Patents

Literature

273results about How to "Achieve lateral movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

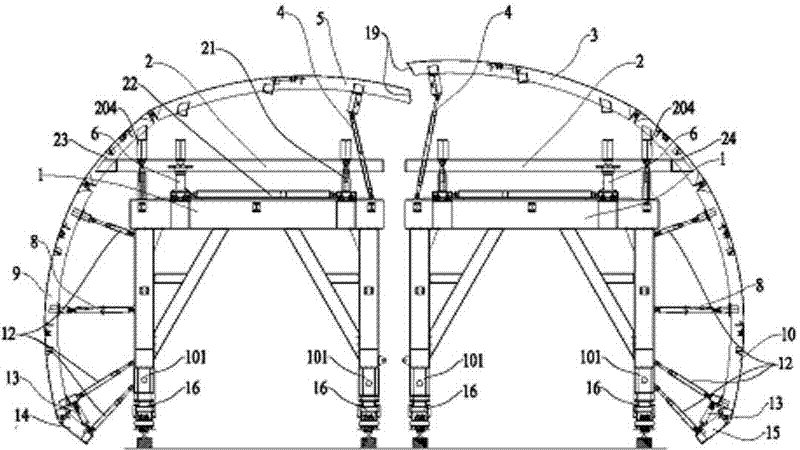

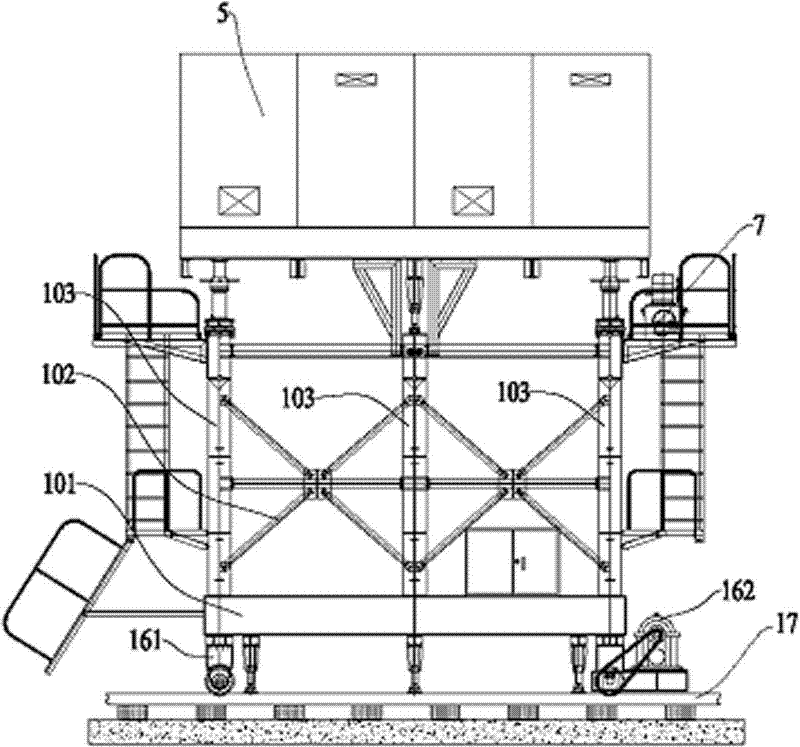

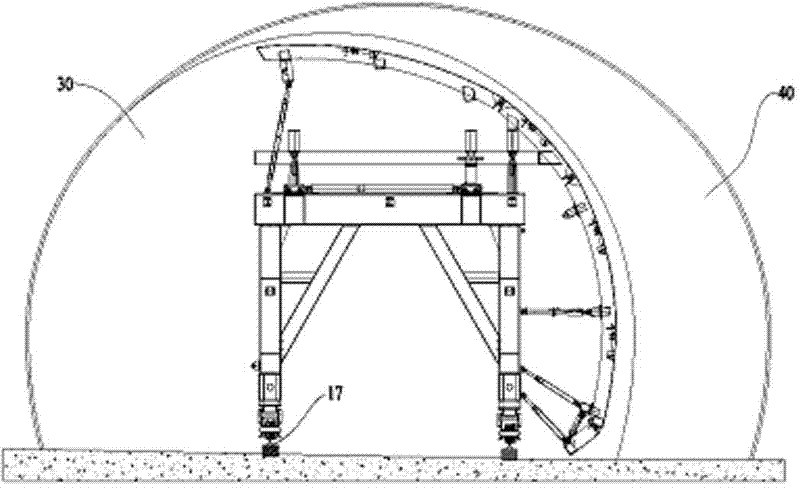

A lining method for a tunnel emergency avoidance zone and a tunnel lining trolley

ActiveCN102296971AImprove lining efficiencyImprove assembly qualityUnderground chambersTunnel liningEngineering

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

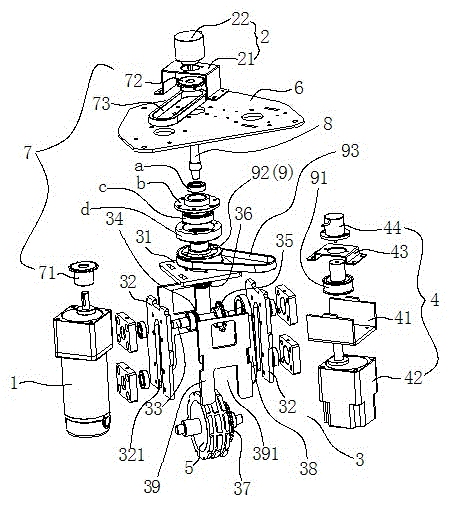

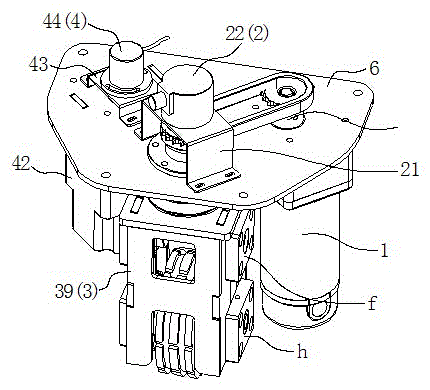

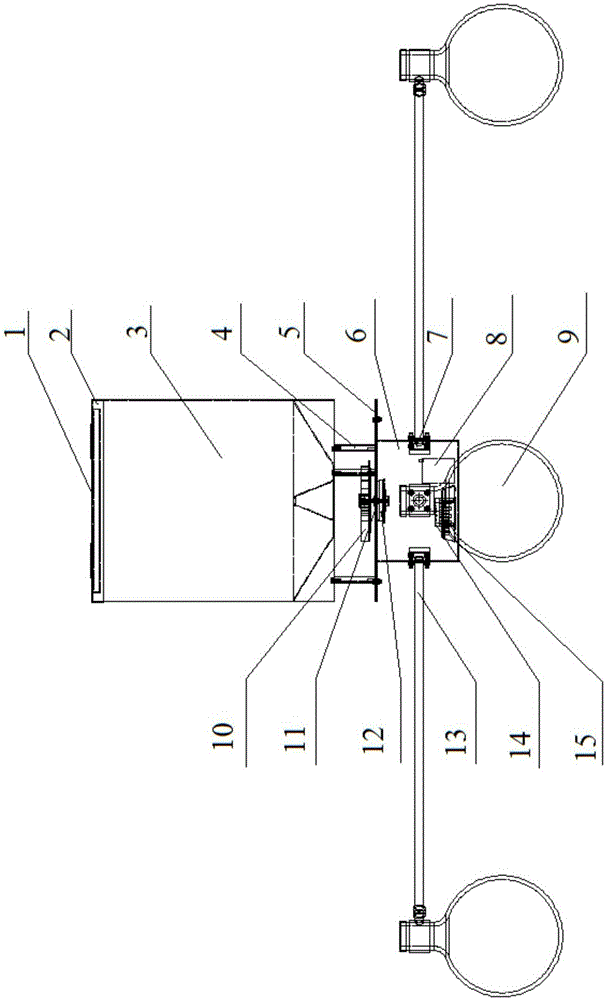

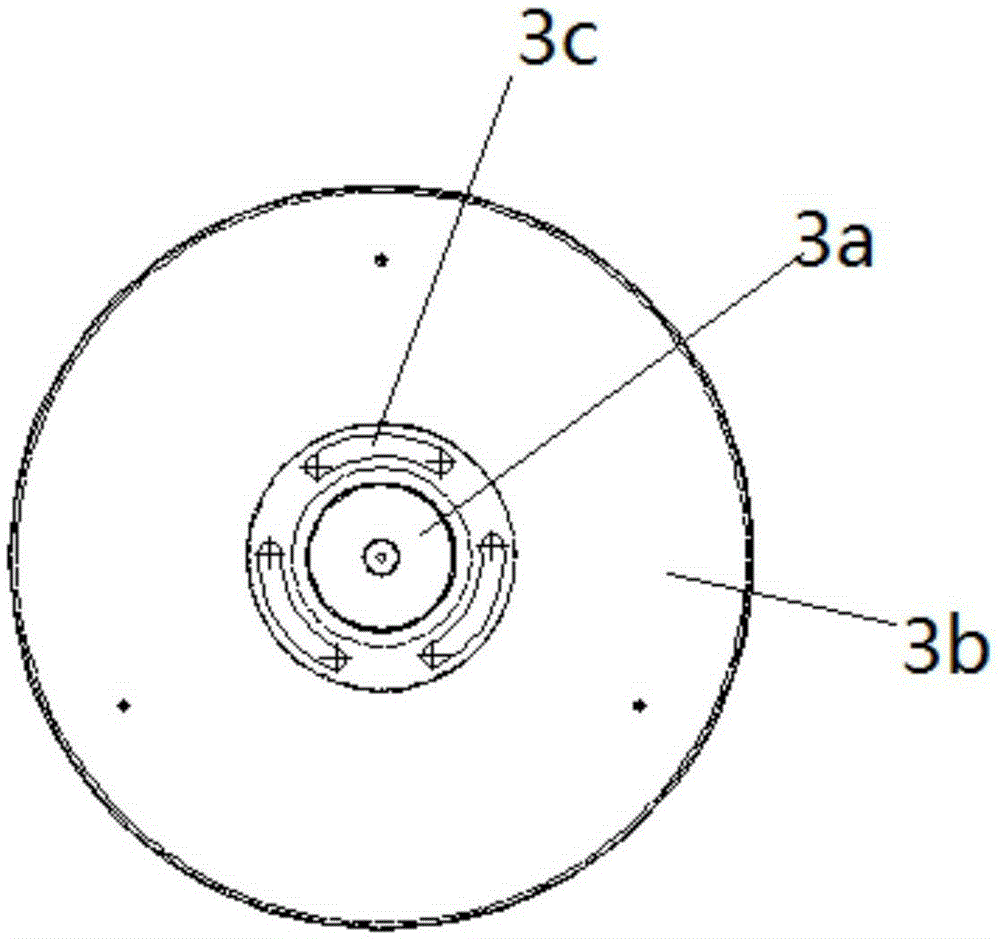

AGV steering wheel drive system module

ActiveCN104986036AChieve progressRealize functionElectrical steeringControl devicesSteering wheelDrive wheel

The invention relates to the technical field of guide transport equipment and discloses an AGV steering wheel drive system module. The AGV steering wheel drive system module comprises a drive unit, a speed feedback unit, a transmission unit, an angle feedback unit and a drive wheel. The drive unit, the speed feedback unit and the angle feedback unit are all arranged on an installation board. One end of the drive unit is connected with the speed feedback unit through a chain wheel mechanism. The speed feedback unit is connected with the transmission unit through a linkage shaft on the connected chain wheel mechanism. The transmission unit is connected with the drive wheel. The linkage shaft is provided with a steering mechanism connected with the angle feedback unit. By the adoption of the AGV steering wheel drive system module, drive power transmission efficiency is high, the accuracy of signals fed back through an encoder and an angle sensor is high, the space occupied by drive steering operation is small, machining cost is low, and installation and maintenance are easy.

