Patents

Literature

38results about How to "Improve commutation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

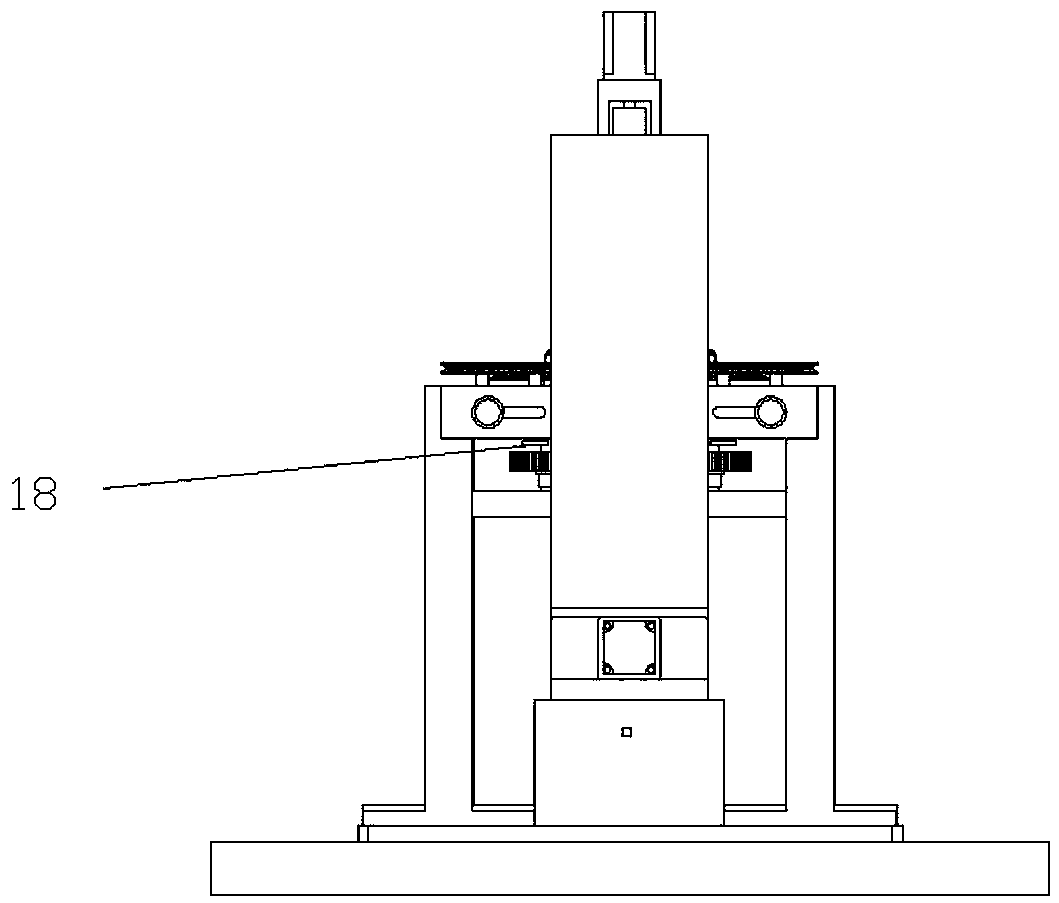

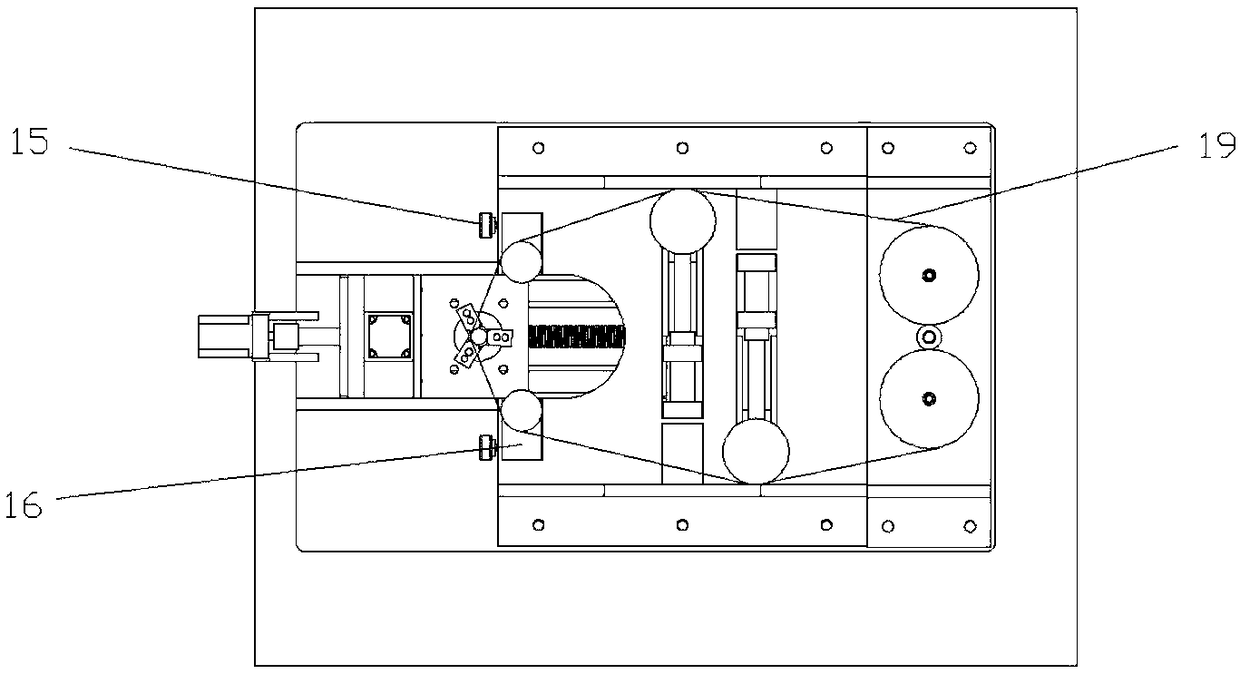

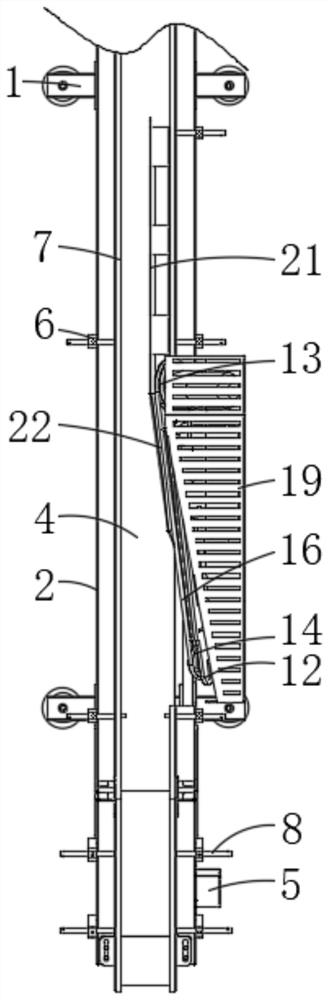

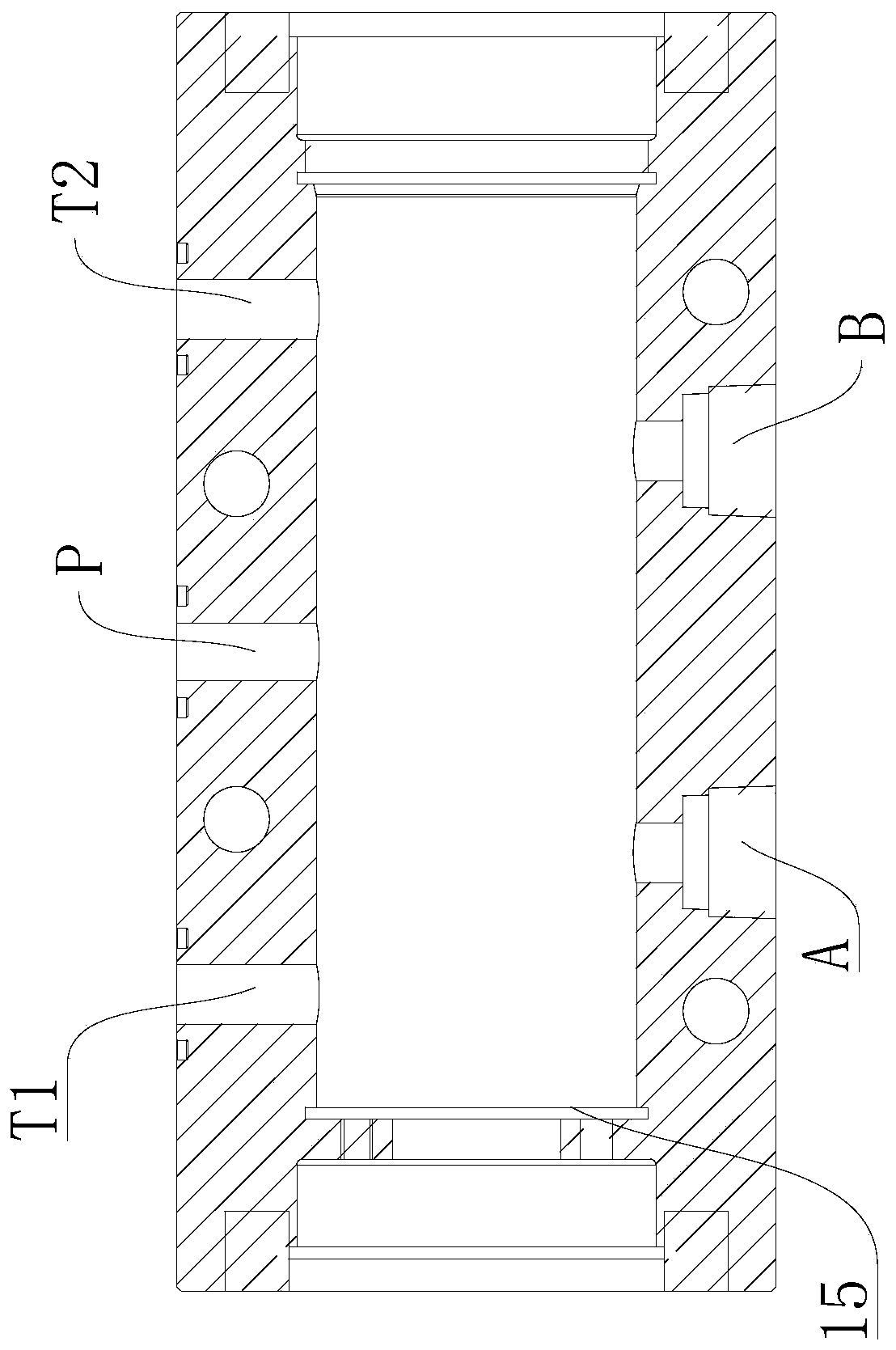

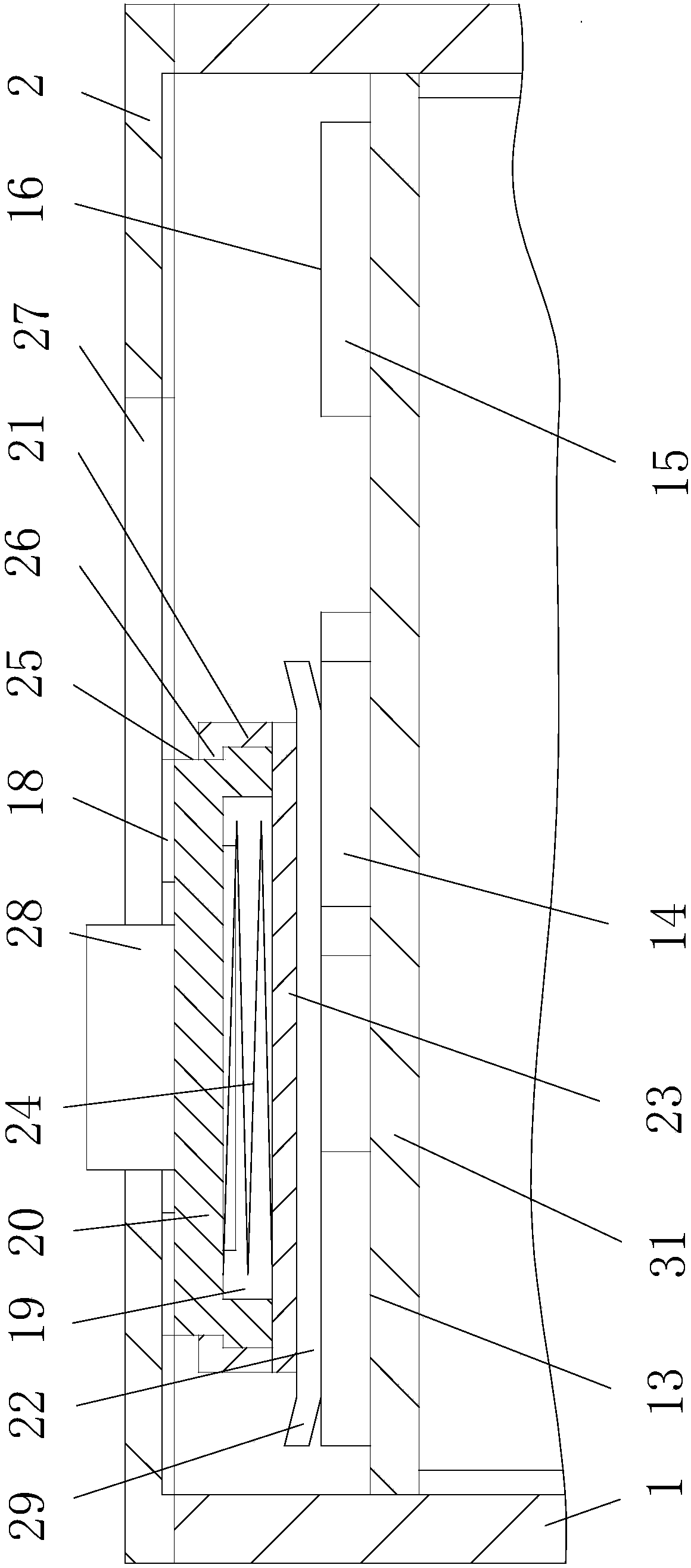

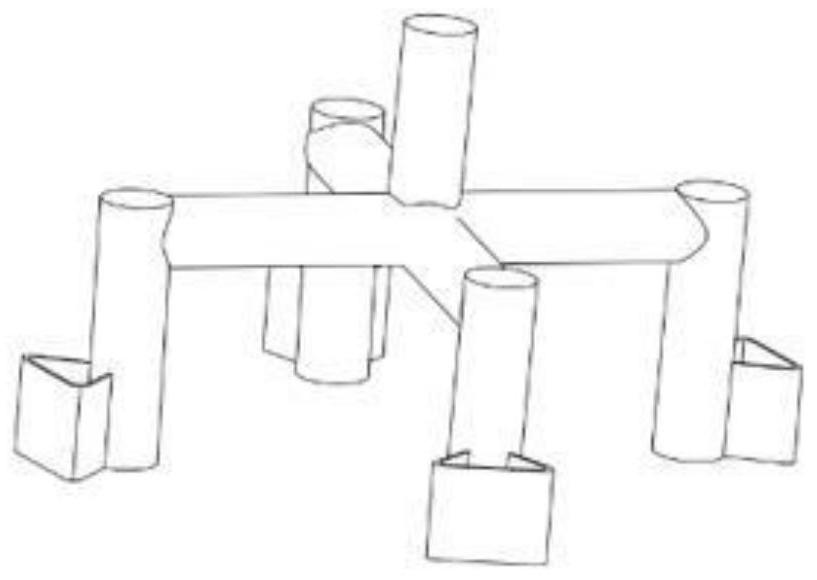

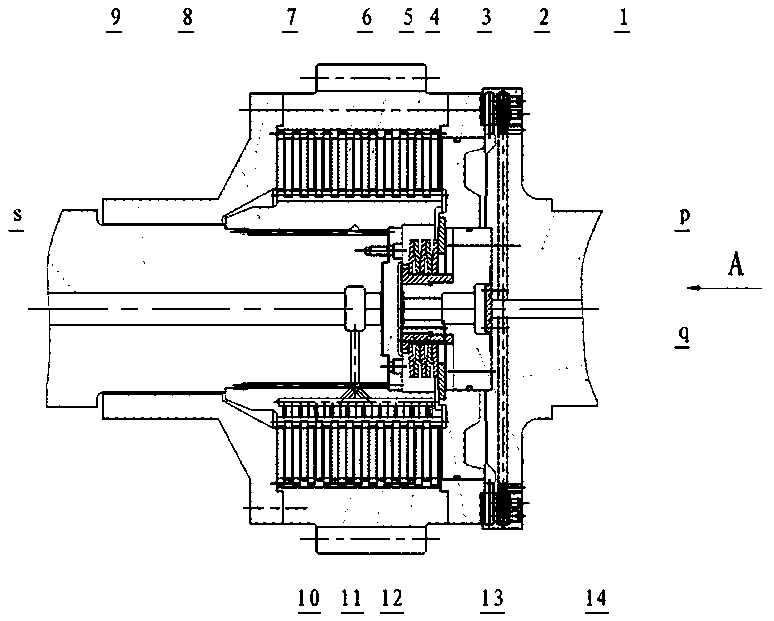

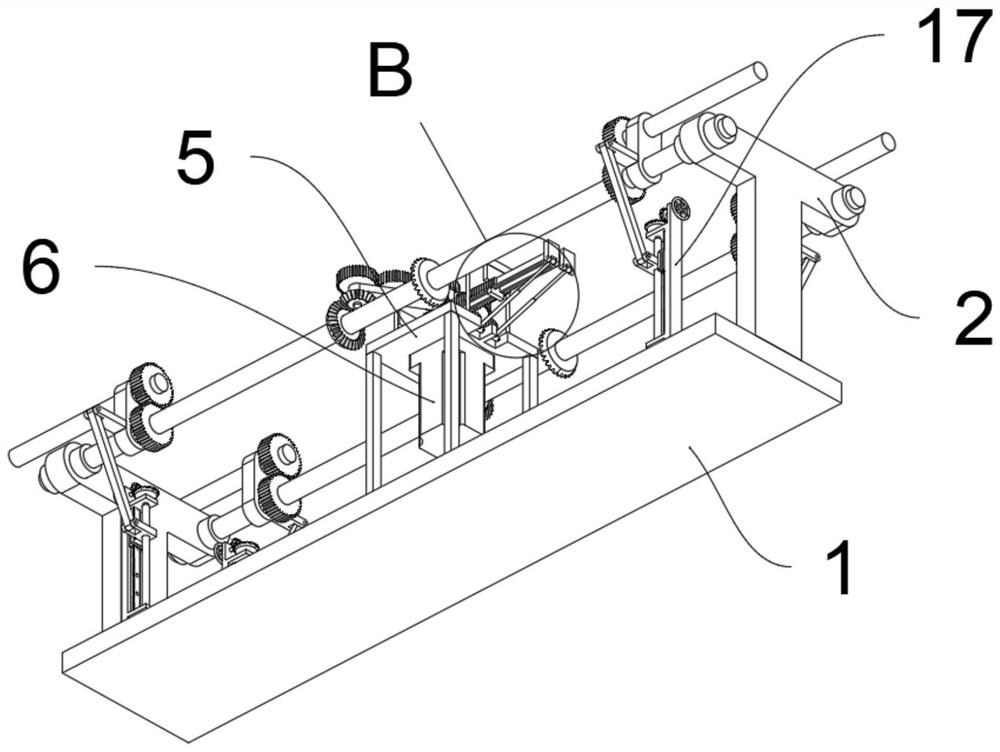

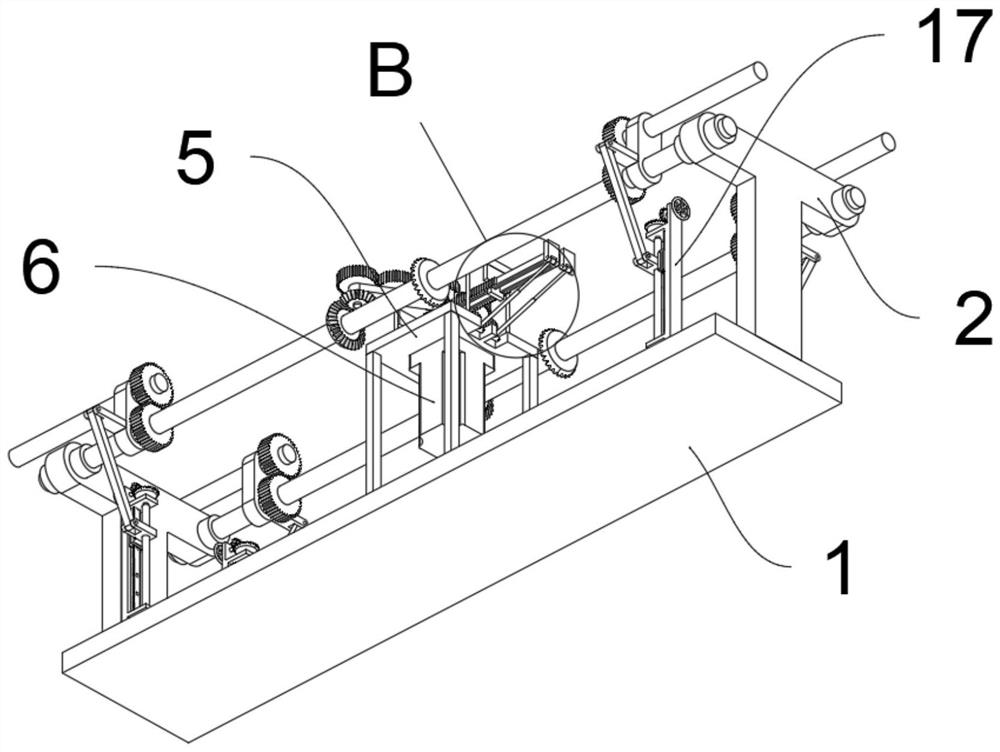

Loading and unloading manipulator system of broaching machine

InactiveCN103331640AGuaranteed servo positioning capabilityCapable of servo positioningProgramme-controlled manipulatorMetal working apparatusHydraulic pumpFuel tank

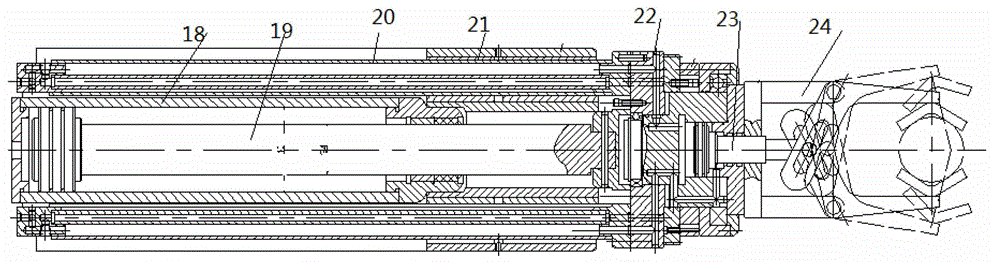

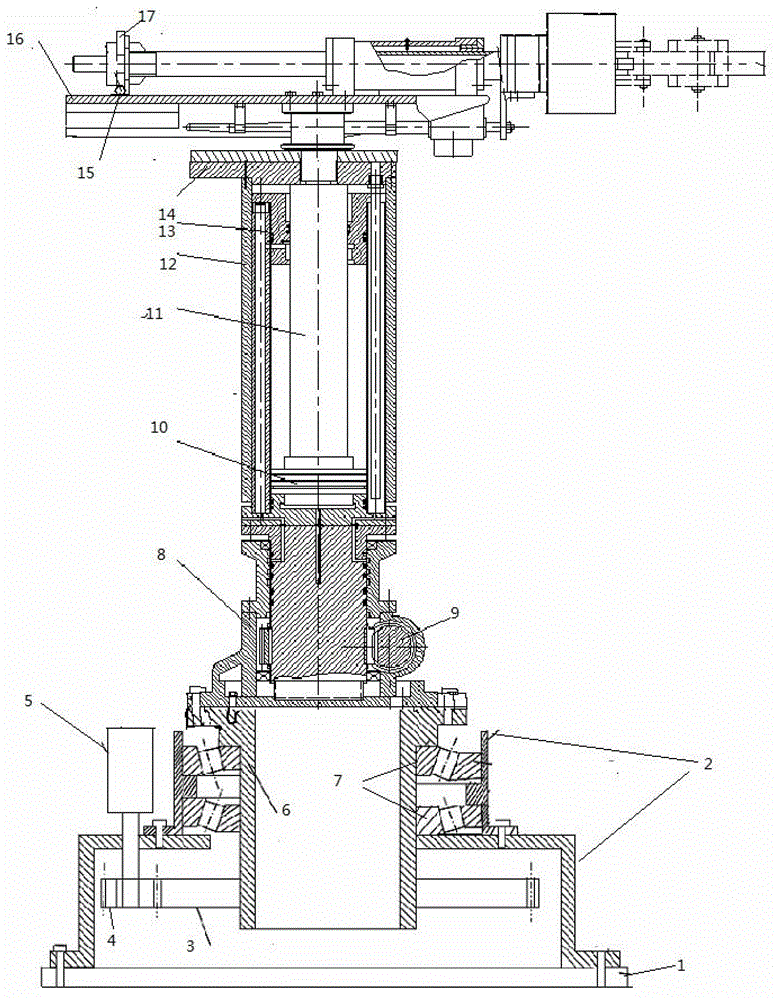

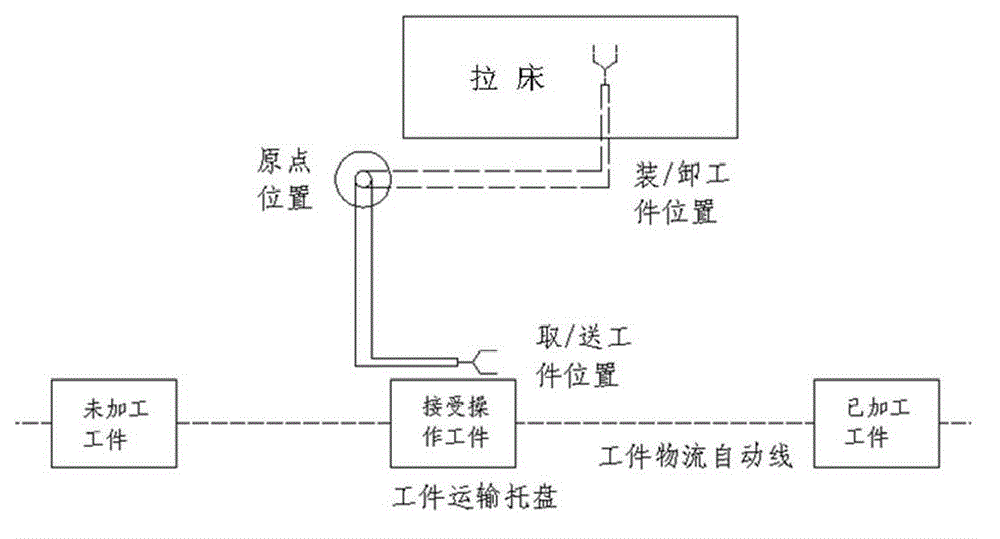

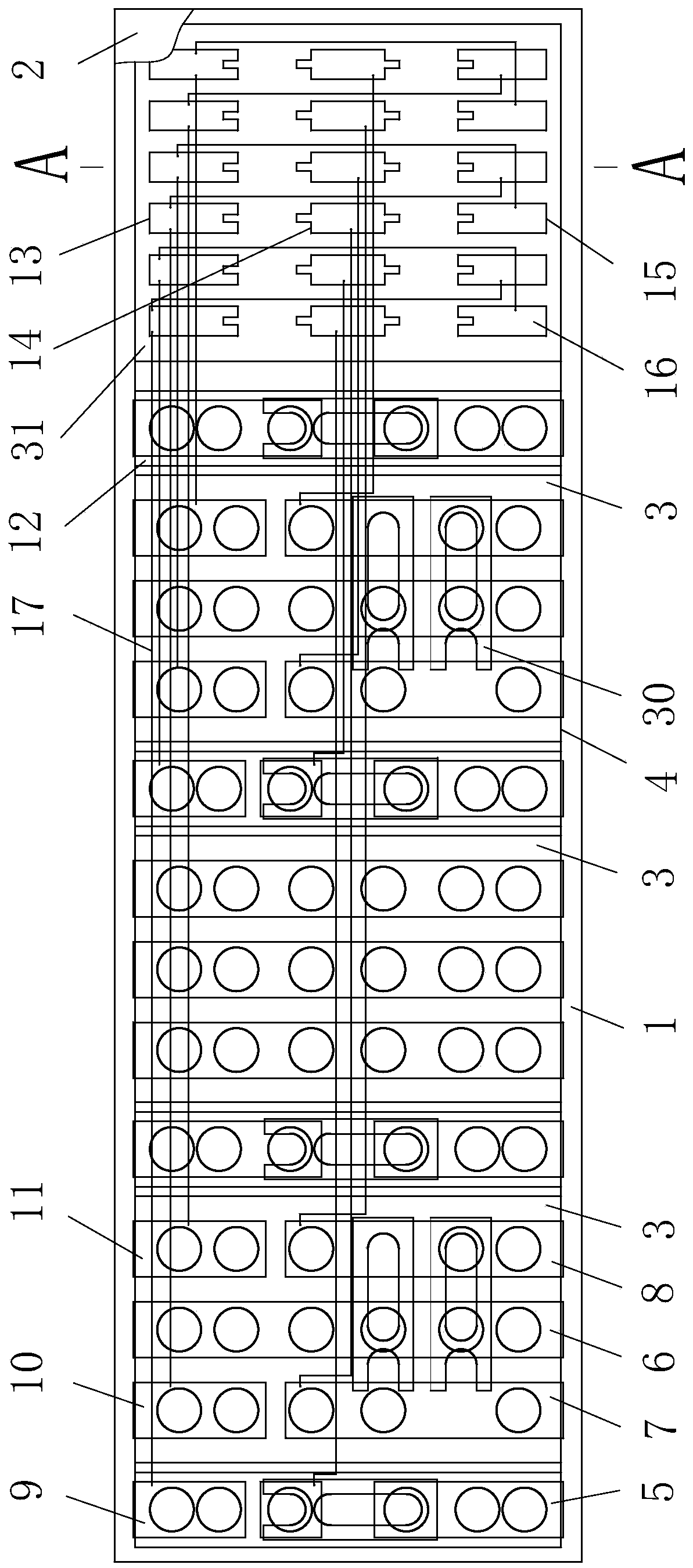

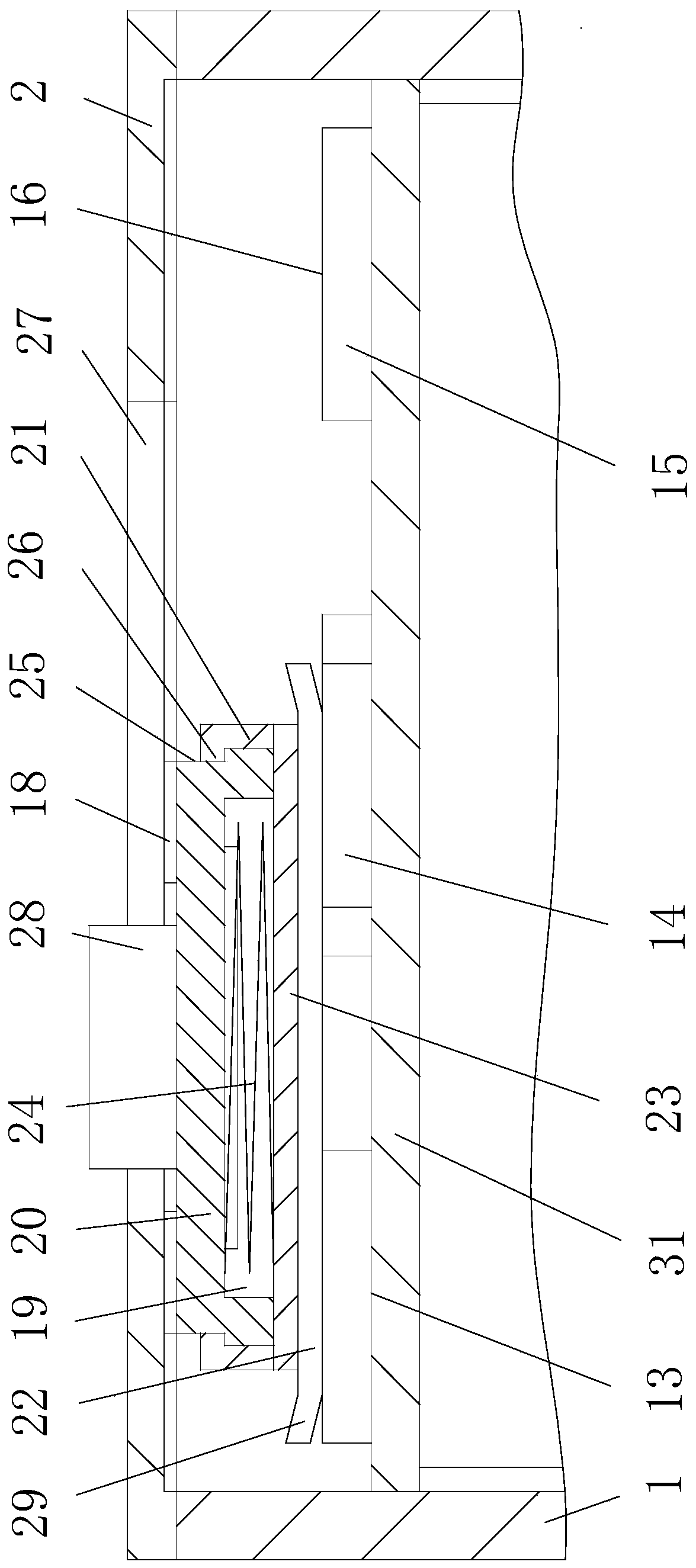

The invention discloses a loading and unloading manipulator system of a broaching machine, which comprises an executing mechanism, a driving mechanism and a hydraulic control mechanism, wherein the driving mechanism comprises a waist seat, a bull gear, a pinion, a stepping motor, a waist revolving shaft, tapered roller bearings, a fixed upright and a rack cylinder; the executing mechanism comprises a rising oil cylinder, a rising oil cylinder piston, a rising oil cylinder piston rod, a rising guide rod, a sleeve, a lifting platform, a rolling bearing, a support plate, a support frame, a translation oil cylinder, a translation oil cylinder piston rod, a guide rod, a guide bushing, an annular sleeve and a manipulator; the manipulator comprises a paw and a telescopic oil cylinder; and the hydraulic control mechanism comprises a three-phase alternating current asynchronous motor, a hydraulic pump, an oil filter, an oil tank, a two-position two-way solenoid directional valve, a one-way valve, a pilot overflow valve, a three-position four-way solenoid directional valve, a speed regulating valve and a hydraulic cylinder. The system can guarantee the positioning control precision, and reduces impact and vibration to the greatest extent, so that the safety of the system is guaranteed.

