Omni-directional moving track

An omni-directional, crawler technology, applied in tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of large power consumption and easy wear of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following describes in detail a specific implementation of an omnidirectional moving crawler with reference to the accompanying drawings.

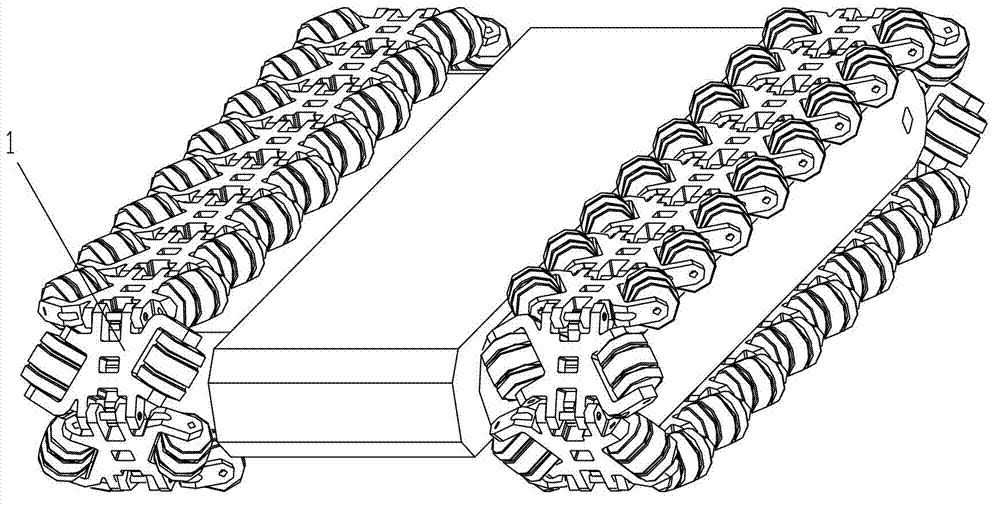

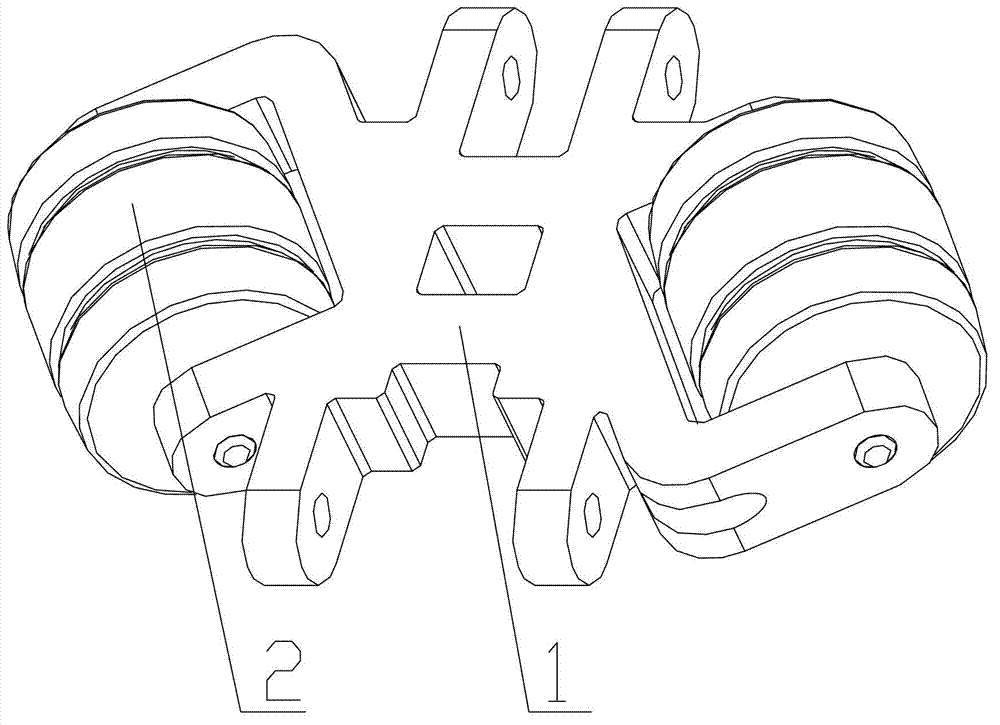

[0011] Such as figure 1 , 2 As shown, an omni-directional moving crawler includes a crawler main body, which is composed of a crawler shoe 1 and a crawler pin. The crawler pin connects the crawler shoe 1 to form a crawler chain ring; there is a hole in the middle of the crawler shoe 1 to mesh with the driving wheel, A traveling wheel 2 is installed on both sides of each track shoe 1, and the traveling wheel 2 is installed on the track shoe 1 through a shaft and a bearing, and can rotate flexibly. The central axes of the walking wheels 2 on both sides of the crawler shoe 1 are parallel to each other, and the included angle between the central axis of the walking wheels 2 and the central axis of the crawler body may be 0 to 90 degrees. The walking wheels are rubber wheels.

[0012] When working, the motor drives the driving wheel to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com