Patents

Literature

338results about "Irregularity removal devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

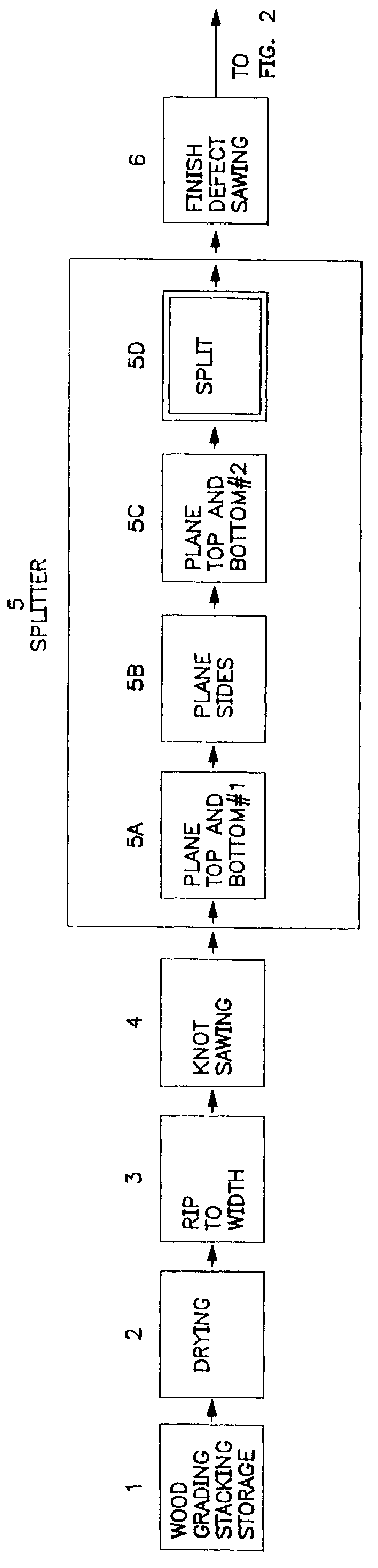

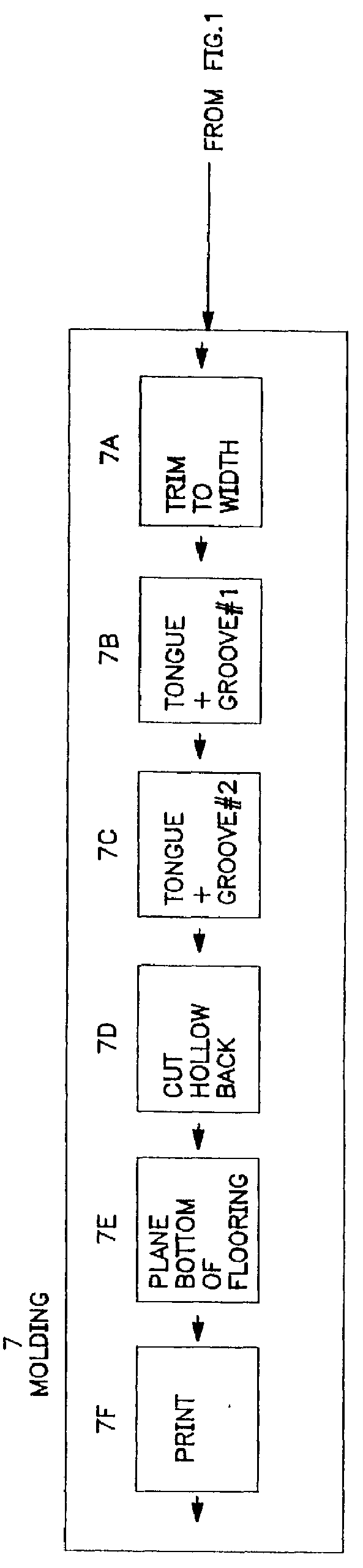

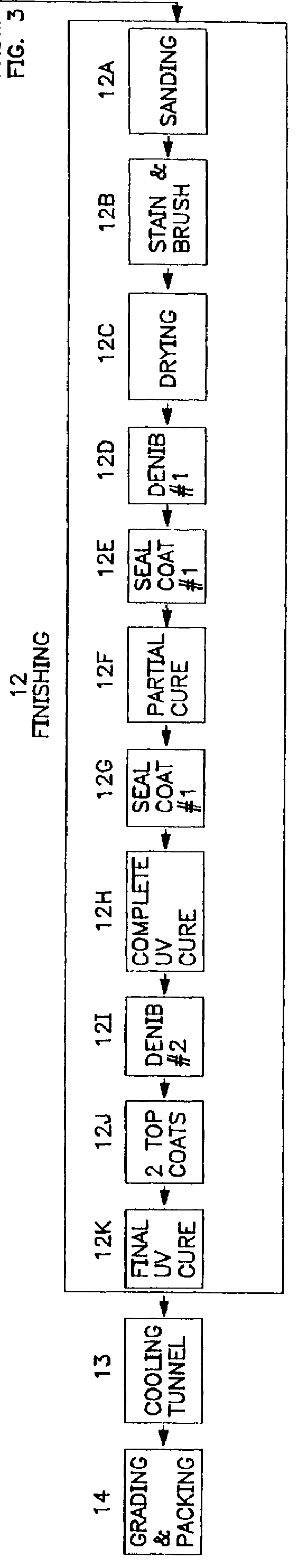

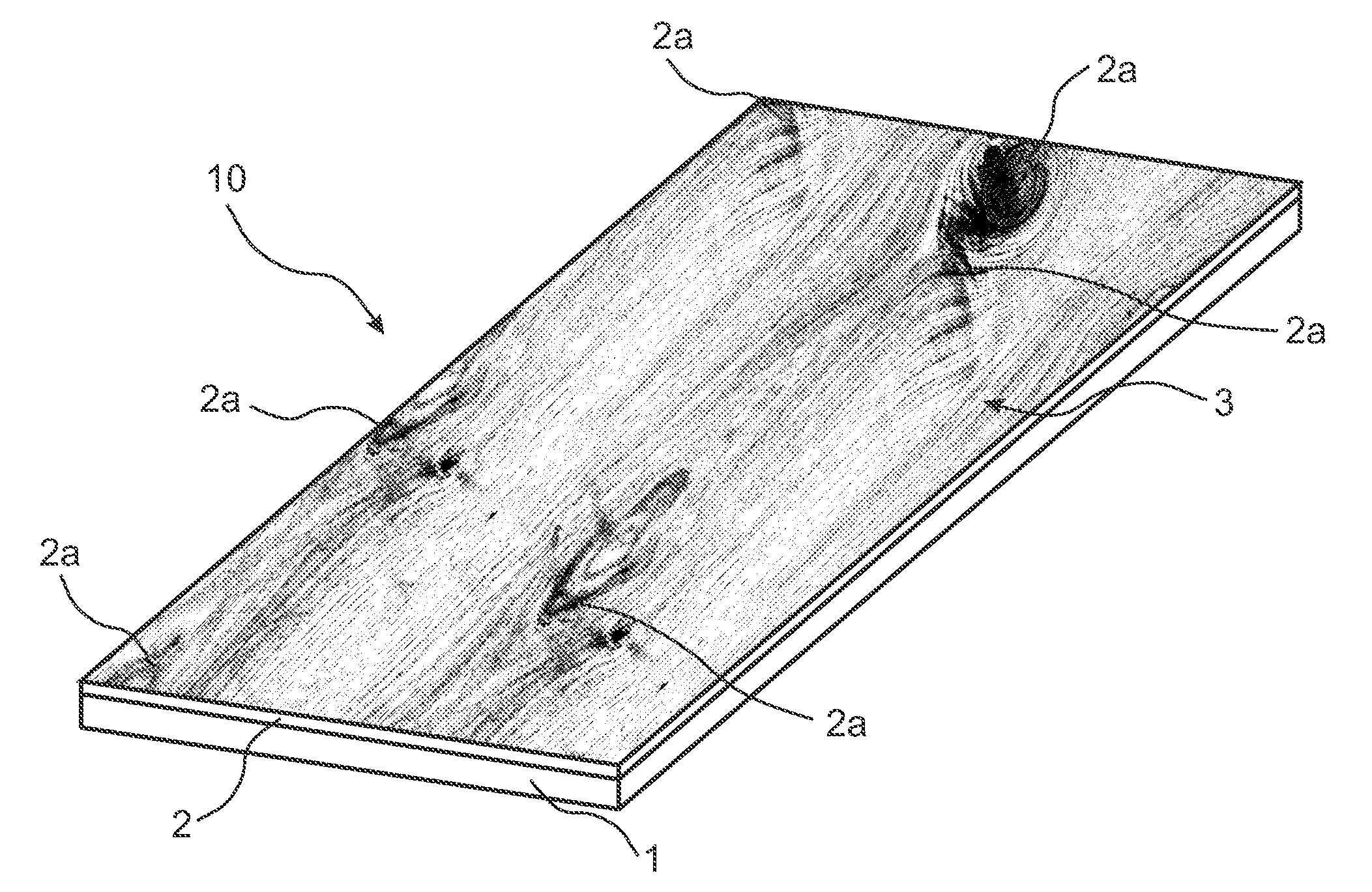

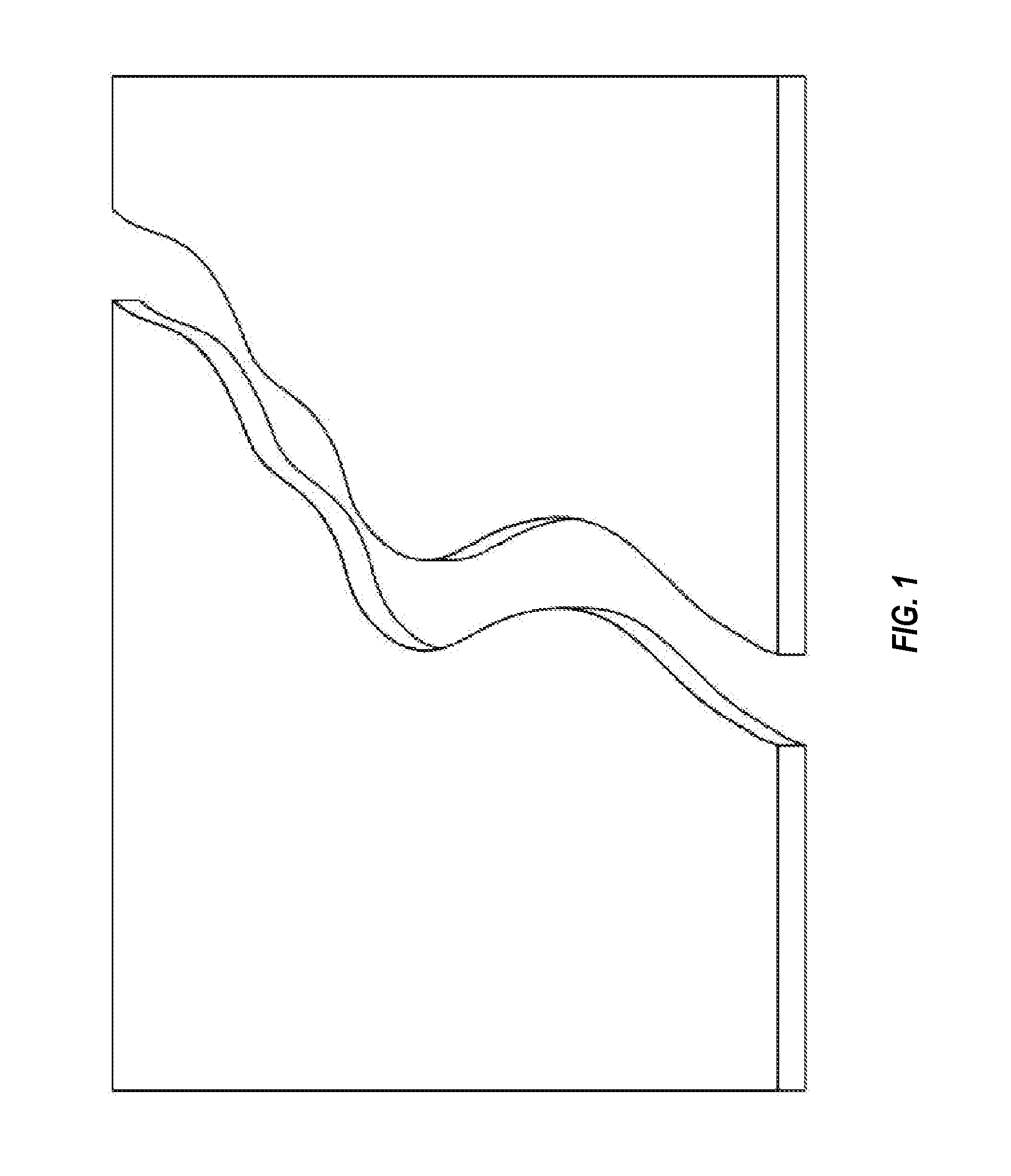

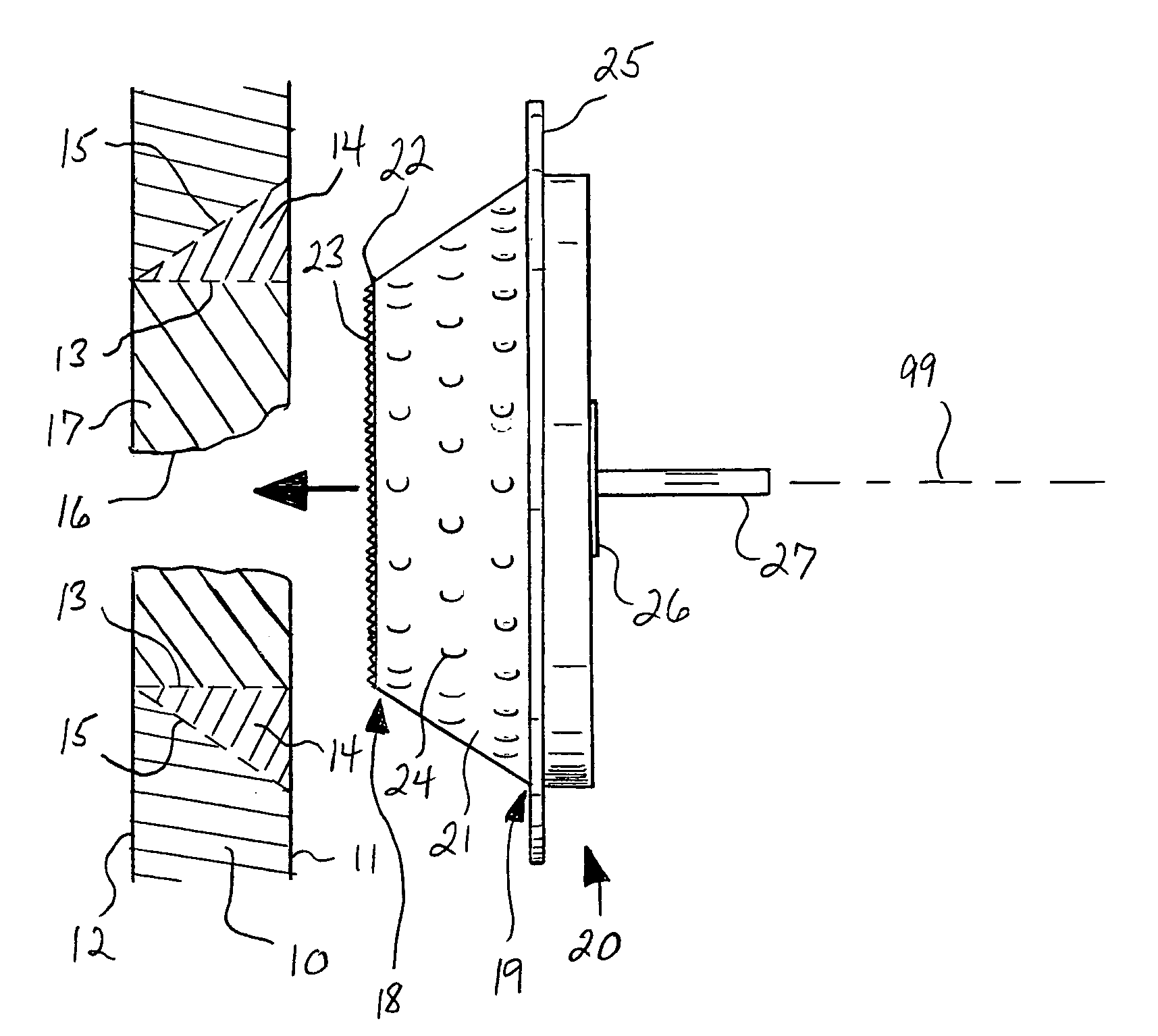

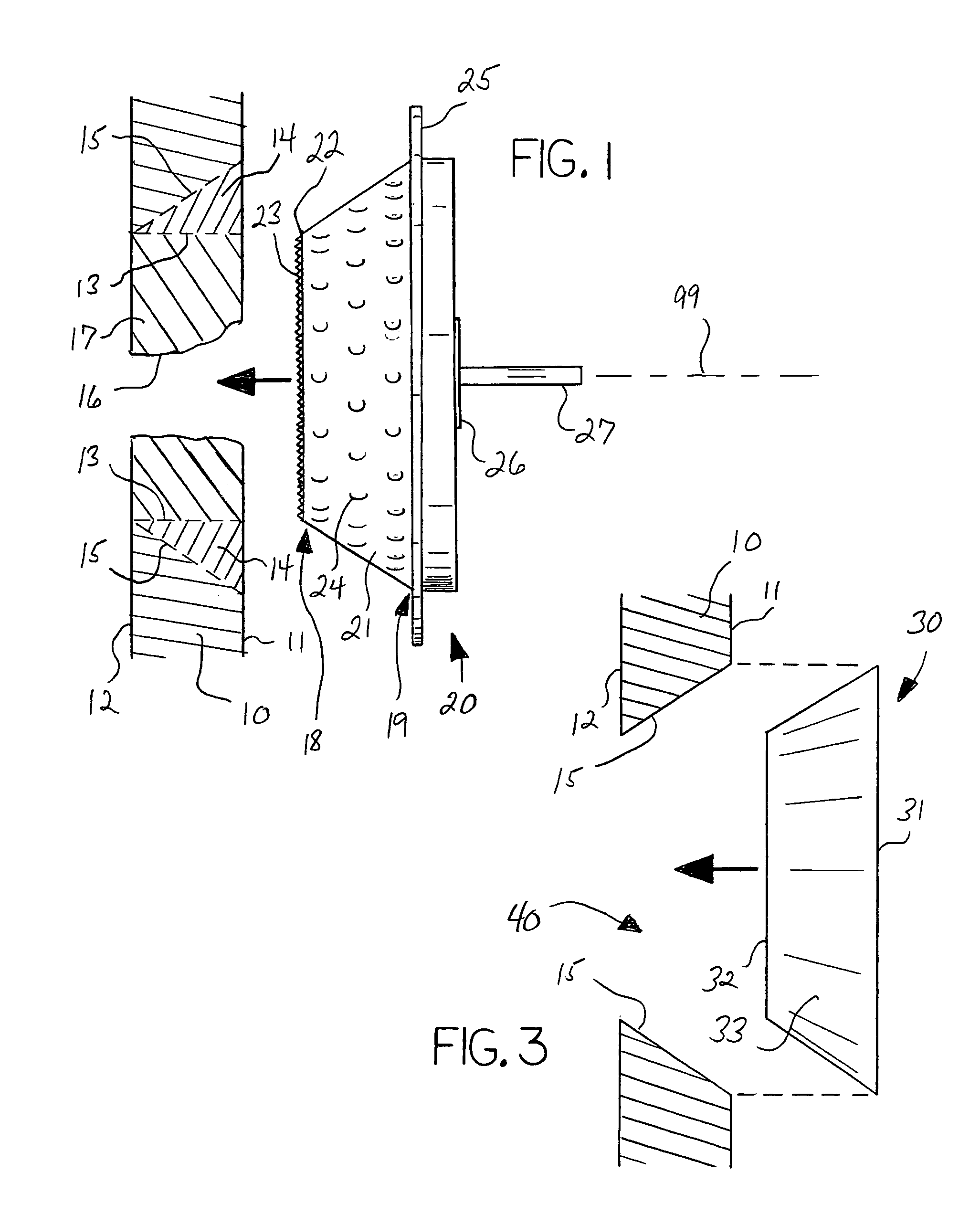

Low profile hardwood flooring strip and method of manufacture

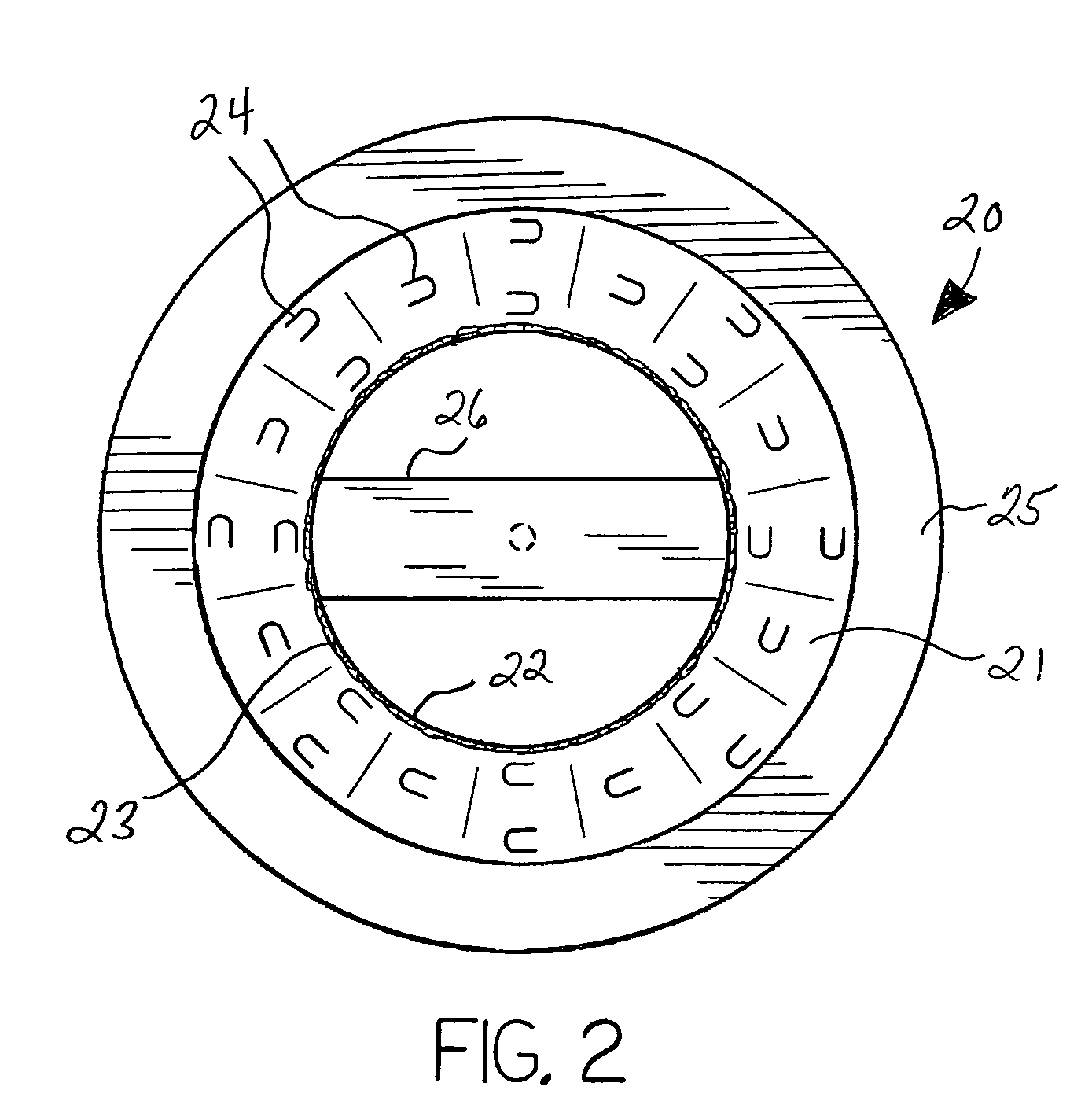

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

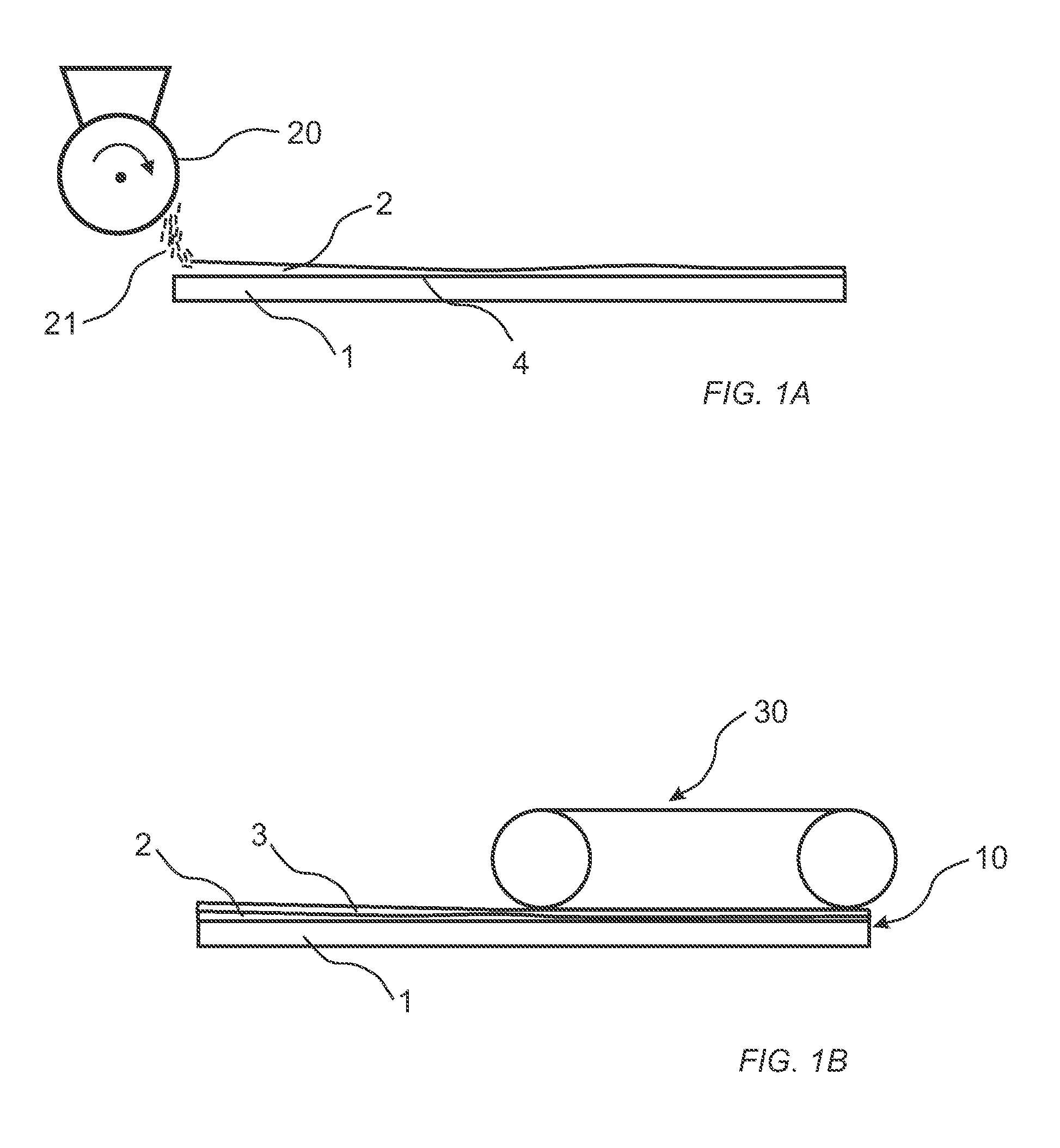

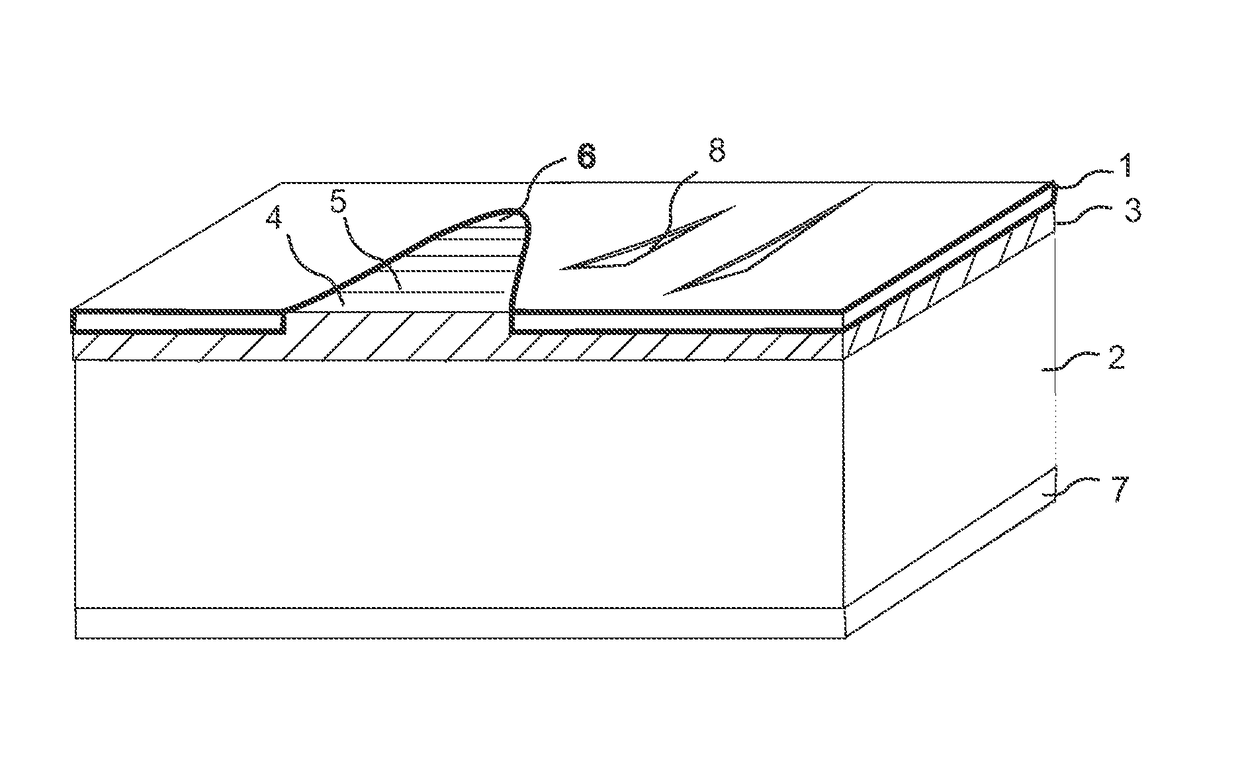

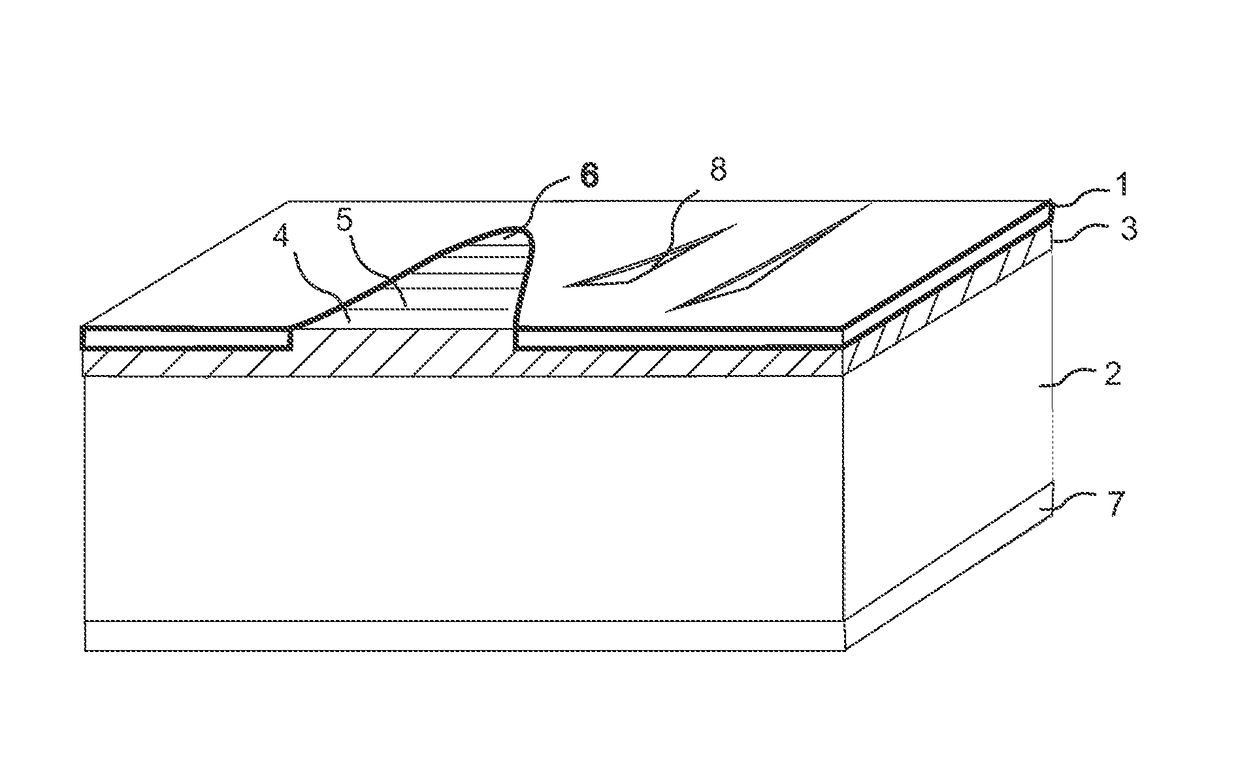

Method of producing a veneered element

ActiveUS20150197943A1Improve wear resistanceDecorative surface effectsOrnamental structuresEngineering

A method of producing a veneered element (10), including providing a substrate (1), applying a sub-layer (2) on a surface of the substrate (1), applying a veneer layer (3) on the sub-layer (2), and applying pressure to the veneer layer (3) and / or the substrate (1), such that at least a portion of the sub-layer (2) permeates through the veneer layer (3). Also, such a veneered element (10).