Owner:ZHEJIANG INT STUDIES UNIV

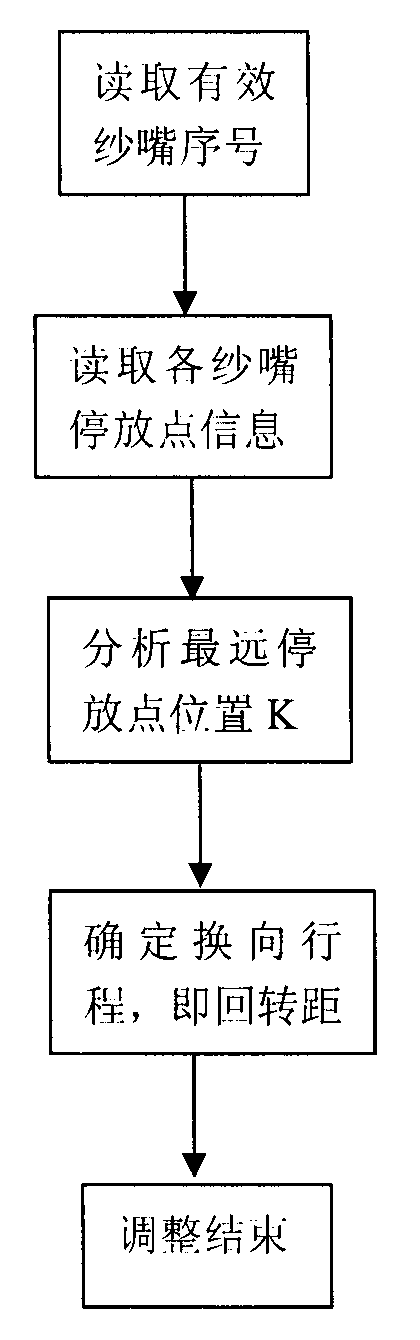

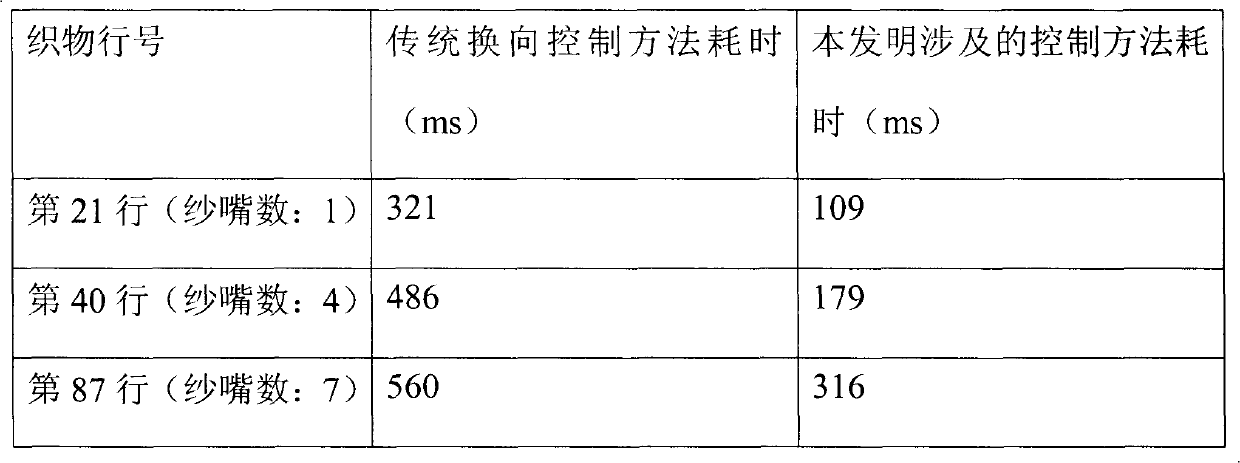

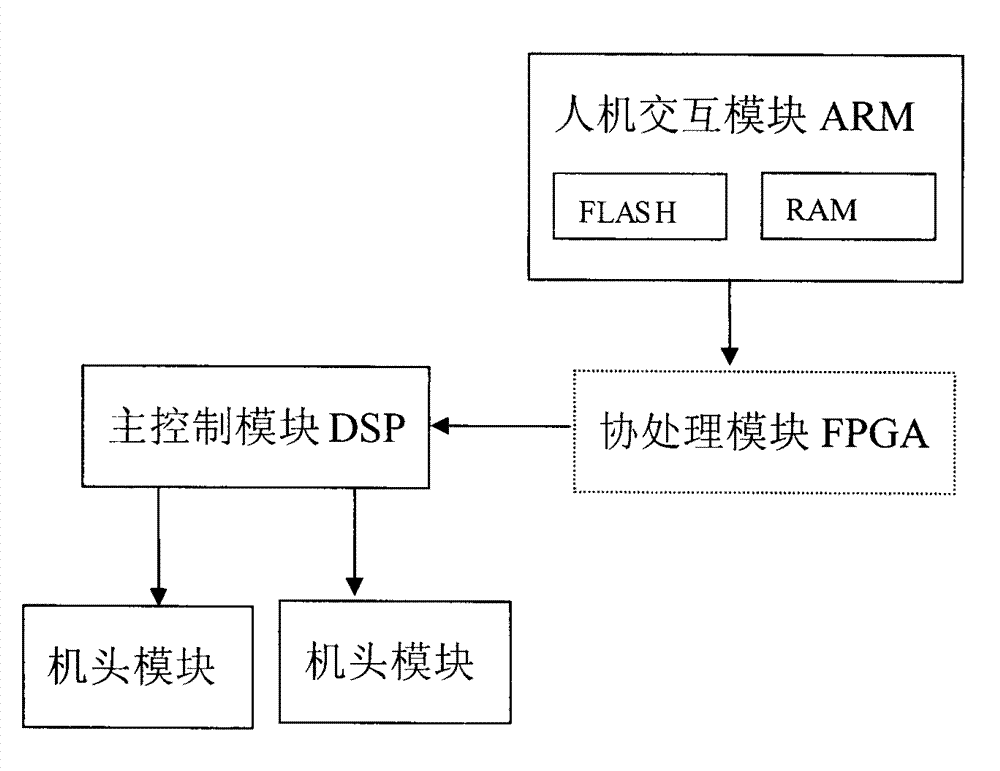

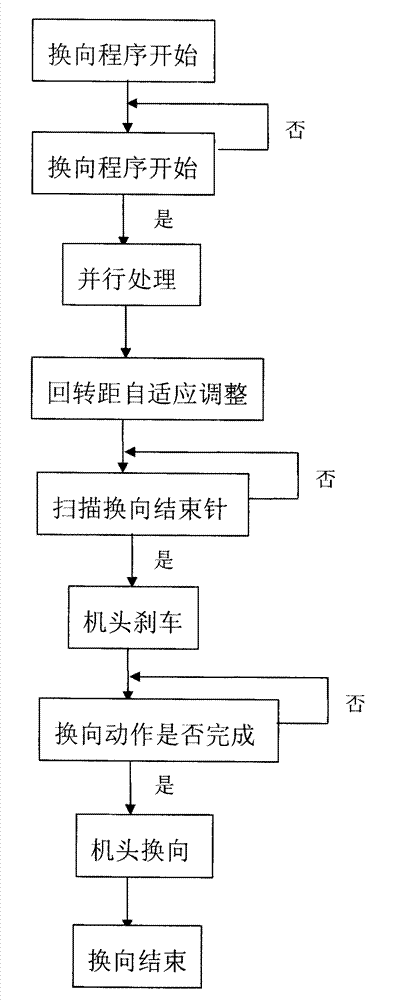

Flat knitting machine nose high speed reversing control method and control system thereof

InactiveCN101950164AAvoid wasting commutation timeImprove commutation efficiencyProgramme controlWeft knittingReverse timeControl layer

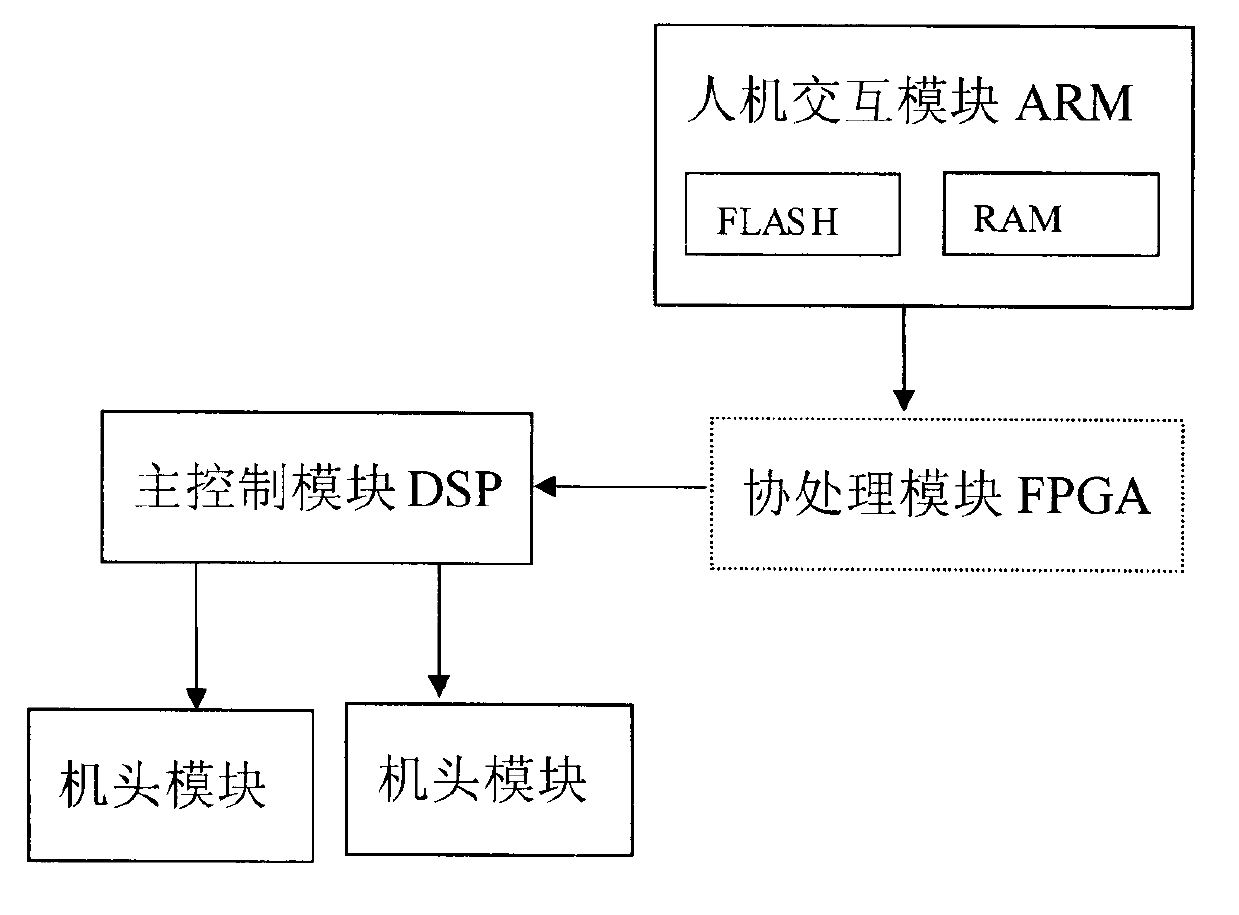

The invention relates to a flat knitting machine nose reversing control method and a control system thereof. The method includes the following steps: 1, data is read; 2, reversing action is executed; 3, back torque is adaptively adjusted; 4, reversing is started; 5 reversing is finished. The control system comprises a main control layer, a human-machine interaction layer and a nose driving layer which are in communication connection with the main control layer as well as a main control module in the main control layer and an assistant processing module which is in communication connection with the main control module; wherein the assistant processing module is in communication connected with a storage module in the human-machine interaction layer, and the main control module is also in communication connection with a nose module and a machine body module which are arranged in the nose driving layer. The invention has the substantial characteristics that: each module in the control system is configured, reversing back torque is calculated in real time, namely the back torque is adaptively adjusted, the nose is controlled to reverse according to concrete real-time back torque, the phenomenon that reversing time is wasted in back torque with preset parameter is avoided, and reversing efficiency is improved, thus improving knitting efficiency.