Owner:东莞云帝斯科研有限公司

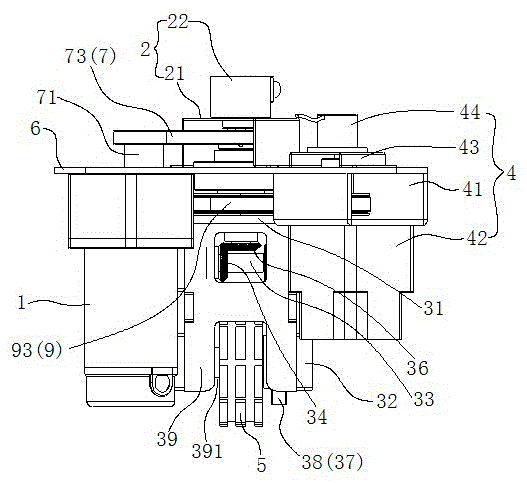

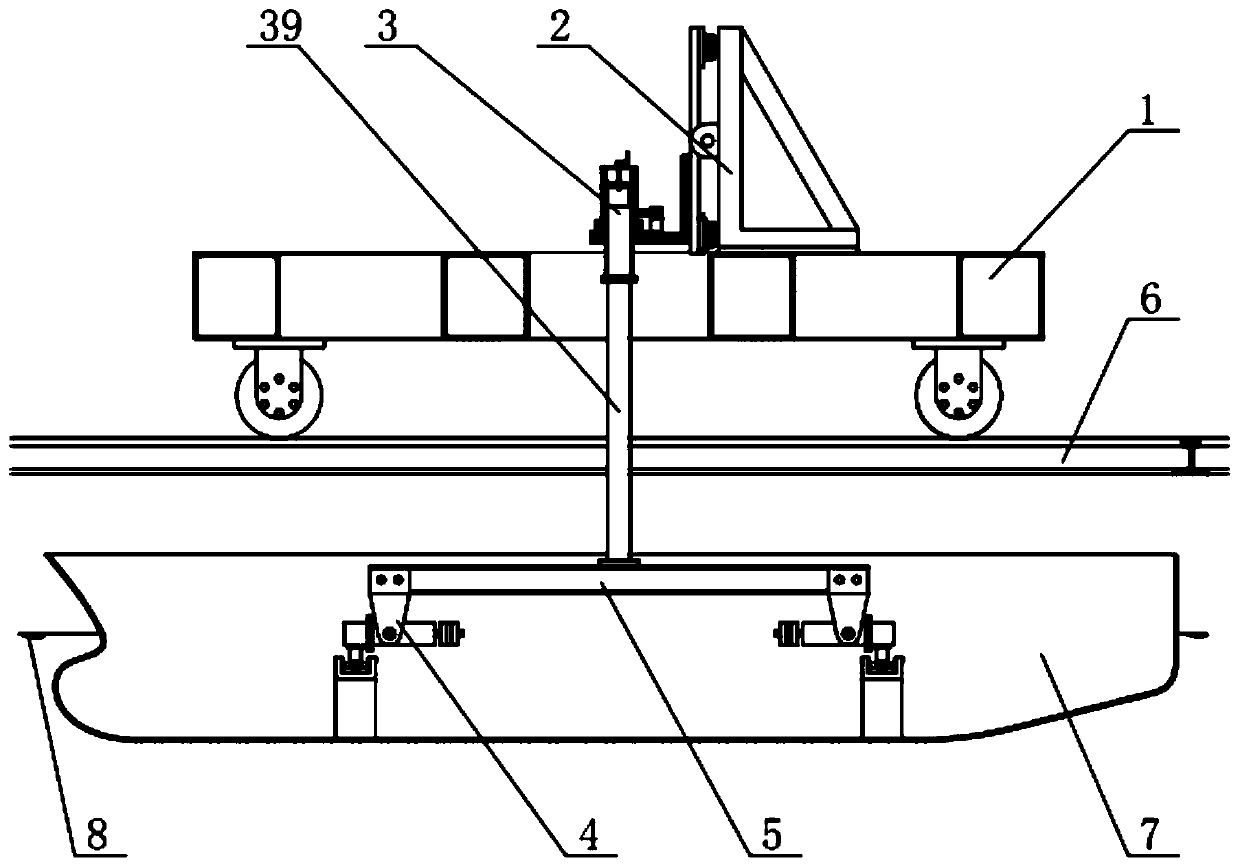

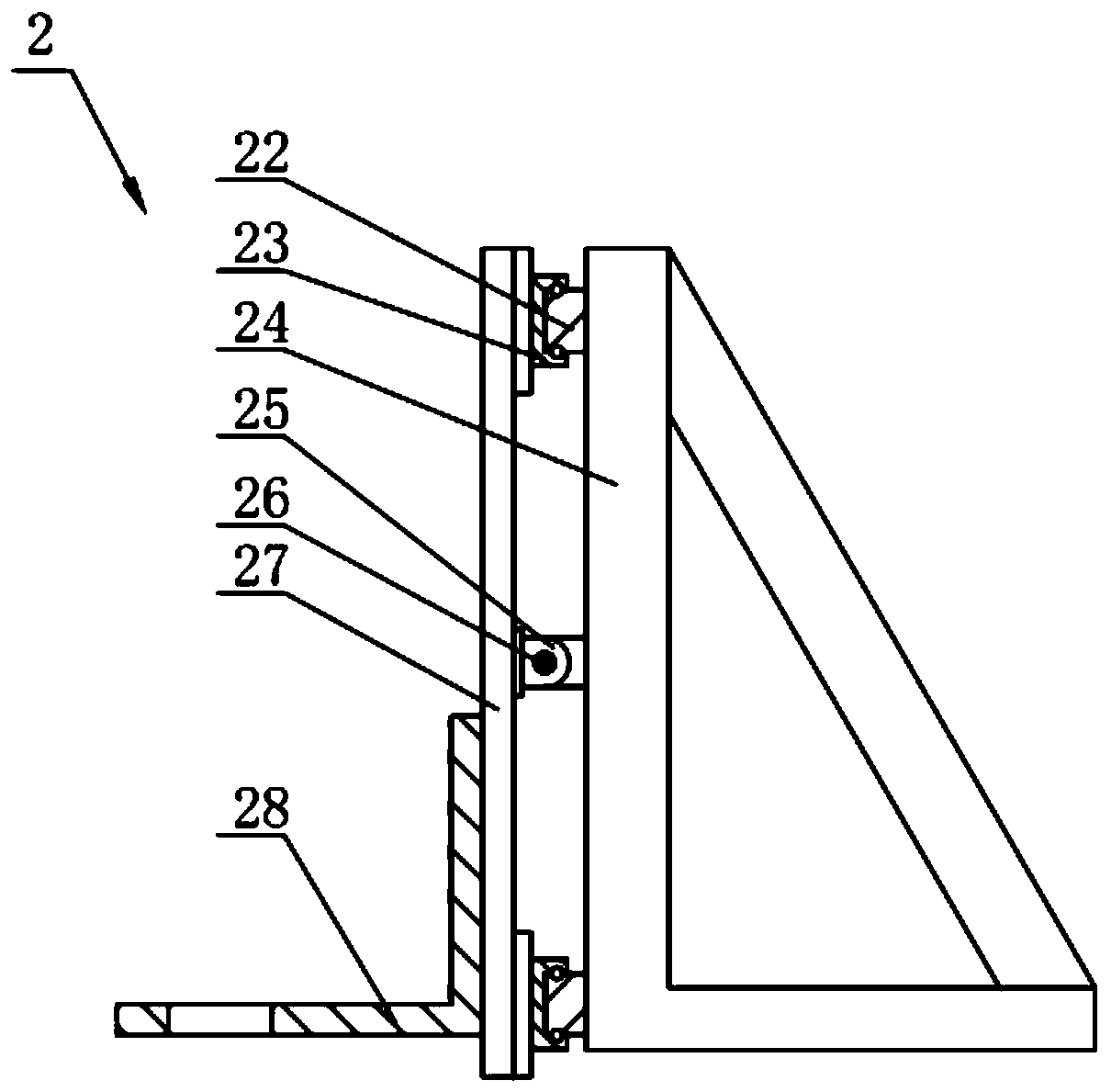

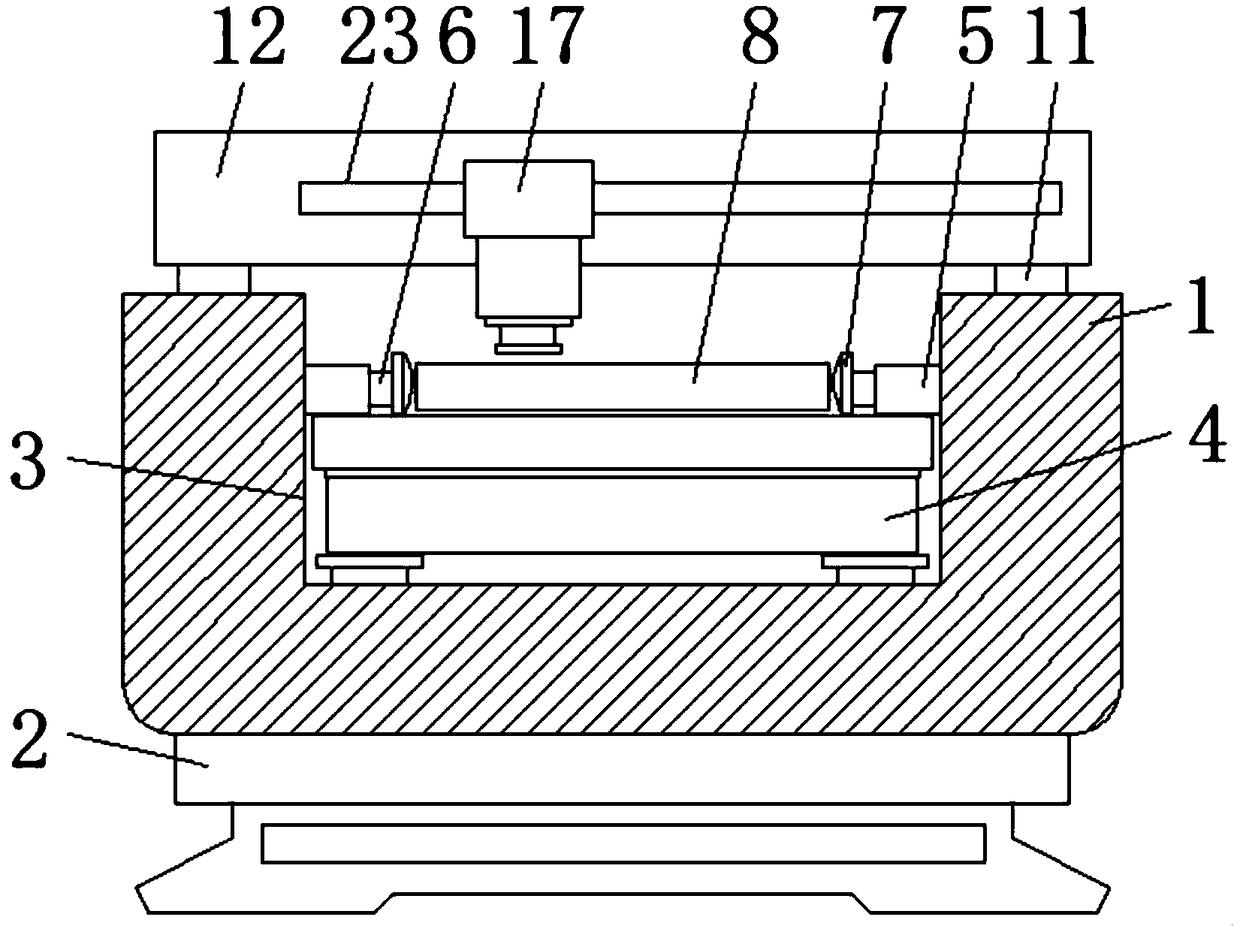

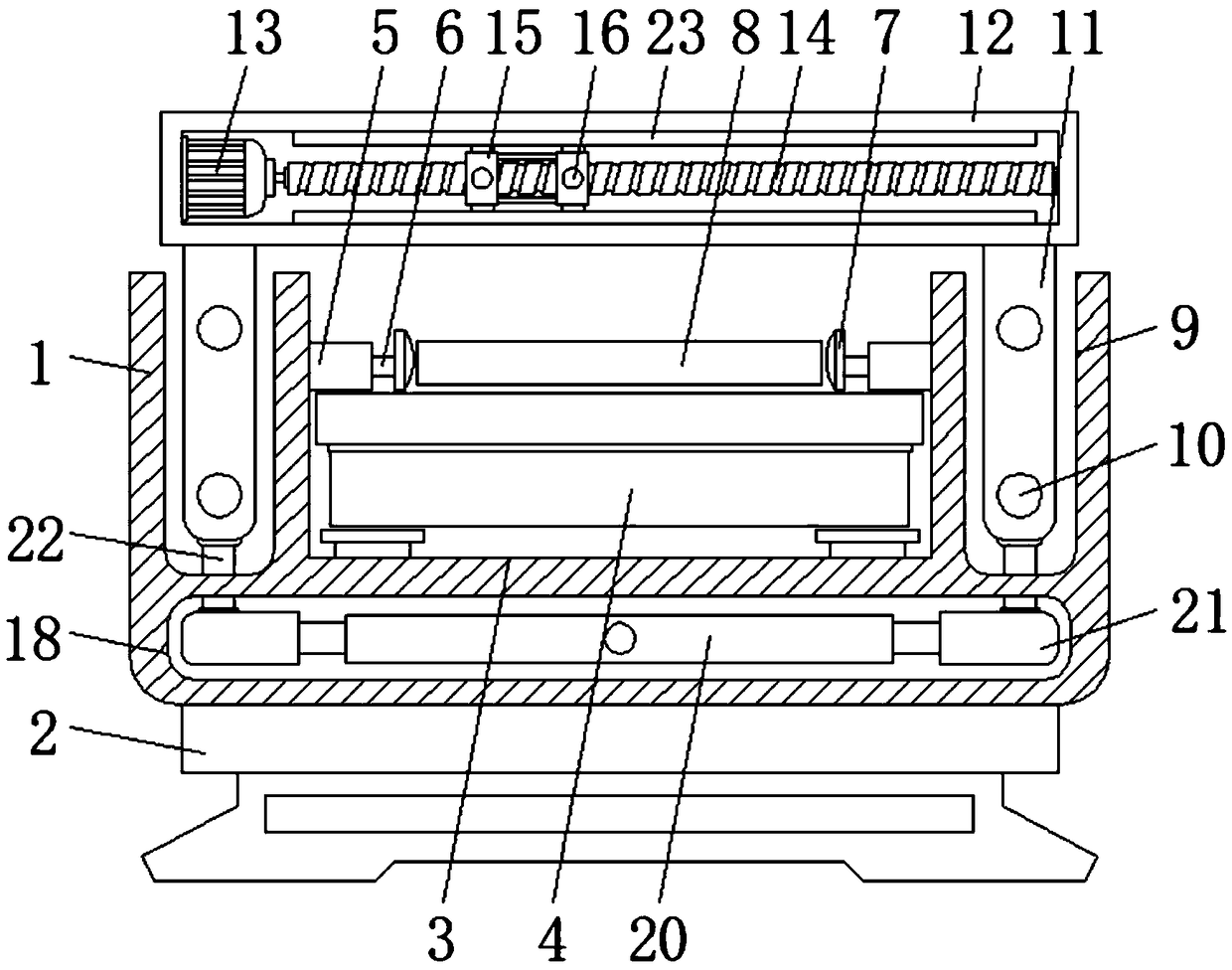

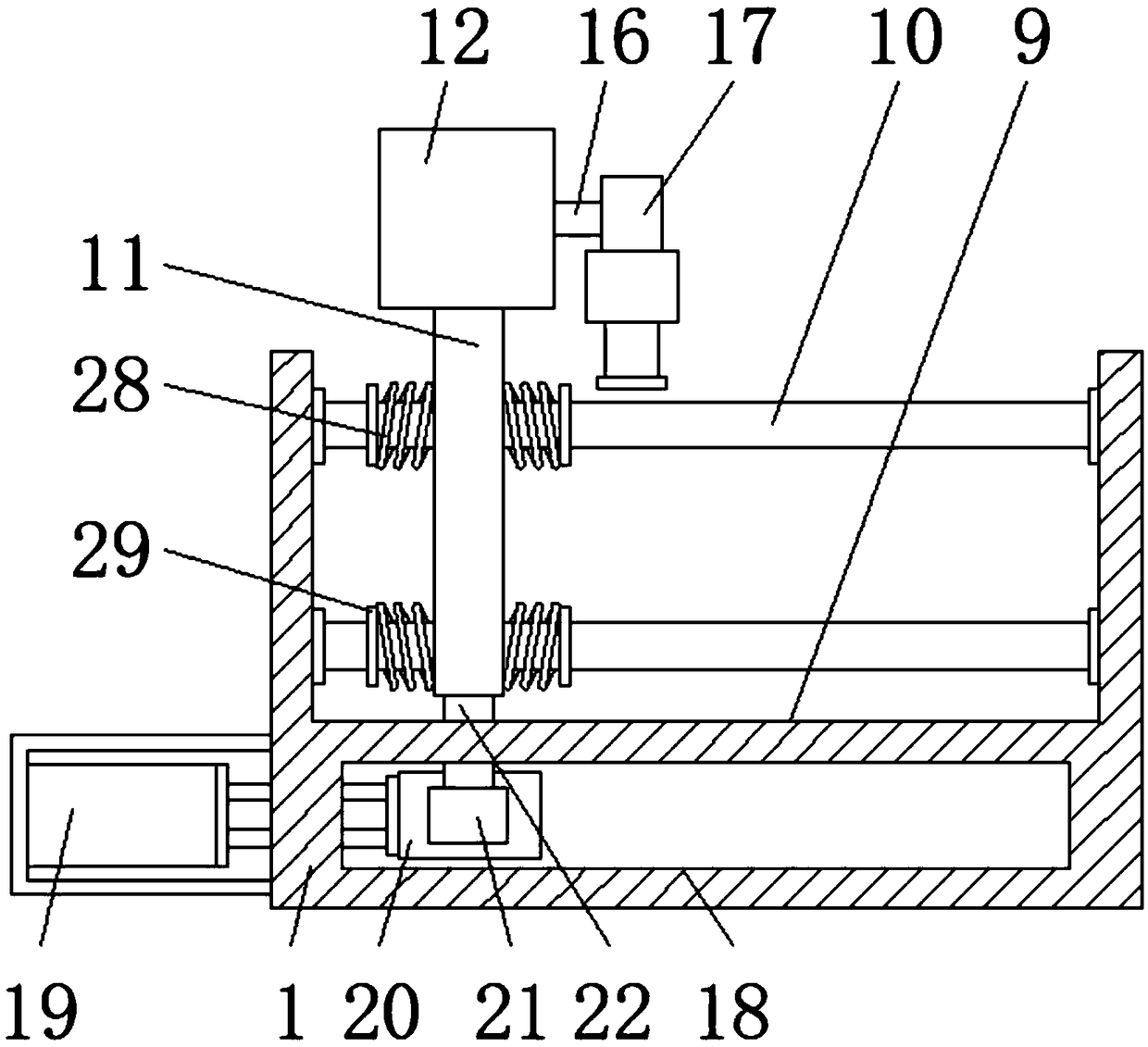

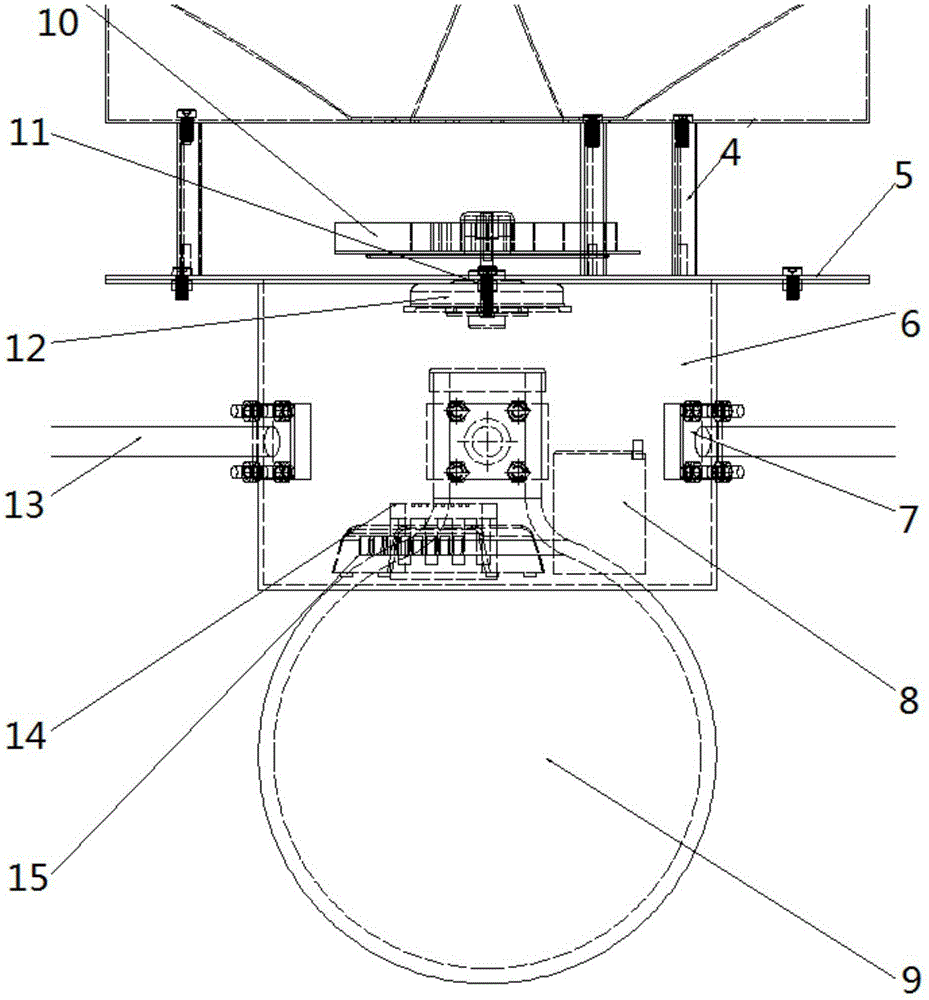

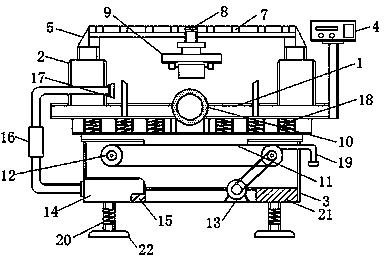

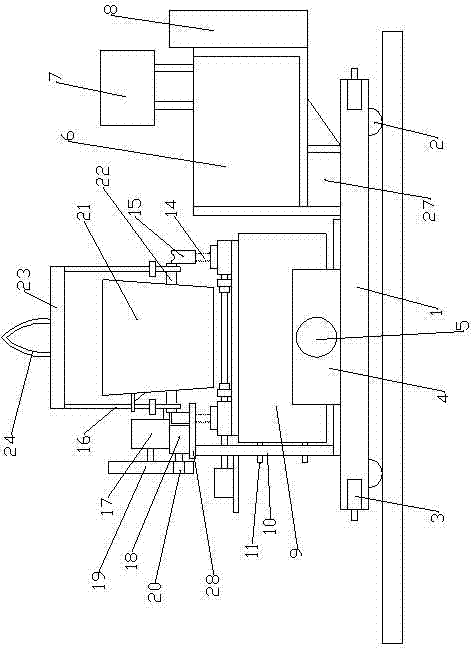

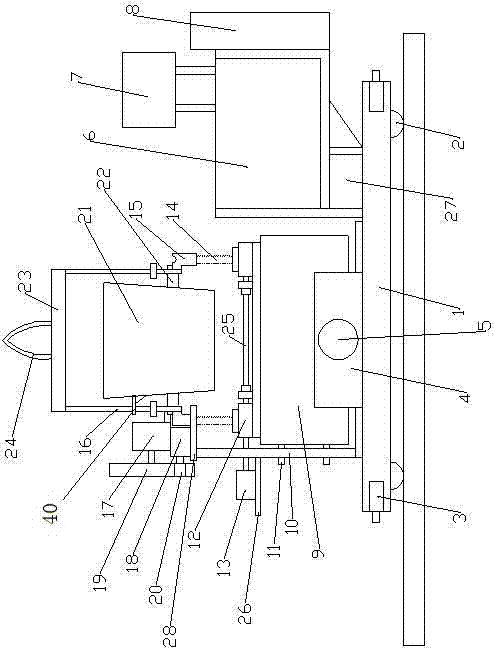

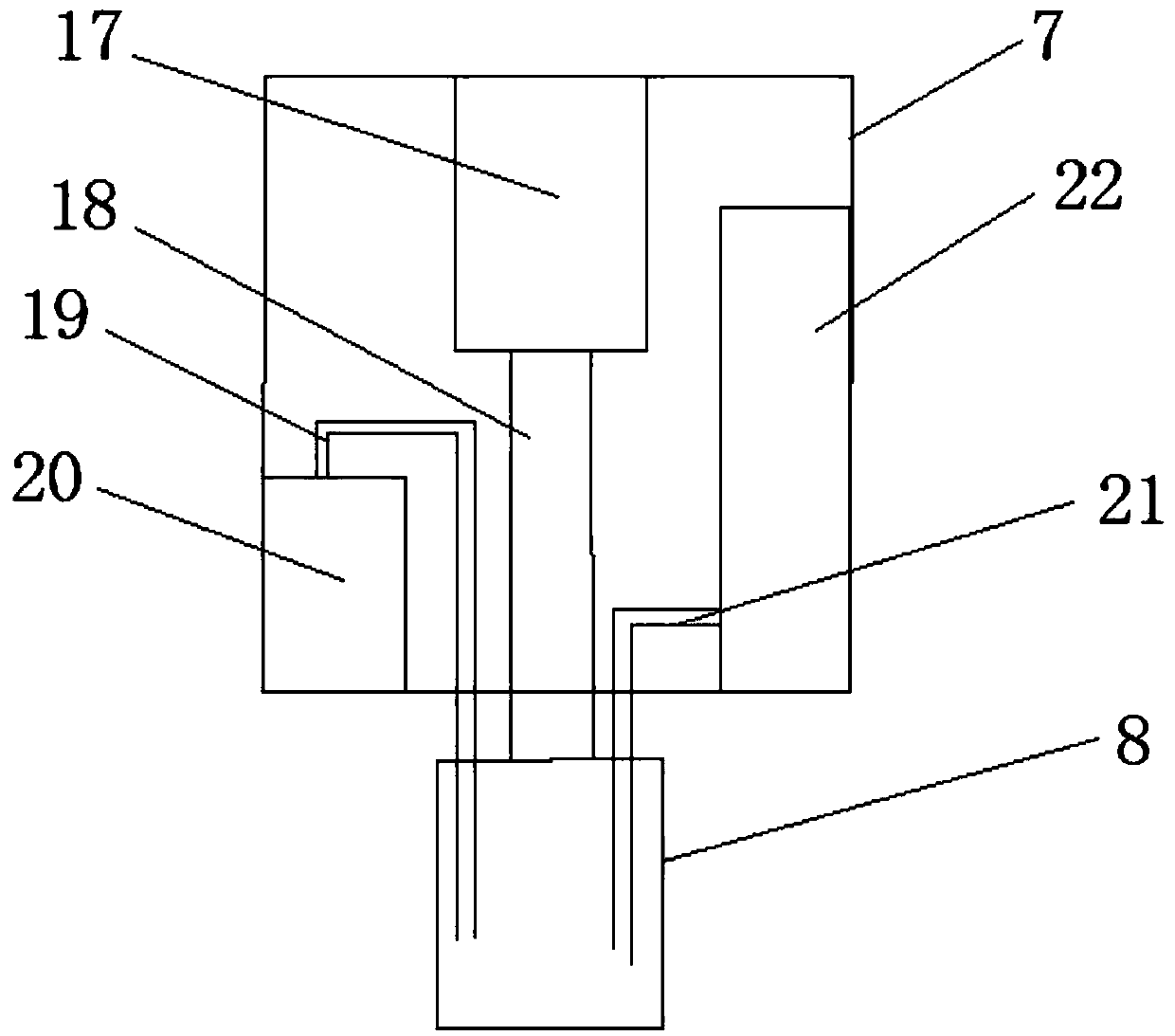

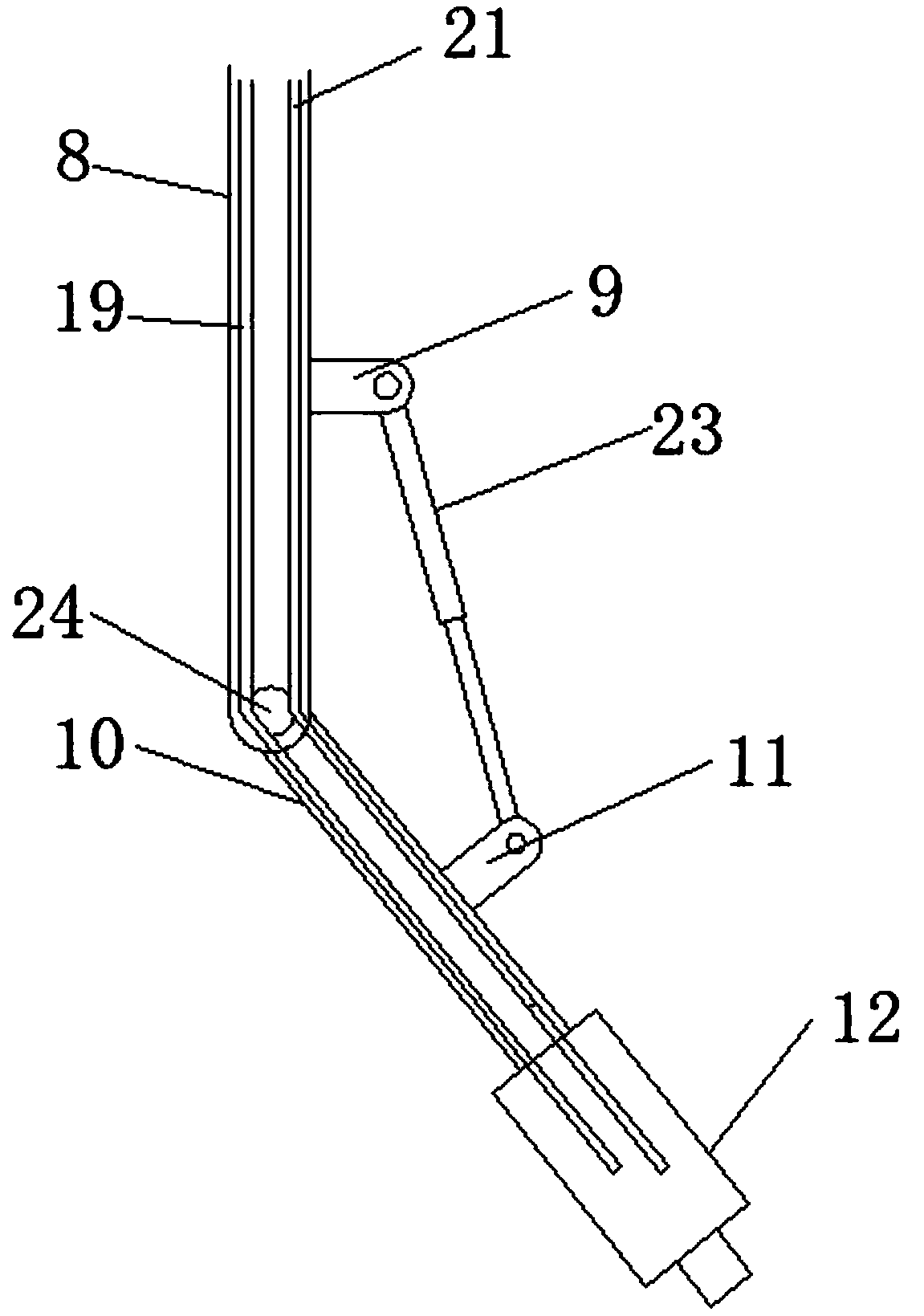

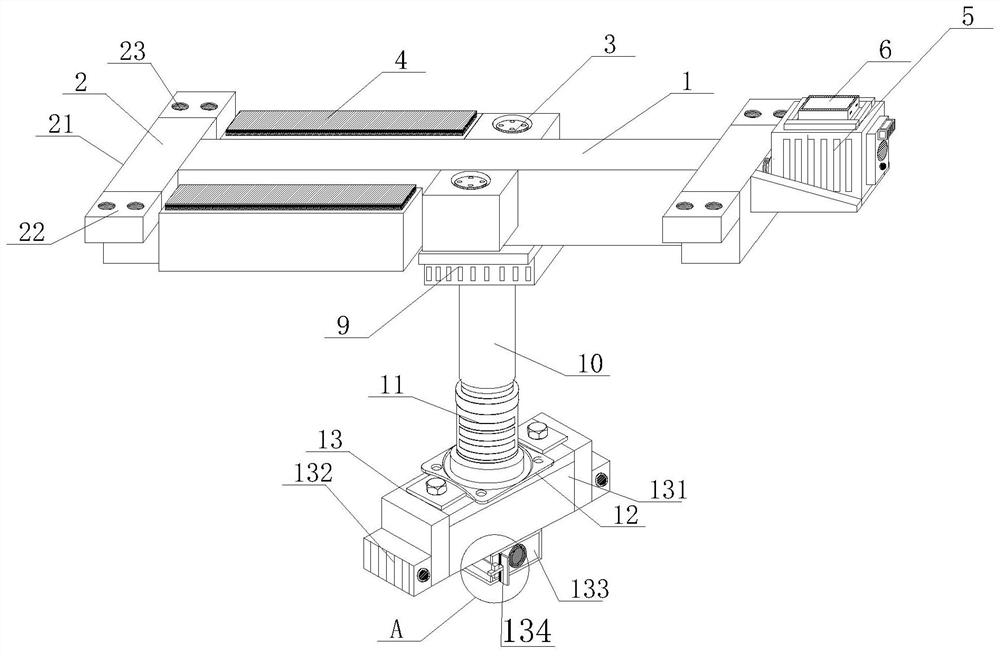

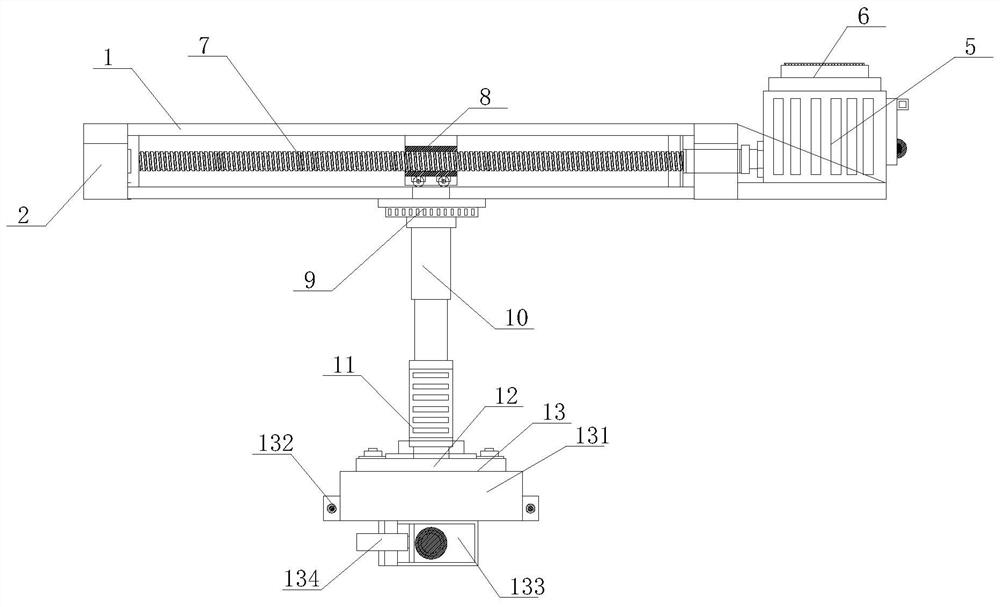

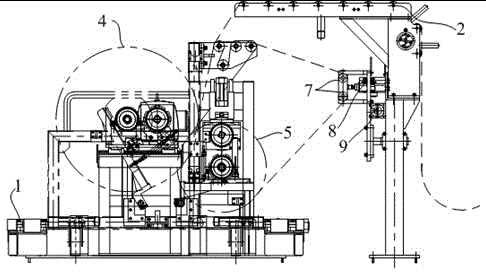

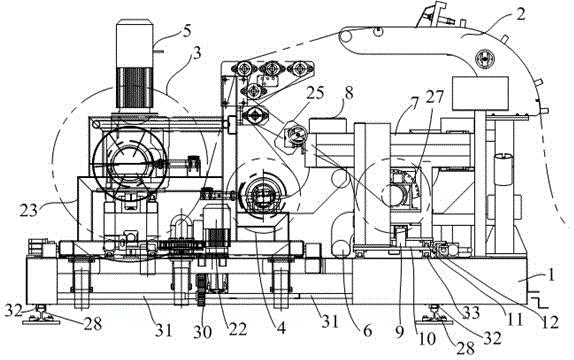

Planar motion mechanism for water ship model maneuverability test

ActiveCN110243570AEasy to getAdjustable initial heel angleHydrodynamic testingTest efficiencyMarine engineering

The invention relates to a planar motion mechanism for water ship model maneuverability test. The planar motion mechanism comprises a trailer, wherein a swaying motion mechanism is arranged on the trailer; an adjusting mechanism is arranged on the swaying motion mechanism; front and back symmetrical balance force-measuring mechanisms which are connected through a transverse beam are fixedly arranged on a ship model; a support rod of the adjusting mechanism is fixedly connected with the transverse beam downwards; the swaying motion mechanism is used for driving the ship model to sway under the driving action of a motor; the adjusting mechanism is used for adjusting the immersion depth of the ship model in cooperation with a nut and a sleeve, and drives a ship model bow to move through an electric cylinder; and the initial transverse dip angle of the ship model is adjusted through the balance force-measuring mechanisms. Through adoption of planar motion mechanism, the swaying, bow swaying and composite movement of the ship model are realized effectively; different transverse dip angles can be set; and fluid dynamic test researching of the ship model while the water surface and near-water surface oscillate periodically and transversely is prompted. The planar motion mechanism is convenient to operate, and has high test efficiency.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