Owner:VÄLINGE INNOVATION AB

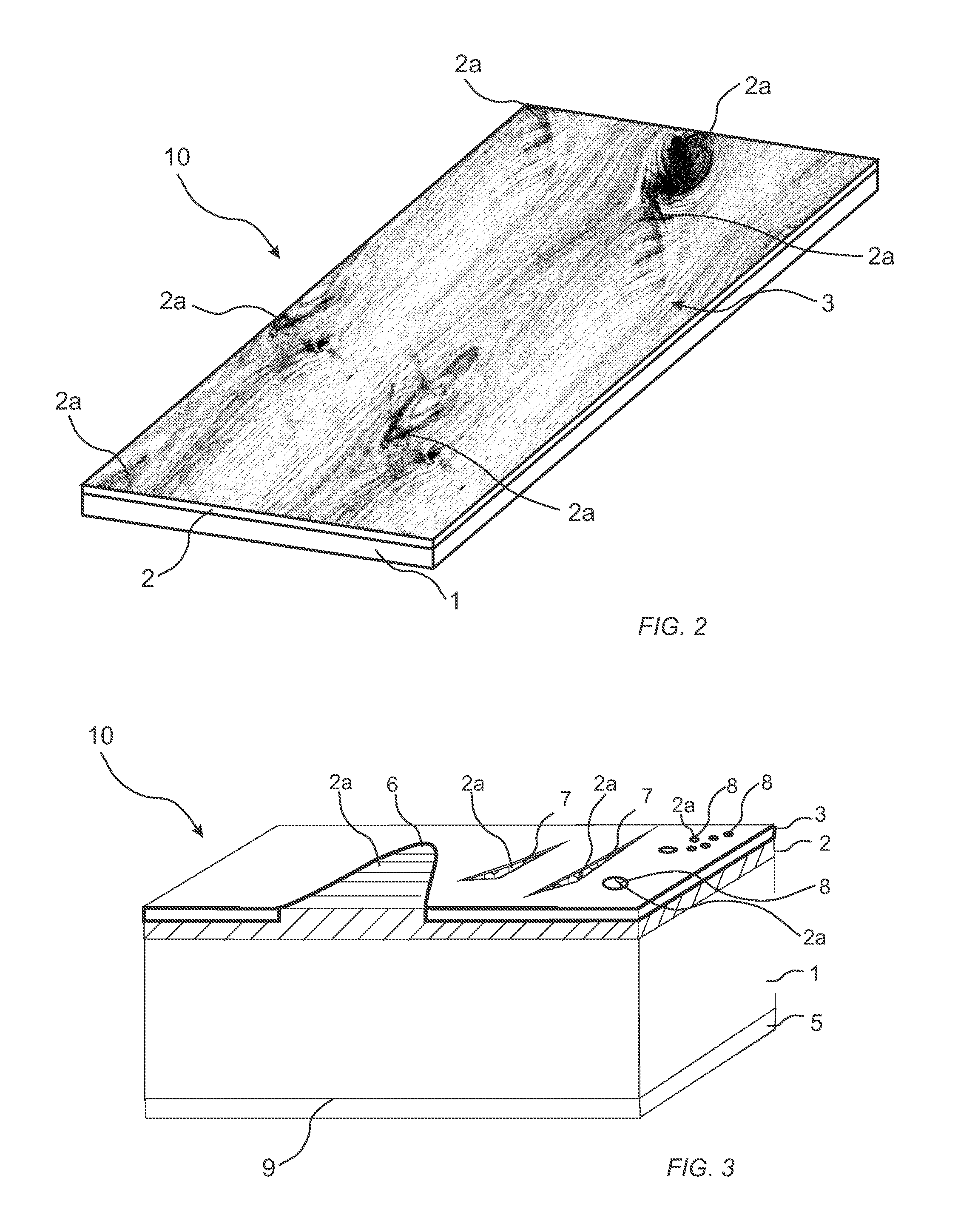

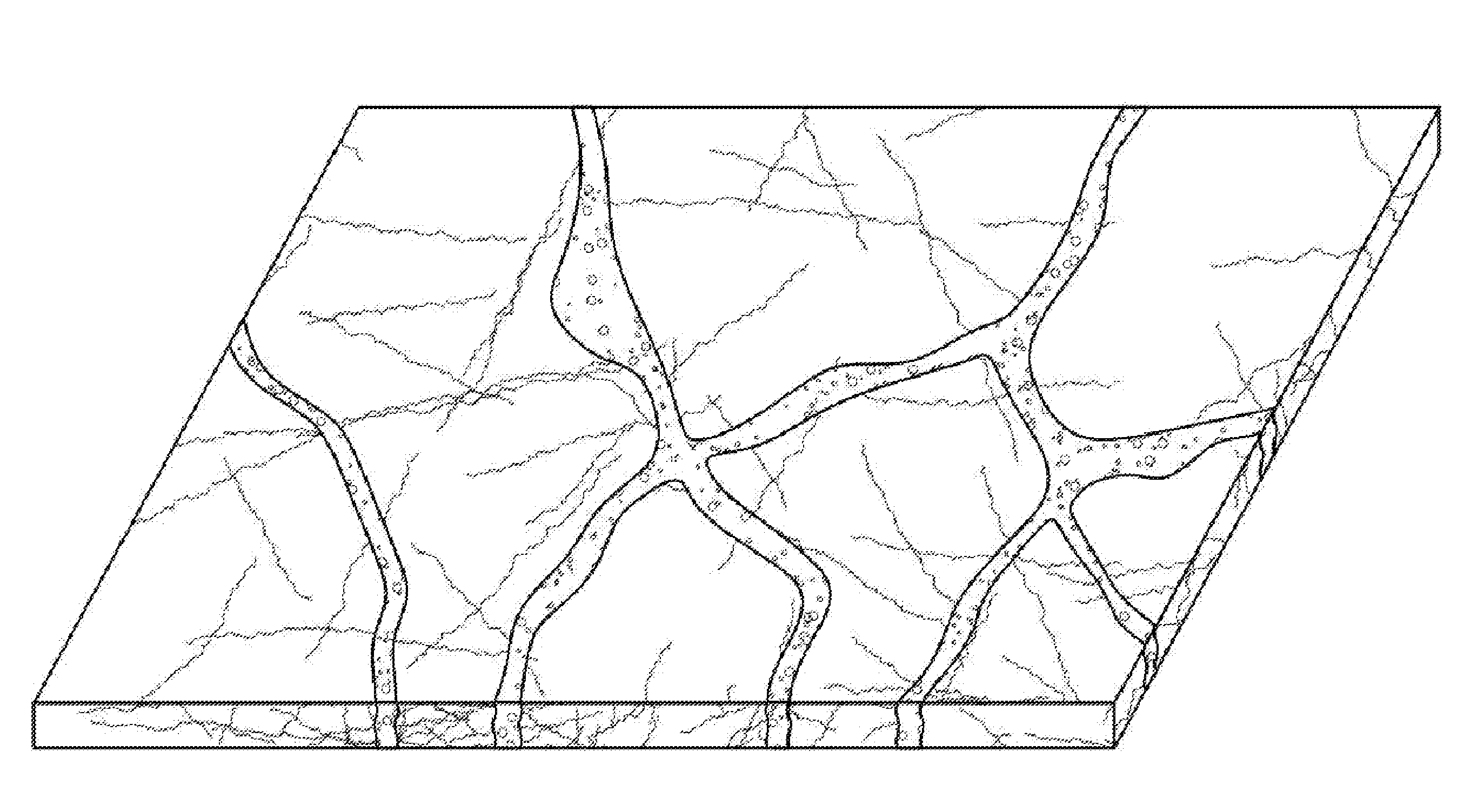

Restructured slab

ActiveUS9469990B2Restore structural integrity and continuityIncrease contrastConstruction materialIrregularity removal devicesSecondary componentEngineering

Owner:RESTRUCTURED SURFACES

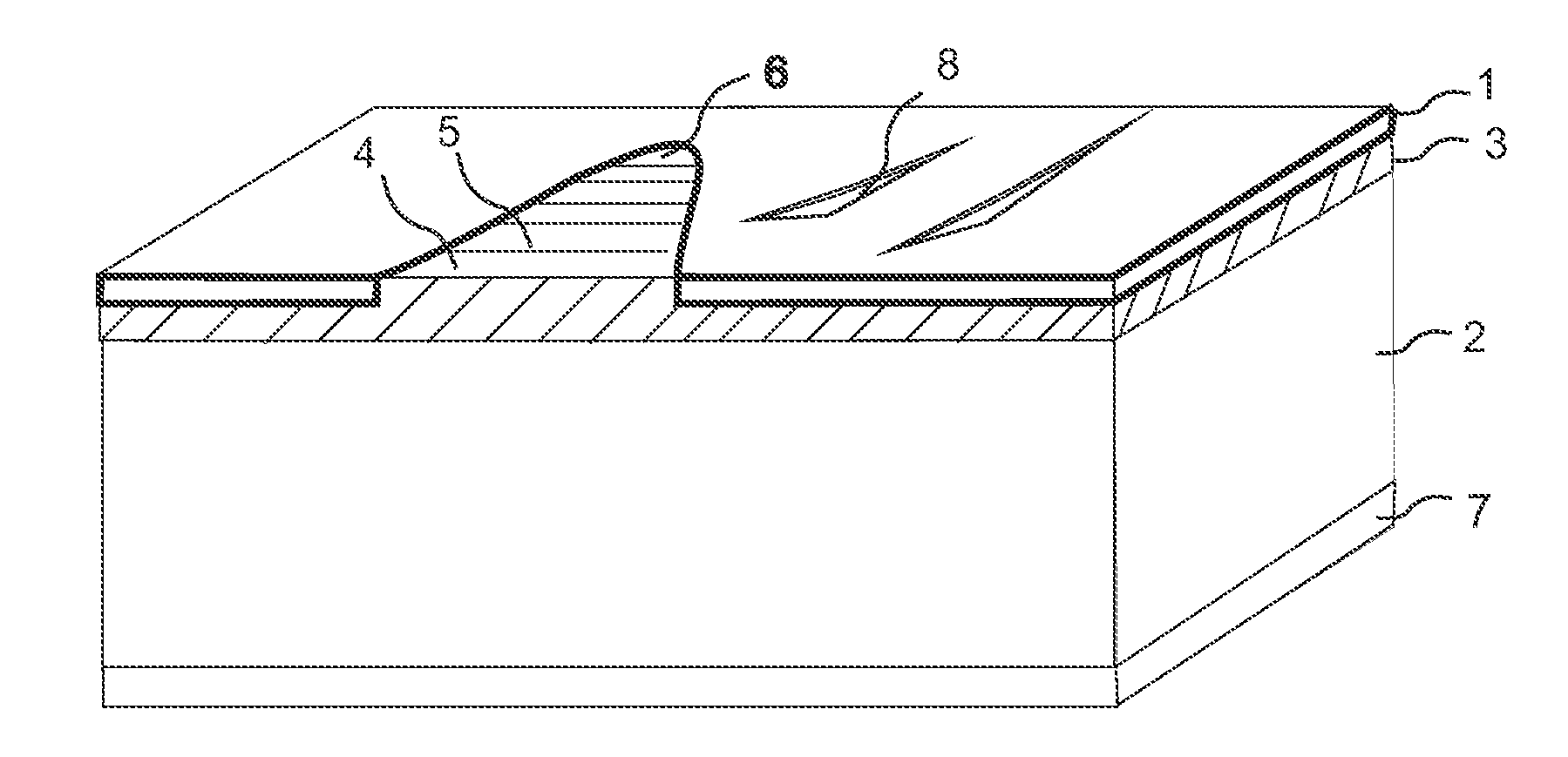

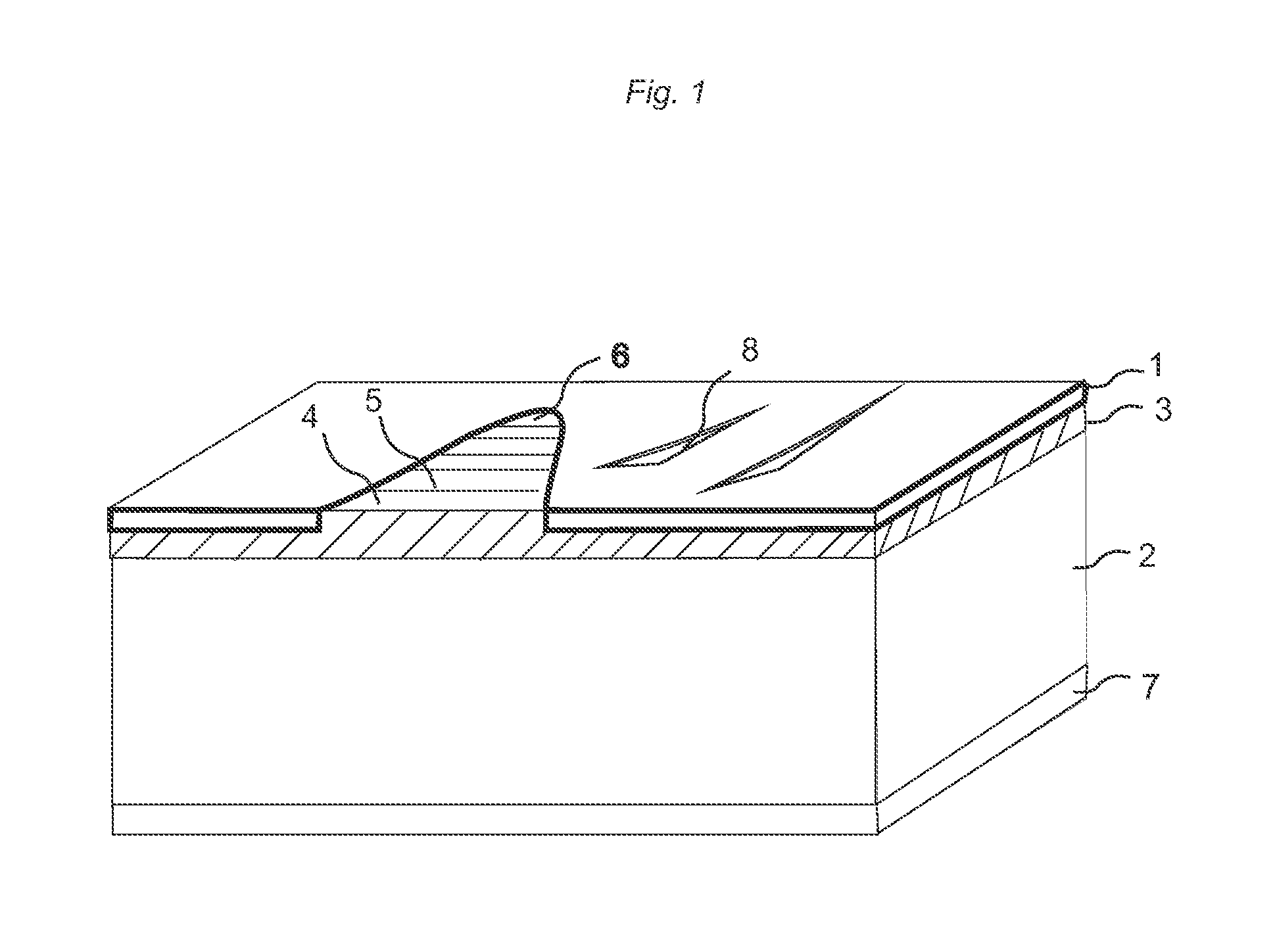

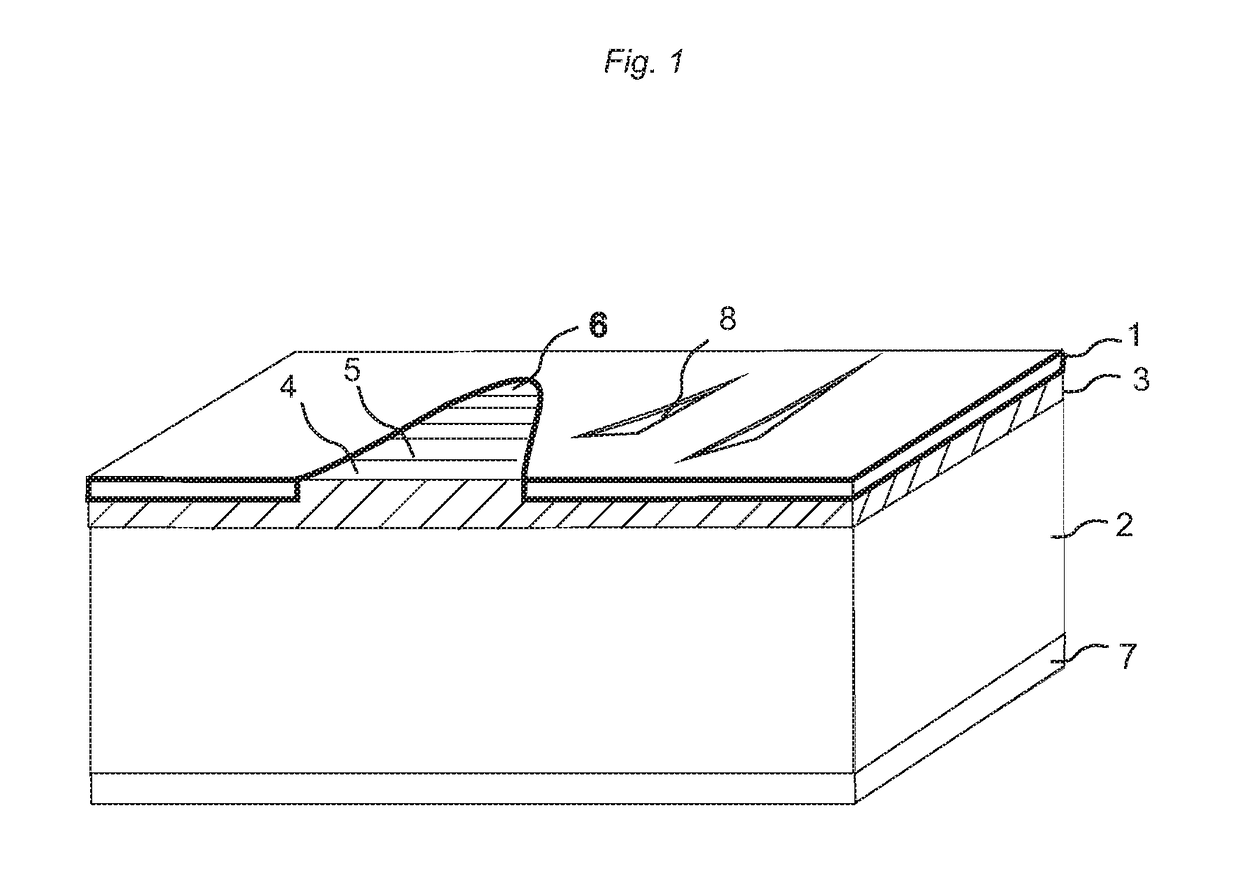

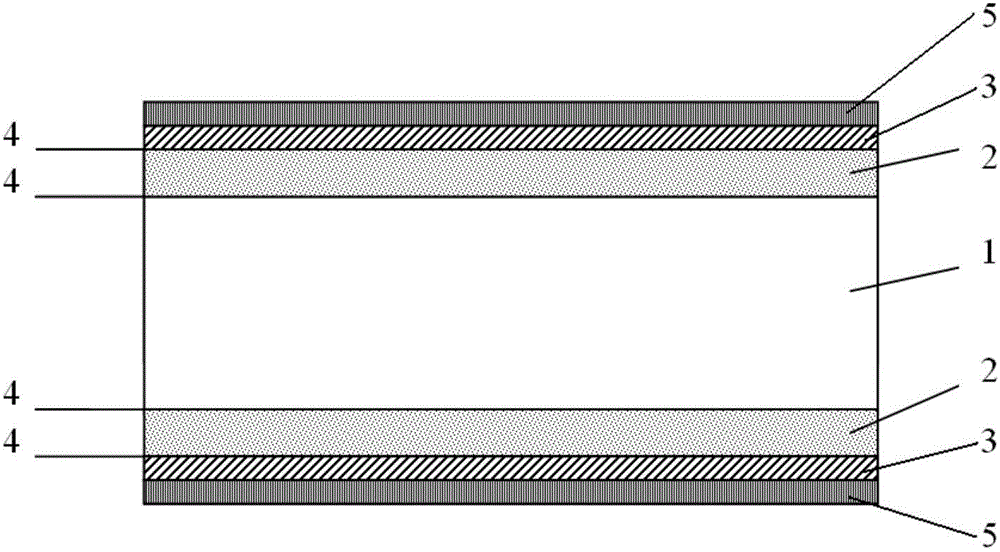

Wood fibre based panel with a surface layer

ActiveUS20150197942A1Attractive surface designSurface property and cost structureDecorative surface effectsSpecial ornamental structuresWood veneerSurface layer

A building panel with a surface layer (1) including a wood veneer, a wood fibre based core (2) and a sub-layer (3) between the surface layer (1) and the core (2). The sub-layer (3) includes wood fibres (4) and a binder (5). The surface layer (1) has surface portions (6) including material from the sub-layer (3). The surface portions (6) including material from the sub-layer (3) extend into the wood veneer.

Owner:VÄLINGE INNOVATION AB

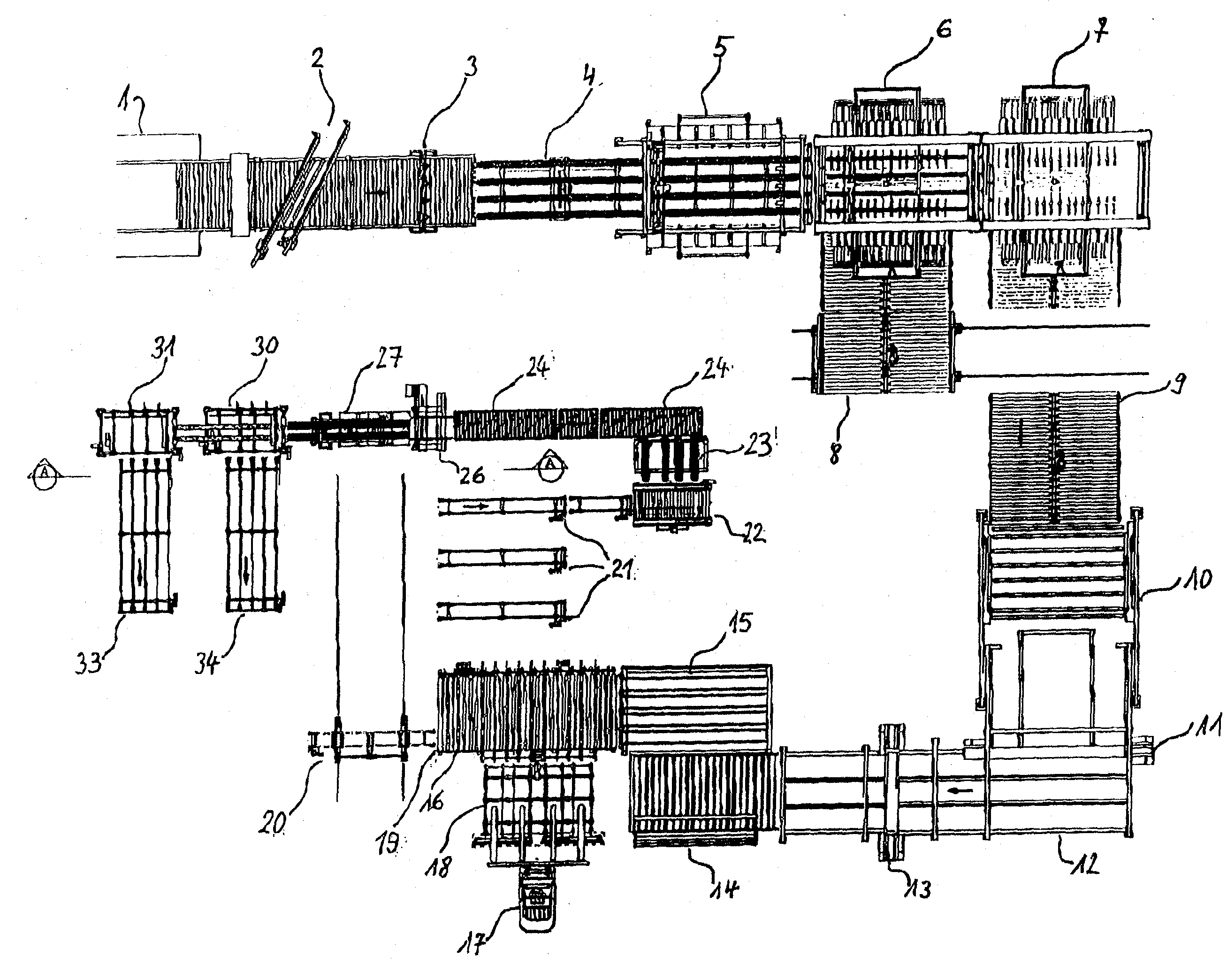

Device for marking and analyzing defects in a system for cutting boards to size made of wood at least in part

InactiveUS20030192412A1Avoid the needMetal sawing accessoriesMaterial analysis by optical meansMarking outEngineering

The invention relates to a device and a method for marking and analyzing detects in a means for cutting-to-size boards of wood at least in part, in which defect detection is combined with marking by a marking means. By an assignment between the detected defects and marks, the steps in the process following cutting-to-size can be controlled as a function of the existence of defects.

Owner:SIEMPELKAMP HANDLING SYST GMBH & CO KG

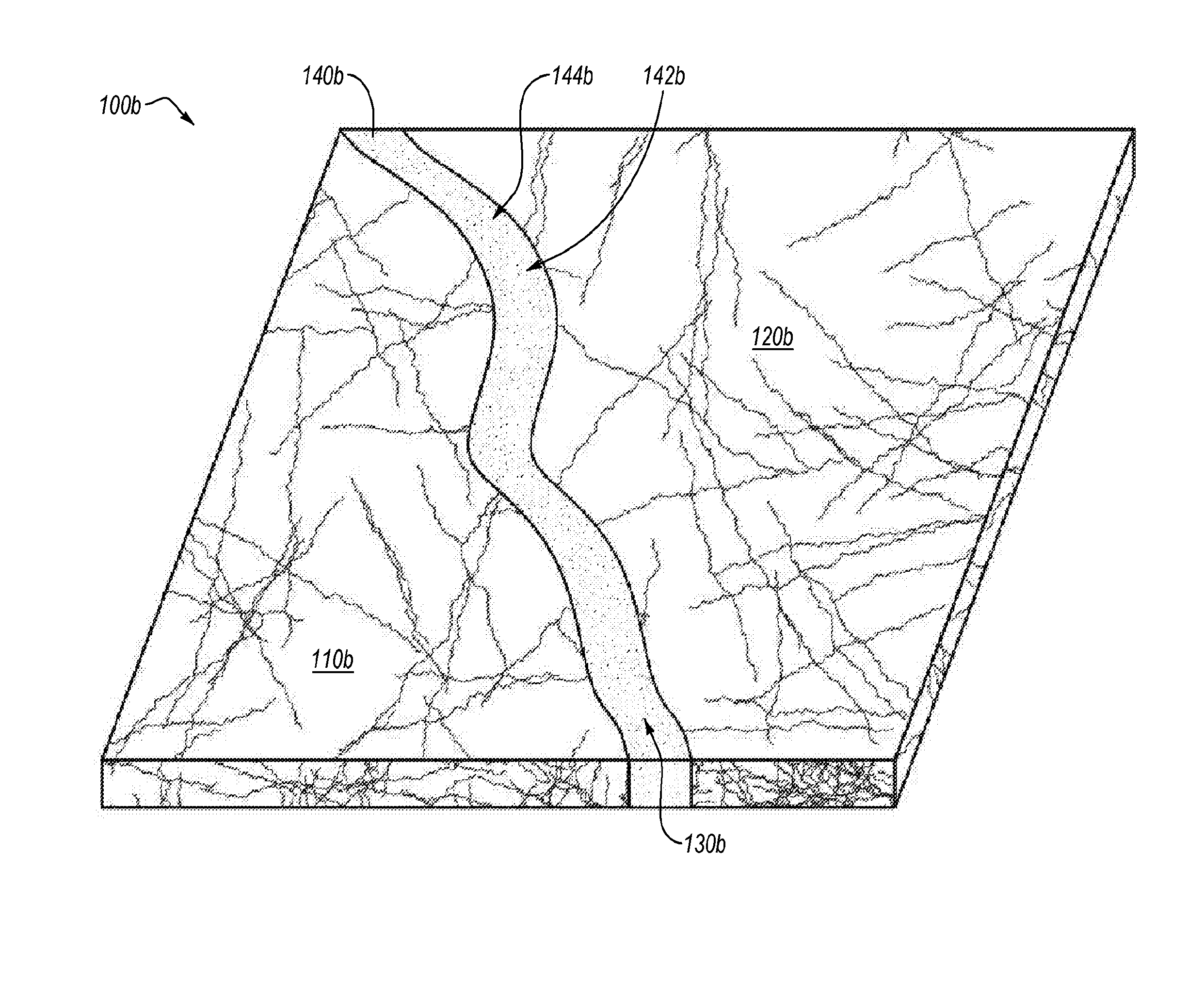

Restructured Slab

ActiveUS20140272250A1Restore structural integrityRestore continuityConstruction materialLayered productsSecondary componentEngineering

A restructured, recycled or repurposed slab such as stone, wood or the like which includes a primary component and a secondary component which fills a fissure, crack or break in the slab. The secondary component being configured to restore the structural integrity and / or providing a continuous surface. The secondary component configured to provide a noticeable contrast in appearance to the primary component.

