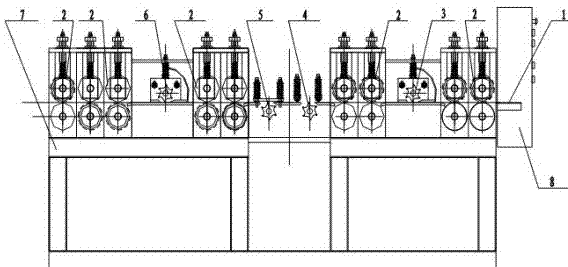

Bamboo splitting machine for preparing bamboo bundles and bamboo bundle preparing method

A technology of deflagging machine and bamboo, which is applied in the direction of manufacturing tools, wood processing appliances, irregular removal devices, etc., can solve the problems of insufficient dipping amount, manual turning of a large amount of labor, difficult dipping, etc., so as to save manpower and improve The effect of bamboo utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

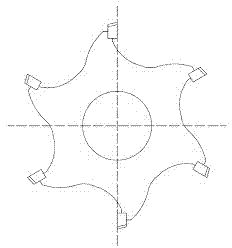

Embodiment 1

[0064] Firstly, the bamboo material is put into the first group of unit dispersing feeding device to remove the bamboo joints, dispersing and flattening through the feeding device 1. The group of circular shaft cutter 3 performs the initial scraping for the first time, and removes the brittle and hard layer on the surface of part of the bamboo yellow; enters the second group of units to decompose the feed device to decompose and flatten, and the second group of unit decompression feed device is also to decompose the bamboo. The yellow part is decomposed; then the next step is to enter the two sets of circular shaft knives 4 and 5 running at high speed, mainly to remove the bamboo green and waxy layer; enter the third group of unit decompression feeding device to decompose and flatten, and the third group of unit decompression The feeding device defrosts the green part of the bamboo; then scrapes the yellow part of the bamboo through the circular shaft knife 6; finally enters th...

Embodiment 2

[0067] This embodiment 2 is the same as embodiment 1 except that the unit deflagging feeding device is changed into the same group of deflapping feeding device.

[0068] The present invention can also install the bamboo rolling and decompressing machine in the mixed combination mode of the unit decomposing feeding device and the decomposing and feeding device of the same group.

[0069] The following is an example of the preferred method:

[0070] ⑴Bamboo pretreatment: slice the bamboo into bamboo pieces with a width of 20-60mm;

[0071] ⑵ Put the bamboo slices and bamboo yellow upwards into the feeding port,

[0072] (3) Put the bamboo slices into the first flattening and decomposing group to remove bamboo joints, flatten and decompose the bamboo yellow surface for the first time;

[0073] ⑷ Scrape the brittle and hard layer on the surface of bamboo yellow with the first circular shaft knife running at high speed;

[0074] (5) Put the bamboo slices into the second flatte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com