Owner:ZHEJIANG SCI-TECH UNIV +1

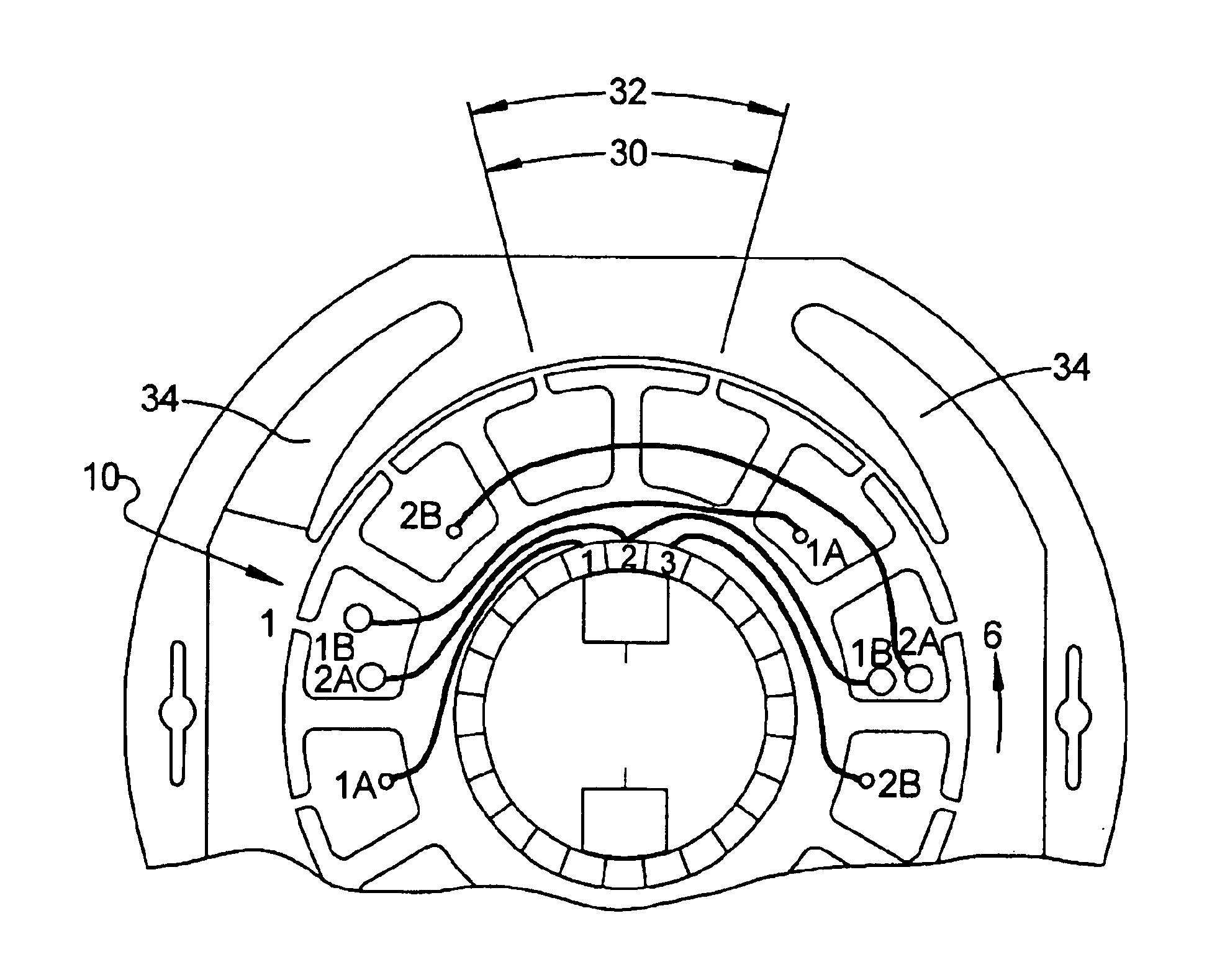

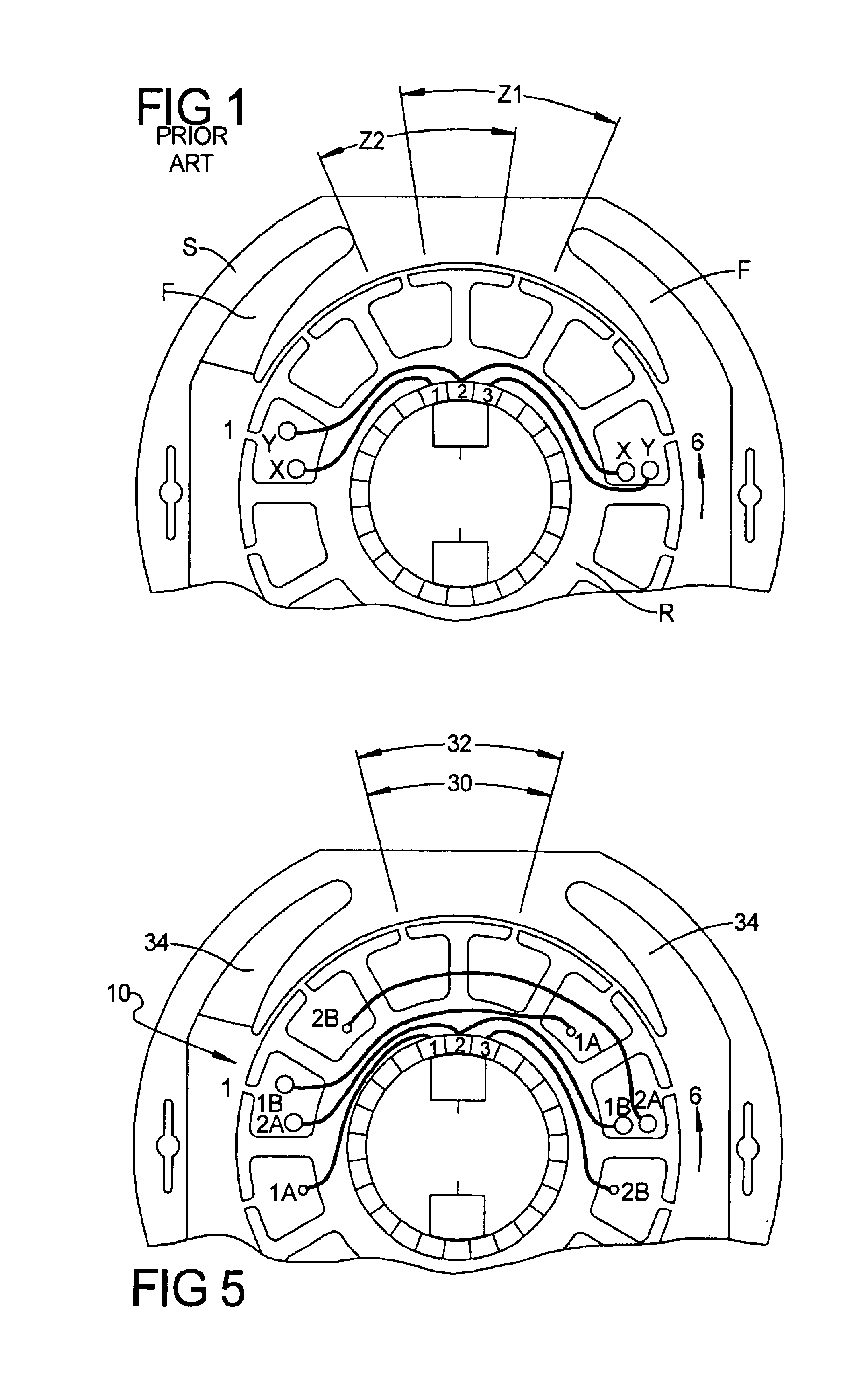

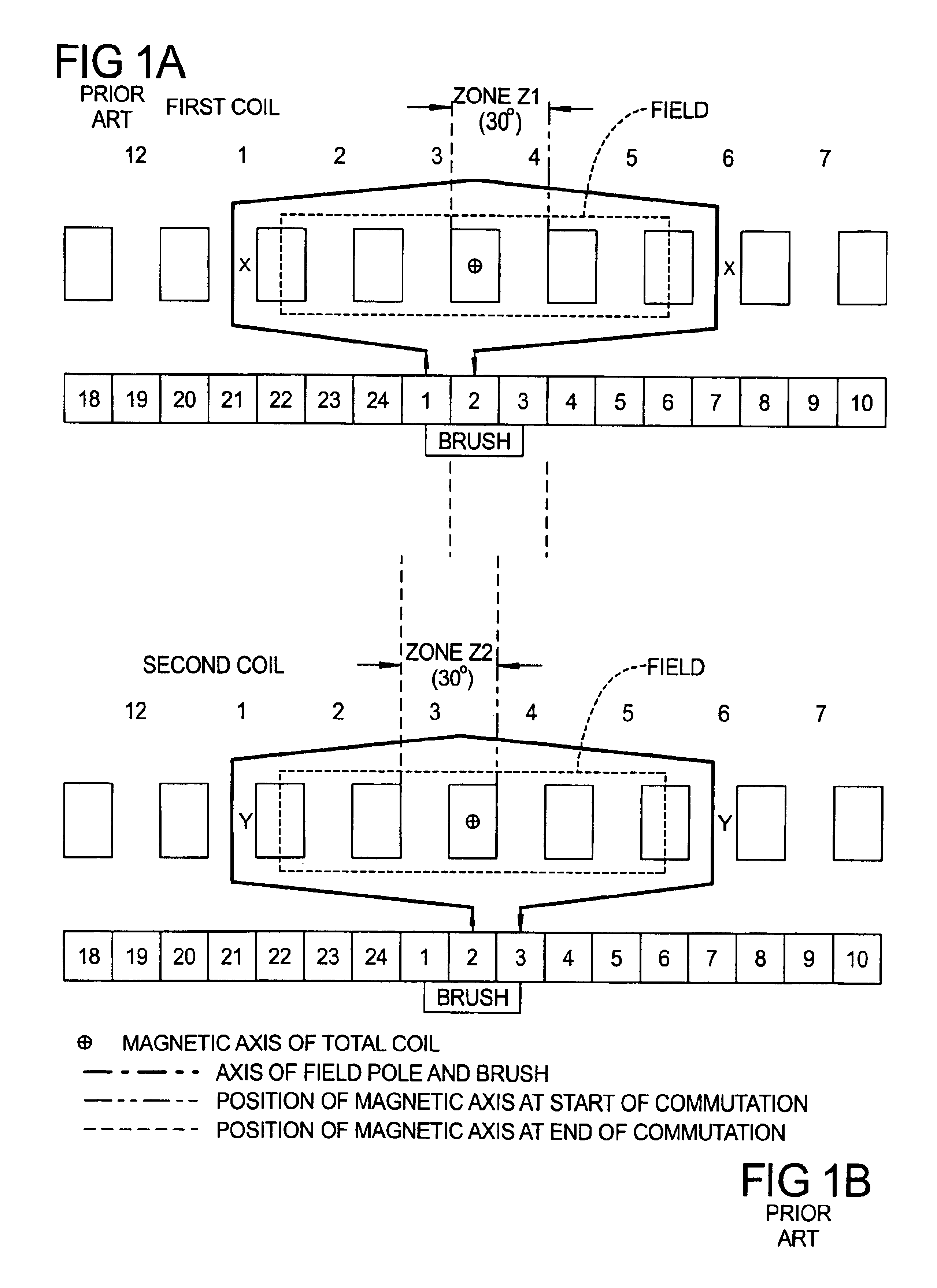

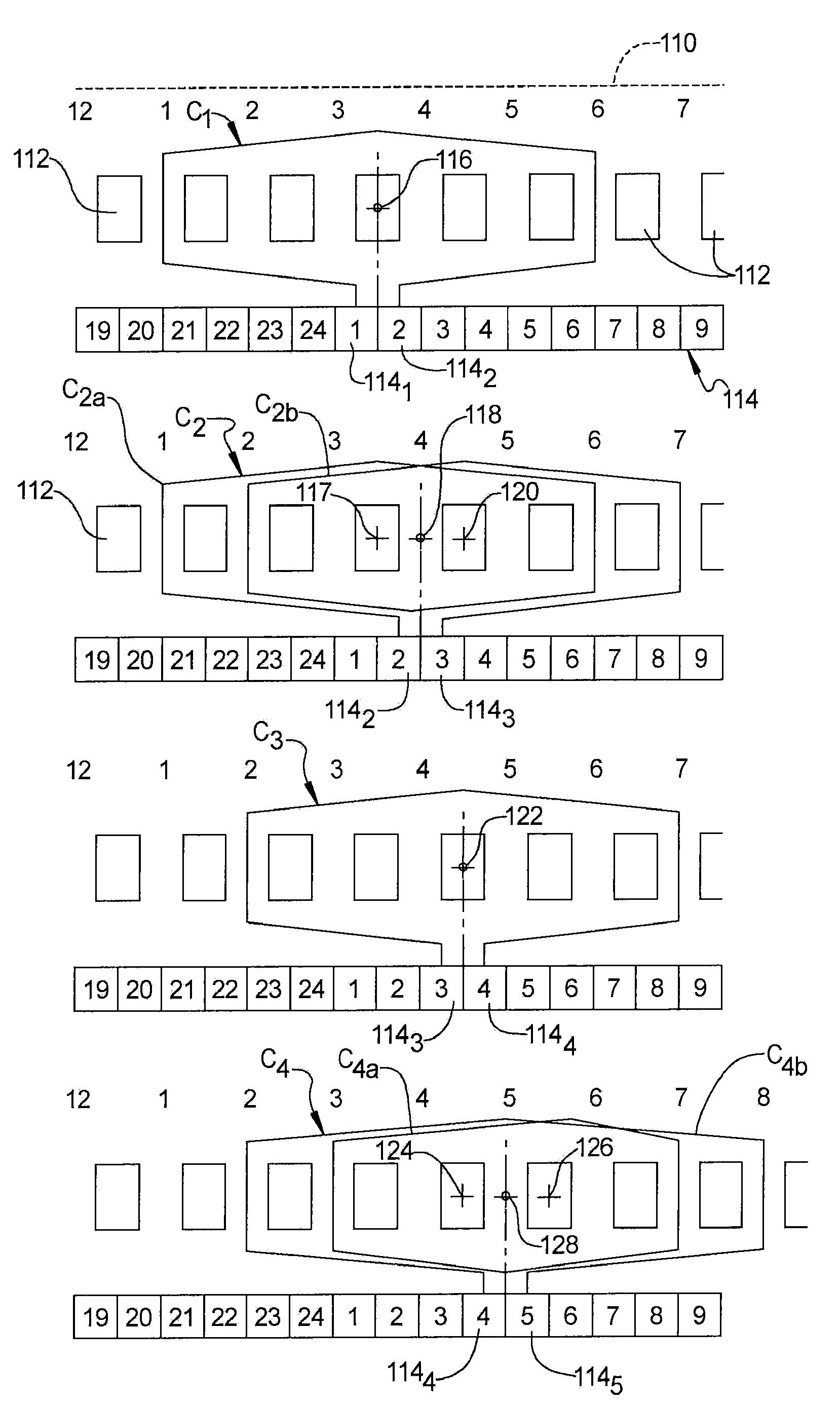

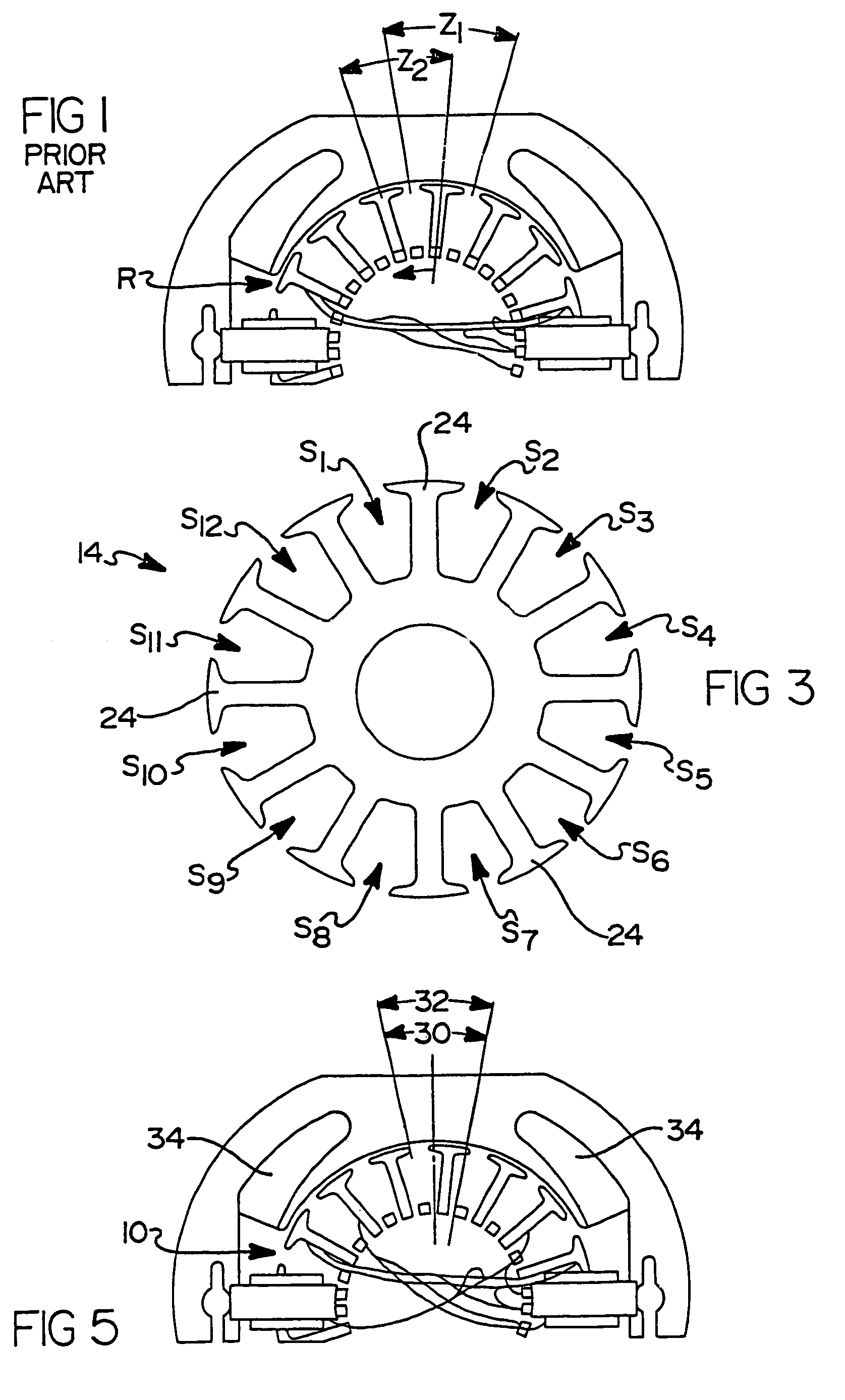

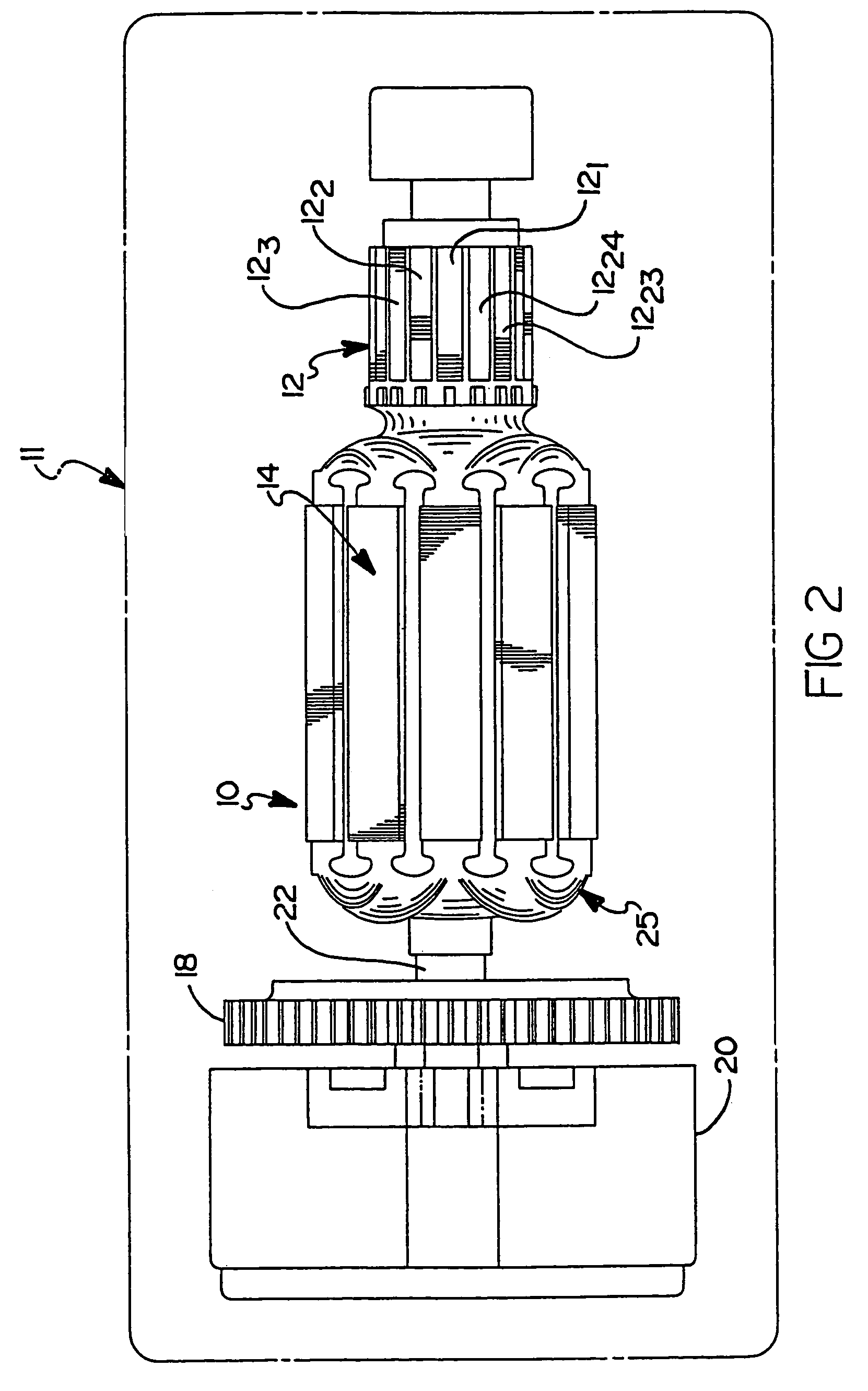

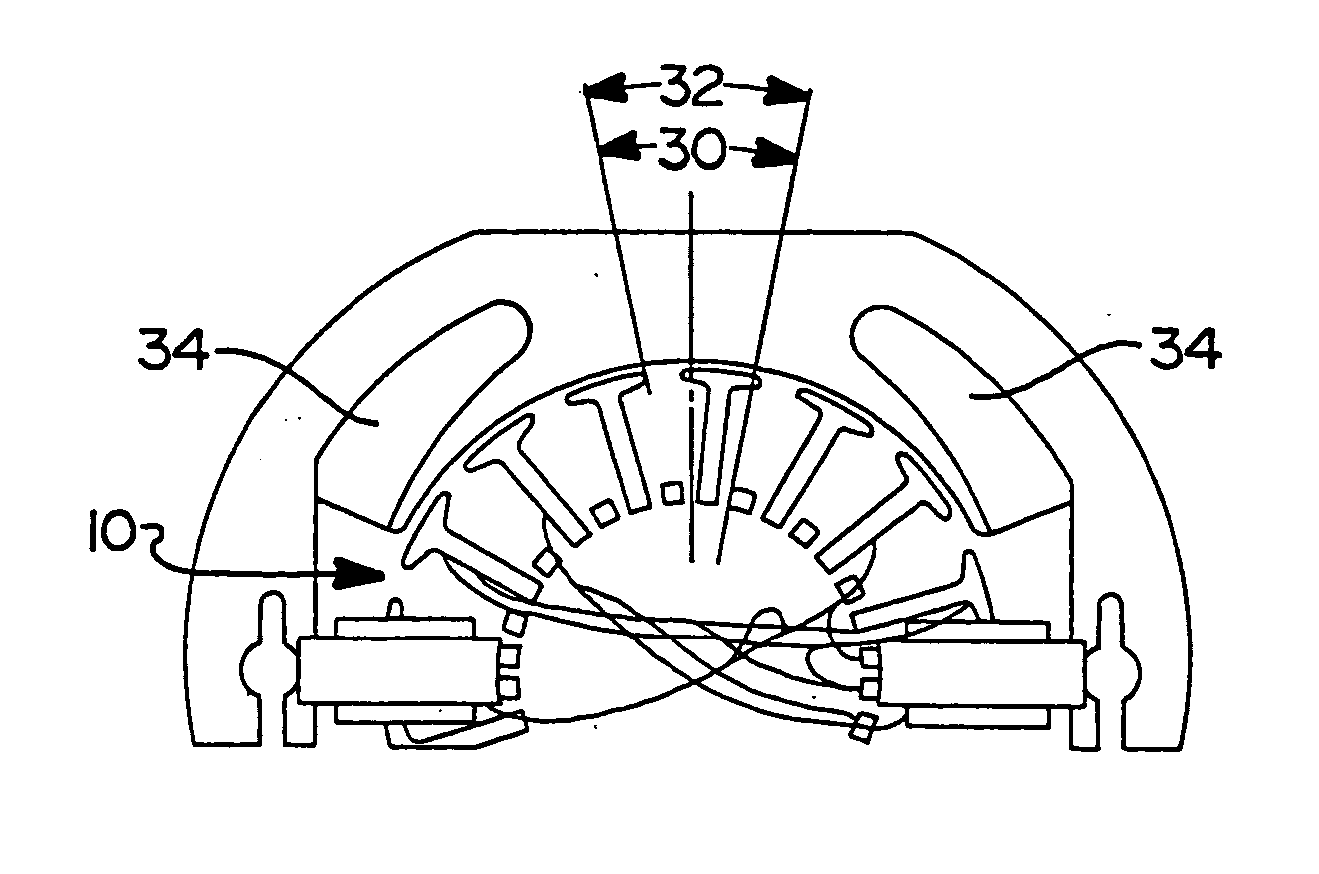

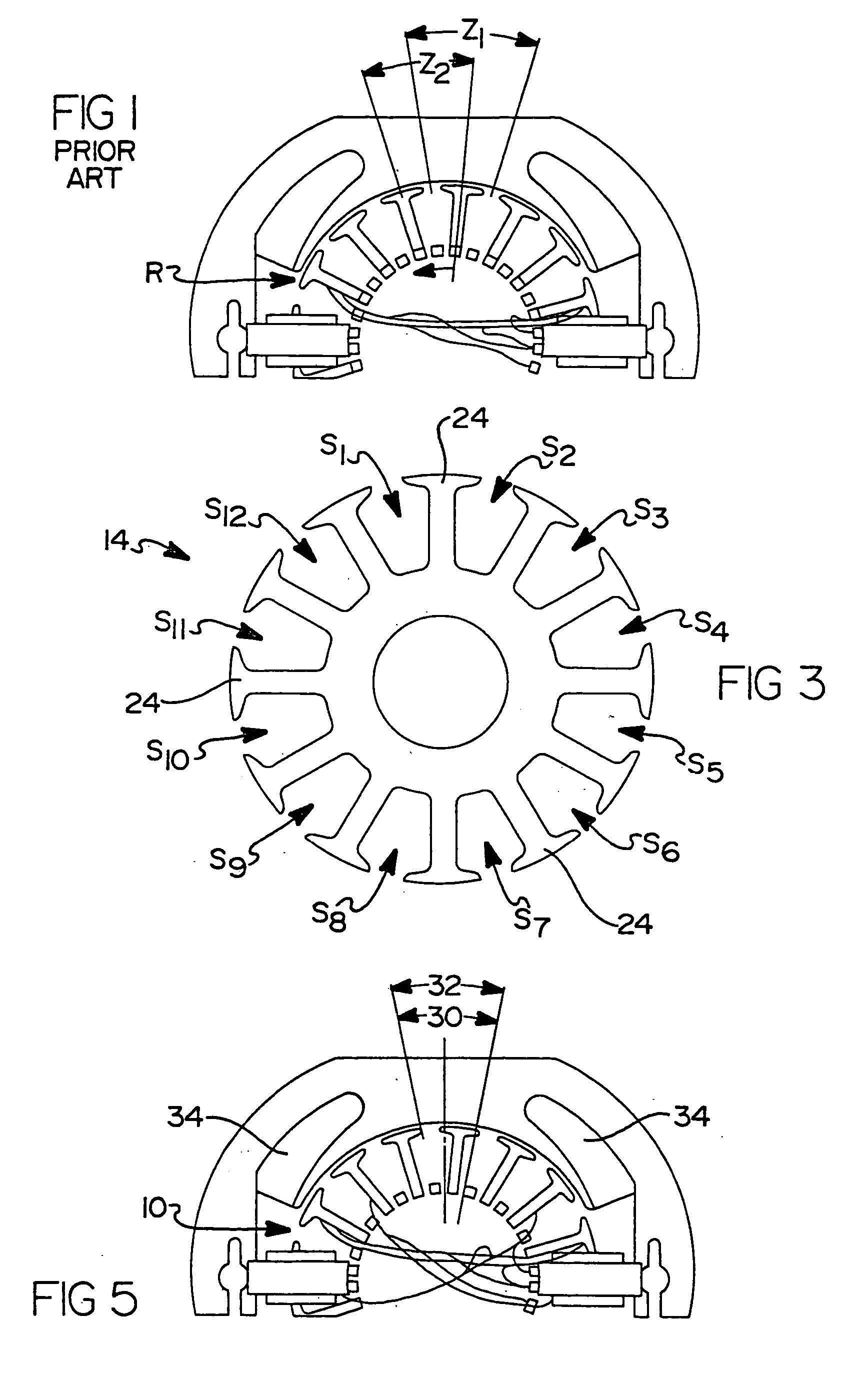

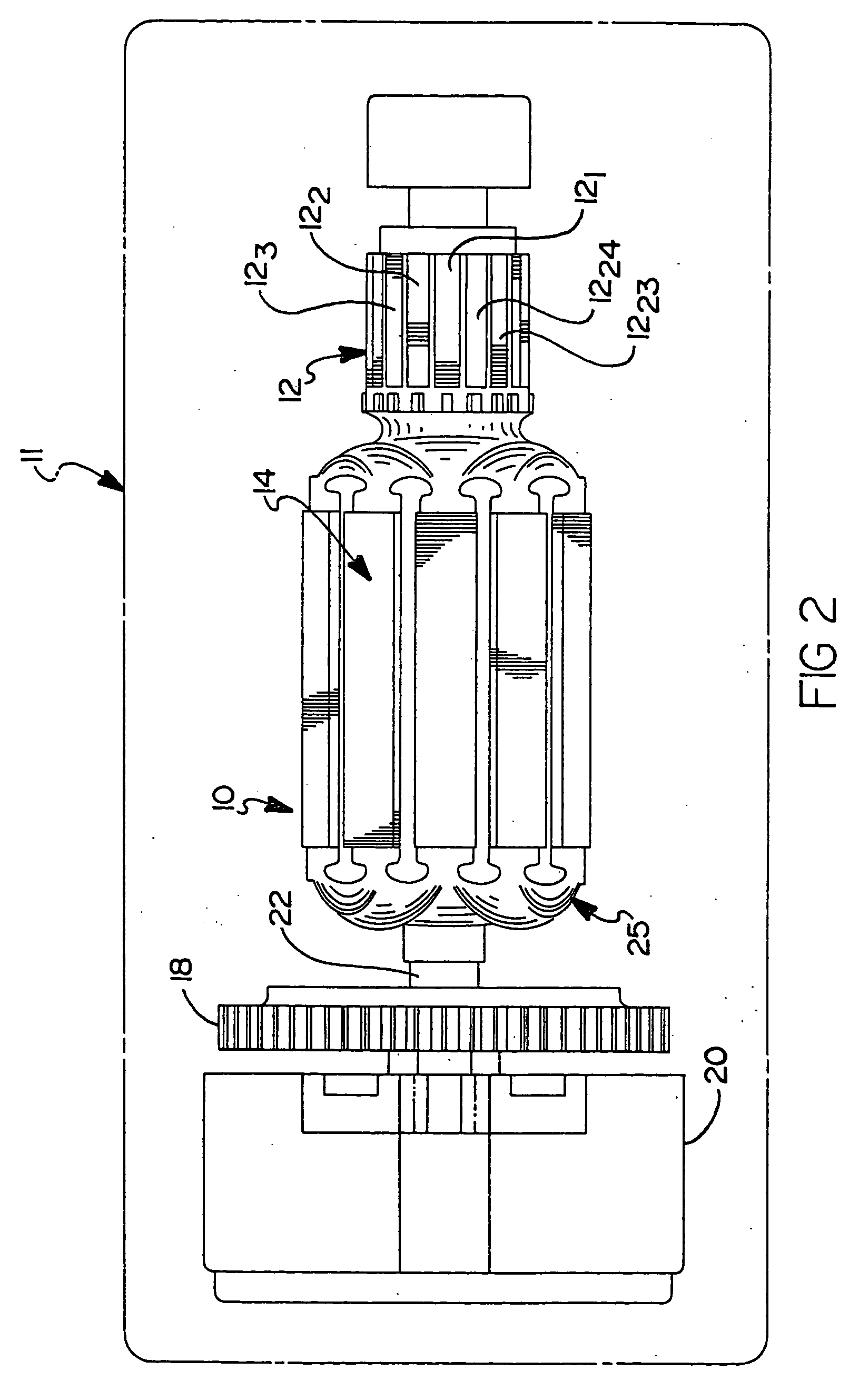

Motor armature having distributed windings for reducing arcing

InactiveUS6930429B2Smoothes out “ unevenness ”Improve commutation efficiencyWindings insulation shape/form/constructionRotary current collectorCouplingElectromagnetic interference

An armature for a brush commutated electric motor having a distributed coil winding arrangement for reducing brush arcing and electromagnetic interference (EMI). The winding pattern involves segmenting each coil into first and second subcoil portions with differing pluralities of turns. Each subcoil portion is wound around separate pairs of spaced apart slots of a lamination stack. Adjacent coils are wound such that one subcoil portion of each is wound in a common slot to therefore form an overlapping arrangement of each pair of adjacently coils. The winding pattern serves to “shift” the resultant magnetic axes of each coil in such a manner so as to significantly reduce brush arcing and the EMI resulting therefrom. The reduction in EMI is sufficient to eliminate the need for EMI reducing components, such as chokes, which have typically been required to maintain EMI to acceptably low levels. Commutation efficiency is also improved by the distributed winding pattern described above because of the reduction in the unevenness of the magnetic coupling between adjacent coils.

Owner:BLACK & DECKER INC

Motor armature having distributed windings for reducing arcing

InactiveUS7274126B2Smoothes out “ unevenness ”Improve commutation efficiencySynchronous generatorsWindings insulation shape/form/constructionElectromagnetic interferenceConductor Coil

An armature for a brush commutated electric motor having a distributed coil winding arrangement for reducing brush arcing and electromagnetic interference (EMI). The winding pattern involves winding a first coil into a first pair of slots of the armature. A second coil having a first subcoil portion is then wound into the same slots as the first coil, while a second subcoil portion of the second coil is wound into a pair of slots that is offset by one slot position from the first pair of slots. The two subcoil portions have the same number of turns, and the total turns of the two subcoil portions equals the number of turns of the first coil. A third coil is then wound in the same slots as the second subcoil portion of the second coil. The third coil has the same number of turns as the first coil. This pattern is repeated around the armature. In a two coil per slot armature, this pattern enables the magnetic axis of each coil to be maintained at a constant angular position relative to the commutator bars to which it is coupled without the need for using uneven numbers of turns for the two subcoil portions of each segmented coil.

Owner:BLACK & DECKER INC

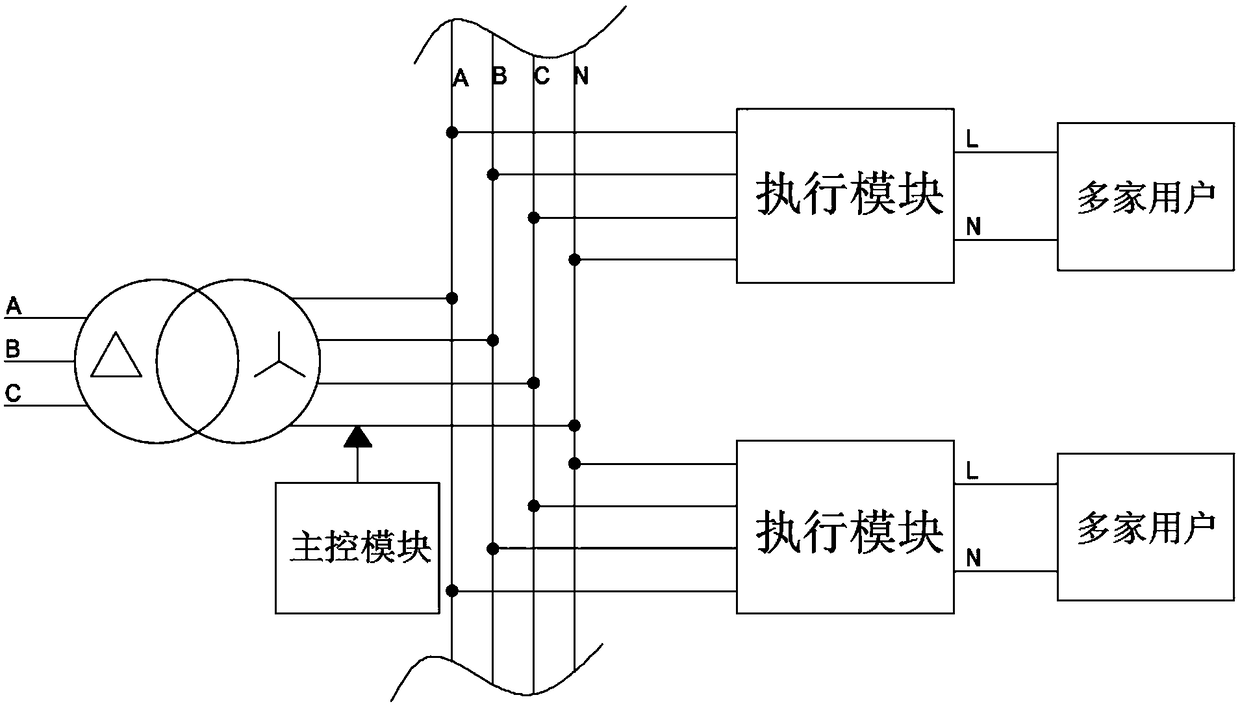

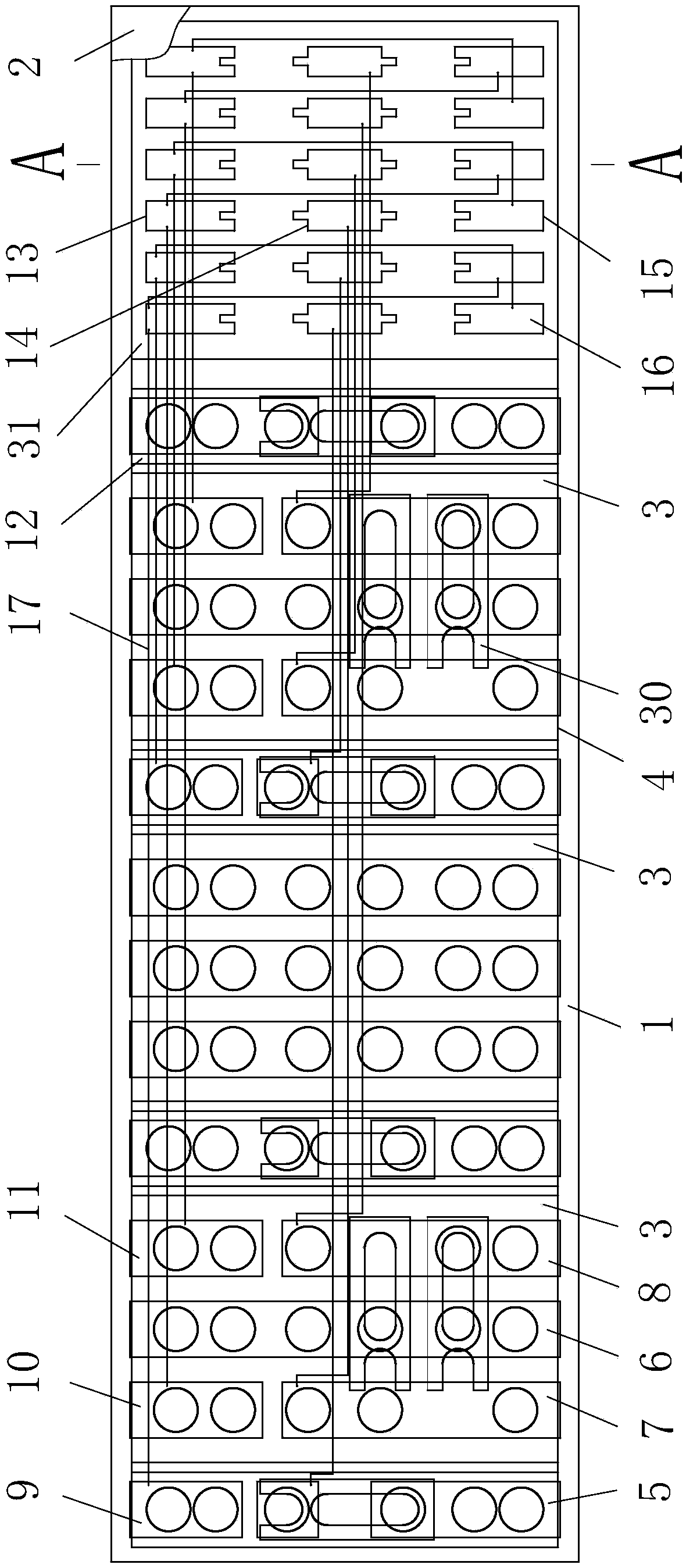

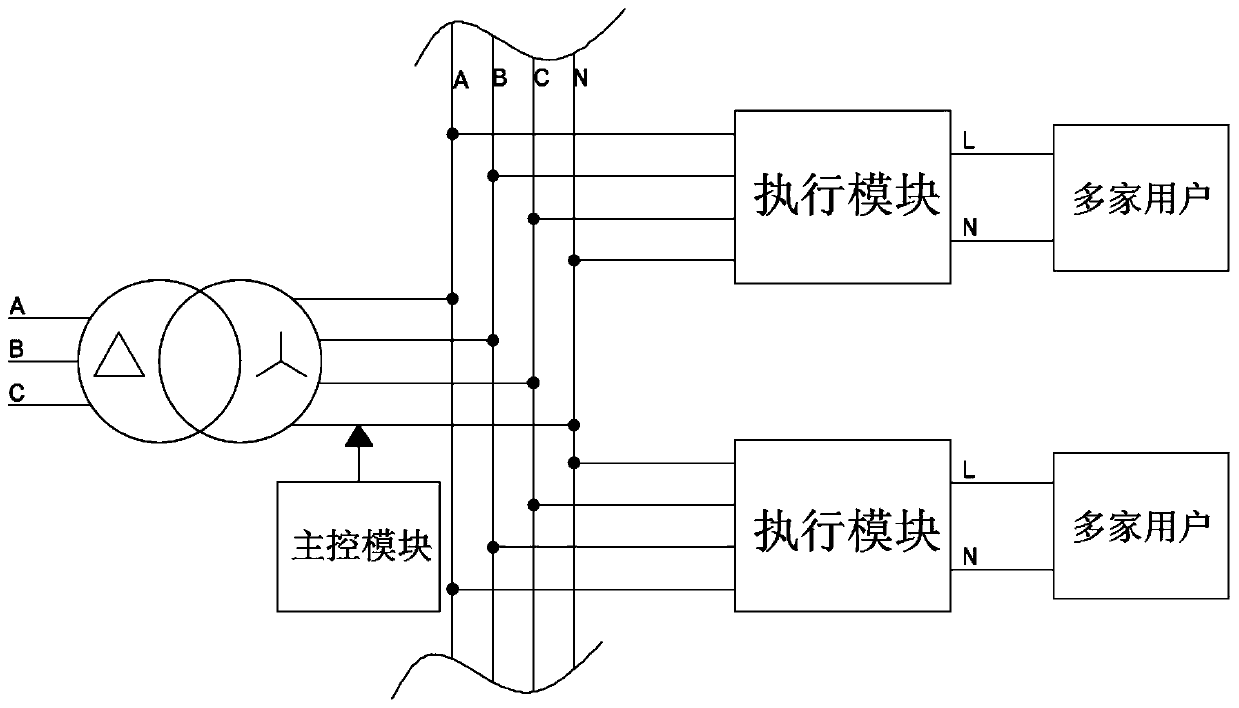

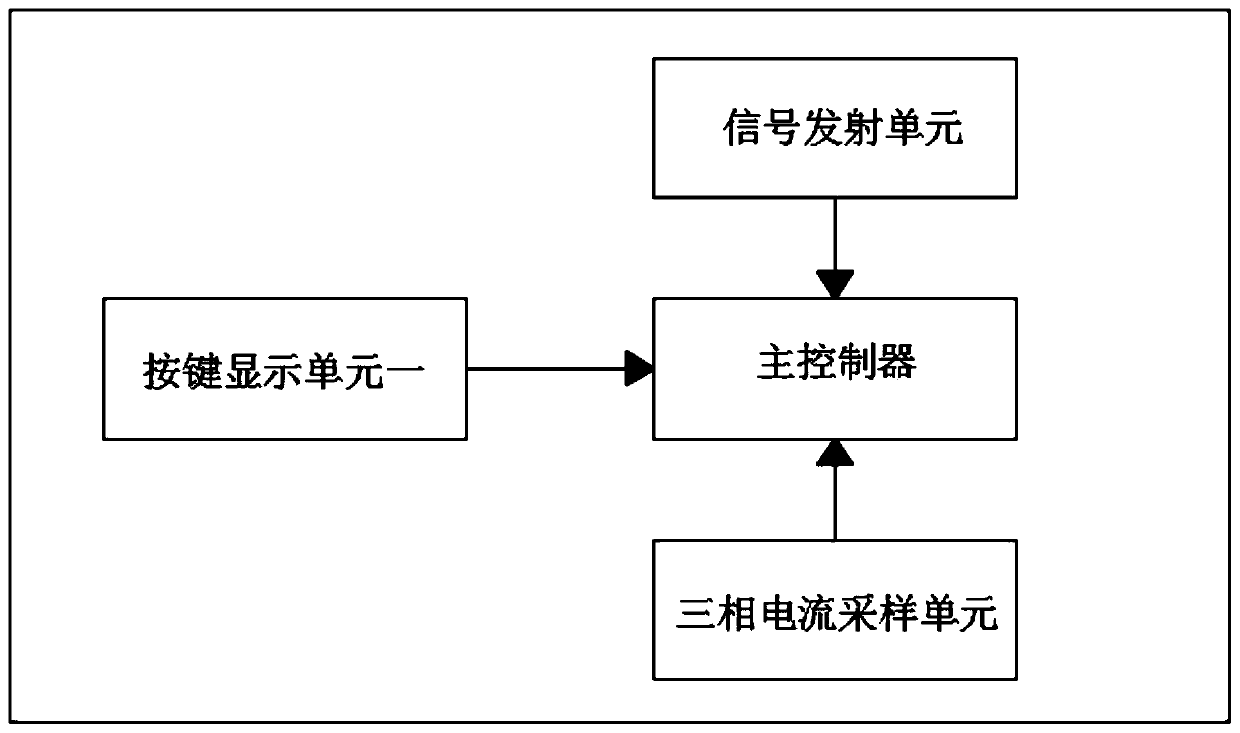

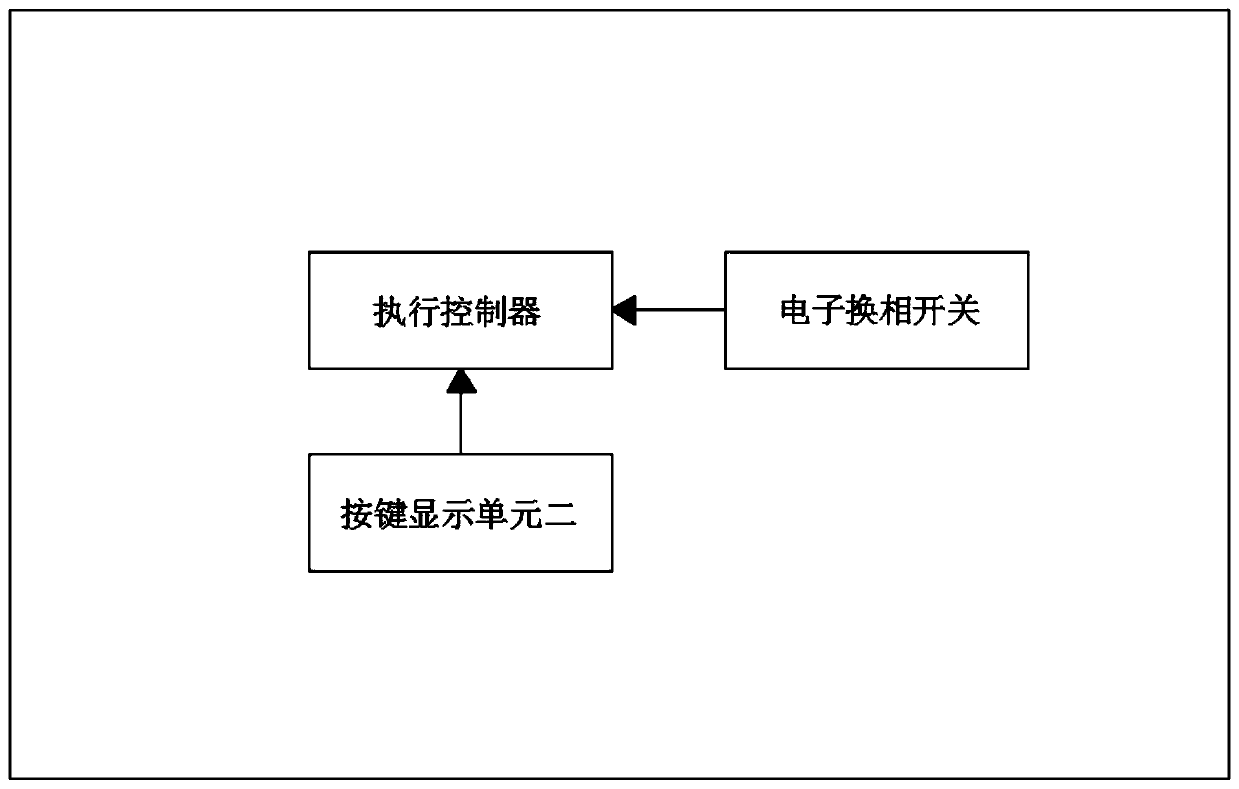

Multifunctional automatic phase changing system for medium/low voltage line and phase changing method thereof

