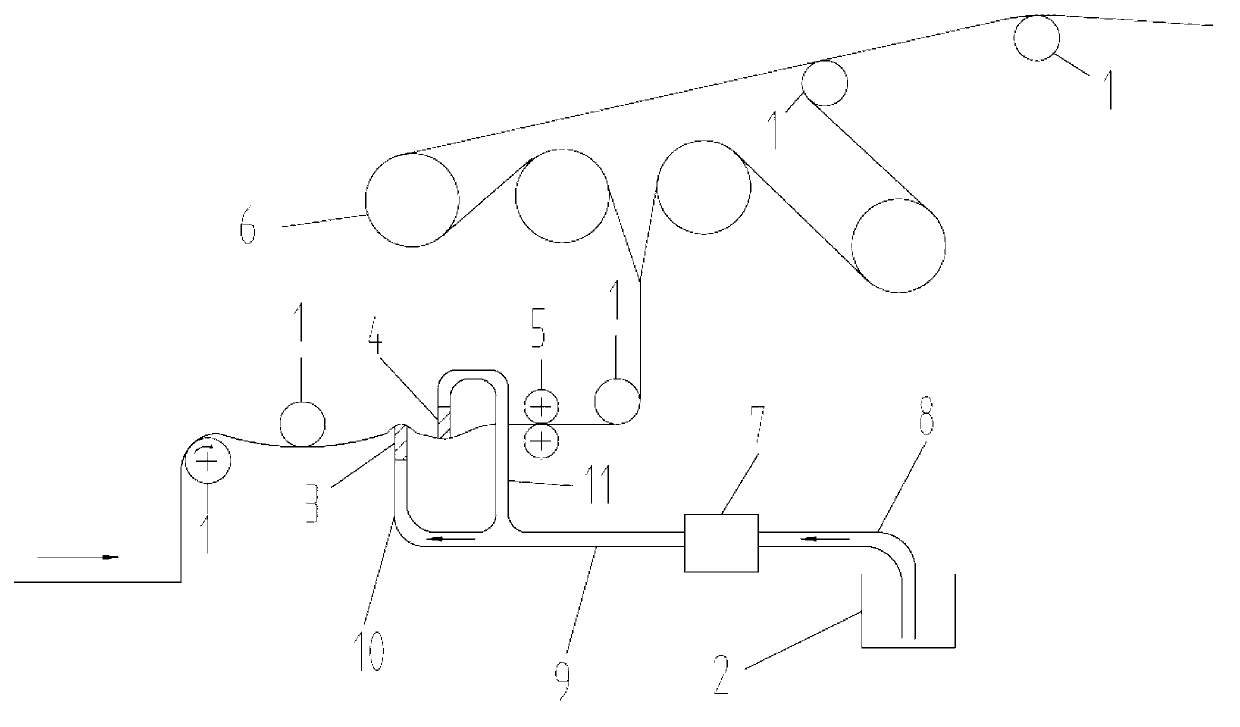

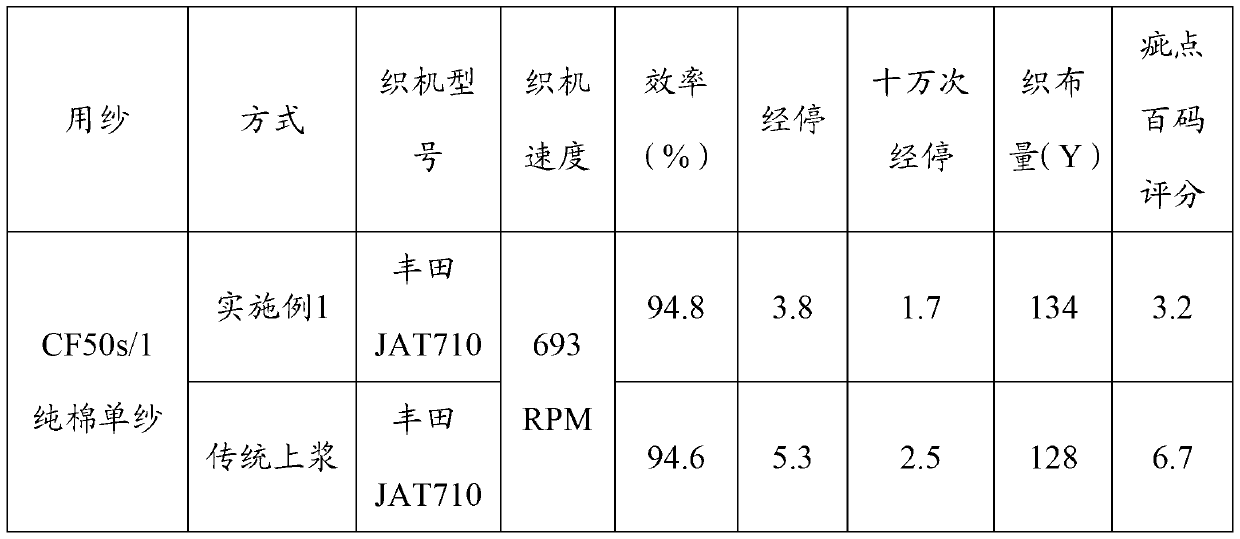

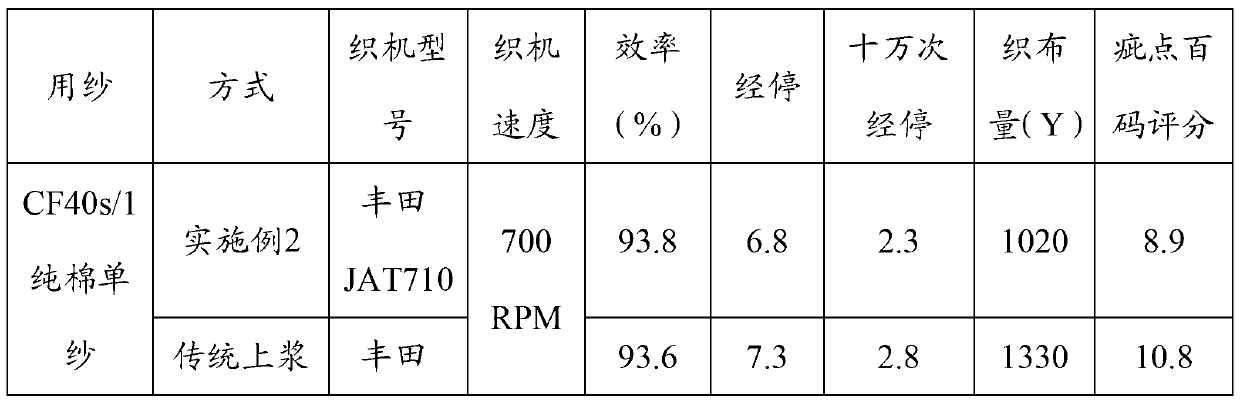

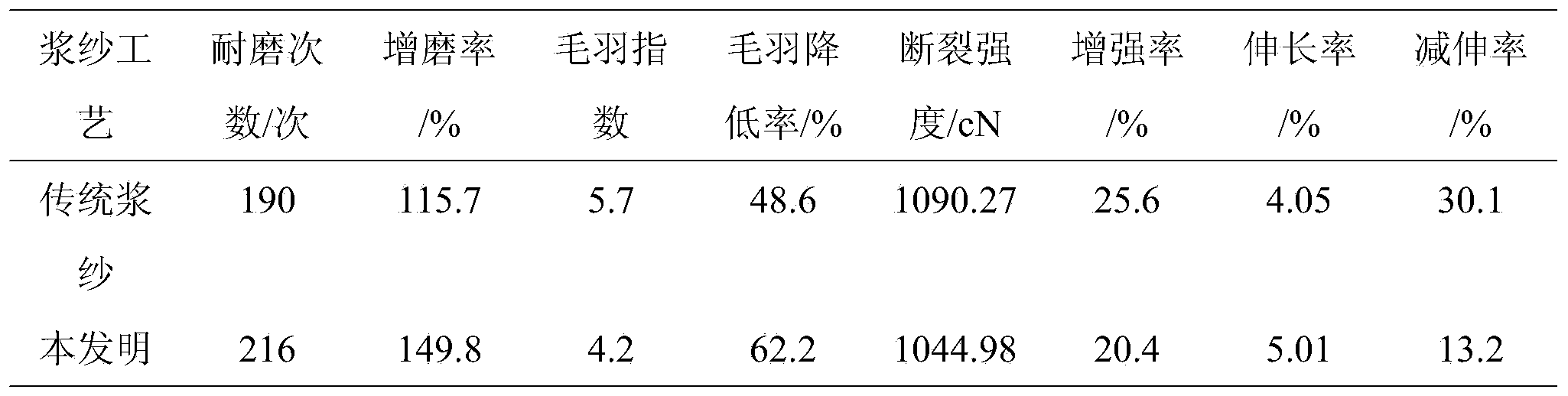

Warp sizing method and application thereof

ActiveCN103103710AEmission reductionReduce water consumptionFibre treatmentLiquid/gas/vapor textile treatmentYarnWastewater

The invention discloses a warp sizing method and an application thereof. The warp sizing method includes the following steps: preparing sizing agents, boiling the sizing agents, foaming, conducting foam sizing, rolling the sizing agents, drying and leasing; foaming ratio and applying amount are controlled by a foam producer in the step of foaming; the foaming ratio is 1:3-30, and the applying amount is 10%-50%; foam formed by the foam producer is instantly and entirely applied to warp yarn through a foam applicator in the step of conducting foam sizing; and the foam applicator is divided into an upper applying head and a lower applying head. The warp sizing method has the advantages of being low in water consumption, little in chemical and wastewater discharge, little in sizing amount, easy to desize, short in yarn drying time, capable of saving energy consumption by 50%-60%, high in production speed, low in cost, continuous in foam applying mode, capable of ensuring uniformity and stability of the applied foam, low in product breakage rate, high in efficiency and good in weaving effect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

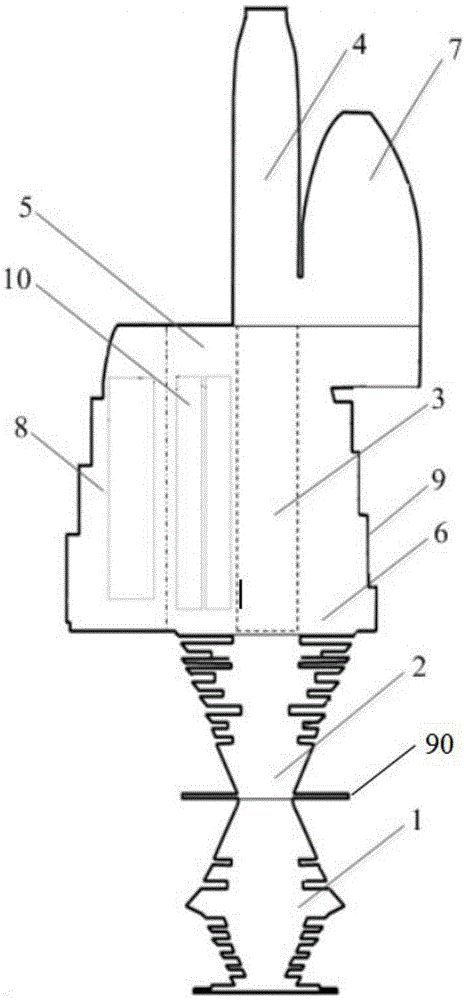

Three-dimensional multilayer pneumatic picking loom

InactiveCN105239256AImprove weaving efficiencyHigh degree of structural automationLoomsYarnAutomation

The invention discloses a three-dimensional multilayer pneumatic picking loom, comprising a wallboard a and a wallboard b which are arranged in parallel, and a rack beam used for supporting is horizontally arranged between the wallboard a and the wallboard b. A horizontal weft insertion mechanism is supported on the wallboard a and the wallboard b. An open harness frame, a weft insertion going part, and a closing mechanism are arranged in sequence along a horizontal moving direction of warp yarns between the wallboard a and the wallboard b. The open harness frame, the weft insertion going part, and the closing mechanism are arranged along a vertical direction and are parallel to each other. The open harness frame is arranged close to the weft insertion mechanism. A yarn carrying device is also arranged between the wallboard a and the wallboard b. Latch needles are arranged under the yarn carrying device. The yarn carrying device is arranged close to the closing mechanism. The inner side of the wallboard b is provided with a main nozzle along a vertical direction. The loom is used to solve problems of an existing three-dimensional loom that automation degree is low and weaving efficiency is low.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Asynchronous alternate push type mine organzine and warp protective screen weave machine

