Patents

Literature

1982results about How to "Avoid getting stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

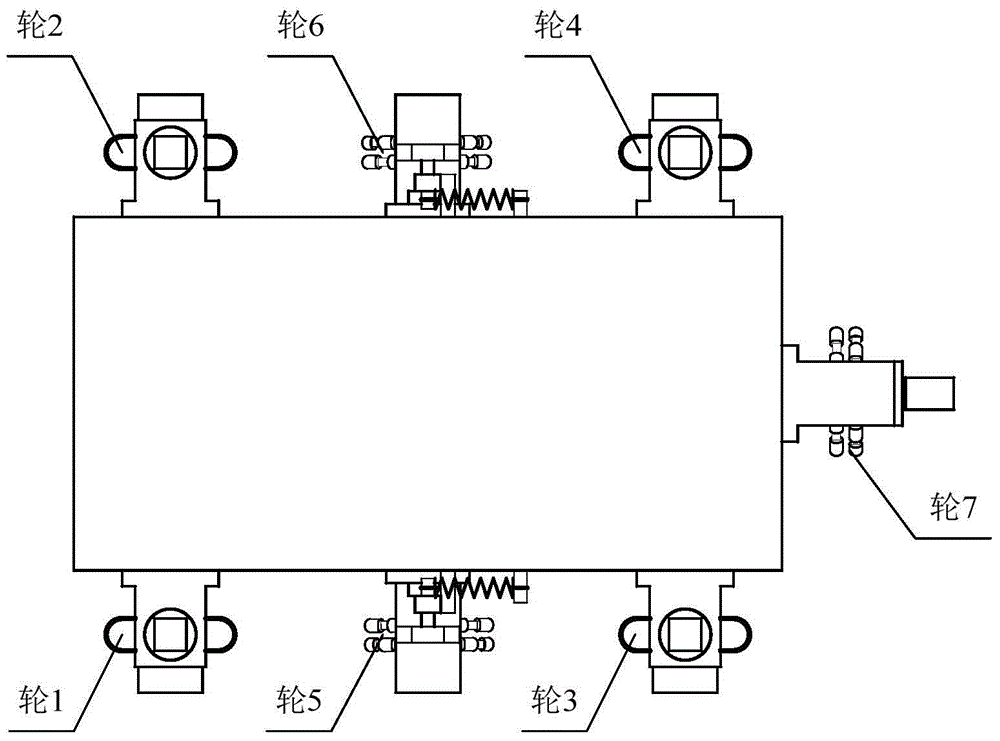

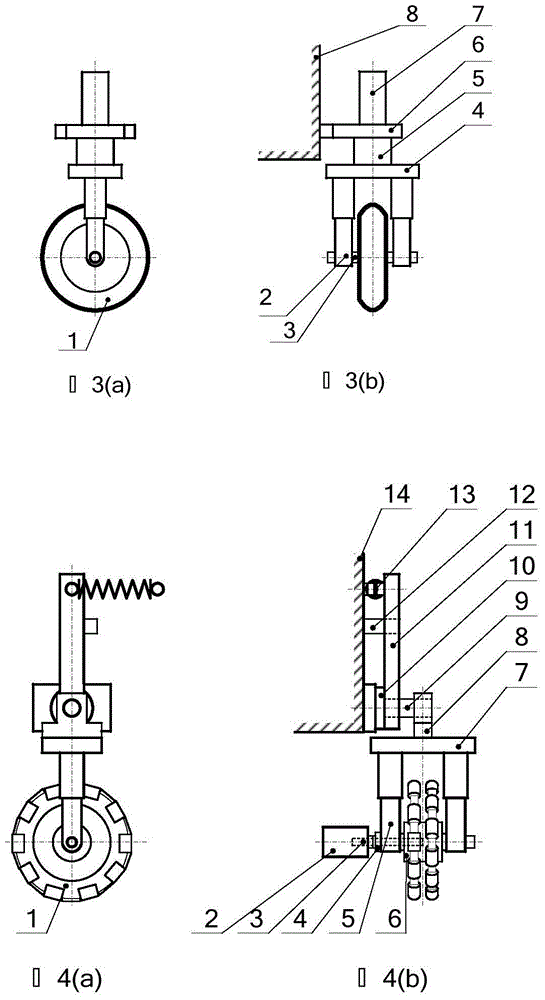

All-around wheeled mobile robot with relative posture detection function

ActiveCN104590414APrevent affecting pose measurement accuracyConcise motion mode discriminant formulaVehiclesDrive wheelSimulation

The invention discloses an all-around wheeled mobile robot with a relative posture detection function. The all-around wheeled mobile robot is characterized in that a chassis is composed of four driving wheels and three driven wheels, each driving wheel can independently perform driving and steering, and through coordinated control, the robot moves flexibly. The chassis moves to drive the three driven wheels to rotate, and through measuring the combination rotation speed of the three omni-directional wheels, the changes of the relative posture of the robot can be detected. The mobile robot is compact in mechanical design structure, a platform has flexible movement performance, the increment of the movement posture of the platform can be automatically detected, and the robot can be stably driven on a complex road surface. Through additionally arranging a vehicle-mounted external sensor, the platform of the mobile robot can be used for performing environment detection, automatic positioning and navigation in the urban environment, and further can detect alien bodies on earth. Due to the combination design of a driven wheel system, low-cost posture detection information easy to calculate is provided for rapid intelligence of the mobile platform and robotization transformation of the mobile platform.

Owner:HEFEI UNIV OF TECH

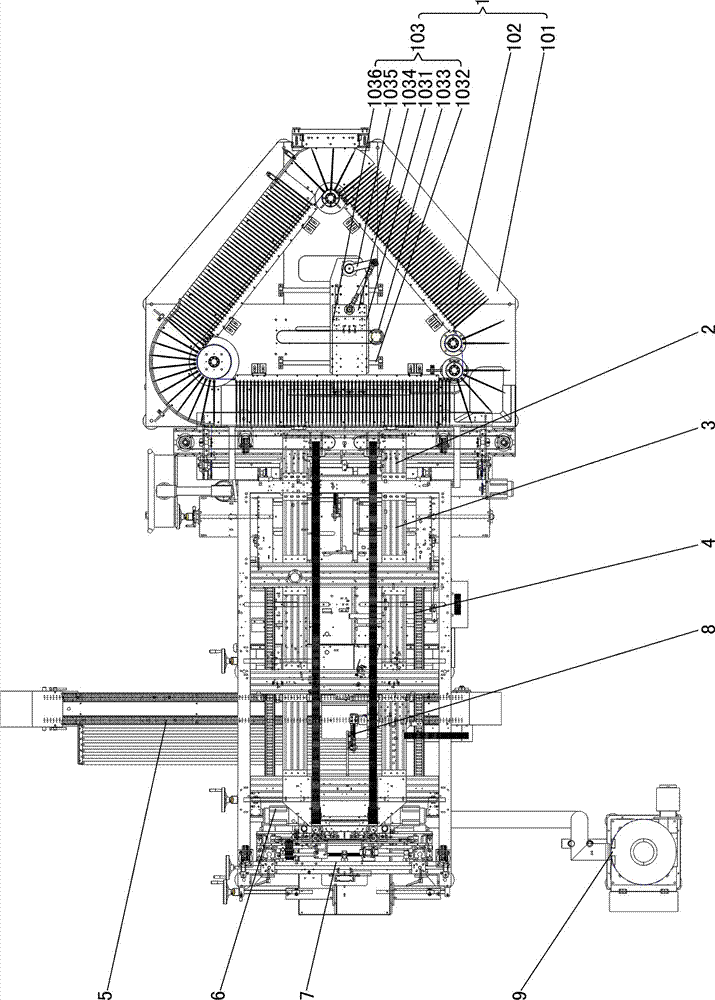

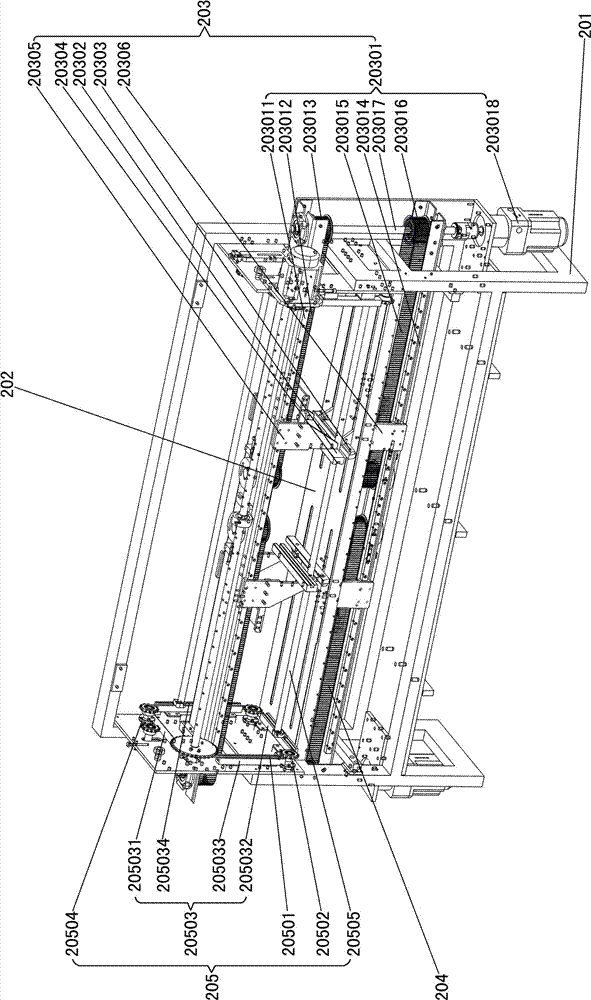

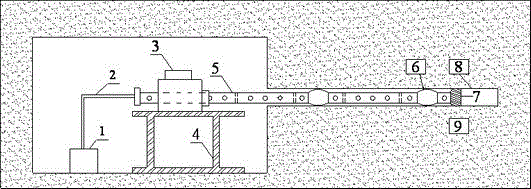

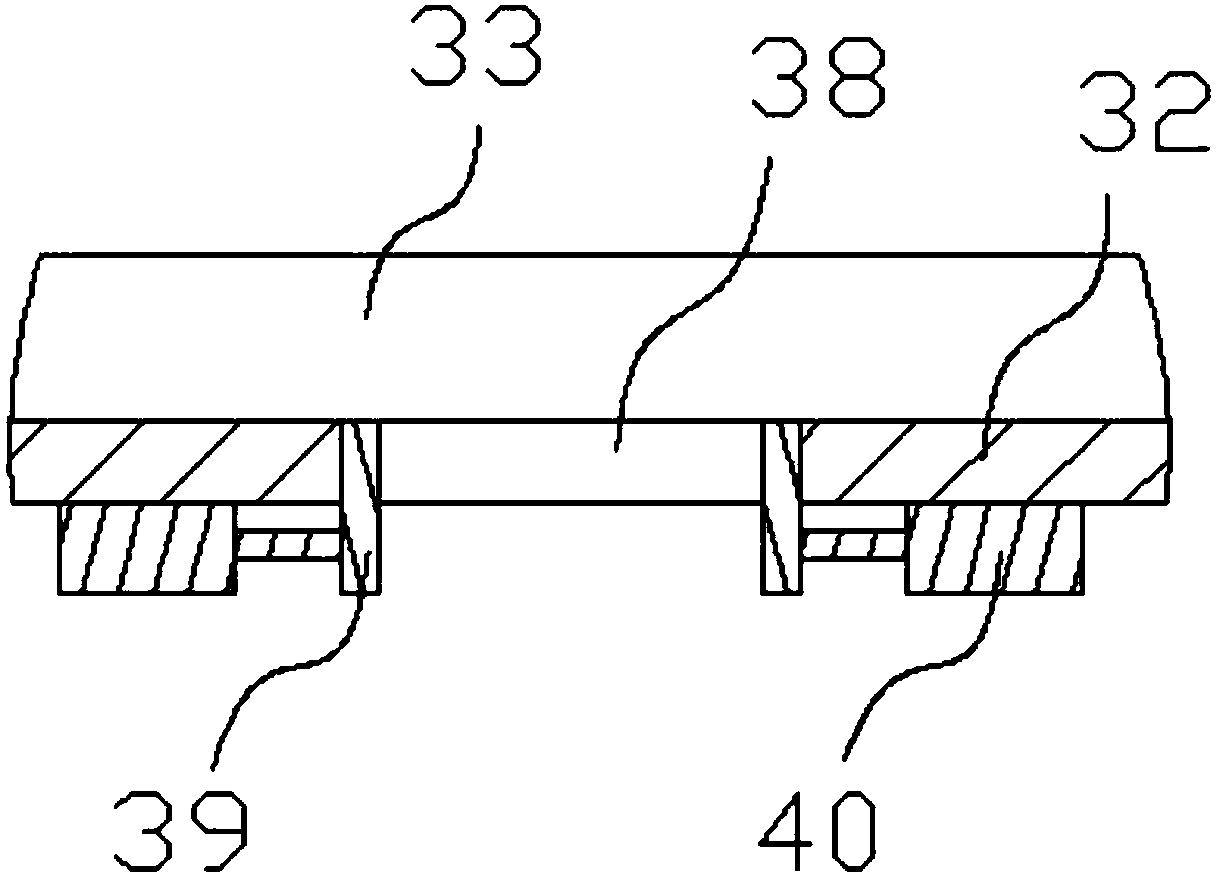

Full-automatic paper diaper packaging production line

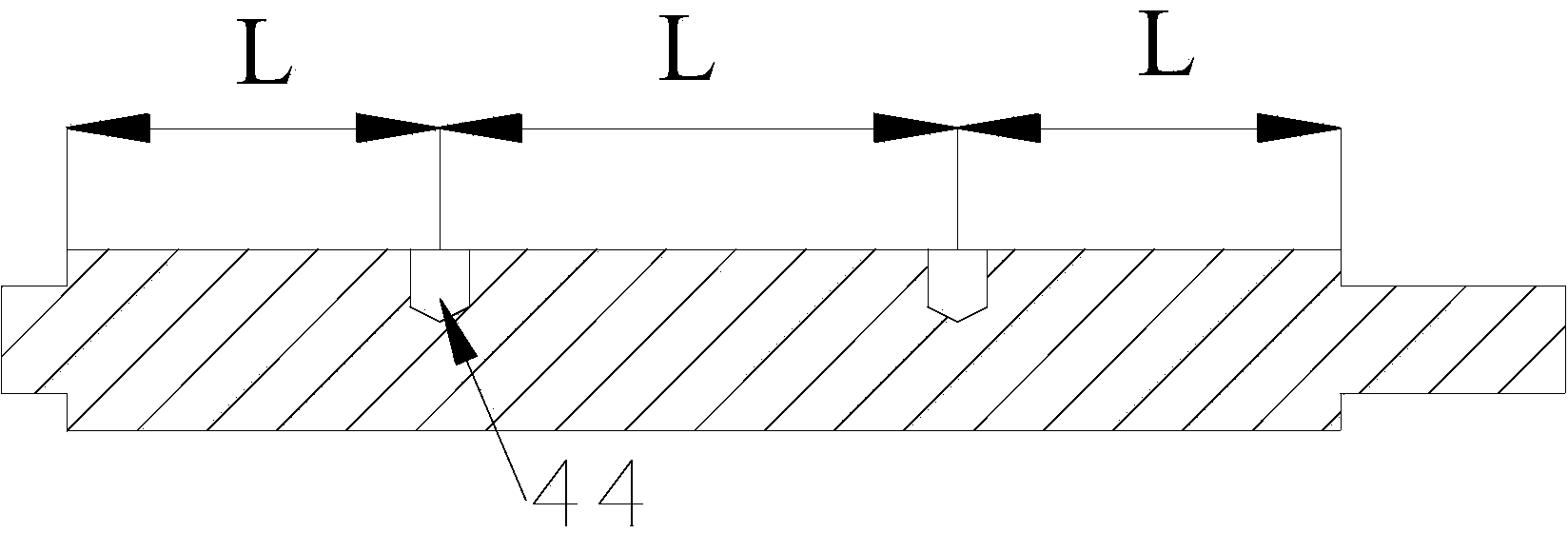

ActiveCN104843248APrecise feedingAvoid getting stuckIndividual articlesStack machineCompression device

The invention relates to a full-automatic paper diaper packaging production line which comprises a stacking machine, pre-compression device, a transition mechanism, a secondary compression device, a bag feeding device, a bag opening device, a packaging, sealing and cutting-off device, a pushing mechanism and an offcut collecting device. The pre-compression device comprises a support, a support plate, a left compression mechanism, a right compression mechanism and a push out mechanism, wherein each of the left compression mechanism and the right compression mechanism comprises a compression translation mechanism, an upper push block and a lower push block, the upper push block and the lower push block are respectively connected with the power output end of the compression translation mechanism, and the upper push block is located above the lower push block. The full-automatic paper diaper packaging production line has the advantages that the upper push blocks and the lower push blocks are respectively driven by independent compression translation mechanisms and are fixed in the middle to perform pre-compression, paper diapers are prevented from being deviated and stuck, production smoothness is increased, and production efficiency is increased; the upper push blocks are separated from the lower push blocks, the friction between the paper diapers and the upper push blocks and the lower push blocks is reduced, and abrasion and scratch of the paper diapers are avoided.