Owner:RESTRUCTURED SURFACES

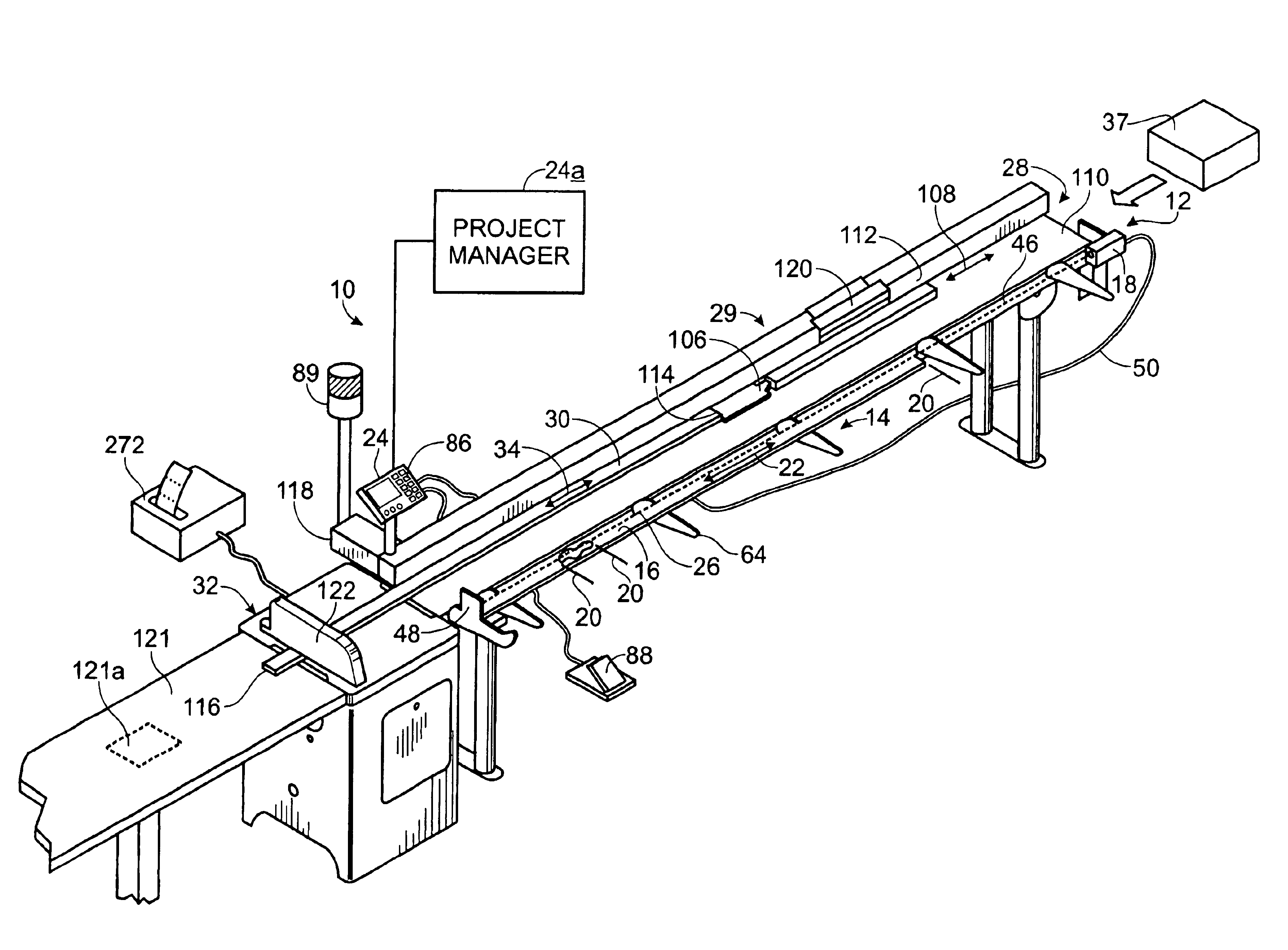

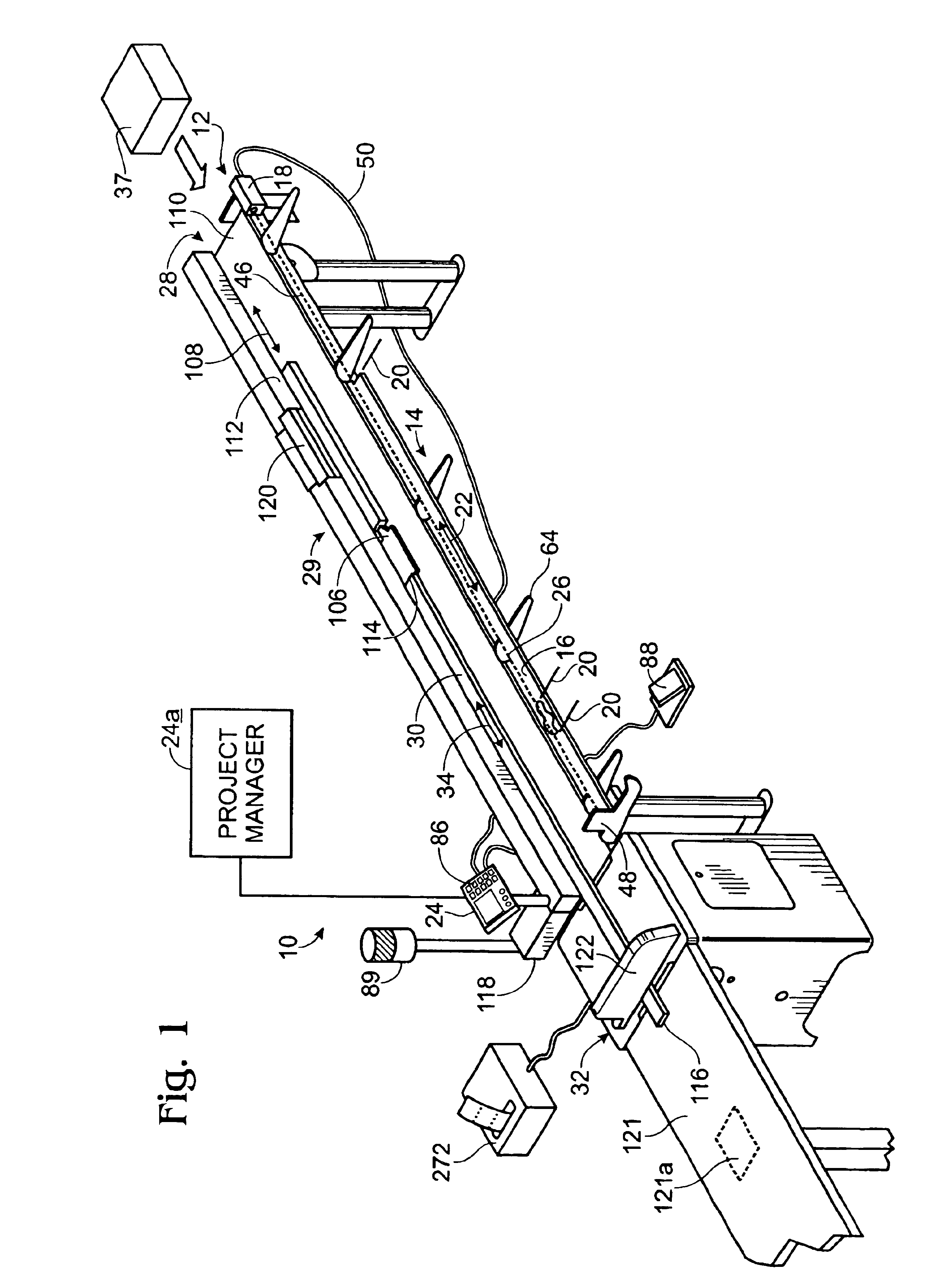

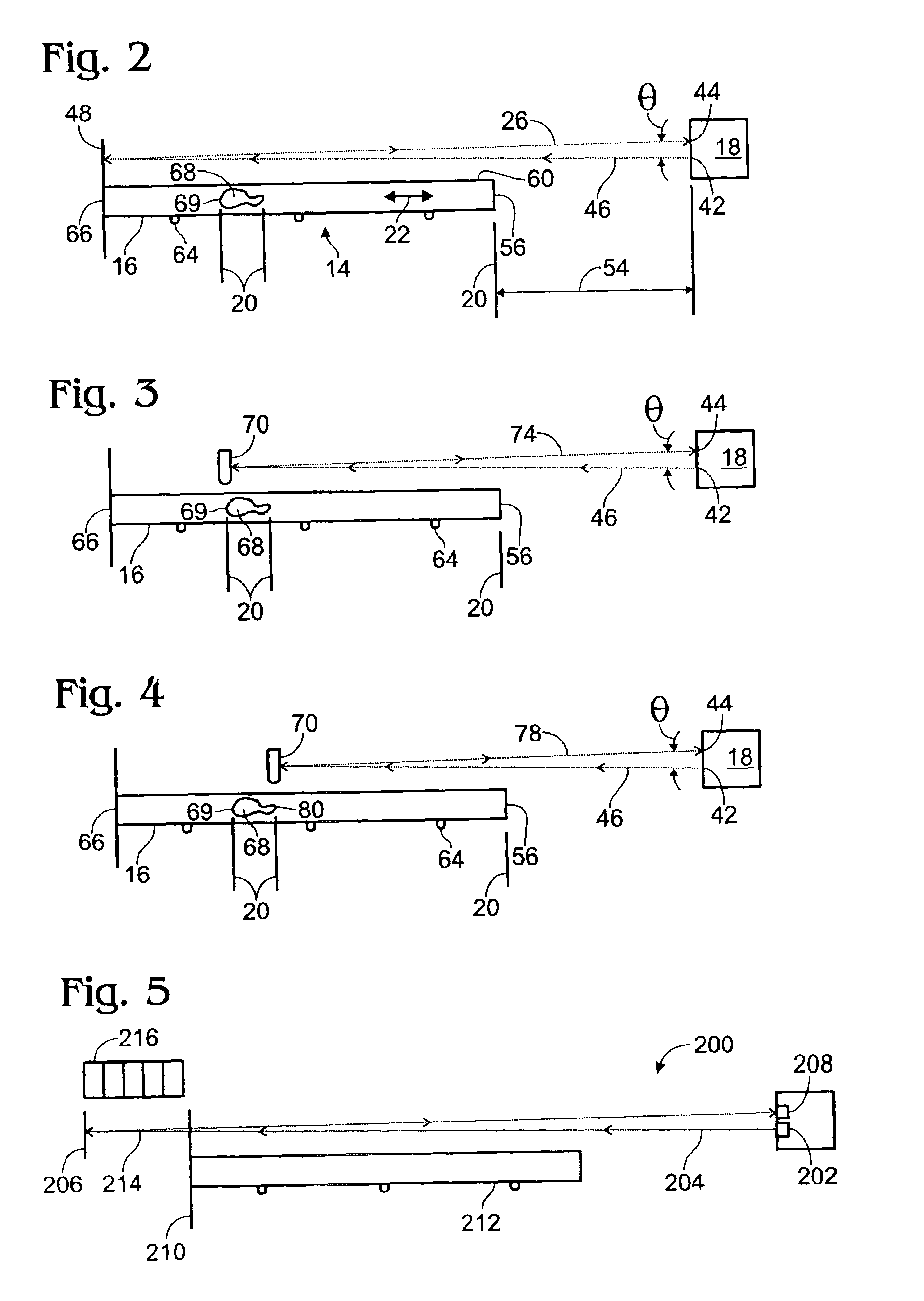

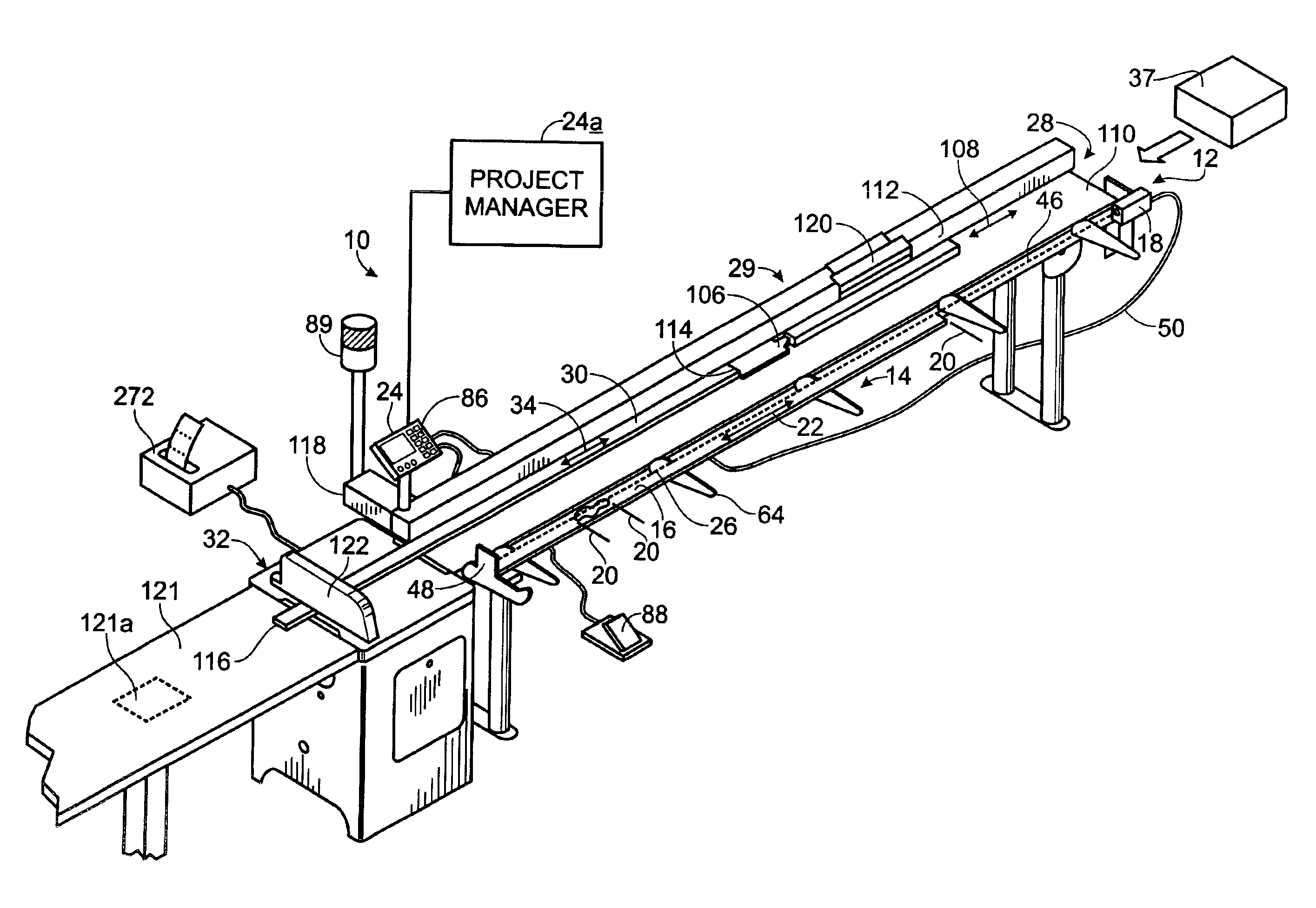

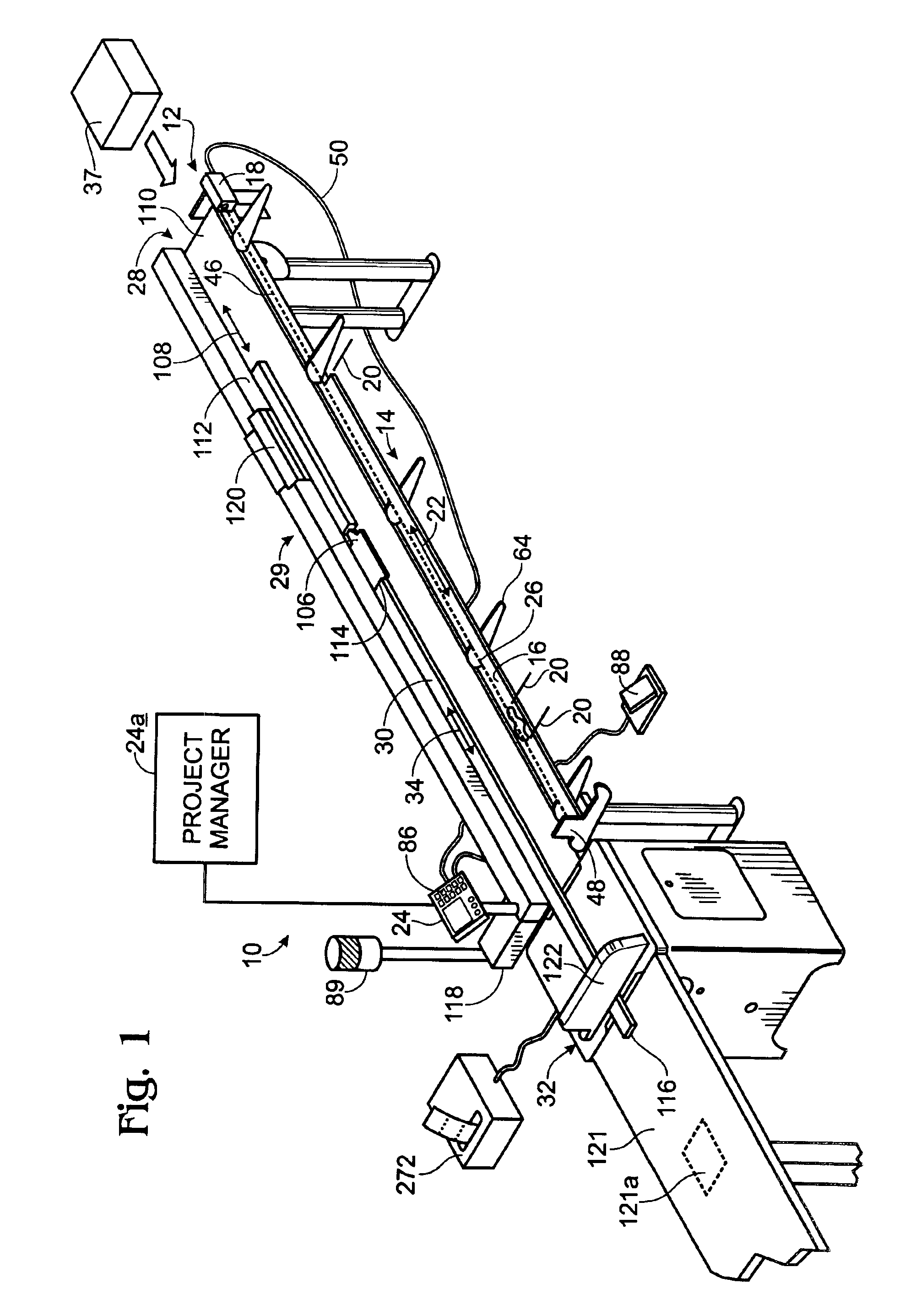

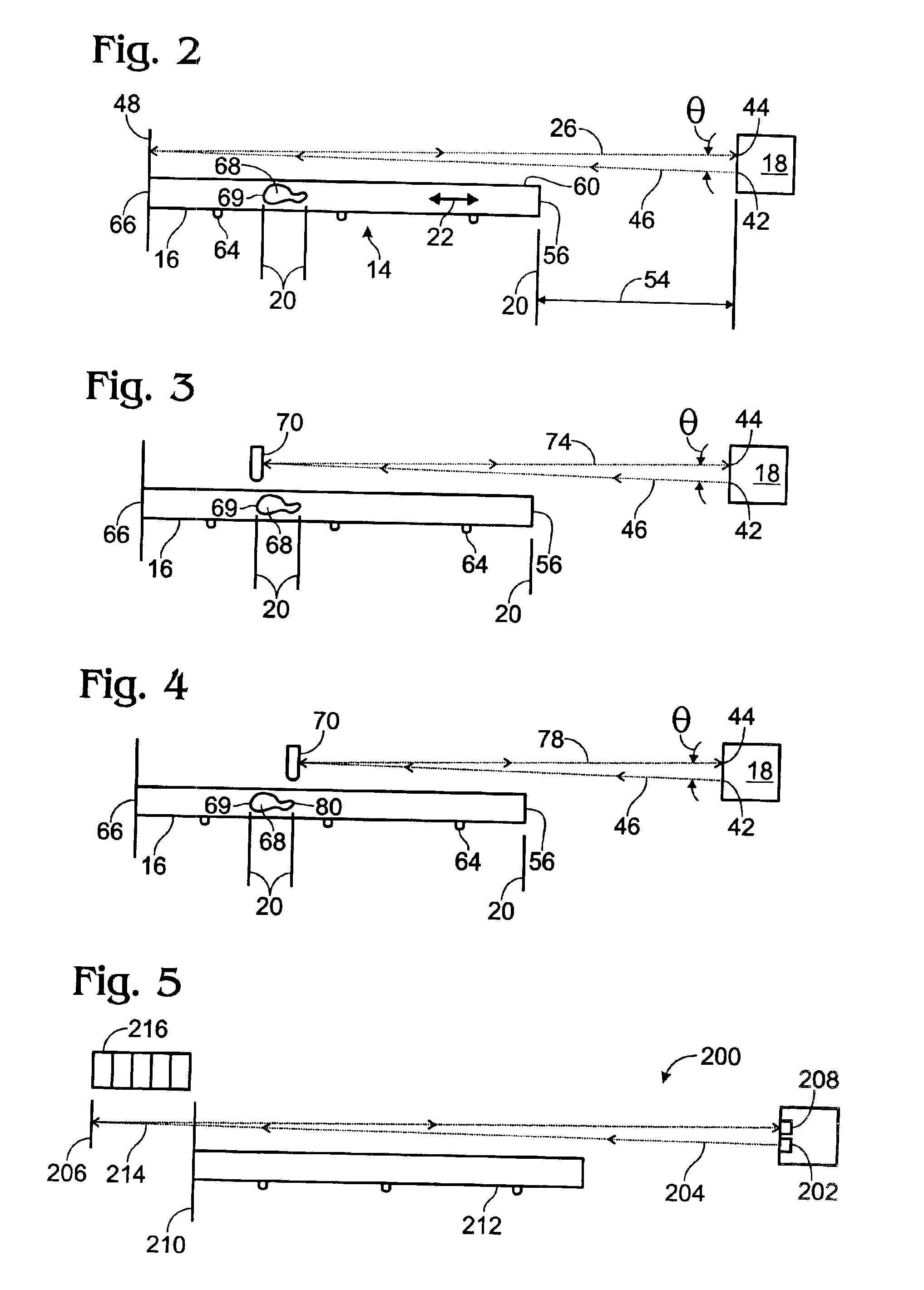

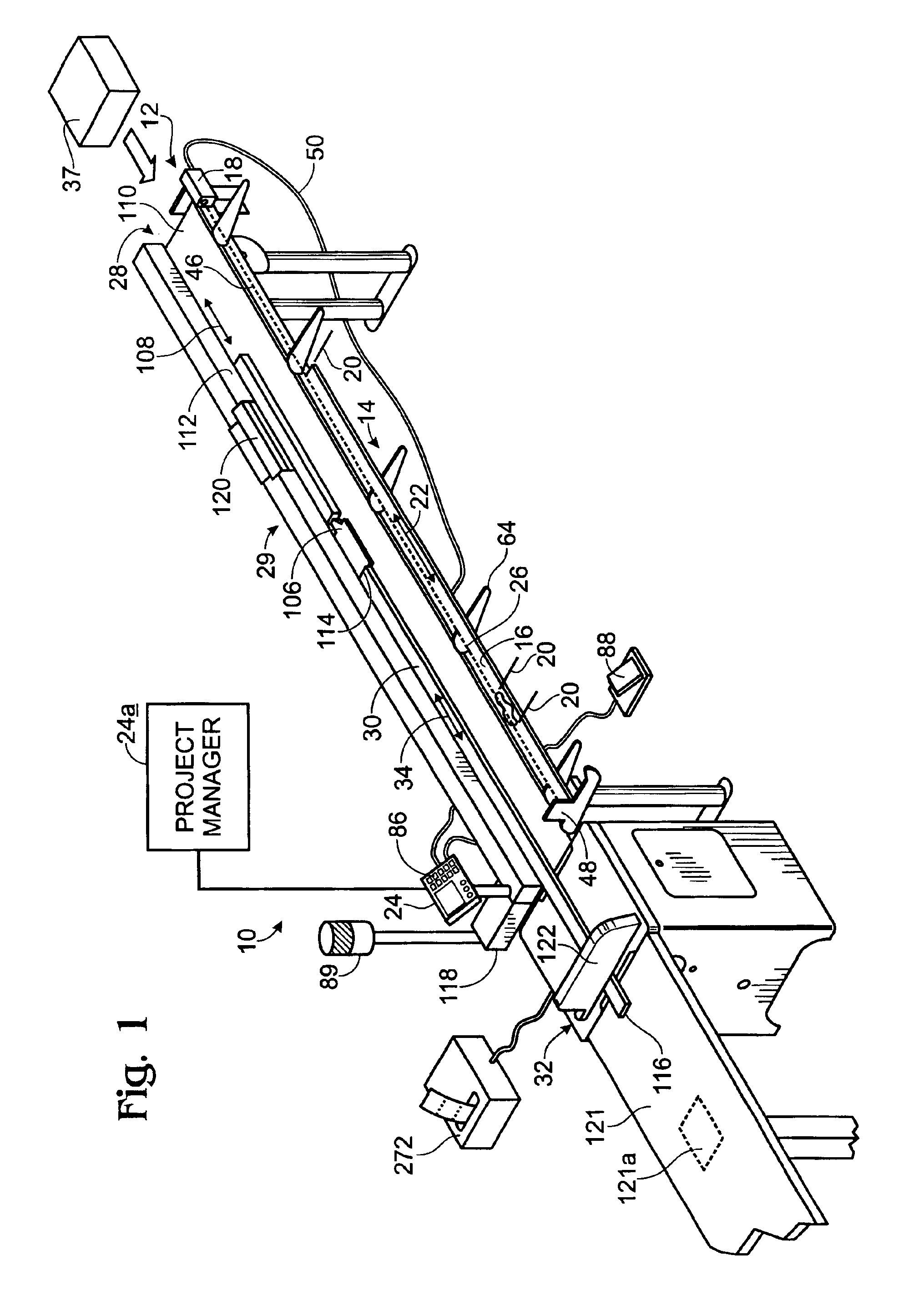

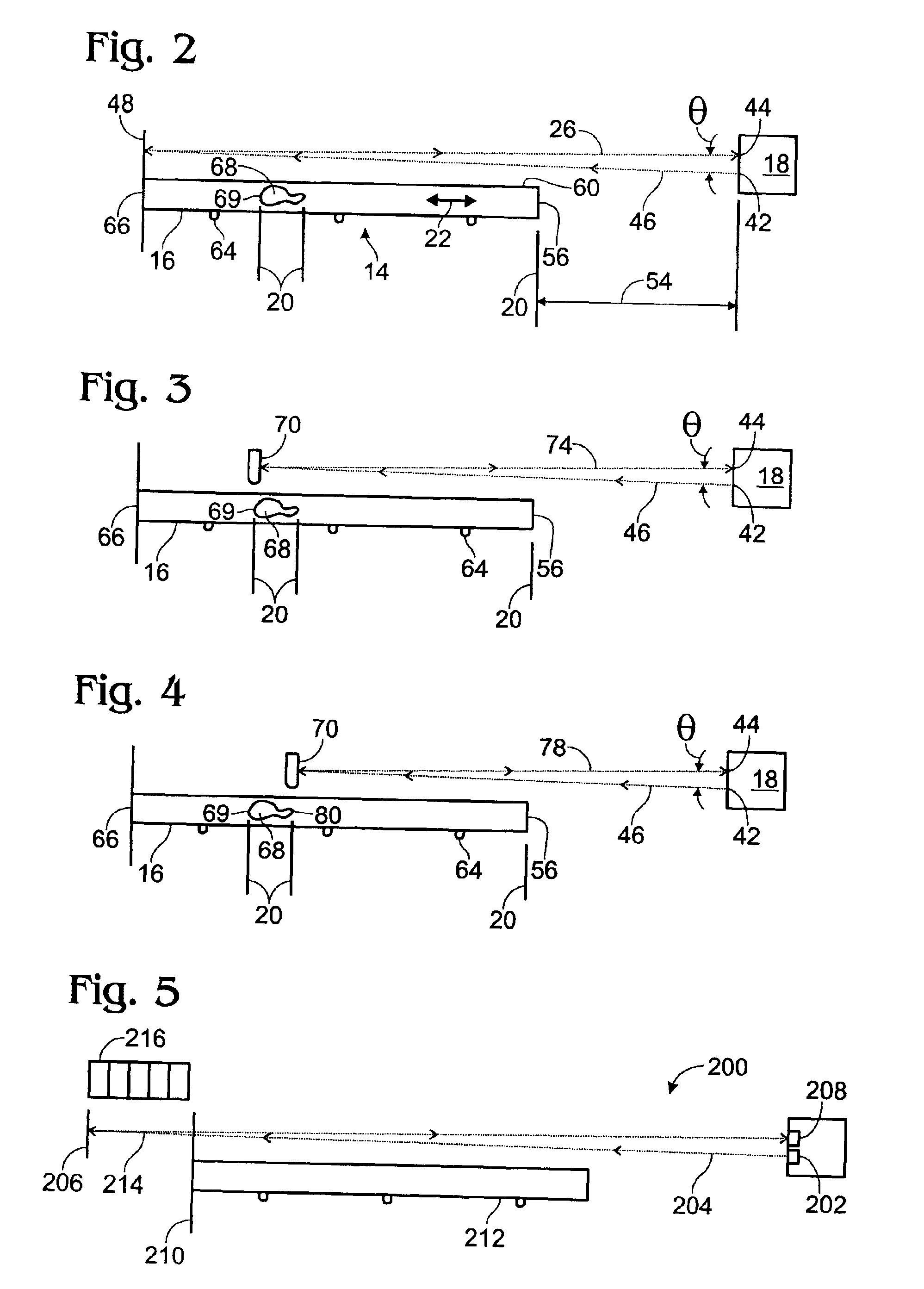

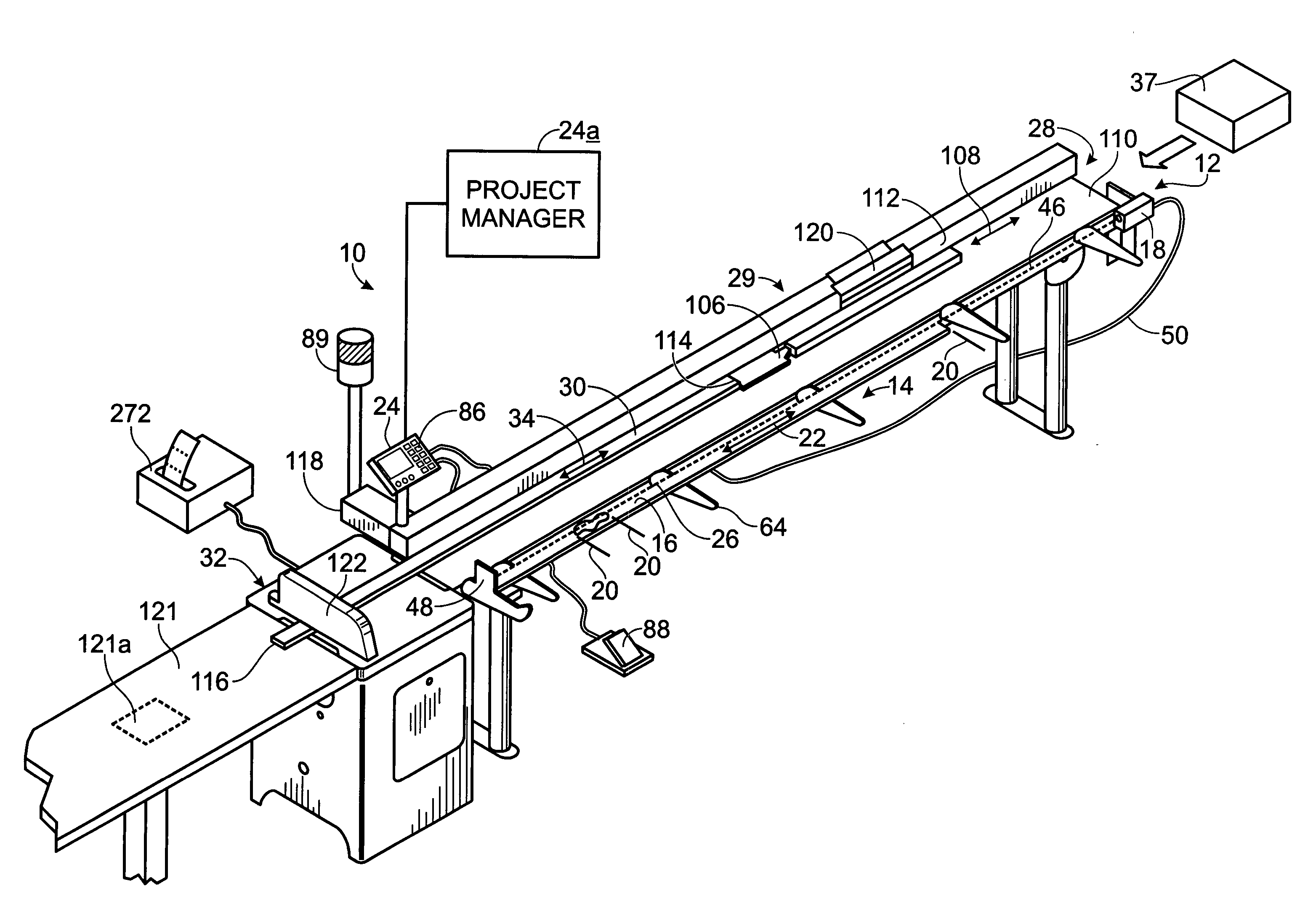

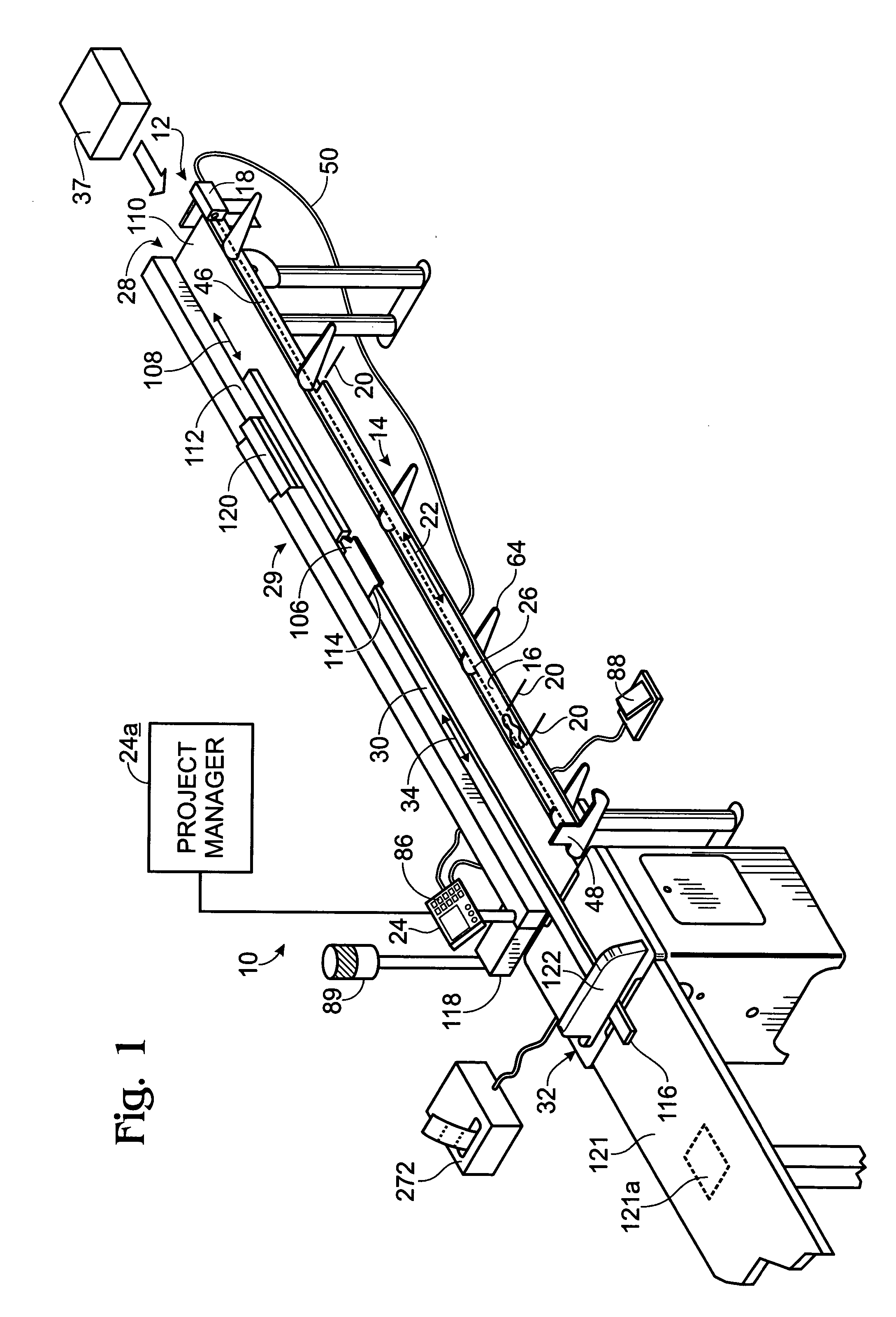

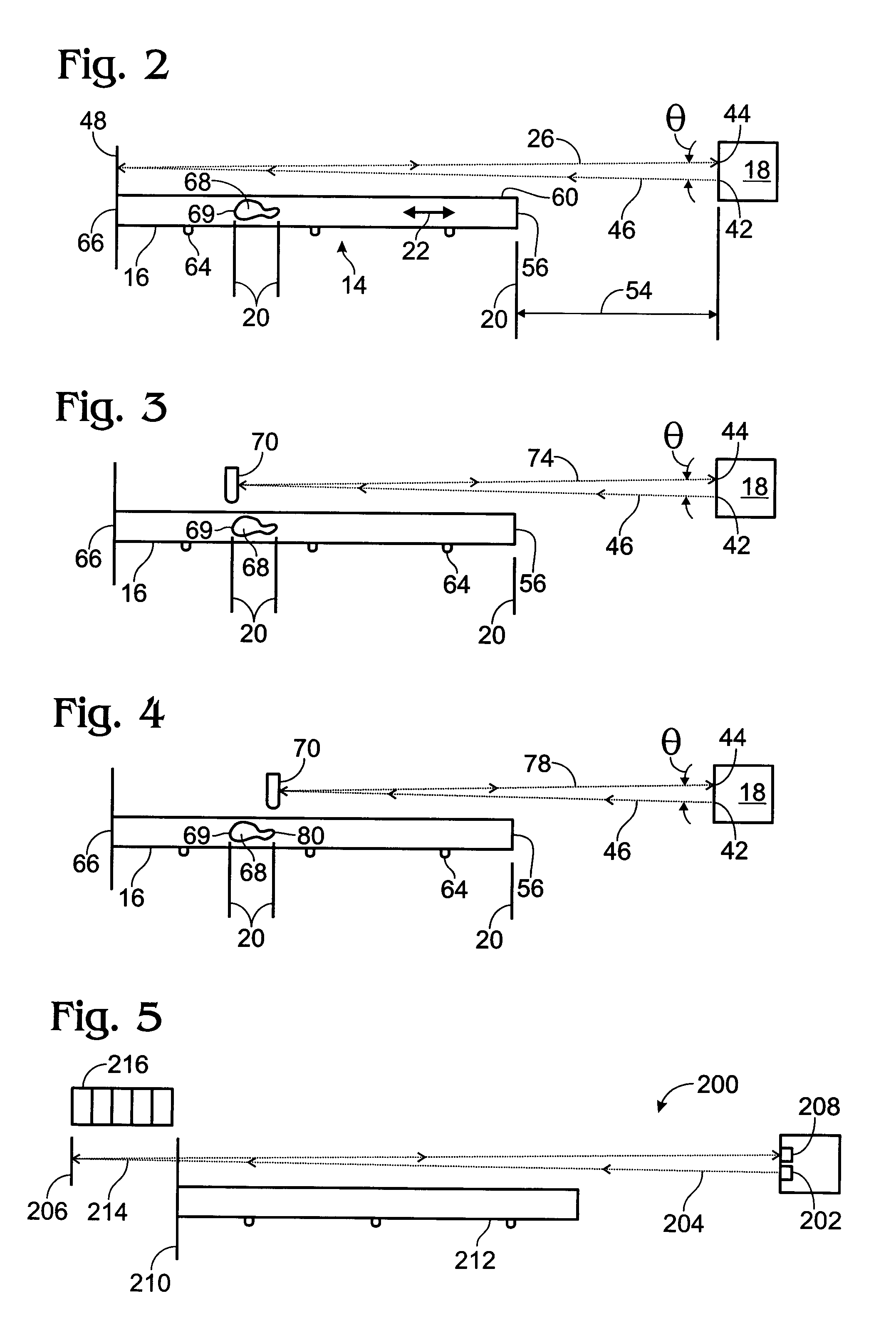

Systems and methods of processing materials

System, including apparatus and method, for processing a material involves automatically measuring the length of a work piece and calculating an optimal plan for cutting the work piece to fulfill cut list requirements.

Owner:PRECISION AUTOMATION

Labeling methods and apparatus

System, including apparatus and method, for processing a material involves automatically printing labels for pieces cut pursuant to a cut list.

Owner:PRECISION AUTOMATION

Wood fibre based panel with a surface layer

ActiveUS10100535B2Attractive surface designSurface property and cost structureDecorative surface effectsSpecial ornamental structuresWood veneerSurface layer

A building panel with a surface layer (1) including a wood veneer, a wood fibre based core (2) and a sub-layer (3) between the surface layer (1) and the core (2). The sub-layer (3) includes wood fibres (4) and a binder (5). The surface layer (1) has surface portions (6) including material from the sub-layer (3). The surface portions (6) including material from the sub-layer (3) extend into the wood veneer.

Owner:VÄLINGE INNOVATION AB

Wood fibre based panel with a surface layer

ActiveUS20190010711A1Attractive surface designSurface property and cost structureDecorative surface effectsSpecial ornamental structuresWood veneerSurface layer

A building panel with a surface layer including a wood veneer, a wood fibre based core and a sub-layer between the surface layer and the core. The sub-layer includes wood fibres and a binder. The surface layer has surface portions including material from the sub-layer. The surface portions including material from the sub-layer extend into the wood veneer.