InactiveCN101596568AReduce labor intensityReduce security risksWire networkAutomatic controlEngineering

The invention belongs to the technical field of metal mesh weave machine, in particular relates to an asynchronous alternate push type mine organzine and warp protective screen weave machine, and solves the problems that the existing metal mesh weave device is high in cost and product quality is difficult to be ensured. The asynchronous alternate push type mine protective screen weave machine is characterized by comprising an organzine guiding delivery mechanism, an organzine upside-down rotating mechanism, a weaving mechanism, a forming mechanism and a shaping mechanism which are sequentially arranged along the warp direction; wherein the shaping mechanism and the forming mechanism are in asynchronous alternate push for weaving the organzine and warp protective screen. The invention has the beneficial effects that: automatic control technique and precision machinery structure are combined, fussy action of manual metal mesh weaving is substituted, labour intensity and security risk of workers is greatly reduced, weaving efficiency is improved, and production cost is reduced; and the invention also has advantages in weaving effects such as weaving evenness of the metal mesh, mesh spacing consistency and the like as well as in device operation simplicity and production cost.

Owner:白路鑫

Vertical bar artificial silk spinning fabric production process

InactiveCN103173912AHighly breathable drapabilityGood shaping effectWoven fabricsPolymer scienceEngineering

The invention discloses a vertical bar artificial silk spinning fabric production process. The fabric comprises warp yarn and weft yarn, 75D ultra-fine denier polyester filament yarn through weak twisting and 75D polyester black yarn are adopted in the warp yarn, and 75D ultra-fine denier polyester filament yarn through weak twisting and 75D glazed artificial filament yarn without twisting are adopted in the weft yarn. The warp yarn process includes the steps: winding, two-for-one twisting, sectional warping and drafting, and the weft yarn process includes the steps: spooling, two-for-one twisting and rewinding. According to the vertical bar artificial silk spinning fabric production process, on the basis of improvement of a device, the problems that viscose fibre is fine denier high-F fiber with low twisting degree, broken filament can be easily generated in the twisting process, and therefore unsmooth wefting insertion can happen easily in the weaving process, weft yarn is stopped and returns in a weaving machine easily, and the like are chiefly solved. Through optimization of weaving process parameters, weaving quality and efficiency are improved, and novel fabric which is like light and thin and transparent real silk is successively developed. Through the vertical bar artificial silk spinning fabric production process, textile is high in ventilation and drapability, and good in shaping effect, and particularly suitable for being used as high-range closed-fit fabric.

Owner:JIANGSU DEHUA TEXTILES

Method and mechanism for equivalently lowering and folding cloth woven by circular knitting machine according to cloth quantity

InactiveCN102051762ALarge amount of clothLow costFolding thin materialsKnittingEngineeringMechanical engineering

The invention discloses a method and a mechanism for equivalently lowering and folding cloth woven by a circular knitting machine according to cloth quantity. The cloth woven by the circular knitting machine is fed out after passing through a buffering temporary storage mechanism which can store the cloth temporarily and is partitioned into three section cloth lengths; the decrement of a third section cloth length on the lower side is equal to the summation of the increment of a first section cloth length and the increment of a second section cloth length; the increment of the first section cloth length is equal to that of the second section cloth length; the increment of the third section cloth length is equal to the summation of the decrement of the first section cloth length and the decrement of the second section cloth length; the decrement of the first section cloth length is equal to that of the second section cloth length; and the three section cloth lengths are mechanically complemented with one another through the buffering temporary storage mechanism, so that cloth above a cloth folding rod which moves and lowers the cloth in a reciprocating way keeps fixed tension, and cloth continuously woven by the circular knitting machine is equivalently lowered and folded on a cloth carrying plate if the cloth above the cloth folding rod keeps the fixed tension.

Owner:PAI LUNG MACHINERY MILL CO LTD

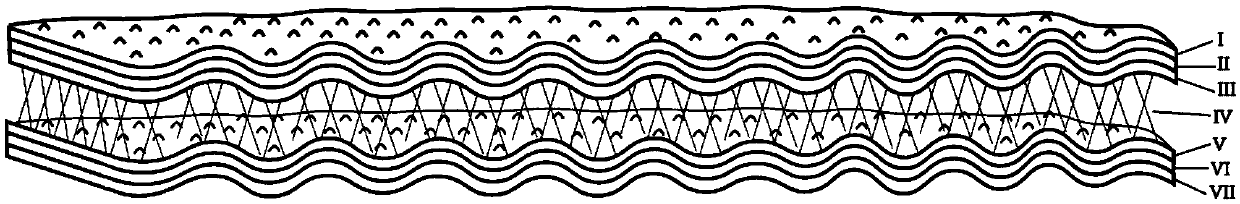

Novel multifunctional three-dimensional conduction fabric, preparation method thereof and application of fabric

InactiveCN109652898AReduce transmittanceImprove shielding effectWoven fabricsHeating element materialsYarnElectromagnetic shielding

The invention relates to a novel multifunctional three-dimensional conduction fabric, a preparation method thereof and an application of the fabric. The three-dimensional conduction fabric sequentially comprises an appearance layer, a functional conduction layer and a fabric protection layer from top to bottom, and the appearance layer, the functional conduction layer and the fabric protection layer are interwoven through stitching warps and stitching wefts or integrally bundled by bundling yarns. The three-dimensional conduction fabric is designable in height, simple in preparation process, high in weaving efficiency and suitable for industrial production, application field of the conduction fabric is widened, and the conduction fabric has wide application prospects in the fields of smartclothing, heating, electronic sensing and electromagnetic shielding.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