Owner:孙少光

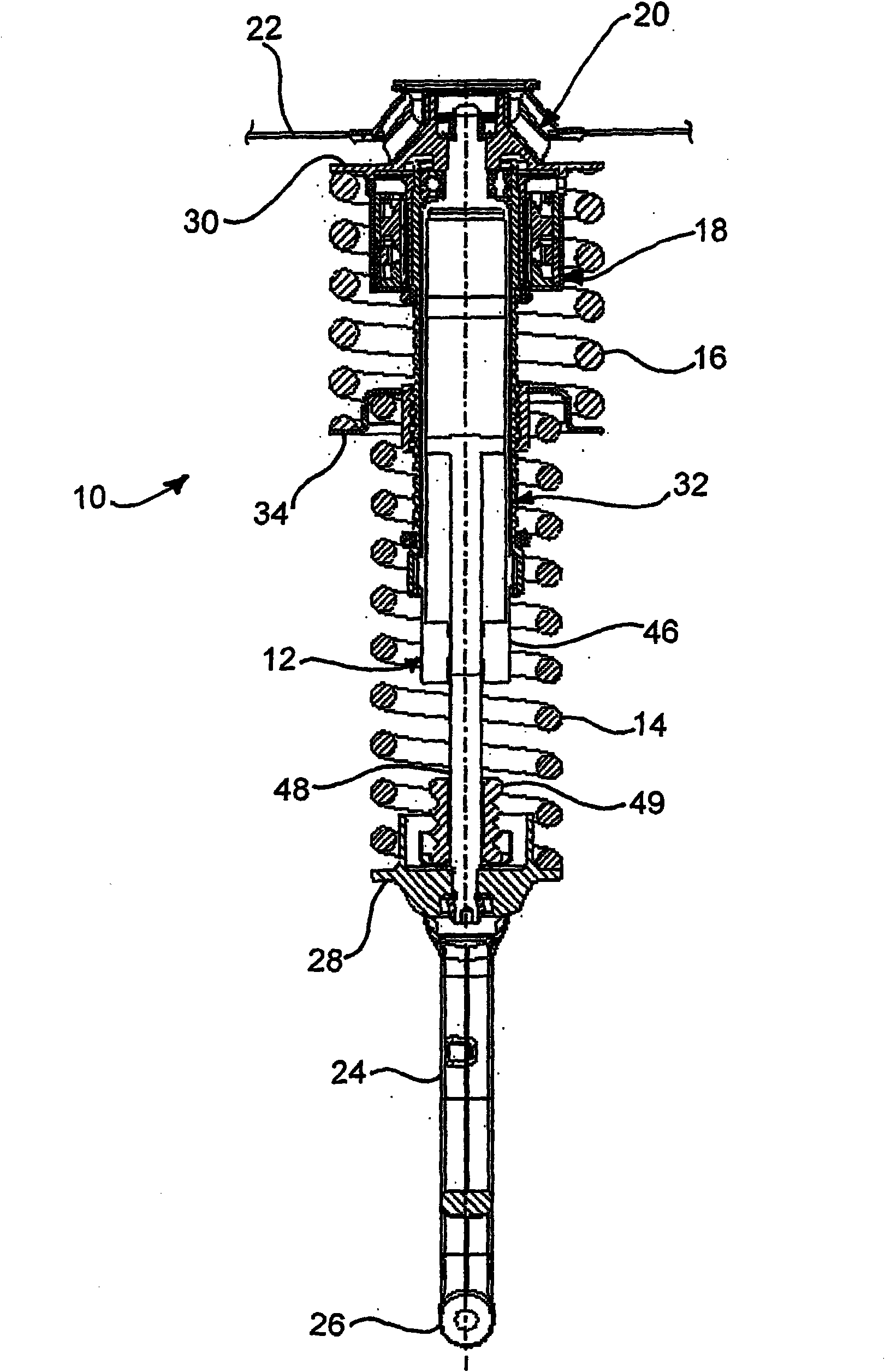

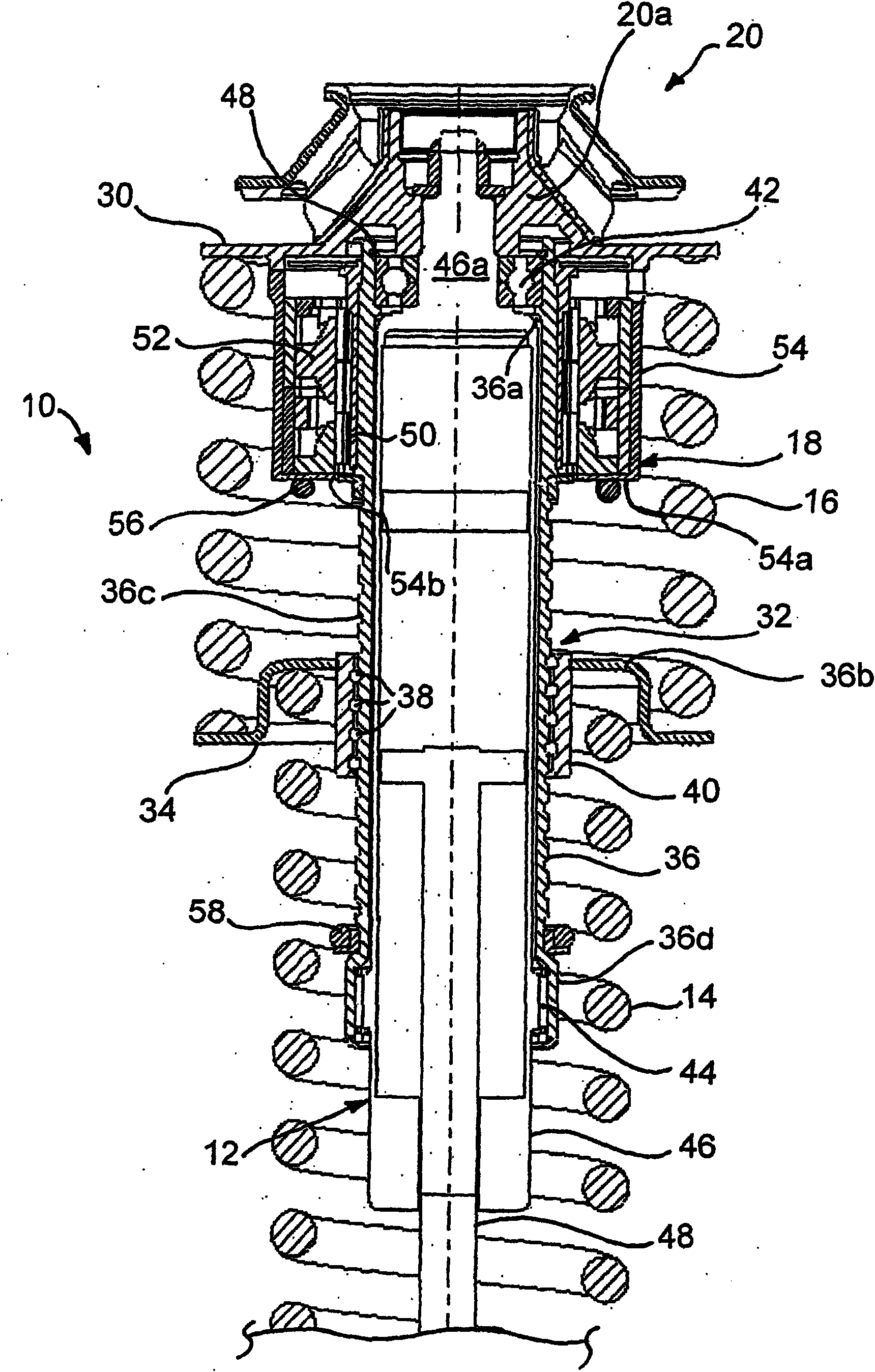

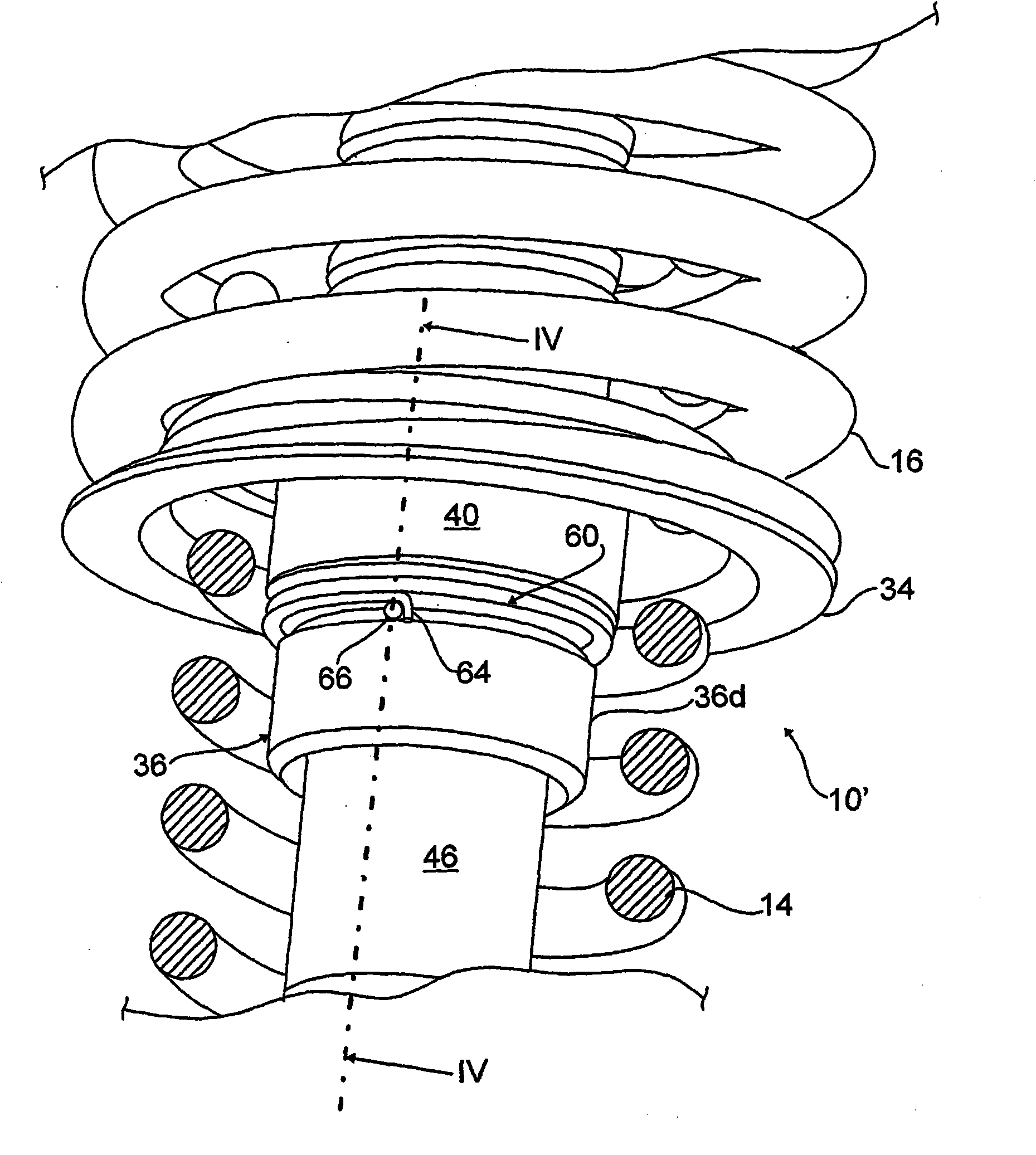

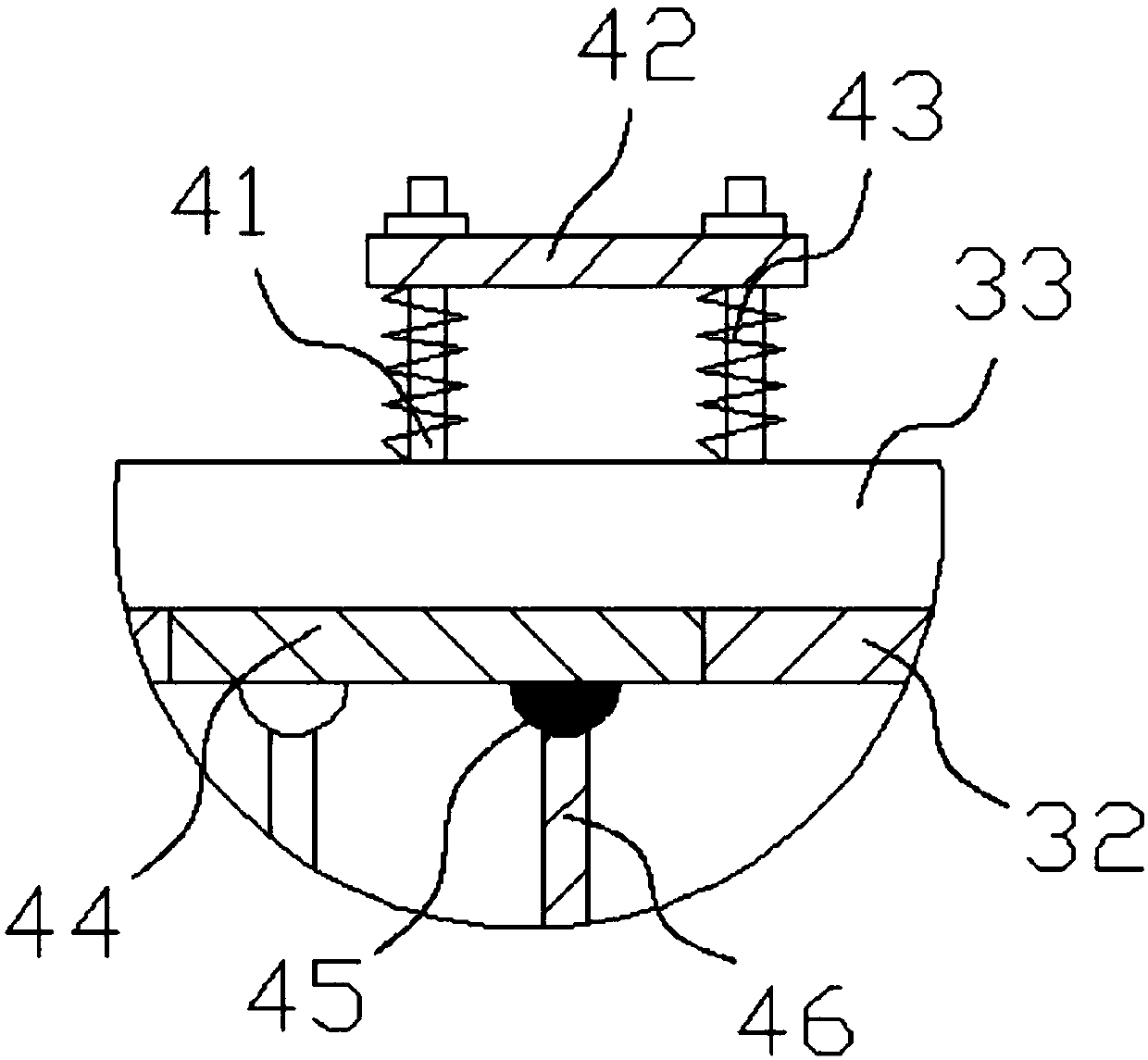

Spring strut arrangement for wheel suspensions of motor vehicles

InactiveCN101896369AWeight advantageReduce reaction forceResilient suspensionsVehicle springsHelical coilShock absorber

The invention relates to a spring strut arrangement for wheel suspensions of motor vehicles formed of a telescoping shock absorber (12), a suspension spring element (14) preferably designed as a helical compression spring, and a storage spring element (16) preferably designed as a helical coil spring, wherein the spring elements (14, 16) are supported by spring caps (28, 30) on the body (22) of the motor vehicle and on a wheel suspension element (24), and third spring cap (34) located therebetween is displaceably guided relative to the body (22) along the longitudinal axis of the shock absorber by means of an electrically driven positioning drive (32) disposed within the spring elements (14, 16), wherein the positioning drive (32) comprises a positioning spindle (36) rotatably supported about the shock absorber and a positioning nut (40) connected to the displaceable spring cap (34). According to the invention, the shock absorber (12) is disposed on the body (22) of the motor vehicle with the damping tube (46) upward, and the positioning spindle (36) is rotatably supported on the damping tube (46).

Owner:AUDI AG

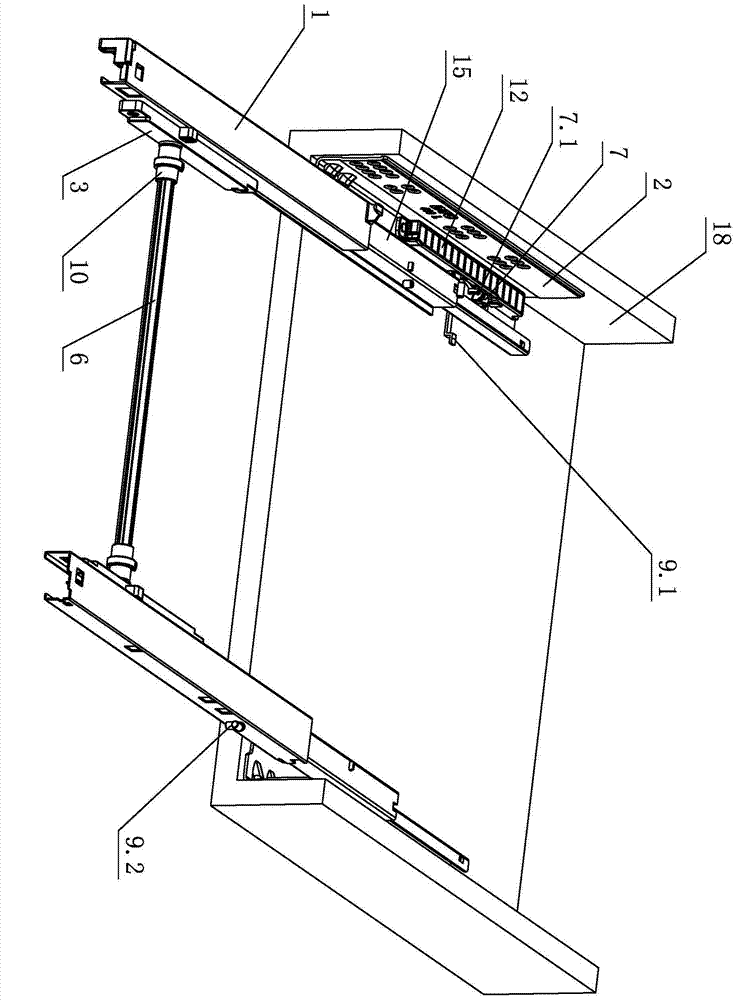

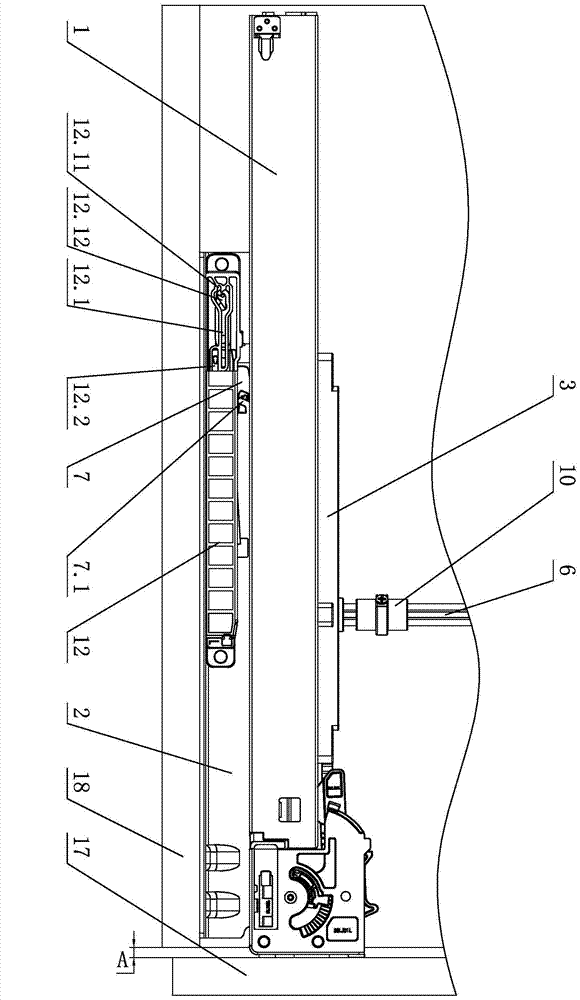

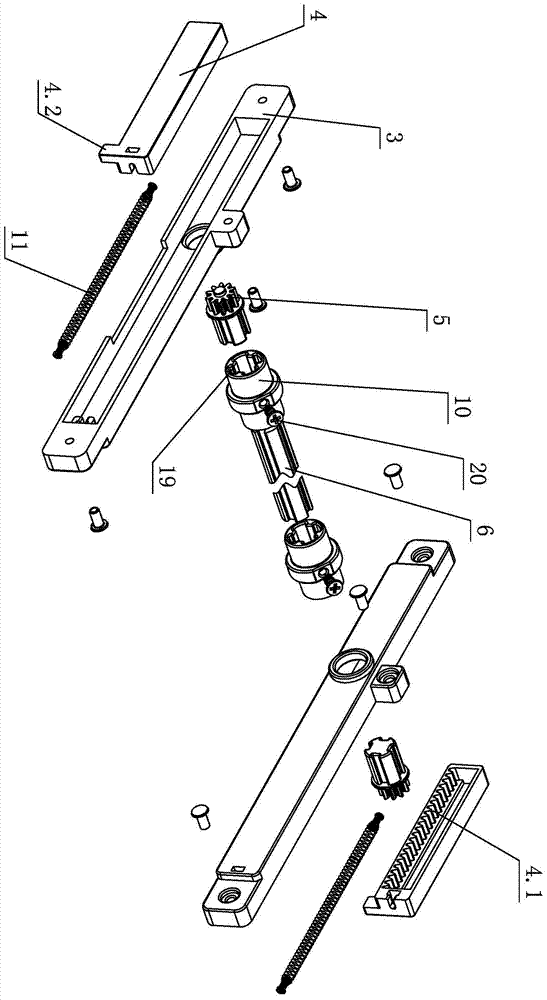

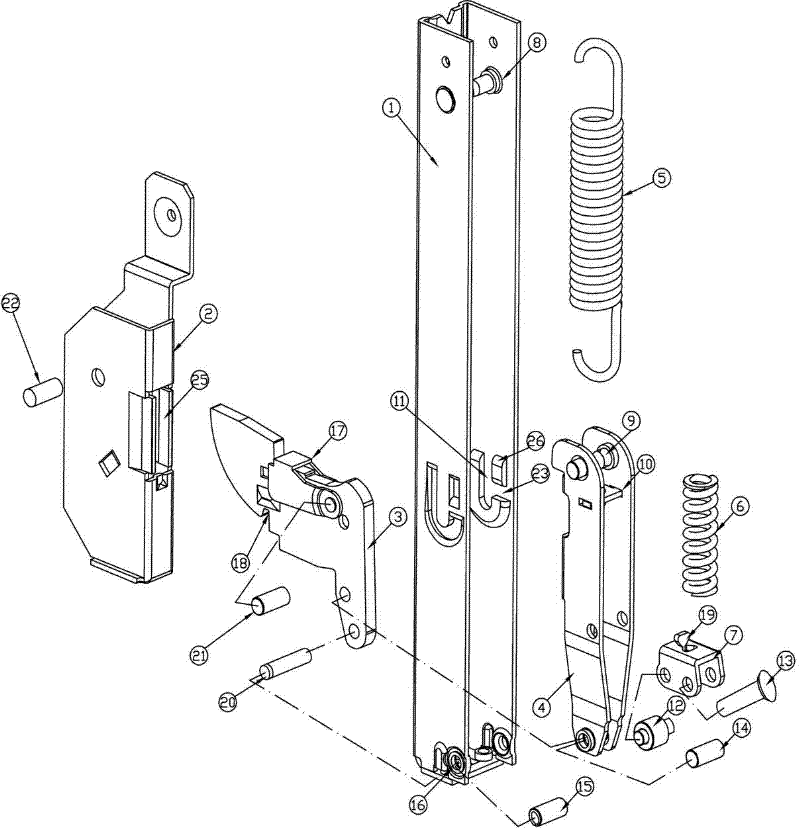

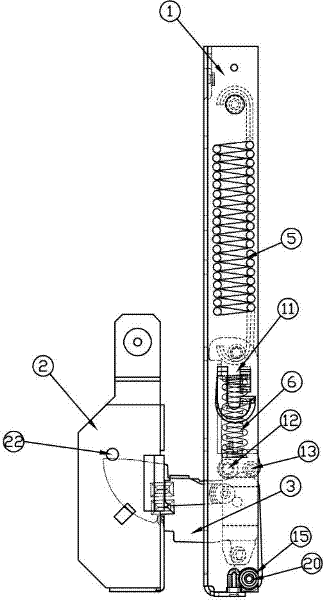

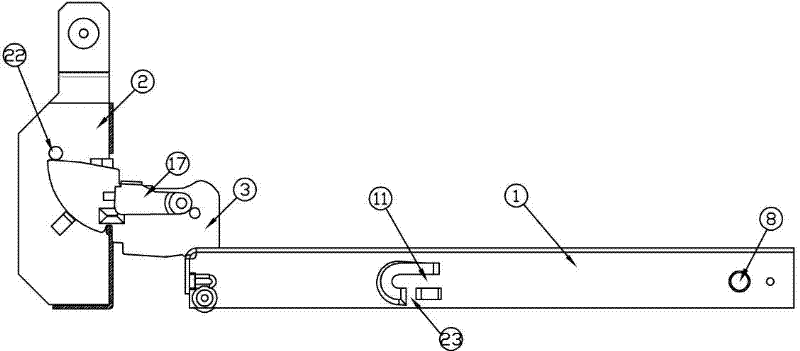

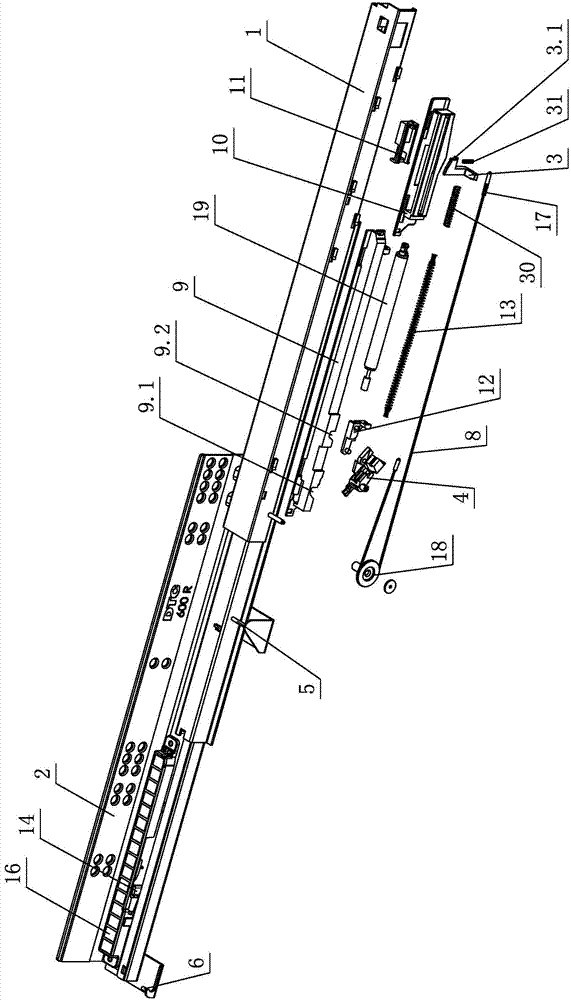

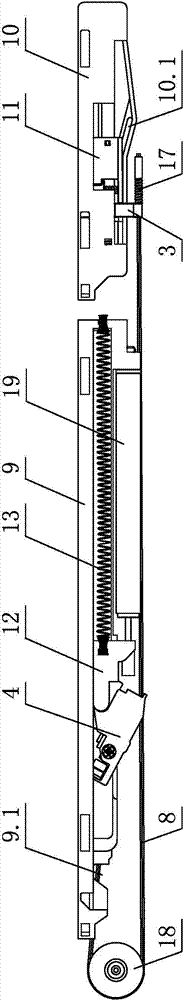

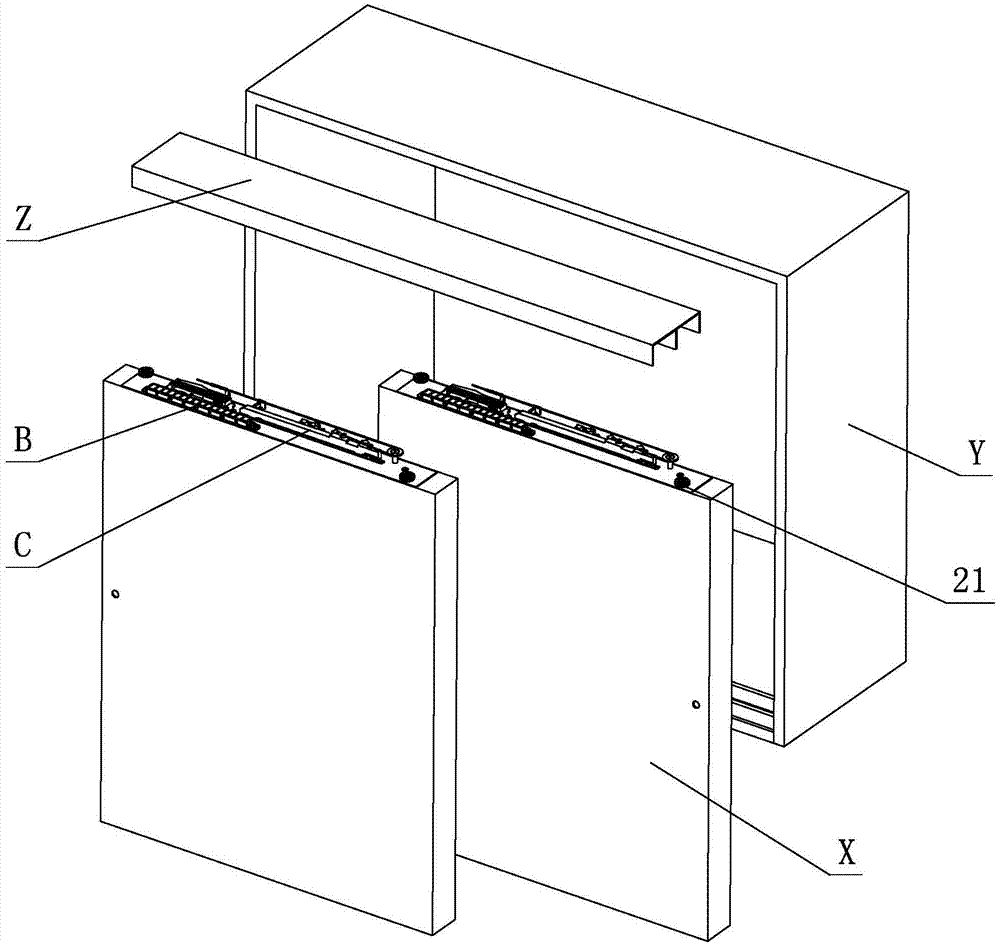

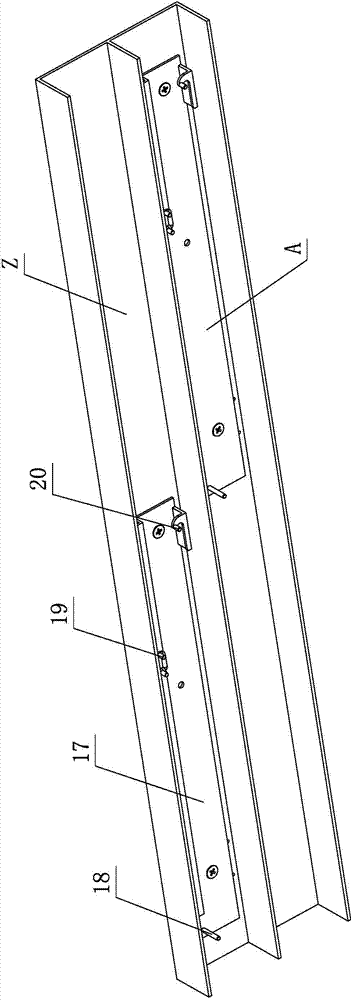

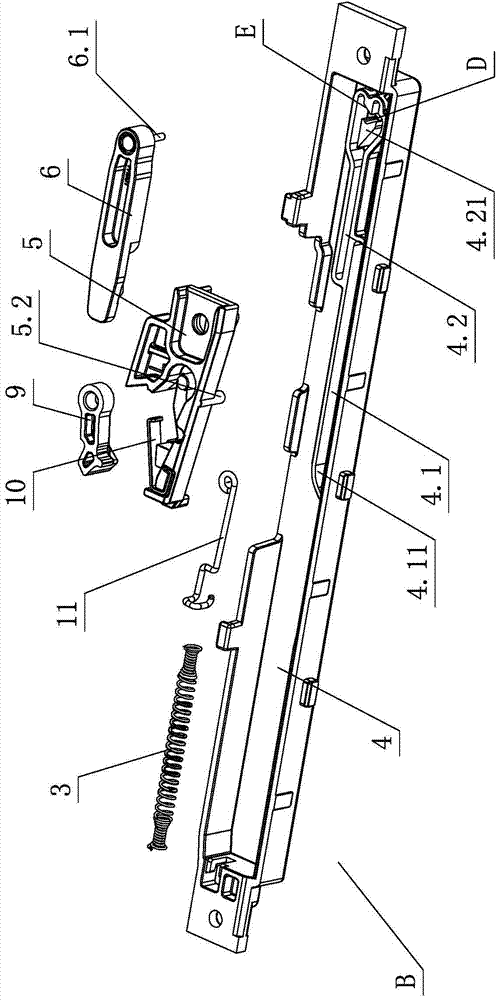

Synchronizing device of drawer sliding rails

A synchronizing device of drawer sliding rails comprises two sets of sliding rail assemblies arranged on a cabinet left side plate and a cabinet right side plate, wherein a drawer is arranged on the sliding rail assemblies and is at least composed of a bottom and a front panel, each sliding rail assembly is at least composed of a movable sliding rail and a fixed sliding rail, a drawer synchronizing device body is arranged on the left movable sliding rail and the right movable sliding rail or the left fixed sliding rail and the right fixed sliding rail and at least comprises a sliding groove base and a sliding block, the sliding block acts on the sliding groove base, racks are arranged on the sliding block, gears mutually meshed with the racks are rotationally arranged on the sliding groove base and correspond to the racks, and the left gear and the right gear are connected through a rotating connecting rod to achieve synchronous opening and closing of the left sliding rail assembly and the right sliding rail assembly; a poking block is arranged on the movable sliding rails or the fixed sliding rails, and a stopping part is arranged on the sliding block and is loaded on the poking block through elasticity of an elastic part at least when a suspending distance A is preserved between the front panel and the cabinet side plates; the sliding block acts on the poking block through the stopping part in at least one segment of travel when the drawer is opened or closed so that the sliding block can slide on the sliding groove base.