ActiveCN108649592AReduce line lossGuarantee power qualityPolyphase network asymmetry elimination/reductionFault location by conductor typesPower qualityDistribution transformer

The invention discloses a multifunctional automatic phase changing system for a medium / low voltage line and a phase changing method thereof. The phase changing system comprises a master control moduleand multiple execution modules; each execution module corresponds to multiple users that are connected in parallel; the master control module comprises a master controller and a three-phase current sampling unit; each execution unit includes an electronic phase changing switch; and the electronic phase changing switch selects, according to a switching command, one phase corresponding to the switching command from three power supply phases of a transformer to supply a power to the multiple users corresponding to the execution modules. According to the multifunctional automatic phase changing system for the medium / low voltage line and the phase changing method thereof, the master control module and the execution modules are provided, lines in a power distribution area are divided, and the multiple execution modules are controlled via the master control module arranged at a power distribution transformer end to switch three phases of each line, so that three-phase power loads of all switched lines tend to balance; and thus, the unbalancedness of the three phases is improved, the line loss of the power distribution area is reduced, the power quality of the users is guaranteed, and thepurposes of saving the energy and reducing an electricity price are implemented.

Owner:ANHUI ZENITH ELECTRICITY & ELECTRONICS

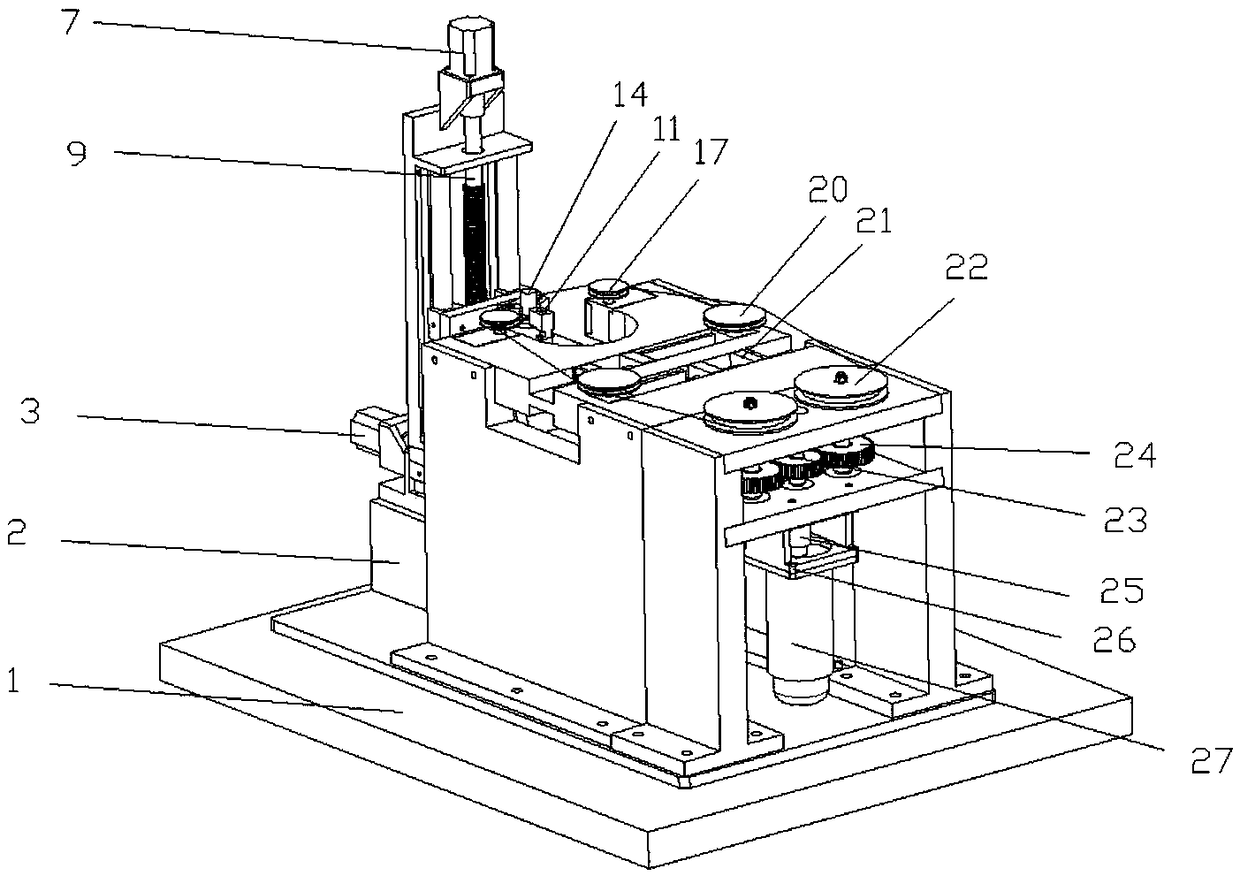

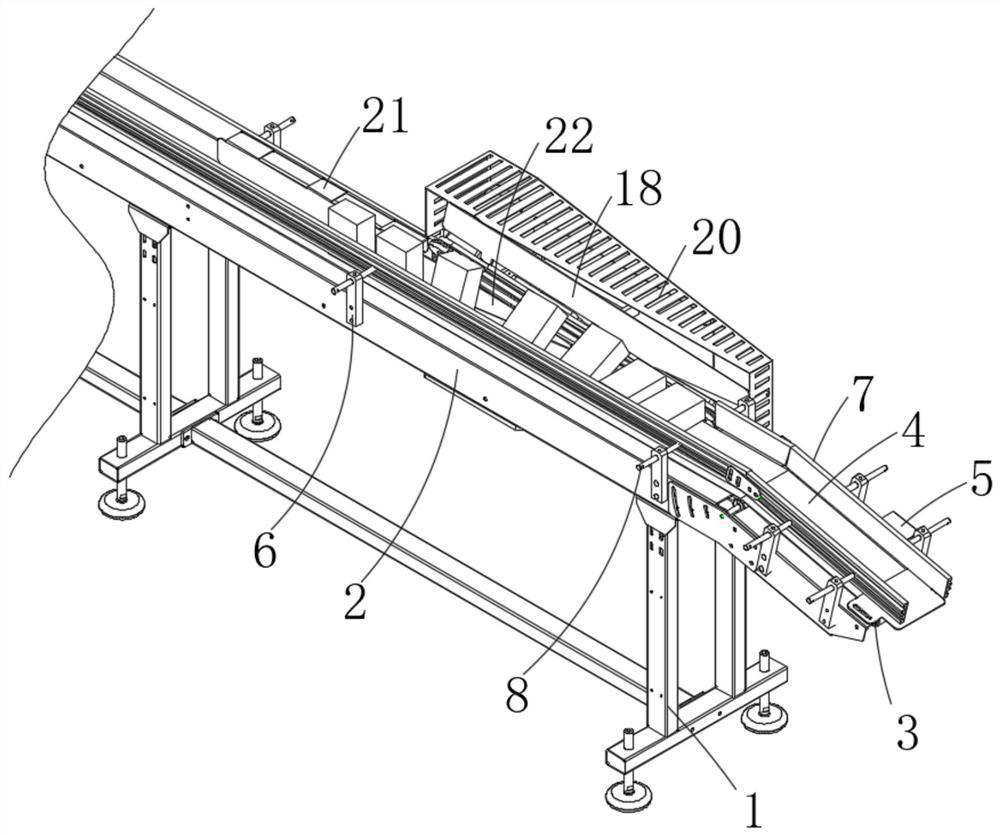

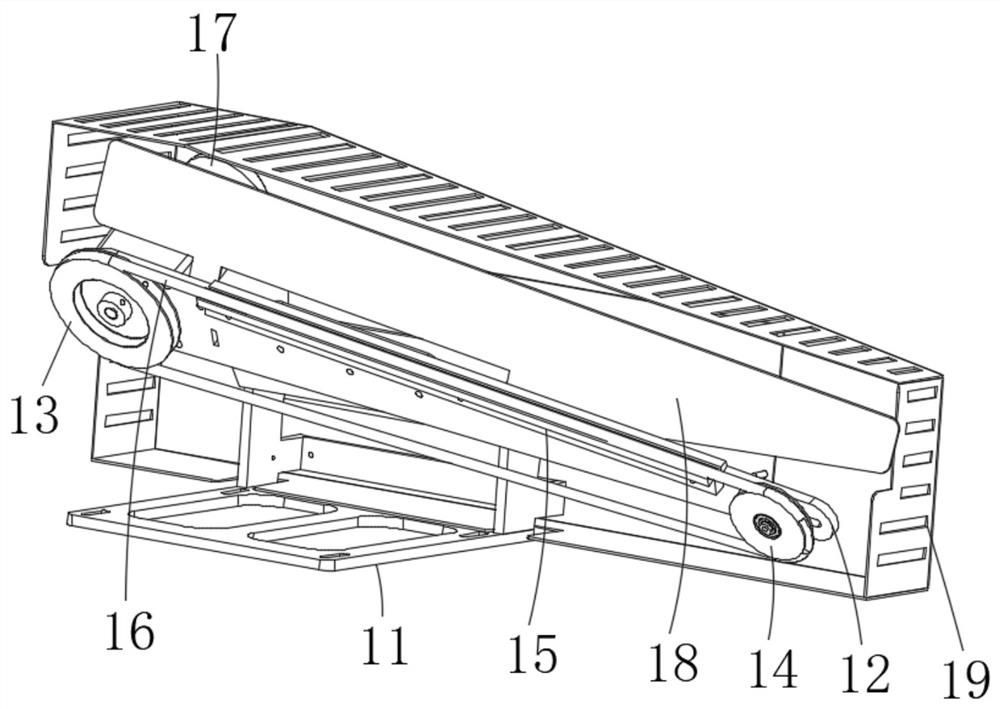

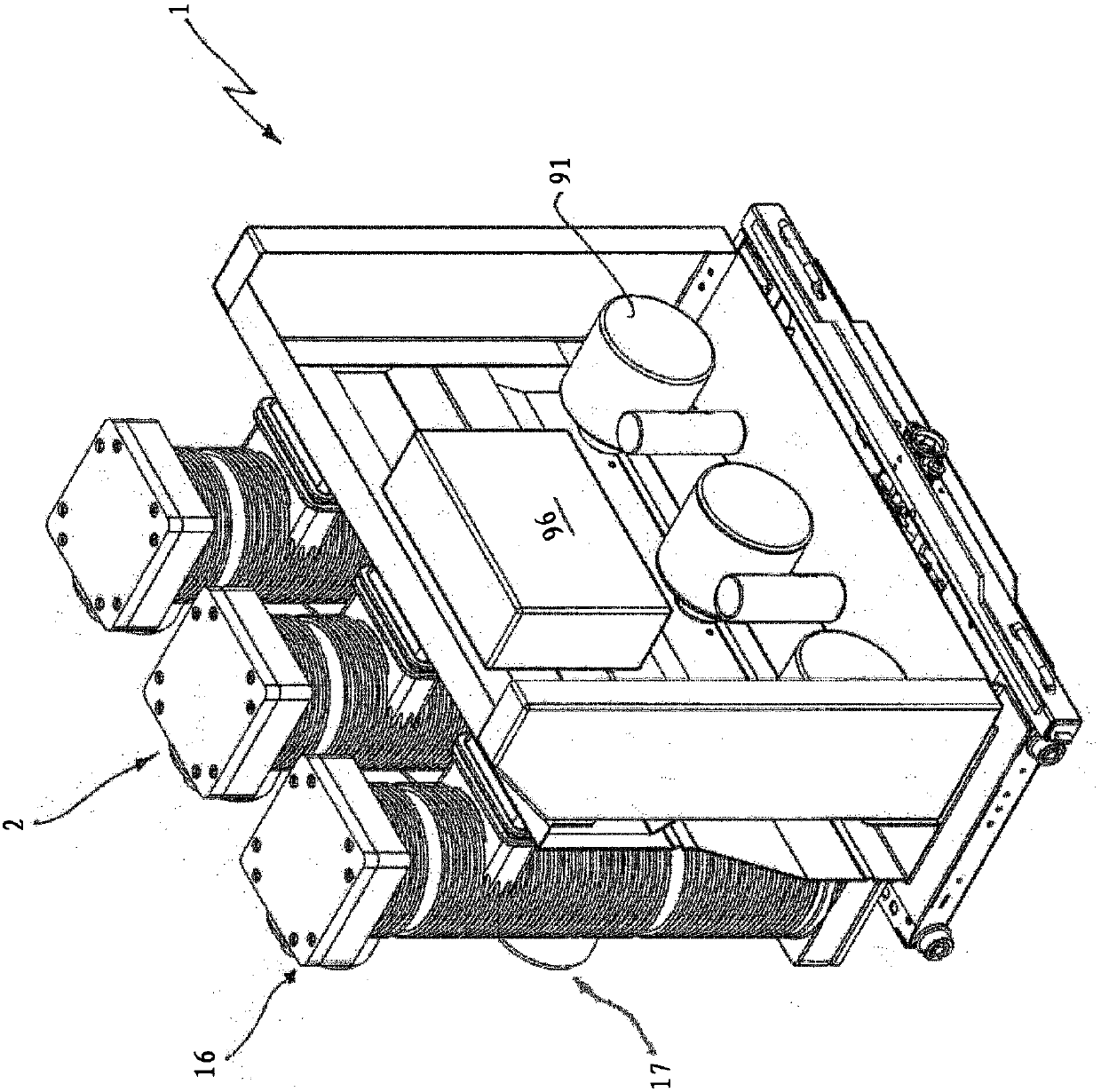

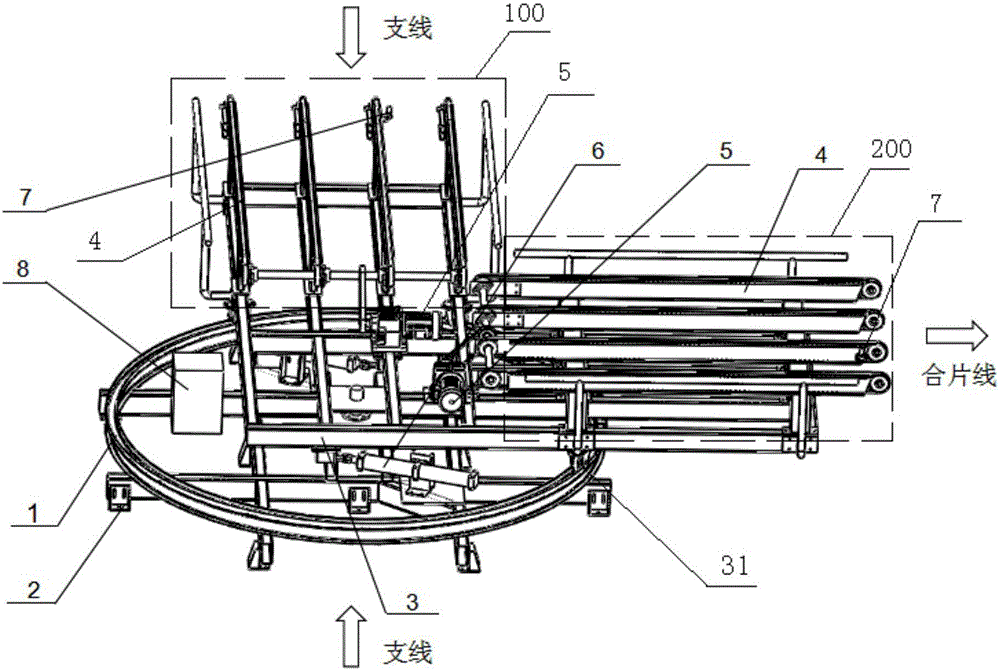

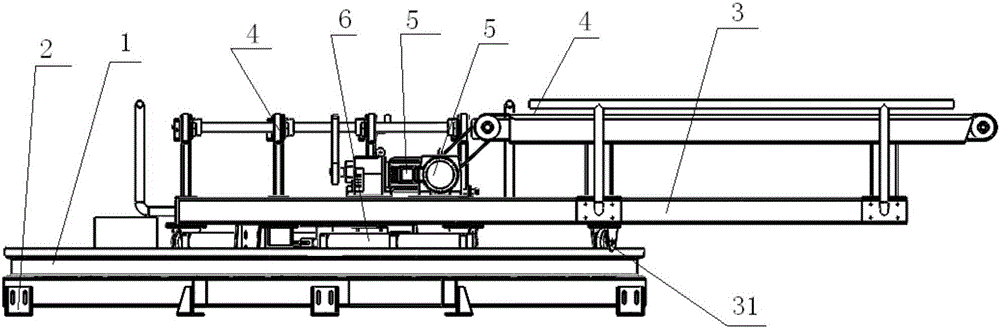

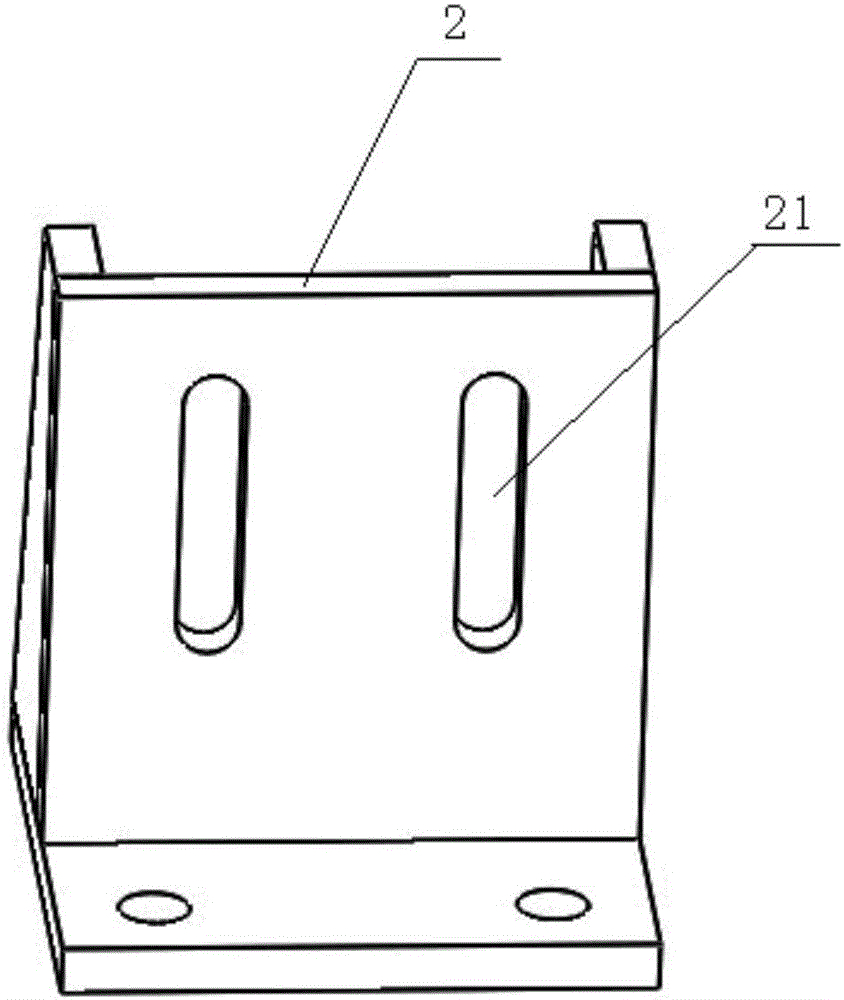

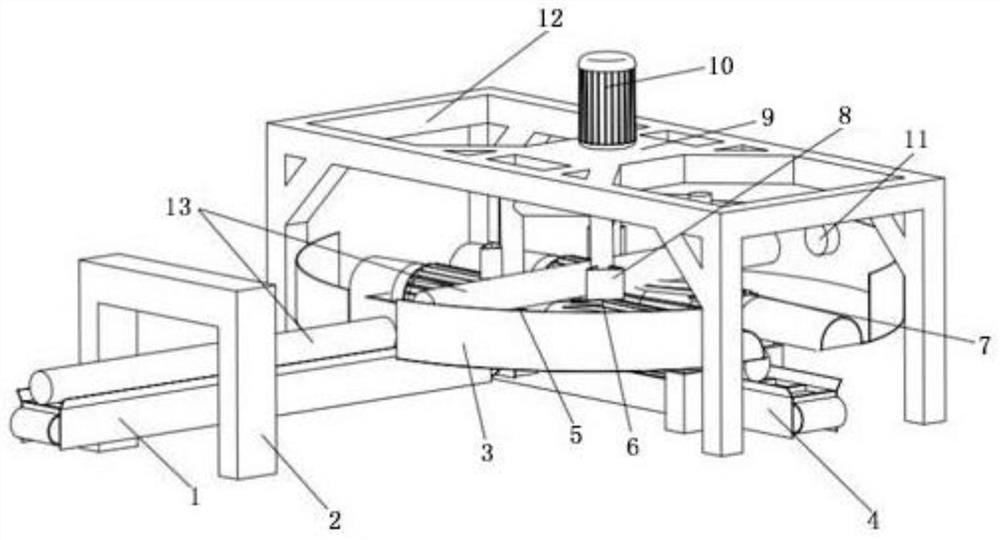

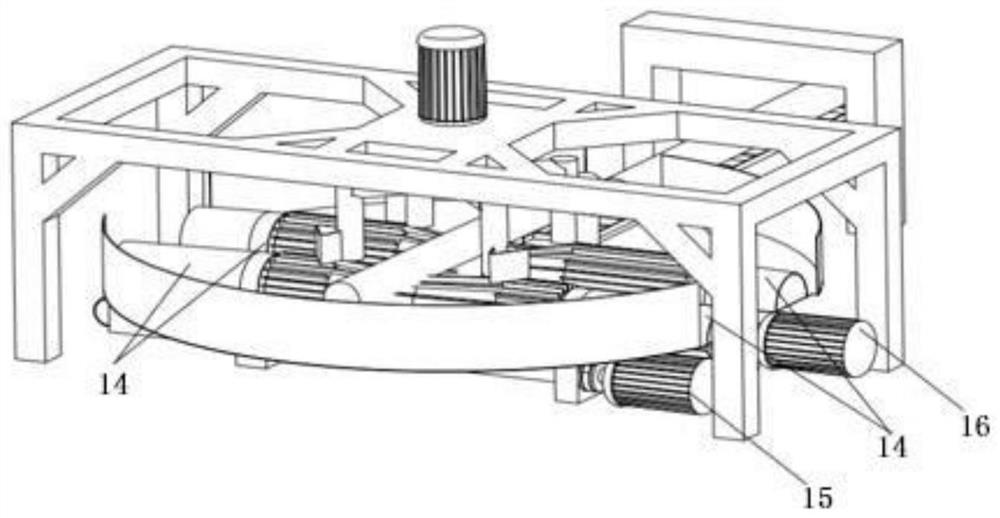

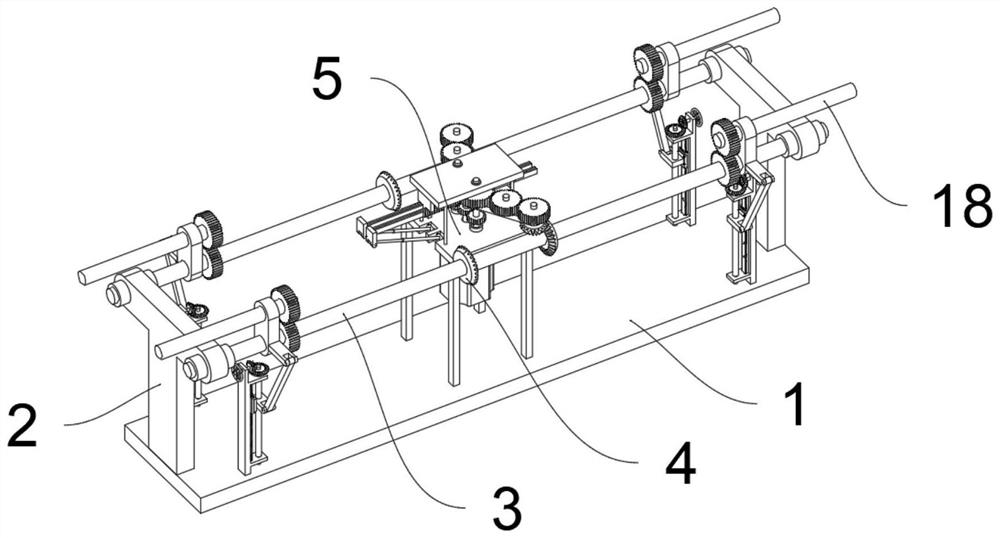

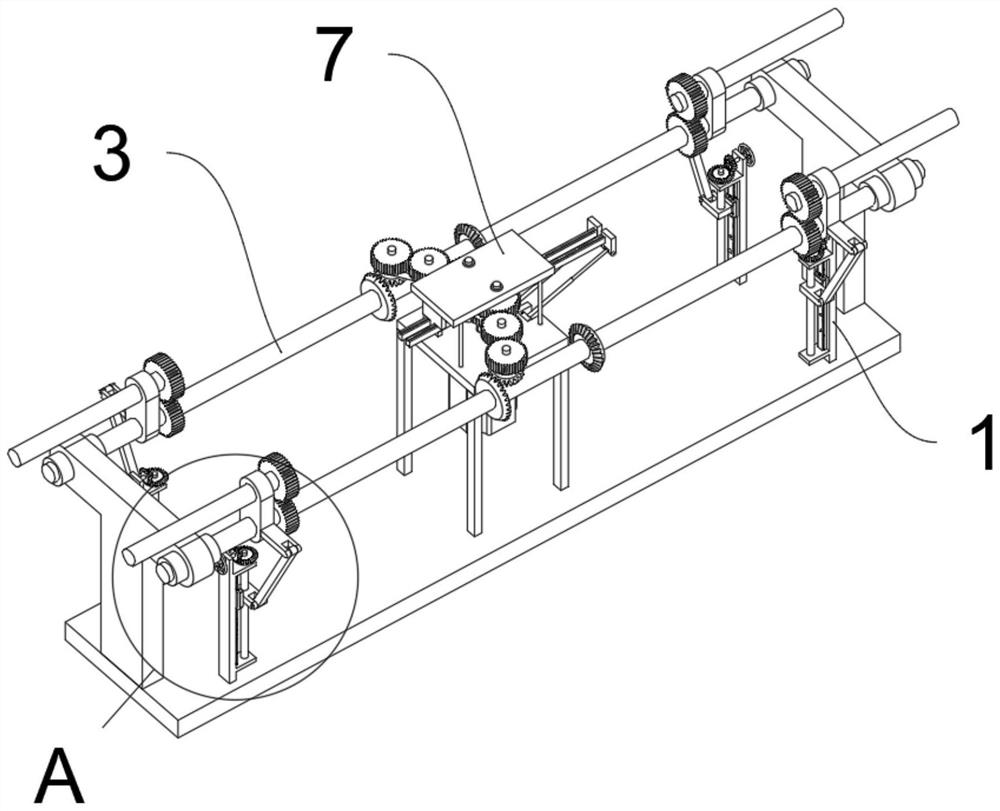

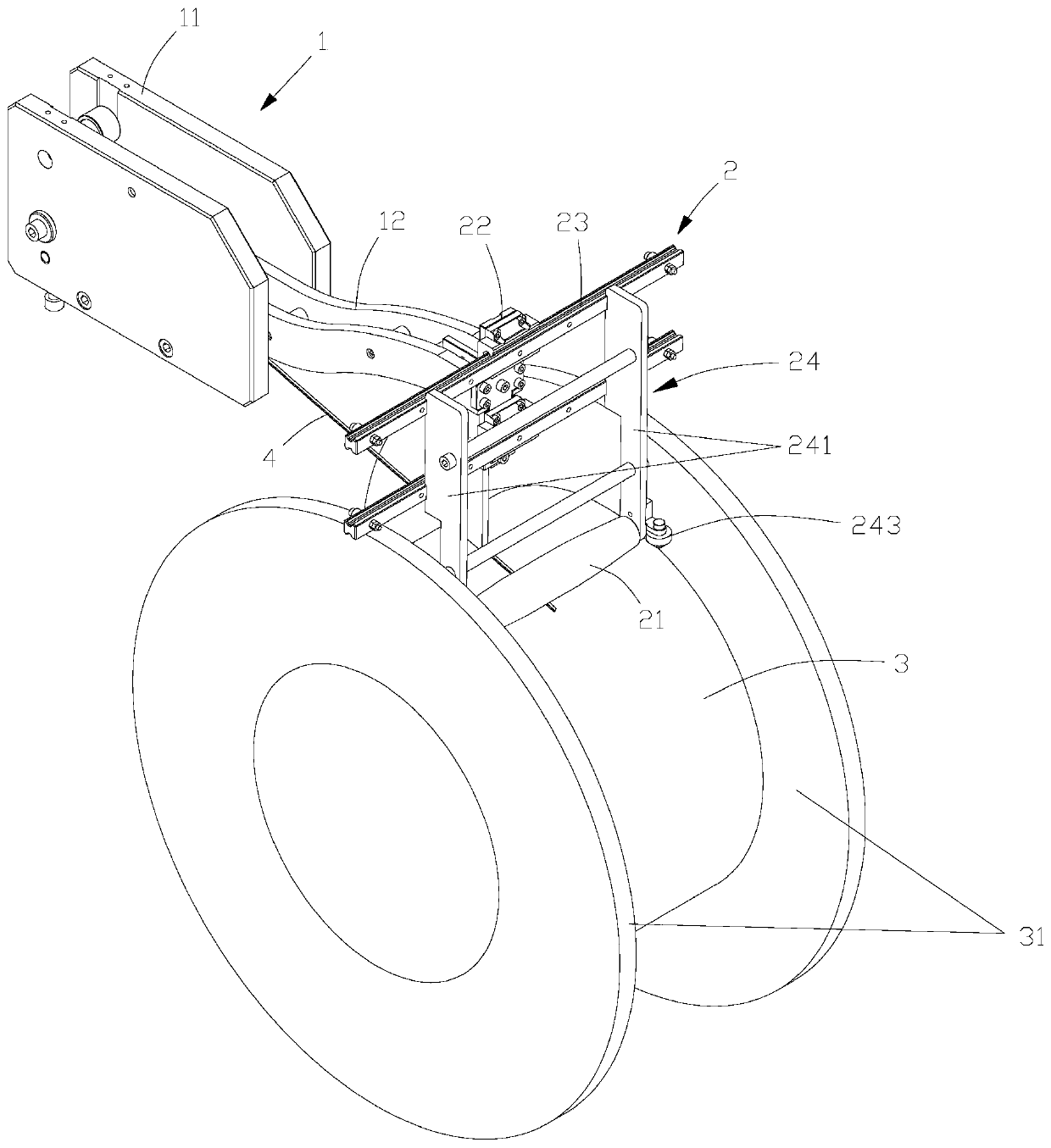

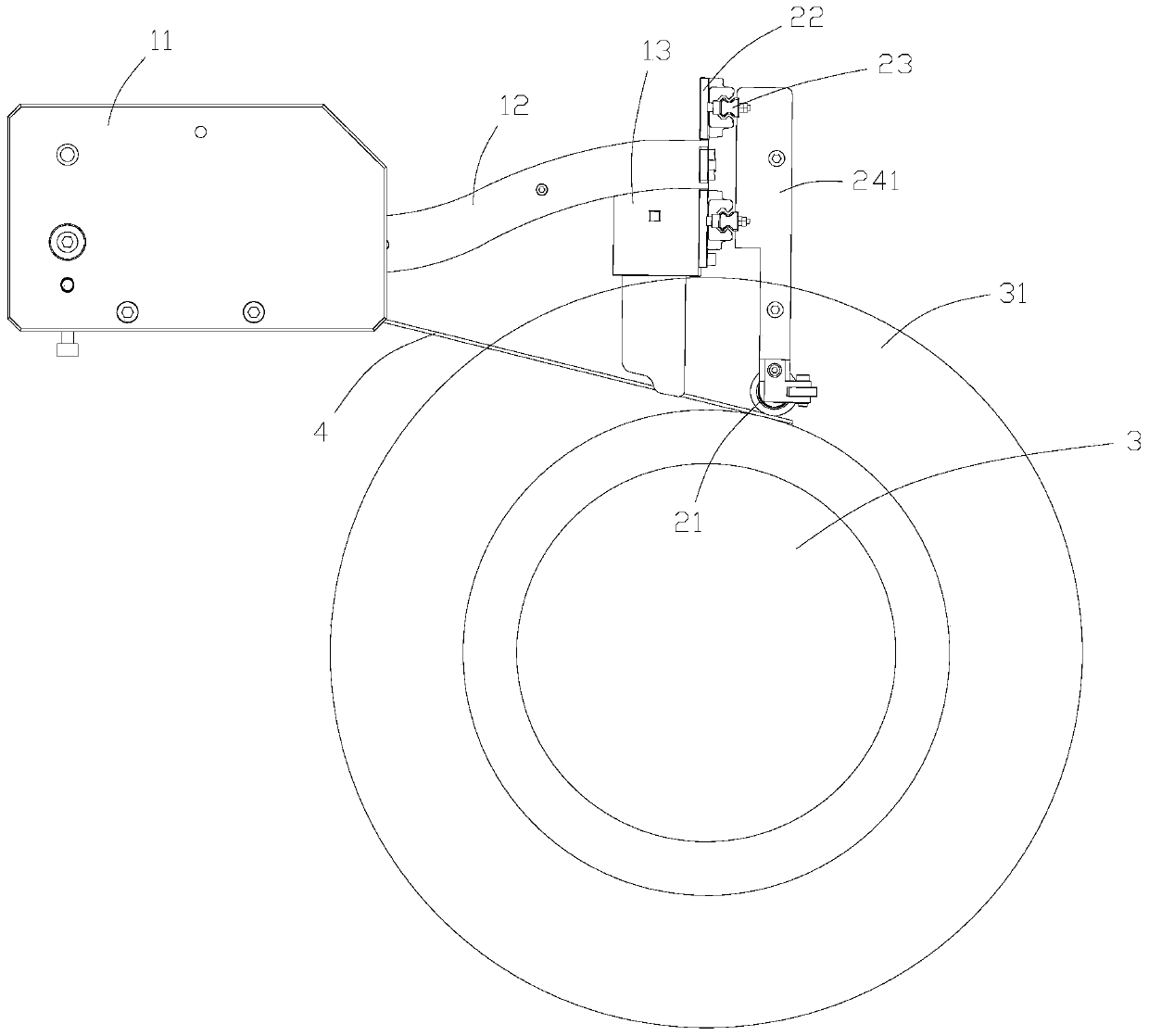

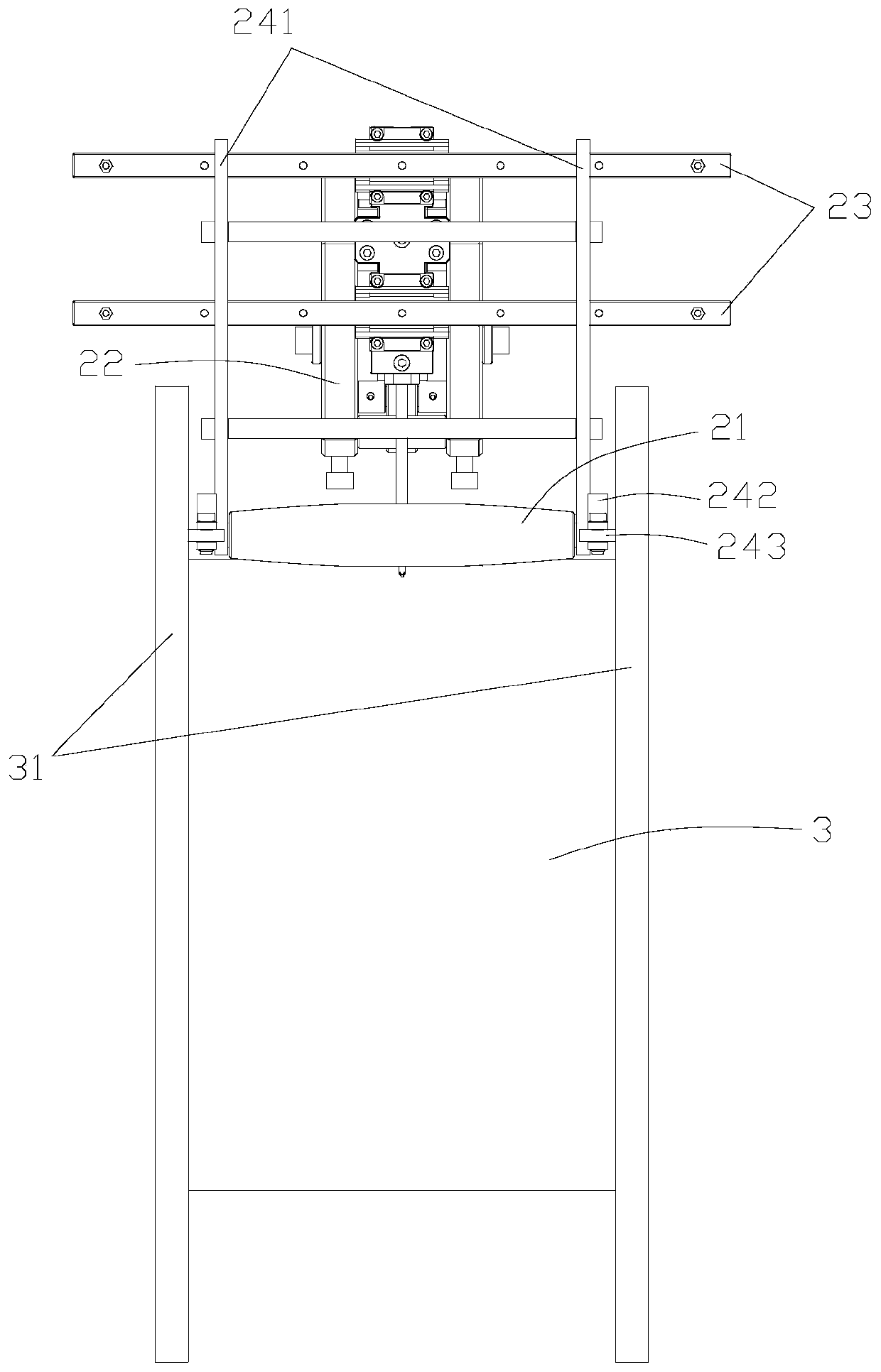

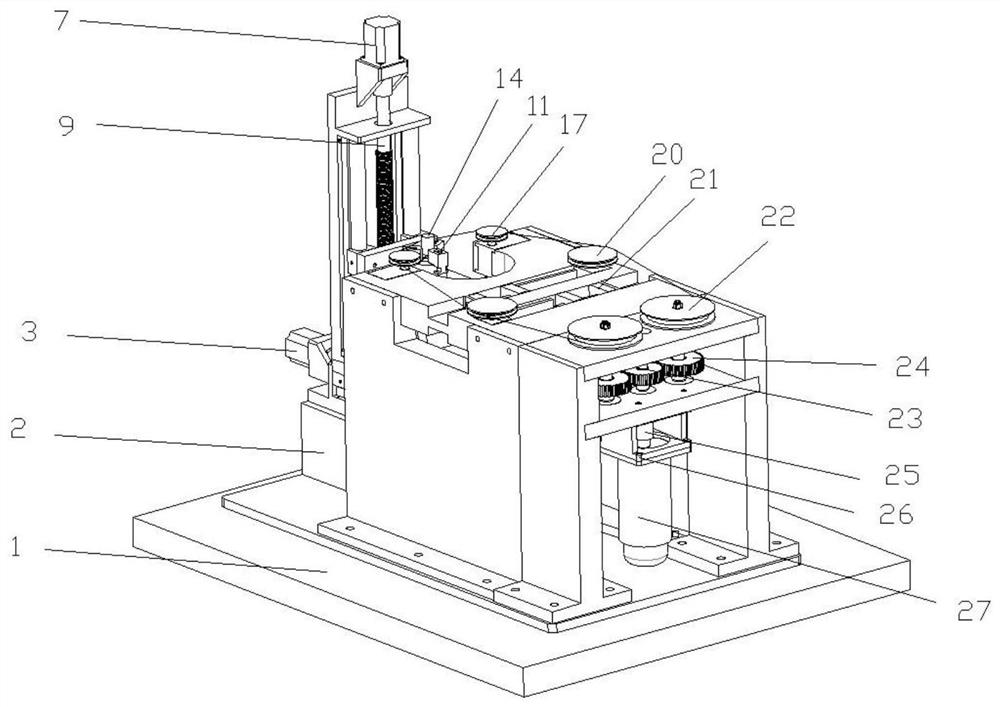

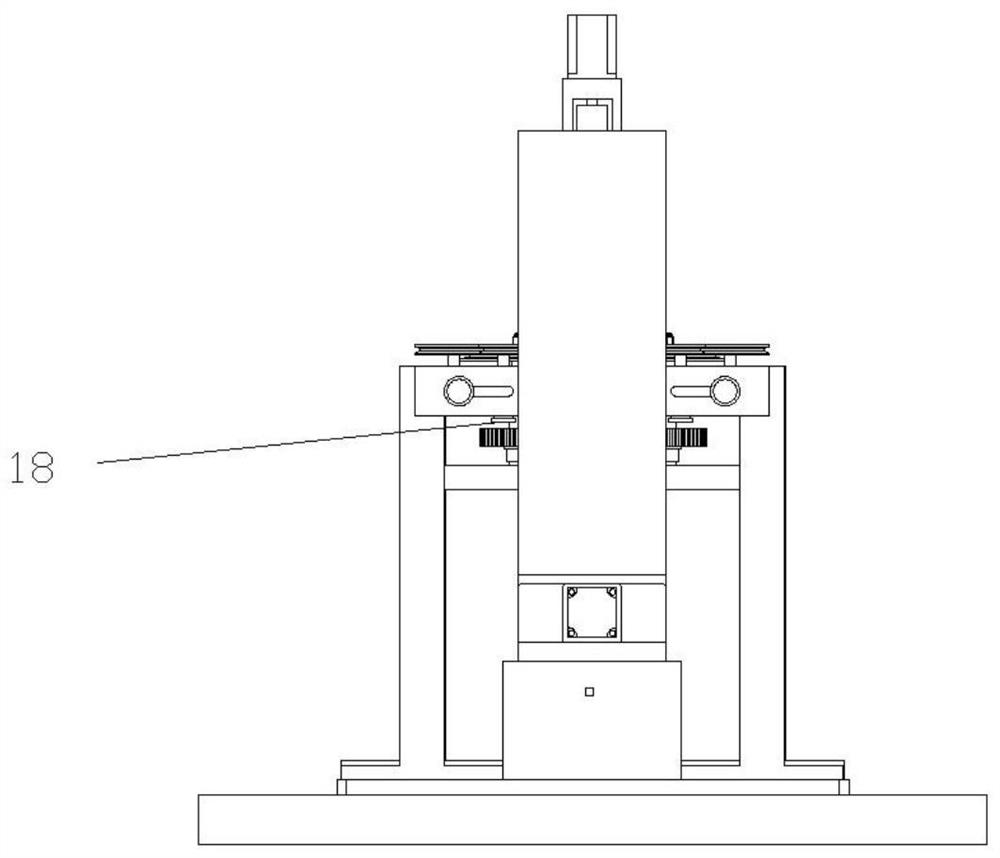

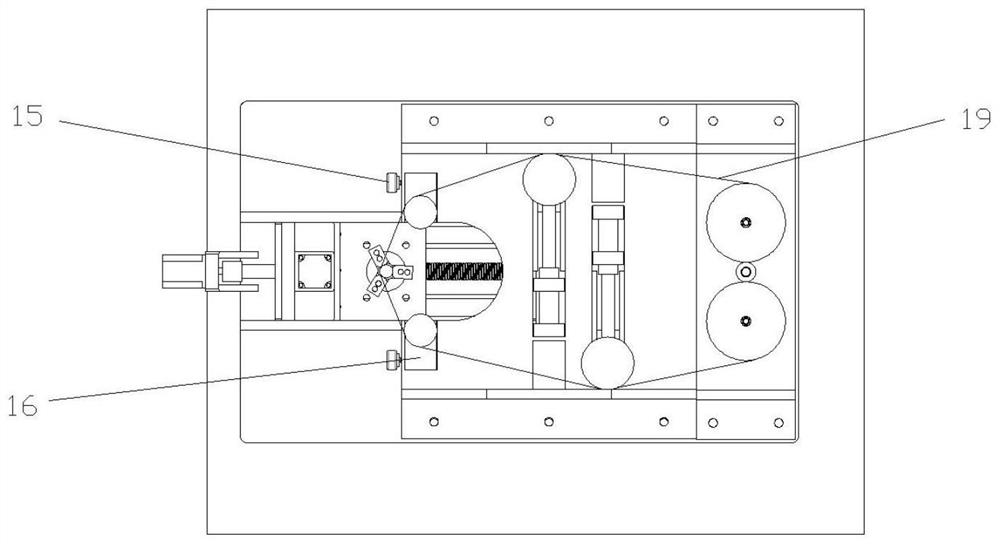

Self-adaption diamond-wire-saw cutting equipment

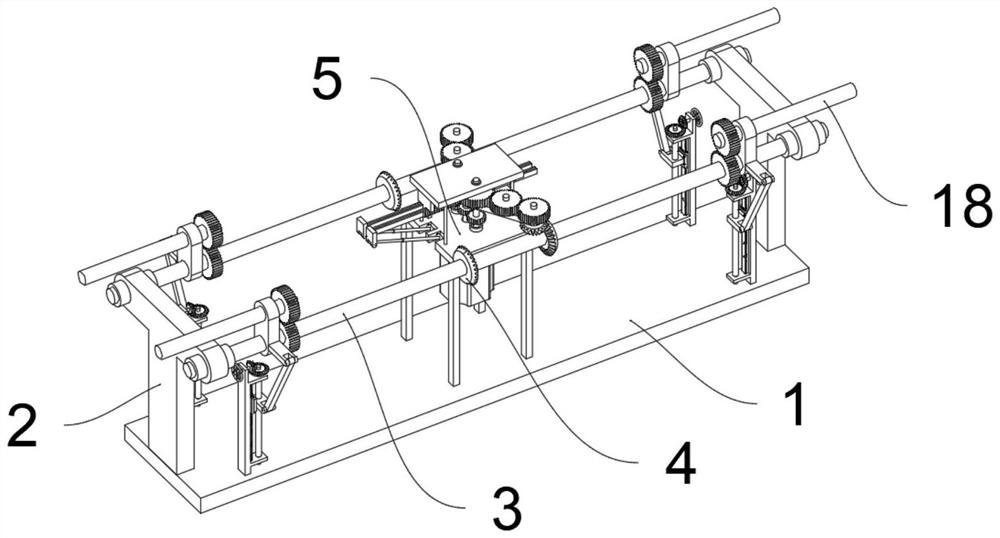

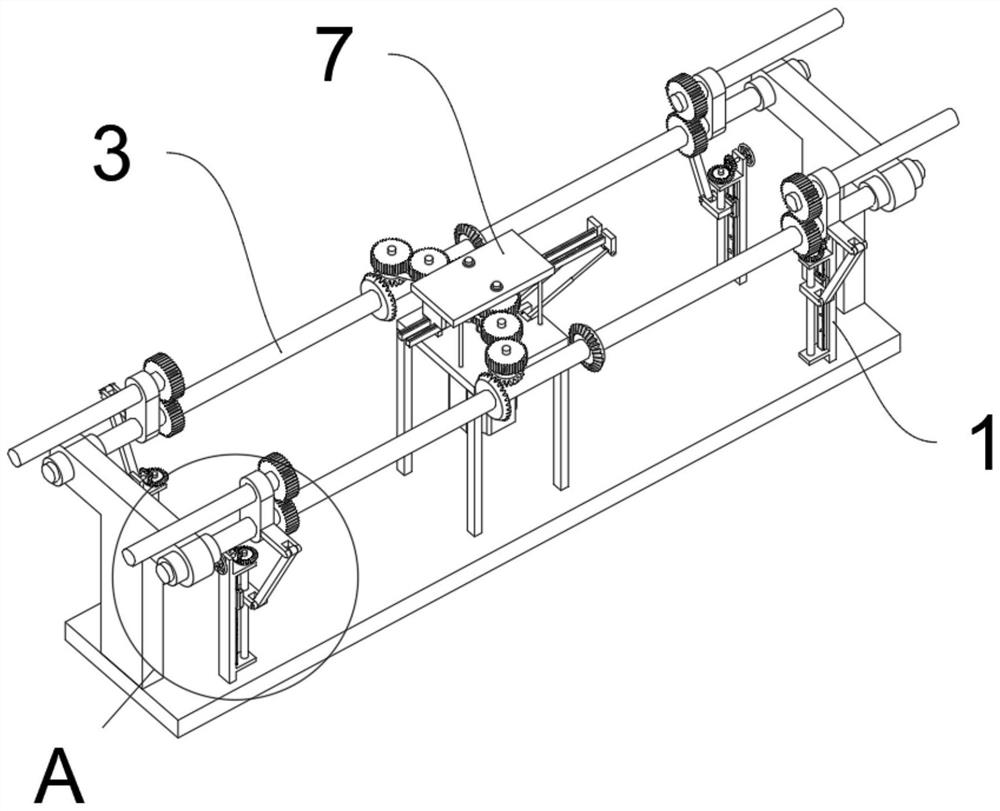

ActiveCN109227976ALarge space for exerciseGuaranteed tensionWorking accessoriesFine working devicesDrive wheelReciprocating motion

The invention discloses self-adaption diamond-wire-saw cutting equipment, and belongs to the technical field of diamond equipment. A rotating crystal ingot workpiece is cut through a diamond wire saw,driving wheels rotating at high speed and rotating back and forth drive the diamond wire saw to reciprocate, the diamond wire saw is tensioned by two tensioning wheels, air cylinders are arranged atthe tensioning wheels to guarantee the diamond wire saw to be in certain tension, and meanwhile two guiding wheels are additionally arranged to guarantee the cutting accuracy and the cutting face form. The rotating crystal ingot workpiece is installed on a three-jaw clamping disc, the three-jaw clamping disc is fixedly connected with a rotating mechanism, and is driven by a rotating motor, the rotating mechanism is fixedly connected with a lifting feeding mechanism, the lifting feeding mechanism is fixedly connected with a horizontal feeding mechanism, and the horizontal feeding mechanism is installed on a working table, and is driven by a stepping motor to feed. The whole device is controlled by a PLC, and is easy to control and convenient to operate.