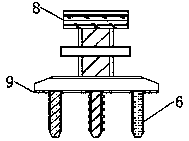

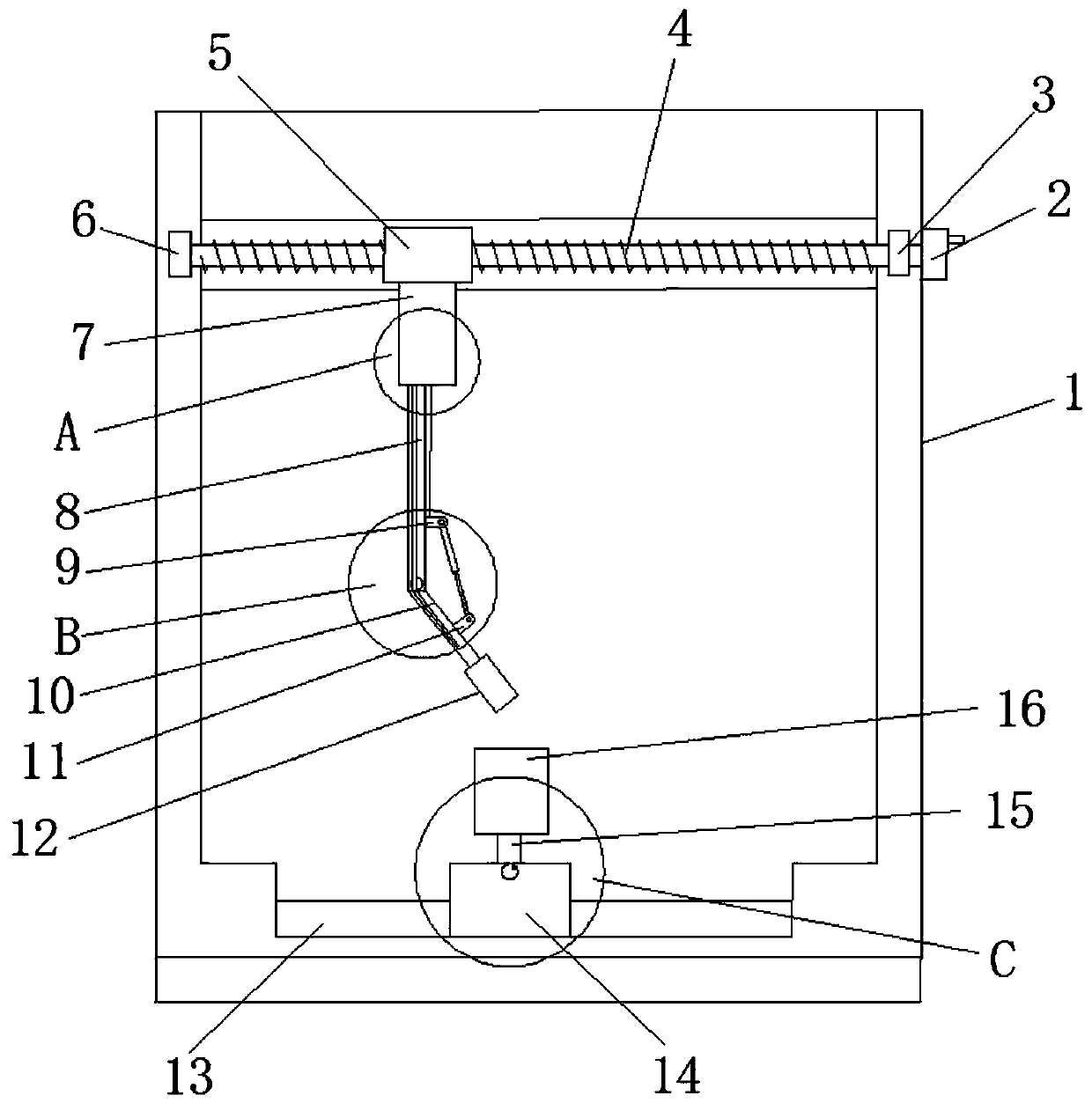

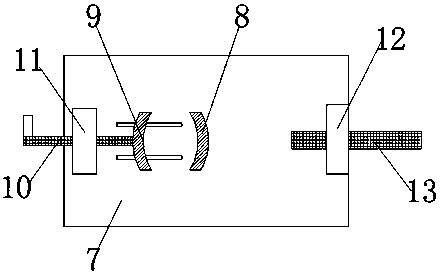

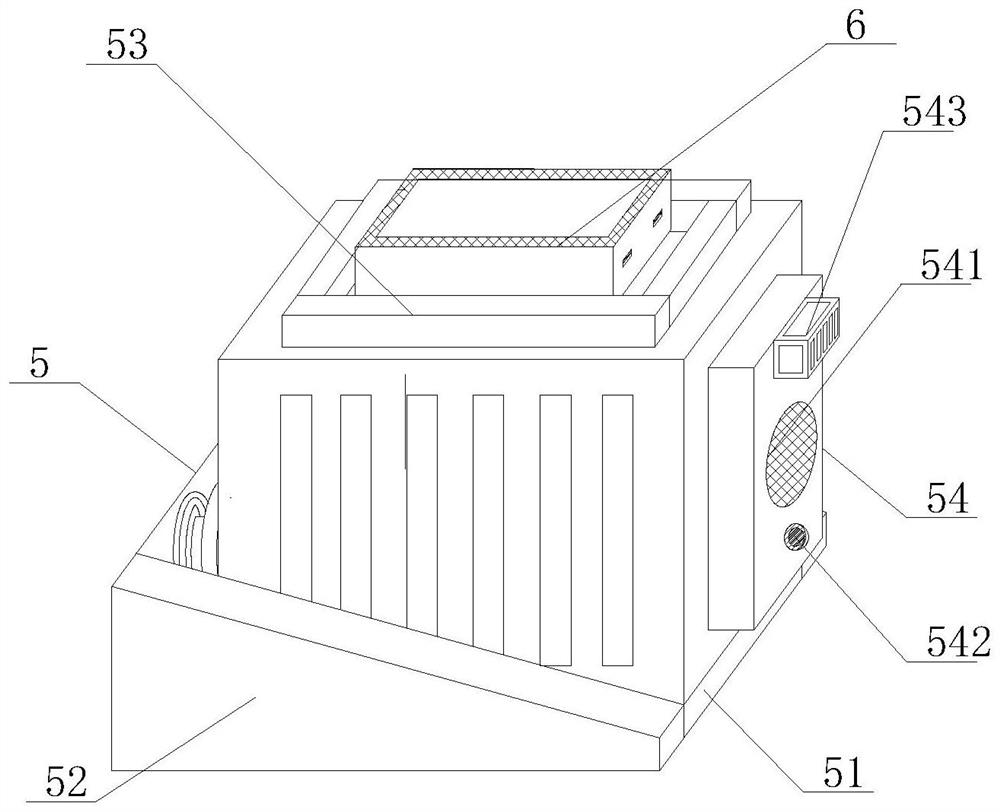

Liquid crystal display module detecting device

ActiveCN108828802ASolve the imperfect functionReduce manufacturing costNon-linear opticsMotor driveLiquid-crystal display

The invention relates to the technical field of liquid crystal display detecting devices, and discloses a liquid crystal display module detecting device. The device comprises a detecting table, the bottom of the detecting table is fixedly provided with a base, a sleeve groove is formed in the middle of the top end of the detecting table, the bottom surface of the sleeve groove is fixedly providedwith a lighting fixture, and sleeves located above the lighting fixture are fixedly mounted on the inner walls of both sides of the sleeve groove. A motor drives a screw to rotate, so that a movable block slides horizontally along a stable groove, the transverse movement of a detecting objective lens is achieved, convenience is provided for the detecting objective lens to detect a liquid crystal display screen transversely, a cover plate is pushed through an electro-hydraulic rod, a support rod drives a slide plate to slide along a fixed rod, the longitudinal movement of the detecting objective lens is achieved, convenience is provided for the longitudinal detection of the liquid crystal display screen by the detecting objective lens, a combination mechanism is used for achieving the lighting detection of the liquid crystal display screen quickly and effectively, convenience is provided for improving the detection efficiency, and detection errors are reduced.

Owner:深圳市百乐奇科技有限公司

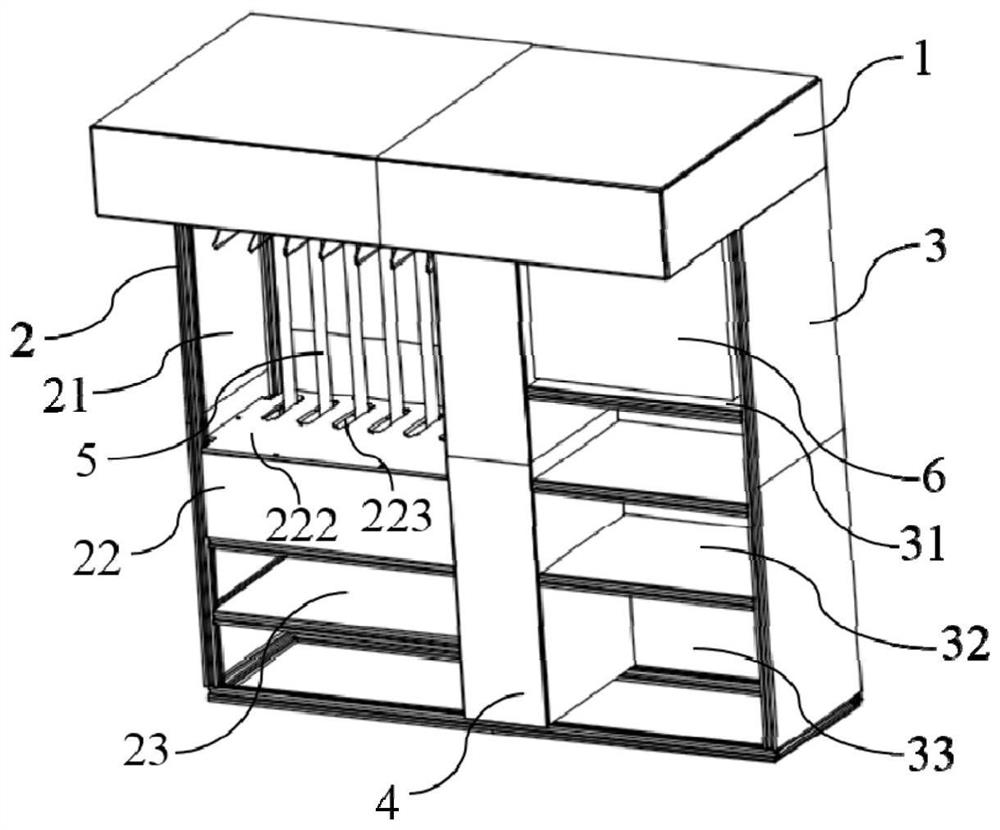

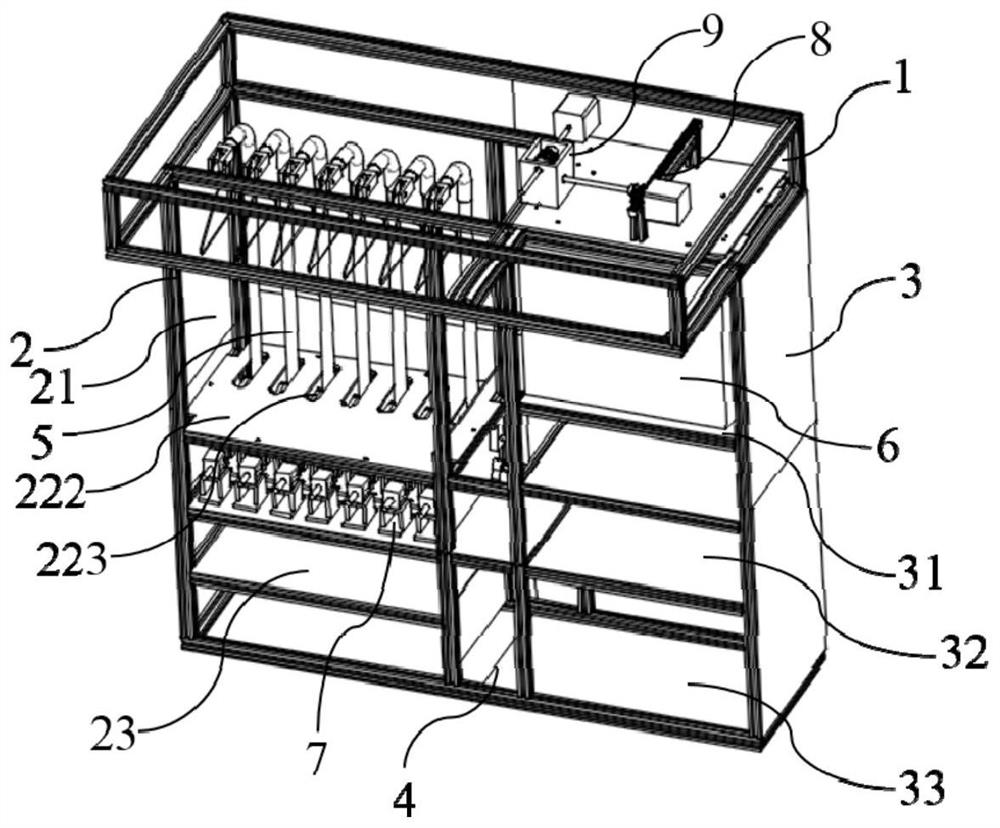

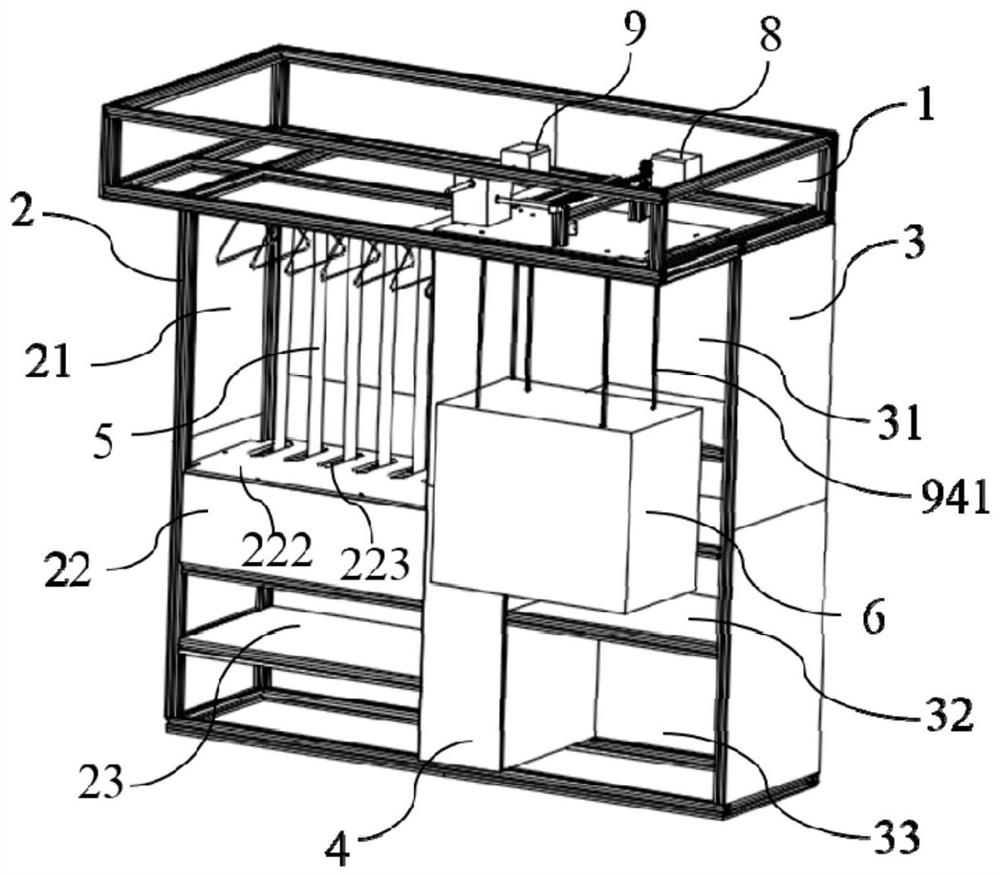

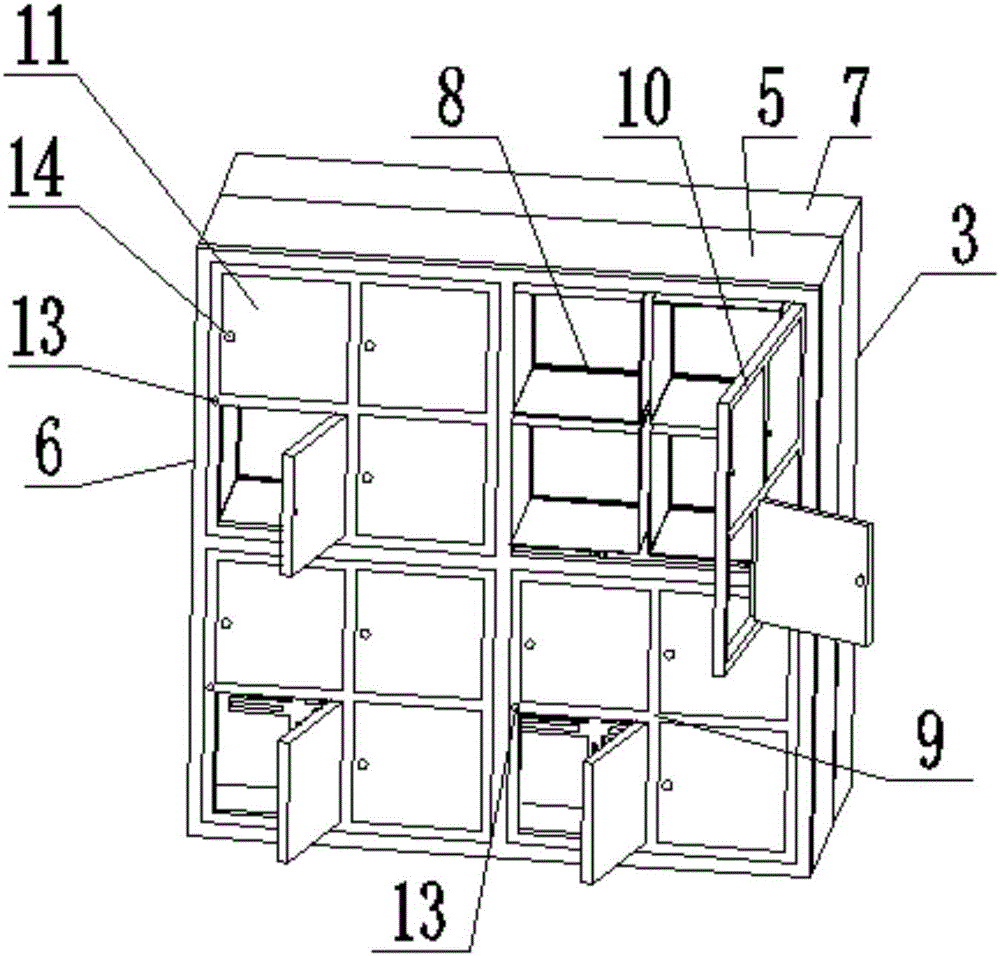

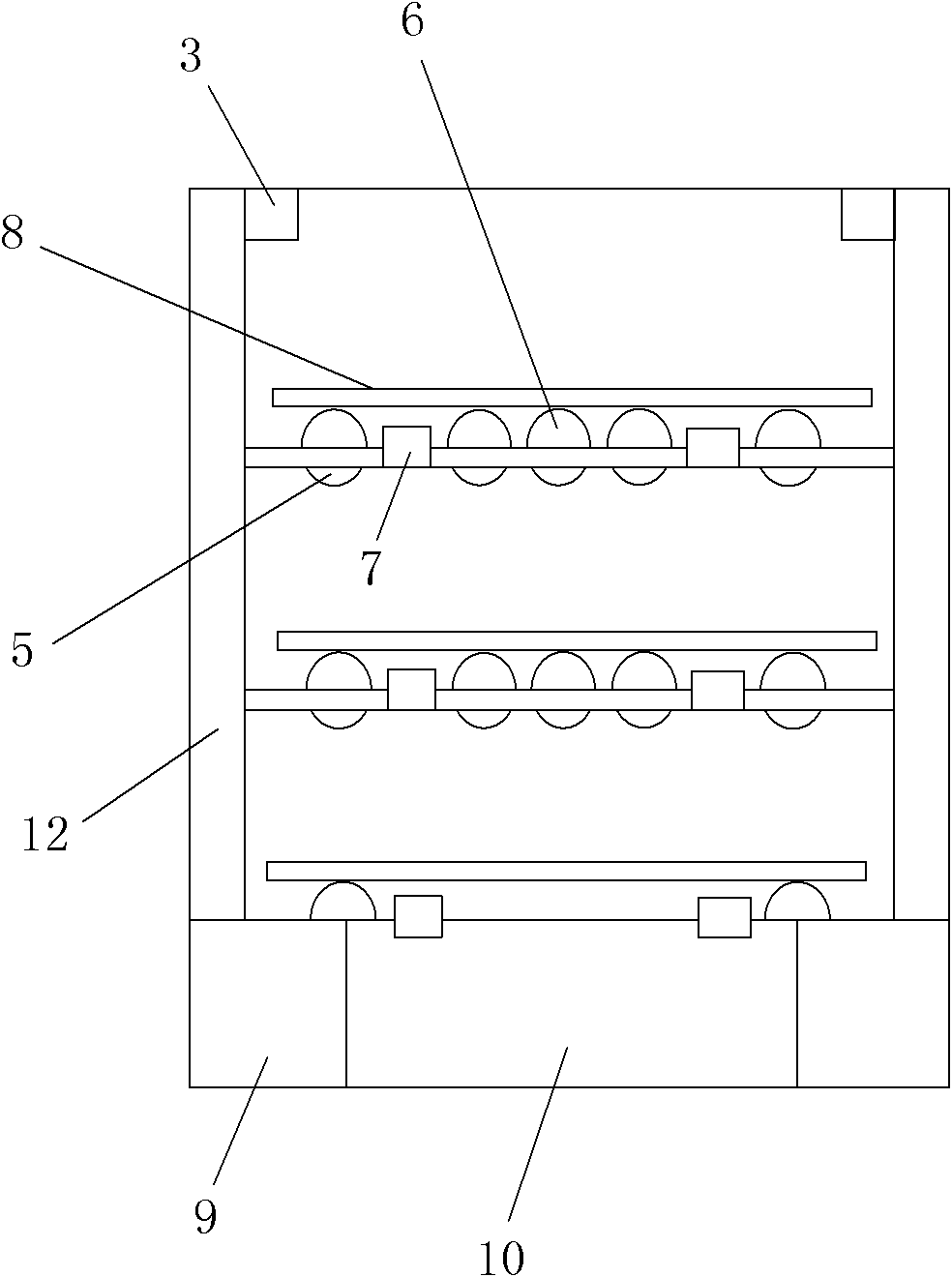

Intelligent wardrobe convenient for taking and hanging clothes and clothes taking and hanging method thereof

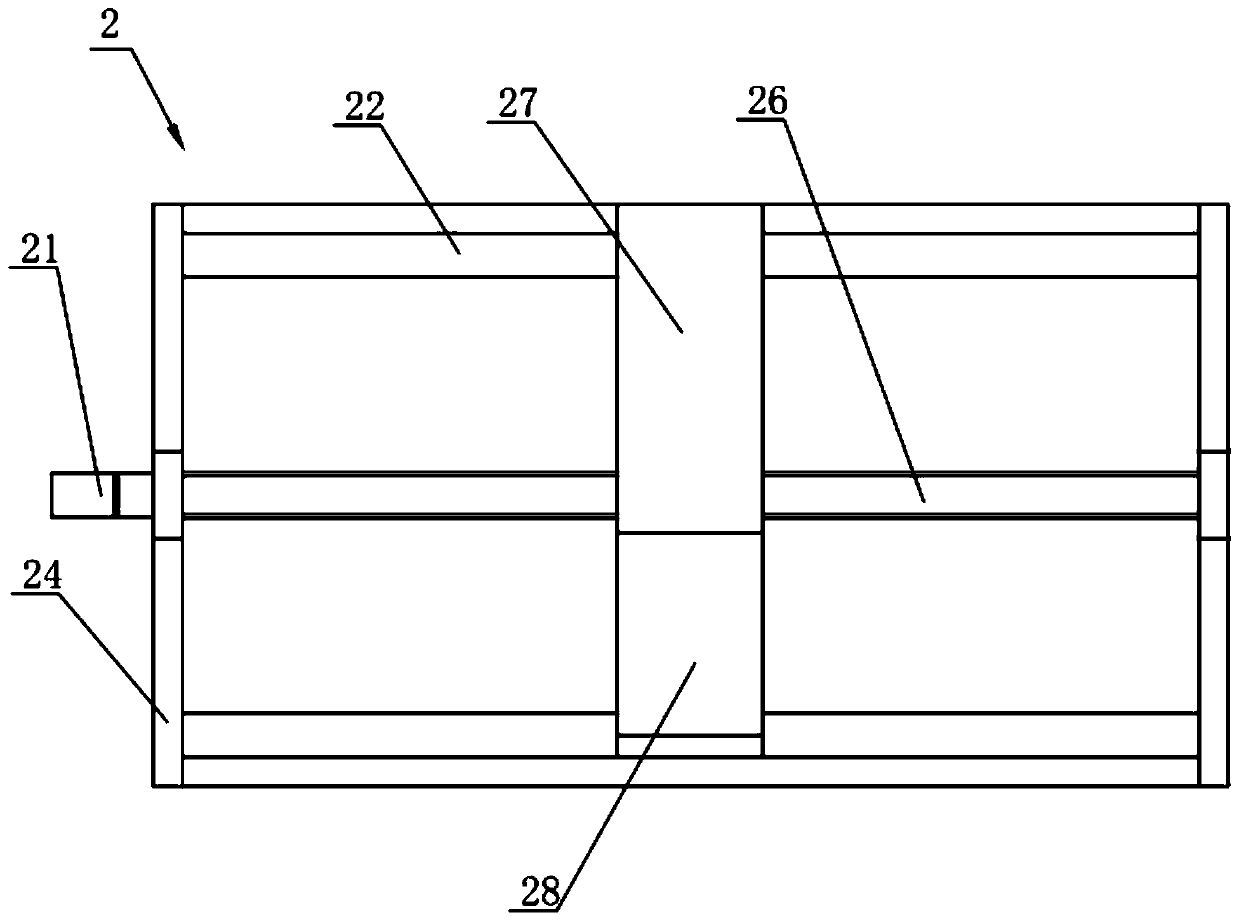

PendingCN112617441AEasy accessHigh degree of humanizationWardrobesFurniture partsElectric controlControl theory

The invention discloses an intelligent wardrobe convenient for taking and hanging of clothes and a clothes taking and hanging method of the intelligent wardrobe, and relates to the technical field of intelligent wardrobes. The intelligent wardrobe comprises a top wardrobe body, a left wardrobe body and a right wardrobe body, wherein an electric control clothes hanging mechanism is vertically installed in a clothes hanging area transversely formed in the upper portion of the left wardrobe body, the lower end of the left wardrobe body is connected with an electromagnetic control mechanism, and the electromagnetic control mechanism controls a corresponding driven mechanism to rotate, so that the electric control clothes hanging mechanism works and people can conveniently take clothes hung at a high position; besides, a transverse moving mechanism and a lifting mechanism are further arranged in the top cabinet and correspond to the upper portion of the right cabinet body, wherein the lifting mechanism is formed by installing a worm wheel and a worm in a matched mode and is in transmission connection with a wire winding shaft and a wire combiner, and therefore axial rotation is converted into longitudinal movement of the movable storage cabinet driven by a steel wire rope, and the occupied space of the transmission mechanism is saved. In addition, the worm wheel and the worm are installed in a matched mode, a self-locking function is achieved, and free falling of the movable storage cabinet after power failure is prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Bait casting machine for net cage aquaculture

ActiveCN105191846AFeeding range can be adjustedGood drainageClimate change adaptationPisciculture and aquariaFrequency conversionAquatic product

The invention relates to a bait casting machine for net cage aquaculture. The bait casting machine for net cage aquaculture comprises a feed box, a buoyancy mechanism, a bait casting disc, a bait casting motor, a time relay and a frequency conversion controller; a conical flow guide platform bulging outward is arranged in the center of the bottom face of the feed box, and a flow guide plate which is correspondingly inclined is arranged at the periphery of the bottom face of the feed box; multiple arc-shaped discharge holes are evenly formed in an annular area between the flow guide plate and the flow guide platform; the bait casting disc is fixedly arranged below the discharge holes, and bait evenly falls onto the bait casting disc in multiple directions through the discharge holes; the bait casting disc is driven by the bait casting motor to rotate, and the bait falling on the bait casting disc is cast into a surrounding water body; the frequency conversion controller of the bait casting motor controls the rotating speed, thereby the casting distance is controlled, and the time relay controls starting and the duration time of the bait casting motor; the distance between each discharge hole and the upper end of a corresponding blade of the bait casting disc is 5-40 mm, when the bait casting disc does not rotate, the bait is warded off by the bait casting disc, no bait is dropped out of the feed box, and when the bait casting disc rotates, the bait is dropped out of the feed box continuously.