Owner:伍志勇

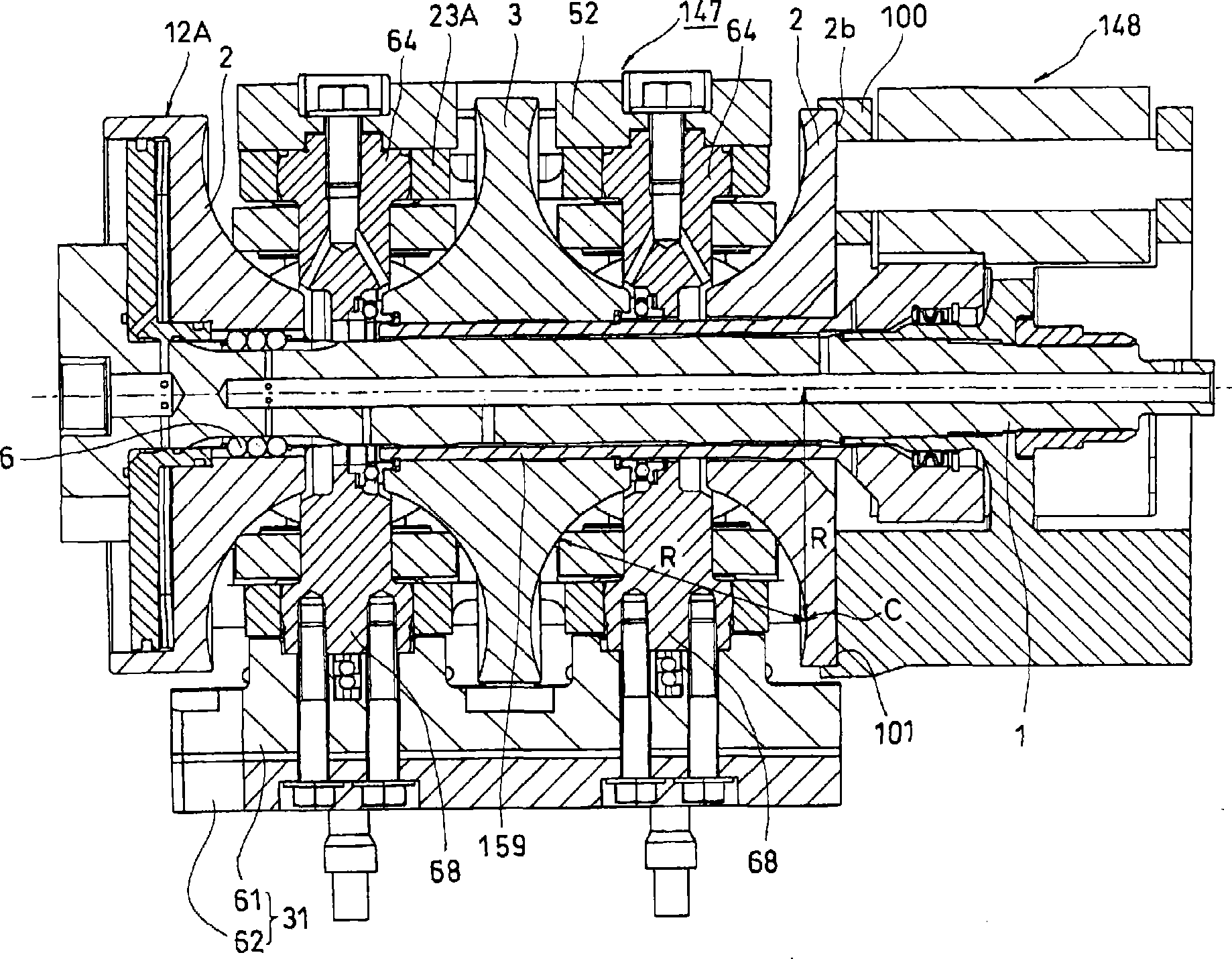

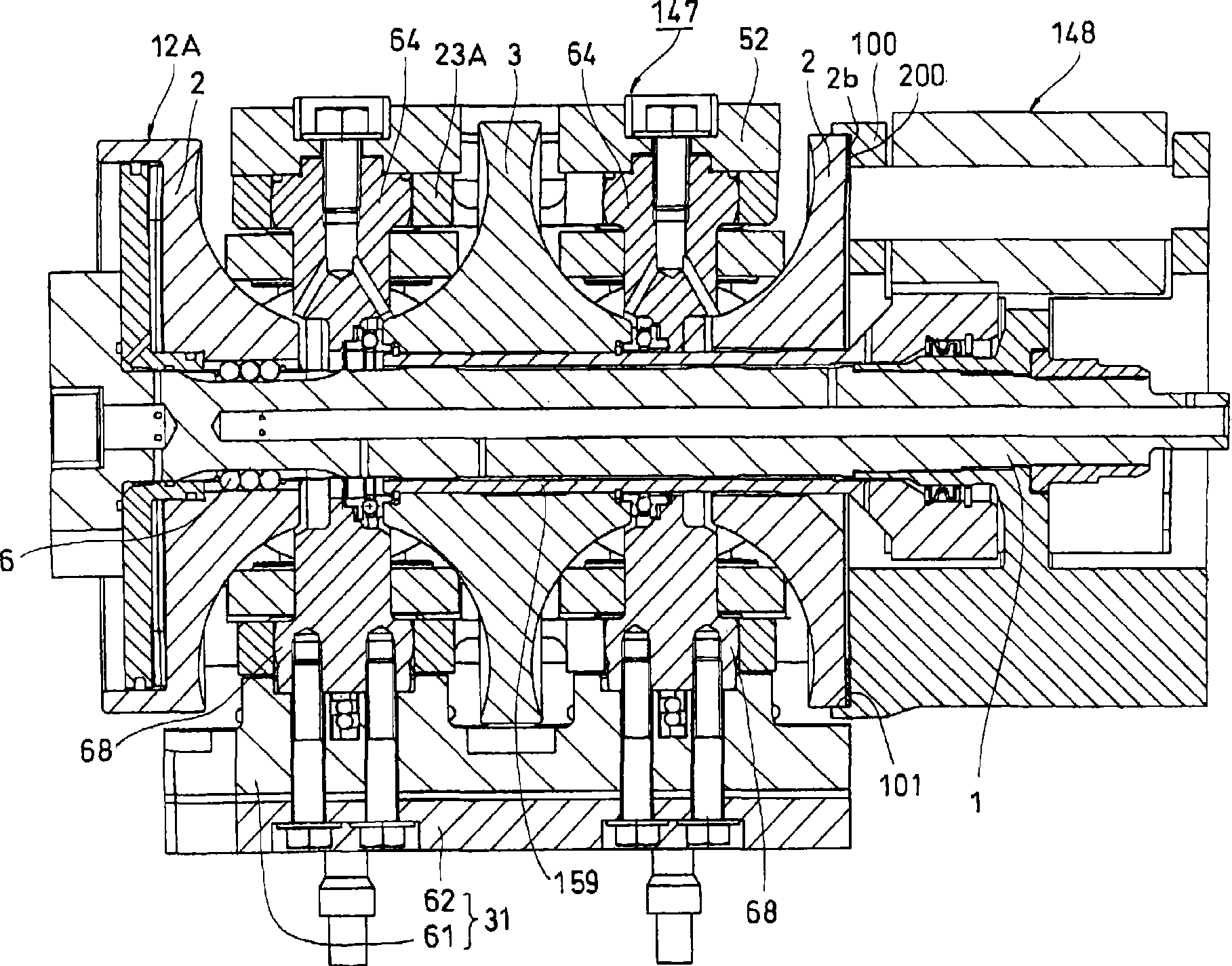

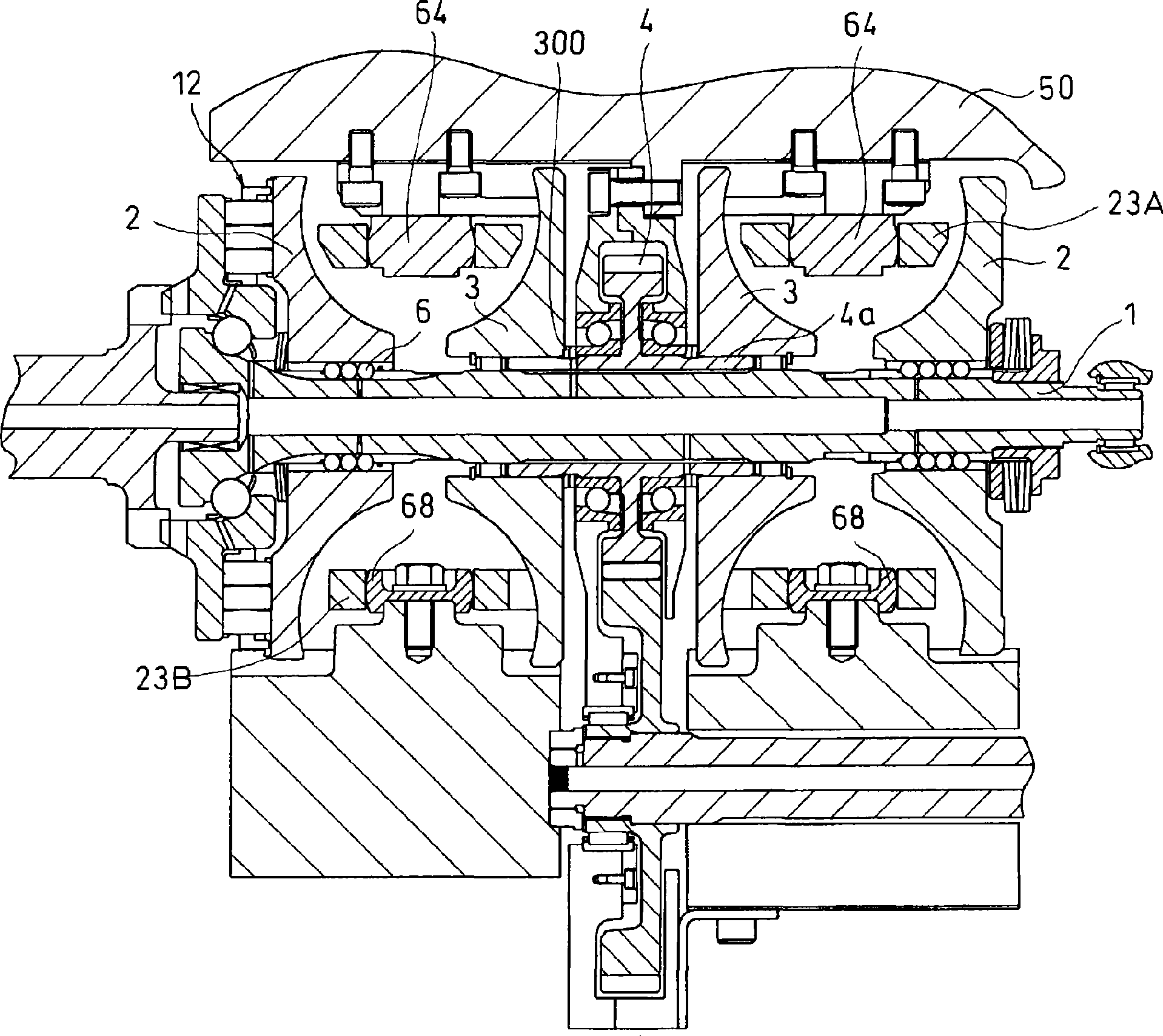

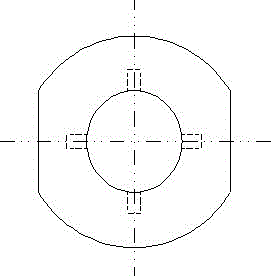

Toroidal type stepless transmission and stepless transmission

InactiveCN101479503AReduce weightAvoid getting stuckFriction gearingsElectric power transmissionGear wheel

A toroidal type stepless transmission where a carrier (100) and a disk (2) are in direct friction contact with each other to allow power transmission between the carrier (100) and the disk (2) by friction force. Accordingly, the transmission does not require processing of gears and claws on the disk or the carrier, which has been required conventionally. As a result, production processes are reduced to enable a considerable reduction in production costs.

Owner:NSK LTD

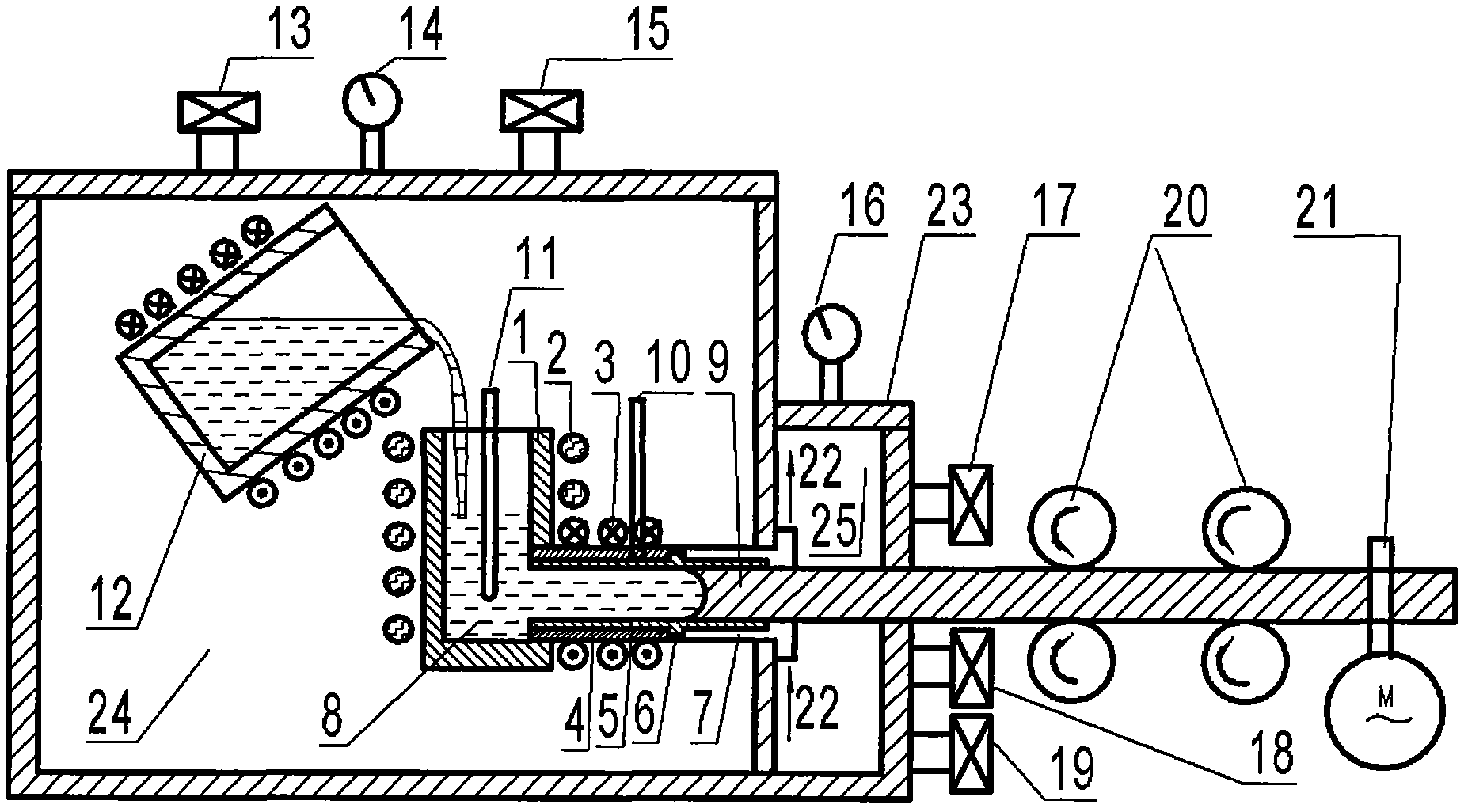

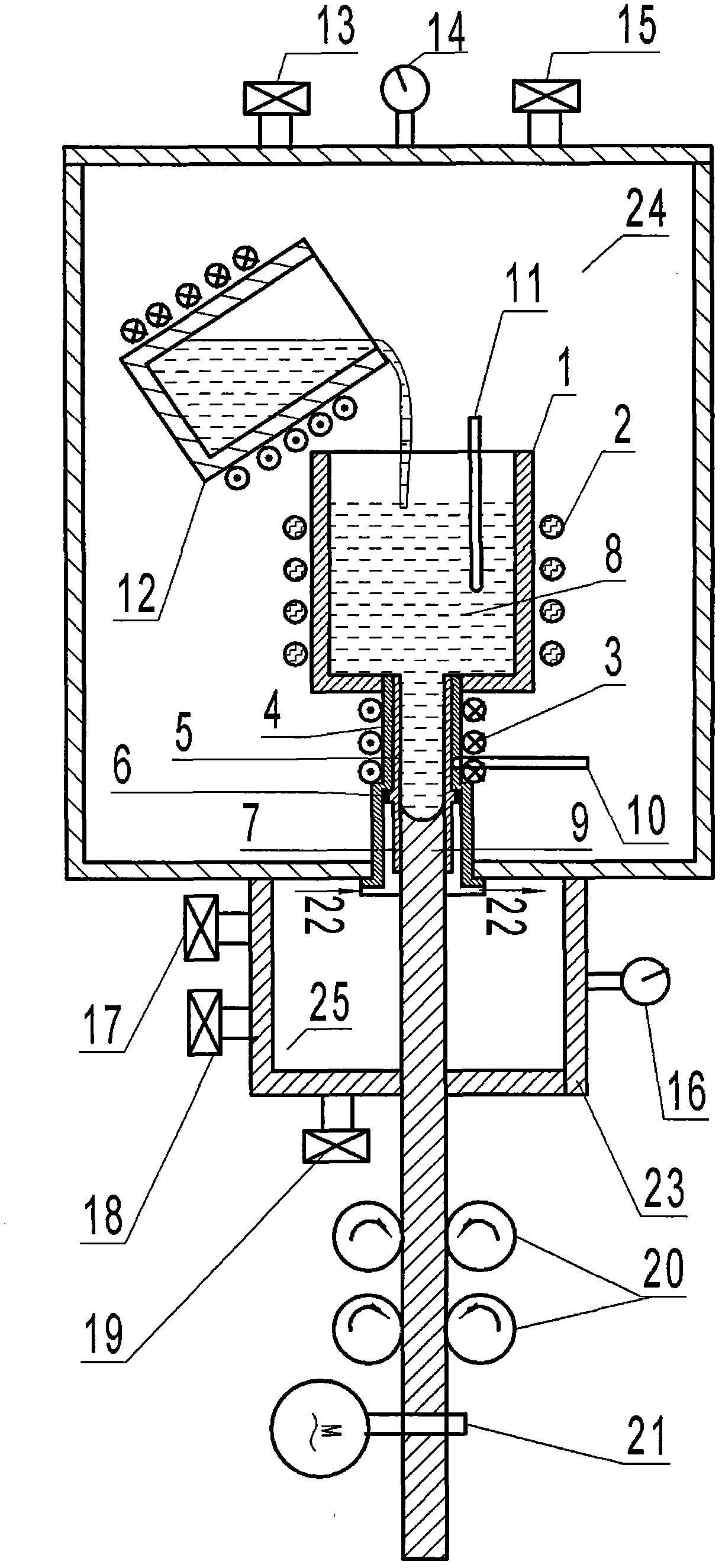

Device and method for continuously preparing bulk amorphous alloy ingots

The invention relates to a device and a method for continuously preparing bulk amorphous alloy ingots, which are characterized in that the preparation device comprises two vacuum chambers which are mutually independent. A main vacuum chamber is used for alloy melting and forming, and an auxiliary chamber is used for balancing pressure to facilitate throwing and secondary cooling. The primary cooling section of the preparation device and the method adopts a graphite pipe to be cast with a water cooling copper model embedding nest and is a main cooling part. The secondary cooling section adopts water cooling or natural cooling modes protected by inert gas and is an auxiliary cooling part. The device and the method have the advantages of having large cooling speed, meeting requirements of the bulk amorphous alloy ingots for formation, being simple in structure and capable of conveniently achieving metal continuous formation control and operation under vacuum inert gas atmosphere, and being strong in adaptability and capable of achieving continuous formation of ingots with various section shapes due to the fact that nesting cast with different inner cavity shapes and sizes, thereby being mainly suitable for continuous manufacture fields of the bulk amorphous alloy ingots.

Owner:王东

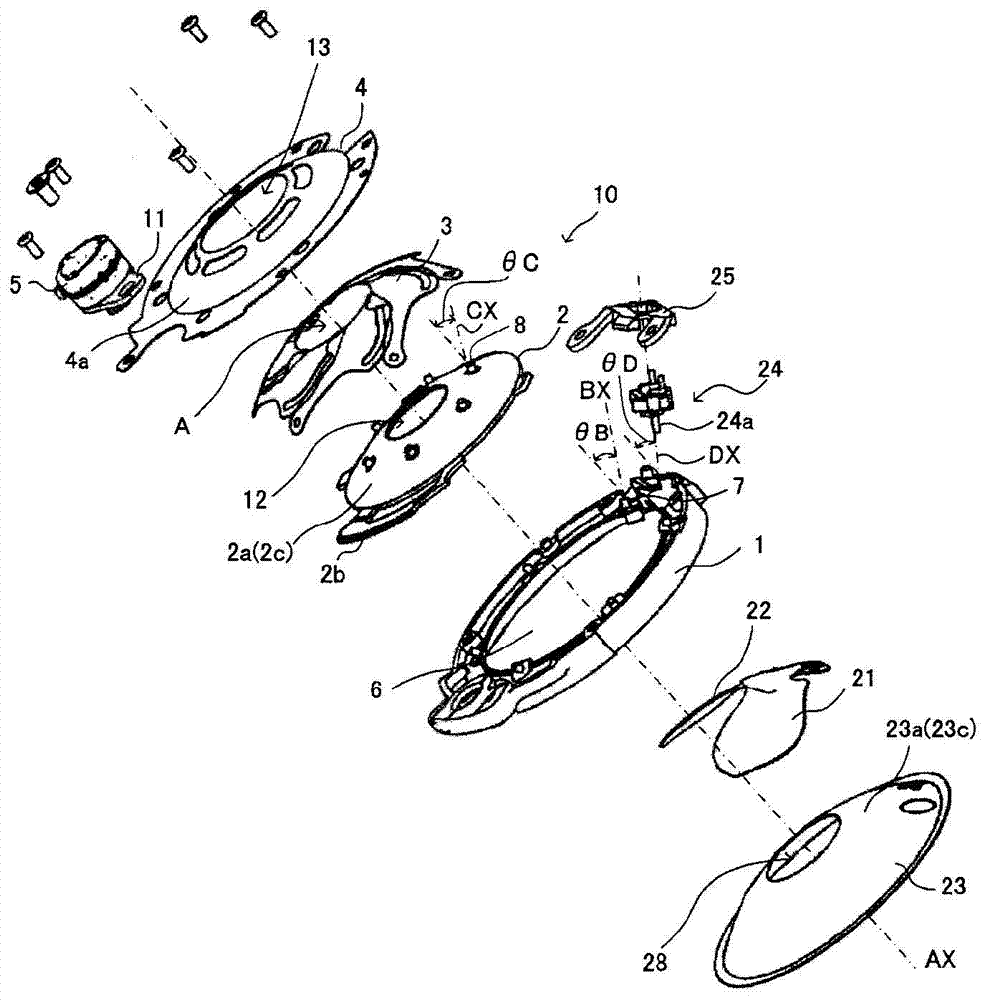

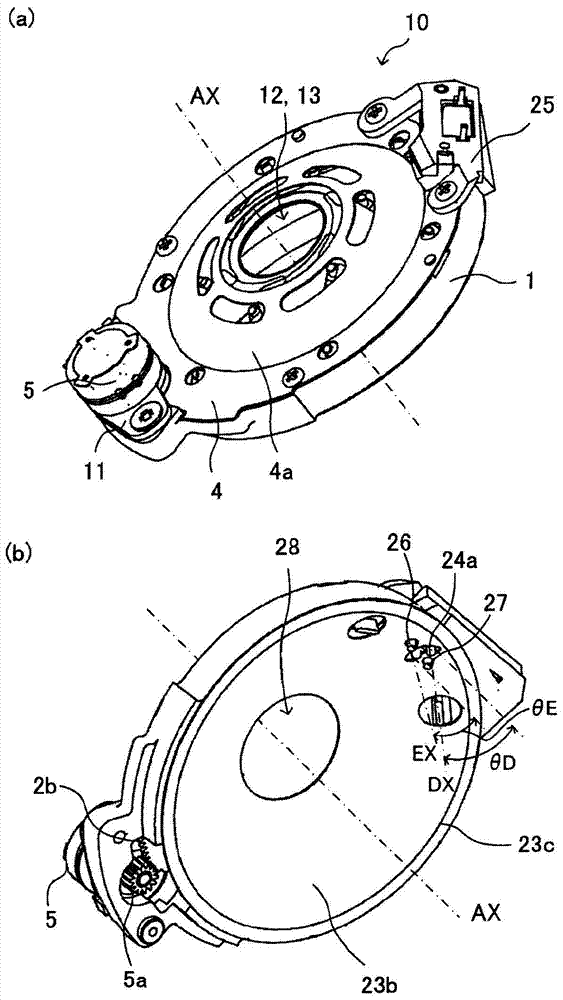

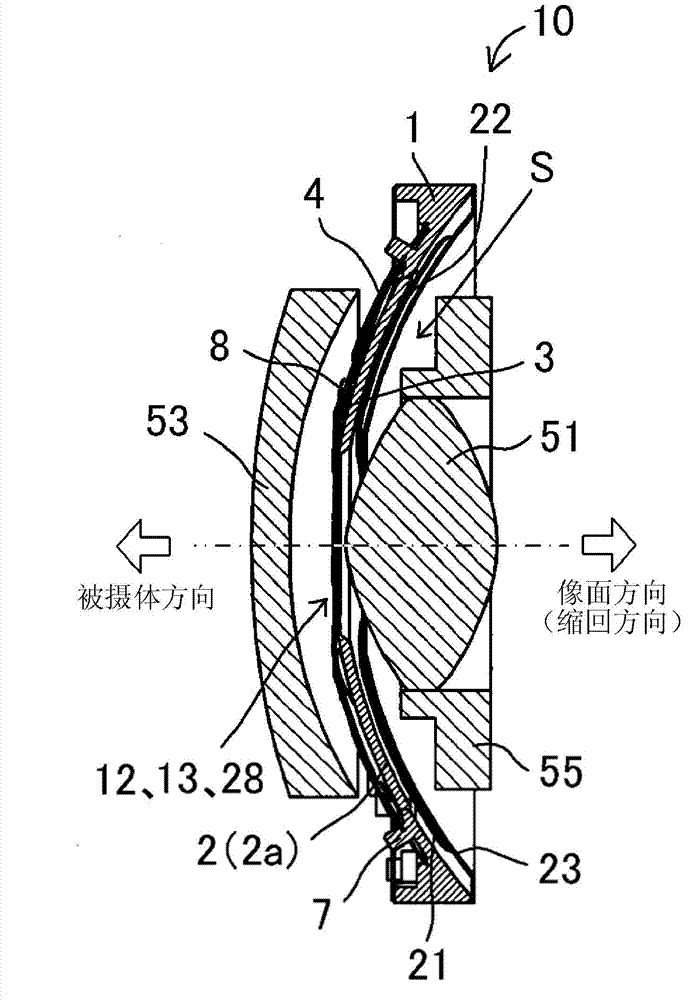

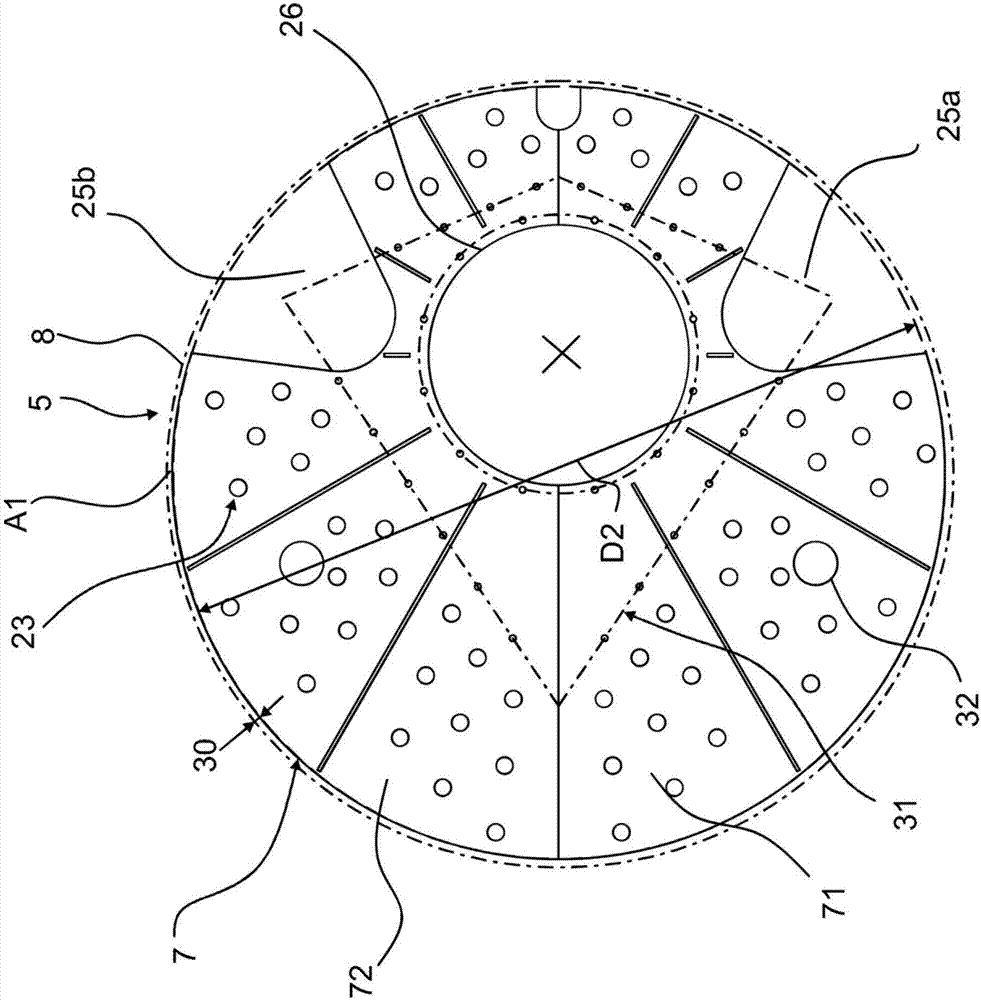

Light quantity adjustment device and optical apparatus

[Problem] To suppress increase in size in the radial direction of a light quantity adjustment device having an aperture blade and a shutter blade, and to make same more compact in the optical axis direction. [Solution] A light quantity adjustment device (10) (Fig. 1) has: an aperture blade (3) having an aperture section (3a) for increasing and decreasing the amount of light passing through light passage openings (12, 13, 28), and a supported section (3b); and a shutter blade (21) having a shutter section (21a) for blocking the passage of light in the light passage openings, and a supported section (21b). The supported sections in the aperture blade and the shutter blade each have a slope (a,ss) on the same side in the optical axis direction relative to an opening surface (P), such that the aperture section and the shutter section are separated in the optical axis direction from their respective supported sections. In addition, a drive member (2) has a recessed shape on one side, from the outer peripheral side through to the inner peripheral side. As a result, a recessed space (S) facing the light passage openings is formed further on the inside in the radial direction than the aperture blade, the drive member, and the shutter blade.