Owner:JIANGSU UNIV OF SCI & TECH

Quick reversing mechanism

PendingCN113525783ARealize online flipImprove turnover efficiencyConveyorsPackaging machinesControl theoryLarge size

The invention relates to the technical field of appearance posture overturning of box type objects, and particularly relates to a quick reversing mechanism. Aiming at the problems of low overturning efficiency and large size in the prior art, the following scheme is proposed: the quick reversing mechanism comprises a support frame and limiting plates; the top of the support frame is fixedly connected with a placing plate; a conveying belt is mounted at the top of the placing plate; the limiting plates are mounted on two sides of the top of the conveying belt; and the two sets of limiting plates are arranged in the length direction of the placing plate. The quick reversing mechanism is reasonable and stable in structure and simple in operation, realizes online overturning of the box type objects, effectively improves the reversing efficiency, can reverse the objects with different specifications and sizes, and is convenient to install and easy to popularize and apply.

Owner:SHANGHAI KUKO PACKING MACHINERY

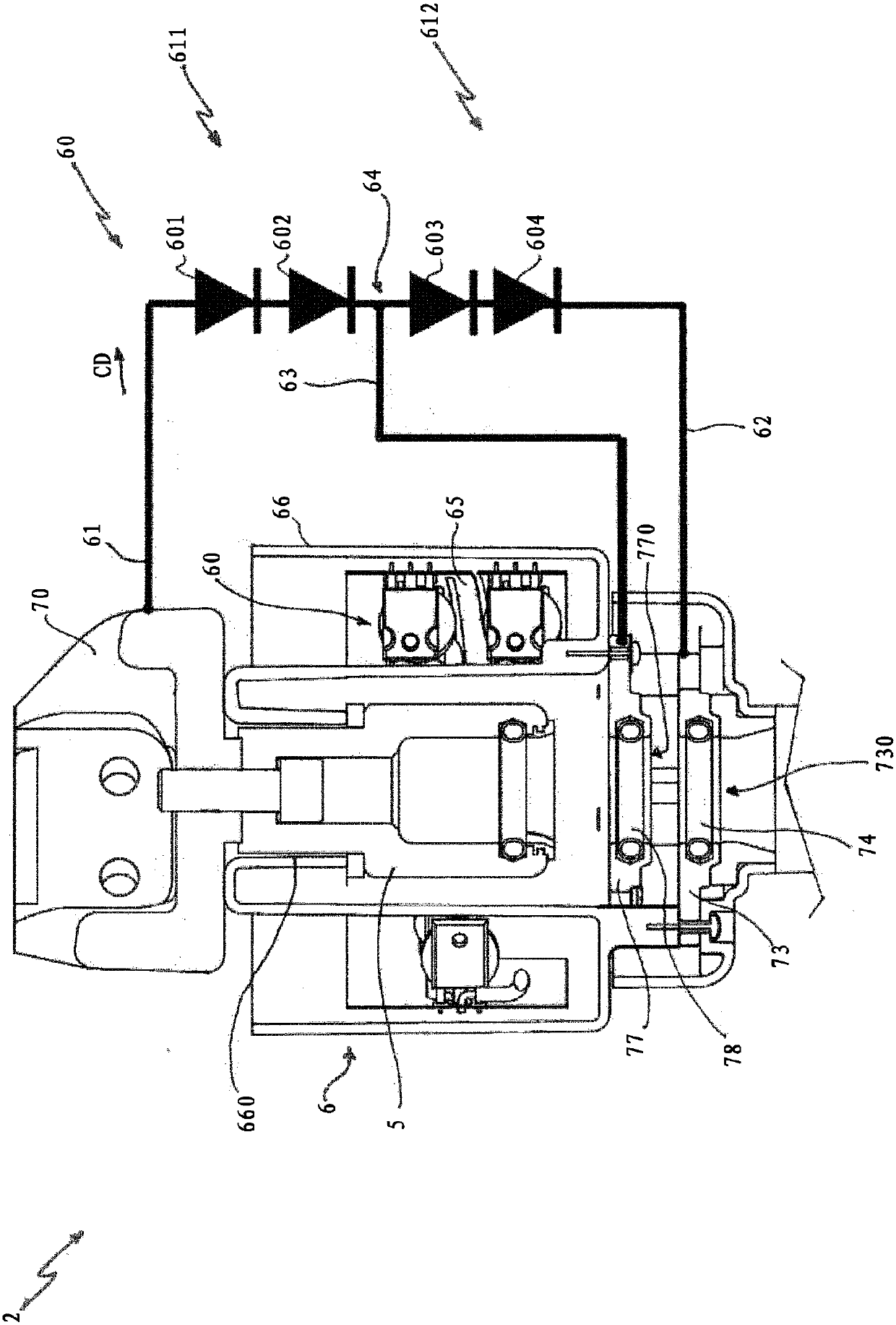

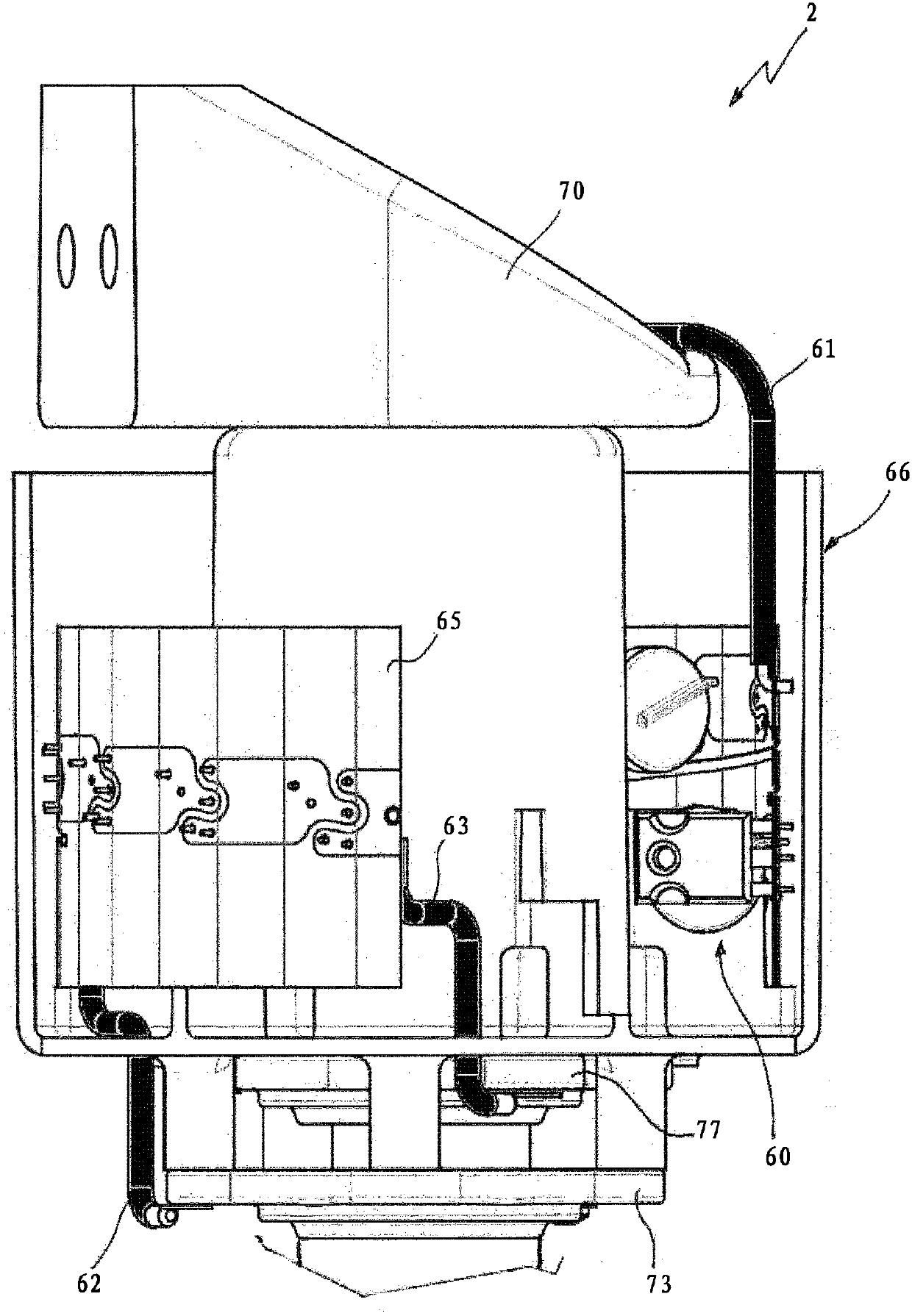

A switching device

ActiveCN107924778AReduce parasitismImprove performancePrinted circuit aspectsElectric switchesElectric power distributionElectrical connection

A switching device (1) for low or medium voltage electric power distribution networks, said switching device comprising: - at least an electric pole (2) comprising a movable contact (4) and a fixed contact (5), which are coupleable / decoupleable one to another; - a circuit assembly (6), which comprises a chain (60) of semiconductor devices (601, 602, 603, 604, 605, 606) adapted to switch in an ON state or in an OFF state depending on the voltage applied thereto, said semiconductor devices being electrically connected in series one to another in such a way that a current can flow according to apredefined conduction direction (CD) when said semiconductor devices are in an ON state. The circuit assembly (6) comprises an input terminal (61), an output terminal (62) and at least an intermediateterminal (63) electrically connected with at least an intermediate electric node (64) positioned between two subsequent semiconductor devices (602, 603, 604, 605). The input terminal (61) is electrically connected with said fixed contact: The input terminal (61), the output terminal (62) and the at least an intermediate terminal (63) are electrically coupleable / decoupleable with / from said movablecontact (4) when said movable contact reaches different positions (P1, P2, P3, P4) during a movement towards / away from said fixed contact (5) in such a way that different groups (611, 612) of semiconductor devices switch in an ON state or in an OFF state at different instants (t2, t3, t4, t6, t7, t8) during the movement of said movable contact, depending on the position reached by said movable contact.