Owner:VÄLINGE INNOVATION AB

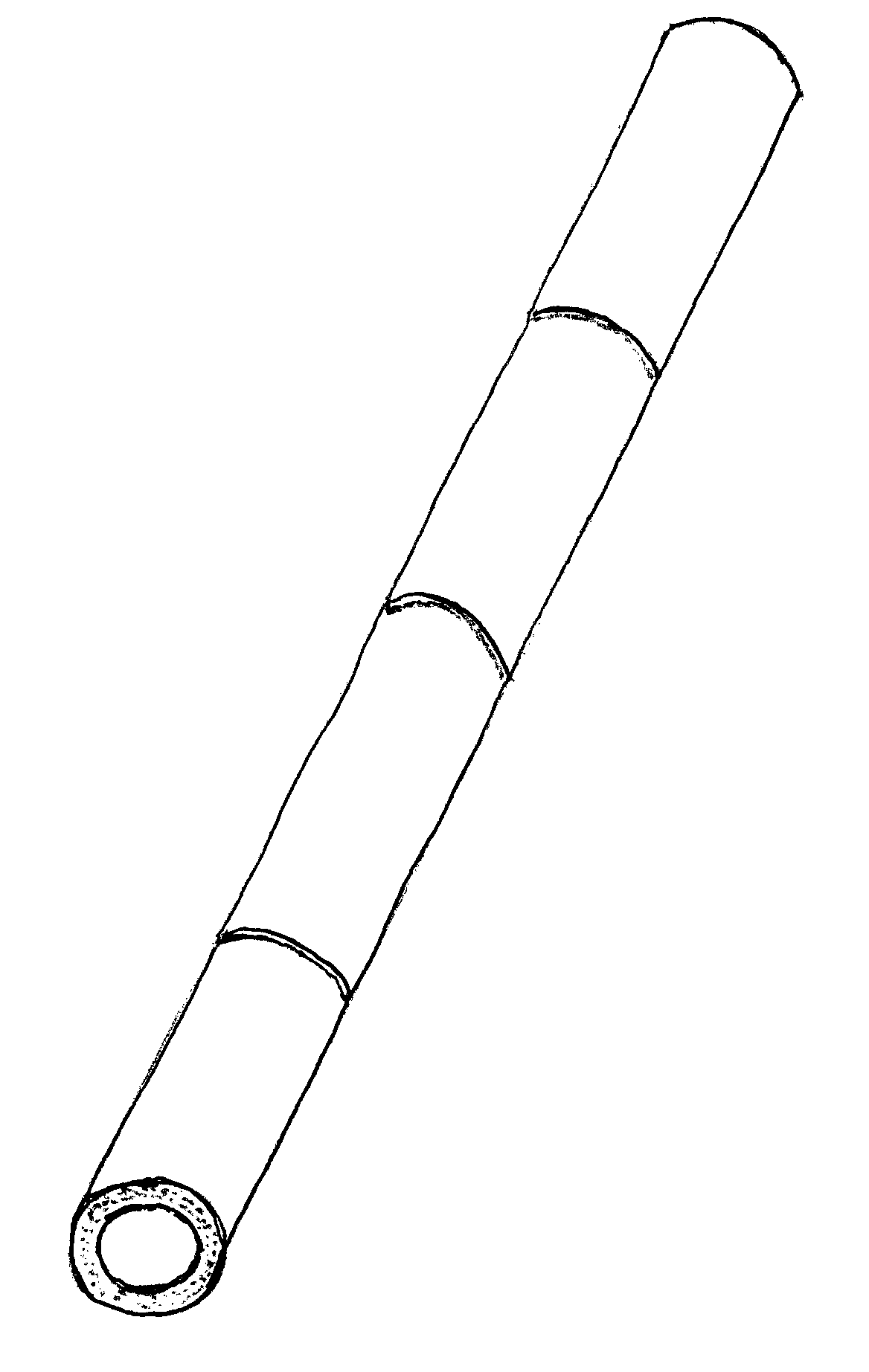

Method for Making Plywood and Dimensional Lumber from Arundo Donax L. or Bamboo

ActiveUS20070125446A1Reduce dependenceConstruction materialCane mechanical workingEngineeringFire retardant

A method of producing a virtually fireproof plywood from perennial grasses such as Arundo donax Ligneous, various bamboo strains, or a blend thereof, by first weaving the stalks of these plants into a mat and then layering these mats and binding each layer with any one of several commercial resins mixed with potash for the purpose of enhancing the board's fire retardant quality. The result is the formation of a finished product with structural board attributes and an exceptionally high flash point in relation to other manufactured board products made from forest materials.

Owner:ABDULNASER ABDULMALIK +1

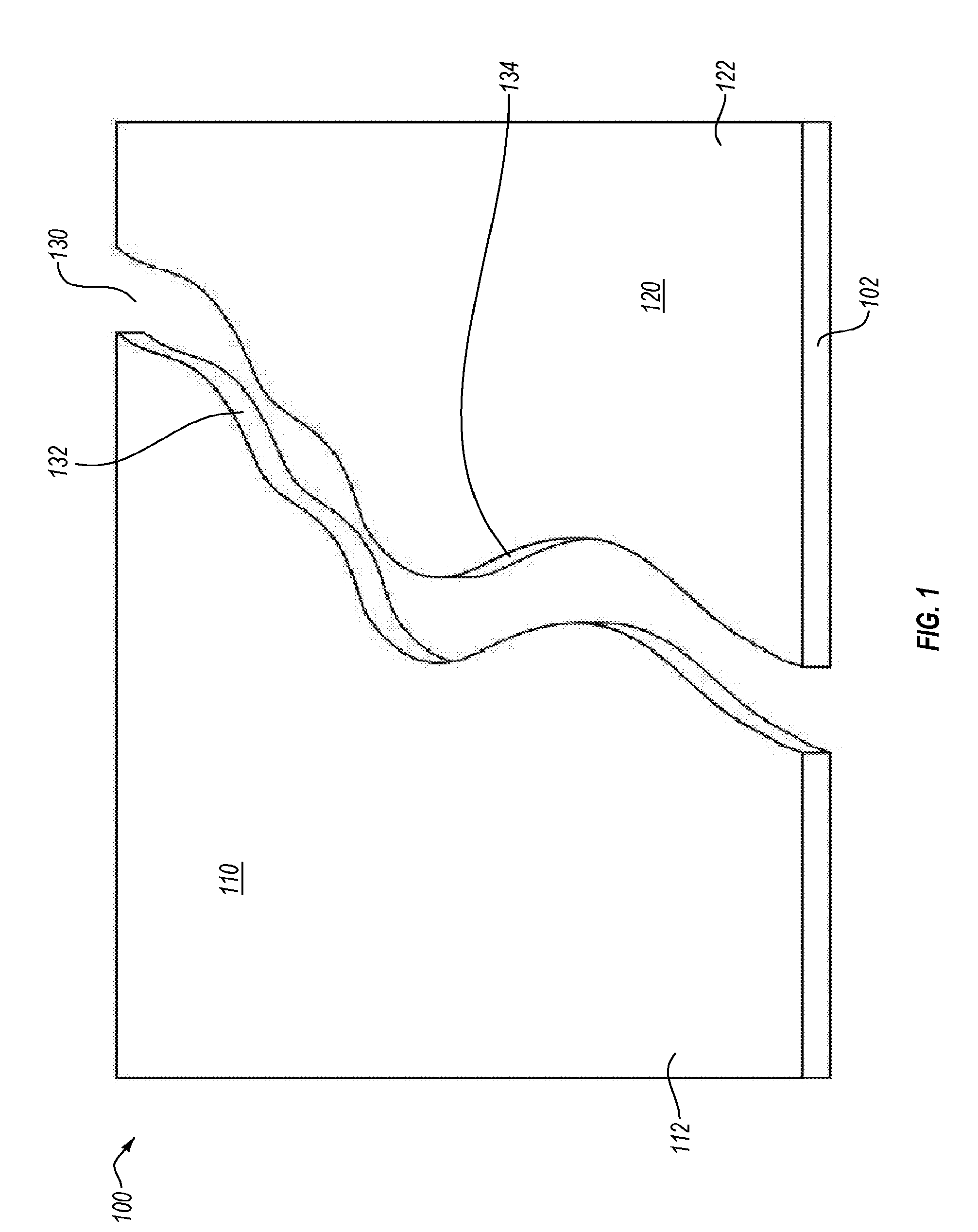

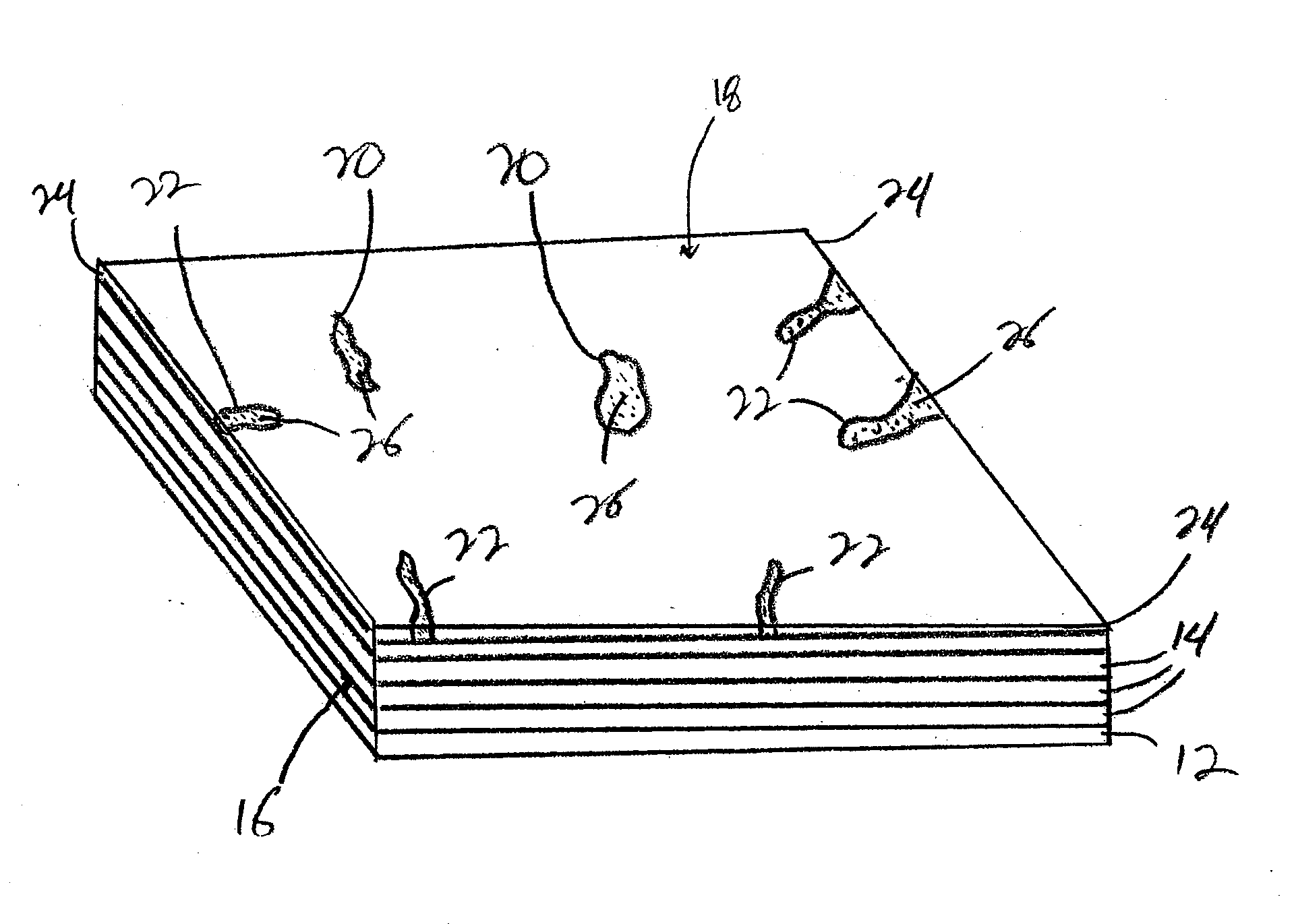

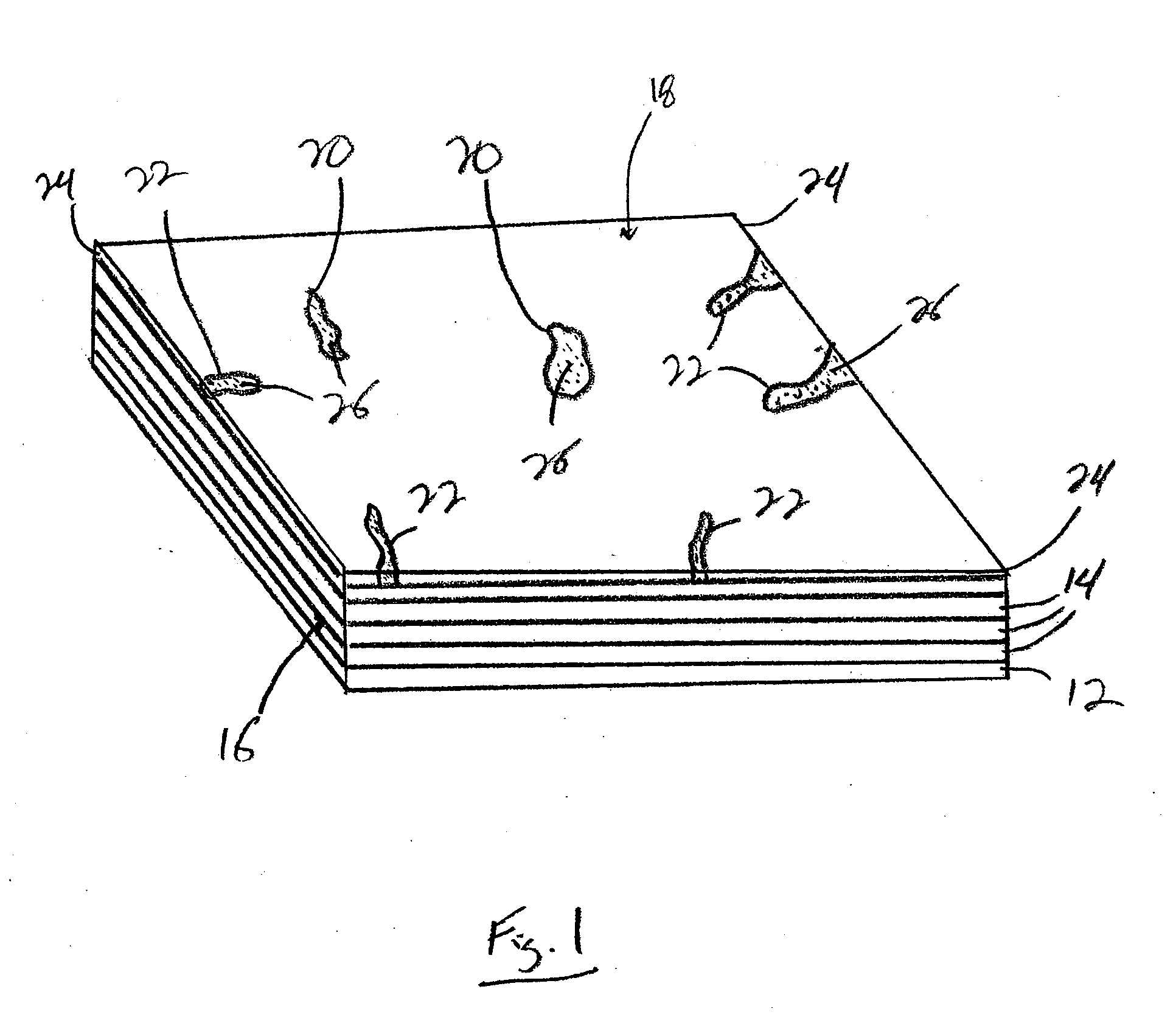

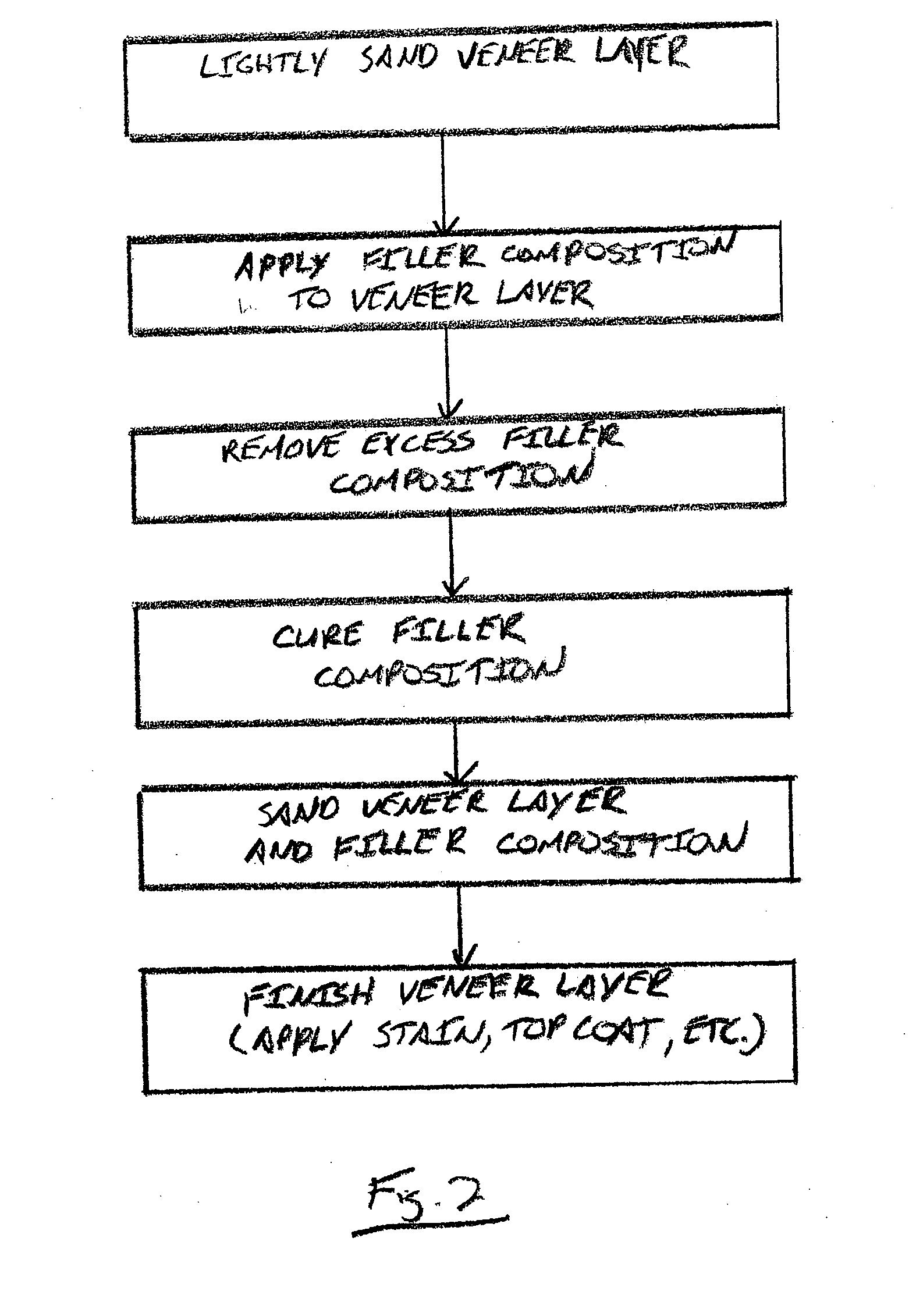

Veneer Filling and Repair Method and Composition

InactiveUS20080152876A1Easily spreadDesired appearanceDecorative surface effectsLayered productsSingle platePolymer chemistry

The present invention is filler composition and a method for applying the filler composition to an engineered hardwood flooring board in order to fill the defects in the veneer layer of the board to provide the desired appearance to the exterior of the board. The filler composition is applied continuously to a veneer layer forming the exterior surface of an engineered hardwood flooring board in a manner such that all defects and cracks in the veneer layer are filled with the filler composition. After application, the excess filler composition is removed from the board such that only the filler composition filling the defects in the veneer layer remains on the board.