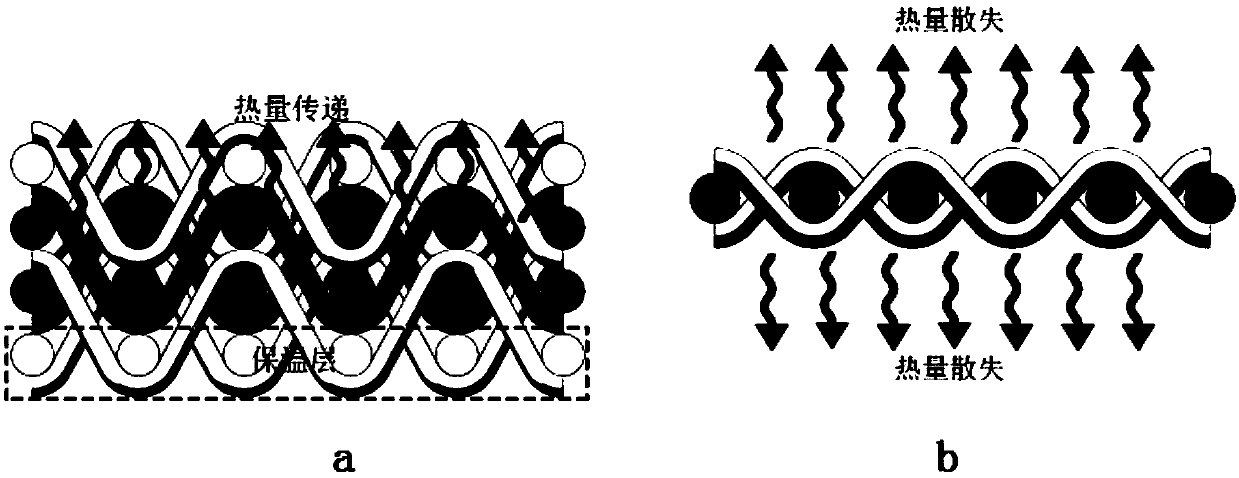

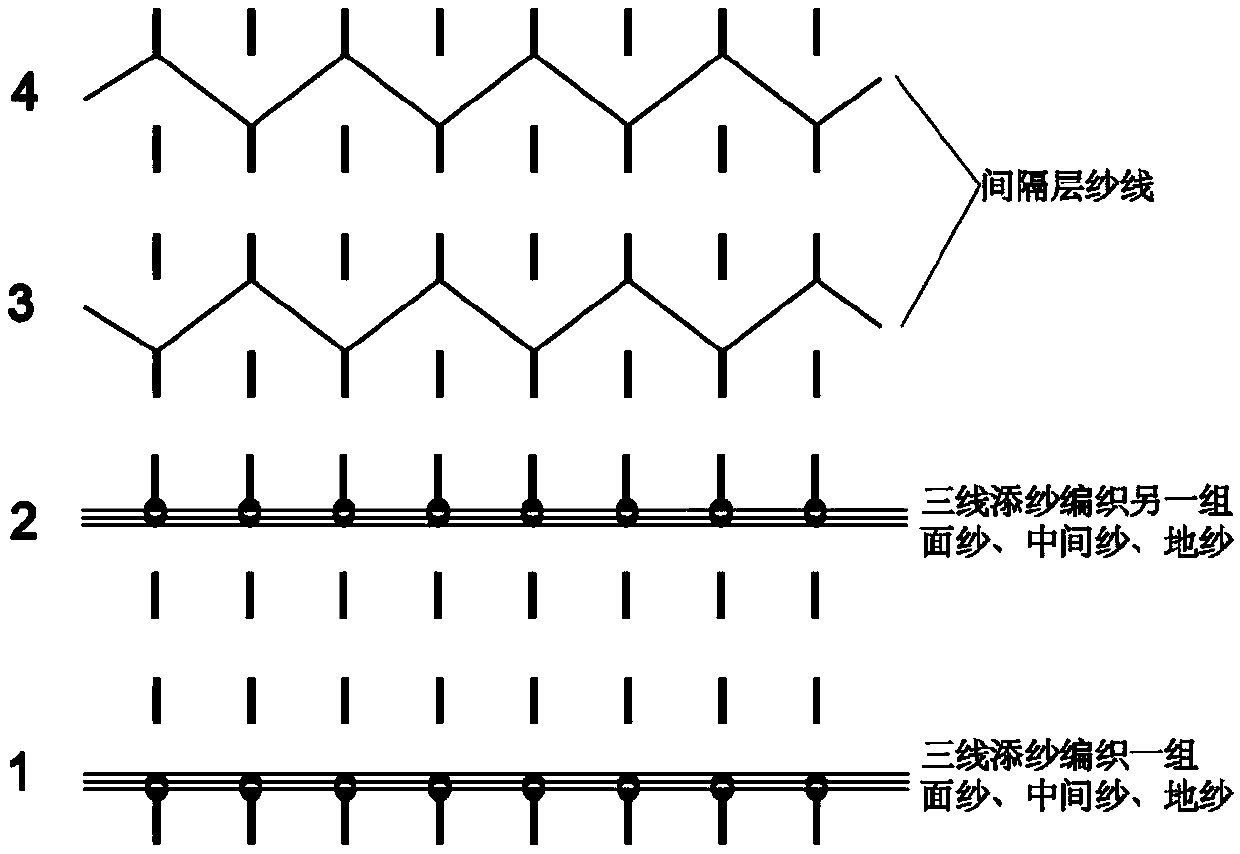

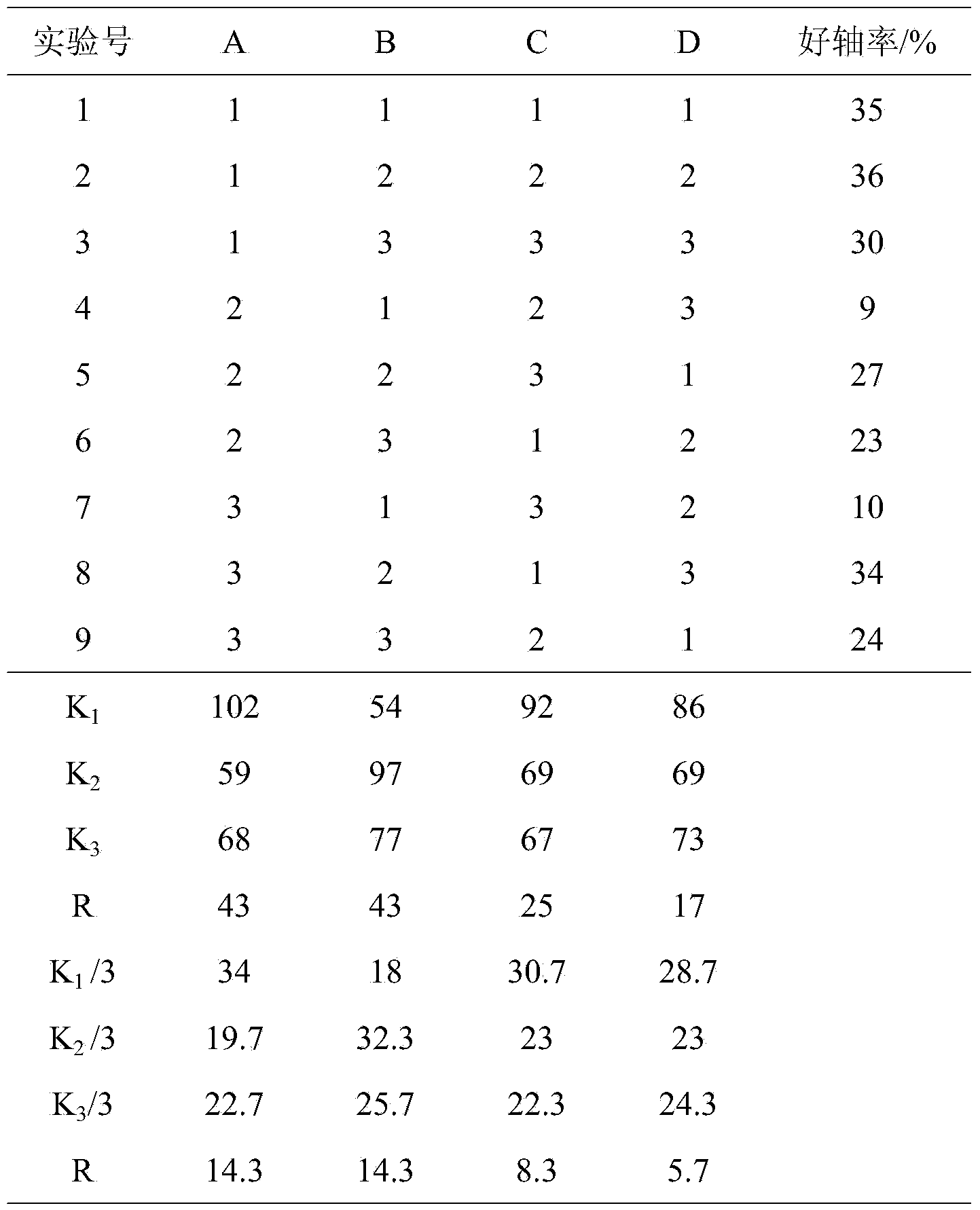

Breathable knitted spacer fabric friction generator and preparation method thereof

ActiveCN109525140APlay a supporting roleOvercome the disadvantage of poor air permeabilityFriction generatorsEngineeringConductive yarn

The invention relates to a breathable knitted spacer fabric friction generator and a preparation method thereof. The method comprises the steps of weaving a top layer and a bottom layer by using a three-wire plating process, controlling the yarn angles of surface yarns, intermediate yarns and ground yarns respectively such that the three yarns are sequentially arranged according to a certain positional relationship and then are woven, at the same time, in the weaving process, performing alternate tucking of spacer wires between a top layer ground yarn and a bottom layer ground yarn with a certain number of spacing stitches to form the breathable knitted spacer fabric friction generator, wherein a top layer surface yarn and a bottom layer surface yarn are at the outmost sides of a compositelayer and are insulating yarns, a top layer intermediate yarn and a bottom layer intermediate yarn are conductive yarns, the top layer ground yarn and the bottom layer ground yarn are opposite and are a triboelectric negative yarn and a triboelectric positive yarn correspondingly, and a spacer layer is composed of a set of spacer wires that are simultaneously connected to the top layer ground yarn and bottom layer ground yarn. The preparation method of the invention has the advantages of simple process and high weaving efficiency, and the obtained knitted spacer fabric friction generator hasgood gas permeability and has excellent promotion value.