Owner:ABB (SCHWEIZ) AG

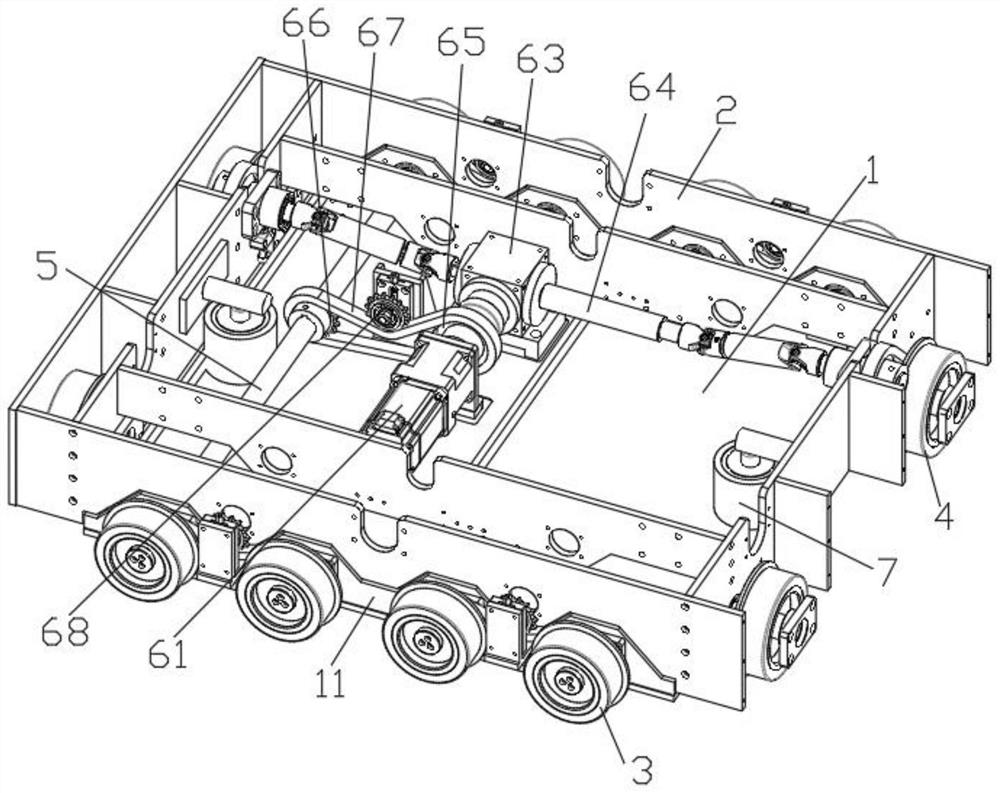

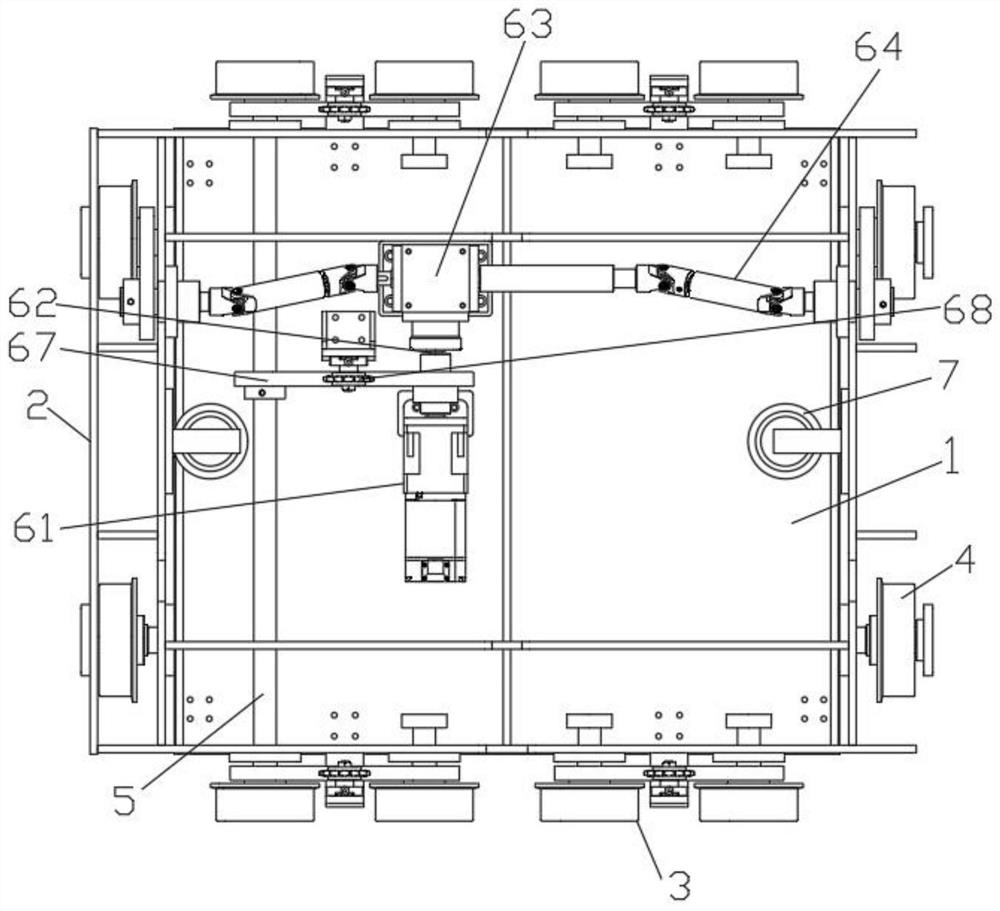

Four-direction driving walking mechanism and logistics shuttle vehicle with same

PendingCN112794013AReasonable structural designAchieve lateral movementMechanical conveyorsLogistics managementDrive shaft

The invention relates to a four-direction driving walking mechanism and a logistics shuttle vehicle with the same. The four-direction driving walking mechanism comprises a chassis, a moving frame, transverse walking wheel sets, longitudinal walking wheel sets and a four-direction driving assembly, wherein a plurality of transverse walking wheel sets arranged at intervals are rotationally arranged on the two sides of the chassis respectively and are arranged in pairs, a transmission shaft is connected between axles of any pair of transverse walking wheel sets, the moving frame is arranged at the upper end of the chassis, a plurality of longitudinal walking wheel sets are rotationally arranged at the two ends of the moving frame respectively and are arranged in pairs, the four-direction driving assembly is installed at the upper end of the chassis and are in transmission connection with the transmission shafts and the axles of any pair of longitudinal walking wheel sets, and a lifting assembly connected with the moving frame is arranged at the upper end of the chassis. The four-direction driving walking mechanism has the advantages that both transverse movement and longitudinal movement can be realized, four directions are driven by one power, and the overall compatibility is improved.

Owner:中烟物流技术有限责任公司

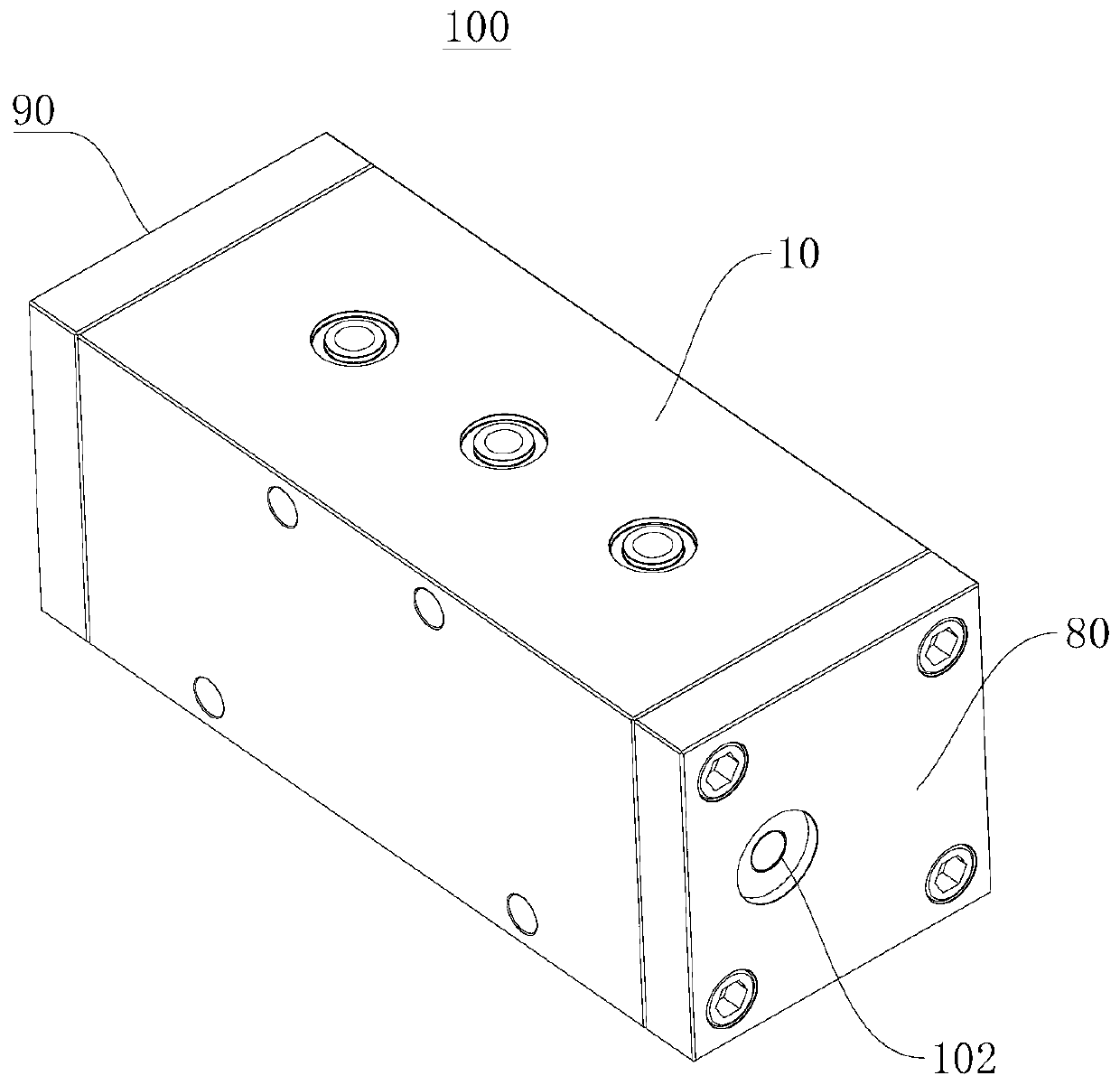

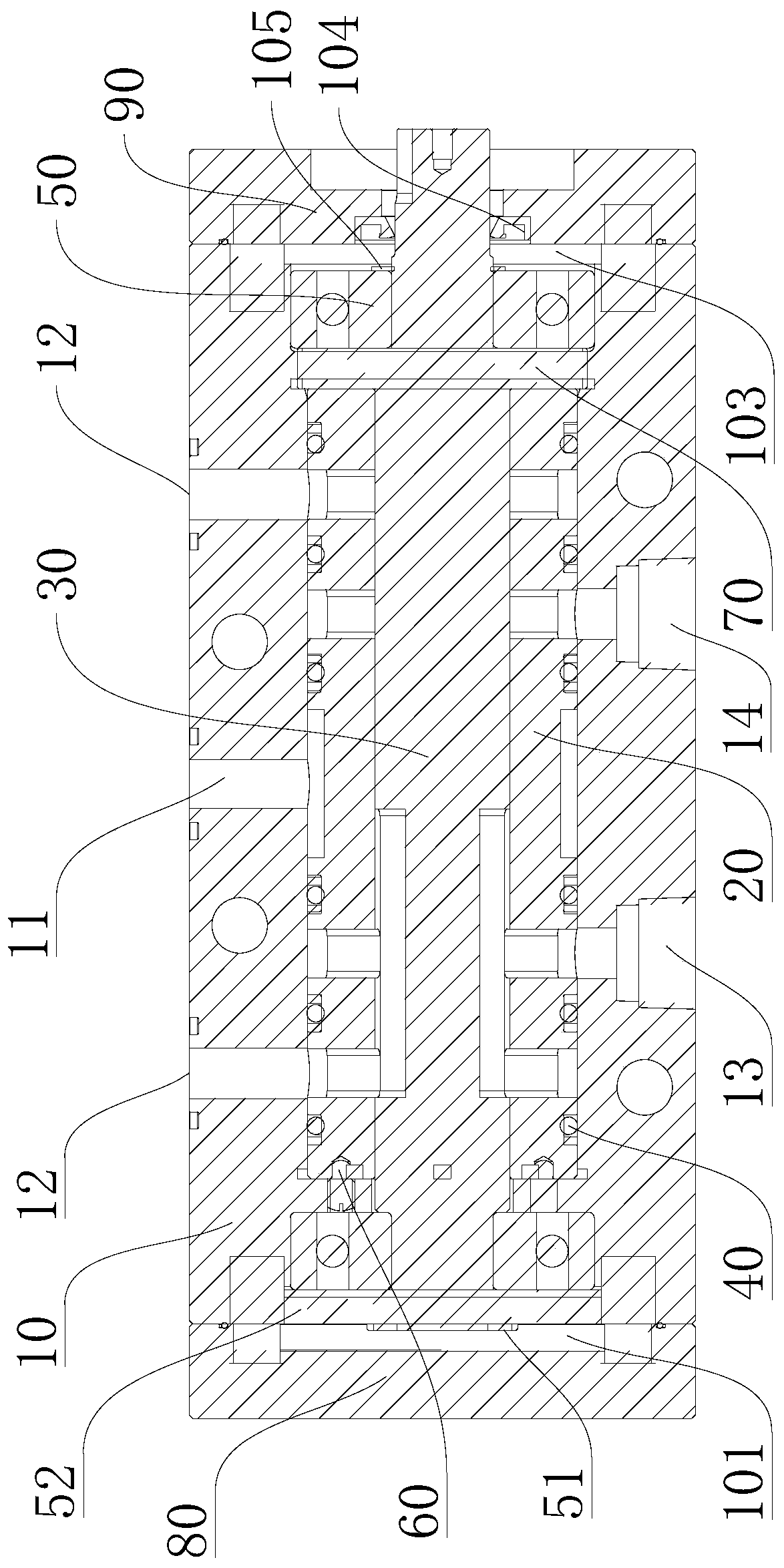

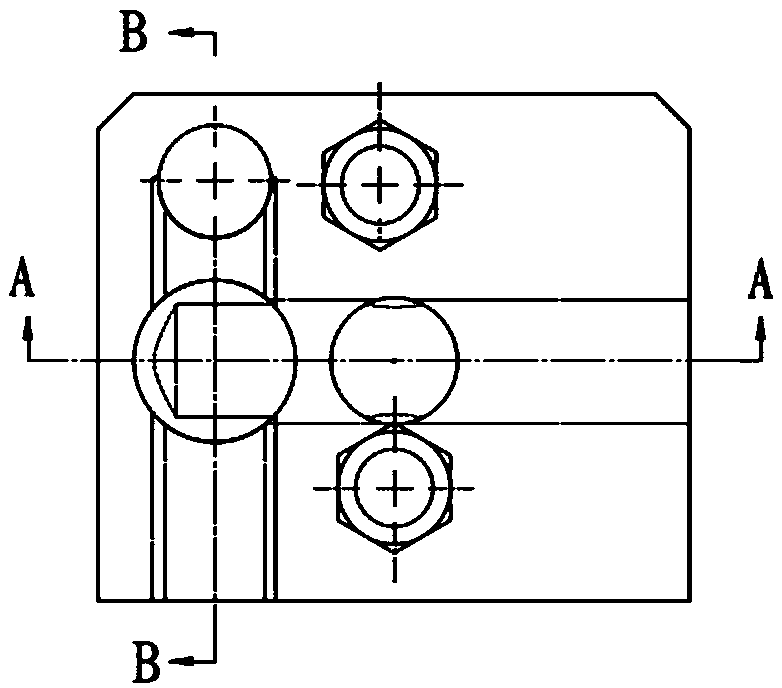

Hydraulic reversing valve and hydraulic reversing device

PendingCN110553081AImprove commutation efficiencyCommutation high frequencyOperating means/releasing devices for valvesServomotor componentsWorking pressurePetroleum engineering

The invention provides a hydraulic reversing valve and a hydraulic reversing device, and relates to the technical field of reversing valves. The hydraulic reversing device comprises a valve body, a valve sleeve and a valve element. The valve body is provided with a first installing cavity and further comprises a pressure oil port, an oil return port, a first work port and a second work port whichcommunicate with the first installing cavity, and the valve sleeve is arranged in the first installing cavity. The valve sleeve is provided with a second installing cavity, the valve sleeve is provided with a plurality of oil grooves in the circumferential direction, and the multiple oil grooves are provided with liquid passing holes communicating with the second installing cavity. The valve element comprises a first liquid passing groove and a second liquid passing groove which are distributed in the axial direction, and the valve element is rotationally arranged in the second installing cavity. The hydraulic reversing valve can meet the usage requirements for the high reversing frequency and high work pressure of execution mechanisms of some devices through combination of the valve body,the valve sleeve and the valve element, cooperation of the liquid passing grooves and the liquid passing holes in the oil grooves and gap seal between the valve element and the valve sleeve. The hydraulic reversing device is formed by the hydraulic reversing valve and a drive mechanism, and the usage requirements can be met as well.