Owner:MAGNUSSON TRYGGVI +1

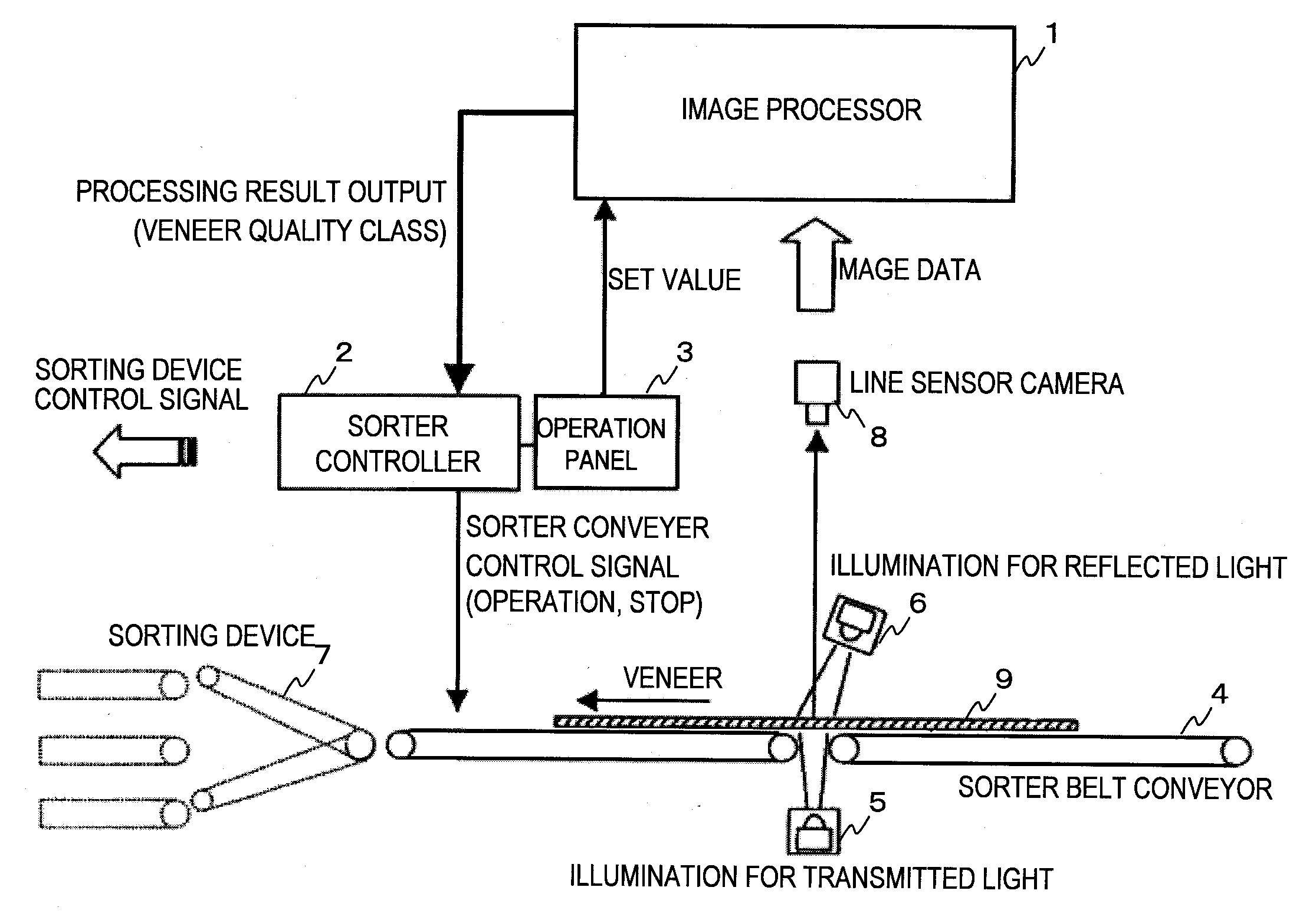

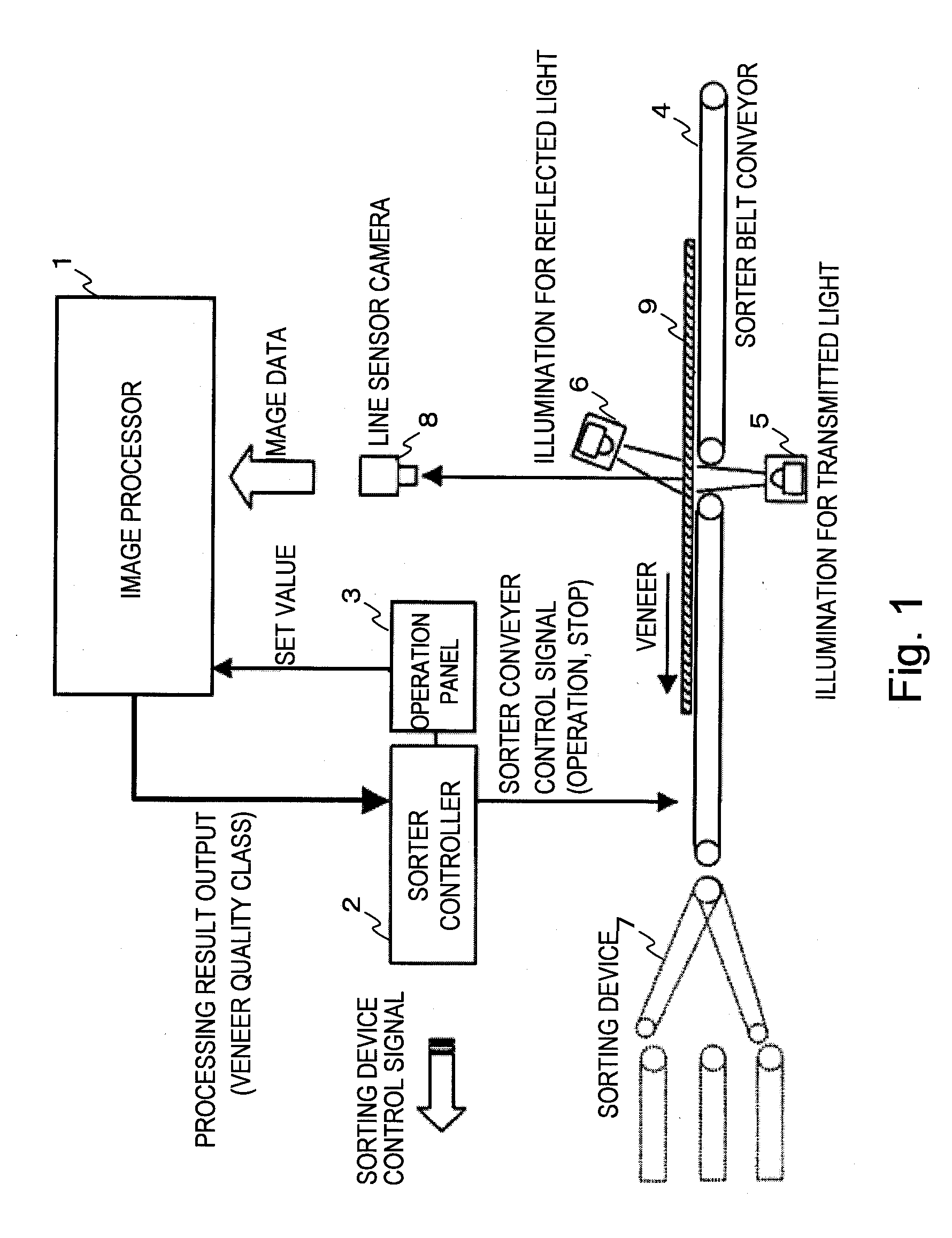

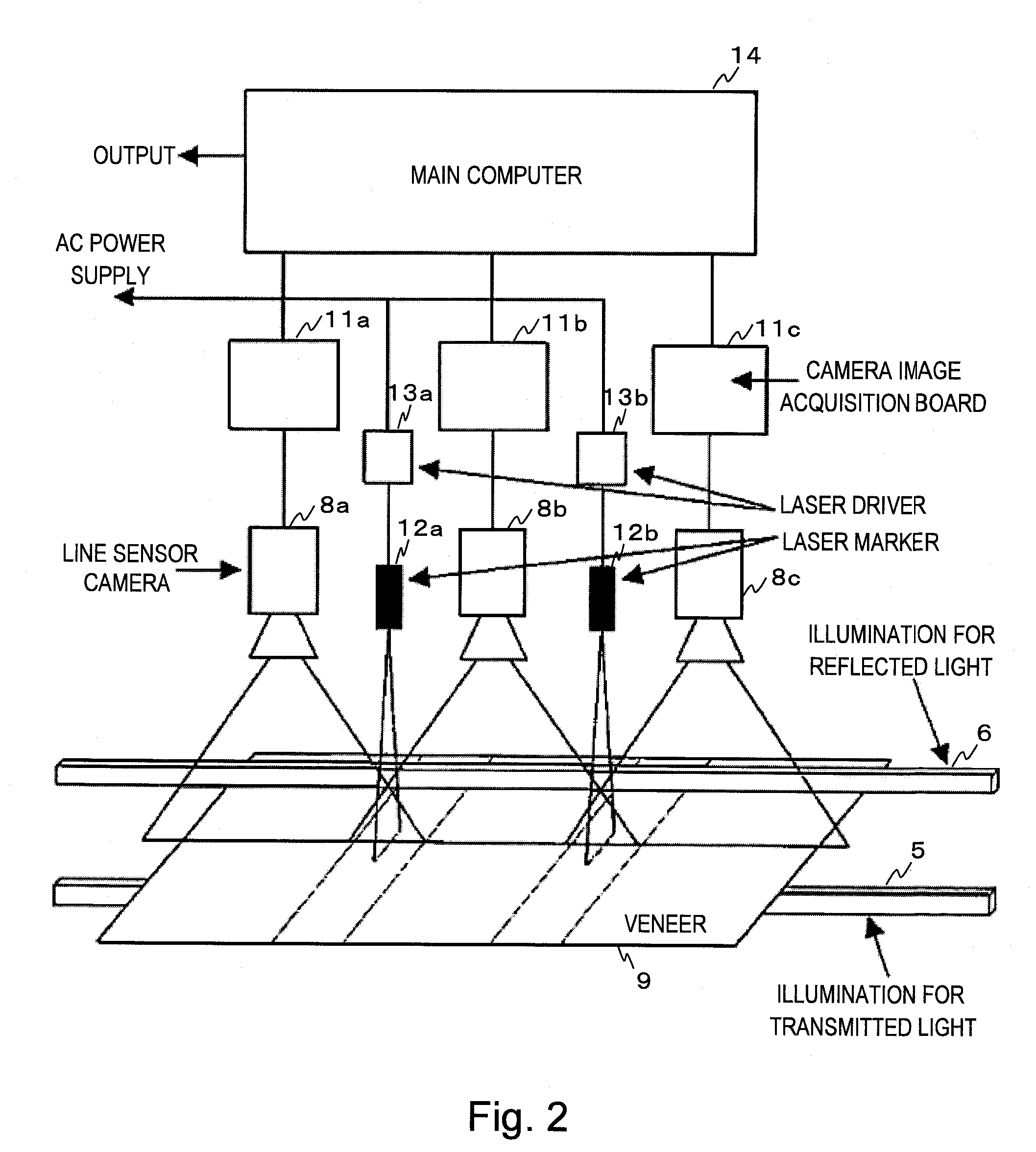

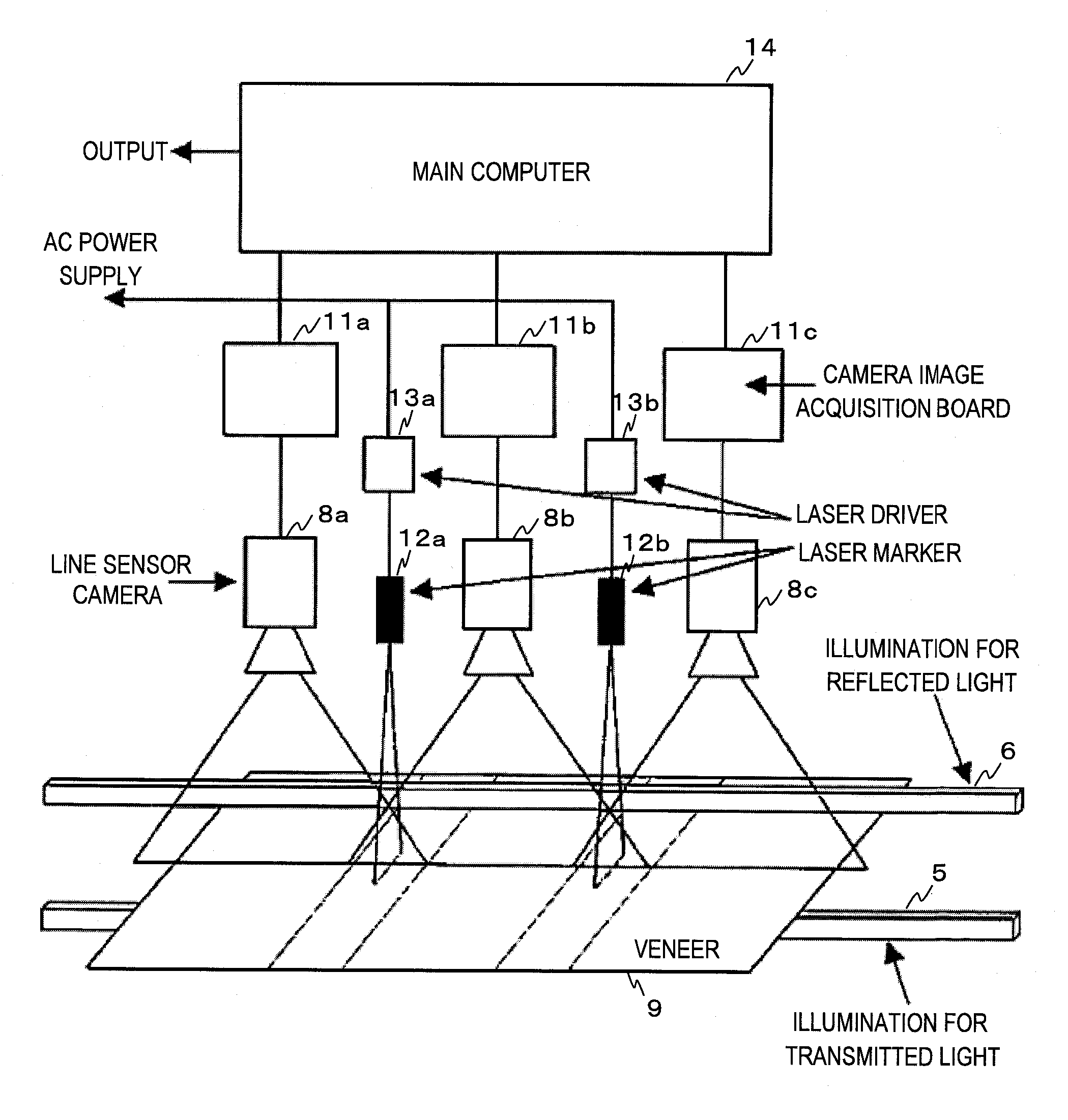

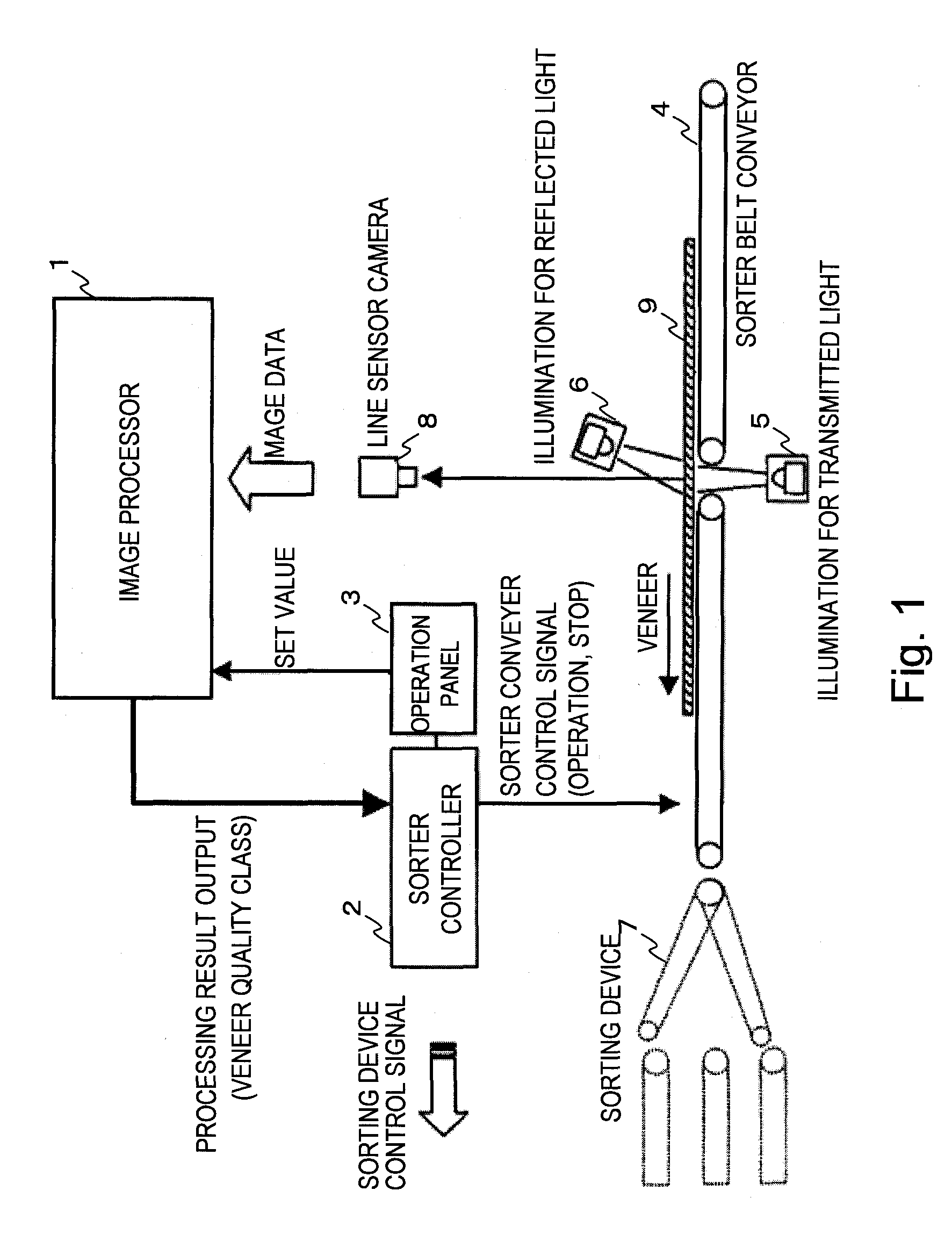

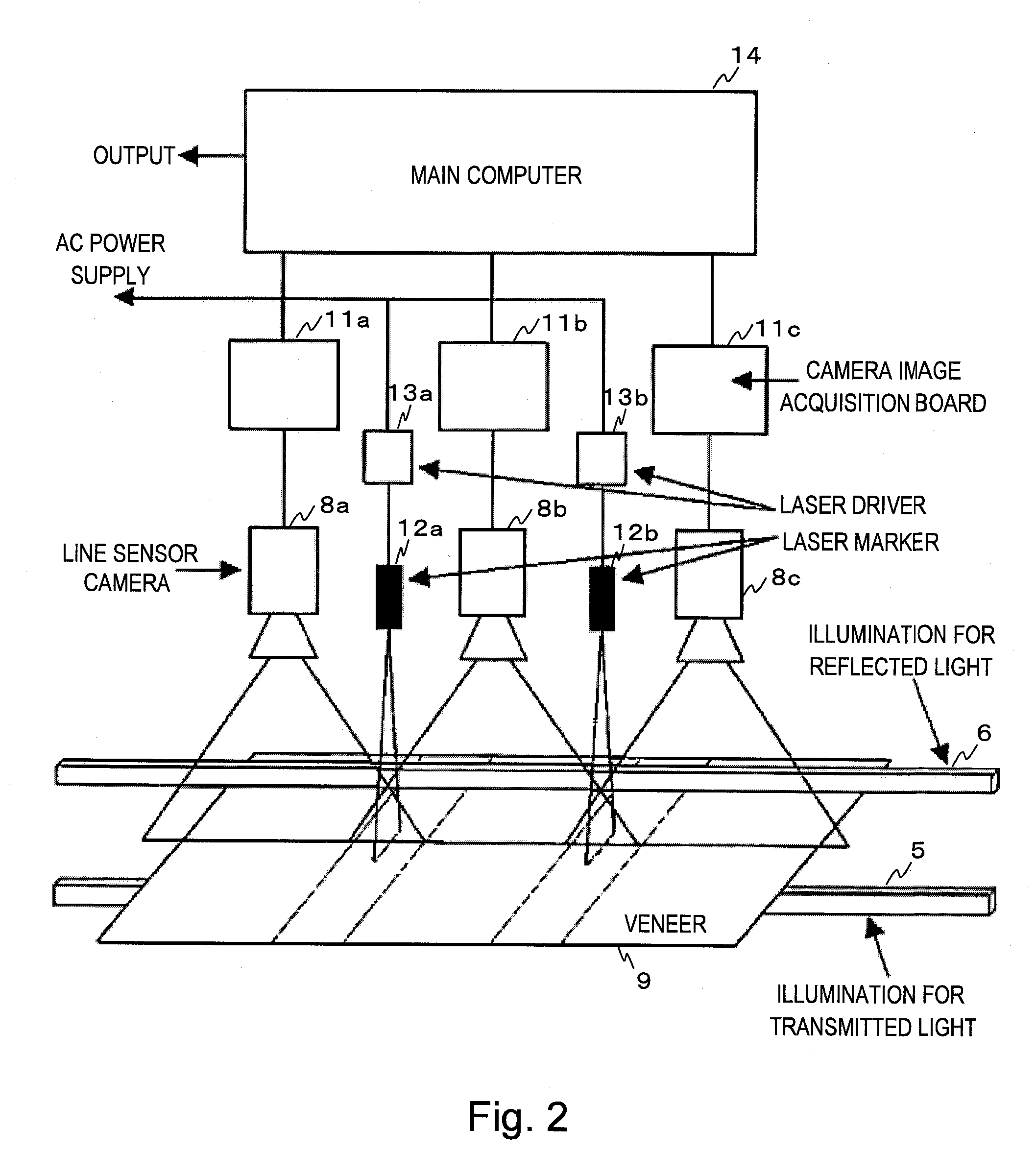

Lumber inspection method, device and program

ActiveUS20100141754A1Easy to getEasy to detectImage enhancementImage analysisColor imageImaging processing

An imaging means captures a color image of lumber. An image processing means obtains the color distribution of the color image captured by the imaging means, compares the obtained color distribution with a predetermined color distribution of normal lumber, judges the obtained color distribution as an abnormal one when it is deviated from the color distribution of normal lumber by a predetermined value or more, and detects a defect of the lumber having the abnormal color distribution deviated by a value larger than the predetermined value in an area on the surface of the lumber captured by the imaging means.

Owner:MEINAN MASCH WORKS INC

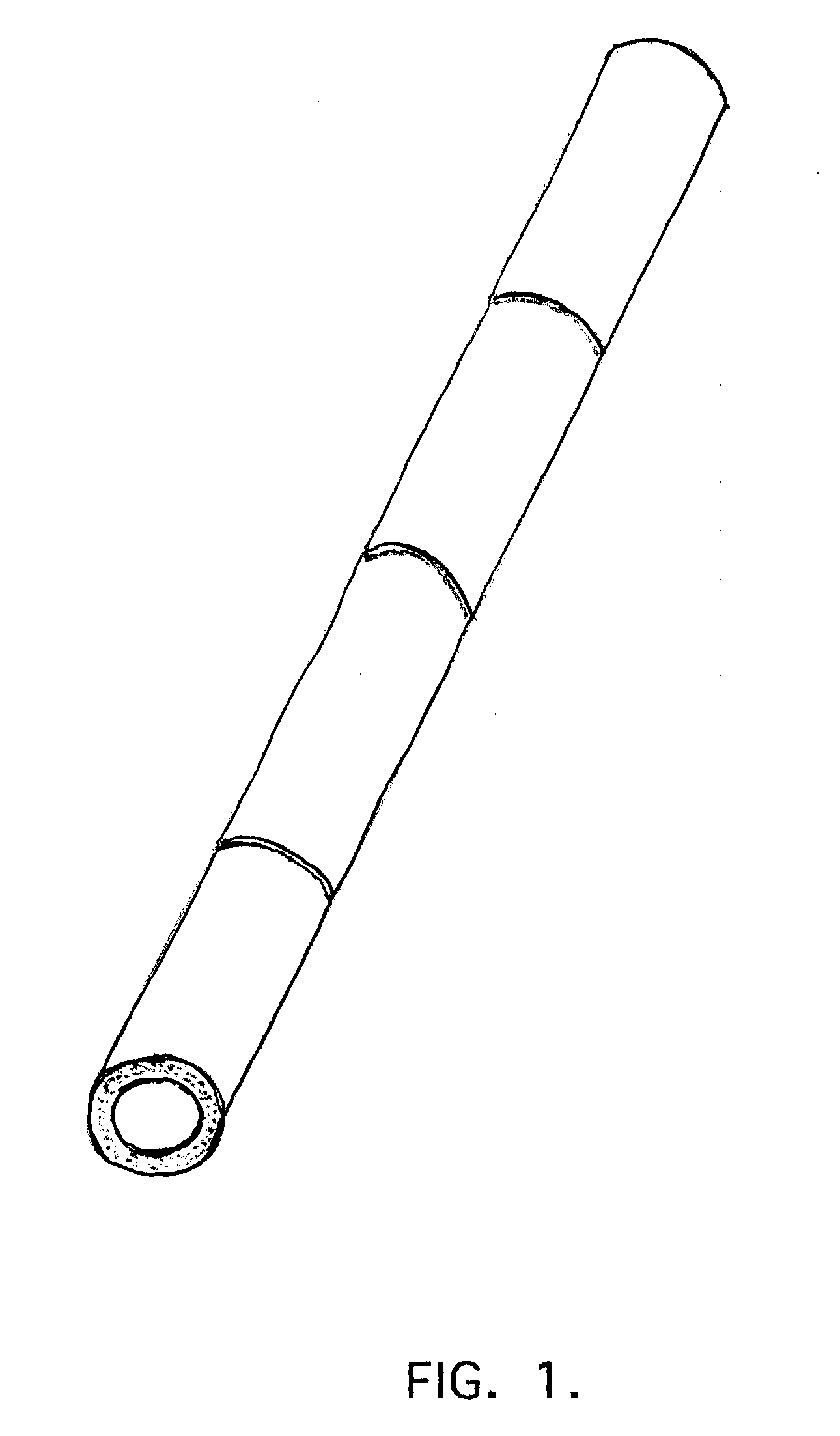

Bamboo splitting machine for preparing bamboo bundles and bamboo bundle preparing method

InactiveCN102922579AIncrease profitSave resourcesIrregularity removal devicesFiberPulp and paper industry

The invention provides a bamboo rolling-compaction splitting machine and a preparation method. The splitting machine comprises a machine frame 7, a feeding port 1, a drive device and a splitting feeding device driven by the drive device, wherein the feeding port 1, the drive device and the splitting feeding device are installed on the machine frame. The splitting feeding device is formed by at least two groups of unit splitting feeding devices arranged in a staggered mode and / or splitting feeding devices in the same groups and a plurality of unit splitting feeding devices arranged at the tail end. Circular shaft cutters respectively used for scraping tabasheer and bamboo green are further installed among the splitting feeding device groups. The bamboo splitting machine removes bamboo joints, bamboo green epidermal layers and tabasheer epidermal layers and performs flattening and splitting for multiple times, so that raw materials are fed through the feeding port and processed into qualified bamboo fiber in one time. In addition, the removed bamboo green epidermal layers and the removed tabasheer epidermal layers are thin, the bamboo green affecting the product quality and with a wax layer and the tabasheer with high brittleness are ensured to be removed, the bamboo utilizing rate is improved, energy consumption is reduced, and the manpower and bamboo resources are saved, and the product performance is obviously higher than and superior to the quality of existing products.

Owner:湖北巨宁竹业科技股份有限公司

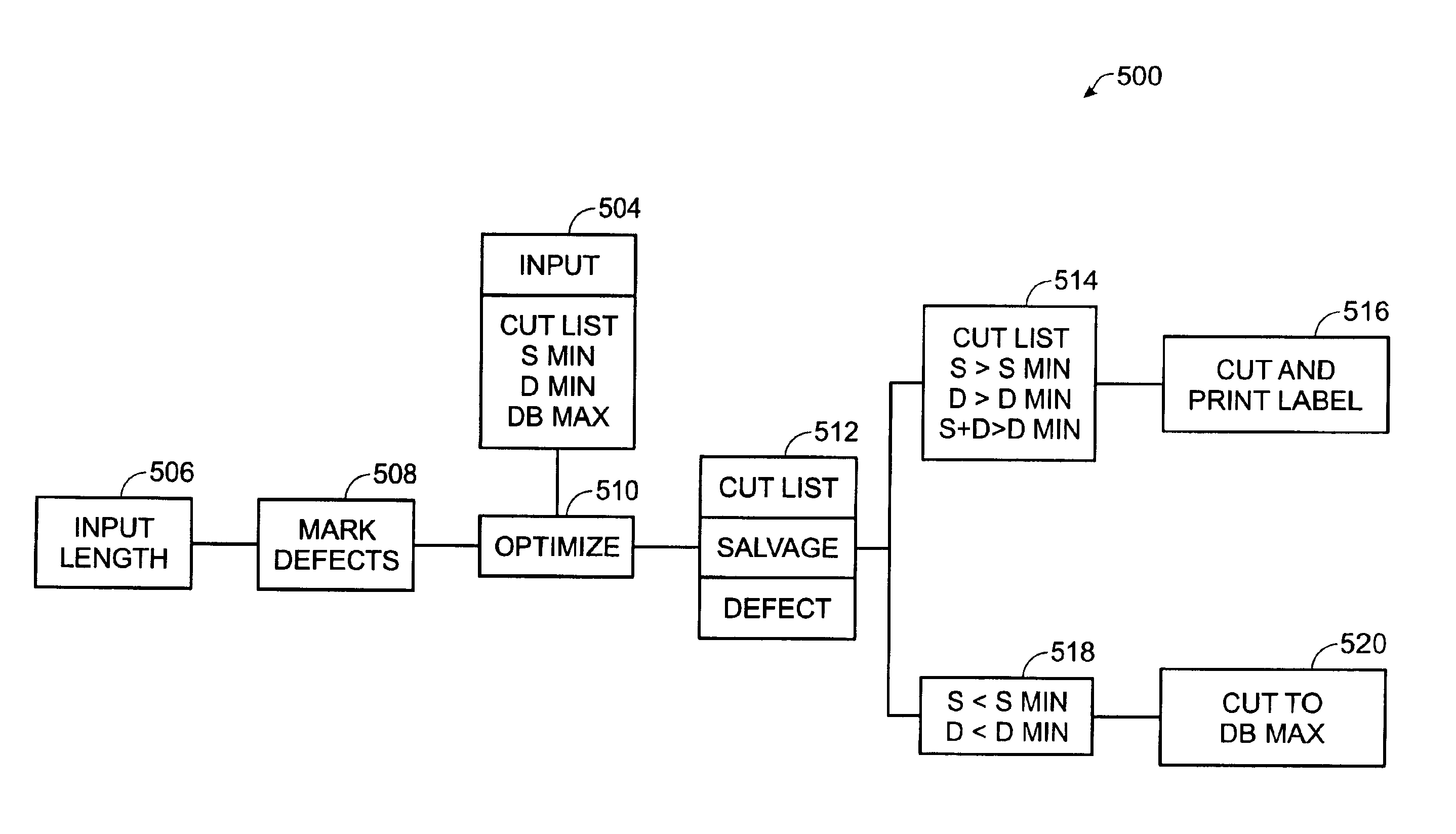

Method to control optimized cutting of stock to satisfy a cut list

A method of processing material involves cutting pieces of material pursuant to a cut list and managing remaining salvage and defect pieces. A computer may be connected to a saw machine, and programmed to optimize cutting of stock to satisfy a cut list. An operator may input a cut list into the computer along with other parameters such as minimum salvage and defect lengths. A printer may be configured to automatically print labels for application to cut pieces.