Owner:SHANGHAI OCEAN UNIV

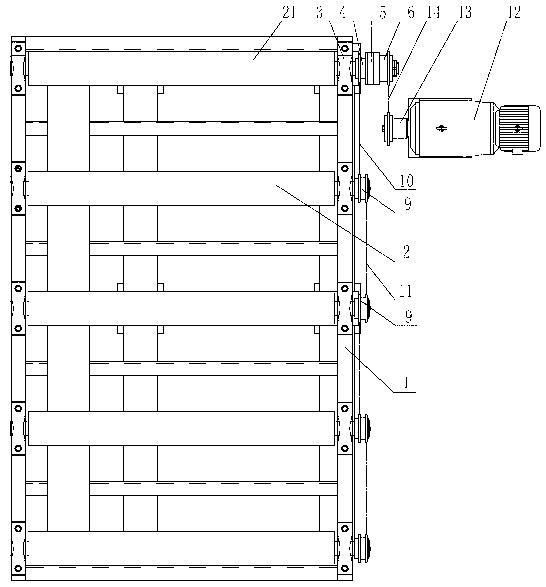

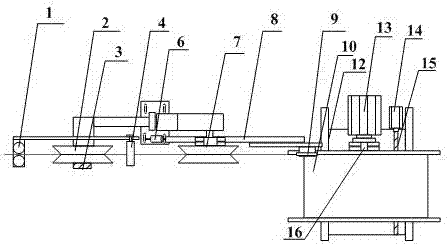

Roller bed conveying device

InactiveCN102935926AAchieve lateral movementSimple structureRoller-waysElectromagnetic clutchEngineering

A roller bed conveying device comprises a frame, rollers and a reduction motor arranged outside the frame. Two ends of the rollers are arranged on the frame through bearing seats. A first chain wheel, an electromagnetic clutch and a second chain wheel are sequentially connected onto a shaft end on one side of a first roller. The second chain wheel is arranged on the shaft end on one side of the first roller through a bearing, locked through a round nut and connected with a clutch end of the electromagnetic clutch. Third chain wheels are connected to a shaft end on one side of another roller. The first chain wheel is connected with the third chain wheels through first chains, and two adjacent third chain wheels are connected through a second chain. An output shaft of the reduction motor is connected with a transmission chain wheel which is connected with the second chain wheel through a third chain. By means of the roller bed conveying device, active and passive transformation of a roller bed can be convenient. In addition, the roller bed conveying device is simple in structure and reliable in operation.

Owner:WUXI HUALIAN PRECISION MACHINERY

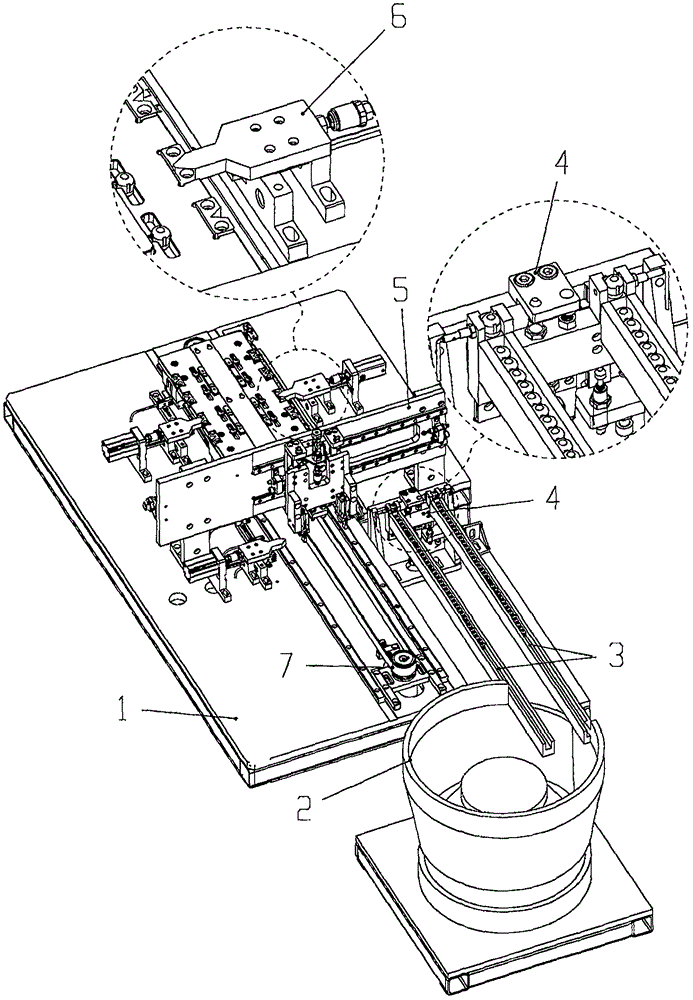

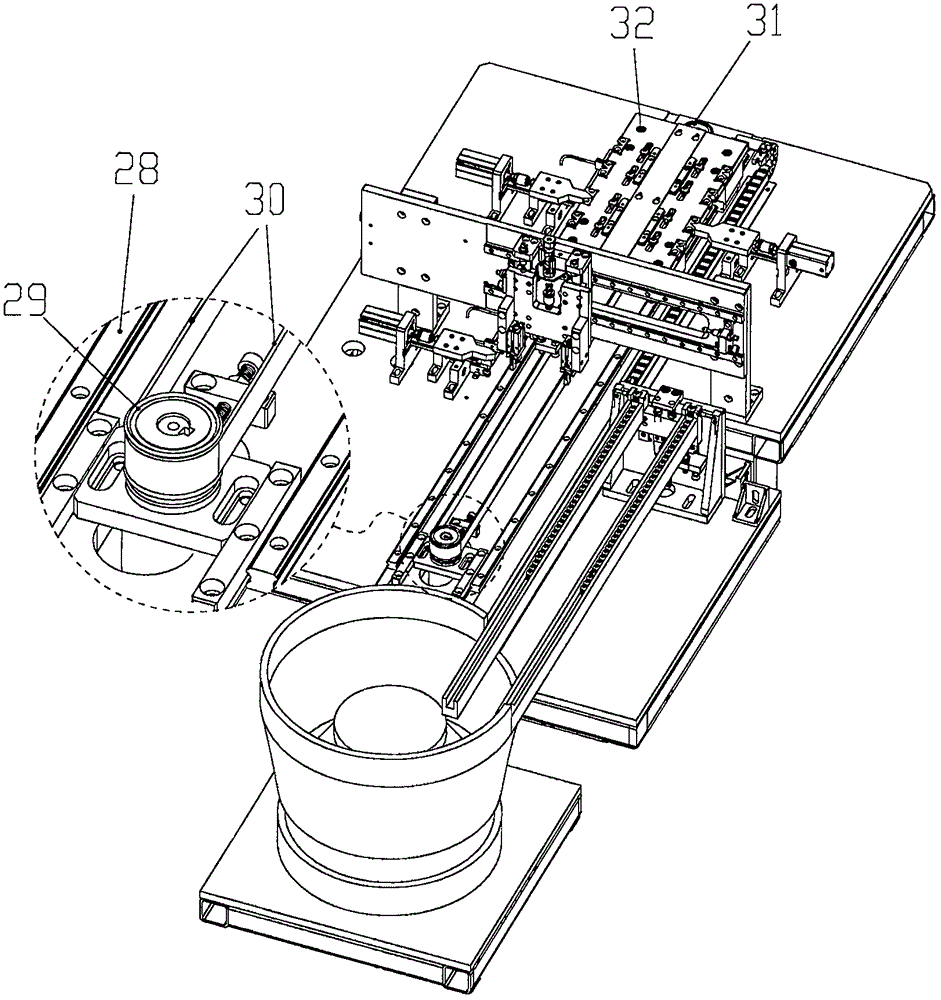

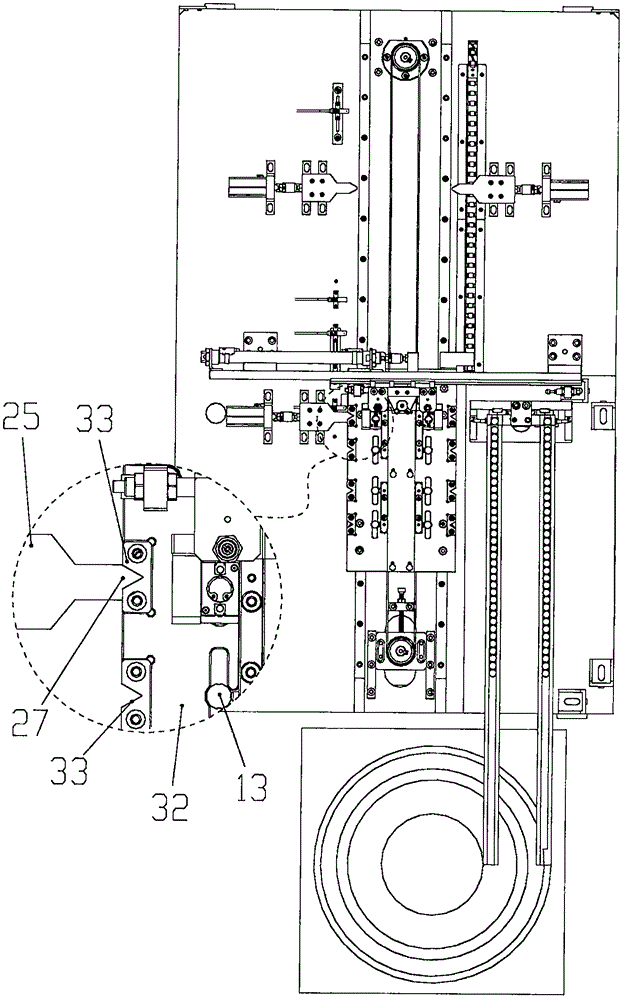

Full-automatic cap nut loading equipment

ActiveCN106271579AFunctionalAchieve lateral movementMetal working apparatusFully automaticEngineering

The invention relates to industrial manufacturing equipment, more in particular to automatic assembling equipment for combining cap nuts, and discloses full-automatic cap nut loading equipment, which comprises a base, a vibration plate for sequentially discharging the cap nuts, a feeding rail for delivering the cap nuts, a loading mechanism for positioning the cap nuts in place for waiting, a loading mechanical hand for delivering the cap nuts onto a tool fixture, a deviation rectification mechanism for improving the positioning accuracy of the tool fixture, and a servo sliding table for delivering the tool fixture. The full-automatic cap nut loading equipment is used for realizing assembling of the cap nuts on the tool fixture without manual intervention, and is fully automatic in operation and high in assembling efficiency, quality and stability.

Owner:嘉兴市兆丰五金科技股份有限公司

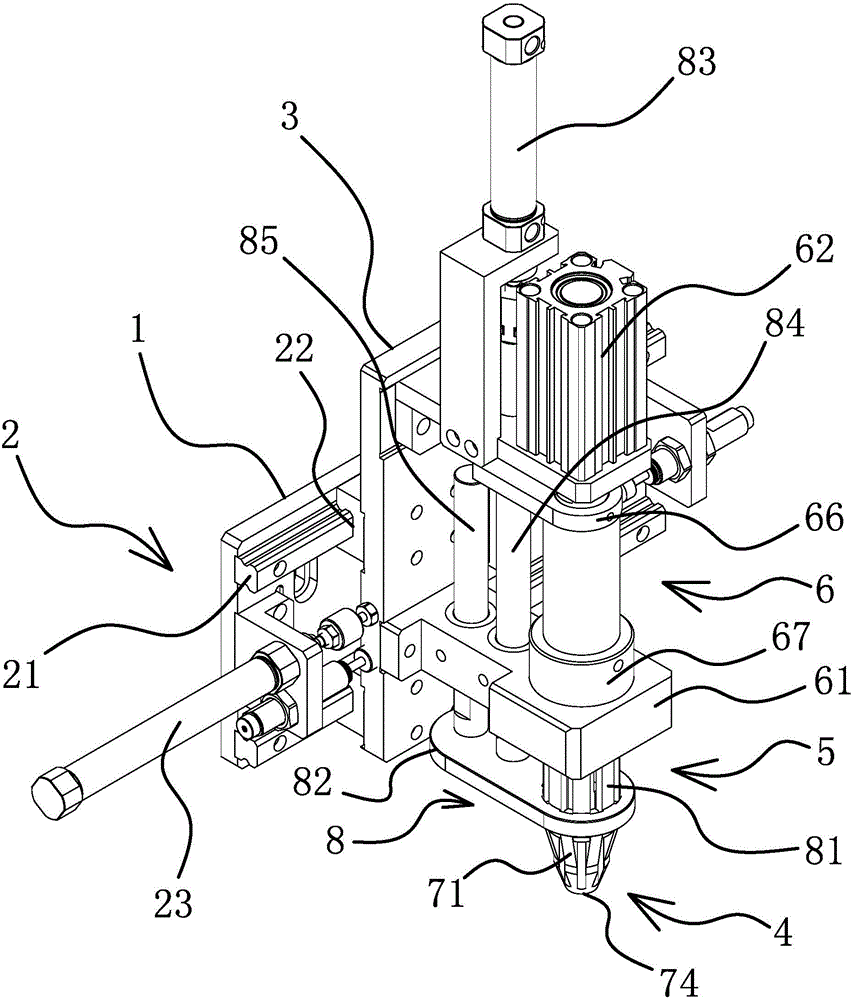

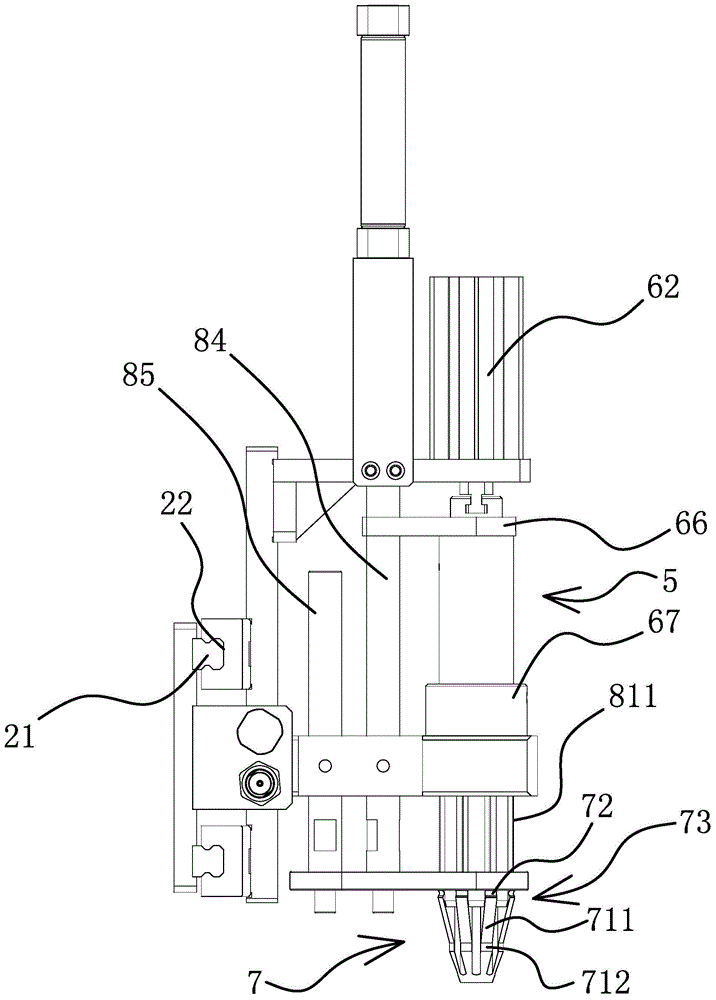

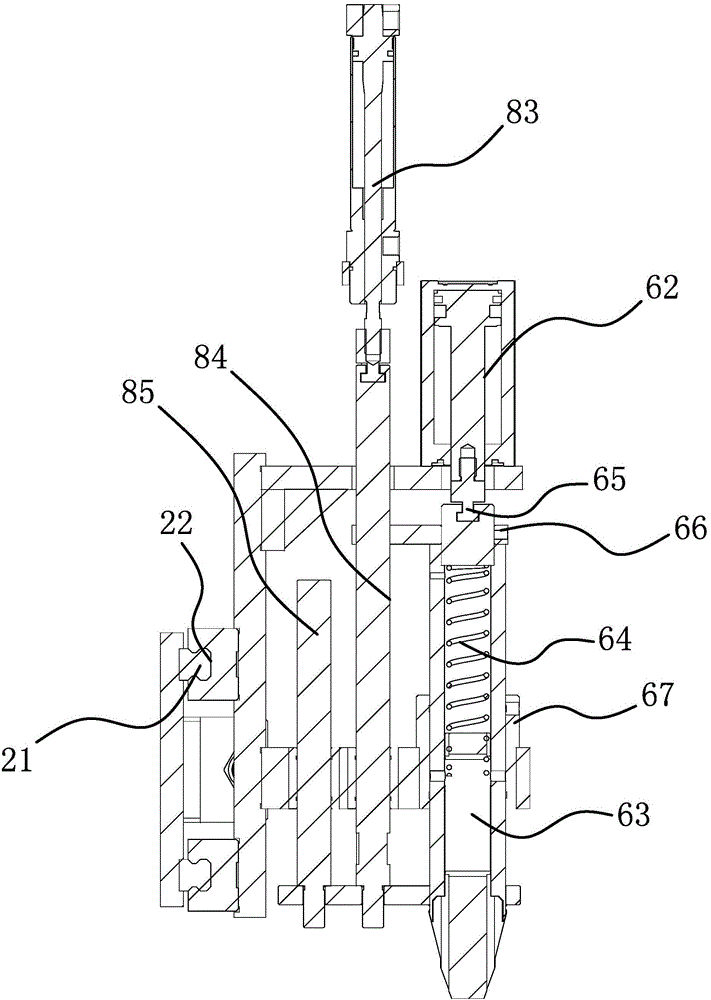

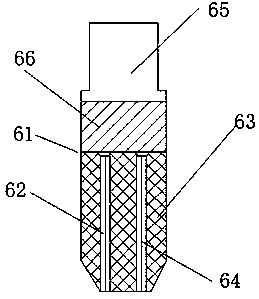

O-shaped ring taking and releasing mechanism

The invention relates to an O-shaped ring taking and releasing mechanism and solves the problems of low assembly efficiency of prior O-shaped rings and the like. The mechanism comprises a frame, a transverse frame capable of moving along the frame transverse direction is arranged on the frame, and a tapered taking claw and an assembly cone are arranged on the transverse frame in a sliding mode and are both connected with a taking and releasing drive structure. A location structure capable of locating the O-shaped ring on the tapered taking claw when the tapered taking claw moves downwards axially is arranged on the tapered taking claw, and an assembly location structure capable of separating the O-shaped ring from the tapered taking claw and locating the tapered taking claw on a work-piece when the assembly cone moves downwards axially is arranged on the assembly cone. The mechanism has the advantages of being simple in structure, high in automatic degree and work efficiency, good in operation stability, capable of achieving taking and releasing of the O-shaped ring and assembling the O-shaped ring on the work-piece and good in assembly effect.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

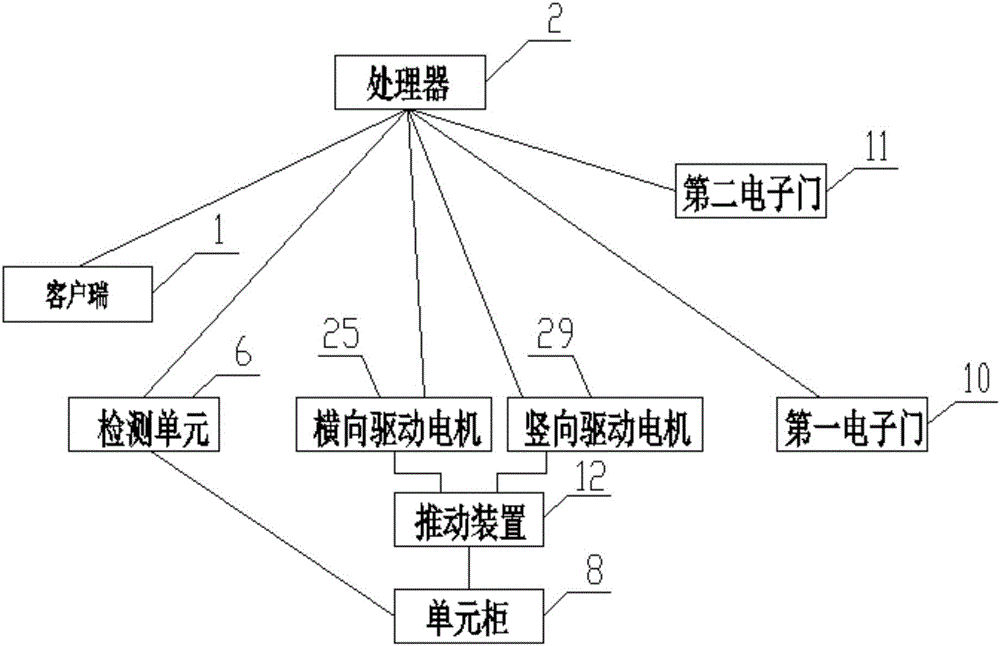

Storage cabinet control system and method

InactiveCN106297054AIncrease storage spaceImprove convenienceCabinetsApparatus for meter-controlled dispensingAutomatic controlControl signal

The invention relates to a storage cabinet control system and method. The system comprises a client side, a processor, a storage cabinet and a detecting unit. The client side is connected with the processor and used for generating a control signal according to touching or pressing; the processor is connected with the storage cabinet, used for processing the control signal to generate a driving signal and further used for carrying out signal processing on an in-place adjusting signal to generate a door opening signal; the storage cabinet is used for pushing a plurality of empty unit cabinets in the storage cabinet to be assembled and adjusted according to the driving signal and further used for opening the multiple unit cabinets according to the door opening signal; the detecting unit is arranged in the storage cabinet, connected with the processor and used for detecting the assembling and adjusting condition of the unit cabinets, and if the unit cabinets are adjusted in place, the in-place adjusting signal is generated. A pushing device can be automatically controlled to move the internal unit cabinets, empty unit cabinet bodies are pushed together to form a cabinet body, and side plates of the unit cabinet bodies are folded to form a larger storage space.