Owner:HANGZHOU TIANYE JACQUARD

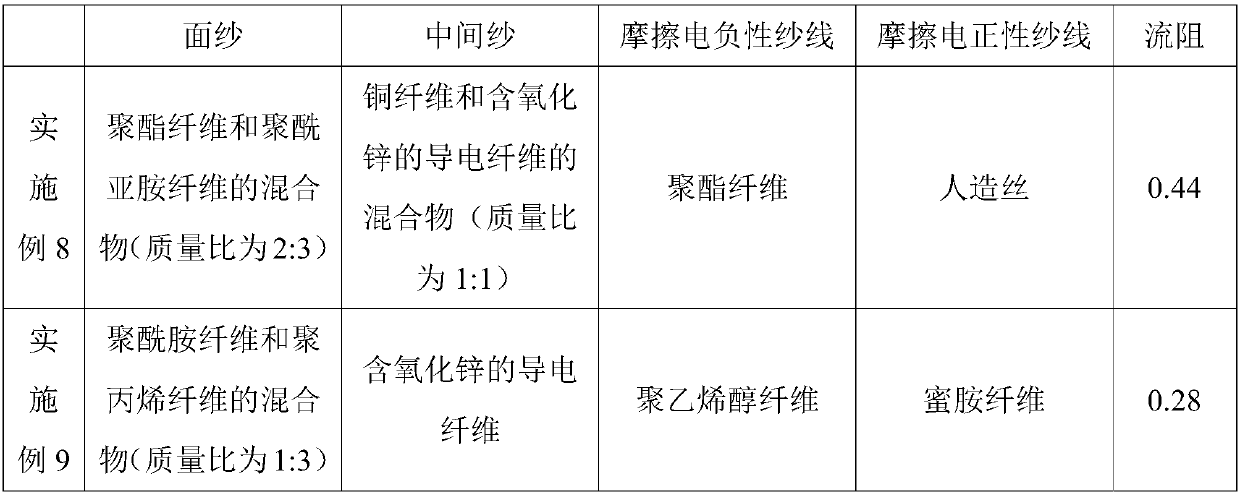

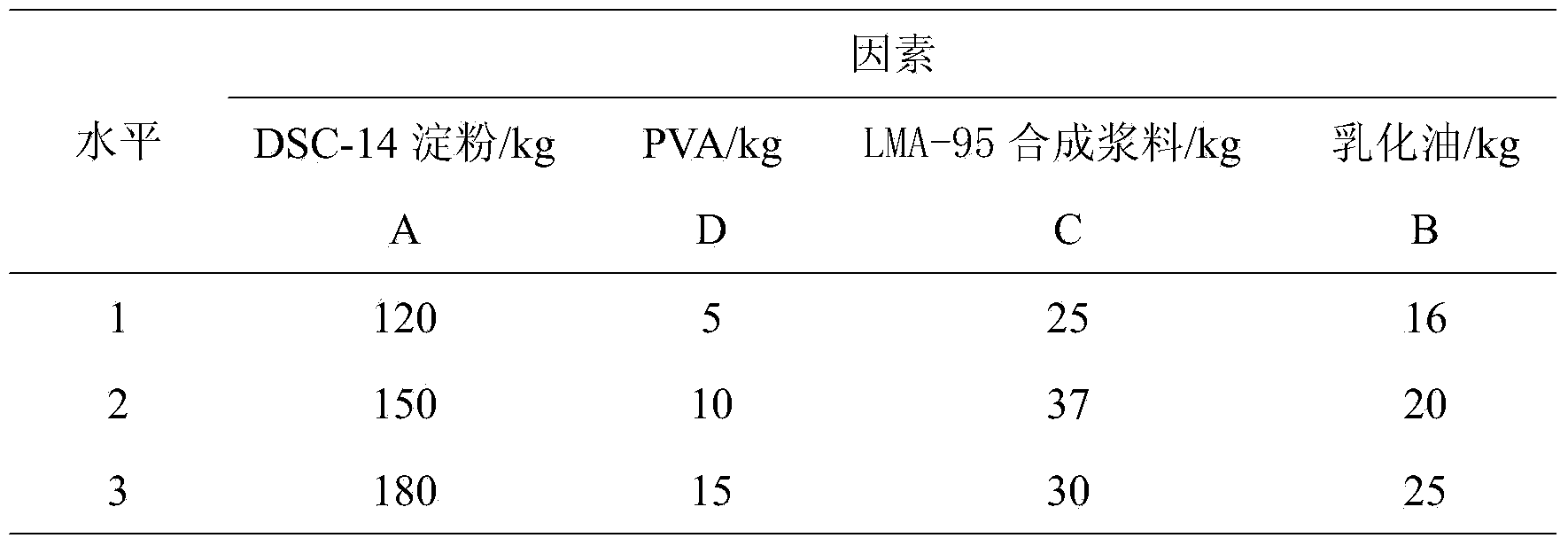

Jean warp sizing slurry and sizing process

ActiveCN103966849AImprove wear resistanceImprove surface propertiesFibre treatmentDenimProcess engineering