Owner:上海羿弓氢能科技有限公司

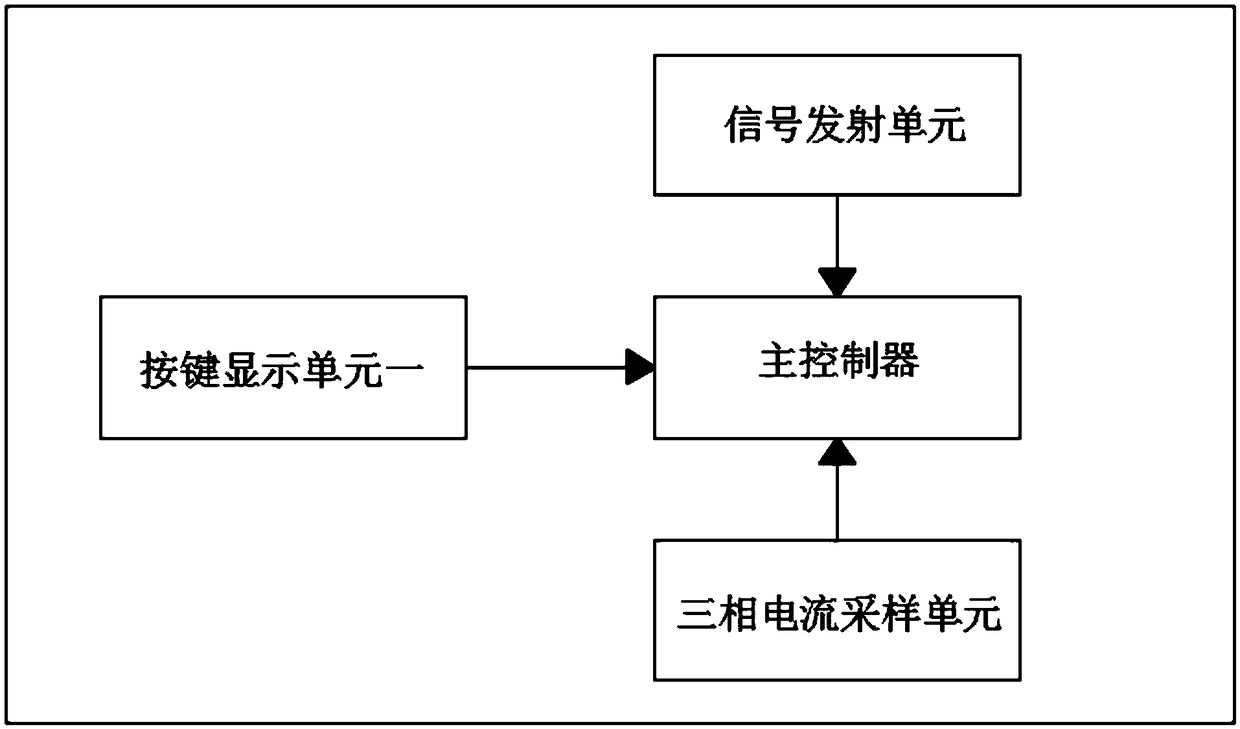

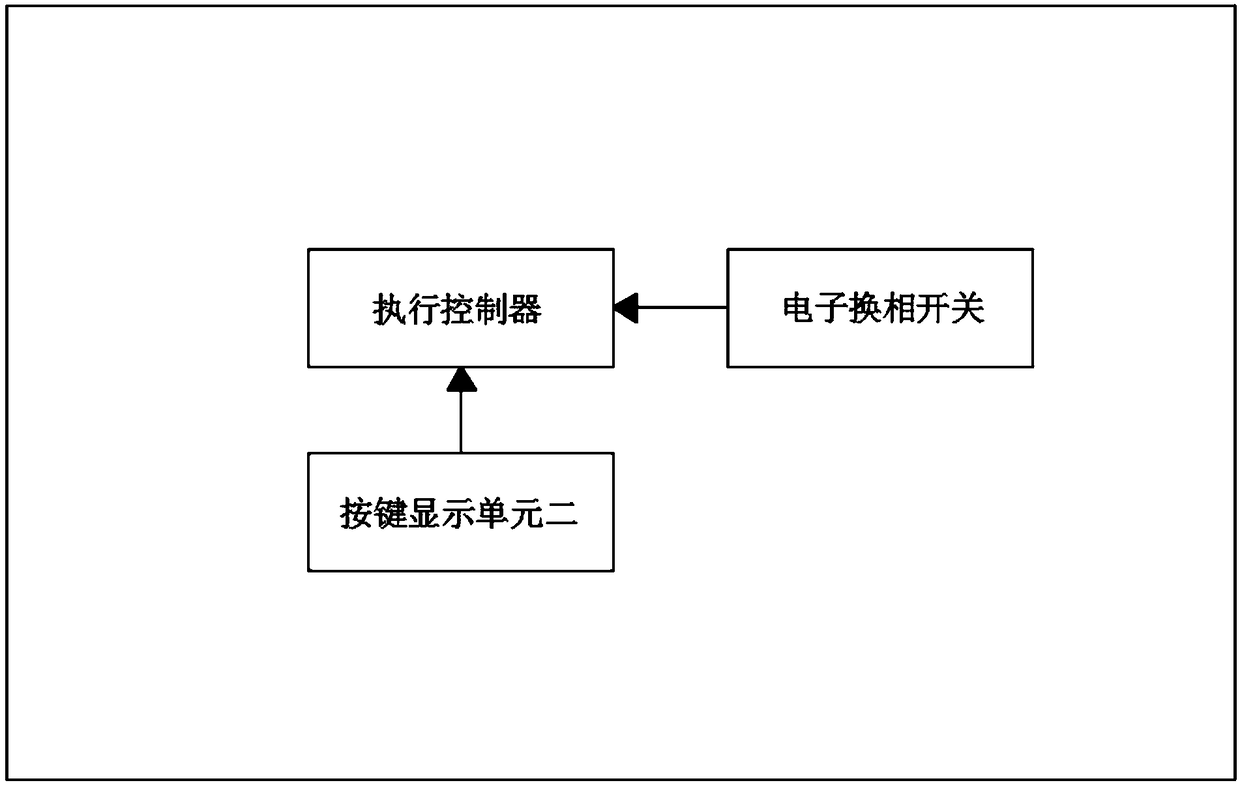

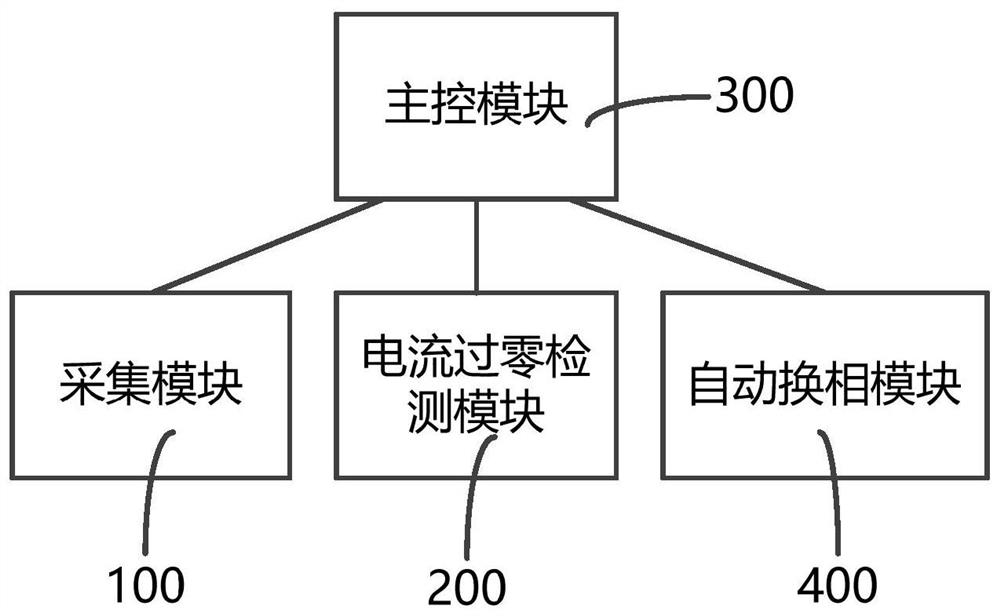

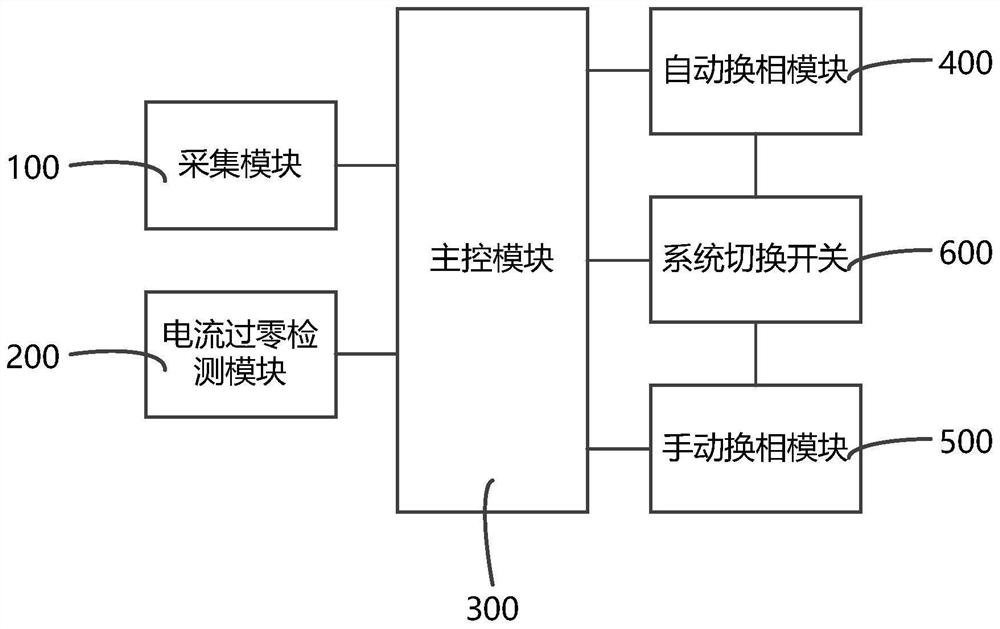

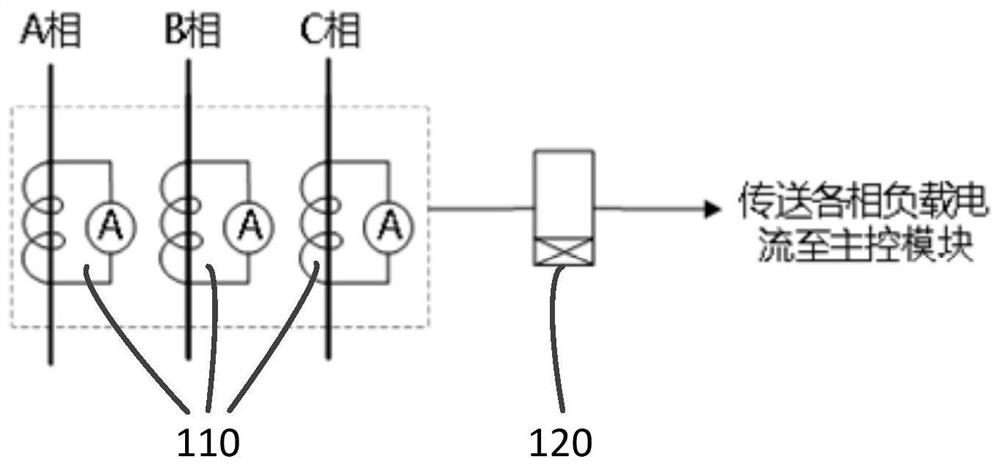

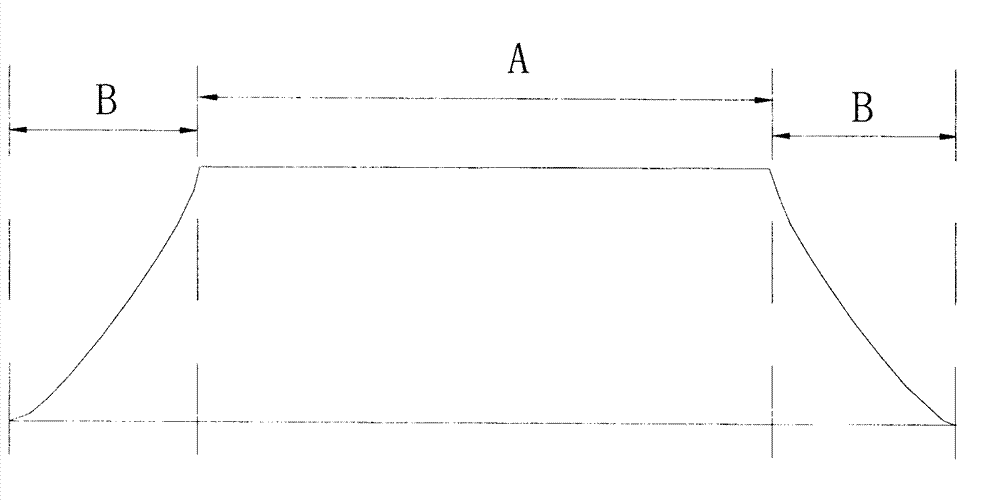

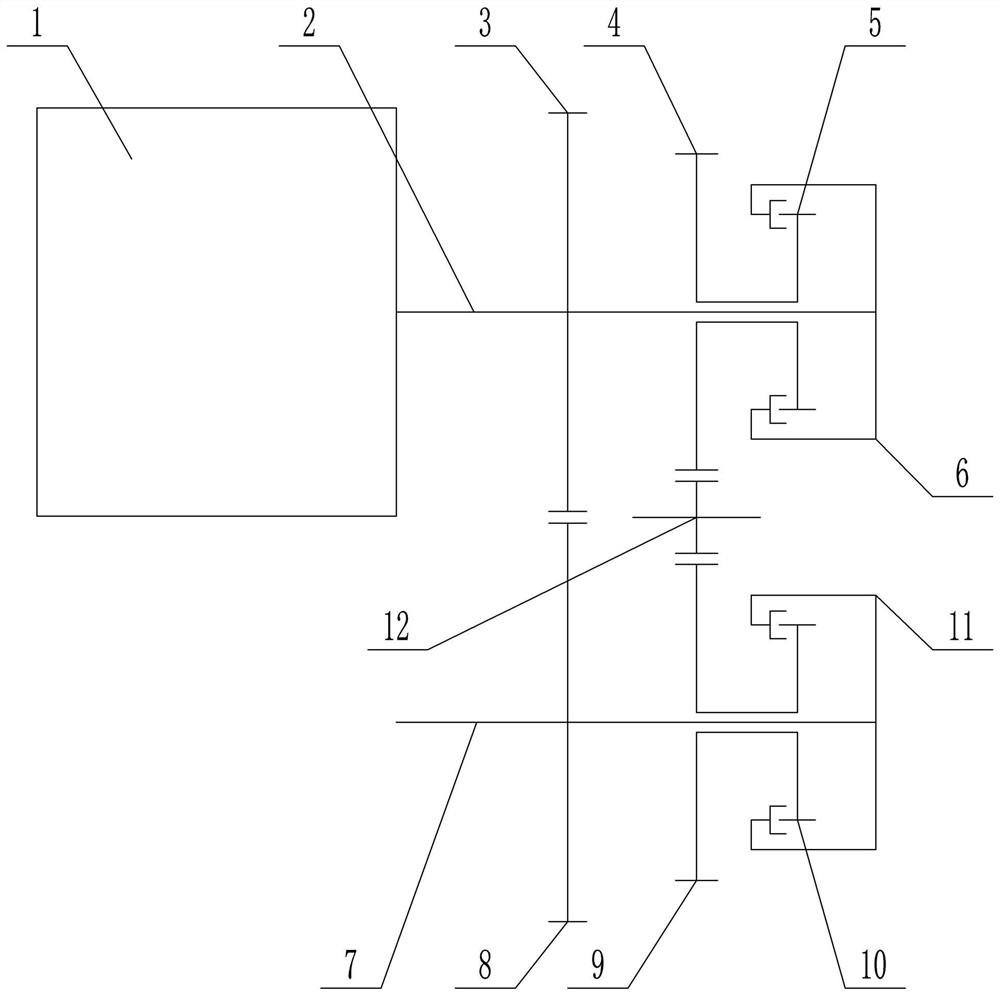

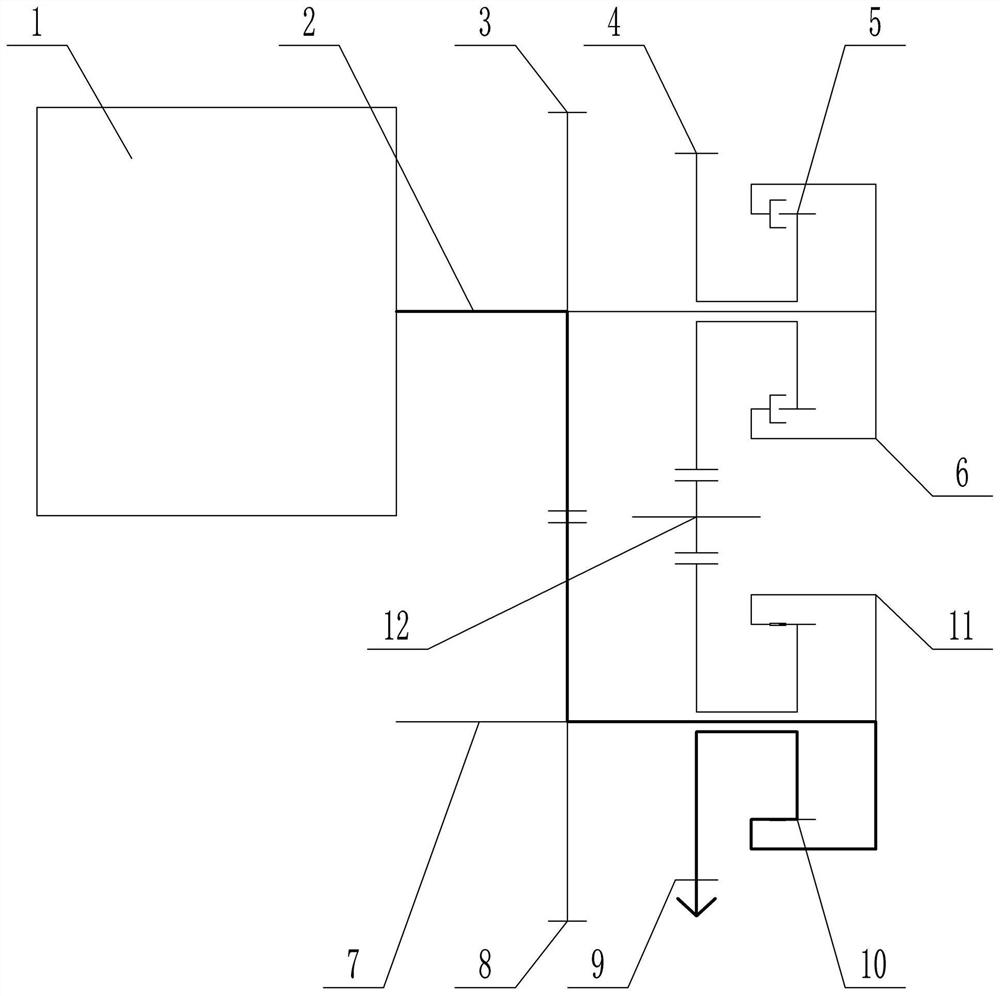

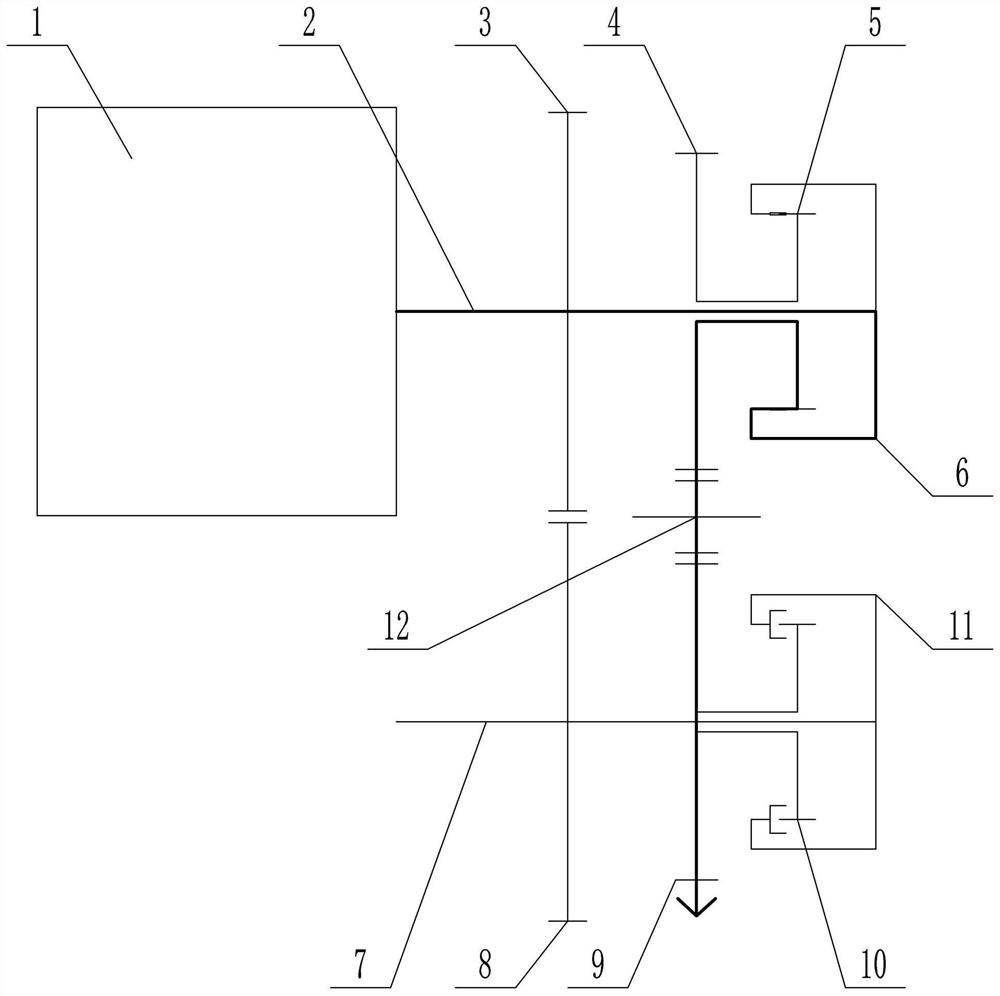

Three-phase imbalance automatic commutation system

PendingCN112018788ASolve the three-phase unbalance problemImprove commutation efficiencyPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationPower gridHemt circuits

The invention relates to the technical field of power supply and distribution devices, and discloses a three-phase imbalance automatic commutation system. Current information of each phase of a three-phase branch in a power grid system is collected through a collection module, a main control module obtains the three-phase unbalance degree of the system according to the current information, and when the three-phase unbalance degree is larger than a preset threshold value, it is judged that phase change processing needs to be carried out. And the main control module compares the circuit information of each phase to judge an overload phase in the three phases. A current zero-crossing detection module detects a current zero-crossing point of three phases, and the main control module outputs acorresponding commutation control signal when the current of an overload phase crosses zero. And an automatic commutation module completes an automatic commutation process according to the commutationcontrol signal. By means of the three-phase imbalance automatic commutation system, an operator can complete automatic commutation under the condition that the tail end load is not powered off, the problem of three-phase imbalance of the tail end load is fundamentally solved, the tedious process of manual commutation is avoided, and the commutation efficiency and the power supply reliability of the system are greatly improved.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

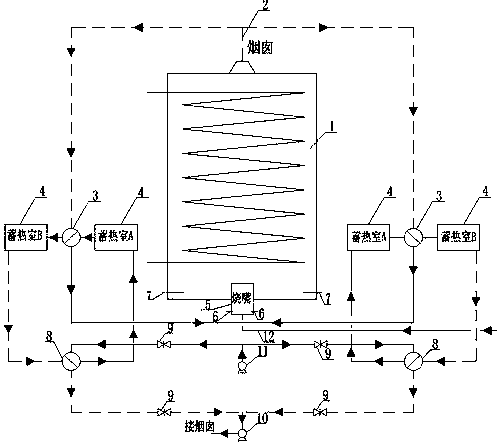

High-efficiency heat accumulation type tube heating furnace system

InactiveCN108072274AReduced convection sectionReduce pipingCombustion processIncreasing energy efficiencyCombustionTube furnace

The invention discloses a high-efficiency heat accumulation type tube heating furnace system and relates to the technical field of tube heating furnaces, energy conservation and emission reduction. The high-efficiency heat accumulation type tube heating furnace system is provided for solving the problems that an existing tube heating furnace is low in thermal efficiency, short in service life, poor in stability and high in system investment. The high-efficiency heat accumulation type tube heating furnace system comprises a tube furnace body, a burner nozzle, heat accumulation chambers, four-way reversing valves, an air blower, induced draft fans, air distribution valves, flame detectors and other devices. The air blower periodically blows combustion air into the left heat accumulation chamber and the right heat accumulation chamber at indoor temperature correspondingly and conducts heat exchange with the corresponding heat accumulation chambers to heat combustion air to 300 DEG C or above. Tail gas periodically passes through the heat accumulation chambers correspondingly and conducts heat exchange with the corresponding heat accumulation chambers, then the temperature of the tailgas is gradually reduced to about 130 DEG C, and then the tail gas is discharged through the induced draft fans. The air and the tail gas are periodically exchanged in the left and right heat accumulation chambers correspondingly to achieve high-efficiency and stable burning. Meanwhile, a traditional convection section is omitted, the exhaust gas temperature is reduced, and the thermal efficiencyis improved. Accordingly, the comprehensive investment of the tube furnace is minimized, and the service life of the tube furnace is prolonged.

Owner:湖北鑫固久技术装备有限公司

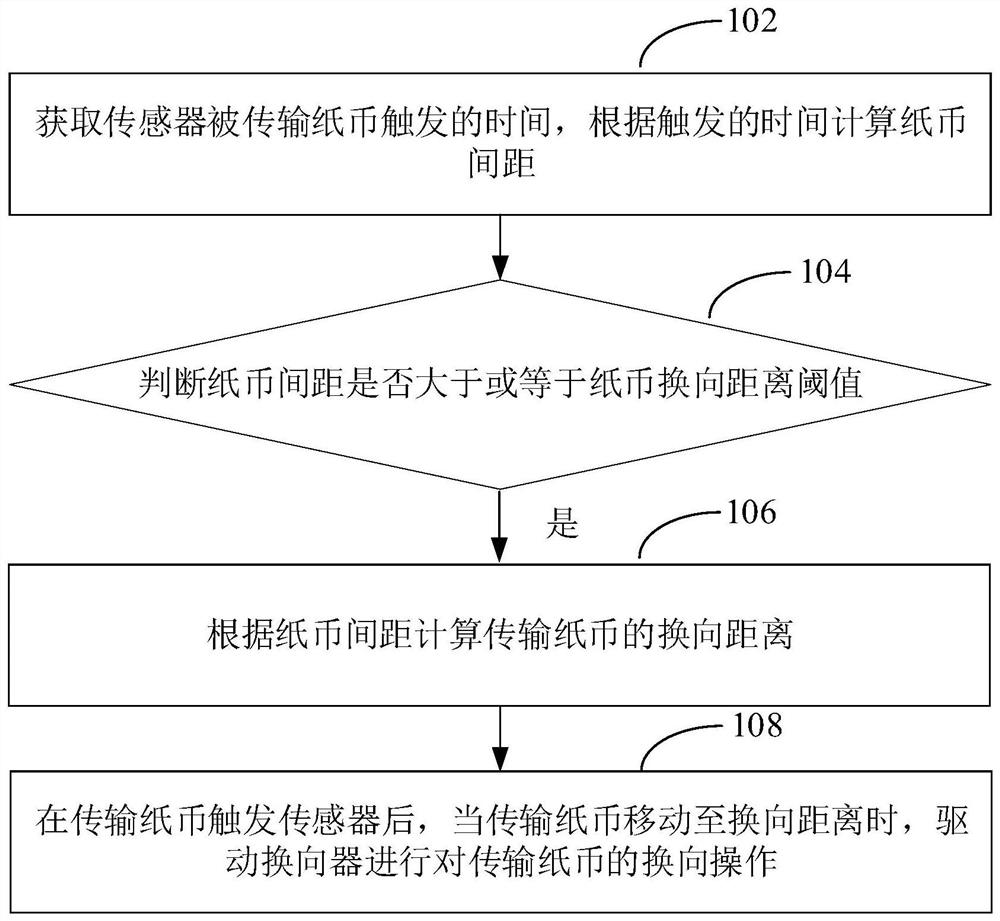

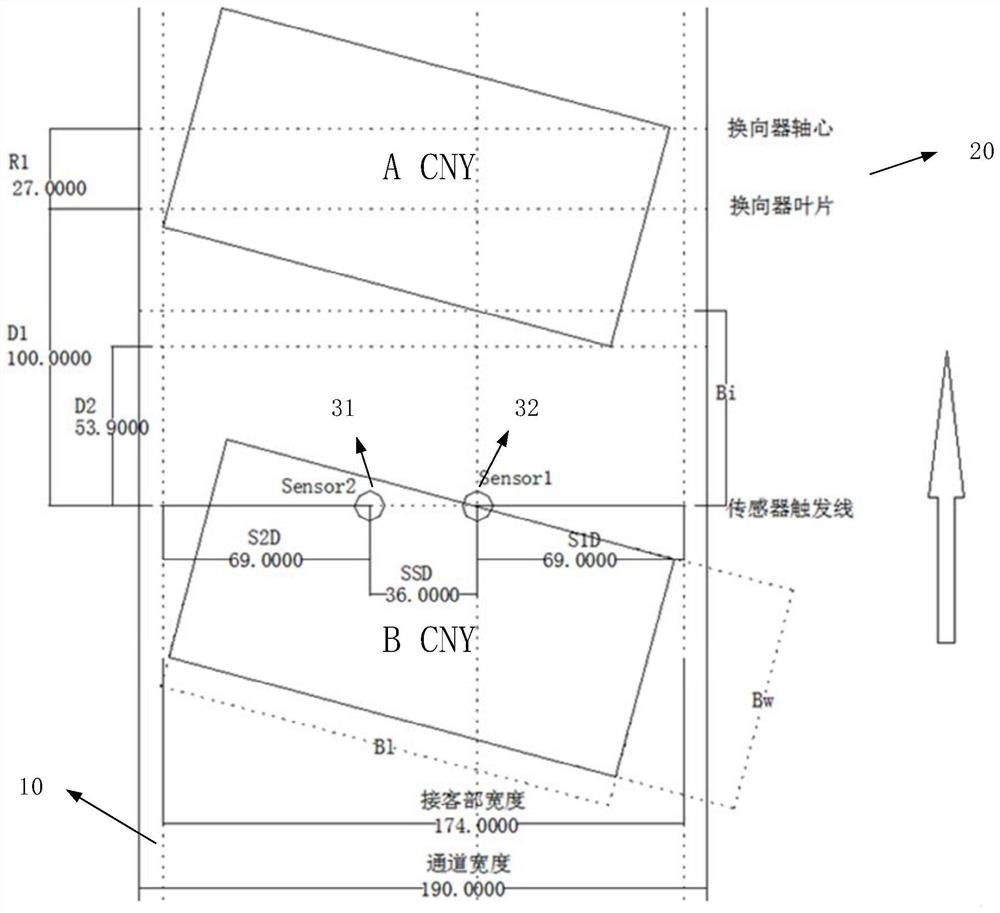

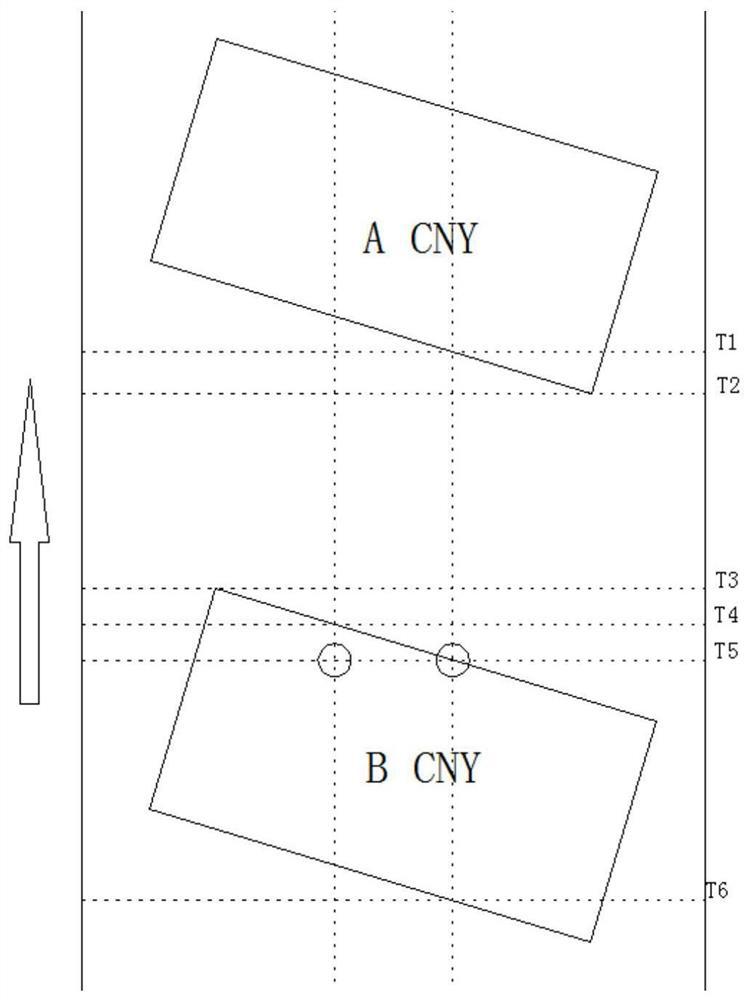

Commutator control method, device and equipment, and medium

PendingCN113256907AReduce jammingSwitch in real timeComplete banking machinesCoin/currency accepting devicesComputer scienceIndustrial engineering

The invention discloses a commutator control method, which comprises the steps of calculating the distance between banknotes with unknown placement forms based on the triggering time of the banknotes, judging whether the banknotes can be reversed normally or not according to the distance between the banknotes, and calculating to obtain the optimal reversing distance of the banknotes. According to the commutator control method, the featrues of placement form, spacing, reversing switching time and the like of the paper money are fully considered, real-time switching of the paper money by the reverser can be realized, the problem of paper money clamping caused by real-time switching of the reverser is reduced, and the reversing efficiency of the equipment is improved. In addition, the invention further provides a commutator control device and equipment, and a storage medium.

Owner:SHENZHEN YIHUA TIME TECH

Switching type phase sequence switching combined conjunction box

ActiveCN107918038AImprove commutation efficiencyGood securityTime integral measurementBreakout boxElectricity

The invention aims at providing a switching type phase sequence switching combined conjunction box, and relates to the power field. The switching type phase sequence switching combined conjunction boxcomprises a conjunction box body, a box cover, a wiring board arranged in the conjunction box body and provided with three voltage and current wiring blocks, and a phase sequence switching switch electrically connected to the first and third voltage and current wiring blocks. Each of the first and third voltage and current wiring blocks comprises an electrical connection assembly and a switchingassembly; the electrical connection assembly comprises a voltage electrical connection column and middle, left and right current electrical connection columns; the switching assembly comprises a voltage switching terminal and left and right current switching terminals; and the middle electrical connection column is electrically connected with the right / left current electrical connection column. When being used for phase sequence adjustment, the switching type phase sequence switching combined conjunction box does not influence power utilization of users, and is higher in phase switching efficiency and higher in safety level.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +2

High-precision guide rail switching control device

PendingCN107043012AHigh commutation accuracyImprove commutation efficiencyConveyor partsMechanical conveyorsEngineeringControl theory

The invention discloses a high-precision guide rail switching control device. The high-precision guide rail switching control device is mounted on the reversing disconnected portion of a main guide rail. A reversing guide rail is arranged on the reversing disconnected portion of the main guide rail. The reversing guide rail and the main guide rail are located on the same horizontal plane. A main guide rail support fixedly connected with the face of a working table is fixed below the main guide rail. The high-precision guide rail switching control device comprises a reversing base arranged on the reversing disconnected portion of the main guide rail, a rotating disc arranged on the reversing base and a rotating air cylinder which is arranged below the rotating disc and controls the rotating disc to rotate. A piston rod of the rotating air cylinder is hinged to the rotating disc. The rotating air cylinder is fixed to the position, below the reversing guide rail, of one side of the main guide rail. A steering guide rail is rotationally connected to the position, at the end of the reversing guide rail, of the other side of the main guide rail. A reversing air cylinder capable of pushing the steering guide rail to do 90-degree steering is fixed to the side, corresponding to the steering guide rail, of the reversing guide rail. According to the high-precision guide rail switching control device, direction switching of the rotating disc and the reversing guide rail is achieved through mechanical control, the reversing precision is high, the reversing efficiency can be effectively improved, and the manual cost can be effectively reduced.

Owner:CHANGZHOU MENTECHS INTELLIGENT EQUIP CO LTD

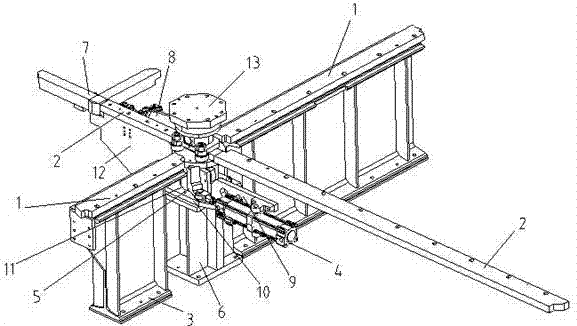

Glass rotating conveying device and glass piece laminating or separating conveying device

ActiveCN106516745AImprove commutation efficiencyWon't scratchCharge manipulationConveyor partsControl systemEngineering

The invention provides a glass rotating conveying device and a glass piece laminating or separating conveying device. The glass rotating conveying device comprises a supporting part, a first conveying part, a second conveying part and a control system; the supporting part comprises a supporting seat and a supporting frame which is rotatably arranged on the supporting seat; the supporting frame is connected with a first driving mechanism; the first conveying part and the second conveying part are arranged on the supporting frame; each of the first conveying part and the second conveying part comprises a glass conveying belt and a second driving mechanism which is used for driving the glass conveying belt to operate bi-directionally; the conveying direction of the glass conveying belt of the first conveying part is perpendicular to the conveying direction of the glass conveying belt of the second conveying part; the control system comprises a controller, and detection sensors which are respectively arranged at the outer ends of the glass conveying belts; the first driving mechanism, the second driving mechanism and the detection sensors are all connected with the controller. According to the glass rotating conveying device and the glass piece laminating or separating conveying device, the glass direction changing efficiency is improved, and glass cannot be scratched in a direction changing process.

Owner:CHINA TRIUMPH INT ENG

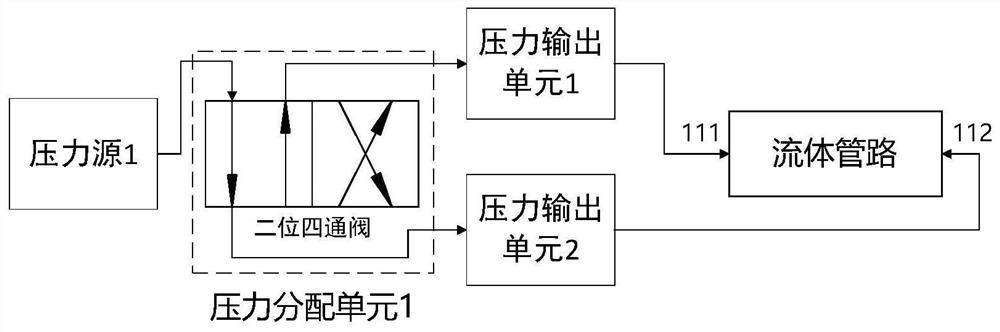

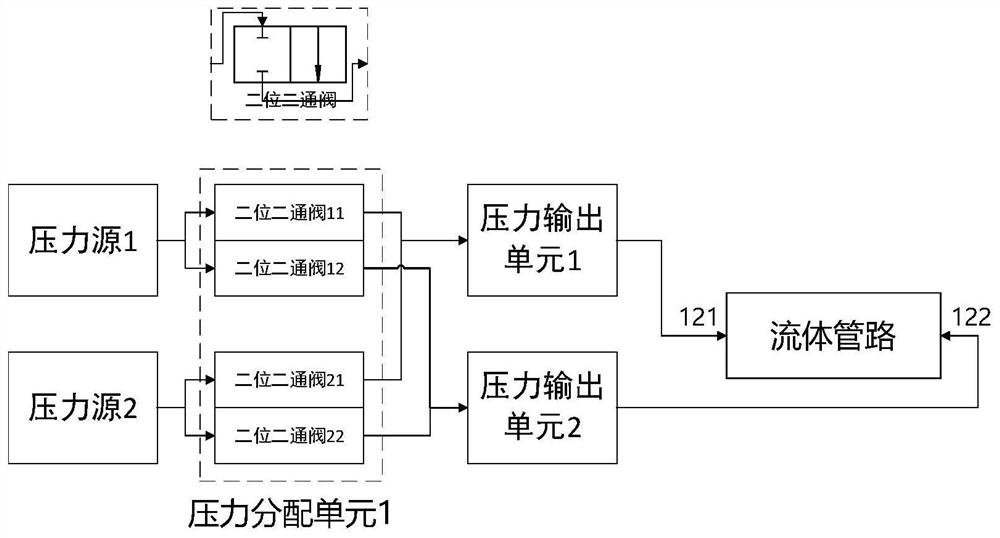

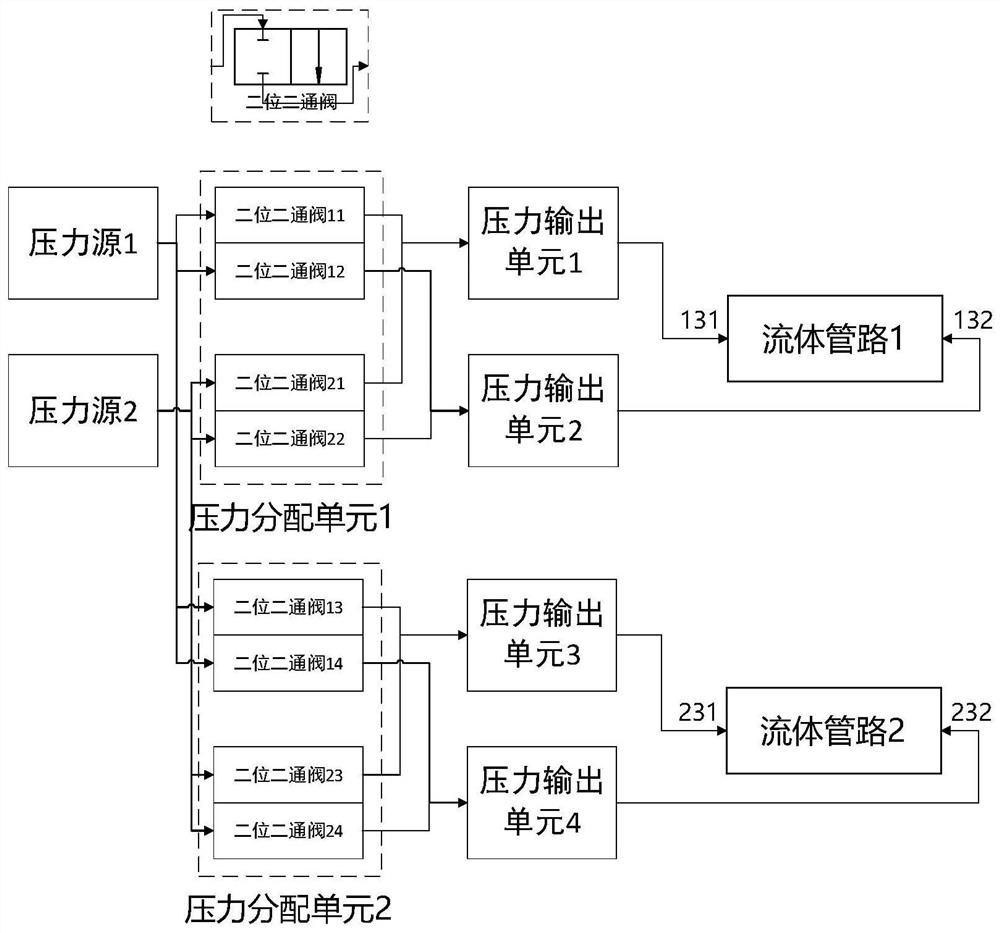

Multidirectional Fluid Drive System Based on Pressure Control and Its Application

ActiveCN109097250BImprove commutation efficiencyQuick changeBioreactor/fermenter combinationsBiological substance pretreatmentsMicrospherePressure control

The invention provides a multi-directional fluid drive system based on pressure control and its application. The system includes at least one pressure source, at least one pressure distribution unit and at least two pressure output units. Using the system, without changing the pressure of the pressure source, the connection relationship between the pressure source and the pressure output unit can be changed through the pressure distribution unit, so as to realize the multi-directional driving and driving direction of the microfluidic, and the rapid movement / stationary Switch to increase the automation of biochemical applications such as bead washing.