Owner:柳州市旭邦科技有限公司

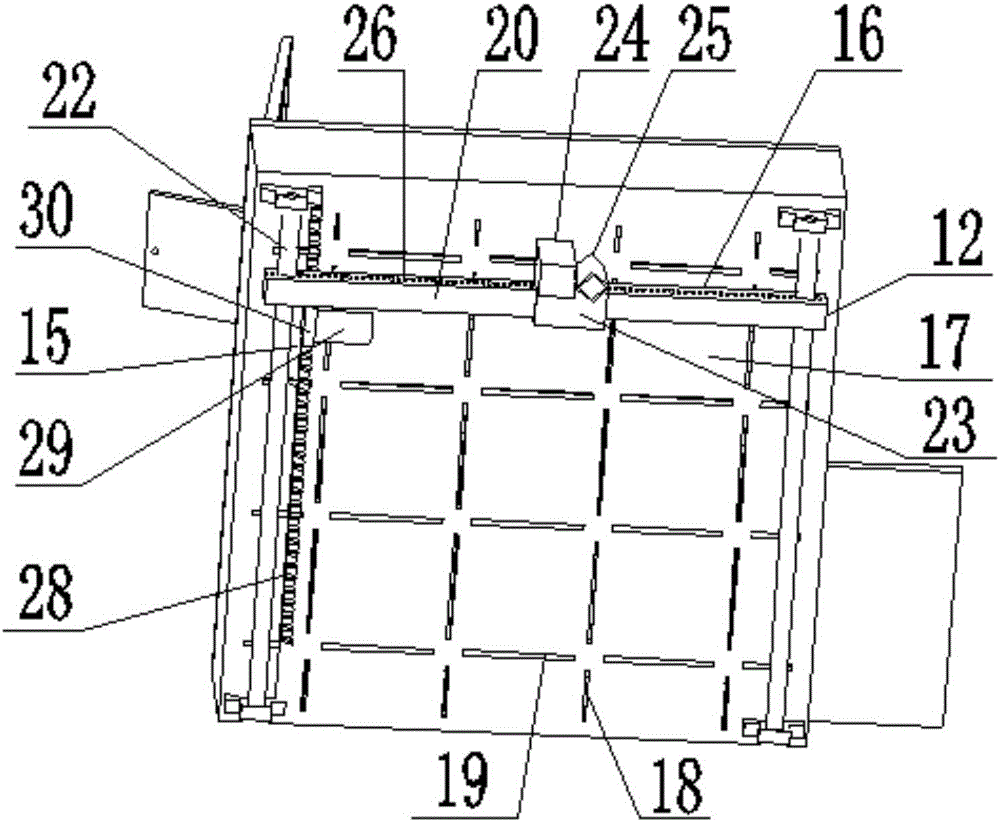

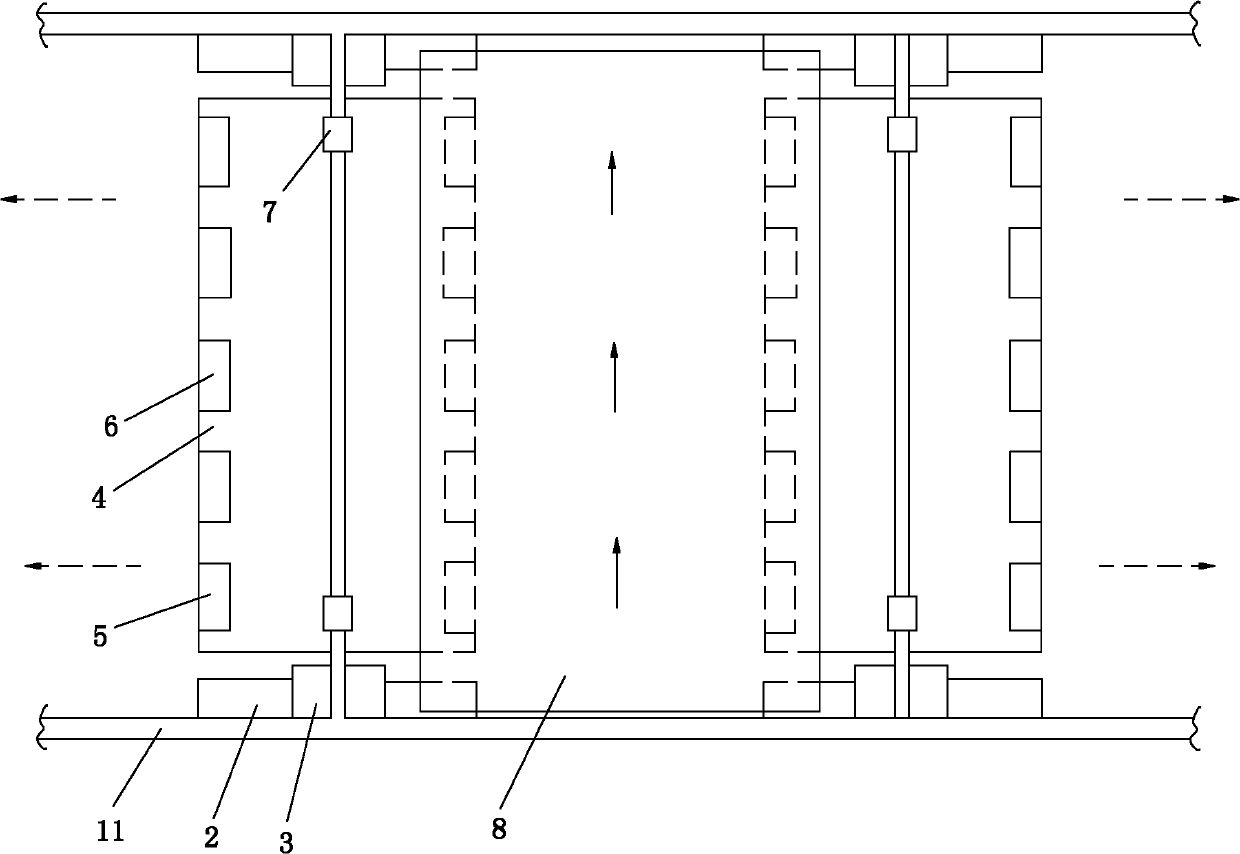

Trolley type fully-mechanized coal mining hydraulic support assembling frame

InactiveCN104100288AAdjustable positionAchieve lateral movementMine roof supportsHydraulic cylinderEngineering

A trolley type fully-mechanized coal mining hydraulic support assembling frame comprises four assembling unit frames and a trolley mechanism. Each assembling unit frame is provided with a platform trolley, wherein a trolley body rotating device is disposed in the middle of the platform trolley, a trolley body rotating hydraulic cylinder is disposed in the trolley body rotating device, an operation rail is disposed on the platform trolley, slideways are arranged on two sides of the platform trolley, sliders are disposed on the slideways, external square tube standing columns are hinged to the sliders, swing hydraulic cylinders are connected between the external square tube standing columns and the sliders, internal square tube standing columns are nested into the external square tube standing columns, standing column lifting hydraulic cylinders are disposed in the internal square tube standing columns, and lifting sliders are connected to the piston rods of the standing column lifting hydraulic cylinders. The trolley mechanism comprises a longitudinally-moving trolley, a longitudinally-moving traction device and a hoisting trolley. The trolley type fully-mechanized coal mining hydraulic support assembling frame has the advantages that heavy objects are hoisted by the hoisting hydraulic cylinder of the hoisting trolley, assembling or disassembling positions can be controlled optionally, flexible assembling and disassembling are achieved, large hoisting height is achieved, large assembling and disassembling space is achieved, and the assembling frame is applicable to assembling and disassembling of various types of hydraulic supports.