Owner:CANON DENSHI KK

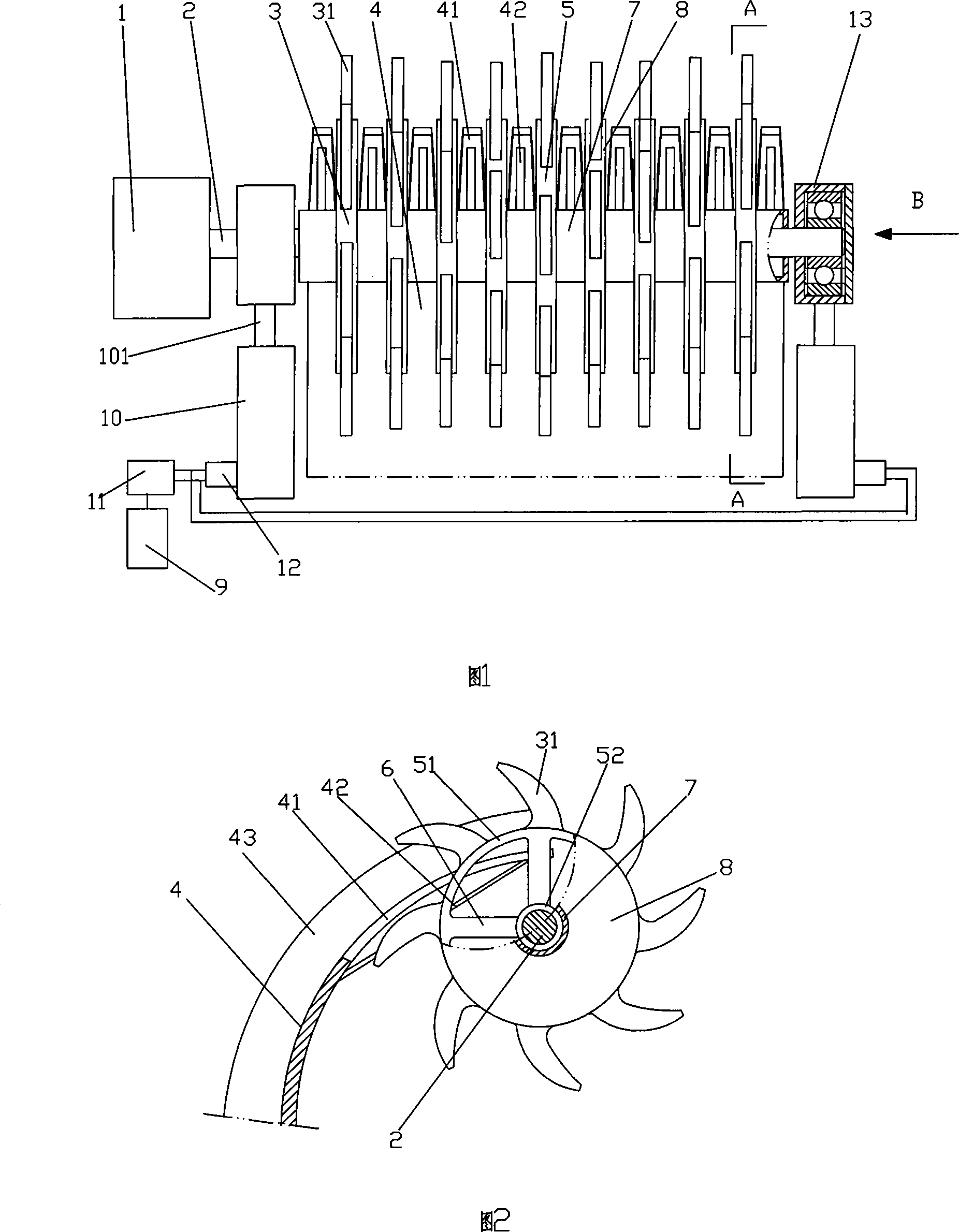

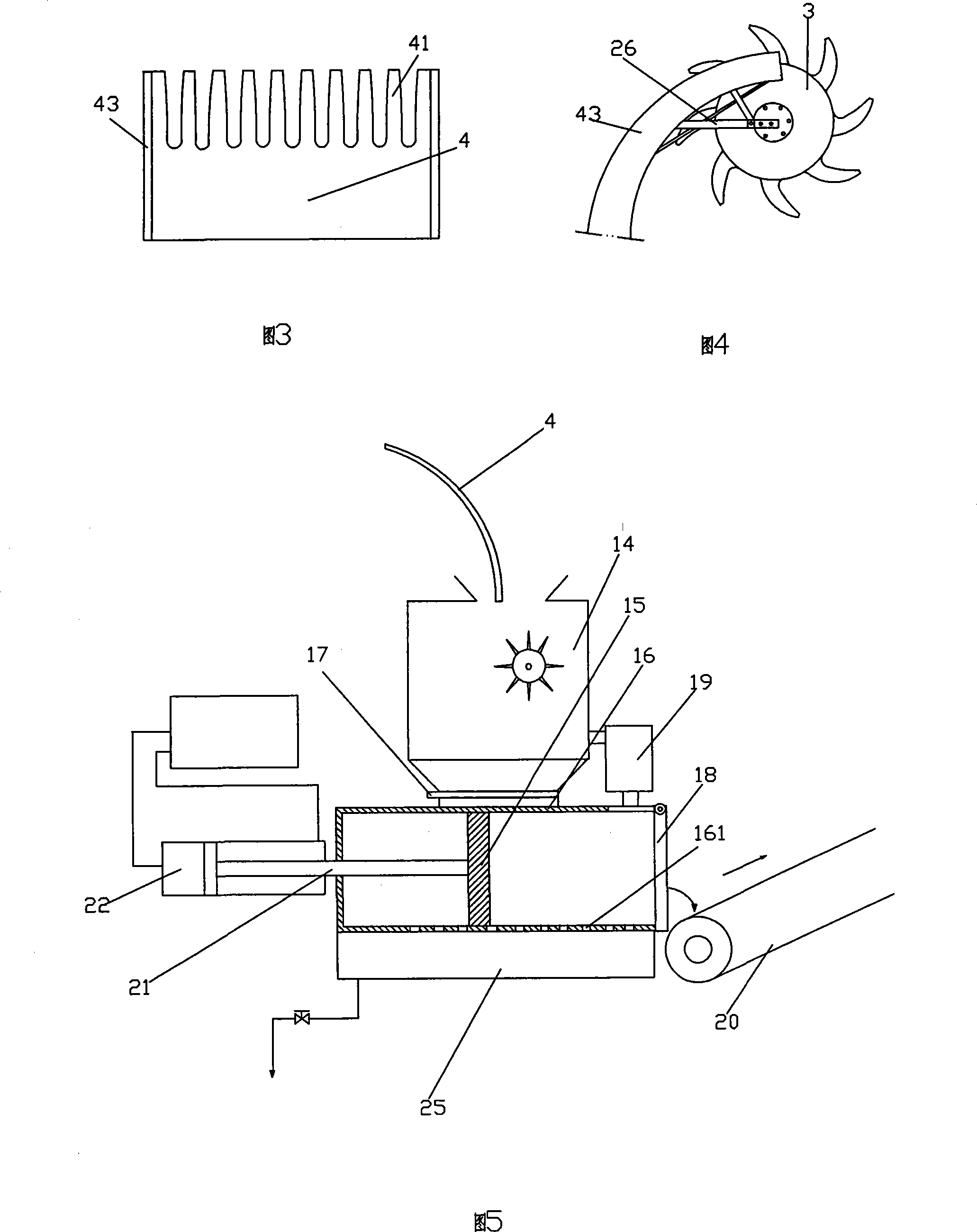

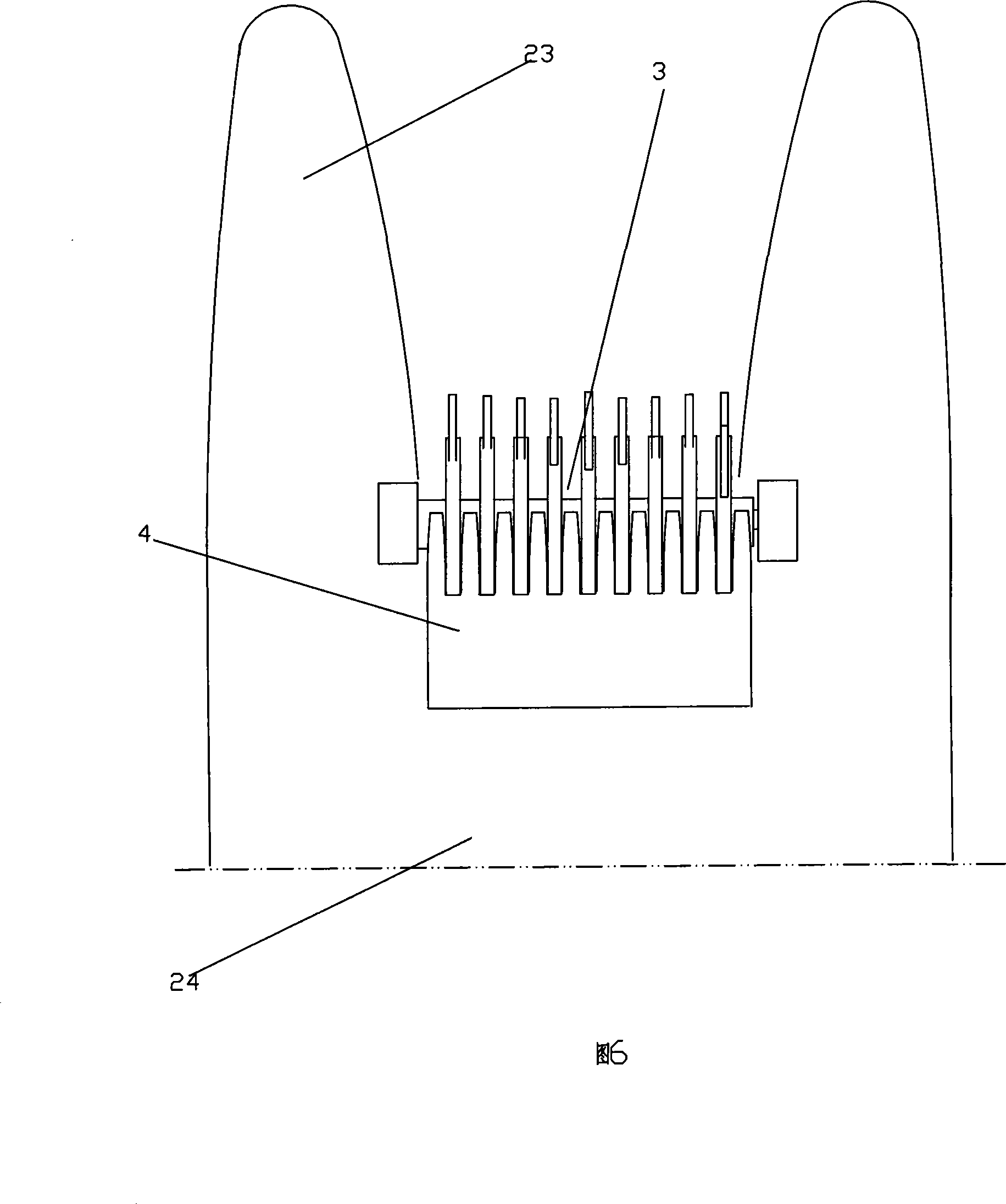

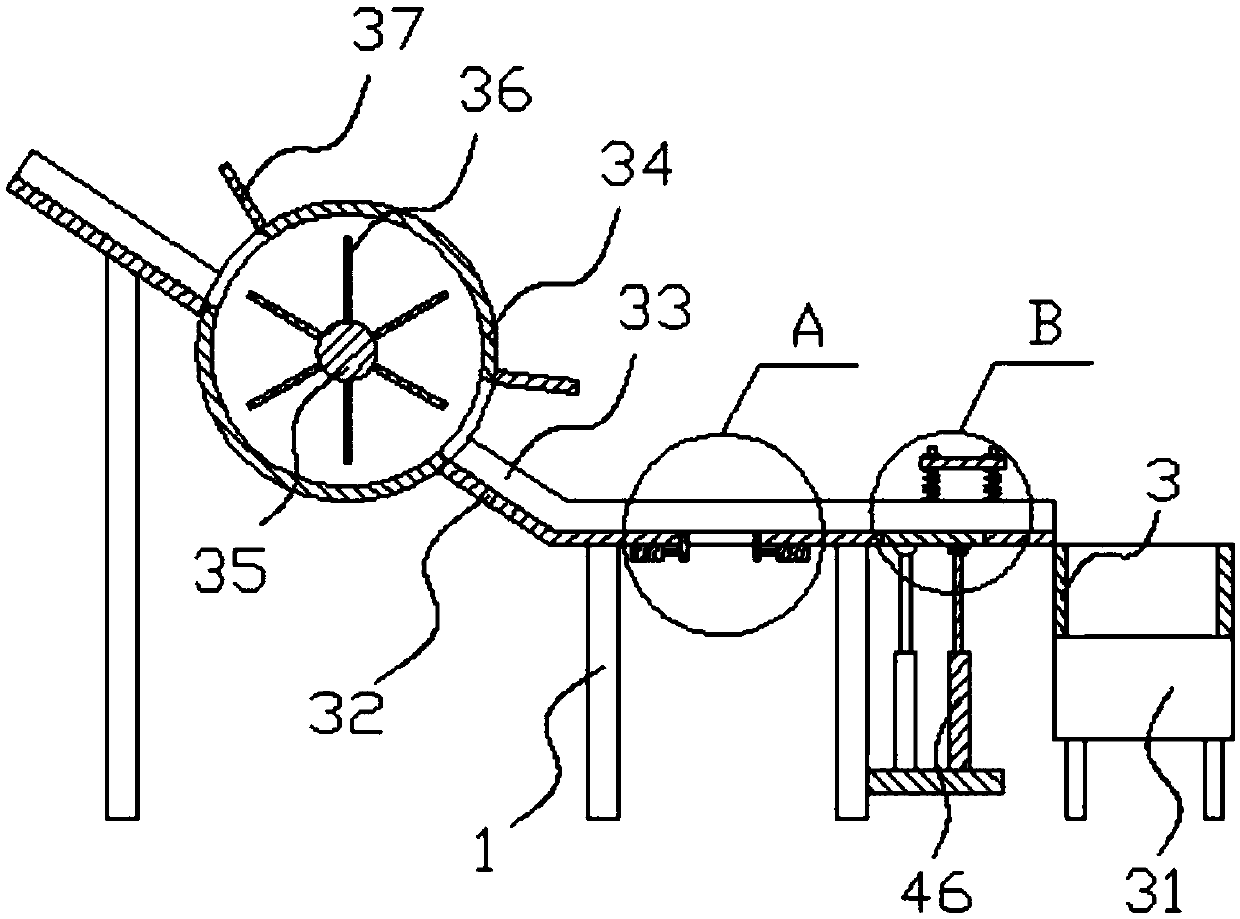

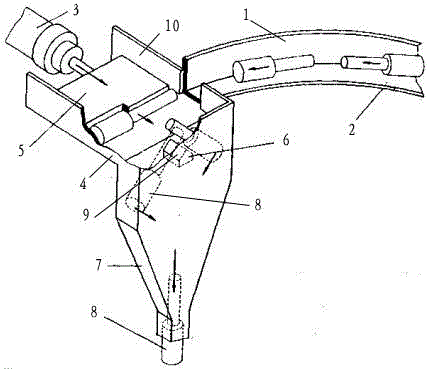

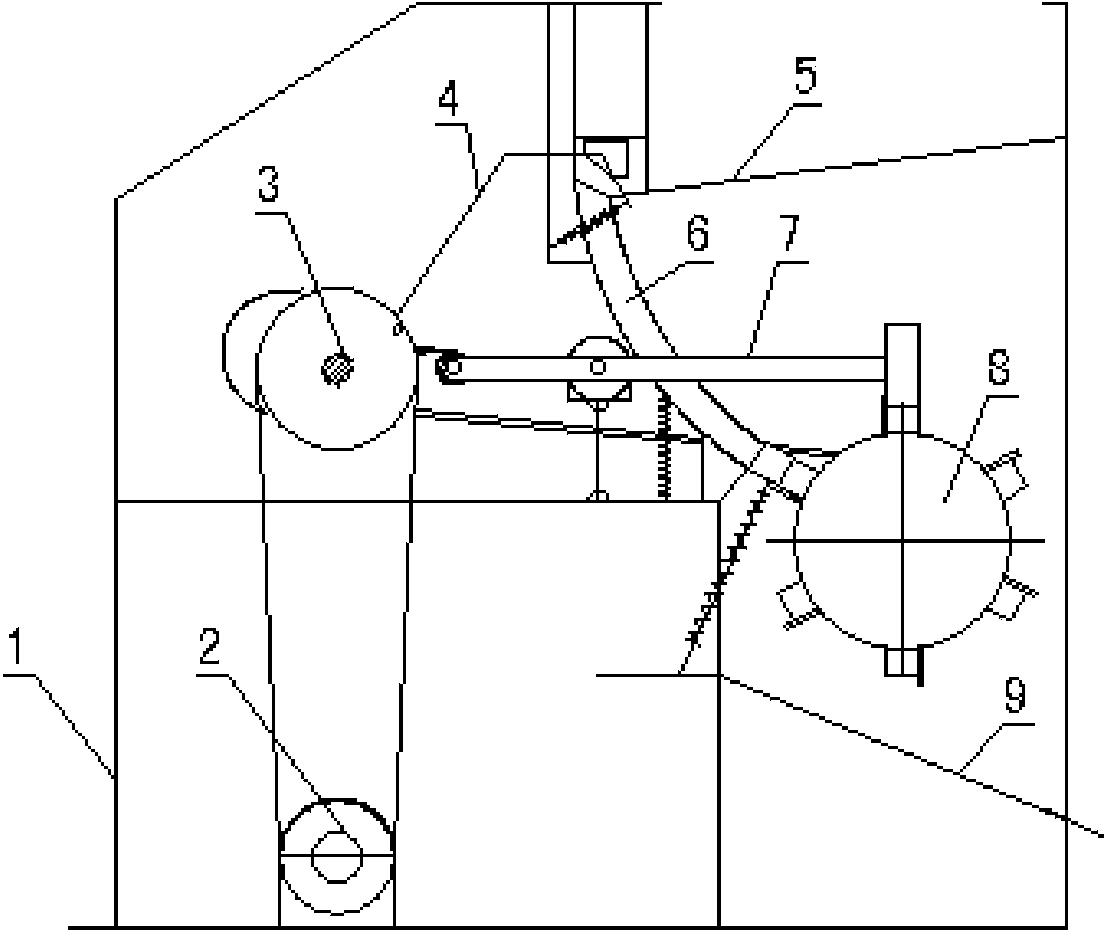

Device for cleaning waters floating material

The invention discloses a water area flotage cleaning device, which comprises a power device, a catcher, a separator and a flotage processing and recycling device, wherein the catcher comprises a rotary shaft and at least one catching gear, the power device matches with the rotary shaft to drive the rotary shaft, the catcher gear is arranged relative to the rotary shaft radial direction and is fixed and matched with the rotary shaft, the separator and the non-rotary part of the catcher are relatively fixed, the separator is arranged from the upper side to the lower side, the upper side is set in a comb gear shape, the comb gear shape is composed of at least two separating gears arranged in axial direction, the adjacent separate gears are arranged on both sides of the catcher gear with a gap to the catcher gears. The invention has simple and compact structure, high mechanic degree, small energy consumption, short flow, small occupancy area, easy operations, high work efficiency, environment protection property, convenient maintenance, simple process, and can maximally save labors, resources and process cost.

Owner:CHONGQING UNIV

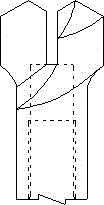

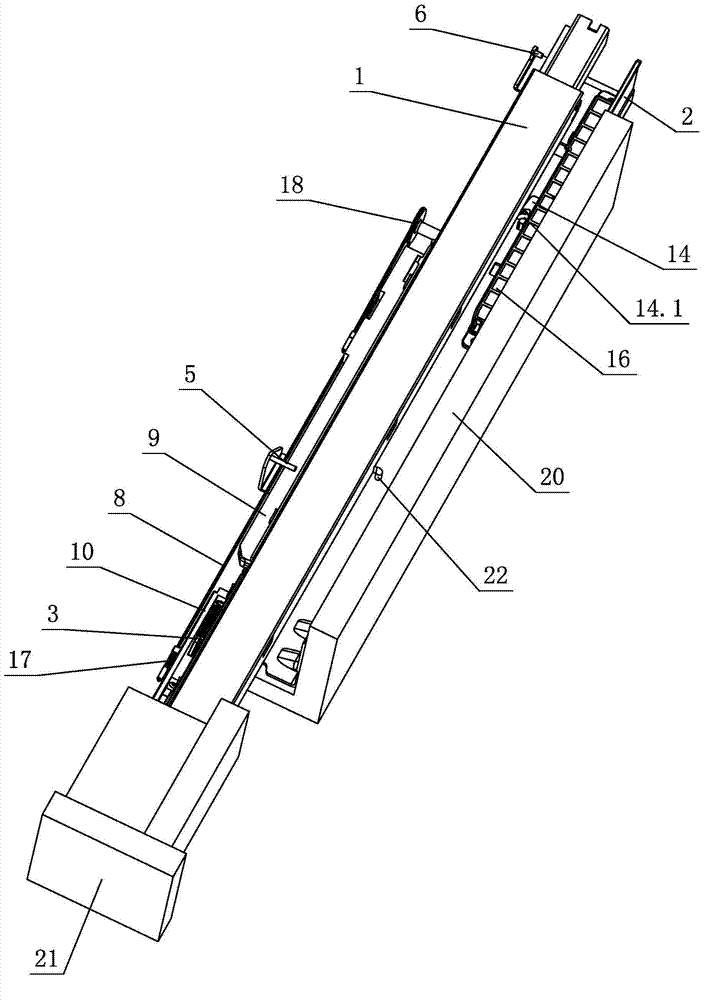

Multiple step type drilling and protecting integrated system and process for soft coal seam

ActiveCN102747953AEffective supportLarge diameterDrill bitsDirectional drillingWhole bodyAir compressor

The invention discloses a multiple step type drilling and protecting integrated system and a process for a soft coal seam. The system mainly comprises an air compressor, a high-pressure rubber hose, a hole protecting drilling machine, a rack, a hole protecting drilling rod, a guider and a simple drill. The process comprises the steps of firstly drilling a hole by using a common drilling rod and a common drill and pulling the common drilling rod and the common drill out of the hole after the hole is formed; then performing second drilling of the formed drill hole by using the hole protecting drilling rod and the simple drill in a matching mode, and simultaneously performing wind-power auxiliary slagging, when an end hole point is drilled, the hole protecting drilling rod is not withdrawn, the whole body is left inside the hole, and hole wall supporting and gas extraction functions are achieved; and finally pulling out and recycling the hole protecting drilling rod through the hole protecting driller after the gas extraction is completed. According to the system and the process, the process is unique, a hole protecting pipe can transmit high-pressure air and can extract gas, the coal dust discharging performance is strong, the hole protecting pipe moves forwards along the drill hole easily, the hole protecting pipe diameter is large, the hole protecting length is long, the problems that the soft coal seam is small in hole protecting pipe diameter and short in feeding distance are solved, and the system and the process are particularly suitable for soft high gas coal seams with a value of a sturdiness coefficient f, which ranges between 0.3 and 0.8.