Owner:PRECISION AUTOMATION

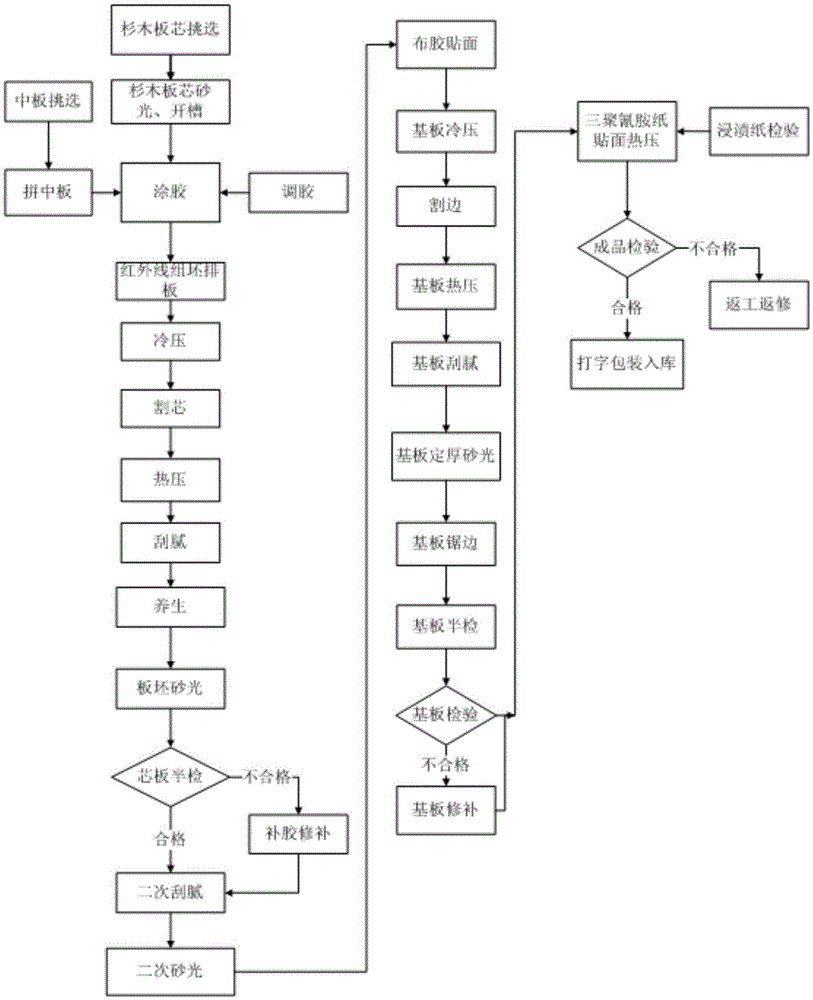

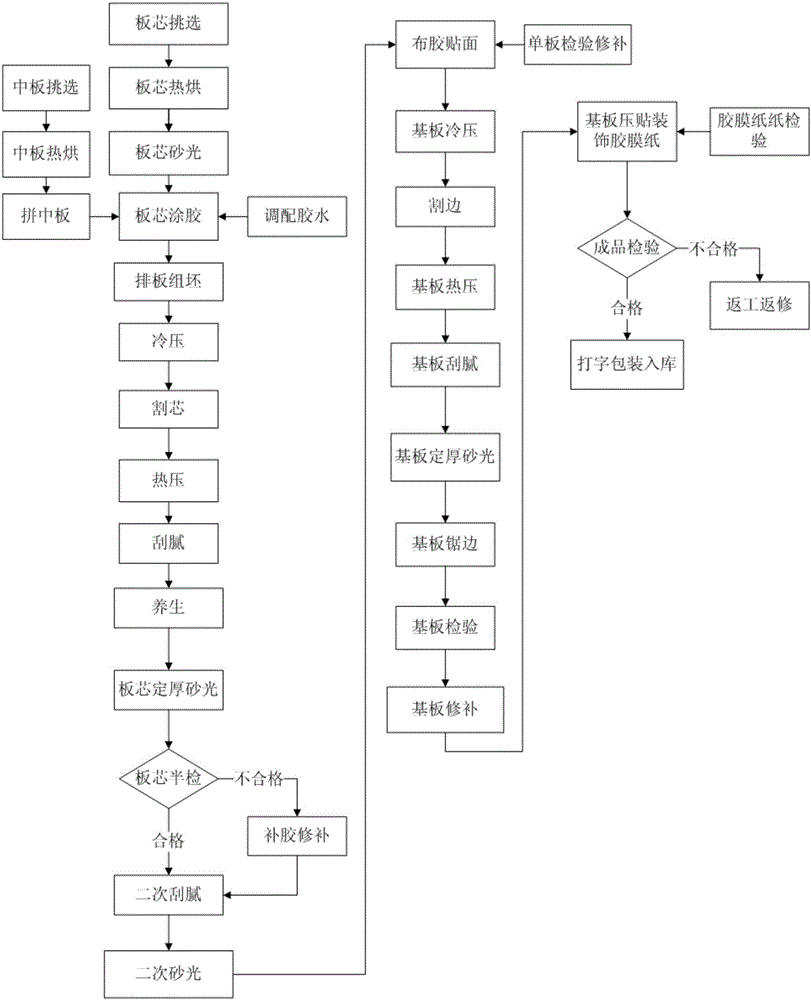

Production process of high-grade fir melamine ecological board

ActiveCN105459221AReduces surface white bloomsReduce defects such as carbonizationOther plywood/veneer working apparatusLaminationInfraredProduct inspection

The invention belongs to the field of board machining and particularly relates to a production process of a high-grade fir melamine ecological board. The process particularly includes the following steps of poplar middle plate selection, poplar middle plate splicing, fir core veneer selection, fir core veneer sanding, fir core veneer slotting, core veneer gluing, infrared ray board arrangement for forming a blank, cold pressing, core cutting, hot pressing, putty application, maintenance, sanding, semi-checking, secondary putty application, secondary sanding, gluing and veneering, base board cold pressing, base board edge cutting, base board hot pressing, base board putty application, base board fixed-thickness sanding, base board edge sawing, base board inspection, repairing, melamine impregnated paper hot pressing and finished product inspection, packaging and warehousing of finished products. The production process has the advantages that fir core veneers are adopted, the hardness, nail-holding ability and static bending strength of the board is improved; eucalyptus middle plates are replaced with poplar middle plates, and the defects that the surface of the finished products is stained and carbonized caused by multiple burrs and scabs on the surfaces of the gum wood are reduced effectively.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Systems and methods for automated material processing

System, including apparatus and method, for processing a material based on data input by manual deflection of a light beam.

Owner:PRECISION AUTOMATION

Environment-friendly solid wood ecological board with formaldehyde removal and bacterium removal functions and production technique thereof

InactiveCN106142238AEfficient removalImprove purification effectOther plywood/veneer working apparatusLamination ancillary operationsSolid woodEnvironmental resistance

The invention provides an environment-friendly solid wood ecological board with formaldehyde removal and bacterium removal functions and a production technique thereof. The environment-friendly solid wood ecological board with the formaldehyde removal and bacterium removal functions comprises a board core, a middle board body, poplar veneer, glue and a formaldehyde removal and bacterium removal decorative film adhesive. The upper surface and the lower surface of the board core are coated with the glue, the board core is covered with the middle board body, and the board core and the middle board body are integrally pressed to form a board blank; the upper surface and the lower surface of the board blank are coated with the glue, the board blank is covered with the poplar veneer, and the board blank and the poplar veneer are integrally formed through cold and hot pressing, so that a base board is manufactured; and the formaldehyde removal and bacterium removal decorative film adhesive and the base board are integrally formed through hot pressing, so that the finished environment-friendly solid wood ecological board is manufactured. According to the environment-friendly solid wood ecological board, the low-formaldehyde E0-level environment-friendly base board is adopted, the formaldehyde content of the manufactured solid wood ecological board can be below 0.3 mg / l, and the solid wood ecological board is economical and environmentally friendly; impregnated paper containing a glue solution having elements with bacterium removal and formaldehyde decomposition functions is adopted so that formaldehyde in air can be effectively removed, and the effect is good and lasting; and meanwhile, the powerful bacterium removal function is achieved, and the environment-friendly solid wood ecological board is beneficial for human health and indoor air purification.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Method for making plywood and dimensional lumber from Arundo donax L. or bamboo

ActiveUS7647957B2Reduce dependenceConstruction materialCane mechanical workingEngineeringFire retardant

A method of producing a virtually fireproof plywood from perennial grasses such as Arundo donax Ligneous, various bamboo strains, or a blend thereof, by first weaving the stalks of these plants into a mat and then layering these mats and binding each layer with any one of several commercial resins mixed with potash for the purpose of enhancing the board's fire retardant quality. The result is the formation of a finished product with structural board attributes and an exceptionally high flash point in relation to other manufactured board products made from forest materials.

Owner:ABDULNASER ABDULMALIK +1

Treatment method for wood surface defects

InactiveCN102632528AWon't fall offPromote infiltrationIrregularity removal devicesPolymer scienceAdhesive

The invention provides a treatment method for wood surface defects. The treatment method comprises the following steps: (1) cleaning up wood surface defect parts; (2) spraying or wetting the peripheries of the defect parts by using alcohol, an acrylic paint or an adhesive; (3) coating the defect parts by directly using the acrylic paint / the isocyanate adhesive or firstly filling in repairing putty and then coating by using the acrylic paint / the isocyanate adhesive; (4) carrying out indoor natural surface drying for over 3 hours or after baking for 20-120 minutes at the temperature of 30-80 DEG C for complete curing, carrying out light sand treatment on the surface for painting to enable the adhesive or paint to evenly penetrate into the defects so as to achieve a better bonding effect, and ensure that the defect parts cannot crack again in the using process of a repaired wood board, and the acrylic paint and the isocyanate adhesive do not have volatility, thus not polluting the environment and being environmentally-friendly.

Owner:GUANGDONG YIHUA TIMBER IND

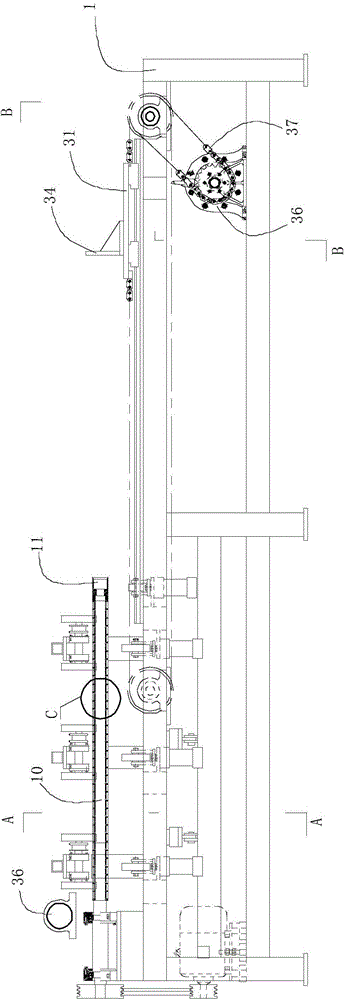

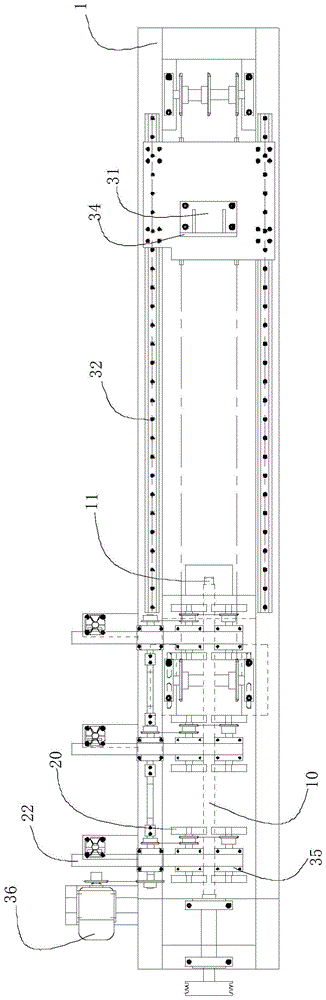

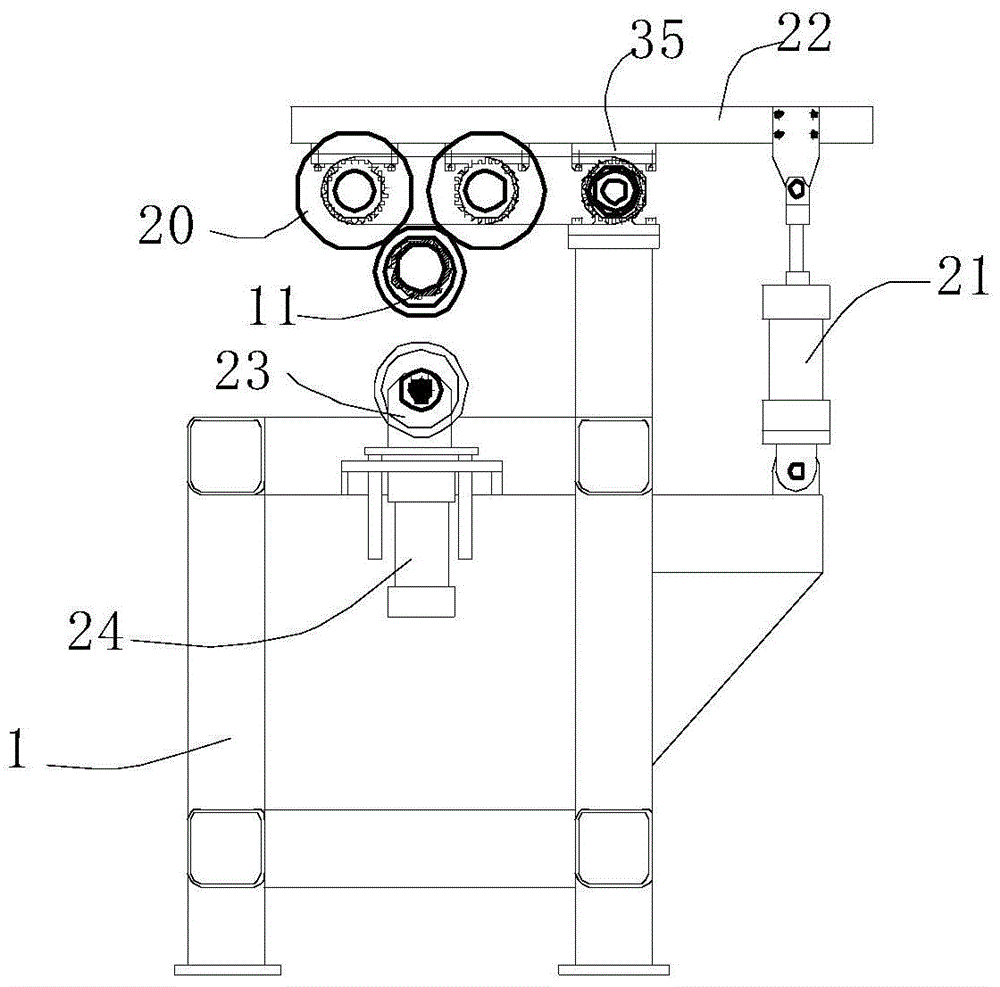

Intelligent veneer patching machine and application method thereof

The invention belongs to the technical field of veneer repair and provides an intelligent veneer patching machine and an application method thereof. The intelligent veneer patching machine comprises afeeding conveying device, a punching device, a discharging conveying device, an image collecting device, a first optoelectronic switch, a mechanical arm, a second optoelectronic switch, a detection device which is not shown in an attached figure and a controller. The controller is electrically connected to all equipment. The intelligent veneer patching machine provided by the invention can feed materials automatically, recognize defect positions on a veneer automatically, match corresponding punches automatically, move below the corresponding punches automatically to blank and put patches ofdifferent sizes automatically to different defect positions by the mechanical arm after blanking. A worker only needs to fix the patches with adhesive tapes, so that the labor cost is saved greatly.

Owner:山东艾雷维特智能科技有限公司

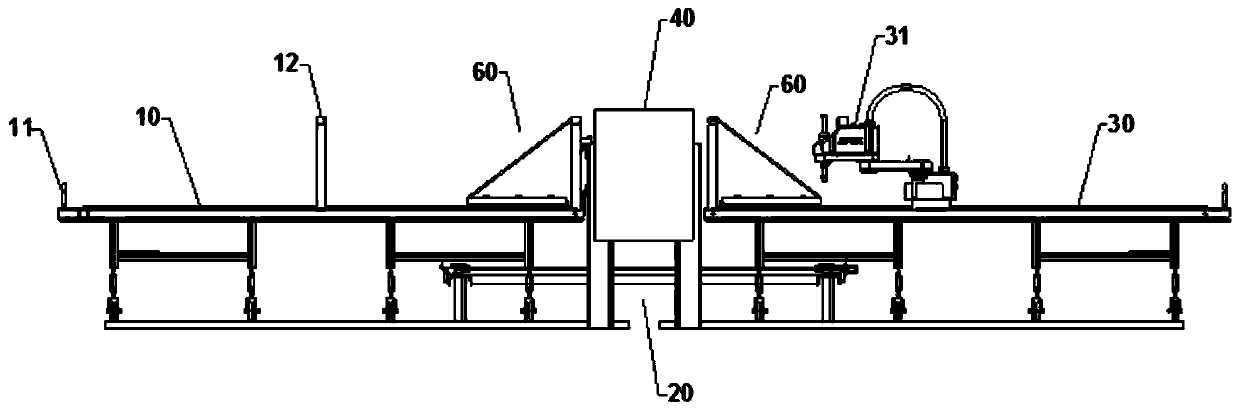

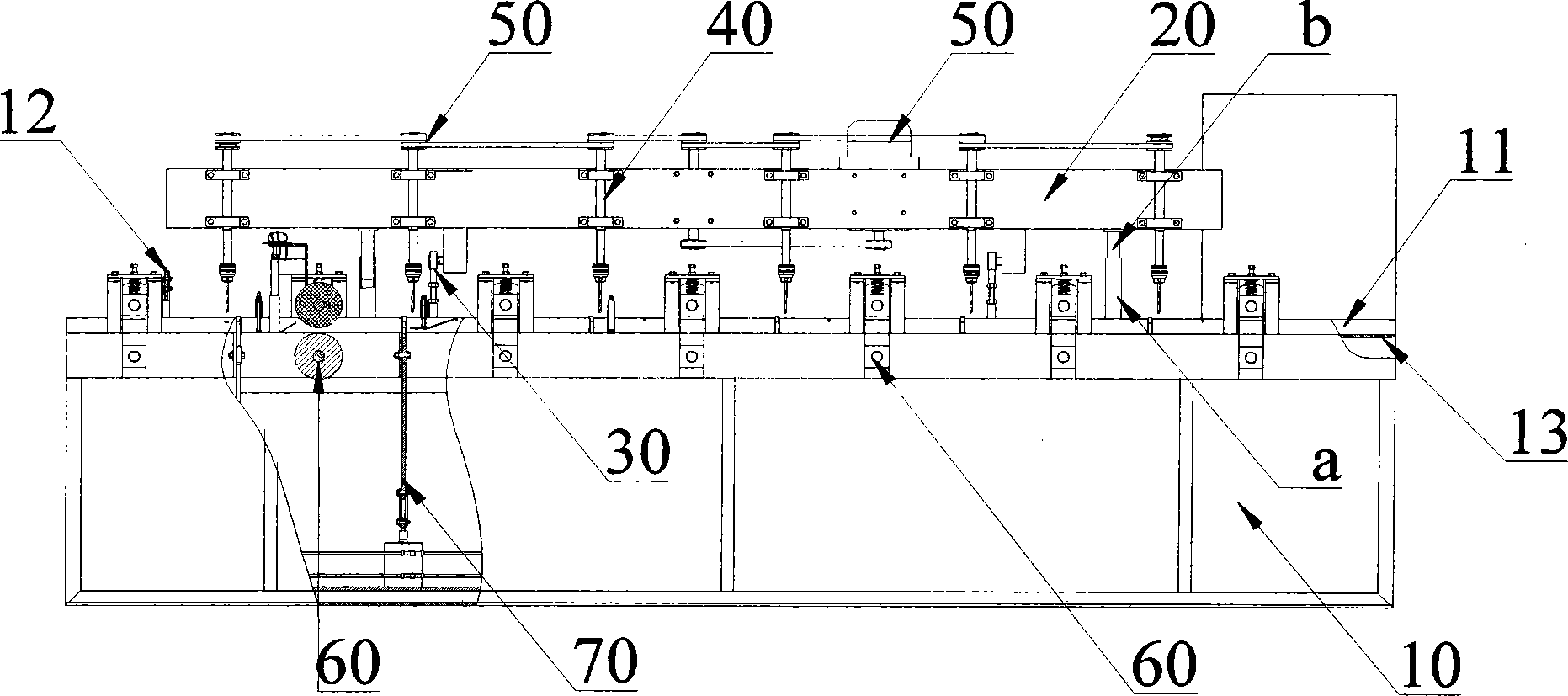

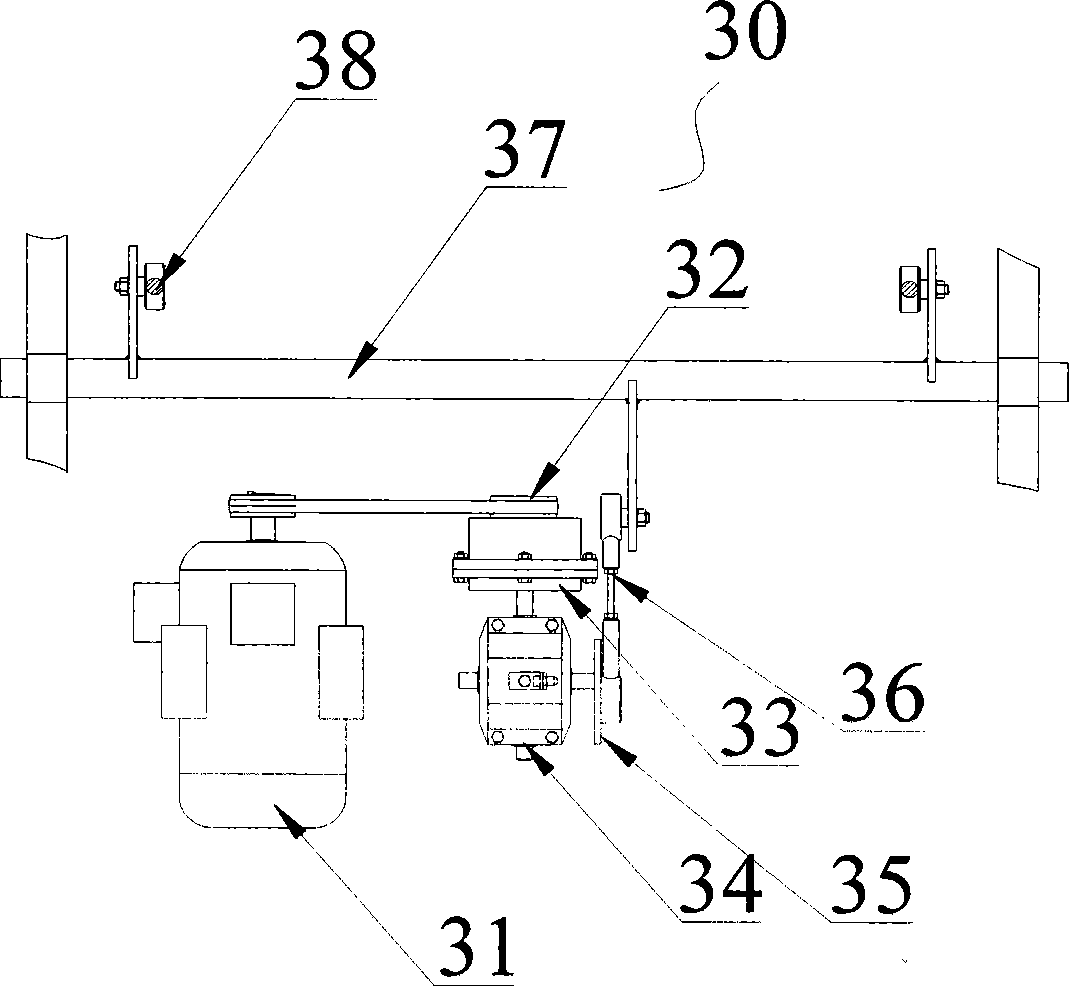

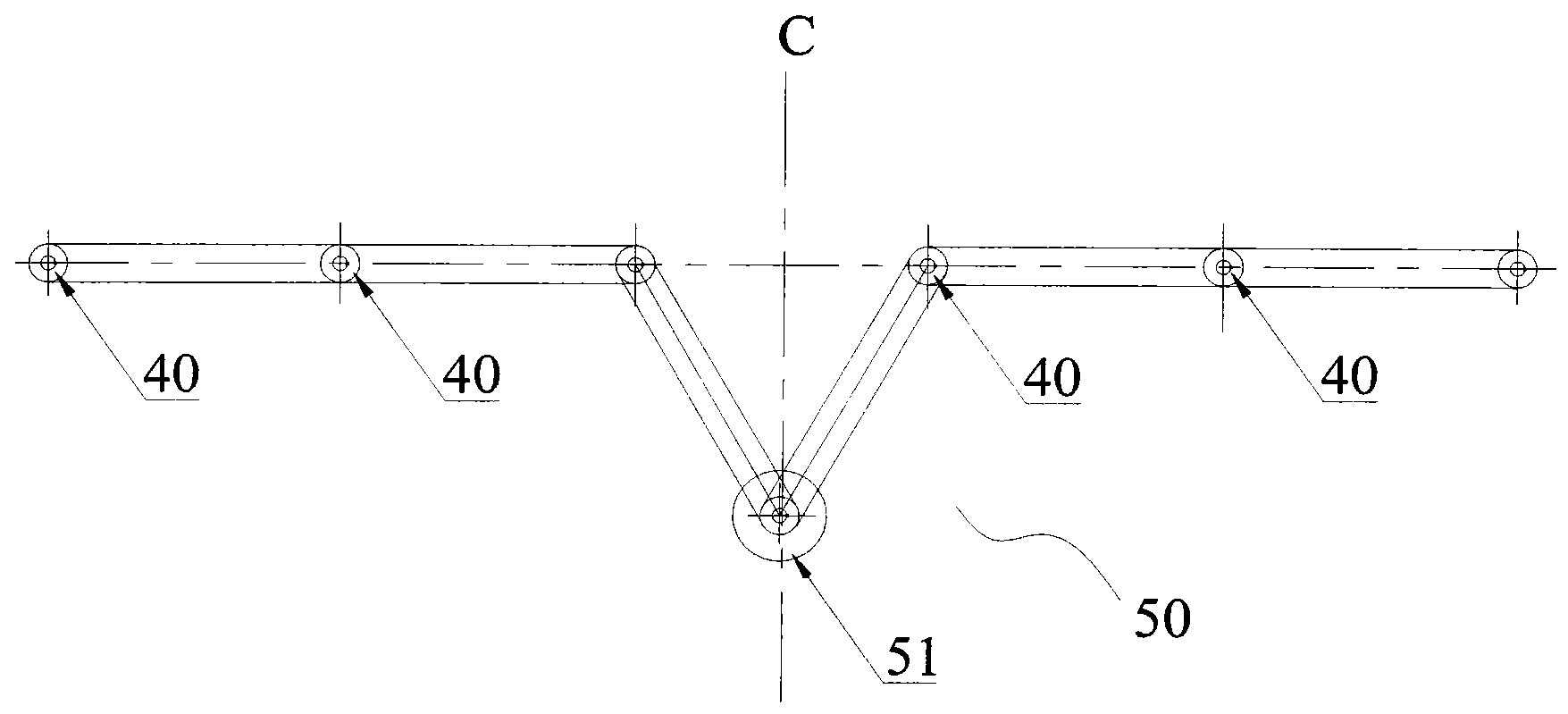

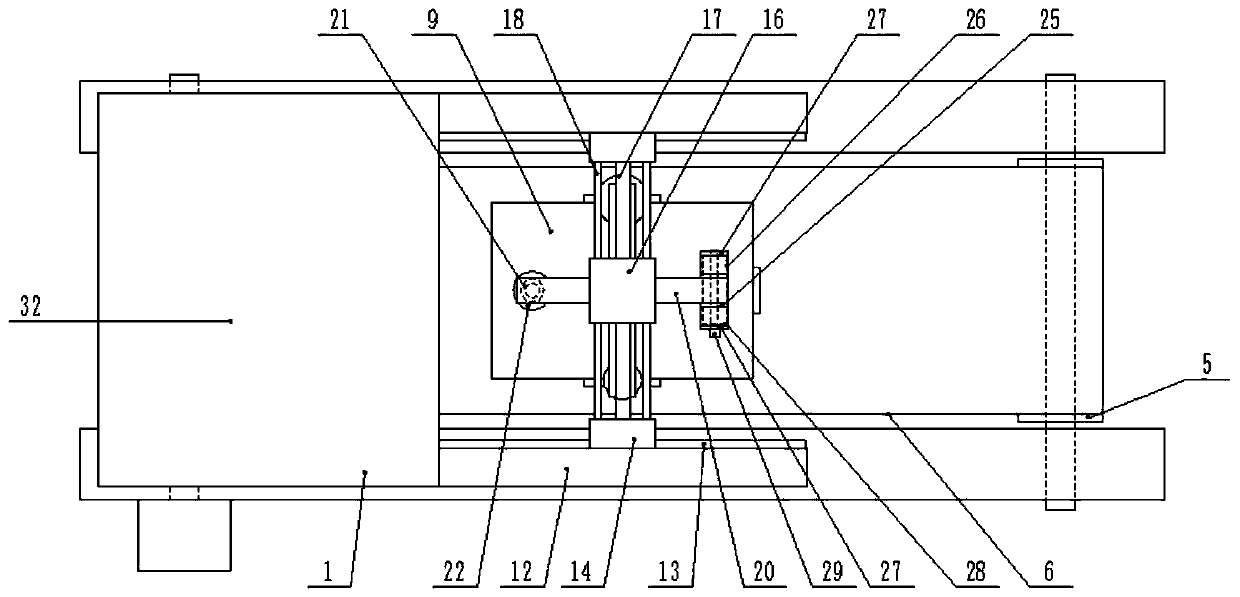

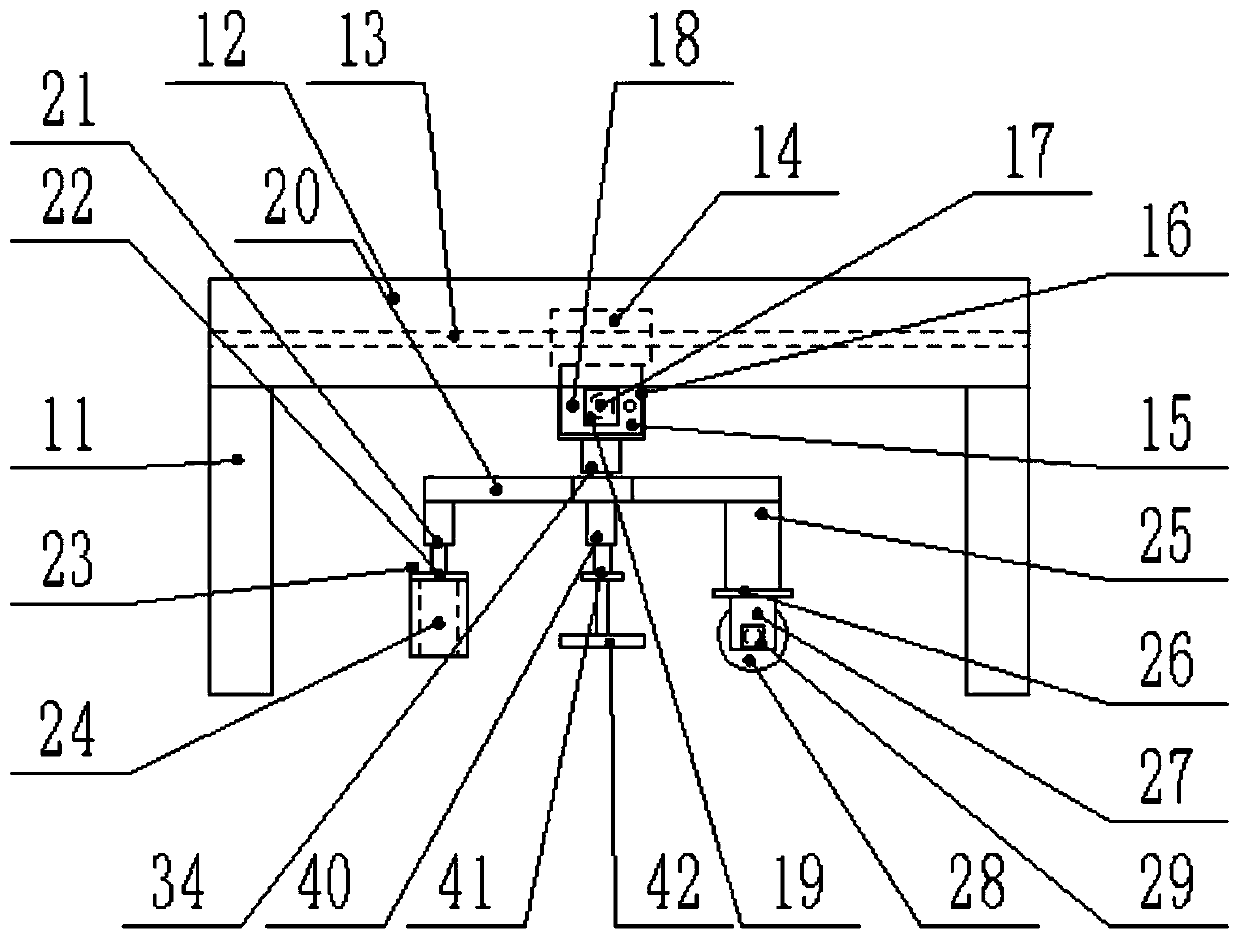

Machine for automatically removing joints of bamboo frame board and drilling holes in bamboo frame board

ActiveCN104029256AConvenience for subsequent useSimple structureStationary drilling machinesIrregularity removal devicesMachine partsEngineering

The invention relates to a machine for automatically removing joints of a bamboo frame board and drilling holes in the bamboo frame board. The machine comprises a worktable, a lifting table, a lifting table rotation mechanism, drill rods, a drill rod transmission mechanism and a machined part transmission mechanism, wherein a machined part feeding opening is formed in one side of the worktable; an opening and closing door is formed in the other side of the worktable; a joint removing cutter is arranged in the machined part feeding opening of the worktable; the lifting table is arranged above the worktable and located between the machined part feeding opening and the opening and closing door; the lifting table transmission mechanism is arranged at the bottom of an inner cavity of the worktable; the lifting table transmission mechanism is connected with the lifting table; a plurality of uniformly-arranged drill rods are arranged on the lifting table; the drill rod is vertical and downward and directly faces a table top of the worktable; the drill rod transmission mechanism is arranged on the lifting table; the drill rod transmission mechanism is connected with the drill rods; the machined part transmission mechanism is arranged on the table top of the worktable; the machined part transmission mechanism, the machined part feeding opening and the opening and closing door are arranged on the same straight line; the machined part transmission mechanism is arranged under the drill rods. When the machine is used, the working efficiency can be improved; meanwhile, groups of holes can be conveniently formed.

