Extensible robot for climbing inner wall of pipeline

A telescopic tube and telescopic technology, which is applied in the direction of special tubes, tube components, mechanical equipment, etc., can solve problems such as insufficient driving force, increased cost, and deviation of the robot from the correct posture position, so as to avoid rollover and jamming, reduce Production cost, the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

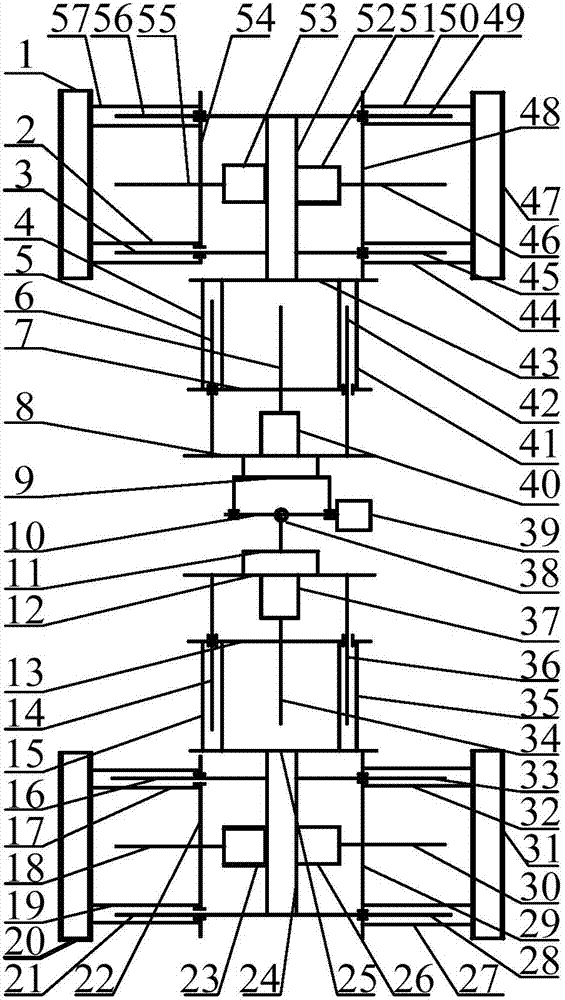

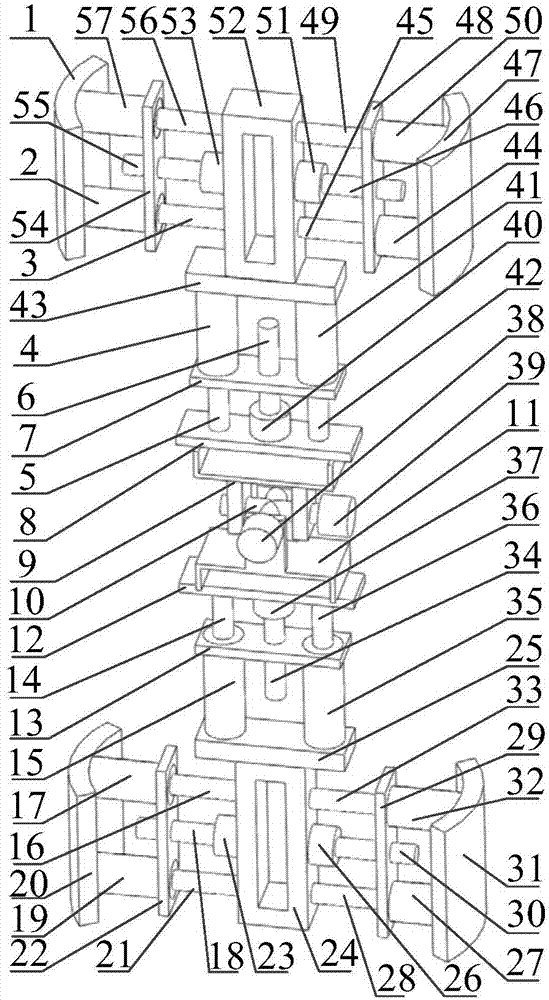

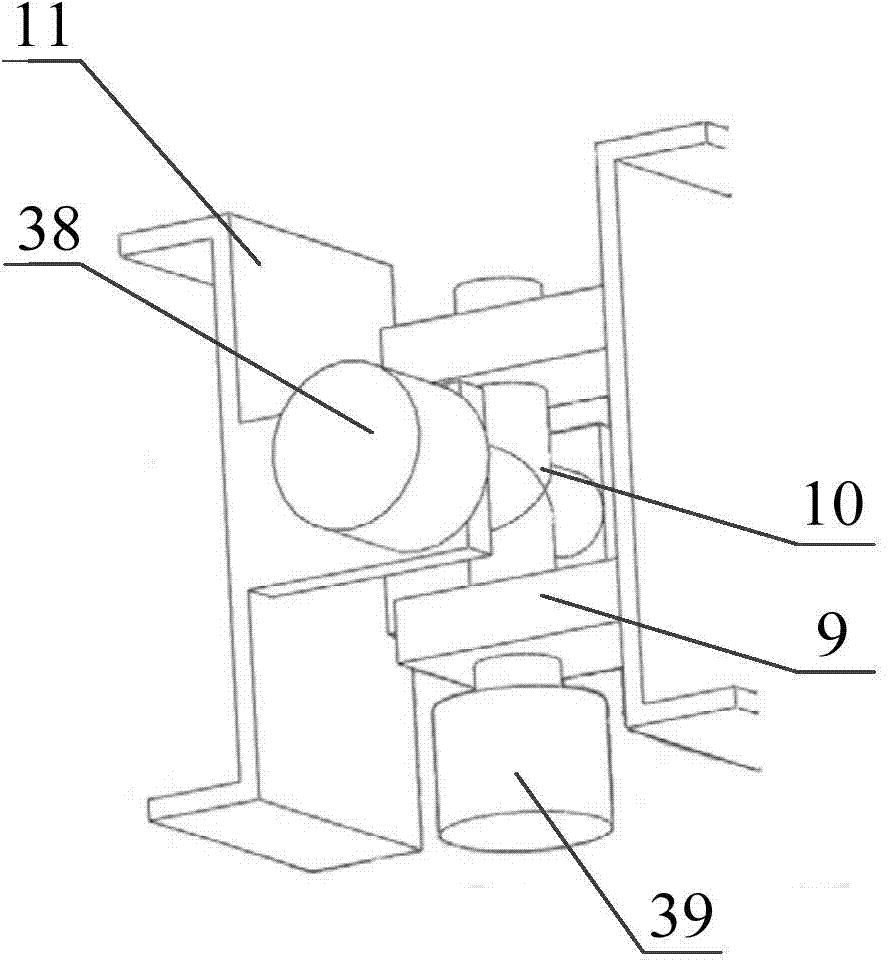

[0025] The robot body of the present invention is a symmetrical structure, with the intermediate connection mechanism as the center of symmetry, part I of the telescopic arm, part II of the telescopic arm, part III of the telescopic arm and part IV of the telescopic arm, part I of the telescopic mechanism of the robot and part II of the telescopic mechanism have the same structure . Part I of the telescopic arm and part II of the telescopic arm, part III of the telescopic arm and part IV of the telescopic arm are respectively installed symmetrically through the arm motor frame, and part I of the telescopic mechanism and part II of the telescopic mechanism are fixedly connected and installed through an intermediate connection mechanism. The structural composition of part I of the telescopic arm, part I of the telescopic mechanism and the intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com