Owner:ANHUI UNIV OF SCI & TECH

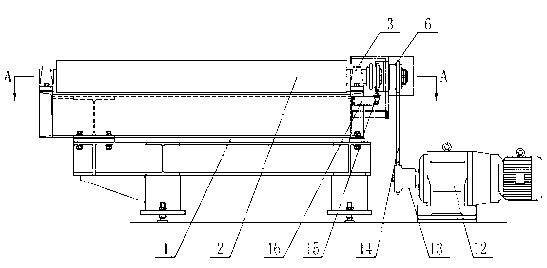

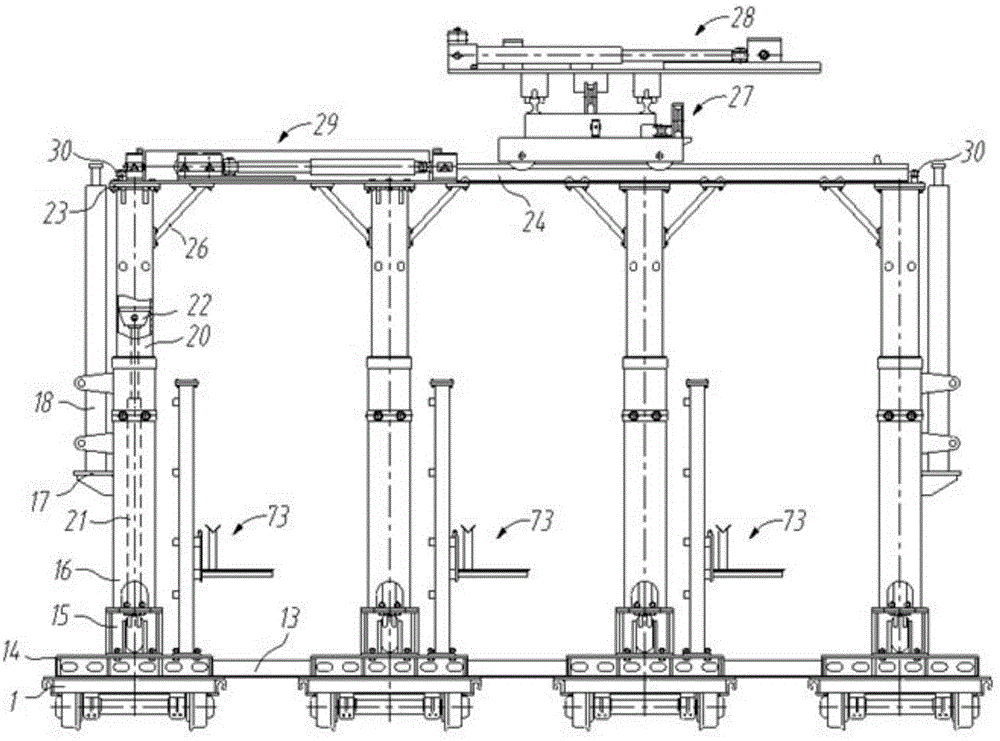

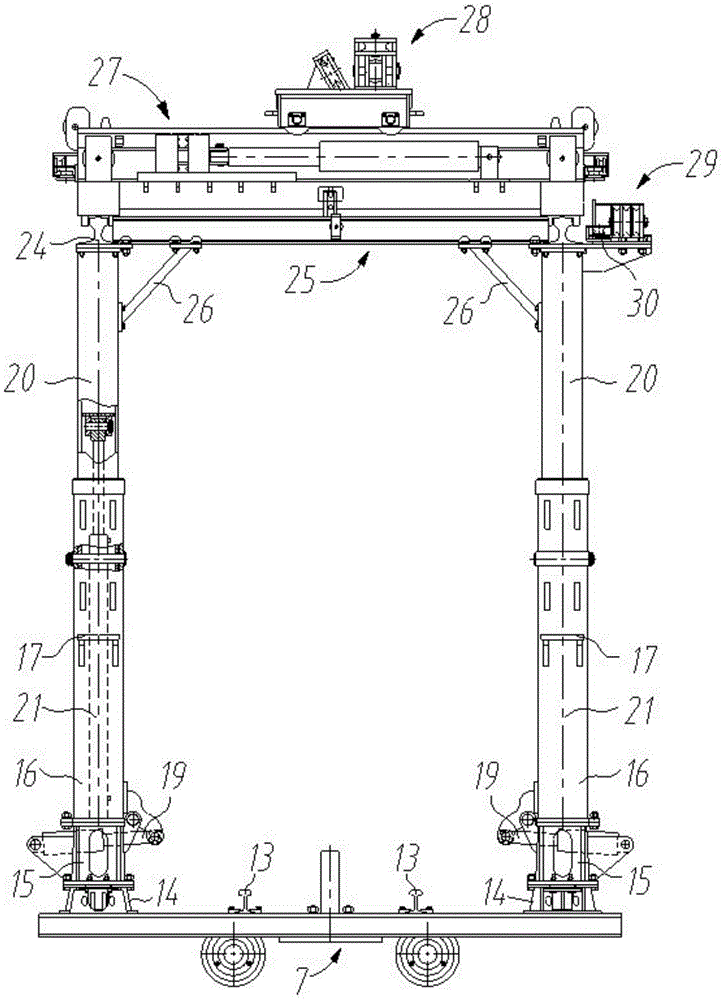

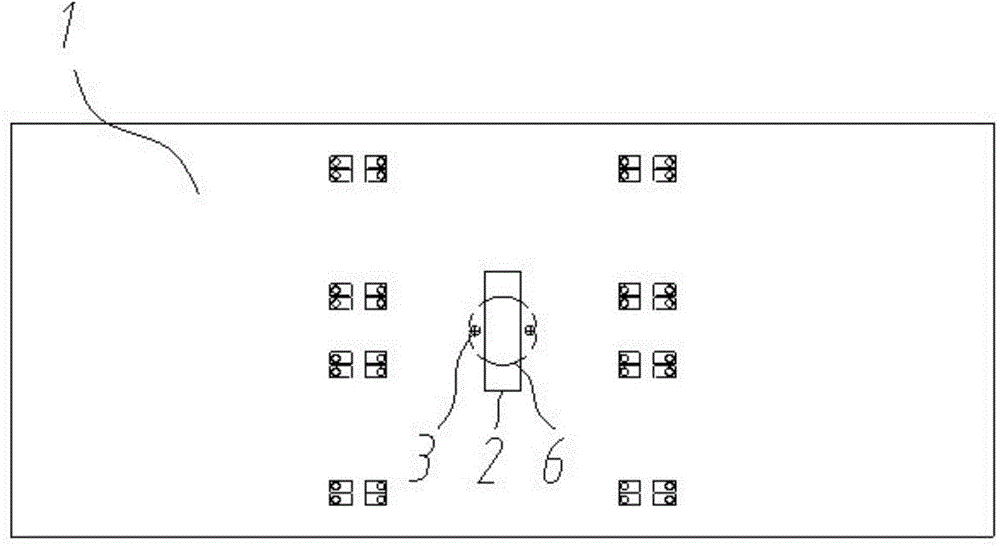

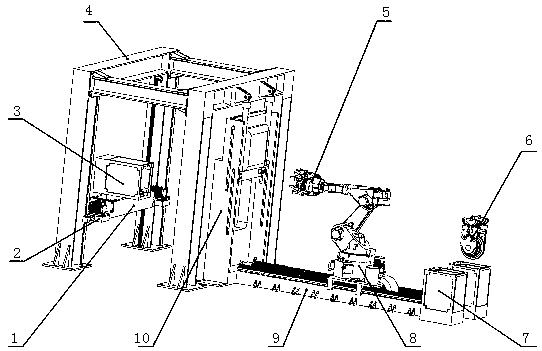

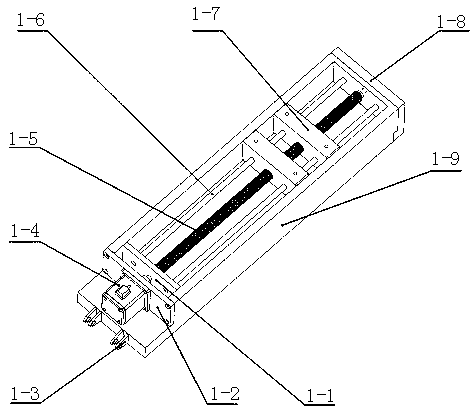

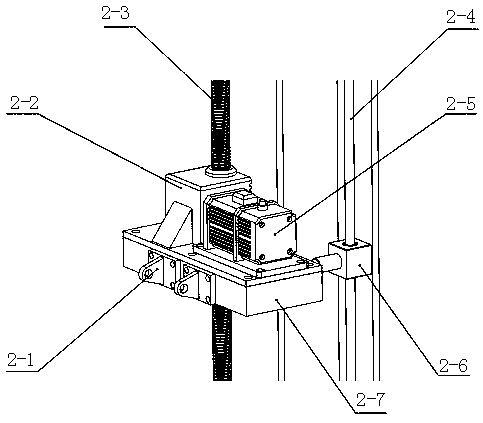

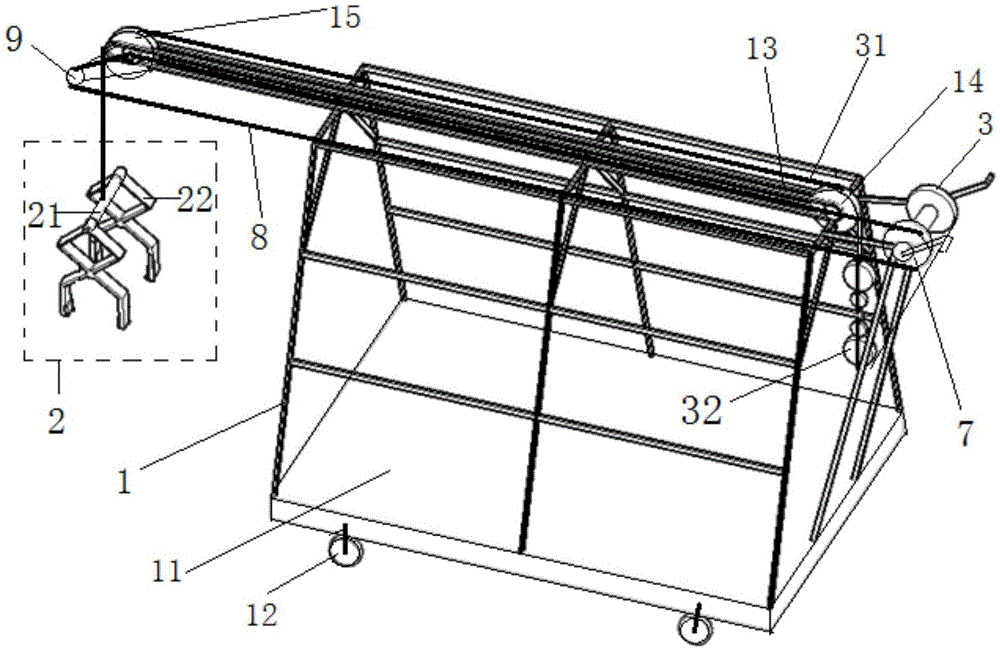

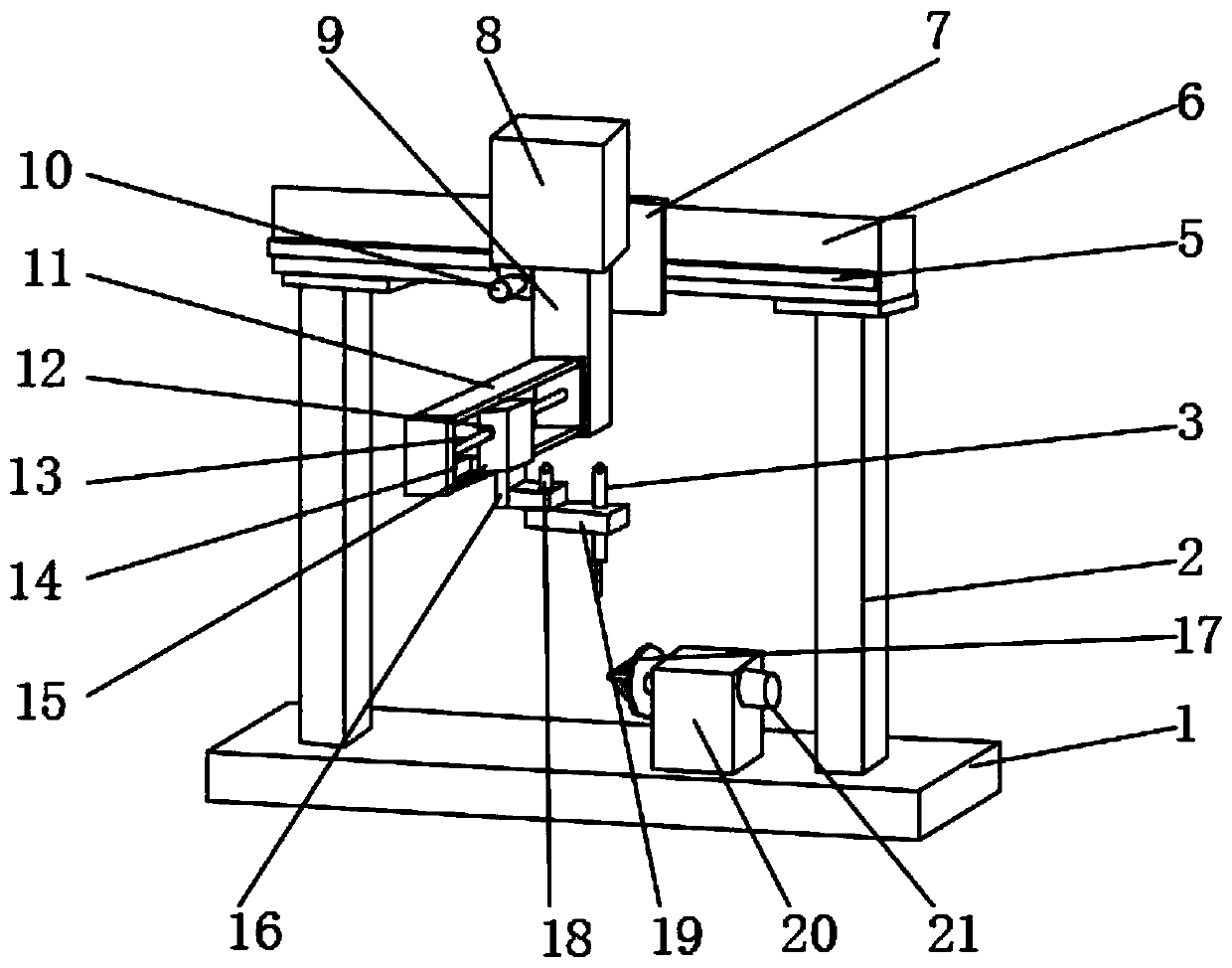

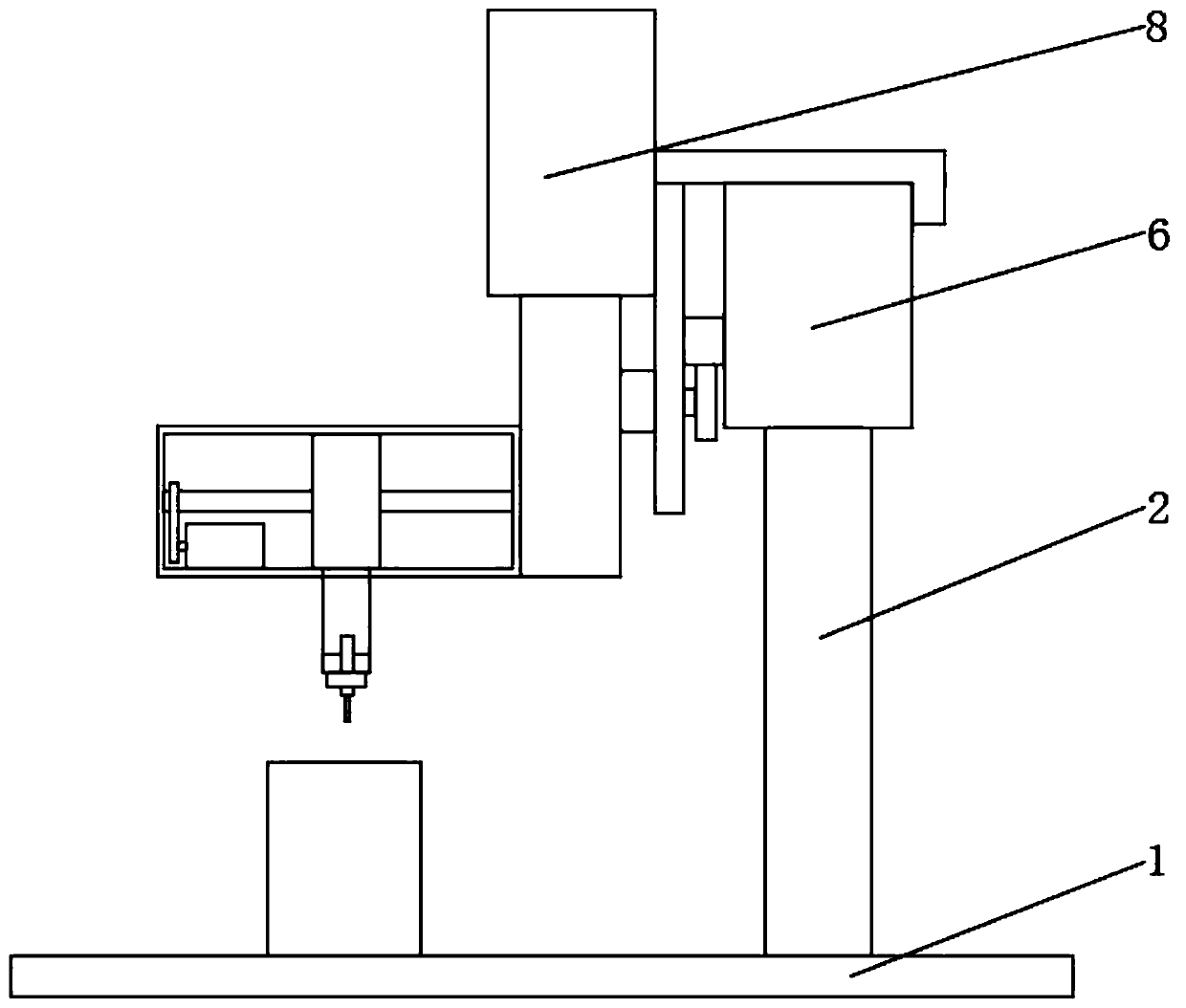

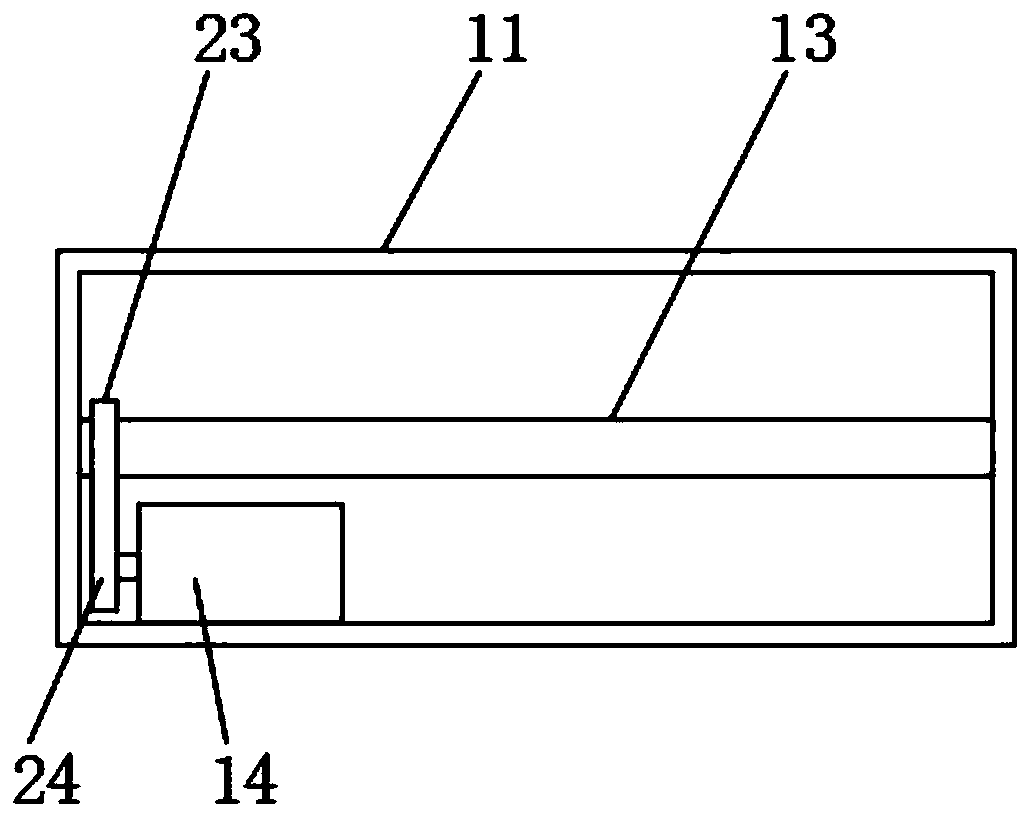

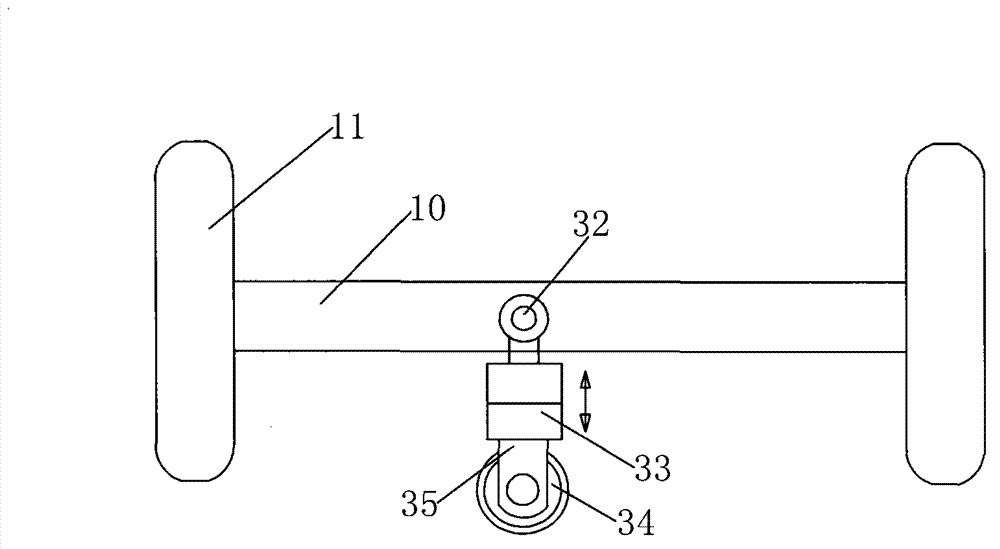

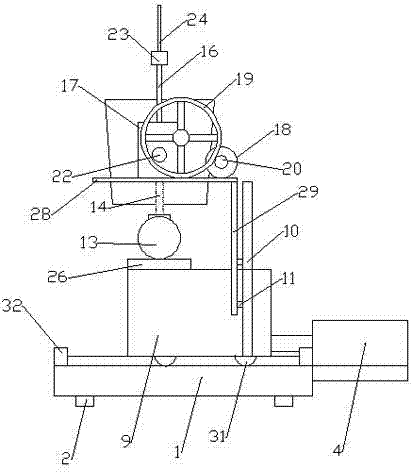

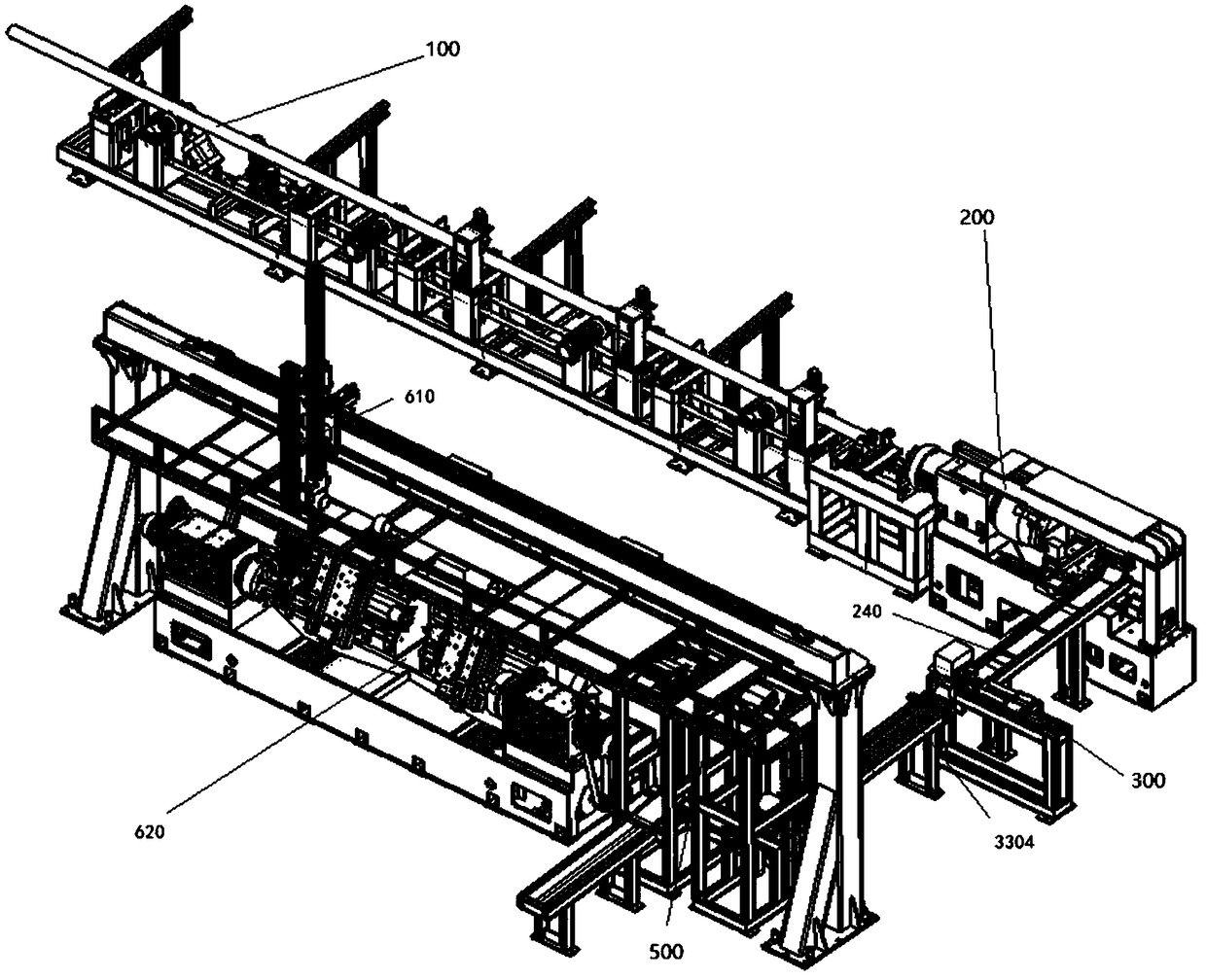

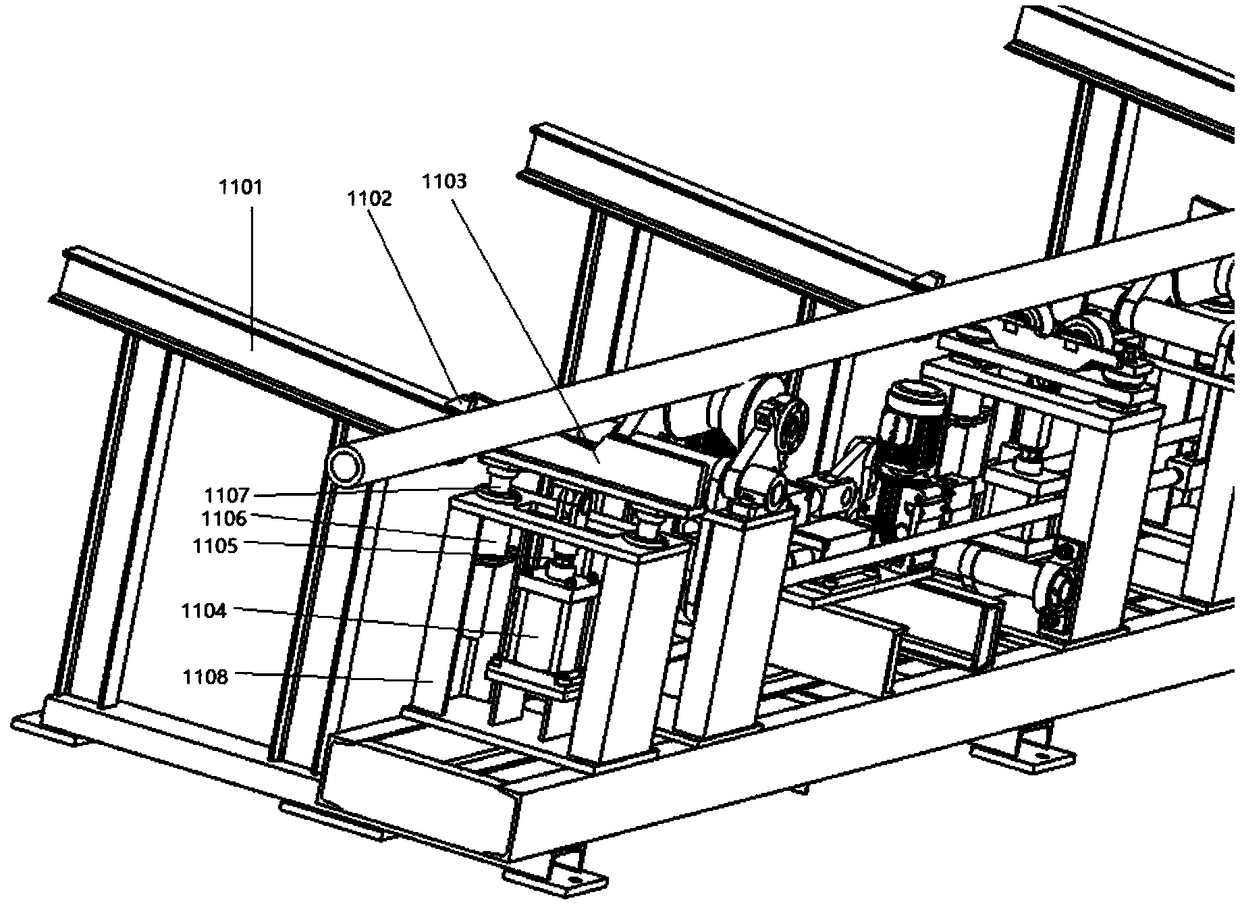

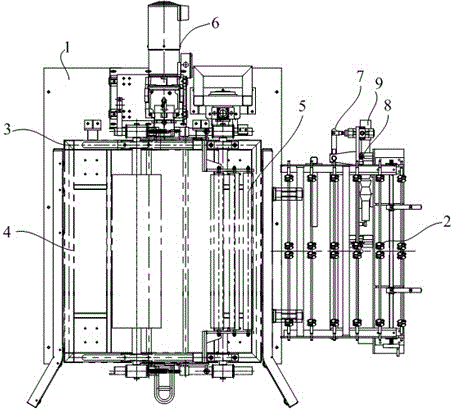

Full cross-section tunneling machine tool changing robot testbed and tool changing simulation method

ActiveCN110625626AAchieve lateral movementReduce R&D costsTunnelsManipulatorProcess simulationTestbed

The invention discloses a full cross-section tunneling machine tool changing robot testbed and a tool changing simulation method. Through the full cross-section tunneling machine tool changing robot testbed and the tool changing simulation method, the problem that the tool changing process simulation condition of a tool changing robot is not good in the prior art is solved. The full cross-sectiontunneling machine tool changing robot testbed comprises a beam frame and a tool storage box used for storing tools. A lifting device and a chamber door mechanism are arranged on the two opposite sidefaces of the beam frame correspondingly. The lifting device is provided with a tool transverse adjusting device. A tool box is arranged on the tool transverse adjusting device. A moving guide rail isarranged between the tool storage box and the chamber door mechanism. A six-axis mechanical arm is arranged on the moving guide rail. The six-axis mechanical arm is provided with a robot end executionmechanism. The full cross-section tunneling machine tool changing robot testbed can simulate different positions and postures of a set to tools on a cutterhead, greatly reduces the research and development cost of the full cross-section tunneling machine tool changing robot automatic tool changing technology and lays the foundation for success research and development of the full cross-section tunneling machine tool changing robot automatic tool changing technology.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Novel numerical control grinder

InactiveCN108081076AWide controllabilityImprove use adaptabilityGrinding machinesAutomatic grinding controlNumerical controlPulp and paper industry

The invention discloses a novel numerical control grinder comprising an operating table, brackets, a base and a control device. The brackets are connected to the two ends of the operating table; the base is connected to the lower end of the operating table; the control device is connected to one sides of the brackets; the upper ends of the brackets are connected with a cross rod, and a sliding groove is formed inside the cross rod; grinding cutters are arranged at the lower end of the cross rod, and one ends of the grinding cutters are connected with a rotating disc; one end of the rotating disc is connected with a sliding block; and the rotating disc is connected with the sliding groove through the sliding block. According to the novel numerical control grinder, the rotating disc is connected to the lower end of the cross rod, the three sets of grinding cutters are connected to the lower end of the rotating disc, thus during workpiece grinding, grinding cutter heads can be rotatably switched through the rotating disc, and self-adaption switching is achieved aiming at the grinding requirements of different workpieces; a conveyor belt is arranged at the upper end of the base and used for guiding the ground workpieces; and the novel numerical control grinder is higher in production automation level, and meanwhile a water tank is arranged in the base and used for cleaning the operating table after workpiece grinding.

Owner:XINCHANG JIAYANG BEARINGS CO LTD

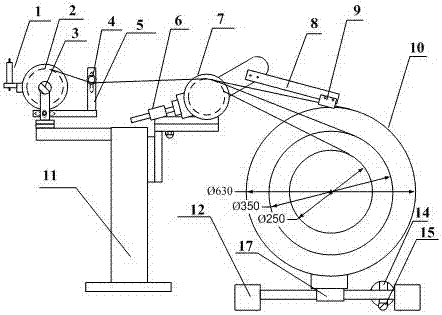

High-speed dense-arrangement wire winding machine used for wire and composite in-channel superconducting wire material

ActiveCN107187934ATorque stabilizationPrevent left and right deviationFilament handlingWinding machineWire rod

The invention discloses a high-speed dense-arrangement wire winding machine used for a wire and a composite in-channel superconducting wire material. The high-speed dense-arrangement wire winding machine comprises a wire feeding system, a rotating servo system controlled by stable torque and a traverse moving platform servo system controlled by high precision displacement. A structure mode that rotating torque controls a servo motor to control wire winding torque to be matched with a wire pressing swinging arm and a counterweight weight is adopted, torque stability of the wire material in the wire winding process is guaranteed, meanwhile, the wire and the composite in-channel superconducting wire material are stably pressed on a wire wheel through a special wire arranging and pressing device, and thus precision of wire arranging is guaranteed. In the transverse moving direction, a transverse moving servo motor is adopted to be matched with a high precision ball lead screw to realize transverse movement of a whole transverse moving platform, and meanwhile a wire speed is fed back into a servo control system through a wire speed detection encoder to guarantee precision of wire arranging. Irreversible damage of torsion of the cross sections produced by the wire and the composite in-channel superconducting wire material to the yield of the superconducting wire material and a superconducting magnet due to the fact that control of a general wire winding machine is unstable is avoided.

Owner:XIAN JUNENG EQUIP TECH CO LTD

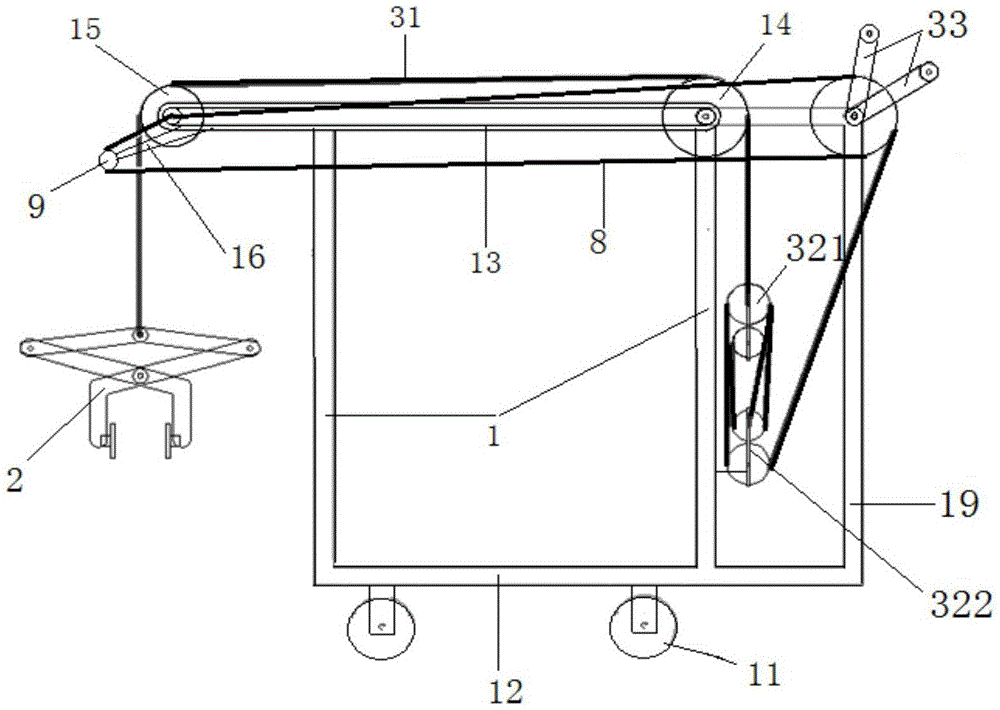

Curbstone construction assisting crane and using method thereof

ActiveCN105544360AEasy and stable clampingRealize lifting movementRoads maintainenceVehicle frameDrive wheel

The invention discloses a curbstone construction assisting crane and a using method thereof. The curbstone construction assisting crane comprises a car frame, wherein a railway is mounted on the car frame, a movable pulley is mounted on the railways, a fixed pulley is mounted at one end of the railway, and is connected with the movable pulley through ropes; a clamp is connected to one ends of the ropes, the other ends of the ropes are connected with a lifting driving wheel through pulley blocks, the lifting driving wheel is mounted on the car frame, a chain wheel is mounted at the tail end of the railway, the chain wheel is connected with a traversing driving chain wheel through a chain, the traversing driving chain wheel is mounted on the car frame, and the movable pulley is fixedly connected to the chain. According to design of the railway, the lifting driving wheel, the fixed pulley, the movable pulley and the clamp, the lifting driving wheel is controlled to rotate and reverse, so that the lifting of the clamp can be realized; according to design of the chain wheel, the traversing driving chain wheel and the chain, the traversing driving chain wheel is controlled to rotate and reverse, so that the horizontal movement of the clamp can be realized; according to design of the special curbstone clamp, curbstones can be more convenient and firm to clamp.

Owner:SHANDONG UNIV

Welding device in pipe rack processing assembly

InactiveCN110000450AAchieve lateral movementAchieve vertical movementWelding/cutting auxillary devicesArc welding apparatusHydraulic cylinderGear drive

The invention discloses a welding tool in pipe rack processing assembly. The welding tool comprises a bottom plate, supporting columns and a transverse shaft, wherein the two sides of the top of the bottom plate are separately equipped with the supporting columns; the bottom ends of the two supporting columns are welded and fixed on the top surface of the bottom plate; the transverse shaft is arranged at the top-end position between the two supporting columns; a box body is arranged on the bottom plate between the two supporting columns; the output end of a second motor drives a drive gear torotate; the drive gear drives a transmission gear to rotate through a chain; the transmission gear drives a lead screw to rotate; the lead screw is in threaded connection to a nut base, so that a movable block moves along the lead screw, and therefore, longitudinal movement of a welding head is realized; and finally, a hydraulic cylinder controls a piston pushing rod to lift, so that movement, ina vertical direction, of the welding head is realized, and the welding head is in contact with a welding point; and the output end of a third motor drives a rotary shaft to rotate, so that a pipe clamp rotates, and therefore, integral welding work of the pipe is accomplished, manual welding is not needed, manual errors are avoided, and welding precision is improved.

Owner:安徽凯贝耐特钣金科技有限公司

Control method for sewing machine

InactiveCN104213338APrecise rotationEasy to useProgramme-controlled sewing machinesSewing-machine control devicesSewing machineData input

The invention relates to a control method for a sewing machine. The method comprises a processor, a main shaft, a needle, a needle plate, an encoder and a cloth dragging machine, wherein the main shaft is used for driving the needle to move up and down; the encoder is arranged on the main shaft; the data output end of the encoder is connected with the encoded data input end of the processor; the needle plate is positioned below the needle; a cloth dragging wheel of the cloth dragging machine is in contact with a workbench of the sewing machine; the output end of the processor is connected with the input end of a motor of the cloth dragging machine. Due to the arrangement of the encoder, an intermittent cloth dragging function is realized, the cloth dragging machine rotates when the needle is positioned above the needle plate and stops rotating when the needle is inserted into cloth, the perfectness ratio of the cloth can be ensured, and the service life of the needle is prolonged.

Owner:张孟杰

Parking assisting device and method

InactiveCN102923102AReasonable structural designSimple driving methodVehicle fittings for lifting and manoeuvringRemote controlParking space

The invention discloses a parking assisting device and a method. The method utilizes the auxiliary parking device. The parking assisting device comprises a support arm, the support arm is arranged at the rear end of the bottom of a vehicle body in a pivotal connection mode, the length of the support arm is larger than the distance from the bottom of the vehicle body to the ground, and a roller is arranged at the other end of the support arm; in one state, the support arm is retracted at the bottom of the vehicle body; and in another state, the support arm is rotated to be in a state of standing at the bottom of the vehicle body under the driving action of a driving mechanism, rear wheel tires are arranged in a suspending mode, and the rear end of the vehicle body is subjected to lateral displacement under the action of the roller. The parking assisting device and the method have the advantages that the implementation cost is low, the operation is convenient, the operation can be achieved through manual control or wireless remote control by drivers, the parking assisting device and the method are safe and convenient, the requirement for size of parking space is greatly reduced, and a vehicle can be accurately parked in space which is half meter larger than the vehicle length.

Owner:刘民成

Full-automatic pouring casting machine

InactiveCN104493148ARealize fully automatic pouringAchieve lateral movementMelt-holding vesselsTurbineIndustrial engineering

The utility model relates to a full-automatic pouring casting machine. A fine-tuning mobile platform is connected with a fine-tuning propulsion motor through a propulsion screw, and two turbine discs are fixedly mounted above the fine-tuning mobile platform. One side of each turbine disc is connected with a turbine rotation motor, and a lifting screw rod is movably mounted at the center of each turbine disc. A lifting platform is fixedly mounted above the lifting screw rod, and a storage bag rotation motor is fixedly mounted on the lifting platform. The outer part of the storage bag rotation motor is sleeved with a storage bag rotation bearing sleeve, and a storage bag hoisting arm is fixedly mounted above the storage bag rotation bearing sleeve. A hoisting connecting rod is connected above the storage bag hoisting arm, and a hoisting ring is arranged above the hoisting connecting rod. A lifting position inducing device is fixedly mounted under one side of the lifting platform, and a horizontal displacement inducing device is fixedly mounted on a base. The full-automatic pouring casting machine realizes flexible adjustment and is accurate in positioning, convenient and fast to use and high in degree of mechanization and automation.

Owner:邢现军

Mold polishing and cleaning equipment

InactiveCN107584354AEasy to recycleEasy to operateEdge grinding machinesGrinding carriagesFuel tankEngineering

The invention discloses mold polishing and cleaning equipment which comprises a box body, wherein a second rocking handle is arranged on a side wall on the top of the box body; the second rocking handle is fixedly sleeved with a second threaded shaft; one end, which is far away from the rocking handle, of the second threaded shaft penetrates through the outer wall of the box body and extends intothe box body; the shaft wall of the second threaded shaft is sleeved with a second supporting block; the bottom of the second supporting block is fixedly connected with a first connecting rod; a cavity is formed inside the first connecting rod; a motor is arranged on a top wall of the first connecting rod; the motor is fixedly sleeved with a rotating shaft; one end, which is far away from the motor, of the rotating shaft is fixedly connected with a second connecting rod; an air blower and a cleaning oil tank are respectively arranged on inner walls of the first connecting rod; one end, which is far away from the first connecting rod, of the second connecting rod is movably connected with a third connecting rod; and a polishing machine is arranged at one end, which is far away from the second connecting rod, of the third connecting rod. The mold polishing and cleaning equipment disclosed by the invention is convenient to operate and convenient in burr recovery, a mold does not need to be polished and cleaned by manual labor, the function of polishing and cleaning the mold in multiple angles can be realized, and the human requirement during operations can be met.