Owner:桃江县永利竹业机械研发有限公司

Device for removing the knots of moso bamboo

InactiveUS20200070381A1Effectively prevent flyingReduce removalCane mechanical workingIrregularity removal devicesMechanical engineeringManual handling

The invention discloses a slub removing device for bamboo processing, which includes a machine body. The machine body is provided with a working cavity, the top wall of the working cavity is provided with a connecting space, the top wall of the connecting space is provided with a grinding cavity. First, the bamboo is inserted between the pressing plate and the butt joint plate. Compared with manual grinding, the device does not need workers to scrape the branches and scrape the bamboo with a sickle. The device only needs to insert the bamboo into the device, and then automatically polish and remove the branches and scraped branches and bamboo chips through the mechanical structure. At the same time, the device can automatically scrape the branches and bamboo chips Discharge the device without manual operation.

Owner:XU YING

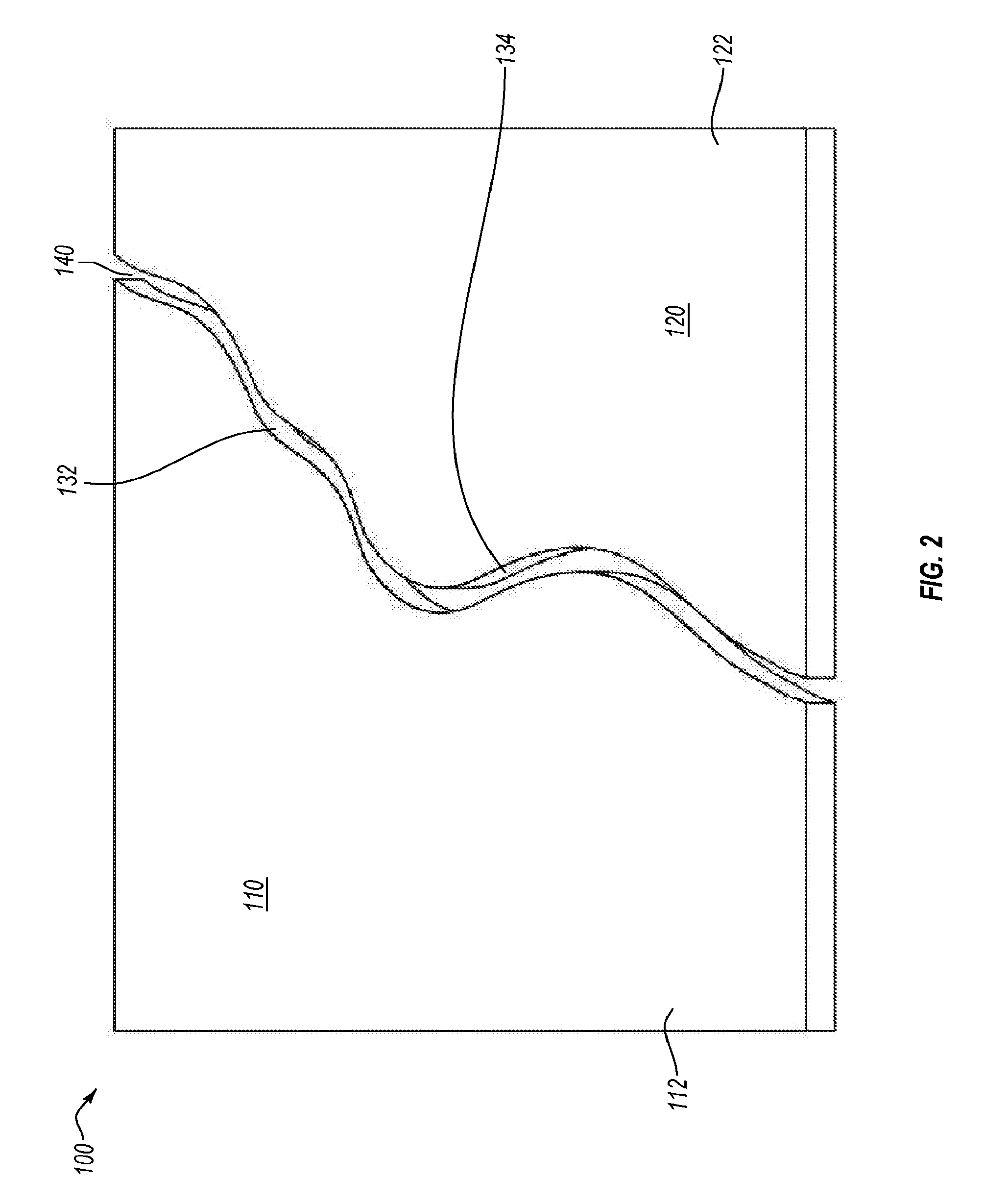

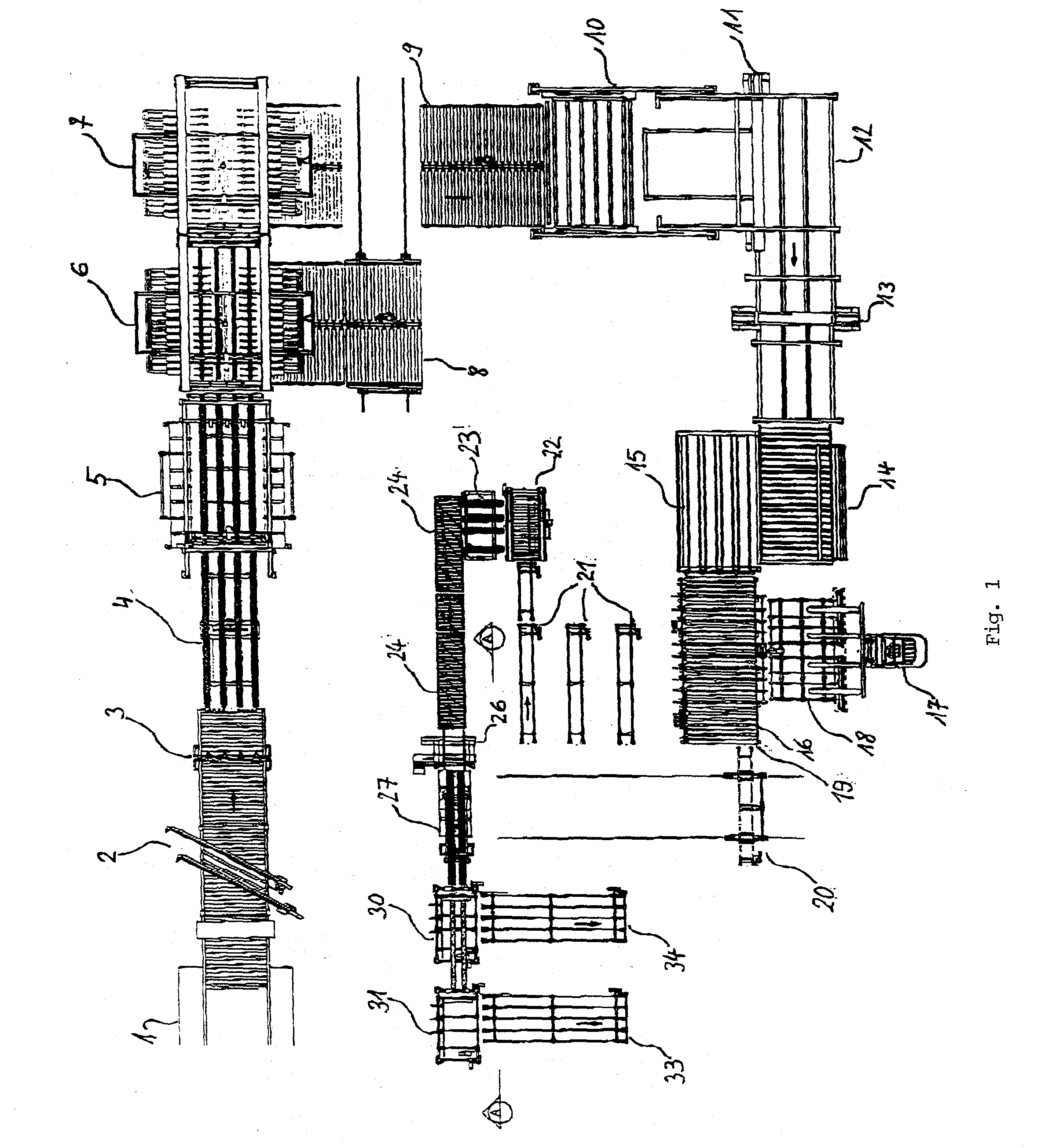

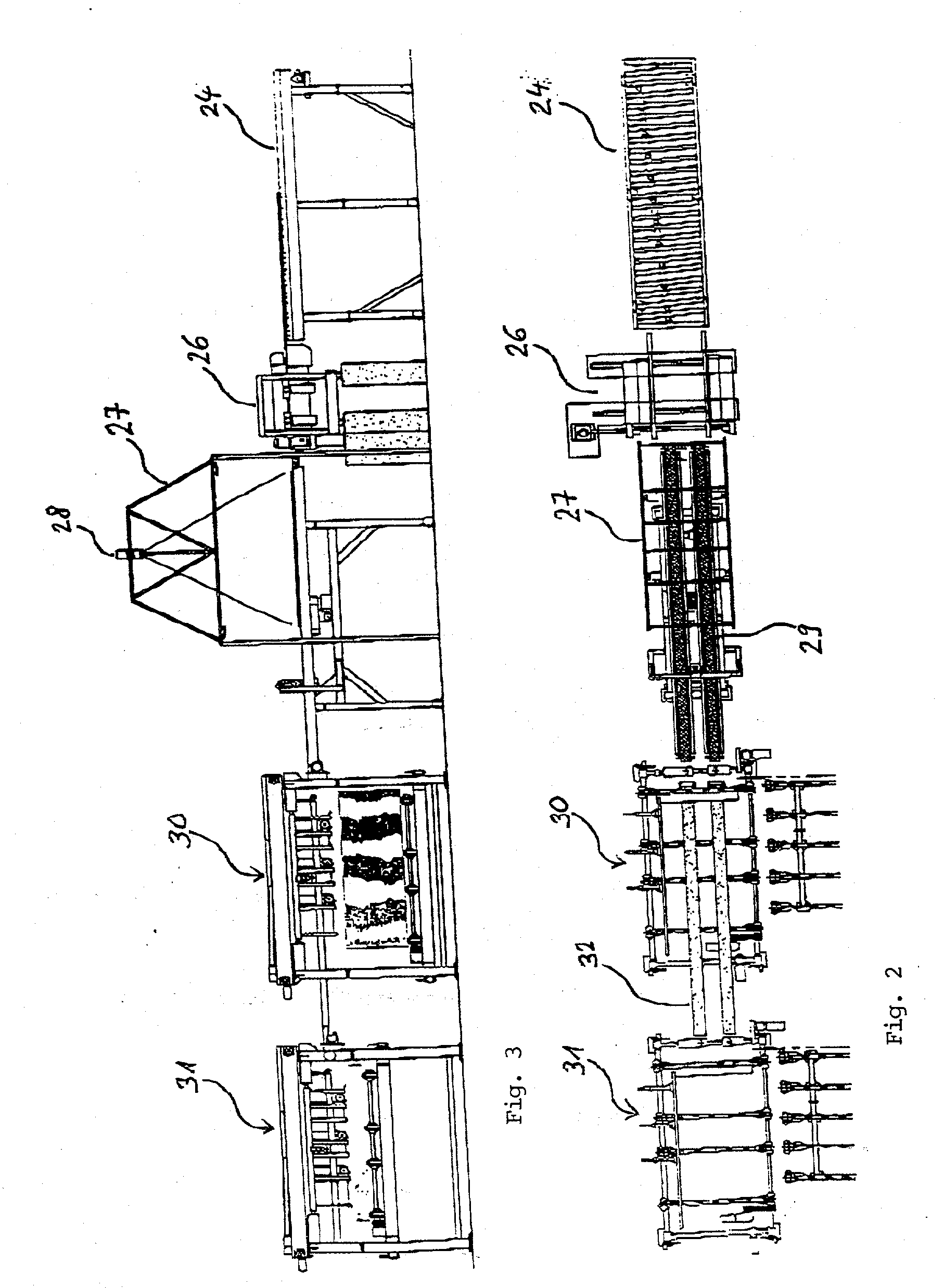

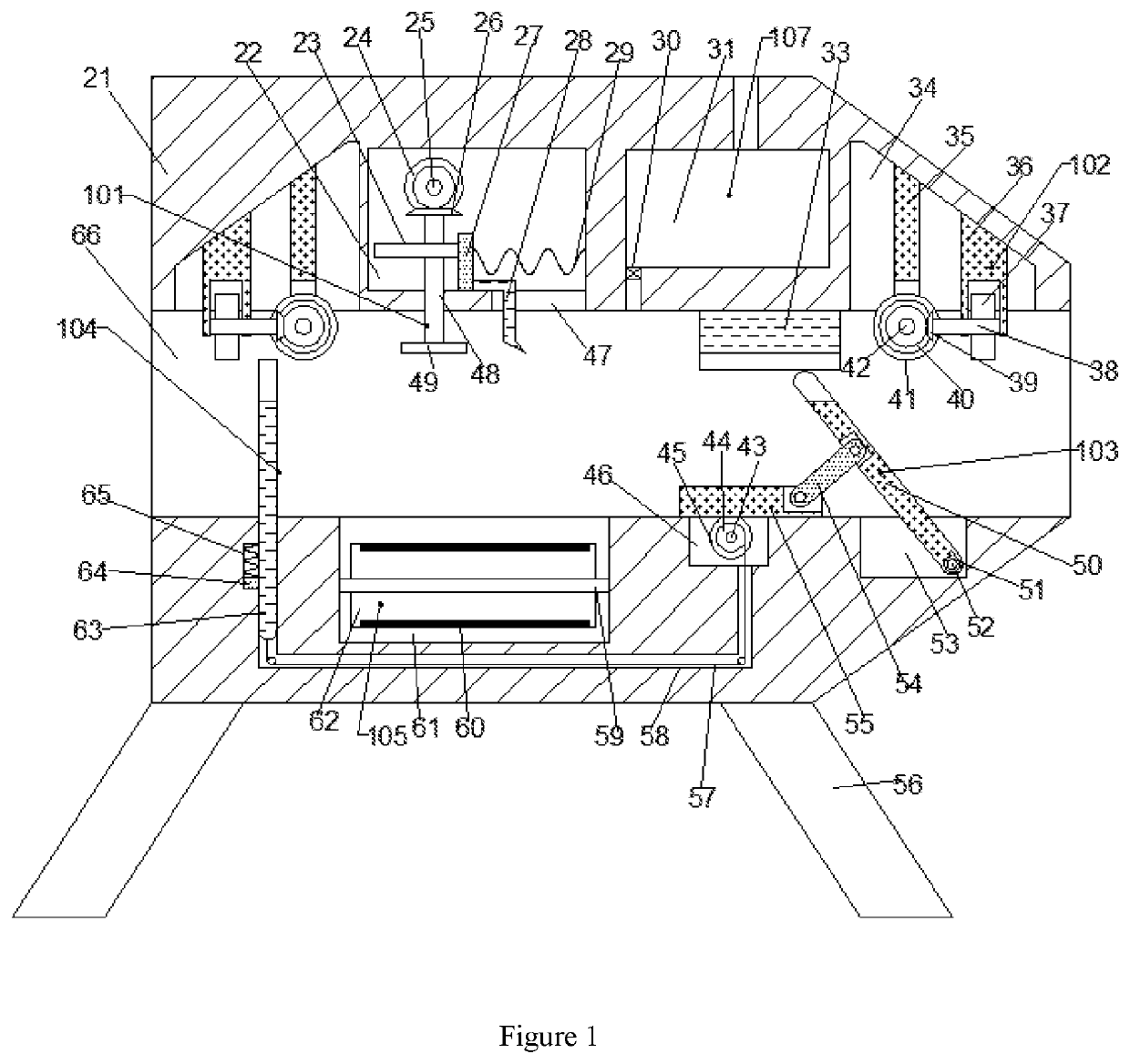

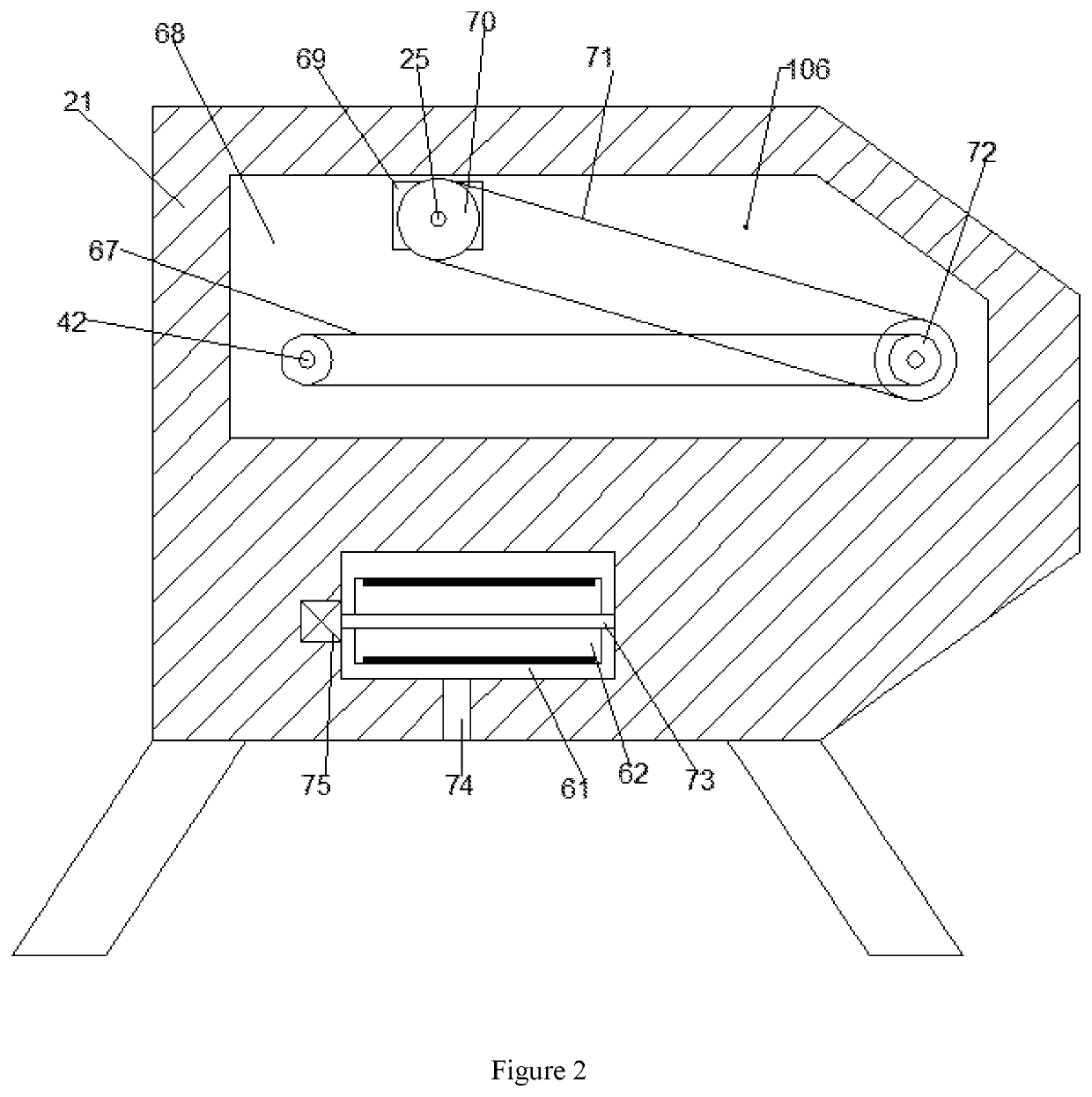

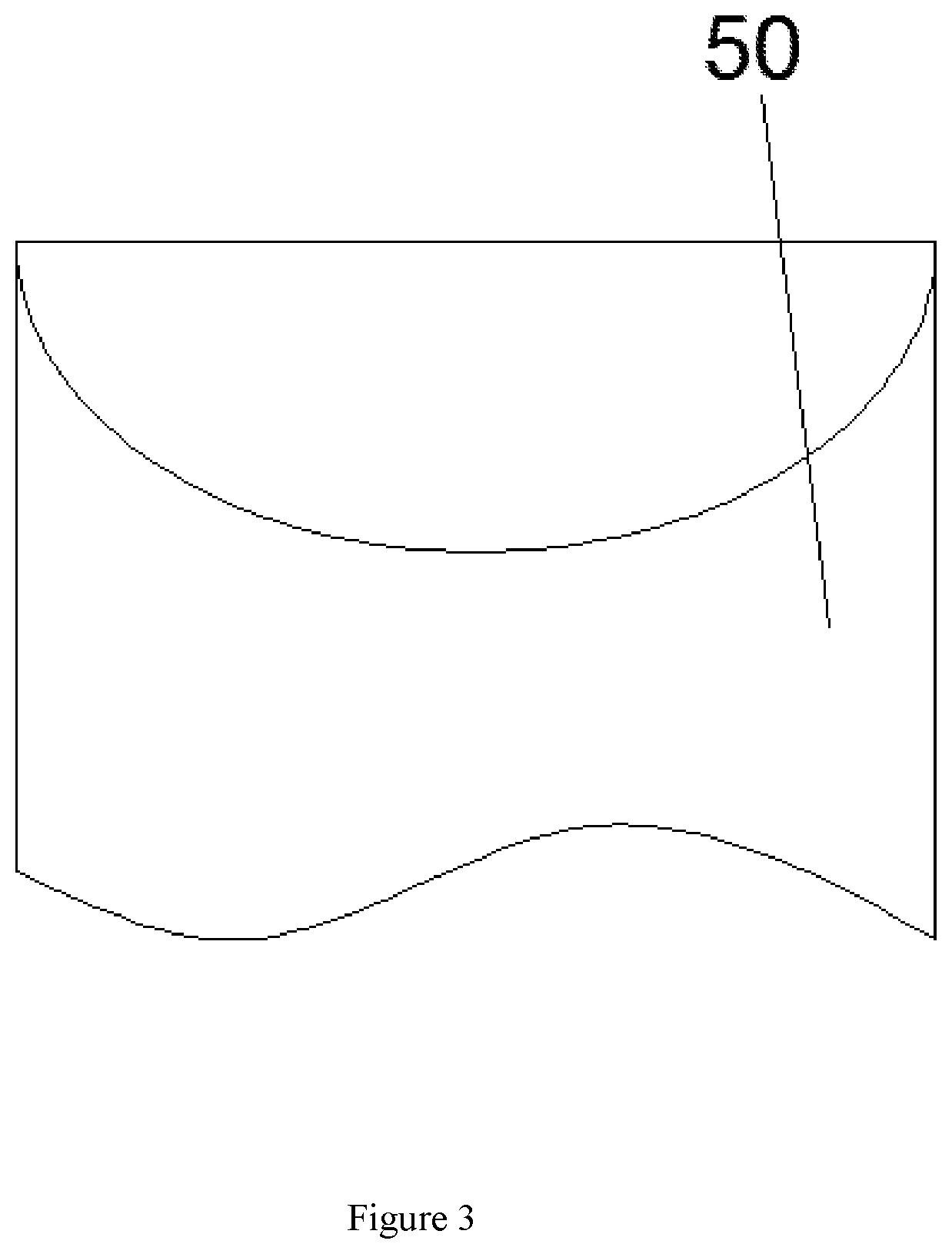

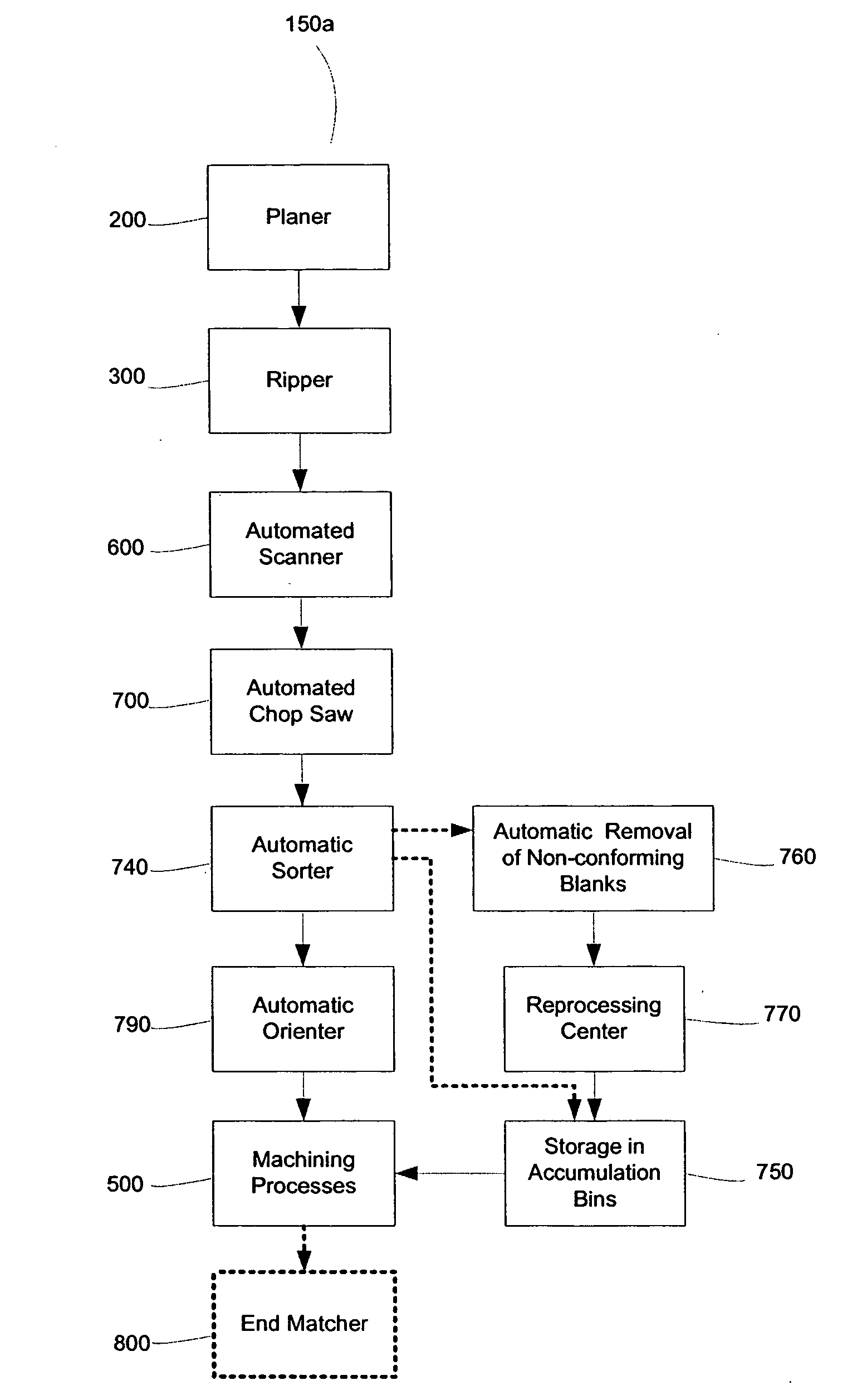

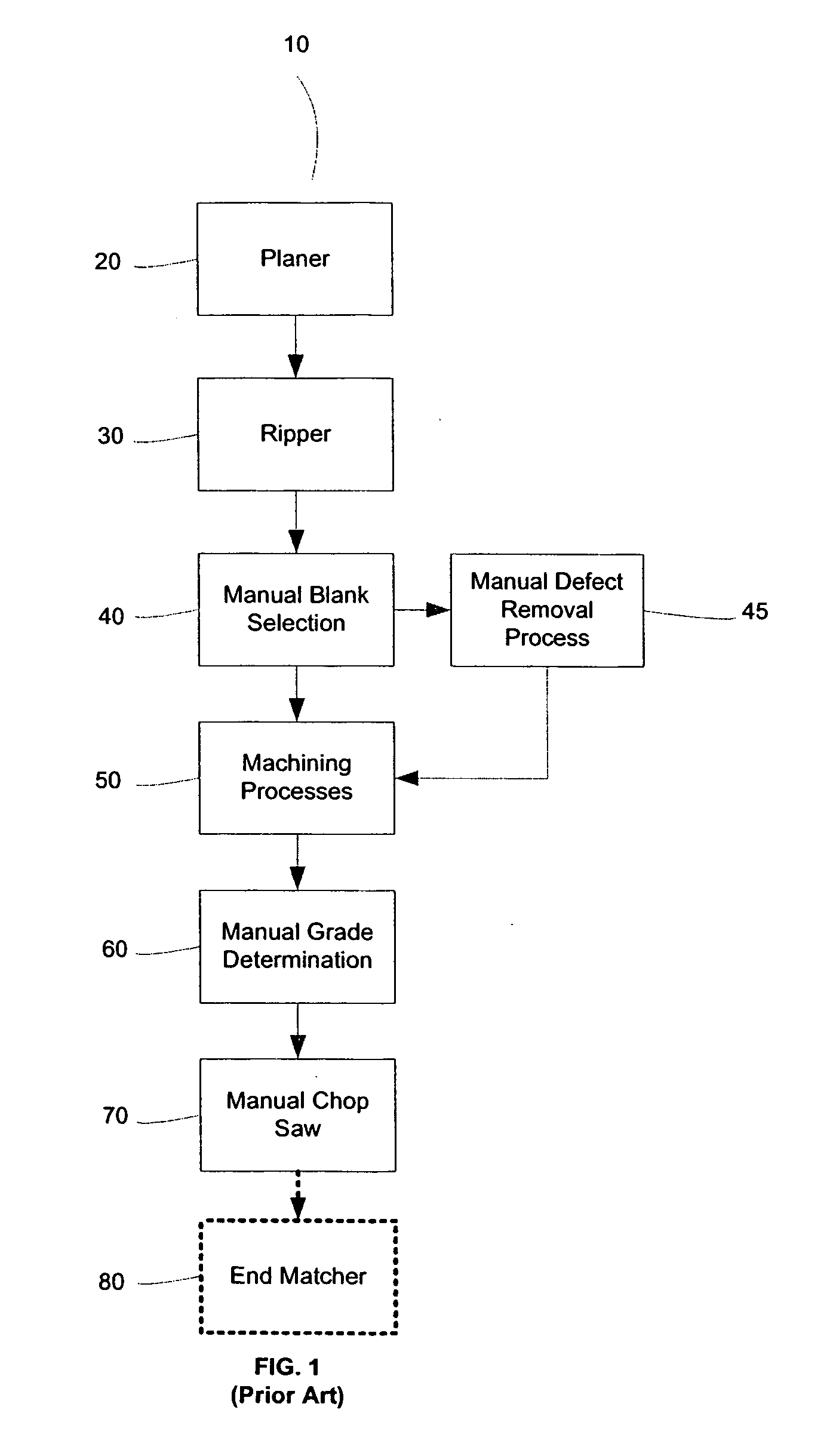

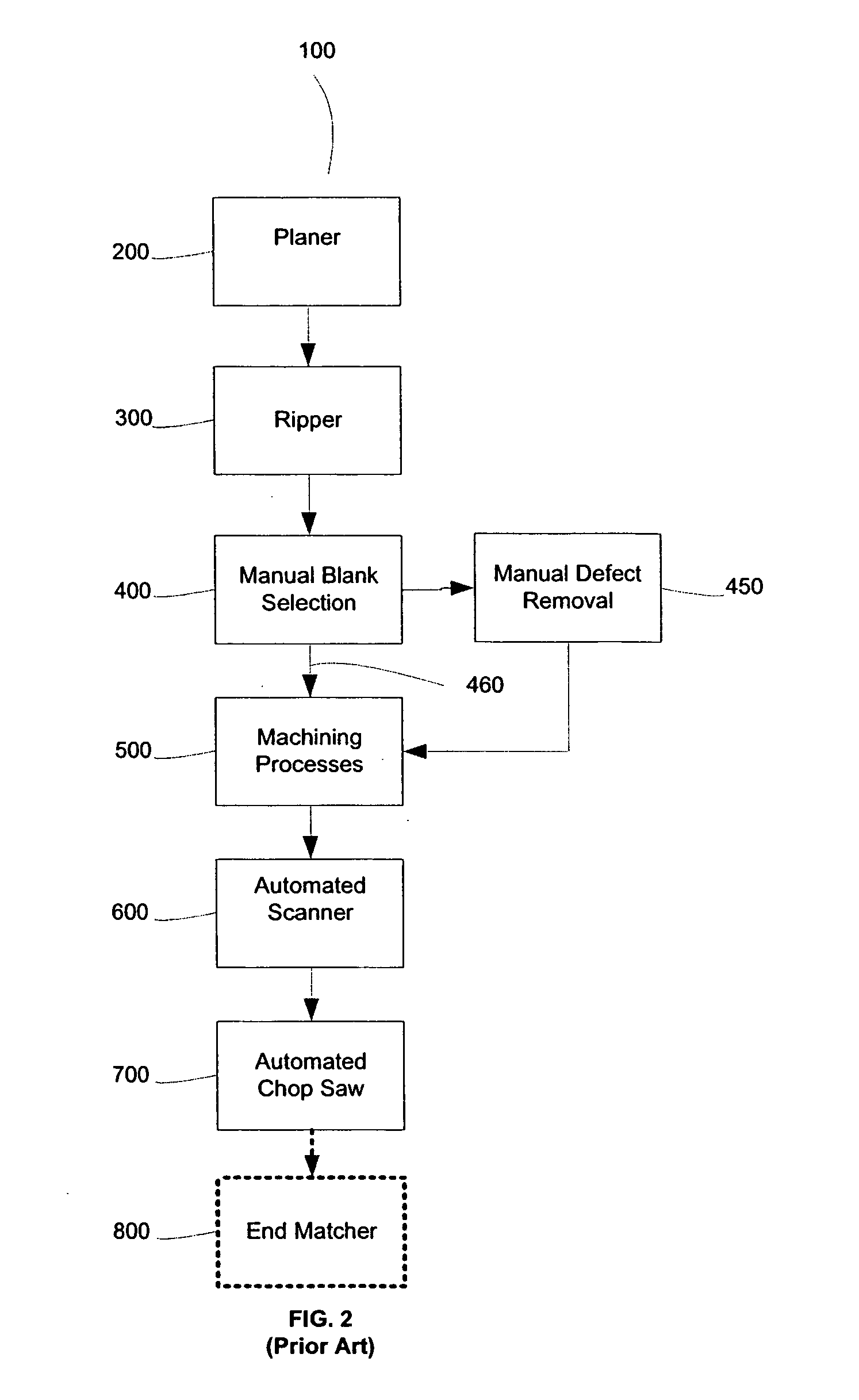

Method for producing wood flooring

InactiveUS20080099105A1Increase valuePromote recoveryMulti-purpose machinesIrregularity removal devicesEngineeringImproved method

The present invention is directed to an improved method for producing wood flooring. This method comprises providing a roughhewn board having an upper and a lower surface and ripping the board to a desired width thereby providing a long length flooring blank. The method further includes scanning the long length flooring blank to maximize value and recovery and then cutting a dimensional flooring blank based on grade and length. The improved method also comprises automatically sorting the dimensional flooring blank based on grade and length, automatically orienting the dimensional flooring blank for downstream machining, and machining the oriented dimensional flooring blank to provide desired features.

Owner:KELLY TIMOTHY

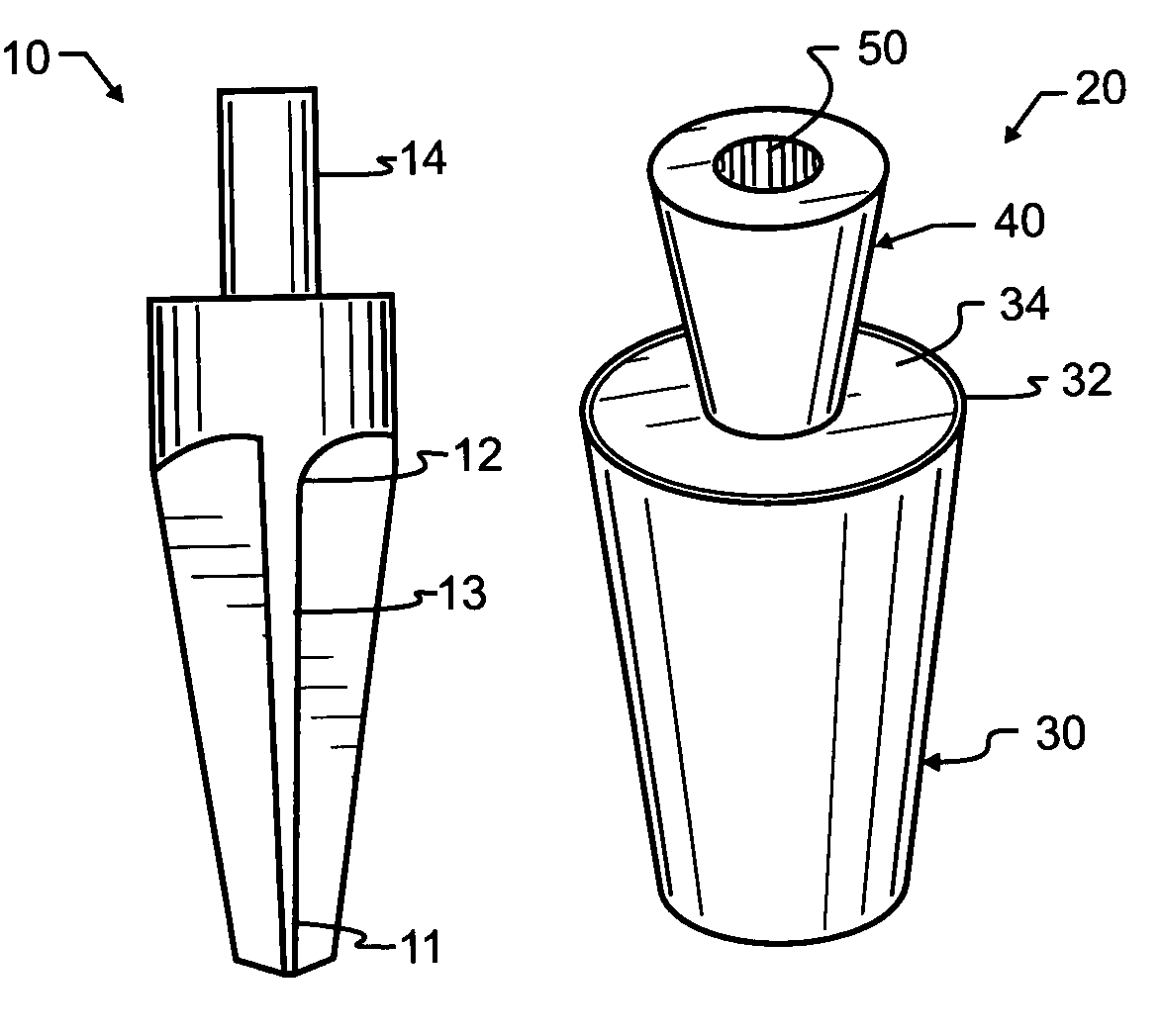

Drywall repair tool and method

A drywall repair tool for repairing a localized defect in drywall, and the method of using same, the tool having a conical abrading surface, a circular cutting rim and an annular abutment collar, whereby rotation of the tool creates a hole having a conical wall, where the inner diameter of the hole is smaller than the outer diameter, such that a replacement plug having a conical wall corresponding to the size and configuration of the conical wall of the hole can be readily positioned within the hole and adhesively secured.

Owner:TRUDEAU WALTER H

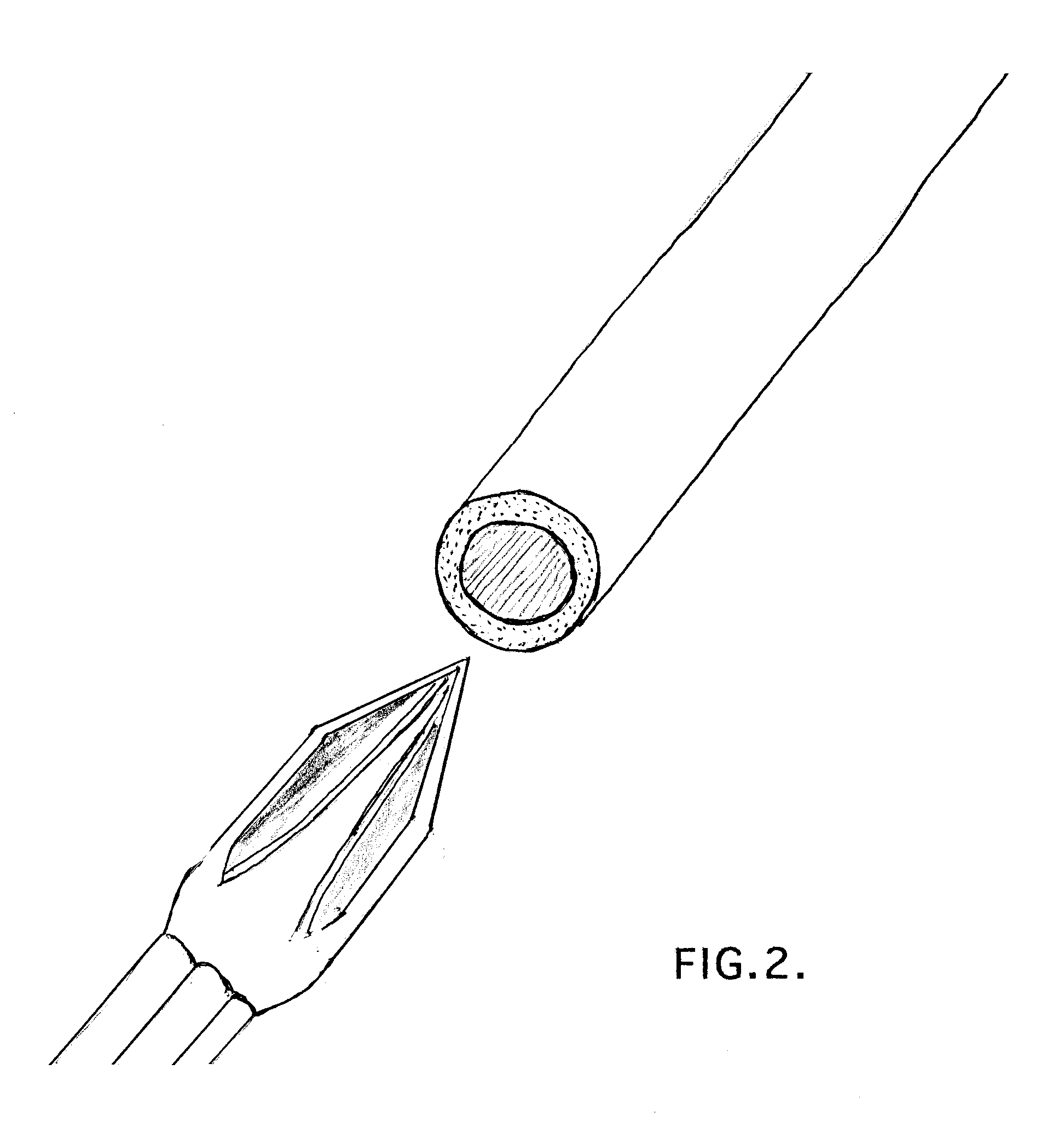

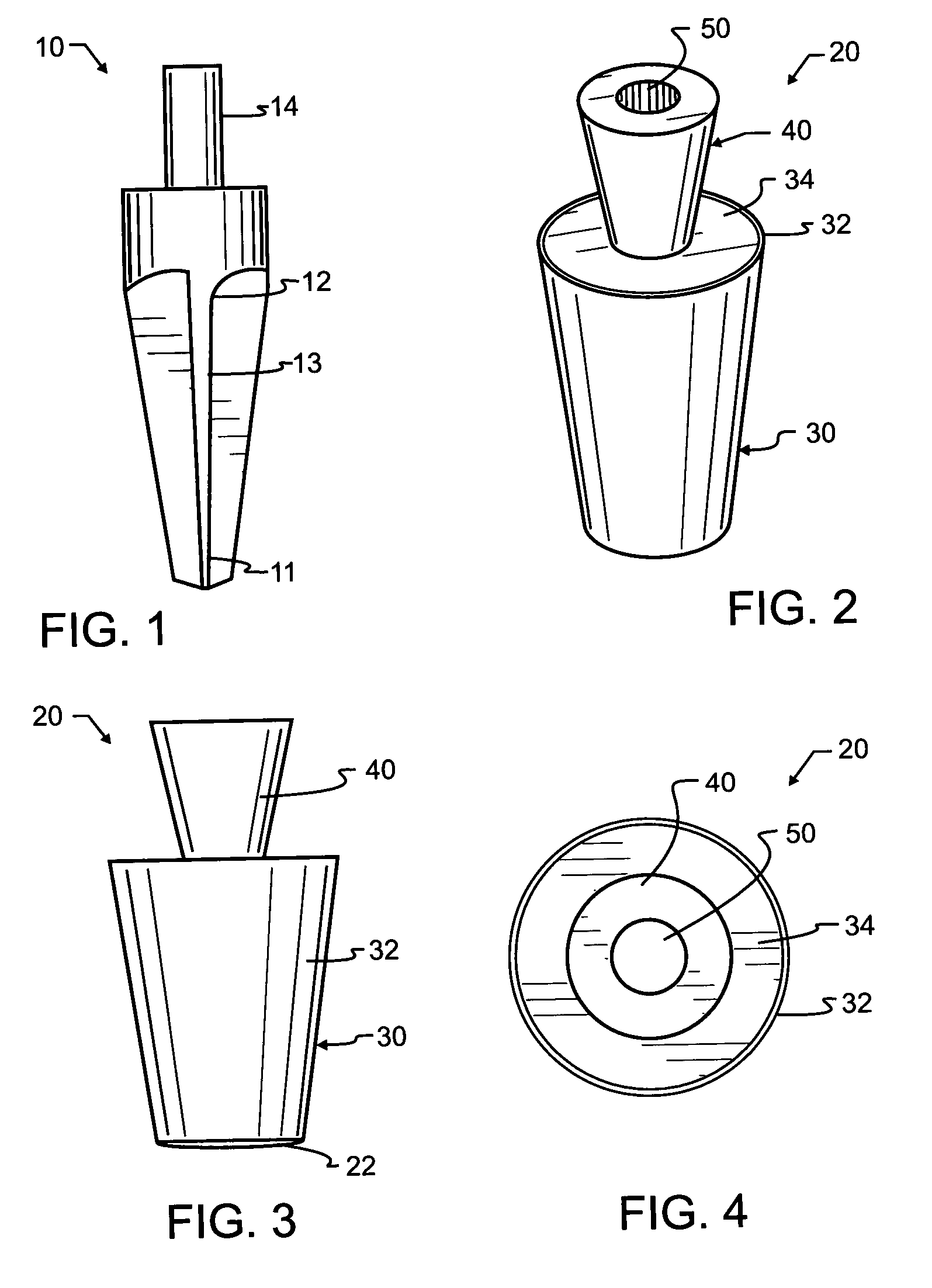

Taper-ream wood repair apparatus and method

InactiveUS6935084B1Eliminate delaysReduce commonplace drip and spillBuilding repairsFoundation repairPilot holeAdhesive

A tapered plug having a compressible and conically tapered outer surface is permeated with a dry, water-activated adhesive. A pilot hole most preferably passes through the center of the tapered plug, ensuring proper alignment for a replacement fastener such as a wood screw or the like to be inserted therein. A handle is additionally provided for ease of installation. A ream useful in association with the plug and a method of installation of the plug are additionally disclosed.

Owner:LARSEN RICHARD D

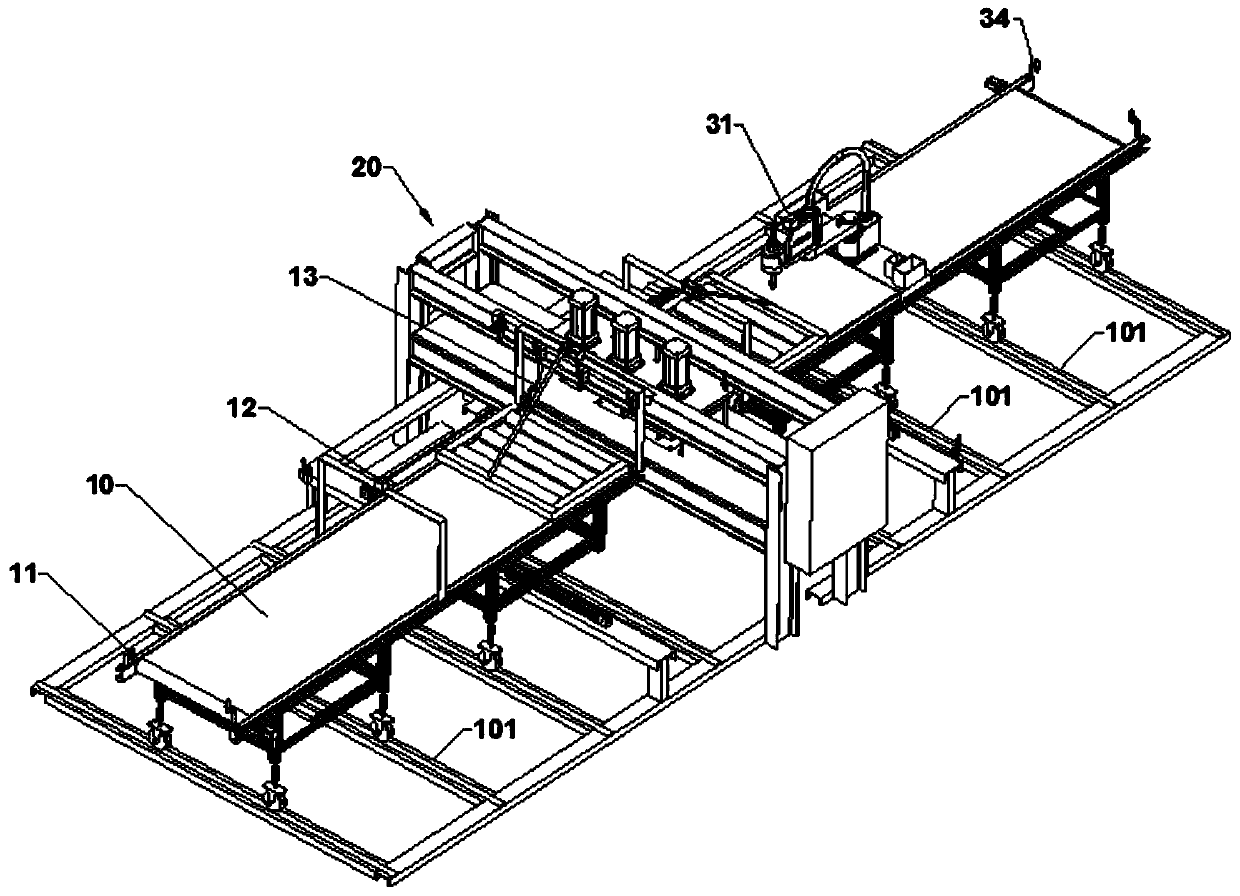

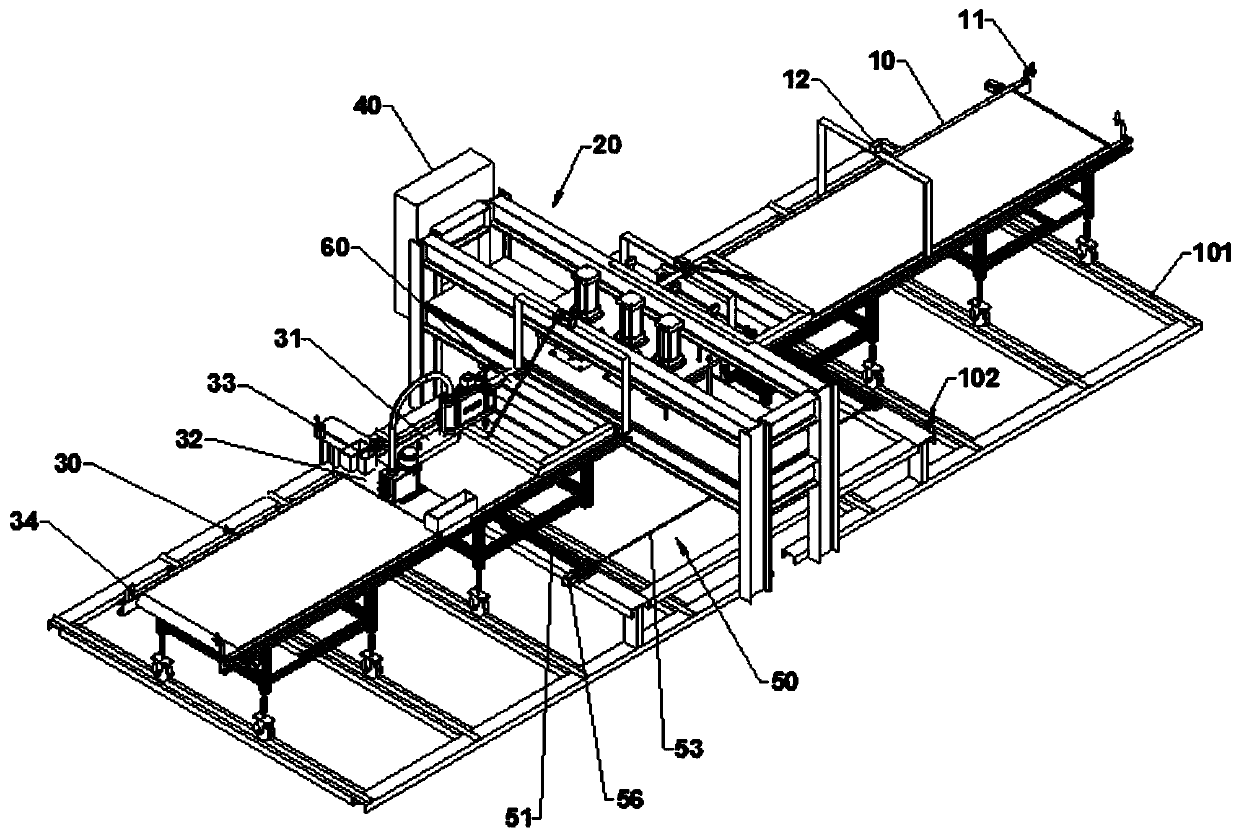

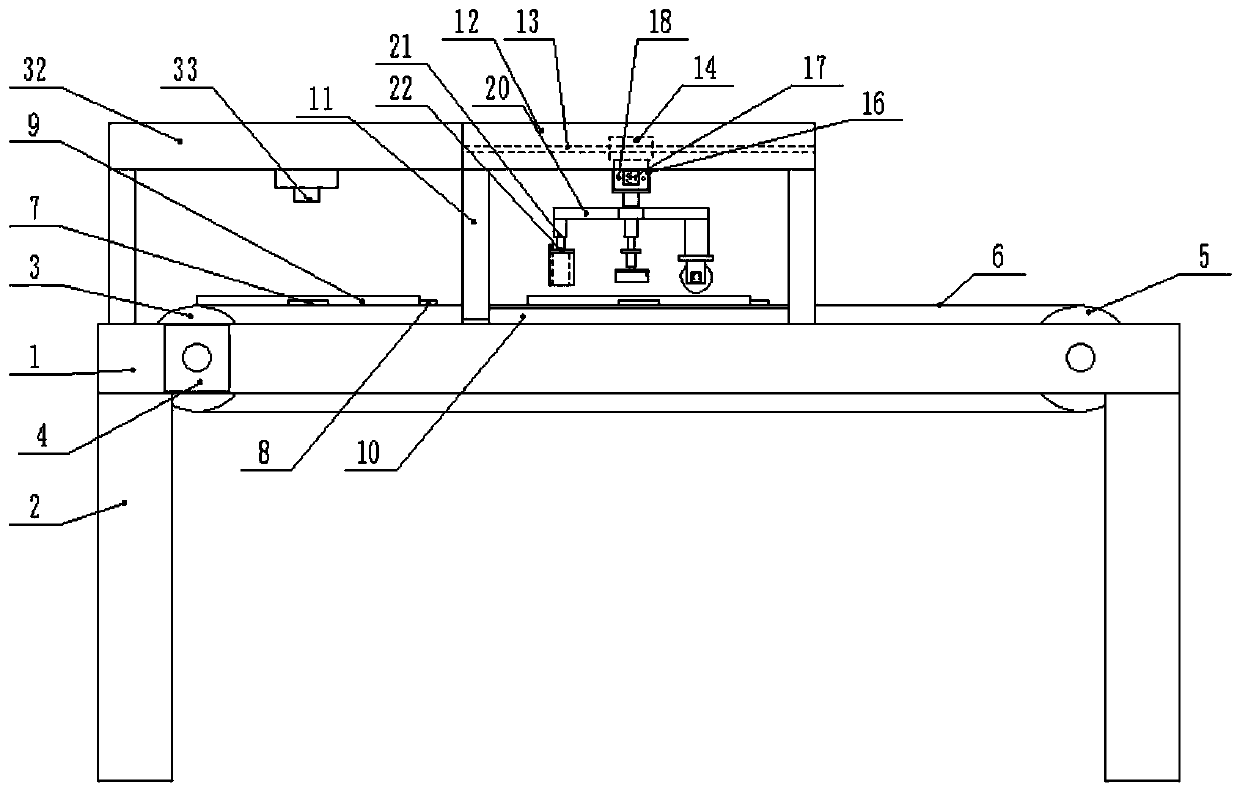

Artificial board rotary cutting block defect repairing device and method of artificial board rotary cutting block defect repairing

PendingCN111168787ARealize one-stop processingIrregularity removal devicesStructural engineeringMonoboard