Owner:CHINA UNIV OF MINING & TECH

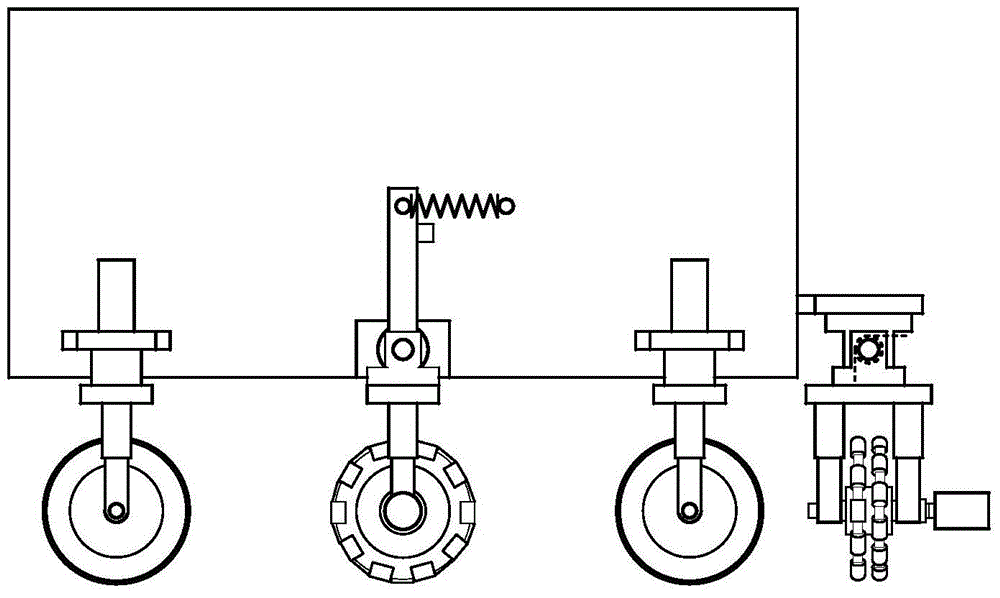

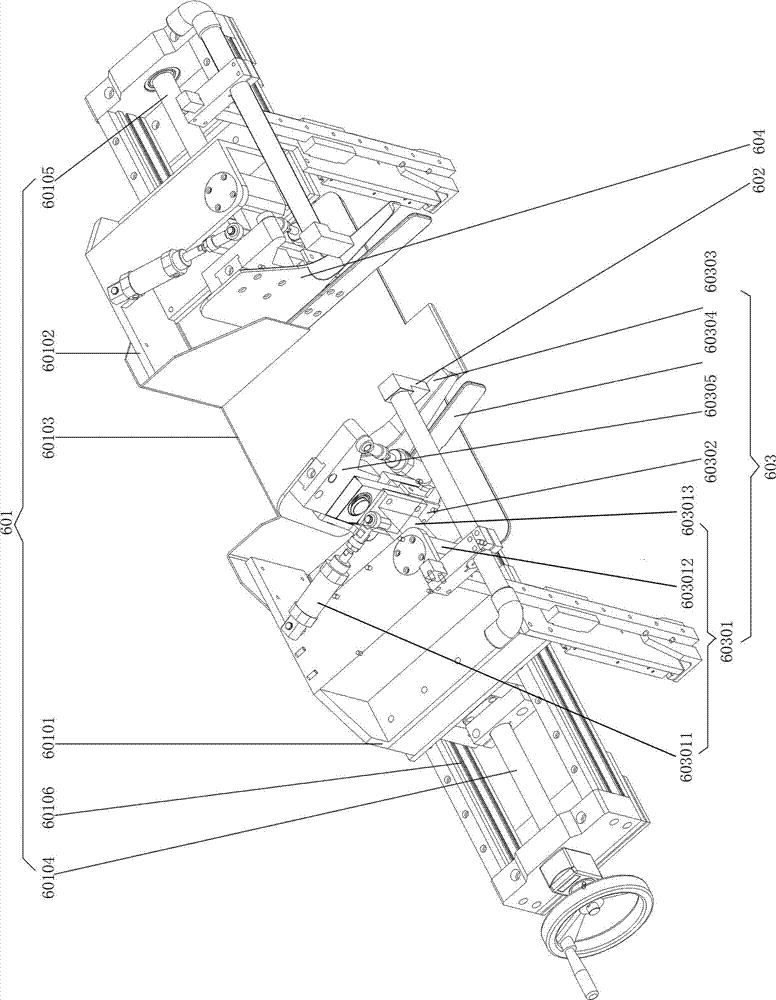

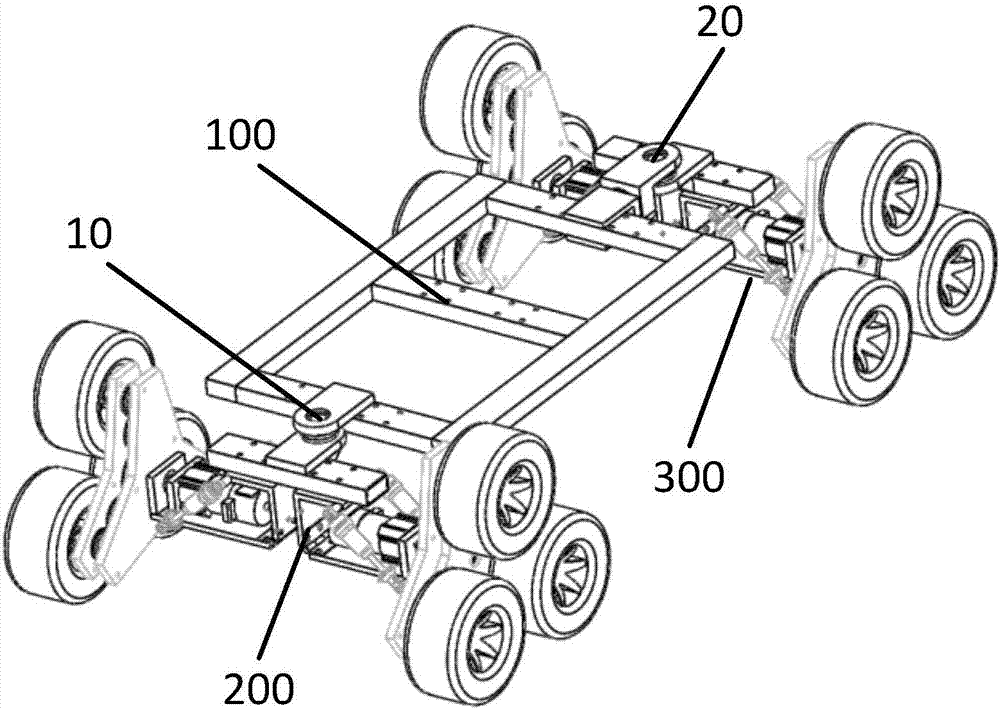

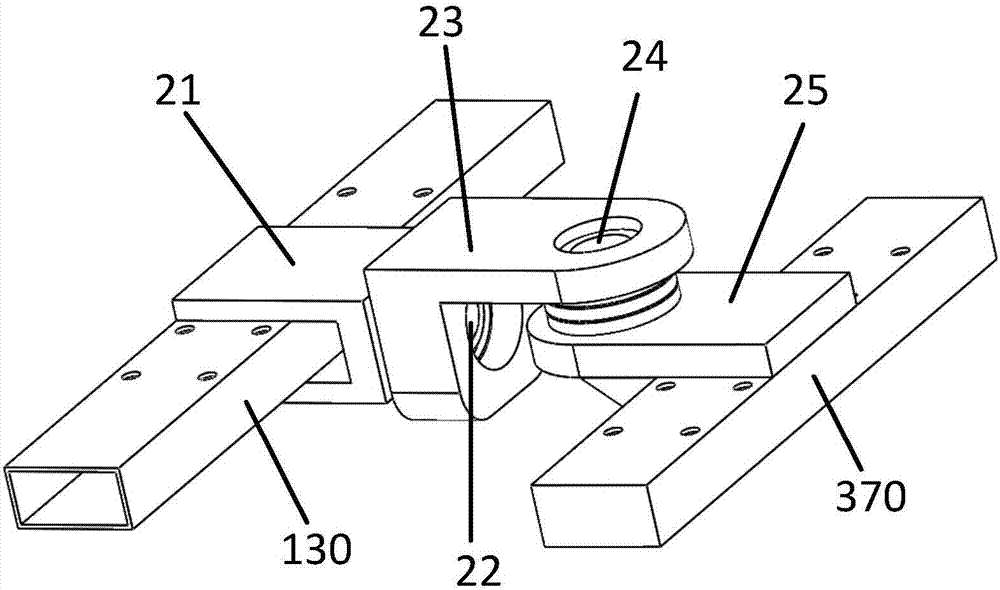

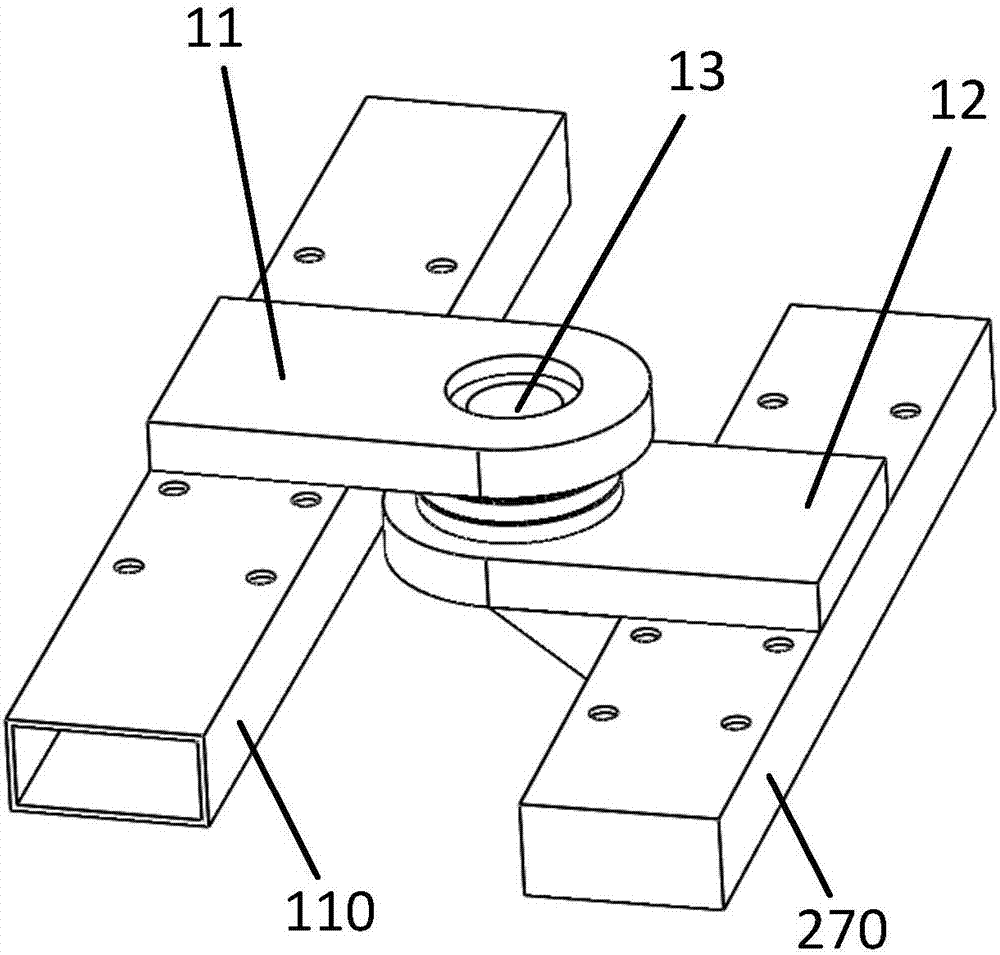

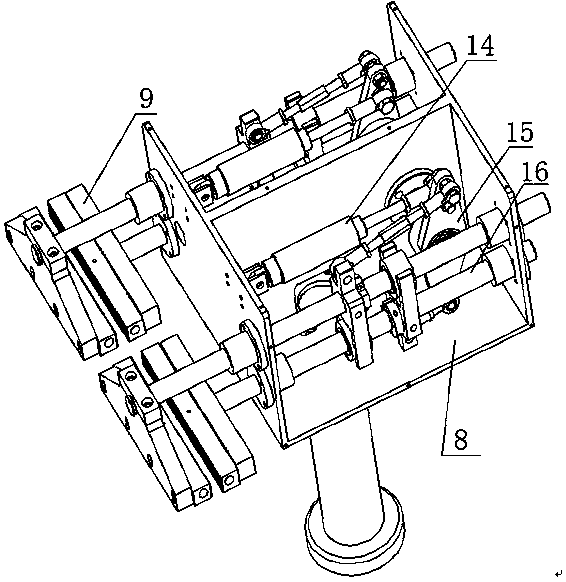

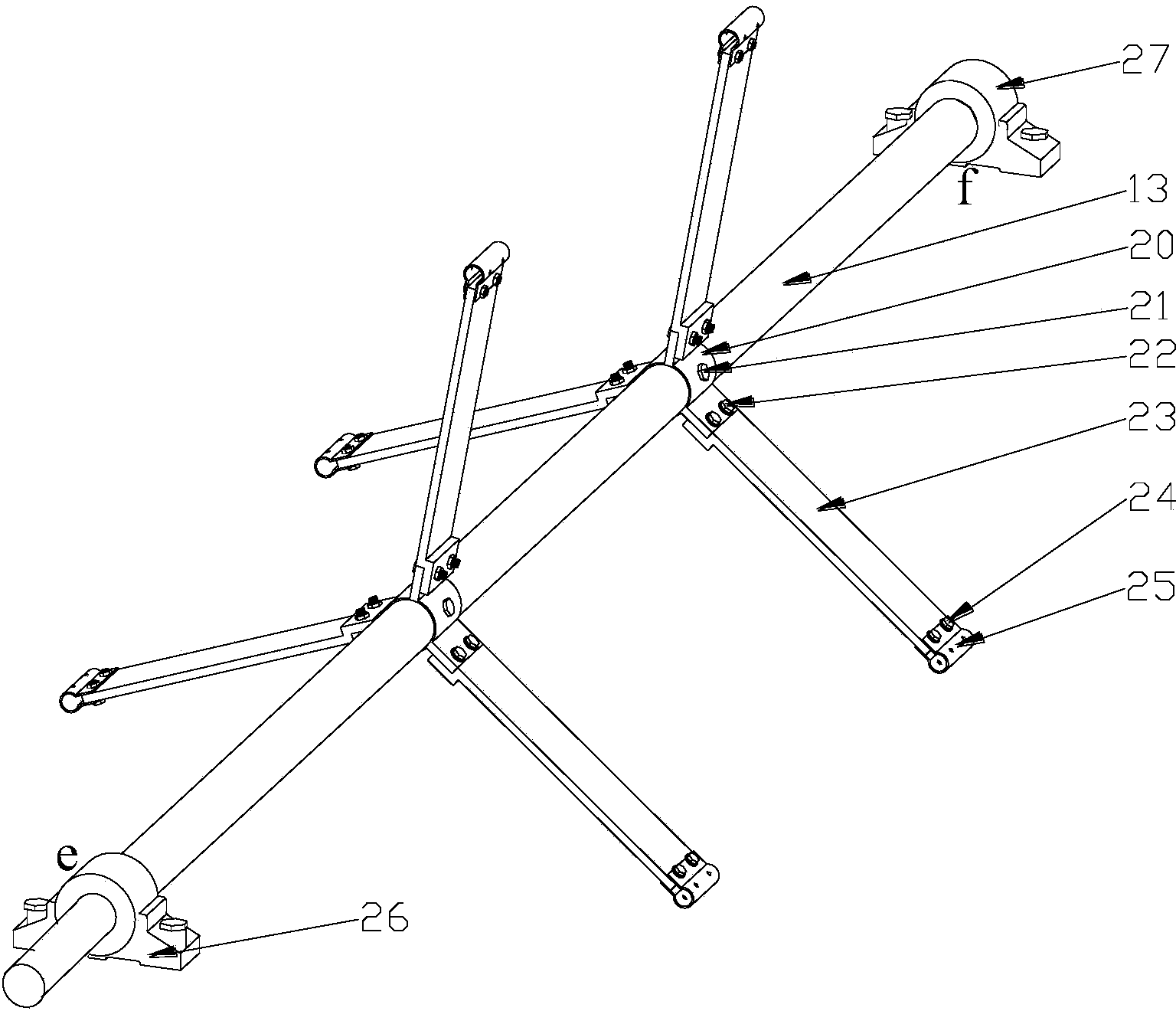

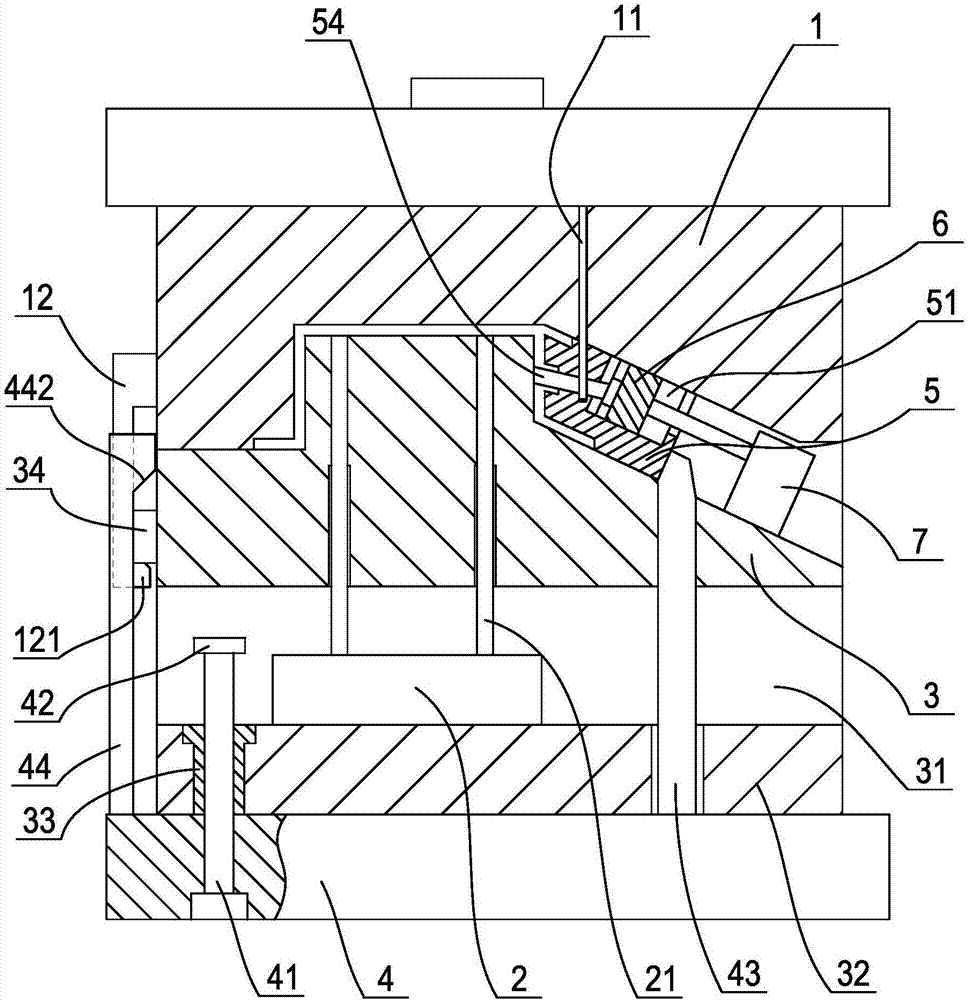

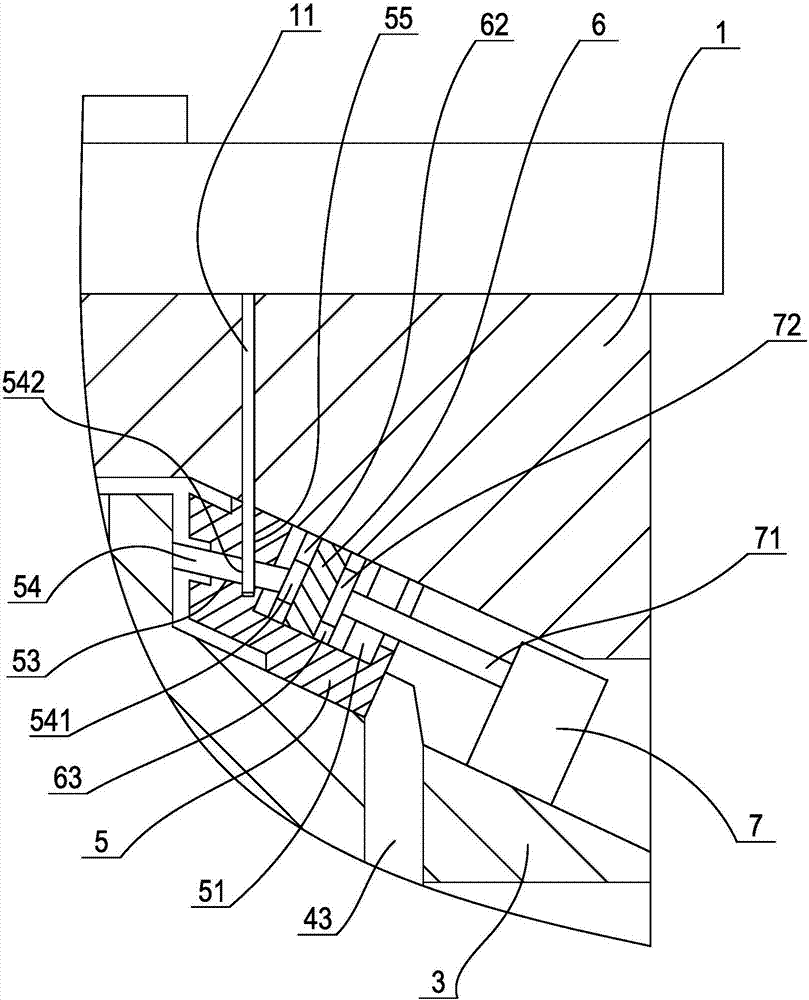

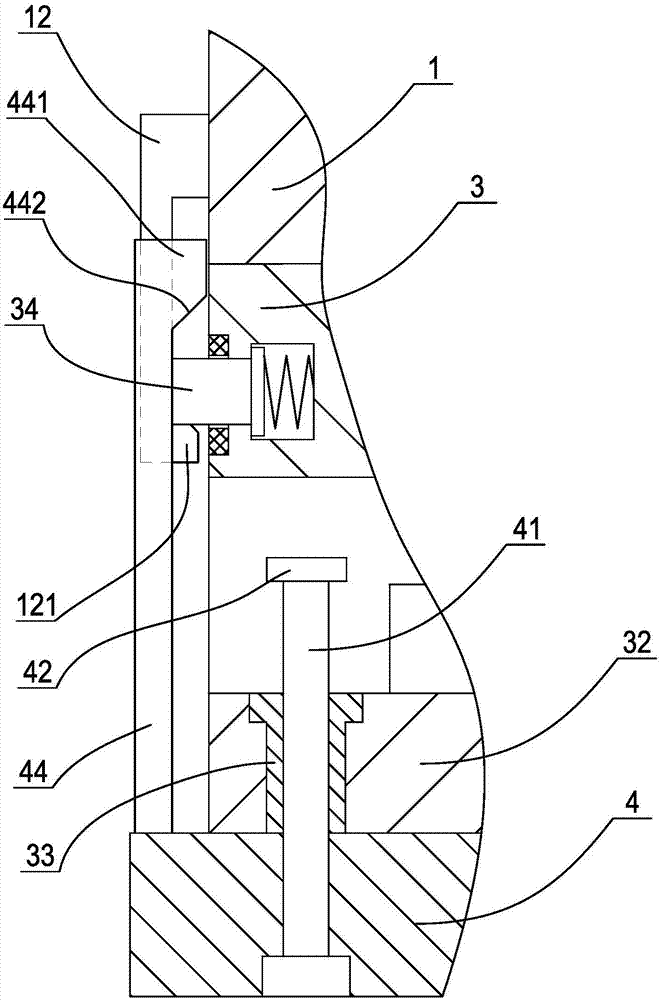

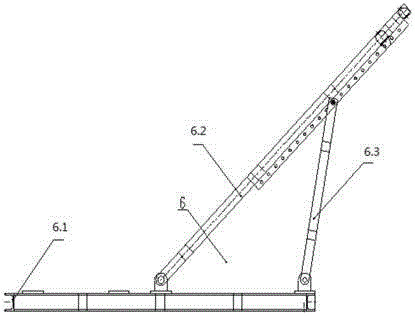

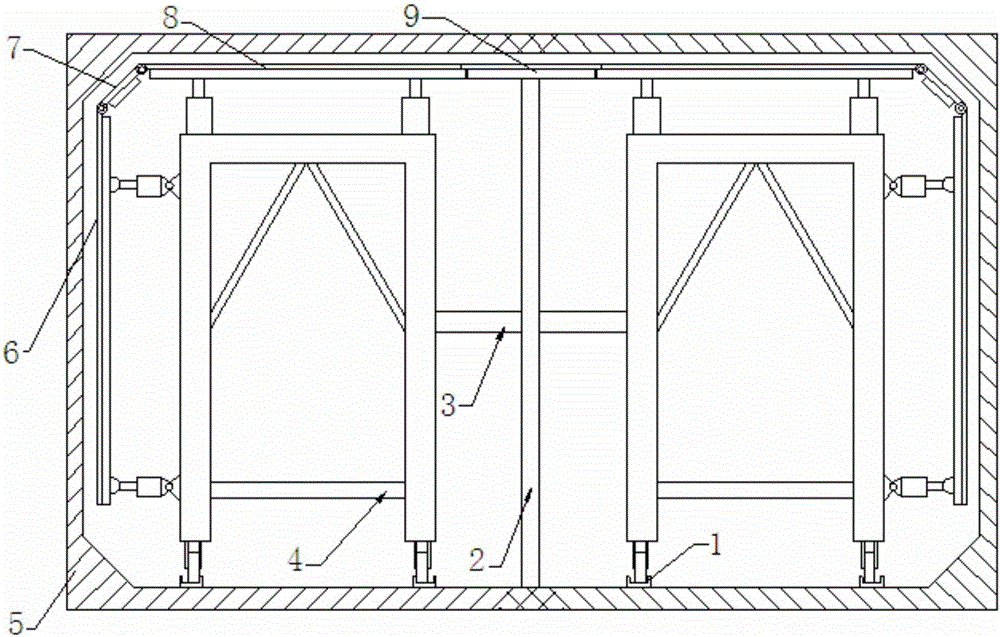

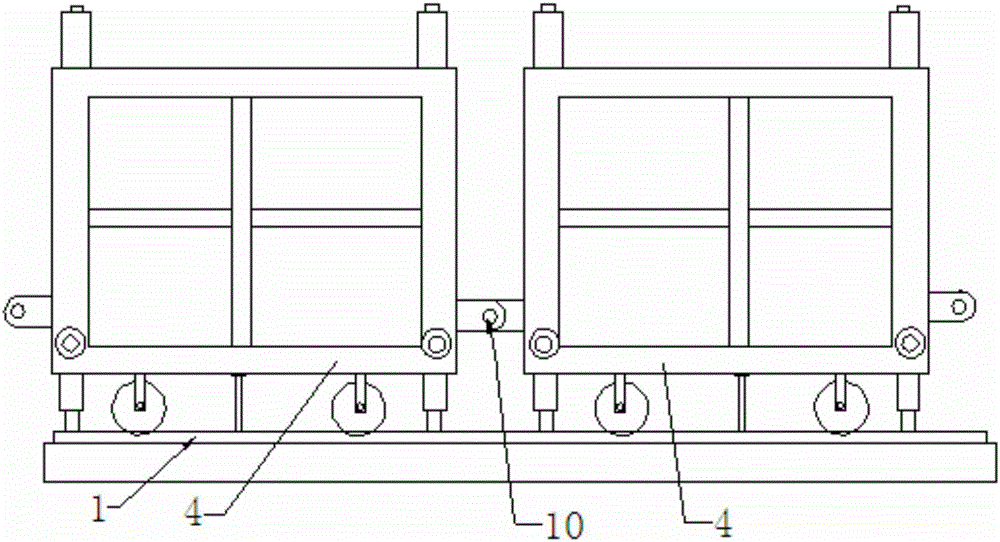

Planet wheel type obstacle-crossing robot suitable for rotating stair

ActiveCN106892014AAvoid getting stuckImprove obstacle performanceVehiclesObstacle crossingAutomotive engineering

The invention belongs to the relevant technical field of obstacle-crossing robots and discloses a planet wheel type obstacle-crossing robot suitable for a rotating stair. The planet wheel type obstacle-crossing robot comprises a vehicle body, a front driving set, a rear driving set, a front hinging shaft structure and a rear hinging shaft structure. The front hinging shaft structure and the rear hinging shaft structure are connected to the reverse front end and the rear end of the vehicle body correspondingly. The front driving set and the rear driving set are connected to the front hinging shaft structure and the rear hinging shaft structure correspondingly. The rear hinging shaft structure comprises a vehicle body rear supporting seat, a horizontal hinging shaft, a hinging frame, a vertical hinging shaft and a rear driving set supporting seat. The vehicle body rear supporting seat is connected to the vehicle body. The rear driving set supporting seat is connected to the rear driving set. The two ends of the horizontal hinging shaft are hinged to the vehicle body rear supporting seat and the hinging frame correspondingly. The two ends of the vertical hinging shaft are hinged to the hinging frame and the rear driving set supporting seat correspondingly.

Owner:HUAZHONG UNIV OF SCI & TECH

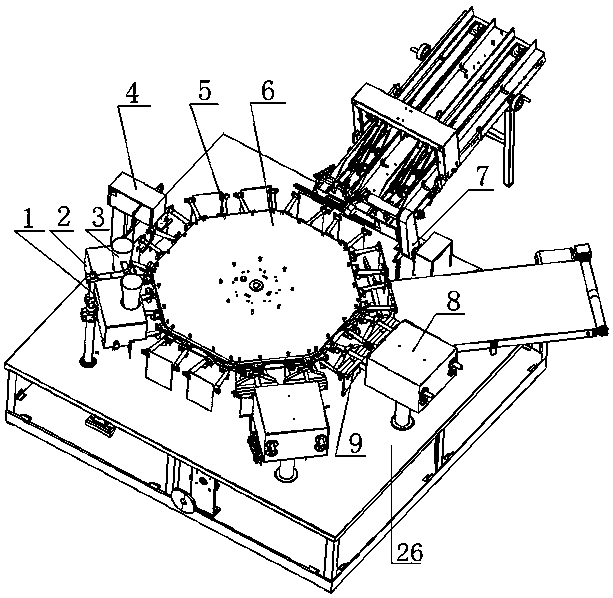

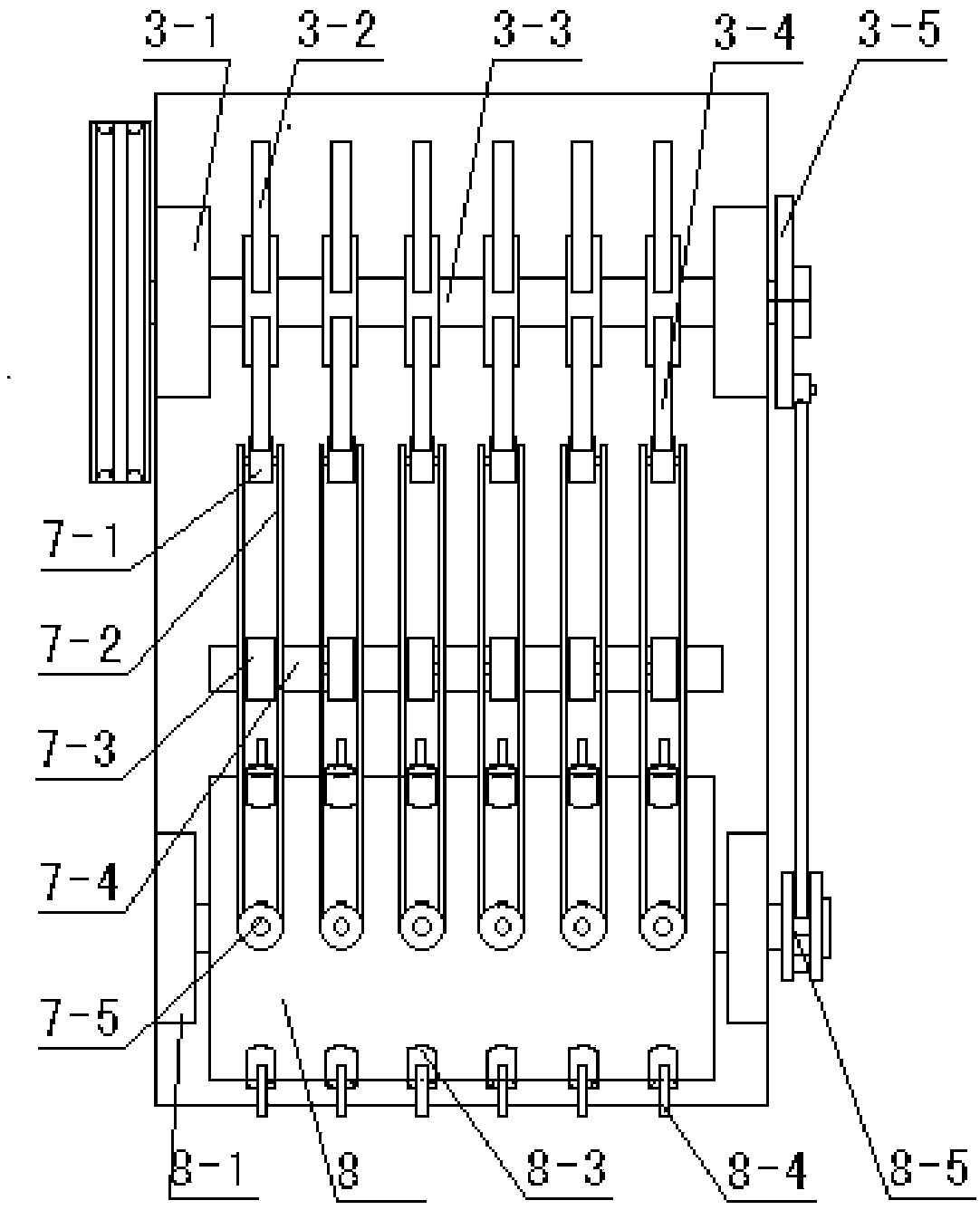

Eight-station two-row packaging machine

ActiveCN103950588AIncrease productionIncrease productivityWrapper twisting/gatheringEngineeringPackaging machine

The invention discloses an eight-station two-row packaging machine, which comprises a large rotating disc, a bag supply device, a bag clamping device, a blanking device, an opening sealing device, a bag opening and air blowing device and a work table top, wherein the blanking device comprises two blanking hoppers, a blanking shaft, a bag supporting connecting rod, bag supporting forks and a regulating screw rod, the two blanking hoppers are simultaneously connected onto the blanking shaft through a blanking hopper fixing device, one bag supporting fork is arranged under each blanking hopper, the bag supporting forks are connected onto the blanking shaft through the bag supporting connecting rod and a fixing frame, and the regulating screw rod is arranged under the bag supporting forks. The number of the blanking hoppers is two, one bag supporting fork is arranged under each blanking hopper, and the number of opening sealing air cylinders, opening sealing rocker rods, opening sealing shafts and opening sealing teeth is two groups, so the yield of a single-machine packaging machine in unit time is doubled, the production efficiency is high, the production period is short, the structure is simple, and the appearance is attractive.