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

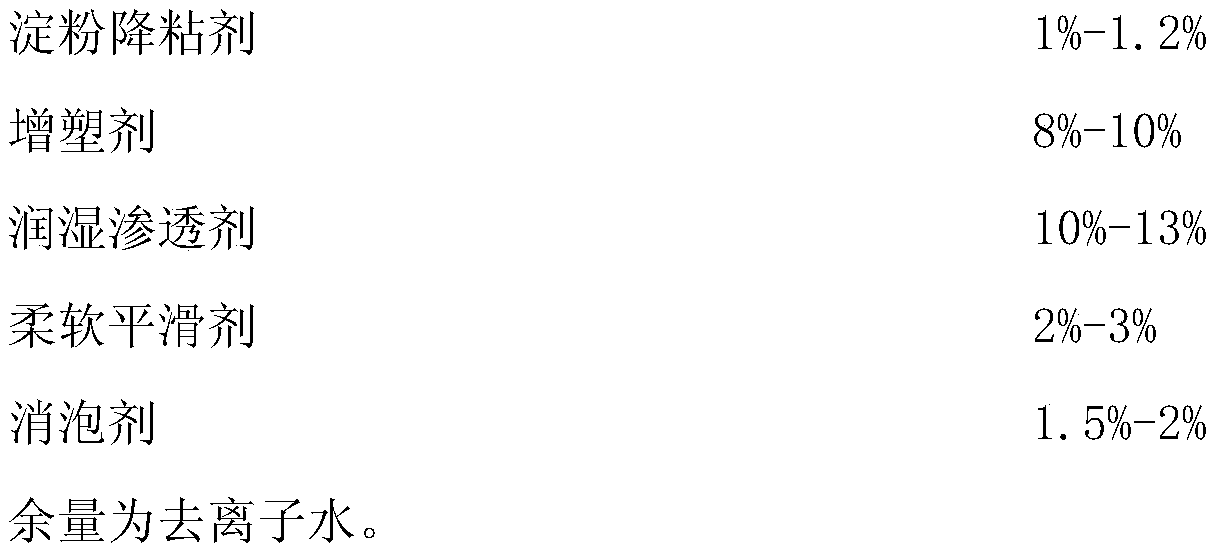

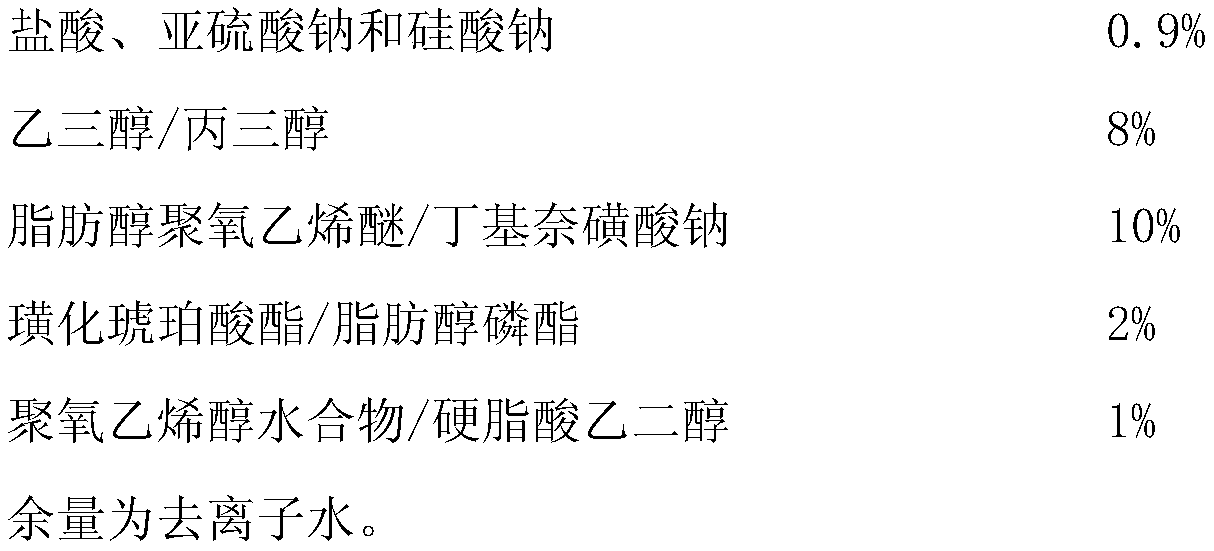

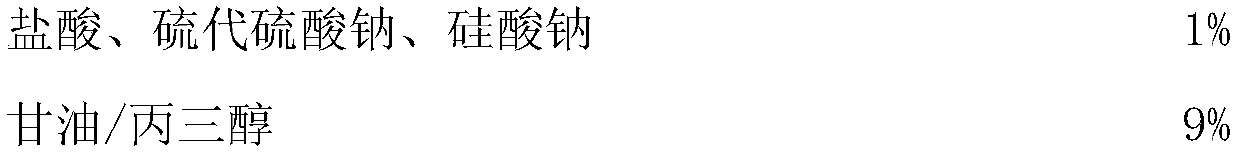

Environment-friendly sizing agent assistant, and preparation method and application of assistant

InactiveCN108004771ANo pollution in the processNot corrosiveDry-cleaning apparatus for textilesVegetal fibresPolyesterPolyvinyl alcohol

The invention discloses an environment-friendly sizing agent assistant, and a preparation method and an application of the assistant. The assistant is mainly applied to sizing of cellulose fibers or blend fibers and is characterized in that the sizing agent comprises 95-98% by mass of main material and 2-5% by mass of assistant, wherein the assistant is prepared from the following raw materials bymass percentage: 1-1.2% of starch viscosity reducer, 8-10% of plasticizer, 10-13% of wetting penetrant, 2-3% of soft smoothing agent, 1.5-2% of defoaming agent and the balance of deionized water. Theassistant is used for pure starch sizing and is applicable to the various cellulose fibers and the cotton-polyester blend fibers; no synthetic sizing agent is added; and PVA (polyvinyl alcohol)-freesizing is achieved in deed.