The invention belongs to the field of artificial board machining devices, and particularly relates to an artificial board rotary cutting block defect repairing device and a method of artificial boardrotary cutting block defect repairing. The device comprises a conveying device, a single-board defect scanning recognition system, a single-board cutting device, a repairing device, a glue coating device, and a glue smearing device, wherein the conveying device is used for conveying a single board; the single-board defect scanning recognition system is used for recognizing defects on the single board by taking a photo of a CCD camera to analyze the photo; the single-board cutting device is used for cutting and treating the defects recognized by the single-board defect scanning recognition system; the repairing device is used for sticking a cutting board cut by the single-board cutting device through a sticky board, and placing a repairing block into a cutting opening; the glue coating device is used for coating glue on a hole cut by the single-board cutting device; and the glue smearing device is used for smearing the glue coated by the glue coating device uniformly. According to the artificial board rotary cutting block defect repairing device, through the conveying device, the single-board defect scanning recognition system, the single-board cutting device, the repairing device,the glue coating device and the glue smearing device, the one-station treatment of single-board defect recognition and repairing is realized.

Owner:杨奠基

Lumber inspection method, device and program

ActiveUS8253793B2Easy to getEasy to detectImage enhancementImage analysisColor imageImaging processing

An imaging means captures a color image of lumber. An image processing means obtains the color distribution of the color image captured by the imaging means, compares the obtained color distribution with a predetermined color distribution of normal lumber, judges the obtained color distribution as an abnormal one when it is deviated from the color distribution of normal lumber by a predetermined value or more, and detects a defect of the lumber having the abnormal color distribution deviated by a value larger than the predetermined value in an area on the surface of the lumber captured by the imaging means.

Owner:MEINAN MASCH WORKS INC

Board repairing method

InactiveCN103056937AOvercome irreparable defectsIncrease profitIrregularity removal devicesEngineeringUltimate tensile strength

The invention provides a board repairing method. The board repairing method includes: step 100, slotting, digging is performed on a cracking portion to form a regular groove; step 200, moulding, a mould matched with the groove in shape and size is manufactured; step 300, filling, the mould manufactured in the step 200 is filled in the groove; step 400, grinding, grinding treatment is performed on the filled position; and step 500, polishing, polishing treatment is performed after the step 400. Through the technical scheme, the board repairing method overcomes the defect that surface cracks of a cracked board cannot be repaired, cracked wood can be reused after being repaired, and utilization rate of the wood is improved greatly. Various tools used in a repairing process are products existing in the prior art and are easy to choose and purchase and each to achieve. The repaired wood has no remarkable repairing trace on the appearance, a whole board is increased at the cracked position, and strength is better.

Owner:FUJIAN DUS WOOD IND

Inner section removal machine for bamboo

ActiveCN104908116AIncrease the level of mechanizationGuarantee the quality of bamboo expansionCane mechanical workingIrregularity removal devicesEngineeringMachining

The invention relates to an inner section removal machine for bamboo. The inner section removal machine comprises a frame and also comprises an inner section removal cutting tool assembly, an axial bamboo feeding mechanism and a radial bamboo positioning mechanism which are fixedly arranged on the frame; the axial bamboo feeding mechanism is corresponding to the inner section removal cutting tool assembly; the radial bamboo positioning mechanism is located on the periphery of the inner section removal cutting tool assembly; the inner section removal cutting tool assembly comprises a cutter shaft, a section breaking cutter, a plurality of scrapers and a plurality of positioning rings; the cutter shaft is driven by a main motor to rotate; the section breaking cutter is arranged at the front end of the cutter shaft; the plurality of scrapers are used for polishing the inner section of the bamboo; the plurality of positioning rings are used for preventing the excessive polishing; the plurality of scrapers and the plurality of positioning rings sleeve the cutter shaft; every positioning ring is arranged between the two corresponding adjacent scrapers. According to the inner section removal machine for the bamboo, the process of the inner section removal of the bamboo is mechanized, the efficiency of the machining link of the inner section removal is improved, and the quality can be effectively guaranteed.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com