Owner:TSINGHUA UNIV +1

Method for manufacturing an armature of an electric motor

InactiveUS20050034293A1Smoothes out “ unevenness ”Improve commutation efficiencySynchronous generatorsAsynchronous induction motorsCouplingElectromagnetic interference

An armature for a brush commutated electric motor having a distributed coil winding arrangement for reducing brush arcing and electromagnetic interference (EMI). The winding pattern involves segmenting each coil into first and second subcoil portions with differing pluralities of turns. Each subcoil portion is wound around separate pairs of spaced apart slots of a lamination stack. Adjacent coils are wound such that one subcoil portion of each is wound in a common slot to therefore form an overlapping arrangement of each pair of adjacently coils. The winding pattern serves to “shift” the resultant magnetic axes of each coil in such a manner so as to significantly reduce brush arcing and the EMI resulting therefrom. The reduction in EMI is sufficient to eliminate the need for EMI reducing components, such as chokes, which have typically been required to maintain EMI to acceptably low levels. Commutation efficiency is also improved by the distributed winding pattern described above because of the reduction in the unevenness of the magnetic coupling between adjacent coils.

Owner:BLACK & DECKER INC

Multifunctional automatic phase change system and phase change method for medium and low voltage lines

ActiveCN108649592BReduce line lossGuarantee power qualityPolyphase network asymmetry elimination/reductionFault location by conductor typesPower qualityPhase currents

Owner:ANHUI ZENITH ELECTRICITY & ELECTRONICS

Flat knitting machine nose high speed reversing control method and control system thereof

InactiveCN101950164BAvoid wasting timeImprove commutation efficiencyProgramme controlWeft knittingReverse timeControl layer

The invention relates to a flat knitting machine nose reversing control method and a control system thereof. The method includes the following steps: 1, data is read; 2, reversing action is executed; 3, back torque is adaptively adjusted; 4, reversing is started; 5 reversing is finished. The control system comprises a main control layer, a human-machine interaction layer and a nose driving layer which are in communication connection with the main control layer as well as a main control module in the main control layer and an assistant processing module which is in communication connection with the main control module; wherein the assistant processing module is in communication connected with a storage module in the human-machine interaction layer, and the main control module is also in communication connection with a nose module and a machine body module which are arranged in the nose driving layer. The invention has the substantial characteristics that: each module in the control system is configured, reversing back torque is calculated in real time, namely the back torque is adaptively adjusted, the nose is controlled to reverse according to concrete real-time back torque, the phenomenon that reversing time is wasted in back torque with preset parameter is avoided, and reversing efficiency is improved, thus improving knitting efficiency.

Owner:ZHEJIANG SCI-TECH UNIV +1

Upper rotary reversing device of log processing production line

PendingCN113501306ASimple structureImprove commutation efficiencyControl devices for conveyorsControl engineeringElectric machinery

The invention discloses an upper rotary reversing device of a log processing production line, which is arranged between a first conveying line and a second conveying line with a certain included angle, and comprises a rotary reversing rod and a double-roller conveying mechanism; the double-roller conveying mechanism is located beside an output end of the first conveying line and comprises a first roller and a second roller which are arranged in parallel; the first roller and the second roller are driven by different conveying motors to rotate; the second conveying line is located directly below the interval between the first roller and the second roller; the rotary reversing rod is arranged above the position between the first roller and the second roller; and the bottom of the rotary reversing rod is provided with a space allowing logs to penetrate through, and the rotary reversing rod is driven by a reversing motor to rotate so as to drive the logs to steer. The upper rotary reversing device of the log processing production line provided by the invention is compact in structure, reliable in reversing and high in production efficiency, and meanwhile conveying equipment is effectively combined.

Owner:FUJIAN UNIV OF TECH +1

Forward and reverse switching device and forward and reverse switching method thereof

PendingCN113738835AReduce internal forceExtended service lifeToothed gearingsGearing controlSeparated stateGear wheel

The invention discloses a forward and reverse switching device and a forward and reverse switching method thereof, and relates to the field of vehicle transmission equipment. The forward and reverse switching device comprises a first transmission mechanism and a second transmission mechanism; the first transmission mechanism comprises a first rotating shaft, a first gear, a second gear, a third gear and a first friction driver; the third gear is connected to the first rotating shaft through the first friction driver; the second transmission mechanism comprises a second rotating shaft, a fourth gear, a fifth gear, a sixth gear and a second friction driver; the sixth gear is connected to the second rotating shaft through the second friction driver; the first gear is externally meshed with the fourth gear; and the second gear is externally meshed with the fifth gear through an idle gear. According to the forward and reverse switching device and the forward and reverse switching method thereof, the first transmission mechanism or the second transmission mechanism is selected to carry out rotary transmission through switching between the combined state and the separated state of two clutches, transmission gears are in an engaged state in the whole switching process, forward and reverse switching can be carried out in a non-stop state, and the forward and reverse switching efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

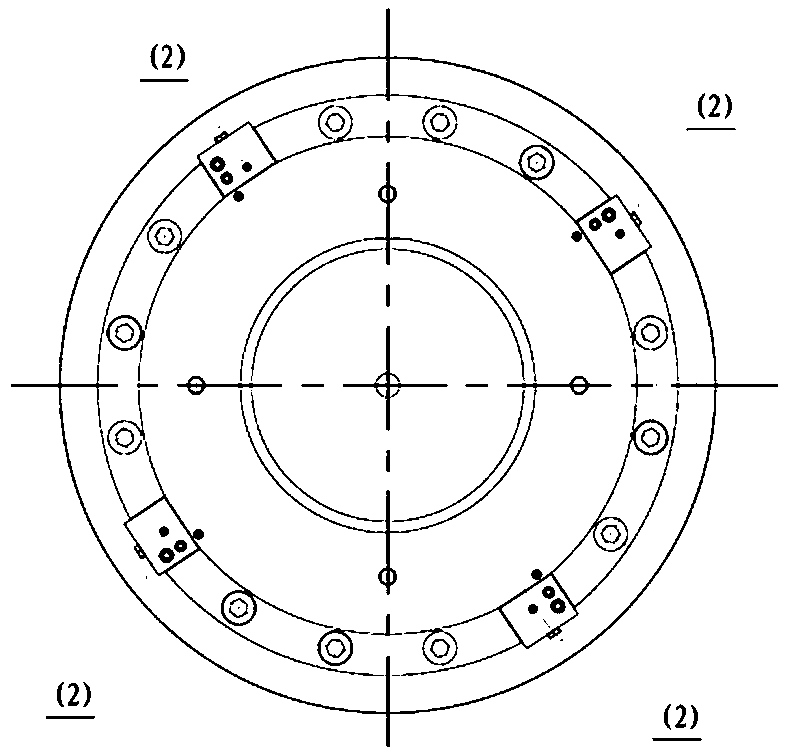

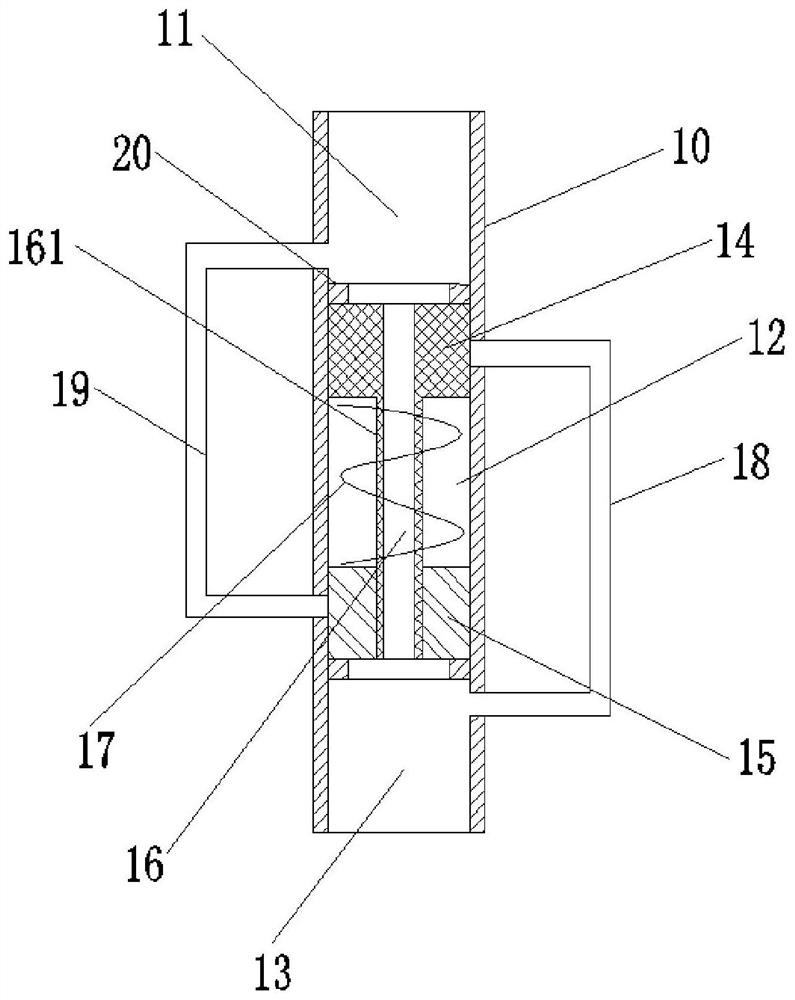

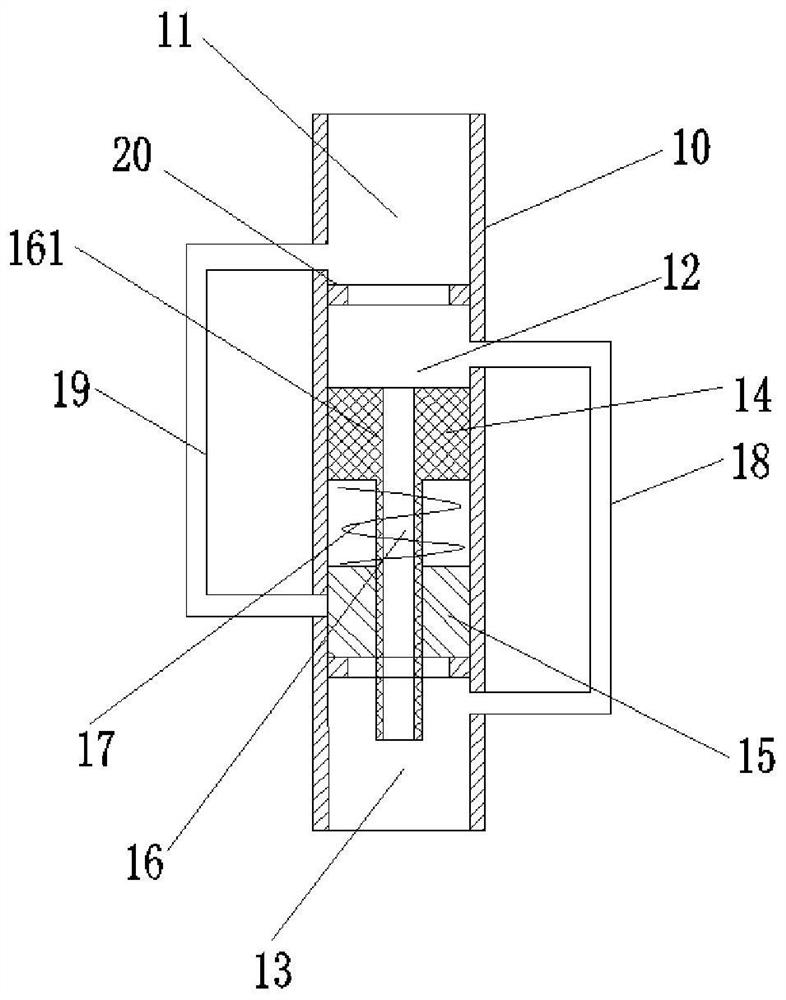

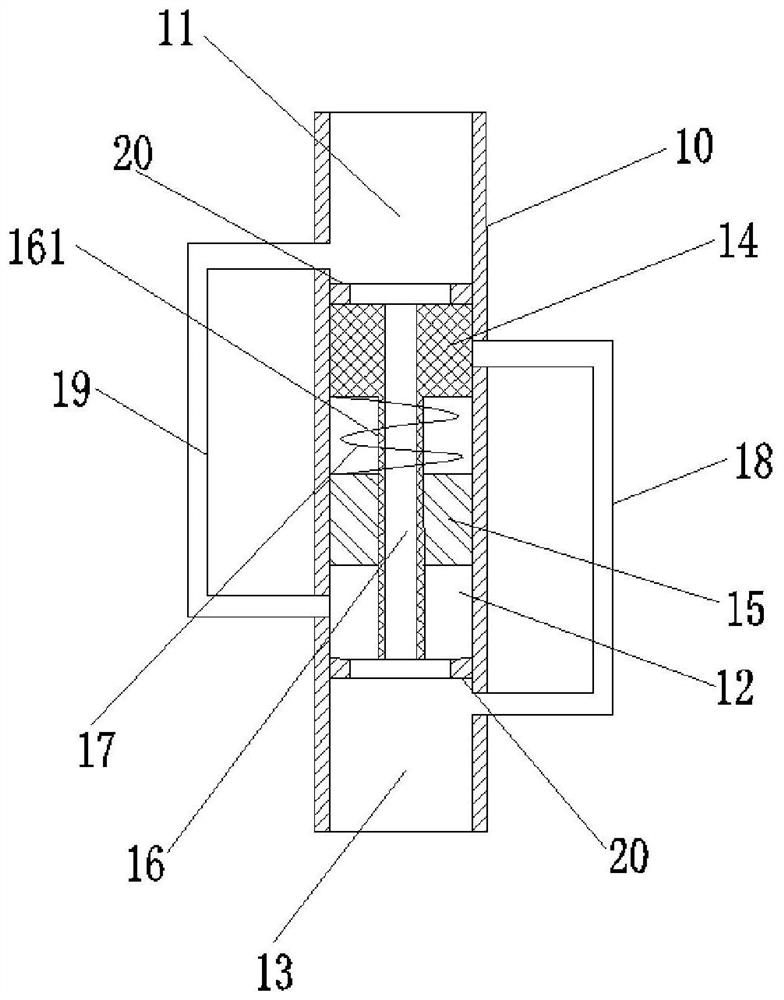

Marine high-power gear box clutch capable of achieving rapid row connection and rapid reversing

PendingCN111005948AImprove mobilityImprove commutation efficiencyFluid actuated clutchesPistonClutch

The invention discloses a marine high-power gear box clutch capable of achieving rapid row connection and rapid reversing. An oil cylinder body is included. A piston is arranged in the oil cylinder body. The piston is connected with a guide ring seat sleeve and the oil cylinder body through an inner hole and an outer ring. The guide ring seat sleeve is fixed on the oil cylinder body through a bolt. Four oil drain valve assemblies are arranged at a top of an outer circle of the oil cylinder body. A gasket is arranged between the piston and the guide ring seat sleeve, a belleville spring is arranged in the piston, and the belleville spring is placed on a spring seat sleeve. Advantages that rapid row connection and reversing are achieved; clutch universality is high; an existing gear box canbe transformed; a price is low; and generalizability is high and so on are possessed.

Owner:HANGZHOU ADVANCE GEARBOX GRP

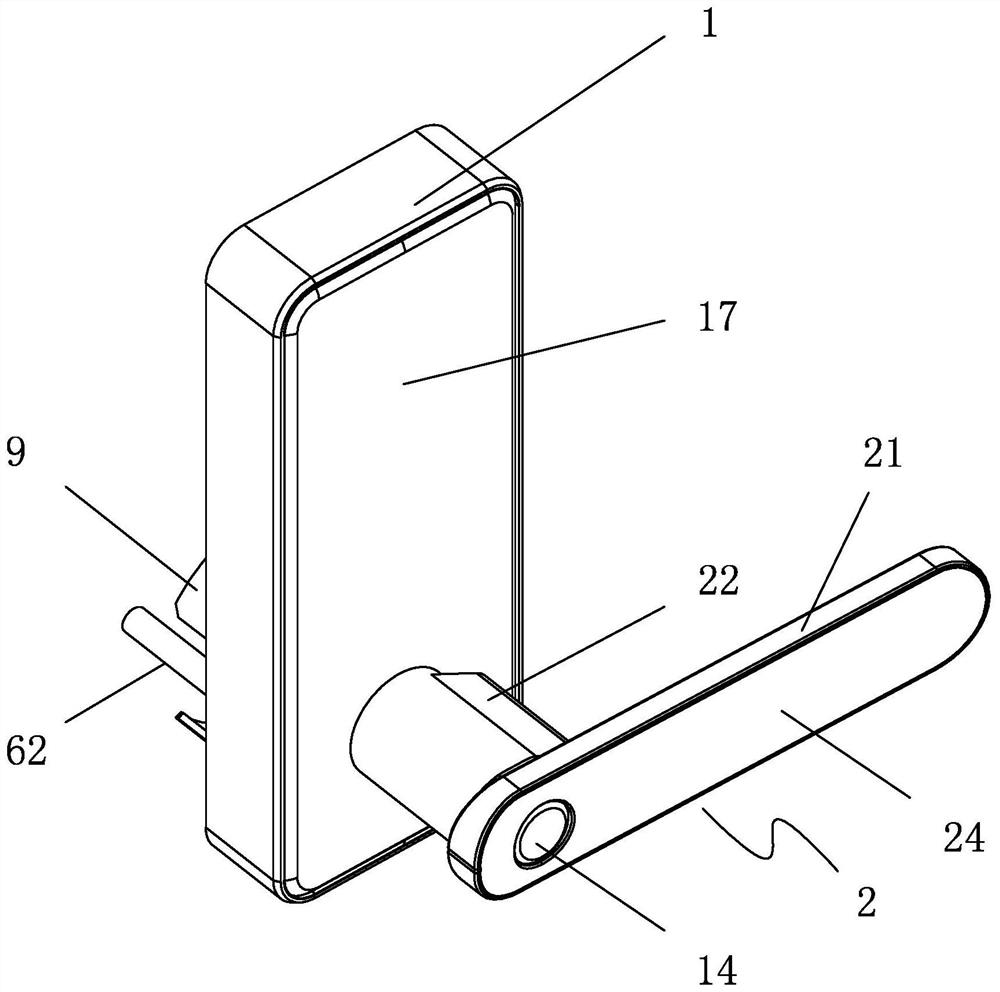

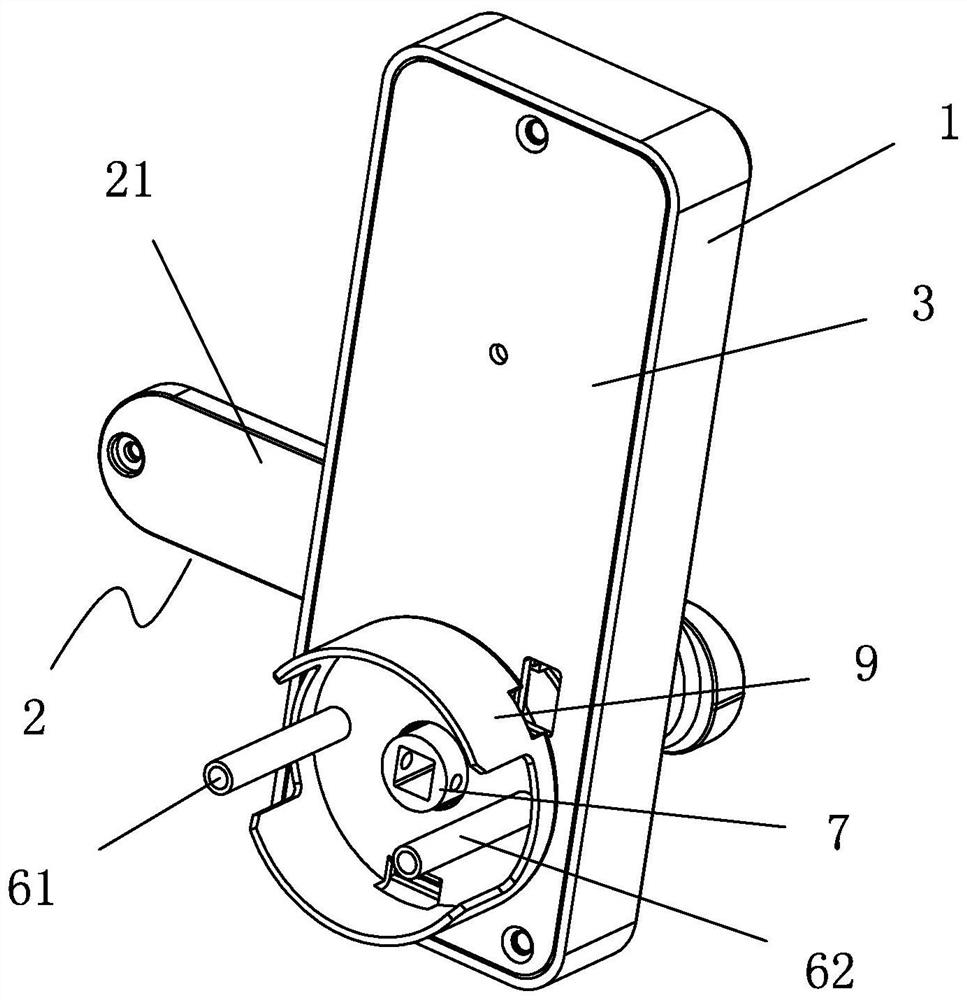

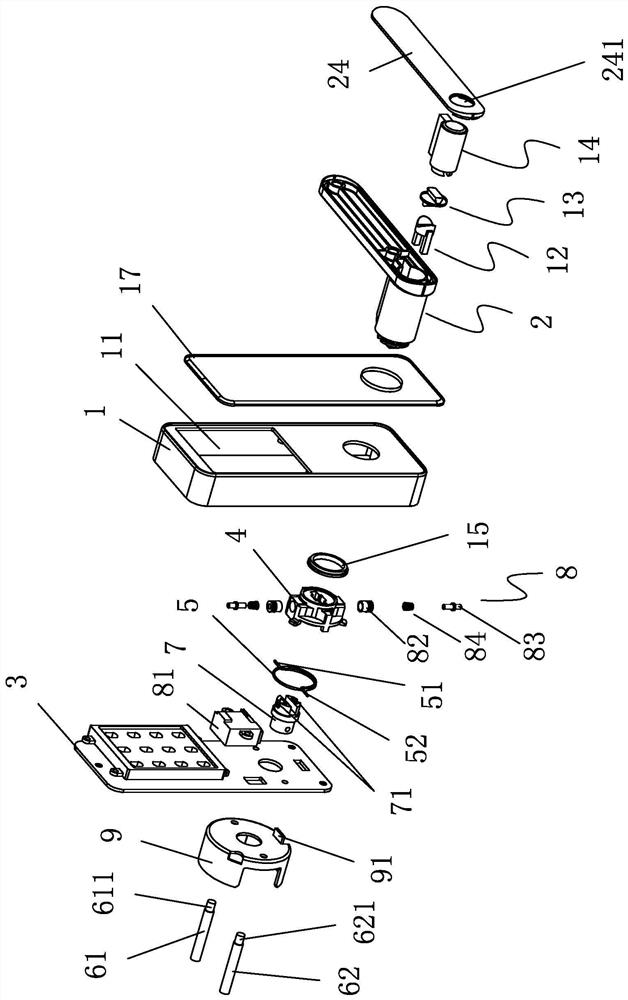

Intelligent lockset with reversing handle and reversing method of intelligent lockset

PendingCN111827784ASimplify commutationImprove commutation efficiencyNon-mechanical controlsLock casingsControl engineeringEngineering

The invention discloses an intelligent lockset with a reversing handle and a reversing method of the intelligent lockset. The intelligent lockset comprises a first lock case and the handle rotatably arranged on the first lock case, an accommodating groove is formed in the first lock case, a fixed plate fixedly connected with the first lock case is arranged at an opening of the accommodating groove, a rotating piece fixedly connected with the handle in the circumferential direction is arranged in the accommodating groove, and a torsional spring is arranged between the rotating piece and the fixed plate. The torsional spring is provided with a first extension column and a second extension column, a first protruding block and a second protruding block correspond to the first extension columnand the second extension column on the same side respectively are symmetrically arranged on the end surface, facing the fixed plate, of the rotating piece, and a first connecting column and a second connecting column are symmetrically arranged on the outer end surface of the fixed plate, wherein part of the first connecting column and part of the second connecting column are inserted into the accommodating groove and the first connecting column and the second connecting column are distributed on the periphery of the rotating piece. According to the intelligent lockset with the reversing handle, the handle reversing mode is simplified, the installation is convenient for users, the handle reversing efficiency is improved, suitable crowds are wide, and the product stability and product valuedegree are high.

Owner:ZHONGSHAN CITY JIXIN CORE LOCK CO LTD

A non-transmission automatic reversing structure based on machinery

ActiveCN111917340BImprove commutation efficiencyEasy to adjustMechanical energy handlingPolyphase induction motor starterHydraulic cylinderGear wheel

Owner:浙江昂科工程技术有限公司

a wire take-up device

ActiveCN110116935BAvoid bruisesSufficient height distanceFilament handlingDental flossingEngineering

The invention belongs to the technical field of zipper dental floss storage equipment, in particular to a wire take-up device. The wire take-up device comprises a guide mechanism, a pressing mechanism, a roller and a driving mechanism; the driving mechanism drives the roller for rotation and periodical axial translation; the guide mechanism comprises a guide base, a connecting rod and a material mouth; the head end of the connecting rod is hinged to the guide base, so that the connecting rod can swing back and forth in the up-down direction; the material mouth is arranged at the tail end of the connecting rod; the material mouth is arranged on the upper side of the roller; the pressing mechanism is arranged on the outer side of the material mouth, and is connected with the tail end of theconnecting rod through a transverse slide rail mechanism; the pressing mechanism comprises a pressing roller positioned at the lower end and capable of rotating; limiting surfaces are arranged on twoopposite sides of the roller; the lower end width of the pressing mechanism is matched with the transverse distance between the limiting surfaces on two sides; the material mouth is arranged above thelower side of the pressing roller; and the roller enables the pressing mechanism to drive the pressing roller to synchronously move through the limiting surfaces. The wire take-up device can relievethe multilayer stacking condition during reversing.

Owner:广东顺德三扬科技股份有限公司

Switching type phase sequence switching combined junction box

ActiveCN107918038BDoes not affect electricity consumptionSimple structureTime integral measurementControl engineeringElectrical connection

The invention aims at providing a switching type phase sequence switching combined conjunction box, and relates to the power field. The switching type phase sequence switching combined conjunction boxcomprises a conjunction box body, a box cover, a wiring board arranged in the conjunction box body and provided with three voltage and current wiring blocks, and a phase sequence switching switch electrically connected to the first and third voltage and current wiring blocks. Each of the first and third voltage and current wiring blocks comprises an electrical connection assembly and a switchingassembly; the electrical connection assembly comprises a voltage electrical connection column and middle, left and right current electrical connection columns; the switching assembly comprises a voltage switching terminal and left and right current switching terminals; and the middle electrical connection column is electrically connected with the right / left current electrical connection column. When being used for phase sequence adjustment, the switching type phase sequence switching combined conjunction box does not influence power utilization of users, and is higher in phase switching efficiency and higher in safety level.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +2

Non-transmission type automatic reversing structure based on machinery

ActiveCN111917340AImprove commutation efficiencyEasy to adjustMechanical energy handlingPolyphase induction motor starterHydraulic cylinderDrive shaft

The invention discloses a non-transmission type automatic reversing structure based on machinery, relates to the technical field of mechanical transmission, and solves the problems of low reversing speed and difficulty in quick reversing due to the fact that a contactor is mainly used for controlling the rotation direction of a three-phase motor to switch the rotation direction in the conventionalrotating shaft reversing process. The non-transmission type automatic reversing structure based on machinery comprises a base. Two driven shaft frames are fixedly arranged on the two sides of the topof the base. The driven shaft frames are each of a T-shaped structure, and two driven shafts are rotationally arranged between the two sides of the tops of the two driven shaft frames. Two sets of reversing gears are fixedly arranged on the outer side of each driven shaft, the reversing gears are bevel gears, the tooth surfaces of the reversing gears on the same side are opposite, a quick reversing function is provided for the reversing shaft brackets by arranging a reversing shaft bracket and a sliding rack, and the hydraulic cylinder is used for driving the sliding rack to move, so the angle of the reversing shaft bracket can be adjusted by meshing the sliding rack with the tooth-shaped structure of the reversing shaft bracket.

Owner:浙江昂科工程技术有限公司

An adaptive diamond wire saw cutting equipment

ActiveCN109227976BLarge space for exerciseGuaranteed tensionWorking accessoriesFine working devicesDrive wheelDiamond wire saw

An adaptive diamond wire saw cutting device. The invention belongs to the technical field of diamond equipment, which uses a diamond wire saw to cut a rotating crystal ingot workpiece, and a driving wheel that rotates at high speed and reciprocates to drive the diamond wire saw to reciprocate, and the diamond wire saw is tensioned by two tensioning wheels , A cylinder is installed at the tension wheel to ensure that the diamond wire saw is in a certain tension, and two guide wheels are added to ensure the cutting accuracy and surface shape. The rotating crystal ingot workpiece is placed on the three-jaw chuck, the three-jaw chuck is fixedly connected with the rotating mechanism, driven by the rotating motor, the rotating mechanism is fixedly connected with the lifting feeding mechanism, and the lifting feeding mechanism is fixedly connected with the horizontal feeding mechanism , The horizontal feed mechanism is placed on the workbench, and the feed is driven by a stepping motor. The overall device is controlled by PLC, which has simple structure and convenient operation.

Owner:江苏中畅精密科技有限公司

Throttle device and air conditioner

ActiveCN109405370BQuick responseImprove reliabilityMechanical apparatusFluid circulation arrangementCapillary TubingEngineering

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com