Owner:邰学兰

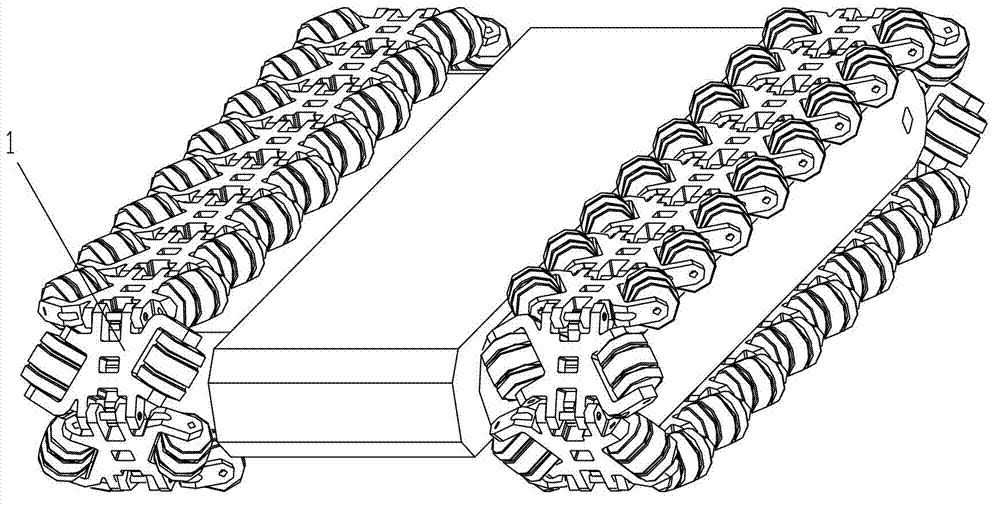

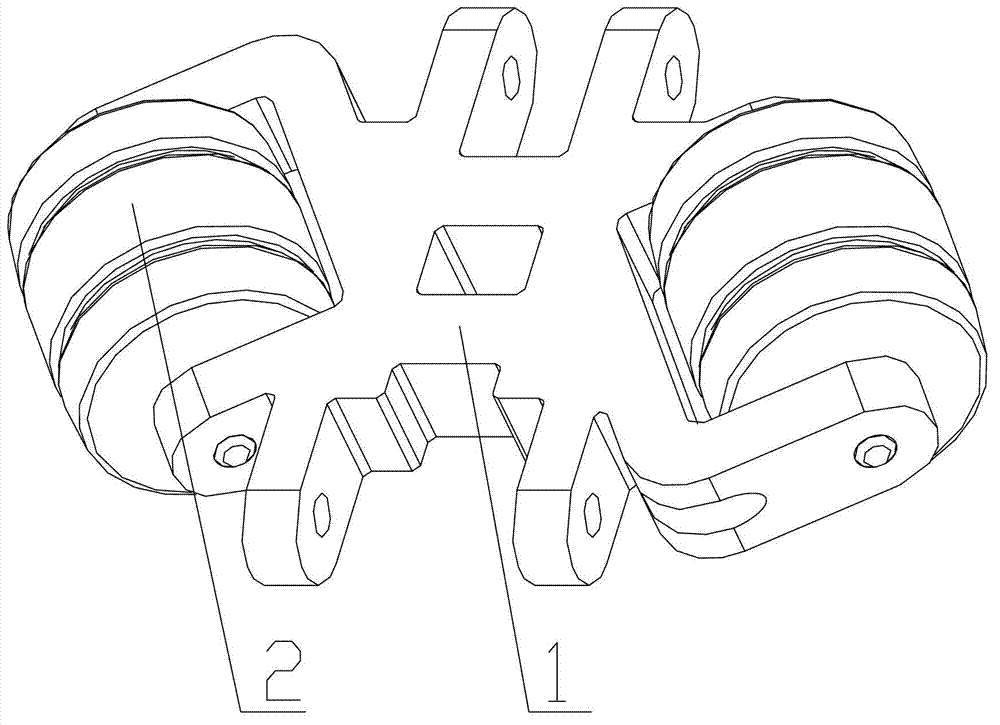

Omni-directional moving track

InactiveCN102756764AFlexible steeringAchieve lateral movementEndless track vehiclesEngineeringPower consumption

The invention provides an omni-directional moving track, comprising a track main body. The track main body is driven to rotate by a driving wheel driven by a motor; the track main body is formed by mutually hinging a plurality of track boards front and back; and traveling wheels capable of randomly rotating around a shaft are mounted at the left side and the right side of the track board. According to the omni-directional moving track provided by the invention, the travelling wheels can be randomly rotate and have small friction with the ground, so that the power consumption of the track movement is small, and the traveling stability is improved. Furthermore, the transverse movement of the track can be realized by rotating a hub wheel through the speed difference of a left track and a right track, so that the sensitive steering can be realized.

Owner:HUNAN AGRICULTURAL UNIV

Automatic wall surface cleaning device

ActiveCN109363568AEffective Balance ShakeEasy to cleanBuilding repairsWindow cleanersSurface cleaning

The invention discloses an automatic wall surface cleaning device. The device comprises a rack, a movable mechanism, a rolling brush assembly and a propulsion device; the rack can move relative to a wall surface to be cleaned; the movable mechanism is movably mounted on the rack; the rolling brush assembly is used for brushing the wall surface and mounted on the movable mechanism so that the rolling brush assembly can get close to or away from the wall surface to be cleaned; the propulsion device is mounted on the rack and used for generating thrust to enable the rack to get close to the wallsurface to be cleaned. According to the automatic wall surface cleaning device, the rolling brush assembly can transversely move relative to the rack so that the rolling brush assembly can get close to or away from the wall surface to be cleaned, the rolling brush assembly can adapt to the uneven wall surface to be cleaned accordingly, and the cleaning effect of the automatic wall surface cleaningdevice is improved; in addition, the propulsion device is mounted on the rack and used for generating the thrust to enable the rack to get close to the wall surface to be cleaned, shake caused by movement of the rolling brush assembly in the cleaning process of the automatic wall surface cleaning device can be effectively balanced, and therefore the whole automatic wall surface cleaning device ismore stable.

Owner:深圳截明电子科技有限公司

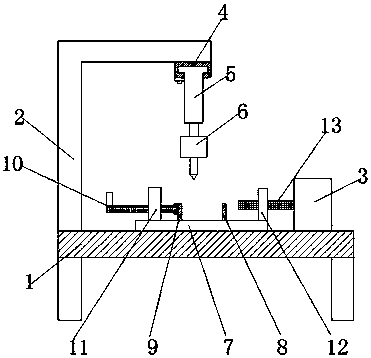

Drilling machine with clamping function for bearing machining

InactiveCN108422225AImprove practicalityThe operation process is simple and convenientLarge fixed membersPositioning apparatusEngineeringMachining process

The invention discloses a drilling machine with the clamping function for bearing machining. The drilling machine comprises a placing plate, a supporting rod is arranged at the upper end of the placing plate and is L-shaped, the lower end of a vertical rod body of the supporting rod is connected to the placing plate in a welded mode, and a transverse rod is welded to the lower end of a horizontalrod body of the supporting rod; a hydraulic rod is connected to the lower end of the transverse rod, a second motor is arranged at the lower end of the hydraulic rod through a screw, a drill bit is arranged at the output end of the second motor, and a movable plate is placed at the upper end of the placing plate. The drilling machine has the advantages that in the using process, a bearing to be machined is placed between a first baffle and a second baffle, a first screw rod is rotated through a handle and drives the second baffle to move, so that the bearing can be clamped through the first baffle and the second baffle, in the machining process, a first motor is rotated, so that the transverse movement of the bearing can be realized, the hydraulic rod can be moved on the transverse rod, the machining position of the bearing can be changed in the longitudinal direction, and therefore the practicability of the drilling machine can be improved.

Owner:ANHUI ZHILIANG INVESTMENT GRP

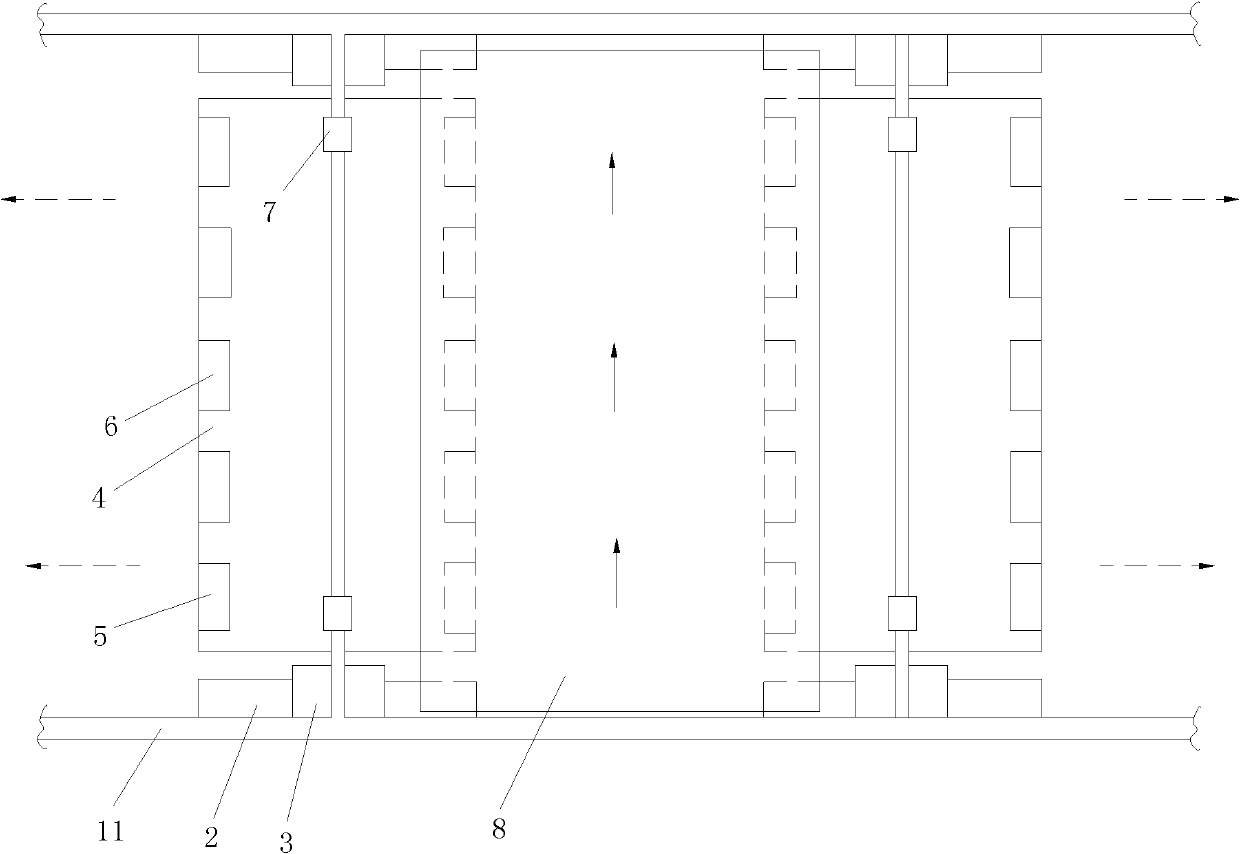

Combined parking system

The invention discloses a combined parking system, which comprises a stereoscopic garage, parking plates, a vertical lifting control system, and a plurality of horizontal shift control systems. A plurality of parking lots are disposed inside the stereoscopic garage from top to bottom, the parking plates are used for parking vehicles, the vertical lifting control system disposed inside the stereoscopic garage is capable of driving the parking plates and the vehicles parked on the parking plates to move up and down synchronously, and the horizontal shift control systems disposed on the parking lots are capable of integrally and horizontally moving while horizontally moving the vehicles parked on the parking lots. The vertical lifting control system comprises a lifting mechanism and a vertical drive motor. Each horizontal shift control system comprises a bearing plate, a shift mechanism and a horizontal drive motor. The combined parking system is reasonable in design, simple in structure, economical, practical, simple in operation and effective in use. Simple installation and test show that a plurality of combined parking systems rested together can be combined into a large-sized garage in a short time, and the requirement of part of existing places on temporary parking is met.

Owner:XIAN DAYU PHOTOELECTRIC TECH

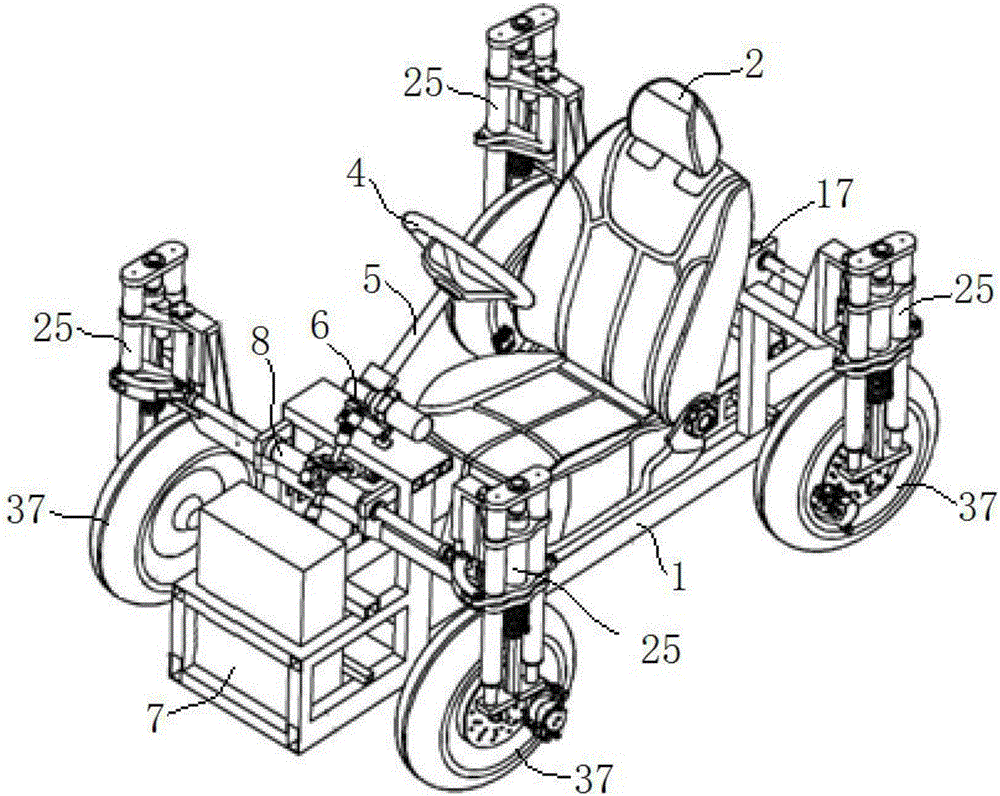

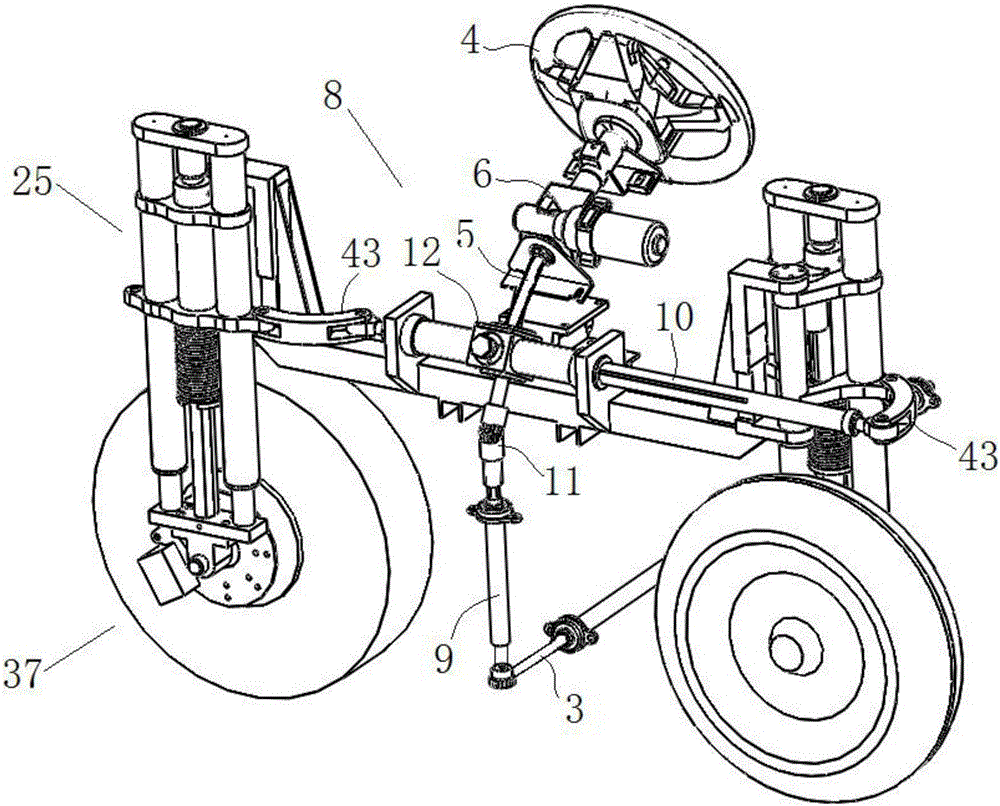

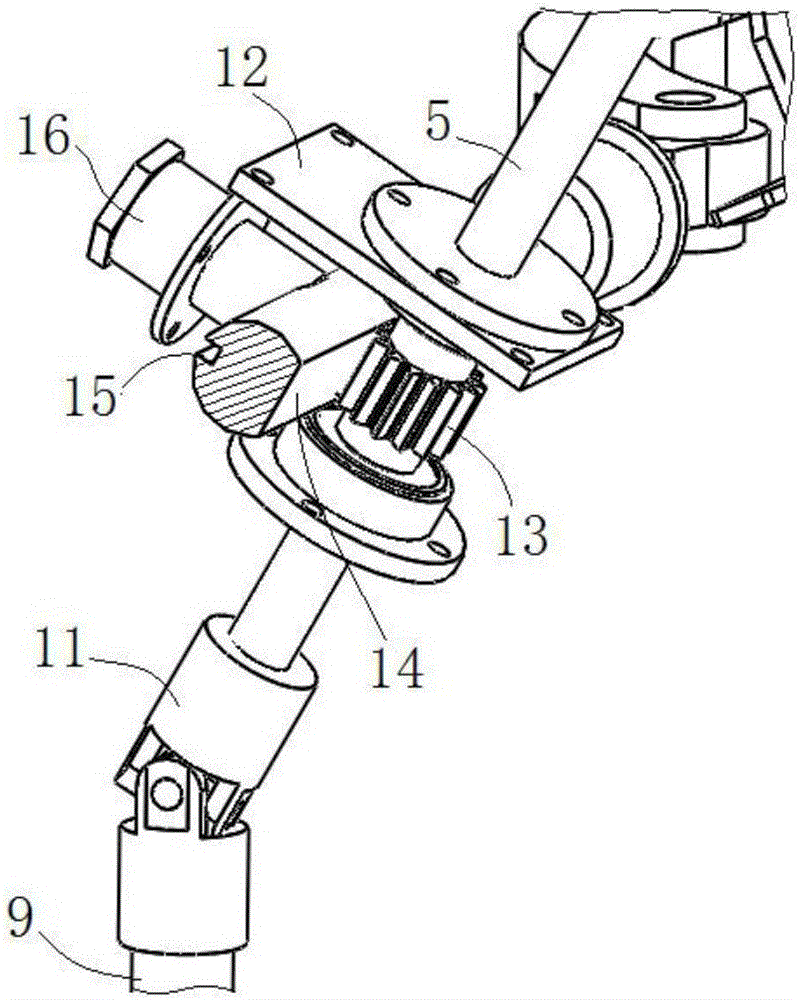

Multifunctional farm machine

ActiveCN106005102AGreat driving forceLarge spanAgricultural vehiclesInterconnection systemsSteering wheelDrive shaft

The invention relates to a multifunctional farm machine. The multifunctional farm machine adopts a four-wheel drive structure and comprises a vehicle chassis, wherein a seat and a steering wheel device are arranged on the vehicle chassis; steering gears are symmetrically arranged on the front side and the rear side of the vehicle chassis and are in transmission connection with a center transmission shaft; the center transmission shaft penetrates through the vehicle chassis; two sides of each steering gear are connected with wheel devices through suspension assemblies; a steering wheel shaft of the steering wheel device is connected with the steering gears. With the adoption of the four-wheel drive structure, a requirement of larger drive force for field tillage is met, and a requirement of larger drive force for climbing and cross-country of a cross-country vehicle is also met; the multifunctional farm machine not only can be taken as the farm machine for field tillage, but also can realize the cross-country function, the whole vehicle chassis and the suspension assemblies all adopt a hollow structure, so that the weight of the whole farm machine is light, and the power demand is reduced.

Owner:HEFEI BAIHENG EQUIP MOLD CO LTD

Cleaning-free intelligent security monitoring camera

ActiveCN112261272AEasy to disassemble and installImprove monitoring capabilitiesTelevision system detailsBatteries circuit arrangementsSurveillance cameraMechanical engineering

The invention discloses a cleaning-free intelligent security monitoring camera, and relates to the technical field of security monitoring. The cleaning-free intelligent security monitoring camera comprises a guide rail, mounting devices are fixedly mounted at two ends of the guide rail, a self-lubricating device is fixedly mounted in the middle of the guide rail, and energy storage devices are fixedly mounted on the front and rear surfaces of the left side of the guide rail; a driving device is fixedly mounted on the right side of the guide rail right end mounting device, a DSP controller is fixedly mounted at the top of the driving device, a lead screw is rotatably connected to the interior of the guide rail through a ball bearing, the right side end of the lead screw is fixedly connectedwith the output end of the driving device, and a sliding device is in threaded connection with the surface of the lead screw. By arranging mounting blocks and hanging plates, fastening bolts can be conveniently connected into the threaded through holes in a threaded mode, so that the camera is hung and mounted at the top of the position needing to be monitored, the ground below the camera can beconveniently monitored, and meanwhile the camera is convenient to disassemble and assemble.

Owner:深圳市特发服务股份有限公司

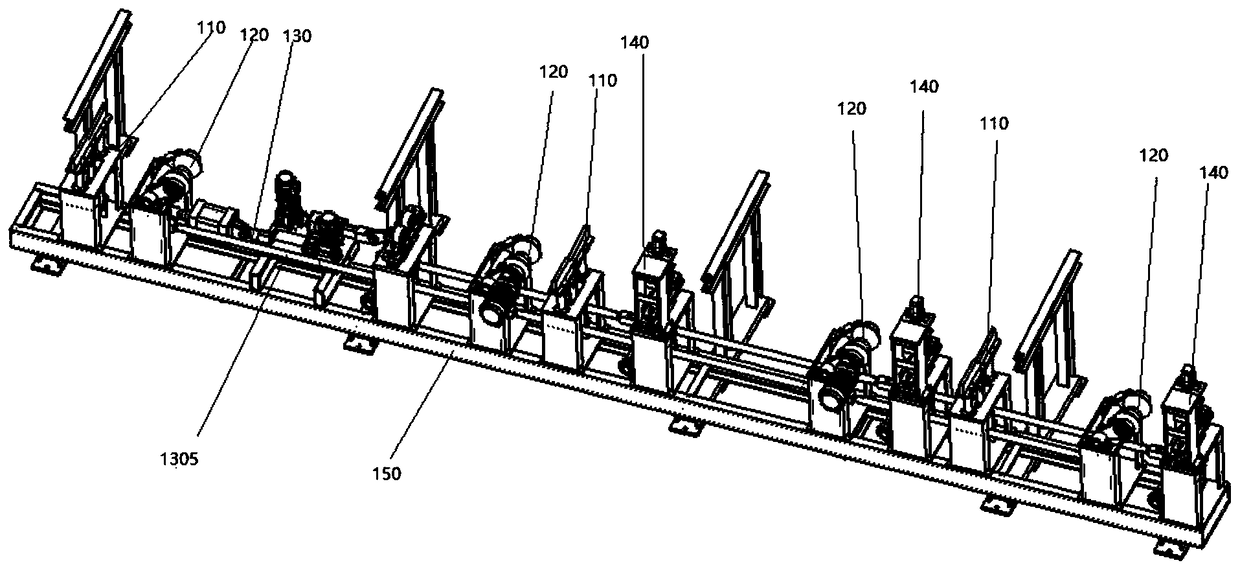

Petroleum casing collar automatic production line

PendingCN109454467AGuaranteed stabilityConsistent positionOther manufacturing equipments/toolsProduction lineElectrical control

The invention discloses a petroleum casing collar automatic production line. The petroleum casing collar automatic production line comprises a long casing conveying device, a long casing cutting device, a marking device, a collar blank conveying device, a lifting device, a mechanical hand structure, a machining device and other multiple process devices; and the long casting cutting device, the marking device, the collar blank conveying device and the lifting device are connected through connection conveying plates. According to the petroleum casing collar automatic production line provided bythe invention, the mechanical devices cooperates with electrical control, the process that taking and conveying of a long casting, turning of the end surface and the outer circle of the long casting,cutting off of the long casing, marking of a collar blank, conveying of the collar blank between planes different in height, mechanical hand grabbing and machine tool machining are automatically and efficiently conducted is achieved, manpower is saved, and the production efficiency is improved.