Owner:QINGDAO YILONG PACKAGING MACHINERY

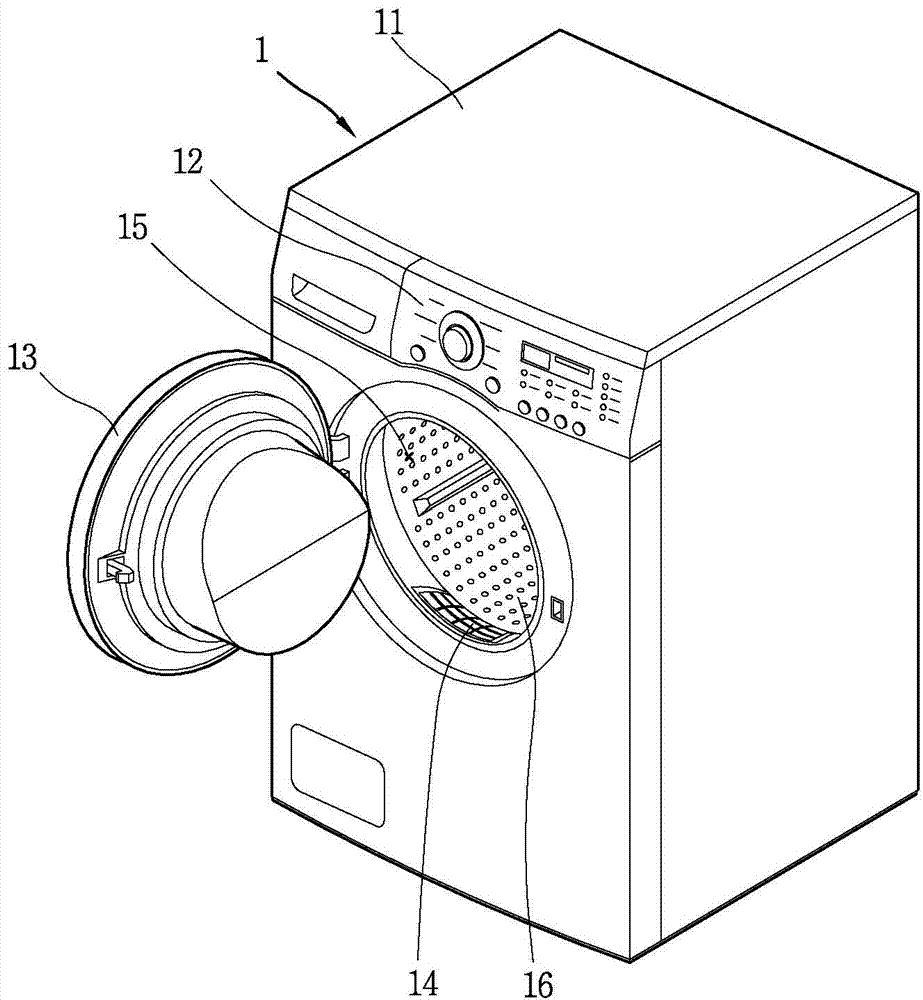

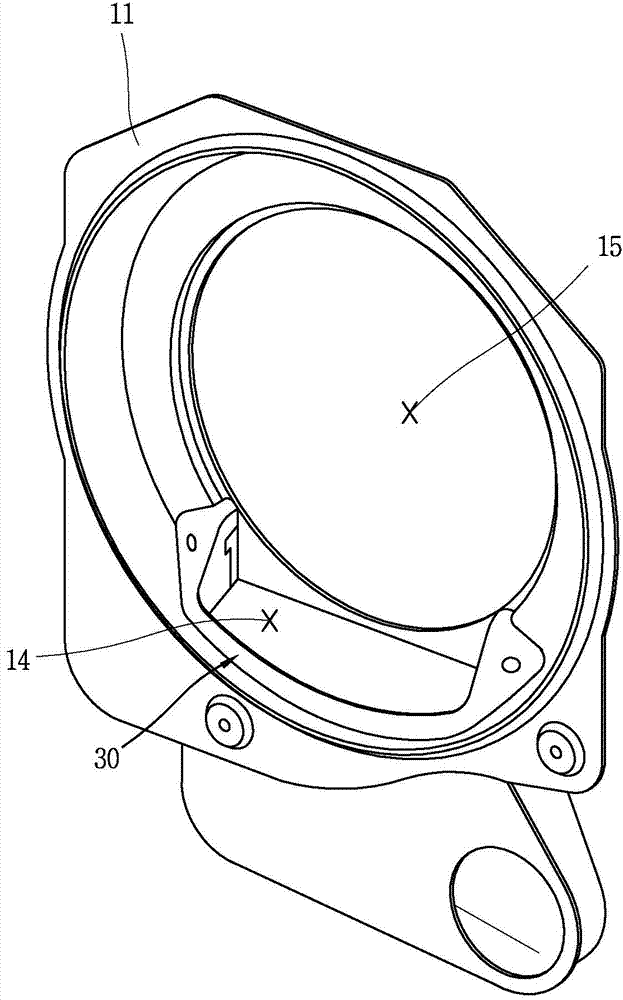

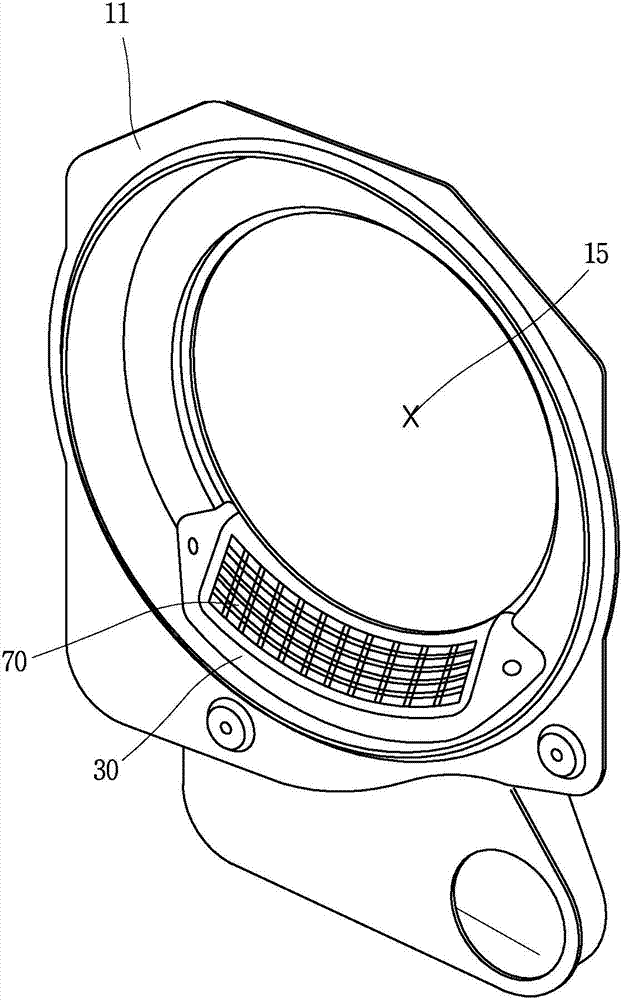

Clothes Treating Apparatus With Detecting Device For Insertion Of Filter

InactiveCN103205879AAvoid getting stuckAvoid dischargePermanent magnet reed switchesDrying gas arrangementsEngineeringMechanical engineering

A clothes treating apparatus includes a filter insertion detecting device that detects whether a filter has been inserted in the clothes treating apparatus. The filter insertion detecting device, which is installed in a clothes drying machine or the like, may be moved in response to insertion of a filter assembly to generate a contact signal that indicates insertion of the filter assembly.

Owner:LG ELECTRONICS INC

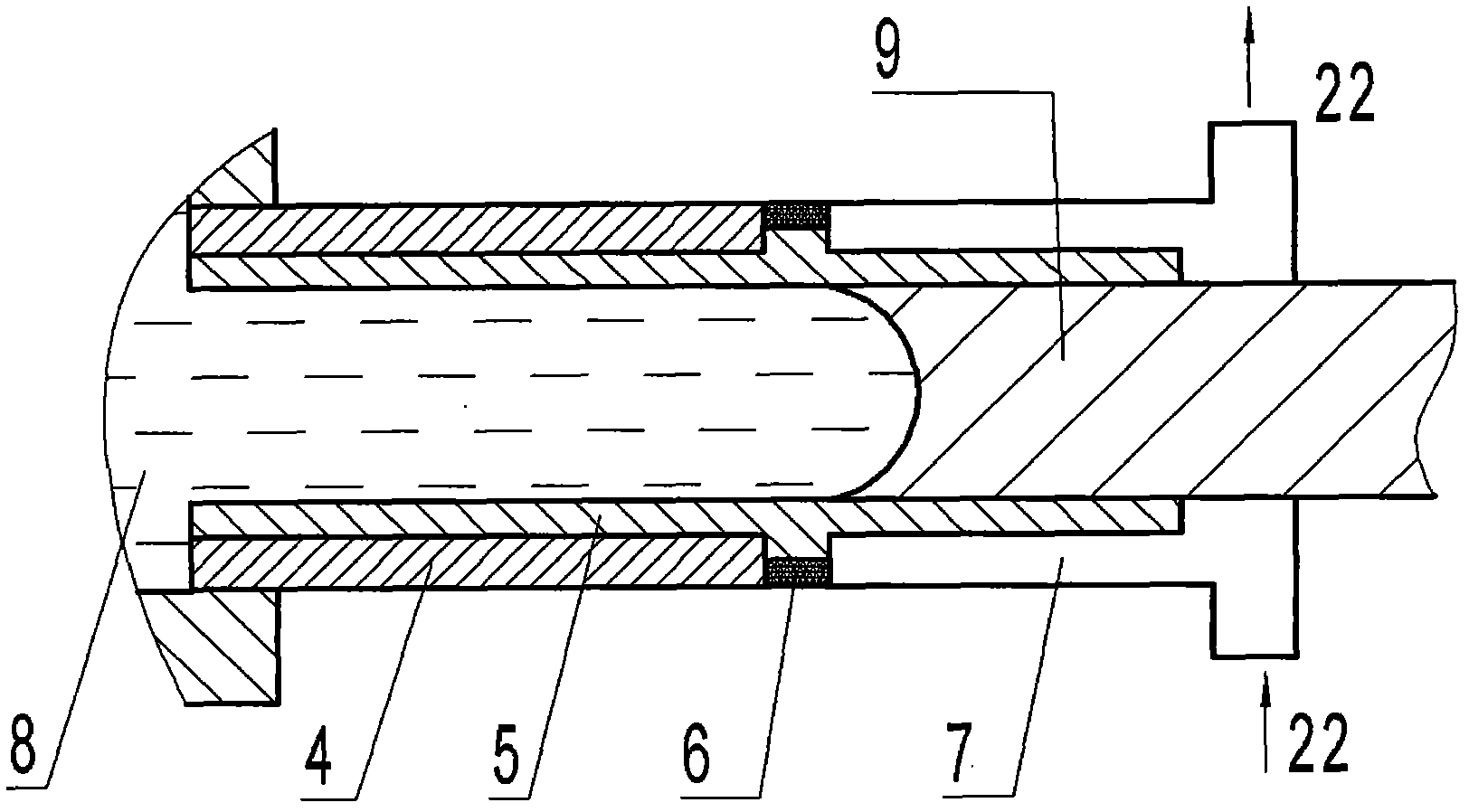

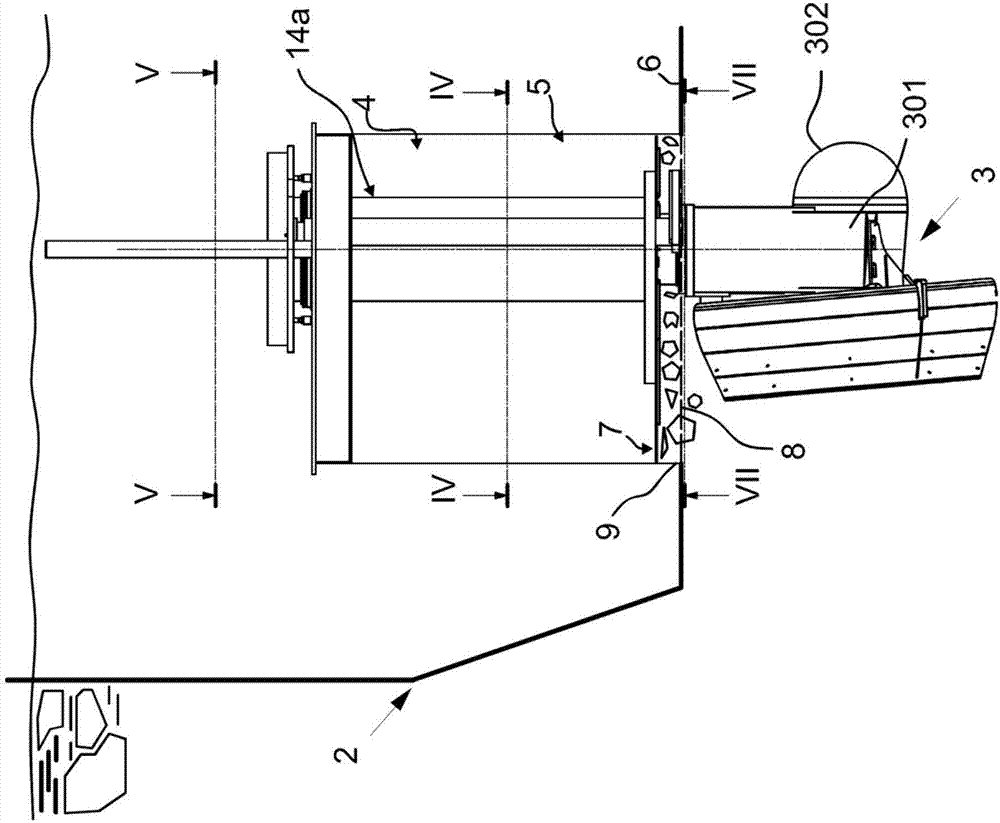

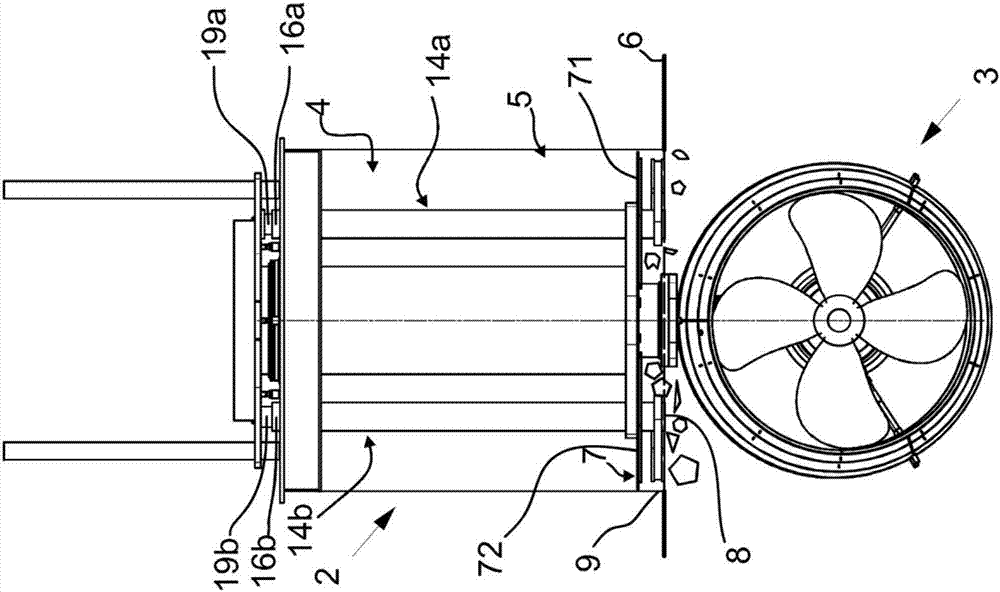

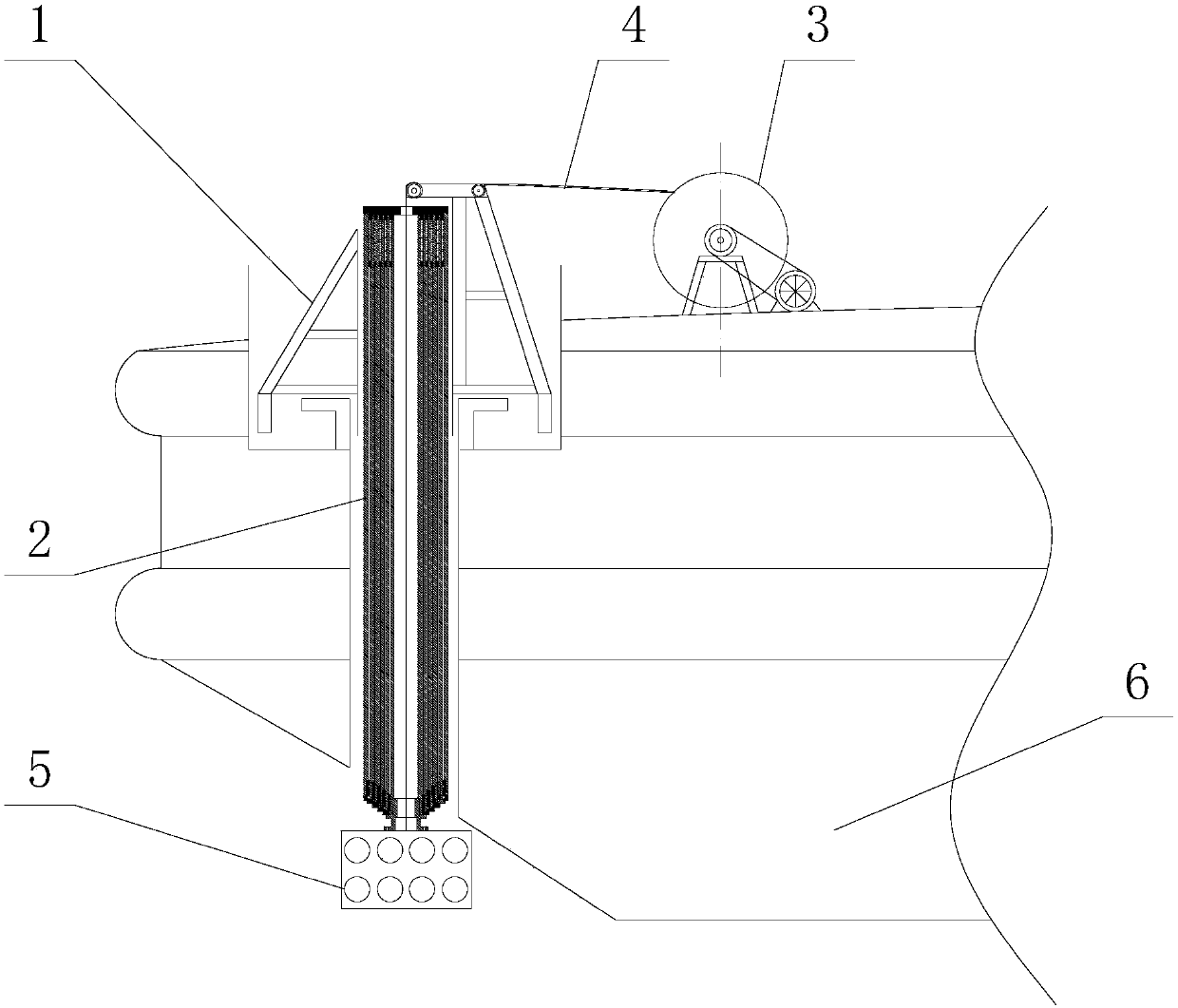

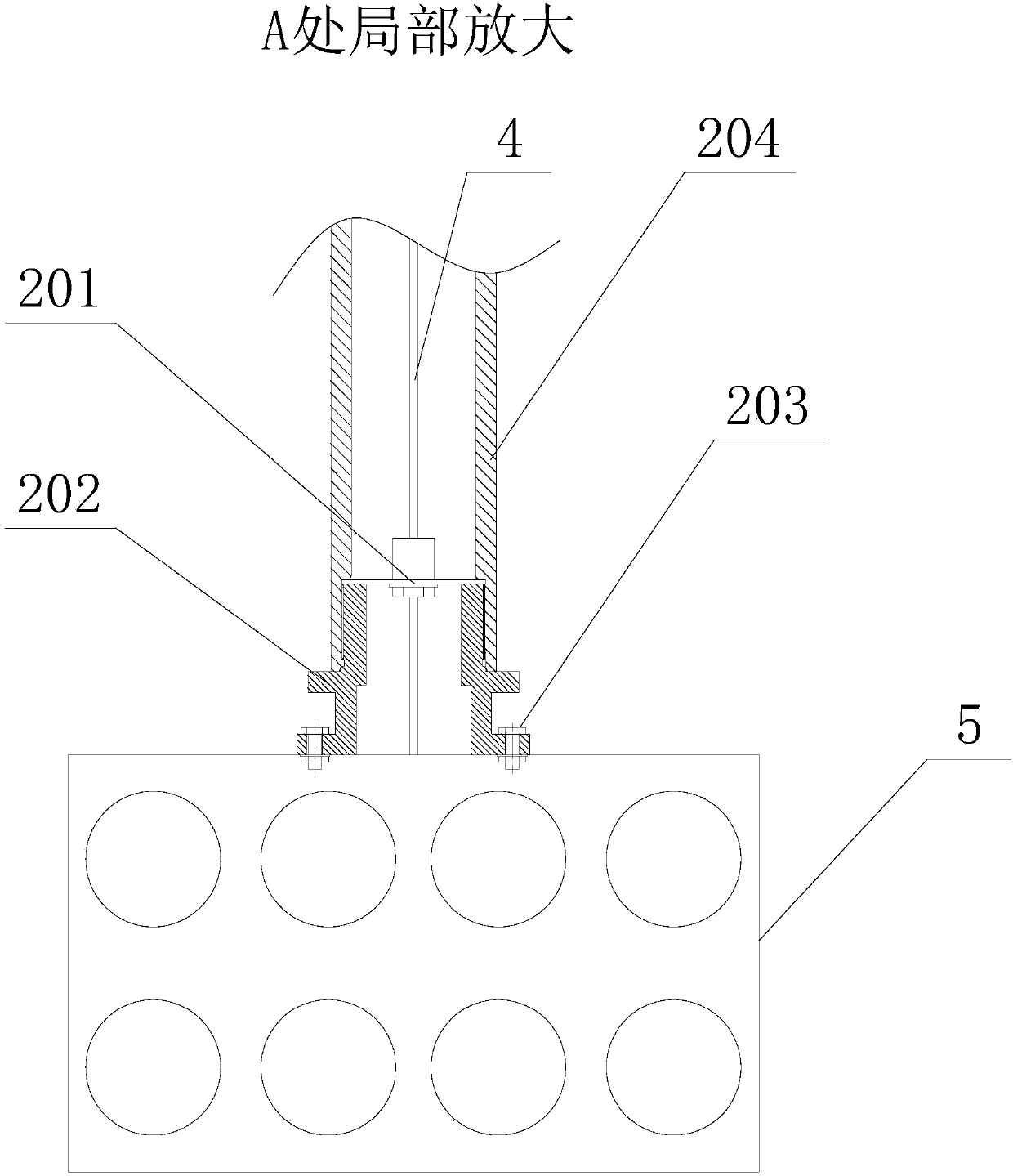

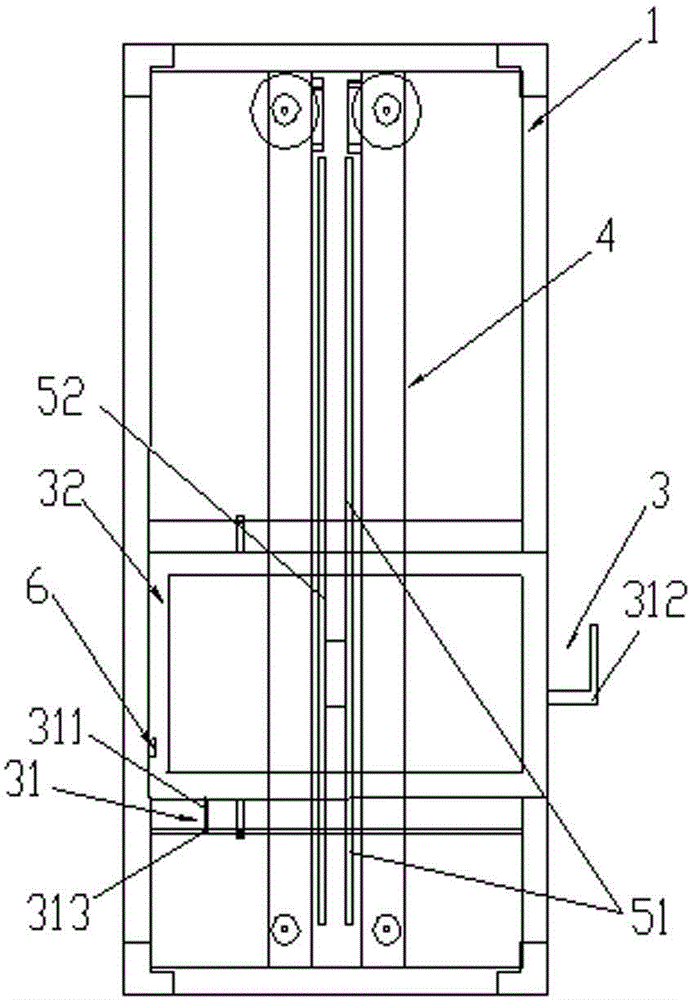

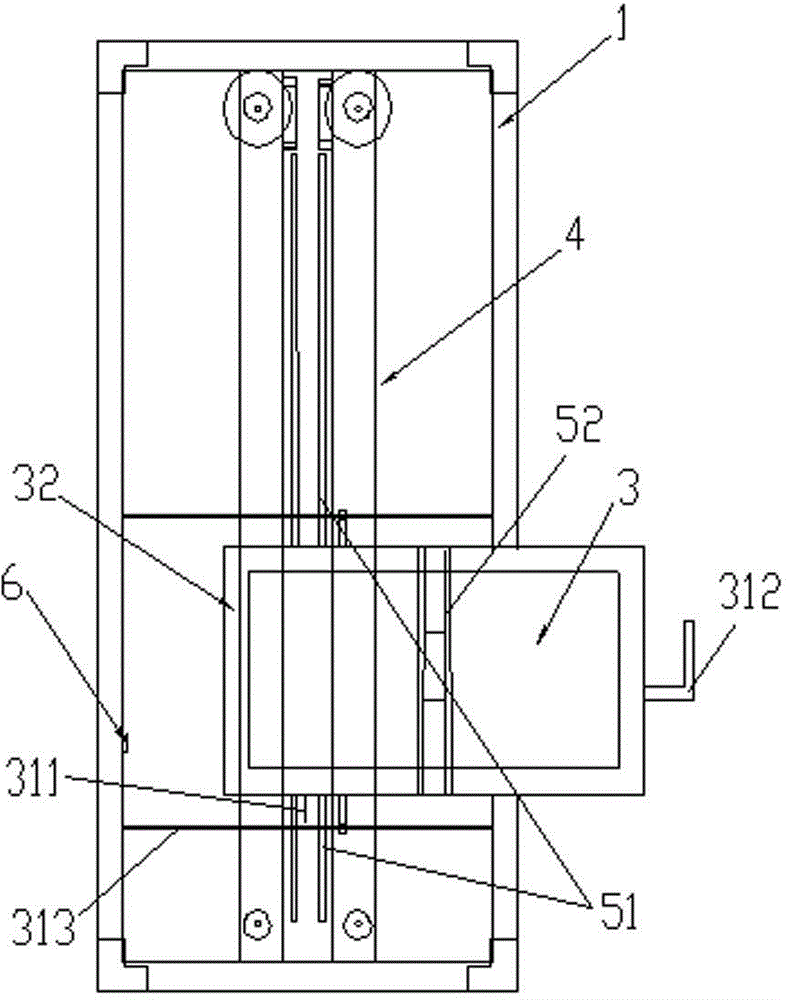

A retractable thruster, a swimming vessel and a method for retracting and ejecting a propeller of the retractable thruster

InactiveCN107054598AAvoid getting stuckAvoid enteringRotary propellersSteering by propulsive elementsPropulsor

A retractable thruster for a swimming vessel is provided, wherein the retractable thruster includes a propeller and a lifting and lowering arrangement which is configured to vertically move the propeller between a retracted position and an ejected position. In the retracted position the propeller is substantially inside a bottom well of the swimming vessel and in the ejected position the propeller is substantially outside the bottom well. The retractable thruster includes a water-permeable protective element configured to be located inside the bottom well above the propeller and configured to vertically move with the propeller. In the ejected position the water-permeable protective element is configured to substantially prevent loose ice from drifting inside the bottom well through the water-permeable protective element and when the propeller is moved from the retracted position to the ejected position, the water-permeable protective element is configured to push ice out of the bottom well.