Owner:ZHEJIANG YUBO TEXTILE CO LTD

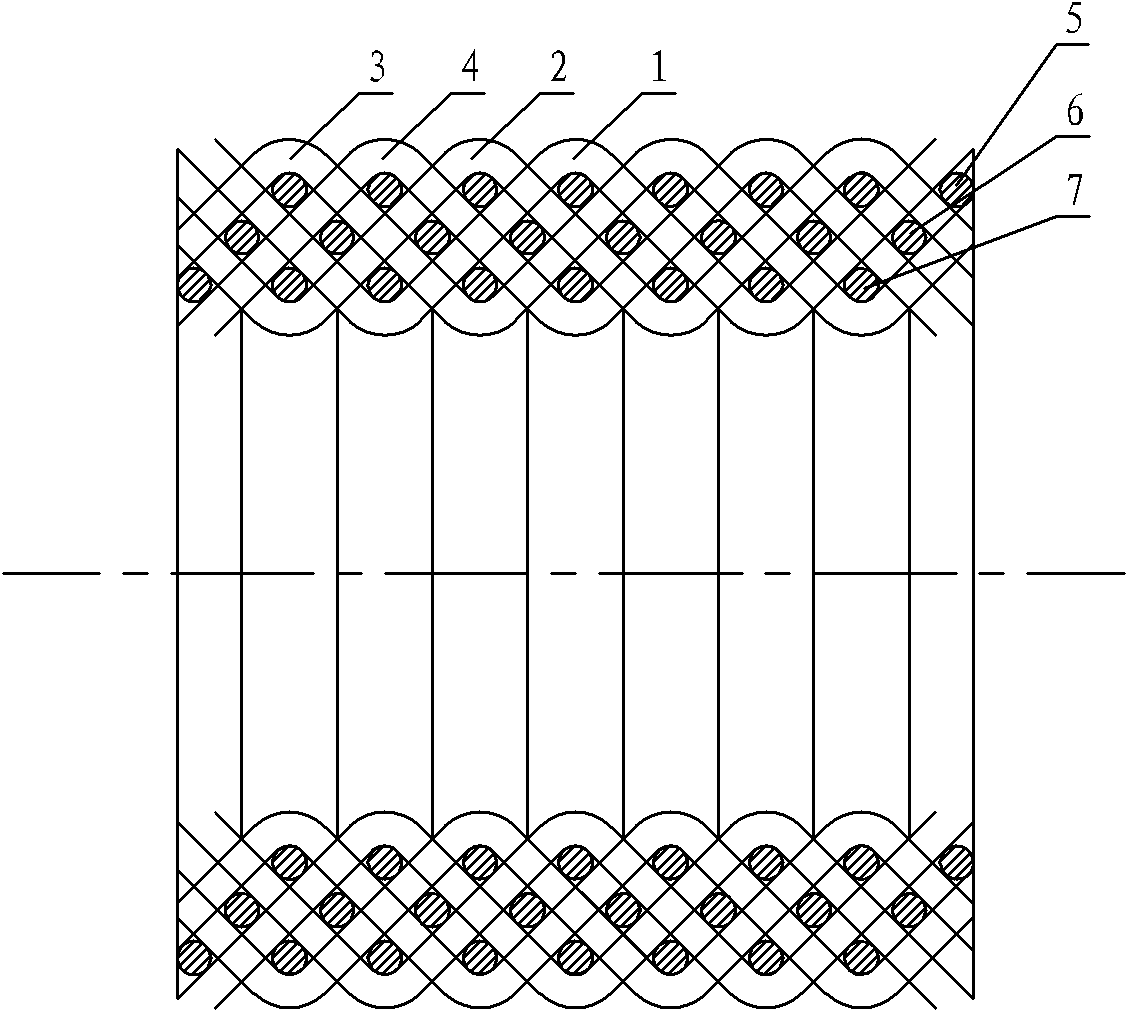

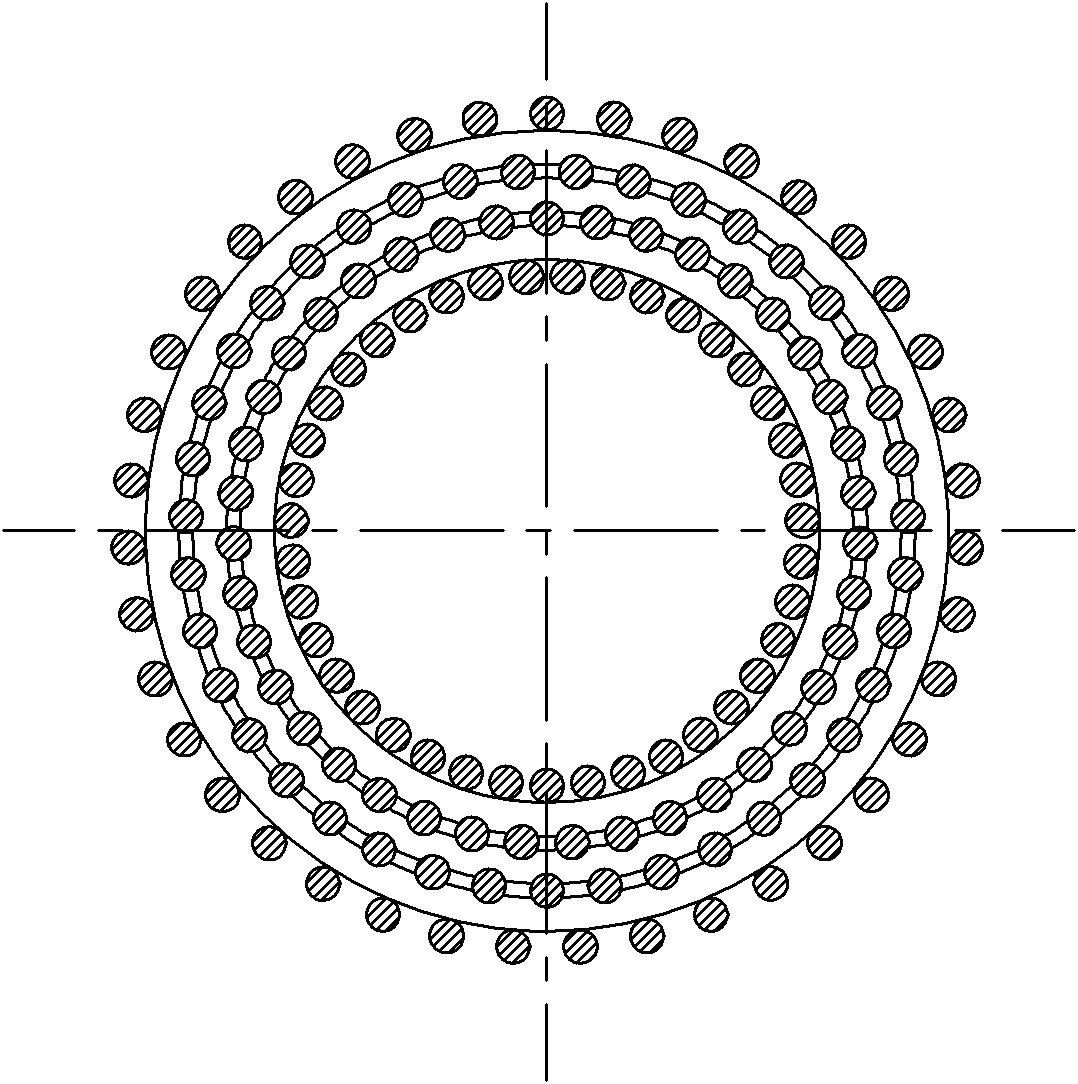

Plain weave three-dimensional multilayer cylindrical or cylindrical special-shaped braided fabric

InactiveCN102373527AFast weavingImprove weaving efficiencyWoven fabricsEngineeringUltimate tensile strength

The invention relates to a plain weave three-dimensional multilayer cylindrical or cylindrical special-shaped braided fabric, which is a three-dimensional continuous cylindrical braided fabric formed by interlacing over three layers of warps and over two layers of wefts, wherein over two other layers of warps are inserted into every layer of warps; every layer of warps and other layers of warps are inserted in sequence layer after layer, and are encircled into a continuous cylinder; and every layer of wefts is orthogonally buckled in every layer of warps and is encircled into a continuous cylinder. In the three-dimensional multilayer braided fabric, every yarn fiber of every layer is tightly interlaced into a whole. The braided fabric has uniform stress, is a continuous cylinder with no seam, and has a tight structure; and the intensity and compression resistance of a cylindrical or cylindrical special-shaped composite material are enhanced effectively.

Owner:常州市郑陆特种纺机专件有限公司

Horizontal knitting machine

The invention mainly relates to a horizontal knitting machine. The horizontal knitting machine comprises a main rack, a needle selection system, a sliding rail assembly, a machine head part, a shuttlepart, a yarn cutting device and a finger splitting system, wherein the needle selection system comprises a roller mechanism, two rollers of the roller mechanism are driven by an independent driving device, the sliding rail assembly is arranged above the needle selection system, the machine head part is arranged on the sliding rail assembly, the machine head part comprises a front machine head assembly and a rear machine head assembly, the driving device is in linkage connection with the front machine head assembly and the rear machine head assembly through a transmission assembly, so that thefront machine head assembly and the rear machine head assembly achieve horizontal reciprocating motion on the sliding rail assembly, the upper end of the machine head part is provided with a shuttleassembly, the shuttle assembly is intermittently driven by the machine head part, the yarn cutting device is connected with the independent driving device for driving, and the finger splitting systemcomprises a fork knife part and a scissors part. The horizontal knitting machine has the advantages that the structure is simple, the horizontal knitting machine is portable and flexible, the operating load is low, the energy consumption is low, the transmission and weaving efficiency is improved, and the maintenance and debugging are convenient, and economic benefits of enterprises is increased.

Owner:ZHEJIANG RUIFENG INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com