Owner:SHANGHAI JIANGAO CNC MACHINE TOOLS

Feedstock tensioning mechanism for garment tailoring equipment

InactiveCN104099778ASensitive controlImprove processing qualitySevering textilesWrinkle skinEngineering

Owner:佛山市顺德区爱斯达科技研发有限公司

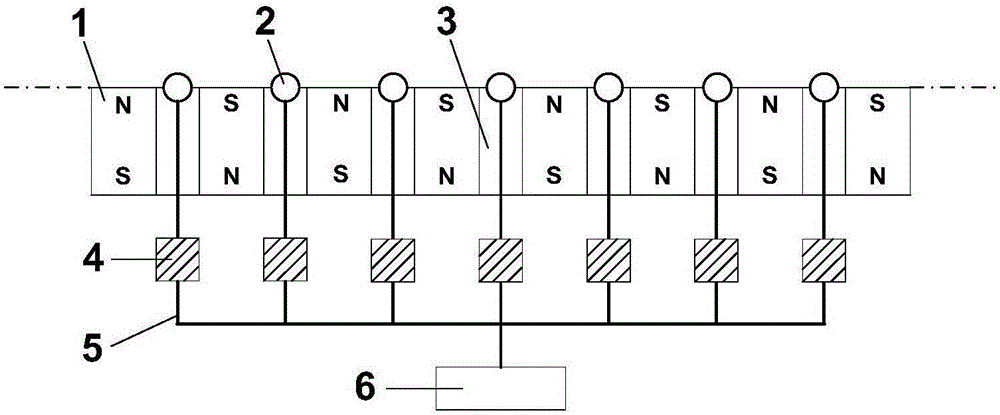

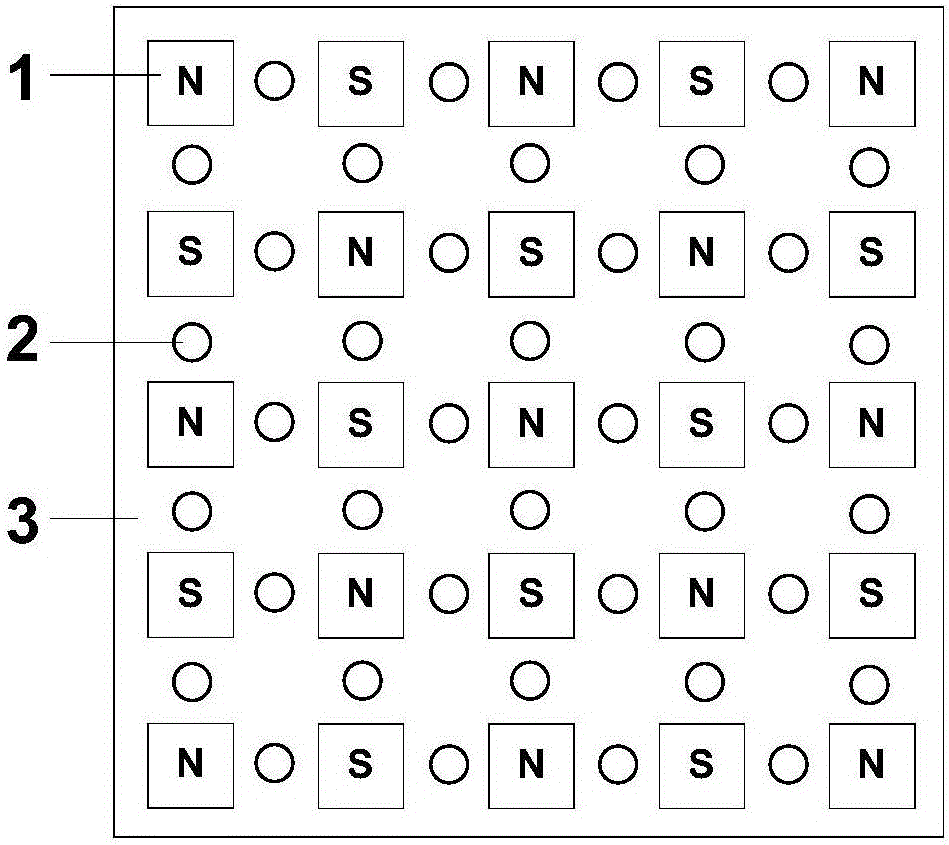

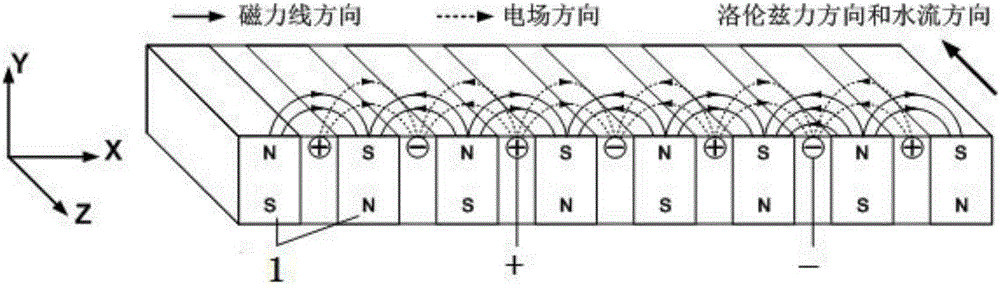

Electromagnetic fluid surface vectored thruster and underwater device adopting thruster

ActiveCN106428497AIncrease flexibilityAchieve lateral movementPropulsive elementsGenerators/motorsNon magneticWork status

The invention discloses an electromagnetic fluid surface vectored thruster and an underwater device adopting the thruster. The electromagnetic fluid surface vectored thruster comprises excitation devices, surface electrodes, insulating non-magnetic-conductive bases, electrode switches, wires and a power supply. The excitation devices and the surface electrodes are distributed on the surface of the electromagnetic fluid thruster in a two-dimensional array mode. The magnetic field directions of the excitation devices are perpendicular to the surface of the thruster, and the magnetic field directions of every two adjacent excitation devices are opposite. Each surface electrode is arranged between every two corresponding excitation devices. Each surface electrode is connected with the power supply through the corresponding switch. Each electrode switch has three work statuses of being connected with a power supply positive pole, connected with a power supply negative pole and turned off, and each electrode switch can only be in one of the three work statuses at the same moment. Each surface electrode can work in one of the three work statuses of being disconnected from the power supply, connected with the power supply positive pole and connected with the power supply negative pole. Every two surface electrodes can work independently. The thruster has vectored thrust, can achieve thrust in any direction, and achieves actions of transverse movement, rolling around the axis and in-situ rotation accordingly, and the movement flexibility of the underwater device is greatly improved.

Owner:SOUTHEAST UNIV

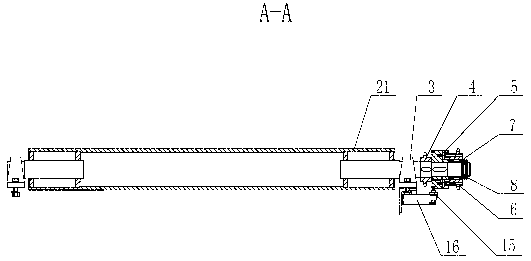

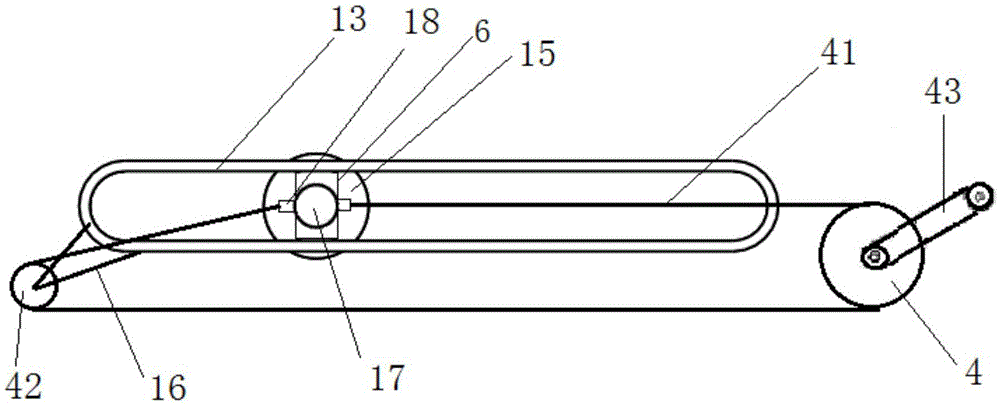

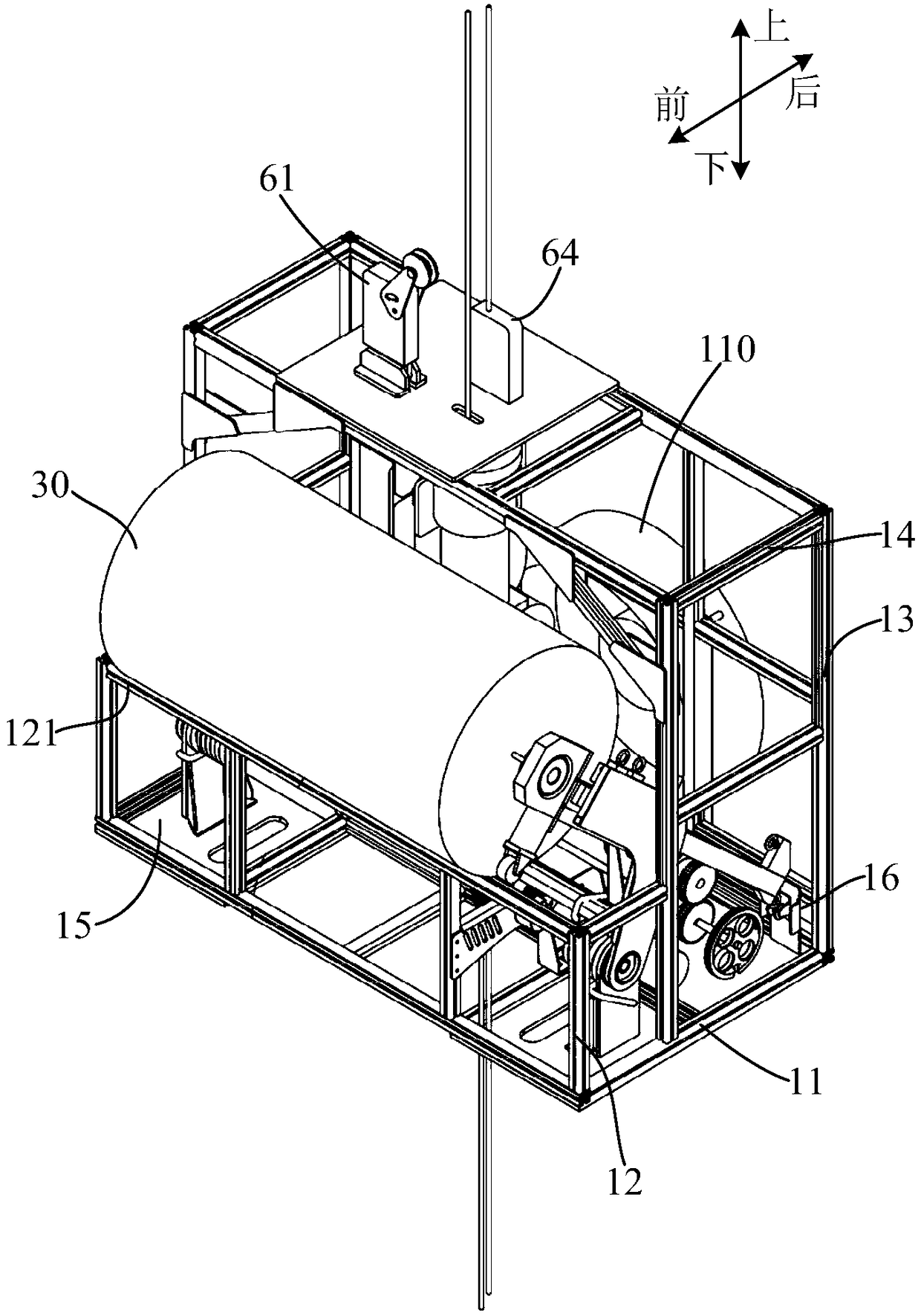

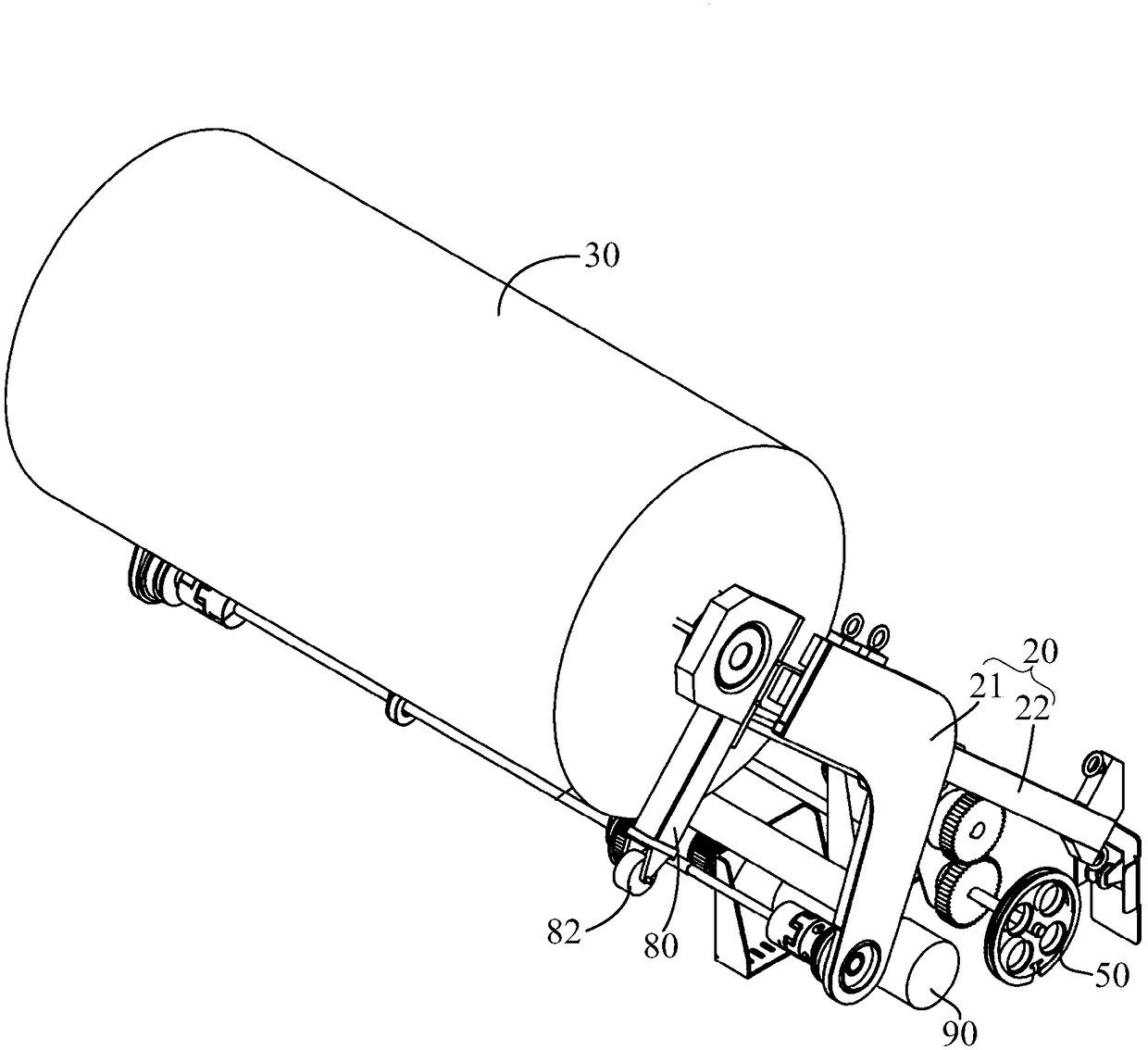

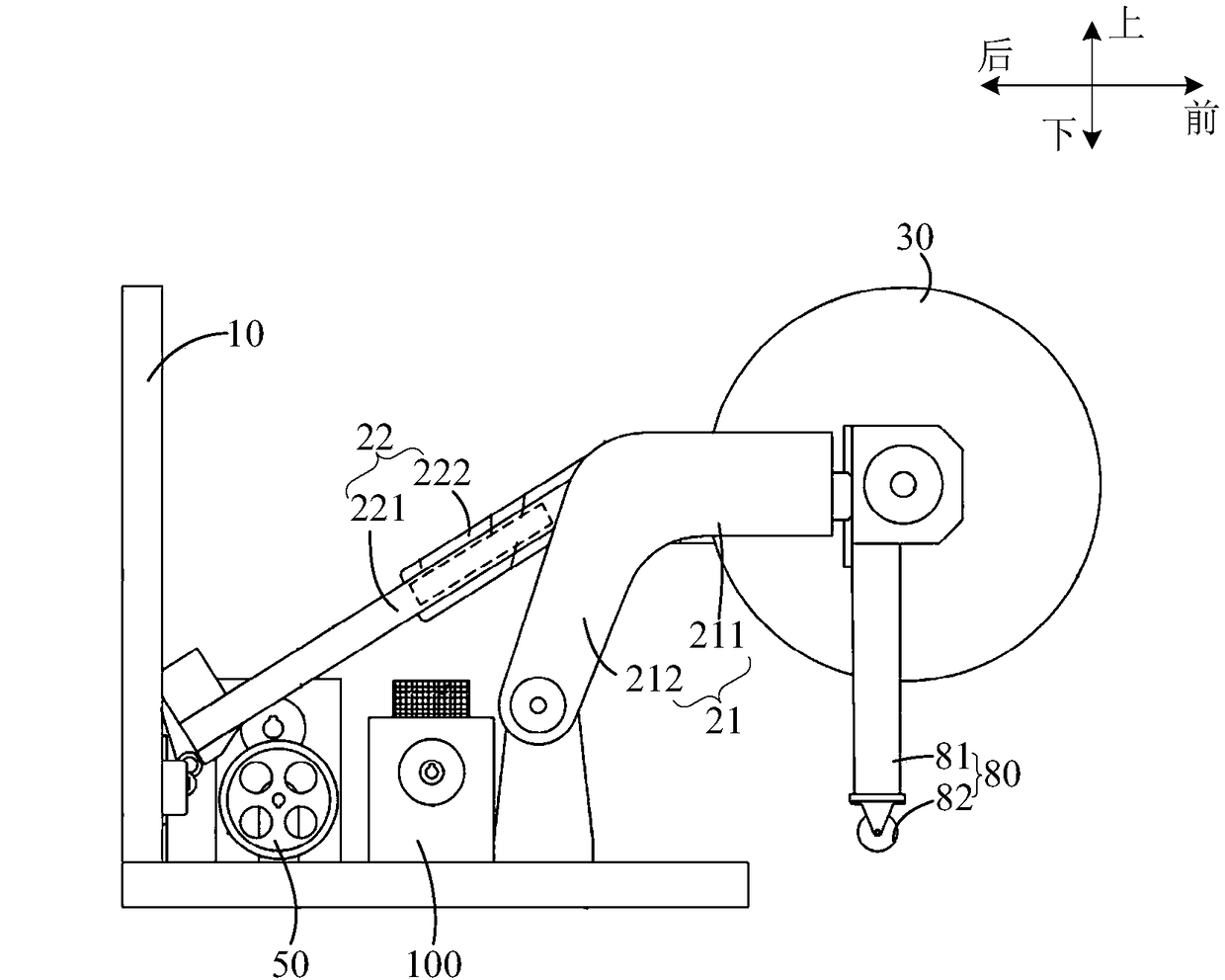

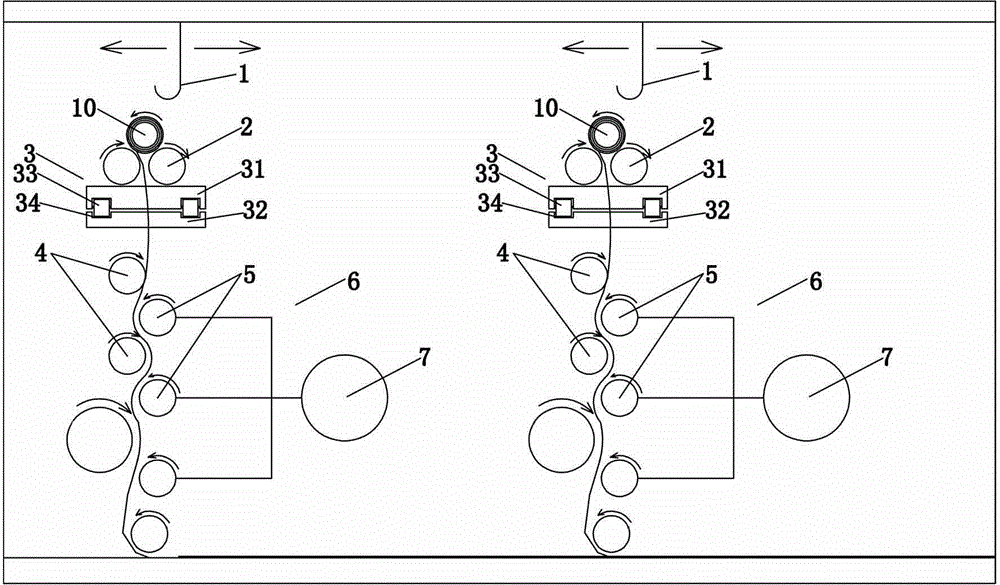

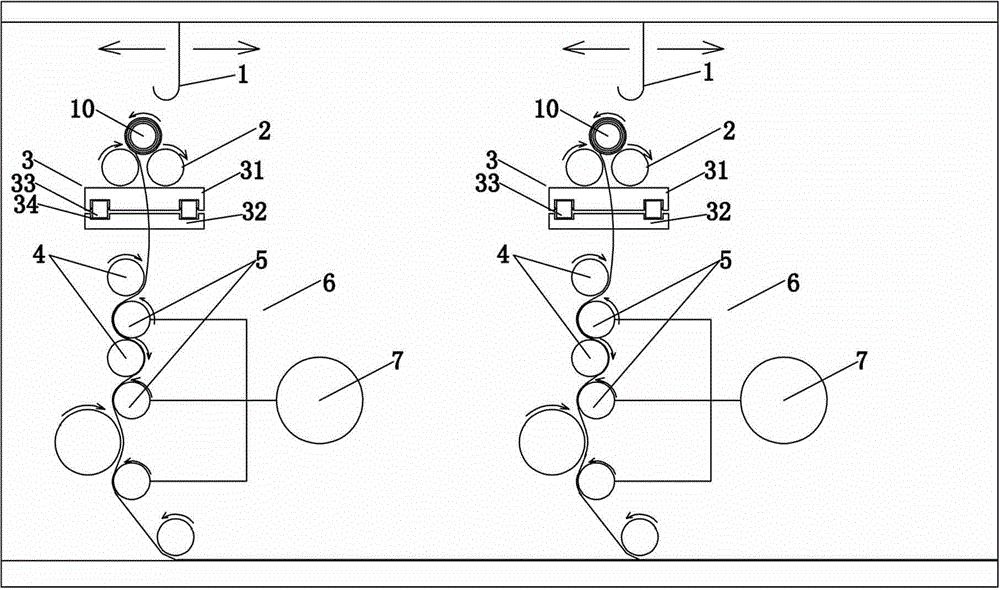

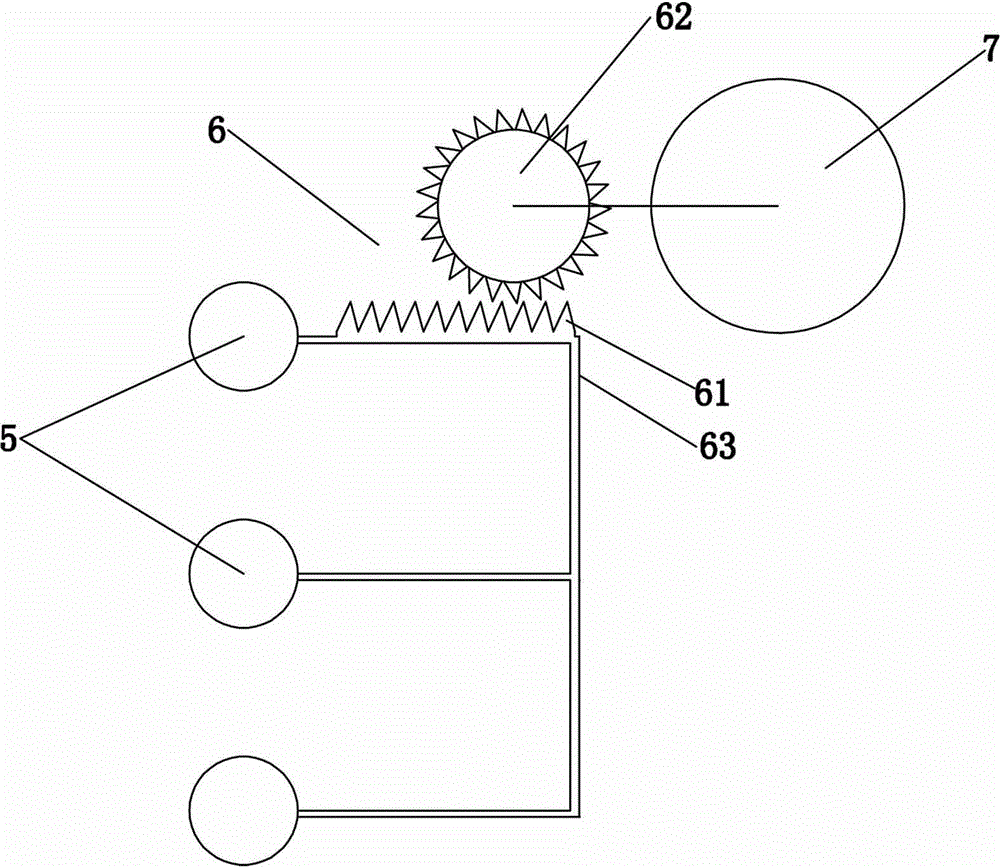

Winding device for 90-degree cord fabric cut-off production line

ActiveCN105293139AAccurate realizationAdjustable spacingArticle deliveryWebs handlingProduction lineControl system

The invention provides a winding device for a 90-degree cord fabric cut-off production line. The winding device can solve the problem that a cloth liner deviation correction mechanism cannot achieve the deviation correction function when the width and the weight of a cloth liner are large in the prior art. The winding device for the 90-degree cord fabric cut-off production line comprises a rack, a cord fabric guide-in device, a cloth liner deviation correction device, a cord fabric winding device, a pneumatic control system and an electrical control system, wherein the pneumatic control system and the electrical control system are matched with all the devices. The cloth liner deviation correction device comprises a deviation correction detection assembly, a cloth liner winding and grabbing mechanism and a lifting roller. The cloth liner winding and grabbing mechanism comprises a deviation correction bottom board capable of moving transversely, two cloth liner winding supports and a mechanical hand capable of moving longitudinally, ascending and descending. Due to the fact that a cloth liner reel is not fixed to a movable trolley, the cloth liner reel can be grabbed by the mechanical hand to a cloth liner reel support, the deviation correction detection assembly is arranged on the cloth liner reel support as well, the cloth liner reel support and the cloth liner reel are driven by the deviation correction bottom board on the rack to move overall so as to achieve deviation correction, and when the width and the weight of tire cord fabric and the cloth liner are very large, deviation correction can be achieved as well.

Owner:MESNAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com