Owner:ROLLS ROYCE PLC

Bamboo splitting machine capable of automatically screening bamboo barrel specification

InactiveCN107803344AGuaranteed accuracyImprove efficiencyWood splittingIrregularity removal devicesHinge angleEngineering

The invention relates to a bamboo breaking machine capable of automatically screening bamboo tube specifications, comprising a frame, a screening device, a bamboo tube blanking device and a bamboo breaking mechanism. The screening device includes a screening conveying plate and a conveying guard plate. The horizontal part of the screening conveying plate is provided with a screening slot and a feeding slot for defective products. The feeding slot for defective products is equipped with a lifting block for feeding defective products. The lower part of the unloading lifting block is provided with a triangular distribution of defective product blanking hinge seats, and the defective product blanking hinge seat is hingedly matched with the cylinder push rod of the defective product blanking lifting cylinder; the present invention adopts a screening groove to match a screening intercepting block Realize a bamboo tube screening with a diameter specification, which can intercept oval and bent bamboo tubes, and set a lowering block for defective products under the screening block to remove the intercepted defective products, ensure the accuracy of screening, and improve the screening and conveying. s efficiency.

Owner:DONGGUAN UNIV OF TECH

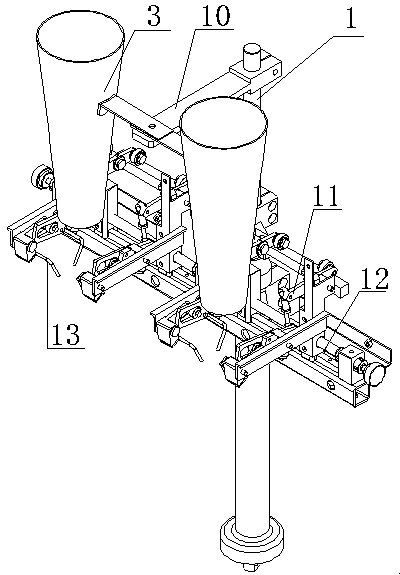

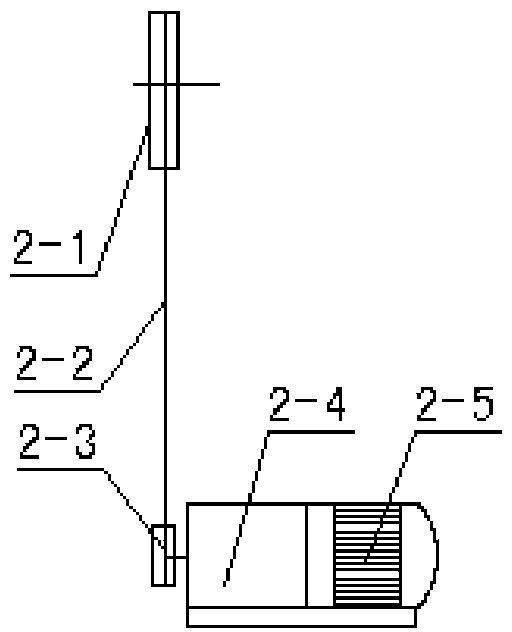

Automatic feeding device for bobbin

The invention provides an automatic feeding device for a bobbin, and belongs to the technical field of textile machines. The automatic feeding device for the bobbin comprises a hopper, a spiral orbit, a feeding air cylinder, a feeding base, a push plate, a stop lever and a bucket-type arrangement box; the feeding base is horizontally arranged; the hopper is in a shape of a circular arc, is horizontally arranged and is connected with the side face of the feeding base; the spiral orbit is arranged in the hopper; the bobbin is arranged on the spiral orbit; the bucket-type arrangement box is arranged below the front end of the feeding base; the feeding air cylinder is arranged at the rear of the feeding base; a piston rod of the feeding air cylinder is connected with the push plate; the push plate is arranged in the feeding base in a front and back sliding manner; the width of the feeding base is 1.1 to 1.2 times of the length of the bobbin; the stop lever is fixedly arranged at the middle of the upper end of the bucket-type arrangement box; two sides of the upper end of the stop lever are respectively provided with a sloping bench. The automatic feeding device for the bobbin, provided by the invention, has the advantages that automatic feeding of the bobbin is realized, the structure is simple, the cost is low, and labor strength is greatly reduced.

Owner:JIAXING TUHUANG CASHMERE CO LTD

Hinge

ActiveCN102400623ASufficient expansion spaceAvoid scalding accidentsCooking vesselsPin hingesNatural stateTorsion spring

The invention relates to a hinge, in particular to a hinge used between a furnace door and a furnace body of an electric steaming furnace. The hinge comprises a hinge rotating component, a hinge fixing seat (2) and a hinge positioning sheet (3), wherein the hinge rotating component comprises a shell (1), a positioning sheet connecting component (4) and a tension spring (5); the lower end of the positioning sheet connecting component (4) is connected with the hinge positioning sheet (3); the upper end of the positioning sheet connecting component (4) is connected with one end of the tension spring (5) through a tension spring lower end fixing rod (9); the side wall of the positioning sheet connecting component (4) is in sliding fit with a limit groove (11) on the shell (1) through a bulge; and the other end of the tension spring (5) is connected with a tension spring upper end fixing rod (8) on the shell (1). The hinge is characterized in that: a distance between the tension spring upper end fixing rod (8) and the tension spring lower end fixing rod (9) is greater than the length of the tension spring (5) in a natural state. The hinge for the electric steaming furnace has a reasonable structure and is higher in sealing property.

Owner:宁波欧燕电器有限公司

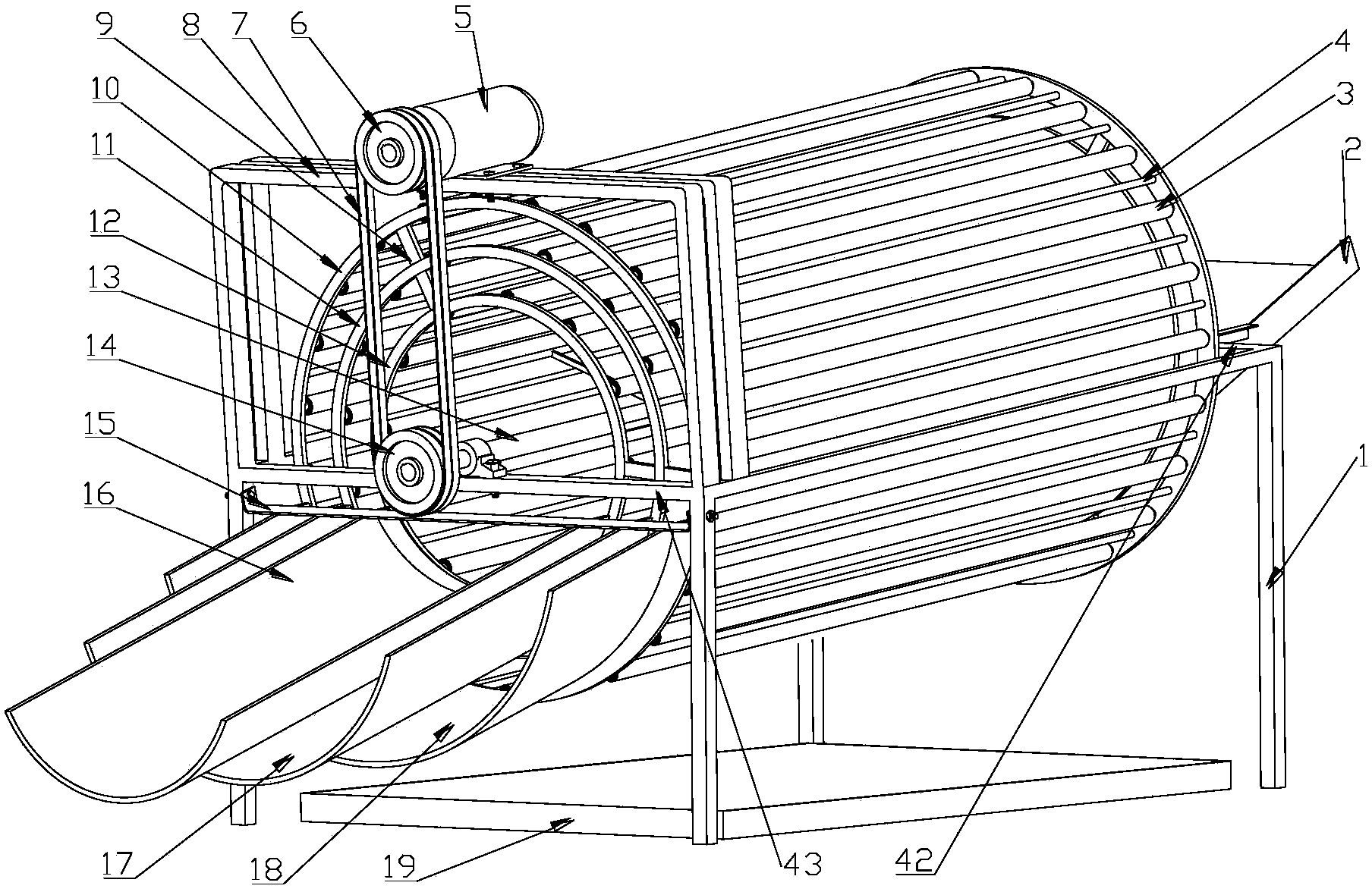

Rotary cage-type walnut classifying screen

ActiveCN103831230APrevent pilesImprove classification accuracySievingScreeningSmall footprintEngineering

The invention relates to a rotary cage-type walnut classifying screen which is high in classifying efficiency and classifying precision, small in occupied area and low in cost and is used for classifying walnuts. The rotary cage-type walnut classifying screen comprises a support. A cage-type classifying screen body is installed on the support and driven by a driving device to rotate. The driving device is installed on the support. One end of the cage-type classifying screen body serves as a feeding end, and the other end of the cage-type classifying screen body serves as a discharging end inclining towards the feeding end. The cage-type classifying screen body is composed of multiple layers of screening cages, the body of each layer of screening cage is composed of cage bars, the distance between every two adjacent cage bars of the innermost layer of screening cage is the largest, the distances are gradually decreased layer by layer, the distance between every two adjacent cage bars of the outermost layer of screening cage is the smallest, and the walnuts are classified by adjusting the distance between every two adjacent cage bars of each layer of screening cage. After fed into the cage-type classifying screen body, the walnuts with different sizes can be left in the screening cages of corresponding classes when the cage-type classifying screen body rotates and are discharged by discharging devices fixed to the support and located at the positions corresponding to the screening cages of the classes respectively.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

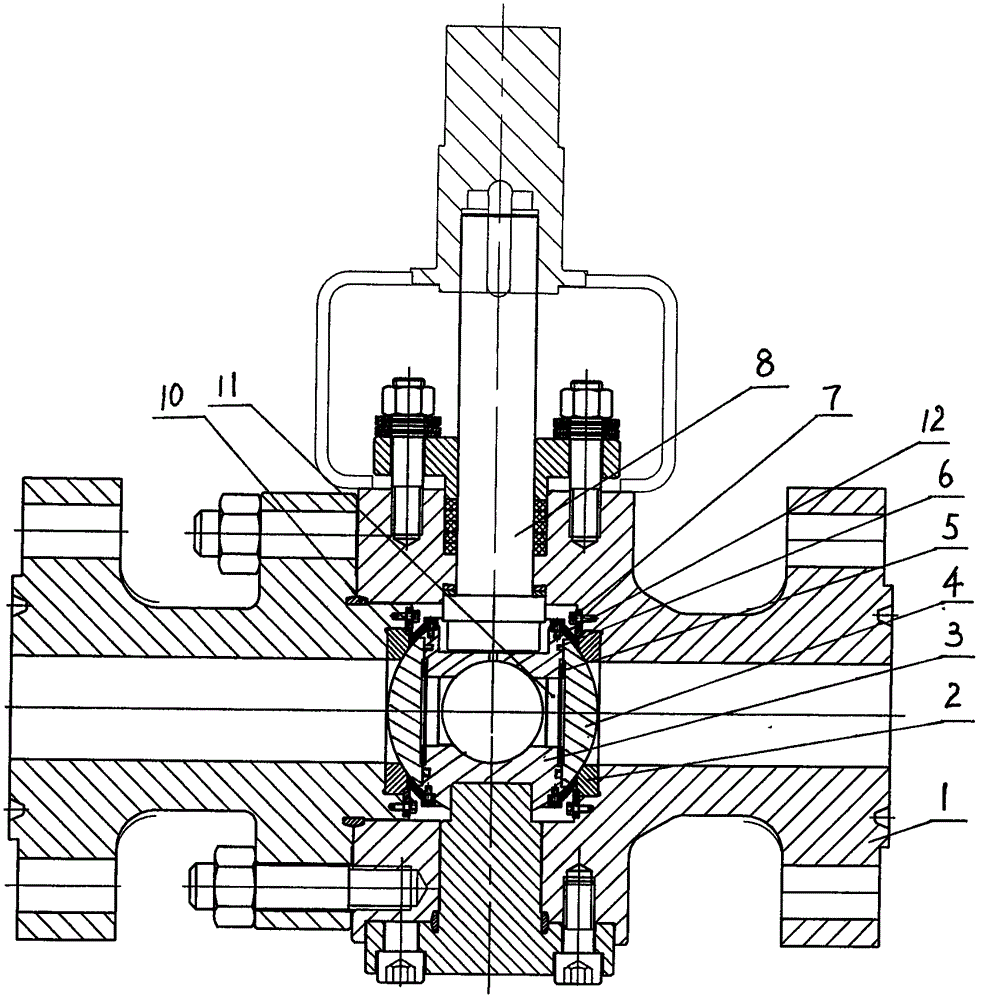

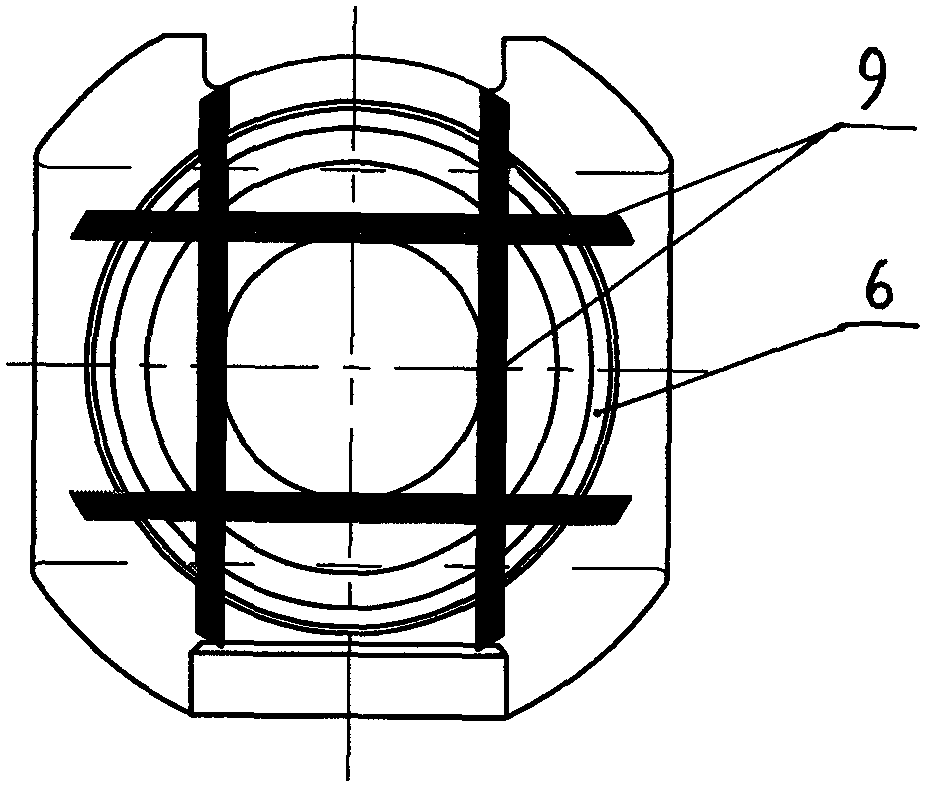

Floating spherical crown dredge type metal sealing ball valve

The invention relates to a floating spherical crown dredge type metal sealing ball valve. The floating spherical crown dredge type metal sealing ball valve comprises a valve body, a valve seat, a ball body and a valve rod, and is mainly characterized in that the two sides of a through hole of the ball body are each provided with one plane; round holes perpendicular to the through hole of the ball body are formed in the centers of the planes on the two sides of the ball body and are each internally provided with one ball clack; the ball clacks are connected with the round holes in the ball body through round convex columns in a movable fit mode; positioning rings are installed at the upper and lower ends of the connection position, between the ball body and each ball clack, of the ball surface; the positioning rings and the valve rod are concentric; an annular spring cavity is manufactured in the position, between each ball clack plane and the ball body plane, of the outer side of the corresponding round convex column in the radial direction; a spring is installed in each annular spring cavity; an annular anti-blocking groove is manufactured in the position, between each ball clack plane and the ball body plane, of the outer side of the corresponding annular spring cavity; medium dredge channels are manufactured in the ball body plane inside each annular spring cavity close to the external circular surface of the corresponding round convex column and are communicated with one another, and the two ends of the medium dredge channels are communicated with the external ball surface of the ball body. The ball clacks float reliably and are good in temperature resistance performance and suitable for high temperature and ultralow temperature working medium conditions.

Owner:王照业

Drawer slide rail system

A drawer slide rail system comprises a slide rail subassembly, wherein the slide rail subassembly is arranged on a side plate of a cabinet and is provided with a drawer; the drawer comprises a bottom plate and a front panel; the slide rail subassembly comprises a movable slide rail and a fixed slide rail; a damping device is arranged on the movable slide rail or the fixed slide rail; when the drawer is closed, the damping device travels by a distance, and an elastic swinging plug A arranged on the damping device touches a shifting nail A arranged at the front end of the fixed slide rail or the movable slide rail; a sliding swinging plug B on the damping device is clamped in a first locking notch in the damping device by a cable, a strap or a rope; when the drawer continues being closed, the sliding swinging plug B touches a shifting nail B arranged at the rear end of the fixed slide rail or the movable slide rail, so that the sliding swinging plug B is released from the first locking notch; and the drawer is automatically closed by a damping spring. A pushing rebounding device is arranged on the movable slide rail, the fixed slide rail or the side plate of the cabinet; when closed, the drawer is automatically stopped at a position which is distant from a pre-stopping position of the side plate of the cabinet by a distance H through an elastic stopping block on the pushing rebounding device, and is positioned by elasticity; and moreover, the drawer is automatically opened by the elastic stopping block.

Owner:伍志勇

Pecan hulling machine

The invention discloses a pecan hulling machine. The pecan hulling machine comprises a machine frame, wherein the machine frame is provided with a feed device, a hulling device, a discharge device and a power transmission device, wherein the feed device comprises a feed hopper and a feed pipe; the hulling device comprises a feed cylinder and a beating rod assembly; a plurality of outwards convex hammer bases are evenly arranged on the circumference of the feed cylinder; a plurality of small concave pits are formed in the inwards concave surfaces of the hammer bases; the beating rod assembly comprises a beating rod idler wheel, a beating rod, a beating rod bearing base, a beating rod hammer and a beating rod spring; the front end and the rear end of the beating rod are provided with the beating rod hammer and the beating rod idler wheel respectively; the middle of the beating rod is hinged to the beating rod bearing base to form a lever fulcrum; the upper end of the beating rod spring is connected to the beating rod; the lower end of the beating rod spring is fixed to the machine frame; the beating rod is driven through a cam mechanism to vertically swing; the cam mechanism comprises a cam and a flat board; the flat board is arranged at the opposite end of the convex surface of the cam. The pecan hulling machine has the advantages that granules of hulled pecans are full and low in degree of breakage, the level of integration and degree of automation are high, the hulling efficiency is high, and cost is low.

Owner:丁孝德

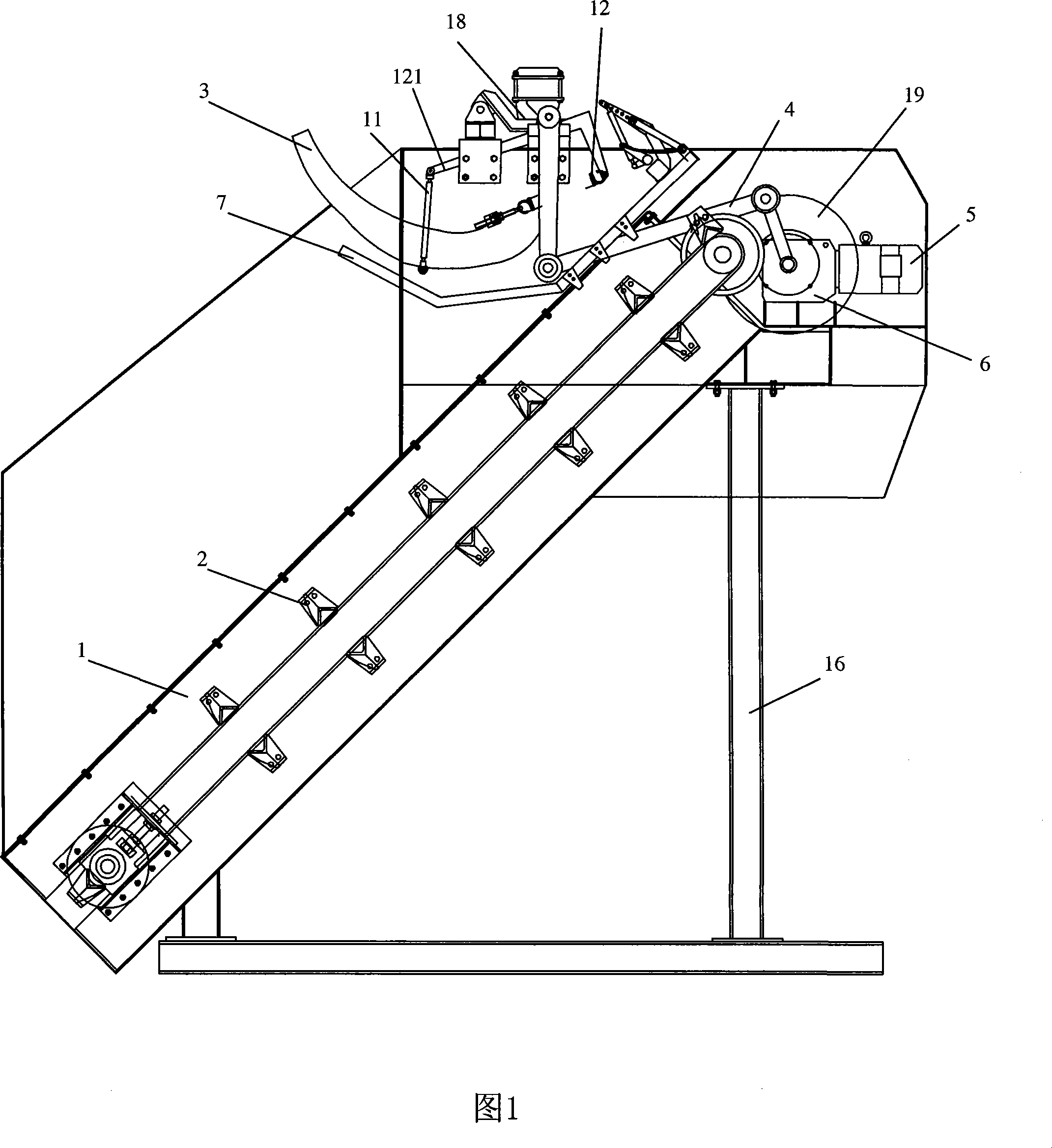

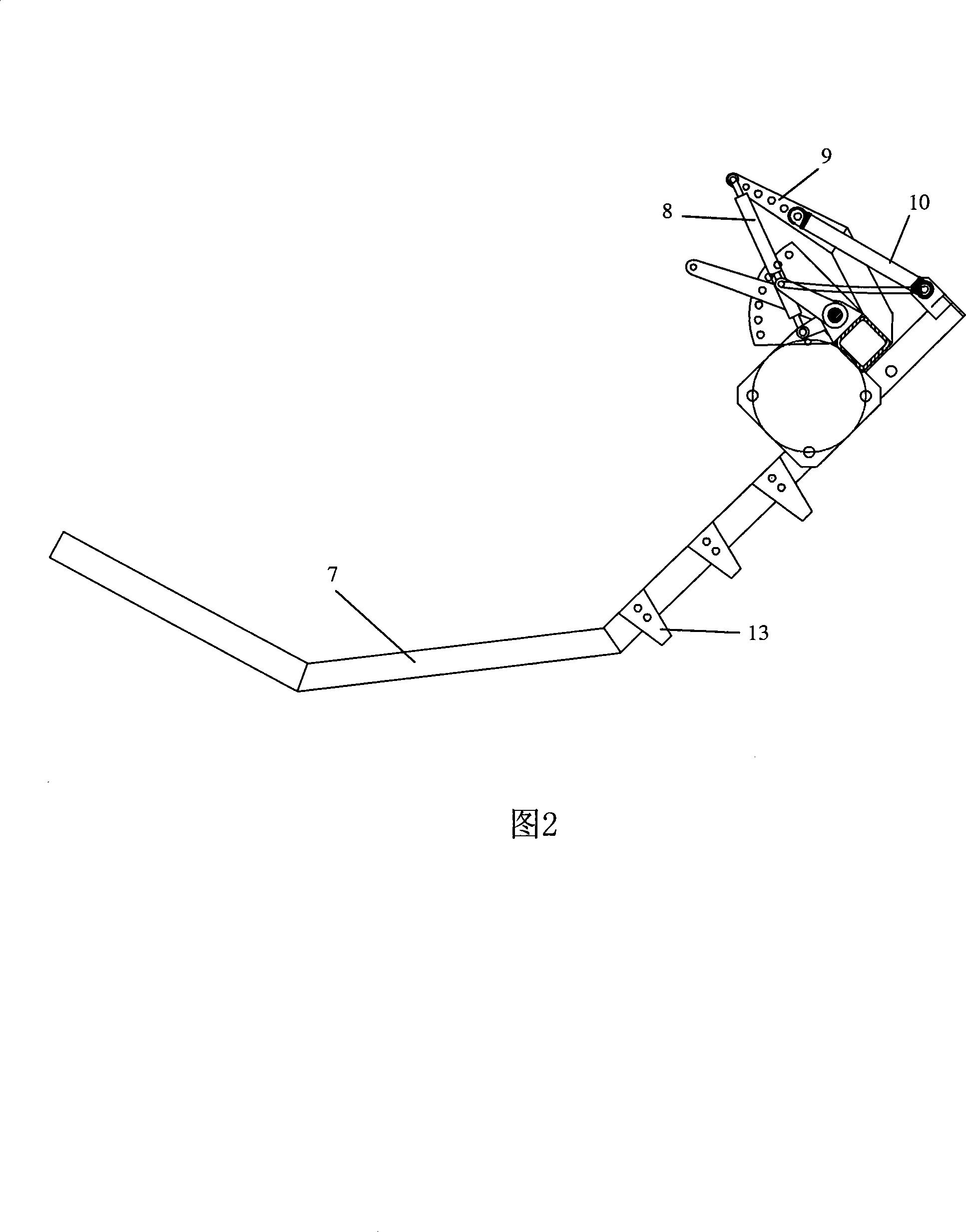

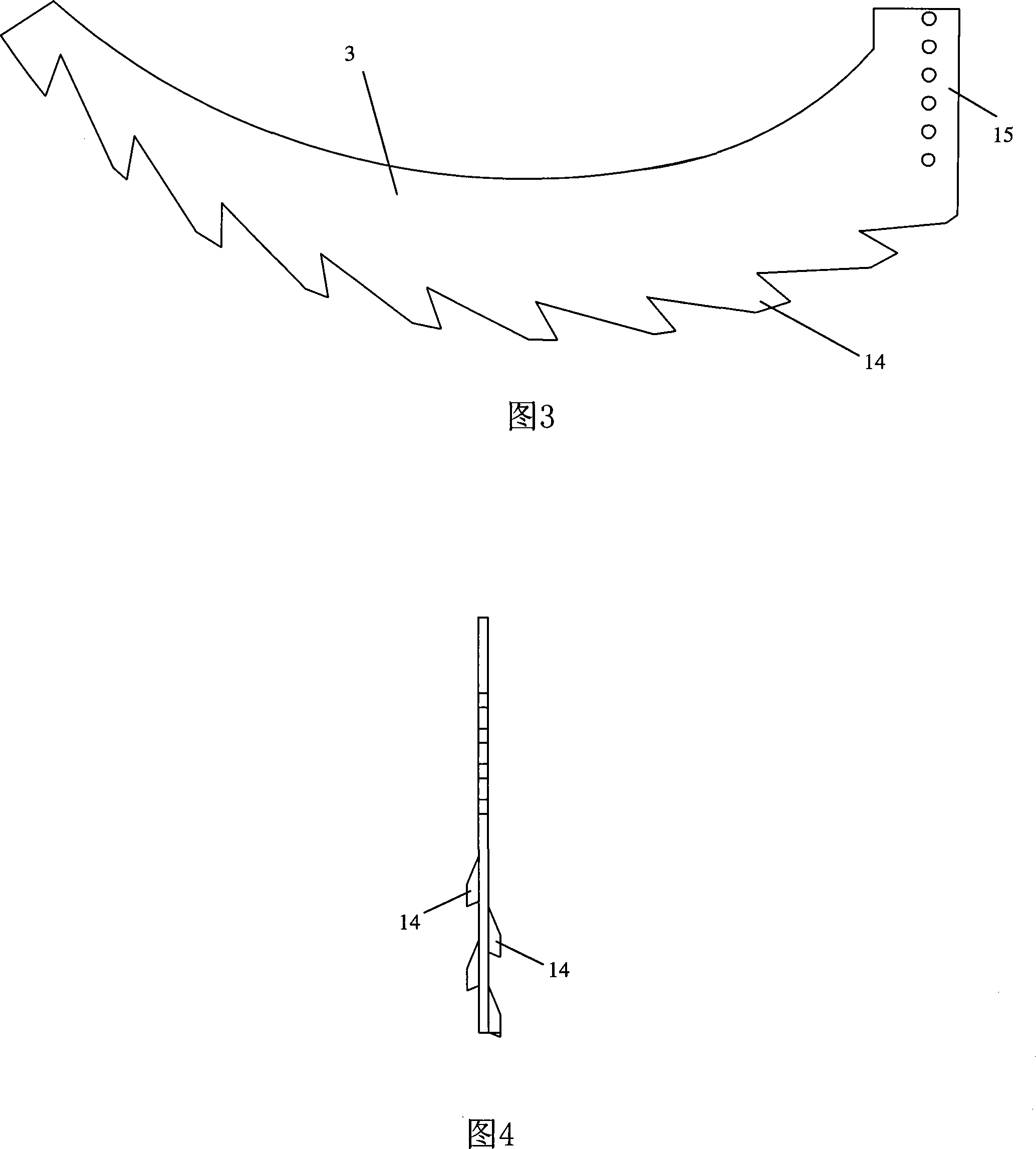

Saw-swinging type bag breaker

InactiveCN101177172AImprove efficiencyReduce labor costsConveyorsArticle unpackingEngineeringCircular disc

The invention provides a swing saw bag breaking machine, which is characterized in that it includes a feeding device and a bag breaking device, wherein the feeding device is a toothed conveyor, and the bag breaking device includes a swing saw device, and the swing saw device includes an arm-shaped The swing saw and the swing mechanism that drives the swing saw also include a thorn bag breaking device and a circular saw device, which have the functional characteristics of reliably and efficiently piercing solid waste bags and bag-in-bags.

Owner:SOUND ENVIRONMENTAL RESOURCES

Injection-molded part forming method requiring two stages of core pulling

Owner:SHENTONG TECH GRP CO LTD

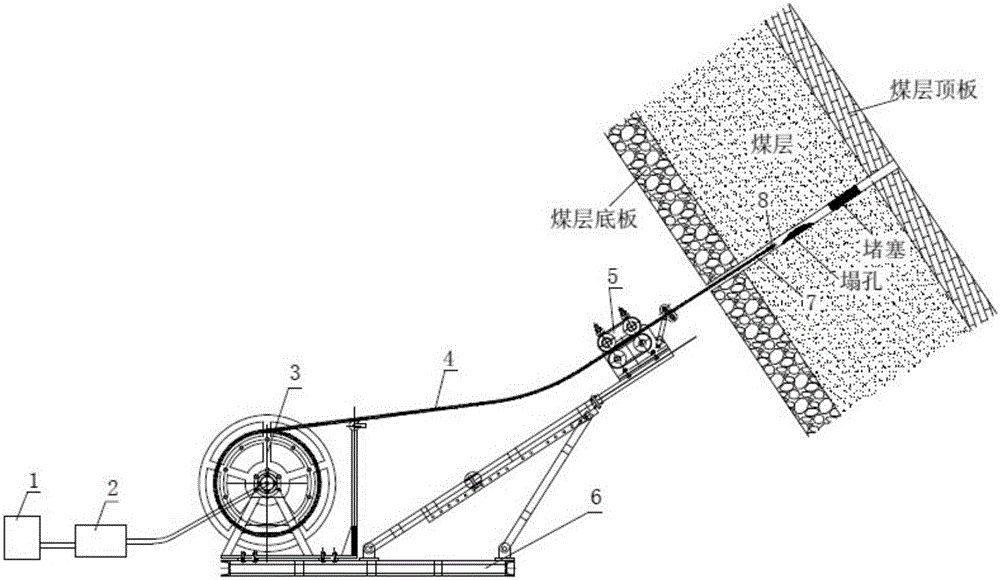

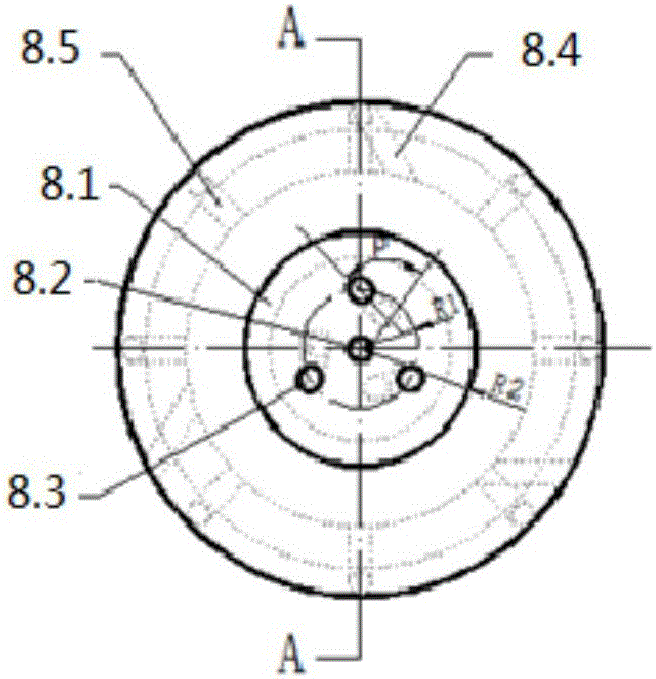

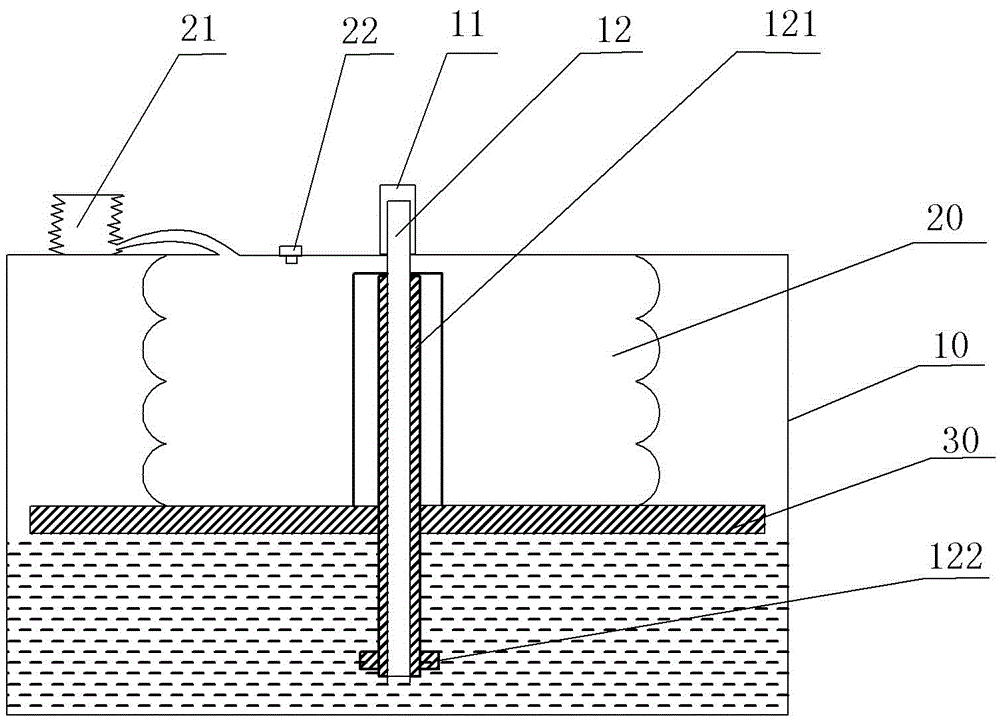

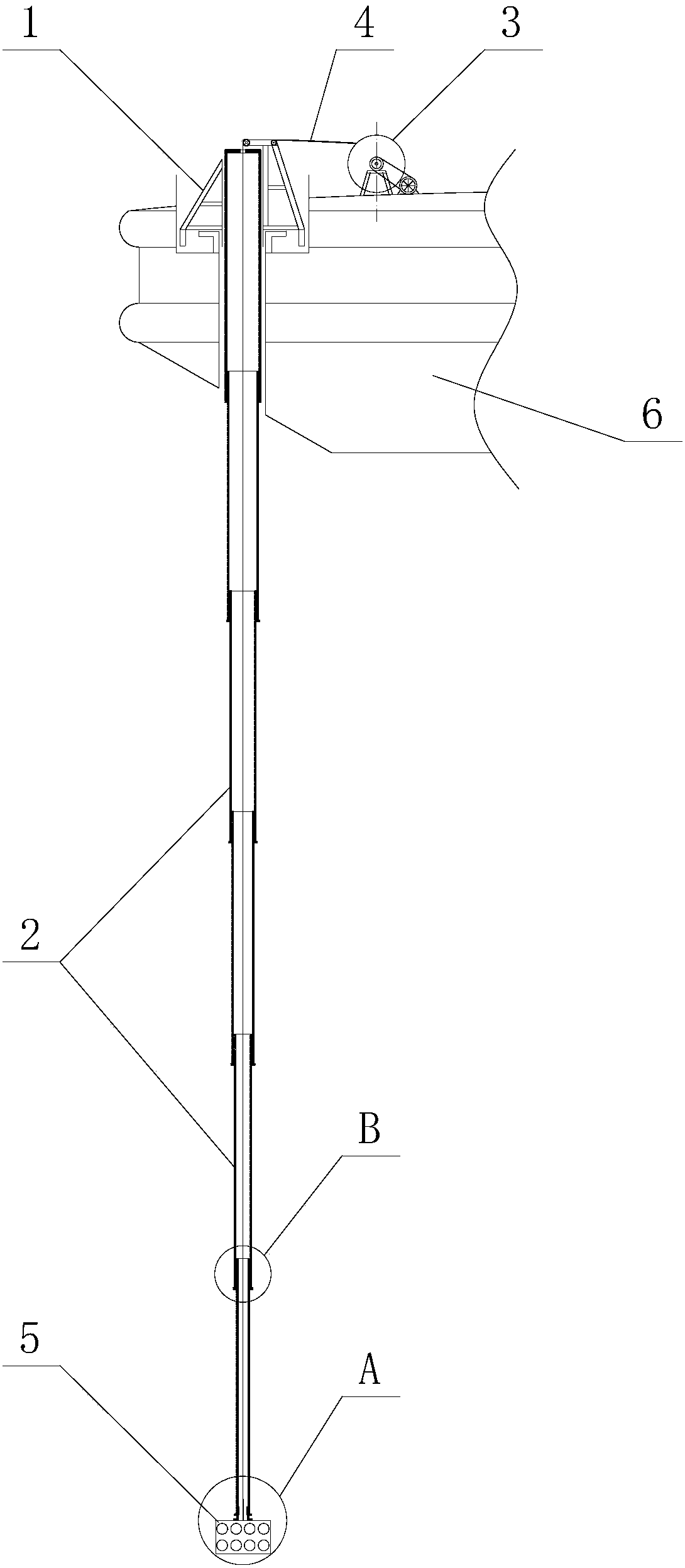

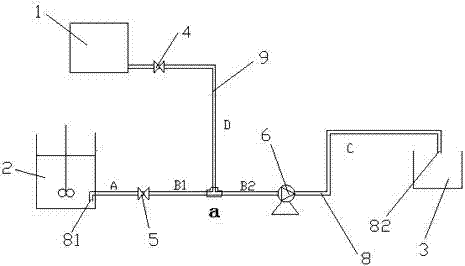

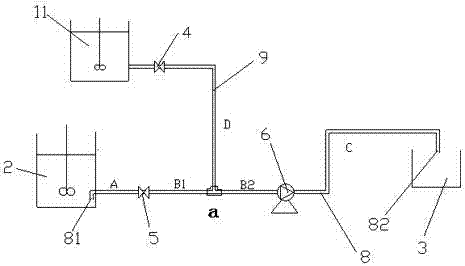

Hole flushing device for coal mine downhole gas extraction drill holes

ActiveCN105089525AImprove rock breaking efficiencyLarge self-propelled thrustDrill bitsDerricks/mastsHigh pressure waterHigh pressure

The invention provides a hole flushing device for coal mine downhole gas extraction drill holes. The hole flushing device comprises a water tank, a high-pressure pump, a high-pressure hard pipe, a high-pressure hose, a self-propelled drill bit, a base, a winch, a pushing mechanism and the like. The winch and the pushing mechanism are fixed to the base. The device can correspond to the drill holes in different positions and at different angles by adjusting all parts of the base. The high-pressure hard pipe can penetrate through the pushing mechanism before being fed into the drill holes. The high-pressure hard pipe can be conveyed forwards along the drill holes through pushing force provided by the pushing mechanism. When high-pressure water passes through the high-pressure hose at the front end of the high-pressure hard pipe and the self-propelled drill bit, high-pressure water jet is generated to conduct rock breaking dredging on collapsed and blocked portions, and self-propelling force is generated. The device is simple in structure, small in overall size and convenient to adjust, and can be conveniently used in coal mine downhole narrow working space. A whole power pipeline can be conveyed in long distance under joint acting force of pulling in front and pushing behind, and the pipeline can be prevented from being clamped. The hole flushing speed is high, efficiency is high, cost can be greatly reduced, and the gas extraction effect is improved.

Owner:CHONGQING UNIV +1

Inflatable anti-oscillation oil tank for motorcycle

The invention belongs to the field of motorcycle accessories, and particularly discloses an inflatable anti-oscillation oil tank for a motorcycle. The inflatable anti-oscillation oil tank for the motorcycle comprises a tank body and a tank cover. An oil filling opening is formed in the tank body and covered with the tank cover. The inflatable anti-oscillation oil tank for the motorcycle further comprises an oil pipe, a floating plate and an air bag. The upper end of the oil pipe is connected with the oil filling opening. The lower end of the oil pipe stretches to the bottom of the tank body. A stopping block is arranged at the lower end of the oil pipe. The floating plate is arranged on the oil pipe in a sleeving mode and located above the stopping block. The air bag is arranged above the floating plate and comprises an air inlet and an air outlet. The air inlet is provided with a one-way valve. An air inlet pipe is connected to the one-way valve. An inflator is connected to the other end of the air inlet pipe. An air outlet hole is formed in the top of the tank body. An air outlet pipe is arranged between the air outlet hole of the tank body and the air outlet of the air bag. An air plug is arranged in the air outlet hole of the tank body. According to the inflatable anti-oscillation oil tank for the motorcycle, the effect of preventing gasoline from oscillating is stable.

Owner:邳州市景鹏创业投资有限公司

Free telescopic ocean profile observation device and method based on large buoys

ActiveCN107860371AEffective observationRealize intelligent judgment functionWaterborne vesselsMeasuring open water movementSurface oceanSurface layer

The invention relates to a free telescopic ocean profile observation device and a method based on large buoys. The free telescopic ocean profile observation device comprises a free telescopic device,an underwater observation module, a data acquisition control module, a power supply module, a communication module and a data receiving and processing module, wherein the free telescopic device is used for providing power for underwater profile observation and accurate positioning of each depth layer; the underwater observation module is used for realizing integration and carrying of various observation sensors to acquire water body profile data; the data acquisition control module is use for intelligently controlling the action of the free telescopic device and the data acquisition of the underwater observation module according to sea conditions and forwarding the data to the communication module; and the communication module communicates with the data receiving and processing module of aland base station. By freely and accurately controlling the layer depth position of the underwater observation module, the free telescopic ocean profile observation device provided by the invention realizes long-term, continuous, fixed-point and real-time observation of the marine water body profile environmental parameters in a certain range under the condition of unattended operation, and breaks the current situation that the existing real-time observation parameters are limited to the surface layer of the sea.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

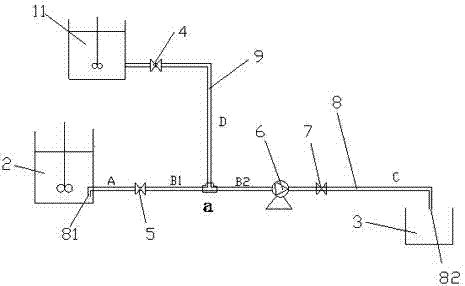

Transportation system and method of high concentration solid granule suspending solution

The invention discloses a transportation system and method of high concentration solid granule suspending solution, wherein the system includes a mixing device for forming the high concentration solid granule suspending solution; a transporting pump and a suspending solution reaching device needing the high concentration solid granule suspending solution, wherein the mixing device, the transporting pump and the suspending solution reaching device are in turn connected via a transporting pipe. The system also includes a clean water device for rinsing the transporting pipe and the transporting pump, which is connected with the transporting pipe via a rinsing pipe; the rinsing pipe of the clean water device is provided with a rinsing valve and the transporting pipe is arranged with a transporting valve. In the mixing device, the feeding pipe port of the transporting pipe is downward bent, and the feeding pipe port of the transporting pipe and the bottom part of the mixing device are formed with a gap. The invention solves the problem in the prior art that the whole system cannot work normally because the solid granules in the suspending solution are deposited in the pipe to block the pipe and clamp the valve and the transporting pump.

Owner:罗文峰

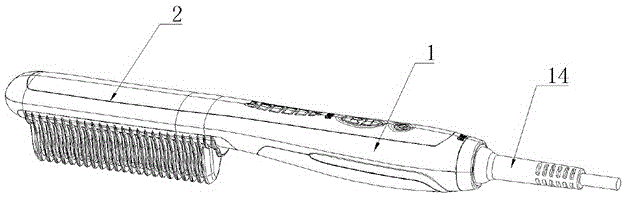

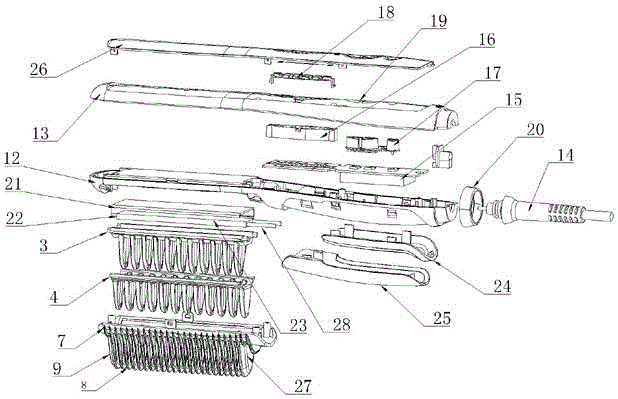

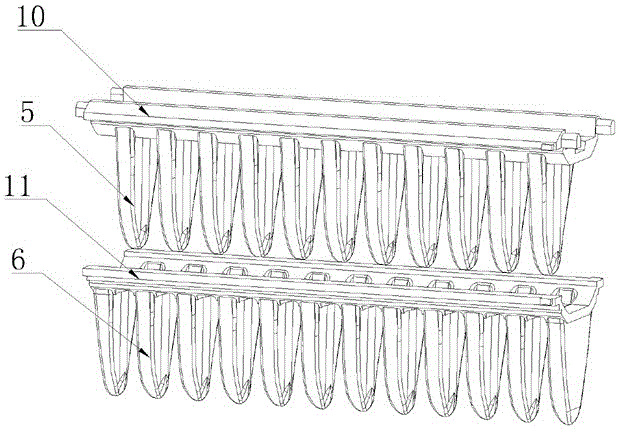

Electric heating hair straightening comb with wavy comb teeth

InactiveCN105105496AQuality assuranceEasy to operateCurling devicesHair combsHair straighteningEngineering

The invention provides an electric heating hair straightening comb with wavy comb teeth. By the adoption of the comb, combing quality can be guaranteed, hair does not get stuck, hair straightening processes can be simplified, and efficiency can be improved. The comb comprises a handle and a comb tooth portion, wherein a heating device and the comb teeth protruding out of the comb tooth portion are arranged in the comb tooth portion, and the comb teeth include upper comb teeth and lower comb teeth which are vertically stacked into a whole; the heating device is attached to the upper comb teeth and transmits heat to the lower comb teeth through the upper comb teeth, upper racks and lower racks are arranged on the upper comb teeth and the lower comb teeth respectively, and the cross section of each upper rack and the cross section of each lower rack are both wavy. Through matched arrangement, a wavy combing area is formed between each upper rack and the adjacent lower rack. The comb is suitable for the hairdressing field.

Owner:ZHUHAI JINDAO ELECTRIC APPLIANCE

Adhesive-tape type carton sealing machine

ActiveCN103144799AEasy to replaceImprove work efficiencyBox making operationsWrapper twisting/gatheringAdhesive beltCarton

The invention relates to an adhesive-tape type carton sealing machine, in particular to an adhesive-tape type carton sealing machine which conveniently and quickly changes an adhesive tape. The adhesive-tape type carton sealing machine comprises a machine seat, an upper machine core, a lower machine core and two conveyors, wherein the upper machine core is arranged at the upper part of the machine seat and is used for adhering and sealing the upper part of a carton body, the lower machine core is arranged at the lower part of the machine seat and is used for adhering and sealing the lower part of the carton body, and the two conveyors are used for conveying the carton body; the lower machine core is arranged at the lower part of the machine seat in a sliding manner; and the sliding direction of the lower machine core is vertical to a conveyance direction of the carton body. The invention aims at providing an adhesive-tape type carton sealing machine which has the advantages that the adhesive tape is convenient to change, and the working efficiency is high, and the carton sealing machine is more suitable for high-speed and large-batch production line.

Owner:SU ZHOU XUENUO MECHANICAL PROD

Flow construction method of underground pipe gallery inner mold system

InactiveCN106759487ASmall spanSave time on the moveArtificial islandsUnderwater structuresAutomatic controlUltimate tensile strength

The invention relates to a flow construction method of an underground pipe gallery inner mold system. A pair of mold frame automatic control units is arranged on the same section of a pipe gallery. During construction, after top mold plates, side mold plates and corner mold plates stretch to design positions, an independent early demounting mold plate is mounted at the clearance position of the two top mold plates; complete supporting is formed by the top mold plates, the side mold plates, the corner mold plates and the early demounting mold plate, and pouring is carried out; after concrete reaches certain strength, the top mold plates, the side mold plates and the corner mold plates retract and move to the next work station along with trolleys; and meanwhile, the early demounting mold plate is kept in a supporting state, the early demounting mold plate is demounted after the concrete reaches certain strength, and the demounted early demounting mold plate and the mold frame automatic control units reaching the next work station cooperate to complete subsequent supporting. According to the method, the mold demounting wait time is shortened, the movement and preparation time of the mold frame automatic control units is saved, and repeated utilization is convenient.

Owner:CHINA FIRST METALLURGICAL GROUP

Damping press rebounding device for sliding door

ActiveCN104763261AReduce daily wear and tearExtended service lifeWing suspension devicesDrawersEngineeringForce direction

The invention discloses a damping press rebounding device for a sliding door. The damping press rebounding device for the sliding door comprises a static component, a moving component, a poking mechanism, a reverse pushing mechanism and a damping mechanism; the poking mechanism comprises a poking base and at least two poking components; the reverse pushing mechanism comprises a pushing component slidably installed on a fixing base by a reverse pushing spring; the damping mechanism comprises a swinging component slidably installed on a positioning frame by a damping spring; the positioning frame is provided with a damper; the moving component is the sliding door; the poking mechanism is installed on the static component; the reverse pushing and damping mechanisms are installed on the sliding door; at least two poking components are the first poking component and the second poking component; while the sliding door is closed for a section of the travel, the second and first poking components respectively act on the pushing component and the swinging component in the sequence, and the elastic force directions of the reverse pushing and damping springs are different; while the sliding door is closed, the first poking component acts on the swinging component, the swinging component acts on the damper, and the closing is achieved by the damping spring; and while the sliding door is opened, a section of the travel is moved along the closing direction, and the sliding door is opened by the reverse pushing spring.

Owner:伍志勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com